Pumping aid device

A sucker rod and centralizer technology, applied in the field of pumping aids, can solve problems such as leakage and large oil leakage, and achieve the effects of ensuring normal operation, prolonging life, and uniform stress and wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

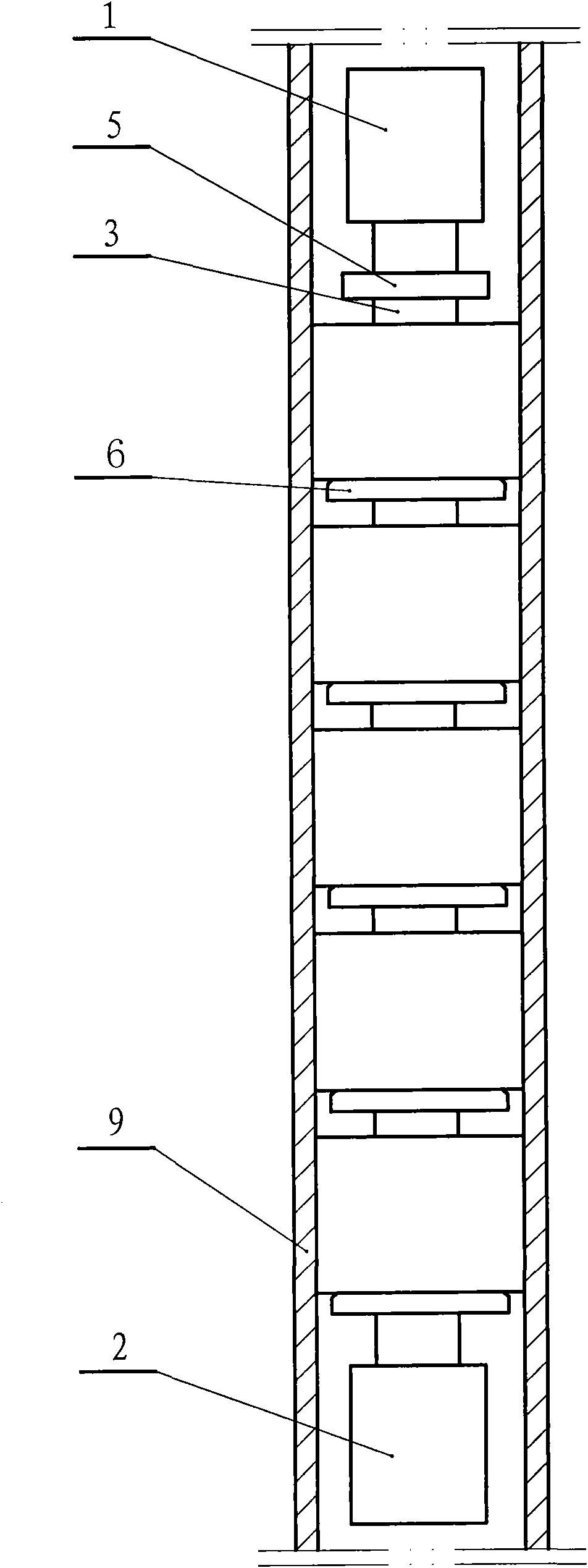

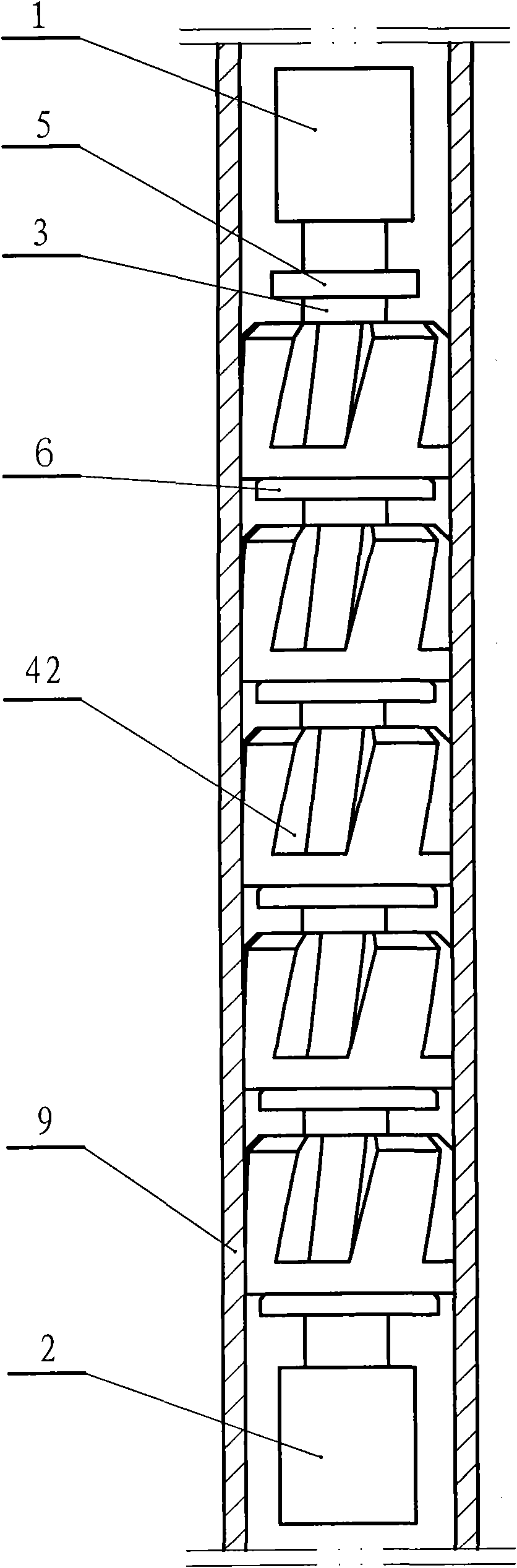

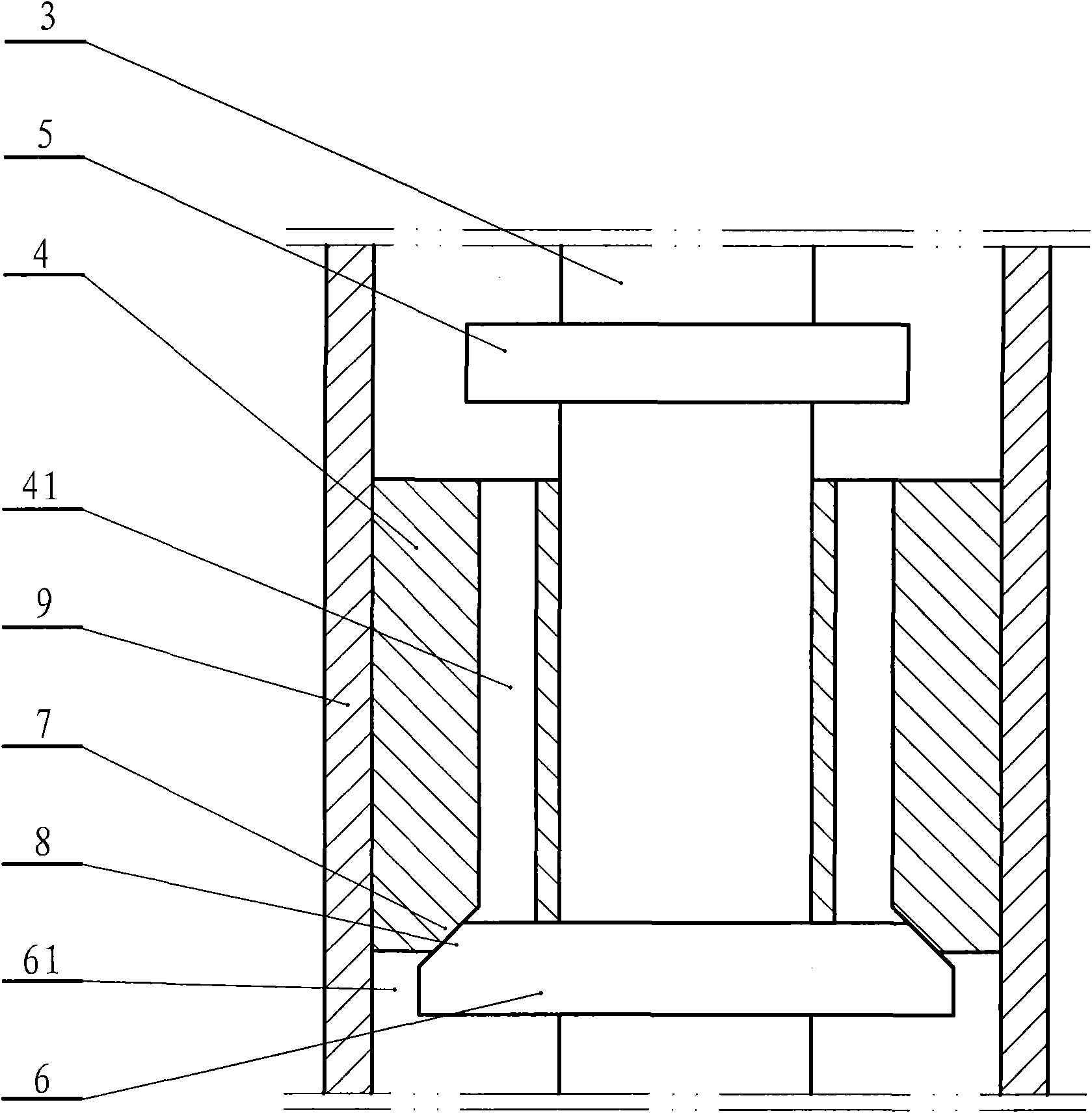

[0032] The pumping aid of the present invention has the structure as attached figure 1 As shown, the sucker rod centralizer is included. The upper and lower ends of the sucker rod centralizer are respectively provided with an upper end connecting device 1 and a lower end connecting device 2 that are compatible with the sucker rod, and a core is provided along the axis of the sucker rod centralizer. The shaft 3 and the core shaft 3 are axially sleeved with a plurality of sliding valve sleeves 4 of tubular structure. The inner surface of the sliding valve sleeve 4 is in sliding connection with the outer surface of the mandrel 3, and the outer surface of the sliding valve sleeve 4 is in sliding connection with the inner surface of the oil well casing 9, and the mandrel 3 above the upper end of each sliding valve sleeve 4 There is an upper baffle ring 5 fixedly connected to the mandrel 3 and having a diameter smaller than the inner diameter of the oil well casing. A sliding valve sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com