Patents

Literature

99 results about "Light-gas gun" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

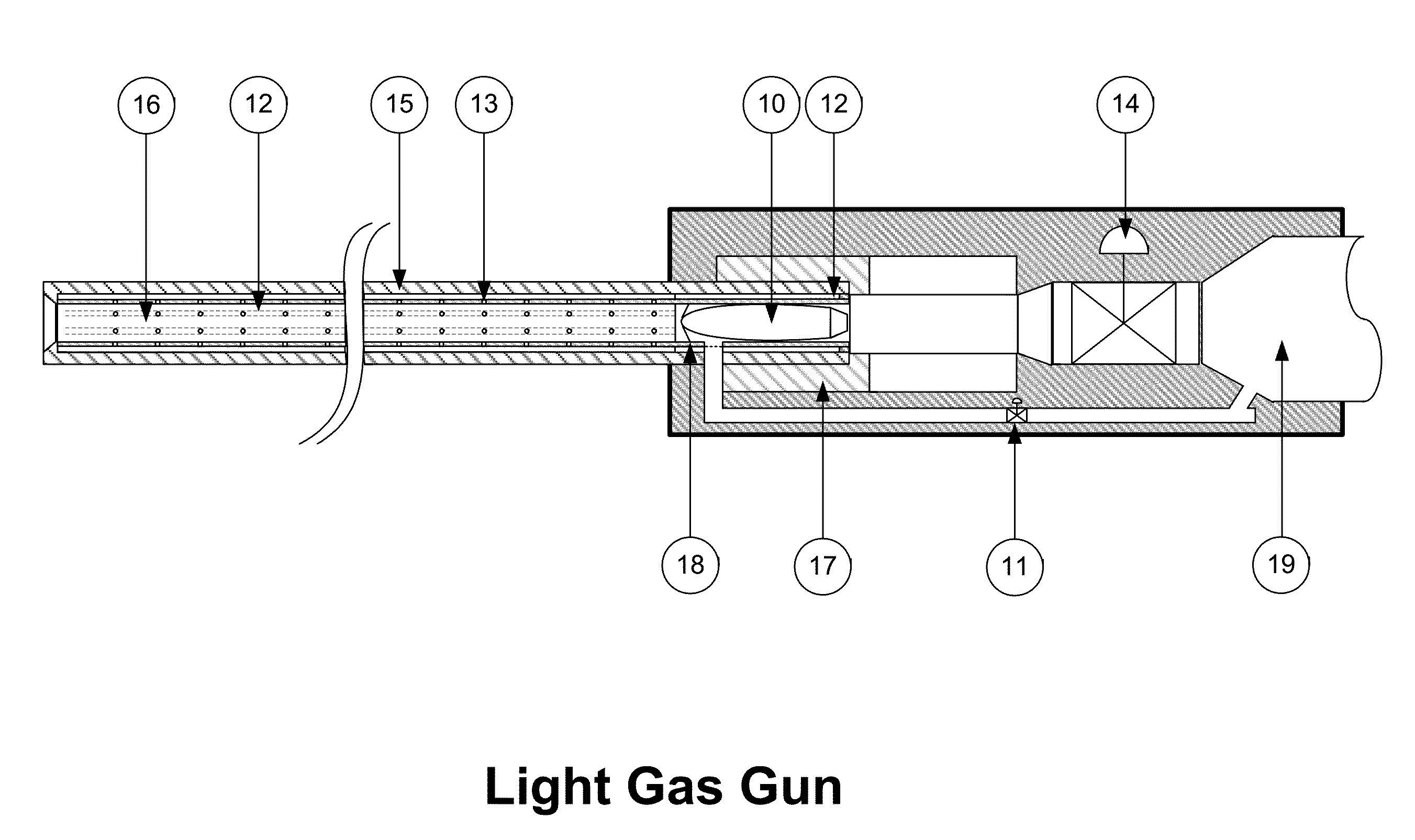

The light-gas gun is an apparatus for physics experiments, a highly specialized gun designed to generate very high velocities. It is usually used to study high-speed impact phenomena (hypervelocity research), such as the formation of impact craters by meteorites or the erosion of materials by micrometeoroids. Some basic materials research relies on projectile impact to create high pressure: such systems are capable of forcing liquid hydrogen into a metallic state.

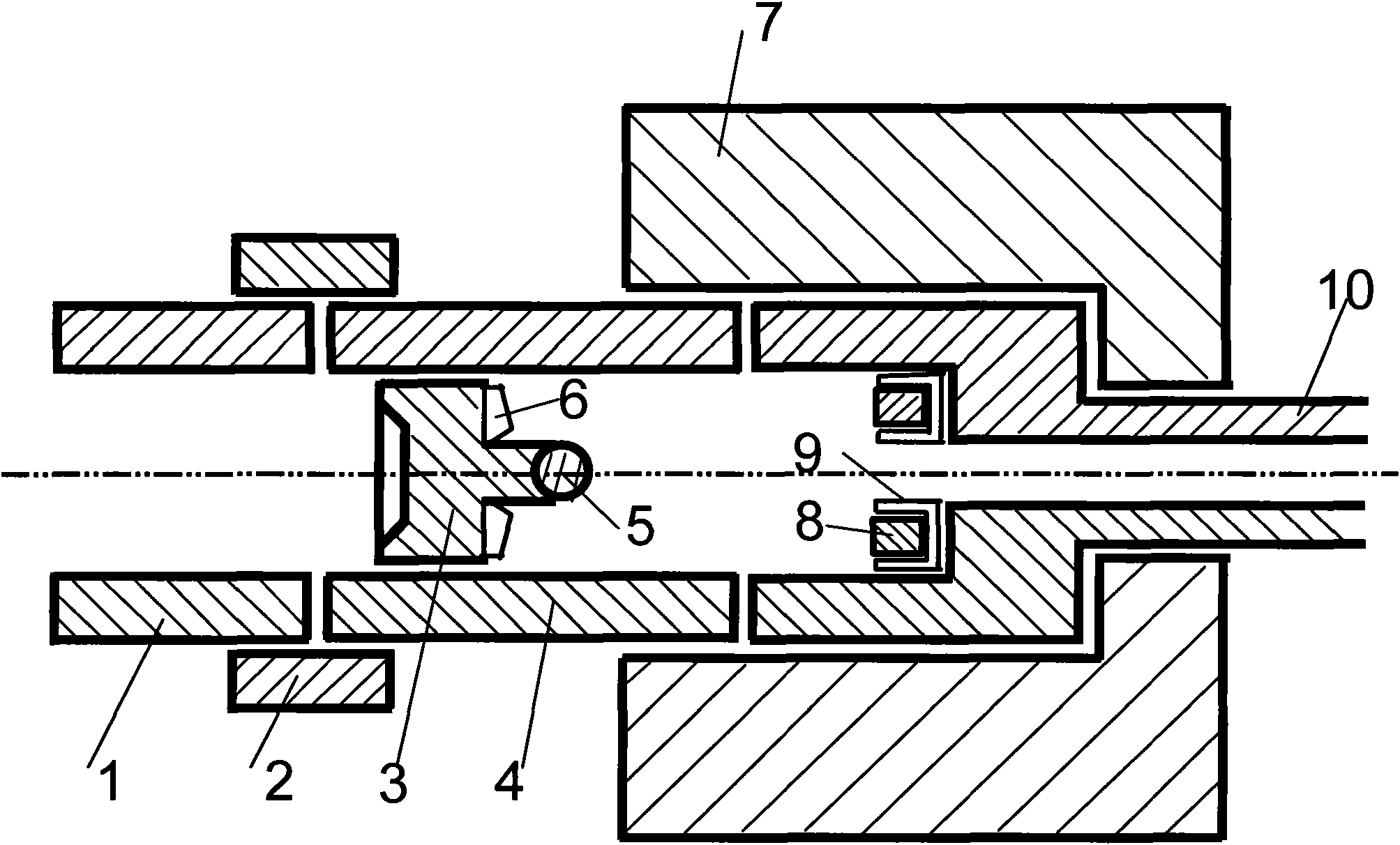

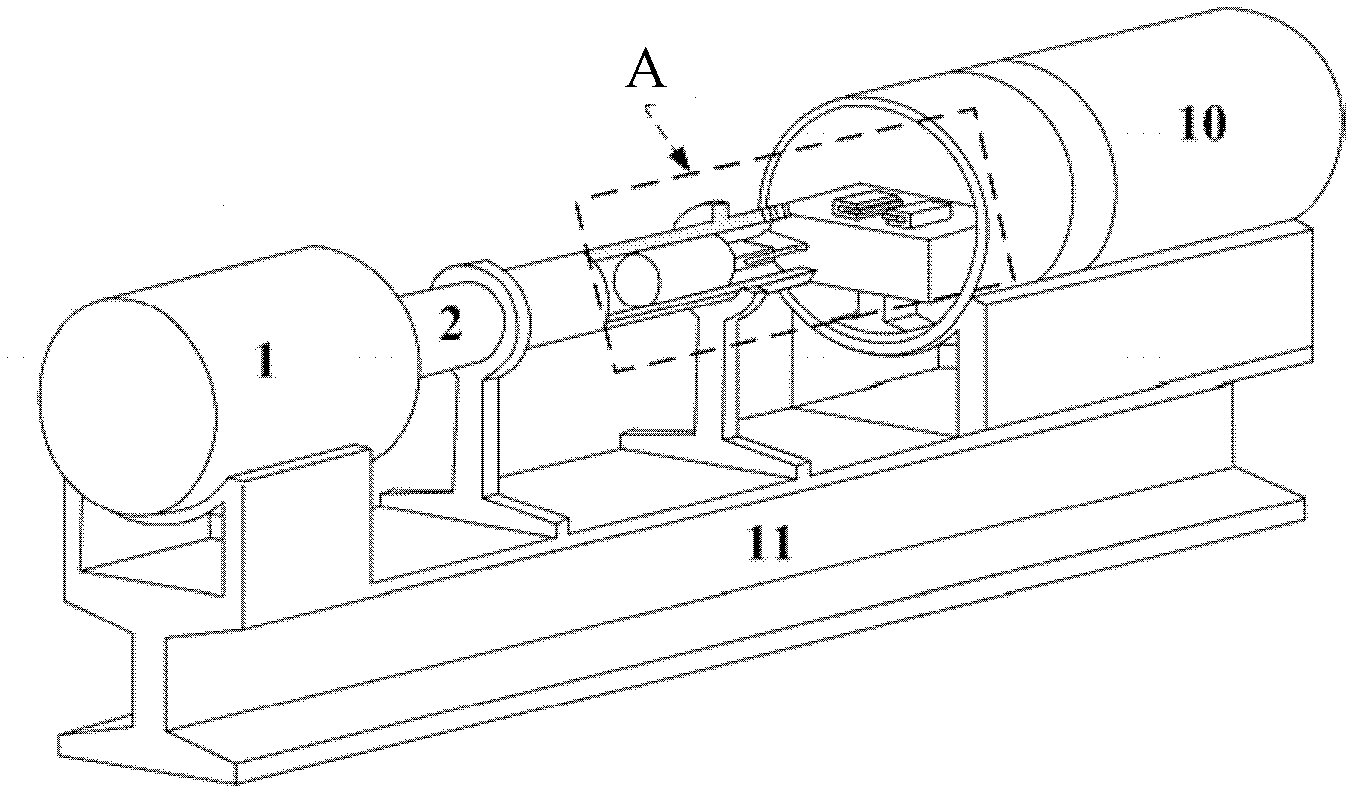

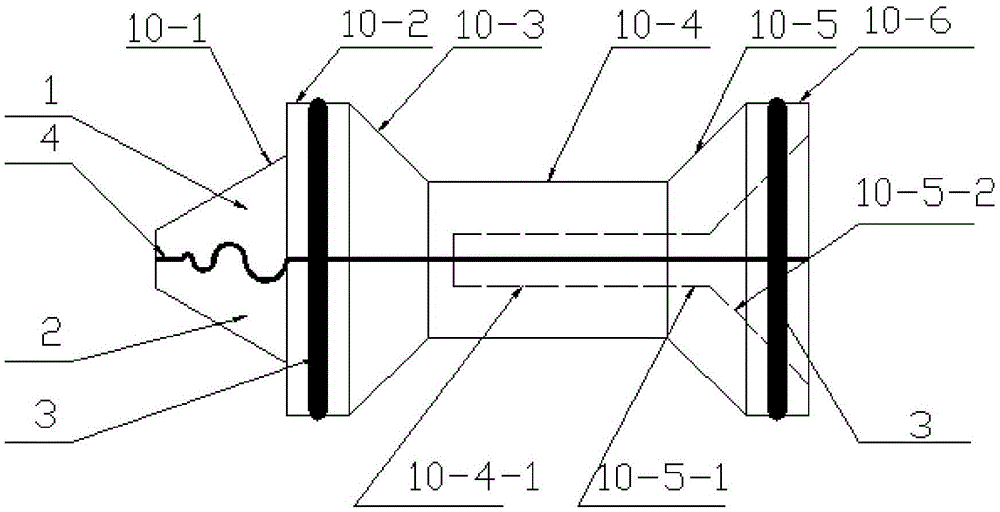

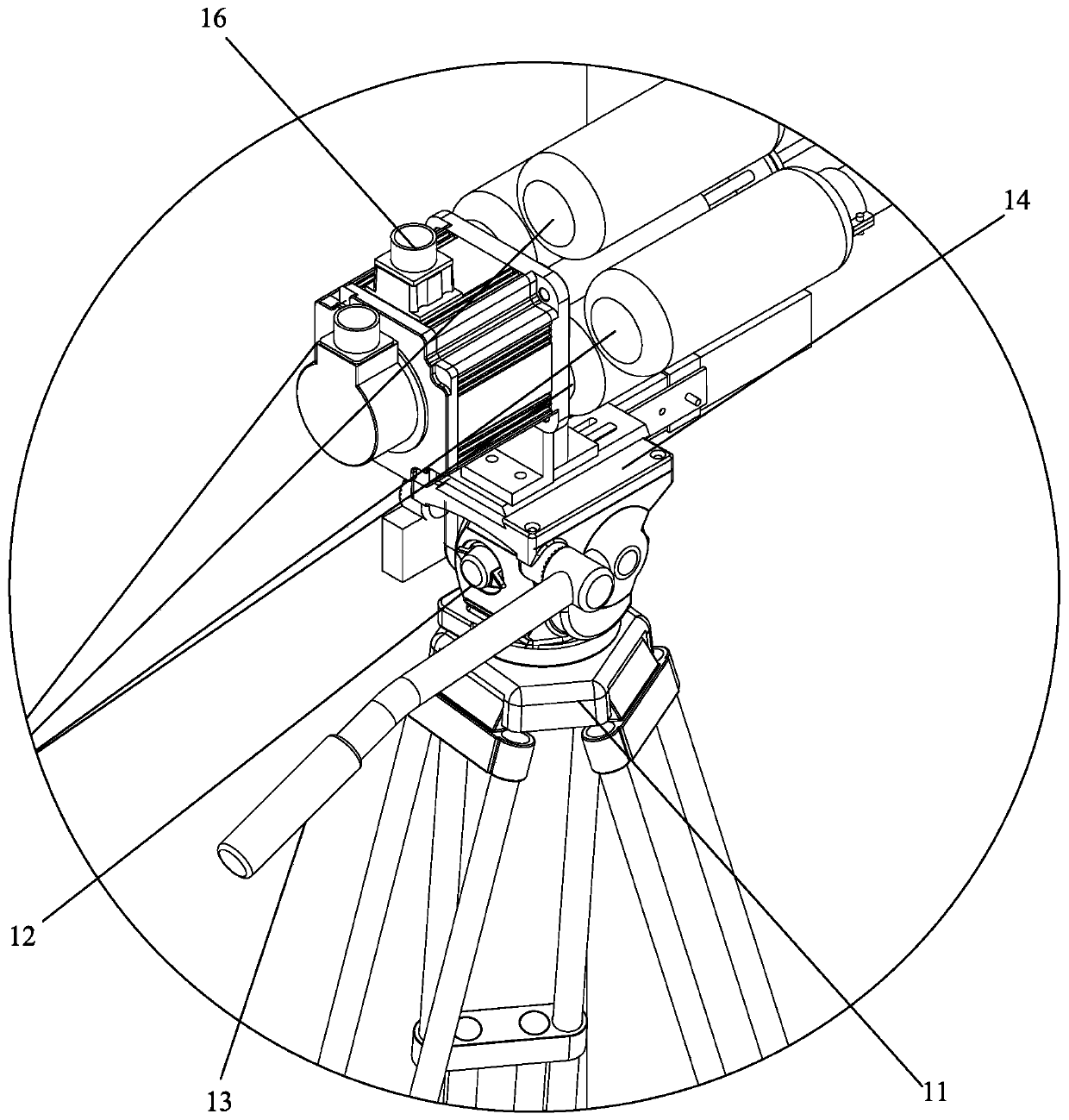

Small two-stage light-gas gun

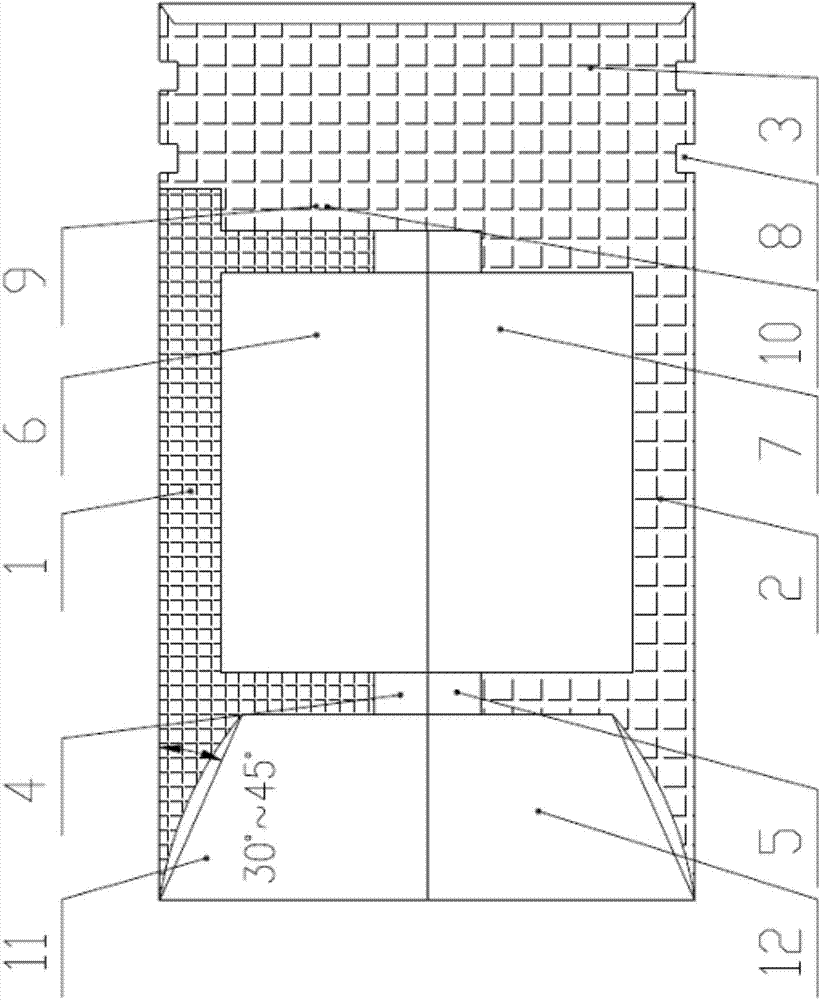

ActiveCN103322857AIncrease the effective areaAvoid damageCompressed gas gunsGas chamberHigh pressure

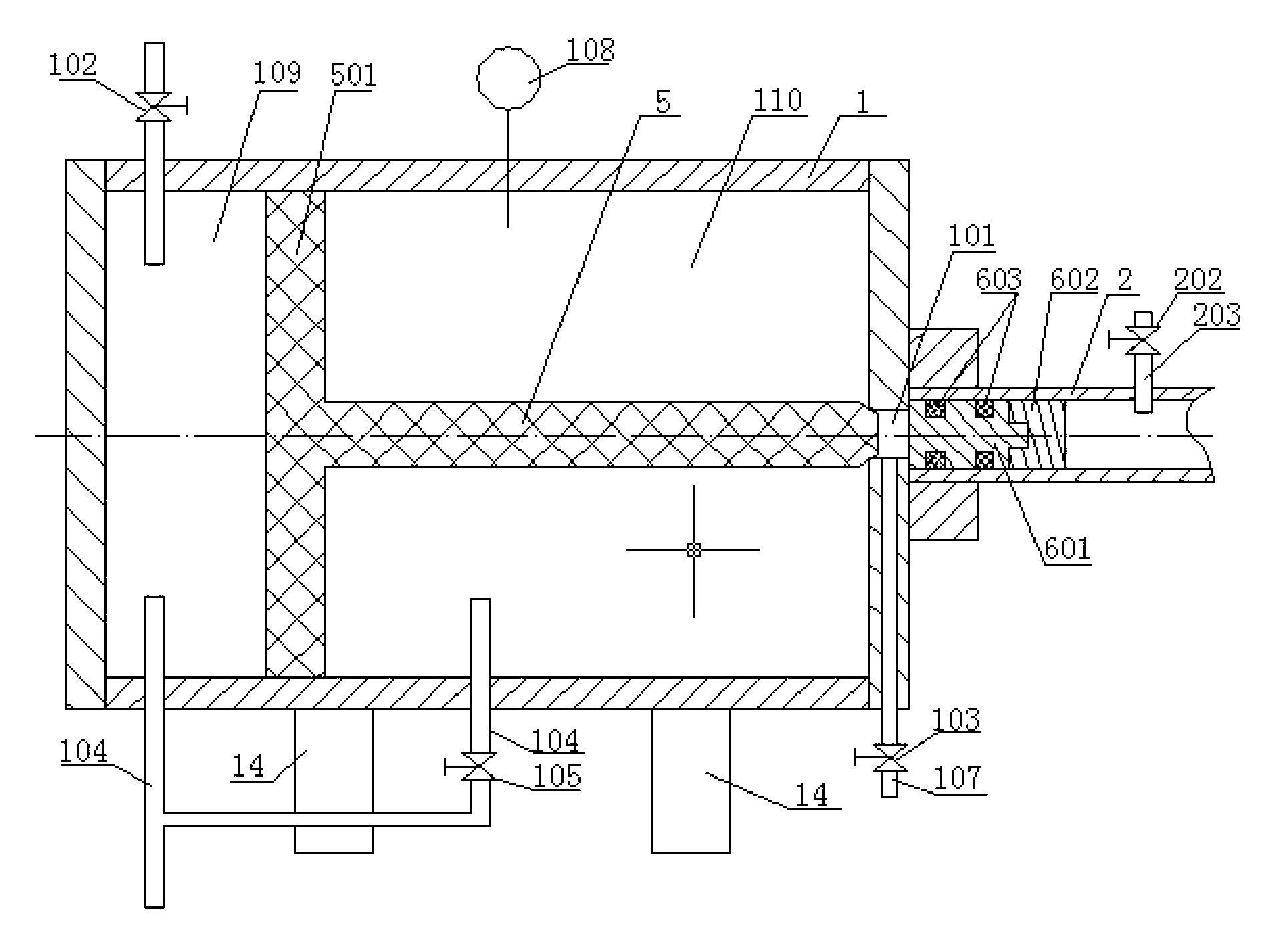

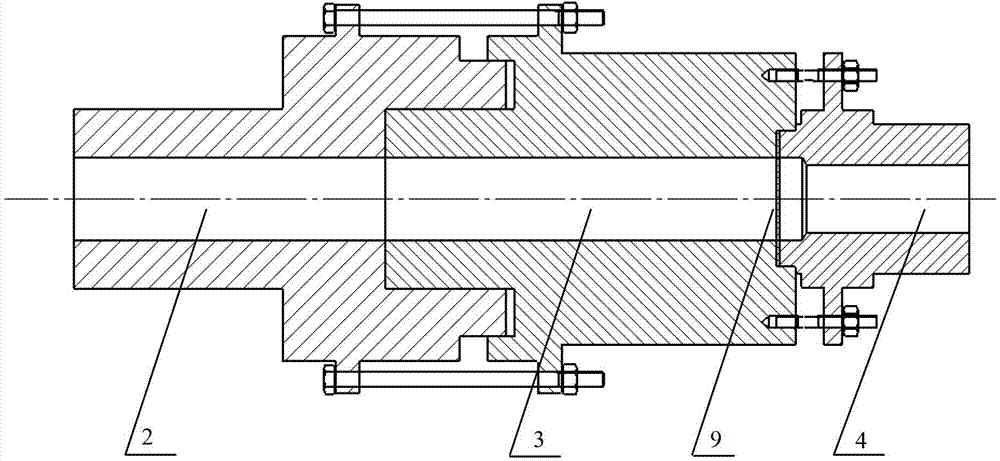

The invention discloses a small two-stage light-gas gun and relates to a light-gas gun. The small two-stage light-gas gun comprises a cylinder barrel, a pressure transmitting tube, a pressing column, a launching tube, a piston handle, a pressure transmitting body, a membrane, a membrane rupturing device, a first sealing ring, a metal sealing ring, a support and a plurality of supporting seats; a piston on the piston handle is in sliding contact with the inner circumferential surface of a gas chamber; one end of the pressure transmitting tube is connected with a gas port in a threaded manner, and the pressure transmitting tube is hermetically connected with the pressing column; the pressure transmitting body is mounted in the pressure transmitting tube; the first sealing ring and the metal sealing ring are mounted in a mounting groove from the inside to the outside, the membrane is hermetically connected with the membrane rupturing device, and the membrane rupturing device is hermetically connected with the launching tube; the cylinder barrel is mounted on the support, and the pressure transmitting tube and the launching tube are respectively detachably connected onto the supporting seats. The small two-stage light-gas gun has the advantages that problems that an existing light-gas gun is driven by gunpowder at a primary stage, accordingly, environments are polluted, occupied space is large, sealing cannot be carried out in a membrane rupturing procedure implemented by the aid of high-pressure gas and the bullet launching speed cannot be increased are solved, and the small two-stage light-gas gun is used in fields of spacecrafts or research on material performance and the like.

Owner:HARBIN INST OF TECH

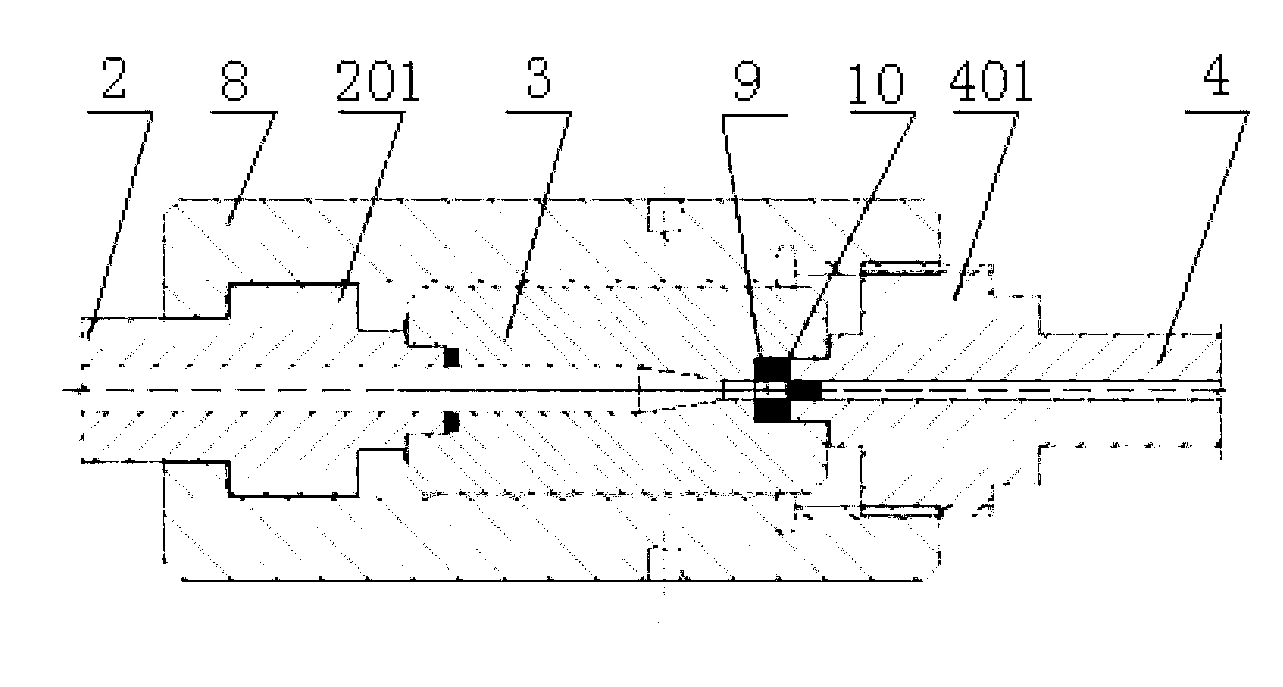

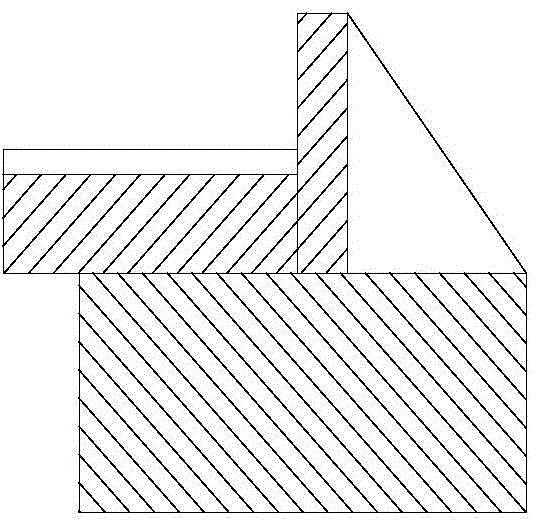

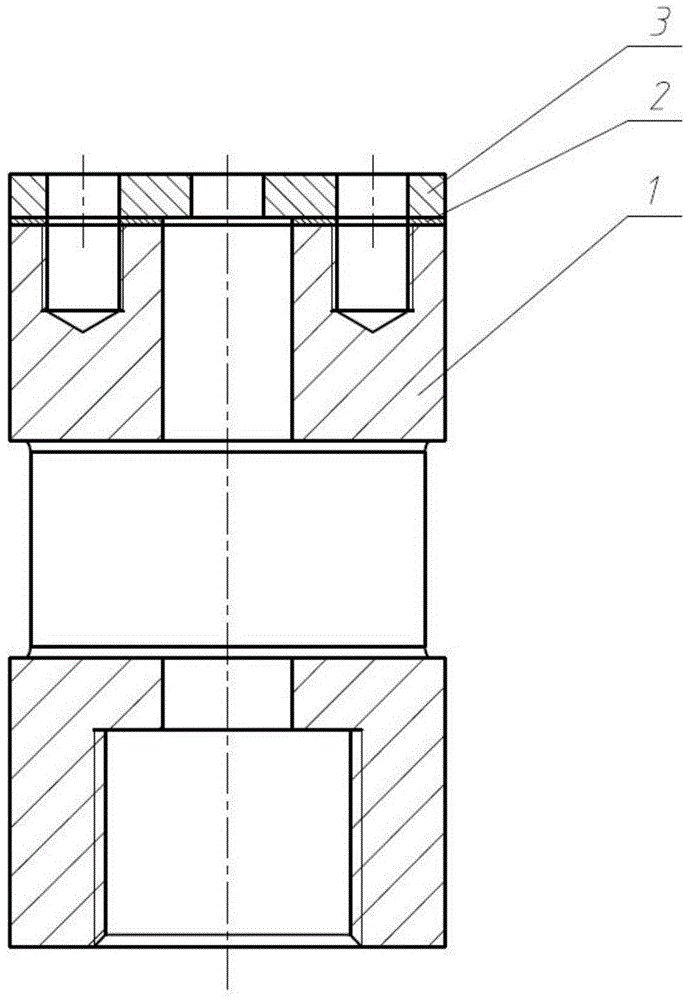

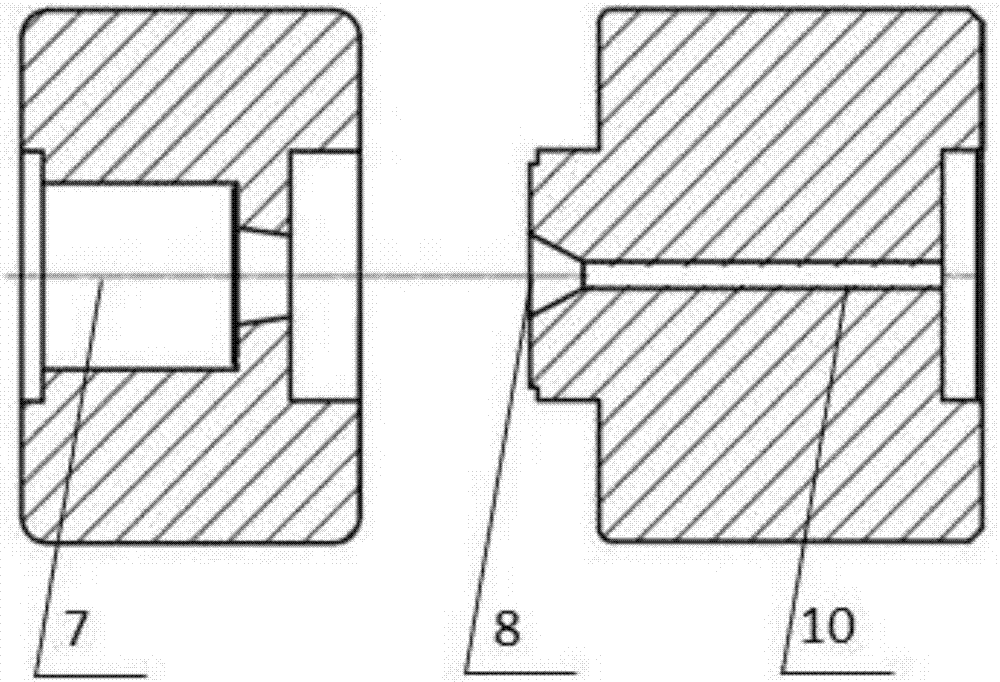

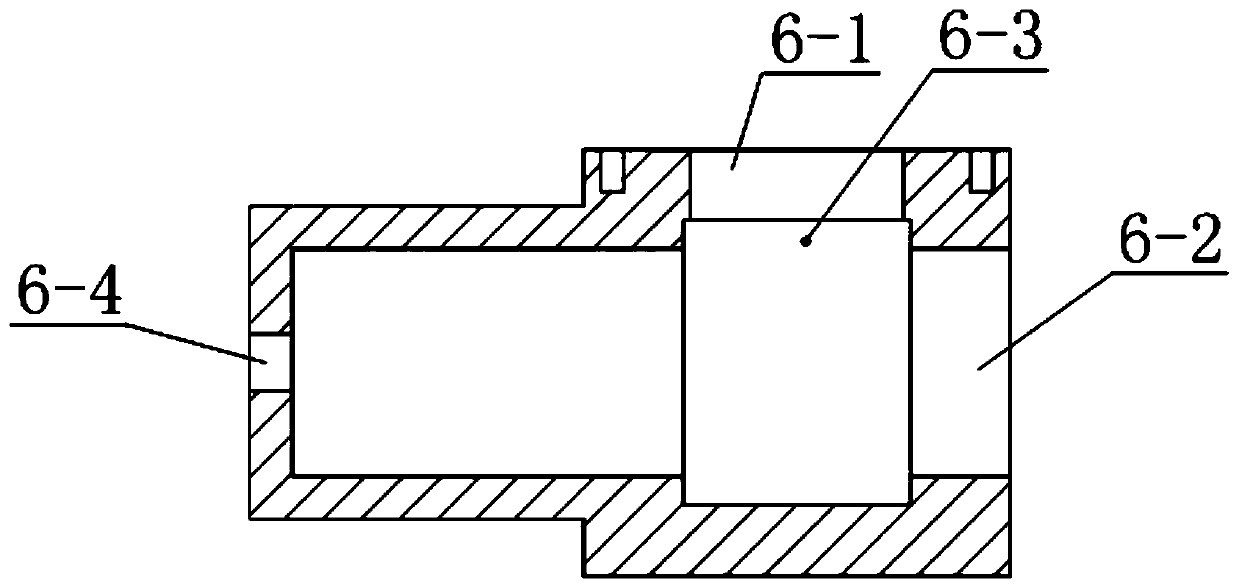

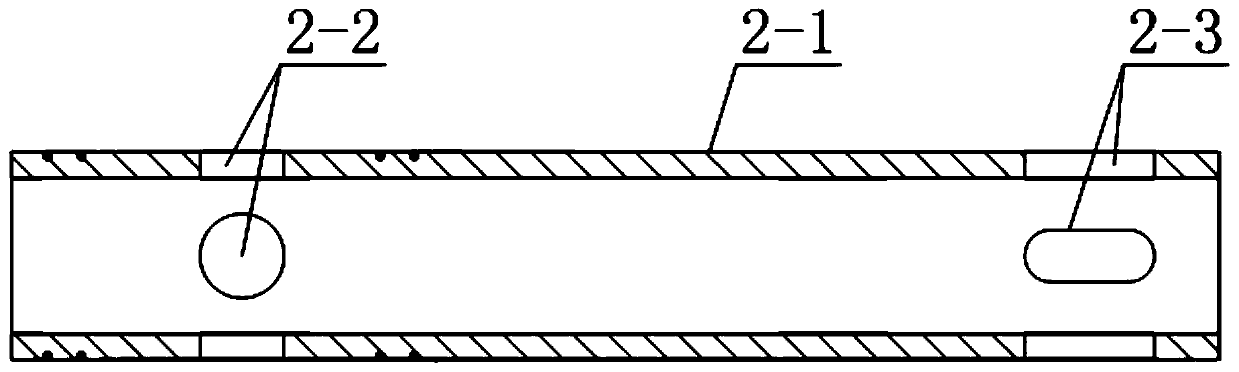

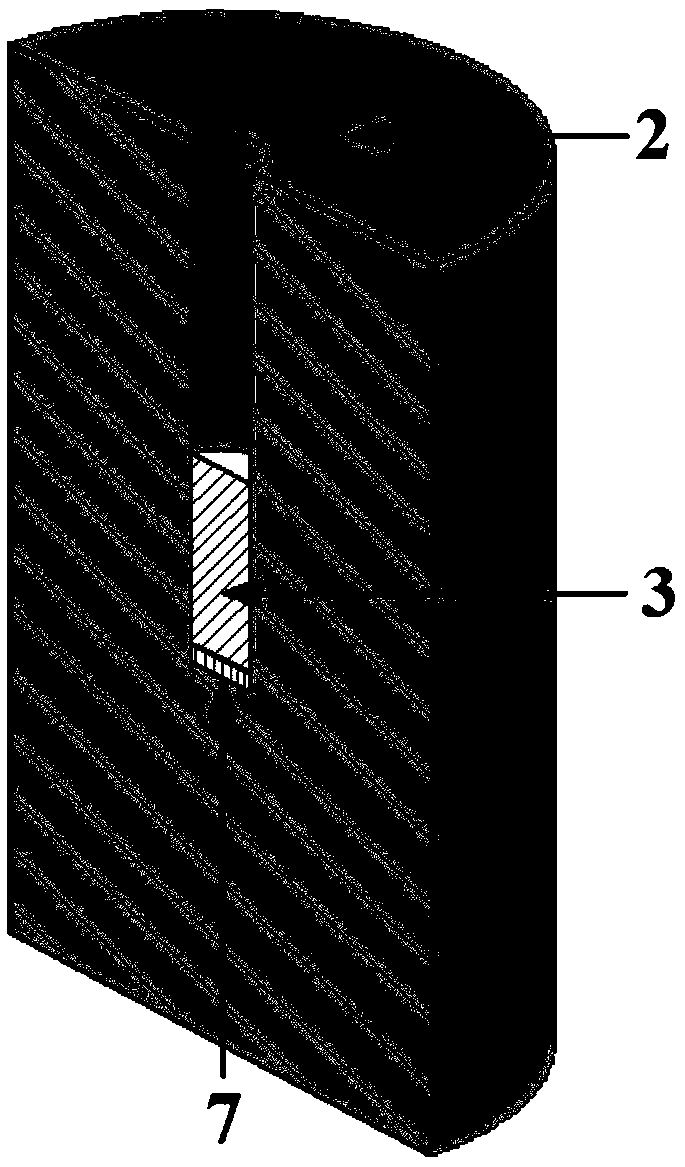

Light-gas gun pneumatic separation sabot

ActiveCN104729364ARealize automatic separationGuaranteed structural strengthProjectilesAerodynamic dragExternal ballistics

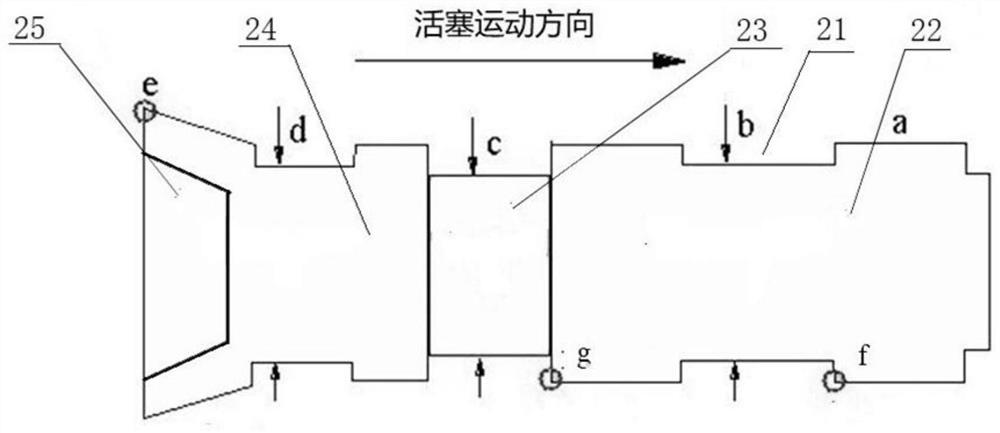

The invention relates to a light-gas gun pneumatic separation sabot, and aims at solving the problems that for an existing sabot, an additional device is needed to conduct separation on the sabot, the effect is not ideal and the cost is increased. The light-gas gun pneumatic separation sabot is composed of an upper supporting disc, a lower supporting disc and a base plate; the upper supporting disc and the lower supporting disc are two corresponding semi-cylinders. An upper half bullet hole is formed in the center of the upper supporting disc, and the middle of the upper half bullet hole is hollowed out to be of a hollow structure; the lower supporting disc and the base plate are formed to be a whole, a lower half bullet hole is formed in the center of the lower supporting disc, and the middle of the lower half bullet hole is hollowed out to be of the hollow structure; two seal grooves are carved on the base plate. The upper half bullet hole of the upper supporting disc corresponds to the lower half bullet hole of the lower supporting disc, a semicircle notch of the upper supporting disc is engaged with a boss of the lower supporting disc, under the condition of not adding a separating device, automatic separation of the sabot and a bullet is achieved through air resistance in a target chamber, and the light-gas gun pneumatic separation sabot has the advantages of improving the external ballistic property of the bullet and reducing the firing cost.

Owner:NORTHWEST INST OF NUCLEAR TECH

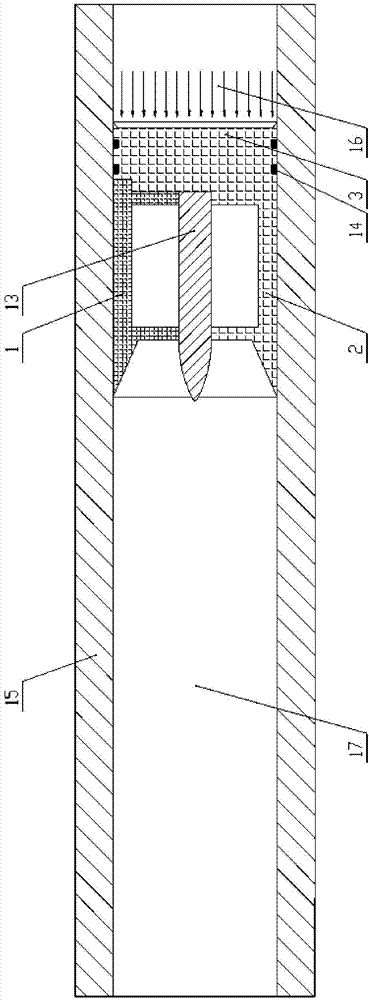

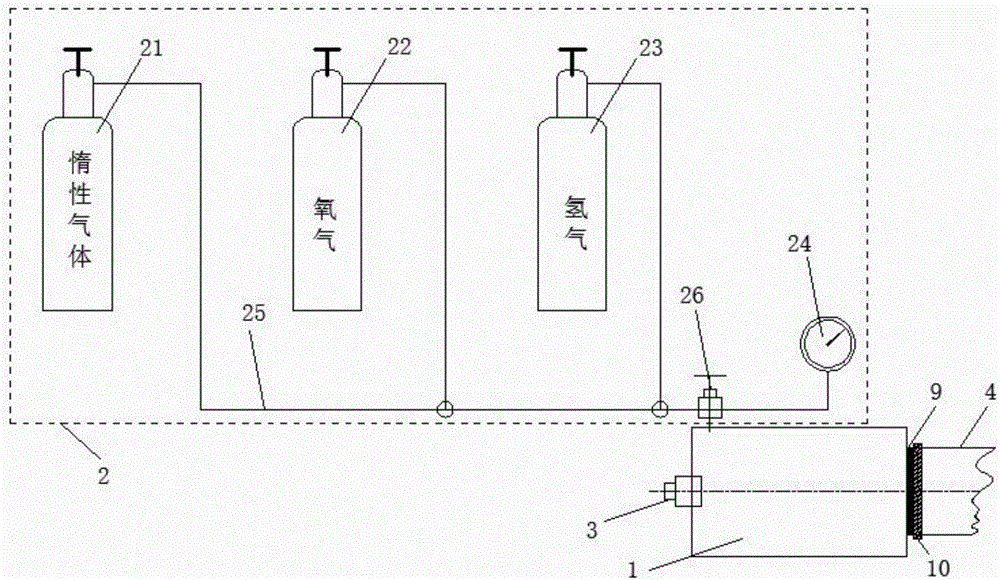

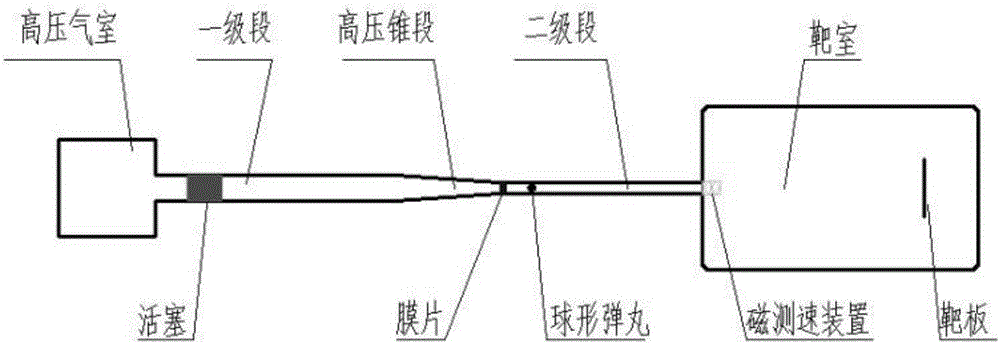

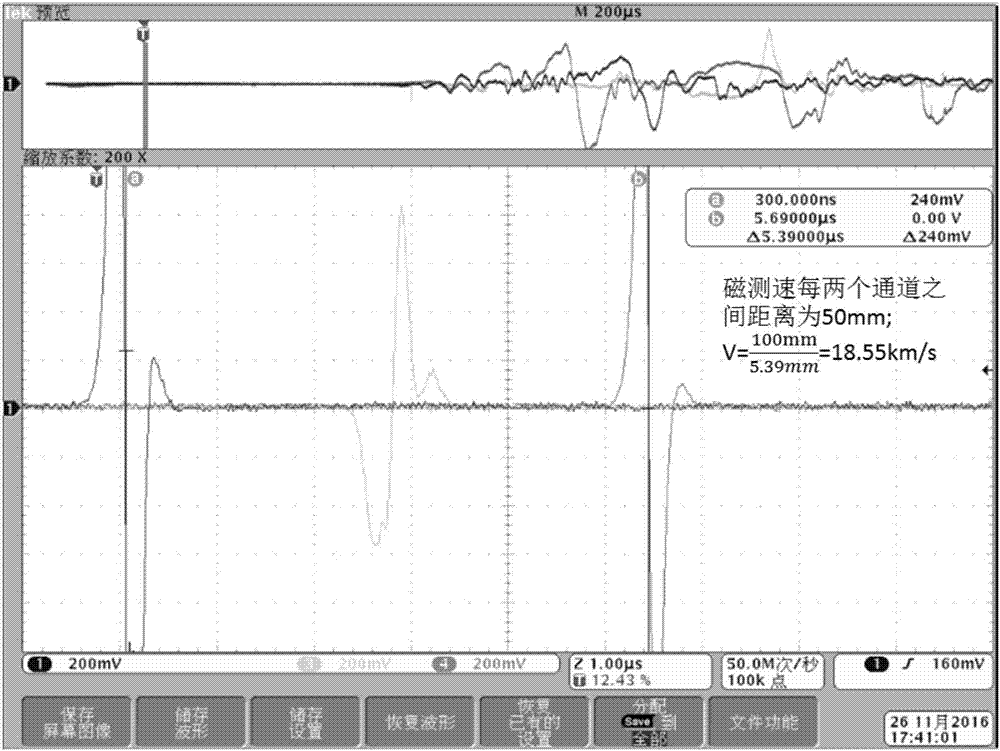

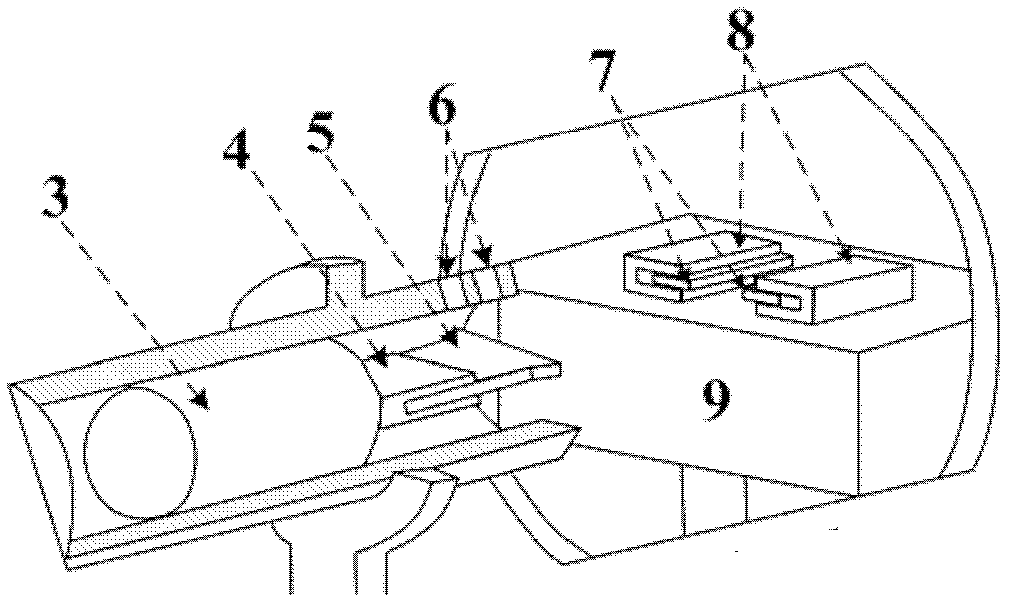

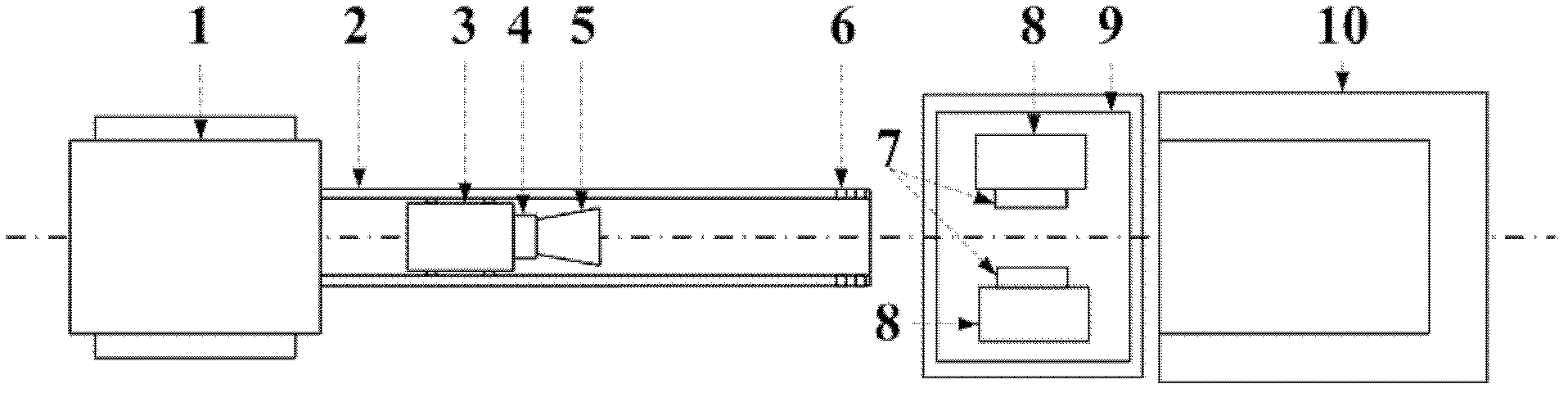

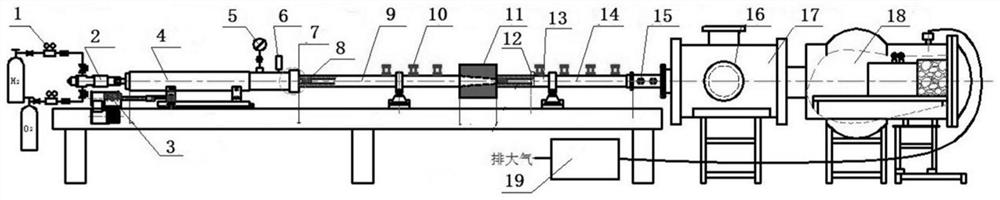

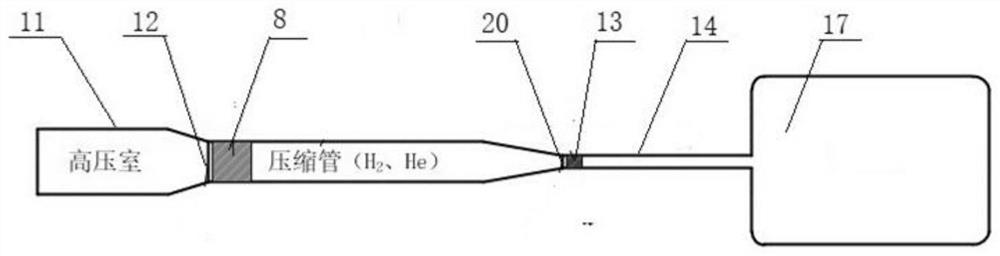

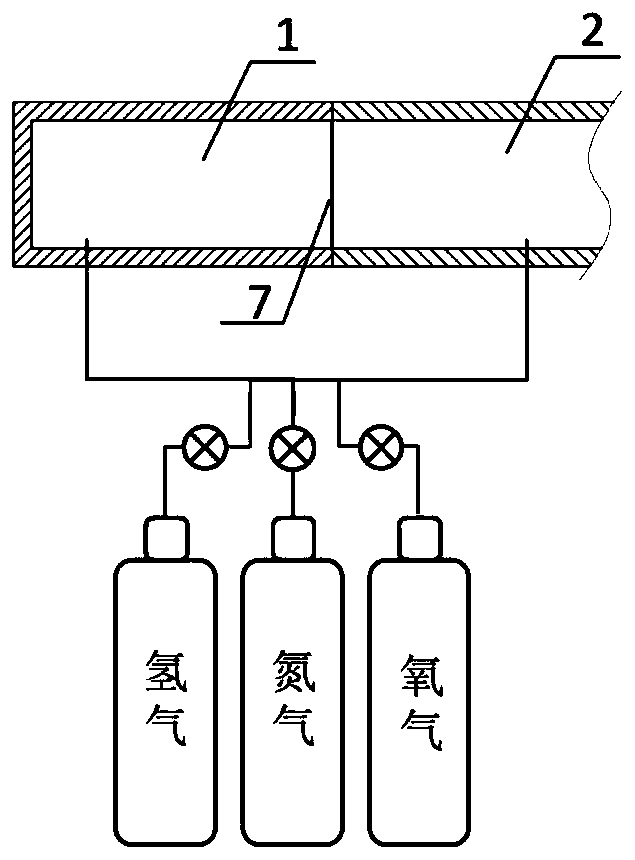

Two-stage light gas gun driven through hydrogen energy

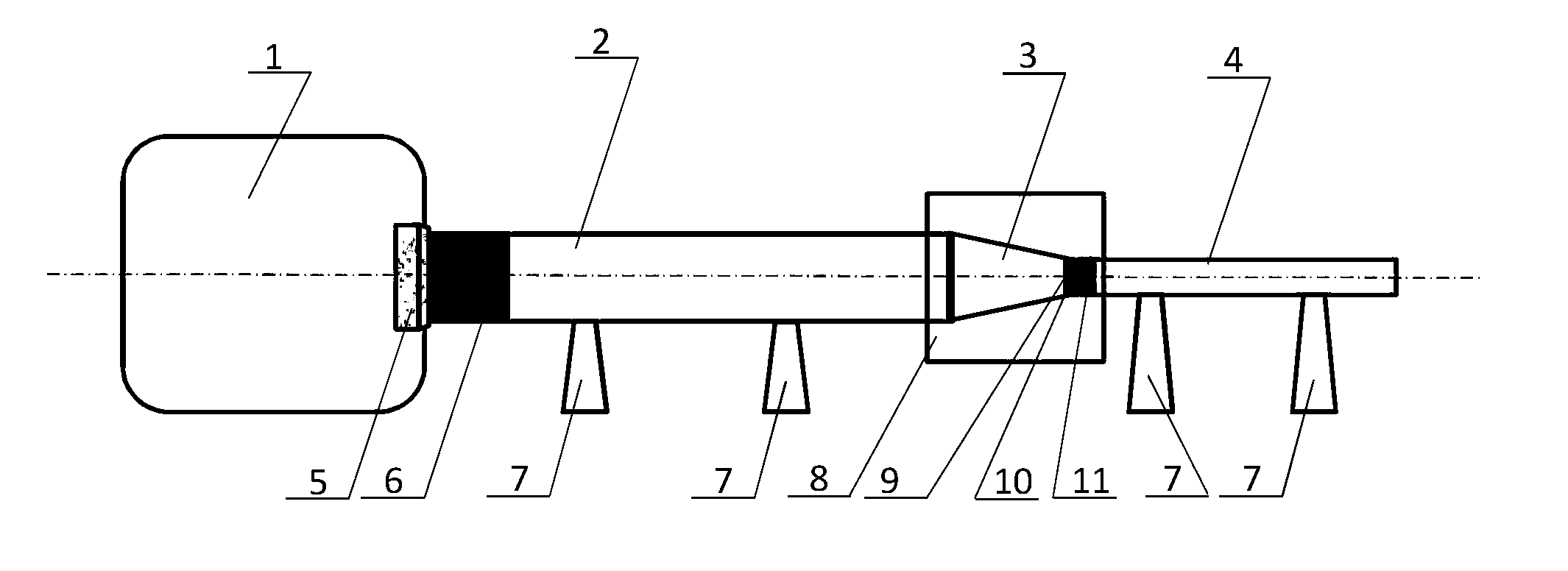

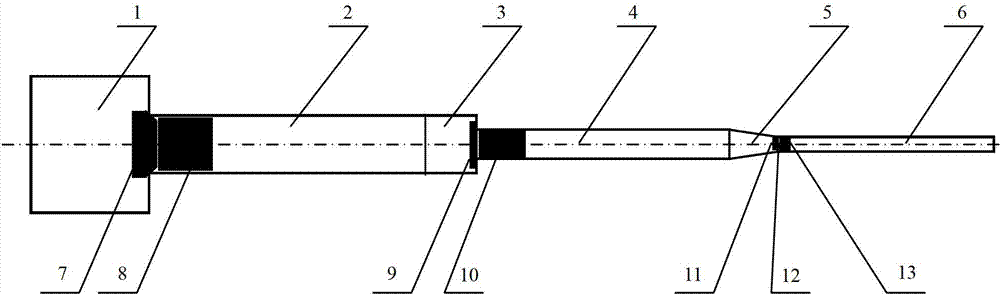

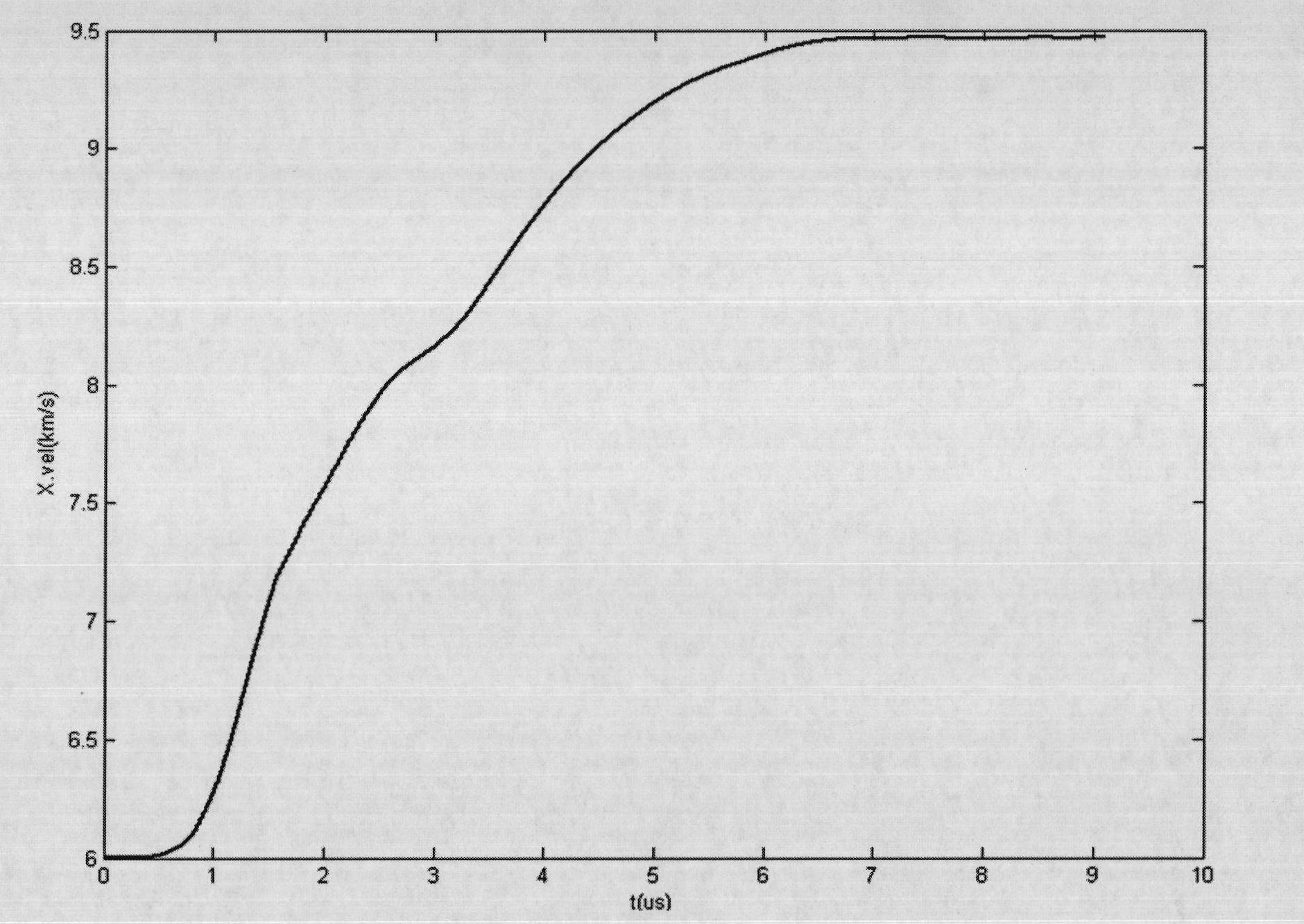

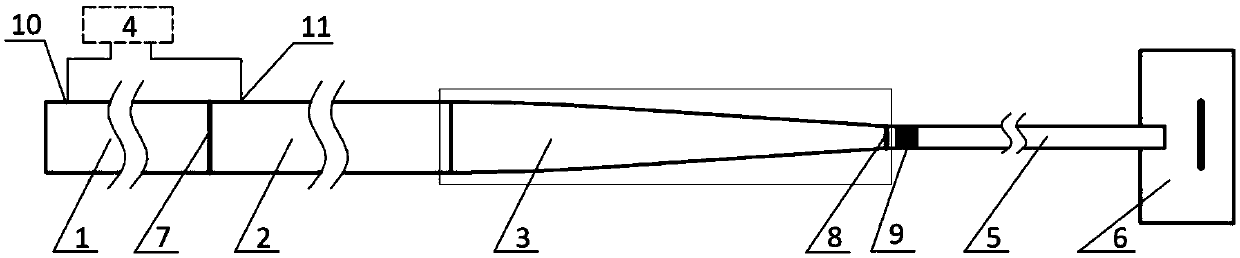

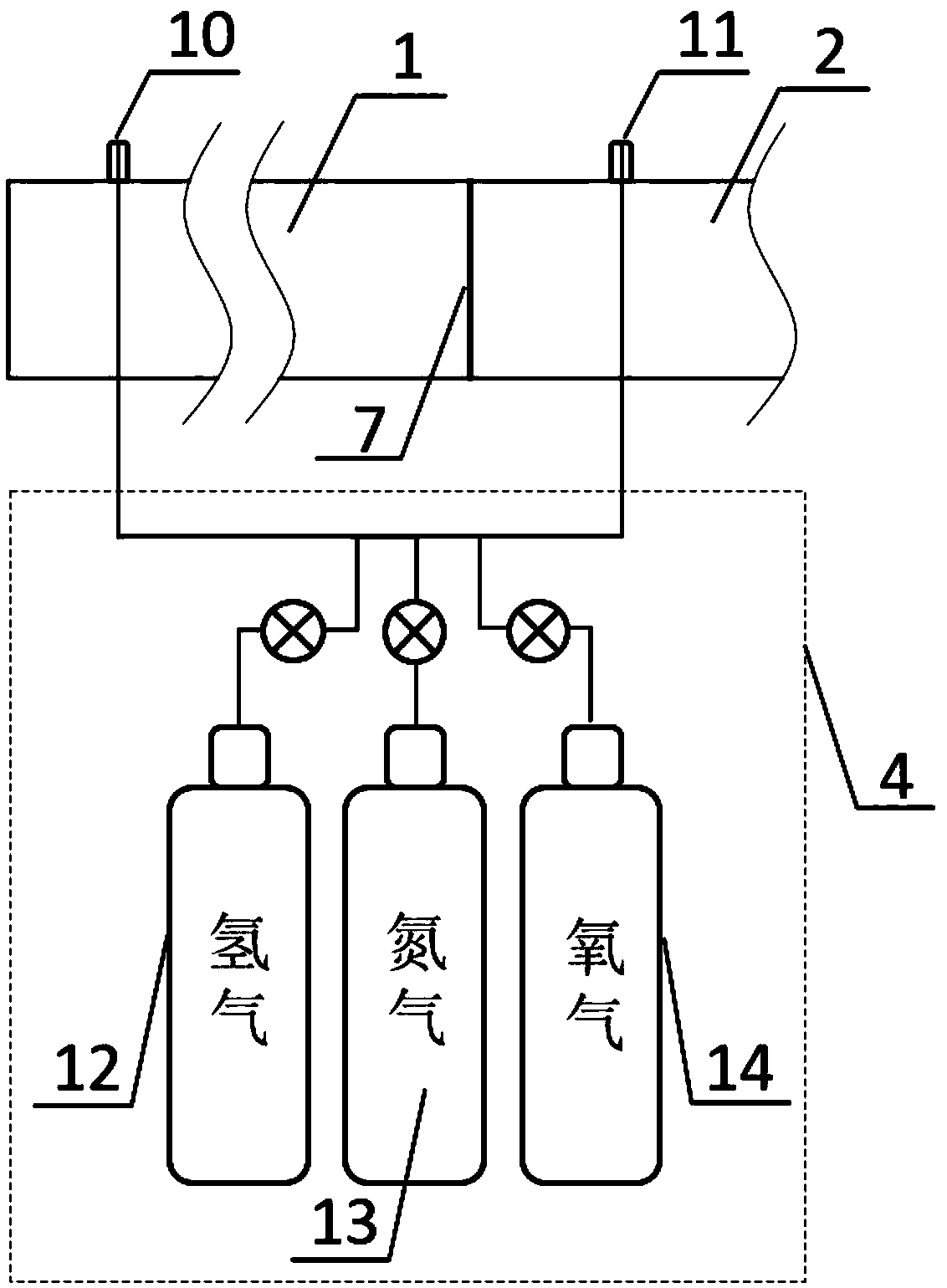

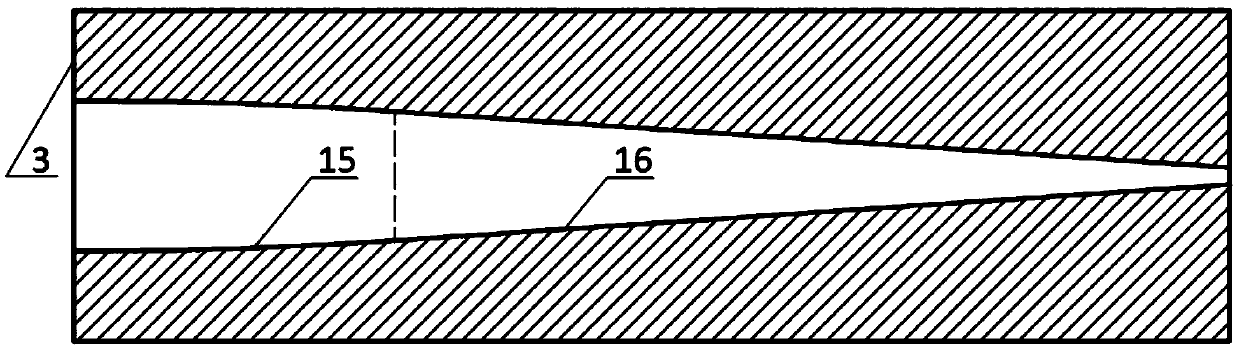

The invention belongs to the technical field of light gas gun experiments, and particularly relates to a light gas gun driven through hydrogen and oxygen mixed gas detonation, in particular to a two-stage light gas gun driven through hydrogen energy. According to the technical scheme, the two-stage light gas gun driven through hydrogen energy comprises a combustor, a gas injection device, an ignition device, a pump pipe, a high-pressure cone section, a transmitting pipe, a target chamber and a magnetic speed testing device, wherein the ignition device is installed at one end of the combustor, the other end, opposite to the end with the ignition device, of the combustor is connected with the pump pipe, and a pump pipe membrane and a pump pipe membrane breaker are arranged at the junction; the gas injection device is used for injecting hydrogen, oxygen and inert gas into the combustor; a piston is arranged in the pump pipe; the large-diameter portion of the high-pressure cone section is connected with the pump pipe; the small-diameter portion of the high-pressure cone section is connected with the transmitting pipe, and a transmitting pipe membrane and a transmitting pipe membrane breaker are arranged at the junction; shots are arranged in the transmitting pipe, and one end of the transmitting pipe is located in the target chamber; and the magnetic speed testing device is installed at the tail end of the transmitting pipe and connected with an oscilloscope. The two-stage light gas gun is driven through hydrogen energy instead of gunpowder, damage to the gun is small, no particular product is generated, and a gun barrel can be cleaned conveniently after experiments.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

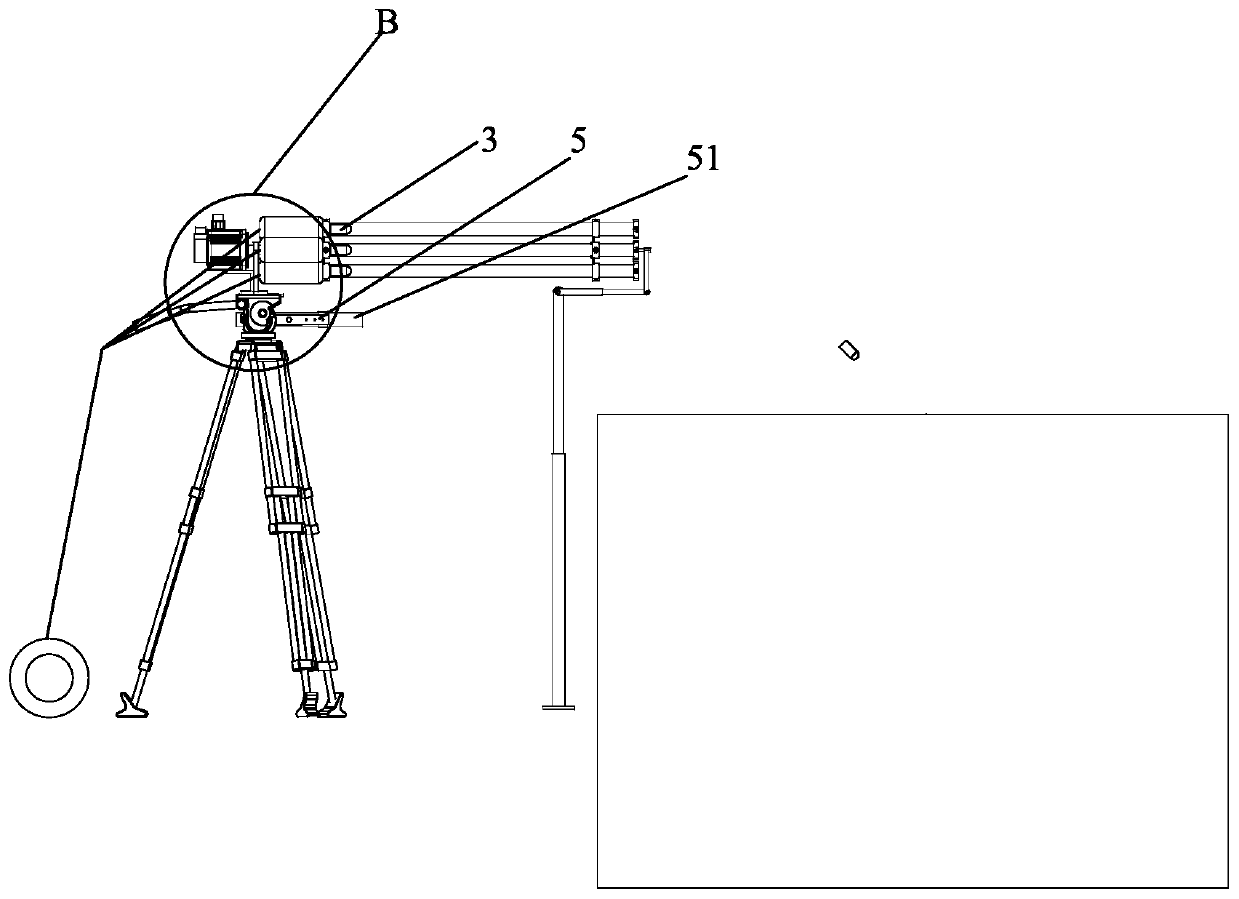

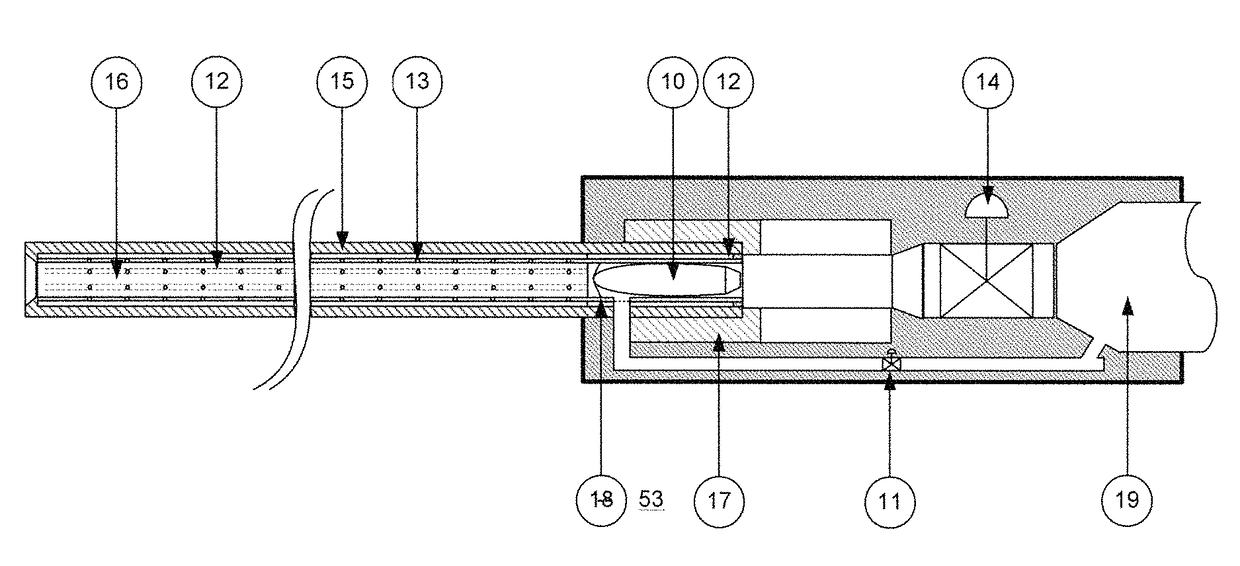

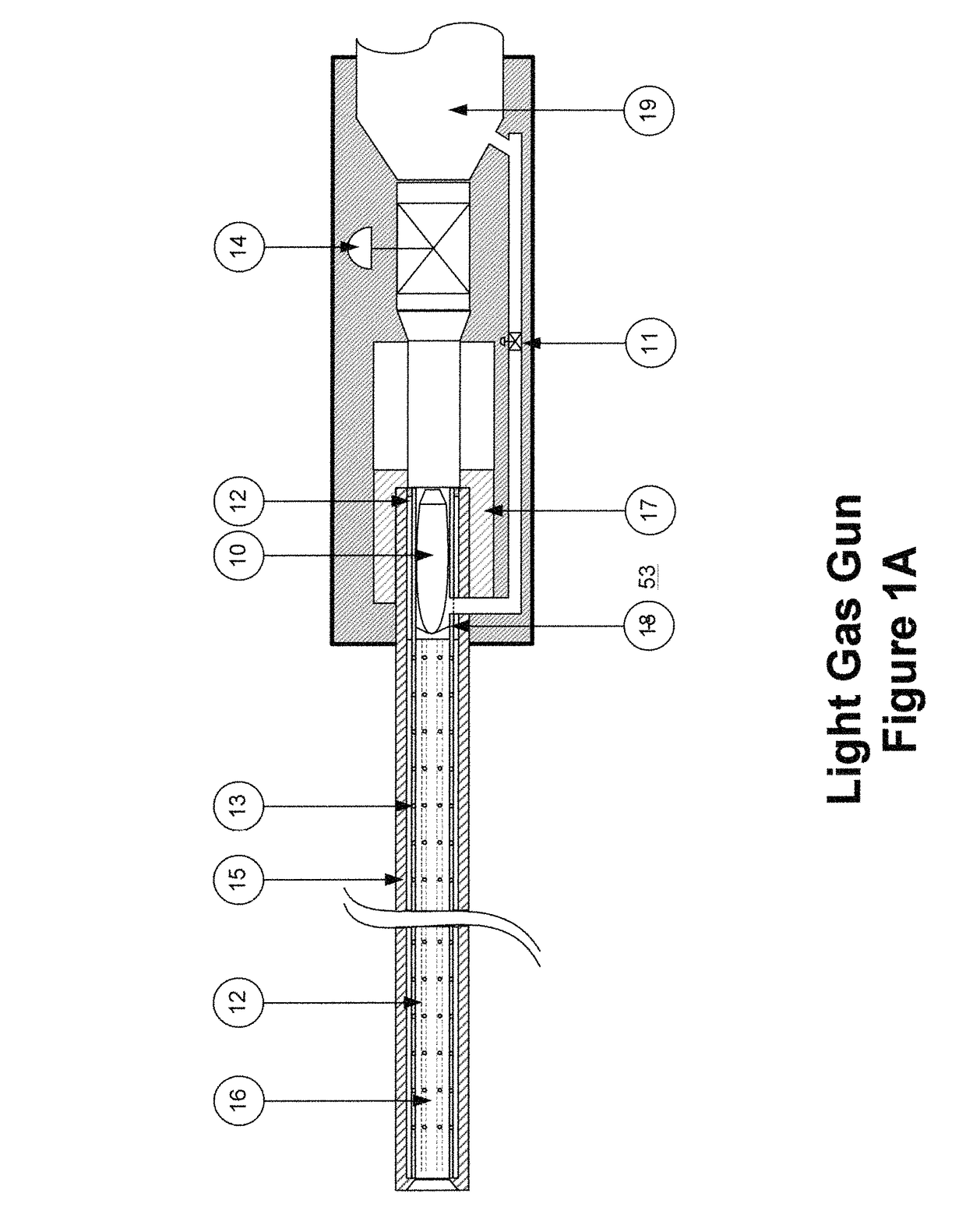

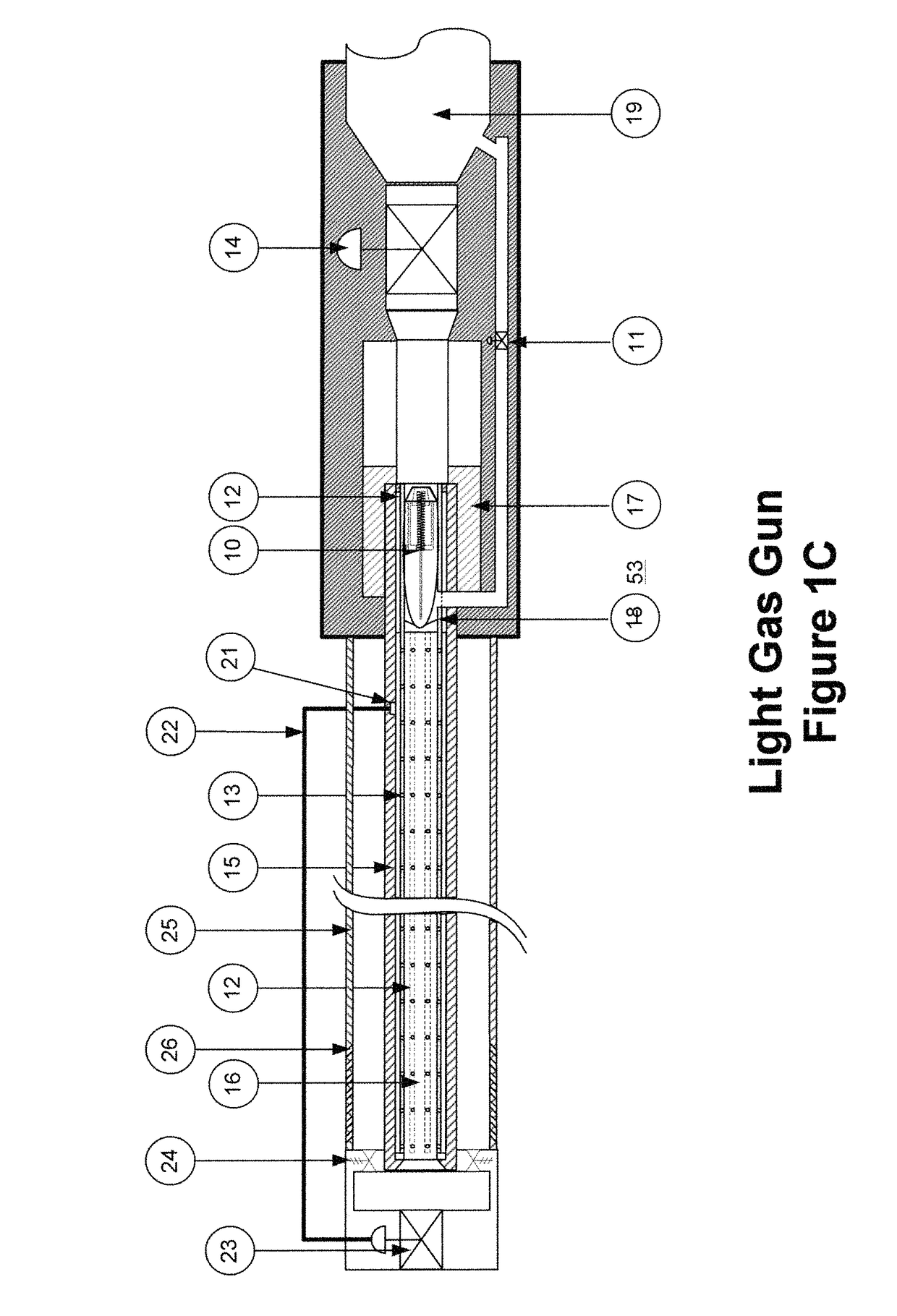

Light Gas Gun

ActiveUS20160161212A1Optimization rangeIncrease lethalityAmmunition projectilesMissile propulsionEngineeringAcoustic signature

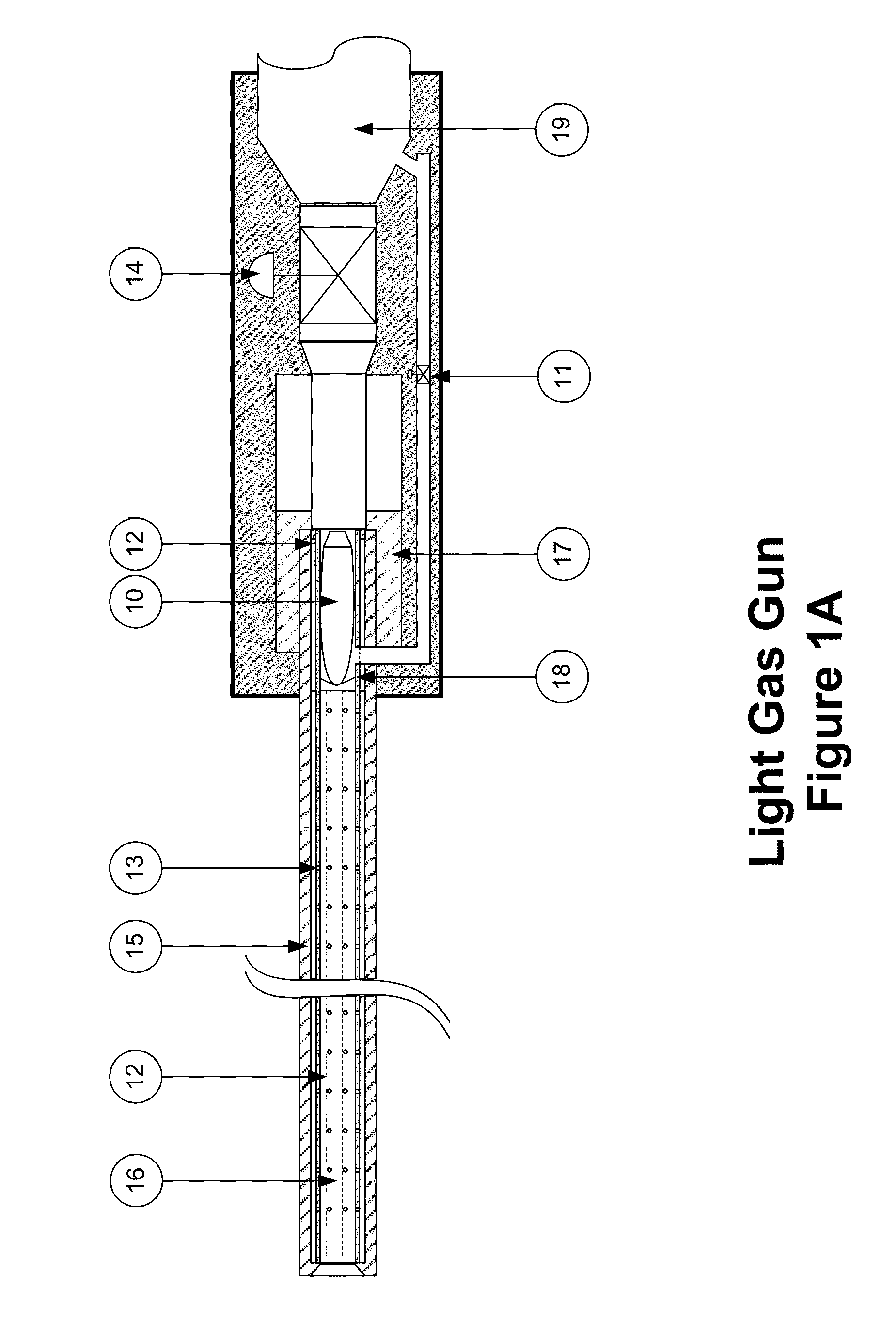

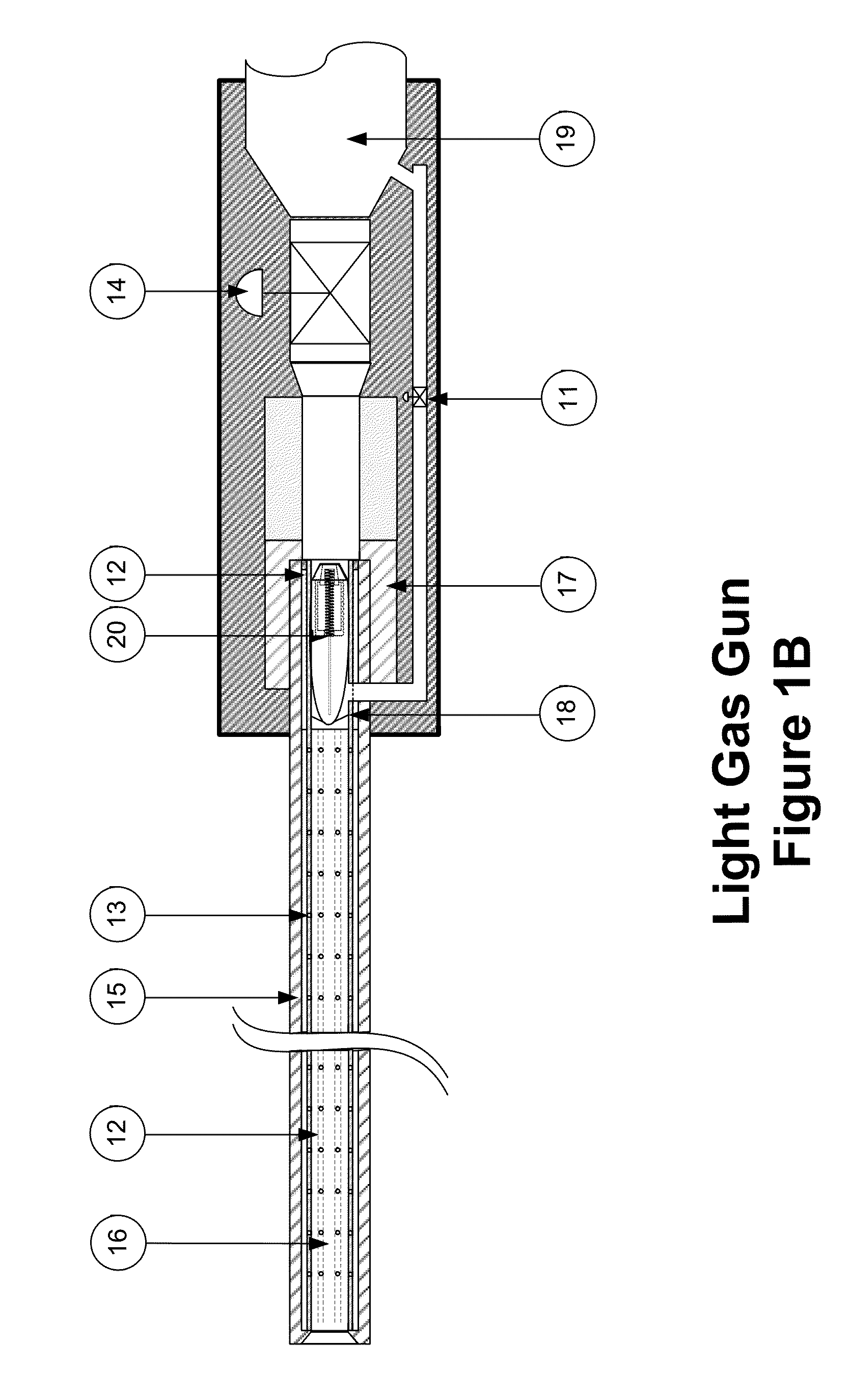

An improved light gas gun launches a projectile in a light gas atmosphere as it travels through a frictionless barrel to achieve high muzzle velocities, decreased acoustic signatures, and increased ranges. The light gas atmosphere is introduced by a purge valve prior to firing or by a muzzle valve that holds a positive light gas pressure on the barrel and breech. The muzzle valve also routes the majority of propellant gases through a suppression canister, reducing the light gas gun's acoustic signature. The frictionless barrel uses light gas propellant routed through gas bearings to keep the projectile centered in the barrel and preclude the projectile from contacting the barrel walls, eliminating barrel wear. The system includes a projectile assembly that stores light gas from the firing and injects it into the boundary layer, reducing drag, increasing range and lethality, and decreasing acoustic signature of the projectile down range.

Owner:BERGERON DAVID WAYNE

Three-level light-gas gun driven by compressed nitrogen

A three-level light-gas gun driven by compressed nitrogen comprises a primary gas chamber, a primary pump tube, a secondary gas chamber, a secondary pump tube, a tertiary gas chamber and a transmitting tube. The primary gas chamber is connected with the primary pump tube, and a quick opening valve is arranged between the primary gas chamber and the primary pump tube; the primary pump tube is connected with the secondary gas chamber; the secondary gas chamber is connected with the secondary pump tube, and a secondary diaphragm is arranged between the secondary gas chamber and the secondary pump tube; the secondary pump tube is connected with the tertiary gas chamber; and the tertiary gas chamber is connected with the transmitting tube, and a tertiary diaphragm is arranged between the tertiary gas chamber and the transmitting tube. A three-level driving mode is adopted, energy utilization efficiency among levels is improved, a severe gas environment in a gun body is improved, and ablation risks of the gun body are reduced; the secondary gas chamber and the tertiary gas chamber are of straight barrel type structures or barrel structures with large cone angles, and the energy utilization efficiency is improved; and a replaceable ablation ring is arranged at the front end of the transmitting tube, the ablation risks of the gun body are reduced, and experimental cost of super-speed transmission is greatly reduced.

Owner:NORTHWEST INST OF NUCLEAR TECH

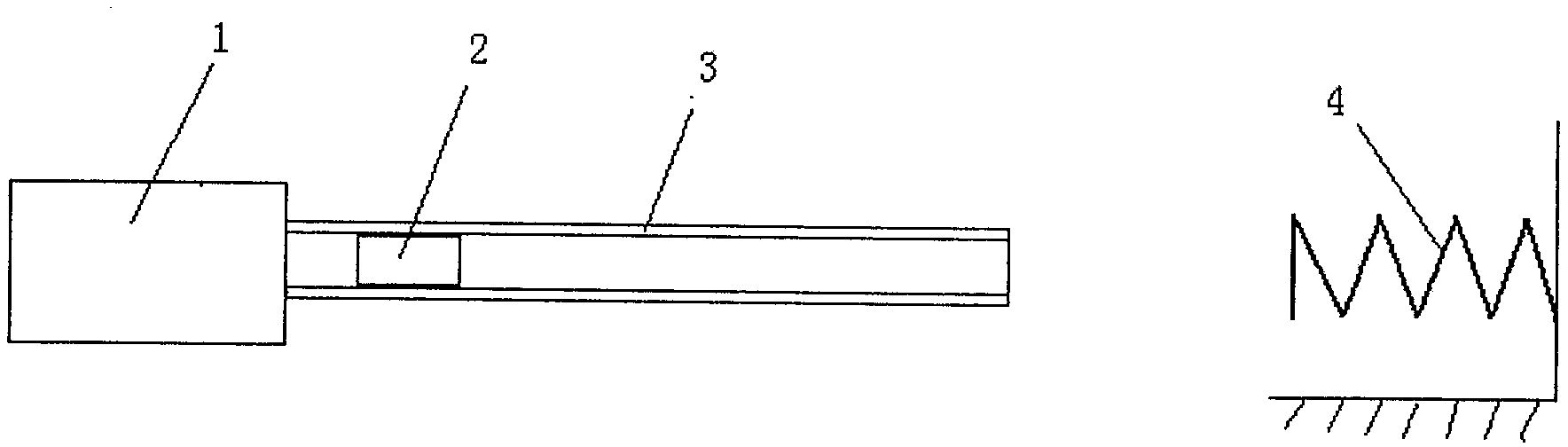

Ball mill impact collision simulation test bed and ball mill impact collision simulation method

InactiveCN104020060AAccurately measure movement speedThe overall structure is simple and reliableMaterial strength using repeated/pulsating forcesData acquisitionImpact acceleration

The invention discloses a ball mill impact collision simulation test bed and a ball mill impact collision simulation method. The ball mill impact collision simulation test bed comprises a light gas gun, a steel ball, a high-speed camera, a dynamic strain gauge, a photoelectric speed measuring device and a data collection device, wherein the steel ball is launched by the light gas gun, the movement speed of the steel ball is measured through the photoelectric speed measuring device, the steel ball impacts a cylindrical rock test sample through a test box, the cylindrical rock test sample strikes a lining plate test sample under the impact load effect, the rock test sample and the lining plate test sample are horizontally arranged in an arc groove of a test box stander, the center of the arc groove is leveled to the center of the steel ball, the accuracy of the impact process is guaranteed, the impact collision process is precisely captured through the high-speed camera, an impact acceleration sensor, a strain plate and the like are arranged on the surface layer of a cushion test sample, an output signal is collected through the dynamic strain gauge and a data collection card, the signal is processed through a computer data processing system, so that the dynamic mechanics performance of a material in the ball mill impact collision process can be accurately achieved.

Owner:CHINA UNIV OF MINING & TECH +2

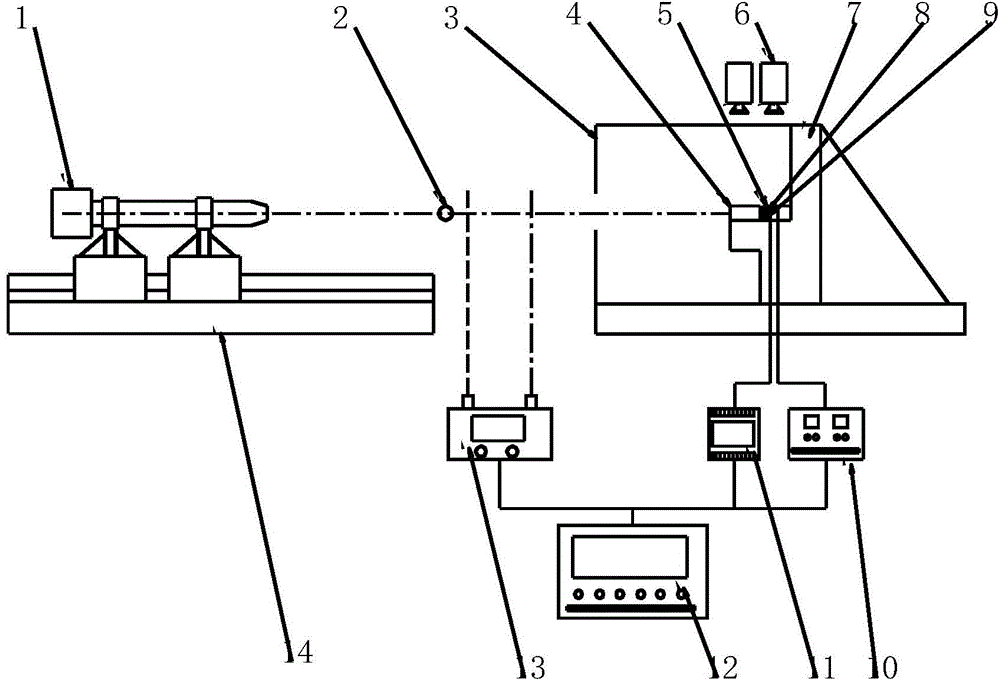

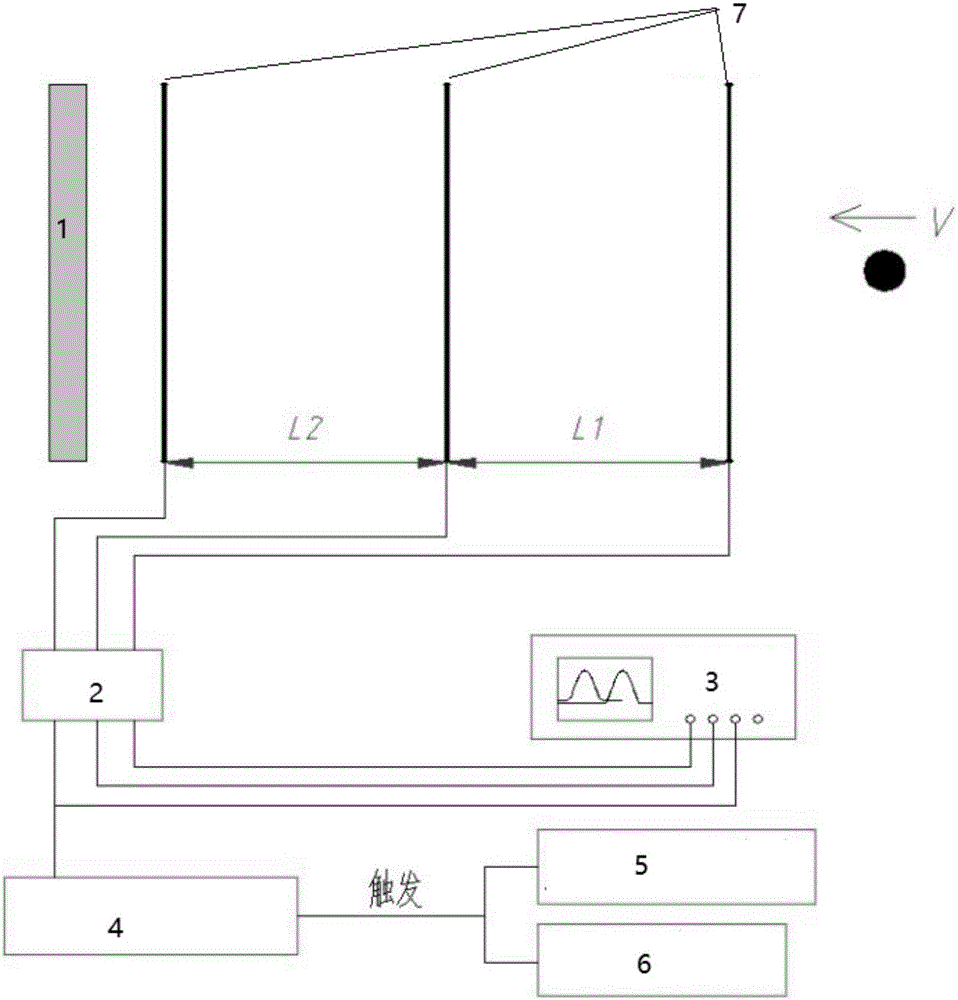

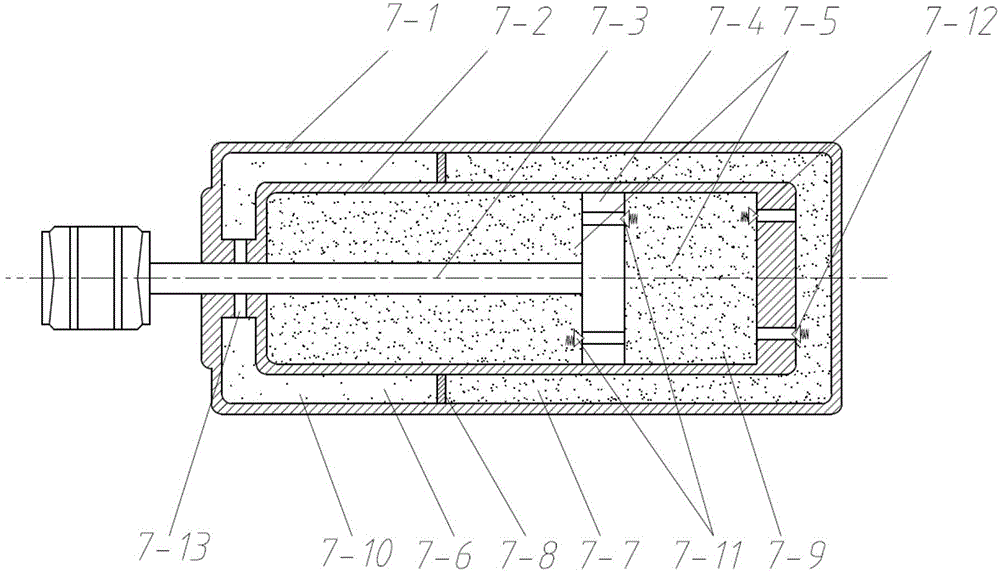

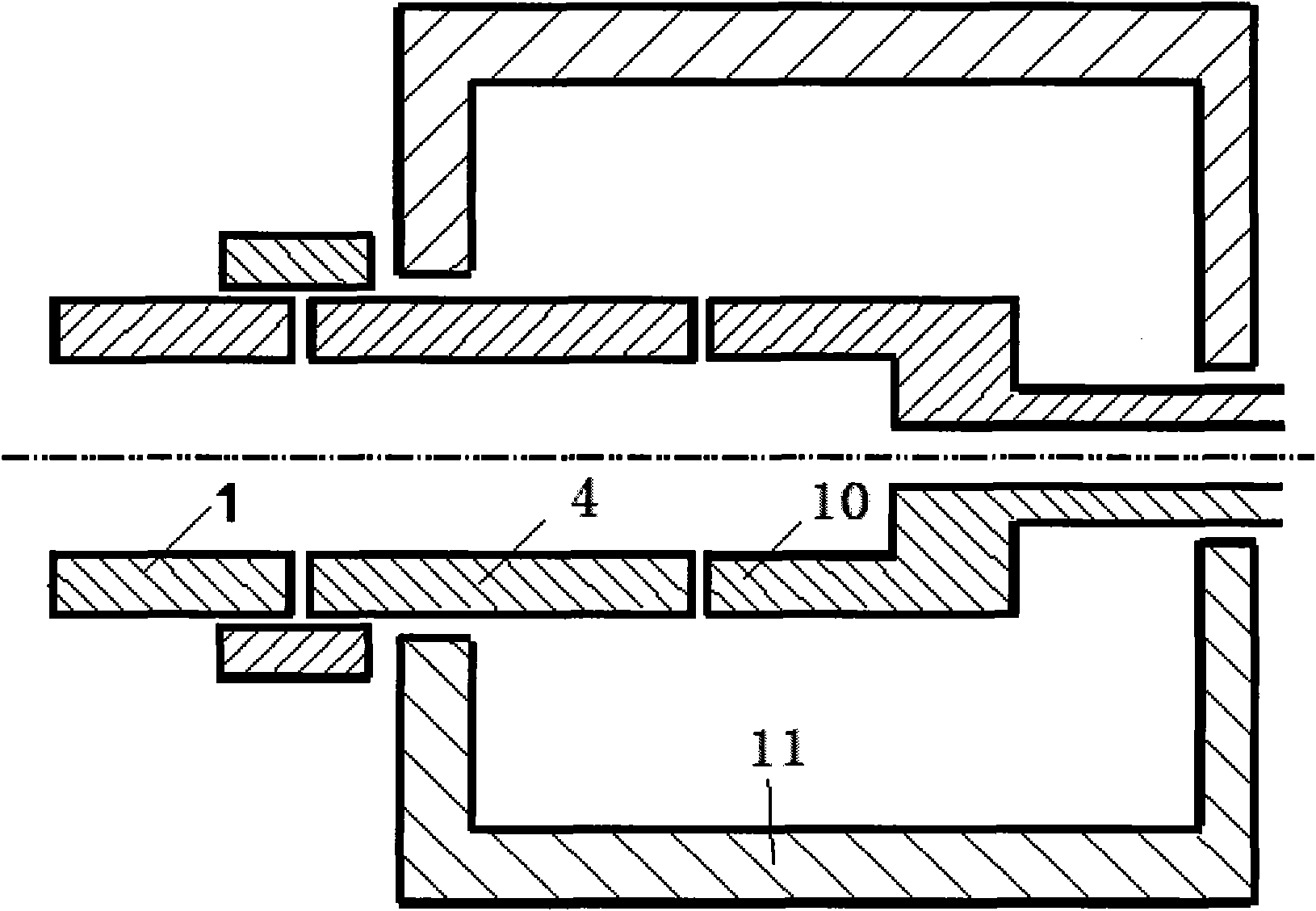

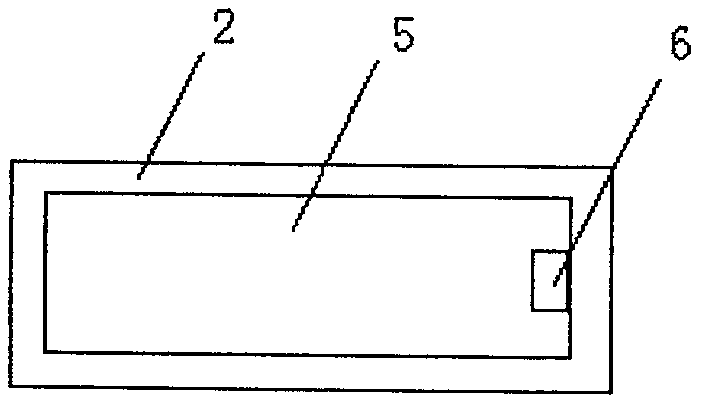

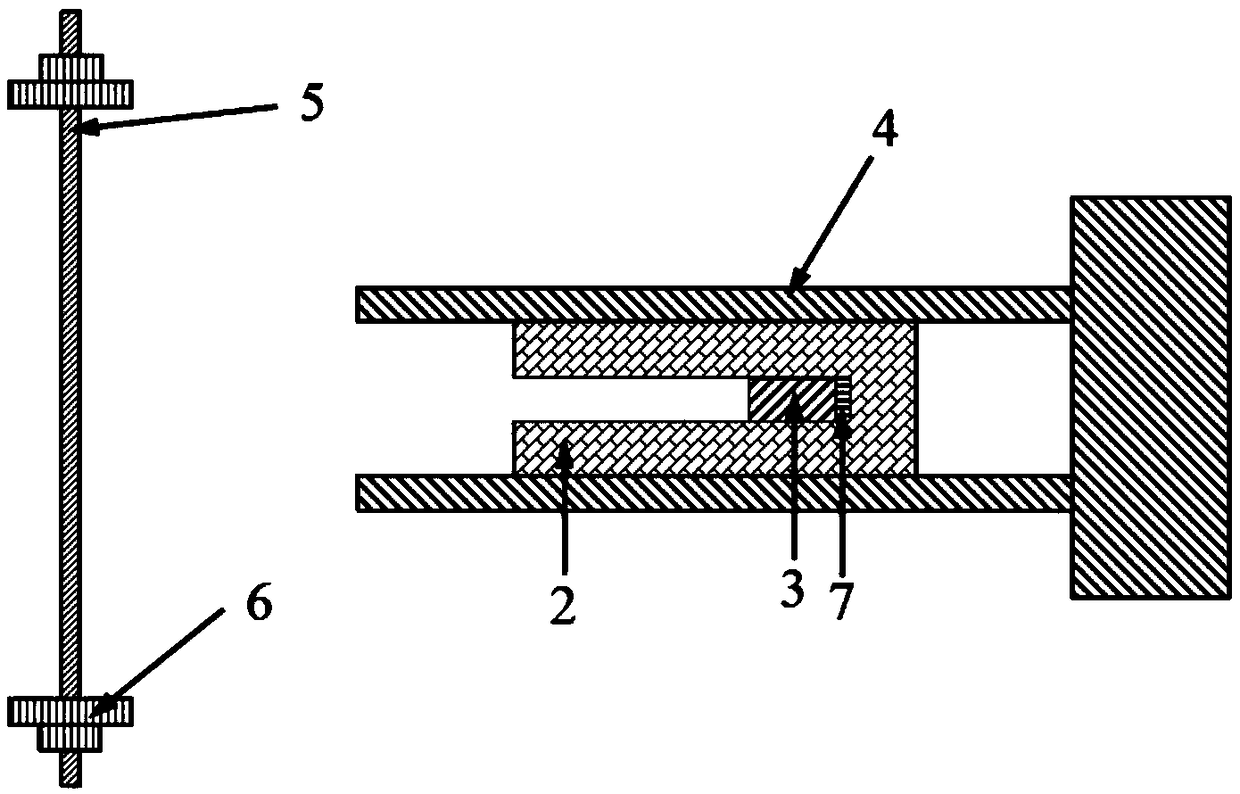

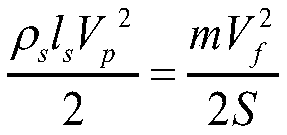

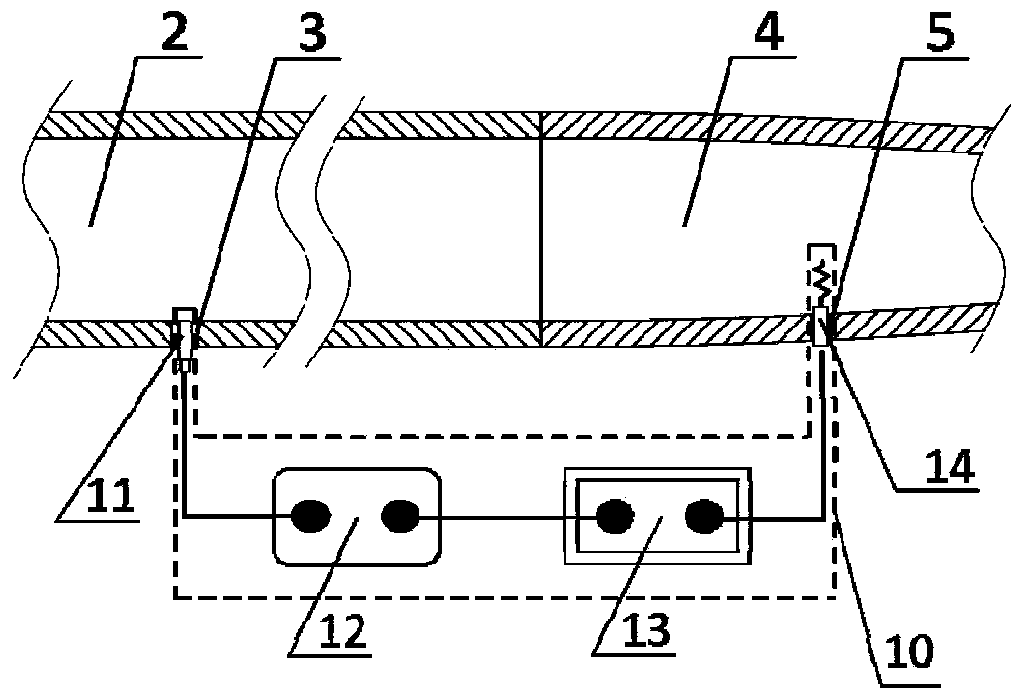

Light-gas gun millimeter-grade bullet velocity measurement system

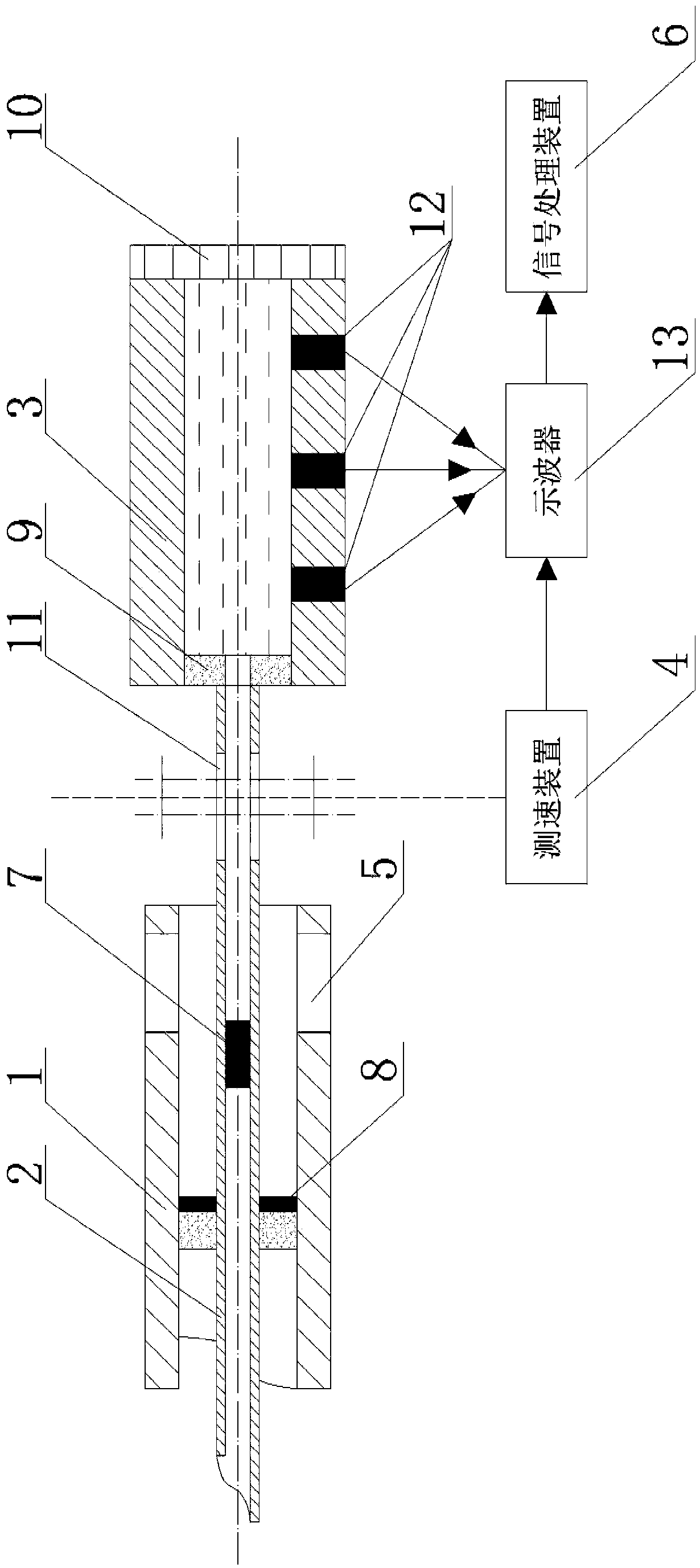

ActiveCN106199053ASolve the problem of synchronous triggeringSimple circuit structureDevices using time traversedElectromagnetic wave reradiationUltra high speedClassical mechanics

The invention belongs to the technical field of a superspeed bump experiment, especially relates to a bullet velocity measurement system, and discloses a light-gas gun millimeter-grade bullet velocity measurement system. The technical scheme of the light-gas gun millimeter-grade bullet velocity measurement system is as follows: two or more than two light screen targets (7) are arranged at intervals, a target plate (1) is arranged behind the last light screen target (7), and a photoelectric diode receiving apparatus (74) in each light screen target (7) is connected to a pulse box (2); one path of the pulse box (2) is connected to an oscilloscope (3), and the other path is connected to a digital signal generator (4); and the digital signal generator (4) is connected with and is used for triggering a superspeed framing camera (5) and an ICCD spectrometer (6). The millimeter-grade bullet velocity measurement system is formed by use of the multiple reflective light screen targets, and the problem of mimimeter-grade bullet velocity measurement during the superspeed bump experiment, the problem of synchronous triggering of matched devices and the defect existing in superspeed bump measurement on a metal bullet through a magnetic velocity measurement apparatus are solved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

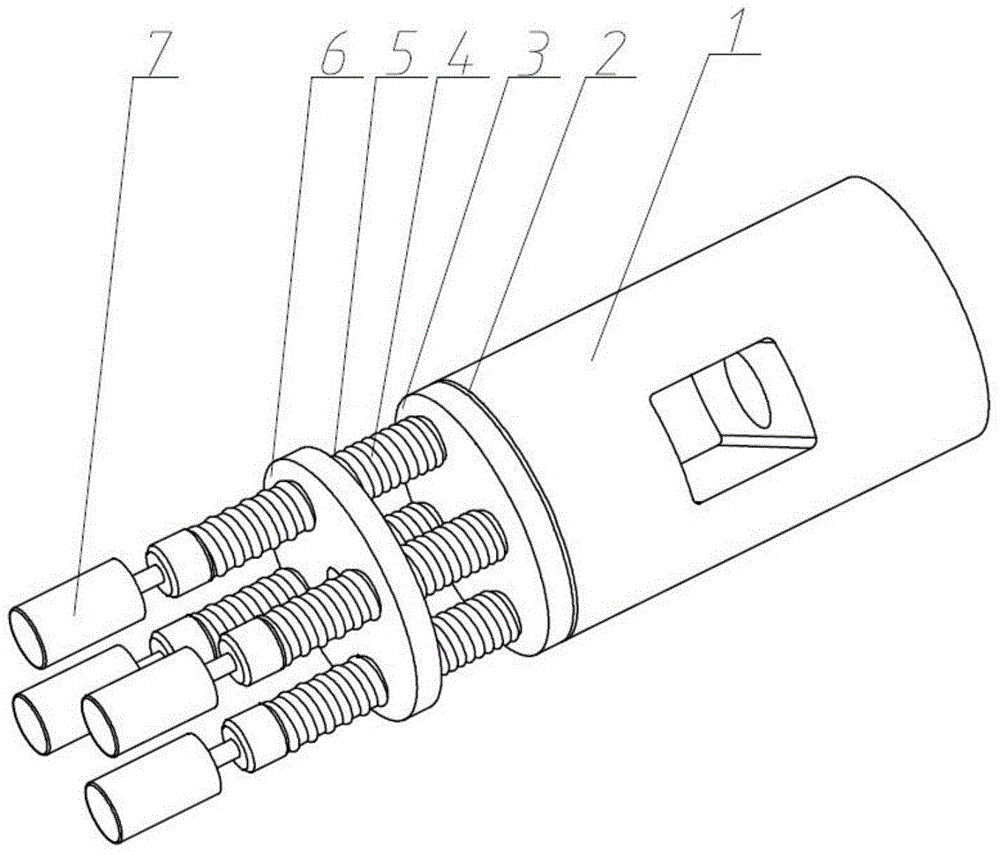

Novel high-speed light-gas gun muzzle bullet-separating vibration damping system

InactiveCN104896005AReduce vibrationMeet strength requirementsSpringsNon-rotating vibration suppressionUltrasound attenuationCoil spring

The invention discloses a novel high-speed light-gas gun muzzle bullet-separating vibration damping system. The system comprises a bullet-separating device cavity connected with a high-speed light-gas gun barrel via threads, and a viscoelastic high-damping rubber gasket and an elastic supporting baffle connected with the bullet-separating device cavity in sequence via a plurality of positioning shafts, each positioning shaft is sleeved by a spiral spring group, the spiral spring group of each positioning shaft is segmented into two parts via a spiral spring separating plate sleeving the positioning shafts, and end parts of the positioning shafts, far away from the bullet-separating device cavity, are connected with double-cylinder bullet-separating vibration dampers via threads. The high-speed light-gas gun muzzle bullet-separating vibration damping system is advantageous in that the occupied space is small, the mass is small, the system is detachable and portable, a bullet holder can be recycled, and the buffer effect is good; the bullet-separating vibration damping system and the barrel and the double-cylinder bullet-separating vibration dampers and the positioning shafts are both connected via the threads so that the dismounting is facilitated; the impact effect on a bullet-separating device by the bullet holder is alleviated via vibration damping spiral springs; and rapid attenuation of the vibration of the bullet holder is realized via the viscoelastic high-damping rubber gasket and the double-cylinder vibration dampers.

Owner:XI AN JIAOTONG UNIV

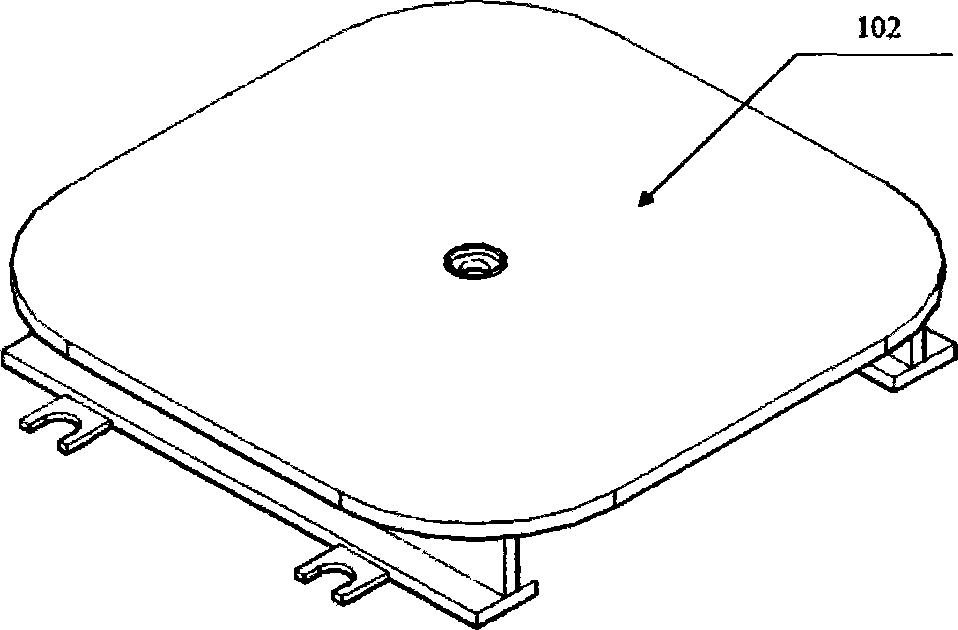

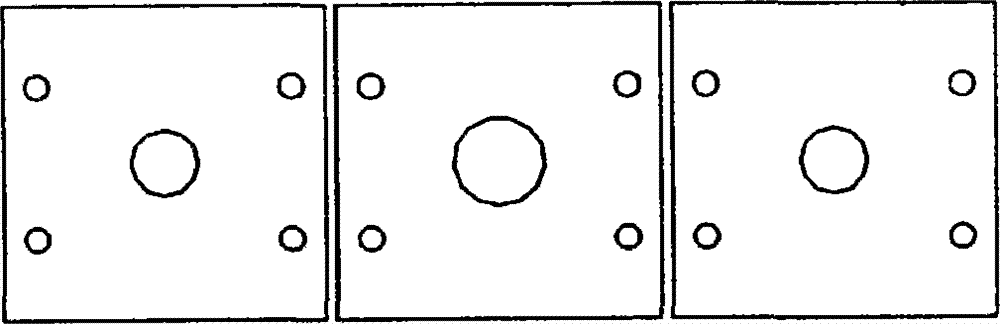

Rotary type high-speed bump test device for circular test piece

InactiveCN104777044ASimple structureIt is convenient to clamp and fix the test pieceStrength propertiesSpeed bumpLight-gas gun

The invention provides a rotary type high-speed bump test device for a circular test piece. The device comprises a rotary base, a rotary panel and a circular test piece fixing device, wherein the rotary base is connected with the rotary panel by a flange plate; the circular test piece fixing device is fixedly connected with the rotary panel; the rotary type high-speed bump test device is fixed in a target cabin of a two-stage light gas gun; the test piece is fixed by the press clamp of the circular test piece fixing device; the circular test piece fixing device is formed by overlapping three flat plates, wherein circular holes formed in the centers of the flat plates have different diameters; the diameter of the hole of the middle flat plate is larger than the diameters of the flat plates arranged at the two sides; the test piece is embedded in the middle flat plate. The rotary type high-speed bump test device is simple in structure and convenient in clamp fixation of the test piece; after the rotary type high-speed bump test device is used, a multi-angle bump test of the circular test piece can be completed according to the actual demand.

Owner:HARBIN INST OF TECH

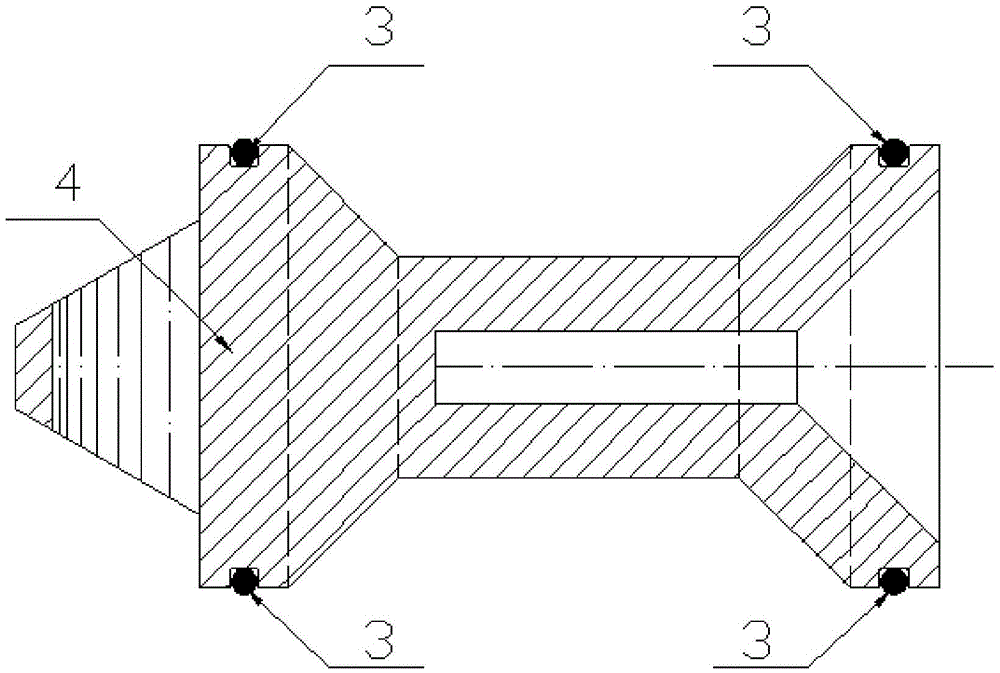

Ultra-high-speed gram-magnitude spherical projectile transmitting device

The invention discloses an ultra-high-speed gram-magnitude spherical projectile transmitting device comprising a two-stage light gas-gun, an extension section and a three-stage accelerating cavity, wherein one end of the extension section is fixedly connected with an outlet of the two-stage light gas-gun, the other end of the extension section is fixedly connected with the connection end of the three-stage accelerating cavity, the three-stage accelerating cavity is designed with a two-section inner diameter, an annular PC resin sleeve is arranged on an annular boss in the cavity towards the extension section, and a high explosive is embedded into the PC resin sleeve; an accelerating unit transmitted by the two-stage light gas-gun comprises a projectile holder, spherical projectiles and annular steel sheets, wherein the projectile holder is in a cylindrical structure, the top of the cylindrical structure is provided with a cylindrical projective end, the annular steel sheets are in sleeve joint with the projective end and are bonded on the front end surface of the projectile holder, and the spherical projectiles are bonded at the projective end of the projectile holder. The ultra-high-speed gram-magnitude spherical projectile transmitting device not only can accelerate gram-magnitude spherical projectiles to 10km / s, but also can ensure that the spherical projectiles are not overheated, has the last length to diameter ratio L / d near 1 and has no primary flyer fragments to follow in order to ensure the effects of space fragment protective structure optimization design and performance evaluation impact test.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

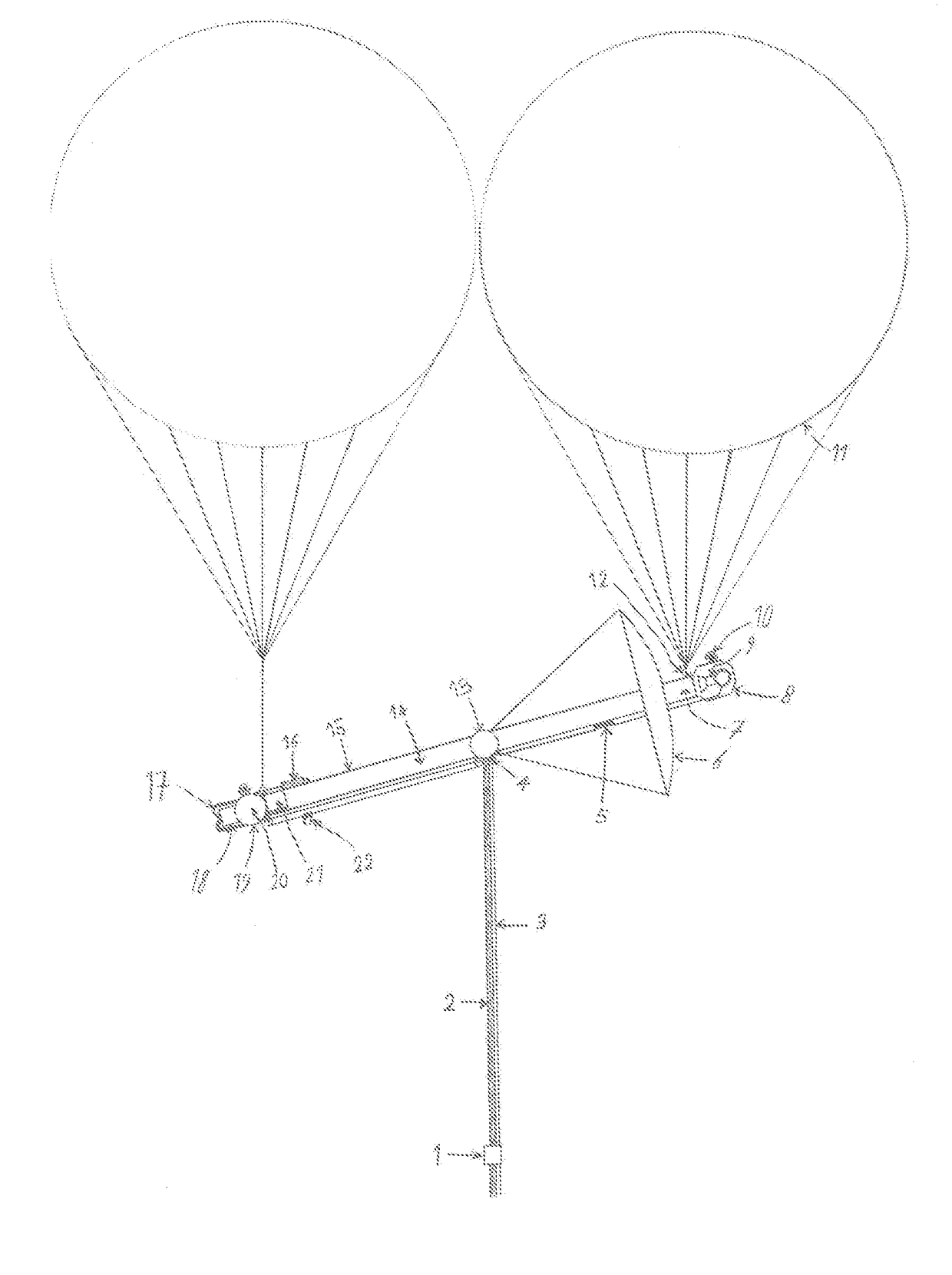

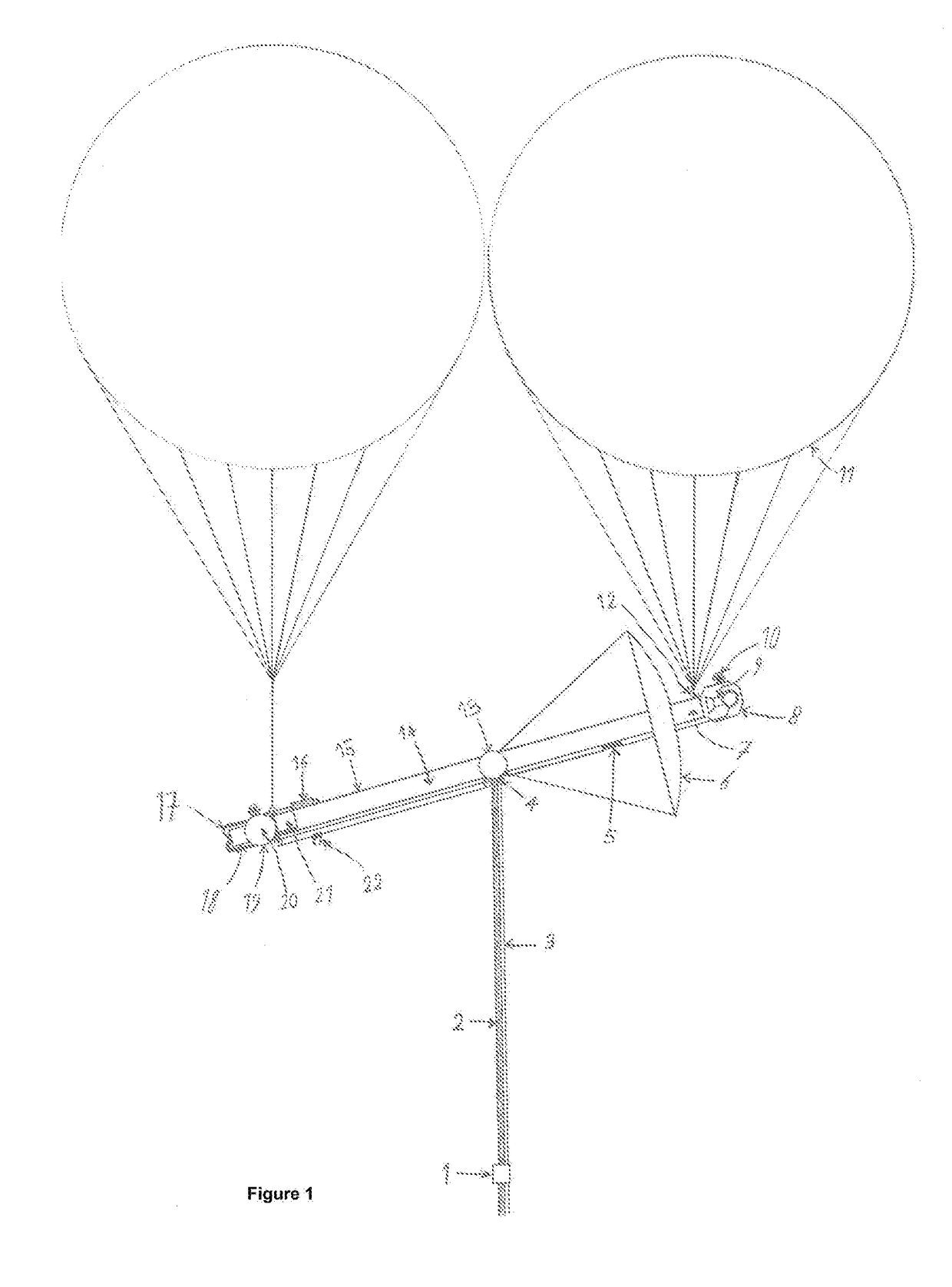

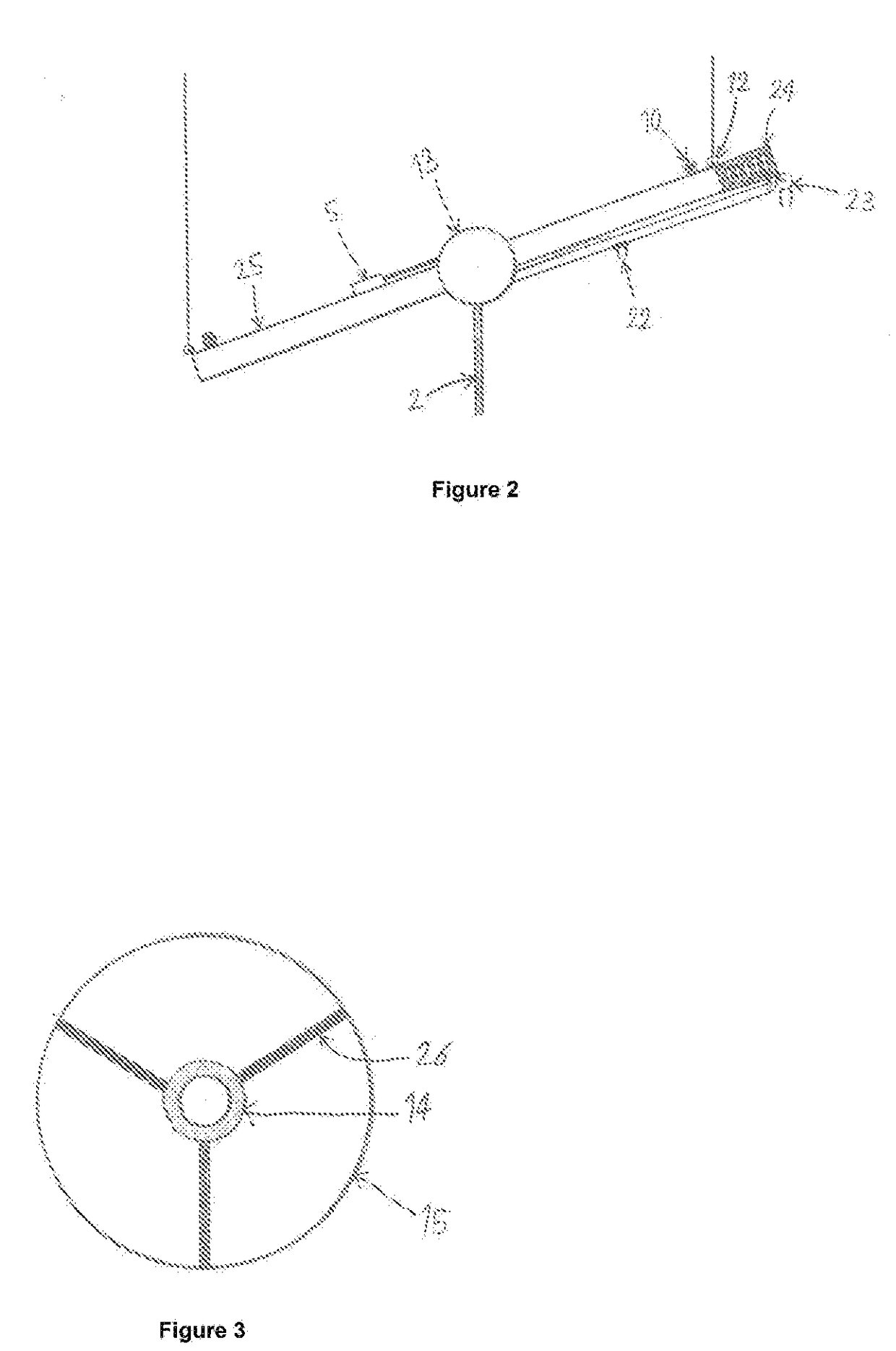

High altitude space launcher

InactiveUS20180134414A1Less velocityShooting angleRocket launchersLaunch systemsElectric forceRocket

Disclosed is a high altitude space launcher system for transferring payloads from surface to orbit at a significantly lower cost than conventional rockets. It comprises a aerostat lifted one stage light gas gun operating in stratosphere that shoots rocket assisted projectiles containing payload at near orbital velocities to a low angle trajectory. Alternatively, to launch acceleration sensitive payloads such as astronauts the light gas gun is replaced with a muzzle loaded conventional gun that shoots a single stage rocket at a much lower velocity. The system is mostly static structure, attached to a tether-elevator that moors it to land or a ship and provided it with electricity and lifts the projectiles to the gun.

Owner:ALIKOUHI ABBAS

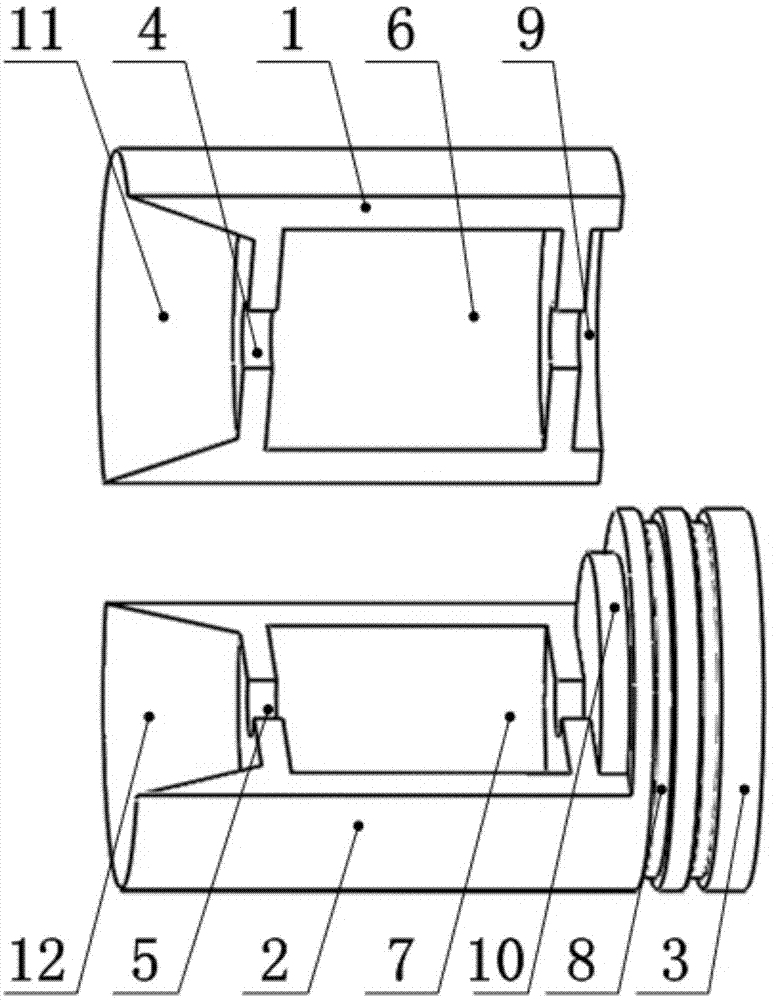

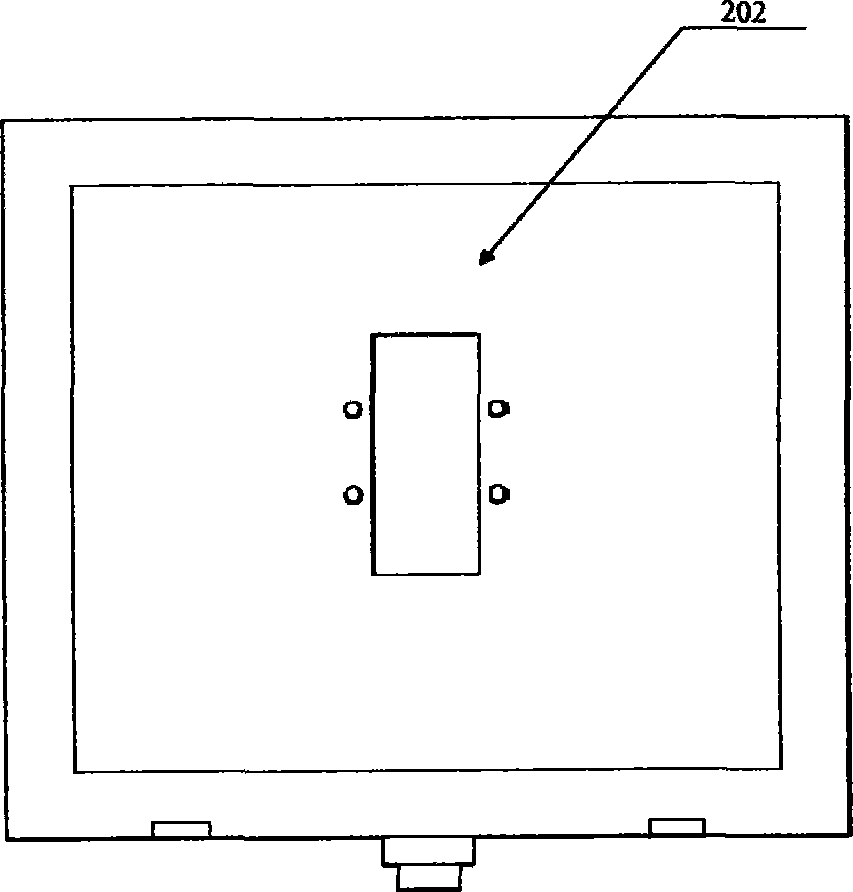

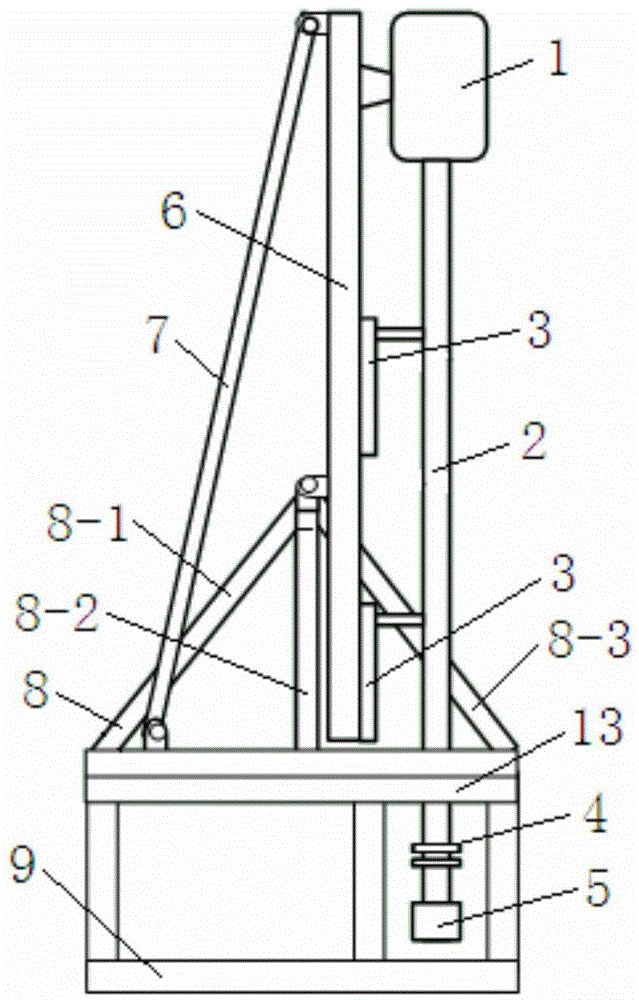

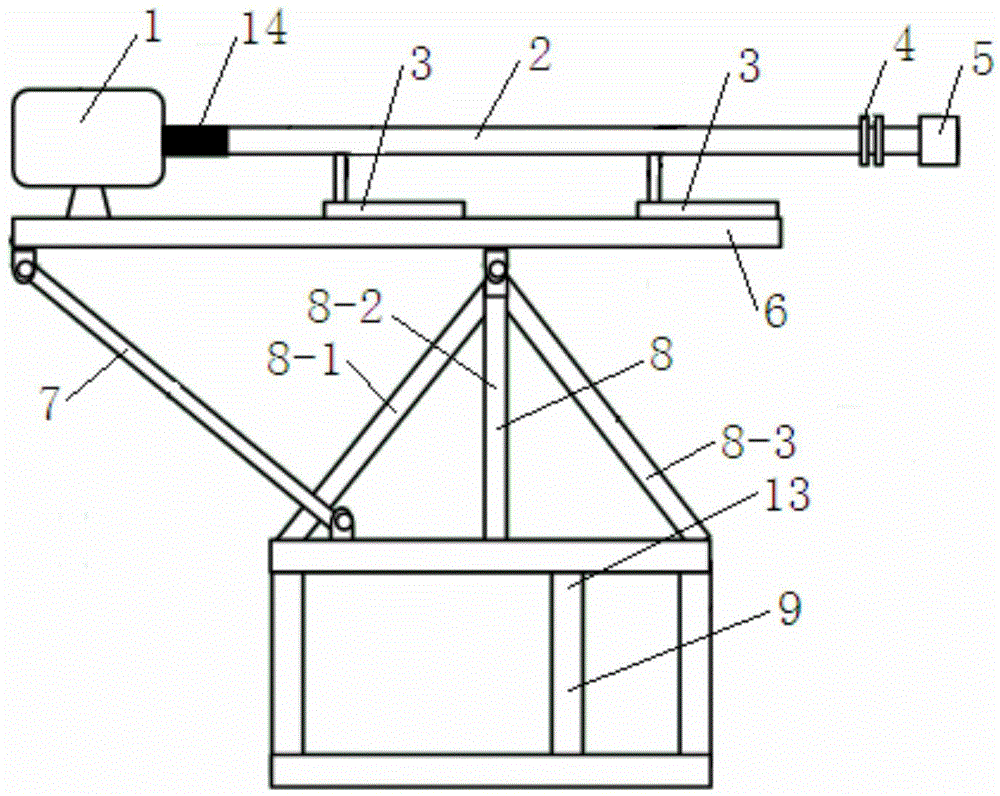

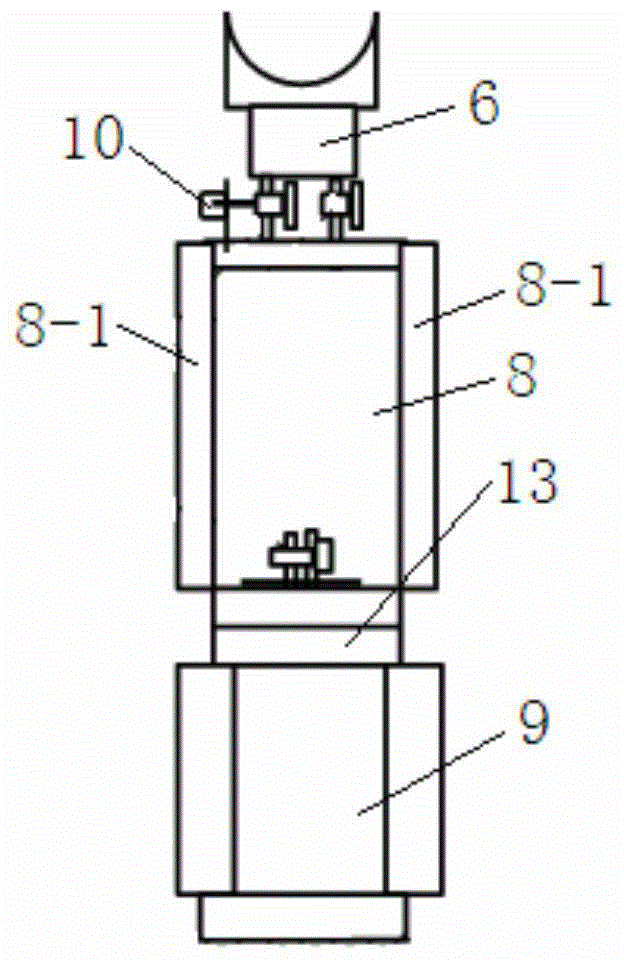

Rotatable light-gas gun device

ActiveCN104534924ALaunch implementationImprove work efficiencyCompressed gas gunsTransducerGas chamber

A rotatable light-gas gun device relates to a light-gas gun and aims at solving the problems of an existing screw rod type rotatable light-gas gun that the utilization is inconvenient, the rotary speed is slower, the working efficiency is lower and the adaptability is poor. The rotatable light-gas gun device comprises a gas chamber, and further comprises an emission tube, a sabot separation device, a supporting platform, a bidirectional hydraulic oil cylinder, a base bracket, an angle transducer and two tachometers, wherein the gas chamber, the emission pipe and the supporting platform are located above the base bracket; the gas chamber and the emission pipe are fixedly arranged on the upper surface of the supporting platform; the sabot separation device comprises a sleeve bucket and a tapered cylinder which are integrally molded; one end of the emission pipe and the gas chamber are communicated and are detachably connected; the other end of the emission pipe is connected with the sleeve bucket; the tapered cylinder is arranged in the emission pipe; the angle transducer is mounted on the base bracket; one end of the bidirectional hydraulic oil cylinder is rotationally connected with one end of the supporting platform, and the other end of the bidirectional hydraulic oil cylinder is rotationally connected with the base bracket. The rotatable light-gas gun device is used for the fields including space vehicles or material performance researches and the like.

Owner:HARBIN INST OF TECH

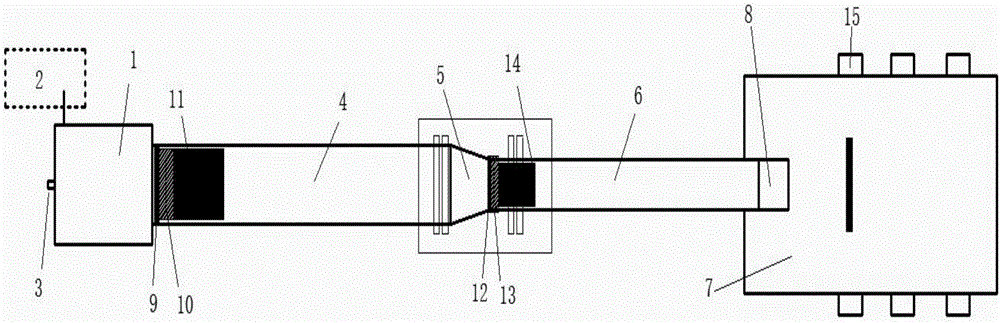

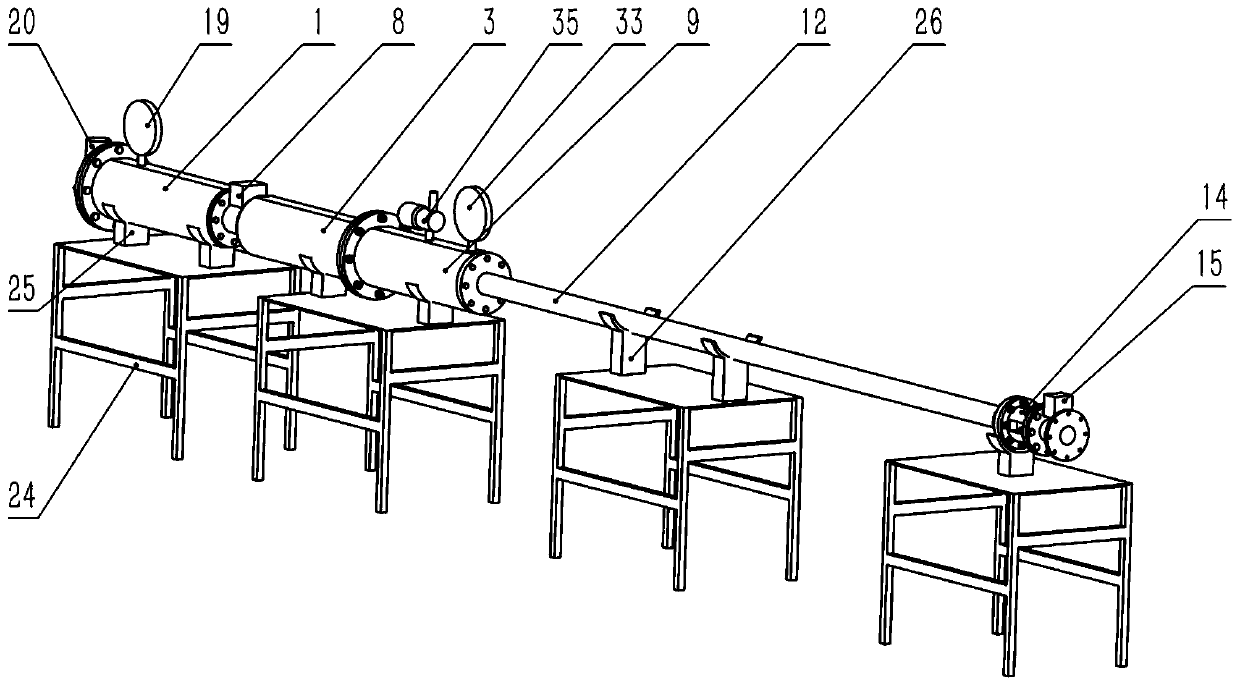

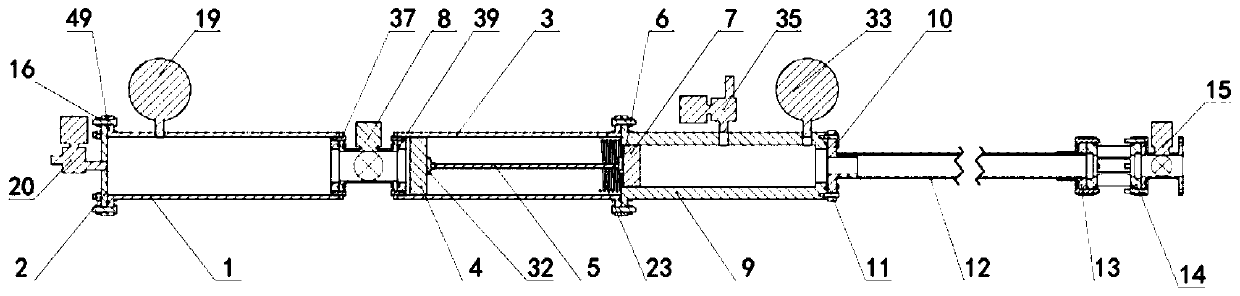

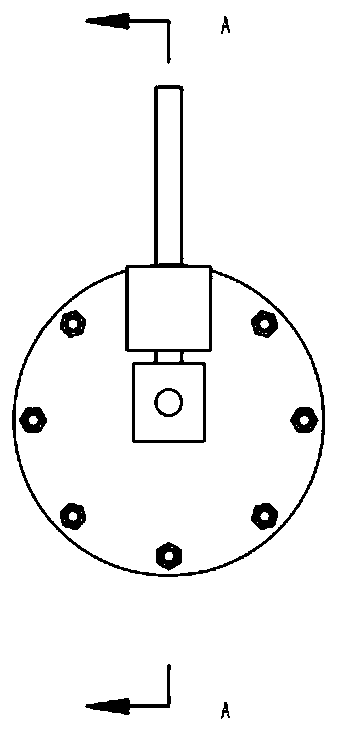

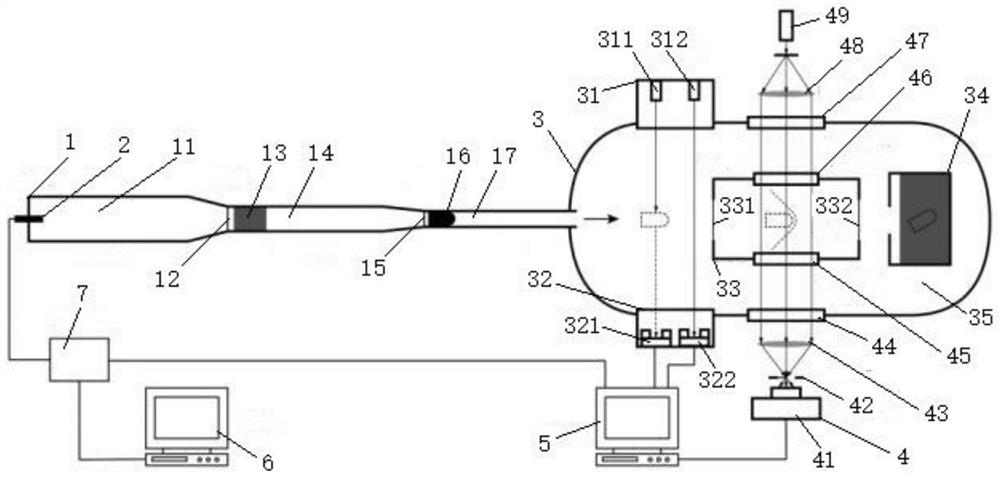

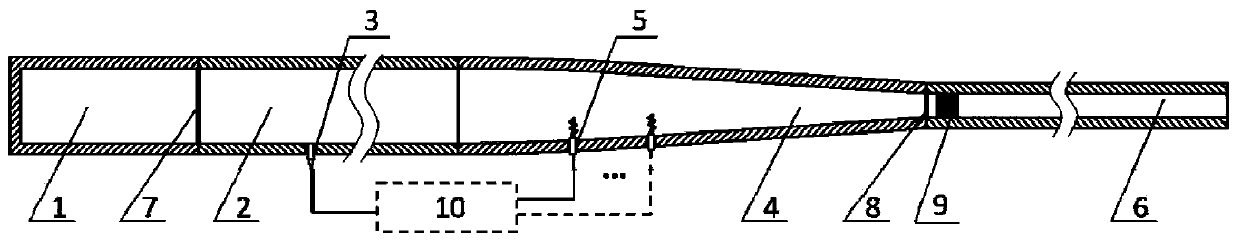

Three-stage light gas gun based on hydrogen and oxygen mixed detonation driving

InactiveCN106895739AReduce the risk of insecurity and instabilityImprove experimental efficiencyCompressed gas gunsCombustion chamberDetonation

The invention belongs to the technical field of ultra-high-speed impact loading test, in particular to a three-stage light gas gun. The technical scheme of the three-stage light gas cannon driven by hydrogen-oxygen mixed detonation is: the ratio of the inner diameter of the first-stage pump tube to the inner diameter of the second-stage pump tube is 2 to 4, and the ratio of the inner diameter of the second-stage pump tube to the inner diameter of the launch tube Between 3 and 5; the aspect ratio of the primary pump tube is 3 to 5, the aspect ratio of the secondary pump tube is 4 to 7, and the aspect ratio of the launching tube is 1 to 2; the cone angle of the primary high pressure cone section The cone angle of the secondary high-pressure cone section is 5°-25°; the combustion chamber is filled with a mixture of hydrogen, oxygen and nitrogen, and the primary pump tube and the secondary pump tube are respectively filled with hydrogen gas to launch The tube is vacuumed. The invention adopts hydrogen-oxygen mixed gas as a driving source, has stronger loading capacity, low pollution, and stably launches a projectile with a mass of 1g at a speed exceeding 10km / s.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

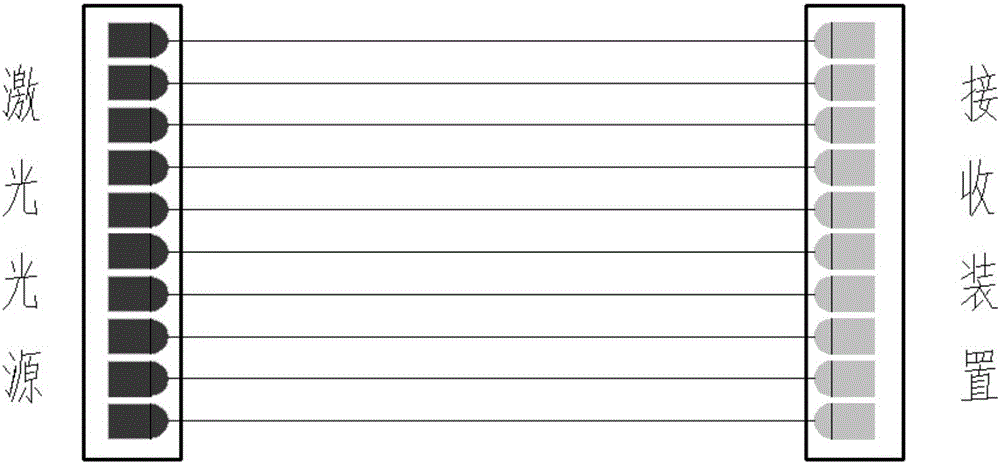

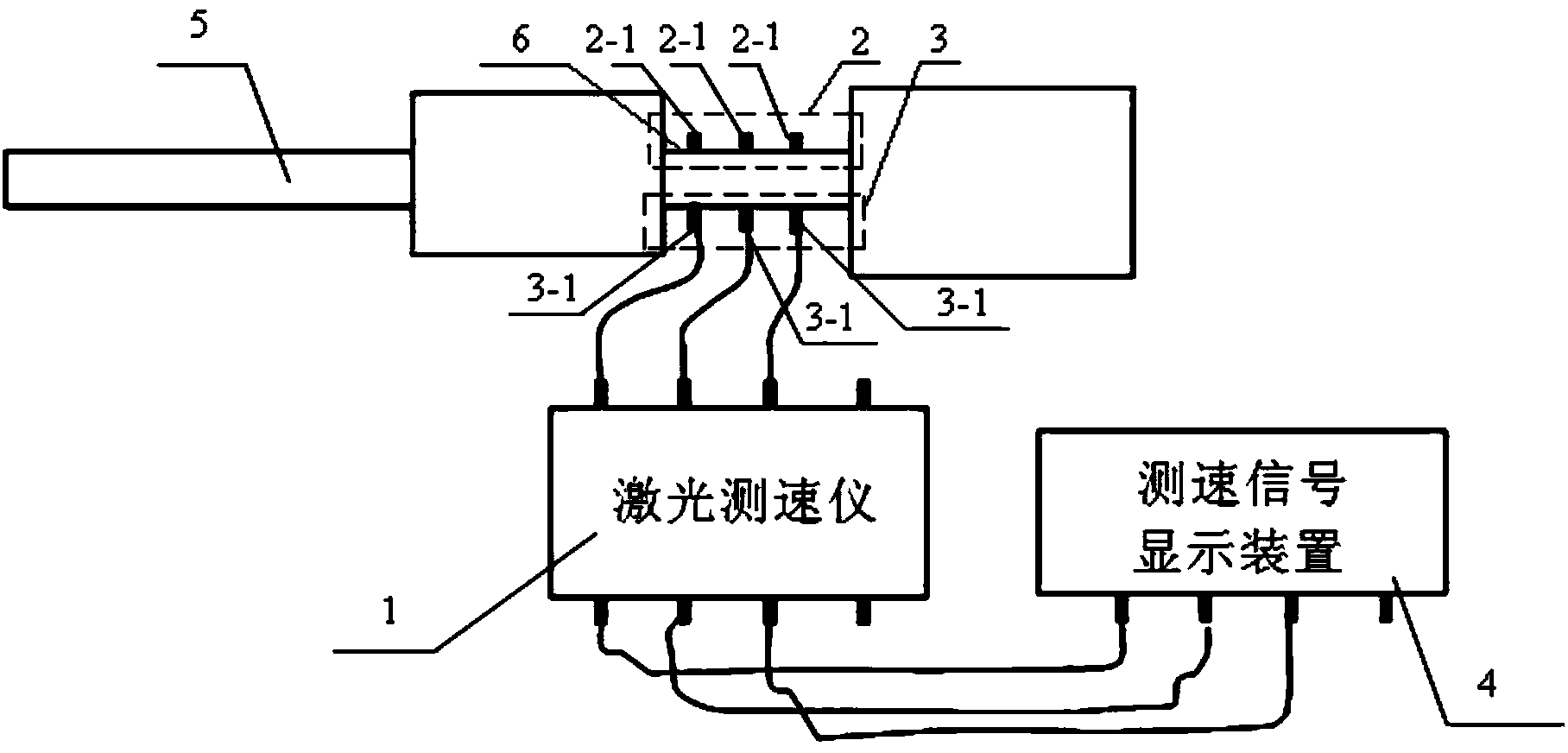

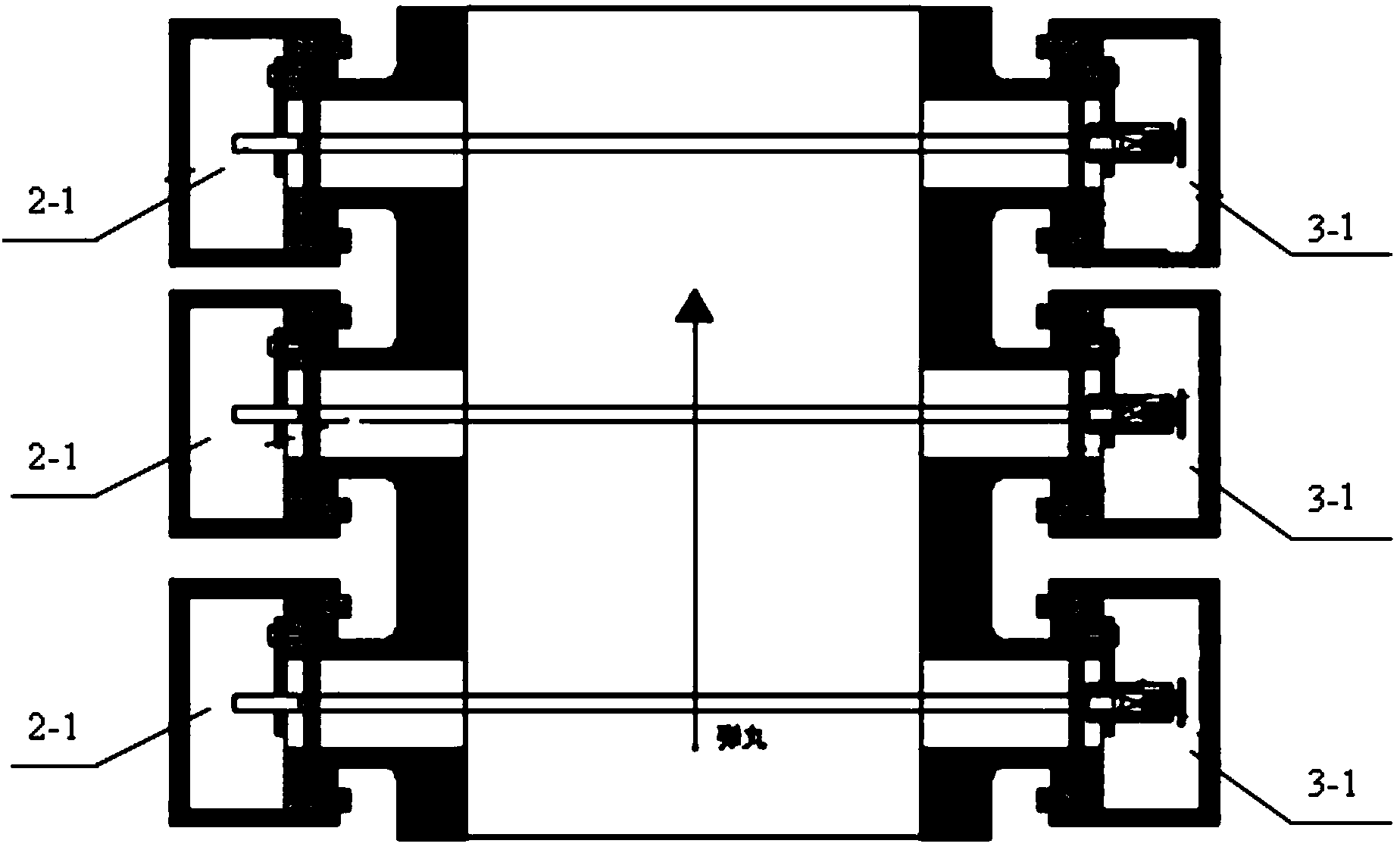

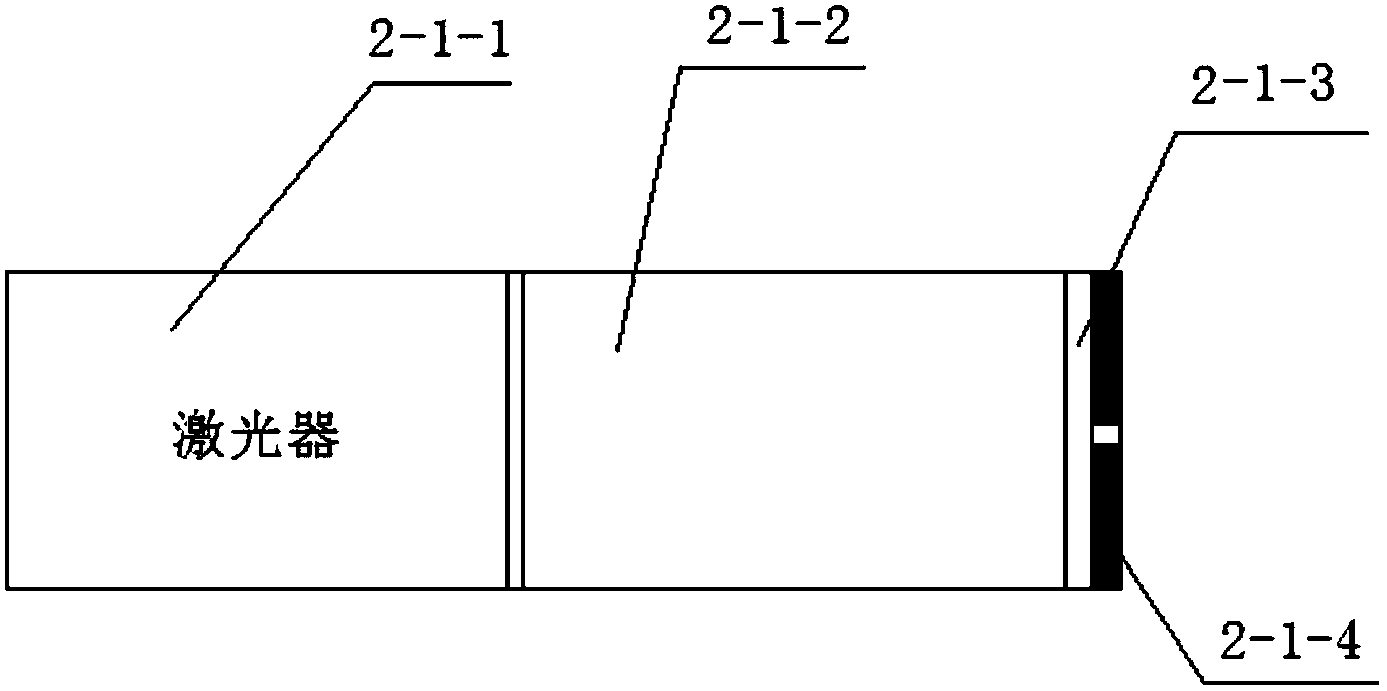

Laser light curtain blocking type speed measuring system for measuring light-gas gun millimeter-level bullet speed

InactiveCN103592458AHigh measurement accuracyReduce duplication of trialsDevices using time traversedElectromagnetic wave reradiationDisplay deviceLaser light

The invention discloses a laser light curtain blocking type speed measuring system for measuring light-gas gun millimeter-level bullet speed and belongs to the field of ground superspeed crash simulation experiments. The problem that an existing light-gas gun millimeter-level bullet speed measuring method is low in accuracy and low in success rate, repeated tests are needed, and accordingly testing cost is high is solved. The system comprises a laser velocimeter, a laser emitting device, a laser light curtain receiving device, a speed measuring signal display device and a speed measuring channel. The outlet end of a light-gas gun bullet launching device is connected with the speed measuring channel, the laser emitting device and the laser light curtain receiving device are arranged on the opposite faces of the speed measuring channel, a speed measuring signal output end of the laser light curtain receiving device is connected with a speed measuring signal input end of the laser velocimeter, and a display signal output end of the laser velocimeter is connected with a display signal input end of the speed measuring signal display device.

Owner:HARBIN INST OF TECH

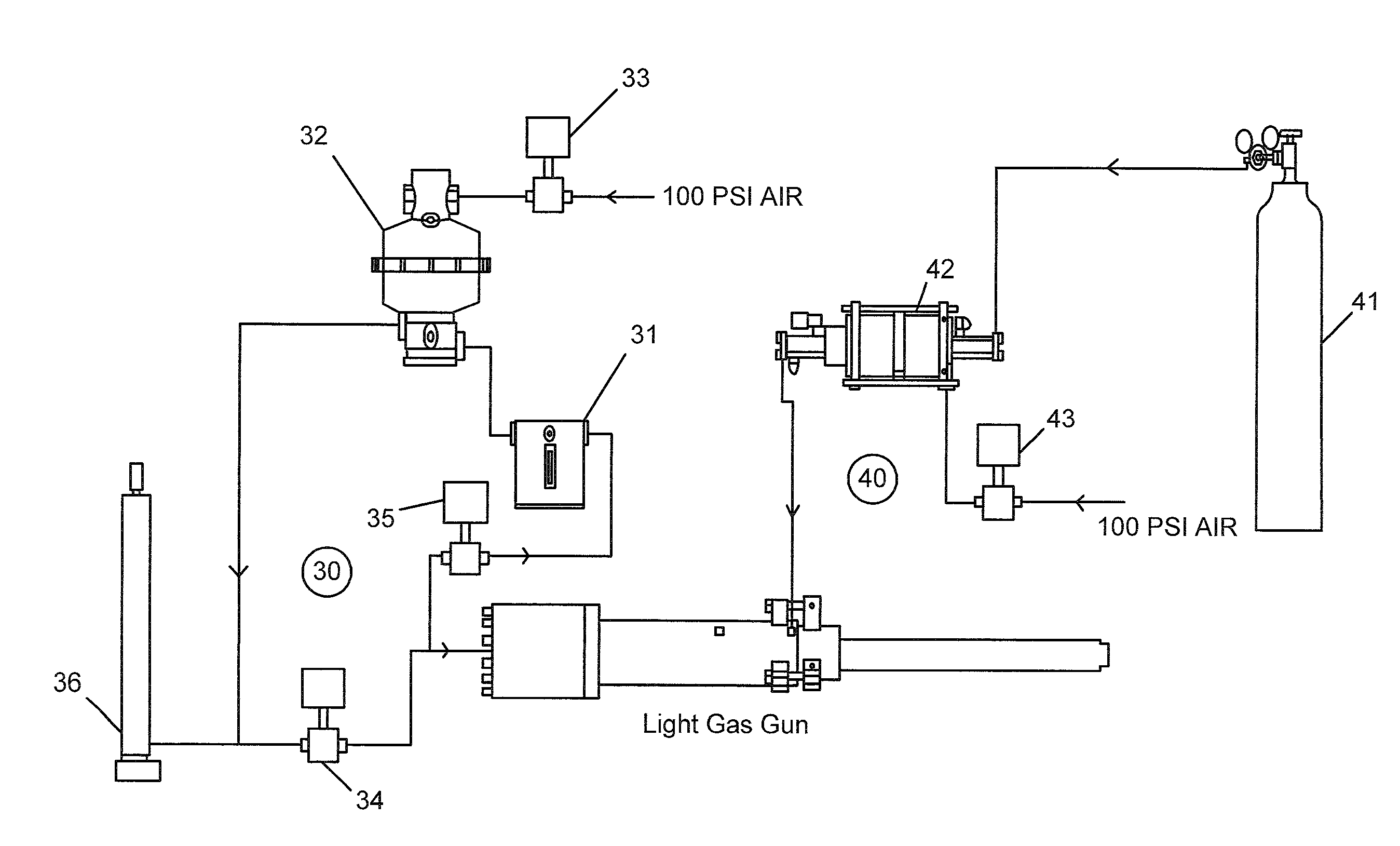

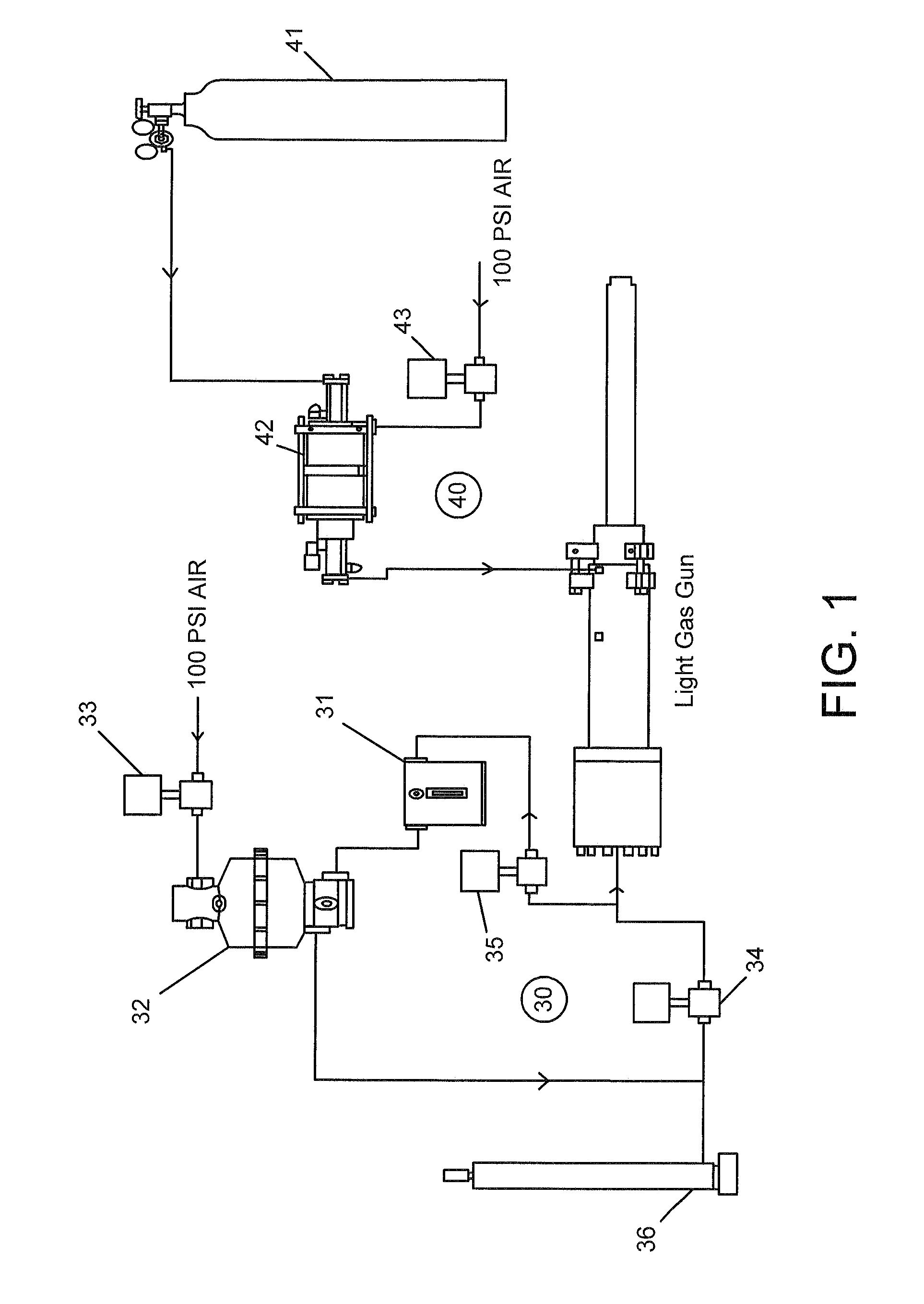

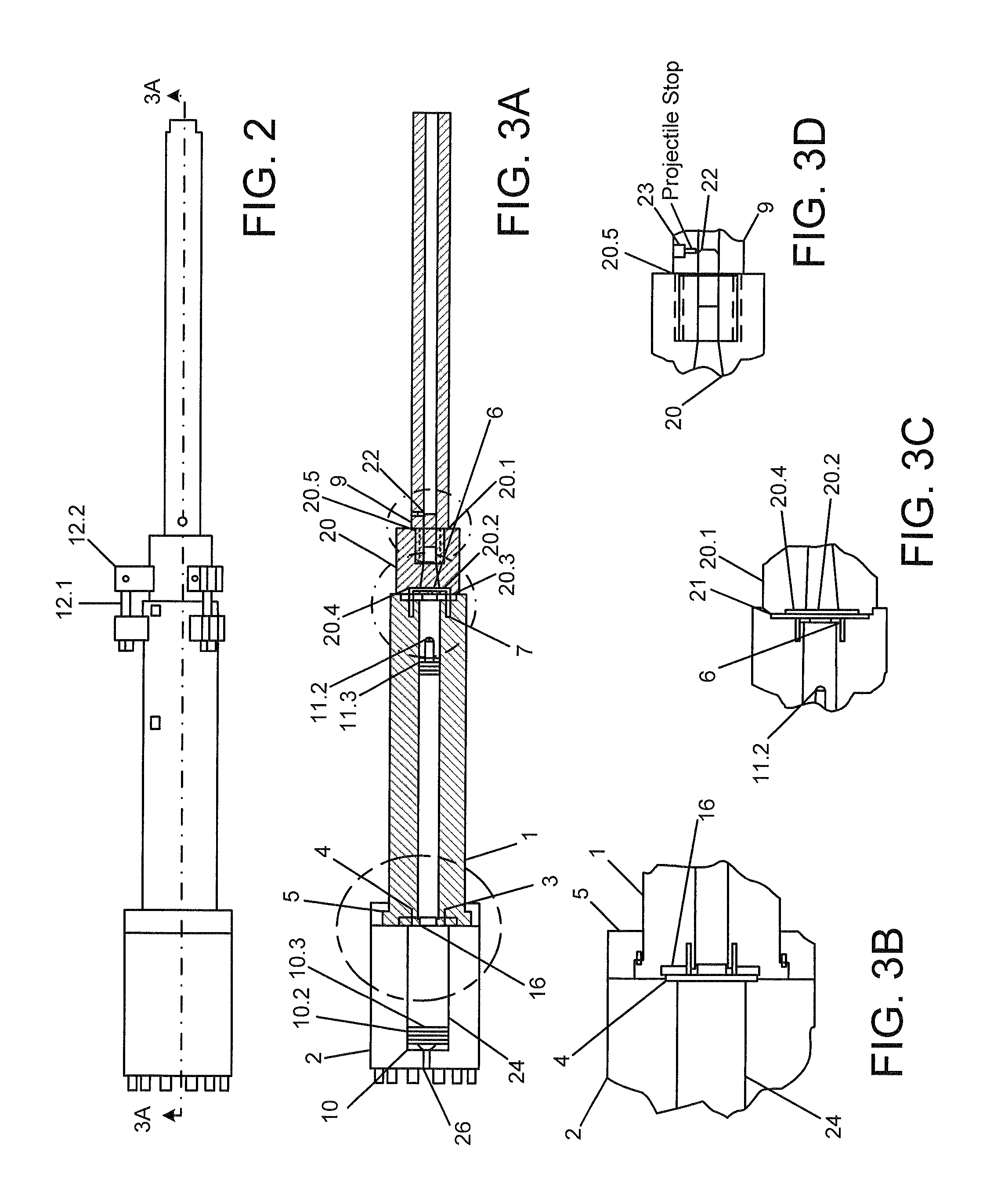

Two-stage light gas gun

ActiveUS8201486B1Make up for deficienciesReduce the cross-sectional areaMissile propulsionEngineeringHigh pressure

A stage light gas gun system and method capable of having a variable power output to match a specific use or application. The light gas gun uses a high pressure hydraulic oil system to provide a propulsive force behind two-stage piston system that is used to compress a light gas. The light gas gun may include a punch formed on the second piston for piercing a rupture disk at a pre-determined point in order to provide predictable performance.

Owner:FUHRMAN MICHAEL L

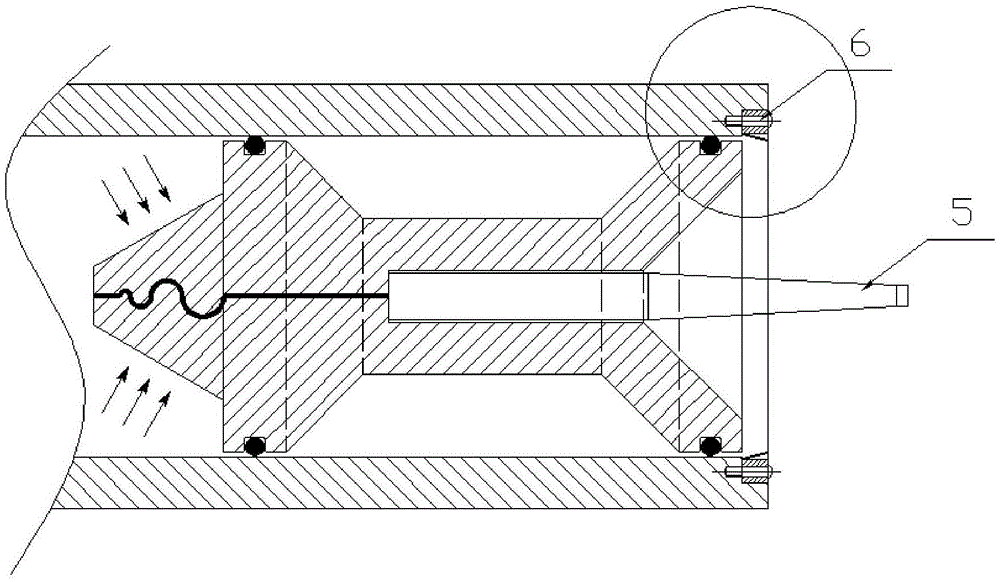

High-speed cutting experiment device based on light-gas gun loading technique

InactiveCN102539265AMeet the requirements of high-speed cutting experimentsWide cutting speedInvestigating machinabilityEngineeringAtmospheric pressure

The invention discloses a high-speed cutting experiment device based on a light-gas gun loading technique. The high-speed cutting experiment device comprises a light-gas gun power loading mechanism, a cutting mechanism, a fixing mechanism and an arresting mechanism, wherein the light-gas gun power loading mechanism is used for pushing the cutting mechanism to fly along a preset orbit at preset speed; the cutting mechanism is used for cutting a workpiece to be processed at high-speed; the fixing mechanism is used for fixing the workpiece to be processed; the arresting mechanism is used for receiving the cutting mechanism which completes cutting; and the light-gas gun power loading mechanism, the cutting mechanism, the fixing mechanism and the arresting mechanism are sequentially arranged along an axis. By adjusting the air pressure of a light-gas gun, the mass of a bullet or the initial position of the bullet, very wide cutting speed can be obtained; and by using the device for high-speed cutting experiments with cutting speed which reaches 30m / s to 150m / s, the demands of the high-speed cutting experiments of most materials can be met.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Light gas gun launcher for simulating explosive shock wave and high speed fragment coupling load

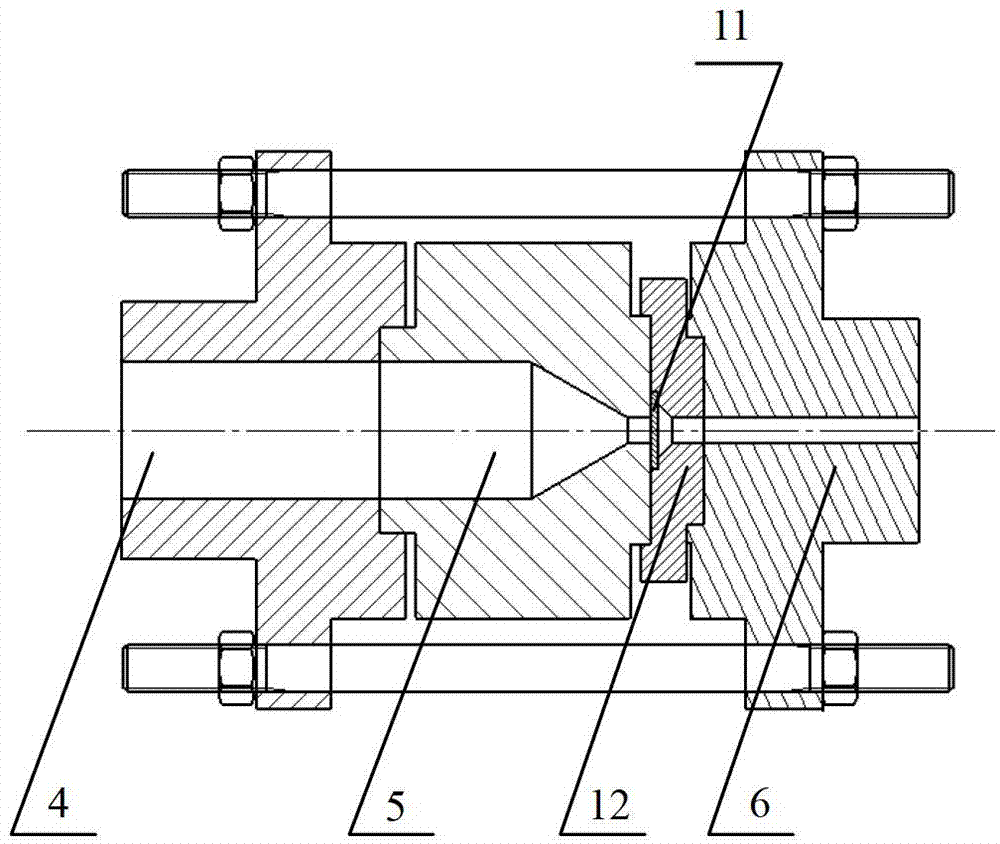

ActiveCN110186324AGood repeatabilityLow experimental qualificationCompressed gas gunsShock waveCoupling

The invention provides a light gas gun launcher for simulating explosive shock wave and high speed fragment coupling load, and belongs to the technical field of light gas gun simulation. According tothe light gas gun launcher, the problems that a live ammunition explosion loading mode is high in qualification requirements for experiment and can not be popularized, while the effectiveness of the live ammunition explosion loading mode can not be determined by fully utilizing a numerical simulation technology are solved. According to the scheme, a small caliber light gas gun launching tube is coaxially arranged in a large caliber light gas gun launching tube through a coupling connector, and a sabot flying plate is arranged in a front end inner cavity between the two tubes; the rear end of the small caliber light gas gun launching tube extends out of a rear port of the coupling connector, and communicates with a small caliber light gas gun high pressure air chamber; an upper port of thecoupling connector communicates with a large caliber light gas gun high pressure air chamber, and a piston is arranged between the large caliber light gas gun launching tube and the rear end of the coupling connector, slid right and left along the inner wall of the coupling connector, and used for opening or closing a channel between the large caliber light gas gun high pressure air chamber and the large caliber light gas gun launching tube; and a high pressure gas storage tank is used for providing a high pressure gas source.

Owner:HARBIN INST OF TECH

Gas detonation driven ultra-high-speed launching system

ActiveCN112902771AOvercoming qualityOvercoming the low speed of soundAmmunition testingAerodynamic testingUltra high speedDetonation

The invention belongs to the technical field of ultra-high-speed launching test experimental equipment, and discloses a gas detonation driven ultra-high-speed launching system in order to overcome the defects that gunpowder is large in molecular mass, the sound velocity is low, products are toxic, and transportation and storage are limited. A launching main body is sequentially connected with a detonation pipe, a compression pipe, a film clamping machine and a launching pipe; the launching main body is installed on a guide rail, and the guide rail is fixedly installed on a supporting frame; and the front end of the launching main body is connected with an oxyhydrogen inflation system through an ignition pipe, the rear end of the launching main body is connected with a test bin through a sealing device, the test bin is connected with a buffer box, and the buffer box is connected with a vacuum system. According to the gas detonation driven ultra-high-speed launching system, a detonation driven two-stage light gas gun technology adopting oxyhydrogen detonation as driving energy instead of the gunpowder is a low-cost and environment-friendly gas gun driving technology without needing initiating explosive devices, and higher efficiency and good launching repeatability are achieved.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

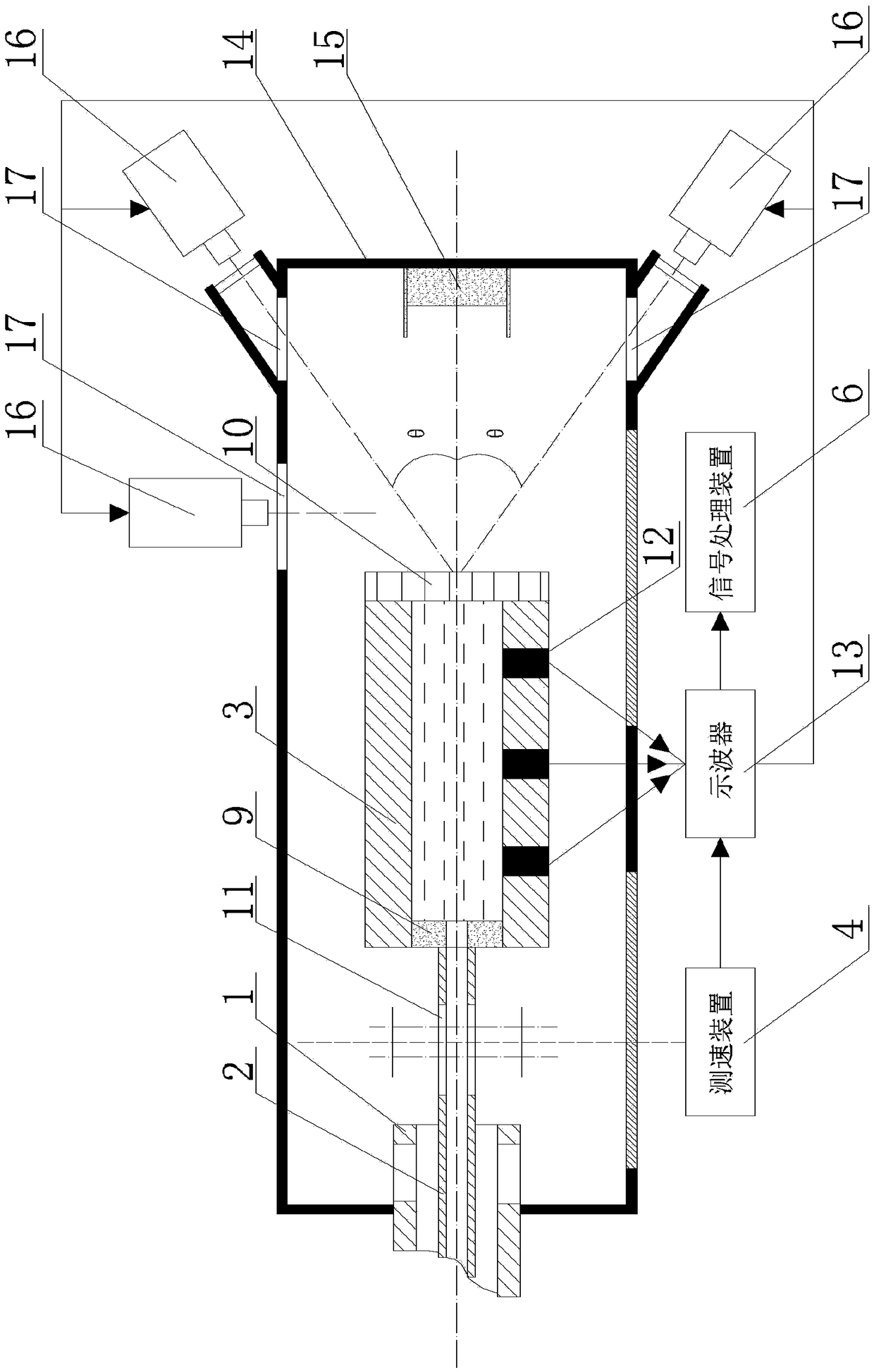

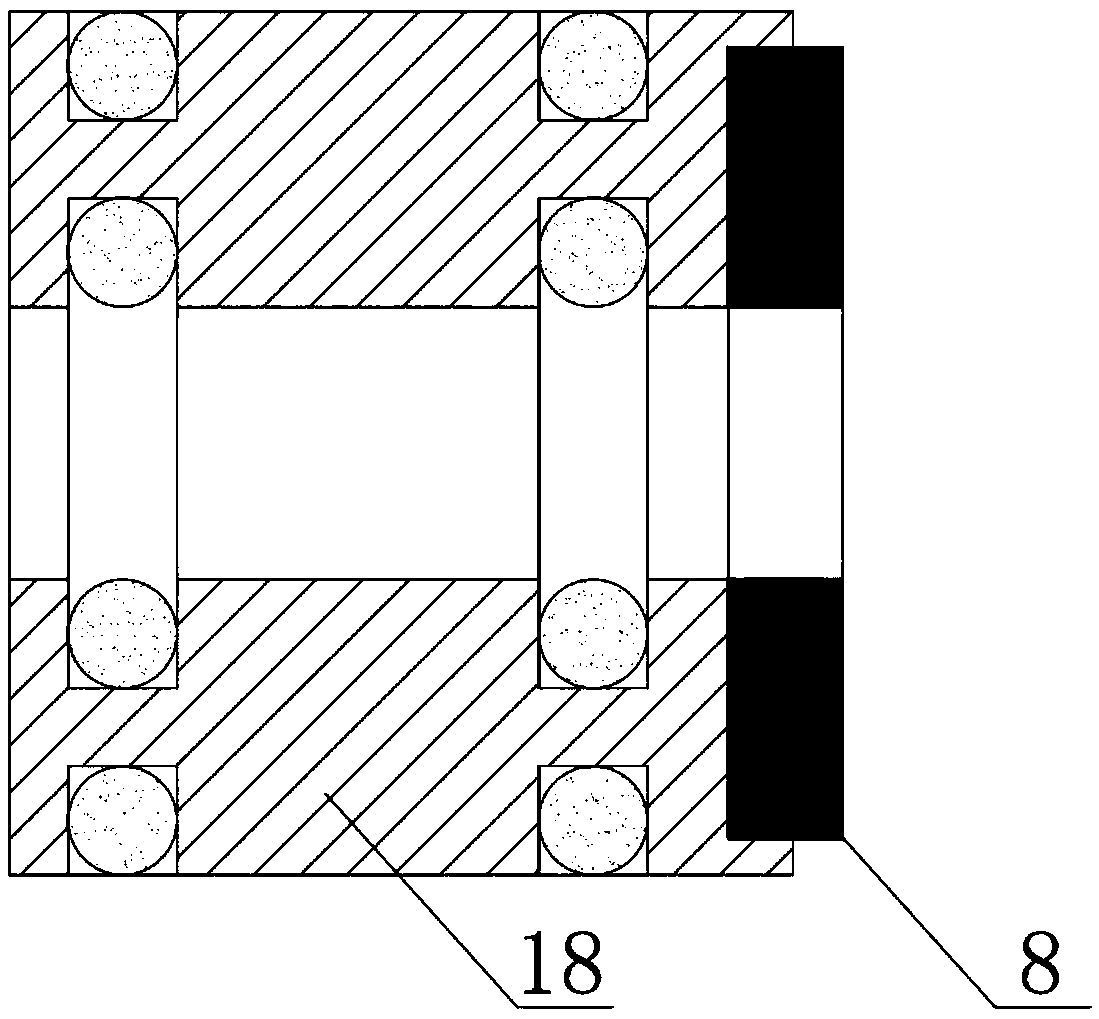

Experimental system of coupling loading of non-drug underwater explosion shock wave and high-speed fragmentation

ActiveCN109506875AGood repeatabilityReduce riskUsing mechanical meansShock testingMeasurement deviceUnderwater explosion

The invention discloses an experimental system of coupling loading of a non-drug underwater explosion shock wave and a high-speed fragmentation, relates to an explosion impact test device, aims to solve the problems that a result obtained by superposing single actions of a underwater explosion shock wave, high-speed fragmentation penetration and a bubble pulsating load is not accurate enough and the lack of necessary experiment verification cannot determine the validity of the effect in the prior art. The experimental system comprises a large-aperture light gas gun launch tube, small-aperturelight gas gun launch tube, an equivalent loading simulator, a speed measuring device, a shock wave measuring device and a signal processing device. The experimental system can realize the characteristic of coupling loading of the explosion shock wave, the high-speed fragmentation and the bubble pulsating load, is suitable for laboratory environment, and is easy to popularize.

Owner:HARBIN INST OF TECH

A Method for Generating Half-sine Acceleration Pulse Waveform in Strong Shock Test

InactiveCN105519261BComplete strong impact test half-sine acceleration pulse waveformShock testingAccelerometerOn board

Owner:中国兵器工业第二〇二研究所

Experimental system and method for simulating composite load of explosion shock wave and single fragment

The invention discloses an experimental system and a method for simulating a composite load of an explosion shock wave and a single fragment. The method comprises steps of: determining parameters, such as the density and the length of a foamed aluminum projectile, the diameter and the depth of an opening, the length and the diameter of a fragment simulated projectile, and the launch speed of a composite projectile, according to the composite load parameters of the shock wave and the fragment desired simulated; preparing a composite projectile based on the determined composite projectile parameters; and ejecting the prepared composite projectile out of the primary light gas gun at the determined speed, thereby forming a composite load of the shock wave and the single fragment desired simulated. According to the experimental system and the method for simulating the composite load of the explosion shock wave and the single fragment a method for scientific researchers and engineering designers to simulate the explosive power of an explosive device with a shell is provided. The method can be widely applied to the simulation test of explosive impact loads in the fields of the transportation, the safety protection, the military, and the like; can effectively save the test cost; and has considerable economic benefits.

Owner:福建卓航特种设备有限公司

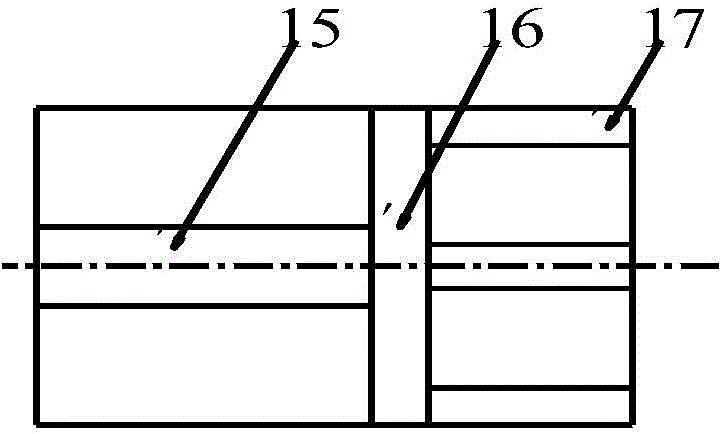

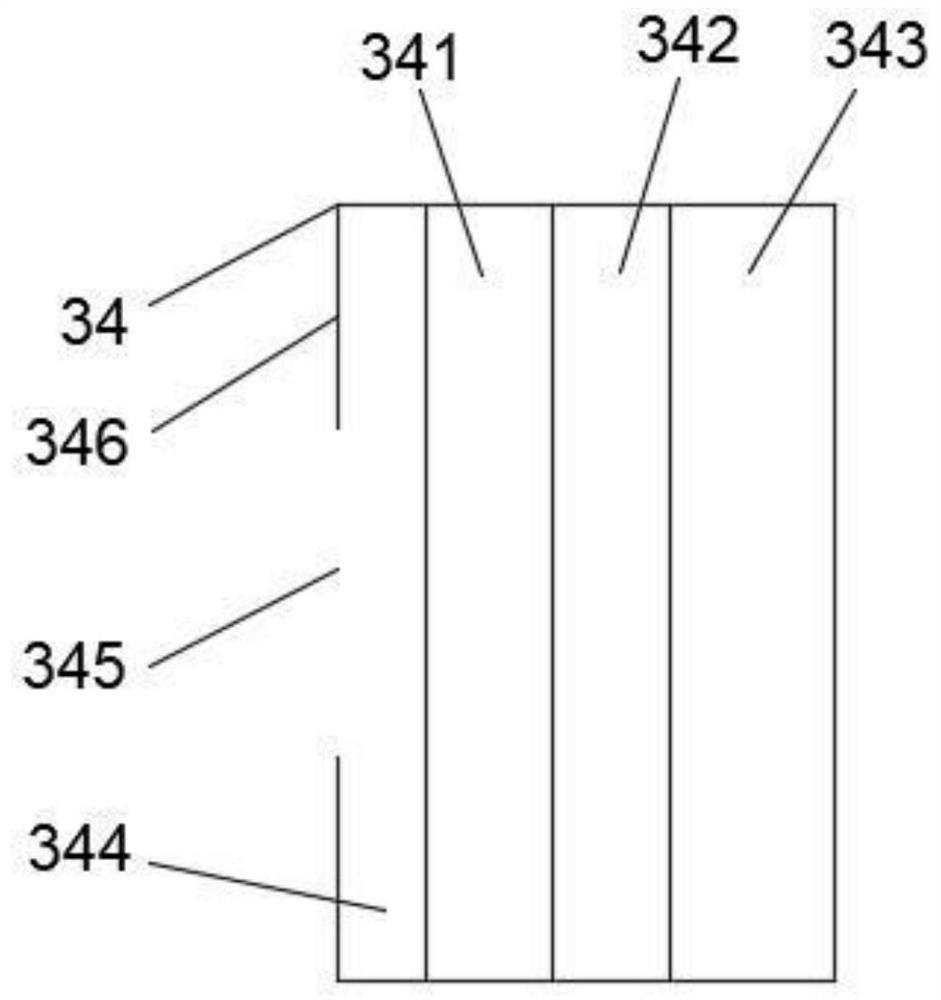

Sabot capable of realizing pneumatic separation through muzzle cutters

ActiveCN105547059ARestrict mutual misalignmentEliminate mutual interferenceAmmunition testingThin layerEngineering

The invention discloses a sabot capable of realizing pneumatic separation through muzzle cutters, and relates to a sabot. By adopting the sabot disclosed by the invention, the problems of a current segmented fractured sabot that close match and integral sealing cannot be realized among segments, so that the stability of accelerated movement of the sabot and a bullet in a bore is affected; and interference can easily occur among the segments during separation of the sabot, so that the speed of the bullet is affected by separation of the sabot are solved. According to the sabot, the upper and lower segments of the sabot are formed by cutting the same rotary body along a symmetrical surface, and the two segments are matched with each other at a tail part divergent conic section through divergent arc teeth; matched surfaces of the upper segment and the lower segment are separately coated with a thin layer of rubber; the front and rear cylindrical sections of the sabot are separately provided with an annular groove; after the upper segment is matched with the lower segment, the two annular grooves are separately provided with a sealing ring, so that the sabot can be arranged in the bore in a slidable manner; the multiple muzzle cutters are arranged on the outer surface of the bore in the outlet direction; and the sealing rings are cut when the sabot leaves the bore, so that pneumatic separation is realized after the sabot leaves the bore. The sabot disclosed by the invention is applicable to the experiment of shooting a subcaliber bullet with a light-gas gun.

Owner:HARBIN INST OF TECH

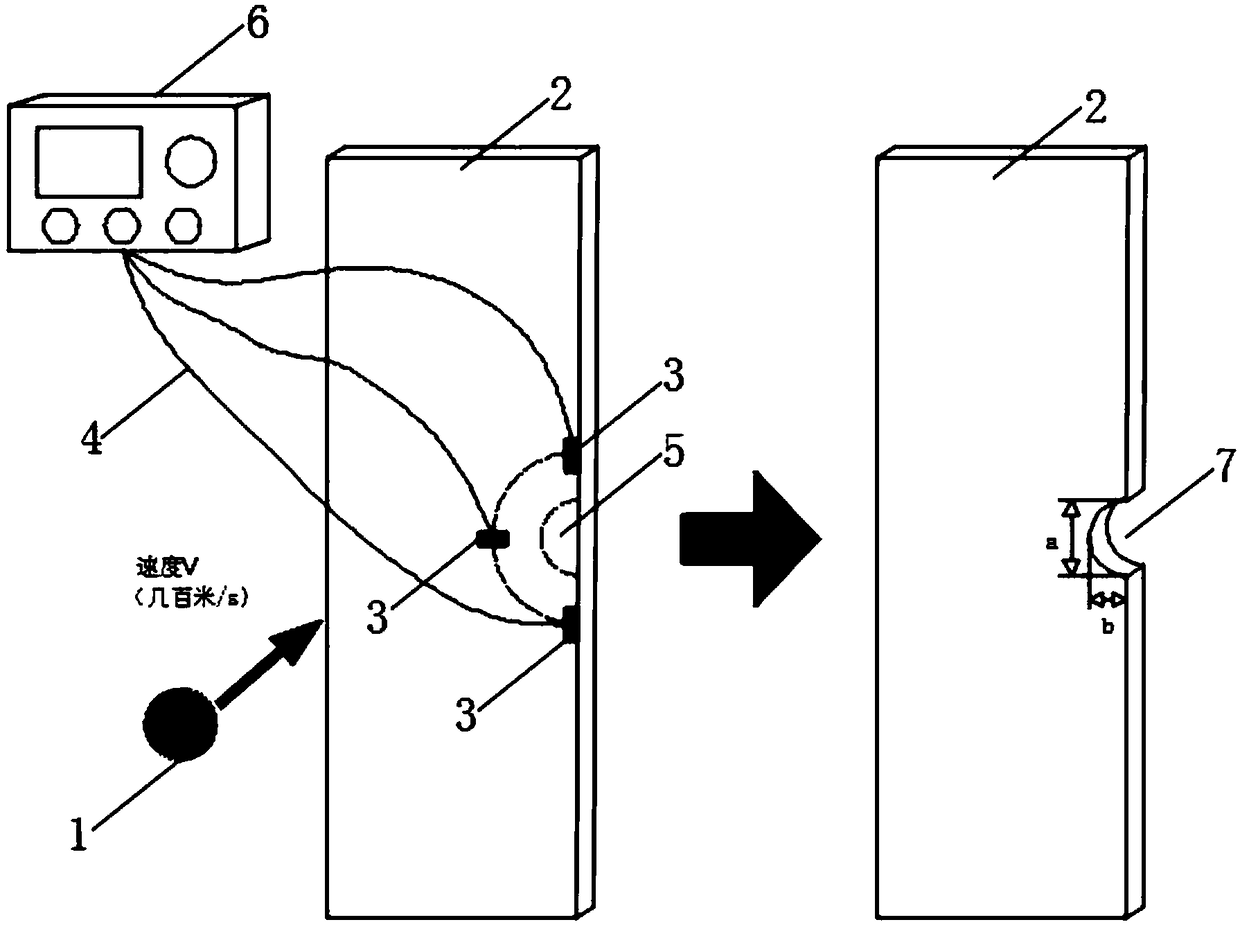

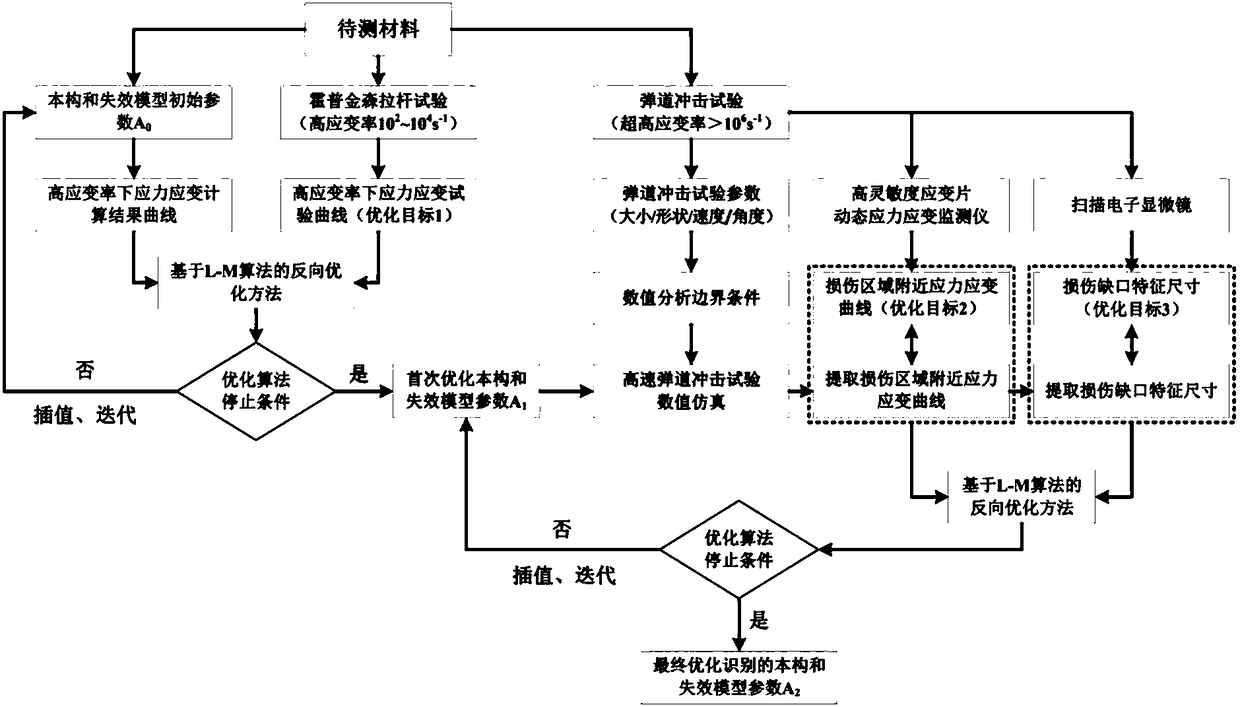

Parameter identification method for constitution and failure model of material under ultra-high strain rate

InactiveCN108169040AAddressing the lack of experimental dataAccurate Kinetic Response Behavior CharacterizationStrength propertiesEngineeringModel parameters

The invention discloses a parameter identification method for a constitution and failure model of a material under an ultra-high strain rate. A dynamic stress-strain curve of the deformation and failure process of the material under a high strain rate is obtained through Hopkinson pull rod test, and the dynamic stress-strain curve of the material under the high strain rate is used as a target forreverse optimization fitting to obtain parameters of the constitution and failure model after the first optimization are obtained; a light gas gun system is used to perform high-speed ballistic impacttests on the material, a high-sensitivity strain gauge is used to monitor the dynamic stress-strain curve of the material near a damage zone, and the feature size of a damage notch can be measured bya scanning electron microscopy; ballistic impact test parameters are used as boundary conditions for ballistic impact numerical simulation, and the dynamic stress-strain curve of the material corresponding to the position of the high-sensitivity strain gauge and the feature size of the damage notch can be extracted; the actually tested dynamic stress-strain curve of the material and the actuallytested feature size of the damage notch are used as targets for reverse optimization fitting to finally obtain the parameters of the constitution and failure model of the material under the ultra-highstrain rate.

Owner:AIR FORCE UNIV PLA

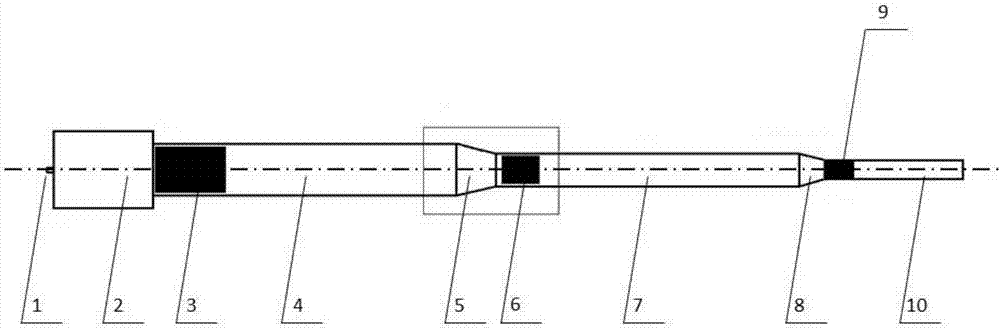

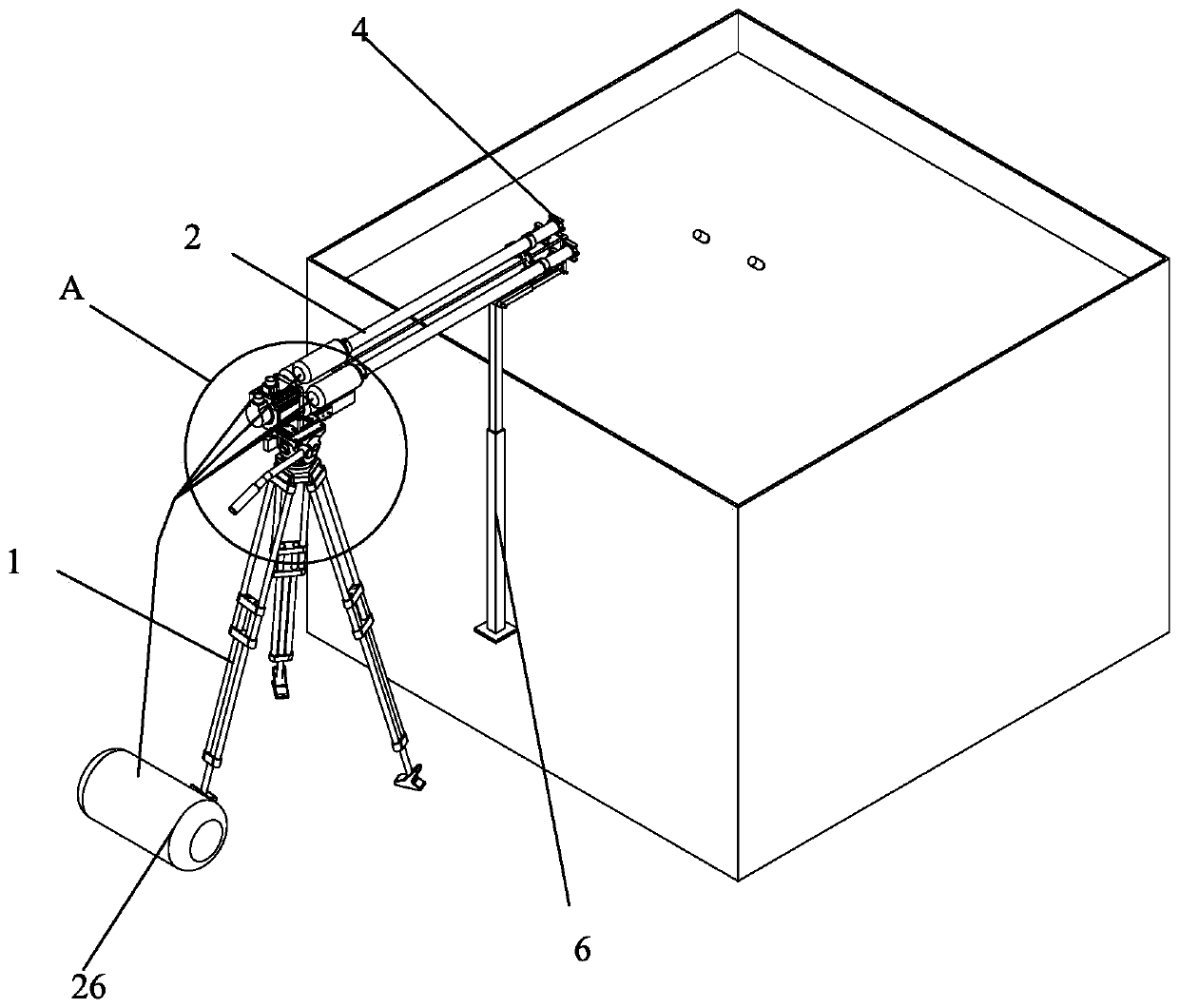

Novel multi-vehicle series water entry light-gas gun launching experimental device

ActiveCN109781383AAchieving inclined entry into the waterAccurate tilt angleHydrodynamic testingGas cylinderEngineering

The invention discloses a novel multi-vehicle series water entry light-gas gun launching experimental device. The device comprises a tripod; a motor and a light-gas gun launching device are fixed ontothe upper surface of a tripod pan-tilt holder; the light-gas gun launching device is provided with a plurality of light-gas gun tubes and a rotating shaft; the output shaft of the motor is connectedwith the rotating shaft; one end of each light-gas gun tube, which is adjacent to the motor, is fixedly provided with a compressed gas cylinder; a vehicle is arranged in one end of each light-gas guntube adjacent to the motor; one end of each light-gas gun tube, which is far away from the motor, is provided with a front-end support; a level is fixed on the tripod; and the light-gas gun tubes areprovided with speed measuring devices respectively. According to the novel multi-vehicle series water entry light-gas gun launching experimental device of the invention, the light-gas guns are adoptedto launch vehicles; the light-gas guns are arranged on the tripod; the inclination angle of the light-gas guns is so accurate that the inclination angle can reach a 0.1 degree-level; by means of a servo motor, the plurality of vehicles can densely enter water at the same position, and can enter water synchronously in a parallel manner at a certain initial speed, and namely, the series water entryand parallel water entry of the vehicles can be realized.

Owner:DALIAN UNIV OF TECH

Light gas gun

ActiveUS9915496B2Optimization rangeIncrease lethalityAmmunition projectilesMissile propulsionEngineeringAcoustic signature

An improved light gas gun launches a projectile in a light gas atmosphere as it travels through a frictionless barrel to achieve high muzzle velocities, decreased acoustic signatures, and increased ranges. The light gas atmosphere is introduced by a purge valve prior to firing or by a muzzle valve that holds a positive light gas pressure on the barrel and breech. The muzzle valve also routes the majority of propellant gases through a suppression canister, reducing the light gas gun's acoustic signature. The frictionless barrel uses light gas propellant routed through gas bearings to keep the projectile centered in the barrel and preclude the projectile from contacting the barrel walls, eliminating barrel wear.

Owner:BERGERON DAVID WAYNE

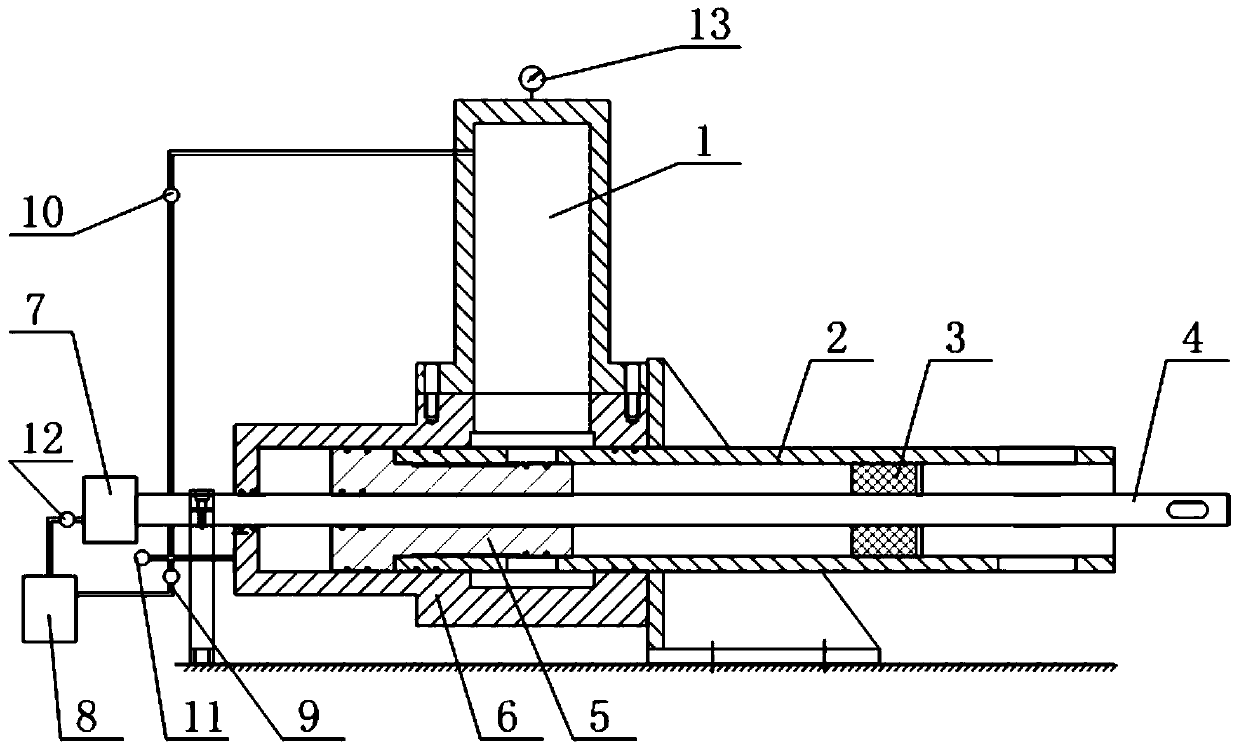

Novel two-stage light-gas gun driven by high pressure air

The invention provides a novel two-stage light-gas gun driven by high pressure air and belongs to the technical field of light-gas gun experiments. The novel two-stage light-gas gun mainly comprises asupport, a first-stage air chamber, a first-stage air chamber electromagnetic valve, a trigger electromagnetic ball valve, a second-stage air chamber, a large piston, a small piston, a launching pipe, an air release device and the like. A two-stage air chamber power source is adopted, the second-stage air chamber is divided into a large piston section and a small piston section, the two inside pistons are in rigid linkage, in the initial state, the first-stage air chamber and the small piston section of the second-stage air chamber are filled with high pressure air, storage and release of thehigh pressure air are controlled by the electromagnetic valve, and thus under the circumstance that initiating explosive devices, hydrogen and other flammable and explosive gases cannot be provided,superspeed flying of an object is achieved through air compression loading. The novel two-stage light-gas gun is safe and reliable, superspeed flying of the object is achieved with a compressed air method, experiment cost is low, and operation is safe, simple and convenient.

Owner:HARBIN ENG UNIV

Combustion light gas gun driven by convergent shock wave reflection induced detonation

PendingCN109539881AImprove operational efficiencySolve solid propellantLaunching weaponsCombustion light-gas gunShock wave

The invention discloses a combustion light gas gun driven by convergent shock wave reflection induced detonation, which comprises a driving section, a driven section, a convergence section, a gas injection device, a launching tube and a target chamber. A pipe body of the driving section is provided with a gas injection hole, one end of the gas injection hole is closed, the other end of the gas injection hole is connected with the driven section, and a diaphragm is arranged at the connection part; a pipe body of the driven section is provided with a gas injection hole; the large diameter part of the convergence section is connected with the driven section, the small diameter part of the convergence section is connected with the launching tube, and the connection part is provided with a launching tube membrane; the gas injection device is used for injecting hydrogen gas and nitrogen gas into the driving section, and injecting hydrogen gas, oxygen gas and nitrogen gas into the driven section and the convergence section; a projectile is arranged in the launching tube, and one end of the projectile is positioned in the target chamber. The light gas gun is formed by inducing detonation after the shock wave is converged and reflected after the membrane is broken, the fuel chemical energy is used for replacing gunpowder or compressed gas for driving, the operation efficiency is high, and the pollution is small; due to the absence of a piston, the structural requirements and damage are smaller and the operating time is only on the order of milliseconds.

Owner:UNIV OF SCI & TECH OF CHINA

Inclined detonation experiment system based on gas detonation driving superspeed launching device

ActiveCN112902770AMix well and evenlyAccurate measurementAmmunition testingUltra high speedThermodynamics

The invention relates to the technical field of combustible gas detonation experiment devices, and provides an inclined detonation experiment system based on a gas detonation driving superspeed launching device. A secondary light gas gun unit is included, the secondary light gas gun unit is connected with an inclined detonation experiment cabin unit and an igniter, the inclined detonation experiment cabin unit is provided with a high-speed photography system, the inclined detonation experiment cabin unit is filled with combustible mixed gas before an experiment is started, and the igniter, the inclined detonation experiment cabin unit and the high-speed photography system are controlled by a computer system; and before the experiment is started, the inclined detonation experiment cabin unit is filled with combustible mixed gas according to a preset working condition and is statically placed, so that the state of the combustible mixed gas is accurately controlled, the combustible mixed gas does not react before the experiment is started, the property of the combustible mixed gas is accurately measured, the purity degree and sufficient and uniform mixing of the combustible mixed gas are guaranteed, and the detonation process of inclined detonation is observed through the high-speed photography system.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Composite ignition type combustion light gas gun

PendingCN110132053ASolve stressAddresses an issue that caused suboptimal launch performanceCompressed gas gunsShock waveDelayed pulse

The invention discloses a composite ignition type combustion light gas gun. The composite ignition type combustion light gas gun comprises a drive section, a driven section, a convergence section, anemitting tube and an ignition control system, wherein one end of the drive section is sealed, and the other end of the drive section is connected to the driven section, and a joint is clamped with a diaphragm; the tube body of the driven section is equipped with a pressure sensor; the front end of the convergence section is connected to the driven section, the rear end of the convergence section is connected to the emitting tube, and the joint of the rear end and the emitting tube is clamped with a diaphragm, and an igniter is mounted on a tube body; a shot is placed on a position, close to the diaphragm, in the emitting tube; and the ignition control system comprises a pressure sensor, a charge amplifier, a digital delay pulse generator. The light gas gun utilizes a composite ignition form, adopts mutual action between detonation waves induced by convergence shock wave reflection and detonation waves forcibly detonated by the igniter to generate intense shock waves, then, the intenseshock waves chase after the shot and are reflected, so that shot-bottom pressure is instantaneously increased, and a gas gun system with higher operation efficiency is developed with a lower price.

Owner:UNIV OF SCI & TECH OF CHINA

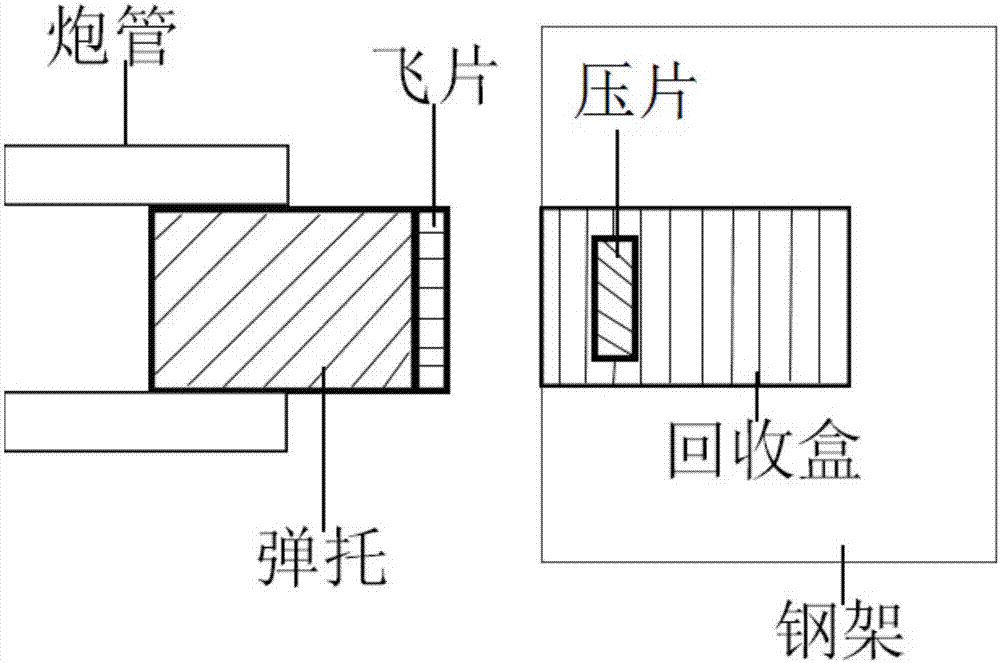

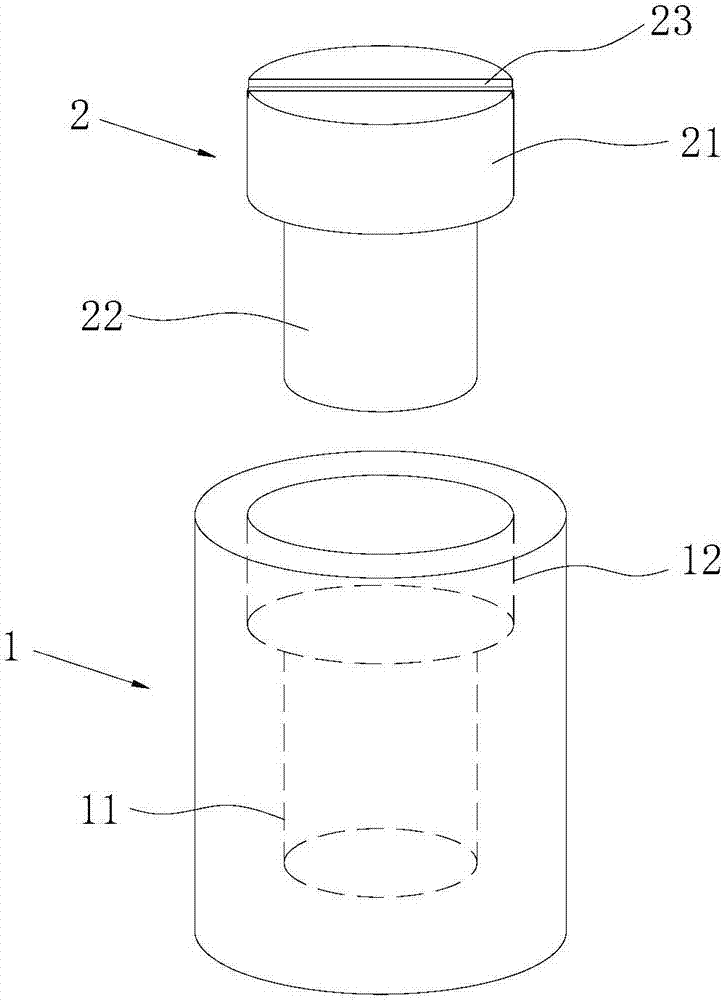

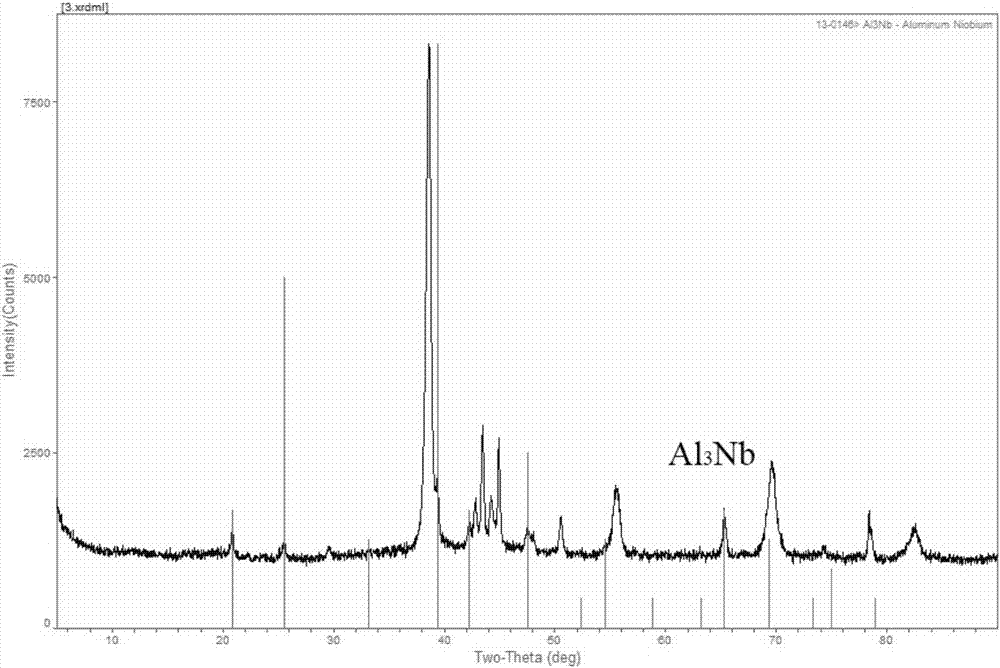

Method for preparing niobium aluminum alloy through shock compression

The invention discloses a method for preparing niobium aluminum alloy through shock compression. The method comprises the following steps of uniformly mixing aluminum powder and niobium powder; weighing the uniformly mixed powder according to set mass, and using a tablet machine for prepressing the powder into a tablet; placing the tablet into a recovery box, screwing up the recovery box, and then placing the recovery box into a high-mass steel frame; using a light-gas gun for driving a flyer plate to impact the recovery box, carrying out shock compression acting on the tablet through a produced shock wave, forming a high-temperature high-pressure environment, and preparing to obtain the niobium aluminum alloy; and using a turning-lathe for taking the niobium aluminum alloy out from the recovery box, and grinding off impurities on the surface of the niobium aluminum alloy. According to the method for preparing the niobium aluminum alloy through shock compression provided by the invention, the characteristic that the preparation of the niobium aluminum alloy is exothermic reaction is utilized, and the advantages of rapid shock-compression loading time of the shock-compression light-gas gun, uniform pressure distribution, fine product granularity, good sintering property and the like are combined, so that high temperature and high pressure can be produced within dozens of nanoseconds to hundreds of nanoseconds so as to prepare the niobium aluminum alloy.

Owner:SOUTHWEST JIAOTONG UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com