Patents

Literature

1084 results about "Central spindle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The central spindle is a microtubule based structure, which forms in between segregating chromosomes during anaphase where the two sets of microtubules, emanating from opposite halves of the cell, overlap, and become arranged into antiparallel bundles by various microtubule associated proteins (MAPs) and motor proteins. The central spindle is widely regarded as a key regulating center for cytokinesis, recruiting proteins for successful cleavage furrow positioning and membrane abscission. For these important roles to be achieved successfully the central spindle has to be carefully regulated to control the size of the overlap region, the alignment of those overlaps and the overall length and symmetry of the structure. Without this regulation, signaling faults in cytokinesis can occur, resulting in unequal chromosome segregation or polyploid cells, greatly increasing the risk of cancer.

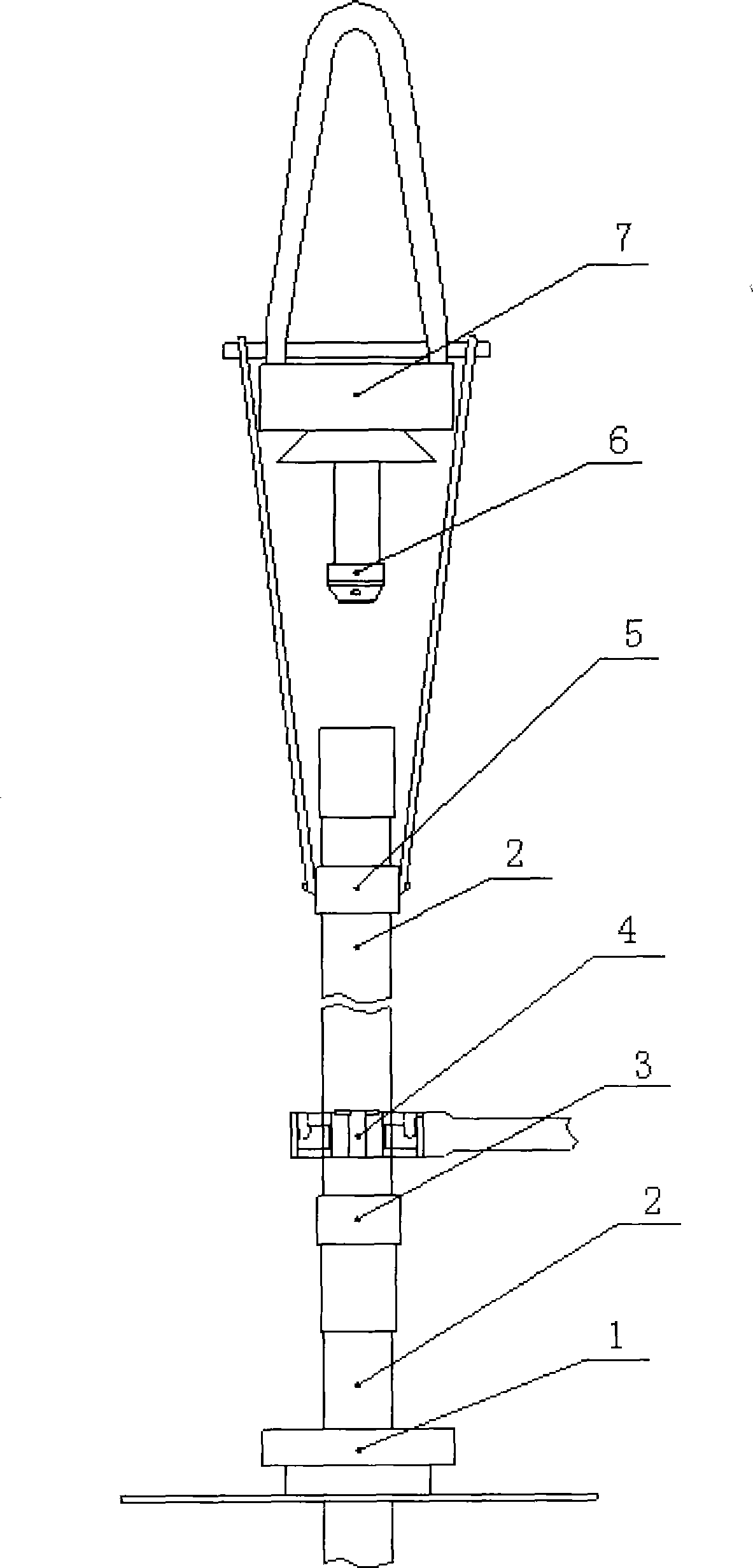

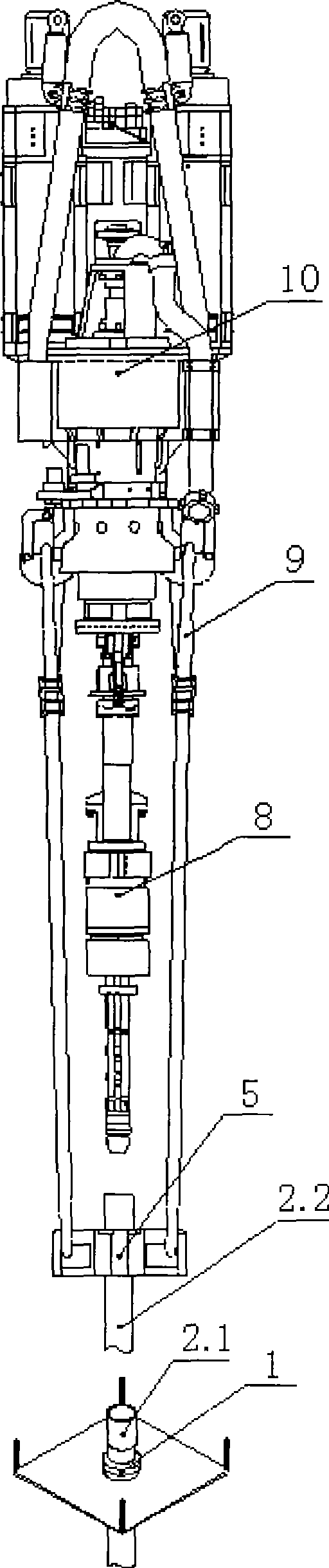

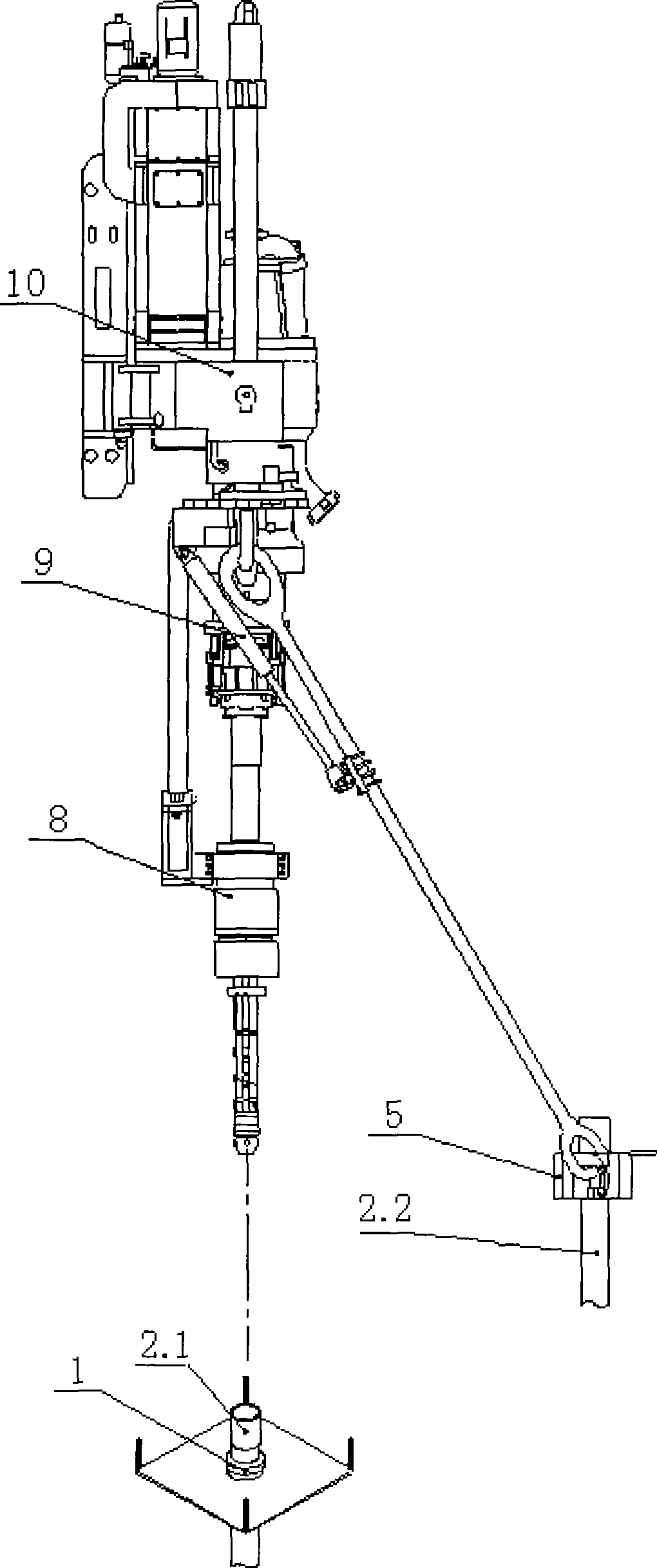

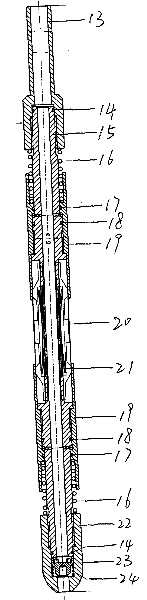

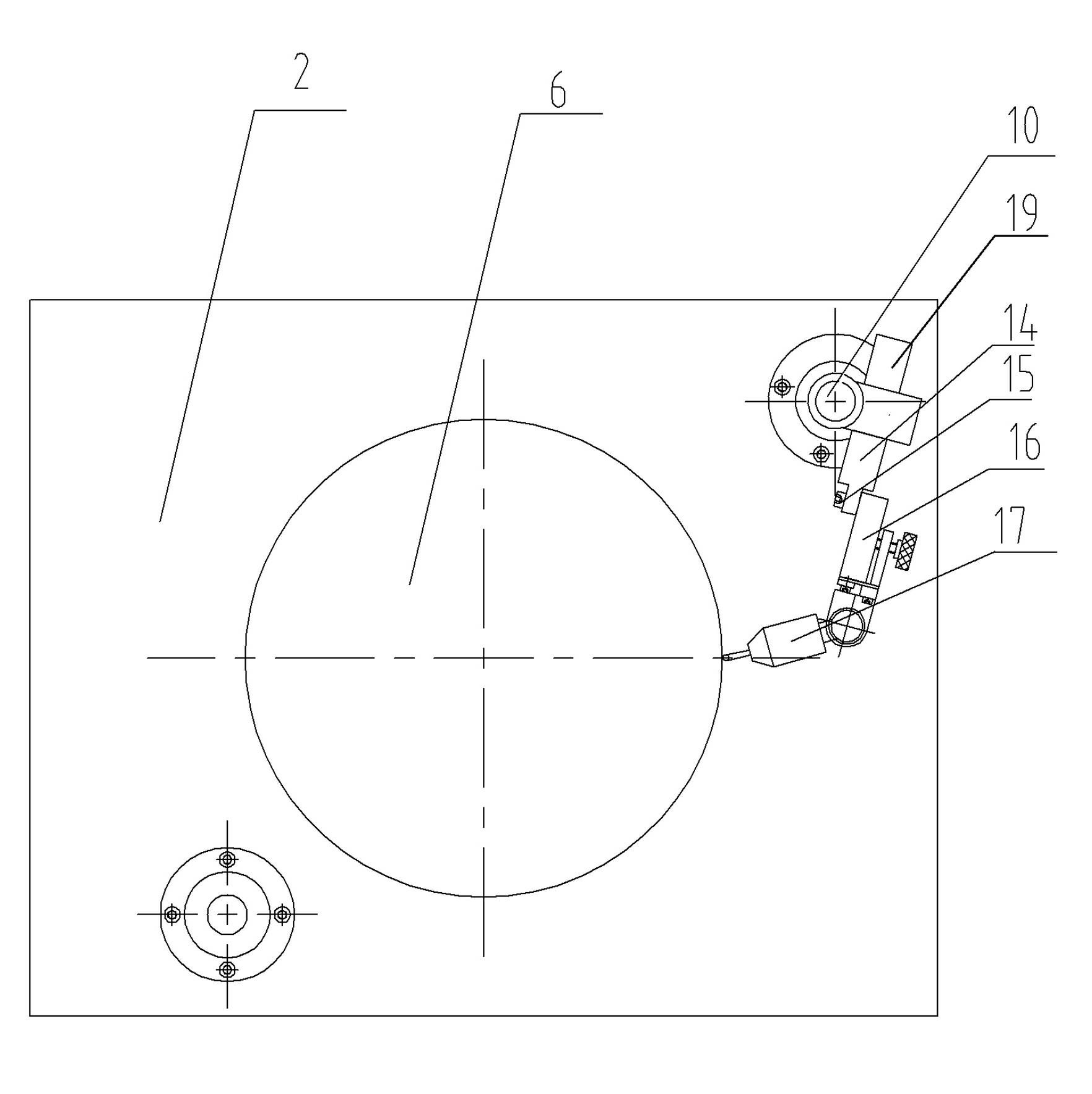

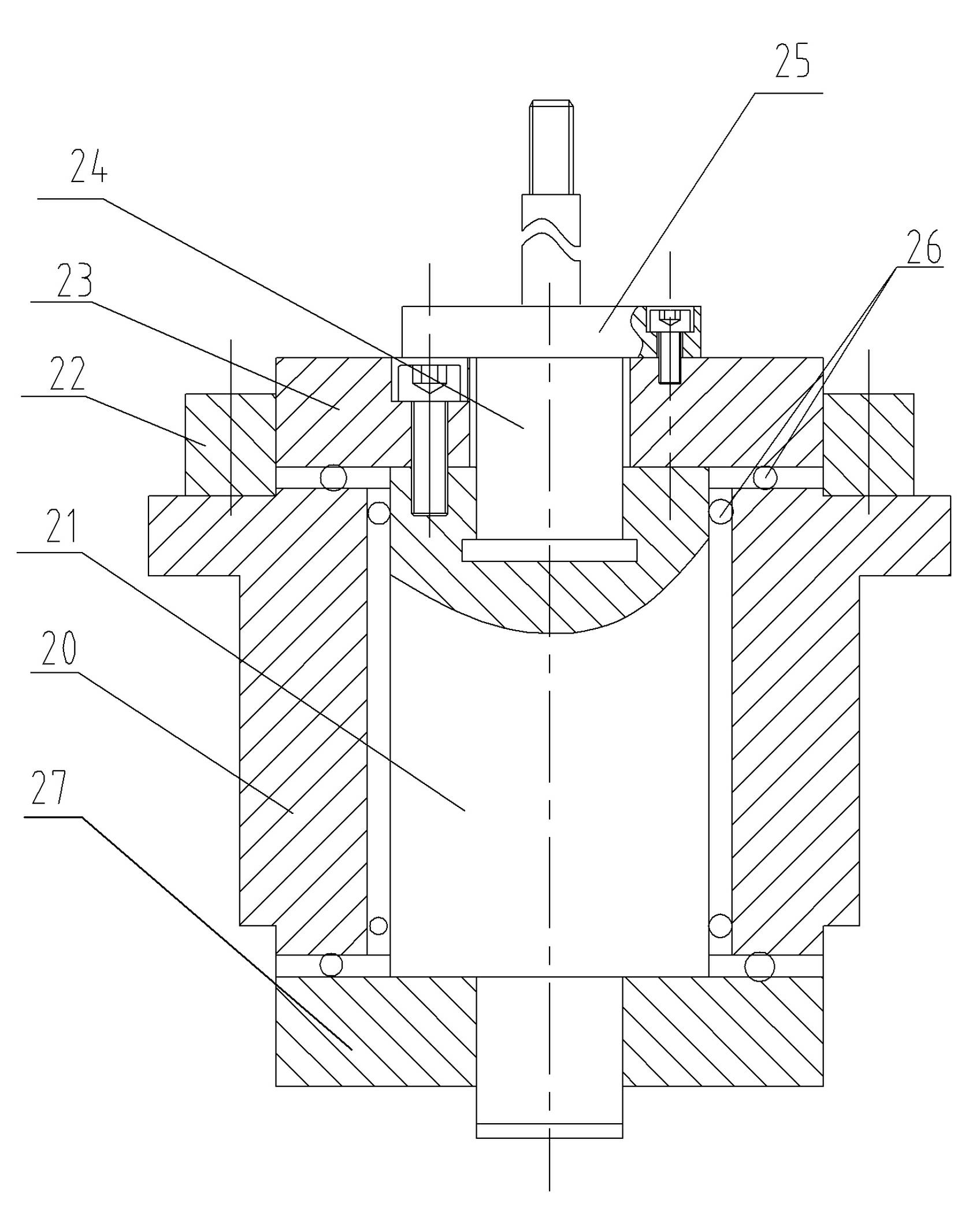

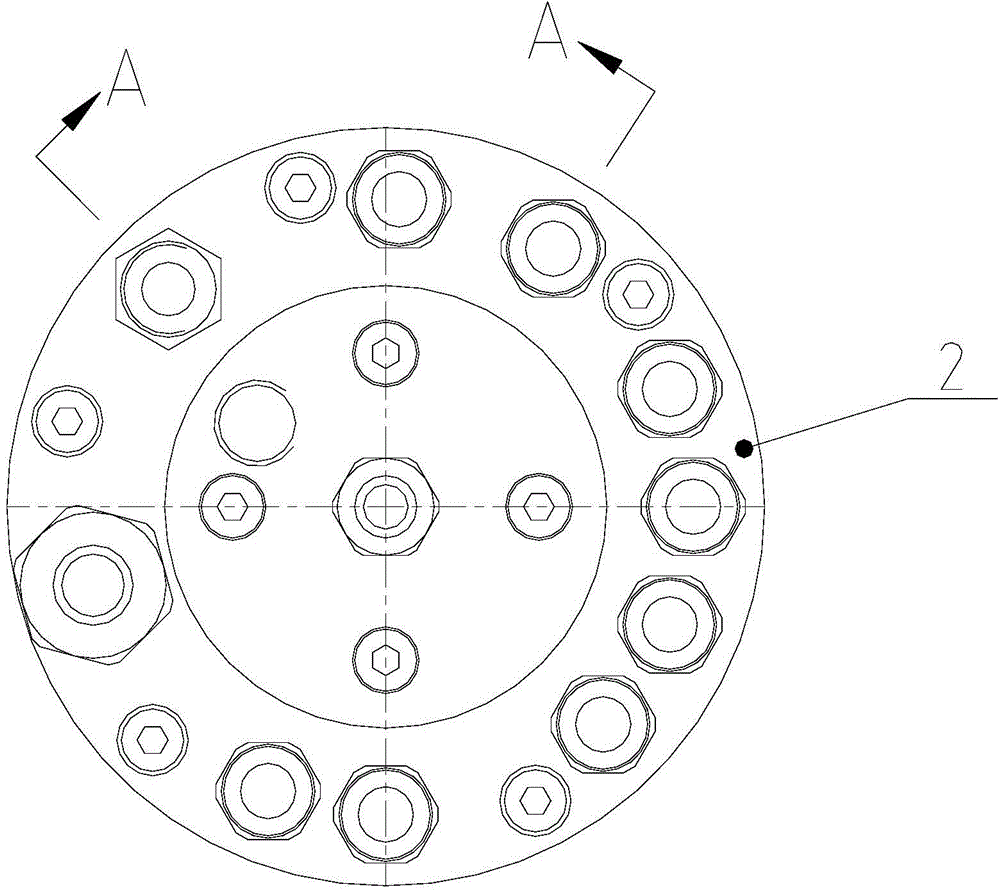

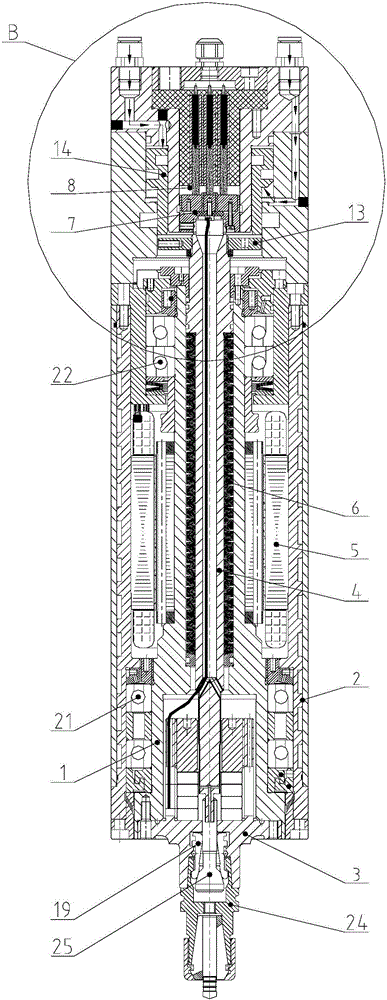

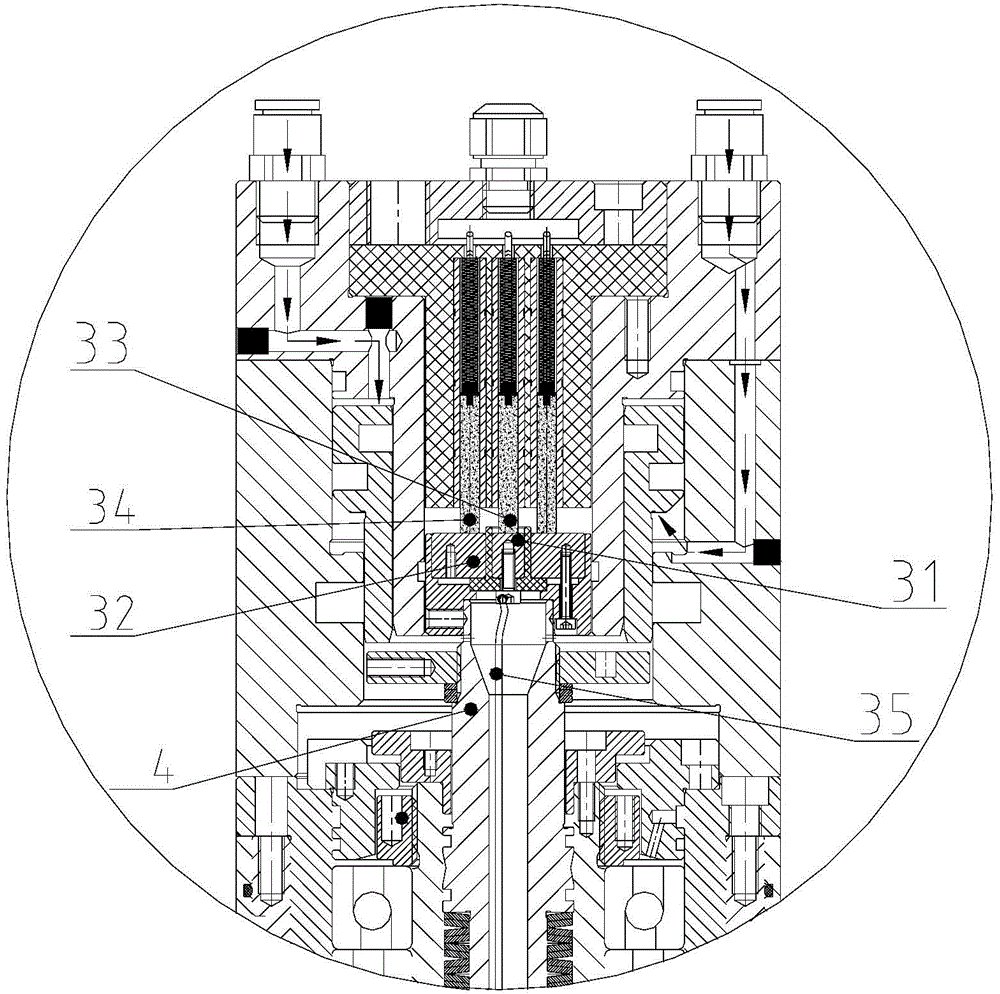

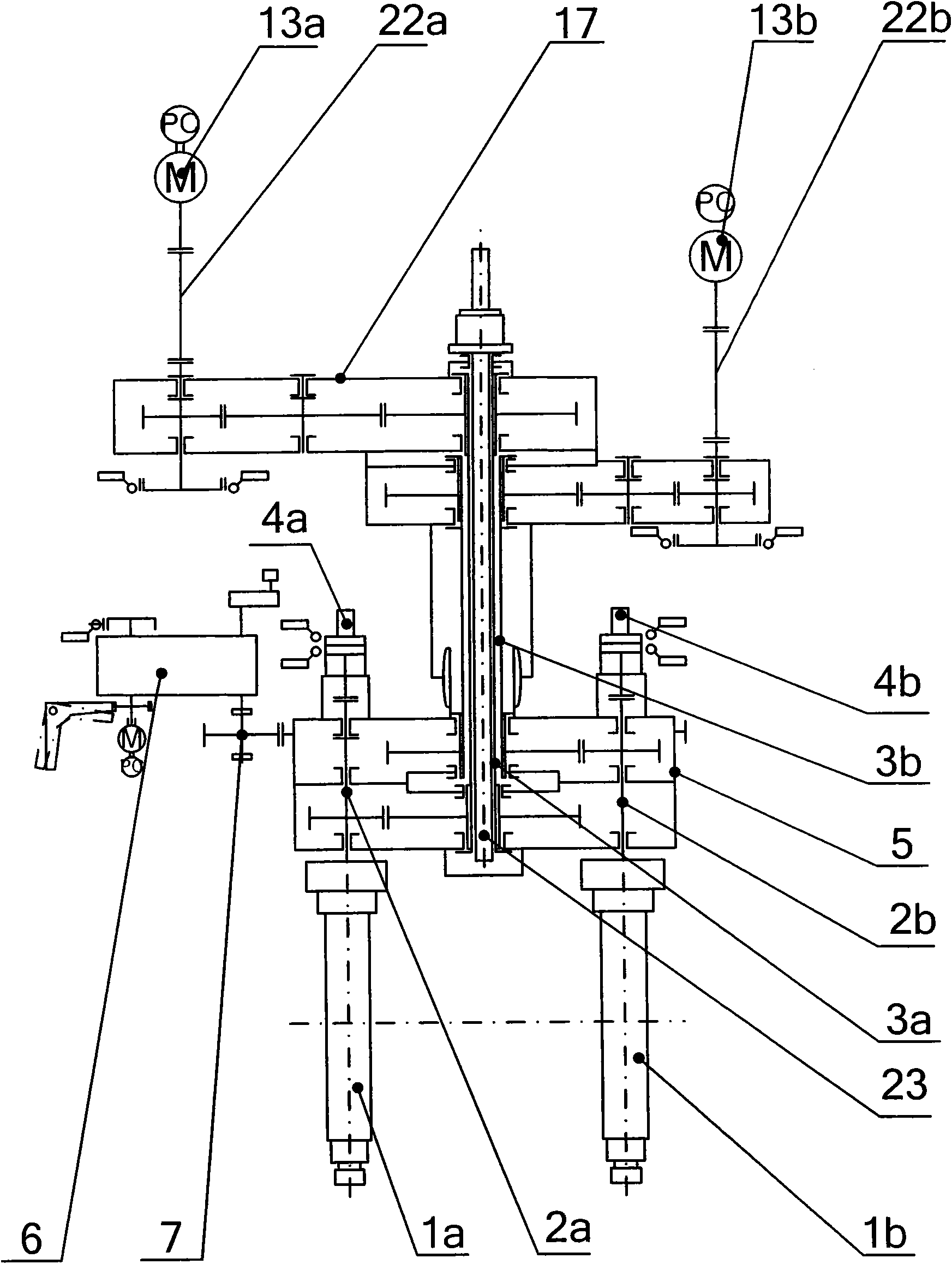

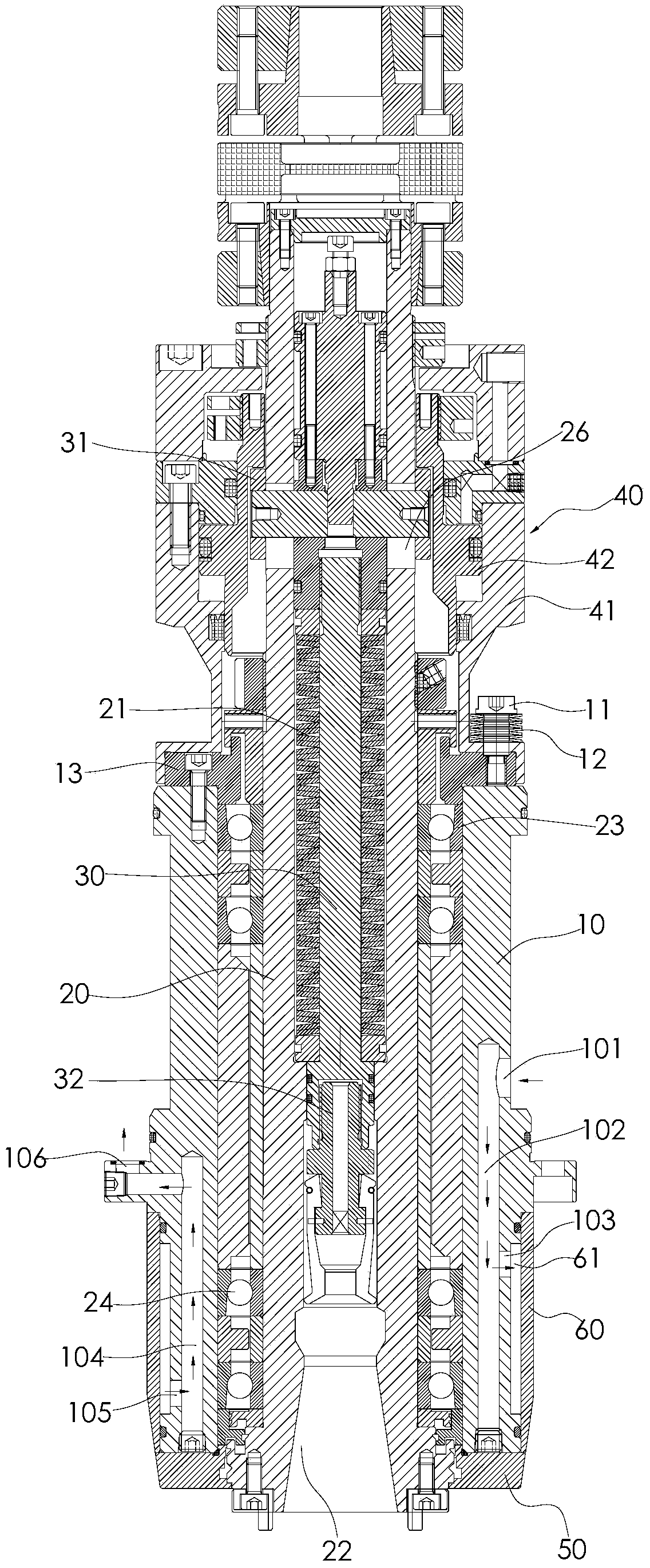

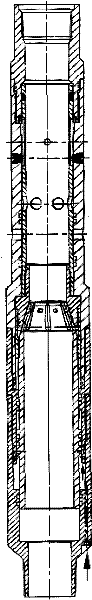

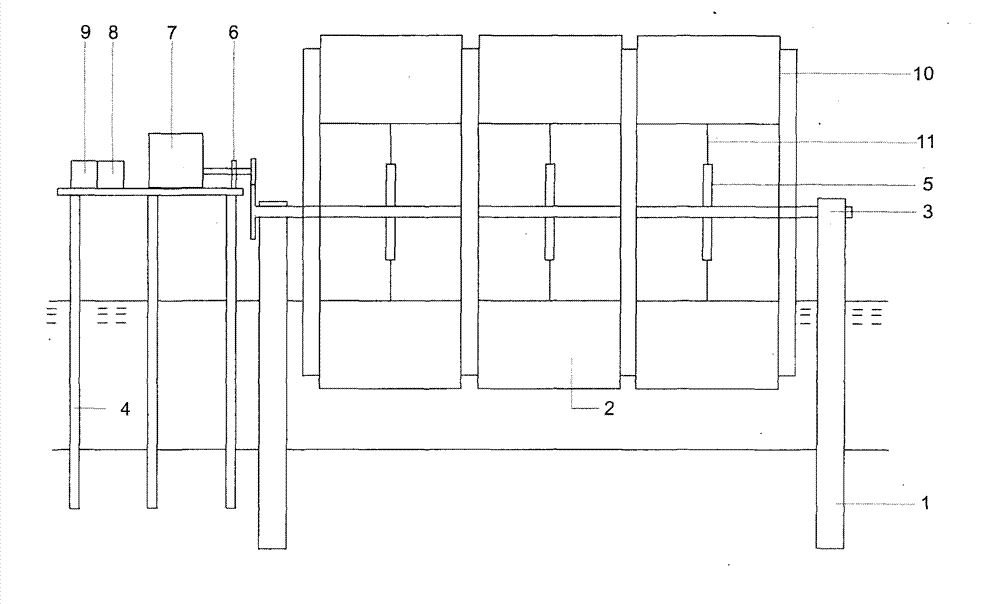

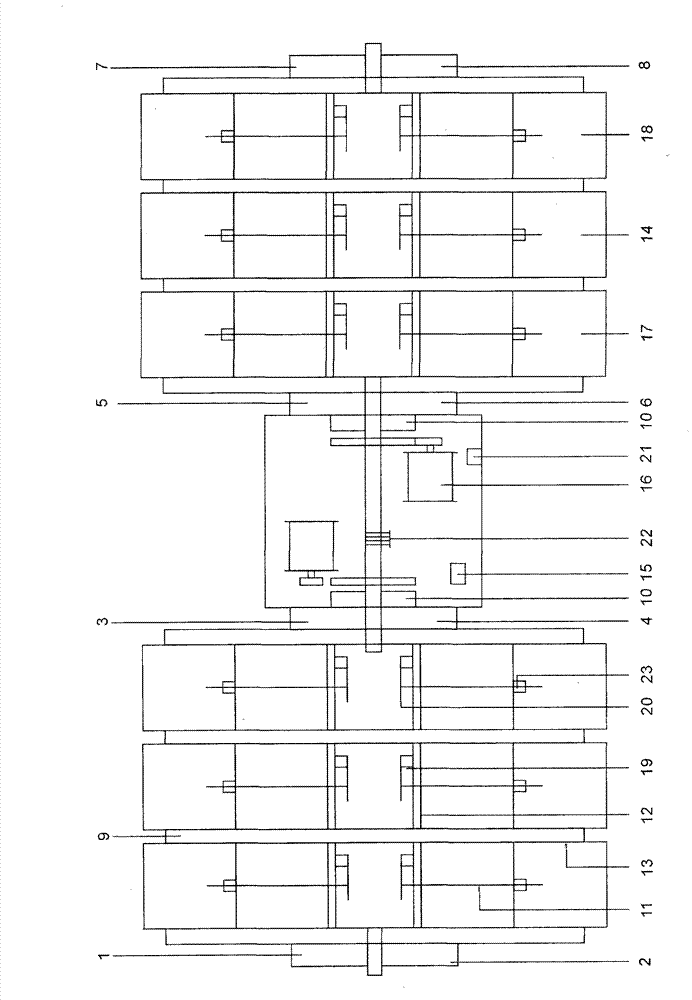

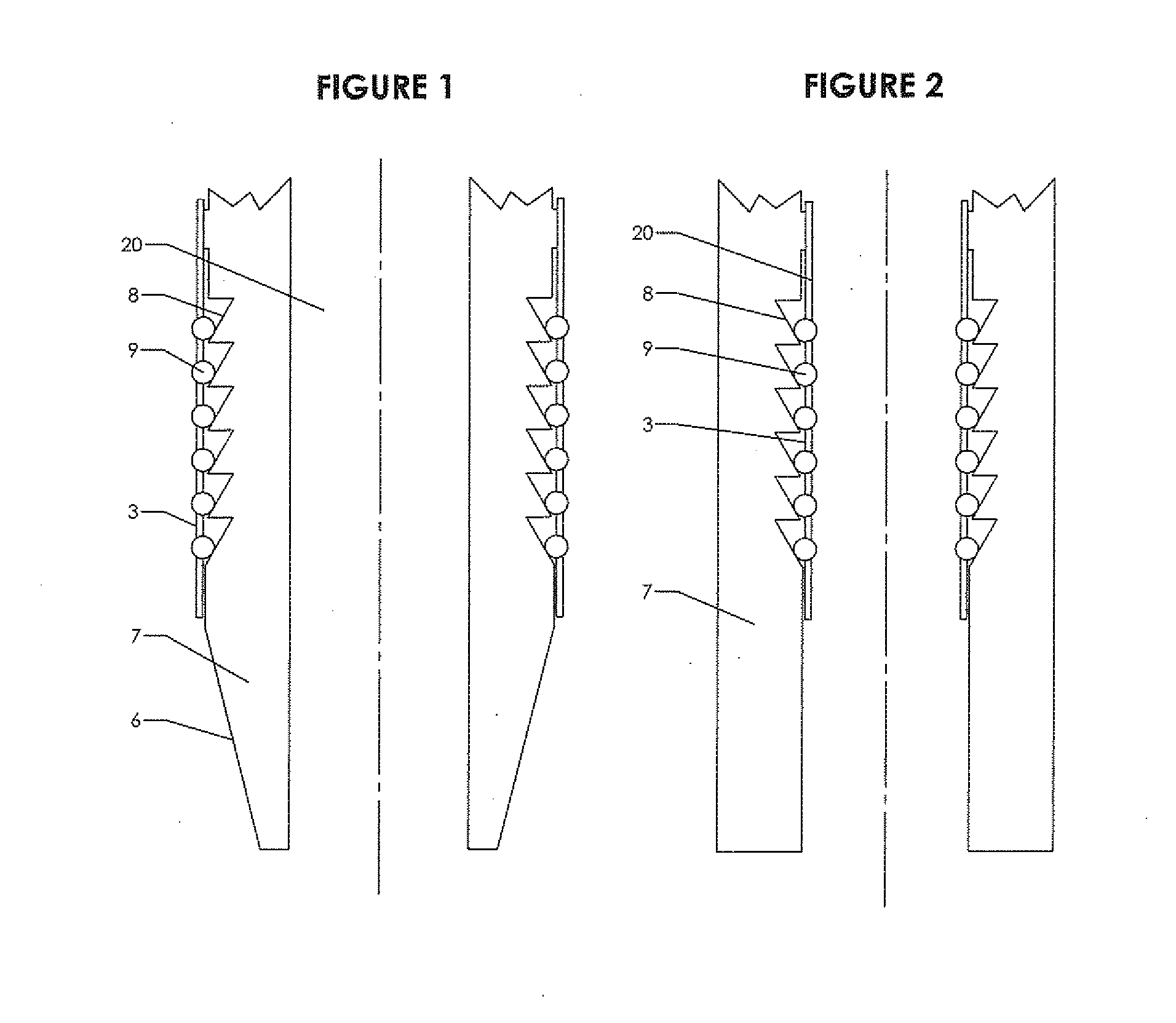

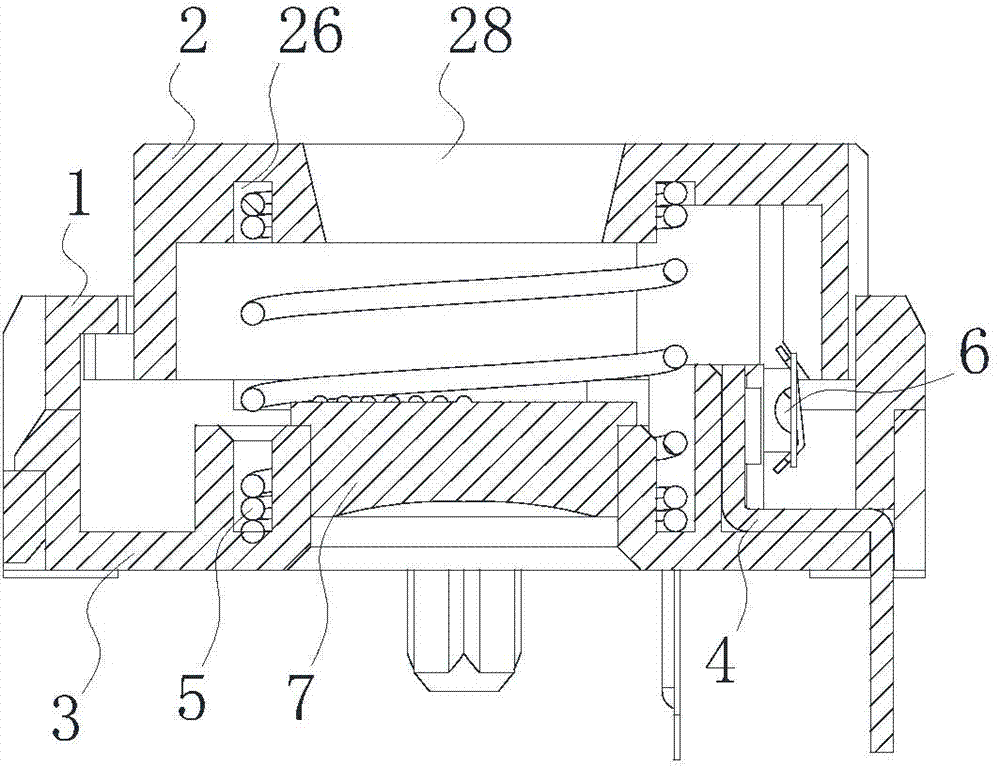

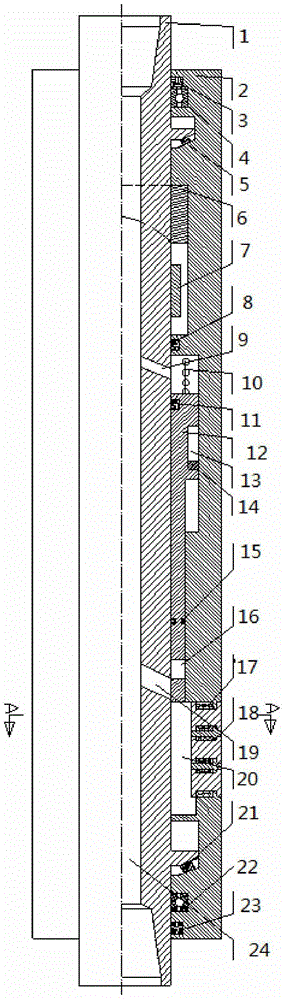

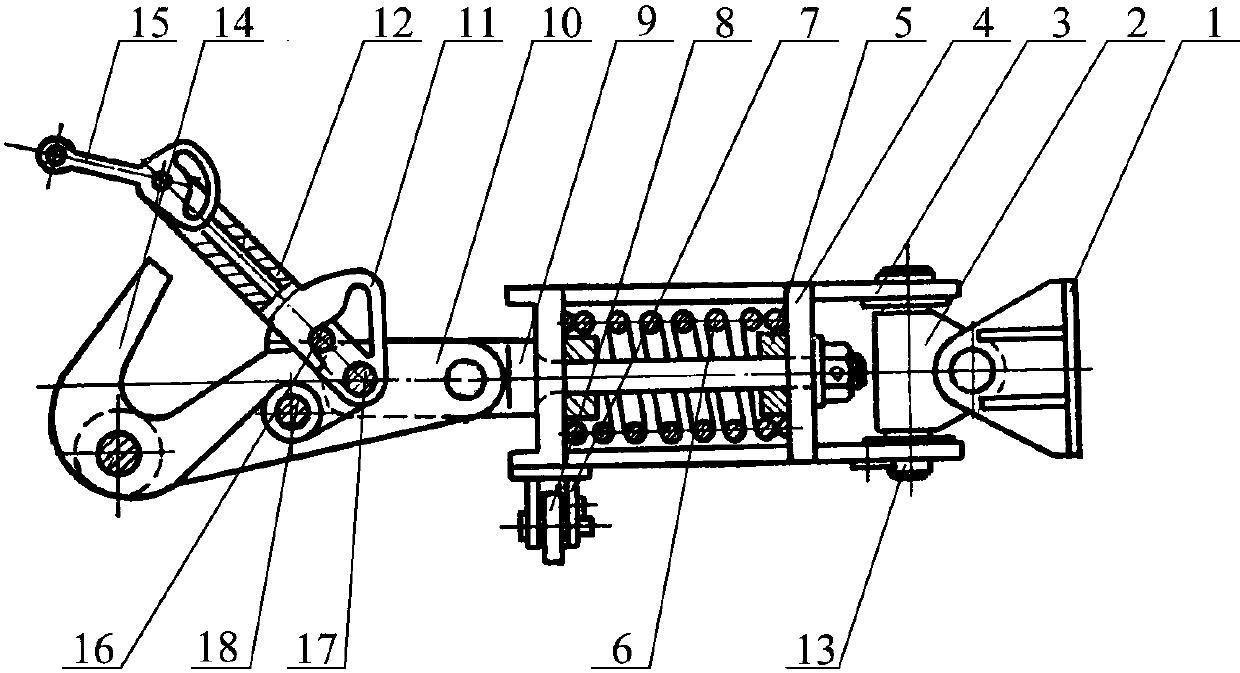

Micromanipulator for enterocoelia minimally invasive surgery

InactiveCN101732093ACompensation errorReduce mechanical structureDiagnosticsSurgical robotsMini invasive surgeryAbdominal cavity

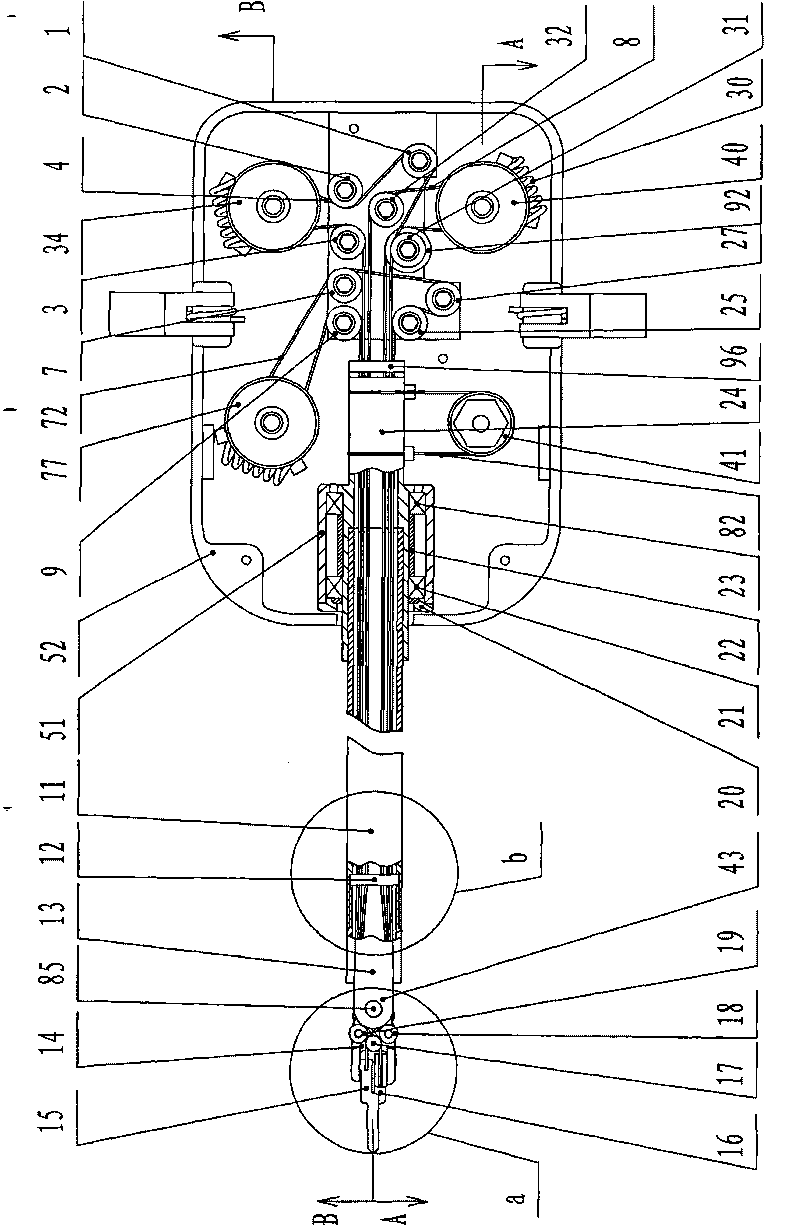

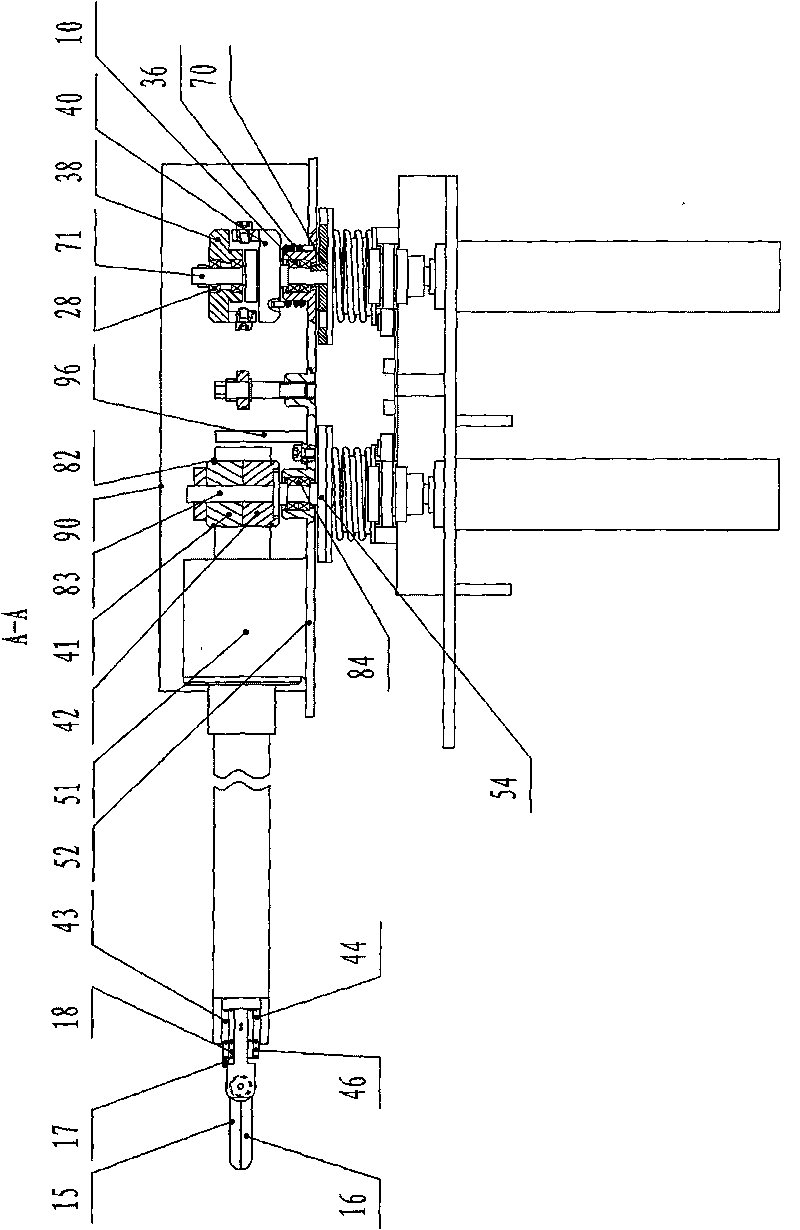

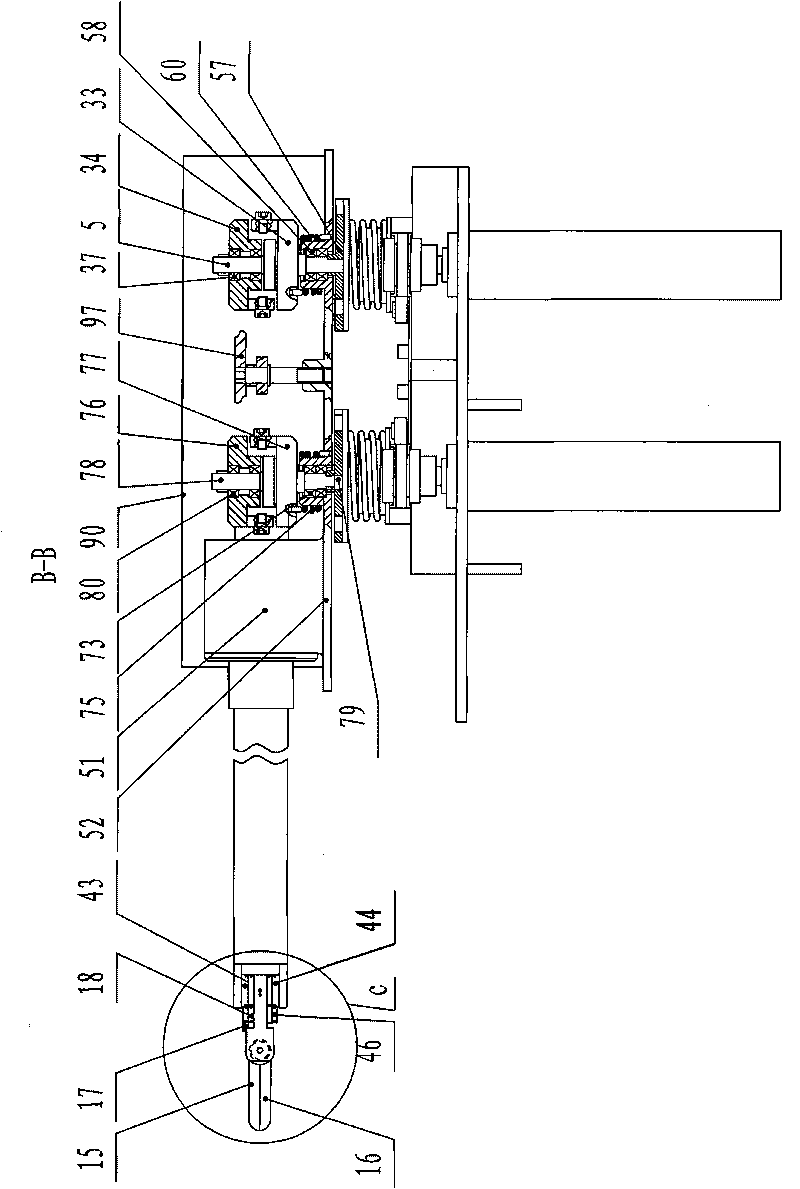

The invention discloses a micromanipulator for enterocoelia minimally invasive surgery, relating to a micromanipulator for minimally invasive surgery. The invention solves the problem of the shortage of micromanipulators in surgical equipment of existing enterocoelia minimally invasive surgery. In the invention, a lower clutch dial is installed on the upper end face of a tooth-form central spindle of a driving box, an upper-finger upper clutch dial of a traction mechanism of the upper finger at the tail end of the surgical equipment is contacted with a corresponding lower clutch dial of the driving box; a lower-finger upper clutch dial of the traction mechanism of the upper finger at the tail end of the surgical equipment is contacted with the corresponding lower clutch dial of the driving box; a wrist upper clutch dial of the traction mechanism of the wrist at the tail end of the surgical equipment is contacted with the corresponding lower clutch dial of the driving box; and an autorotation upper clutch dial of an autorotation mechanism at the tail end of the surgical equipment is contacted with the corresponding lower clutch dial of the driving box. The micromanipulator of the invention is convenient for rapidly exchanging surgery tools, thereby increasing the nimbleness of surgery action, and meeting the requirements in various aspects such as size, function and clamping force an the like on the micromanipulator, thus being applicable to enterocoelia minimally invasive surgery.

Owner:HARBIN INST OF TECH

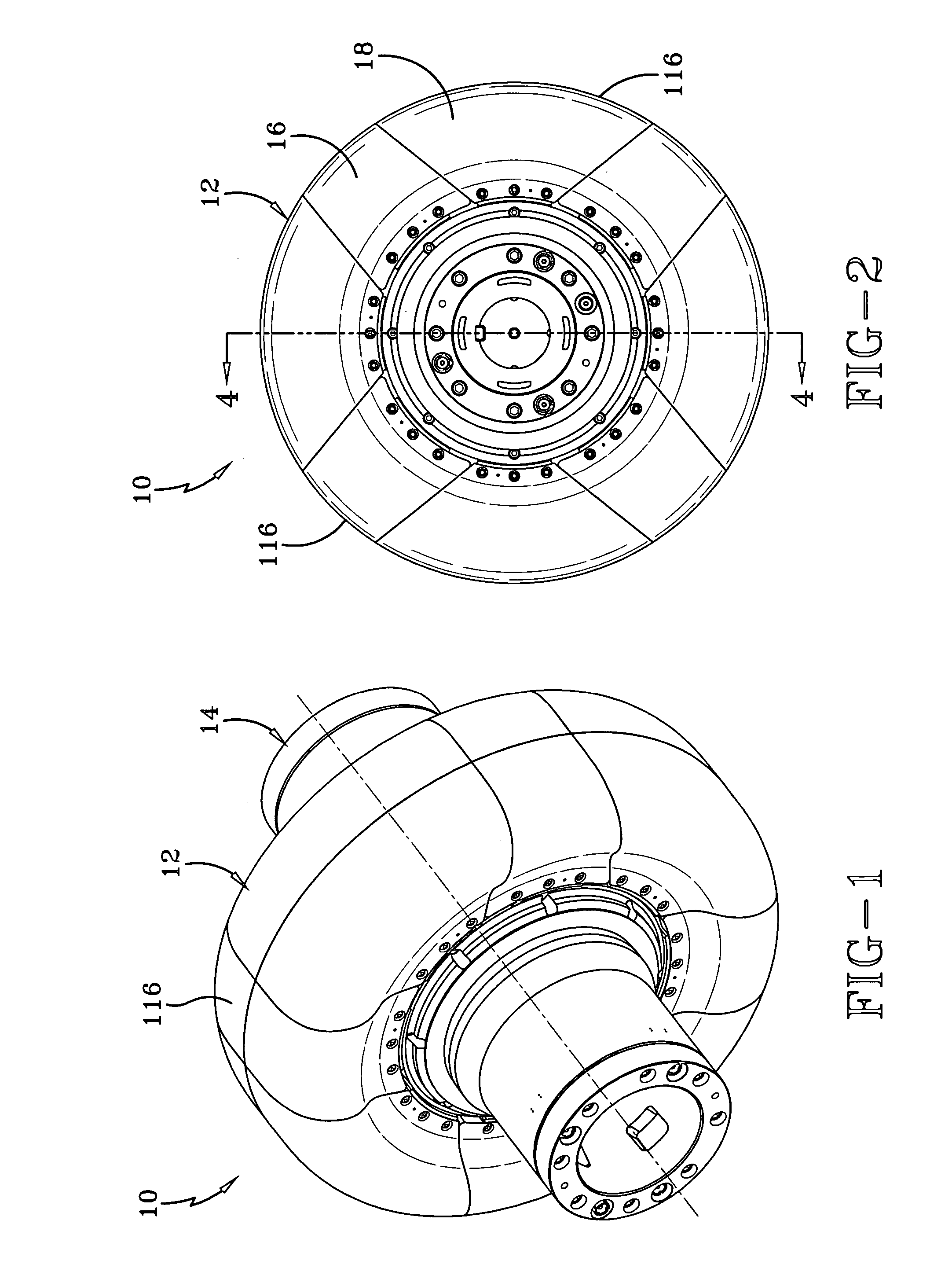

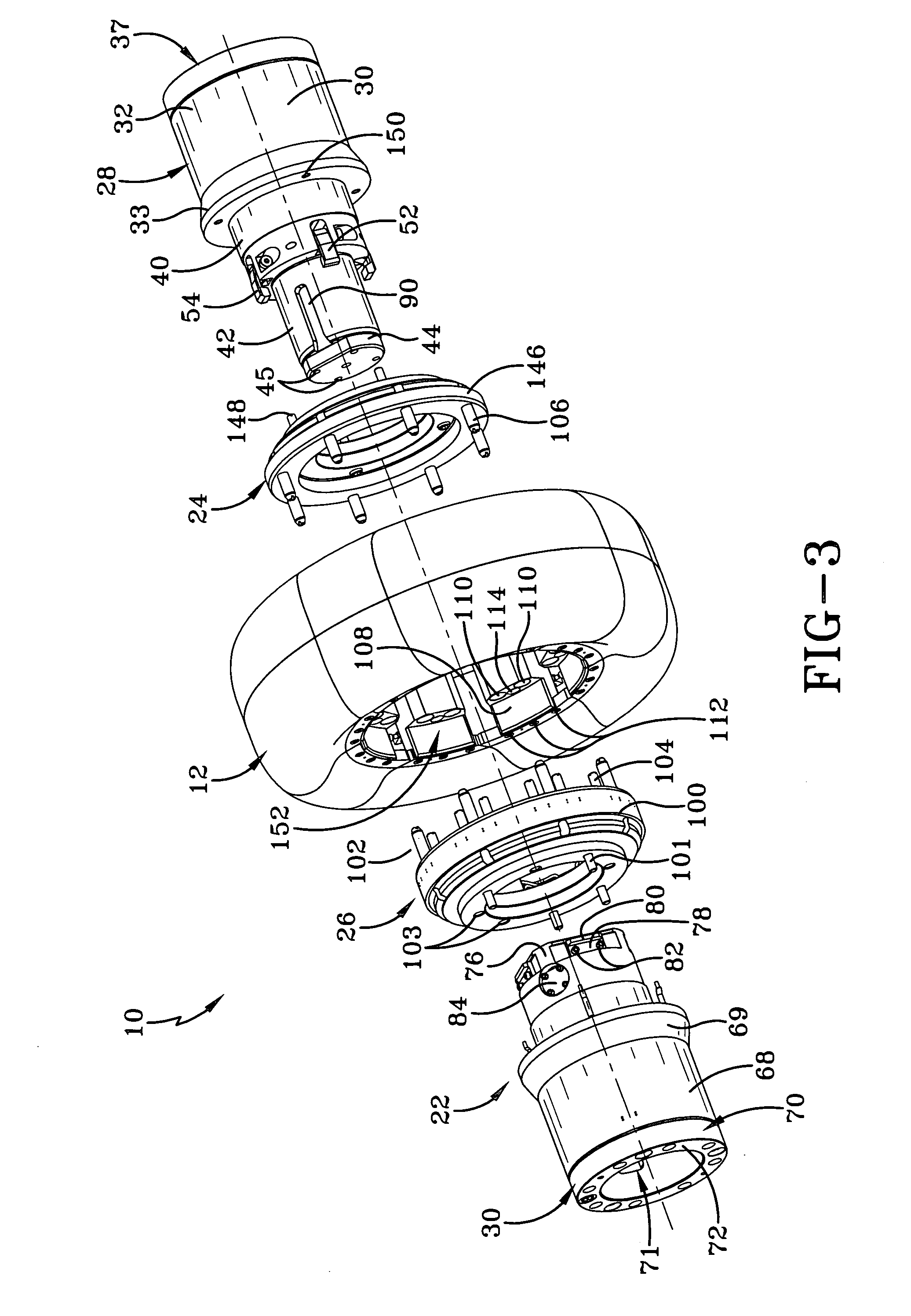

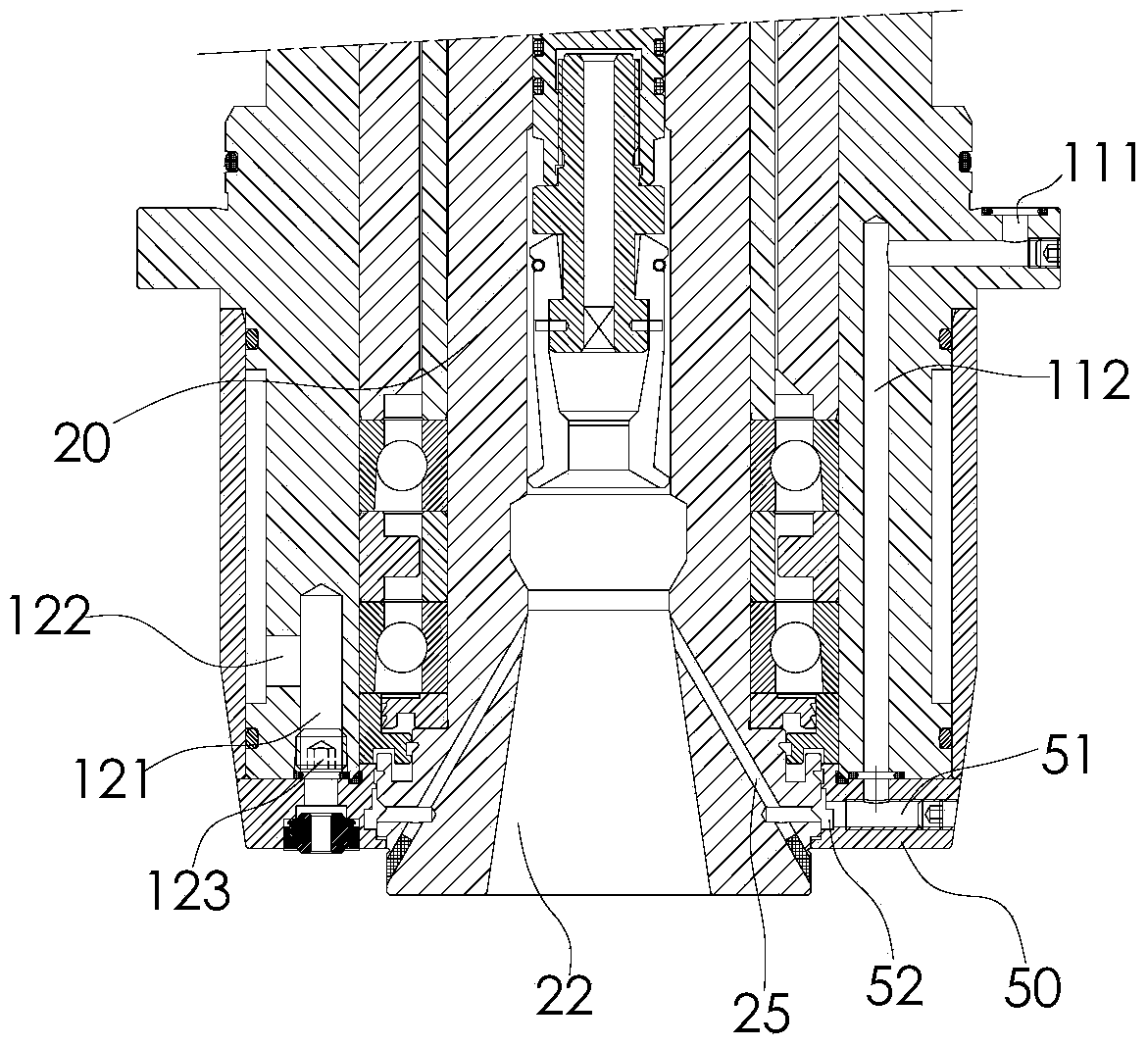

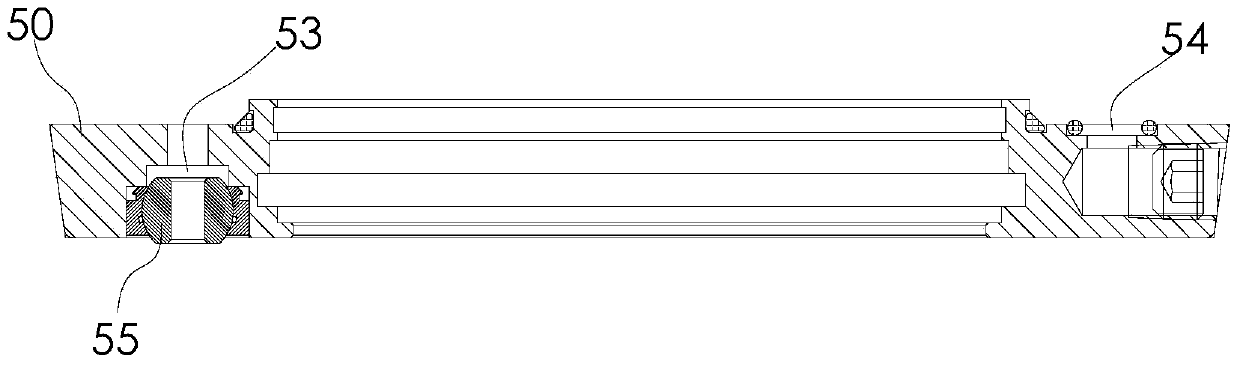

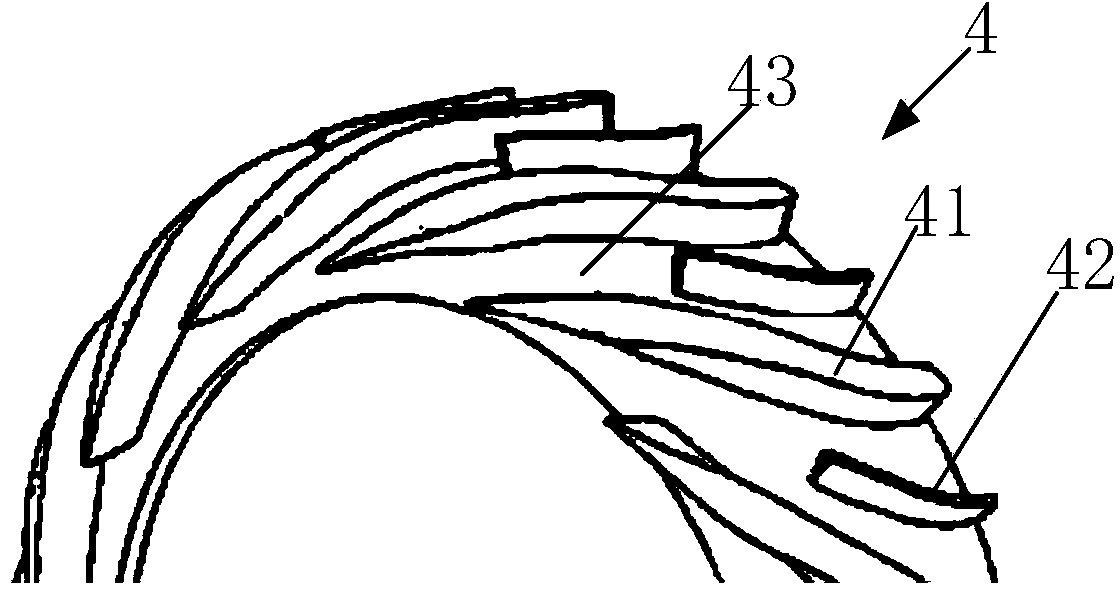

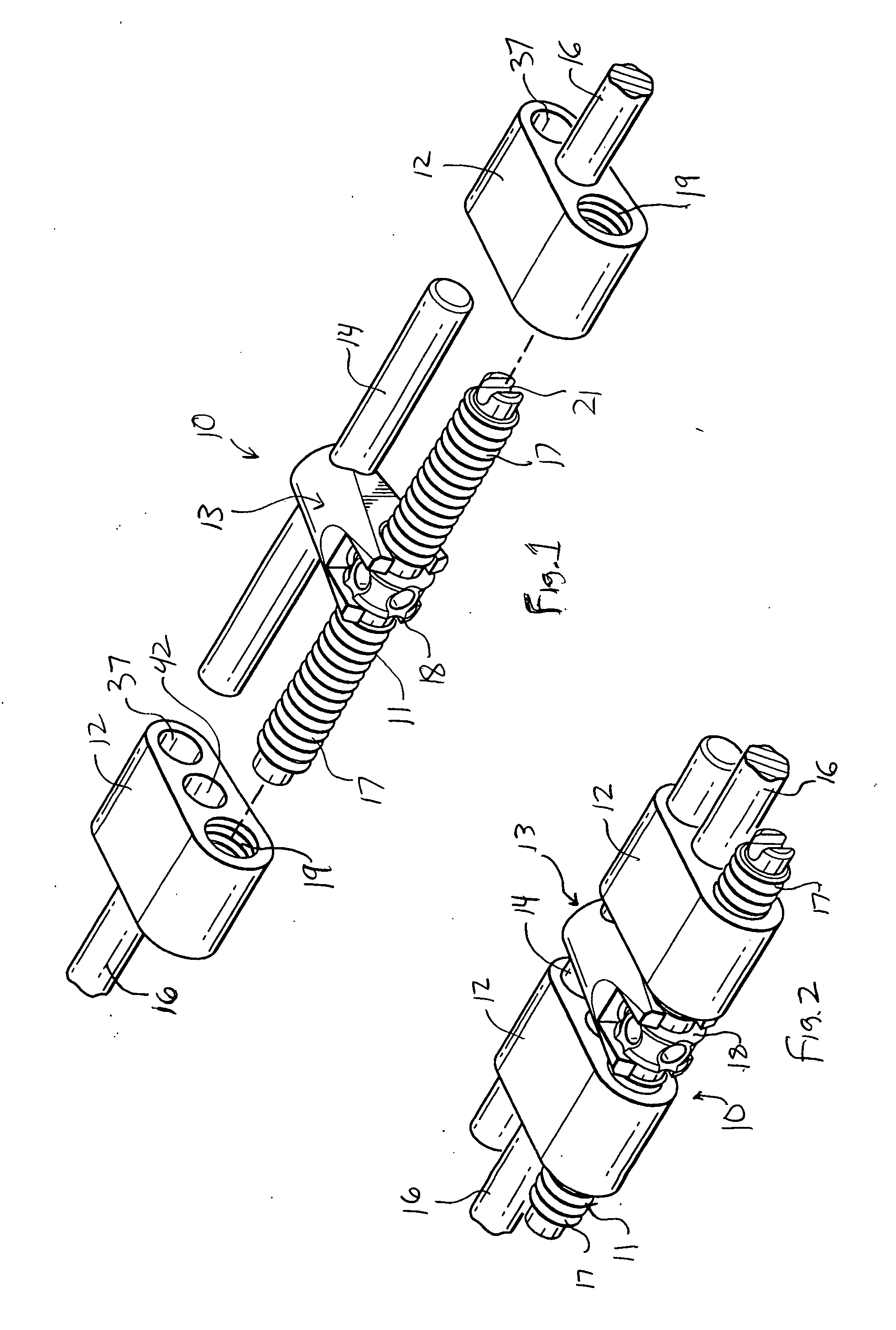

Tire building core latching and transport mechanism

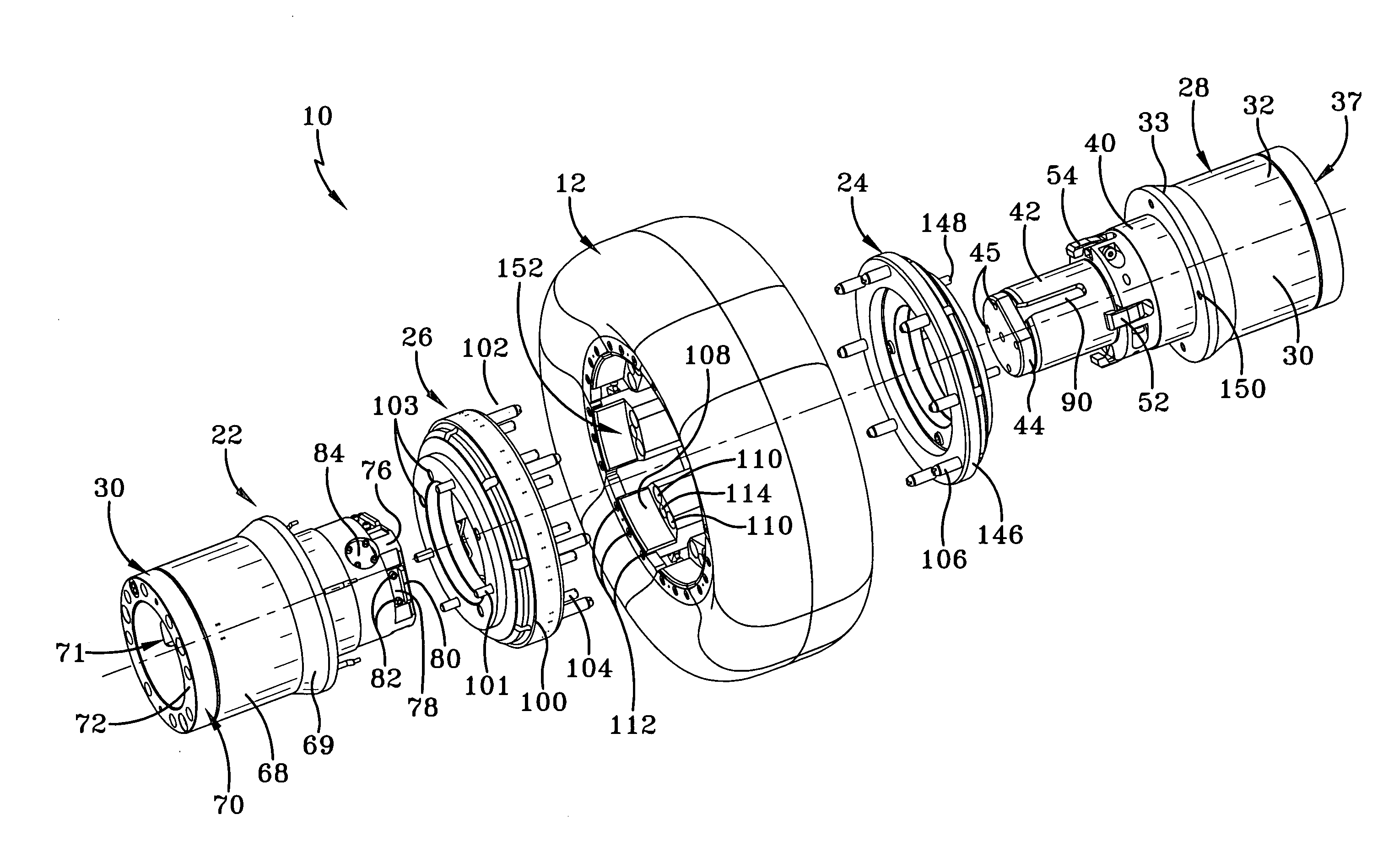

A tire building core assembly includes a shell assembly is formed by a plurality of shell segments and includes a central spindle-receiving throughbore. Two spindle units meet in axial alignment within the shell assembly throughbore and retain the shell segments in an expanded configuration forming a toroidal tire building surface. An open socket may be formed in a protruding end of one or both spindle units, the socket configured to couple with an end of an external arm mechanism. A latching mechanism moves between engaged and disengaged positions for releasably couple the one spindle unit to the second spindle unit within the shell assembly throughbore.

Owner:THE GOODYEAR TIRE & RUBBER CO

Method for top-driving casing job of drilling apparatus

ActiveCN101487377AHigh degree of automationSimplify the work processDrilling machines and methodsTop driveWell drilling

A method for casing job by using a top drive drilling unit is applied to the petrol cementing technique field, and is characterized in that a casing elevator is used for lifting a single casing which is buckled with a casing string oppositely; a top-driven casing device is driven to tightly clamp the single casing; the top drive drilling unit is driven to revolve, which allows the single casing to be connected with the casing string; an air slips of a drill stand is loosed, which allows a top-driven flying ring and the casing elevator to support the single casing and the casing string; the single casing and the casing string are lowered; the air slips of the drill stand is used for fixing the single casing; slurry is poured to the interior cavities of the single casing and the casing string through a chief axis hydrophthalmia of the top drive drilling unit and a central spindle hydrophthalmia of the top-driven casing device; and finally, all the casing strings are lowered to the well bottom. The method has the advantages of reducing working equipments, simplifying working process, being capable of revolving casing string and cycling slurry timely according to the actual needs, increasing the automatic degree of the casing job, and improving the production efficiency and safety.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

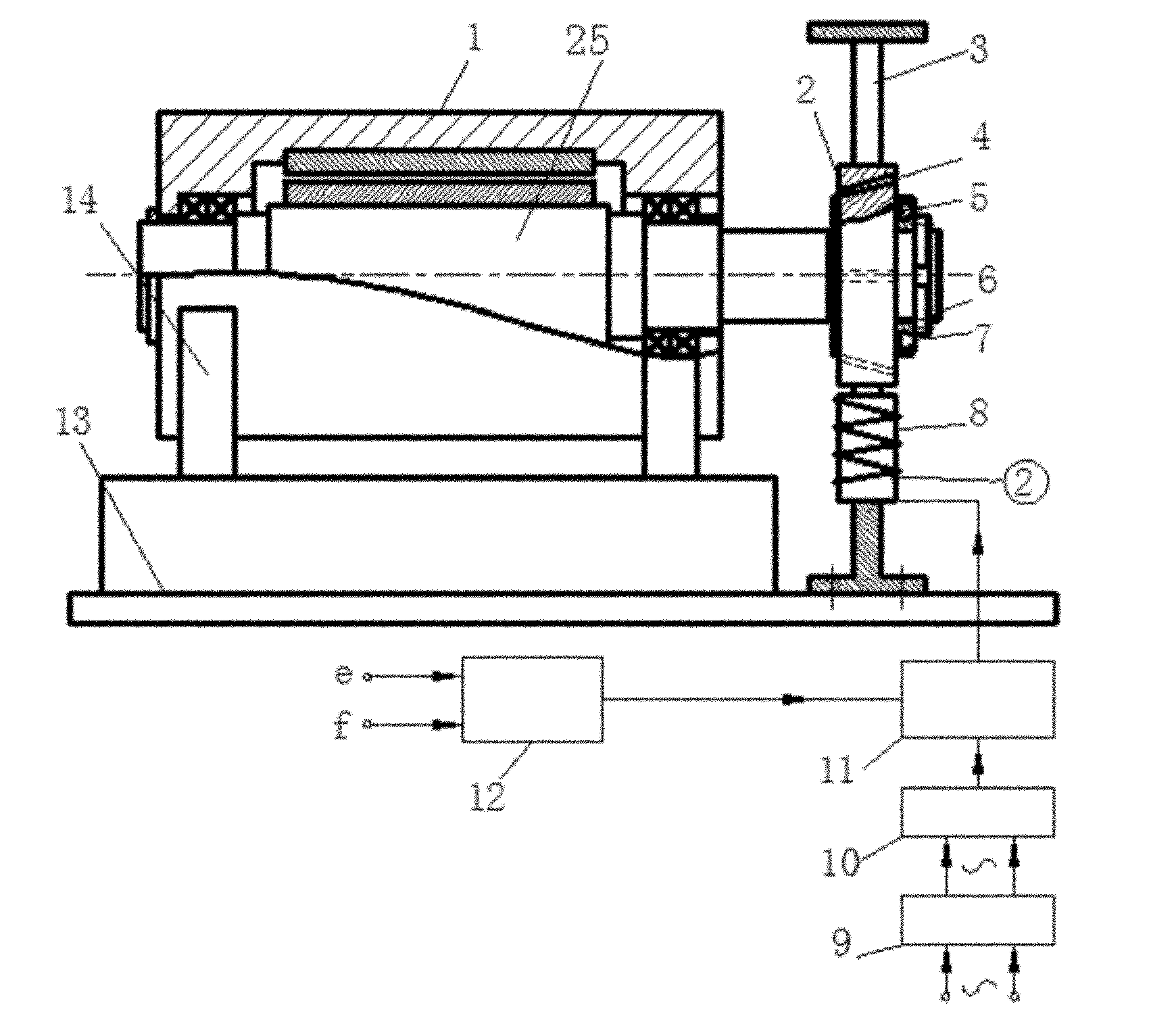

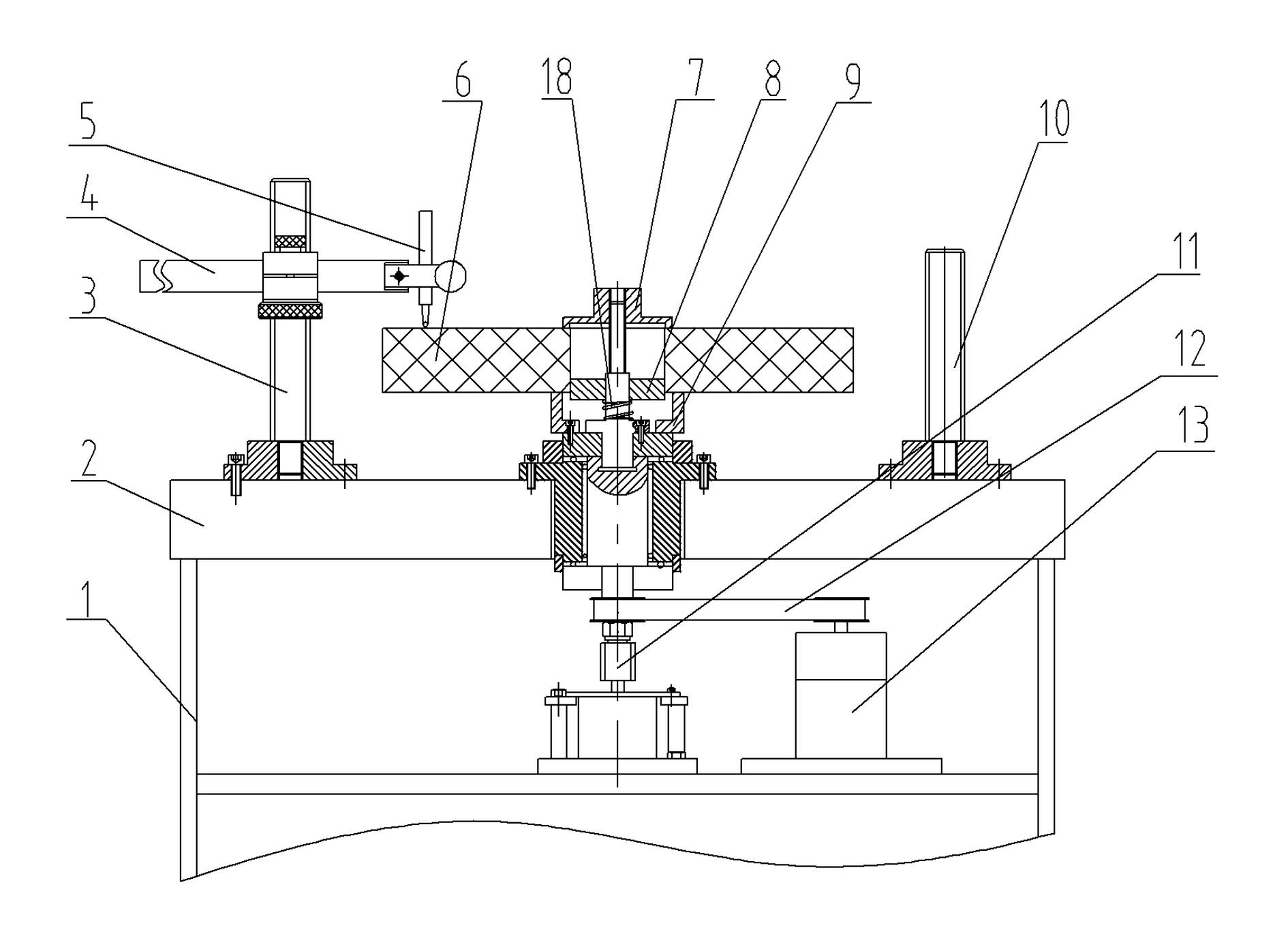

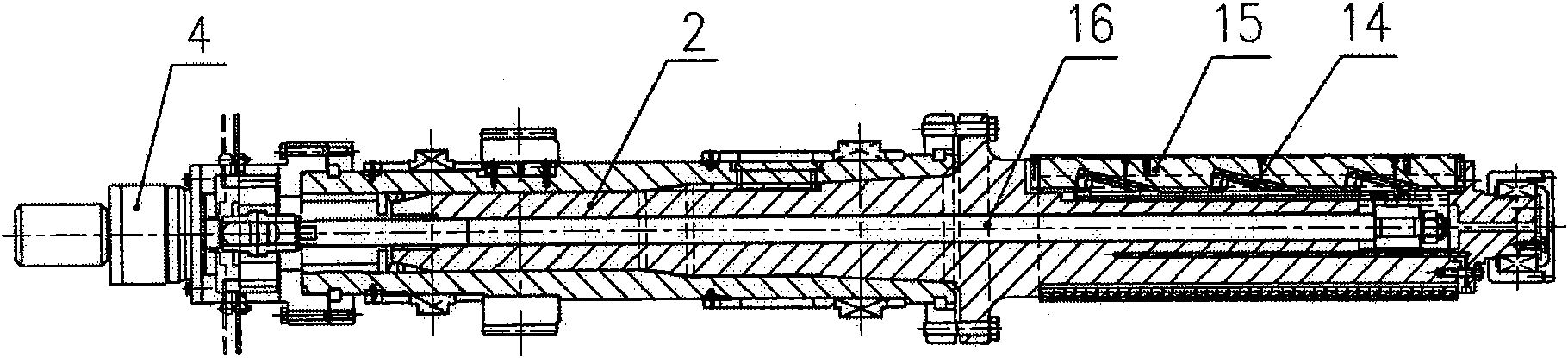

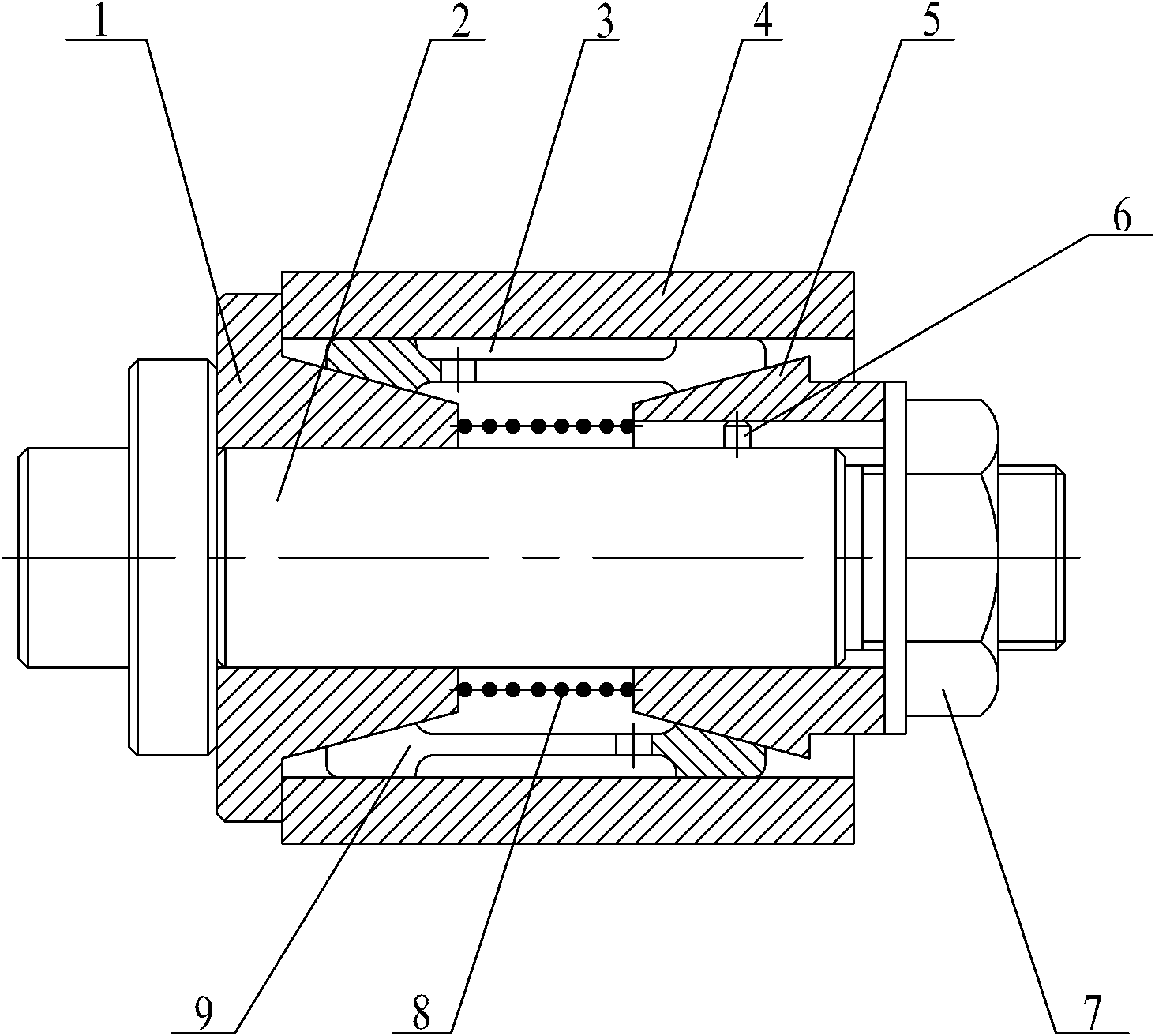

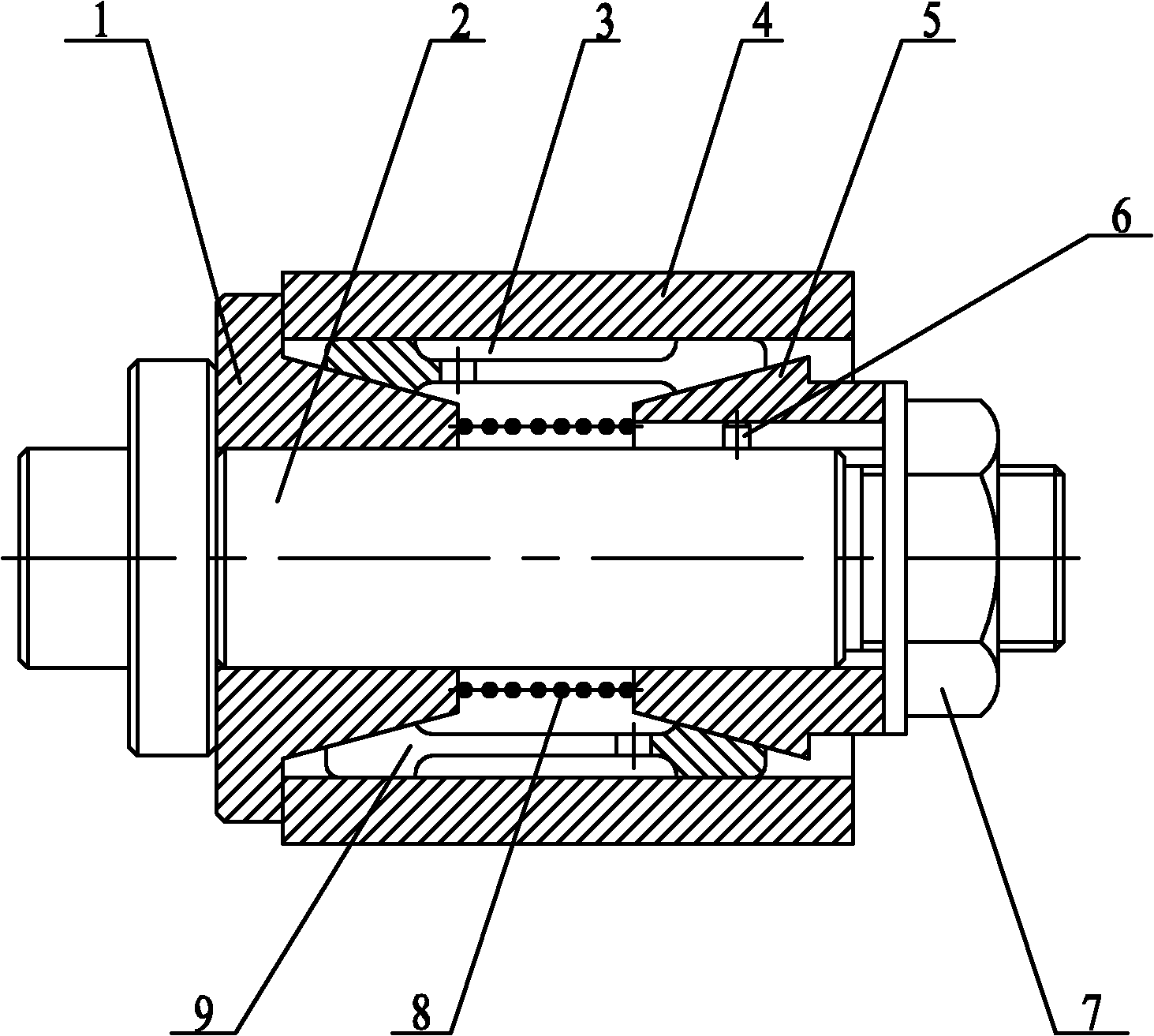

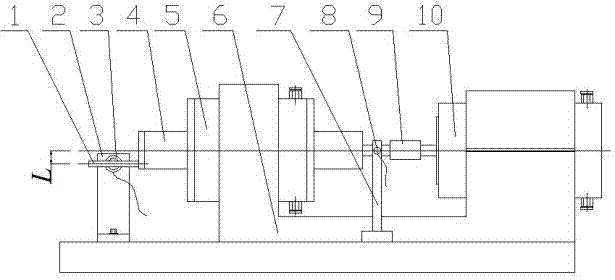

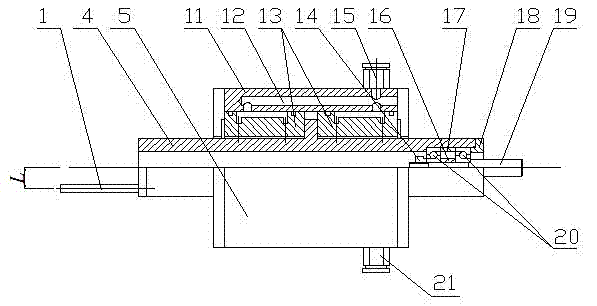

Non-contact electromagnetic loading device for high speed electric spindle

InactiveCN102109416ASolve the problem of difficult loadingImprove reliabilityMachine part testingCircular discTransformer

The invention discloses a non-contact electromagnetic loading device for a high speed electric spindle, wherein the mechanical part of the device is as follows: an electric spindle is fixed on a supporting seat; a central spindle is sleeved in the inner cavity of the electric spindle; one end of the central spindle is coaxially sleeved with a circular loading disc; a balancing device is arranged at the outer end of the circular loading disc; the circular loading disc is provided with an inclined through hole along the axial direction; an integral bracket is arranged around the circular loading disc; a radial force loading electromagnet is arranged on the lower part of the integral bracket and wrapped with direct current excitation coils (1) and (2); a left torque loading electromagnet and a right torque loading electromagnet are respectively arranged on two sides of the integral bracket; each of the left and right torque loading electromagnets is wrapped with the direct current excitation coils (3) and (4); the electric part of the device comprises a PWM (pulse width modulation) switch power amplifier; the output end of the PWM switch power amplifier is simultaneously connected with a magnetic field controller and the direct current excitation coils (1), (2), (3) and (4) while the input end of the PWM switch power amplifier is orderly connected with a diode rectification circuit and a rectifier transformer; and the magnetic field controller is connected with an industrial control machine. The device provided by the invention solves th difficult loading problem in the performance analysis test of the high speed electric spindle.

Owner:XIAN UNIV OF TECH

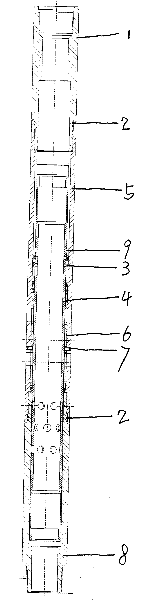

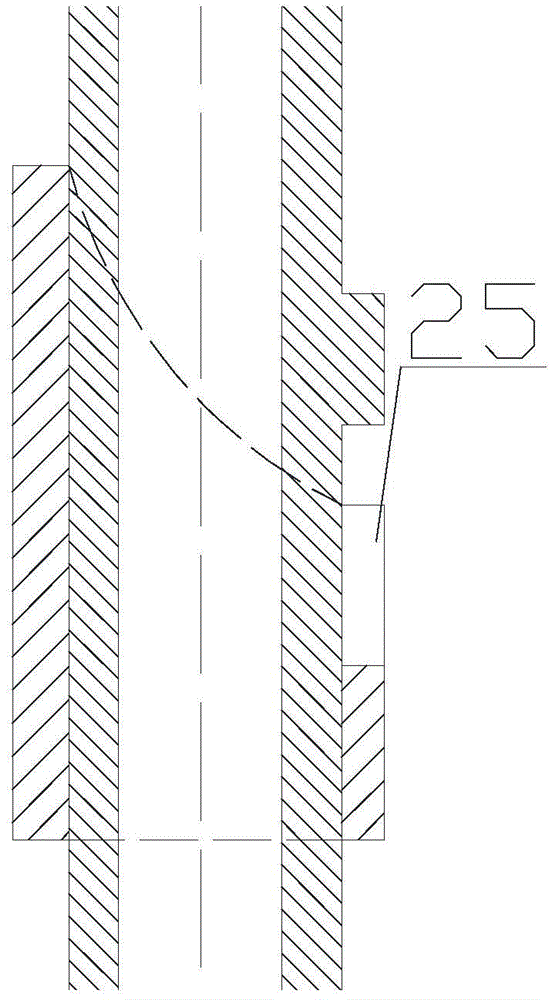

A multiple switch sliding sleeve device

ActiveCN102261231AGuaranteed tightnessAvoid insufficient frictionWell/borehole valve arrangementsSealing/packingUpper jointControl switch

The invention relates to a segmentally improved underground tool device, in particular to a repeated switch sliding sleeve device which comprises a switch sliding sleeve and a switch tool, wherein the switch sliding sleeve comprises a switch sliding sleeve upper joint, a sliding sleeve, an outer barrel, an opening bushing and a switch sliding sleeve lower joint which are connected with one another sequentially; the switch tool comprises a switch upper joint, a central spindle, a spring, a limiting sleeve and a tap which are connected with one another sequentially; and a switch can be placed in the sliding sleeve to control switching-on and switching-off of the switch sliding sleeve. By the repeated switch sliding sleeve device, a connection state or a disconnection state of each section of flow channel can be selected randomly, so that a full drift diameter of a pipe column is realized and the repeated switch sliding sleeve device is easy to operate.

Owner:XINJIANG SINOGASOLINEEUM ENG

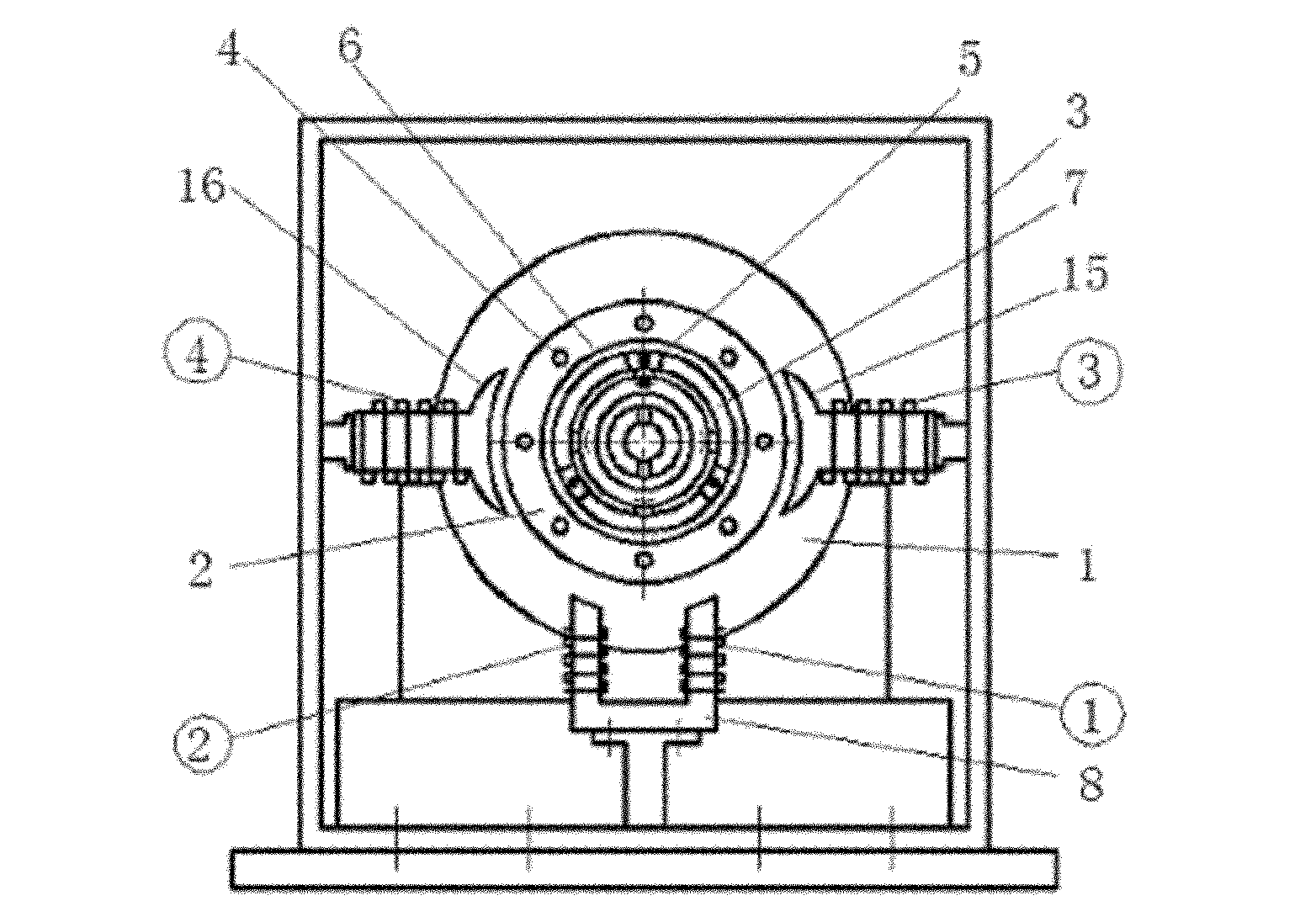

Jump detector for grinding wheel circle

InactiveCN102128587AGuaranteed validityGuaranteed coaxialityUsing electrical meansUsing optical meansMeasurement costEngineering

The invention discloses a jump detector for a grinding wheel circle. A rotary fixture is rotatably arranged on a workbench. The rotary fixture comprises a spindle, wherein the spindle is provided with a central spindle part used for being coaxially spliced and matched with a central hole of a grinding wheel to be detected. A gland and a tray, which are used for clamping and fixing a grinding wheel to be detected, are correspondingly fixed above and below the central spindle part on the spindle. On the workbench, the outer side of the circumference of the grinding wheel to be detected is provided with a detector for detecting the jump of the end face circle and the jump of the radial circle of the grinding wheel to be detected. The detector comprises a sensor installing rack fixedly arranged on the workbench, wherein the sensor installing rack is provided with a first displacement sensor used for detecting the jump of the end face circle of the grinding wheel to be detected and a second displacement sensor used for detecting the jump of the radial circle of the grinding wheel to be detected. By adopting the jump detector, personal errors brought by manual measurement are avoided, the measurement efficiency is efficiently increased, and the measurement cost is reduced.

Owner:LUOYANG BEARING SCI & TECH CO LTD

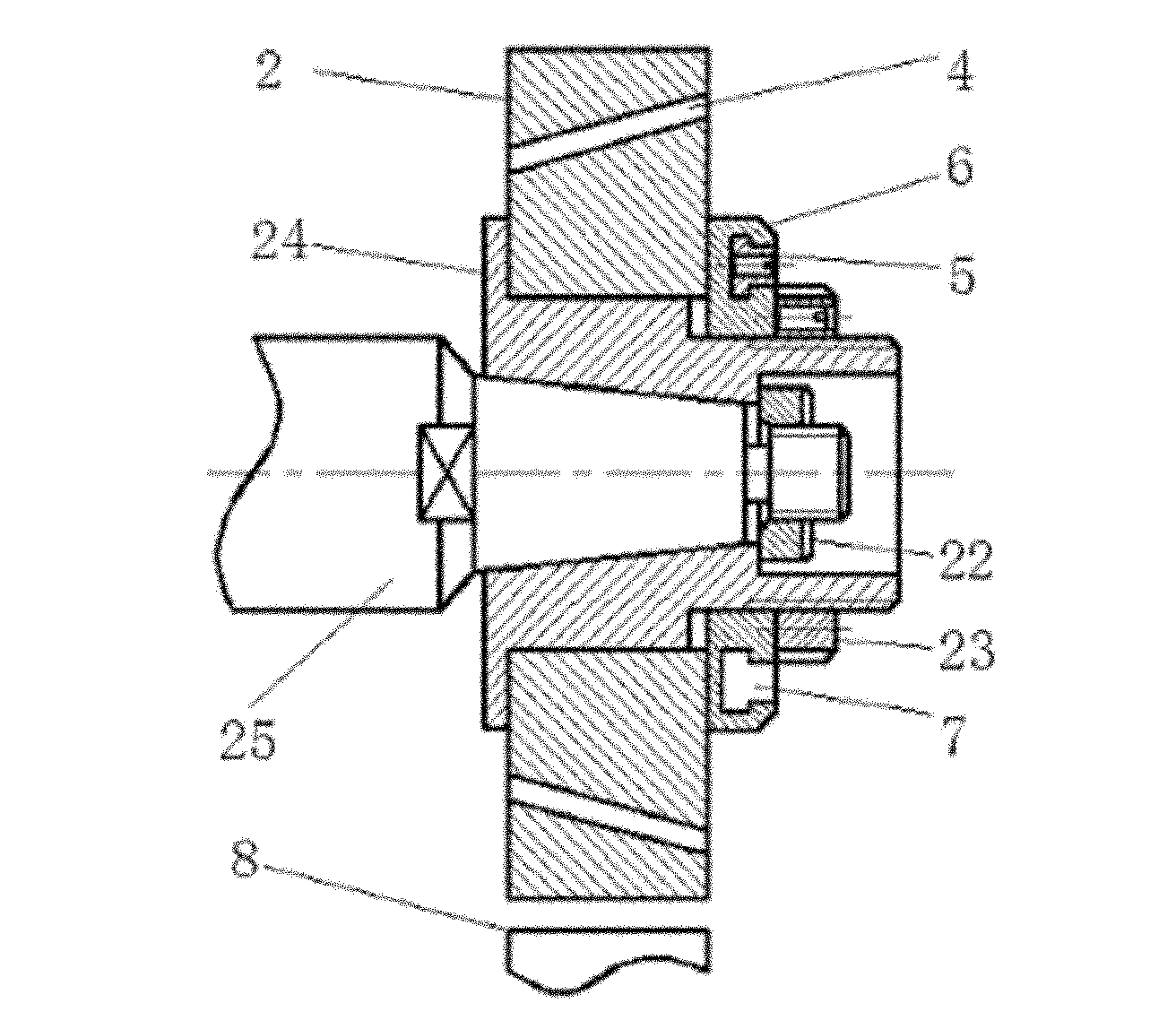

Improved electric spindle

ActiveCN104439298AAvoid windingReduce wearLarge fixed membersPositioning apparatusElectricityUltrasonic sensor

The invention discloses an improved electric spindle which comprises a machine body, a stator and a central spindle assembly mounted in the machine body. The central spindle assembly is provided with a rotor matched with the stator. The central spindle assembly comprises a hollow central spindle and a pull rod located in the central spindle. An ultrasonic transducer is fixedly arranged at the lower end of the central spindle, a mounting cavity is formed in the ultrasonic transducer, and a pull claw is arranged in the mounting cavity. The electric spindle further comprises an amplitude-change pole which is provided with a cutter, and the upper end of the amplitude-change pole is mounted between the ultrasonic transducer and the pull claw. The pull claw is movably arranged at the lower end of the pull rod in a sleeving mode, and a strutting part is arranged on the pull rod. A driving part which is used for driving the pull rod to move downwards and driving the strutting part to be away from the pull claw to enable the pull claw to be automatically contracted is mounted in the machine body. An elastic element is mounted between the pull rod and the central spindle. The improved electric spindle can improve the processing effect, and further can prolong the service life of the cutter. Moreover, the abrasion of a center carbon brush and an outer carbon brush can further be reduced, and assembling is easy.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

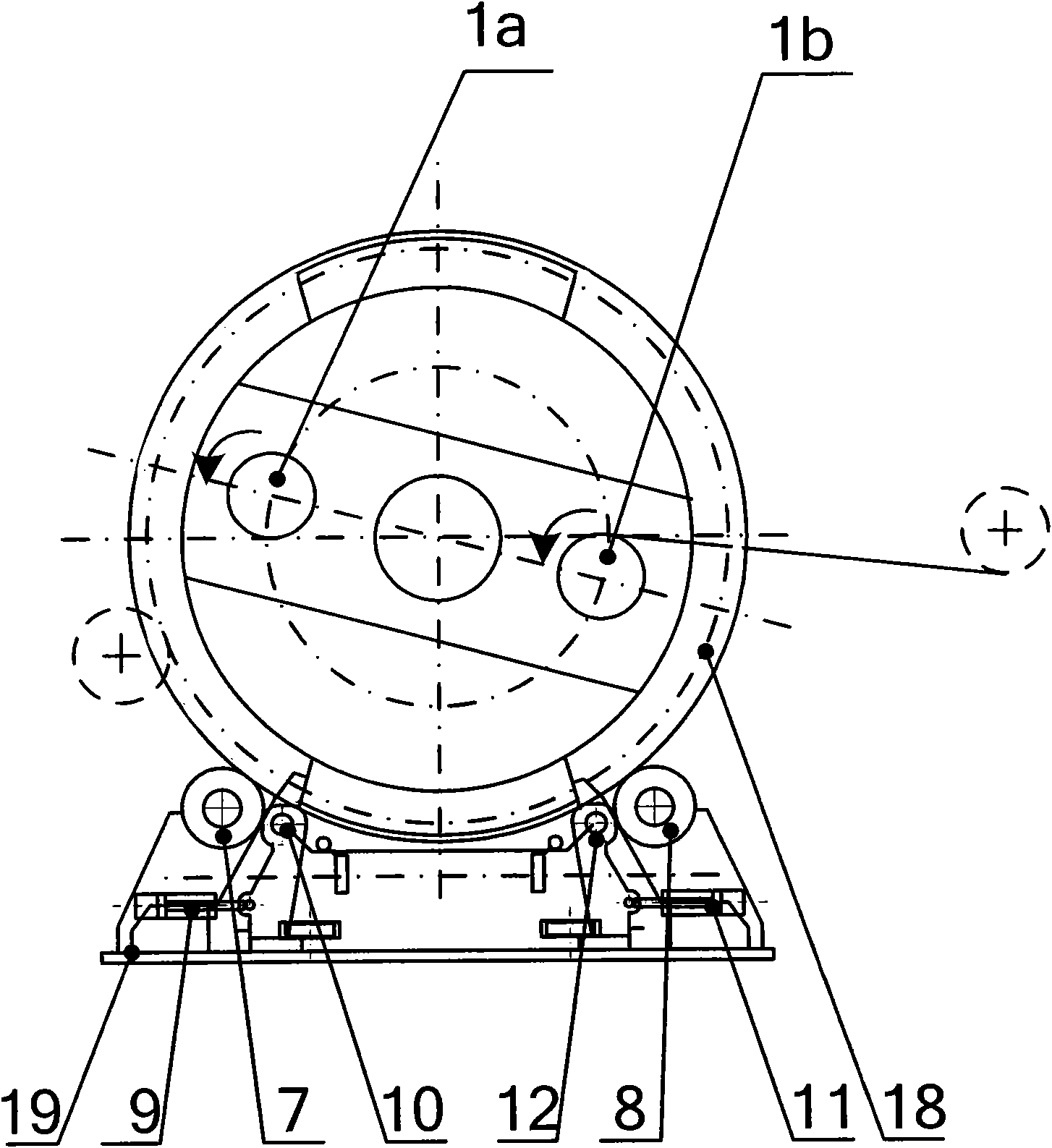

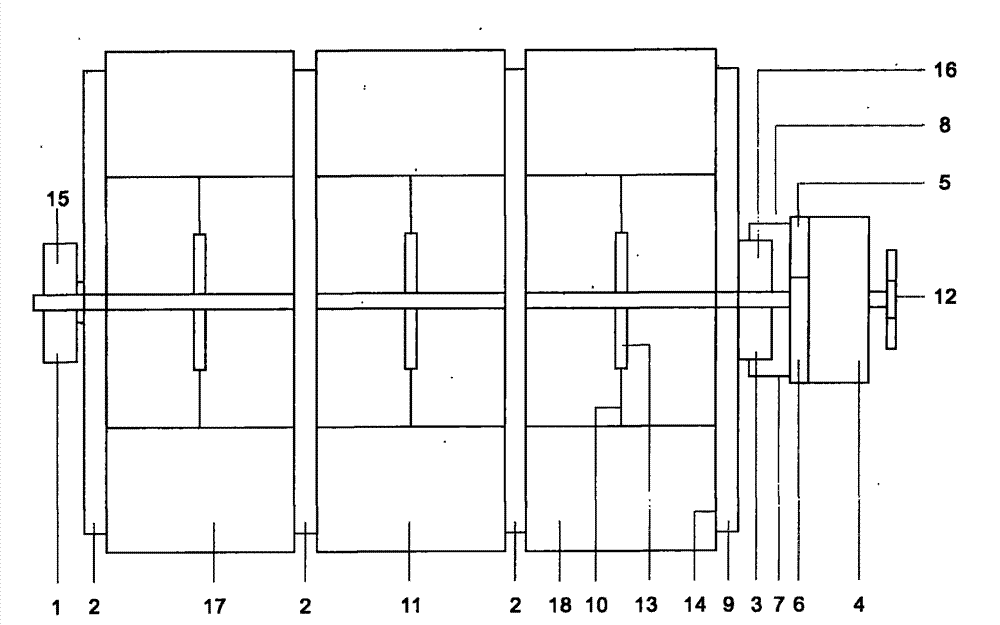

Dual-reel coiler

ActiveCN101642783AAchieve expansion and contractionContinuous coilingHydraulic cylinderSocial benefits

The invention belongs to the forming technical field, and relates to a dual-reel coiler. The coiler is arranged at an outlet of a cold-strip steel tandem mill; two reels are arranged in a rotary box body; the reels rotate around respective central spindle; the central spindles are driven by the input of two hollow shafts with public axes respectively, and the reels are driven by a rotating hydraulic cylinder to realize dilatation; large gear rings at the periphery of the rotary box body are engaged with gears, are supported by a guide roller, and are driven by a driving device to rotate; a brake is driven by a braking hydraulic cylinder to brake, and a clamping device is driven by a clamp hydraulic cylinder to clamp; and the reels transfer motion by a separate motor through a gear deceleration system, and are arranged in the public rotary box body (rotating disc) capable of rotating around the spindles so as to realize continuous and alternant strip steel reeling. The dual-reel coilercan obviously improve productivity, improve the quality of steel coils, save installation space and bring considerable economic and social benefits, and can be applied to cold tandem mill sets.

Owner:CISDI ENG CO LTD

High-speed direct connection spindle

ActiveCN103737408AGuaranteed to workAvoid enteringLarge fixed membersChucksBody positionsEngineering

The invention relates to a high-speed direct connection spindle. The high-speed direction connection spindle comprises an engine body, a central spindle, a pull rod, a reset spring and an oil cylinder assembly, wherein the central spindle is pivoted in the engine body through an upper bearing and a lower bearing arranged at the upper end and the lower end of the engine body, and a conical hole is formed in the bottom end of the central spindle, wherein the diameter of the conical hole is increased from top to bottom in sequence; the lower end of the pull rod is connected with a pulling claw which is matched with the conical hole and used for fixing a cutter, and the upper end of the pull rod is fixedly provided with a cutter hitting disk; the reset spring is arranged between the central spindle and the pull rod; the oil cylinder assembly comprises a cylinder body positioned above the top of the engine body and a piston arranged at the interior of the cylinder body and used for propping against the cutter hitting disk downwards; the cylinder body is movably provided with a plurality of connecting pieces in a penetrating manner, the part, penetrating through the lower end of the cylinder body, of each connecting piece is fixedly connected to the engine body, and each connecting piece is connected with an elastic element in a sleeving manner. The cylinder body of the oil cylinder is arranged on the engine body in a floating manner, and the axial thrust applied to the central spindle when a cutter is assembled or disassembled on the oil cylinder can be counteracted, so that a bearing is protected from being damaged, and the service life of the bearing is prolonged.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

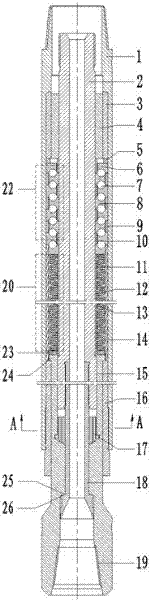

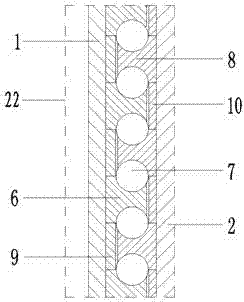

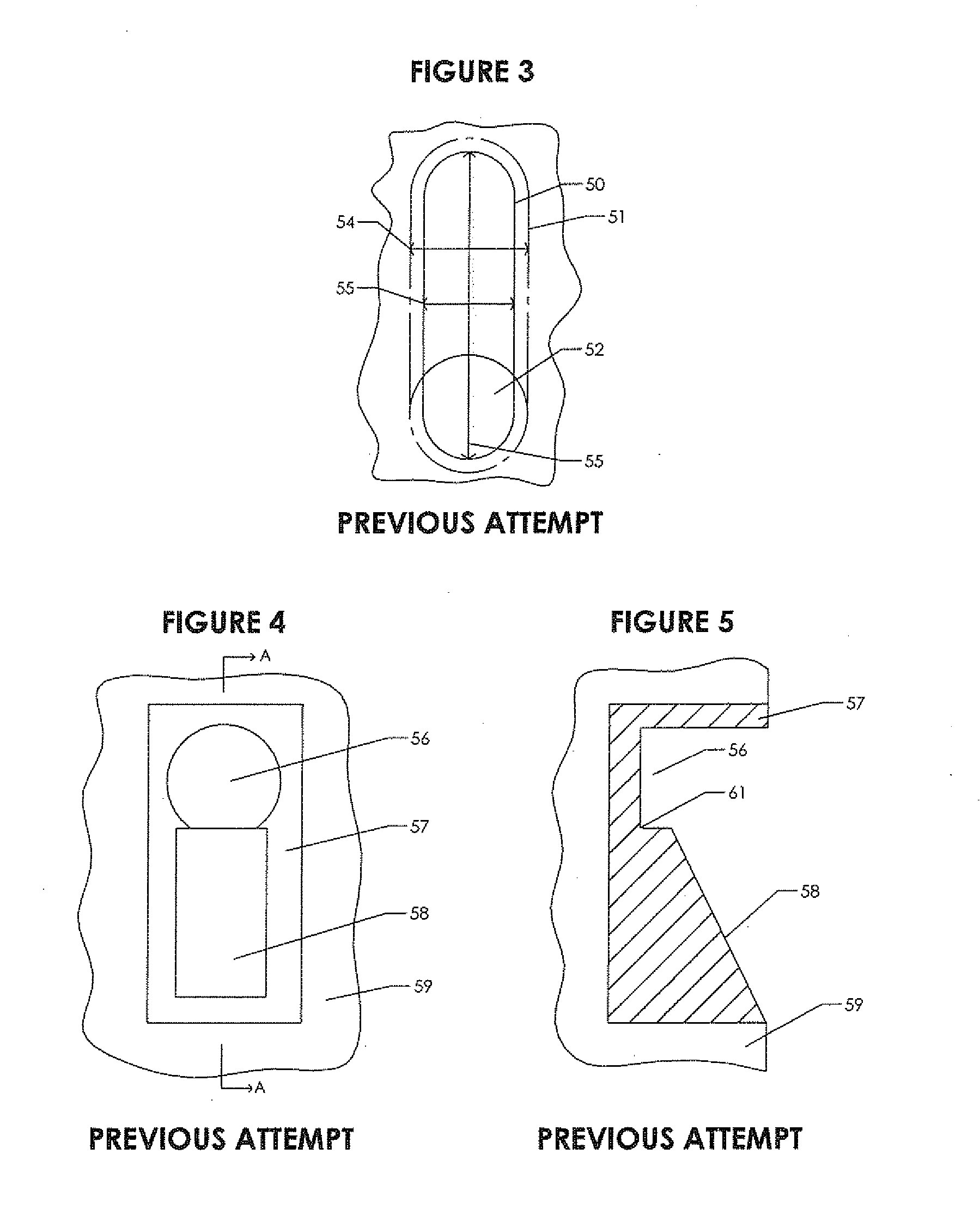

Self-formed ball seat sliding sleeve

ActiveCN102345452AAvoid pitching errorsImprovementWell/borehole valve arrangementsSealing/packingSplit ringSelf forming

The invention provides a self-formed ball seat sliding sleeve. The self-formed ball seat sliding sleeve comprises an upper joint (1), a split ring (2), a retaining ring (3), a screwed plug sliding key (4), an outer cylinder (5), a sliding sleeve (6), a ball seat (7), inverted V-shaped open slots (18), a self-locking sleeve (8), a fixing sleeve (9), an air cavity (19), a sliding central spindle (10), shear pins (11), shear pin holes (16), a pressure-bearing cavity (15) and a lower joint (12) which are sequentially connected together. Compared with the prior art, the self-formed ball seat sliding sleeve provided by the invention has the advantages of ensuring the same inner diameter of pipe columns, avoiding ball-throwing misoperation, achieving more perfect reformation and high efficiency, lowering accident rate and being convenient for use.

Owner:XINJIANG SINOGASOLINEEUM ENG

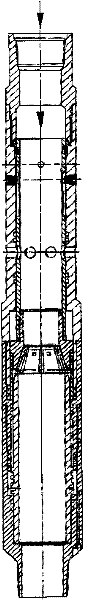

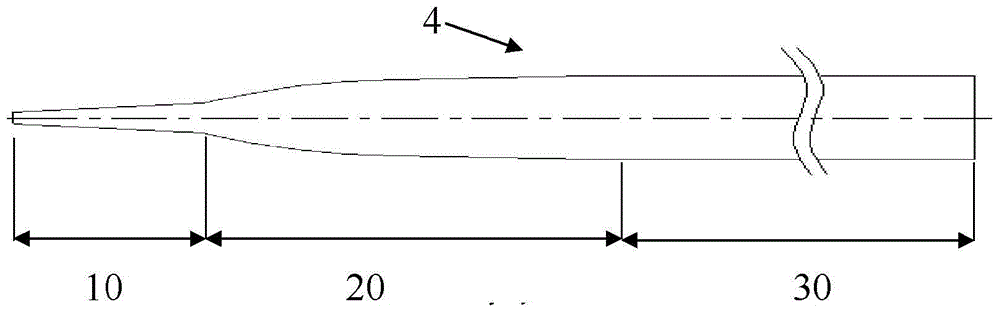

A driving shaft assembly of a screw drilling tool with a vibration damping function

ActiveCN102268961ASimple structureShorten the lengthRotating vibration suppressionDrilling rodsDrive shaftScrew thread

The invention discloses a screw drill transmission shaft assembly which is used in oil and gas drilling and can reduce the drill vibration, prolong the service life of the drill and improve the mechanical drilling rate. The screw drill transmission shaft assembly consists of a shell, an upper transmission shaft, an upper radial bearing static sleeve, an upper radial bearing dynamic sleeve, a loadbearing group, a vibration reducing device, a lower transmission shaft, a lower short section, a central spindle and the like. The technical scheme is that: the upper transmission shaft is mounted inthe shell; the upper radial bearing static sleeve and the upper radial bearing dynamic sleeve are cooperatively mounted in an annular space formed by the shell and the upper transmission shaft; the load bearing group is mounted at the lower ends of the upper radial bearing static sleeve and the upper radial bearing dynamic sleeve; the vibration reducing device is mounted at the lower end of the load bearing group; when in work, a spline slot of the upper transmission shaft is matched with a spline of the lower transmission shaft; the lower short section is in threaded connection with the shell; and the central spindle is in threaded connection with the upper transmission shaft. The screw drill transmission shaft assembly disclosed by the invention does not increase the length of the lowerdrill, brings relatively little influence on the bottom drill combination, and can be applied to the angle building operation and curved borehole.

Owner:SOUTHWEST PETROLEUM UNIV

Device capable of elastically clamping two ends of long hole

InactiveCN102069207AEasy to removeRemove effectiveExpansion mandrelsProcess qualityMechanical engineering

The invention relates to a device capable of elastically clamping two ends of a long hole. The device comprises a central spindle, wherein a left taper sleeve is arranged at one end of the central spindle, and a right taper sleeve is arranged at the other end; elastic clamping heads are arranged at correspondingly connected ends of the left taper sleeve and the right taper sleeve; a plurality of flexible open slots are evenly distributed on peripheral surfaces of the elastic clamping heads; and the ends of the left and right taper sleeves connected with the elastic clamping heads are both extended into the elastic clamping heads. The elastic clamping device provided by the invention is simple in structure and low in manufacturing cost and has the following advantages: when a locknut is screwed, the right taper sleeve can be pushed to move to cause the elastic clamping heads to extend outwardly, thus achieving the purpose of fastening and installing a workpiece; in addition, when the locknut is loosened, the elastic clamping heads shrink and the processed workpiece is convenient to remove; the workpiece is fixed effectively and reliably, and the stability of process quality is improved greatly; since the elastic clamping heads have low requirements on hole tolerance of a blank to be processed, the manufacturing cost is reduced; since the elastic clamping device provided by the invention is convenient to clamp, the work efficiency is improved greatly; and the elastic clamping device provided by the invention has a wide application scope and longer service life because of no sliding friction.

Owner:WUXI YINLIAN GEAR MACHINERY CO LTD

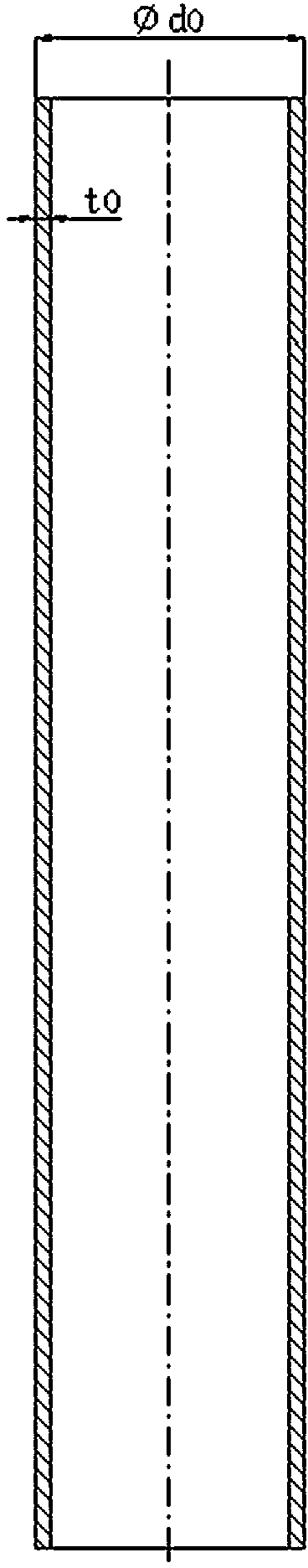

Processing method of high-strength titanium alloy thin-walled tube stock

The invention relates to a processing method of high-strength titanium alloy thin-walled tube stock, belonging to the field of material processing. The processing method comprises the following steps: 1) ingot casting titanium alloy at the temperature of 1100-1200 DEG C, cogging and forging, heating obtained bar stock to the temperature of 900-950 DEG C, conducting heat preservation for 30-50 minutes, and one-time hot-rolling on a rapid forging press to obtain titanium alloy forged bars; 2) finishing and drilling the titanium alloy forged bars to obtain tube blank; 3) preheating a central spindle to be spinned before hot spinning, with the preheating temperature not lower than the temperature of 350 DEG C; and conducting heat preservation on the tube blank at the temperature of 700-750 DEG C for 30-40 minutes, and multichannel hot spinning process; and 4) finishing the interior and exterior of the obtained hot spinned tube blank, and cold spinning and forming on a cold spinning machine to obtain finished products of the tube blank. The processing method adopts rapid forging blank making and spinning process for processing the titanium alloy thin-walled tube stock with higher requirements for room temperature strength and deformation resistance, has simple processing equipment and easy molding, and can effectively improve the quality and yield of alloy tube blank.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

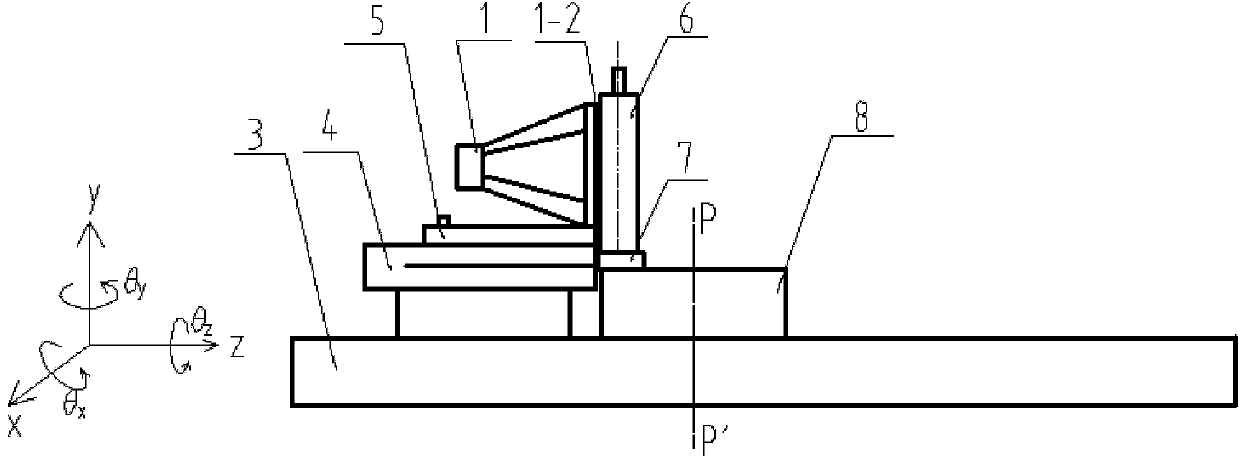

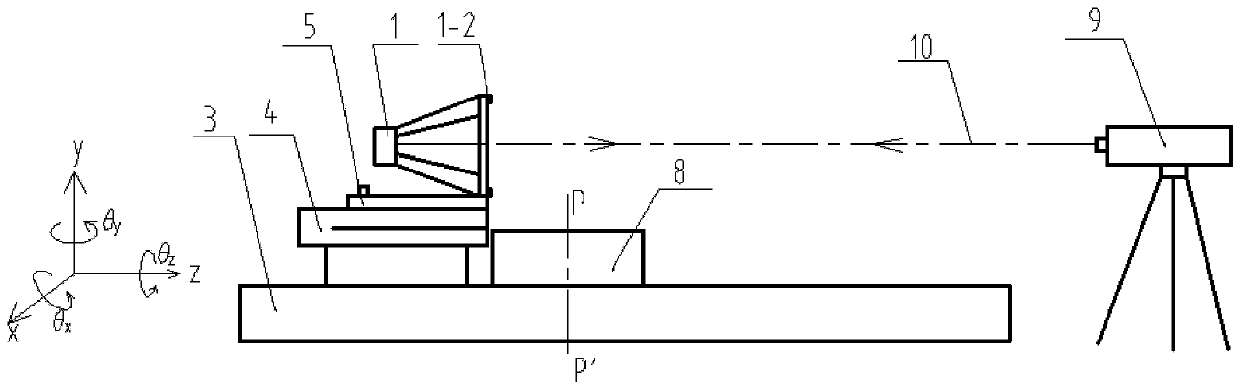

Angle measurement precision detecting device of aspect angle monitor for satellite

The invention discloses an angle measurement precision detecting device of an aspect angle monitor for a satellite. A small plane mirror is connected to a mounting base plane position of the aspect angle monitor; the aspect angle monitor for the satellite is arranged on a two-dimension inclined platform and is placed on a two-dimension translation platform; a double-faced simulation swing mirror is arranged on a three-dimension adjusting platform and is placed on a digital display turntable; a first autocollimator and a second autocollimator are placed on a lifting support; the two-dimension translation platform, the digital display turntable and the lifting support are placed on a table top of a detection platform; a central spindle is sleeved in a central hole of the digital display turntable; a standard circular device is placed on a standard block and is close to the central spindle; laser beams emitted by a laser align with a central prism of a five-mirror reflector to form a detection standard optical axis; a dial indicator is fixed on the detection platform; a gauge block is placed above the digital display turntable and between the aspect angle monitor for the satellite and the double-faced simulation swing mirror; one face of the gauge block is close to the mounting base plane of the aspect angle monitor for the satellite; and the other face of the gauge block is close to a first optical surface of the double-faced simulation swing mirror.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

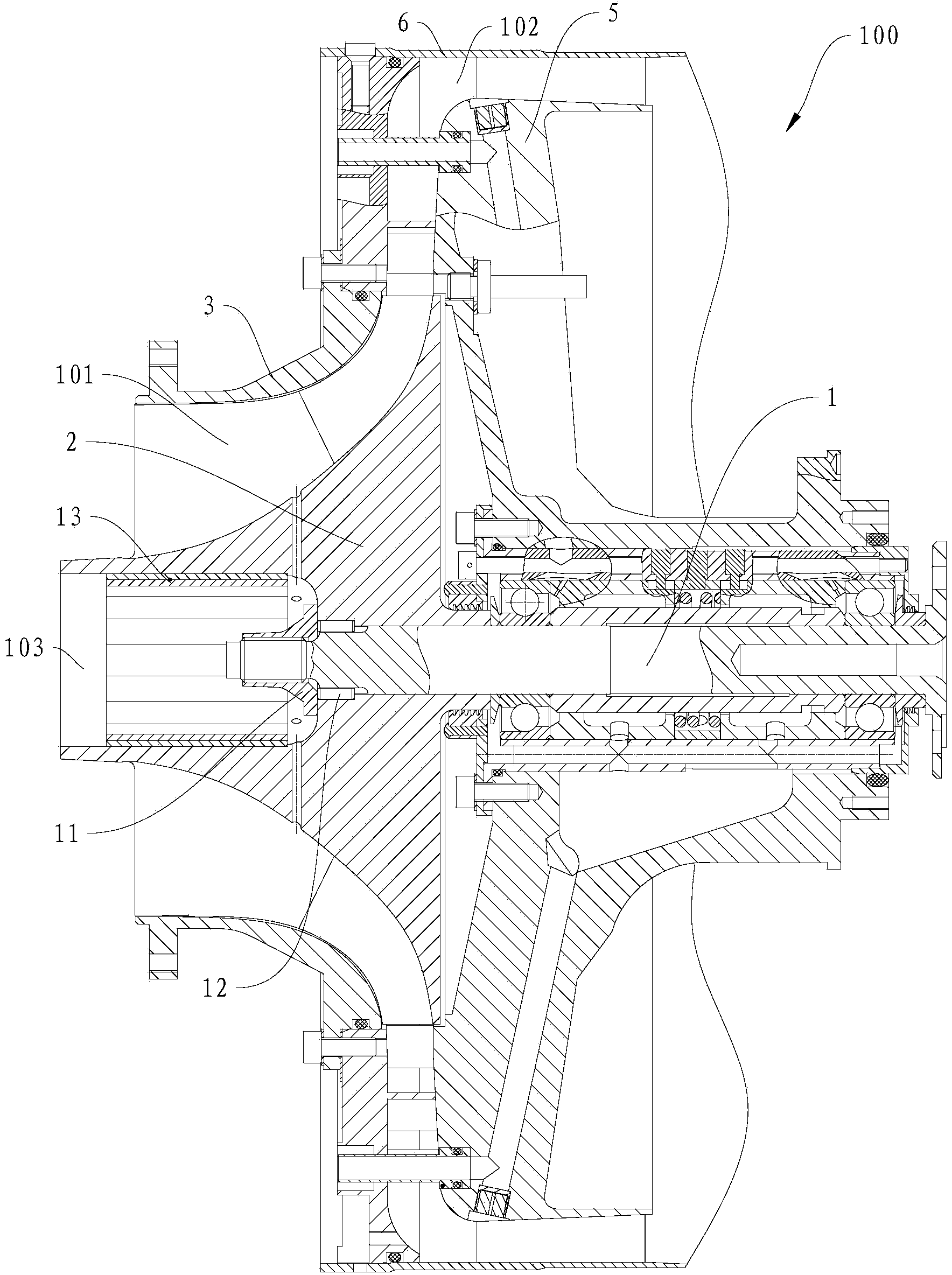

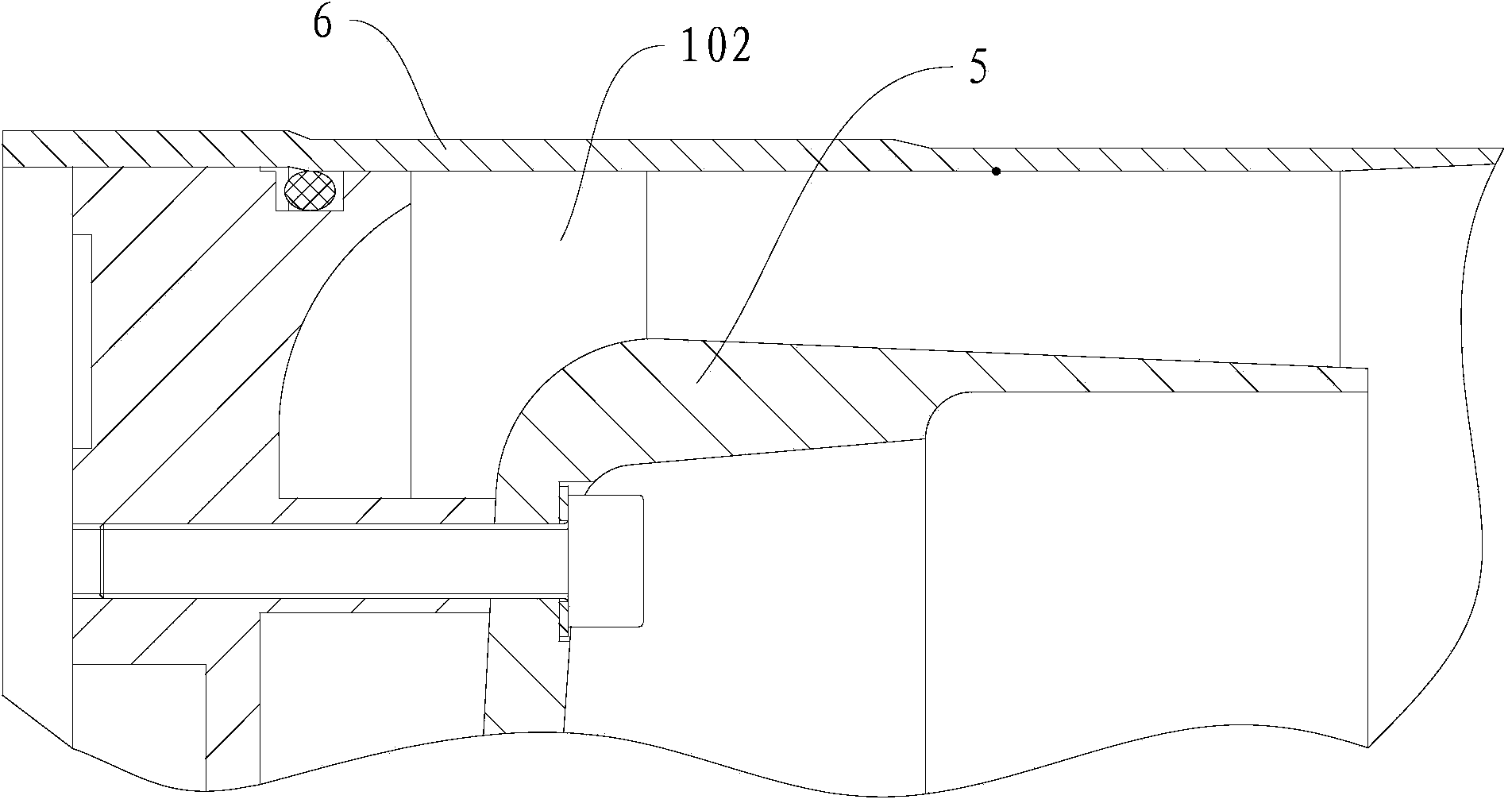

Centrifugal compressor

ActiveCN104343734AReduce in quantityReduce the numberEngine manufacturePump componentsAxial compressorJet engine

The invention discloses a centrifugal compressor. The centrifugal compressor comprises a central spindle, a centrifugal vane wheel, a centrifugal machine box, a continuous pressure expander and a pressure expander machine box, wherein the centrifugal vane wheel is arranged on the central spindle in a sleeving mode; the centrifugal machine box is arranged around the centrifugal vane wheel, and a first airflow passage is formed between the centrifugal machine box and the centrifugal vane wheel; the continuous pressure expander is connected with the centrifugal vane wheel and is positioned at the outlet of the first airflow passage, and the continuous pressure expander is a vane pressure expander; the pressure expander machine box is connected with the centrifugal machine box and surrounds the continuous pressure expander, and a second airflow passage communicated with the first airflow passage is formed between the pressure expander machine box and the continuous pressure expander. According to the centrifugal compressor in the embodiment, due to the adoption of a centrifugal structure, the disadvantage of an axial-flow compressor on the application of a small turbojet engine is overcome. Meanwhile, with the structure, the amount of components is reduced relative to a traditional centrifugal compressor.

Owner:BEIJING POWER MACHINERY INST

(Ultra-large) hydroelectric power plant

ActiveCN102878007AExtended service lifeReduce pollutionReaction enginesEngine componentsWater turbineSquare kilometer

Owner:陈永远

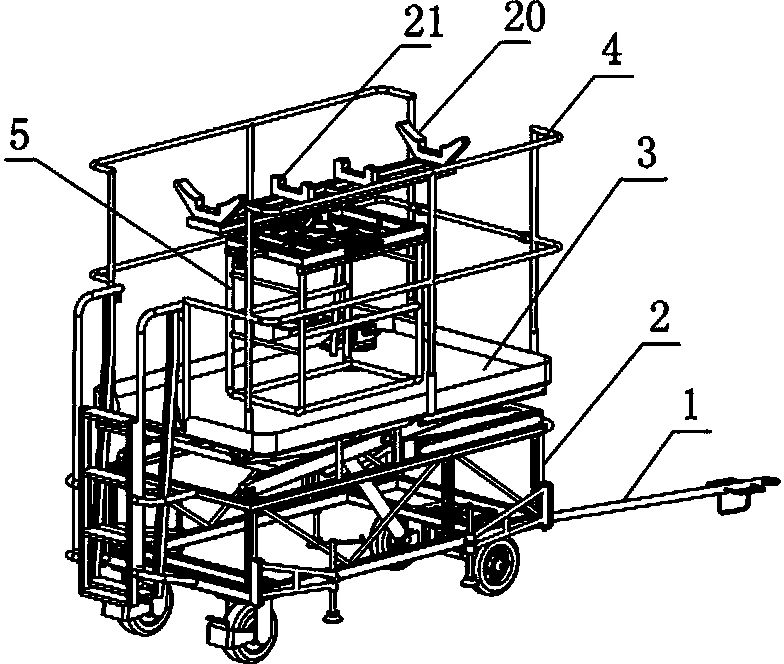

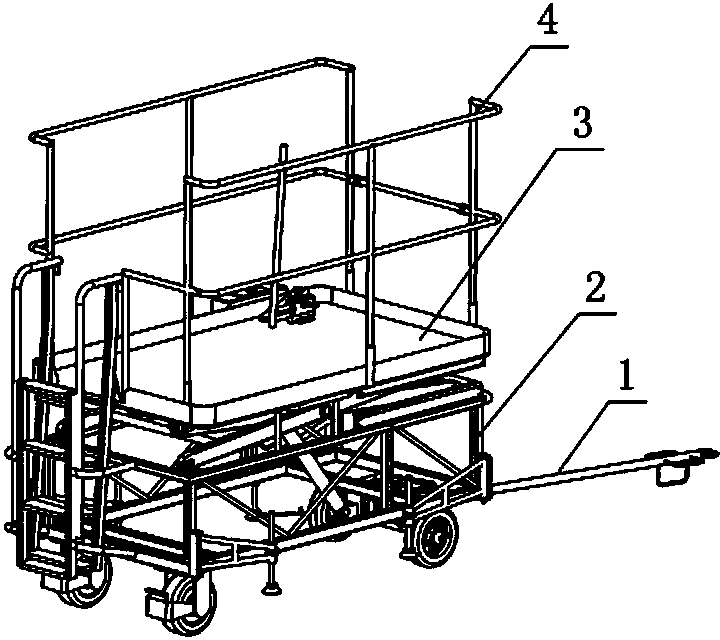

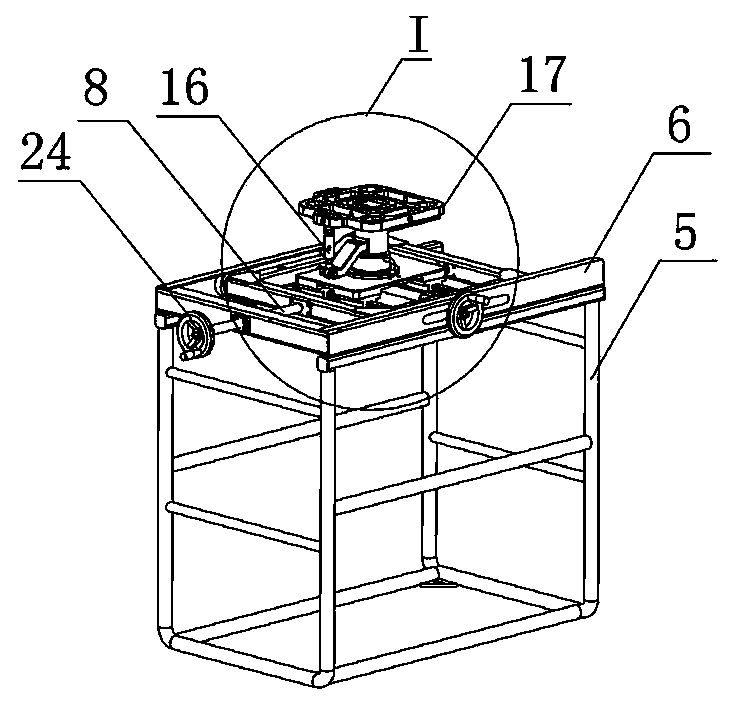

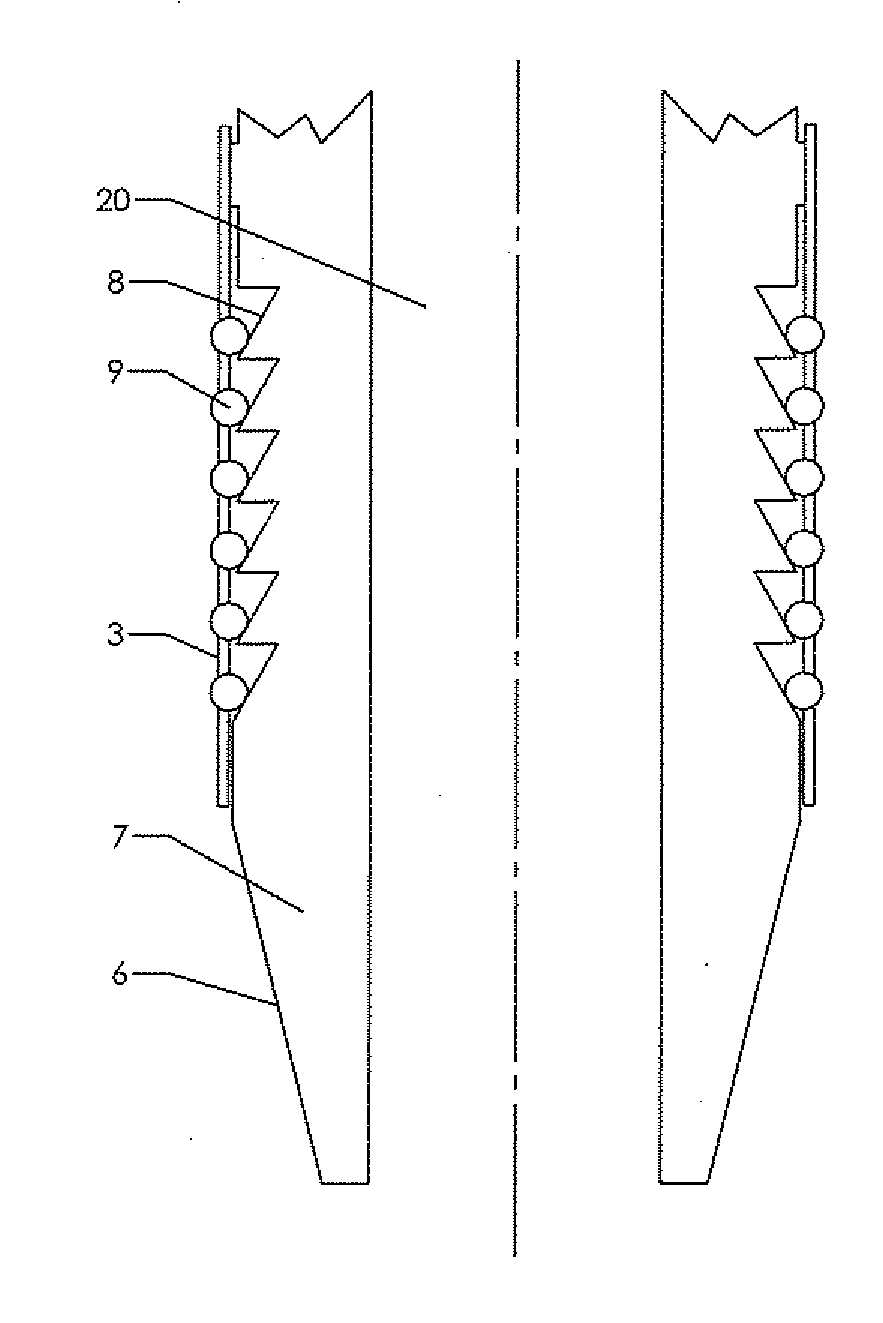

Hanging object lifting and installing car

The invention discloses a hanging object lifting and installing car, which comprises a car body, a hanging installation adjusting mechanism and a comprehensive bracket, wherein the car body is formed by a movable car frame, a scissor-type hydraulic lifting and descending platform arranged on the movable car frame, and a guard bar arranged on the scissor-type hydraulic lifting and descending platform. The hanging object lifting and installing car has the advantages of simple structure, easiness in manufacturing and convenience in assembling and disassembling. The adjustment of five degrees of freedom required during a hanging installation operation process can be realized through a mechanical transmission mechanism. The horizontal moving and the lengthways moving of hanging objects are realized through a lengthways towing plate and a horizontal towing plate; screw-thread telescopic loop bars on end parts of a lengthways cantilever and a horizontal cantilever are used for realizing the adjustment of lengthways pitching and horizontal pitching of the hanging objects; a support shaft sleeve rotatably sleeving a central spindle through a deep groove ball bearing body realizes the 360-degree adjustment of the hanging objects in the horizontal direction; an arc-shaped support bracket on a cross beam of the comprehensive bracket is mainly used for bearing the cylindrical hanging objects; a rectangular support bracket is mainly used for bearing beam body hanging objects.

Owner:ZHENGZHOU AIRCRAFT EQUIP

Tubular running device and method

ActiveUS20130292136A1Protective threadOperation much safer and more operationally efficientDrilling rodsFluid removalTop driveEngineering

A method and apparatus for running tubular(s) into a well bore for use with a top drive or power swivel comprising a make-up assembly with inner and outer members, one of which has an array of ramped or inclined surface(s) while the other is an inner or outer cage with rolling support(s) with or without a central spindle and openings which may also be referred to as tubular engagement apparatus wherein relative movement of the members urges the rolling support(s) to protrude radially through the openings to engage a tubular internally or externally. Also provided is an elevator assembly with elevator links and transfer elevators to position tubular for engagement by the make-up assembly.

Owner:2M TEK

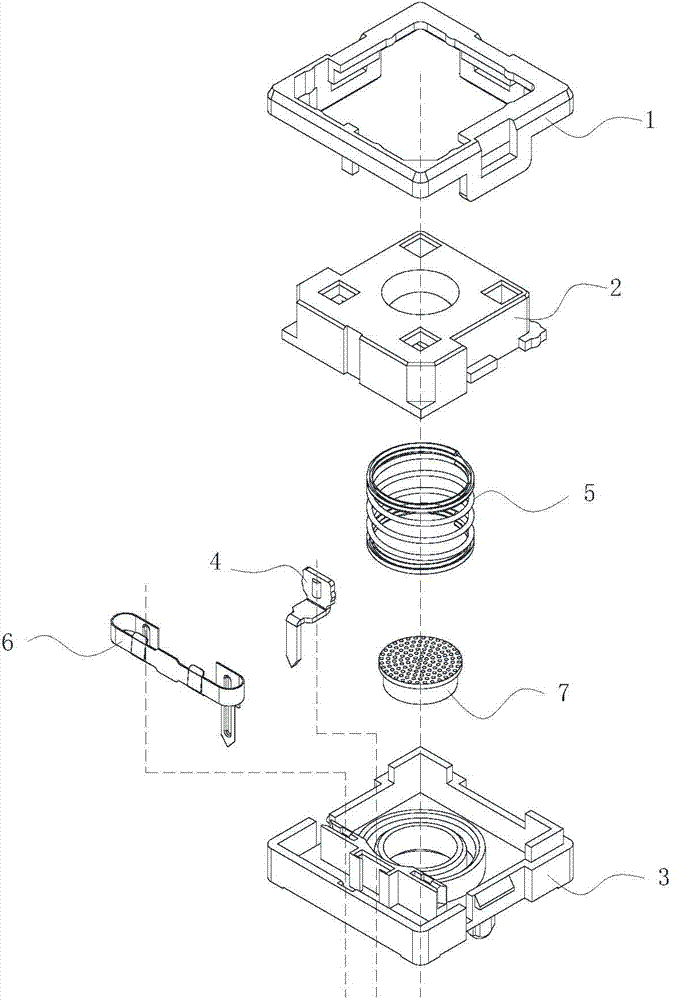

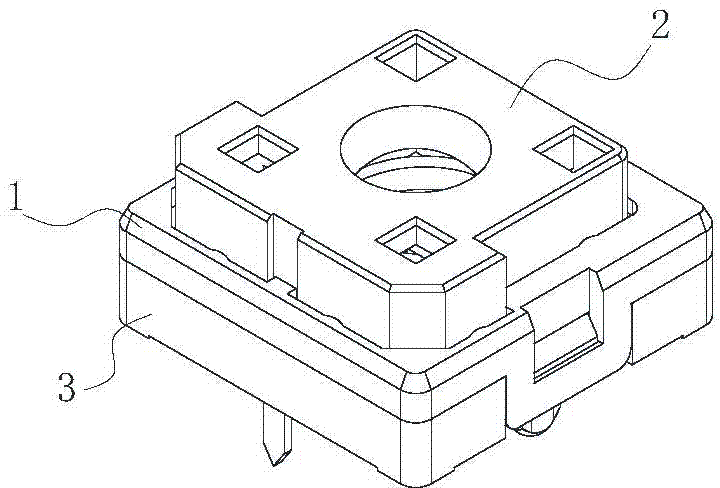

Ultrathin reset mechanism of small mechanical switch, and small mechanical switch

InactiveCN104851727AReduce thicknessImprove experienceLegendsElectric switchesContact methodEngineering

The invention belongs to the field of mechanical keyboard equipment, and provides an ultrathin reset mechanism of a small mechanical switch, and a small mechanical switch formed by the ultrathin reset mechanism. The ultrathin reset mechanism is mainly formed by a base whose upper surface is provided with a second spring fixing circular groove, a central spindle whose lower surface is provided with a first spring fixing circular groove, and springs in the two spring fixing circular grooves. The small mechanical switch is mainly formed by the ultrathin reset mechanism, a static terminal, and a movable terminal. Beneficial effects of the ultrathin reset mechanism and the small mechanical switch are that thickness is ultrathin, the ultrathin reset mechanism can be applied in laptop keyboard and other ultrathin equipment occasions, stress of the central spindle is uniform and consistent, and seesaw phenomenon would not occur, user experience is better; an LED lamp is on the middle position, and light casting is more uniform, and added light-transmitting lens has effects of gathering light and scattering light more uniformly; a simple and stable contact method of the movable terminal and the static terminal is provided; and the whole device is higher in stability.

Owner:DONGGUAN GAOTE ELECTRONICS

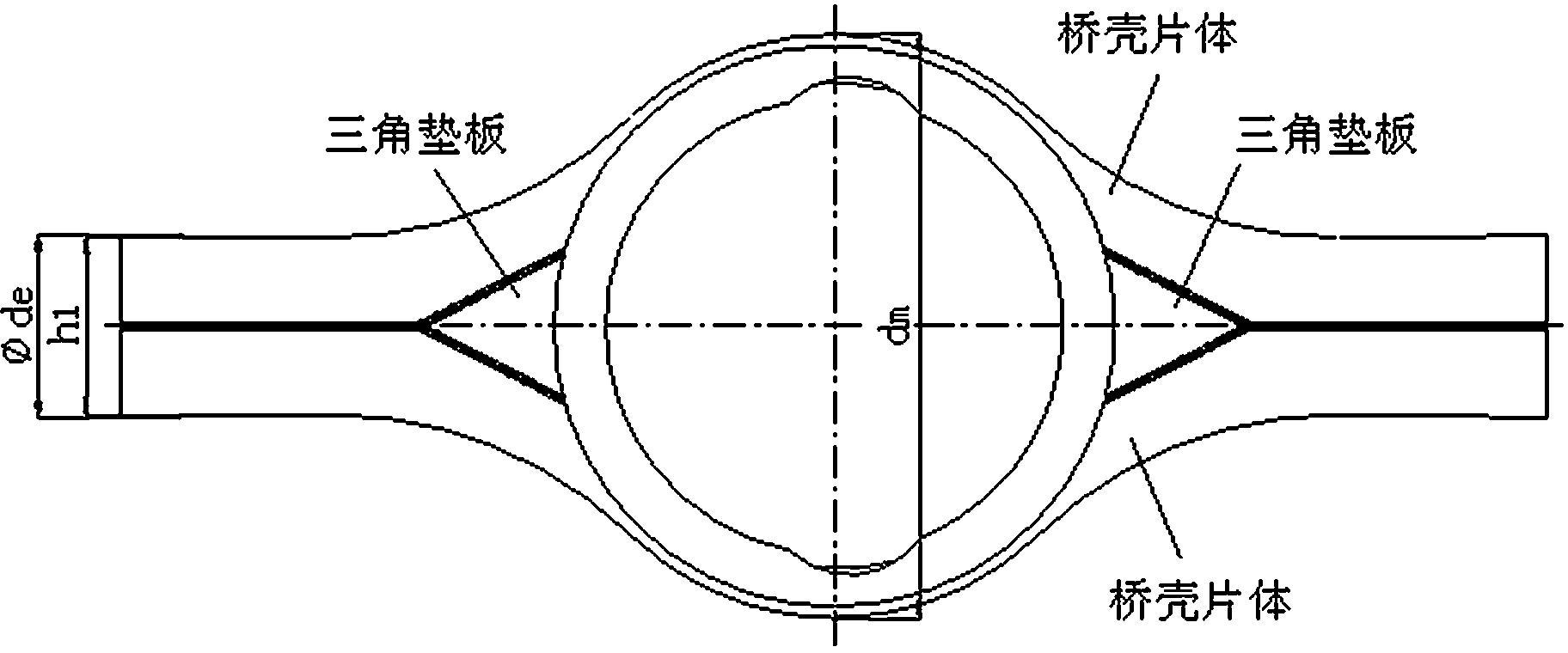

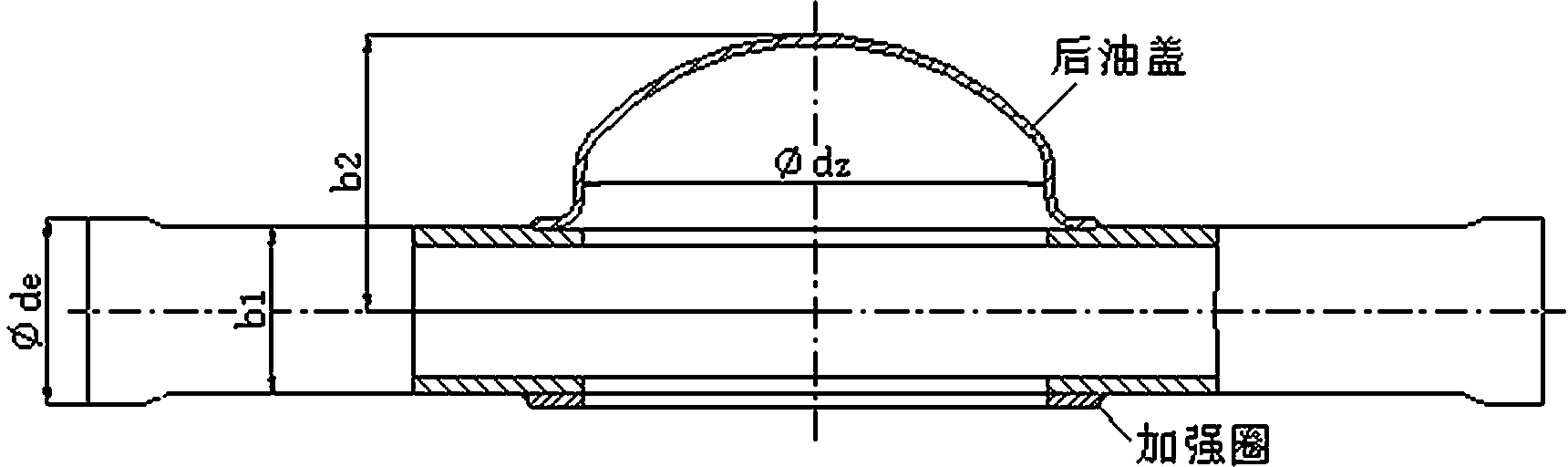

Integral forming method of weldless axle housing of heavy truck

ActiveCN103252404AReasonable distribution of wall thicknessIncreased strength and rigidityHousing FirstTruck

The invention discloses an integral forming method of a weldless axle housing of a heavy truck. According to the method, reversed central spindle necking is carried out on two sides of the axle housing first, then hydro-bugling is carried out on the middle of the axle housing to obtain a bulging tube blank with sizes of two sides of the axis different, and then necking is carried out on two ends of the axle housing to obtain a preformed tube blank; ends of the preformed tube blank are sealed by a left pressure head and a right pressure head of a die and liquid is filled in the axle housing on a four-way hydraulic machine, integral press-forming is carried out on the preformed tube blank from the upper side, the lower side, the front side and the back side through an upper module, a lower module, a front module and a back module to obtain an axle housing tube fitting, a hemispherical rear oil cap is arranged on the rear side of an axle package part, and the front side of the axle package part is a plane; a round hole is punched in the front side of the axle package, the rear oil cap is reshaped with a stamping die, and then an axle housing workpiece is obtained. The heavy truck axle housing manufactured with the method is weldless, high in strength and rigidity, high in shape accuracy, good in wall thickness distribution, and low in manufacturing cost. Compared with a traditional hydro-bugling technique, the method has the advantages that liquid pressure needed in a manufacturing process is reduced by more than 60% and the tonnage of forming equipment is reduced by more than 50%.

Owner:QINHUANGDAO TONGQIAO TECH CO LTD

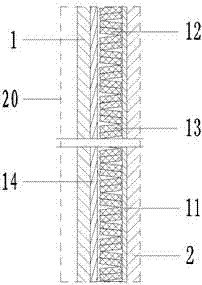

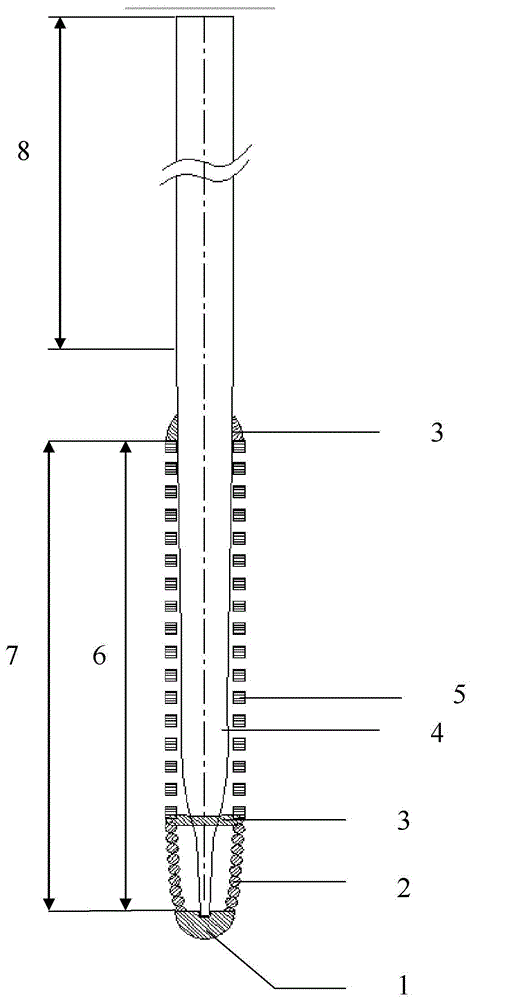

Medical guide wire and conveying system

InactiveCN104623790AGood flexibilityImprove visibilityGuide wiresHydrophilic coatingPolymer coatings

The invention provides a medical guide wire and a conveying system. The medical guide wire comprises a reducing central spindle and a protective jacket. The reducing central spindle comprises a linear equal-diameter section, a streamline reducing section and a linear reducing section from the near end to the far end, wherein the diameter of the linear equal-diameter section, the diameter of the streamline reducing section and the diameter of the linear reducing section decrease in sequence. The protective jacket is arranged at least around the streamline reducing section and the linear reducing section of the reducing central spindle. The protective jacket further comprises a developing spring ring and a metal tube of a hollowed-out structure, the metal tube and / or the spring ring are / is coated with a high-molecular polymer coating, and the high-molecular polymer coating is coated with a hydrophilic coating. Compared with existing medical guide wires, the medical guide wire has excellent comprehensive performance.

Owner:MICROPORT NEUROTECH SHANGHAI

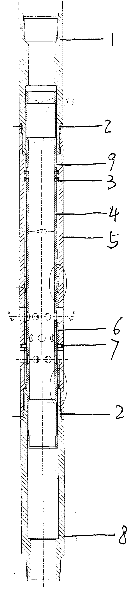

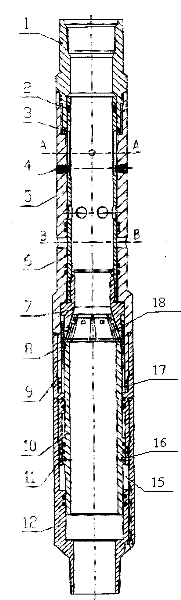

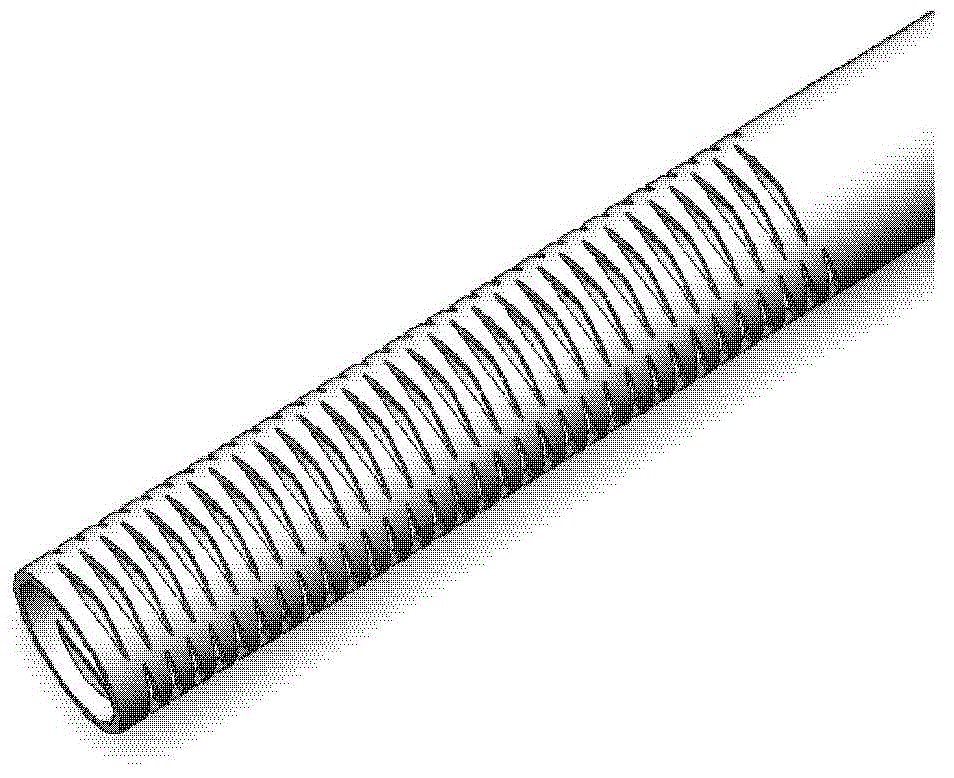

Rotary steering well drilling device

ActiveCN105525875AReal-time adjustmentImprove controlDirectional drillingAutomatic control for drillingWell drillingControl valves

The invention relates to a rotary steering well drilling device in the field of well drilling tools. The rotary steering well drilling device is mainly composed of a central spindle, a positioning cylinder, a positioner, a positioning key, a tension spring, a control valve, a control pin, a compression spring, an offset block, a bearing and a sealing device. The central spindle is connected with a drill column and a drill bit. During deflecting, an offset mechanism stretches out, the drill column and a well hole are eccentric, the positioning cylinder and the offset mechanism do not rotate, the drilling pressure and the torque are transmitted to the drill bit through the central spindle, and therefore a deflecting section can conduct rotary and directional drilling. During angle holding, the offset mechanism retracts back, the drill column and the well hole are concentric, the drilling pressure and the torque are transmitted to the drill bit through the central spindle, and therefore an angle holding section conducts rotary drilling. The rotary steering well drilling device is high in deflecting capability, wide in application range and capable of greatly reducing the well drilling cost of a well of a complex structure, and meanwhile the rotary steering well drilling device has the beneficial effects of being simple and reliable in structural design, convenient to machine, large in transmission torque, stable in operation and the like.

Owner:CHINA PETROCHEMICAL CORP +1

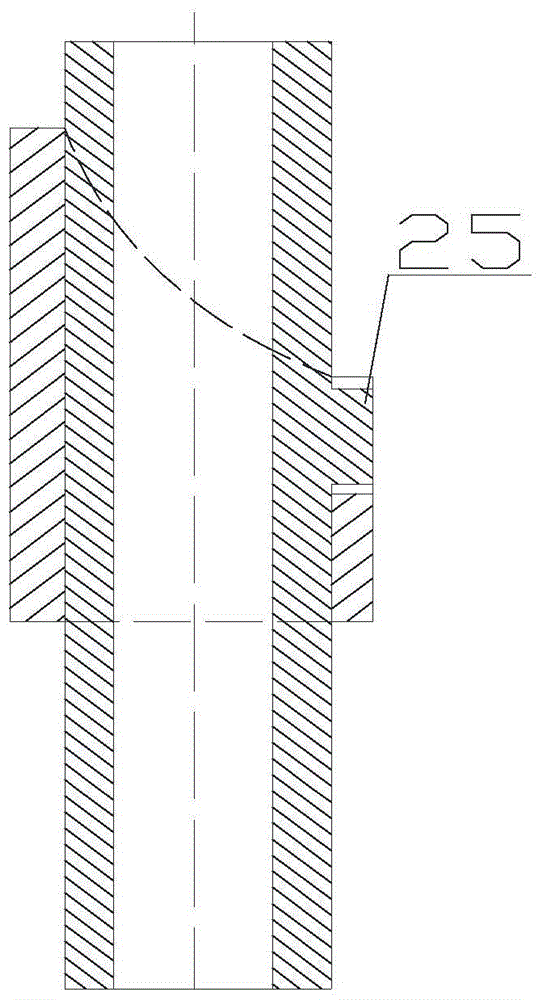

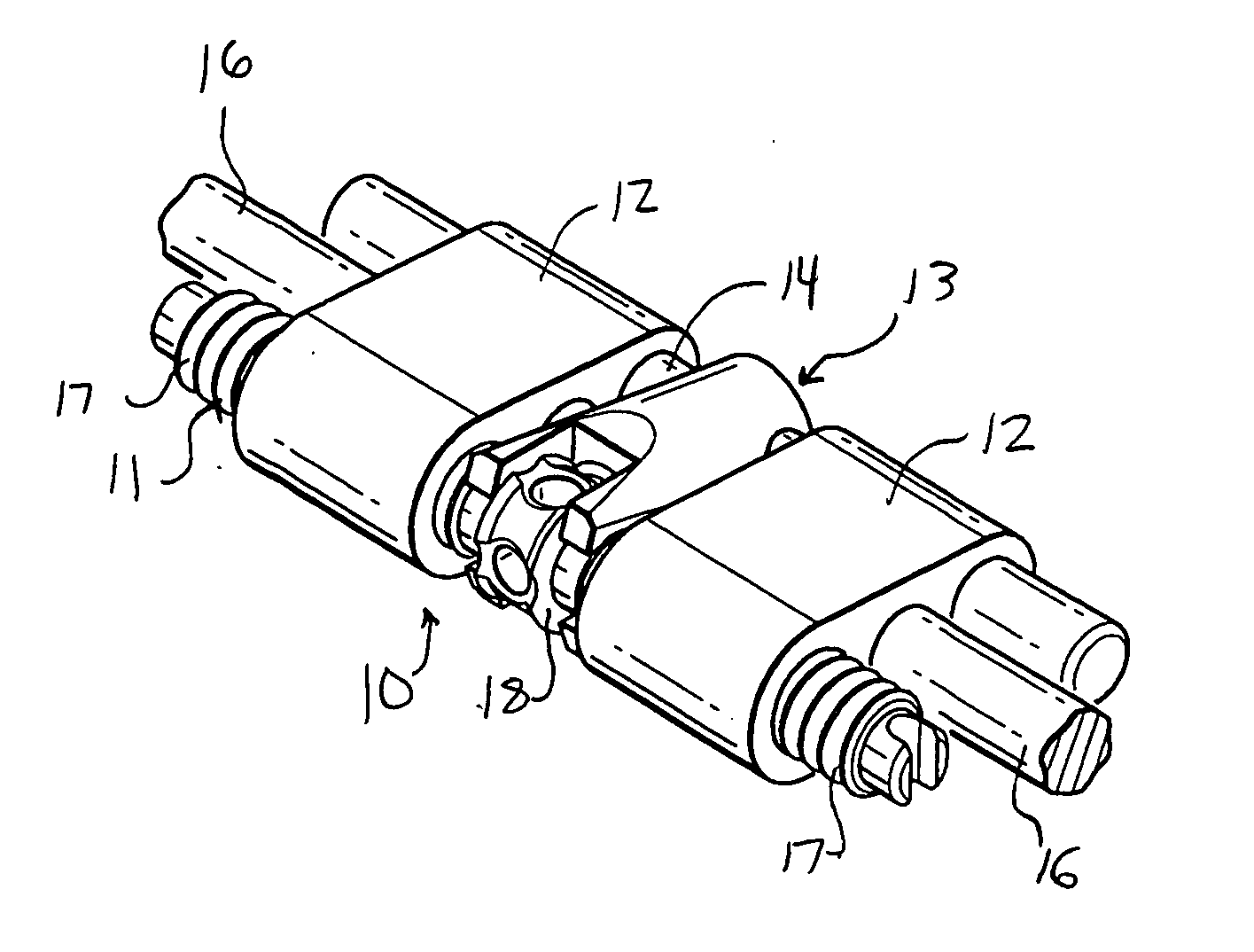

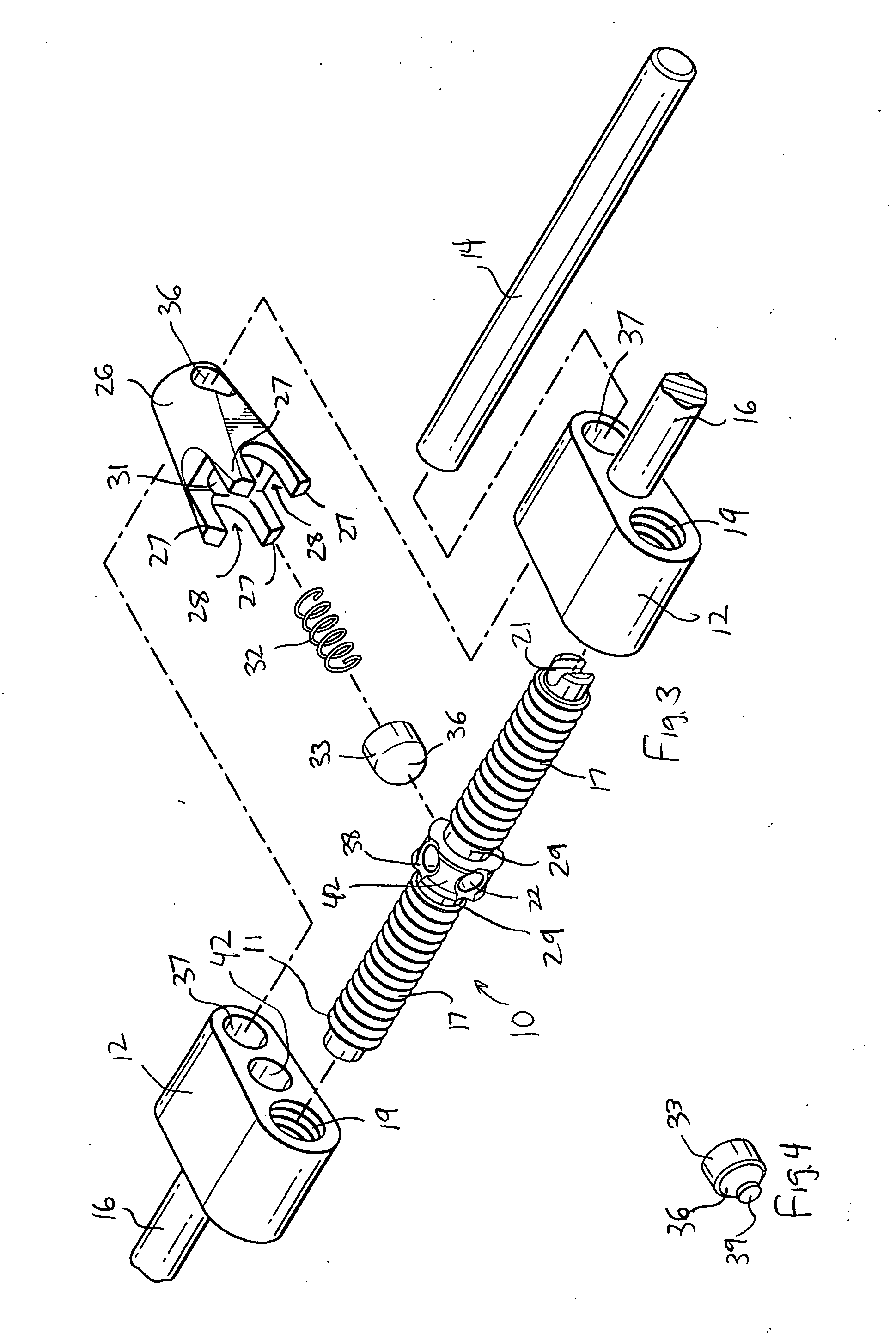

Orthodontic force module

InactiveUS20070275341A1Less sensitive to mechanical breakageMore protective effectOthrodonticsDental toolsLocking mechanismDetent

An orthodontic force mechanism according to the invention includes an elongated jack screw having at a pair of end portions, at least one of which is threaded, and a central spindle section between the end portions, which spindle section has at least two intersecting radial through-holes therein. A pair of nut housings are mounted on the end portions of the jack screw, at least one of which is threadedly coupled to a threaded end portion of the jack screw. A lock mechanism is mounted on the central spindle section, which lock mechanism includes a spring-loaded detent configured to engage an end opening of each of the through holes in the spindle section when such through hole is in alignment with the detent, such that the spindle cannot rotate relative to the lock mechanism when the detent is inserted into a through-hole, and is free to rotate relative to the lock mechanism when the detent is clear of a through hole. The detent can be moved out of engagement with a through hole using a tool inserted into that through hole from its opposite end, such that a distal end of the tool pushes the detent out of the through-hole, and the same tool can then be used to rotate the jack screw.

Owner:HANKS STEPHEN D

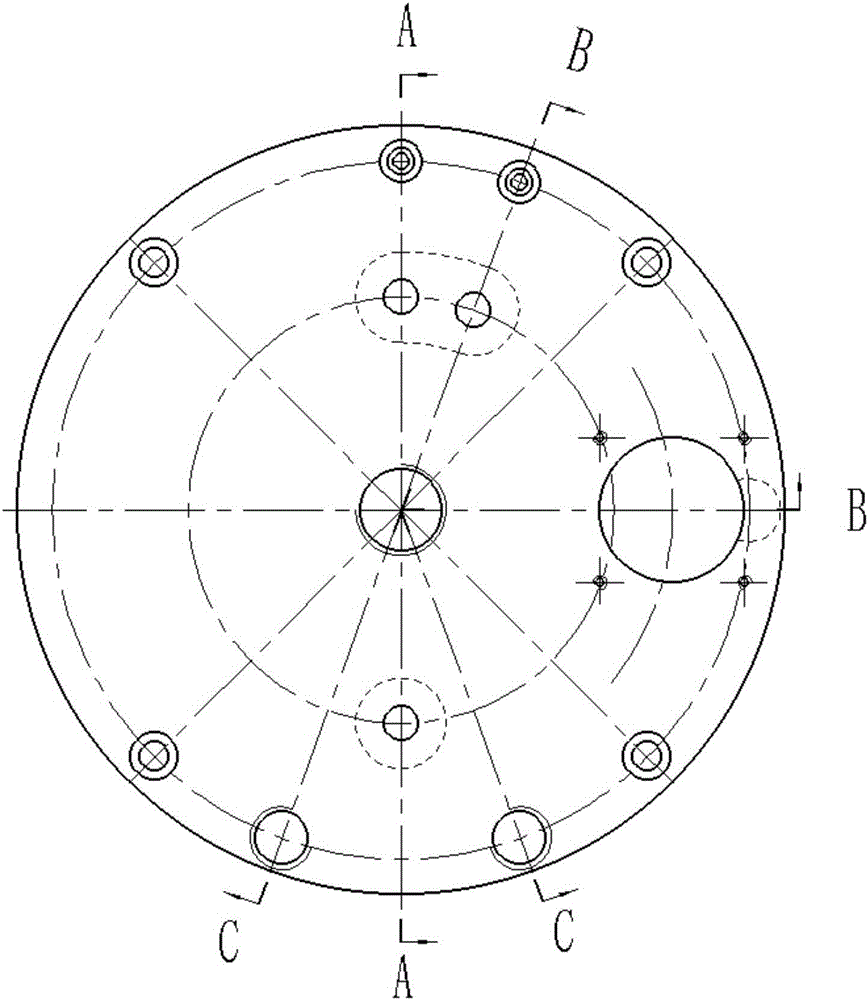

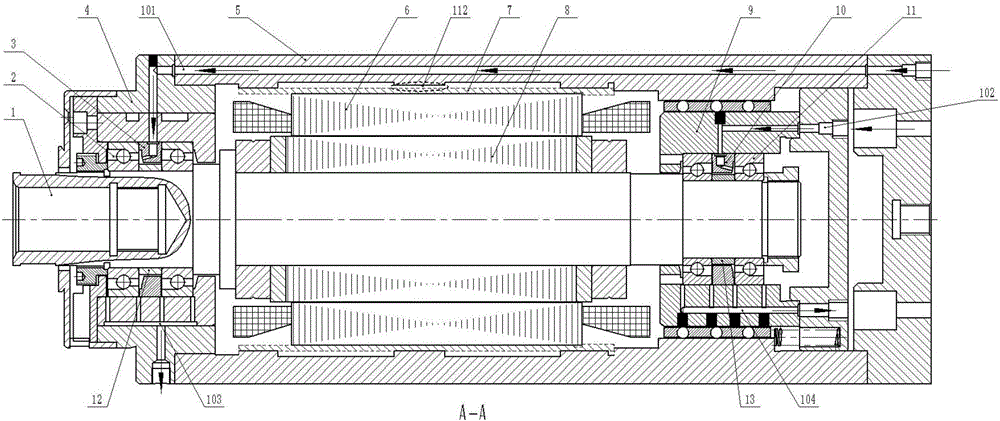

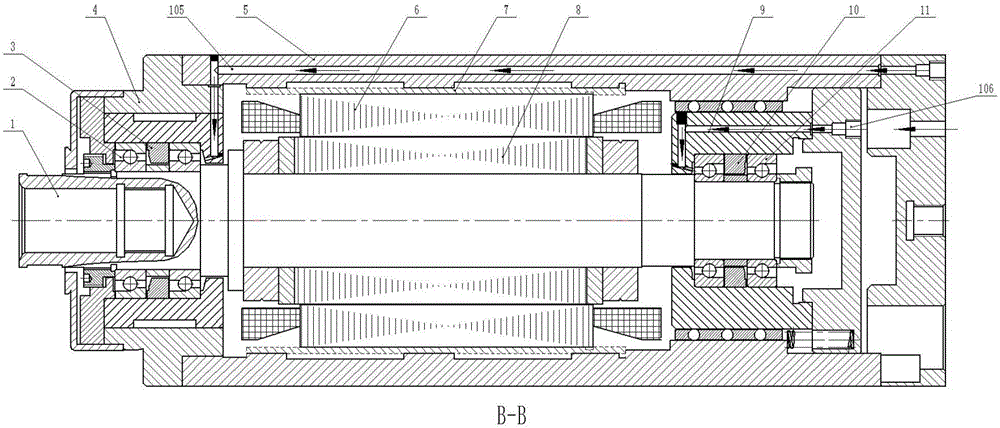

High-speed oil-gas lubrication electric spindle achieving precise oil supplying

ActiveCN106735335AGuaranteed accuracyAchieve reliabilityLarge fixed membersMaintainance and safety accessoriesGas lubricationCentral spindle

The invention discloses a high-speed oil-gas lubrication electric spindle achieving precise oil supplying, and belongs to the technical field of electric spindles. The overall electric spindle comprises a shell, and a stator is fixed in the shell; a front bearing chamber and a back bearing chamber are connected to the two ends of the shell respectively, and two bearings are connected in series in each bearing chamber, wherein the two bearings are separated through an inner bearing isolation pad and an outer bearing isolation pad; a central spindle is supported by the front bearings and the back bearings and provided with a rotor matched with the stator; each bearing is provided with an oil-gas lubrication oil line; annular cooling grooves are formed in the front bearing chamber and the shell respectively; the bearing shell is provided with oil-gas inlets and an oil-gas outlet, an oil-gas pipeline penetrates through the shell, the bearing chambers and the outer bearing isolation pads, the tail end of the pipeline is provided with an oil-gas nozzle, and each bearing is provided with an independent oil delivery line, an independent nozzle and an independent oil return line. Accordingly, by designing the independent oil-gas lubrication oil lines, nozzles and oil return lines, precise control over oil-gas lubrication parameters of the bearings is achieved, the lubricating effect of the bearings is improved, and the performance of the electric spindle is enhanced.

Owner:泰安海纳轴研科技有限公司

Spring tow hook

The invention discloses a spring tow hook which comprises a tow hook body (14), a buffering device and a joint (2). The buffering device is composed of a spring rack (3), a spring pressing plate (4), a spring (6) and a spring central spindle (9), wherein the spring pressing plate (4) is movably mounted on the spring rack (3) and can move along the spring rack (3) in the axial direction, the spring (6) is located between the spring rack (3) and the spring pressing plate (4), the spring central spindle (9) is located in the spring (6), one end of the spring central spindle (9) is fixedly connected with the spring pressing plate (4), the other end of the spring central spindle (9) extends out of the spring rack (3) and is connected with the tow hook body (14), and the joint (2) is mounted on the spring rack (3) through a spring rack pin shaft (13). According to the spring tow hook, the reliable spring buffering measurement is used, the buffering spring is used for absorbing impact energy which is then converted to heat energy, and therefore the purpose that impact on mechanical equipment is reduced as much as possible is achieved.

Owner:张晓荣

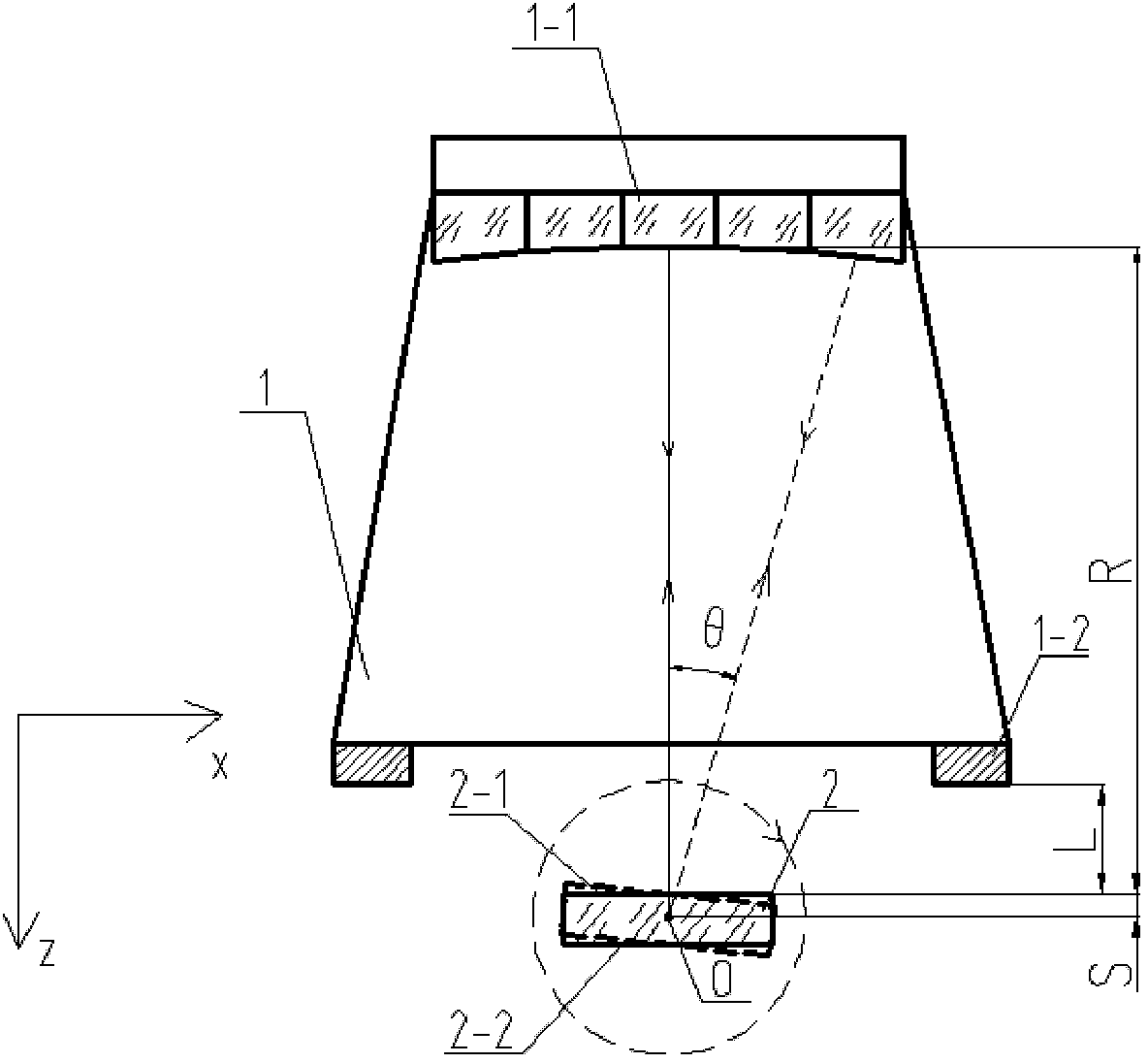

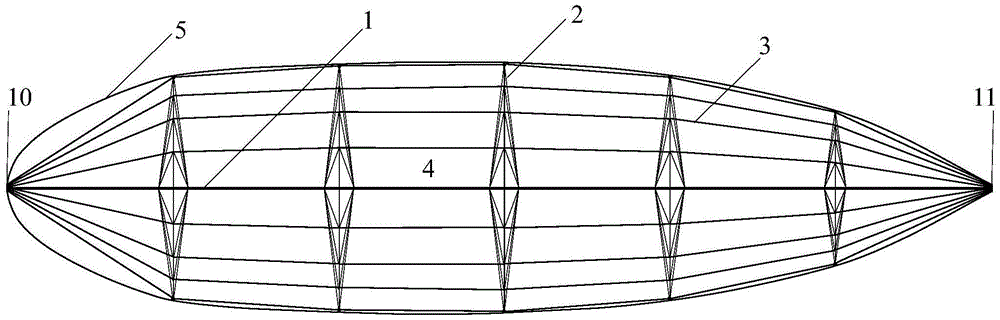

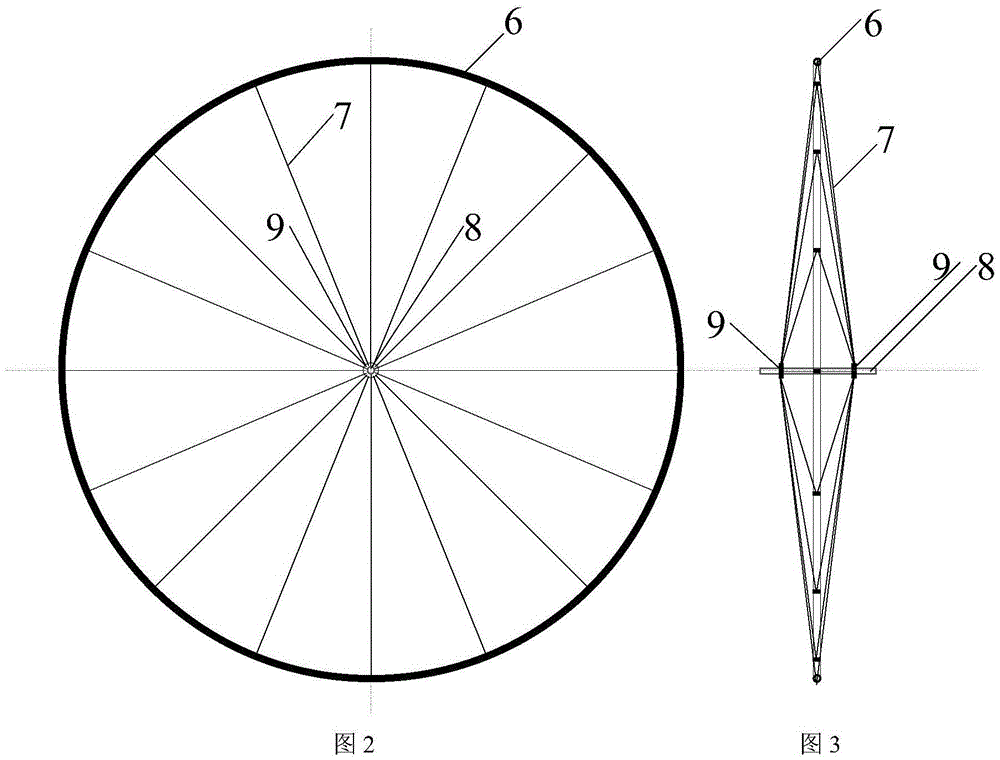

Rigid structure system of large airship

PendingCN105644761AImprove mechanical stabilityImprove mechanical propertiesRigid airshipsPre stressRigid structure

The invention relates to a rigid structure system of a large airship. The rigid structure system of the large airship comprises a prestressed structure system and a flexible outer envelop structure. The prestressed structure system is composed of a central spindle, a plurality of prestressed stiffening rings and longitudinal connecting rods. The central spindle is located in the longitudinal center of an airship envelop and penetrates through the head and tail of the airship envelop, the concentric prestressed stiffening rings are arranged on the central spindle, the outer ends of the prestressed stiffening rings are connected through the longitudinal connecting rods, and the closed structure system is formed. According to the flexible outer envelop structure, a thin film material is used for being wrapped outside the structure. The rigid structure system improves the overall mechanical property and flight capacity of the large airship, the large airship can ascend / descend in a shape-preserving mode, and the airship has good flight capacity in a specified atmospheric environment and return capacity in an emergency state.

Owner:付功义 +3

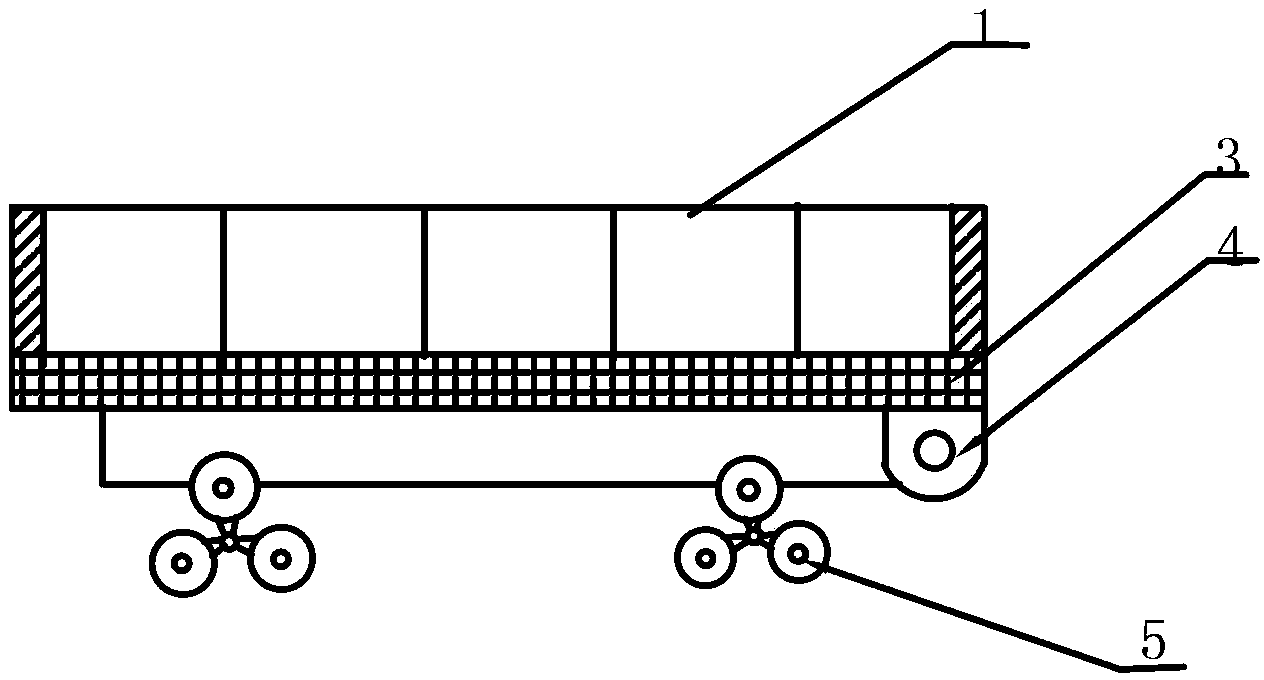

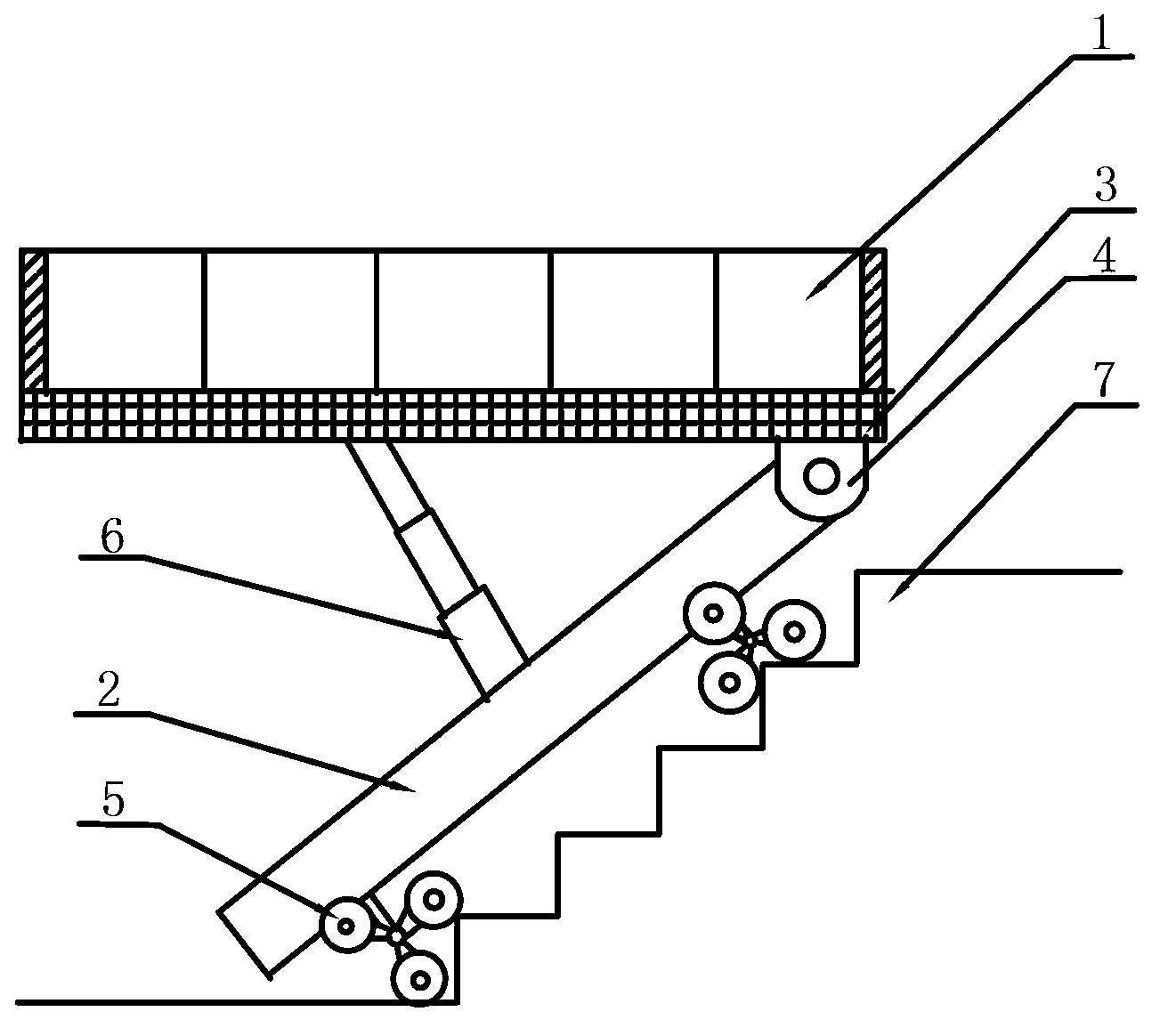

Stairs-climbing trolley

InactiveCN104340245AGuaranteed stabilityNot easy to flipHand carts with multiple axesHand cart accessoriesEngineeringRoad surface

A stairs-climbing trolley comprises a compartment, a bottom plate and wheels disposed under the bottom plate. A carrier is fixed to the lower end of the compartment. Two sides of the tail end of the carrier are provided with a pair of lugs. The tail end of the bottom plate is movably connected with the lugs of the carrier through a rotating shaft. The middle of the bottom end of the carrier is connected with the bottom plate through a telescopic bar. Each wheel structure comprises a central spindle and wheel sets, each which is composed of three planetary wheels and two of which are arranged on two sides of the central spindle; the three planetary wheels are evenly distributed at 120-degree angles around the central spindle. The stairs-climbing trolley can travel on the horizontal roads and can also climb a slope or stairs; during climbing the stairs, the trolley can keep articles in the compartment stably and rarely turned over; the stairs-climbing trolley is simple in structure and low in manufacturing costs and can help people climb upstairs and downstairs with less labor consumed and conveniences brought.

Owner:周斌龙

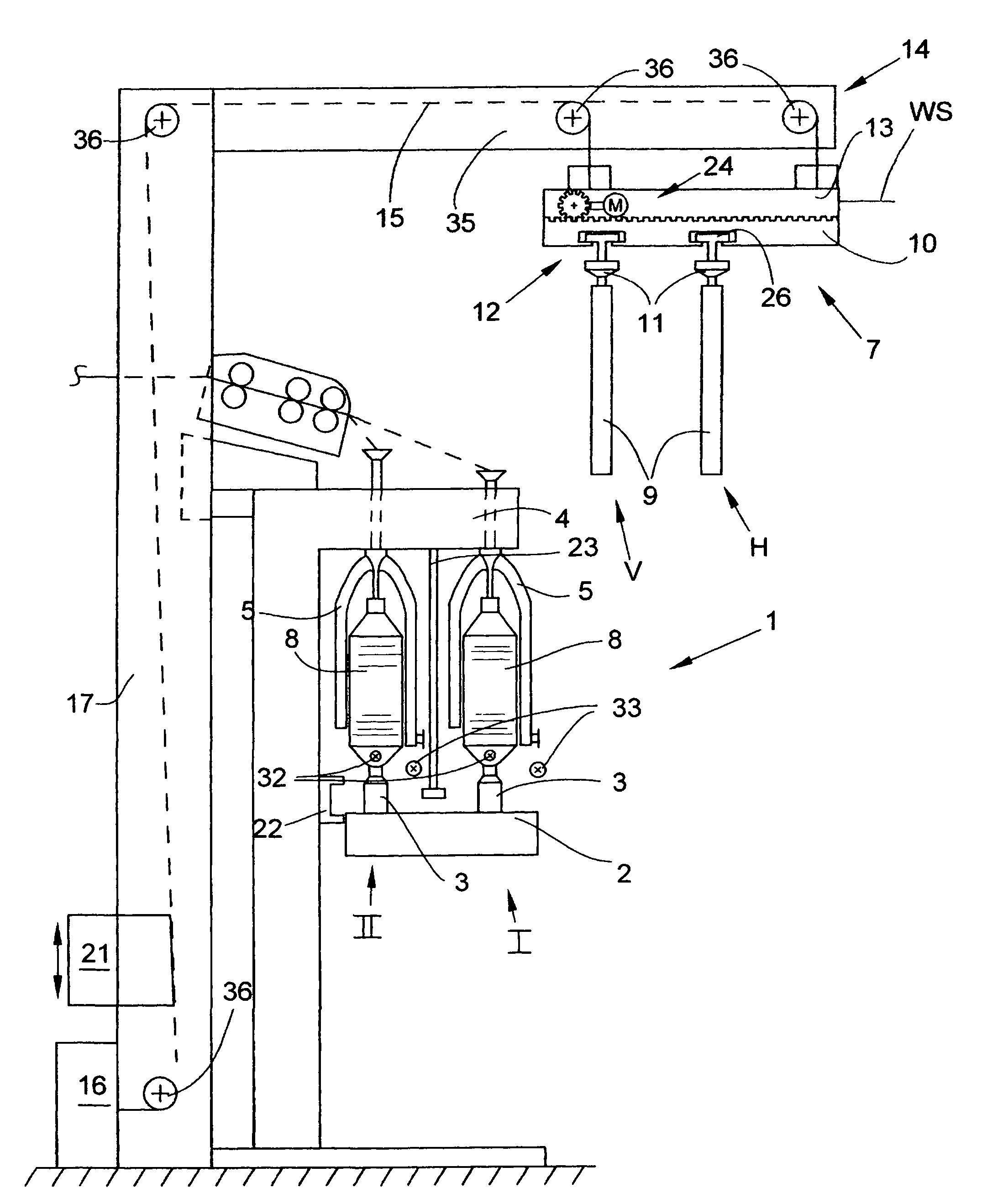

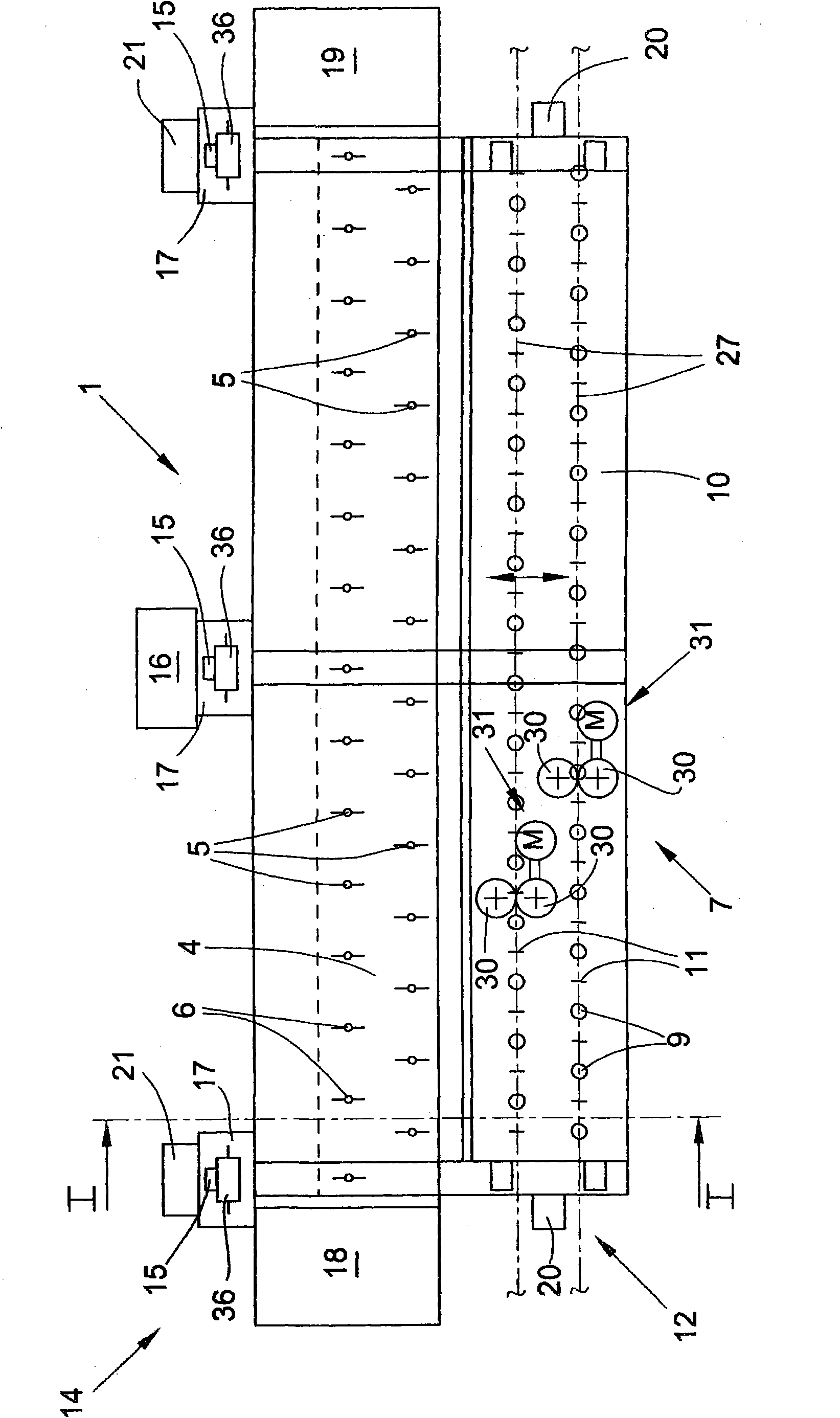

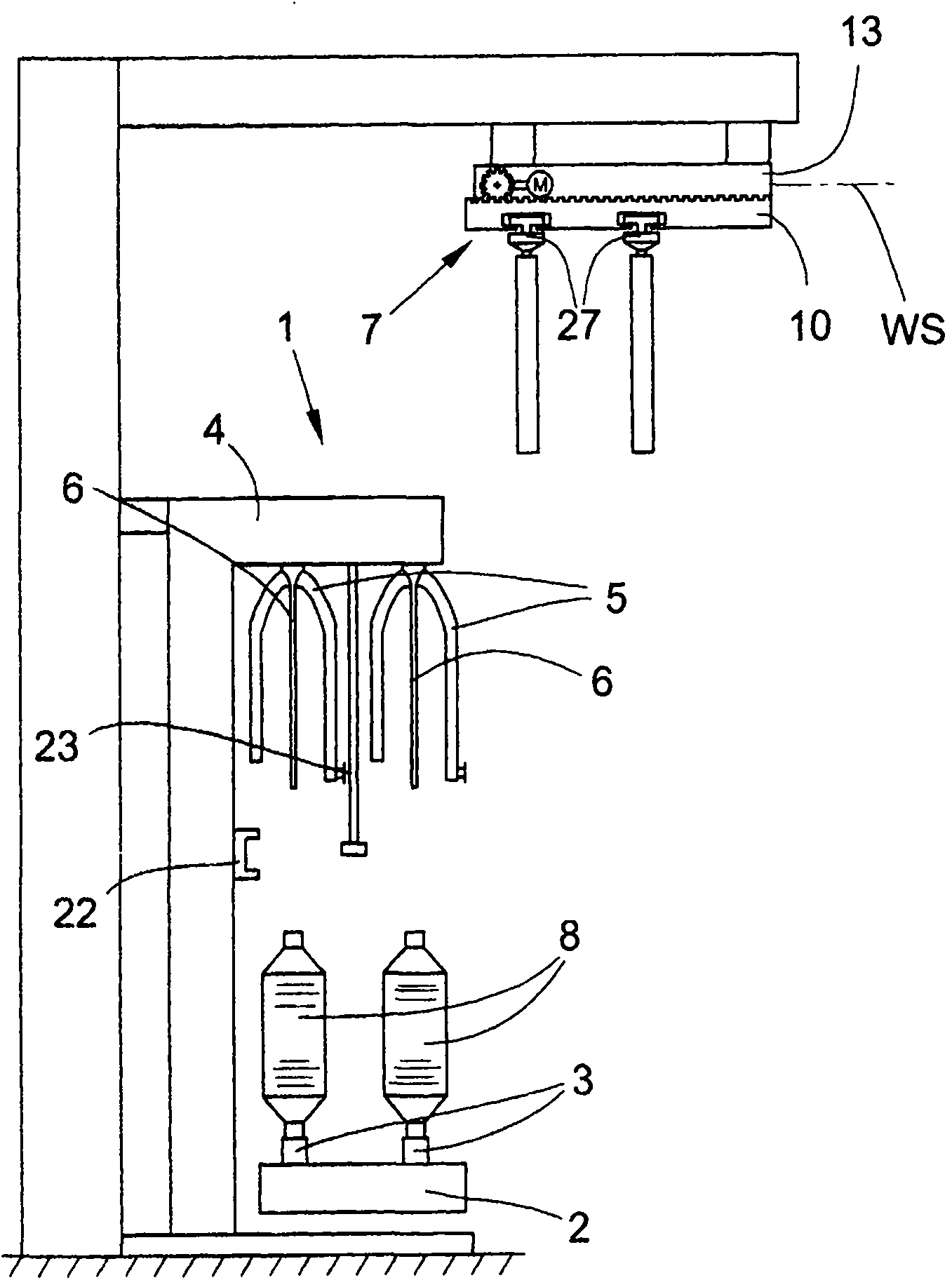

Reel change device for roving machine

ActiveCN101988224AEasy loadingReliable receptionFilament handlingTextiles and paperBobbinEngineering

The present relates to a reel change device for a roving machine. The roving machine is provided with a bobbin rail which can be equipped with a mode that the vertical shifting is allowed, and is provided with a flyer rail which is fixedly equipped. The flyers of the flyer rail are respectively provided with a central spindle blade. The reel change device is provided with a replacement platform which is movably equipped and is provided with a transport mechanism. The transport mechanism is provided with a tube support which is used for suspending and conveying roving bobbins and hollow bobbins. The reel change device (7) is provided with a base component (13) which can be adjusted vertically. The base component is connected with an outer frame structure (14) which bestrides the roving machine (1). A change platform (10) is configured on the base component (13) and can move into the riving machine (1) from a front surface so the hollow tube supports (11) of the conveying mechanism (12) and the tube supports (11) equipped with the hollow bobbins can be positioned to accurately preset positions in the area of the bobbin rail (2). The conveying mechanism (12) is composed of an annular conveyor (26) or two suspension type frame sets (27).

Owner:SAURER GERMANY GMBH & CO KG

Device for testing dynamic friction torque of precise micro rolling bearing

InactiveCN102778313AOutstanding FeaturesHighlight significant progressMachine bearings testingWork measurementFriction torqueCoupling

The invention relates to a device for testing the dynamic friction torque of a precise micro rolling bearing. The device comprises a machine base, an air static pressure suspension bearing block, two sets of tested bearings, a driving electric spindle, a pressure sensor and a speed sensor, wherein the two sets of tested bearings are arranged in a central hole of a suspension shaft in the air static pressure suspension bearing block; a rotary central spindle is sleeved in the central hole of the two sets of tested bearings and is connected with the driving electric spindle through a rubber hose flexible coupling; the pressure sensor is arranged on the part close to the left end of the suspension shaft; and the speed sensor is arranged on the part close to the right end of the suspension shaft. The dynamic friction torque of the tested bearings can be tested in real time in a start process, a stop process and an operation process with different rotation speeds.

Owner:SHANGHAI UNIV

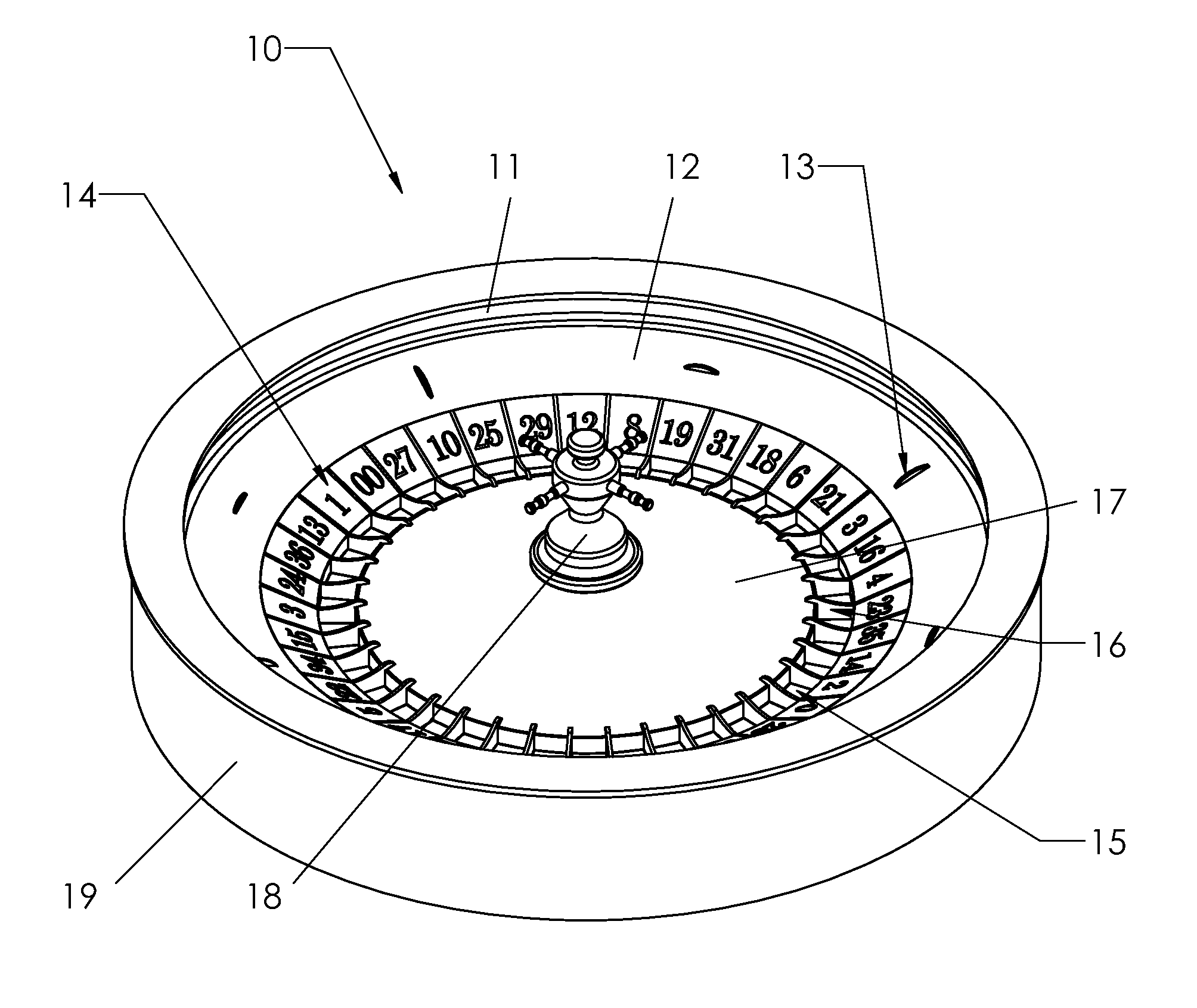

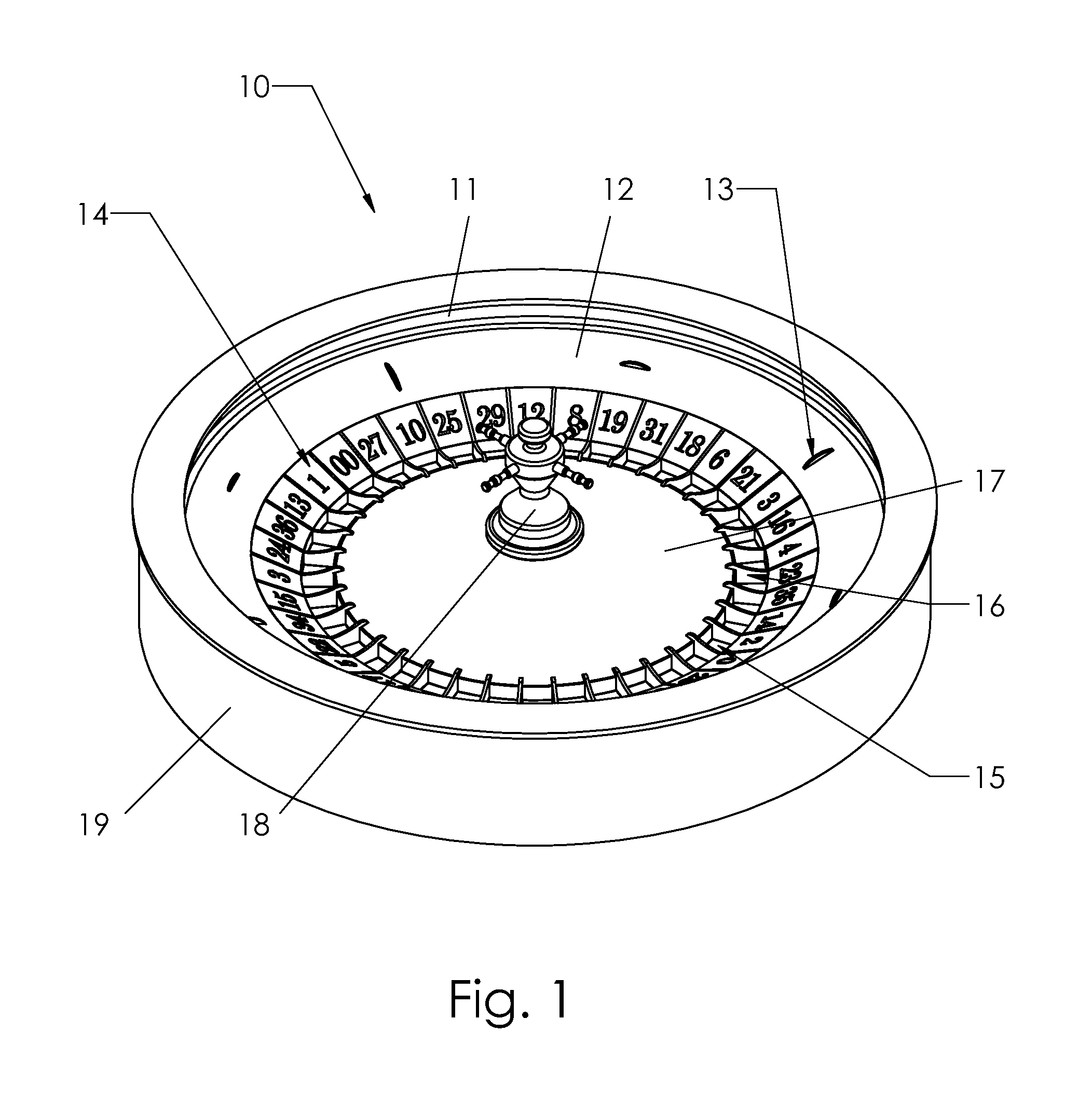

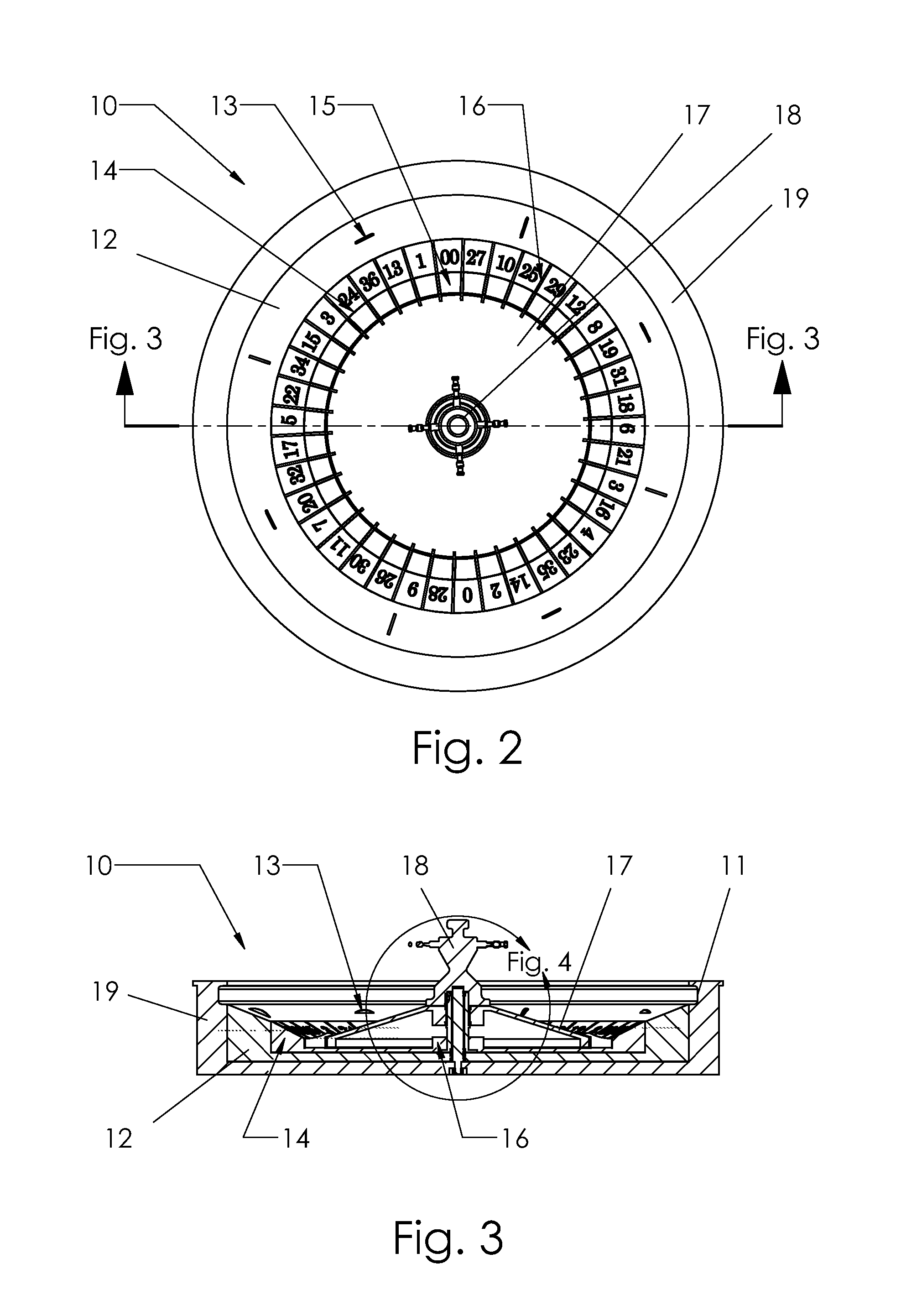

Roulette wheel having reduced bias

InactiveUS20120175840A1Less chance of biasReduces the affect that any single elementCard gamesRoulette gamesEngineeringGrinding wheel

A roulette wheel includes a central spindle, a wheelhead and turret unit freely rotatable around the central spindle, a cone freely rotatable around the central spindle independently of the wheelhead and turret unit, and a lower ball track. The lower ball track can be stationary or can be freely rotatable around the central spindle independently of the wheelhead and turret unit and of the cone.

Owner:ZERGA JOSEPH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com