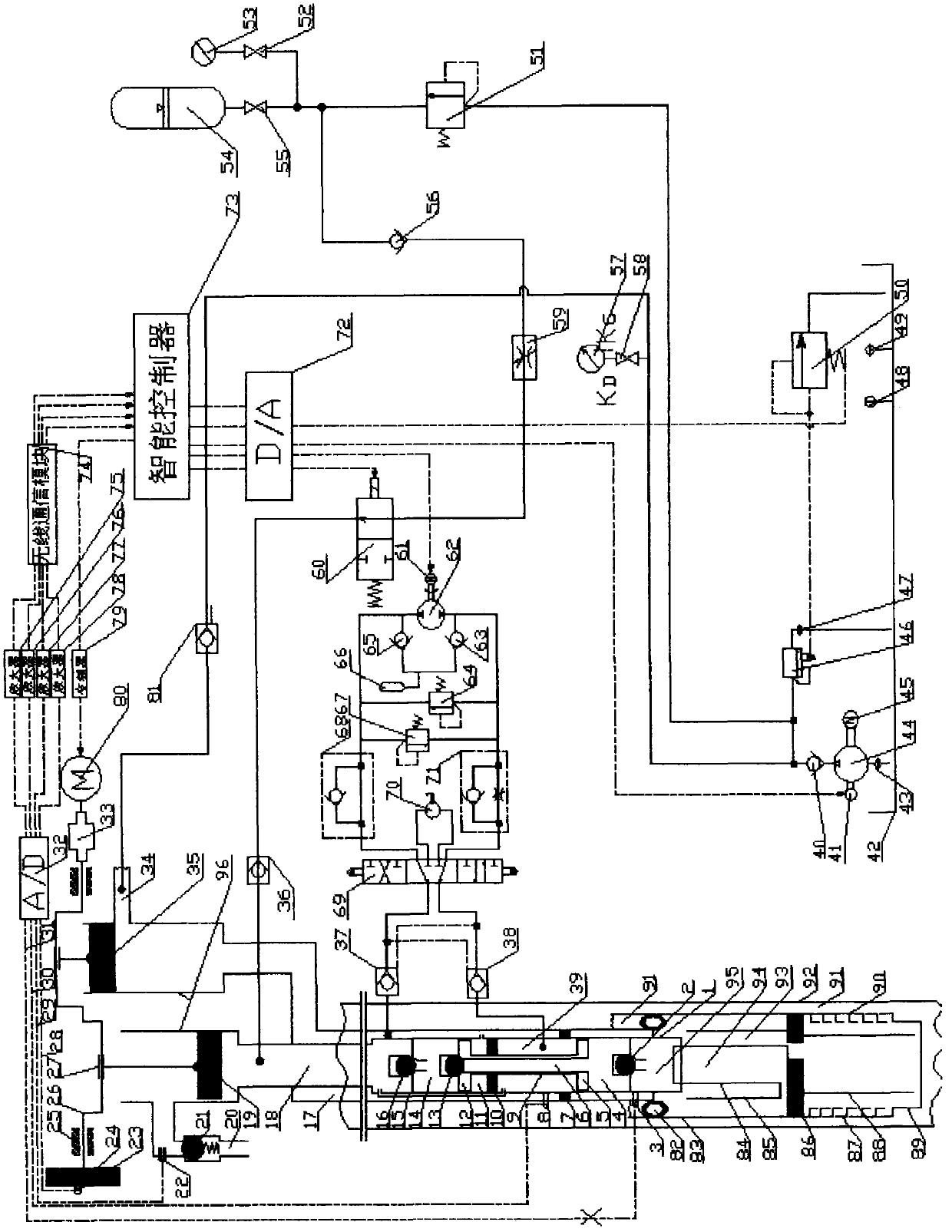

Pulsating reciprocating type hydraulic pumping unit

A pumping unit, reciprocating technology, applied in the field of pulsating reciprocating hydraulic pumping unit, can solve the problems of high installed power, poor braking control, low efficiency, etc., achieve the requirements of light weight, reduce working conditions, avoid large The effect of a horse-drawn trolley

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

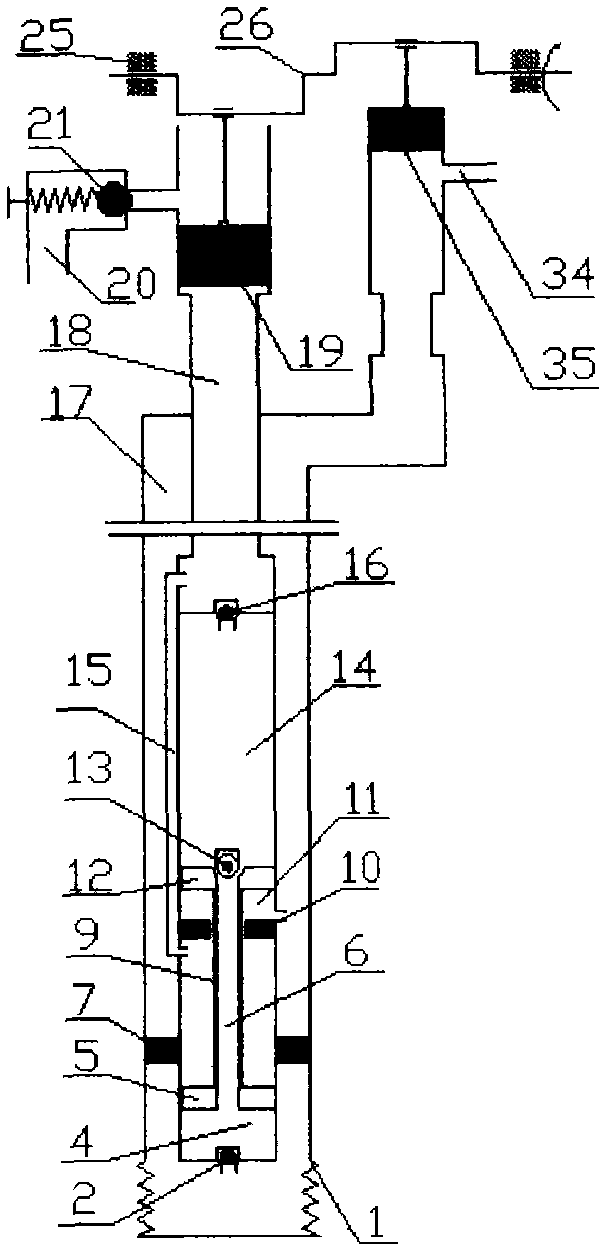

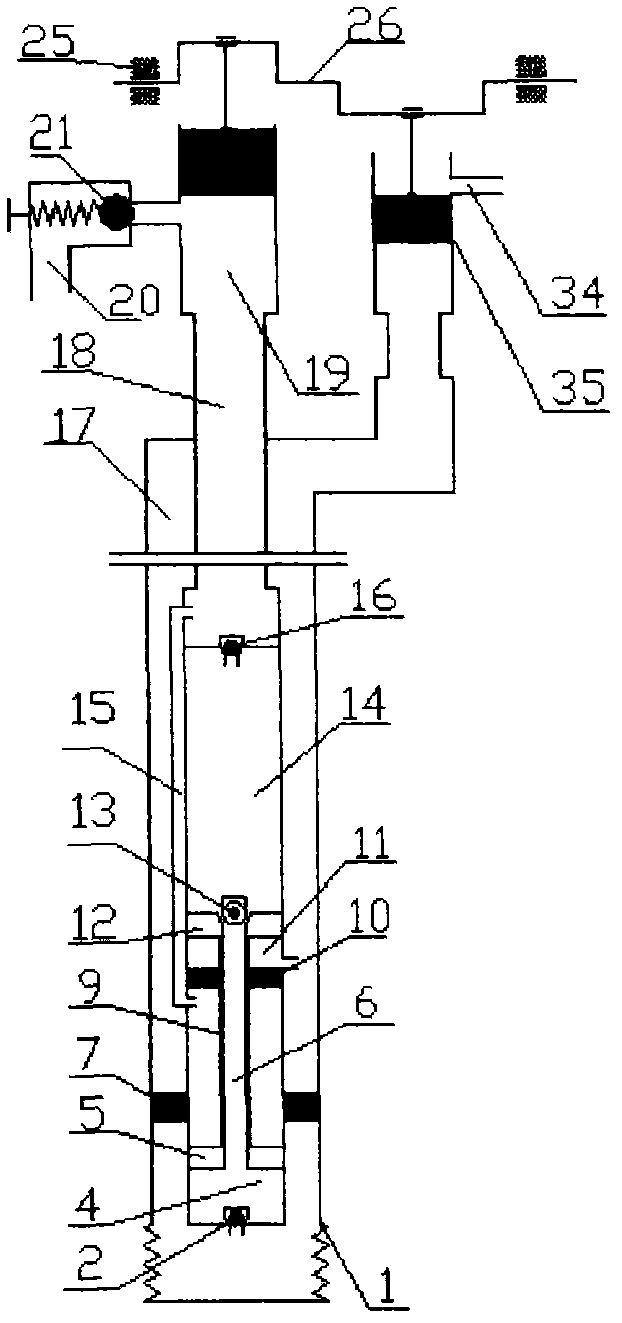

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] refer to figure 1 , the oil-gas mixture will go through the whole process of the oil-gas separator, that is, the crude oil (containing gas) enters the wellbore 90, and during the upstroke of the pump, the oil-gas mixture goes down from the liquid inlet pipe 87 and enters the central pipe 88, and some large bubbles are released from the mixture. It is separated from the middle and goes upward, discharged from the liquid inlet hole 92, and enters the oil jacket annulus 91 to complete the first separation, that is, gravity separation. However, most of the small air bubbles are still carried by the liquid to continue upward through the central tube 88, and enter the spiral tube 84 through the special joint 86. After the mixed liquid enters the spiral channel 93, the liquid and the gas make circular motions along the axis at the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com