Light-gas gun pneumatic separation sabot

A pneumatic separation and light gas cannon technology, which is applied in the direction of projectiles, offensive equipment, weapon types, etc., can solve problems such as poor separation effect, difficult separation of bomb holders, and complex structure of the light gas cannon system, so as to reduce negative weight and intensify Separate, versatile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

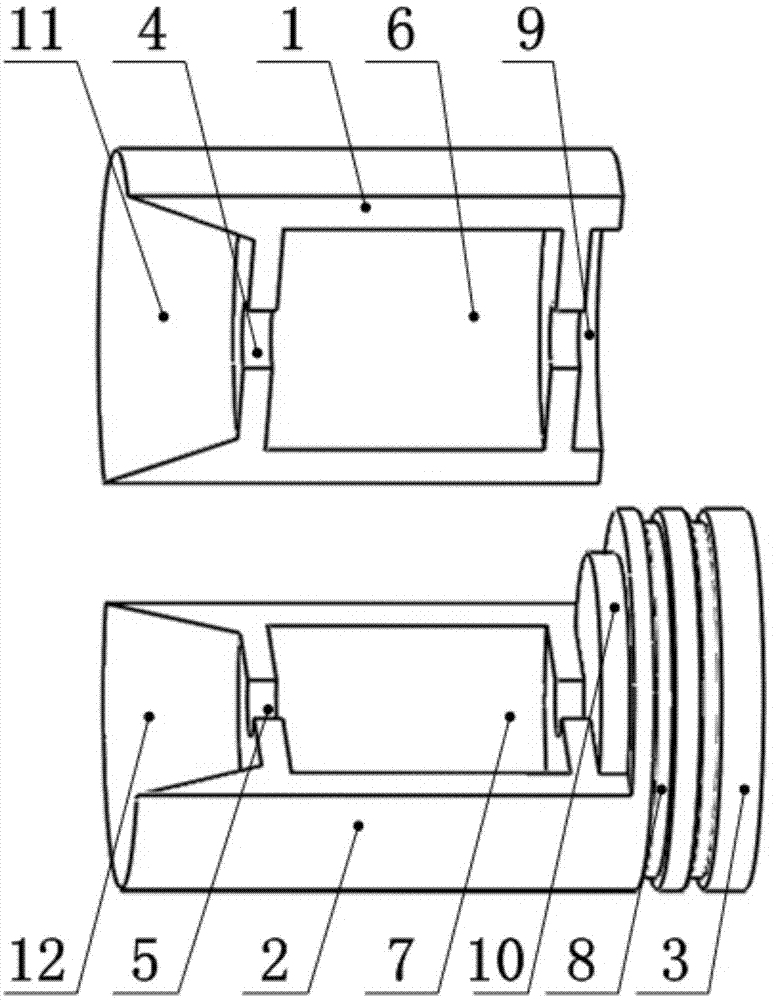

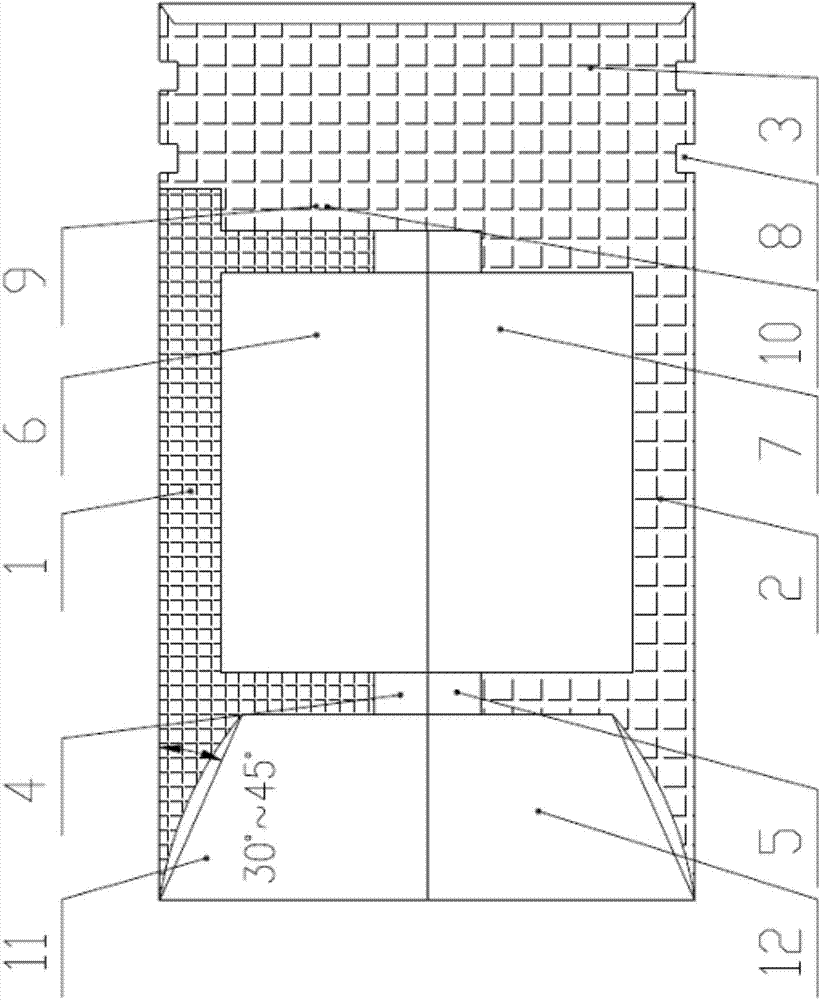

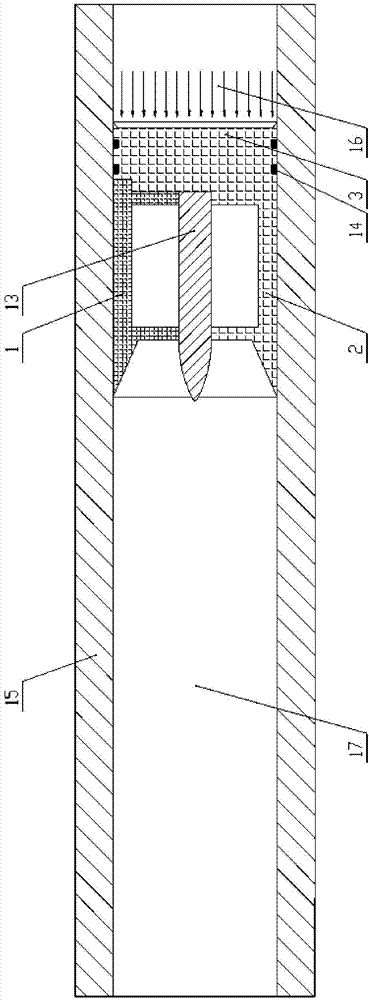

[0032] Embodiment one: (see figure 1 , figure 2 ) The present embodiment is made up of upper support valve 1, lower support valve 2 and base plate 3; upper support valve 1 and lower support valve 2 are two corresponding half cylinders, and the front end of upper support valve 1 is designed with air vortex structure 11, and the center There are projectile holes 4; the lower support valve 2 and the base plate 3 form an integral body, the base plate is necessary in the present invention, and plays the role of transmitting high-pressure gas pressure, and the front end of the lower support valve 2 is designed with a gas valve corresponding to the upper support valve 1 The vortex structure 12 has a projectile hole 5 in the center; the bottom plate 3 is engraved with two sealing grooves 8 . The upper half of the projectile hole 4 of the upper support valve 1 corresponds to the lower half of the projectile hole 5 of the lower support valve 2, and the semicircular gap 9 of the upper ...

Embodiment 2

[0033] Embodiment two: (see figure 2 ) The difference between this embodiment and the previous embodiment is that the construction lines of the air vortex structure 11 and the air vortex structure 12 can be straight lines or arcs. The angle between the straight line and the outer wall of the support valve is 30°-45°; the arc is tangent to the outer wall of the support valve, and the angle between the chord and the outer wall of the support valve is 30°-45°.

Embodiment 3

[0034] Embodiment three: (see figure 1 , figure 2 ) The difference between the third embodiment and the first embodiment is that the middle of the upper support valve 1 is hollowed out into a hollow structure 6 , and the middle of the lower support valve 2 is hollowed out into a hollow structure 7 corresponding to the upper support valve 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com