Patents

Literature

509 results about "Titanium boride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Titanium diboride (TiB2) is an extremely hard ceramic which has excellent heat conductivity, oxidation stability and resistance to mechanical erosion. TiB2 is also a reasonable electrical conductor, so it can be used as a cathode material in aluminium smelting and can be shaped by electrical discharge machining.

Short fiber-particle synergetically-reinforced copper-based composite material and preparation method thereof

The invention relates to a copper-based composite material, and particularly relates to a short fiber-particle synergetically-reinforced copper-based composite material which is prepared through powder metallurgy. Short fibers and particles are used as reinforced phases, the content of the short fiber is 0.1-0.1 wt%, and the content of reinforcement particles is 0.1-10 wt%. The short fibers can be carbon nanotubes, carbon nanofibers, ceramic short fibers, and the like, and the particles used as reinforced phases can be aluminum oxide, zirconium oxide, magnesium oxide, titanium dioxide, silicon carbide, titanium carbide, tungsten carbide, silicon nitride, aluminum nitride, titanium nitride, titanium diboride, Ti3SiC2, and the like. The composite material is prepared through the steps of mixing, forming, sintering and processing, and the room temperature and the high temperature strength of the composite material can be increased by more than 3 times in comparison with those of pure copper; the electrical conductivity of the composite material can reach more than 80% of that of pure copper; the thermal conductivity of the composite material can reach more than 70% of that of pure copper; the coefficient of friction of the composite material can be reduced to be below 70% of that of pure copper; and the wear rate of the composite material can be reduced to be below 50% of that of pure copper.

Owner:UNIV OF SCI & TECH BEIJING

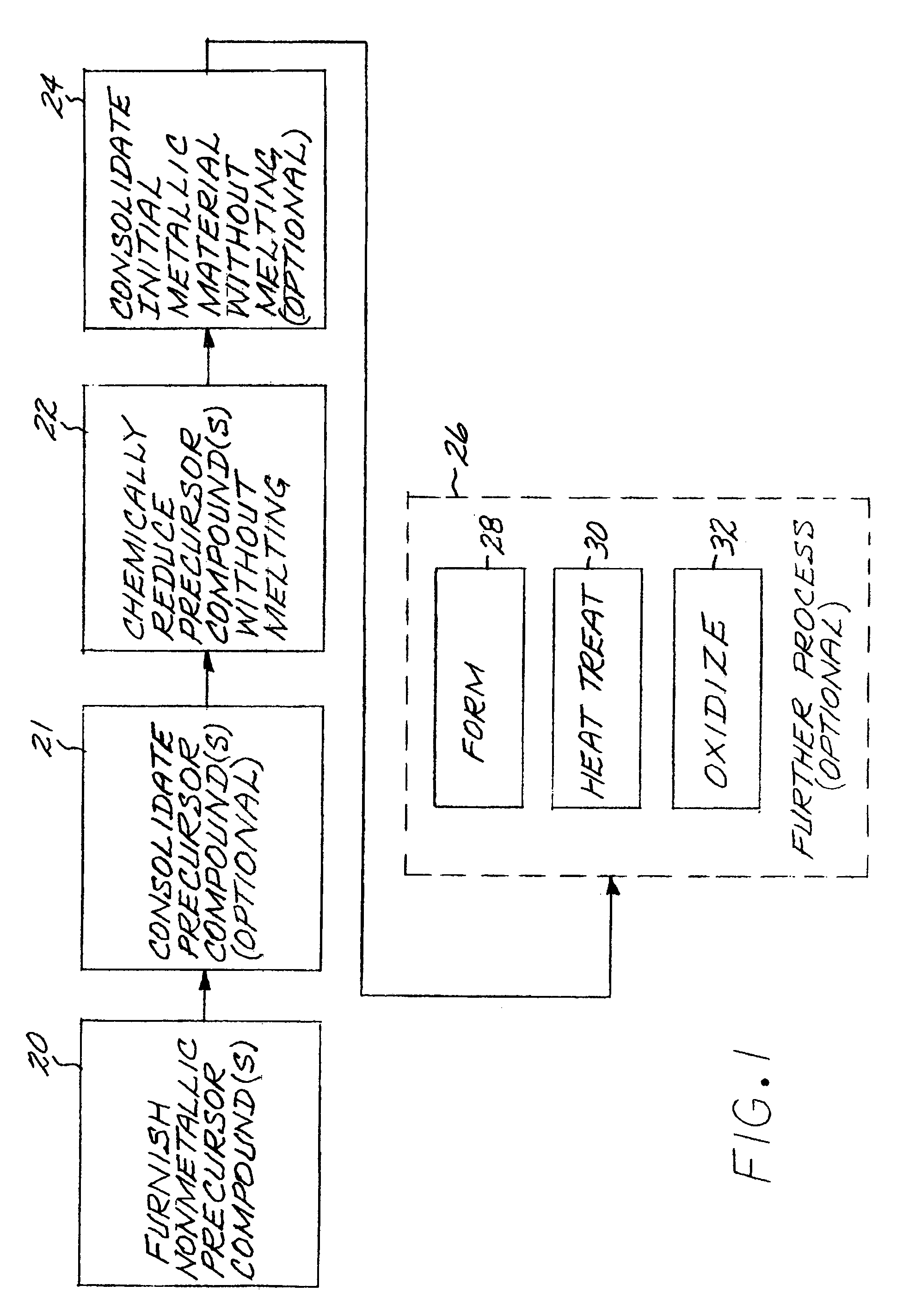

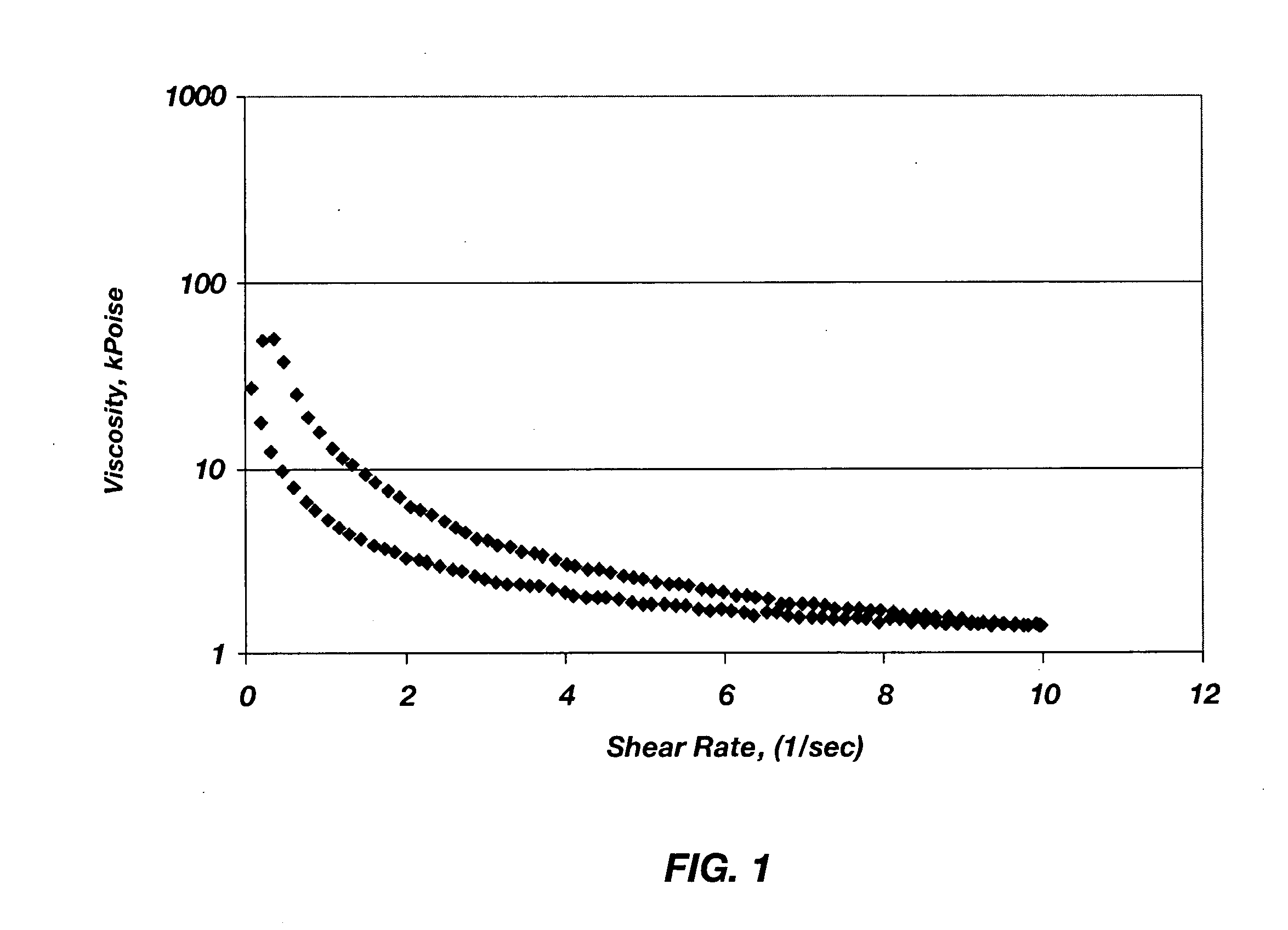

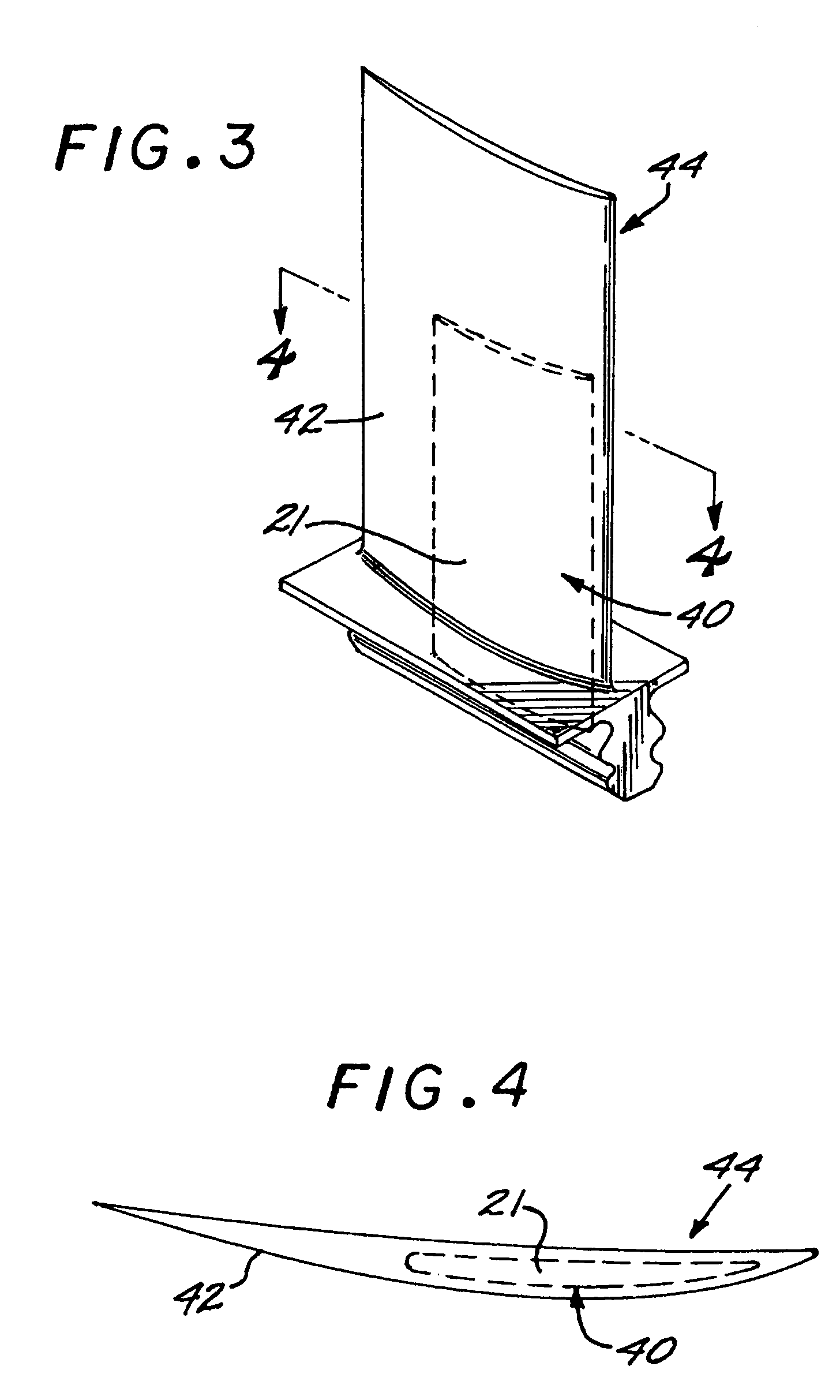

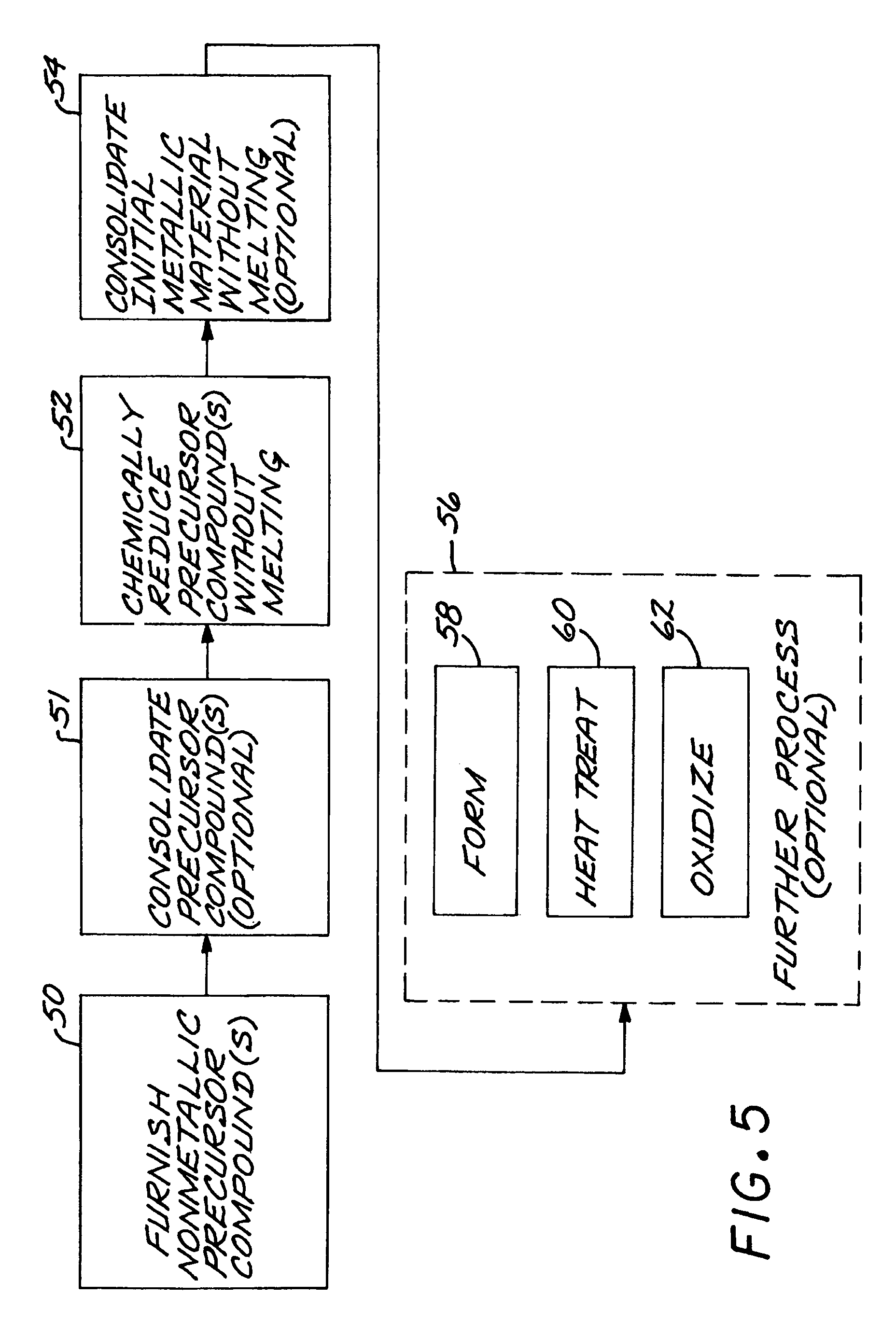

Method for producing a titanium metallic composition having titanium boride particles dispersed therein

InactiveUS7410610B2Reduce incidenceMaintain good propertiesPump componentsBlade accessoriesElemental compositionRoom temperature

An article made of constituent elements is prepared by furnishing at least one nonmetallic precursor compound, wherein all of the nonmetallic precursor compounds collectively contain the constituent elements. The constituent elements include a titanium-base metallic composition, boron present at a level greater than its room-temperature solid solubility limit, and, optionally, a stable-oxide-forming additive element present at a level greater than its room-temperature solid solubility limit. The precursor compounds are chemically reduced to produce a material comprising a titanium-base metallic composition having titanium boride particles therein, without melting the titanium-base metallic composition. The titanium-base metallic composition having the titanium boride particles therein is consolidated without melting.

Owner:GENERAL ELECTRIC CO

Titanium boride coatings on titanium surfaces and associated methods

InactiveUS7264682B2High wear and corrosion and oxidation resistanceResistance to galling and seizureSolid state diffusion coatingMetal boridesBorideTitanium surface

Owner:UNIV OF UTAH RES FOUND

Lightweight dry refractory

A dry refractory composition having superior insulating value. The dry refractory composition also may have excellent resistance to molten metals and slags. The composition includes filler lightweight material, which may be selected from perlite, vermiculite, expanded shale, expanded fireclay, expanded alumina silica hollow spheres, bubble alumina, sintered porous alumina, alumina spinel insulating aggregate, calcium alumina insulating aggregate, expanded mulllite, cordierite, and anorthite, and matrix material, which may be selected from calcined alumina, fused alumina, sintered magnesia, fused magnesia, silica fume, fused silica, silicon carbide, boron carbide, titanium diboride, zirconium boride, boron nitride, aluminum nitride, silicon nitride, Sialon, titanium oxide, barium sulfate, zircon, a sillimanite group mineral, pyrophyllite, fireclay, carbon, and calcium fluoride. The composition also may include dense refractory aggregate, which may be selected from calcined fireclay, calcined Chamotte, a sillimanite group mineral, calcined bauxite, pyrophyllite, silica, zircon, baddeleyite, cordierite, silicon carbide, sintered alumina, fused alumina, fused silica, sintered mullite, fused mullite, fused zirconia, sintered zirconia mullite, fused zirconia mullite, sintered magnesia, fused magnesia, sintered spinel, and fused spinel refractory grog, a heat activated bonding agent, and a dust suppressant.

Owner:ALLIED MINERAL PROD

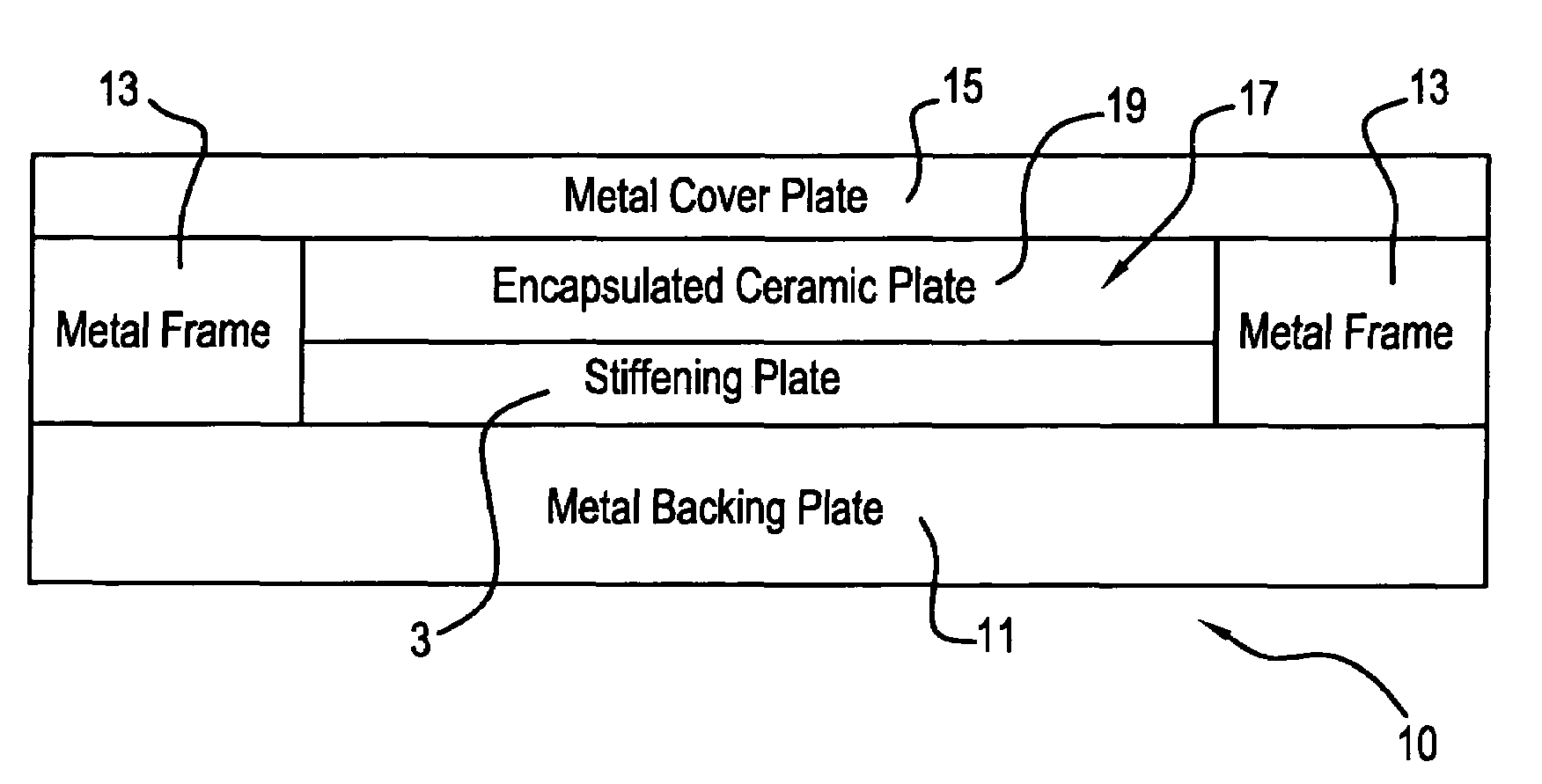

Multiple dispersion strengthening copper-base composite material prepared in situ and preparation method thereof

InactiveCN101613816APromote generationImprove organizational structureTitanium carbideSelf generation

The invention discloses a multiple dispersion strengthening copper-base composite material produced in situ and a preparation method thereof; the reinforced phase comprises at least three of the following substances: titanium carbide, zirconium carbide, alumina, titanium boride, aluminum carbide, chromium oxide, zirconia, graphite and copper; wherein, the contents of titanium carbide, zirconium carbide, alumina, titanium boride, chromium oxide and zirconia are not less than 0.3% and not more than 5%, the content of aluminum carbide is not less than 0.1% and not more than 5%, the content of graphite is not less than 0.1% and not more than 1% and the balance is copper. The particle size of the reinforced phase is between 10nm to 10mu m. The preparation method adopts ball milling; pressing, sintering and squeezing processes and the technological parameters are optimized and controlled properly to obtain the multiple dispersion strengthening copper-base composite material. Because the in situ self-generation technology is adopted and various reinforced phase methods are combined, the material of the invention has higher high-temperature strength and better electroconductibility and anti-creep property compared with the traditional ceramic particle strengthening copper-base composite material.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

Powder metallurgy titanium alloy and preparation method thereof

InactiveCN101962721AImprove mechanical propertiesImprove performanceCompression moldingLanthanum hexaboride

The invention provides powder metallurgy titanium alloy and a preparation method thereof. The powder metallurgy titanium alloy comprises the following components in percentage by mass: 2 to 7 percent of Al, 2 to 8 percent of Mo, 2 to 6 percent of V, 2 to 10 percent of Ag, 0.1 to 3.0 percent of LaB6 and the balance of titanium and inevitable impurities. The method comprises the following steps of: weighing titanium powder, aluminum powder, molybdenum powder, aluminum-vanadium intermediate alloy powder, silver powder and lanthanum hexaboride powder with certain particle size according to the mass percentage of the components; uniformly mixing the powder by a mixing method; preparing a green compact with a certain shape by a compression molding process; placing the green compact in a vacuum hot pressing sintering furnace to sinter; and cooling the green compact along with the furnace to obtain silver and titanium boride particle-containing powder metallurgy titanium alloy. The technological process is simple; the silver powder is added during the mixing of the materials to improve the molding property of the green compact; the lanthanum hexaboride powder is added to perform reaction in situ so as to generate titanium boride dispersion enhanced matrix alloy; the compactness of the sinter compact is further improved by hot pressing sintering; and thus the novel powder metallurgy titanium alloy with high compactness and high strength is obtained.

Owner:CENT SOUTH UNIV

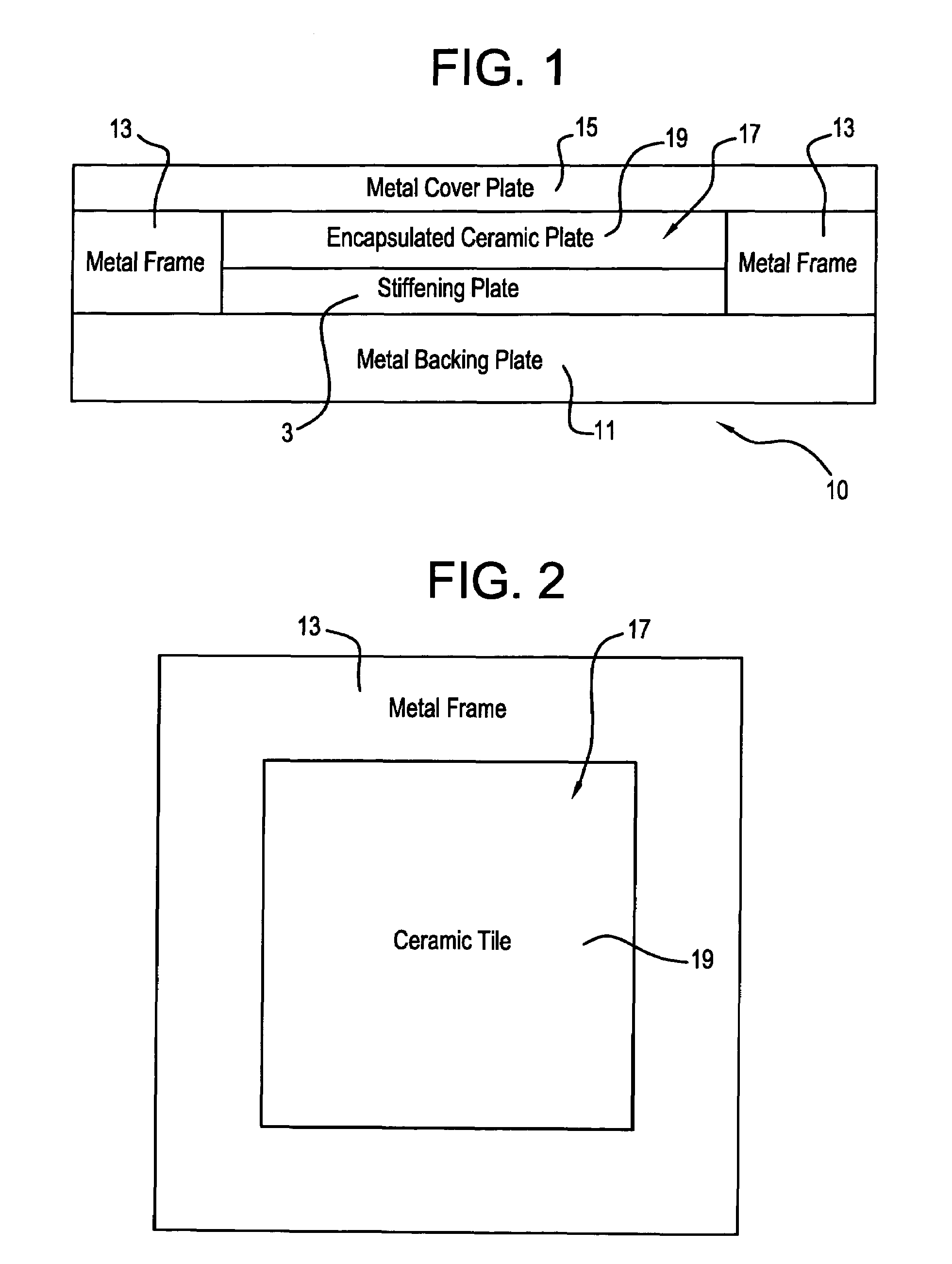

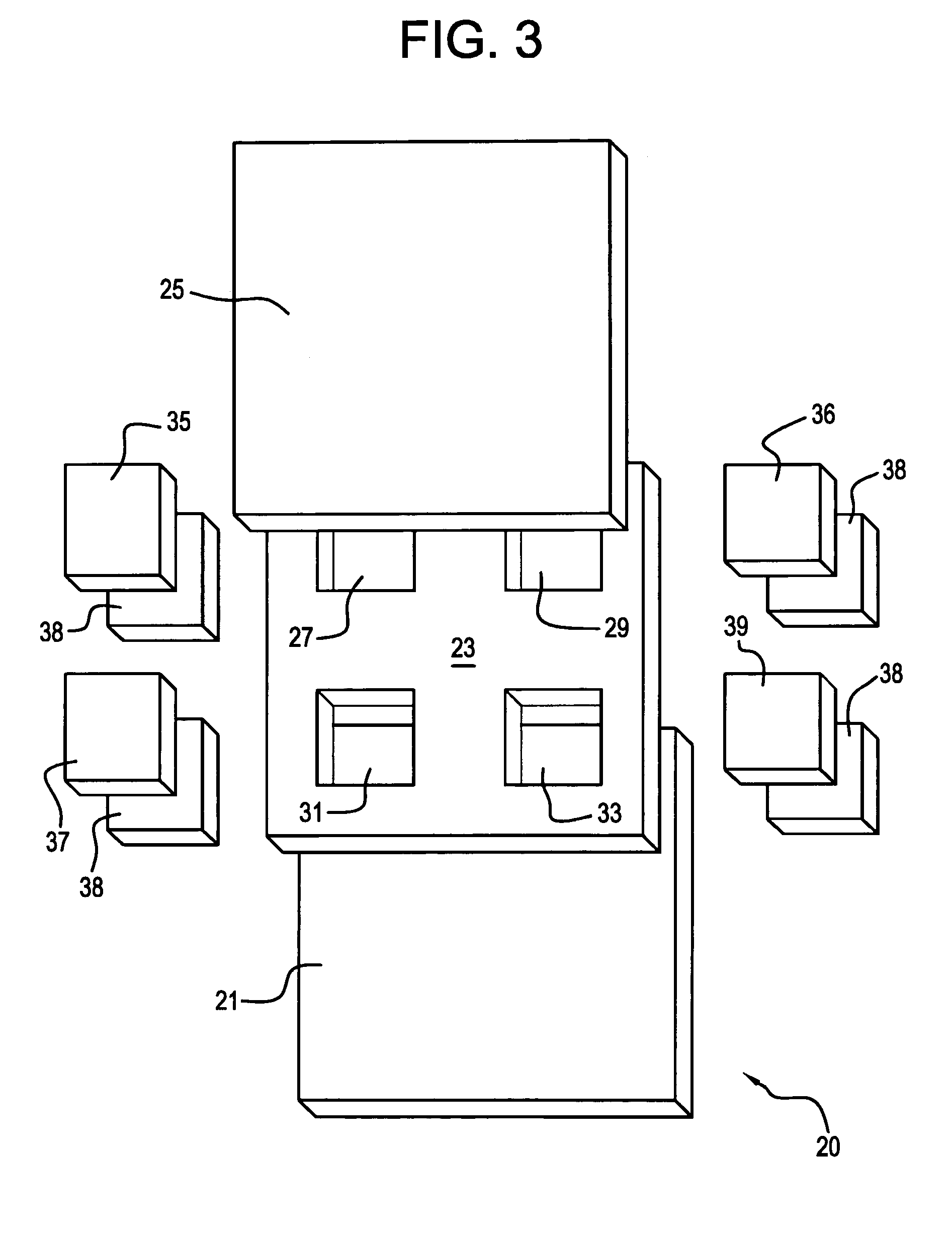

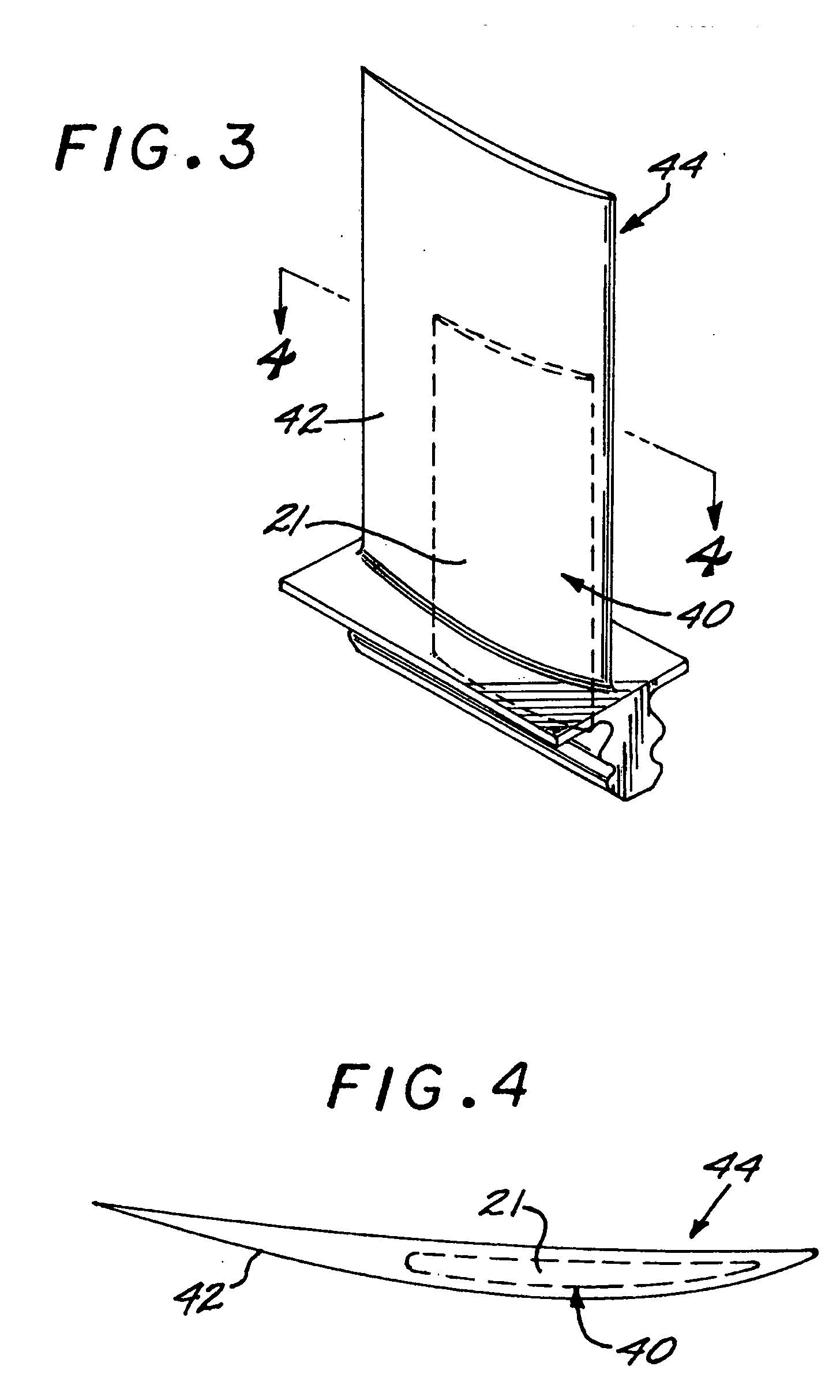

Ceramic armor and method of making by encapsulation including use of a stiffening plate

InactiveUS7069836B1Improve simplicityDoor/window protective devicesArmoured vehiclesCeramic compositeBoron carbide

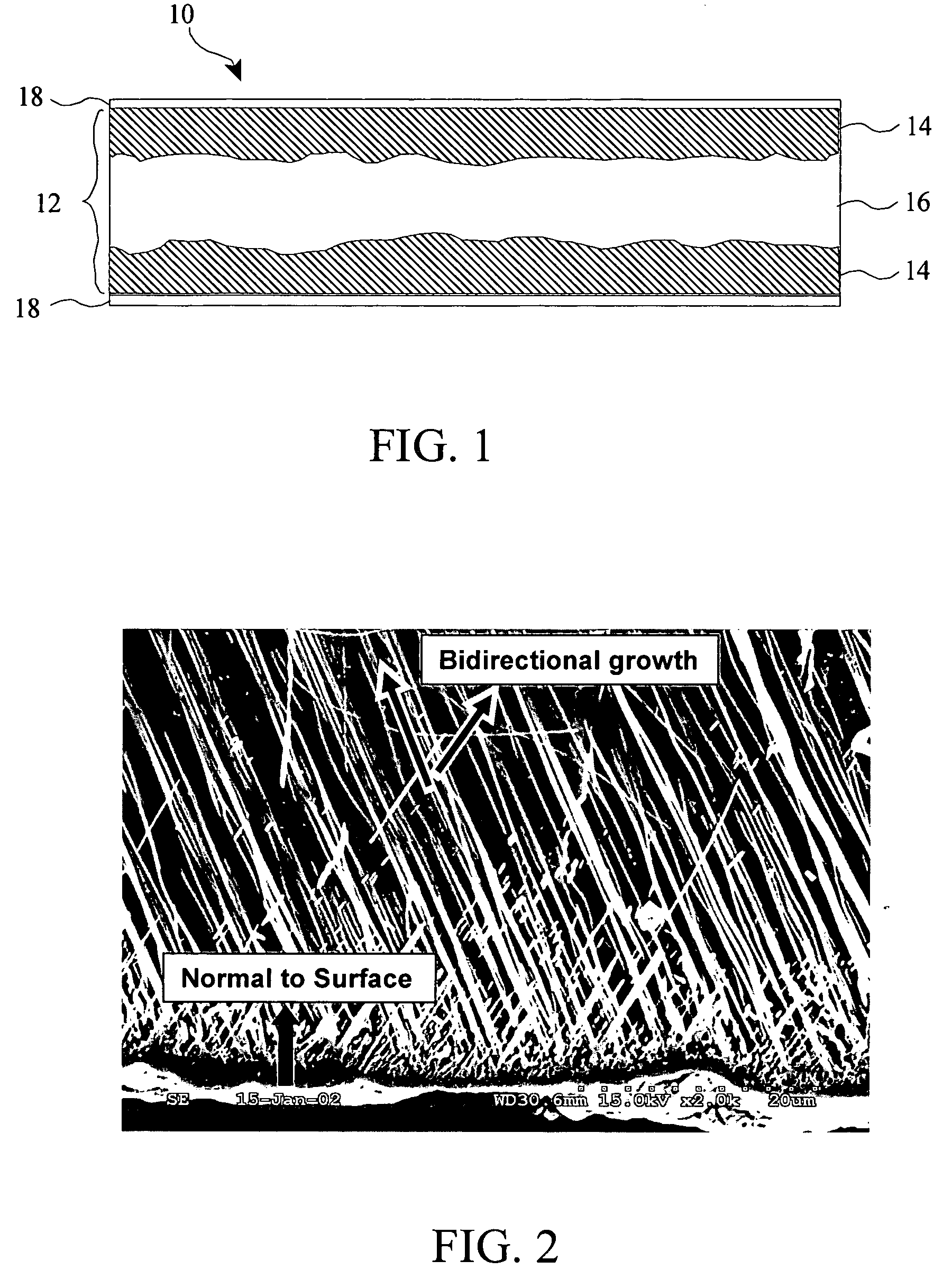

A ceramic armor is disclosed in several embodiments. In a first embodiment, a metal base plate has a metal frame assembled on it having a central opening into which the ceramic material and stiffening plate are placed. A cover plate is placed over the frame to enclose the ceramic material on all sides. In a second embodiment, the frame has an open central area that has two crossing walls that define four sub-chambers. Four sets of ceramic material and stiffening plate are placed in the respective sub-chambers and a covering plate is placed over them. In a further embodiment, the frame has a plurality of cavities mechanically formed in it. A stiffening plate and a ceramic tile or plate are placed in each cavity and a cover plate is placed over the frame. The metal used to encapsulate the ceramic material may, if desired, comprise a Titanium alloy such as Ti-6Al-4V, and the ceramic material may comprise Silicon Carbide, Boron Carbide, Tungsten Carbide, Titanium Diboride, Aluminum Oxide or Aluminum Nitride. The stiffening plate is preferably made of a Ti—TiB cermet composite but may also be comprised of an armor ceramic such as WC, TiB2, Al2O3 or B4C. A hot pressing procedure is carried out on the armor to cause the metal to plastically deform about the encapsulated ceramic material.

Owner:BAE SYST ADVANCED CERAMICS

Probe needle material, probe needle and probe card each using the same, and inspection process

ActiveUS20100194415A1Maintain contact stabilityNot abraded heavilyElectrical measurement instrument detailsElectrical testingProbe cardHafnium

Disclosed is a probe needle material used for producing a probe needle which is used in contact with an inspection object to inspect electrical characteristics of the inspection object, comprising not less than 0.1% by volume but not more than 3.5% by volume of at least one compound selected from the group consisting of titanium boride, zirconium boride, hafnium boride, niobium boride, tantalum boride, chromium boride, titanium carbide, zirconium carbide, hafnium carbide, vanadium carbide, niobium carbide, tantalum carbide, zirconium oxide, hafnium oxide and chromium oxide and the balance of a tungsten alloy mainly consisting of tungsten.

Owner:KK TOSHIBA +1

Titanium boride coatings on titanium surfaces and associated methods

InactiveUS20050208213A1High wear and corrosion and oxidation resistanceResistance to galling and seizureLiquid surface applicatorsSolid state diffusion coatingParticulatesSolid particle

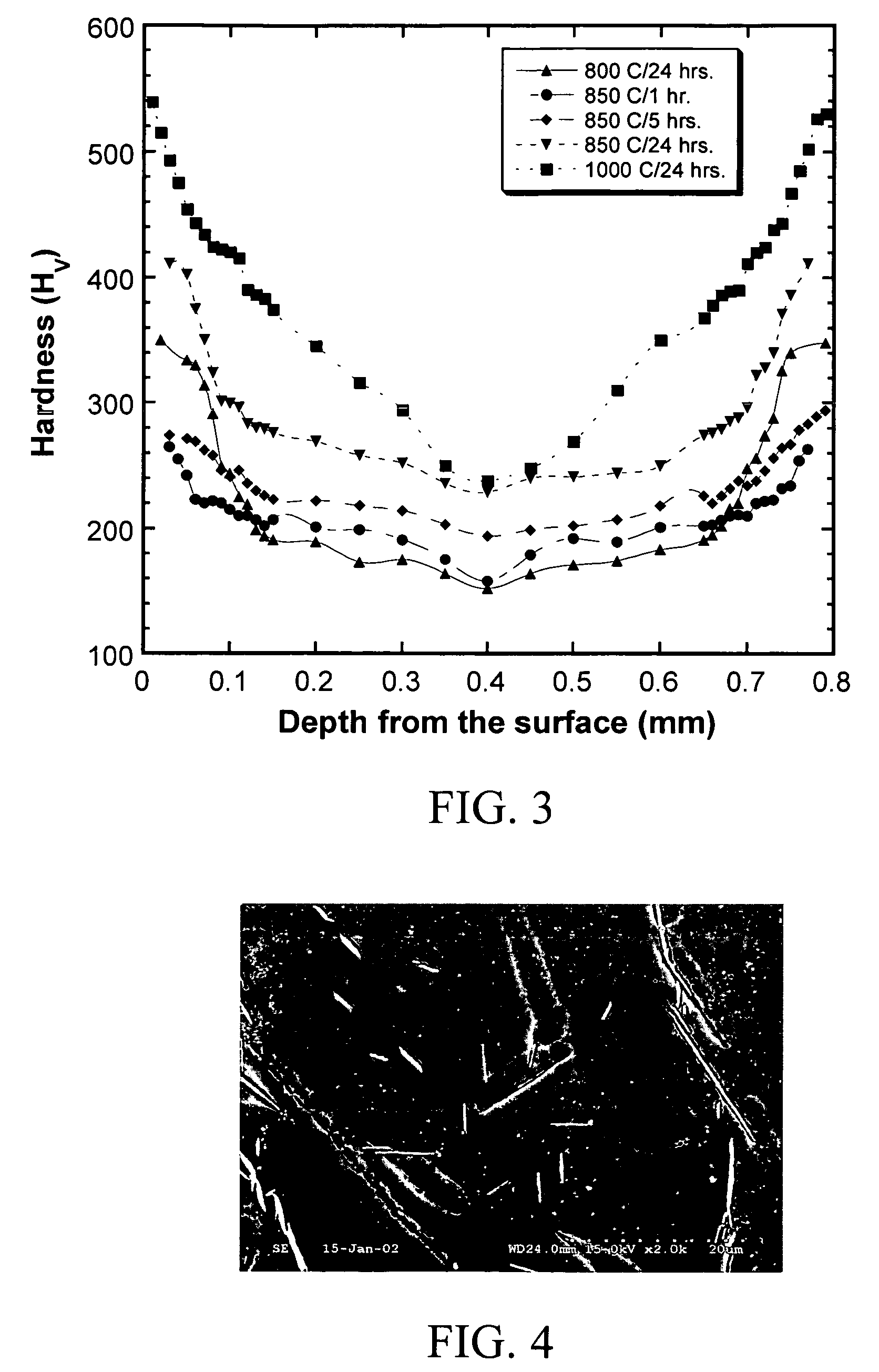

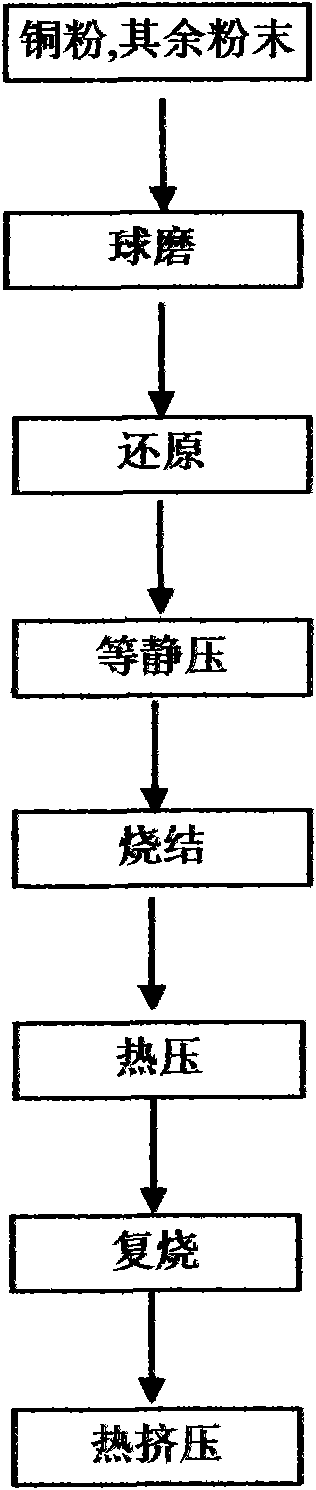

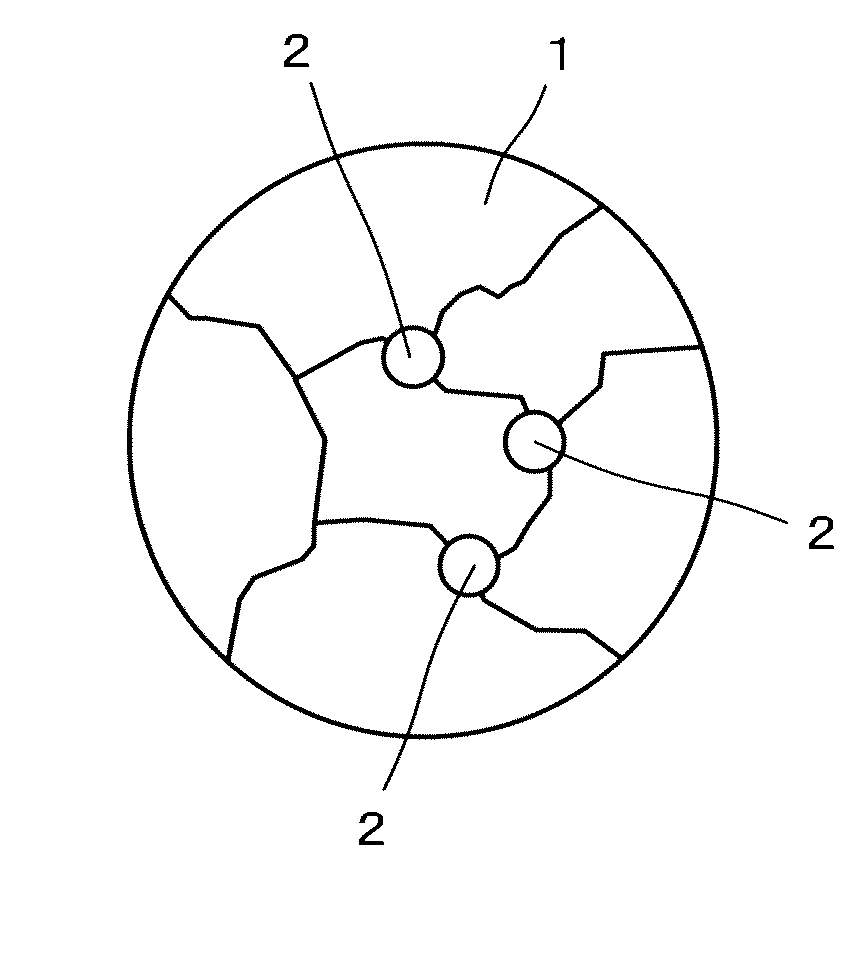

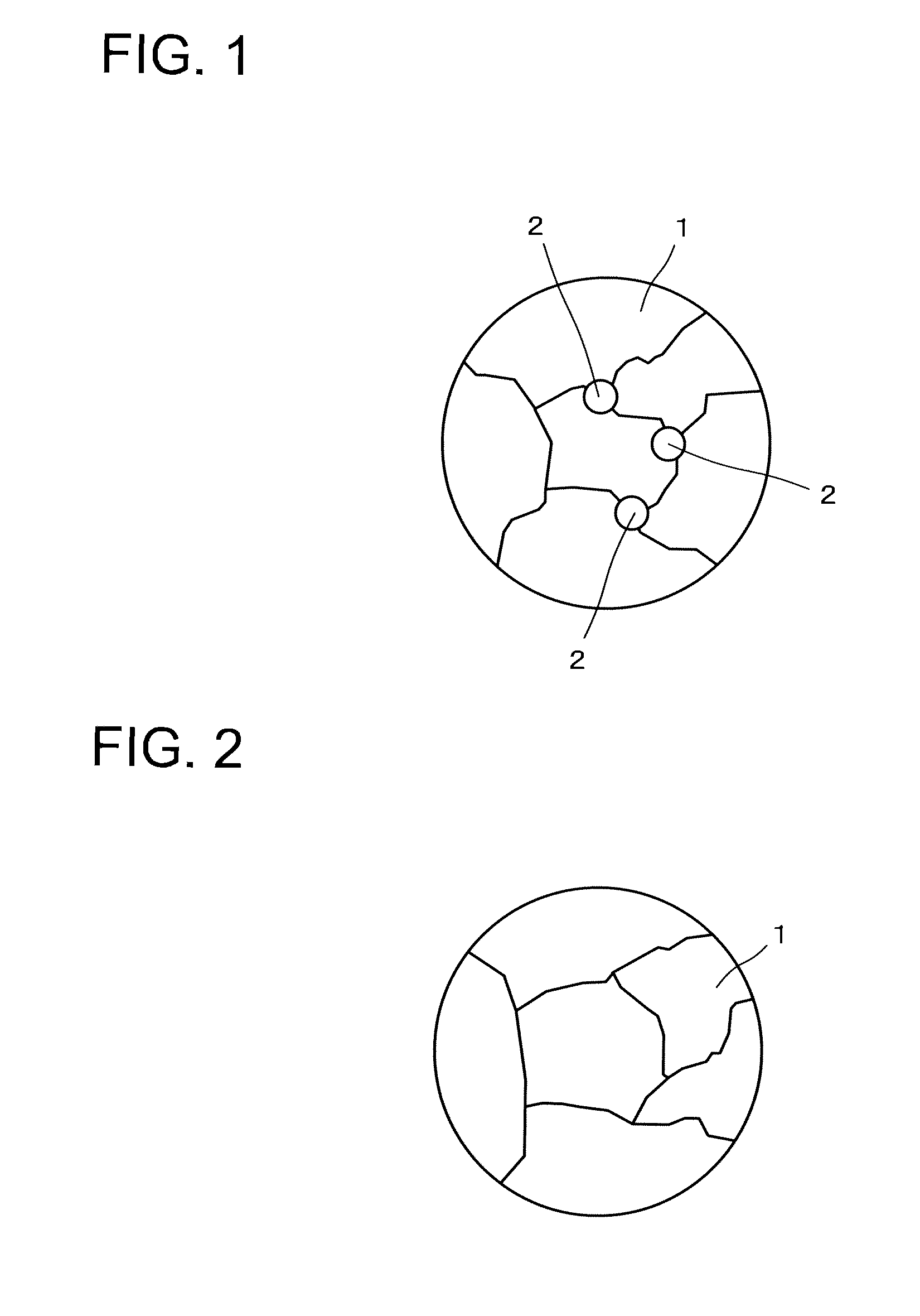

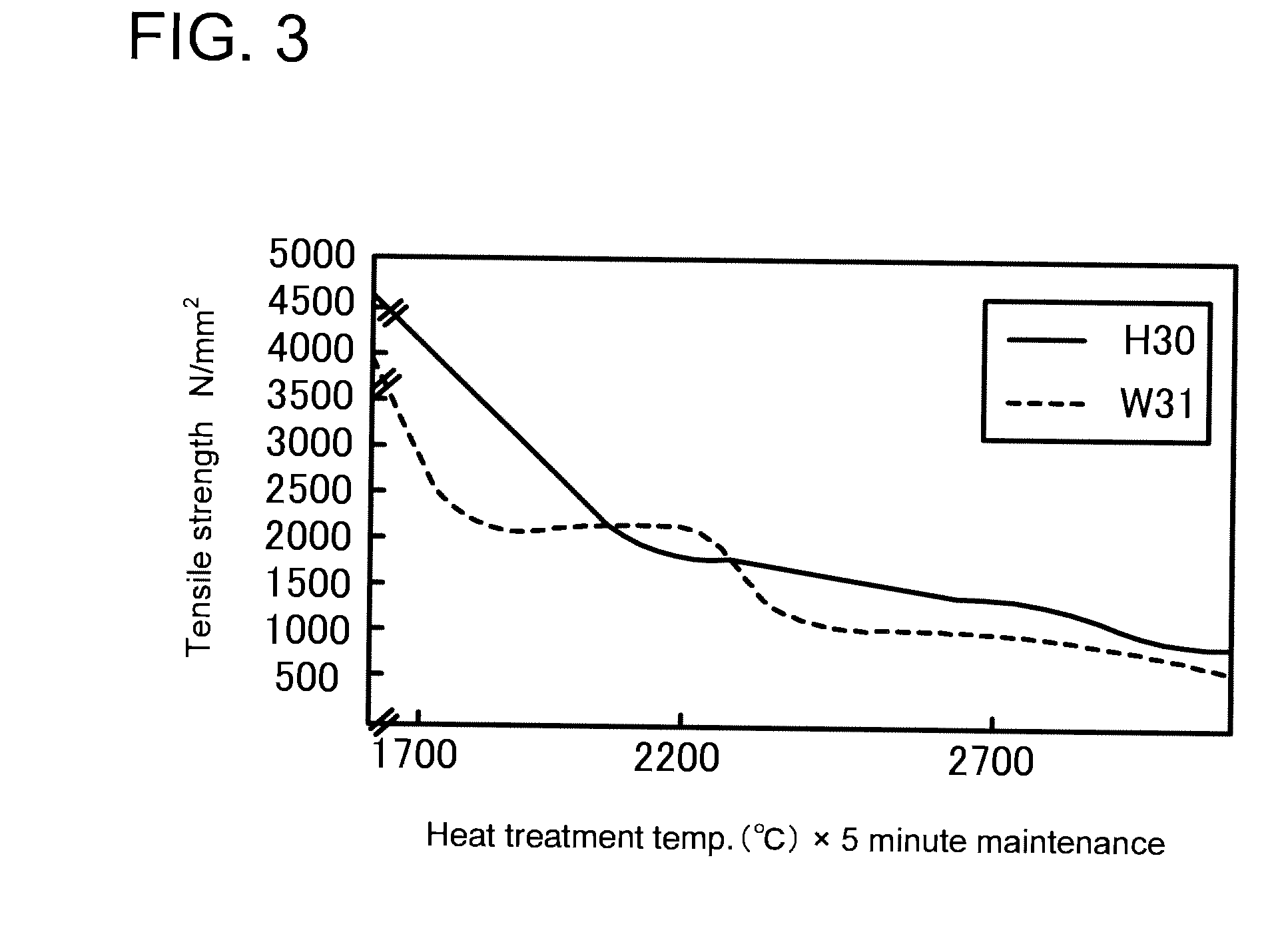

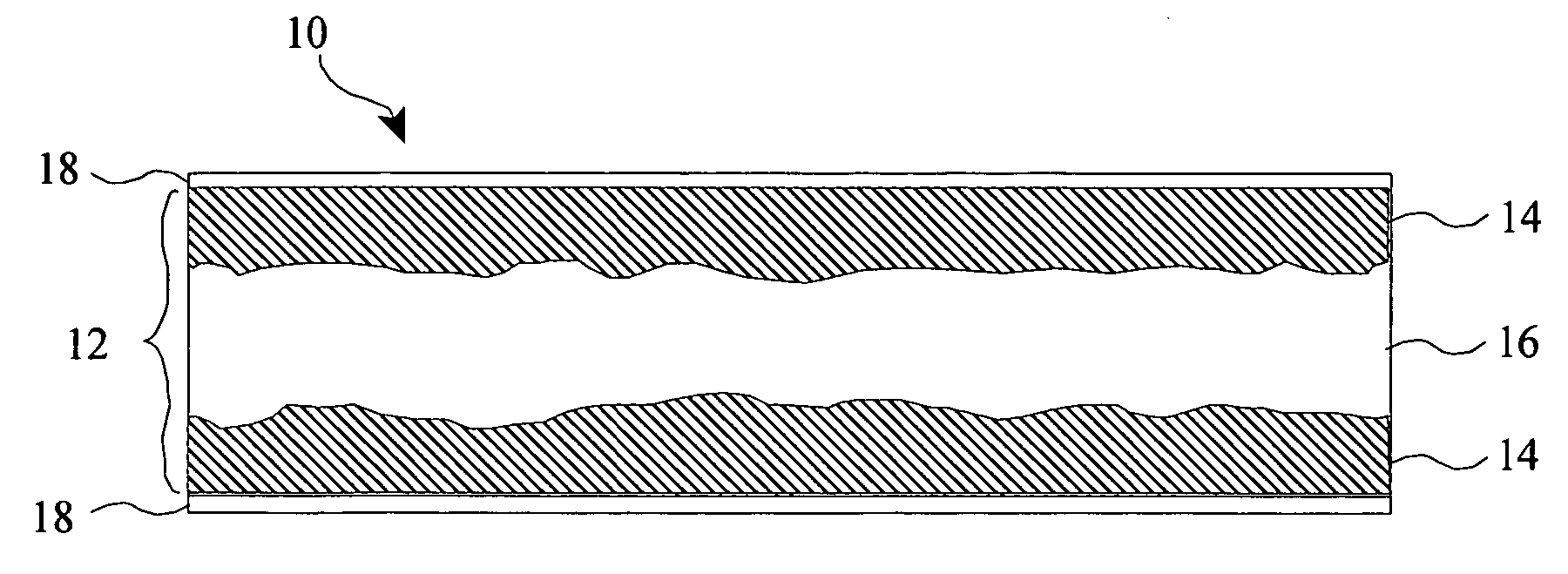

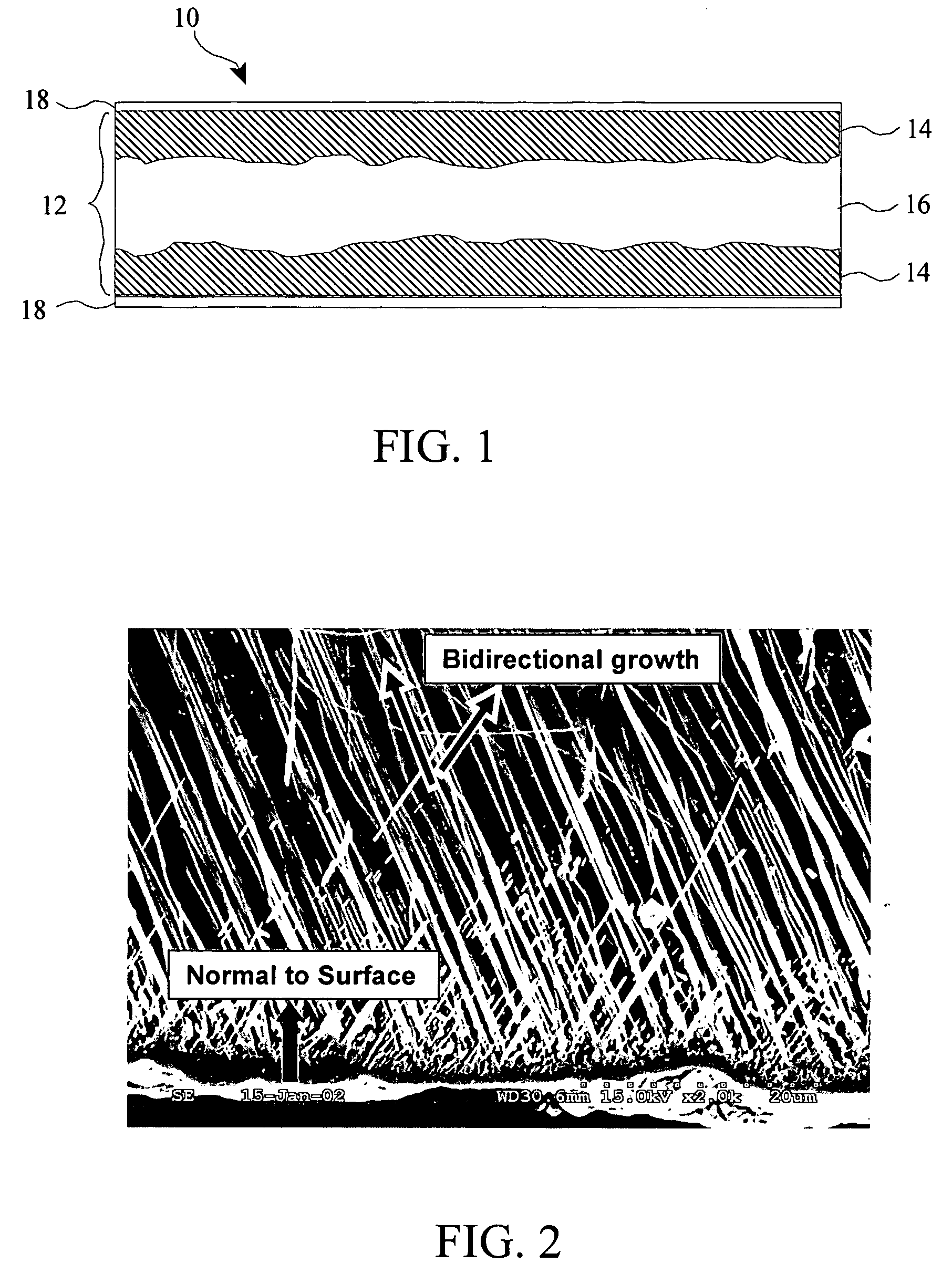

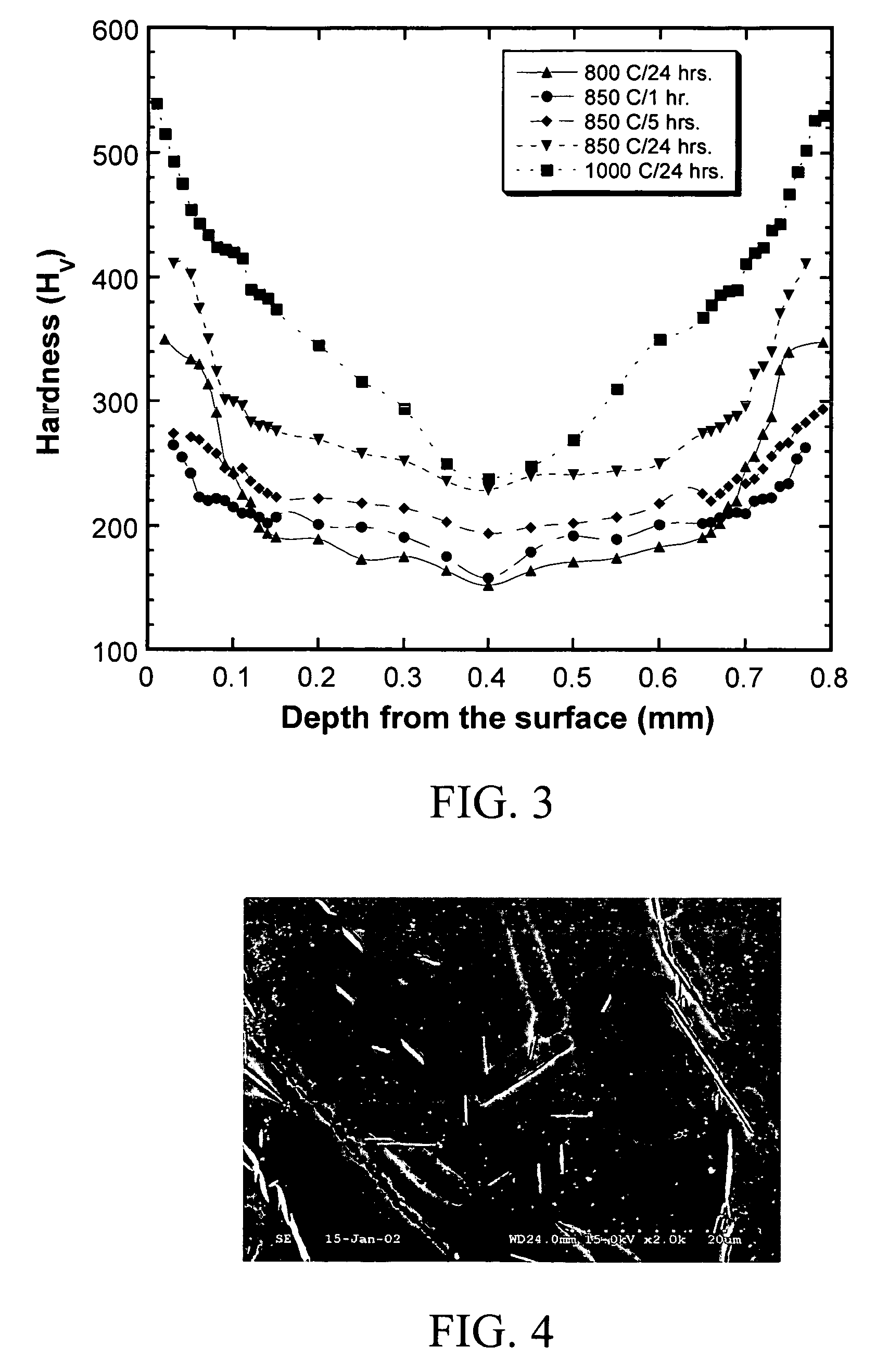

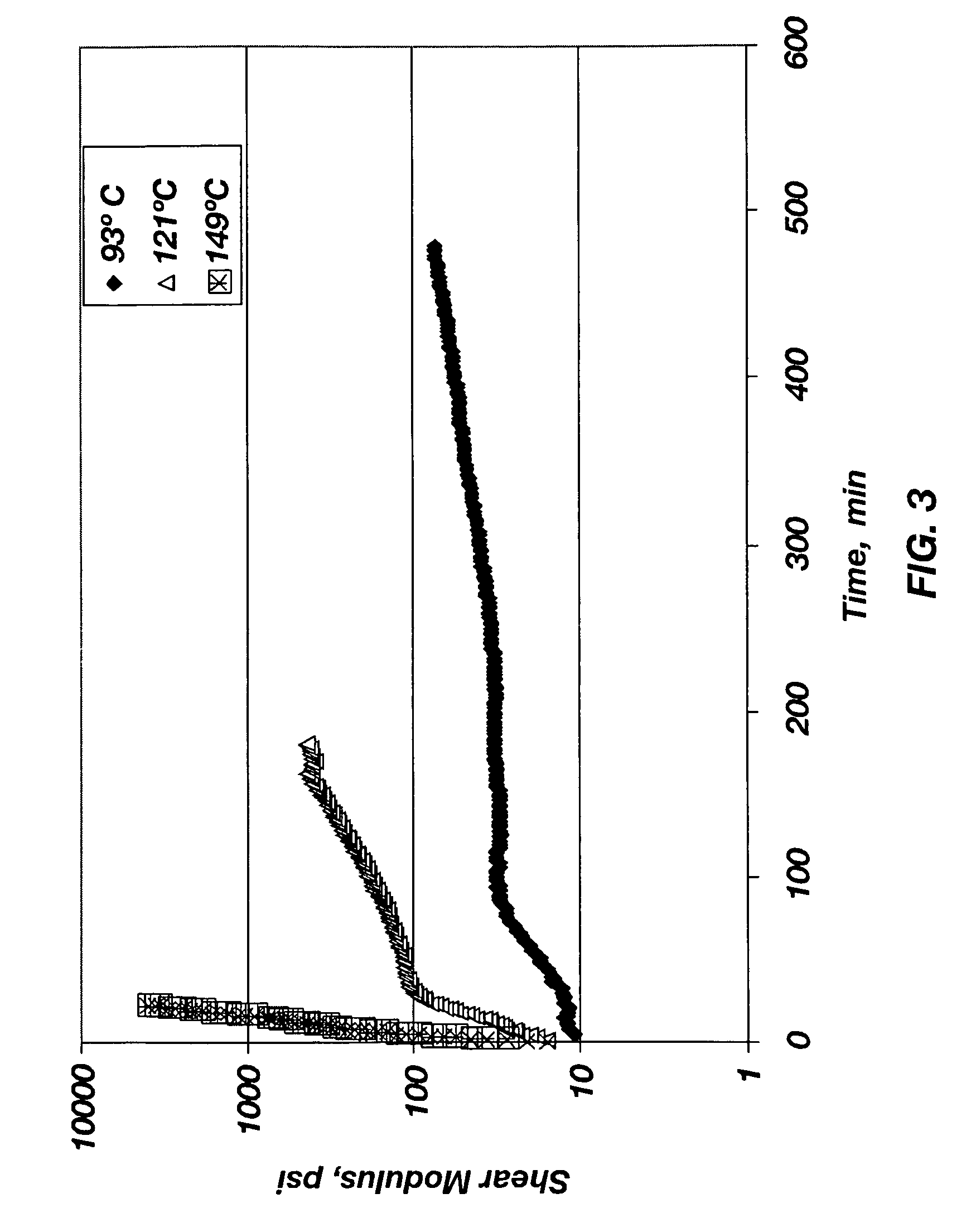

A borided titanium article can include a titanium mass having titanium monoboride whiskers infiltrating inward from a surface of the titanium mass to form an integral surface hardened region. The titanium mass can be almost any titanium based metal or alloy such as high purity titanium, commercial grade titanium, α-titanium alloy, α+β titanium alloy, β-titanium alloy, titanium composite, and combinations thereof. Borided titanium articles can be formed by methods which include providing a titanium mass, contacting a surface of the titanium mass with a boron source medium, and heating the titanium mass and boron source medium to a temperature from about 700° C. to about 1600° C. The boron source medium can include a boron source and an activator selected to provide growth of titanium monoboride whiskers. The boron source medium can be provided as a solid particulate mixture, liquid mixture, or as a gaseous mixture. During heating, boron from the boron source infiltrates into the titanium mass and forms titanium monoboride whiskers which improve the surface hardness, wear resistance, oxidation resistance, and corrosion resistance of the treated surface. The titanium monoboride whiskers can be controlled to have the desired dimensions, depending on the application requirements. Boriding titanium surfaces using these methods, provides a relatively inexpensive and effective process for improving the surface properties of titanium which are then useful in a wide variety of applications.

Owner:UNIV OF UTAH RES FOUND

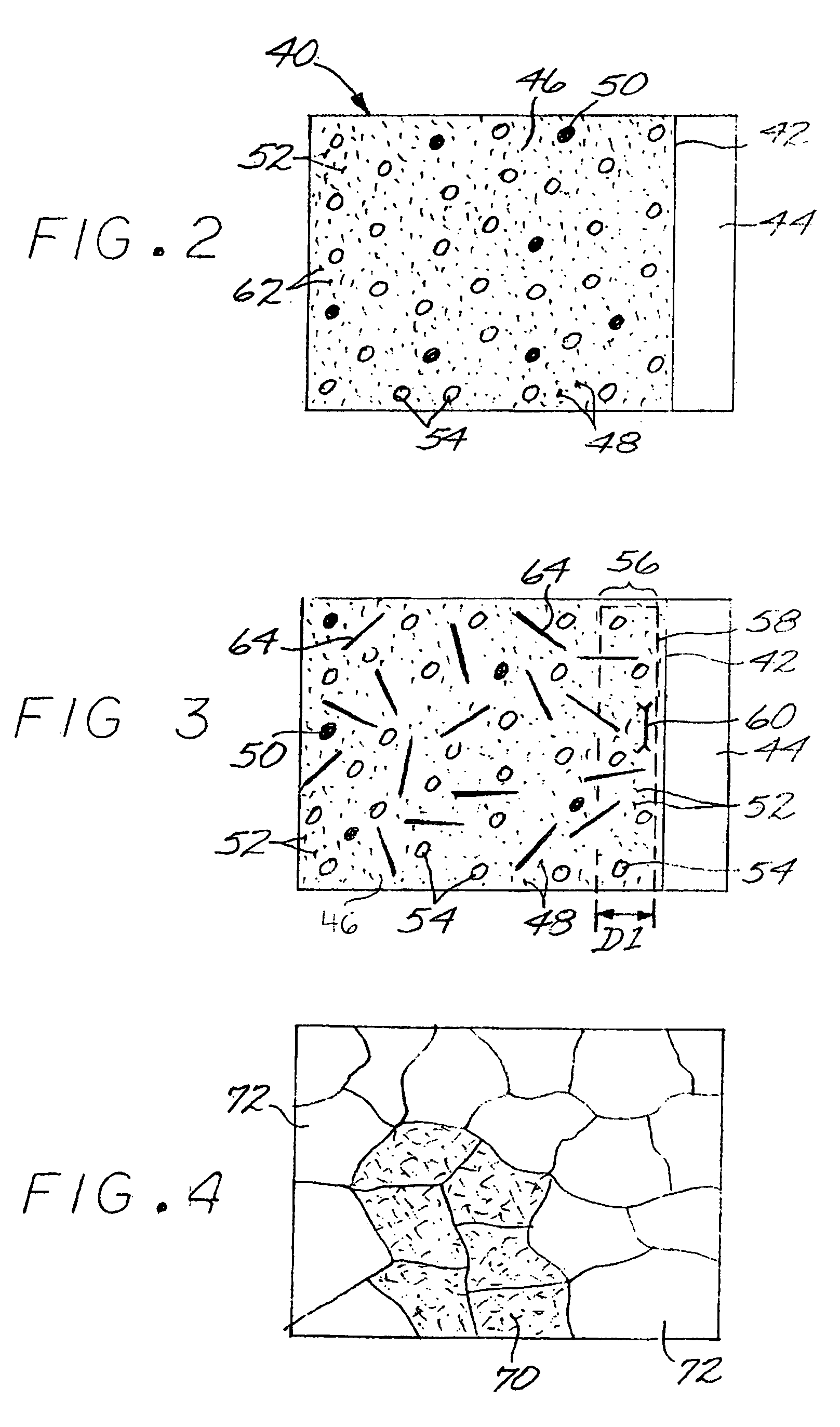

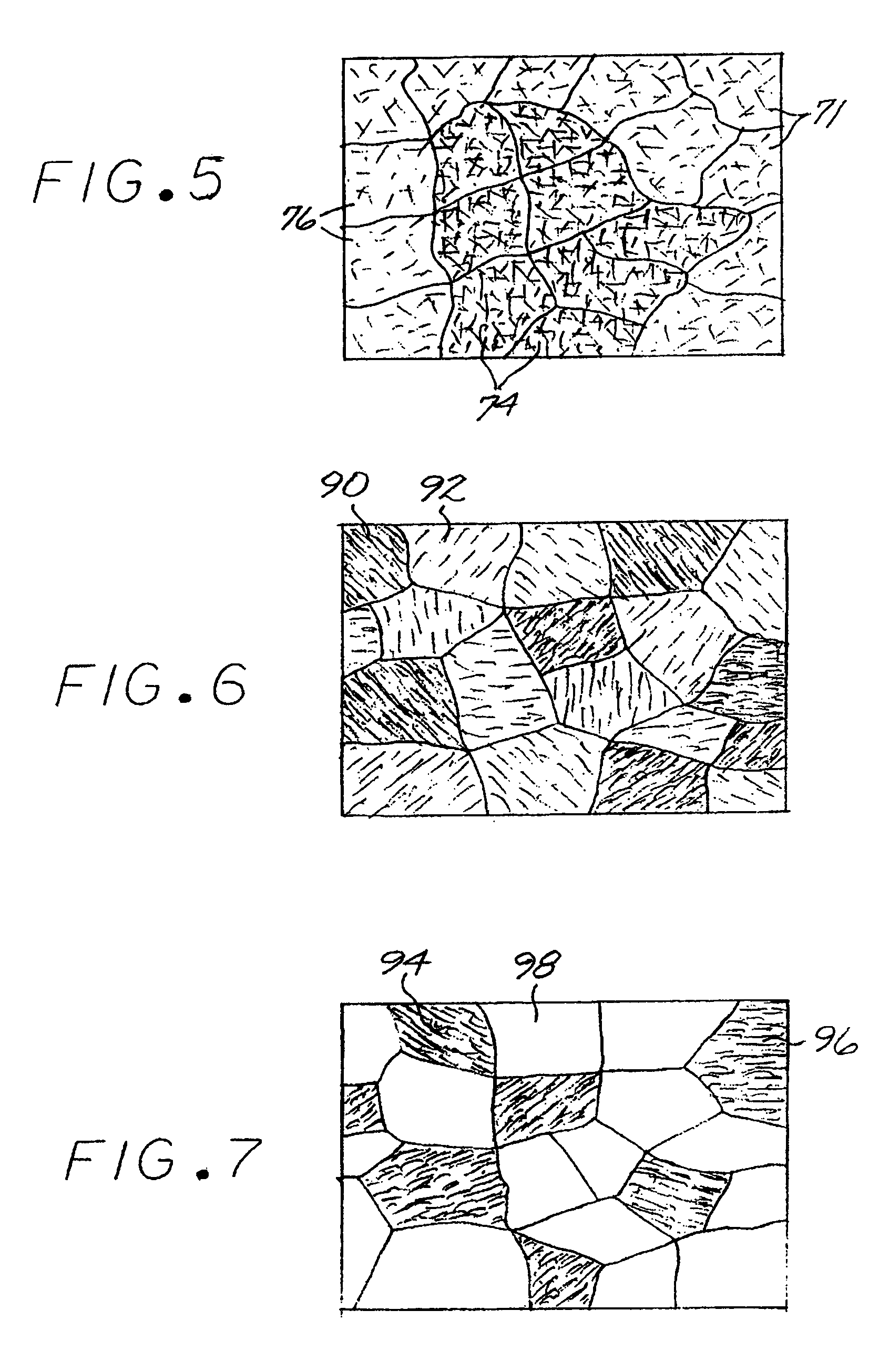

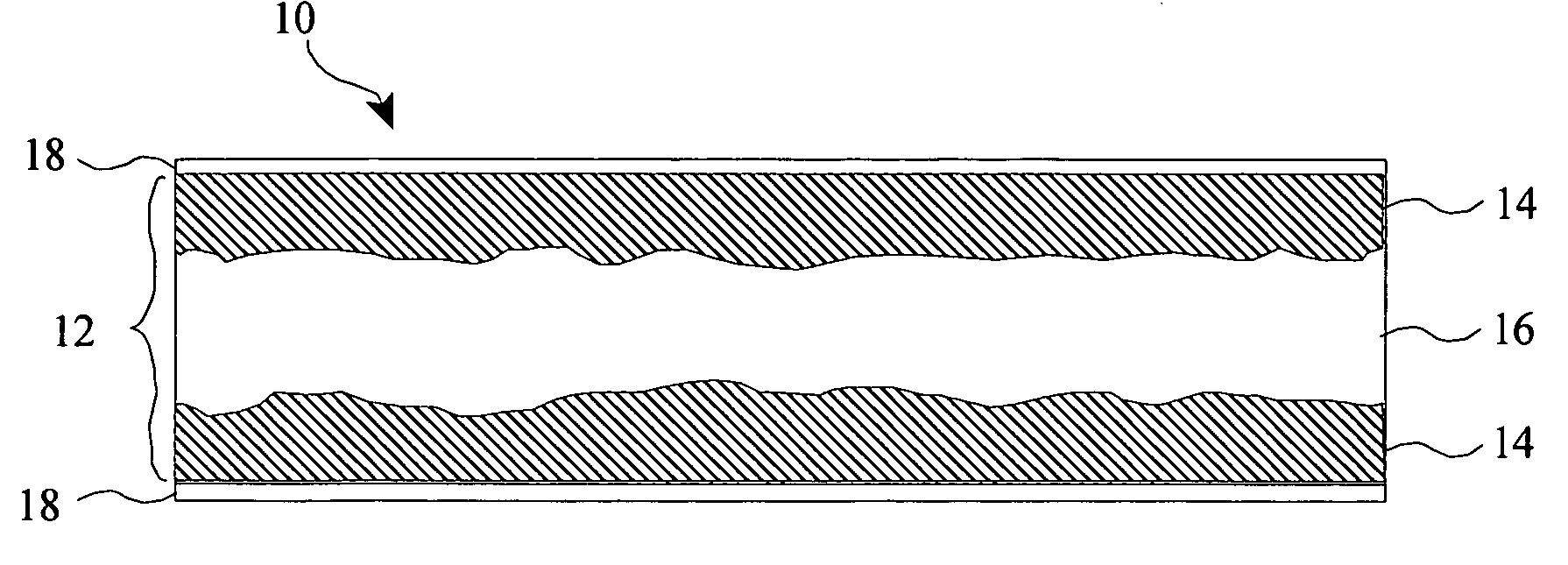

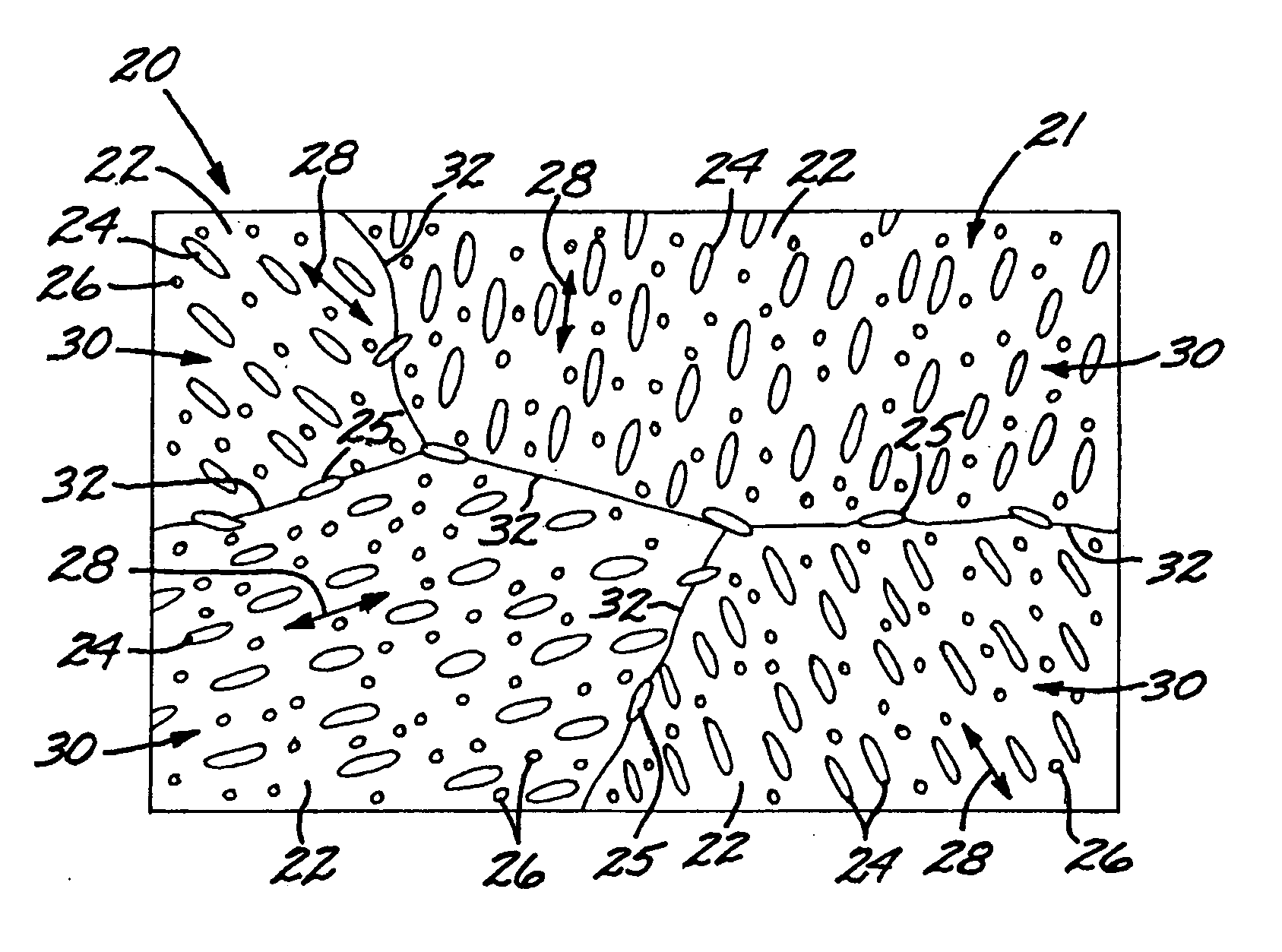

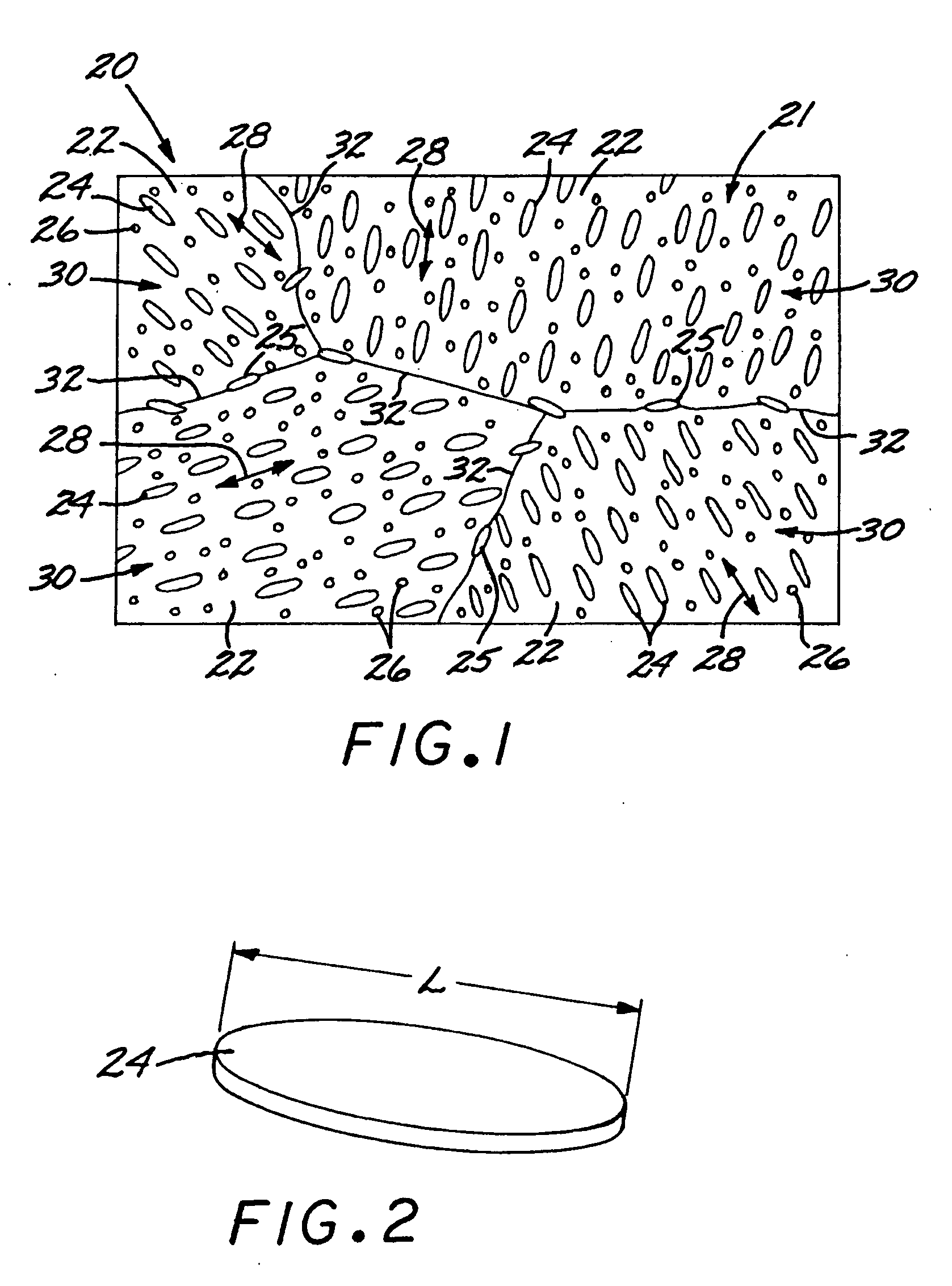

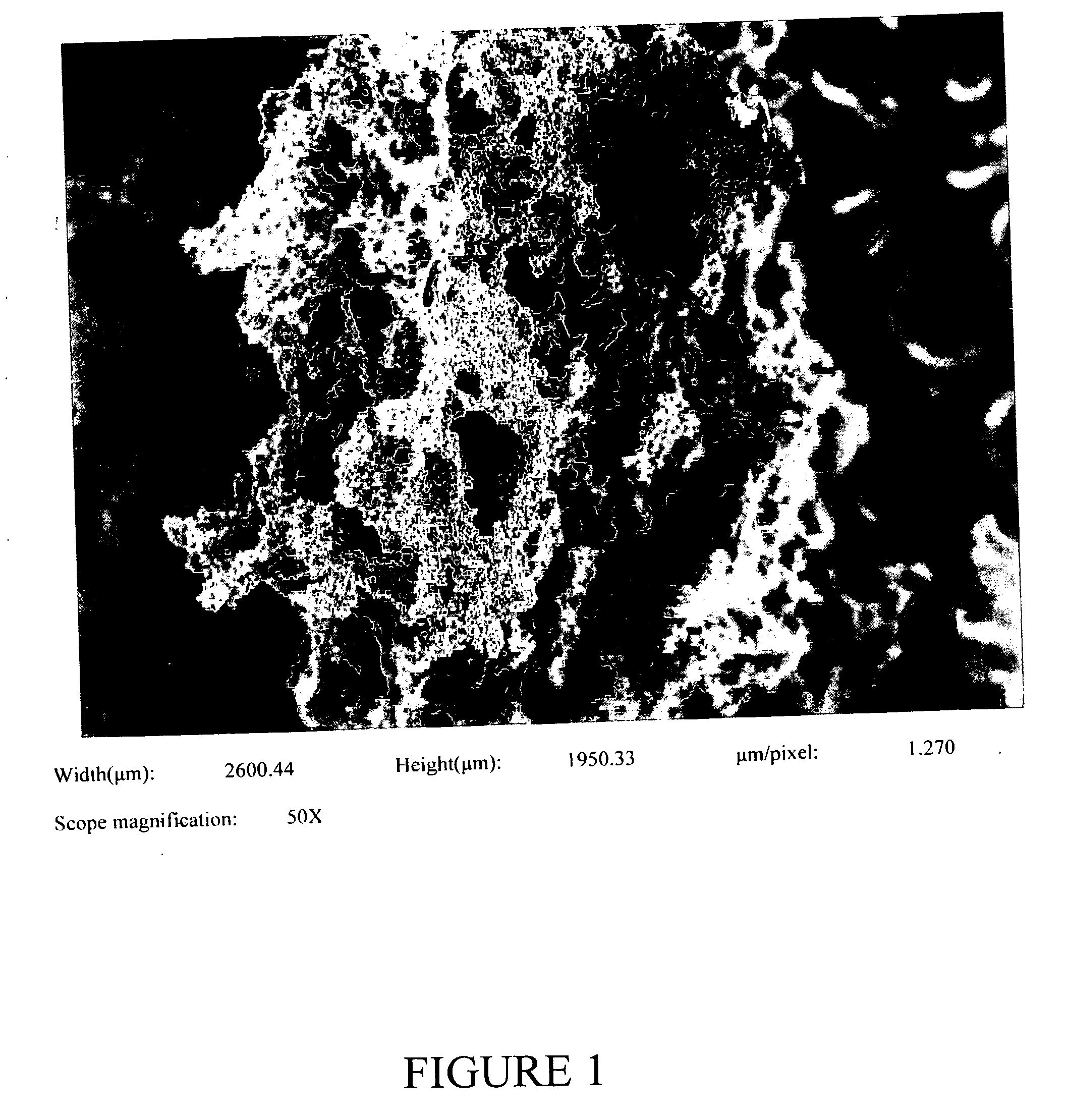

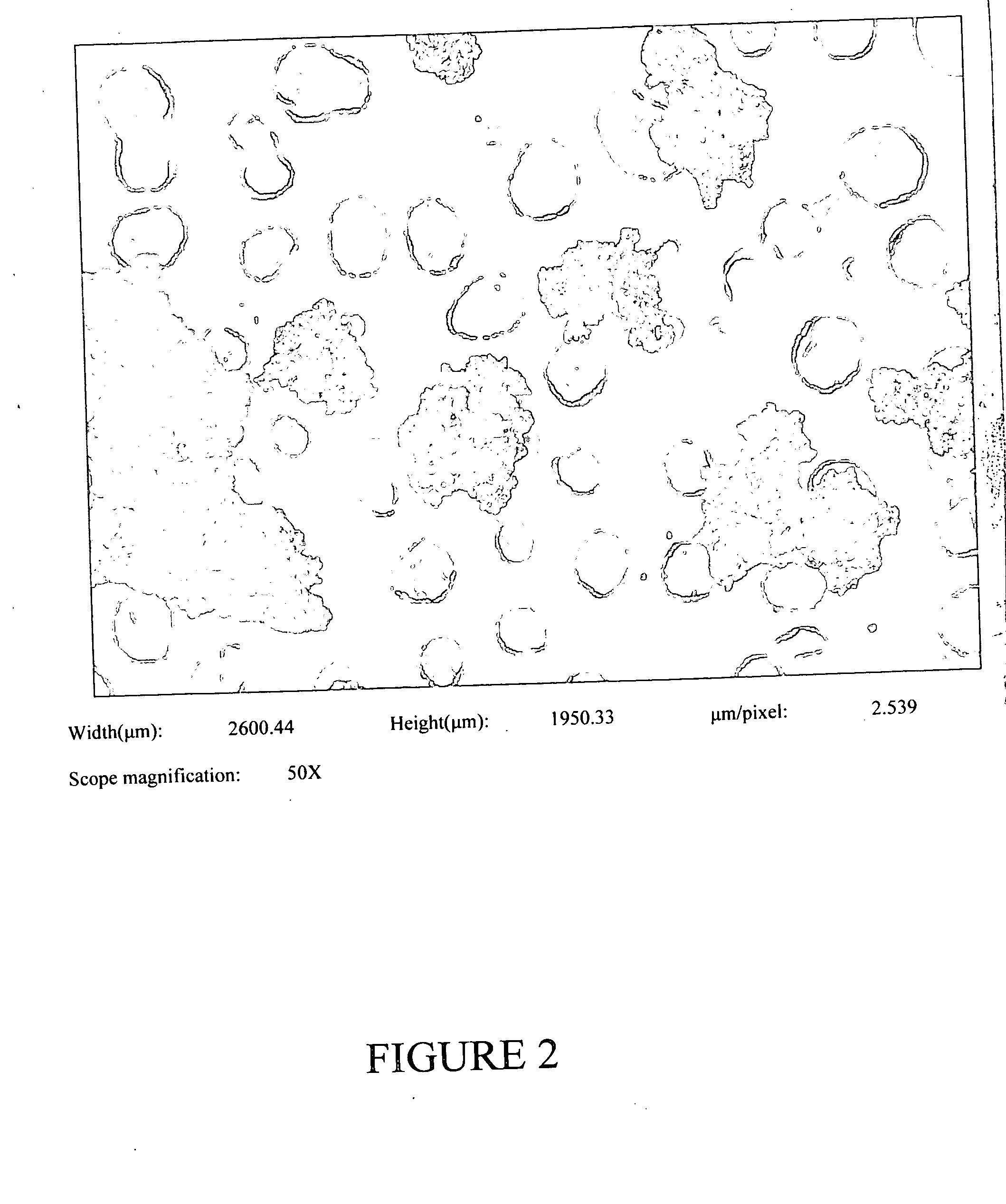

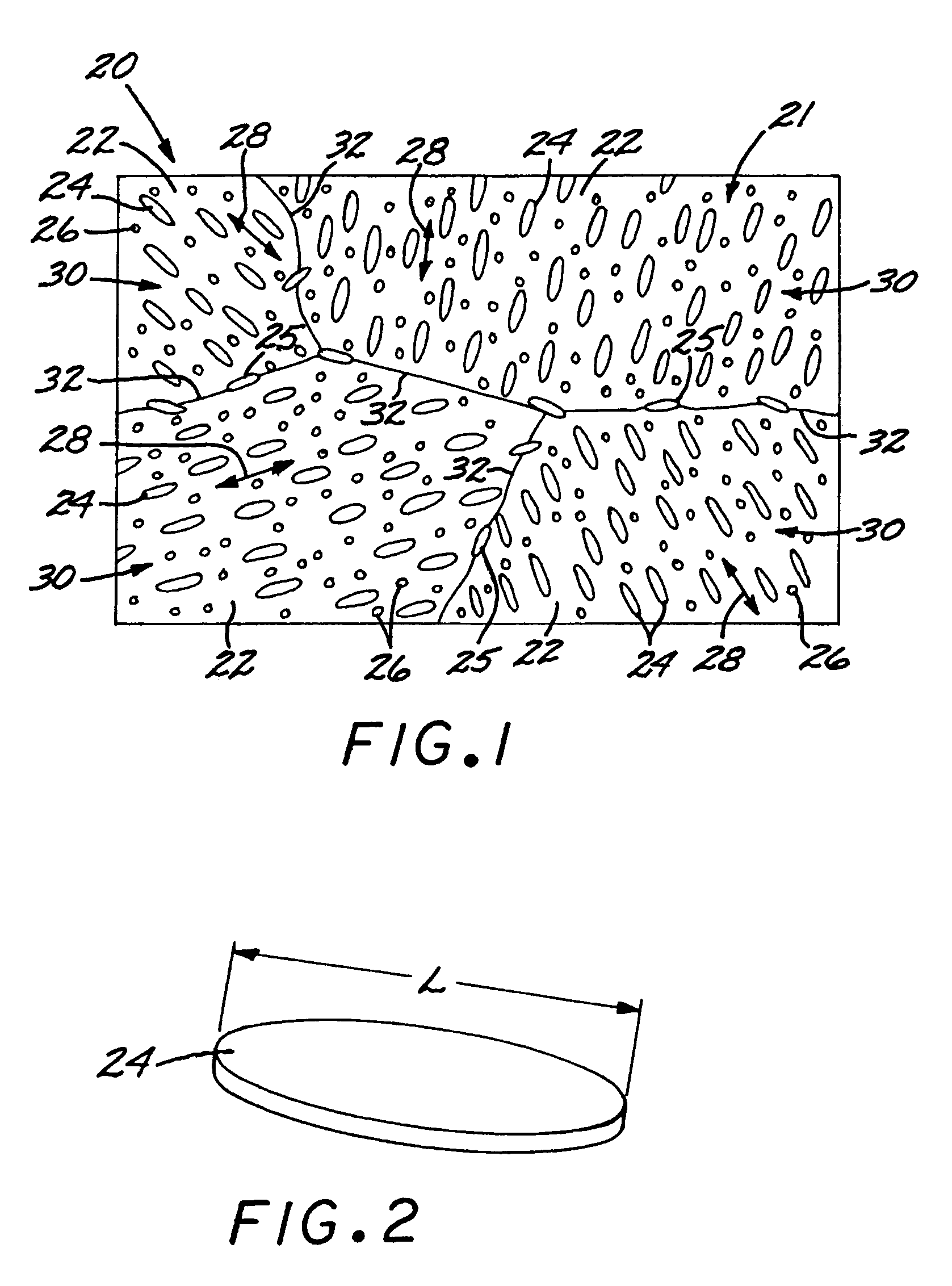

Article having a dispersion of ultrafine titanium boride particles in a titanium-base matrix

ActiveUS20060102255A1Improve creep strengthImprove static strengthThin material handlingMaximum dimensionMicrometer

An article includes a microscale composite material having a matrix with more titanium than any other element, and a dispersion of titanium boride particles in the matrix. At least about 50 volume percent of the titanium boride particles have a maximum dimension of less than about 2 micrometers.

Owner:GENERAL ELECTRIC CO

Ceramic material suitable for repair of a space vehicle component in a microgravity and vacuum environment, method of making same, and method of repairing a space vehicle component

A precursor of a ceramic adhesive suitable for use in a vacuum, thermal, and microgravity environment. The precursor of the ceramic adhesive includes a silicon-based, preceramic polymer and at least one ceramic powder selected from the group consisting of aluminum oxide, aluminum nitride, boron carbide, boron oxide, boron nitride, hafnium boride, hafnium carbide, hafnium oxide, lithium aluminate, molybdenum silicide, niobium carbide, niobium nitride, silicon boride, silicon carbide, silicon oxide, silicon nitride, tin oxide, tantalum boride, tantalum carbide, tantalum oxide, tantalum nitride, titanium boride, titanium carbide, titanium oxide, titanium nitride, yttrium oxide, zirconium, diboride, zirconium carbide, zirconium oxide, and zirconium silicate. Methods of forming the ceramic adhesive and of repairing a substrate in a vacuum and microgravity environment are also disclosed, as is a substrate repaired with the ceramic adhesive.

Owner:COI CERAMICS

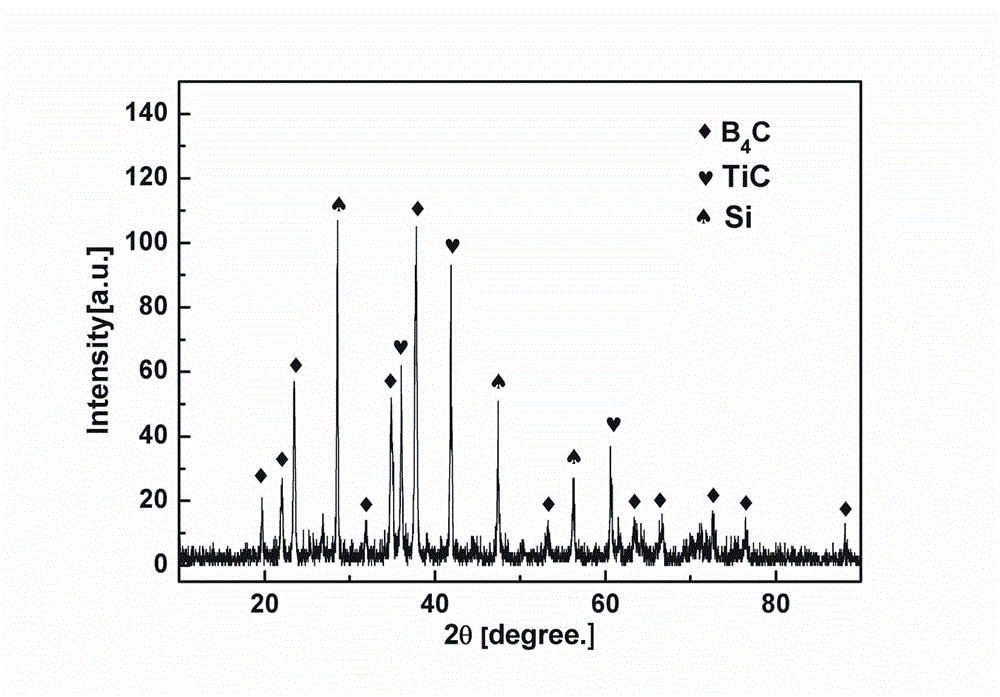

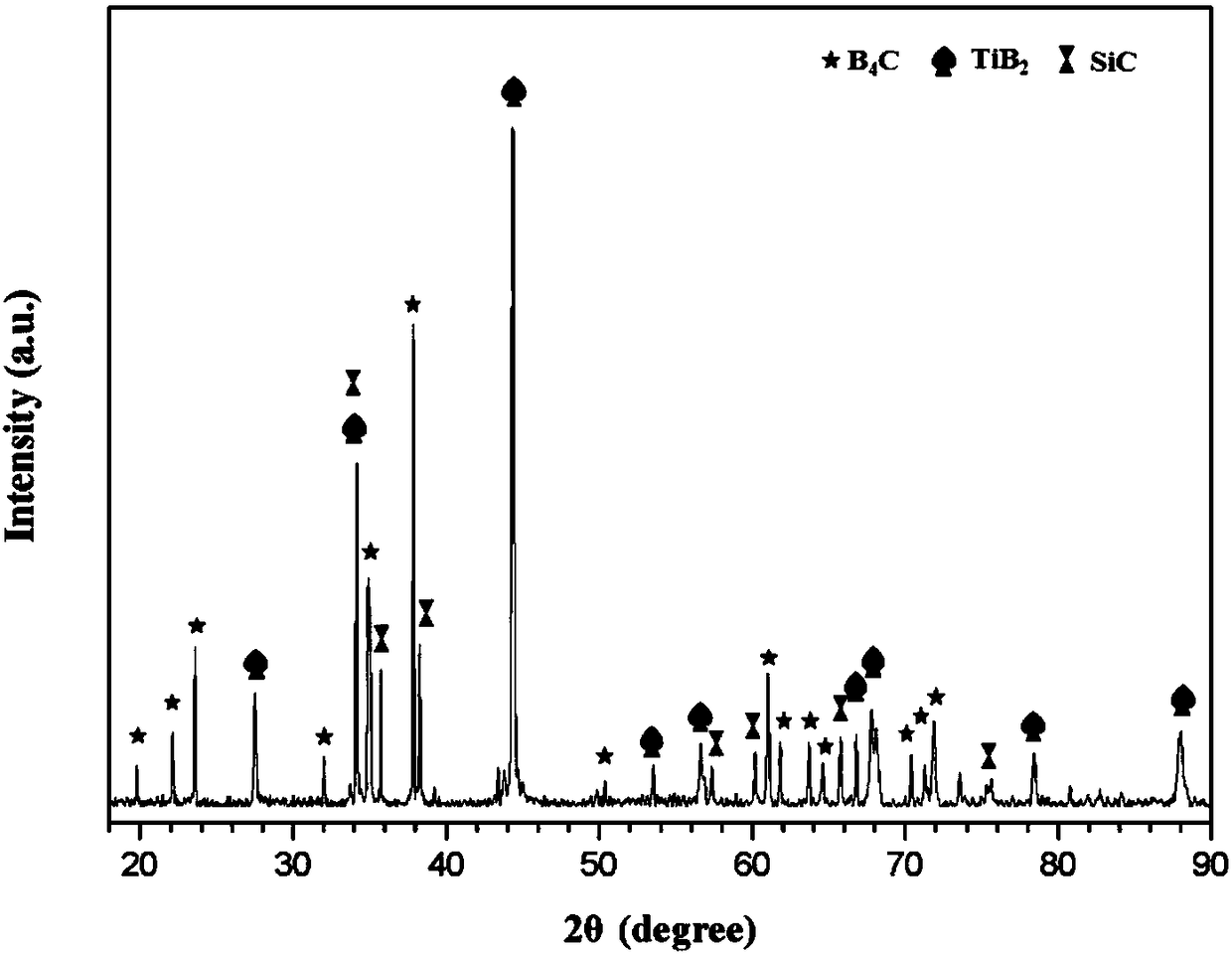

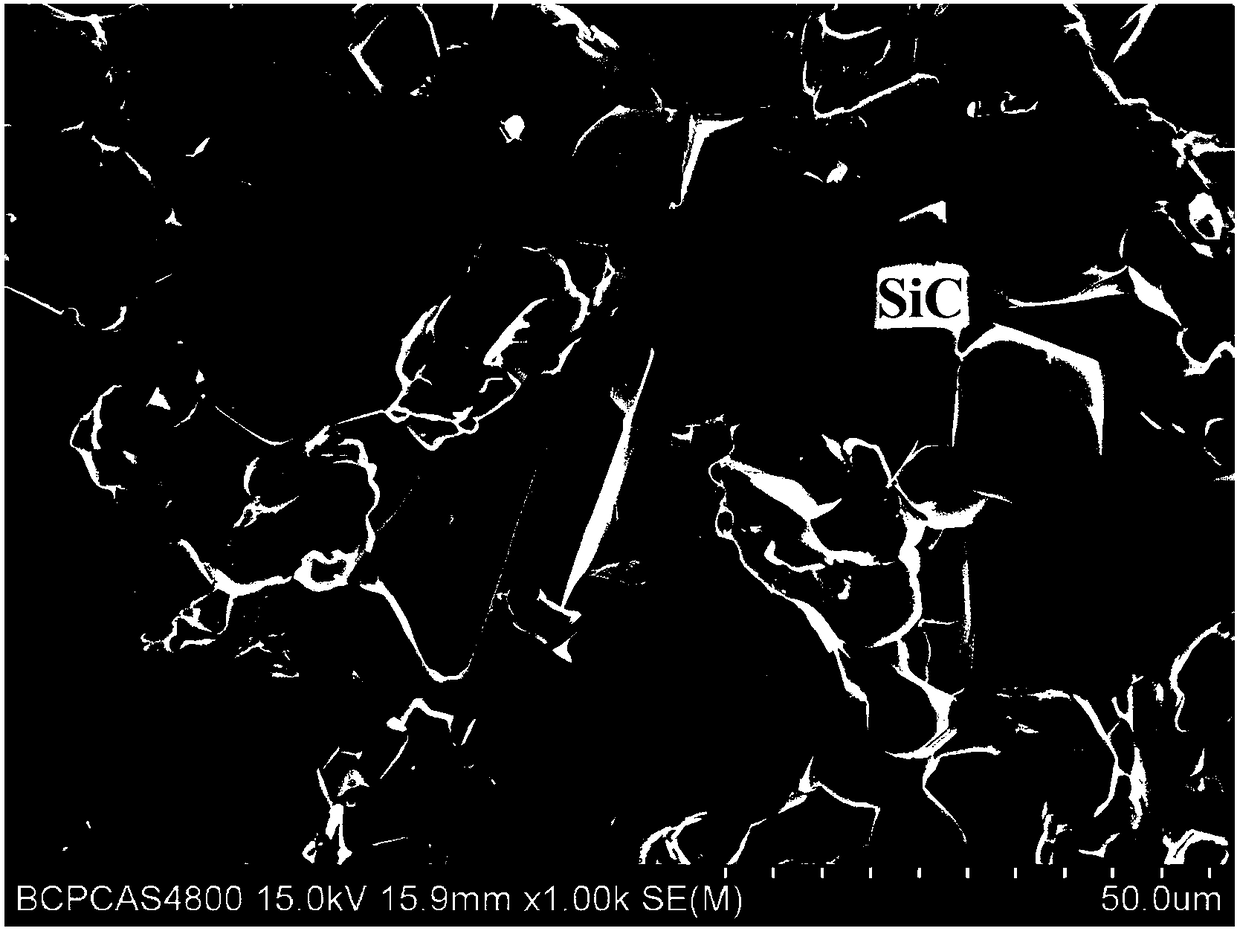

High-hardness ceramic composite material of boron carbide-titanium boride-silicon carbide and preparation method thereof

The invention relates to a high-hardness ceramic composite material of boron carbide-titanium boride-silicon carbide and a preparation method thereof, and belongs to the technical field of a ceramic material. The composite ceramic is prepared from boron carbide, silicon carbide and silicon powder in a hot-pressing sintering manner via reaction. The composite ceramic contains 50-90wt% of boron carbide, 27-5.4wt% of titanium boride and 23-4.6wt% of silicon carbide. The defects of overhigh sintering temperature, and difficulty of improvement of the toughness and the hardness at the same time of the existing boron carbide ceramic are solved; carbon generated by reaction of the boron carbide and the titanium boride is removed by monatomic silicon; and the carbon for reducing the hardness of the base material is converted into hard material silicon carbide which is evenly dispersed, so as to play roles in enhancing the toughness and improving the material hardness. The high-toughness boron carbide composite ceramic can be prepared at low temperature on the premise of not reducing the hardness of a base body.

Owner:WUHAN UNIV OF TECH

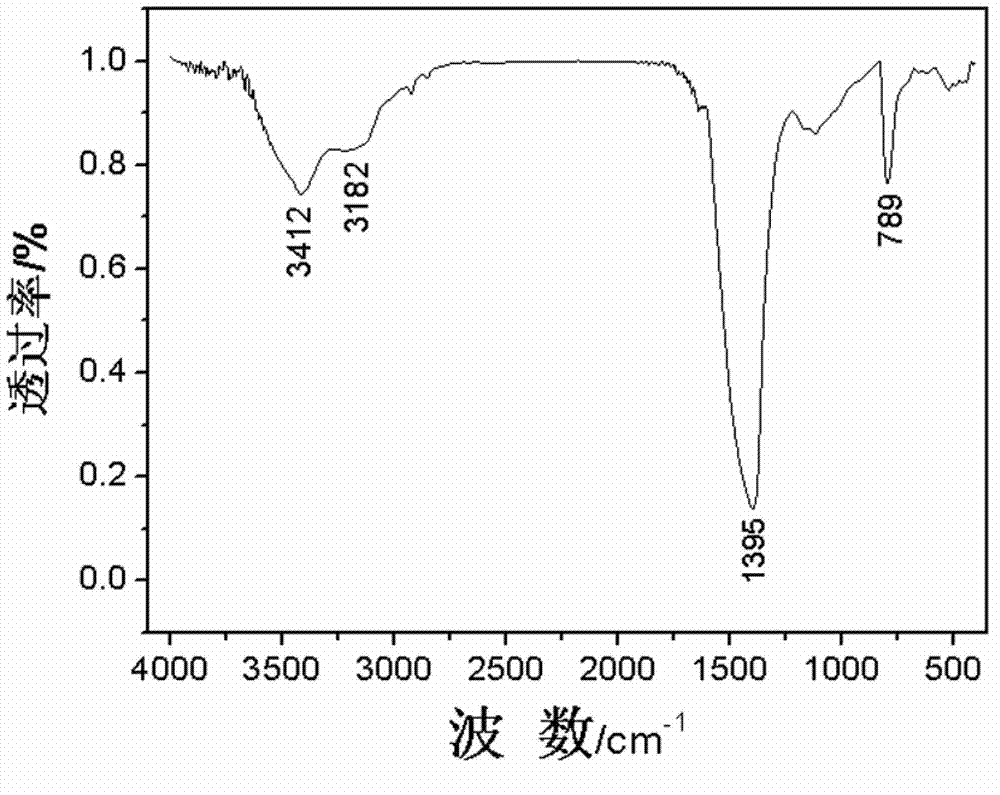

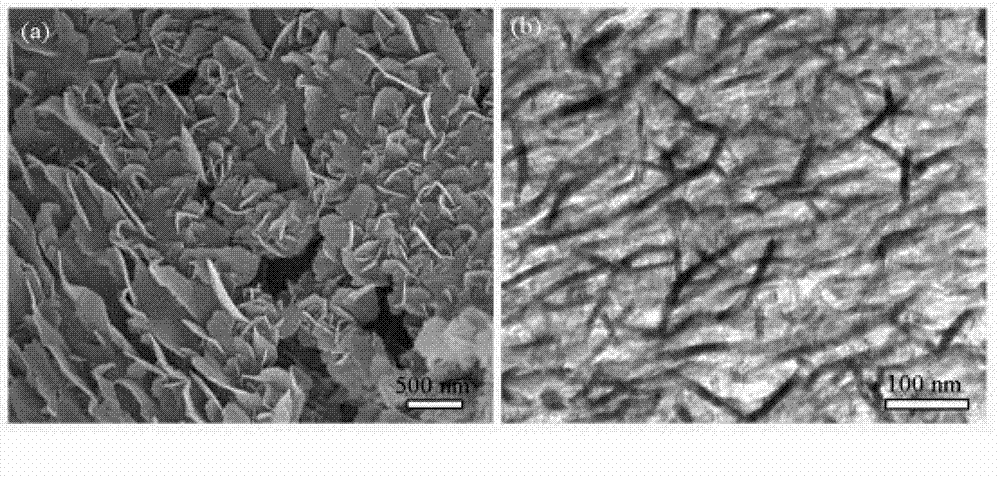

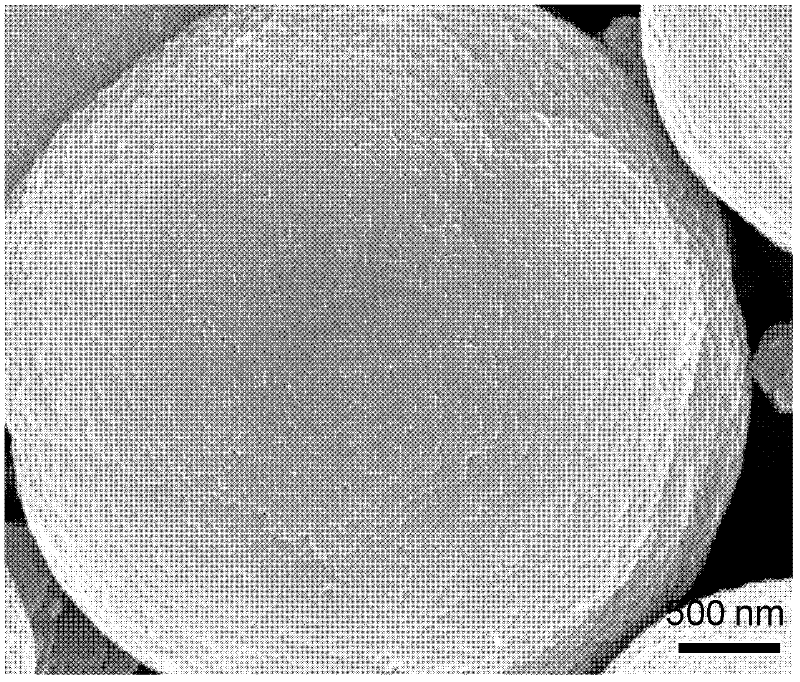

Hexagonal boron nitride two-dimensional ultrathin nanometer sheet as well as preparation method and application thereof

InactiveCN103043634ALow reaction temperatureIncrease productionMaterial nanotechnologyNitrogen compoundsHexagonal boron nitrideHeat stability

The invention discloses a hexagonal boron nitride two-dimensional ultrathin nanometer sheet as well as a preparation method and application thereof and belongs to the technical field of nanometer materials. According to the invention, metal boride (such as calcium boride, lanthanum boride, magnesium boride, titanium boride and the like) is adopted as a boron resource; ammonium salt (such as ammonium chloride, ammonium bromide, ammonium nitrate and the like) is adopted as a nitrogen source; and the hexagonal boron nitride two-dimensional ultrathin nanometer sheet with the thickness of 0.5-4.0nm is obtained through the reaction under a mild condition (at the temperature of 500-600 DEG C). The invention aims to realize the macro-quantity preparation of the hexagonal boron nitride two-dimensional ultrathin nanometer sheet at the mild temperature by adopting cheaper raw materials; the preparation method has the advantages of saving the energy, simplifying the experimental step and greatly reducing the product cost; and due to the high heat conductivity, heat stability and chemical stability, the hexagonal boron nitride two-dimensional ultrathin nanometer sheet can be applied to the fields of heat dissipation materials, polymer filling materials, catalyst carriers and the like.

Owner:SOUTH CHINA AGRI UNIV

Polyester polymer and copolymer compositions containing titanium and yellow colorants

There is provided a process for increasing the yellowness of polyester polymer particles, preforms, bottles, and concentrates, containing a polyester polymer such as polyethylene terephthalate and copolymers by adding a yellow colorant and reheat agent particles comprising titanium, alloys of titanium, titanium nitride, titanium boride, titanium carbide, or combinations thereof to a melt phase polymerization process for making the polyester polymer to adding any one of the colorant or particles to a polyester polymer.

Owner:EASTMAN CHEM CO

High purity zirconium boride / hafnium boride and preparation of superhigh temperature ceramic target material

The invention discloses a method for preparing a high-purity ultrahigh-temperature ceramic target material which belongs to the technical field of ceramic target materials, and in particular provides a method for preparing high-purity zirconium / hafnium boride powder and a ceramic target material thereof. The method comprises the steps of taking high-purity Zr powder, Hf powder and high-purity B powder as raw materials, adopting a self-propagating method to prepare high-purity ZrB2 and HfB2 powder respectively and then adopting a high-temperature high-pressure hot-pressing molding process to prepare a high-purity dense zirconium / hafnium boride ultrahigh-temperature ceramic target material, wherein the relative density of the target material reaches 95 to 99 percent. Relative to the prior art, metal powder in the method is slightly excessive when the materials are mixed, so as to make up for the metal loss during self-propagating reaction and further guarantee the component unicity of products. Relative to pressureless sintering, the sintering temperature needed in the method is greatly lowered; in addition, as the hot-pressing process adopts two-stage temperature, blank is uniform in temperature field, so as to ensure that the target material with uniform density can be obtained in the late hot-pressing process.

Owner:有研资源环境技术研究院(北京)有限公司

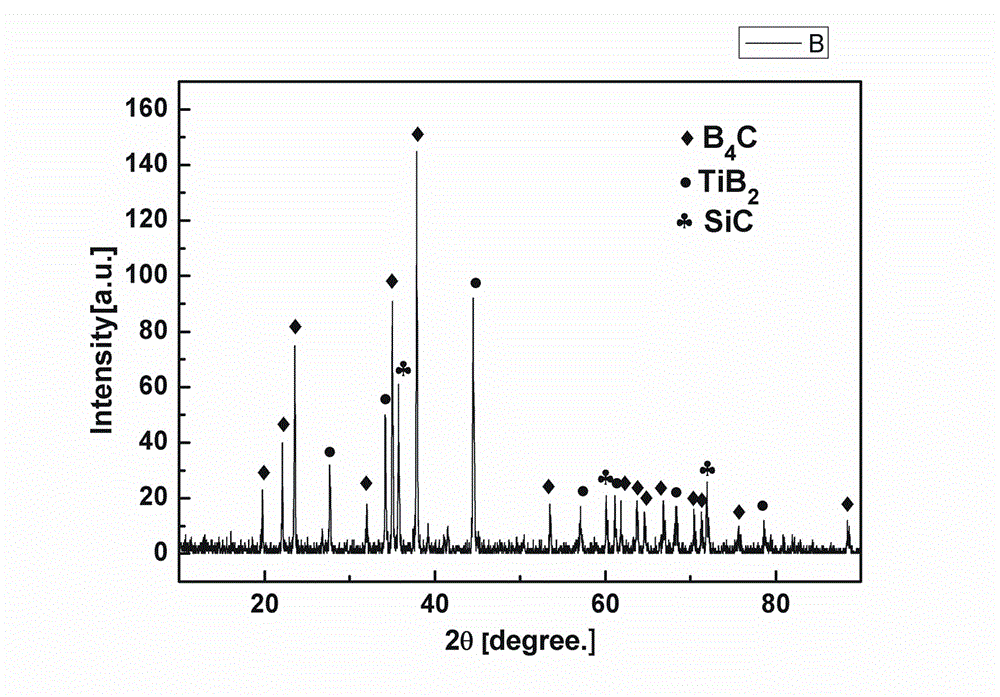

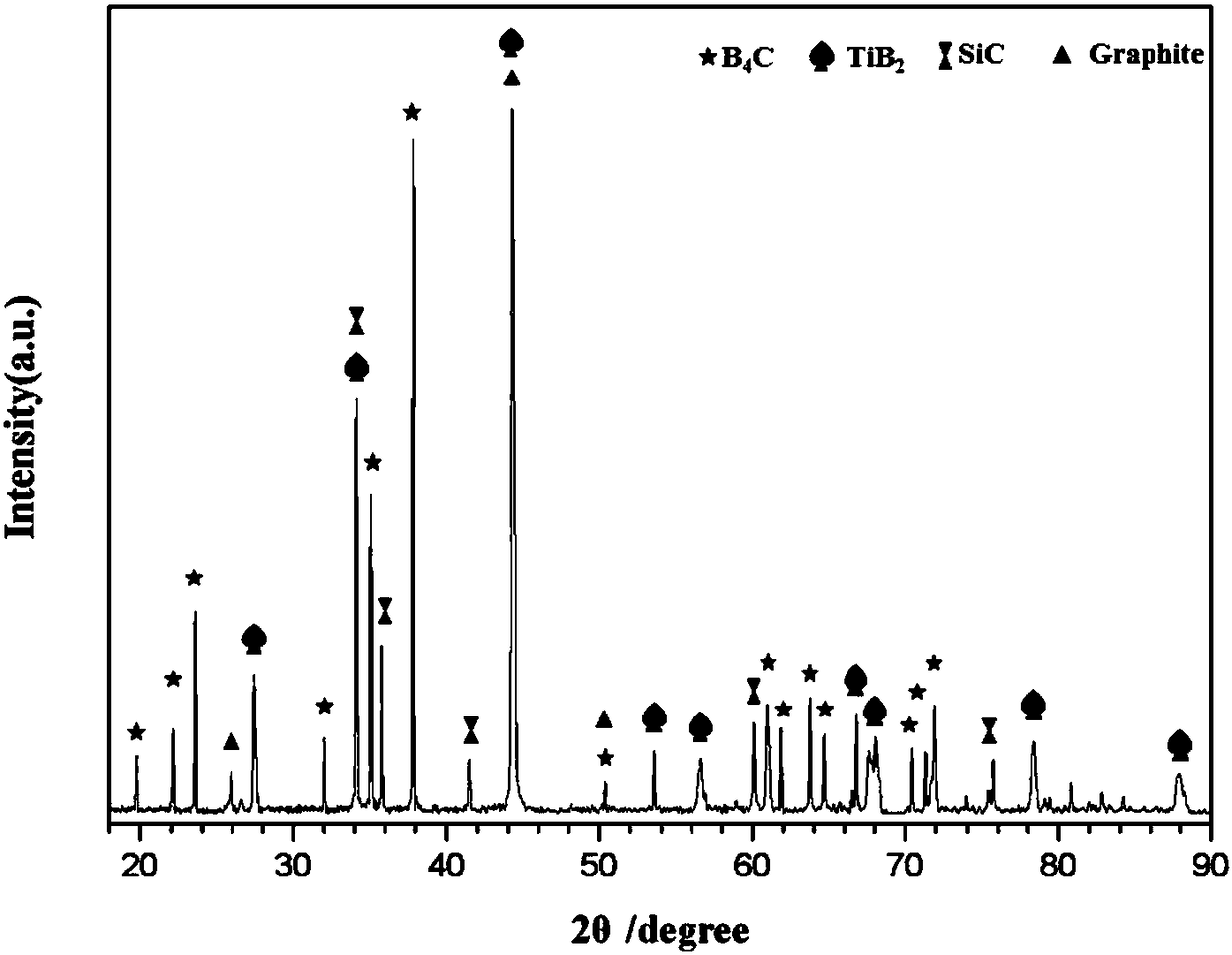

Boron carbide-titanium boride multiphase ceramic material and pressureless sintering preparation method thereof

The invention relates to a boron carbide-titanium boride multiphase ceramic material and a pressureless sintering preparation method thereof, and belongs to the technical field of structural ceramics.Calculated by using total mass of a multiphase ceramic raw material as 100%, the boron carbide-titanium boride multiphase ceramic material is prepared from the following components according to a mass percent: 50%-80% of boron carbide powder, 10%-30% of titanium boride powder, 3%-20% of amorphous carbon powder, and 5%-30% of silicon powder. The method comprises the following steps: mixing raw materials and adding to medium solution, ball-milling and mixing to obtain mixed slurry; after drying the mixed slurry, grinding, sieving to obtain powder; performing compression mould forming on the powder, and performing isostatic cool pressing to obtain a green body; and performing high-temperature pressureless sintering on the green body in vacuum or a protecting gas to obtain the boron carbide-titanium boride multiphase ceramic material. The toughness of the material is apparently improved, the production cost is greatly reduced, and the material can be extensively suitable for the fields ofnuclear power, light armored protection and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Titanium boride-zirconium boride-silicon carbide self-lubricating composite ceramic material and preparation method thereof

The invention belongs to the technical field of engineering materials and particularly relates to a titanium boride-zirconium boride-silicon carbide self-lubricating composite ceramic material and a preparation method thereof. Powdery TiB2 is used as the matrix material of the ceramic material, ZrB2 is used as a strengthening phase, SiC is used as a toughening phase ingredient, wherein the percents by volume of the ingredients are as follows: 55.0-85.0% of TiB2, 10.0-40.0% of ZrB2 and 5.0% of SiC. According to the preparation method provided by the invention, a reaction film with a lubrication function is formed on the material surface through the chemical reaction of the titanium boride-zirconium boride-silicon carbide self-lubricating composite ceramic material under the action of high-temperature friction, thus realizing self lubrication; and the composite ceramic material of the invention has the advantages of high strength, high bending strength, high fracture toughness and the like and can be used for the preparation of metal cutting tools, bearings, nozzles, etc.

Owner:LUOYANG INST OF SCI & TECH

Titanium boride

Owner:CRISTAL US INC

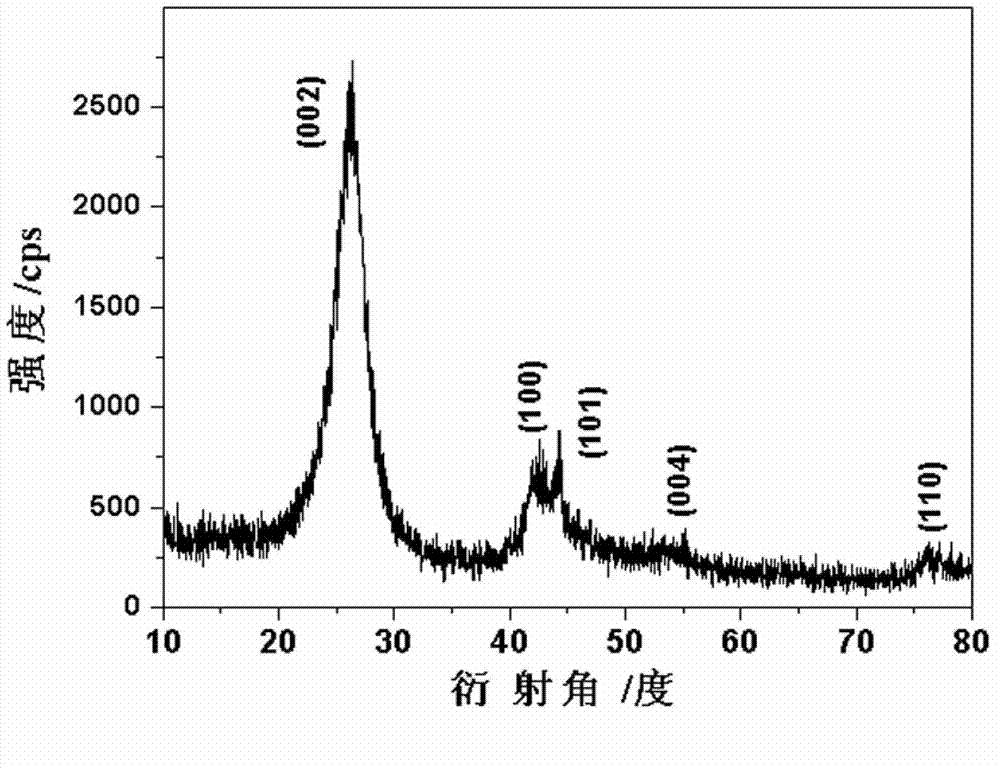

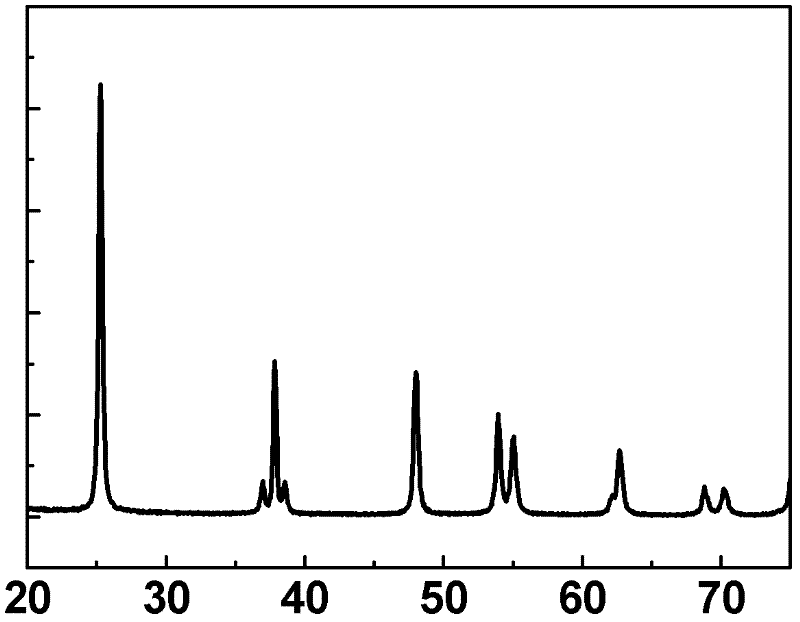

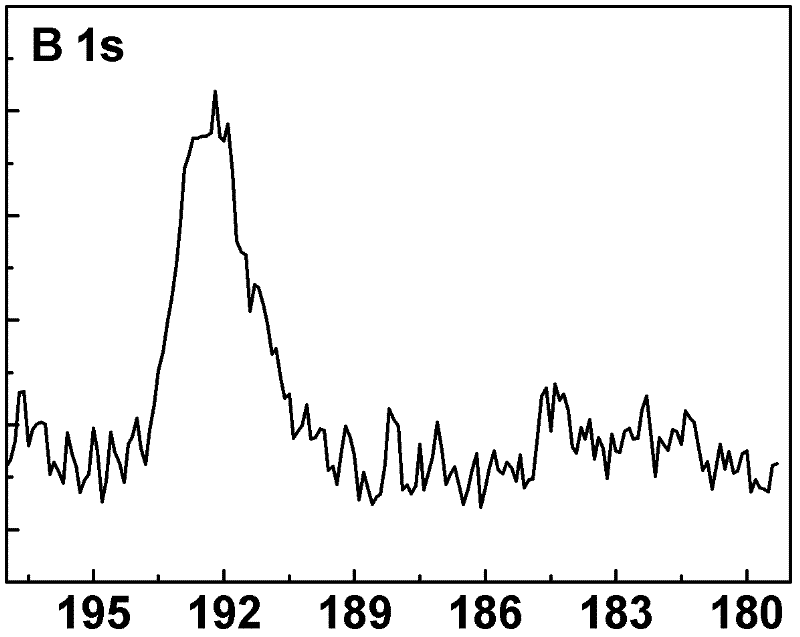

Method for preparing boron-doped titanium dioxide crystal containing specific crystal plane

ActiveCN102343260ASolve the problem of selectivitySolving activityCatalyst activation/preparationCooking & bakingLight Activity

The invention relates to the field of photocatalysis materials, in particular to a method for preparing a boron-doped titanium dioxide crystal containing a specific crystal plane. The method comprises the following steps of: loading titanium boride serving as a precursor into a reaction kettle of an acid solution containing different anions; sealing the reaction kettle; putting the reaction kettle into a baking oven for heating; taking a reaction sample out; washing with deionized water and drying to obtain a boron-doped titanium dioxide crystal containing a specific crystal plane in an acid system containing anions; and further thermally treating the boron-doped titanium dioxide crystal under different atmospheres, adjusting the distribution of boron in the crystal, and introducing a newheteroatom. In the invention, the boron-doped titanium dioxide crystal can be directly prepared by taking the titanium boride as the precursor and taking the anions as a morphology control agent, andthe surface of the boron-doped titanium dioxide crystal consists of an identifiable crystal plane, so that effective adjustment and control of the electronic structure of the photocatalysis material are effectively realized, and the defects of poor reaction selectivity and unavailable invisible light activity of the photocatalysis material are overcome.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Ceramic material suitable for repair of a space vehicle component in a microgravity and vacuum environment, method of making same, and method of repairing a space vehicle component

A precursor of a ceramic adhesive suitable for use in a vacuum, thermal, and microgravity environment. The precursor of the ceramic adhesive includes a silicon-based, preceramic polymer and at least one ceramic powder selected from the group consisting of aluminum oxide, aluminum nitride, boron carbide, boron oxide, boron nitride, hafnium boride, hafnium carbide, hafnium oxide, lithium aluminate, molybdenum silicide, niobium carbide, niobium nitride, silicon boride, silicon carbide, silicon oxide, silicon nitride, tin oxide, tantalum boride, tantalum carbide, tantalum oxide, tantalum nitride, titanium boride, titanium carbide, titanium oxide, titanium nitride, yttrium oxide, zirconium diboride, zirconium carbide, zirconium oxide, and zirconium silicate. Methods of forming the ceramic adhesive and of repairing a substrate in a vacuum and microgravity environment are also disclosed, as is a substrate repaired with the ceramic adhesive.

Owner:COI CERAMICS

Boron-containing titanium alloy powder for additive manufacturing and preparation method thereof

ActiveCN107841654AGuaranteed uniformityImprove performanceAdditive manufacturing apparatusTi 6al 4vImpurity

The invention discloses boron-containing titanium alloy powder for additive manufacturing and a preparation method thereof and belongs to the technical field of titanium alloy materials. The boron-containing titanium alloy powder comprises the chemical components of, by weight, 4.5%-5.5% of Al, 3.5%-4.5% of V, 0.05%-1% of B and the balance Ti and inevitable impurity elements. Compounding is conducted according to the required alloy components, raw materials such as titanium boride and titanium sponge are mixed evenly and then pressed into an electrode; the electrode is subjected to vacuum consumable smelting into an ingot; and the ingot is forged into a bar, and then the bar is prepared into the titanium alloy powder through a non-crucible induction melting gas atomizing method. The detection result of the structural performance of a member manufactured by adopting the boron-containing titanium alloy powder shows that compared with existing Ti-6Al-4V powder, the boron element is addedso that cylindrical crystals caused by the temperature gradient in the additive manufacturing process can be weakened significantly, meanwhile crystal grains can be refined, and the mechanical performance of a material is improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Electrode active material for lead-acid storage battery

InactiveCN106876666AHigh specific powerIncrease specific energyLead-acid accumulatorsCell electrodesTitanium nitrideAtomic cluster

The invention discloses an electrode active material for a lead-acid storage battery. The electrode active material comprises lead powder and a non-metallic titanium compound; the lead powder comprises one or more kinds of metal lead powder, ball-milling lead powder, Barton lead powder, Pb<2>O powder, PbO powder, Pb<2>O<3> powder, Pb<3>O<4> powder and PbO<2> powder; and the non-metallic titanium compound comprises one or more kinds of titanium sulfide, titanium nitride, titanium boride, titanium carbide, titanium hydride, titanium hydroxide, titanium silicide, a symbiotic blend of the abovementioned compounds on an atomic micro level or atomic cluster level, and doped compounds formed by doping the abovementioned compounds with one or more kinds of F, Sb, Sn, Ca, Bi, Co, Ca, Al, Mg, N, P, O and C. By virtue of the electrode active material for the lead-acid storage battery with an improved formula, the specific power, specific energy, charging-discharging efficiency, cycle life, low-temperature performance and the like of the lead-acid storage battery can be obviously improved.

Owner:杨春晓

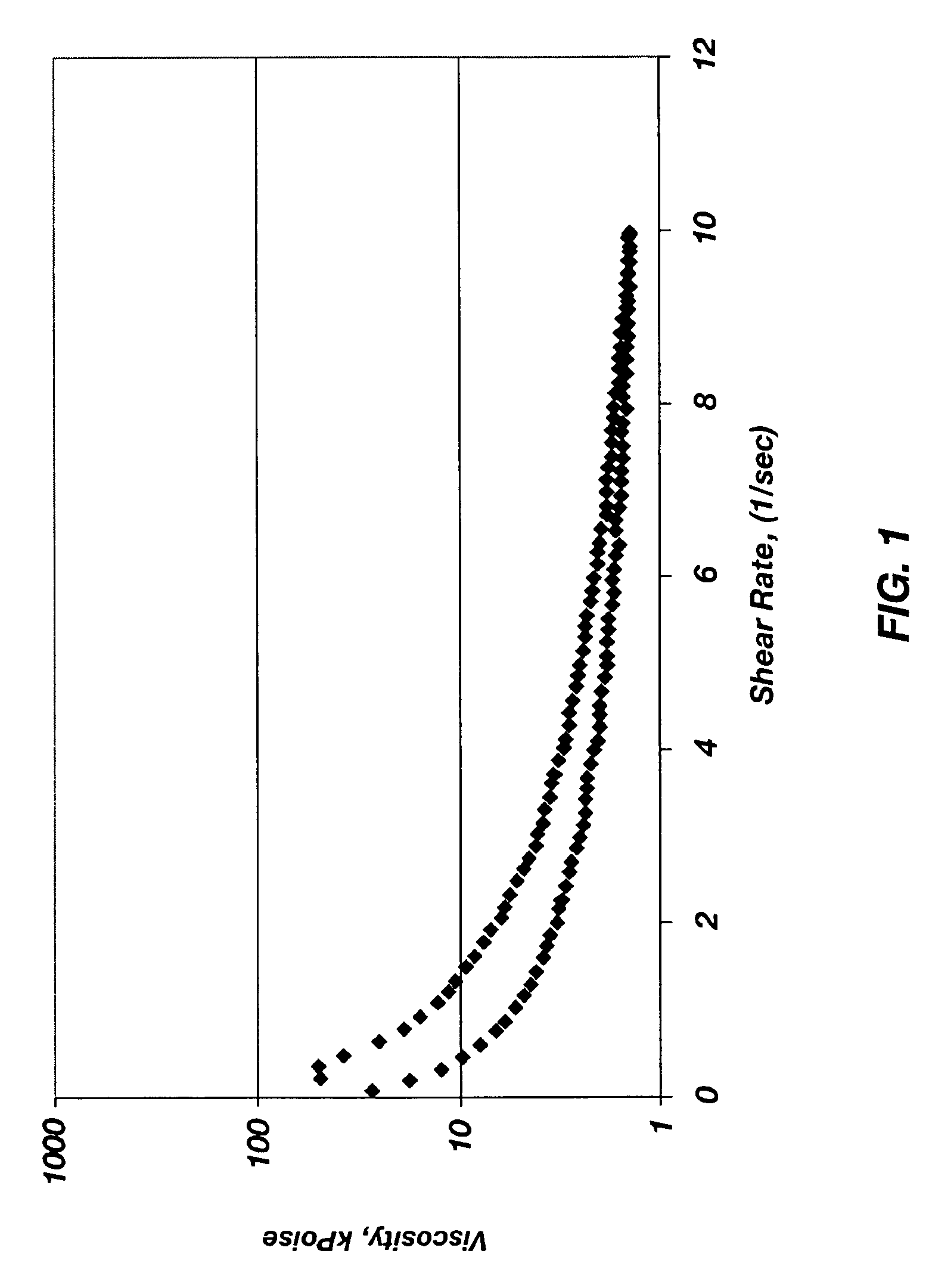

Large granular spherical metal ceramic nano composite spraying powder

The invention relates to macro aggregate ball shape metal ceramic nm compounding spray coating powder that contains titanium diboride 50-70wt%, cobalt 10-24wt%, chromium powder 6-13wt%, tungsten boride 5-11%, and the other is rare earth powder. Mixing the powder according to the ratio, wet method ball milling, centrifuging, pressure spraying graining, vacuum heat treatment technology and grain classifying process, the 20-45um and 45-75um granularity of powder would be gained. It has good abrasion resistant, high temperature resistant and corrosion resistance capability.

Owner:SHANGHAI JIAO TONG UNIV

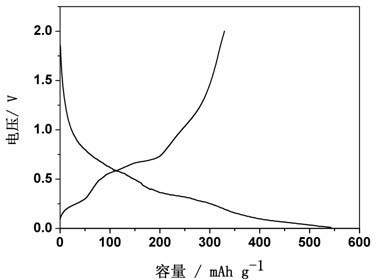

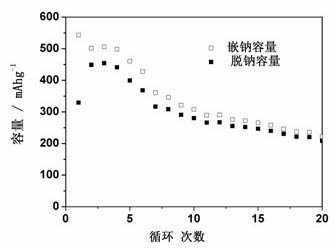

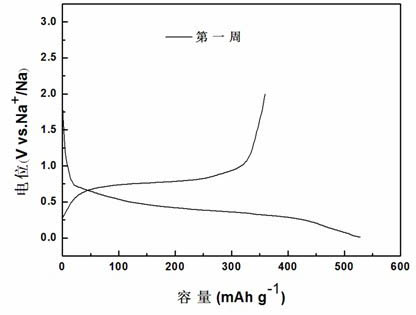

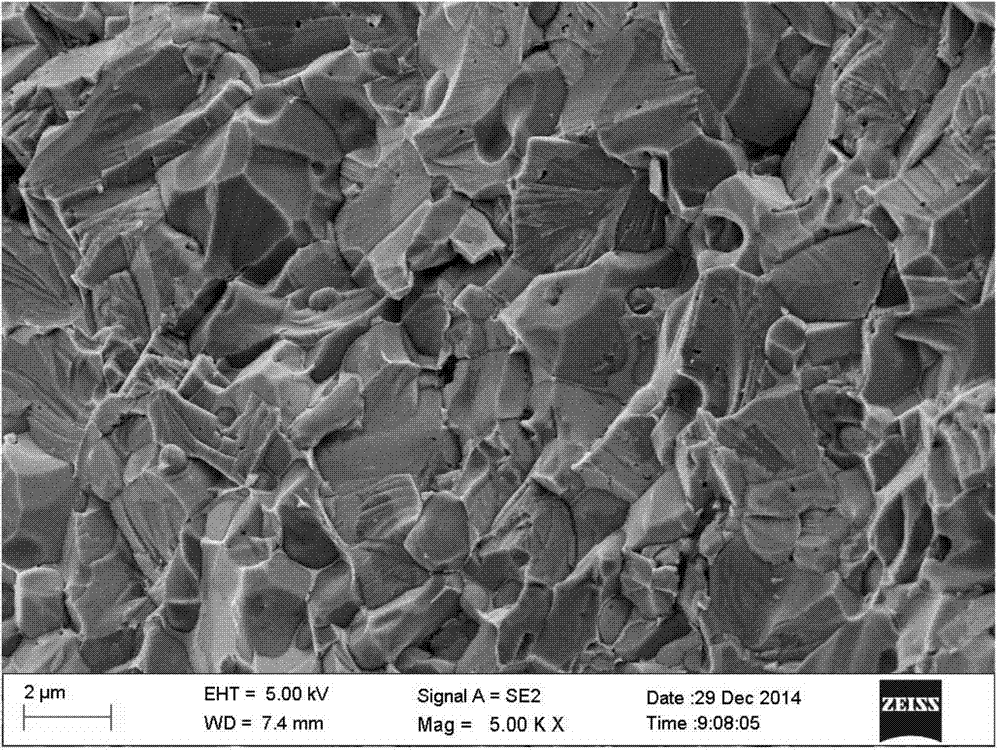

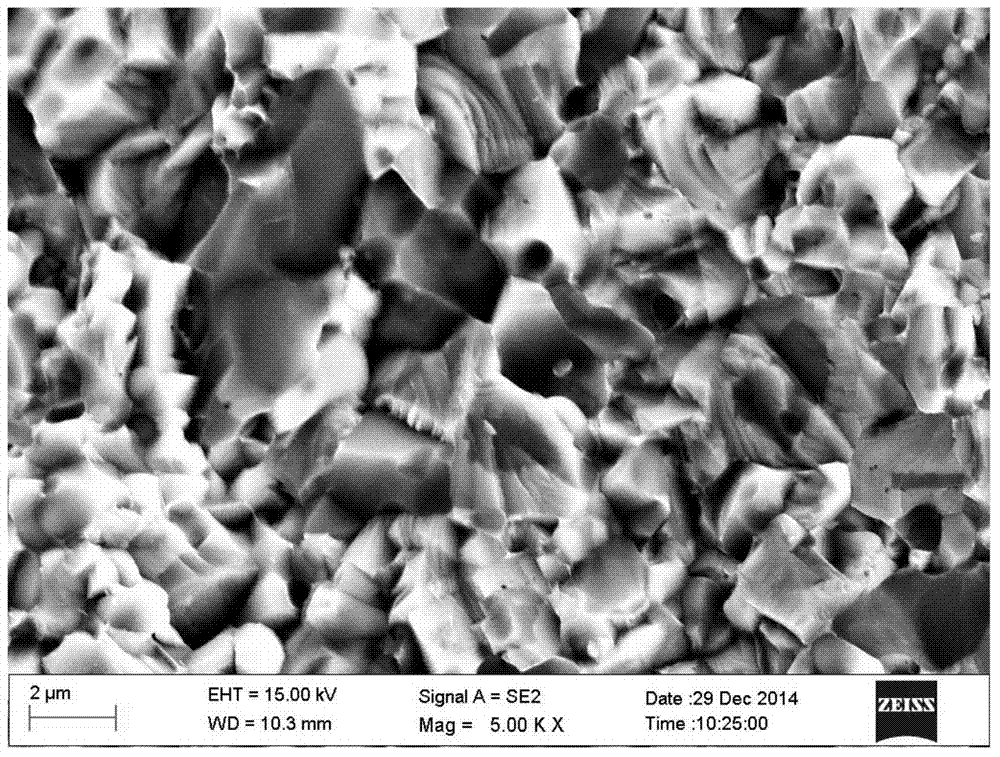

Anode material of lithium-ion battery

InactiveCN102544462AGood sodium intercalation and desorption capacityHigh reversible capacityCell electrodesSecondary cellsElectrochemical responseConductive polymer

The invention discloses an anode material of a lithium-ion battery. The anode material can form alloy with sodium (Na). The anode material consists of metal M which can form the alloy with Na ions and an inert medium A, wherein the metal M which can form the alloy with the Na ions is one or more of stannum (Sn), antimony (Sb) and plumbum (Pb); and the inert medium A is one or more of a carbon material, a conducting polymer, copper (Cu), iron (Fe), aluminum (Al), titanium (Ti), silicon carbide (SiC), titanium carbide (TiC), wolfram carbide (WC), titanium nitride (TiN) and titanium boride (TiB). In the material, the metal M and the Na can be alloyed or de-alloyed through electrochemical reaction, and energy conversion is performed; and the inert medium A is mainly used for scattering, stabilizing and electrically conducting the material. The anode material of the lithium-ion battery is high in specific capacity, low in cost and environment-friendly.

Owner:WUHAN UNIV

Method for preparing novel energy conservation inert anode material for zinc electrodeposition

ActiveCN101343758AShort production processDecrease cell voltagePhotography auxillary processesElectrodesMolten stateLead dioxide

The invention relates to a novel energy conserving inert anode material preparation method used for zinc galvanic deposition. The method adopts a multi-pulse galvanic deposition method to prepare and obtain lead-lead dioxide-titanium boride-cerium dioxide-polyanion composite plating layer (Pb-PbO2-TiB2-CeO2-PAN) energy conserving inert anode material on the aluminum base body, and when the composite electrode material is uaded in the metal galvanic deposition, a compact film layer is formed on the anode surface, to cause the anode to be in a non-molten state; the adoption of the composite electrode can obviously reduce the voltage of the galvanic deposition cell, and the electric consumption is reduced; simultaneously the electroplating solution cost of the invention is low, the equipment investment is less, the land occupation is less, and the effect is rapid; and the cell voltage can be reduced by 0.2 to 0.5V when zinc galvanic deposition is performed, and the current efficiency is improved by 1 to 3 percent.

Owner:晋宁理工恒达科技有限公司

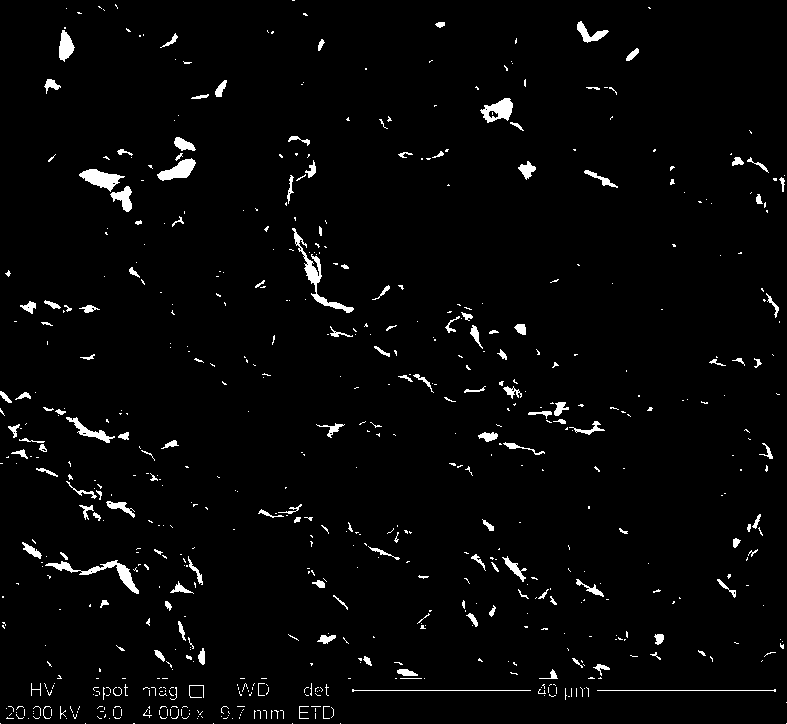

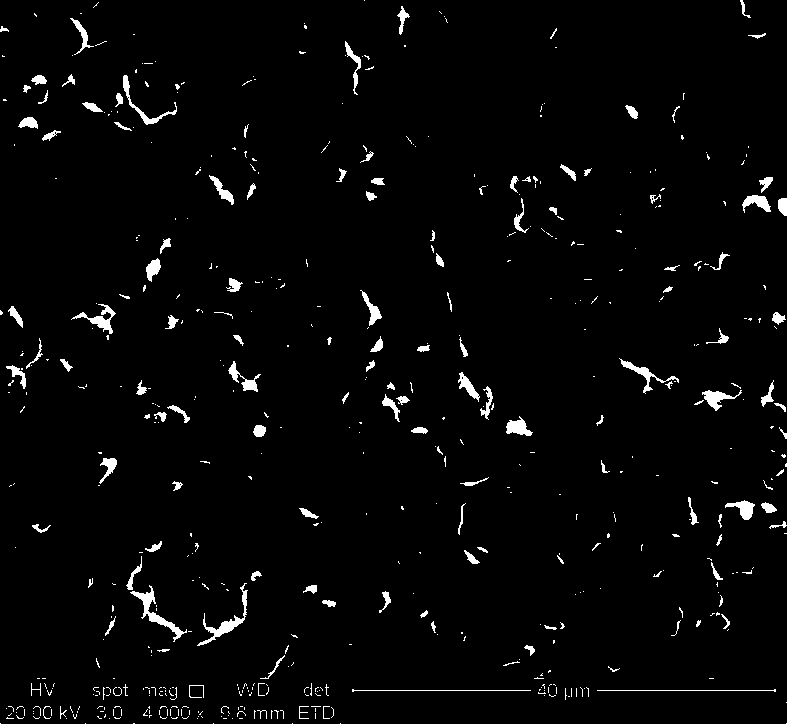

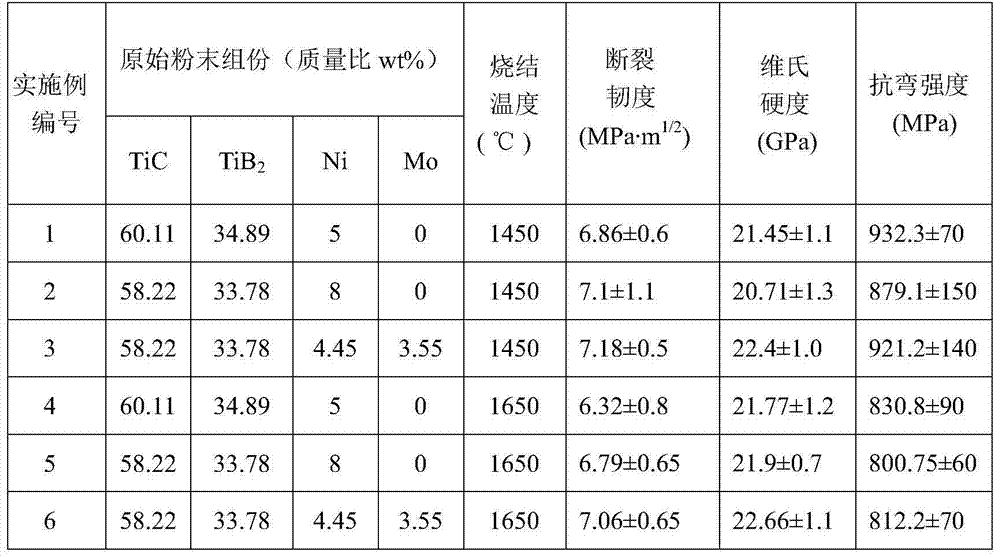

Preparation method of titanium boride compounded titanium carbide-based metal ceramic cutter material

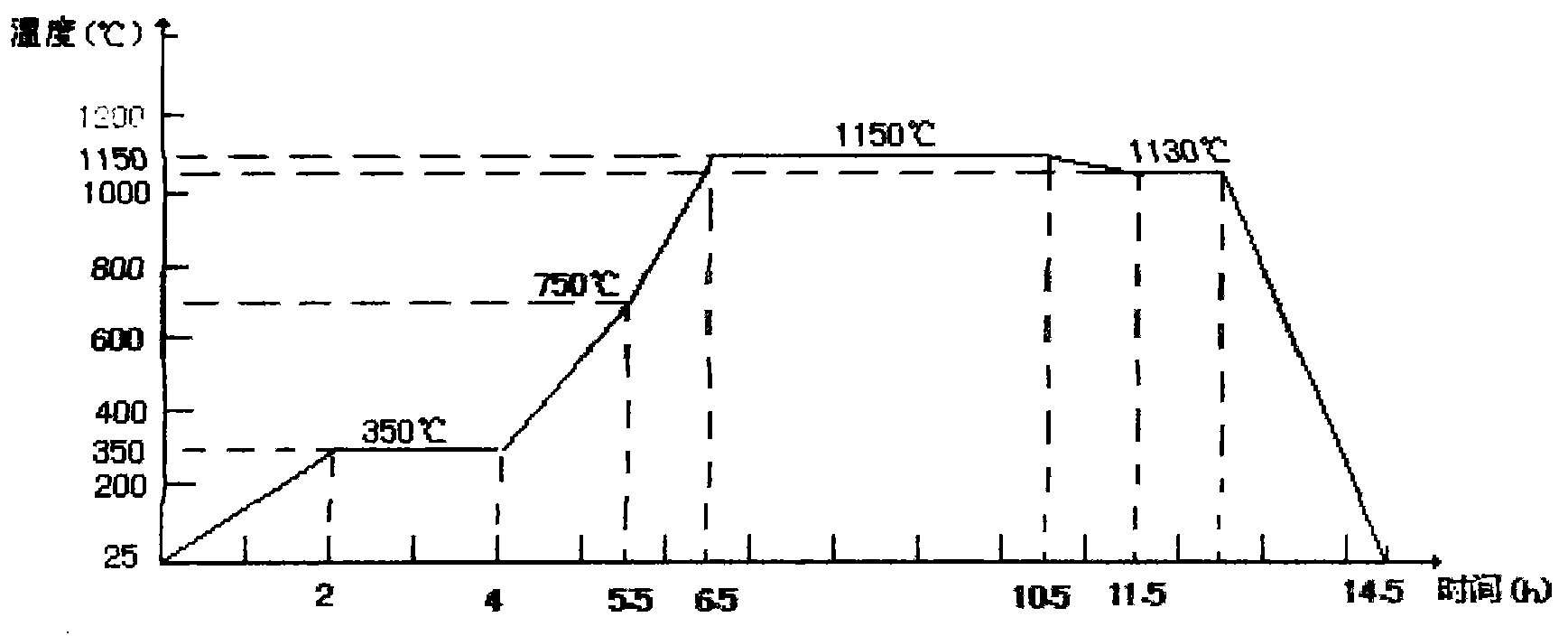

The invention relates to a novel material and particularly relates to a preparation method of a titanium boride compounded titanium carbide-based metal ceramic cutter material. The titanium boride compounded titanium carbide-based metal ceramic cutter material comprises the following primary powder in percentage by mass: 58.22wt%-60.11wt% of TiC, 33.78wt%-34.89wt% of TiB2, 0-3.55wt% of Mo and 4.45wt%-8wt% of Ni. A preparation process comprises the following steps: respectively filling a ball milling cylinder with TiC and TiB2 in a formula, and carrying out wet milling for 48 hours in alcohol by virtue of a tungsten carbide ball; carrying out vacuum drying at 100-120 DEG C, filtering by virtue of a 100-mesh sieve, and packaging for later use; weighing primary powder Ni and Mo and ball-milled TiC and TiB2 by mass, and mixing, carrying out wet milling for 48 hours, carrying out vacuum drying, and packaging for later use; weighing mixed powder by weight in a cutter preparation process, adding the mixed powder into a graphite mold, and carrying out vacuum sintering; heating from the room temperature to 700 DEG C at a heating rate of 50DEG C / min, and maintaining the temperature for 2min; and heating from 1450 DEG C to 1650 DEG C at the heating rate of 50DEG C / min, and carrying out thermal pressure sintering forming when a pressure of 32MPa is applied and the temperature is maintained for 30min. The preparation process is simple, stable, low in cost and high in efficiency; when the high hardness of the prepared cutter material is preserved, the bending strength and the fracture toughness are improved; and the prepared cutter material can be applied to other high-temperature wear-proof structural components.

Owner:SHANDONG UNIV

Cubic Boron Nitride Compact

InactiveUS20080302023A1Poor EDM-cuttabilityImprove conductivityPigmenting treatmentOther chemical processesBorideAluminium carbide

A polycrystalline cubic boron nitride compact which comprises greater than 75 volume % and not greater than 90 volume % cubic boron nitride particles, the cubic boron nitride particles comprising particles of at least two average particle sizes, and a binder phase constituting the balance of the compact and comprising at least one titanium compound selected from titanium boride, titanium nitride, titanium carbide and titanium carbonitride and at least one aluminium compound selected from aluminium oxide, aluminium boride, aluminium nitride, aluminium carbide and aluminium carbonitride.

Owner:GOUDEMOND IAIN PATRICK +2

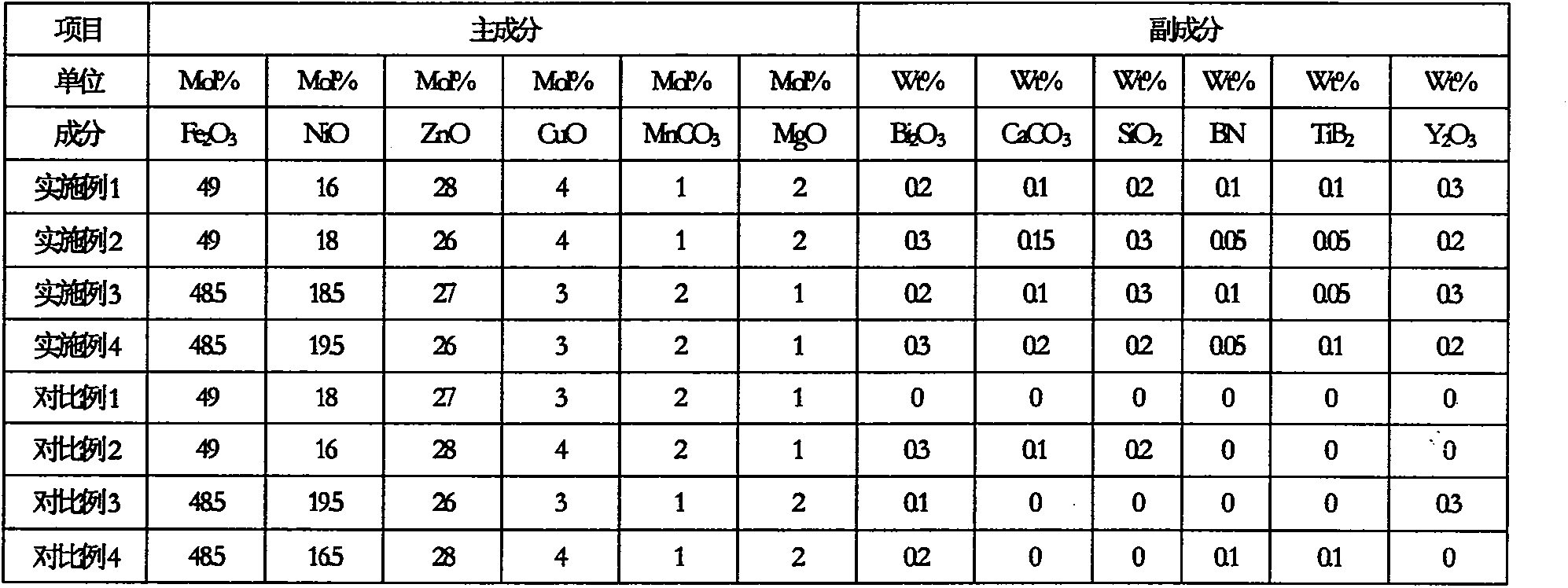

NiZn soft magnetic ferrite and preparation method thereof

A NiZn soft magnetic ferrite and a preparation method thereof. The NiZn soft magnetic ferrite contains main components and auxiliary components. The main components comprise ferric oxide, nickel oxide, zinc oxide, copper oxide, manganese carbonate and magnesium oxide; and the auxiliary components comprise bismuth oxide, calcium carbonate, silica, boron nitride, titanium boride and yttrium oxide (rare earth oxide). A material obtained by the preparation method has high permeability, high BS, high strength and high thermal shock resistance, and can meet the performance requirements of soft magnetic ferrite materials for an SMD power inductor.

Owner:ZHAOQING CHAMPION FERRITE TECH

Article having a dispersion of ultrafine titanium boride particles in a titanium-base matrix

ActiveUS7531021B2Reduce incidenceHigh operating temperatureThin material handlingMaximum dimensionMicrometer

An article includes a microscale composite material having a matrix with more titanium than any other element, and a dispersion of titanium boride particles in the matrix. At least about 50 volume percent of the titanium boride particles have a maximum dimension of less than about 2 micrometers.

Owner:GENERAL ELECTRIC CO

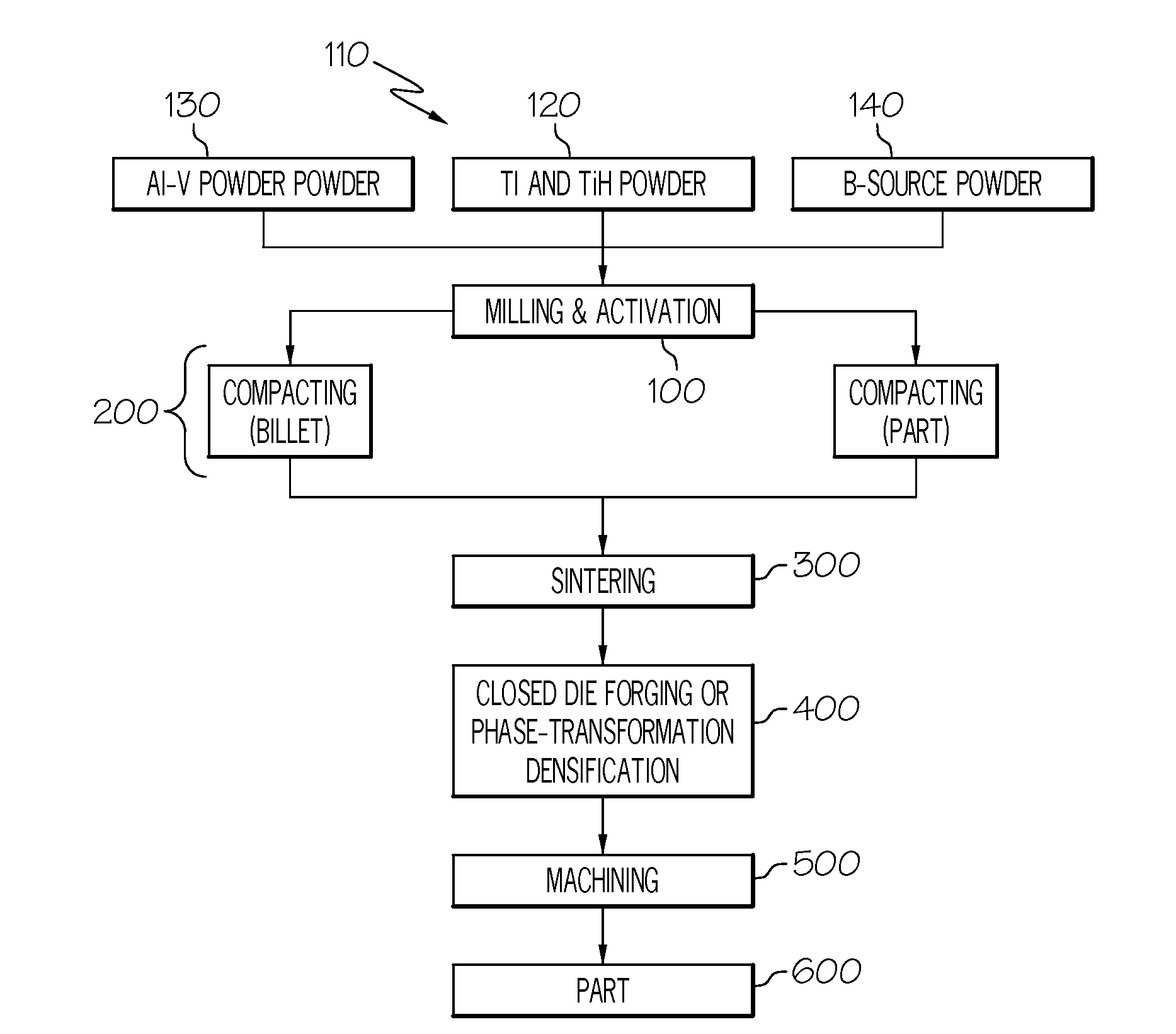

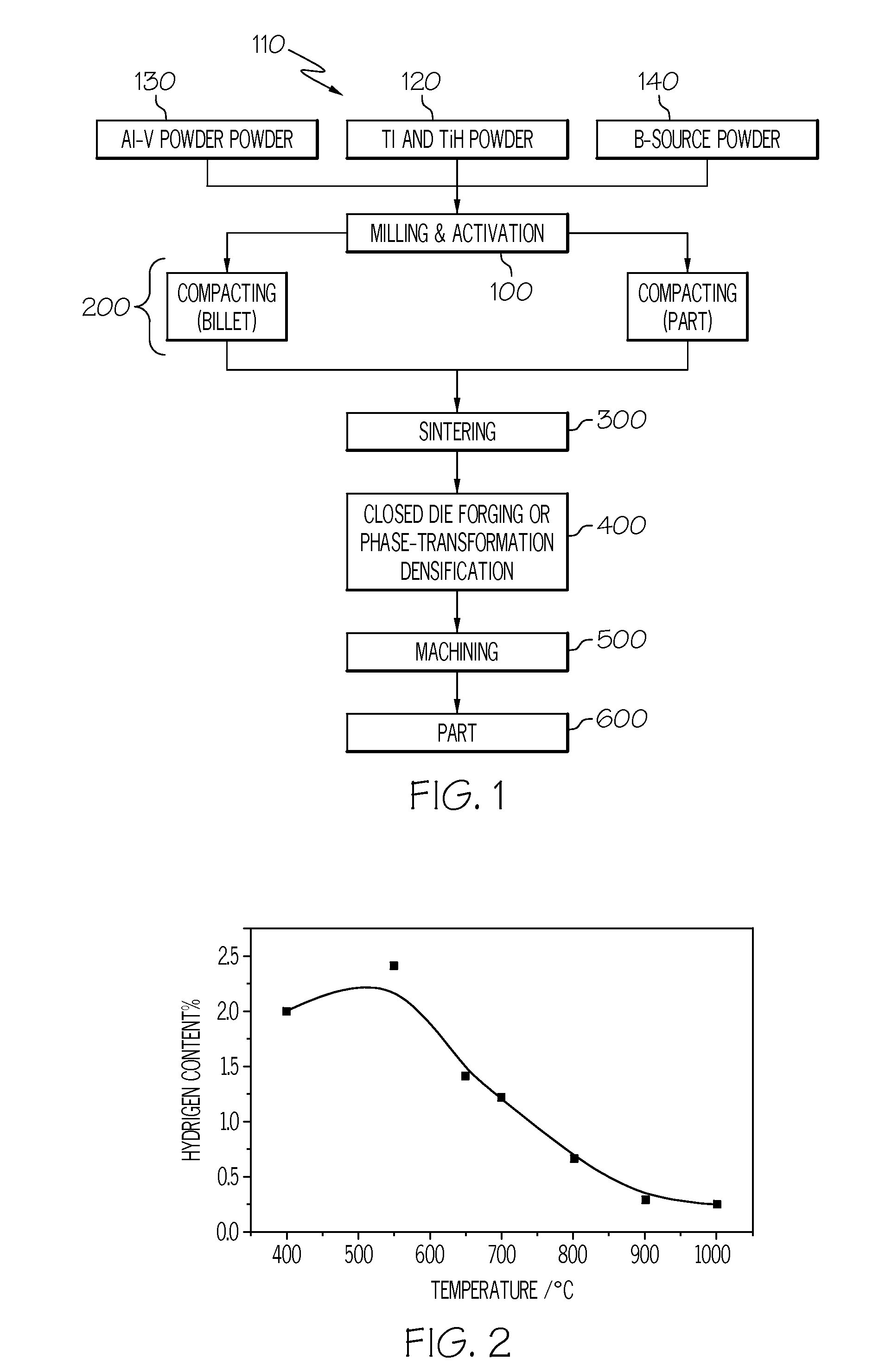

METHOD OF MAKING TITANIUM ALLOY BASED AND TiB REINFORCED COMPOSITE PARTS BY POWDER METALLURGY PROCESS

A method of preparing a titanium-based metal matrix composite. In one form, titanium hydride can be added to substantially pure titanium, an alloying material and a source of boron such that a mixture of these materials can be compacted and sintered in a powder metallurgy process to produce a component made up of a titanium boride reinforced titanium alloy. In another form, the substantially pure titanium, alloying material and source of boron could be vigorously mixed (with or without the titanium hydride) to such an extent that oxide films that may have built up on the titanium precursor can be removed to minimize the presence of oxygen in the manufactured component.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com