Patents

Literature

121 results about "Impact velocity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

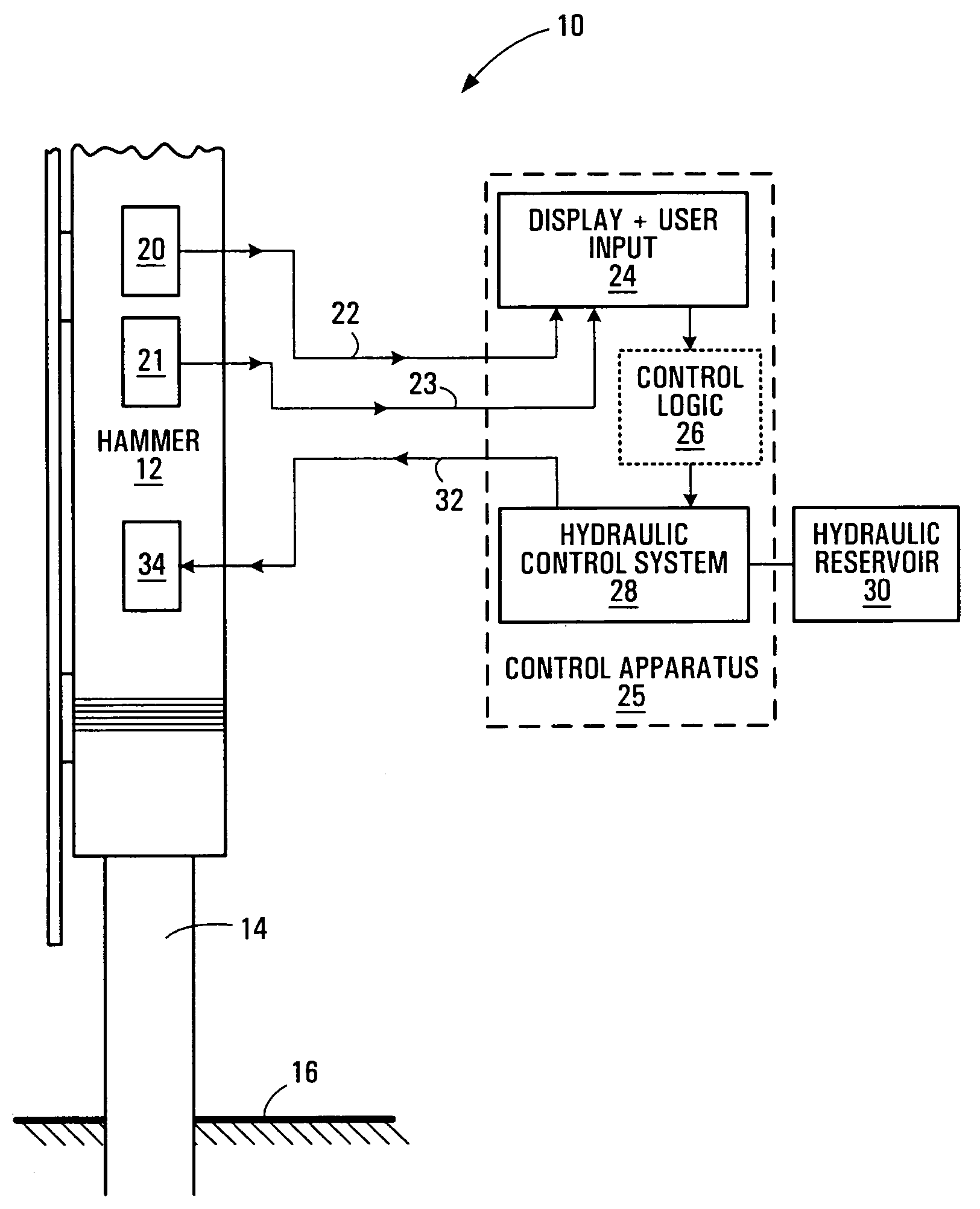

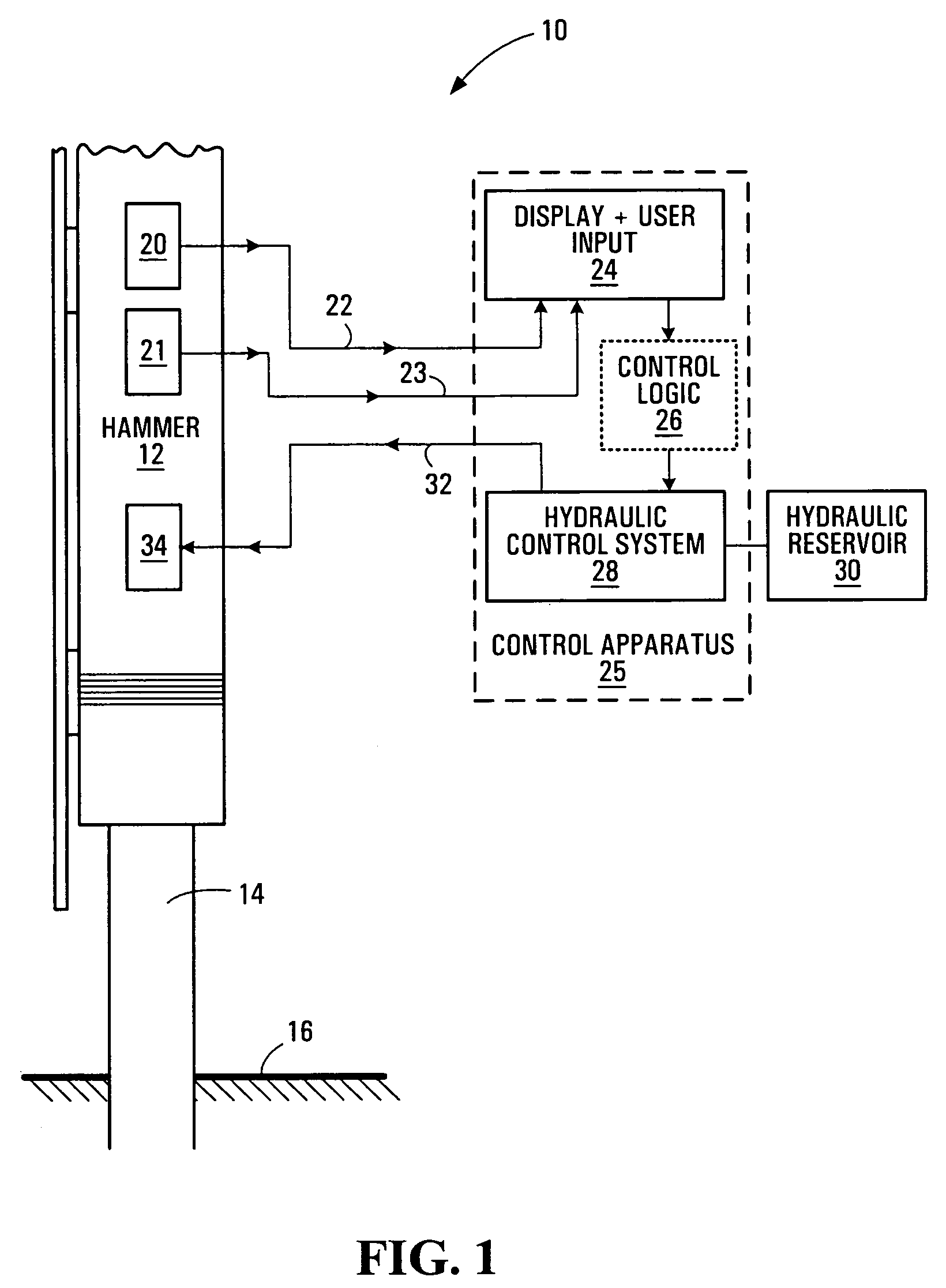

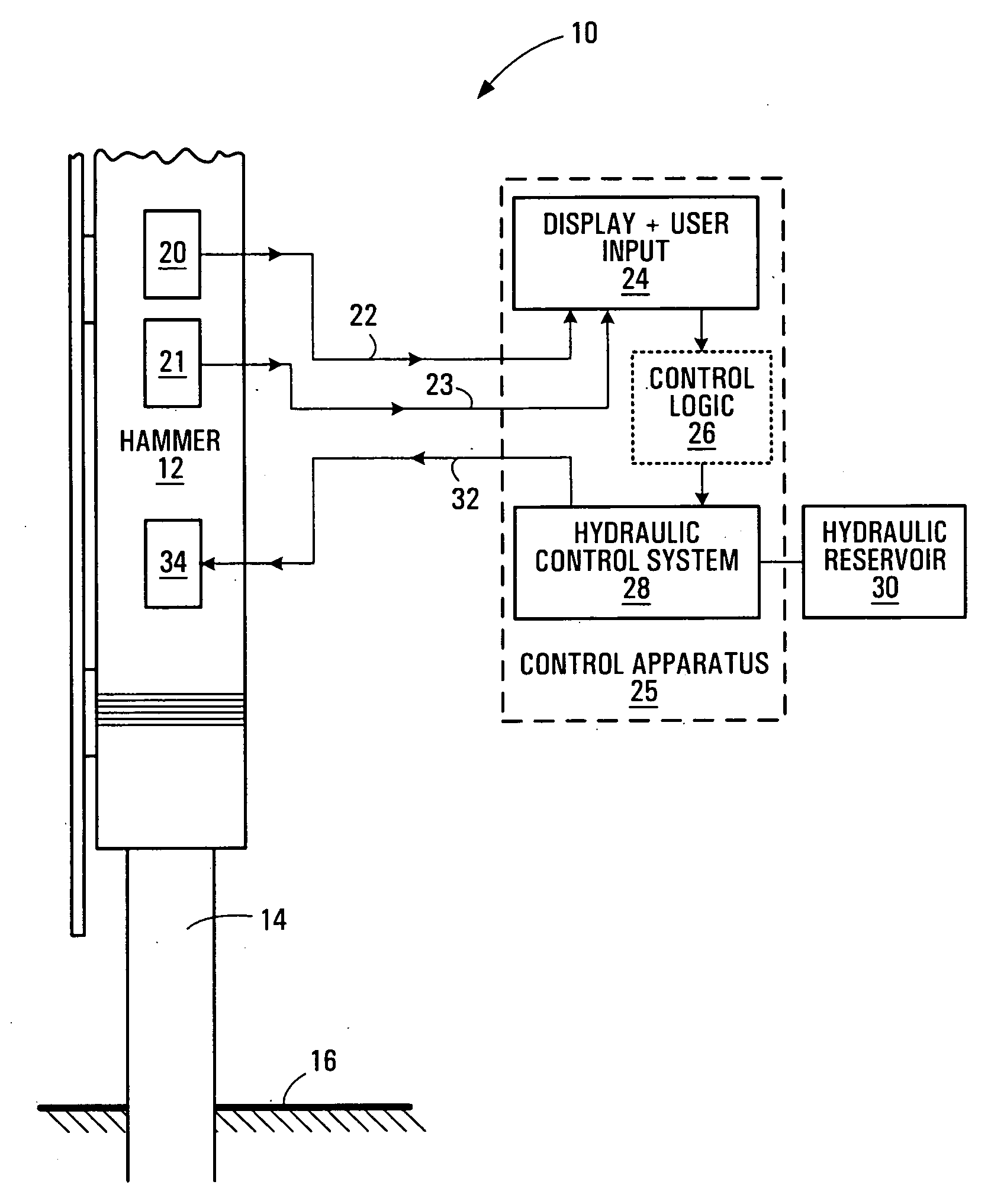

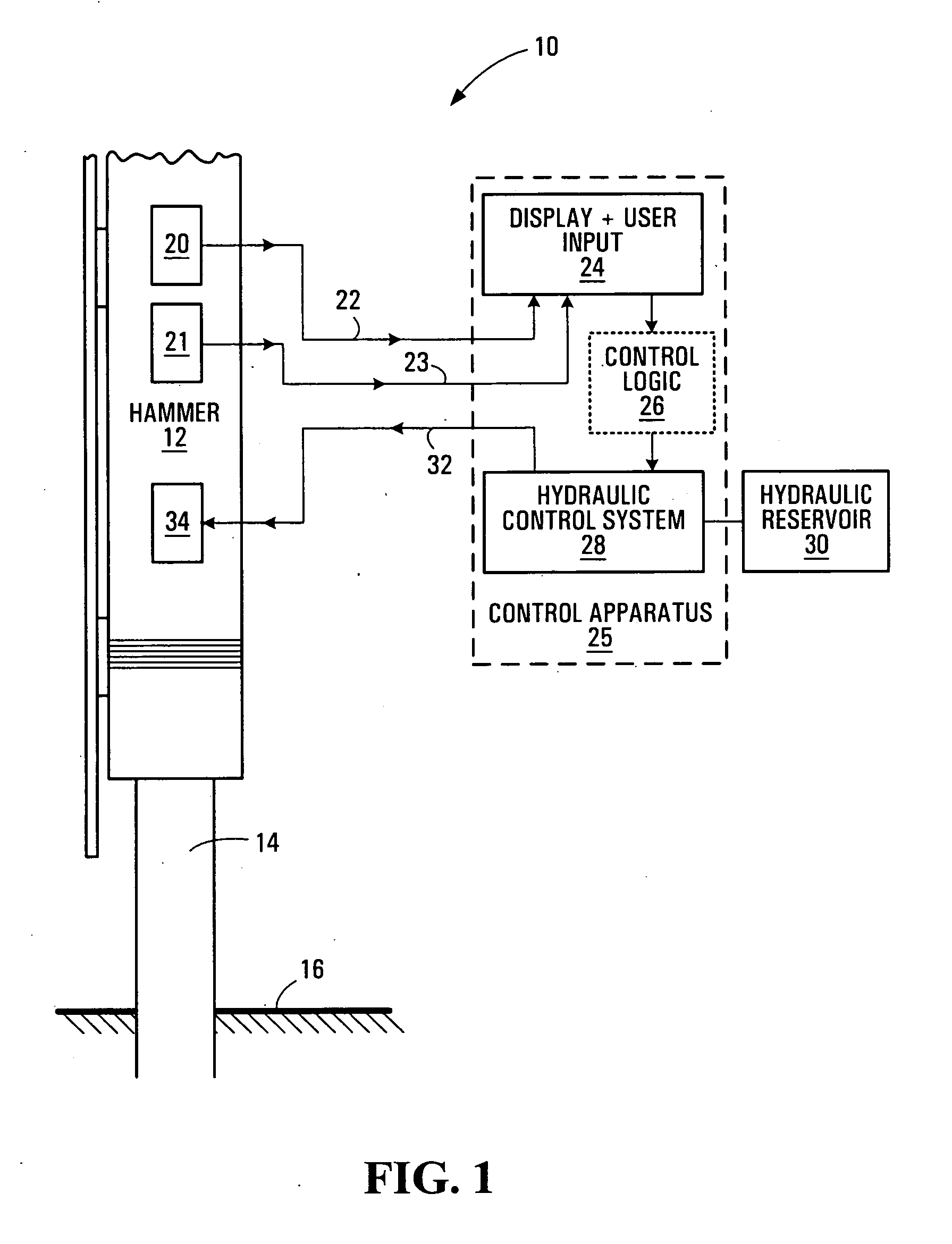

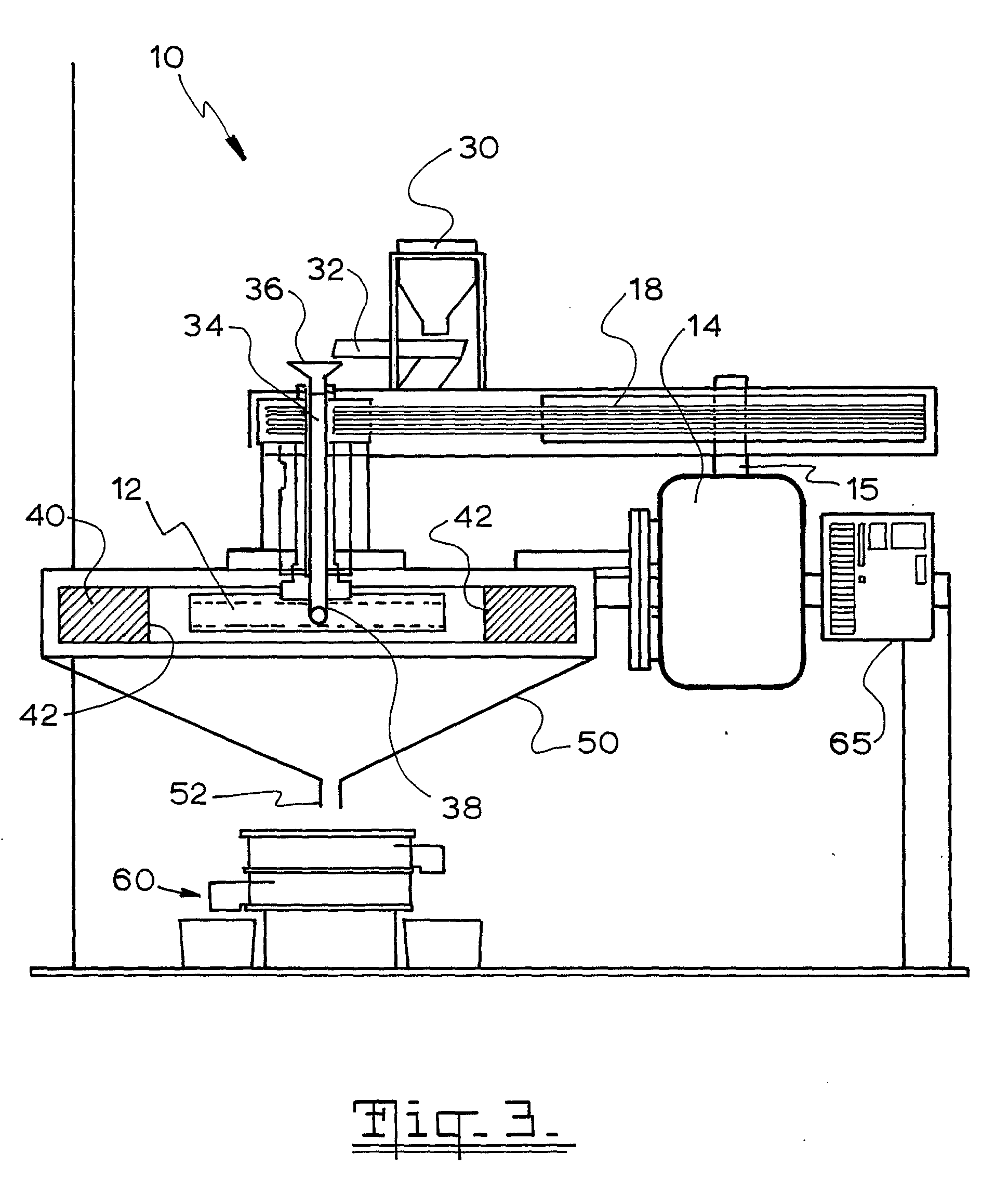

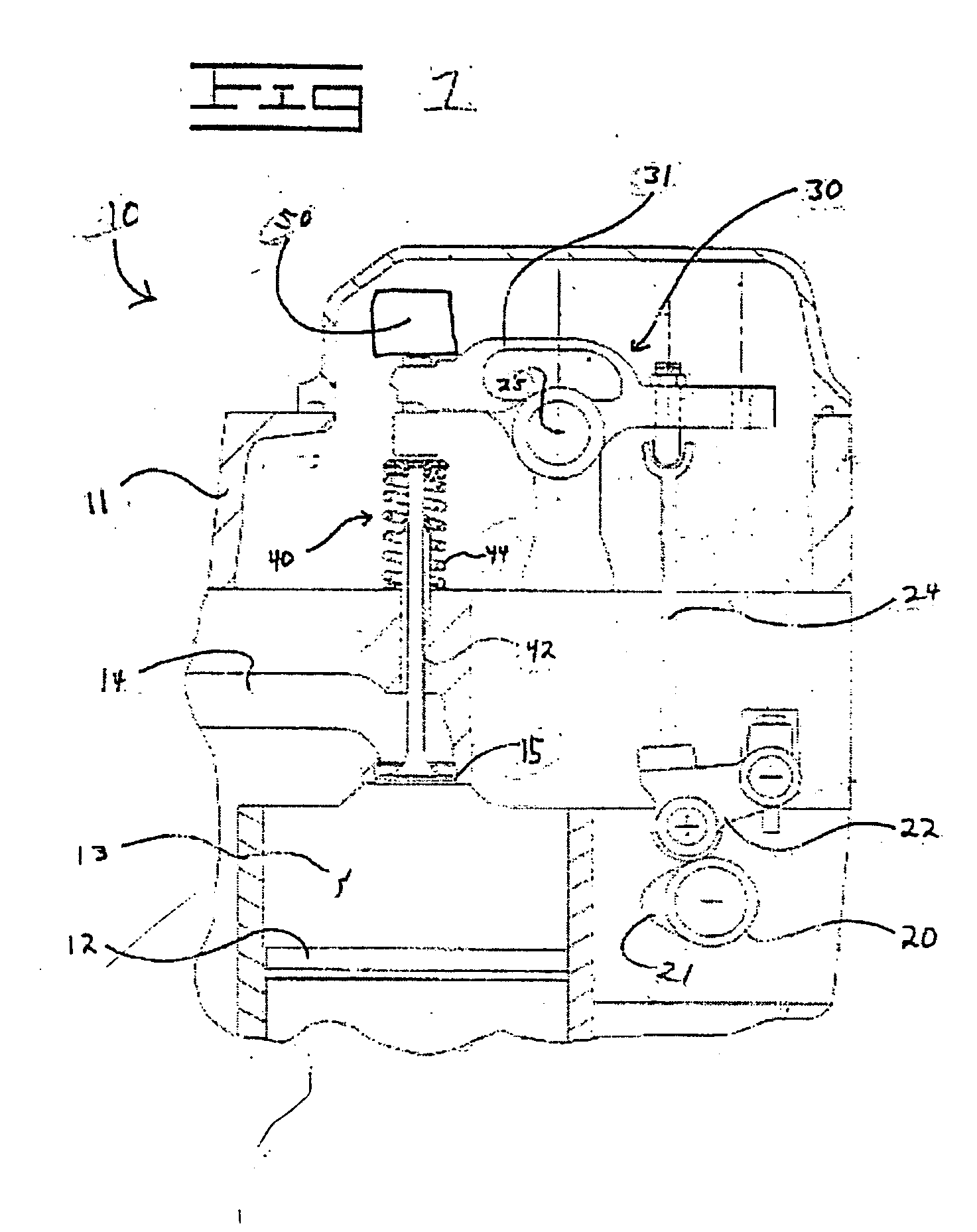

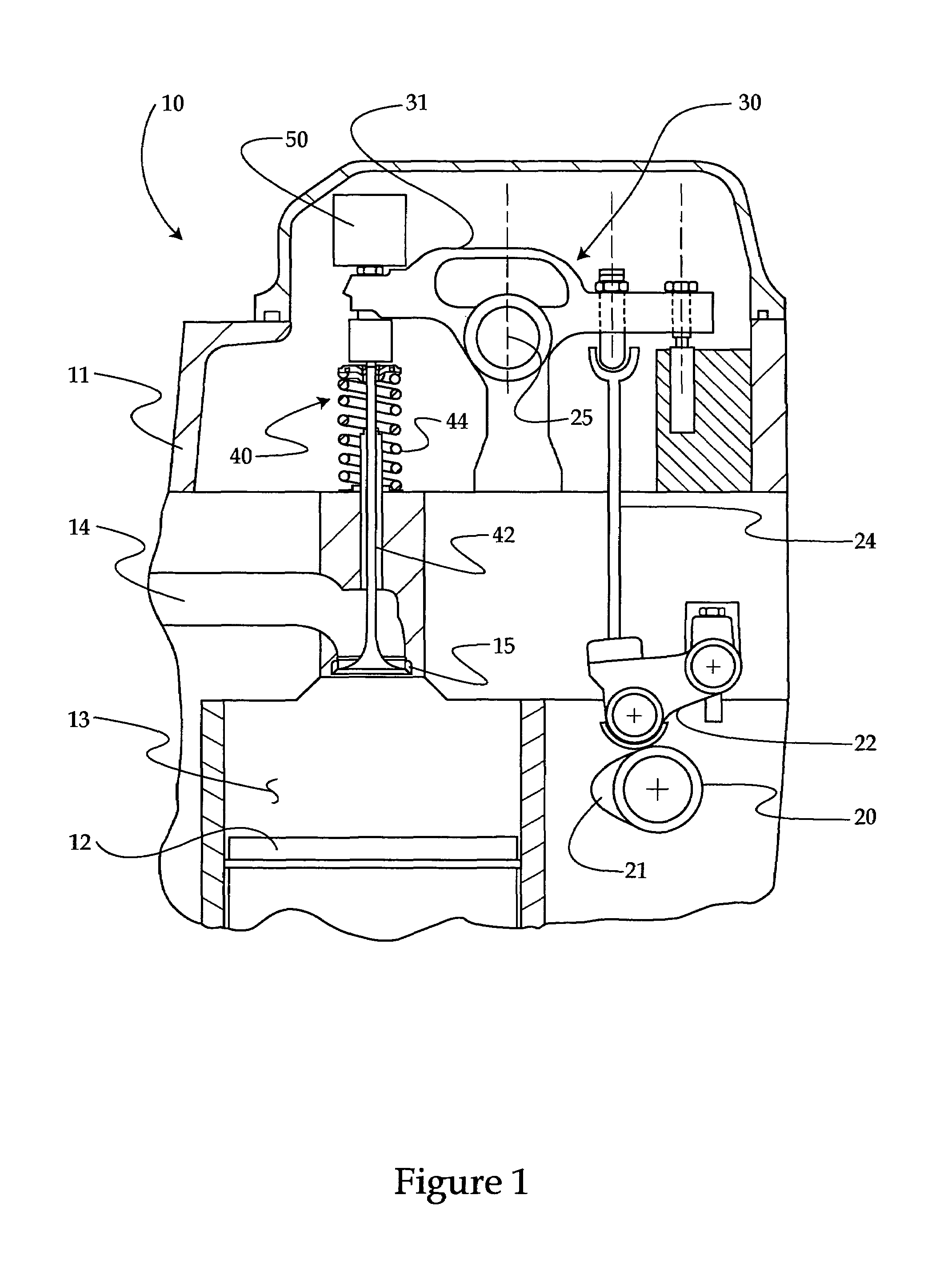

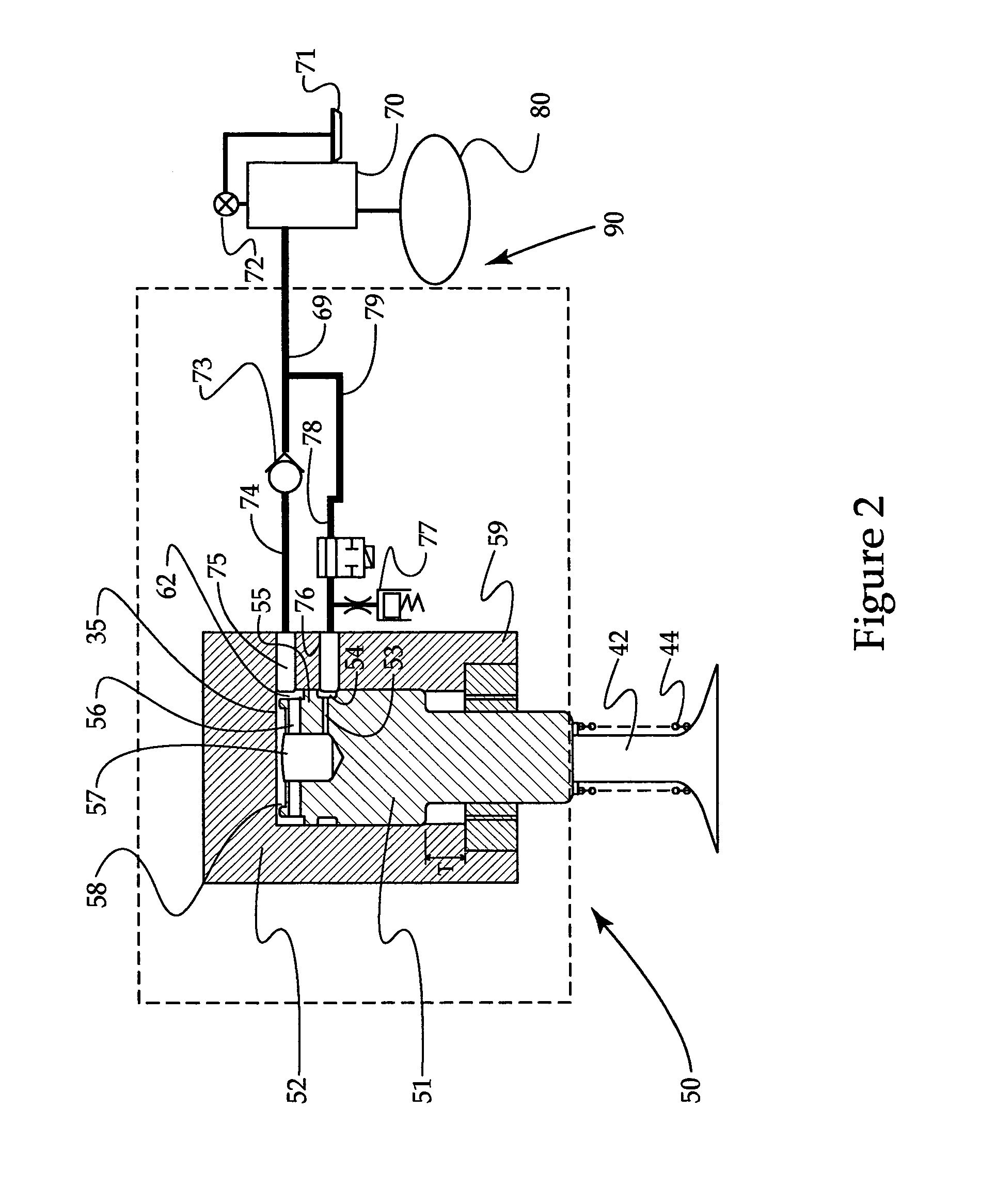

Pile driving control apparatus and pile driving system

ActiveUS7404449B2Reduce impact speedReciprocating drilling machinesDerricks/mastsVibration controlControl system

A pile driving control apparatus for a pile driving system includes a hydraulic control system that controls a throttle of a pile driving hammer, and thereby controls an impact velocity of the hammer with a pile. A controller provides a control signal to the hydraulic control system. Based on the control signal, the hydraulic control system controls an impact velocity of the hammer during a subsequent hammer stroke. The controller may determine one or more control parameters such as sound pressure at a sound control location during a hammer stroke, vibration at a vibration control location during a hammer stroke, an impact force imparted to the pile during a hammer stroke, and / or actual pile capacity of the pile, and provide to the hydraulic control system a control signal based on the determined control parameter(s).

Owner:BERMINGHAM FOUND SOLUTIONS LTD

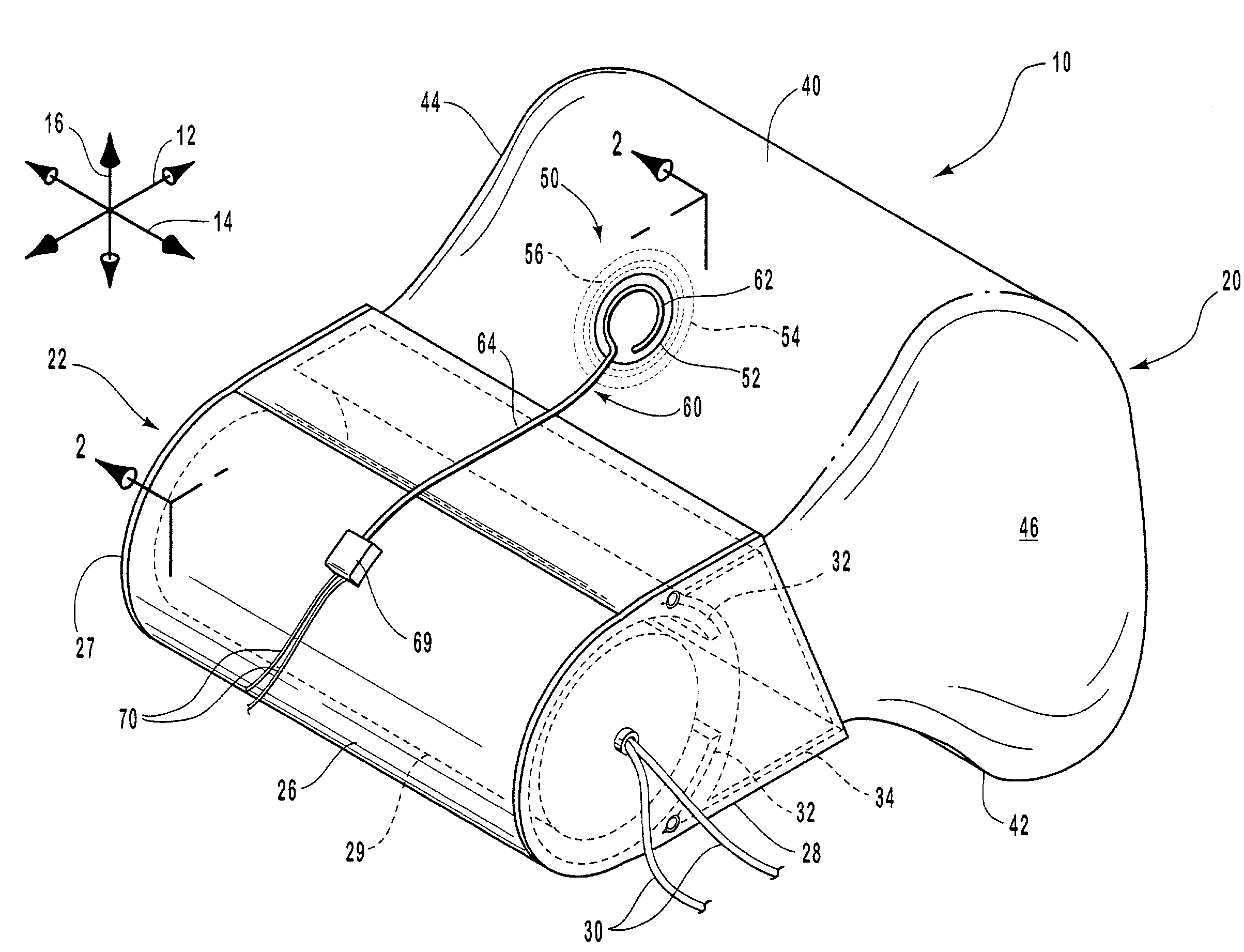

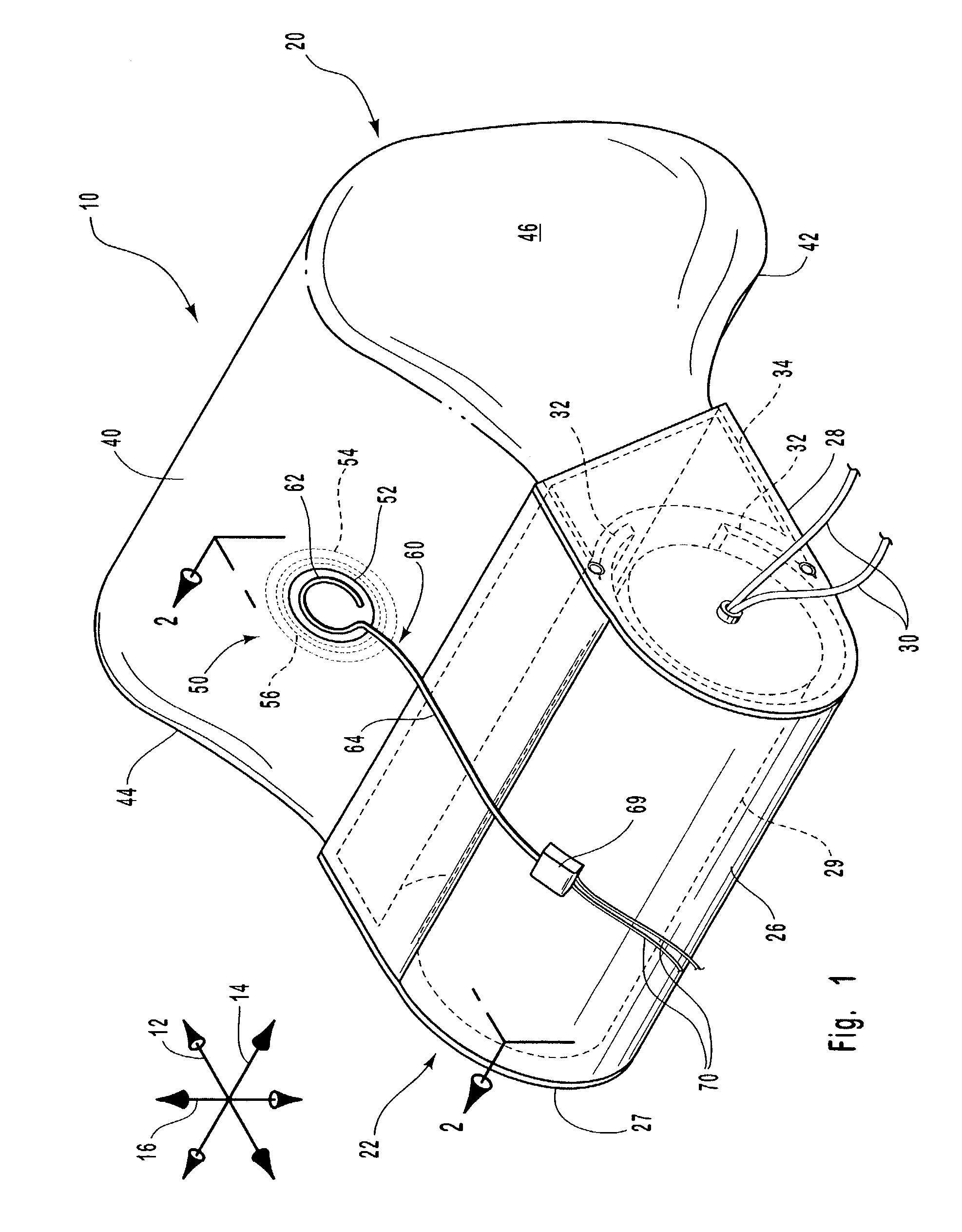

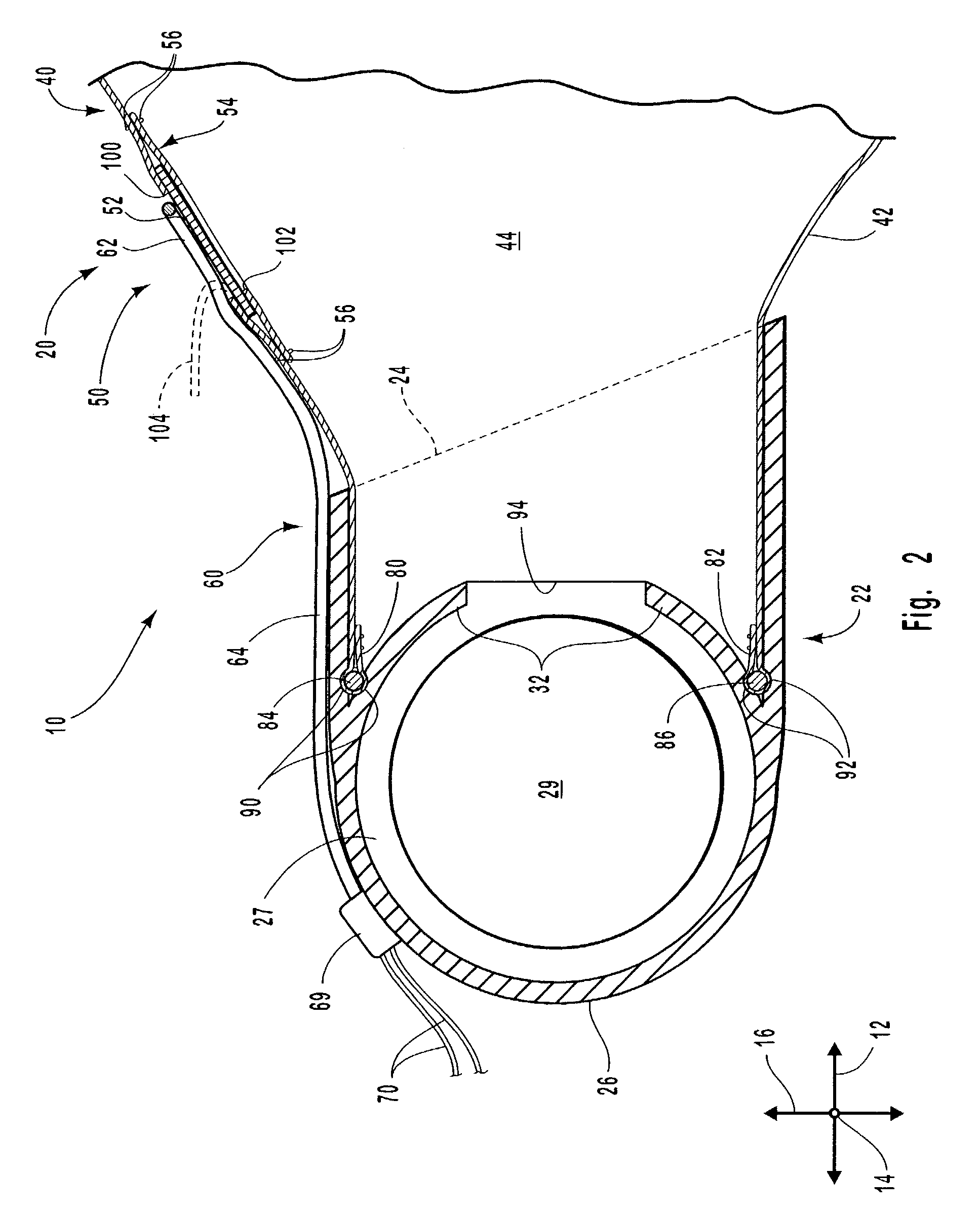

Active venting apparatus and method for airbag systems

InactiveUS6971671B2Rapidly stiffnessReduce stiffnessPedestrian/occupant safety arrangementAmmunition storageImpact velocityEngineering

Enhanced airbag modules and associated methods are provided. An airbag module according to the invention may have a cushion with a venting portion. During normal vehicle operation, the venting portion may be closed so that inflation gas is not permitted to flow through the venting portion. A pyrotechnic may be ignited to open the venting portion when venting is desired. The pyrotechnic may be directly attached to the venting portion to burn through or mechanically rupture the venting portion, thereby forming an exit port. Alternatively, the venting portion may have a flap that can be detached from the housing by ignition of a pyrotechnic to permit venting through an exit port of the housing. The pyrotechnic may then be disposed within a fastener designed to fracture upon ignition of the pyrotechnic to release the flap from attachment to the housing. The pyrotechnic may, for example, be an initiator or rapid deflagration cord (RDC). The cushion may thus be more stiffly inflated for a high velocity collision, or less stiffly inflated in the case of a lower impact velocity or an out-of-position occupant.

Owner:AUTOLIV ASP INC

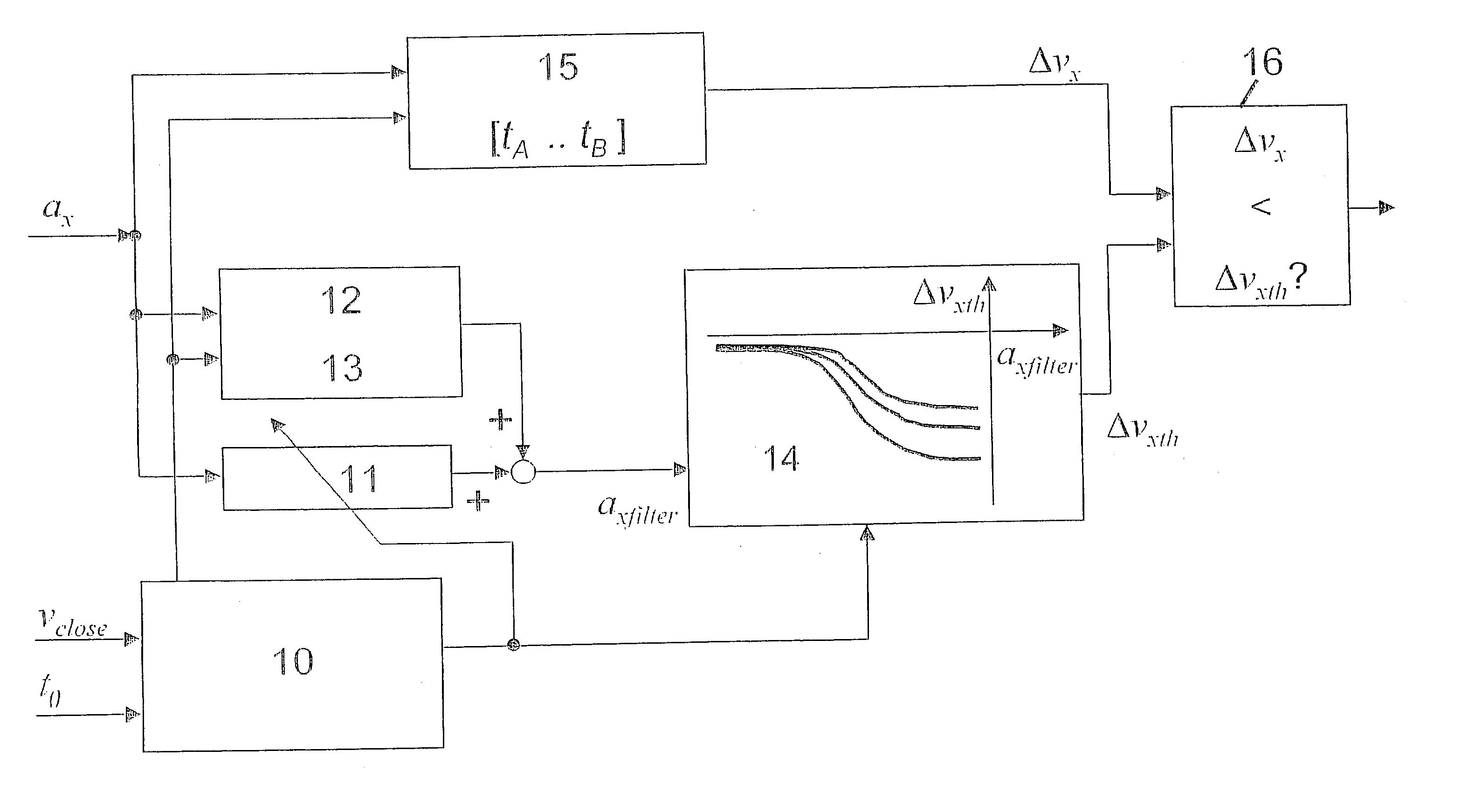

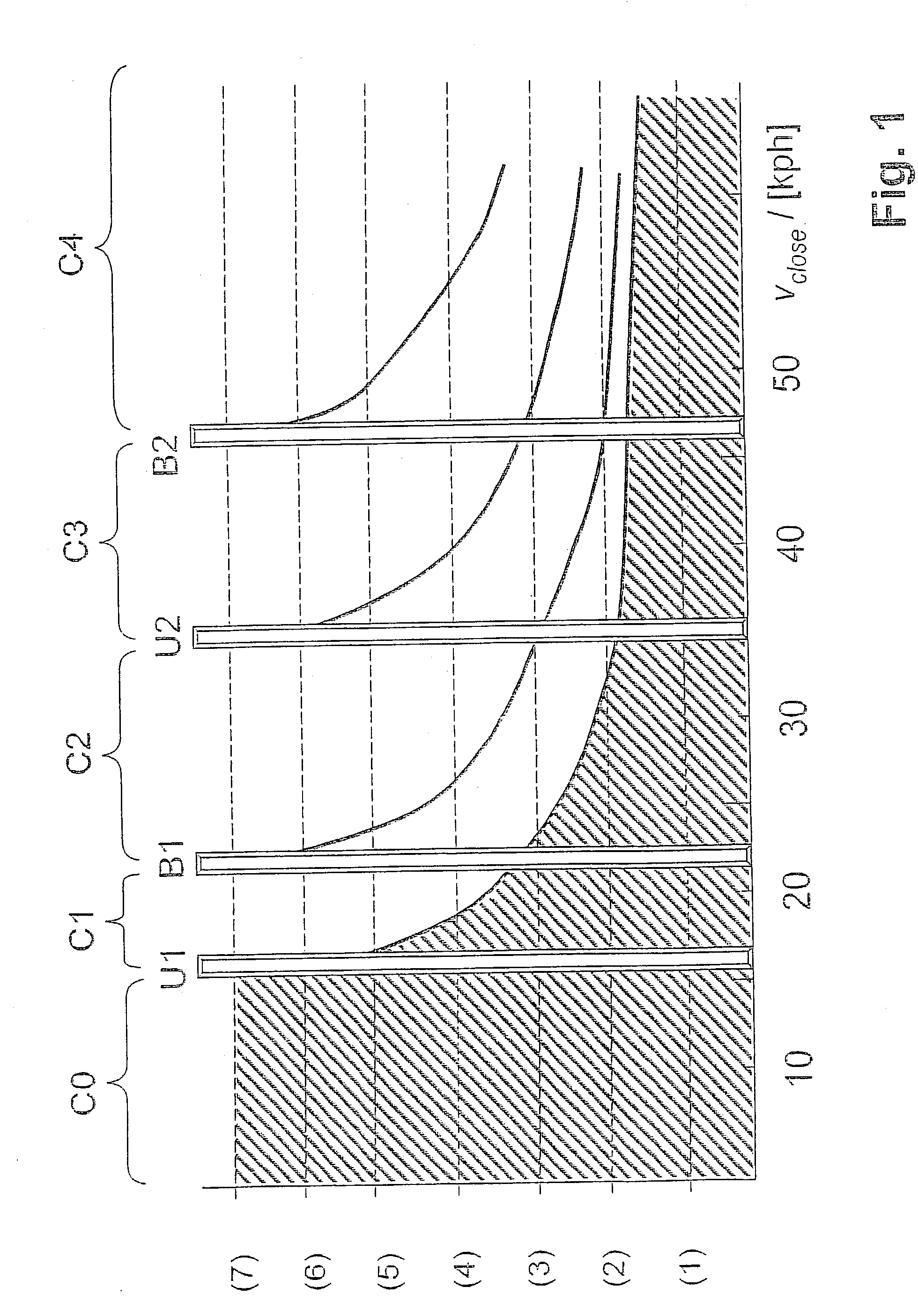

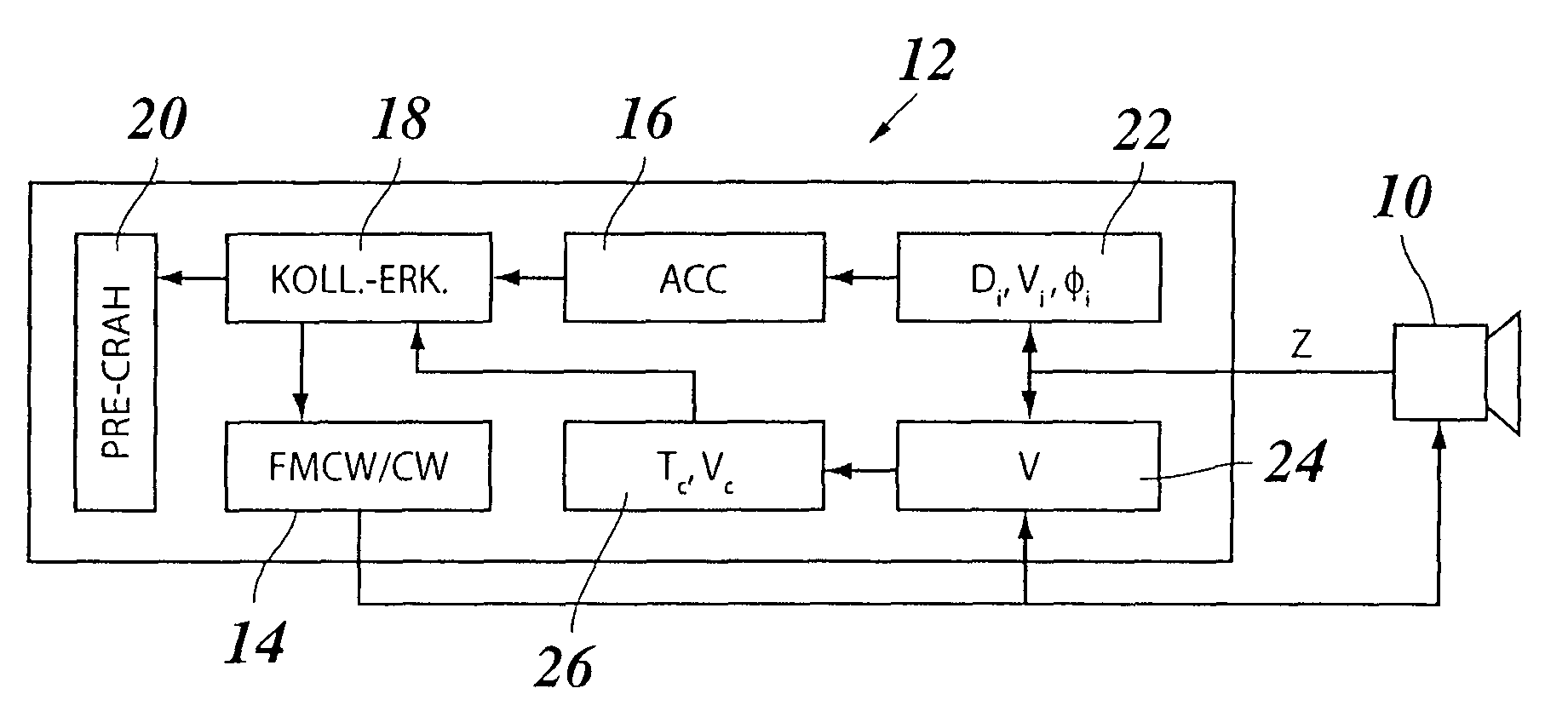

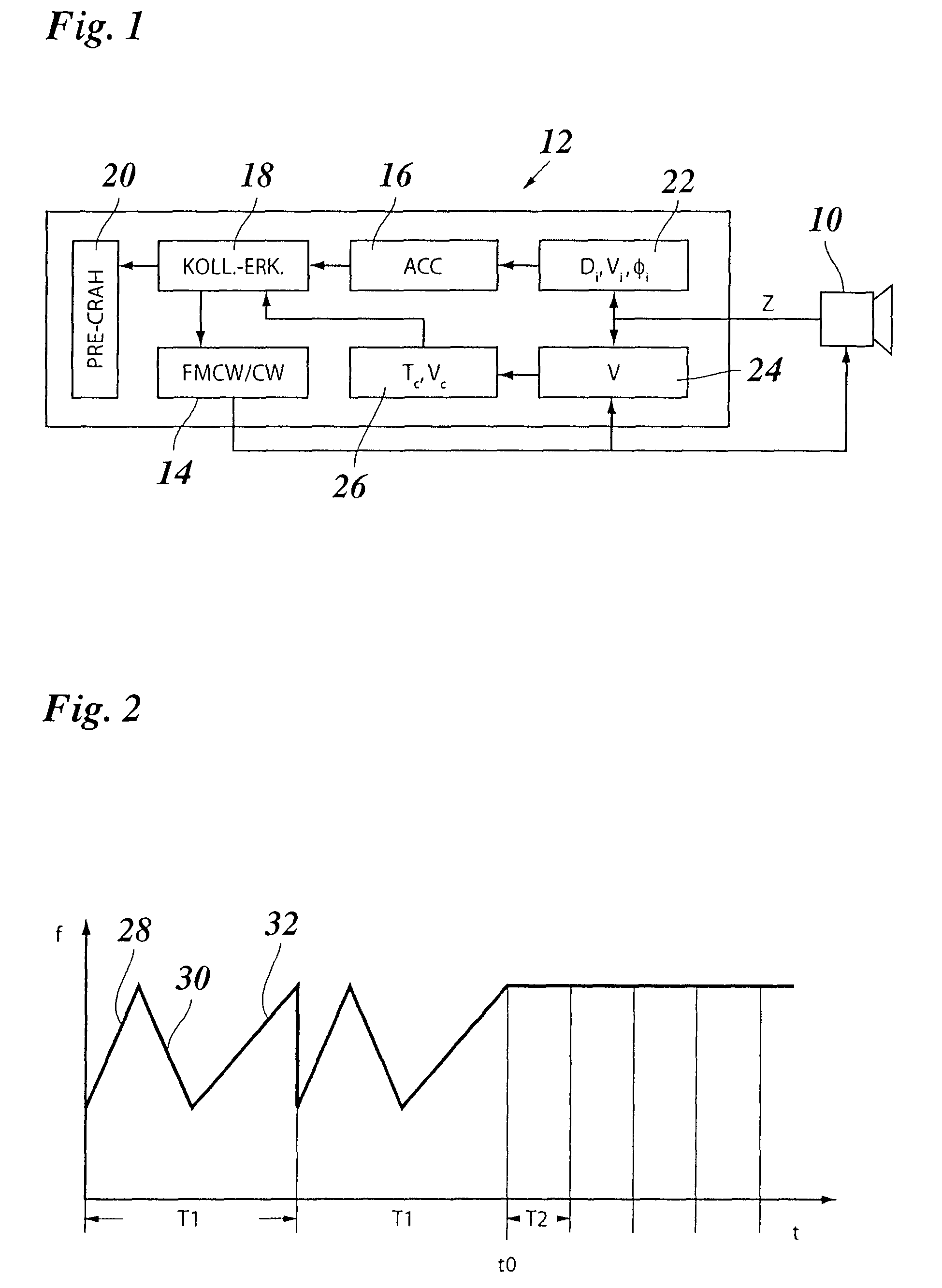

Method for triggering means of restraint in a motor vehicle

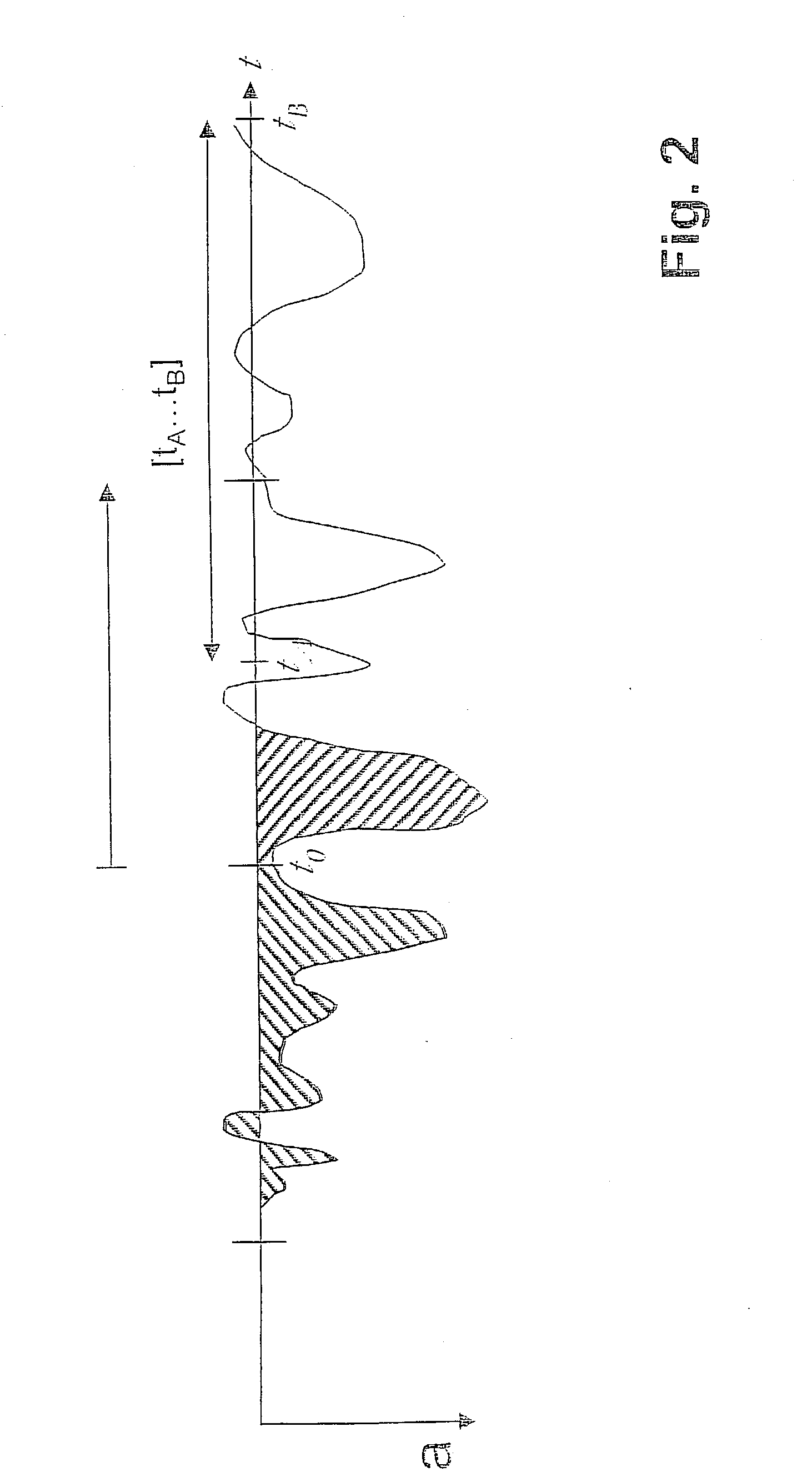

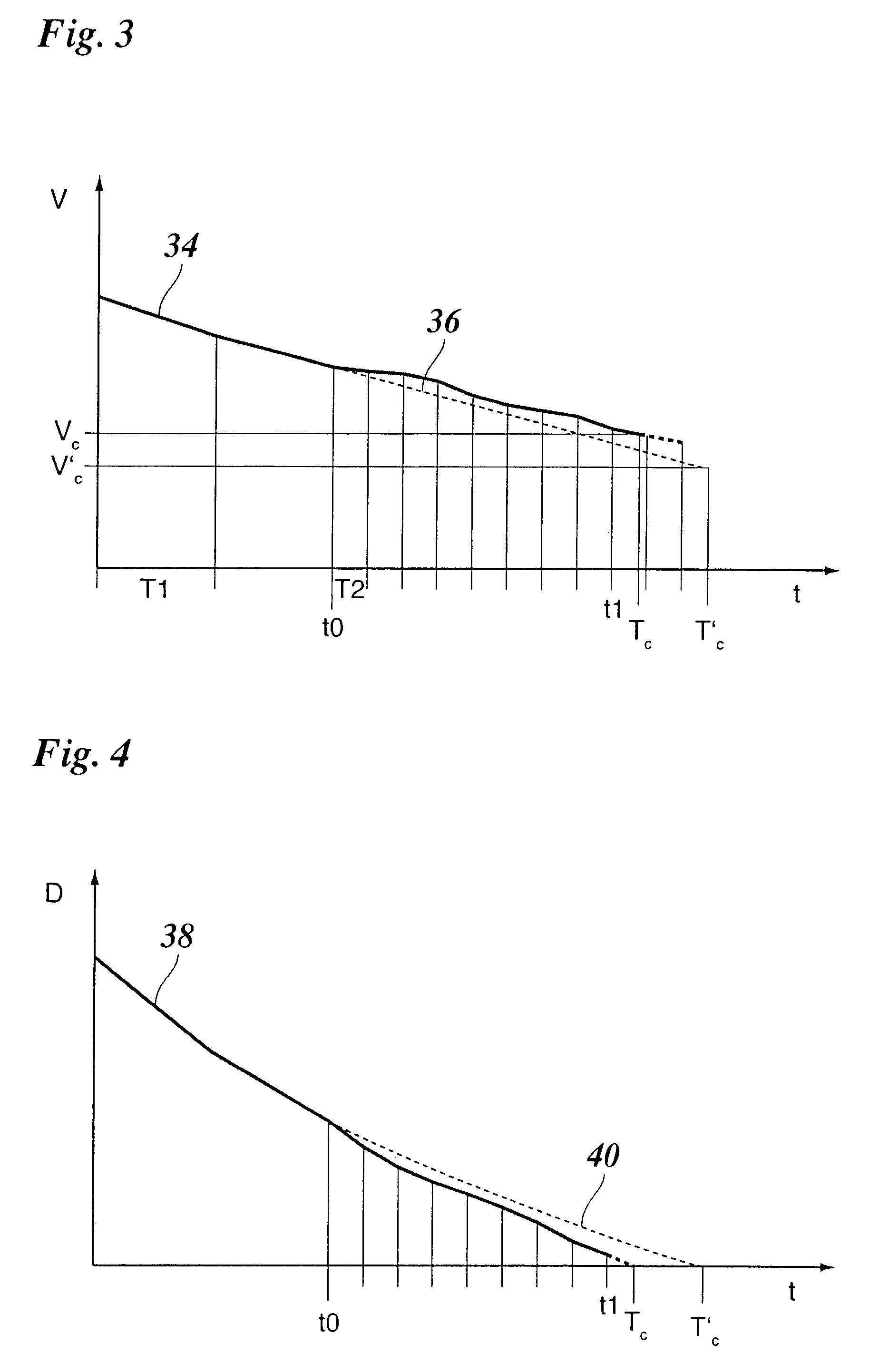

A method is described of triggering restraint means in a motor vehicle in the event of an impact and / or a collision with an object, in which the triggering of restraint means, such as airbags and seatbelt tighteners, is better adapted to the concrete impact situation and, in particular, unnecessary triggering of restraint means may be avoided. In the context of this method, the time characteristic of the acceleration is detected in the form of at least one acceleration signal ax. The time characteristic of a velocity DELTAvx is generated from the acceleration signal ax. A threshold value DELTAvxth for the velocity DELTAvx is then determined as a triggering criterion. For this purpose, the impact velocity vclose and the instant of impact t0 are established with the aid of a pre-crash sensor system even before the impact. The impact situation is classified with reference to the impact velocity vclose. With the aid of the classification of the impact situation, a triggering time window [tA . . . tB] is determined, in which the time characteristic of the velocity DELTAvx is generated and, in parallel to this, the threshold value DELTAvxth for the velocity DELTAvx is established from the acceleration signal ax, the classification of the impact situation being taken into consideration.

Owner:ROBERT BOSCH GMBH

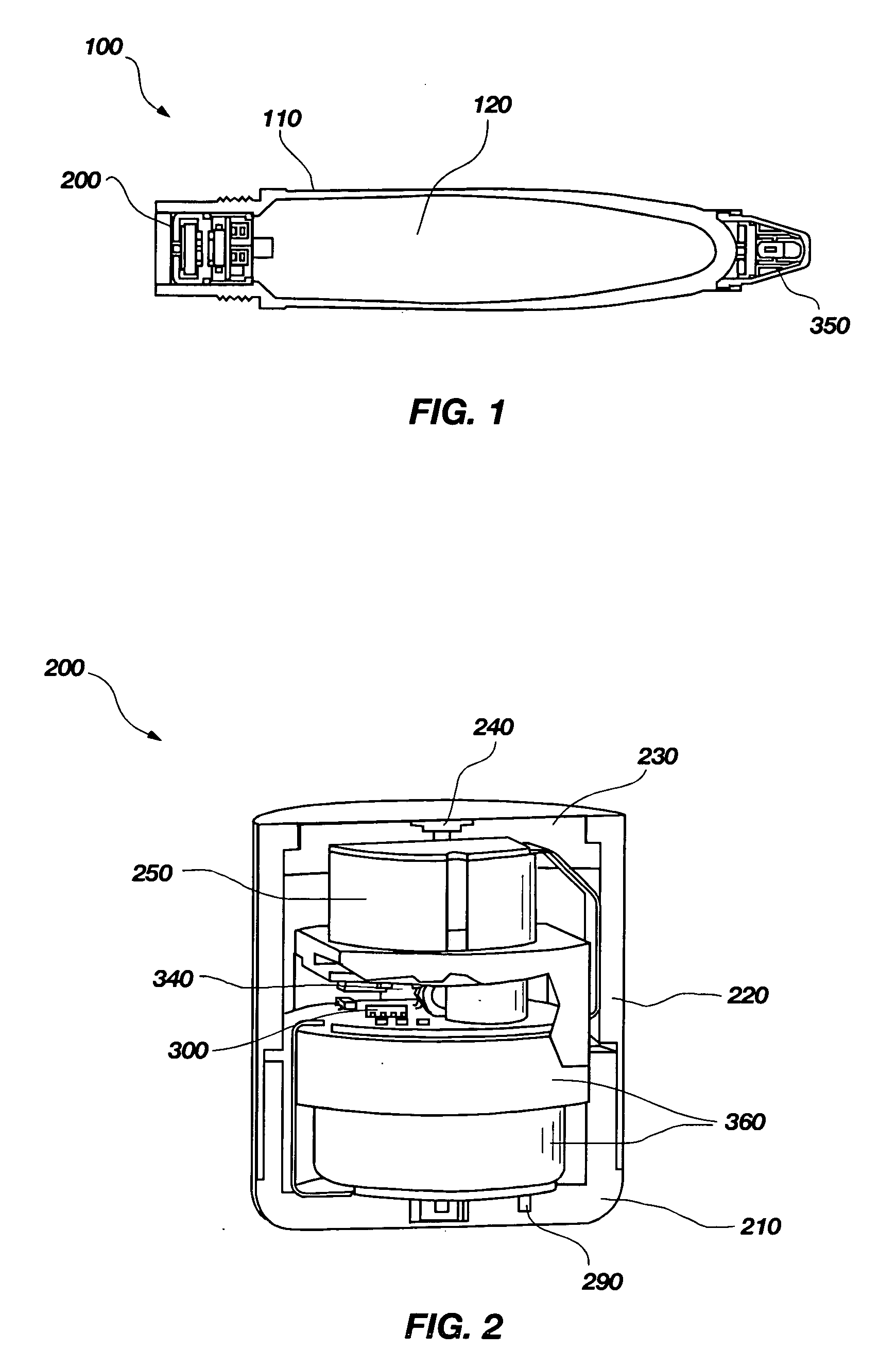

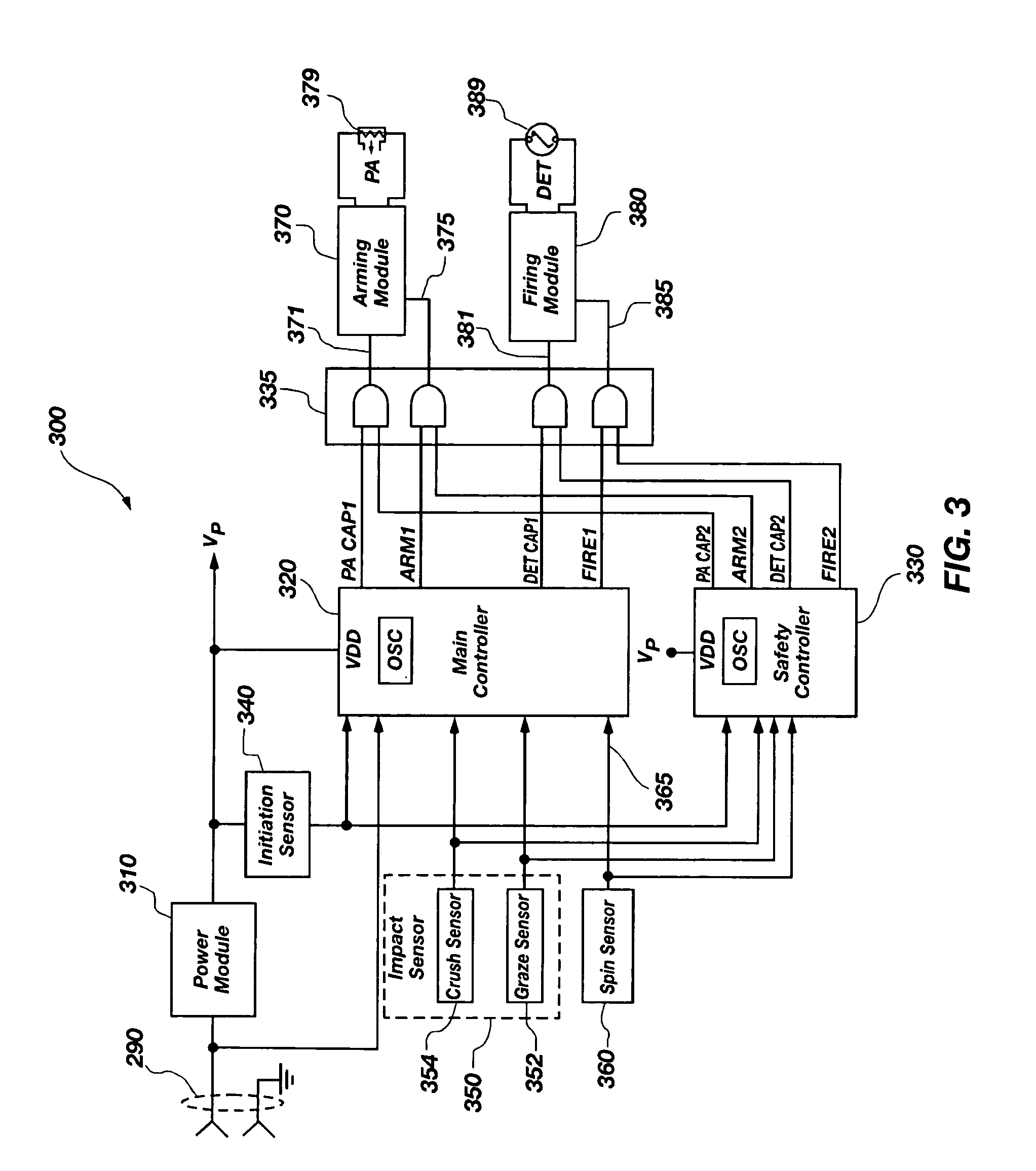

Method and apparatus for autonomous detonation delay in munitions

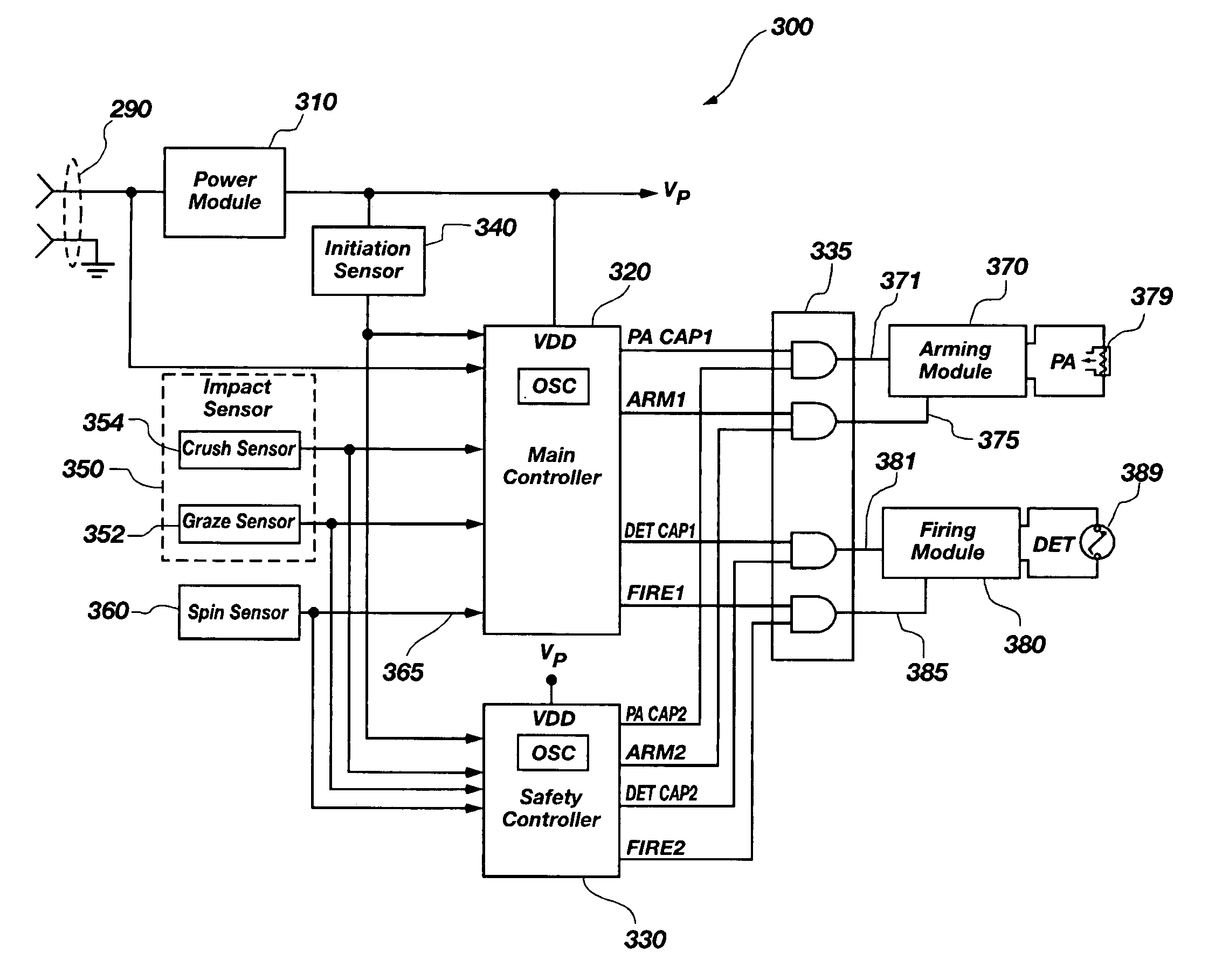

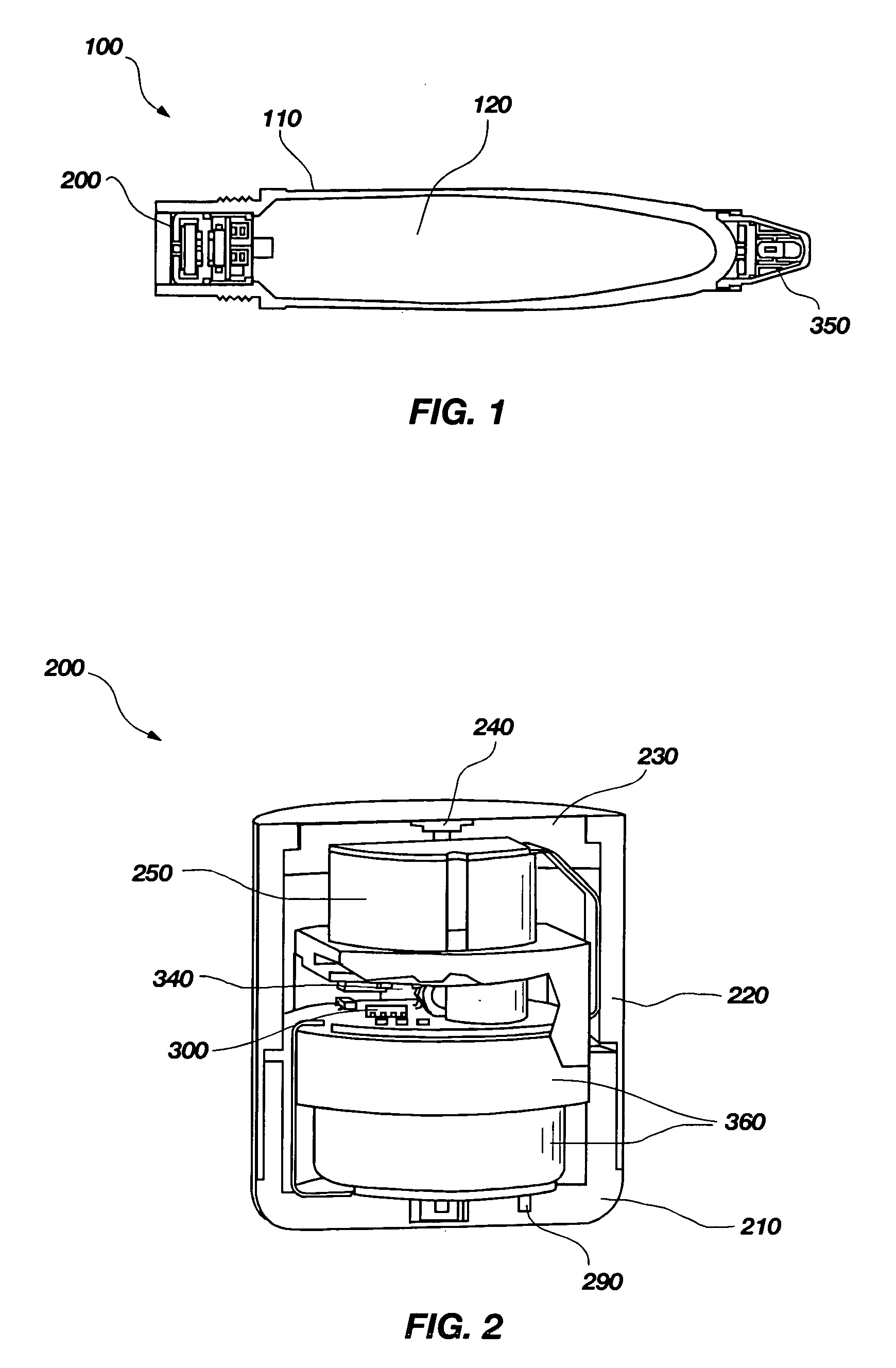

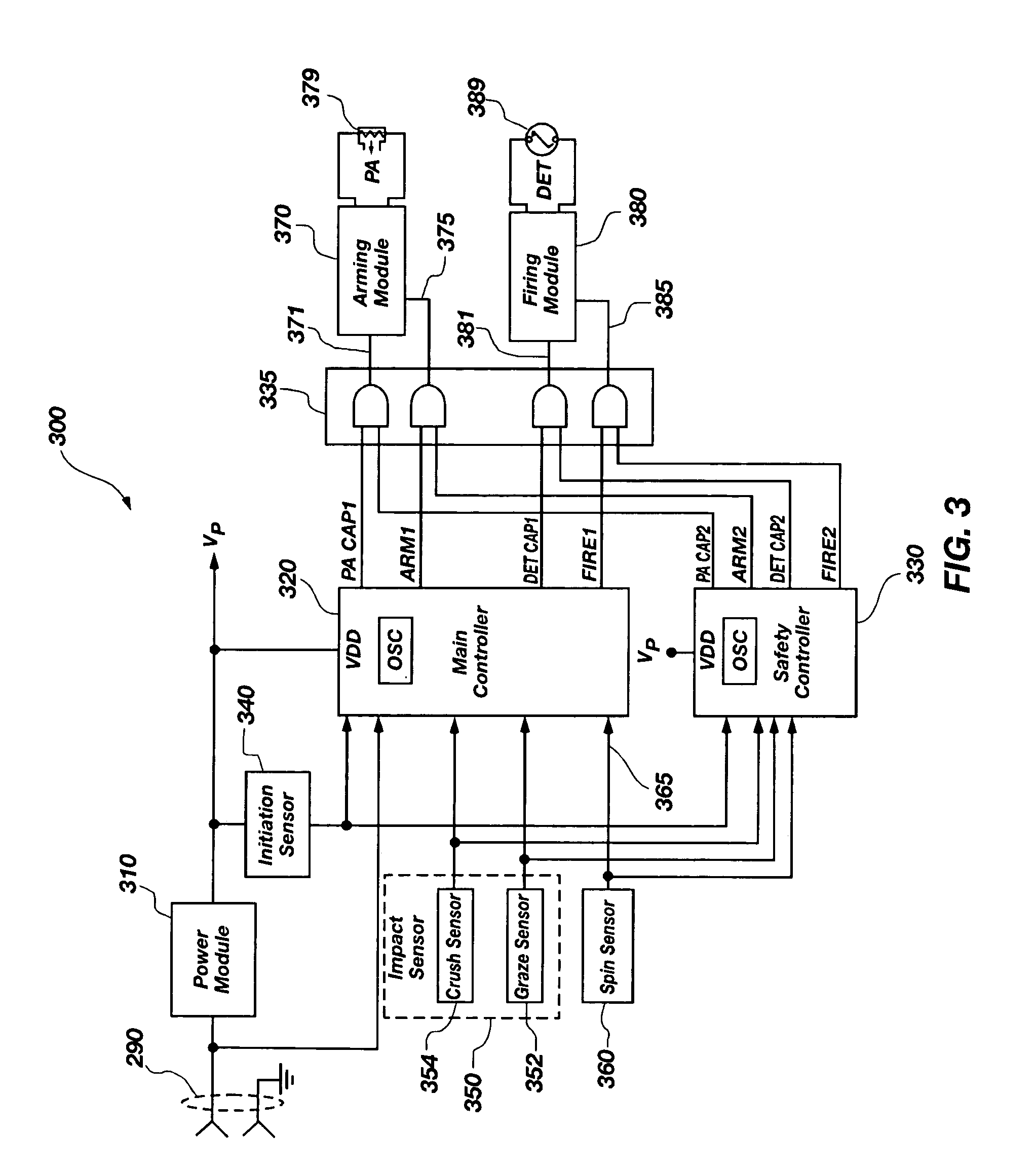

A detonation timing apparatus and method of determining a detonation time is disclosed. The detonation timing apparatus comprises an initiation sensor, at least one impact sensor, and at least one controller. The at least one controller may be configured for sensing an initiation event associated with the initiation sensor and sensing an impact event associated with the at least one impact sensor. The at least one controller is further configured for determining an impact velocity estimate proportional to a temporal difference between the initiation event and the impact event, using the impact velocity estimate to determine the detonation delay, and generating the detonation event at the detonation delay after the impact event. The timing apparatus and method of determining a detonation time may be incorporated in a fuze, which may be incorporated in an explosive projectile.

Owner:NORTHROP GRUMMAN SYST CORP

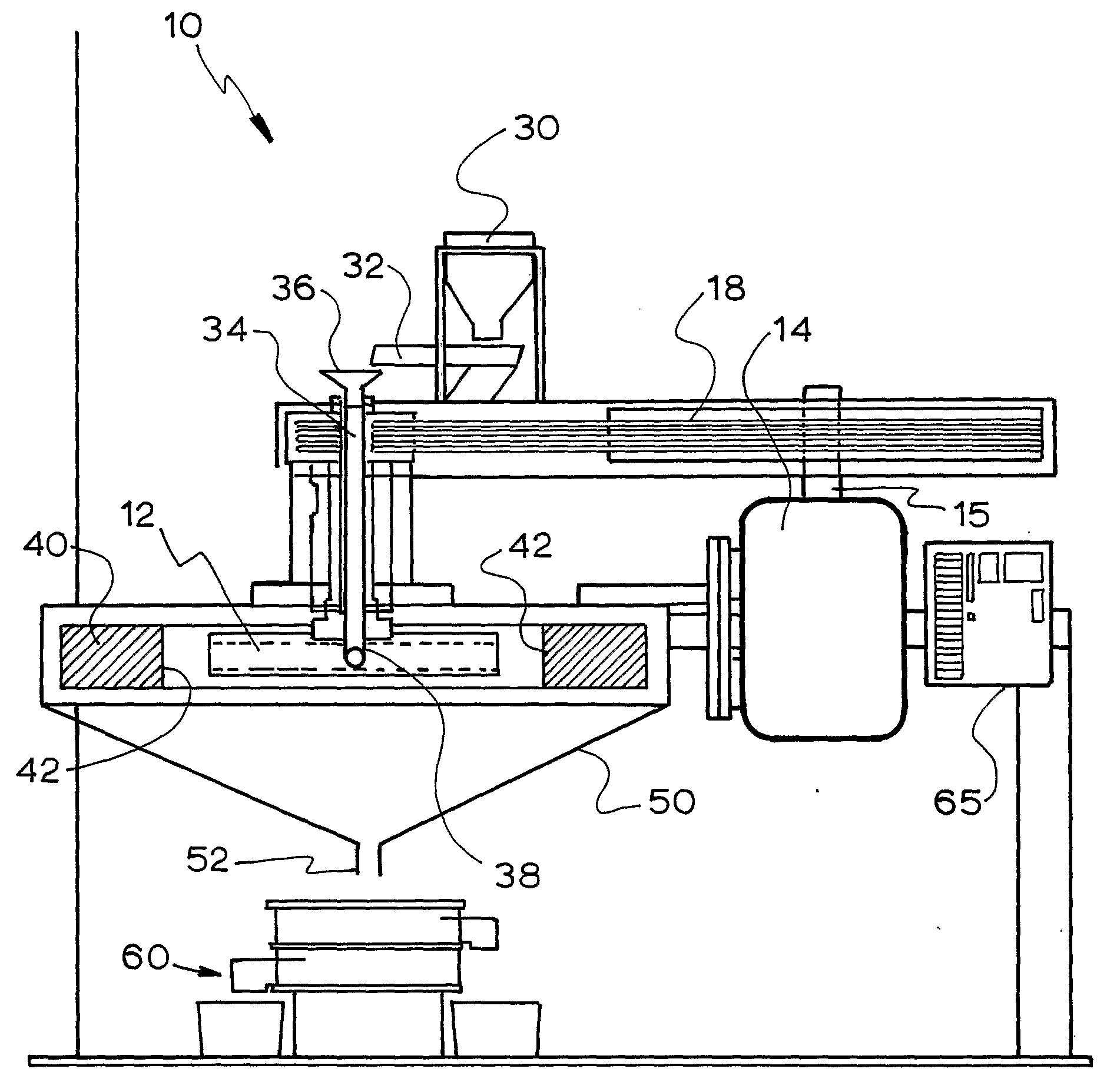

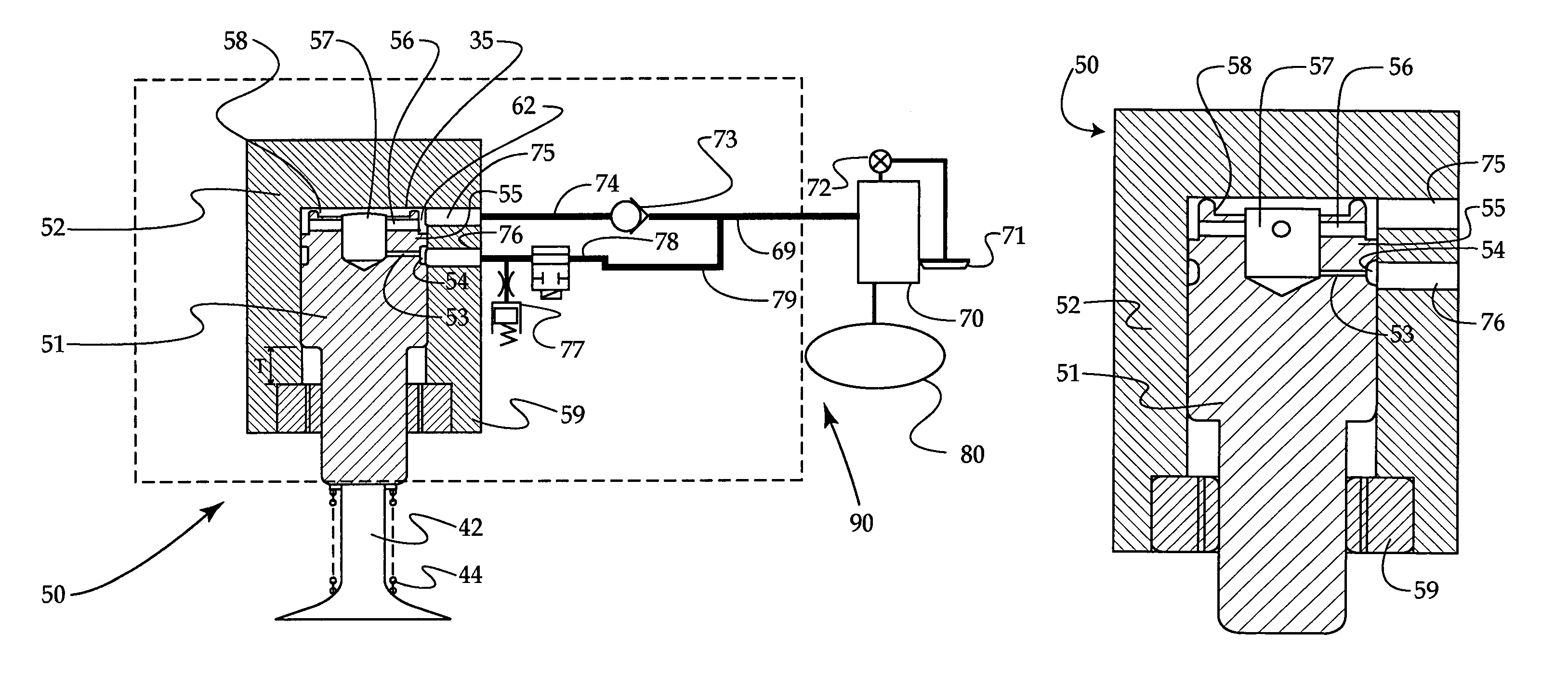

Pile driving control apparatus and pile driving system

ActiveUS20070074881A1Reduce impact speedReciprocating drilling machinesDerricks/mastsVibration controlControl signal

A pile driving control apparatus for a pile driving system includes a hydraulic control system that controls a throttle of a pile driving hammer, and thereby controls an impact velocity of the hammer with a pile. A controller provides a control signal to the hydraulic control system. Based on the control signal, the hydraulic control system controls an impact velocity of the hammer during a subsequent hammer stroke. The controller may determine one or more control parameters such as sound pressure at a sound control location during a hammer stroke, vibration at a vibration control location during a hammer stroke, an impact force imparted to the pile during a hammer stroke, and / or actual pile capacity of the pile, and provide to the hydraulic control system a control signal based on the determined control parameter(s).

Owner:BERMINGHAM FOUND SOLUTIONS LTD

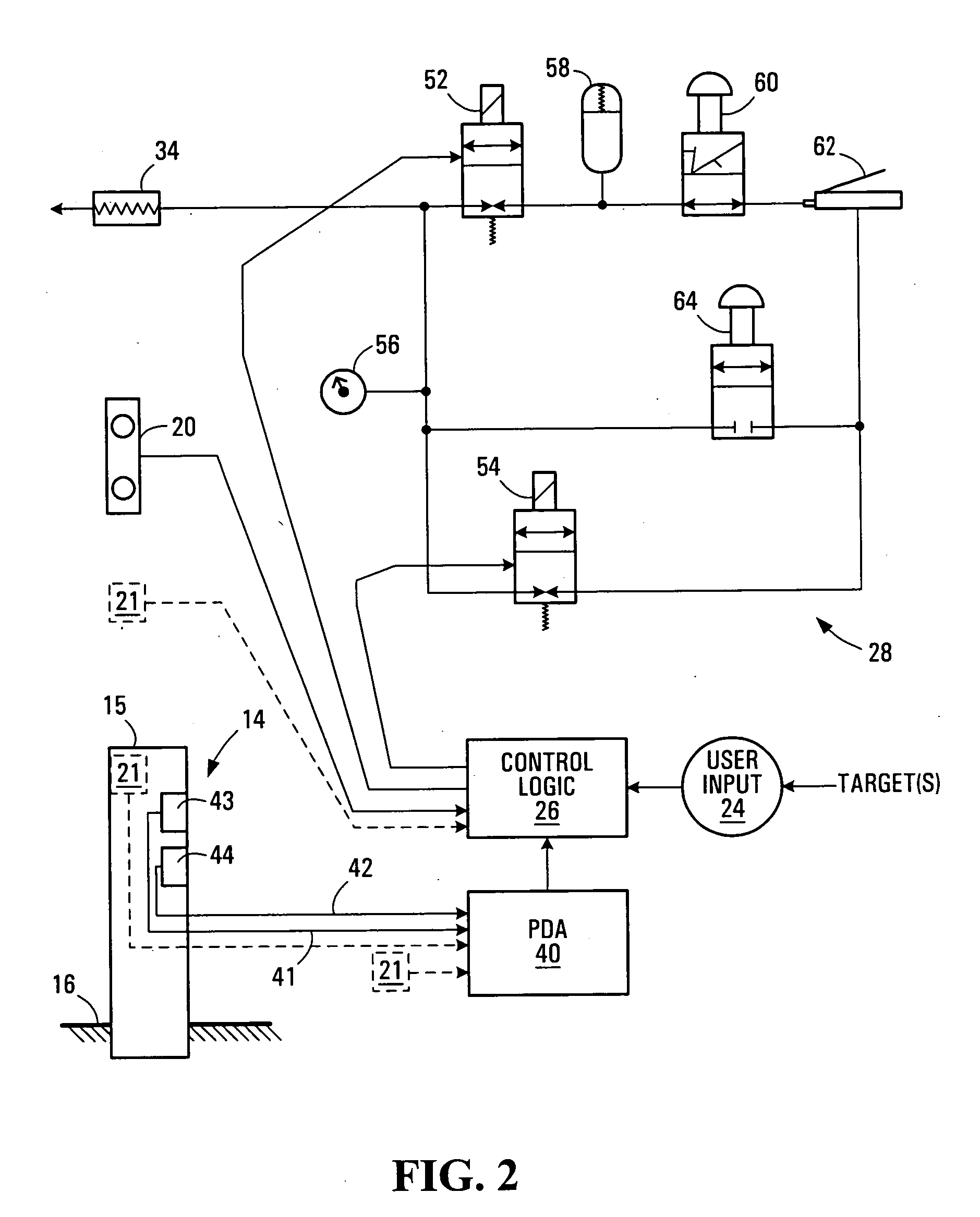

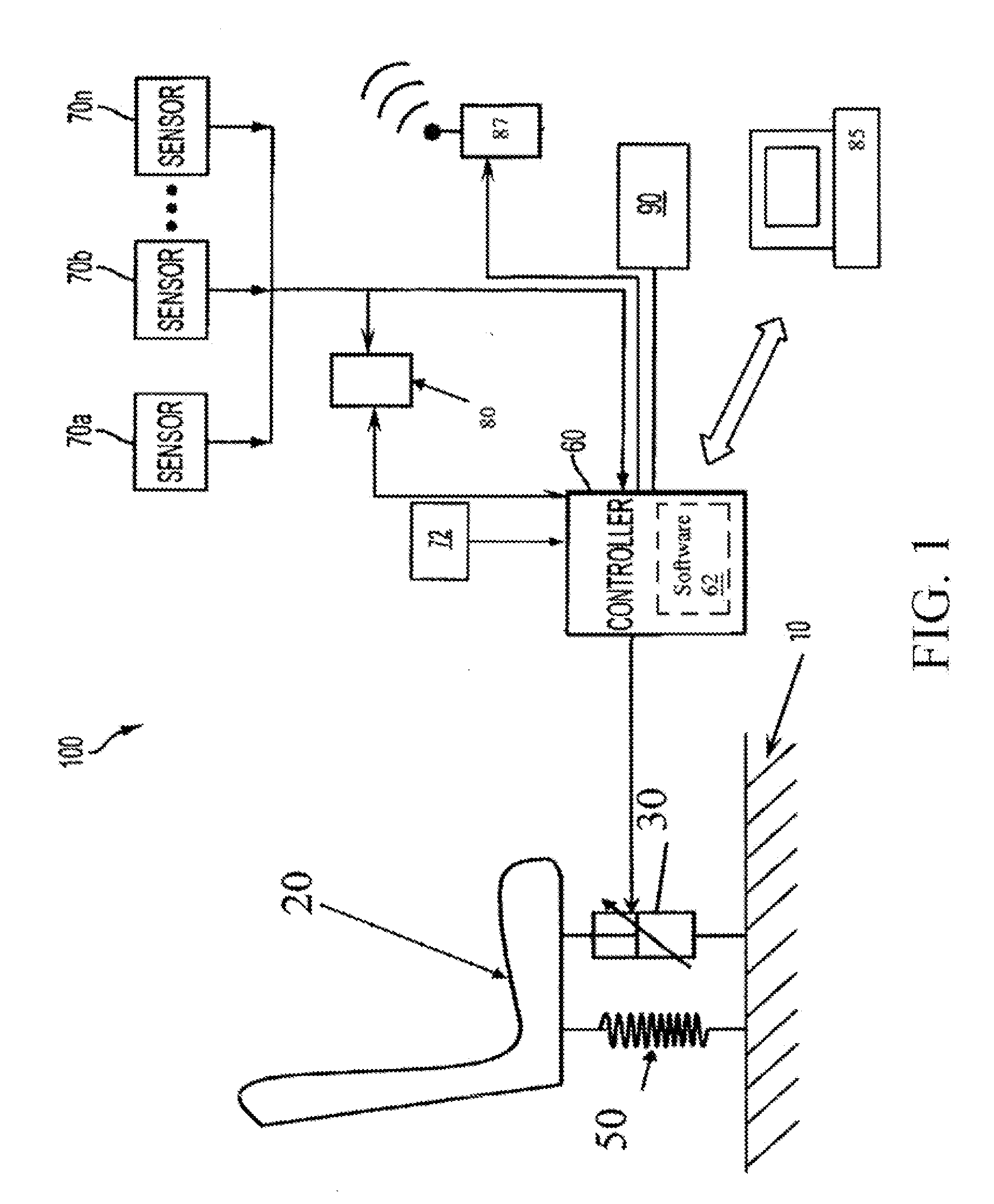

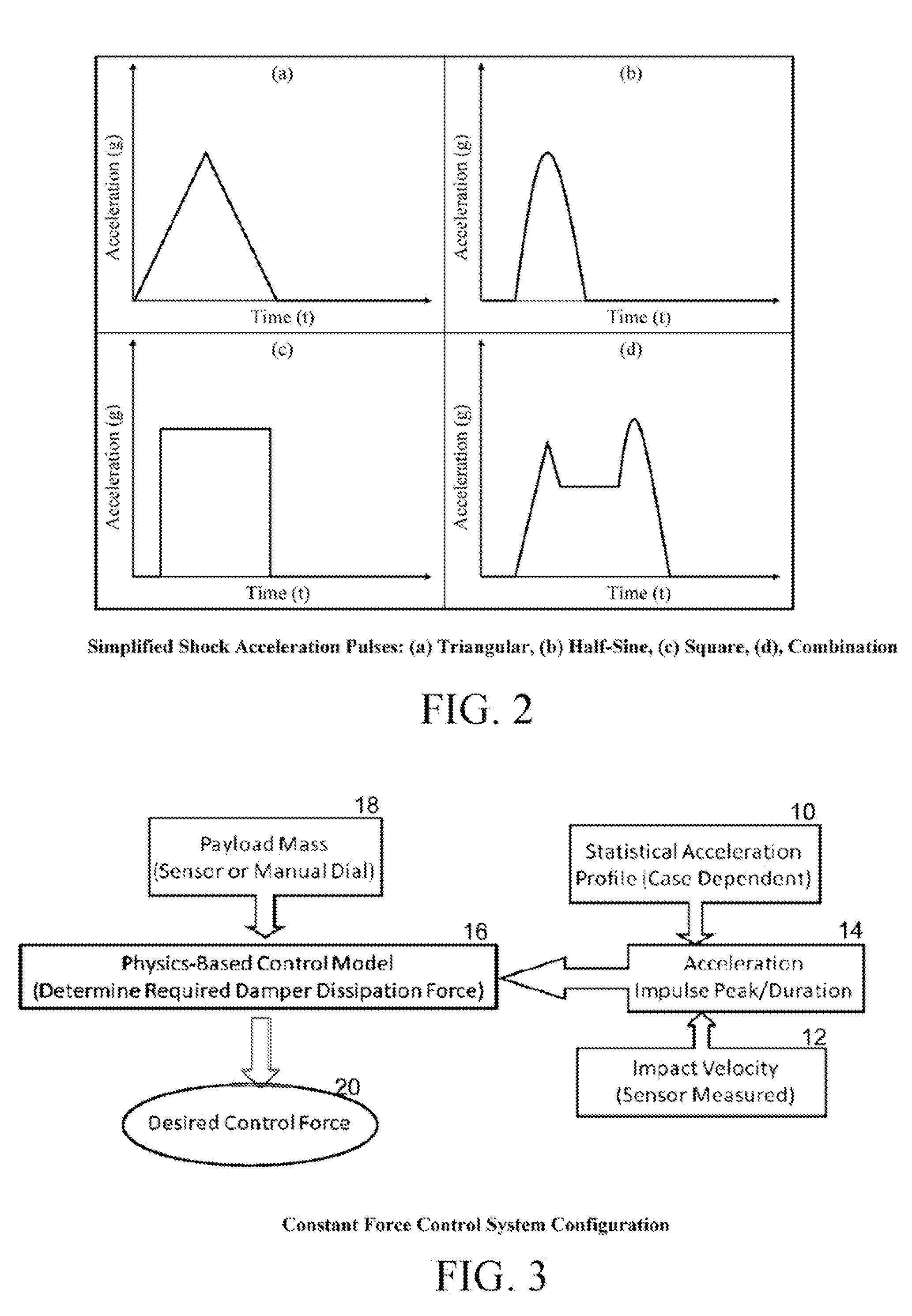

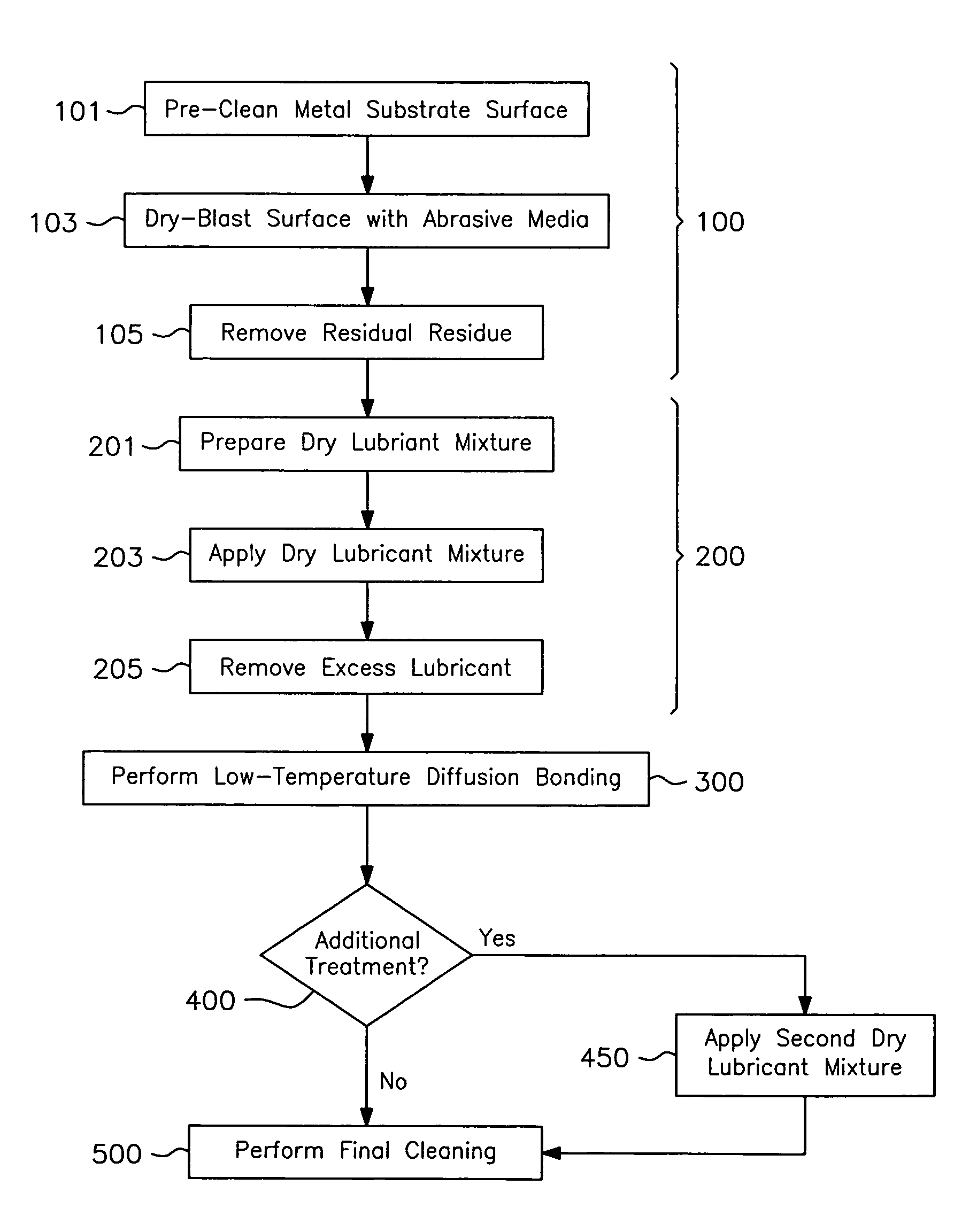

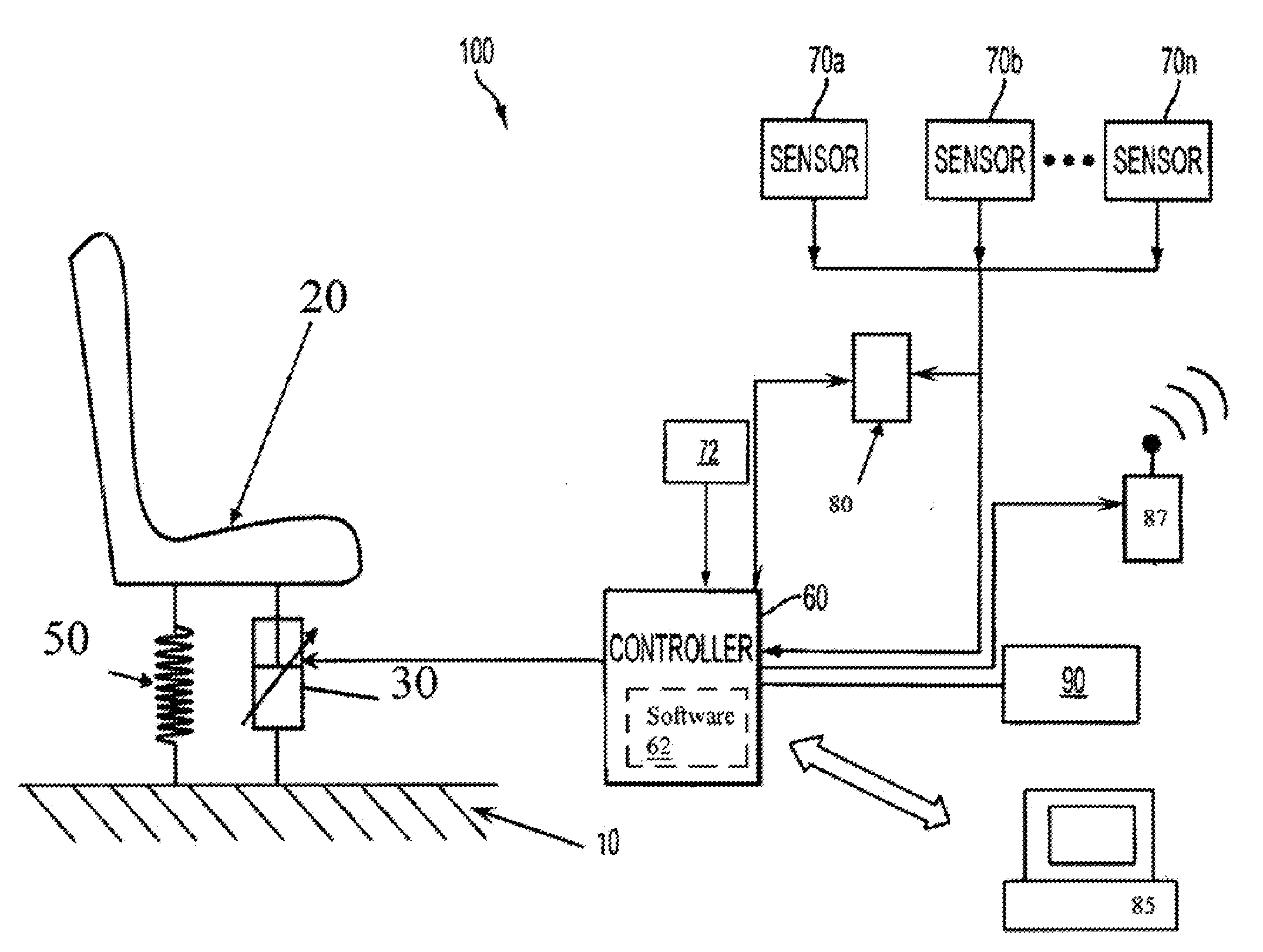

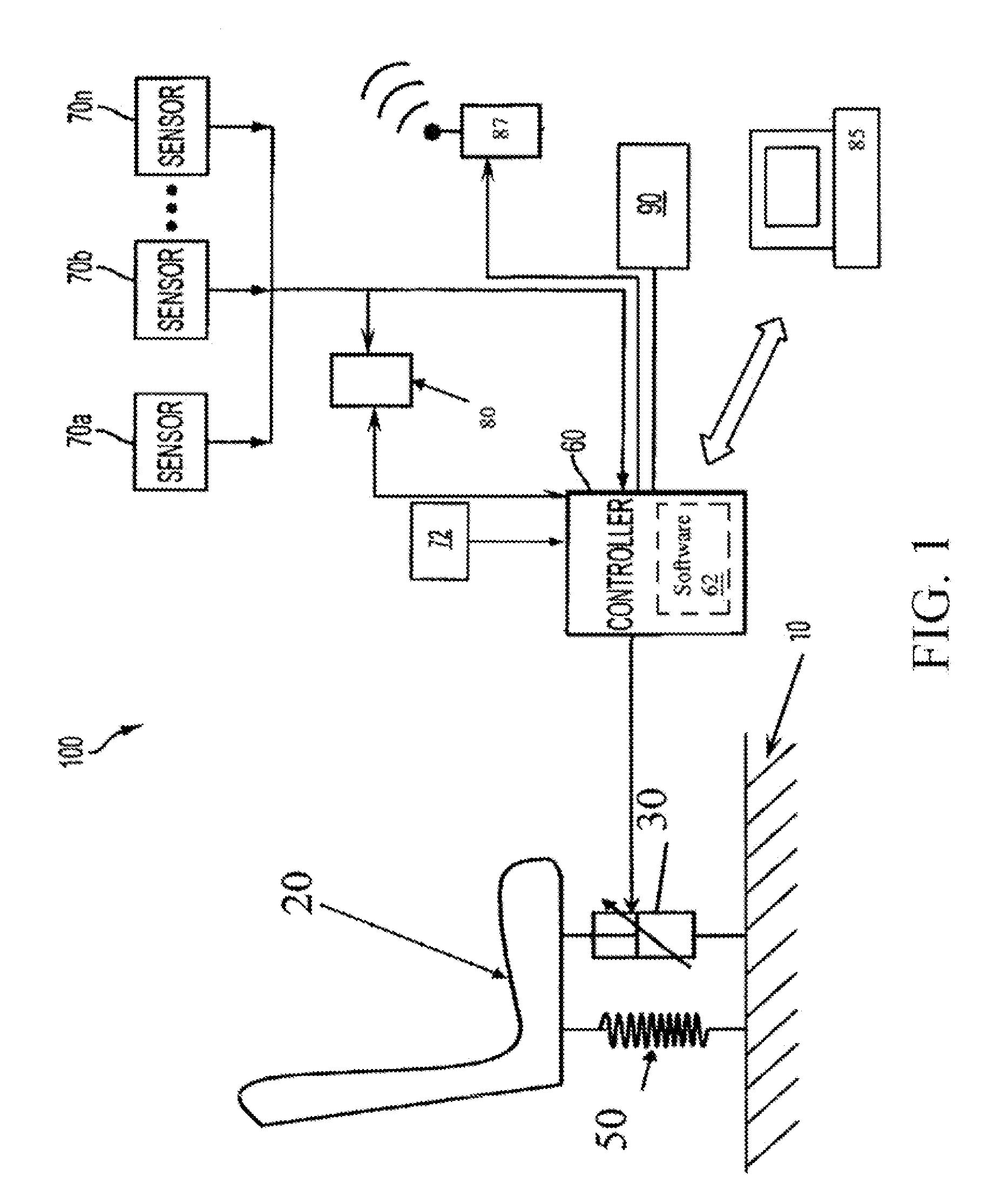

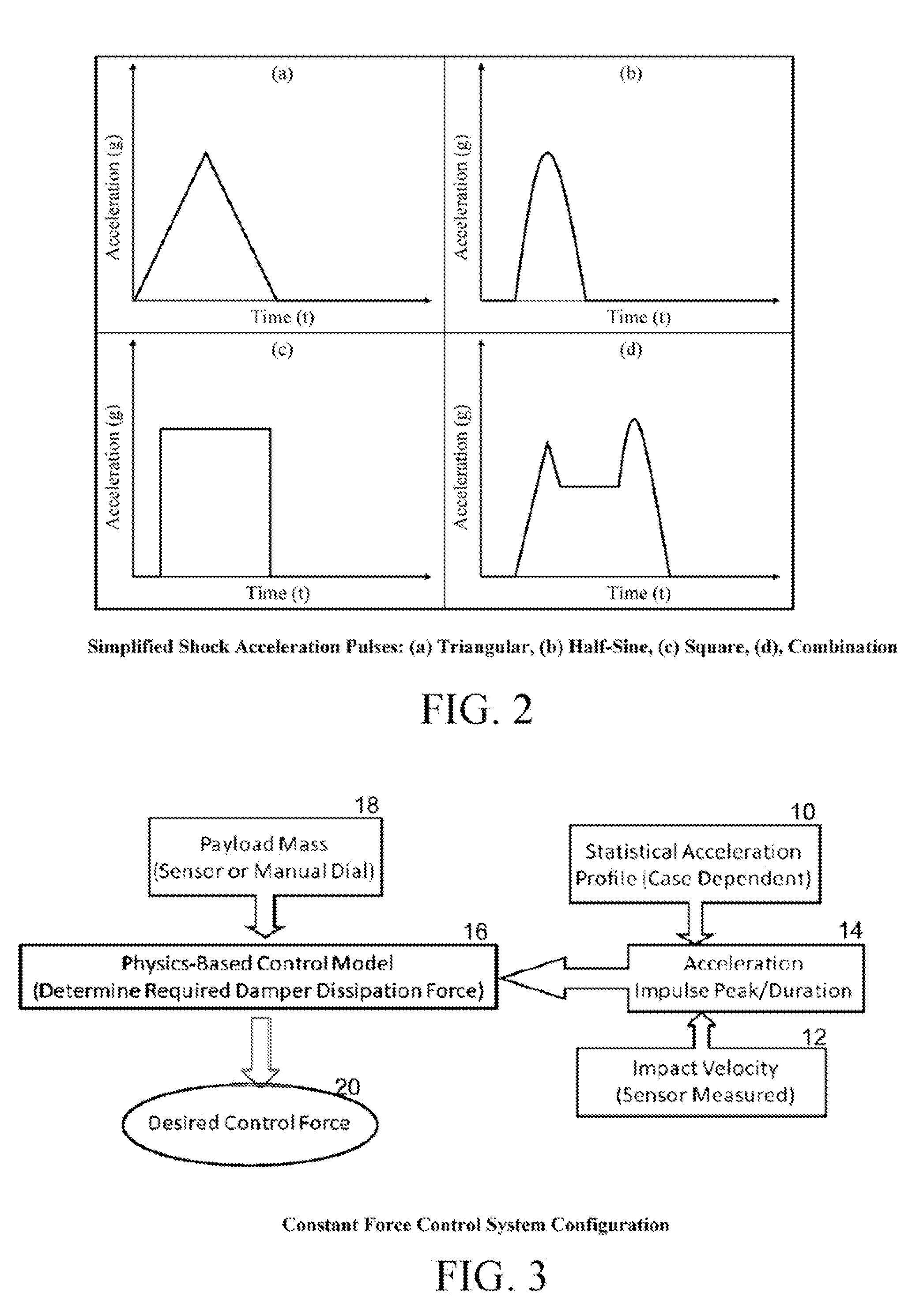

Constant force control methodology for shock absorption

InactiveUS20100332079A1Prevent vehicle occupant injuryAvoid injurySpringsDigital data processing detailsConstant forceAcceleration amplitude

A Constant Force Control methodology and system utilizing integrated sensors and unique control algorithms to determine required applied force to mitigate shock events in an adaptive energy absorption system, typically comprising of a spring and an adjustable energy absorber or damper element. By utilizing an expected acceleration profile and event duration for an anticipated shock event an acceleration amplitude can be determined from a measure impact velocity. From this and a measured payload mass a system controller can determine the force necessary to be applied by the energy absorber in order to stop the payload over the full desired length of the available energy absorber stroke in order to minimize the forces experienced by the payload.

Owner:INNOVITAL LLC +1

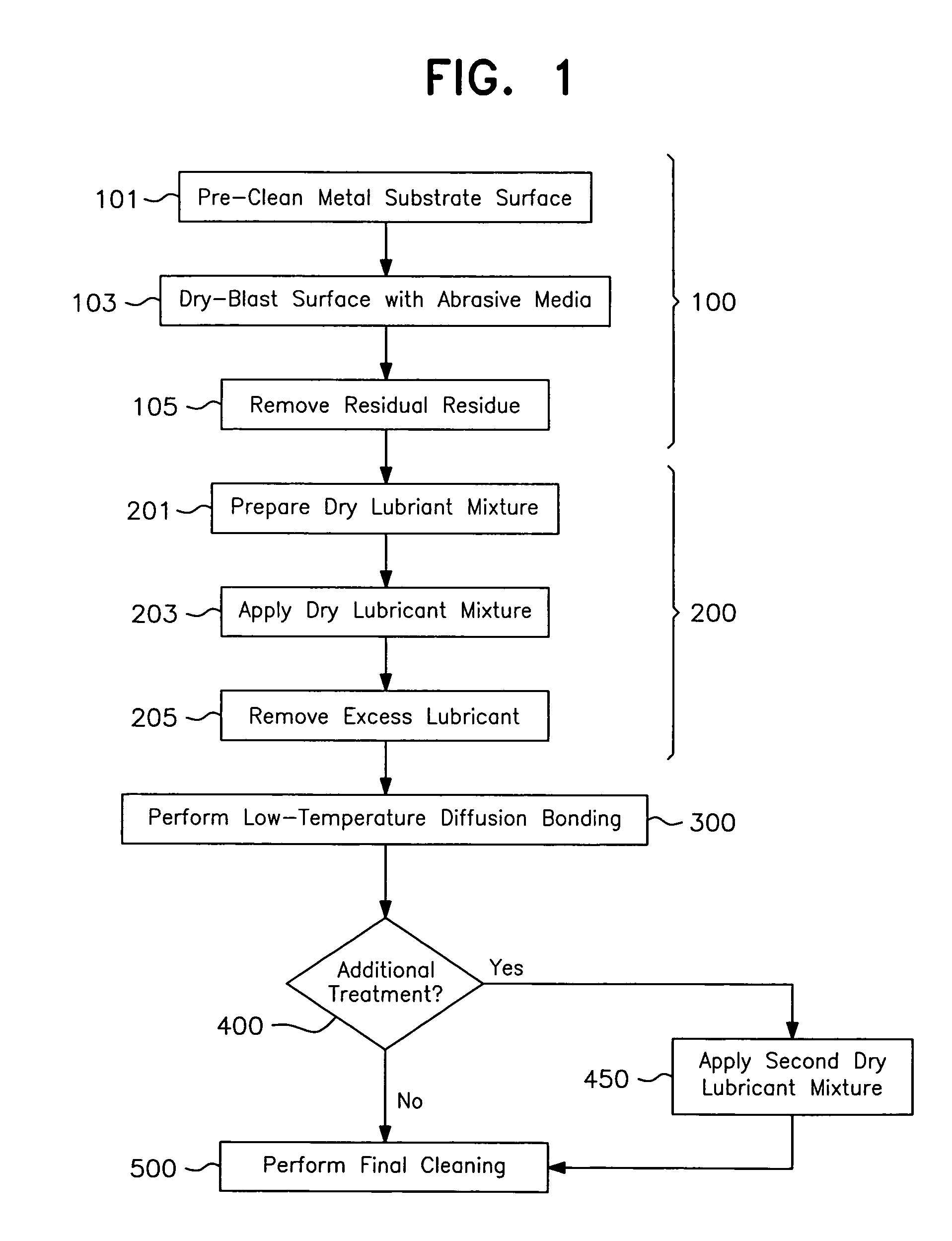

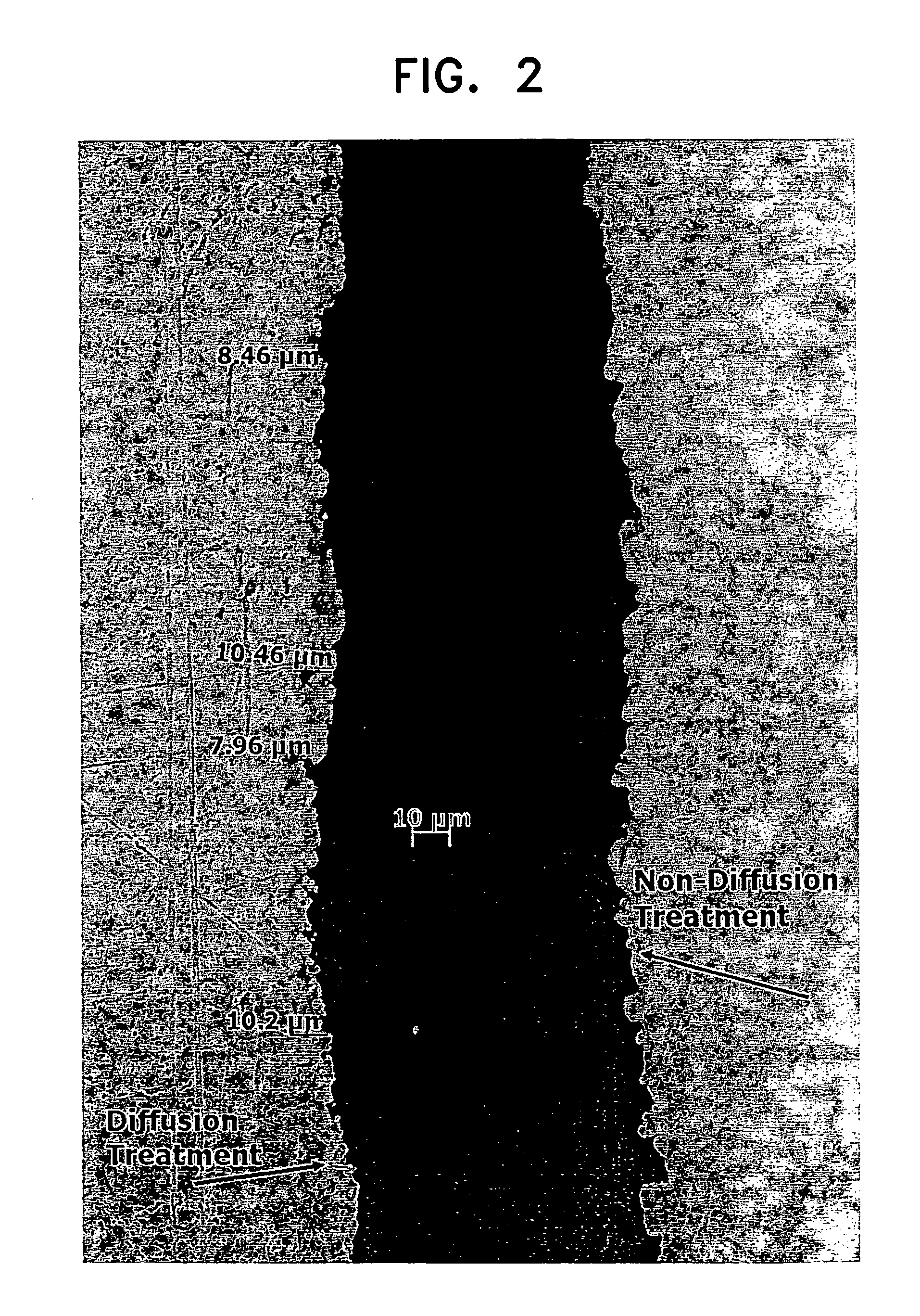

Surface for reduced friction and wear and method of making the same

InactiveUS7687112B2Improve performanceFine surfaceLayered productsPretreated surfacesImpact velocityMechanical impact

A process for producing an enhanced friction reducing surface by bonding a dry lubricant to a substrate by way of high velocity mechanical impact and low temperature diffusion bonding, and the friction-reduced surface produced thereby. A process for bonding the dry lubricant by peening and concurrently obtaining a desired dimpling or surface texturizing by appropriate selection of peening particle size and hardness relative to the substrate, as well as impact velocity against the substrate, is also provided.

Owner:KINETITEC CORP

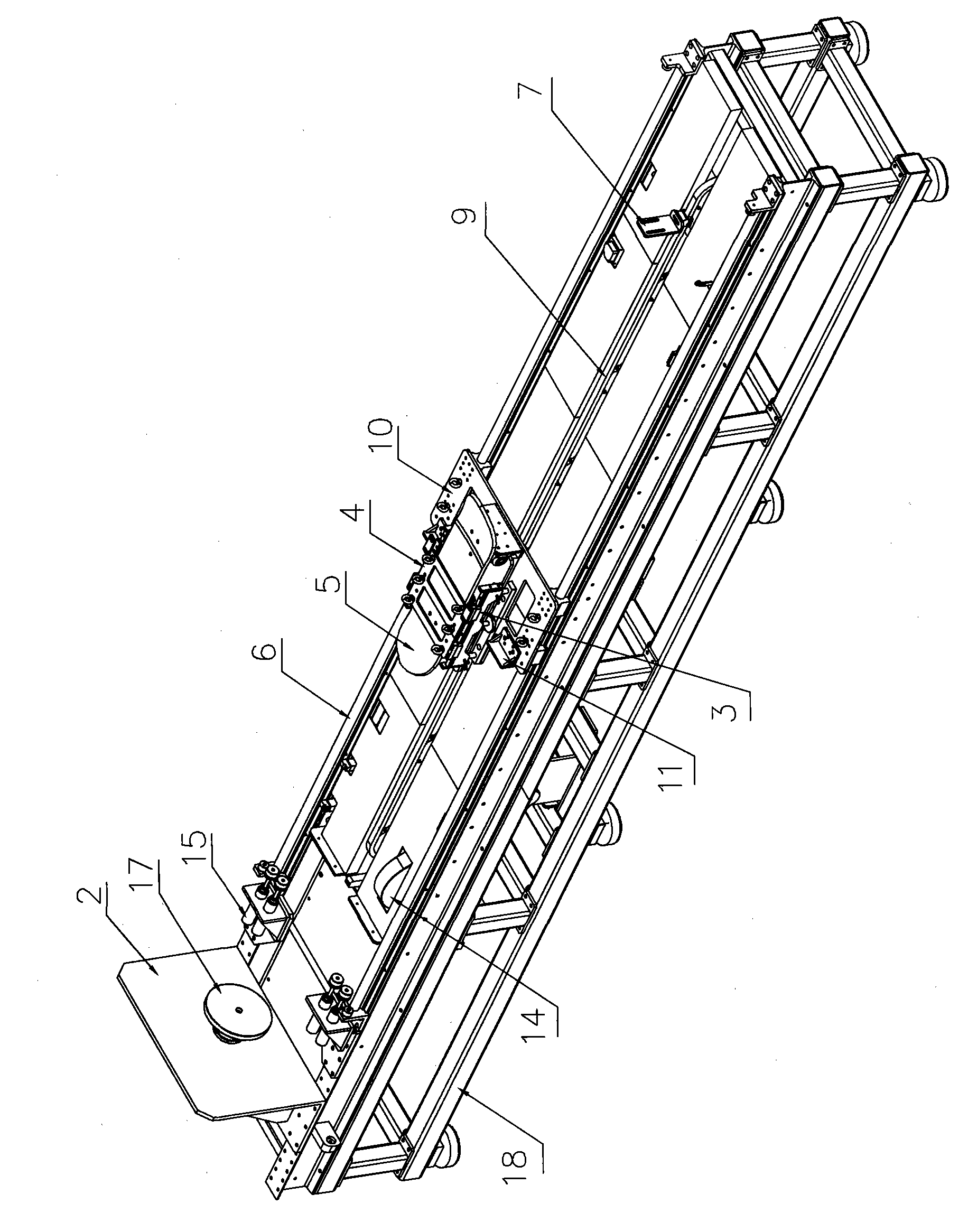

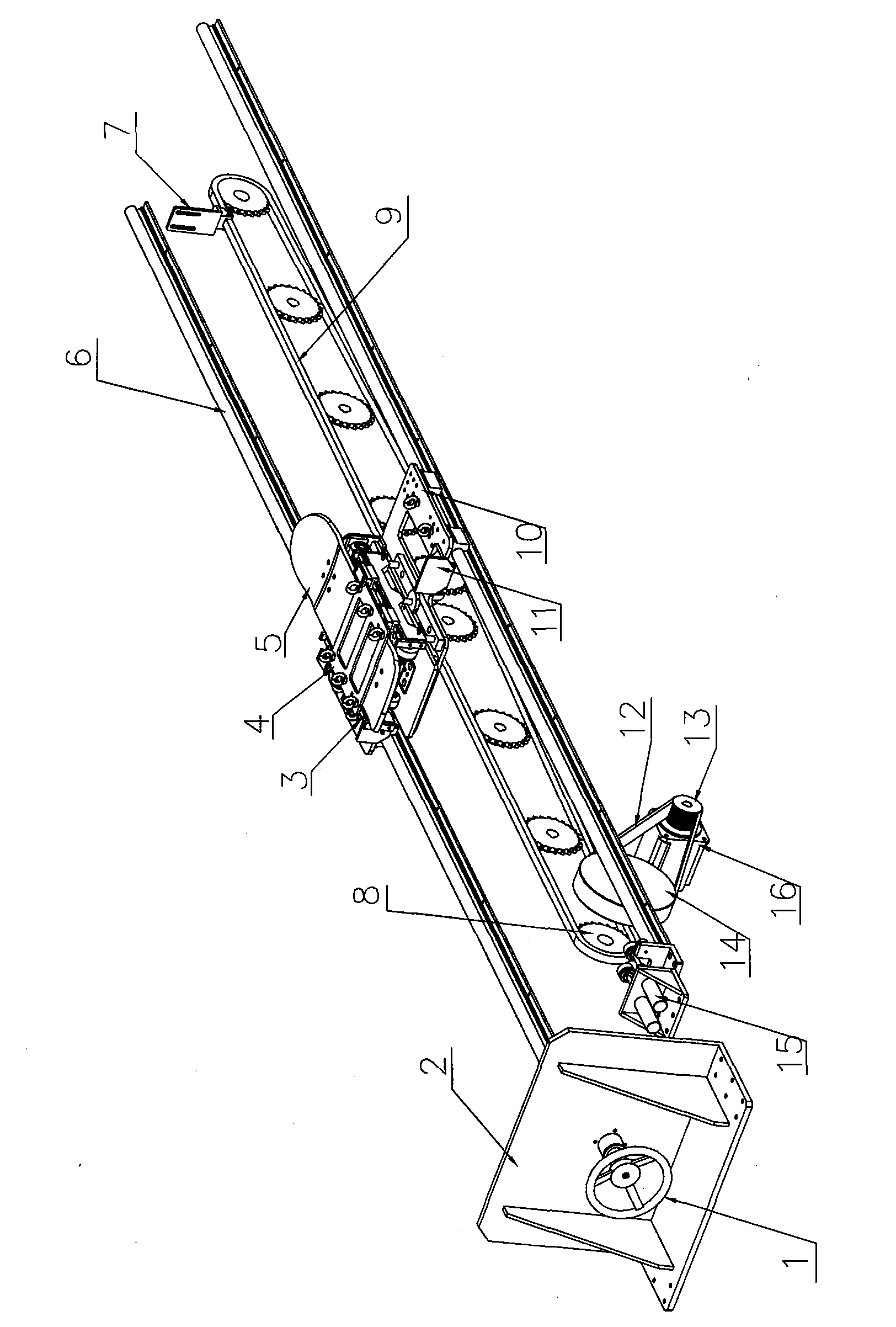

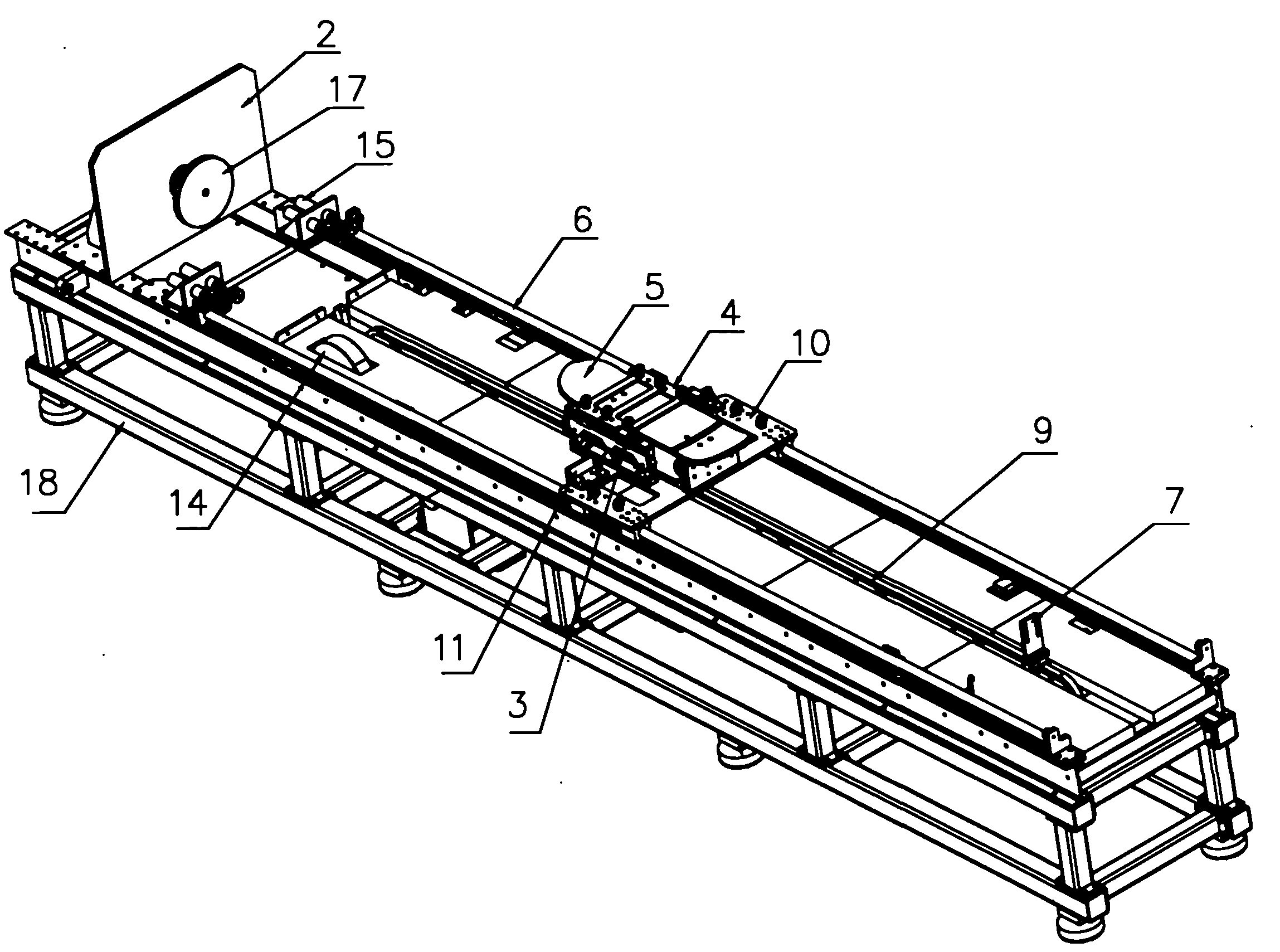

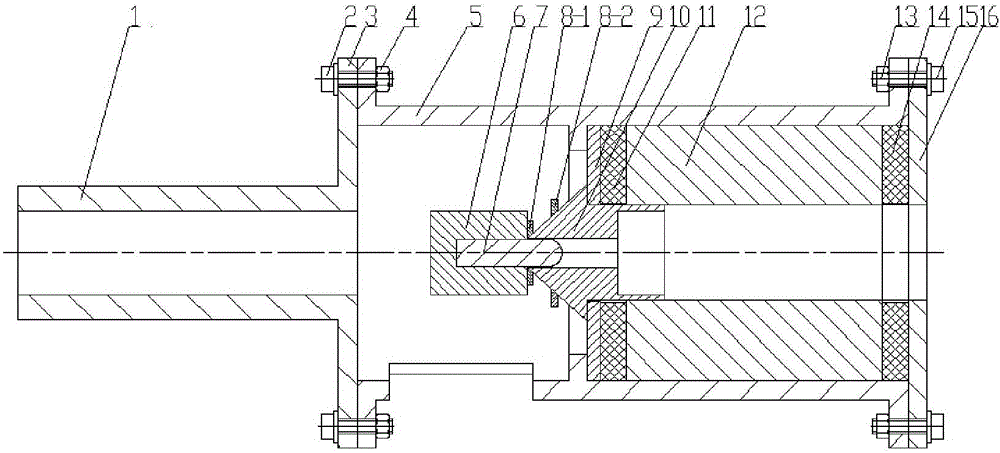

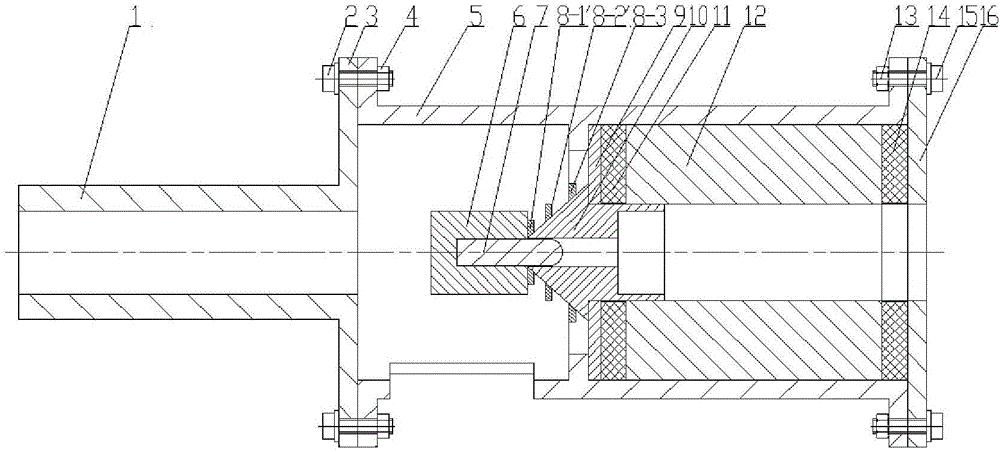

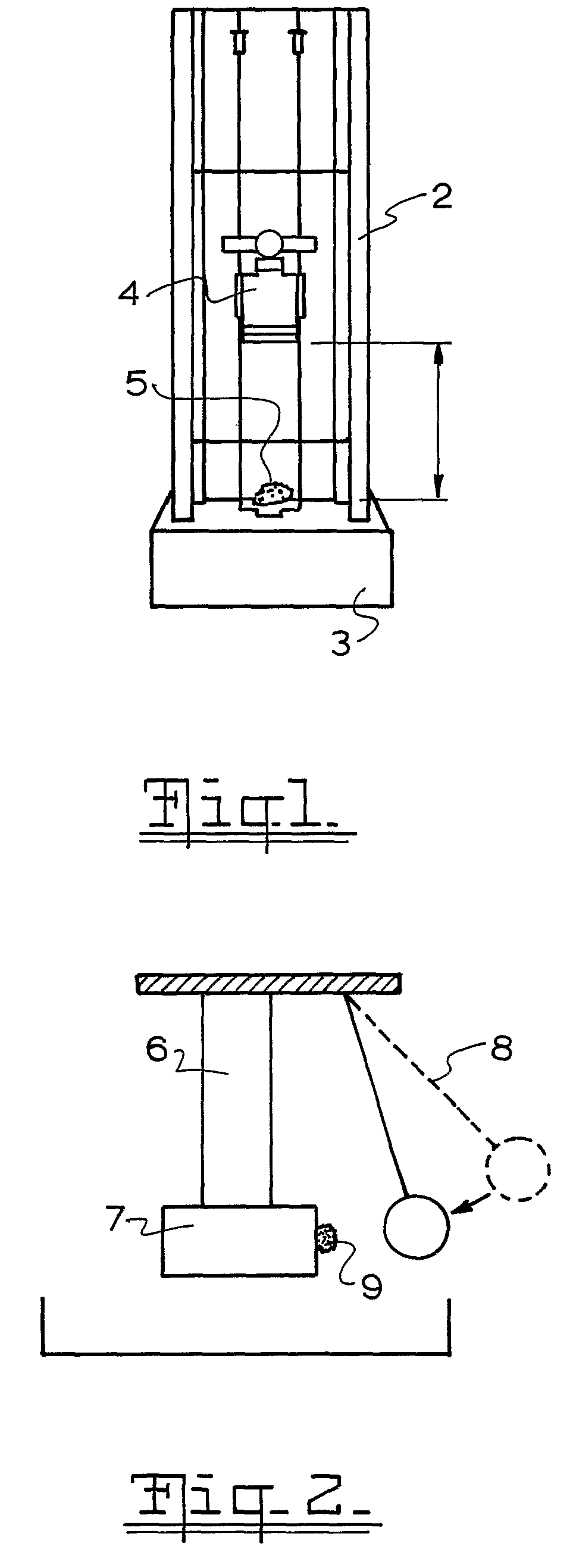

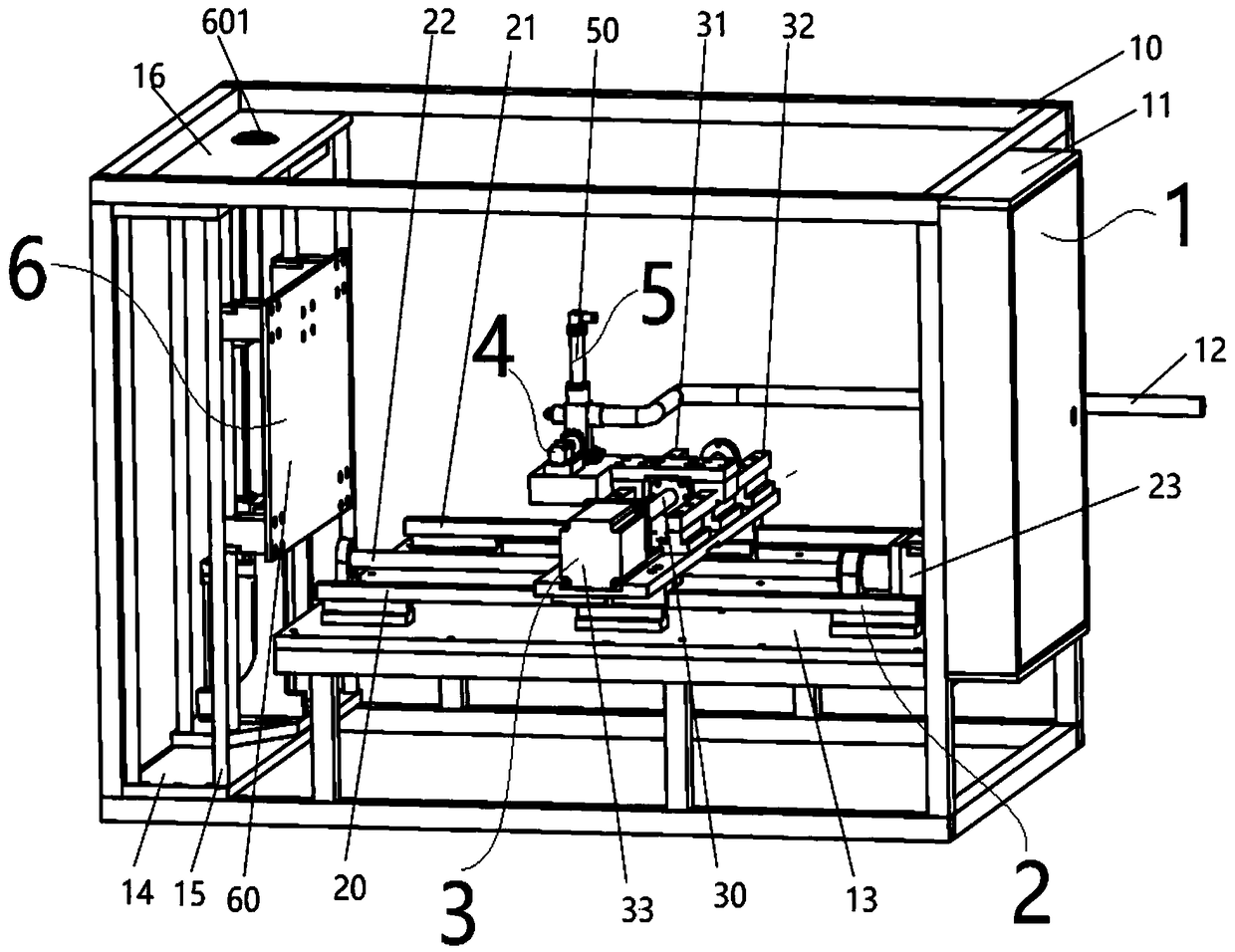

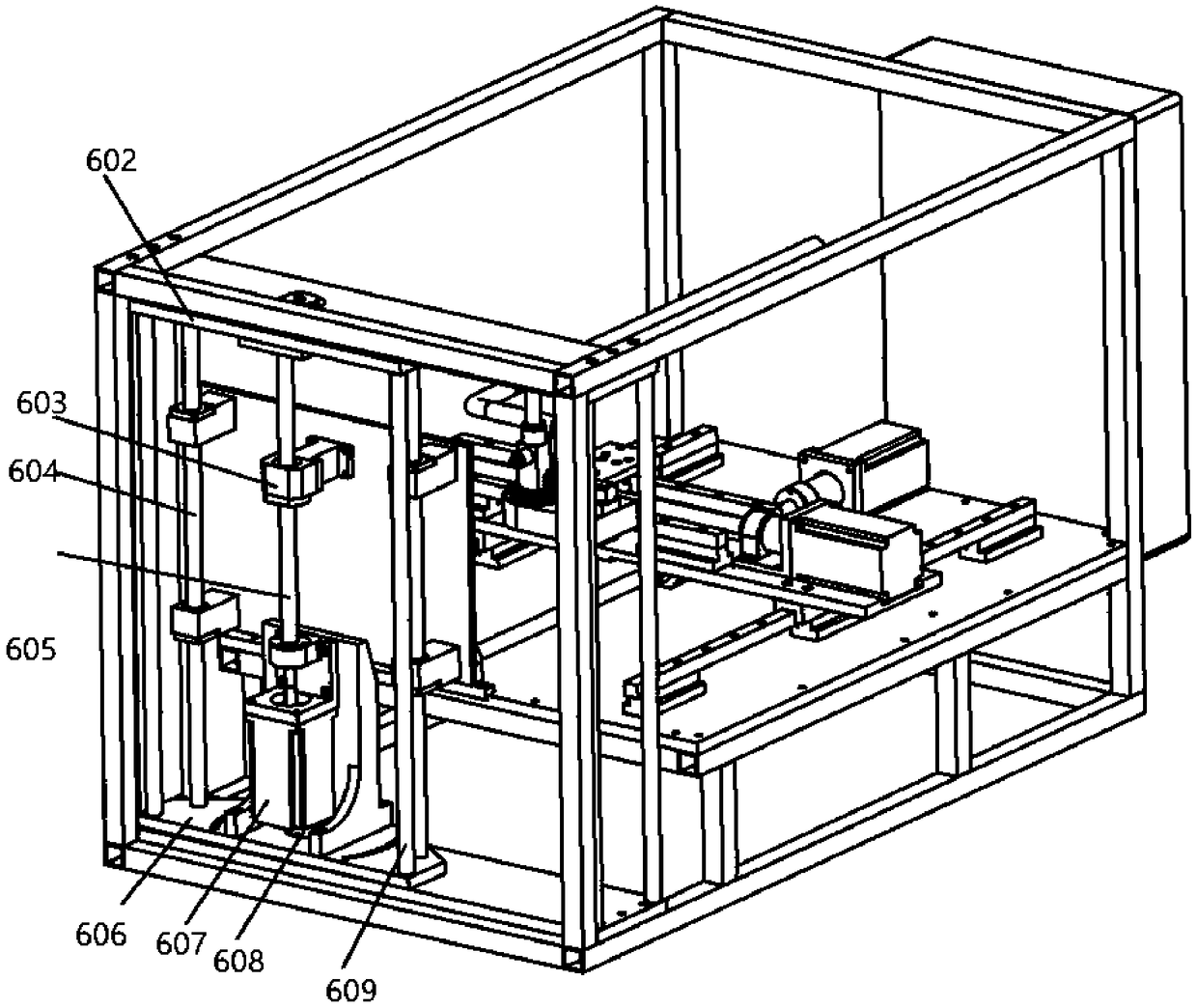

Impact tester for scooter

InactiveCN102147324AThe impact speed can be adjusted arbitrarilyThe test results are scientific and reasonableShock testingImpact velocityEngineering

The invention relates to the technical field of buggy detection equipment, in particular to an impact tester for scooter. The impact tester for scooter comprises a frame, a chain, a driving mechanism for driving the chain to move along the frame, a control box for adjusting the impact speed, a moveable plate capable of sliding along the movement direction of the chain and an installation base for clamping the scooter, wherein the frame is a rectangular stereo frame, the driving mechanism is arranged on the frame, the control box is connected with the driving mechanism, the installation base is connected with the moveable plate in a rail connection manner, a counter weight is placed on the installation base, the chain is fixedly provided with a push plate which is used for pushing the moveable plate to slide, a bumper block is arranged at the front end of the moveable plate, and the front end of the frame is provided with a bump plate which is used for collision with the front end of the scooter and is provided with a bumper for collision with the bumper block. According to the invention, based on a mechanism structure, a kinetic-energy impact barrier can be generated for the scooter on the rails and the impact speed can be adjusted randomly as needed; and the impact tester is applicable for various scooters and a detection result is scientific and reasonable.

Owner:东莞市恒宇仪器有限公司

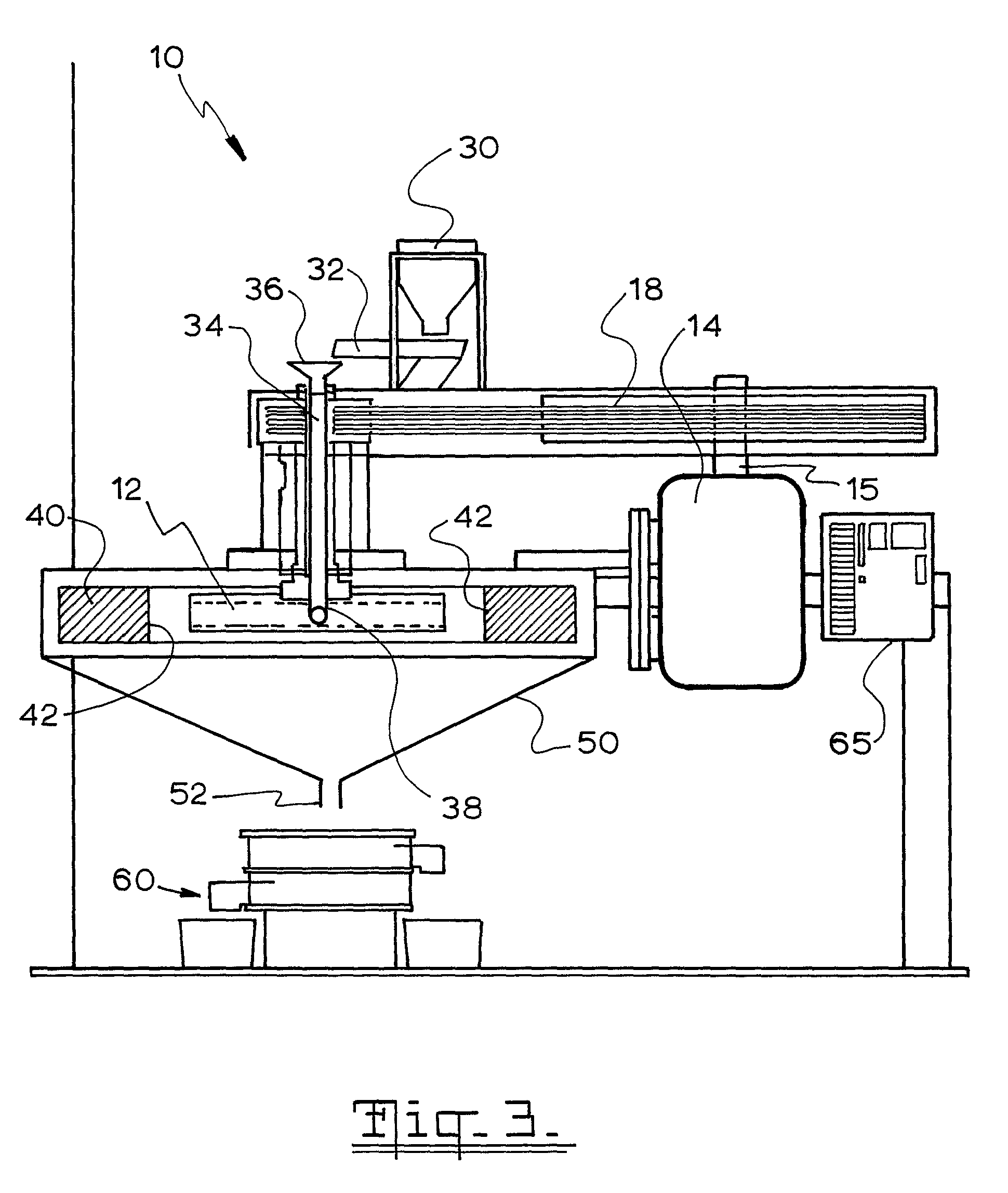

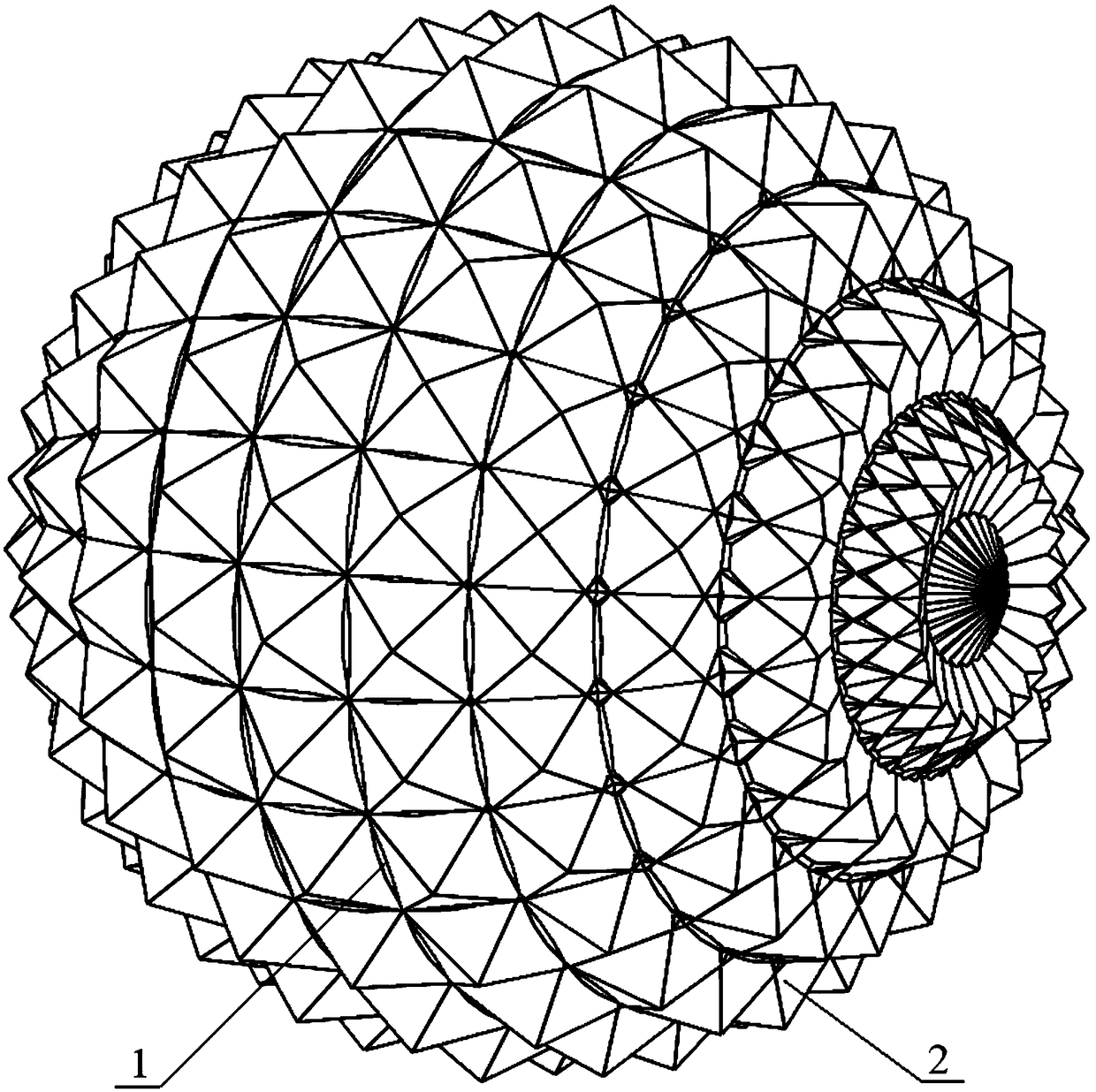

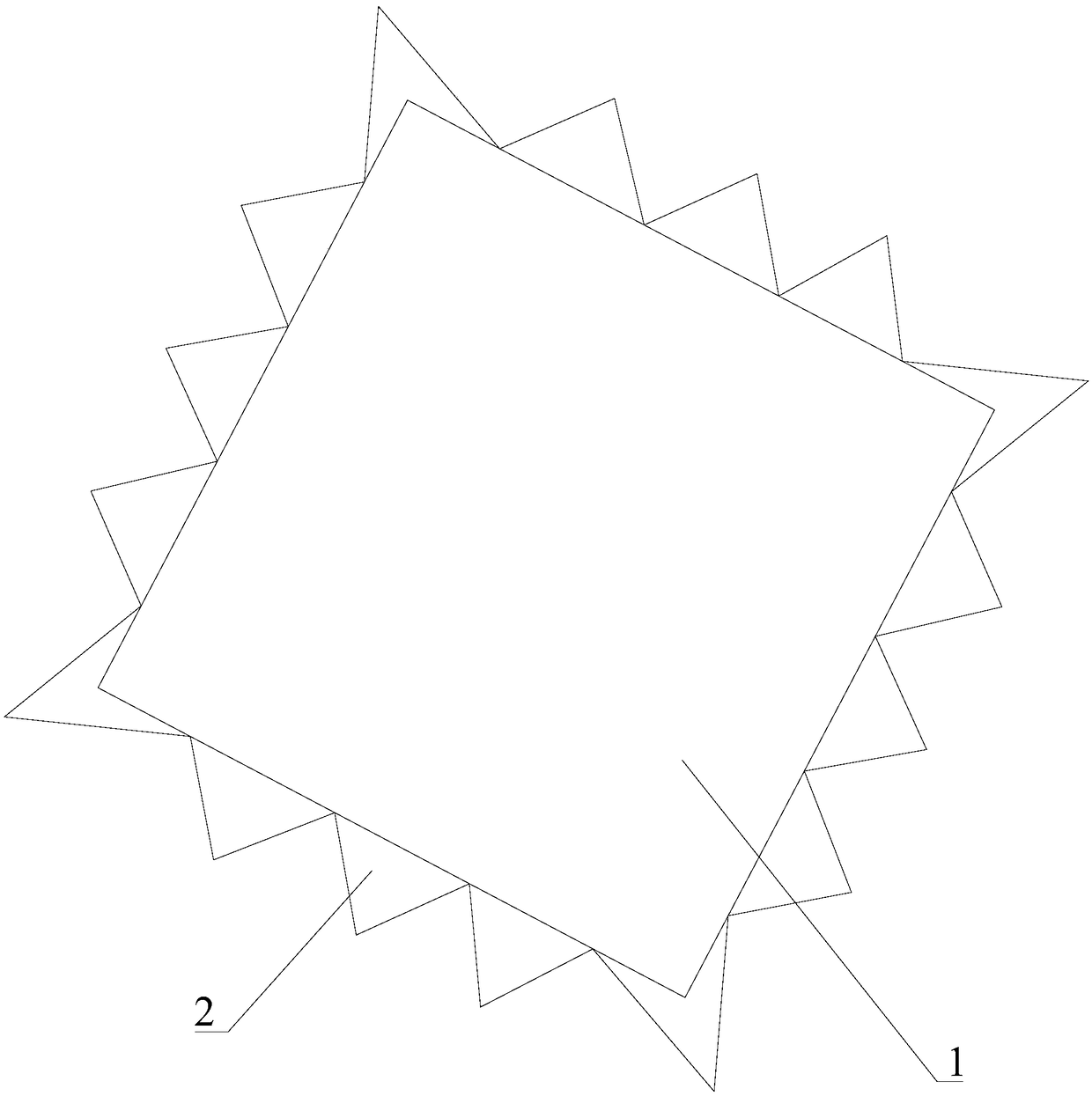

Apparatus for Determining Breakage Properties of Particulate Material

InactiveUS20090199625A1High precisionQuick and easy analysisAcceleration measurementParticle size analysisControl systemImpact velocity

An apparatus for determining the breakage properties of a particulate material, the apparatus including: a support; a rotor mounted relative to the support and including at least one guide channel through which a particle of the particulate material is guided in use, the guide channel having an inlet and an outlet; a drive associated with the rotor; a feed channel for feeding particles of the particulate material to the inlet of the guide channel; a stator associated with the rotor and including an impact surface that is radially spaced from a circumferential edge of the rotor; and a collector for collecting pieces of the particulate material following impact; wherein the apparatus is provided with a control system for accurate control and adjustment of impact velocity of the particulate material with the impact surface.

Owner:THE UNIV OF QUEENSLAND

Method and apparatus for autonomous detonation delay in munitions

A detonation timing apparatus and method of determining a detonation time is disclosed. The detonation timing apparatus comprises an initiation sensor, at least one impact sensor, and at least one controller. The at least one controller may be configured for sensing an initiation event associated with the initiation sensor and sensing an impact event associated with the at least one impact sensor. The at least one controller is further configured for determining an impact velocity estimate proportional to a temporal difference between the initiation event and the impact event, using the impact velocity estimate to determine the detonation delay, and generating the detonation event at the detonation delay after the impact event. The timing apparatus and method of determining a detonation time may be incorporated in a fuze, which may be incorporated in an explosive projectile.

Owner:NORTHROP GRUMMAN SYST CORP

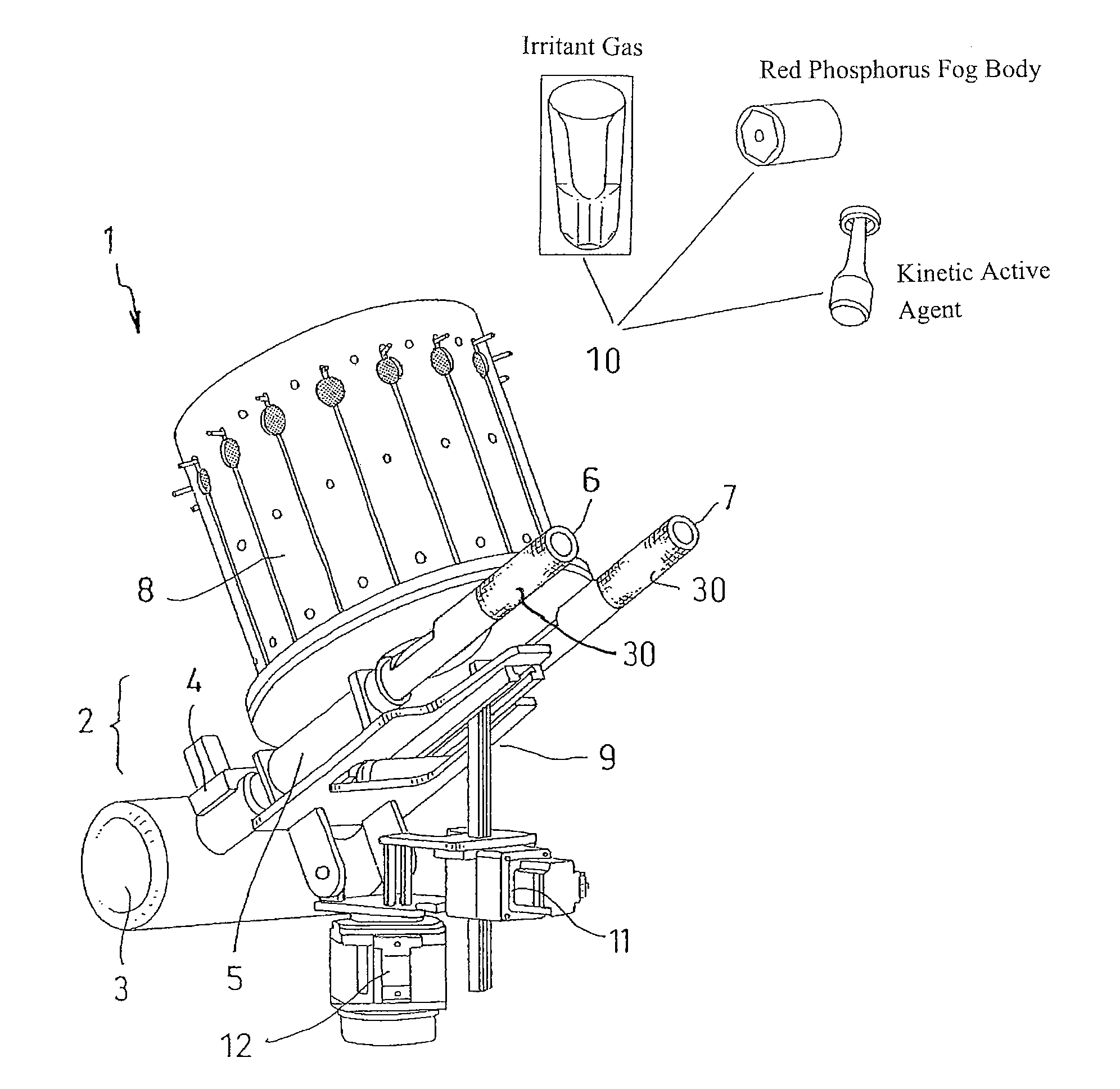

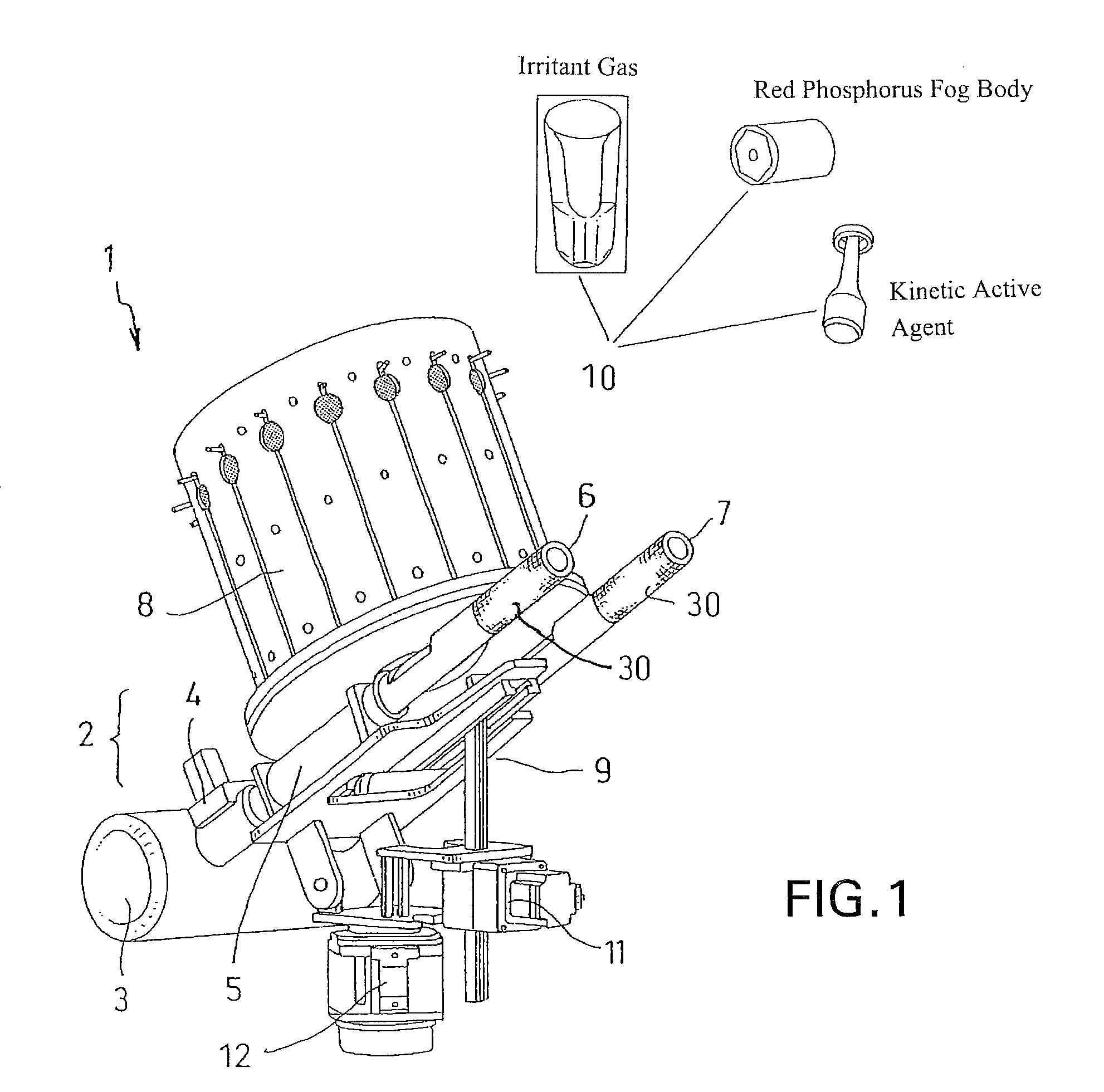

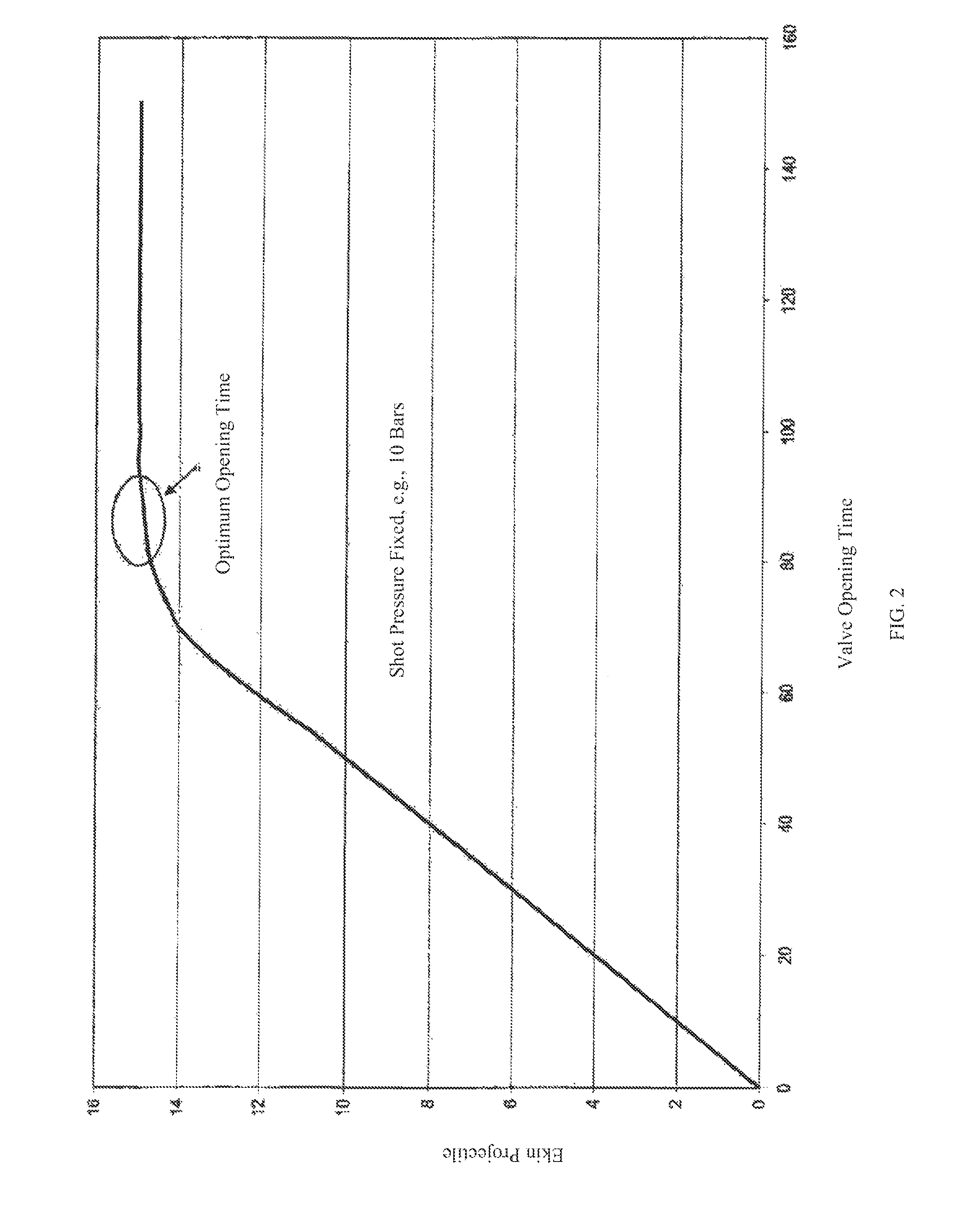

Weapon, in particular range-controlled compressed air weapon

The invention pertains to a weapon that provides a range control (2), by means of which it is possible to set firing velocity, and thus impact velocity, of the ammunition or active bodies (10) to a distance to be discharged in such a way that, in particular, the non-lethal ammunition (10) continues to have a non-lethal effect. To this end, a type of pneumatic weapon (1) is described that, with the use of a shot pressure control, e.g. by means of a proportional pressure regulator (3), and / or additionally in combination with breech technology and valve technology, has a continuously variable range control.

Owner:RHEINMETALL WAFFE MUNITION GMBH

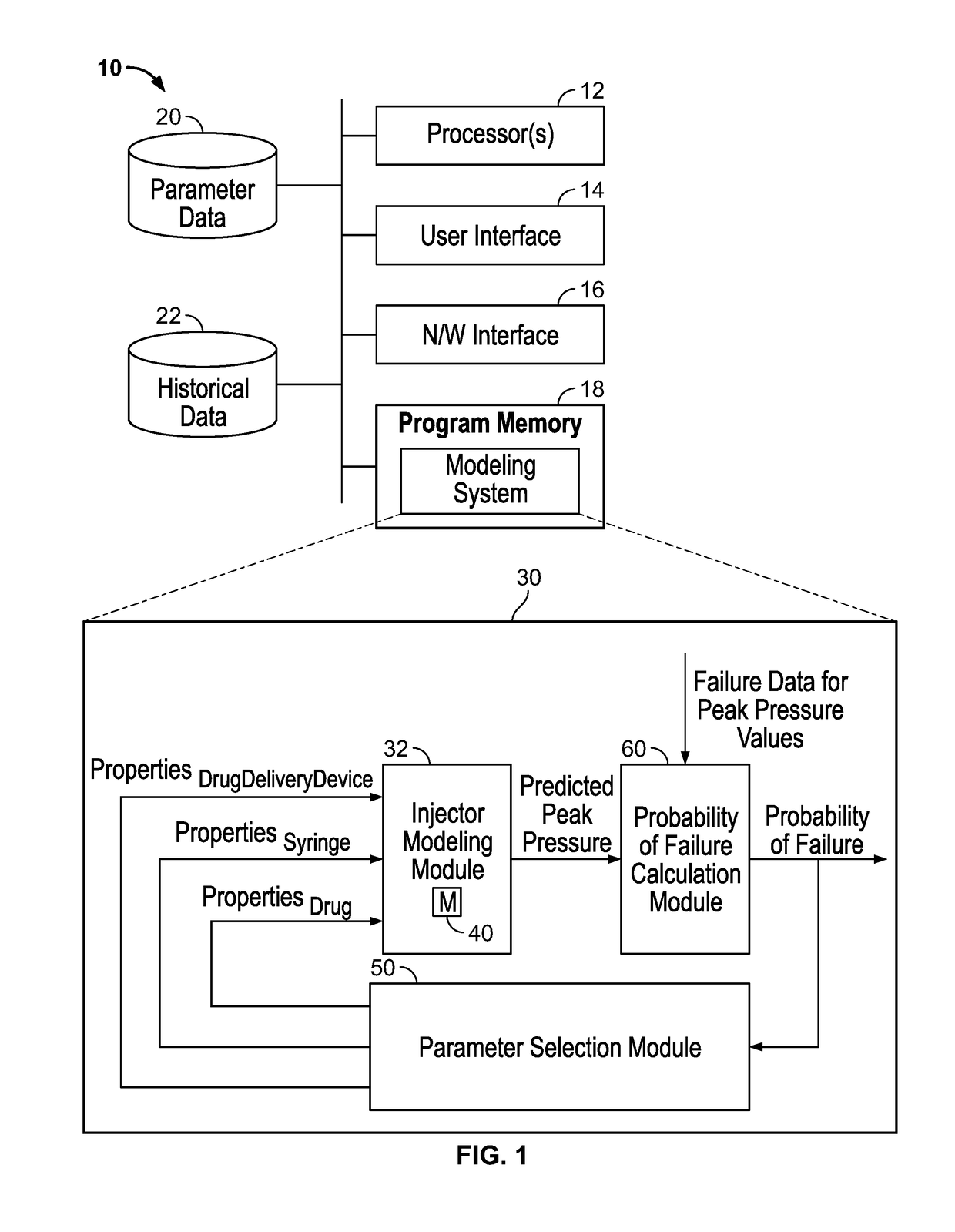

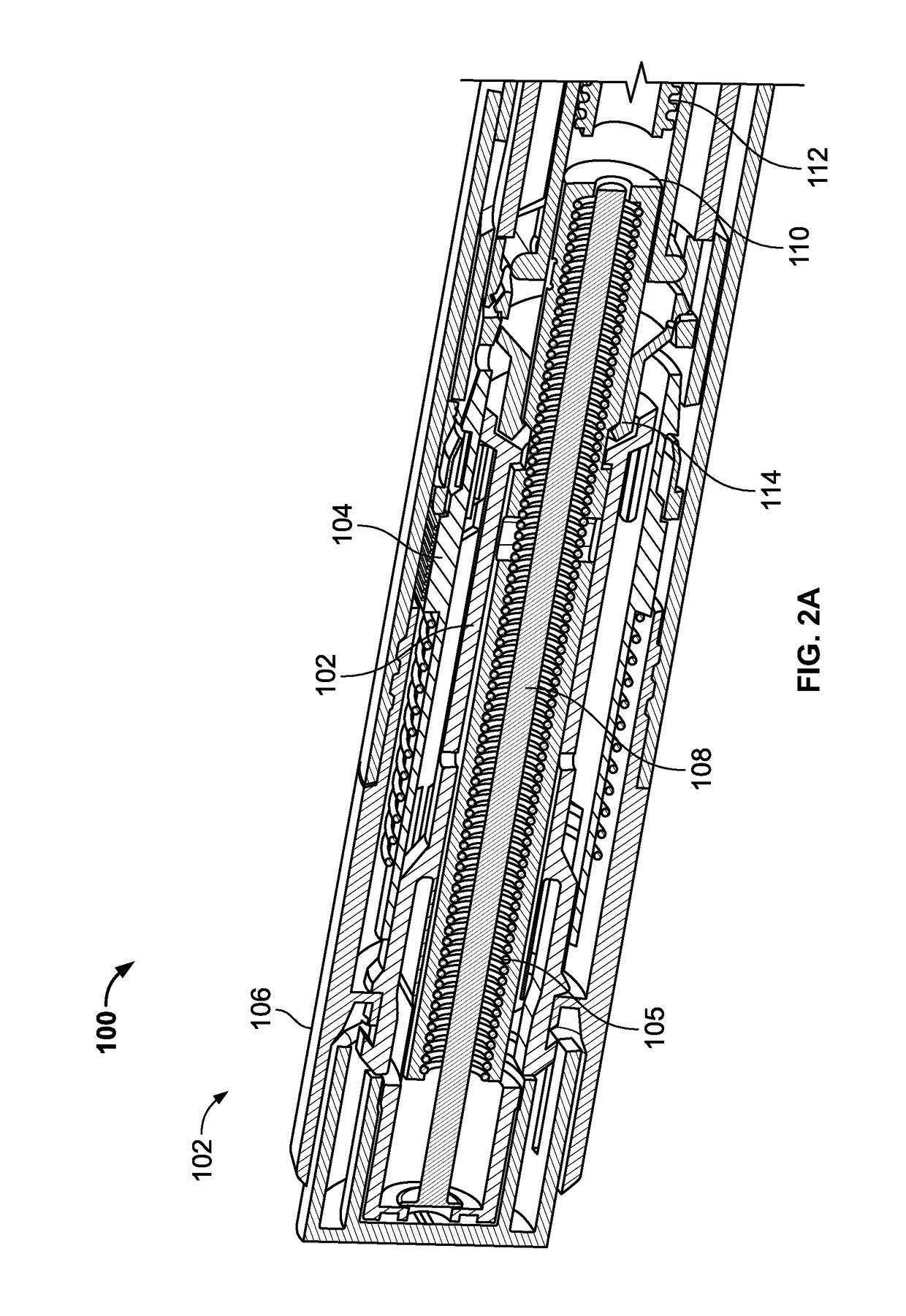

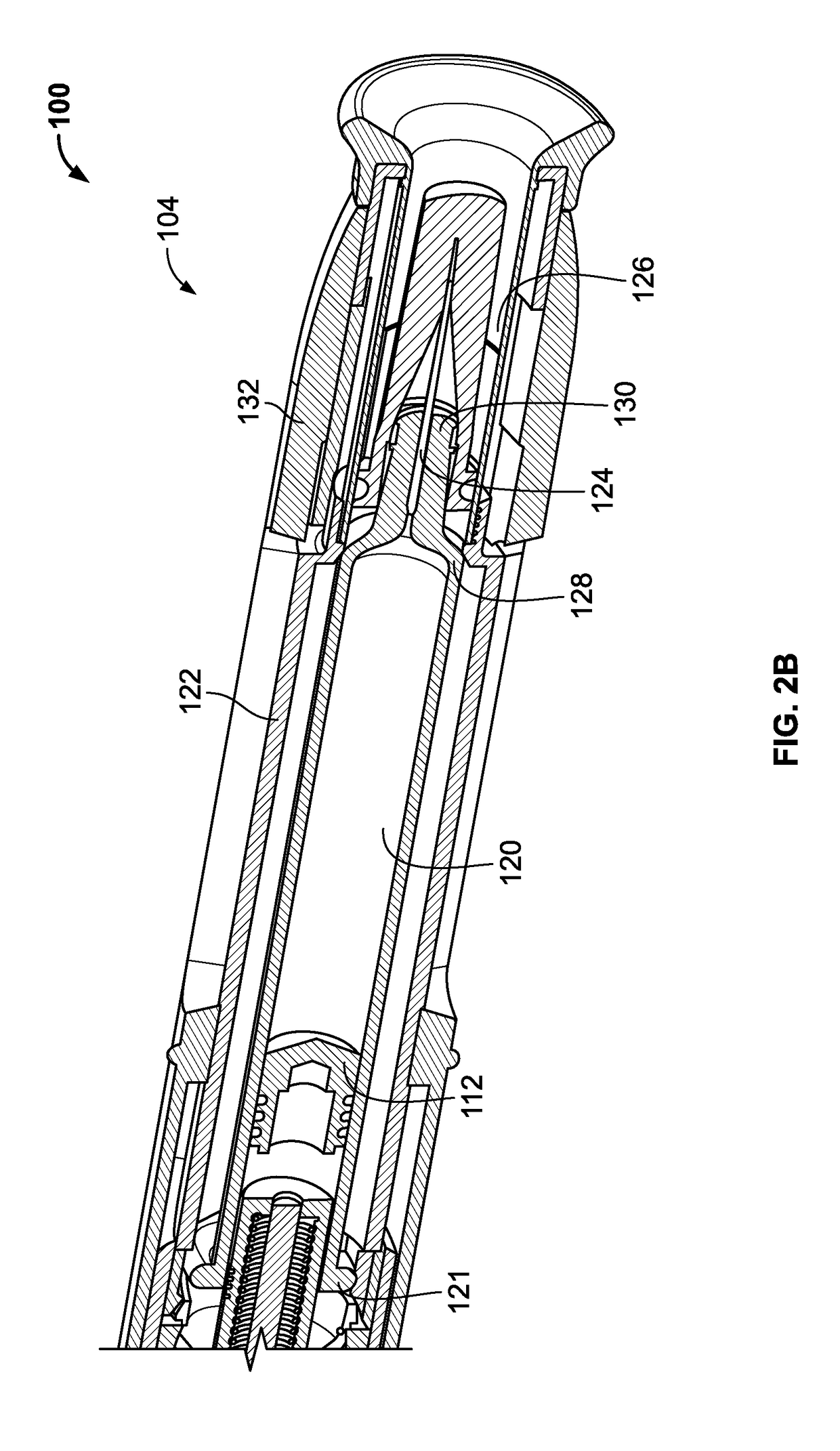

Reducing probability of glass breakage in drug delivery devices

A method for determining predicted failure rates of drug injection devices includes receiving a set of parameters that specify physical properties of (i) a syringe, and (ii) a liquid drug, and (iii) a drug injection device configured to deliver the liquid drug to a patient via the syringe. The method further includes receiving failure rate data that specifies a measured rate of failure of the drug injection device in response to various peak pressures within the syringe, applying the received set of parameters to a kinematic model of the drug injection device to determine a predicted peak pressure within the syringe, including determining the predicted peak pressure as a function of impact velocity of the liquid drug, determining a probability of failure of the drug injection device using (i) the received failure rate data and (ii) the predicted peak pressure, and providing an indication of the determined probability of failure to an output device.

Owner:AMGEN INC

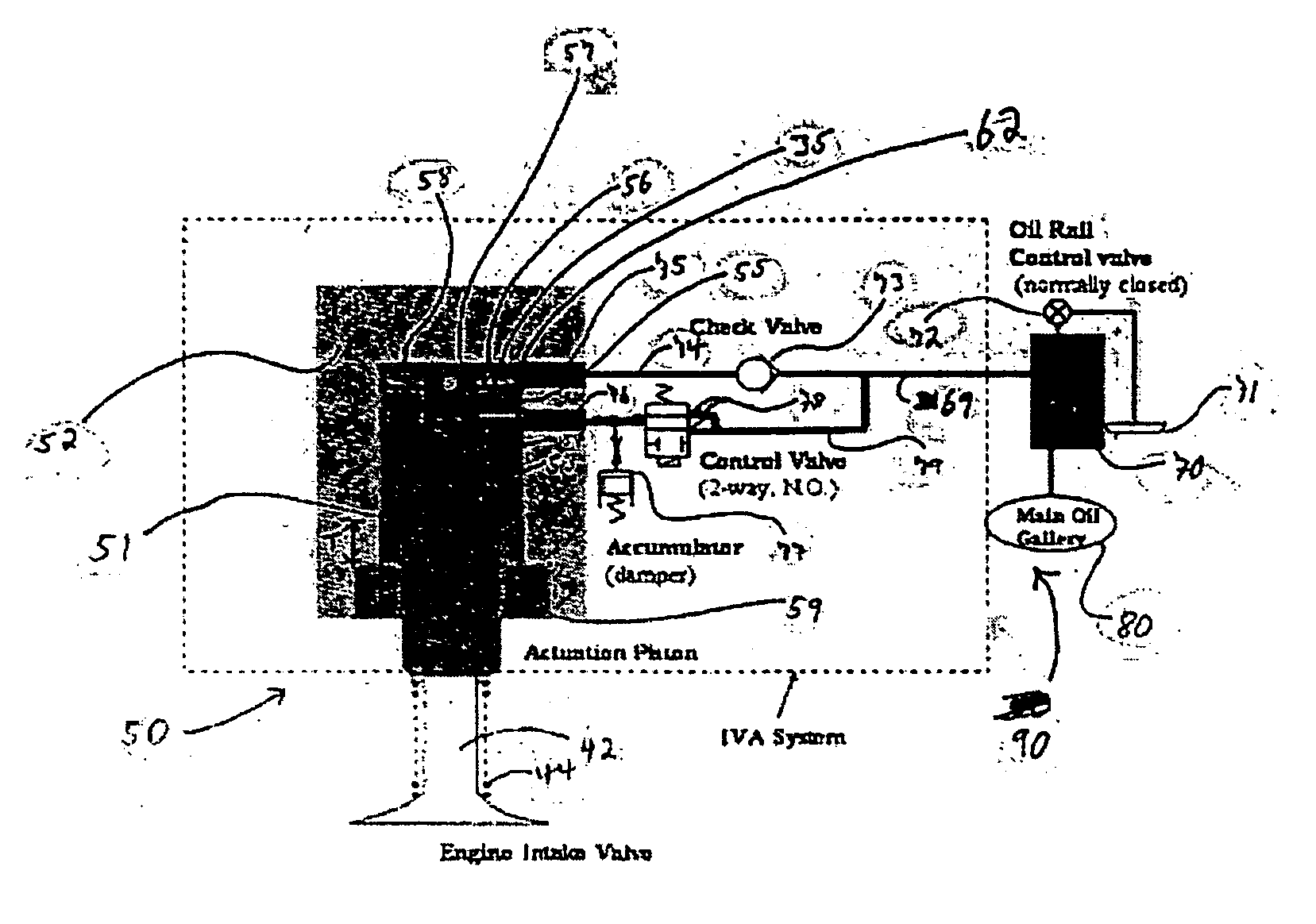

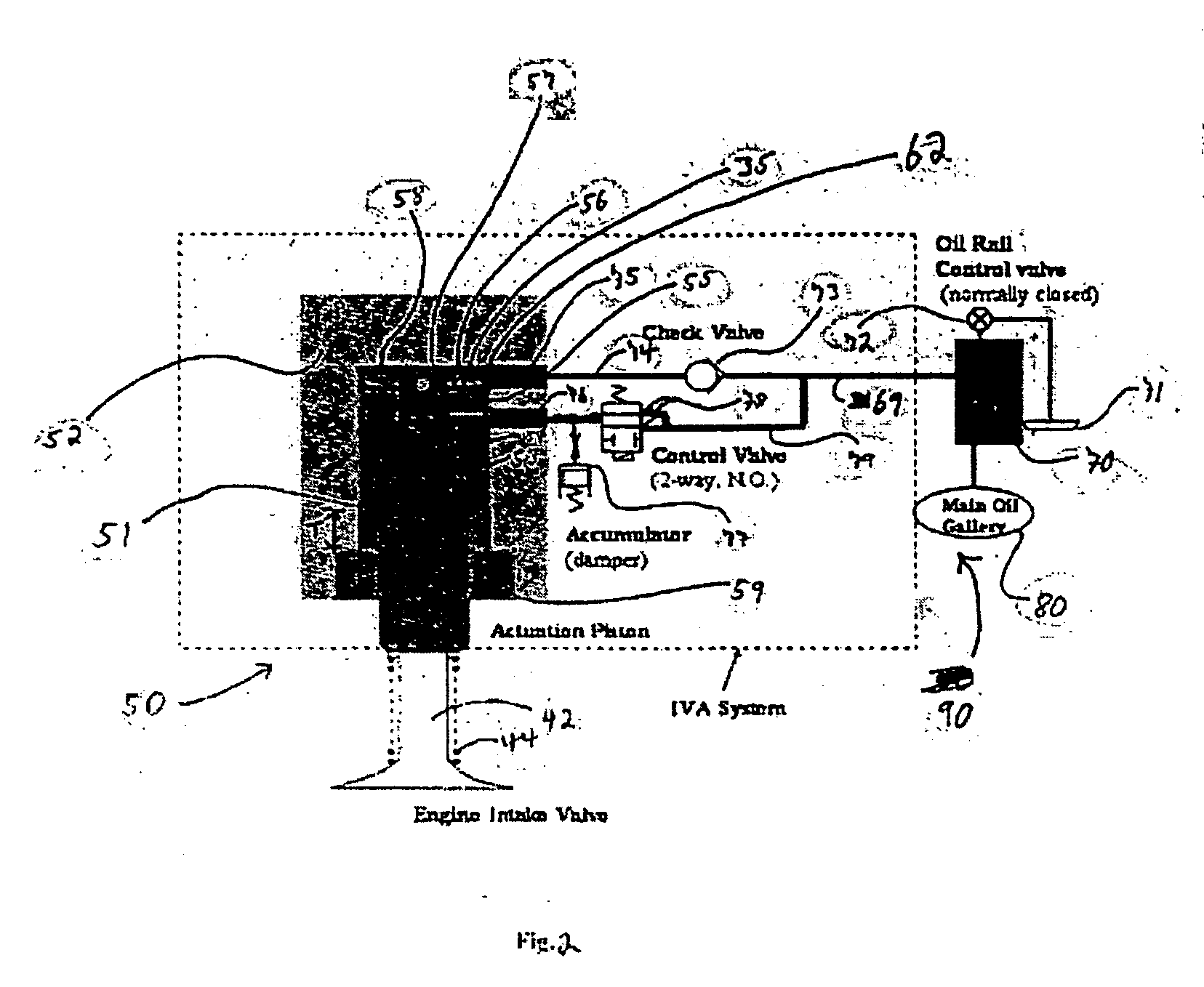

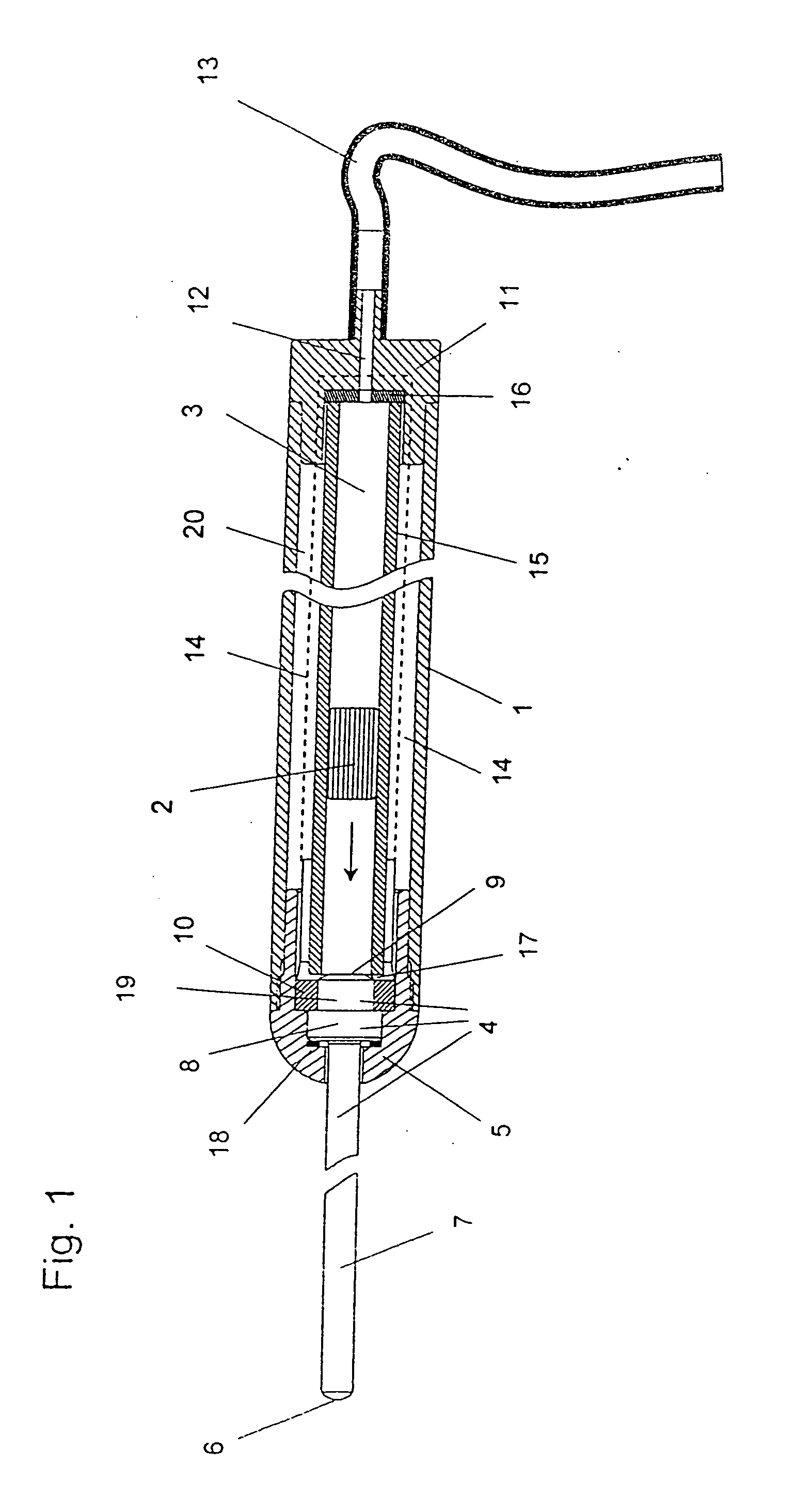

Internal combustion engine valve seating velocity control

InactiveUS20050132987A1Reducing valve seating impact velocityReduce impact speedMachines/enginesNon-mechanical valveReciprocating motionImpact velocity

The present disclosure provides an engine having a gas exchange valve and an actuator for the gas exchange valve, and also a method of reducing valve seating impact velocity. The actuator includes a body having a fluid inlet and a fluid outlet. A plunger is reciprocable in the body and has a travel distance between an advanced position and a retracted position, the plunger and body defining a chamber. A flow restriction orifice is disposed in at least one of the plunger and the body, and the chamber is in unrestricted fluid communication with the outlet over a first portion of the travel distance and in restricted fluid communication with the outlet by way of the orifice over at least a second portion of the travel distance.

Owner:CATERPILLAR INC

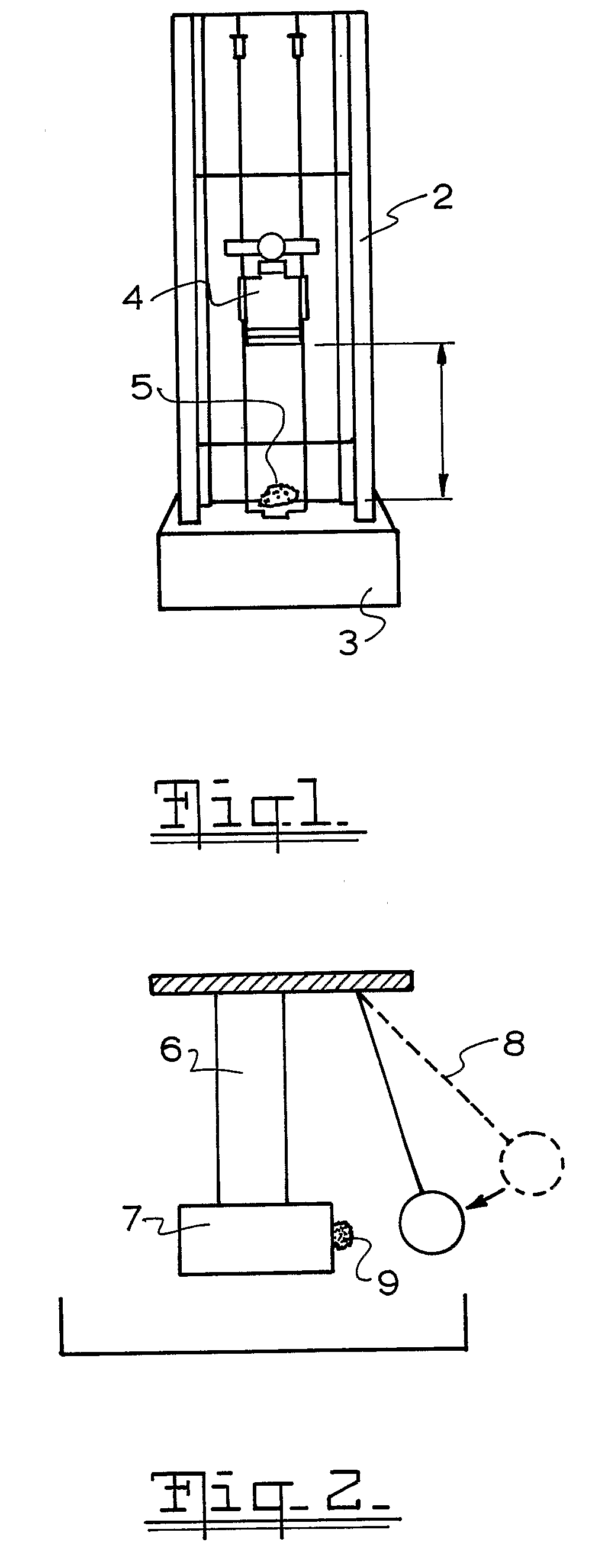

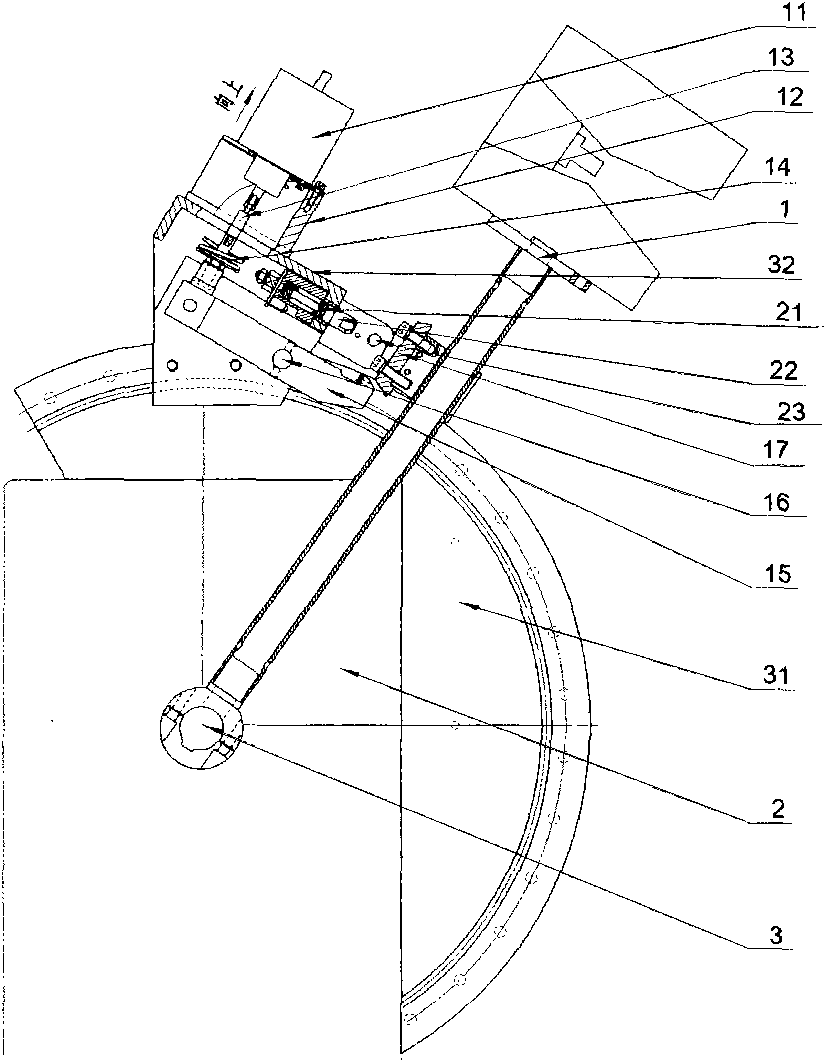

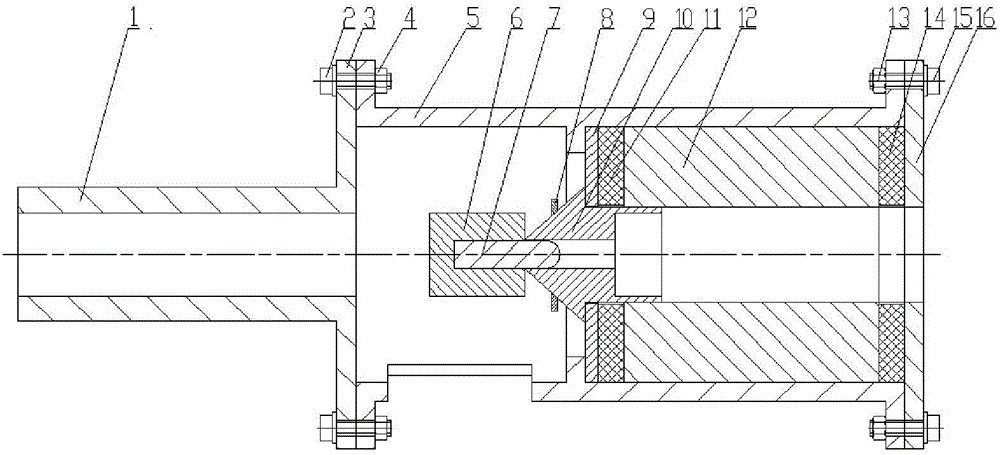

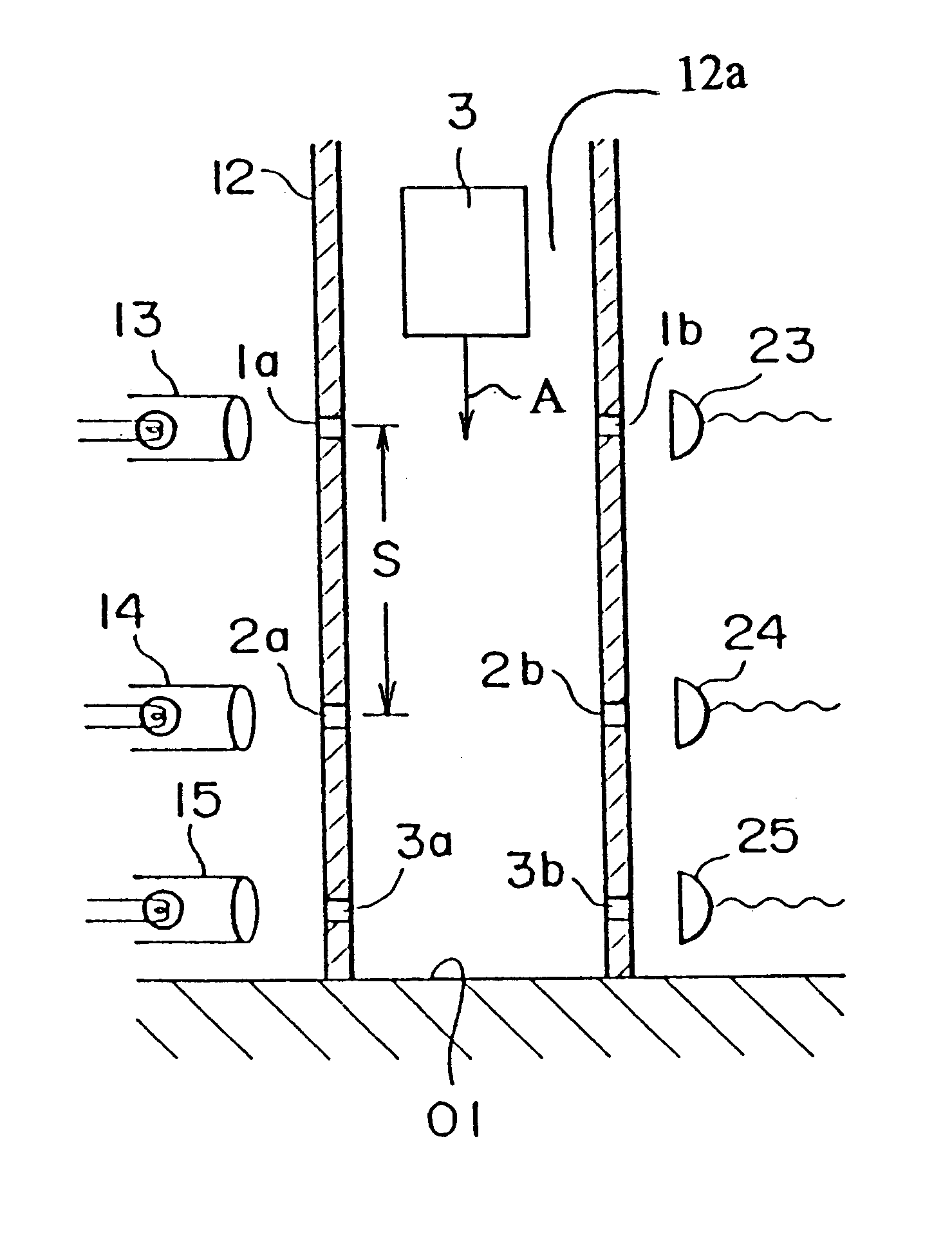

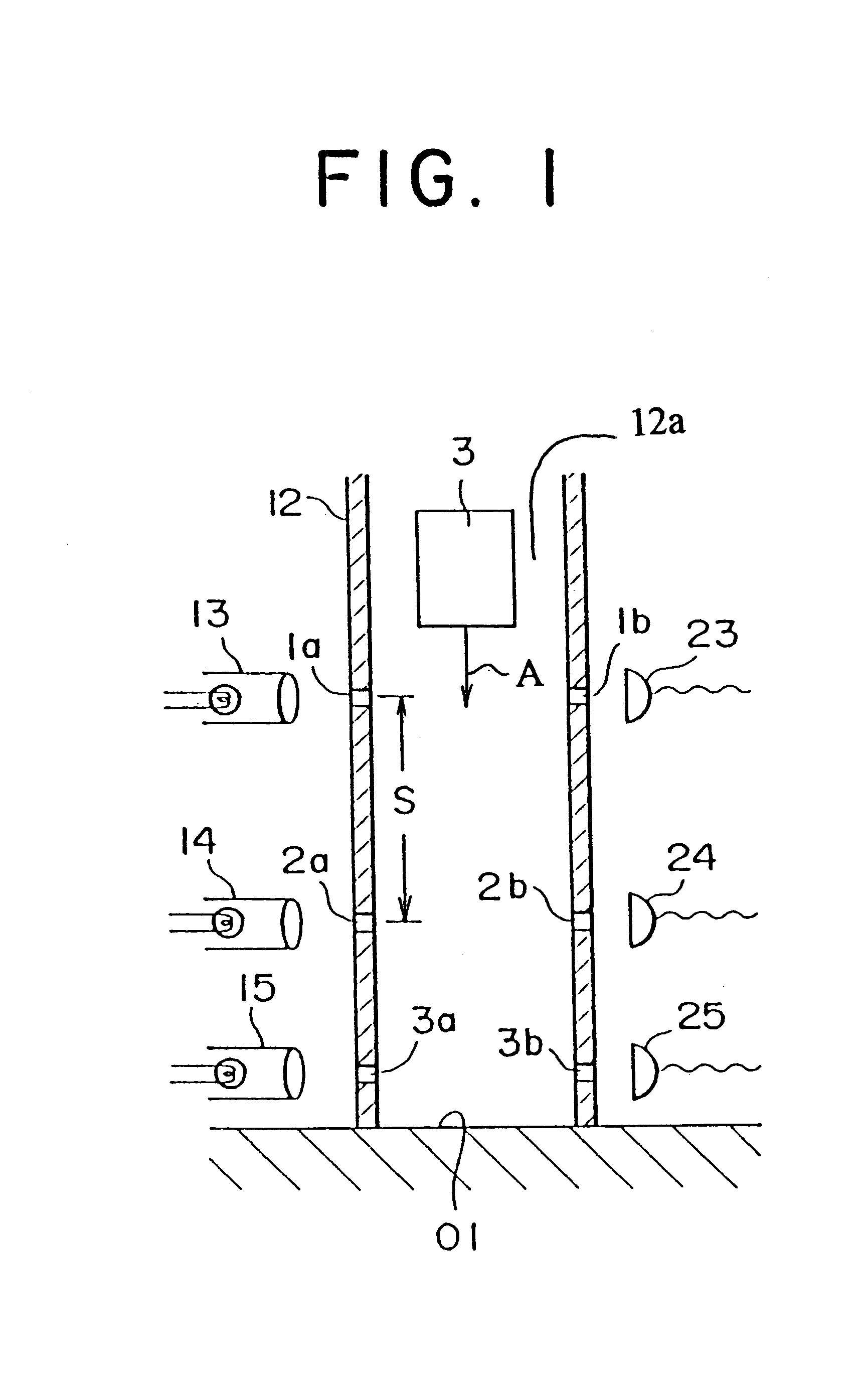

Pendulum hanging and swinging mechanism for oscillography impact testing machine

The invention discloses a pendulum hanging and swinging mechanism for an oscillography impact testing machine, which comprises a main machine, a pendulum, an off-hooking device, a buffer unit and a lifting-swinging angle adjusting device, wherein the pendulum is connected with the main machine through a pendulum rotating shaft; the off-hooking device comprises electromagnetic absorbing iron and a supporting seat for supporting the electromagnetic absorbing iron, the outer side of the supporting seat is provided with a pull rod which is connected with one end of a spring, the other end of the spring is connected with a hook shaft which is provided with a hook, and the hook is connected with a hammer hook; the buffer unit comprises a buffer spring which is connected with a buffer head, and the outer side of the buffer head is provided with a limit switch; and the lifting-swinging angle adjusting device comprises an adjusting disc provided with an arc chute. The pendulum hanging and swinging mechanism applied to the same pendulum of the same oscillography impact testing machine can accurately and quantitatively change the impact velocity and the impact energy, and widen a larger space for impact performance tests of materials.

Owner:上海聚德永升测控系统有限公司

Internal combustion engine valve seating velocity control

InactiveUS7228826B2Reduce impact speedOperating means/releasing devices for valvesMachines/enginesReciprocating motionImpact velocity

The present disclosure provides an engine having a gas exchange valve and an actuator for the gas exchange valve, and also a method of reducing valve seating impact velocity. The actuator includes a body having a fluid inlet and a fluid outlet. A plunger is reciprocable in the body and has a travel distance between an advanced position and a retracted position, the plunger and body defining a chamber. A flow restriction orifice is disposed in at least one of the plunger and the body, and the chamber is in unrestricted fluid communication with the outlet over a first portion of the travel distance and in restricted fluid communication with the outlet by way of the orifice over at least a second portion of the travel distance.

Owner:CATERPILLAR INC

Projectile and projectile support separating device under high-speed impacts of large-mass projectile

The invention discloses a projectile and projectile support separating device under high-speed impacts of a large-mass projectile. The projectile and projectile support separating device comprises a support, a separator, a speed reduction ring, a cushion plate, a buffering rubber pad, an inertia body and a baffle. The support is a cylinder with the two ends provided with flange plates and a boss machined on the inner wall. The support is connected with a flange plate on a gun barrel and the baffle through the flange plates. The separator, the cushion plate, the buffering rubber pad and the inertia body are arranged in the support. The end, facing the gun barrel, of the separator is in a conical shape, the other end of the separator is in a cylindrical shape, and the separator is provided with a penetrating step type center through hole. The outer circumference of the conical end of the separator is sleeved with the speed reduction ring, and the cylindrical end is positioned through a center through hole in the cushion plate. The projectile and projectile support separating device has the beneficial effects that the strong impact load can be borne, the time of the reverse impact load acting on a projectile support can be prolonged, the requirement for separation of the projectile and the projectile support under the high impact speed of the large-mass projectile is met, the additional damage of a target due to the impact of the projectile support on a target plate is effectively avoided, and repeated usage can be achieved.

Owner:XIAN MODERN CHEM RES INST

Rebound-type hardness tester

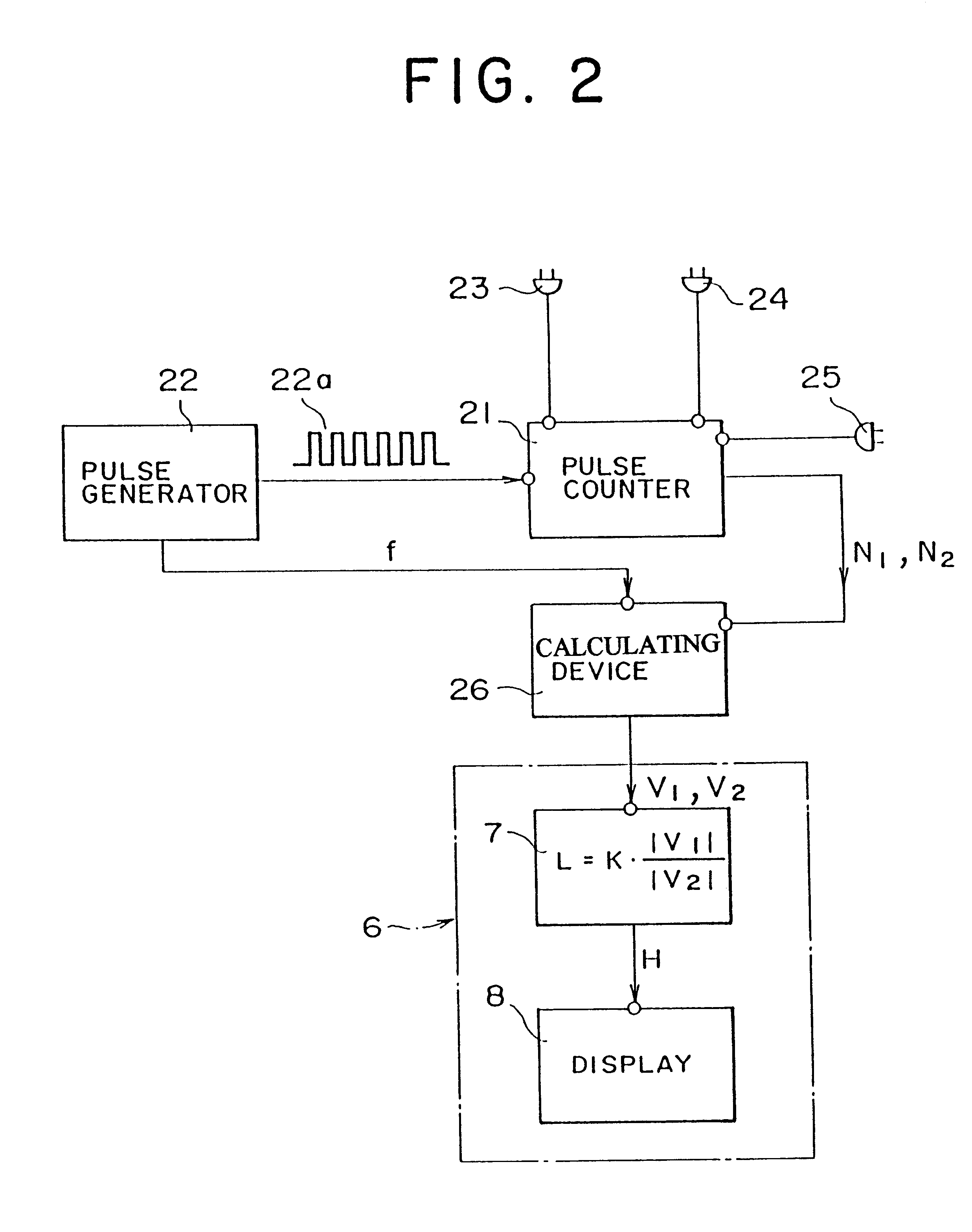

A rebound-type hardness tester comprises a tubular member and an indenter hammer for undergoing axial movement therein in forward and rearward directions and for impacting a specimen and rebounding therefrom. A first detecting device detects the indenter hammer during movement thereof in the forward and rearward directions. A second detecting device detects the indenter hammer after detection thereof by the first detection device during movement of the indenter hammer in the forward direction, and detects the indenter hammer before detection thereof by the first detection device during movement of the indenter hammer in the rearward direction. A measuring device measures first and second timing values corresponding to different times elapsed from the detection of the indenter hammer by the first and second detection devices. A calculating device calculates an impacting velocity and a rebounding velocity of the indenter hammer in accordance with the first and second timing values and a distance between the first and second detecting devices. A processing device calculates a hardness of the specimen in accordance with the impacting velocity and the rebounding velocity calculated by the calculating device.

Owner:MITUTOYO CORP

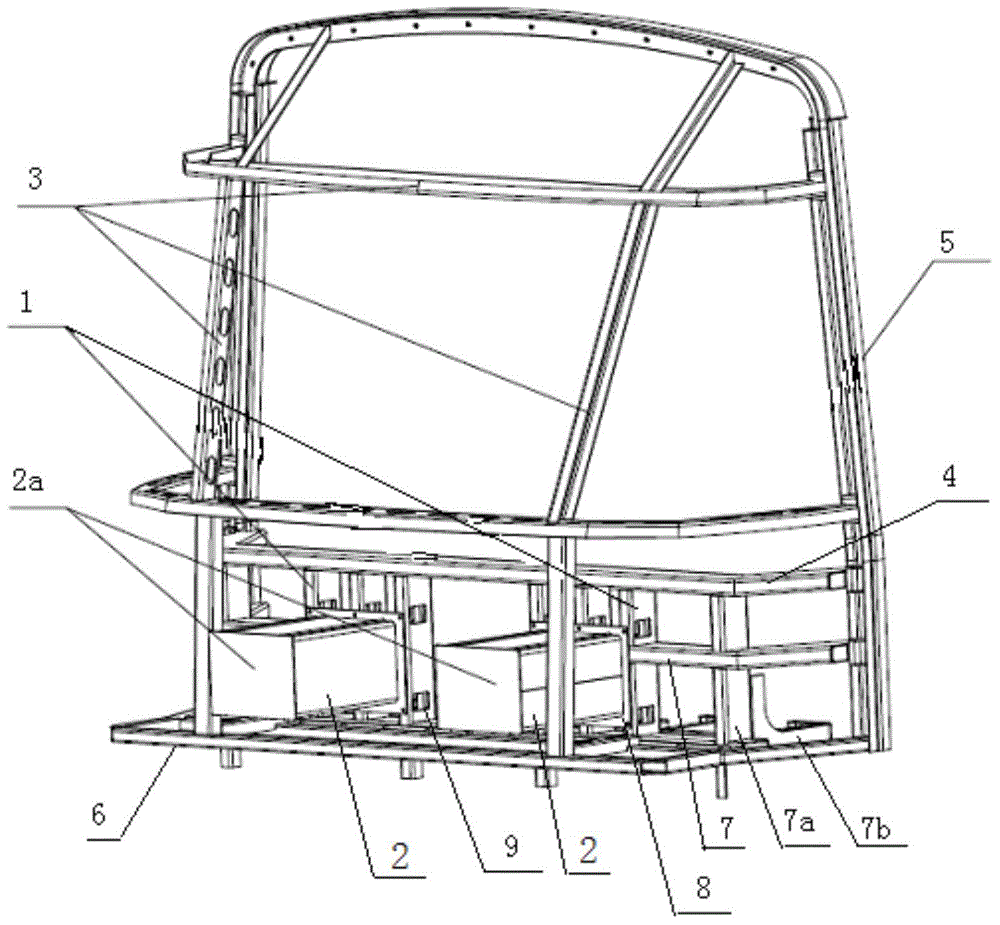

Energy absorption structure for railway vehicle cab

ActiveCN104442857AImprove energy absorptionControl deformationRailway wheel guards/bumpersAxle-box lubricationEnergy absorptionImpact velocity

The invention relates to an energy absorption structure for a railway vehicle cab. The energy absorption structure for the railway vehicle cab comprises energy absorption components, stopping pillars and cab front end frameworks. The stopping pillars are fixed on structural members of the cab, the stopping pillars are arranged below a panel at the front end of a control board of the cab, and the energy absorption components are fixed on the stopping pillars. The length of each energy absorption component is at least 600 mm. According to the energy absorption structure for the railway vehicle cab, due to the arrangement of the energy absorption components with large energy absorption capacity, the energy absorption structure and a vehicle coupler can bear the impact velocity of 36 km / h together; meanwhile, the stopping pillars are arranged so that the structure can be strengthened, and the backward diffusion caused by impact deformation is prevented; in addition, the rigidity of the cab front end frameworks is weakened, the energy absorption structure can participate in the deformation energy absorption process during impact, and thus the deformation energy absorption capacity of the energy absorption structure is effectively improved.

Owner:CRRC QINGDAO SIFANG CO LTD

Radar system for motor vehicles

InactiveUS7786926B2Accurate measurementFunction increasePedestrian/occupant safety arrangementRadio wave reradiation/reflectionRadar systemsImpact velocity

Owner:ROBERT BOSCH GMBH

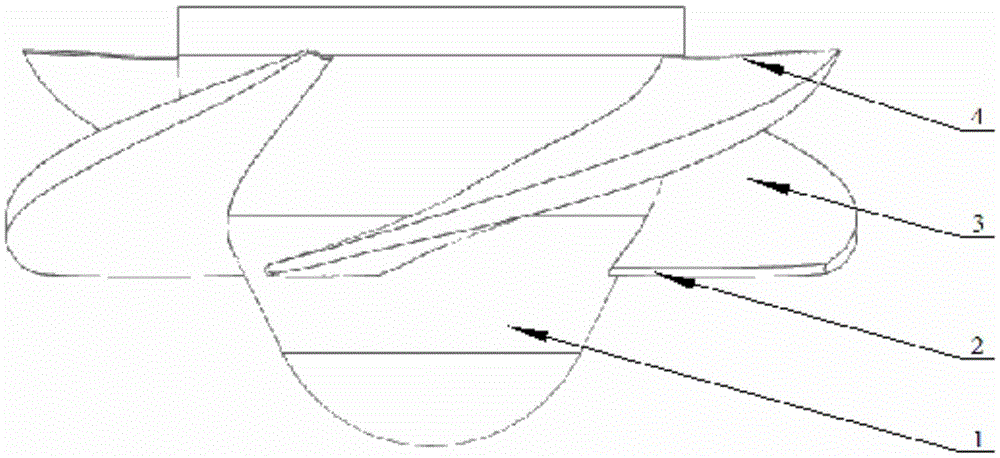

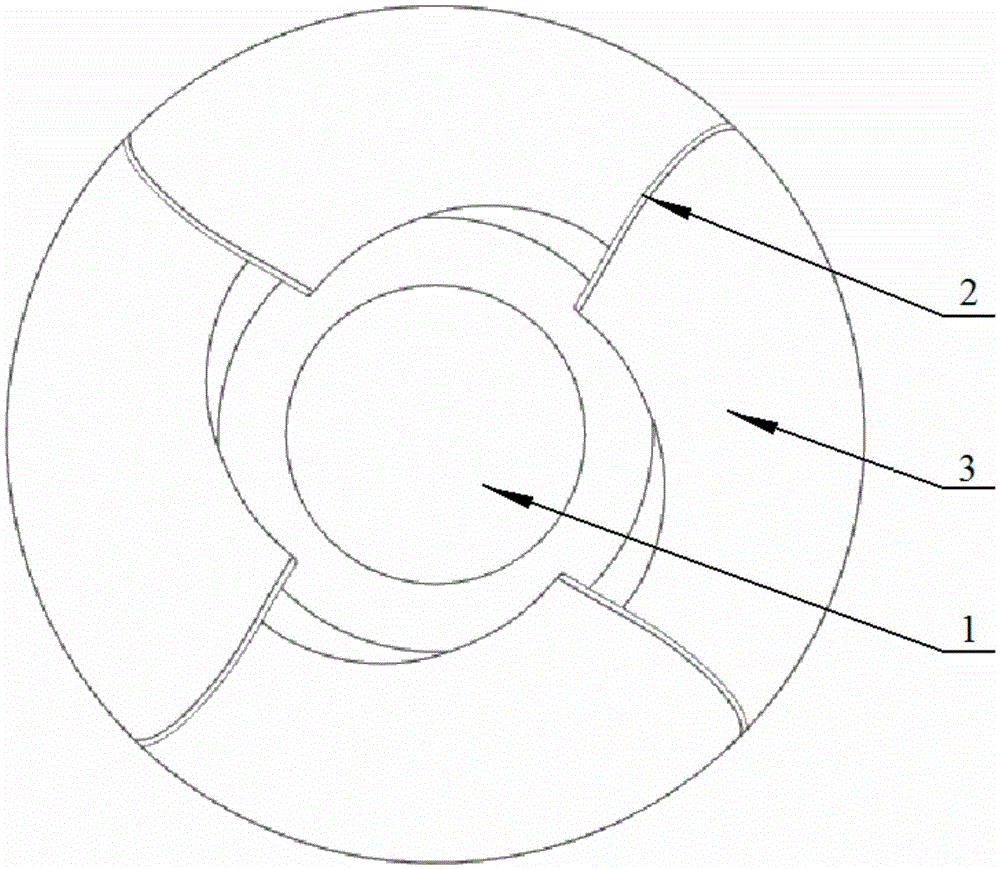

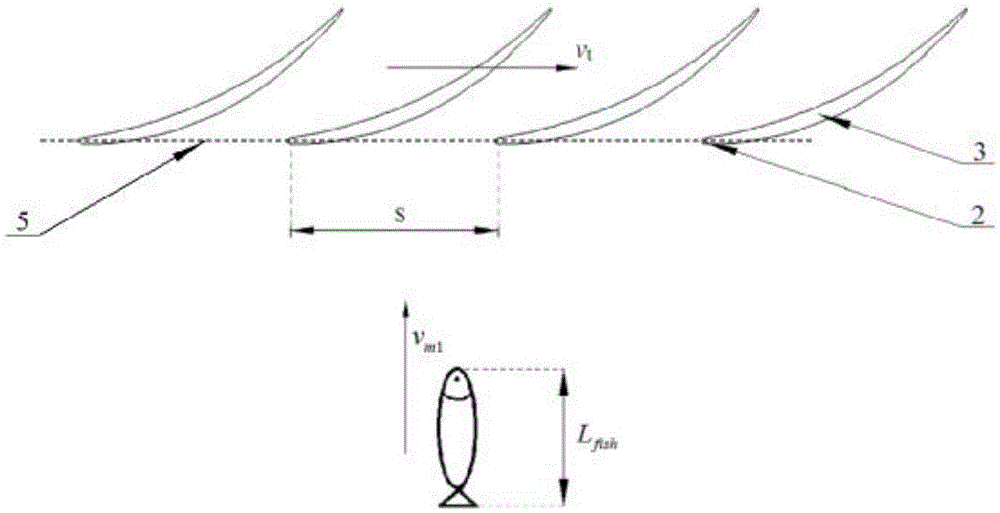

Designing method of fish-friendly axial flow pump based on fish survival rate prediction

InactiveCN105626573AImprove survival rateReduce the probability of impactPump componentsPumpsAxial-flow pumpMathematical model

The invention provides a designing method of a fish-friendly axial flow pump based on fish survival rate prediction. A relation between a pump design parameter and the fish passing survival rate is predicted by adopting a mathematical model, and thus a fish-friendly design of an axial flow pump is guided. The mathematical model is mainly composed of the blade leading edge impact probability and the impact death rate; the impact probability is a ratio of the time that fishes pass through the cross section of passage of the blade leading edge and the time needed by an impeller rotating around a blade pitch; the impact death rate is relevant to the impact velocity, the fish length and the thickness of the blade leading edge; and the impact velocity adoptsa velocity component of a vertical leading edge. The fish-friendly axial flow pump design comprises the following steps: lowering the blade leading edge impact probability by adopting two blade impellers, lowering the impact death rate by adopting the blade leading edge with linear sweepforward protraction, and ensuring good hydraulic performance by virtue of airfoil parameter design. According to the designing method, a fish survival rate prediction model is high in goodness of fit to an experiment value, and the fish-friendly axial flow pump designed by guidance can greatly lower the fish death rate.

Owner:JIANGSU UNIV

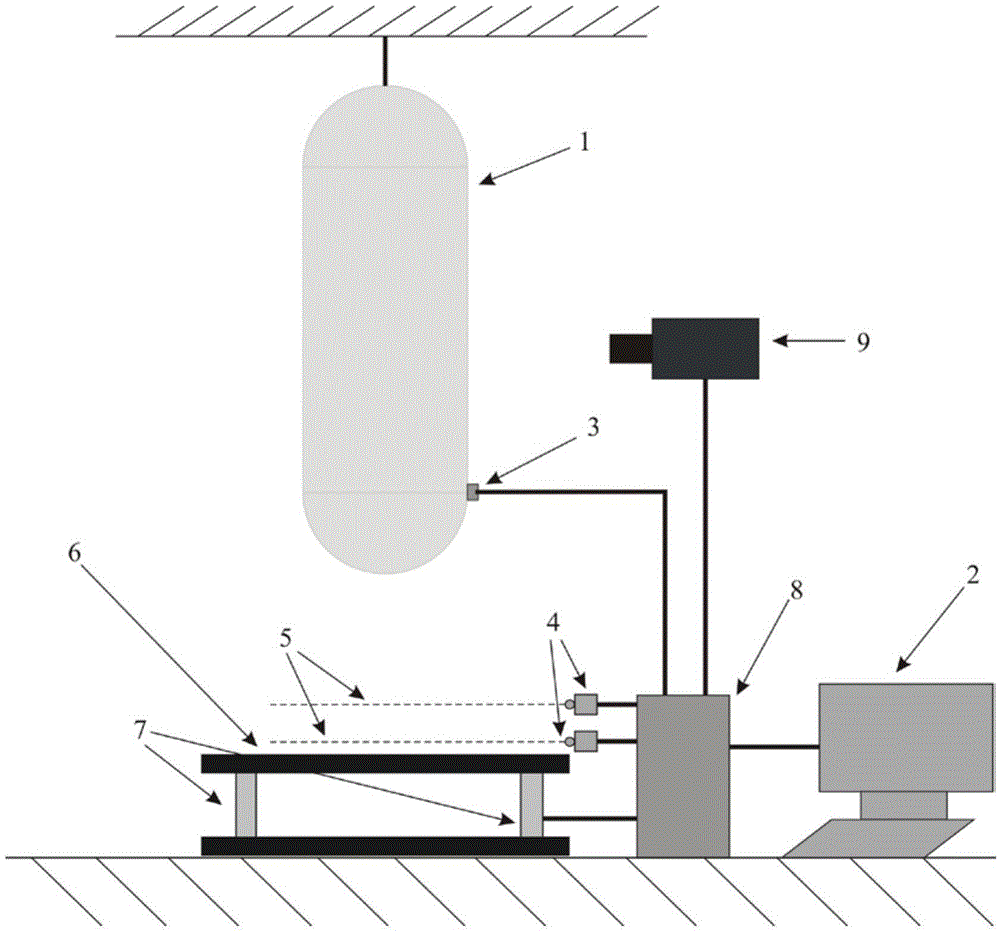

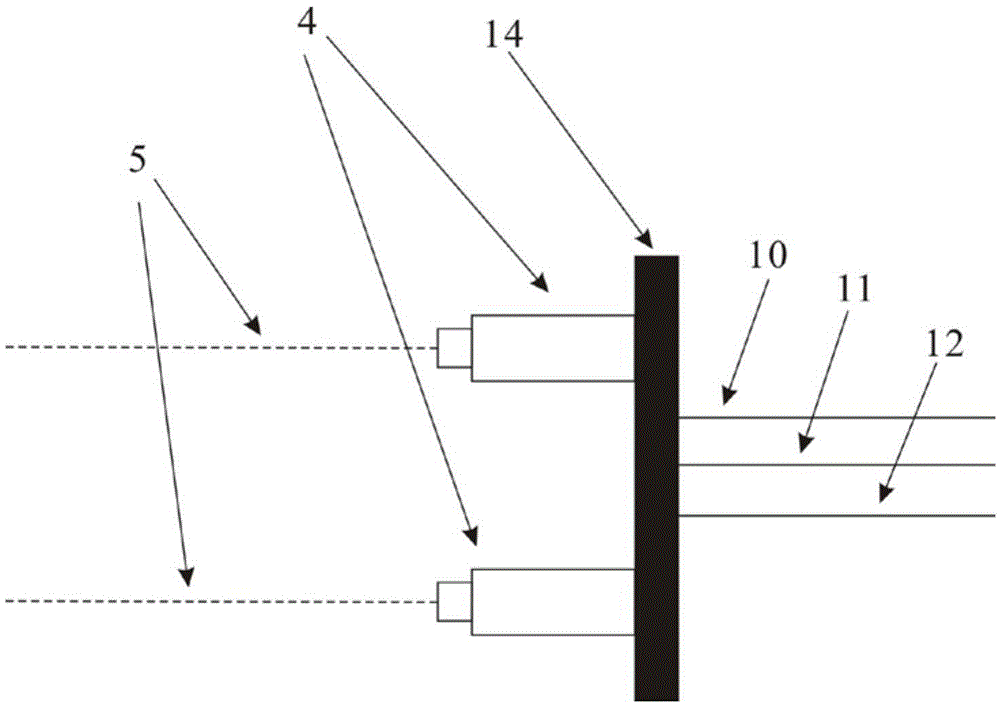

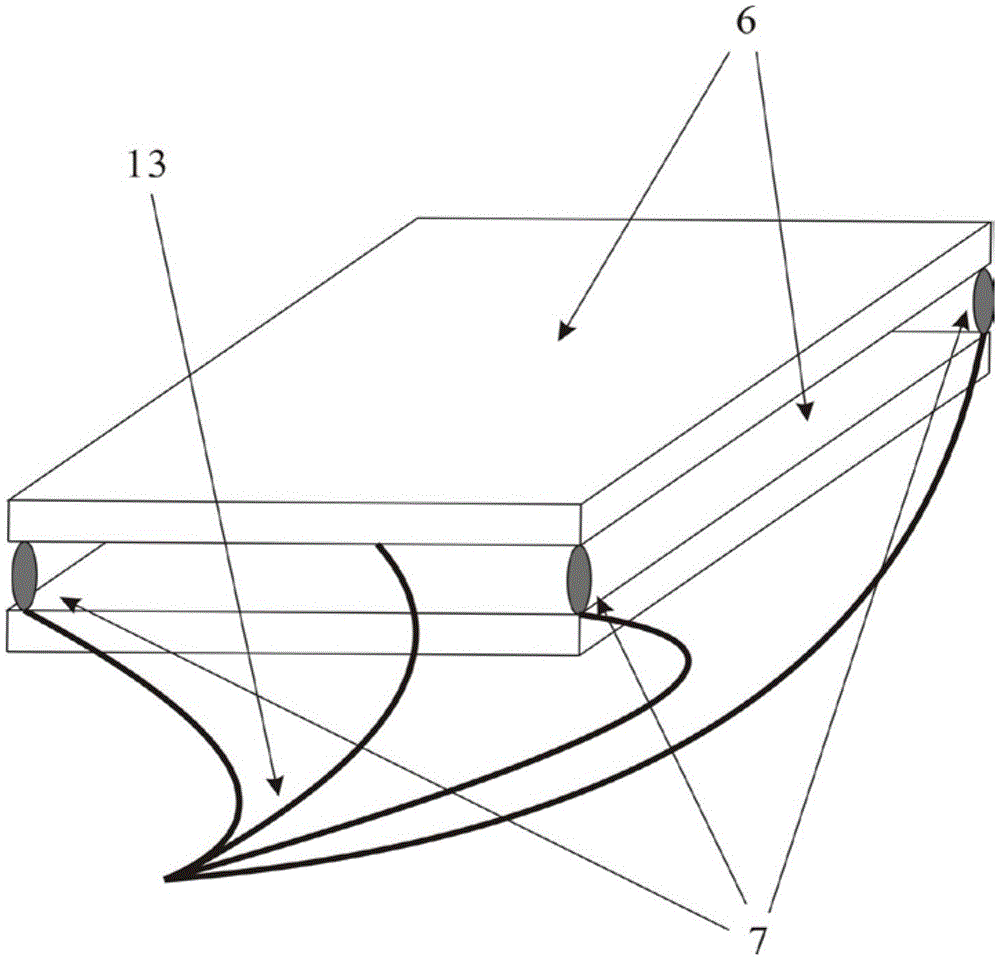

Impact dynamic characteristic test device and test method of inflatable flexible structure

ActiveCN105628321AContinuous adjustment of internal pressureEasy to adjustShock testingData acquisitionImpact velocity

The invention discloses an impact dynamic characteristic test device and test method of an inflatable flexible structure. An impact velocity value of the flexible structure is measured by a photoelectric sensing velocity-measuring system. An impact resultant force-time history curve of an impact process of the flexible structure is measured through a force-measuring platform. An accelerated speed-time history curve of the impact process is measured through an acceleration sensor which is adhered to the flexible structure surface and next to an impact region. An impact deformation process of the flexible structure is recorded by a high speed camera. Photoelectric signals, acceleration signals, and force signals are all transmitted to a data collection analyzer and converted to electronic signals through the data collection analyzer and input to a computer. The computer performs digital-to-analogue conversion on the signals to obtain a whole dynamic characteristic curve of a test object, and records the whole impact deformation process shot by the high speed camera. Thus the impact dynamic characteristic test device and test method of the inflatable flexible structure can provide verification and reference for the impact dynamics numerical simulation of the inflatable flexible structure. The structure device is simple and clear, is convenient to use, and has strong applicability.

Owner:BEIHANG UNIV +2

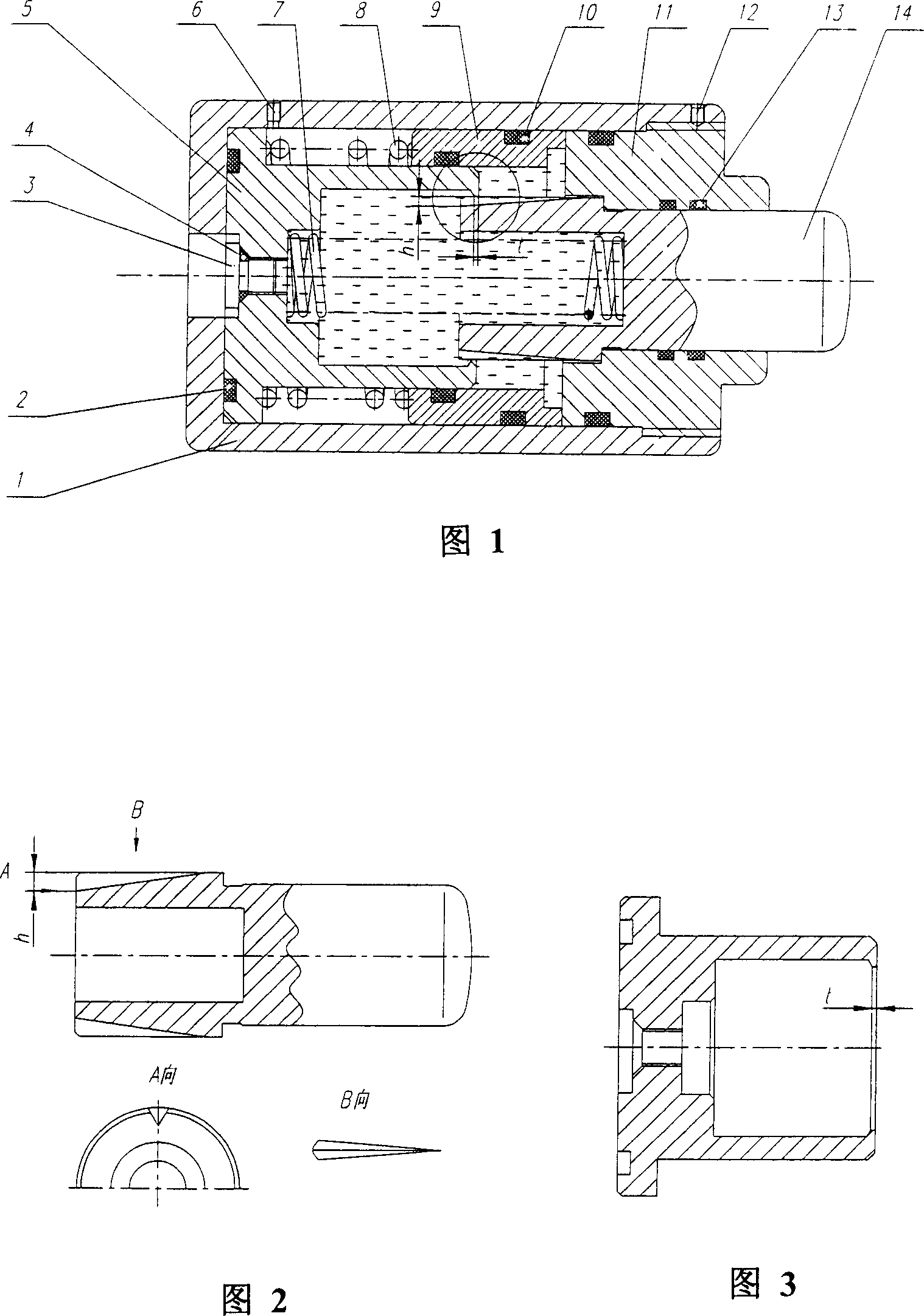

Flow-throttling hole hydraulic buffer

InactiveCN1978936AFull performanceWith the ability to automatically adapt to the impact speedSpringsShock absorbersImpact velocityEngineering

The invention discloses a throttling orifice hydraulic buffer. It includes buffer body, inner and outer back springs, throttling wall, supercharge sliding sleeve, buffering contact. The cylindrical surface of the buffering contact and the throttling wall is set two grooves set throttling orifice to block oil moving. The invention has impact velocity automatic adaptability, can keep shock absorbing capacity stable by adapting the variety of the hydraulic oil viscosity under major temperature variety.

Owner:710TH RES INST OF CHINA SHIPBUILDING IND CORP

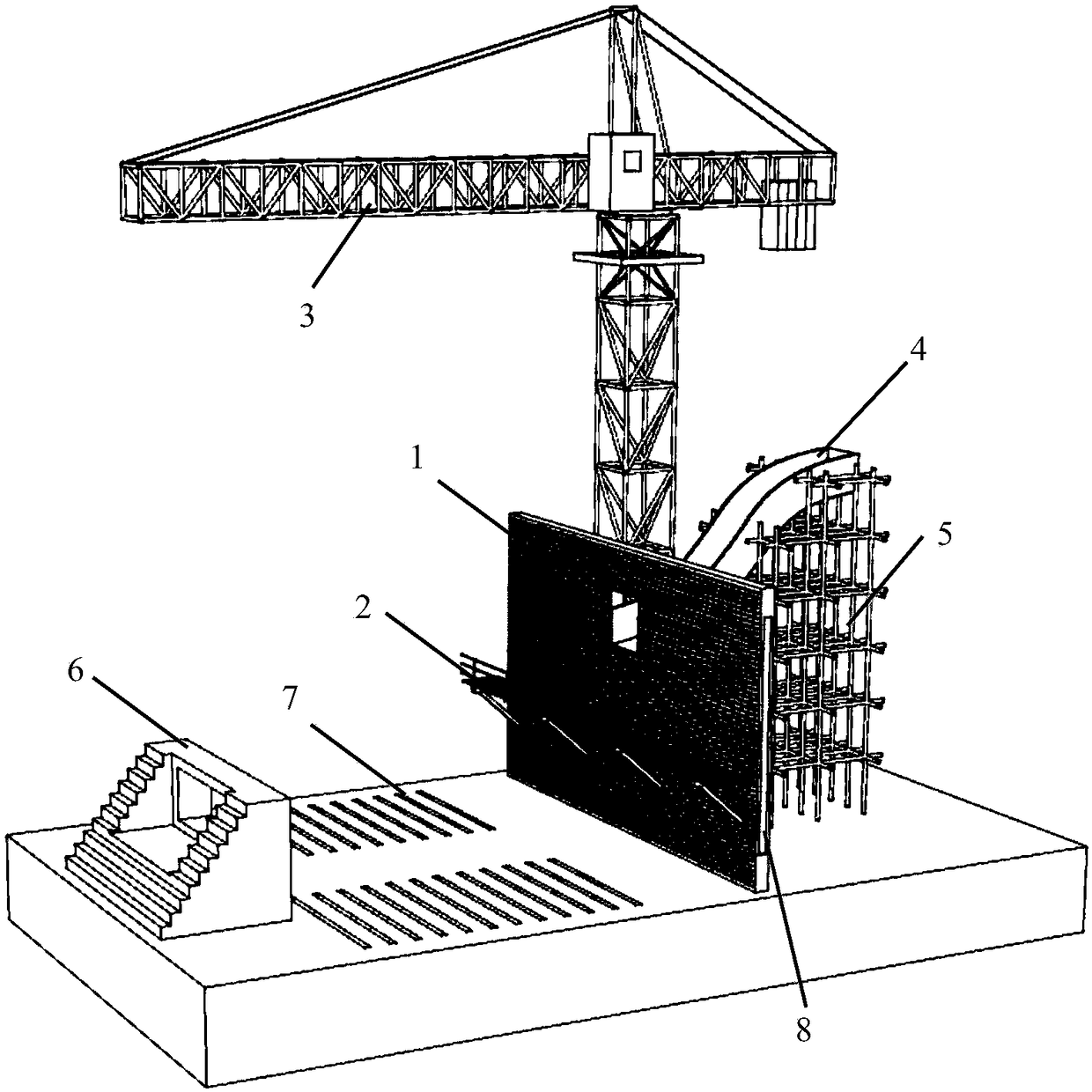

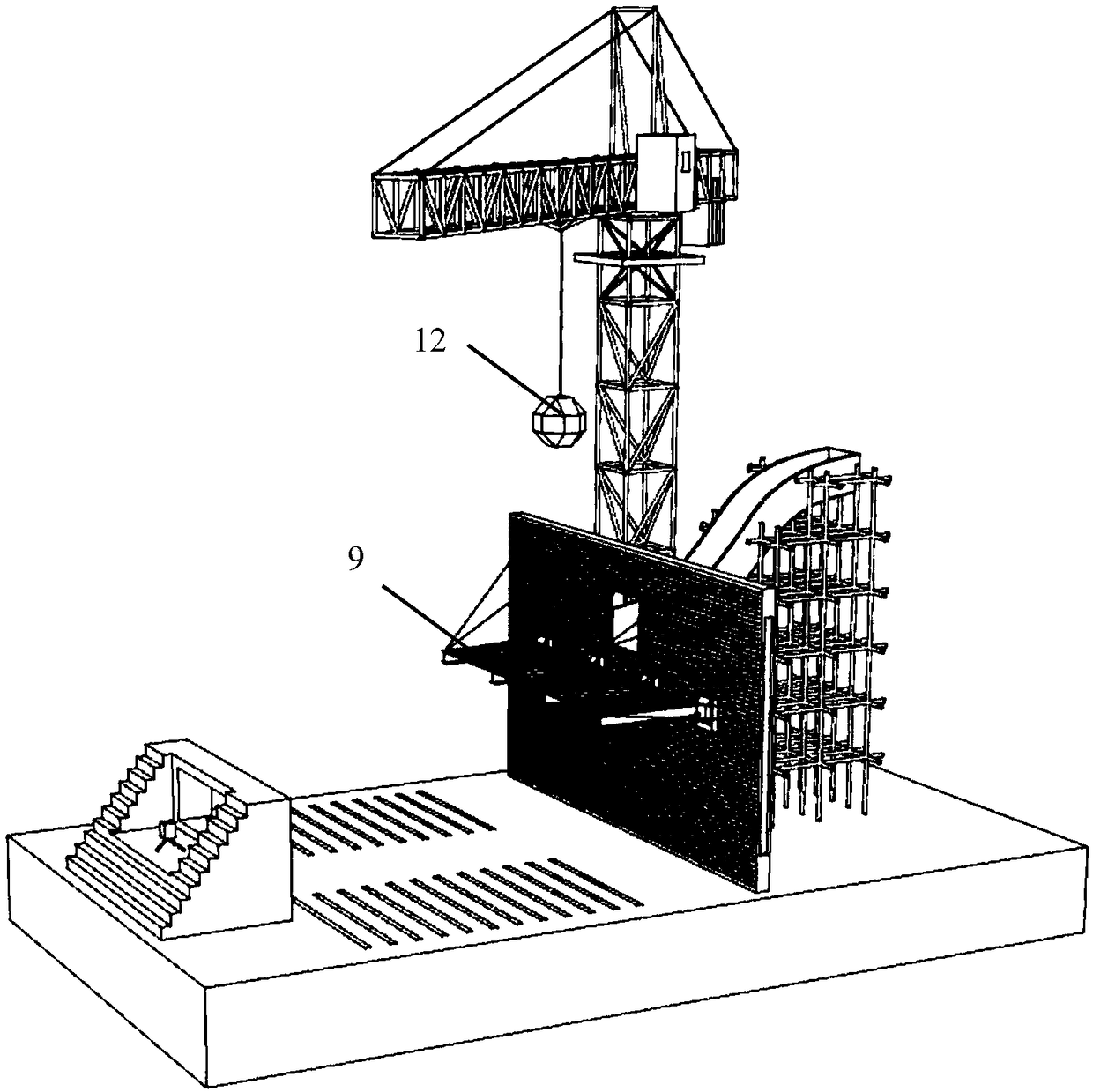

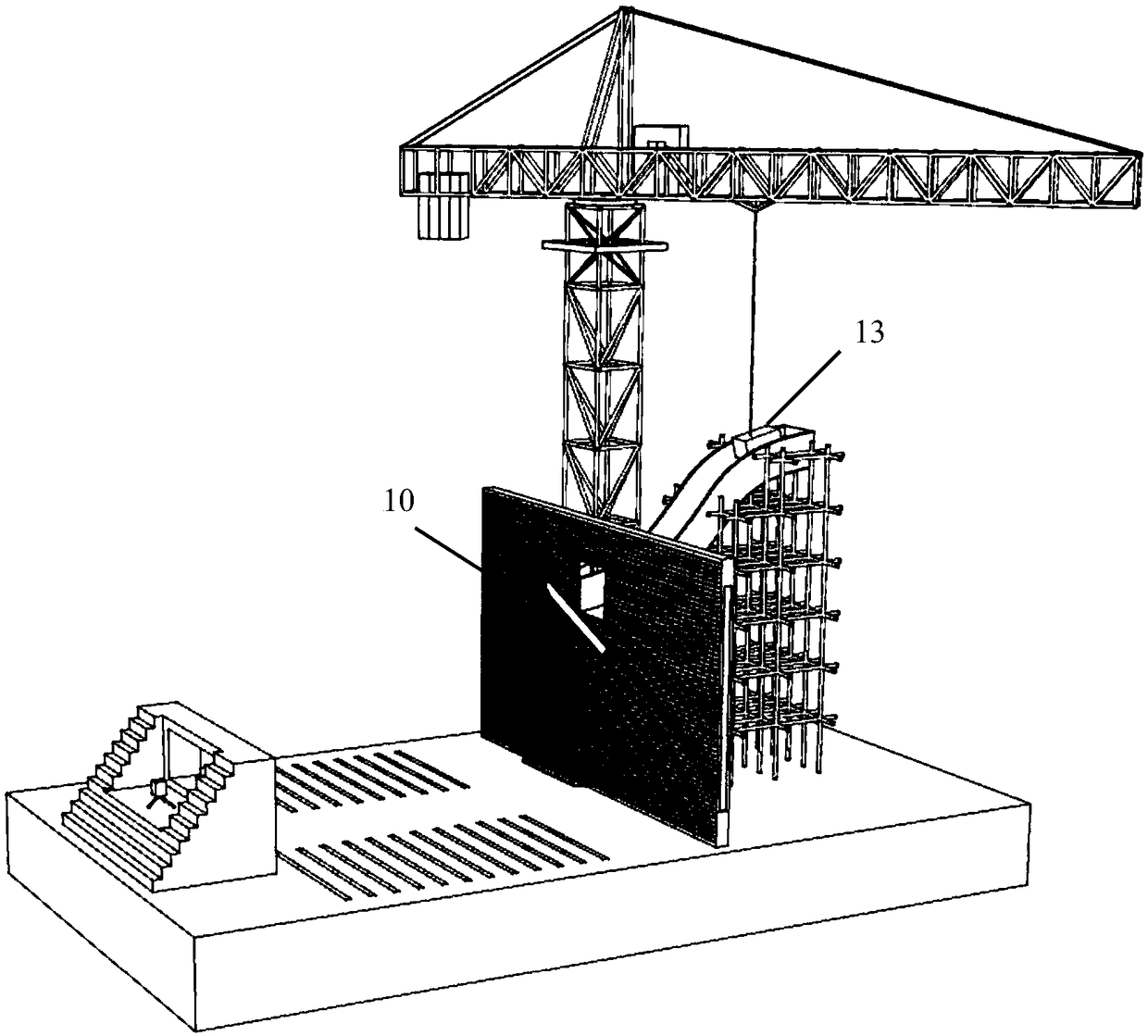

Large-scale integrated platform capable of full-scale impact test of various flexible protective structures

InactiveCN109186916AReduce testing costsImprove efficiencyProtective constructionShock testingData acquisitionImpact velocity

The invention provides a large-scale integrated platform capable of full-scale impact test of various flexible protective structures. The platform comprises the following parts: a reaction wall for installing a passive flexible protective net test model and a curtain net test model, a detachable construction platform, a ground anchor trench for installing a flexible shed tunnel test model, a lifting device for lifting and releasing an impact test block and an impact slider, a slide and a slide support for providing horizontal impact velocity of the impact slider, an observation platform for erecting a high speed camera, and a set box for burying sensor data lines. The large-scale integrated platform provided by the invention can be built in the nearest site, and the test site is not limited by the on-site environment, which obtains low experiment cost and high efficiency, and can conveniently and repeatedly perform the impact test and data acquisition.

Owner:SOUTHWEST JIAOTONG UNIV

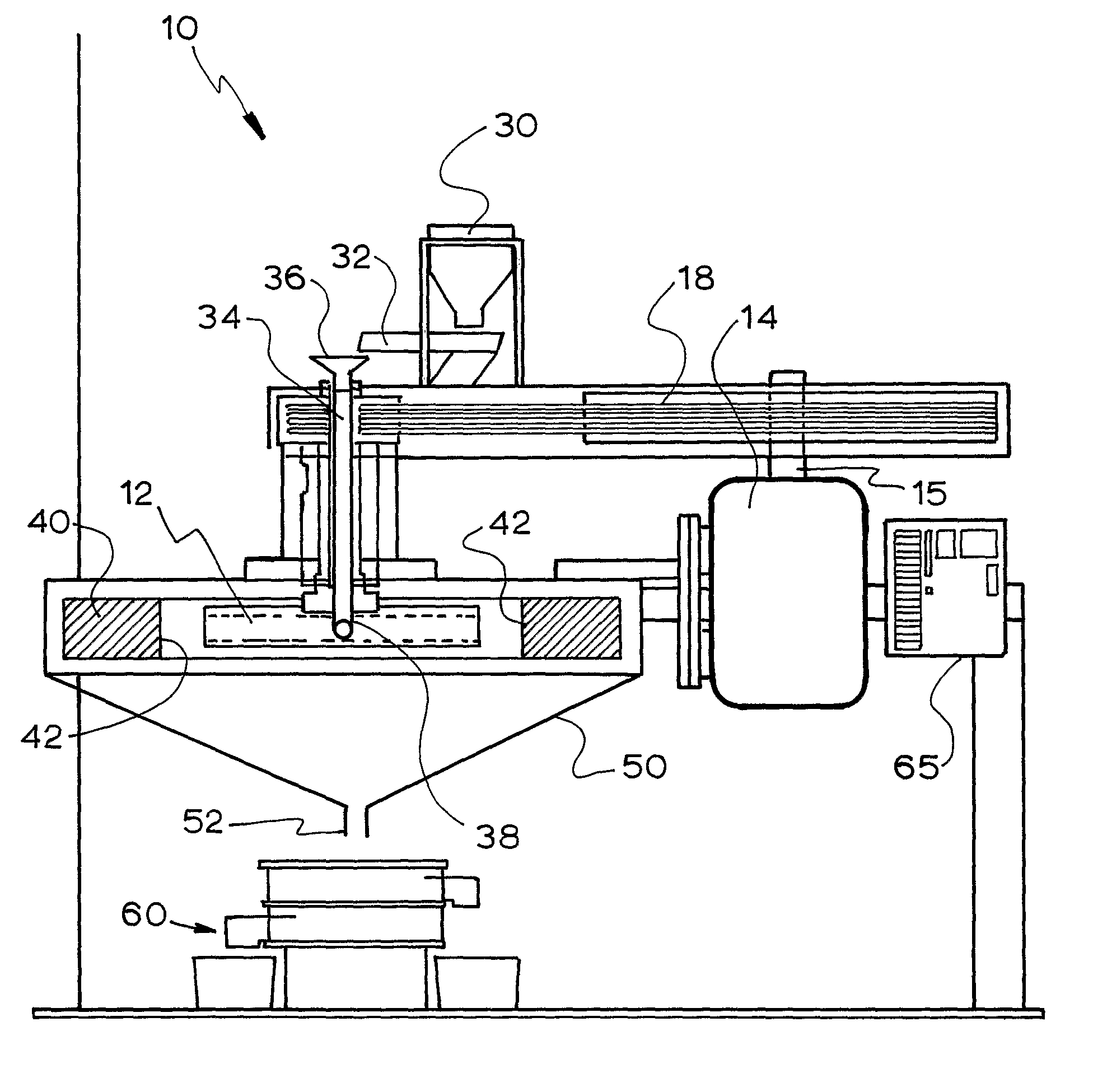

Apparatus for determining breakage properties of particulate material

InactiveUS8272247B2High precisionQuick and easy analysisMaterial strength using tensile/compressive forcesAcceleration measurementControl systemImpact velocity

An apparatus for determining the breakage properties of a particulate material, the apparatus including: a support; a rotor mounted relative to the support and including at least one guide channel through which a particle of the particulate material is guided in use, the guide channel having an inlet and an outlet; a drive associated with the rotor; a feed channel for feeding particles of the particulate material to the inlet of the guide channel; a stator associated with the rotor and including an impact surface that is radially spaced from a circumferential edge of the rotor; and a collector for collecting pieces of the particulate material following impact; wherein the apparatus is provided with a control system for accurate control and adjustment of impact velocity of the particulate material with the impact surface.

Owner:THE UNIV OF QUEENSLAND

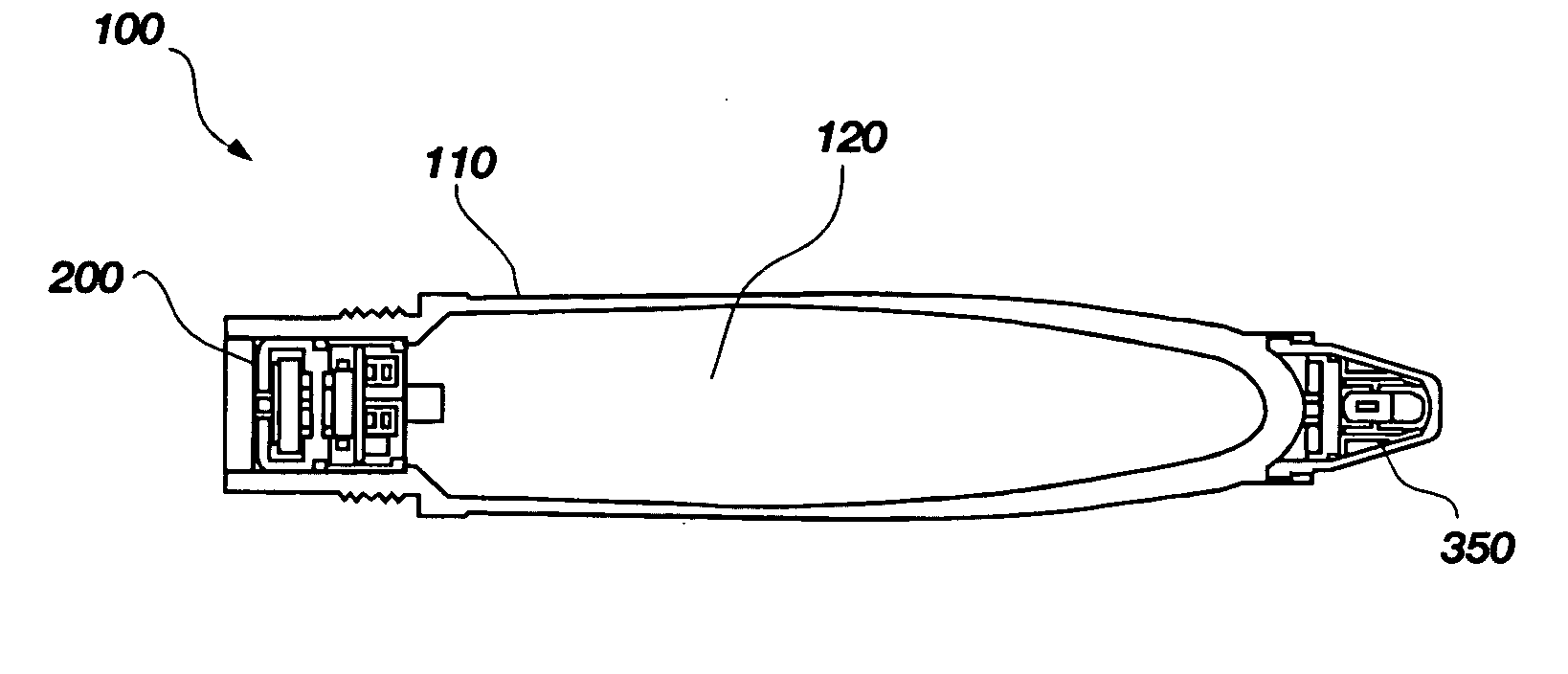

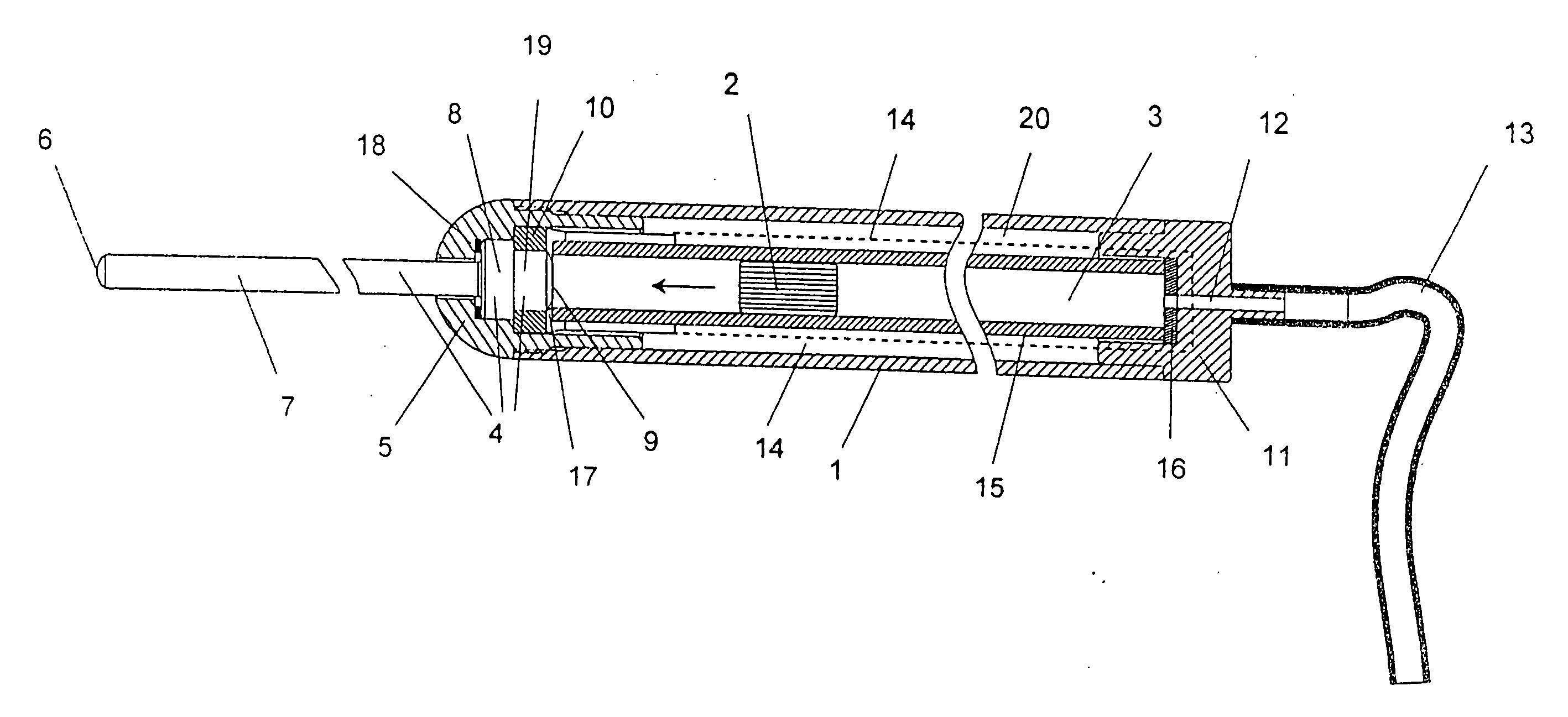

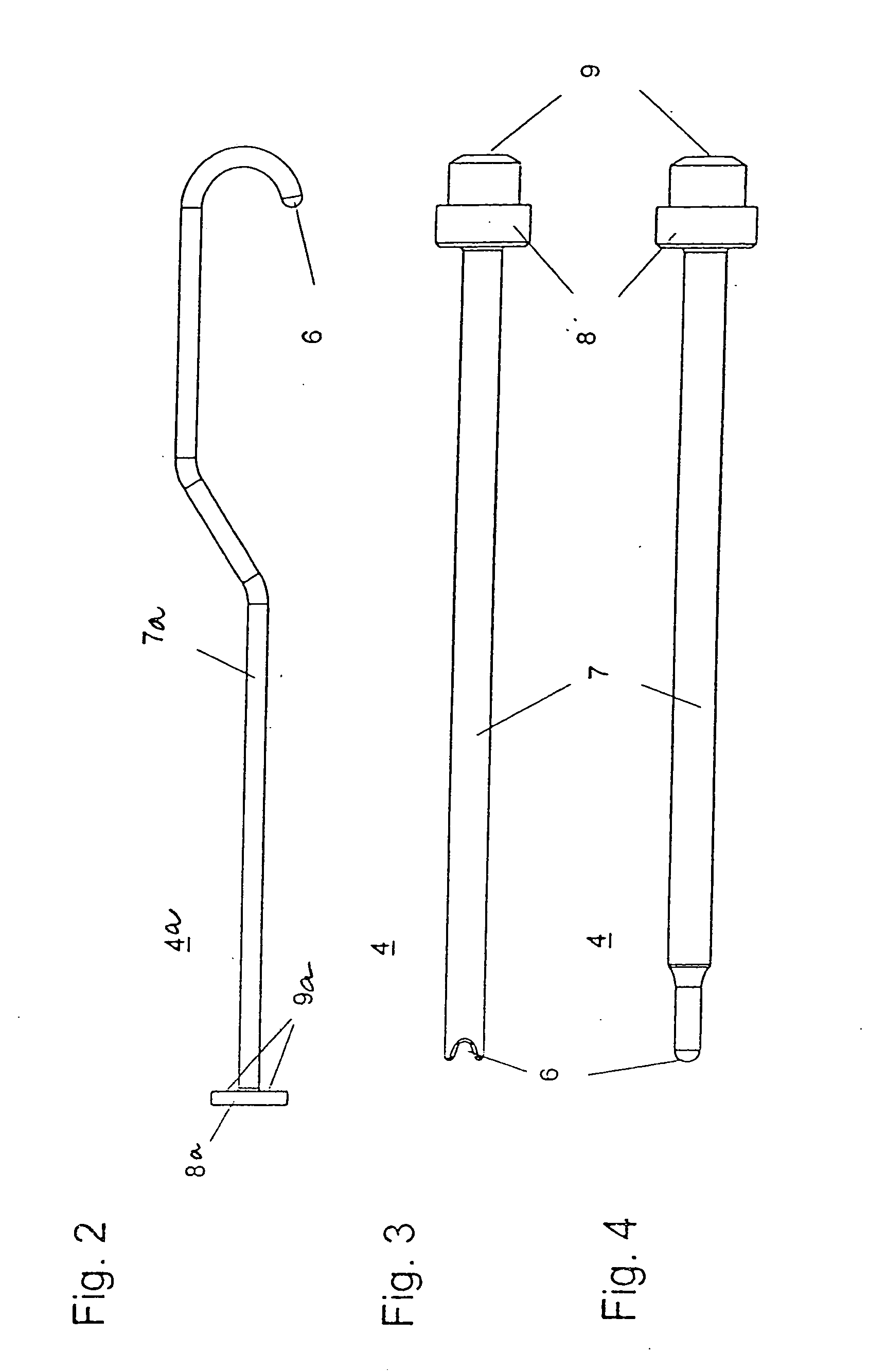

Device and method for removing tooth applications such as brackets

InactiveUS20060064864A1Painless and simple and quick debondingOthrodonticsMetal working apparatusElectrical conductorImpact velocity

A device and method for removing tooth applications such as brackets, wherein a force may be applied to the application via a transmission element for debonding the application from the tooth. The transmission element has an impulse conductor for receiving and transmitting an impulse, and an output surface for transmitting the impulse onto the application. Advantageously, the impulse is applied by an accelerated mass to an input surface of the transmission element. The mass is accelerated to a predetermined impact velocity by an acceleration device and impacts on the input surface so as to couple the impulse into the impulse conductor of the transmission element.

Owner:FERTON HLDG

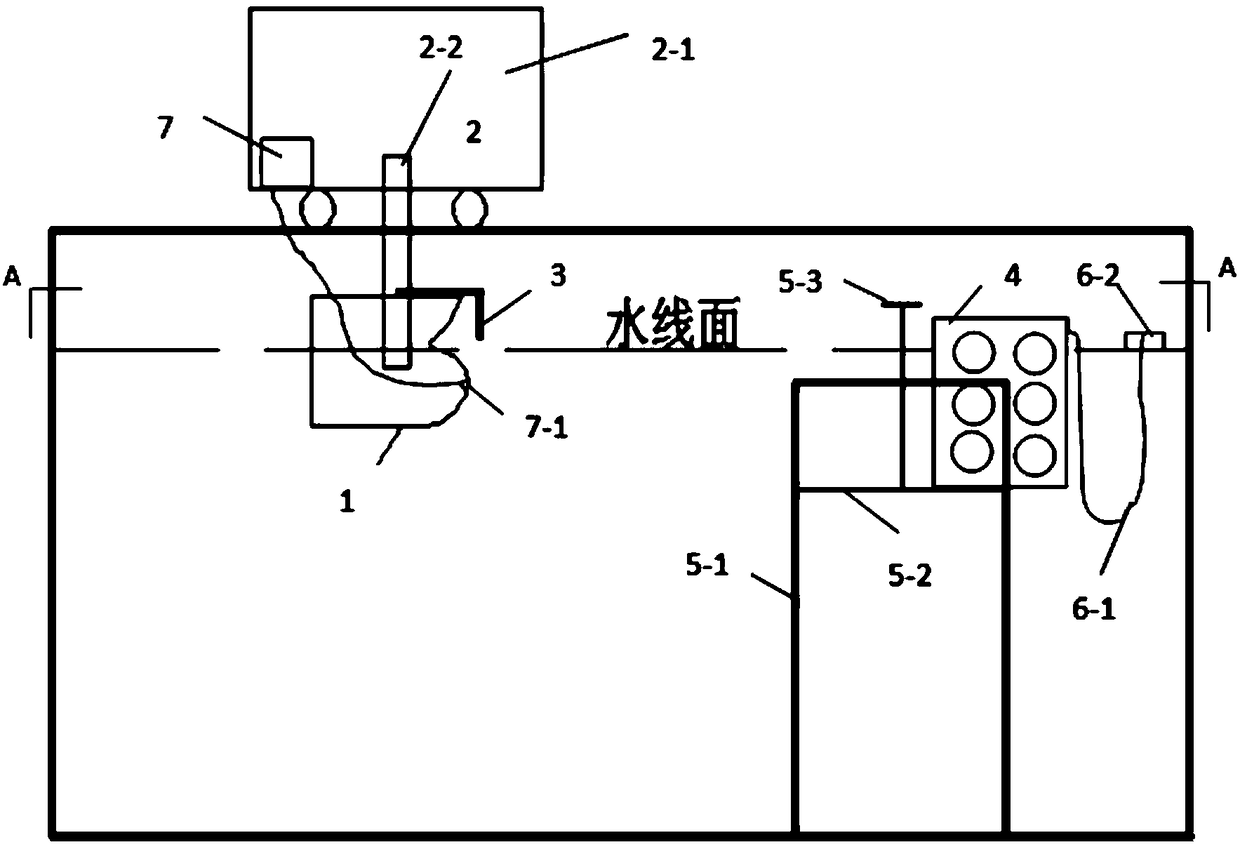

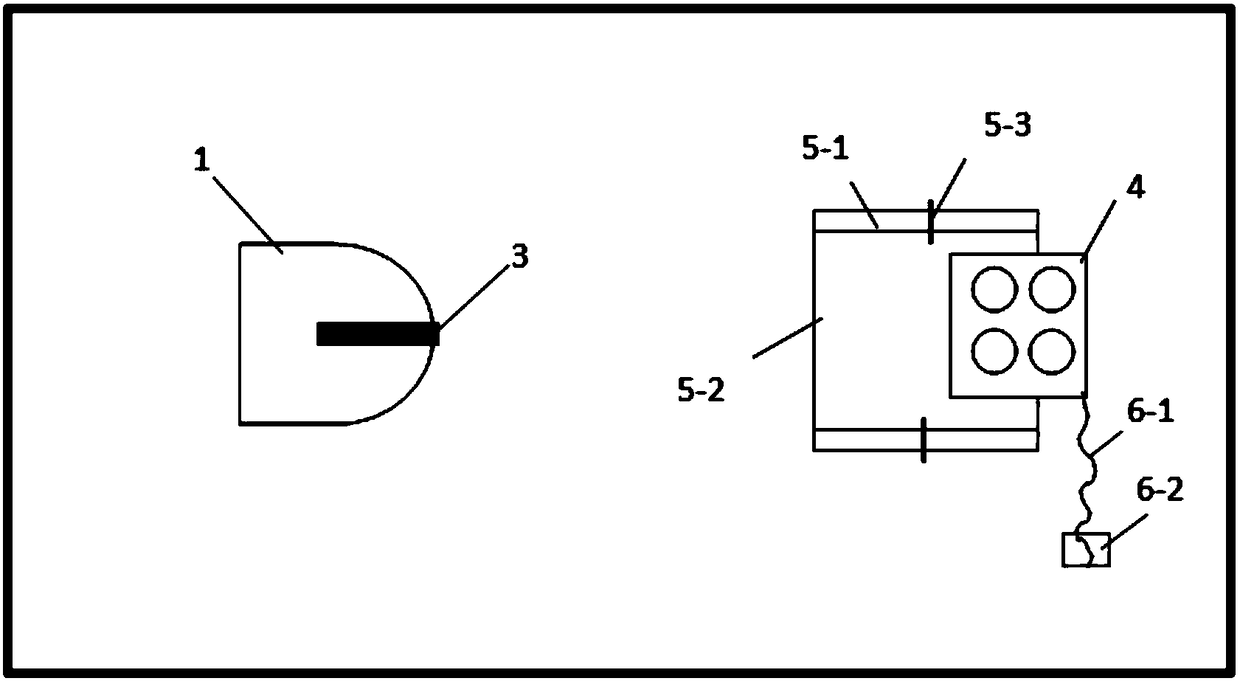

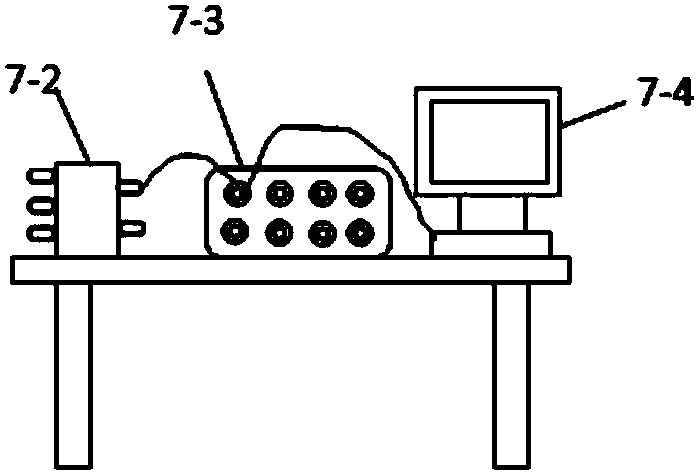

Simulation device and simulation method for simplified calculation of ship-ice collision in water medium

ActiveCN108750002ATo achieve the purpose of decouplingExact load inputVessel designingBody shapeImpact velocity

The invention discloses a simulation device for simplified calculation of ship-ice collision in a water medium which comprises a water tank, wherein a lifting support frame is arranged in the water tank; an ice body model is arranged on the support frame; a ship model is arranged in the water tank; a guide rail is arranged on the water tank; a towing device is arranged on the guide rail; the towing device is connected with the ship model through a towing truss, a pressure sensor is arranged at the top end of the ship, and the pressure sensor is sequentially connected with a charge amplifier, amulti-channel signal collector and a computer; the ship collides with the ice body model through the driving of the towing device so as to acquire the collision data through the pressure sensor. On the premise of not using ice material, the device can carry out high-pressure loading with different ice body shapes, ice body masses, impact speeds, impact positions, ship model floating states and impact angles, the real situation of the collision between the ship and the ice can be reflected well, the cost is low, the operation is easy, and the risk is small.

Owner:JIANGSU YANGZI XINFU SHIPBUILDING CO LTD

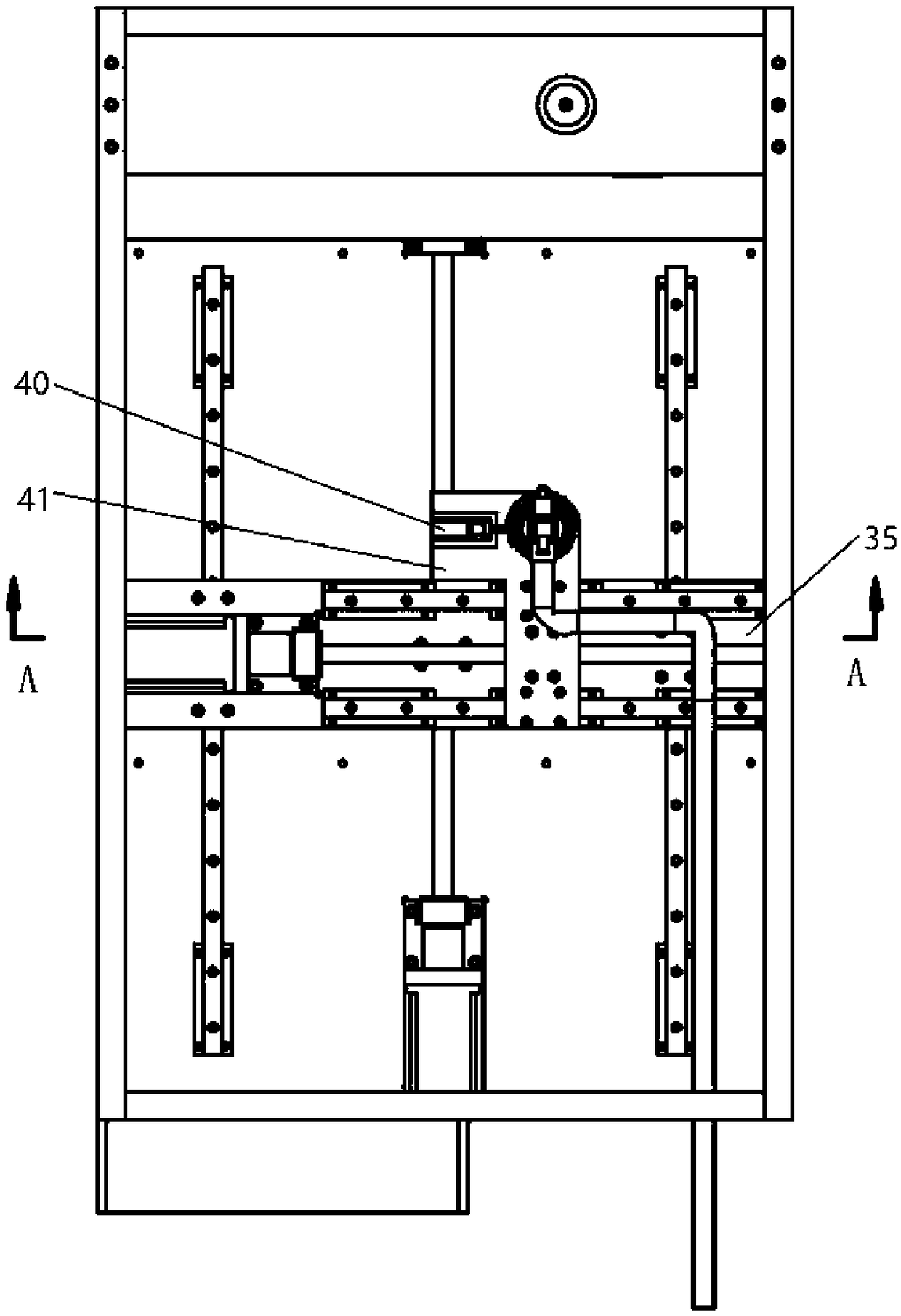

High pressure water jet cleaning experimental device

ActiveCN108806456ASimple resultEasy to operateEducational modelsCleaning using liquidsInjection pressureJet flow

The invention discloses a high pressure water jet cleaning experimental device, comprising an experimental table body module, a target distance adjustment module, a lateral movement drive module, a nozzle fixing and incident angle adjustment module, a pressure measurement module and a target fixing and adjustment module. Before an experiment, a special mold is used for preparing a sample from dirt, the sample is loaded on the target fixing and adjustment module, and then the experiment is carried out. The high-pressure water jet cleaning experimental device can digitally display the cleaning process and effects, and can intuitively display the jet action process. Relevant experimental tests can be completed by changing the type of the dirt target and jet parameters such as injection pressure, jet impact velocity, target distance, traverse speed, and an incident angle. The cleaning effect is comprehensively evaluated by measuring the cutting depth, width and mass loss of the dirt sample. The economic evaluation is carried out by recording energy consumption and water consumption, and the optimum cleaning parameters are found by observing and recording the peeling form of the dirt.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

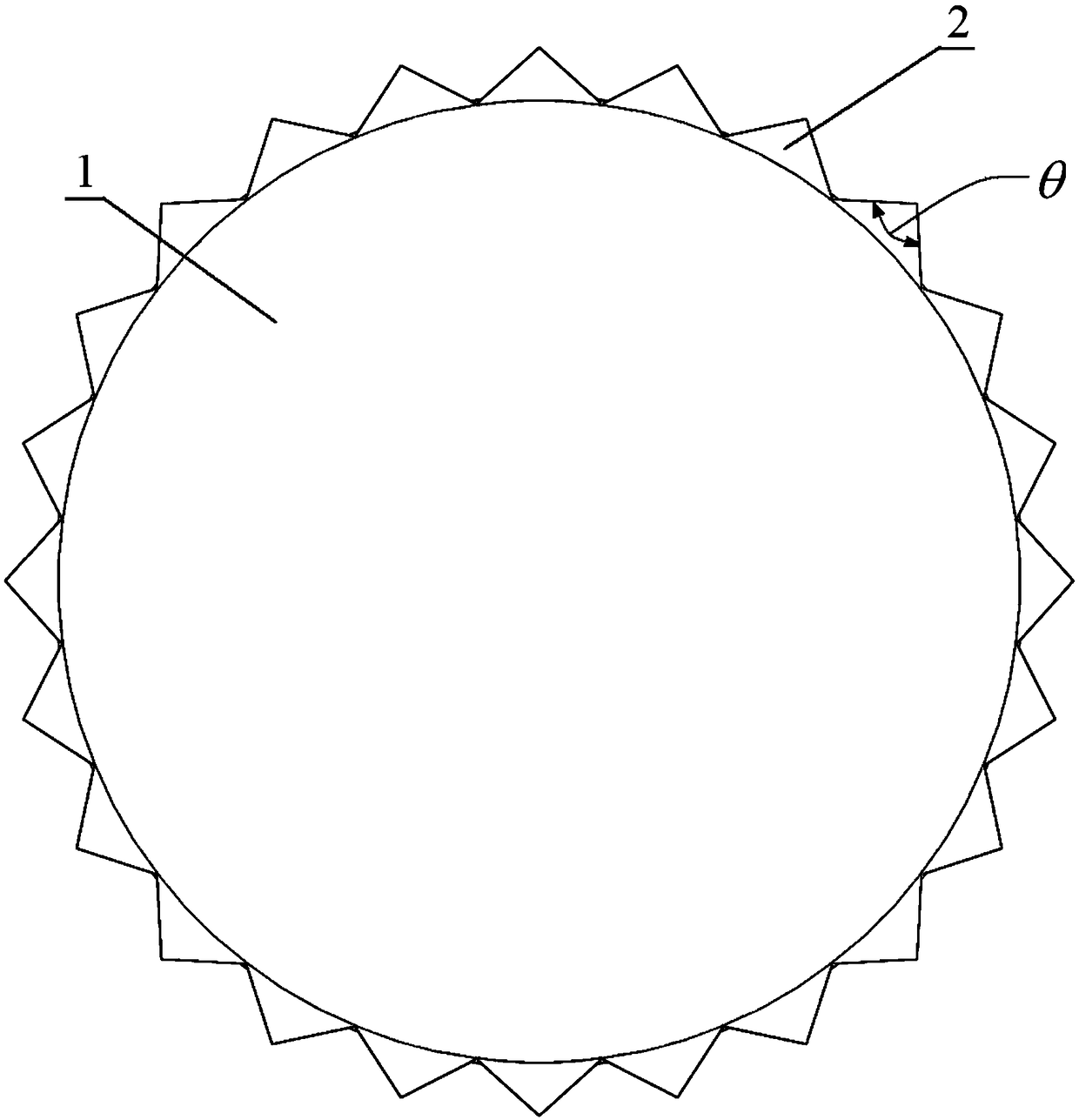

Throwing glass breaking ball

InactiveCN108771798AAchieve broken glass rescueQuick rescueBuilding rescueBreak the glassImpact velocity

The invention discloses a throwing glass breaking ball. The throwing glass breaking ball comprises a body, and a plurality of bulges arranged on the outer surface of the body, and the bulges are the members with the hardness higher than the hardness of the tempered glass. When the glass breaking operation is required, the glass breaking ball can be thrown into the tempered glass by hands or usinga device, because the hardness of the bulges on the glass breaking ball is higher than that of the tempered glass, and when the bulges hit the glass surface, the stress limit of the tempered glass surface is broken through, the tempered glass is broken, and the glass breaking purpose is achieved. When the glass breaking ball is used for breaking the glass, because the bulges are arranged on the outer surface of the body, the glass breaking can be achieved without the high throwing speed through the shape bulges making contact with the glass, and the advantages of being high in efficiency, lowin impact speed and high in safety are achieved; and the long-distance glass breaking can be achieved through a throwing way, and when the glass breaking rescue is needed during the fire in high-risebuildings and other, the personnel safe rescue and rapid rescue can be achieved.

Owner:平裕(成都)科技有限公司

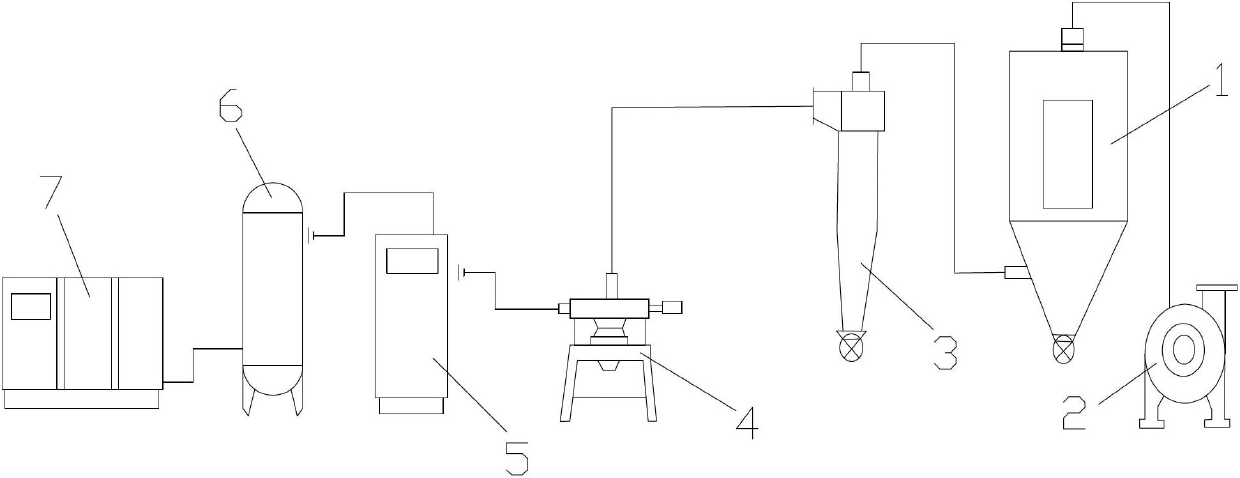

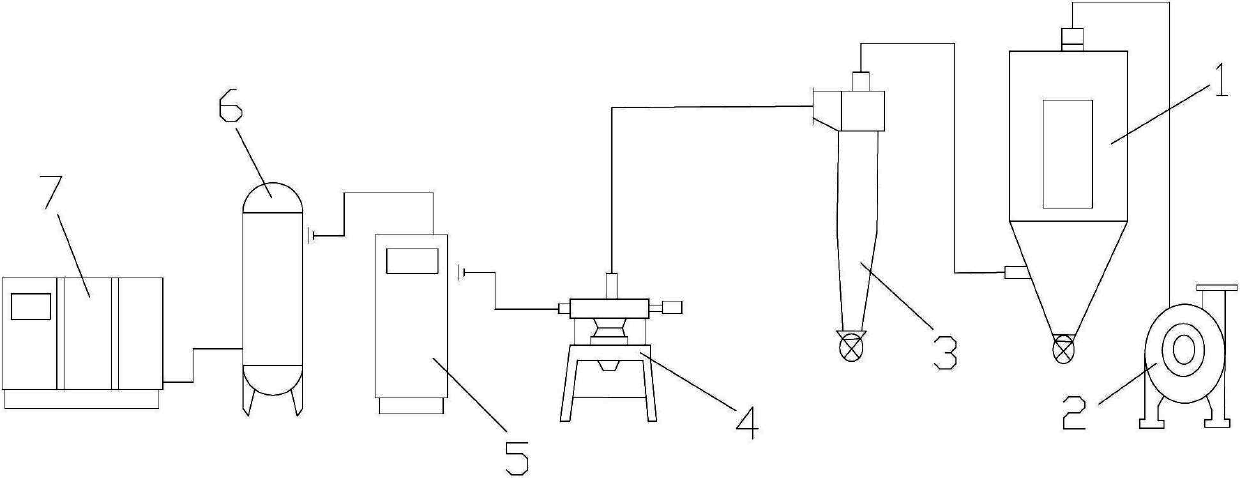

Supersonic jet milling system

InactiveCN102671747ASmall particle size distribution rangeReasonable structural designGrain treatmentsLow noiseGas compressor

The invention provides a supersonic jet milling system, which relates to the technical field of powder material milling. A main body comprises an air compressor, an air storage tank, an air freeze dryer, a supersonic jet mill, a cyclone separator, a dust remover and a draught fan, wherein the right end of the air compressor is connected with the air storage tank; the right end of the air storage tank is connected with the air freeze dryer; the right end of the air freeze dryer is connected with the supersonic jet mill; the right end of the supersonic jet mill is connected with the cyclone separator; the right end of the cyclone separator is connected with the dust remover; and the right end of the dust remover is connected with the draught fan. The supersonic jet milling system is reasonable in structural design, has the advantages of low noise and no vibration and is suitable for a dry type ultrafine milling process; since the impact velocity is high, particles 1-10 micrometers in size are very easy to obtain, and coarse particles in a product can be continuously and circularly milled, so the product with uniform particles and a small particle size distribution range can be obtained.

Owner:李莉

Constant force control methodology for shock absorption

InactiveUS8311705B2Avoid injuryMinimize the shock induced load experiencedVehicle seatsSpringsConstant forceAcceleration amplitude

A Constant Force Control methodology and system utilizing integrated sensors and unique control algorithms to determine required applied force to mitigate shock events in an adaptive energy absorption system, typically comprising of a spring and an adjustable energy absorber or damper element. By utilizing an expected acceleration profile and event duration for an anticipated shock event an acceleration amplitude can be determined from a measure impact velocity. From this and a measured payload mass a system controller can determine the force necessary to be applied by the energy absorber in order to stop the payload over the full desired length of the available energy absorber stroke in order to minimize the forces experienced by the payload.

Owner:INNOVITAL LLC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com