A driving shaft assembly of a screw drilling tool with a vibration damping function

A technology for screw drilling tools and transmission shafts, which is applied in the direction of rotation vibration suppression, driving devices for drilling in boreholes, drill pipes, etc., and can solve problems such as reducing the normal service life, falling accidents, loosening of screw drilling tool connections, etc., to achieve The effect of reducing drilling cost, reducing tripping and improving life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

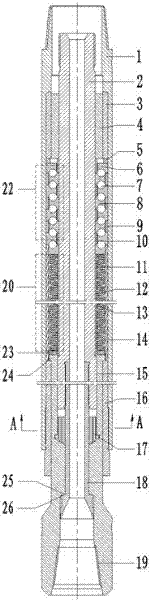

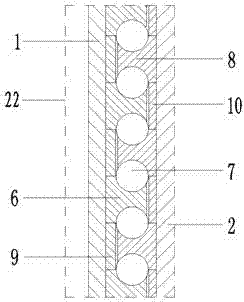

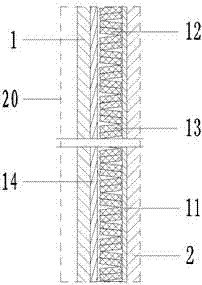

[0013] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a screw drilling tool transmission shaft assembly with vibration damping function of the present invention is composed of a housing 1, an upper transmission shaft 2, an upper radial bearing static sleeve 3, an upper radial bearing movable sleeve 4, and a load bearing group 22 , vibration damping device 20, lower transmission shaft 15, lower short joint 16 and mandrel 18, etc., its structural features are: the upper transmission shaft 2 is installed inside the housing 1, and the lower end of the upper transmission shaft 2 has a spline groove 21; the upper diameter The outer wall and inner wall of the static bearing sleeve 3 cooperate with the inner wall of the housing 1 and the outer wall of the upper radial bearing movable sleeve 4 respectively, and the inner wall of the upper radial bearing movable sleeve 4 cooperates with the upper transmission shaft 2; the bearing bearing group 22 is installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com