Patents

Literature

1061results about "Expansion mandrels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

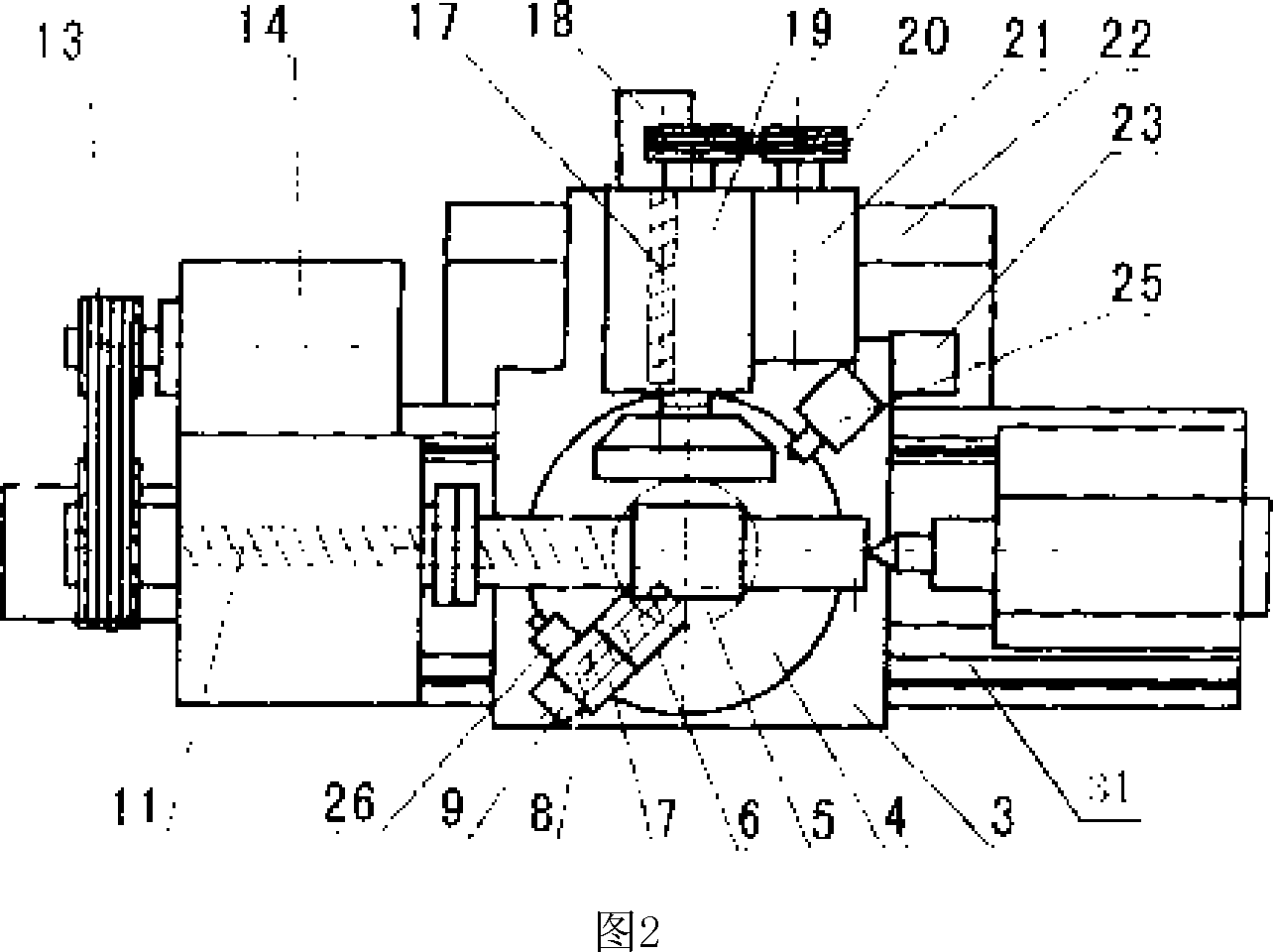

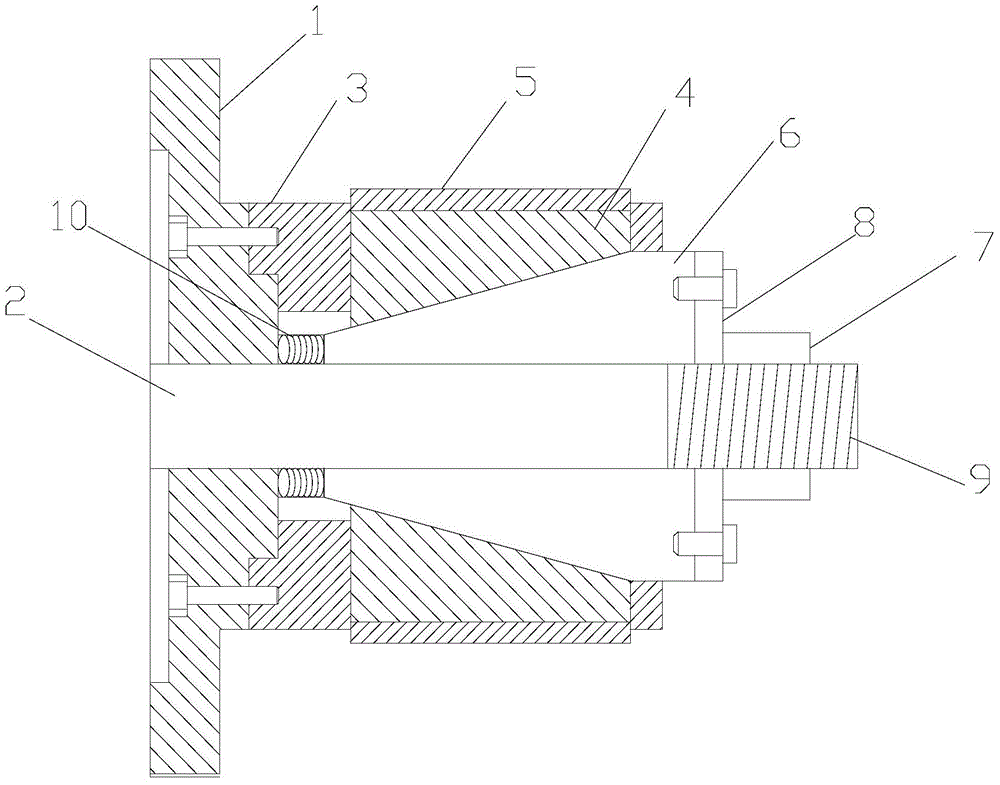

Thin-wall round pipe turning and clamping device

InactiveCN104607681AReasonable designCompact structureExpansion mandrelsEngineeringUltimate tensile strength

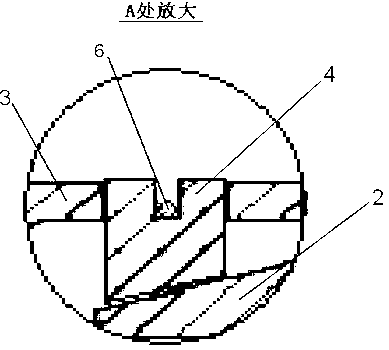

The invention discloses a thin-wall round pipe turning and clamping device. The thin-wall round pipe turning and clamping device comprises a slide block bracket for slidingly mounting inclined surface slide blocks, a screw rod for slidingly mounting and supporting taper sleeves, and a clamping base, wherein the slide block bracket and the screw rod are both fixedly mounted at one end of the clamping base; the taper sleeves are slidingly mounted on the screw rod; at least two inclined surface slide blocks fitting the taper sleeves to tightly eject workpieces from the inner sides are slidingly mounted on the slide block bracket; elastic cushion blocks are respectively arranged between all the inclined surface slide blocks and the workpieces; fastening nuts for tightly pressing the taper sleeves are arranged at the ends of the screw rod; and antiskid washers are arranged between the fastening nuts and the end surfaces of the taper sleeves. The thin-wall round pipe turning and clamping device has the characteristics of reasonable design, simple structure, good use effect, high machining precision, convenience for disassembly of the workpieces, low labor intensity, high production efficiency, low production cost and convenience for promotion and application.

Owner:XIAN ZHIYUE ELECTROMECHANICAL TECH

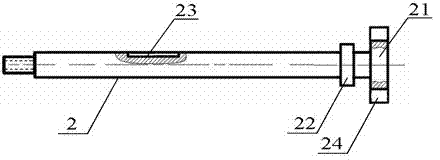

Expansion shaft

The invention relates to an expansion shaft which comprises a cylindrical main body of the expansion shaft. The expansion shaft is characterized in that a hole in the same coaxial line of the main body is formed in the main body, an ejector rod in the same coaxial line of the hole is arranged in the hole, one end of the ejector rod is inserted into the main body, the other end of the ejector rod is connected with the end of the main body through threads, the ejector rod is provided with tapered ejection blocks, at least two radial through holes are arranged in positions, corresponding to the tapered ejection blocks, of the main body, an expansion rod is inserted into the radial through holes, and the lower end of the expansion rod presses the tapered ejection blocks in an abutted mode. The expansion shaft has the advantages of being simple in structure, convenient to use, easy to maintain and detect and low in cost.

Owner:TIANJIN JINWANFANG STEEL STRUCTURE

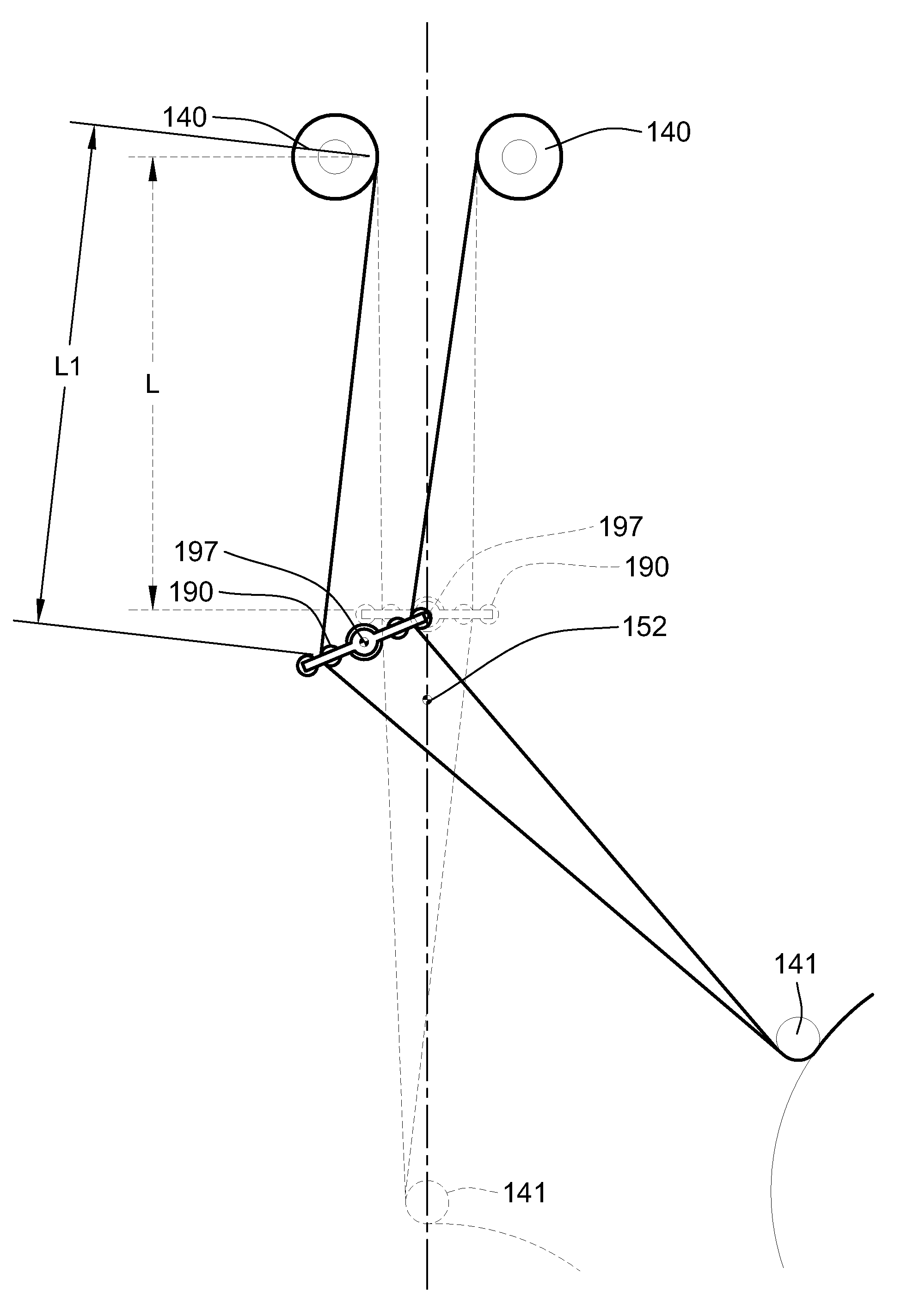

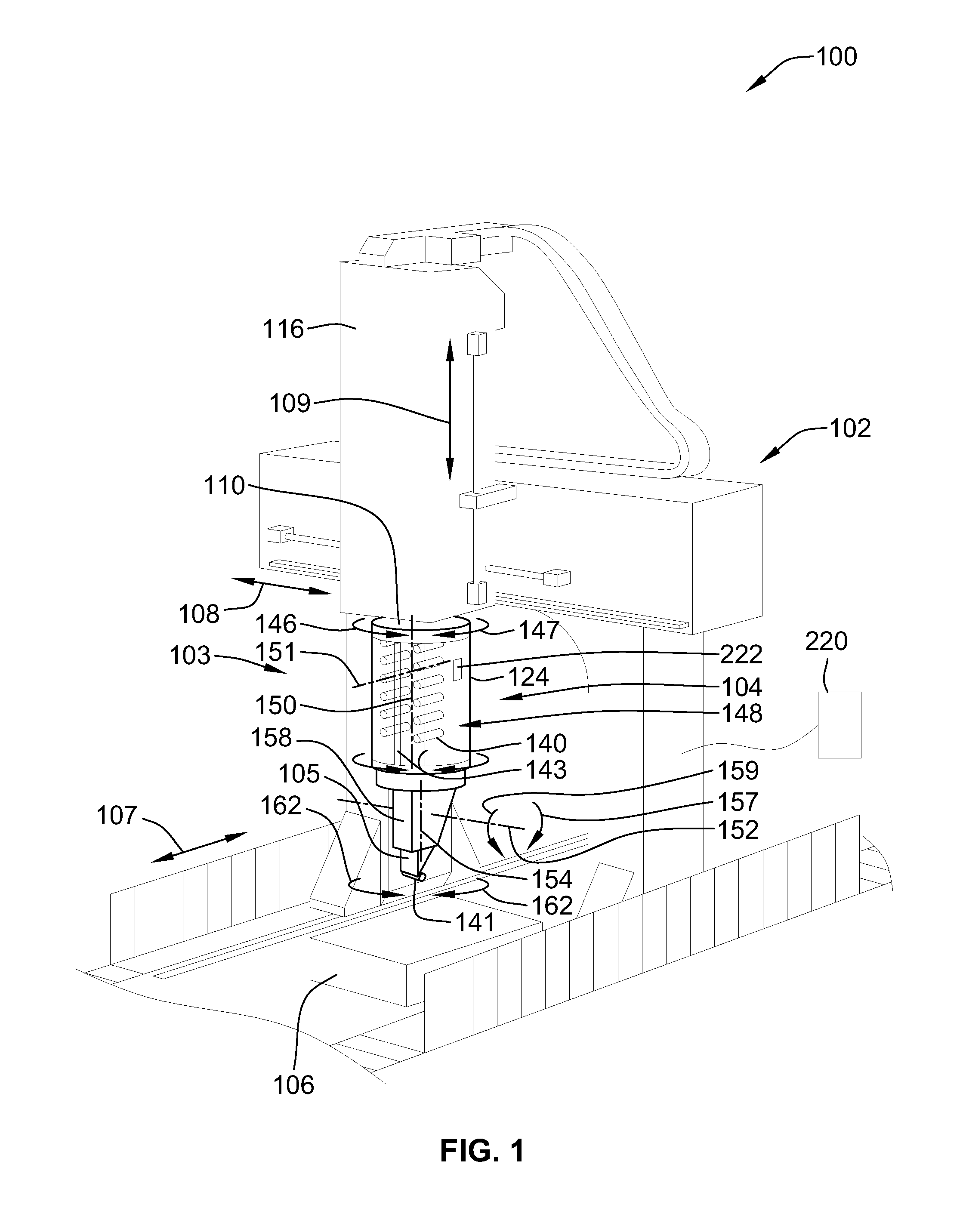

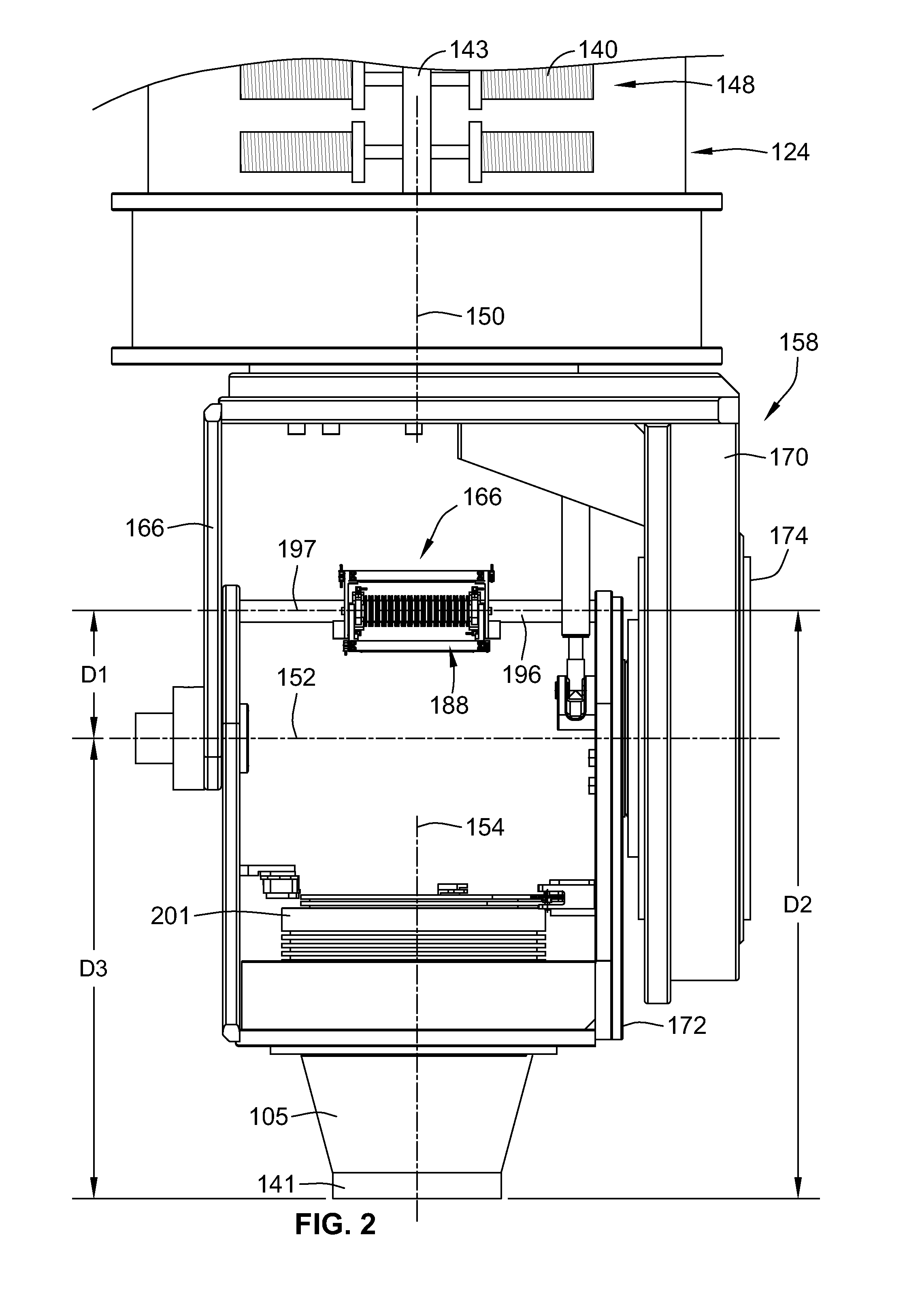

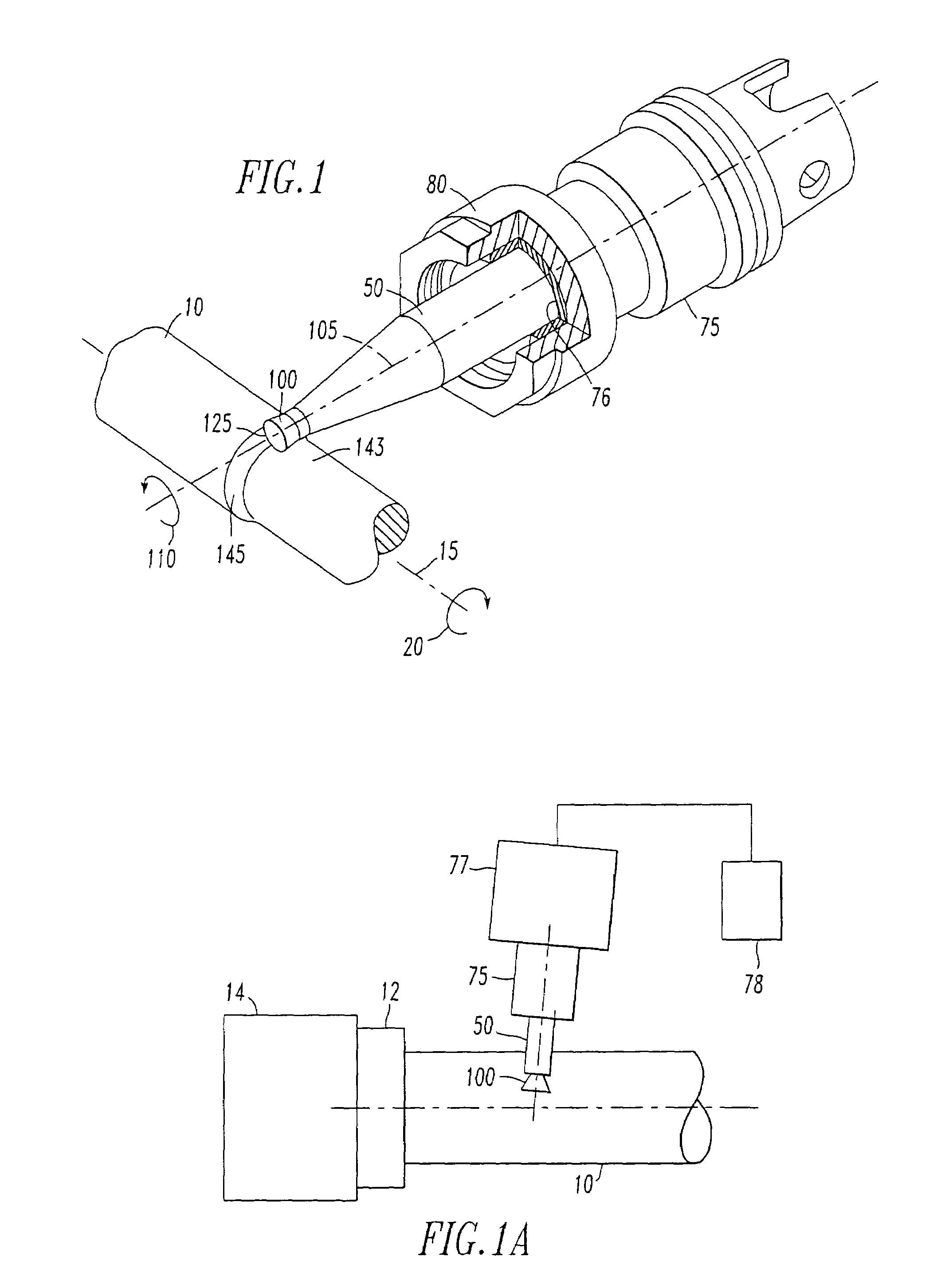

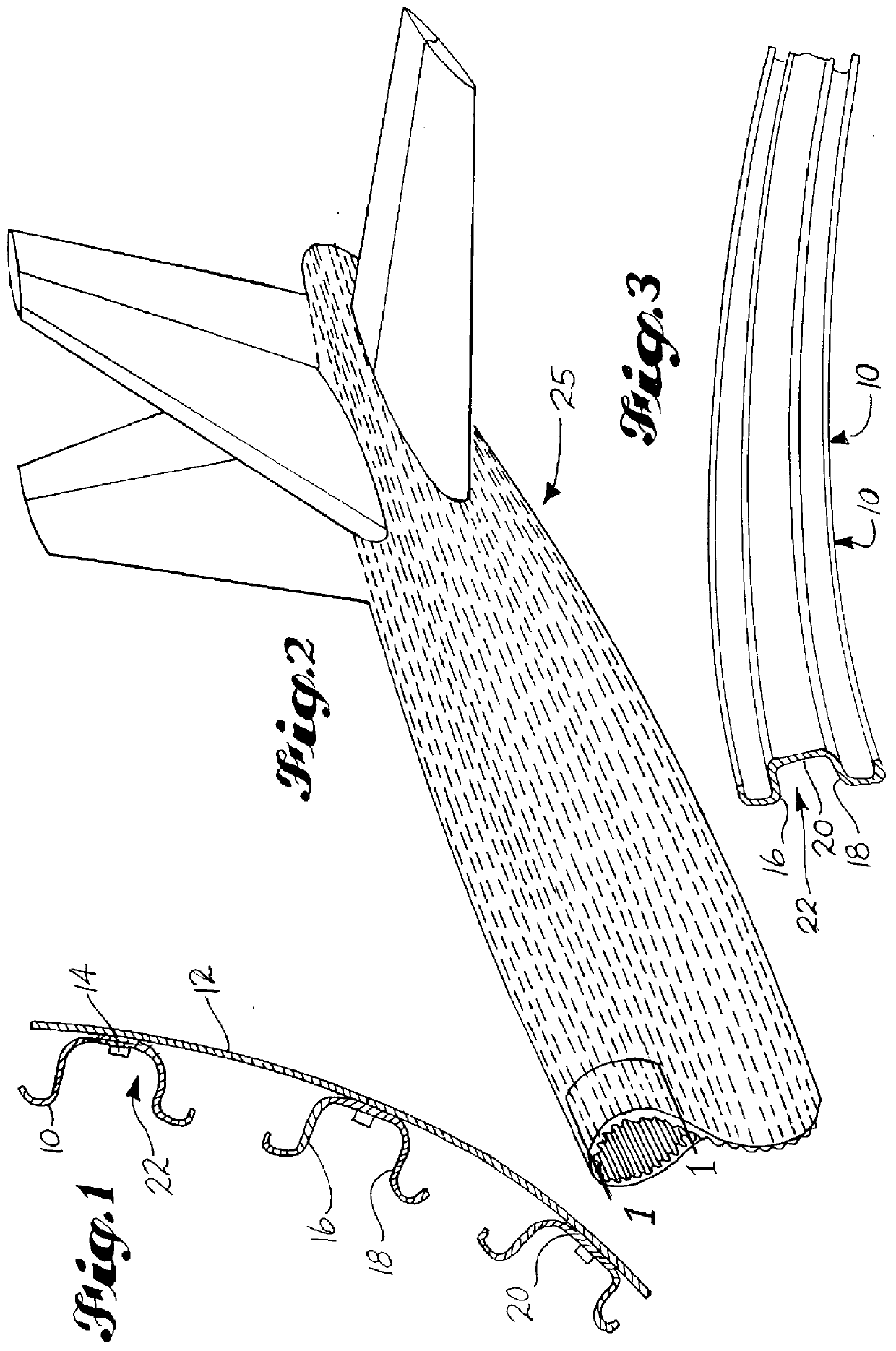

Fiber delivery apparatus and system having a creel and fiber placement head with polar axis of rotation

ActiveUS8534338B2Improve protectionReduce any negative affects on fiber towsEngine sealsLamination ancillary operationsFiberDegrees of freedom

A fiber placement system including positioner and a fiber delivery apparatus having a creel assembly and a fiber placement head is provided. The positioner moves the entire fiber delivery apparatus including the creel assembly and the fiber placement head via at least three linear degrees of freedom. The fiber delivery apparatus includes an articulating wrist for moving the fiber placement head relative to the creel assembly. The fiber placement apparatus is substantially free of linear degrees of freedom within the fiber tow paths between the spools and the fiber placement head. One or more rotational degrees of freedom may be provided along the tow path. In one embodiment, the interface between the fiber delivery apparatus and the positioner is laterally offset such that a portion of the creel axially overlaps with vertical ram of the positioner.

Owner:INGERSOLL MACHINE TOOLS

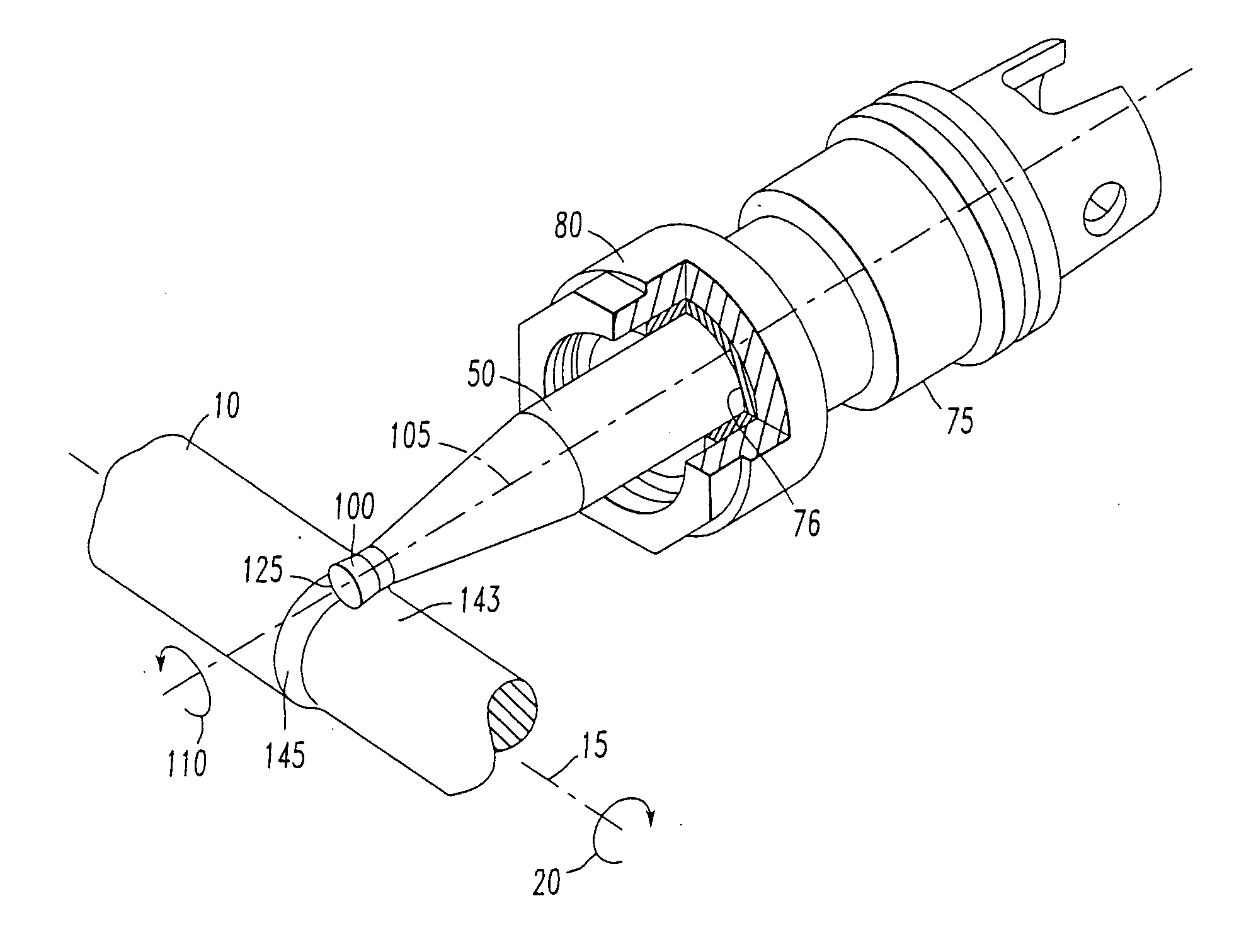

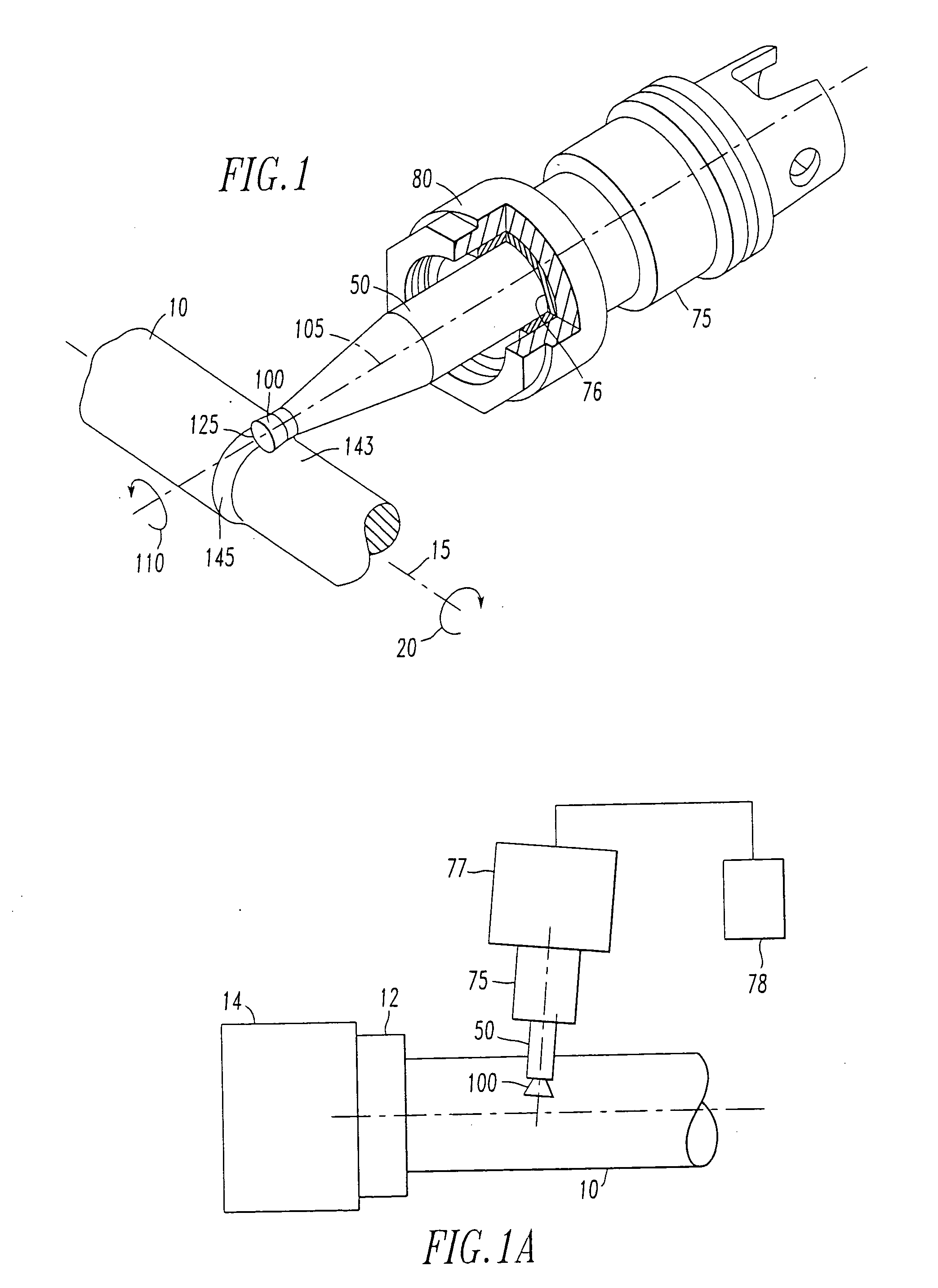

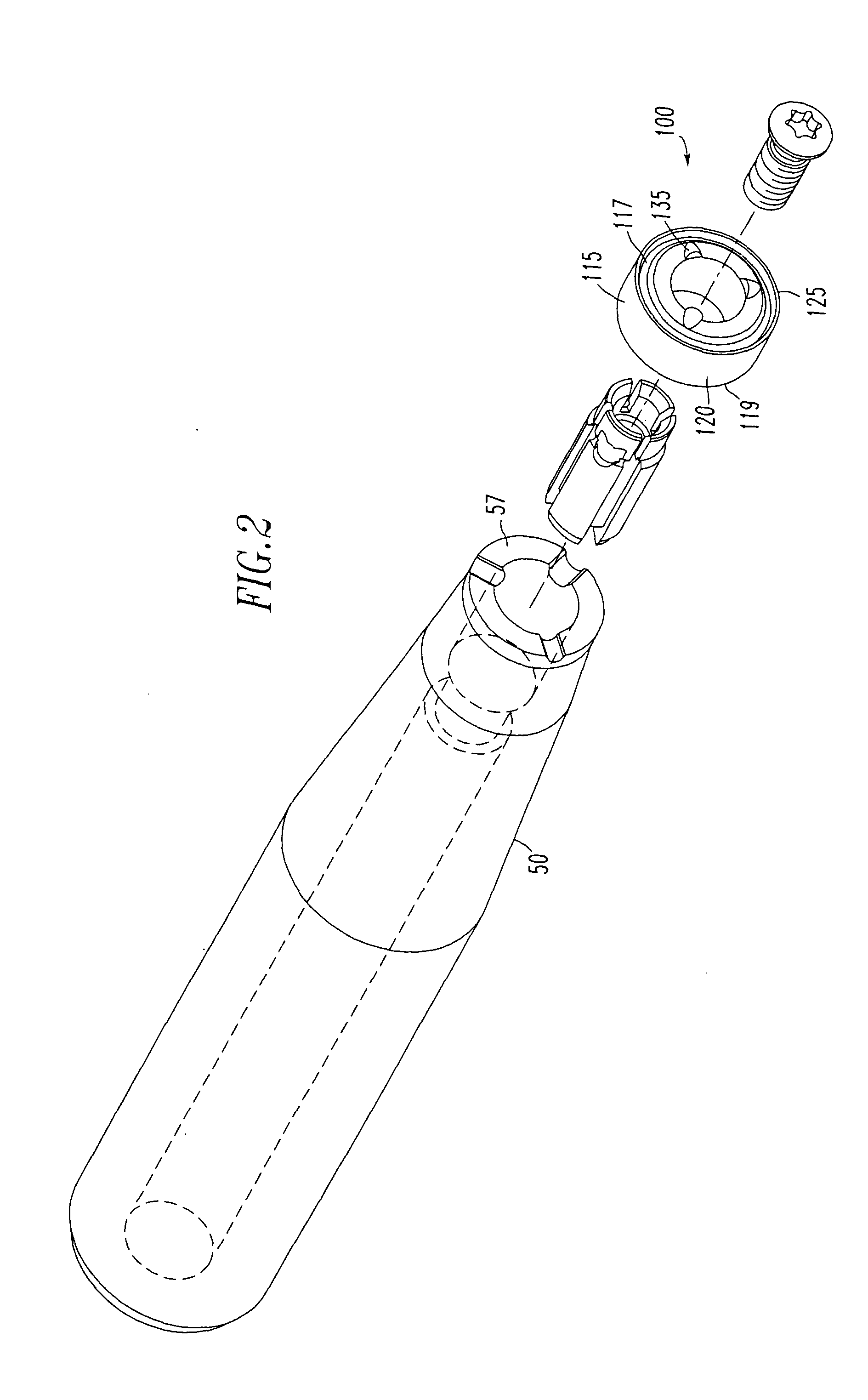

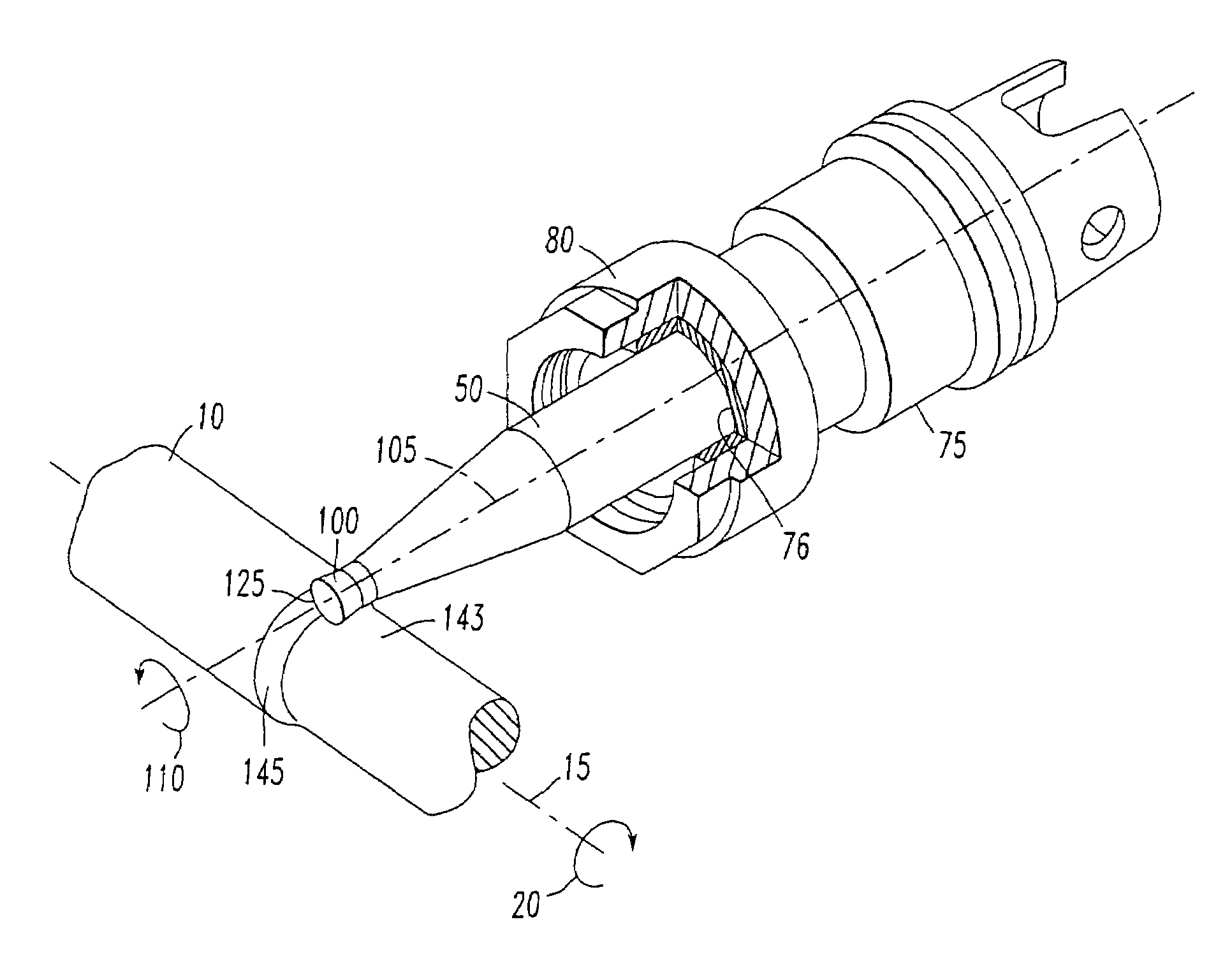

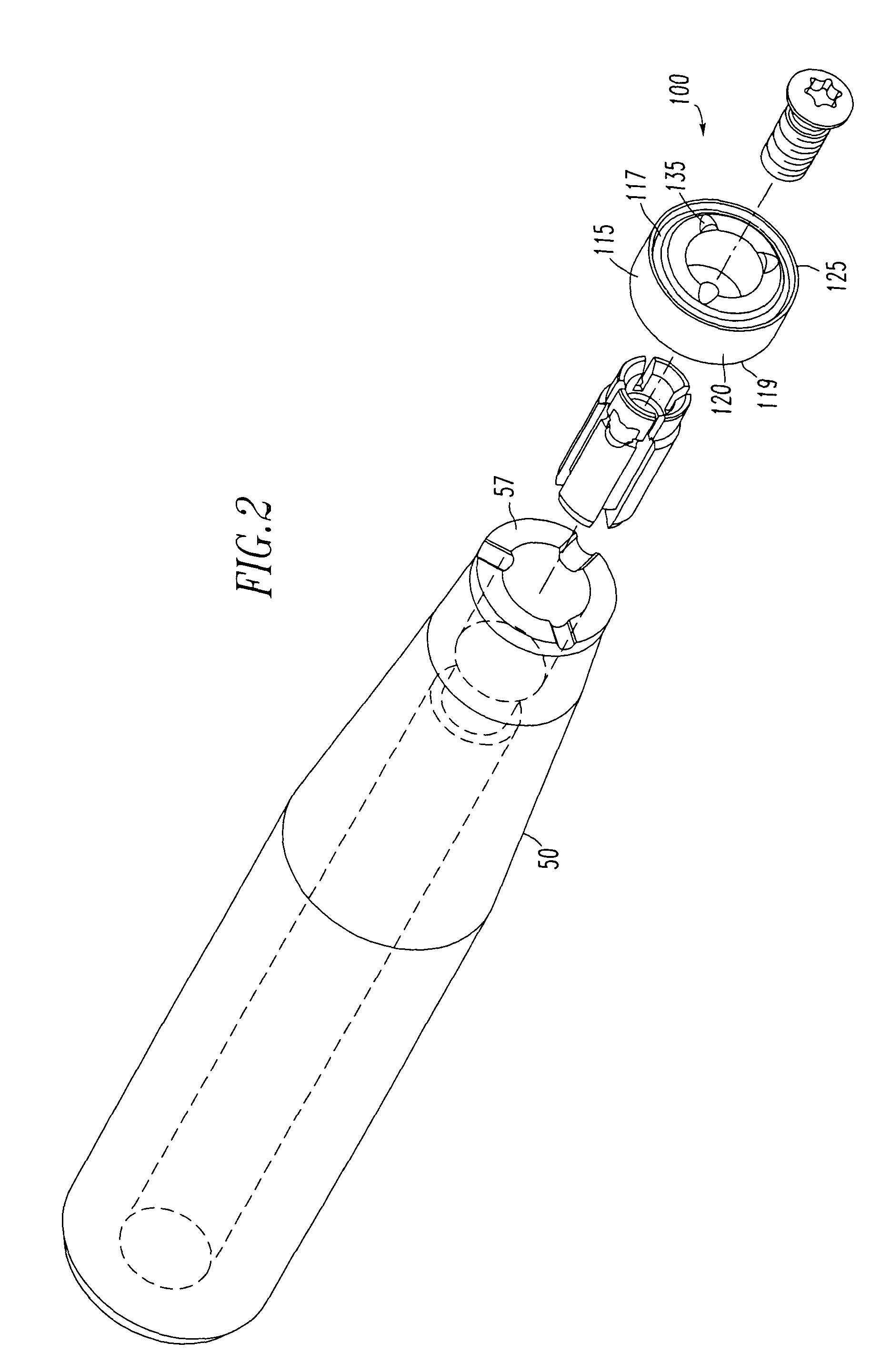

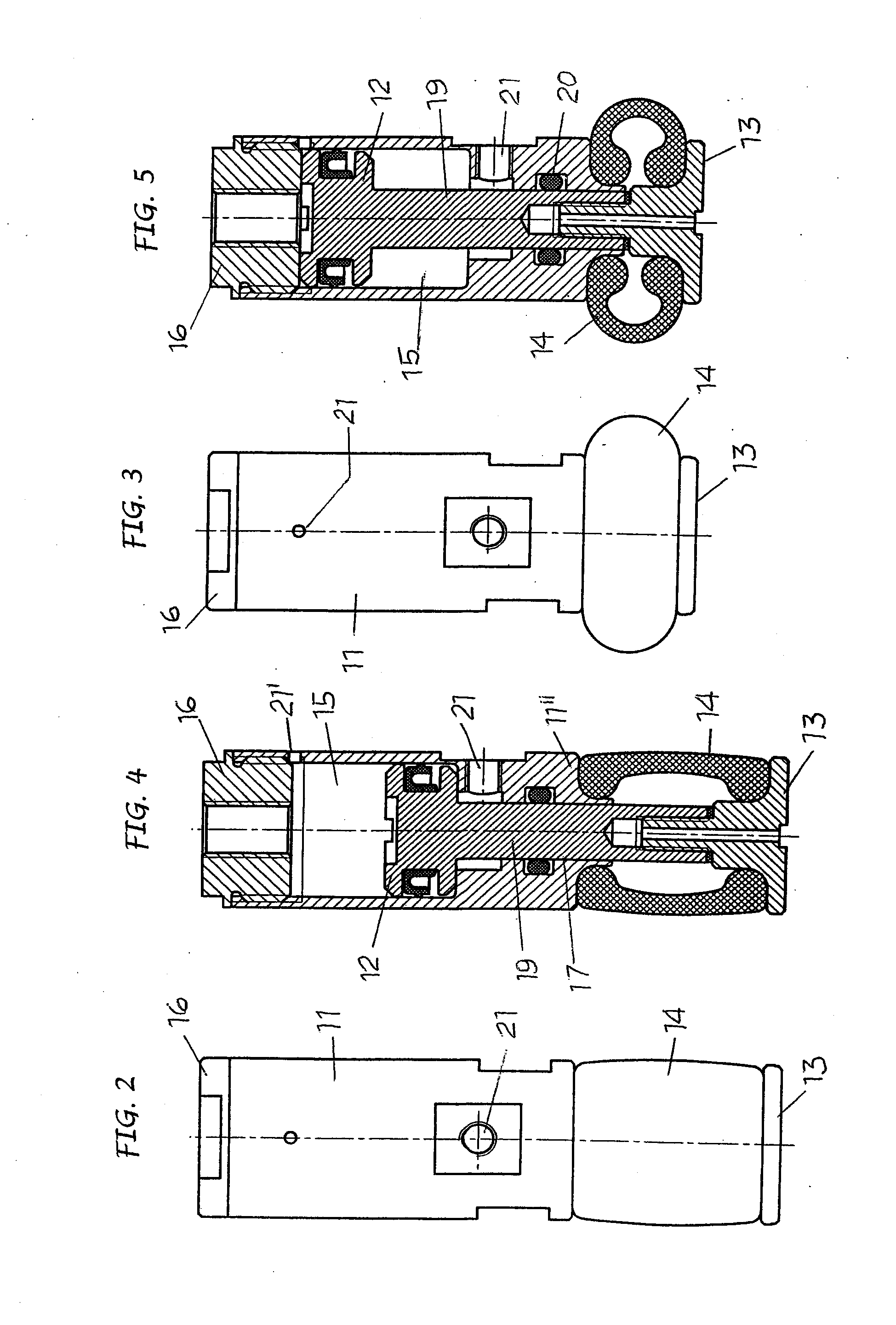

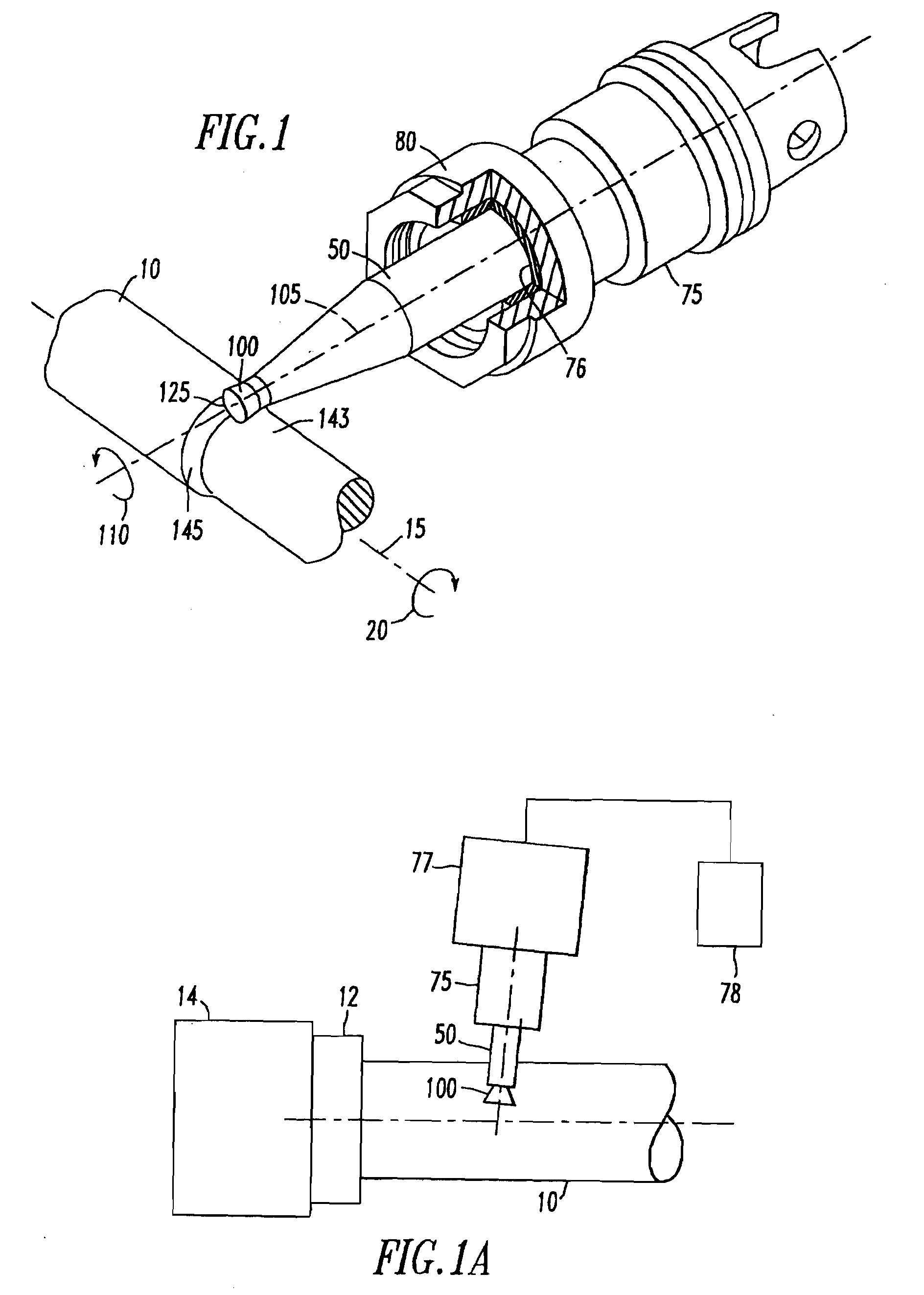

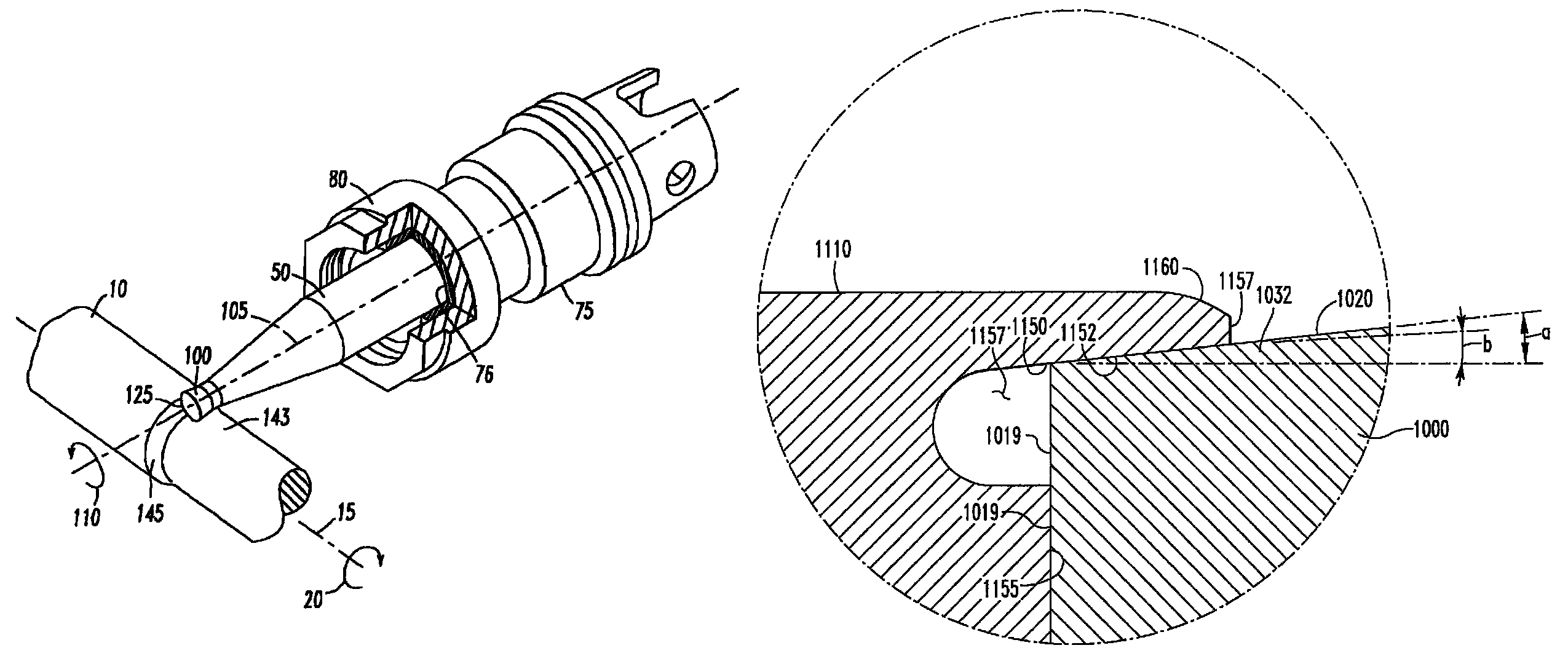

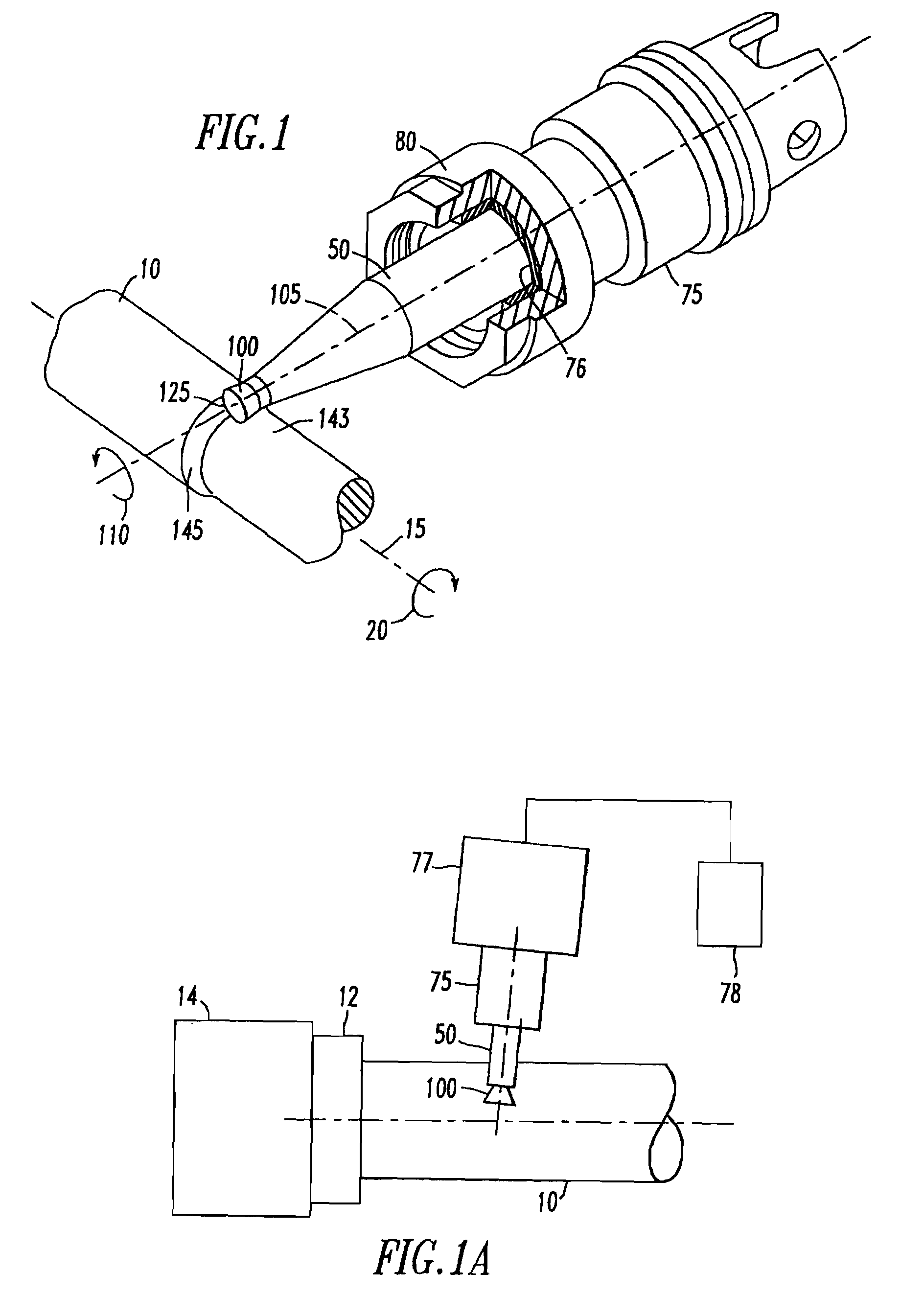

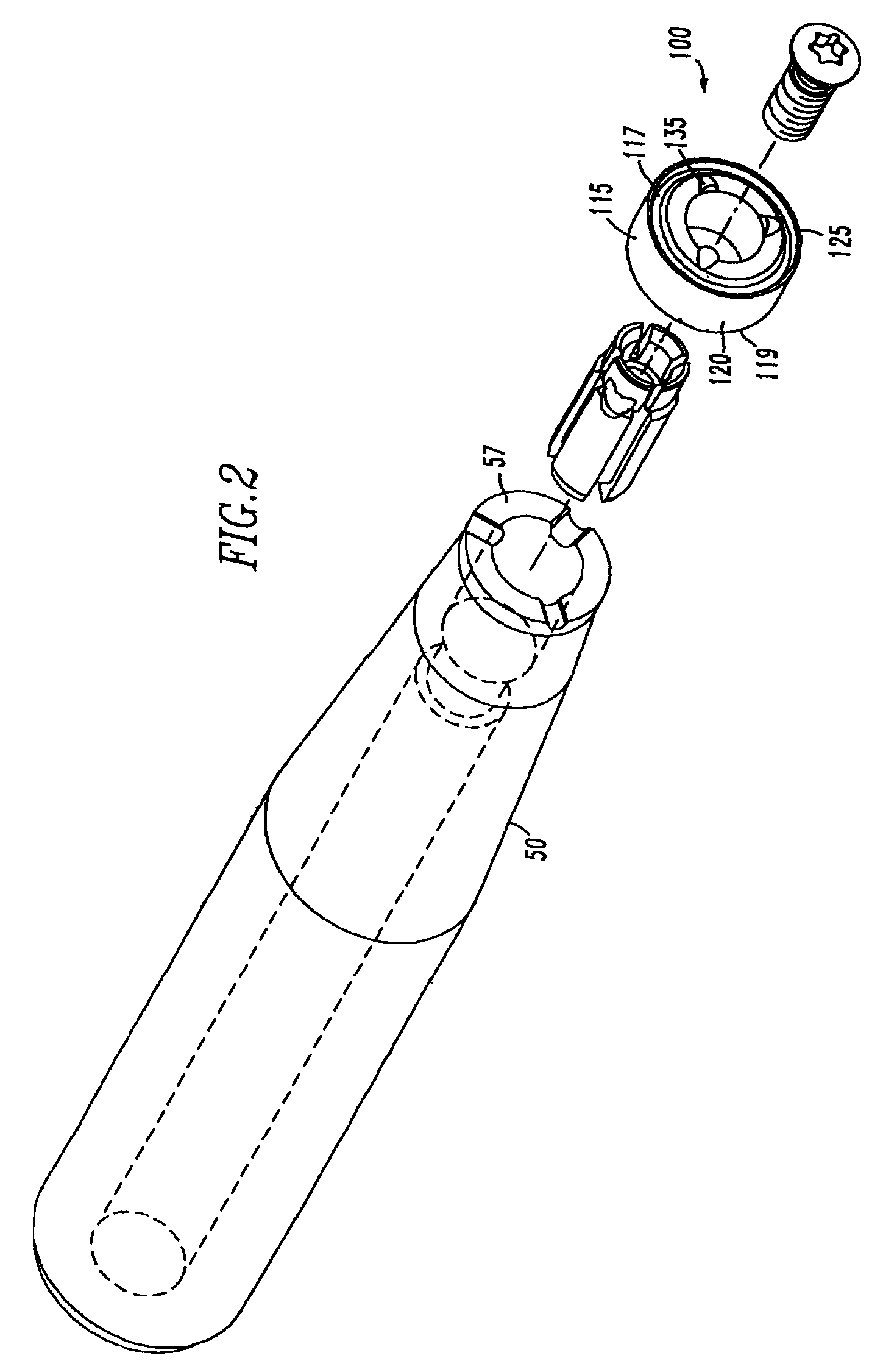

Method and assembly for rotating a cutting insert during a turning operation and inserts used therein

A cutting insert rotated about its axis may be utilized during a metalworking operation and applied against the rotating workpiece to enhance tool performance. A method, including an assembly with a rotatable insert mounted to a toolholder may be utilized to achieve this result.

Owner:KENNAMETAL INC

Method and assembly for rotating a cutting insert during a turning operation and inserts used therein

A cutting insert rotated about its axis may be utilized during a metalworking operation and applied against the rotating workpiece to enhance tool performance. A method, including an assembly with a rotatable insert mounted to a toolholder may be utilized to achieve this result.

Owner:KENNAMETAL INC

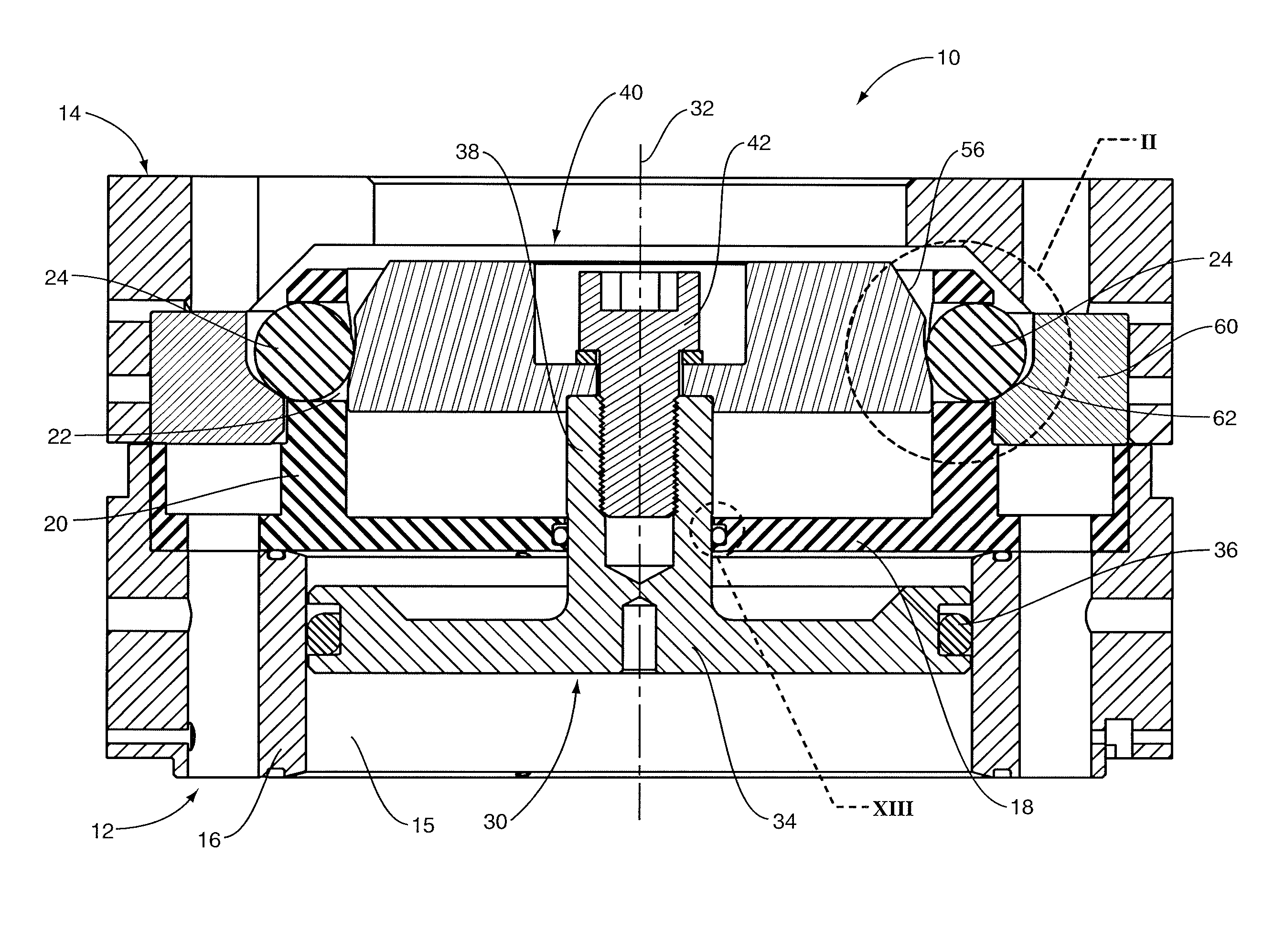

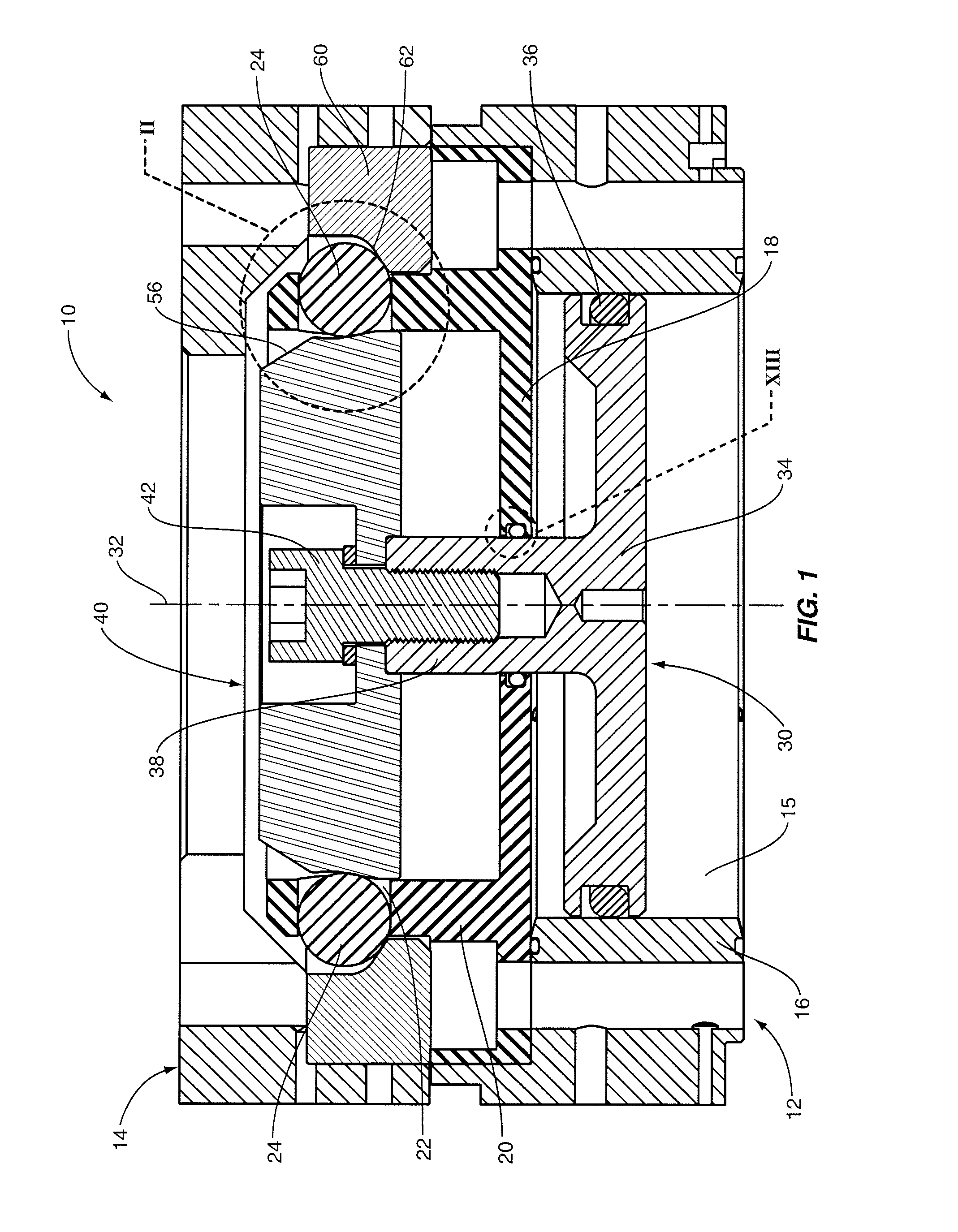

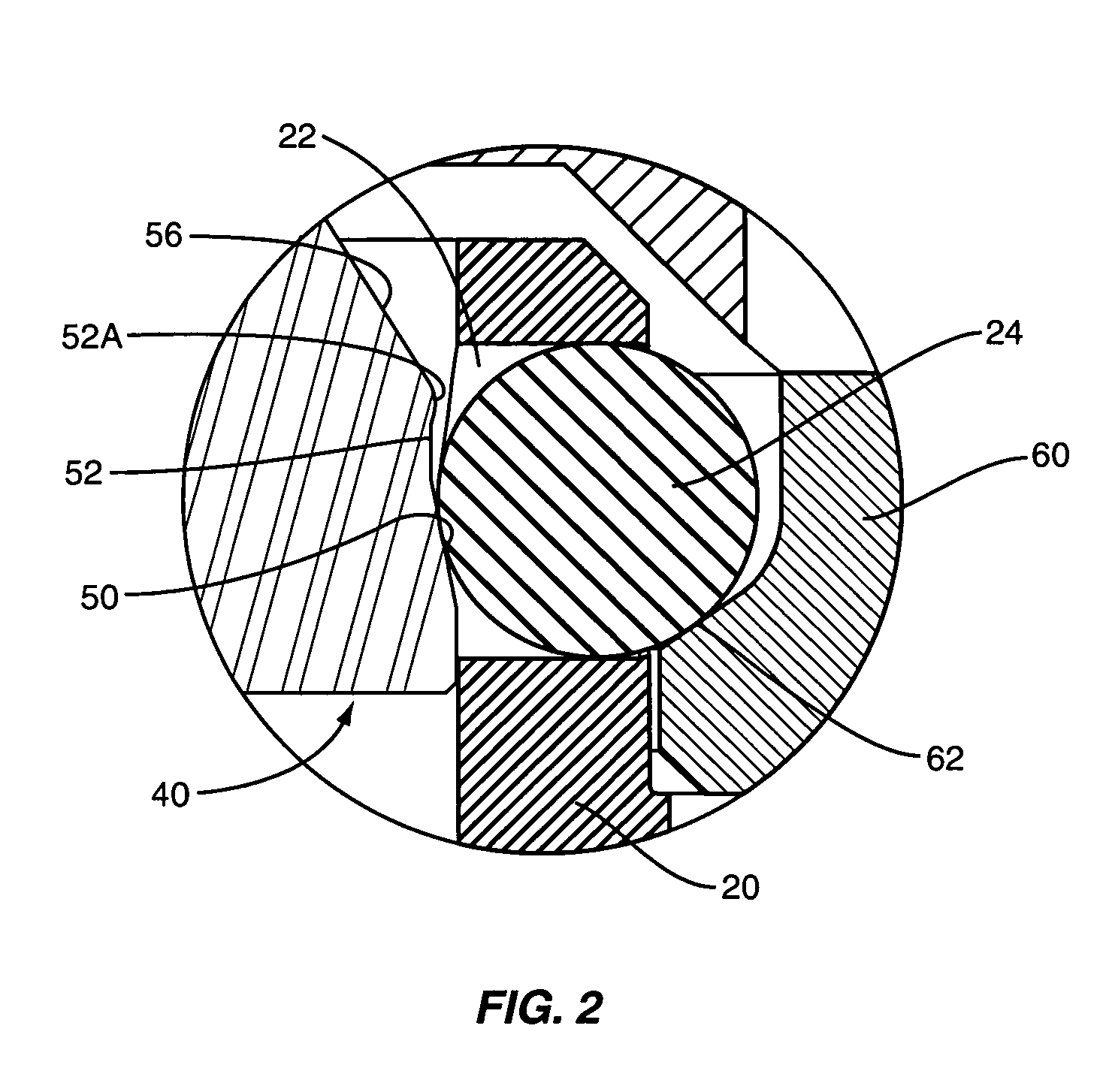

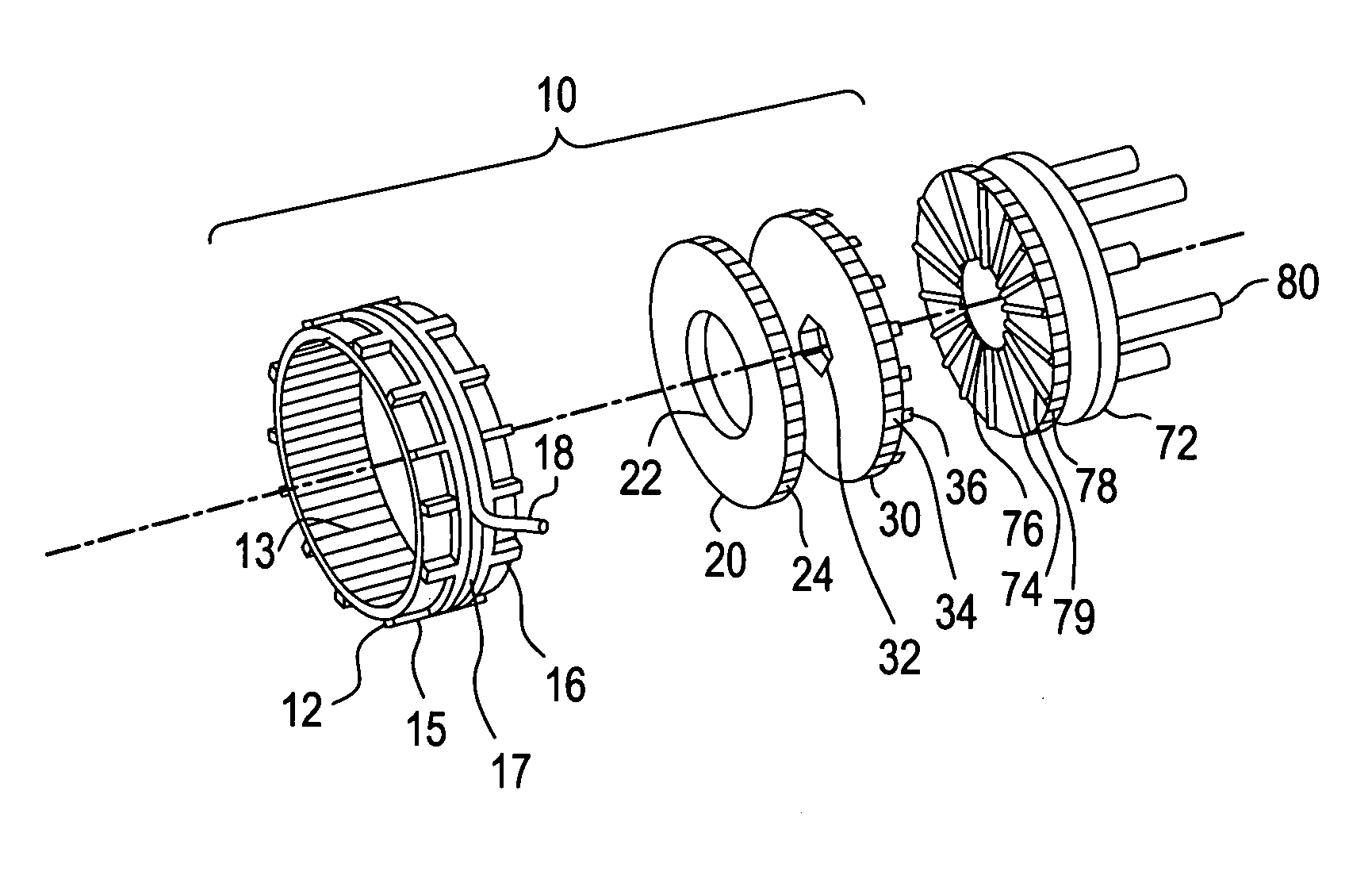

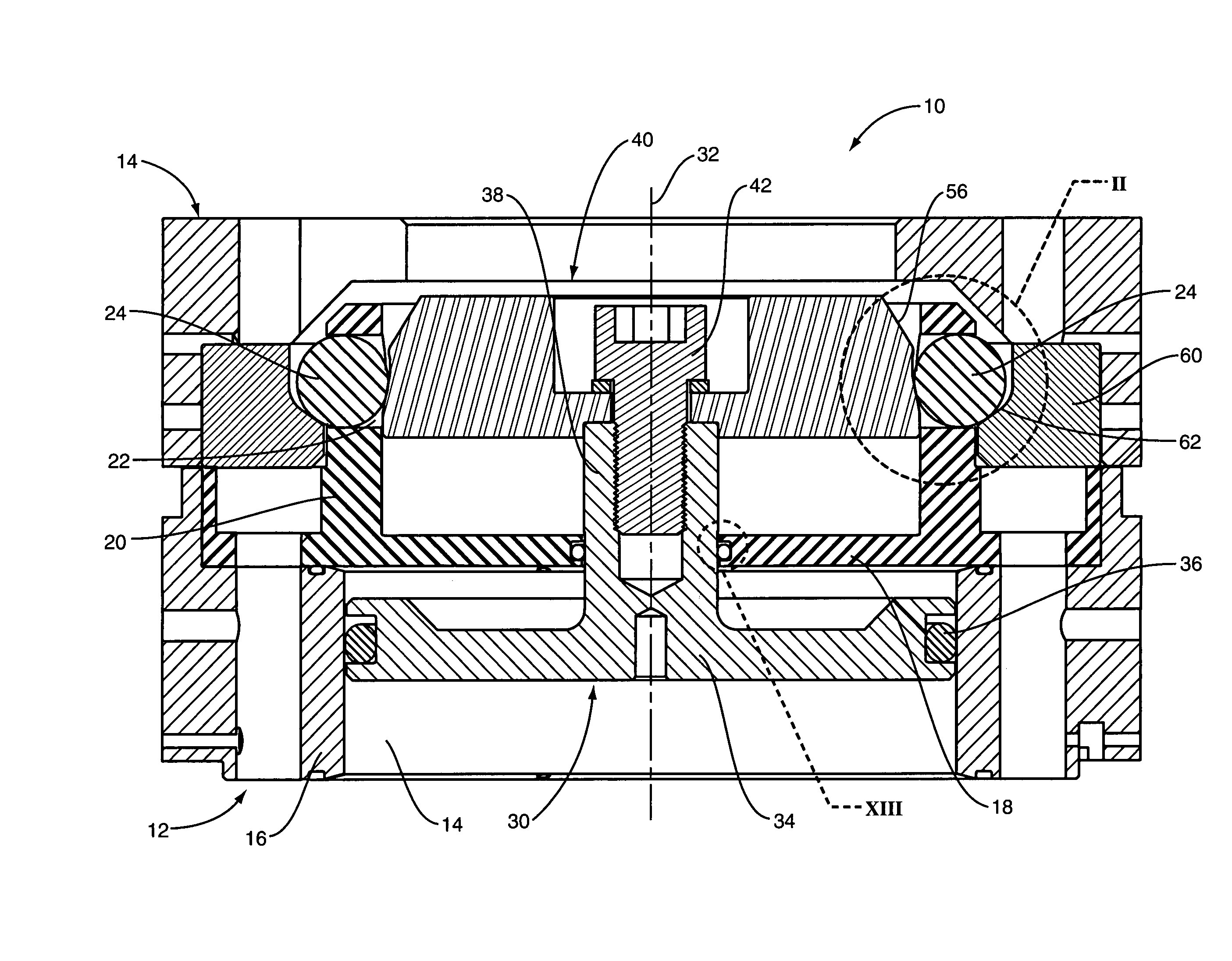

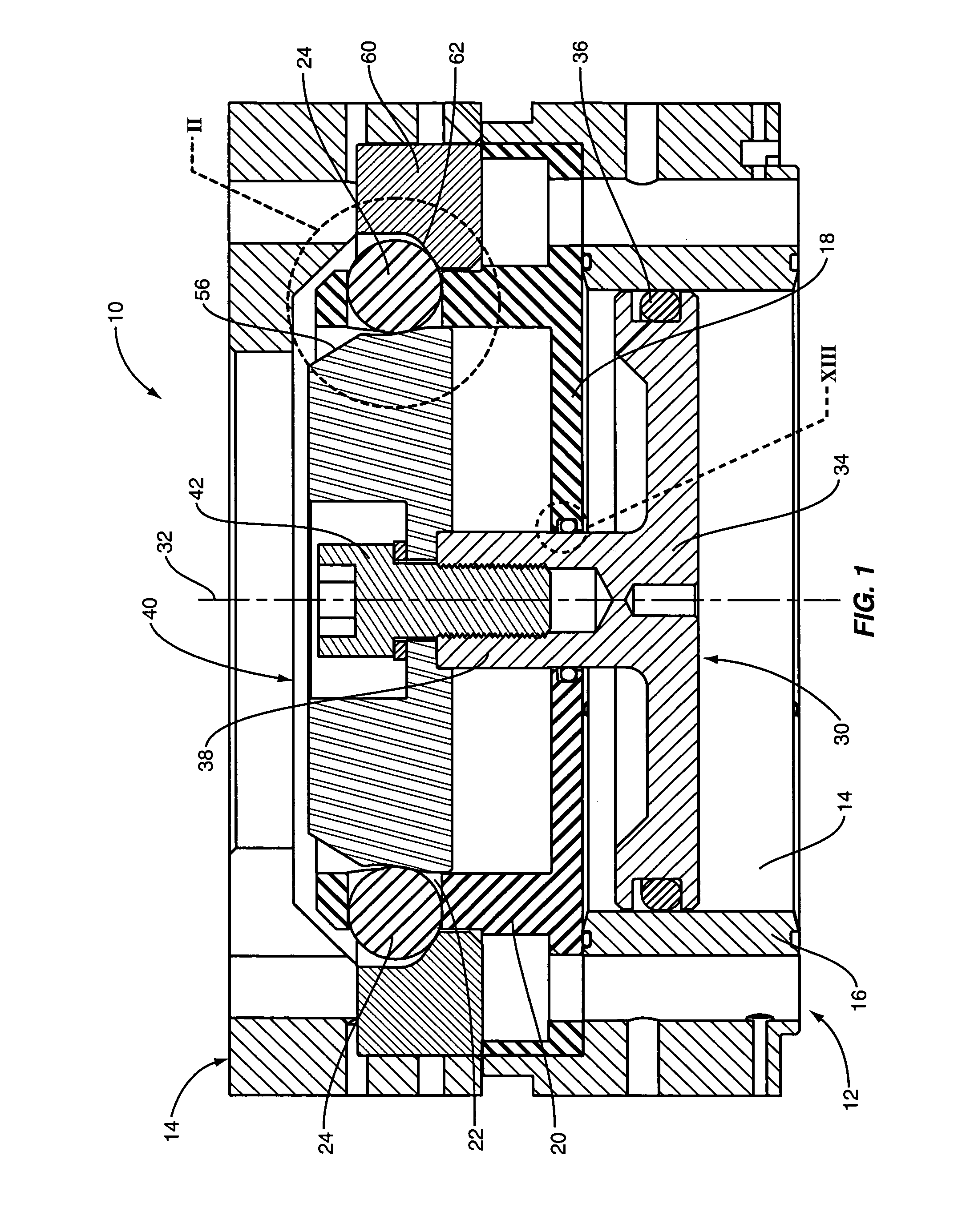

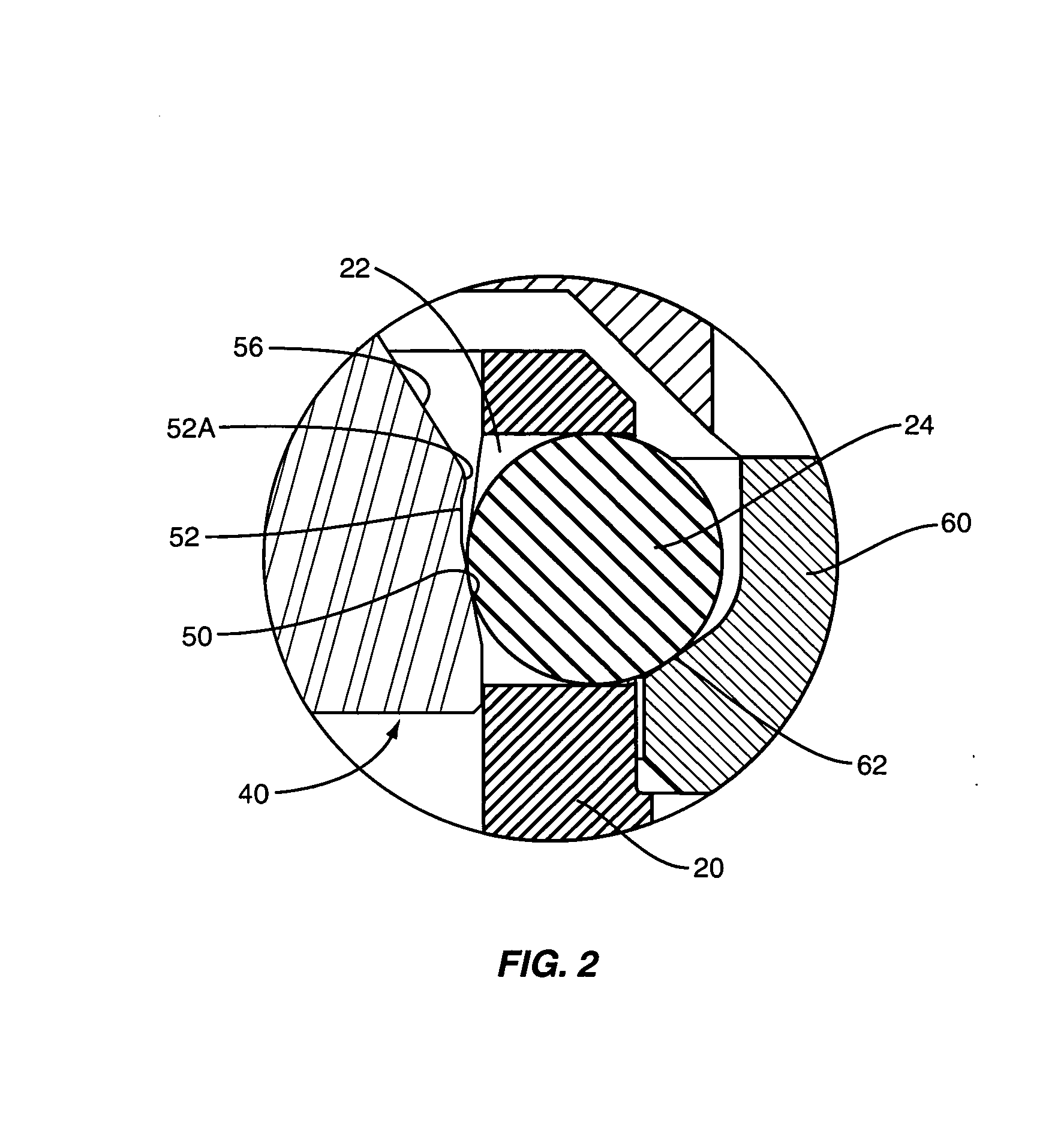

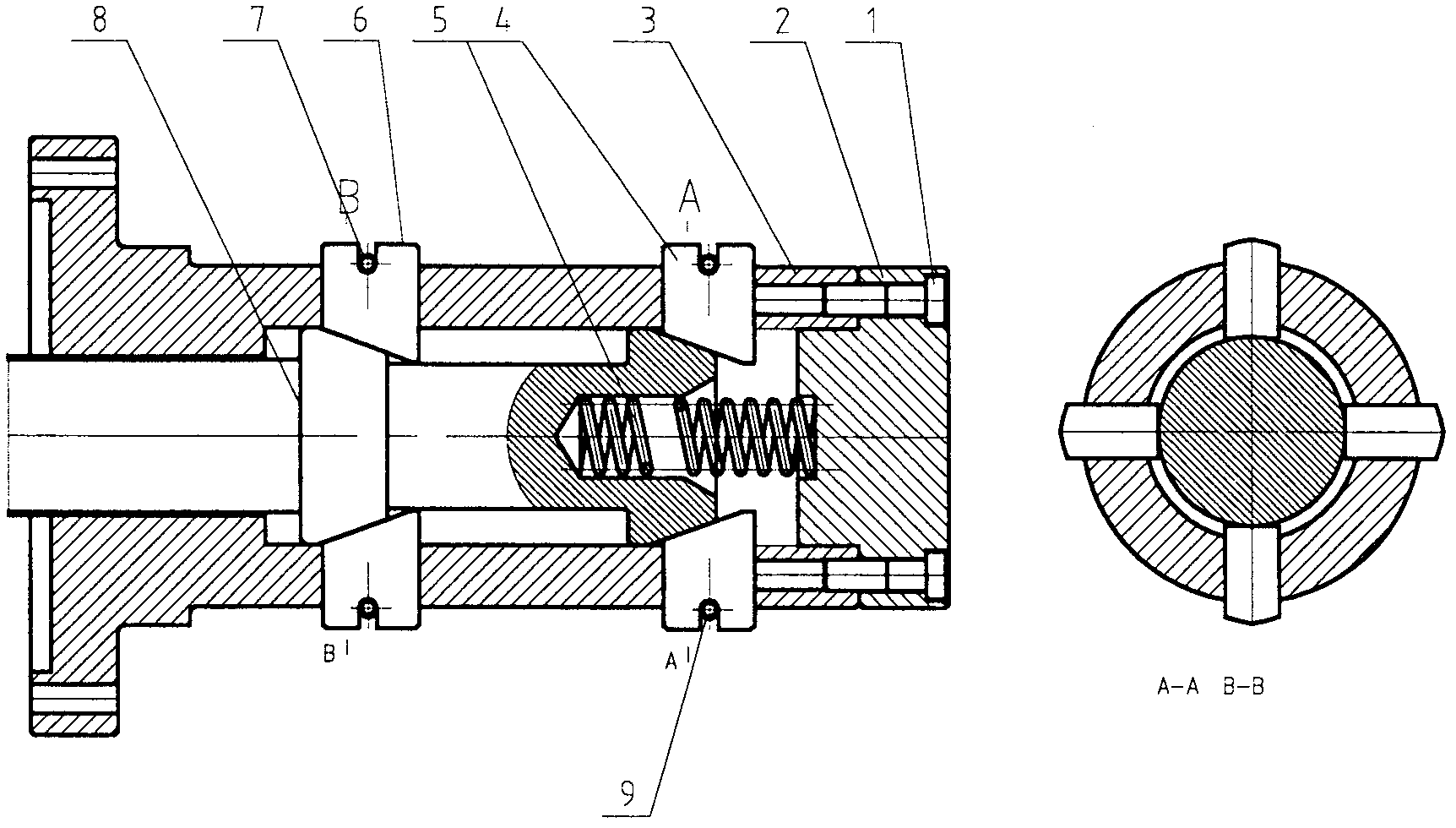

Robotic tool changer

A robotic tool changer having a master unit and a tool unit adapted to be coupled together. Movably mounted in the master unit of the robotic tool changer is a piston that is movable between locked and unlocked positions. The piston includes a contact area having an unlocking surface, a failsafe surface and a locking surface. Also provided is a series of rolling members contained within a retention area that are actuated by the piston to lock the master unit to the tool unit. For example, the piston engages the rolling members and urges them into a locked relationship with a bearing race that forms a part of the tool unit. To prevent the inadvertent or accidental movement of the piston from the locked position to the unlocked position, the piston is provided with a retarding surface generally disposed between the locking surface and the unlocking surface on the piston for retarding the movement of the piston as the piston moves from the locked position to the unlocked position.

Owner:ATI INDAL AUTOMATION

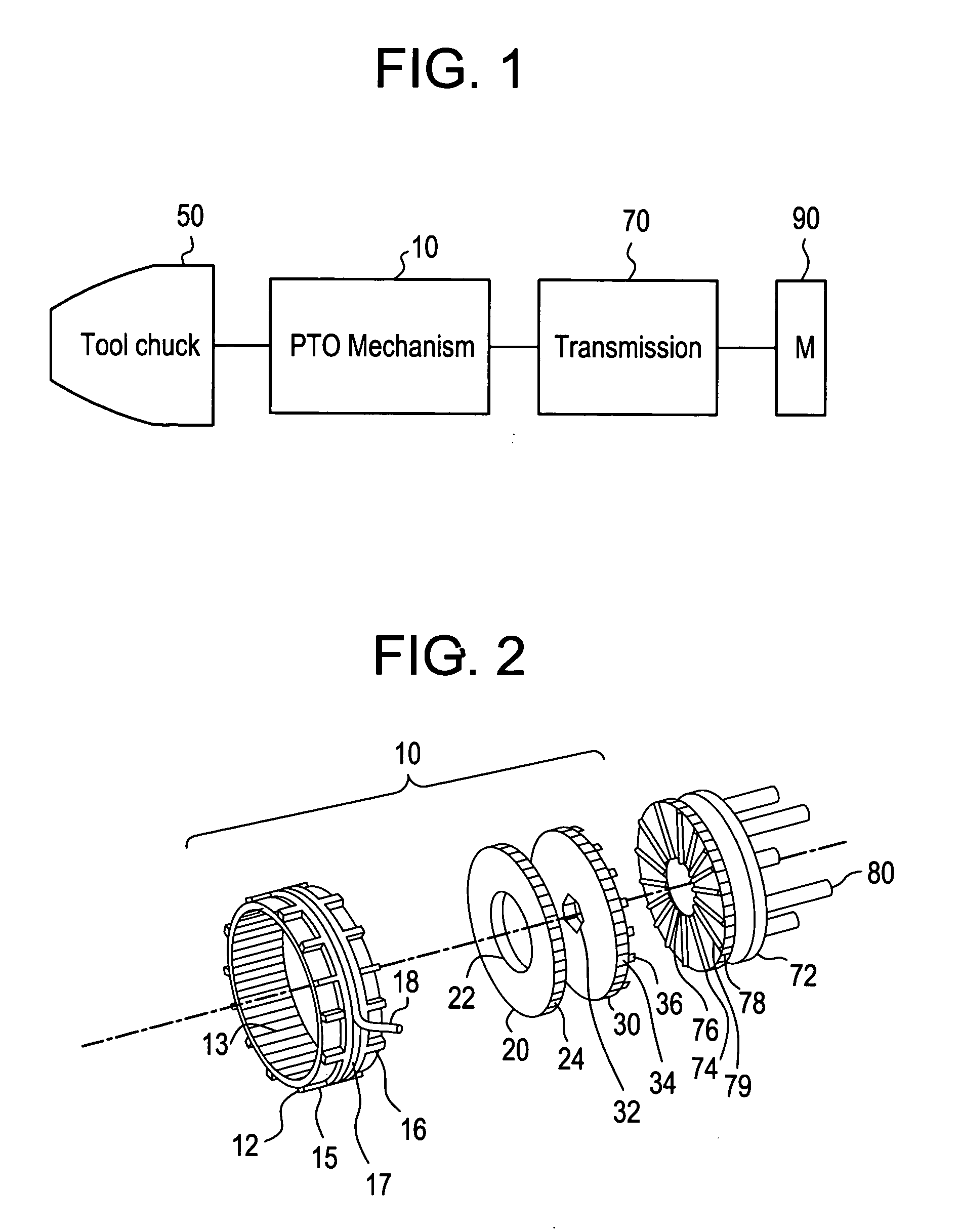

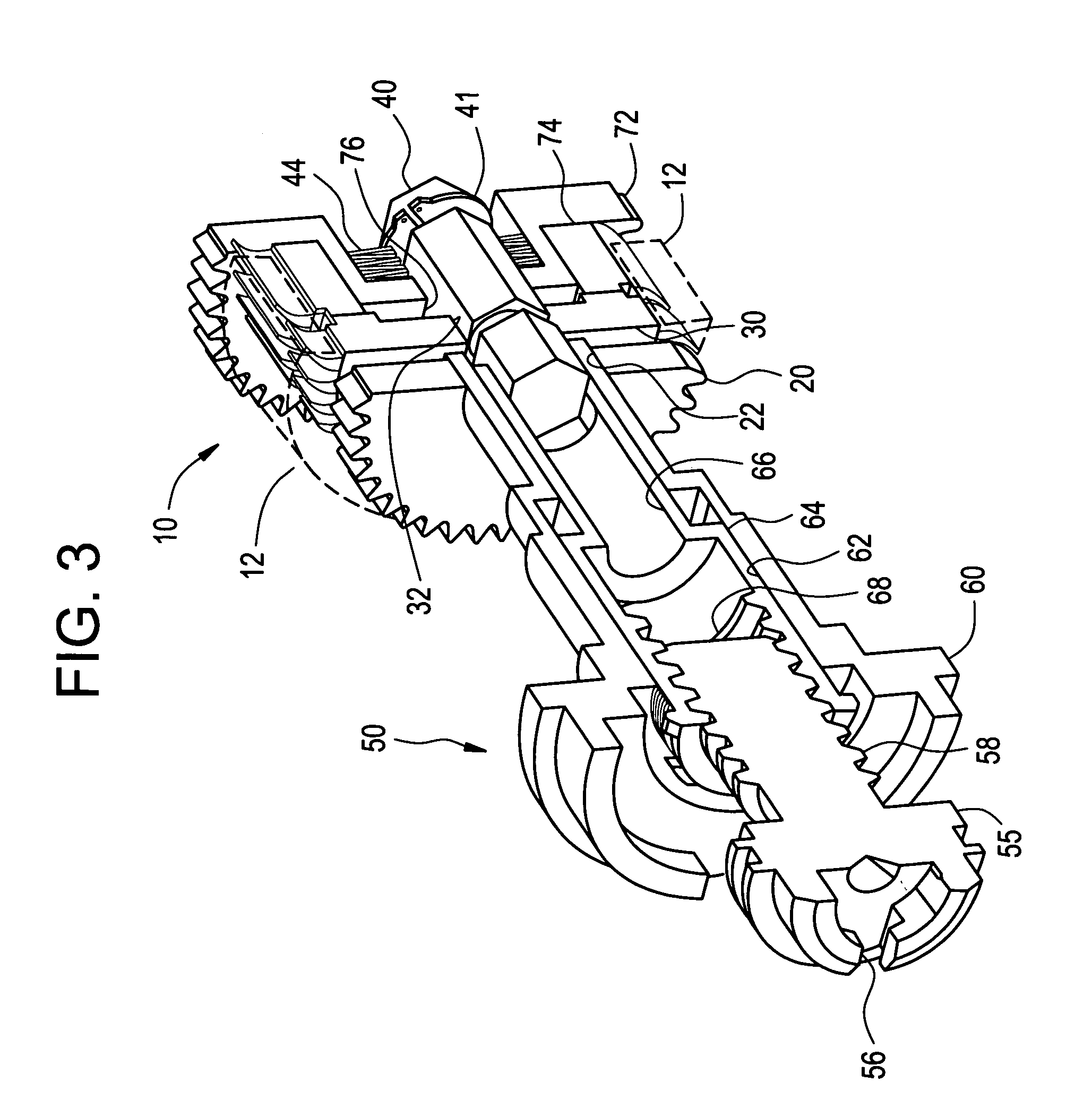

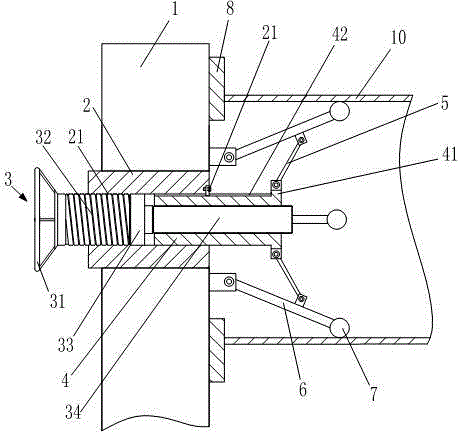

Tool chuck with power take off and dead spindle features

A power driver may include a housing, a tool chuck and a power take off mechanism. The tool chuck may have an input shaft mounted for rotation on the housing. The input shaft may support chuck jaws. A chuck actuating shaft may be mounted for rotation on the input shaft. The power take off mechanism may be connected to the tool chuck. The power take off mechanism may be adjustable into a DRILL DRIVE MODE to rotationally drive the input shaft and the chuck actuating shaft together as a unit, and a CHUCK MODE to rotationally drive the chuck actuating shaft relative to the input shaft. The power take off mechanism may be internal of the housing. The power take off mechanism in the CHUCK MODE may rotationally fix the input shaft to the housing.

Owner:BLACK & DECKER INC

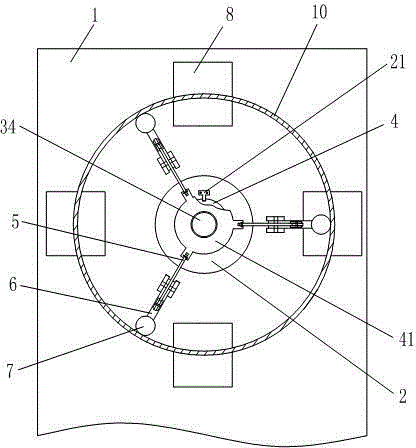

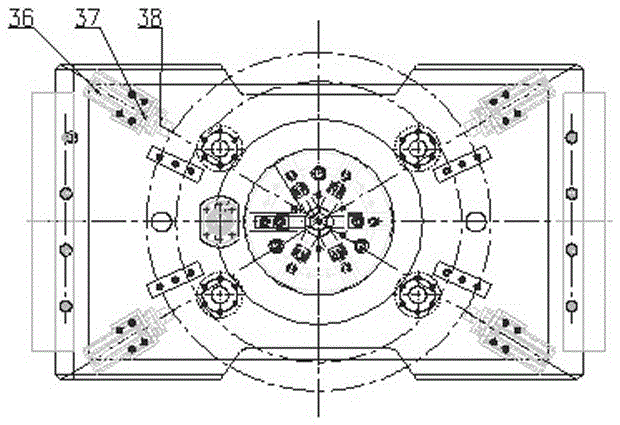

Locating clamp for pipeline machining

InactiveCN104625549AEasy to fixReduce labor intensityWork clamping meansWelding/cutting auxillary devicesBlock matchScrew thread

The invention relates to a locating clamp for pipeline machining. The locating clamp comprises a machine frame. A guide sleeve is fixedly installed on the machine frame, and one end of the guide sleeve is provided with internal threads. A threaded rod is connected to the guide sleeve. A fixed rotating wheel, external threads matched with the internal threads, a sliding portion matched with the guide sleeve in a sliding mode and a lead screw axially extending from the center of the sliding portion are sequentially arranged on the threaded rod. The lead screw is connected with a sliding sleeve matched with the guide sleeve in a sliding mode through threads. The end, extending out of the guide sleeve, of the sliding sleeve forms a hinged portion. The sliding sleeve is provided with a sliding groove. One side of the guide sleeve is fixedly connected with a guide block matched with a guide groove. At least three connecting rods are hinged to the hinged portion. The connecting rods are movably hinged to the supporting rods. The threaded rod and the lead screw are driven by the rotating wheel to rotate, so that the sliding sleeve is driven to horizontally move under the action of the guide sleeve and the guide block, and then the connecting rods drive the supporting rods to tightly support or release the pipeline; in this way, the pipeline is conveniently fixed and is convenient disassemble, the labor intensity of workers is relieved, and production efficiency is improved.

Owner:WUXI XINQITE PLATE WORK MACHINE

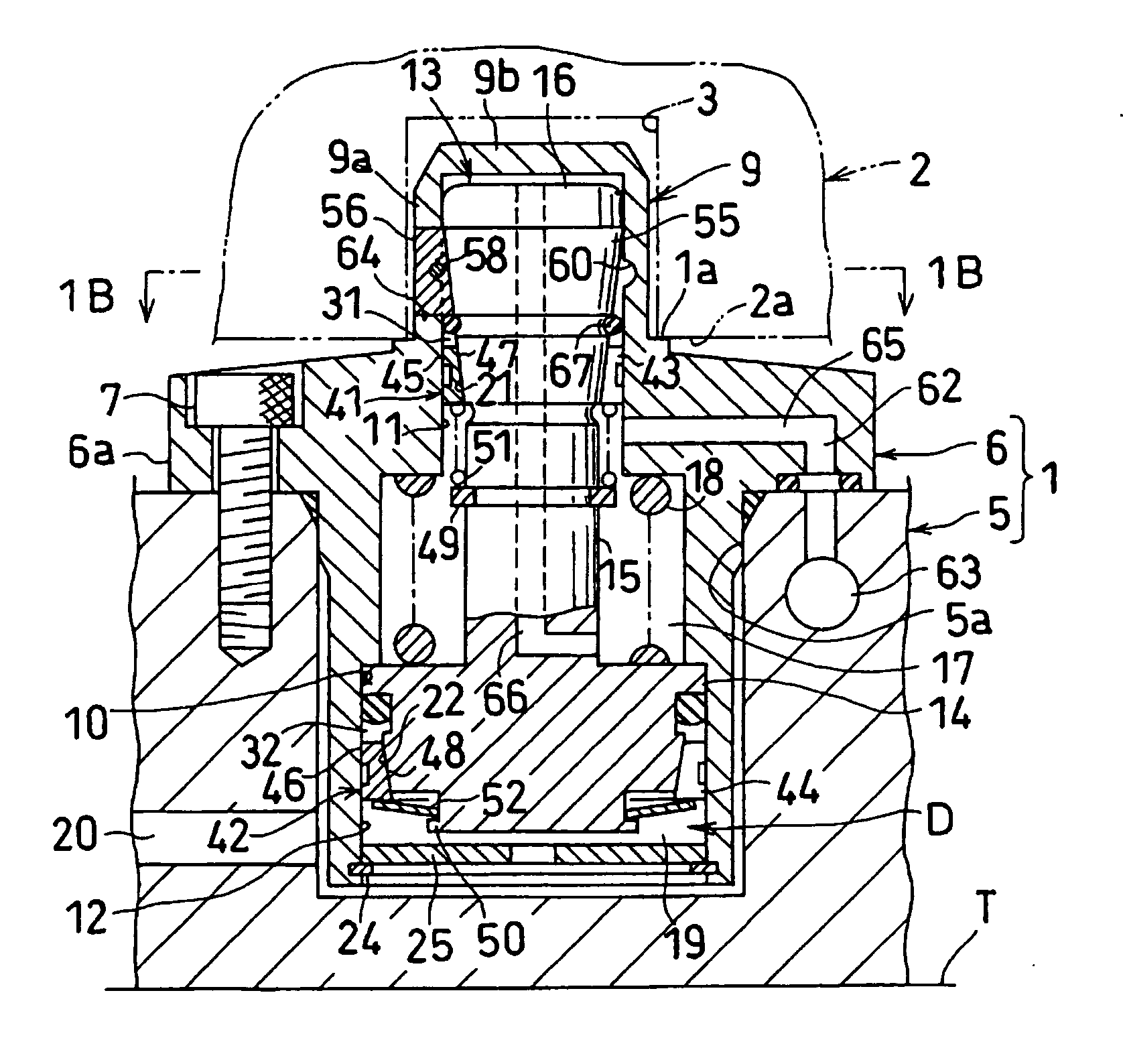

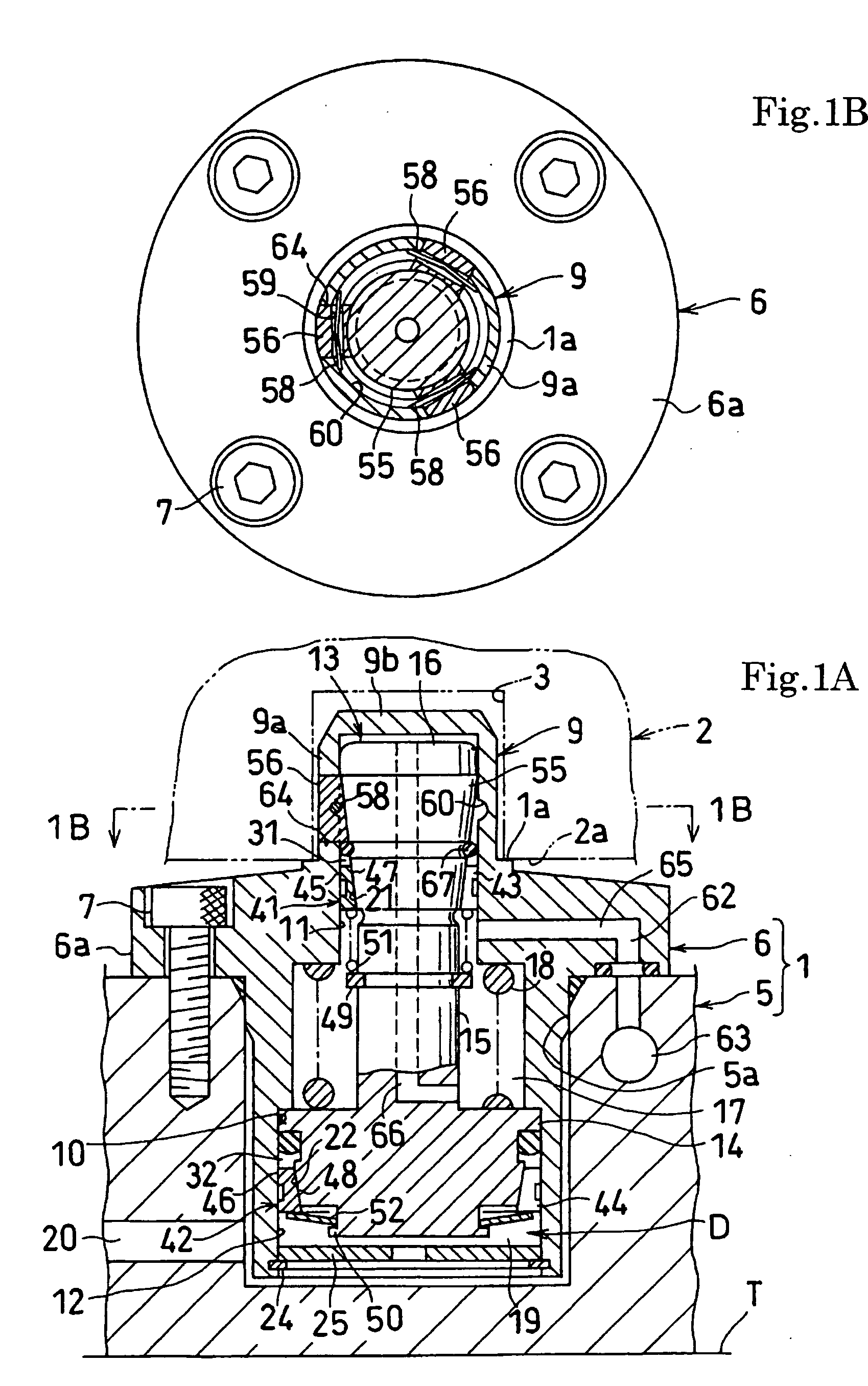

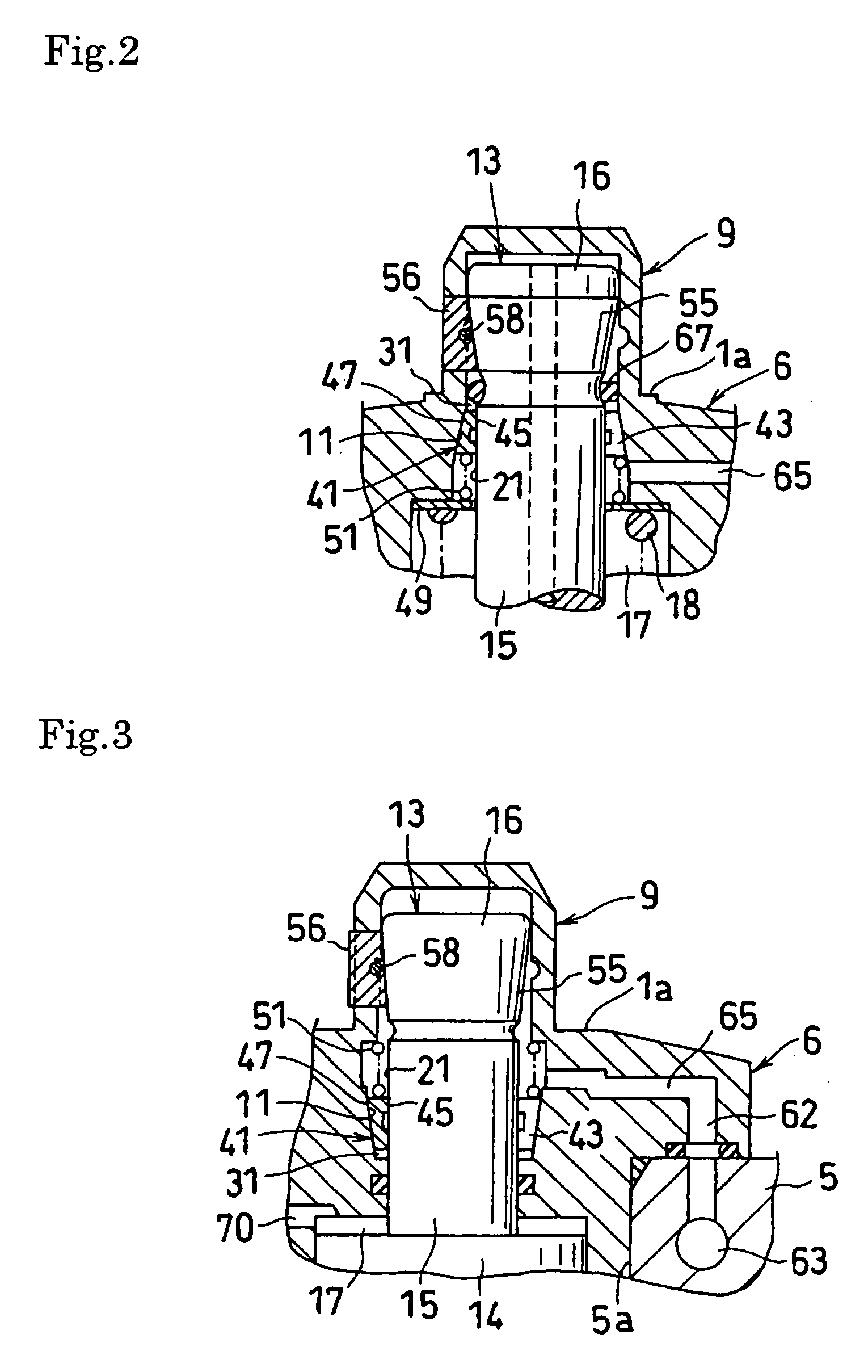

Aligning drive mechanism and positioning apparatus having this mechanism

InactiveUS20060049568A1Improve accuracyMachine framesLarge fixed membersEngineeringLocation Equipment

A housing (6) is provided in a reference block (1). An annular plug (9), which is to be inserted into a positioning hole (3) of a work pallet (2), is projected upward from the housing (6). An output member (13) is inserted into a guide hole (10) of the housing (6) vertically movably. An upper end of the output member (13) is inserted into the annular plug (9), and a plurality of pressing members (56) are supported on a peripheral wall (9a) of the annular plug (9) radially movably. An annular aligning space (31) is formed between a guided portion (21) of the output member (13) and the guide hole (10). A shuttle member (41), which is diametrically expandable and contractible, is inserted into the aligning space (31). The shuttle member (41) is urged upward by a spring (51).

Owner:KOSMEK LTD (JP)

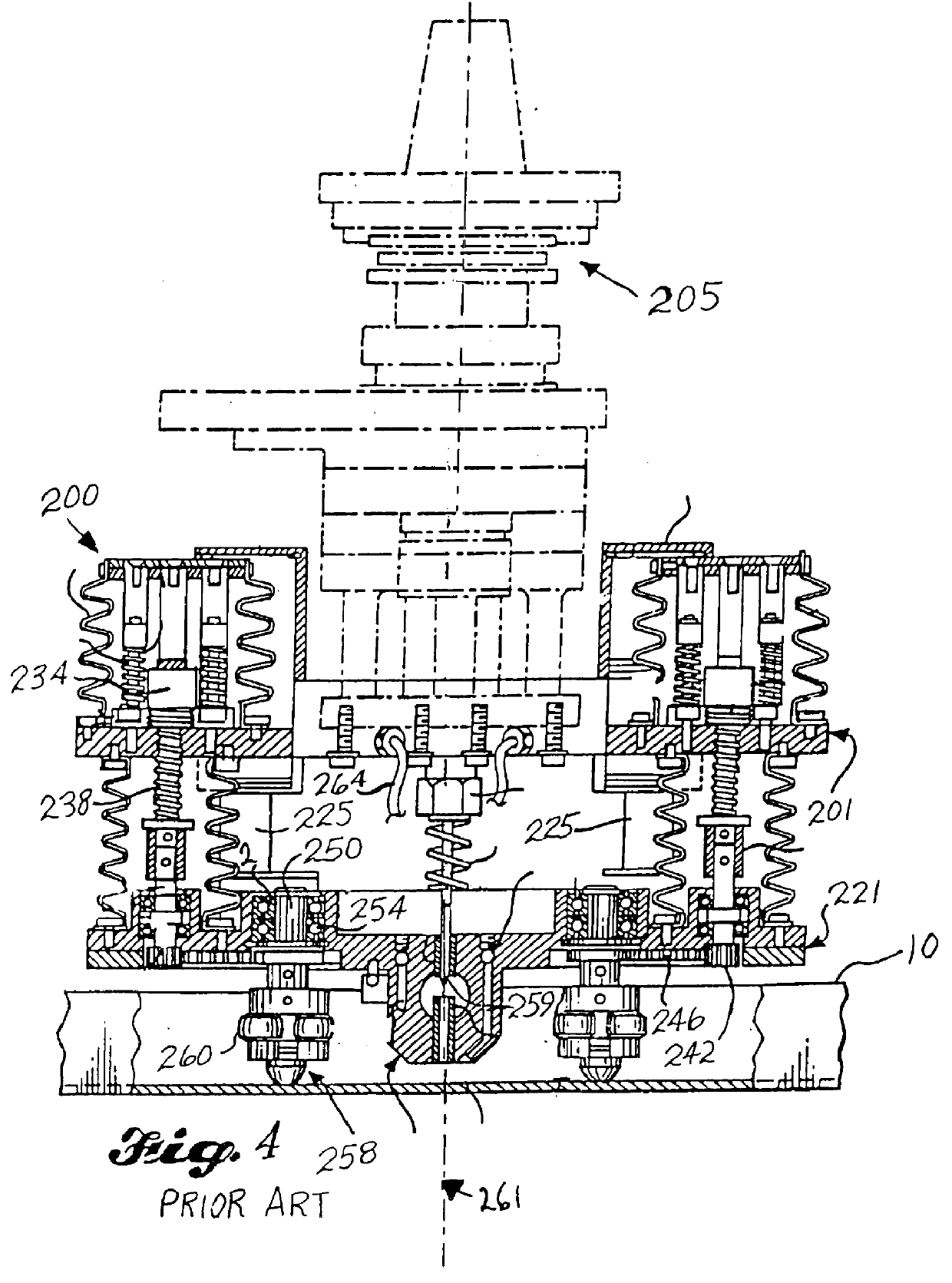

Robotic tool changer

ActiveUS20070235949A1Prevent movementGripping headsExpansion mandrelsEngineeringMechanical engineering

A robotic tool changer having a master unit and a tool unit adapted to be coupled together. Movably mounted in the master unit of the robotic tool changer is a piston that is movable between locked and unlocked positions. The piston includes a contact area having an unlocking surface, a failsafe surface and a locking surface. Also provided is a series of rolling members contained within a retention area that are actuated by the piston to lock the master unit to the tool unit. For example, the piston engages the rolling members and urges them into a locked relationship with a bearing race that forms a part of the tool unit. To prevent the inadvertent or accidental movement of the piston from the locked position to the unlocked position, the piston is provided with a retarding surface generally disposed between the locking surface and the unlocking surface on the piston for retarding the movement of the piston as the piston moves from the locked position to the unlocked position.

Owner:ATI INDAL AUTOMATION

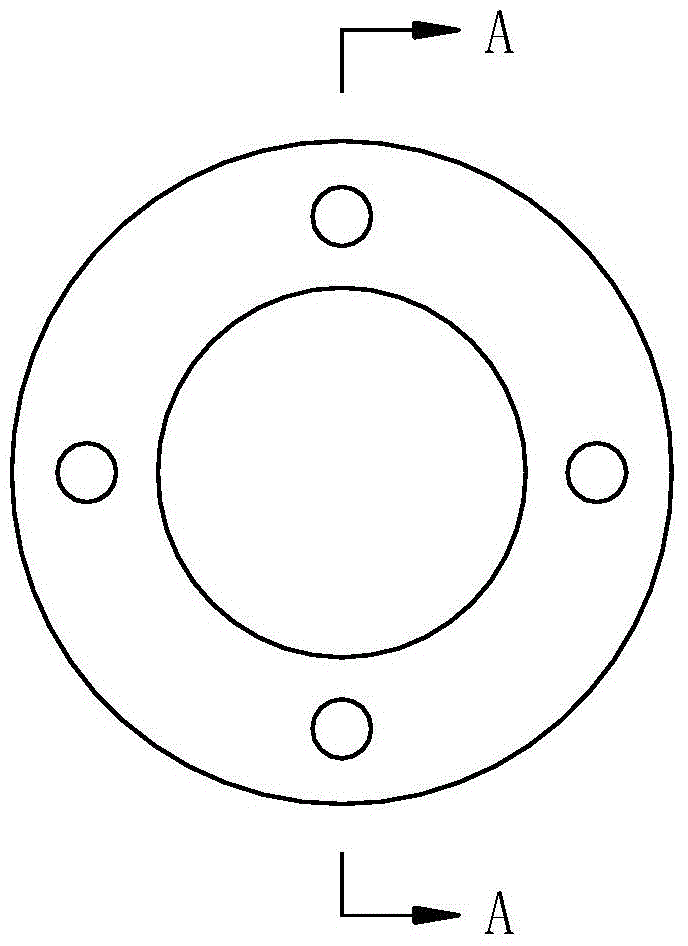

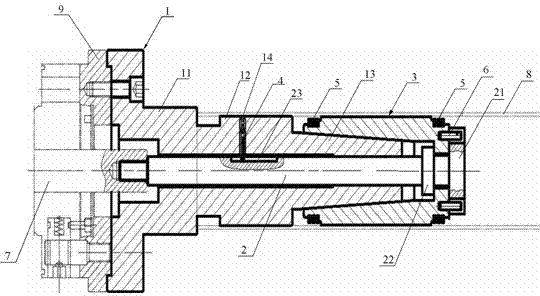

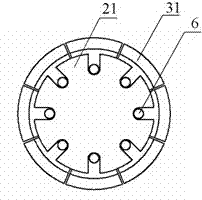

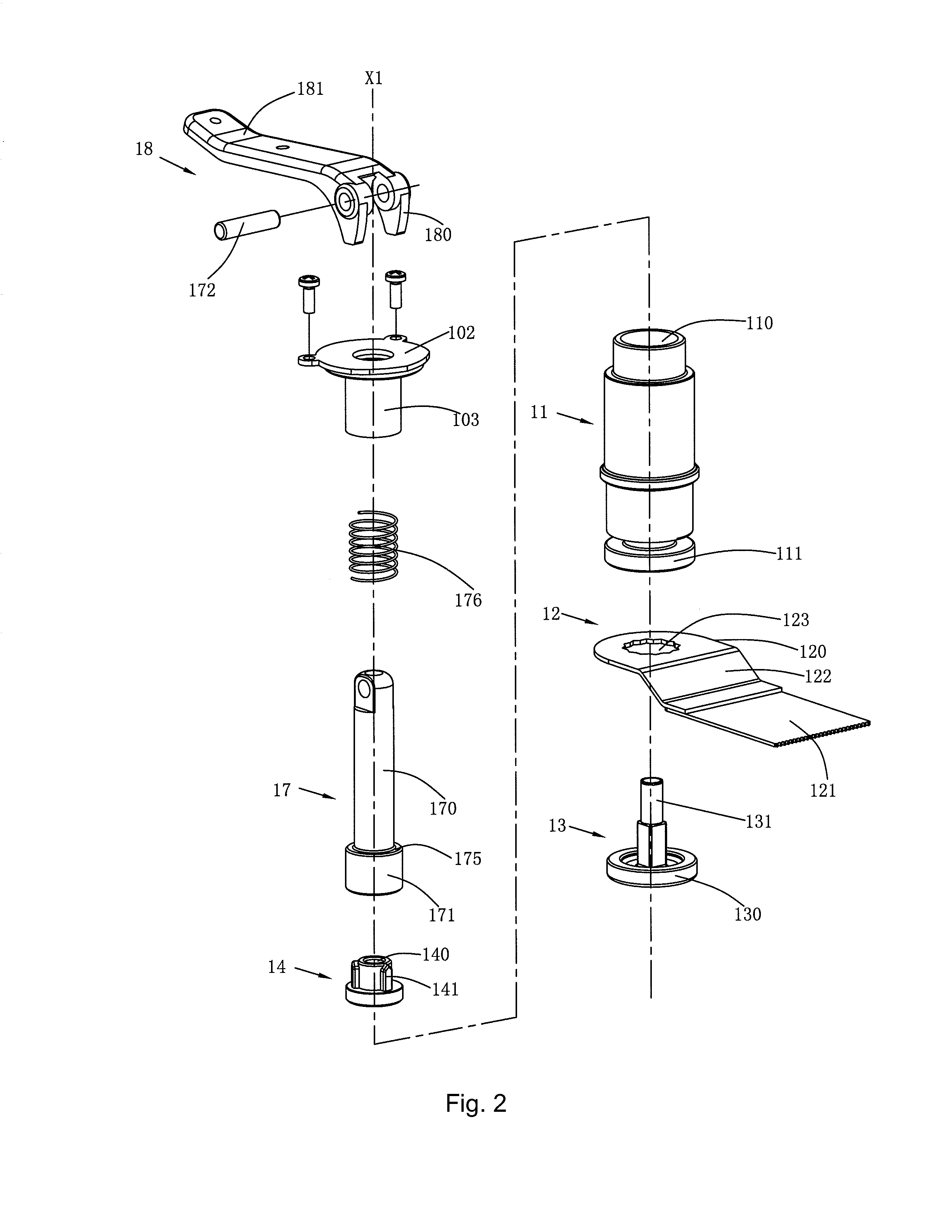

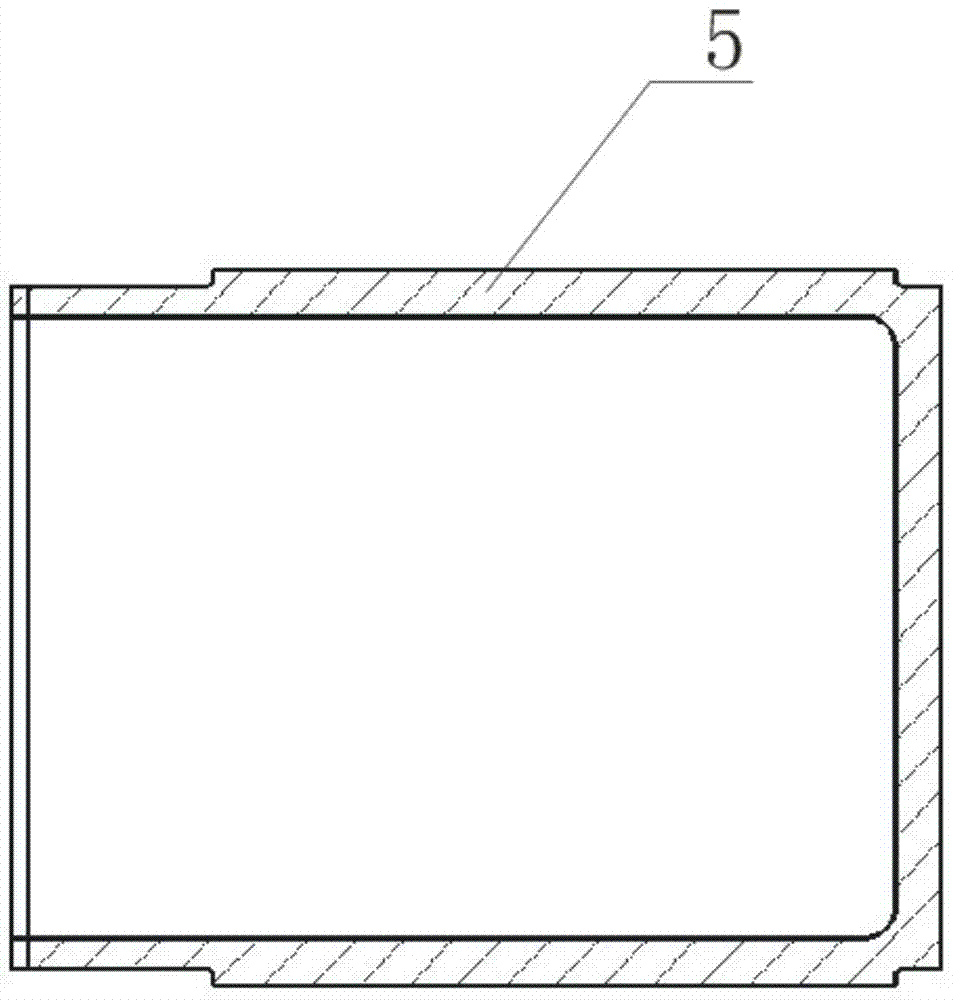

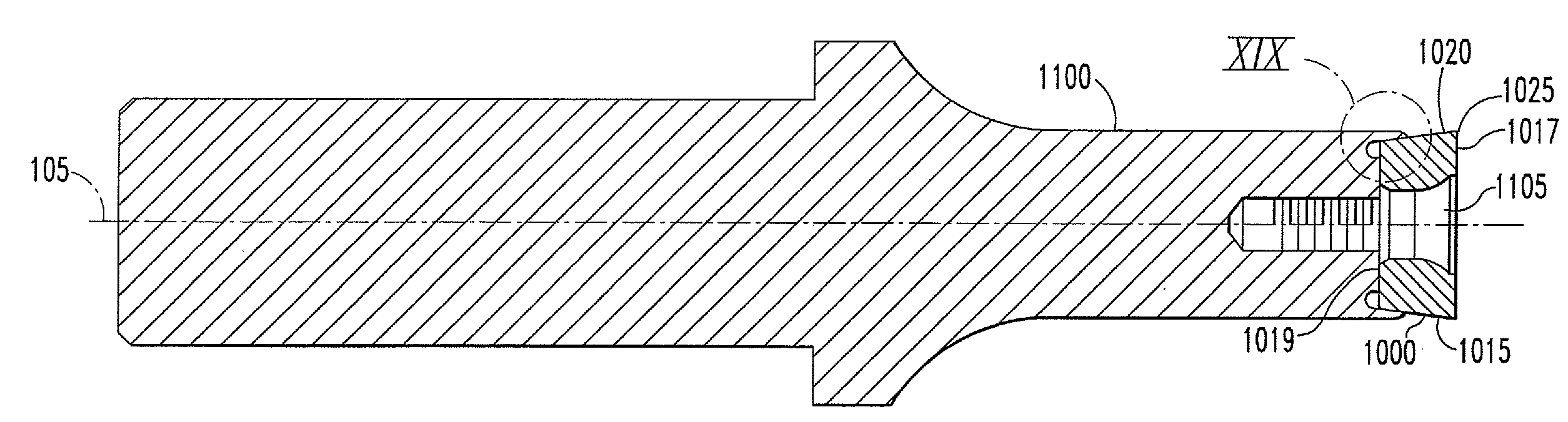

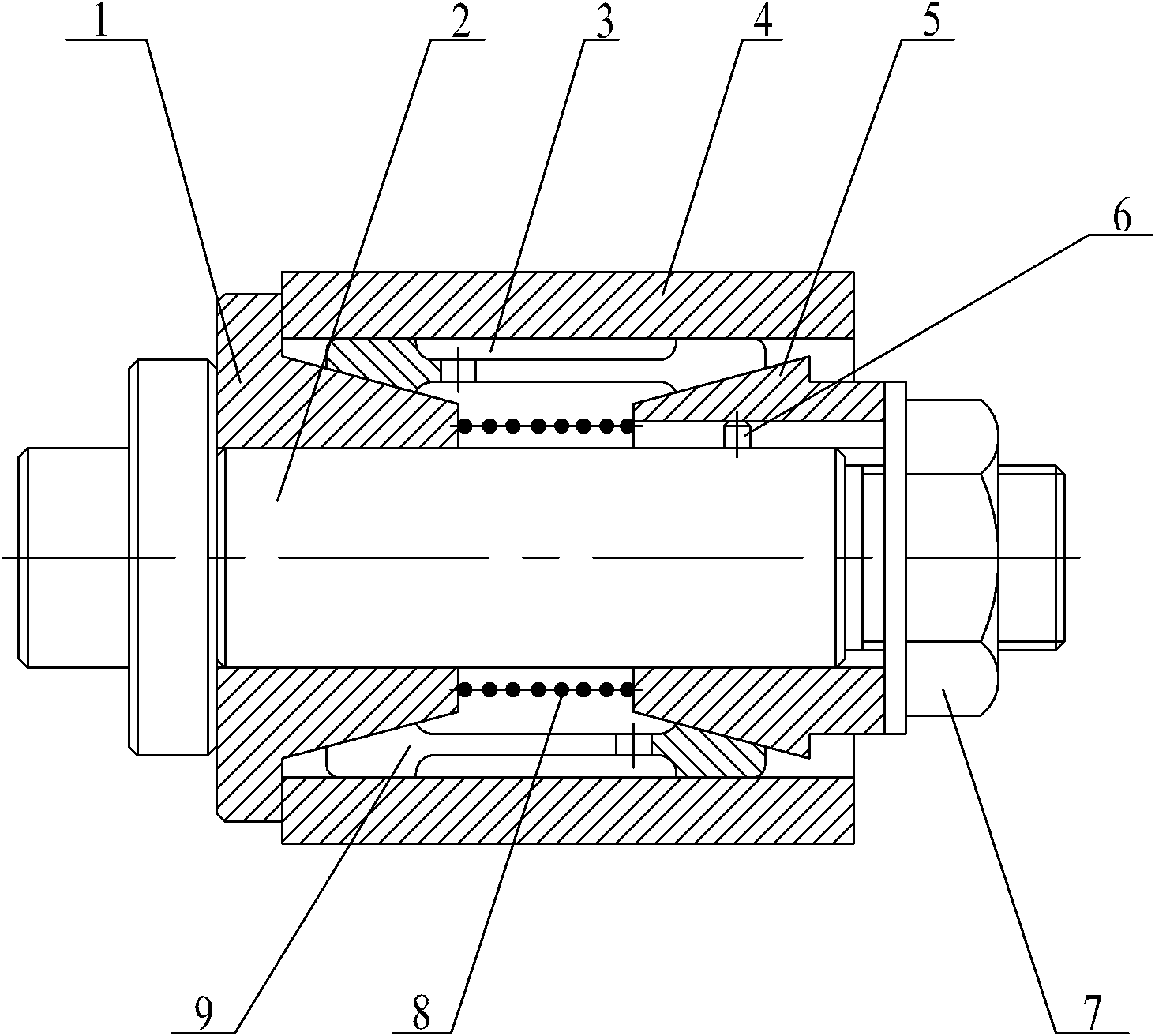

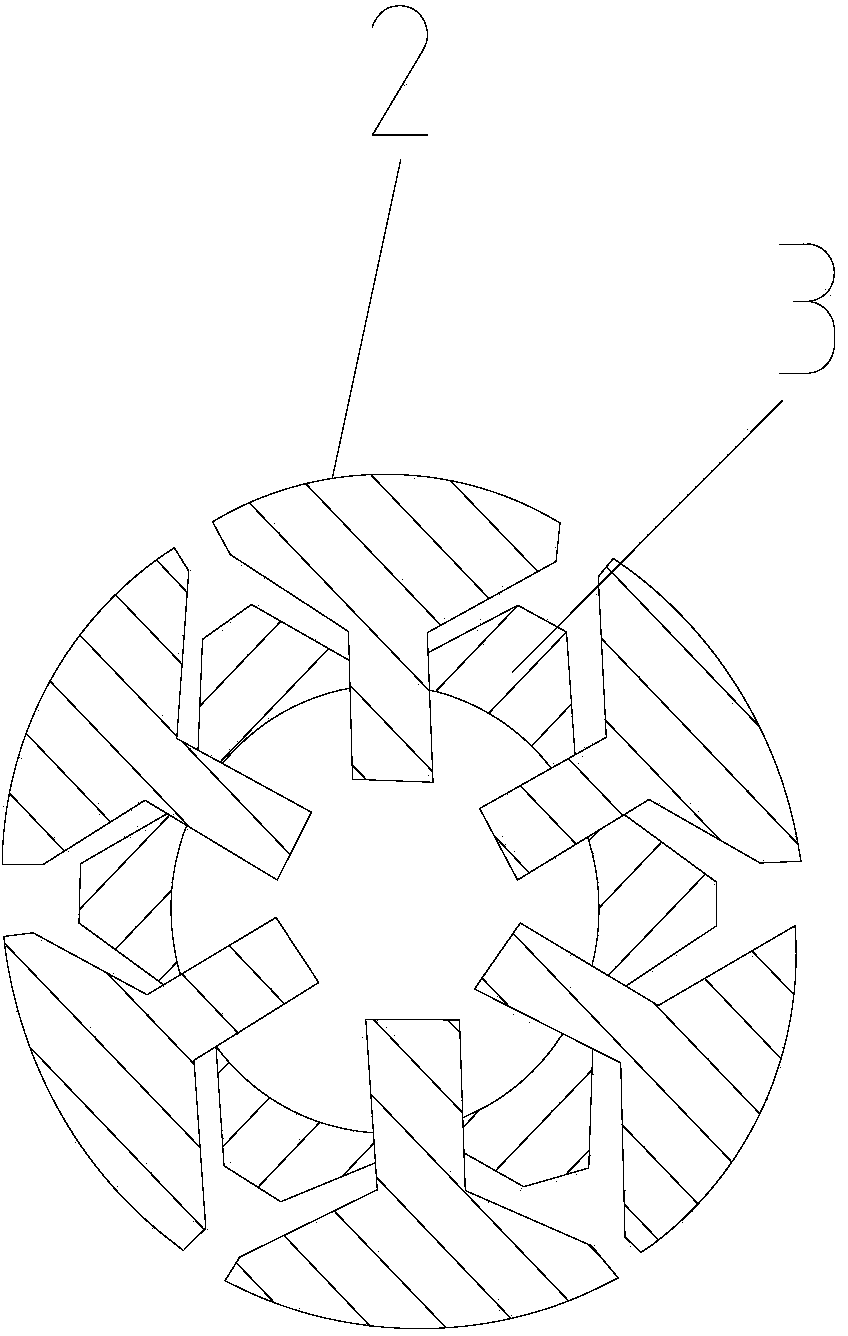

Automatic expansion core clamp for thin-walled cylinder parts

InactiveCN103962598AImprove rationalityImprove reliabilityExpansion mandrelsProduction rateIntegrated design

The invention discloses an automatic expansion core clamp for thin-walled cylinder parts. The automatic expansion core clamp comprises a core shaft and a cylindrical expansion sleeve, wherein the core shaft consists of a fixing part, a limiting part and a taper shaft part; the inner wall of the cylindrical expansion sleeve is tapered; a through hole is formed in the closed end of the expansion sleeve; grooves are formed in the outer walls of two ends of the expansion sleeve; a retainer ring is arranged in each groove; a connecting shaft extends into central through holes in the core shaft and the expansion sleeve; one end of the connecting shaft is connected with a piston rod; a flange is arranged at one end, positioned outside the expansion sleeve, of the connecting shaft; a limiting flange is formed at the position close to the inner side surface of the closed end of the expansion sleeve; an axial key groove is formed in the outer wall, corresponding to a screw hole, of the connecting shaft; a screw is arranged in the screw hole, and one end of the screw extends into the key groove. By using a hydraulic source as a power source, the labor intensity is further alleviated, and the labor production rate is increased; the clamp is directly connected with a machine tool spindle through the screw, so that the rotation accuracy of the clamp is ensured; by virtue of the integrated design of the clamp, the reasonableness and the reliability of a clamp structure are greatly improved.

Owner:CHINA NTAIONAL NUCLEAR TIANJIN MACHINERY

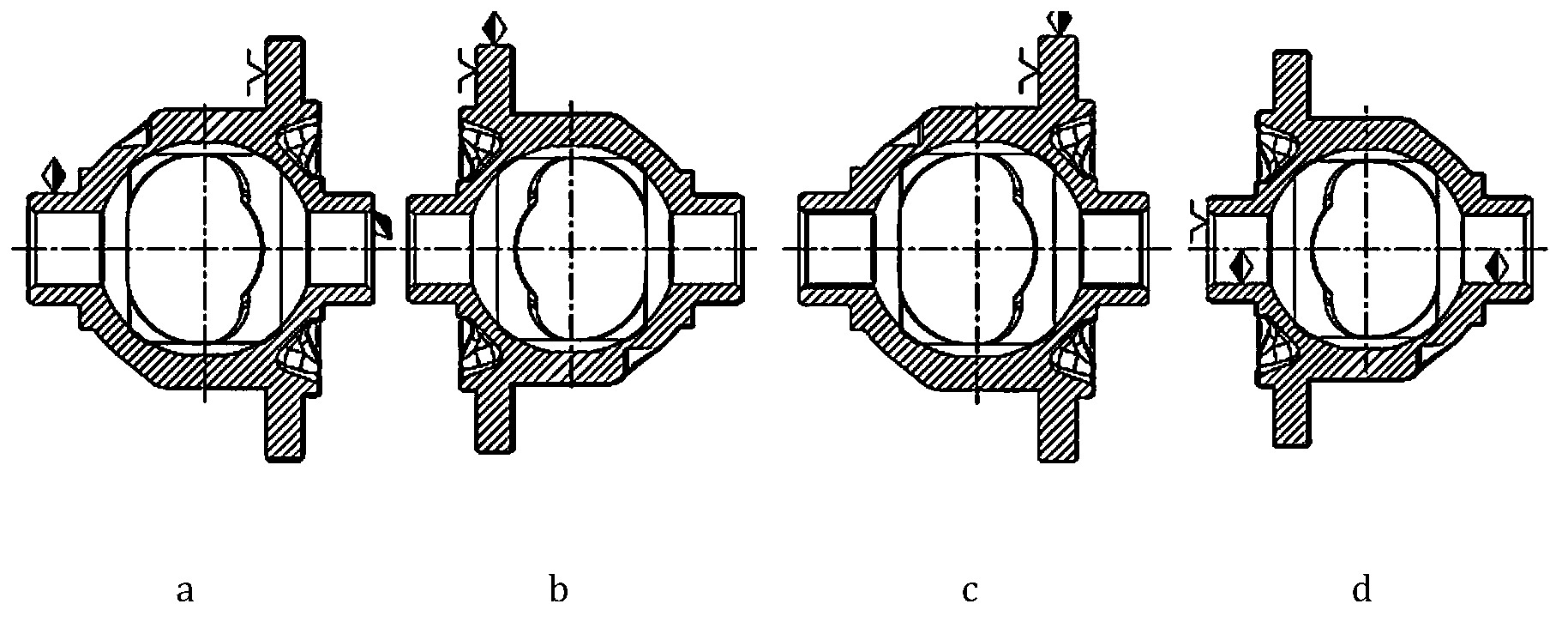

Device and process for machining differential housing

ActiveCN103753322ARealize batch production processingRealize inputWork clamping meansExpansion mandrelsNumerical controlCar manufacturing

The invention belongs to the technical field of automobile manufacturing and discloses a device and process for machining a differential housing. The device is composed of a rotary jig, an internally-expanding lathing jig and a spherical surface lathing jig, wherein the rotary jig is arranged on a machining center and comprises an operation part with the two ends arranged on the machining center through rotating assemblies, and the internally-expanding lathing jig and the spherical surface lathing jig are arranged on a common numerically-controlled lathe. Synchronous machining of two parts can be achieved through the high-precision rotary jig when the machining center is used for machining various axial inner holes, and therefore efficiency is higher; a high-precision numerically-controlled indexing table is applied to the jigs, rotating accuracy is as high as 20'' or higher, and precision of the critical size of a product is better guaranteed; the parts can be automatically clamped and dismounted by the jigs through numerical control programs, and therefore labor can be saved.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

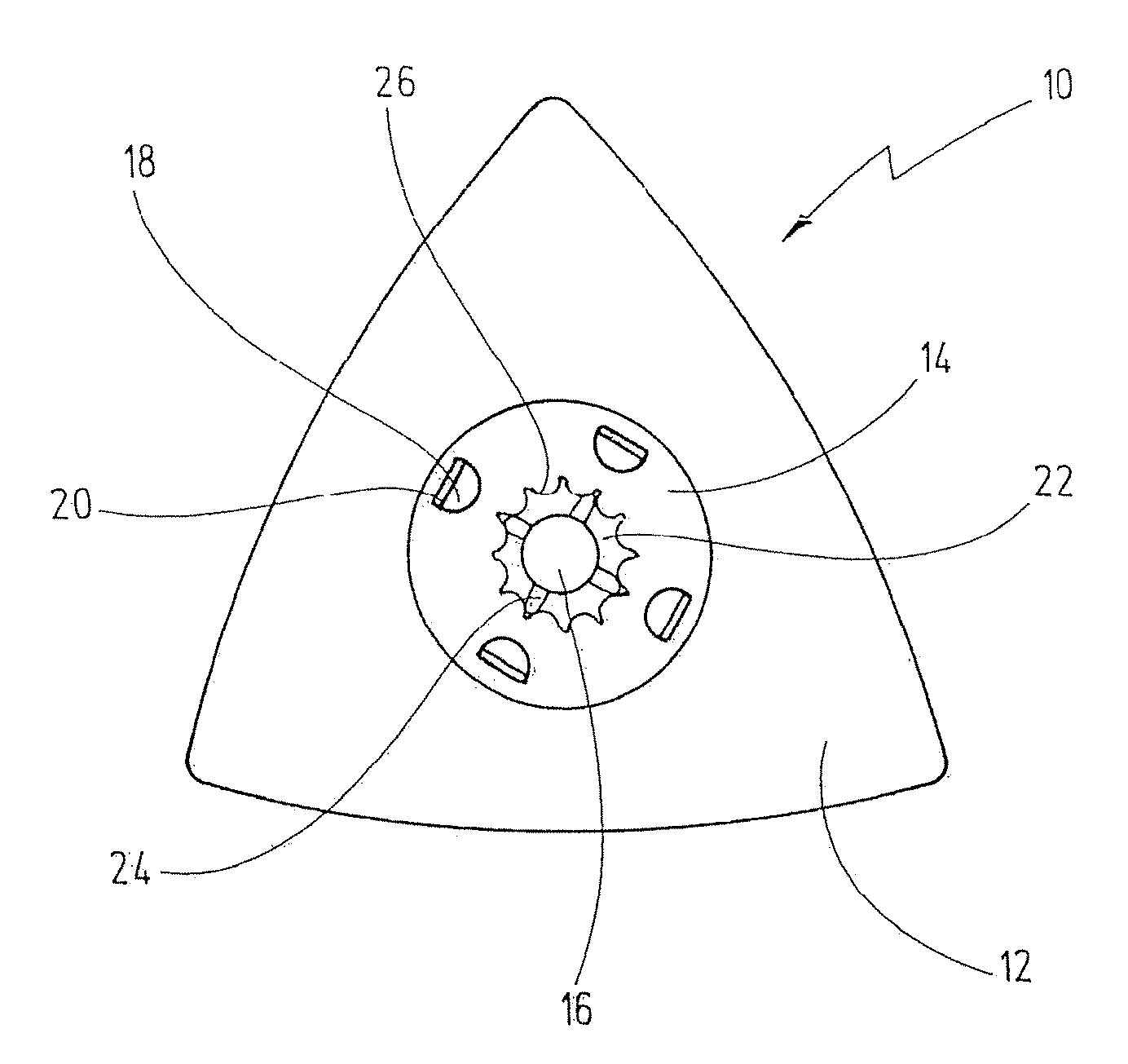

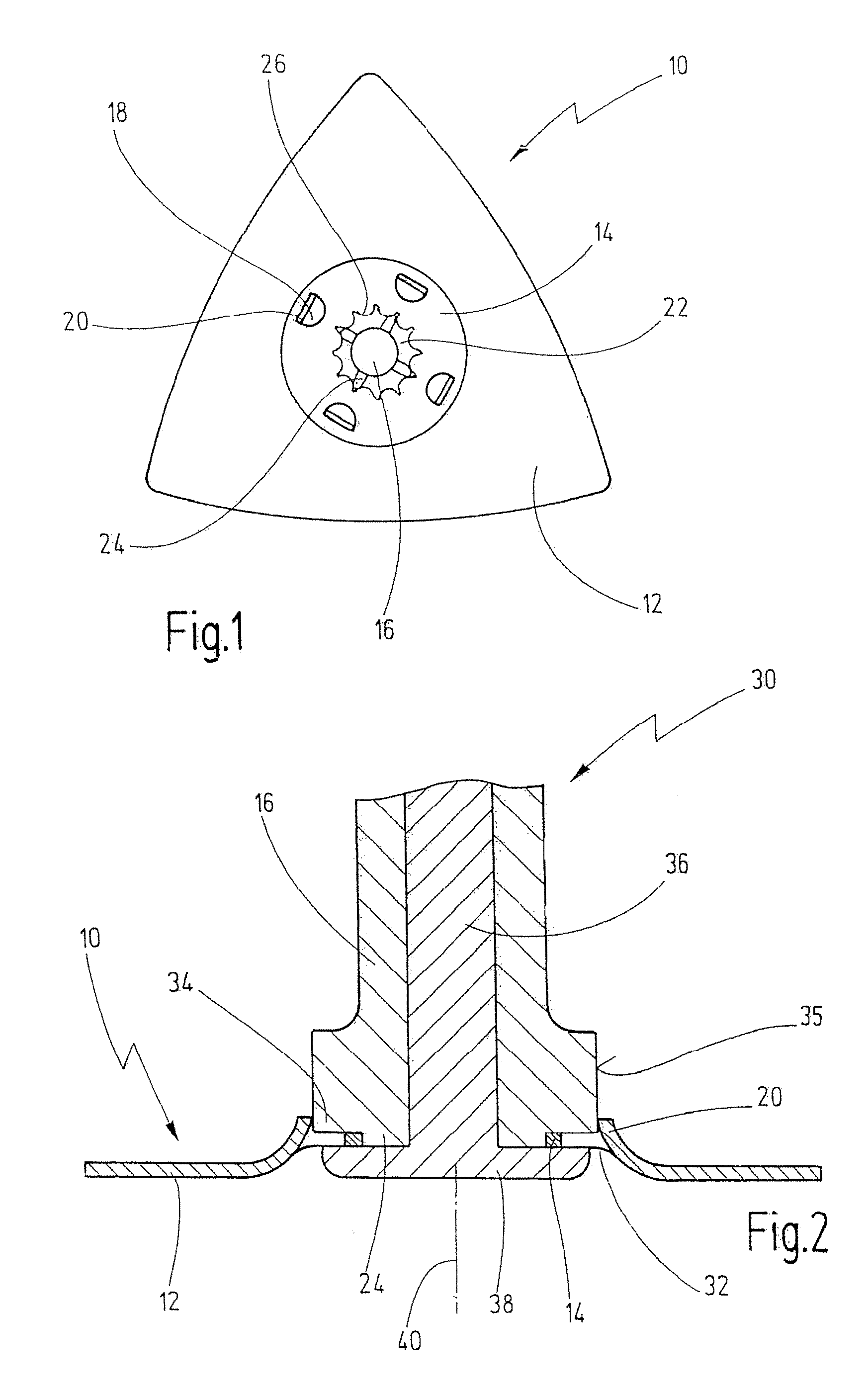

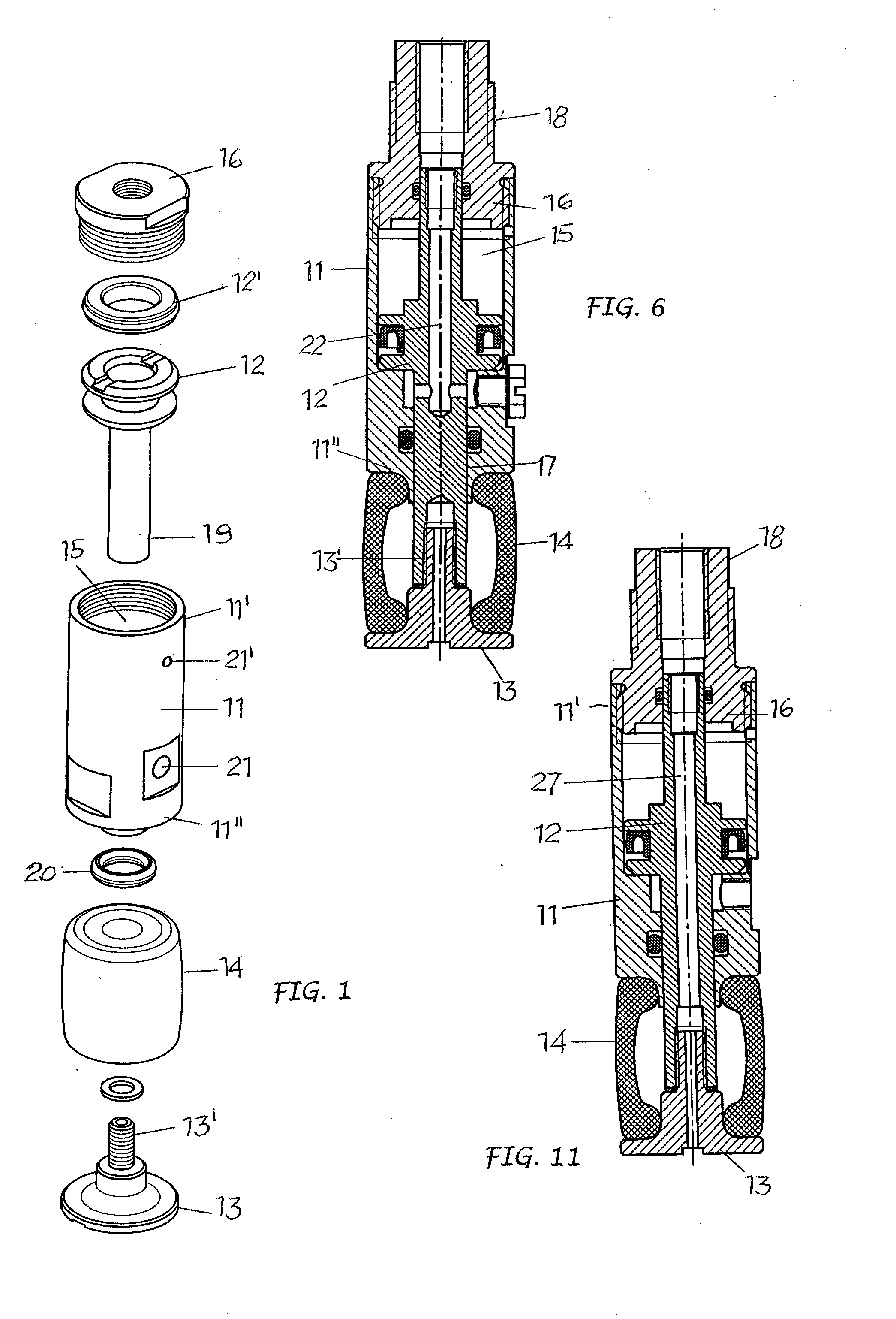

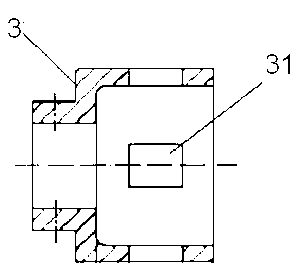

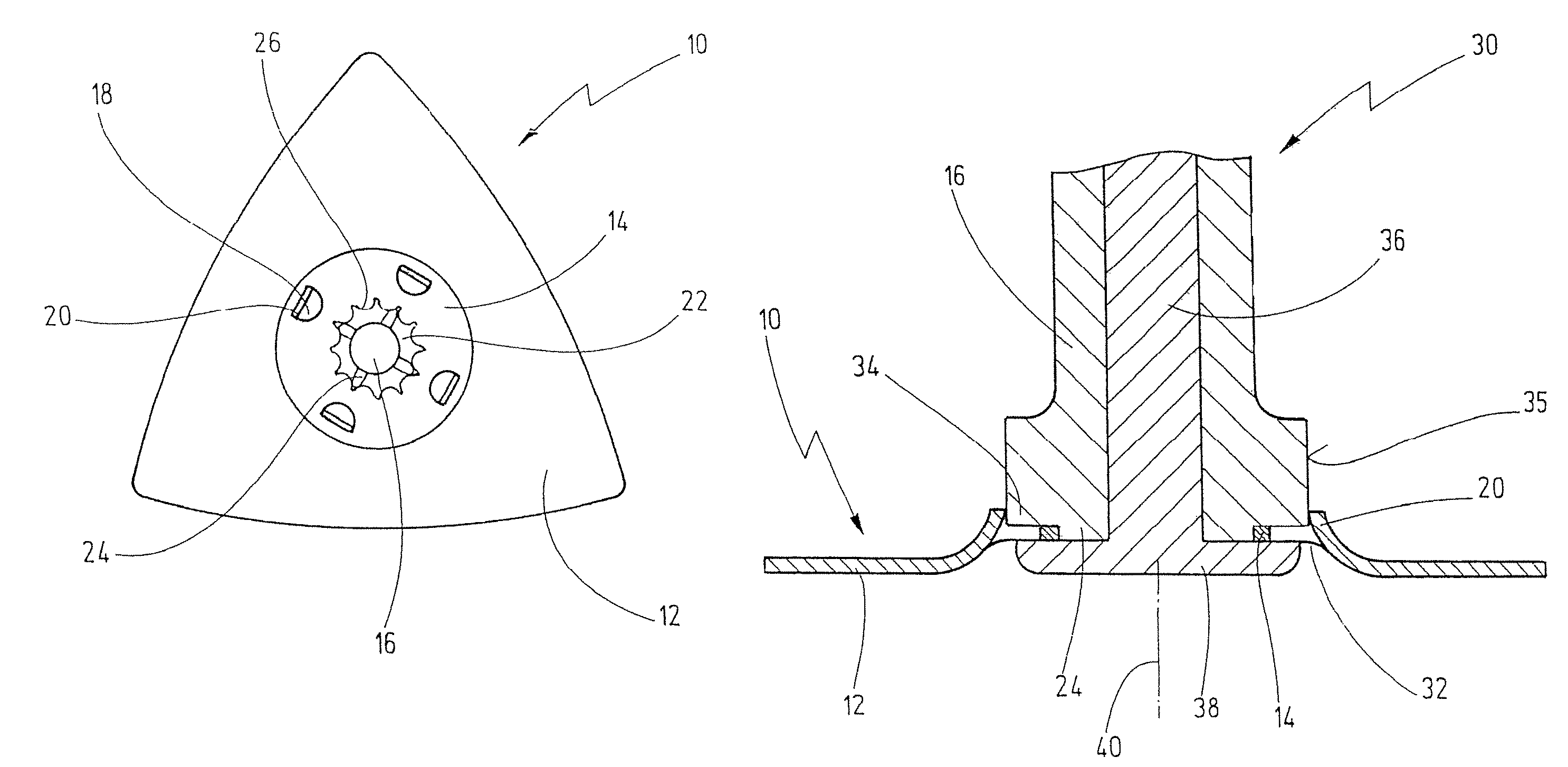

Tool-Mounting Attachment

InactiveUS20080057846A1Precise seatingPrecise seating of the mounting opening of the tool on the drive shaftGrinding wheel securing apparatusRevolution surface grinding machinesDrive shaftEngineering

The invention discloses a tool having a work plate which has a mounting area with a mounting opening for mounting the plate on a drive shaft of a drive, preferably an oscillatory drive, the mounting opening being suitably configured for being seated on the drive shaft, wherein centering elements, projecting toward the drive shaft, are provided for centering the tool on the drive shaft.

Owner:C & E FEIN

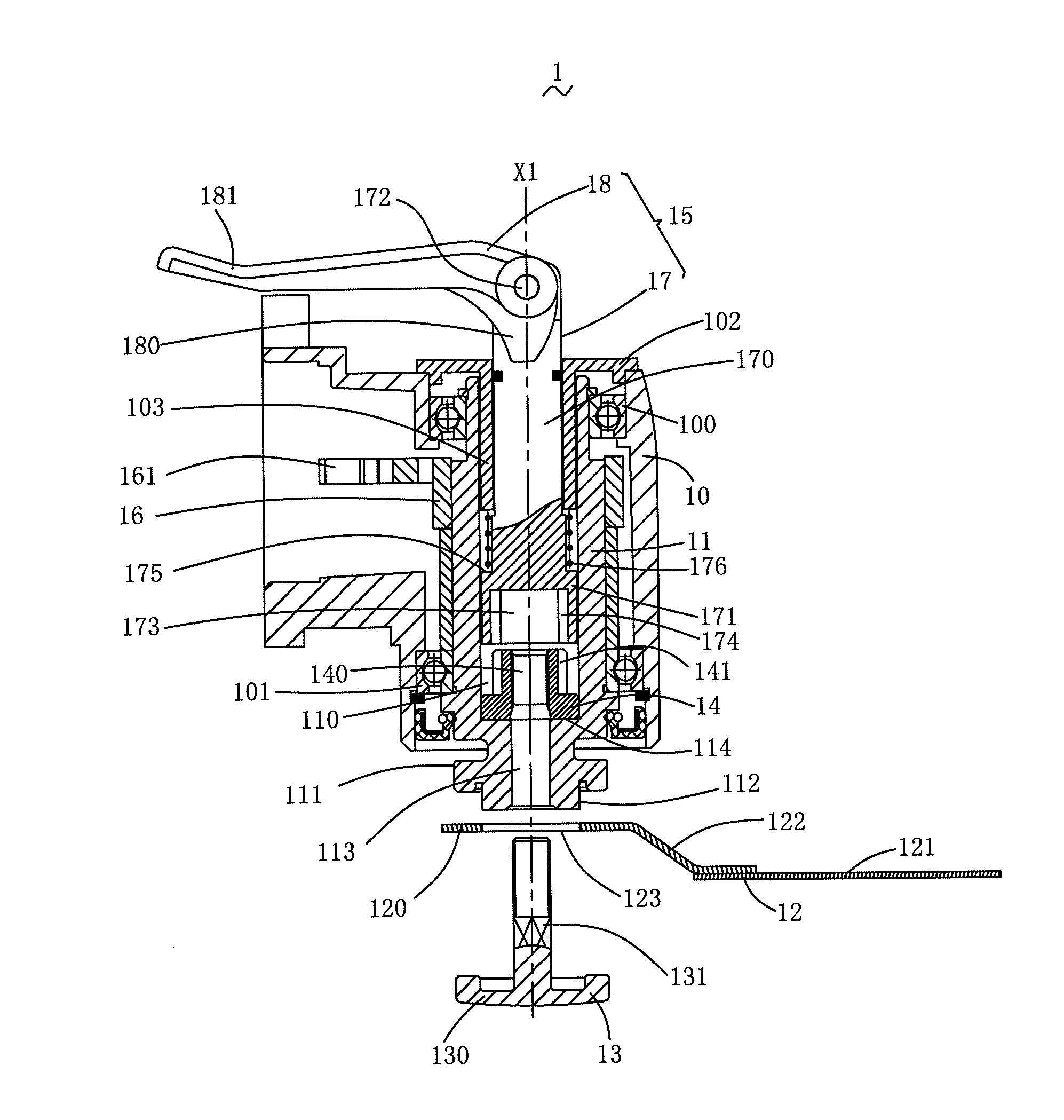

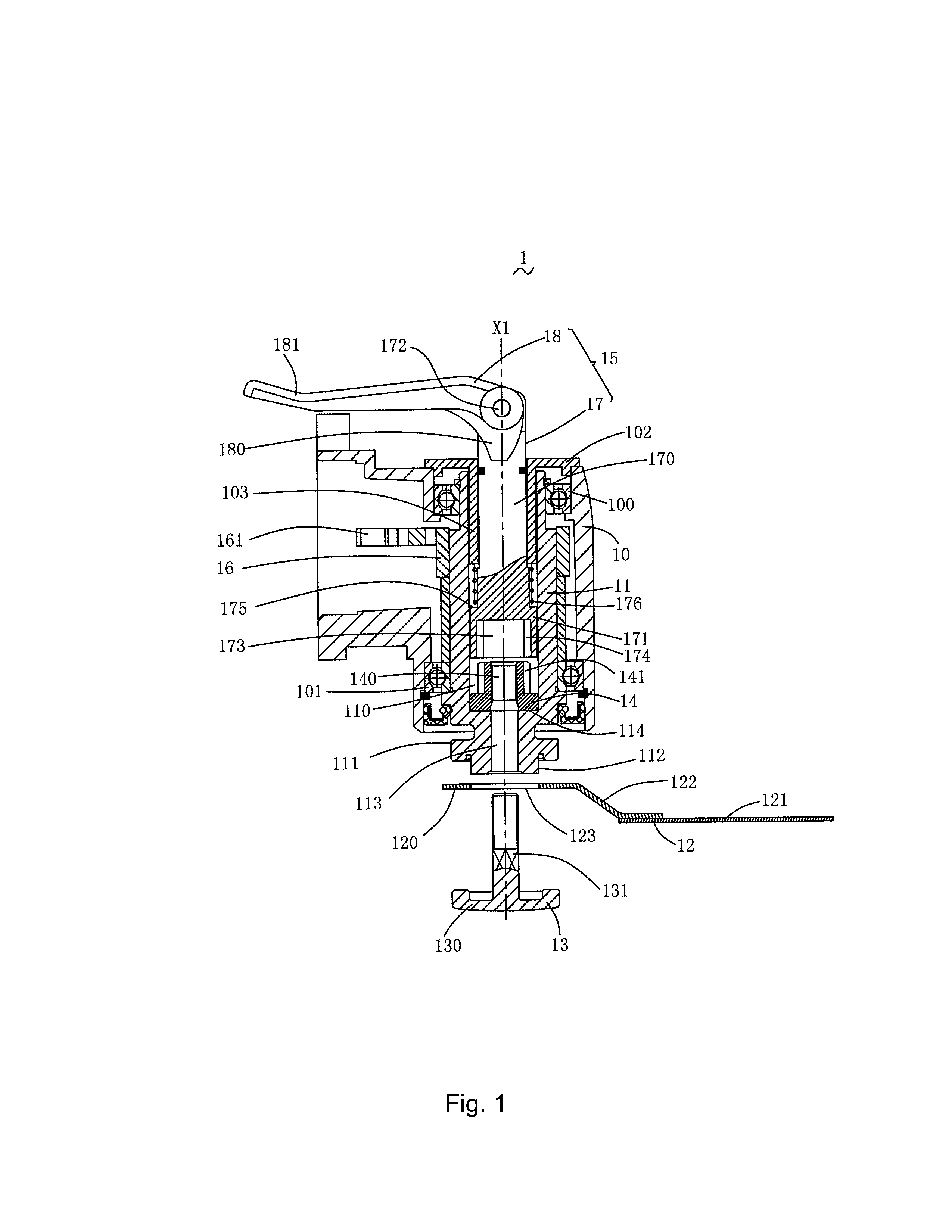

Power tool and operation method thereof

InactiveUS20130180747A1Prevent slippingImprove work efficiencyGrinding wheel securing apparatusPortable grinding machinesAxial pressureControl engineering

The power tool includes a housing, an output shaft for fixing and driving a head to work, the output shaft being provided with a receiving portion extending out of the housing, a locking member for locking the head on the receiving portion of the output shaft, a fastener supported on the output shaft for fastening the locking member, and a driving mechanism rotatably displaced on the housing. The driving mechanism is operable to rotate along a first direction to make the fastener and the locking member screwed, and also is operable to rotate along a direction opposite to the first direction to loosen the fastener and the locking member. The power tool can assemble or disassemble the head quickly and provide a stable axial press to avoid the slippage of the head without any other auxiliary tools. Meanwhile, the operation method of the power tool is easy and reliable.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

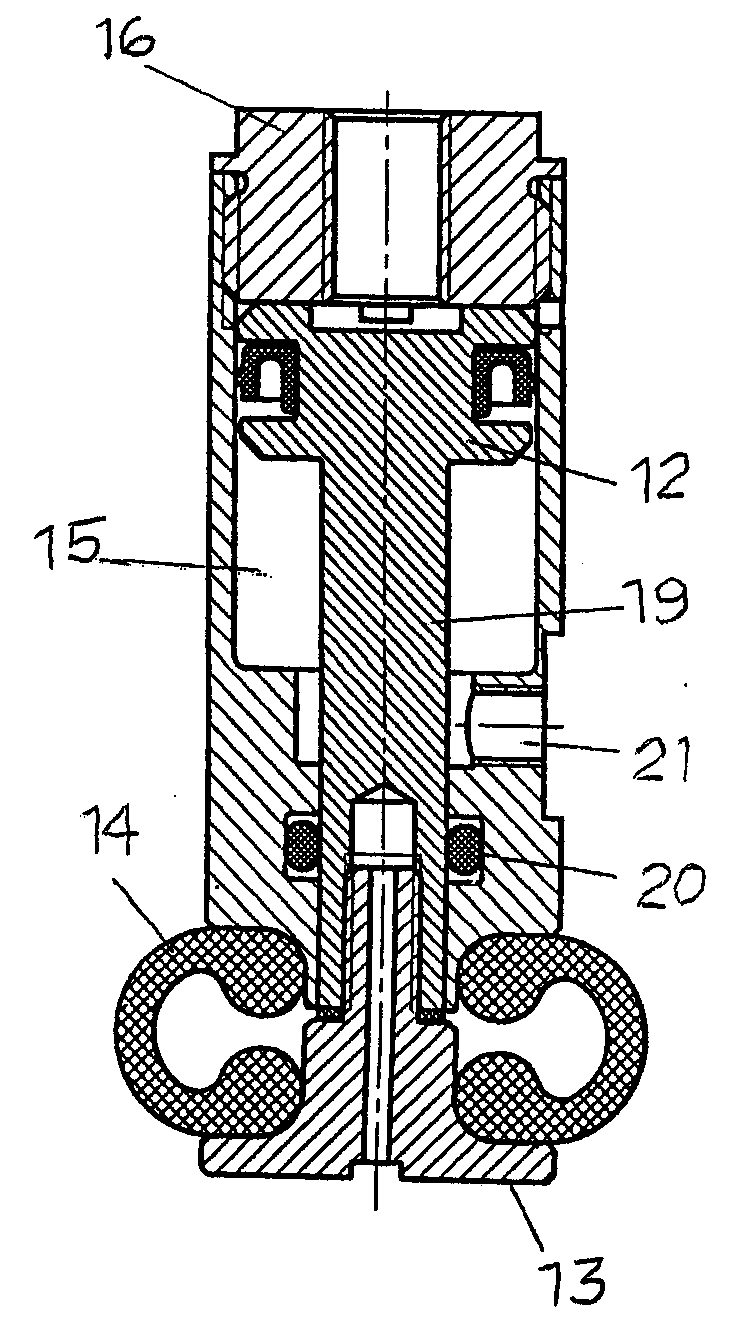

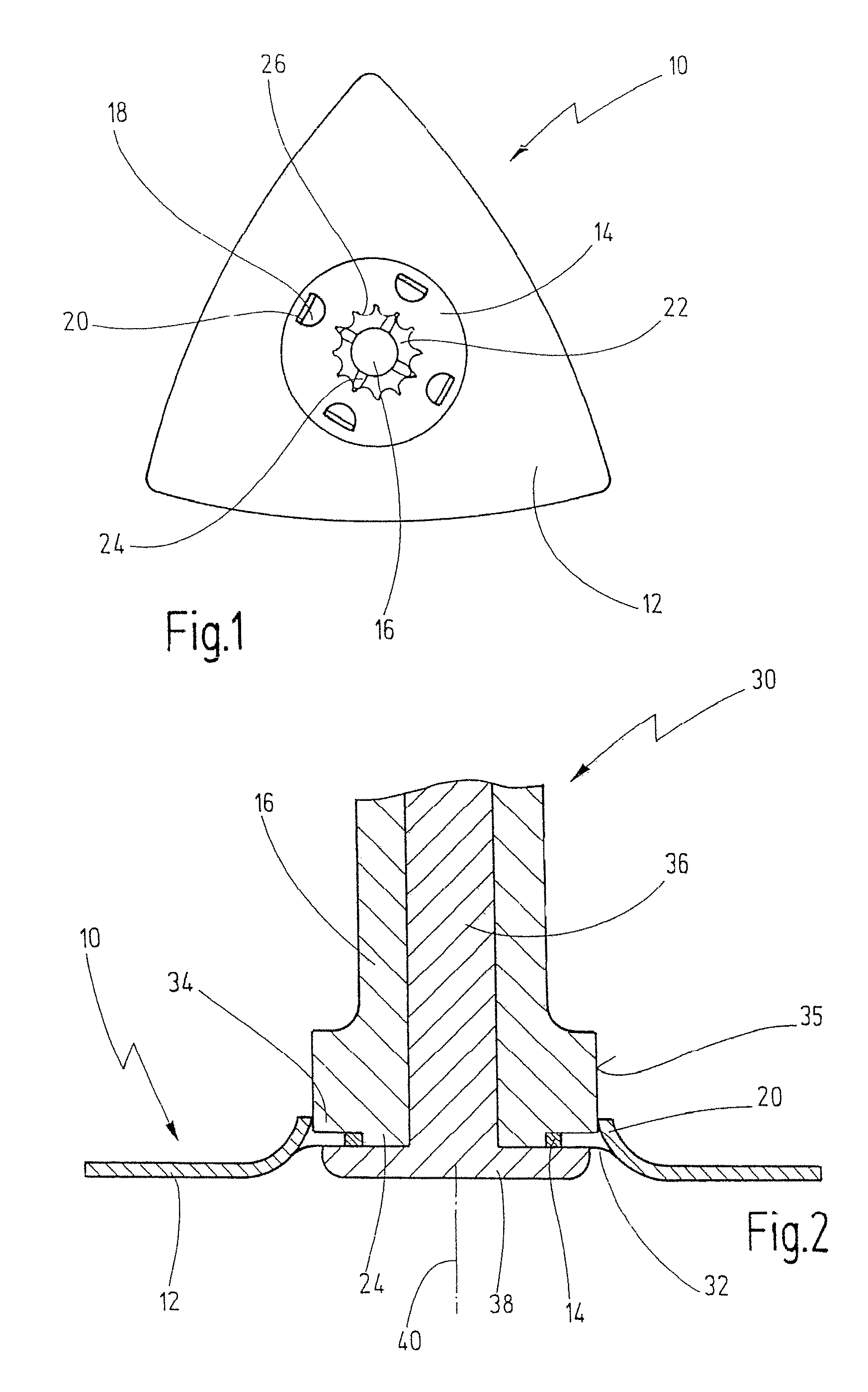

Expandable finger gripper

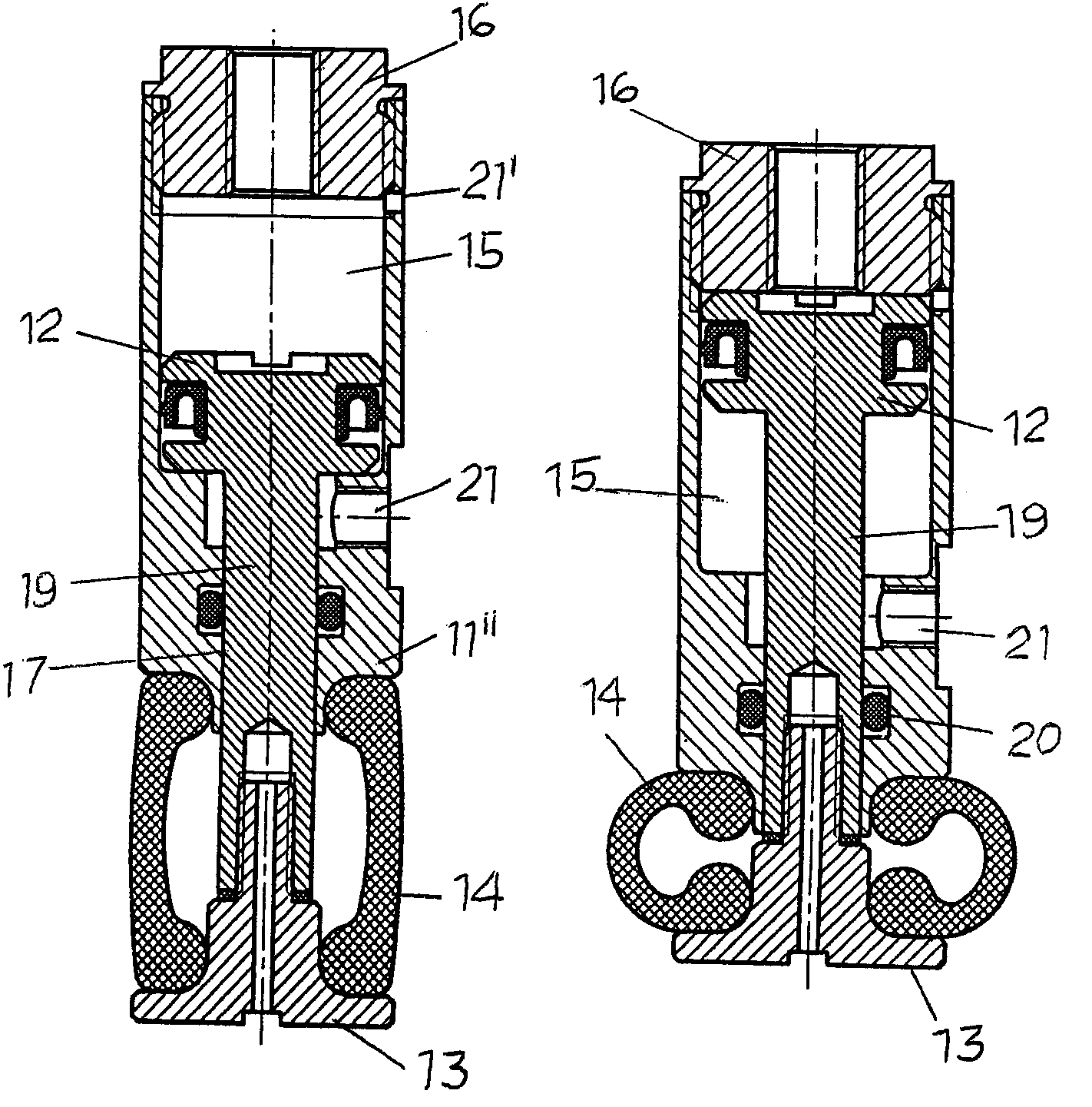

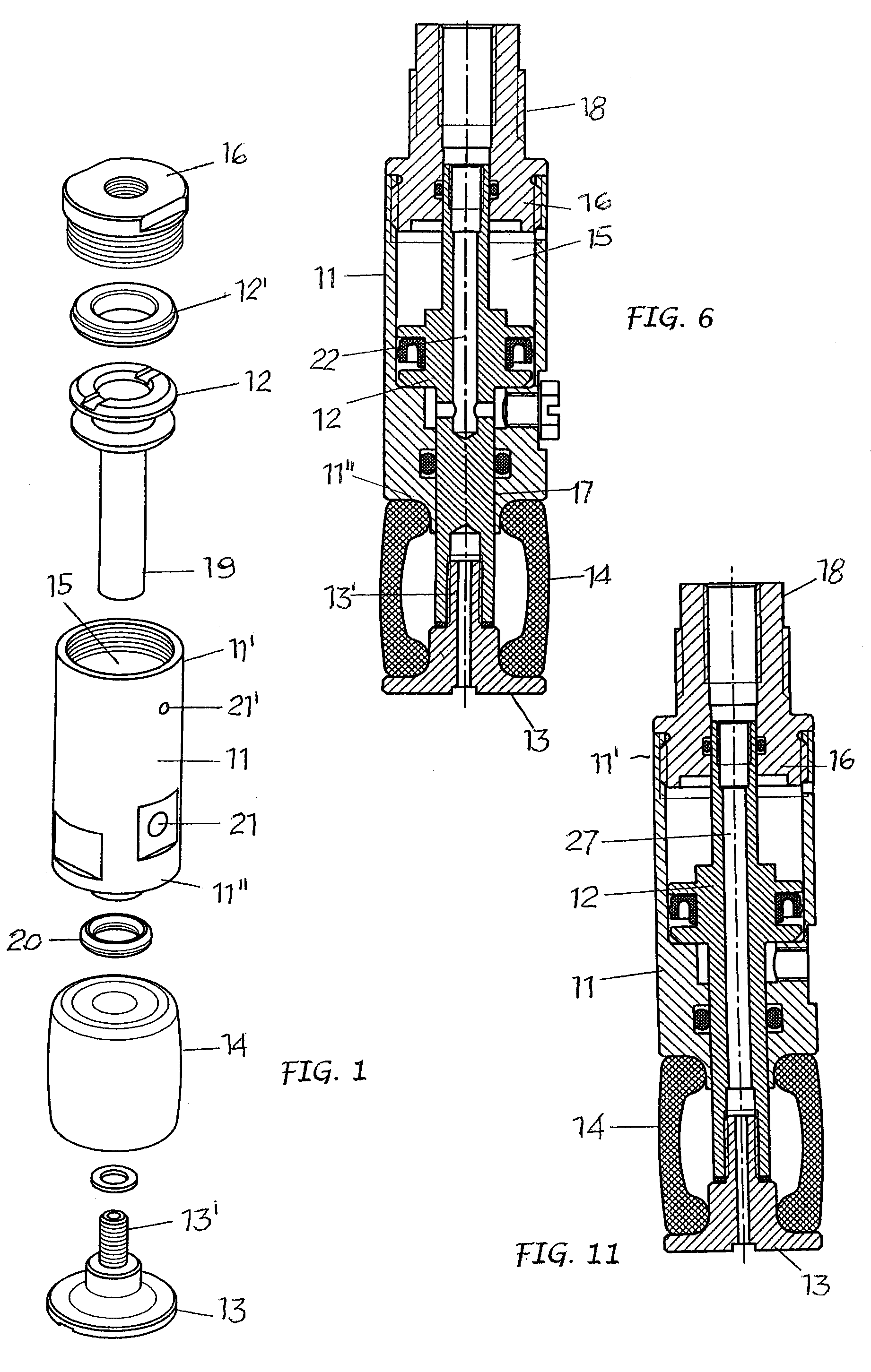

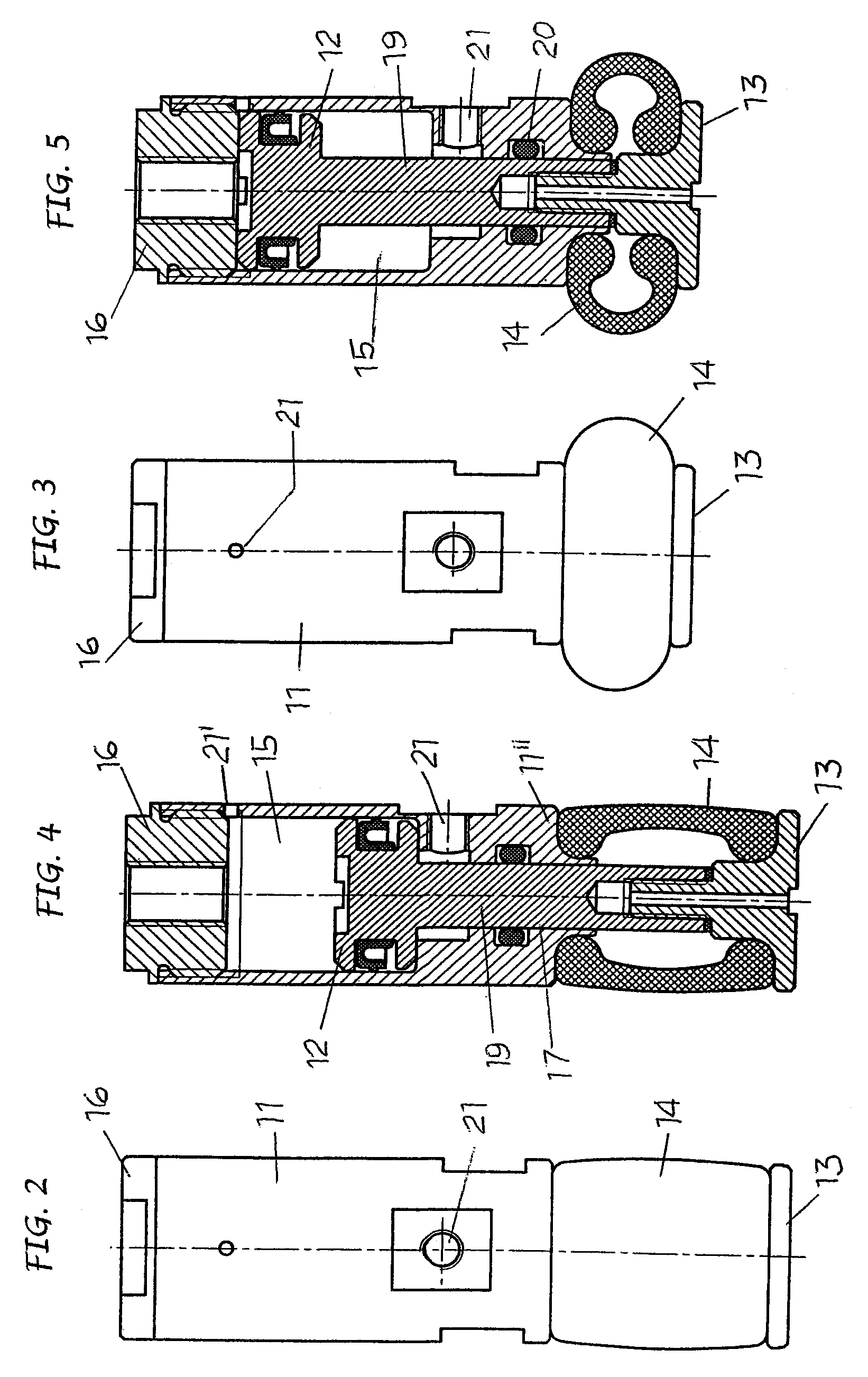

ActiveUS20070222245A1Long and efficient life-spanEasy to replaceSleeve/socket jointsGripping headsEngineeringPiston

The invention concerns a pneumatically controlled finger gripper that comprises a supporting body (11) with a proximal and a distal end, a pneumatic control piston (12) guided and moving alternatively in said body, a compression disk (13) connected to, and moving axially with, said piston relatively at the distal end of said supporting body, and a flexible gripper element (14) assembled between said compression disk (13) and said distal end of the supporting body (11) and moving between a contracted and expanded position in response to the movements of the control piston with the compression disk between an inactive and active position.

Owner:GIMATIC SRL

Machining clamp for outer wall of blind-hole thin-wall sleeve part and using method thereof

ActiveCN103495755AImprove clamping effectAvoid clampingExpansion mandrelsMachining deformationEngineering

The invention discloses a machining clamp for the outer wall of a blind-hole thin-wall sleeve part and a using method of the machining clamp. The clamp comprises a core shaft and a fastening nut connected on the core shaft through threads. The core shaft is sleeved with an elastic clamping sleeve, the elastic clamping sleeve is overall cylindrical, cones with the large outsides and the small insides are arranged at the two ends of the elastic clamping sleeve, a conical surface is arranged at the tail end of the core shaft, the tail end of the core shaft is matched with the elastic clamping sleeve, the core shaft is further sleeved with a taper sleeve, the taper sleeve is arranged between the fastening nut and the elastic clamping sleeve, and the conical surface of the tapper sleeve is arranged in the elastic clamping sleeve. The design of the elastic clamping sleeve with two expansile ends is adopted in the clamp, the inner diameter of the part is centered when the elastic clamping sleeve expands, the opening end and the inner bottom end of the part are simultaneously clamped, the function of bidirectional clamping is achieved, then the locating and clamping effect of the clamp is enhanced, the clamping and machining deformation of the external circle of the thin-wall sleeve part can be effectively prevented when finish machining is carried out on a lathe and a grinding machine, machining quality is guaranteed and improved, and therefore production efficiency is improved, and machining cost is lowered.

Owner:贵州凯星液力传动机械有限公司

Lathe fixture

Owner:陶晓明

Assembly For Rotating A Cutting Insert During A Turning Operation And Inserts Used Therein

A cutting insert rotated about its axis may be utilized during a metalworking operation and applied against the rotating workpiece to enhance tool performance. The cutting insert is secured within a toolholder having features to secure the insert but at the same time make for efficient removal of the insert from the toolholder.

Owner:KENNAMETAL INC

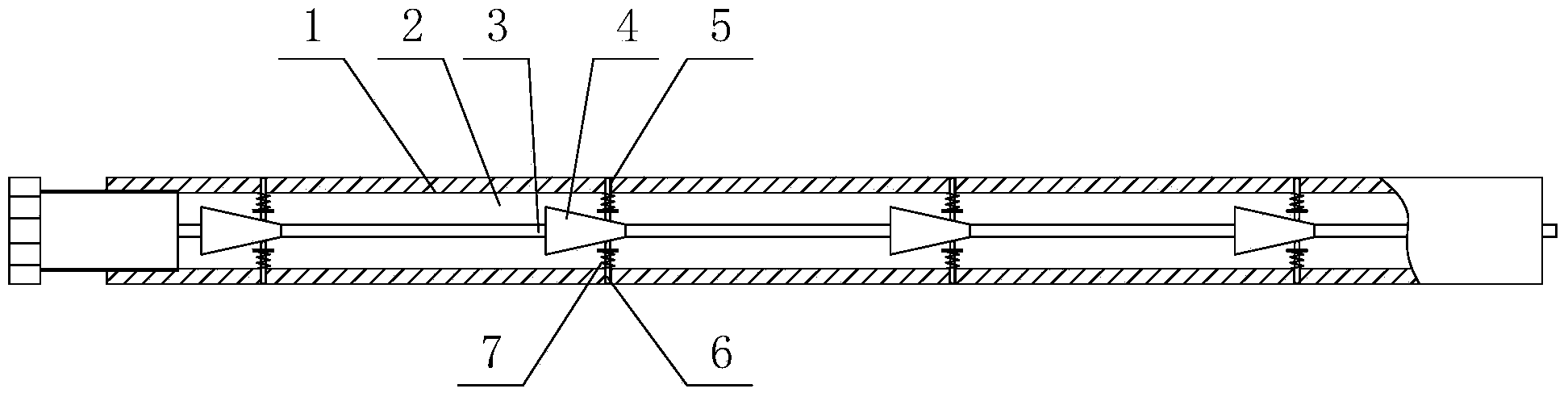

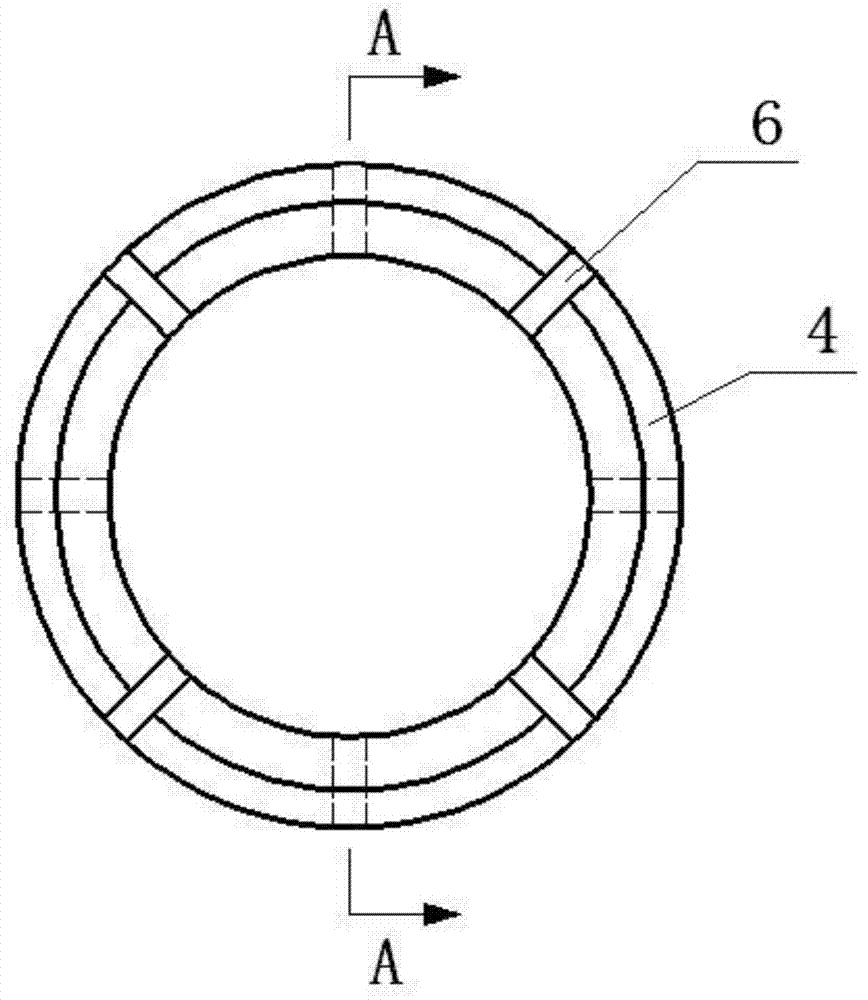

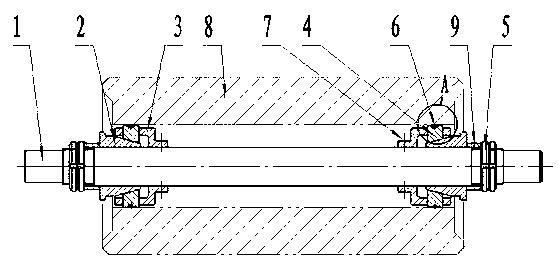

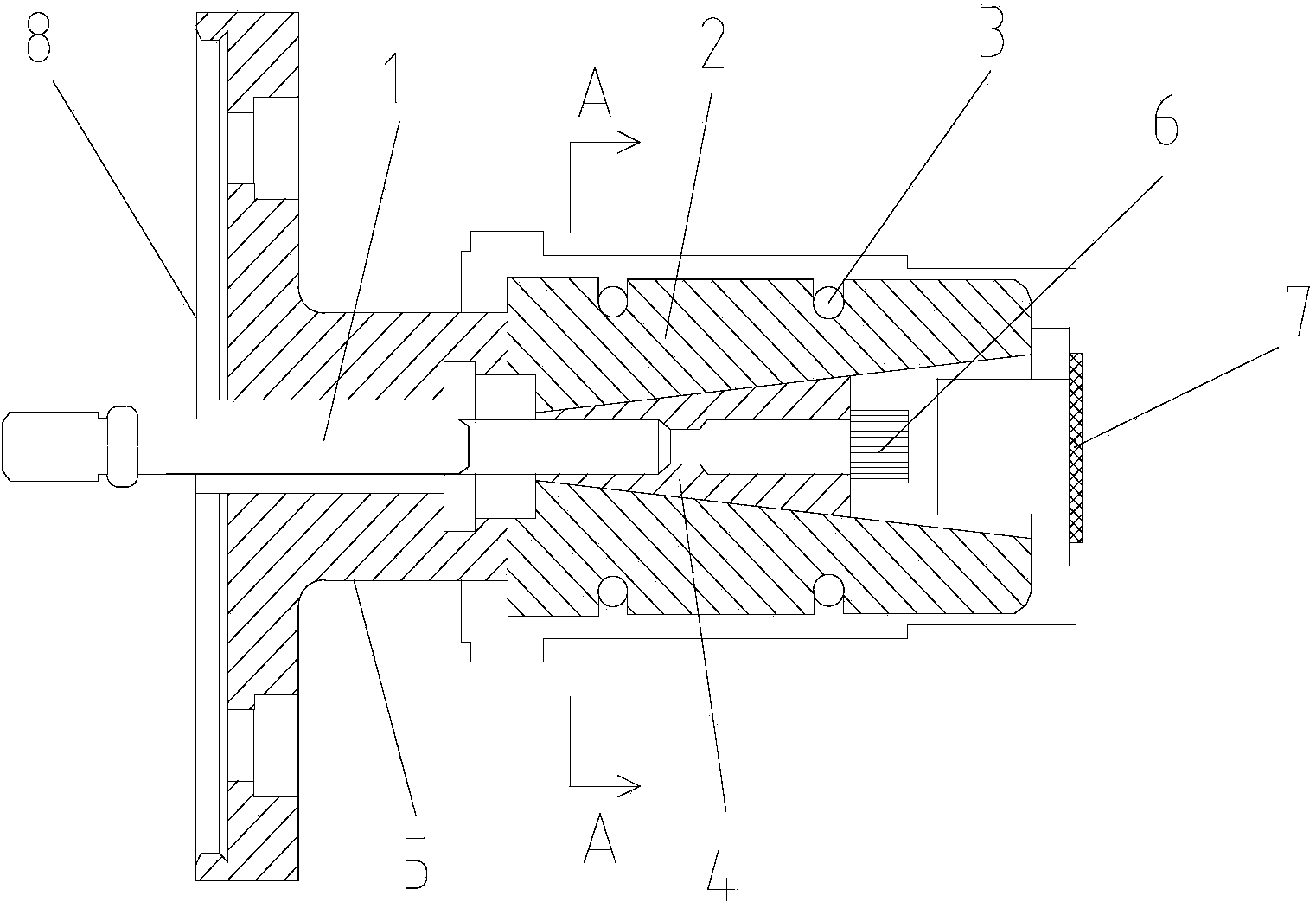

Special fixture for processing outer circle of long-cylinder part

The invention relates to a machining fixture, and discloses a special fixture for processing an outer circle of a long-cylinder part. Guide sleeves, taper sleeves and lock nuts are mounted at the two ends of a central spindle of the special fixture symmetrically and sequentially from inside to outside; the guide sleeves are in large-small end structures; the small ends of the guide sleeves are fixed with the central spindle by set screws; through holes are formed in casings at the large ends of the guide sleeves; ejection blocks are arranged in the through holes; cambered surfaces and grooves are arranged and formed at the outer ends of the ejection blocks; taper surfaces are arranged at the inner ends of the ejection blocks; cones of the taper sleeves eject the taper surfaces of the ejection blocks; and annular springs are mounted around the grooves of the ejection blocks. According to the special fixture, radial ejection block ejecting workpieces are added on the basis of axial clamping; radial motion during the processing of the outer circles of the workpieces is avoided; the centering precision is high; with the adoption of the matched design of the guide sleeves and the taper sleeves, and added shaft sleeves, centering clamping can be adjusted conveniently according to the length and an inner hole of the long-cylinder part; and the generality of the tool fixture for processing the outer circle of the long-cylinder part is improved.

Owner:XINYU IRON & STEEL CO LTD

Tool-mounting attachment

InactiveUS7695352B2Precise seating of the mounting opening of the tool on the drive shaftGrinding wheel securing apparatusRevolution surface grinding machinesDrive shaftEngineering

The invention discloses a tool having a work plate which has a mounting area with a mounting opening for mounting the plate on a drive shaft of a drive, preferably an oscillatory drive, the mounting opening being suitably configured for being seated on the drive shaft, wherein centering elements, projecting toward the drive shaft, are provided for centering the tool on the drive shaft.

Owner:C & E FEIN GMBH & CO KG

Expandable finger gripper

ActiveUS7475927B2Long and efficient life-spanEasy to replaceSleeve/socket jointsGripping headsEngineeringPiston

A pneumatically controlled finger gripper having a supporting body (11) with a proximal and a distal end, a pneumatic control piston (12) guided and moving alternatively in the body, a compression disk (13) connected to, and moving axially with, the piston relatively at the distal end of the supporting body, and a flexible gripper element (14) assembled between the compression disk (13) and the distal end of the supporting body (11) and moving between a contracted and expanded position in response to the movements of the control piston with the compression disk between an inactive and active position.

Owner:GIMATIC SRL

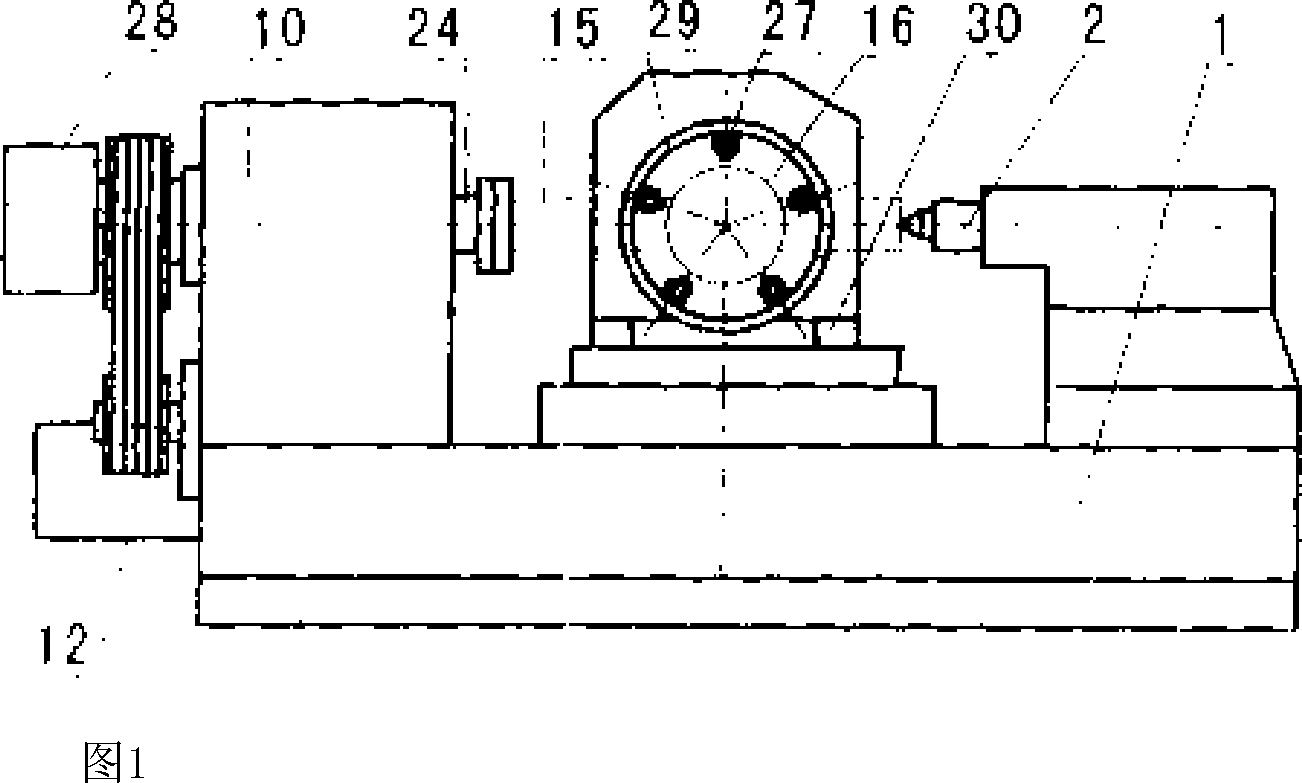

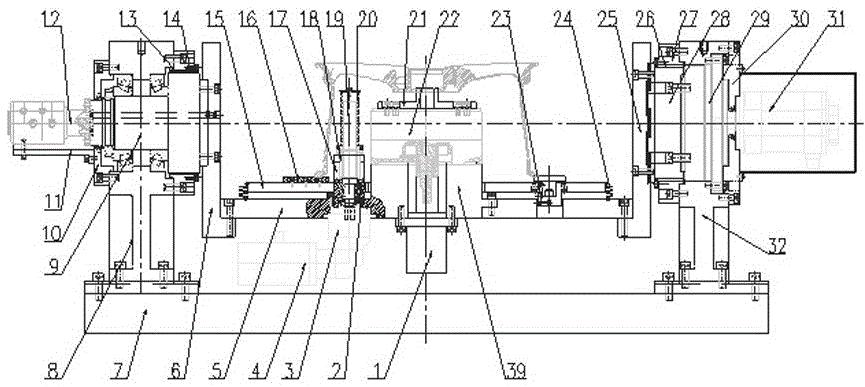

Numerically controlled ball grinding vehicle

InactiveCN101053935ASimple structure and principleImprove scalabilitySpherical surface grinding machinesMeasurement/indication equipmentsNumerical controlElectric machinery

The present invention relates to a numerical control ball milling machine tool, which comprises a lathe bed (1) provided with a main shaft servo drive motor (14), a clamp arranged above the lathe bed (1), a lathe bed saddle (3) provided with a rotating table (4) which is connected with a B-shaft servo drive motor (23) and is provided with a tool rest slide (6), a tool rest (7) fixedly arranged above the tool rest slide (6), and a wheel-head device (29) arranged behind the lathe bed saddle (3). In the present invention, the sphericity workpiece is processed by the tool and the wheel-head device arranged on one machine tool; the workpiece is clamped once in the whole course of processing, thereby, not only the processed precision can be ensured, but also the automaticity can be greatly improved, so that the labour force is saved, and the production efficiency and the production quality are improved. The machine tool of the present invention has a simple structure and principle, easy operation, and excellent expansibility.

Owner:ZHEJIANG HUZHOU BEIDAO CNC PRECISE MACHINERY

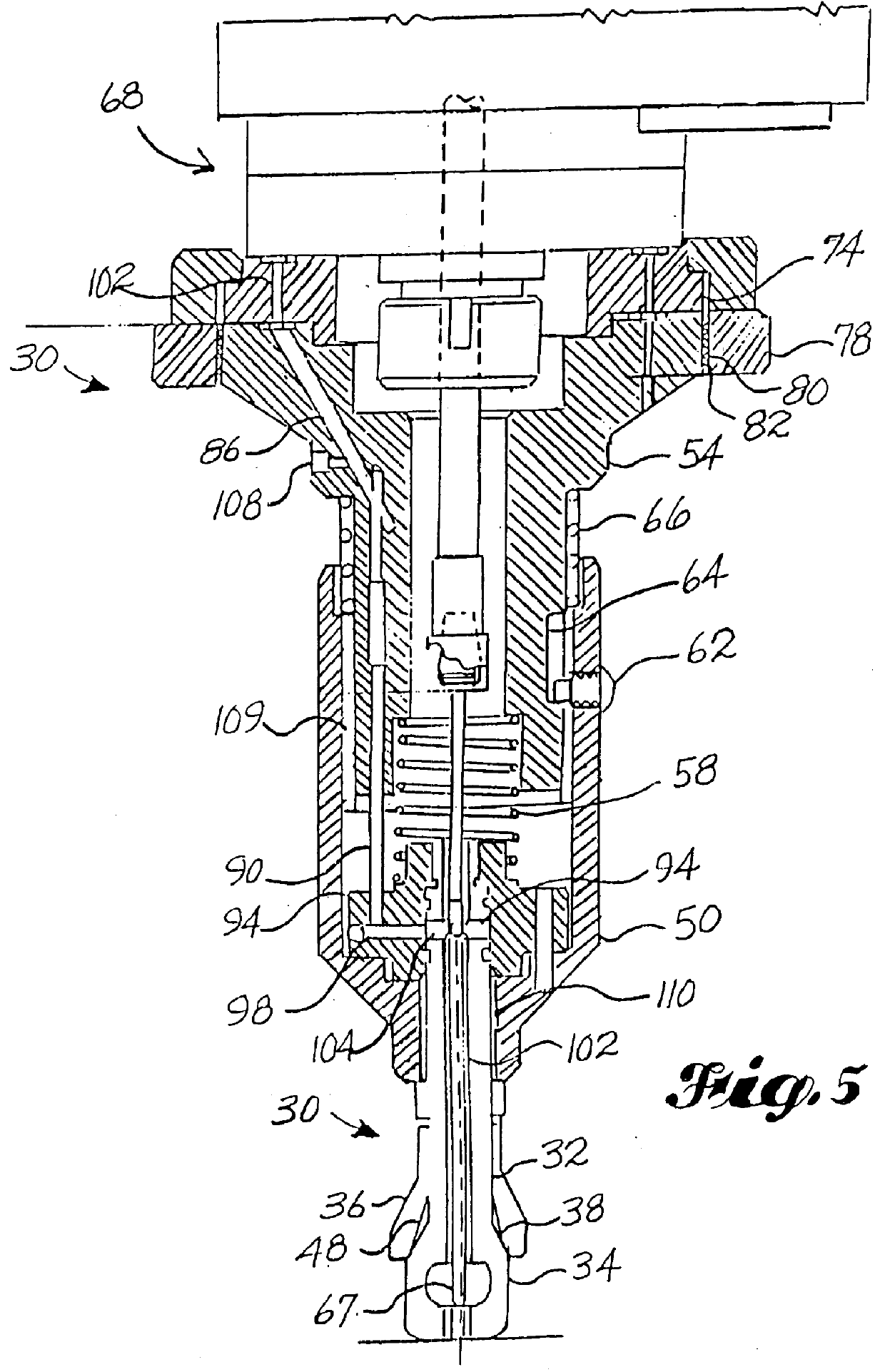

Self-centering end effector

An end effector (30) adap ttachment to and accurate positioning by a robot is provided for positioning a channel-shaped workpiece (10) at a desired position and drilling an accurately located positioning hole in the work piece, even if the workpiece is curved or has a compound contour. The end effector (30) includes a conventional speeder assembly (68) with a taper that can be grasped by the robot and rotated for transfer of torque to the speeder assembly. A flange base (54) is attached to the speeder assembly (68) and has a central opening to accommodate a drill bit (67). A housing assembly (50) is slidably mounted around the flange base (54) through a linear bearing (109). An index shaft (32) is slidably mounted partially within the housing assembly (50) through a second linear bearing (110). A collet (36) is concentrically mounted slidably about the index shaft (32). The collet (36) is adapted to expand radially when it is forced over a wider portion (34) of the index shaft (32). The radial expansion of the collet (36) provides the necessary force to position the channel-shaped workpiece (10).

Owner:THE BOEING CO

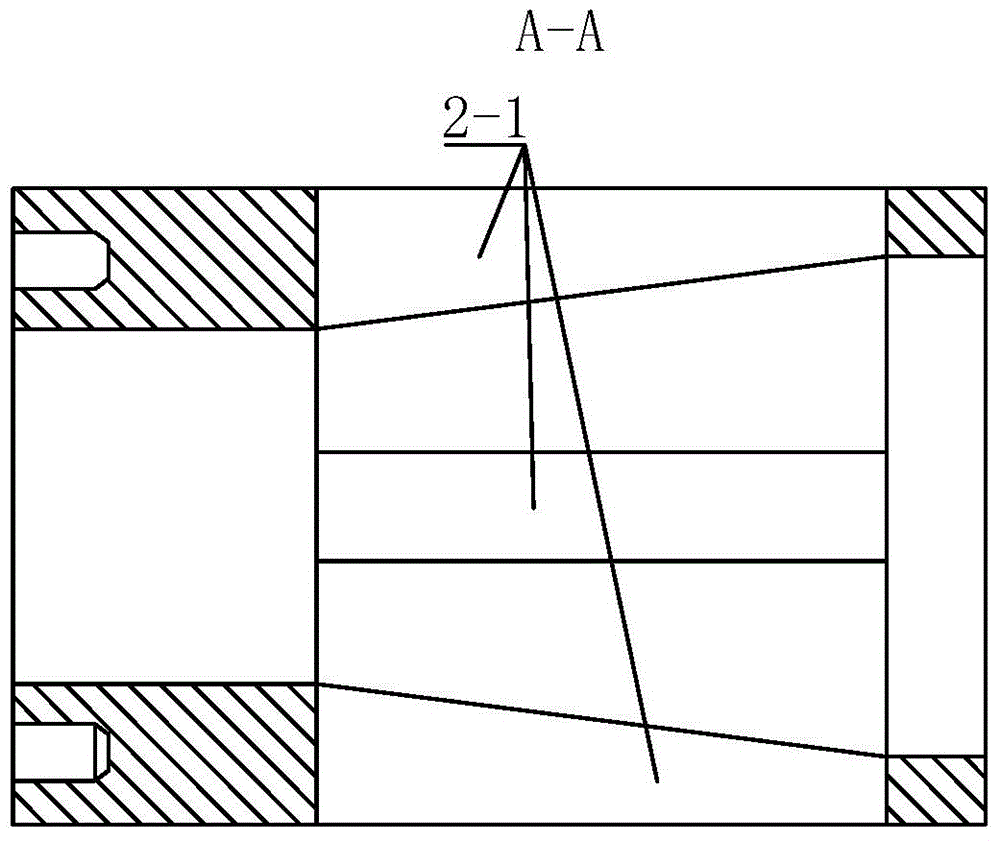

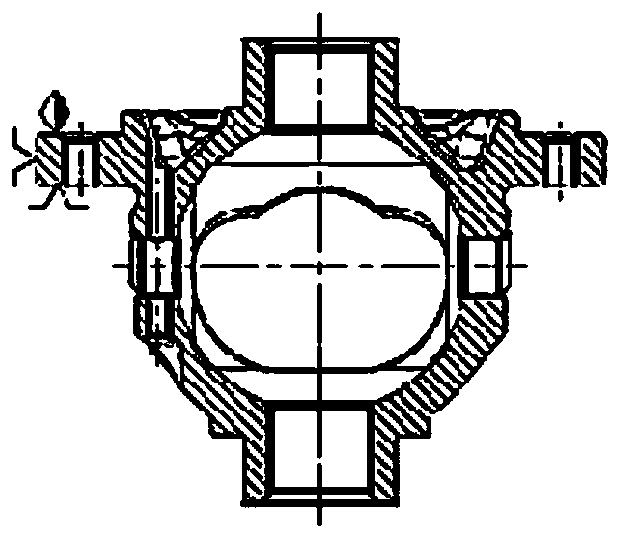

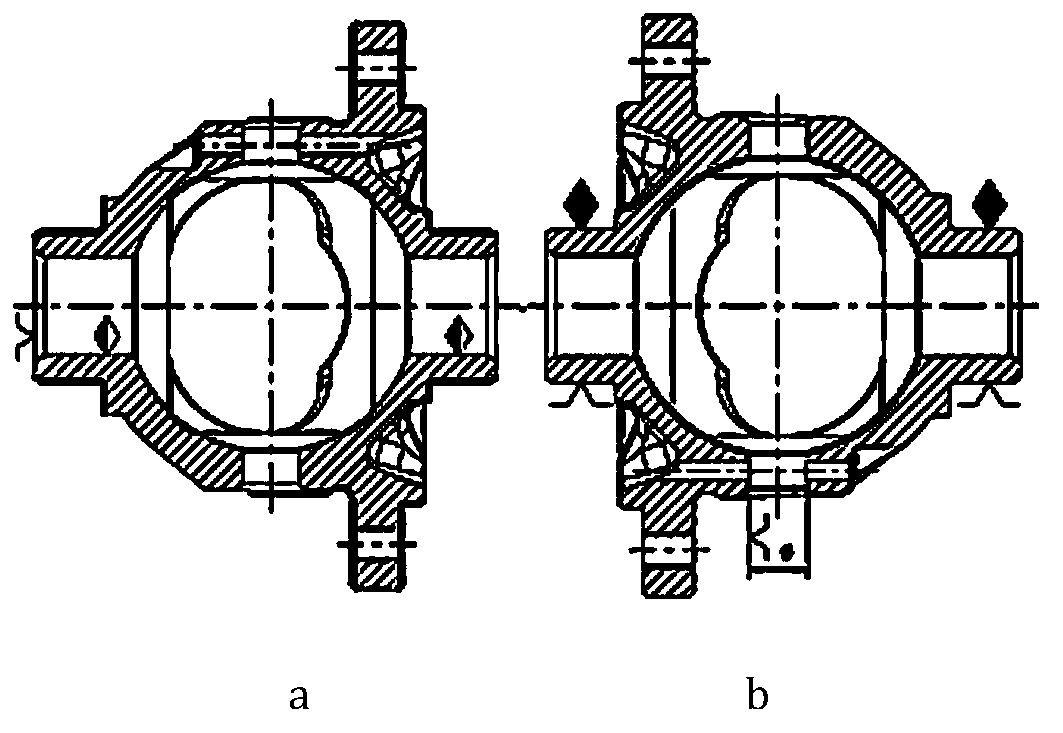

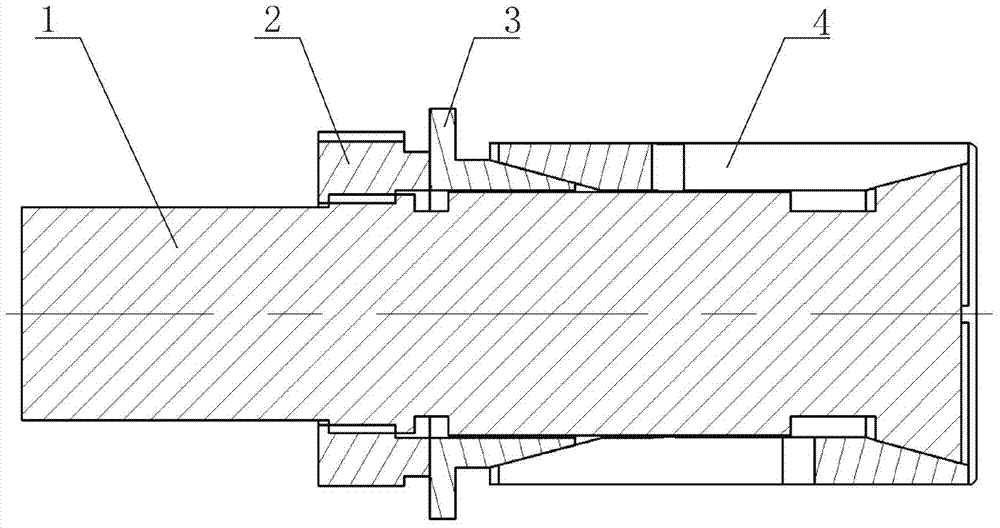

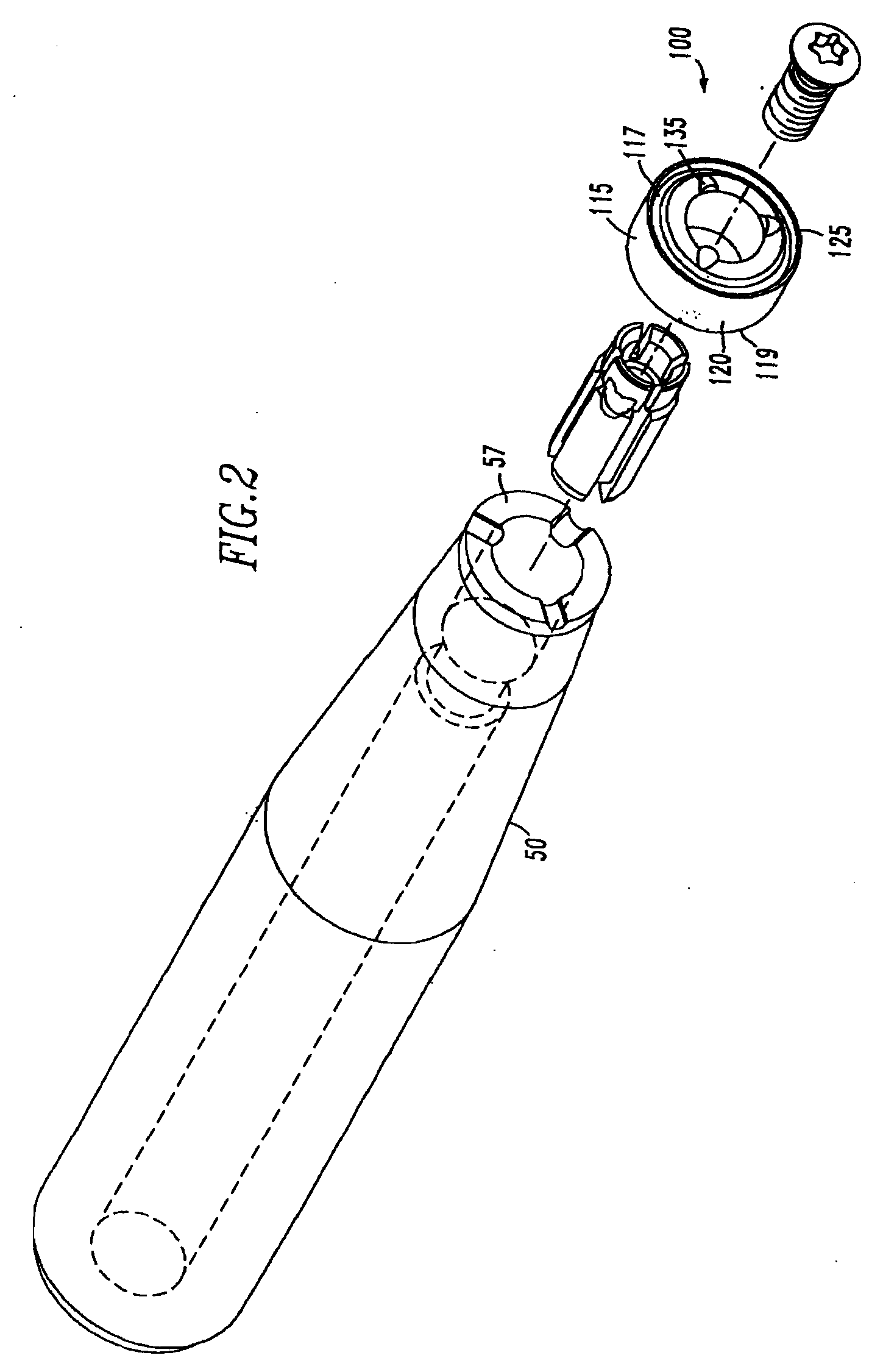

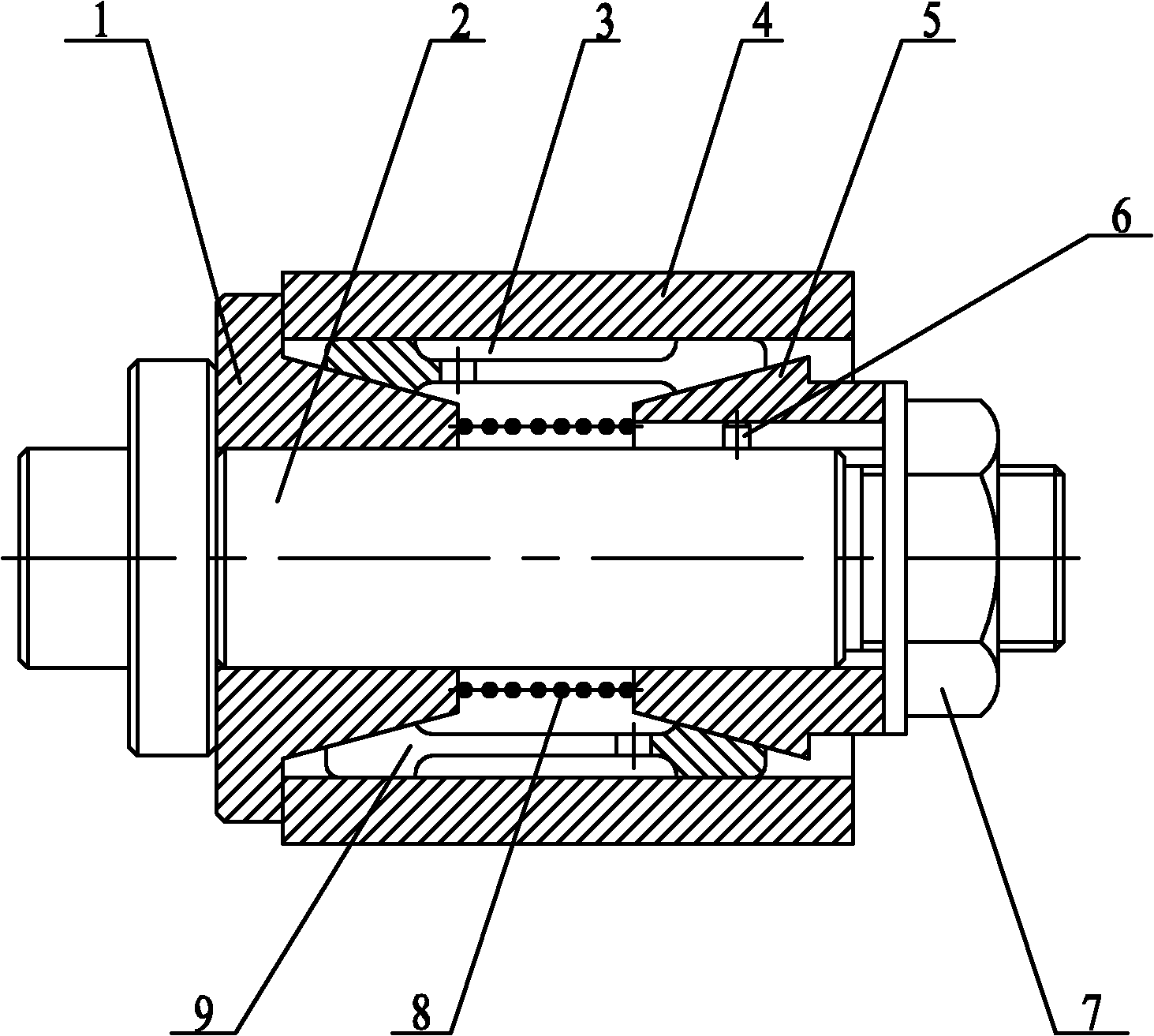

Device capable of elastically clamping two ends of long hole

InactiveCN102069207AEasy to removeRemove effectiveExpansion mandrelsProcess qualityMechanical engineering

The invention relates to a device capable of elastically clamping two ends of a long hole. The device comprises a central spindle, wherein a left taper sleeve is arranged at one end of the central spindle, and a right taper sleeve is arranged at the other end; elastic clamping heads are arranged at correspondingly connected ends of the left taper sleeve and the right taper sleeve; a plurality of flexible open slots are evenly distributed on peripheral surfaces of the elastic clamping heads; and the ends of the left and right taper sleeves connected with the elastic clamping heads are both extended into the elastic clamping heads. The elastic clamping device provided by the invention is simple in structure and low in manufacturing cost and has the following advantages: when a locknut is screwed, the right taper sleeve can be pushed to move to cause the elastic clamping heads to extend outwardly, thus achieving the purpose of fastening and installing a workpiece; in addition, when the locknut is loosened, the elastic clamping heads shrink and the processed workpiece is convenient to remove; the workpiece is fixed effectively and reliably, and the stability of process quality is improved greatly; since the elastic clamping heads have low requirements on hole tolerance of a blank to be processed, the manufacturing cost is reduced; since the elastic clamping device provided by the invention is convenient to clamp, the work efficiency is improved greatly; and the elastic clamping device provided by the invention has a wide application scope and longer service life because of no sliding friction.

Owner:WUXI YINLIAN GEAR MACHINERY CO LTD

Expansion fixture device

The invention relates to the technical field of fixtures, in particular to an expansion fixture device. The expansion fixture device is characterized by being composed of a pull rod, flat section bodies, extension springs, a wedge block and a fixture body. A center through hole is formed inside the fixture body, and the pull rod is arranged inside the center through hole. The outer surface of the right side of the fixture body is provided with six evenly-distributed axial long grooves in a milling mode, and the six flat section bodies capable of forming a complete circle are arranged in the axial long grooves. The exterior of each flat section body is provided with a groove, and the extension springs are arranged in the grooves in a sleeved mode. The lower surface of each flat section body is provided with a conical surface. The wedge block is arranged in the center hole of the fixture body, connected with the pull rod through threads and provided with six evenly-distributed inclined grooves which are matched with the conical surfaces of the lower portions of the flat section bodies respectively, and a hexagon screw head is welded to the right end face of the wedge block. The expansion fixture device is simple in structure, and the wedge block is of a complete circle type.

Owner:CHANGZHOU CHANGOU METAL PROD

Expansion fixture suitable for blank surfaces

The invention relates to an expansion fixture suitable for blank surfaces. The fixture comprises a flange, a mandrel fixed in the center of the flange, and a retainer connected with the flange through a bolt. A plurality of sliders are evenly distributed in the circumference direction of the retainer, a cushion block is fixed to each slider, a conical expansion sleeve is further arranged between the retainer and the mandrel, the conical expansion sleeve is tightly connected with the sliders, a spring is connected between the front end of the conical expansion sleeve and the flange, and the tail end of the conical expansion sleeve is provided with a fastening nut arranged on the mandrel in a sleeving mode. The expansion fixture has the advantages of being simple in structure, capable of improving production efficiency, capable of being used for machining the blank surfaces with different diameters and the like.

Owner:CHANGZHOU YINBAO NICKEL NETWORK

Assembly for rotating a cutting insert during a turning operation and inserts used therein

Owner:KENNAMETAL INC

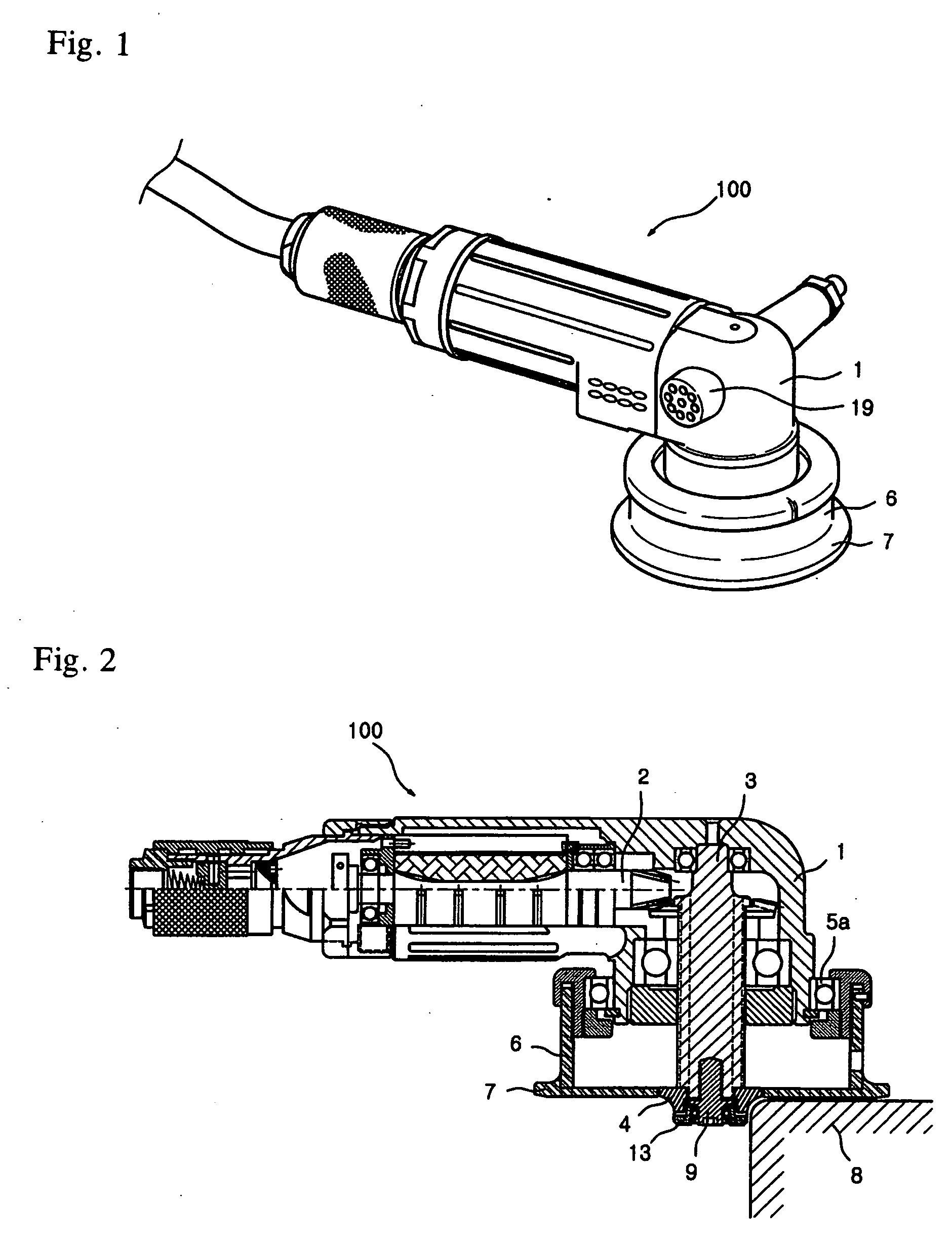

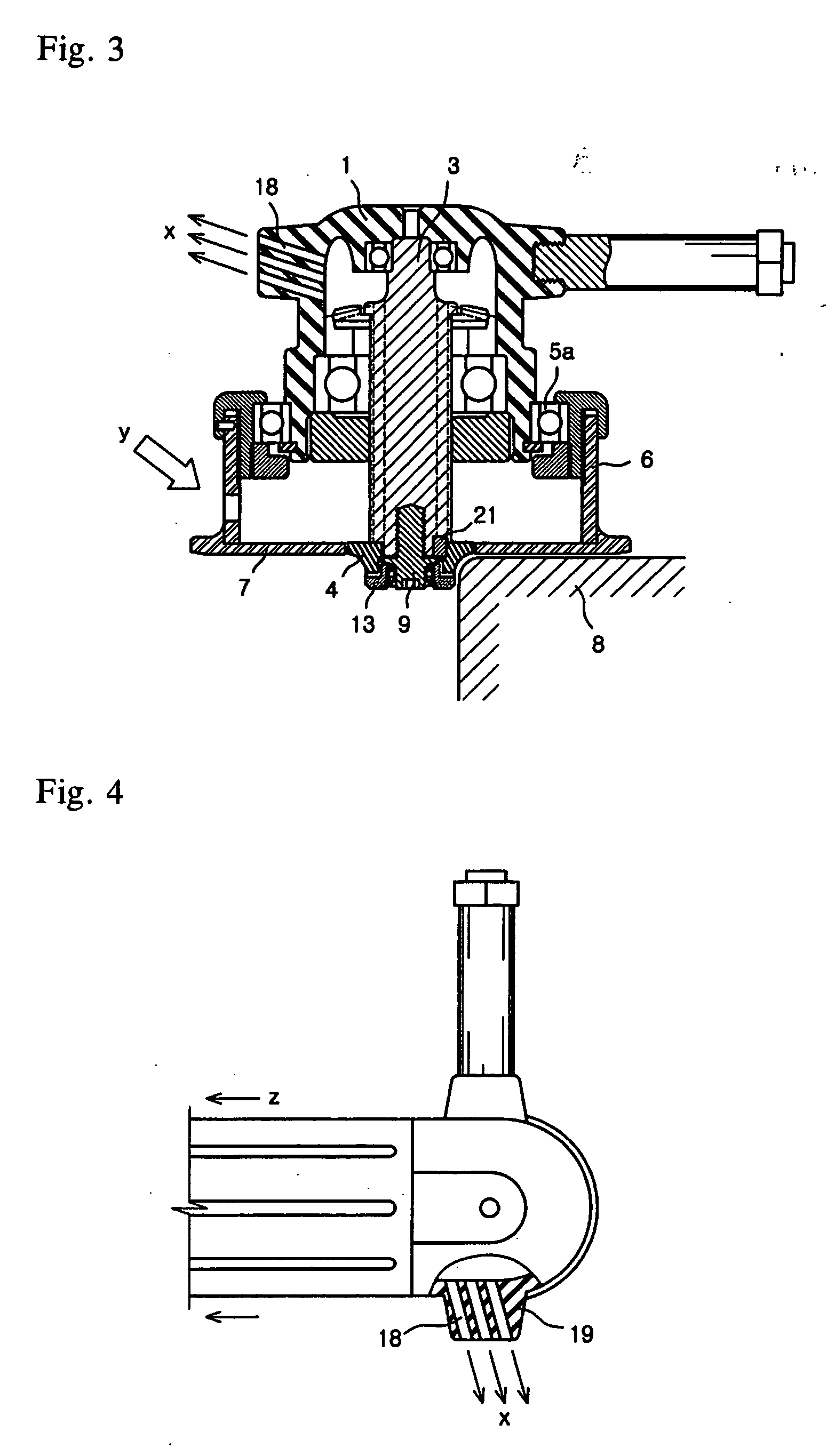

Chamfering air tool

InactiveUS20060120818A1Easy to shapeEliminate cut chipTransportation and packagingMilling cuttersRotational axisDrive shaft

A chamfering air tool includes a driving shaft rotated by air pressure in a casing, a rotary shaft perpendicularly combined to the driving shaft for rotation, and a cutter fixed to the rotary shaft. Air holes are formed through the rotary shaft in a length direction. Air discharge groove is formed in the cutter. Air hole communicated with the air hole is formed in the fixing bolt head. Air path is formed in the fixing bolt head to keep a predetermined gap from the cutter. Guide ring having a diameter approximate to a lower end of the cutter is rotatably mounted to the fixing bolt head. Thus, air is blown to air hole of the rotary shaft, air hole formed in the fixing bolt head, air path formed between the cutter and the guide ring, and air discharge groove of the cutter, thereby eliminating cut chips and cooling the cutter.

Owner:CHOI CHEOL HWAN

Wheel fixture

InactiveCN106624927AAdvanced technologyHigh degree of automationWorkpiecesExpansion mandrelsReduction driveBatch machine

The invention discloses a wheel fixture. When the wheel fixture is used, the wheel width is detected in the first place, a servo motor I drives a lead screw to rotate, a supporting block and a lifting plate are automatically adjusted to proper heights through nuts, a mechanical arm places a wheel above an end face block, an air tight device is pressed down, and an oil cylinder pulls a chuck so that a clamping jaw can tighten a wheel central hole in an expanding manner; meanwhile, four air cylinders make a clamping block tightly press the outer side of the wheel, and the wheel is completely positioned; at the moment, a wheel bolt hole can be drilled and machined; after machining is completed, a servo motor II makes a right shaft, a right ear plate and a turning-over part rotate by a certain angle through a speed reducer II; high-pressure oil is introduced into a cavity between a left expansion sleeve and a left end cover II and a cavity between a right expansion sleeve and a right end cover II, and the left expansion sleeve and the right expansion sleeve tightly lock a left shaft and the right shaft respectively. The wheel fixture is applicable to drilling machining of wheels of different outer circle diameters, different central hole diameters and different wheel width sizes and particularly applicable to mixed routing and automated batched machining production.

Owner:CITIC DICASTAL

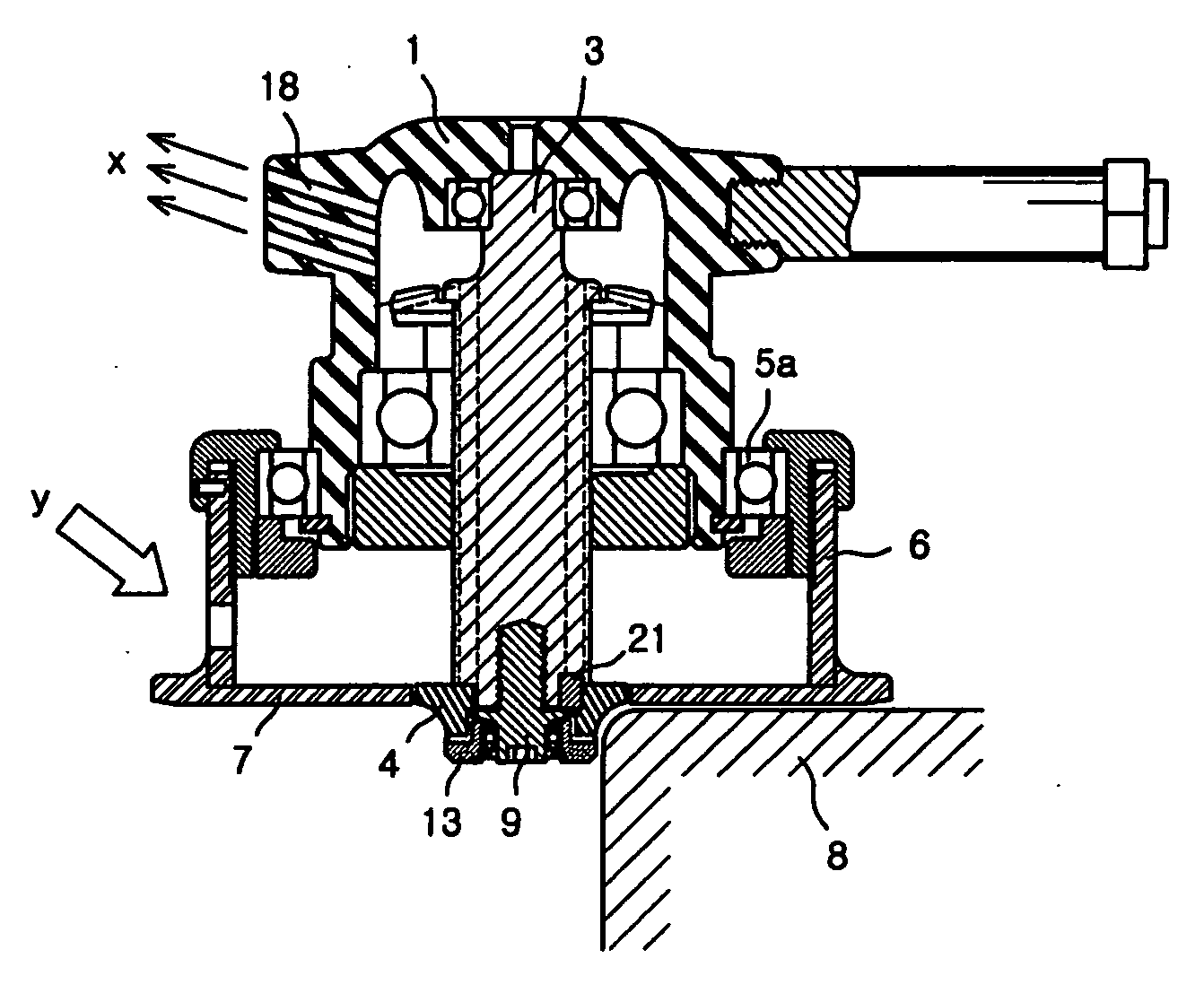

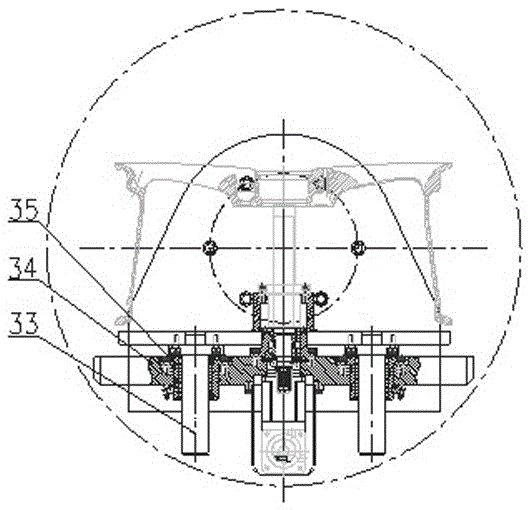

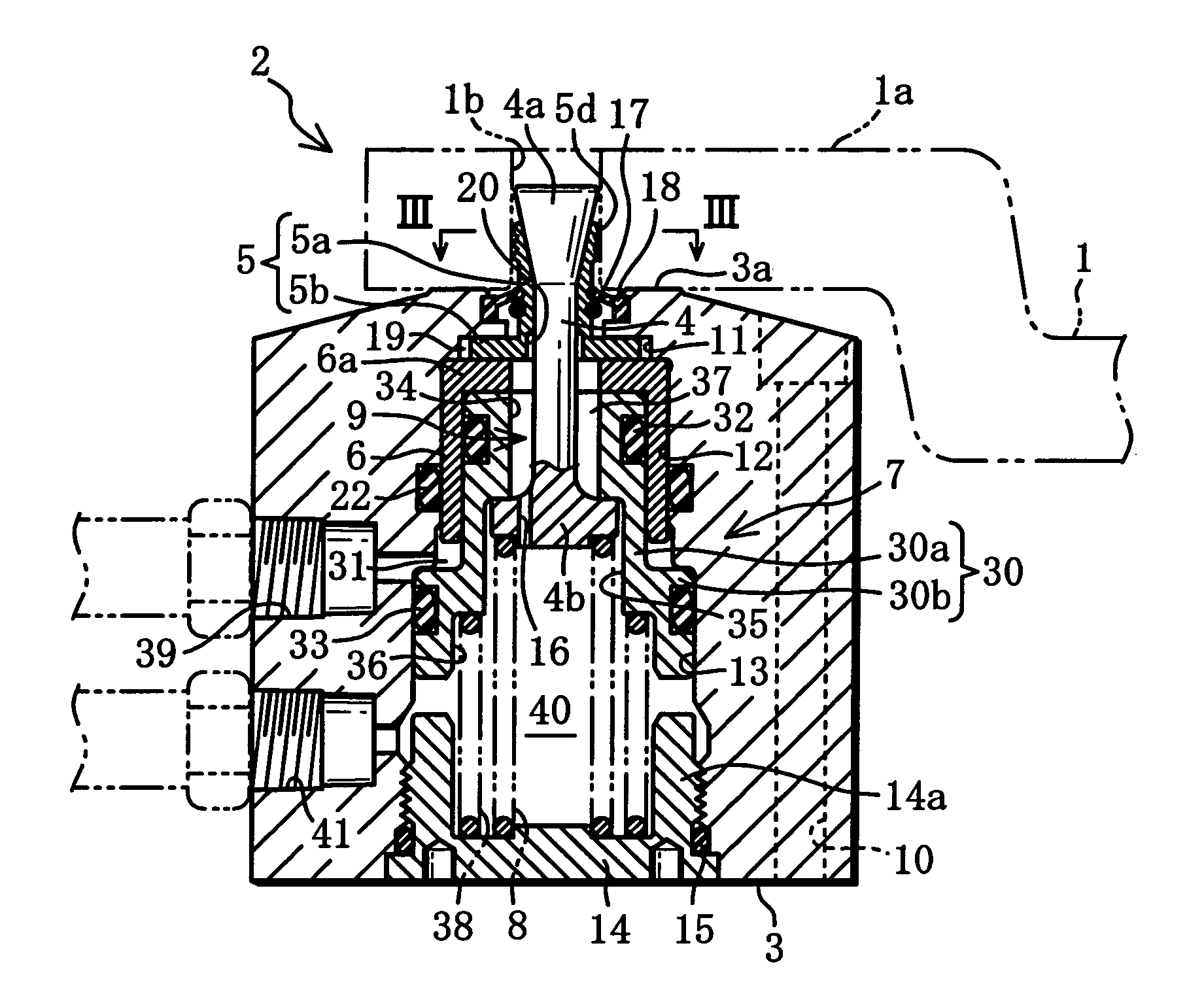

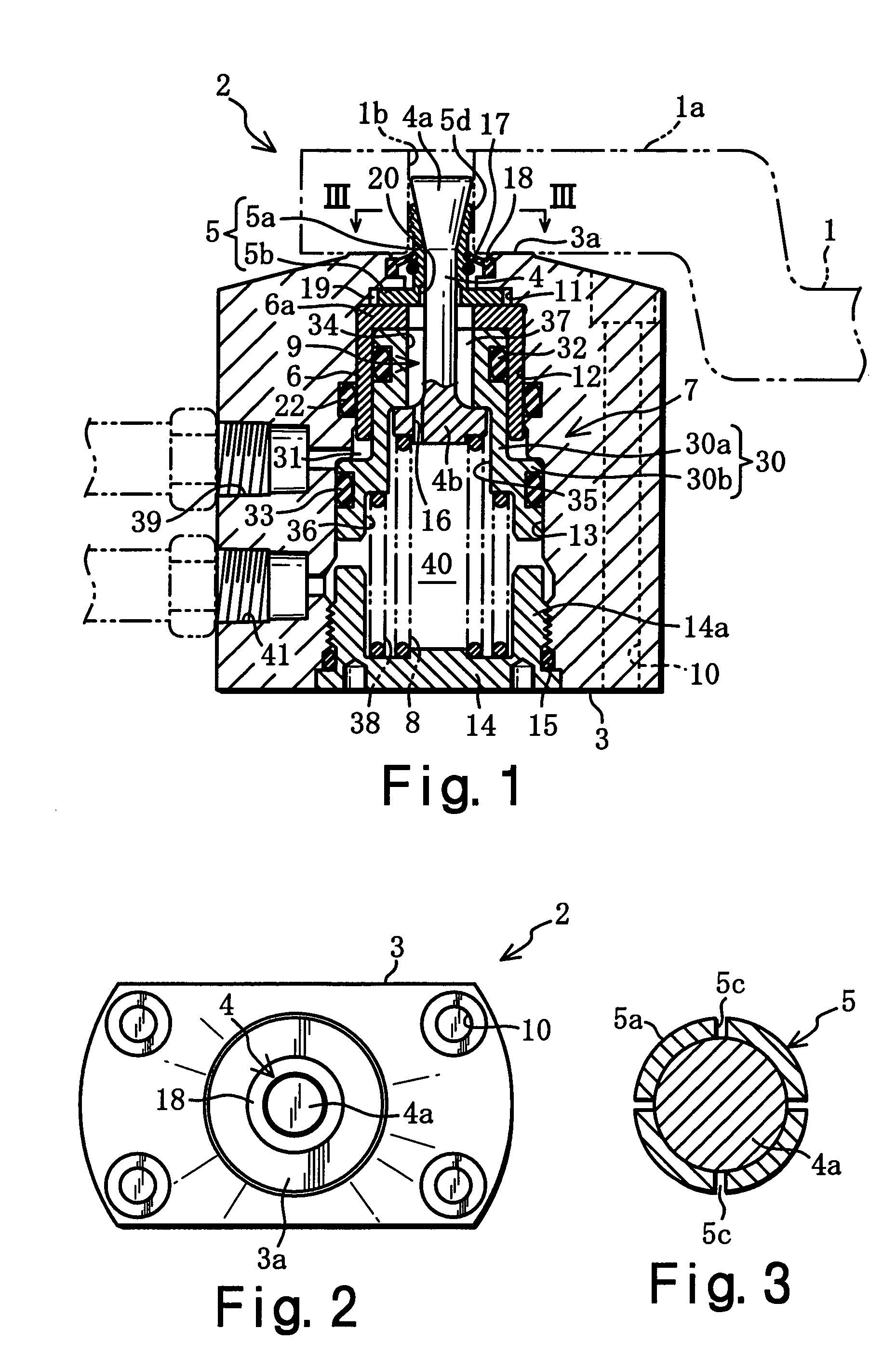

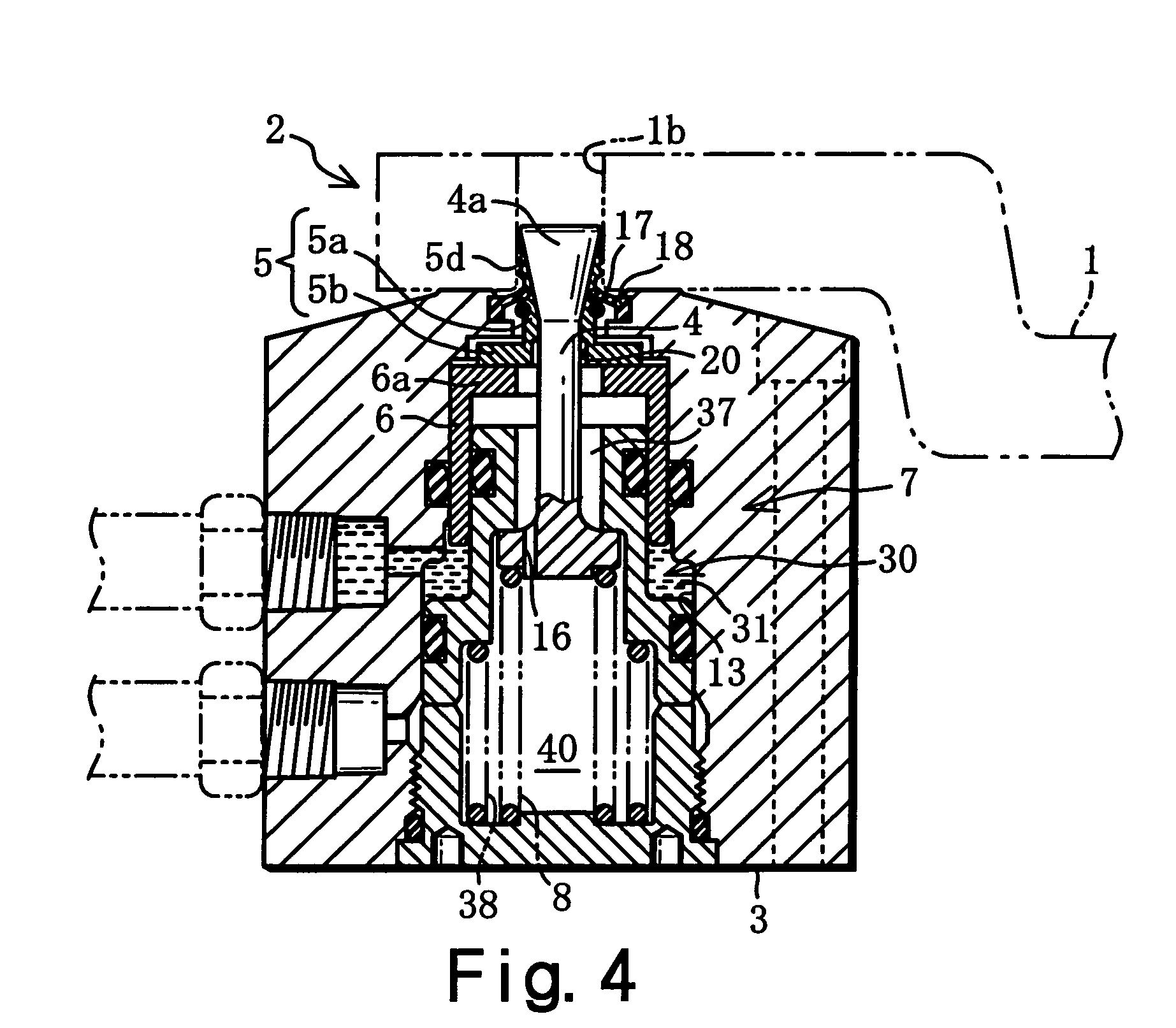

Clamping device

A clamping device 2 is provided with a hydraulic cylinder 7 for biasing a collet member 5 upward via a collet supporting member 6 and driving a pull rod 4 downward. A piston member 30 has a greater pressure receiving area than the collet supporting member 6 in the circular hydraulic chamber 31 of the hydraulic cylinder 7. Therefore, the hydraulic cylinder 7 can drive the pull rod 4 downward while the collet member 5 is biased upward. Meanwhile, the collet 5a of the collet member 5 is resiliently deformed in a diametrically expanding manner to engage in the vertical bore 1b of a workpiece 1 while slightly moving downward, ensuring a secure locking of the workpiece 1 to a workpiece receiving surface 3a.

Owner:PASCAL ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com