Apparatus and system to drill a bore using a laser

a laser and laser technology, applied in the direction of drilling pipes, directional drilling, borehole/well accessories, etc., can solve the problems of affecting drilling performance, and achieve the effect of extending the bore section, facilitating the unimpeded impingement of laser light, and reducing drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

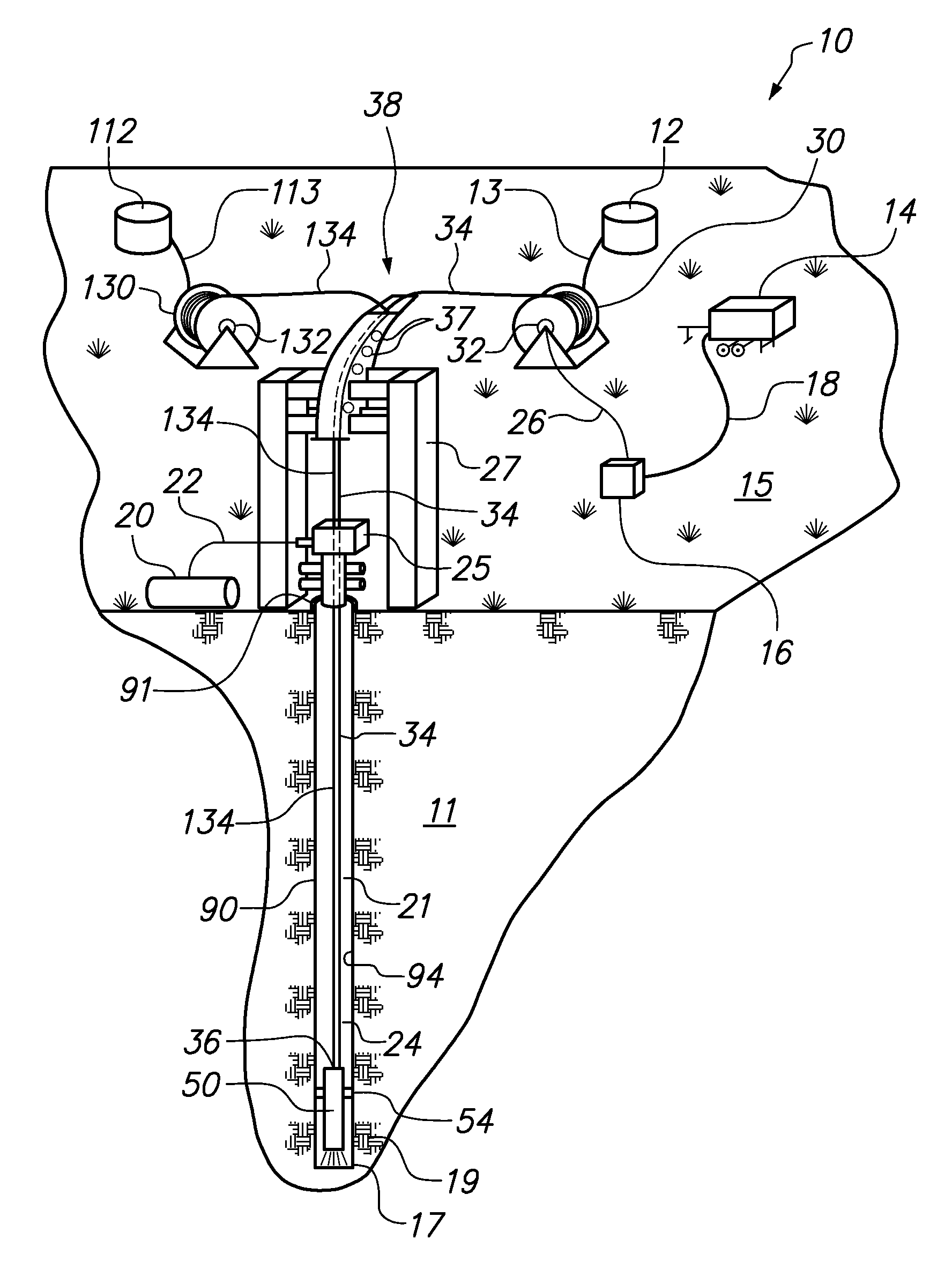

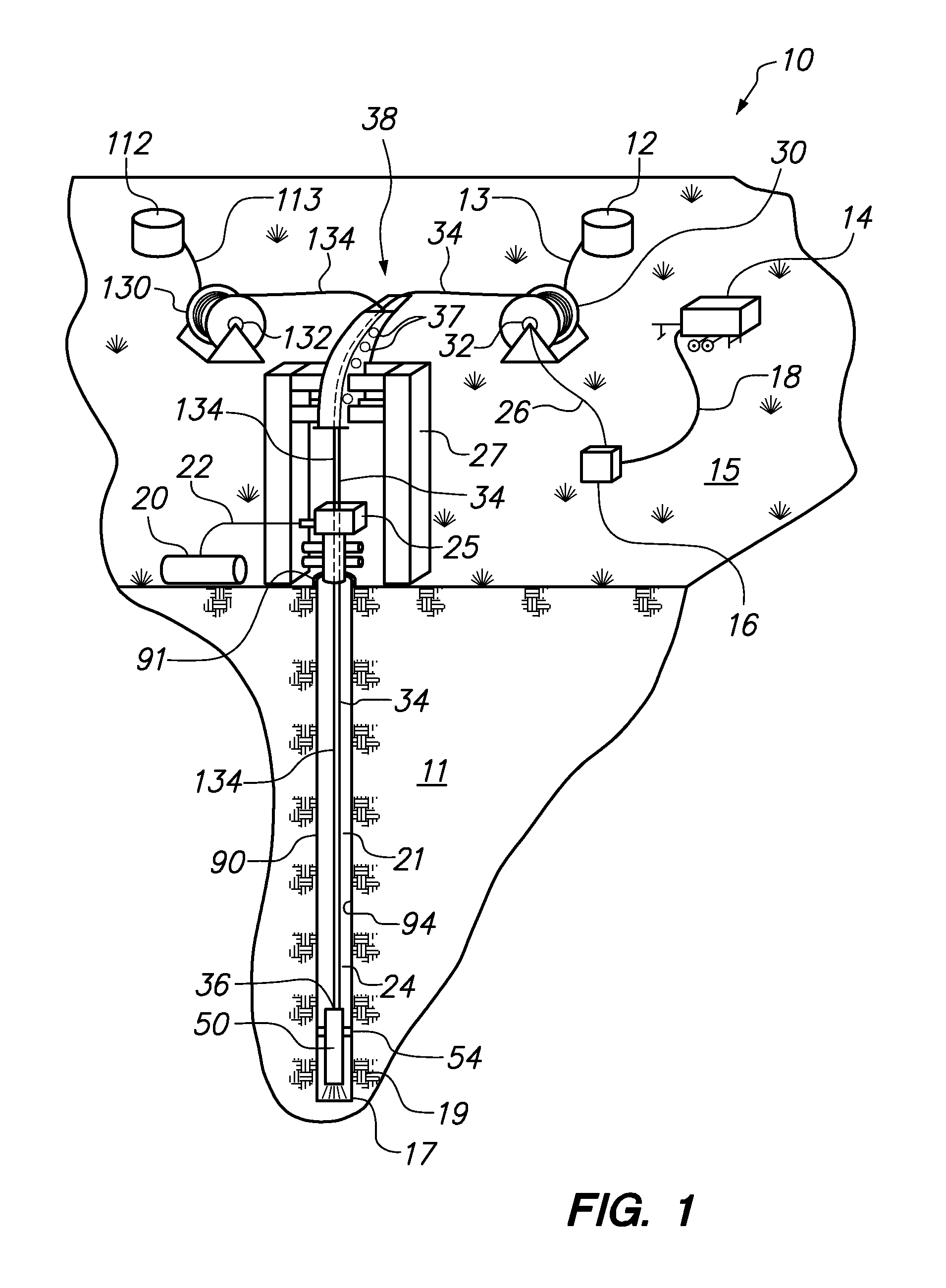

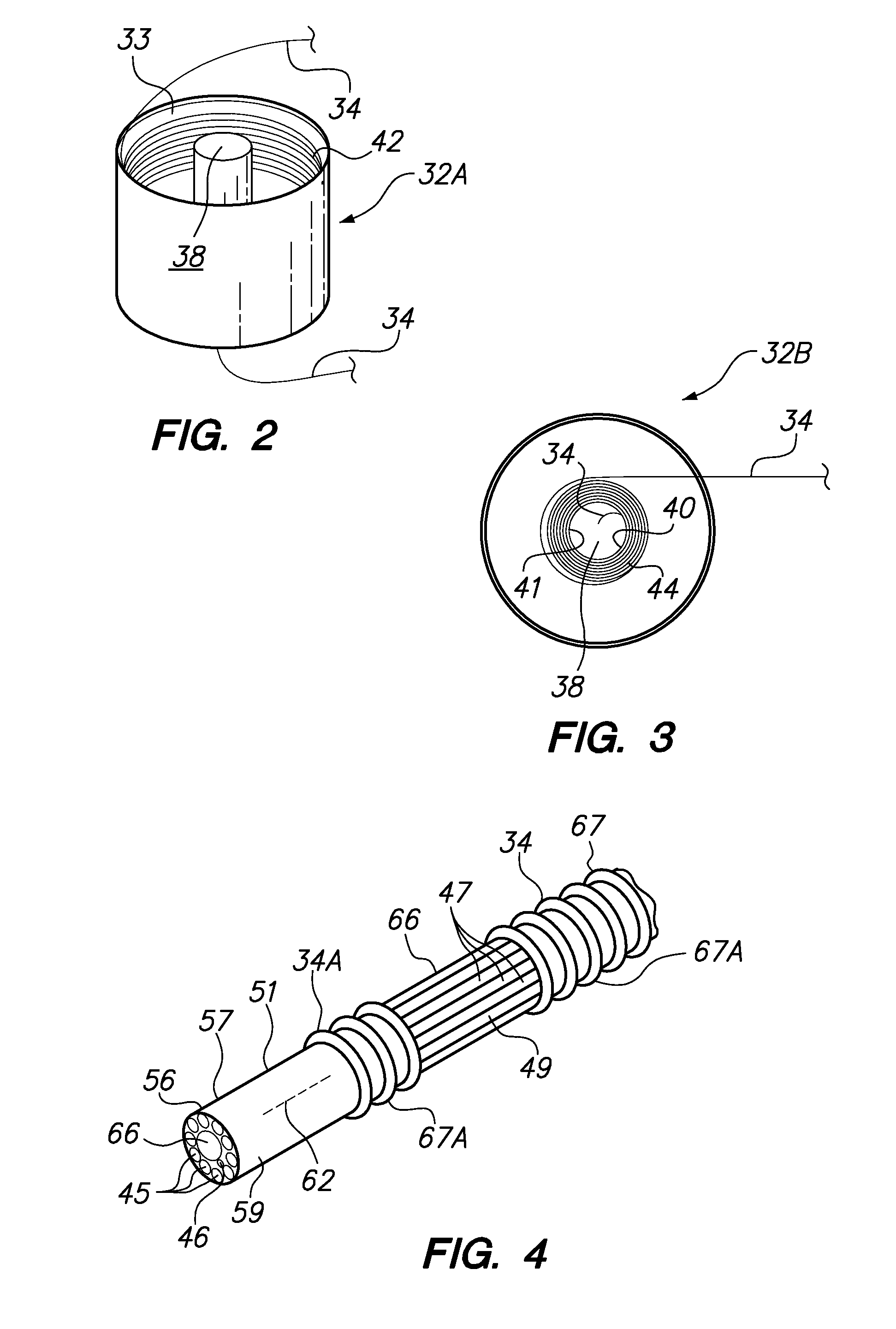

[0035]One embodiment of the present invention provides an apparatus and system to extend an earthen bore section comprising a first elongate umbilical to position a deflection member within a primary bore and a second elongate umbilical connected at a leading end to a drill head. The second umbilical and the drill head cooperate with the deflection member to position and controllably advance the drill head to extend a lateral bore intersecting the primary bore. The first umbilical includes a fluid conduit to pressurize, expand and deploy one or more deployable seals on the deflection member to engage and seal against the wall of the bore. The second umbilical also includes a fluid conduit to provide fluid to the drill head. In one aspect, the fluid provided to the drill head through the second umbilical displaces laser-obstructing materials from a laser light path intermediate a laser emitting portion of the drill head and a targeted portion of a bore wall to be extended using the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com