Patents

Literature

300results about How to "Easy to hit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

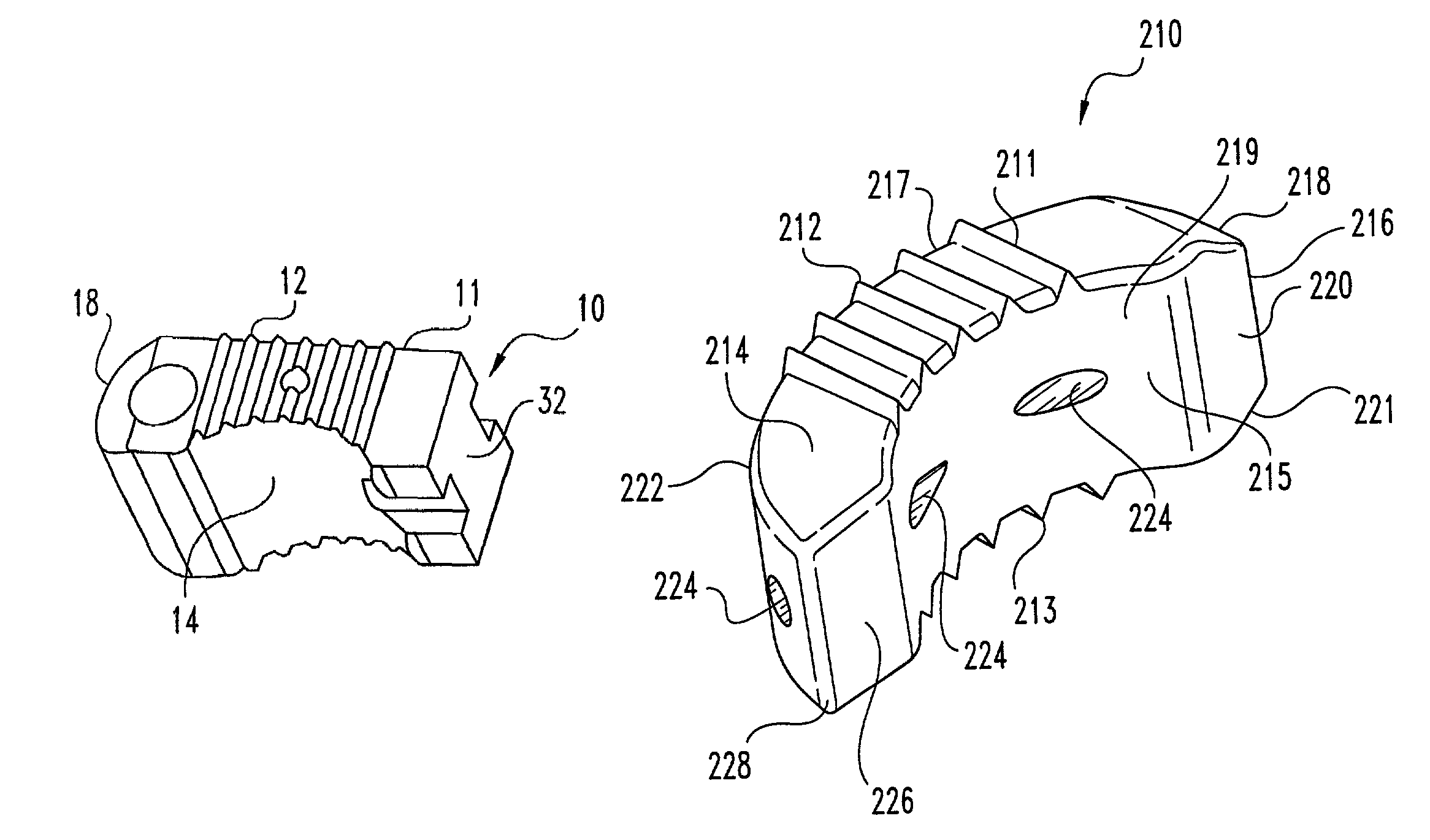

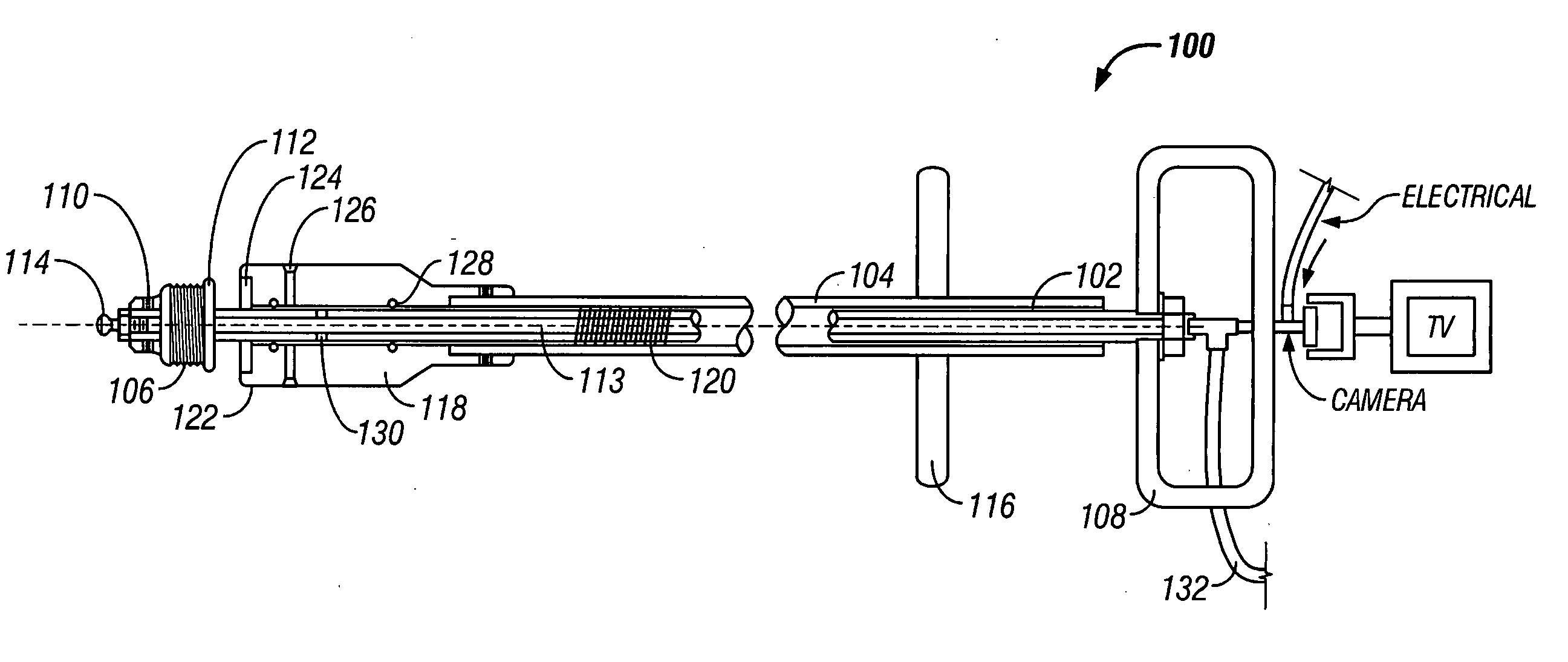

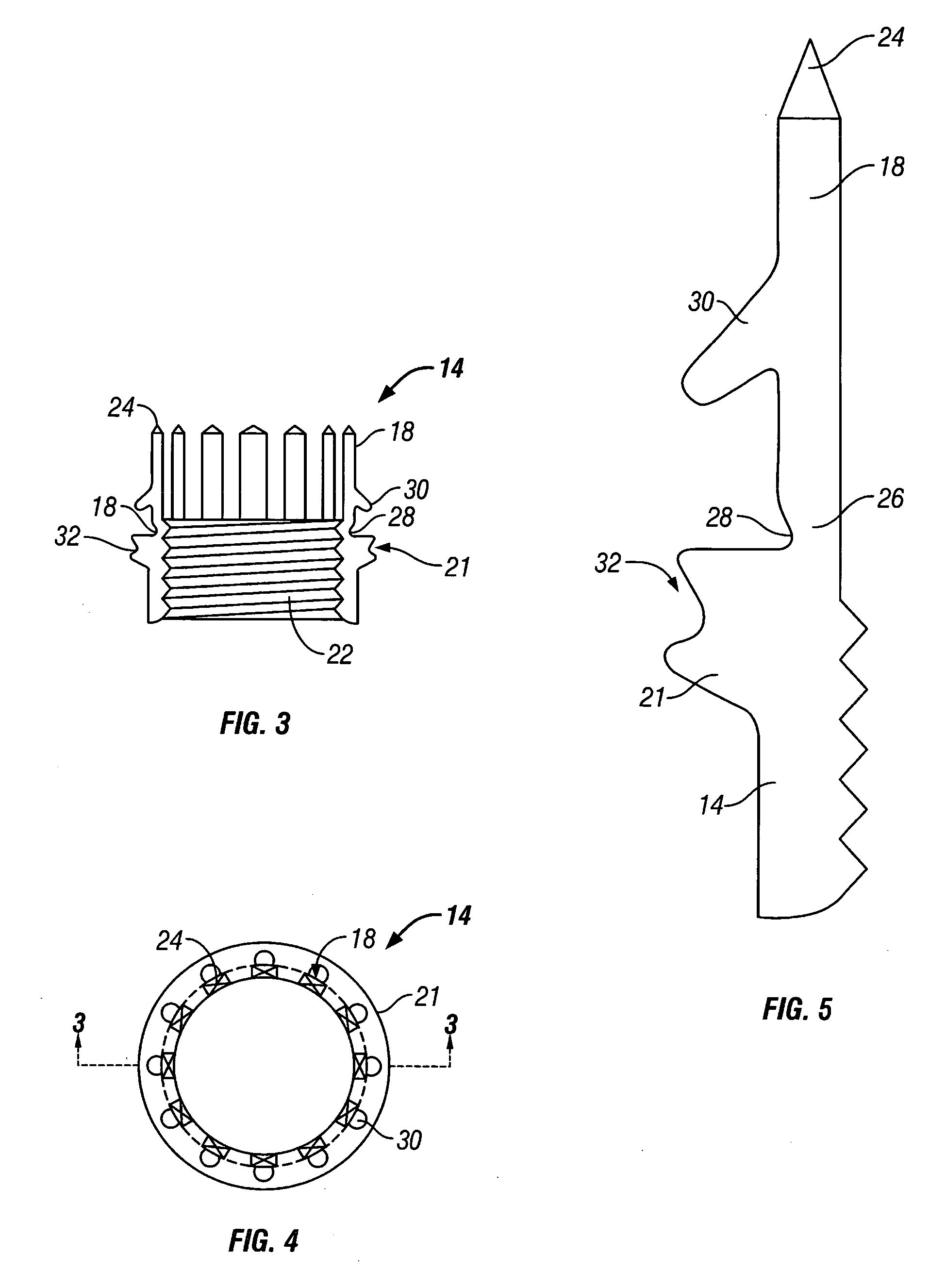

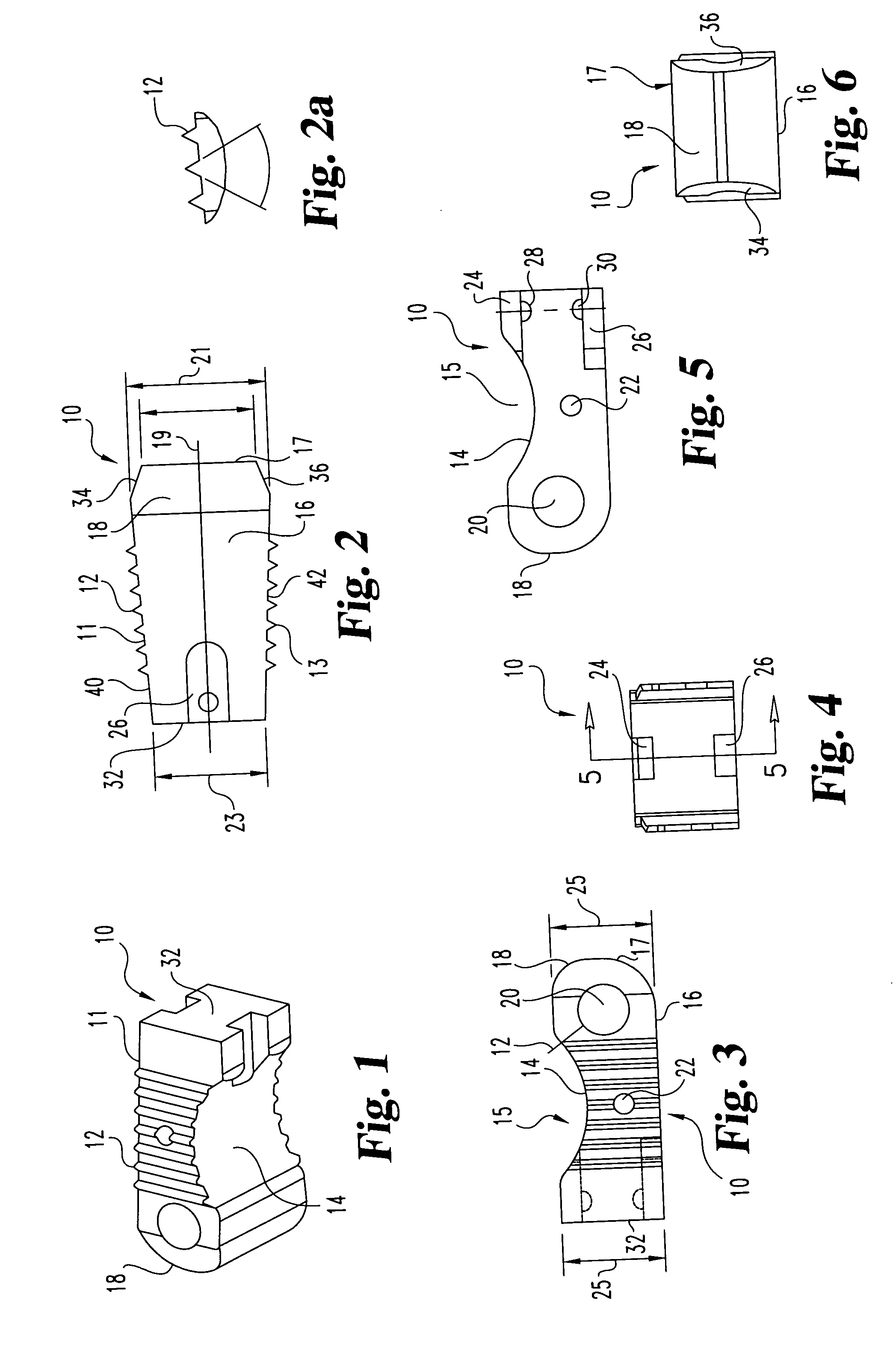

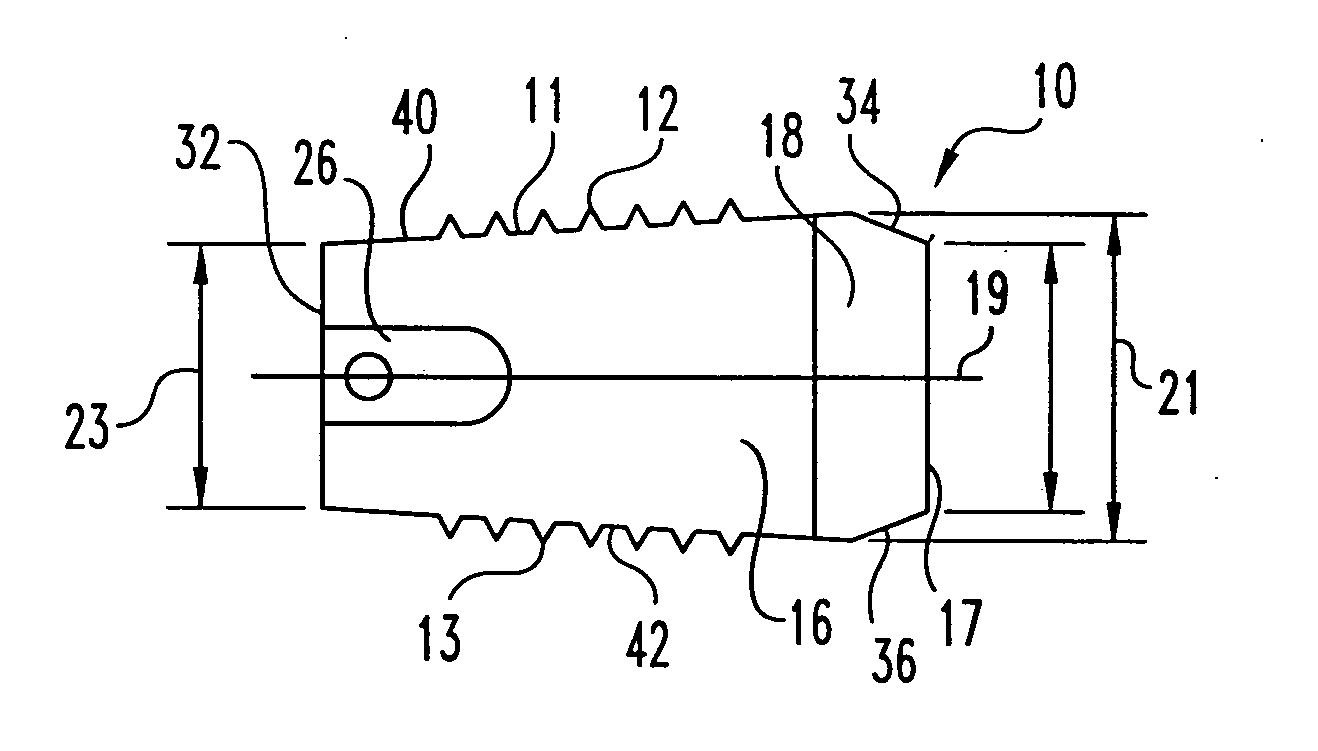

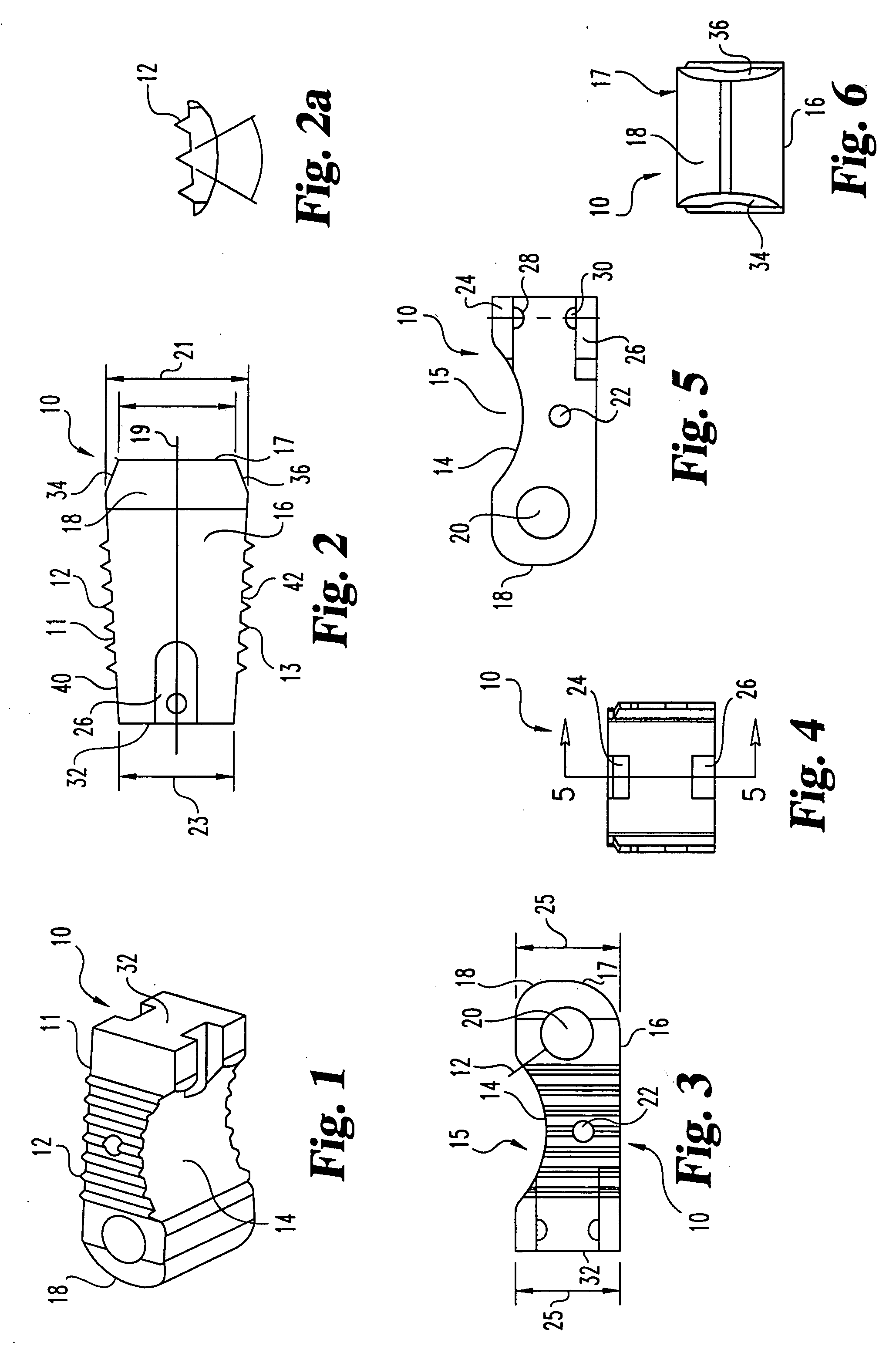

Interbody fusion grafts and instrumentation

InactiveUS7479160B2Maintain disc heightMaintain distractionInternal osteosythesisBone implantMedicineDonor bone

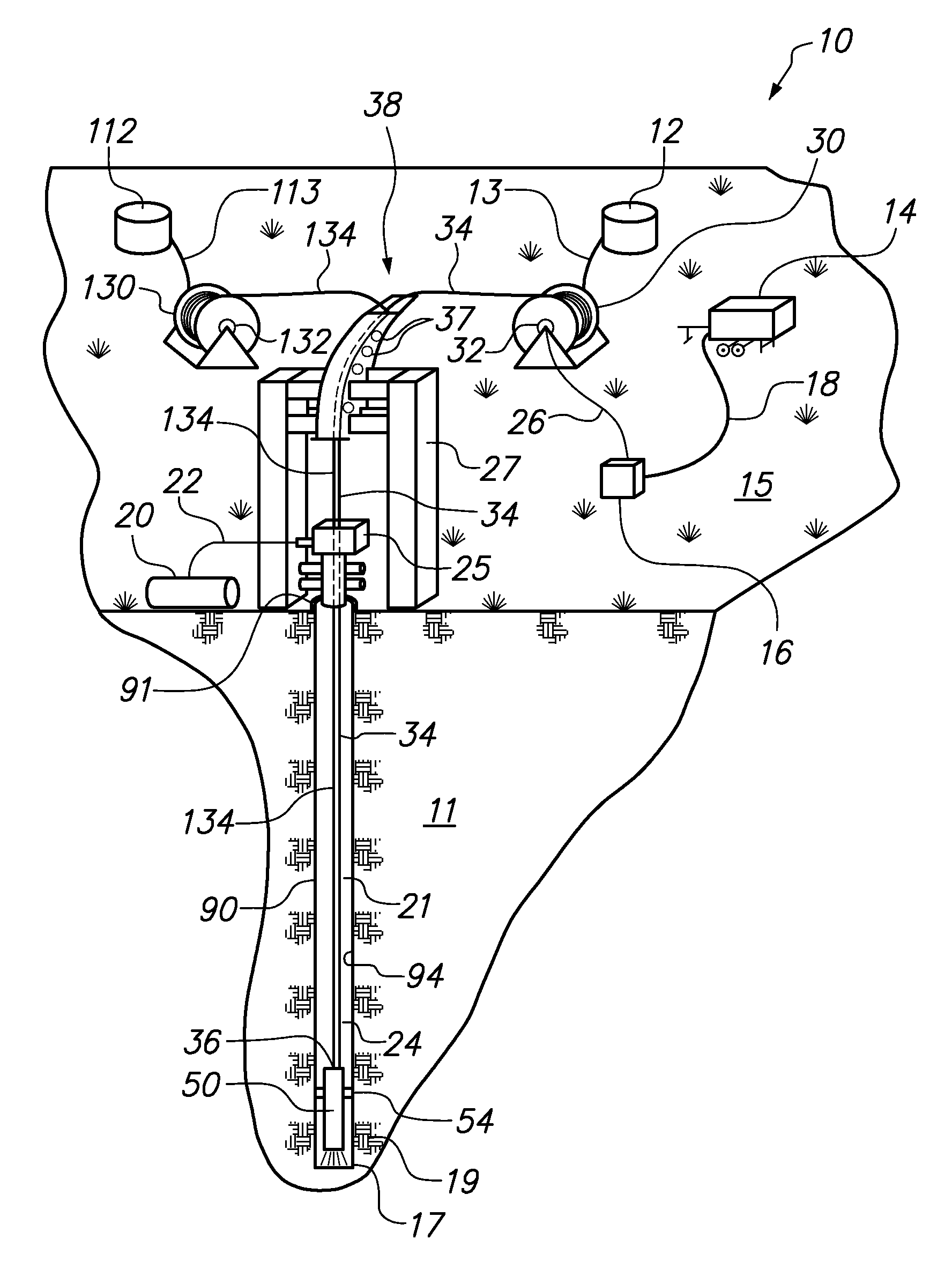

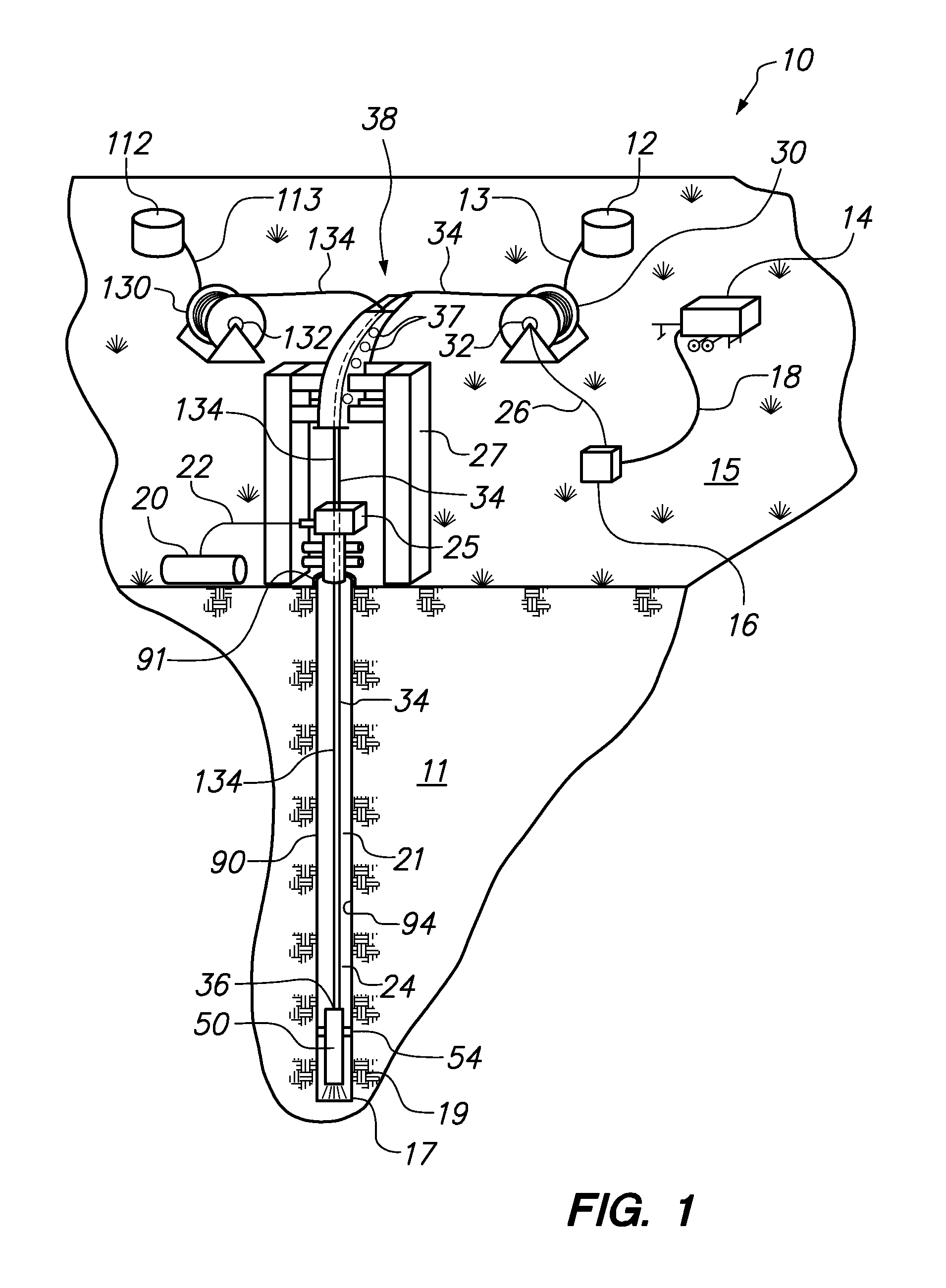

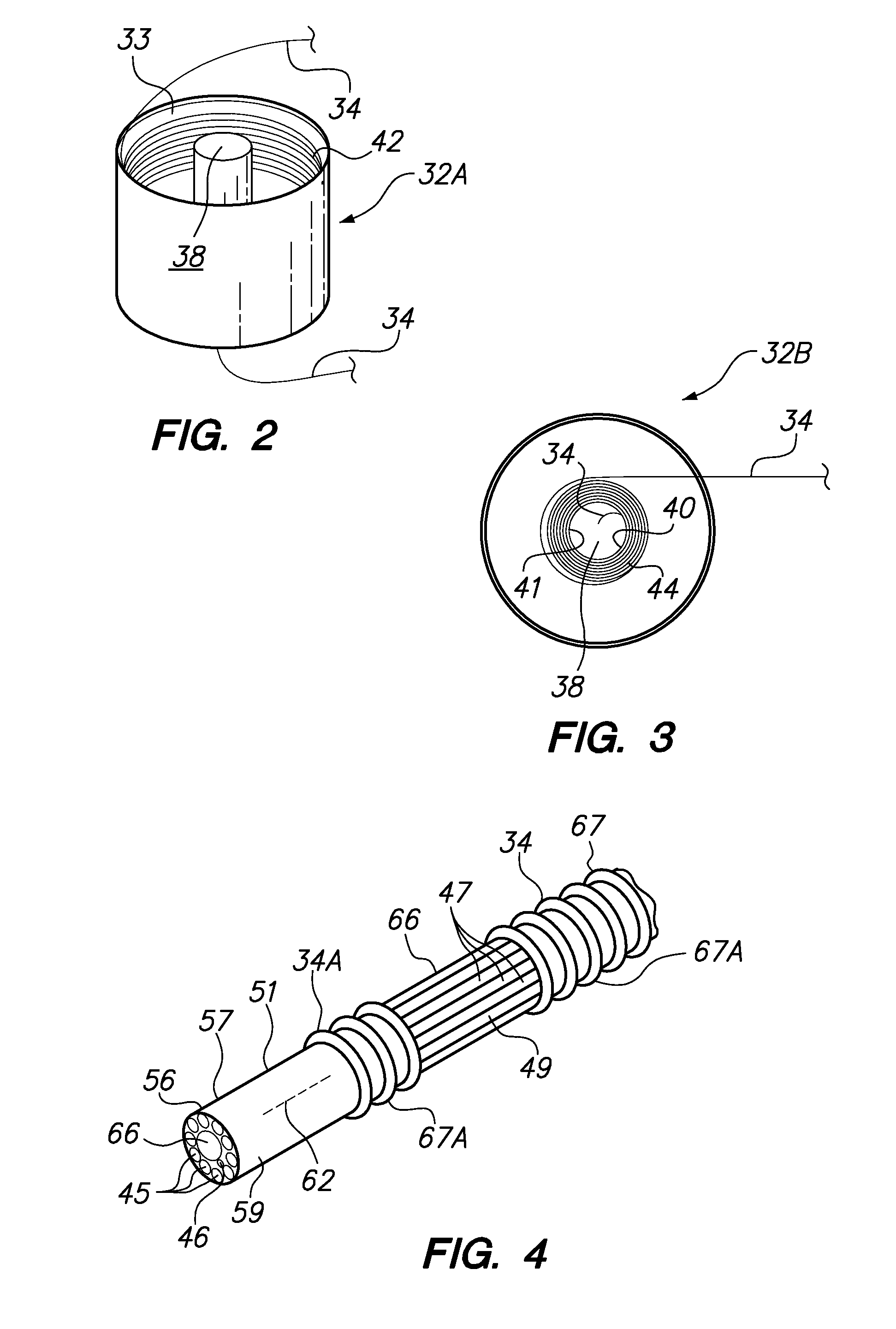

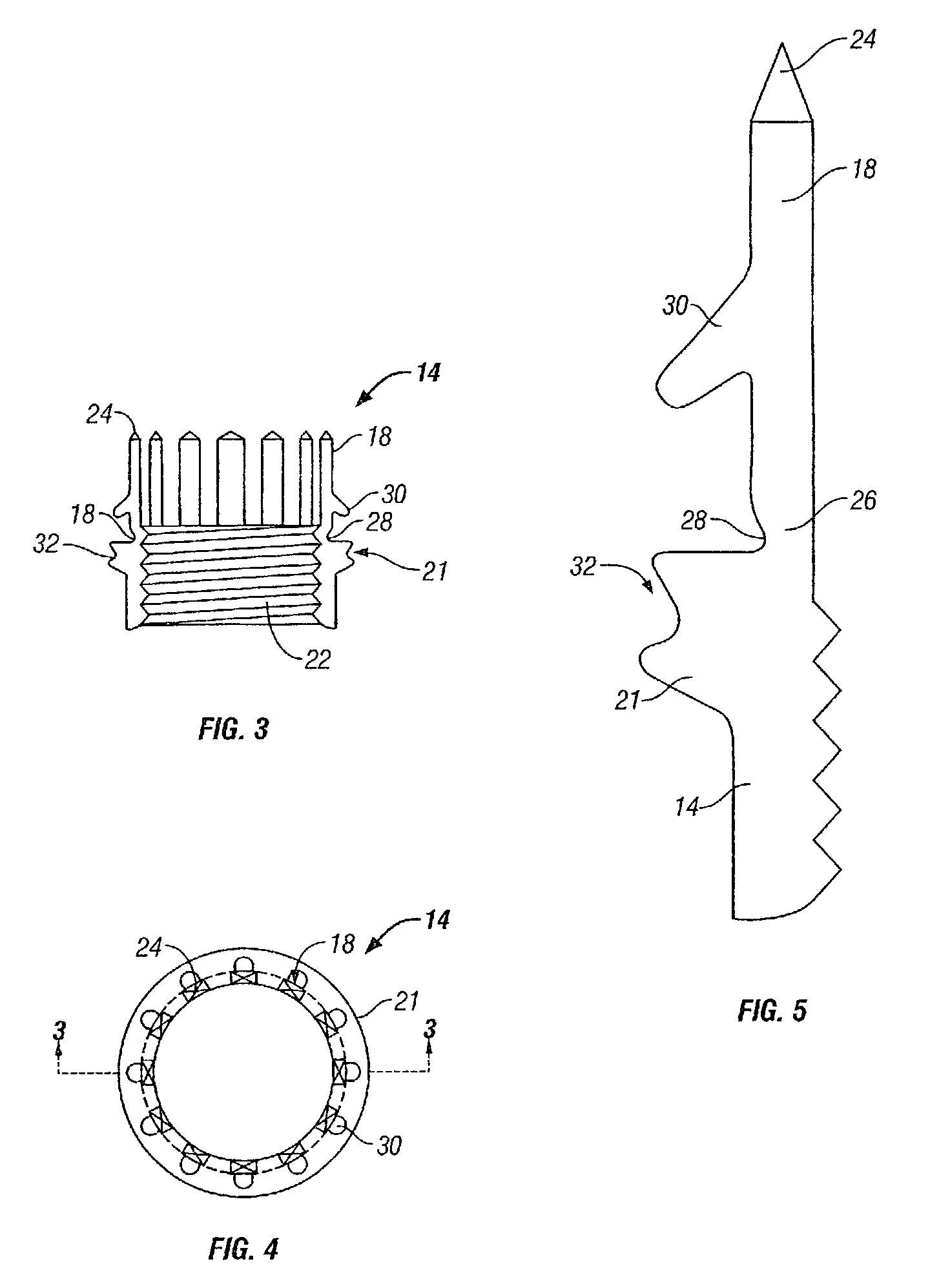

This invention relates to implants formed from donor bone for use in lumbar interbody fusion procedures and instruments for performing such procedures. The implants are formed to include a concave surface formed from a portion of the medullary canal of a long bone. The concaved surface defines a recess in the implant that serves as a depot for osteogenic material. Specific instruments for inserting the implants prepared according to this invention and for preparing the intervertebral space to receive the implants are also provided.

Owner:WARSAW ORTHOPEDIC INC

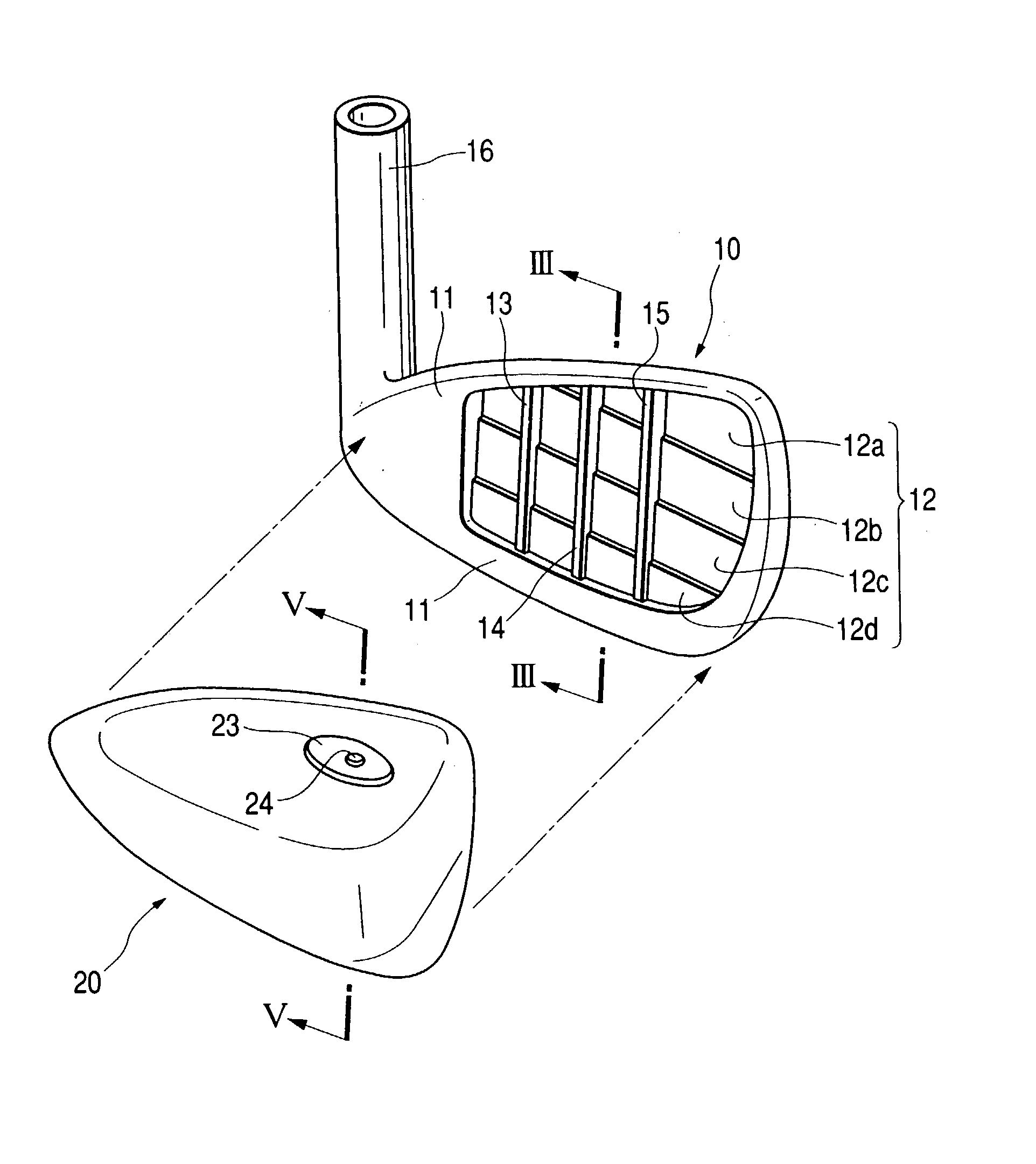

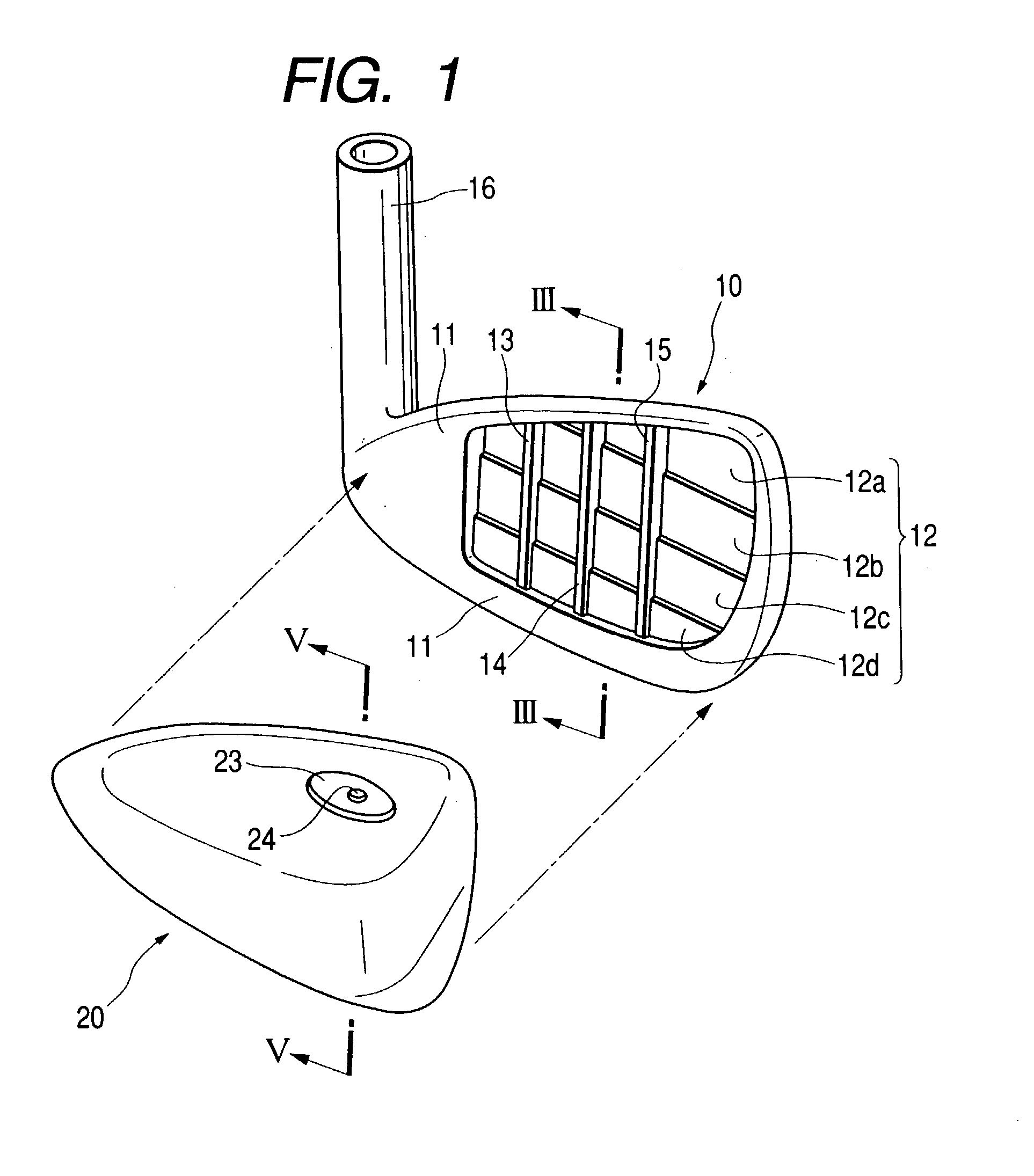

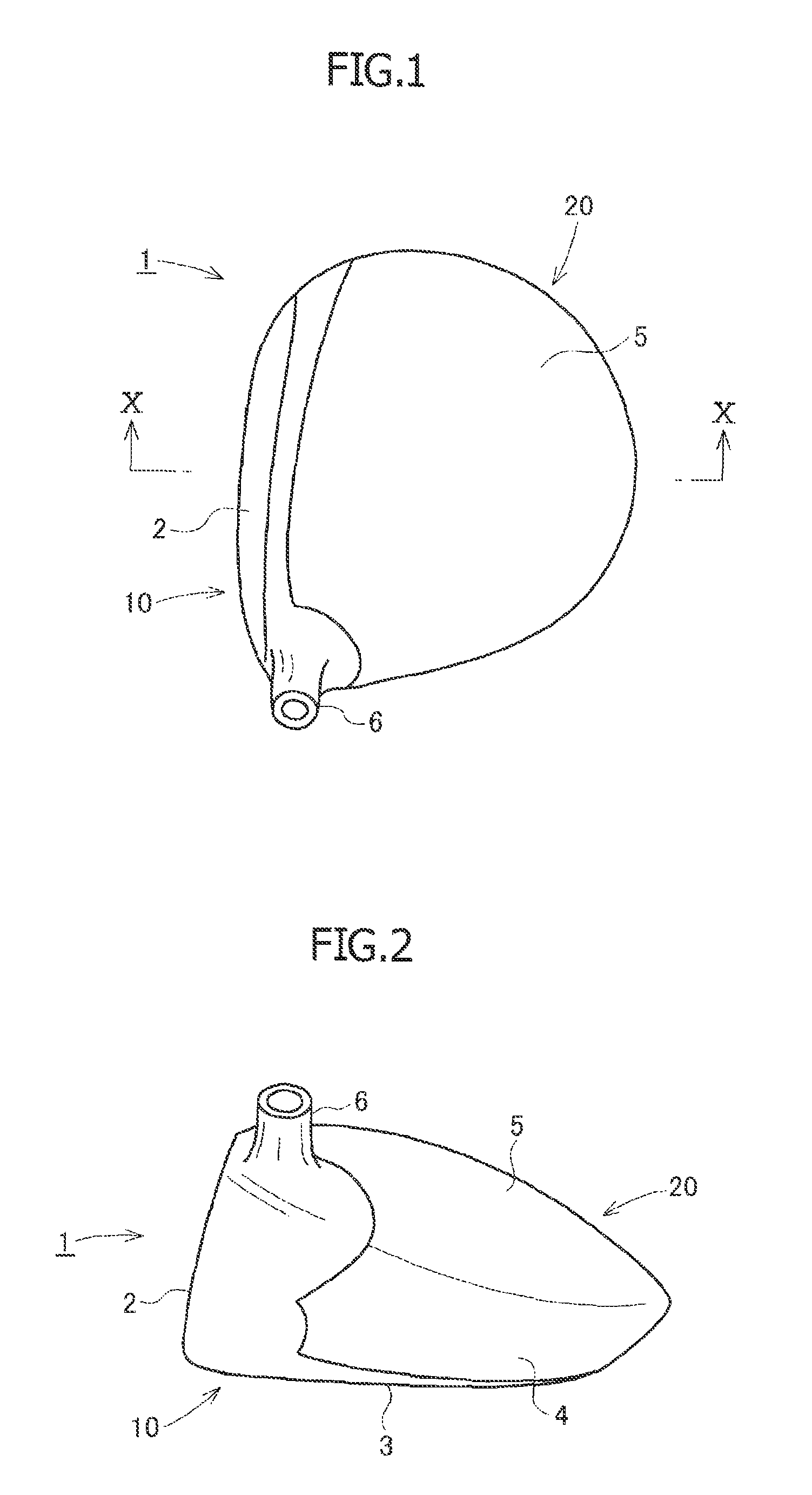

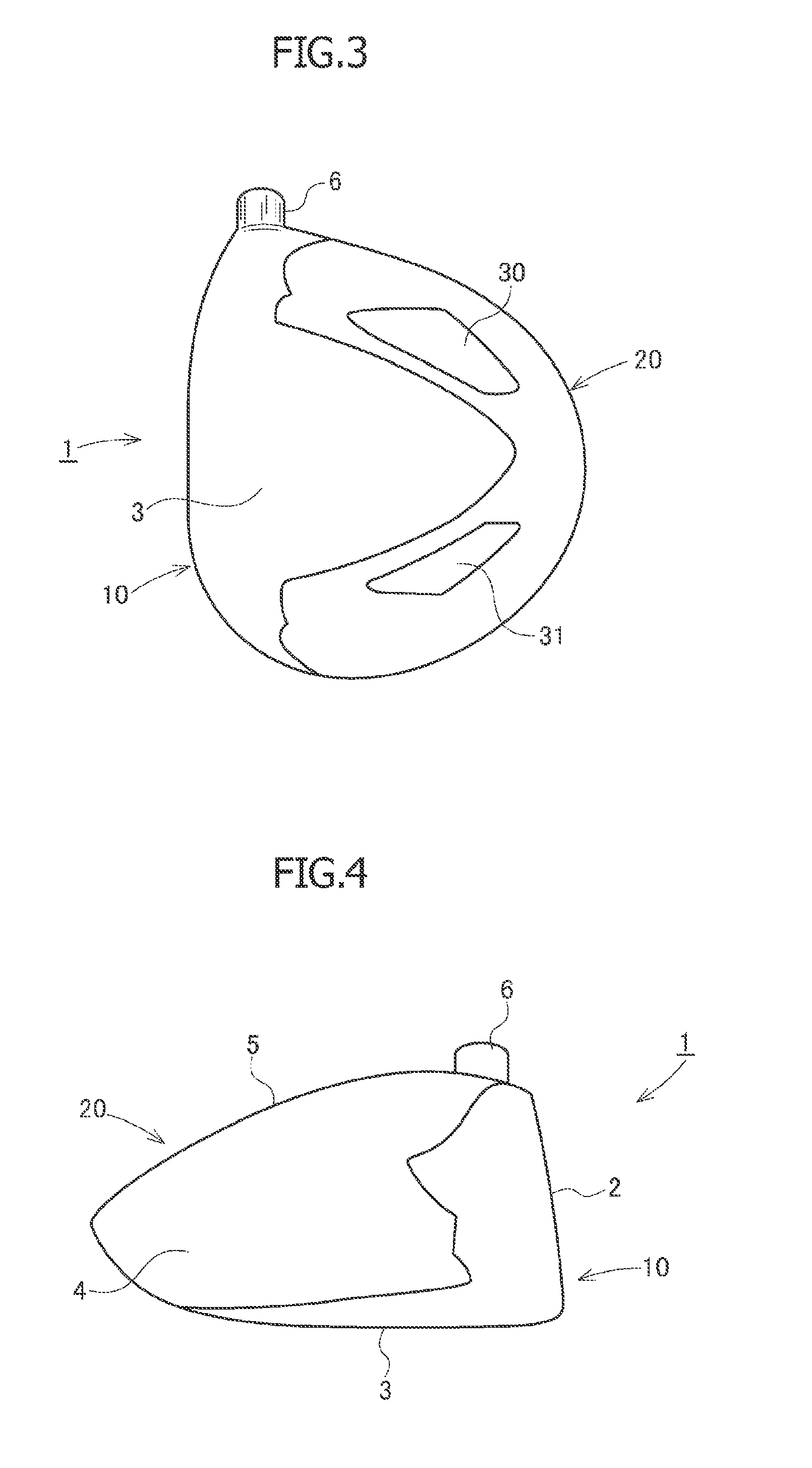

Golf club head and golf club set

A golf club head is formed by integrally welding a face portion and a back portion with each other. The face portion has a circumferential edge portion in its back surface. The circumferential edge portion is made of a flat surface all over its circumference. In the rear surface of the face portion, the part other than the circumferential edge portion is formed as a recess portion. In the bottom surface of the recess portion, a first bottom surface which is the deepest, a second bottom surface which is the second deepest, a third bottom surface which is the third deepest, and a fourth bottom surface which is the shallowest are formed in descending order. Three ribs are provided vertically to extend through the recess portion.

Owner:BRIDGESTONE SPORTS

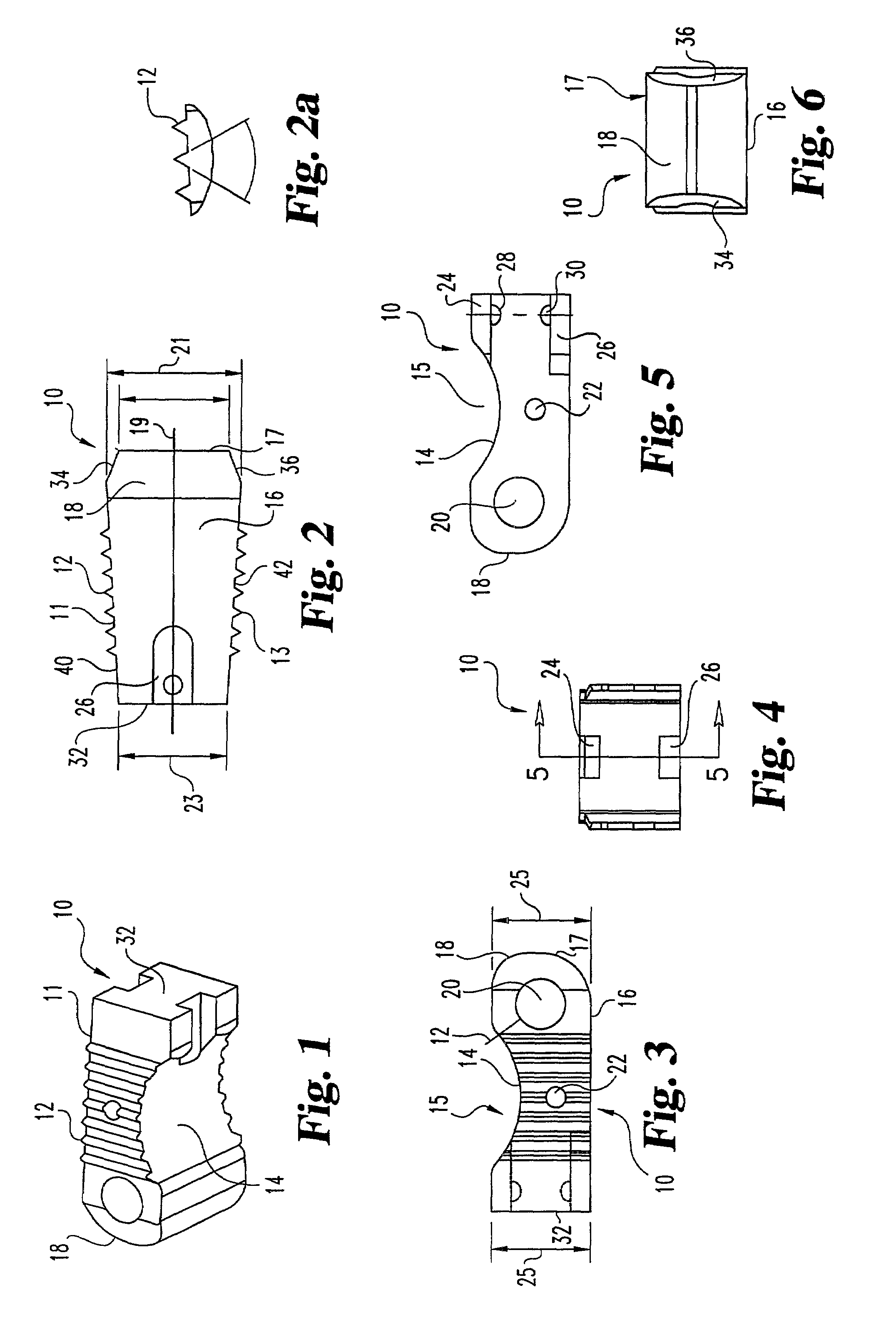

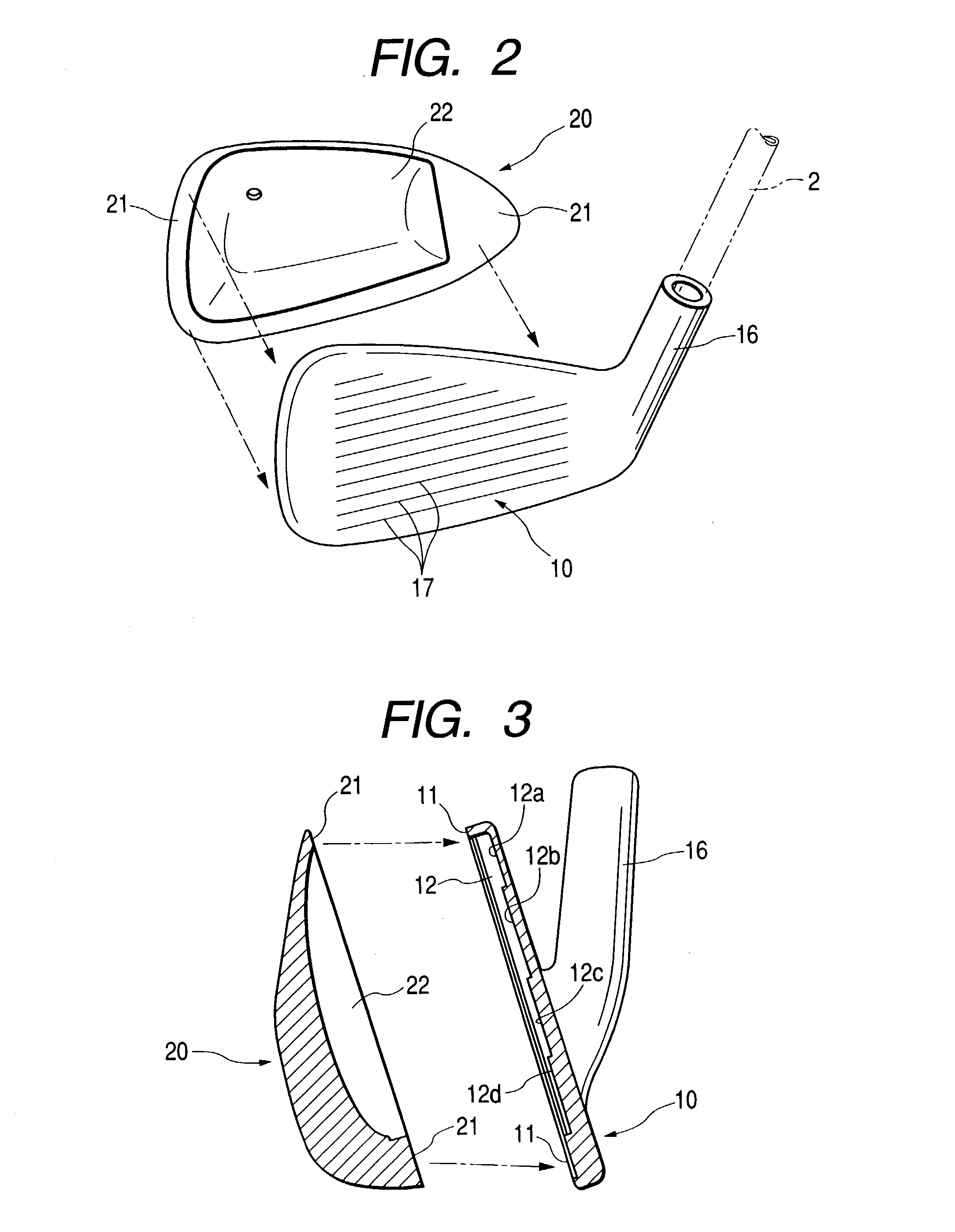

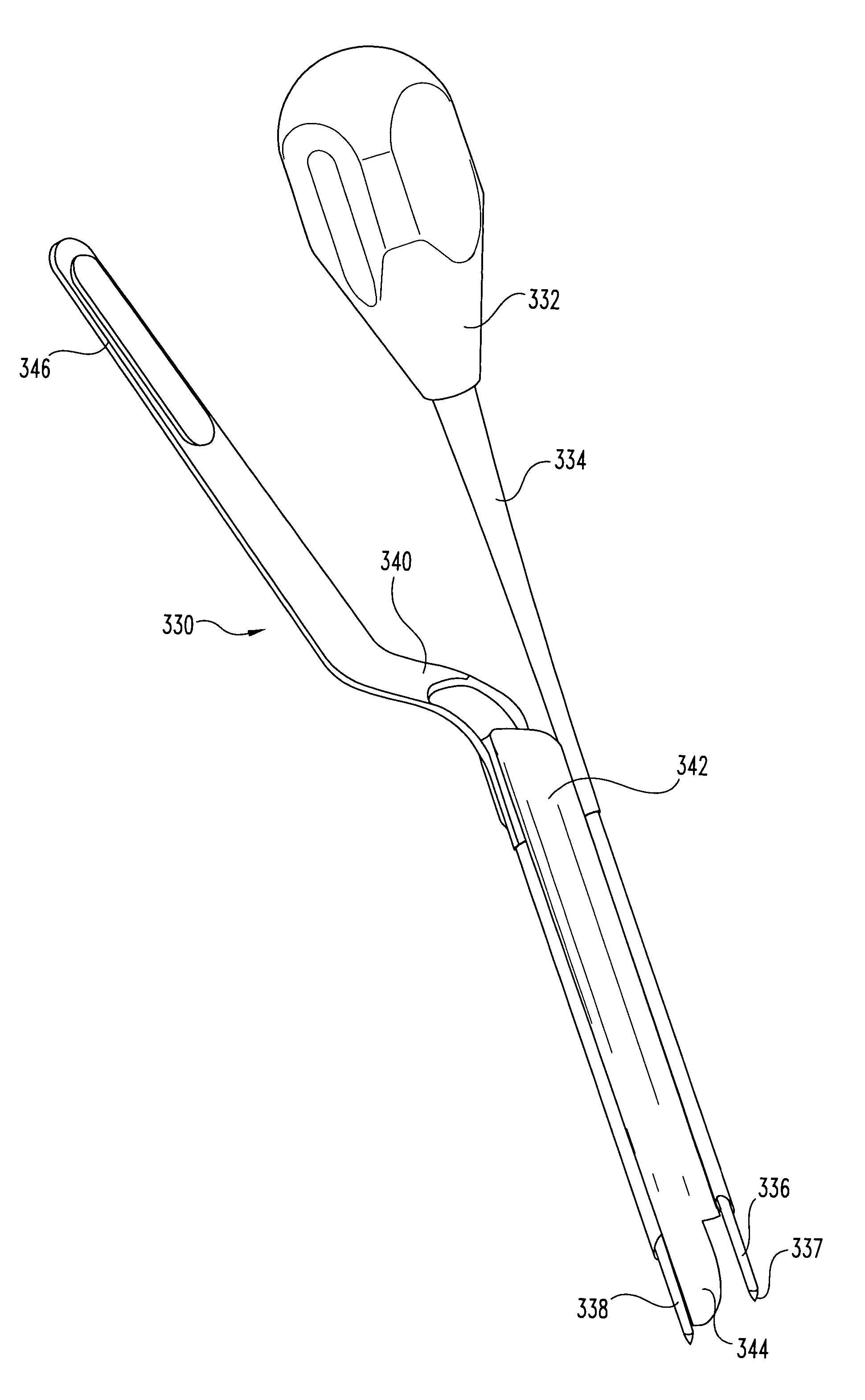

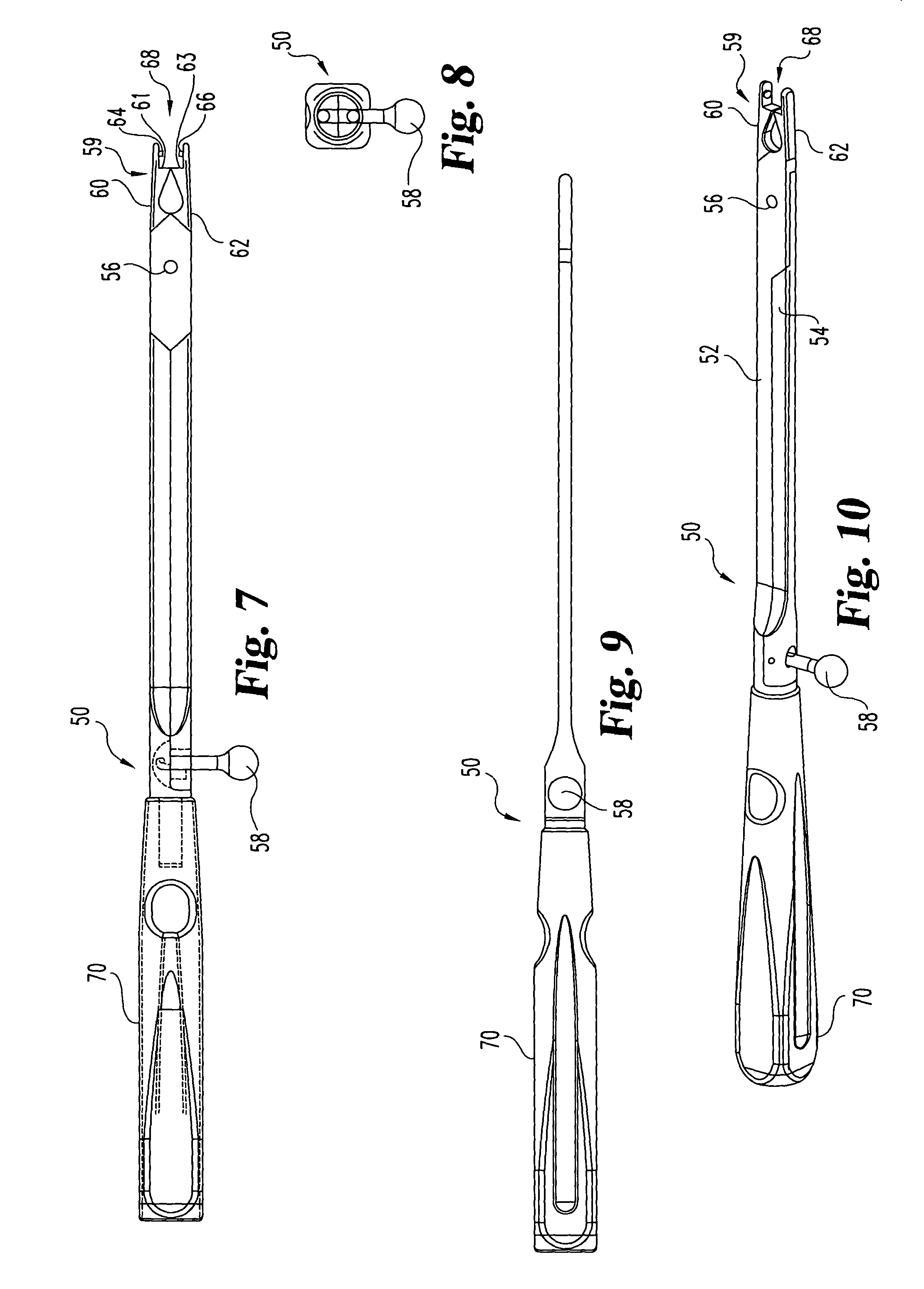

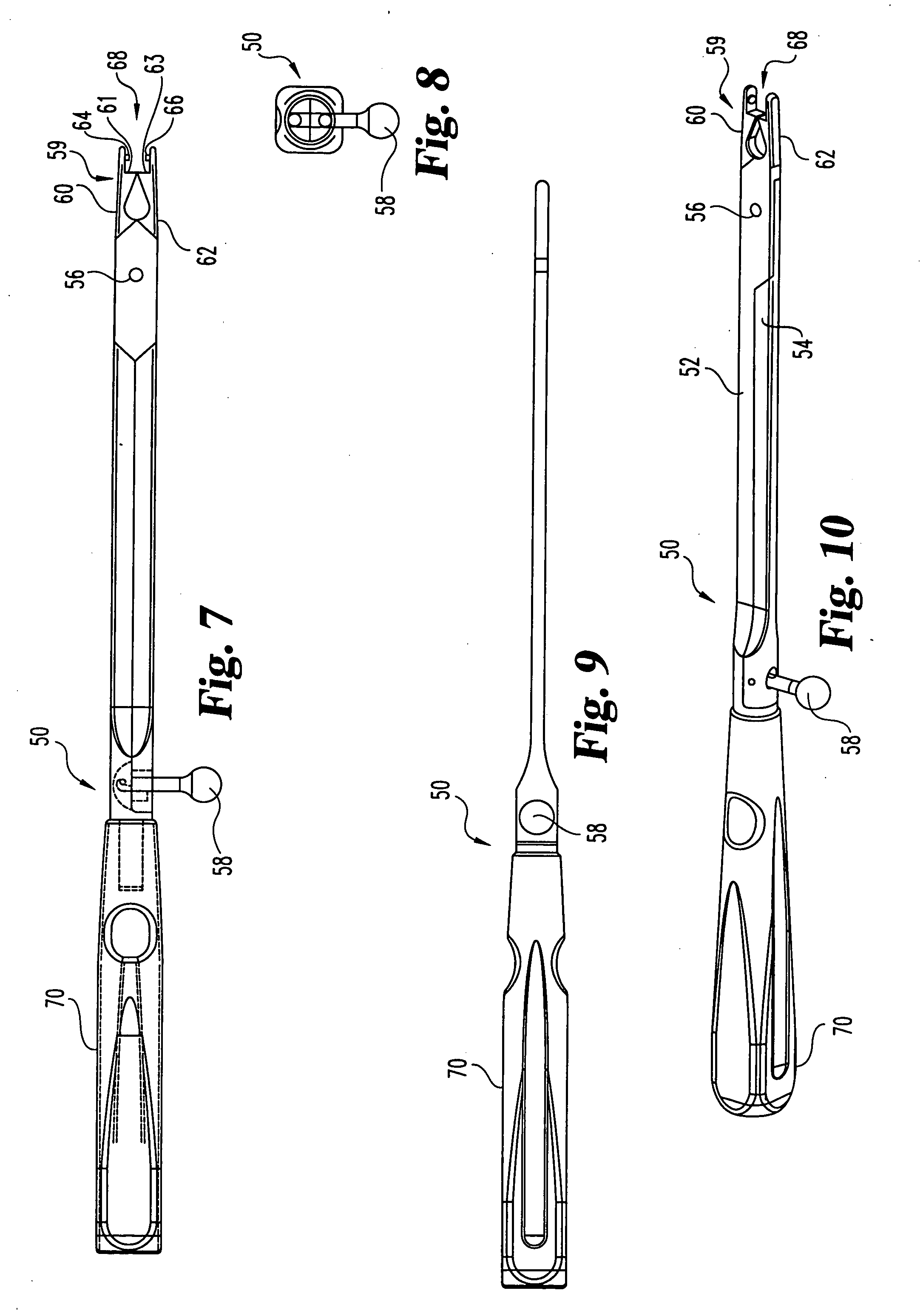

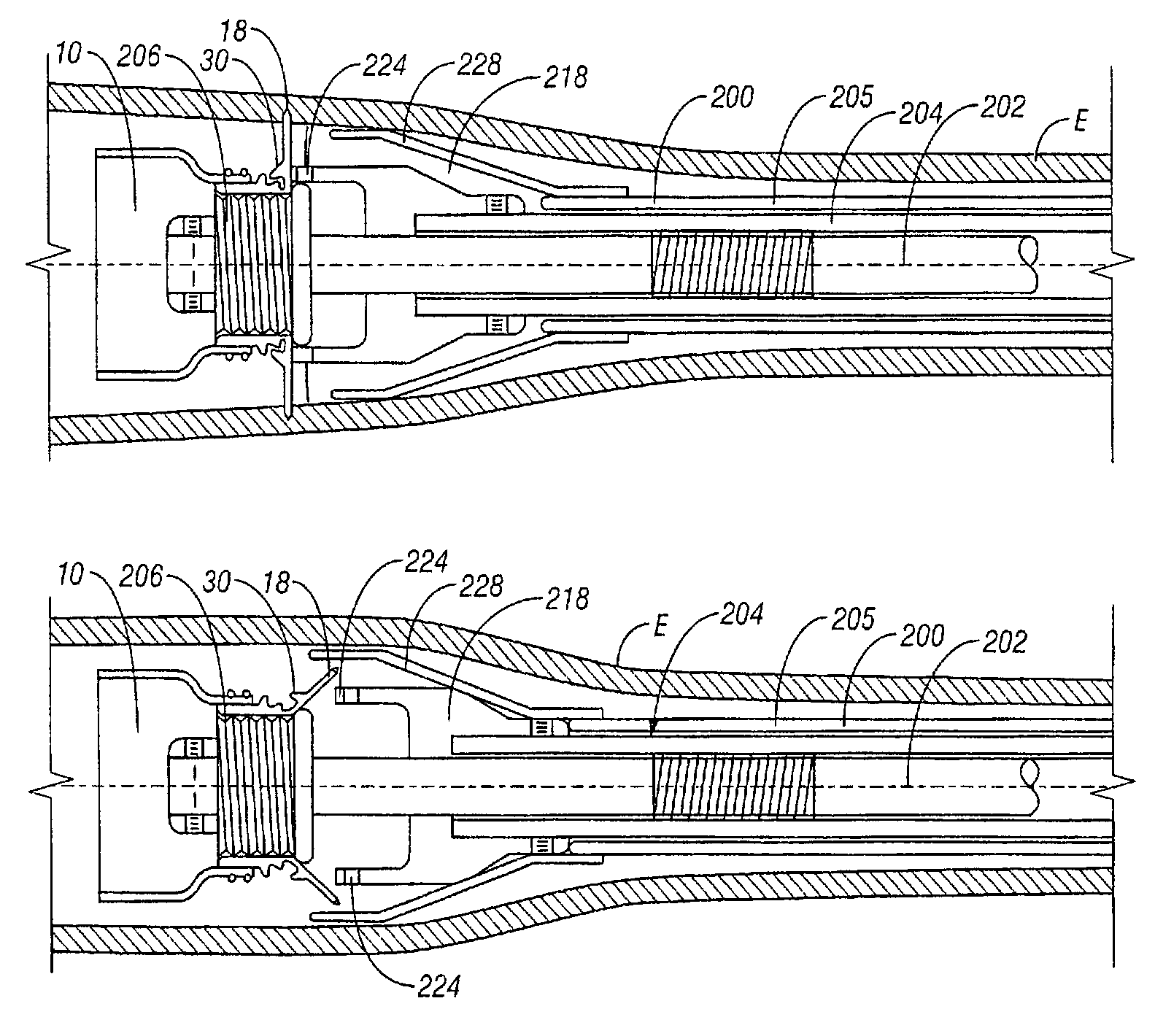

Perorally removeable anti-reflux valve implantation

InactiveUS20060041319A1Easy to closeEasy to bendEar treatmentHeart valvesReflux valveVacuum assisted

Disclosed are esophageal anti-reflux valve prostheses, and tools and procedures for peroral implantation and extraction of the prostheses. The prostheses disclosed have a semipermeable membrane to allow retrograde passage of gas, magnets disposed at a distal end of the sleeve to facilitate closure, and an outwardly bendable array of spikes that are longitudinally aligned for peroral insertion and lockable into a radially outwardly deployed configuration to keep the prosthesis from dislocating after implantation. The implantation tool has inner and outer concentric tubes, the inner tube releasably threadably connected to the prosthesis, the outer tube reverse threaded with the inner tube to advance a distal headpiece to engage, deploy and lock the spikes into the deployed configuration. A vacuum assist can be used to help impact the lumen wall on the spikes. The extraction tool is similar to the implantation tool with an inner tube for threadably engaging the prosthesis, an outer tube with a distal crown with a plurality of shoes to unseat and unlock the spikes, and an overtube shield to receive the spikes and facilitate extraction of the prosthesis.

Owner:REFLUX CORP

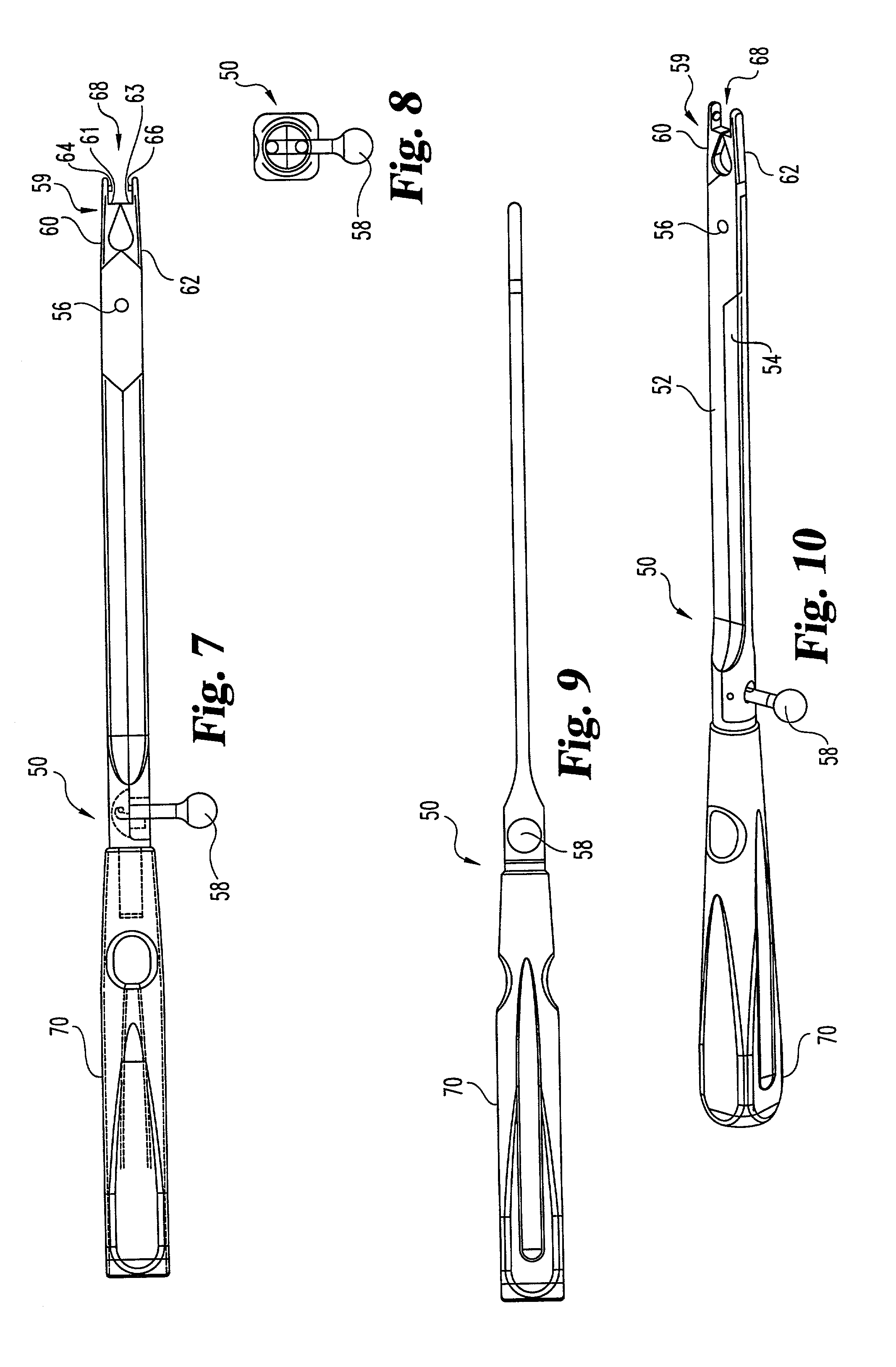

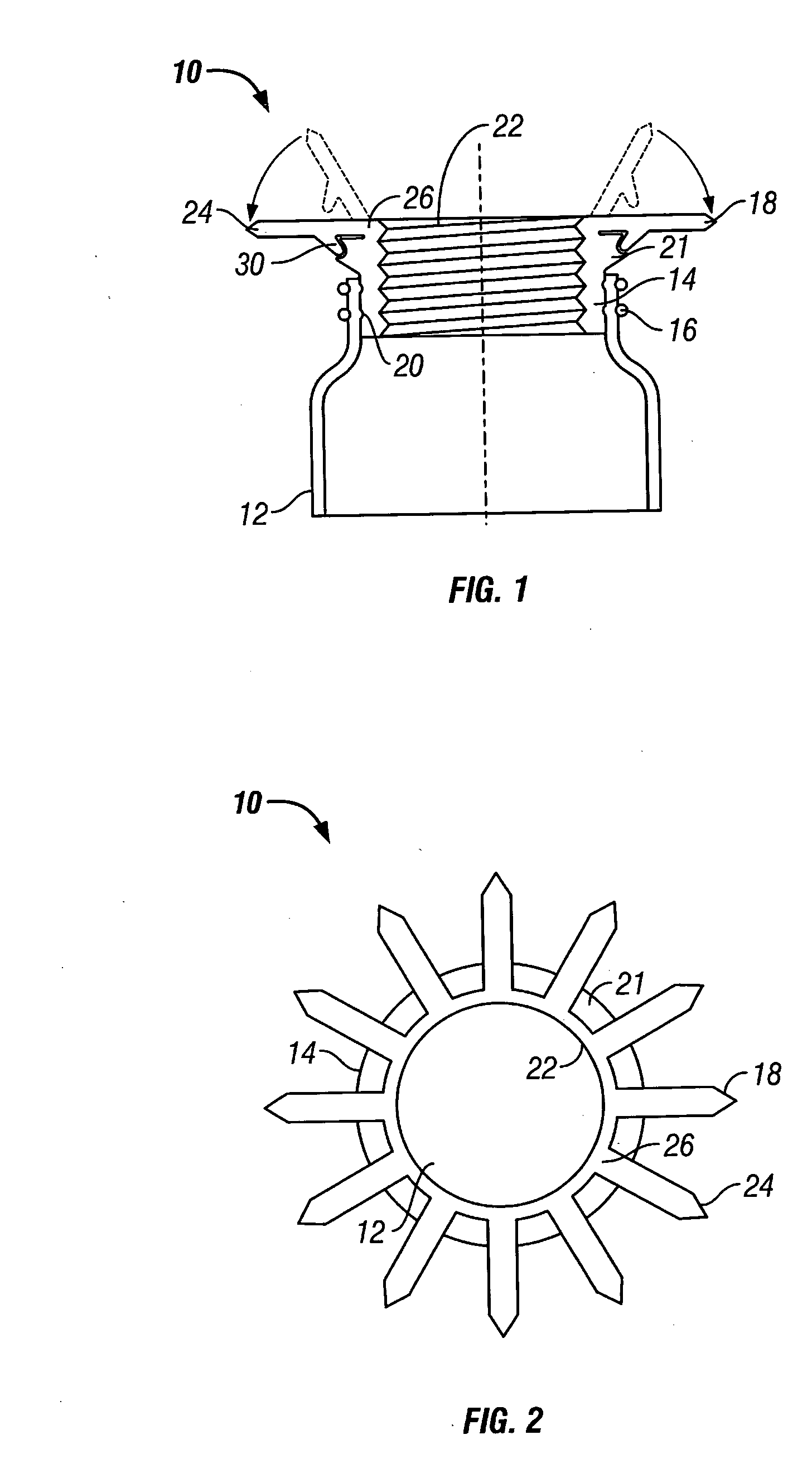

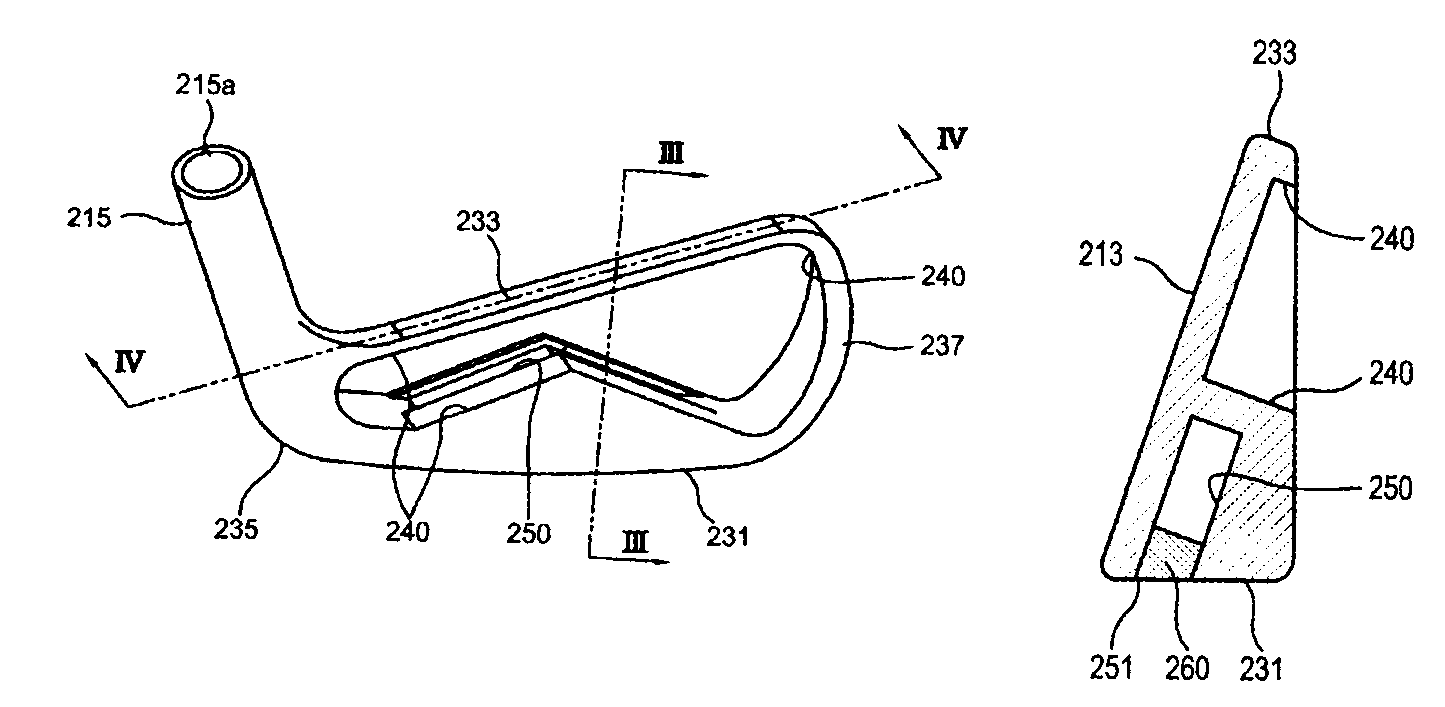

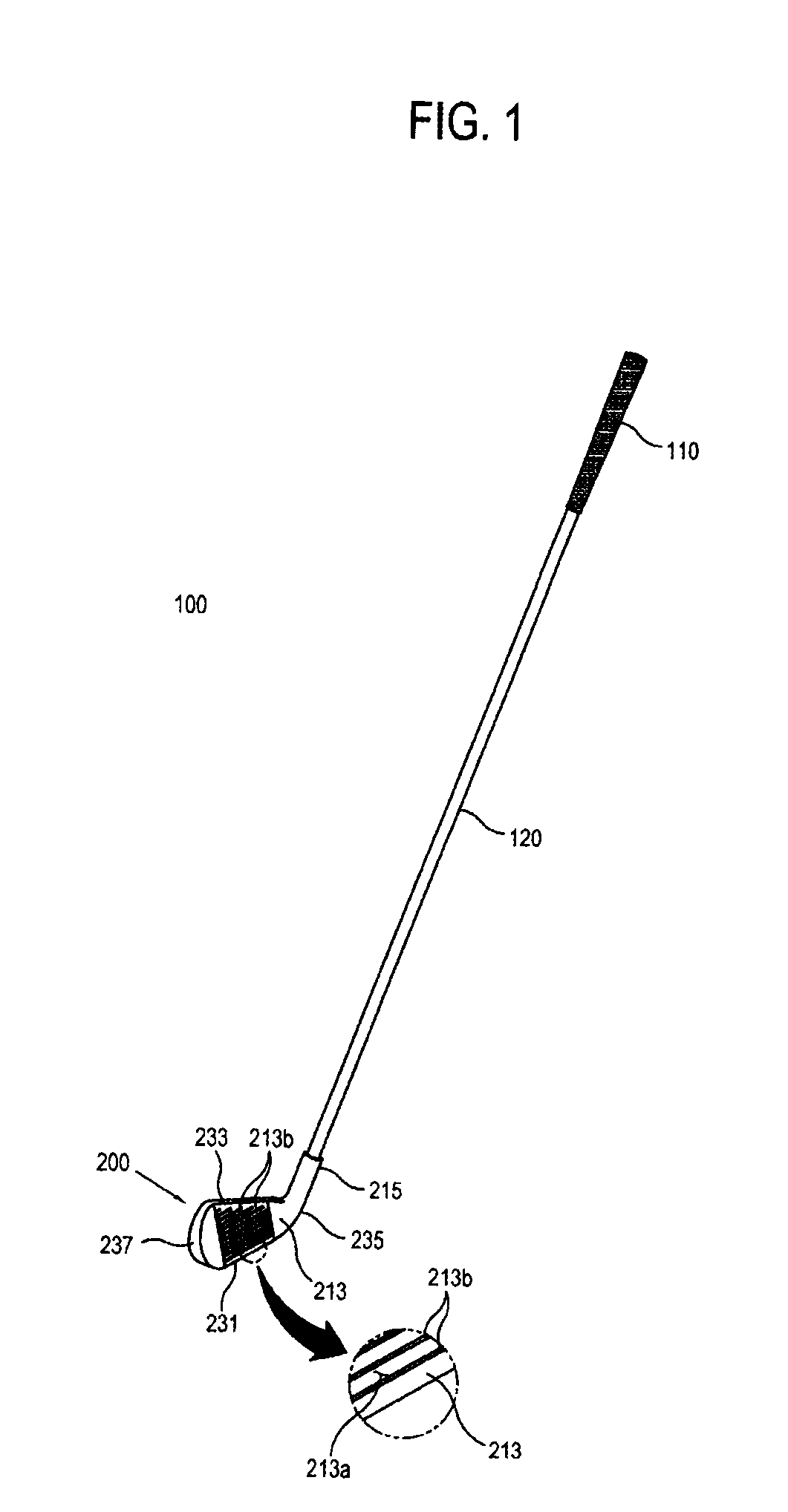

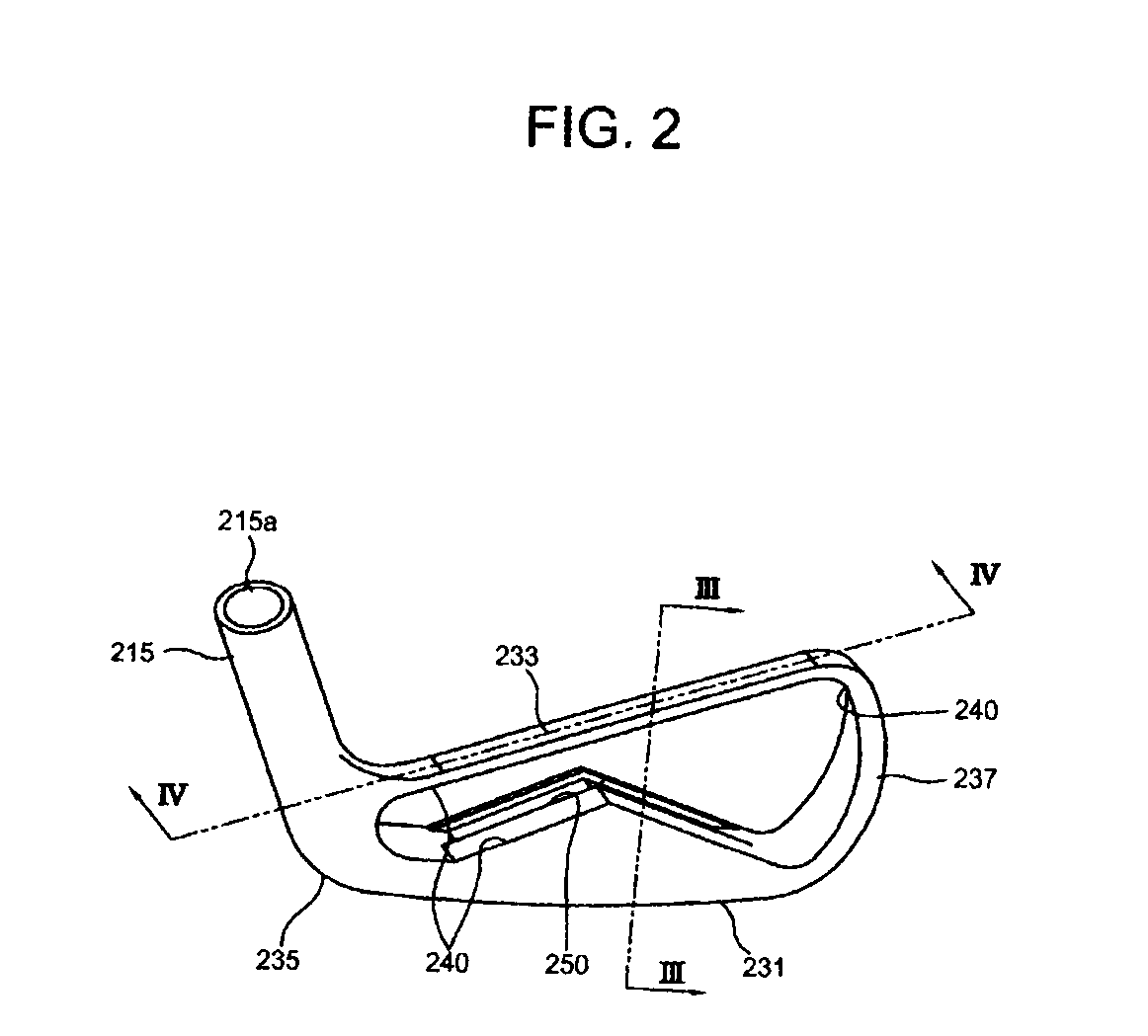

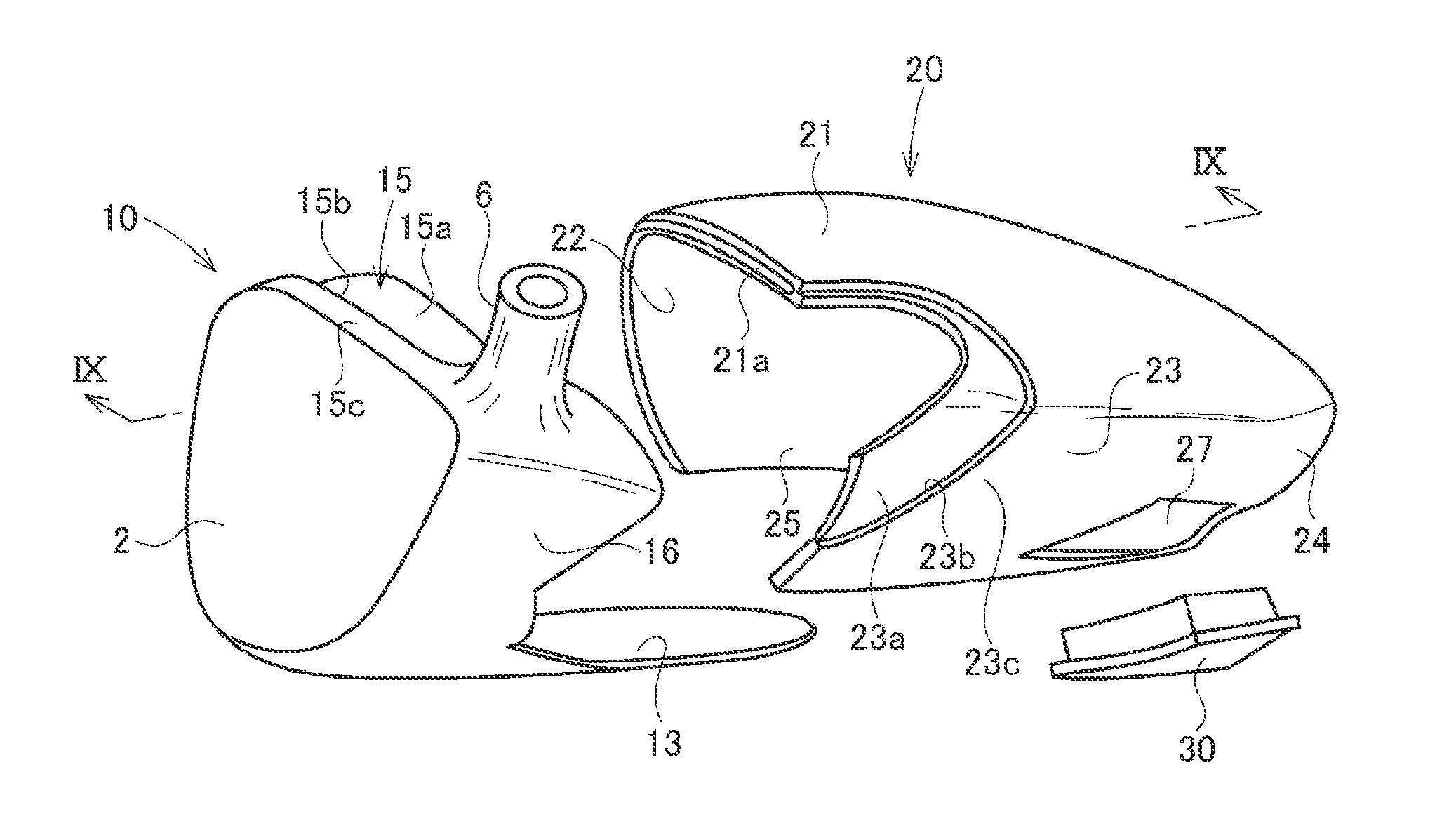

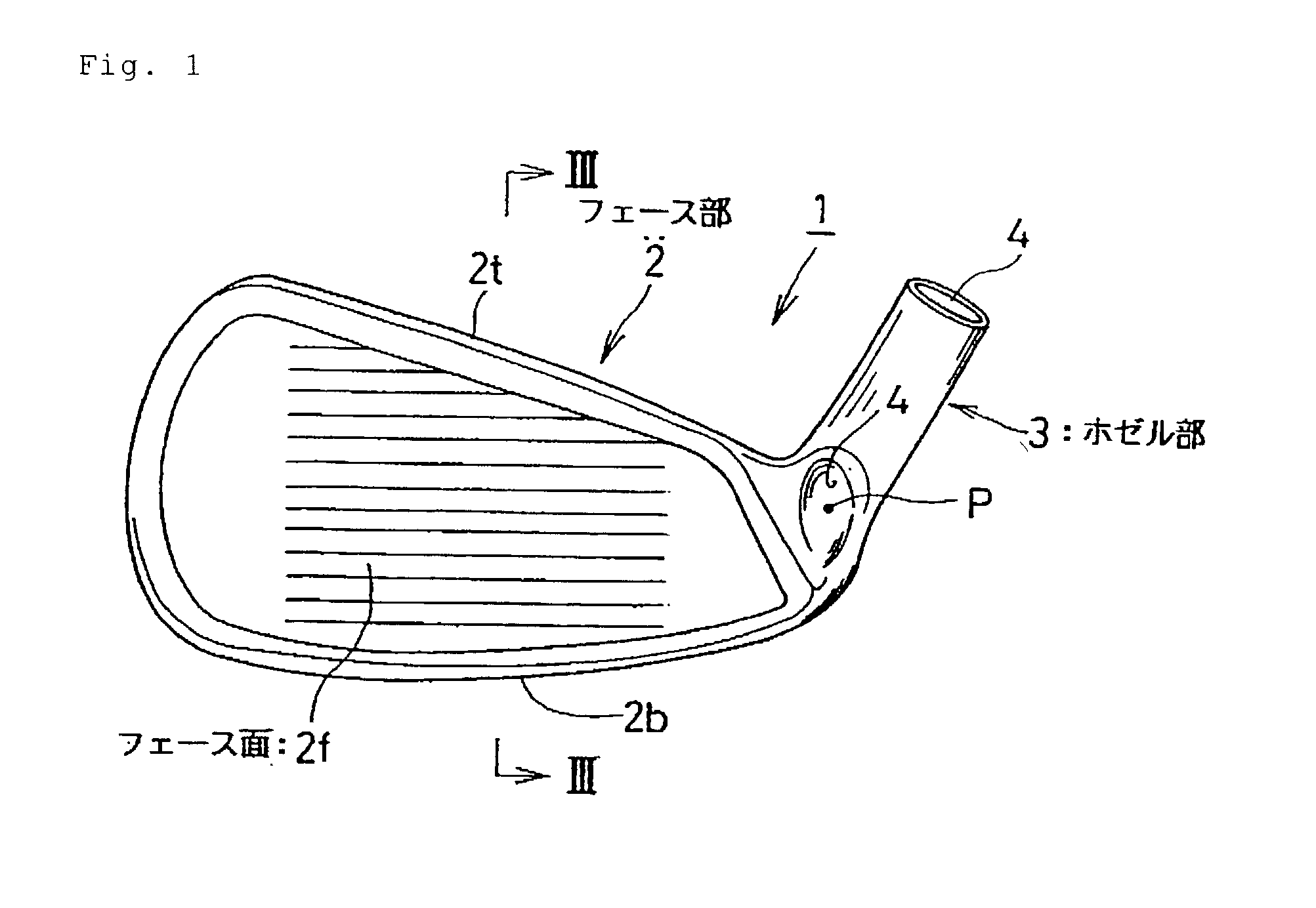

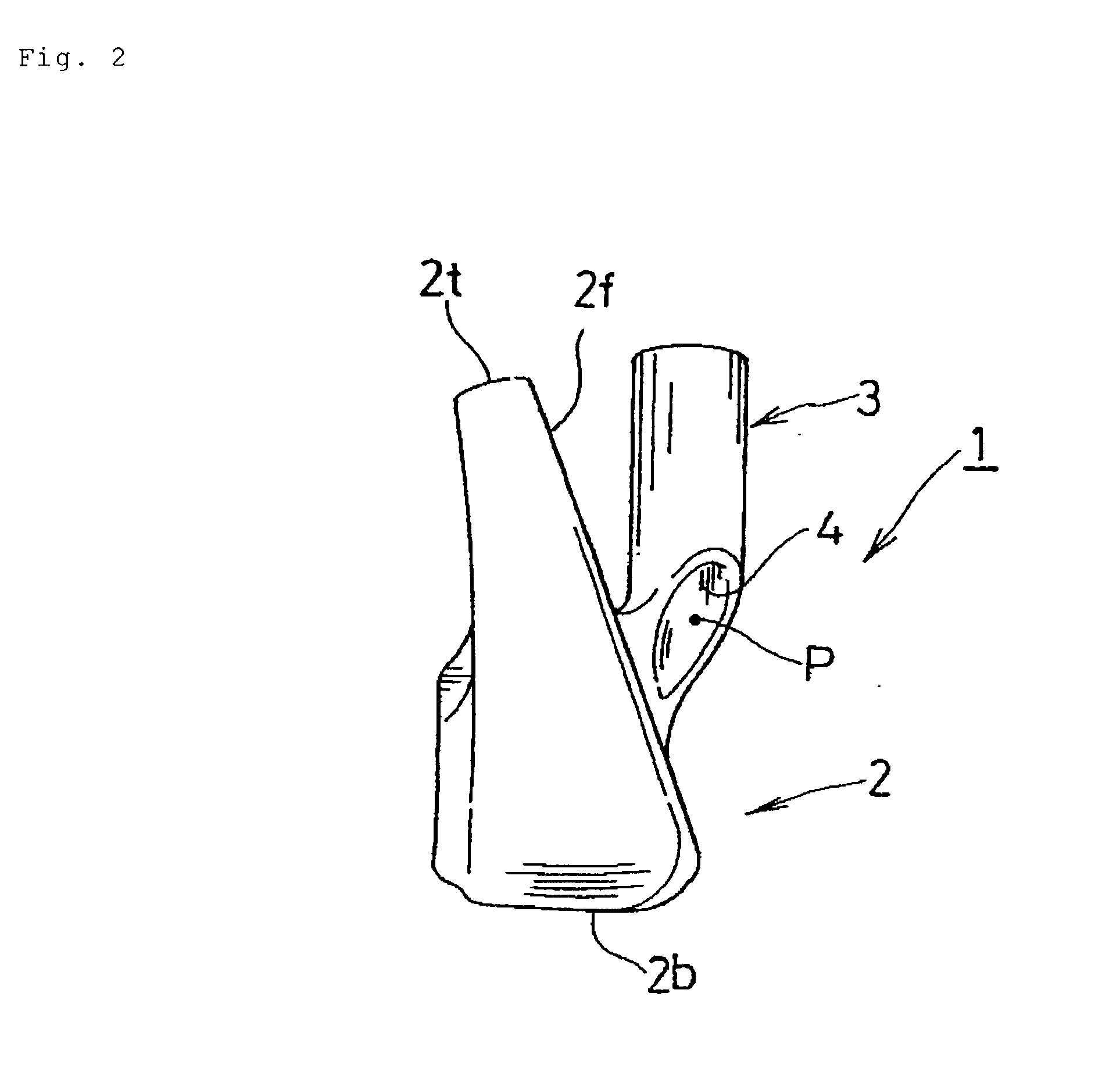

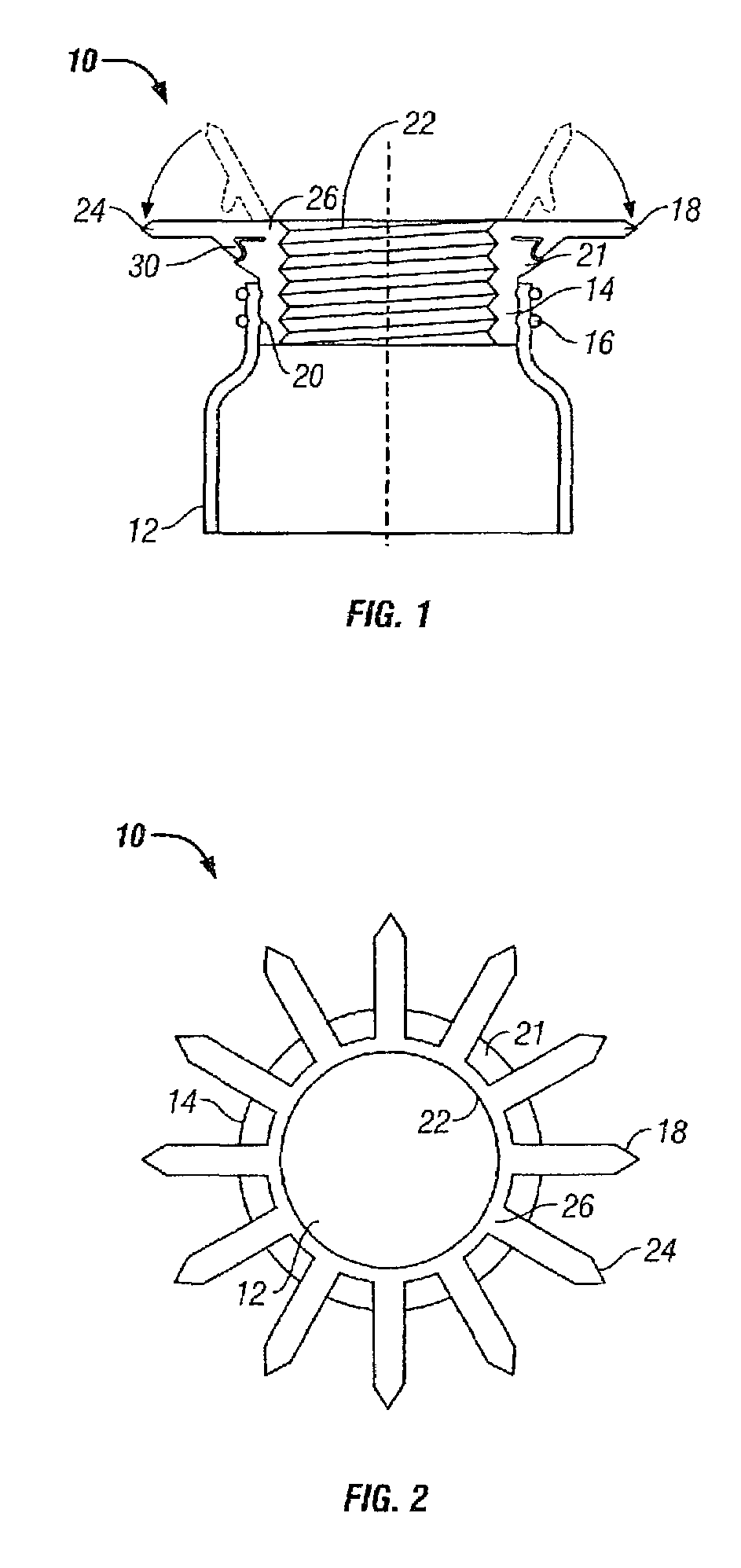

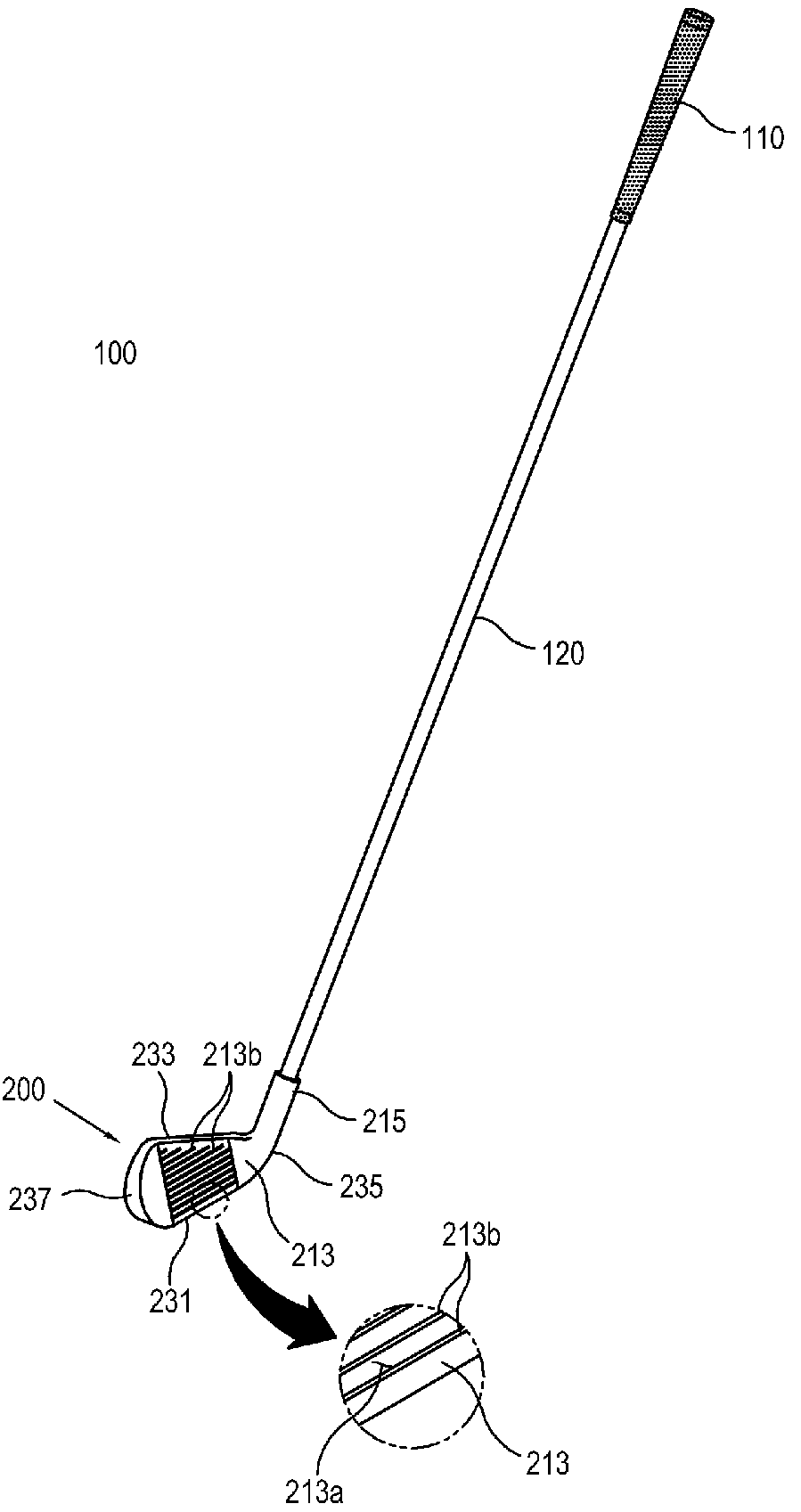

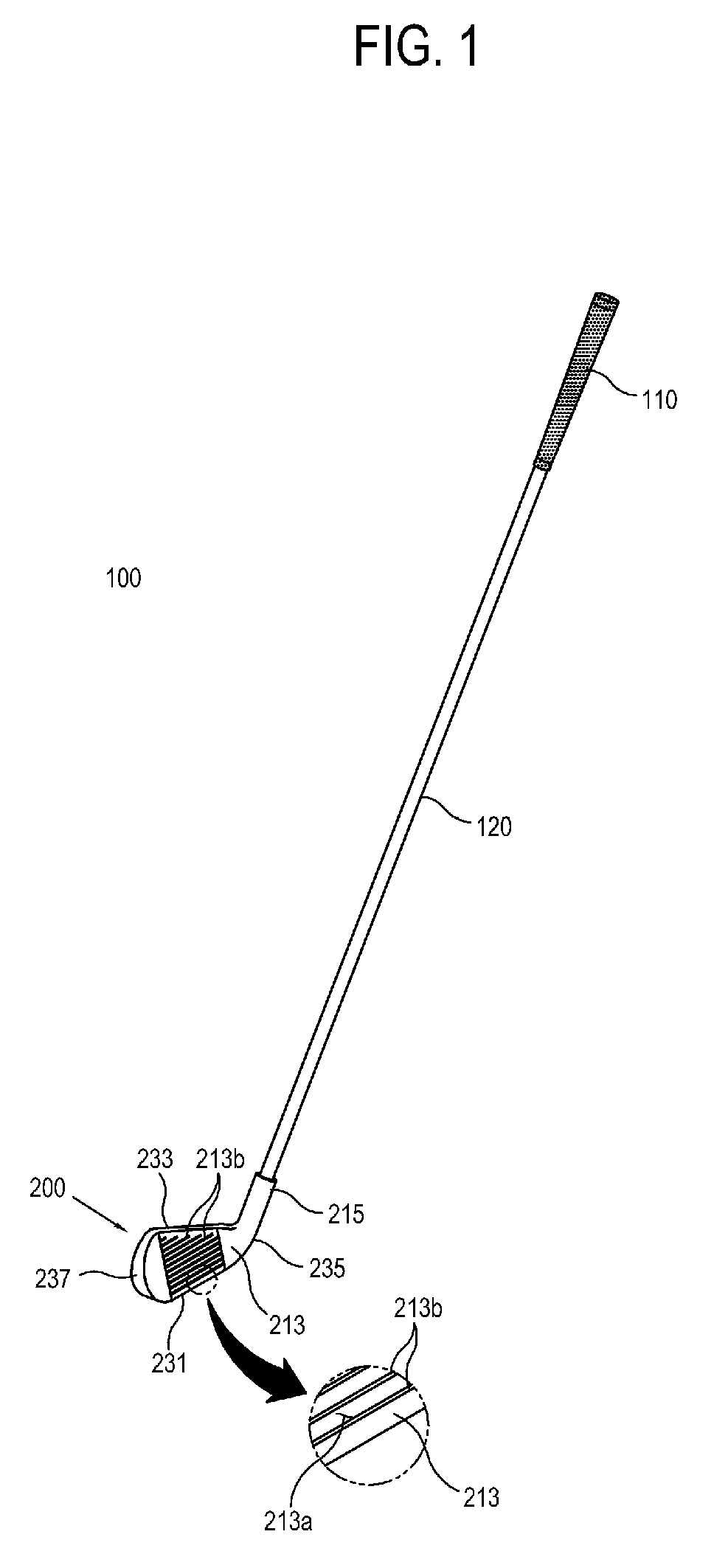

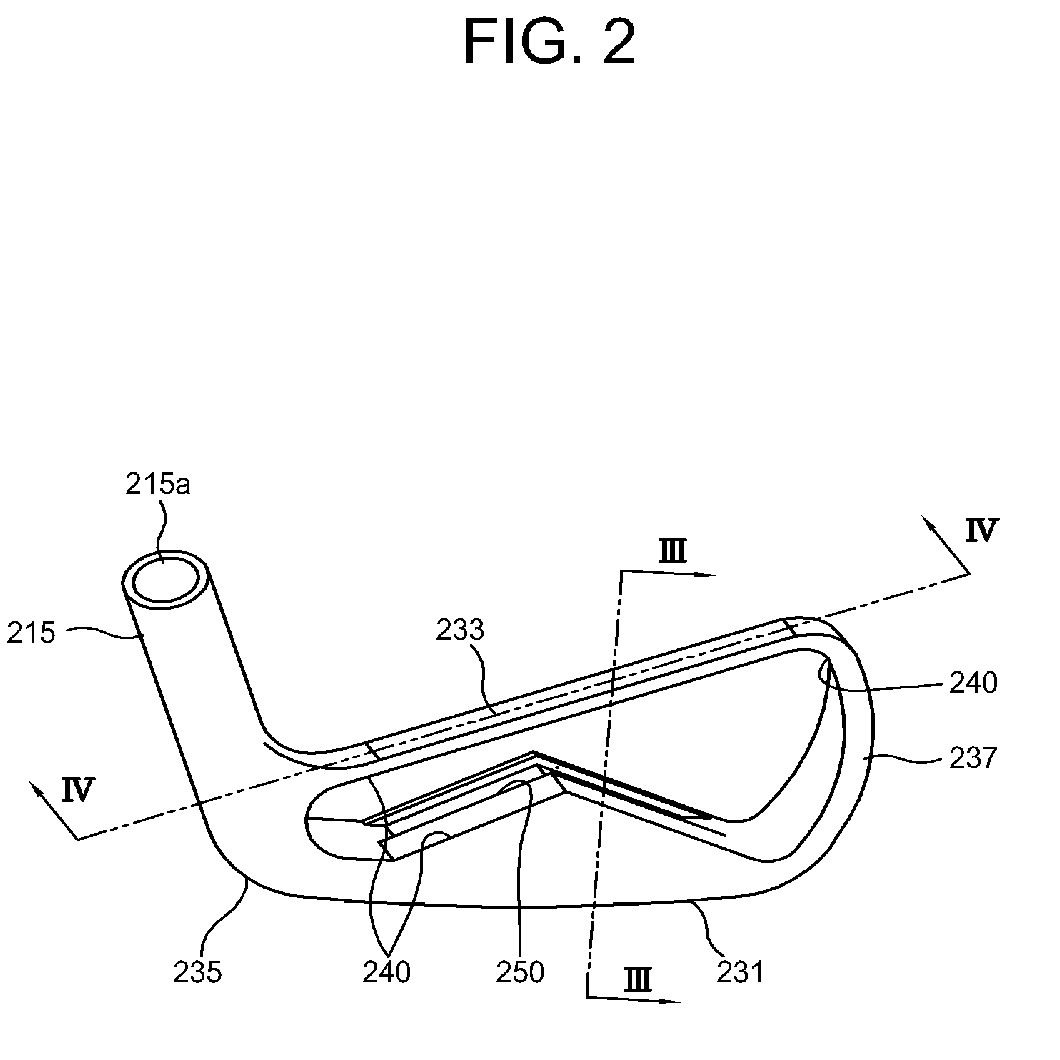

Forged iron head and golf club having the same

InactiveUS7867105B2Easy to hitIncrease flight distanceGolf clubsRacket sportsEngineeringMechanical engineering

A forged iron head for a golf club has a face for hitting a golf ball, a top and a sole extending to upper and lower parts of a rear side of the face, a heel and a toe disposed between the sole and the top, a cavity disposed in the rear side of the face and surrounded by the sole, the top, the heel and the toe and a hosel coupled with a shaft extending from a first side of the face and having a handle part to be gripped by a player. The head comprises a hollow part with an opening formed from the sole toward a first side of the cavity, and a sole cover which closes the opening. The formation of the hollow part lowers the centroid of the iron head, thereby improving flight distances and direction of a golf ball.

Owner:LIMEGLOBAL

Golf club head

A hollow golf club head includes a face portion, a sole portion, a side portion, a crown portion, and a hozel portion. A main portion of the crown portion is made of a fiber reinforced resin. The fiber reinforced resin portion includes a bulk molding compound (BMC) molded body. At least the face portion, a leading edge of the crown portion continuous with the face portion, and a center portion of the sole portion in a toe-heel direction are made of a metal. Alternatively to this configuration, the face portion may be provided with a metal faceplate, a portion subsequent to the face portion may include a BMC molded body, and a rear portion of the crown portion may include a molded laminate of prepreg sheets. The height of center of gravity may be 24 mm or less.

Owner:BRIDGESTONE SPORTS

Interbody fusion grafts and instrumentation

InactiveUS7625374B2Maintain disc heightMaintain distractionBone implantDiagnostic markersDonor boneIntervertebral space

This invention relates to implants formed from donor bone for use in lumbar interbody fusion procedures and instruments for performing such procedures. The implants are formed to include a concave surface formed from a portion of the medullary canal of a long bone. The concave surface defines a recess in the implant that serves as a depot for osteogenic material. Specific instruments for inserting the implants prepared according to this invention and for preparing the intervertebral space to receive the implants are also provided.

Owner:WARSAW ORTHOPEDIC INC

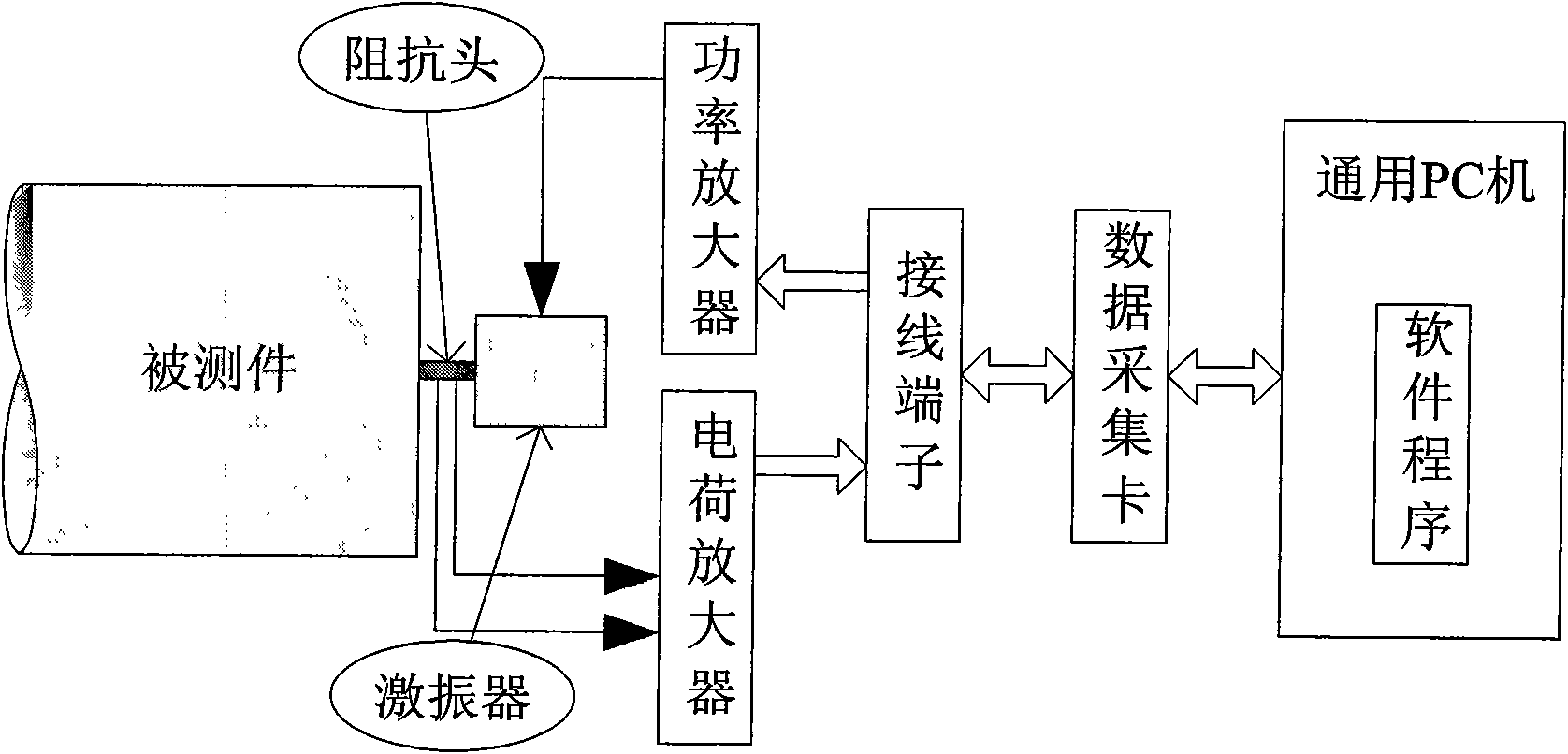

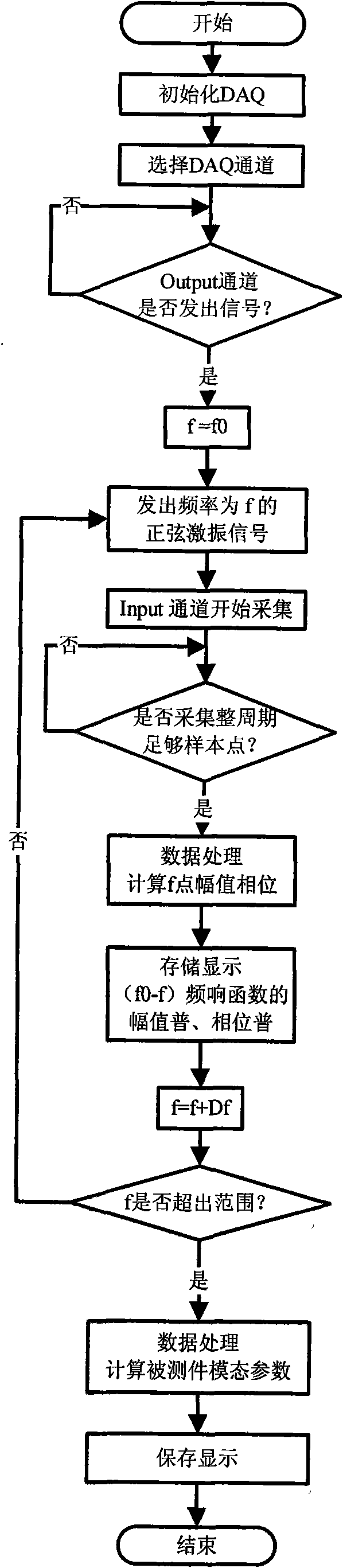

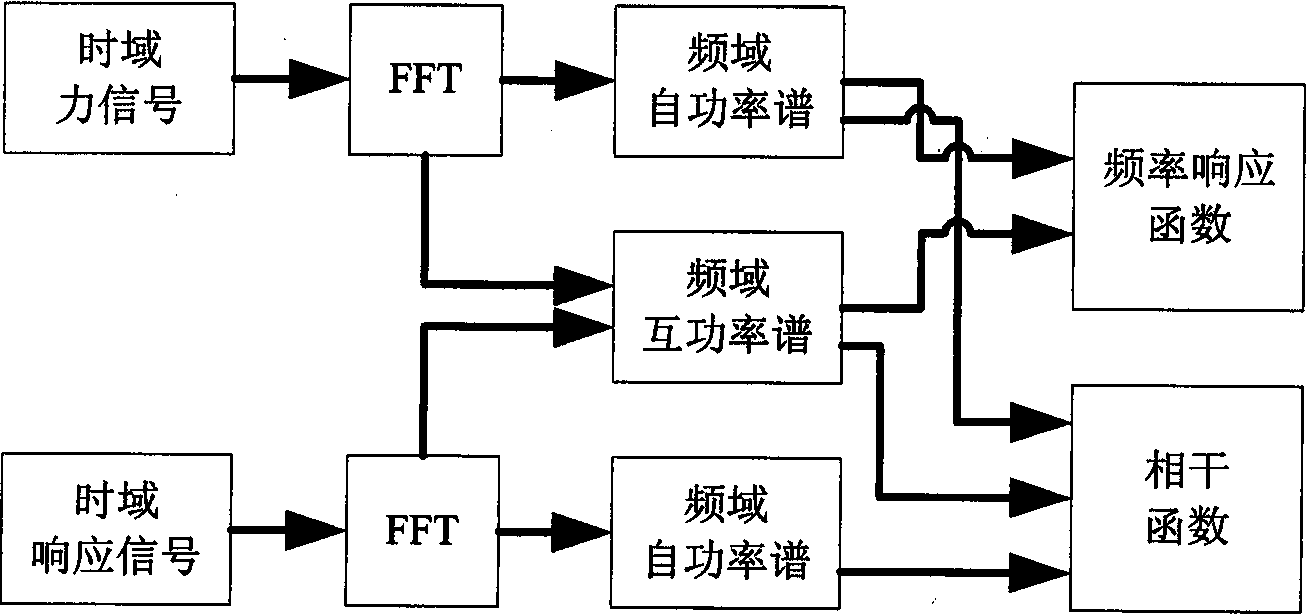

System and method for measuring time-sharing quick steady-state sine sweep excitation frequency response function

InactiveCN101561342AEasy to operateLarge excitation powerVibration testingShielded cableData acquisition

The invention relates to a system and a method for measuring time-sharing quick steady-state sine sweep excitation frequency response function, which belong to the technical field of vibration tests. An excitation system adopts a vibration exciter and a power amplifier. A force sensor and a vibration sensor are adopted to measure an exciting force signal and a vibratory response signal of the system at the same time. A charge amplifier is adopted to condition and filter the signals. A data acquisition system connects a data acquisition card with a connecting terminal through a high-performance shielded cable and is connected with a general computer to acquire and send data. The generation of a sweep signal and the data processing, analysis, storage and display of an exciter response signal are achieved by adopting software based on the general computer. The system and the method achieve quick steady-state sine sweep excitation, the complete cycle sampling of the exciter response signal, and precise and reliable frequency response function curve. The test system is guided by computer programs and is finished automatically, the test method is precise and reliable, and the system and the method have important meaning on testing the dynamic properties of structural elements.

Owner:BEIJING UNIV OF TECH

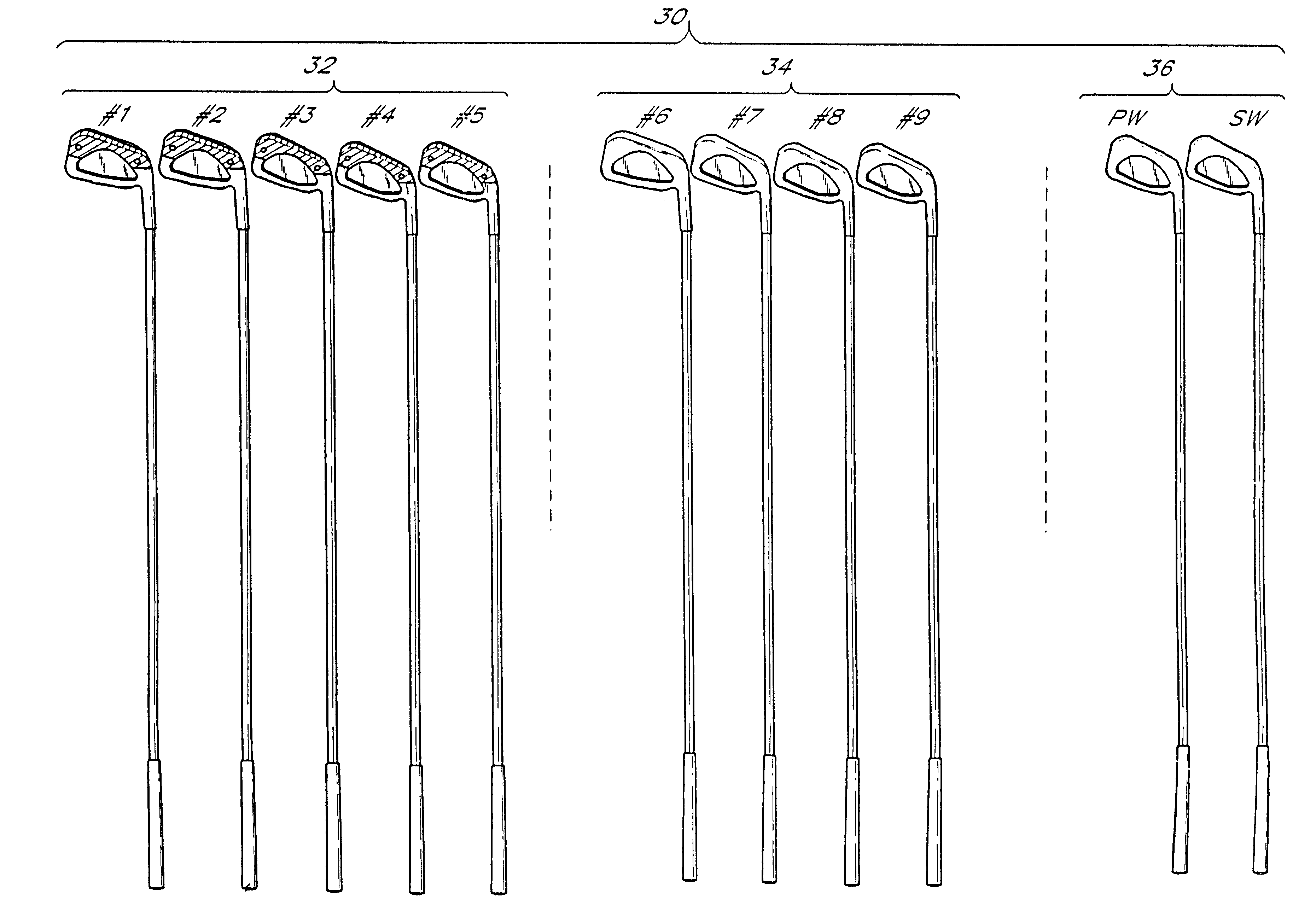

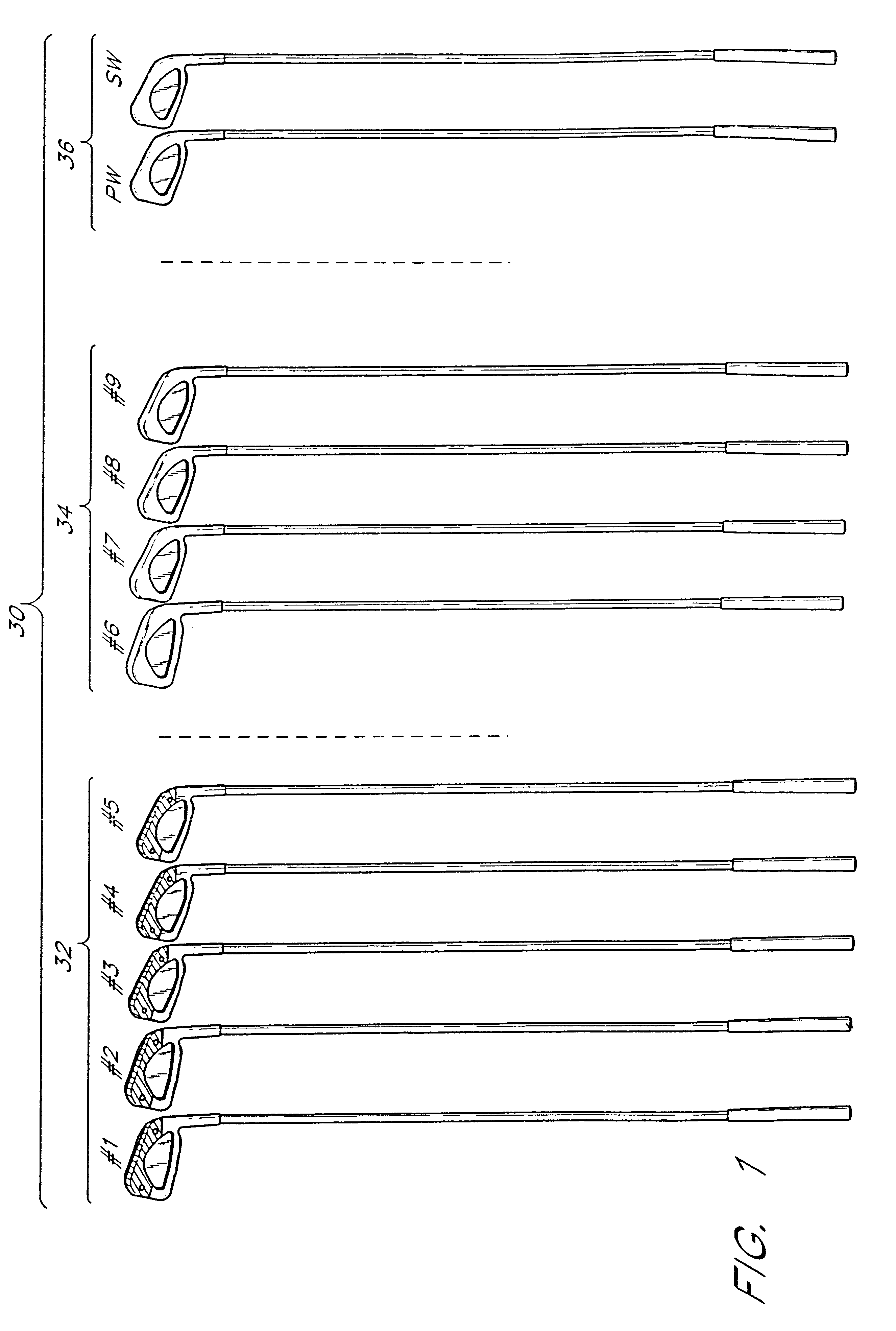

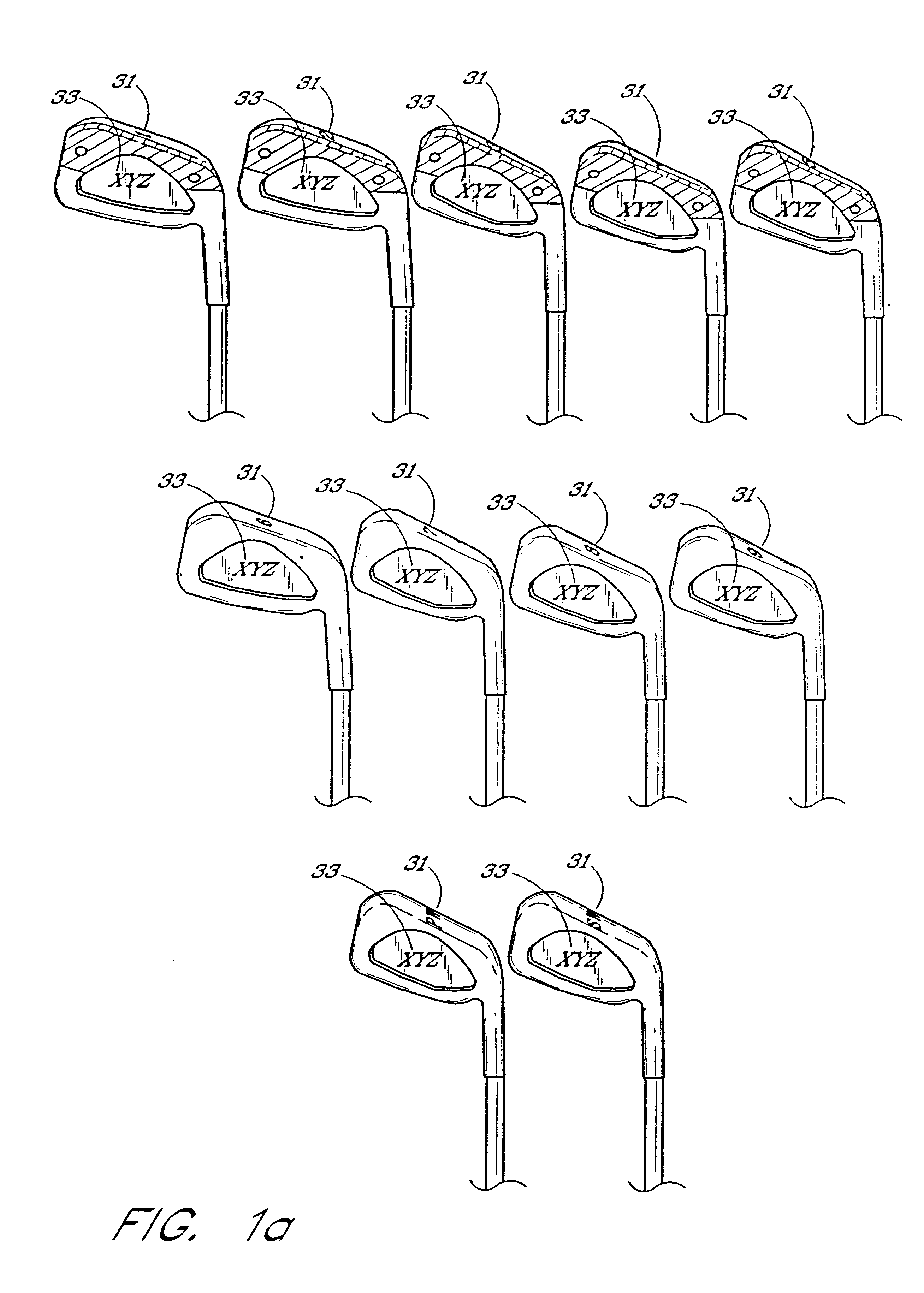

Correlated set of golf clubs

InactiveUS6358158B2Improve controllabilityRaise the possibilityGolf clubsRacket sportsHigh densityMetallic materials

Disclosed is a set of golf clubs. The clubs are divided into at least a first group and at least a second group of golf clubs. The first group desirably comprises a plurality of club heads each having a main body of low density metallic material. The second group of golf clubs desirably comprises a plurality of club heads each having a main body of higher density metallic material than the density of the metallic material of the main body of each of the heads of the first group. The first group of clubs desirably comprises lower numbered clubs than the second group of clubs.

Owner:TAYLOR MADE GOLF

Iron type golf club head

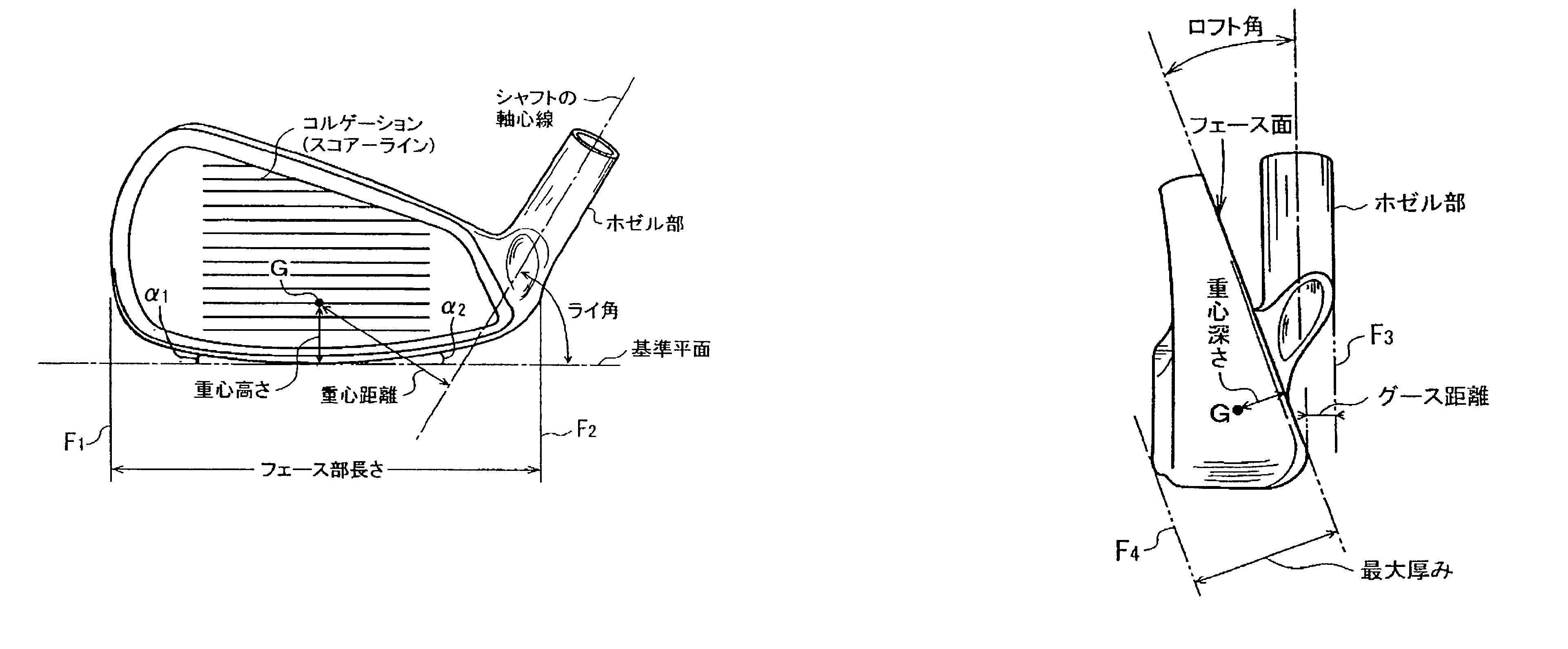

An iron type golf club head including a face portion having a planar face surface, and a hosel portion connected to the heel side of the face portion. A shaft insertion hole is provided in the hosel portion so as to penetrate the hosel portion. The distance from the center of gravity is 28-33 mm, the height of the center of gravity is 12-21 mm, the depth of the center of gravity is 5-15 mm, and the goose distance is 4-15 mm.

Owner:BRIDGESTONE SPORTS

Interbody fusion grafts and instrumentation

InactiveUS20050261681A9Maintain disc heightMaintain distractionInternal osteosythesisBone implantDonor boneIntervertebral space

This invention relates to implants formed from donor bone for use in lumbar interbody fusion procedures and instruments for performing such procedures. The implants are formed to include a concave surface formed from a portion of the medullary canal of a long bone. The concaved surface defines a recess in the implant that serves as a depot for osteogenic material. Specific instruments for inserting the implants prepared according to this invention and for preparing the intervertebral space to receive the implants are also provided.

Owner:WARSAW ORTHOPEDIC INC

Method and device for table tennis robot to predict table tennis ball trajectory

The invention discloses a method and a device for a table tennis robot to predict a table tennis ball trajectory and belongs to the technical field of robots. The method comprises the steps of collecting position coordinates of two points during flying of a table tennis ball, predicting the flying trajectory of the table tennis ball through a time difference and position information, analyzing and judging whether the trajectory is located in a hitting area of the table tennis robot or not, and sending decision information (best hitting point or protection information) to the robot. If the trajectory is located in the hitting area, the robot hits the ball through real-time action planning. The device comprises two position detection modules, a real-time processing module and a communication module. By the aid of the method and the device, the flying trajectory of the table tennis ball can be predicted effectively in real time, so that the table tennis robot can finish a hitting action. The method and the device have the advantages of being simple in algorithm, high in practicability, low in cost, high in environmental adaptability and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

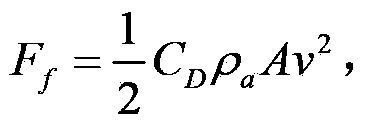

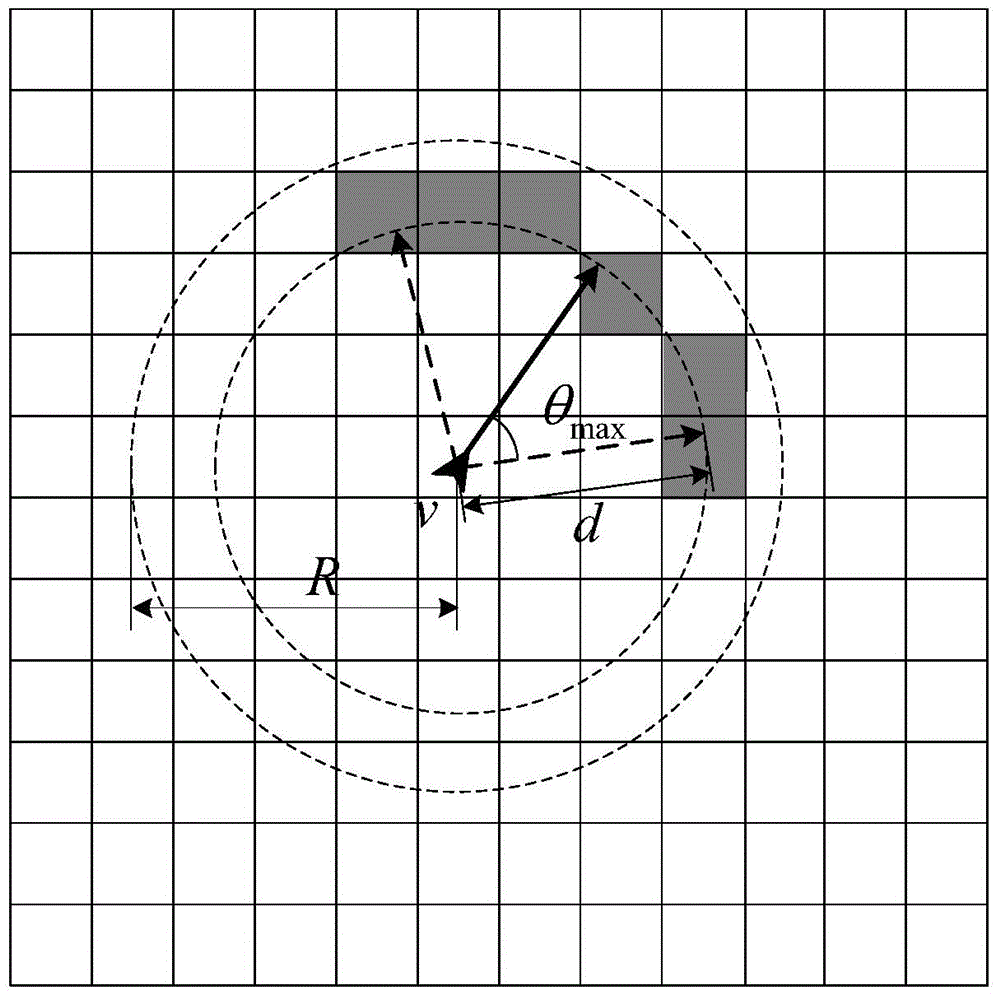

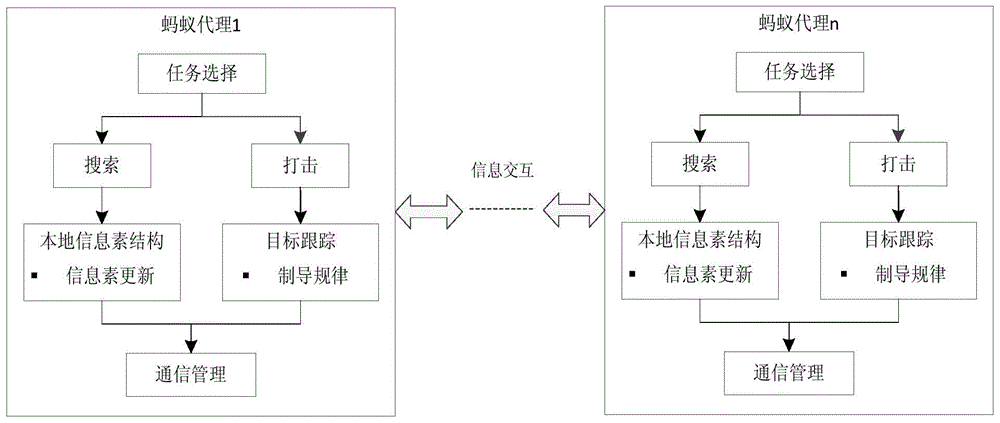

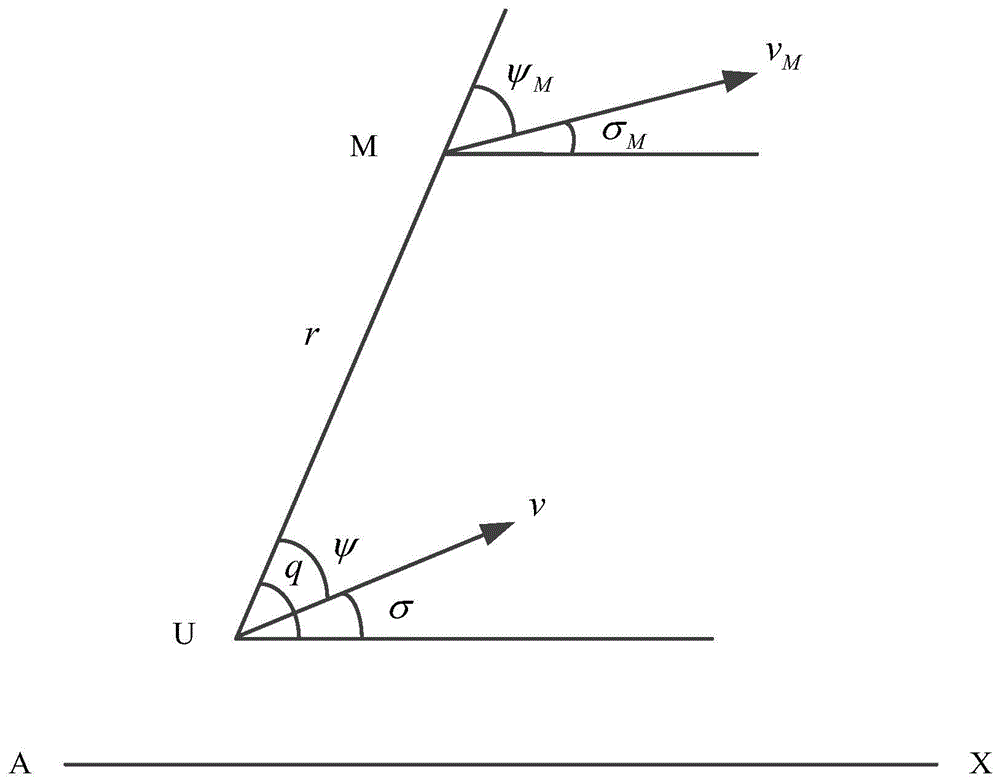

Multi-unmanned-aerial-vehicle intelligent cooperation observe/act method for multiple dynamic targets

InactiveCN104881043AEasy to hitAchieve reconnaissanceTarget-seeking controlUncrewed vehicleReal-time computing

The invention discloses a multi-unmanned-aerial-vehicle intelligent cooperation observe / act method for multiple dynamic targets. The method includes the steps: firstly, discretizing a task area, and making the motions of unmanned aerial vehicles correspond to the motions of grids in a discrete space on the basis of the mobility of the unmanned aerial vehicles; secondly, on the basis of an ant colony algorithm, performing cooperation searching in the task area, wherein each ant agent represents one unmanned aerial vehicle, has positioning, sensing, memorizing, moving, attacking, communicating and self-updating capabilities like an unmanned aerial vehicle platform, and also is restricted by the performance of the unmanned aerial vehicles; and thirdly, the ant agents enabling, for searched targets, the unmanned aerial vehicles to track and attack moving targets through a guidance method based on a parallel approaching method. During the process, ant searching and ant tracking and attacking are carried out alternatively, thereby achieving continuous observe / act effects for the task area.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Apparatus and system to drill a bore using a laser

InactiveUS20140231147A1Easy to hitIncrease the sectionDrilling rodsDerricks/mastsLaser lightEngineering

A system to extend a lateral bore section using laser light comprises a first umbilical connected to a deflection member having a drive gear, a lateral exit port and at least one deployable seal intermediate a proximal end and the lateral exit port, and a second umbilical having an exterior movable by the drive member through a pathway of the deflection member ending at the lateral exit port to controllably advance a drill head connected to a leading end of the second umbilical. Optical fibers of the second umbilical transmit laser light from a surface end to optical elements in the drill head that condition laser light for heating a targeted portion of a bore wall. The first umbilical positions the deflection member within a primary bore section, and the second umbilical is controllably advanced to extend a lateral bore by the drive gear of the deflection member.

Owner:SLD ENHANCED RECOVERY

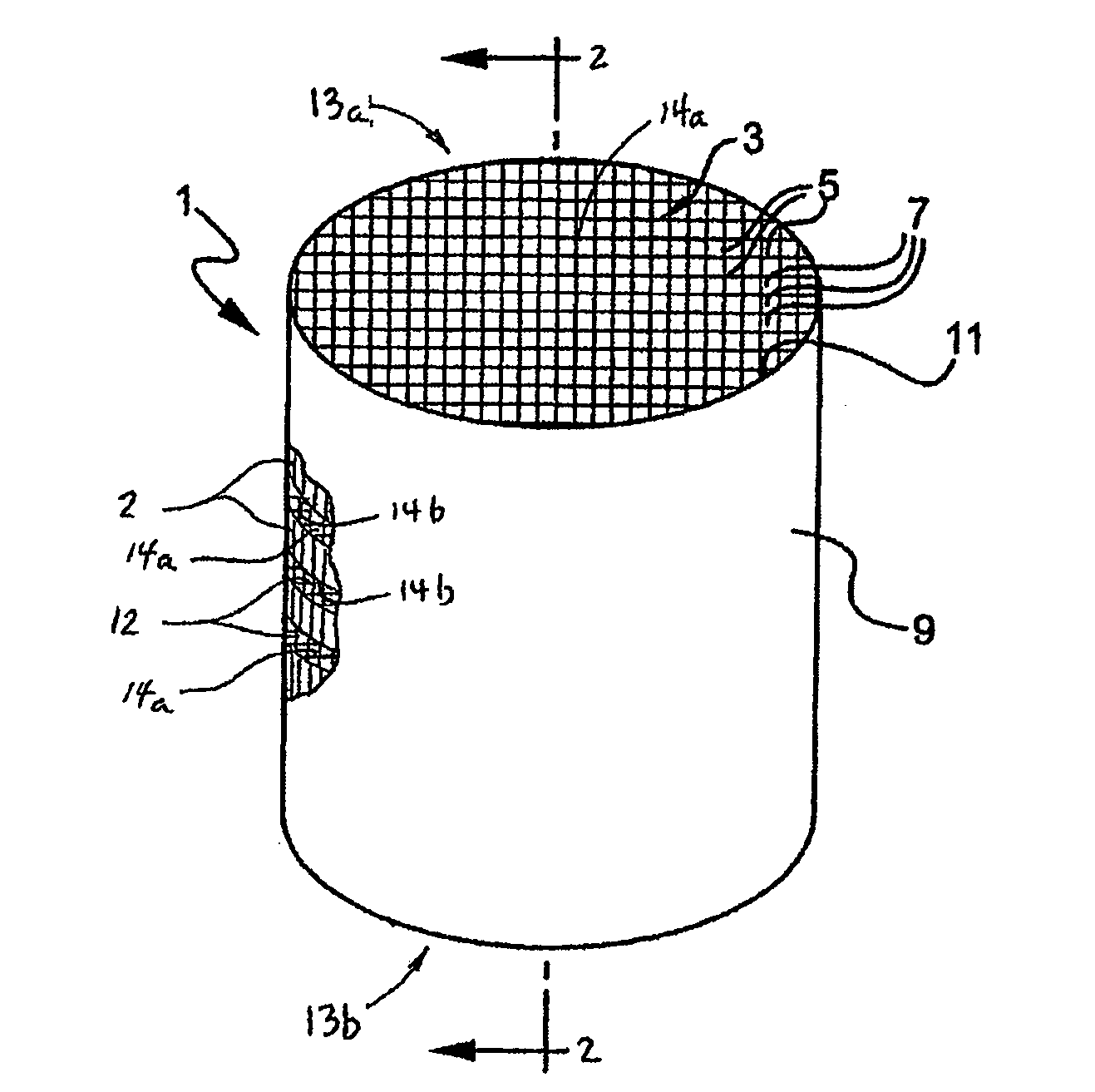

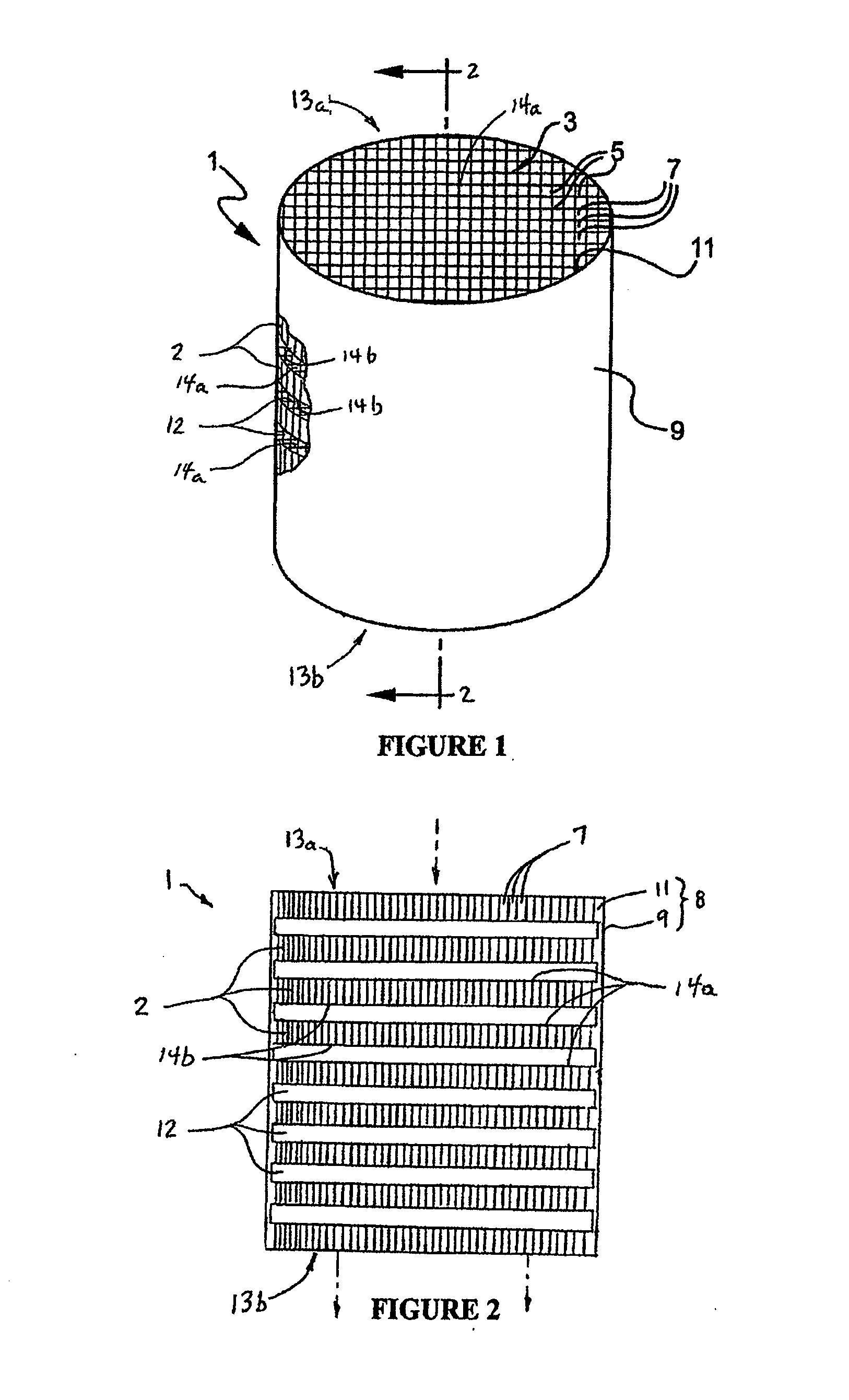

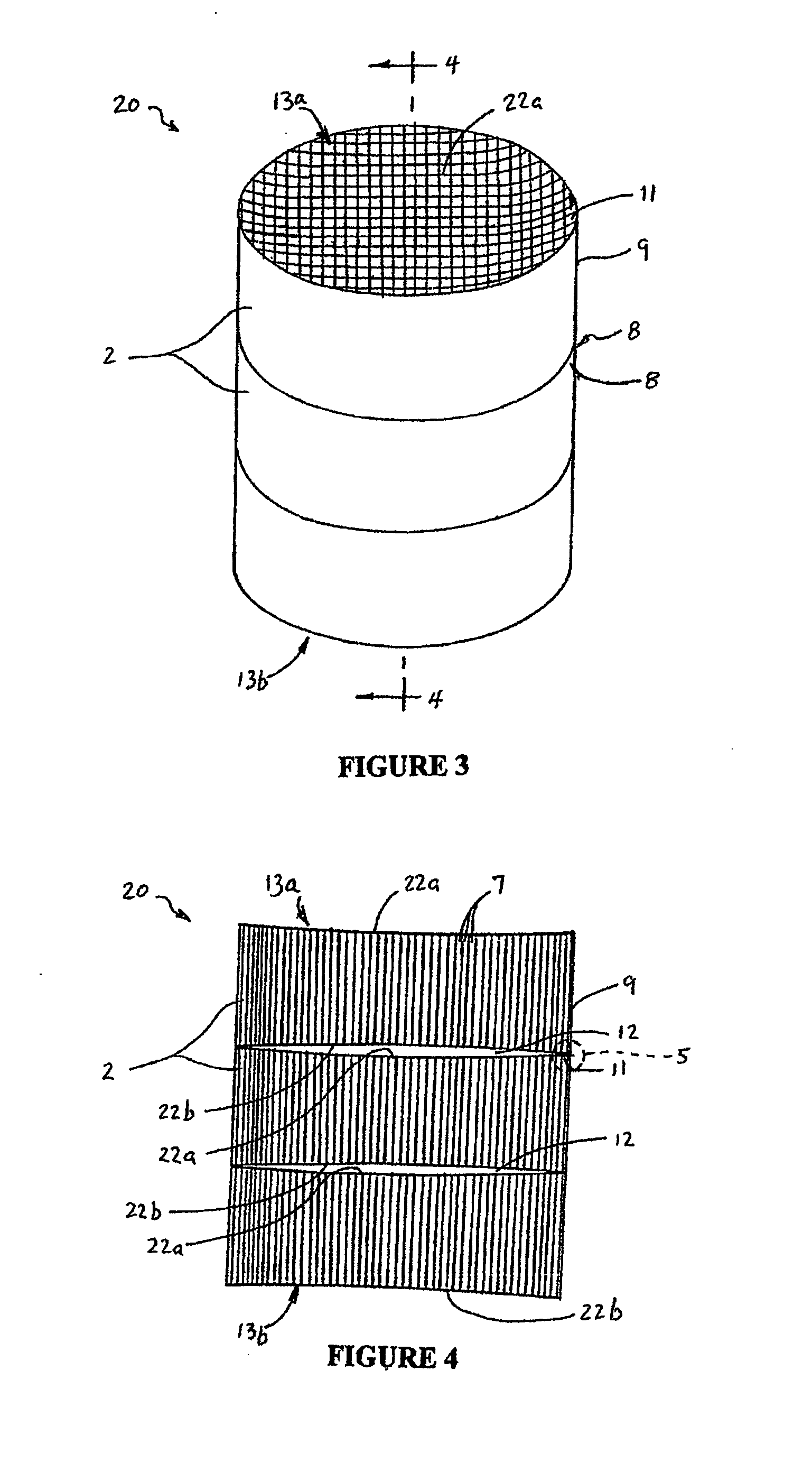

Fluid treatment device having multiple layer honeycomb structure and method of manufacture

ActiveUS20090041635A1Improve device performancePrevent leakageCombination devicesInternal combustion piston enginesHoneycomb structureMultiple layer

A device for treating fluids, such as automotive exhaust gases is provided, as well as a method of manufacturing such a device. The invention provides a honeycomb structure, a matrix of ceramic walls that defines a plurality of parallel, fluid-conducting cells oriented along an axis, arranged in a stacked or discontinuous configuration between an inlet and outlet, where adjacent layers of honeycomb structure are separated by layers of air spaces. Each matrix layer has opposing faces that defines the inlets and outlets of the cells, and a peripheral portion or peripheral region including an outer skin. The peripheral portions or peripheral regions of adjacent stacked ceramic layers are mutually contiguous to prevent fluid flowing through the stacked ceramic layers from leaking between said outer skins.

Owner:CORNING INC

Perorally insertable/removable anti-reflux valve

Disclosed are esophageal anti-reflux valve prostheses, and tools and procedures for peroral implantation and extraction of the prostheses. The prostheses disclosed have a semipermeable membrane to allow retrograde passage of gas, magnets disposed at a distal end of the sleeve to facilitate closure, and an outwardly bendable array of spikes that are longitudinally aligned for peroral insertion and lockable into a radially outwardly deployed configuration to keep the prosthesis from dislocating implantation. The implantation tool has inner and outer concentric tubes, the inner tube releasably threadably connected to the prosthesis, the outer tube reverse threaded with the inner tube to advance a distal headpiece to engage, deploy and lock the spikes into the deployed configuration. A vacuum assist can be used to help impact the lumen wall on the spikes. The extraction tool is similar to the implantation tool with an inner tube for threadably engaging the prosthesis, an outer tube with a distal crown with a plurality of shoes to unseat and unlock the spikes, and an overtube shield to receive the spikes and facilitate extraction of the prosthesis.

Owner:REFLUX CORP

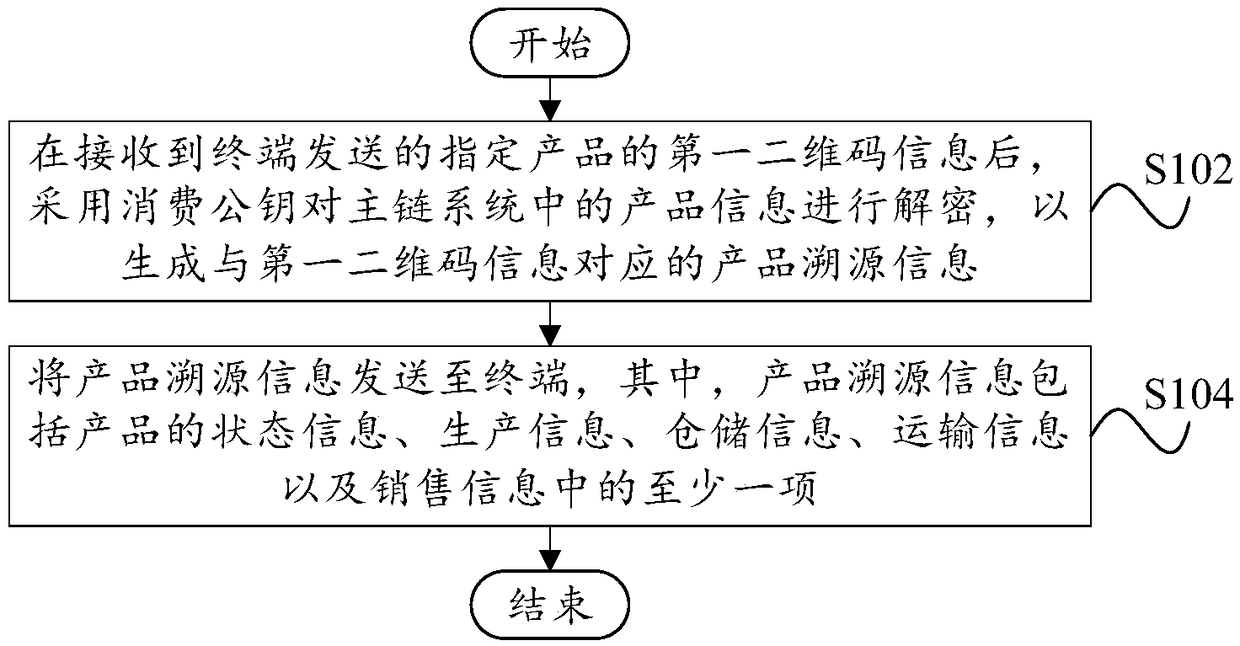

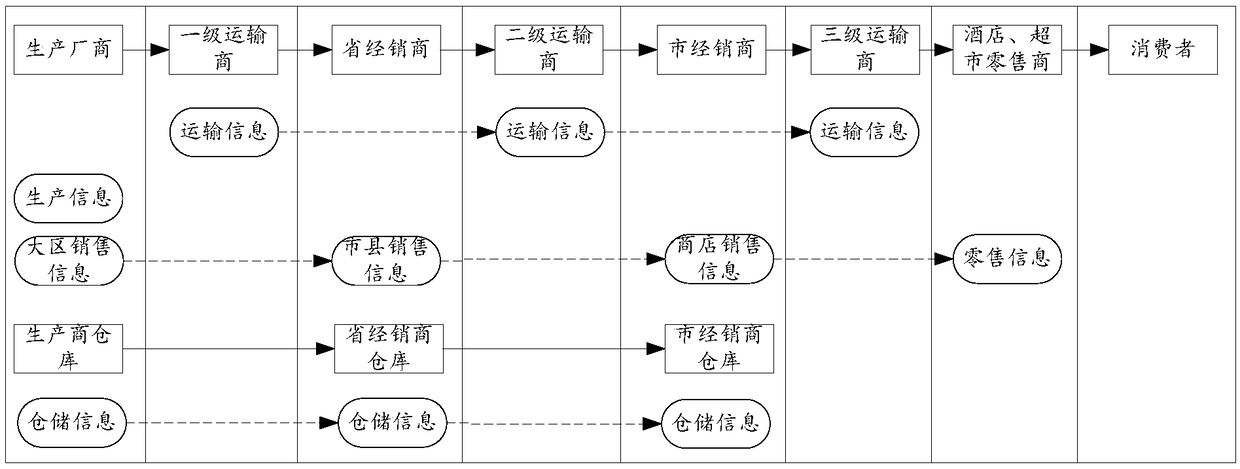

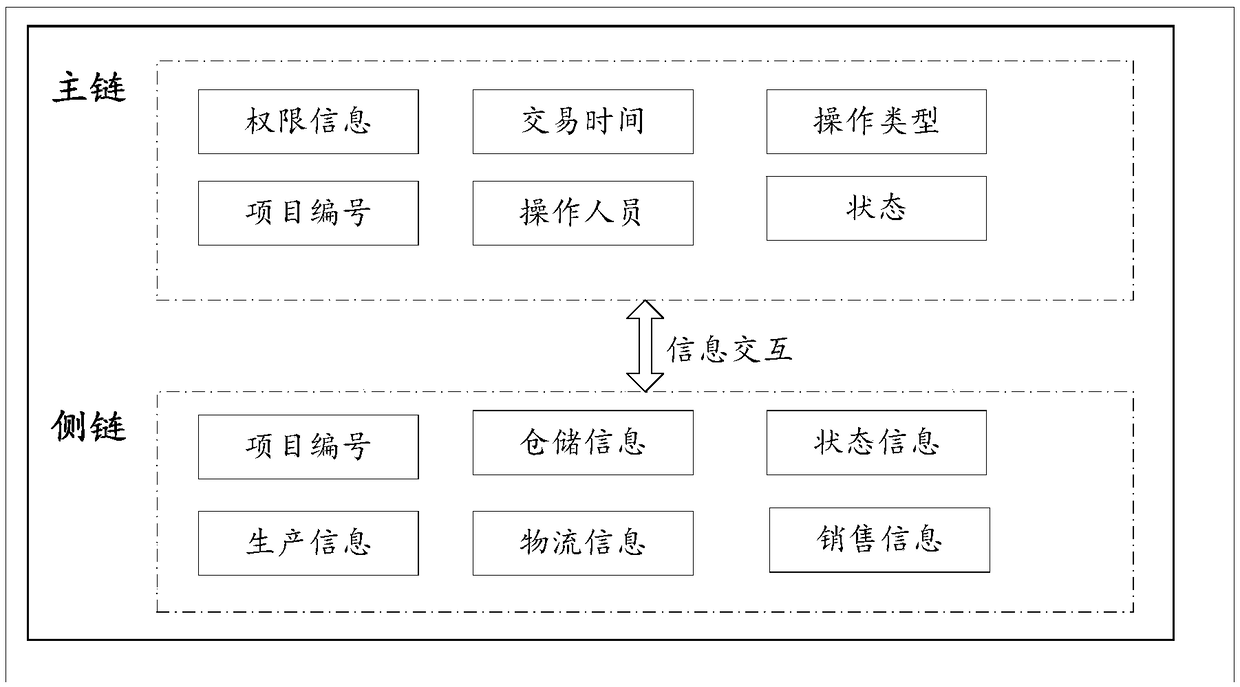

A liquor traceability system based on block chain

InactiveCN109146516AIncrease profitGuaranteed real-timeParticular environment based servicesUser identity/authority verificationProduct traceabilityComputer terminal

The invention provides a liquor traceability system based on a block chain, comprises a traceability method, a traceability device, a server and a storage medium, wherein, the traceability method based on a block chain comprises the following steps: after receiving the first two-dimensional code information of a designated product sent by a terminal, decrypting the product information in a main chain system by using a consumption public key to generate product traceability information corresponding to the first two-dimensional code information; the product traceability information being transmitted to the terminal, wherein the product traceability information includes at least one of status information, production information, warehousing information, transportation information and sales information of the product. The technical proposal of the invention can effectively supervise each link of product production and sales, can reliably trace the source of product sales process, is conducive to cracking down on fake and inferior products, and protects the rights and interests of consumers and manufacturers.

Owner:佛山鑫达智汇科技有限公司

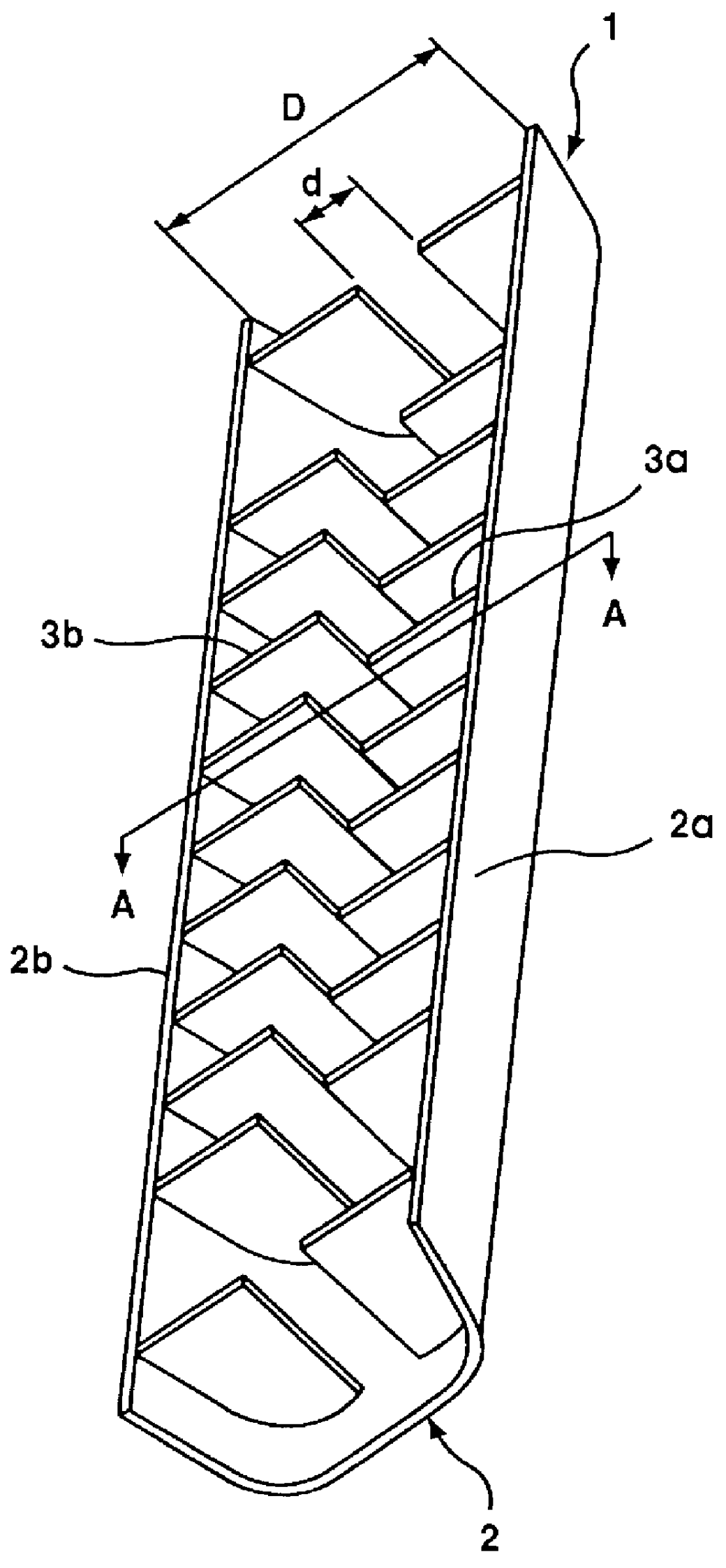

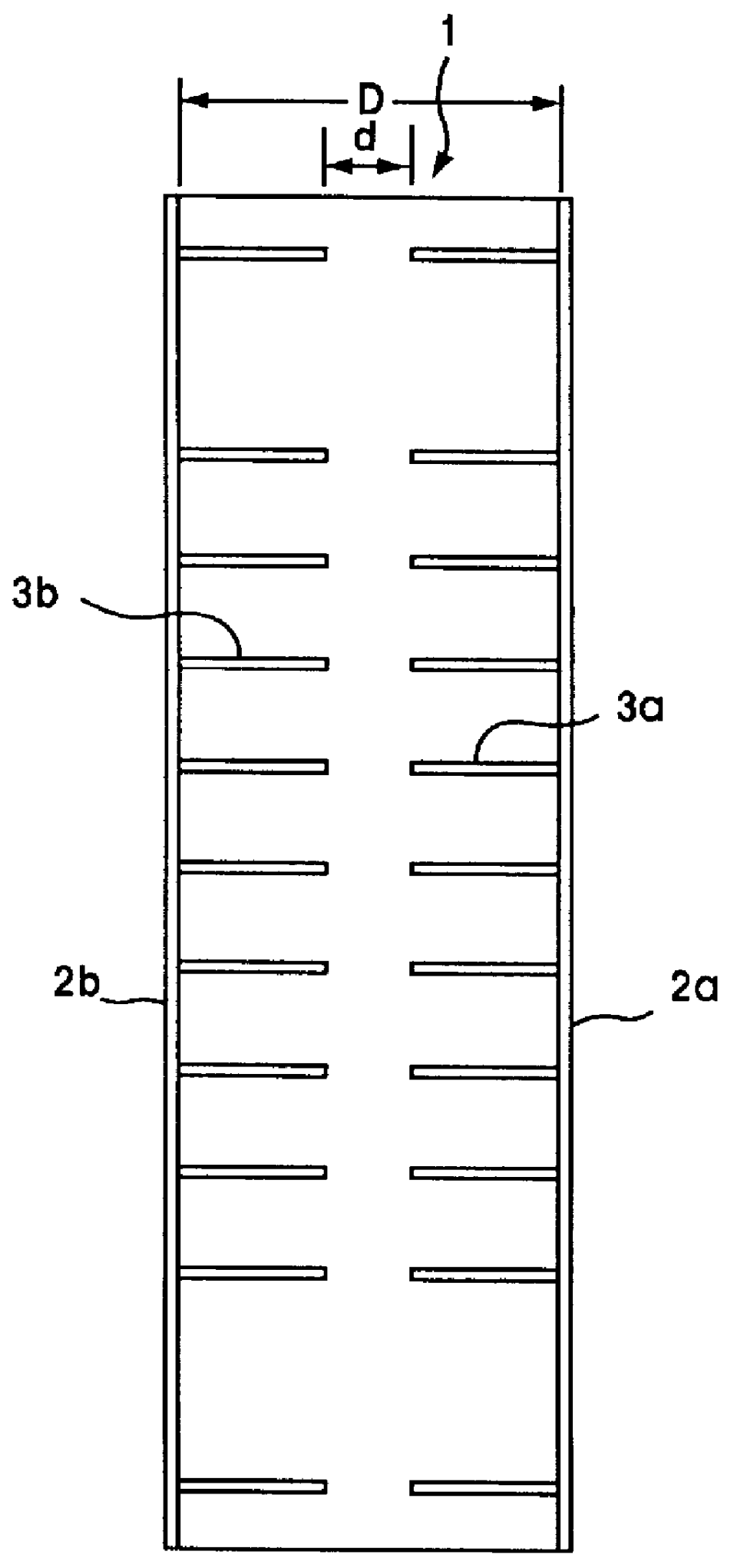

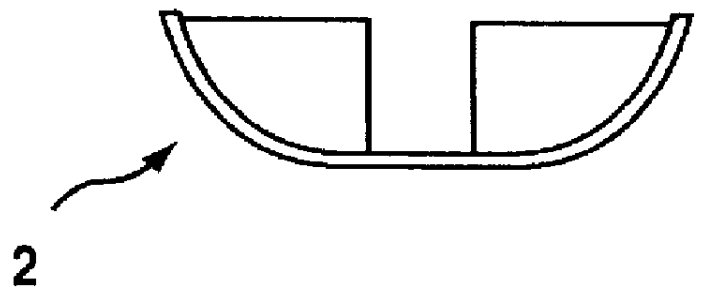

Vehicular pillar cover

InactiveUS6068320AImprove elastic deformation abilityReduce areaVehicle seatsPedestrian/occupant safety arrangementEngineeringMechanical engineering

A vehicular pillar cover which is drastically improved in a performance for absorbing and damping an impact. The vehicular pillar cover comprises ribs (3a and 3b) staggered in a body (2) having a generally C-shaped or folded section, at a suitable spacing, and so extended generally at a right angle with respect to the longitudinal direction of the body (2) from the individual side wall portions (2a and 2b) of the body (2) as to form gaps between the opposed side wall portions and cut-off portions (4a and 4b) in the upper faces of the ribs (3a and 3b) and along the inner side shape of the body (2).

Owner:TECHNO POLYMER CO LTD

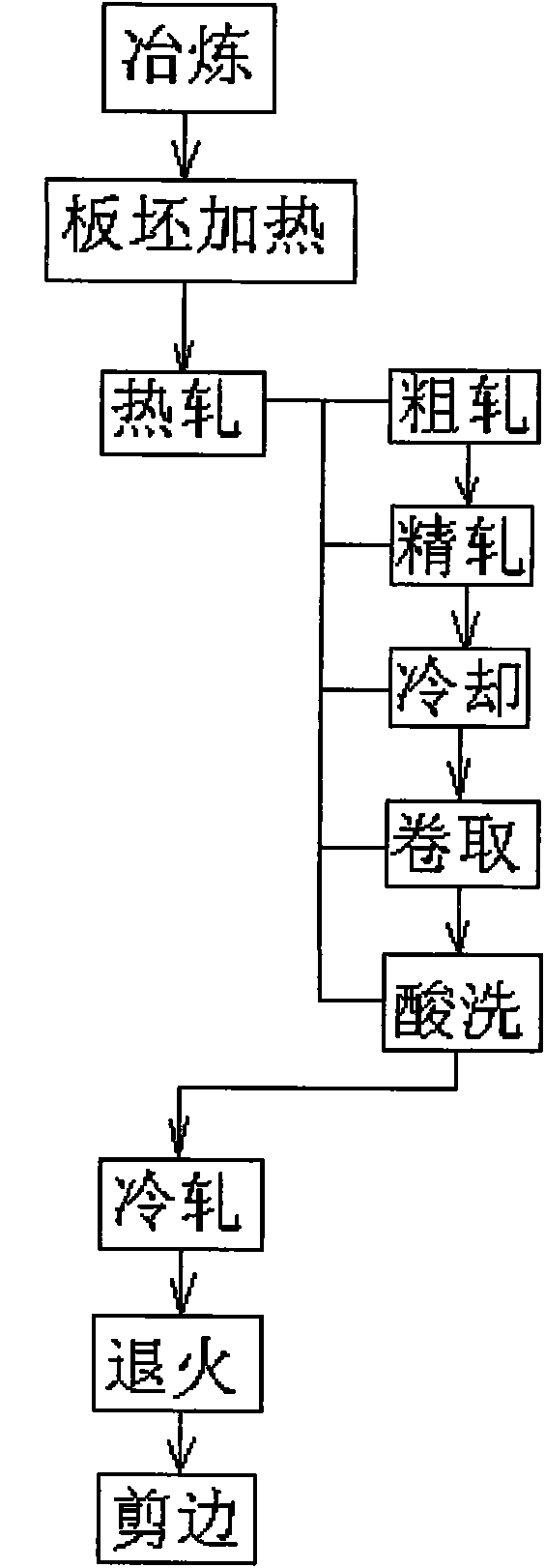

Manufacture method for preventing edge crack generated during low-carbon cold rolling of paper-thin strip steel

InactiveCN101811134AThe chemical composition is simple and easy to controlSimple designTemperature control deviceMetal rolling arrangementsAcid washingStrip steel

The invention relates to a manufacture method for preventing edge crack generated during low-carbon cold rolling of paper-thin strip steel, which sequentially comprises the steps: melting, plate blank heating, coarse milling, fine milling, cooling, coiling, acid washing, cold rolling, annealing and finishing and edge cutting, wherein the edge is not cut during steel coil acid washing, and the circular arc-shaped edge is maintained when the steel enters the cold rolling work procedure after the acid washing. The same plate temperature different in the plate blanking heating is lower than or equal to 40 DEG C, and the side pressure amount of the coarse milling is smaller than or equal to 50 mm. The final rolling temperature of the fine rolling is between 880 and 920 DEG C, an auxiliary vertical roller F1E of a machine frame F1 has the side pressure amount of 3 to 10 mm. The cooling is the laminar cooling of fast front section cooling with the cooling speed between 15 and 30 DEG C / s. The coiling temperature is between 650 and 710 DEG C. The single-edge cutting amount during the edge cutting is controlled between 5 and 7 mm, and the double-edge cutting amount is controlled between 10 and 14 mm. The thickness of cold rolling finished products of strip steel is between 0.15 and 0.45 mm, and the pressing rate is between 87.1 and 95 percent. The invention can solve the problem of edge crack of the paper-thin strip steel in the prior art.

Owner:NINGBO IRON & STEEL

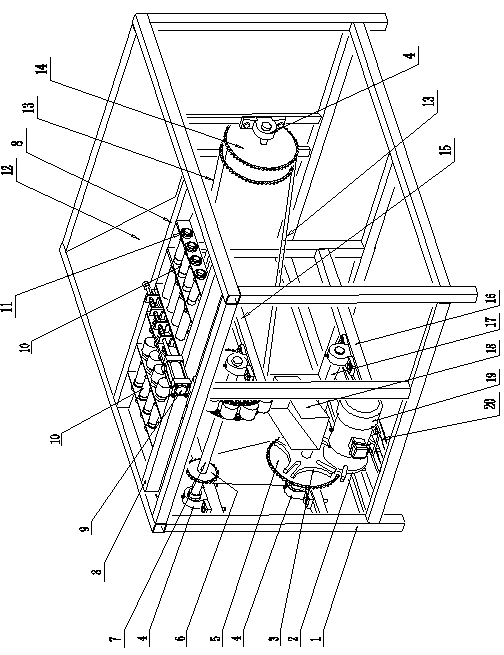

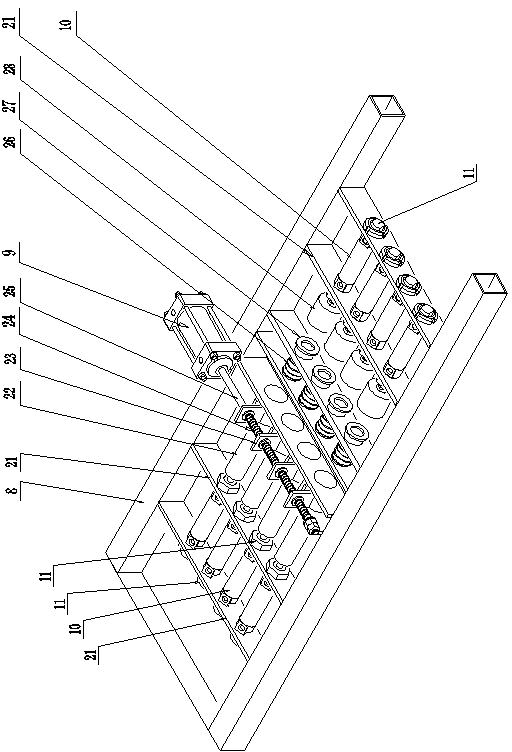

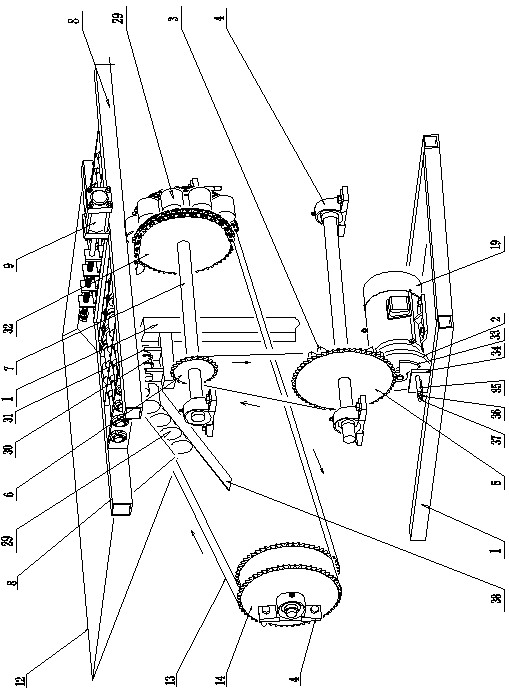

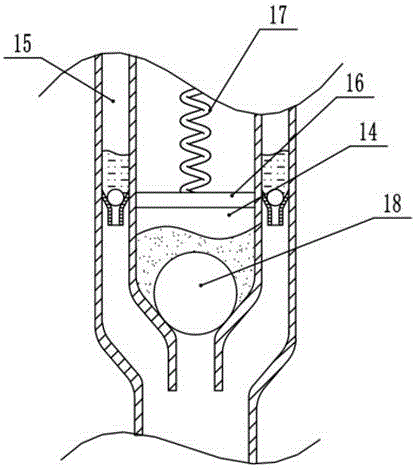

Pneumatic walnut hull breaking machine

The invention provides a pneumatic walnut hull breaking machine and belongs to the field of forest fruits. The pneumatic walnut hull breaking machine consists of a machine frame, a transmission control device, a feeding mechanism and a hull breaking device. The hull breaking device is installed on the machine frame and consists of impact cylinders and holding cylinders which are installed among partition plates of a working rack in a connecting mode. The transmission control device is installed under the front portion of the machine frame and consists of an electric motor, a poking wheel, a control cam, a driving chain wheel, a grooved wheel, side-by-side front end chain wheels, a driven chain wheel, side-by-side back end chain wheels, a clamping switch, a holding switch and a strike switch, wherein the poking wheel, the control cam and the electric motor are sleeved coaxially, the driving chain wheel and the grooved wheel are sleeved on a lower shaft, the side-by-side front end chain wheels and the driven chain wheel are sleeved on an upper shaft, the side-by-side back end chain wheels are installed at the back portion of the machine frame, and the clamping switch, the holding switch and the strike switch are installed at the lower portion of the machine frame at intervals. The driving wheel, the driven wheel, the front end chain wheels and the back end chain wheels are respectively linked through chains, a material box is installed at the back portion of the working rack, a slot is arranged on one wall of the box, and the feeding mechanism is arranged under the position tightly close to the slot and consists of the side-by-side chains, rotary rollers installed on the chains at intervals in a connecting mode, rolling plate supporting the rotary rollers and tensioning chain wheels. The pneumatic walnut hull breaking machine is strong in adaptability on walnut types, complete in walnut hull separation, few in broken walnut nuts and high in hull breaking efficiency.

Owner:XINJIANG AGRI UNIV

Forged iron head and golf club having the same

InactiveUS20090298615A1Easy to hitIncrease flight distanceGolf clubsRacket sportsHeel-and-toeEngineering

The present invention relates to a forged iron head and a golf club having the same. A forged iron head according to the present invention comprises a provisionally-forged member which is shaped like a substantial iron head with an original material; a head is forged the provisionally-forged member as a desired shape and has a face provided a face surface hitting a golf ball, a top and a sole extending to an upper part and a lower part of a rear side of the face, respectively, a heel and a toe disposed between the sole and the top and extending to the rear side of the face, a cavity disposed in the rear side of the face and surrounded by the sole, the top, the heel and the toe and a hosel coupled with a shaft extending from a first side of the face and having a handle part to be gripped by a player; the head comprising a hollow part which has an opening formed from the sole toward a first side of the cavity, further comprising a sole cover which closes the opening. Thus, a lowered centroid may be achieved, and flight distances and direction of a golf ball may improve. Also, credibility of the golf club may improve.

Owner:LIMEGLOBAL

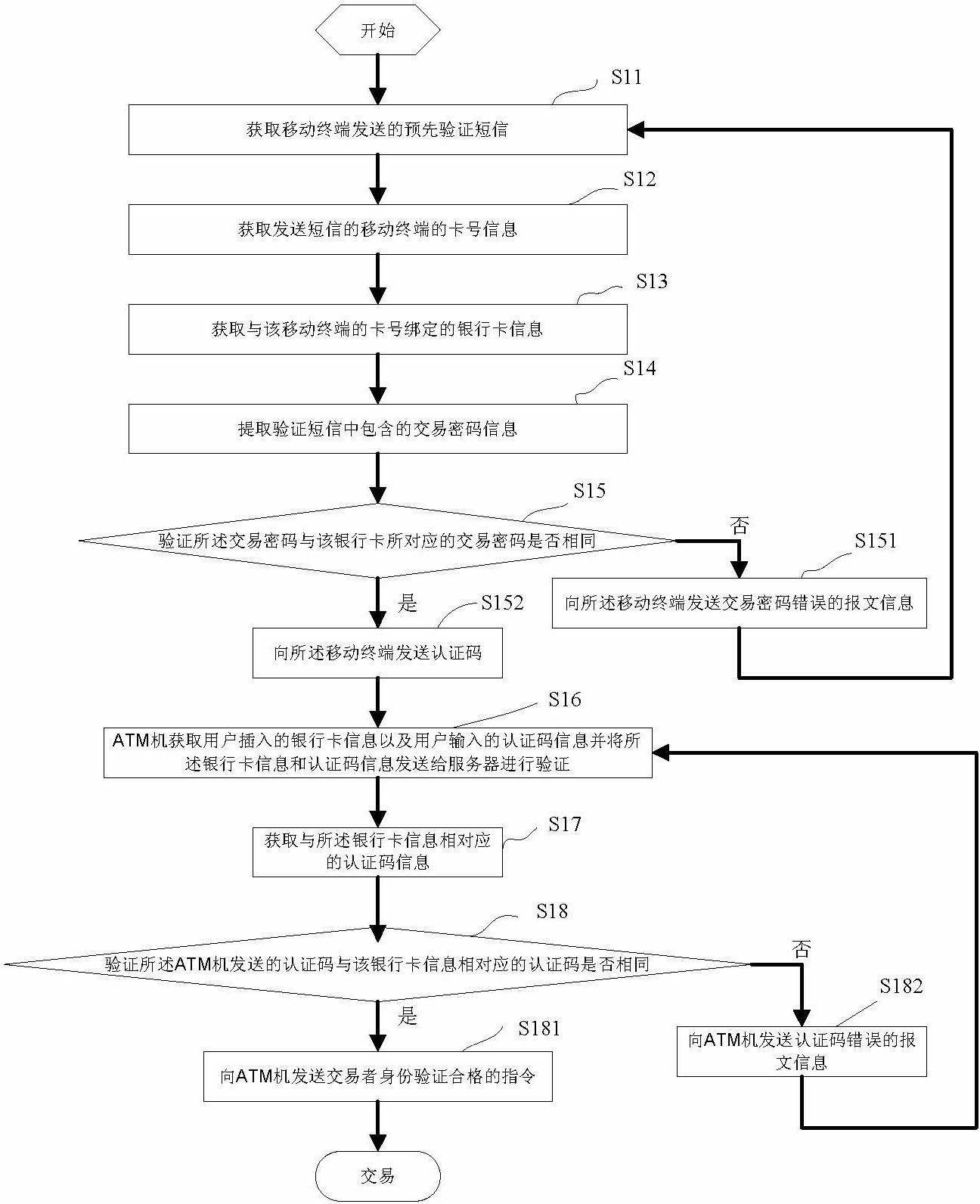

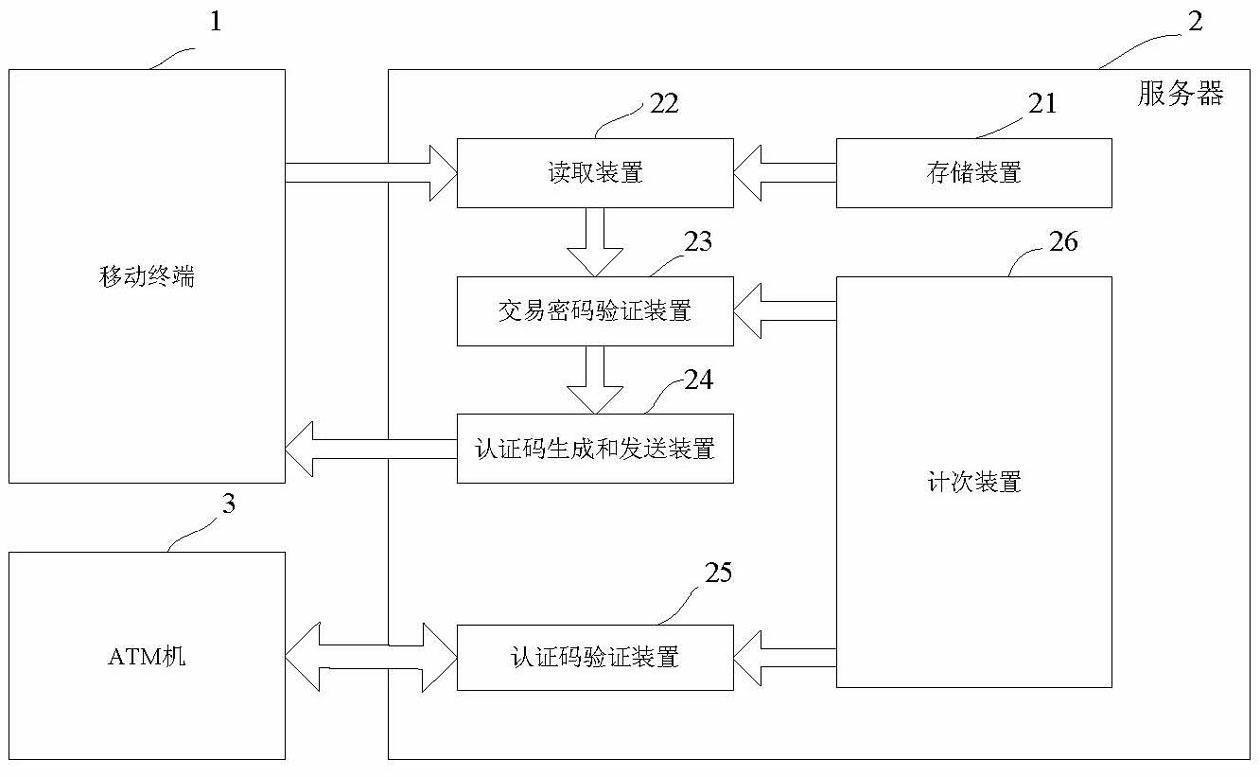

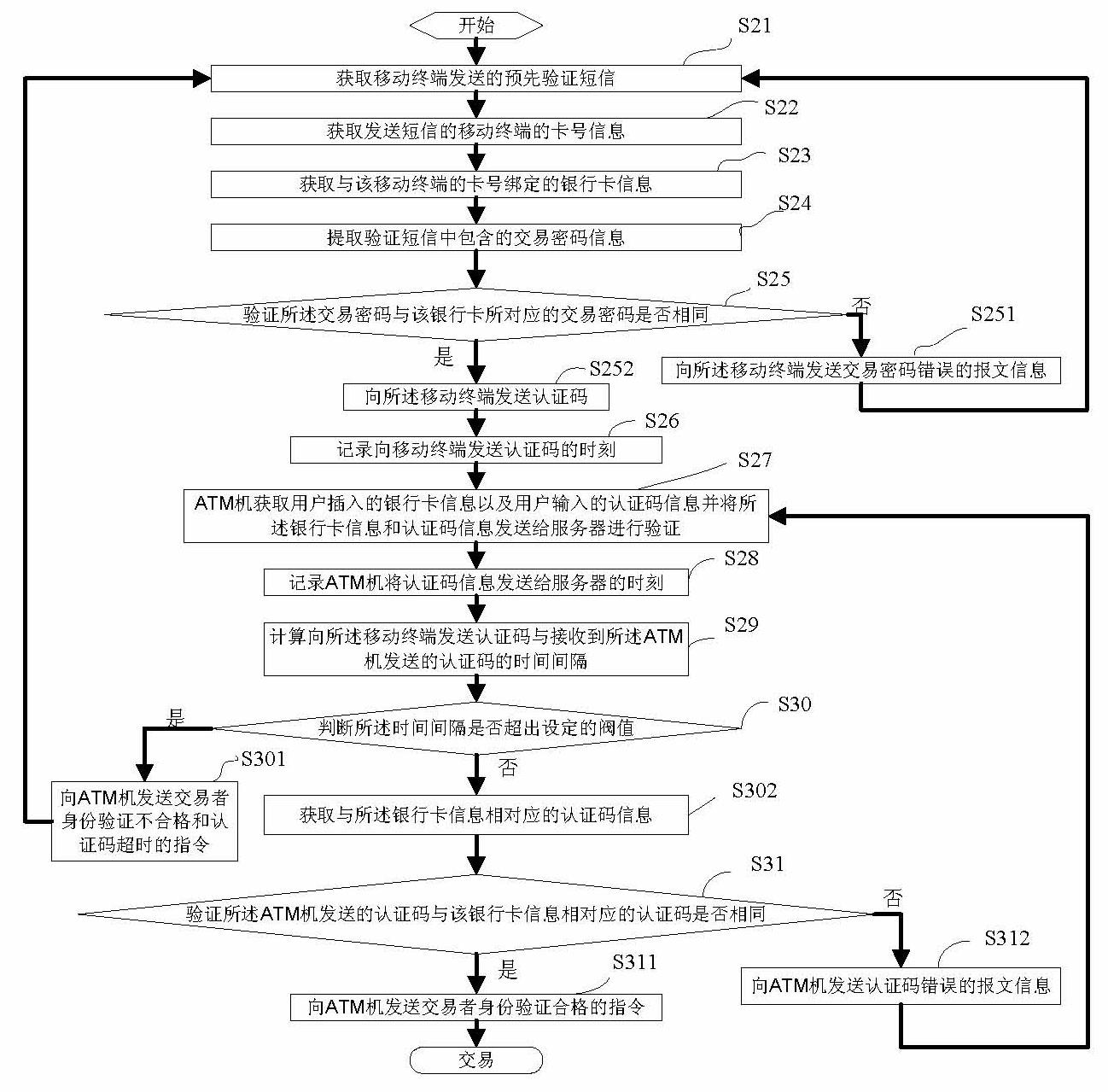

Method and system for verifying trader identity on ATM (Automatic Teller Machine)

InactiveCN102368338AImprove securityNo insecurityAcutation objectsPayment architectureUser inputPassword

The invention belongs to the technical field of financial transaction security and relates to a method and system for verifying a trader identity on an ATM (Automatic Teller Machine). The method comprises the steps of: acquiring a withdrawing password of a bank card by using a mobile terminal, sending the withdrawing password to a server in a short message manner, sending an authentication code after the withdrawing password is verified to have authenticity by the server, sending the authentication code input by a user to the server for verification by the ATM, determining whether the authentication code input by the user is identical to the authentication code sent by the server to the mobile terminal or not, if so, judging that the authentication code is correct and verifying the information of the bank card inserted by the user at the same time, verifying whether the information of the bank card is identical to the information of the bank card bound to an SIM (Subscriber Identity Module) card of the mobile terminal or not, if so, judging the identity of a withdrawer to be legal, and allowing the withdrawer to enter transaction operation of a next step. The method and the system disclosed by the invention have the advantages of high security, simple method, simplicity for user operation, and wide applicable range.

Owner:冯林

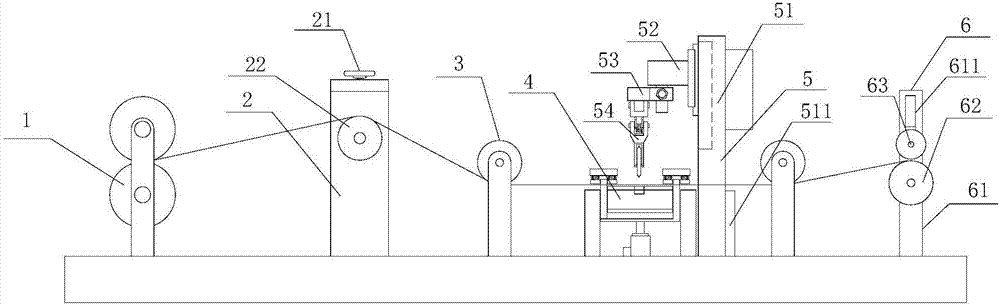

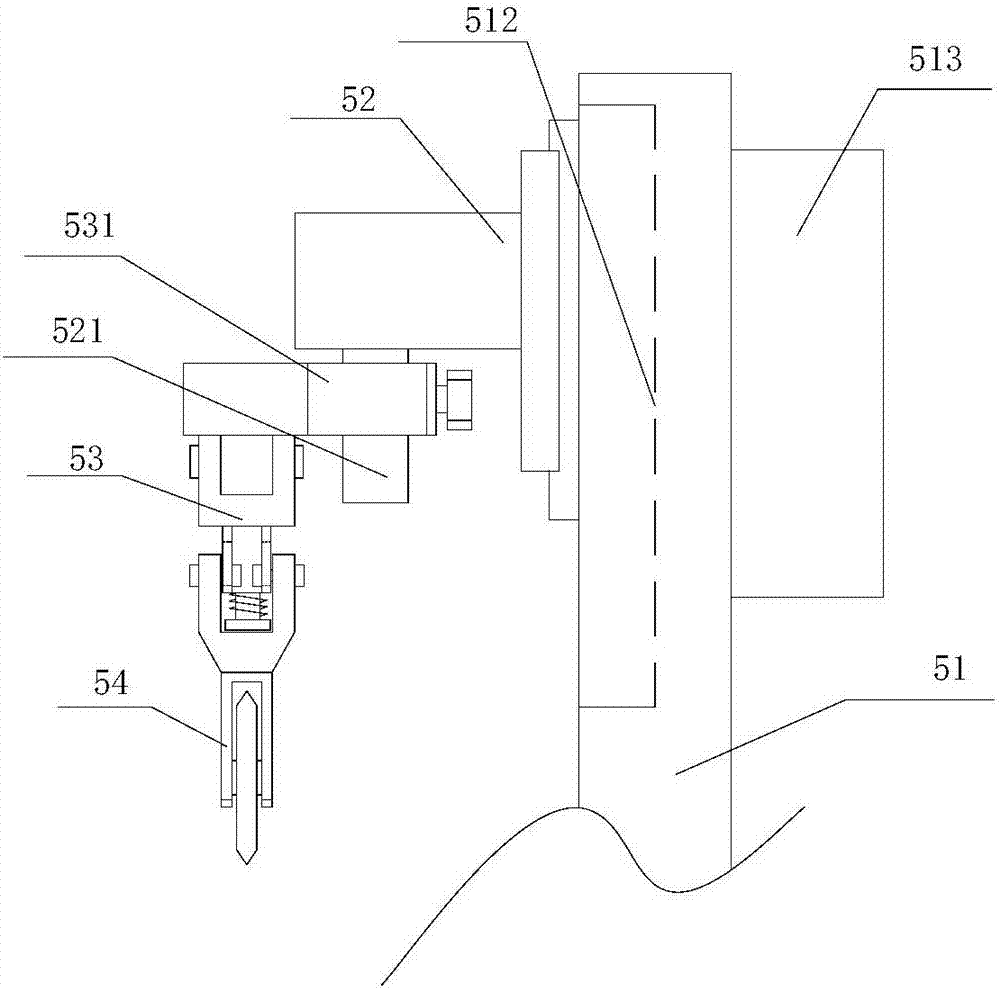

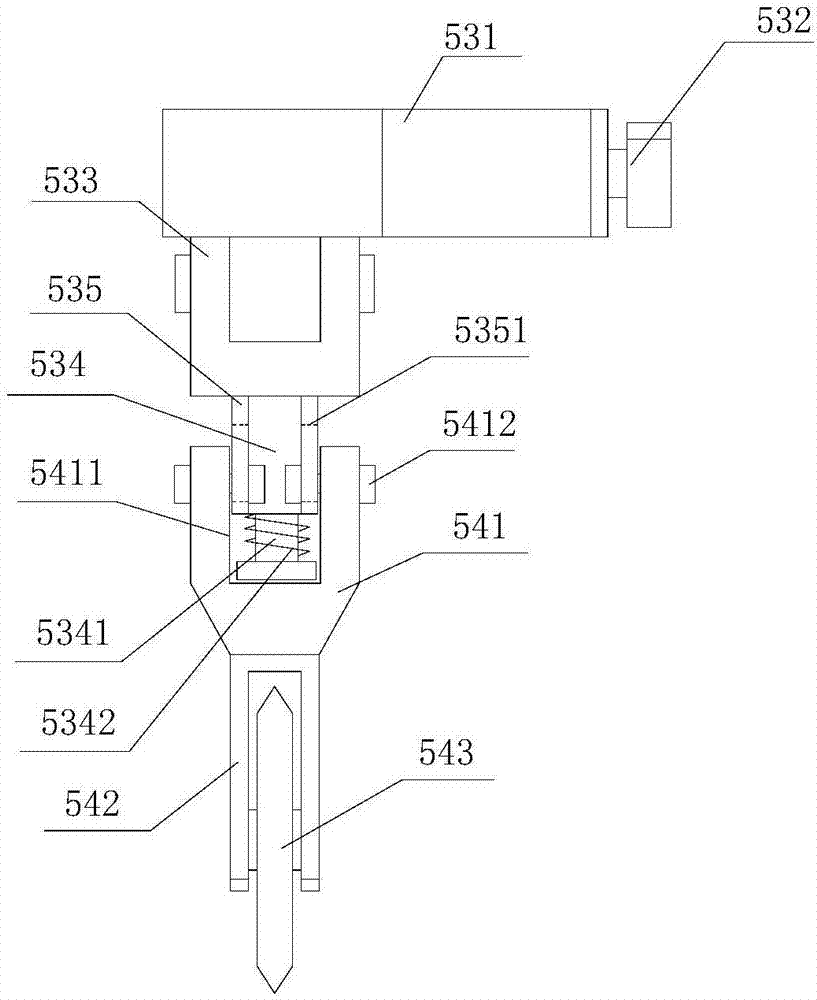

Cloth cutting device

ActiveCN107142704AReduce cloth deformationReduce impactSevering textilesEngineeringMechanical engineering

The invention provides a cloth cutting device comprising a transport roller device, an adjustable guide roller mechanism, an auxiliary roller assembly, a press unit, a cutter and a rolling device; the press unit is provided with a tool rest; two sides of the tool rest are provided with a press mechanism; the cutter is arranged above the press unit; two sides of the cutter are provided with the auxiliary roller assembly; the cutter is provided with a vertical slide seat; a transverse slide seat is arranged on the vertical slide seat; one side of the transverse slide seat is provided with a buffer mounting rack; a cutter assembly is arranged below the buffer mounting rack; the cloth on the transport roller device passes the guide roller assembly, the auxiliary roller assembly, the press unit and the rolling device in sequence along the transport direction; the press unit can press tight the cloth on two sides of the tool rest, thus maximumly reducing the cloth deformation level, and ensuring the cutting process to be stable; the cutter assembly is provided with the buffer mounting rack, thus reducing bumps between the cutter and the tool rest in a cutting process, and reducing the cutter wearing.

Owner:杭州世佳布艺有限公司

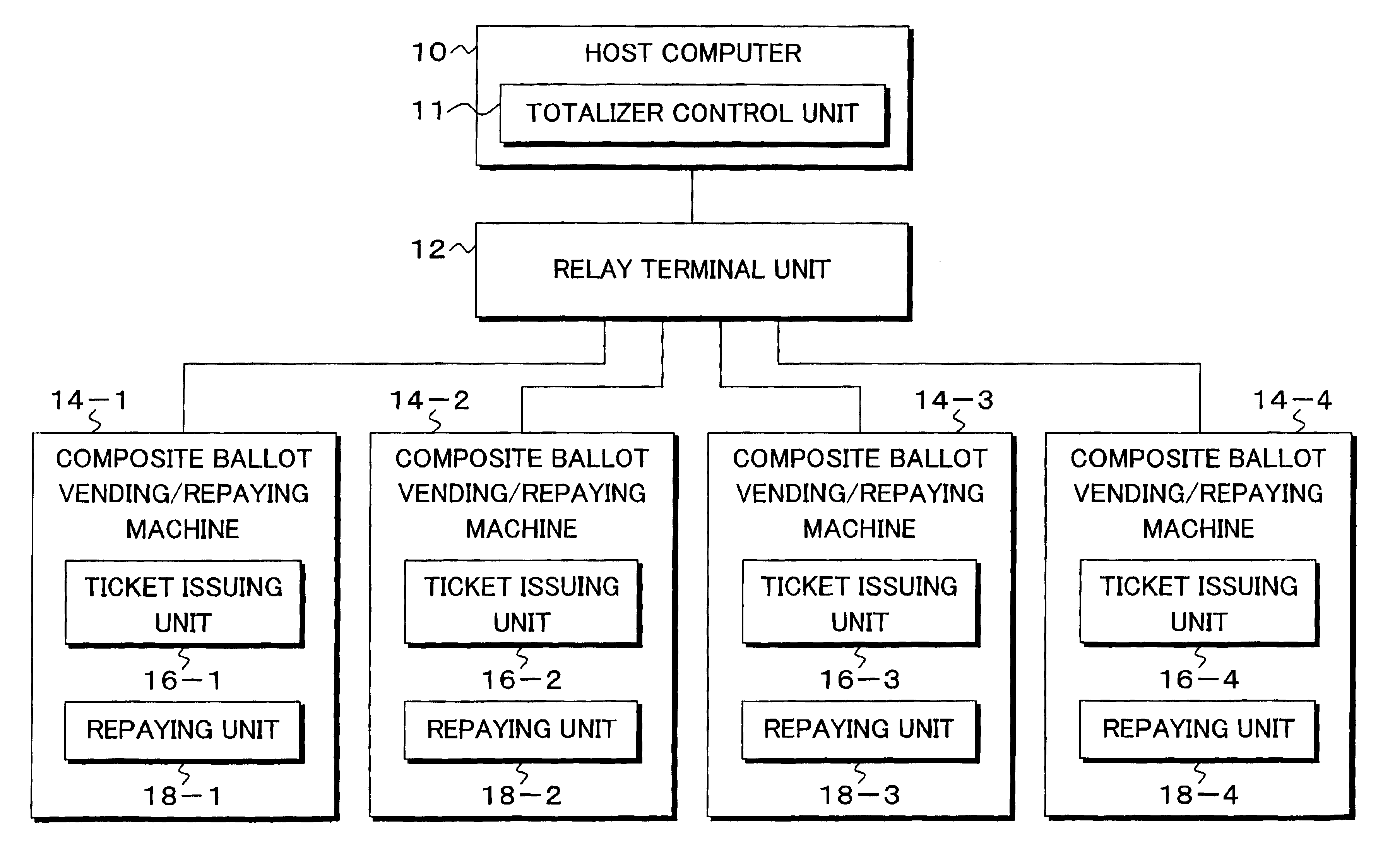

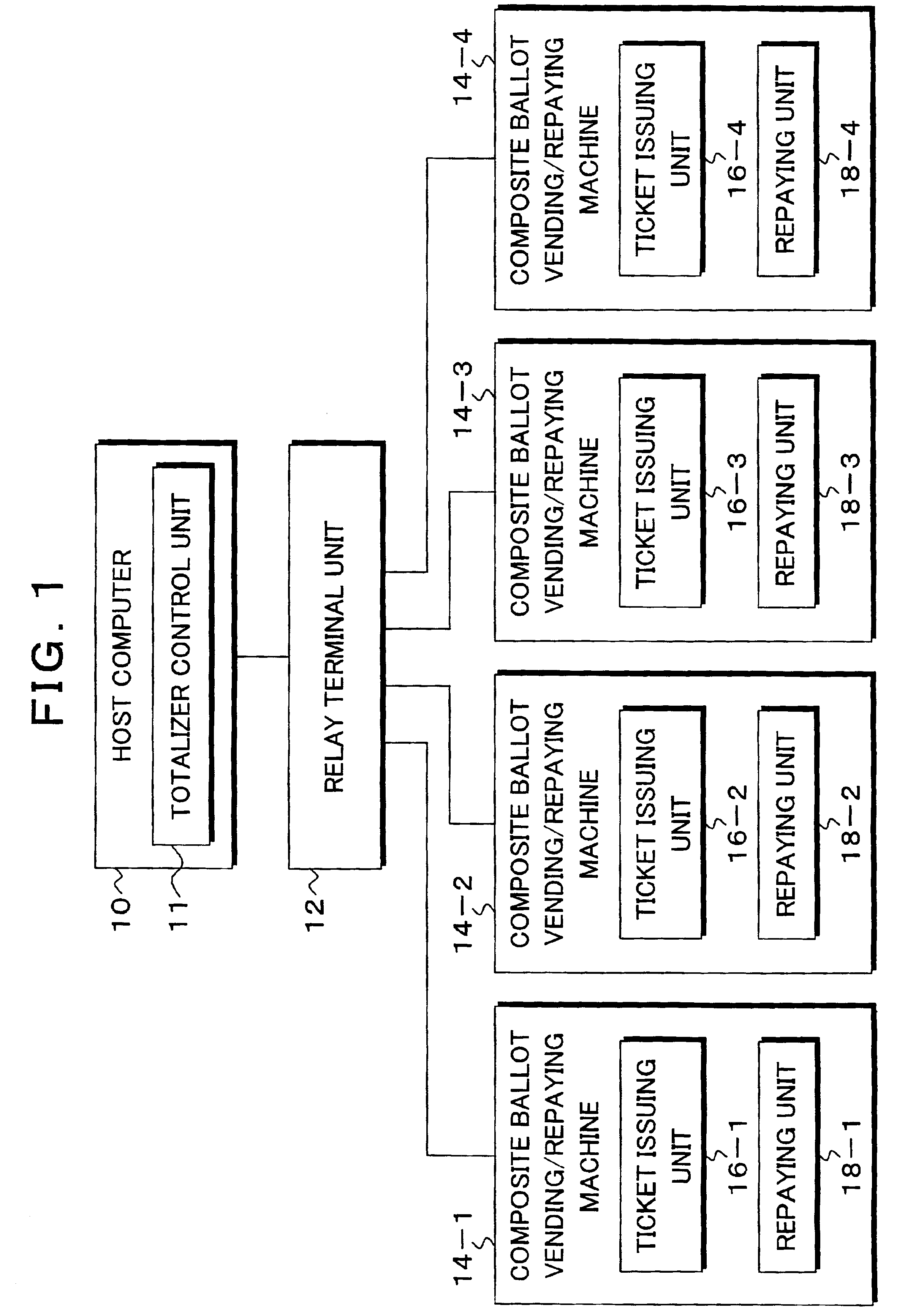

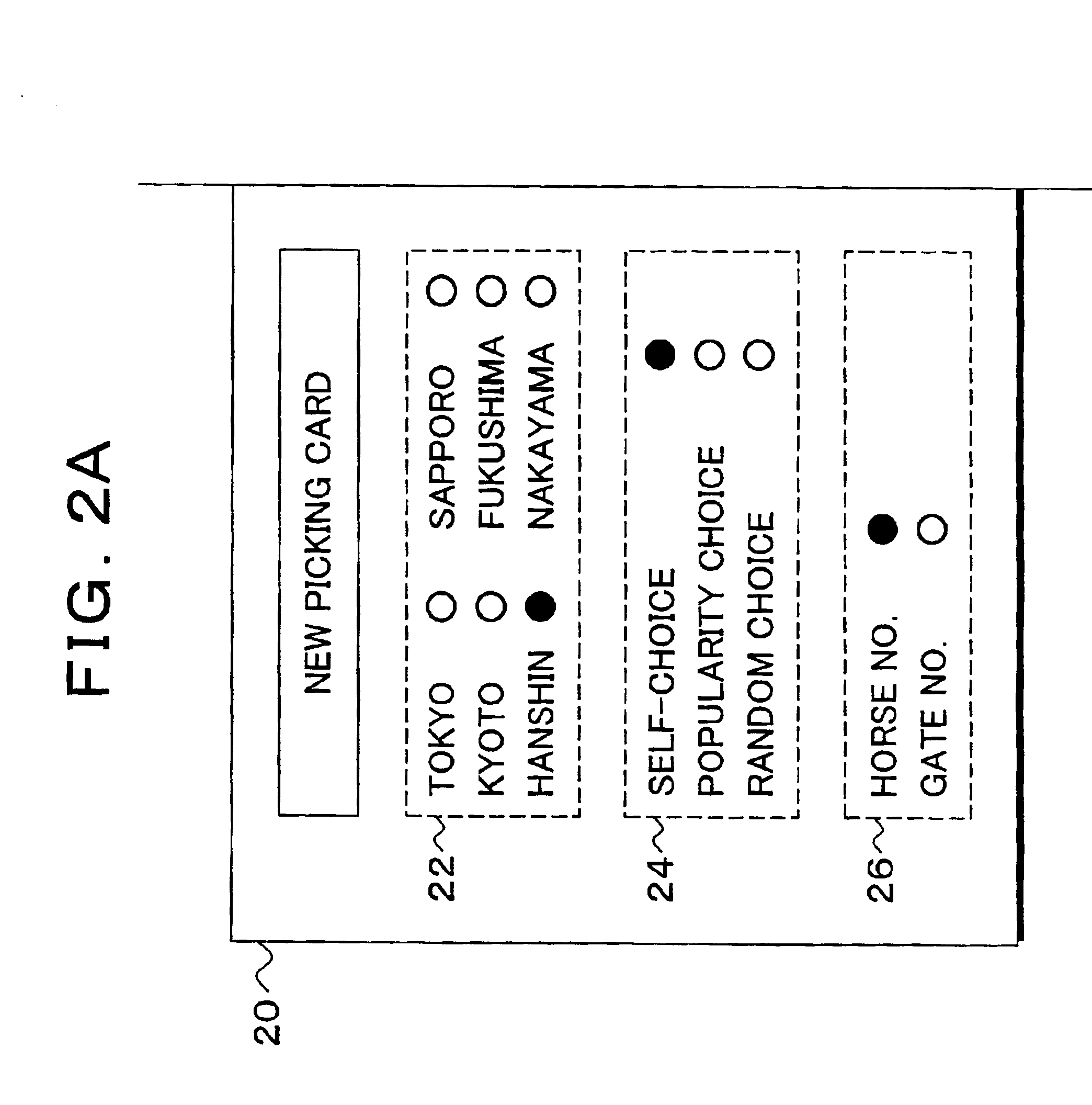

Totalizator terminal, winning horse picking method and program

InactiveUS6875104B2Increase probabilityEasy to hitVoting apparatusData processing applicationsPurchasingComputer science

The totalizator terminal of the present invention comprises a ticket issuing unit which selects an odd or even horse or gate number of a horse expected to be the first for all races, and a repaying unit which determines an amount of repayment for a picking ticket by dividing a total amount of repayment accounting for a prescribed ratio relative to a total amount of purchases by a number of hits. The ticket issuing unit vends picking tickets by recognizing the result of selection of the odd or even horse or gate number of the horse expected to be the first as specified by a purchaser for races 1 to 12. The ticket issuing unit can also vend picking tickets by automatically selecting the most popular horse upon purchasing or at random an odd or even horse or gate number.

Owner:FUJITSU LTD

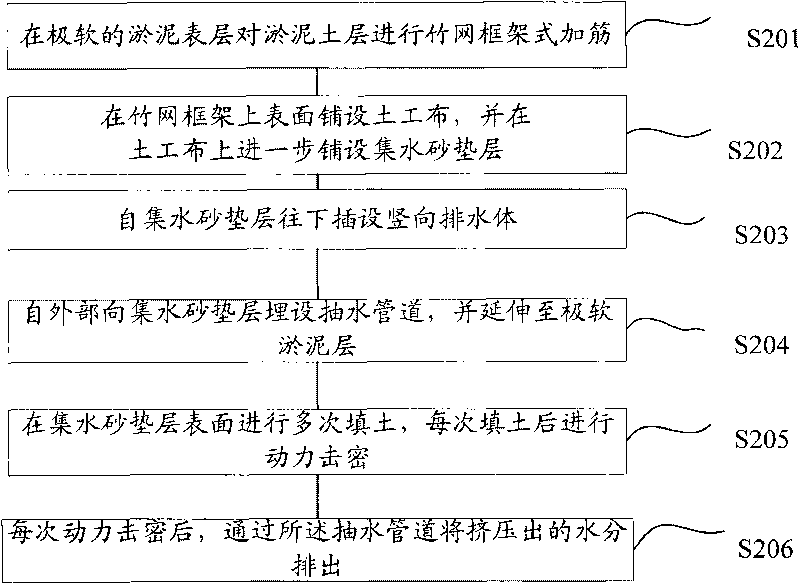

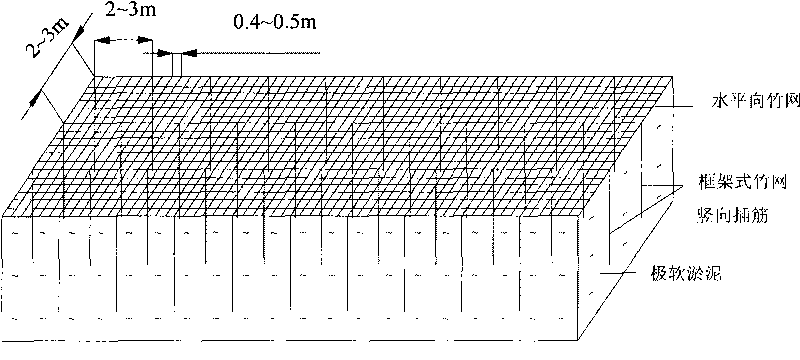

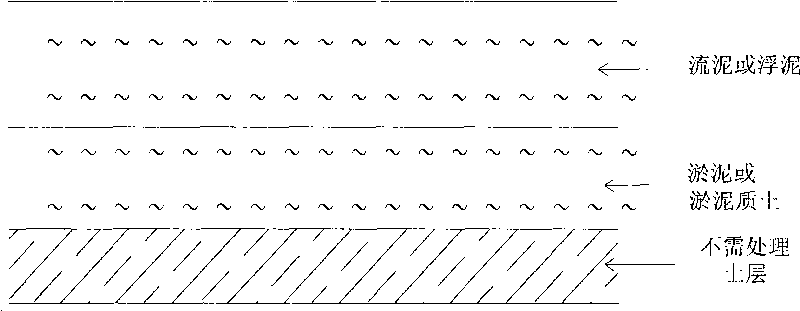

Quick strengthening method of extremely soft sludge

InactiveCN101736734AEasy to hitShorten the reinforcement periodSoil preservationSurface layerDynamic compaction

The invention discloses a quick strengthening method of extremely soft sludge. The method lays out an area of a to-be-constructed site firstly according to a project plan and comprises the following steps: (1), carrying out bamboo web frame-type reinforcement on a sludge soil layer on an extremely soft sludge surface layer; (2), laying geotextile on the upper surface of a bamboo web frame and further laying a water-collecting sand bed on the geotextile; (3), inserting a vertical water drain body downwards from the water-collecting sand bed; (4), burying a water-pumping pipeline from the outside to the water-collecting sand bed and extending the pipeline to an extremely soft sludge layer; (5), filling soil on the surface of the water-collecting sand bed time after time and carrying out dynamic compaction after filling soil every time; and (6), discharging extruded water through the water-pumping pipeline after finishing dynamic compaction every time, and quickly dissipating excess pore pressure of sludge soil caused by soil filling load and dynamic compaction load. Compared with the conventional methods, the quick strengthening method can greatly shorten a construction period and also reduce construction cost.

Owner:郭艳景 +1

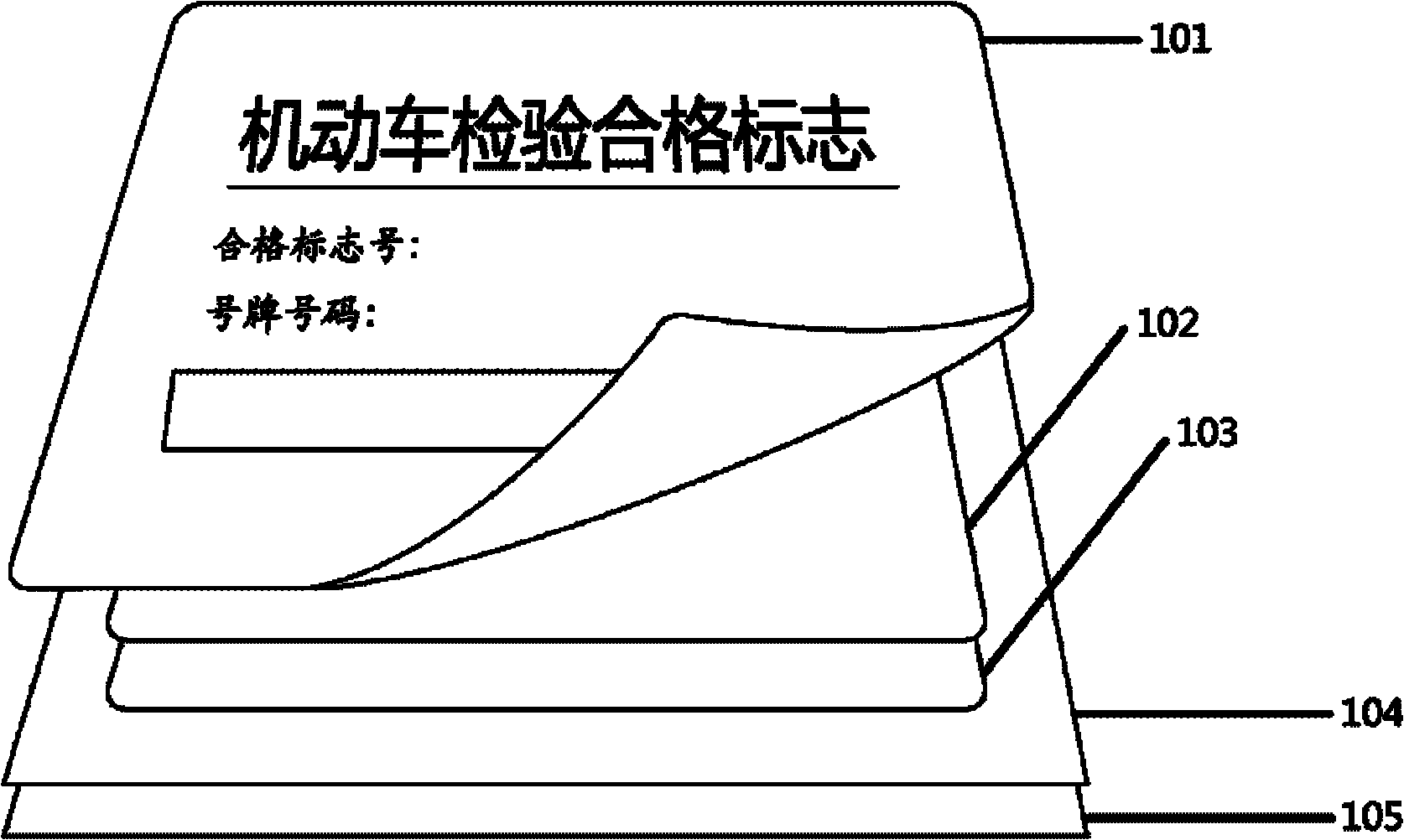

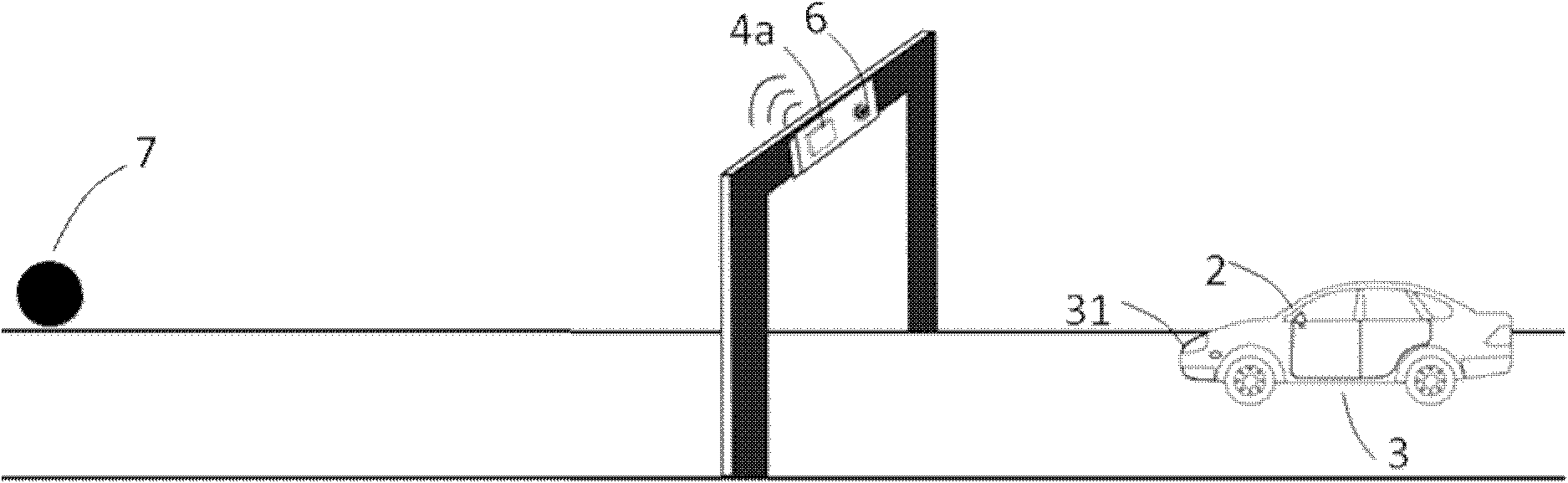

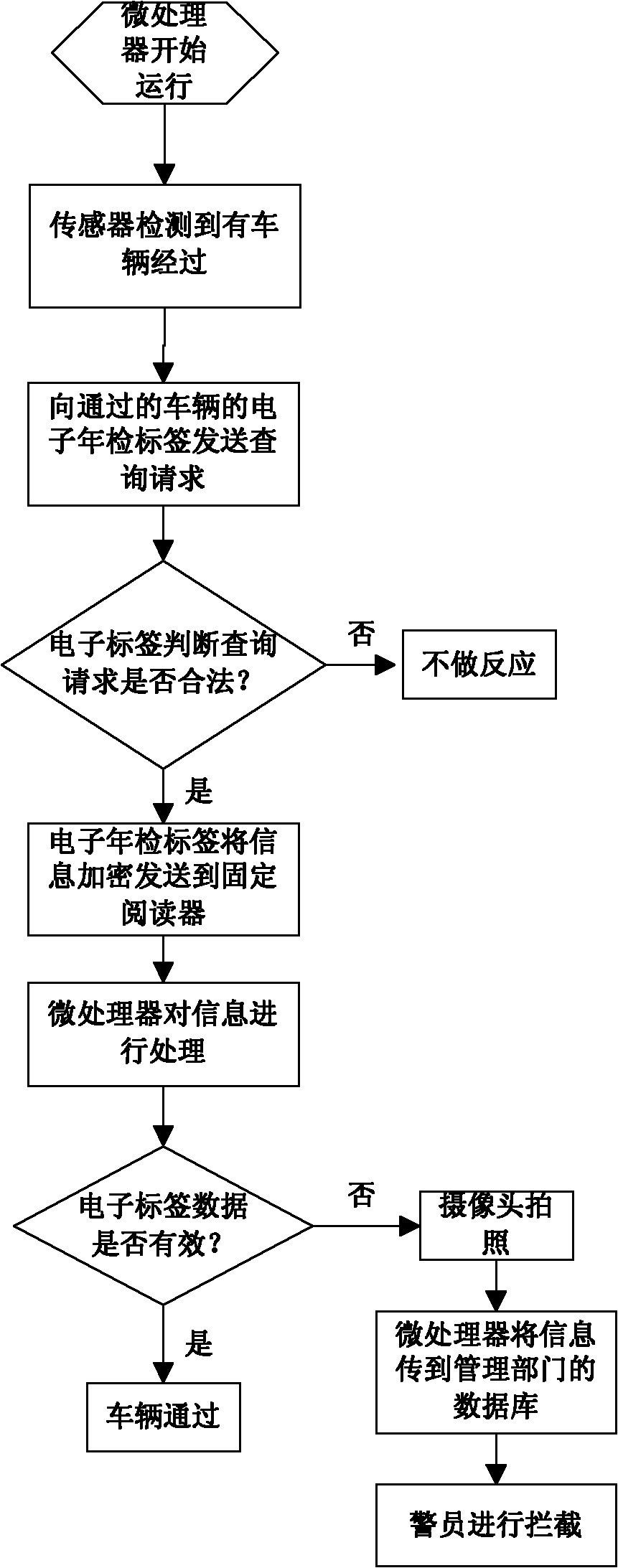

Vehicle checking method based on thin paper electronic AS (annual survey) tag

ActiveCN102254435AEasy to judge accuratelyReduce labor intensityRoad vehicles traffic controlCo-operative working arrangementsEmbedded systemInertia

The invention discloses a vehicle checking method based on thin paper electronic AS (annual survey) tag. The method comprises the following steps that: firstly, a vehicle management department writes the AS (annual survey) information of a vehicle into a thin paper electronic AS tag in a read-only form, and the owner of the vehicle adheres the tag to the corresponding position of the vehicle; then, according to different checking modes adopted by traffic policemen, different checking devices are adopted, the information in the electronic AS tag is read by a reader in the device; and finally, a system carries out automatic determination, validation or comparison on the identification situations and identification information in various modes, and judges whether the vehicle can pass the vehicle checking according to the obtained comparison result. In the method, through taking the paper electronic AS tag as a core carrier, under the condition of not changing the appearance, shape and management method of the existing AS tag, the effect of comprehensive net-falling, key striking and association of activity and inertia is achieved by using different checking methods, thereby not only improving the efficiency, but also enhancing the police mobility and broadening the scope of inspection, so that the vehicle checking is more hidden and flexible.

Owner:GUANGZHOU HUABIAO SCIENCEAND TECH DEV CO LTD

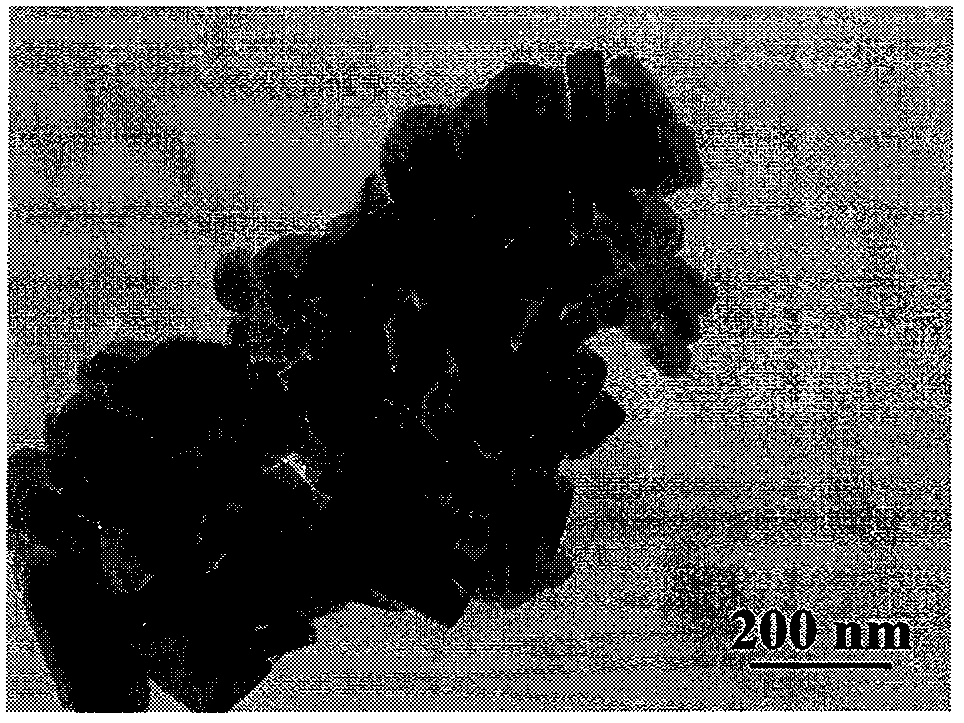

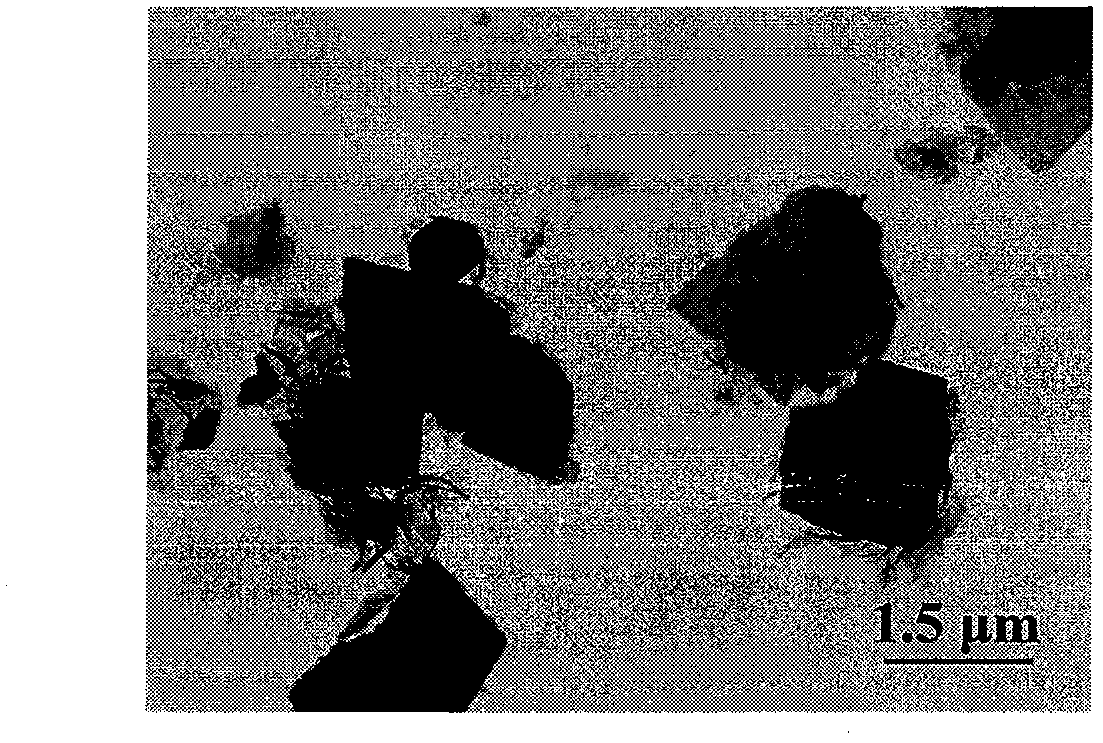

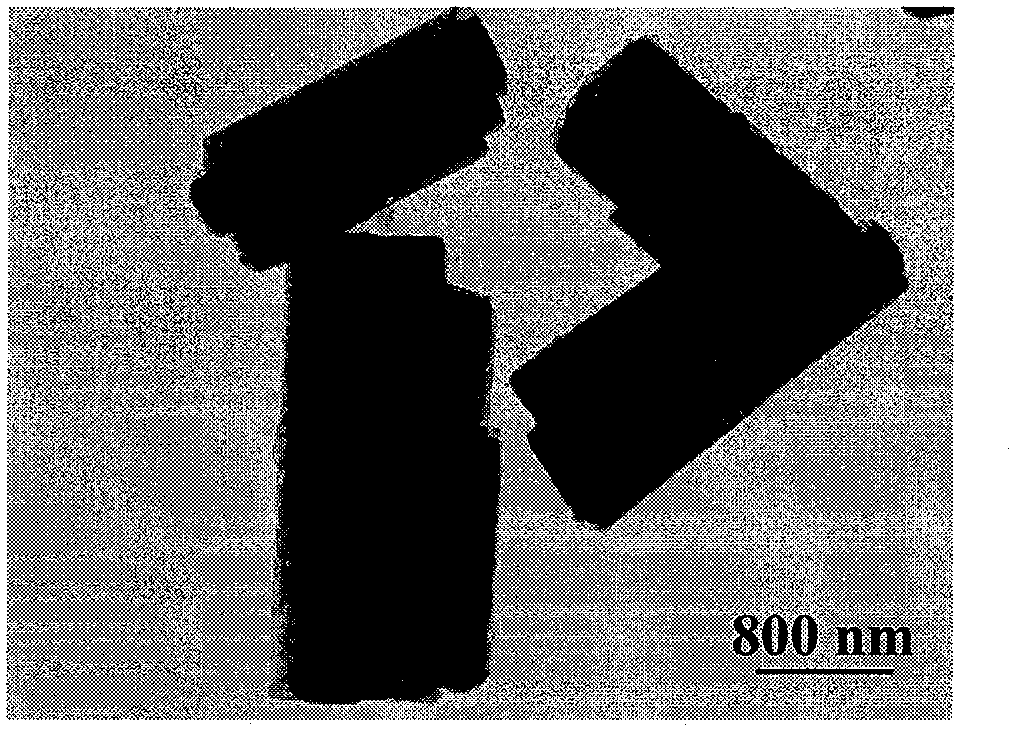

Efficient zinc phosphate micro-nano anticorrosion agent preparation method

InactiveCN103896235AUniform sizeGood dispersionMaterial nanotechnologyAnti-corrosive paintsWater bathsMicro nano

The invention belongs to the field of inorganic chemistry, and particularly relates to an efficient zinc phosphate micro-nano anticorrosion agent preparation method, wherein the product is applied in the field of metal heavy corrosion. According to the present invention, a cycle ultrasonic cavitation effect and a high-temperature high-pressure water bath thermal effect are adopted to perform synchronous and synergetic regulation to prepare the efficient zinc phosphate micro-nano anticorrosion agent, wherein the synchronous and synergetic effect of the two effects is adopted so as to make the product system be well dispersed, ensure the uniformity of crystal nucleation and effectively solve the difficult problem of difficult synchronous regulation on the particle size and the crystallization degree of the nanometer crystal, and a microwave heating mode is adopted to dry the product so as to reduce the agglomeration; the prepared micro-nano zinc phosphate product has advantages of high purity, complete crystallinity, narrow particle size distribution, good dispersion and the like, wherein the effective corrosion protection time of the zinc phosphate micro-nano anticorrosion agent is up to 1056 h and is far superior to the effective corrosion protection time of the commercially available zinc phosphate anticorrosion material; and the method has characteristics of simple process and low cost, and is suitable for large-scale production.

Owner:EAST CHINA UNIV OF SCI & TECH

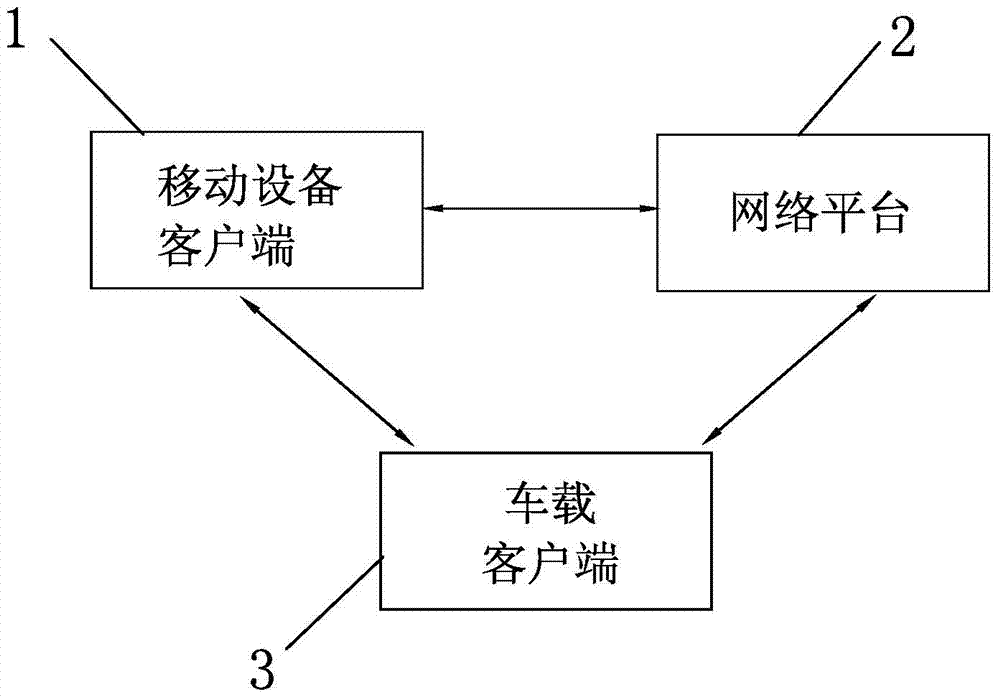

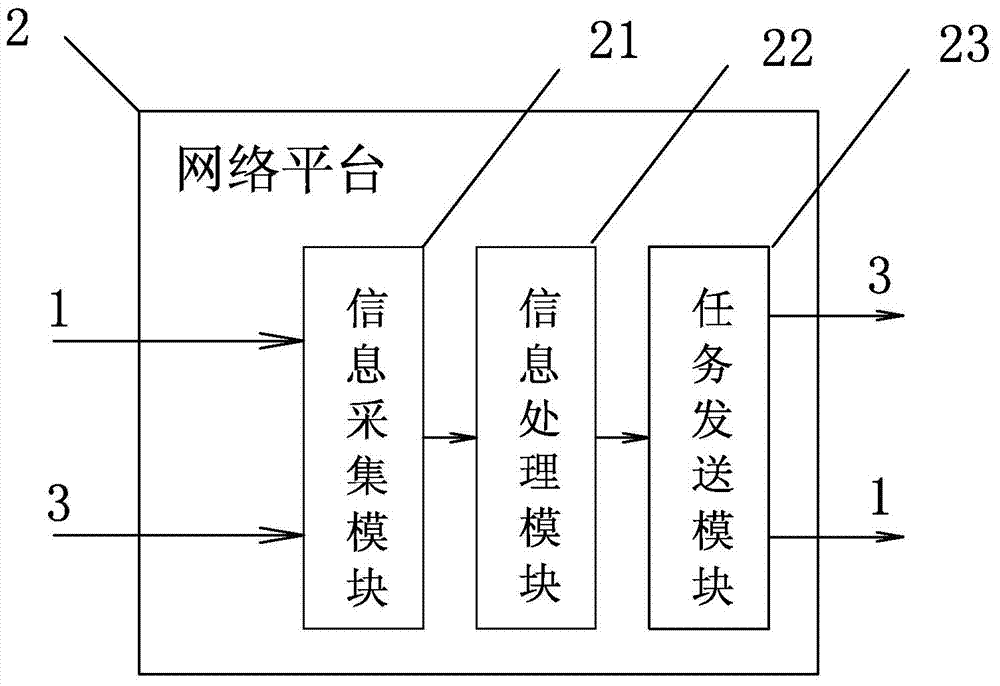

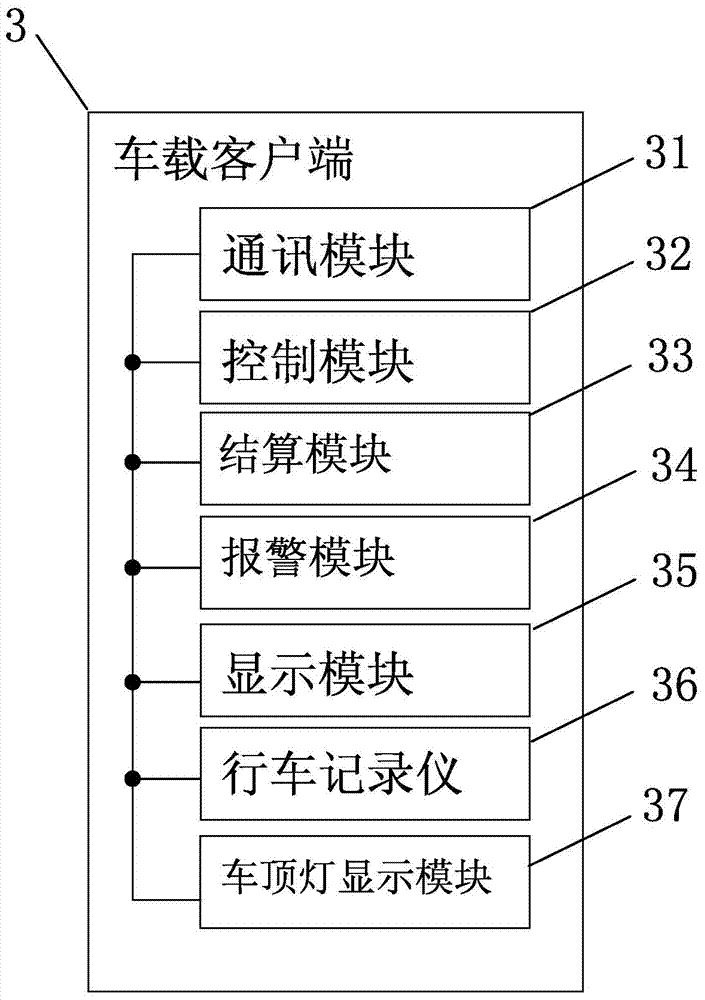

Taxi calling management settlement system and method

InactiveCN104123834AEasy to manageEasy to recordRoad vehicles traffic controlTransmissionPasswordComputer module

The invention discloses a taxi calling management settlement system which comprises a mobile device client, a network platform and a vehicle-mounted client. The network platform is connected with the mobile device client and the vehicle-mounted client through a communication network or a computer network. The mobile device client transmits a taxi calling request to a taxi calling server. The network platform transmits a car distributing command to taxis meeting the condition. The vehicle-mounted client comprises a communication module, a control module, a settlement module and an alarm module. The settlement module comprises a bank card settlement unit and a password and fingerprint input unit. A taxi calling management settlement method is further provided. The system and method integrates taxi calling, taxi distributing, security check, alarming and settlement process, greatly facilitates quick and safe trip of passengers, has good humanized management on the taxis and overcomes the shortcomings in the prior art in the field.

Owner:北京艾亿沃德电子有限公司 +1

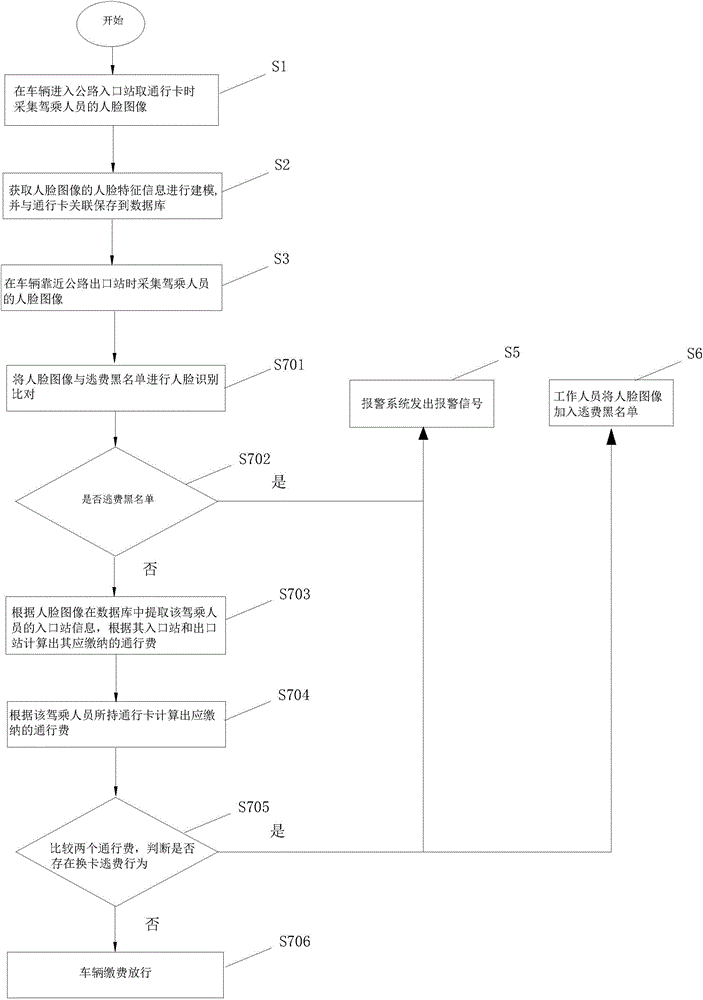

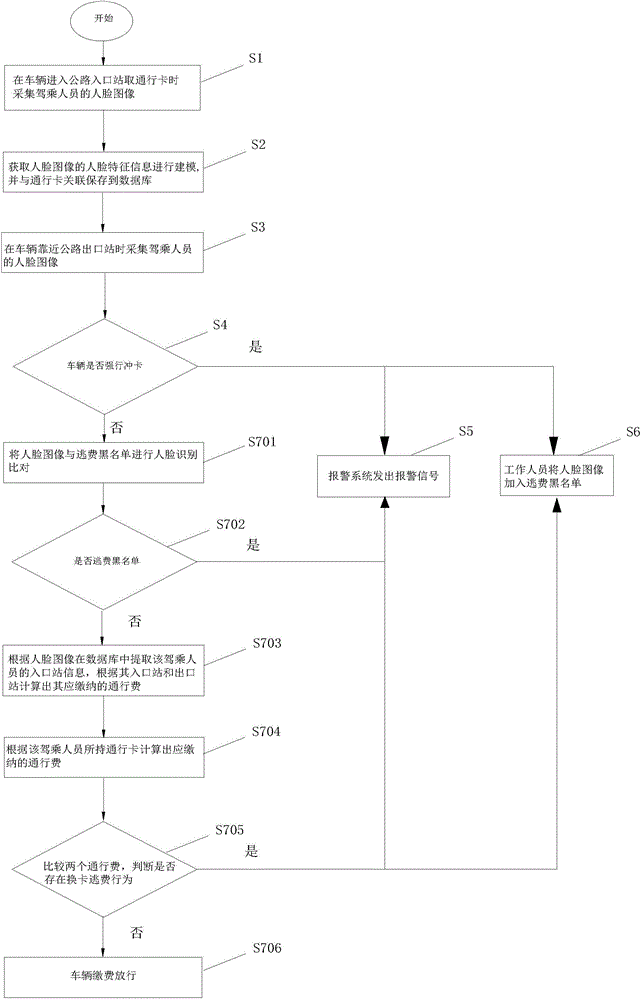

Method for preventing fee evasion on highways on basis of face recognition technologies

ActiveCN104574547AStrengthen rectificationEnsure traffic orderTicket-issuing apparatusCharacter and pattern recognitionArtificial intelligenceRoad traffic

The invention relates to the field of security and protection monitoring, in particular to a method for preventing fee evasion on highways on the basis of face recognition technologies. The method includes steps of (a), acquiring face images of drivers and passengers when vehicles run into entrance stations of the highways and access cards are fetched; (b), acquiring face feature information of the face images acquired in the step a, modeling the face feature information, correlating the face feature information with the access cards and storing the face feature information in databases; (c), acquiring face images of the drivers and the passengers when the vehicles are close to exit stations of the highways; (d), comparing and analyzing the face images acquired in the step c and the information in the databases and correspondingly processing the face images according to comparison results. The method has the advantages that deployment and control can be implemented in advance, the method is favorable for striking traffic illegal activities, regulation on the highlighted traffic illegal activities such as traffic escape and violation checkpoint rushing can be strengthened, transport order of road traffic and the personal and property safety of the public can be guaranteed, and toll loss of the highways can be reduced.

Owner:GUANGDONG POYA INFORMATION & TECHNOLOGY CO LTD

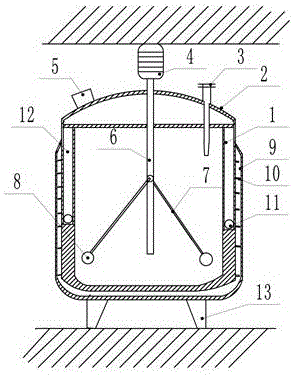

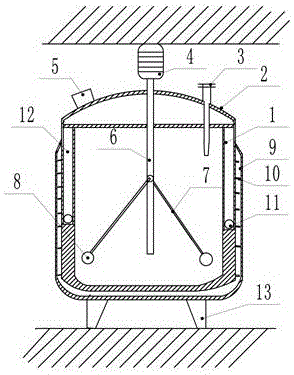

Anti-wall-adhering reaction kettle

ActiveCN106669565AEnhance detackification effectTemperature monitoringRotary stirring mixersTransportation and packagingEngineering

The invention belongs to the field of chemical equipment, and particularly discloses an anti-wall-adhering reaction kettle. The anti-wall-adhering reaction kettle comprises a kettle body, wherein the inner wall of the kettle body is made from a non-ferromagnetic material, and provided with an isolated cavity; a movable block which can be attracted by a magnetic substance is arranged in the isolated cavity; the top end of the kettle cover is provided with a driver which is fixed to the machine frame; the driver is rotatablely connected with a stirring unit positioned in the kettle body; the stirring unit comprises a stirring shaft; a plurality of stirring rods are hinged on the stirring shaft; and the working end of each stirring rod is fixedly provided with a stirring magnetic block. The anti-wall-adhering reaction kettle has the advantages of simple structure, uniform stirring and obvious anti-adhering effect.

Owner:重庆依尔双丰科技有限公司

Submerged arc welding wire for superstrength pipeline steel and production method thereof

InactiveCN102069320AHigh strengthIncrease contentArc welding apparatusWelding/cutting media/materialsSubmerged arc weldingCopper plating

The invention relates to a submerged arc welding wire for superstrength pipeline steel and a production method thereof. The technical scheme is that: the submerged arc welding wire comprises the following components in percentage by weight: 0.04 to 0.06 percent of C, 1.40 to 2.00 percent of Mn, 0.70 to 1.10 percent of Mo, 2.00 to 2.60 percent of Ni, 0.80 to 1.20 percent of Cr, 0.10 to 0.30 percent of Cu, less than or equal to 0.0005 percent of B, less than or equal to 0.01 percent of S, less than or equal to 0.01 percent of P and the balance of Fe and inevitable impurities. The production method comprises the following steps of: adding 0.01 to 0.5 weight percent of composite additive when the components are smelted, forming a square billet in a pouring way, hot-rolling the square billet to form a steel wire rod with the diameter of Phi 5.5 to Phi 7.5mm, removing oxide skin from a surface, drawing the steel wire rod to form the welding wire with the diameter of Phi 3.2 to Phi 4.0mm and performing copper plating, wherein the composite additive is added in form of cored wire. The welding wire produced by the method is welded together with an SJ105 welding flux so as to achieve the tensile strength sigmab of more than or equal to 910MPa and the impact toughness Akv at -30 DEG C of more than or equal to 84J of a weld metal, and is suitable for the submerged arc welding of X120 pipeline steel with superstrength.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com