Titanium boride

a technology of titanium boride and ti powder, which is applied in the field of titanium boride, can solve the problems that no current approach to boron addition to ti powder can achieve this type of distribution, and achieve the effect of removing concerns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

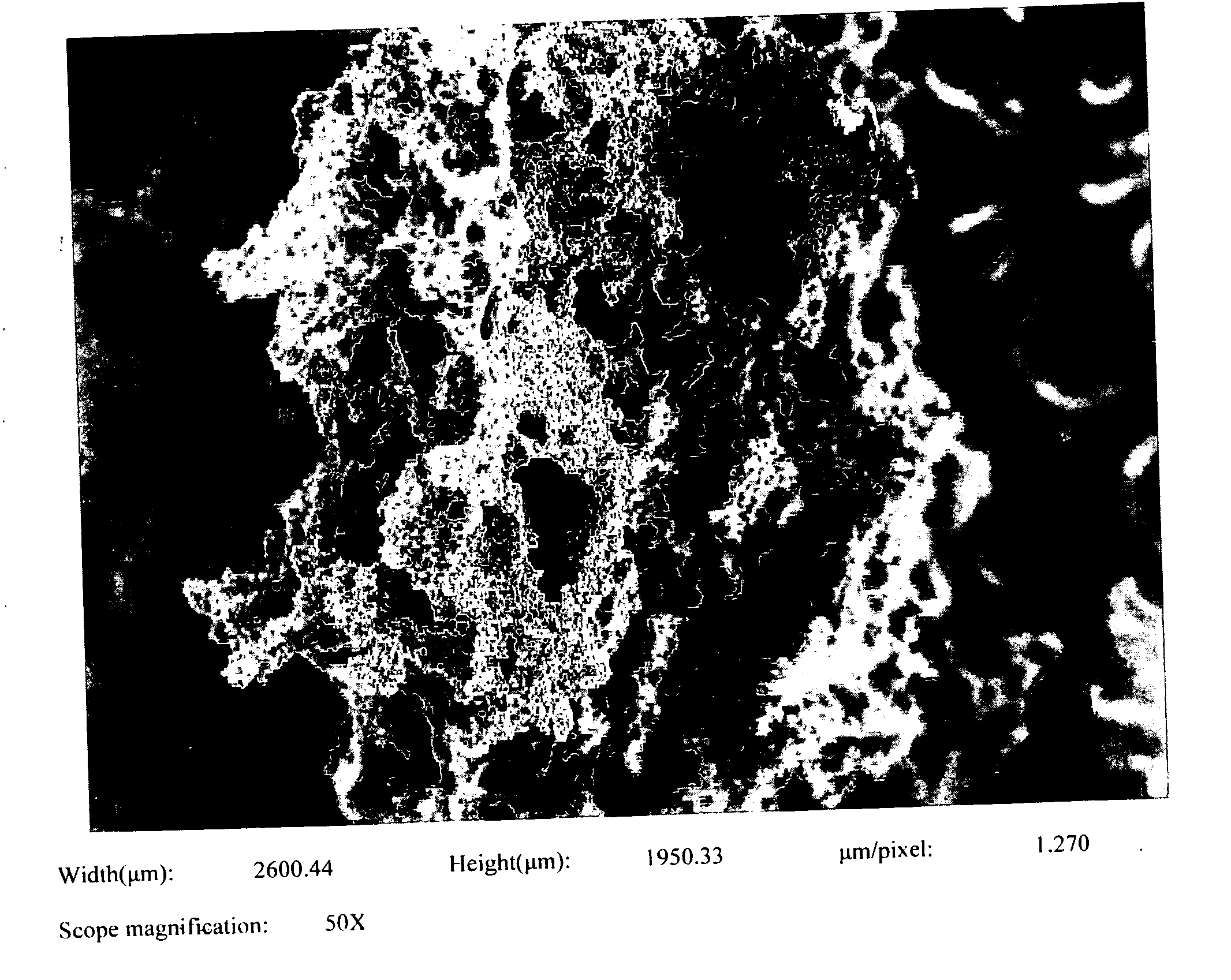

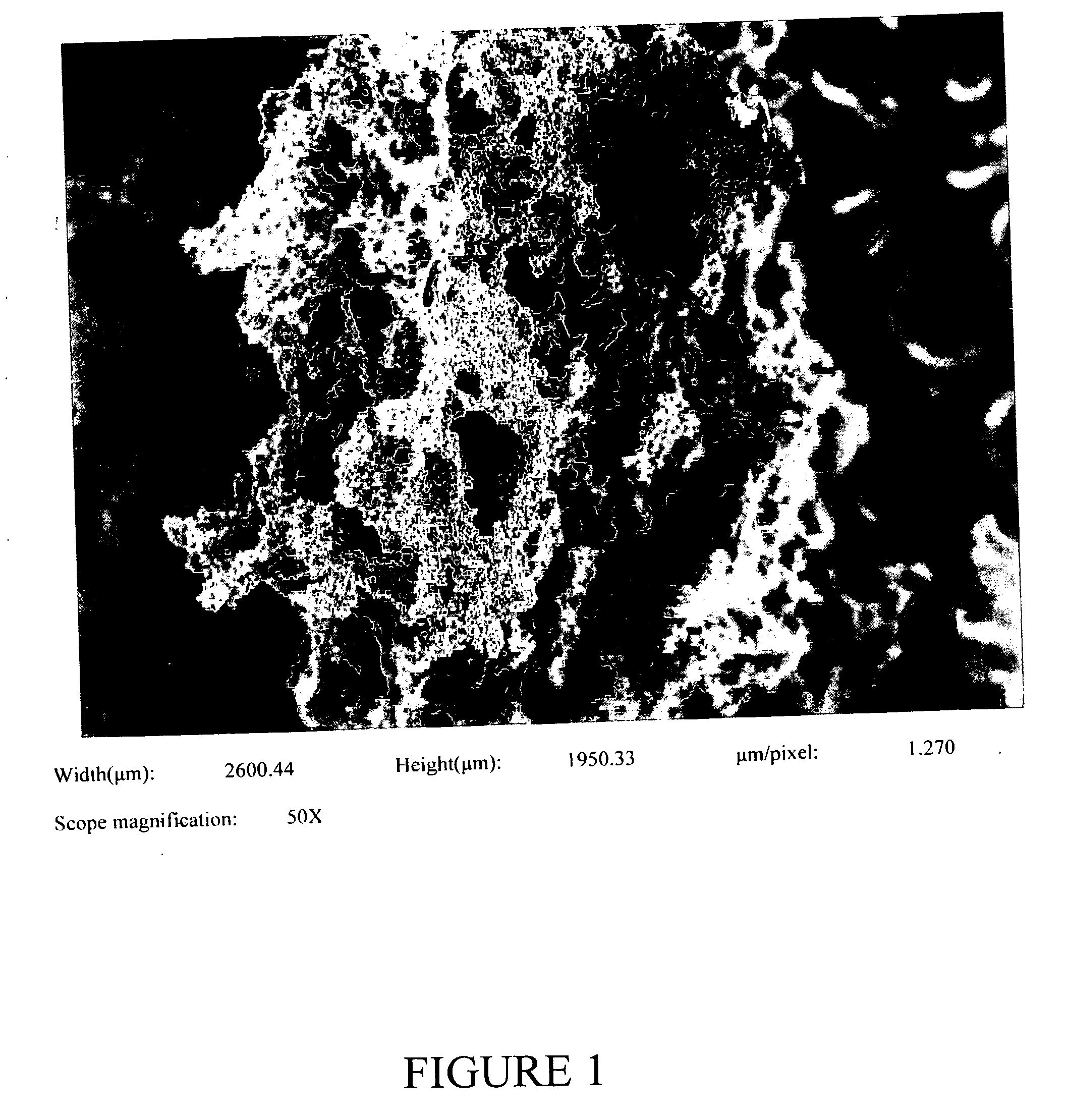

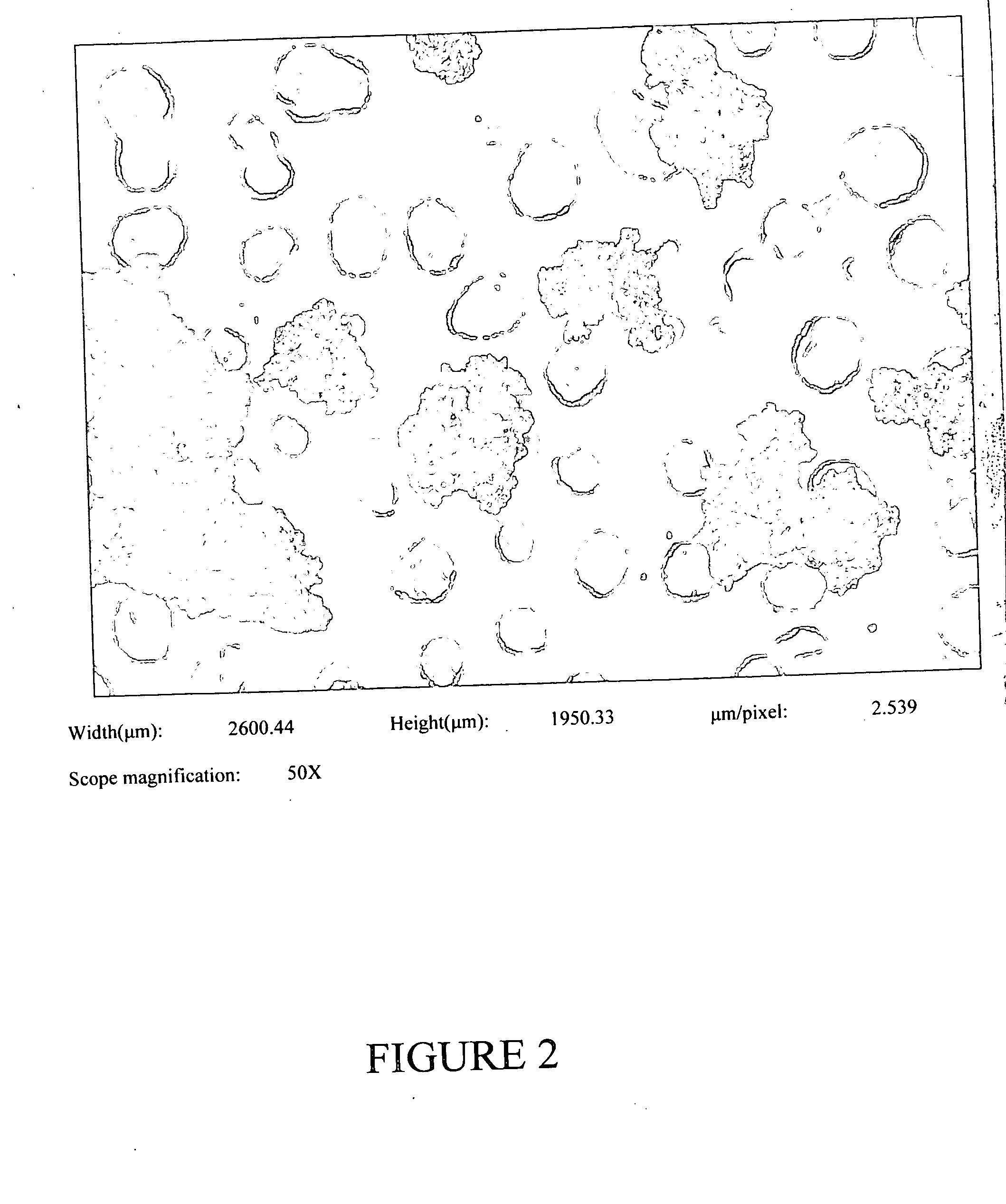

Image

Examples

Embodiment Construction

[0022] Using the Armstrong method described in the above three identified patents and application Ser. No. 11 / 186,724 filed Jul. 21, 2005, the entire application is herein incorporated by reference.

[0023] The equipment used to produce the 6 / 4 alloy with submicron titanium boride substantially uniformly dispersed therein is similar to that disclosed in the aforementioned patents disclosing the Armstrong Process with the exception that instead of only having a titanium tetrachloride boiler 22 as illustrated in those patents, there is also a boiler for each constituent of the alloy connected to the reaction chamber by suitable valves. Boron addition is from a boiler for BCl3. The piping acts as a manifold so that the gases are completely mixed as they enter the reaction chamber and are introduced subsurface to the flowing liquid sodium, preferably at least at sonic velocity, as disclosed in the incorporated patents. Upon subsurface contact with the liquid metal the halides immediately...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com