PTC (Positive Temperature Coefficient) heat-conducting ink and preparation method thereof

A technology of heat-conducting ink and ink, which is applied in ink, household utensils, applications, etc., can solve the problem of high energy consumption in the process, and achieve the effects of uniform heat distribution, simple operation of the preparation method, and fast heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of PTC heat-conducting ink of the present invention may further comprise the steps:

[0034] (1) Mix and stir the conductive filler B, semi-crystalline polymer and solvent, dry and grind to obtain conductive particles with PTC effect.

[0035] The conductive filler B is a combination of one or more of carbon black, graphite, graphene, titanium diboride, and metal micropowder; the semi-crystalline polymer is fatty alcohol, phase change wax, polyethylene wax, mustard A combination of one or more of acid amides; the solvent is a combination of one or more of xylene, ethyl acetate, N,N-dimethylformamide, and ethylene glycol butyl ether acetate.

[0036] The conductive filler B, the semi-crystalline polymer, and the solvent are mixed in a mass ratio of 1:1.2-1.5:12-15.

[0037] Specifically, weigh a certain mass of conductive filler B, semi-crystalline polymer, and solvent according to the mass ratio, mix and stir for 1 hour, then dry and grind to obt...

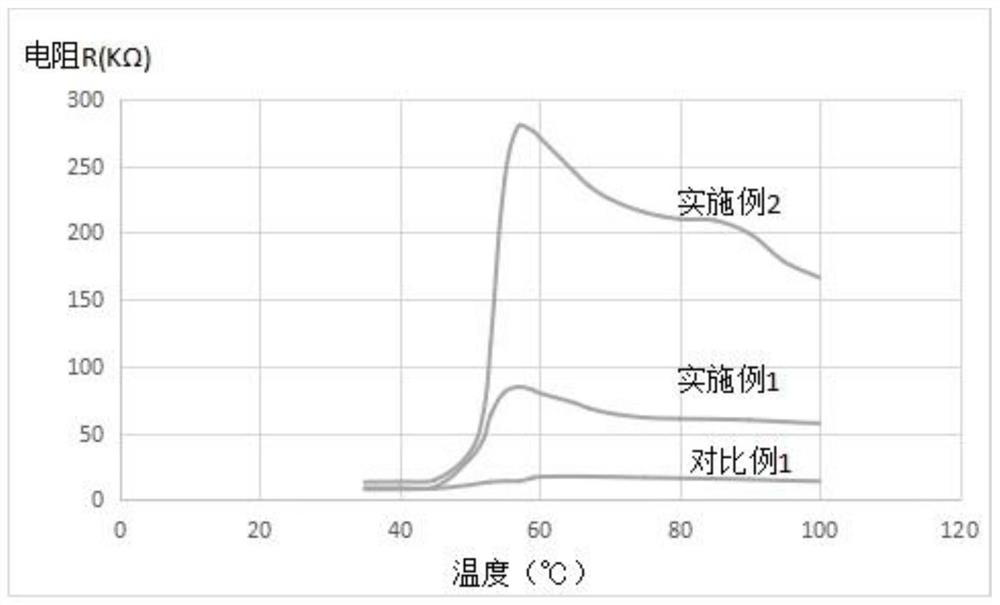

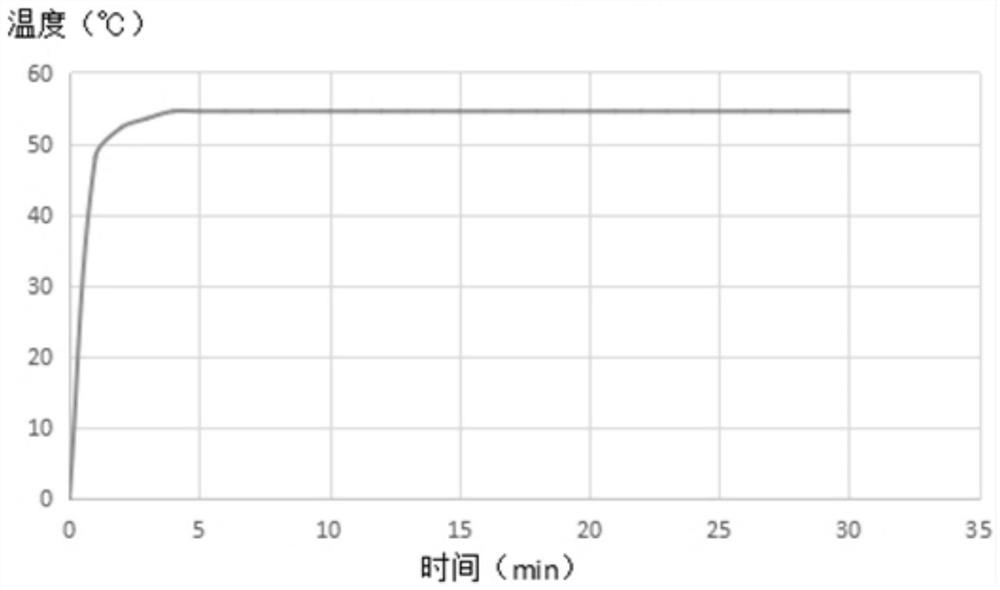

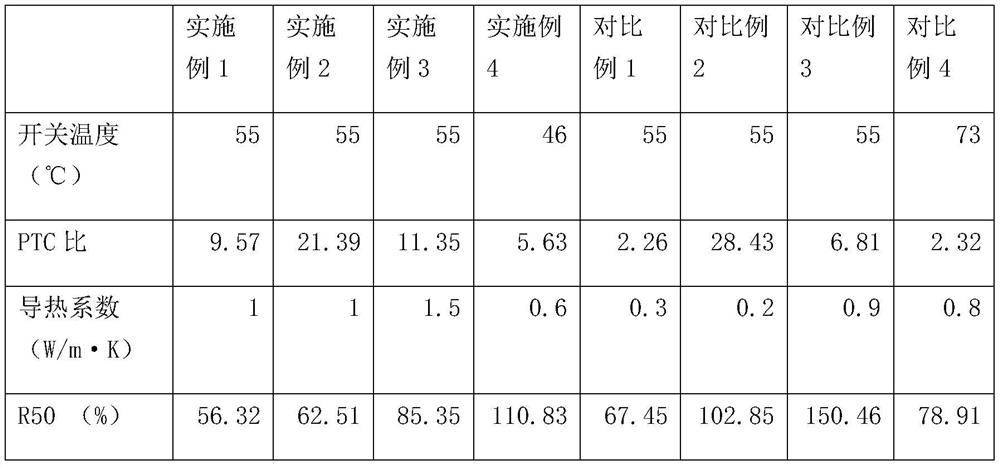

Embodiment 1

[0058] Take 60g of phase-change wax (melting point 60°C) and dissolve it in 600g of xylene, add 50g of carbon black, stir with a mixer for 1 hour, dry the solvent, and grind to obtain PTC1.2-60 (PTC conductive particles, phase-change wax and carbon black The mass ratio is 1.2, and the melting point of the phase change wax is 60°C).

[0059] Get 30g of acrylic resin, dissolve in 30g of dimethylbenzene, fully stir, mix evenly, obtain clear acrylic resin solution;

[0060] Add 10g of PTC1.2-60, 5g of alumina, and 0.1g of KH550 to the above solution, disperse at high speed, stir evenly, grind thoroughly with a three-roll mill, and then filter with an 80-mesh filter bag to obtain thermally conductive PTC ink.

Embodiment 2

[0062] Take 60g of phase-change wax (melting point 60°C) and dissolve it in 600g of xylene, add 40g of carbon black, stir with a mixer for 1 hour, dry the solvent, and grind to obtain PTC1.5-60 (PTC conductive particles, phase-change wax and carbon black The mass ratio is 1.5, and the melting point of the phase change wax is 60°C).

[0063] Get 30g of acrylic resin, dissolve in 30g of dimethylbenzene, fully stir, mix evenly, obtain clear acrylic resin solution;

[0064] Add 10g of PTC1.5-60, 5g of alumina, and 0.1g of KH550 to the above solution, disperse at high speed, stir evenly, fully grind with a three-roll mill, and then filter with an 80-mesh filter bag to obtain thermally conductive PTC ink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com