Patents

Literature

35results about How to "Low temperature control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for determination of the concentration of particles in multi-component fluid systems

InactiveUS20070119239A1Low temperature controlVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesFluid systemLarge particle

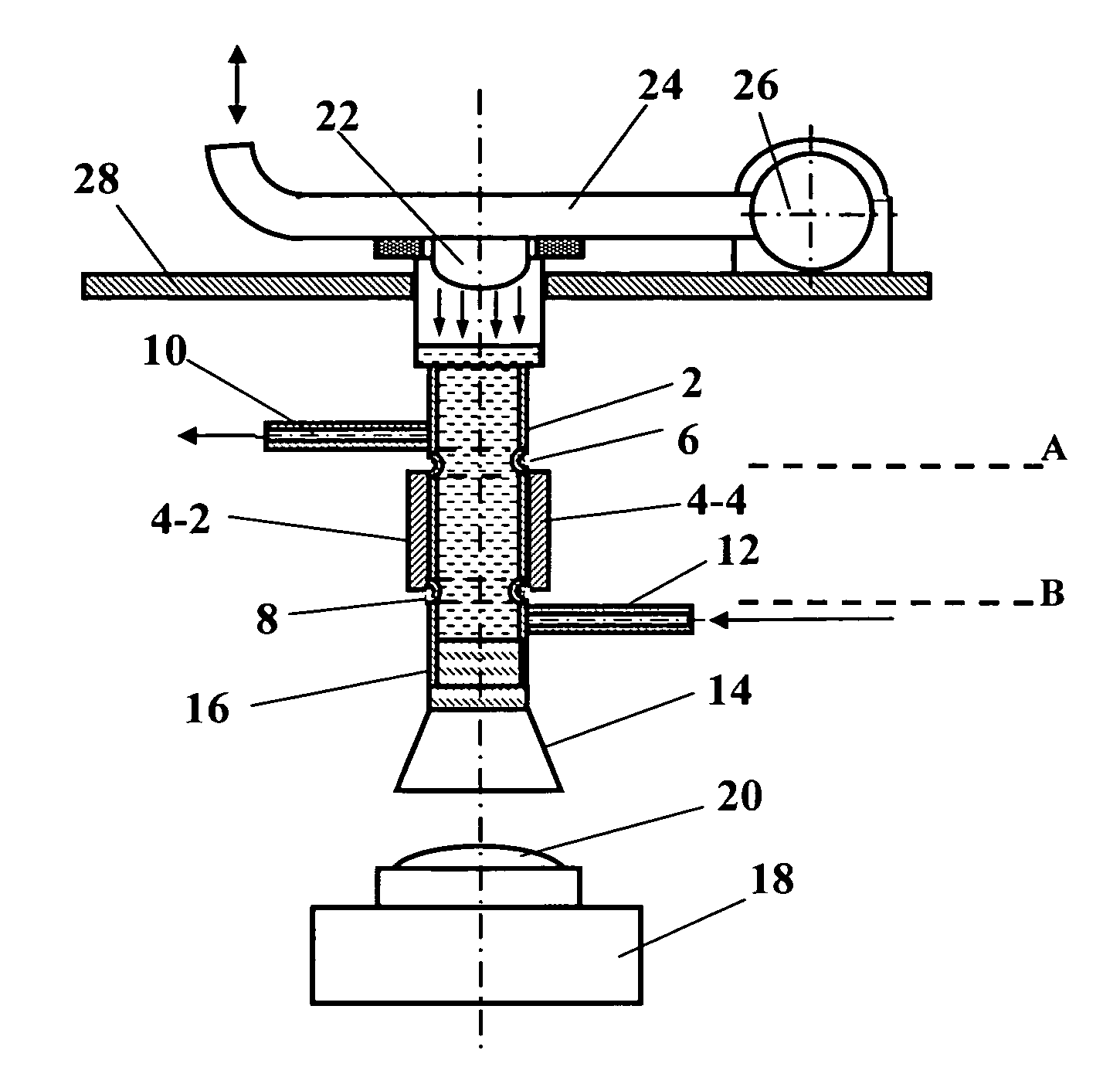

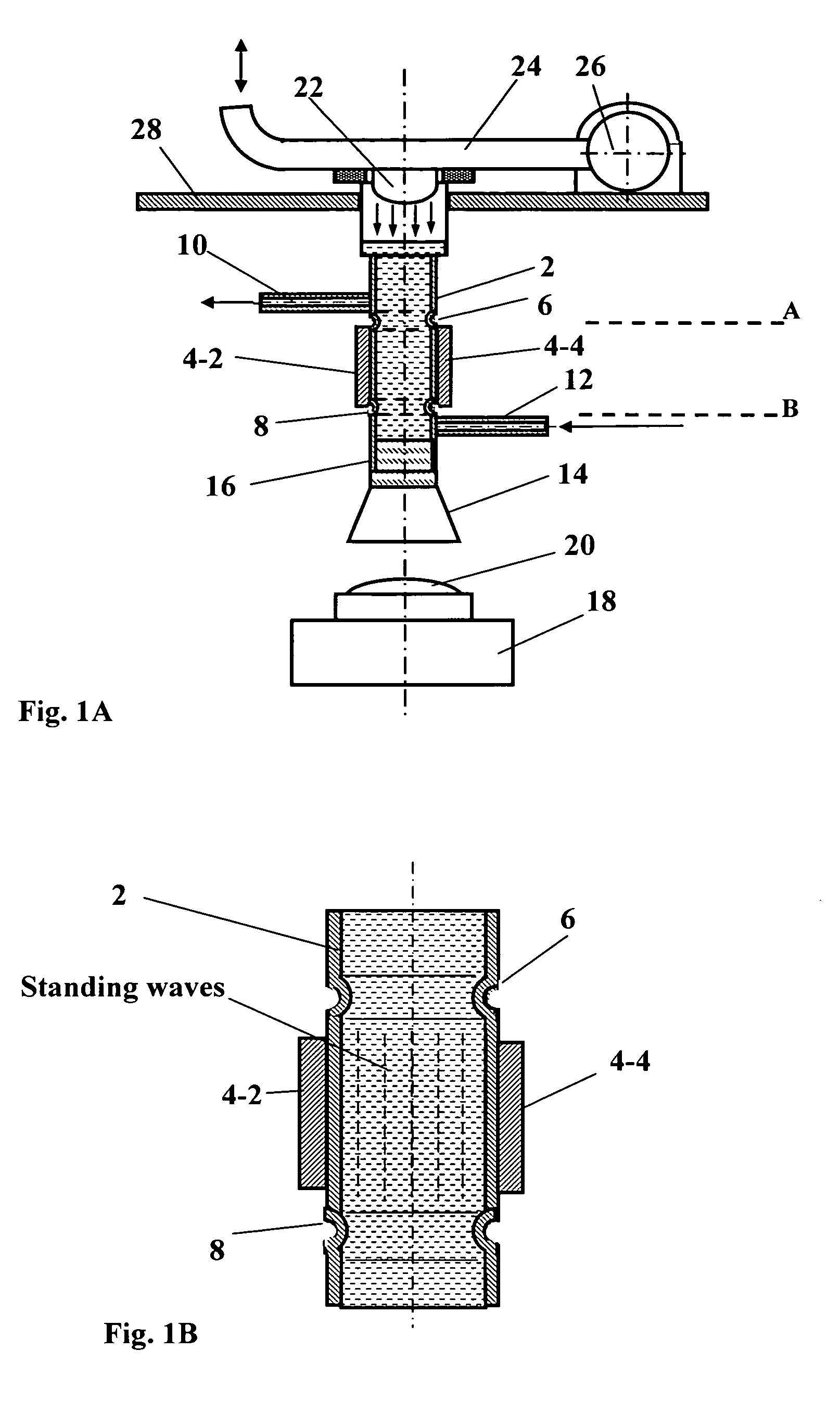

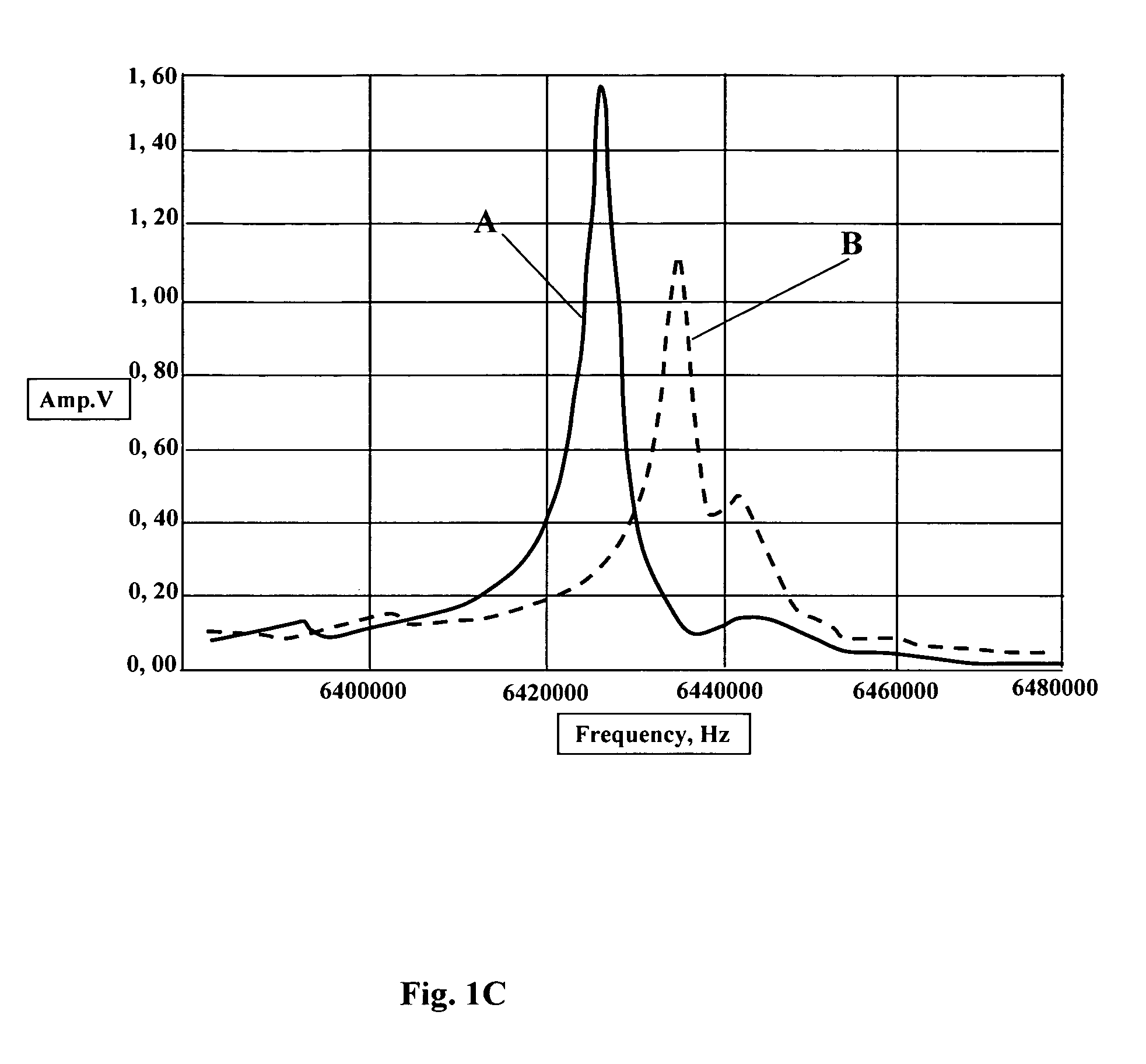

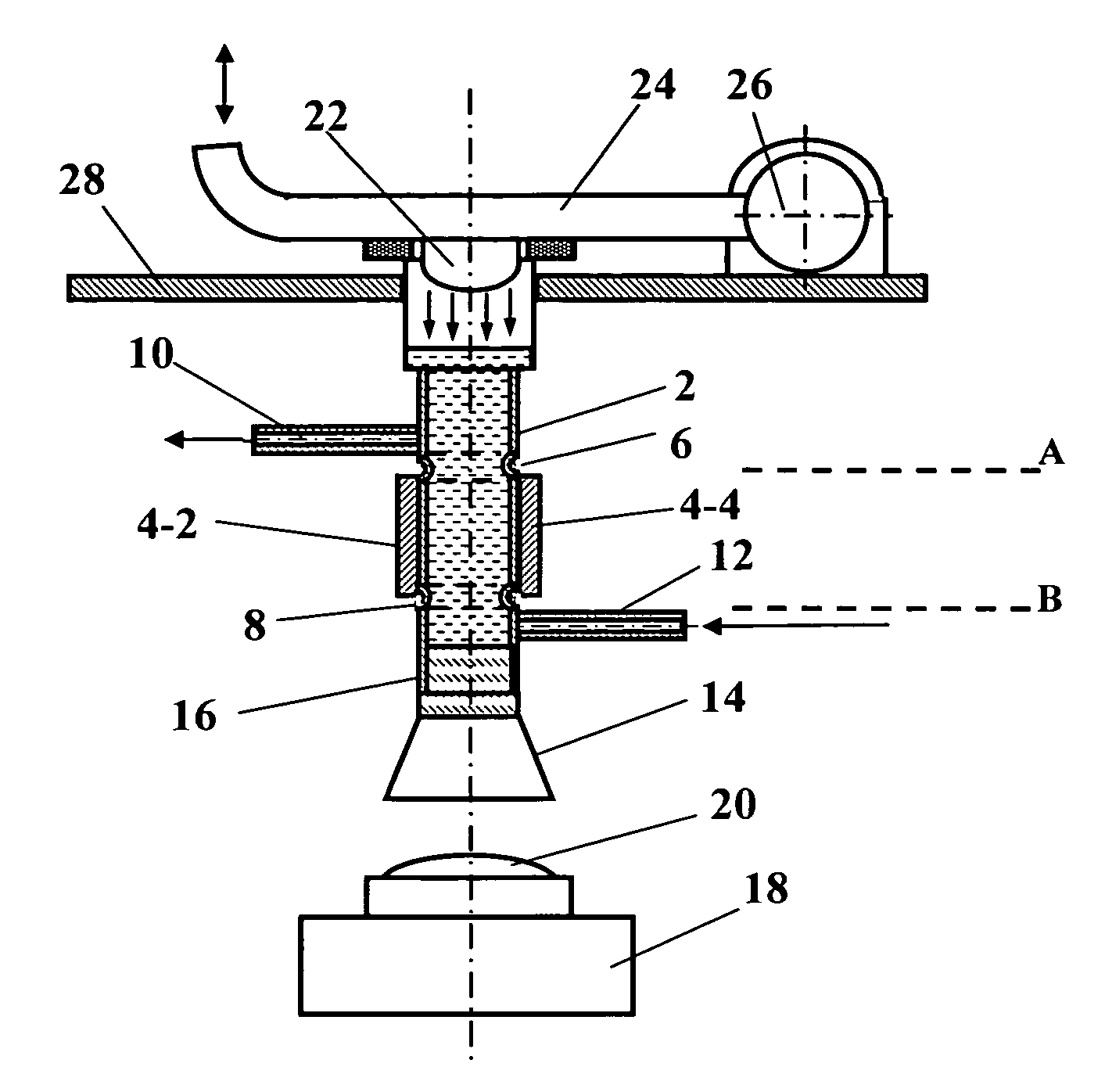

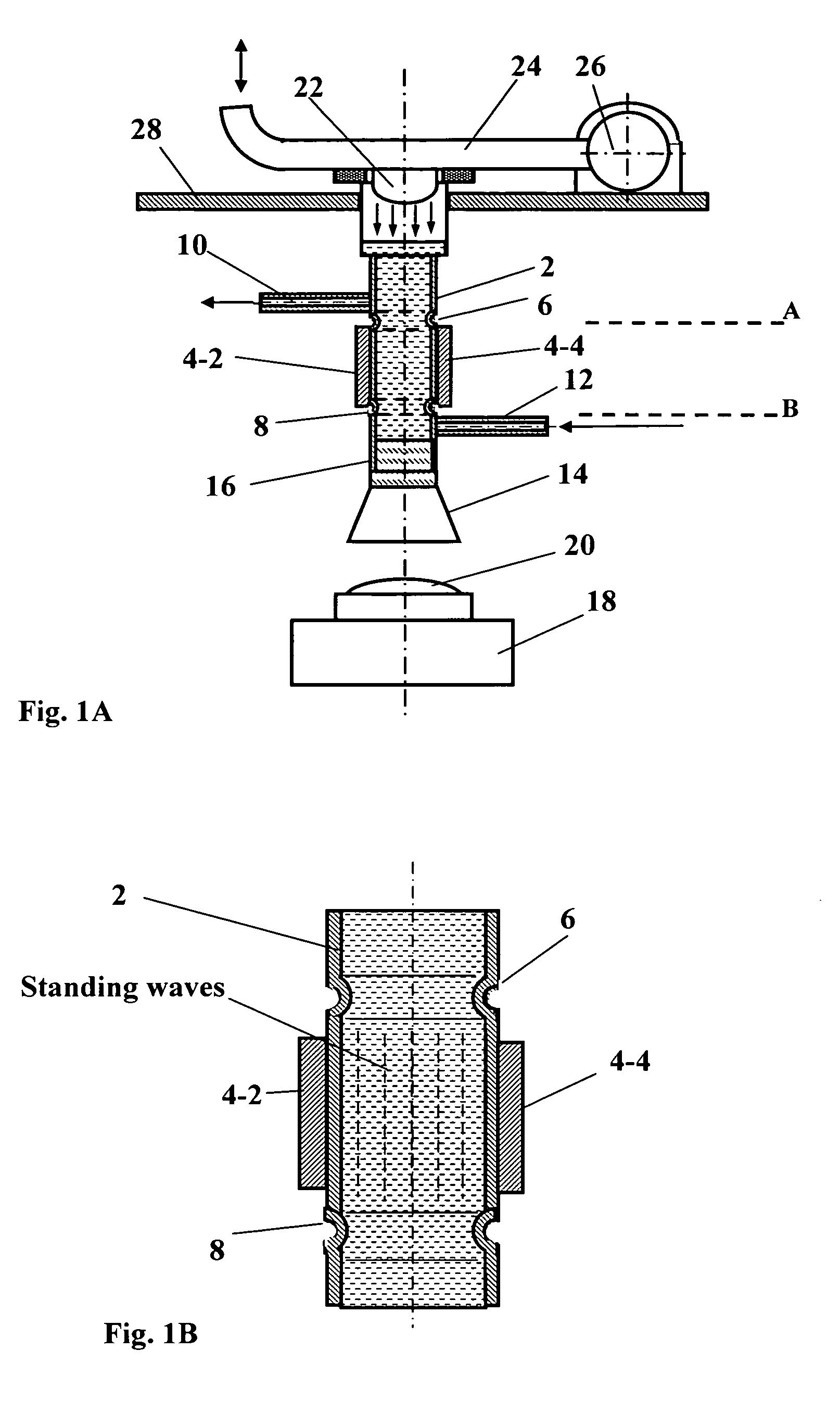

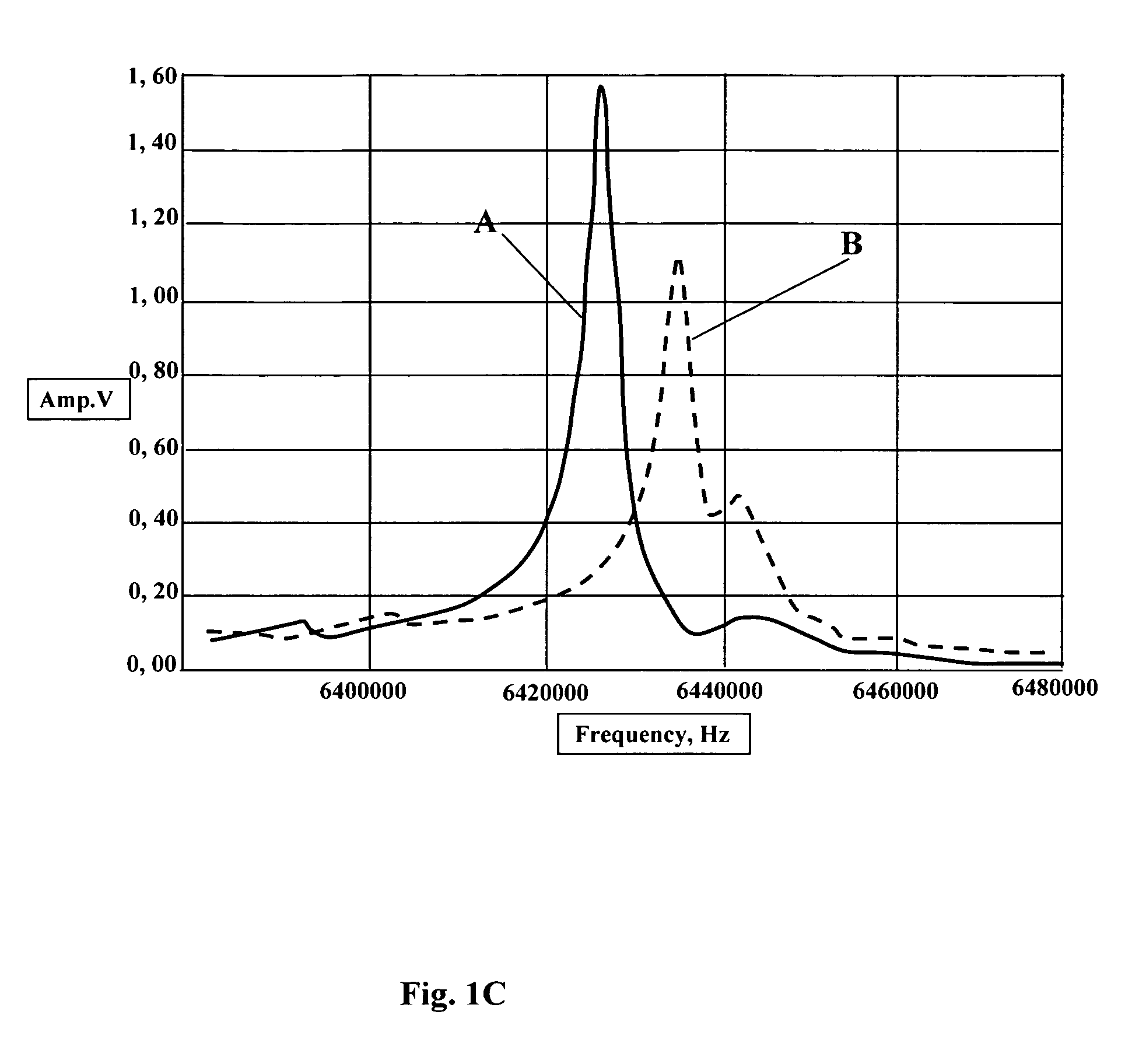

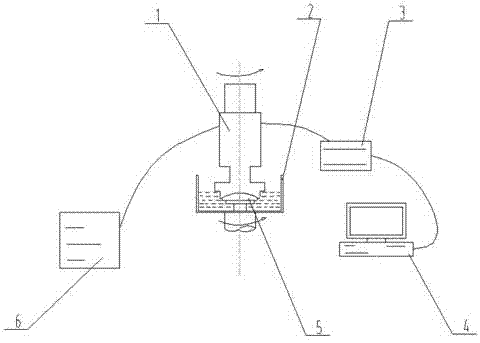

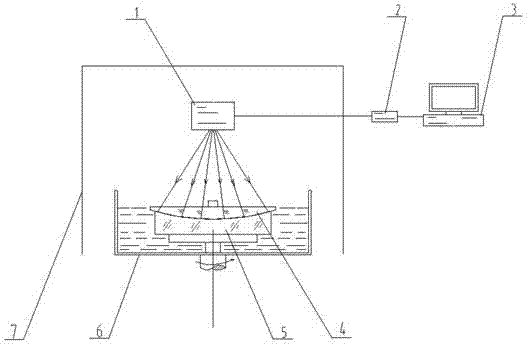

A method for determining the concentration of a large particle component in a multi-component system. The method requires first separating and concentrating the large particle component of the system by acoustic means and then measuring an acoustical parameter of the separated large particle component. The invention also provides for an apparatus for determining the concentration of large particles in a multi-component fluid system. The apparatus is comprised of an acoustic standing wave resonator, at least one acoustic standing wave generating source, electronic circuitry for actuating, controlling and processing the acoustic standing wave generating source and means for measuring at least one parameter of the multi-component system after the large particles have been concentrated and aggregated by the generated standing wave(s).

Owner:NANOALERT ISRAEL

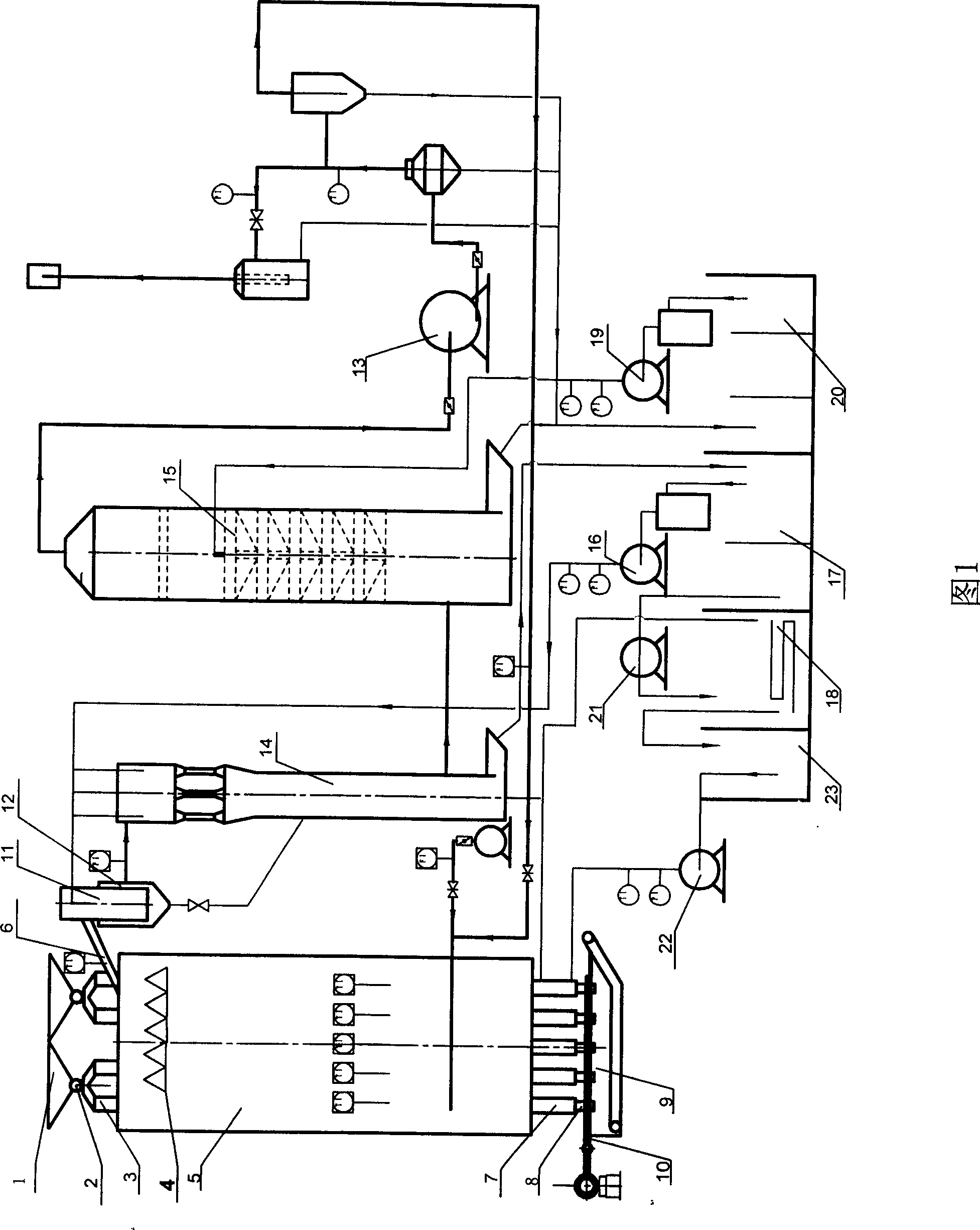

Low-temperature coal carbonization manufacturing technique

ActiveCN1966612AGive full play to the maximum capacityIncrease productionIndirect heating destructive distillationTemperature controlCarbonization

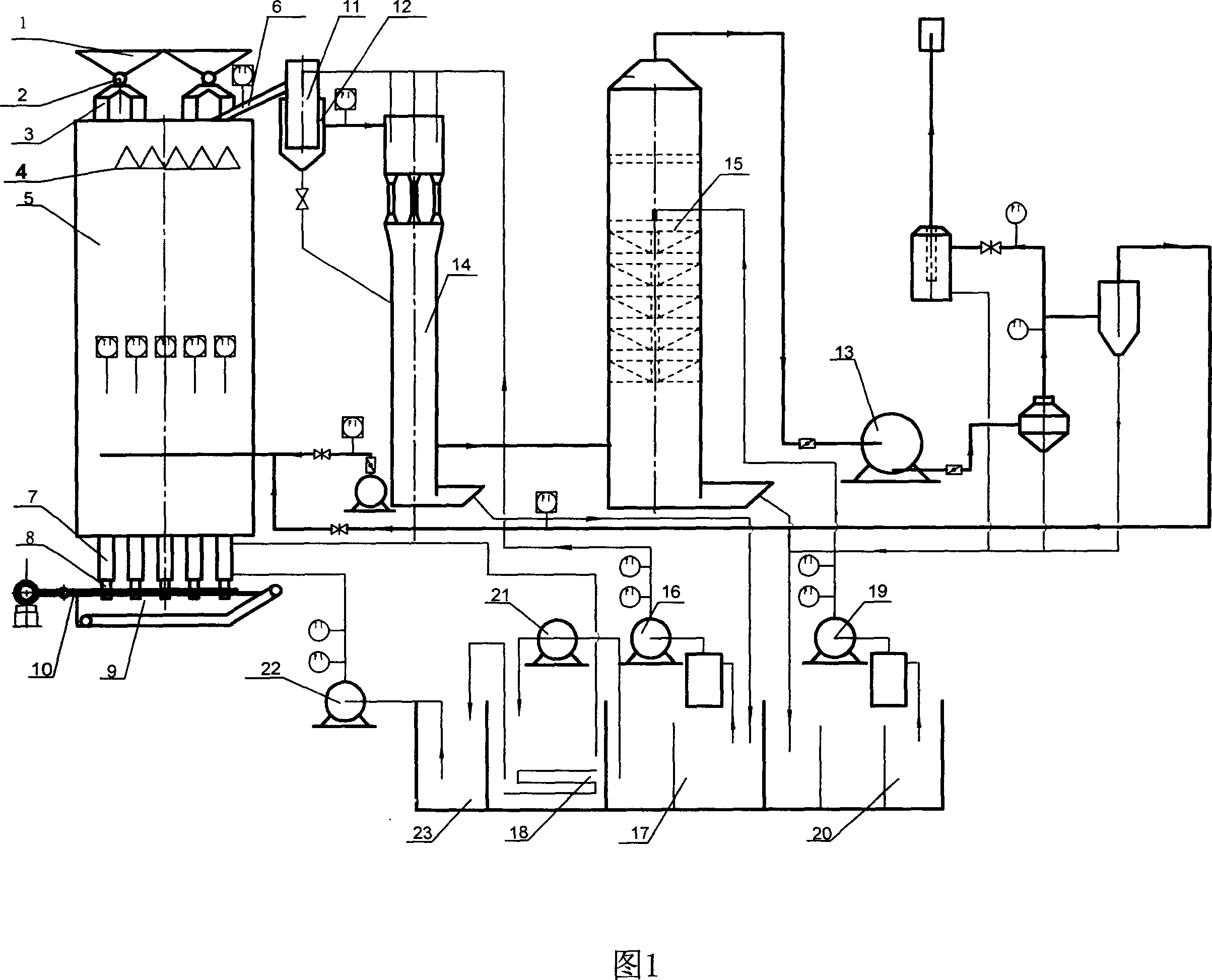

The invention disclosed a low temperature coal dry distillating process which includes the following steps: choosing the material coal; the coal goes through coal cup, roller, and assistant coalbox to get into collecting umbrella and being separated; pre-heating the coal in the drying stage; dry-distillating at 100-550DEG C for about 4h, the temperature of heating region is 700-800DEG C to decrease the content of semi-coal to less than 6%; cooling the semi-coal through the water-cooling jacket box. The heat in the stove is all absorbed by the coal in the invention. It needs less time to dry distillate the coal and it's quite direct and simple. The invention adopts big containing space, the heating gas is provided uniformly to the bottom of the stove so the stove throughput is 3 times more than the traditional stove; it can heat the material more uniformly and it need less temperature control; the tar yield has been increased and the recovery rate has been increased from less than 50% to 80% or more.

Owner:SHAANXI SHENMU SAN JIANG COAL CHEM

Method and apparatus for determination of the concentration of particles in multi-component fluid systems

InactiveUS7484414B2Low temperature controlVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesFluid systemLarge particle

A method for determining the concentration of a large particle component in a multi-component system. The method requires first separating and concentrating the large particle component of the system by acoustic means and then measuring an acoustical parameter of the separated large particle component. The invention also provides for an apparatus for determining the concentration of large particles in a multi-component fluid system. The apparatus is comprised of an acoustic standing wave resonator, at least one acoustic standing wave generating source, electronic circuitry for actuating, controlling and processing the acoustic standing wave generating source and means for measuring at least one parameter of the multi-component system after the large particles have been concentrated and aggregated by the generated standing wave(s).

Owner:NANOALERT ISRAEL

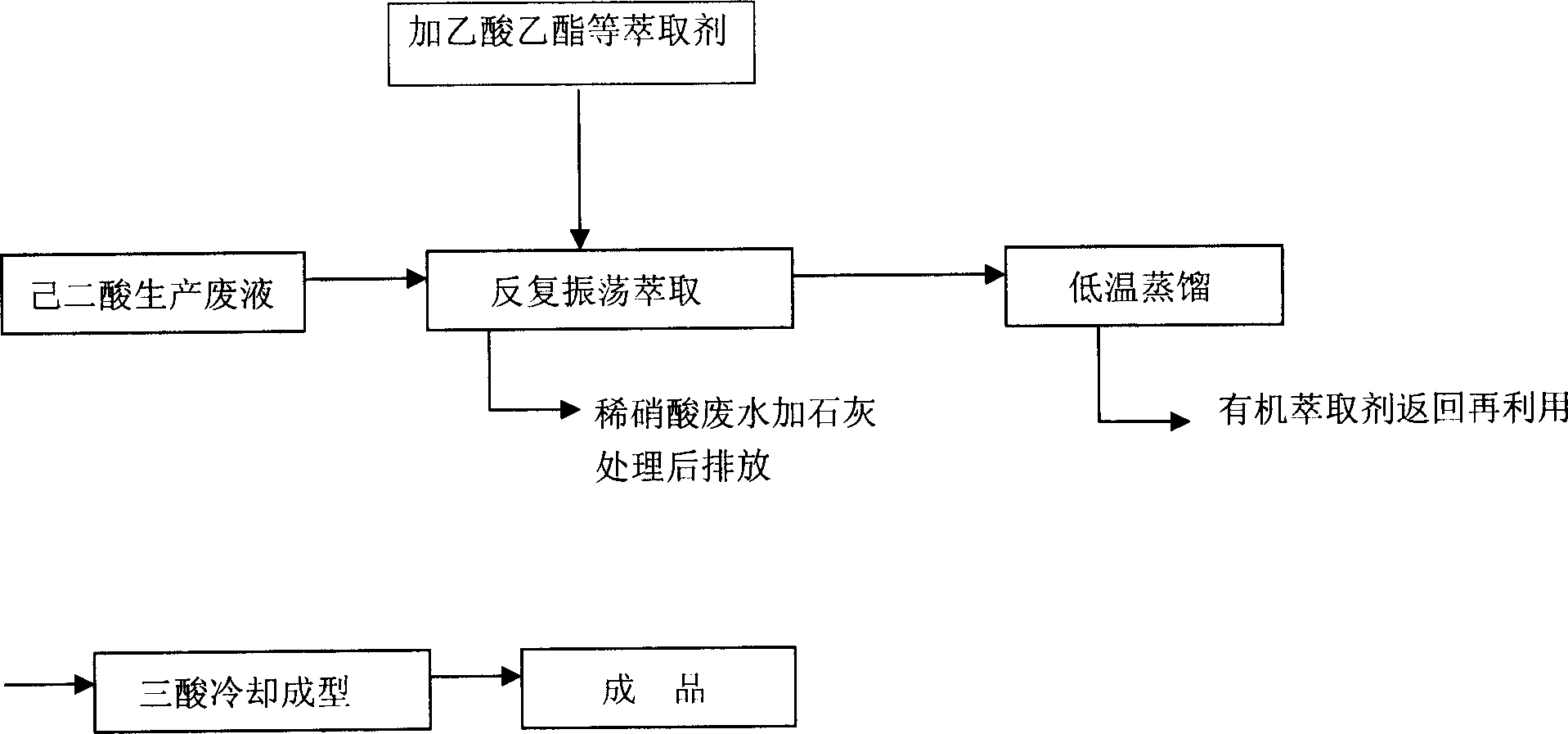

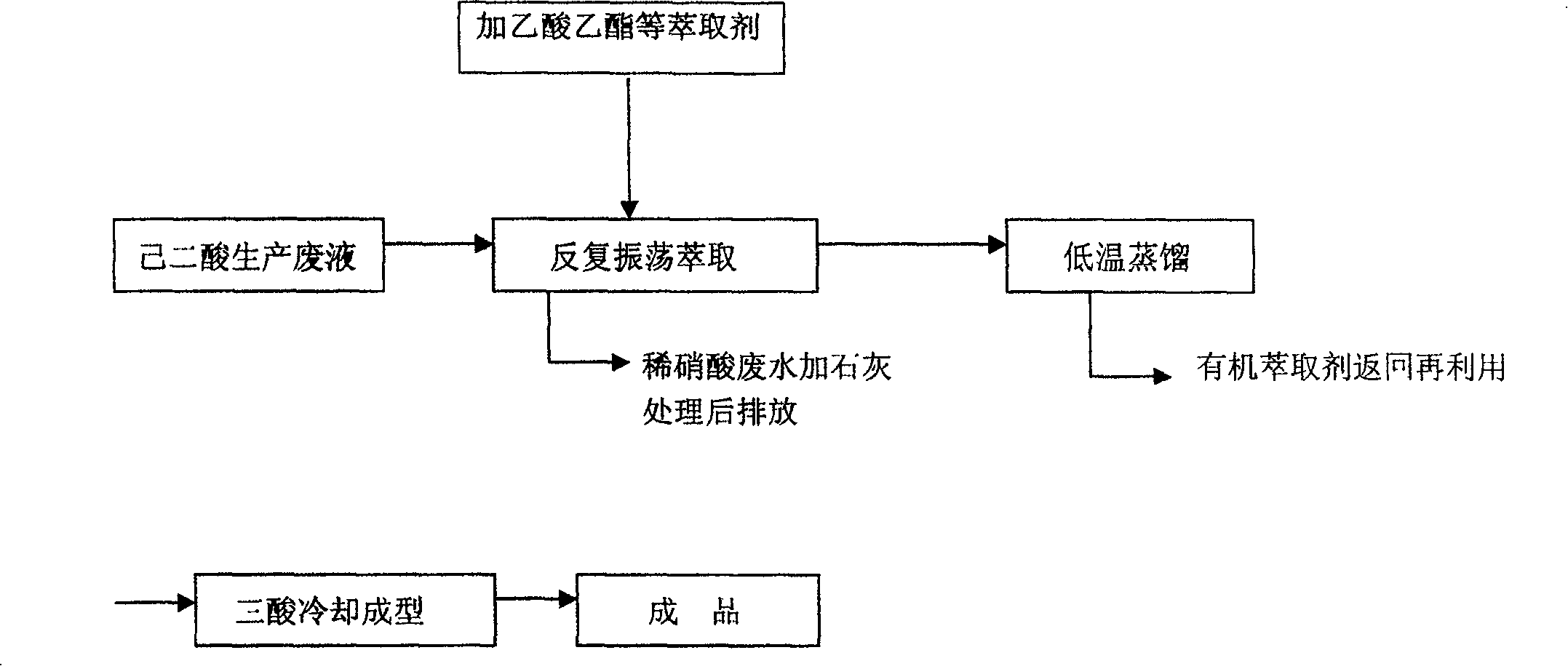

Method of treating hexane diacid preparation waste liquid

InactiveCN1907941AHighlight substantiveSignificantly progressiveNature of treatment waterWater/sewage treatment by extractionLiquid wasteAcetic acid

This invention provides a treatment method for waste liquid from adipic acid production with simple process, good effect and low cost. Said method comprises: (1) adding waste liquid from adipic acid production and the extraction agent of ethyl acetate with the same volume as the waste liquid in an extraction equipment, vibrating and extracting, and standing to stratify the water and organic item, and flowing out the water and the remained extract containing three acids (adipic acid, glutaric acid and succinic acid), (2) repeating above steps to extract, (3) distilling the three acids-bearing extract no longer to be treated, evaporating the extraction agent of ethyl acetate, recycling, cooling the remainder and molding to obtain the three acids, and (3) adding alkaline substance to the water no longer to be treated, adjusting its pH within a range of 7-8, and discharging or taking it as liquid fertilizer. The approach is an advanced and mature technology with low energy consumption and no pollution. The three acid obtained have good quality and high efficiency.

Owner:李强国

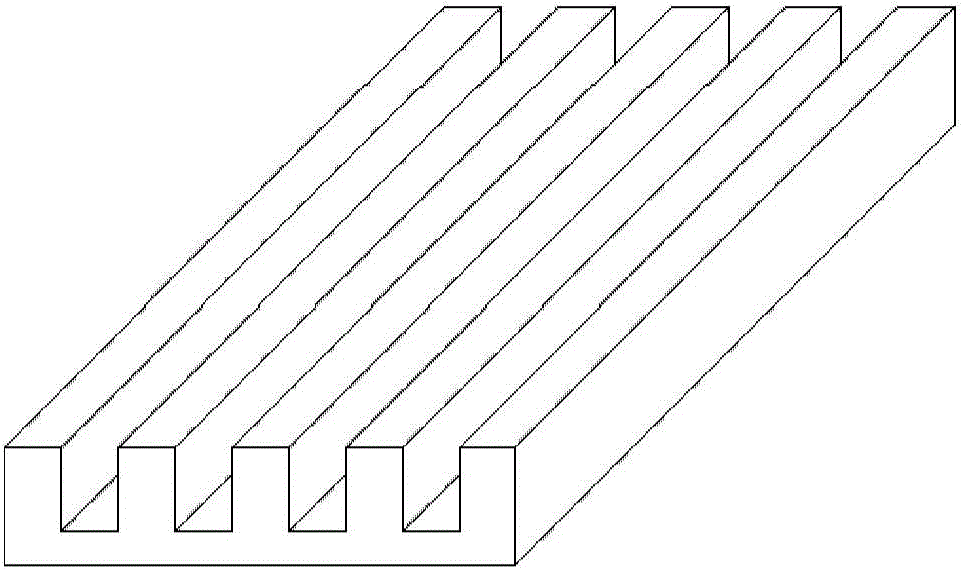

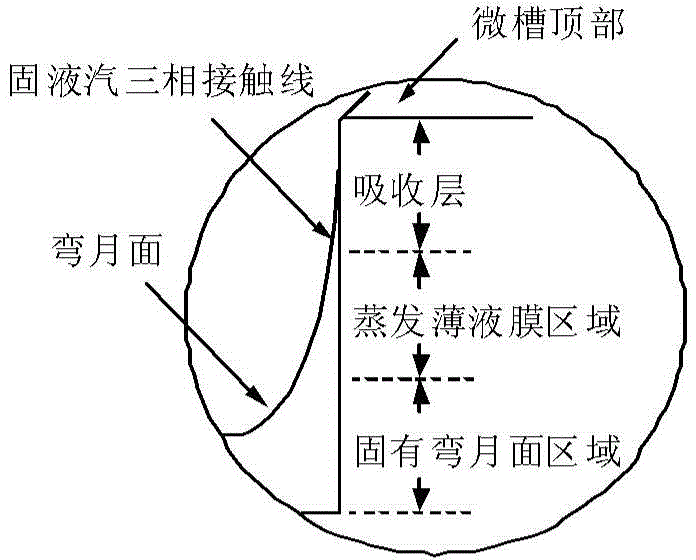

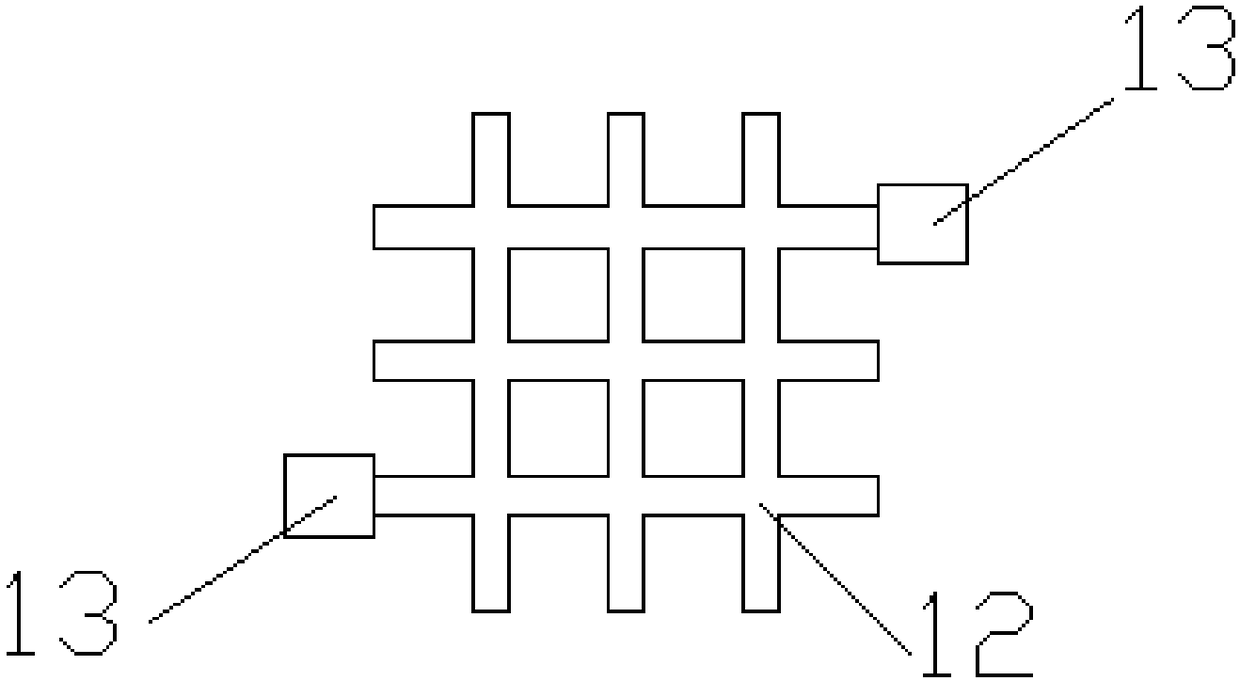

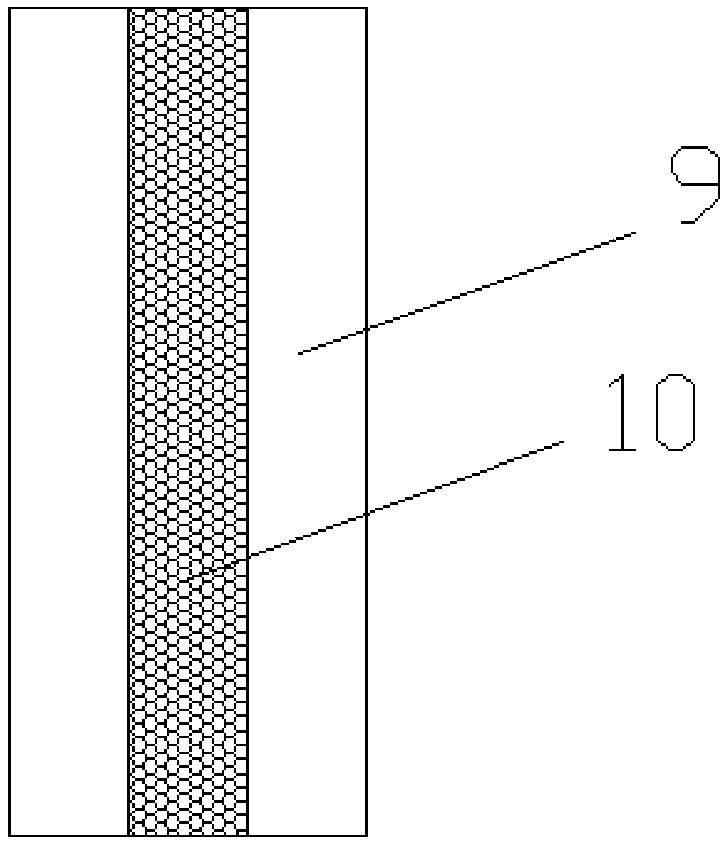

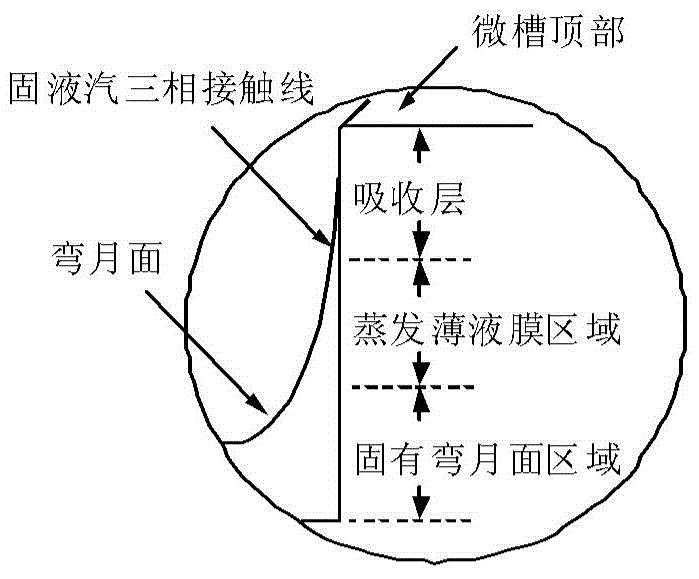

Microchannel phase-change heat transfer device

ActiveCN103824825AGood for heatImprove heat extraction capacitySemiconductor/solid-state device detailsSolid-state devicesTemperature controlShape-memory alloy

The invention provides a microchannel phase-change heat transfer device. The microchannel phase-change heat transfer device includes an outer heat dissipation body and a microchannel heat sink; the outer heat dissipation body is of a cylindrical structure of which one side is closed; the microchannel heat sink is made of a shape memory alloy material and is of a platy structure; the microchannel heat sink is embedded at one un-closed end of the cylindrical structure of the outer heat dissipation device, such that a closed cavity can be formed; and the closed cavity is filled with a liquid working medium; a surface of the microchannel heat sink, which faces the inner side of the closed cavity, is provided with a plurality of hundred-micron-level microchannels; trained micro ribs are located between every two adjacent microchannels; and the depth of the microchannels above a preset temperature is greater than the depth of the microchannels below the preset temperature. With the microchannel phase-change heat transfer device of the invention adopted, the heat removal ability of a microchannel structured surface can be improved, and the overheating degree of the microchannel structured surface can be reduced, and therefore, the temperature of a heat-emitting device can be controlled to be lower.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Gelatinizer mother liquor for porous water-permeable concrete and preparation method thereof

The invention discloses a gelatinizer mother liquor for porous water-permeable concrete and a preparation method thereof. The gelatinizer mother liquor comprises, by weight, 57.0-58.0% of water, 19.0-20.0% of calcium chloride, 2.0-2.5% of ferrous chloride, 2.5-3.0% of ferrous sulfate, 3.0-3.5% of iron chloride, 1.5-2.0% of sodium chloride, 2.5-3.0% of sodium sulfate, 2.0-2.5% of magnesium sulfate, 1.5-2.5% of potassium sulfate, 2.4-3.0% of ammonia chloride, 0.1% of a stabilizing agent and 0.1% of a dispersant. The preparation method comprises respectively mixing the above materials and water to obtain a calcium chloride solution, an iron chloride solution, a magnesium sulfate solution, a potassium sulfate solution, a ferrous chloride solution, a ferrous sulfate solution, a sodium sulfate solution, a sodium chloride solution and an ammonia chloride solution and mixing all the solutions. The gelatinizer mother liquor improves concrete aggregate bonding performances, water permeability after construction and anti-compression and anti-bending strength, is convenient for maintenance, has a long novel road maintenance period, has mixing uniformity and improves production efficiency.

Owner:宁波天露新材料科技有限公司

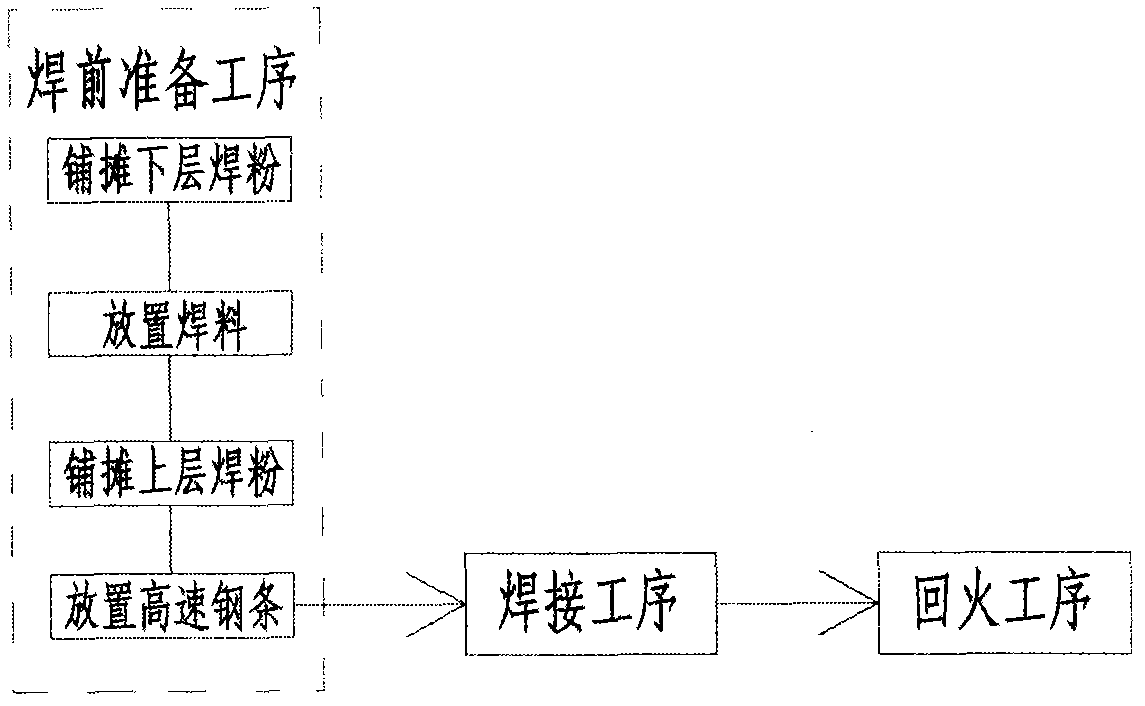

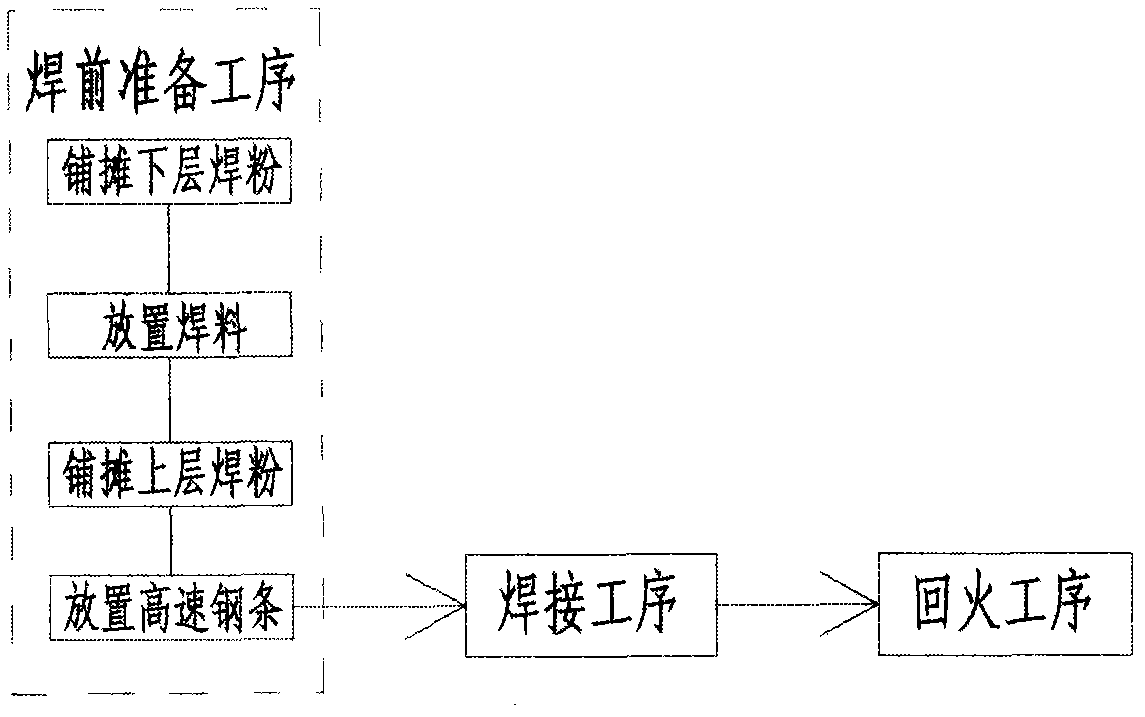

Process method for welding high-speed steel bars

ActiveCN102528302AImprove firmnessImprove heating efficiencyWelding/cutting auxillary devicesAuxillary welding devicesMaterials scienceHigh-speed steel

The invention provides a process method for welding high-speed steel bars. The process method comprises a preweld preparation procedure and a welding procedure; the preweld preparation procedure comprises the following steps in sequence: spreading a layer of welding powder on a base plate, stacking welding flux on the welding powder, spreading a layer of welding powder on the welding flux again, and placing high-speed steel bars on the upper layer of welding powder; superaudiable induction heating equipment is used during the welding procedure; and the base plate on which the welding powder and the welding flux are placed and the high-speed steel bars in the preweld preparation procedure are placed in the superaudiable induction heating equipment, the superaudiable induction heating equipment is started to increase the welding temperature to 1080 minus or plus 5 DEG C, and after the welding powder and the welding flux are melted completely between the base plate and the high-speed steel bars, the superaudiable induction heating equipment is turned off, and the base plate on which the high-speed steel bars are welded is taken out. The process method has the advantages that the firmness of welding is good and the abrasion resistance is better.

Owner:DONGE LIYUAN MACHINERY KNIFE

Preparation method of dried tofu

InactiveCN108782776AImprove anti-corrosion functionWith preservation functionFood preservationOther dairy technologyTea Tree extractAllium sativum

The invention discloses a preparation method of dried tofu. The preparation method comprises the following steps: selecting bean agricultural products and performing peeling; performing soaking treatment on the peeled bean agricultural products; adding an alkaline matter and regulating the pH value to 9-10; then proportionally mixing the soaked bean agricultural products with water; grinding the bean agricultural products into pulp by using a pulping machine; adding a garlic extracting solution and a tea tree extracting solution, performing thorough mixing and filtering the pulp to obtain beanmilk; boiling the obtained bean milk into cooked bean milk; proportionally adding an acidic material and performing curdling after the bean milk is boiled; performing pressing and cutting to obtain bean curd blanks after the bean milk is curdled; and pickling and drying the obtained bean curd blanks to obtain the dried tofu. The preparation method of the dried tofu solves the problem that in an existing preparation method of dried tofu, the preservation time of the dried tofu is prolonged by adding food preservatives, which disagrees with the production requirements of green nuisance-free organic foods.

Owner:郑州新农源绿色食品有限公司

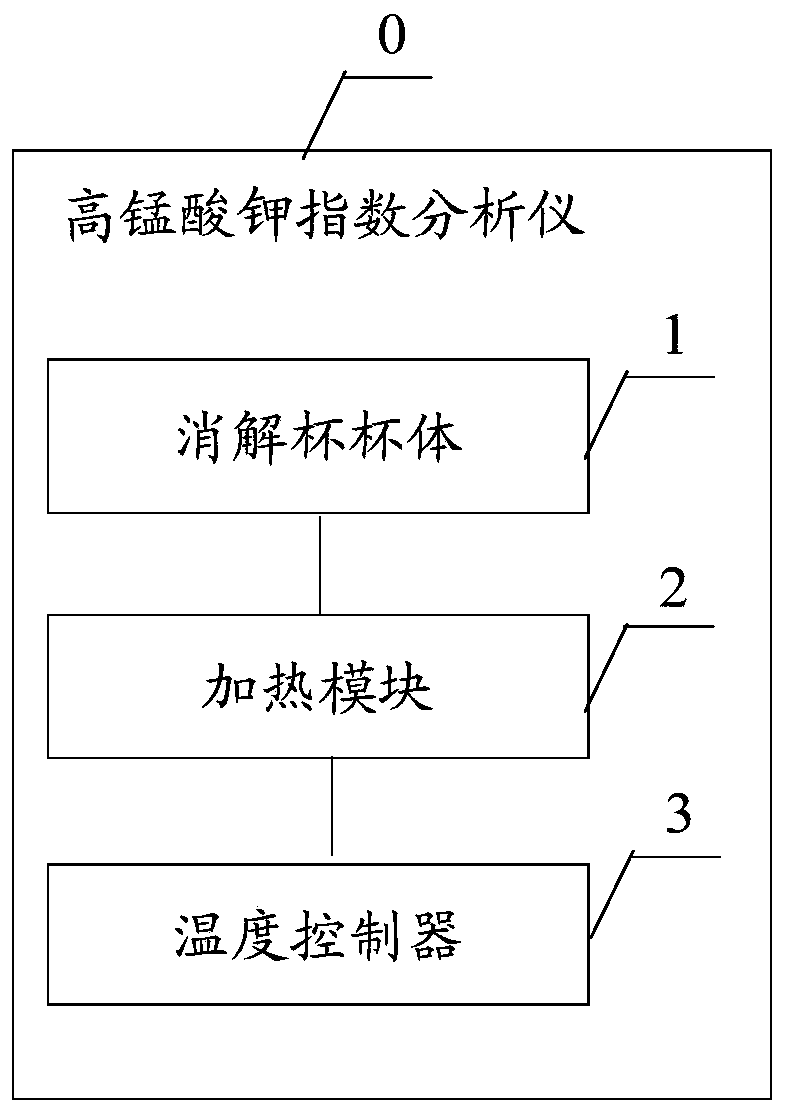

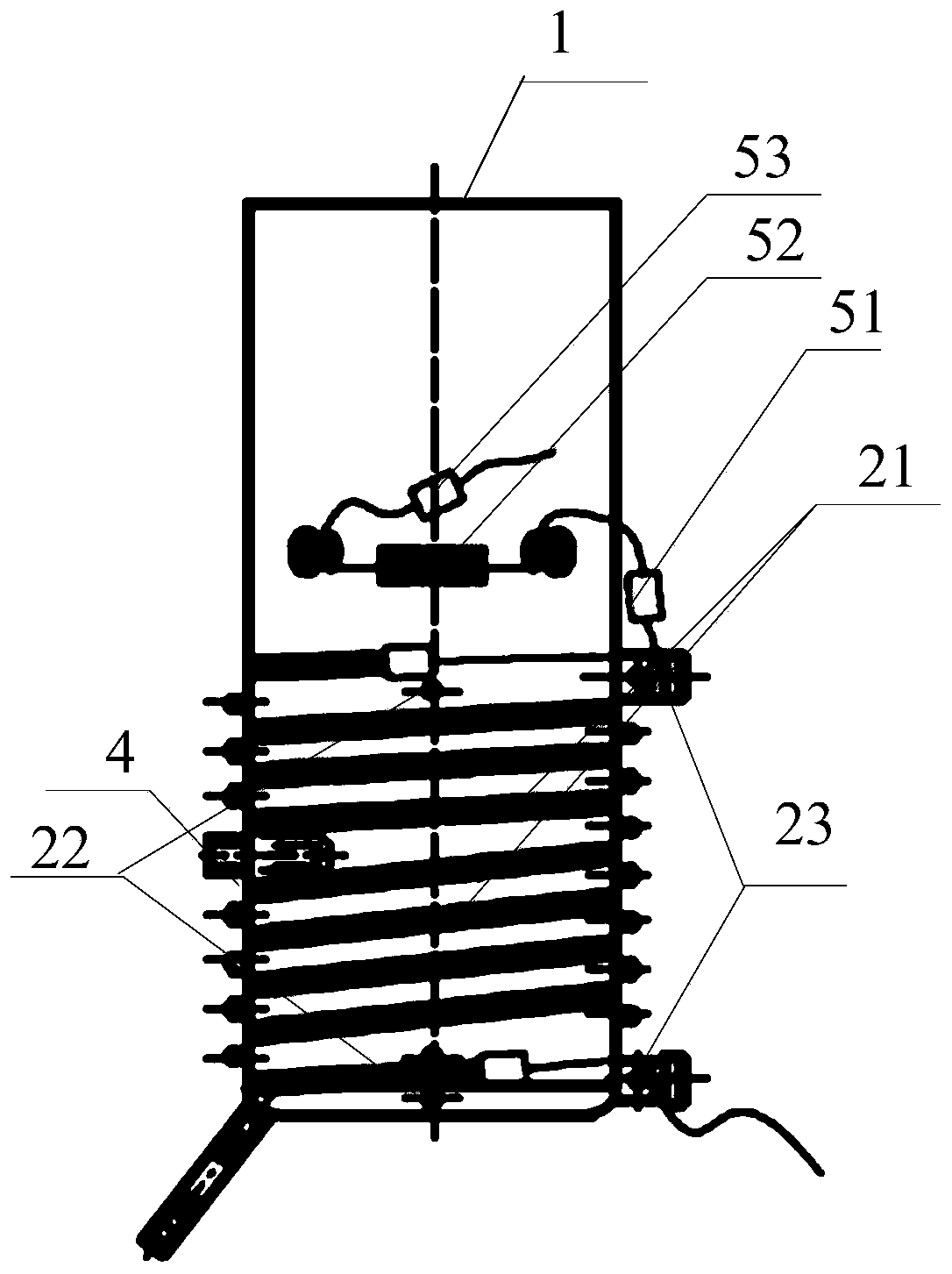

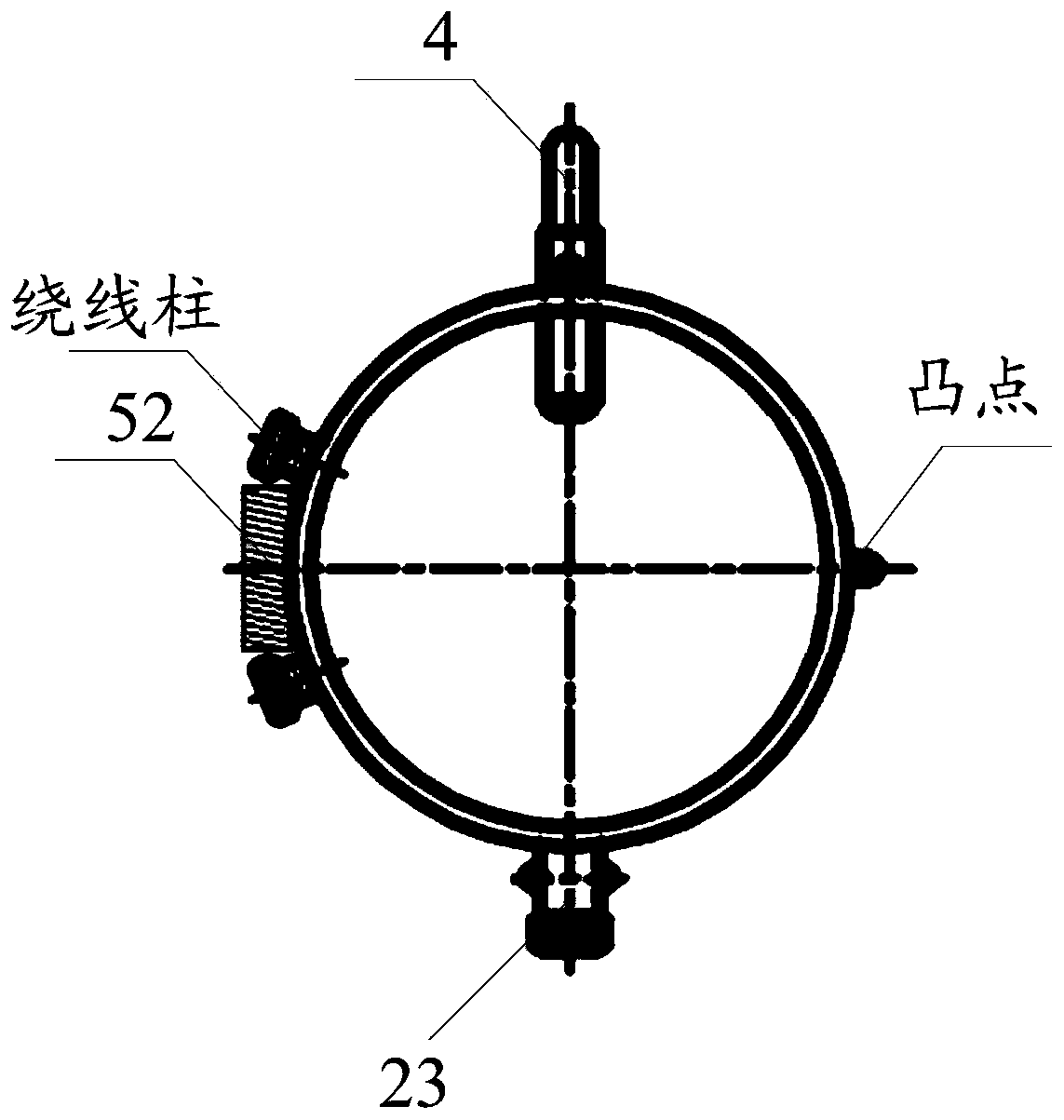

Potassium permanganate index analyzer

ActiveCN111006934AAvoid exceptionLow temperature controlGeneral water supply conservationPreparing sample for investigationTemperature controlTemperature curve

The embodiment of the invention discloses a potassium permanganate index analyzer. The potassium permanganate index analyzer comprises a digestion cup body, a heating module arranged on the outer sideof the digestion cup body, and a temperature controller connected with the heating module. The heating module comprises a heating belt which is attached to and wound on the outer side of the digestion cup body at equal intervals, a plurality of convex points which are used for fixing the heating belt and are arranged on the outer side of the digestion cup body, and two wrapping posts. The starting end and the terminal end of the heating belt are respectively connected with the corresponding wrapping posts through wiring terminals; the first type of convex points are arranged on the left sideand the right side of the digestion cup body, the convex points on the same side are distributed at equal intervals, the second type of convex points are arranged below a starting winding ring and a stopping winding ring of the heating belt, the convex points on the same horizontal plane are symmetrically distributed on the front side and the rear side of the digestion cup body, and the number ofthe convex points is determined by the length and width of the heating belt. And the temperature controller controls the heating power of the heating module according to a real-time temperature of a reaction solution and a standard temperature curve. According to the invention, high-efficiency and accurate water quality detection can be realized.

Owner:HANGZHOU GREAN WATER SCI & TECH INC

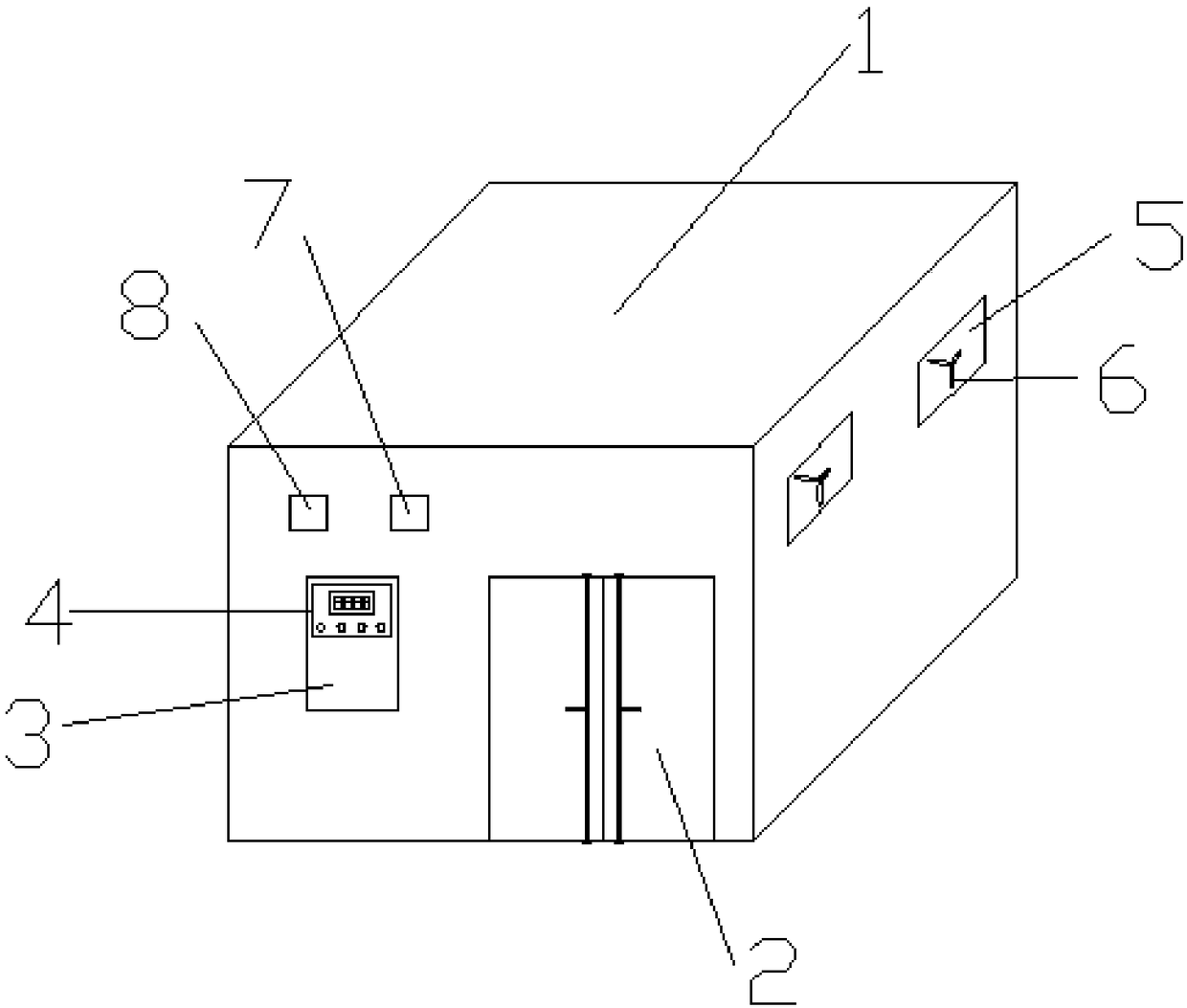

Edible fungus drying room

InactiveCN108800774ALow costEasy to getDrying solid materials with heatDrying gas arrangementsTemperature controlInsulation layer

The invention discloses an edible fungus drying room. The edible fungus drying room comprises a room body; a heat insulation layer is arranged in a wall body partition layer of the room body, a plurality of drying racks are arranged in the drying room, a heating pipe is arranged on each drying rack, and heating devices are further mounted at the two ends of each heating pipe; a moisture exhaustingopening is formed in the wall body of the drying room, a suction fun is mounted in the moisture exhausting opening, and a temperature sensor and a humidity sensor are arranged in the drying room; andan access door and a transparent window are arranged on the outer wall of the drying room, a control box is arranged above the exterior of the window and comprises a display frequency, a temperaturecontrol device, and a suction fan control switch, the humidity sensor is connected with the suction fan control switch, the input end of the temperature control device is connected with the temperature sensor, the output end of the temperature control device is connected with the heating devices, and the display frequency is connected with the humidity sensor and the temperature sensor. The temperature and humidity in the drying room can be displayed in real time.

Owner:金义财

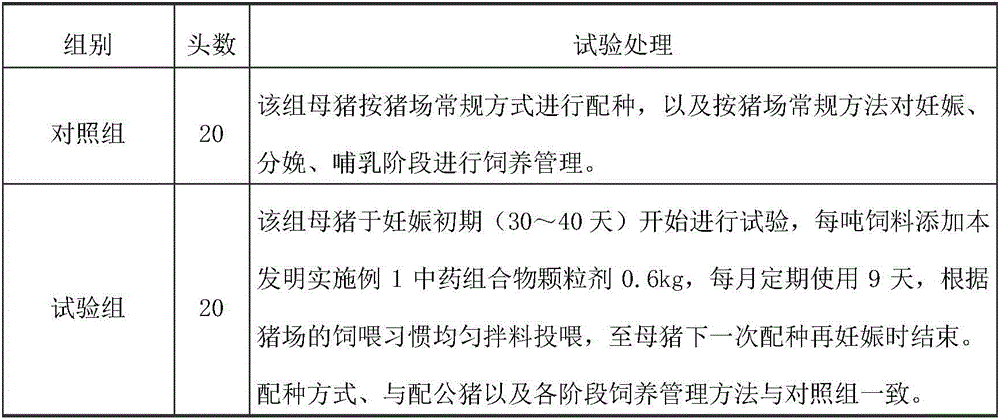

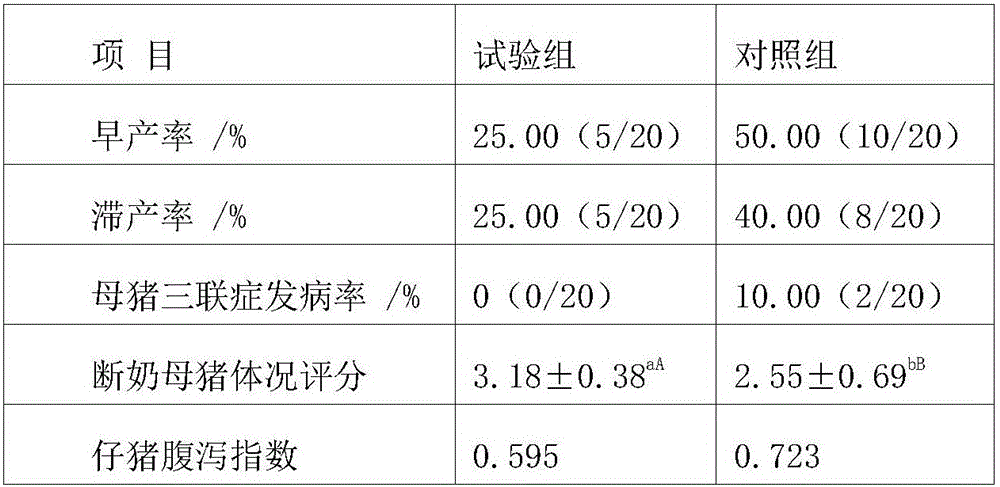

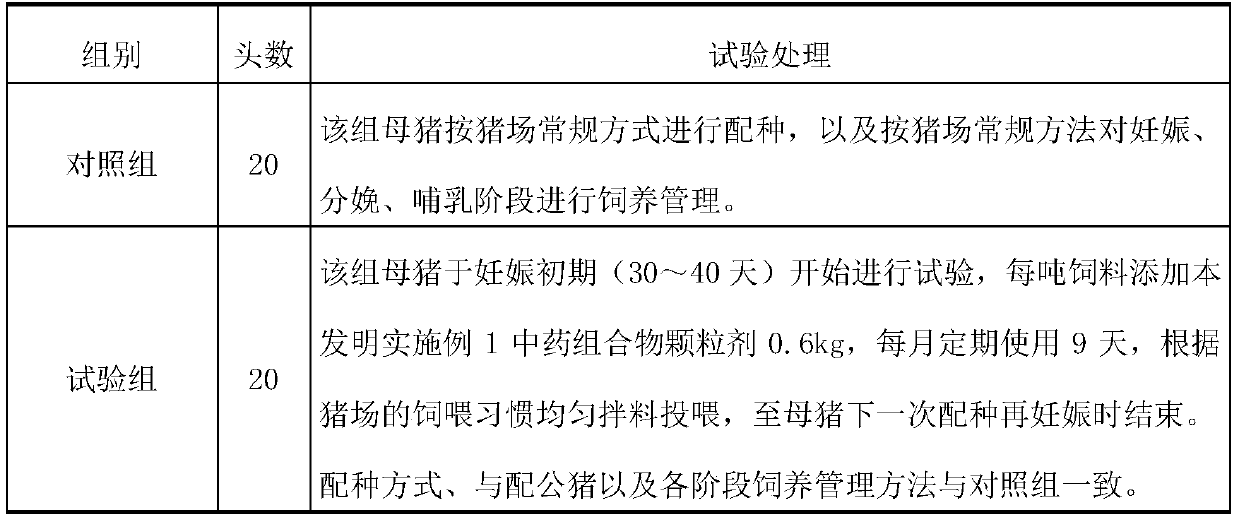

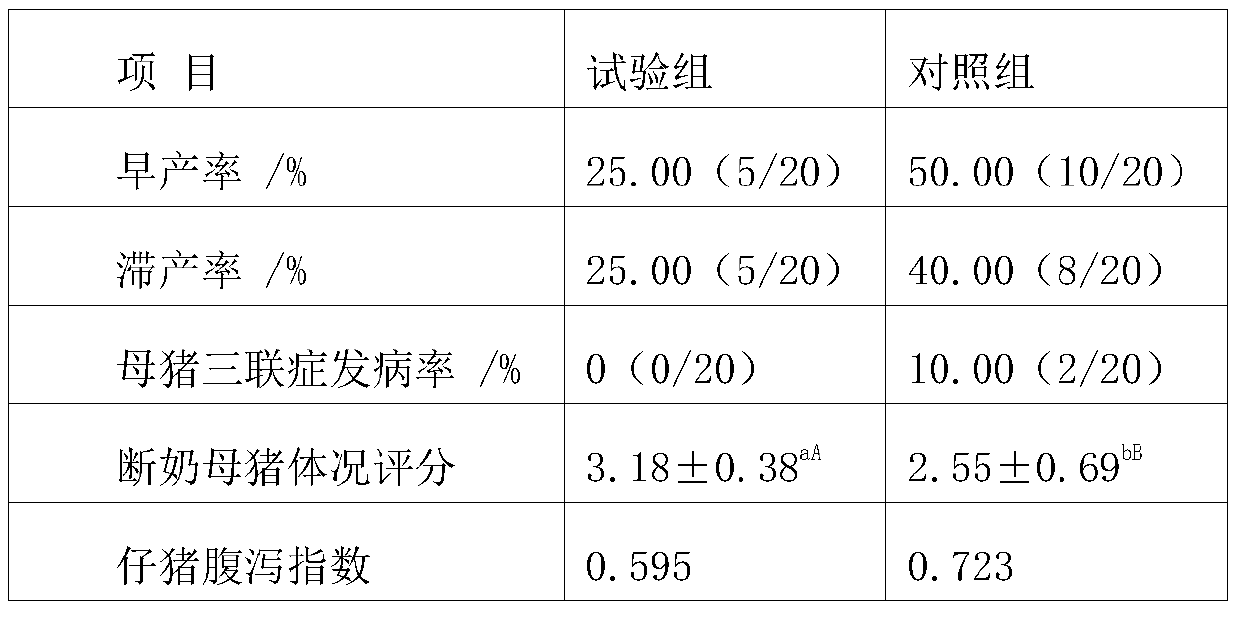

Application of traditional Chinese medicine composition in preparing drugs for improving reproductive performance of sows

ActiveCN105816563AImprove farrowing performanceImprove immunityGranular deliveryImmunological disordersPig farmsLicorice roots

The invention relates to the technical field of traditional Chinese medicines, in particular to application of a traditional Chinese medicine composition in preparing drugs for improving reproductive performance of sows .The traditional Chinese medicine composition is prepared from licorice roots, herba houttuyniae, radix sophorae flavescentis, radix isatidis, folium isatidis and milkvetch roots and prepared into granules .A traditional Chinese medicine extract containing multiple ingredients is prepared according to suitable proportions, the obvious synergistic effect is achieved, the application range is widened, the effect of improving the farrowing performance and immunity of the sows is achieved, and the health condition of the sows is obviously improved .Meanwhile, the milk yield of the sows is increased, the quality is improved, and meanwhile growth and development and the health condition of suckling piglets are improved .Therefore, the traditional Chinese medicine composition is specially suitable for disease prevention and health care and a guarantee of the reproductive performance of the sows in a large-scale pig farm.

Owner:SHANDONG DEZHOU SHENNIU ANIMAL HEALTH PROD CO LTD

Optical element processing method based on thermal accelerated corrosion

The invention provides a lapping and polishing method based on thermal accelerated corrosion, which mainly solves the problems of high cost and low processing efficiency for current processing of optical elements, especially aspherical optical elements. The optical element processing method based on thermal accelerated corrosion comprises the following steps: 1. determining a processing target shape; 2. determining the amount to be removed for points on a surface of a workpiece to be processed according to the determined target shape and the shape of the workpiece to be processed; 3. setting the temperature and the dwell time of corrosion liquid on the points on the workpiece to be processed according to the amount to be removed for the points on the surface of the workpiece to be processed determined in step 2; 4. performing corrosion to obtain the processing shape determined in step 1. The method of the invention is high in efficiency and low in cost.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

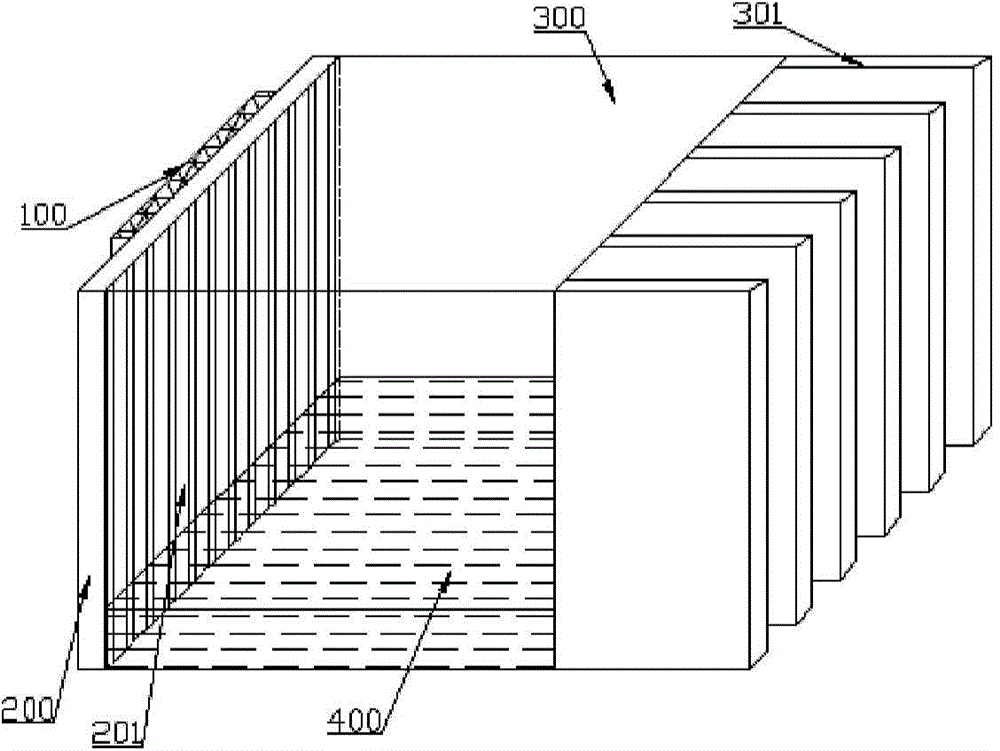

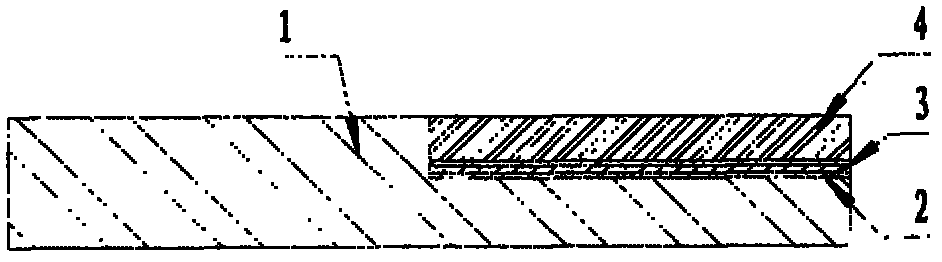

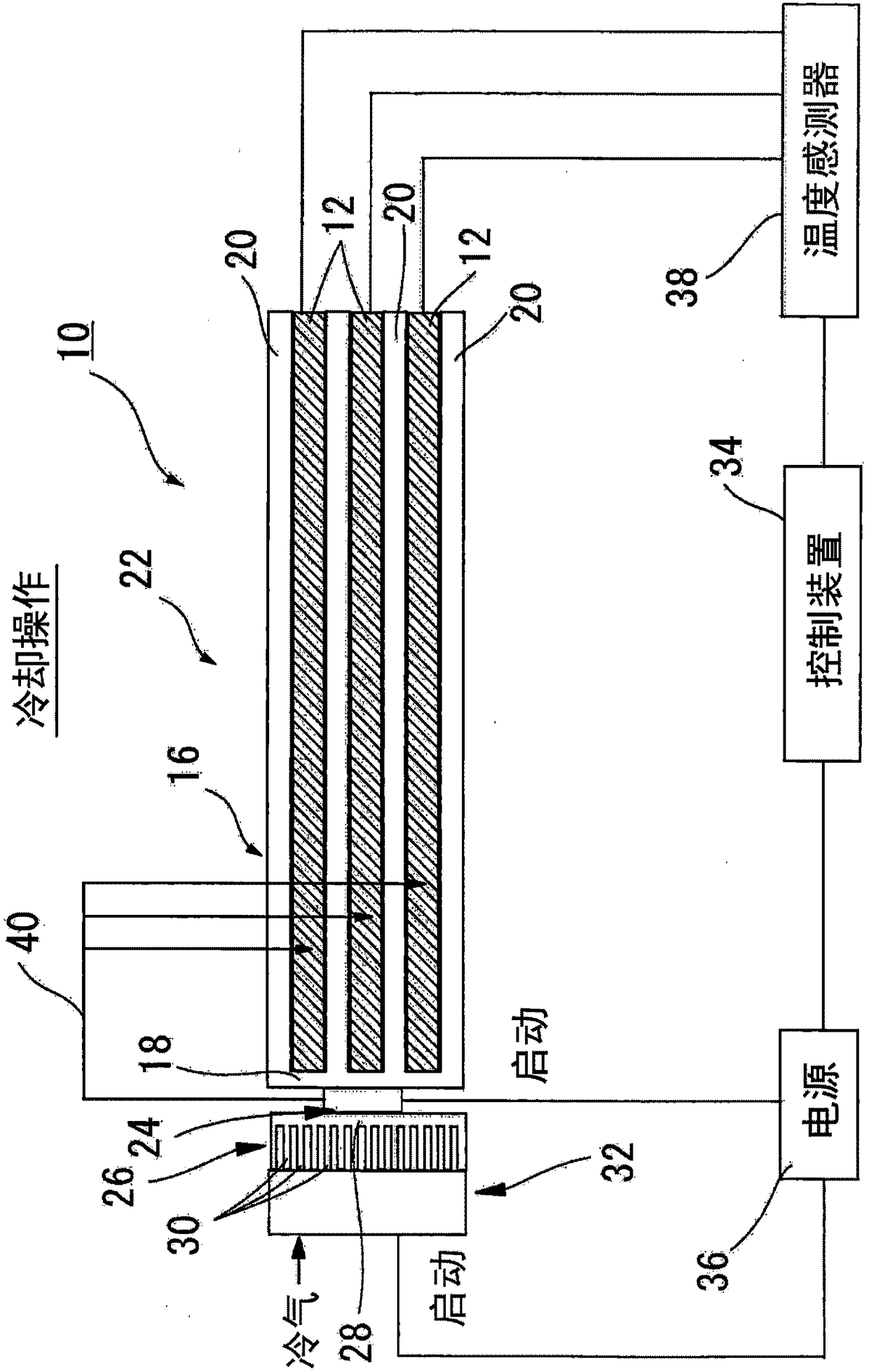

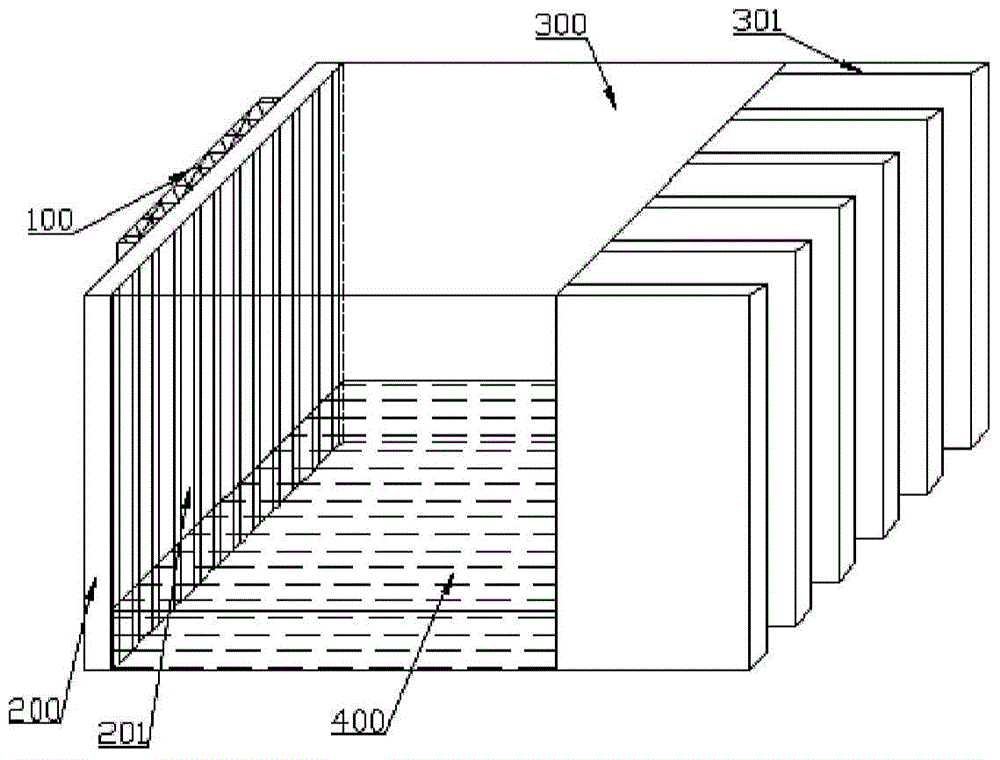

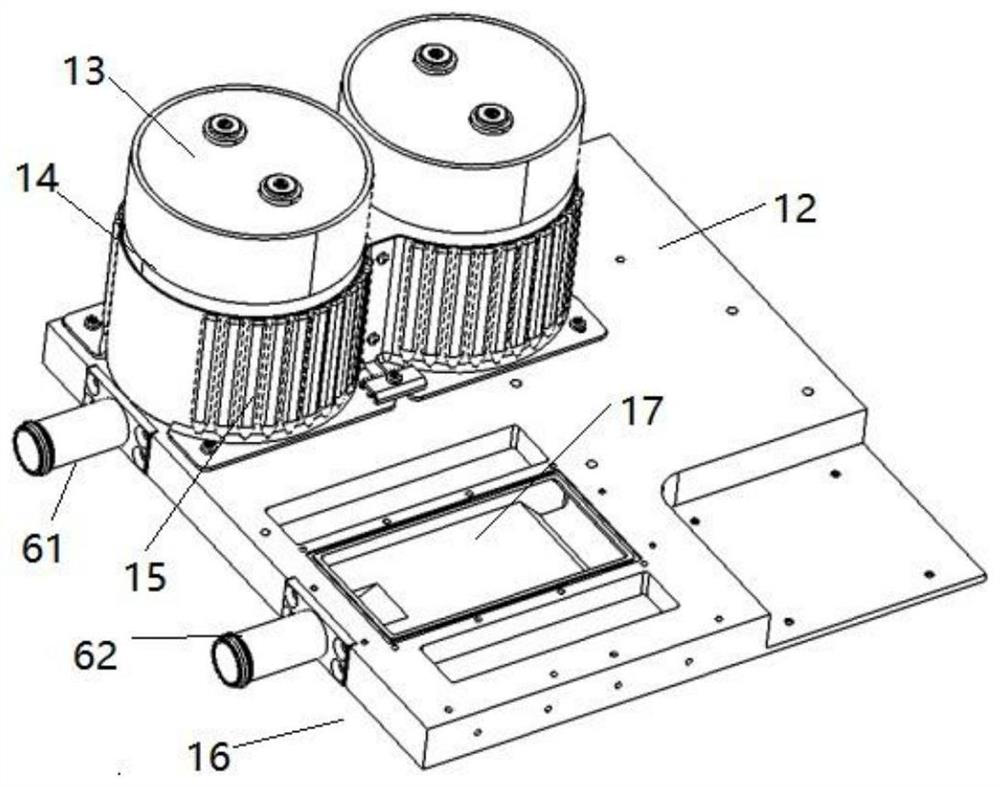

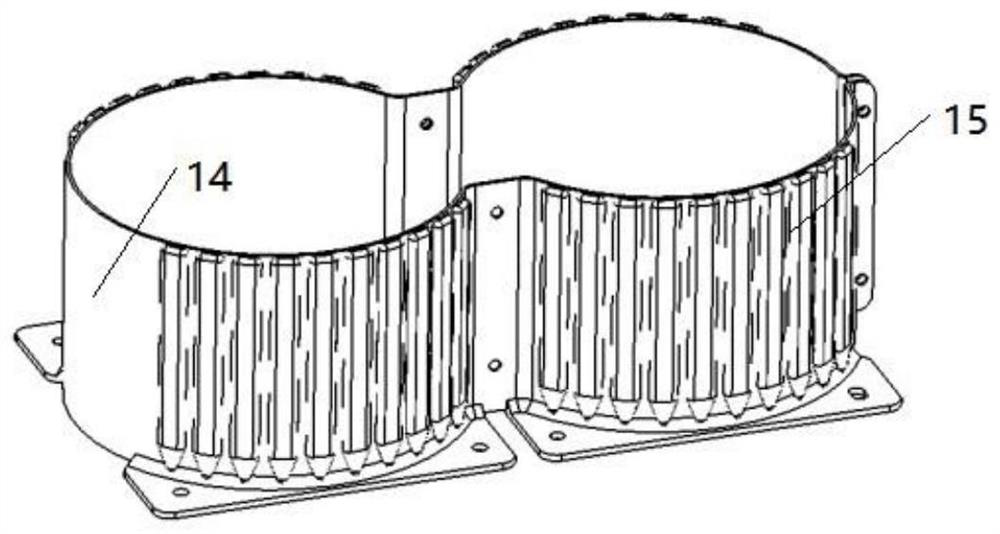

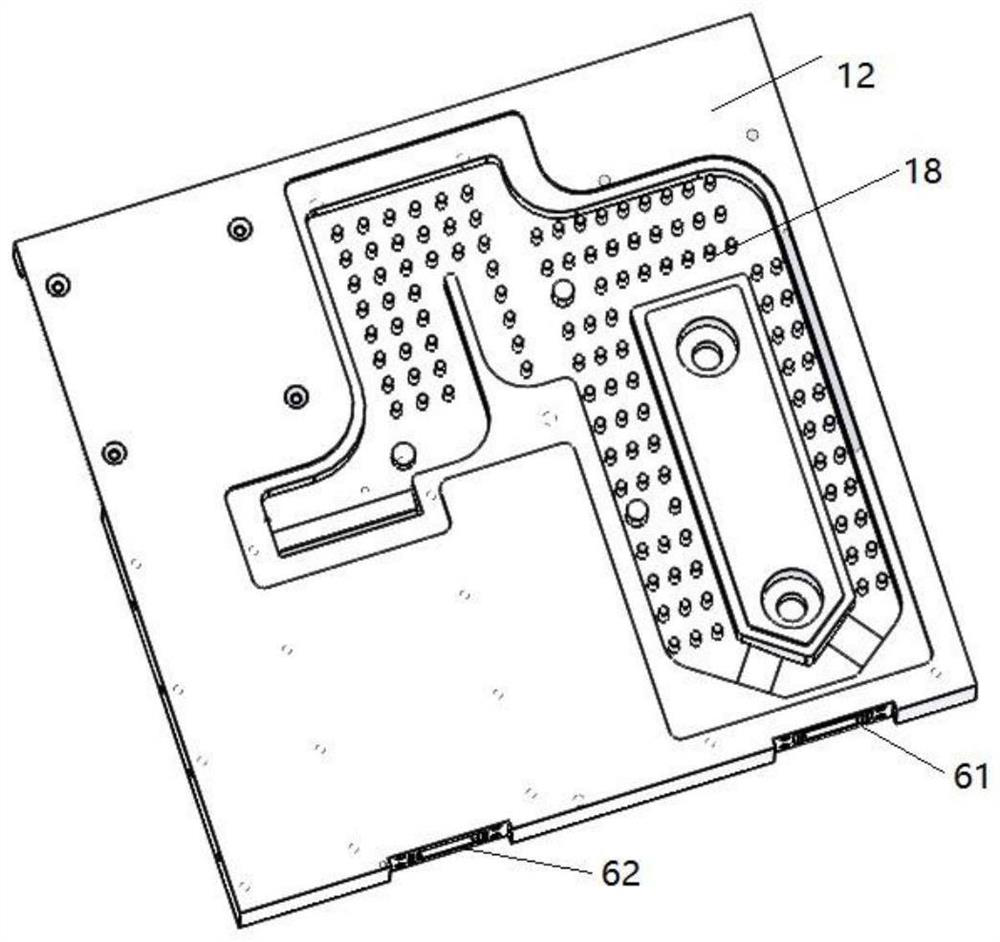

Battery pack temperature control/power feed system

ActiveCN108886189ALow temperature controlReduced parts countSecondary cellsTemperature controlMiniaturization

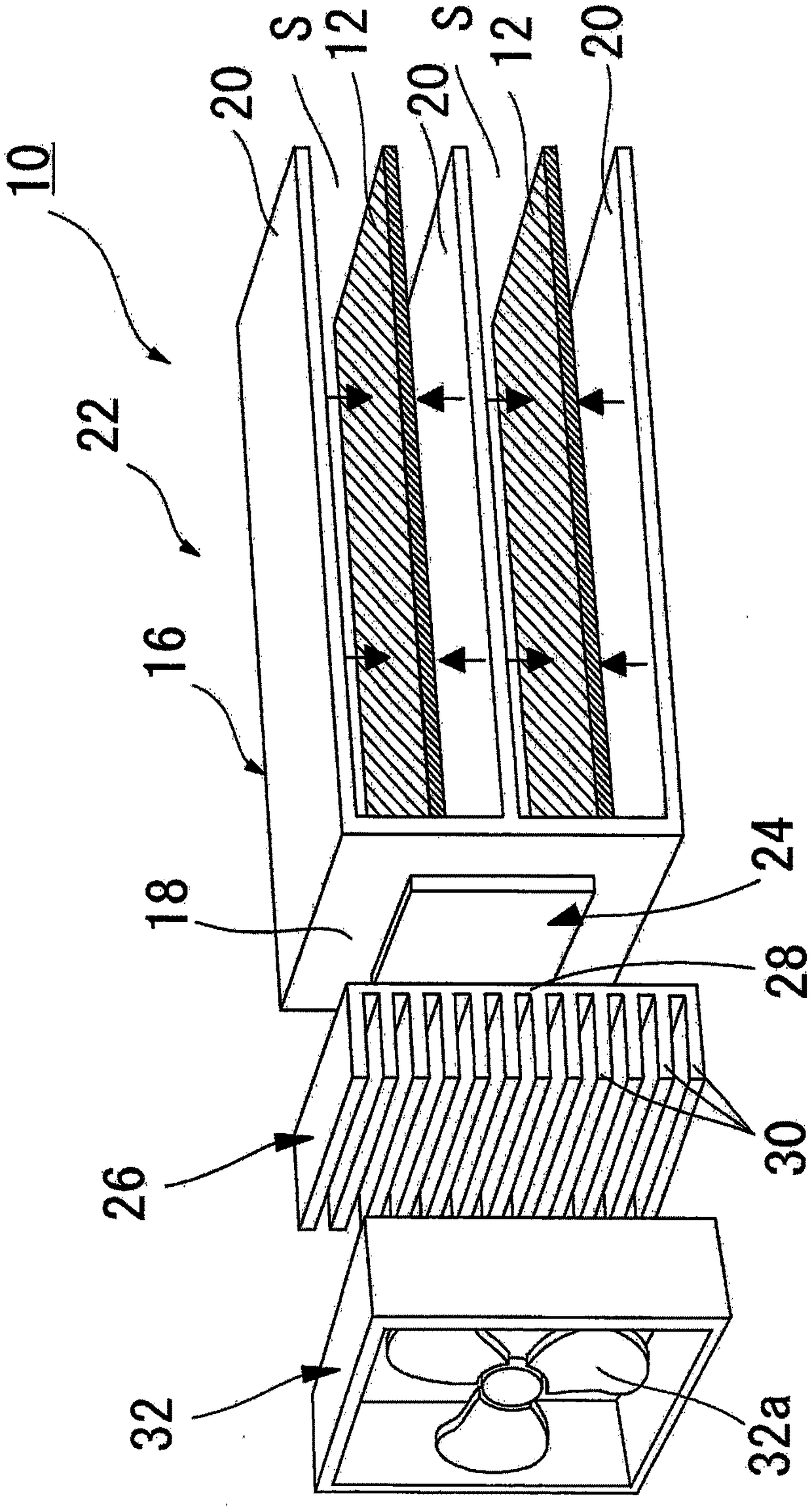

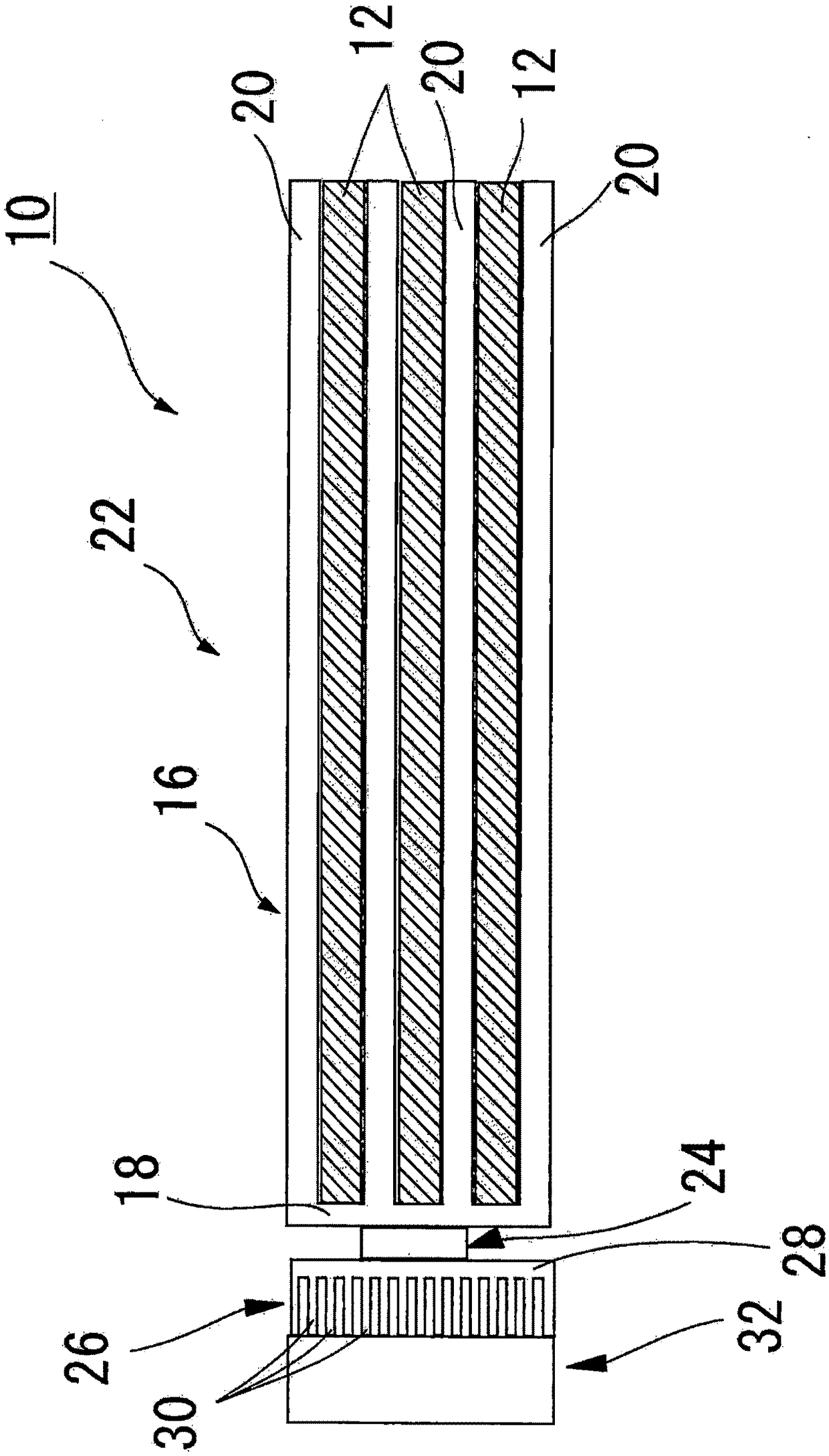

To provide a battery pack temperature control / power feed system in which a battery cell can be heated or cooled in a planar configuration, said system having highly exceptional heating efficiency andcooling efficiency, stable battery performance, a small number of components, and an uncomplicated structure, while making it possible to reduce the size and thickness as well as cost. A battery packtemperature control / power feed system 10 provided with: a battery part 22, which is formed by laminating a plurality of battery cells 12 and a plate-shaped vapor chamber 16 interposed between the battery cells 12; a thermoelectric element 24 positioned so as to adhere tightly to the end surface of one end of the vapor chamber 16 (lateral vapor chamber 18); and a heat sink part 26 equipped with a plurality of fins 30 that are formed extending at a predetermined spacing from each other, the end surface of the heat sink part 26 adhering tightly to the thermoelectric element 24; and a fan part 32positioned facing the fins 30 of the heat sink part 26.

Owner:LEADING EDGE ASSOC CO LTD +1

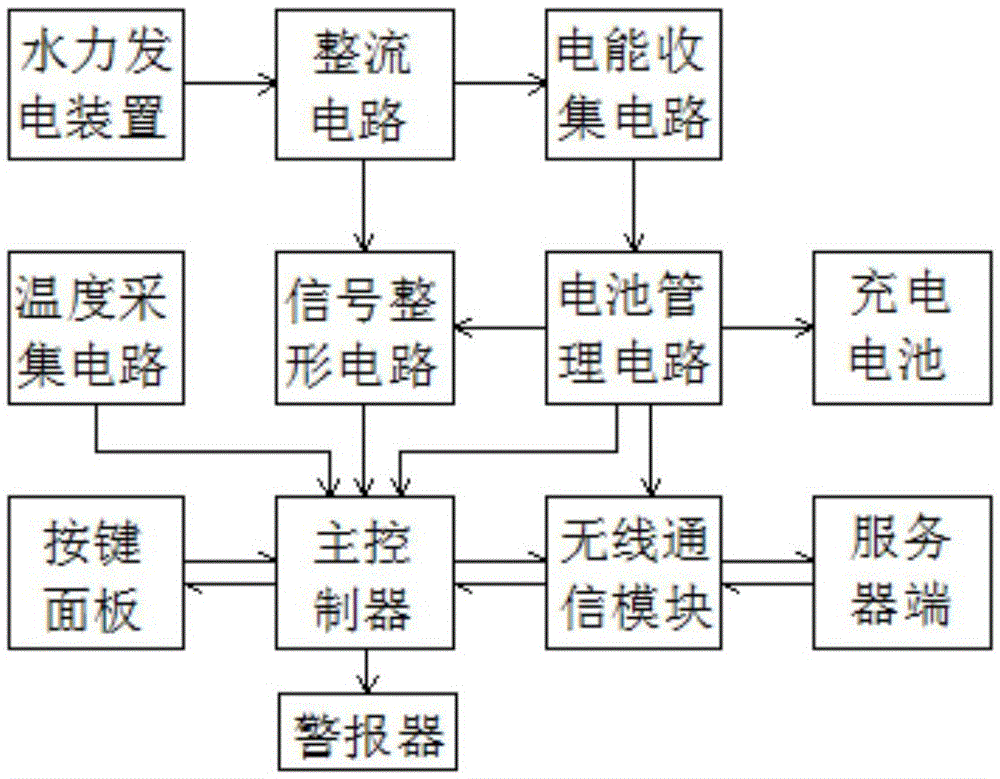

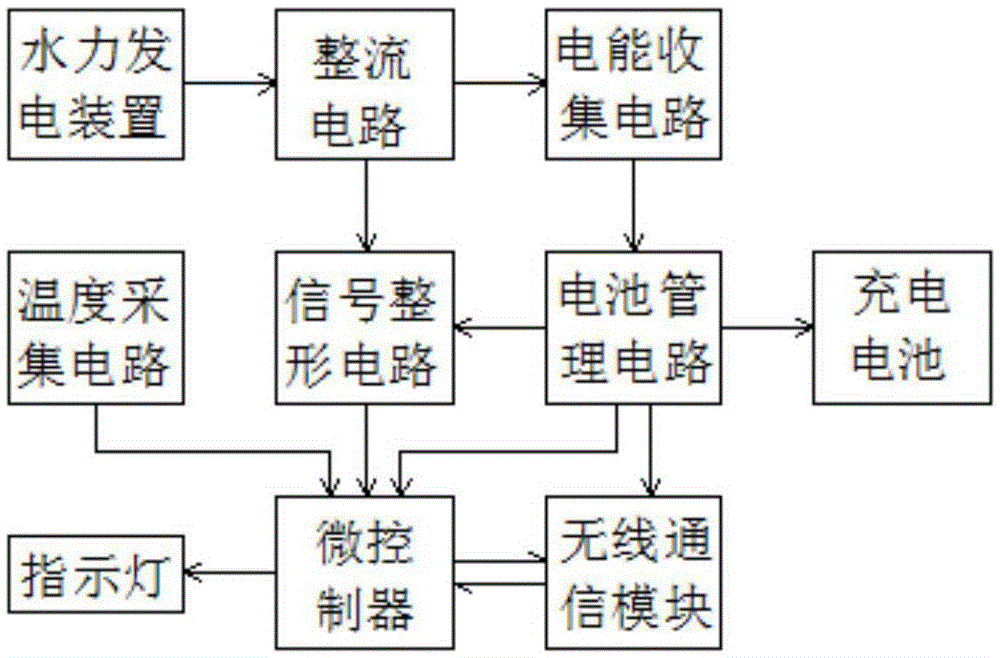

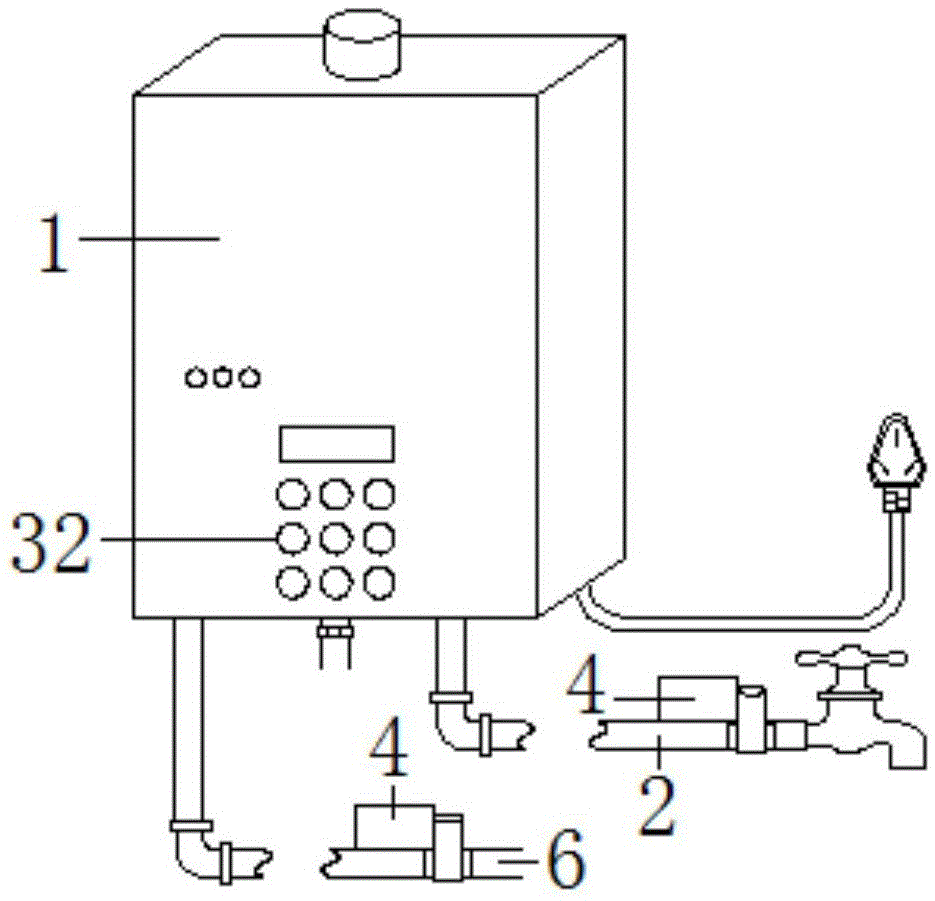

Controller for self-powered front-and-back-end temperature sensing gas water heater

InactiveCN105546833ASmart and convenient to useIntuitive Water InformationFluid heatersMachines/enginesMicrocontrollerWireless control

The invention discloses a controller for a self-powered front-and-back-end temperature sensing gas water heater which comprises a main controller arranged in a gas water heater and two monitors which are respectively arranged on a hot water pipe and a cold water pipe, wherein the main controller and the monitors respectively comprise a wireless communication module, a hydraulic electrogenerating device and a charging battery. According to the invention, water current energy is converted into electric energy by the hydraulic electrogenerating device and is stored in the charging battery, so as to achieve the technical effects of self power supply and energy storage; a microcontroller is used for analyzing water current flow rate information, a temperature sensor is used for acquiring the temperature information of a cold water terminal, a hot water initial end and a hot water terminal, wireless transmission of the wireless communication module realizes the technical effects of wireless control and information transmission, and the monitored information is transmitted to a server side to be stored as big data for research; and the overall design is practical and convenient and meets the future development trend of smart home.

Owner:SUZHOU CHUANGBICHENG ELECTRONICS TECH CO LTD

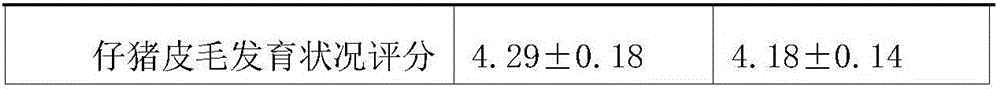

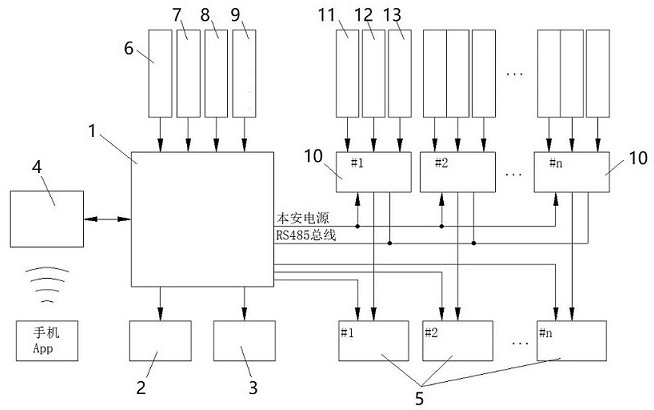

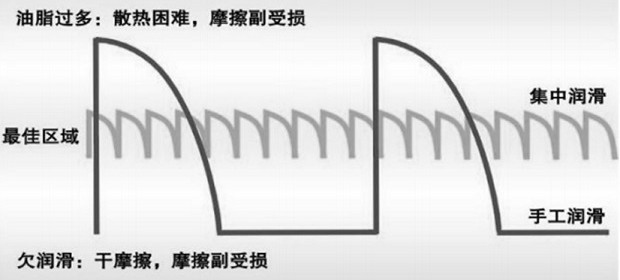

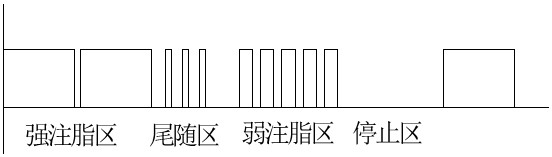

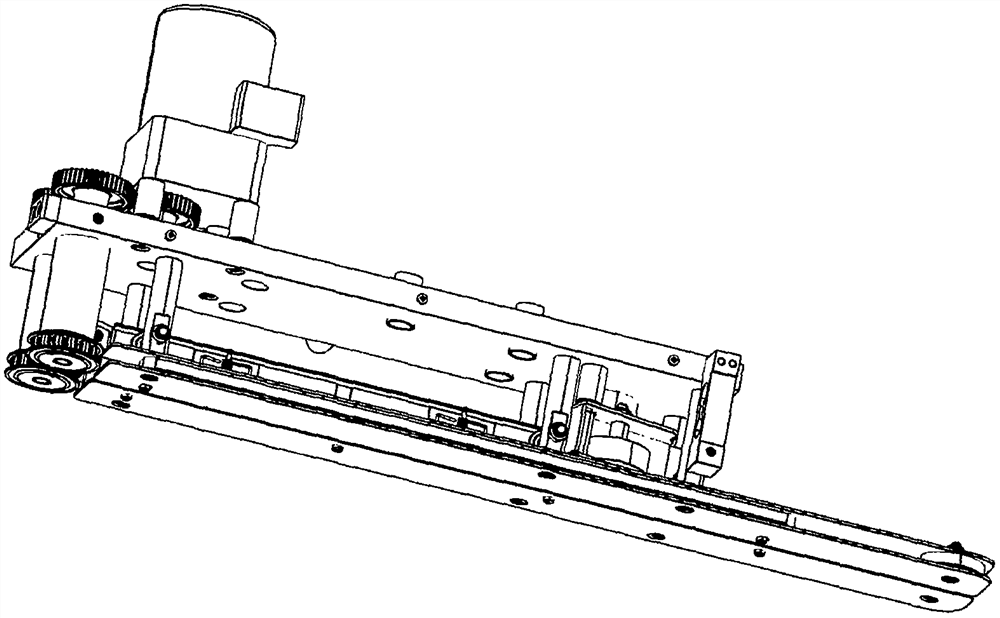

Intelligent lubricating system for coal mine belt conveyor and intelligent grease injection method

ActiveCN113074311ALow failure rateReduce labor intensityEngine temperatureConveyorsTemperature controlMonitoring system

The invention relates to an intelligent lubricating system for a coal mine belt conveyor and an intelligent grease injection method. A PLC control box is separately connected with a grease supplementing pump and a grease injection pump. The PLC control box is connected with a monitoring system upper computer, and the monitoring system upper computer is networked with an underground monitoring system. A temperature sensor, a vibration sensor and a blockage sensor form a group of sensor parts, and the temperature sensors and the vibration sensors are mounted at the machine head or the machine tail of the belt conveyor. An intelligent boxes are in one-to-one correspondence with oil path controllers, and each intelligent box is provided with a group of sensor parts. The intelligent grease injection mode of the intelligent boxes comprises a strong grease injection area, a weak grease injection area and a stop area. According to the intelligent lubricating system for the coal mine belt conveyor and the intelligent grease injection method, the intelligent lubricating design is adopted, the fault rate of a belt conveyor bearing is greatly reduced, the temperature of the bearing is controlled within a certain range, vibration and noise are obviously reduced, and the expected effect is achieved; and due to intelligent lubrication, the breakdown time of equipment is greatly shortened, the consumption of spare part materials is greatly reduced, meanwhile, the labor intensity of workers is reduced, and remarkable economic benefits and social benefits are obtained.

Owner:维克森(北京)科技有限公司

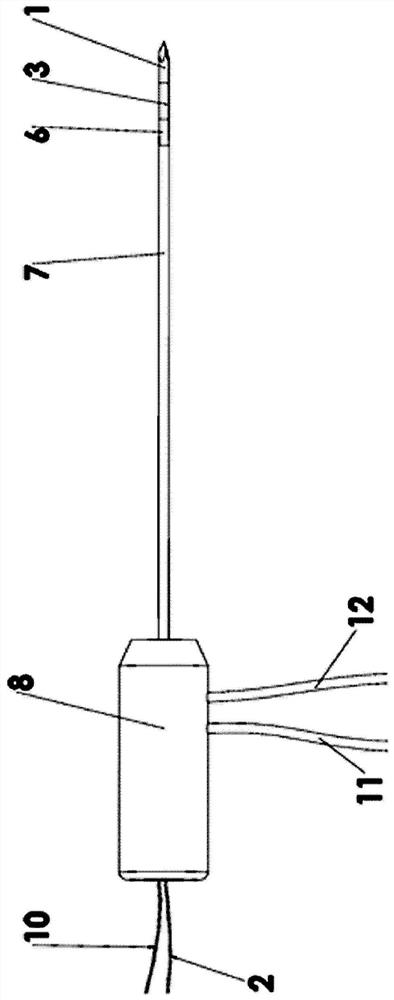

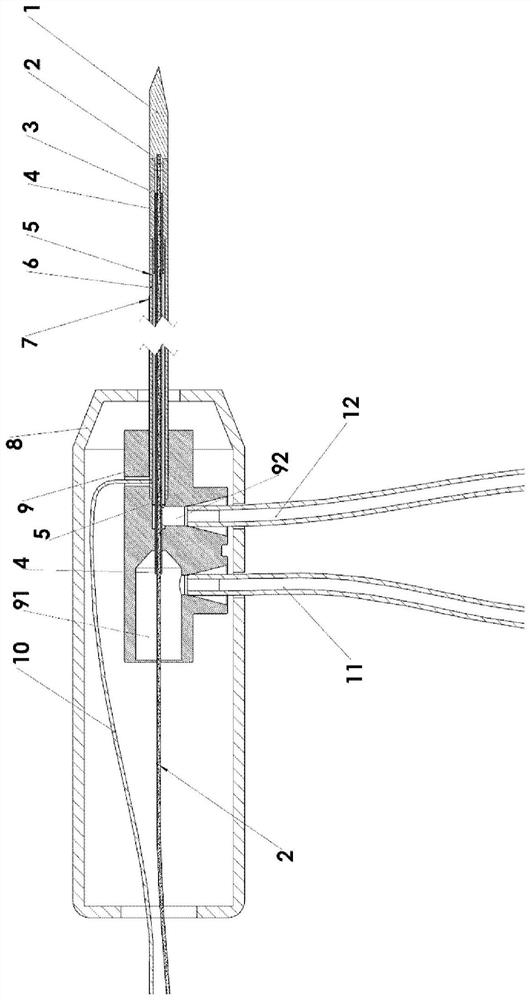

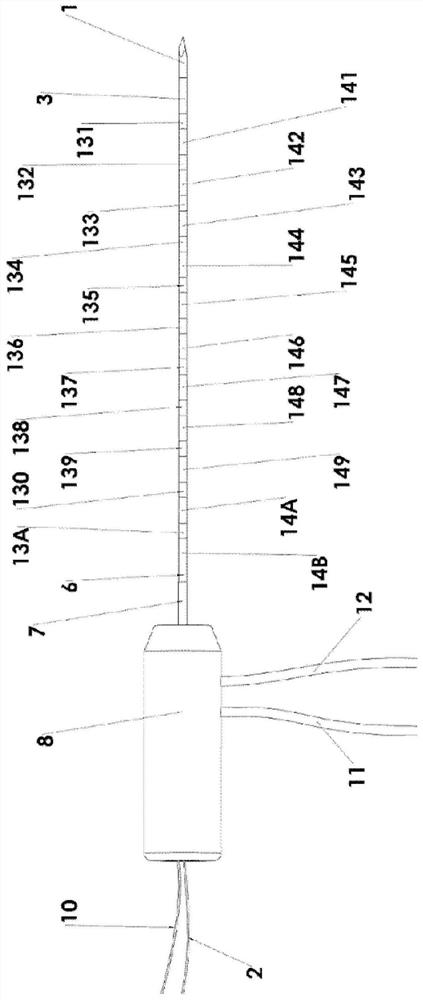

Multipole electroporation ablation needle and electroporation ablation equipment adopting multipole electroporation ablation needle

PendingCN113069201AReduce in quantityReduced collateral damageSurgical needlesSurgical instruments for heatingNuclear medicineMetal electrodes

The invention discloses a multipole electroporation ablation needle and electroporation ablation equipment adopting the multipole electroporation ablation needle. The multipole electroporation ablation needle comprises a needle rod, wherein the needle rod is provided with at least two metal electrodes; every two metal electrodes can be set into mutual electric insulation, and each metal electrode is provided with an electrode connecting conductor of which one end is connected with high-voltage output equipment and can be independently set into a positive electrode or a negative electrode at will; and in addition, the multipole electroporation ablation needle can carry out high-voltage discharging electroporation ablation between any two metal electrodes. The electroporation ablation needle can reduce insertion injuries, a focus on any position of the needle rod can be subjected to ablation under a situation that the depth of the electrode needle is not moved, surgical time is shortened, and the pain of a patient is lightened.

Owner:SINOSURGICAL HEALTHCARE TECH ZHEJIANG CO LTD

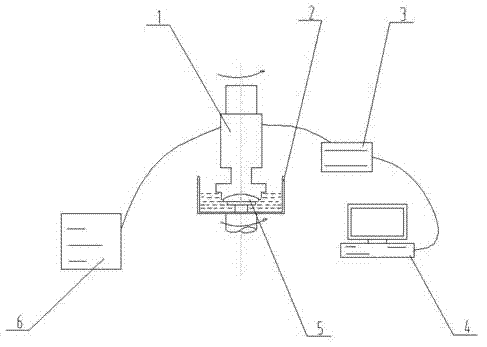

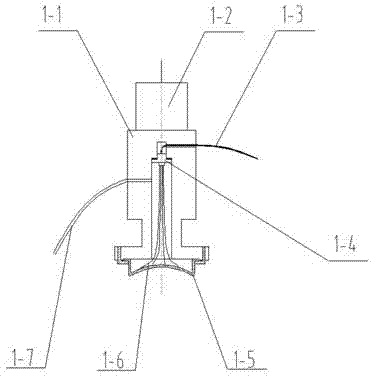

Airbag-type grinding-polishing device based on control corrosion

InactiveCN102785145AAchieve lappingReduce processing difficultyOptical surface grinding machinesAutomatic grinding controlMaterial removalEngineering

The invention provides an airbag-type grinding-polishing device based on control corrosion, which mainly solves the problems of the existing optical element and especially of the non-spherical optical element that machining cost is high and the machining efficiency is low. The airbag-type grinding-polishing device based on the corrosion control comprises an airbag-type polishing head which is connected with an air pump, the airbag-type polishing head comprises an airbag which is arranged on a polishing head main body, and the airbag-type polishing head also comprises a load bearing mechanism and a corrosive liquid storage groove, wherein one side of the load bearing mechanism is used for bearing a machined element. Due to the adoption of the airbag-type grinding-polishing device, the integral grinding and polishing rather than the ring-band trimming polishing of the non-spherical surface can be realized, and the machining difficulty of the non-spherical surface can be reduced to the machining level of a spherical surface; in addition, the chemical corrosion mechanism is introduced into the optical machining, and the acceleration of the corrosion speed is realized through the heating, so that the material removal level of the optical element can be remarkably improved, the milling grinding work of the large non-spherical degree can be completed, and the grinding and the polishing of the non-spherical surface can be realized on the same machine tool.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Process for producing chitosan

A process for preparing chitosan used in food, textile and medicine fields features use of shrimps shell and crab leg as raw materials, and includes such steps as selecting raw material, alkali and acid treating three times, and deacetylating while water washing twice for thoroughly removing protein, fat, colour and calcium to obtain macro-molecular high-viscosity chitosan. Its advantage is high yield up to 94.6%.

Owner:广东梅雁蓝藻有限公司

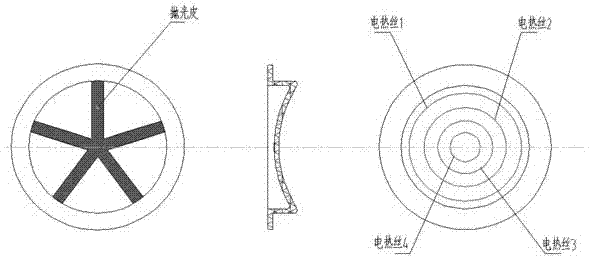

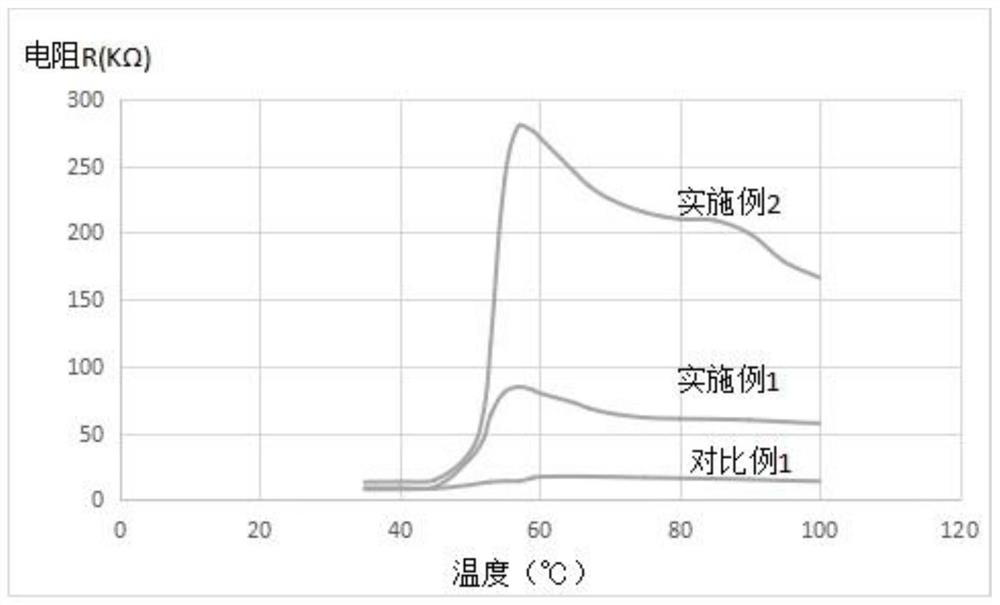

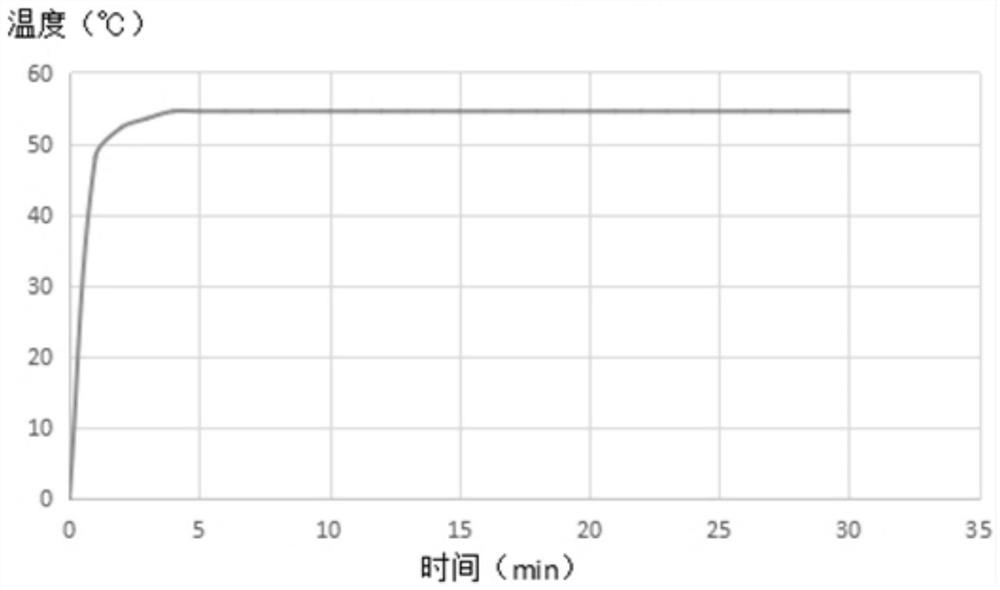

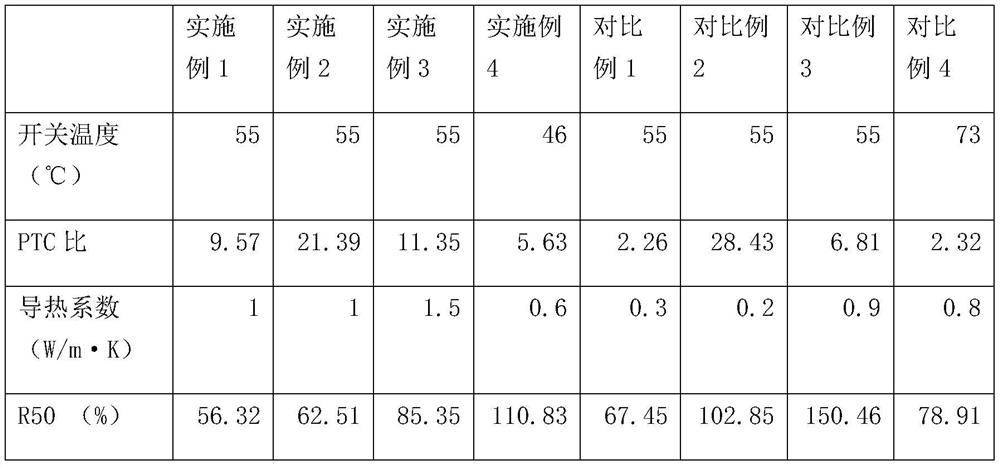

PTC (Positive Temperature Coefficient) heat-conducting ink and preparation method thereof

ActiveCN114231093AImprove thermal conductivityImprove temperature resistanceInksXylyleneEthylic acid

The invention relates to PTC (Positive Temperature Coefficient) heat-conducting ink and a preparation method thereof, and relates to the technical field of heat-conducting ink. The PTC heat-conducting ink comprises conductive particles, a heat-conducting filler A, a coupling agent and a solution, and the mass ratio of the conductive particles to the heat-conducting filler A to the coupling agent to the solution is (1-1.2): (0.5-2): (0.003-0.01): (4.5-6); the conductive particles comprise a conductive filler B, a semi-crystalline polymer and a solvent, the conductive filler B is one or a combination of more of carbon black, graphite, graphene, titanium diboride and metal micro powder, and the solvent is one or a combination of more of xylene, ethyl acetate, N, N-dimethylformamide and ethylene glycol butyl ether acetate; the heat-conducting filler A is one or a combination of more of aluminum oxide, zinc oxide, magnesium oxide, aluminum nitride and boron nitride; the solution comprises a binder and a solvent. The PTC heat-conducting ink disclosed by the invention is low in temperature control, good in heat conductivity, high in PTC ratio, stable in room-temperature resistance and fast in response; and the preparation method is simple to operate and can be suitable for large-scale production.

Owner:东莞市博恩复合材料有限公司

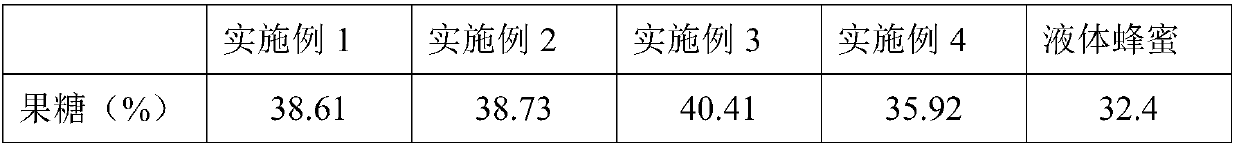

Honey candy and preparation method thereof

InactiveCN109717281ALower melting temperatureSolve the shapelessConfectionerySweetmeatsWhite oilDextrin

The invention relates to a honey candy. The honey candy comprises the following raw materials in parts by mass: 80-90% of honey, 1-5% of gelatin, 5-15% of resistant dextrin, 0.1-0.8% of an emulsifier,0.1-0.5% of white oil and the balance of water. The invention also relates to a preparation method of the honey candy. In the invention, the adding amount of the honey reaches 80-95%, the process issimple, and the content of honey in the prepared solidified honey candy is high. Meanwhile, the temperature is controlled to be low in the manufacturing process, and the original nutrient elements ofthe honey can be preserved.

Owner:SHANGHAI GUANSHENGYUAN FOOD

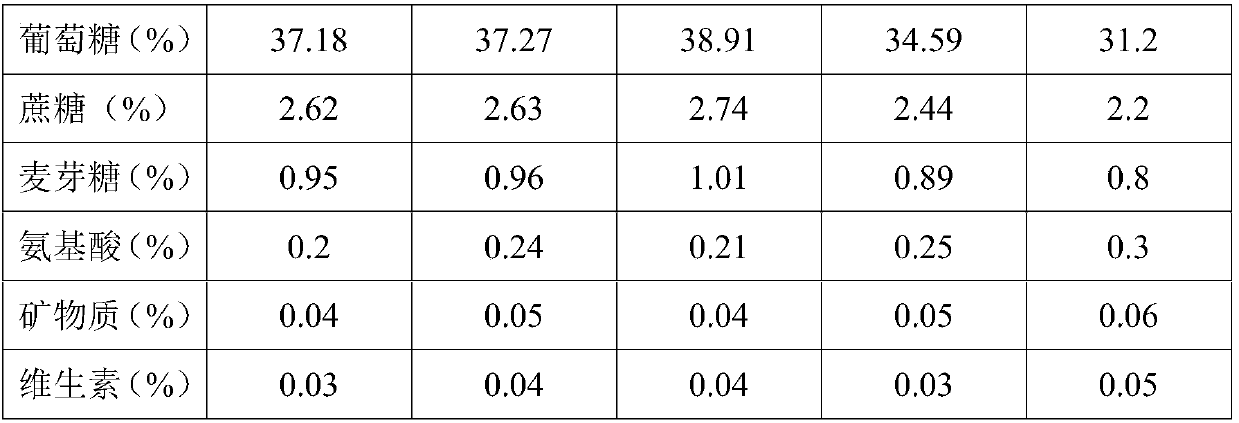

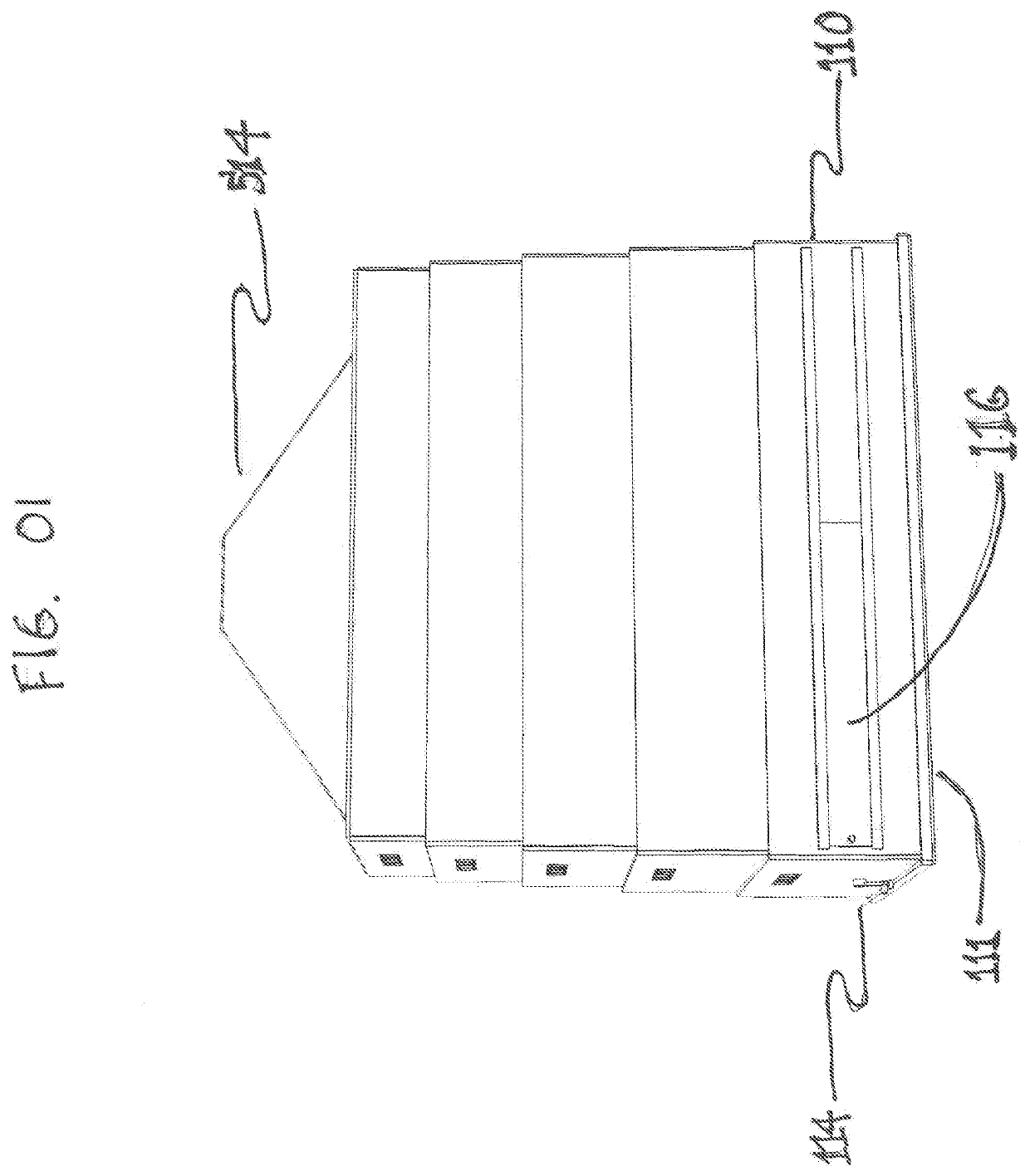

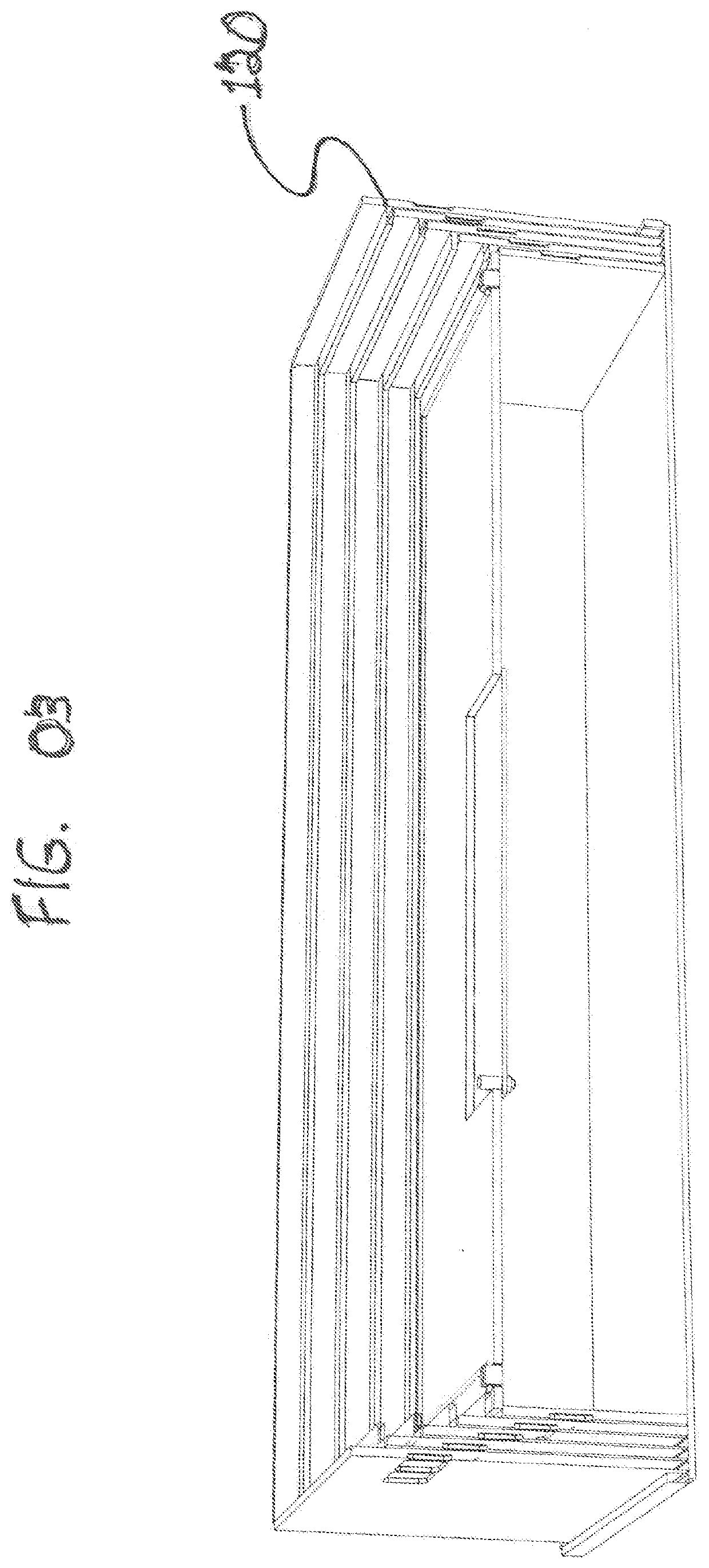

Portable three-in-one food griller, food smoker and fire pit

ActiveUS20200146505A1Low temperature controlEasy to transportDomestic stoves or rangesLighting and heating apparatusStructural engineeringSmoked food

The apparatus is a portable three-in-one food griller, food smoker and fire pit in which the sidewalls can nest into a compact self-contained unit for easy transportation. In one variation, there are five rectangles with four walls that encompass a void that can be configured and stacked for use as a grill, a smoker or a fire pit. The bottom rectangle can contain an adjustable air inlet door and a grate for holding a fire source. The top rectangle can contain an adjustable air outlet door in the ceiling with a thermometer. The second, third and forth rectangles can contain various configurations of grates for grilling food, smoking food or use as a fire pit. After use, rectangles two through five can fit and nest into the first rectangle (the base) and be latched to the floor section forming a self-enclosed compact and transportable rectangle box with a carrying handle.

Owner:BELL PAUL DAVID

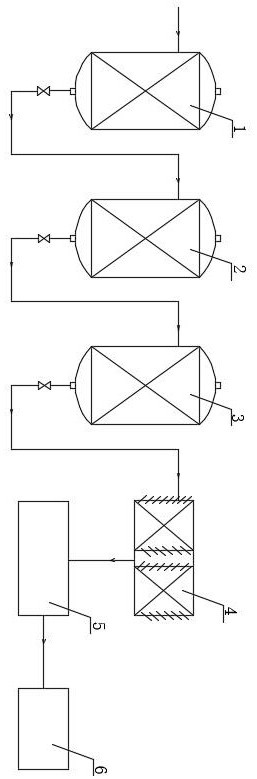

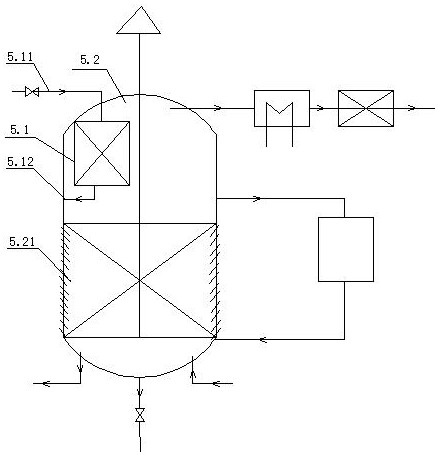

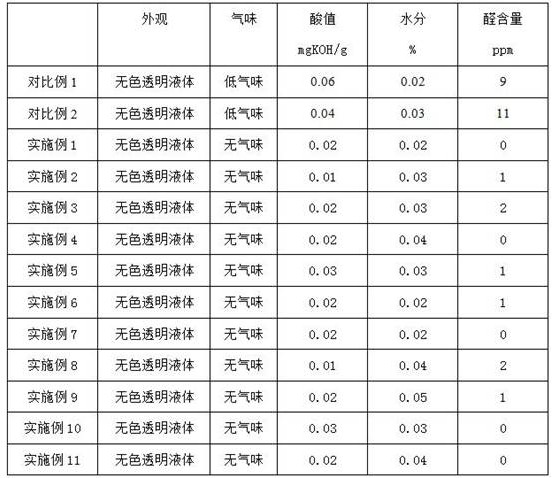

Preparation process of odorless phosphate flame retardant

PendingCN114478620AShort stayGood separation of impuritiesDispersed particle separationMolecular distillationActivated carbonUltrasonic oscillation

A preparation process of an odorless phosphate flame retardant belongs to the technical field of preparation of phosphate flame retardants, and comprises the following specific steps: sequentially performing the steps of crude product synthesis, alkali washing, water washing, activated carbon adsorption, ultrasonic oscillation, ultra-high-speed centrifugal molecular distillation and filter pressing to obtain the phosphate flame retardant. The method comprises the following steps: firstly, adsorbing aldehyde odor substances in a product by adopting activated carbon; secondly, an ultra-high-speed centrifugal molecular distillation device with a built-in ultrasonic oscillator is adopted to replace traditional dehydration equipment such as a kettle type or a film evaporator. The phosphate flame retardant prepared by the invention is colorless, transparent and odorless, the low acid value is less than or equal to 0.04 mgKOH / g, the low water content is less than or equal to 0.05%, and the low aldehyde content is less than or equal to 2ppm.

Owner:淮安晨化新材料有限公司

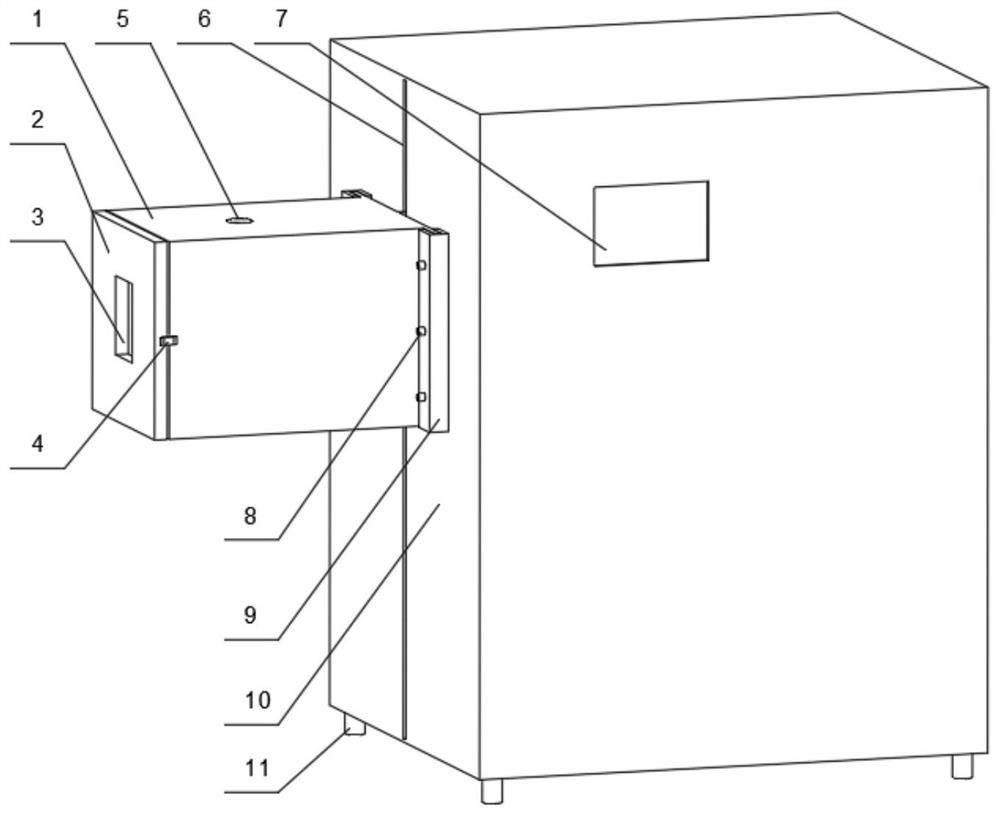

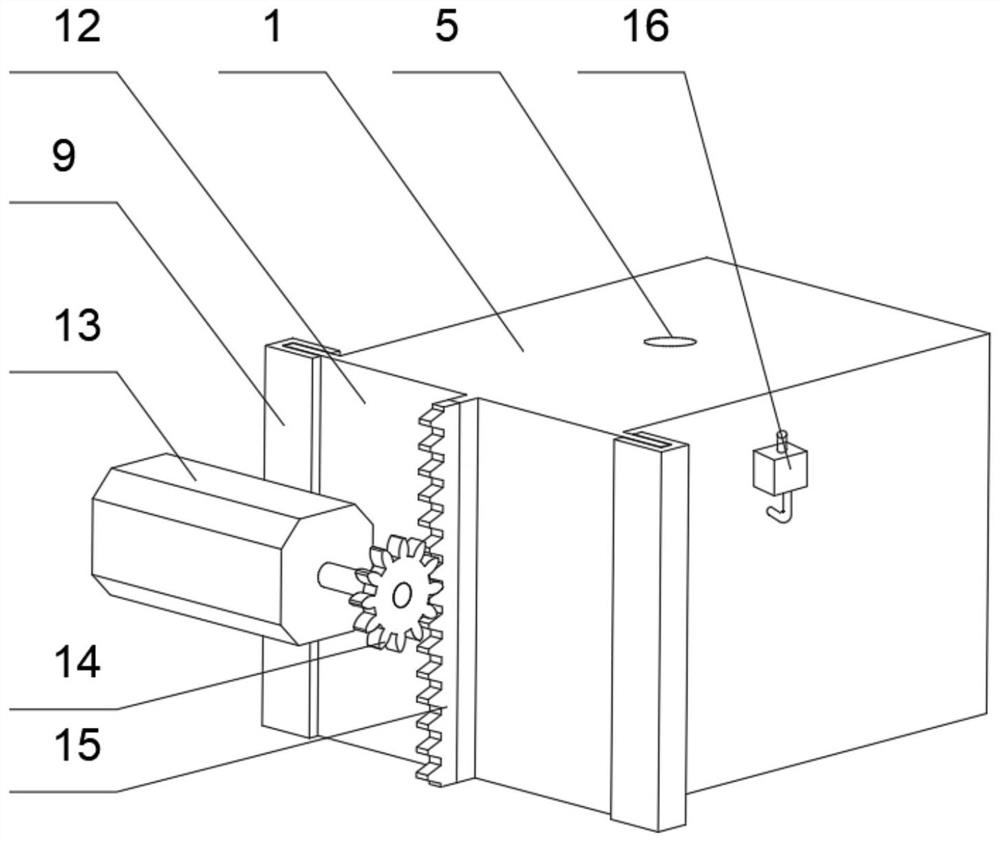

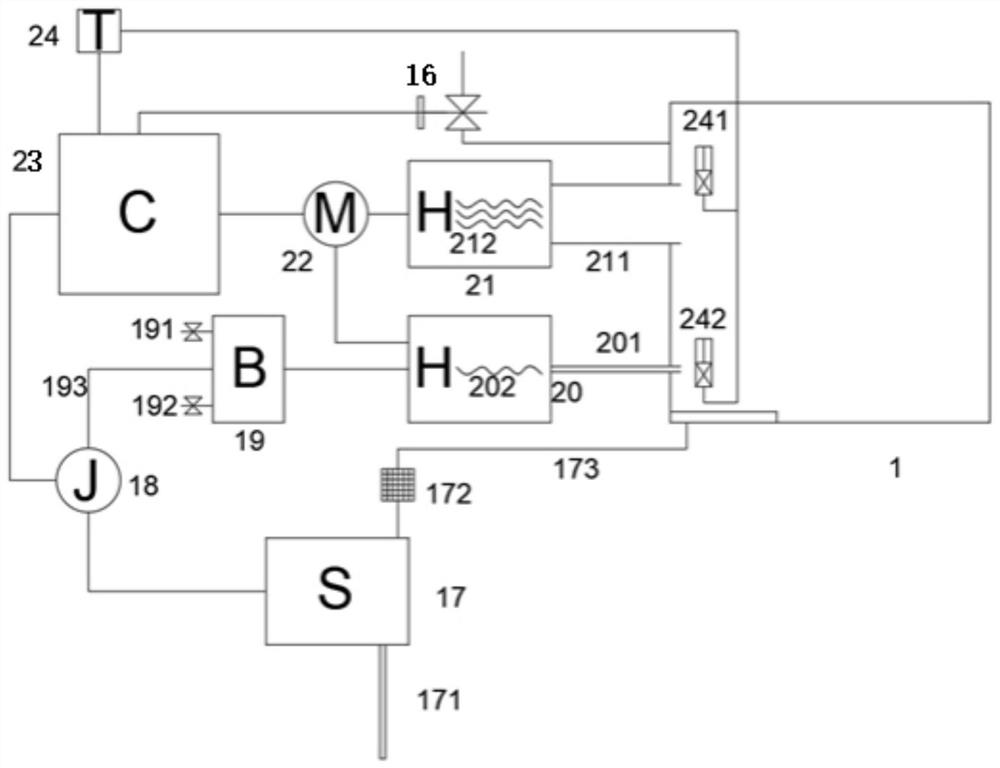

Controllable temperature and humidity environment box and control circuit

PendingCN113253780AControl high temperatureLow temperature controlSimultaneous control of multiple variablesPhysicsElectric machinery

The invention provides a controllable temperature and humidity environment box and a control circuit. The controllable temperature and humidity environment box comprises a main environment box body, a fixed supporting box body, a motor, a high-temperature control unit, a low-temperature control unit, a humidity control unit, a control instrument panel, a temperature and humidity instrument and a fan; one side of the main environment box body is connected with one side of the fixed supporting box body, the motor is installed on the inner wall of the side, close to the main environment box body, of the fixed supporting box body, and the fixed supporting box body is connected with the motor and adjusts the height through the motor; the high-temperature control unit is installed on the inner wall of the side, close to the fixed supporting box body, of the main environment box body, the low-temperature control unit is installed on the side, perpendicular to the fixed supporting box body, of the main environment box body, and the humidity control unit is installed in the fixed supporting box body. High temperature, low temperature and humidity of the main environment box body can be controlled in a high-precision and high-stability manner, the control panel can set program control related parameters, and temperature and humidity are increased and reduced at a certain speed as a cycle test working condition.

Owner:SHANGHAI JIAO TONG UNIV

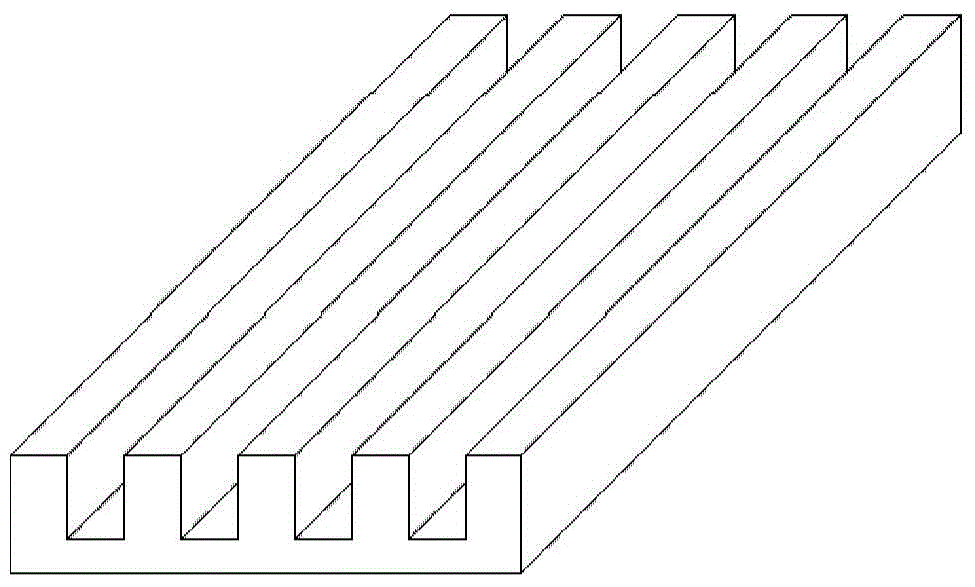

Micro-channel phase change heat device

ActiveCN103824825BIncrease heatImprove heat extraction capacitySemiconductor/solid-state device detailsSolid-state devicesShape-memory alloyEngineering

The invention provides a microchannel phase-change heat transfer device. The microchannel phase-change heat transfer device includes an outer heat dissipation body and a microchannel heat sink; the outer heat dissipation body is of a cylindrical structure of which one side is closed; the microchannel heat sink is made of a shape memory alloy material and is of a platy structure; the microchannel heat sink is embedded at one un-closed end of the cylindrical structure of the outer heat dissipation device, such that a closed cavity can be formed; and the closed cavity is filled with a liquid working medium; a surface of the microchannel heat sink, which faces the inner side of the closed cavity, is provided with a plurality of hundred-micron-level microchannels; trained micro ribs are located between every two adjacent microchannels; and the depth of the microchannels above a preset temperature is greater than the depth of the microchannels below the preset temperature. With the microchannel phase-change heat transfer device of the invention adopted, the heat removal ability of a microchannel structured surface can be improved, and the overheating degree of the microchannel structured surface can be reduced, and therefore, the temperature of a heat-emitting device can be controlled to be lower.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

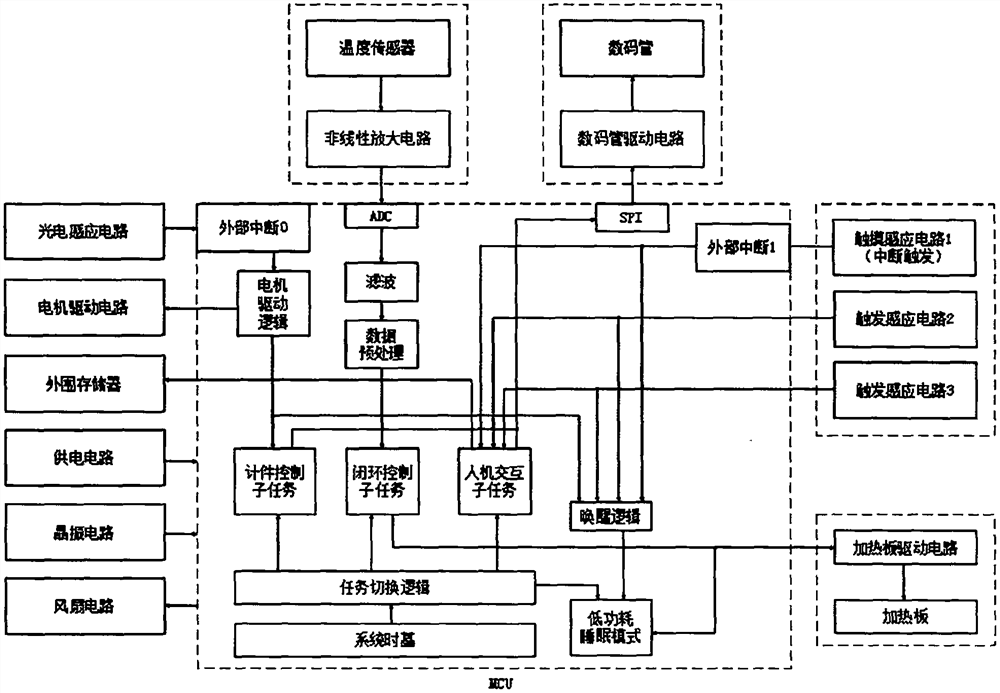

Control method of medical sterilization packaging bag sealing machine

ActiveCN112678275AReduce energy consumptionLow temperature controlWrapper twisting/gatheringElectric machineryBiomedical engineering

The invention discloses a control method of a medical sterilization packaging bag sealing machine. A closed-loop control subtask is executed according to parameters set in the last working process after power-on self-test, the remaining running time of a motor is refreshed when a photoelectric sensor detects that a sterilization packaging bag passes, meanwhile, a piece counting control task is hanged up , after the closed-loop control single cycle control is completed, skipping is carried out to execute a piece counting task once, then skipping is carried out to execute a closed-loop control subtask unconditionally, when the rising edge of a touch sensing circuit arrives, a heating plate and the motor are turned off, direct skipping is carried out to a human-computer interaction task, after the setting is completed through a human-computer interaction interface, skipping is carried out to the closed-loop control subtask, when the operation is not performed for more than 1200 seconds and no sterilized packaging bag passes through the sealing machine, skipping is carried out to a low-power-consumption sleep mode, and in the mode, once the sterilized packaging bag is detected to try to be in contact through the sealing machine or any touch key, awakening logic is executed, and skipping is carried out to execute a closed-loop control subtask.

Owner:宁波智能制造技术研究院有限公司

Capacitor multi-channel water-cooling rapid heat dissipation device

PendingCN114566379AIncrease cooling areaImprove export performanceCapacitorsReactive power compensationCapacitanceThermodynamics

The invention discloses a capacitor multi-channel water-cooling rapid heat dissipation device which comprises a multi-channel water-cooling plate, a capacitor is arranged on the top face of the multi-channel water-cooling plate, the periphery of the capacitor is fixed to the top face of the multi-channel water-cooling plate through bolts, and a heat pipe heat dissipation frame is arranged on the periphery of the capacitor in a surrounding mode. A plurality of heat dissipation pipes are evenly arranged on the periphery of the heat pipe heat dissipation frame, the heat dissipation pipes are parallel to the axial direction of the capacitor, and a water cooling mechanism is arranged in the multi-channel water cooling plate. Through a heat dissipation mode of combining metal heat conduction and water-cooling heat dissipation, the multi-channel water-cooling plate and the heat pipe heat dissipation frame both adopt independent mounting modules, so that the cost is lower, the production is more efficient and more convenient, the reliability is higher, and the maintenance is more convenient.

Owner:天津市云驱科技有限公司

Low-temperature coal carbonization manufacturing technique

ActiveCN1966612BGive full play to the maximum capacityIncrease productionIndirect heating destructive distillationTemperature controlCarbonization

The invention disclosed a low temperature coal dry distillating process which includes the following steps: choosing the material coal; the coal goes through coal cup, roller, and assistant coalbox to get into collecting umbrella and being separated; pre-heating the coal in the drying stage; dry-distillating at 100-550DEG C for about 4h, the temperature of heating region is 700-800DEG C to decrease the content of semi-coal to less than 6%; cooling the semi-coal through the water-cooling jacket box. The heat in the stove is all absorbed by the coal in the invention. It needs less time to dry distillate the coal and it's quite direct and simple. The invention adopts big containing space, the heating gas is provided uniformly to the bottom of the stove so the stove throughput is 3 times morethan the traditional stove; it can heat the material more uniformly and it need less temperature control; the tar yield has been increased and the recovery rate has been increased from less than 50% to 80% or more.

Owner:SHAANXI SHENMU SAN JIANG COAL CHEM

Method of treating hexane diacid preparation waste liquid

InactiveCN100410229CReduce energy consumptionCreate pollutionNature of treatment waterWater/sewage treatment by extractionLiquid wasteAcetic acid

This invention provides a treatment method for waste liquid from adipic acid production with simple process, good effect and low cost. Said method comprises: (1) adding waste liquid from adipic acid production and the extraction agent of ethyl acetate with the same volume as the waste liquid in an extraction equipment, vibrating and extracting, and standing to stratify the water and organic item, and flowing out the water and the remained extract containing three acids (adipic acid, glutaric acid and succinic acid), (2) repeating above steps to extract, (3) distilling the three acids-bearing extract no longer to be treated, evaporating the extraction agent of ethyl acetate, recycling, cooling the remainder and molding to obtain the three acids, and (3) adding alkaline substance to the water no longer to be treated, adjusting its pH within a range of 7-8, and discharging or taking it as liquid fertilizer. The approach is an advanced and mature technology with low energy consumption and no pollution. The three acid obtained have good quality and high efficiency.

Owner:李强国

Application of a traditional Chinese medicine composition in preparation of medicine for improving reproductive performance of sows

ActiveCN105816563BImprove farrowing performanceImprove immunityGranular deliveryImmunological disordersPig farmsAdditive ingredient

The invention relates to the technical field of traditional Chinese medicine, in particular to the application of a traditional Chinese medicine composition in the preparation of medicines for improving the reproductive performance of sows. into granules. The traditional Chinese medicine extract with multiple components is prepared in an appropriate proportion, has obvious synergistic effect, broadens the scope of use, has the effect of improving sows' farrowing performance and immunity, and obviously improves the health of sows. At the same time, it increases the lactation quantity and quality of sows, and simultaneously improves the growth and health of suckling piglets. Therefore, it is particularly suitable for the prevention and health care of sow diseases in large-scale pig farms and the guarantee of reproductive performance.

Owner:SHANDONG DEZHOU SHENNIU ANIMAL HEALTH PROD CO LTD

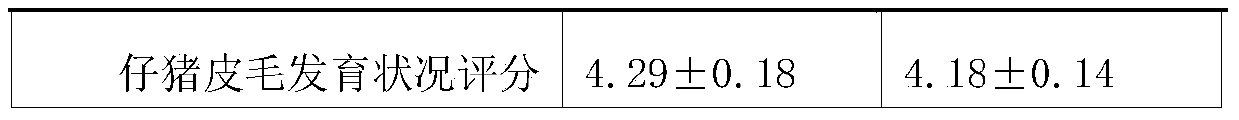

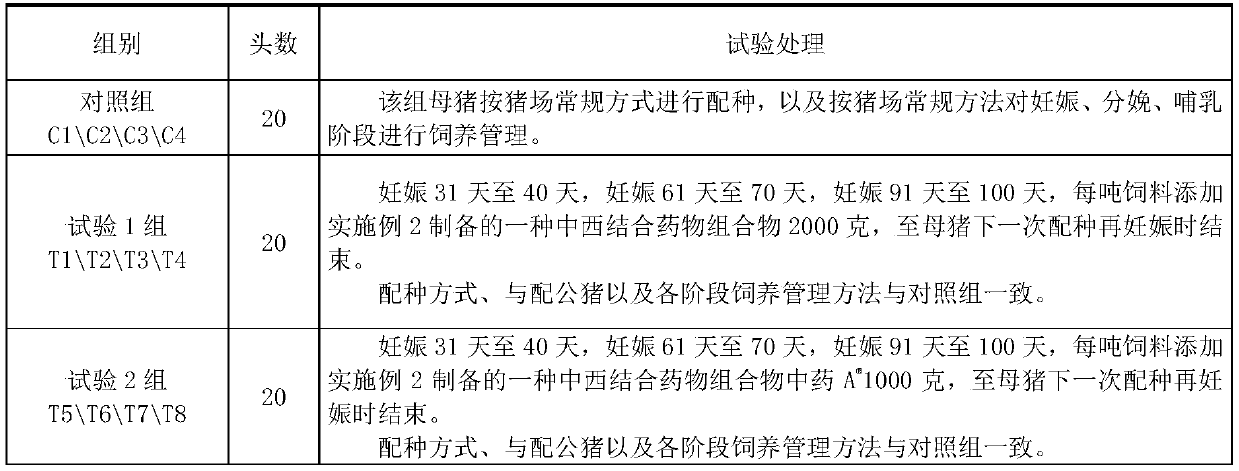

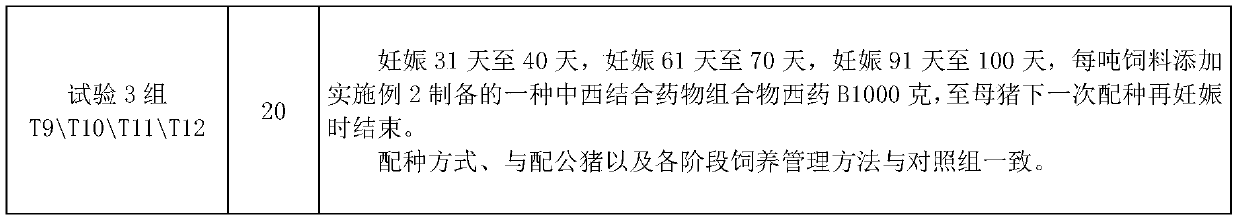

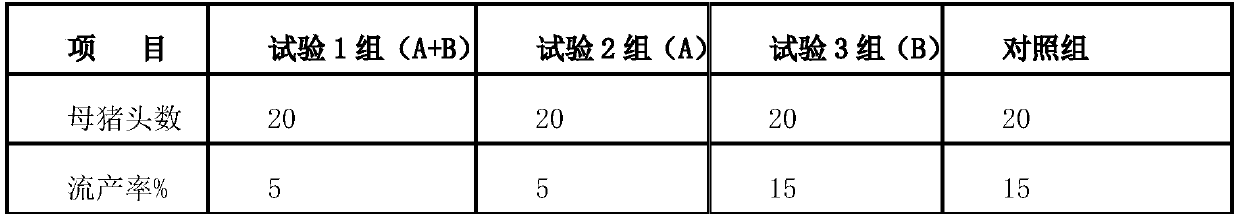

Traditional Chinese medicine and western medicine composition, preparation method and application thereof

InactiveCN109925376AImprove farrowing performanceImprove immunityAntibacterial agentsOrganic active ingredientsPig farmsWestern medicine

The invention relates to the technical field of application of traditional Chinese medicine and western medicine combination, in particular to a traditional Chinese medicine and western medicine composition, a preparation method and application thereof. The traditional Chinese medicine and western medicine composition is composed of a traditional Chinese medicine portion A and a western medicine portion B. The traditional Chinese medicine portion A is composed of, by weight parts, 30-50 parts of herba epimedii, 30-50 parts of radix astragali, 10-20 parts of radix sophorae flavescentis, 10-20 parts of licorice root, 20-30 parts of radix isatidis, 10-15 parts of indigowoad leaves, and 5-20 parts of heartleaf houttuynia herb. The western medicine portion B is composed of, by weight parts, 10-40 parts of tilmicosin, 30-70 parts of monostearin, 0-50 parts of hardened oil, 0-10 parts of HPMCP and 0-10 parts of PVAP. The effect of combination of the traditional Chinese medicines and western medicines (A+B) is obviously superior to the use of traditional Chinese medicine portion A or western medicine portion B alone, especially in the health care of large-scale pig farms, and the promotionand application and industrialization prospects of large-scale pig farms are very broad.

Owner:SHANDONG DEZHOU SHENNIU ANIMAL HEALTH PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com