Patents

Literature

407results about "Thermal drilling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

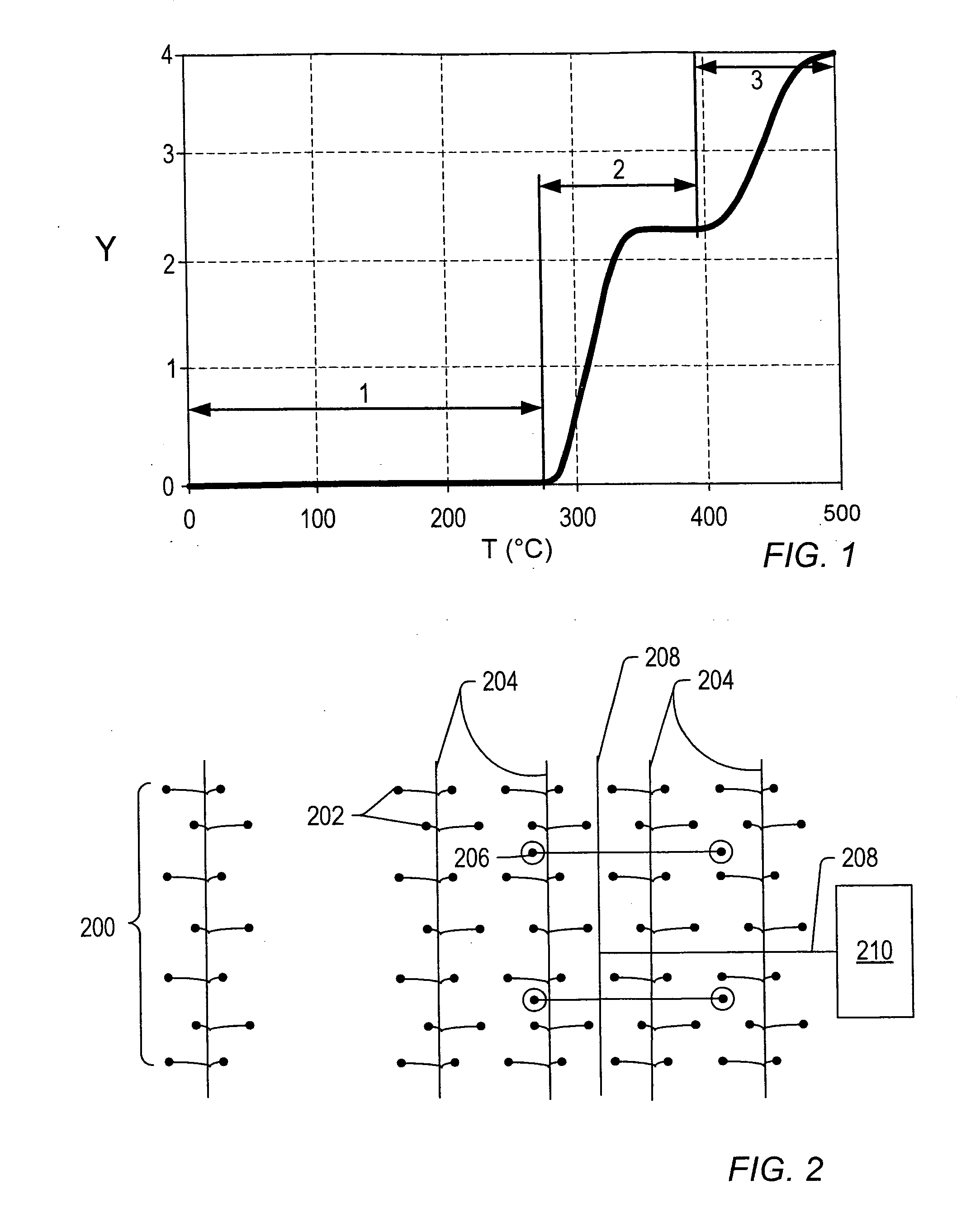

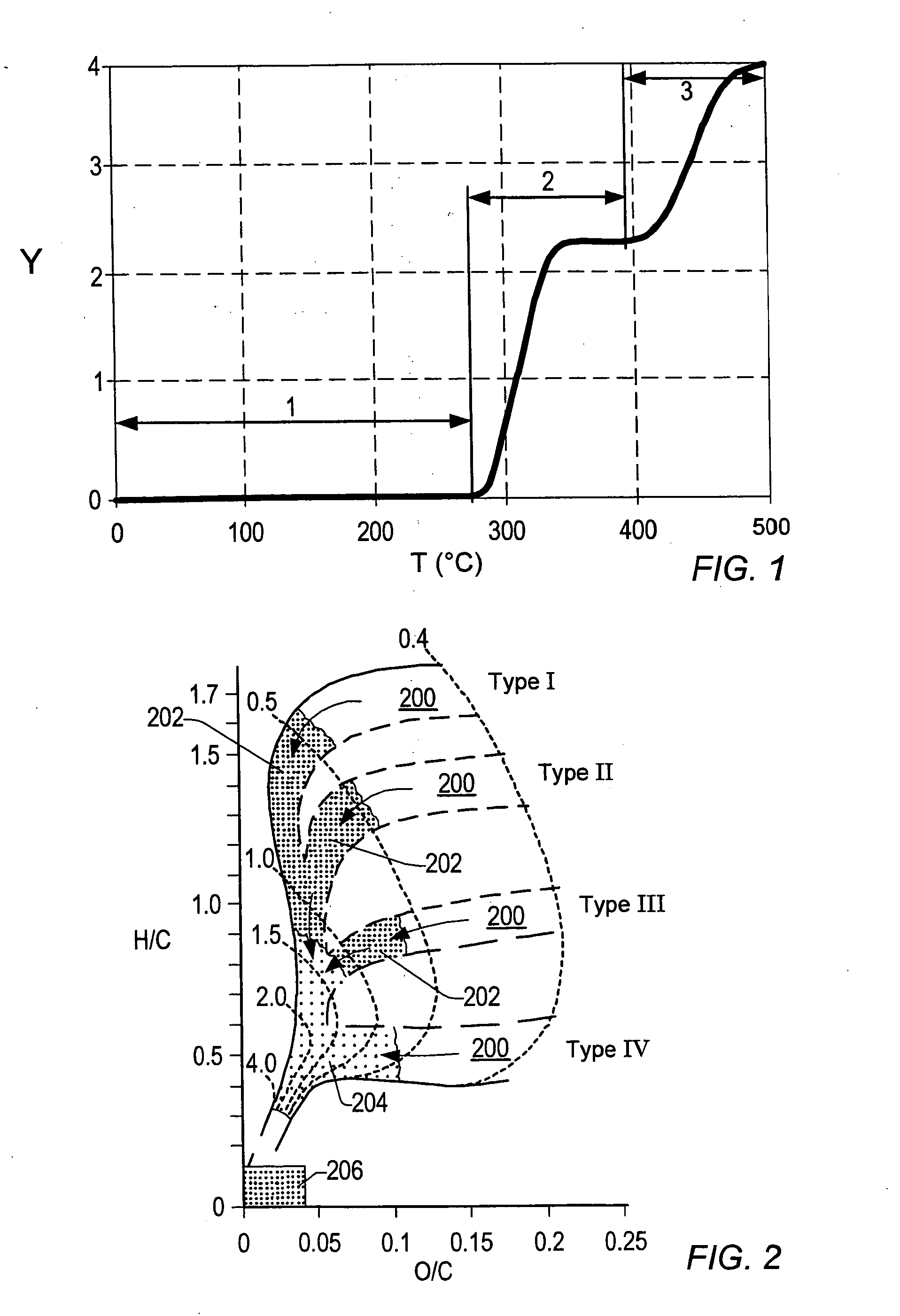

Variable frequency temperature limited heaters

InactiveUS20050006097A1Avoid deformationReduce heatThermal drillingInsulationElectrical resistance and conductancePower flow

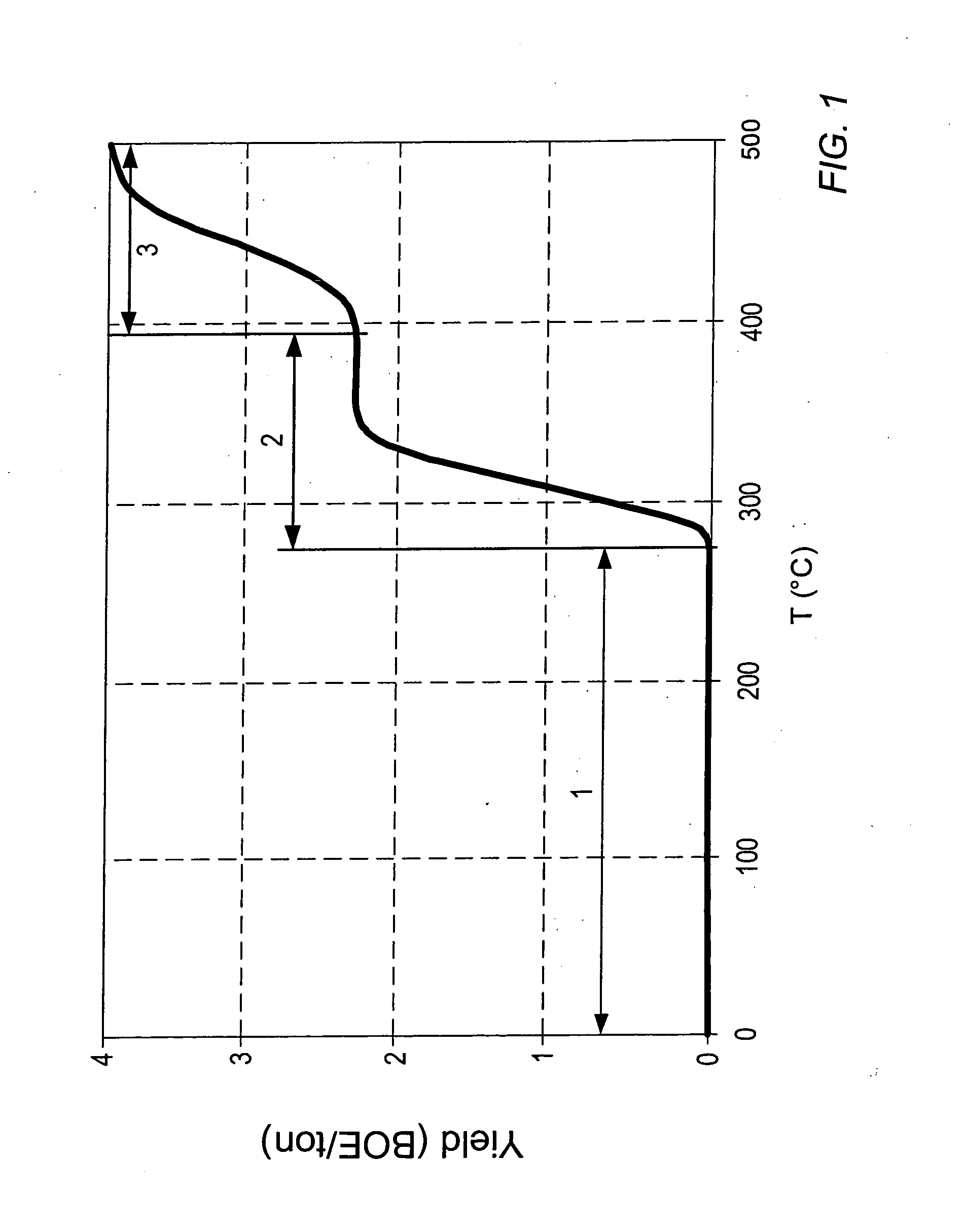

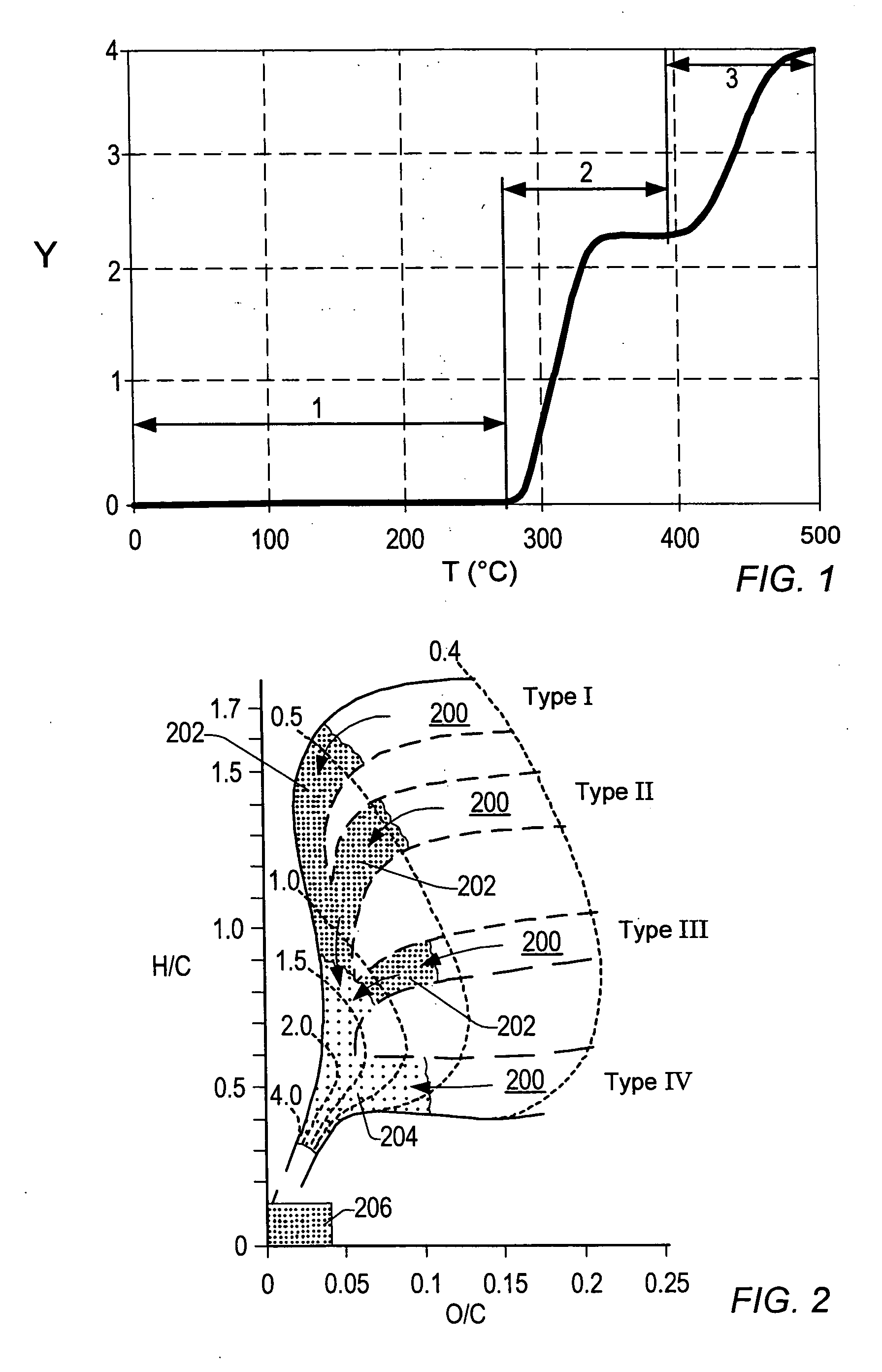

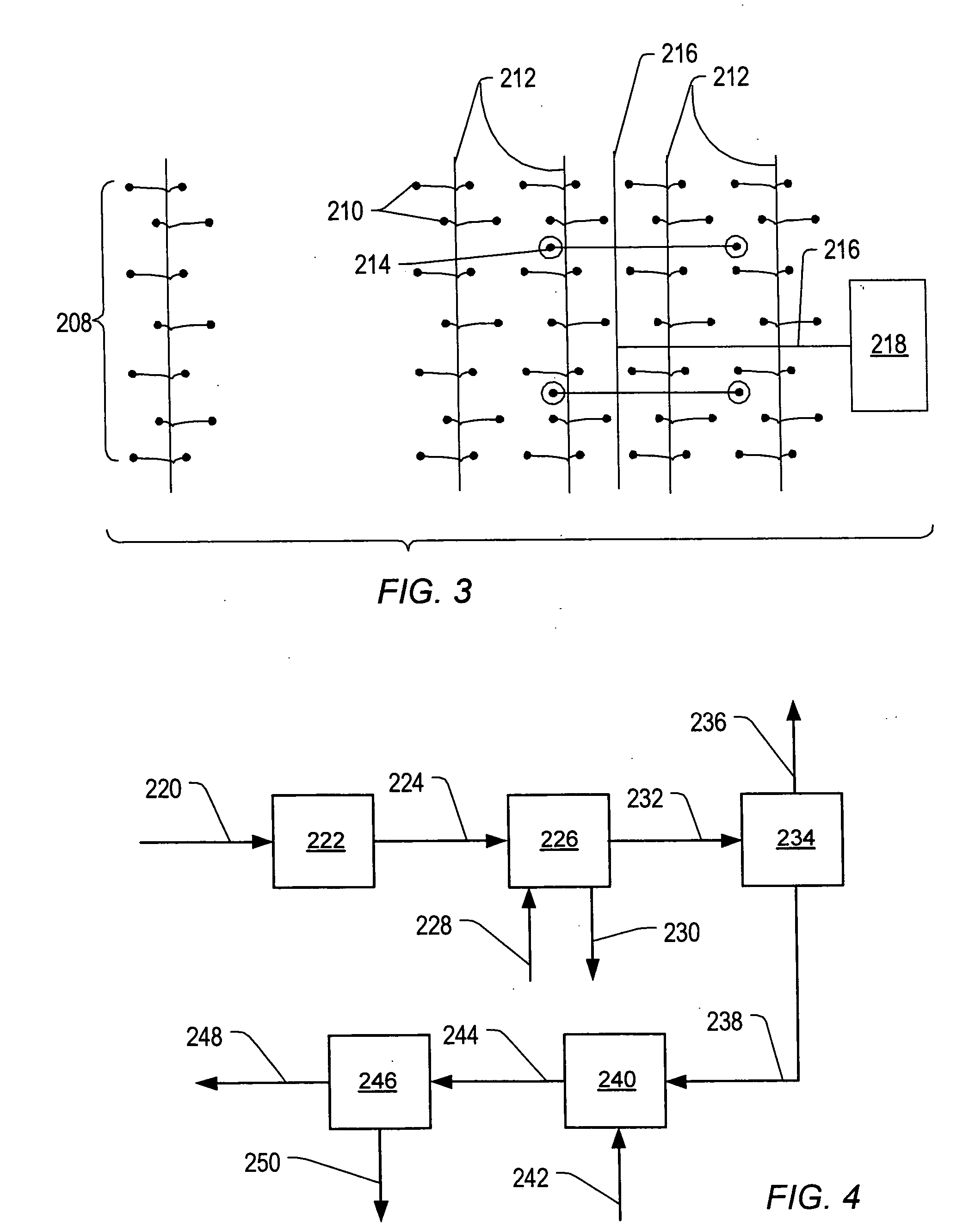

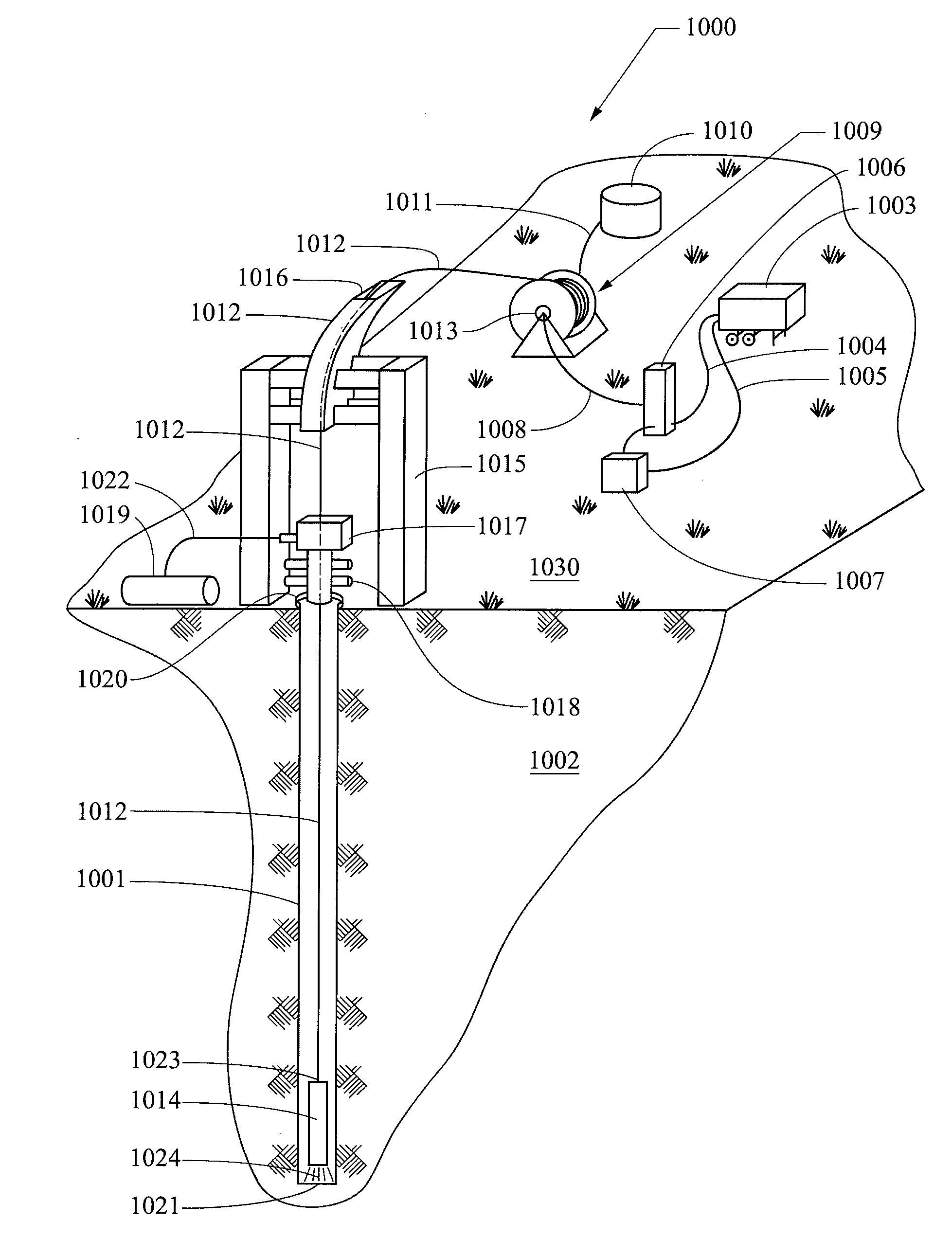

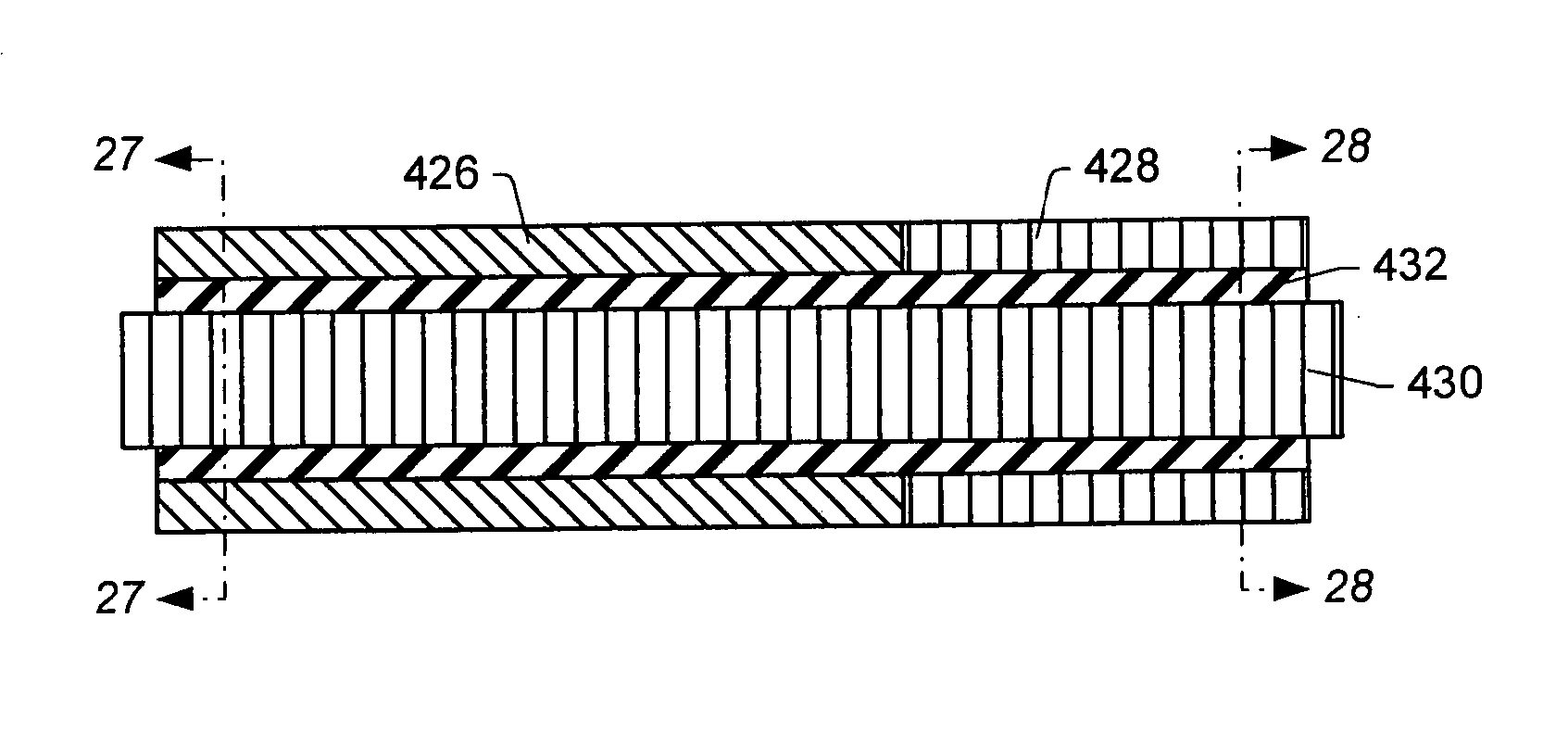

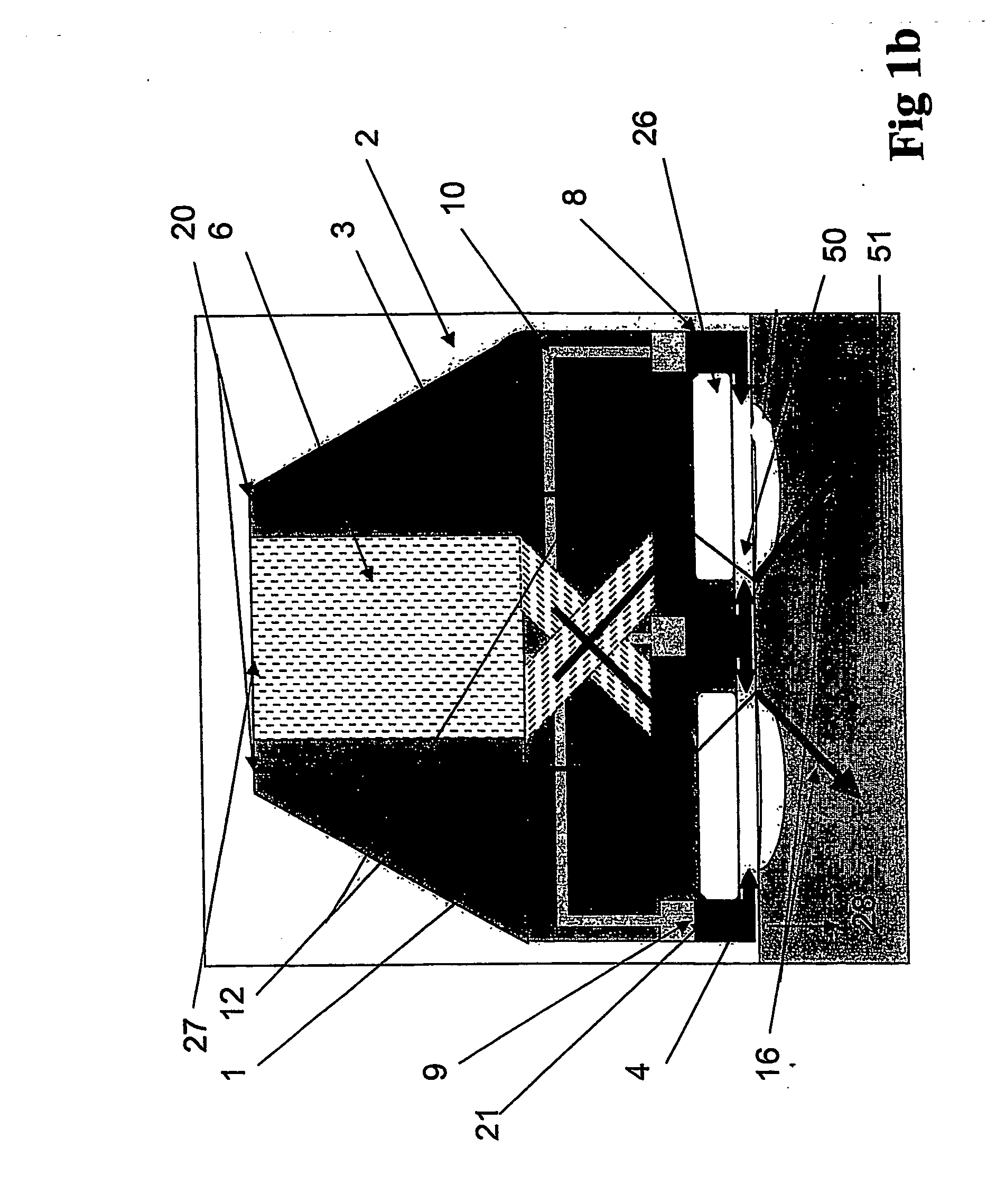

A heater system may include an alternating current supply and an electrical conductor. Alternating current may be applied to one or more electrical conductors at a frequency between about 100 Hz and about 1000 Hz. The electrical conductors may be located in a formation. The electrical conductors may resistively heat upon application of the alternating electrical current. At least one of the electrical conductors may include an electrically resistive ferromagnetic material. The electrical conductor may provide a reduced amount of heat above or near a selected temperature. Heat may transfer from the electrical conductor to a part of formation.

Owner:SHELL OIL CO

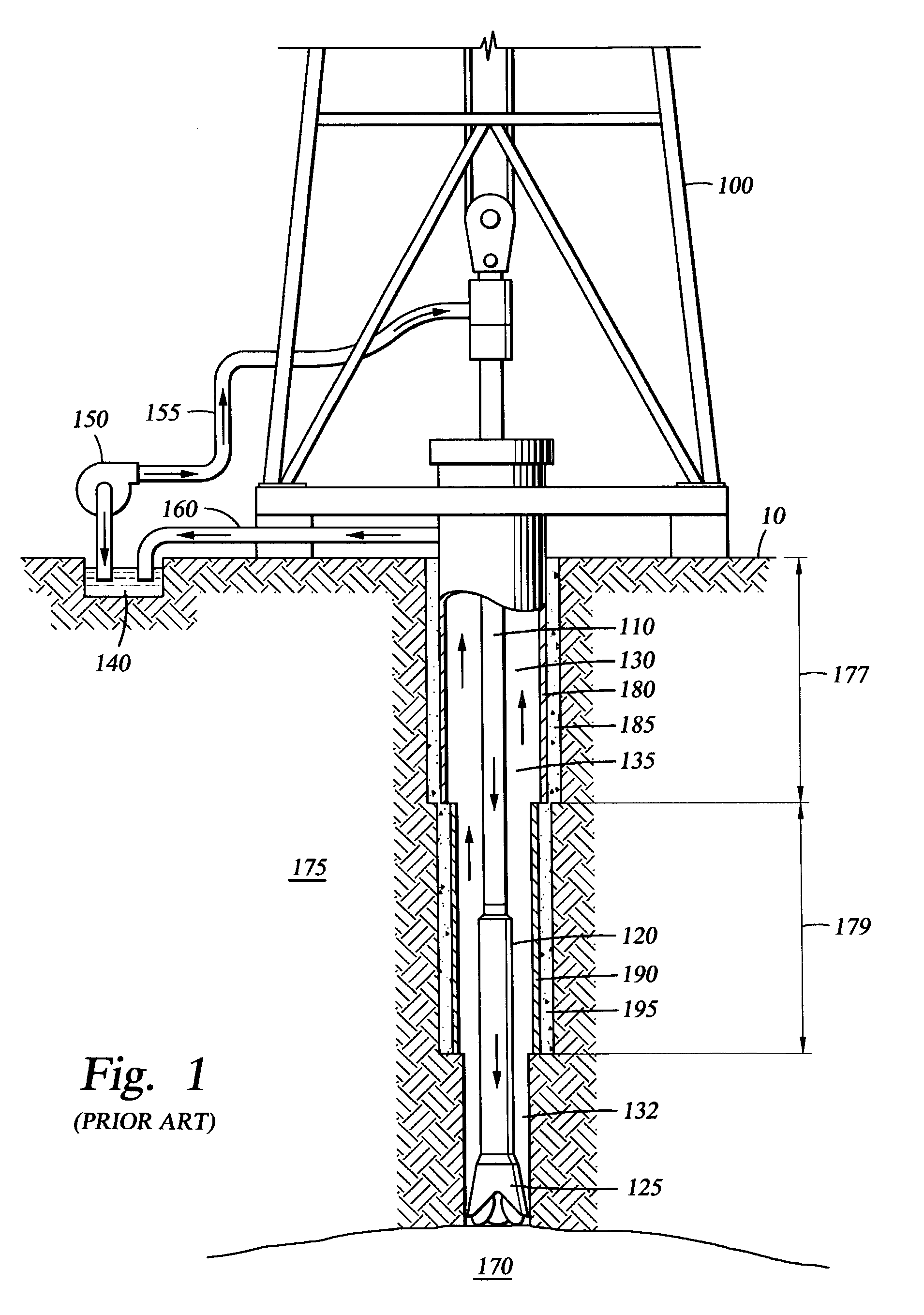

Drilling, perforating and formation analysis

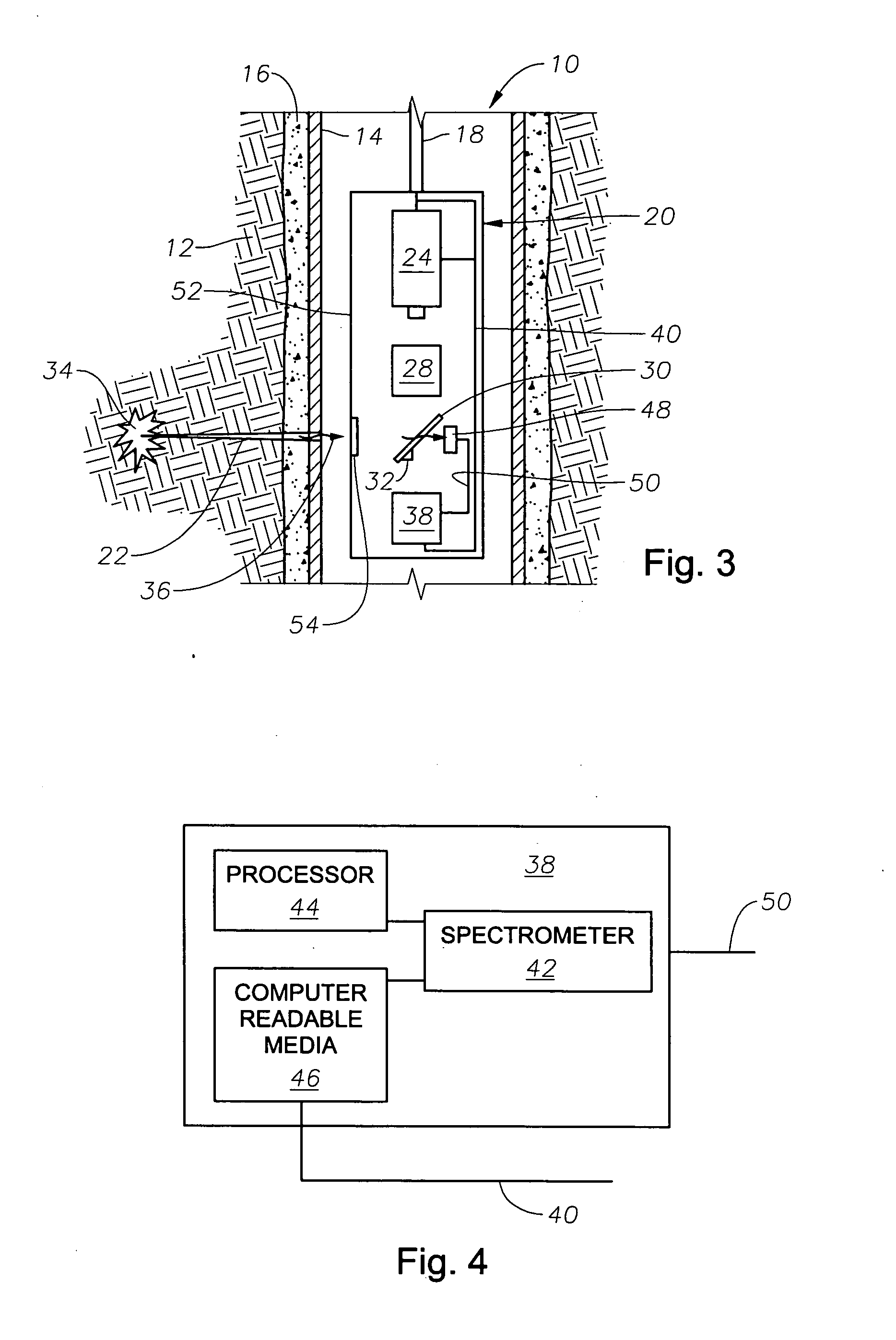

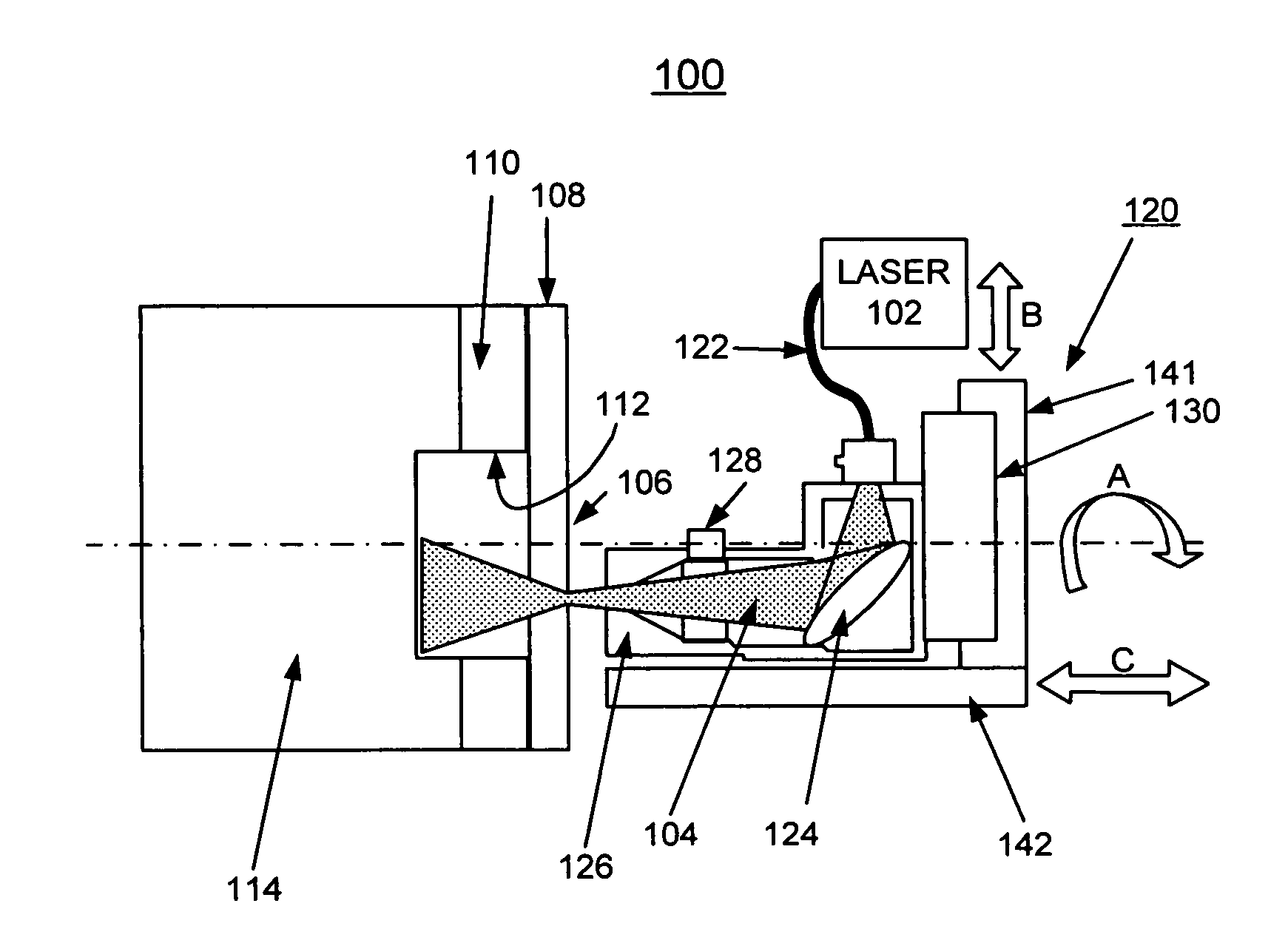

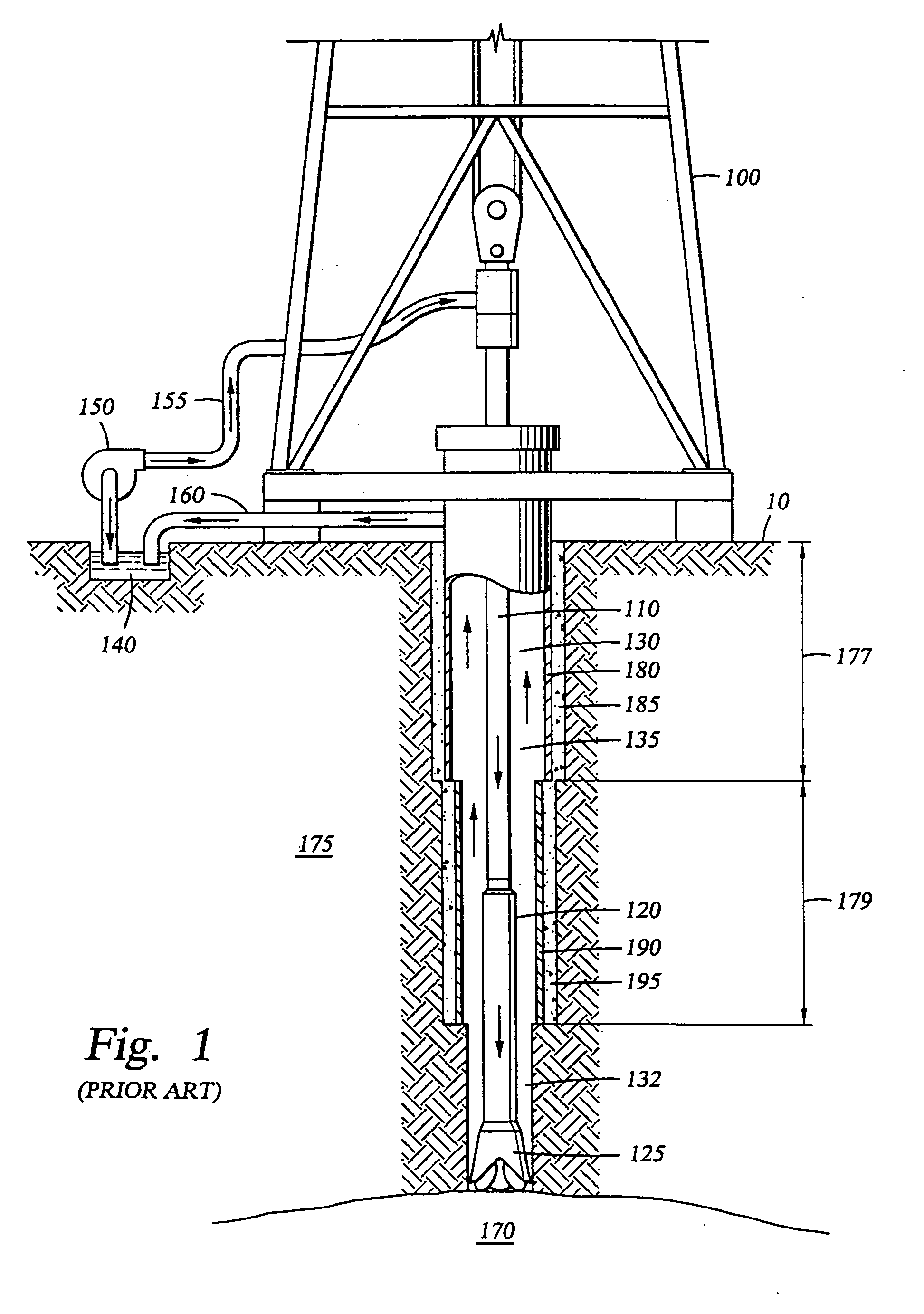

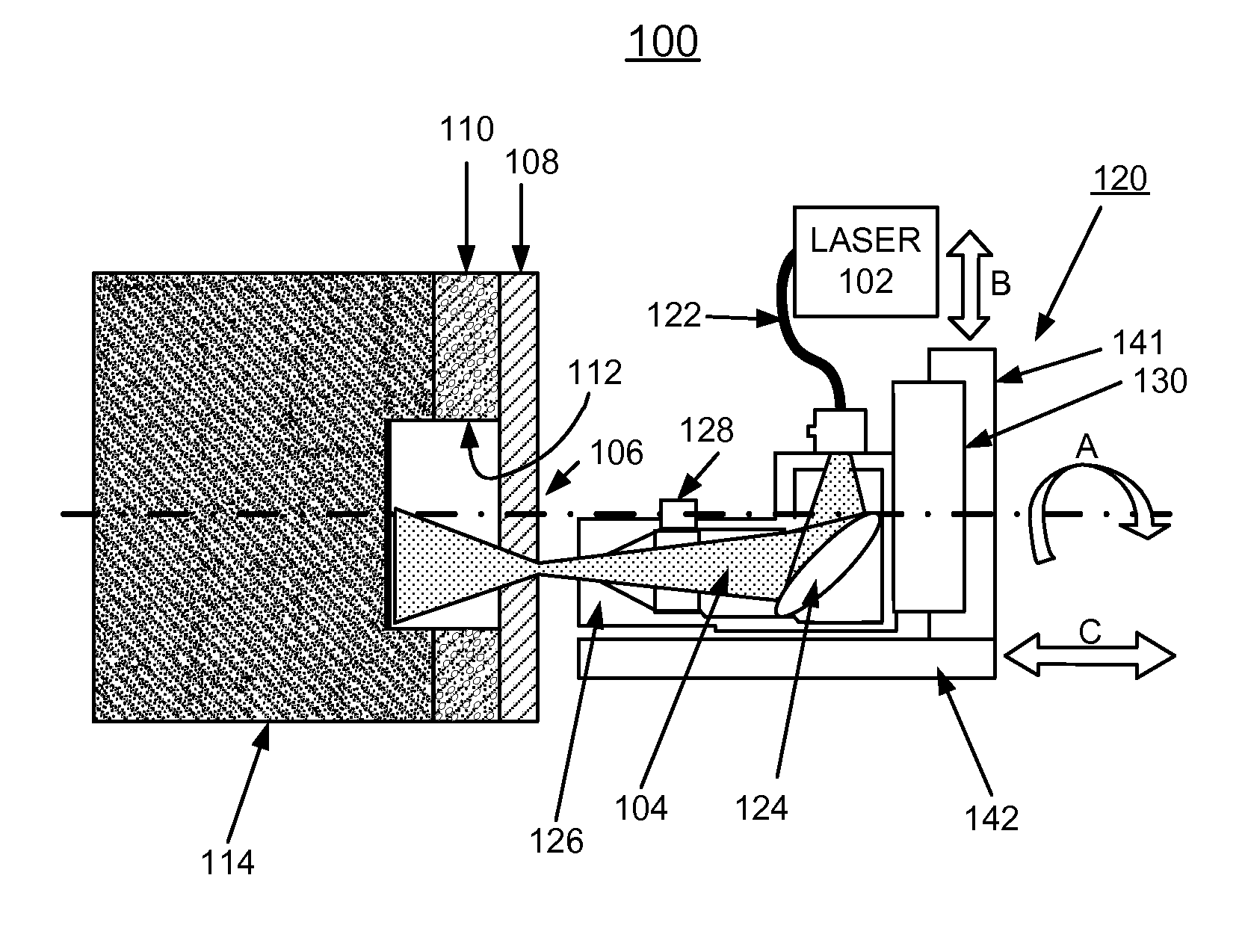

ActiveUS20060102343A1Easy to useImprove breathabilitySpectrum investigationConstructionsMaterial removalWell drilling

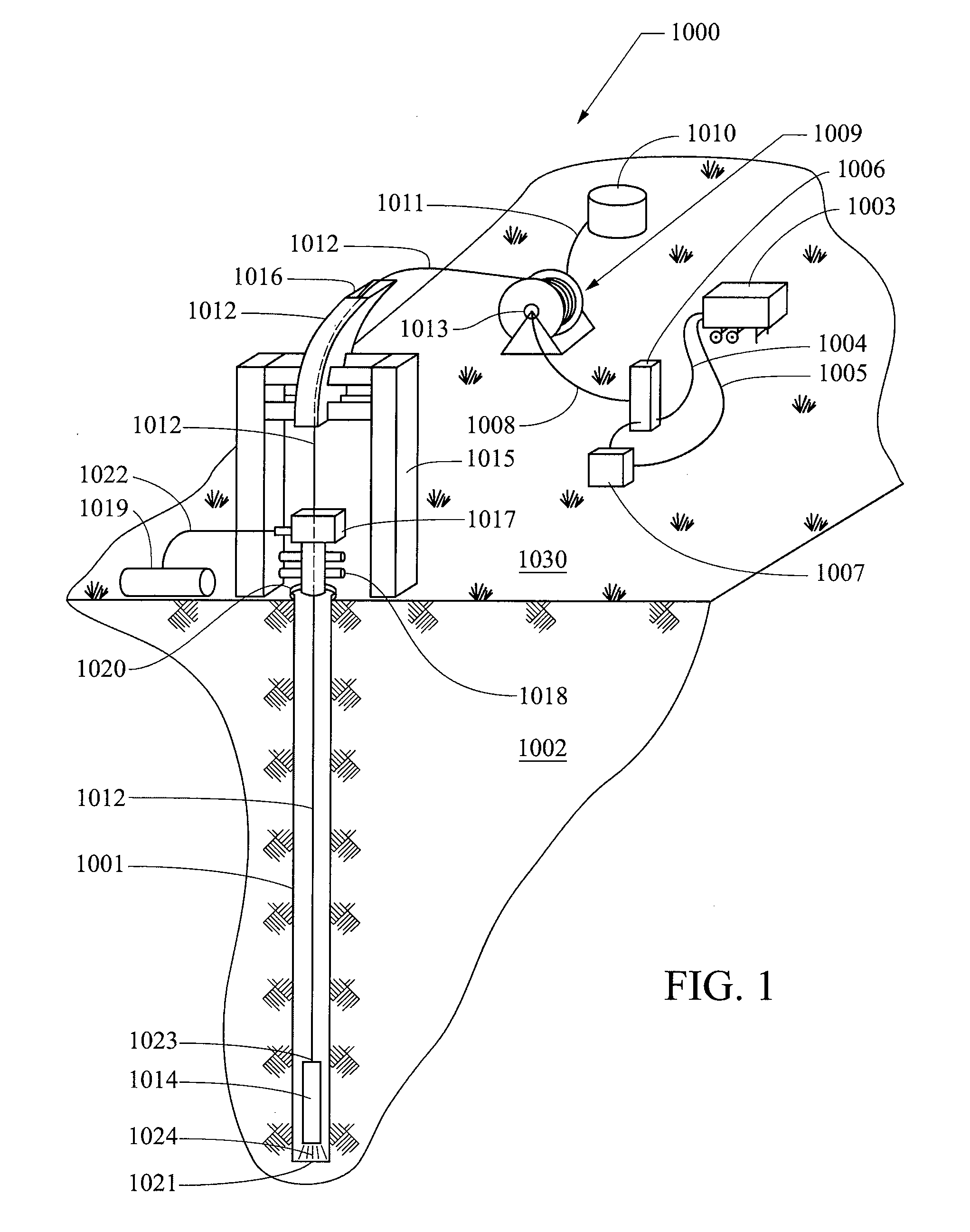

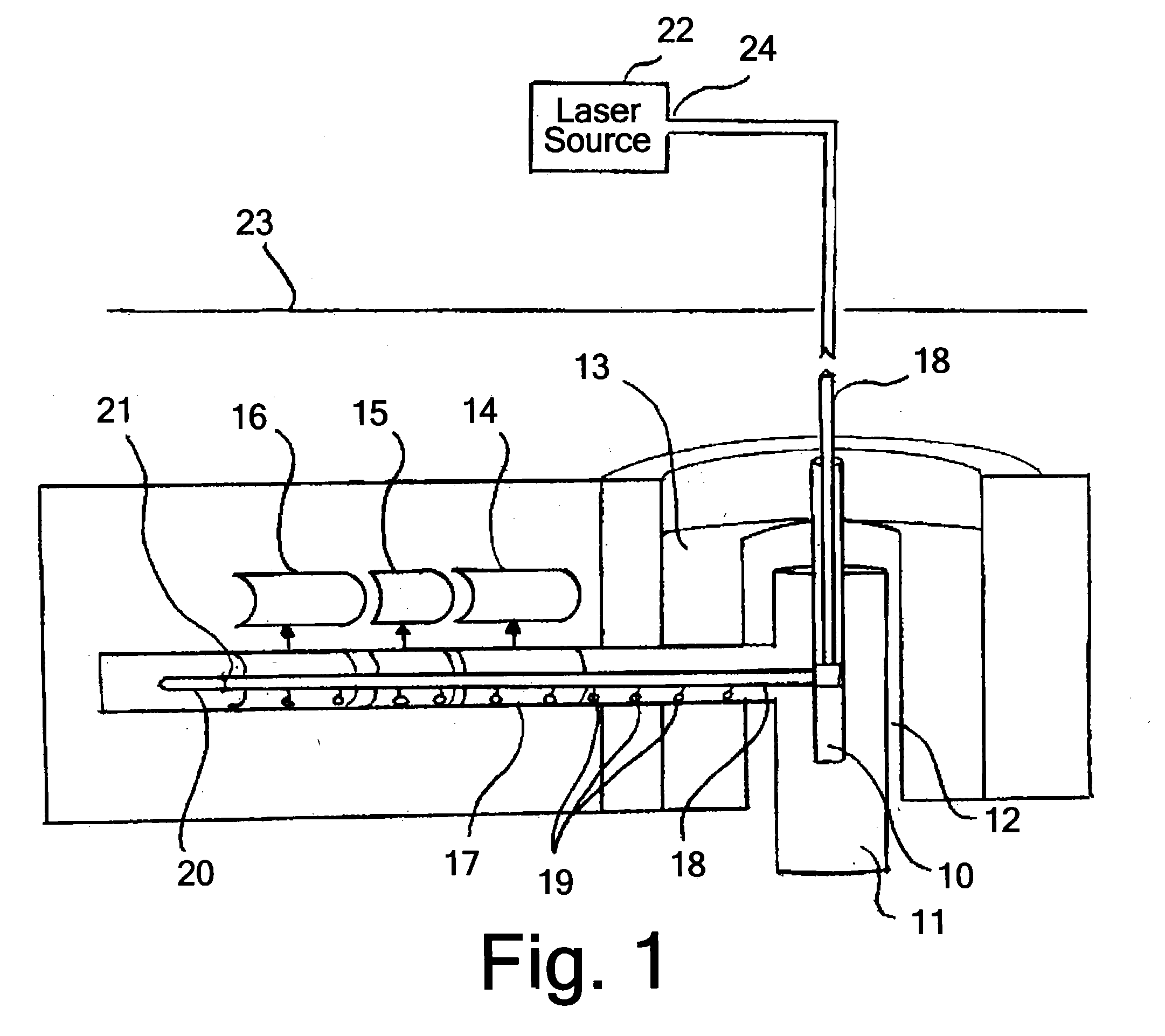

A system and method of drilling and / or perforating uses a laser beam to remove material, such as to perforate the casing, cement and formation or drill a well bore. The system and method can further or alternately encompass material analysis that can be performed without removing the material from the well bore. The analysis can be performed apart from or in connection with drilling operations and / or perforating the casing, cement and formation. The analysis can be used in a feed back loop to adjust material removal, adjust material analysis, determine the location of future material removal, and for other uses.

Owner:HALLIBURTON ENERGY SERVICES INC

Subsurface heaters with low sulfidation rates

Owner:SHELL OIL CO

Temperature limited heaters with high power factors

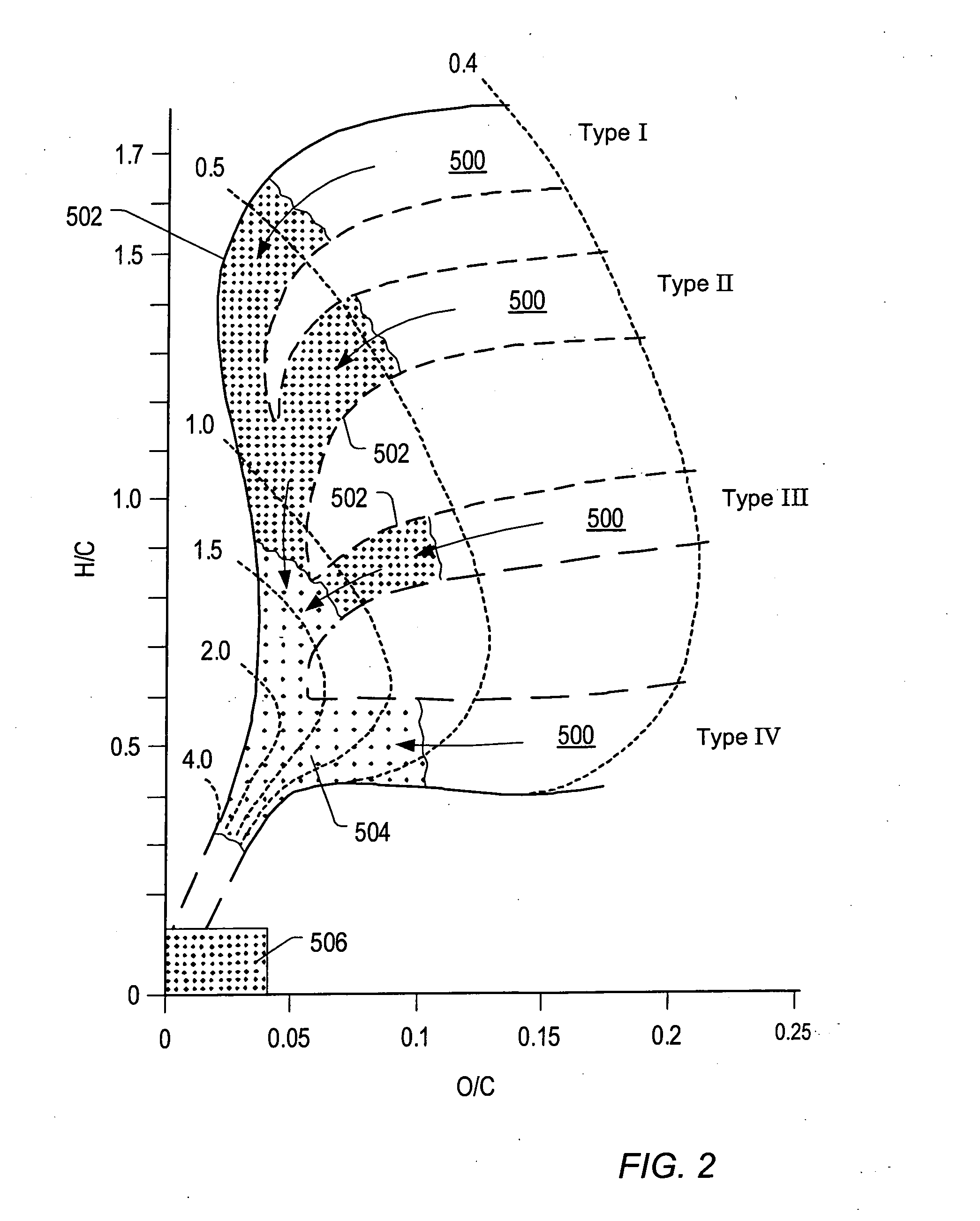

Certain embodiments provide a heater. The heater includes a ferromagnetic member. The heater also includes an electrical conductor electrically coupled to the ferromagnetic member. The electrical conductor is configured to conduct a majority of time-varying electrical current passing through the heater at about 25° C. The heater is configured to provide a first heat output below the Curie temperature of the ferromagnetic member. The heater is configured to automatically provide a second heat output approximately at and above the Curie temperature of the ferromagnetic member. The second heat output is reduced compared to the first heat output.

Owner:SHELL OIL CO

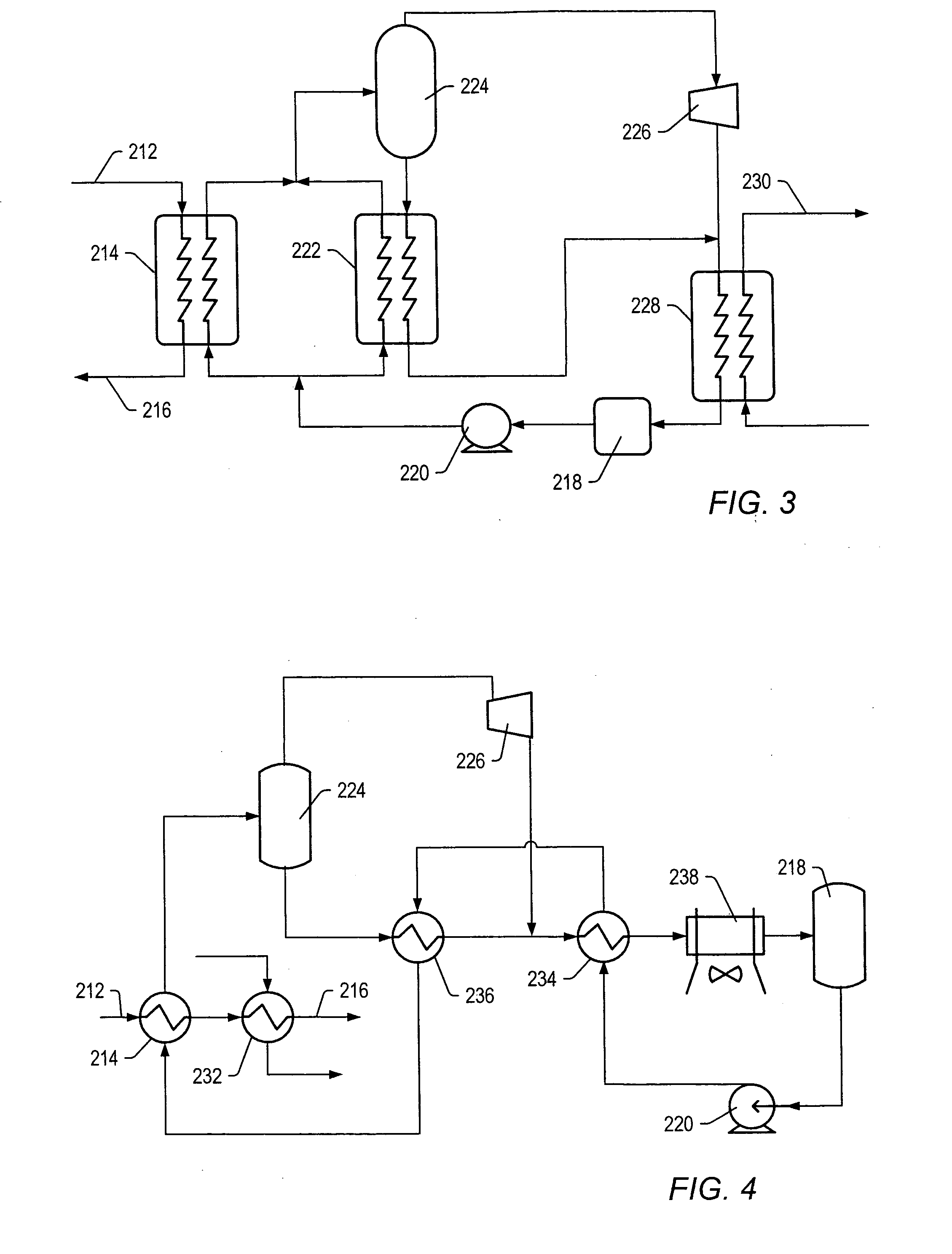

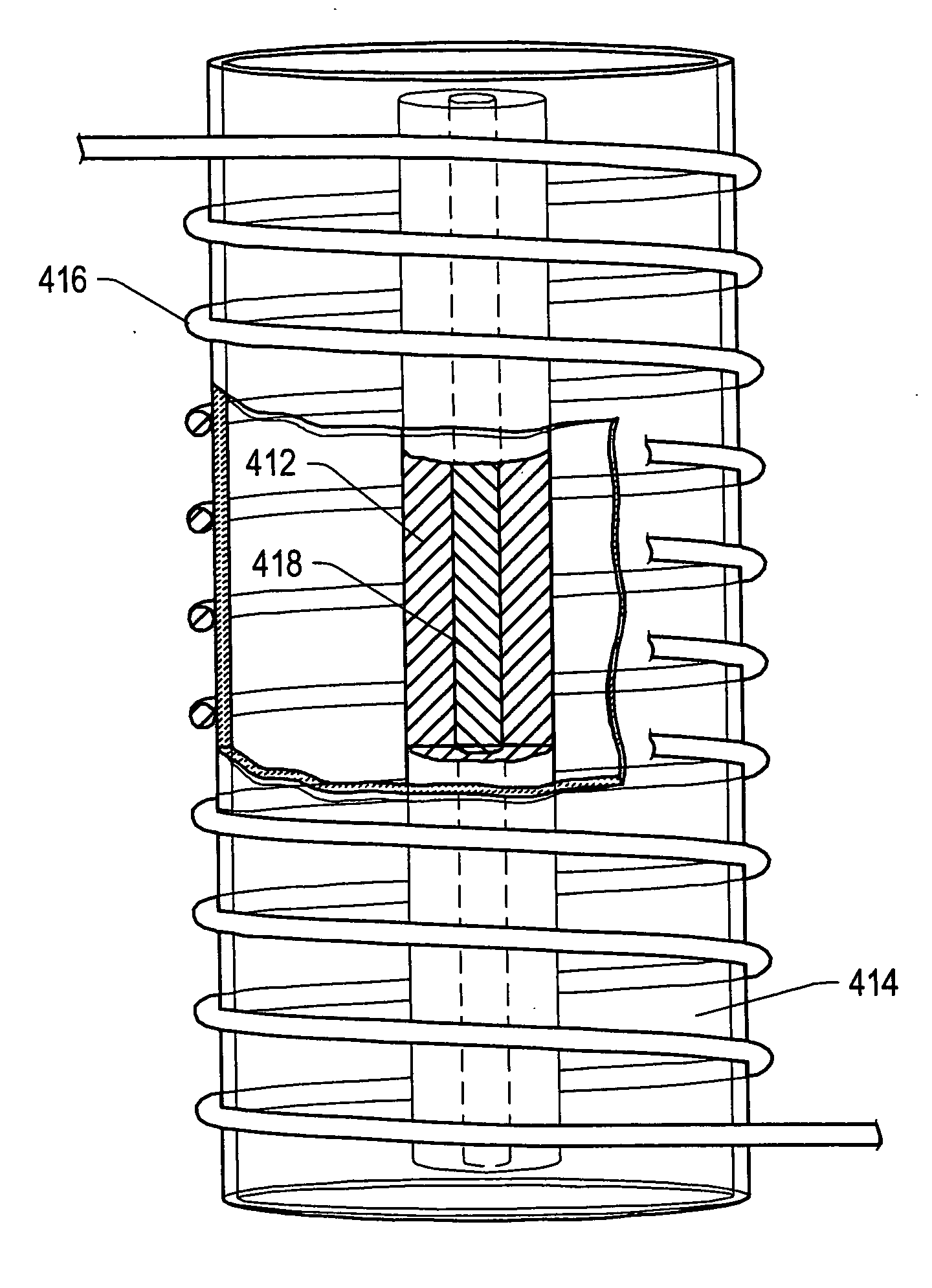

Temperature limited heaters with thermally conductive fluid used to heat subsurface formations

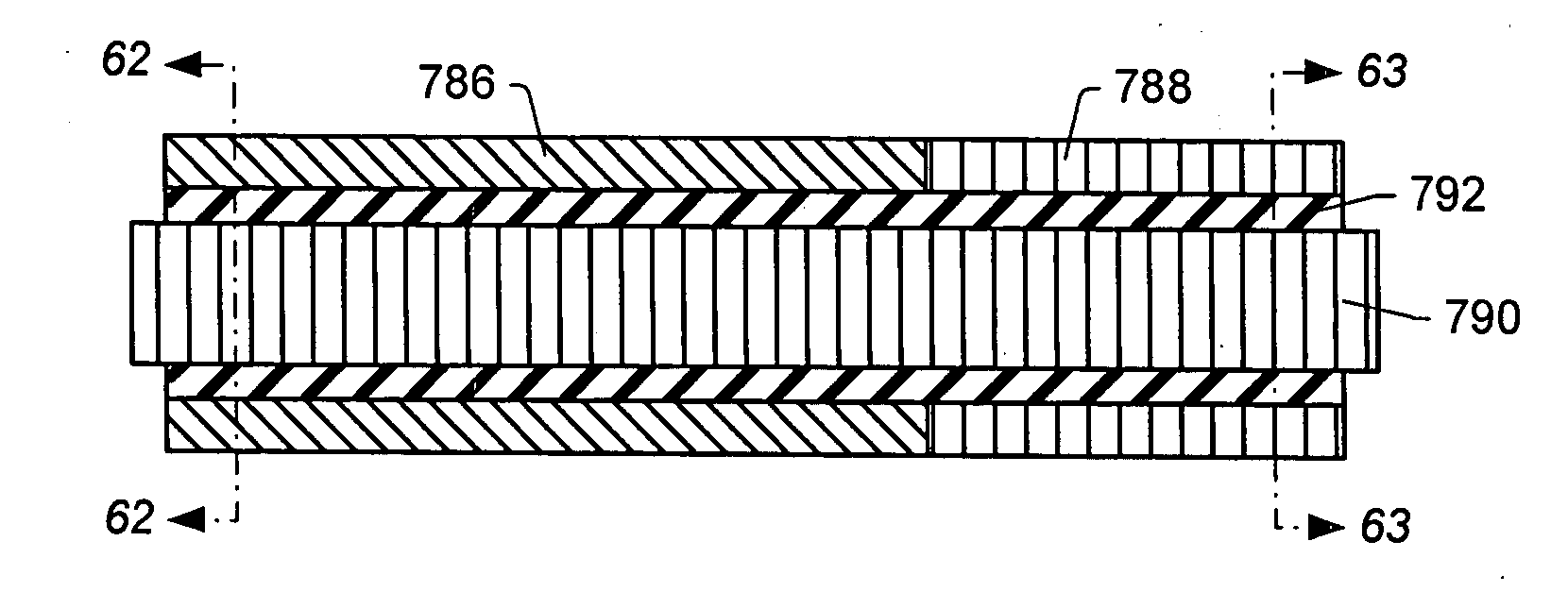

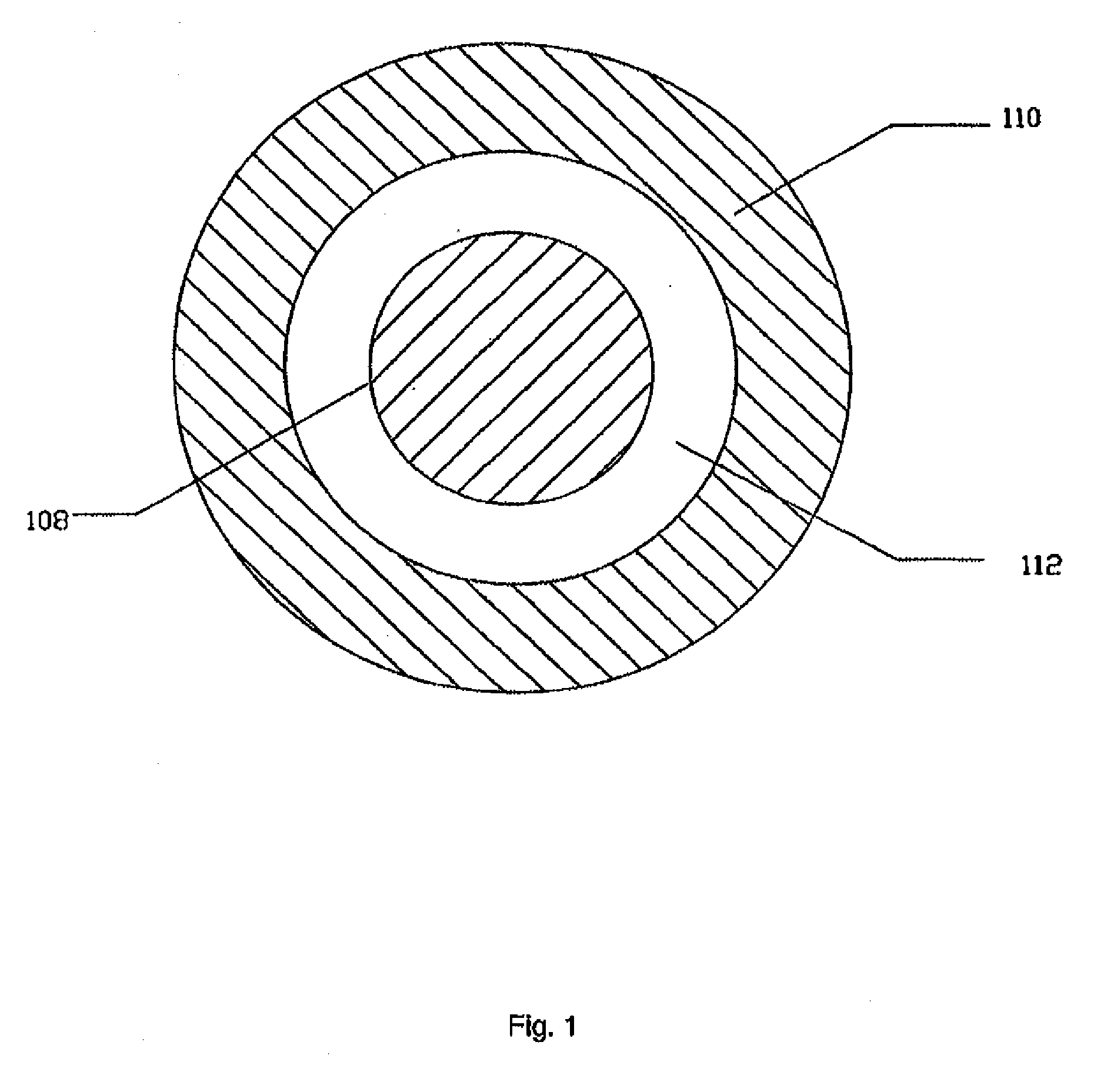

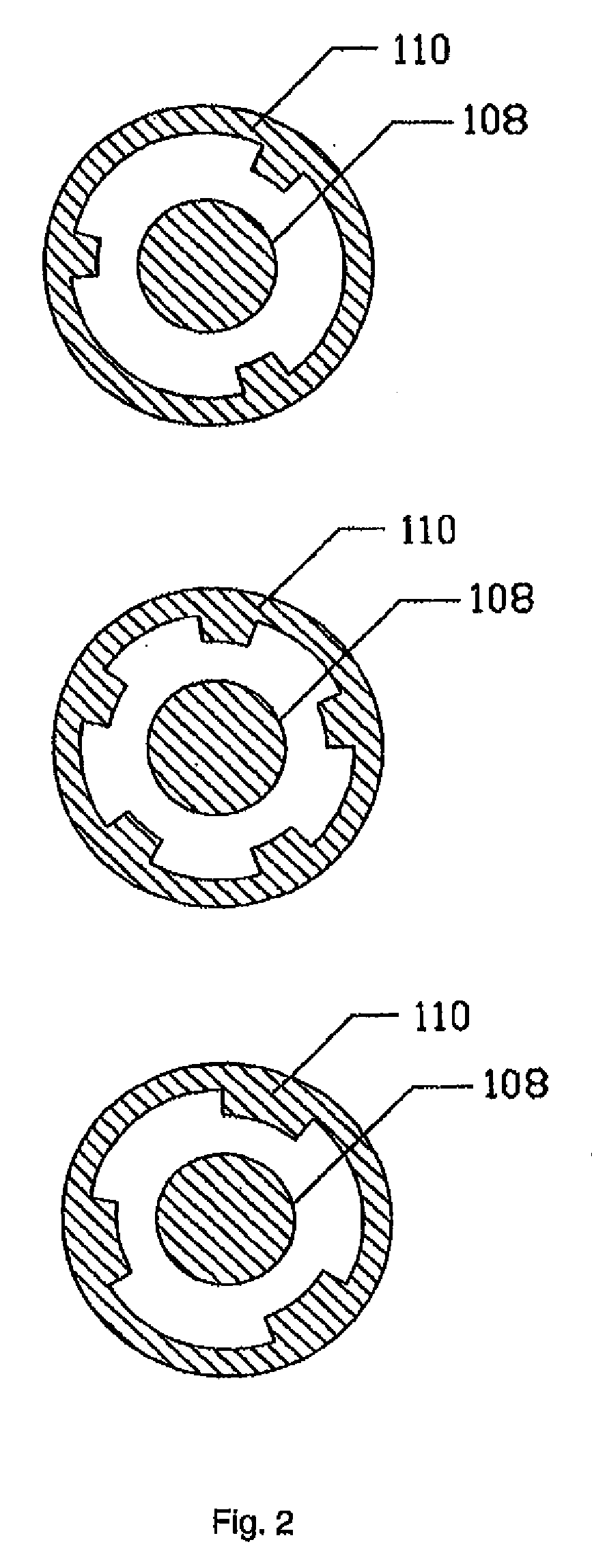

InactiveUS20050269090A1Improve thermal conductivityThermal drillingInsulationEngineeringElectrical current

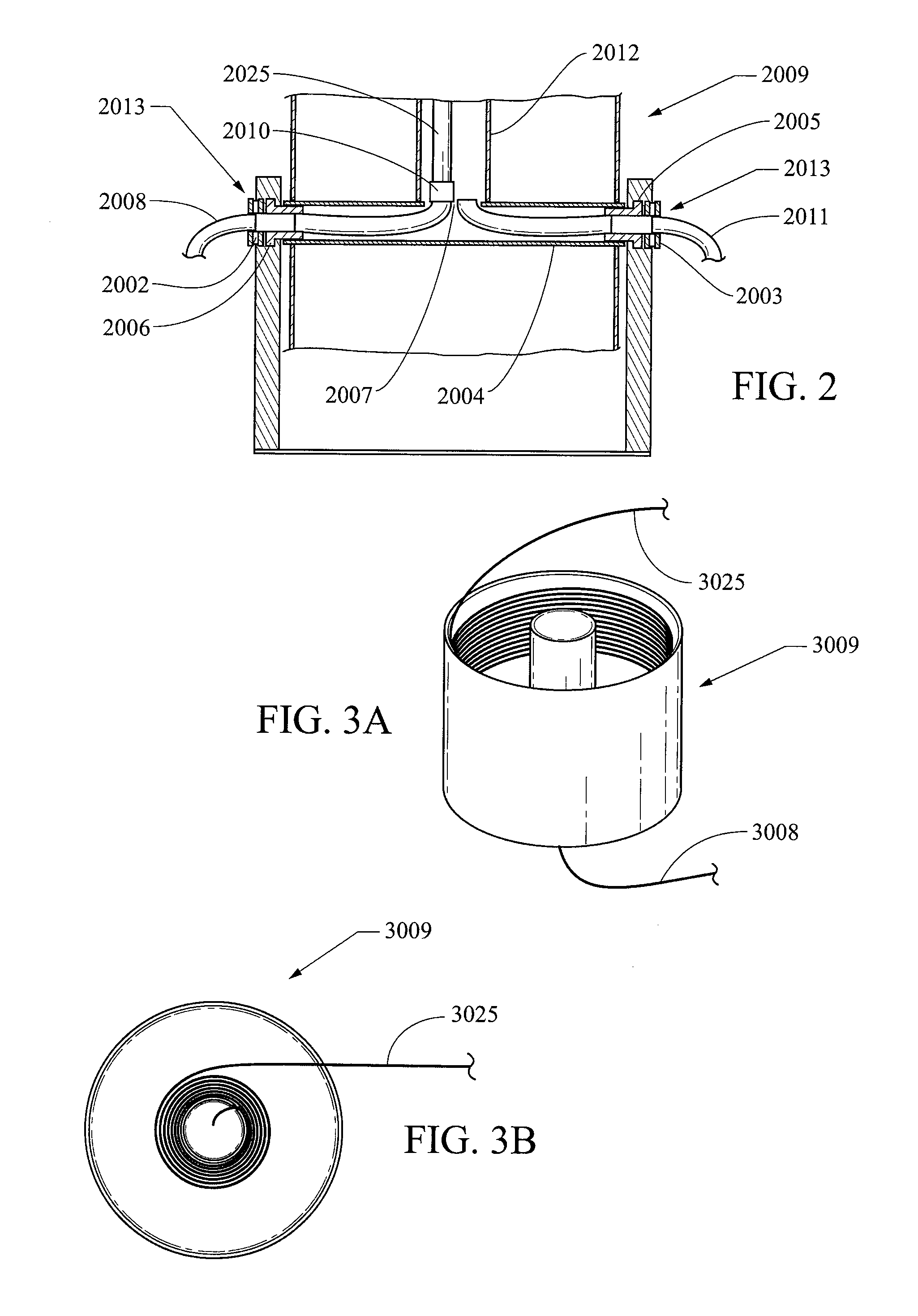

Certain embodiments provide a system including a heater. The heater includes one or more electrical conductors. The heater is configured to generate a heat output during application of electrical current to the heater. The heater includes a ferromagnetic material. A conduit at least partially surrounds the heater. A fluid is located in a space between the heater and the conduit. The fluid has a higher thermal conductivity than air at standard temperature and pressure (STP) (0° C. and 101.325 kPa). The system is configured to provide (a) a first heat output below a selected temperature when time-varying electrical current is applied to the heater, and (b) a second heat output near or above the selected temperature when time-varying electrical current is applied to the heater.

Owner:SHELL OIL CO

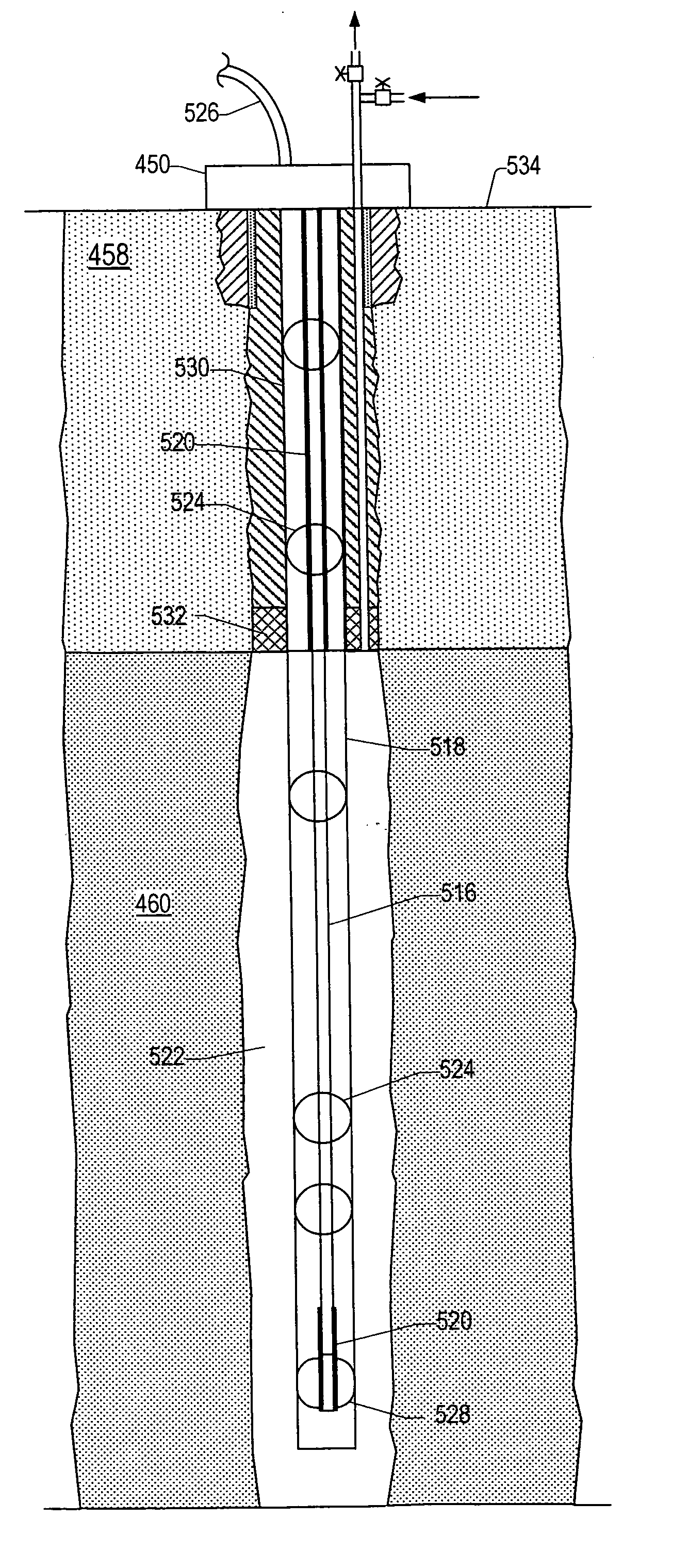

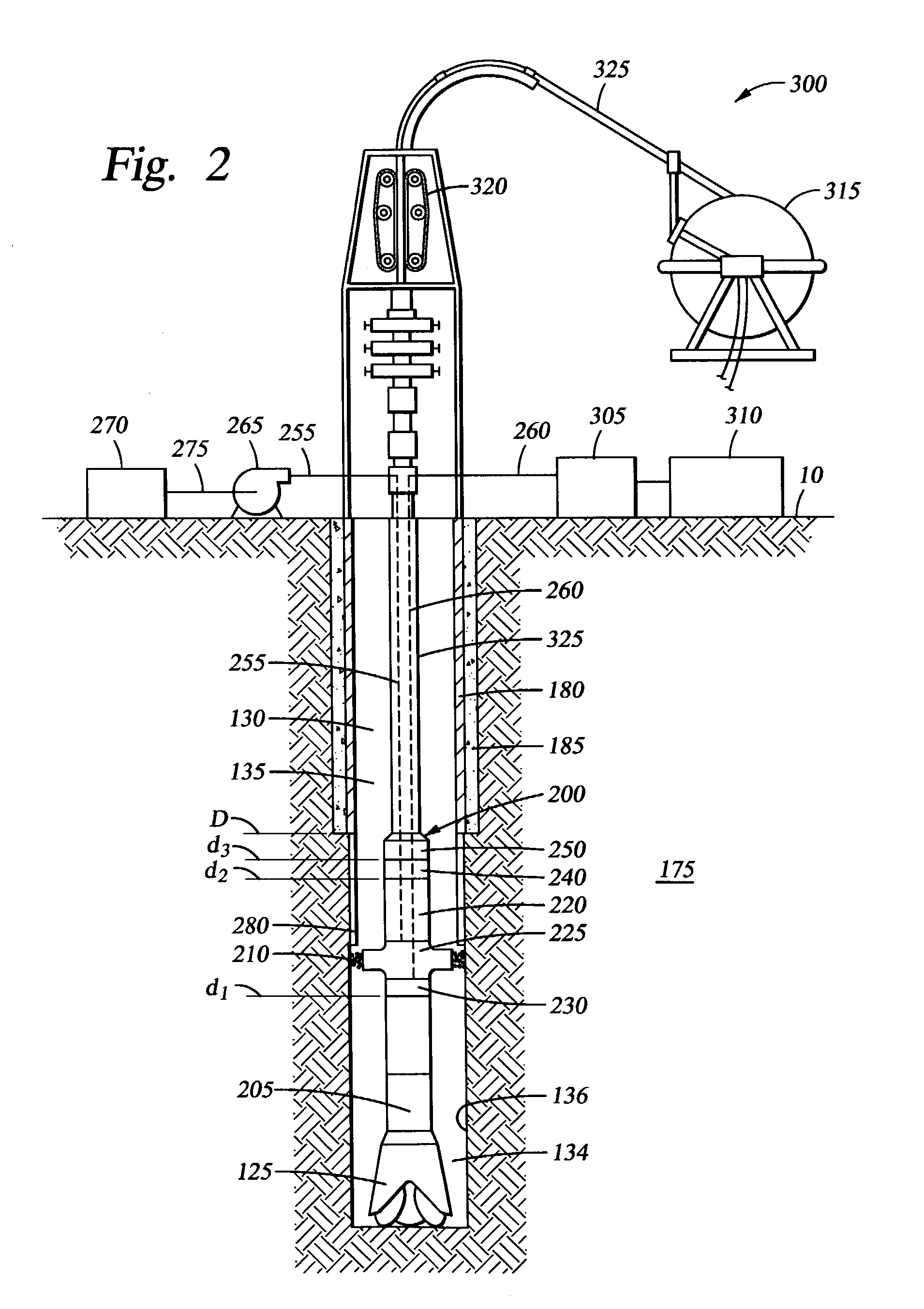

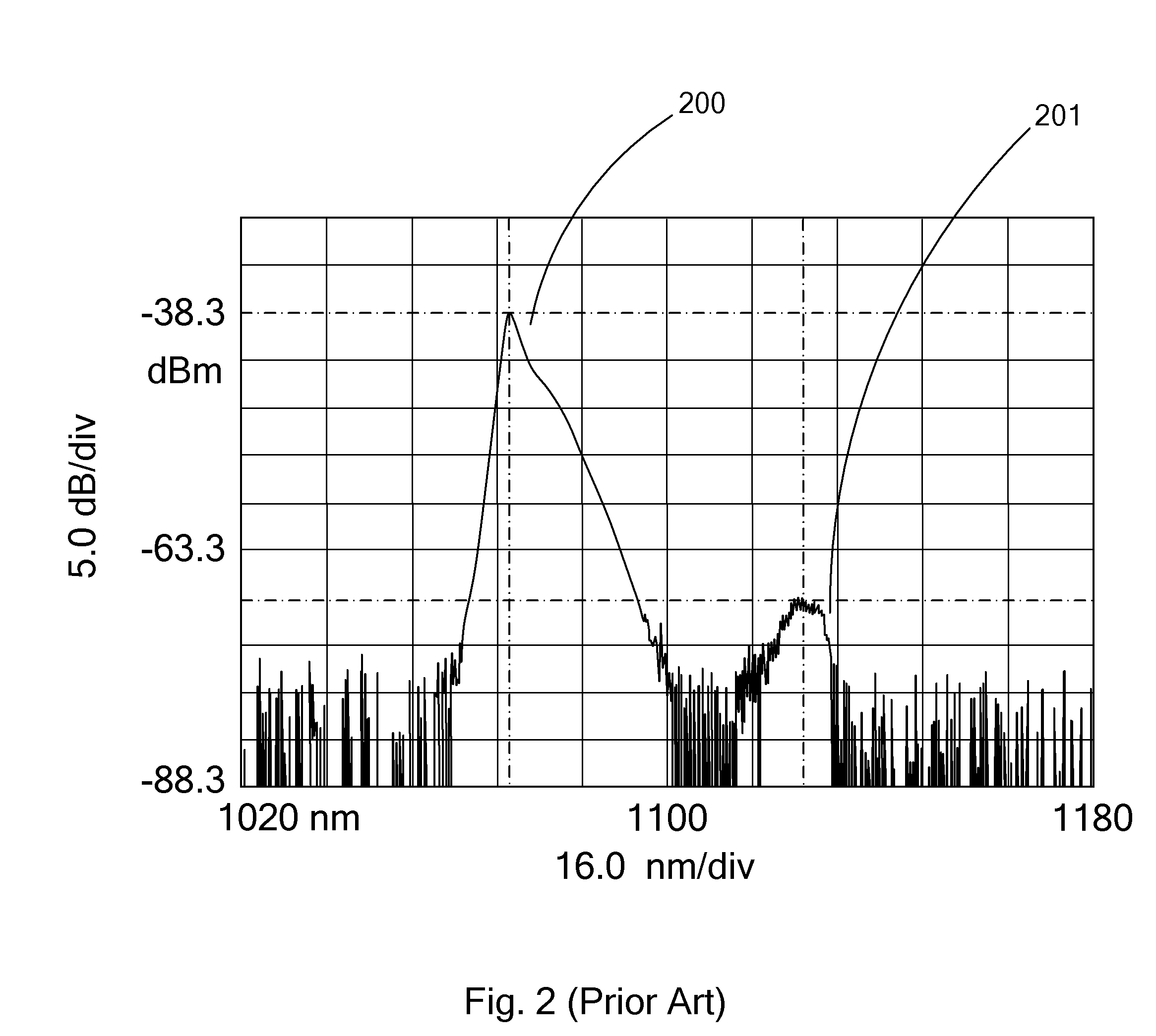

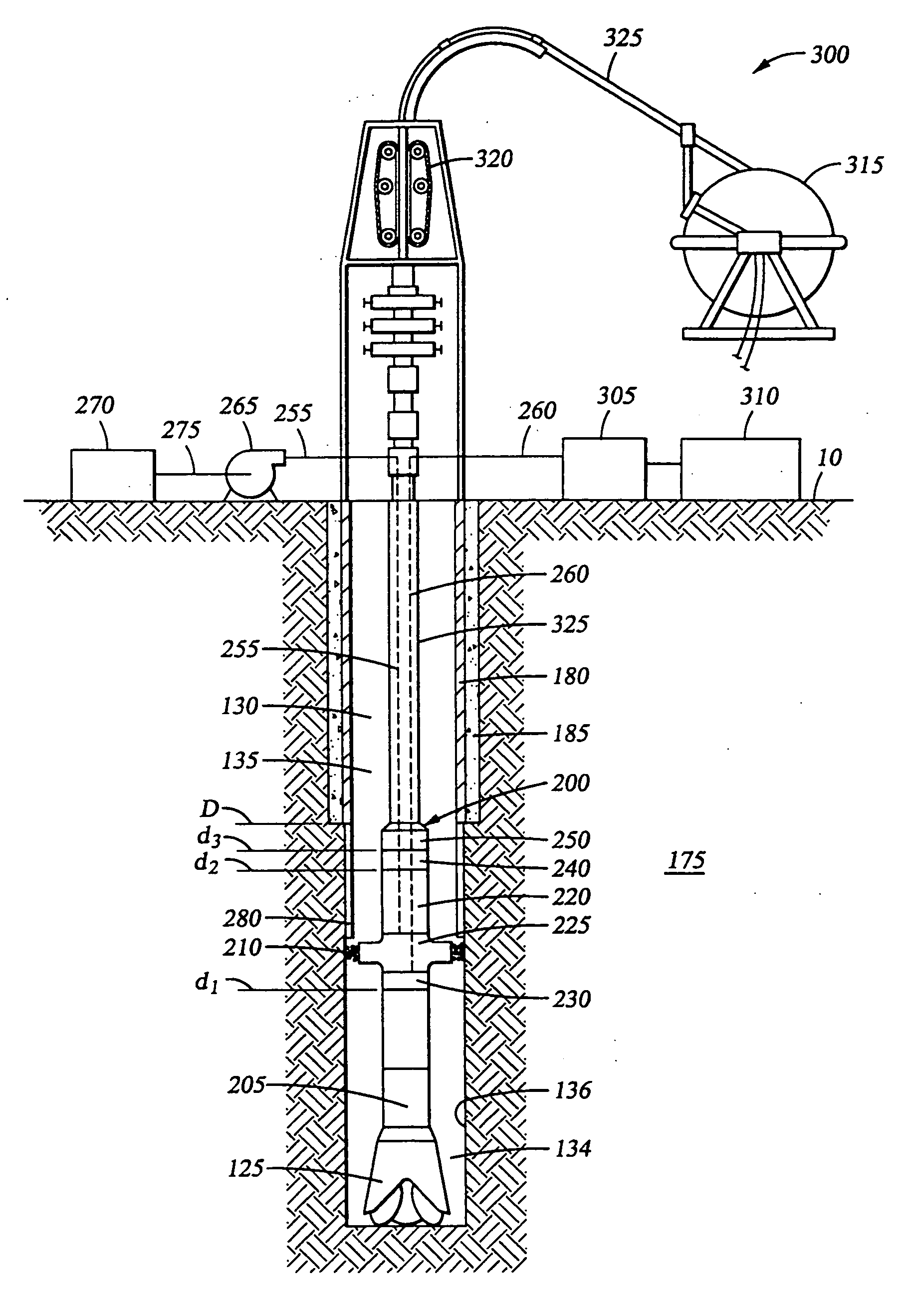

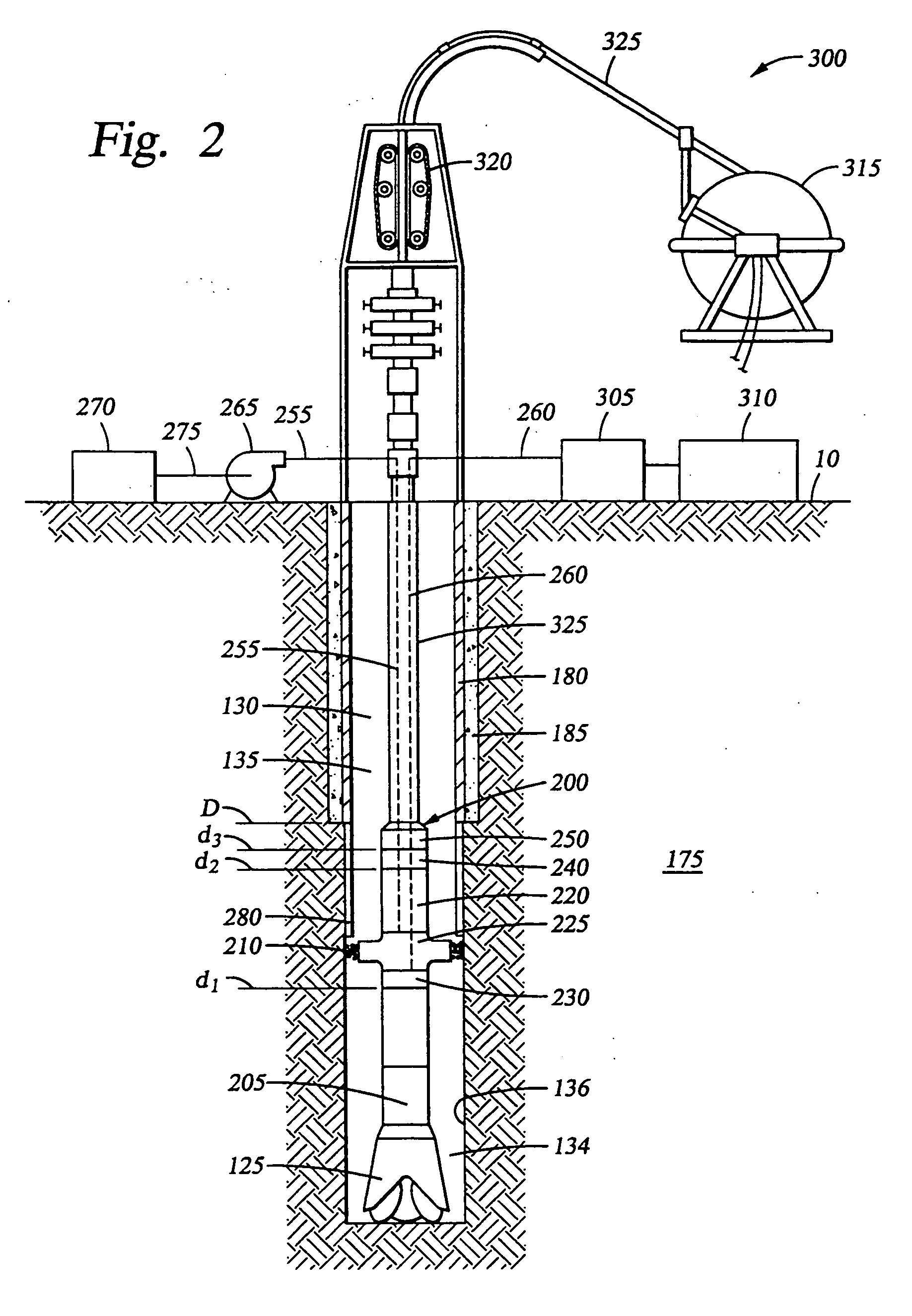

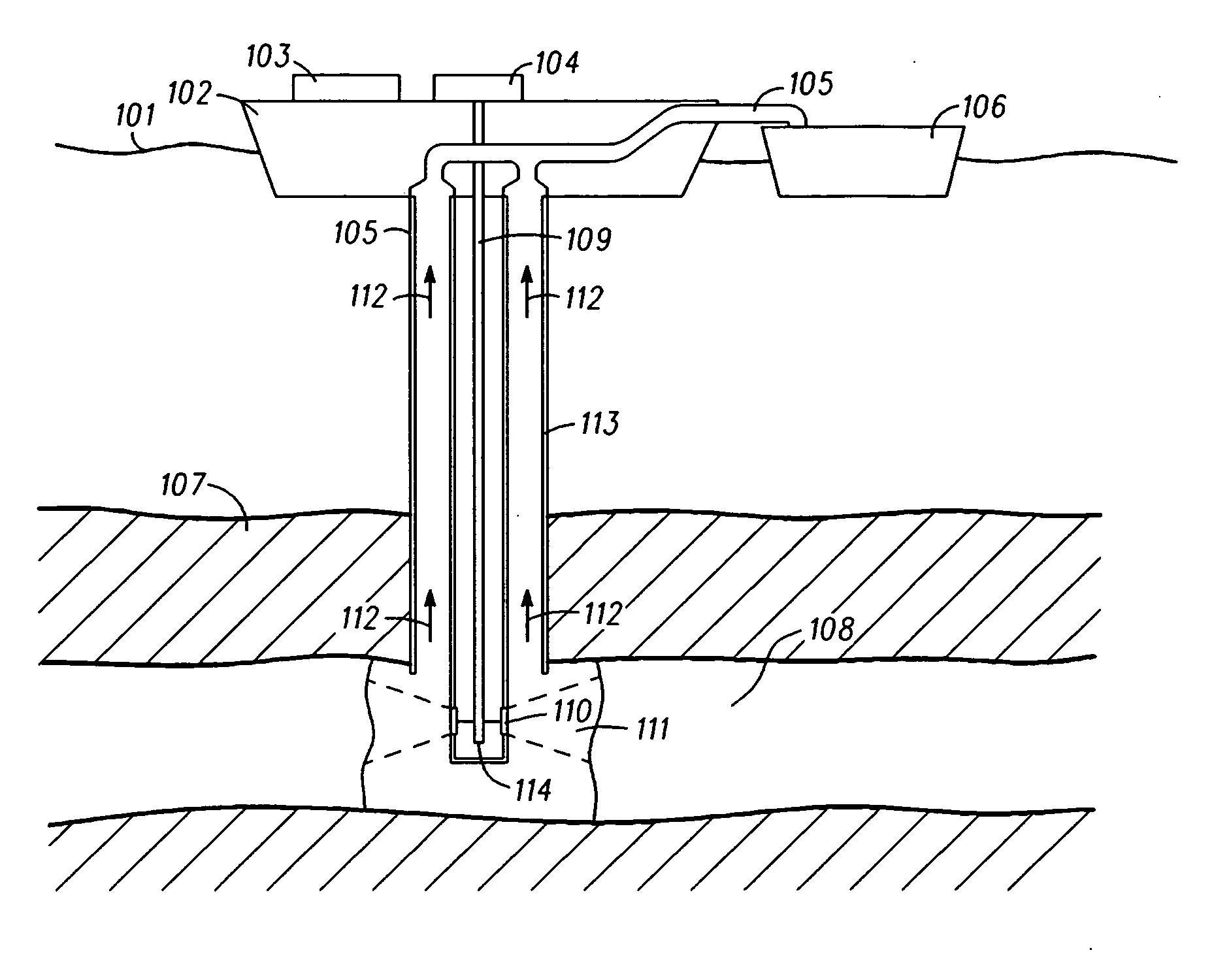

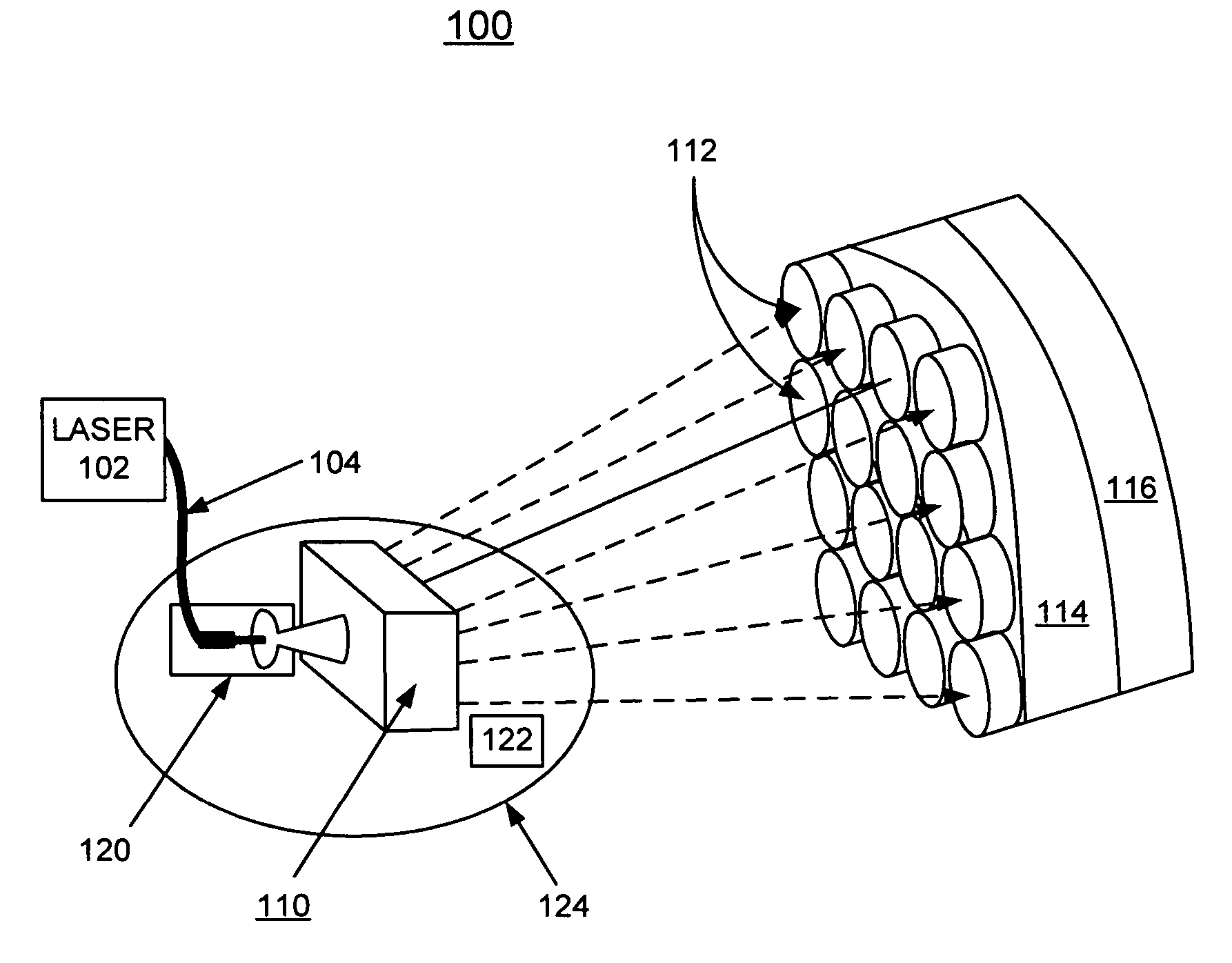

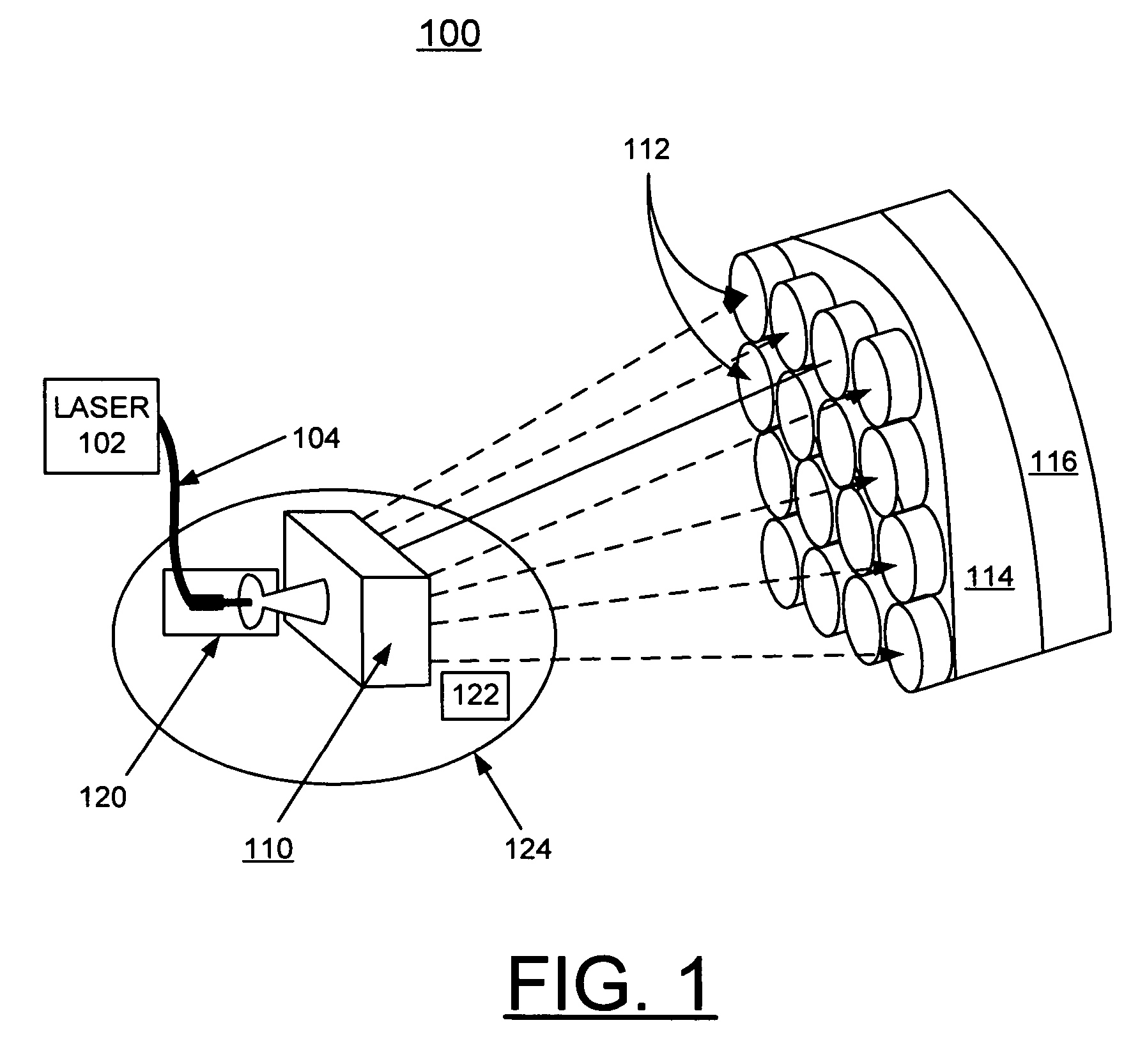

Method and apparatus for delivering high power laser energy over long distances

ActiveUS20100044106A1Suppressing nonlinear scattering phenomenonIncrease the lengthDrill bitsLaser using scattering effectsHigh power lasersOptoelectronics

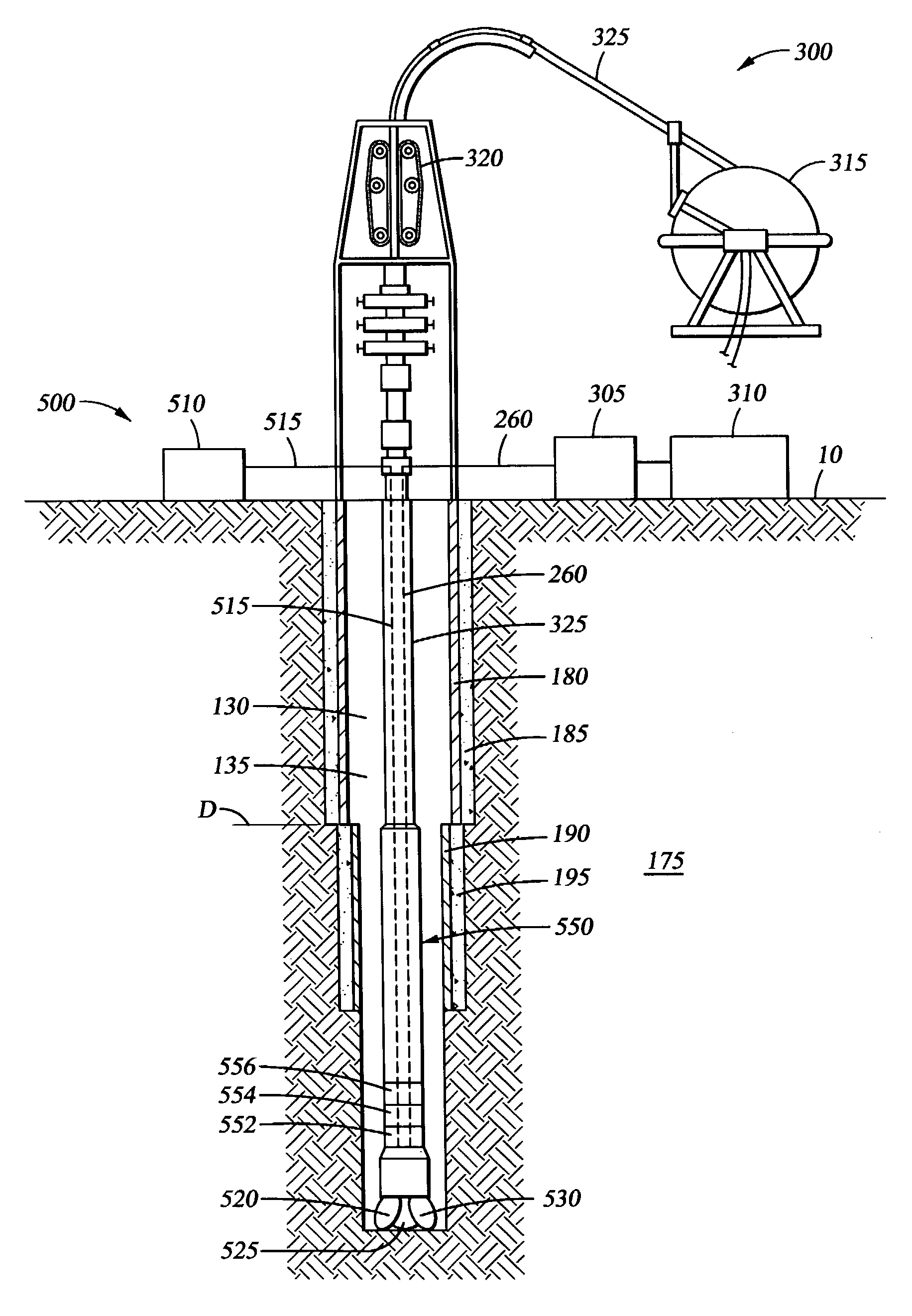

There is provided a system, apparatus and methods for the laser drilling of a borehole in the earth. There is further provided with in the systems a means for delivering high power laser energy down a deep borehole, while maintaining the high power to advance such boreholes deep into the earth and at highly efficient advancement rates.

Owner:FORO ENERGY

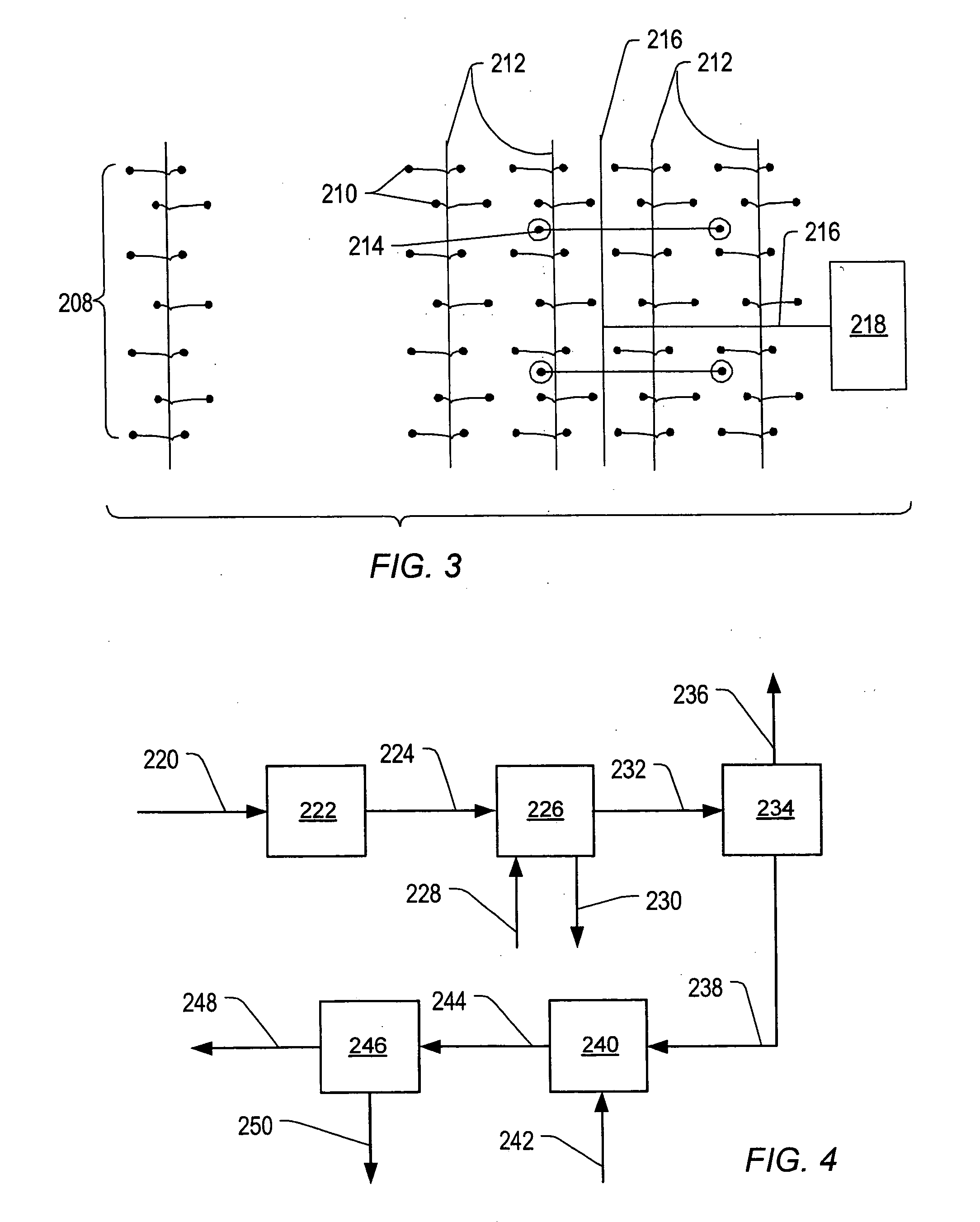

Reducing viscosity of oil for production from a hydrocarbon containing formation

ActiveUS20050269091A1Viscosity of fluidLow viscosityThermal drillingInsulationElectrical resistance and conductanceElectrical conductor

Certain embodiments provide a method for treating a hydrocarbon containing formation. The method includes applying electrical current to one or more electrical conductors located in an opening in the formation to provide an electrically resistive heat output. The heat is allowed to transfer from the electrical conductors to a part of the formation containing hydrocarbons so that a viscosity of fluids in the part and at or near the opening in the formation is reduced. Gas is provided at one or more locations in the opening such that the fluids are lifted in the opening towards the surface of the formation. The fluids are produced through the opening.

Owner:SHELL OIL CO

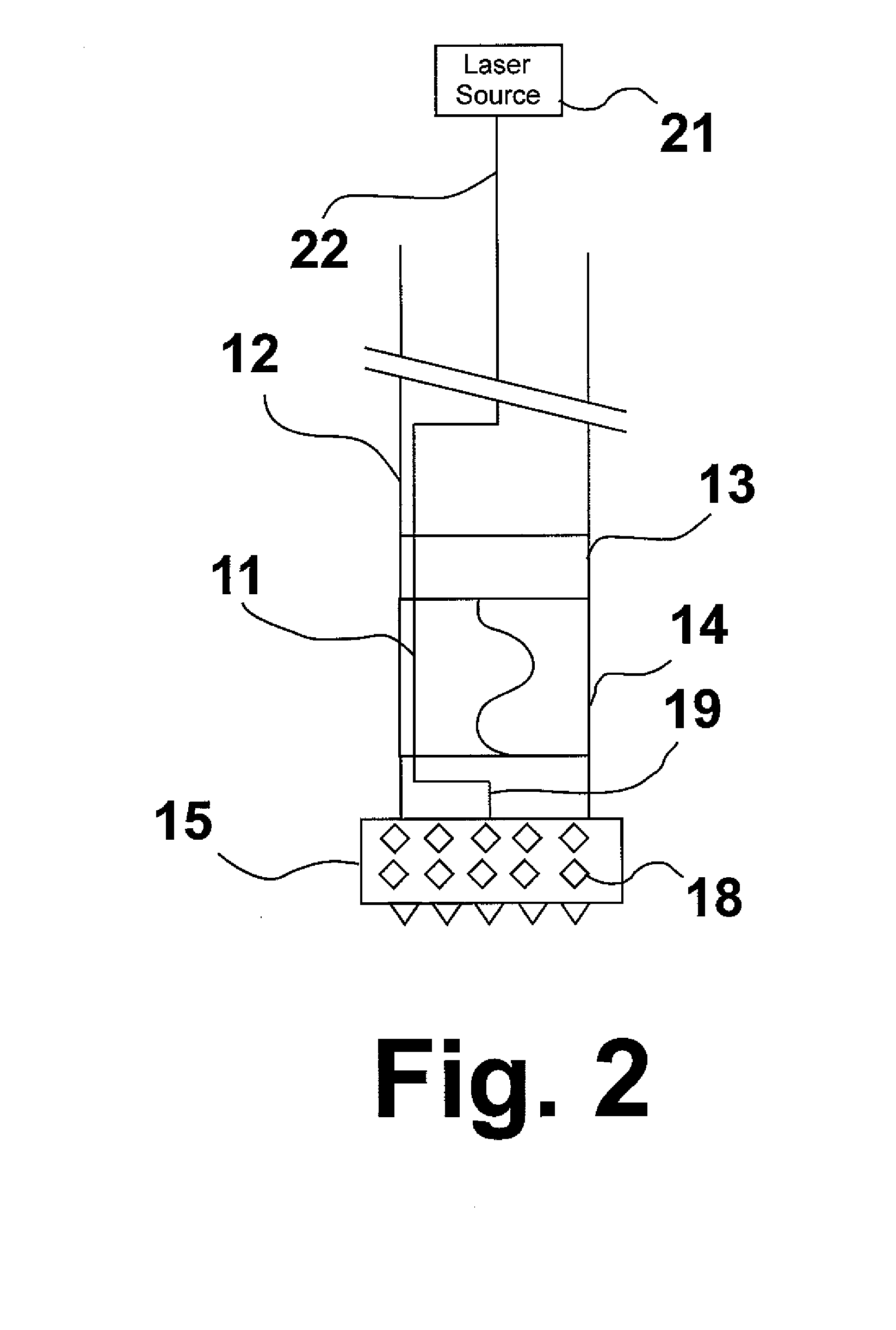

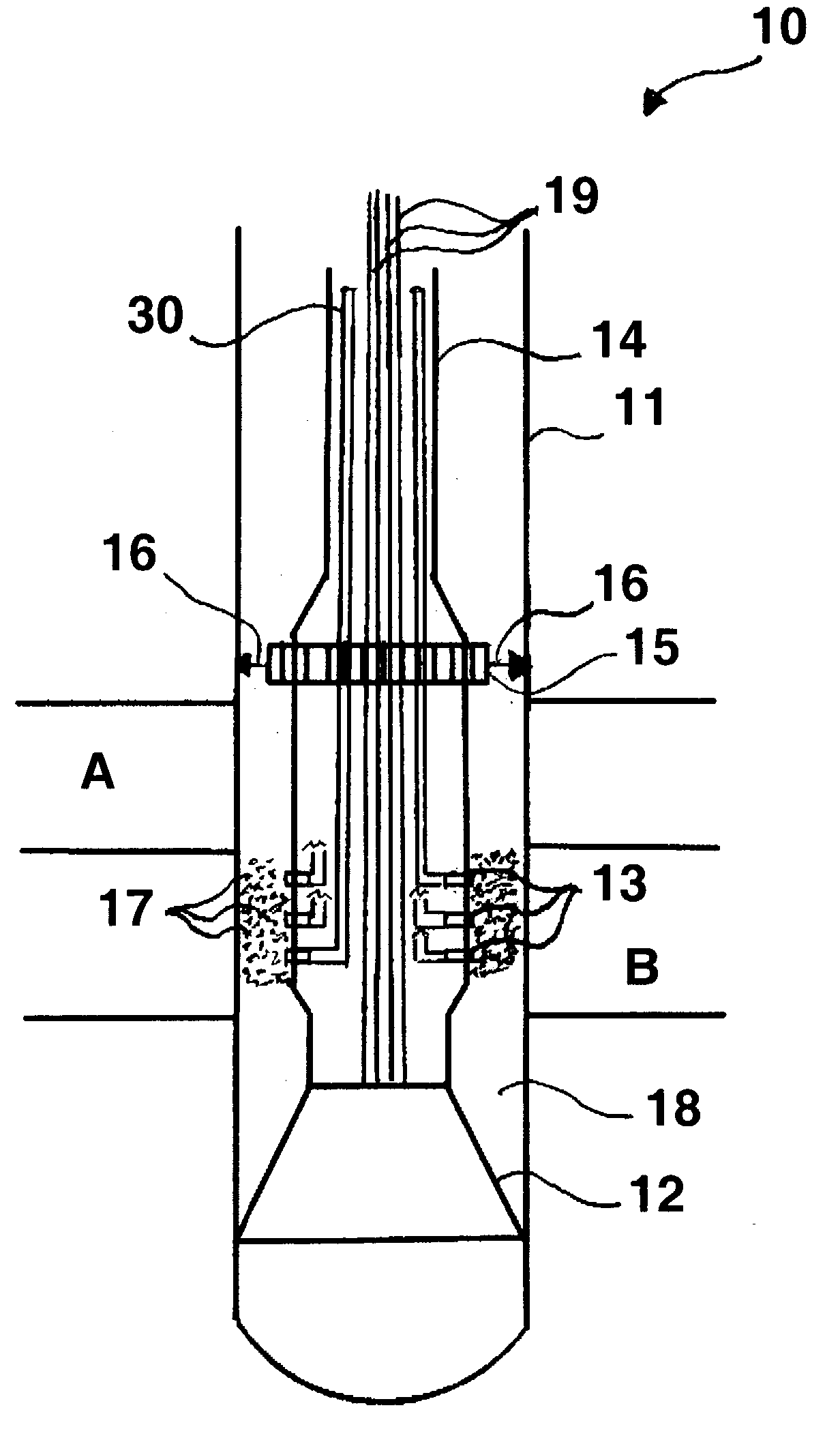

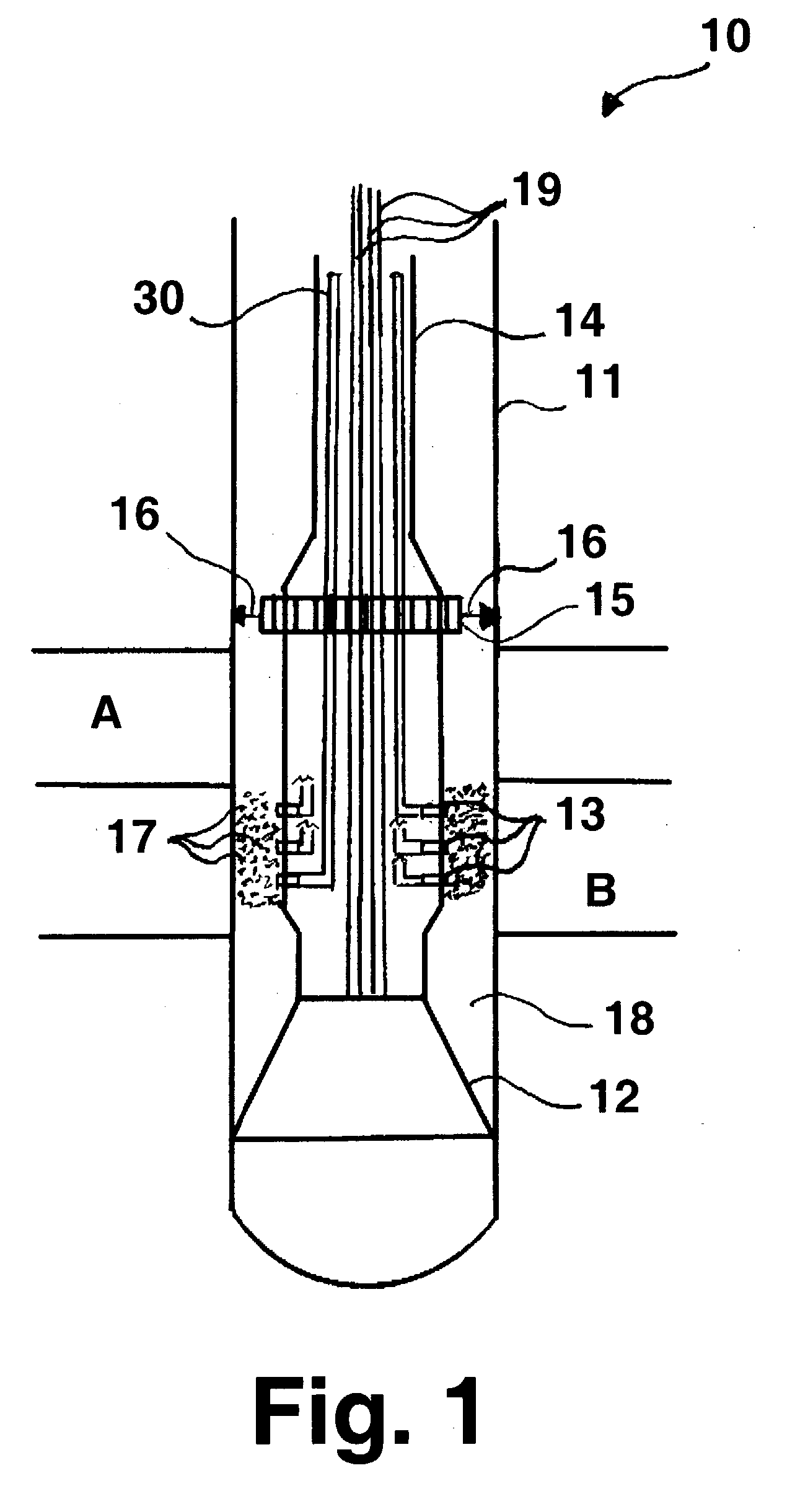

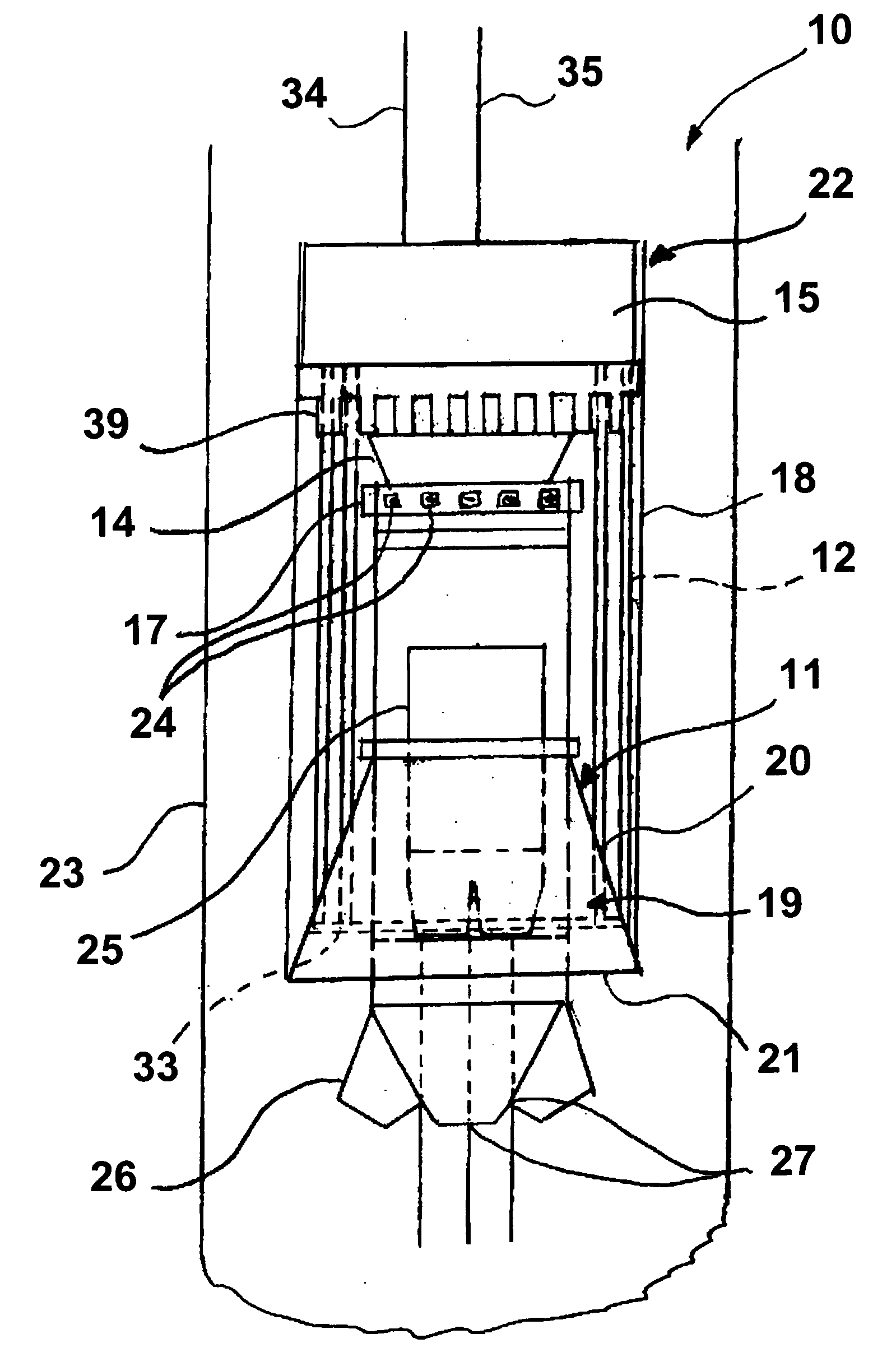

Fiber optics laser perforation tool

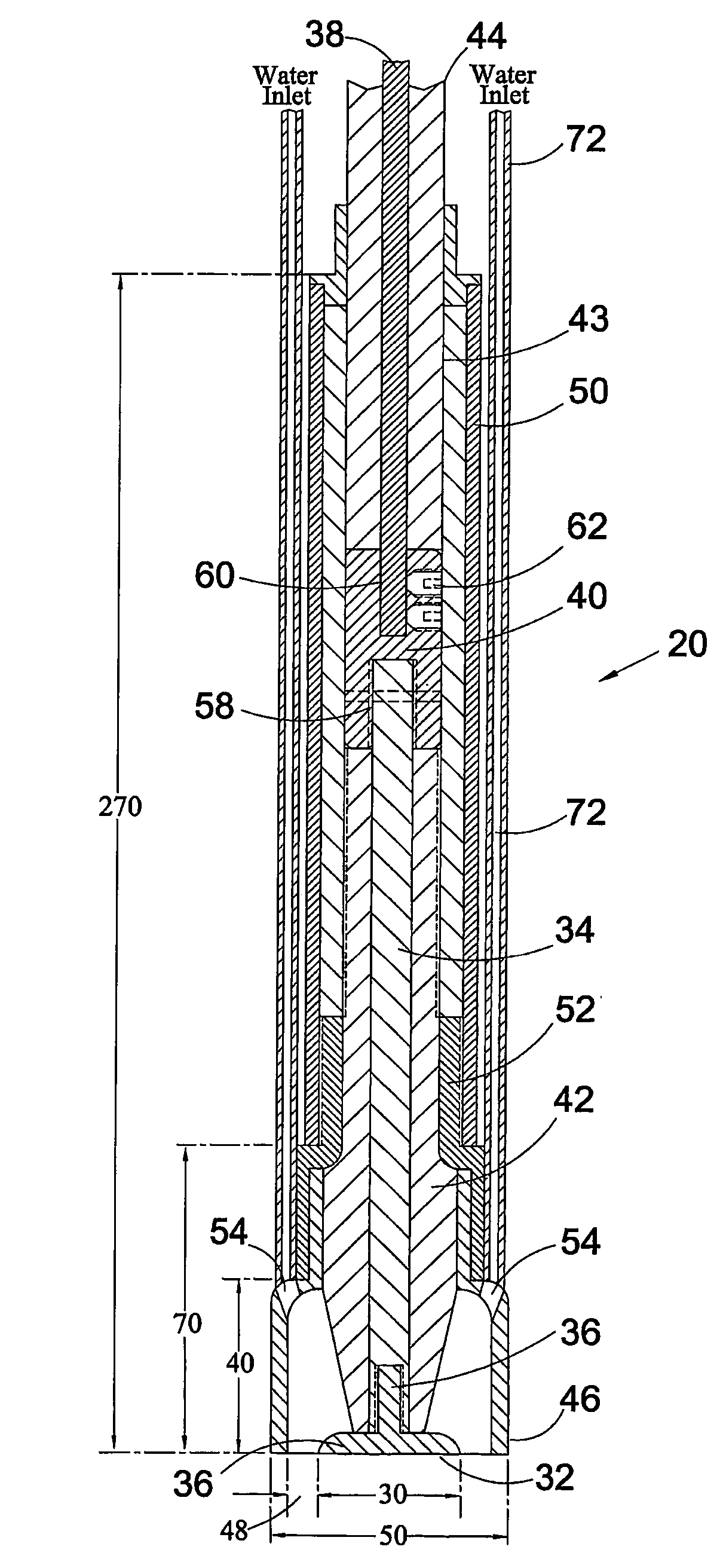

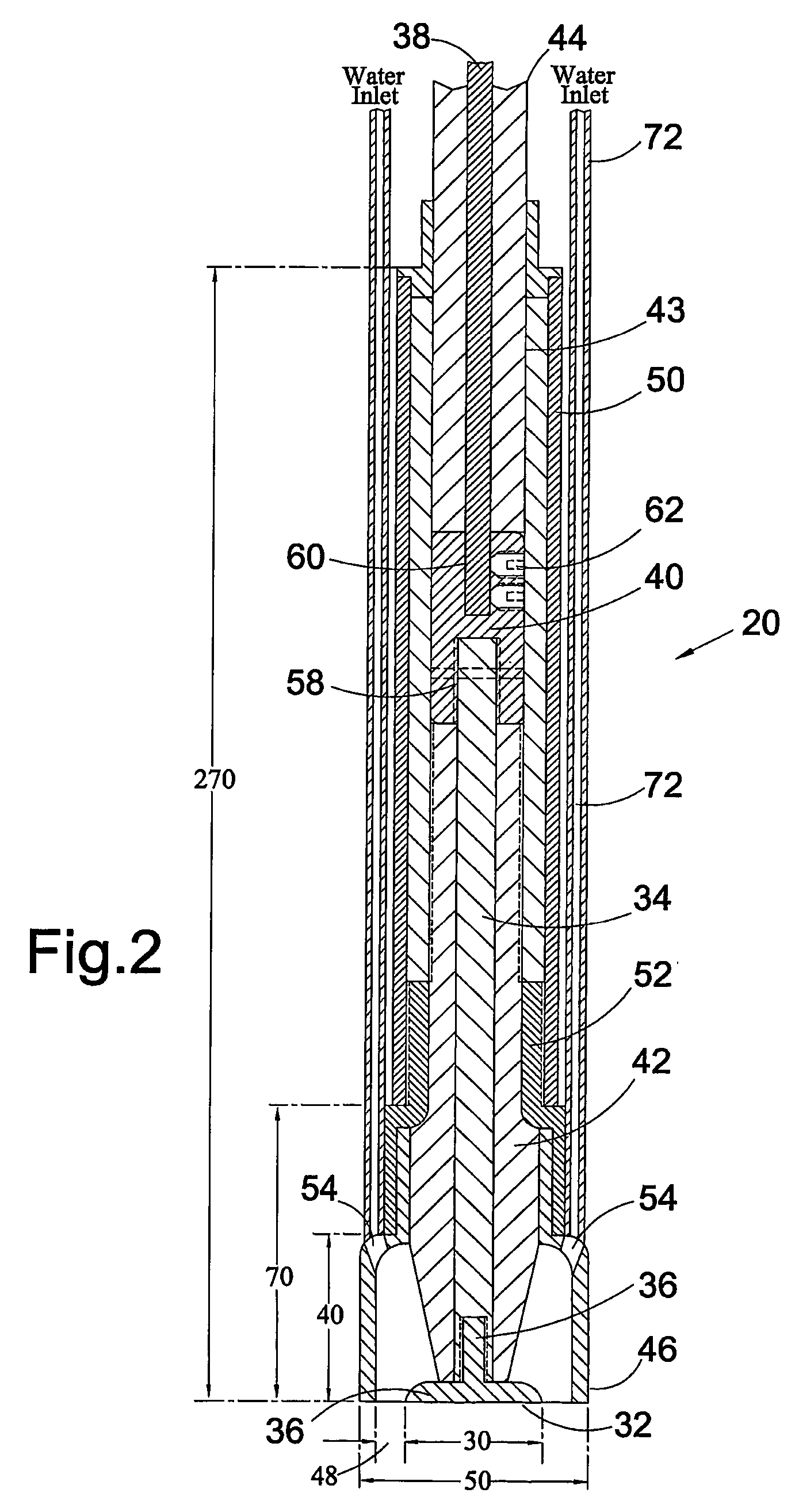

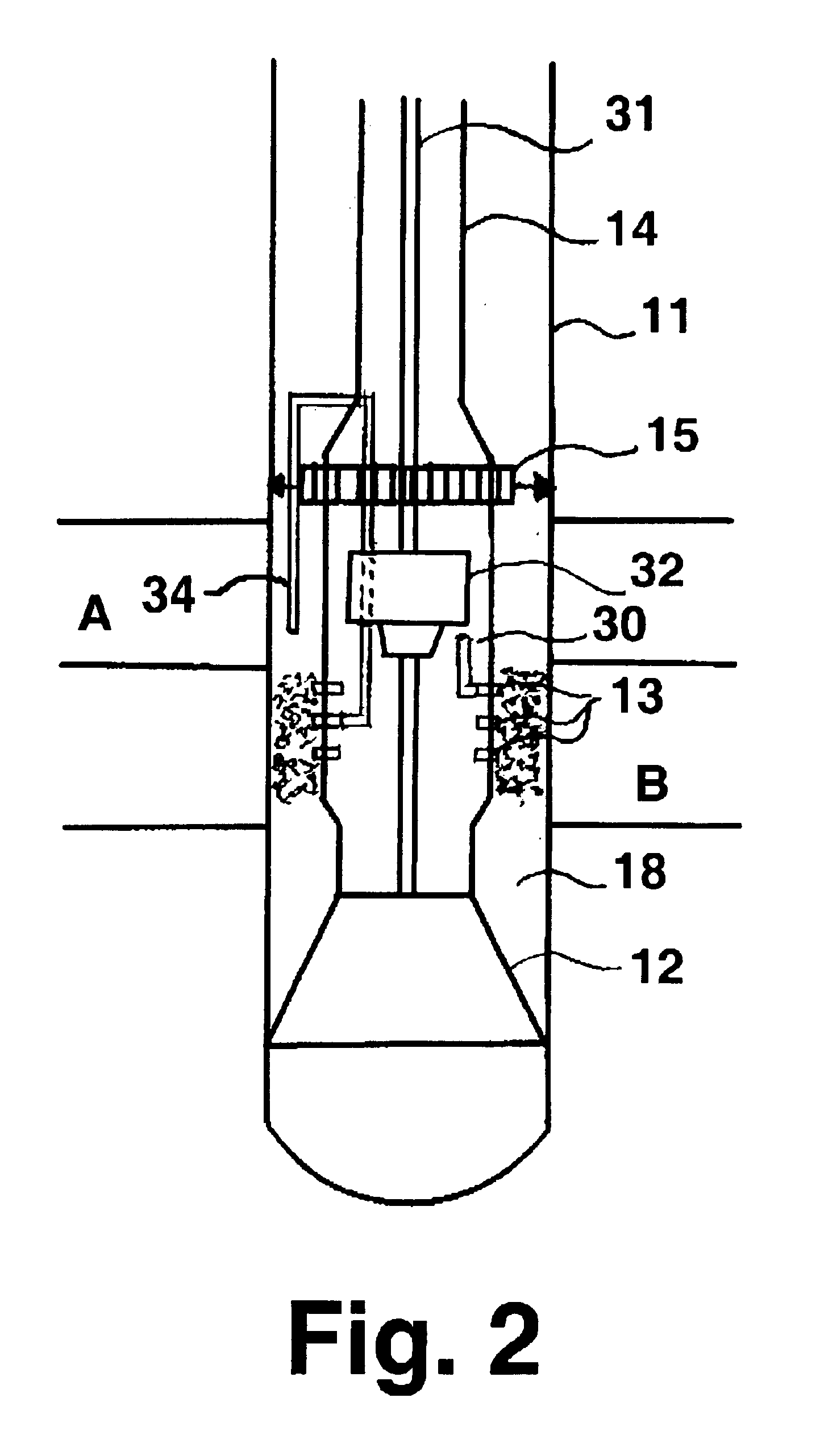

InactiveUS6888097B2Eliminate damageReduce productionDisloding machinesThermal drillingFiberOptoelectronics

Owner:GAS TECH INST

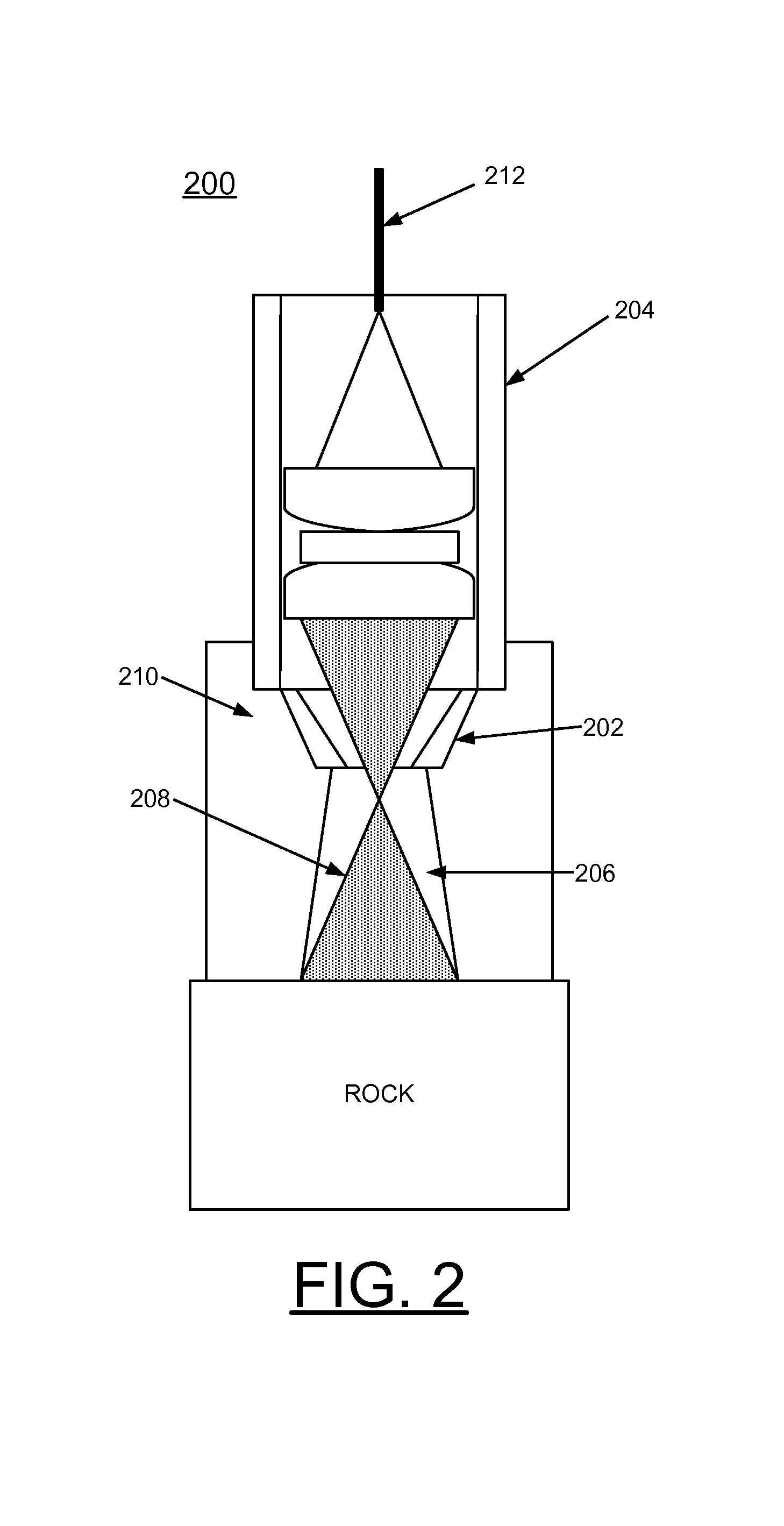

Fiber optics laser perforation tool

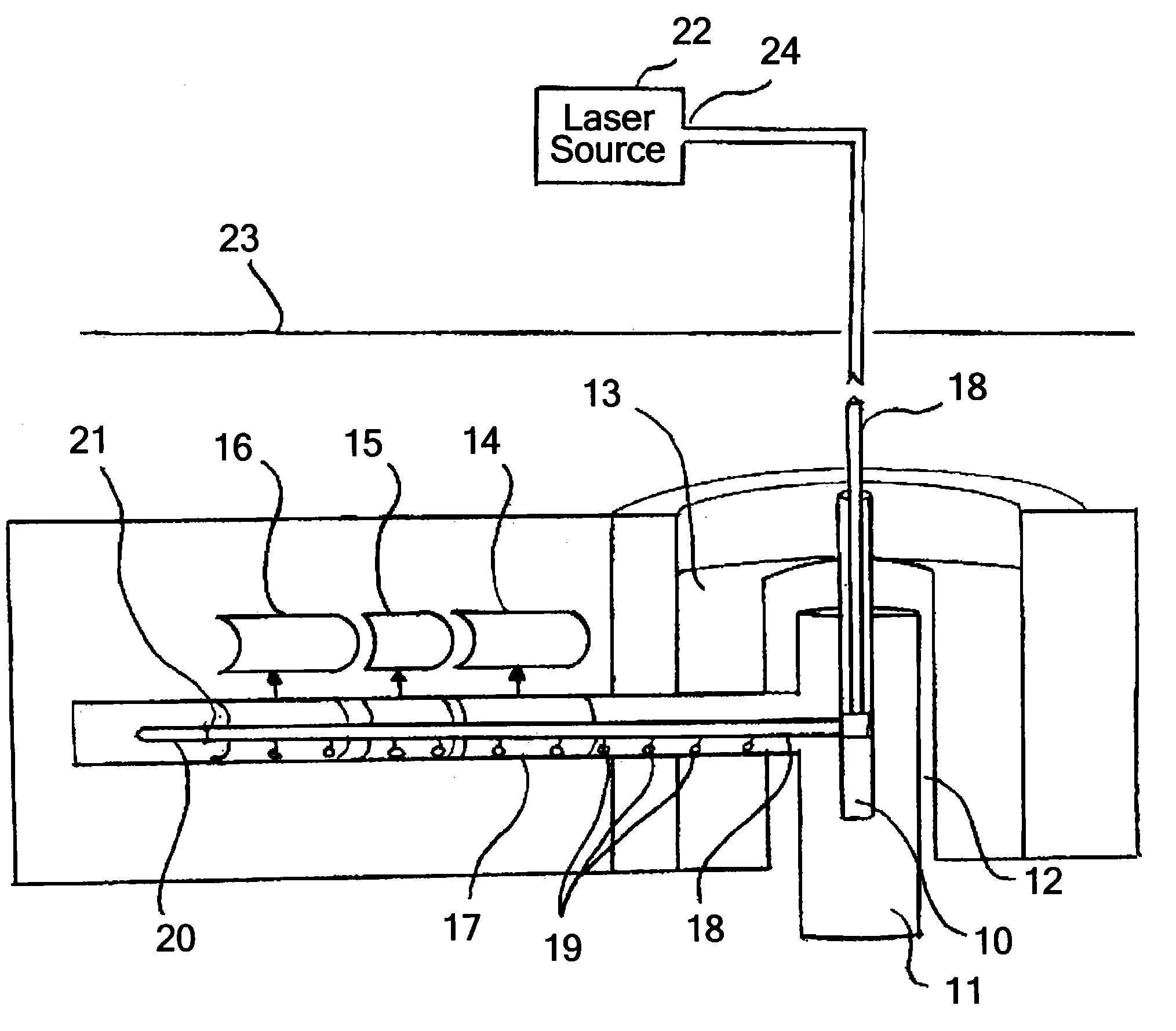

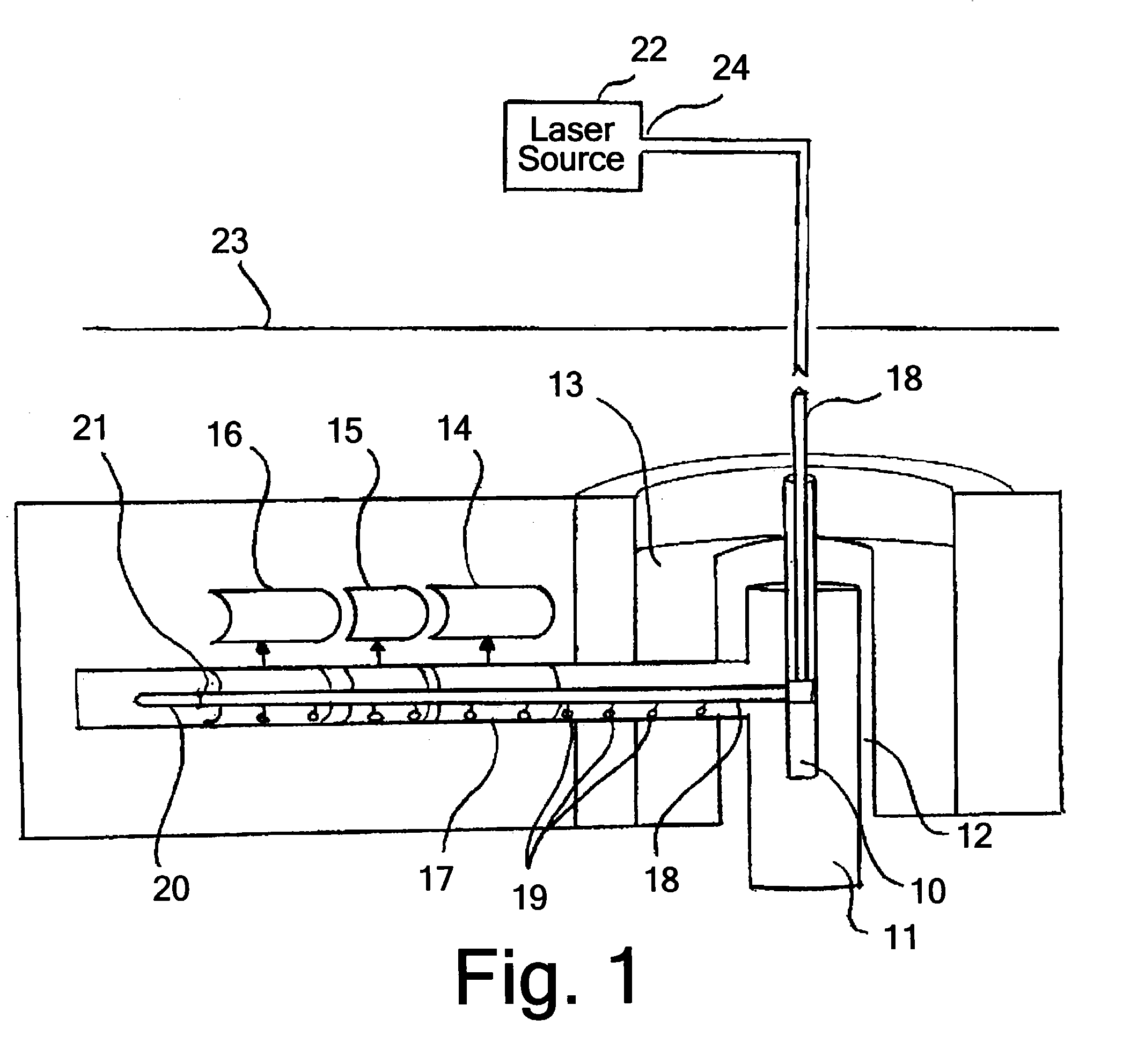

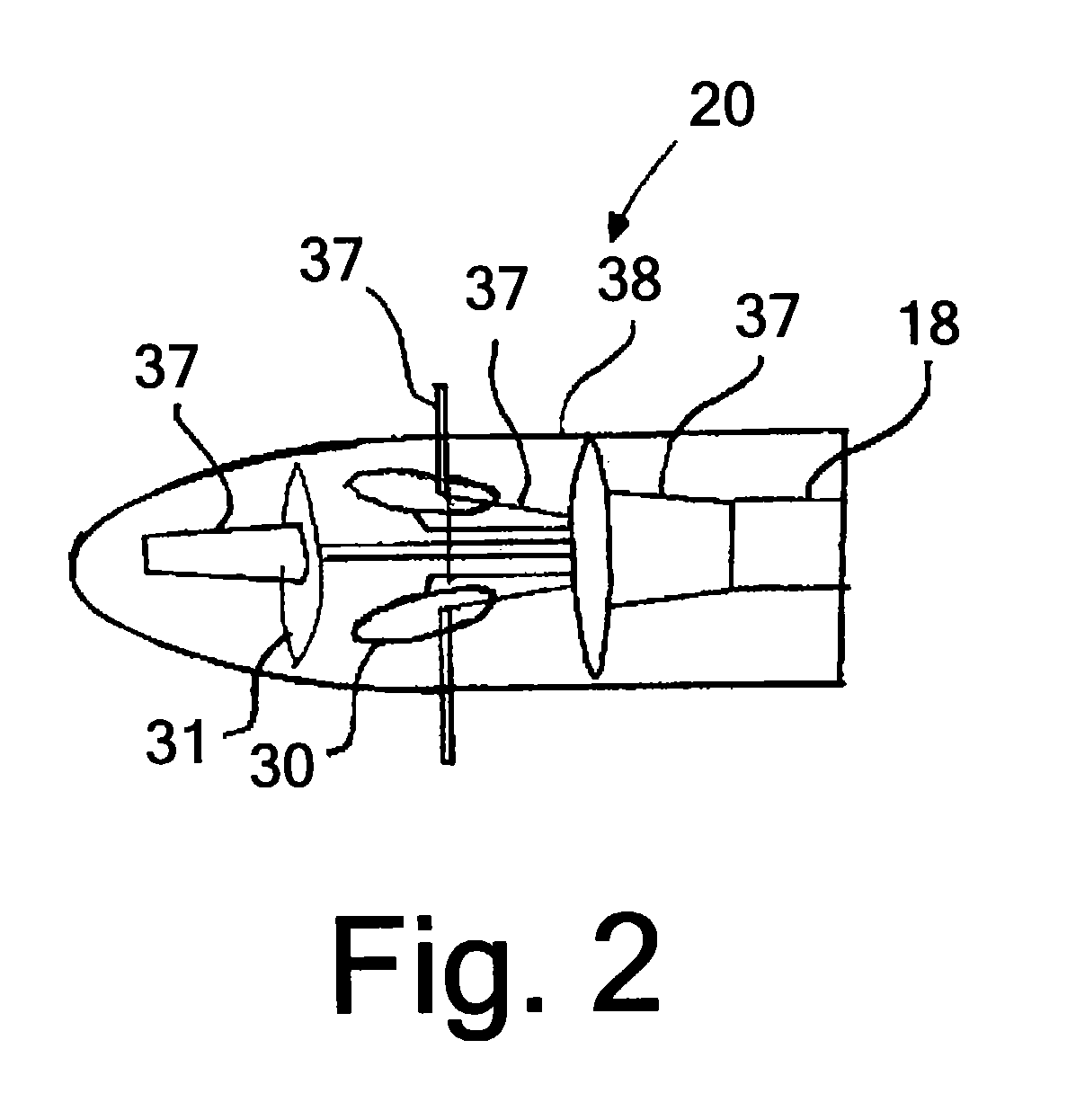

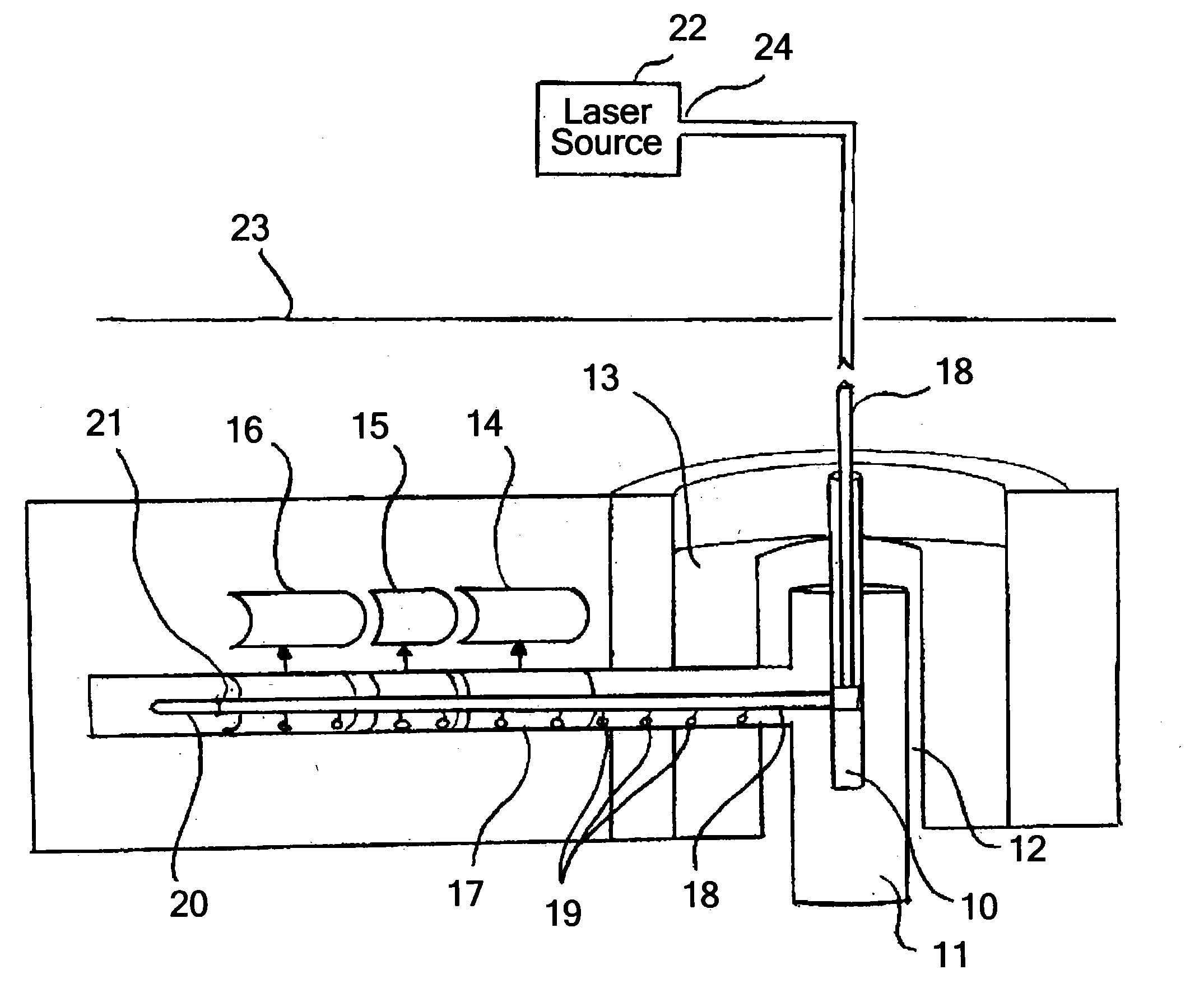

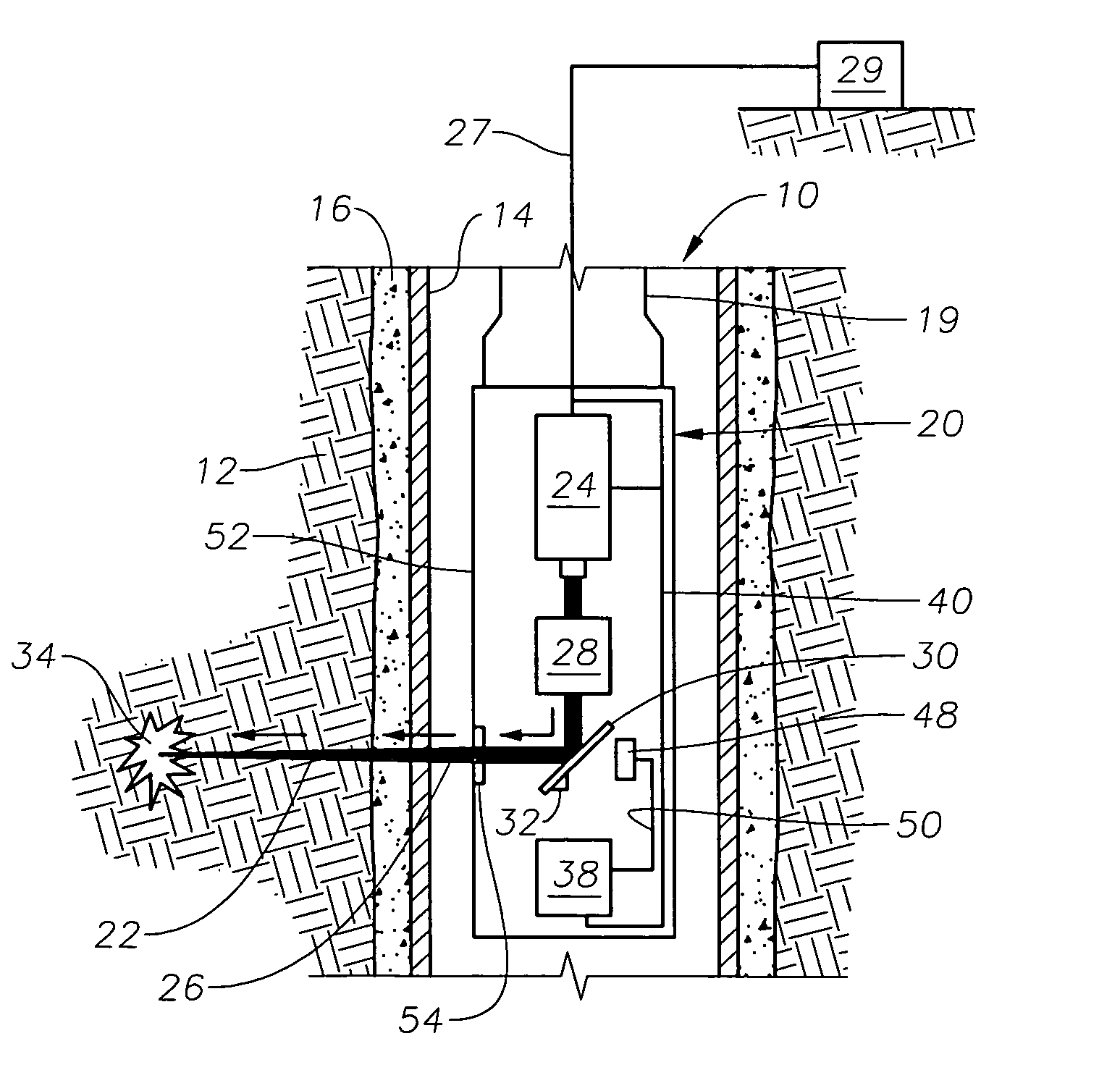

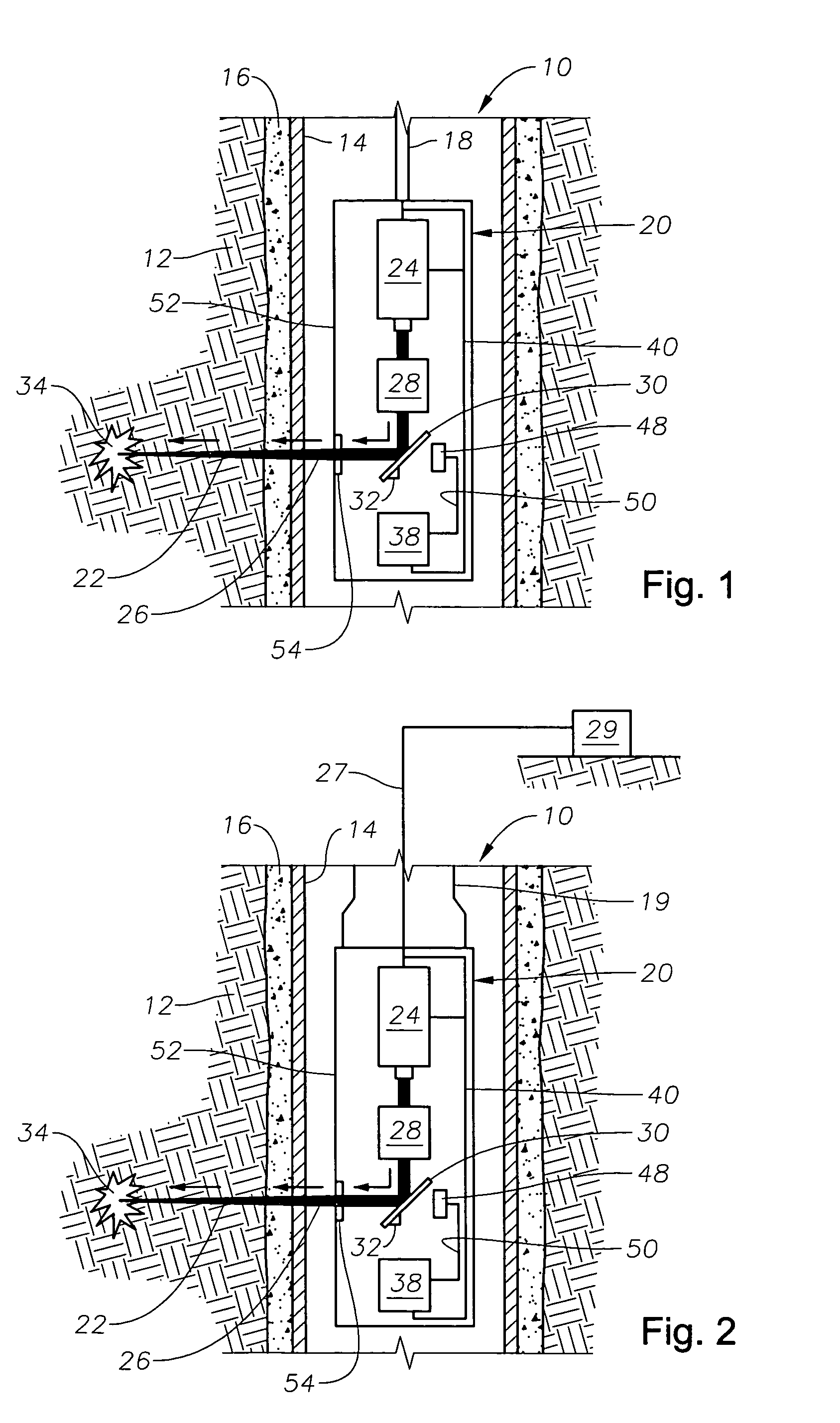

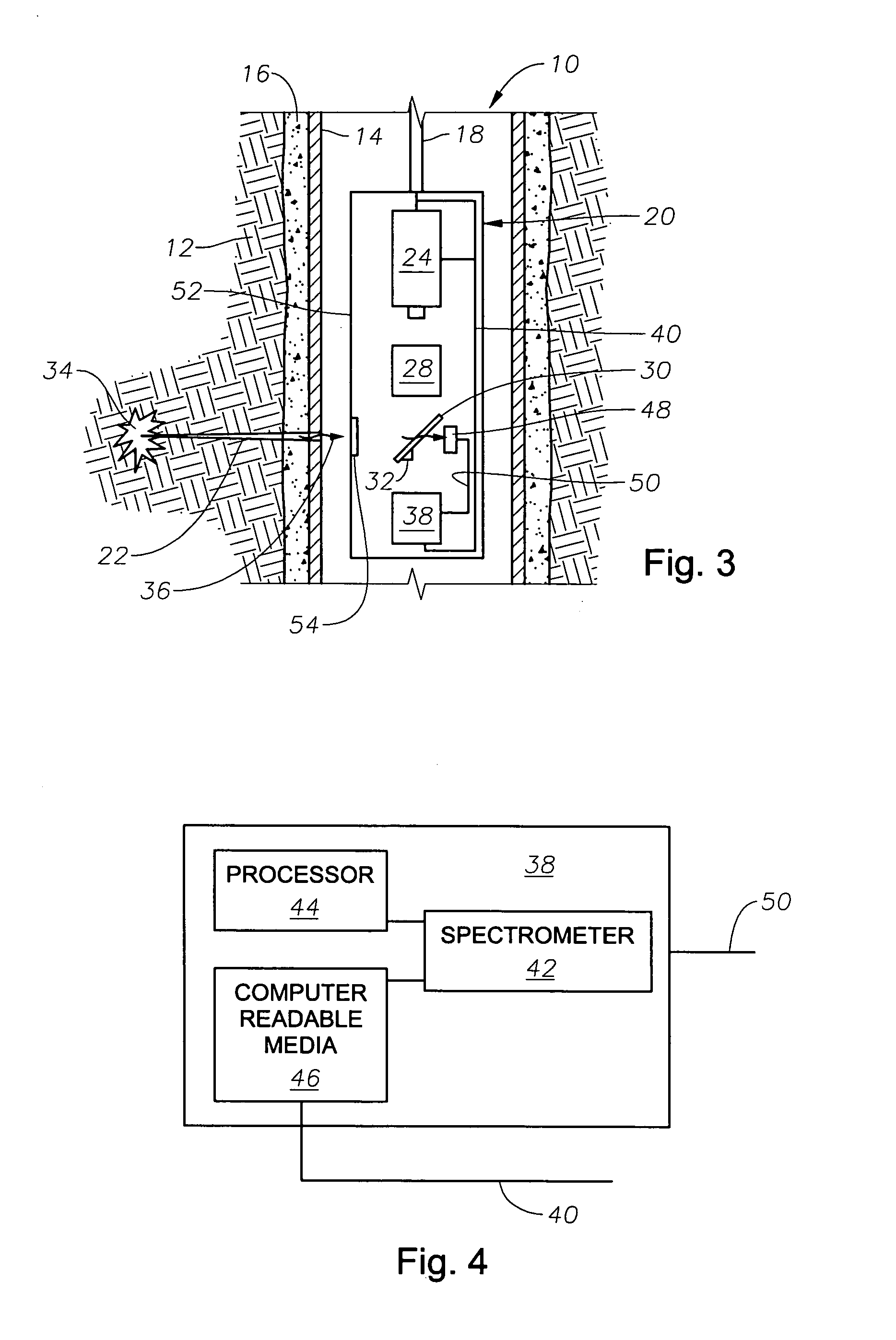

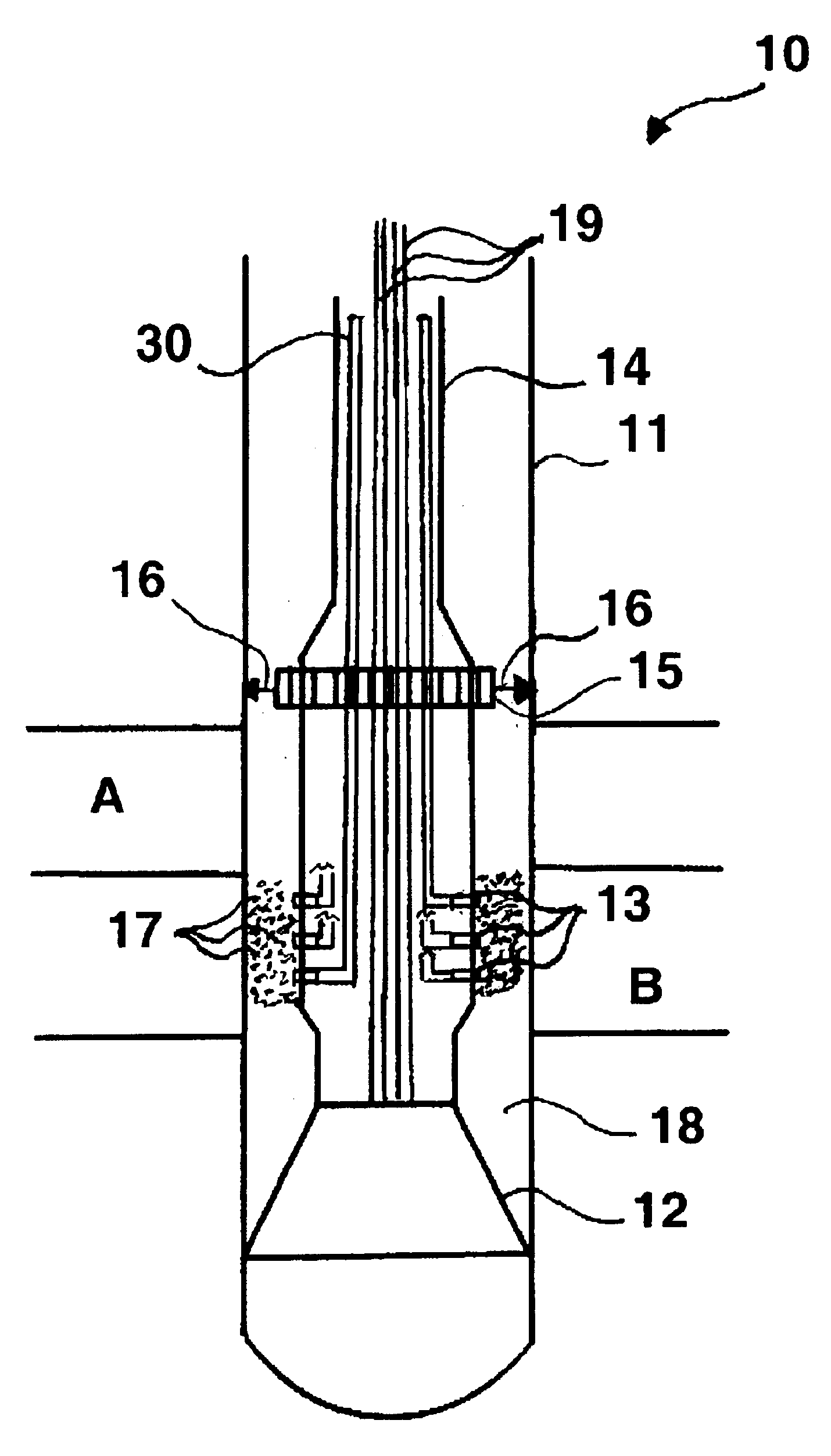

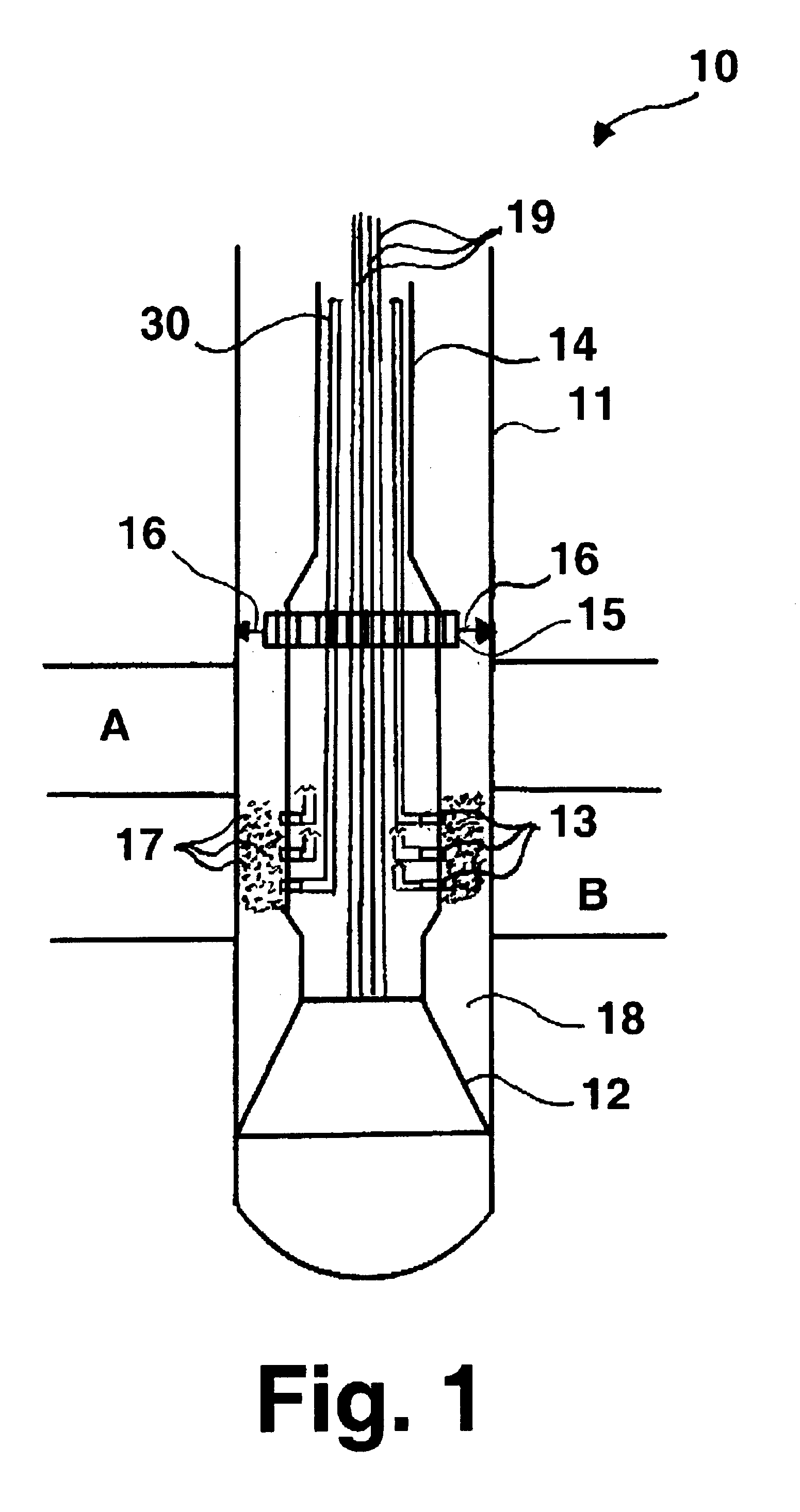

InactiveUS20040256103A1Eliminate damageReduce productionDisloding machinesThermal drillingFiberOptoelectronics

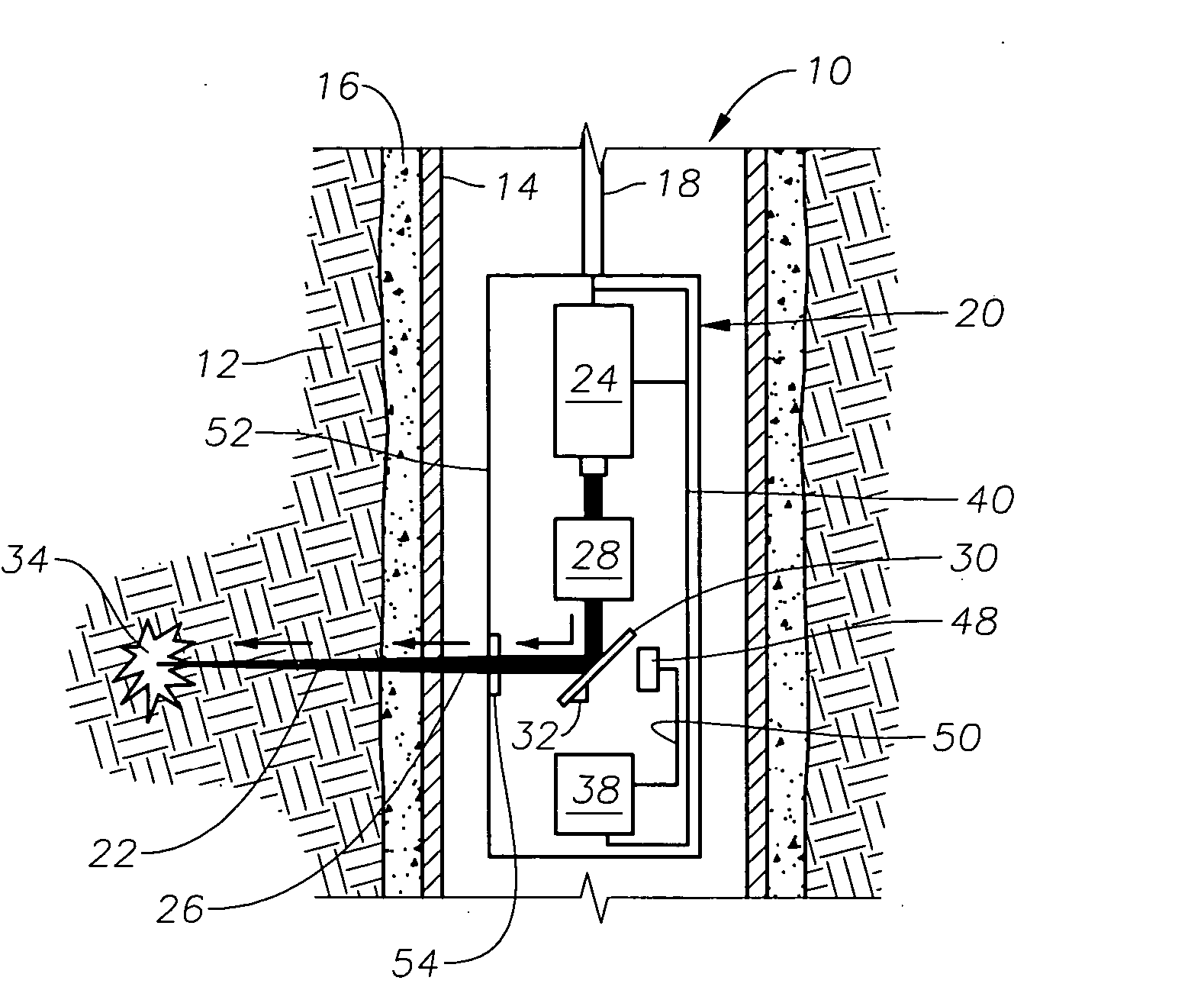

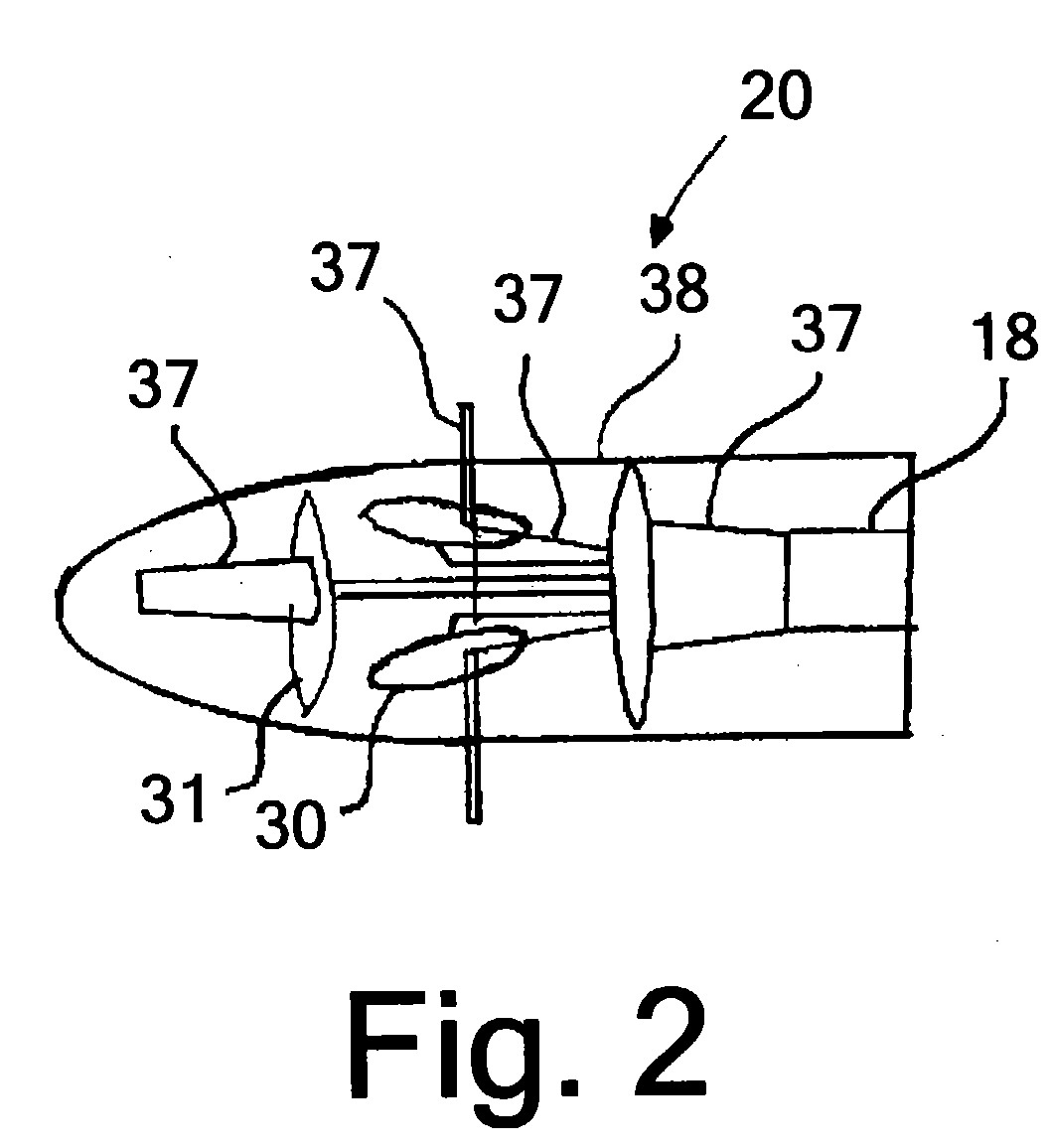

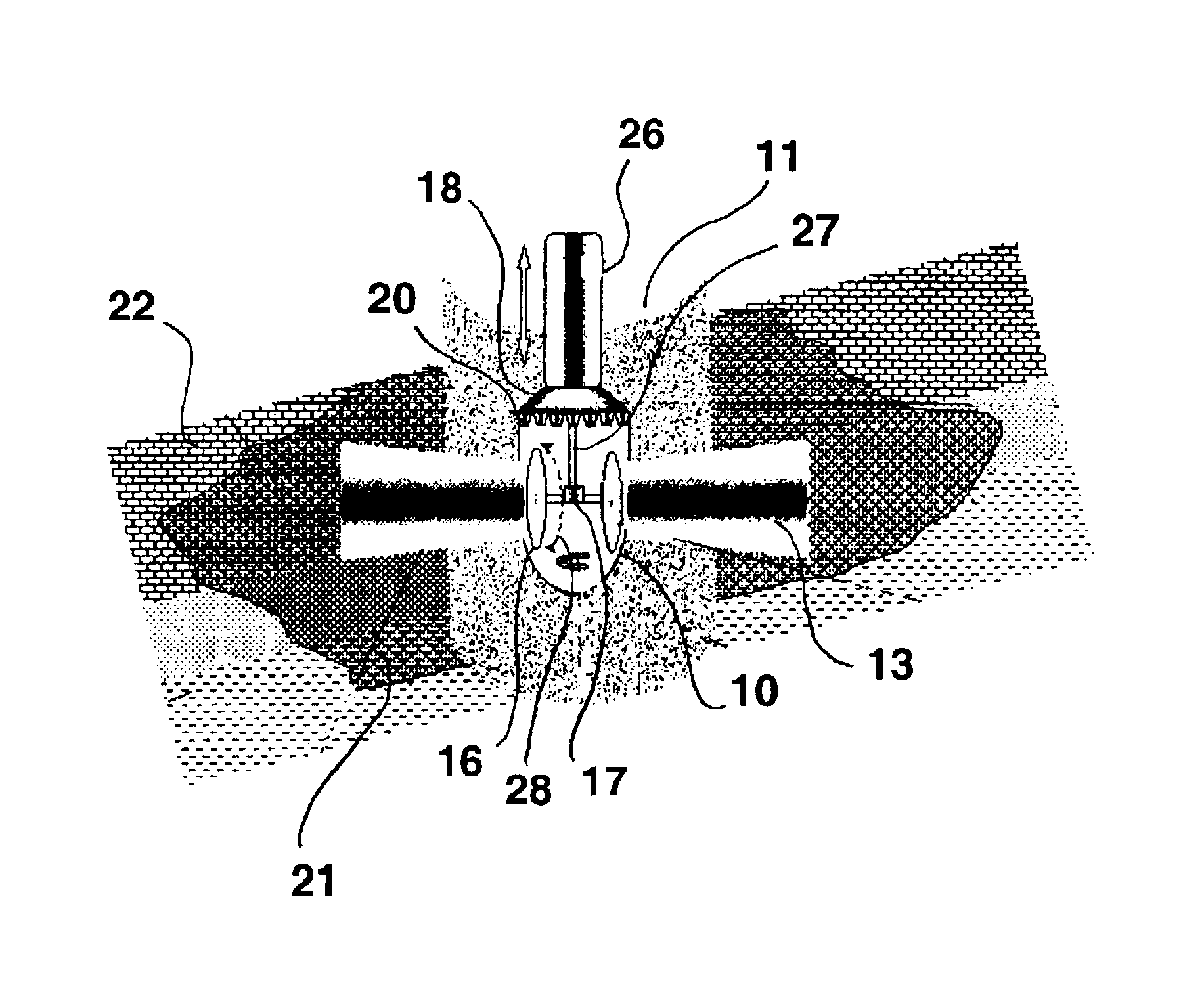

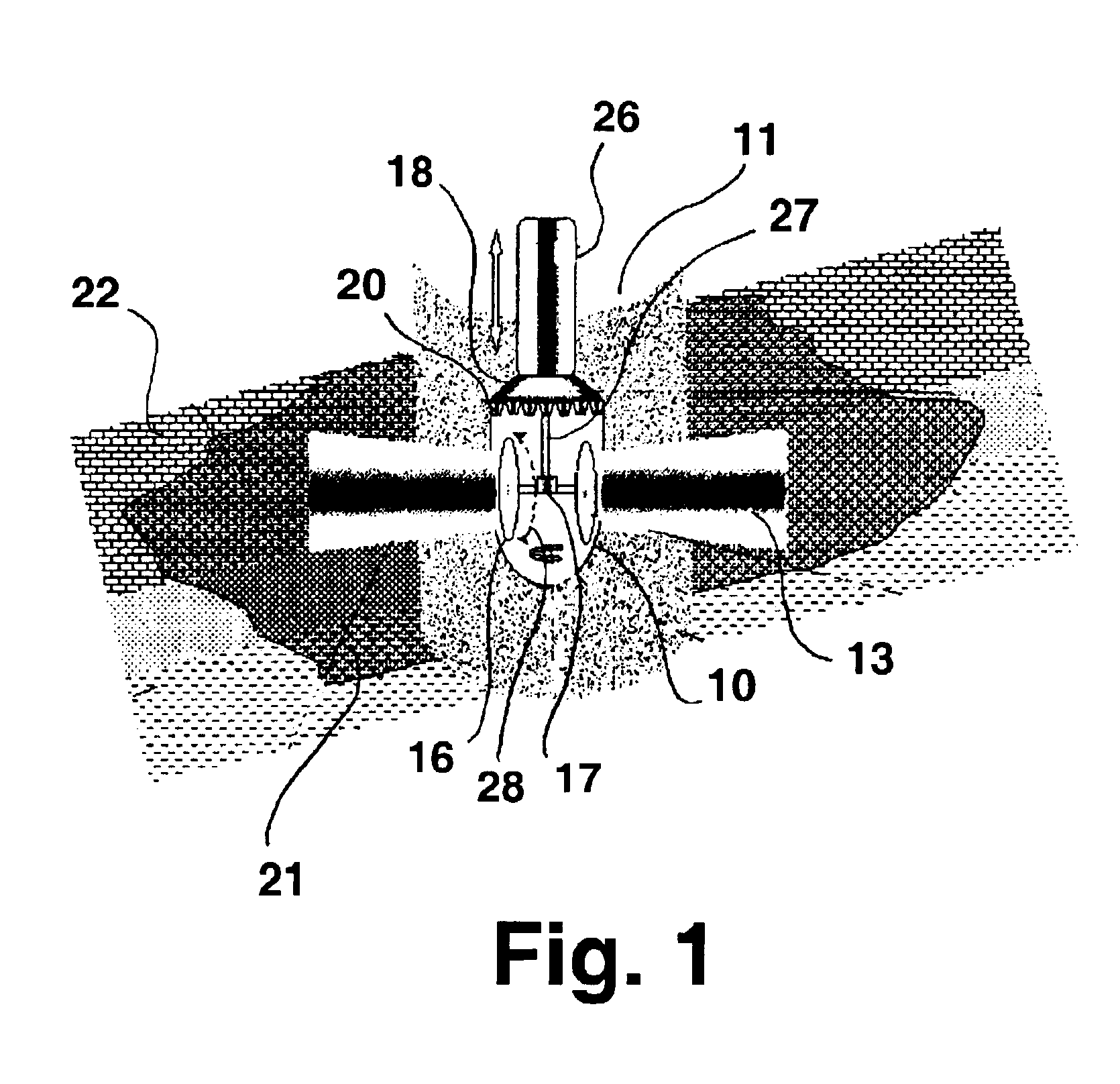

An apparatus for perforation of wellbore walls, which apparatus includes a fiber optic cable having a laser input end and a laser output end. A laser source is operably connected to the laser input end and a laser head is connected to the laser output end. The laser head includes a laser control components for controlling at least one laser beam characteristic. Laser head control elements for controlling the motion and location of the laser head are operably connected to the fiber optic cable. The laser head is enclosed in a protective housing, which protects the fiber optic cable and elements, such as reflectors and lenses for controlling the laser beam emitted by the fiber optic cable disposed therein, from the harsh environments encountered in downhole operations.

Owner:GAS TECH INST

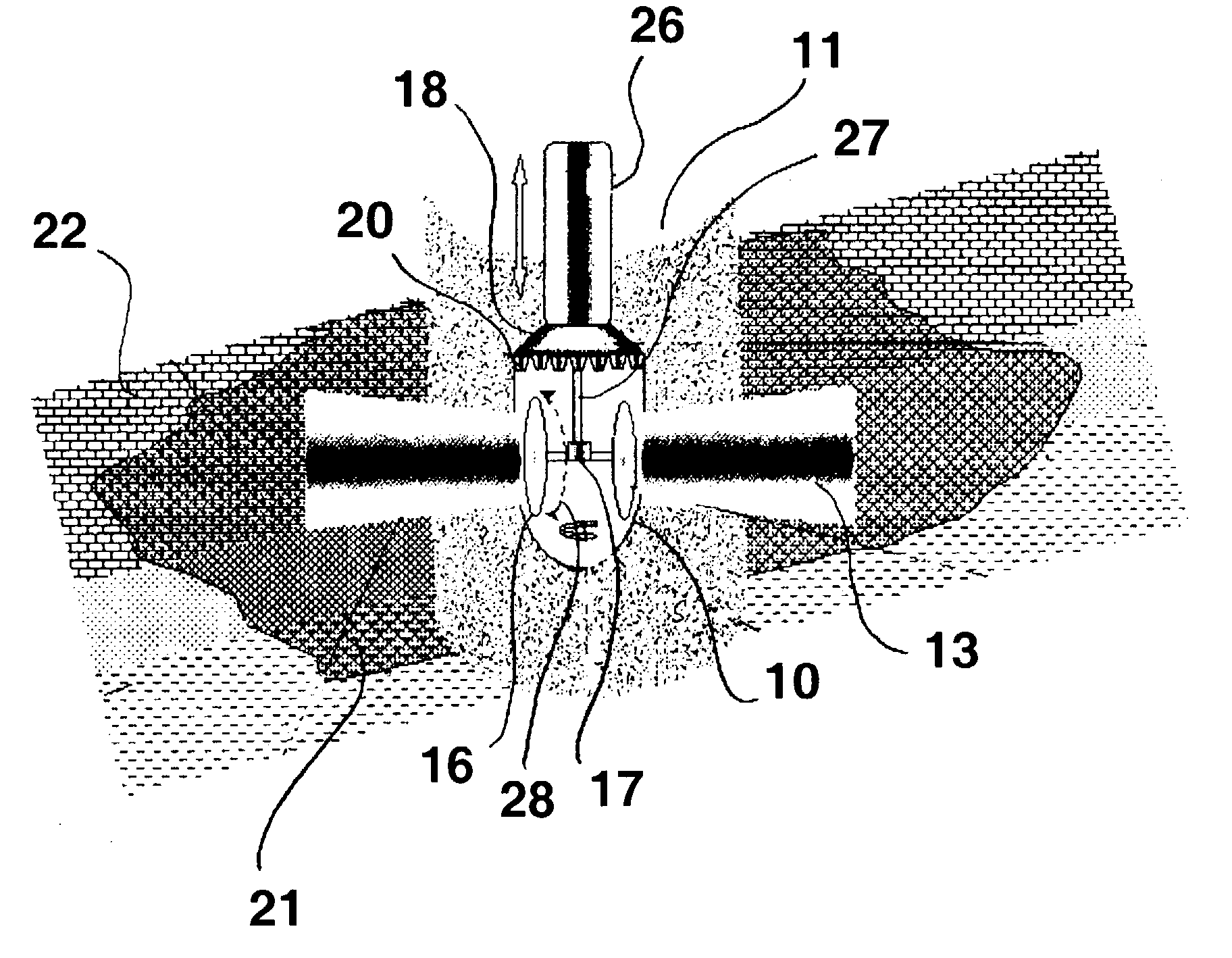

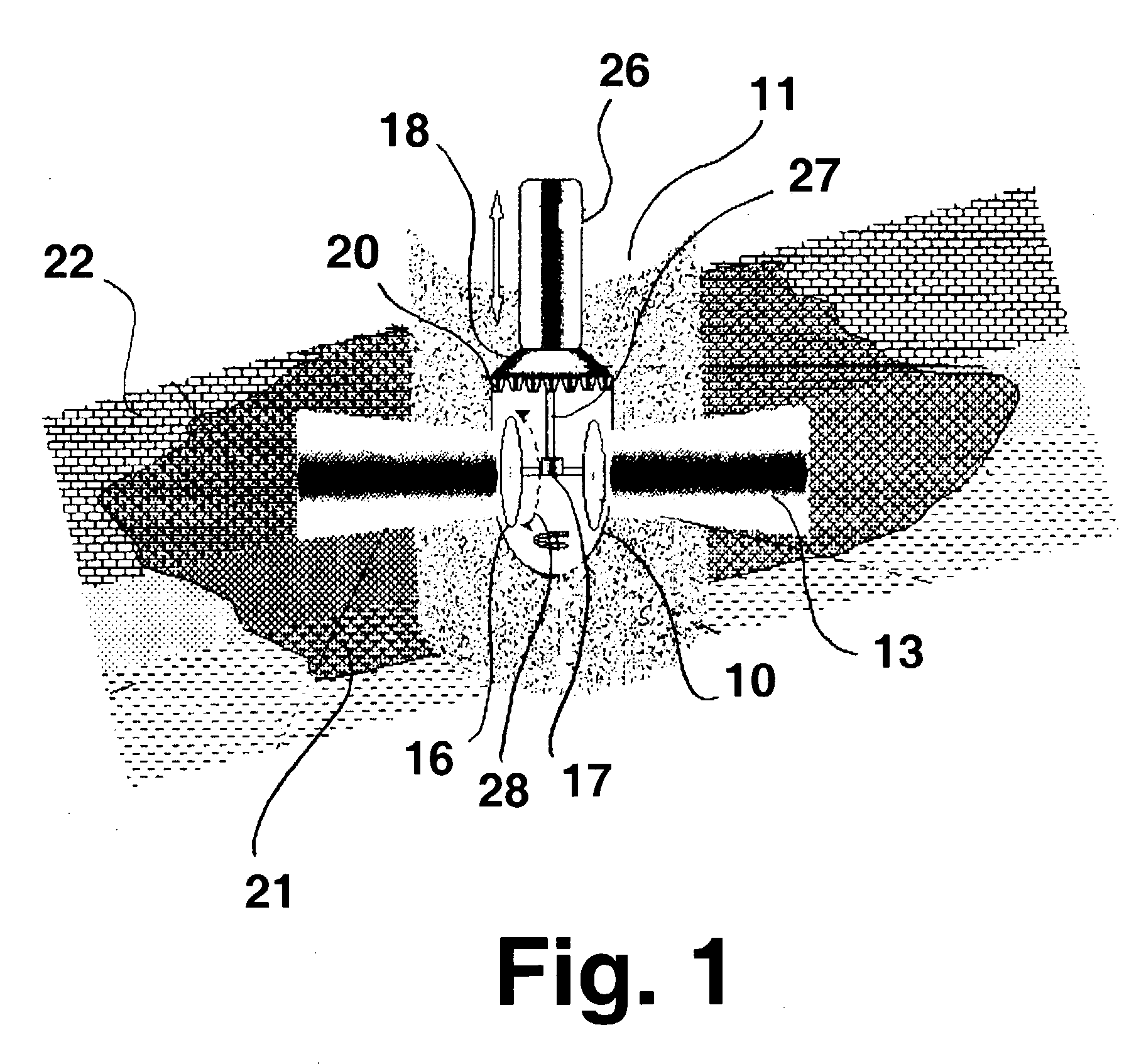

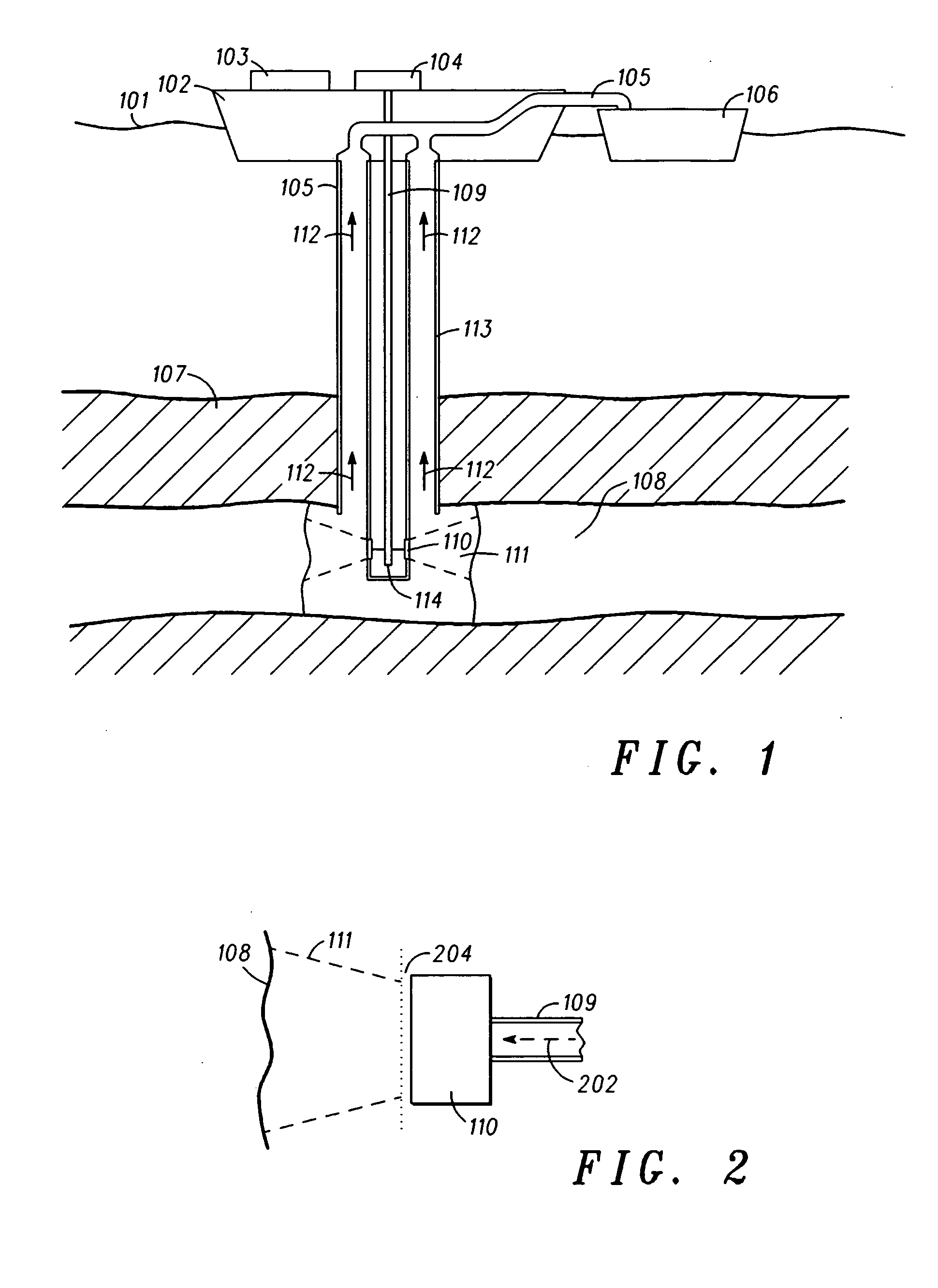

Laser wellbore completion apparatus and method

InactiveUS6880646B2Increase flow rateLow viscosityDisloding machinesThermal drillingMolecular physicsLaser

A method and apparatus for providing fluid flow into a wellbore in which an apparatus having at least one laser energy output is lowered into the wellbore and the at least one laser energy output is directed at a wall of the wellbore. At least a portion of the wall is heated using the at least one laser energy output, whereby flow of a fluid into the wellbore is initiated and / or- enhanced.

Owner:GAS TECH INST

Laser wellbore completion apparatus and method

InactiveUS20040206505A1Low viscosityIncrease flow rateDisloding machinesThermal drillingMolecular physicsWellbore

A method and apparatus for providing fluid flow into a wellbore in which an apparatus having at least one laser energy output is lowered into the wellbore and the at least one laser energy output is directed at a wall of the wellbore. At least a portion of the wall is heated using the at least one laser energy output, whereby flow of a fluid into the wellbore is initiated and / or- enhanced.

Owner:GAS TECH INST

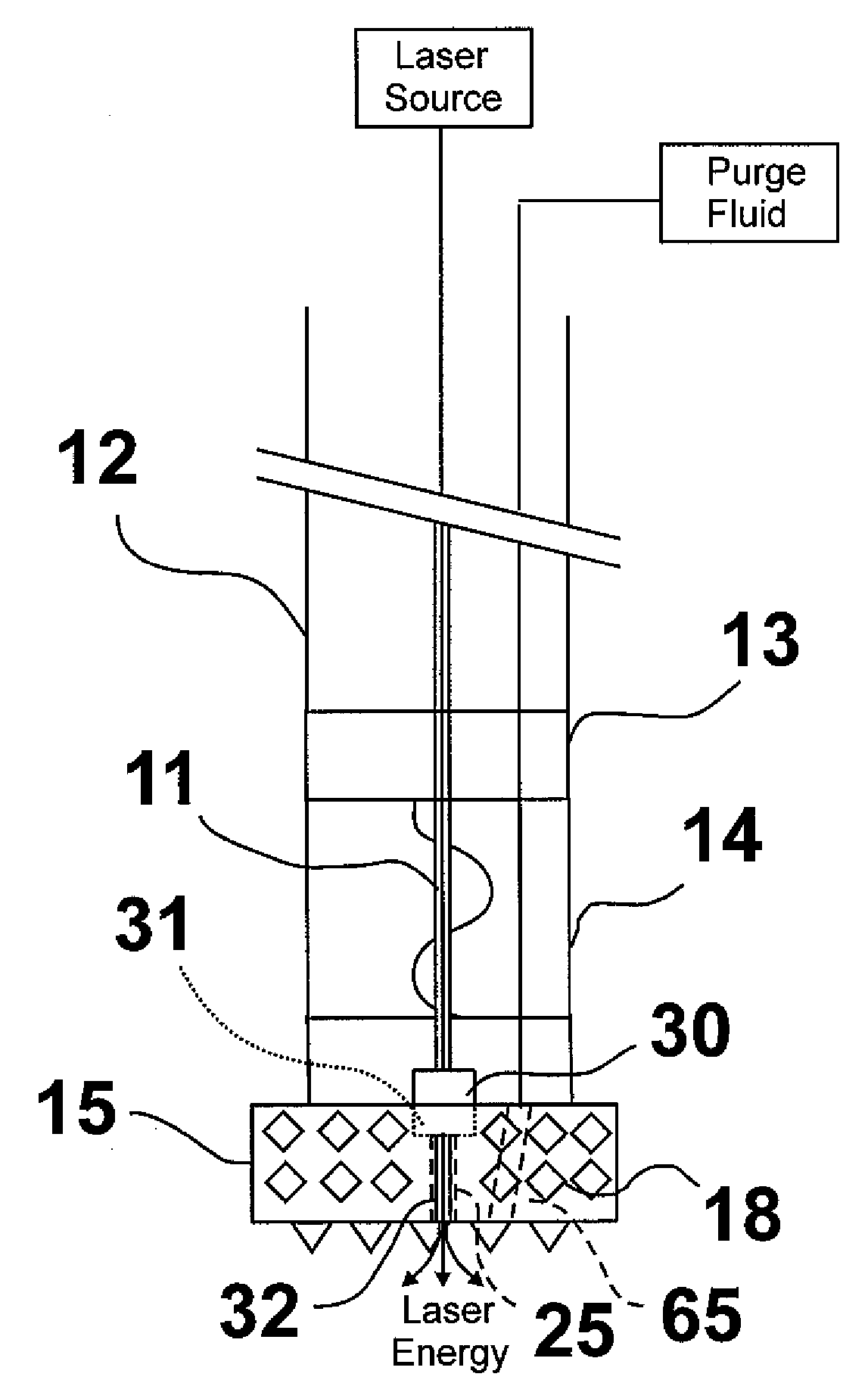

Drilling, perforating and formation analysis

ActiveUS7490664B2Easy to useWithout usingSpectrum investigationConstructionsMaterial removalWell drilling

A system and method of drilling and / or perforating uses a laser beam to remove material, such as to perforate the casing, cement and formation or drill a well bore. The system and method can further or alternately encompass material analysis that can be performed without removing the material from the well bore. The analysis can be performed apart from or in connection with drilling operations and / or perforating the casing, cement and formation. The analysis can be used in a feed back loop to adjust material removal, adjust material analysis, determine the location of future material removal, and for other uses.

Owner:HALLIBURTON ENERGY SERVICES INC

Determination of thermal properties of a formation

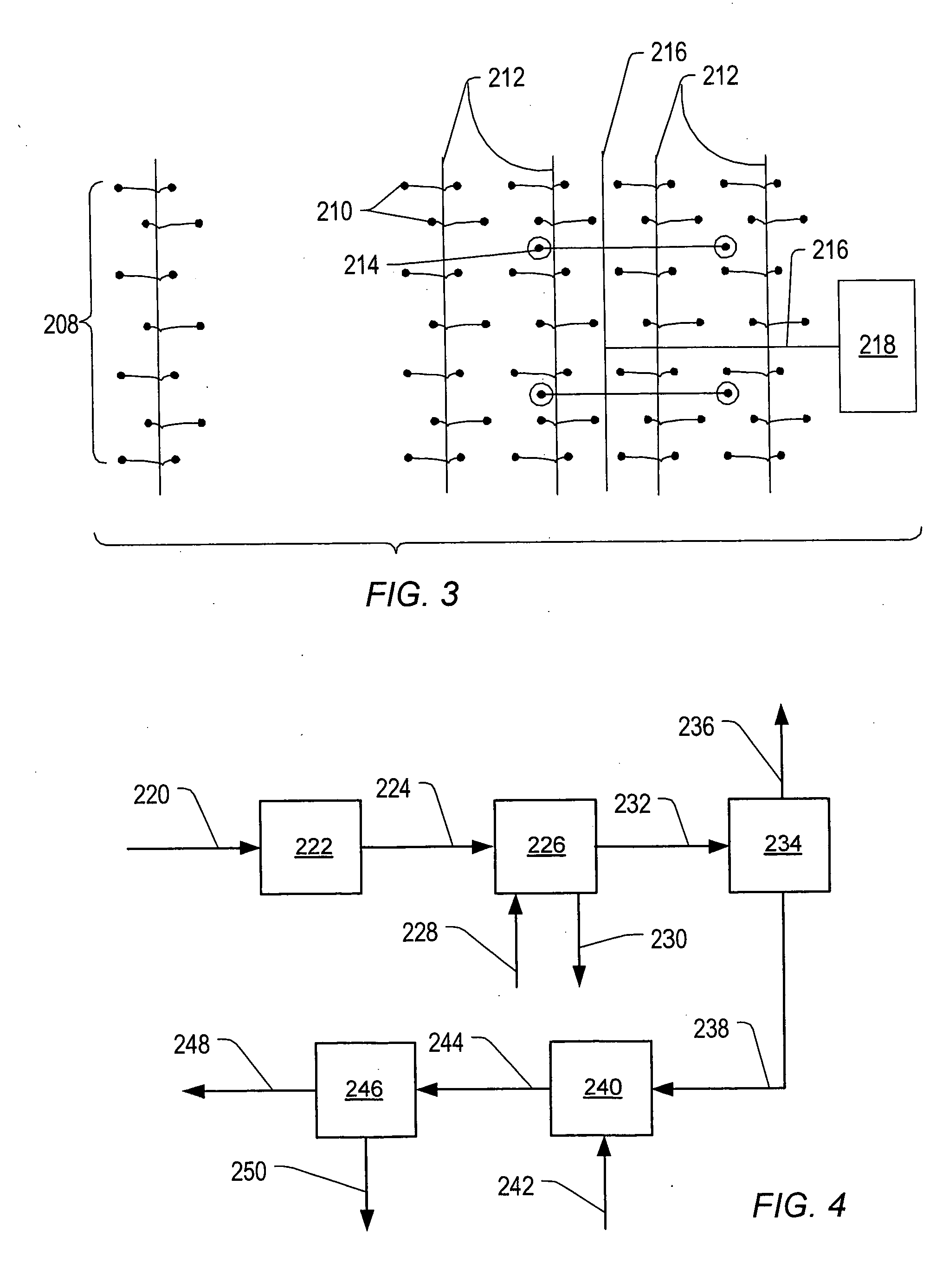

The present invention relates to methods and apparatus for making in situ thermal property determinations utilizing a heat source employed in wellbore stabilization procedures, well drilling, or well perforating, for example. In particular, using a heat source, such as a laser driller, to enable formation temperature measurements. Based on these measurements, thermal properties of the formation may be inferred.

Owner:HALLIBURTON ENERGY SERVICES INC

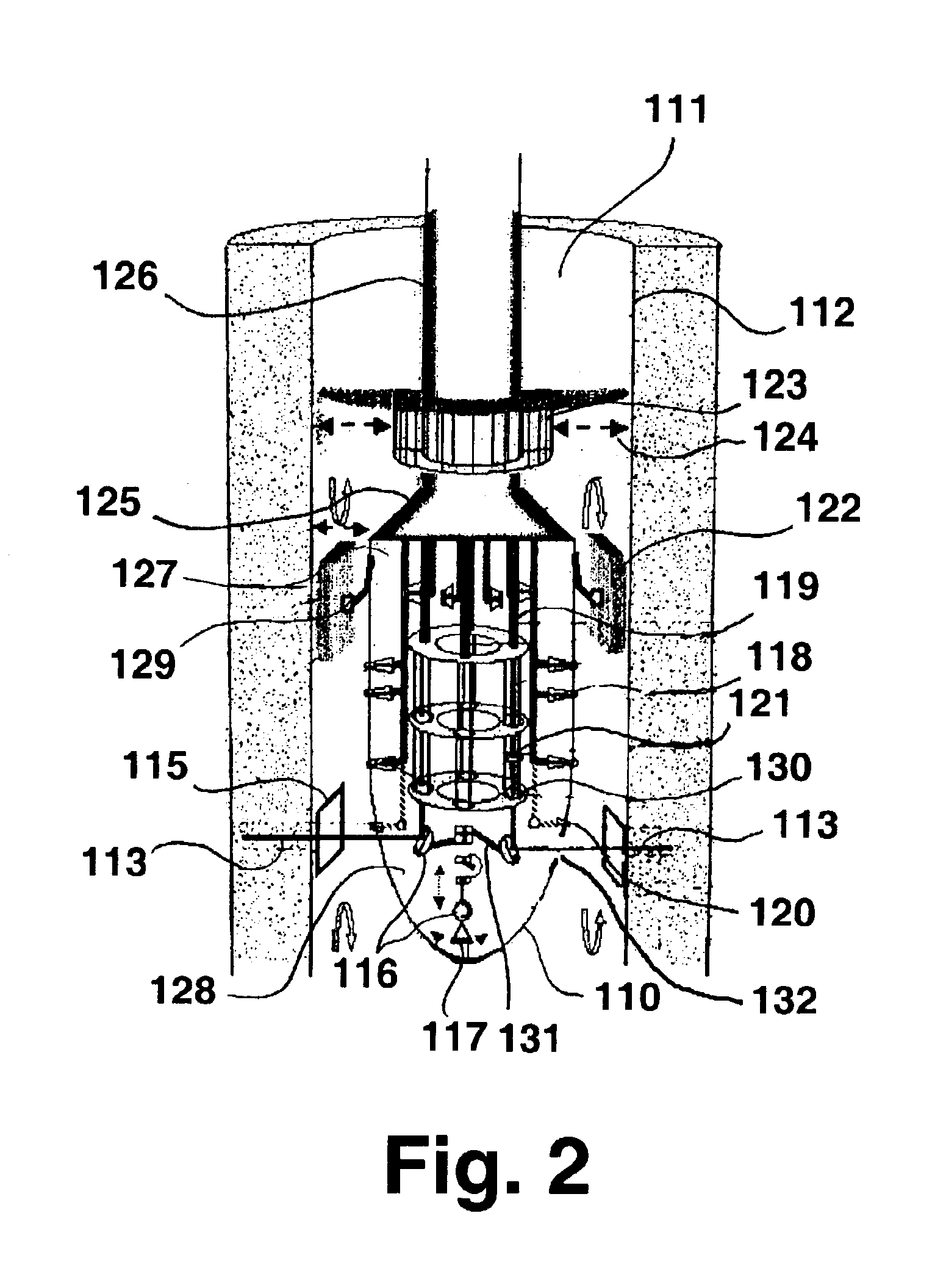

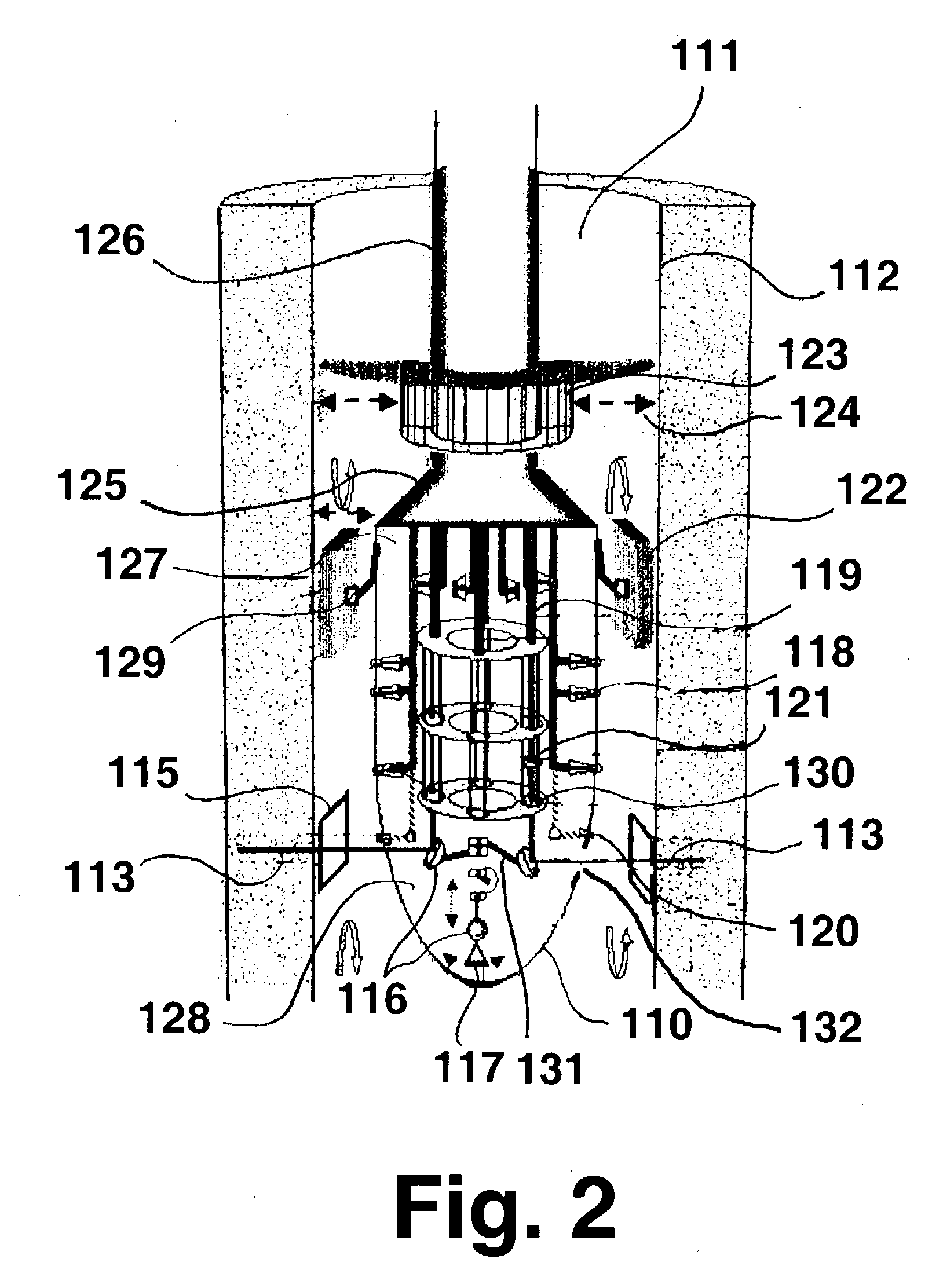

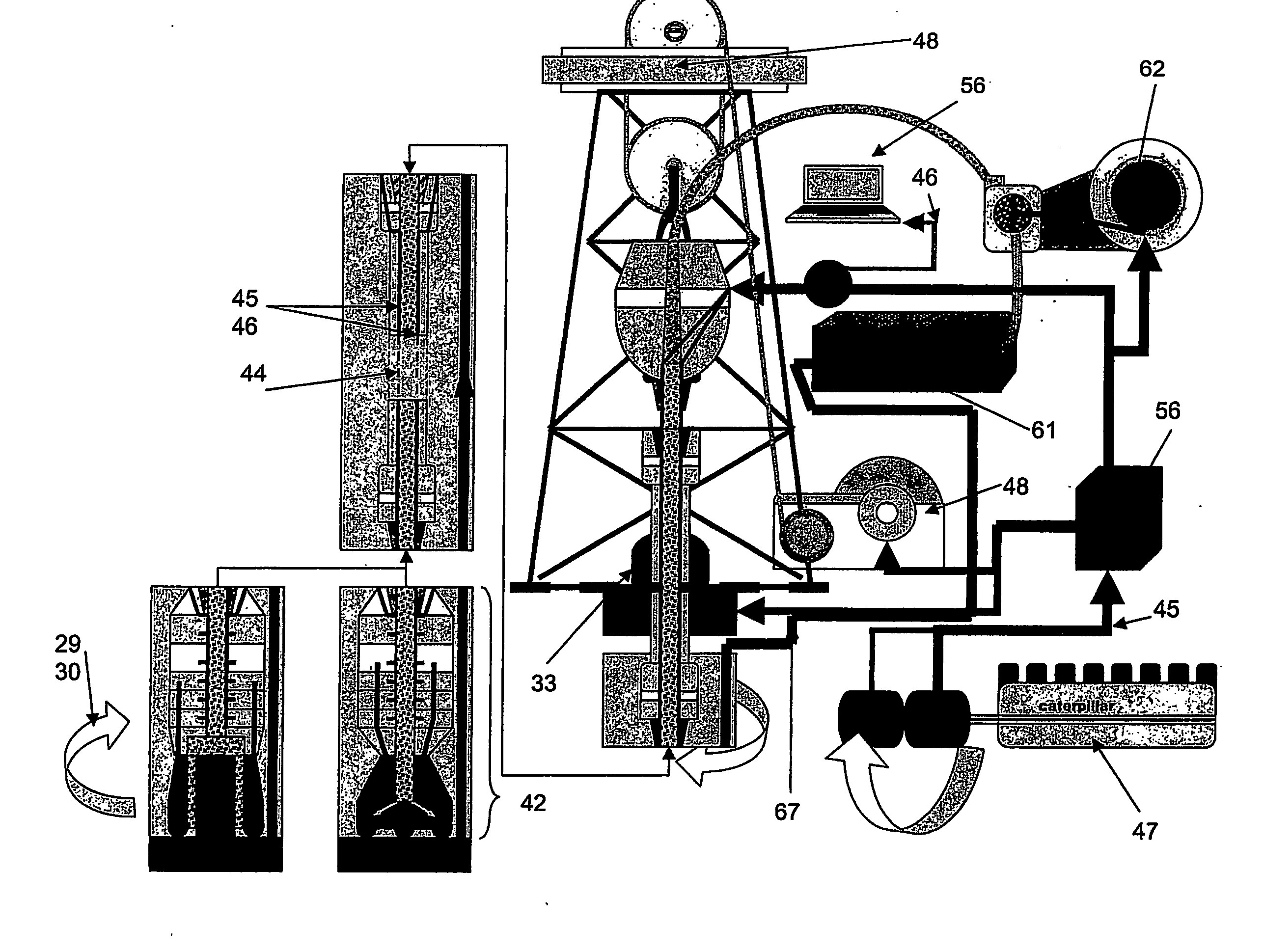

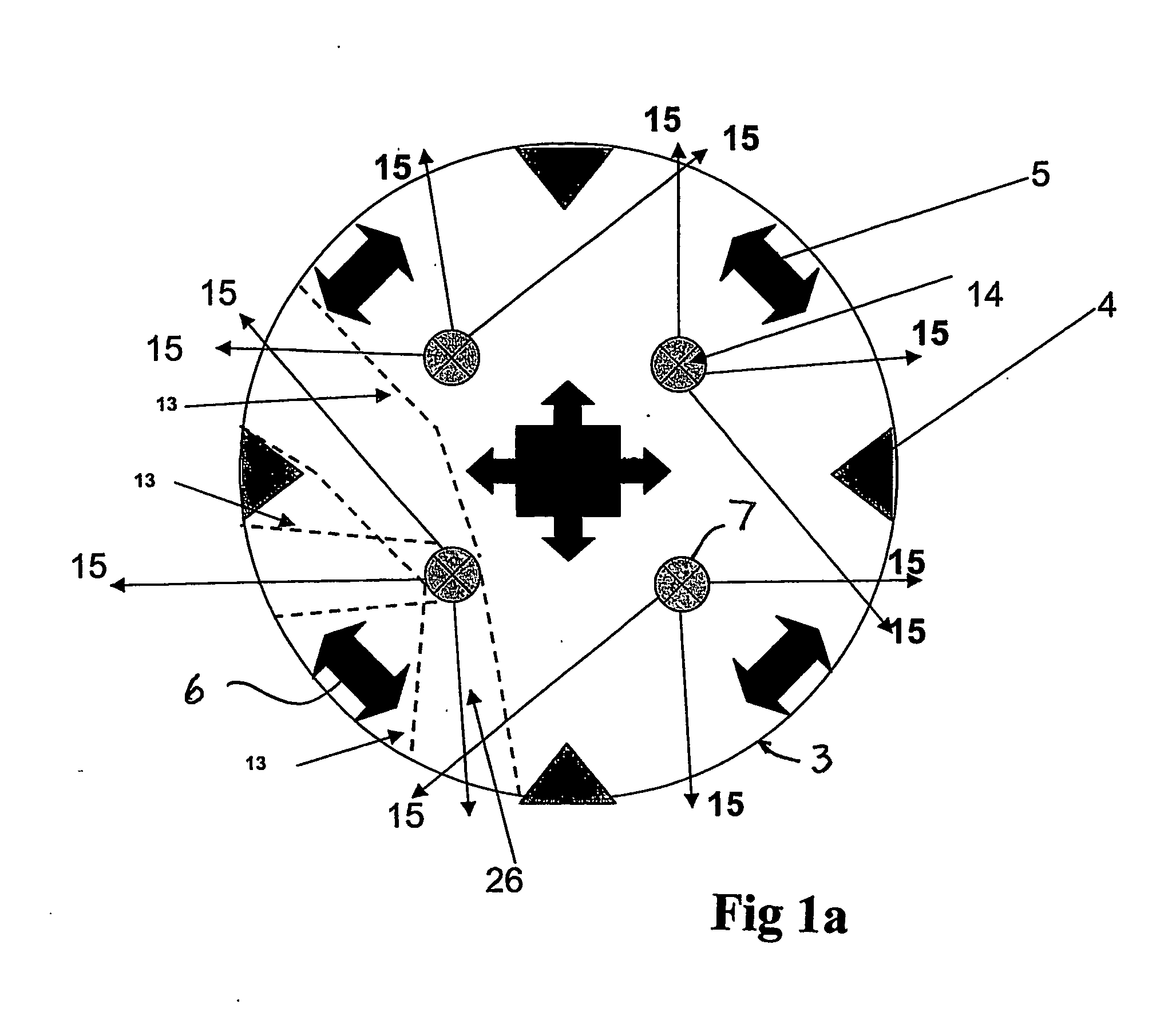

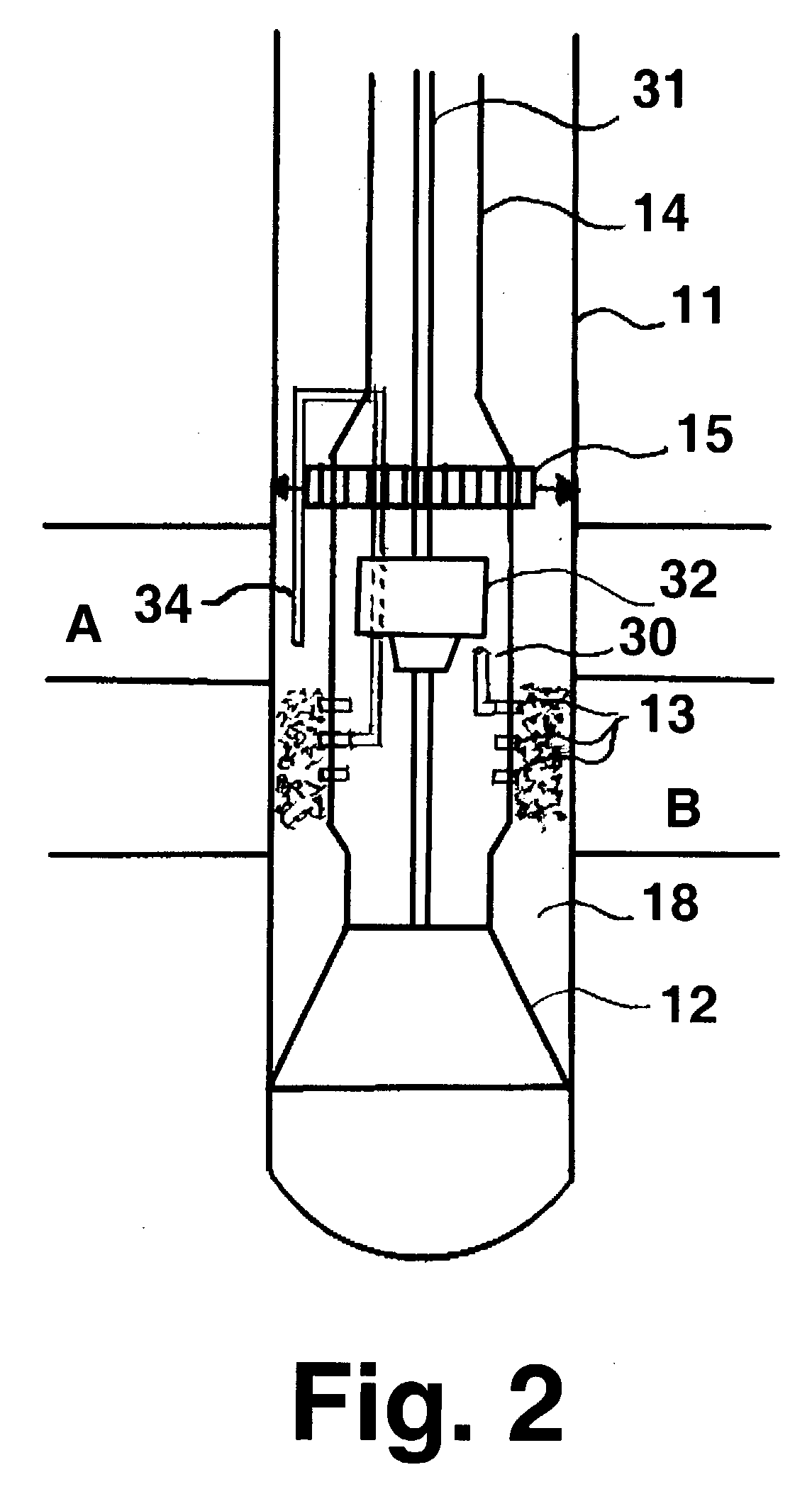

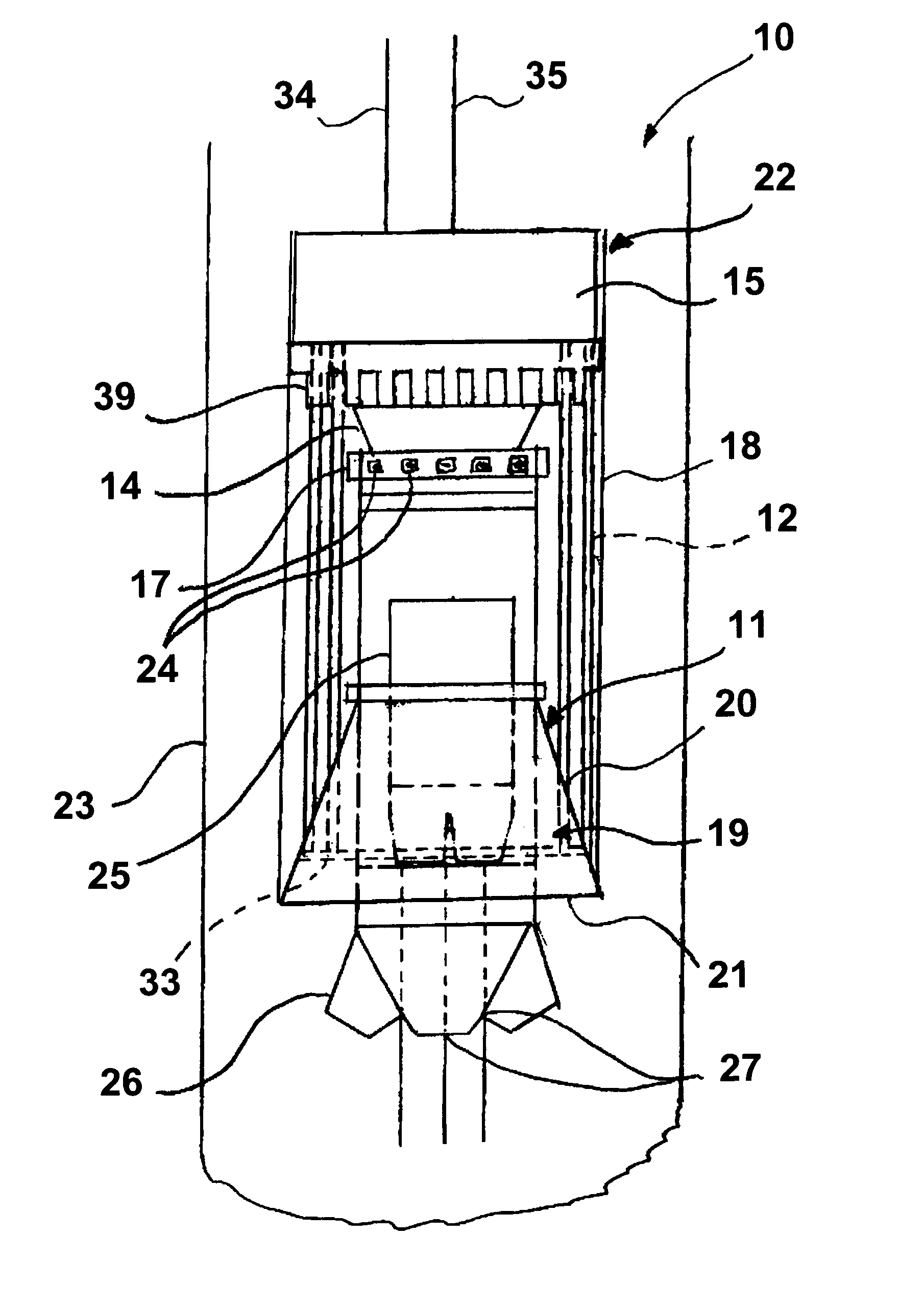

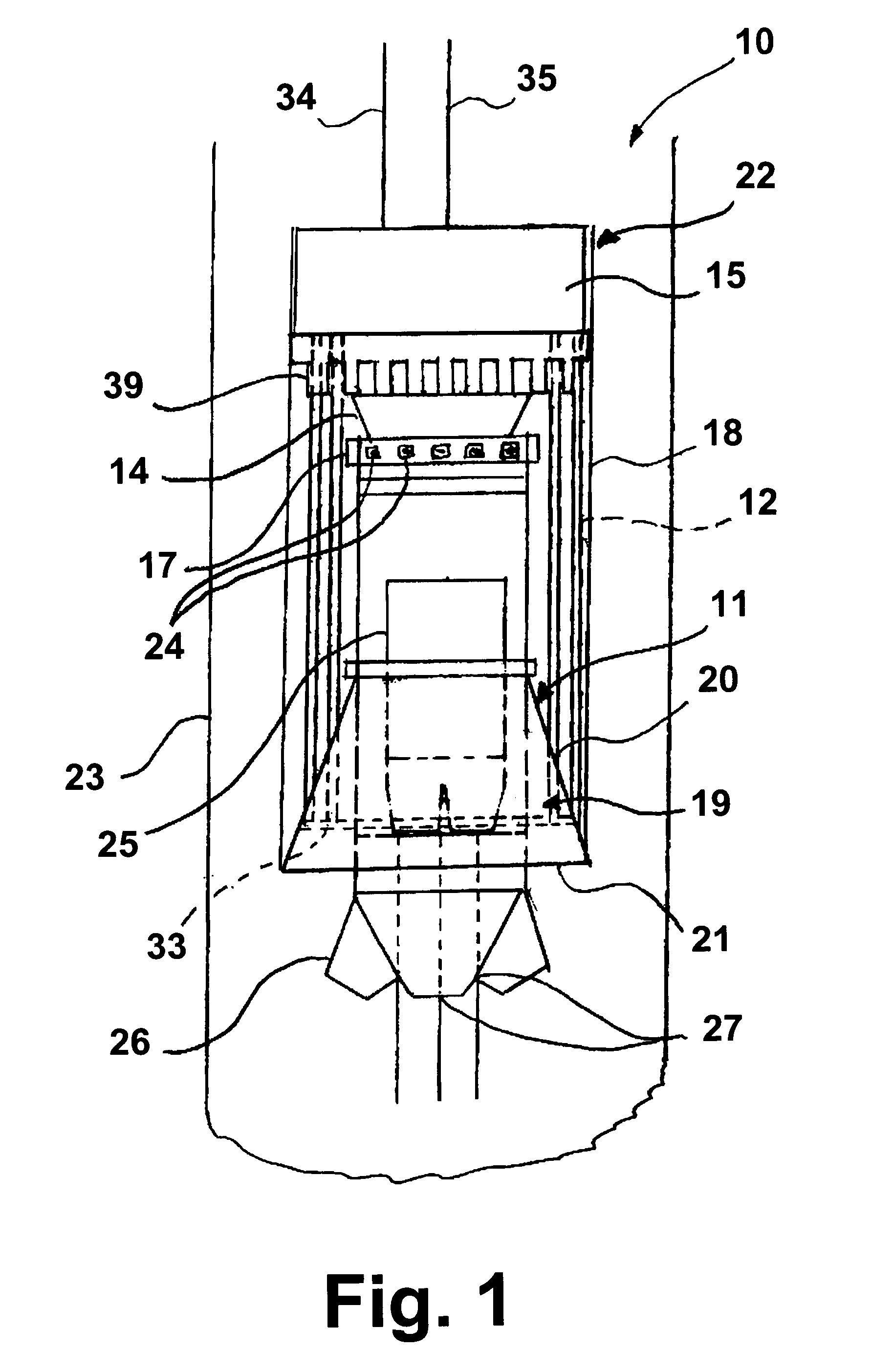

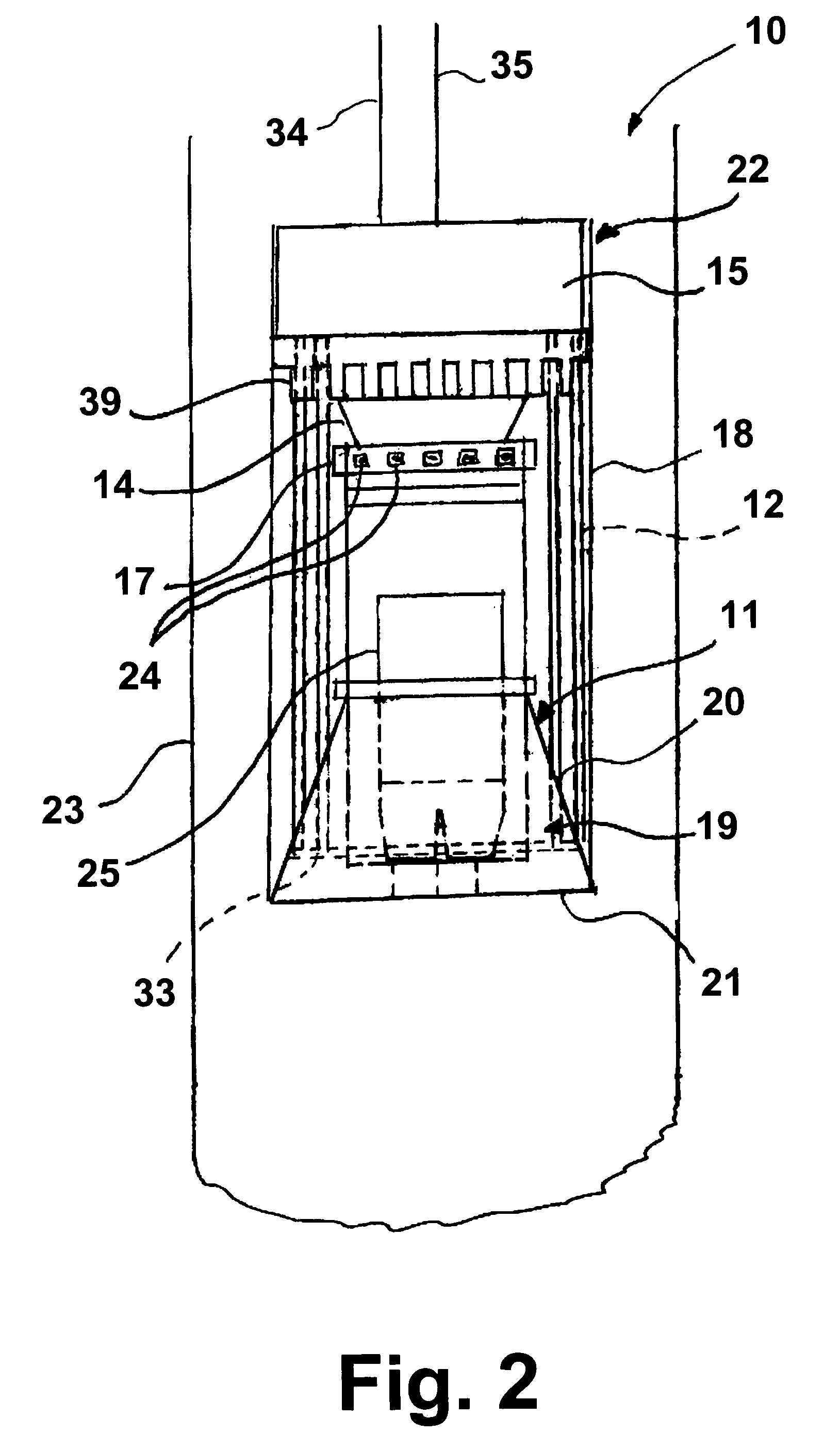

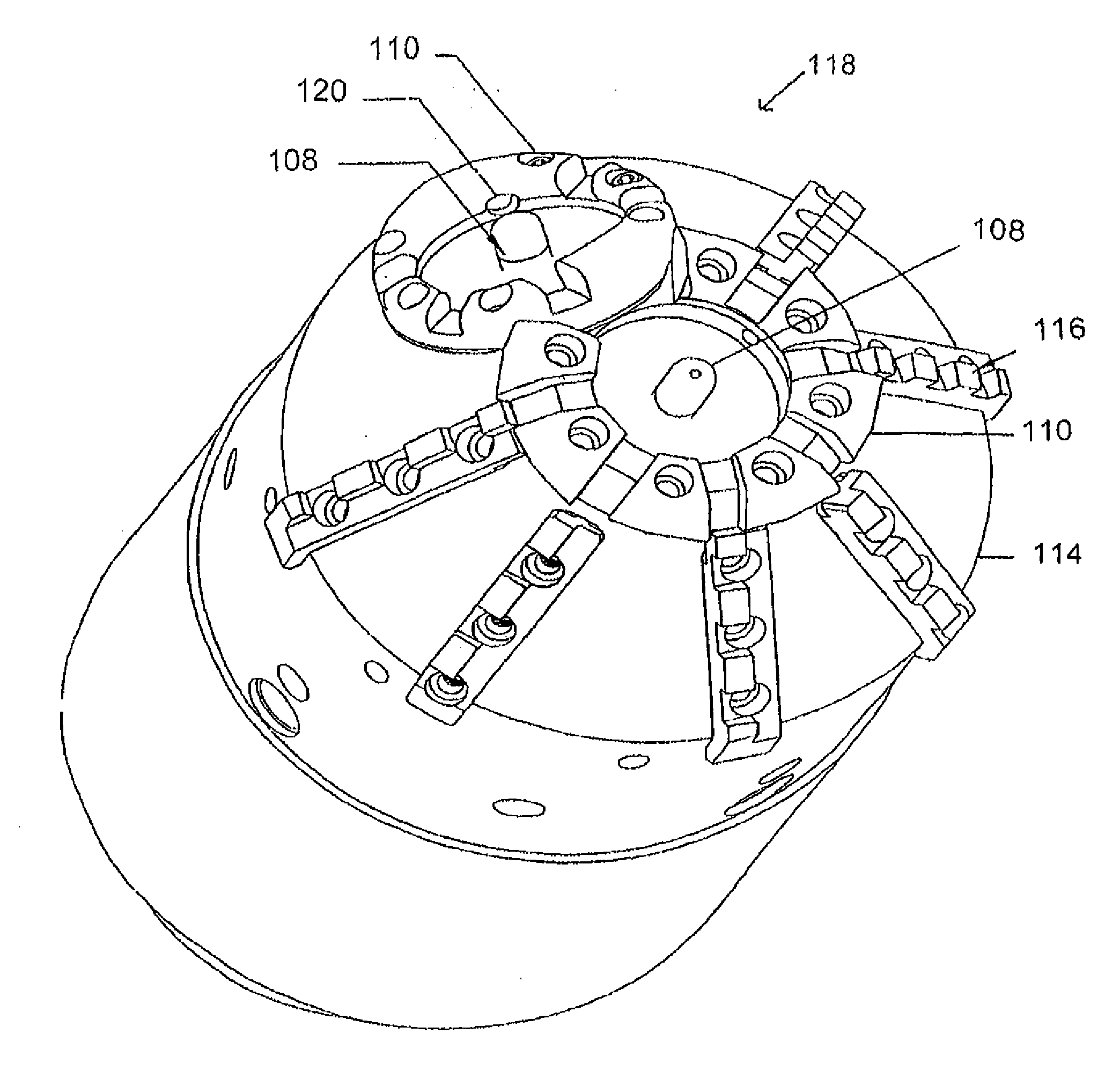

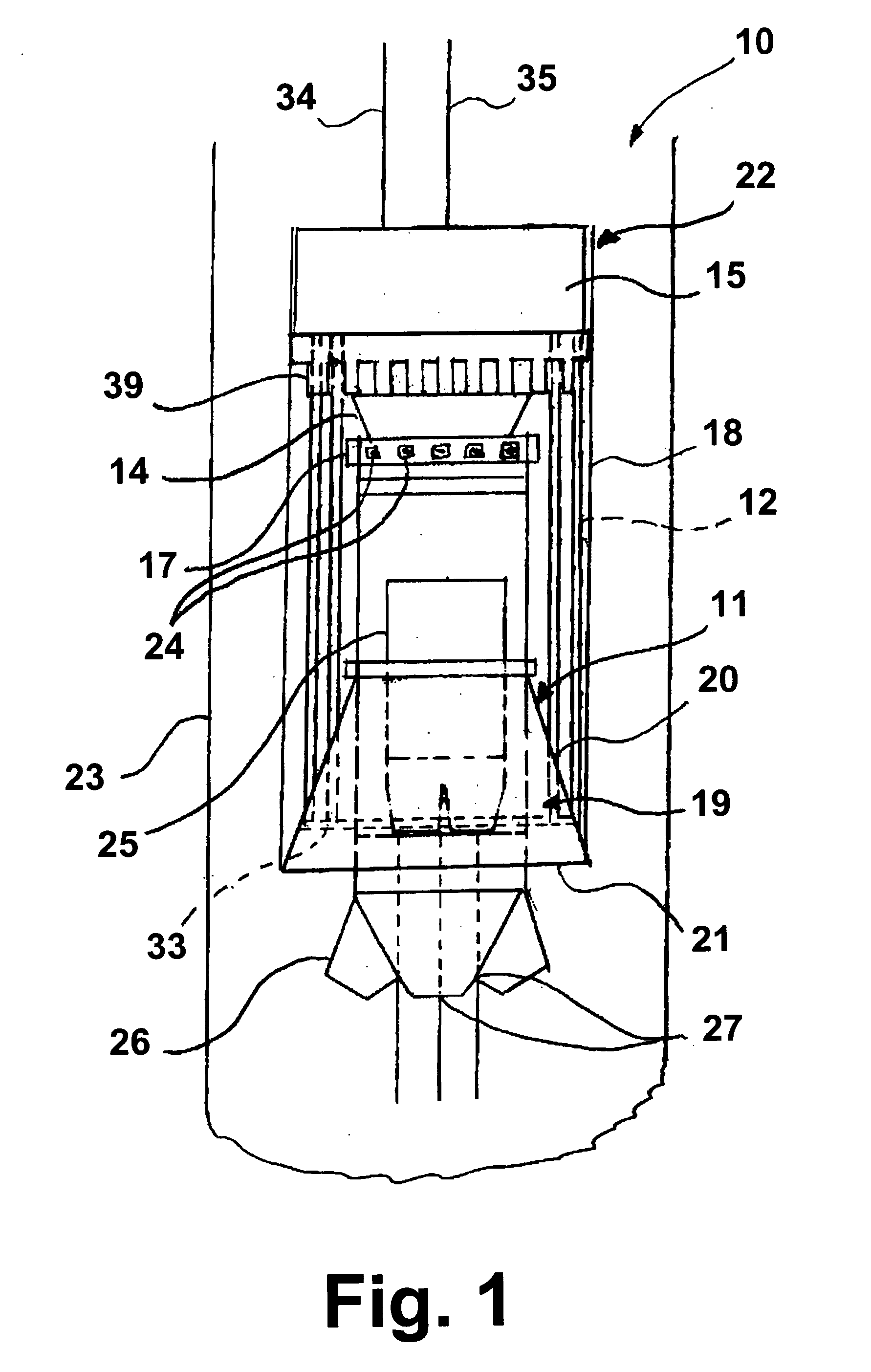

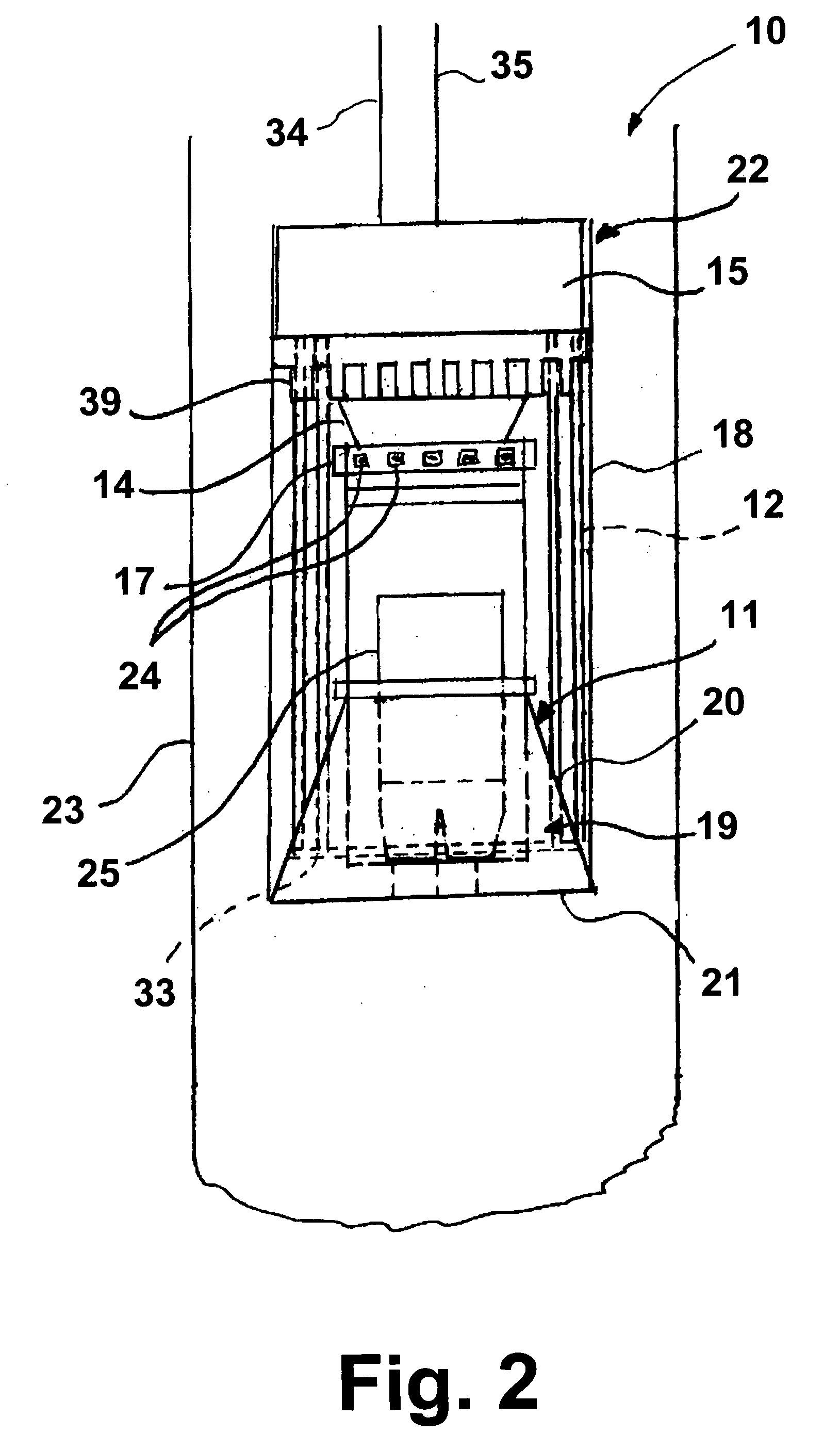

Method, Drilling Machine, Drill bit and Bottom Hole Assembly for Drilling by Electrical Discharge by Electrical Discharge Pulses

ActiveUS20090133929A1Efficiently provideIncrease drilling speedDrill bitsDisloding machinesElectric dischargeClosed loop

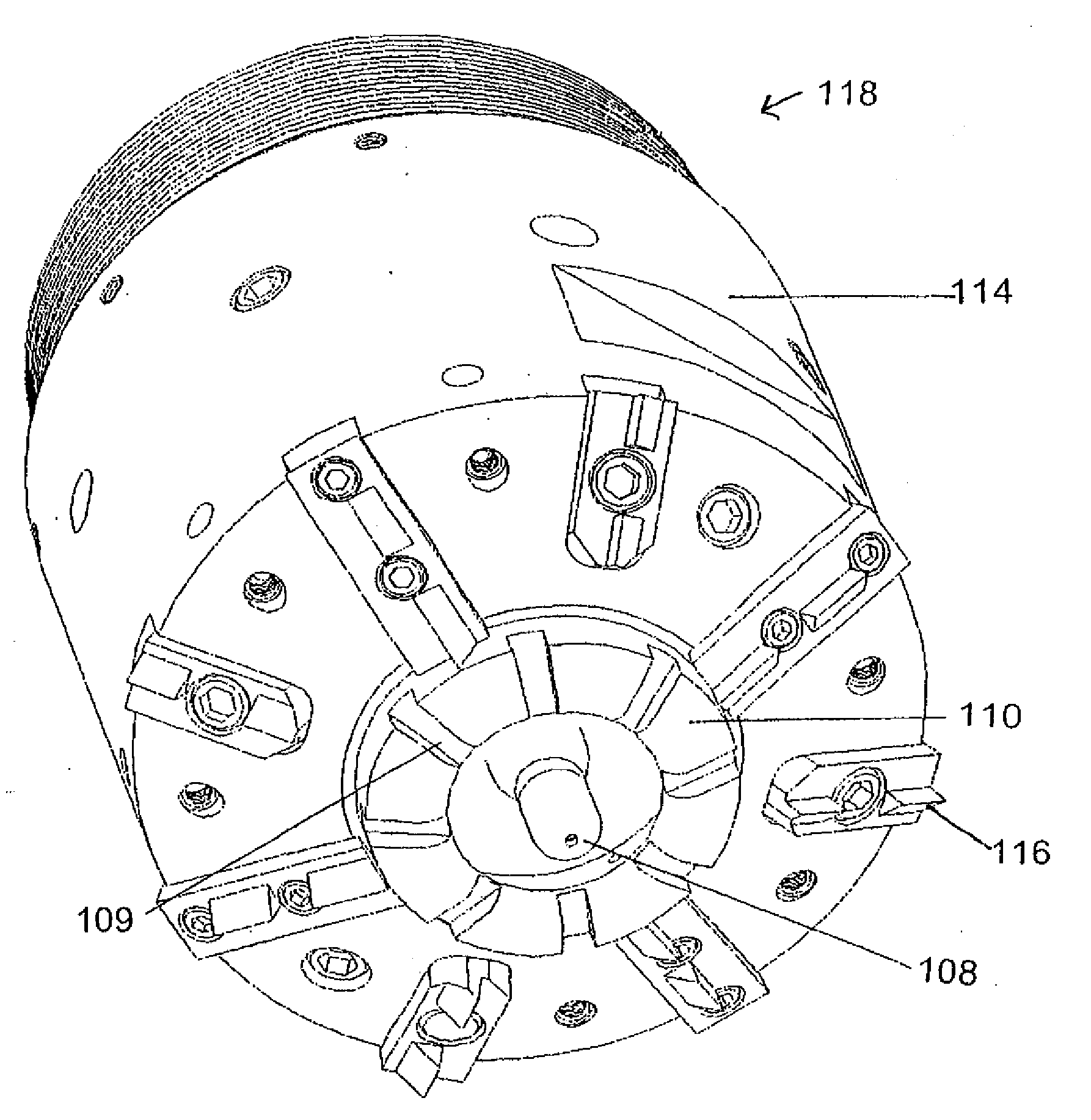

Machine for ground drilling, with a circulating fluid, by the utilization of electric discharge generated by high-voltage pulses between electrodes. It may comprise: —A drill-bit 1 with electrodes movable relative to each other, so that bottom-hole physical contact be secured for all the electrodes 4 on all bottom-hole topographies. —Pointed hydraulic nozzles for jetting the fluid, to remove primary cuttings and with pressure expansion across the nozzles 7 at no less than 4 MPa. —A high-voltage pulse generator deployed down-hole at a minimum distance from the drill-bit 1. —A rotating or oscillating bit causing the borehole cross-sectional excavation to occur, and electric discharge between a plurality of electrodes situated on the bit face along one or a few radii and tangents. —A bottom hole assembly for annular hole-making with core storage, transportation, down-hole closed loop discharge fluid circulation. A discharge fluid storage may be incorporated. A drilling method is also described.

Owner:UNODRILL

Pulsed Electric Rock Drilling Apparatus with Non-Rotating Bit and Directional Control

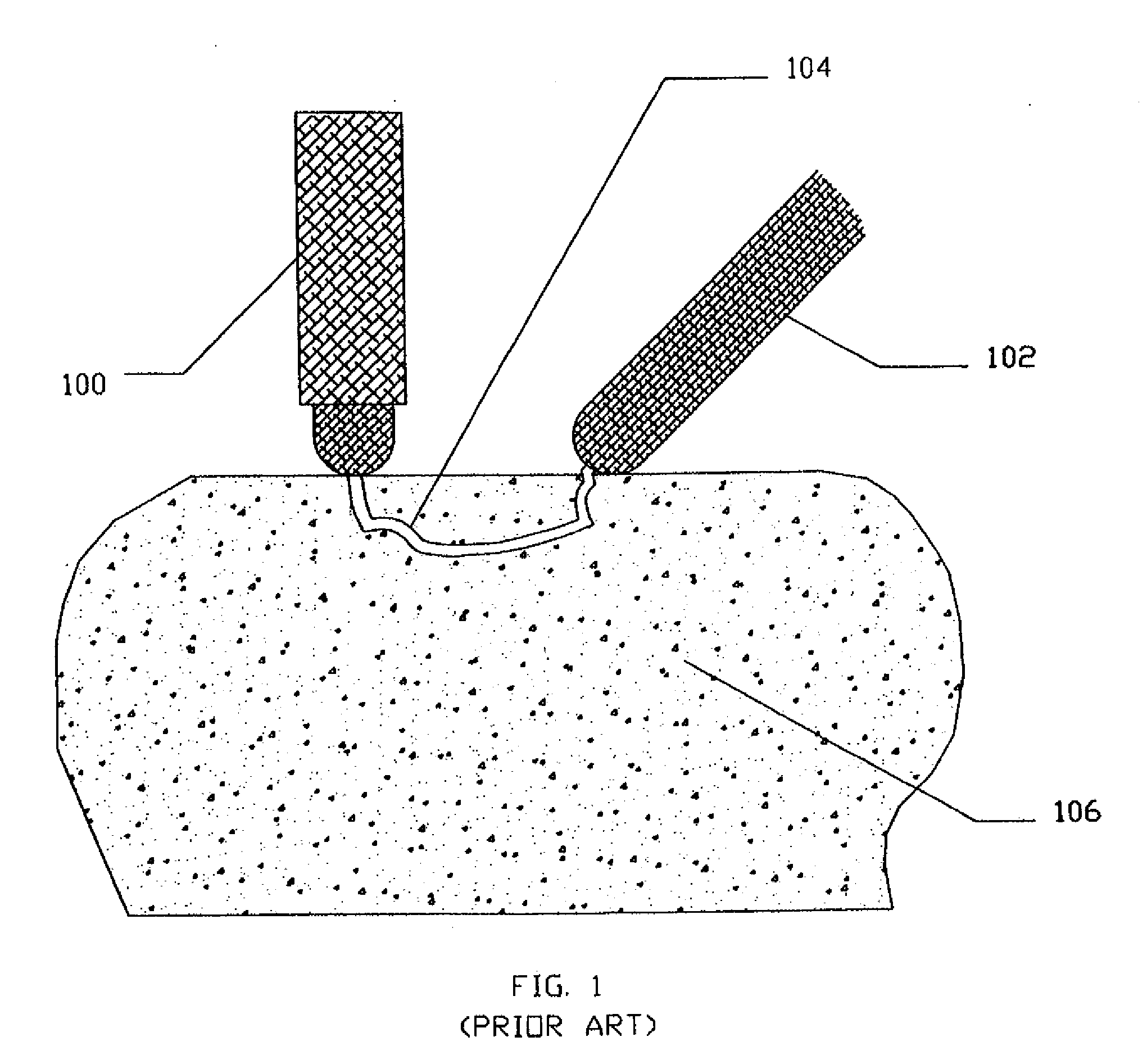

The present invention provides for pulsed powered drilling apparatuses and methods. A drilling apparatus is provided comprising a bit having one or more sets of electrodes through which a pulsed voltage is passed through a mineral substrate to create a crushing or drilling action. The electrocrushing drilling process may have, but does not require, rotation of the bit. The electrocrushing drilling process is capable of excavating the hole out beyond the edges of the bit with or without the need of mechanical teeth.

Owner:SDG LLC

Methods of using a laser to perforate composite structures of steel casing, cement and rocks

ActiveUS20060231257A1Improve breathabilityReduce hole taperingDisloding machinesThermal drillingHigh power lasersSmall fragment

Apparatus and methods of using lasers are provided for the perforation of oil and gas well casings and rock formations. A rock removal process called laser spallation is provided that utilizes a combination of laser-induced thermal stress and laser induced superheated steam explosions just below the surface of the laser / rock interaction to spall or fracture the rock into small fragments that can then be easily removed from the rock formation. The use of high power laser beams of kilowatt level is provided to rapidly cut the steel casings and perforate into the formation. Techniques of the invention increase permeability and reduce hole tapering while perforating a deep hole in reservoir rock formations.

Owner:UCHICAGO ARGONNE LLC +1

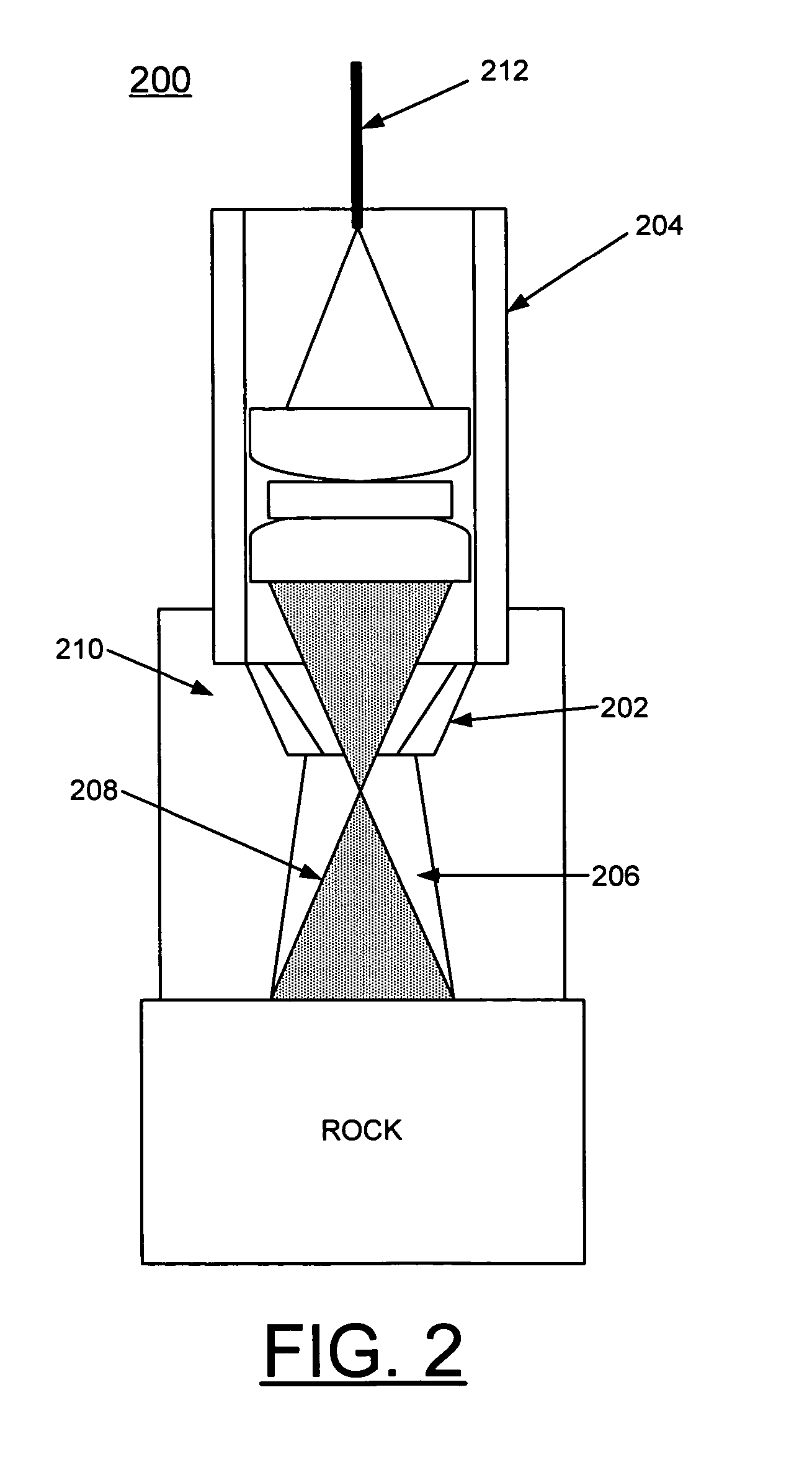

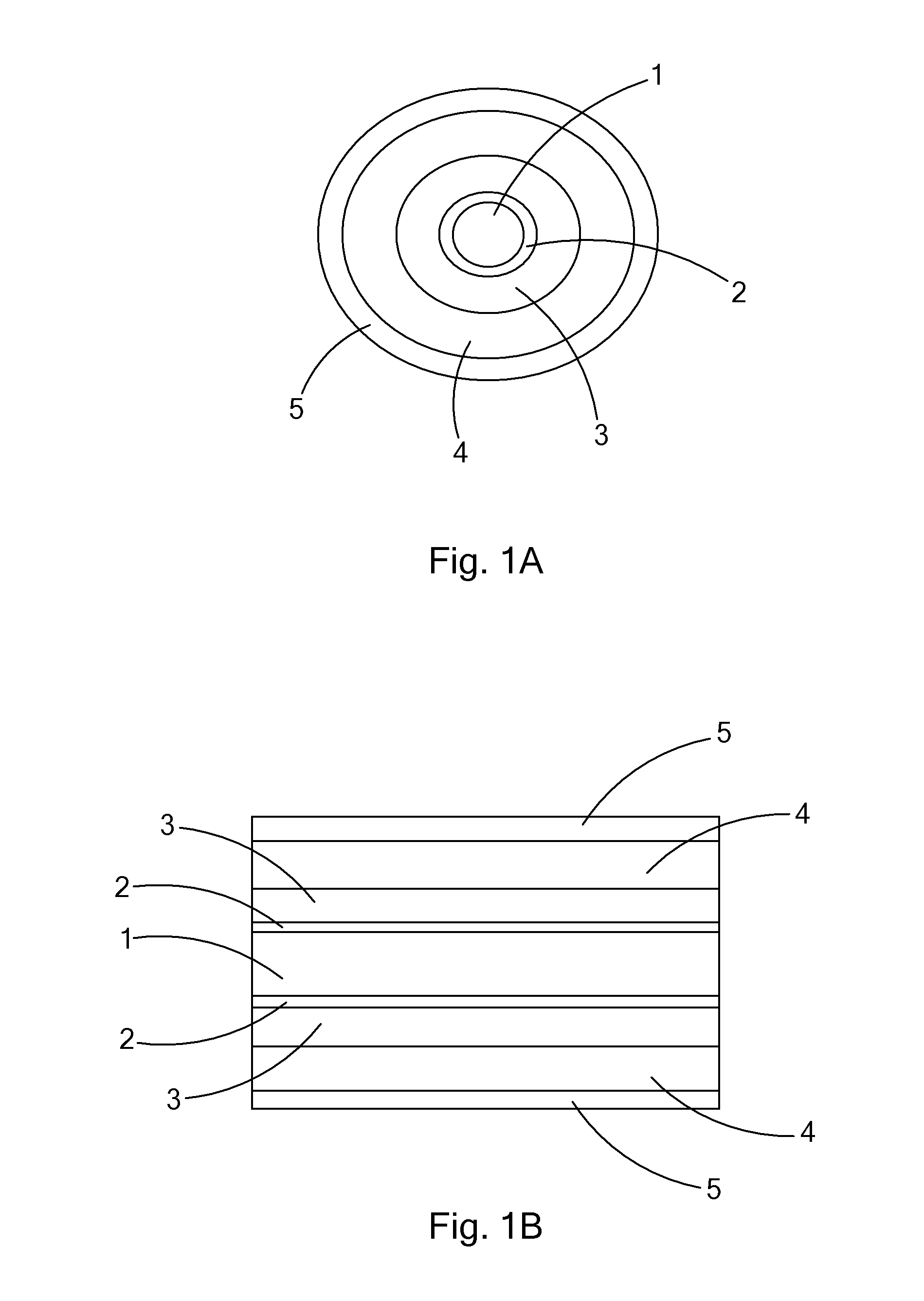

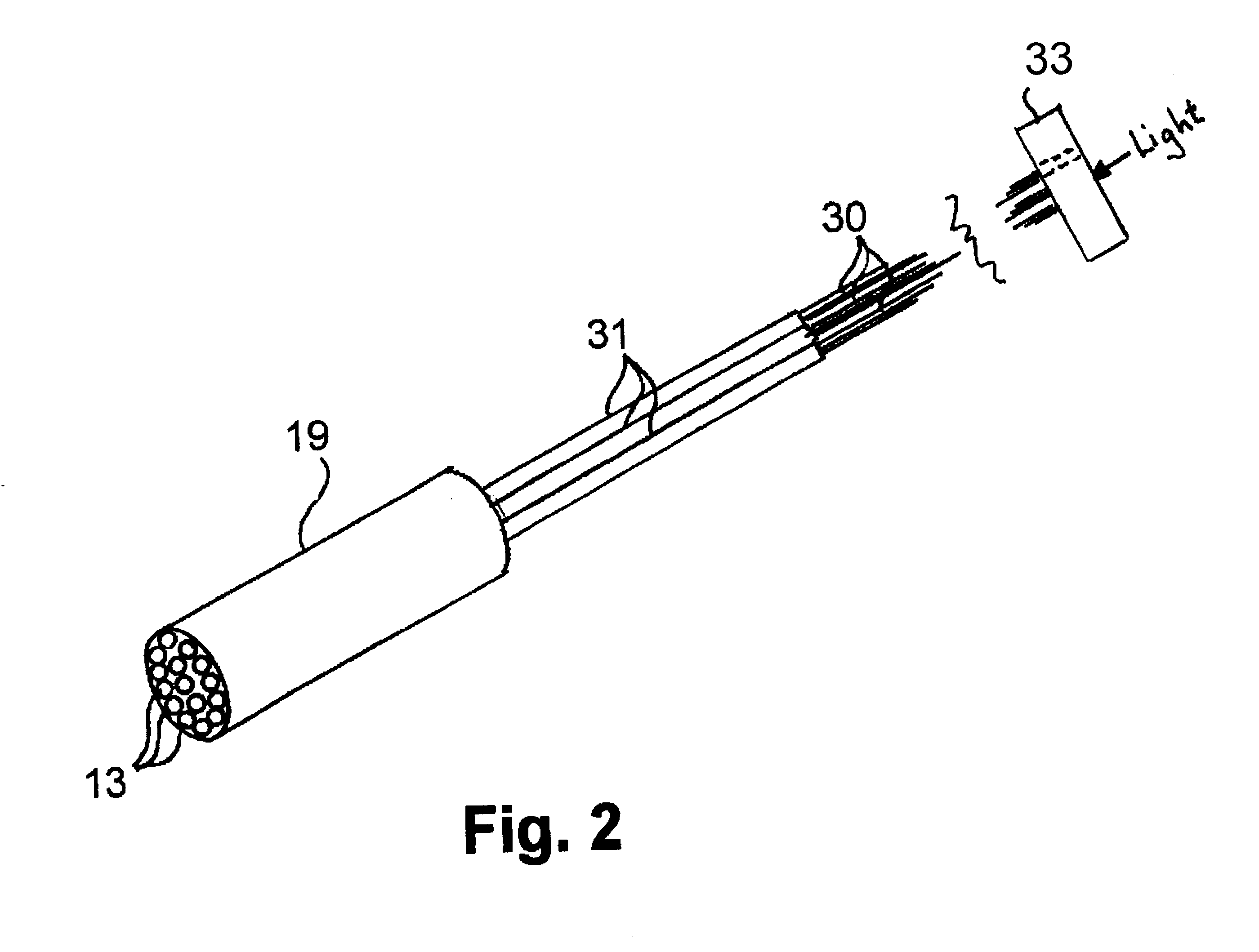

Optical Fiber Cable for Transmission of High Power Laser Energy Over Great Distances

ActiveUS20100215326A1Easy to transportIncrease powerGlass optical fibreDrill bitsHigh power lasersEngineering

There is provided a system and apparatus for the transmission of high power laser energy over great distances without substantial power loss and without the presence of stimulated Raman scattering. There is further provided systems and optical fiber cable configurations and optical fiber structures for the delivering high power laser energy over great distances to a tool or surface to perform an operation or work with the tool or upon the surface.

Owner:FORO ENERGY

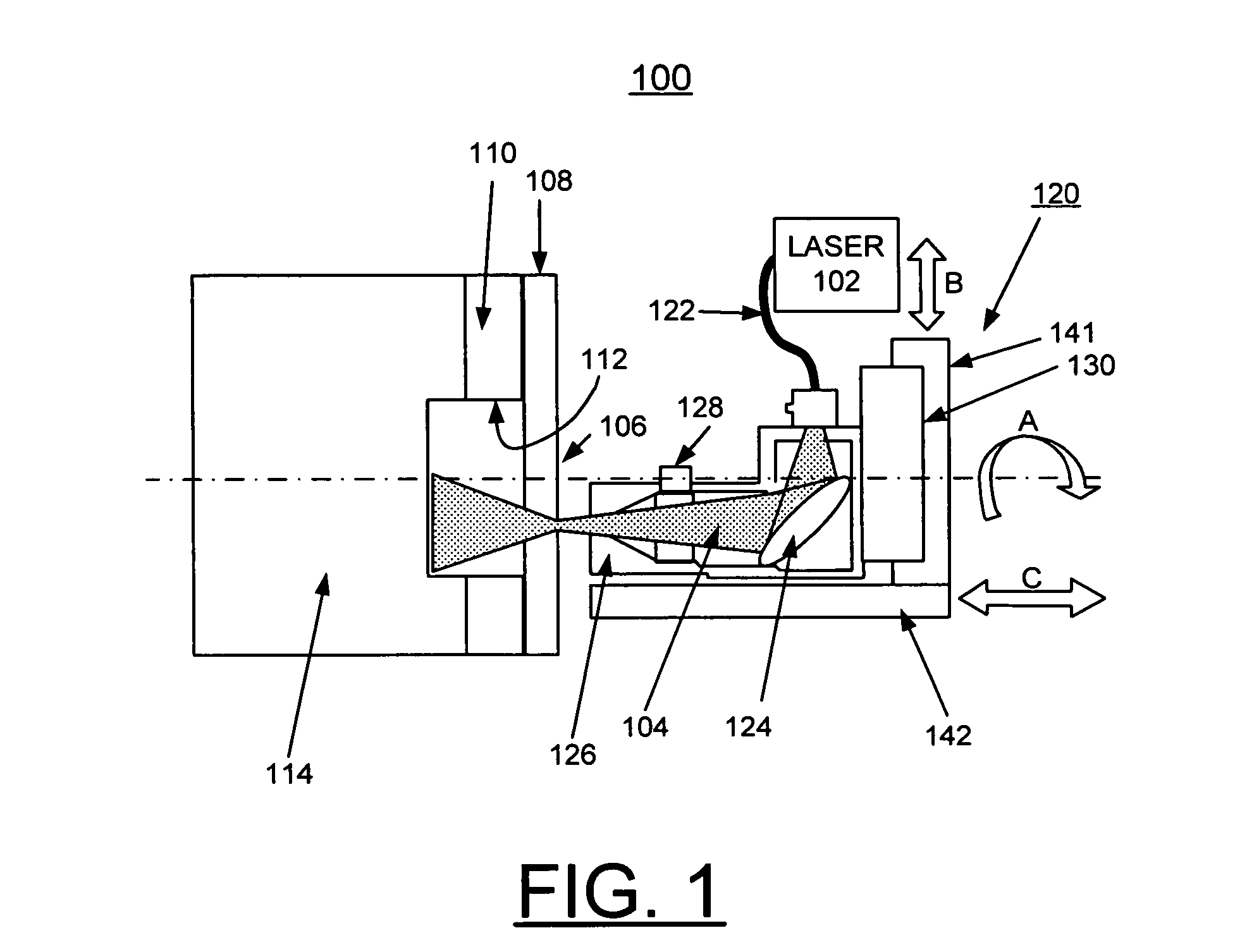

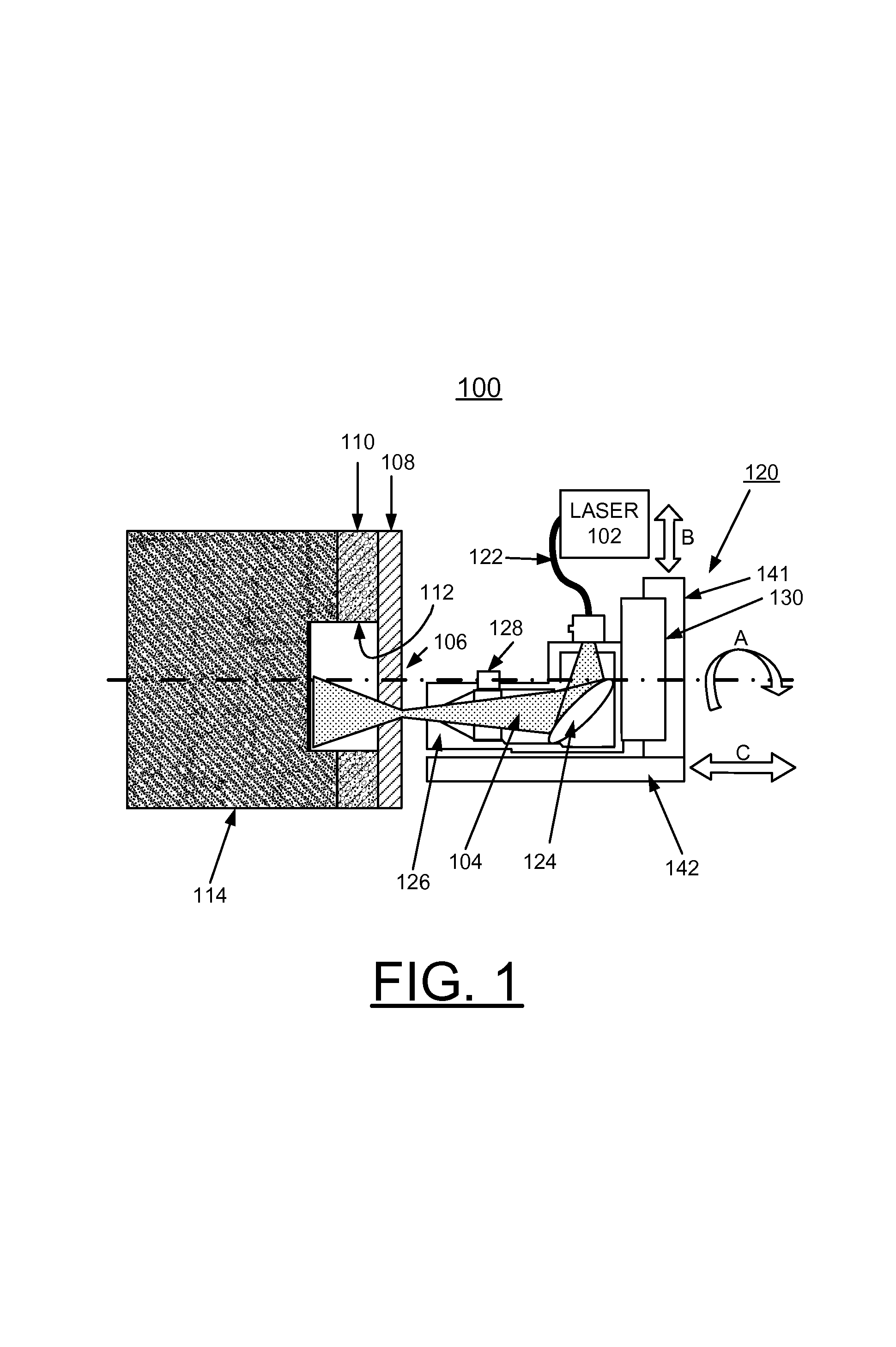

Downhole lens assembly for use with high power lasers for earth boring

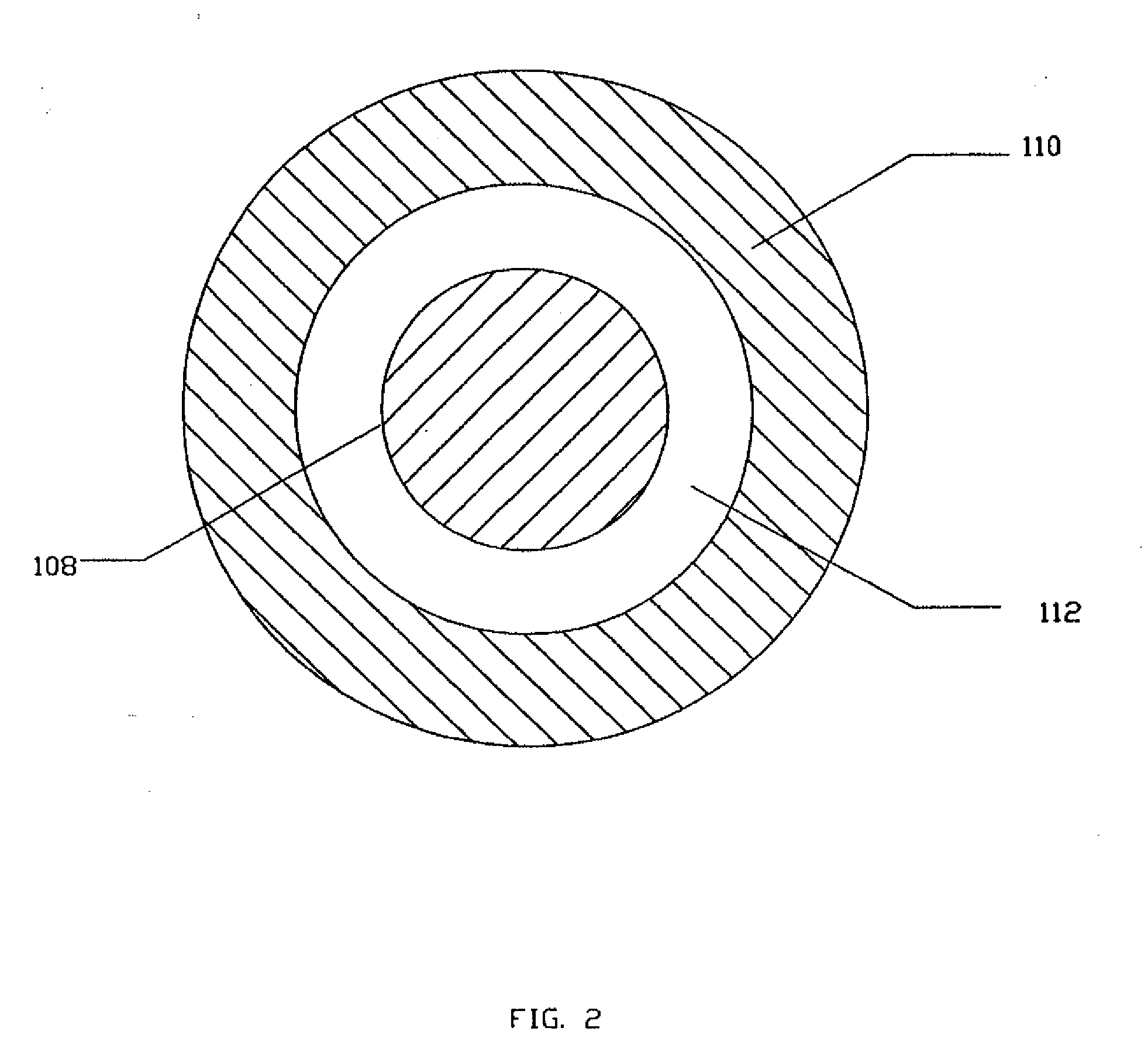

InactiveUS6755262B2Difficult to controlRelative position is not easyEarth drilling toolsDisloding machinesFiberHigh power lasers

An earth boring apparatus at least partially locatable within a borehole. The apparatus includes a plurality of optical fibers, each of which has a proximal fiber light energy input end and a distal fiber light energy output end. At least one focal lens is disposed at the distal fiber light energy output end. The focal lens is made up of a plurality of focal elements, each of which corresponds to the distal fiber light energy output end of at least one optical fiber. The focal lens is arranged to receive light energy from the corresponding distal fiber light energy output end of the at least one optical fiber and focus it outwardly from the distal fiber light energy output end.

Owner:GAS TECH INST

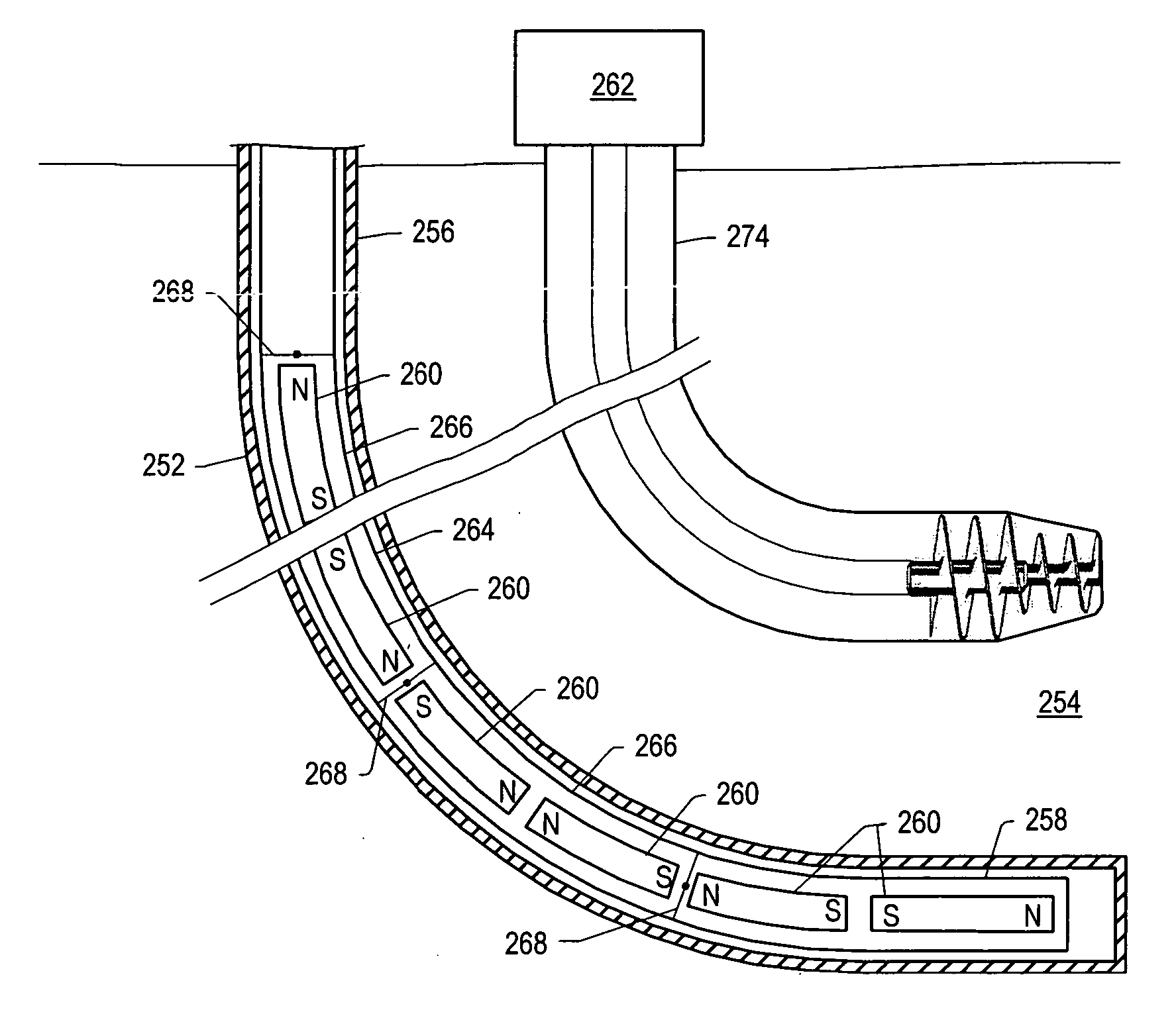

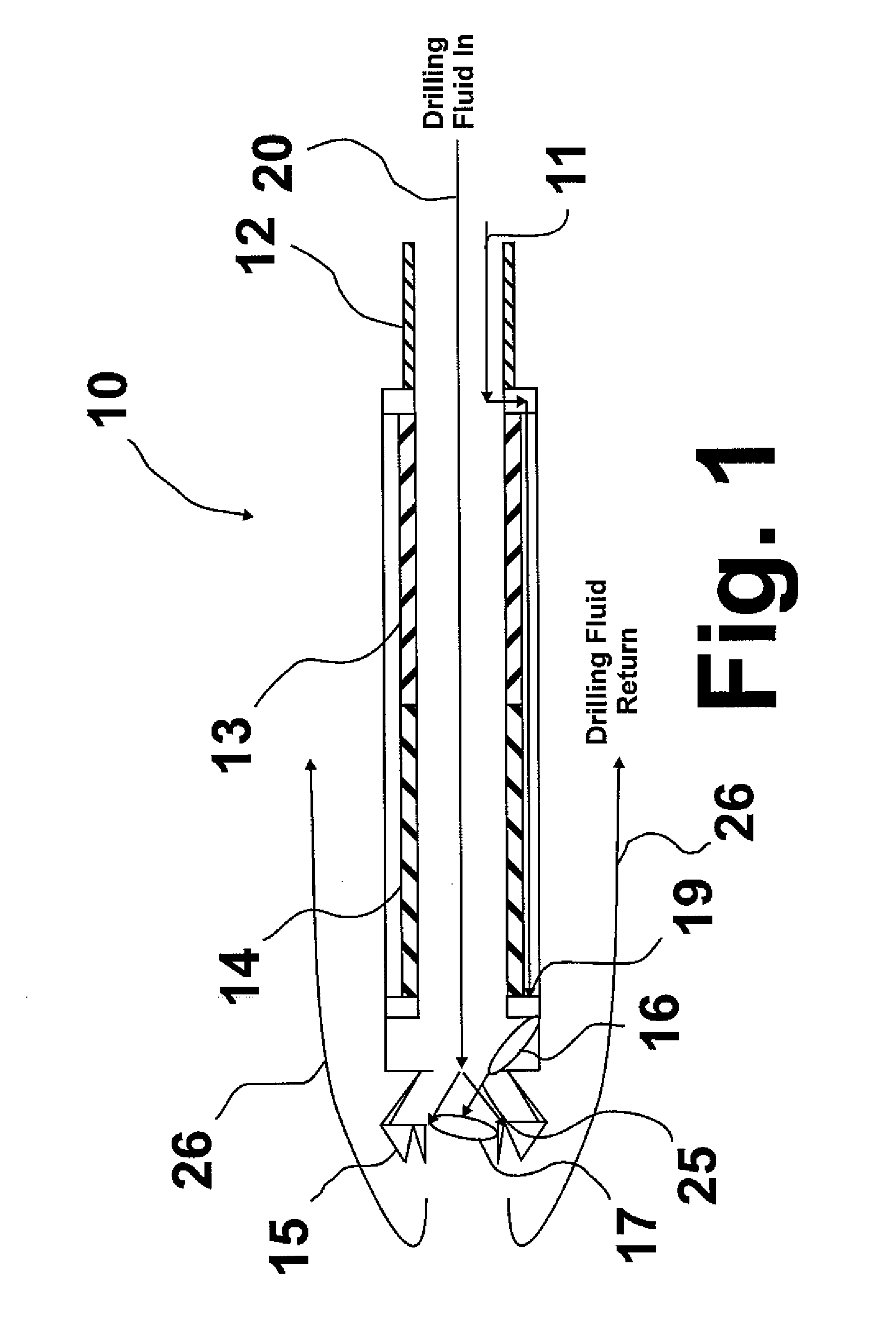

Laser assisted drilling

An apparatus for drilling underground having at least one optical fiber for transmitting light energy from a laser energy source disposed above ground to an underground drilling location and a mechanical drill bit having at least one cutting surface and forming at least one light transmission channel aligned to transmit light from the at least one optical fiber through the mechanical drill bit by way of the at least one light transmission channel.

Owner:GAS TECH INST

Plasma channel drilling process

Material is removed from a body of material, e.g. to create a bore hole, by plasma channel drilling. High voltage, high energy, rapid rise time electrical pulses are delivered many times per second to an electrode assembly in contact with the material body to generate therein elongate plasma channels which expand rapidly following electrical breakdown of the material causing the material to fracture and fragment.

Owner:STRATHCLYDE UNIV OF

Assembly and method for determining thermal properties of a formation and forming a liner

A method comprises heating a formation adjacent a selected depth level within a wellbore extending into the formation, forming a temporary liner in the wellbore, measuring a first temperature of the formation at the selected depth level at a first time after heating the formation, measuring a second temperature of the formation at the selected depth level at a second time after heating the formation, and combining the temperature measurements to derive an indication of thermal properties of the formation. An apparatus comprises a coiled tubing drillstring extending into a wellbore, an assembly supported by the drillstring, the assembly comprising an extruder that extrudes a liner material onto a wall of the wellbore, a heat source that heats the liner material and a formation, and at least one temperature sensor that measures a temperature of the formation.

Owner:HALLIBURTON ENERGY SERVICES INC

Laser liner creation apparatus and method

A method and apparatus for forming an in situ borehole liner in which a laser beam from a laser energy assembly disposed within a transparent drill head enclosure of a drill head assembly is directed into a rock formation to be drilled and a portion of the rock formation is melted, forming molten rock. The drill head assembly is directed into the molten rock forming a borehole having a borehole wall. At least one air stream from the drill head assembly is directed into the molten rock forming the molten rock against the borehole wall after which the molten rock against the borehole wall is cooled, forming a borehole liner.

Owner:GAS TECH INST

Laser spectroscopy/chromatography drill bit and methods

A drilling apparatus for well-boring having a drill bit assembly which includes a laser cutting assembly and a vacuum assembly. The vacuum assembly is adapted to intake vapors generated by the laser cutting assembly proximate the drill bit assembly during operation of the drilling apparatus. The collected vapors may then be processed by a chromatographic analyzer to determine the characteristics of the rock formation being drilled.

Owner:GAS TECH INST

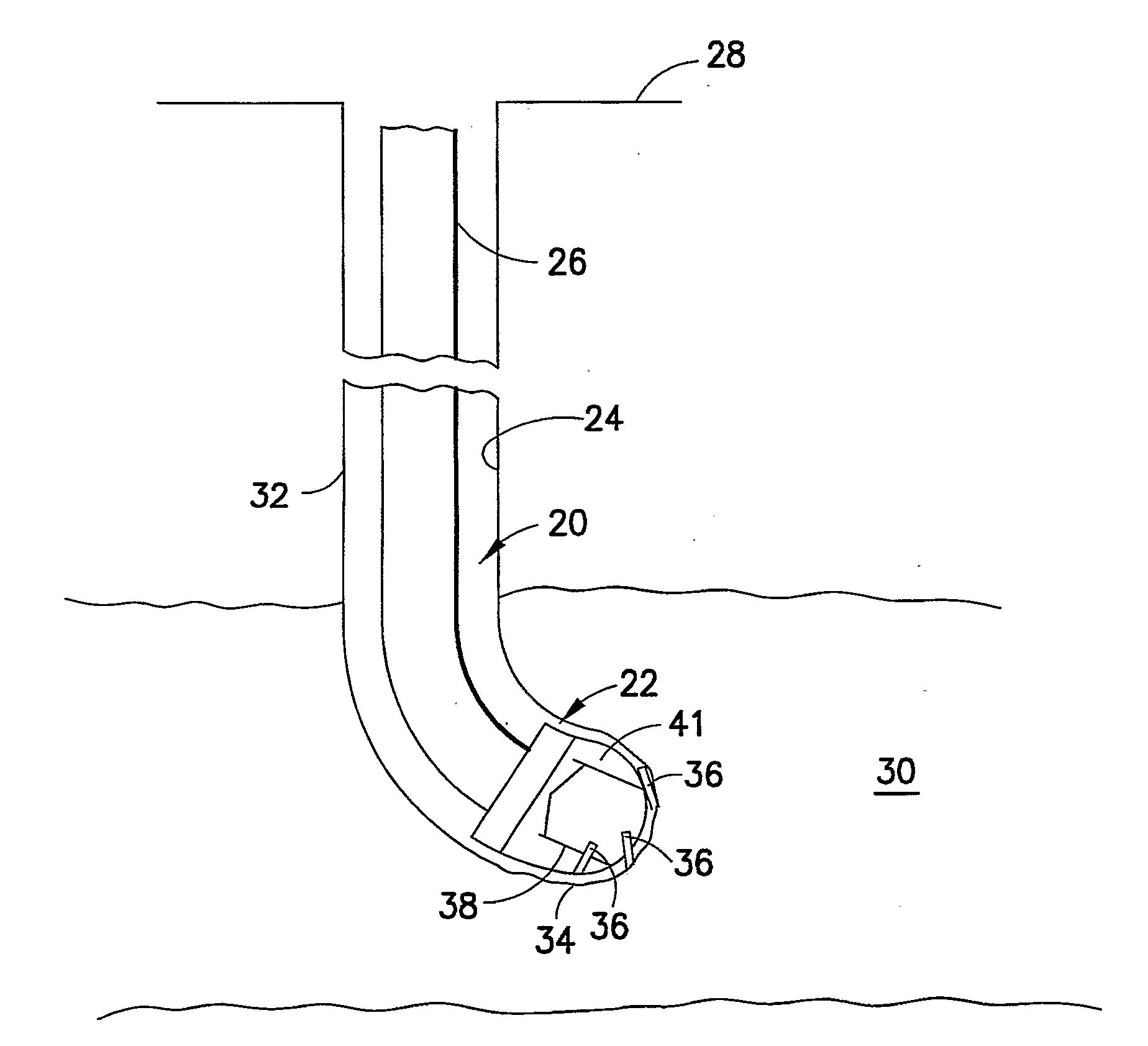

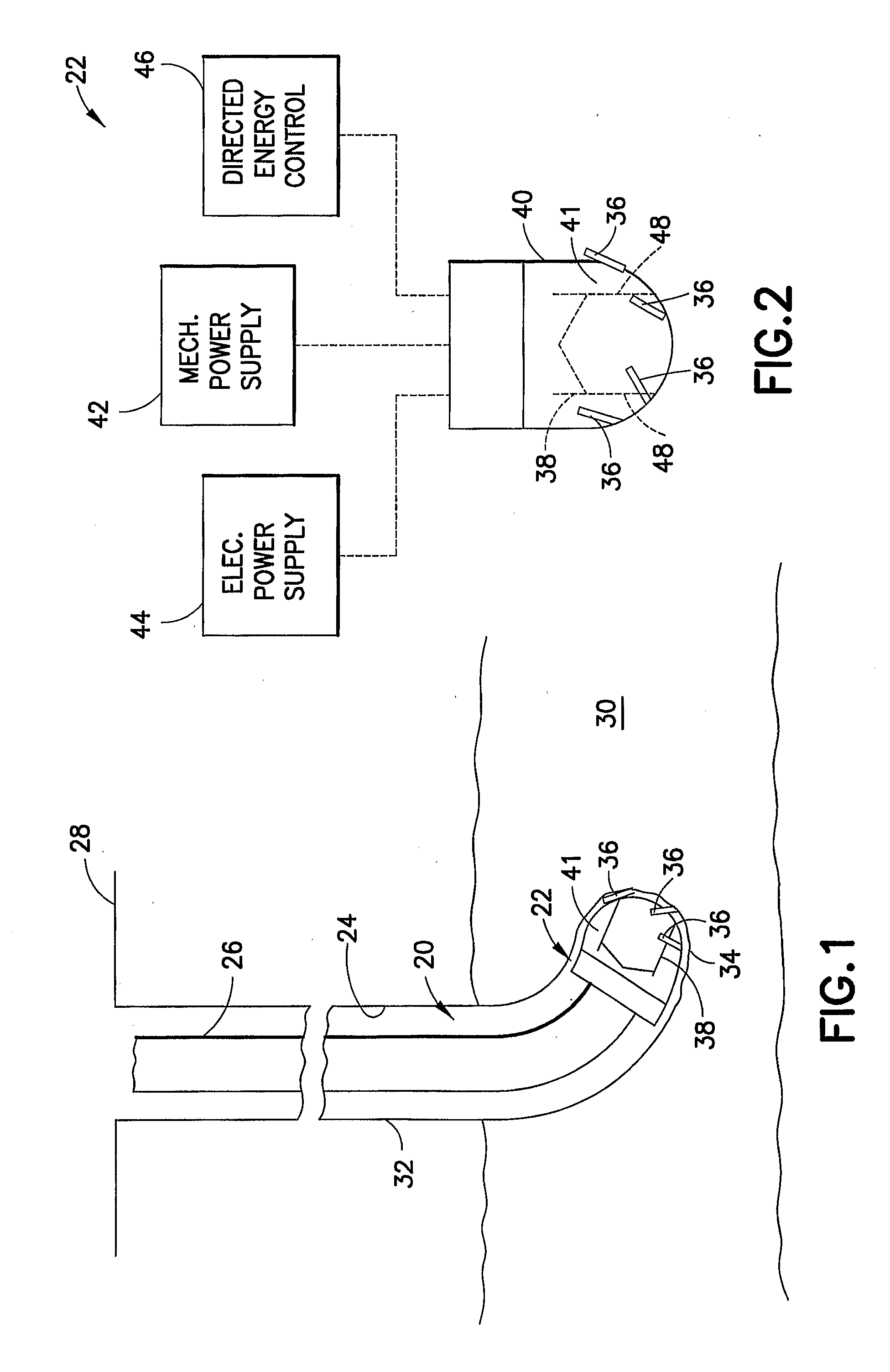

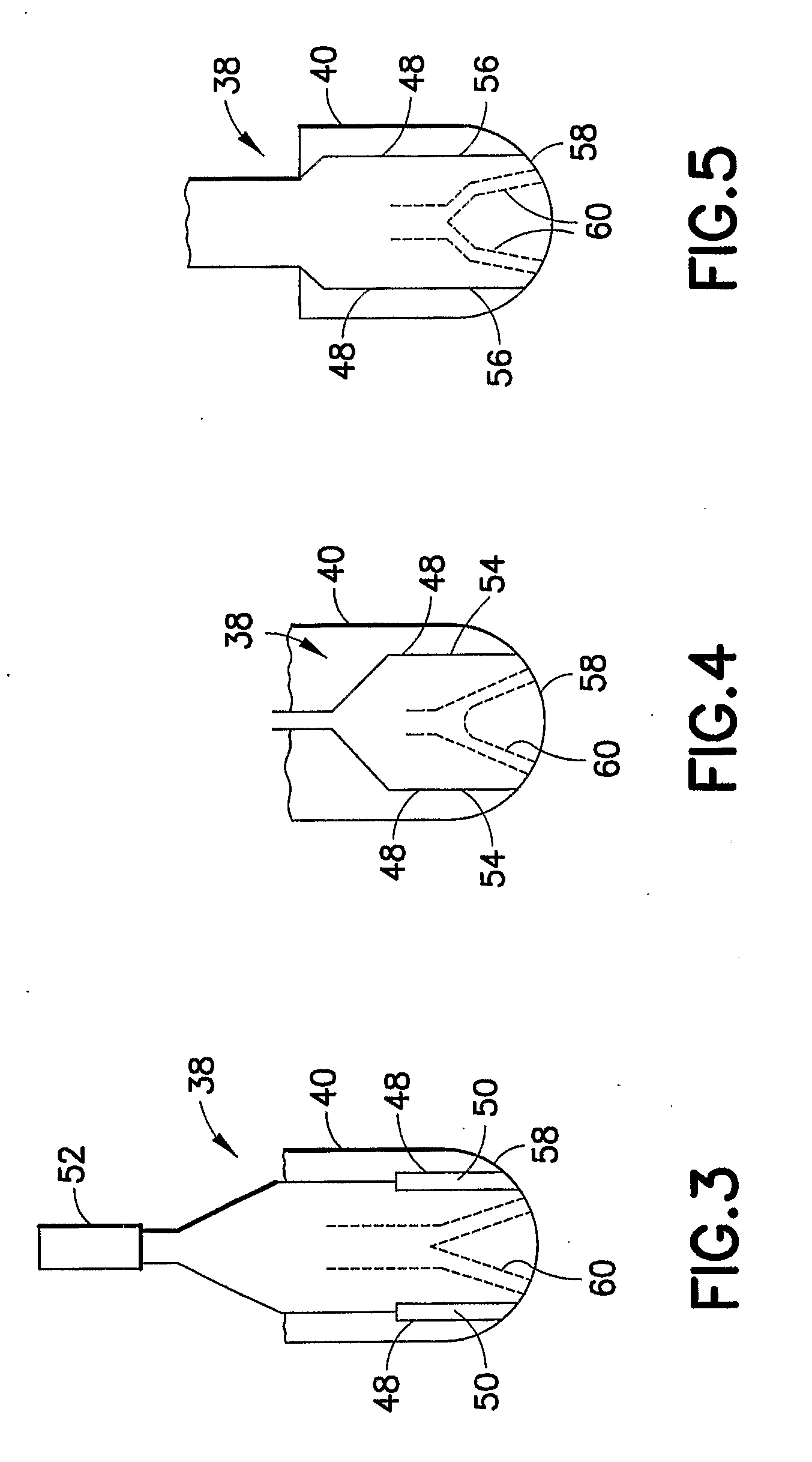

System and Method for Drilling a Borehole

A system and method is provided for drilling a wellbore including a rotary drill bit with a bit body having a plurality of mechanical cutters to cut away formation material as the wellbore is formed; and a directed energy mechanism to direct energy into the formation such that energy from the directed energy mechanism causes fracturing of surrounding material to facilitate drilling in the direction of the directed energy.

Owner:SCHLUMBERGER TECH CORP

Apparatus and Method for Electrocrushing Rock

The present invention provides for pulsed power breaking and drilling apparatuses and methods. The present invention comprises two pulsed power systems coordinated to fire one right after the other. The first pulsed power system, comprising a spiker, may create a high voltage pulse that breaks down the insulative properties of the substrate and may create an arc channel in the substrate. It is designed for high voltage but low energy, at high impedance. The second pulsed power system, comprising a sustainer, is designed to provide high current into the arc, but at low voltage, thus better matching the impedance of the arc and achieving much more efficient energy transfer.

Owner:SDG LLC

Laser liner creation apparatus and method

InactiveUS6851488B2Eliminate requirementsEarth drilling toolsDisloding machinesLaser beamsGeophysics

A method and apparatus for forming an in situ borehole liner in which a laser beam from a laser energy assembly disposed within a transparent drill head enclosure of a drill head assembly is directed into a rock formation to be drilled and a portion of the rock formation is melted, forming molten rock. The drill head assembly is directed into the molten rock forming a borehole having a borehole wall. At least one air stream from the drill head assembly is directed into the molten rock forming the molten rock against the borehole wall after which the molten rock against the borehole wall is cooled, forming a borehole liner.

Owner:GAS TECH INST

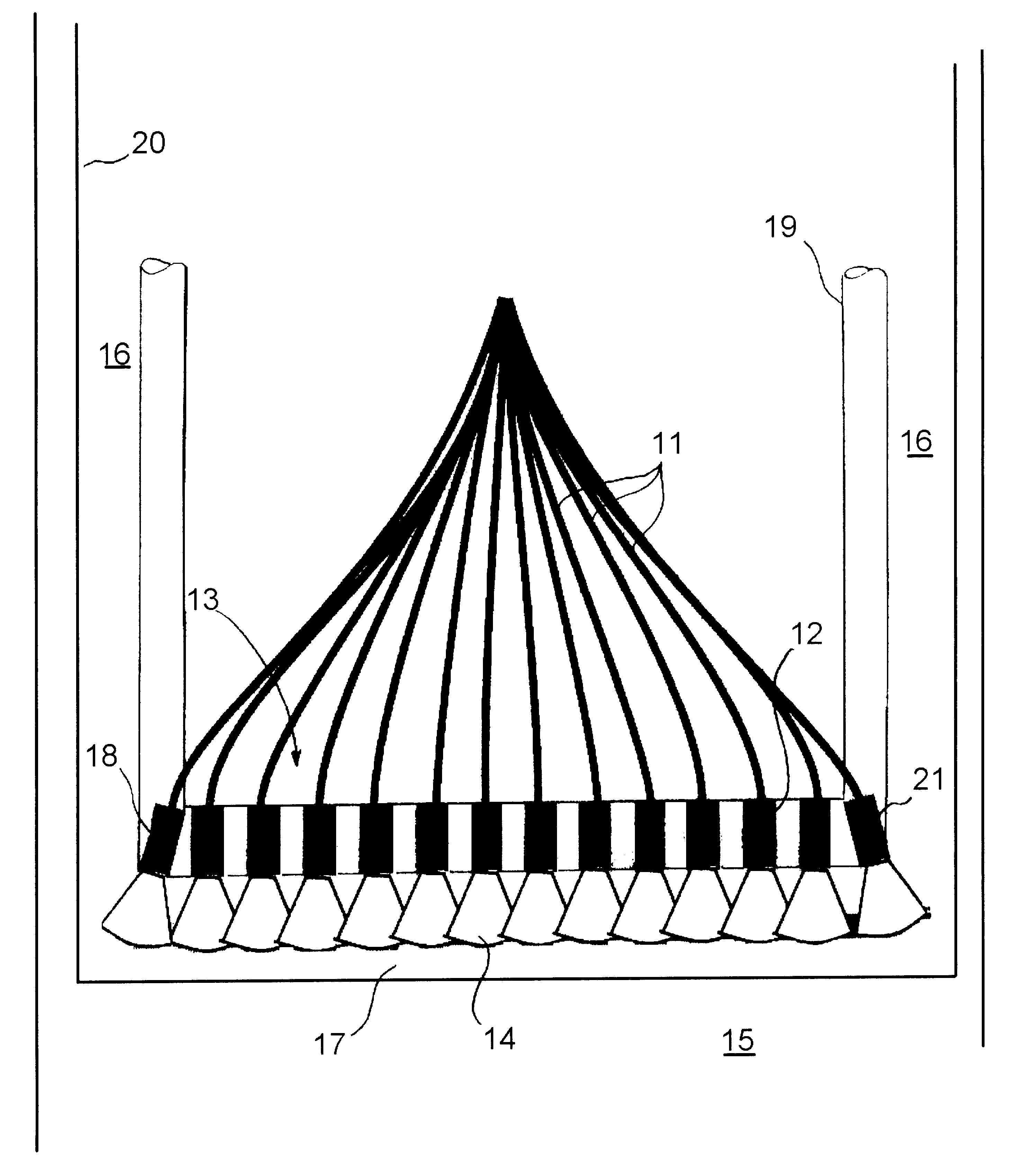

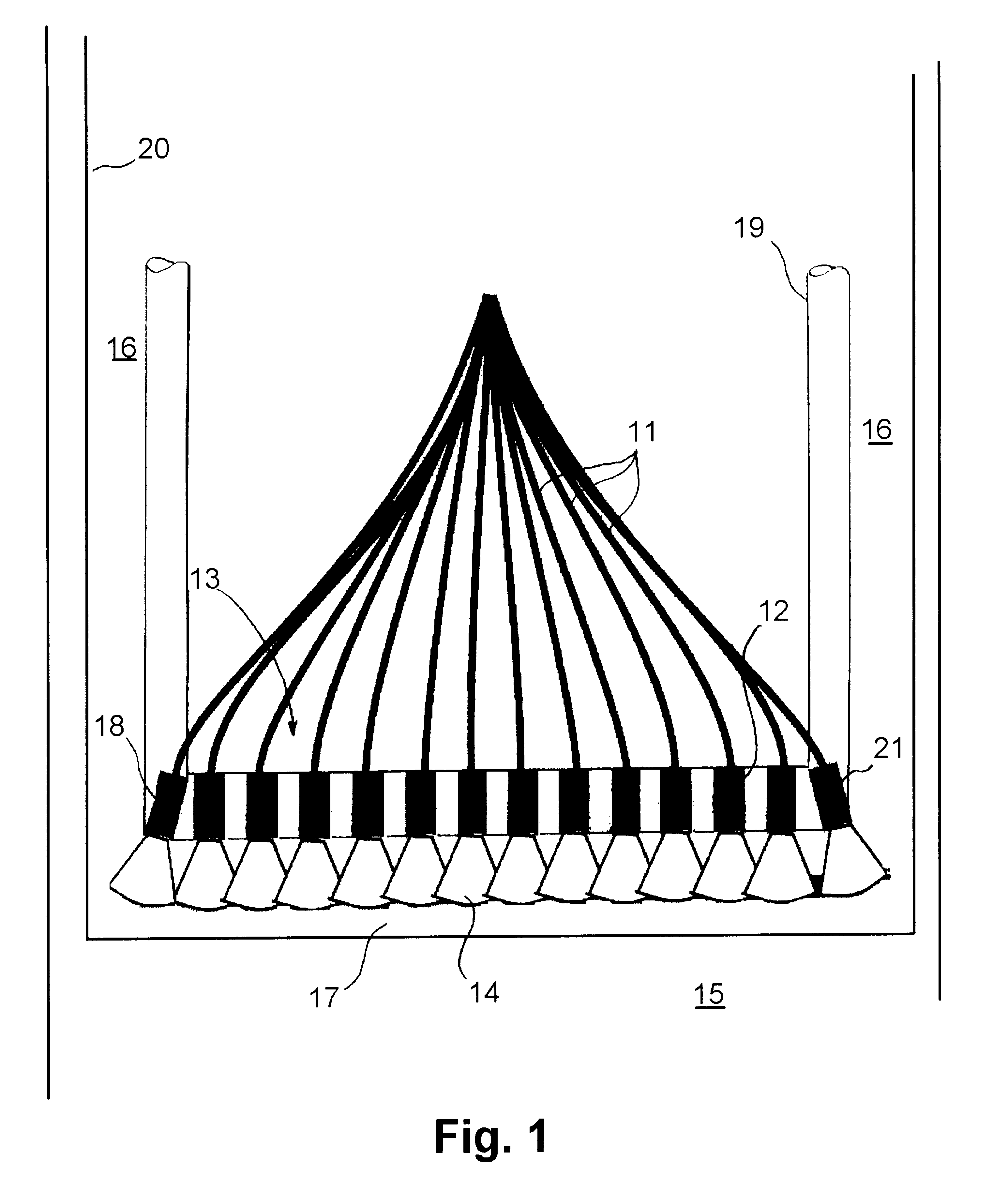

Methane extraction method and apparatus using high-energy diode lasers or diode-pumped solid state lasers

InactiveUS20070267220A1Efficient productionConstructionsDisloding machinesFiberDiode-pumped solid-state laser

A method and apparatus for extracting methane gas from methane hydrate. The method includes heating the methane hydrate with a laser apparatus. The laser apparatus includes a diode laser or a solid state laser that is pumped with a diode laser. The laser is guided to a working end of a tool with a fiber optic bundle. The tool is guided to heat the methane hydrate with the laser, which emanates from a beam expander at the working end of the tool. The tool can be modified for removing obstructions of methane hydrate in pipelines. Also, the tool can be modified for extracting methane from mined methane hydrate, which is in a container. The characteristics of diode lasers or diode-pumped solid state lasers such as efficiency, size, nature of operation, environmental impact and durability, make methane gas extraction from methane hydrate economically feasible.

Owner:NORTHROP GRUMAN CORP

Methods of using a laser to perforate composite structures of steel casing, cement and rocks

ActiveUS7487834B2Improve breathabilityReduce hole taperingDisloding machinesThermal drillingHigh power lasersSmall fragment

Owner:UCHICAGO ARGONNE LLC +1

Laser spectroscopy/chromatography drill bit and methods

ActiveUS20050269132A1Reduce the amount of damageReduces amount of wearSurveyDrill bitsWell drillingSpectroscopy

A drilling apparatus for well-boring having a drill bit assembly which includes a laser cutting assembly and a vacuum assembly. The vacuum assembly is adapted to intake vapors generated by the laser cutting assembly proximate the drill bit assembly during operation of the drilling apparatus. The collected vapors may then be processed by a chromatographic analyzer to determine the characteristics of the rock formation being drilled.

Owner:GAS TECH INST

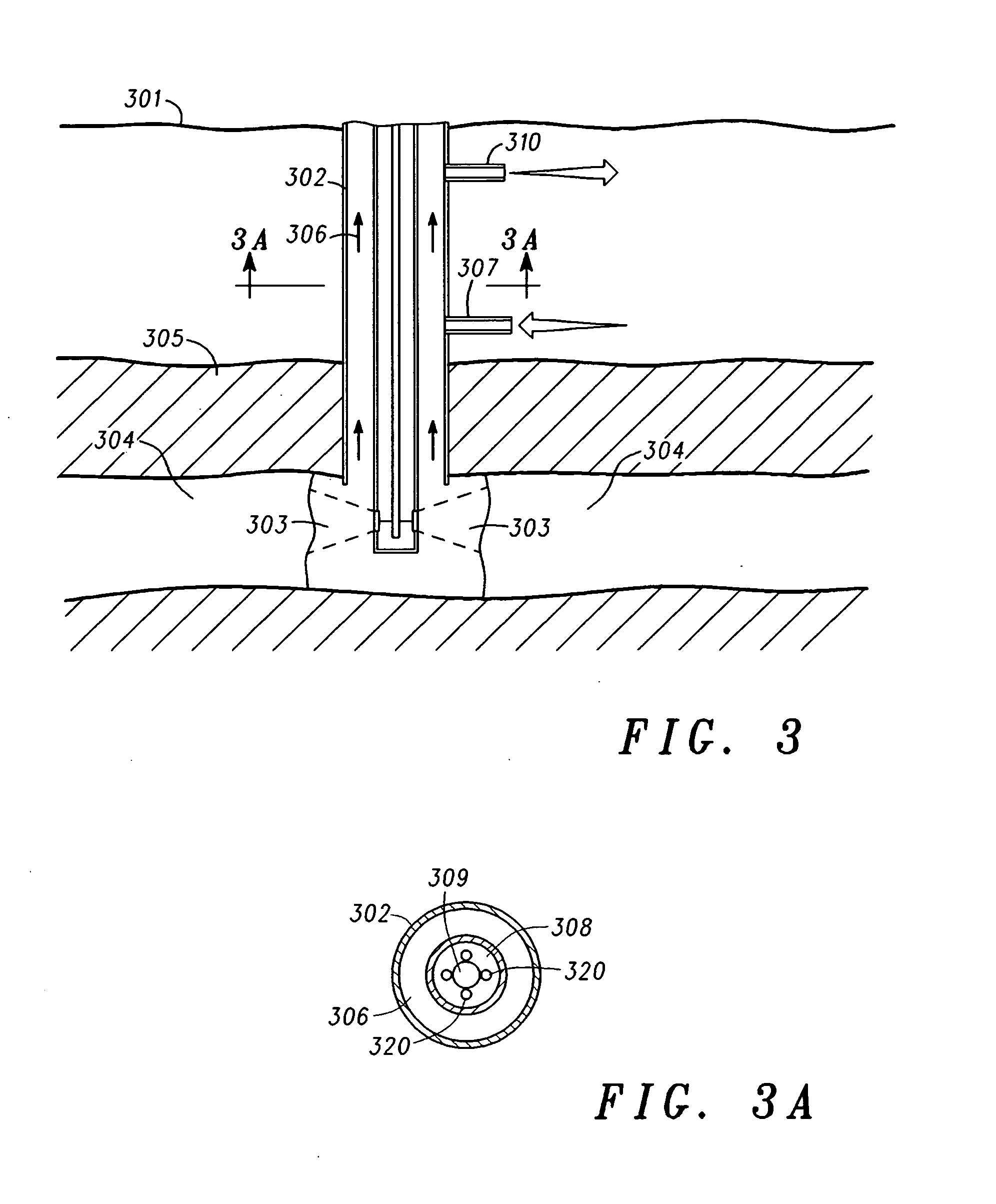

Methods of using a laser to spall and drill holes in rocks

ActiveUS20060237233A1Energy efficiencyProtection is necessaryEarth drilling toolsDisloding machinesSmall fragmentClassical mechanics

Apparatus and methods of using lasers are provided for spalling and drilling holes into rocks. A rock removal process is provided that utilizes a combination of laser-induced thermal stress and laser induced superheated steam explosions just below the surface of the laser / rock interaction to spall the rock into small fragments that can then be easily removed by a purging flow. Single laser beams of given irradiance spall rock and create holes having diameter and depth approximately equal to the beam spot size. A group of the single laser beams are steered in a controllable manner by an electro-optic laser beam switch to locations on the surface of the rock, creating multiple overlapping spalled holes thereby removing a layer of rock of a desired diameter. Drilling of a deep hole is achieved by spalling consecutive layers with an intermittent feed motion of the laser head perpendicular to the rock surface.

Owner:UCHICAGO ARGONNE LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com