METHOD OF MAKING TITANIUM ALLOY BASED AND TiB REINFORCED COMPOSITE PARTS BY POWDER METALLURGY PROCESS

a technology of titanium alloy and powder metallurgy, which is applied in the field of ceramic-reinforced metal alloys, can solve the problems of reducing tib is unstable by itself, and the stiffness value reduces the efficiency advantages of titanium, so as to improve the functionality of the finished componen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

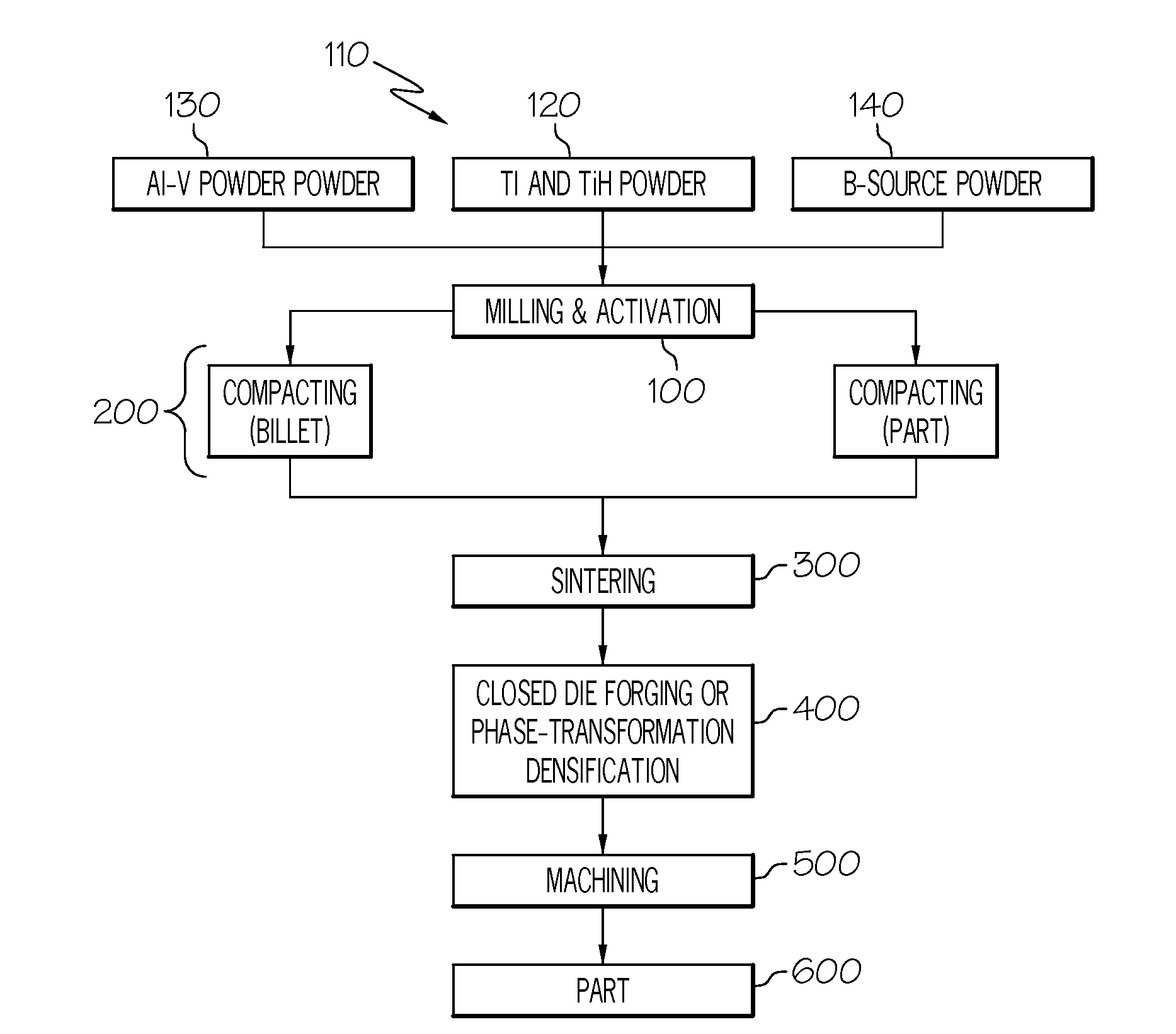

[0033]Referring initially to FIG. 1, the mixing, compacting and sintering steps, as well as optional post-sintering steps, are shown schematically. The first step involves mixing 100. As shown, at least four different constituent materials are used, including elemental titanium or other substantially pure form of titanium 110, titanium hydride 120, an alloying material 130 and a boron source material 140. There are numerous approaches known to those skilled in the art to mixing constituent materials; some such methods include ball mill mixing, vibration mill mixing and V-type mixing. These conventional methods are generally suitable for their intended purpose, viz. the relatively even distribution of the precursor materials in a mixture of such materials.

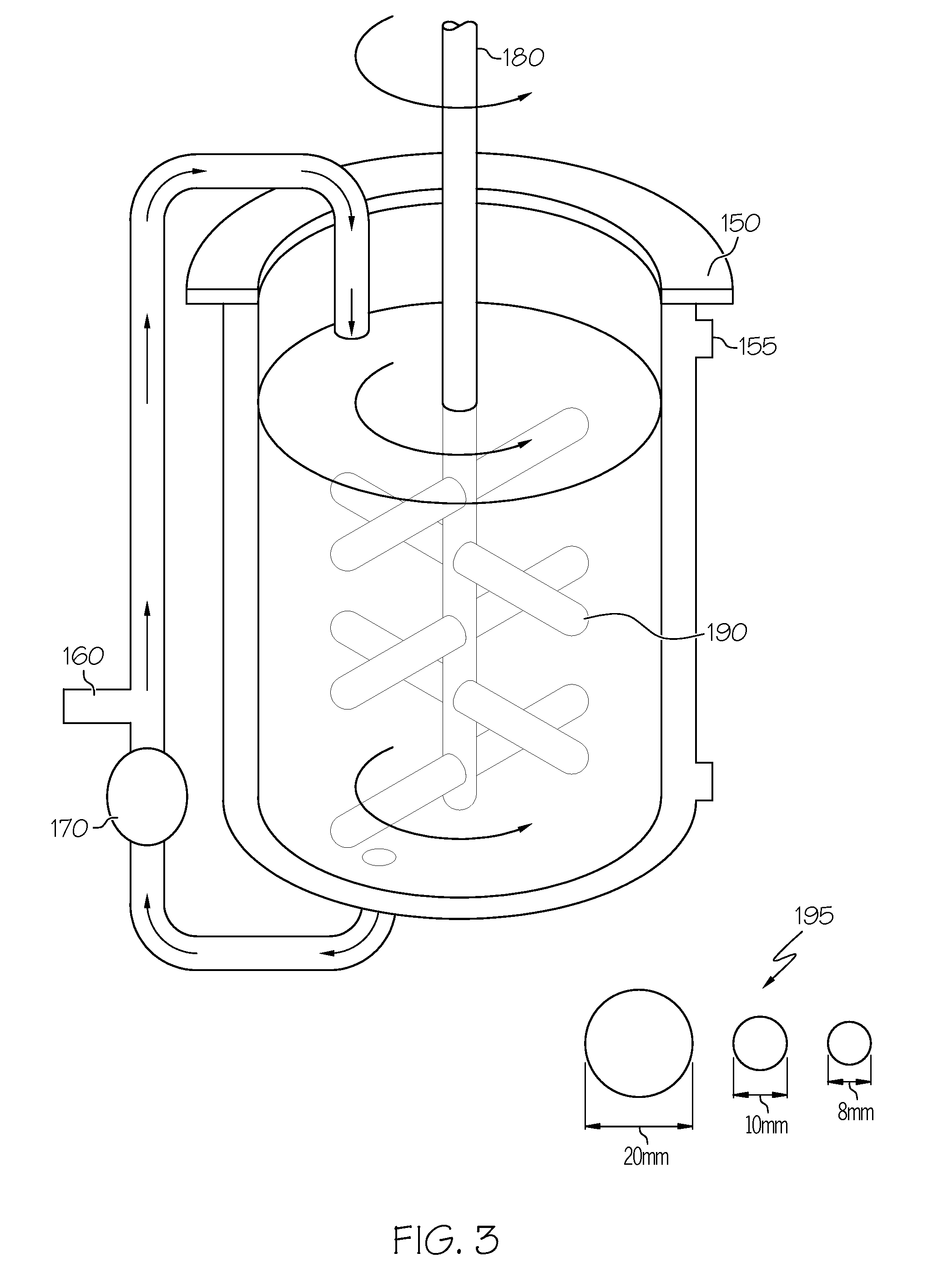

[0034]Referring next to FIG. 3, the present inventors have discovered that modifications to these conventional mixing approaches can be employed to improve the properties of the mixed precursors, specifically as it relates to powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com