Locating clamp for pipeline machining

A technology for positioning fixtures and pipes, applied in positioning devices, manufacturing tools, metal processing equipment, etc., can solve the problems of welding workers' cervical and lumbar spine damage, low production efficiency, and increased welding difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below according to the drawings and embodiments.

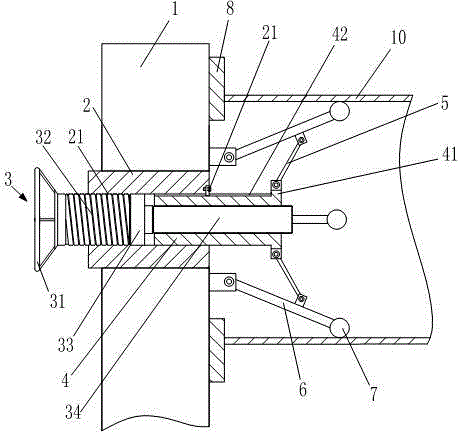

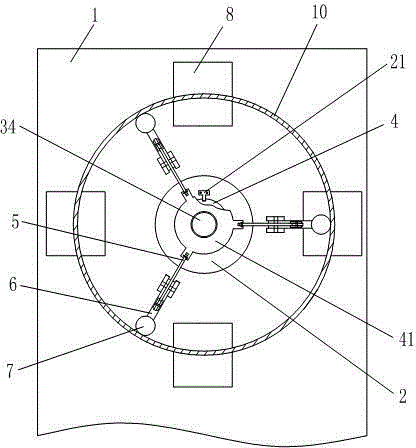

[0012] Such as figure 1 and figure 2 As shown, a positioning fixture for pipeline processing described in the embodiment of the present invention includes a frame 1, a guide sleeve 2 with an internal thread 21 at one end is fixedly installed on the frame 1, the guide sleeve 2 is connected with a screw rod 3, The screw rod 3 is successively provided with a fixed runner 31, an external thread 32 matched with the internal thread 21, a sliding part 33 slidingly fitted with the guide sleeve 2, and a screw rod 34 axially extending from the center of the sliding part 33. The rod 34 is threadedly connected with a sliding sleeve 4 that is slidingly matched with the guide sleeve 2, and the end of the sliding sleeve 4 extends out of the guide sleeve 2 to form a hinge portion 41. The sliding sleeve 4 has a chute 42, and one side of the guide sleeve 2 is fixedly connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com