Patents

Literature

1925 results about "Peening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

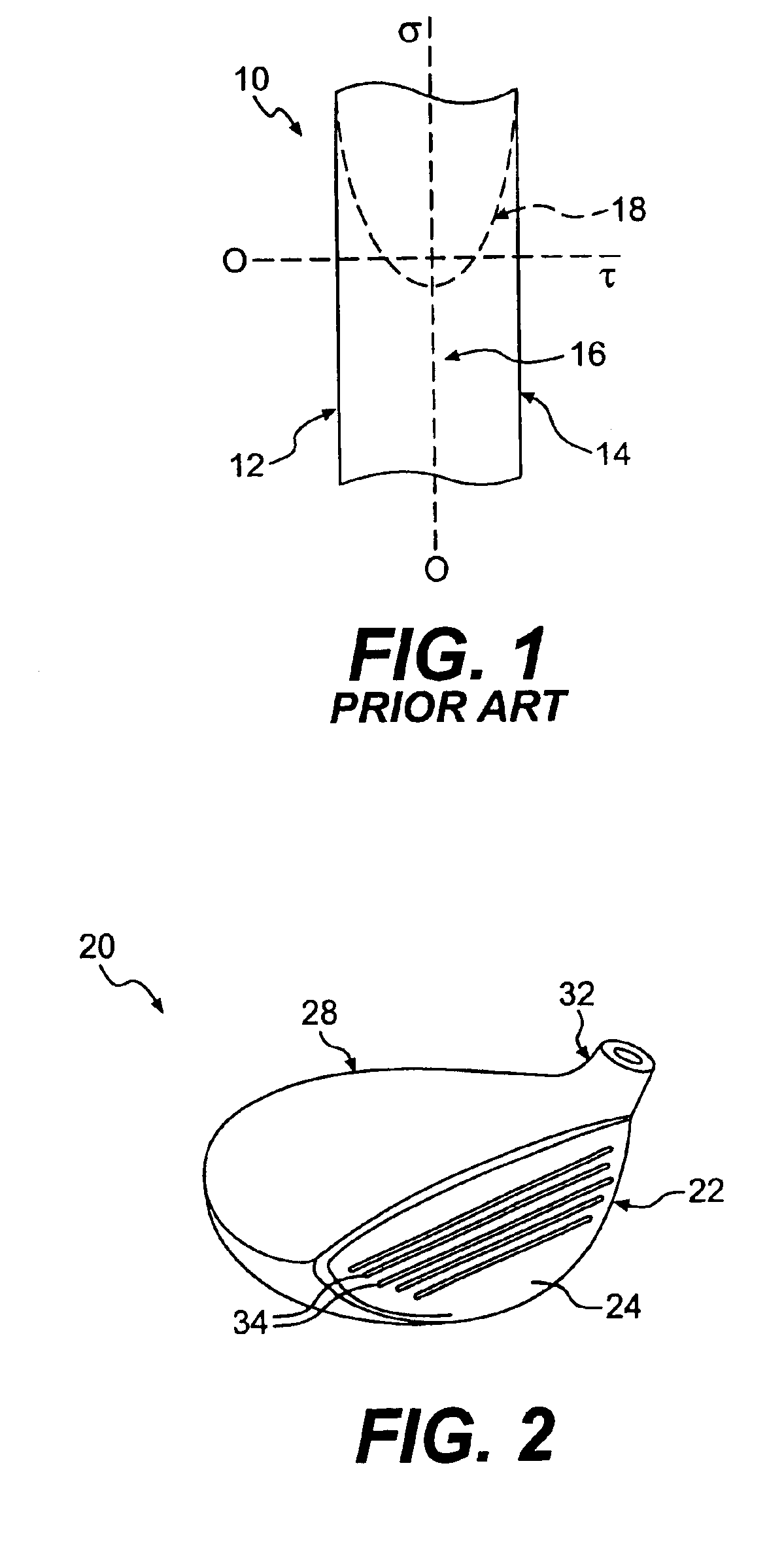

Peening is the process of working a metal's surface to improve its material properties, usually by mechanical means, such as hammer blows, by blasting with shot (shot peening) or blasts of light beams with laser peening. Peening is normally a cold work process, with laser peening being a notable exception. It tends to expand the surface of the cold metal, thereby inducing compressive stresses or relieving tensile stresses already present. Peening can also encourage strain hardening of the surface metal.

Tungsten/powdered metal/polymer high density non-toxic composites

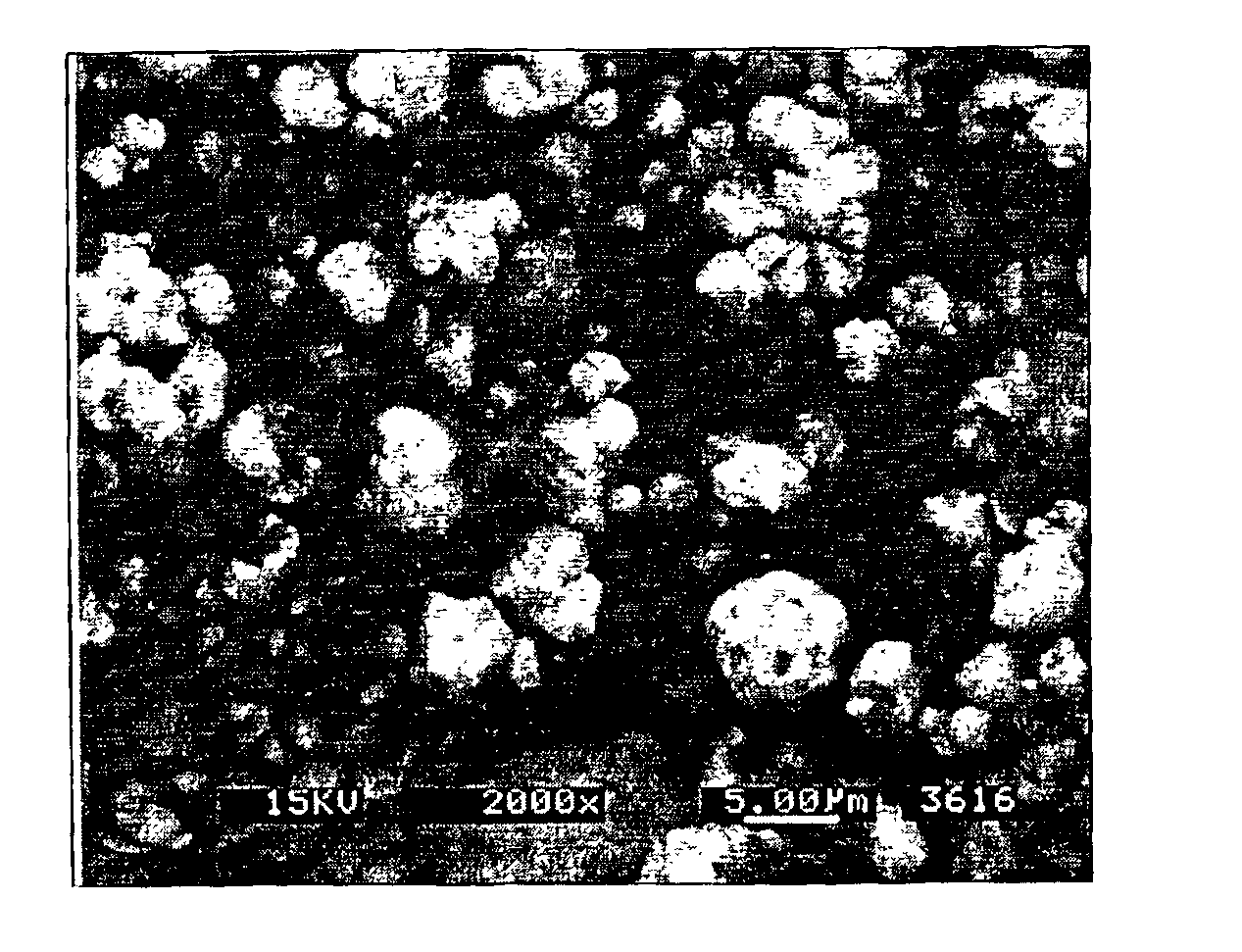

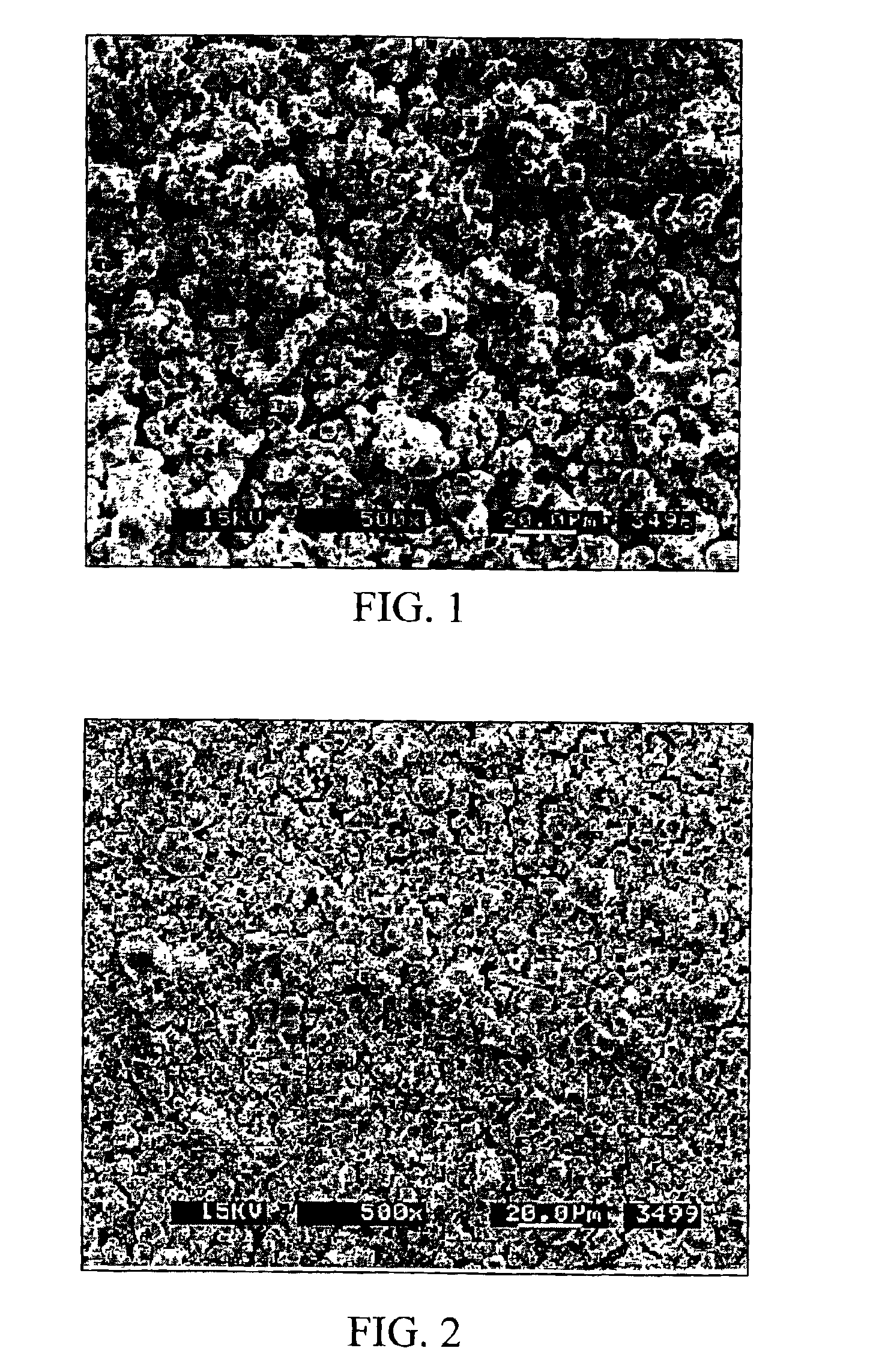

InactiveUS6916354B2High bulk densityAmmunition projectilesShotgun ammunitionHigh densityVolumetric Mass Density

Owner:ELLIOTT CARTRIDGE COMPANY CANADA

Investment precision casting technology for producing automobile I-shaped front axle

InactiveCN101147954ALess investmentReduce manufacturing costFoundry mouldsFoundry coresSteelmakingWax

The present invention relates to a fusible pattern precision casting process for producing automobile H-shaped front axle. Said casting process includes the following steps; (1), preparing wax pattern; (2), applying coating material onto the wax pattern surface for several times, spreading sand and making the coating material hardened pattern shell be primarily formed, removing wax and forming pattern shell; (3), firing pattern shell; (4), pouring the molten steel into the pattern shell, before steel-smelting having to make analysis of charge mixture ratio, in the course of smelting steel having to make on-the-spot sample analysis and furnace rear analysis, adding required additive and deoxidant so as to make the molten steel be reached to the defined chemical components requirement; (5), removing pattern shell from obtained automobile H-shaped front axle casting, cleaning sand and cutting spure; (6), grinding, finishing and checking casting; (7), making quenching and tempering, heat treatment; (8), making correction and shot blasting treatment; and (9), making metalworking treatment.

Owner:NANPING AUTO FORGING & STAMPING FACTORY

Technological process for producing super-thick plate

InactiveCN101439348AQuality improvementLow costTemperature control deviceElectron beam welding apparatusElectro-slag remeltingVacuum chamber

The invention relates to a process for producing an ultra-thick plate and belongs to the field of rolling and producing an ultra-thick steel plate in the metallurgical industry. The invention mainly overcome the defect of producing the ultra-thick steel plate by a traditional model casting manufacturing blank and an electro-slag remelting manufacturing blank. The method comprises the following steps: cutting and fixing lengths of the blanks, mechanically conditioning the blanks (eliminating, leveling and cleaning a single-surface oxide layer of a casting blank with a milling machine, a planer or a shot blast); clamping an assembly (relatively superposing the cleaning surfaces of the two blanks after processing, placing the two blanks oppositely and clamping the blanks); mounting the blanks in a vacuum chamber of an electronic beam welding machine for purpose of vacuuming; sewing the assembly on the electronic beam welding seal edge, heating the assembly in a furnace and rolling the assembly through temperature control; and then producing the ultra-thick steel plate. Compared with the traditional electro-slag remelting production process, the process has the advantages of high production efficiency, reduced electric power consumption, less investment of production devices and low production cost. Compared with the traditional die casting production process, the process solves the problem of segregation and looseness of a large-scale die casting ingot center part; the finished product ratio is high; and the finished product ratio of blank assembly is over 90 %.

Owner:SHANDONG IRON & STEEL CO LTD

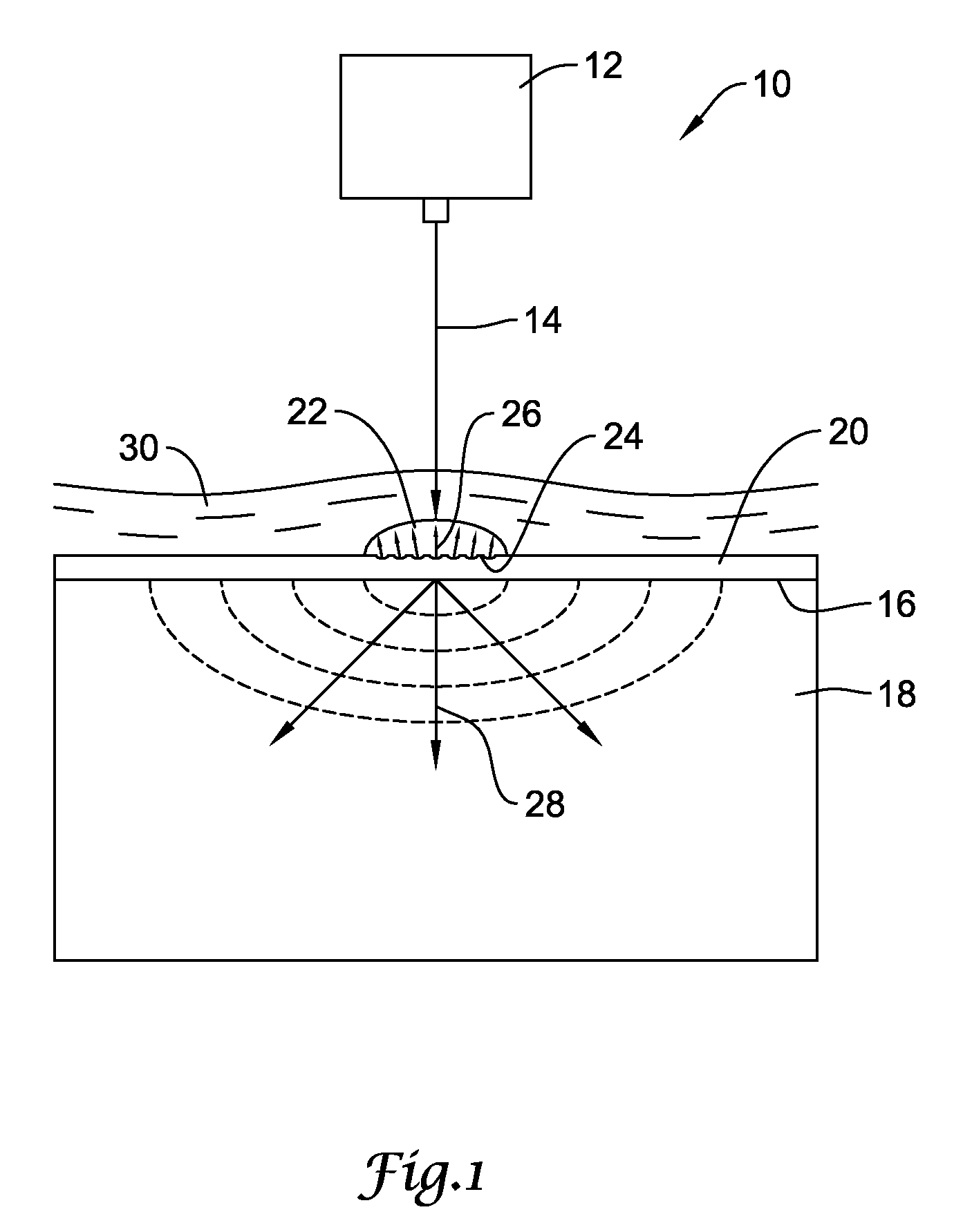

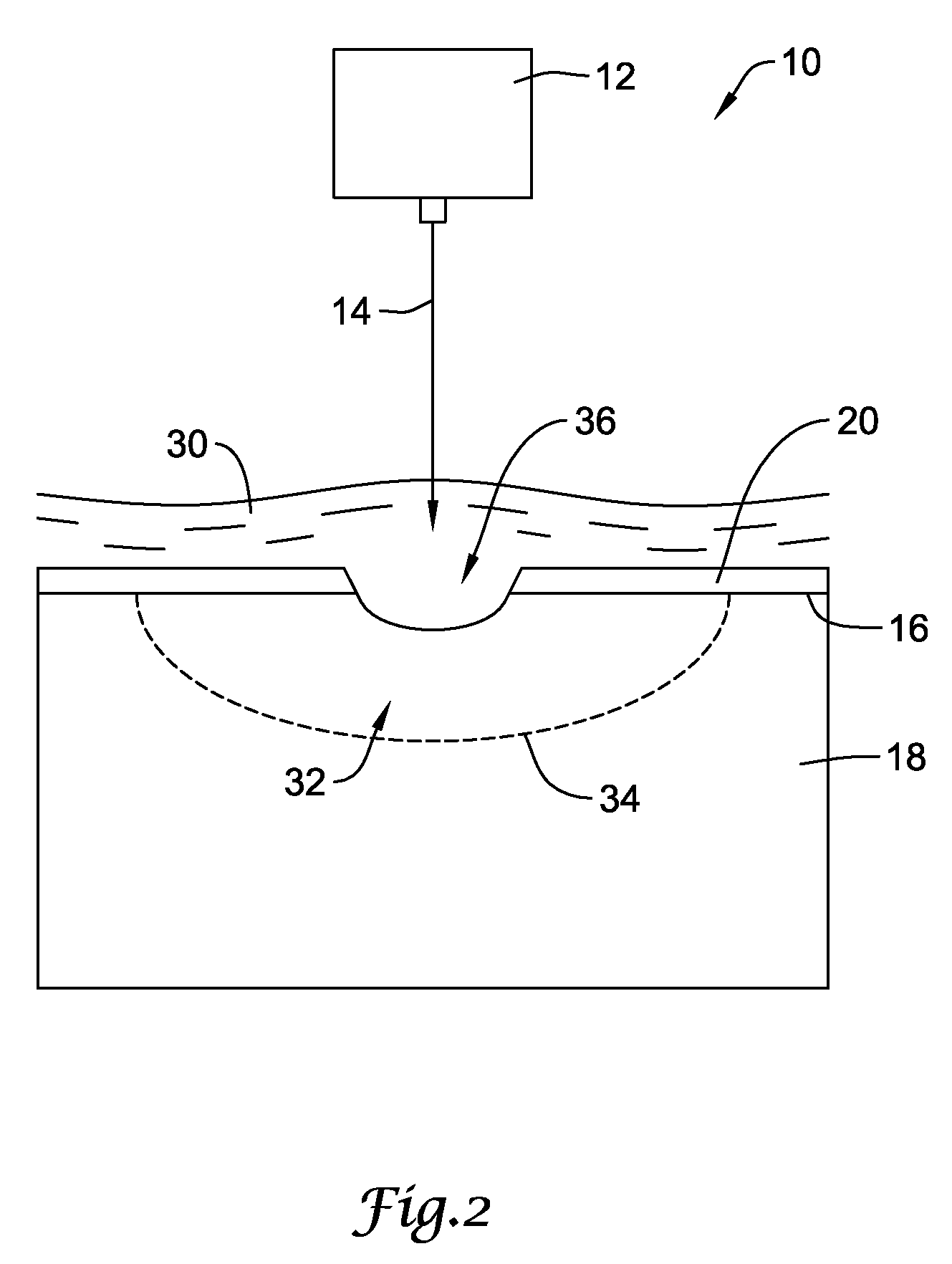

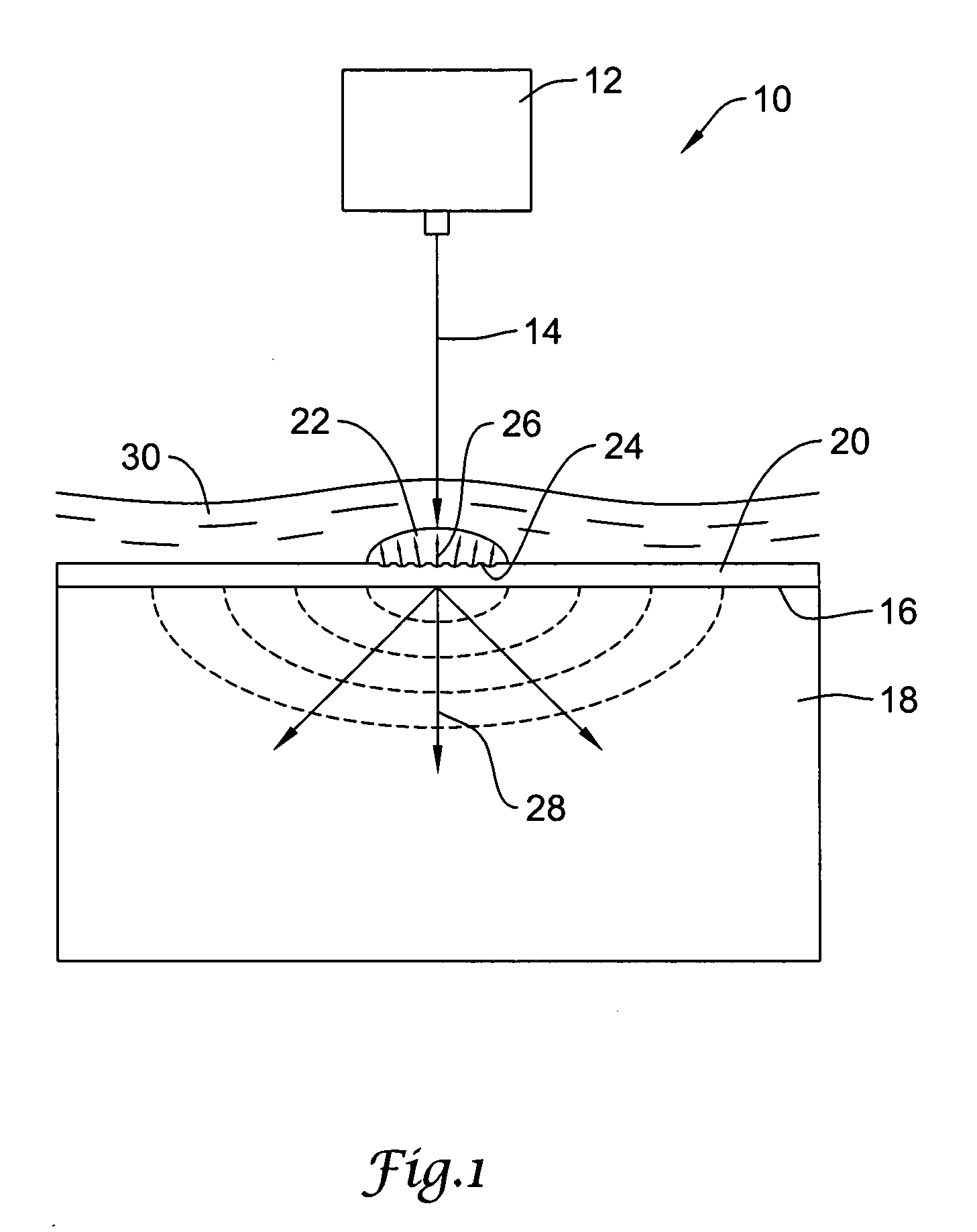

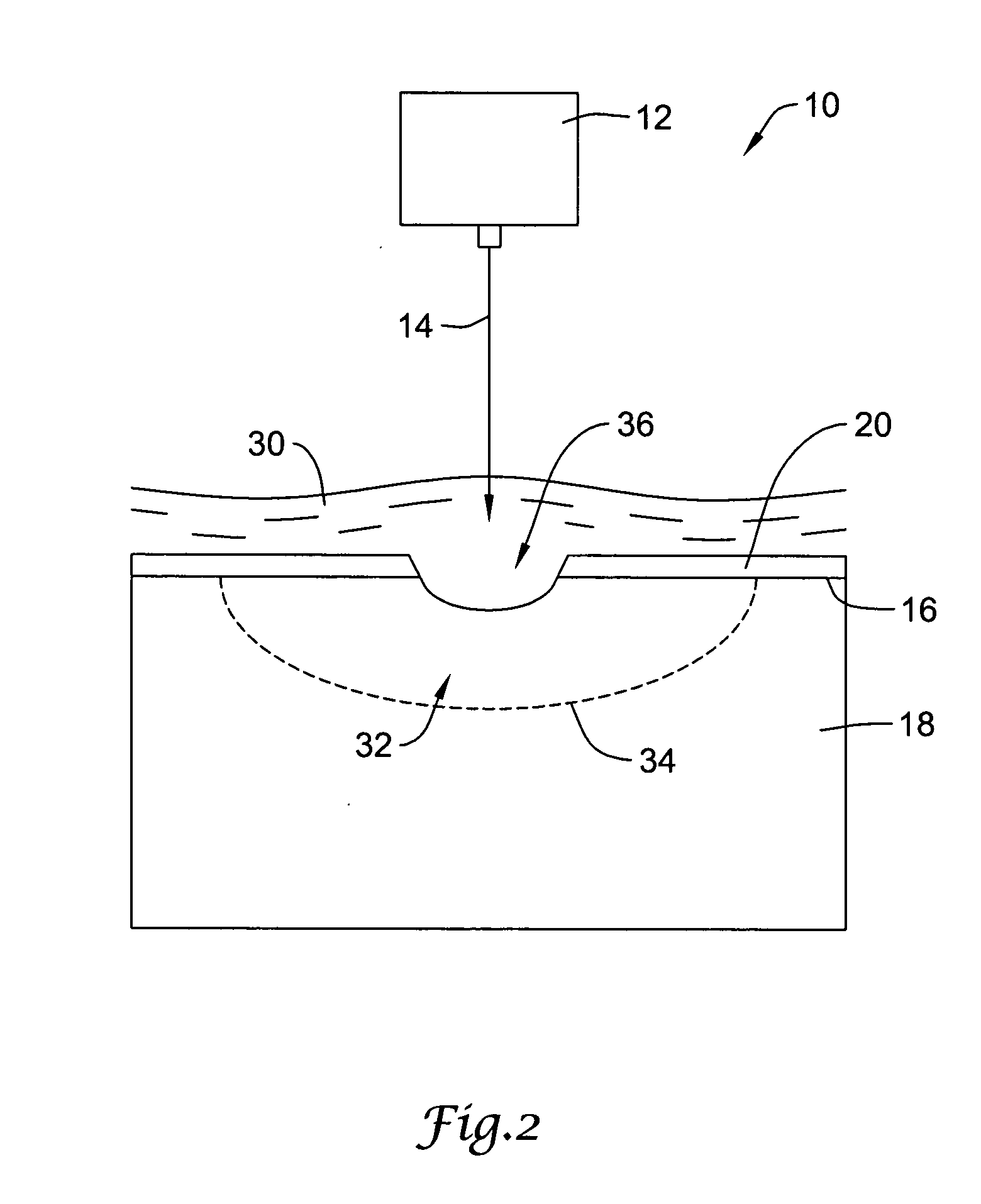

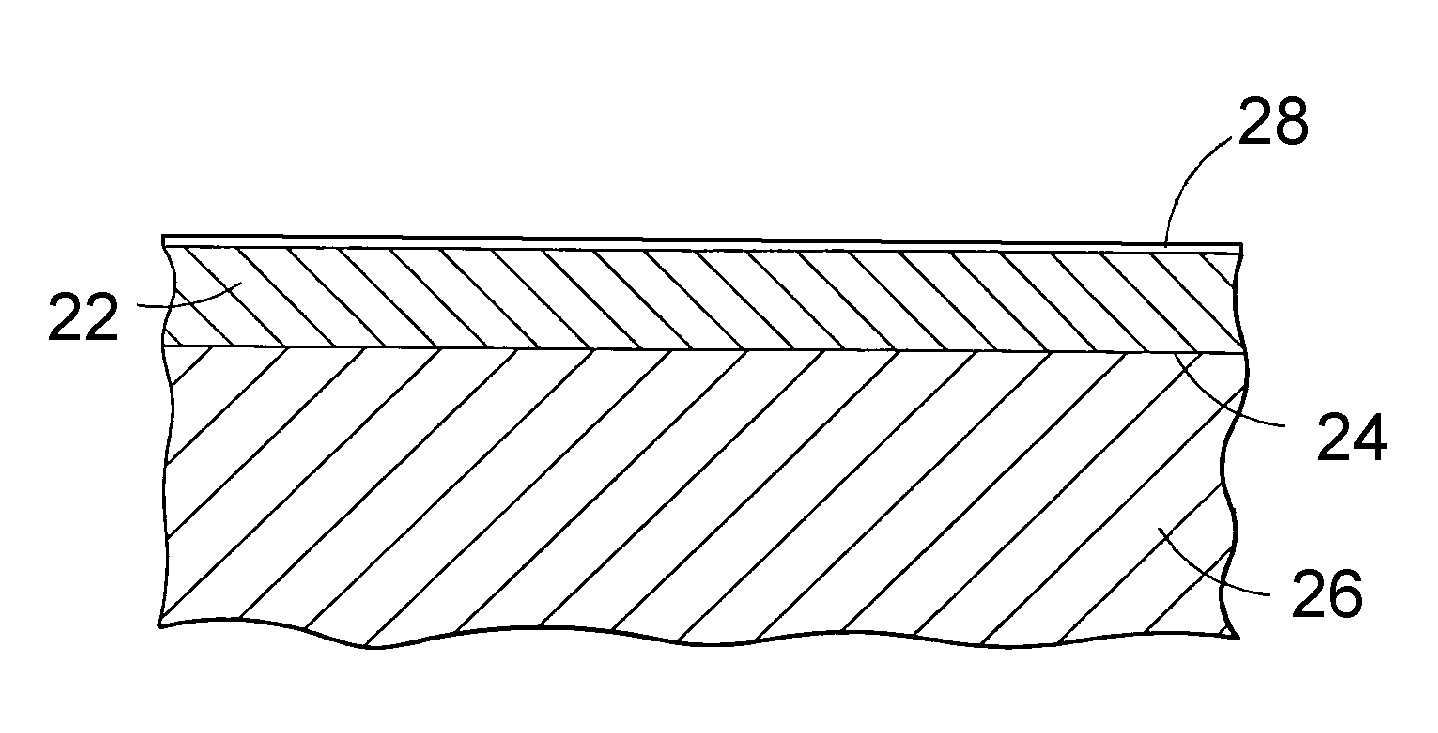

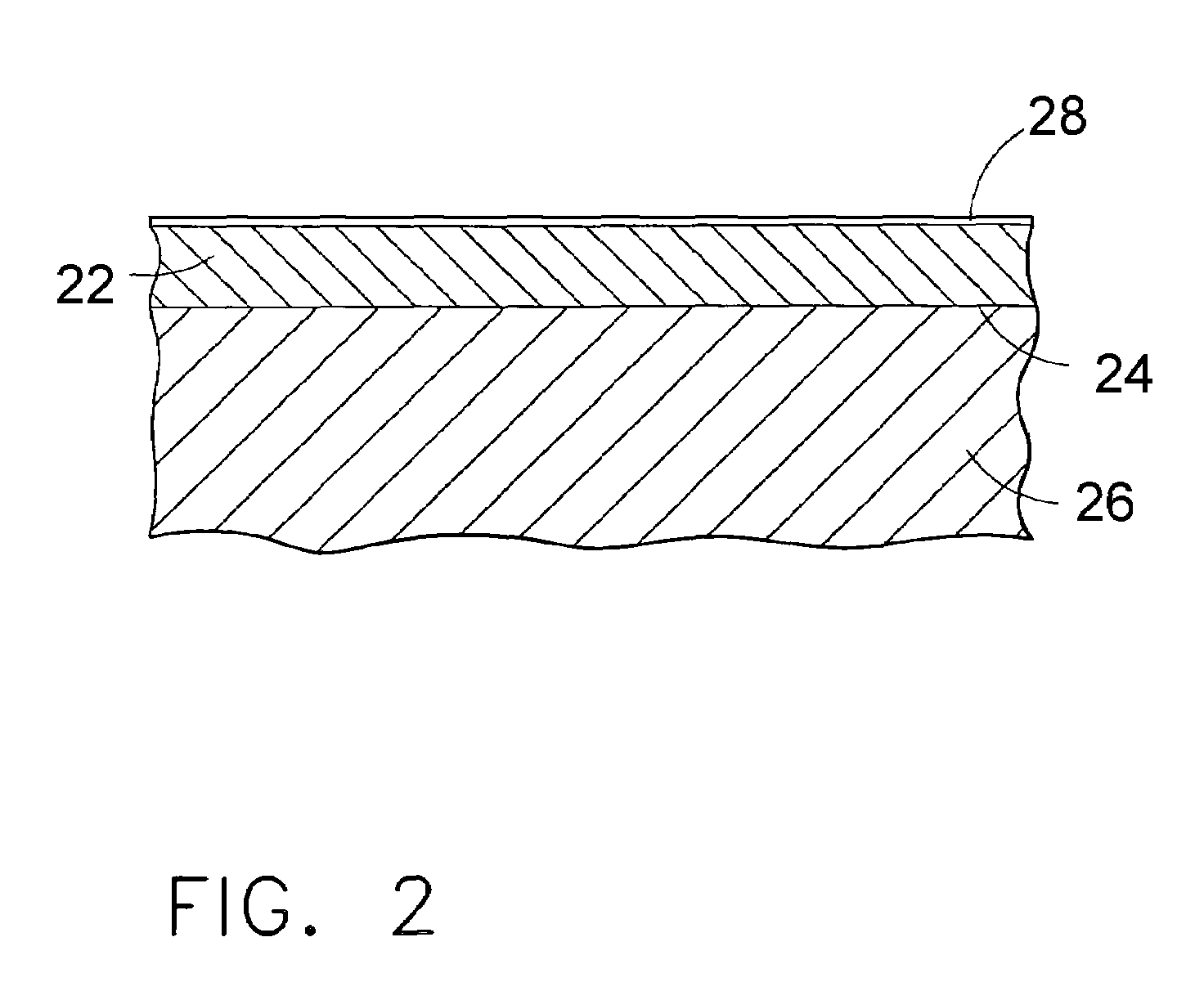

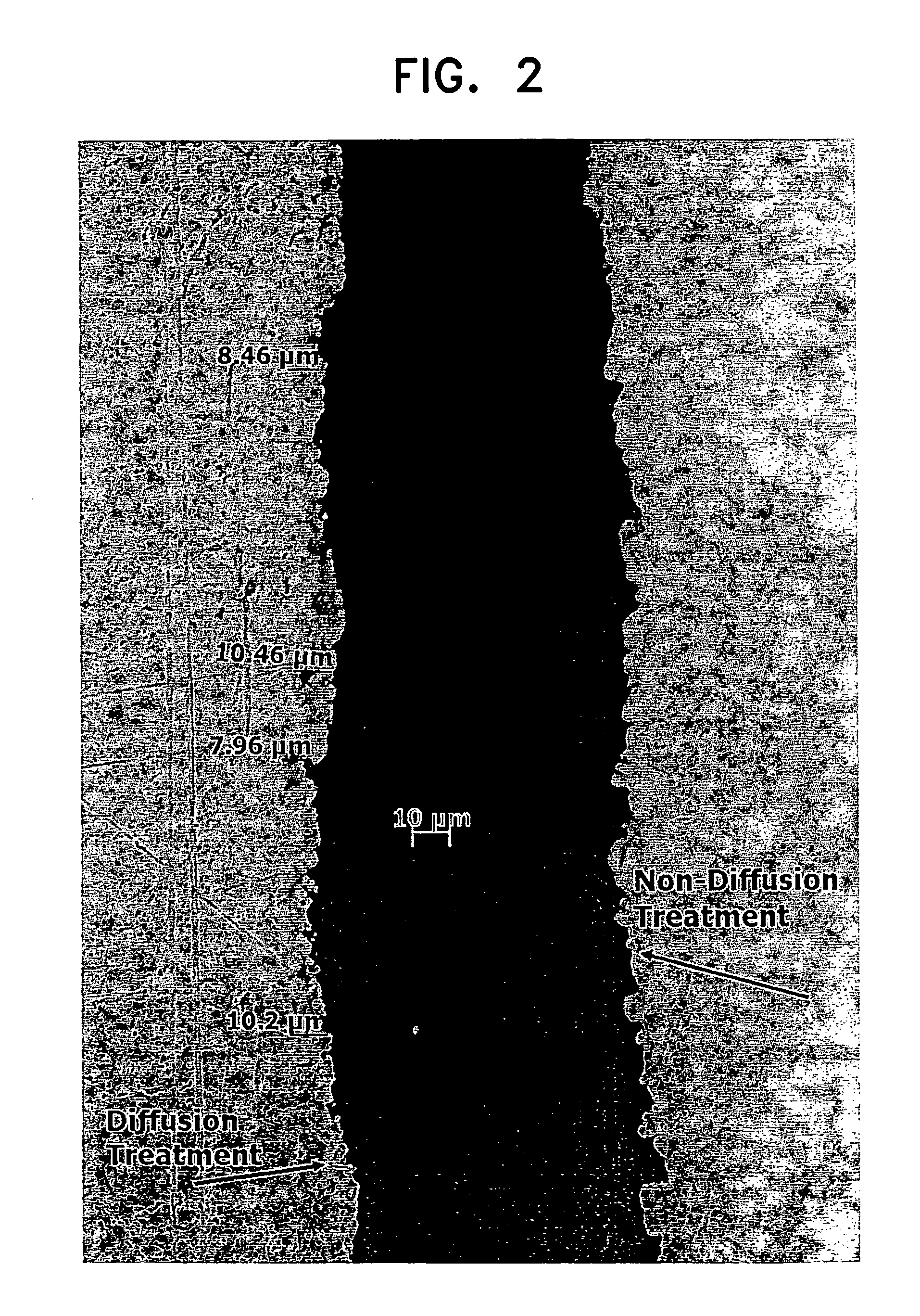

Laser shock peening of medical devices

InactiveUS20090043228A1Improve fatigue strengthIncrease flexibilityStentsCatheterShock waveTarget surface

A laser shock peening process for producing one or more compressive residual stress regions in a medical device is disclosed. A high-energy laser apparatus can be utilized to direct an intense laser beam through a confining medium and onto the target surface of a workpiece. An absorption overlay disposed on the target surface of the workpiece absorbs the laser beam, inducing a pressure shock wave that forms a compressive residual stress region deep within the workpiece. Medical devices such as stents, guidewires, catheters, and the like having one or more of these compressive residual stress regions are also disclosed.

Owner:BOSTON SCI SCIMED INC

Laser shock peening of medical devices

A laser shock peening process for producing one or more compressive residual stress regions in a medical device is disclosed. A high-energy laser apparatus can be utilized to direct an intense laser beam through a confining medium and onto the target surface of a workpiece. An absorption overlay disposed on the target surface of the workpiece absorbs the laser beam, inducing a pressure shock wave that forms a compressive residual stress region deep within the workpiece. Medical devices such as stents and guidewires having one or more of these compressive residual stress regions are also disclosed.

Owner:BOSTON SCI SCIMED INC

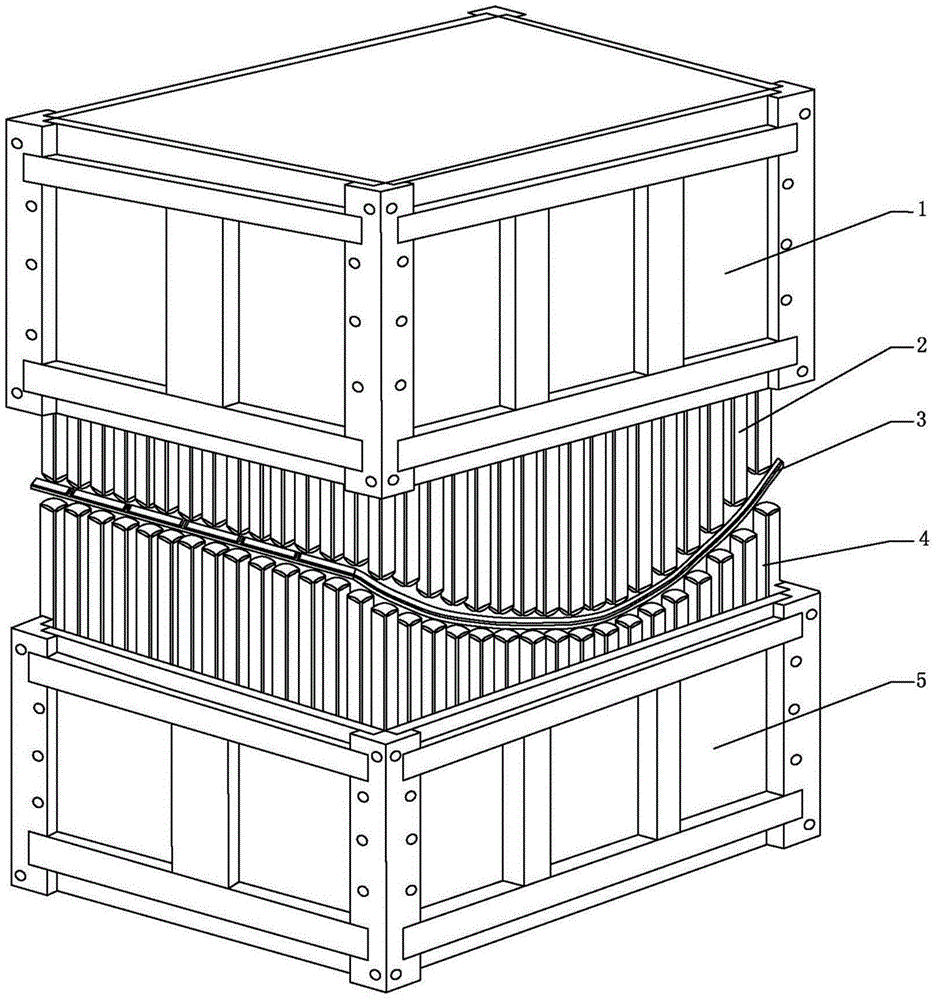

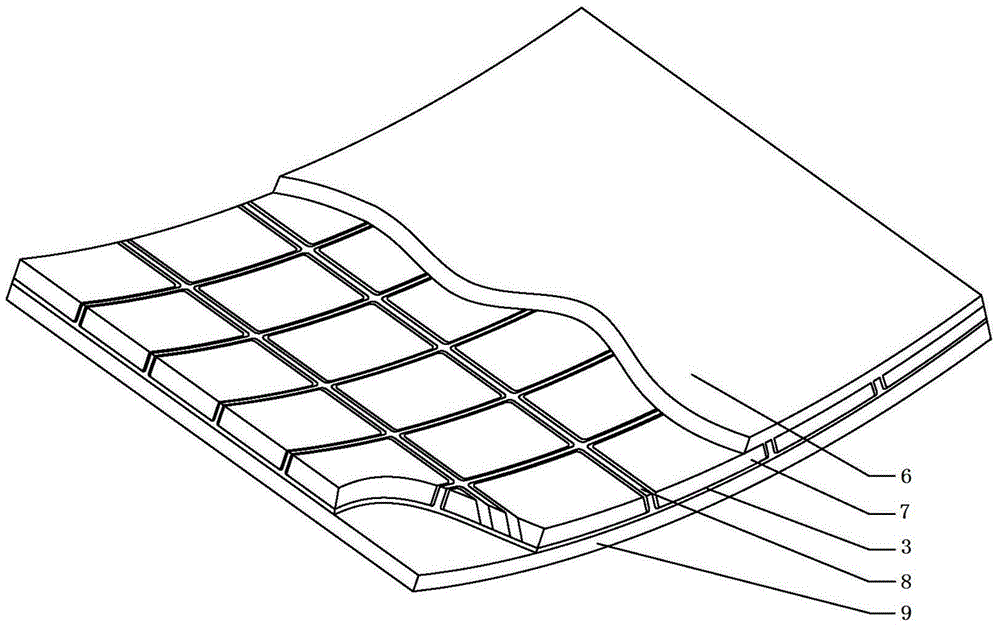

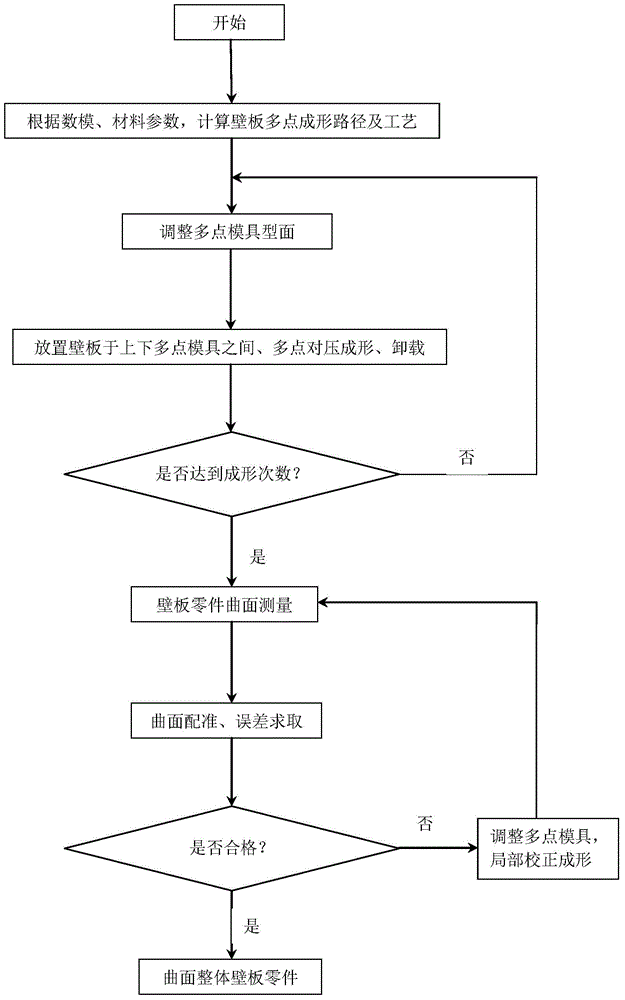

Multi-point forming method for whole aluminum alloy wall plate of aircraft

InactiveCN104646475ASolve efficiency problemsSolve the problem that cracks are prone to occur and cause the overall wall panel to be scrappedShaping toolsMetal working apparatusRocketDouble curvature

The invention discloses a multi-point forming method for a whole aluminum alloy wall plate of an aircraft. The multi-point forming method comprises the following steps of arranging the whole aluminum alloy wall plate with ribs between an upper multi-point die and a lower multi-point die of a quick reconstructing die surface, filling a filling material between the ribs, arranging an elastic cushion between the wall plate and the multi-point die, and gradually forming a whole aluminum alloy wall plate part with ribs by a die pressing method along a controllable deformation path. The multi-point forming method has the advantages that by utilizing the quick and adjustable characteristic of the reconstructing multi-point die surface, the wall plate parts with different geometric shapes and double curvatures can be processed by one set of equipment; compared with the traditional rolling and bending forming method and the pressing and bending forming method, the stress of the wall plate is uniform, and the forming quality can be guaranteed; compared with the shot peen forming method and the aging forming method, the deformation amount is large, and the forming efficiency is high; the method can be used for forming the whole aircraft wall plate with different rib structures and the double curvatures, the problems of large size and high rib in the whole wall plate forming process are solved, and the method can be applied to the manufacturing of other large ribbed curvature parts of aircrafts, rockets and the like.

Owner:JILIN UNIV

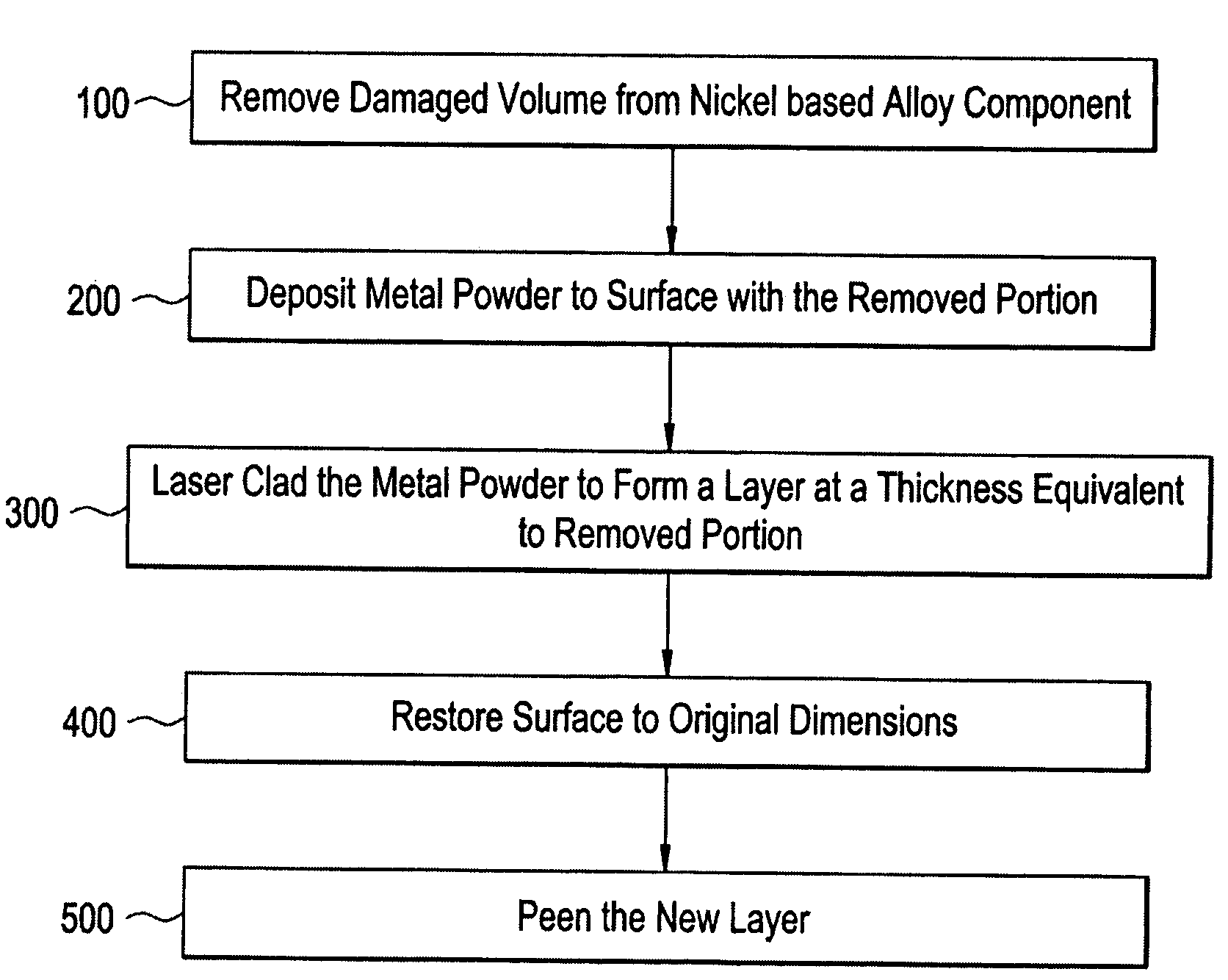

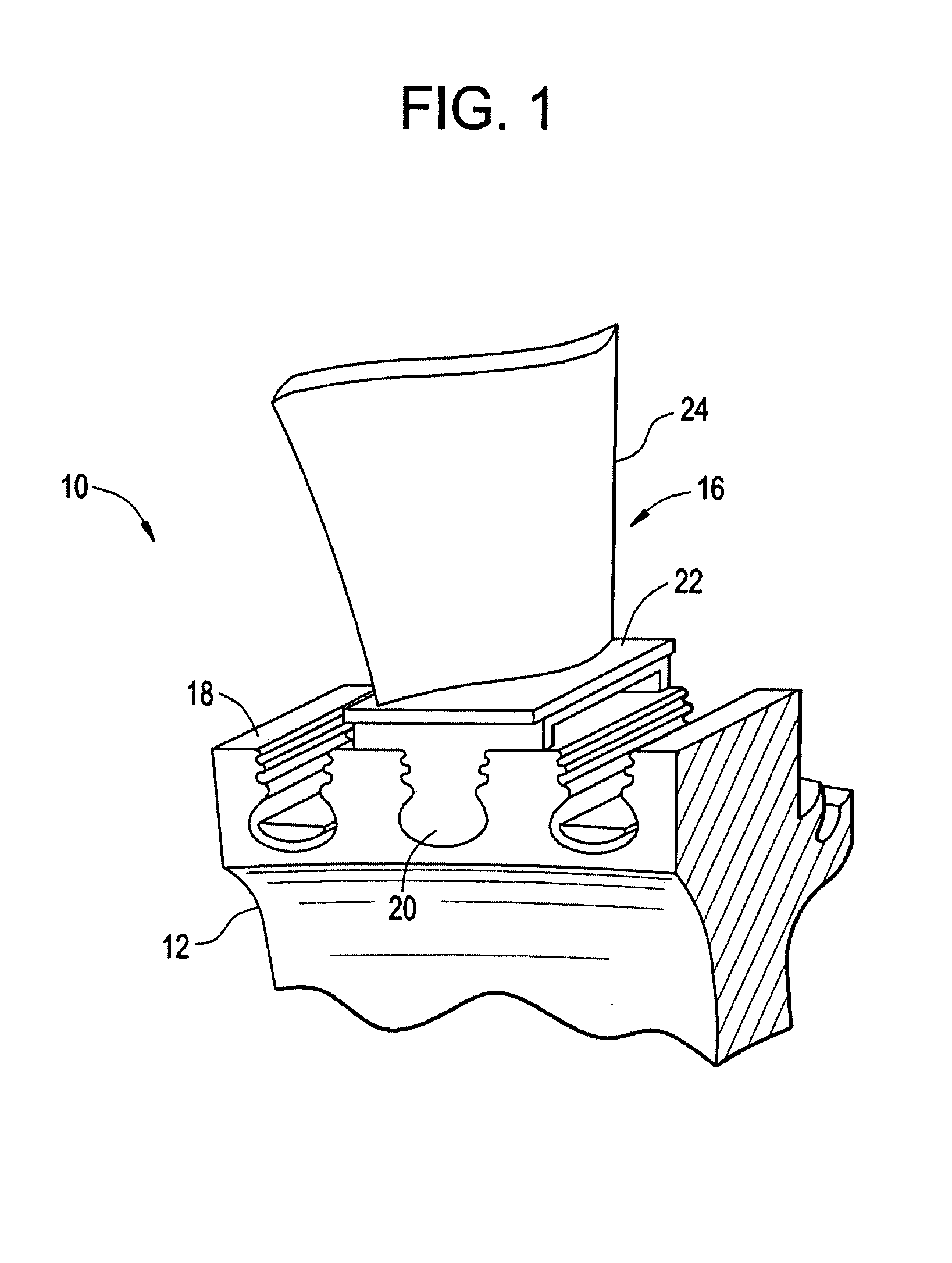

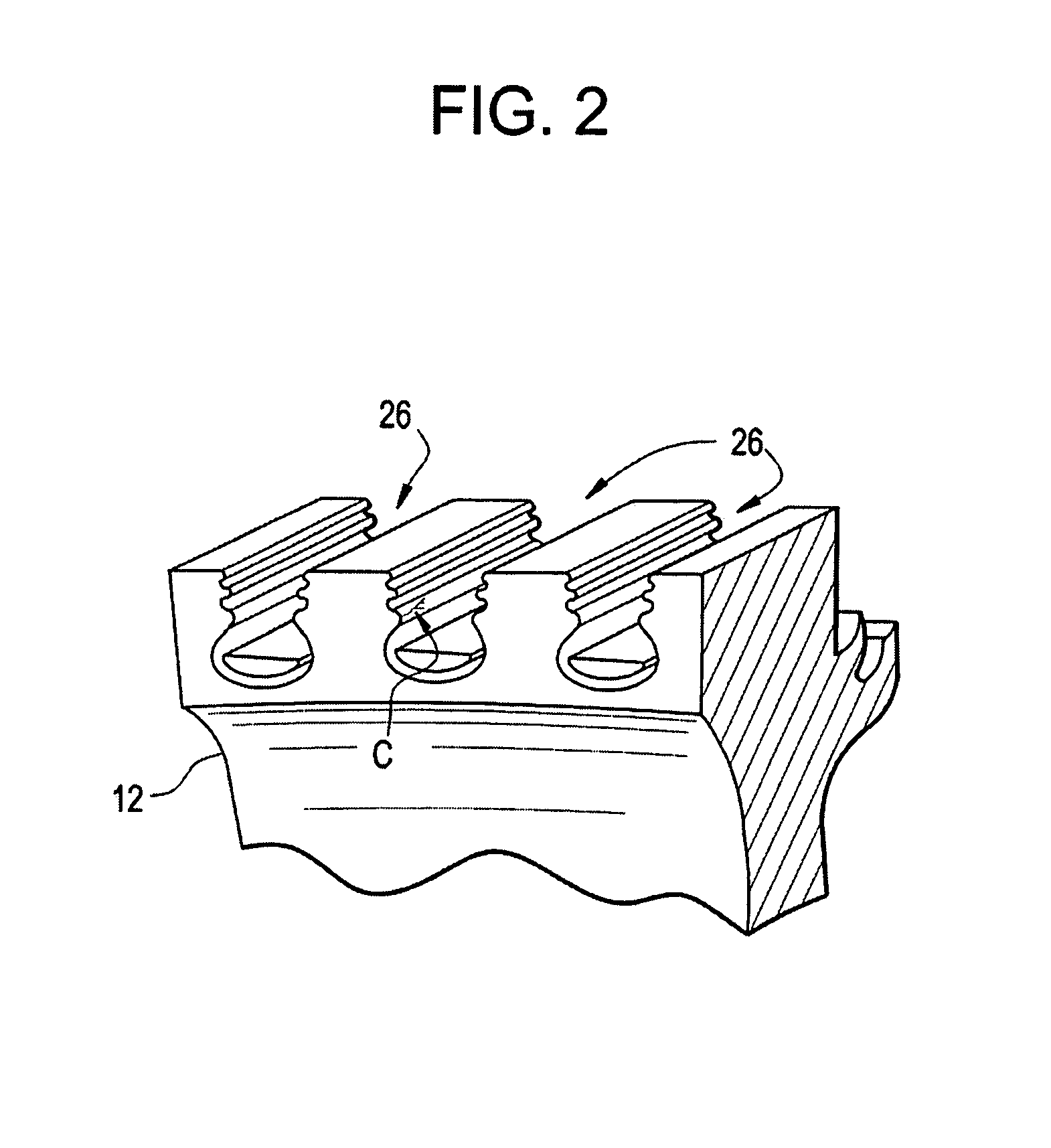

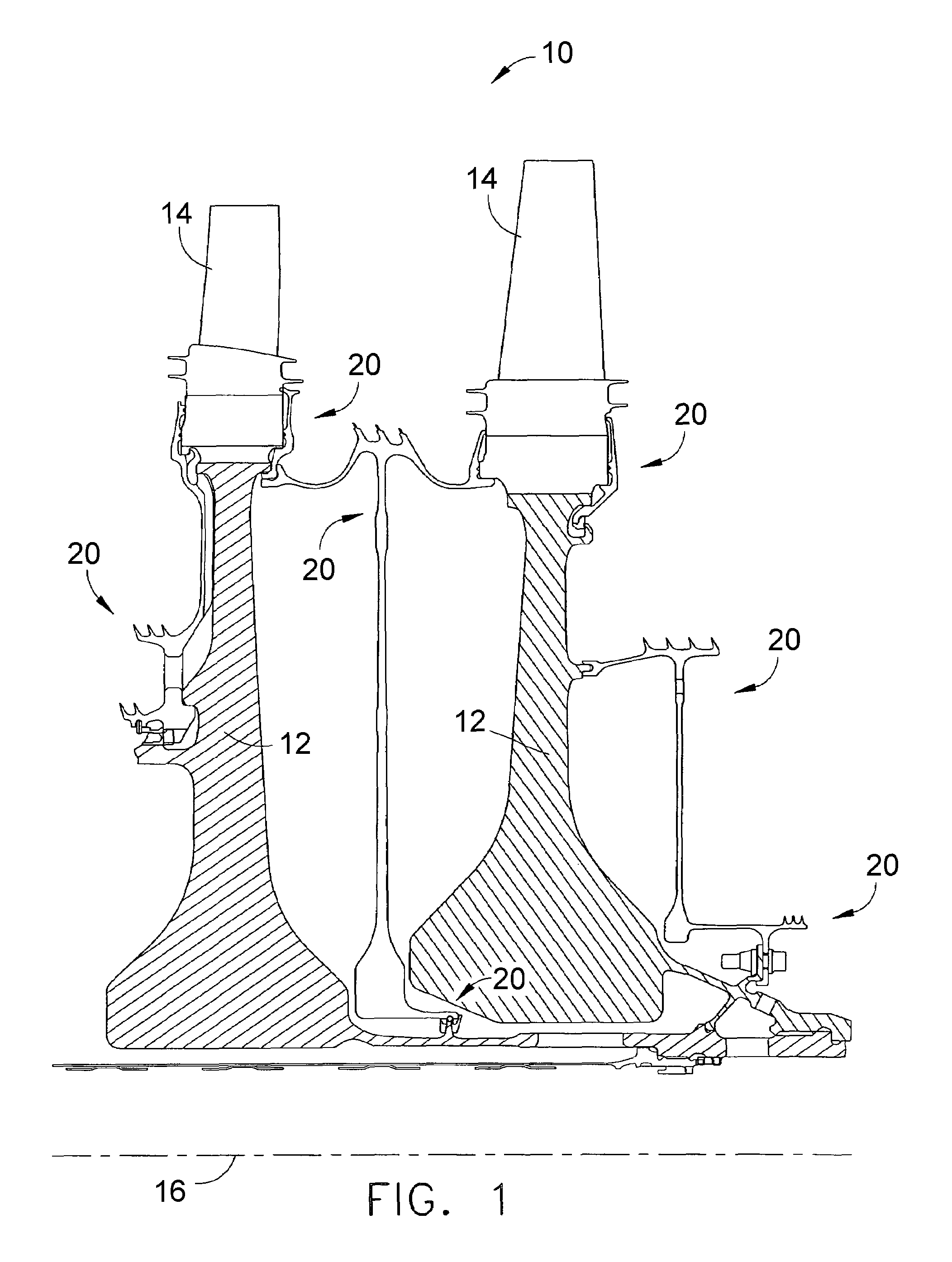

Method of Repairing Nickel-Based Alloy Articles

Methods for repairing nickel based alloy articles such as gas turbine rotors generally includes a removing a damaged portion of the articles and laser cladding a high temperature nickel based alloy powder thereto to form a solid layer. The process can be repeated until a desired thickness is obtained. Optionally, a peening process subsequent to laser cladding can be implemented to introduce compressive stress to the solid layer formed by laser cladding.

Owner:GENERAL ELECTRIC CO

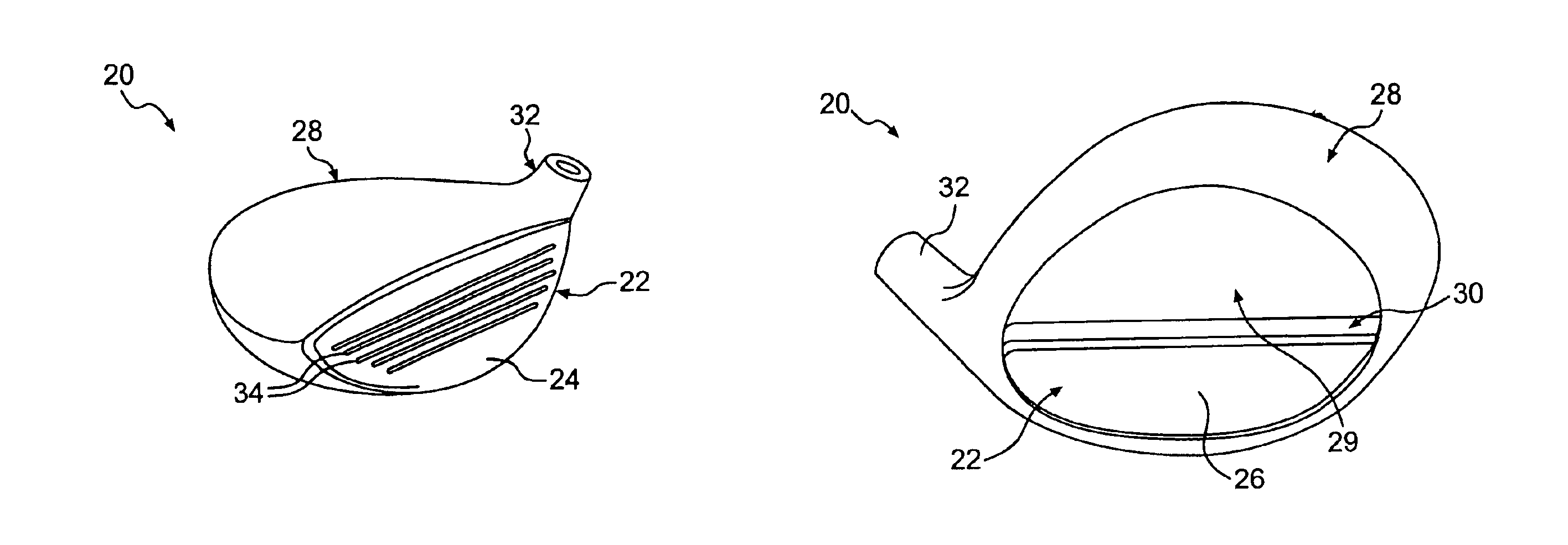

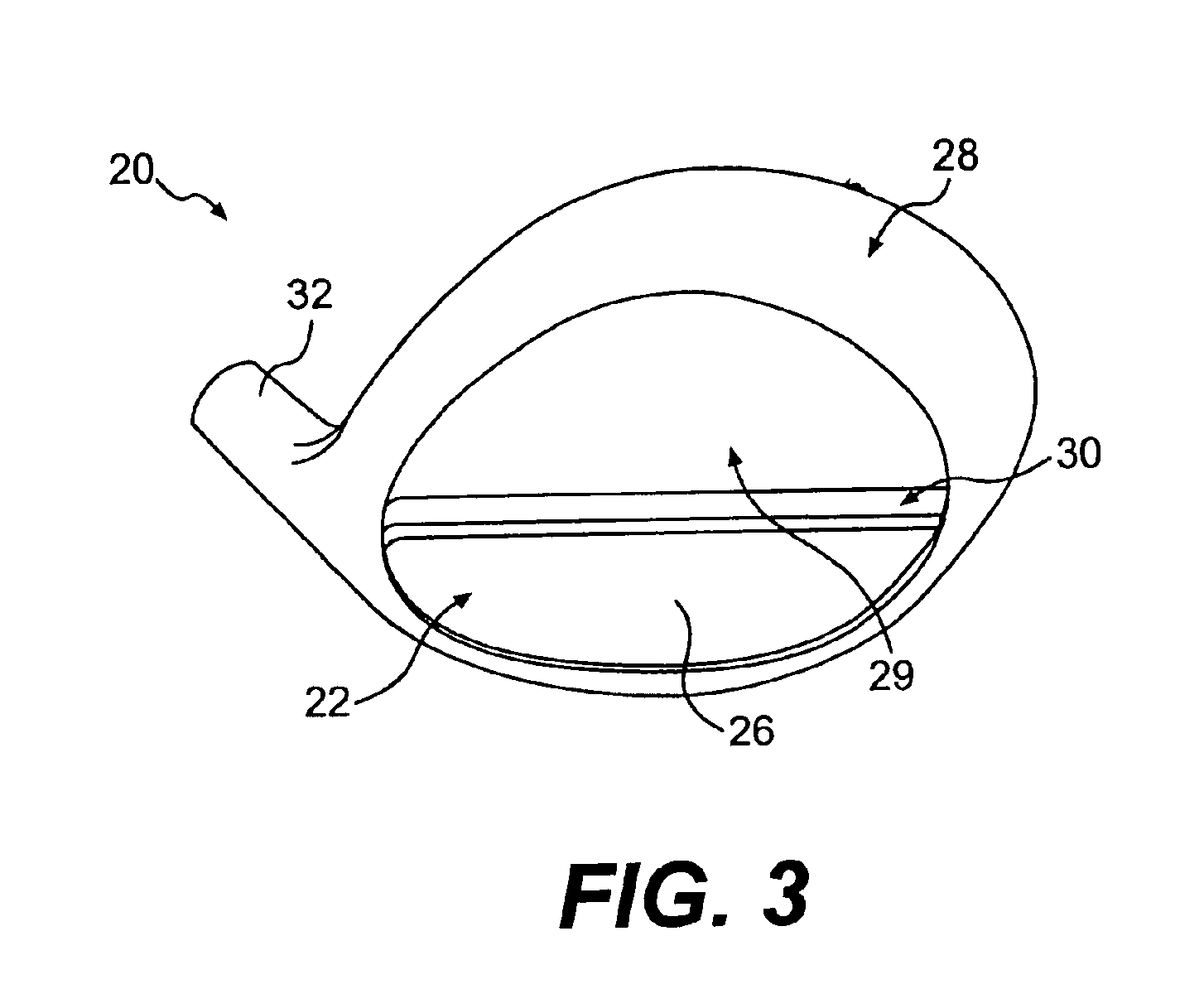

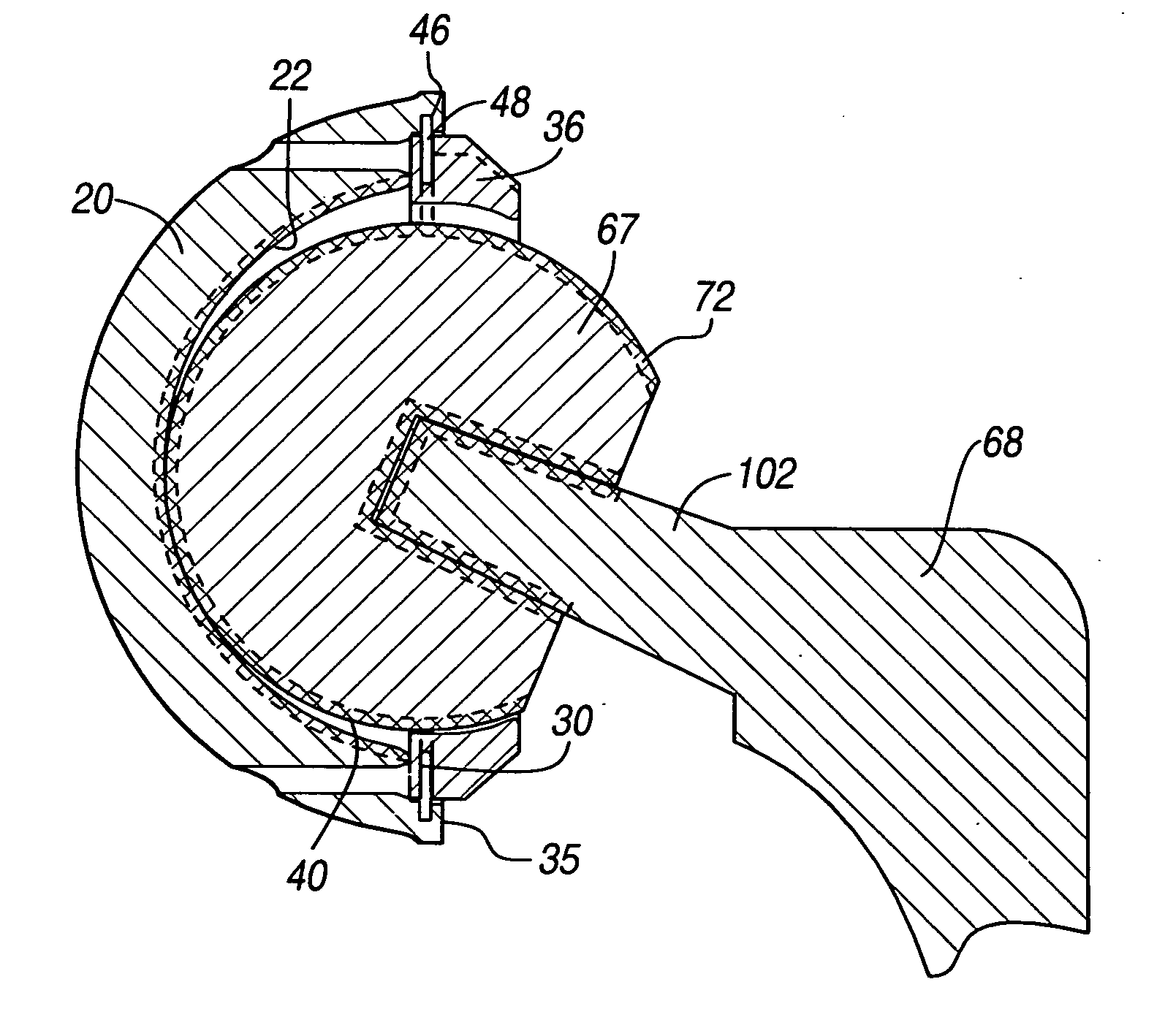

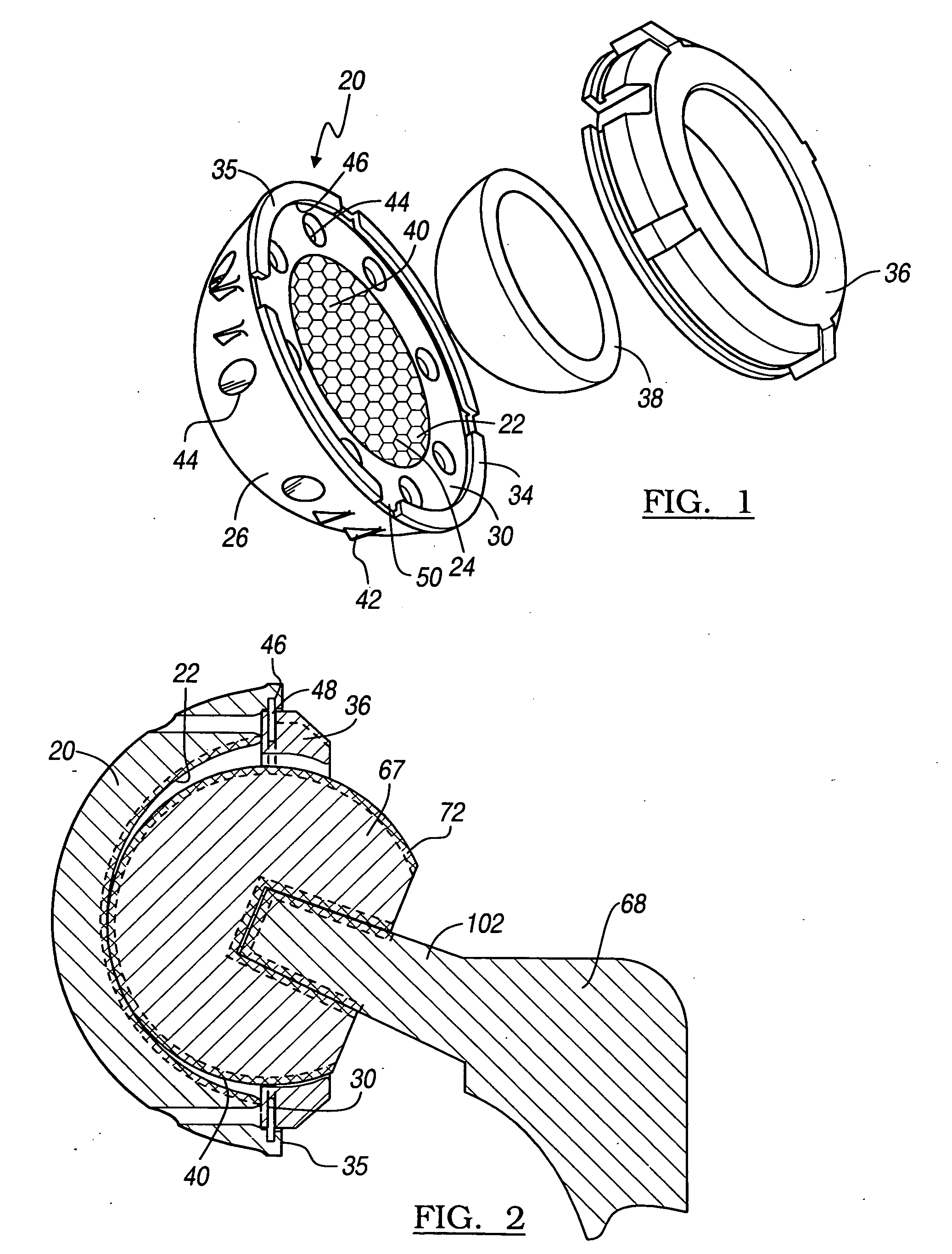

Peen conditioning of titanium metal wood golf club heads

Owner:ACUSHNET CO

Method and apparatus for surface hardening implants

A method for producing a prosthetic having metal articulating surfaces is disclosed. The method includes impinging at least a portion of the articulating surface with high energy laser electromagnetic radiation, to form a lasershot peened surface. A hardened portion of the surface is then post-processed to form a layer having a predetermined finish.

Owner:BIOMET MFG CORP

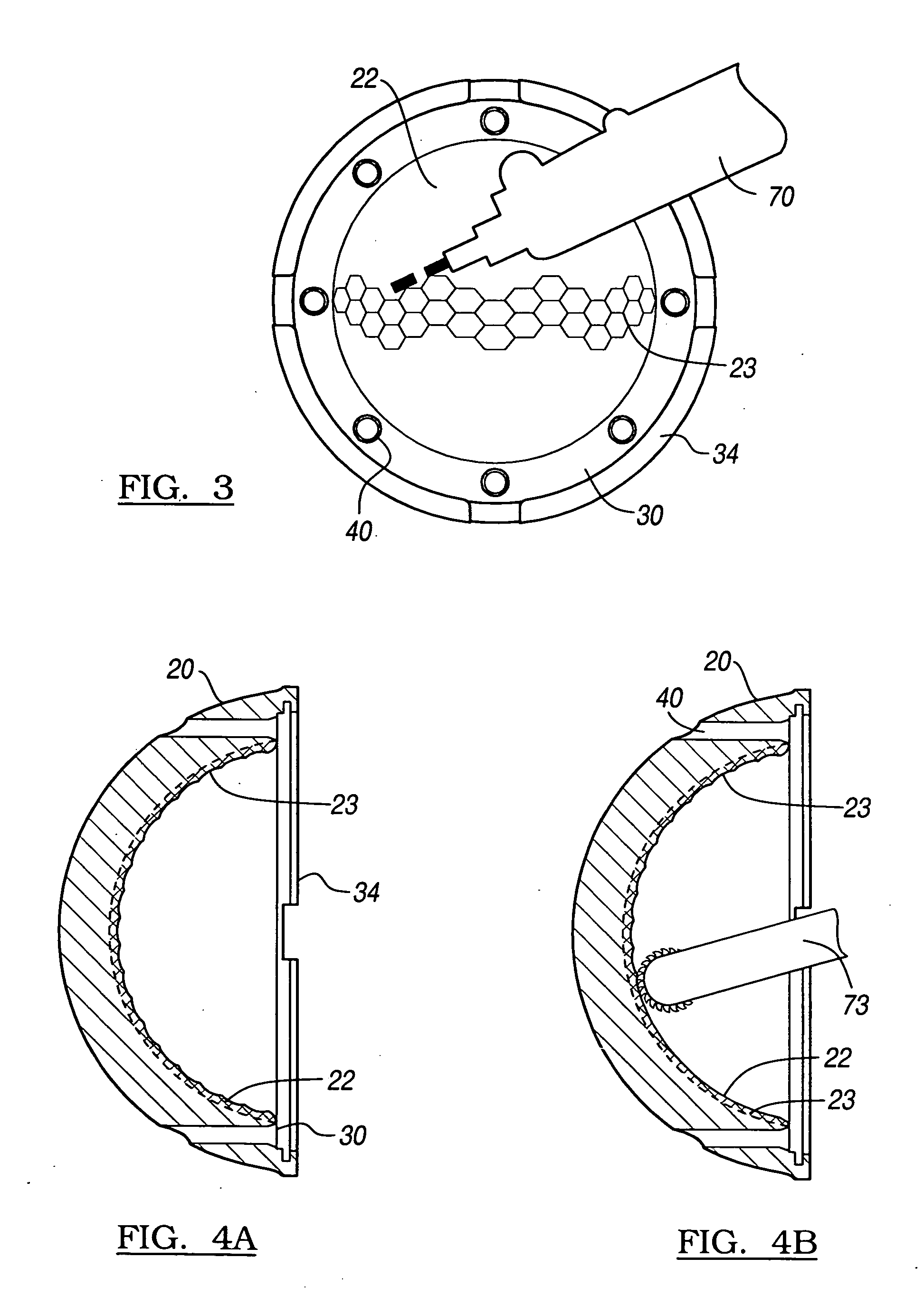

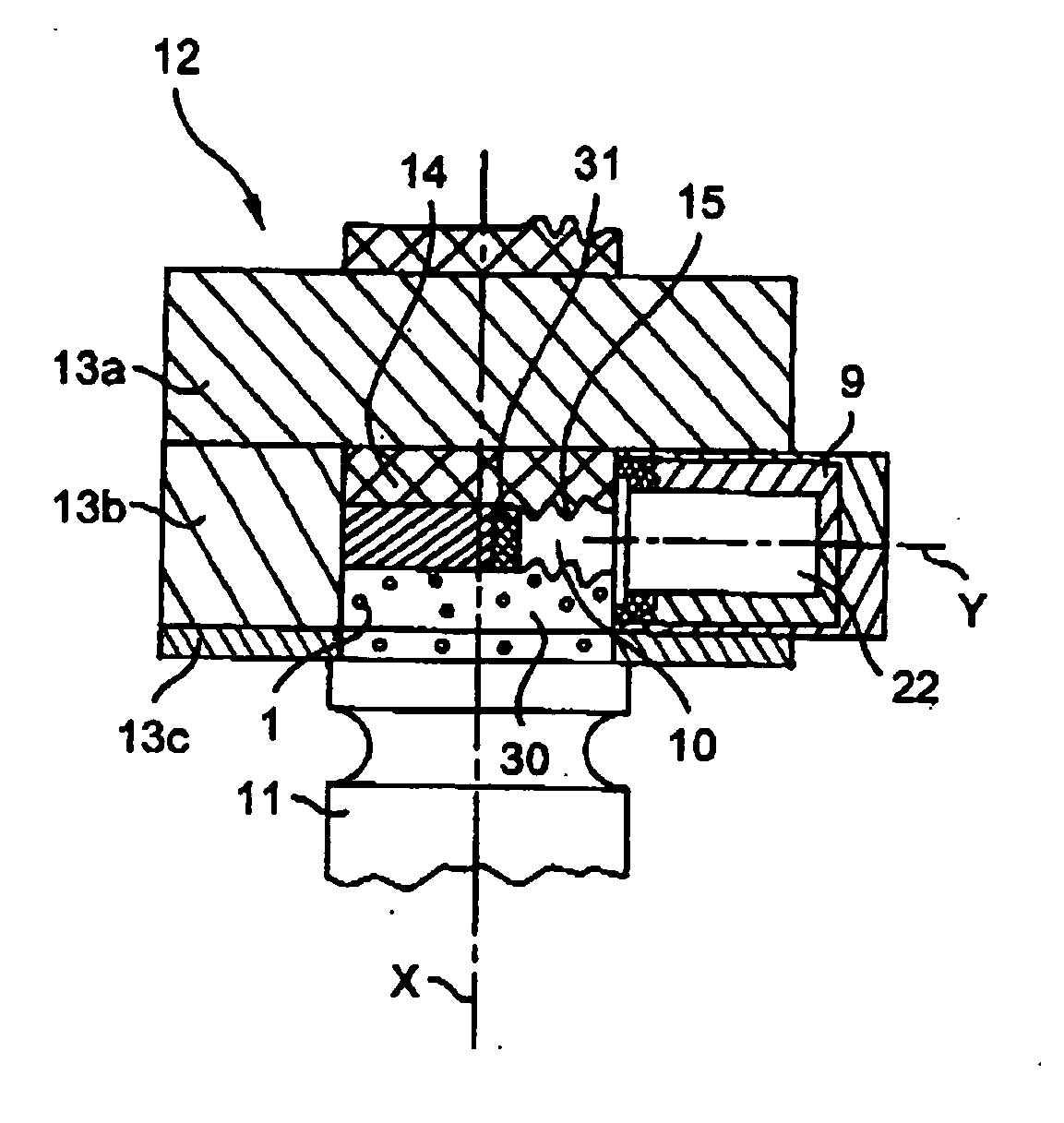

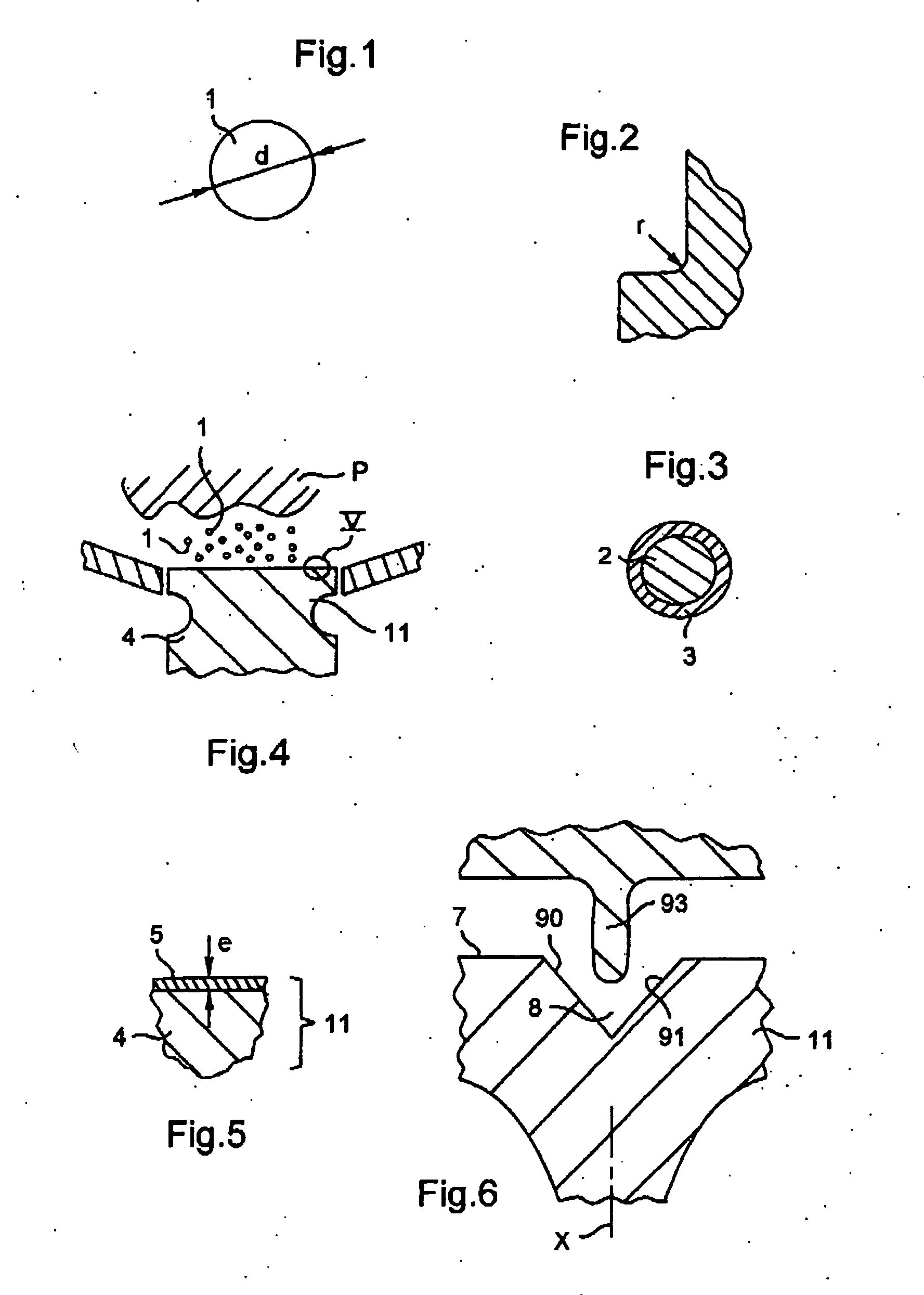

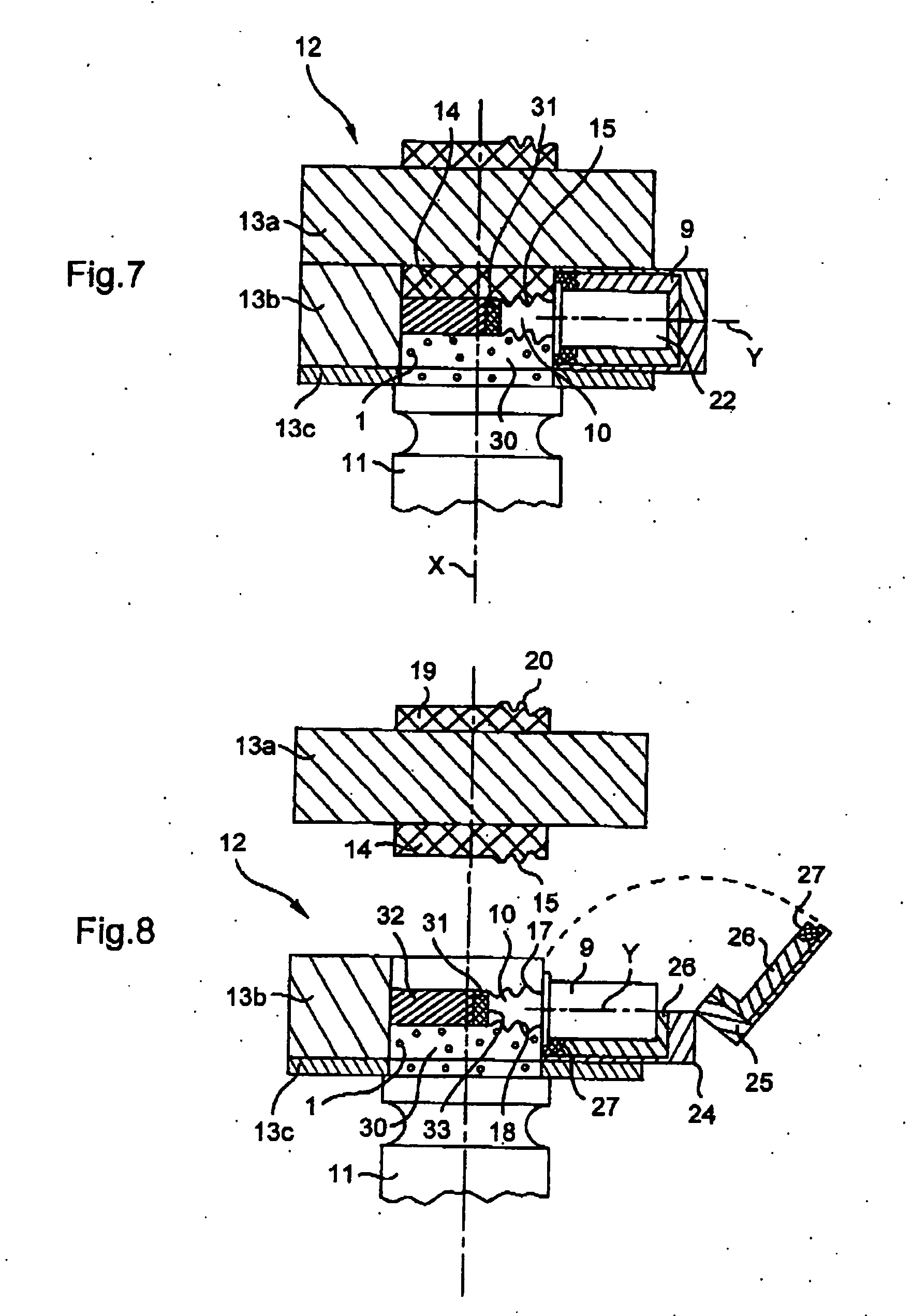

Method for the ultrasonic peening of large sized annular surfaces of thin parts

InactiveUS6289705B1Inhibits initiation and propagationImprove fatigue strengthBurnishing machinesVibratory devicesPeeningMaterials science

A method of so-called "ultrasonic" peening is described for peening large sized annular surfaces on thin parts. The method uses a microbead mist vibrated in a chamber with an opening so that the surface that is to be peened makes at least five movements past the opening of the peening chamber during peening so as to reduce deformation of the part.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

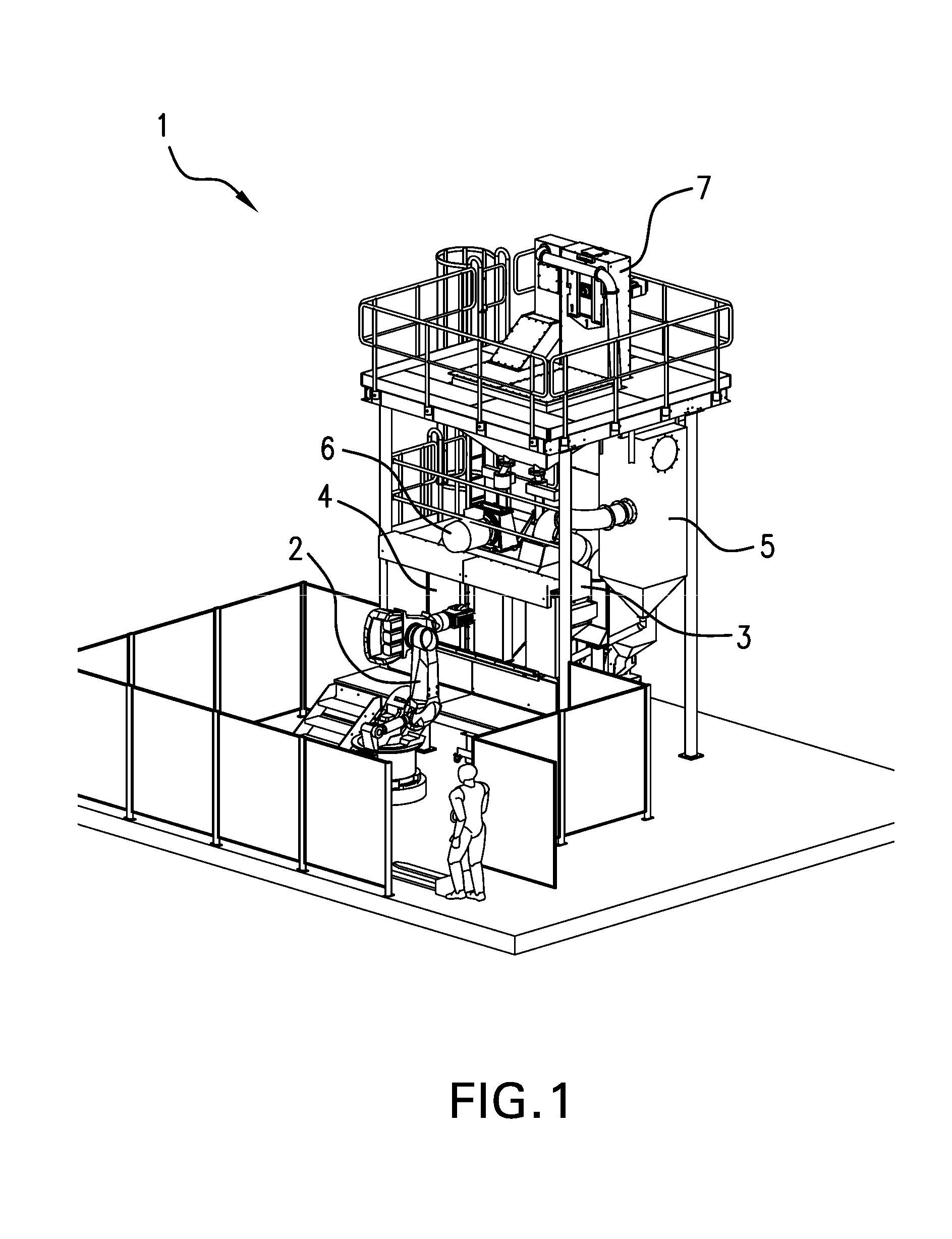

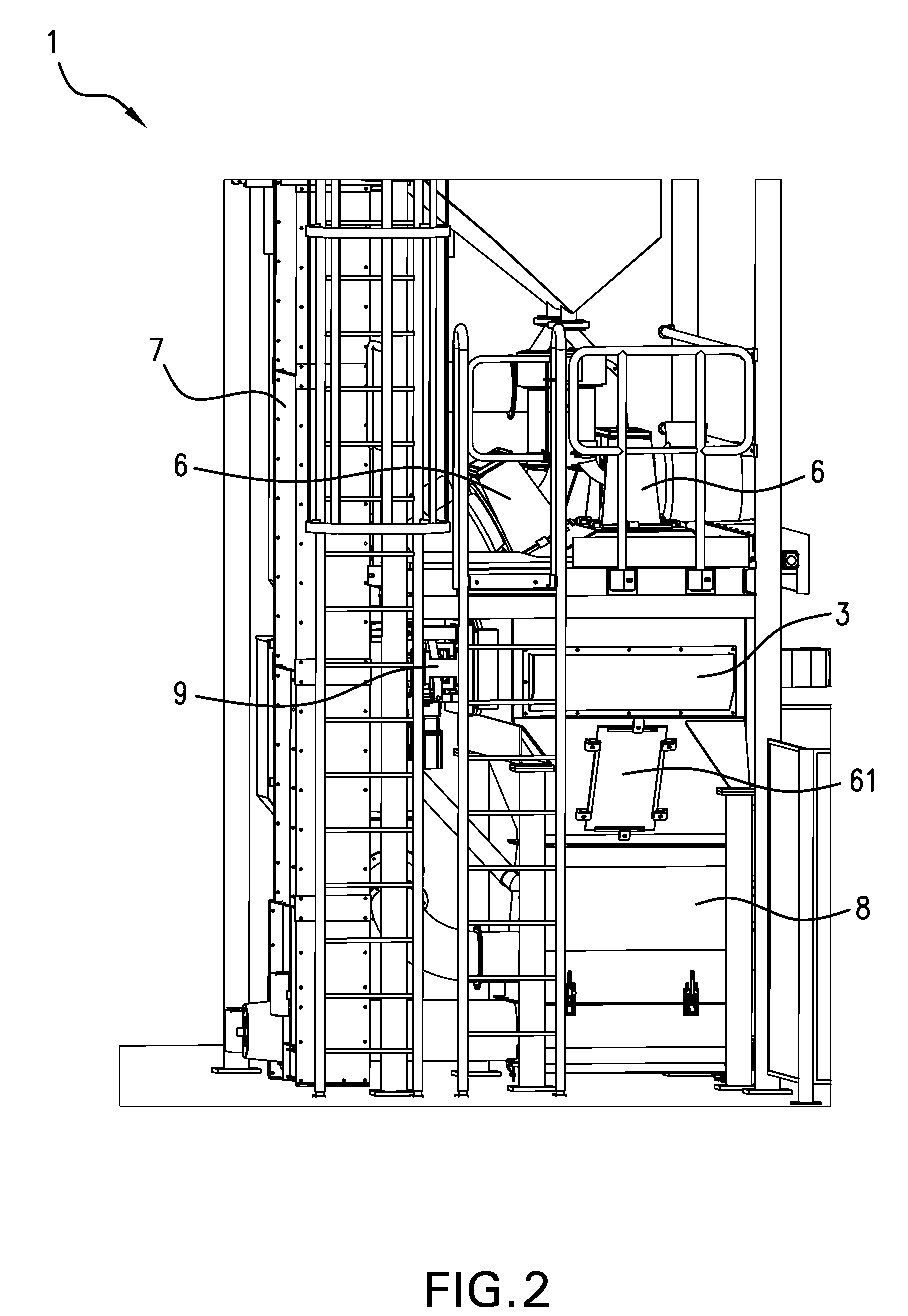

Shot-blasting installation for blasting work pieces made from light metal alloys

InactiveUS7421872B2Promote accumulationValve arrangementsFluid-tightness measurementAbrasive blastingEngineering

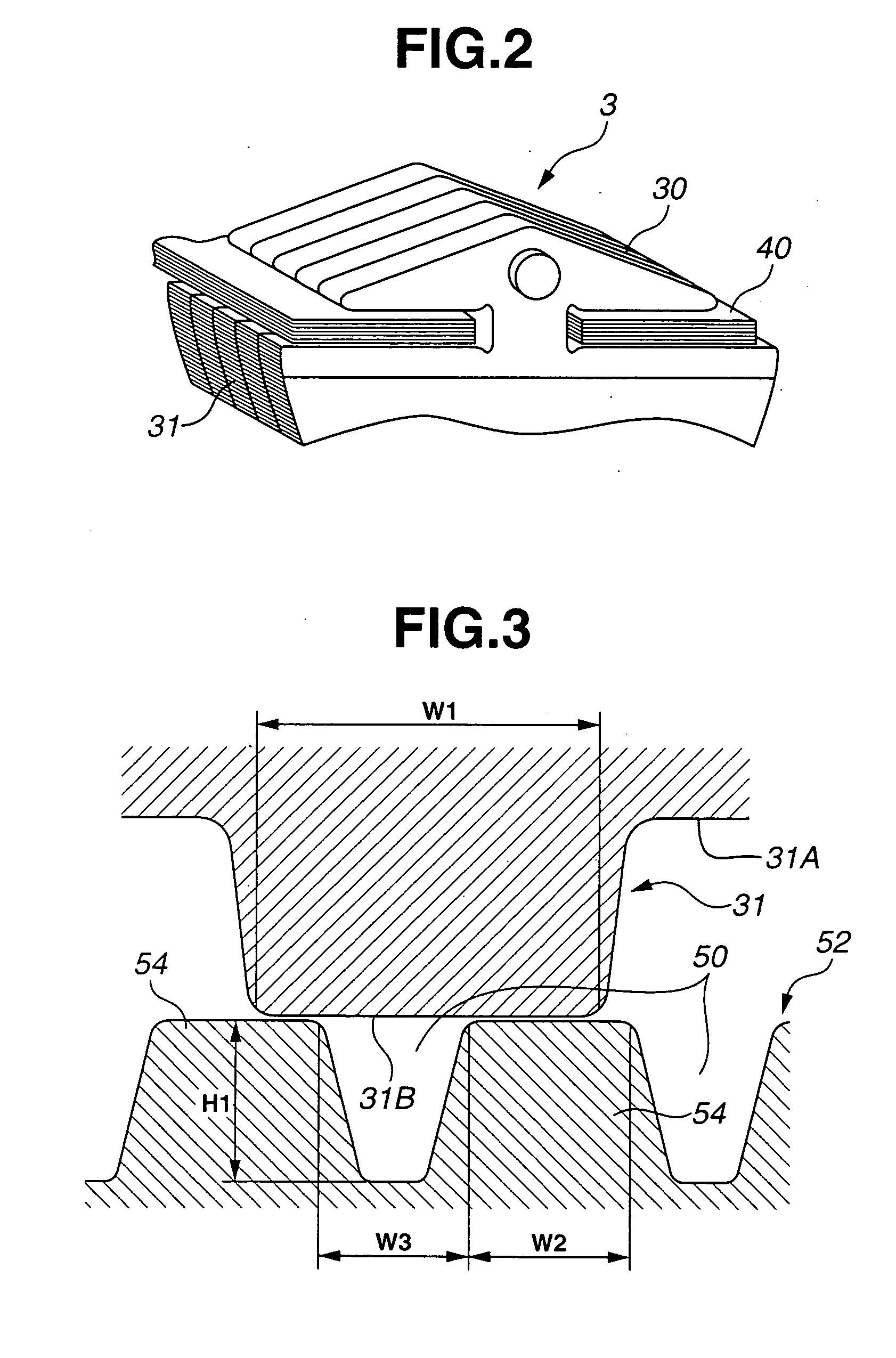

A shot-blasting installation (1) for blasting work pieces (30) made from light metal alloys, comprising at least one blasting chamber (3) for receiving the work pieces that are to be blasted, at least two blasting wheels (6) arranged in walls of the blasting chamber for introducing a blasting agent into the blasting chamber, and a separator (8) for separating the mixture of blasting agent and material that has been removed by blasting, wherein the separator (8) is arranged directly beneath the blasting chamber (3), and wherein a manipulator (10) for handling the cast work piece (30) during blasting is arranged in the blasting chamber (3).

Owner:DISA IND

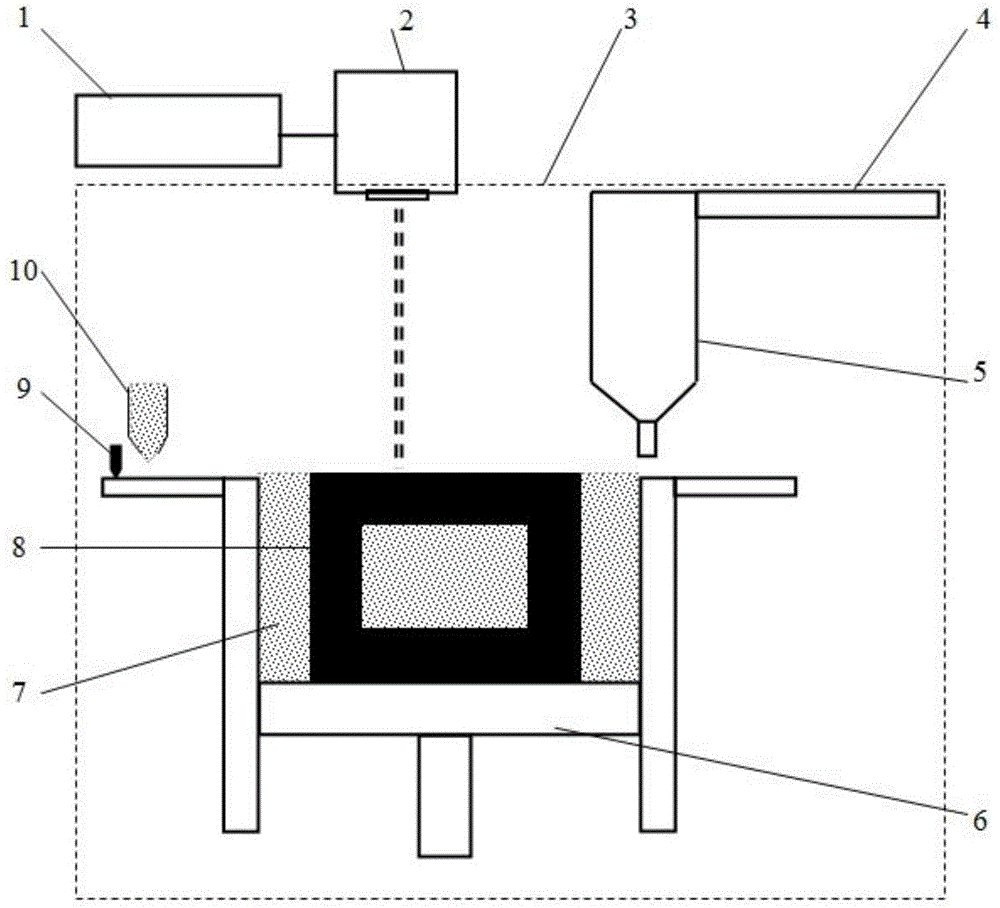

High-energy beam-ultrasonic composite additive manufacturing method for metal materials

InactiveCN104525944AHigh dimensional accuracyHigh performance controlIncreasing energy efficiencyHigh energyMechanical property

The invention discloses a high-energy beam-ultrasonic composite additive manufacturing method for metal materials and belongs to the field of additive manufacturing (3D printing) of metal materials. The method comprises the steps that based on the technical principle of layer-by-layer accumulation of additive manufacturing, metal forming materials are melted through high-energy beams; after the metal forming materials are melted / solidified layer by layer to accumulate to a certain number of layers, the solidified layers are subjected to ultrasonic peening to have compressive plastic deformation, so the internal stress and the internal defects of formed parts are eliminated, and crystalline grains are refined; afterwards, the process of layer-by-layer melting / solidifying accumulation and the process of ultrasonic peening are continued until the whole forming process of metal members is completed. According to the method, real-time layer-by-layer treatment is performed on the solidified layers through ultrasonic peening, so the internal stress and the internal defects can be effectively reduced or eliminated, the crystalline grains can be refined, and the mechanical property of the metal members through additive manufacturing can be improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

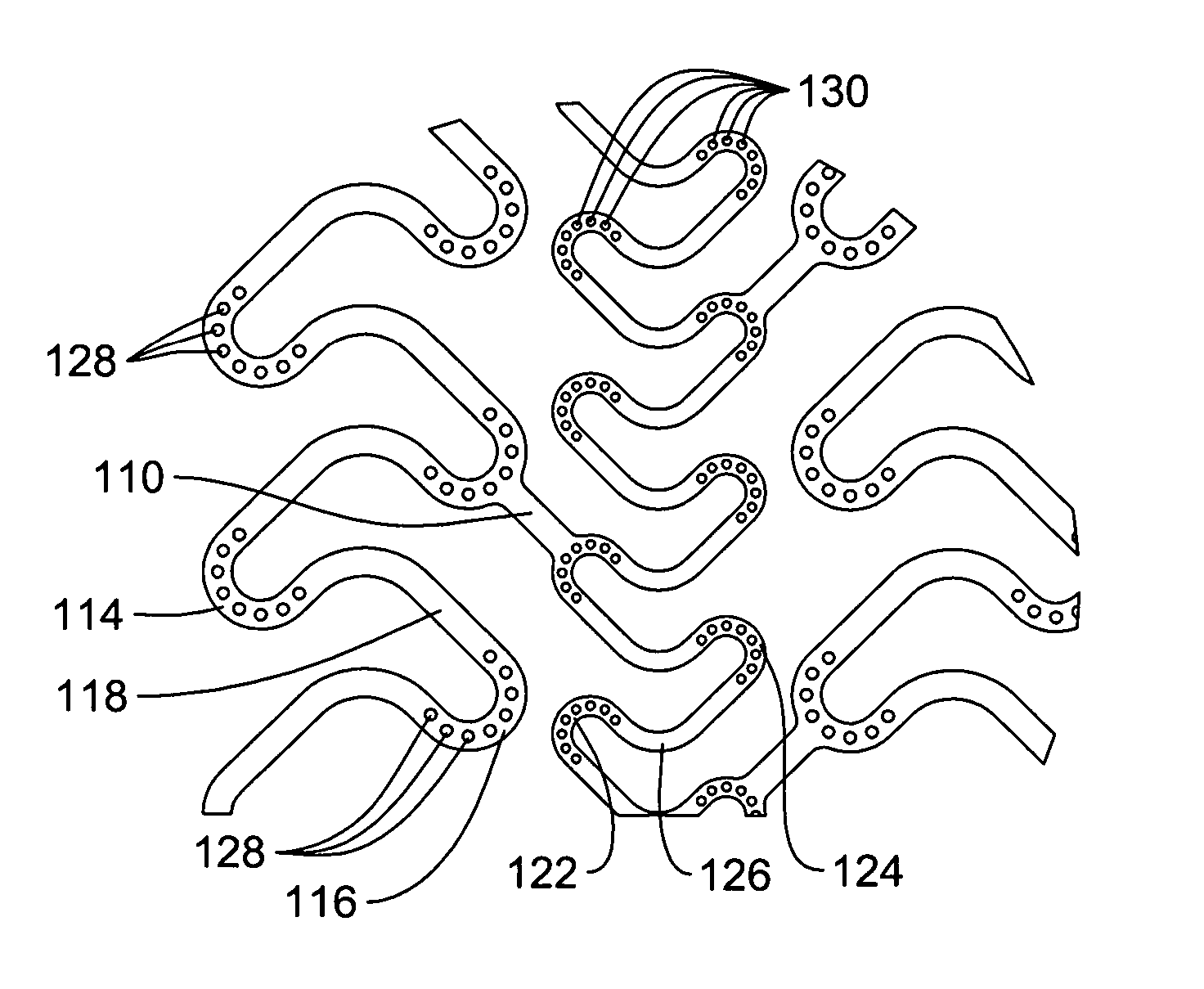

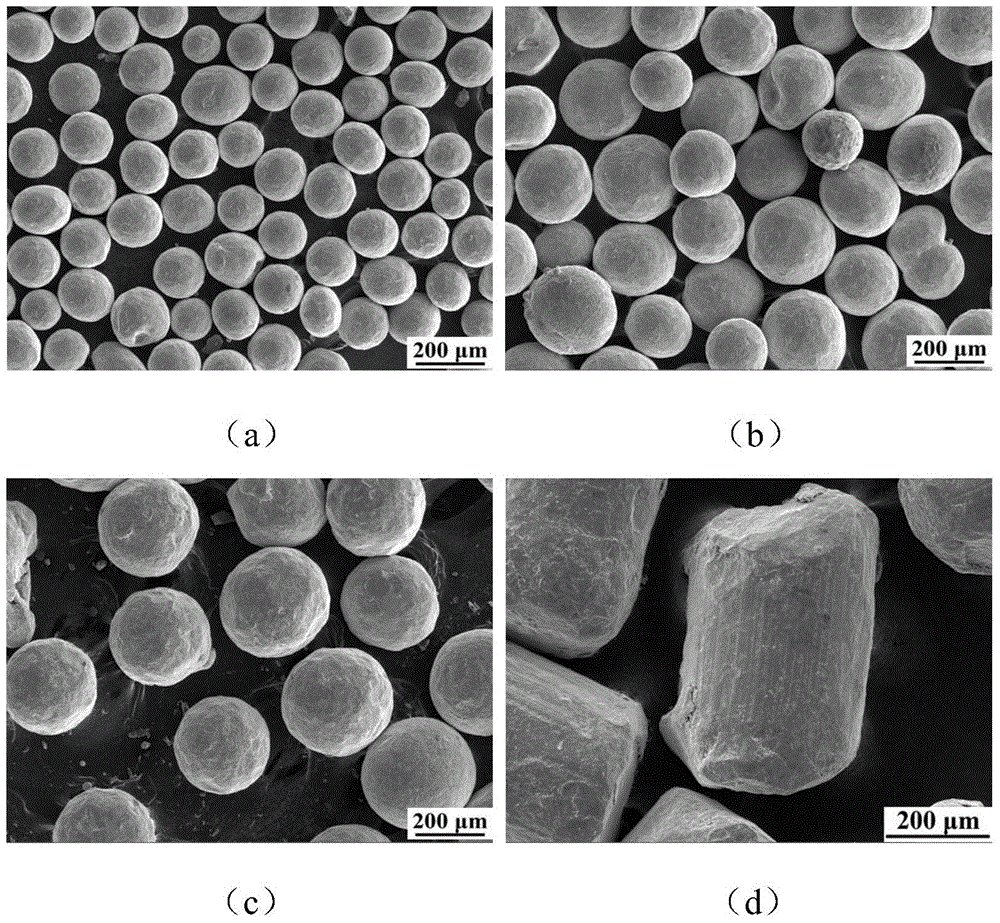

Shot, devices, and installations for ultrasonic peening, and parts treated thereby

InactiveUS20060021410A1Easy and quick to treatShorten treatment timeVibratory devicesMaximum dimensionMetallurgy

Shot for use in a peening installation, the shot having: hardness greater than or equal to 800 HV; density greater than or equal to 8 g / cm3; and pieces having a maximum dimension less than or equal to 1.5 mm.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Manufacturing method of integral herringbone gear shaft

ActiveCN101804548AImprove bending strengthSmall diameterMaterials preparationManufacturing cost reduction

The invention discloses a manufacturing method of an integral herringbone gear shaft, which comprises the following steps that: material preparation: a center hole is drilled on one end of a work piece; primary machining; primary detection; heat treatment; secondary machining; secondary detection; rough milling; chamfering at the gear end; coating anti-carburizing layers on both ends of the herringbone gear shaft so that the depth of a carburized layer is 3.55 to 3.95mm, and quenching so as to enable the hardness of a gear part to reach HRC58 to 62, and to enable the hardness of the heart to reach HRC28 to 33; carrying out shoot peening on a gear surface; tertiary machining; gear shaping; external grinding; fine milling; and inspection. The manufacturing method of the integral herringbone gear shaft has the advantages of improving the bending strength of the gear root, reducing the manufacturing cost and improving the manufacturing precision.

Owner:SHANGHAI ZHENHUA HEAVY IND GRP NANTONG TRANSMISSION MACHINERY

Turbine component protected with environmental coating

ActiveUS7364801B1Suitable for useReliable long-term protection from oxidation and hot corrosionMolten spray coatingPropellersSolid solutionCobalt

An environmental coating suitable for use on turbine components, such as turbine disks and turbine seal elements, formed of alloys susceptible to oxidation and hot corrosion. The environmental coating is predominantly a solid solution phase of nickel, iron, and / or cobalt. The coating contains about 18 weight percent to about 60 weight percent chromium, which ensures the formation of a protective chromia (Cr2O3) scale while also exhibiting high ductility. The coating may further contain up to about 8 weight percent aluminum, as well as other optional additives. The environmental coating is preferably sufficiently thin and ductile to enable compressive stresses to be induced in the underlying substrate through shot peening without cracking the coating.

Owner:GENERAL ELECTRIC CO

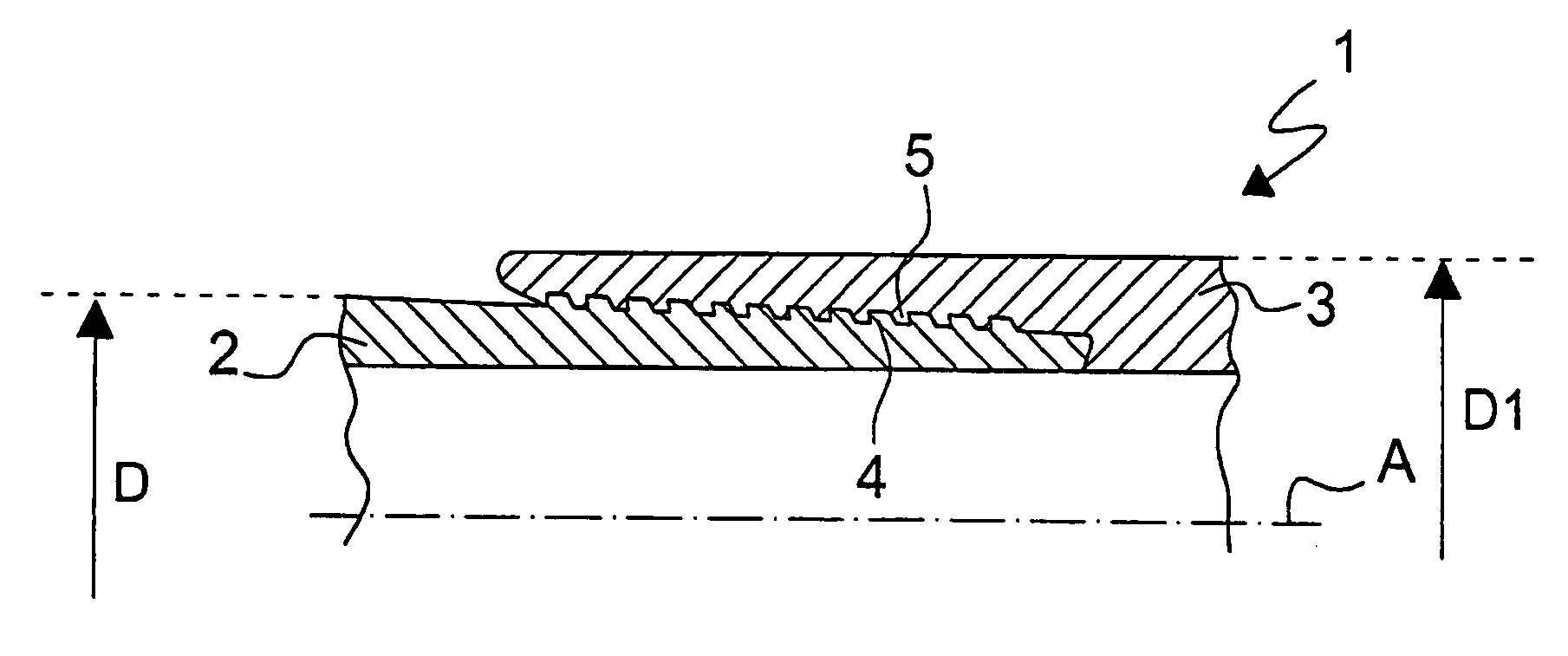

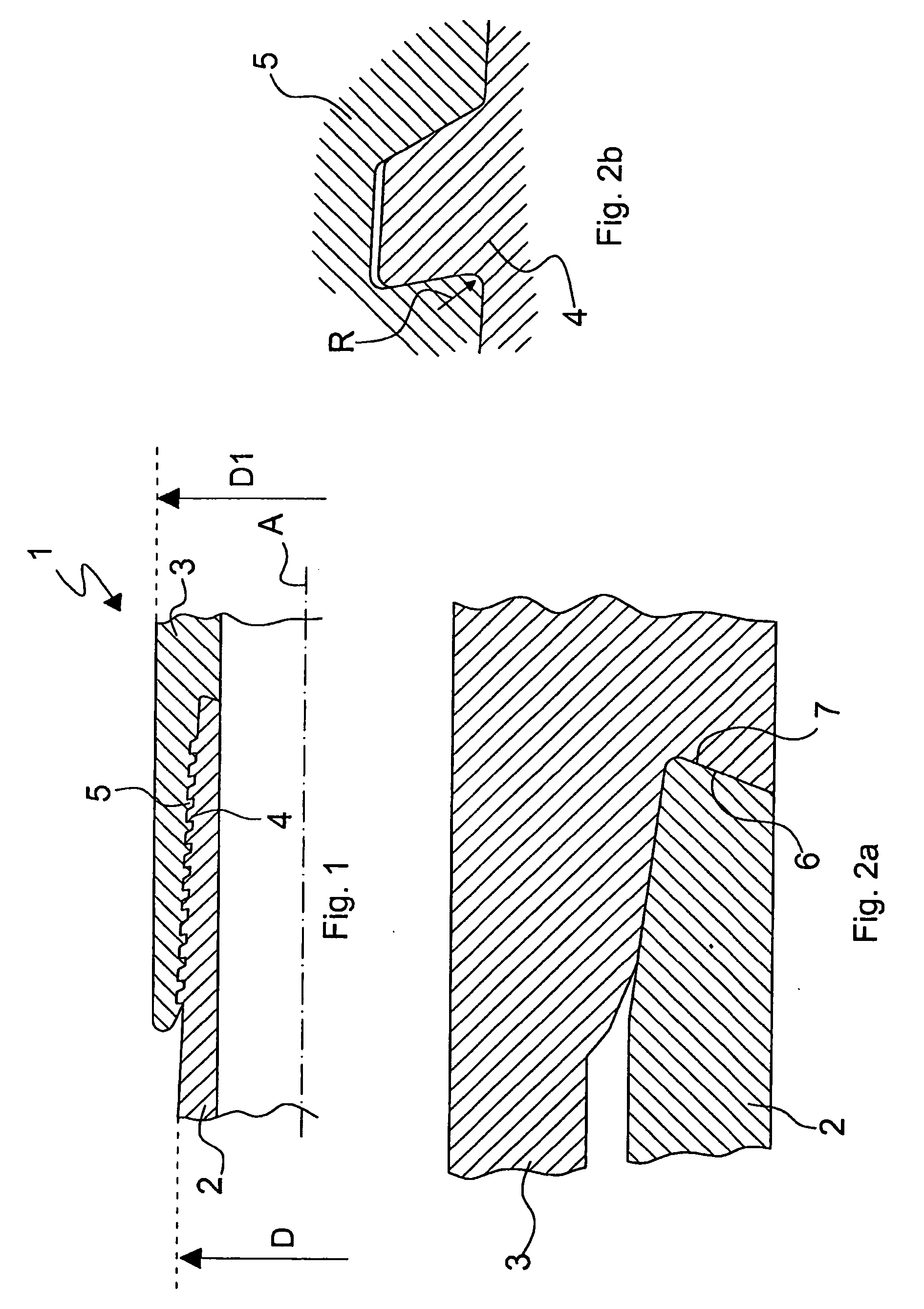

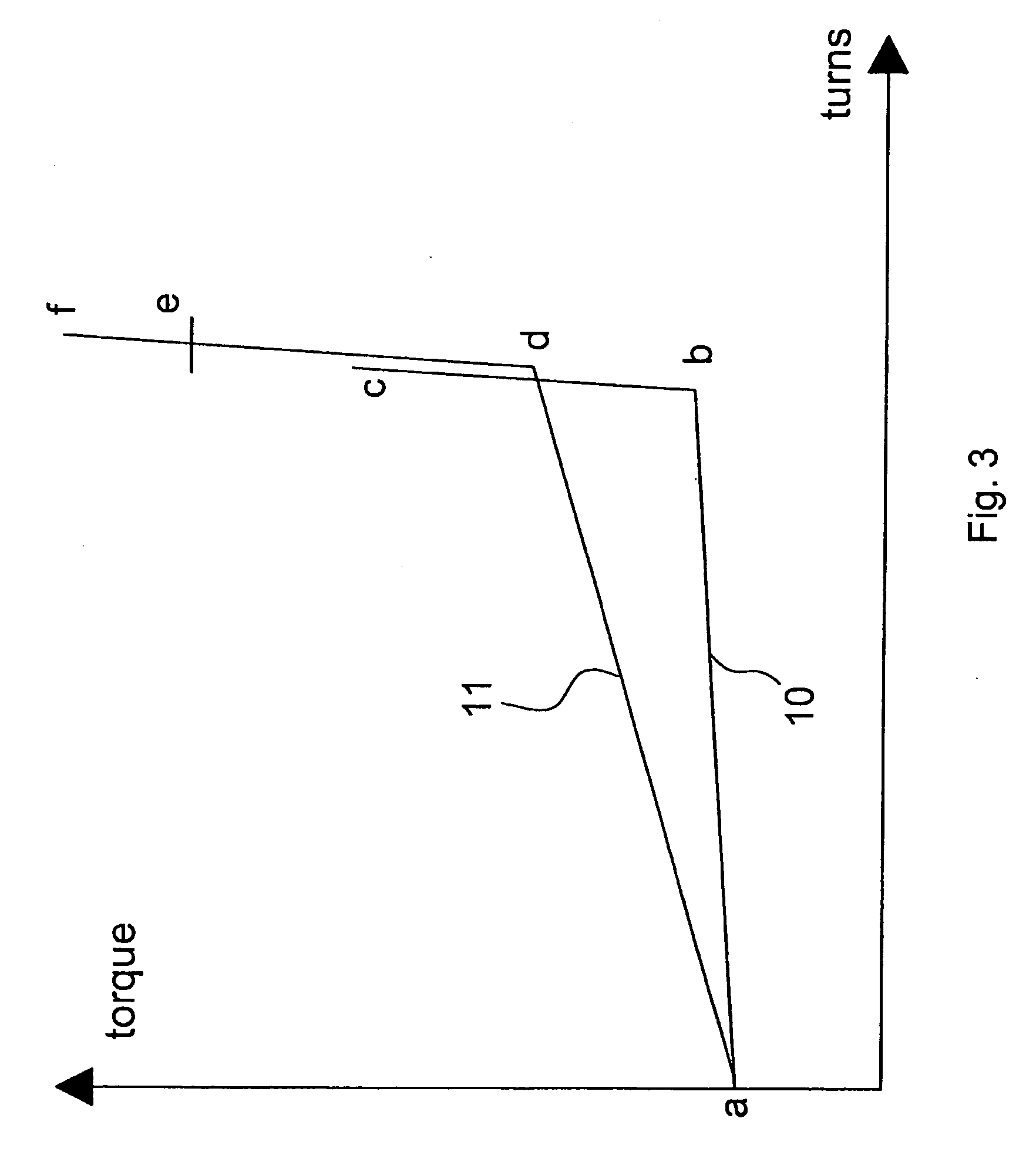

Threaded joint with high radial loads and differentially treated surfaces

ActiveUS20110042946A1Improve fatigue lifeImprove fatigue resistanceDrilling rodsPipe elementsEngineeringScrew thread

A threaded joint has an interference between thread roots of pin and thread crests of the box of value comprised between 1% and 5% of the average thickness of the connection, and a root to load flank radius R comprised in the range of 0.2 mm and 0.4 mm and a surface treatment comprising shot peening applied to the beginning and end of the threaded zone of the pin. In other embodiments the interference can be between thread roots of box and thread crests of the pin.

Owner:TENARIS CONNECTIONS

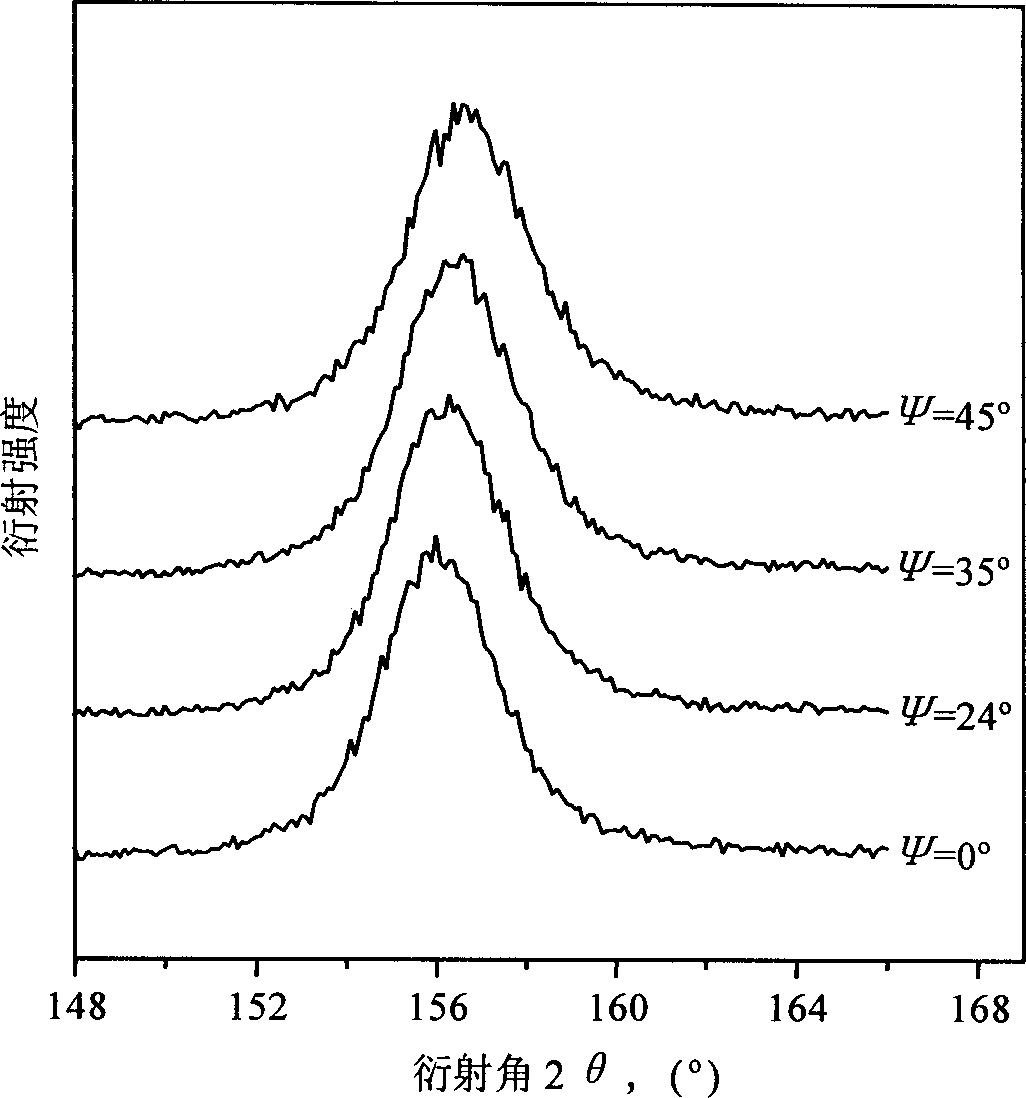

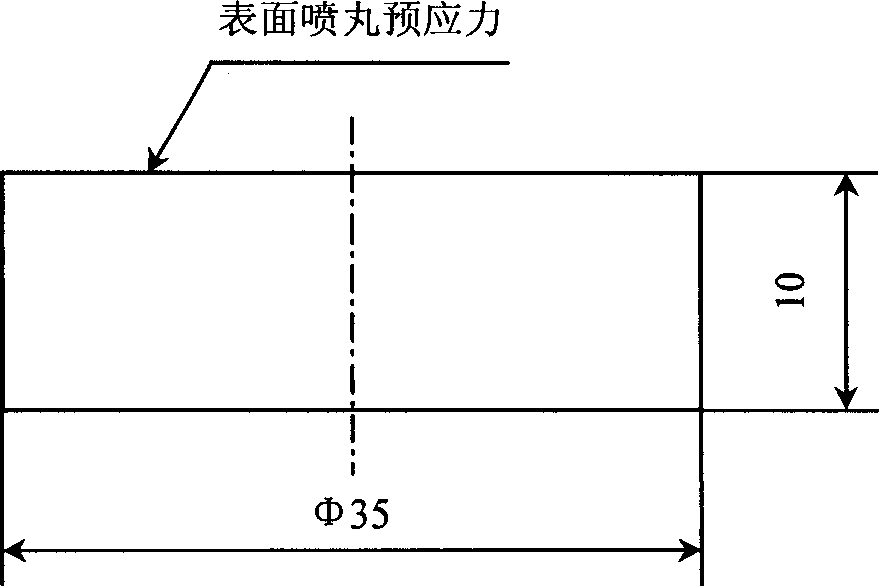

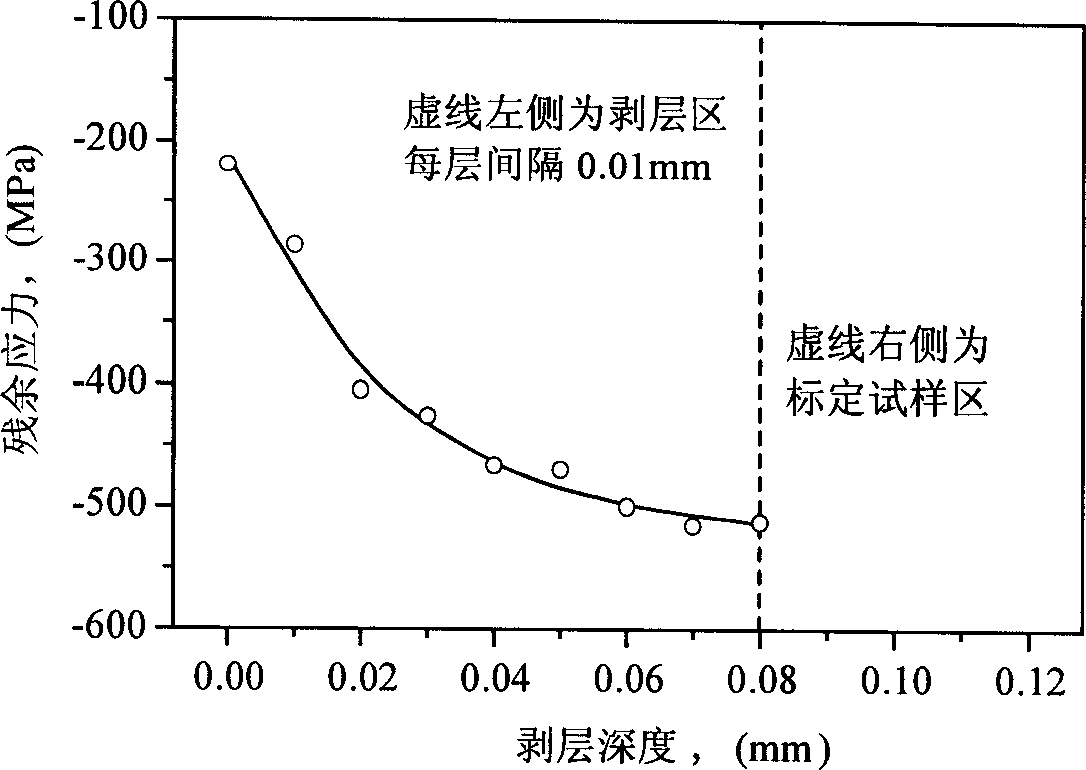

Production of X-ray stress measuring calibrated sample

InactiveCN1645091AEasy to carryBeautiful surfaceMaterial analysis using wave/particle radiationPreparing sample for investigationSurface stressStress measurement

A method for preparing calibration test sample of X ray stress measurement includes removing phenomenon of crystal particle coarsening and crystal face preferred orientation, carrying out short blasting treatment for semiproduct of the sample, stripping layer by layer for portion with greater stress gradient by electrochemical corrosion, carrying out X ray stress measurement and calibrating out work surface of the sample by utilizing relation curve of stress to layer depth.

Owner:SHANGHAI JIAO TONG UNIV

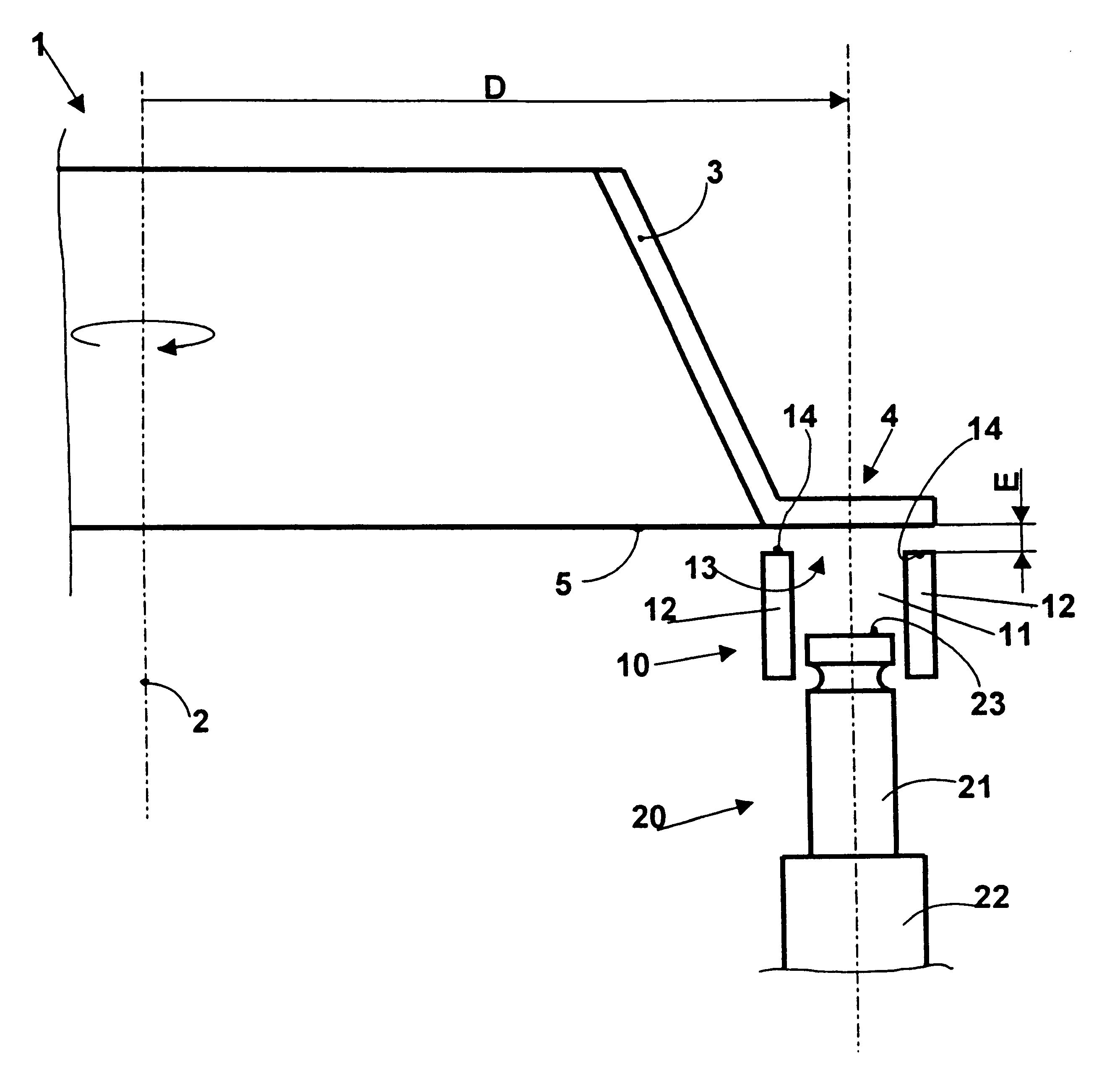

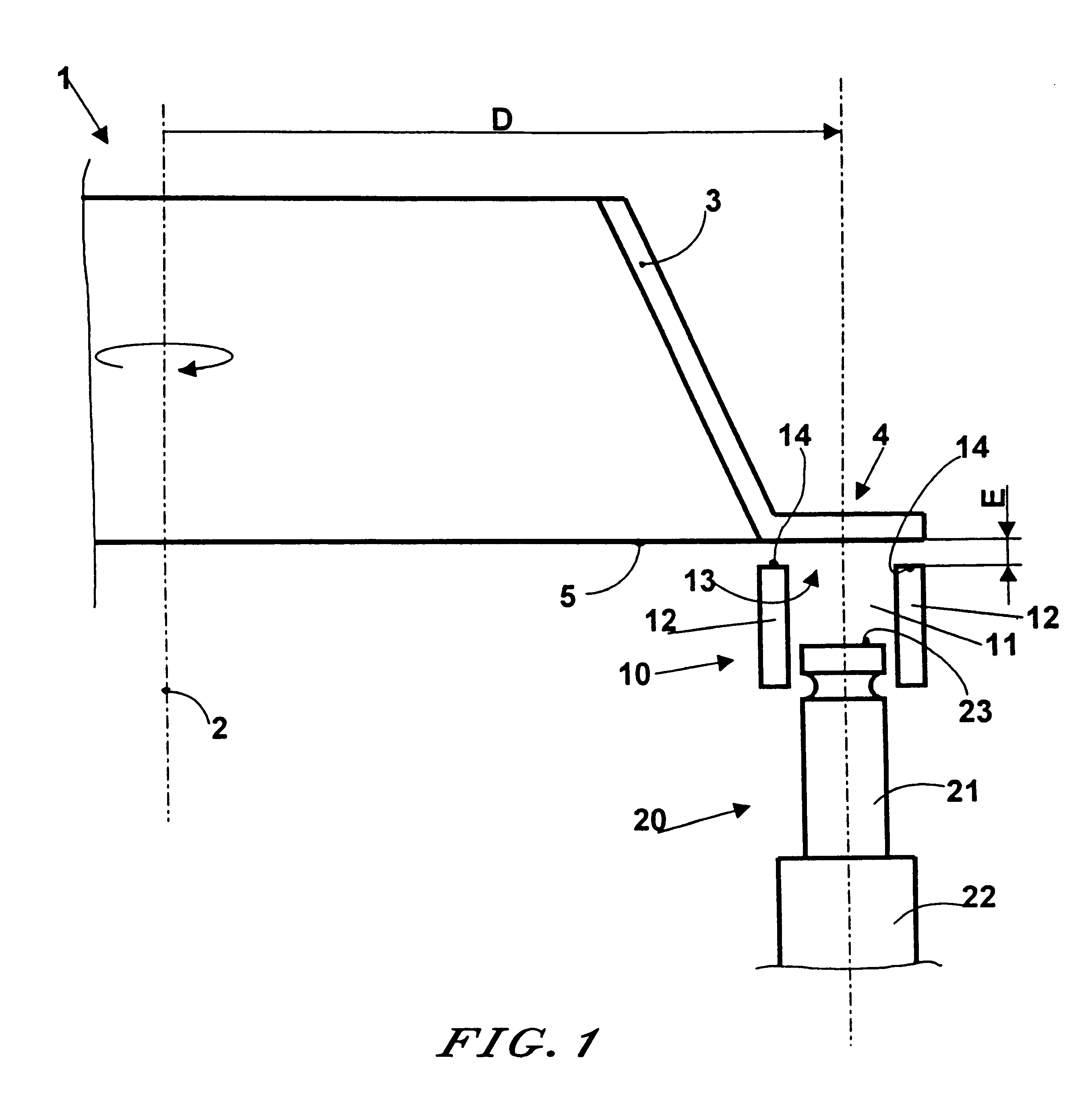

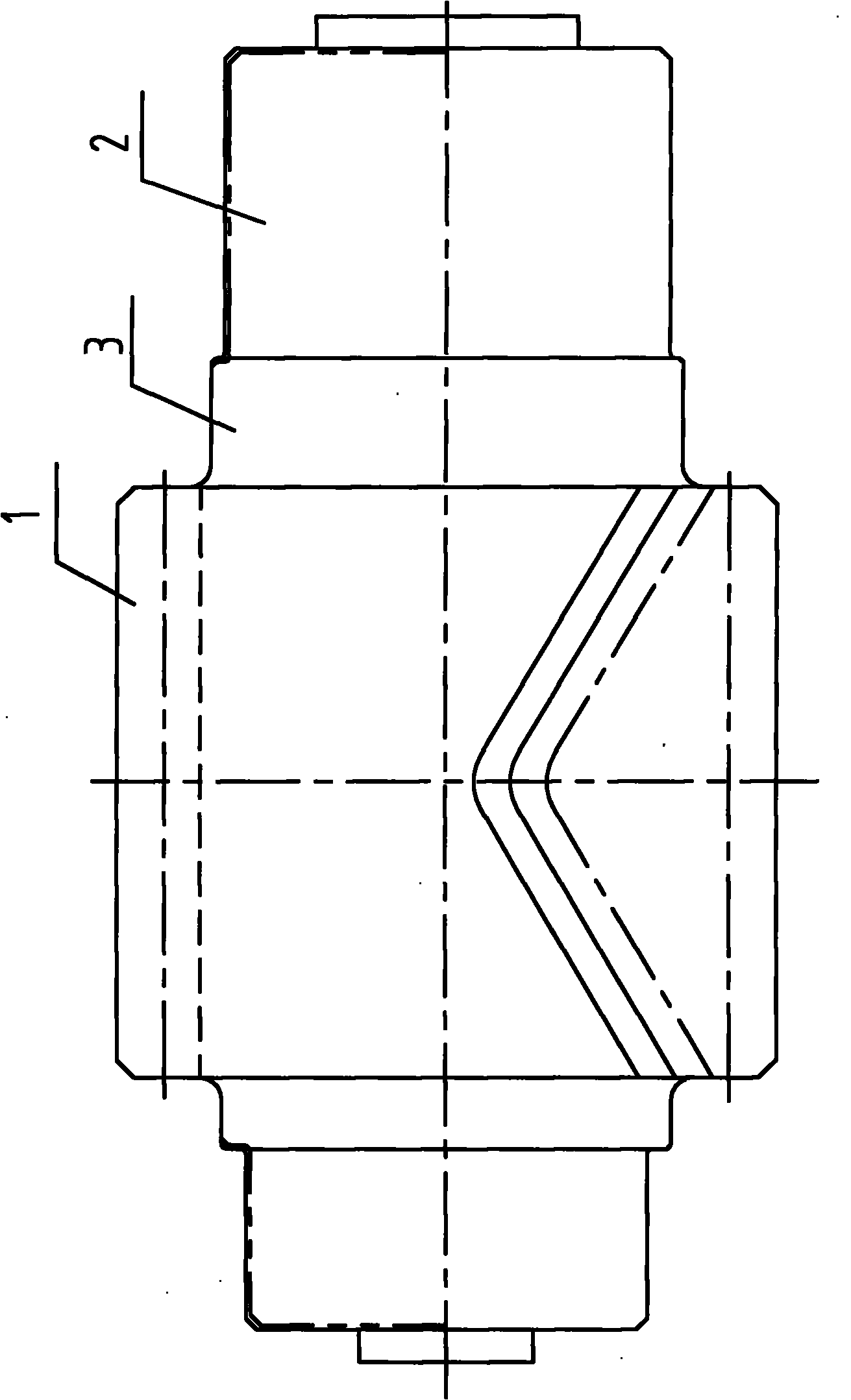

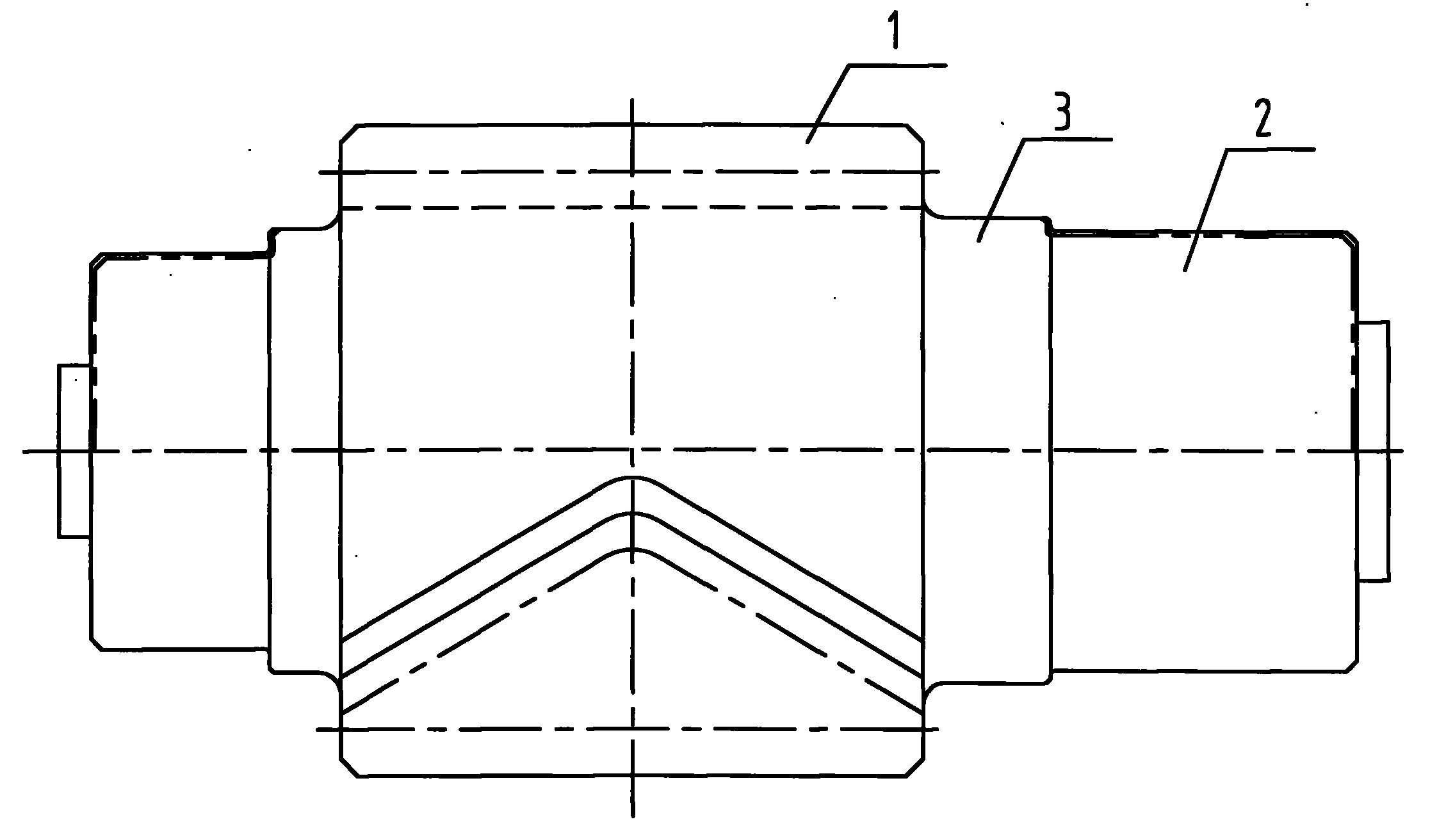

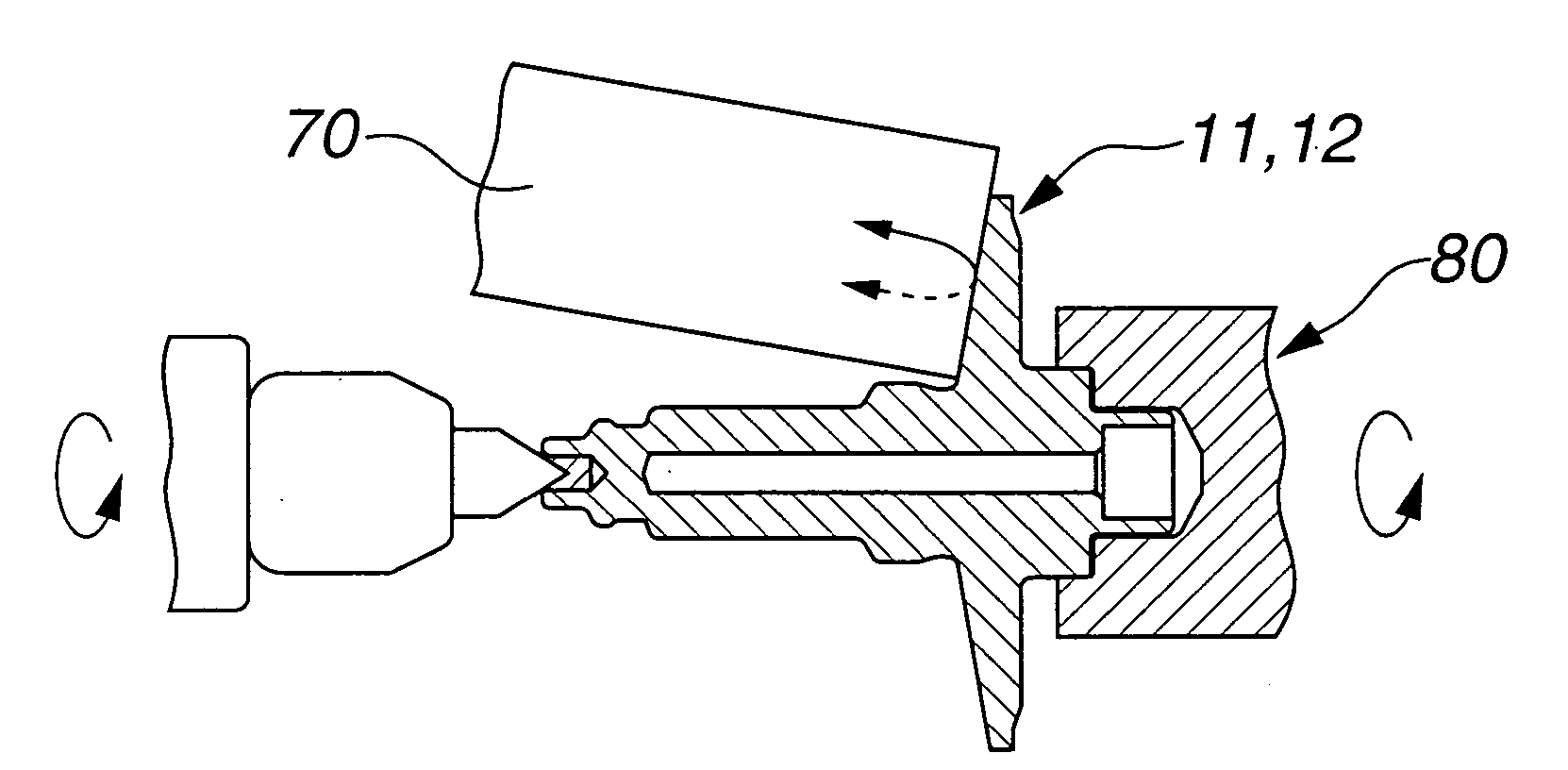

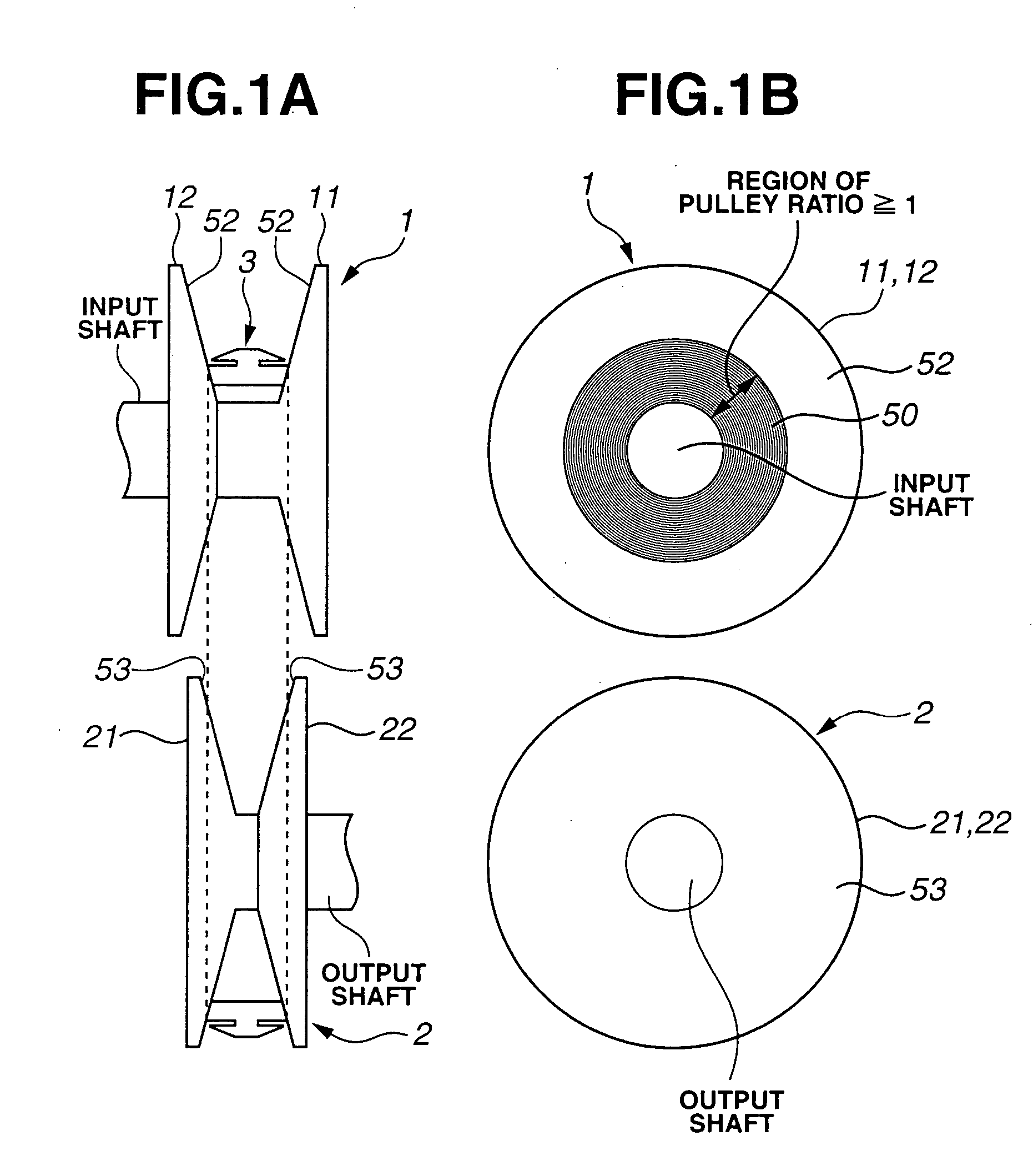

Process for producing a pulley for a continuously variable belt drive transmission

InactiveUS20050217111A1Increase frictionHigh dimensional accuracyGearingPortable liftingPeeningPulley

A process for producing a pulley for a belt drive CVT, including subjecting tapered surfaces of a preform of at least one of input and output pulleys to surface hardening, subjecting the surface-hardened tapered surfaces of the preform to hard turning to form microgrooves radially spaced from one another thereon, between which microprojections are formed, and reducing a height of the microprojections. Alternatively, a process for producing a pulley for a belt drive CVT, including subjecting tapered surfaces of a preform of at least one of input and output pulleys to surface hardening, subjecting the surface-hardened tapered surfaces of the preform to shot peening, and subjecting the shot-peened tapered surfaces of the preform to finishing to form microgrooves having a substantially equal pitch thereon.

Owner:JATCO LTD

High Durability Structures of Amorphous Alloy and a Method of Forming

Articles of bulk-solidifying amorphous alloys with improved durability and fatigue resistance, and more specifically articles of bulk-solidifying amorphous alloys subjected to a surface treatment, such as shot-peening, which creates deformations in the exterior surface, and methods of improving the durability and fatigue resistance of bulk-solidifying amorphous alloys using a surface treatment, such as shot-peening.

Owner:CRUCIBLE INTPROP LLC

Crack controlling means for laser deposition formed metal parts

InactiveCN1737197AImprove coagulation stateImprove liquidityMetallic material coating processesLaser beam welding apparatusClosed loop feedbackClosed loop

The invention relates to a crack-controlling method of metal parts by laser melting formation in laser material processing domain, which comprises closed-loop control of fused bath temperature, which comprises the two specific steps of exerting closed-loop feedback control on fused bath temperature by using optical imaging system and PID control device with calorific radiation transmitted from melting zone and adjusting horsepower of laser, and introduction of ultrasonic vibration, which comprises the specific steps of introducing ultrasonic vibration under the piece of work when forming by laser melting. The invention can deduce residual stress and crack, improve structure and can be used in multiple relative domains such as forming, manding and surface peening by laser melting.

Owner:SHANGHAI JIAO TONG UNIV

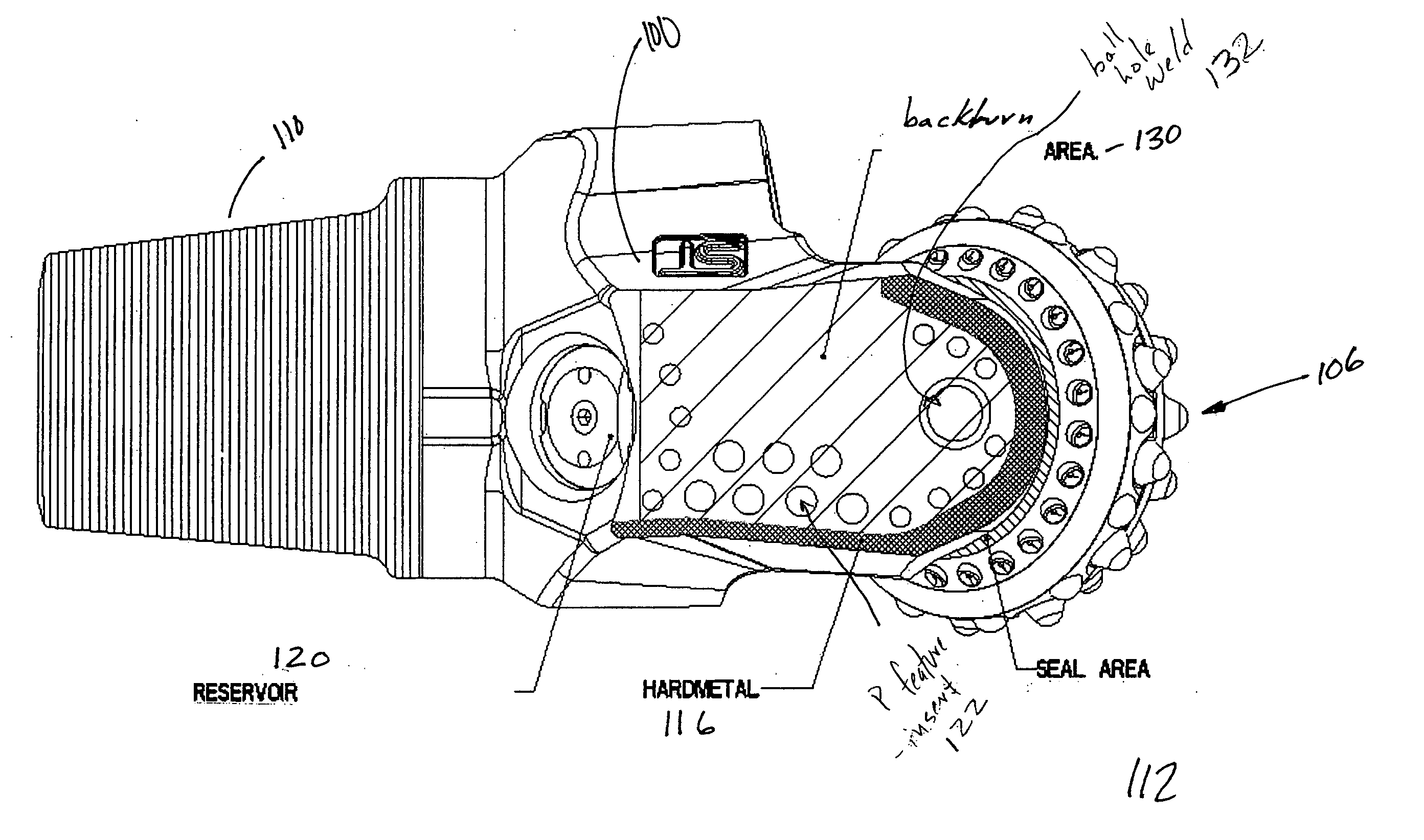

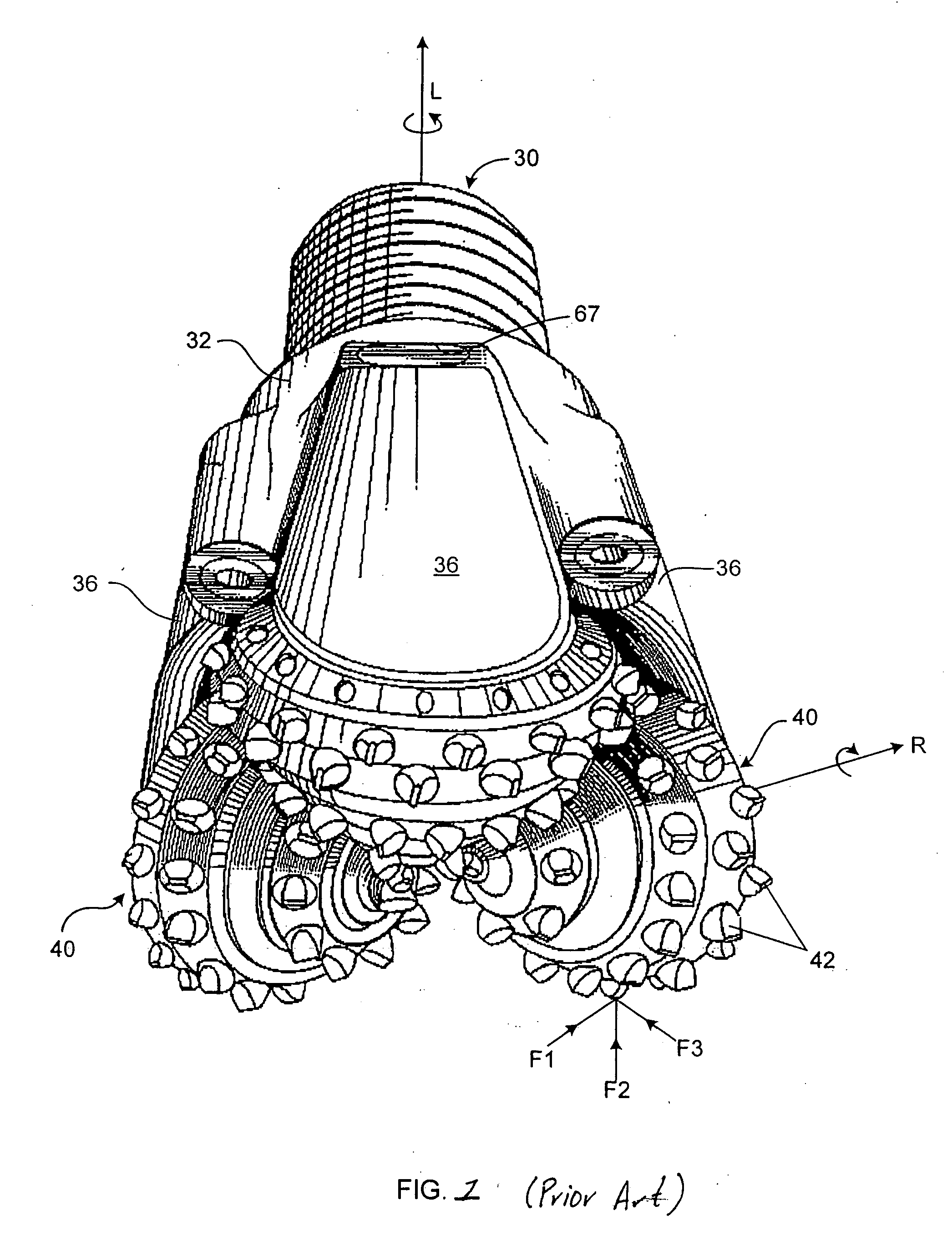

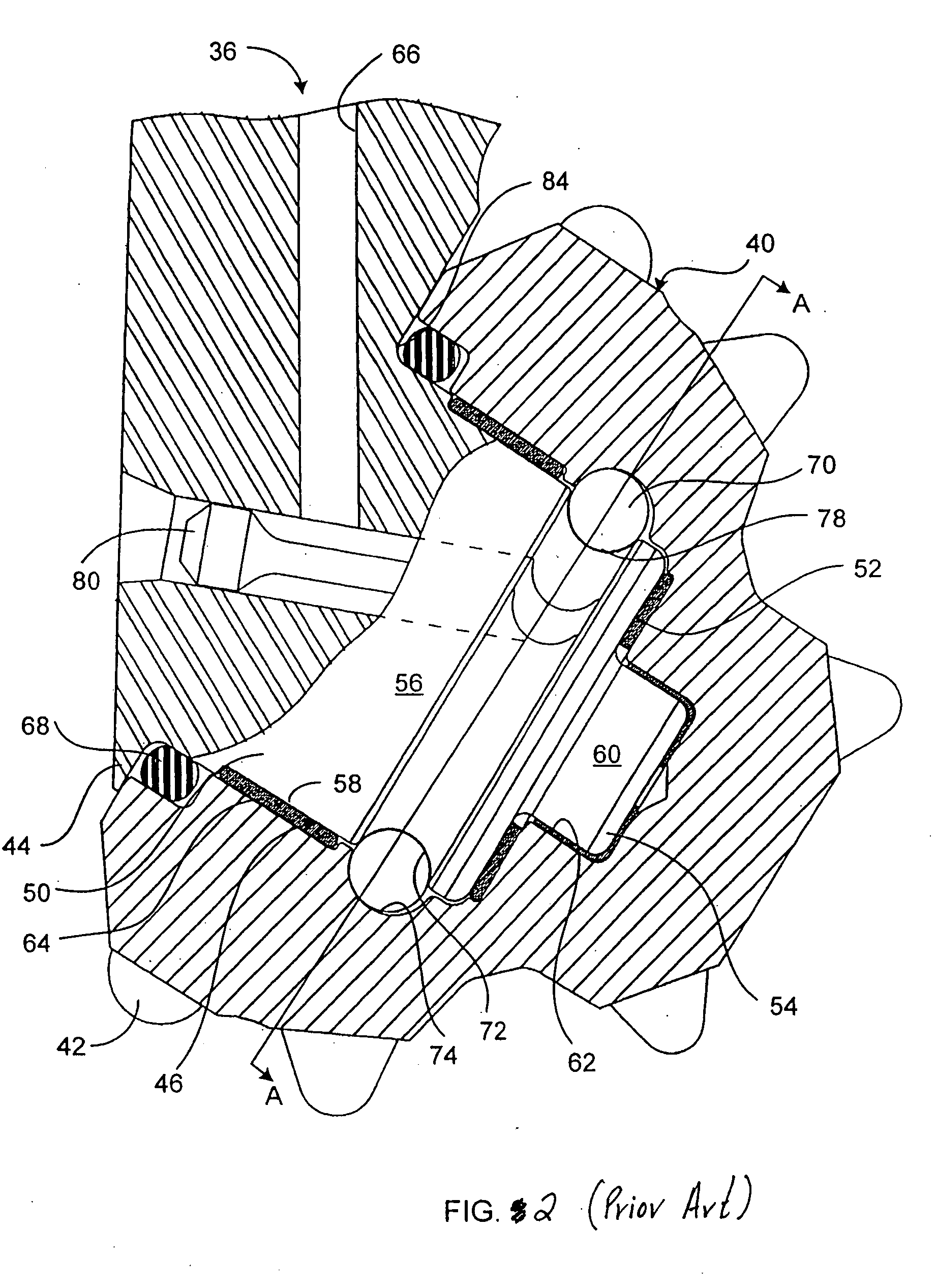

Drill bit having increased resistance to fatigue cracking and method of producing same

The present invention relates to a roller cone drill bit that includes a bit body adapted to be rotated about a longitudinal axis, where the bit body has at least one leg depending therefrom, wherein the leg comprises a treated portion that provides a residual compressive stress, and a roller cone rotatably mounted on a journal. The treated portion treatment may comprise one selected from shot peening, laser-shock peening, and hammer peening. Further, the present invention relates to a method of manufacturing a roller cone drill bit that includes inducing a compressive stress, through plastic deformation, in at least a portion of at least one leg depending from a bit body. The inducing a compressive stress may comprise one selected from shot peening, laser-shock peening, and hammer peening.

Owner:SMITH INT INC

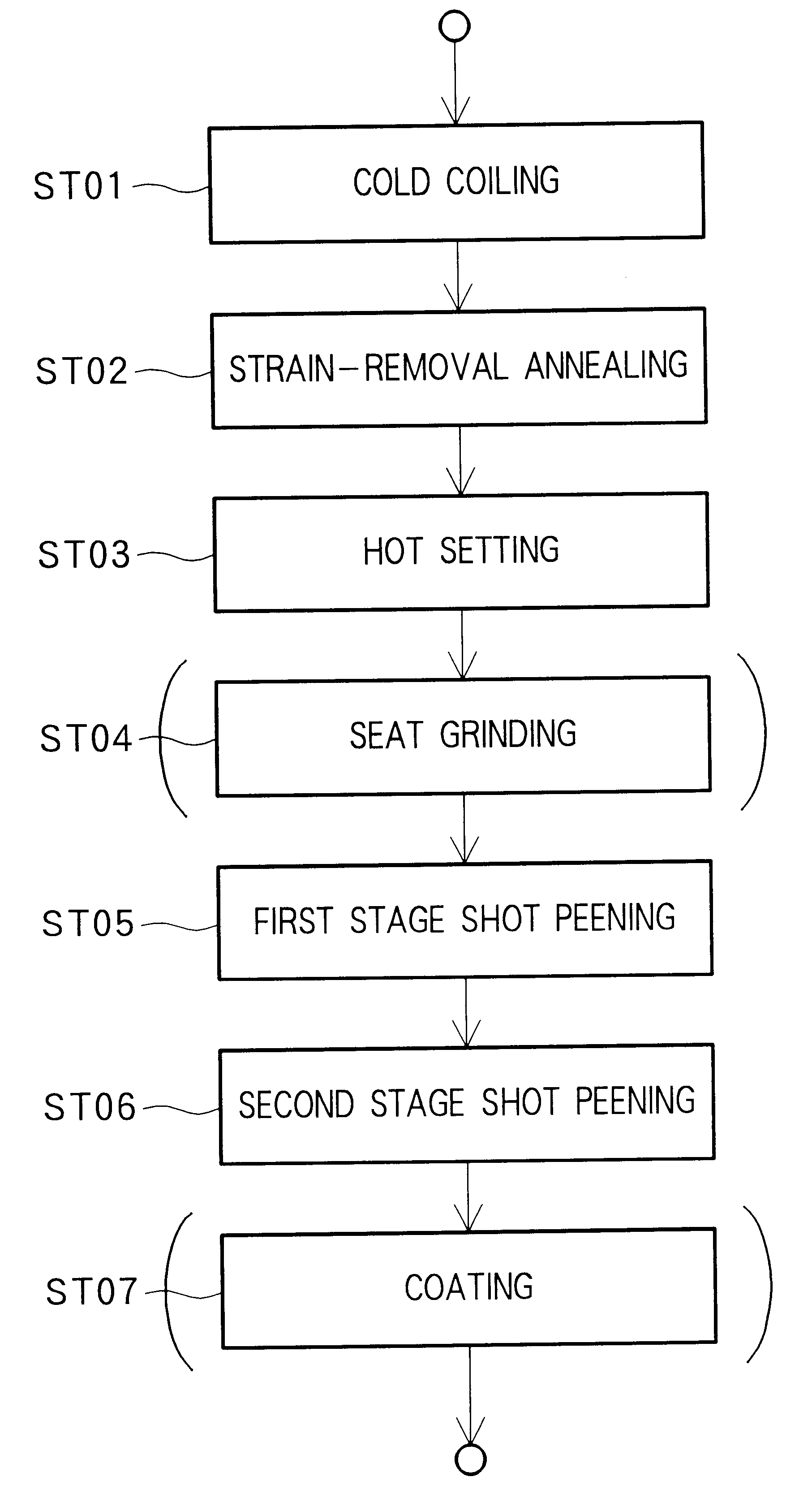

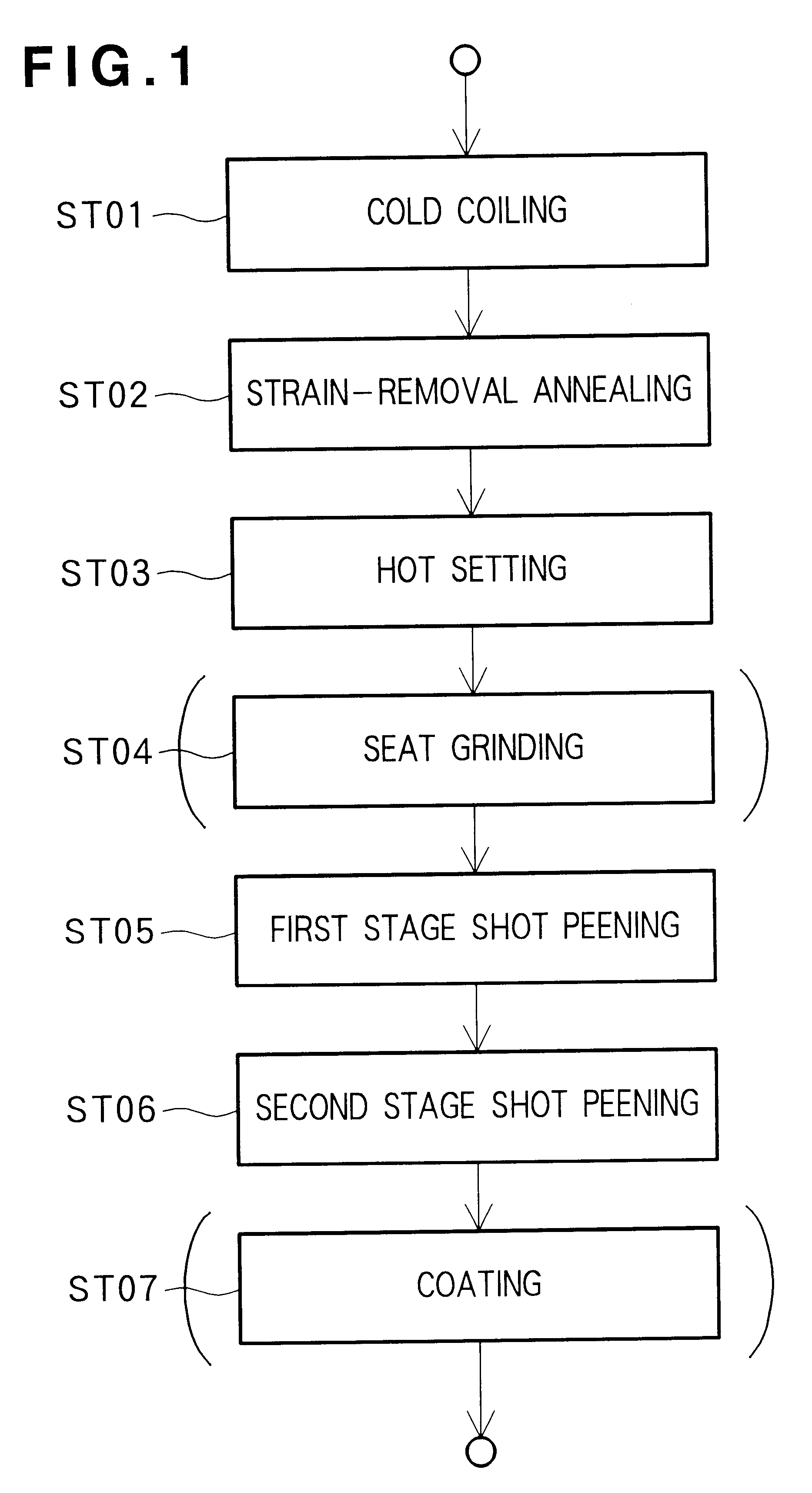

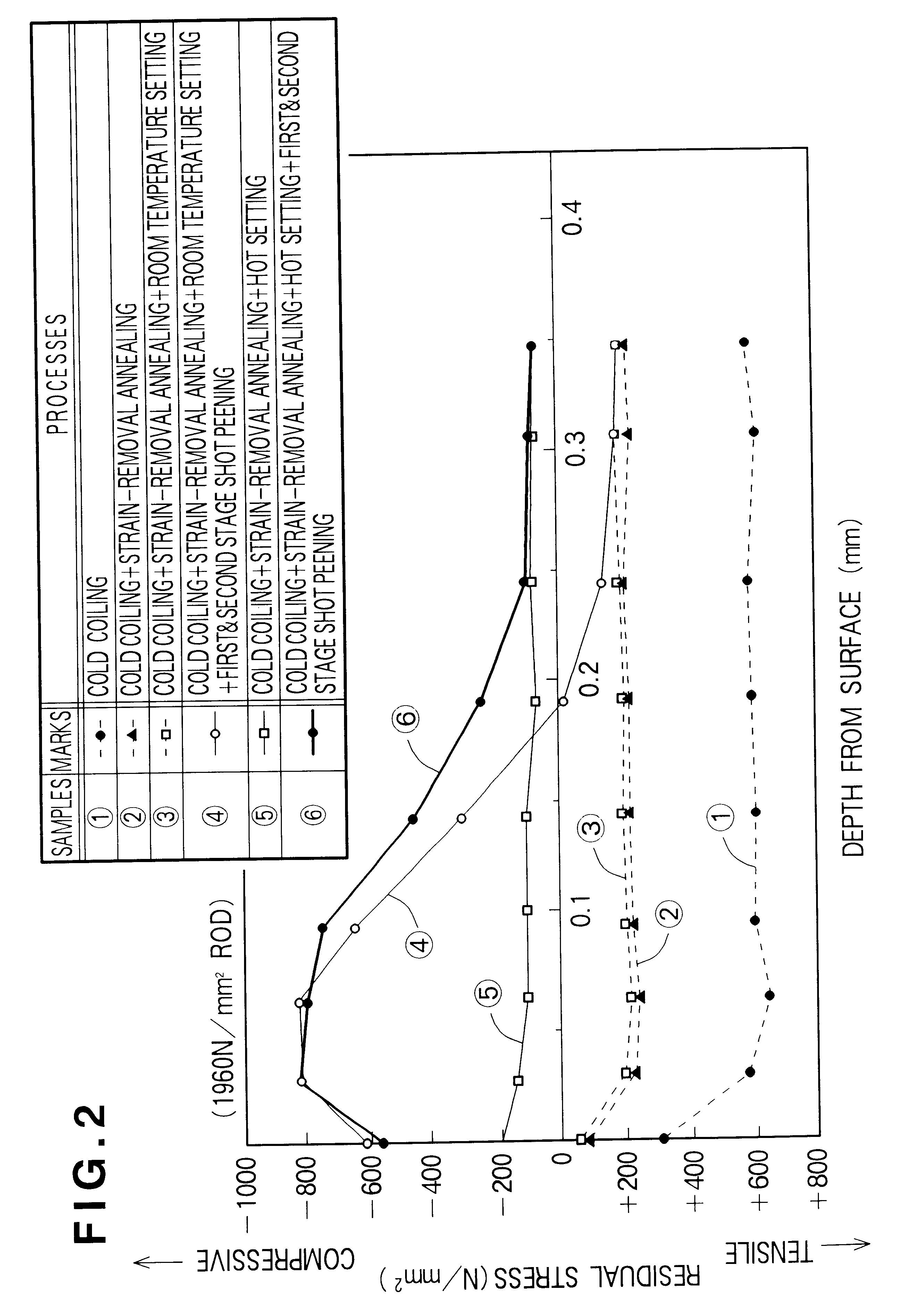

Manufacturing method of suspension spring for car

A method for manufacturing a coiled spring having a high fatigue strength to be used for example as a suspension spring of a car using a rod of tensile strength 1910 to 2020 N / mm2 and diameter 8 to 17 mm. In a cold coiling step, the rod is formed into a coil. Annealing is then carried out to remove strains having arisen inside the coil during the coiling step. A hot setting step of utilizing surplus heat from the annealing step and applying a predetermined load to the coil to compress it for a predetermined time is then carried out. After that, multi-stage shot peening is carried out on the coil.

Owner:SHOWA CORP

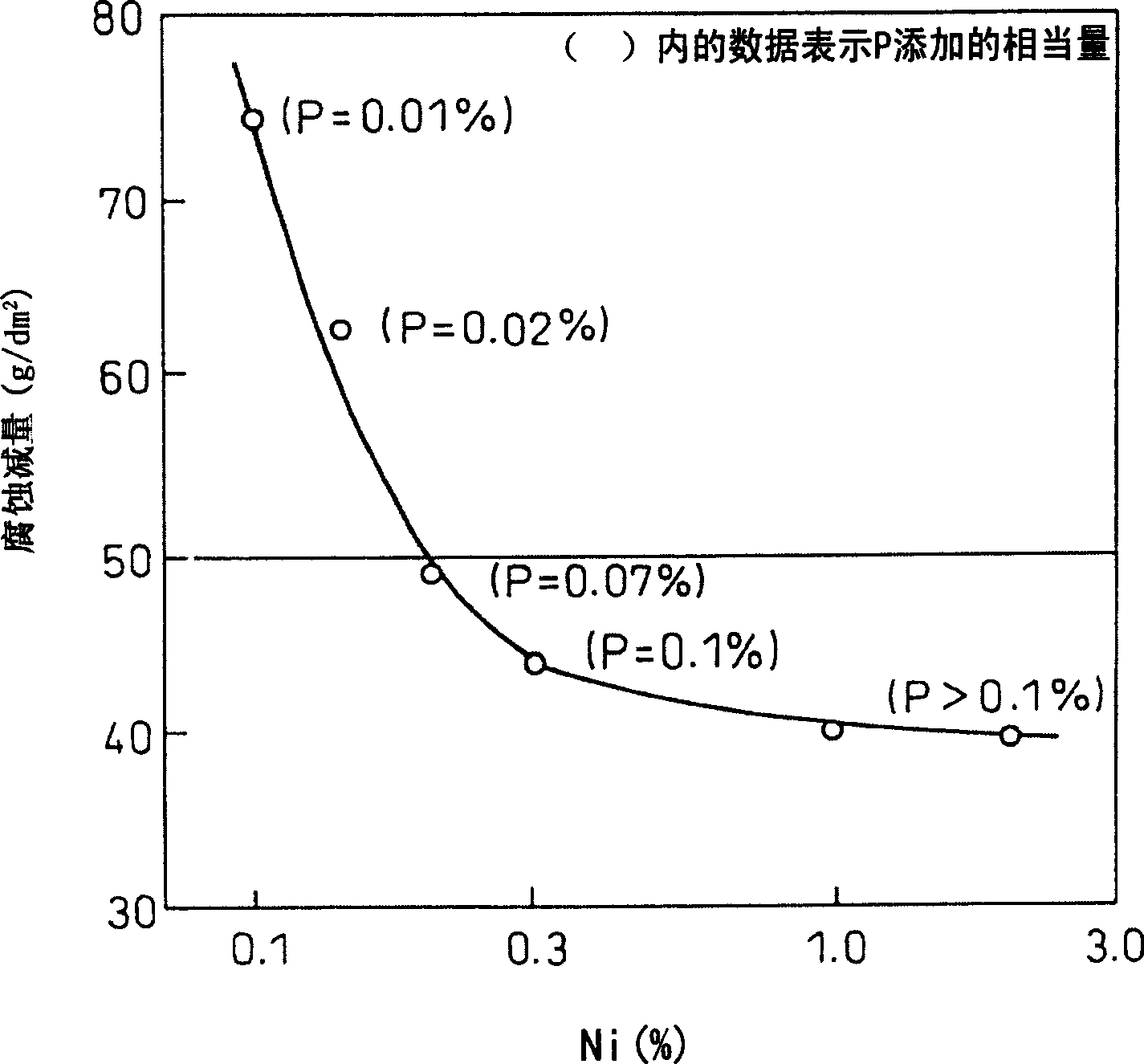

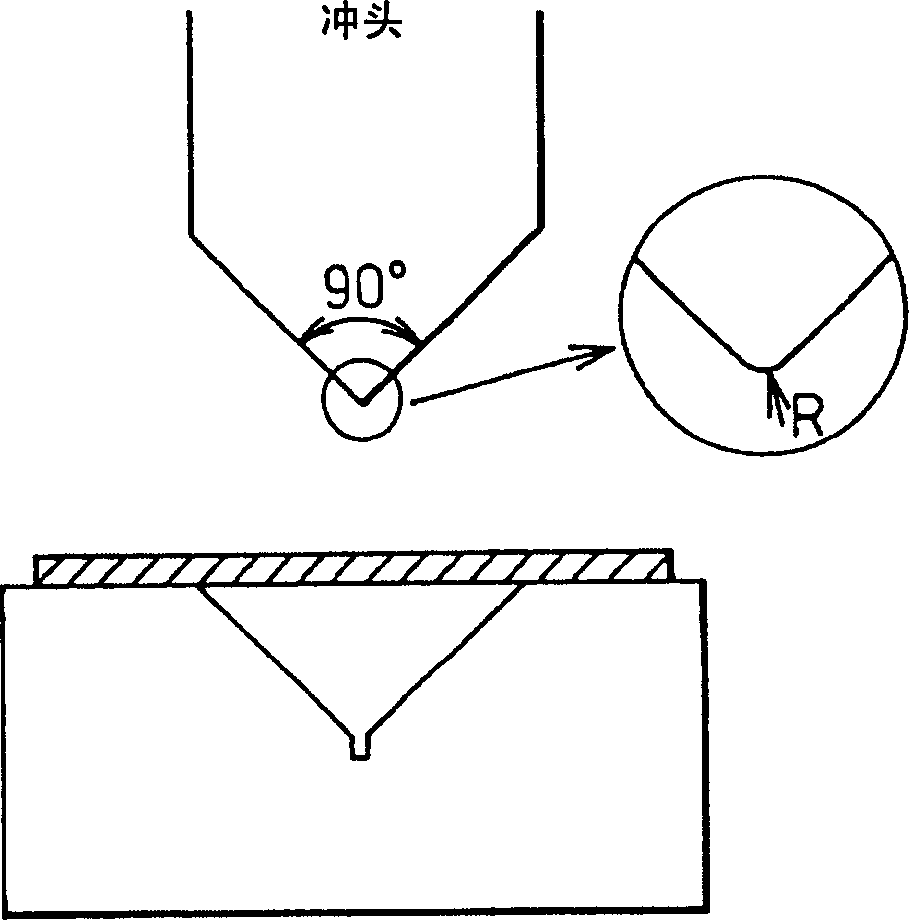

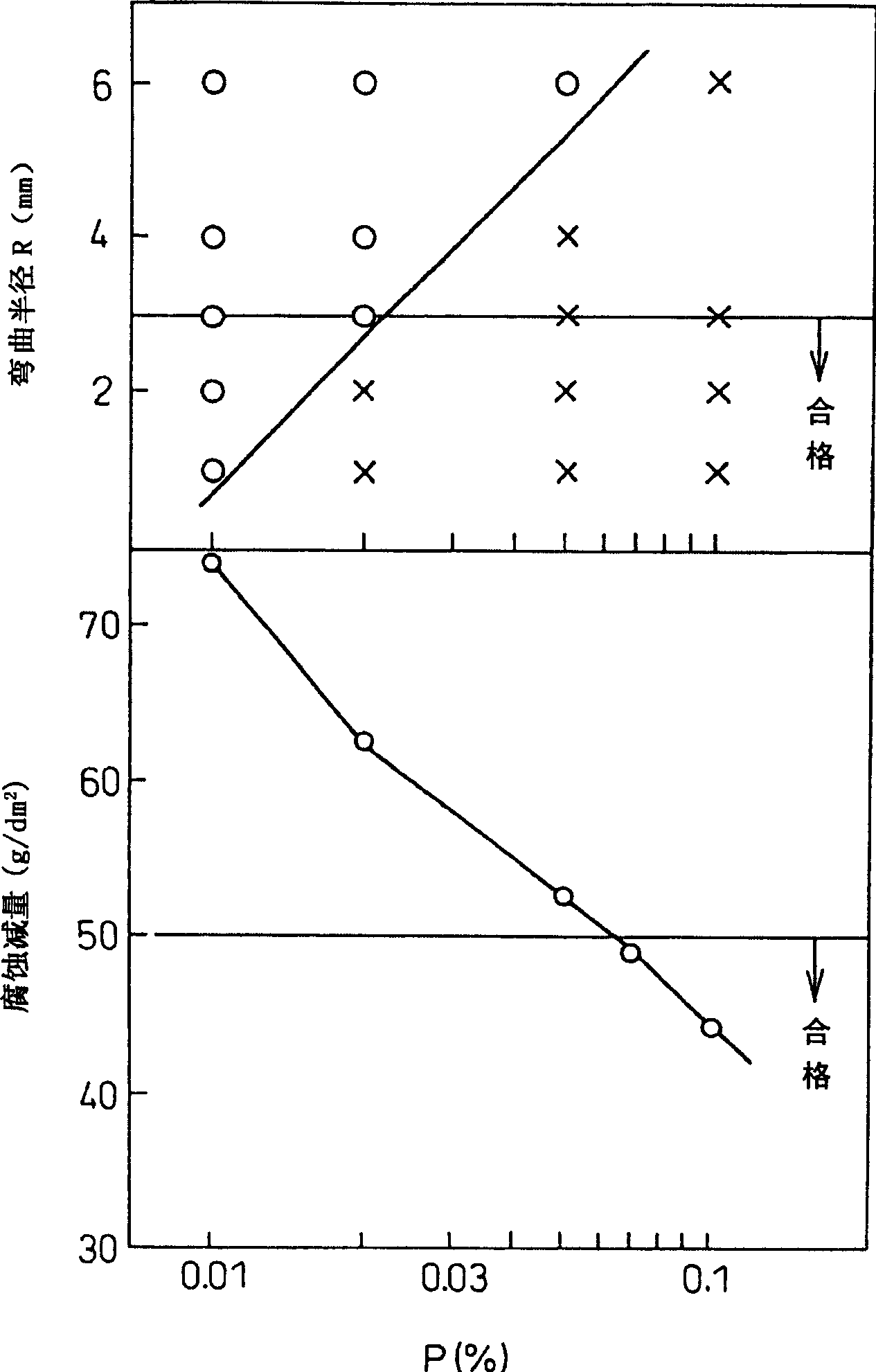

Atmosphere corrosion resisting steel plate having high strength and excellent bending formability and method for production thereof

The present invention: provides a steel material that withstands bending work after blasting or the like and has weather resistance while securing an ultra-high strength of 700 MPa or higher in terms of yield strength, and a method for producing said steel sheet; and is a weather-resistant high strength steel sheet excellent in bendability, said steel sheet containing, in mass, C: 0.05 to 0.15%, Si: 0.5% or less, Mn: 0.5 to 2.0%, p: 0.02% or less, S: 0.005% or less, Ni: 0.2 to 2.0%, Cu: 0.2 to 0.5%, and Cr: 0.2 to 1.0%, and one or more of Ti: 0.03 to 0.2%, Nb: 0.01 to 0.07%, V: 0.01 to 0.07%, and B: 0.0005 to 0.0050%, with the balance consisting of Fe and unavoidable impurities, and being produced by heating it to a temperature of 1,200 DEG C or higher, thereafter finish-rolling it in the temperature range from 850 DEG C to 950 DEG C, and coiling it in the temperature range from 500 DEG C to 650 DEG C. <IMAGE>

Owner:NIPPON STEEL & SUMITOMO METAL CORP

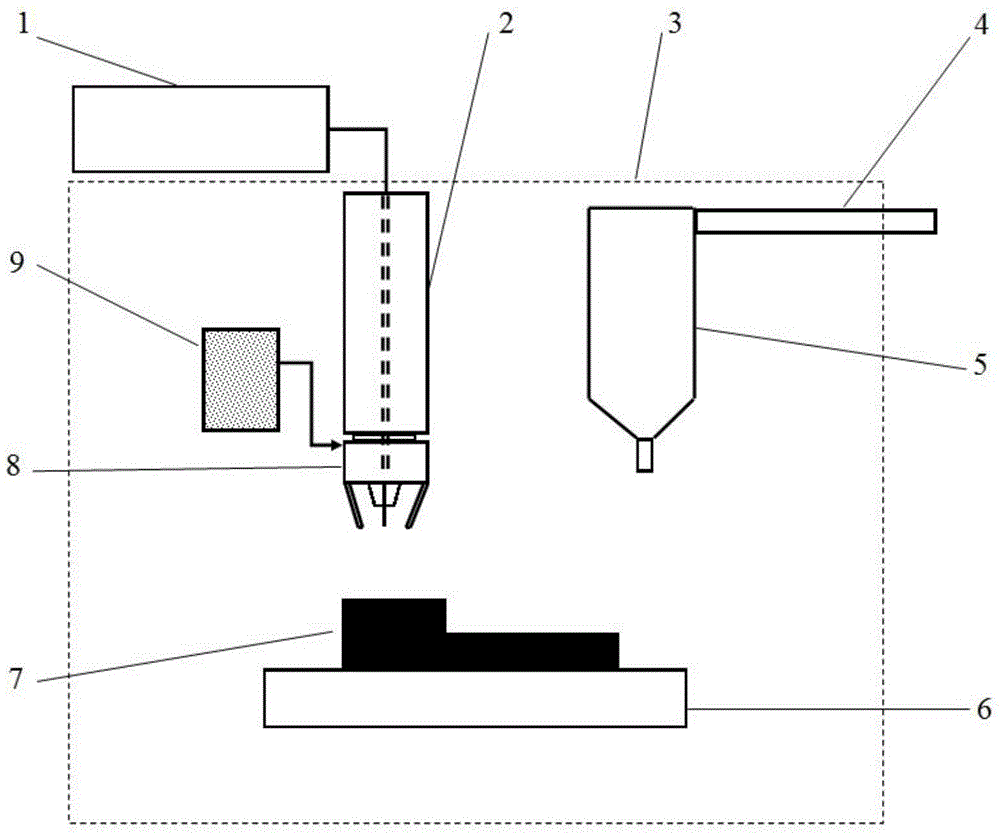

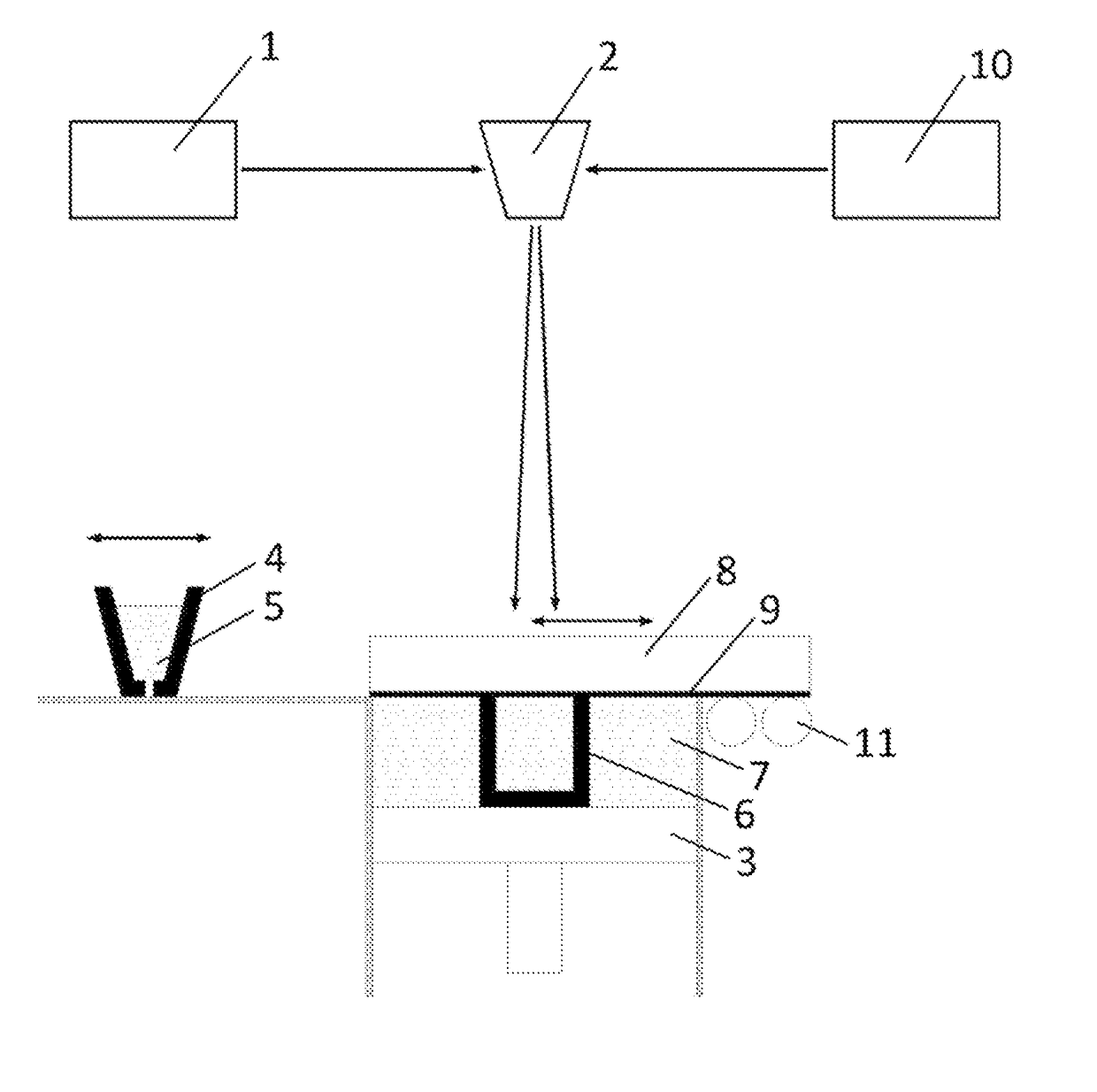

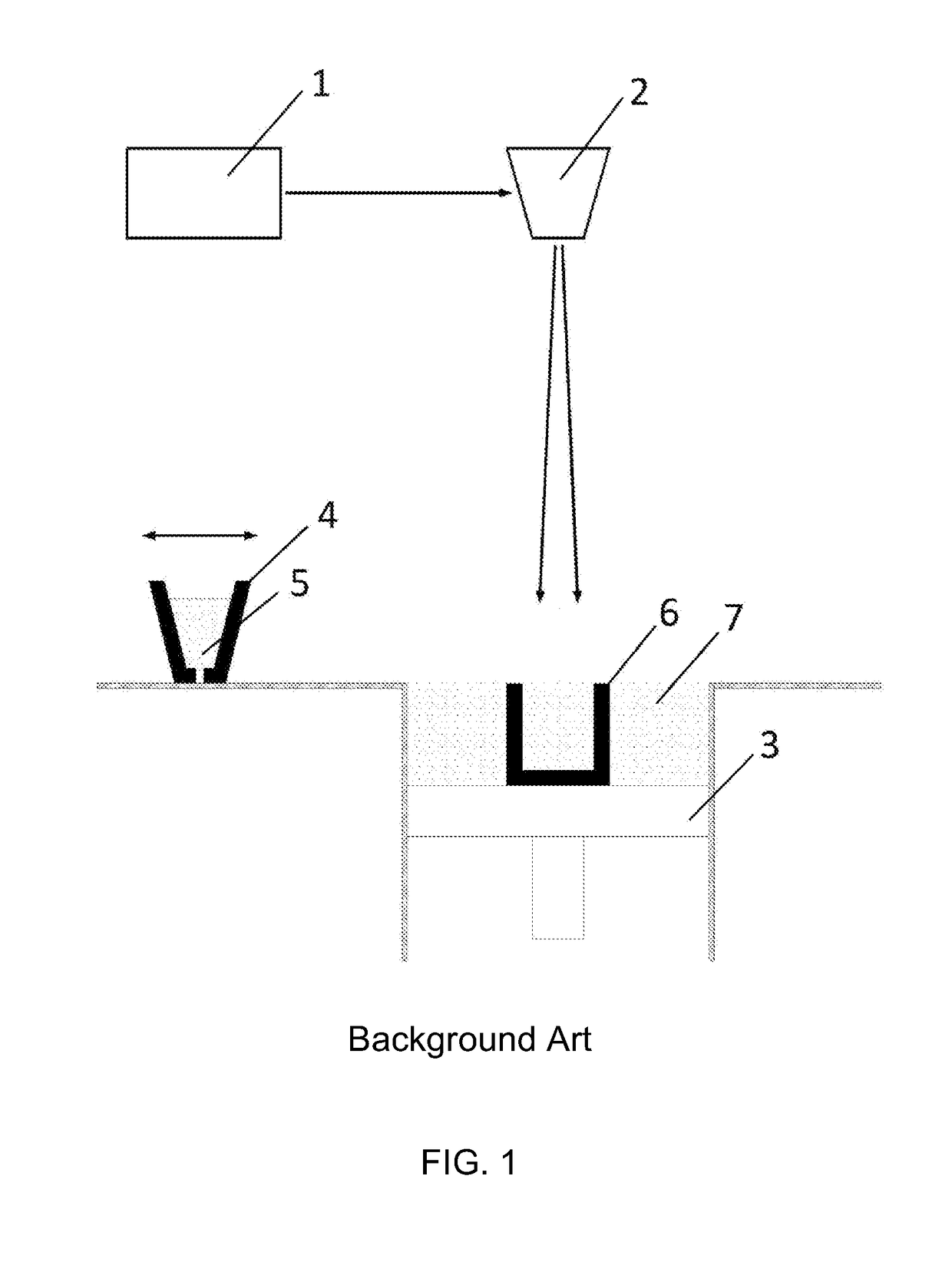

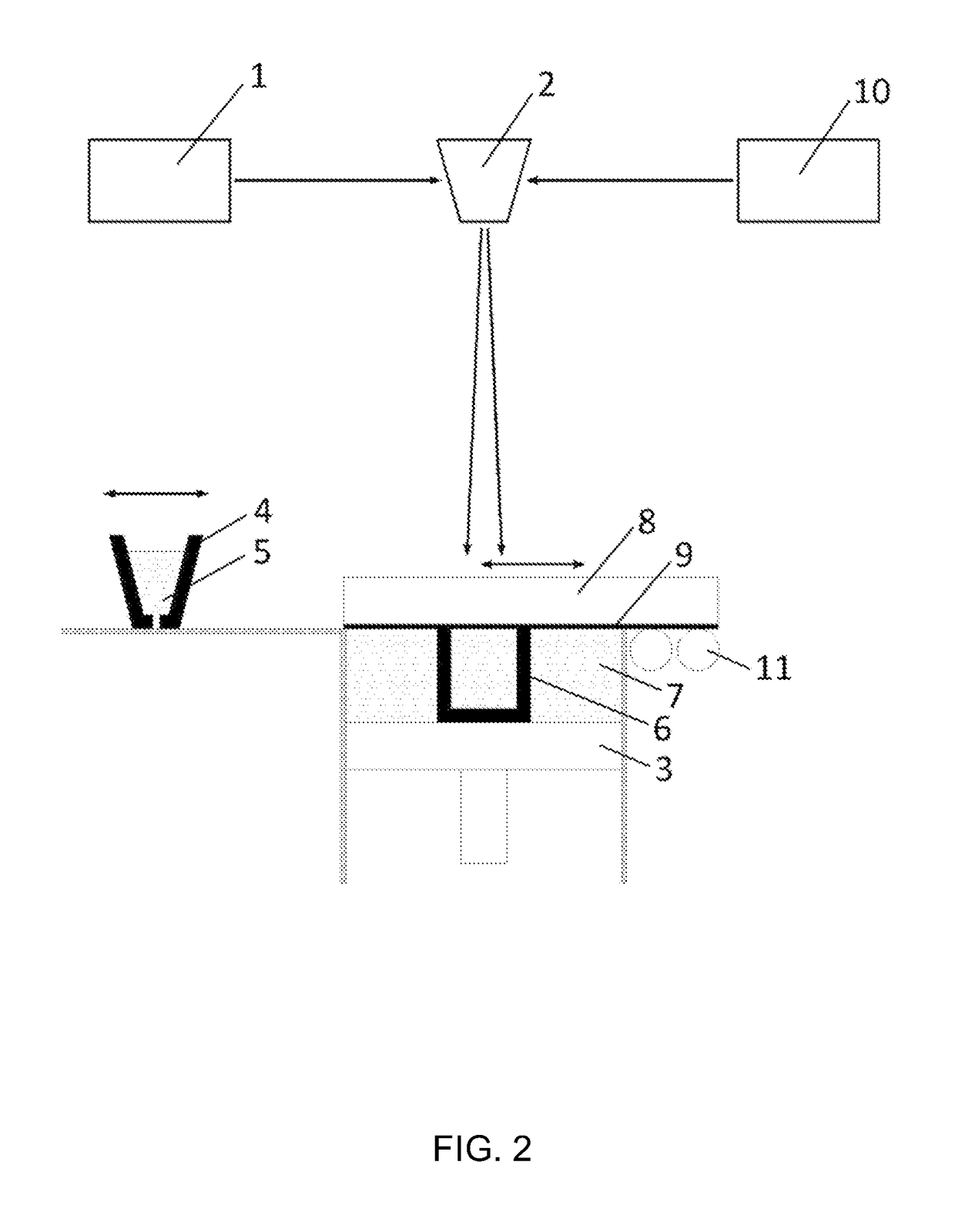

Method and Device for Implementing Laser Shock Peening or Warm Laser Shock Peening During Selective Laser Melting

ActiveUS20170087670A1Additive manufacturing apparatusIncreasing energy efficiencySelective laser meltingMechanical property

A method for manufacturing an object including the steps of forming layers by adding successive layers of material to form the object by selective laser melting (SLM), and inducing plastic deformation and residual stress into solidified material of at least one of the successive layers of material to improve mechanical properties and a fatigue resistance of the object, wherein the plastic deformation and the residual stress are induced by a laser.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

Method for eliminating residual stress in welding by ultrasonic peening and use thereof

InactiveCN102002581AImprove stress distributionSimple processProcess efficiency improvementAlternating currentPeening

The invention relates to a method for eliminating residual stress in welding by ultrasonic peening and use thereof. The method is implemented mainly by using an ultrasonic peening device which comprises an ultrasonic wave generator, an acoustic system and a machine frame, wherein the ultrasonic wave generator and the acoustic system are arranged on the machine frame; the acoustic system has an energy transducer; the ultrasonic wave generator converts 50Hz power frequency alternating current power in a grid into ultrasonic frequency 20kHz alternating current power for exciting the energy transducer of the acoustic system; and the energy transducer of the acoustic system converts electric energy into mechanical vibration at the same frequency and transmits the ultrasonic frequency mechanical vibration to a weld joint in a workpiece at the temperature of 400 to 800 DEG C, so that a deep enough plastic deformation is formed on the surface of the weld joint part. The method which adopts a simple process has high-efficiency, energy-saving and environmentally-friendly characteristics and other characteristics in the elimination of the residual stress generated in a repair and welding process of a cast steel piece such as a swing bolster and a side frame. In addition, the method improves the stress distribution and fatigue strength of the weld joint.

Owner:CRRC YANGTZE CO LTD

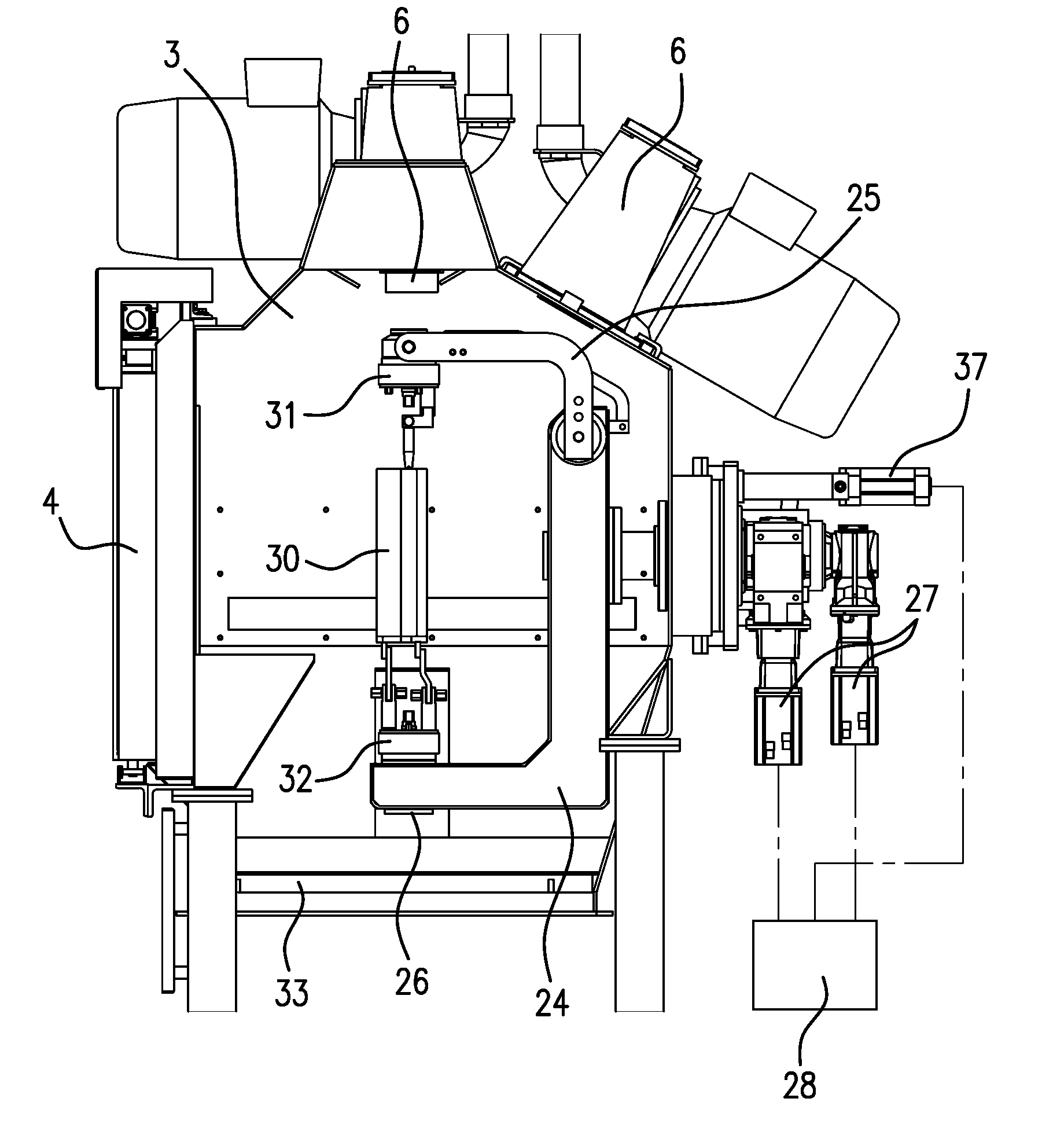

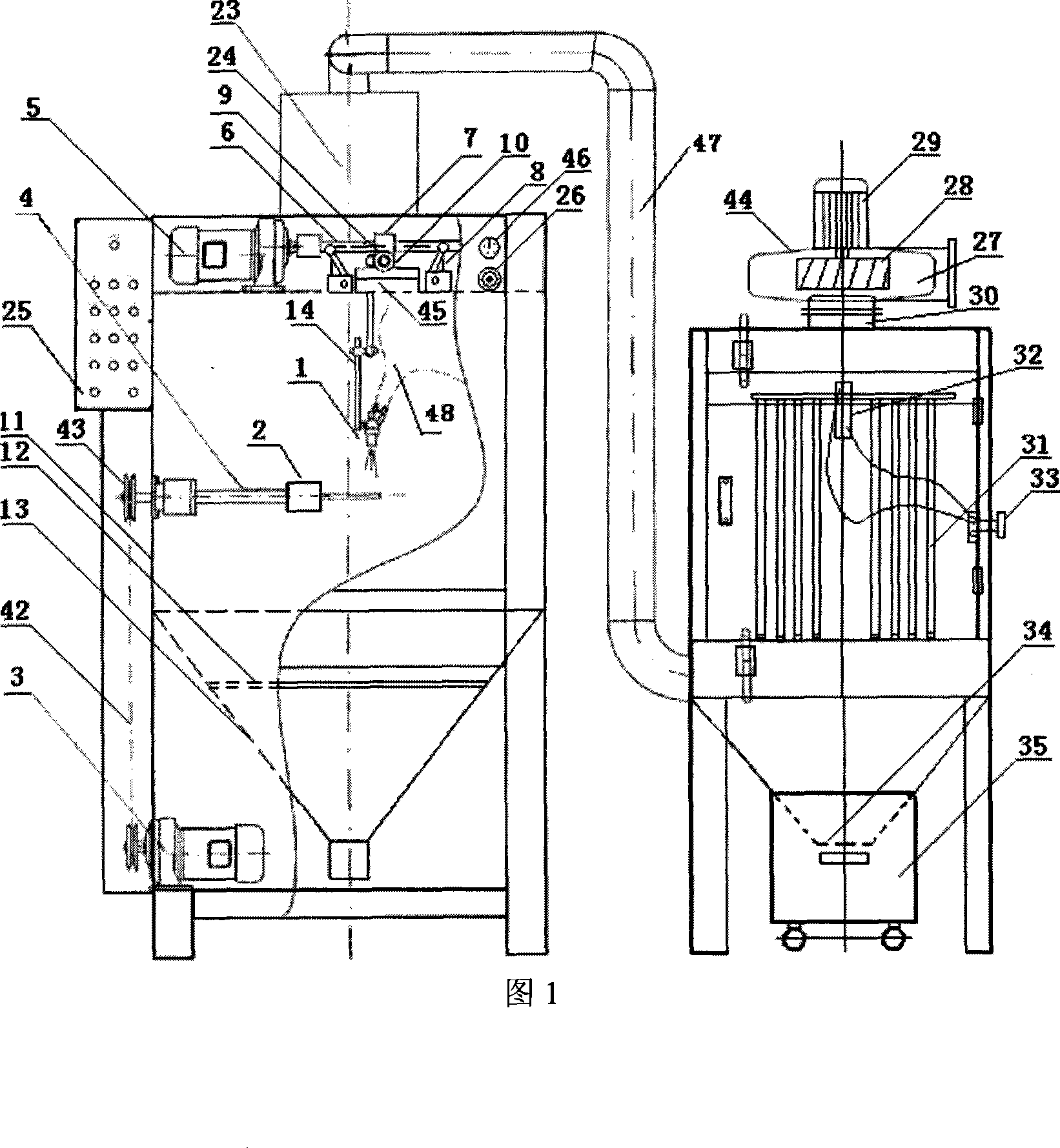

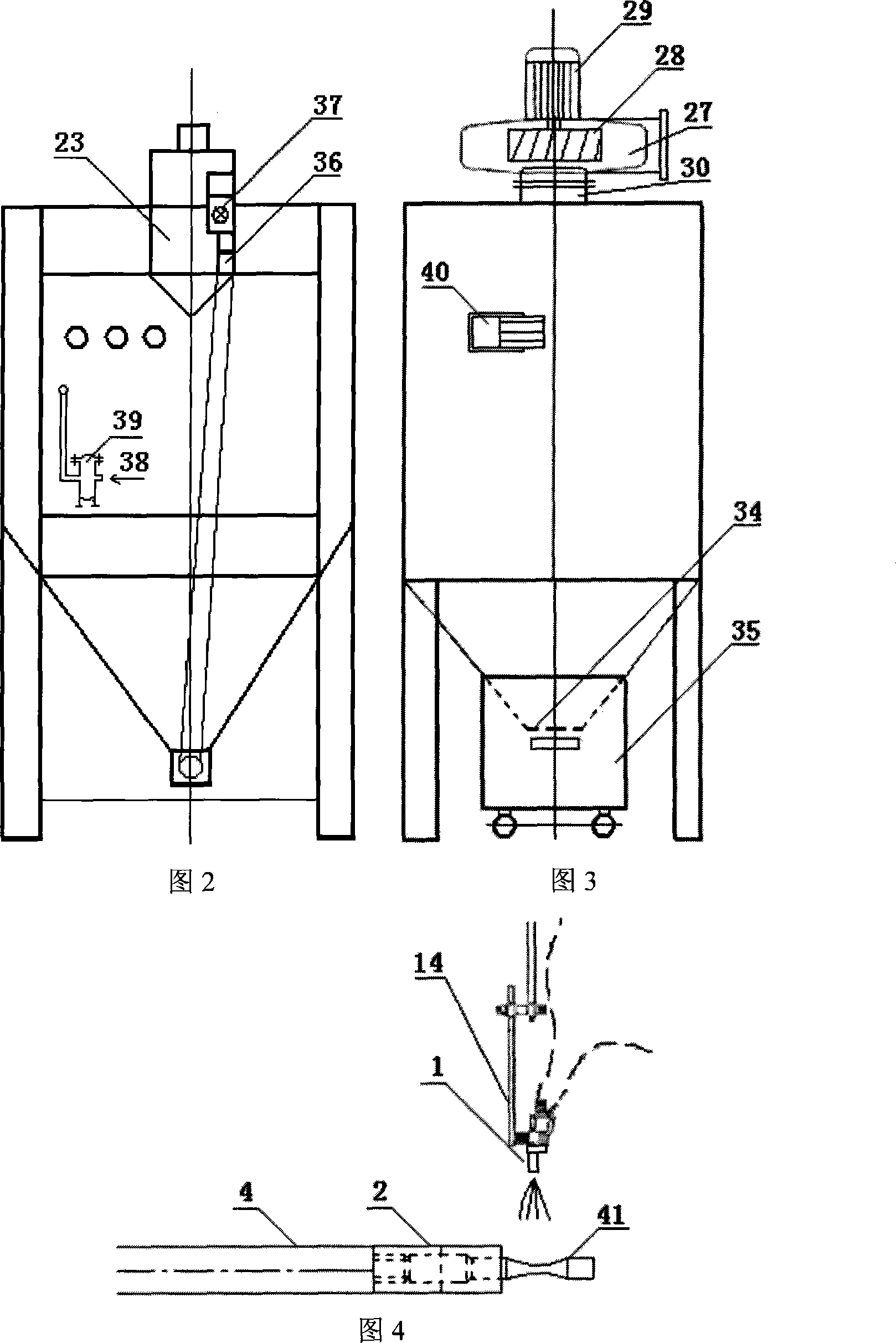

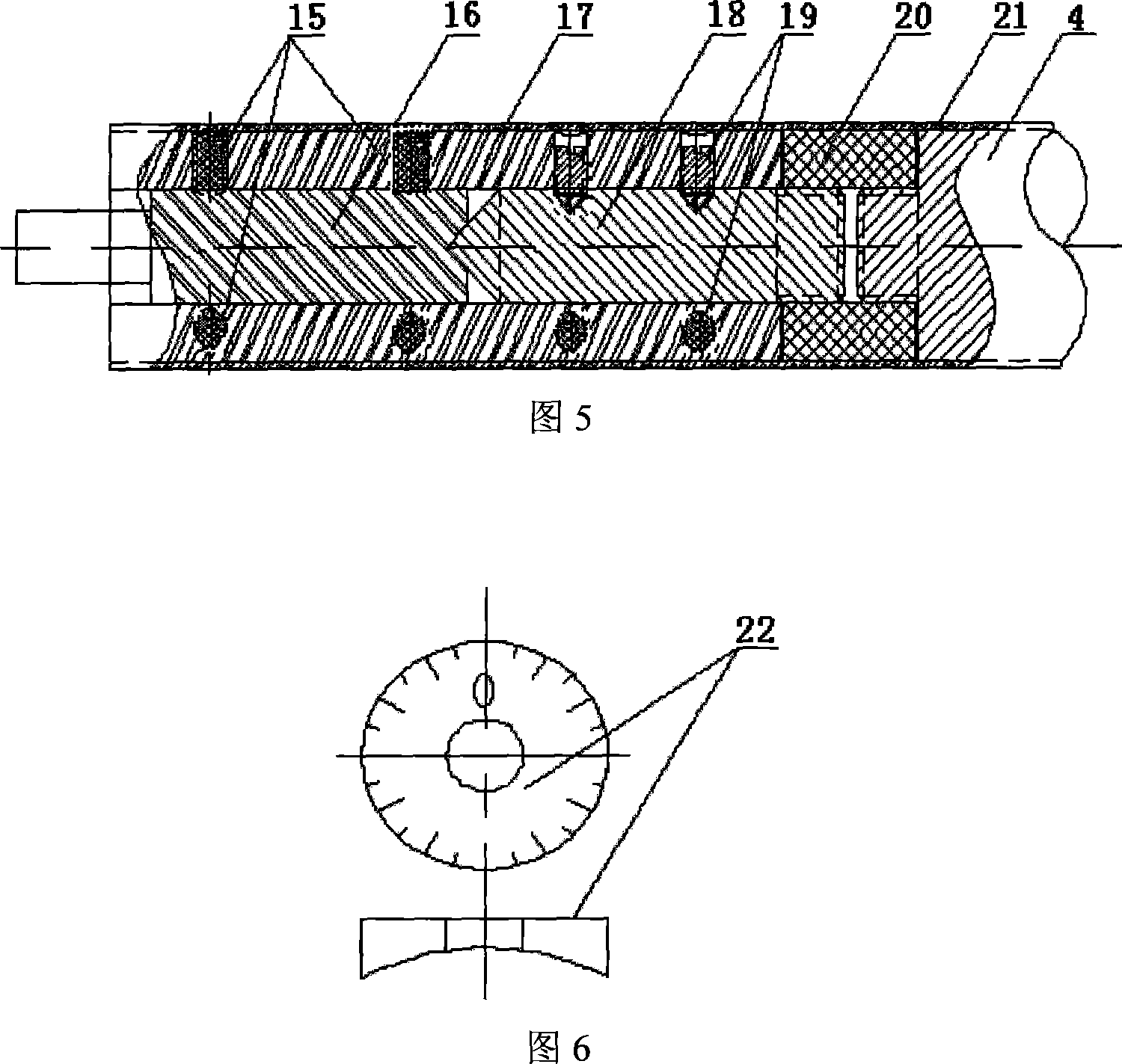

Shot peening machine for processing surface deformation strengthening treatment to magnesium alloy sample

InactiveCN101214633AGuaranteed concentricityGuaranteed parallelismImpeller wheelsBlast gunsAir compressionAbrasive blasting

The present invention relates to a device in the technical field of material processing, in particular to a peener which carries out the surface deformation strengthening process on magnesium alloy samples. The present invention comprises a main peening system, an upper whirlwind separation system, a dedusting system, an air compression system and an electric system, wherein, the upper whirlwind separation system is positioned on the upper end of the main peening system, the lower part of the upper whirlwind separation system is communicated with the main peening system, the upper part is connected with the dedusting system, which is positioned outside the main peening system, the air inlets of both the dedusting system and the main peening system are connected with the air compression system, and the electric system is connected with the main peening system, the upper whirlwind separation system, the dedusting system and the air compression system. The present invention can conveniently assemble and disassemble the samples of the shaft class, the range of the generated peening strenghth is wide, the effect and uniformity of peening is good, and moreover, pollution can be prevented.

Owner:SHANGHAI AIERSI LIGHT ALLOY

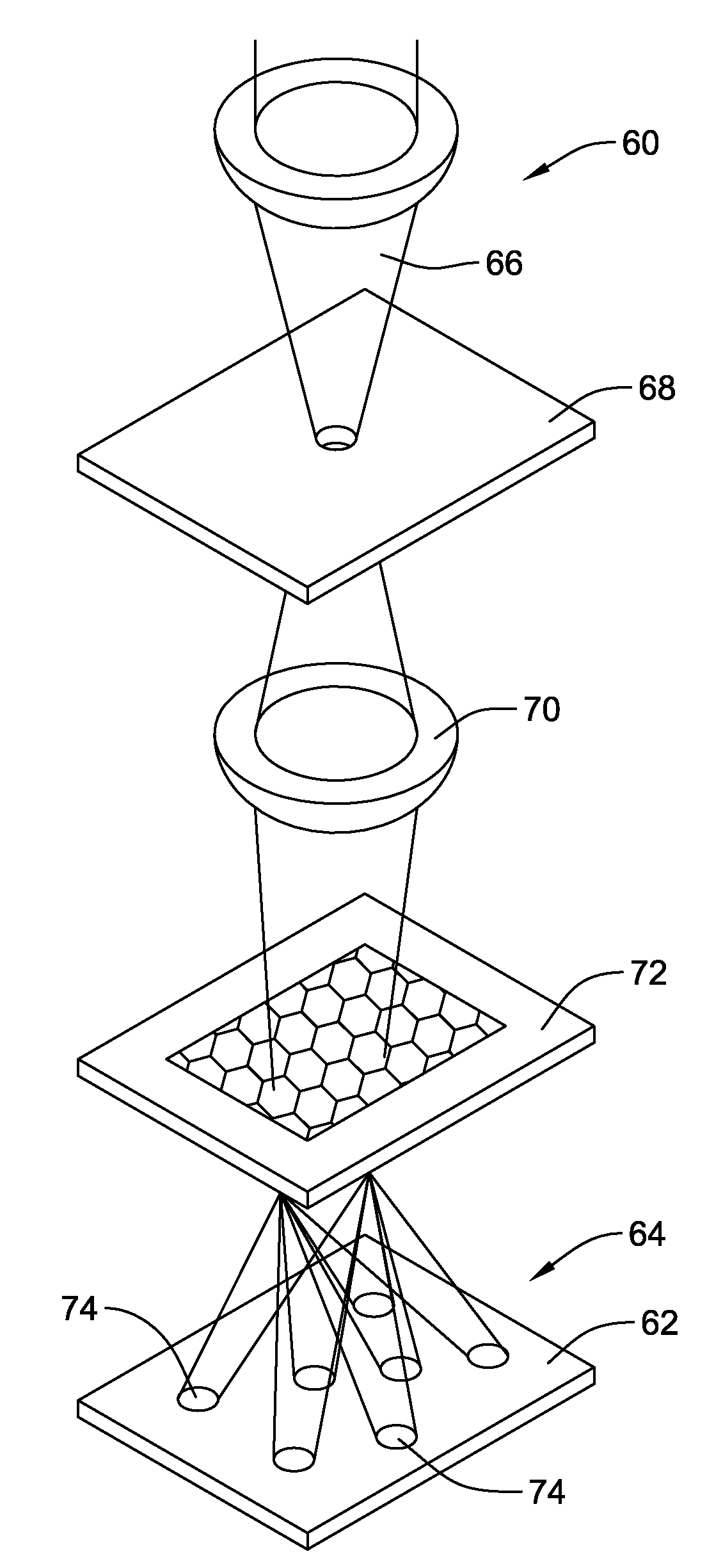

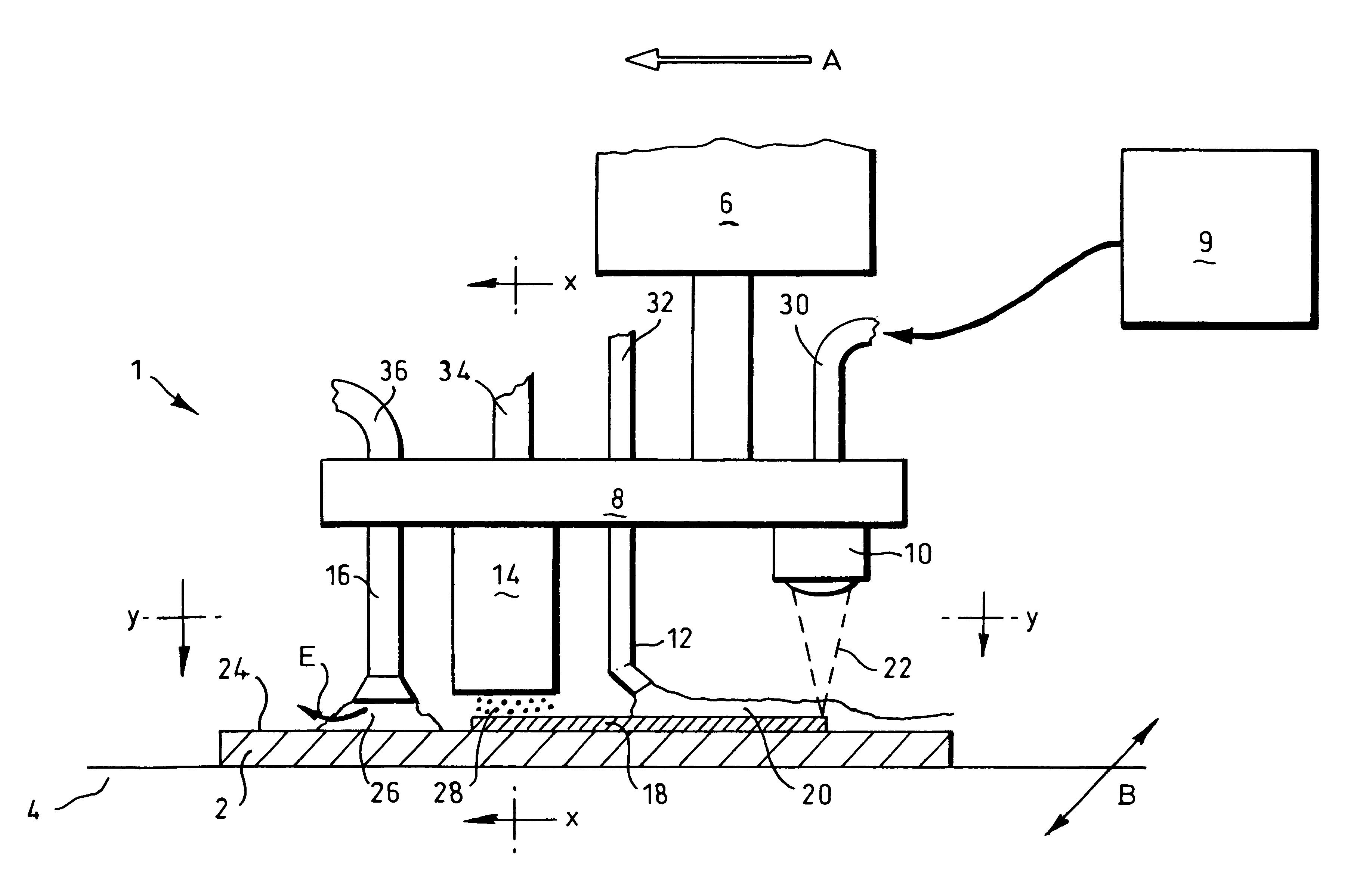

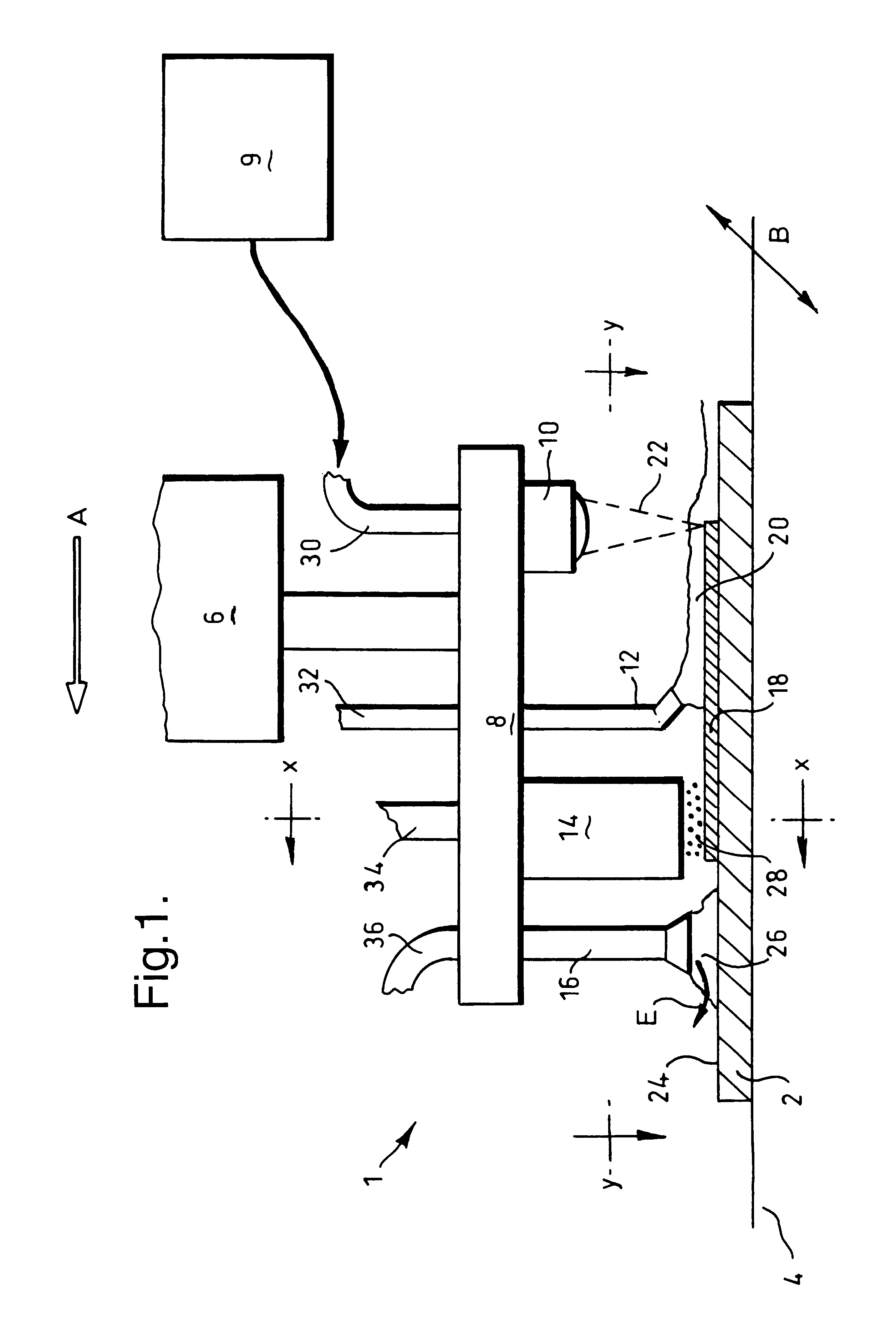

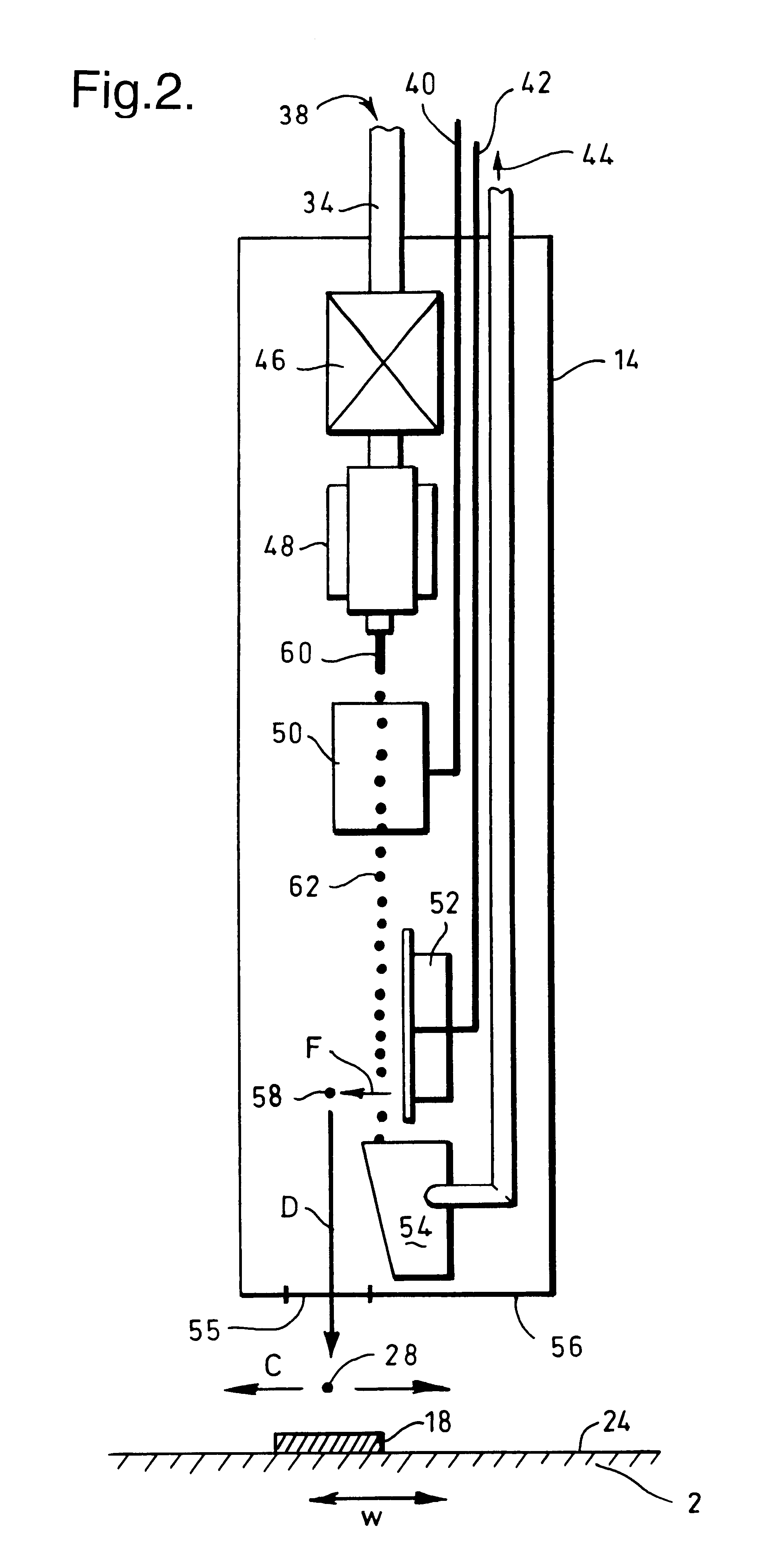

Method and apparatus for improving material properties

InactiveUS6923877B1Less time-consumeLess time-consumingPretreated surfacesInductances/transformers/magnets manufactureLaser beamsPeening

A method and apparatus for improving the properties of a material of a workpiece by laser shock peening in which an overlay which is opaque to a laser beam, and an overlay which is translucent to said laser beam, are applied to a surface of a workpiece. The translucent overlay being applied on top of and over the opaque overlay. A laser beam is then directed at the said surface to which the overlays have been applied to vaporize the opaque overlay and laser shock peen the surface of the workpiece to produce a region of compressive residual stress in said surface. The overlays and the laser beam being applied concurrently, in a single operation, as the surface of the workpiece is traversed so that as each point on the surface to be treated is traversed the opaque overlay, translucent overlay, and laser shock peening are applied sequentially to that point. The opaque overlay is preferably an ink layer which is applied by printing on the surface. The apparatus, which in particular is arranged for carrying out this method, comprises the means for applying the overlays and for directing the laser beam at the surface all mounted upon a common tool head.

Owner:ROLLS ROYCE PLC

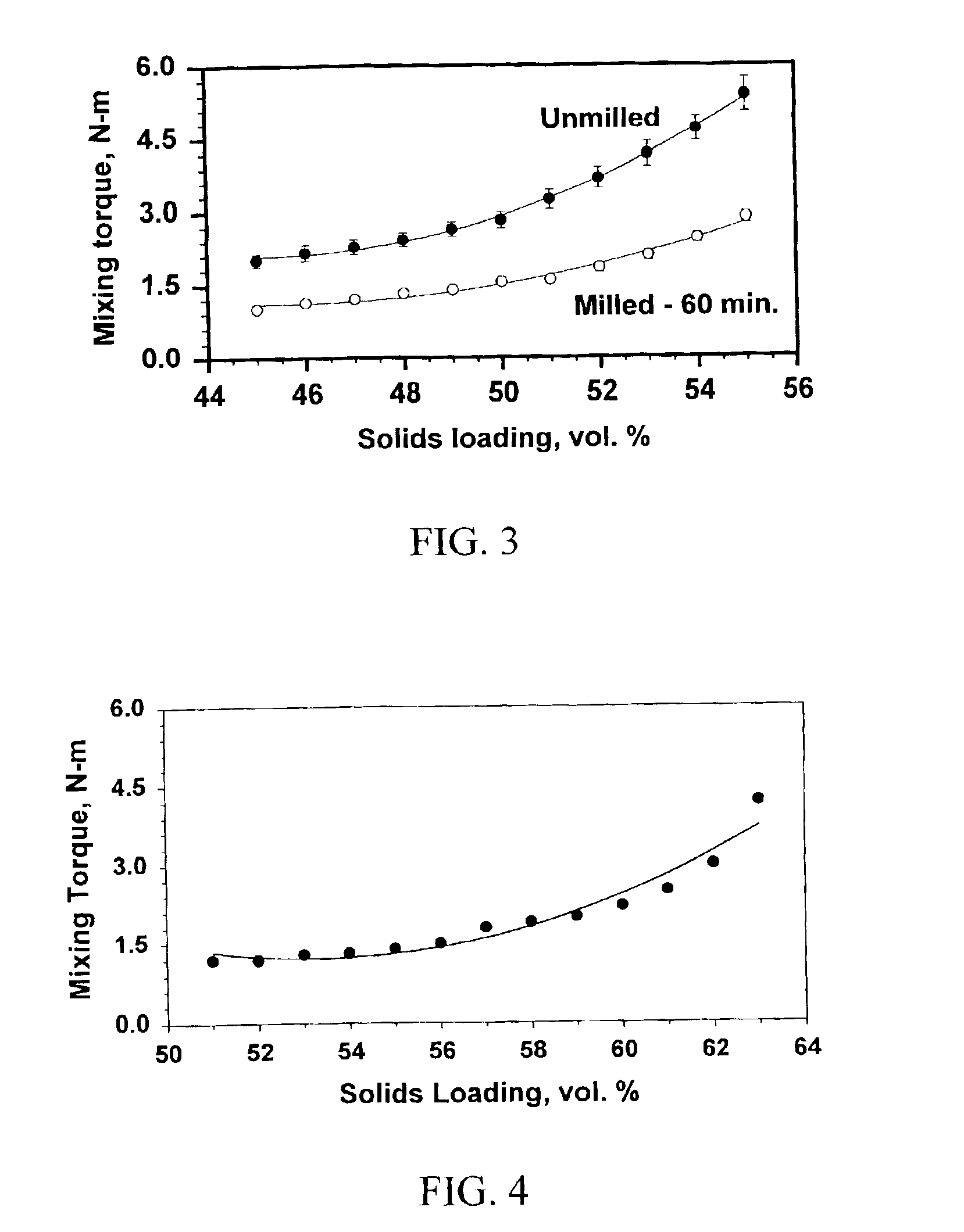

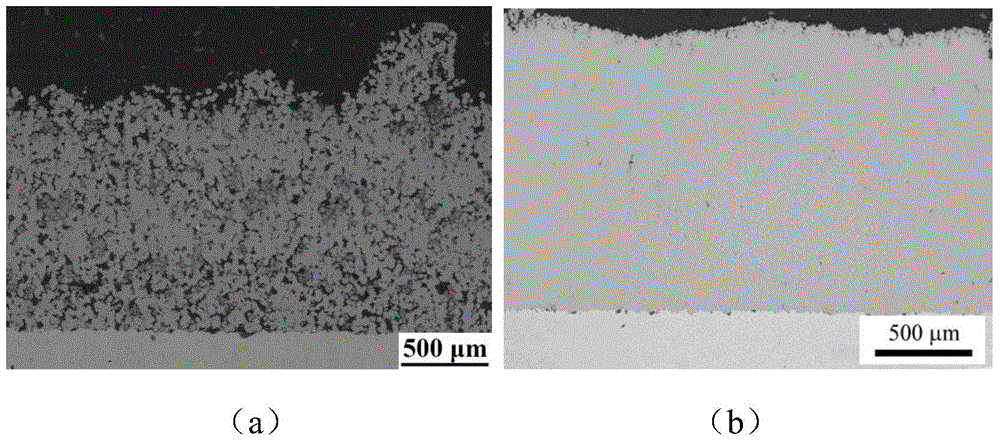

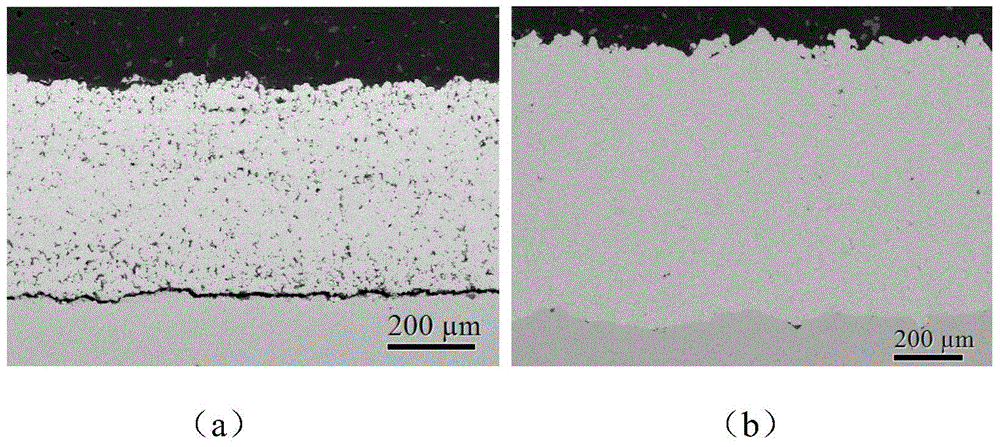

Preparation method of high density cold spraying metal/metal-based sedimentary body and application thereof

ActiveCN104894554AAchieve densificationImprove conductivityHeat inorganic powder coatingMaterials processingPeening

The invention discloses a preparation method of a high density cold spraying metal / metal-based sedimentary body and an application thereof, which belongs to the technical field of material processing. The method comprises the following steps: 1)taking ceramic particles, cermet particles, fine metal or an alloy as shot blast particles; taking fine metal with a single component, the alloy, metal and a metal-based composite material, or, taking a mixture of two or more than two of fine metal, the alloy or an intermetallic compound as deposition material powder; and 2)employing a cold spraying technology for spraying a mixture of the shot blast particles and the deposition material powder on the surface of the matrix to prepare the high density cold spraying metal / metal-based sedimentary body. According to the method, obvious increasing of particle speed and deposition temperature is not required, operation is simple, the deposition body has more excellent conductivity, thermal conductivity, higher corrosion resistance, wear resistance and higher mechanical property, so that the deposition body can be used for preparing the coating with high conductivity, high heat conduction, high corrosion resistance and high wear resistance as well as high mechanical property workpiece.

Owner:XI AN JIAOTONG UNIV

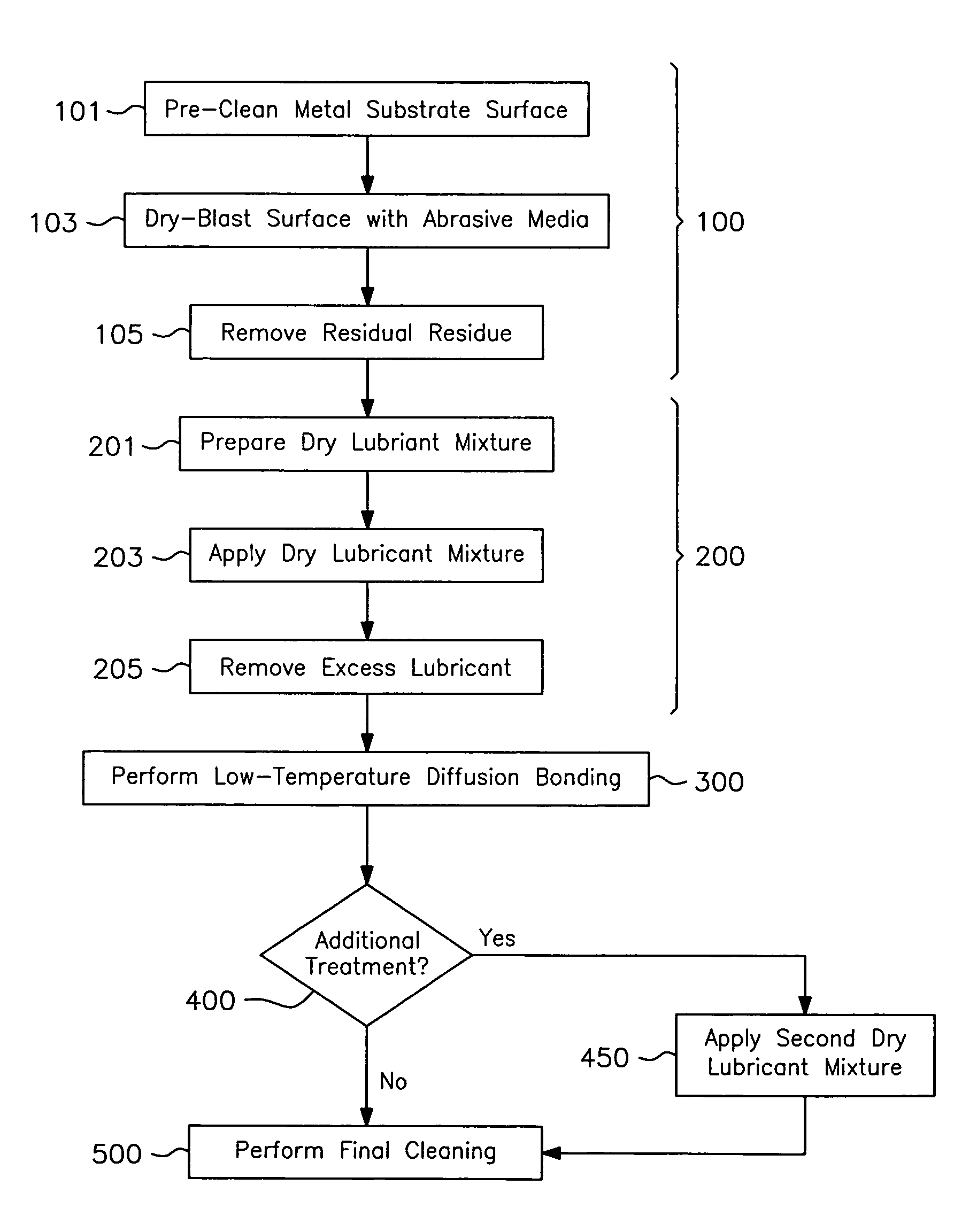

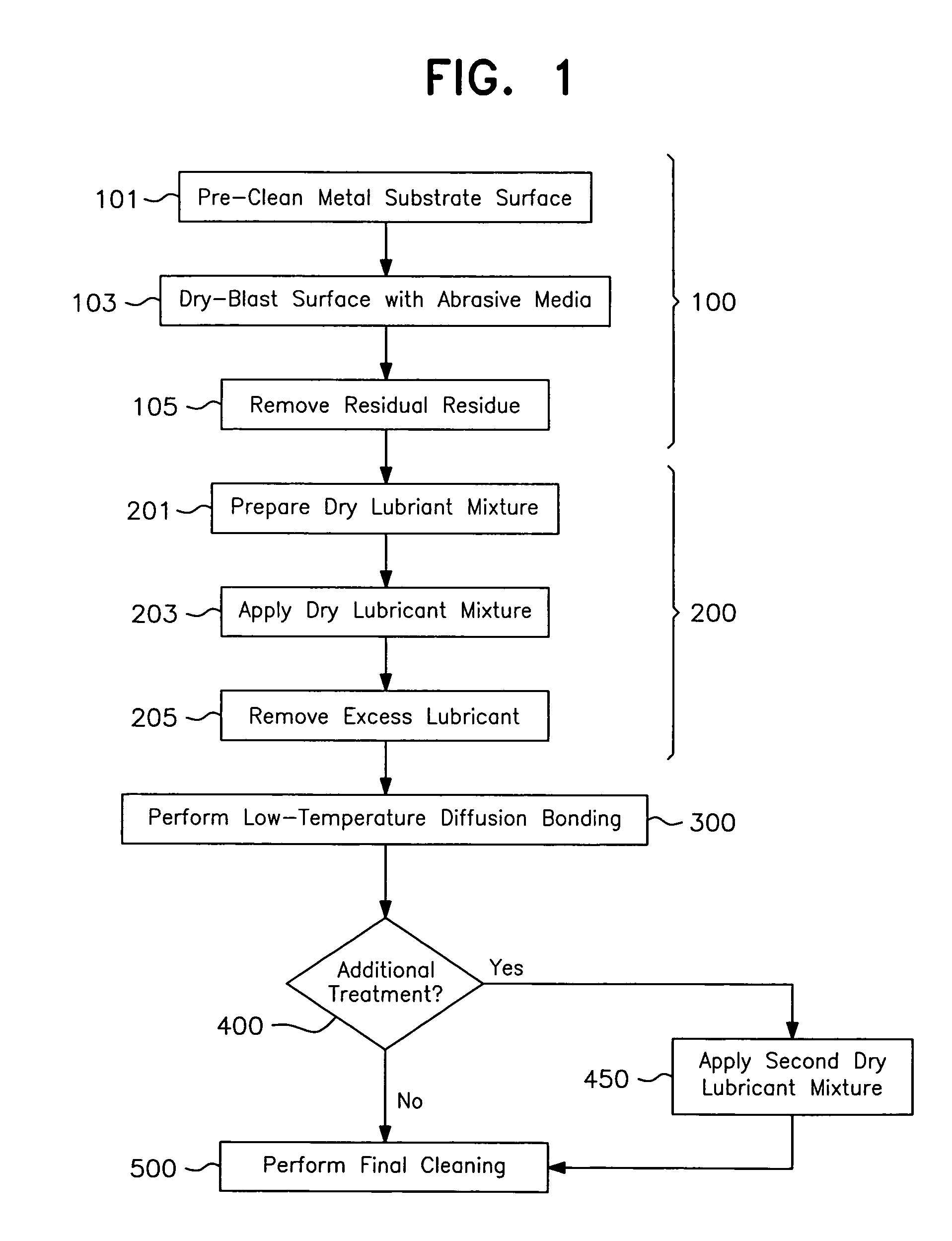

Surface for reduced friction and wear and method of making the same

InactiveUS7687112B2Improve performanceFine surfaceLayered productsPretreated surfacesImpact velocityMechanical impact

A process for producing an enhanced friction reducing surface by bonding a dry lubricant to a substrate by way of high velocity mechanical impact and low temperature diffusion bonding, and the friction-reduced surface produced thereby. A process for bonding the dry lubricant by peening and concurrently obtaining a desired dimpling or surface texturizing by appropriate selection of peening particle size and hardness relative to the substrate, as well as impact velocity against the substrate, is also provided.

Owner:KINETITEC CORP

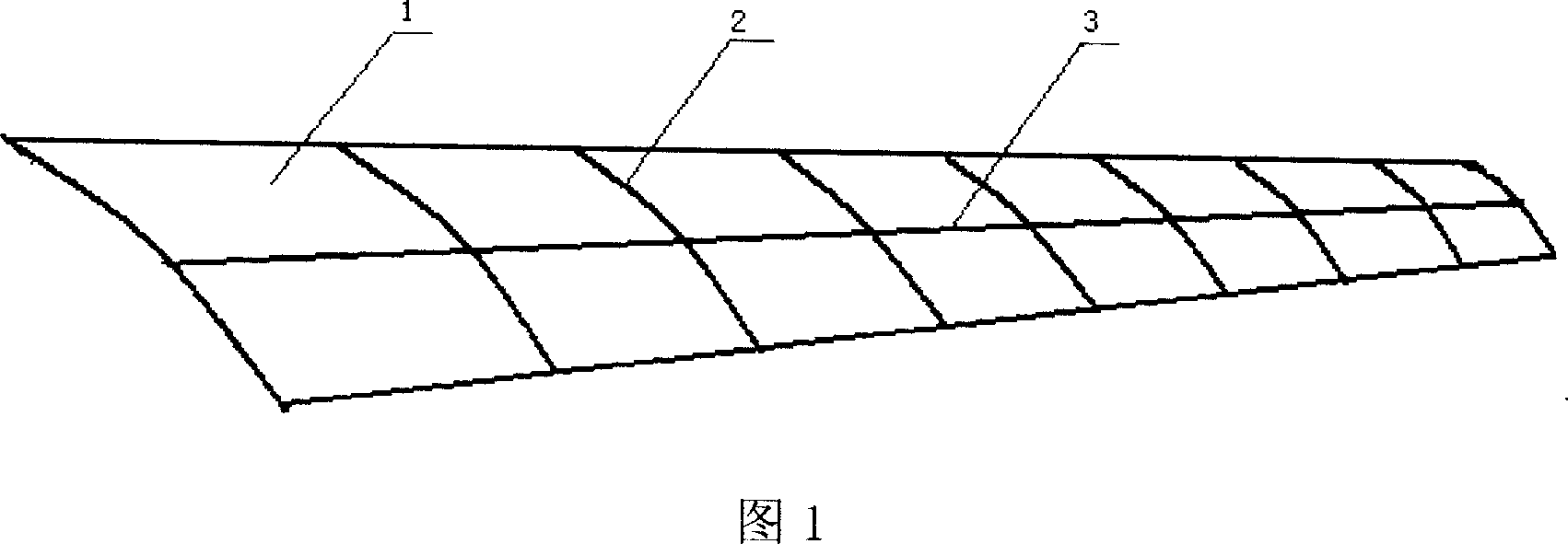

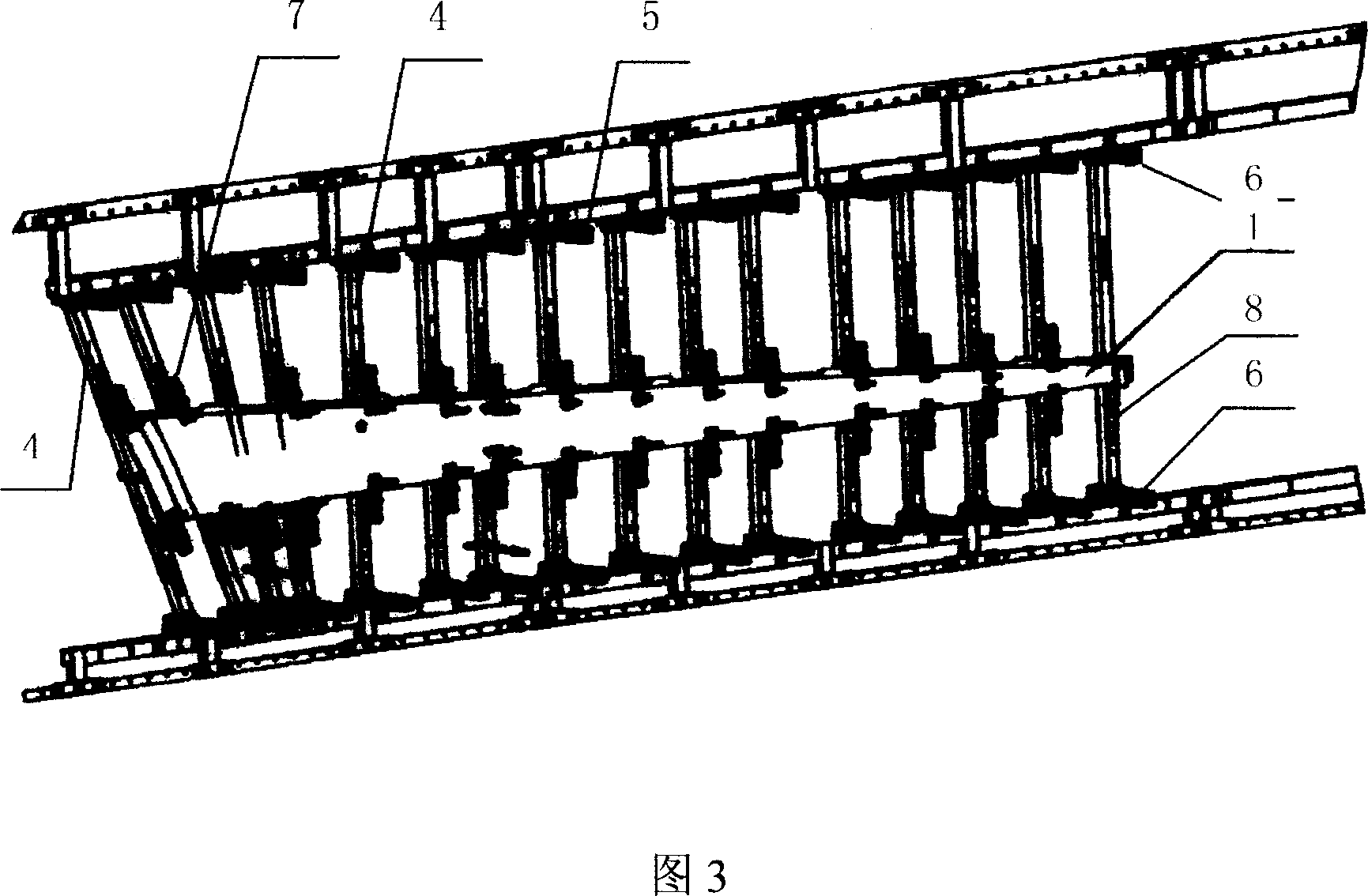

Prestressing shot-blasting formation technique for double-curved wallboard

A pre-stressing and grit-blasting technique for shaping a double-curvature plate wall used as the thick jacket of large airplane features that a pre-stressing fixture unit is used to pre-bend a plate longitudinally and transversely and fix it for applying a pre-stress to it while the grits are blasted onto said plate for obtaining a needed shape.

Owner:XIAN AIRCRAFT IND GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com