A pumping drive control and detection analysis device based on adaptive analysis

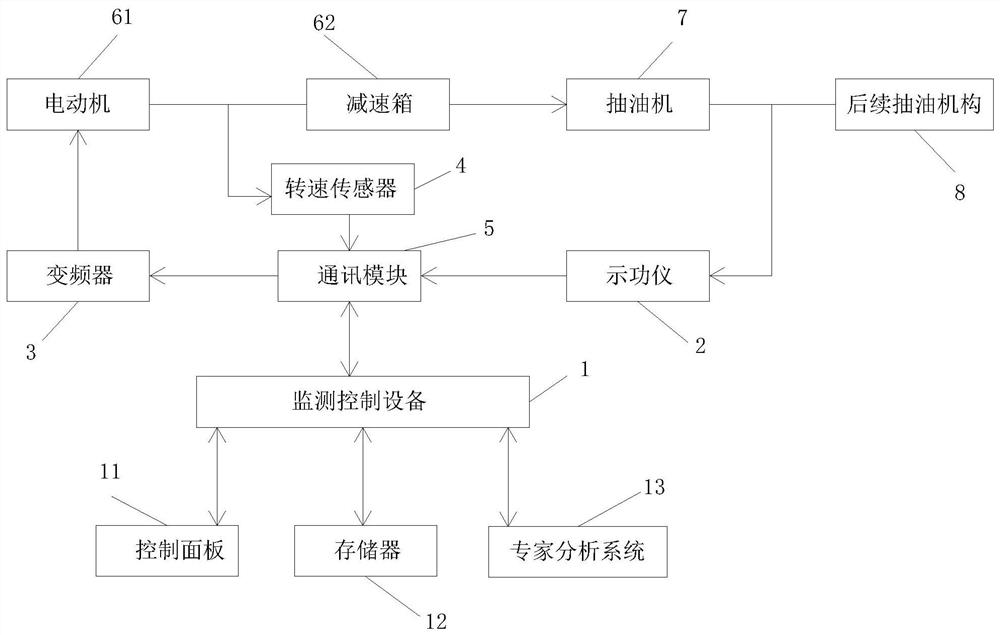

A drive control and analysis device technology, applied in transmission devices, measuring devices, mechanical measuring devices, etc., can solve the problem of not clearly adapting to the driving law curve, etc., and achieve the goal of reducing oil consumption, improving oil pumping efficiency, and increasing life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

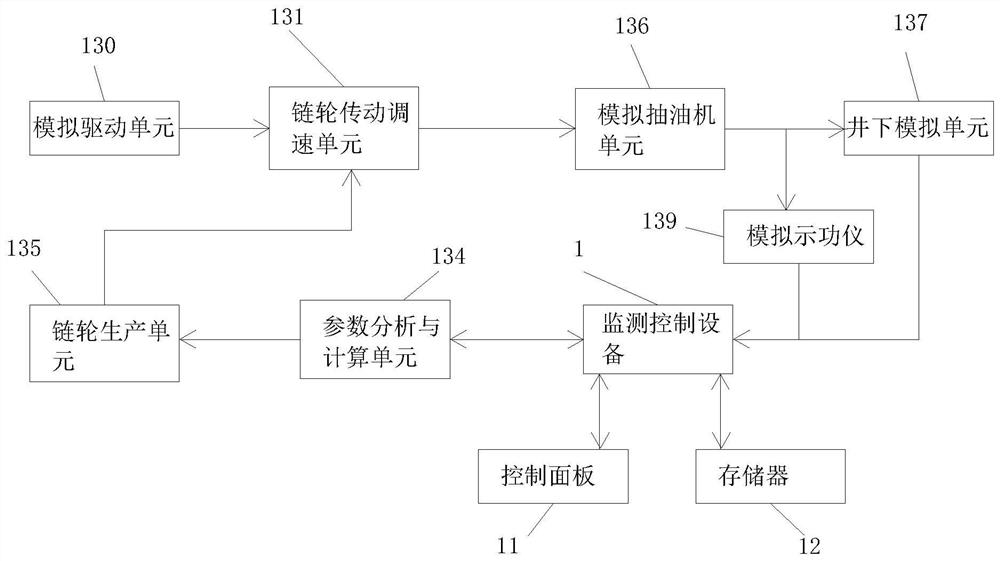

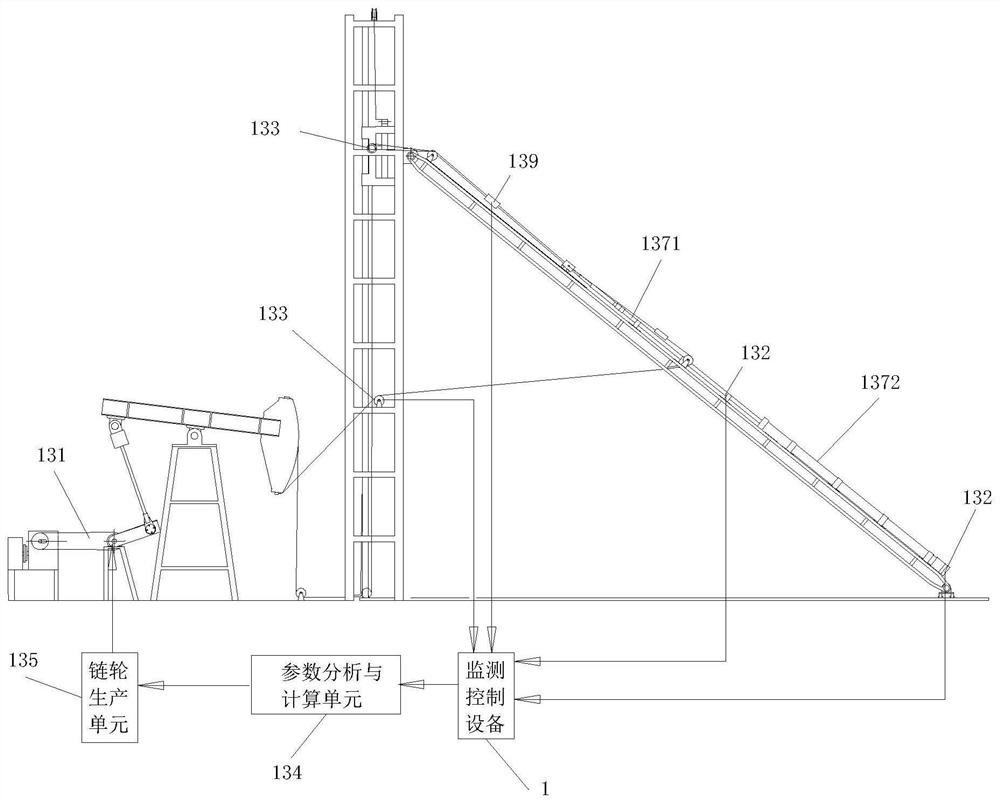

[0030] Embodiment 1: as Figure 7 as shown, Figure 7 The medium simulation device includes a simulation drive unit, a sprocket transmission speed control unit, a simulation pumping unit, a downhole simulation unit and a simulation dynamometer; taking Well X in Jiangsu Oilfield as an example, the stroke is 2.86 meters, the stroke frequency is 2.8, and the pump diameter is 31 mm, the pump depth is 1601.80 meters, the maximum load is 48.73kN, the minimum load is 21.96kN, and the daily liquid production volume is 2.99 cubic meters. When the oil well system is running, the dynamometer diagram is obtained through the dynamometer. The dynamometer diagram is input into the monitoring and control equipment of the expert system, and the profile of the driven sprocket is elliptical through the parameter analysis and calculation unit. Therefore, the long-short axis ratio of the driven elliptical sprocket is 2:1, and the rotation center is the long axis. The upper bias, the gear ratio o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com