Waste plastic film impurity separating machine

A technology of plastic film and separator, applied in the direction of solid separation, filter screen, grid, etc., can solve the problems of inability to achieve rapid and continuous separation, inability to apply agricultural film, low degree of automation, etc., and achieve simple structure, low cost, high speed improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below through specific examples.

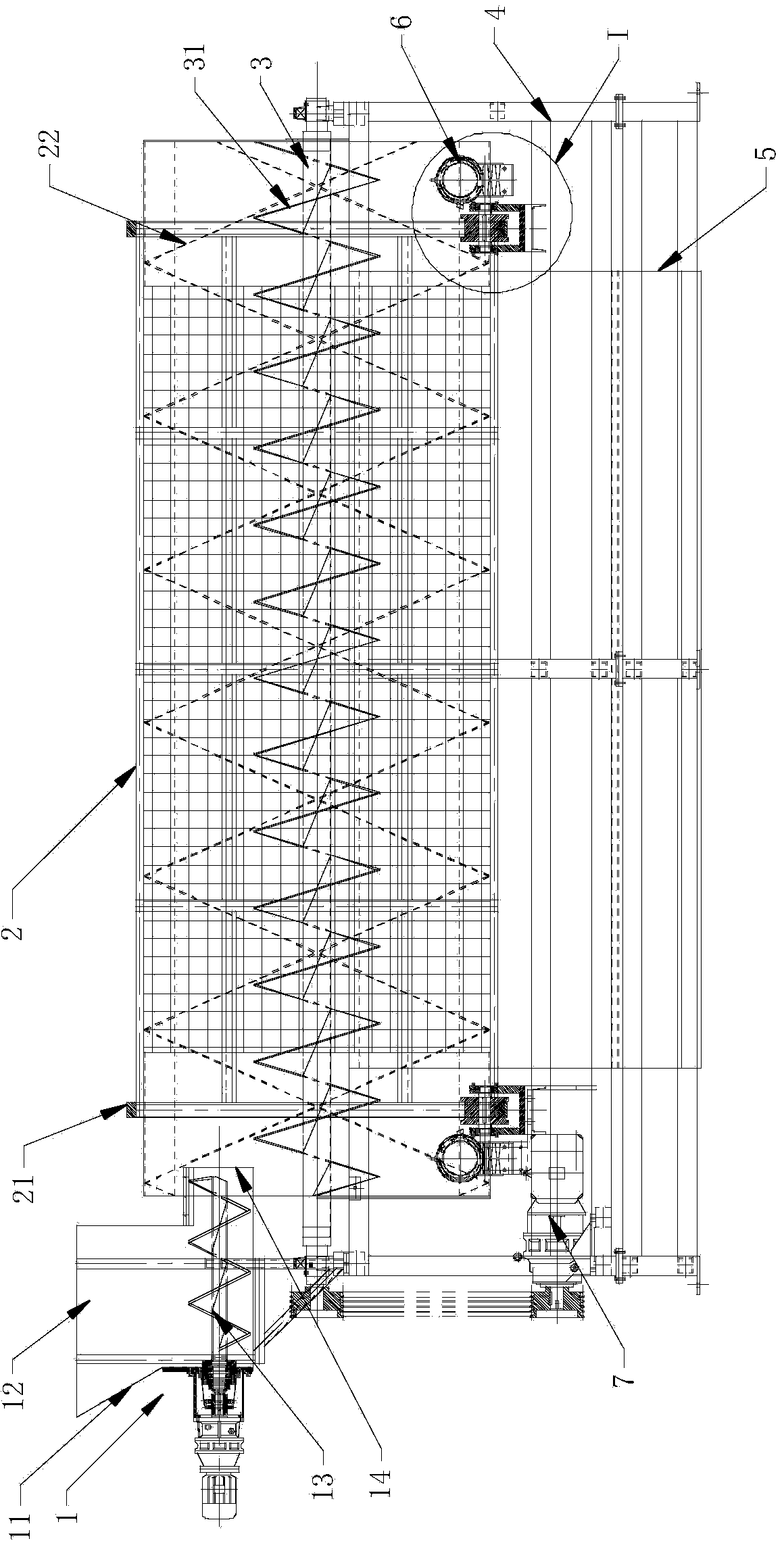

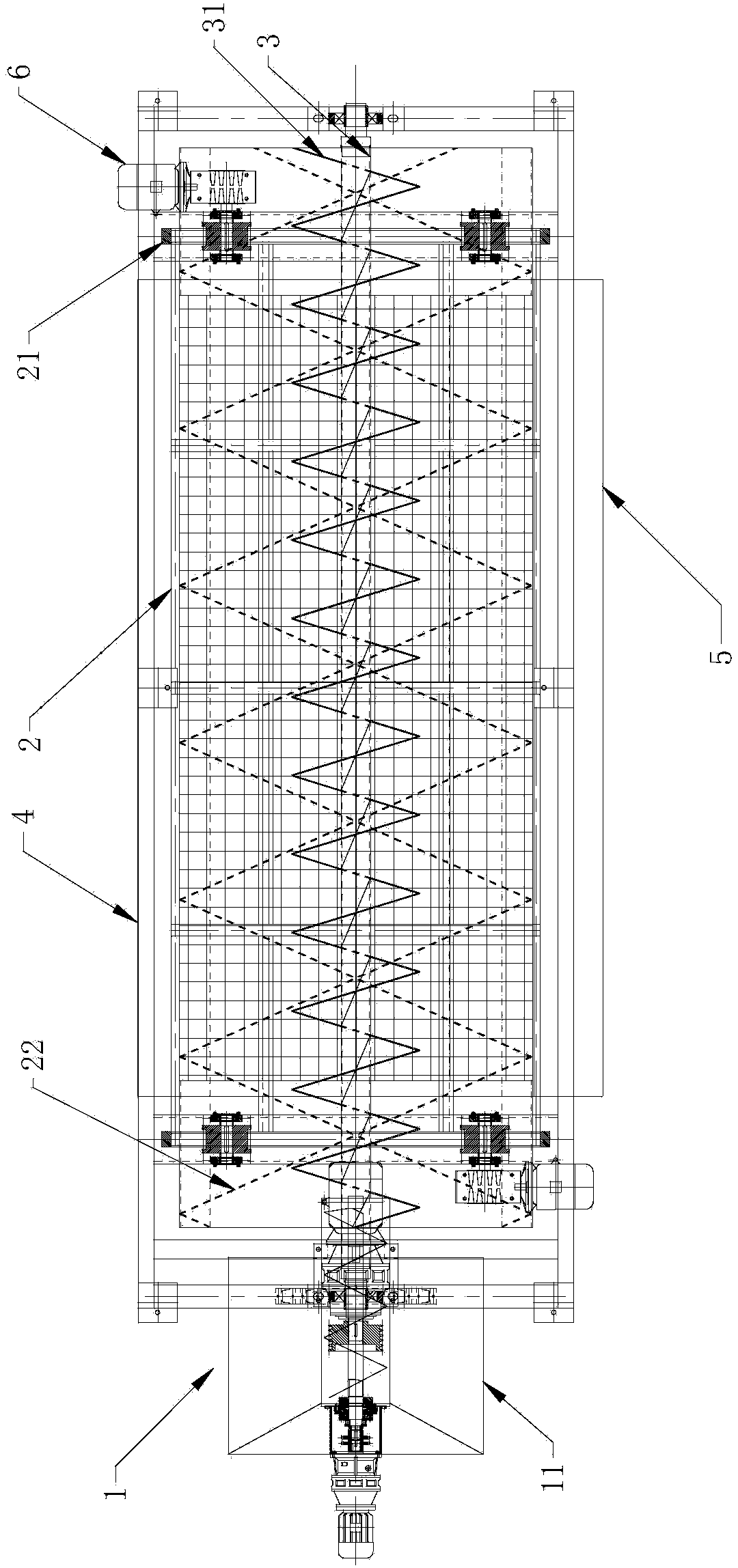

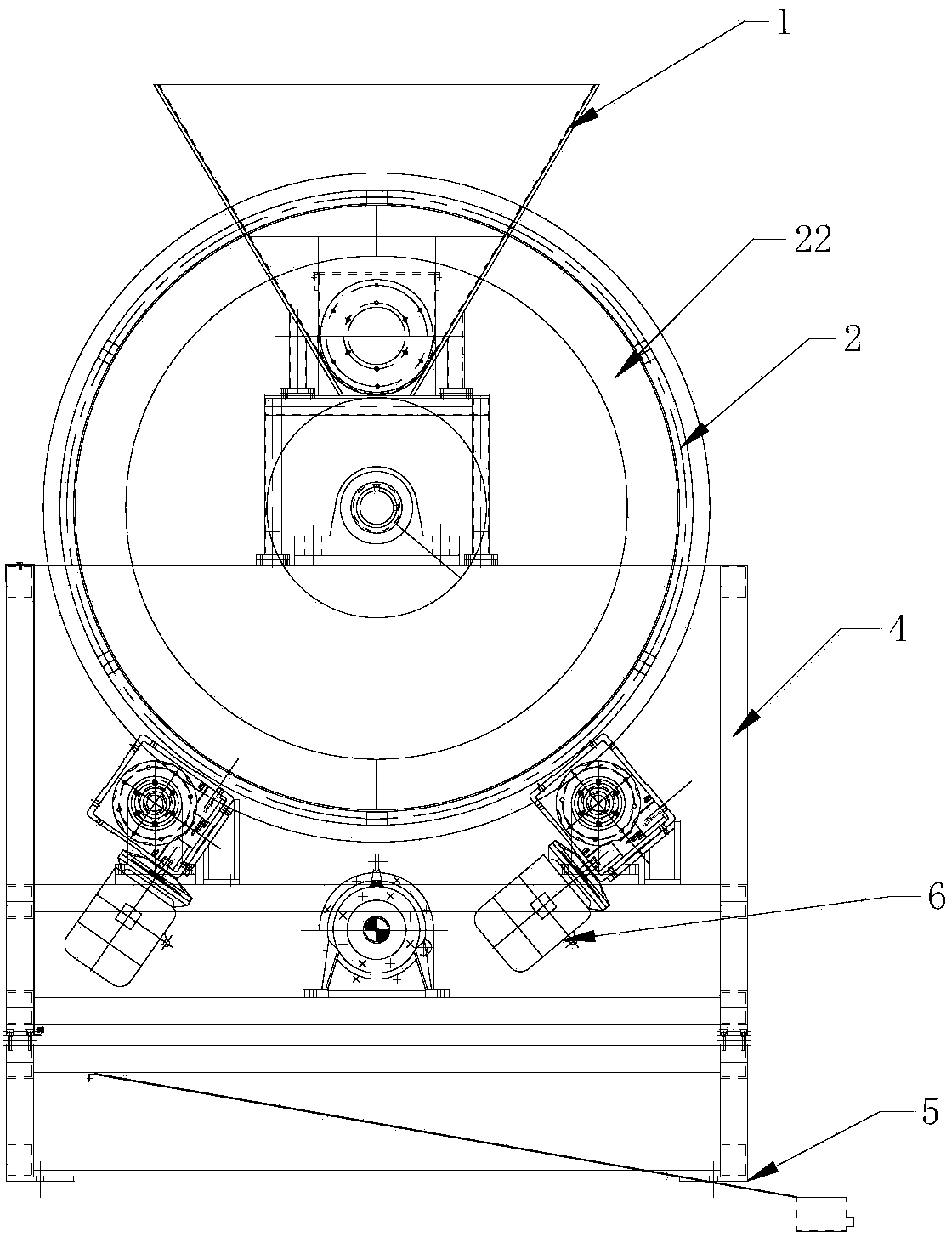

[0021] like Figures 1 to 4 As shown, a waste plastic film impurity separator includes a frame 4, a sieve cylinder 2 with openings at both ends, a pusher spindle 3, a feeding mechanism 1 and an impurity discharge device 5, and the sieve cylinder 2 is axially horizontal Rotatingly installed on the frame 4, one end of the sieve cylinder 2 is the feed end, and the other end is the discharge end. Several sieve holes are arranged on the peripheral wall of the sieve cylinder 2, and the inner peripheral wall of the sieve cylinder 2 is provided with a spiral Pushing material blade 22, this pushing material blade 22 is preferably double-headed spiral pushing material blade 22, can accelerate the propulsion speed of material like this; This sieve cylinder 2 is transmission-connected with sieve cylinder rotating power device 6; Described material pushing main shaft 3 rotates Installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com