Patents

Literature

57results about How to "Improve oil pumping efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

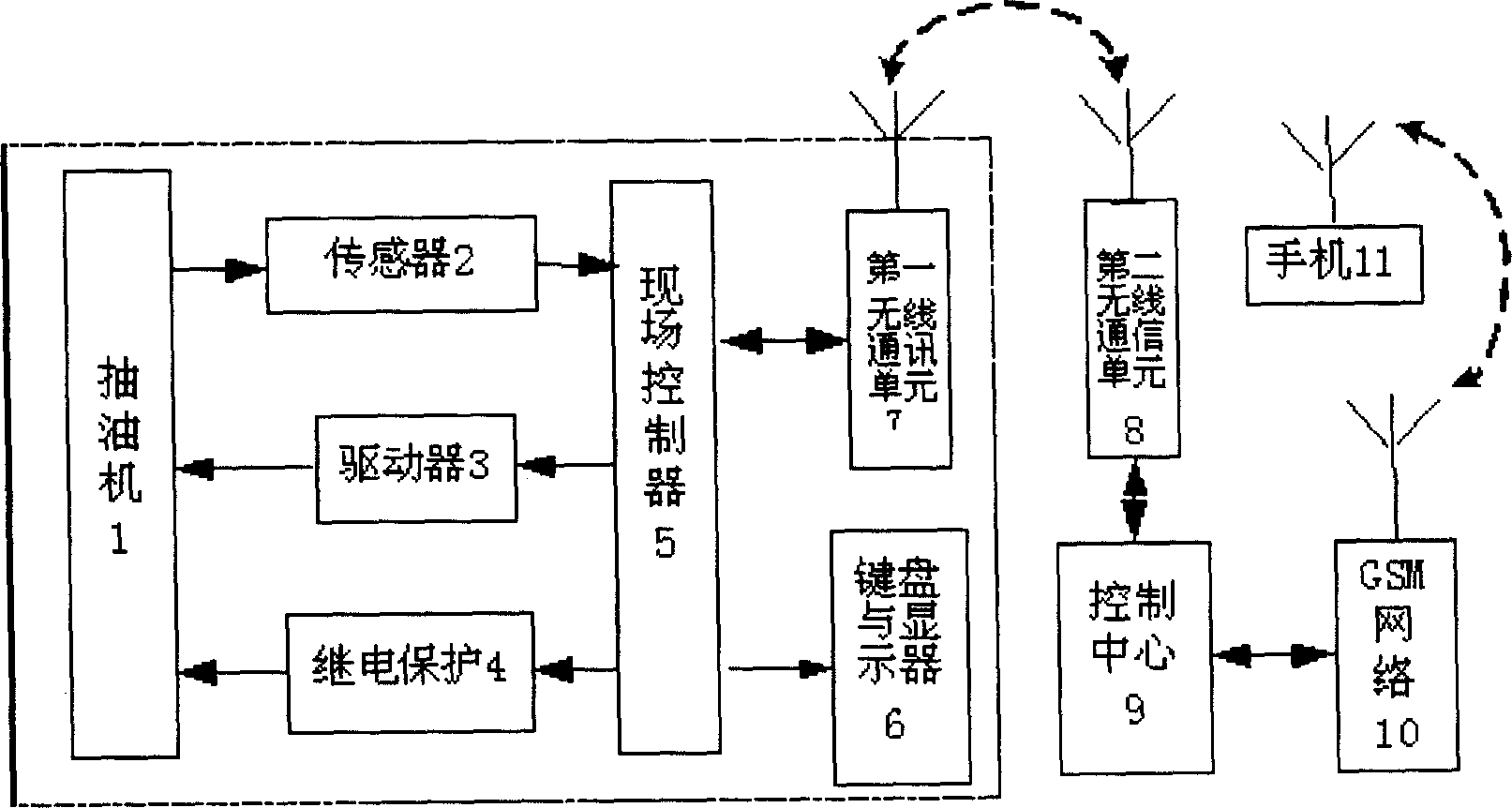

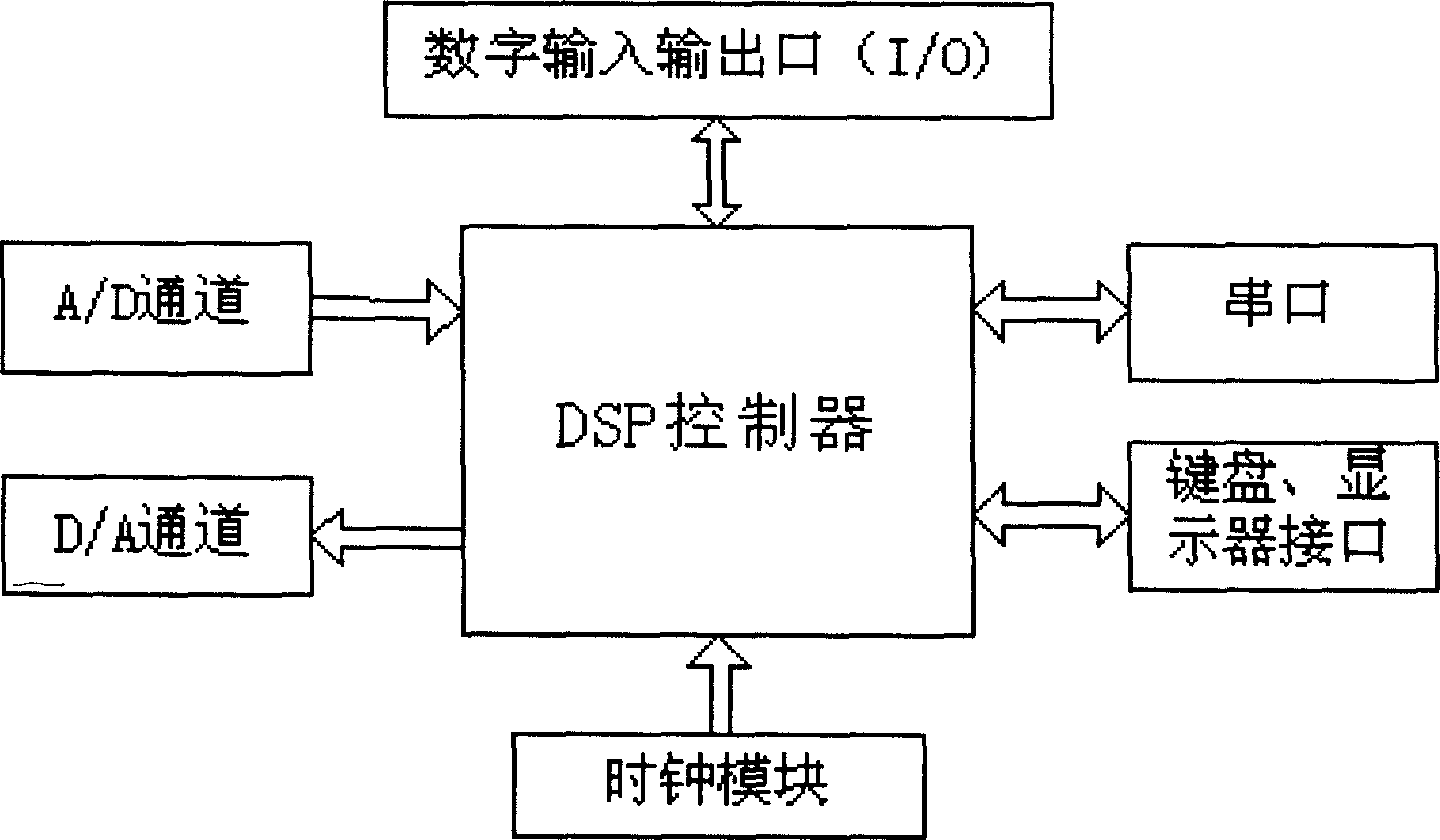

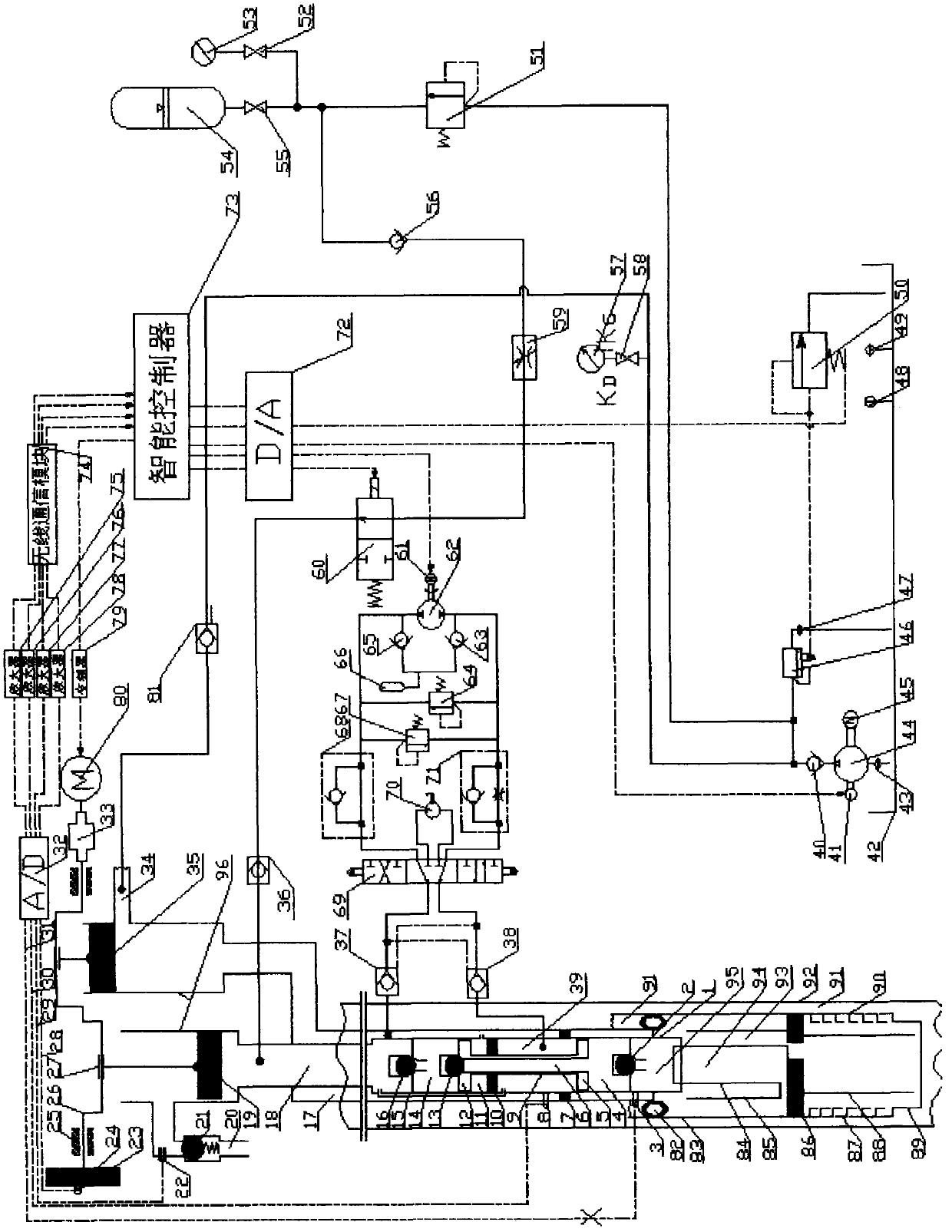

Energy saving system of networked measuring and controlling pumping units

InactiveCN1916413AImprove working conditionImprove management levelPump controlPositive-displacement liquid enginesDisplay deviceControl theory

A network detecting and controlling system of pumping unit is featured as dynamically collecting pressure and displacement on-site data of pumping unit by transducer then sending said data to on-site controller, using driving controller to make motor of pumping unit regulate speed, measuring parameter of power supply subsystem by relay protective unit to judge out overpressure and overcurrent protection of motor and controller on pumping unit, carrying out remote communication with the second radio communication unit (RCU) in remote monitor and information management system through the first RCU, connecting the second RCU to control center being used to contact with mobilephone through GSM.

Owner:CHANGQING GASOLINEEUM EXPLORATION BUREAU +1

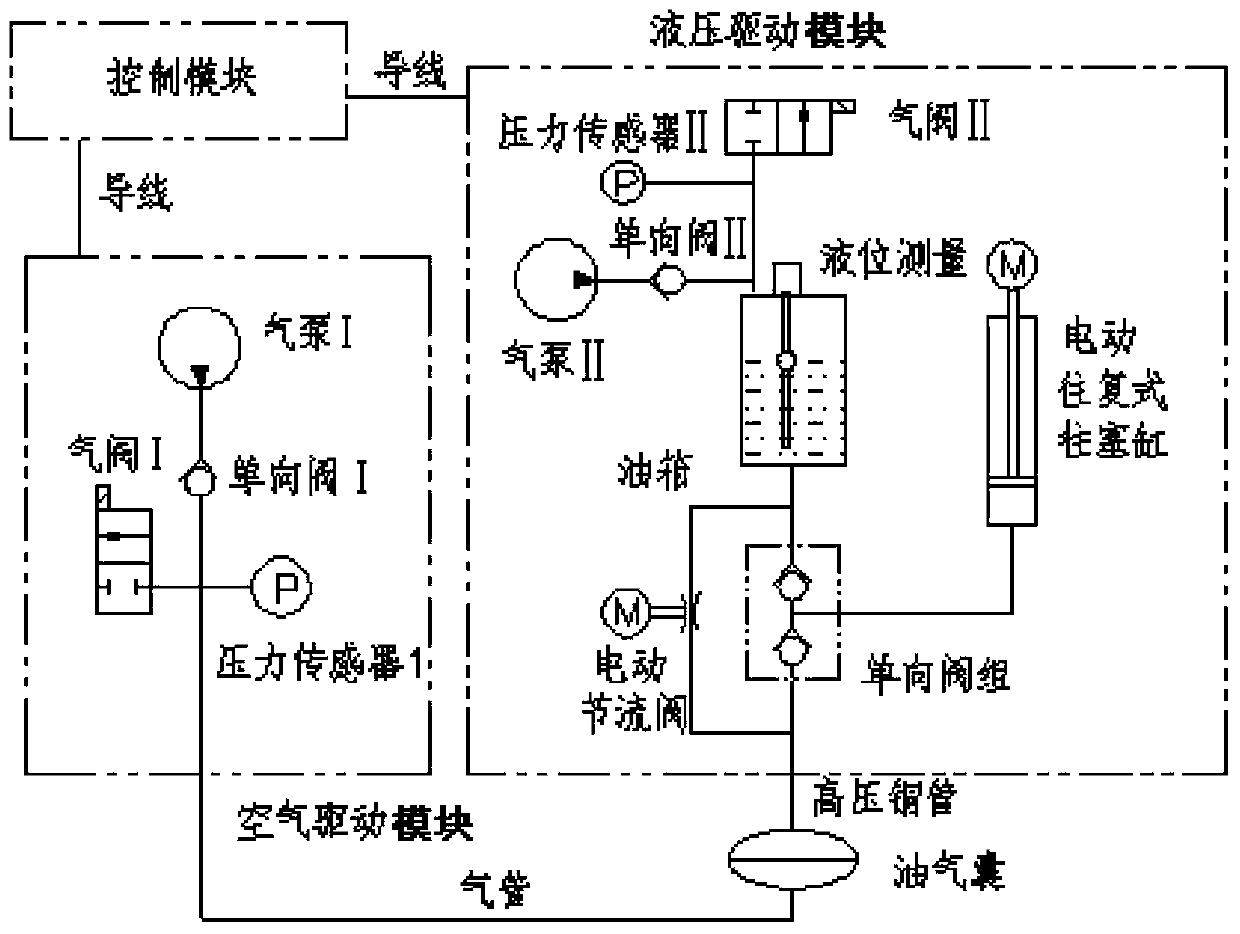

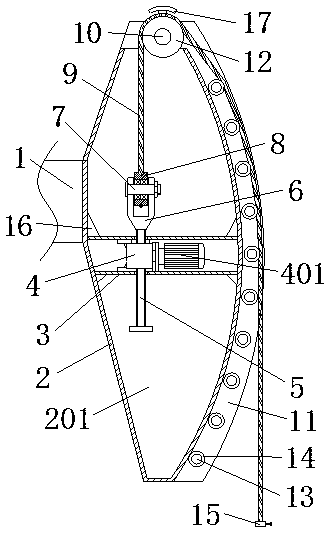

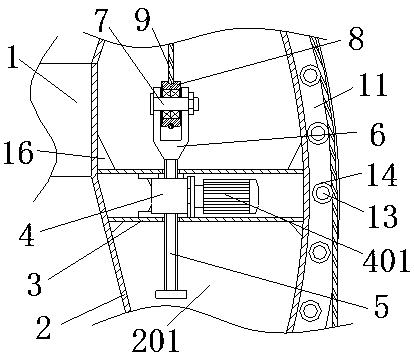

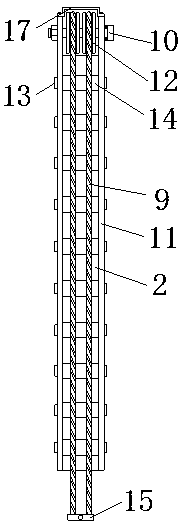

Reciprocating buoyancy regulating unit for autonomous profile buoy platform

InactiveCN103466047AIncrease fuel tank volumeIncrease the volume of the oil pocketWaterborne vesselsBuoysBuoyancy regulationThrottle

The invention provides a reciprocating buoyancy regulating unit for an autonomous profile buoy platform. The reciprocating buoyancy regulating unit comprises a control module, an air drive module, a hydraulic drive module, an oil-air bag, and a high-pressure copper pipe. The air drive module comprises an air pump I, a one-way valve I, a pressure sensor I and an air valve I. The hydraulic drive module comprises a plunger cylinder, an oil tank, a one-way valve set, an electric throttle valve, a one-way valve II, an air pump II, a pressure sensor II and an air valve II. The control module is connected with the air pump I, the air valve I and the pressure sensor I in the air drive module through wires. The control module is connected with the air pump II, the pressure sensor II, the air valve II, a level sensor, the plunger cylinder and the electric throttle valve in the hydraulic drive module through wires. The control module is used for controlling actions of devices connected thereto. The reciprocating buoyancy regulating unit has the advantages that oil quantity adjustment is increased greatly to increase buoyancy adjustability in a buoy without changing the size of the buoy.

Owner:710TH RES INST OF CHINA SHIPBUILDING IND CORP

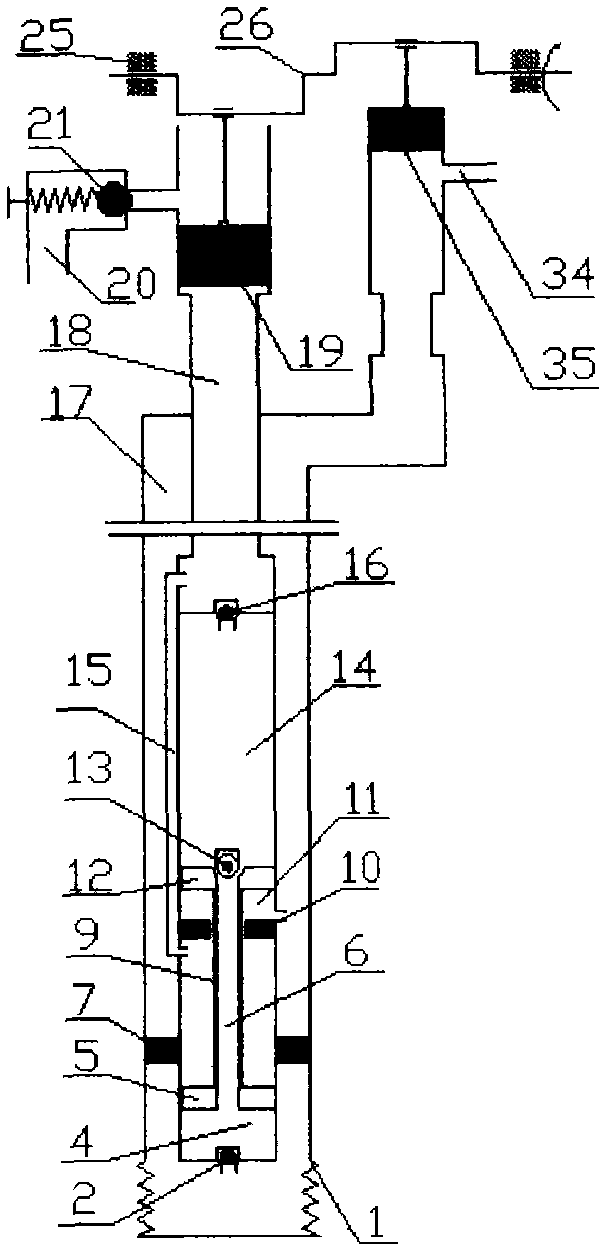

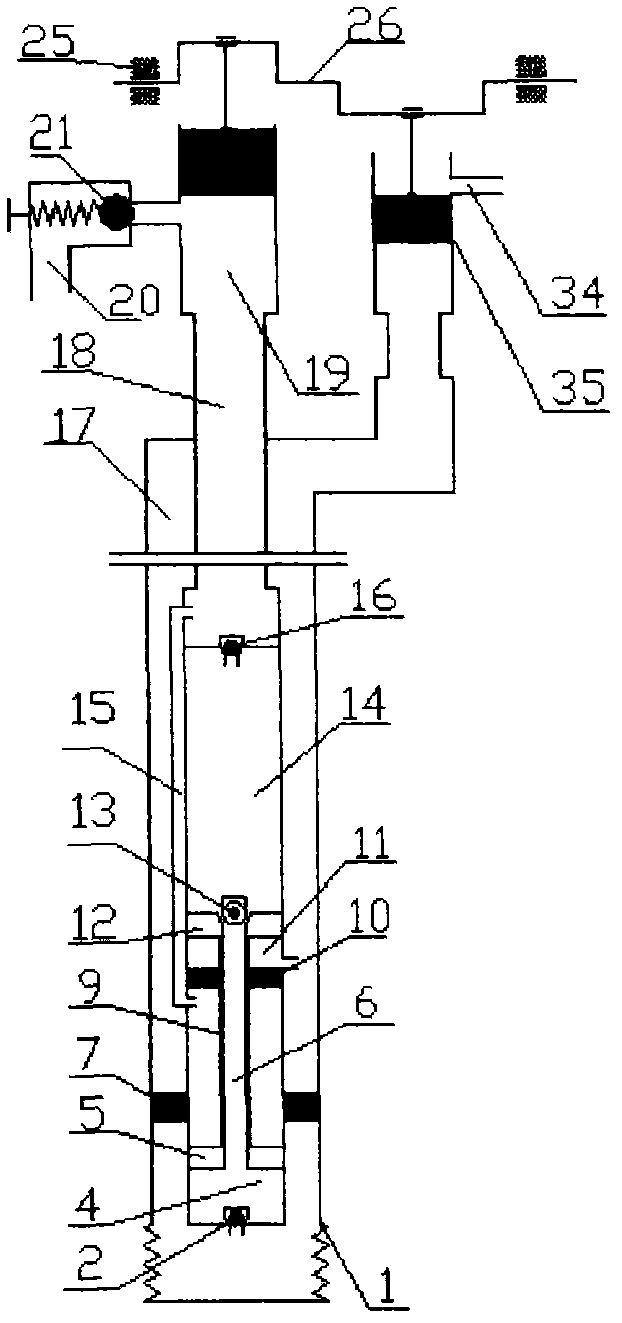

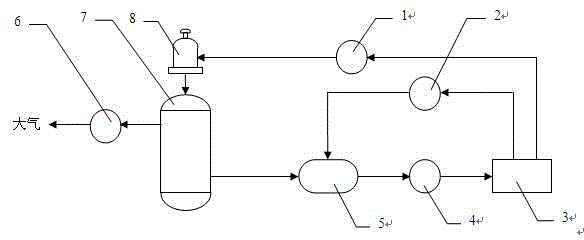

Pulsating reciprocating type hydraulic pumping unit

InactiveCN102434127AControl speedLow working conditionsFluid removalPump controlVapor–liquid separatorFluid replacement

The invention discloses a pulsating reciprocating type hydraulic pumping unit, which comprises a balanced type piston pump, a piston rod, a pulsating type piston pump, another pulsating type piston pump, an oil outlet valve, an oil filling valve and piston valve, a gas-liquid separator, a fluid replacement loop and a safe loop. The gas-liquid separator is arranged at the lower end of a pumping unit, the balanced piston pump is arranged at the middle part of the pumping unit, and the pulsating type piston pump is arranged at the upper end of the pumping unit. The pulsating reciprocating type hydraulic pumping unit disclosed by the invention has the characteristics of simple structure, convenience for operation, high efficiency, flexibility and strong applicability.

Owner:INNER MONGOLIA UNIV OF TECH

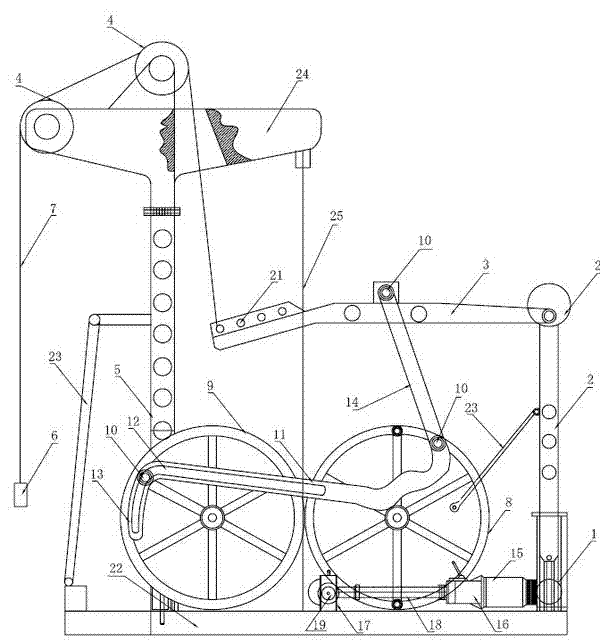

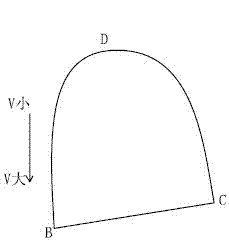

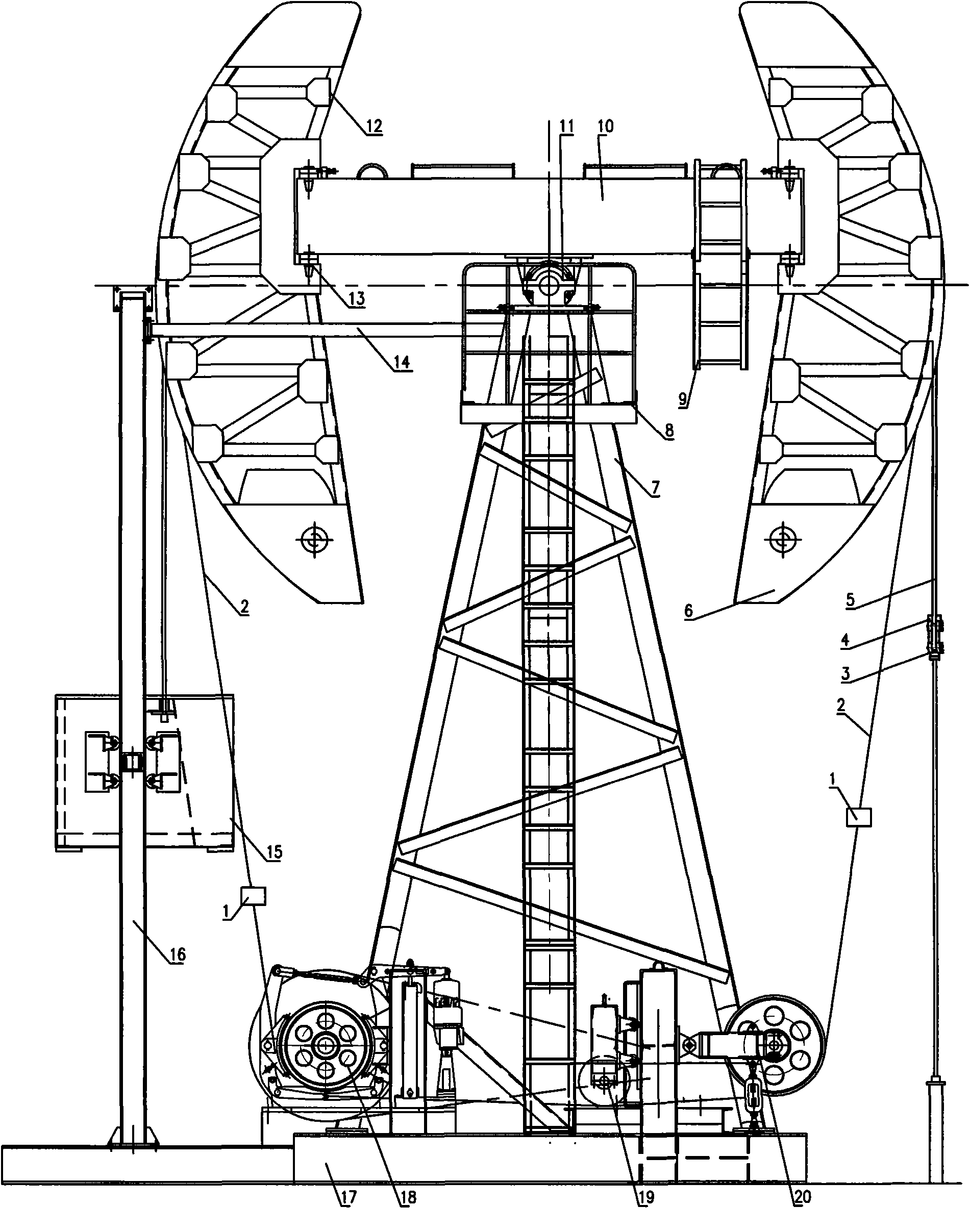

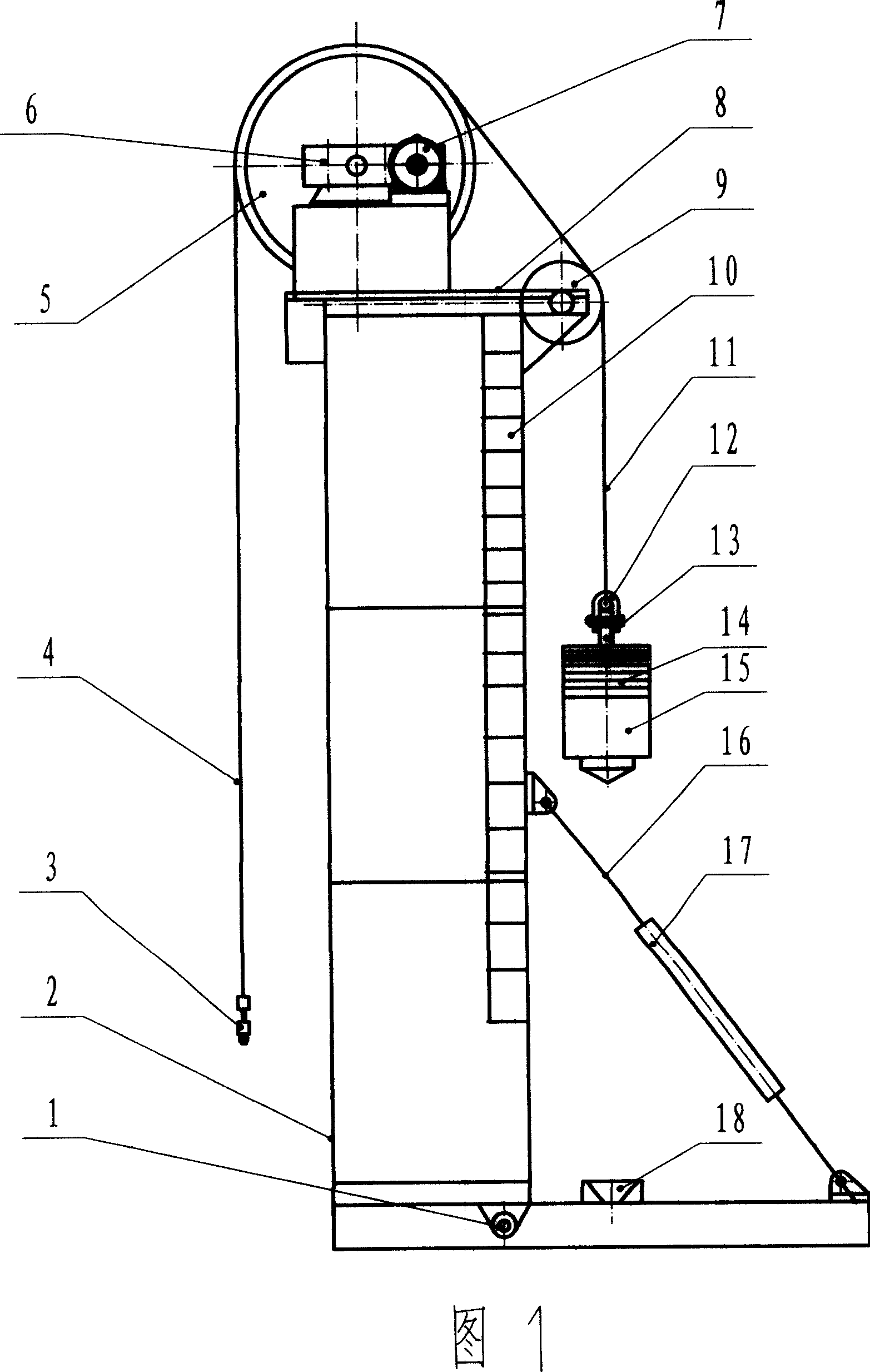

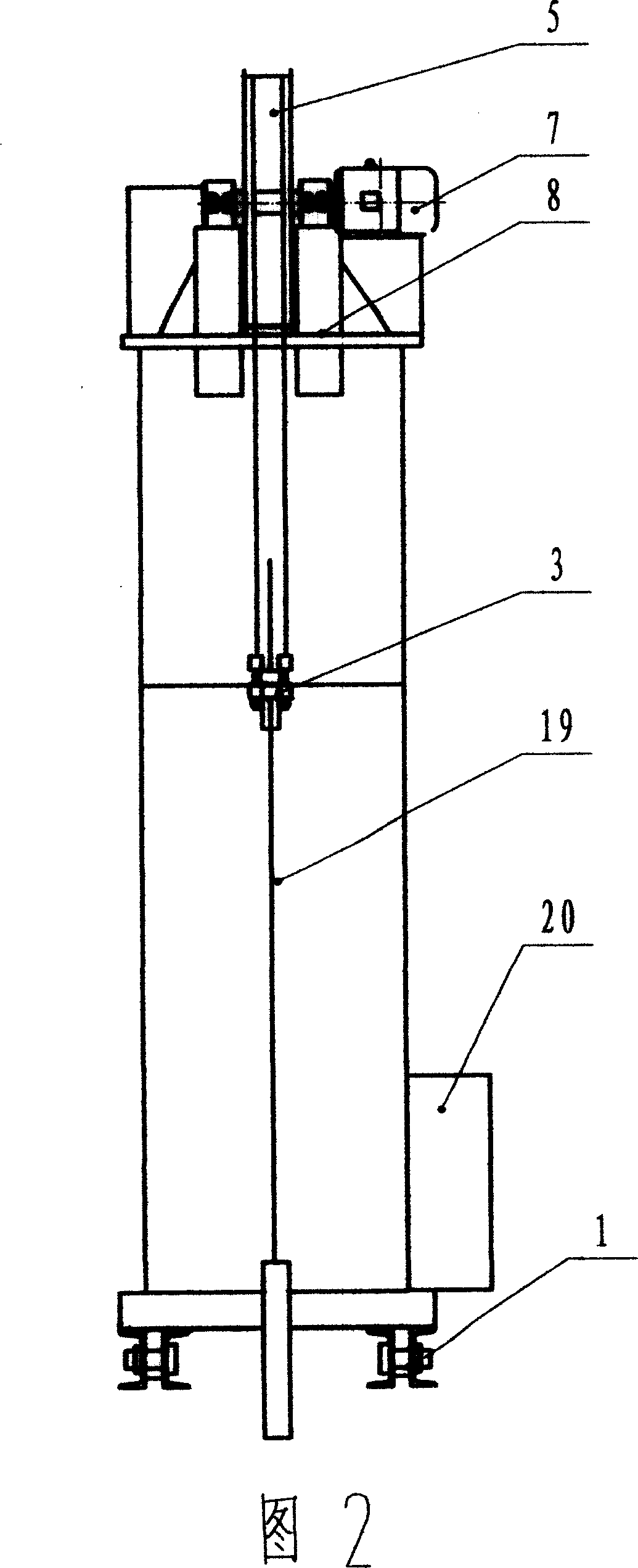

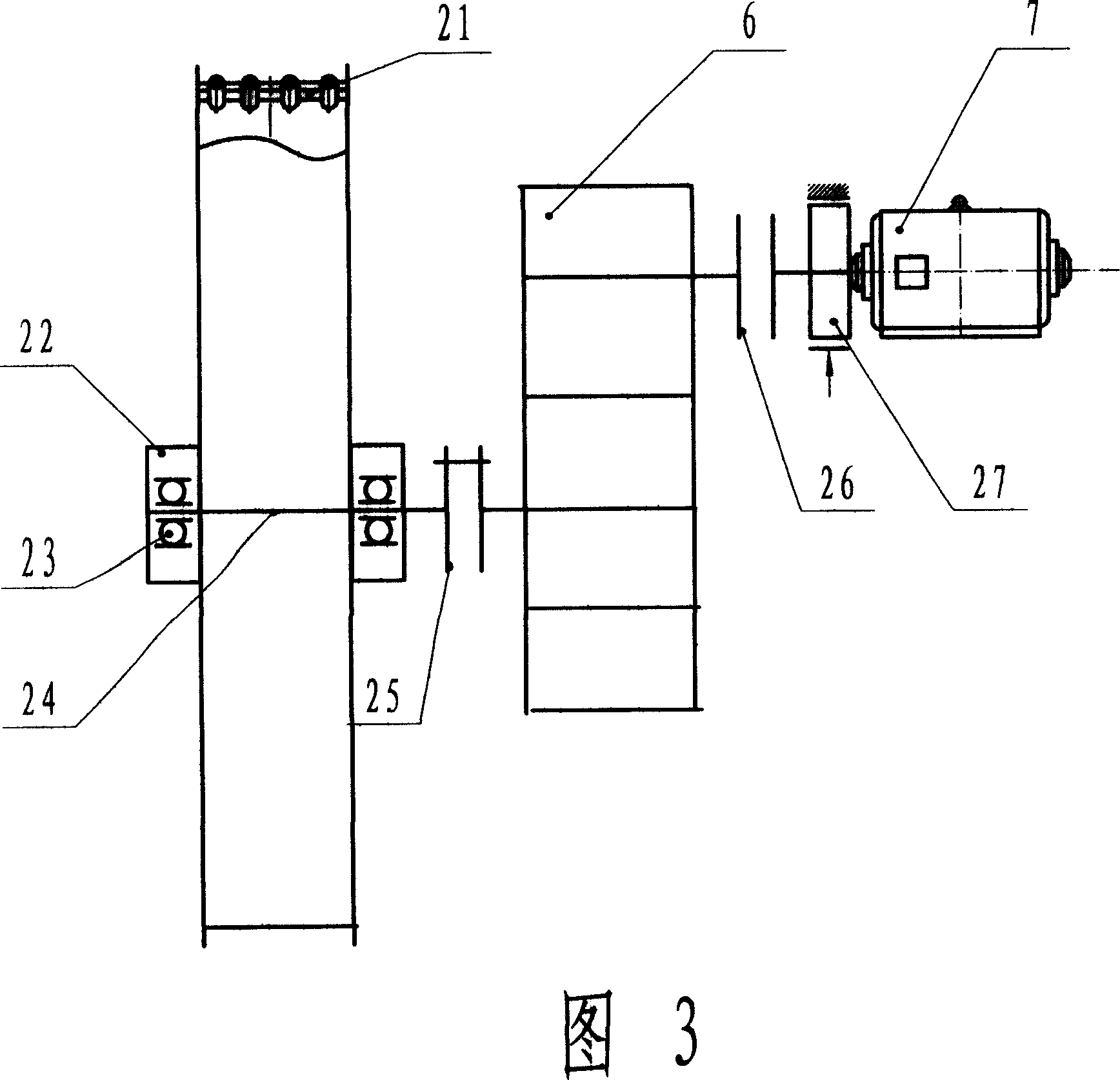

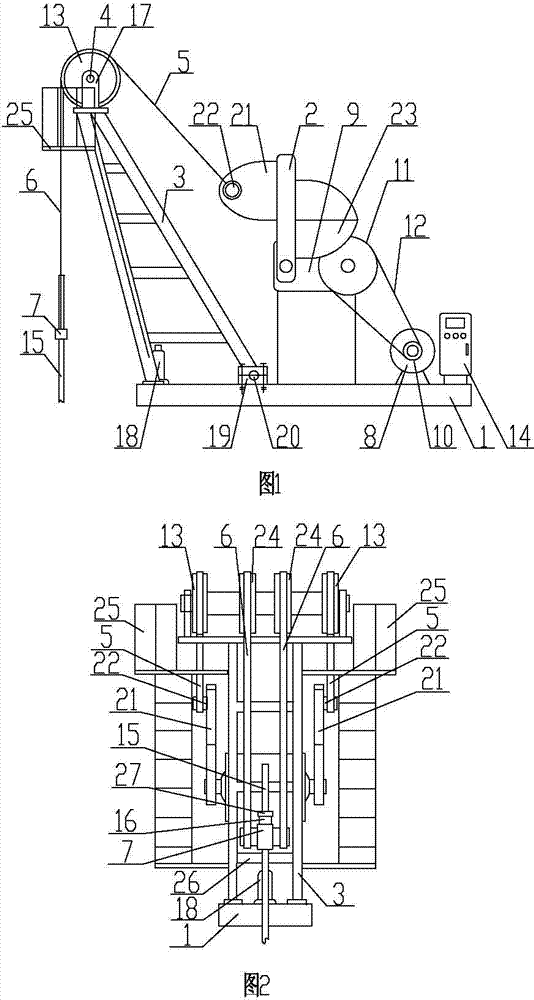

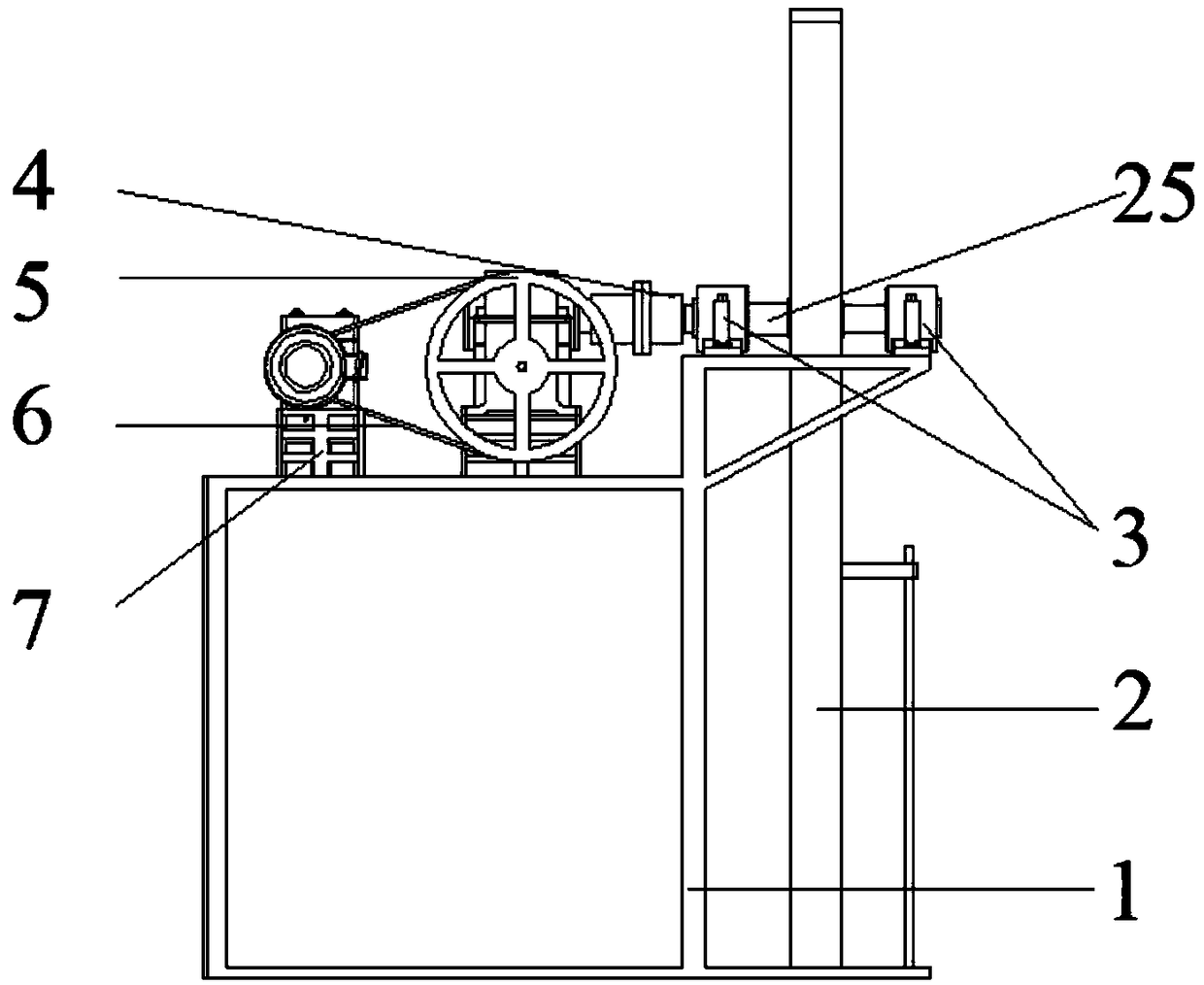

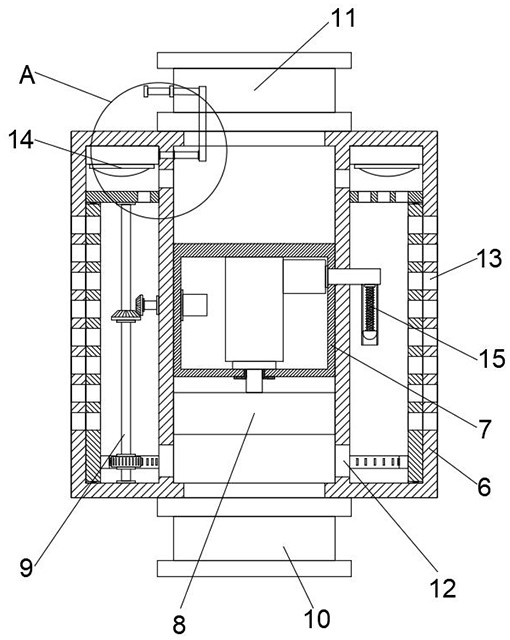

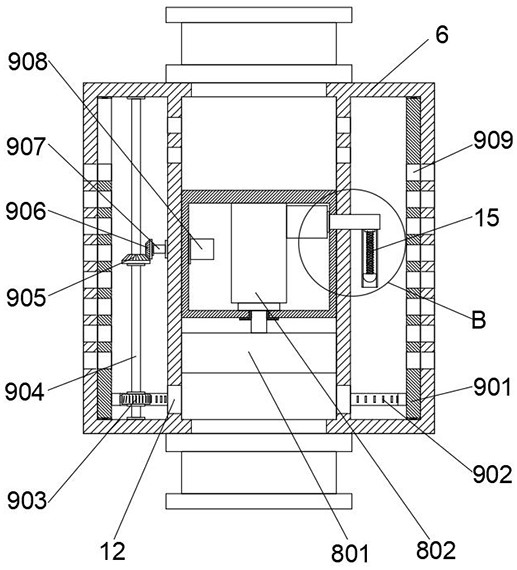

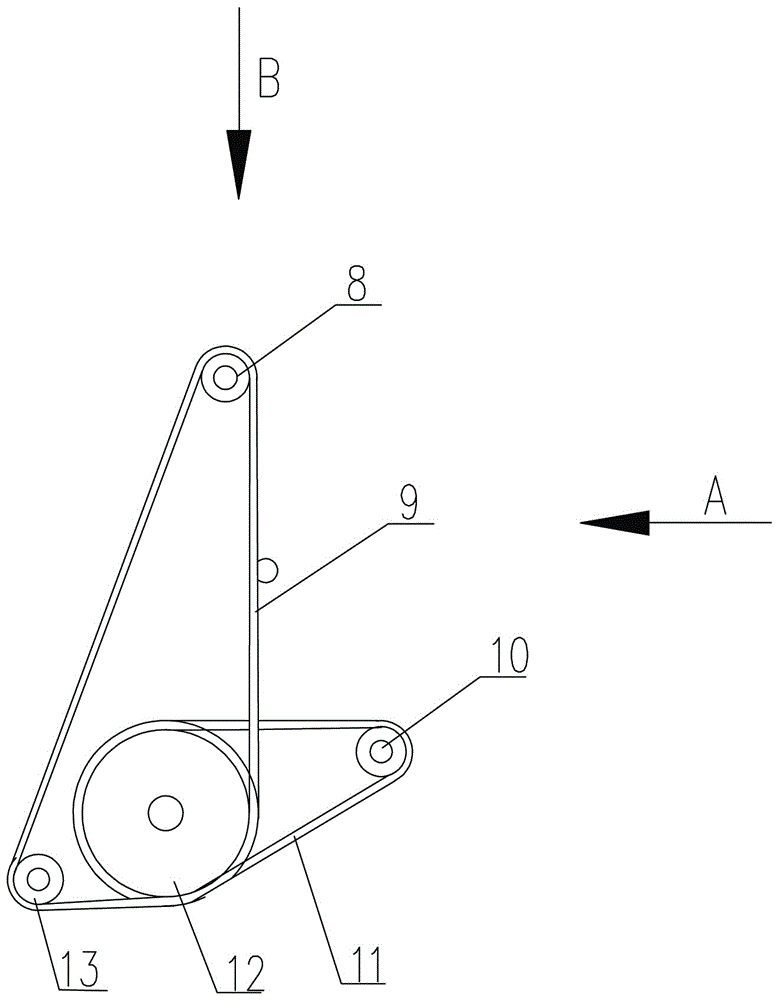

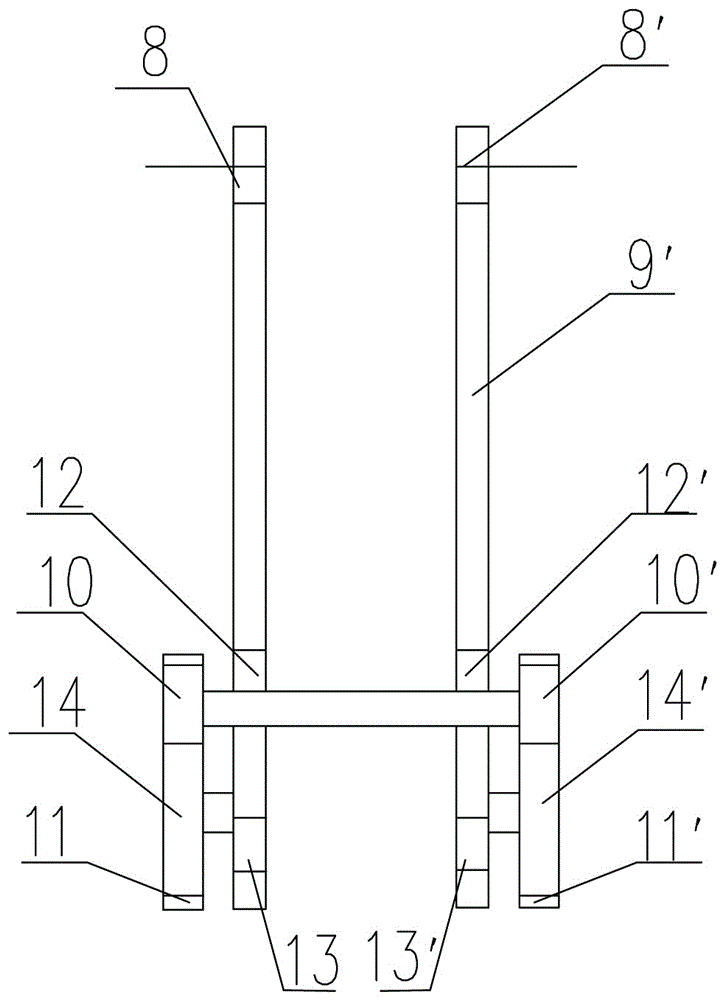

Automatic speed-changing wide-swing-angle oil pumping machine

InactiveCN102808602ASolve the oil spill problemImprove oil pumping efficiencyGearingFluid removalCrankshaftPulley

The invention relates to the technical field of oil extraction machinery, in particular to an automatic speed-changing wide-swing-angle oil pumping machine. The automatic speed-changing wide-swing-angle oil pumping machine comprises an electric motor, a speed changing mechanism, a swing arm support, a swing arm arranged on the swing arm support, a support provided with a fixed pulley and a wellhead oil pumping device, wherein the speed changing mechanism is connected with a driving crankshaft wheel, the driving crankshaft wheel is meshed with a driven crankshaft wheel, the driving crankshaft wheel is connected with a connecting piece through a bearing, one end of the connecting piece is connected with the driven crankshaft wheel, the other end of the connecting piece is connected with the swing arm through a connecting rod, a sliding chute is arranged on the connecting piece of which one end is connected with the driven crankshaft wheel, and a bearing on the driven crankshaft wheel is sleeved in the sliding chute. The automatic speed-changing wide-swing-angle oil pumping machine disclosed by the invention has the advantages that when the two crankshaft wheels are in rotation, since the position of the bearing of a driven pulley is changed, the position of the connecting piece can be also correspondingly changed, a motion trail of the connecting rod is affected by the motion of the connecting piece, the speed of the wellhead oil pumping device in the up-stroke is higher than that in the down-stroke, the oil leakage problem existing in an oil pumping process is avoided, and the oil pumping efficiency is increased.

Owner:德阳振华机械设备制造有限公司

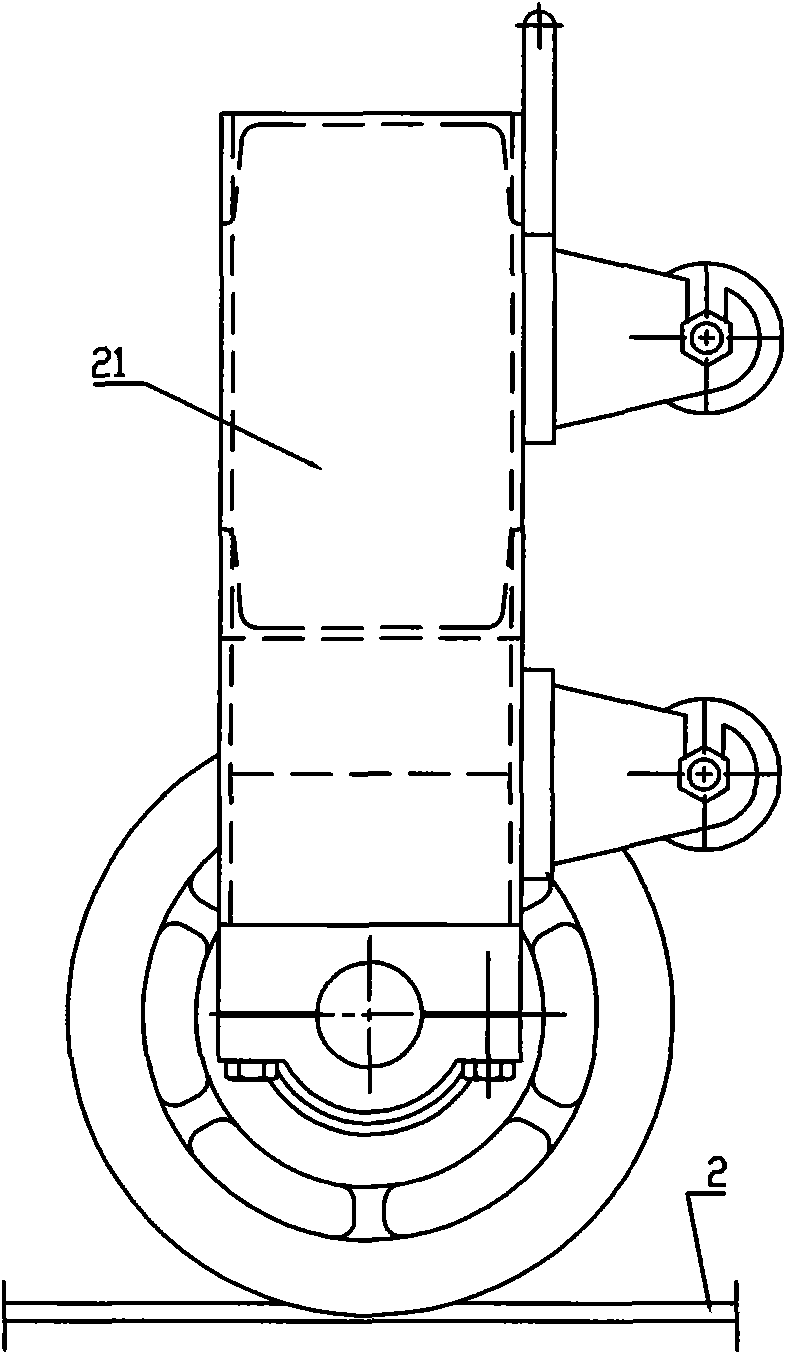

Dual horsehead fine balance energy-saving walking beam pumping unit

ActiveCN101672173AReduced bearing forceReduce loadFlexible member pumpsGearingRemote controlEconomic benefits

The invention discloses a dual horsehead fine balance energy-saving walking beam pumping unit comprising a waling beam assembly, a bracket assembly, a power assembly and a brake assembly. The middle part of the walking beam assembly is articulated with the upper end of the bracket assembly through a central bearing base; the front and rear ends of the walking beam assembly are respectively connected with a front horsehead and a rear horsehead; the front and rear horseheads are respectively connected with one end of a hauling steel rope; the other end of the hauling steel rope is respectively connected with a reel of the power assembly; the front horsehead is provided with a rope hanger, and the rear horsehead is provided with a balance block; the bracket assembly is provided with a tensionmechanism assembly and a buffer mechanism assembly; and the steel rope winds through the tension mechanism assembly and the buffer mechanism assembly to realize tension and buffer. The invention solves the problems of much material consumption of the regular beam-pumping unit and large impact load of a vertical pumping unit, and the like, has reasonable design, realizes remote control, monitors the parameter variation of the pumping unit at any time and ensures favorable social and economic benefits.

Owner:河南双发石油装备制造股份有限公司

All balance long stroke oil pump

InactiveCN1924288AImprove impact resistanceImprove anti-overload performanceFluid removalReciprocating motionElectric machinery

This invention provides balance long impact oil extraction device, which comprises motor, automatic brake, decelerator input axis, decelerator, decelerator output axis and sheave parts on shell top platform, wherein, the drive rope is connected to hanging device and ring through drive rope fix device two end set inside sheave parts; the hanging rope and ring are connected through light bar and match parts; when sheave rotates, it drives rope and match drive rope for synchronous reverse movement.

Owner:北京华能通达能源科技有限公司

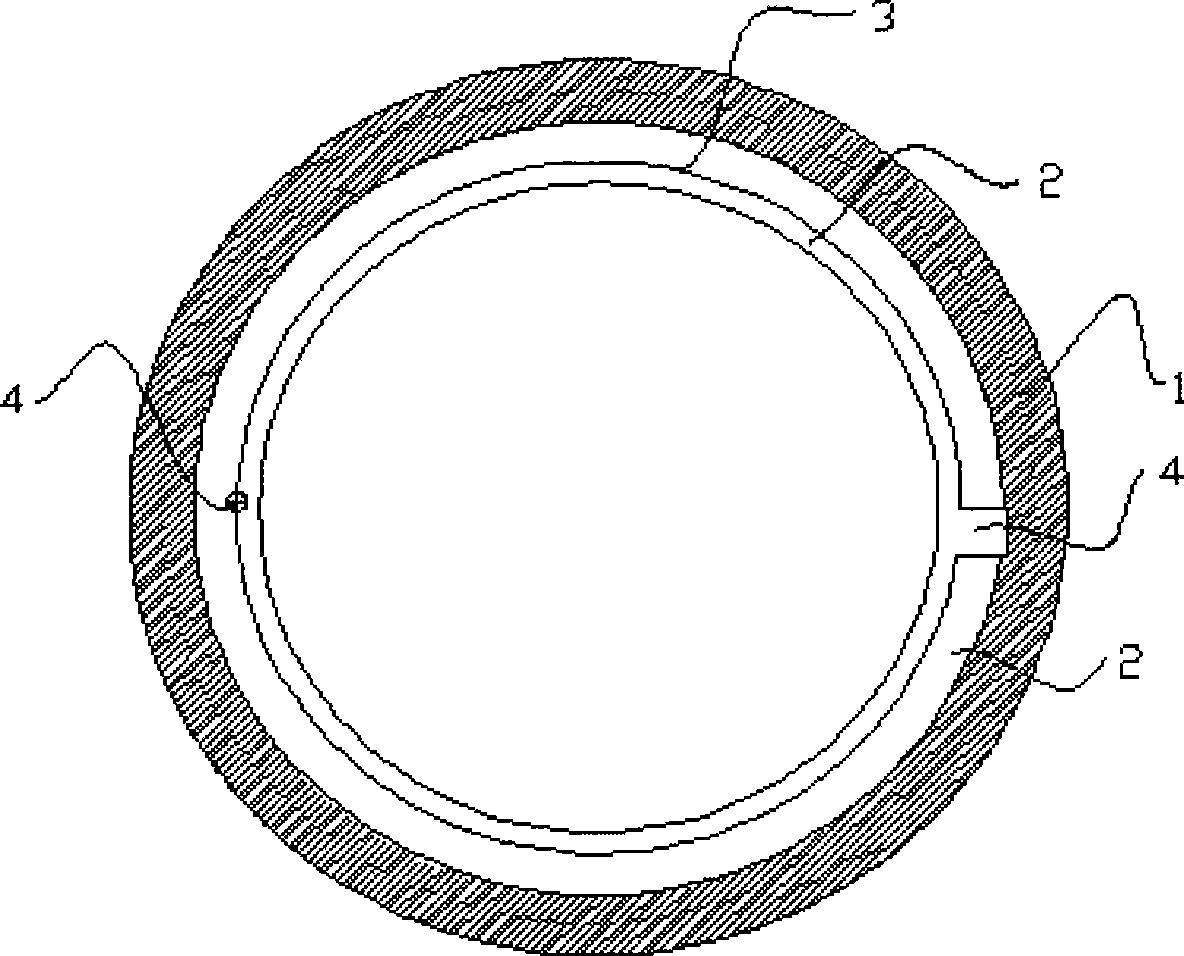

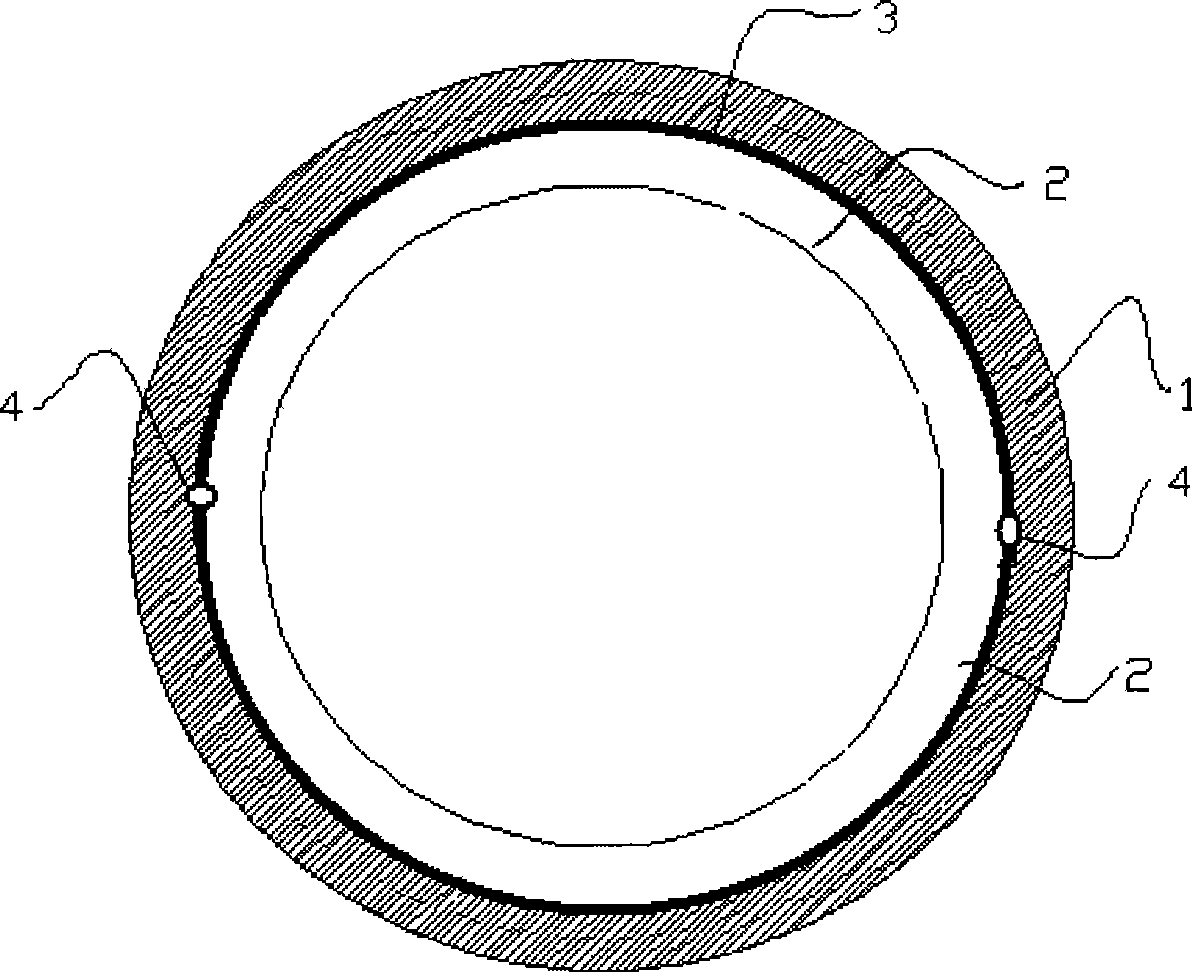

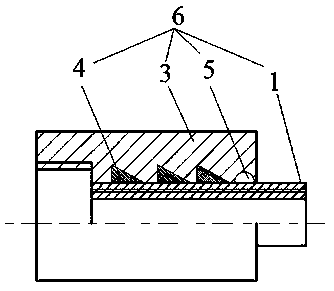

Hot diaphragm type ultrahigh molecular weight polyethylene composite oil pumping pipe

ActiveCN101476447AImprove oil pumping efficiencyIncrease temperatureDrilling rodsDrilling casingsHeat conductingPetroleum

The invention relates to an oil pumping tube for an oil well, in particular to an ultra-high molecular weight polyethylene composite oil pumping tube with a hot film heating layer. The oil pumping tube belongs to the technical field of petroleum industry. The hot film type ultra-high molecular weight polyethylene composite oil pumping tube comprises a metal outer tube and an ultra-high molecular weight polyethylene inner tube, wherein an electroheat film is preset in an inner tube interlayer, and the electroheat film covers an insulation heat transfer layer; the insulation heat transfer layer is made of insulation heat transfer materials of mica, quartz sand, plutonium tetrafluoride ethylene, heat conduction silicone grease, and the like. The heat conduction silicone grease is preferable. The tail end of the electroheat film is connected with a heat sensor and a temperature controller, and a metal powder heat-conducting medium layer is coated between the inner tube and the insulation heat transmission layer of the electroheat film. The product of the oil pumping tube improves the oil pumping efficiency and reduces the oil pumping cost.

Owner:江苏联冠科技发展有限公司

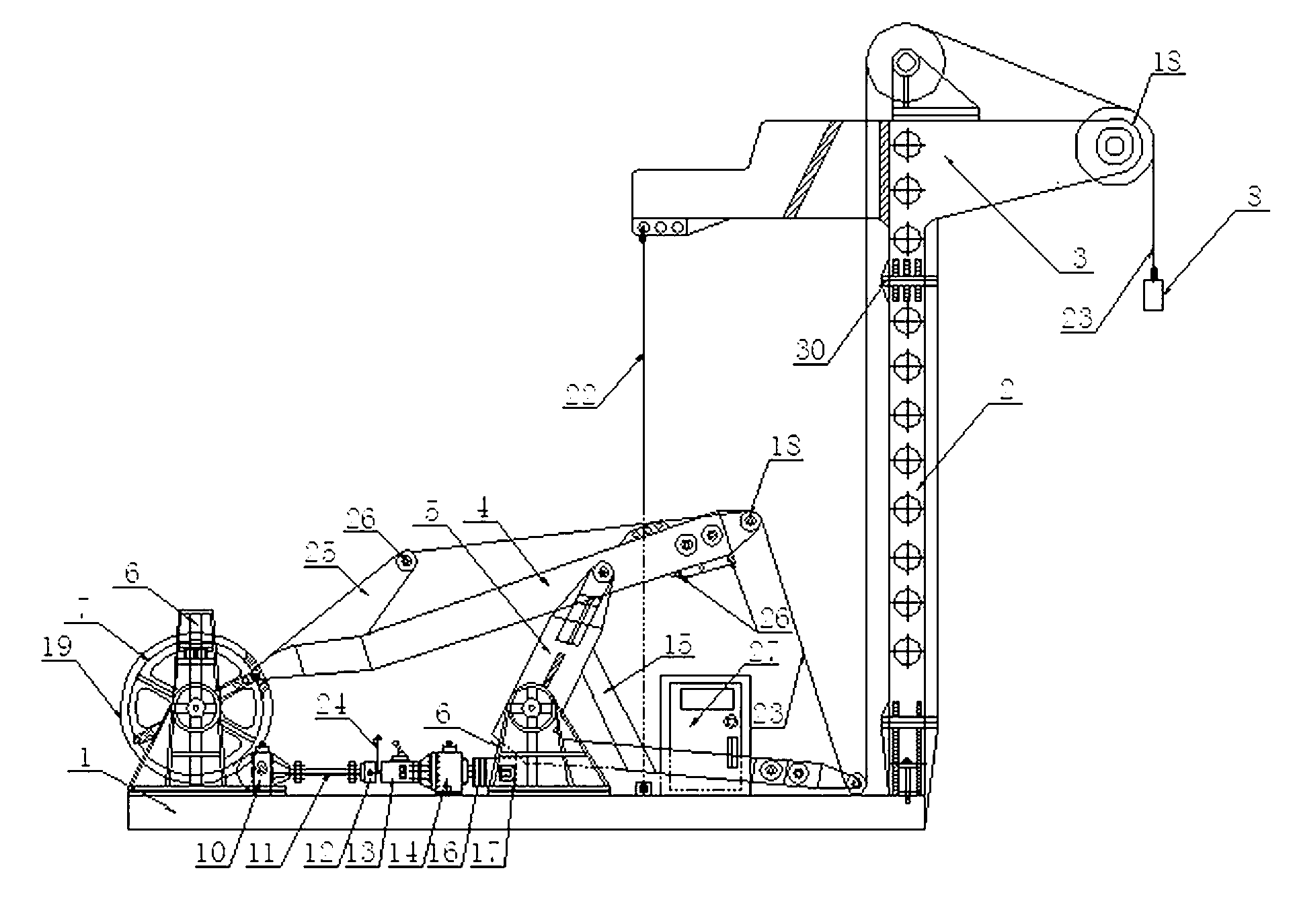

Flexible-beam pumping unit

The invention discloses a flexible-beam pumping unit which comprises a base, a power machine, cranks, a hoisting sheave support, a transmission mechanism, pumping ropes, a power hoisting sheave set, a pumping hoisting sheave set and a beam hanger. The power machine is fixedly mounted on the right portion of the base, and the cranks are fixedly mounted on power output shafts of the power machine; the hoisting sheave support is fixedly mounted on the left portion of the base. The flexible-beam pumping unit has the advantages that the flexible-beam pumping unit is reasonable and compact in structure and convenient to use; power transmission ropes and the pumping ropes drive a pumping rod and a plunger of a downhole oil pump, so that a pumping effect can be realized, equipment can be lightened and shortened, and the flexible-beam pumping unit is low in material consumption, convenient to maintain and low in expense; the speeds can be regulated by a motor under the control of a variable-frequency controller, and the ascending speed and the descending speed of the pumping rod can be regulated via the quantity of loads, so that the flexible-beam pumping unit is high in pumping speed when the quantity of downhole oil is high and is low in pumping speed when the quantity of downhole oil is low, and an intelligent pumping procedure can be implemented; energy consumption can be reduced while safety pumping is guaranteed, and the pumping efficiency can be improved; the customized hoisting sheave support can rotate rightwards to avoid a wellhead, so that on-site well repair operation can be facilitated.

Owner:张学海

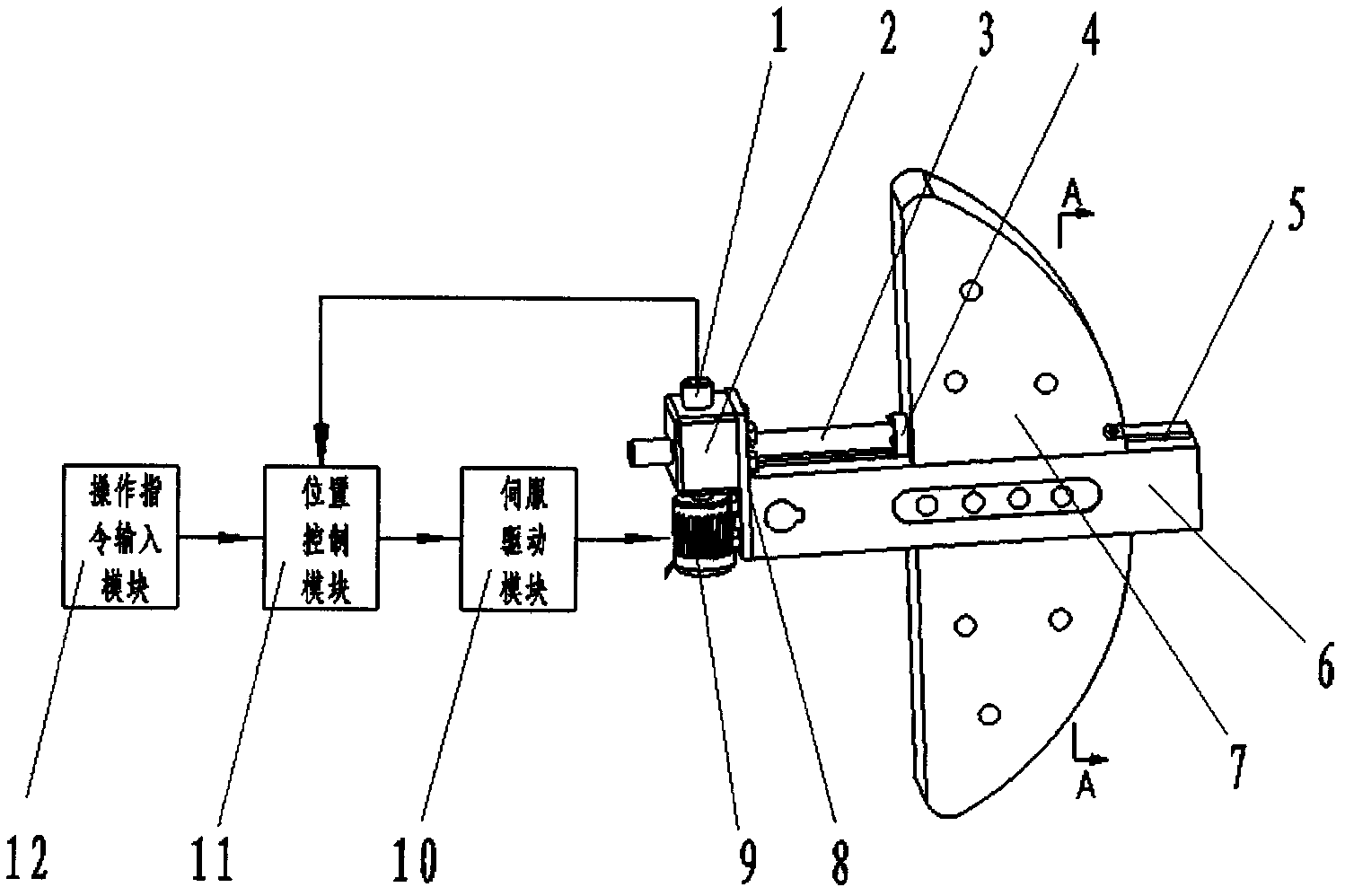

Automatic adjusting device for locations of balance blocks of petroleum pumping unit

InactiveCN102562007AIncrease power consumption and fuel outputShorten adjustment timeCranksFluid removalOperating instructionElectric machine

The invention discloses an automatic adjusting device for locations of balance blocks of a petroleum pumping unit. An operating instruction inputting module (12) of the device is connected into a location control module (11), an output signal of an encoder (1) is connected into the location control module (11), the location control module (11) is connected into a servo driving module (10), the servo driving module (10) is connected into a motor (9), an output shaft of the motor (9) is connected with an input end of a worm (13) of a worm gear and worm speed reducer (2), the encoder (1) and the motor (10) are coaxially mounted at a non-input end of the worm (13), and an end of a lead screw (3) is fixedly connected with a balance block (7) via a flange (4). An operating instruction is inputted into the operating instruction inputting module (12) so as to adjust the location of the balance block (7) on a crank (6). The automatic adjusting device can be operated in a running state, is high in adjustment precision, and saves labor and time.

Owner:周彦

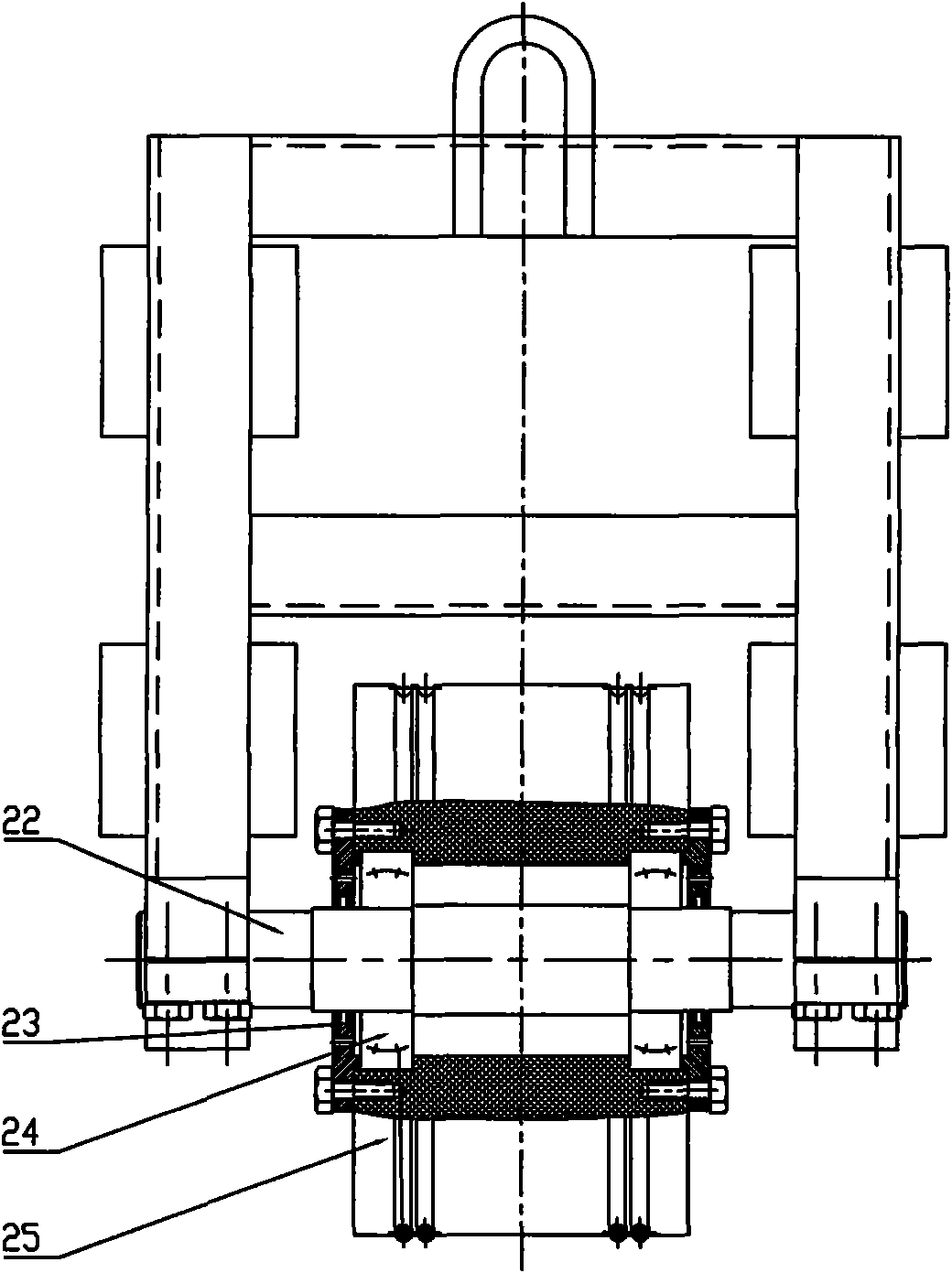

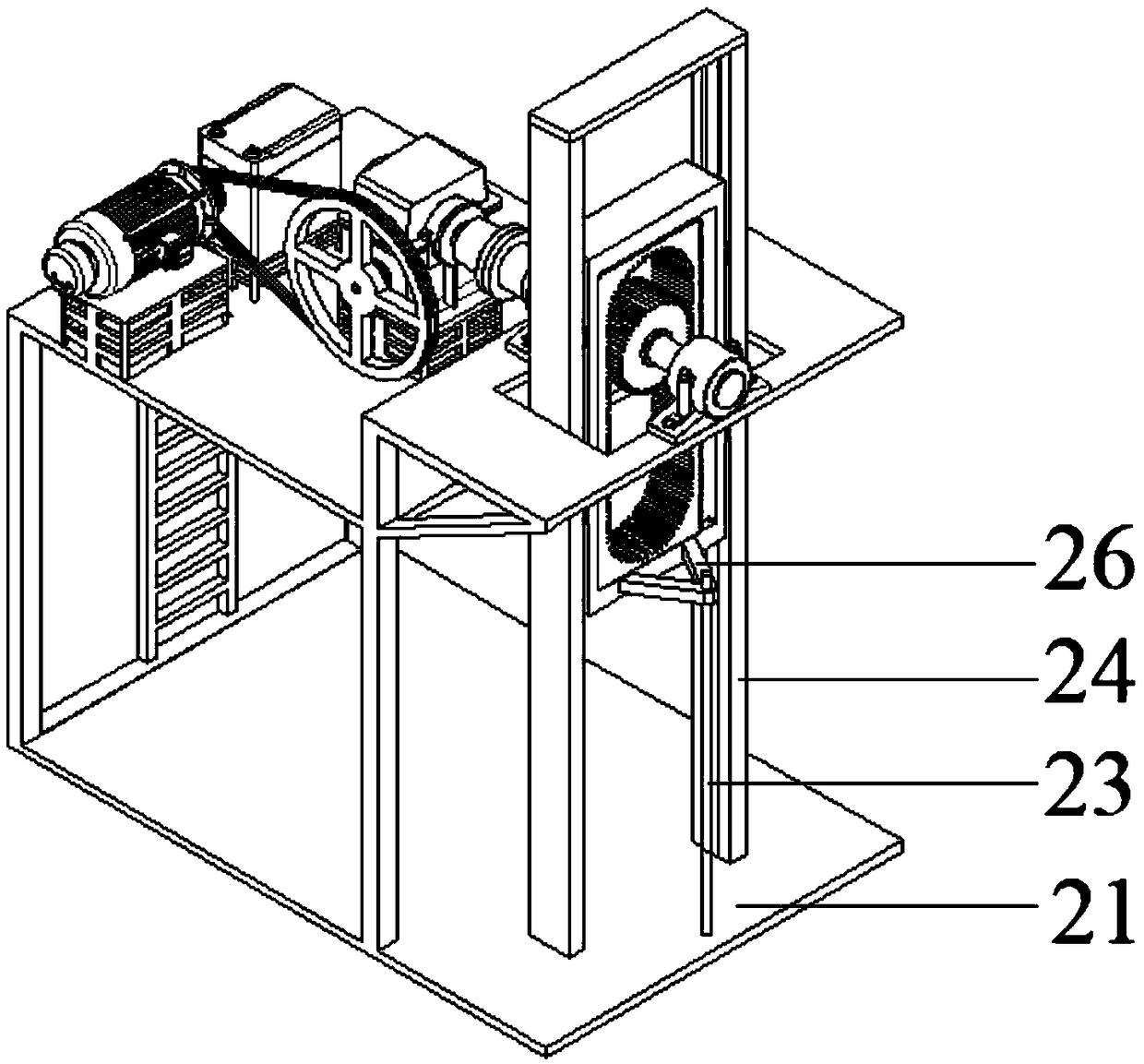

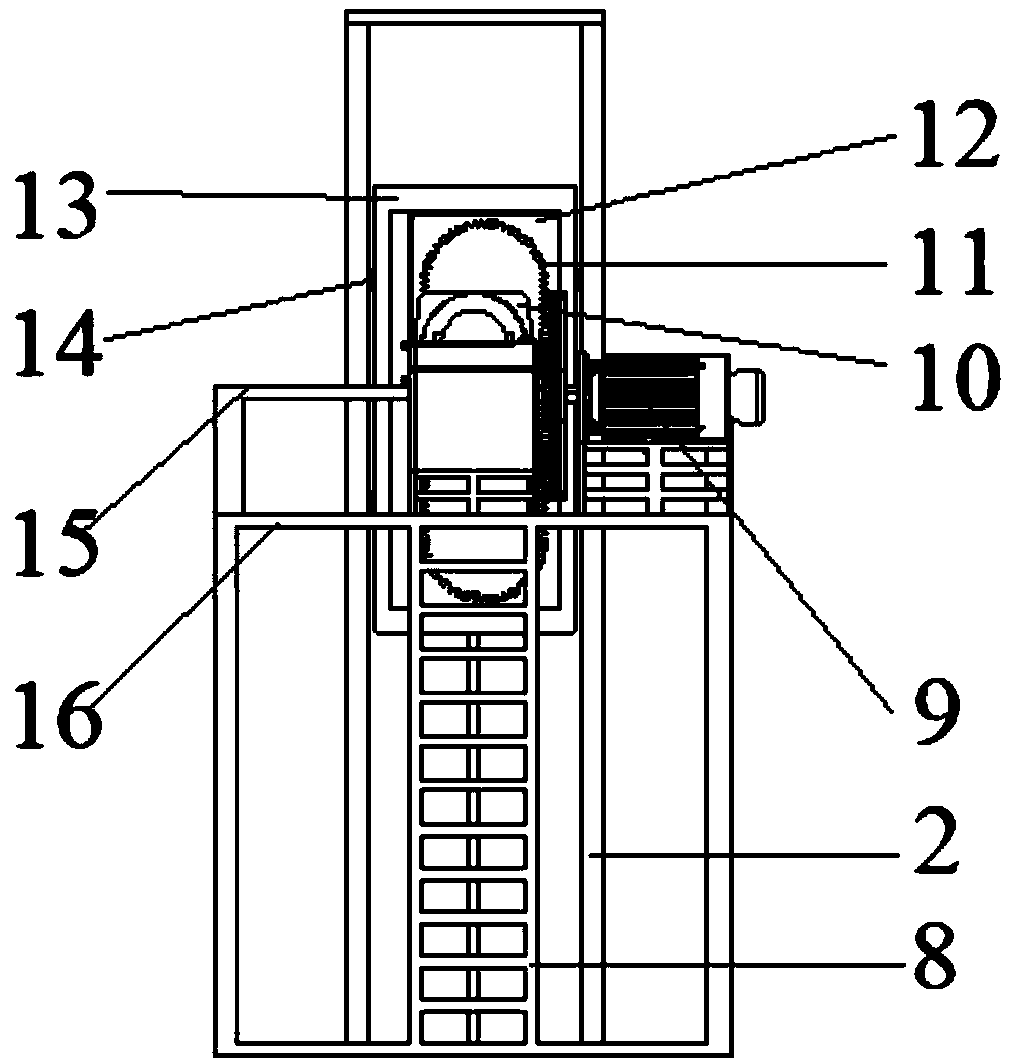

Worm gear transmission pumping unit and method

ActiveCN109267973ARealize one-stage transmission decelerationLarge transmission ratioFluid removalLinear motionCoupling

The invention discloses a worm gear transmission pumping unit and a method. The unit comprises a frame, a transmission mechanism and an annular reversing mechanism. The frame comprises a base, a platform support frame, an escalator, a low platform and a high platform, wherein the low platform is provided with three transmission support frames for fixedly installing a worm gear reducer, a variablefrequency speed control motor and a super capacitor respectively; the middle of the high platform is provided with a rectangular for mounting the annular reversing mechanism, and the annular reversingmechanism is connected to the transmission mechanism through a coupler. The worm gear reducer can achieve first-stage transmission deceleration and large transmission ratio, the mating surfaces of aworm and a gear are in linear contact, the bearing capacity is much larger than the gear deceleration, the worm gear meshing is multi-tooth meshing, the transmission is stable, and the noise is low. The annular reversing mechanism converts rotary motion of the variable frequency speed control motor into vertical linear motion of a polish rod connecting frame by meshing of a gear and a ring gear toachieve reciprocating motion of a sucker rod.

Owner:XI'AN PETROLEUM UNIVERSITY

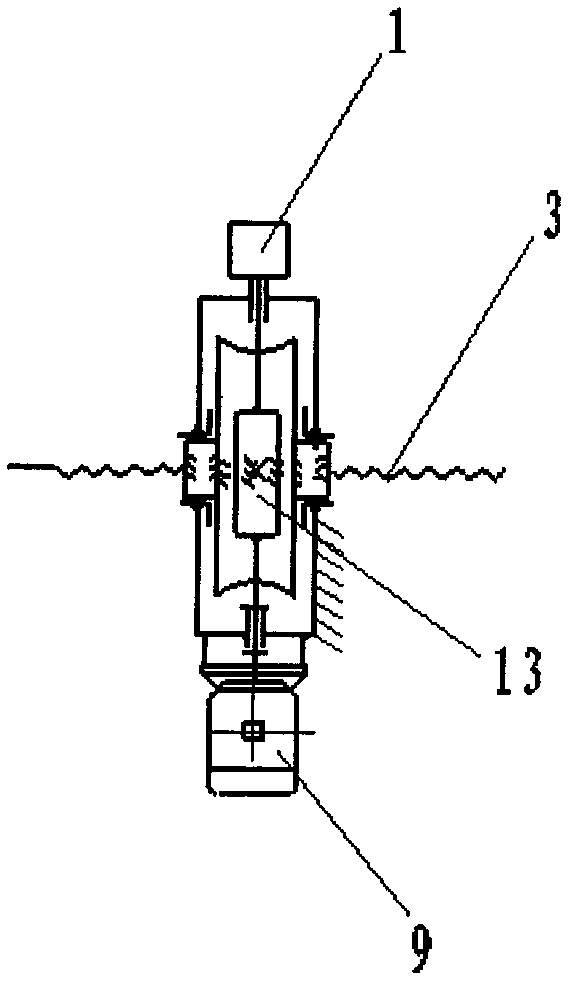

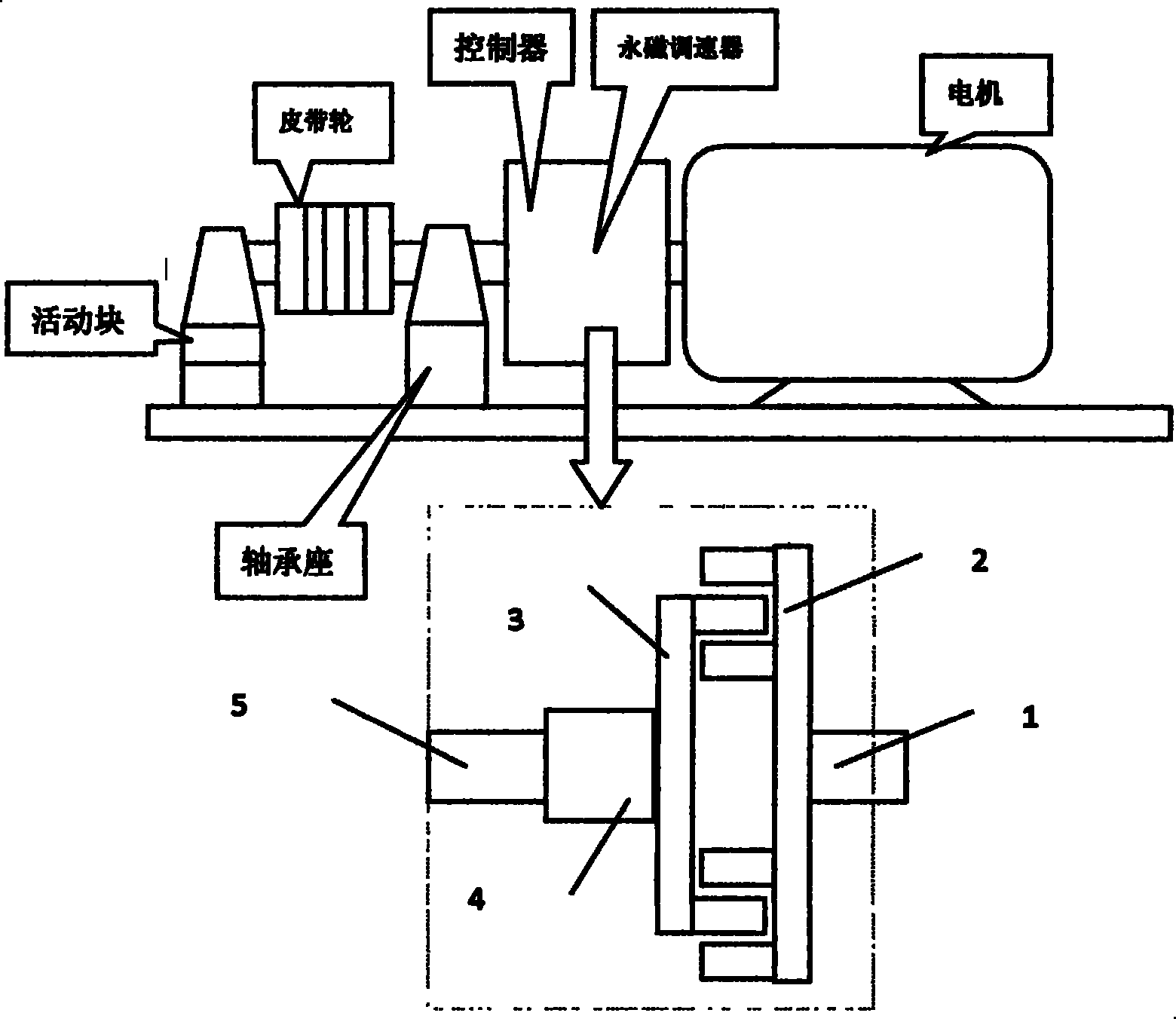

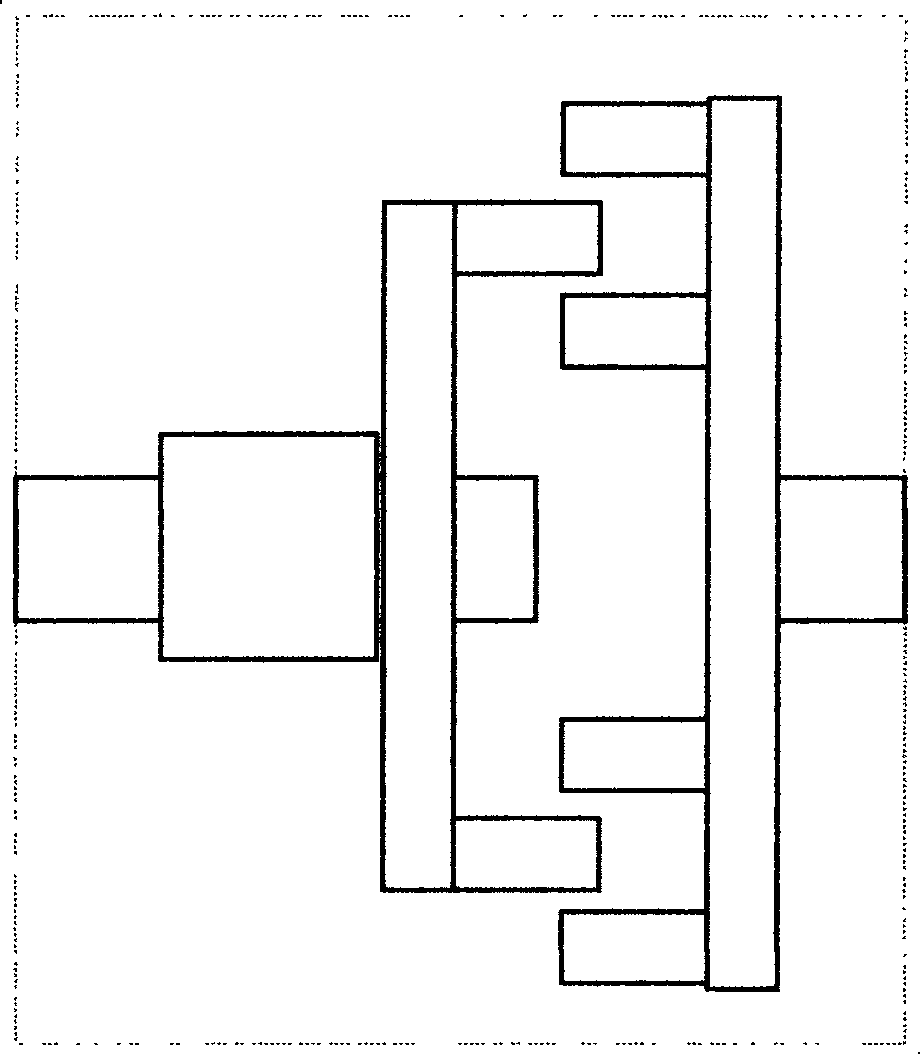

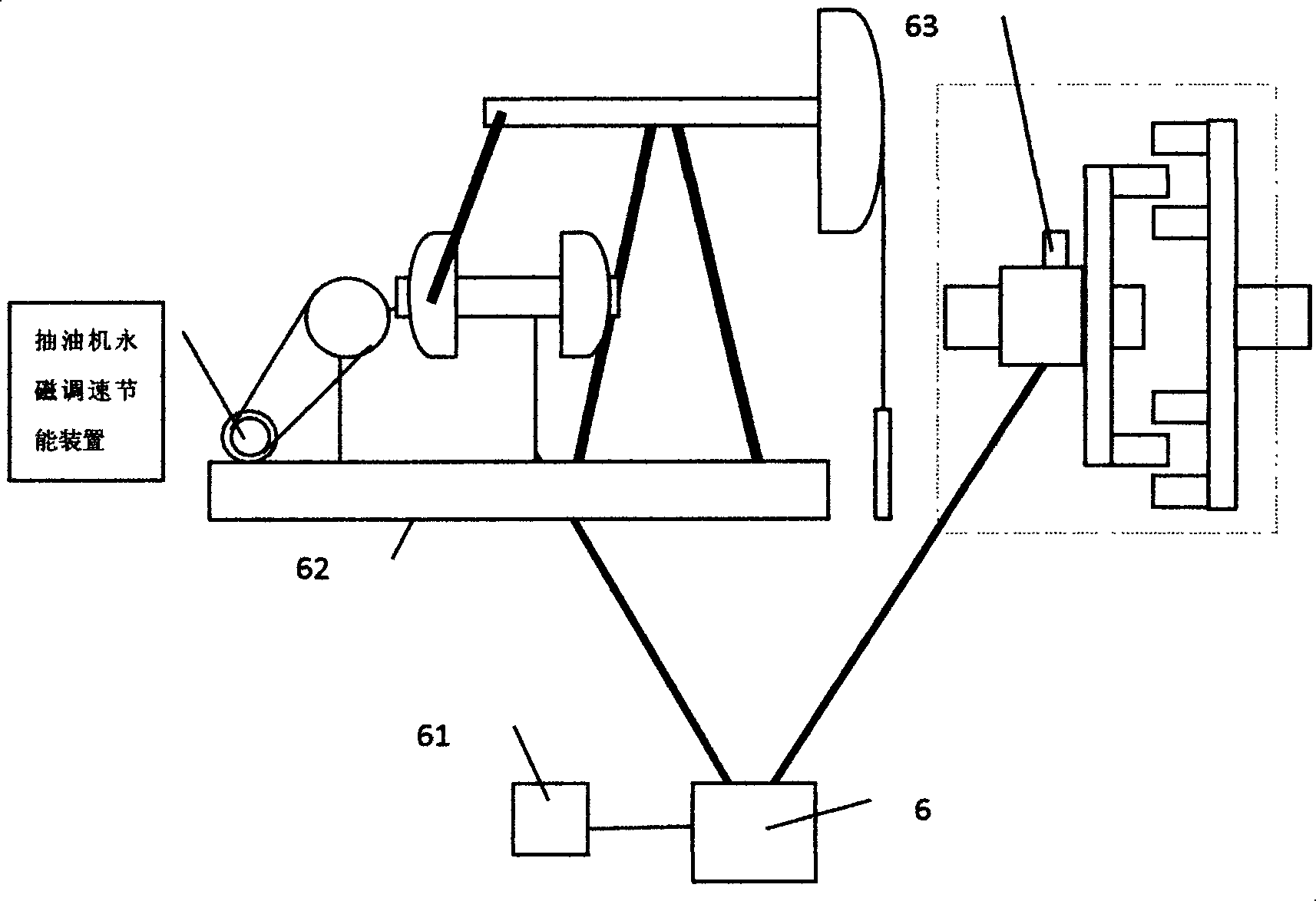

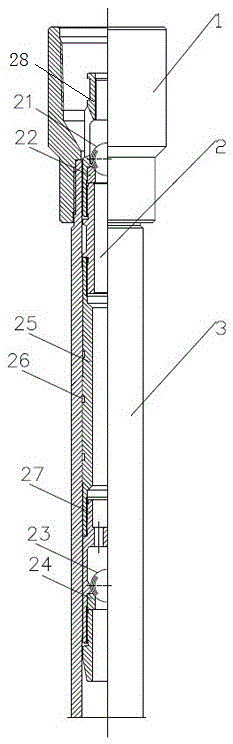

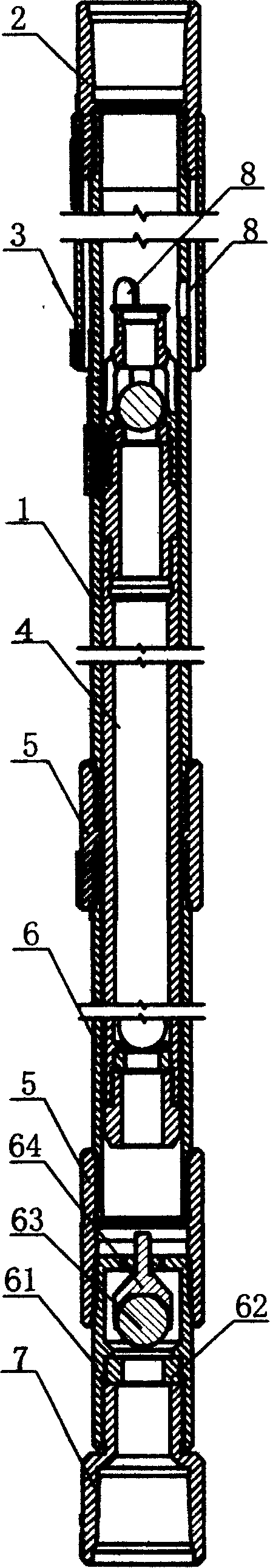

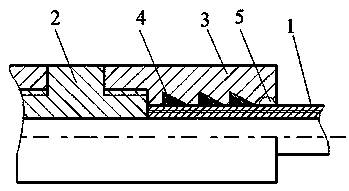

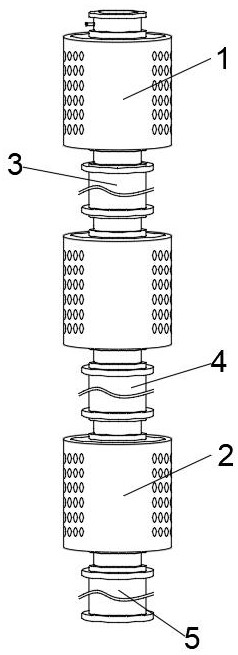

Pumping unit permanent magnet speed regulation and energy conservation device

InactiveCN103475187AImprove oil pumping efficiencyNo pollution in the processDynamo-electric gearsDynamo-electric gear controlElectrical conductorDrive shaft

The invention relates to a pumping unit permanent magnet speed regulation and energy conservation device. The pumping unit permanent magnet speed regulation and energy conservation device is mainly composed of a permanent magnet speed regulation mechanism, a belt pulley drive mechanism and a rotating speed control system. The permanence magnet speed regulation mechanism comprises a permanent magnet plate, a conductor plate, a brake, a transmission shaft and a speed regulation mechanism, wherein the permanent magnet plate does not make contact with the conductor plate, torque is cut and delivered by magnetic lines of force through relative rotation, the speed regulation mechanism regulates the relative position of the permanent magnet plate and the conductor plate to regulate the magnetic coupling area so that speed regulation can be achieved, and the brake is used for preventing the rotating speed of the permanent magnet plate from being out of control. The belt pulley drive mechanism comprises a bearing seat, a belt pulley and a transmission shaft. The rotating speed control system comprises a controller, a displayer and a rotating speed and position detection device mechanism, wherein the controller is an intelligent device controlled by a central processor, controls the rotating speed of the belt pulley in a preset work mode according to collected parameters such as the rotating speed and the position, and sends operation parameters to the displayer. According to the pumping unit permanent magnet speed regulation and energy conservation device, the aims of saving energy and improving the oil pumping efficiency can be achieved by accurately controlling the working state of a pumping unit.

Owner:TIANJIN PERMANENT MAGNETIC ENERGY SAVING TECH +1

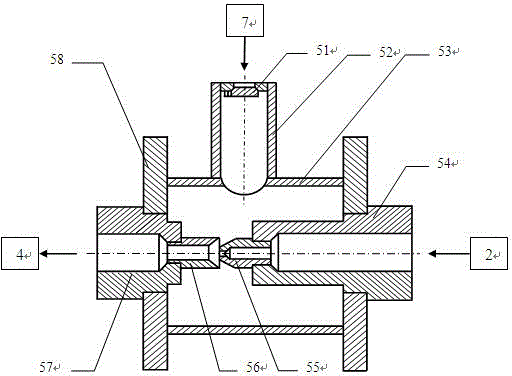

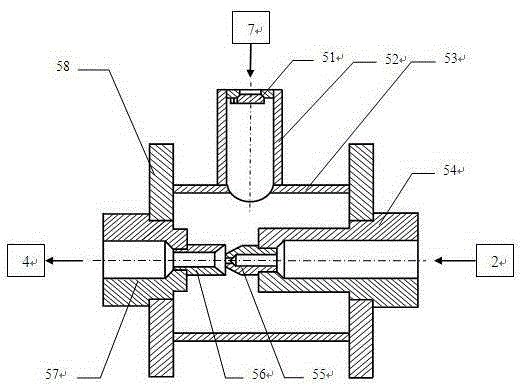

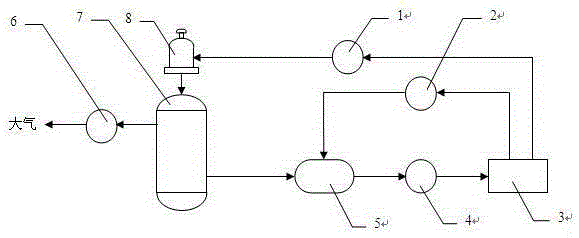

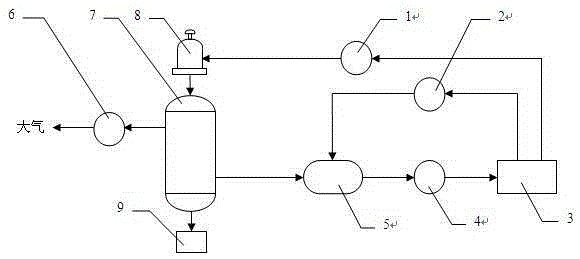

Supercharger and centrifugal vacuum oil purifier with supercharger

ActiveCN103603831AReduce oil suction negative pressureImprove working environmentJet pumpsMachines/enginesHigh pressureCheck valve

The invention discloses a supercharger and a centrifugal vacuum oil purifier with the supercharger. The supercharger is characterized by comprising a check valve, a vacuum tank oil inlet pipe, a supercharger shell, a high-pressure oil pump connecting pipe, a high-pressure oil-ejecting pipe, a pressure-mixing pipe, an oil-well pump connecting pipe and flanges, the two ends of the supercharger shell are sealed and connected by the flanges into a sealed body, the high-pressure oil pump connecting pipe is inserted into the supercharger shell, and the high-pressure oil-ejecting pipe is arranged at the tail end of the high-pressure oil pump connecting pipe; the oil-well pump connecting pipe is inserted in the supercharger shell, and the outlet end of the high-pressure oil-ejecting pipe is connected with the inverted-frustum-shaped inlet end of the pressure-mixing pipe in a jet-flow mode; the vacuum tank oil inlet pipe is perpendicularly communicated with the supercharger body in the radial direction; the check valve is arranged in the input pipe opening of the vacuum tank oil inlet pipe. The oil purifier comprises an oil-purifying pump, an oil tank, an oil-well pump, a vacuum tank pump, a vacuum tank and an oil purifying device, and is characterized by further comprising a supercharging oil pump and the supercharger.

Owner:TIANJIN YIOU MACHINERY MFG CO LTD

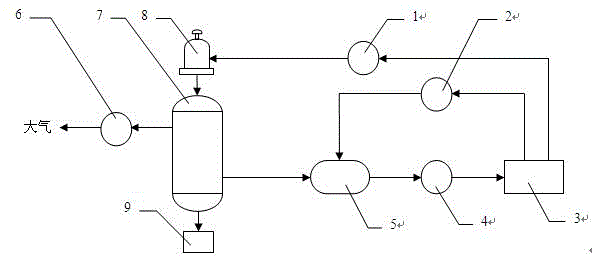

Pumping unit time sharing speed adjusting device

InactiveCN106762589AChange the power frequencyReduce wearFlexible member pumpsFluid removalElectric machineryTime-sharing

The invention relates to a pumping unit time sharing speed adjusting device. The device comprises a travel position detecting device, a control device and a man-machine interaction device; the travel position detecting device and the man-machine interaction device are respectively connected with the control device; an output end of the control device is connected with a pumping unit motor mounted on the ground; the travel position detecting device is used for detecting an operation position of a pumping unit; the man-machine interaction device is used for receiving and displaying speed adjusting control parameters input by users; and the control device is used for changing the power supply frequency of the pumping unit motor according to the operation position information of the pumping unit and the speed adjusting control parameters, so that the pumping unit motor rotates according to a first speed at the lower stroke of the pumping unit, and rotates according to a second speed at the upper stroke of the pumping unit, wherein the first speed is lower than the second speed. The pumping unit time sharing speed adjusting device can solve the problems of reducing the pumping efficiency and adding wear of pumping rods and oil pipes due to incapability of adjusting the upper stroke and lower stroke speeds of the pumping rods in the prior art.

Owner:杨欢

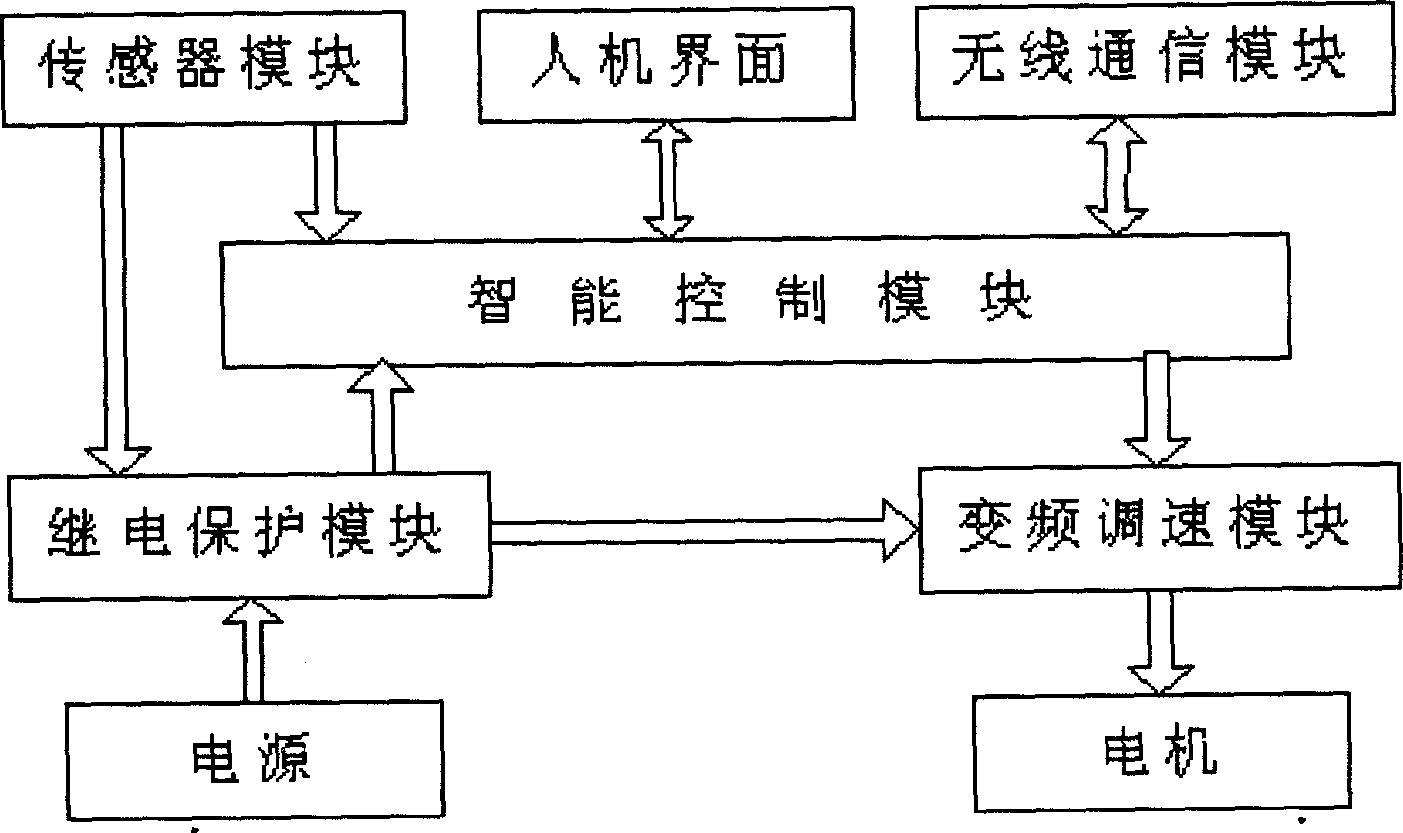

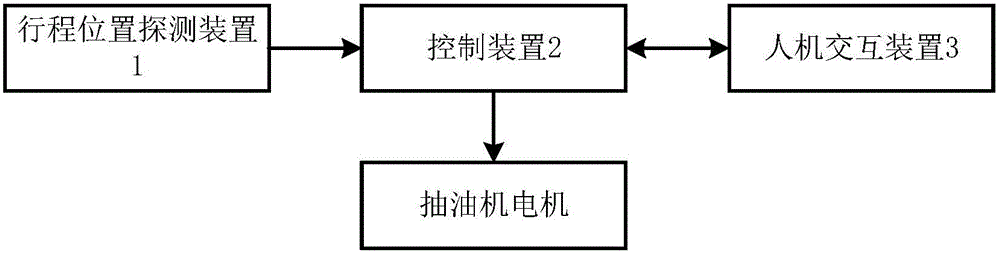

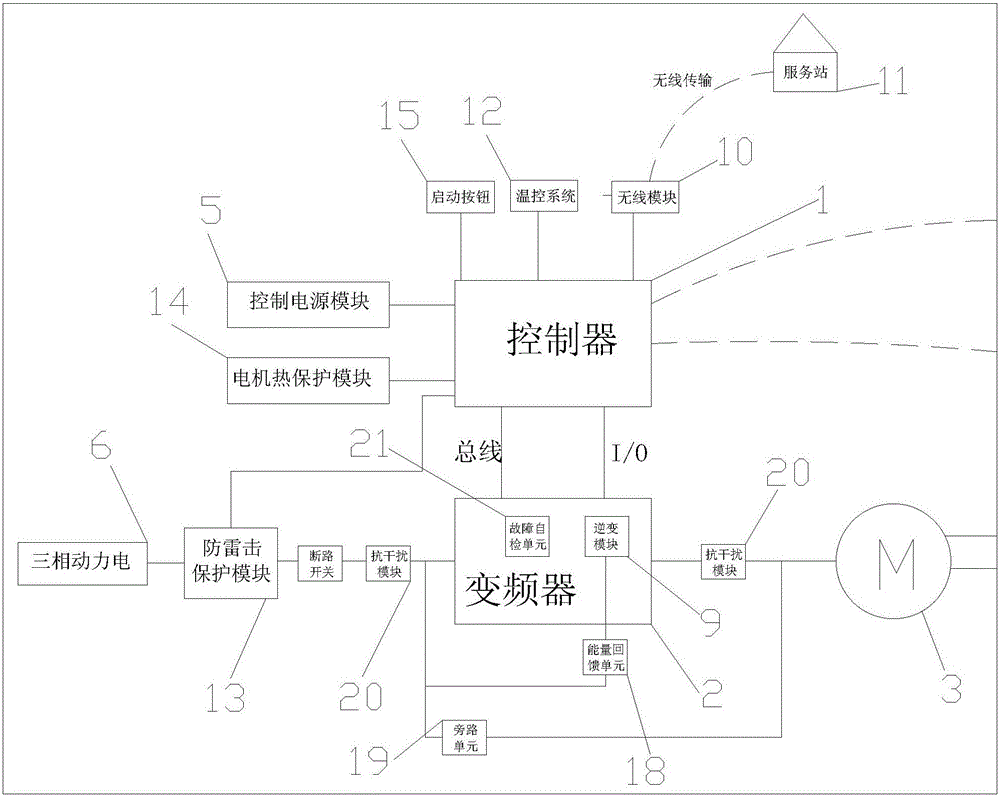

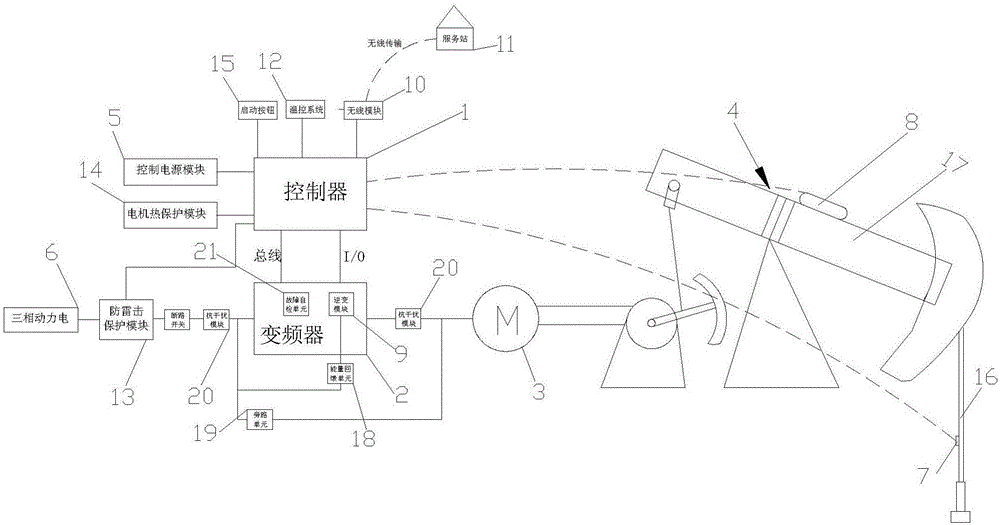

Intelligent control device applied to oil-field pumping unit

PendingCN106761576AImprove oil pumping efficiencyIncrease productionAC motor controlFluid removalElectricityFrequency changer

The invention relates to an intelligent control device applied to an oil-field pumping unit. The intelligent control device comprises a controller, a frequency converter, a motor, the pumping unit, a control power supply module, three-phase dynamic electricity and a sensor. The three-phase dynamic electricity is connected with the control power supply module and the frequency converter separately; the control power supply module is connected with the controller; the controller controls the frequency converter to drive the motor to rotate; the motor is connected with the pumping unit; the pumping unit comprises a sucker rod and a walking beam; and the sensor is arranged on the walking beam of the pumping unit and used for sensing the position of the sucker rod and transmitting data to the controller. According to the intelligent control device, the situation that when the sucker rod moves upward, the speed is high, and when the sucker rod moves downward, the speed is slow at the time of oil pumping can be realized; the pump efficiency is increased while pump leakage is reduced; the oil pumping efficiency and the oil yield of the pumping unit are improved; and the function of energy saving is achieved, operation is stable and reliable, the service life is long, and higher practical value is achieved.

Owner:上海芑创电子技术有限公司

Multifunctional double arm interaction double-drive-wheel self-speed-changing pumping unit

ActiveCN103061719AImprove oil pumping rateImprove oil pumping efficiencyFluid removalDrive wheelReciprocating motion

The invention discloses a multifunctional double arm interaction double-drive-wheel self-speed-changing pumping unit which comprises a lifting arm assembly, a lifting rope, a wellhead pumping unit, two drive wheels, a first power arm and a second power arm. The drive wheels are connected with a speed change mechanism. One end of the first power arm is located between the two drive wheels and movably connected with the same while the other end of the first power arm is provided with a fixed pulley and a lifting rope fixing hole. One end of the second power arm is movably connected with the first power arm while the other end of the second power arm is provided with a fixed pulley. The second power arm is provided with a base point. The second power arm reciprocates around the base point. One end of the lifting rope is fixedly connected with the wellhead pumping device through a fixed pulley on the lifting arm assembly. The other end of the lifting rope is fixed in the lifting rope fixing hole on the first power arm sequentially through the fixed pulley on the second power arm and the fixed pulley on the first power arm. By the pumping unit, stroke frequency can be adjusted conveniently, upstroke speed is increased, pumping efficiency is improved, and more oil can be pumped out of oil wells.

Owner:德阳振华机械设备制造有限公司

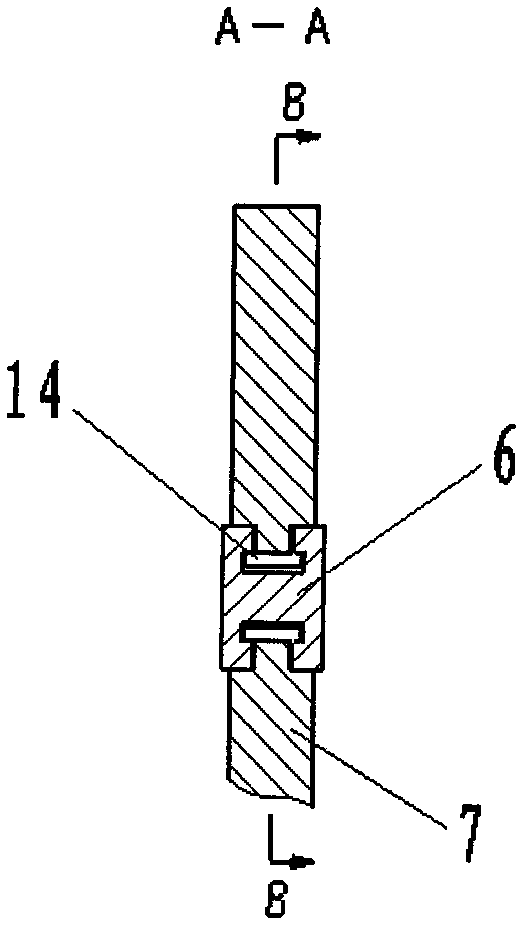

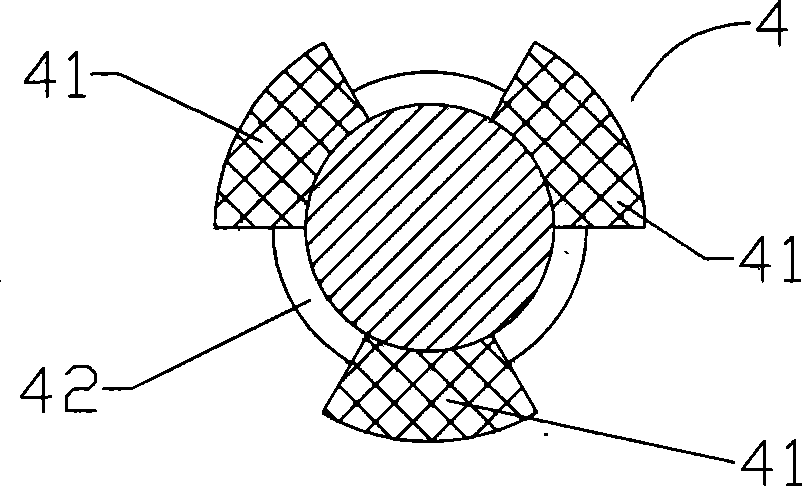

Pumping-improvement centralizer of pumping rod

InactiveCN101446182AReduce pressure difference between upper and lowerReduce frictionDrilling rodsDrilling casingsEngineeringPressure difference

The invention relates to a pumping-improvement centralizer of pumping rod, comprising a central rod; wherein, the two ends of the central rod are provided with joints; the central rod is provided with a first centralizing body and a second centralizing body; the first centralizing body comprises three first centralizing claws; the second centralizing body comprises three second centralizing claws; when the pumping rod moves downwards, the first centralizing body moves upwards under the action of friction force, the first centralizing body and the second centralizing body are separated, and crude oil flows upwards by a clearance between the first centralizing claw and the second centralizing claw; when the pumping rod moves upwards, the first centralizing body moves downwards under the action of friction force, and the first centralizing body slides into the clearance of the second centralizing body to form a piston; when the pumping rod moves upwards and downwards, the first centralizing body and the second centralizing body can have the centralization function and prevent the friction between the pumping rod and the pumping pipe; when the pumping rod moves upwards, the pressure difference of the upper pressure and the lower pressure of the piston can be reduced and the pumping efficiency is improved.

Owner:刘献春

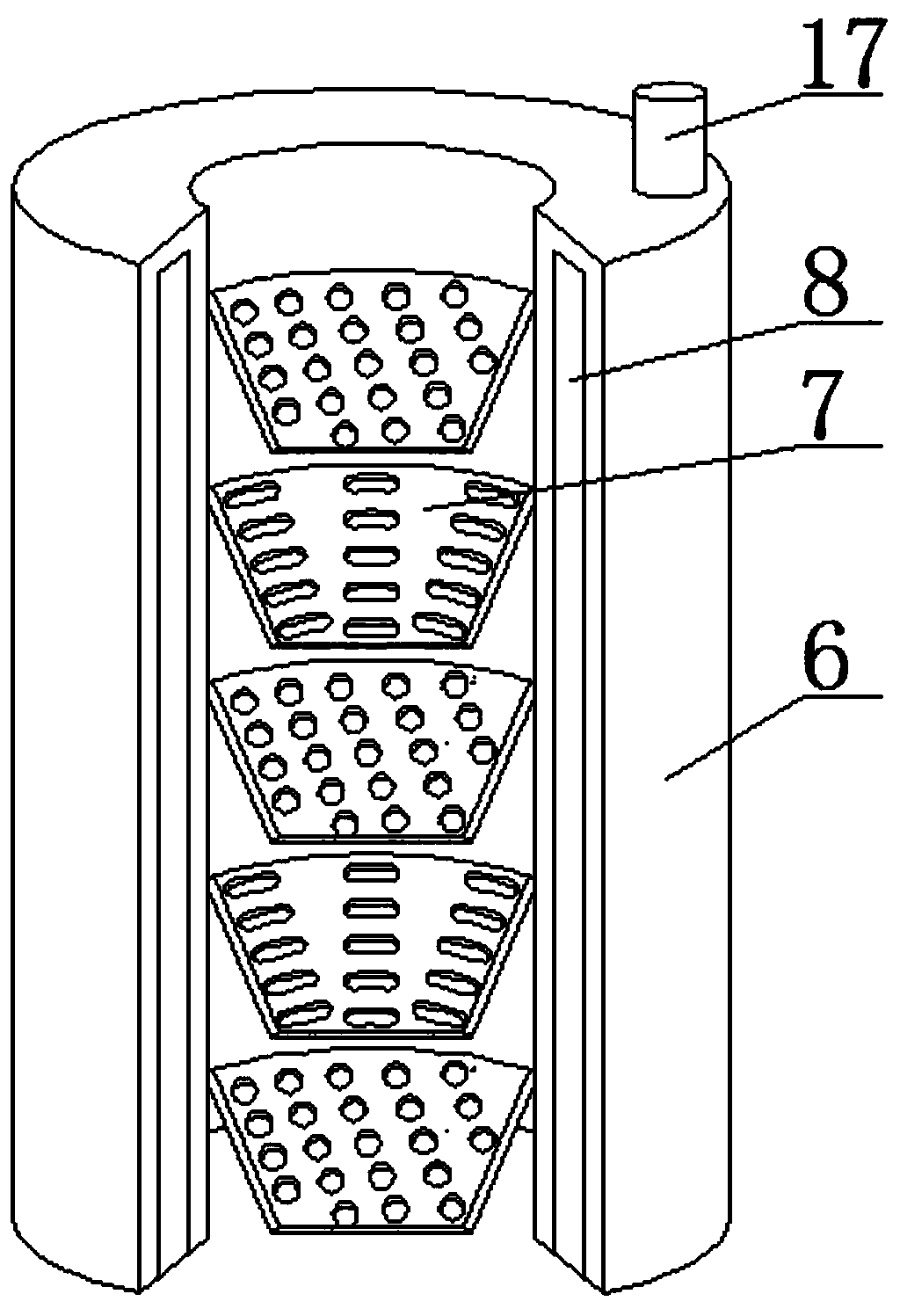

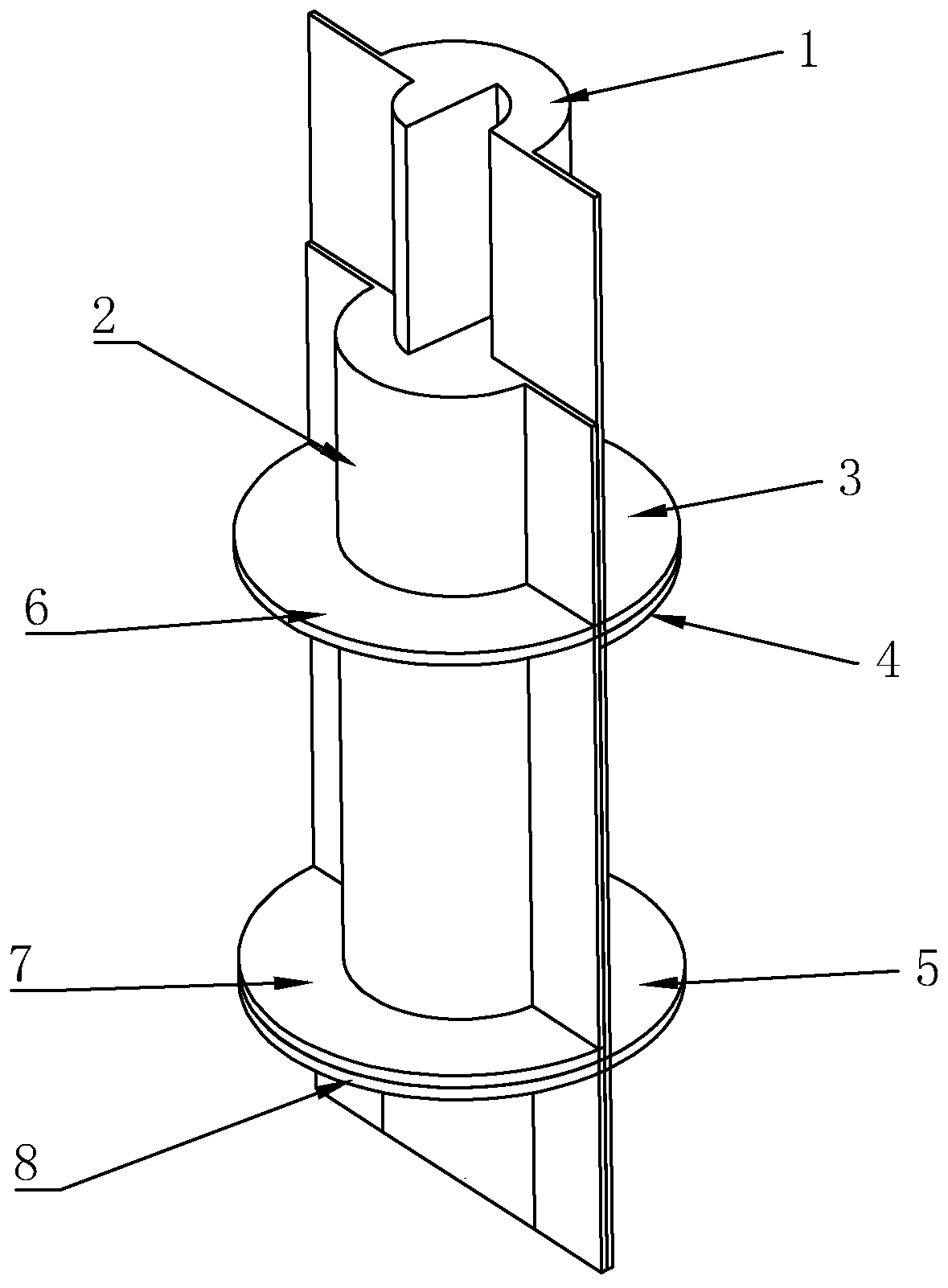

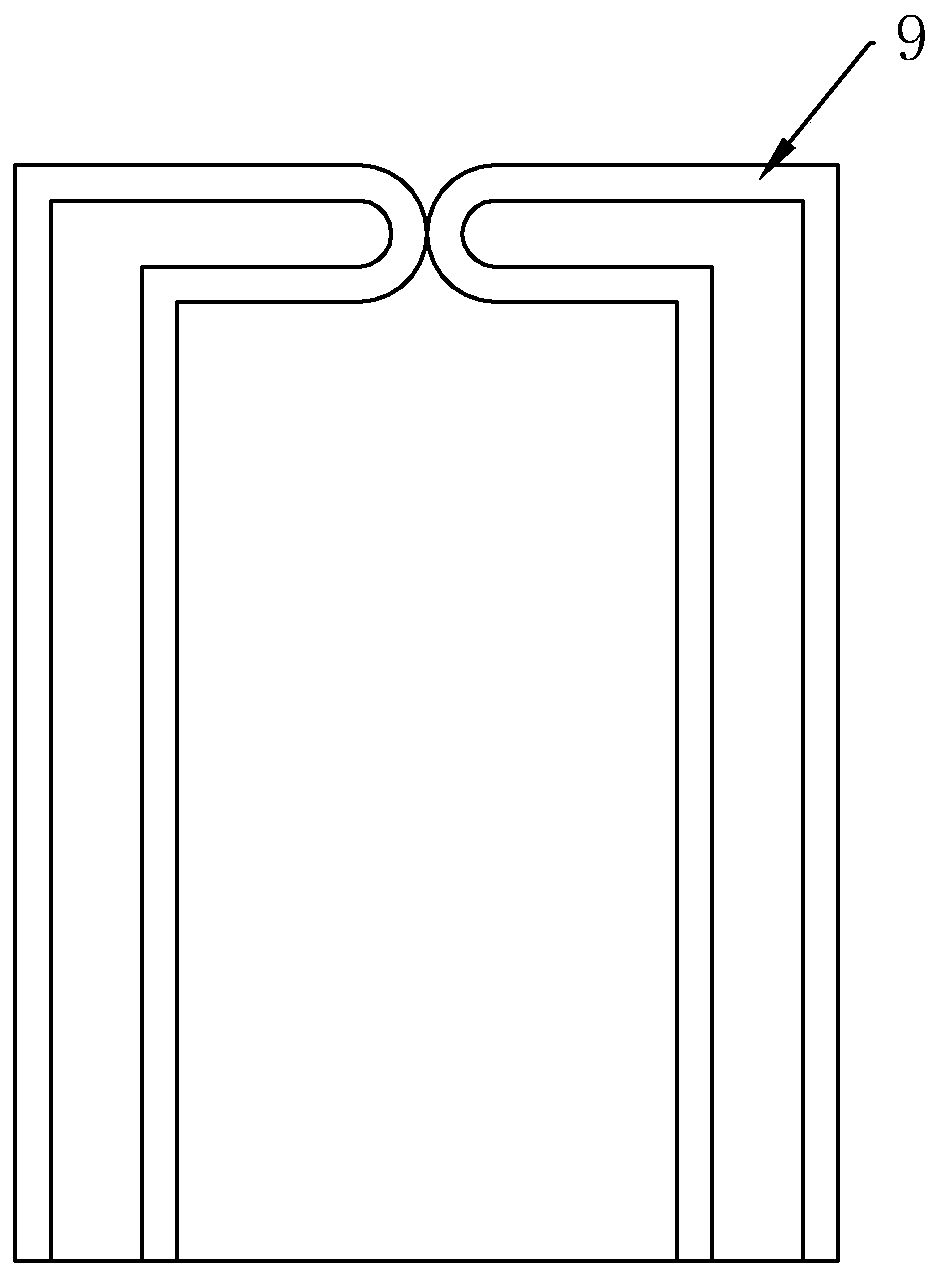

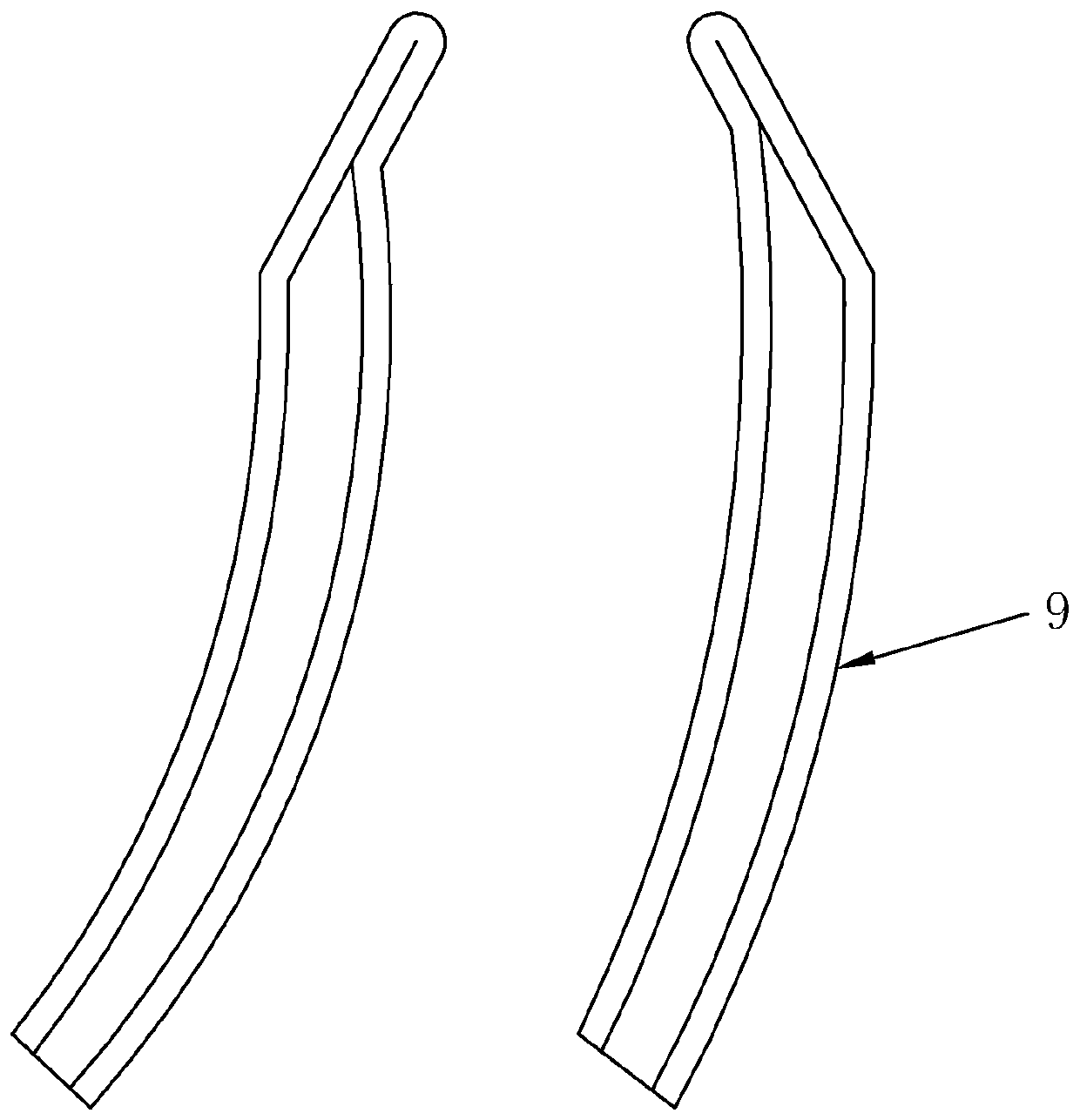

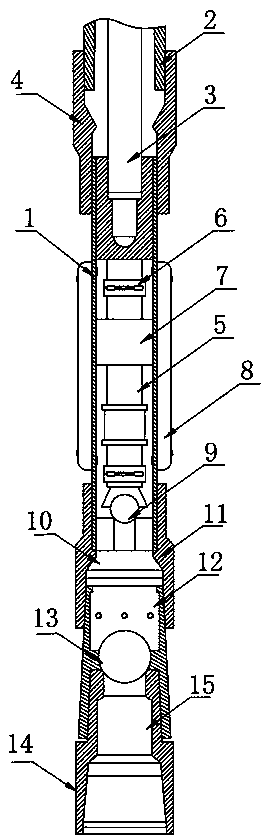

Pumping aid device

InactiveCN102418498AImprove oil pumping efficiencyStop the leakDrilling rodsFluid removalReciprocating motionEngineering

The invention discloses a pumping aid device. The pumping aid device is provided with a central spindle along an axis; a plurality of sliding valve bushes are sleeved on the circumference of the central shaft in the axial direction; the upper end of each sliding valve bush is provided with an upper baffle ring; the lower end of each sliding valve bush is provided with a sliding valve bush seat; a sealing structure is arranged between the sliding valve bush and the sliding valve bush seat; and the distance between the upper baffle ring and the sliding valve bush seat is greater than the length of the sliding valve bush; and an oil hole is formed between the upper and lower ends of the sliding valve bush. The outer surface of the upper part of at least one sliding valve bush is provided with a plurality of spiral grooves. A through spiral groove oil hole is formed between the radial inner side of the sealing structure of the lower end of the sliding valve bush and the spiral groove. When a pumping rod does reciprocating motion in the vertical direction in an oil well sleeve, all the sliding valve bushes slide fro and back between the upper baffle rings and the sliding valve bush seats, the sealing structures between the sliding valve bushes and the sliding valve bush seats are closed and opened repeatedly, and crude oil can be continuously lifted in a multilevel relay mode; and the pumping aid device can obviously improve oil pumping efficiency of a deep oil well and has obvious economic and social benefit.

Owner:BEIJING ZUNHONG TECH DEV

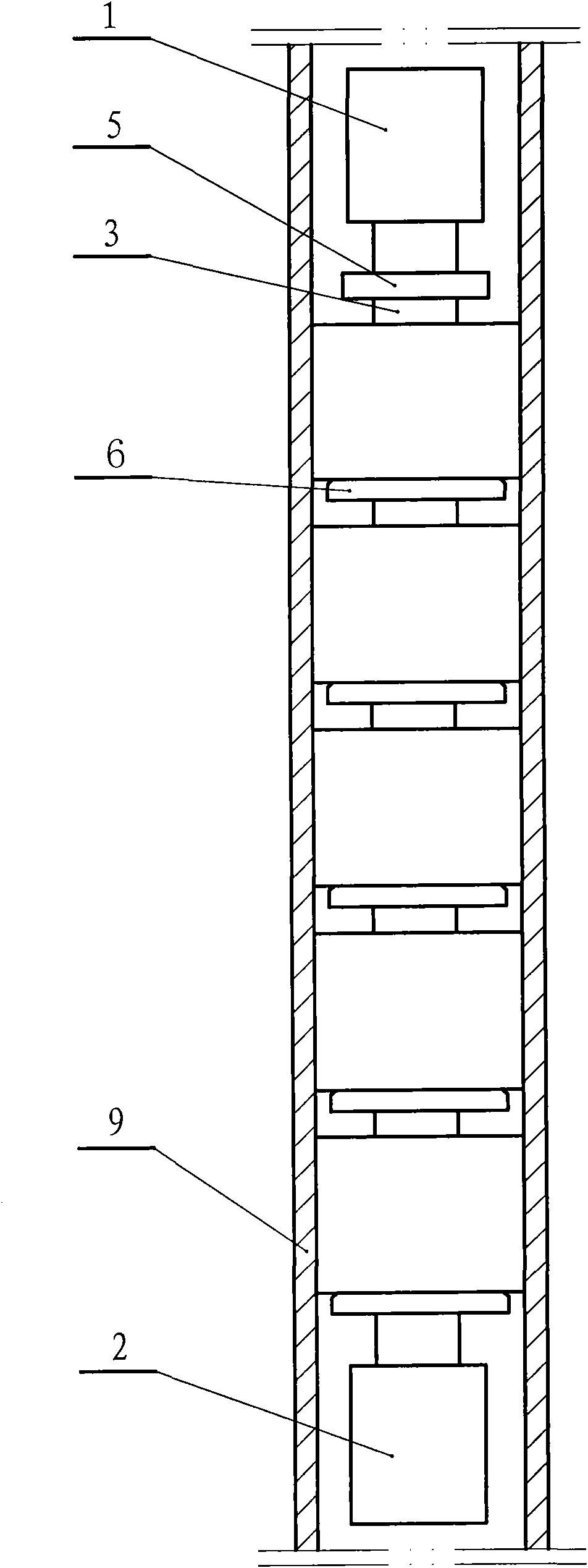

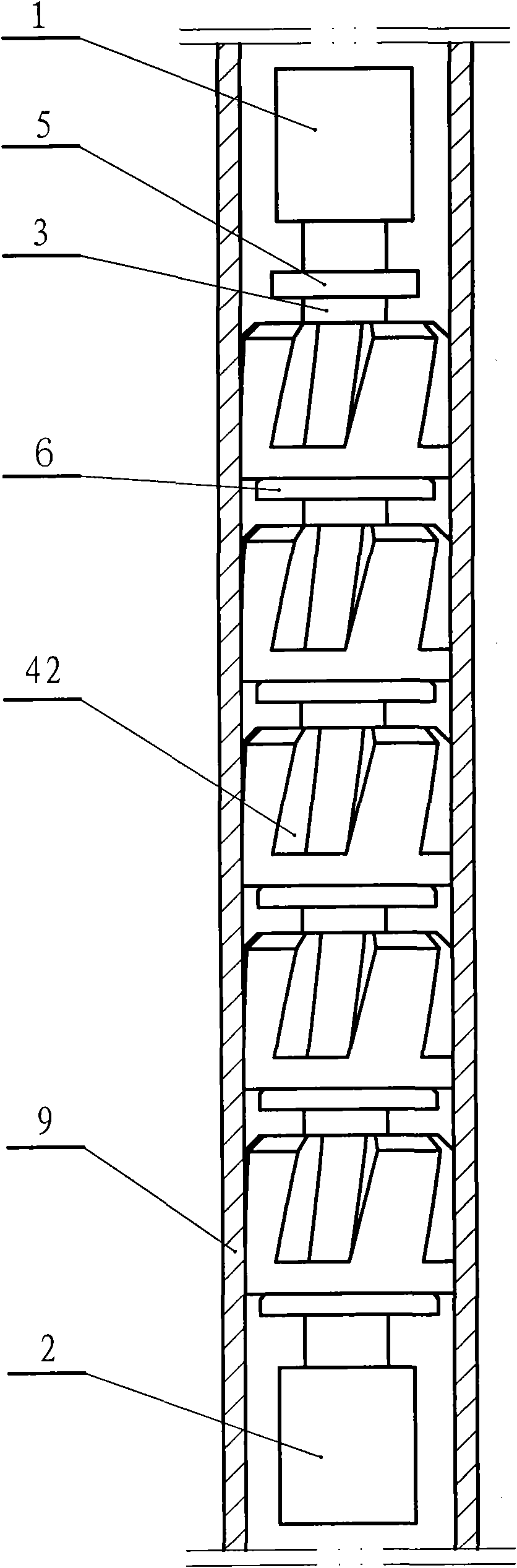

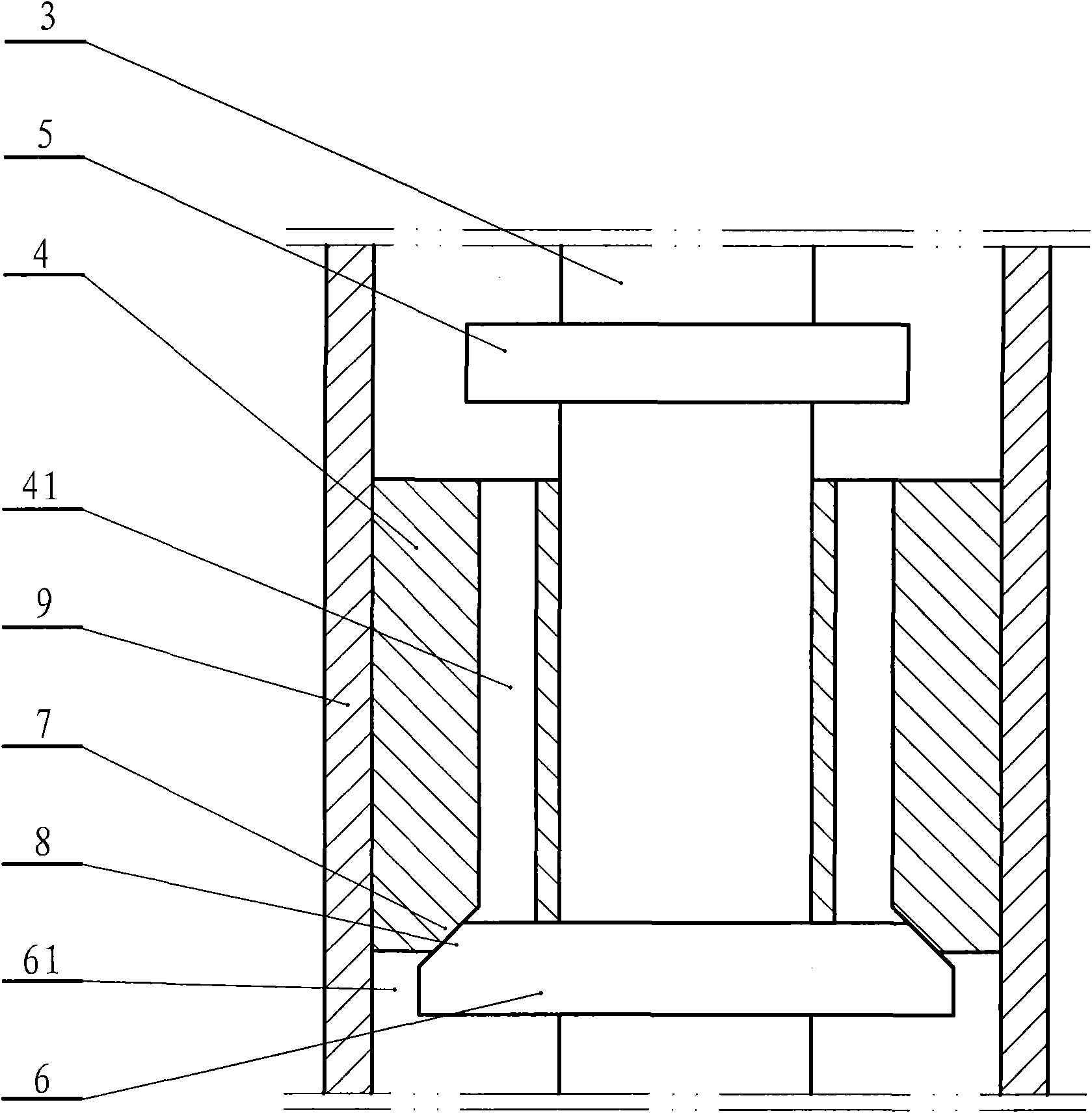

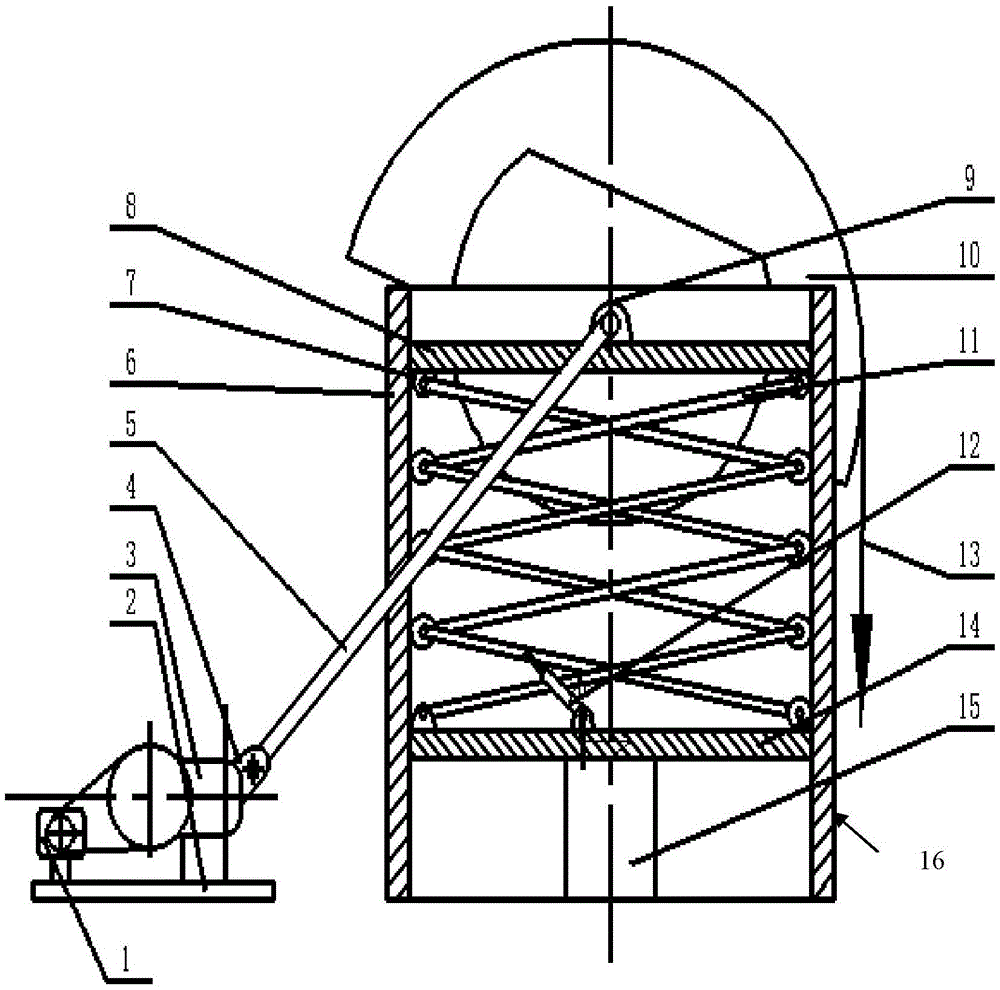

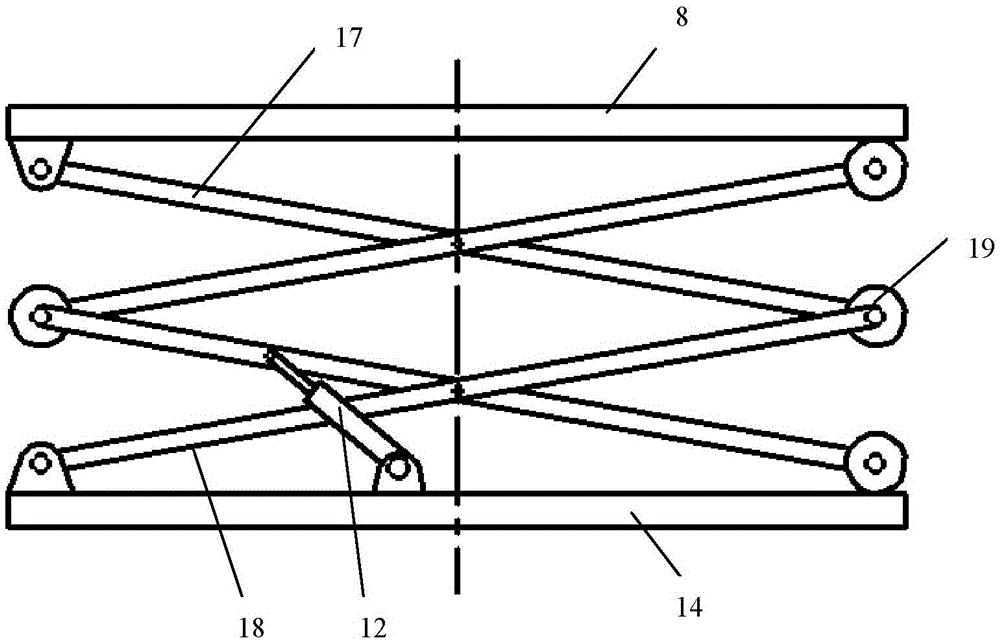

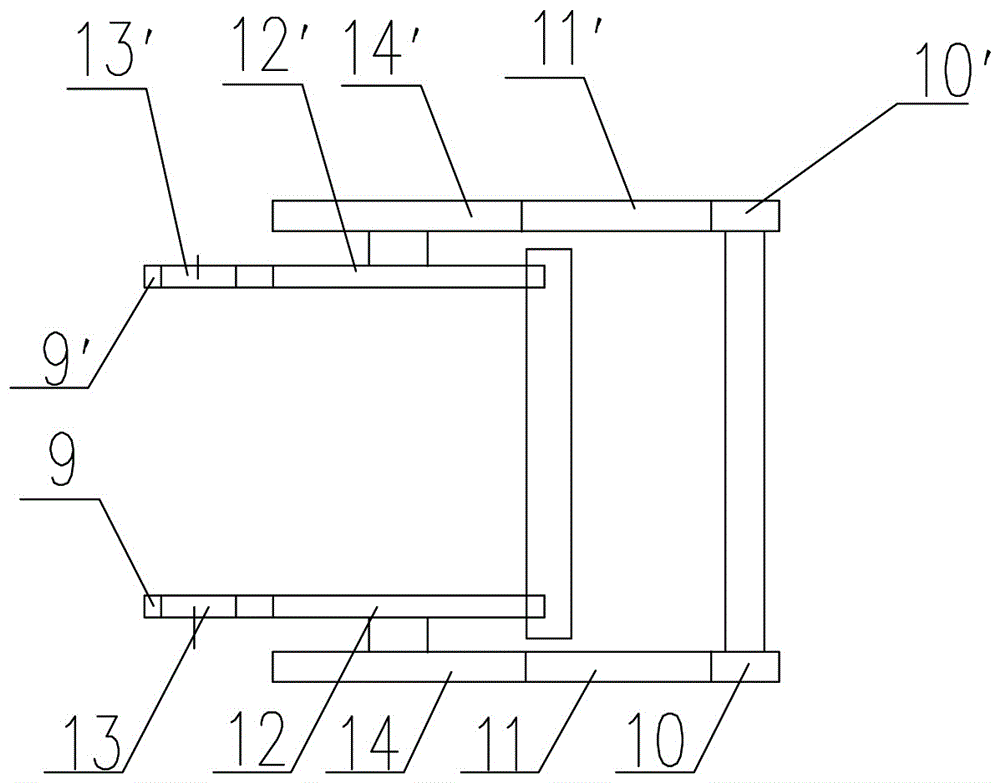

Scissors fork type extended-range pumping unit

A scissors fork type extended-range pumping unit comprises a motor, a motor supporting base, a speed reducer, a crank, a rocker, an installing support, a scissors fork supporting arm hinged shoe, an upper supporting platform, a horsehead hinged shoe, a horsehead, a scissors fork type lifting mechanism, a hydraulic device, a polished rod lifting rope, a lower supporting platform and a supporting base. Structures of a double-action wheel type pumping unit and a pedal single-arm walking beam extended-range pumping unit are used for reference, a range extending device is improved by adopting the scissors fork type lifting mechanism, and the stroke of the pumping unit is effectively lengthened by using the characteristics of providing enough lifting height and saving space of the scissors fork type lifting mechanism. The characteristics that the scissors fork type mechanism bears heavy loads and moves stably are used, and the mechanism moves more smoothly, and the oil pumping efficiency is improved. Different performance requirements of pumping units in large, medium and small sizes can be met by changing the structure of the scissors fork type lifting mechanism.

Owner:CIVIL AVIATION UNIV OF CHINA

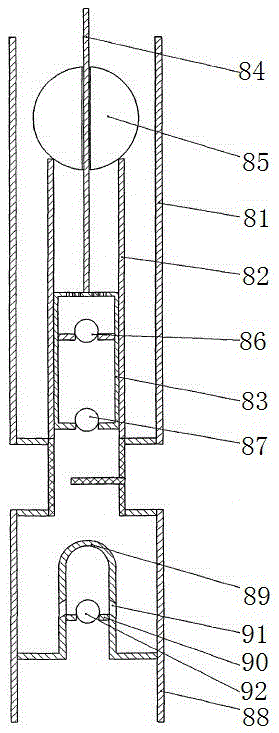

Tubing oil well pump

InactiveCN105649962AGuaranteed storage effectImprove pumping efficiencyPositive displacement pump componentsFlexible member pumpsEngineeringPumpjack

The invention relates to a tubing oil well pump. The tubing oil well pump comprises a fixed valve and a protection cover for preventing impurities from falling in the fixed valve. The fixed valve comprises a fixed valve seat and a valve ball matched with the fixed valve seat; and a sedimentary cavity is formed in the periphery of the protection cover, and the fixed valve seat and the valve ball are located on the outer side of the protection cover. The valve ball and the fixed valve seat are located on the outer portion of the protection cover; and under the condition of ensuring the storage capacity of the sedimentary cavity, the radial size of the valve ball and the radial size of the fixed valve seat are not limited by the protection cover, the diameter of the fixed valve seat can reach the maximum as far as possible, the radius of the valve ball is made to be maximum as far as possible, and the oil pumping efficiency of the tubing oil well pump is improved as far as possible.

Owner:王中阳

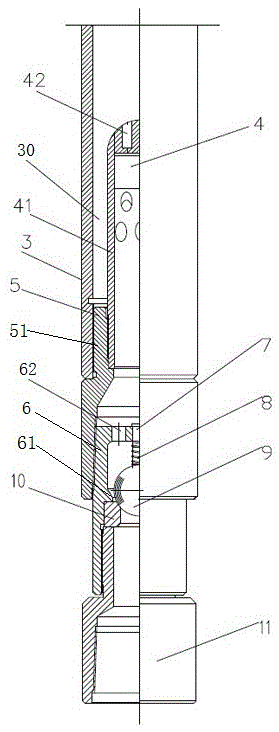

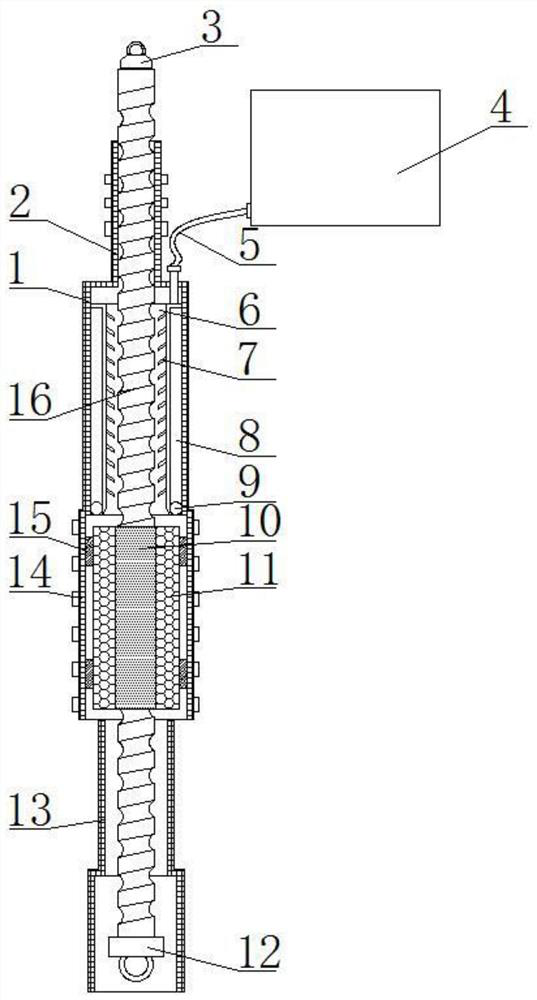

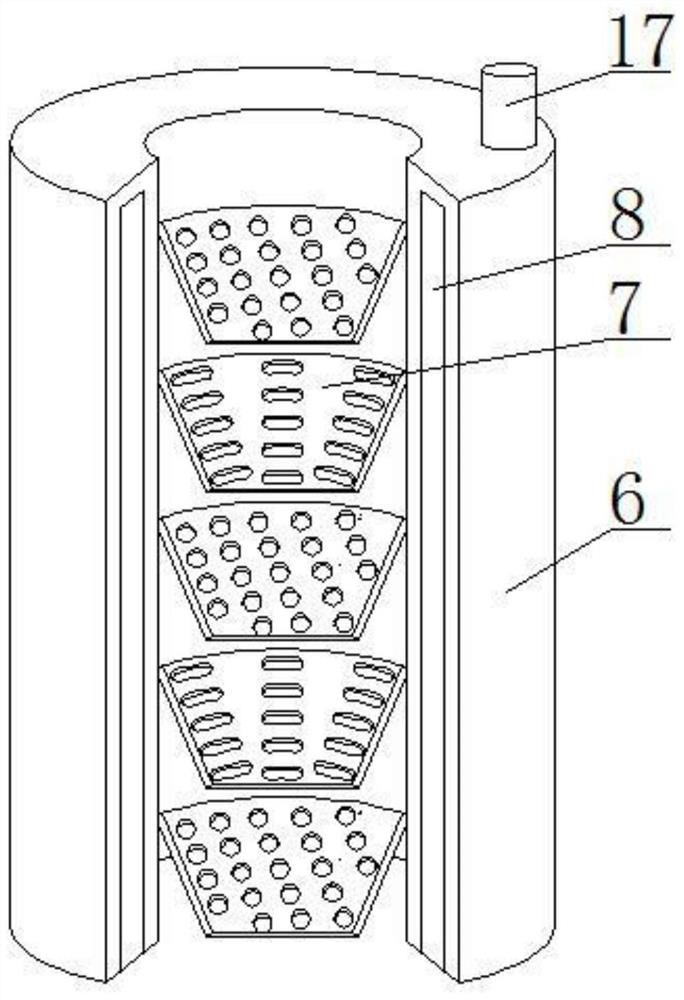

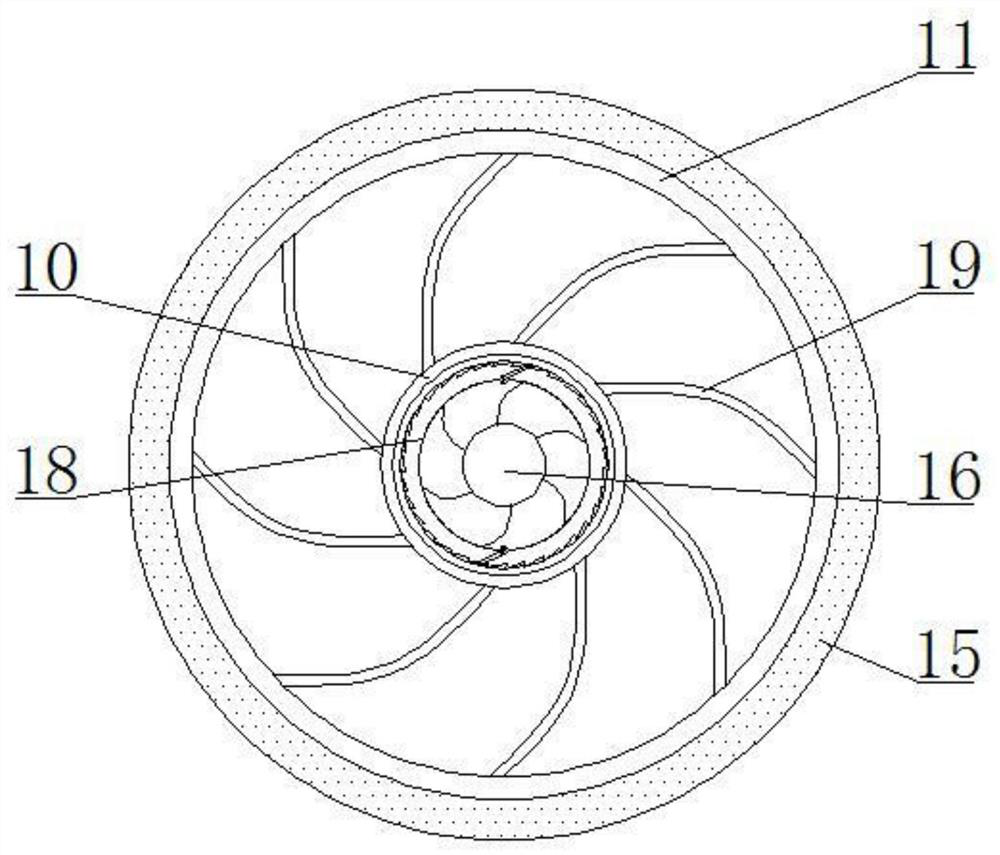

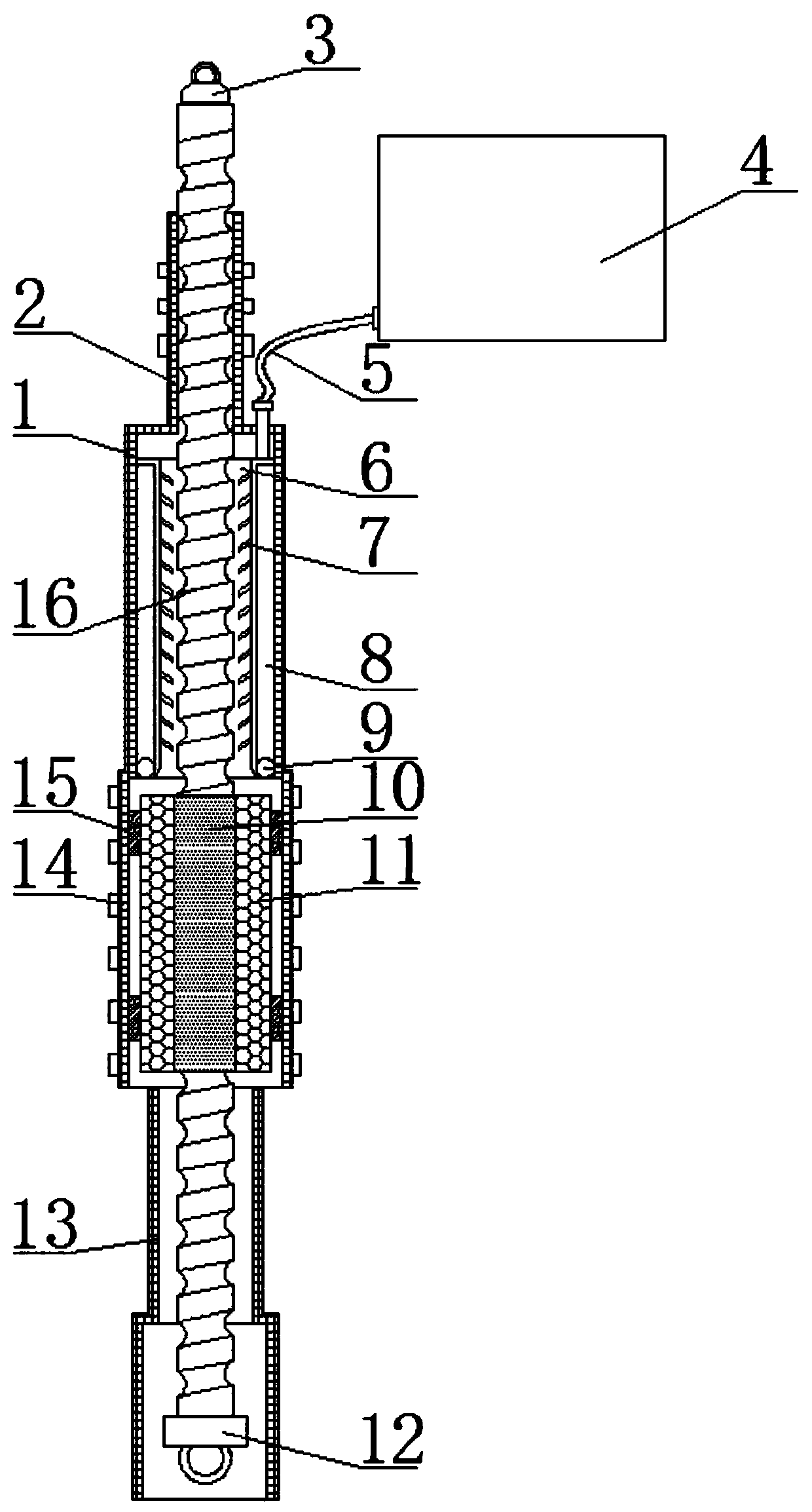

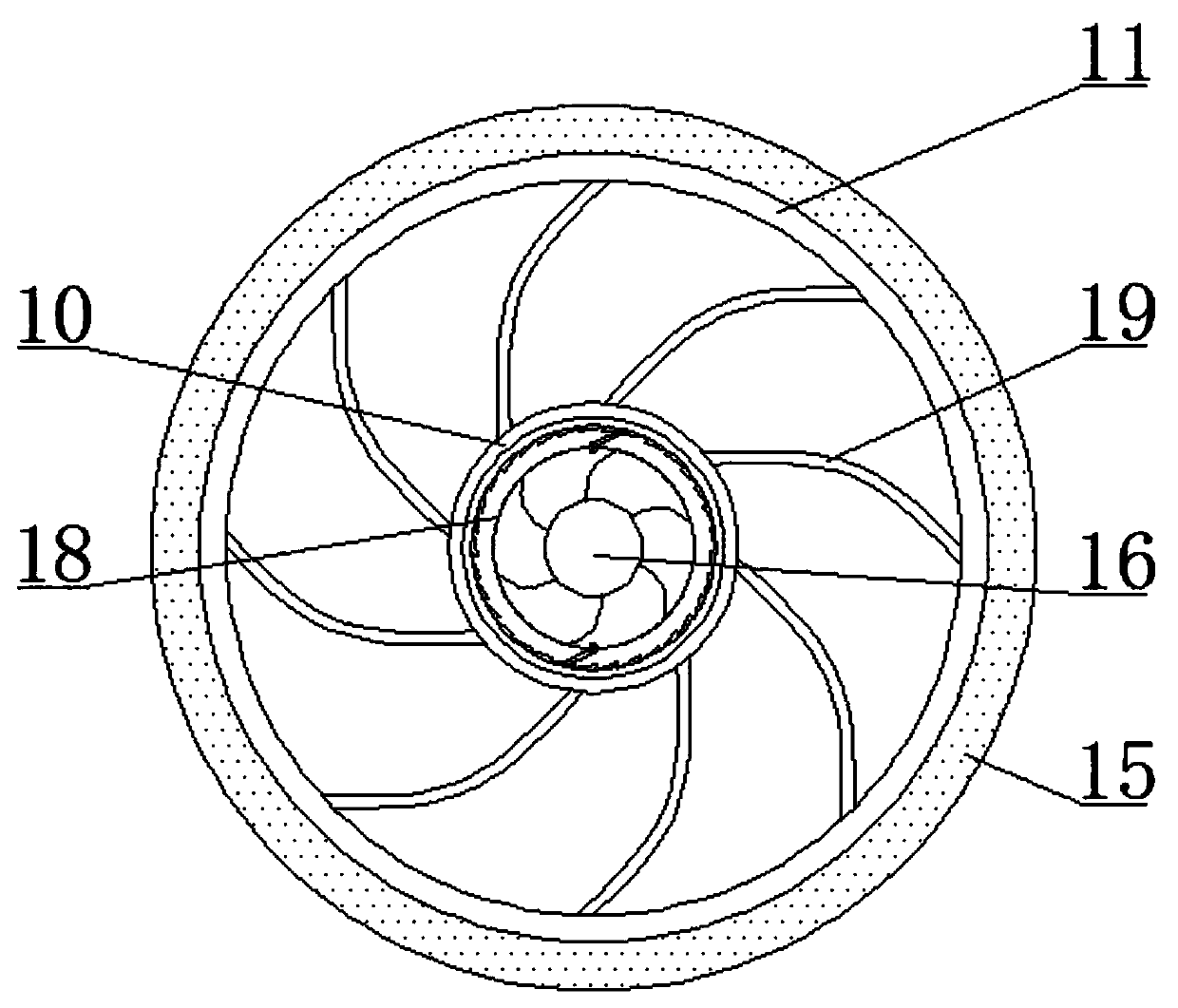

A pump injection agent mixing device for pumping wells

ActiveCN111236903BImprove utilization efficiencyFully mixedFluid removalWell/borehole valve arrangementsImpellerGear drive

The invention relates to the technical field of oil well equipment, and discloses a pumping well under-pump injection agent mixing device. The device comprises a connecting sleeve pipe and an injection agent storage device; the top of the connecting sleeve pipe fixedly communicates with an upper connector, a screw is movably sleeved inside the upper connector, an upper hook is movably installed atone end, located above the upper connector, of the screw, and a fixed sleeve is movably sleeved inside the connecting sleeve pipe. According to the pumping well under-pump injection agent mixing device, by connecting the screw with a sucker rod, the screw, a flying gear and the connecting sleeve are matched, the screw is driven by the power of a pumping unit to move up and down, so that the flying gear drives an impeller device to rotate, so that the oil on the belt of the pumping unit is fully mixed with the medicament at the impeller device, the utilization efficiency of the medicament is improved, the installation of the device is simple, special power equipment is not needed, and the economic investment is low.

Owner:山东赛纳石油科技有限公司

Pumping well under-pump injection agent mixing device

ActiveCN111236903AImprove utilization efficiencyFully mixedFluid removalWell/borehole valve arrangementsImpellerGear drive

The invention relates to the technical field of oil well equipment, and discloses a pumping well under-pump injection agent mixing device. The device comprises a connecting sleeve pipe and an injection agent storage device; the top of the connecting sleeve pipe fixedly communicates with an upper connector, a screw is movably sleeved inside the upper connector, an upper hook is movably installed atone end, located above the upper connector, of the screw, and a fixed sleeve is movably sleeved inside the connecting sleeve pipe. According to the pumping well under-pump injection agent mixing device, by connecting the screw with a sucker rod, the screw, a flying gear and the connecting sleeve are matched, the screw is driven by the power of a pumping unit to move up and down, so that the flying gear drives an impeller device to rotate, so that the oil on the belt of the pumping unit is fully mixed with the medicament at the impeller device, the utilization efficiency of the medicament is improved, the installation of the device is simple, special power equipment is not needed, and the economic investment is low.

Owner:山东赛纳石油科技有限公司

Heavy spherical pump with double oil filling

InactiveCN101191483AIncrease the oil inlet speedImprove oil pumping efficiencyFlexible member pumpsFluid removalPump chamberPetroleum

The invention discloses a double inlet oil heavy ball pump, which comprises a pump cylinder; a plurality of holes are arranged on the cylinder walls of the pump cylinder in the reciprocating stroke of a plunger piston component; during the lifting process of the plunger piston component, the petroleum enters the pump chamber from a guiding valve at the lower end of the pump, while the plunger component is lifted up to an upper limit position, the petroleum at the outside of a defueling pump simultaneously enters the pump chamber through the holes; the double oil inlet function speeds up the oil inlet and improves the oil pumping efficiency; during petroleum exploitation, in particular to the heavy petroleum development, after the plunger component falls to the bottom of the pump chamber, the holes on the pump cylinder are exposed and are communicated with the inner and outer walls of the pump above the plunger component, that is, heavy petroleum thinner can be added from the upper end of a defueling pipe from the ground. The invention has short working period; the labor intensity of the petroleum workers is reduced.

Owner:王洪渤

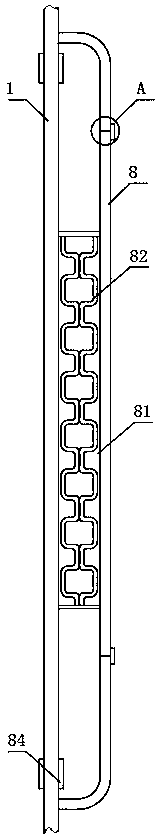

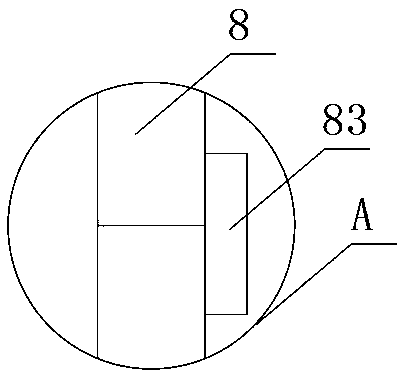

Carbon fiber hollow heating rod column

InactiveCN110778280AImprove efficiencyReduce replacement and maintenance costsDrilling rodsInsulationAdhesive cementFiber

The invention discloses a carbon fiber hollow heating rod column which comprises a plurality of carbon fiber hollow sucker rods and a metal hollow double-end joint. Each carbon fiber hollow sucker rodcomprises a metal joint, an adhesive, a seal ring and a carbon fiber hollow pipe. One end of each metal joint is bonded to the outer side of one end of the corresponding carbon fiber hollow pipe through the adhesive, an inner thread is arranged at the other end of each metal joint, outer threads adaptive to the inner threads of the metal joints are arranged on the outer sides of two ends of the metal hollow double-end joint, two ends of the metal hollow double-end joint are in threaded connection to the metal joints at one ends of the two carbon fiber hollow pipes, and each seal ring is arranged at the end, bonded to the pipe wall of the corresponding carbon fiber hollow pipe, of the corresponding metal joint. The carbon fiber hollow heating rod column has the beneficial effects that thecarbon fiber hollow sucker rods are connected and communicate through the metal hollow double-end joint, so that the problem that the using effect of the carbon fiber hollow sucker rods is affected directly in use of the carbon fiber hollow sucker rods as a result of wax precipitation or viscosity in an oil well is solved, the oil suction efficiency is improved, and the replacement and maintenancecosts are lowered.

Owner:大庆市汇成科技开发有限公司

Non-pumping-stopping automatic collide pump mechanism for pumping unit

PendingCN110454119AImprove oil pumping efficiencyReduce manufacturing costConstructionsFluid removalEngineeringPulley

Owner:陈志国 +1

Two-way sucker rod

ActiveCN110541676BHigh strengthExtended service lifeDrilling rodsWell/borehole valve arrangementsEngineeringCheck valve

The invention discloses a two-way sucker rod comprising an inner pipe and suction rods arranged in the inner pipe. Partition plates are connected in the inner pipe, and the inner pipe is partitioned into a left containing cavity and a right containing cavity. The suction rods include the first suction rod and the second suction rod. The first suction rod and the second suction rod are spliced to form a cylinder shape. The first suction rod is in the left containing cavity. The second suction rod is in the right containing cavity. End plates are arranged on the upper potion and the lower portion of each containing cavity correspondingly. Check valves are connected to the end plates. Each end plate in the right containing cavity is provided with the two corresponding check valves with opposite valve opening directions. A valve plate capable of being switched between valve openings is arranged between every two corresponding check valves. A power conversion device is arranged above the suction rods. The second suction rod is connected with a horsehead through the power conversion device. The first suction rod is directly connected to the horsehead through a traction rope. When the horsehead rises, the first suction rod is driven to rise; and when the horsehead falls, the second suction rod is lifted upwards through the power conversion device. The oil suction effect can be achieved when the horsehead rises and falls, and the oil suction efficiency is improved.

Owner:DAQING DANFENG PETROLEUM TECH DEV CO LTD

A double-layer steel pipe expandable external packer

ActiveCN114352230BRealize free switchingSolve the impact on qualitySurveyFluid removalControl roomOil production

The invention relates to the technical field of external packers, in particular to a double-layer steel pipe expansion type external packer, which is connected to the central control room based on the regional network signal, including a main structure, a split structure, a main connecting pipe and a split connecting pipe , there is at least one split structure, the top of the split structure is connected to the split structure through the main connecting pipe, the two split structures are connected through the split connecting pipe, and the lowest end of the split structure is installed with an extension Pipe; the present invention realizes synchronous extraction and partial extraction of single oil layer and multi-oil layer oil body, and also detects the oil pressure through the set pressure detection component during the oil pumping process, and cooperates with the set bottom seal component and ring side seal component And expansion sealing components, to realize the free switching of multi-layer pumping, partial closure and overall closure of the oil production site, improve the quality of oil pumping and the stability of the oil pumping process, and enhance the efficiency of oil pumping.

Owner:DONGYING BAIHUA GASOLINEEUM TECH DEV

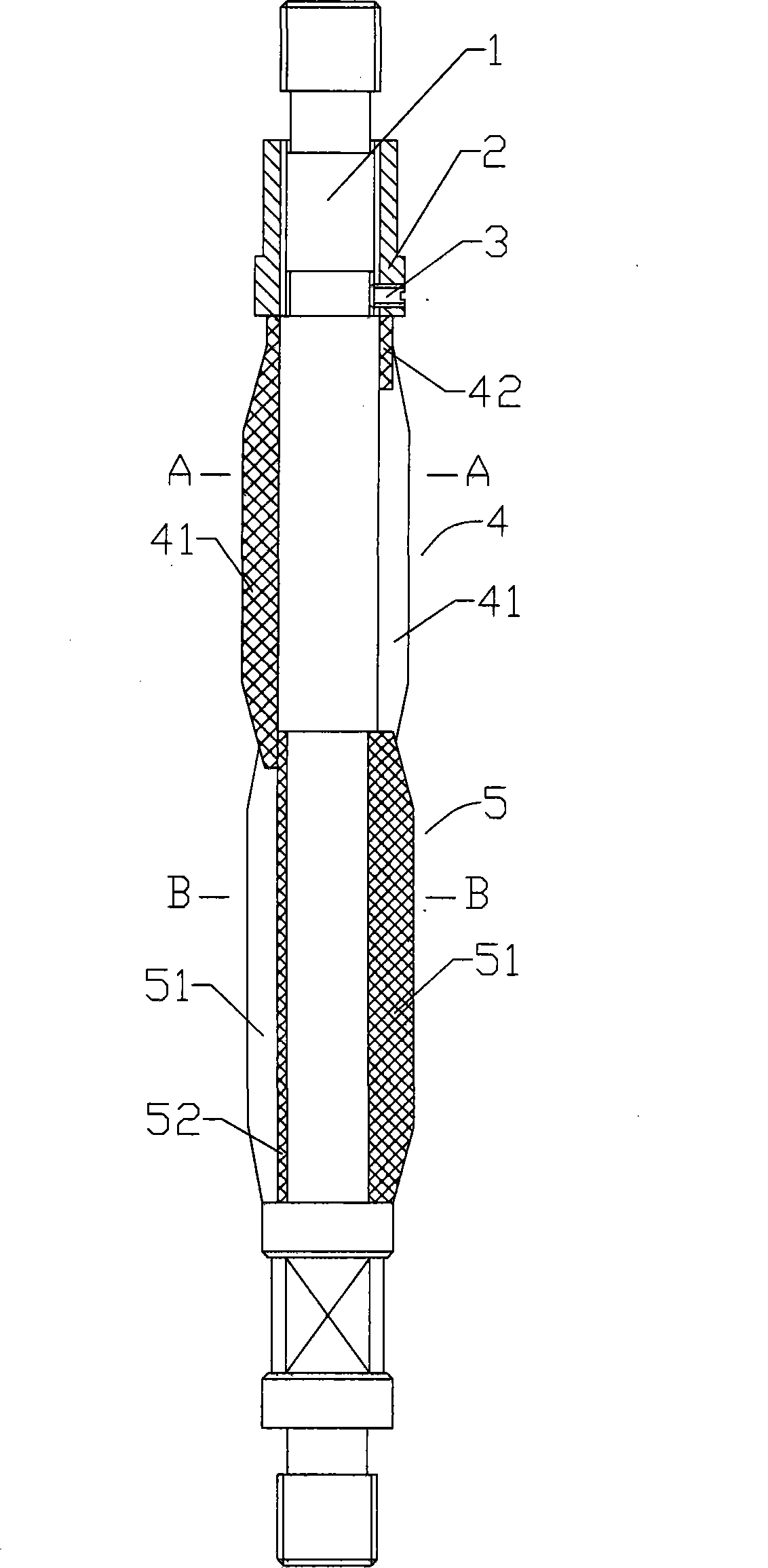

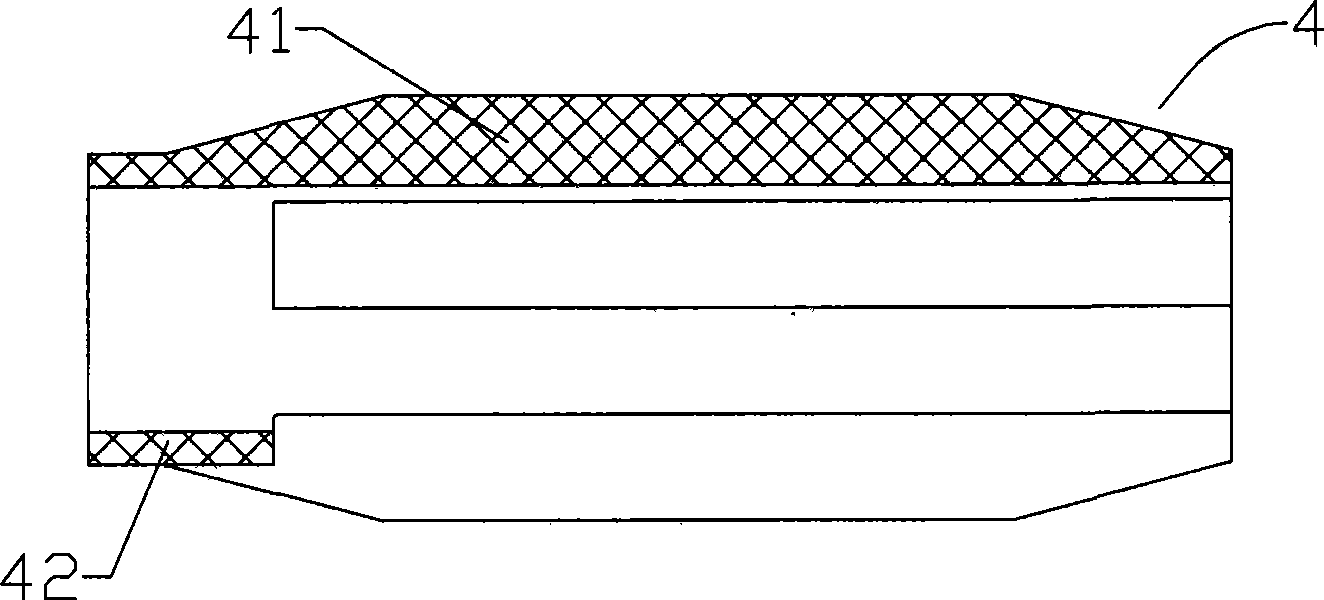

Single-reversing oil pumping unit with triangular chains

The invention relates to a single-reversing oil pumping unit with triangular chains. The single-reversing oil pumping unit comprises a reversing turning wheel, a weight basket, a sucker rod and a reversing mechanism. A steel wire rope is wound across one end of the reversing turning wheel to be connected with the sucker rod, and the other end of the steel wire rope is connected with the reversing mechanism through the weight basket. The reversing mechanism comprises a fixing rack and a lifting power mechanism arranged on the fixing rack. The lifting power mechanism comprises first front and rear upper-right positioning adjustment chain wheels, second front and rear upper-left positioning adjustment chain wheels, first front and rear lower-right large positioning guiding chain wheels, second front and rear lower-left large positioning guiding chain wheels, first front and rear lower-right small positioning guiding chain wheels and second front and rear lower-left small positioning guiding chain wheels. The single-reversing oil pumping unit has the advantages that since the triangular lifting power mechanism is adopted, the sucker rod can stay for 4-5 seconds when running to the horizontal chains, accordingly the sucker rod can have the time to retract, the oil pumping time is much longer than the non-oil pumping time, the oil pumping efficiency is effectively improved, and the oil pumping quantity is effectively increased.

Owner:董少明

Long plunger oil pump for preventing sand and scale

PendingCN111005860AImprove efficiencyImprove work efficiencyShaking/oscillating/vibrating mixersPositive displacement pump componentsPistonEngineering

The invention discloses a long plunger oil pump for preventing sand and scale, and particularly relates to the field of oil pumps. The long plunger oil pump comprises an outer barrel. An oil outflow barrel is fixedly mounted on the top of the outer barrel, an oil outflow valve is fixedly mounted in the oil outflow barrel, the oil outflow valve is fixedly sleeved with a top protective sleeve, the outer barrel is fixedly sleeved with a sand separating box located below the oil outflow valve, a long plunger located below the oil outflow valve is fixedly mounted in the outer barrel, the middle ofthe long plunger is fixedly sleeved with a plug cone, the upper end and the lower end of the long plunger are fixedly sleeved with stirring assemblies, and the bottom of the long plunger is fixedly sleeved with a lower oil outflow valve. In the actual operation process, when the oil outflow valve descends, a piston sleeve is stored inwards through air pressure, thus, leak holes are formed, at themoment, sticky oil and gravel located at the bottom are rapidly discharged, the gravel is finally removed from the positions where the amount of the gravel is maximal, and it is guaranteed that the oil pump runs normally.

Owner:大庆喜利科技有限公司

Supercharger and centrifugal vacuum oil purifier using the supercharger

ActiveCN103603831BReduce oil suction negative pressureImprove working environmentJet pumpsMachines/enginesJet flowTurbocharger

Owner:TIANJIN YIOU MACHINERY MFG CO LTD

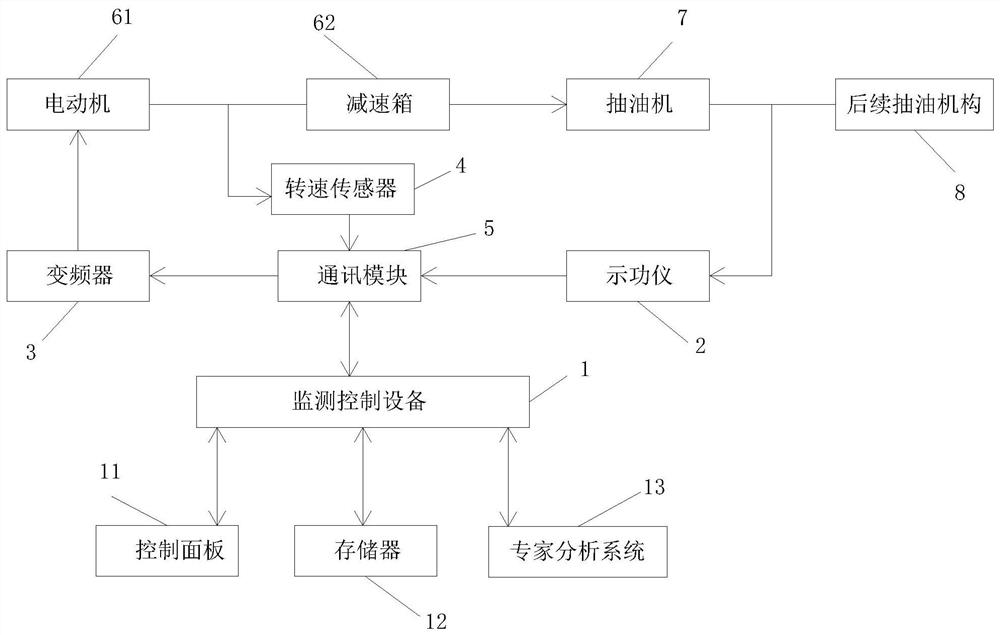

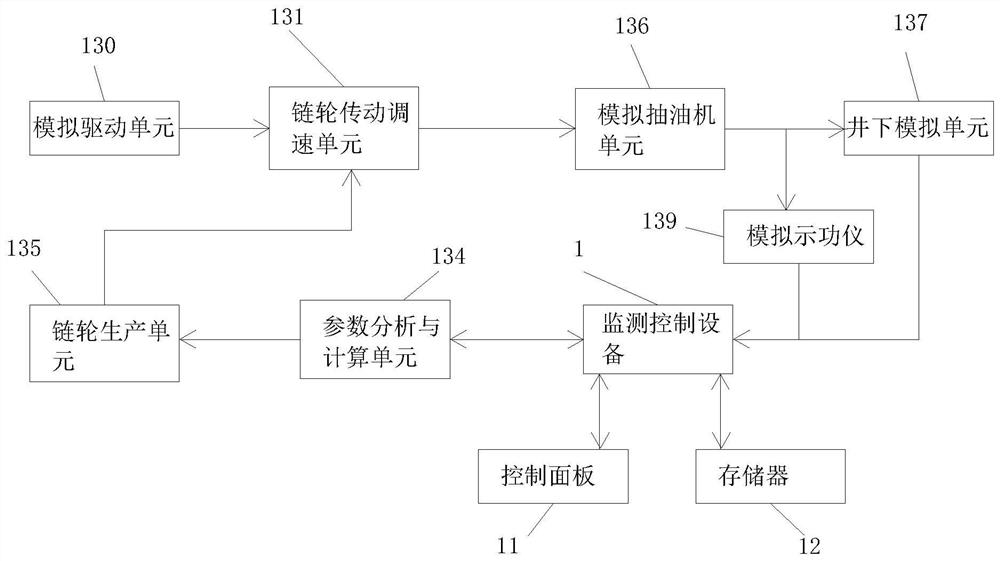

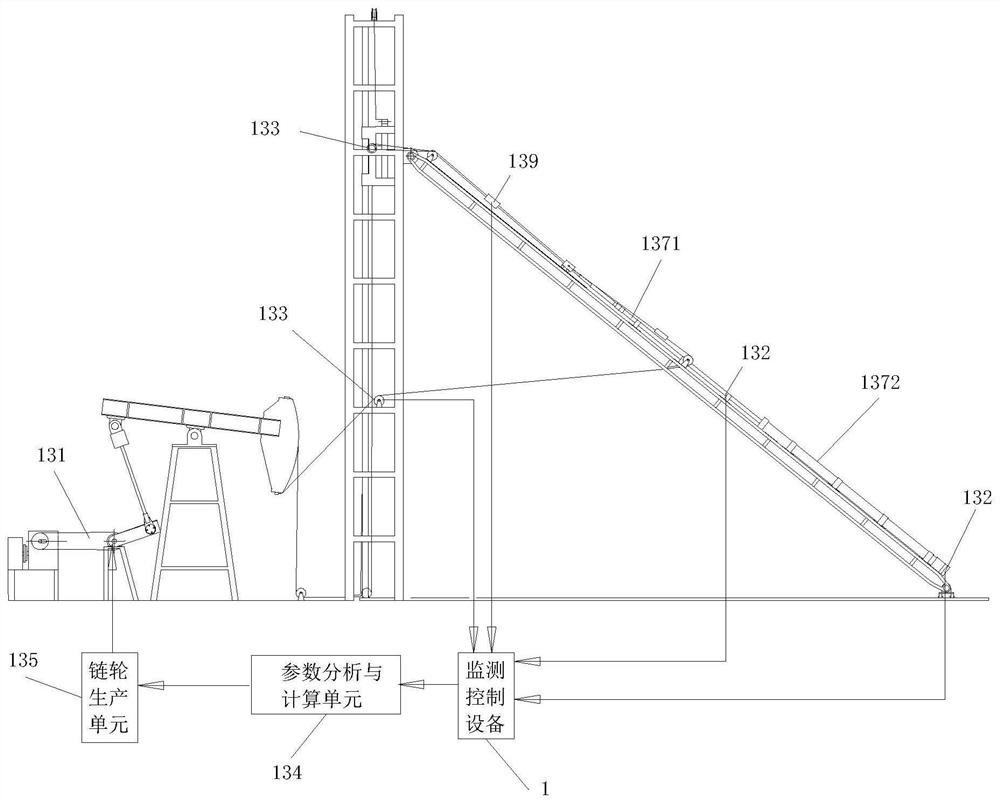

A pumping drive control and detection analysis device based on adaptive analysis

ActiveCN110617038BExtend your lifeImprove oil pumping efficiencyConstructionsFlexible member pumpsMotor driveTransverter

The invention relates to a pumping drive control and detection and analysis device based on self-adaptive analysis, comprising: monitoring and control equipment, a dynamometer, a frequency converter, a rotational speed sensor and a communication module; the monitoring and control equipment and the communication module are connected to each other, and the communication module The output end of the pumping unit is connected to the inverter, drive unit, pumping unit, and dynamometer in turn, and then connected to the input end of the communication module. The drive unit is also connected to the communication module through a speed sensor, and the pumping unit is also connected to the subsequent pumping mechanism for monitoring and control. The equipment includes a control panel, a memory and an expert analysis system; the present invention utilizes the expert analysis system to simulate and analyze the power conditions of the pumping unit obtained on the spot, the production capacity conditions of the oil well, etc., and obtain the optimal driving law curve of the pumping unit motor, thereby Adaptively change the driving mode of the pumping unit motor to achieve flexible control, so that it can match the working conditions of the oil wells on site, improve pumping efficiency, reduce pumping consumption, and increase the life of the pumping system.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com