Projectile and projectile support separating device under high-speed impacts of large-mass projectile

A projectile carrier and separation device technology, which is applied in the direction of projectiles, offensive equipment, weapon types, etc., can solve the problems of high impulse, the bell mouth structure can not meet the requirements, and the momentum increase of large-mass projectiles, so as to realize the separation and lifting structure Strength and impact stability, effective separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

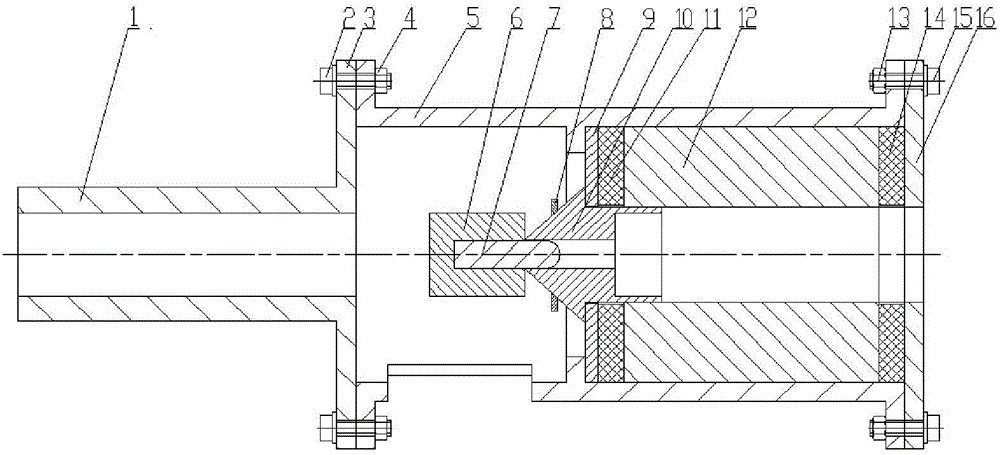

[0024] Comply with the above technical solutions, such as figure 1 , Figure 4 — Figure 6As shown, the first preferred embodiment of the present invention includes a bracket 5 , a separator 12 , a deceleration ring 8 , a backing plate 9 , a first rubber cushion 11 , an inert body 12 , a second rubber cushion 14 and a baffle 16 . The support 5 is a steel cylinder with a boss processed on the inner wall. The two ends of the cylinder are respectively equipped with a second flange 5-1 and a third flange 5-3. The second flange 5 -1 and the third flange 5-3 are respectively provided with 6 uniformly distributed through holes 5-4, and the support 5 passes through the through holes on the second flange 5-1 and the third flange 5-3 5-4 Use the first screw 2, the first nut 4, the second screw 13 and the second nut 15 to connect with the flange 3 and the baffle plate 16 on the gun barrel 1 respectively; There are three evenly distributed vent holes 5-2 on the circumference, the size ...

Embodiment 2

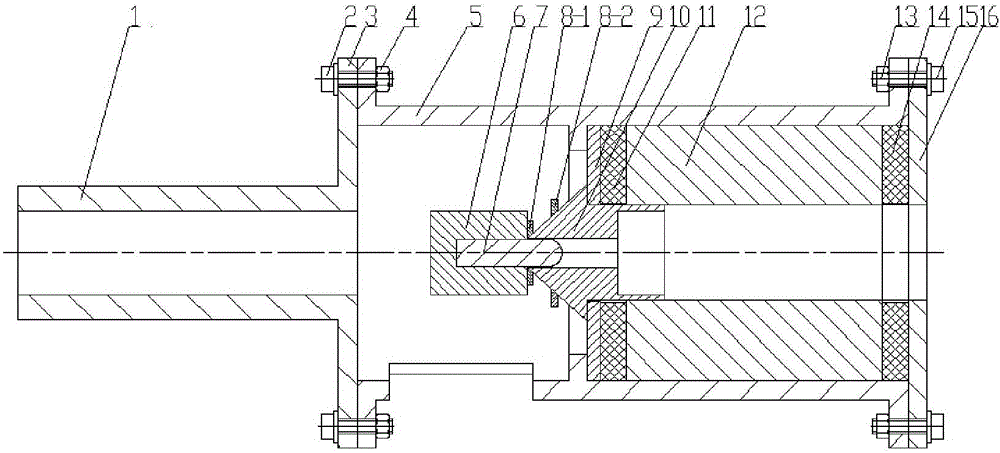

[0037] The overall structure and the material of the projectile support separation device under the high-speed impact of the large-mass projectile are the same as that of Embodiment 1. The difference between the second preferred embodiment and the first preferred embodiment is that in order to enable the present invention to operate at a higher speed ( greater than 500m / s) to realize the complete separation of projectile and bullet holders. Two deceleration rings are installed on the separator 10, which are respectively the first deceleration ring 8-1 and the second deceleration ring 8-2, and the first deceleration ring 8-1 and the second deceleration ring 8-2. The distance between the second deceleration ring 8-2 and the conical mouth of the separator 10 is respectively 0mm, 1 / 2 the conical length, the diameter of the first deceleration ring 8-1 and the second deceleration ring 8-2 is the largest with the central variable diameter hole The aperture ratio is 2.5:1, the thicknes...

Embodiment 3

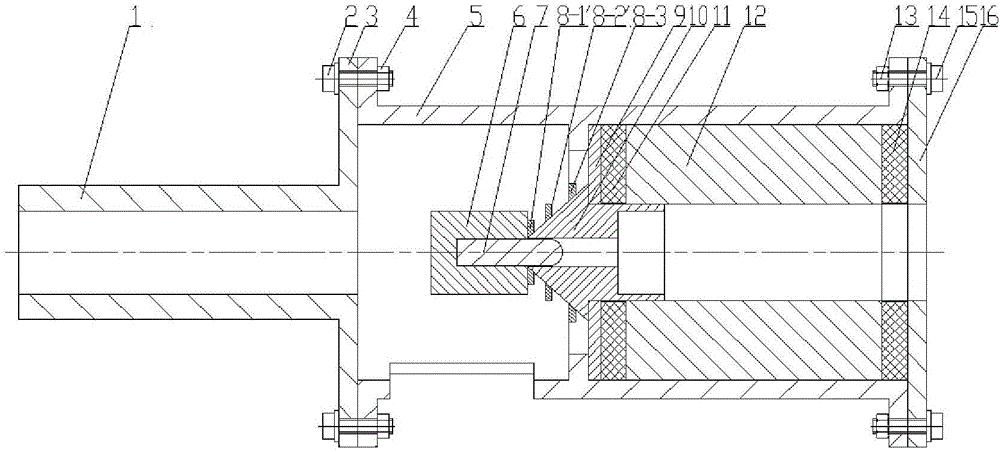

[0043] The overall structure and the material of the projectile carrier separation device under the high-speed impact of the large-mass projectile are the same as in Embodiment 1. The difference between the third preferred embodiment and the first preferred embodiment is that in order to enable the present invention to operate at a higher speed ( greater than 550m / s) to realize the complete separation of projectiles and projectile supports, three deceleration rings are installed on the separator 10, which are respectively the third deceleration ring 8-1', the fourth deceleration ring 8-2' and the fifth deceleration ring 8-3, The distances between the third deceleration ring 8-1', the fourth deceleration ring 8-2', the fifth deceleration ring 8-3 and the conical mouth of the separator 10 are respectively 0mm, 1 / 3 conical length and 1 / 3 conical Shape length, the ratio of the diameter of the third deceleration ring 8-1', the fourth deceleration ring 8-2' and the fifth deceleration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com