Patents

Literature

637results about How to "Difficult to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Molecular wire transistor (MWT)

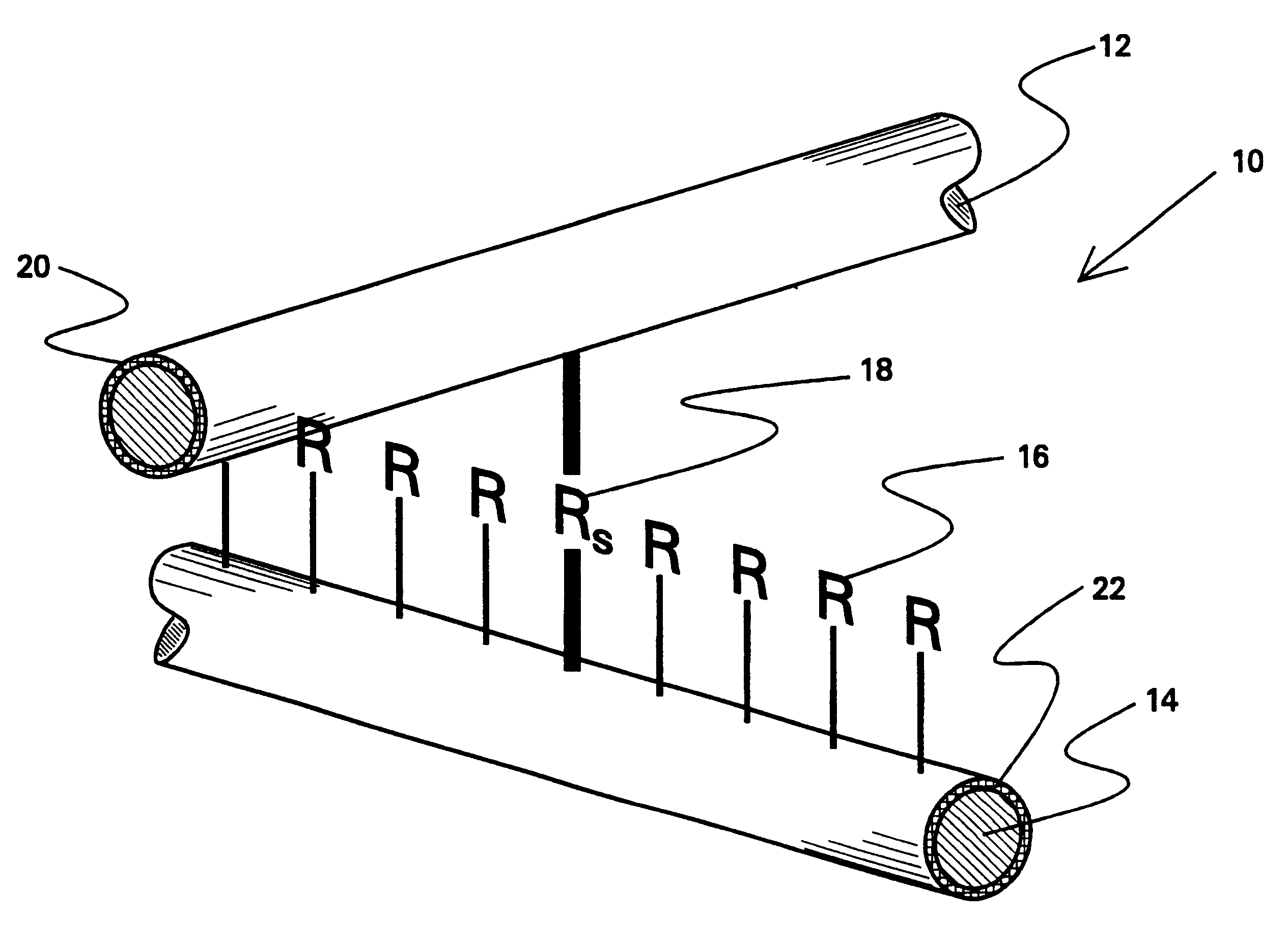

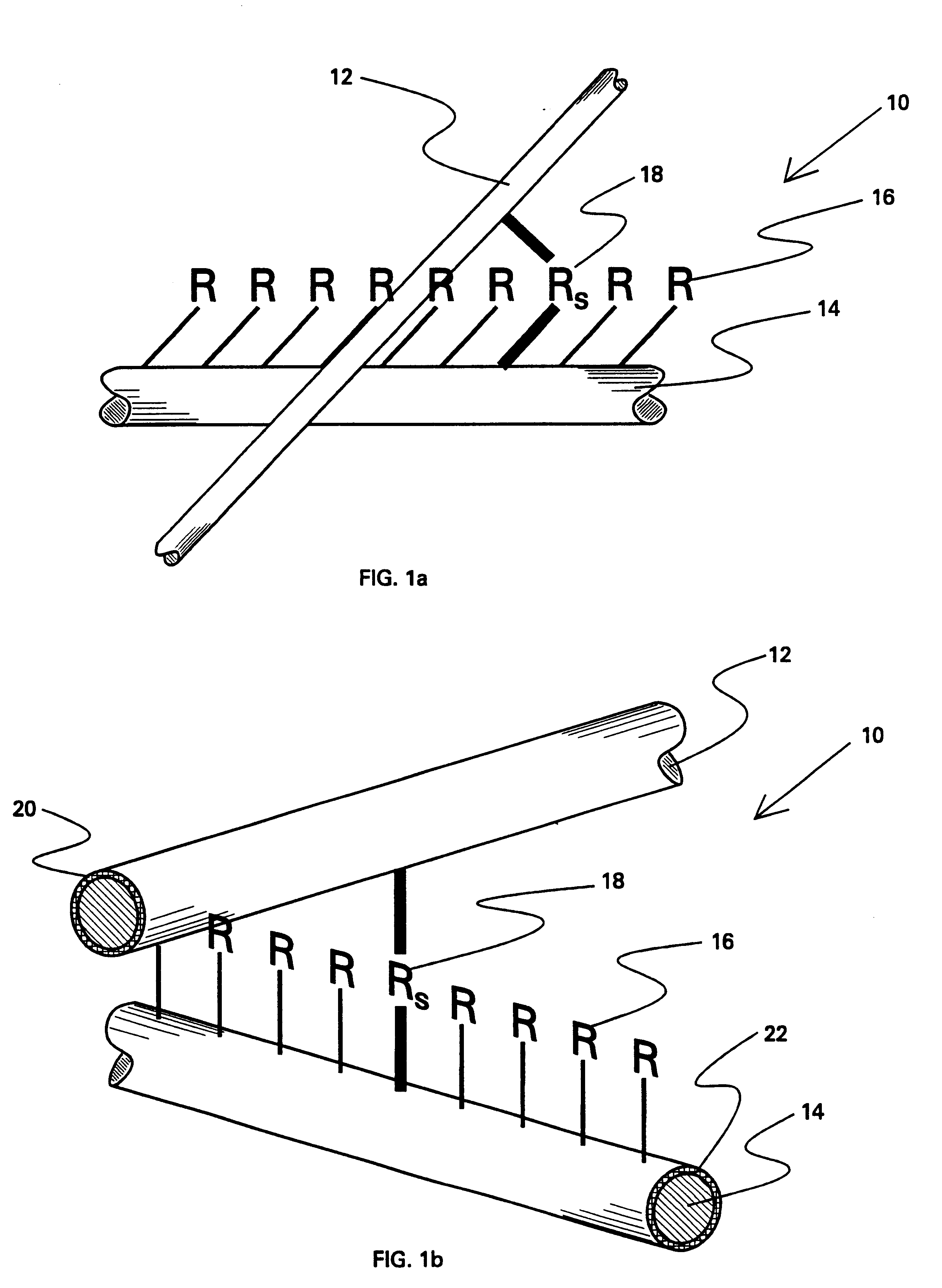

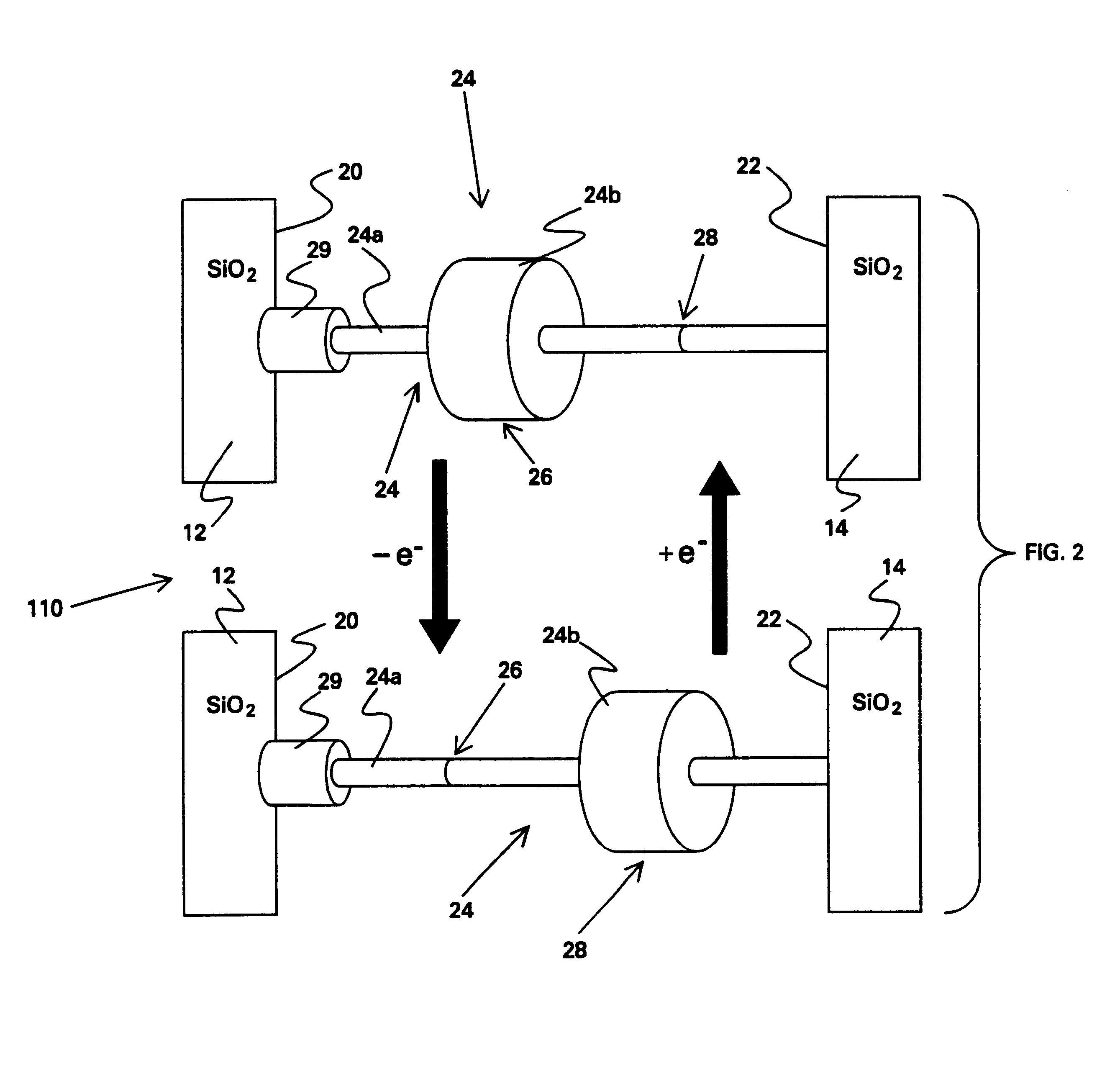

Bipolar and field effect molecular wire transistors are provided. The molecular wire transistor comprises a pair of crossed wires, with at least one of the wires comprising a doped semiconductor material. The pair of crossed wires forms a junction where one wire crosses another, one wire being provided with Lewis acid functional groups and the other wire being provided with Lewis base functional groups. If both wires are doped semiconductor, such as silicon, one is P-doped and the other is N-doped. One wire of a given doping comprises the emitter and collector portions and the other wire comprises the base portion, which is formed by modulation doping on the wire containing the emitter and collector at the junction where the wires cross and between the emitter and collector portions, thereby forming a bipolar transistor. Both NPN and PNP bipolar transistors may be formed. Analogously, one wire may comprise doped semiconductor, such as silicon, and the other wire a metal, the doped silicon wire forming the source and drain and the metal wire forming the gate by modulation doping on the doped silicon wire where the wires cross, between the source and drain, to form a field effect transistor. Both P-channel and N-channel FETs may be formed. The construction of both bipolar transistors and FETs on a nanometer scale, which are self-aligned and modulation-doped, is thereby enabled.

Owner:HEWLETT PACKARD DEV CO LP

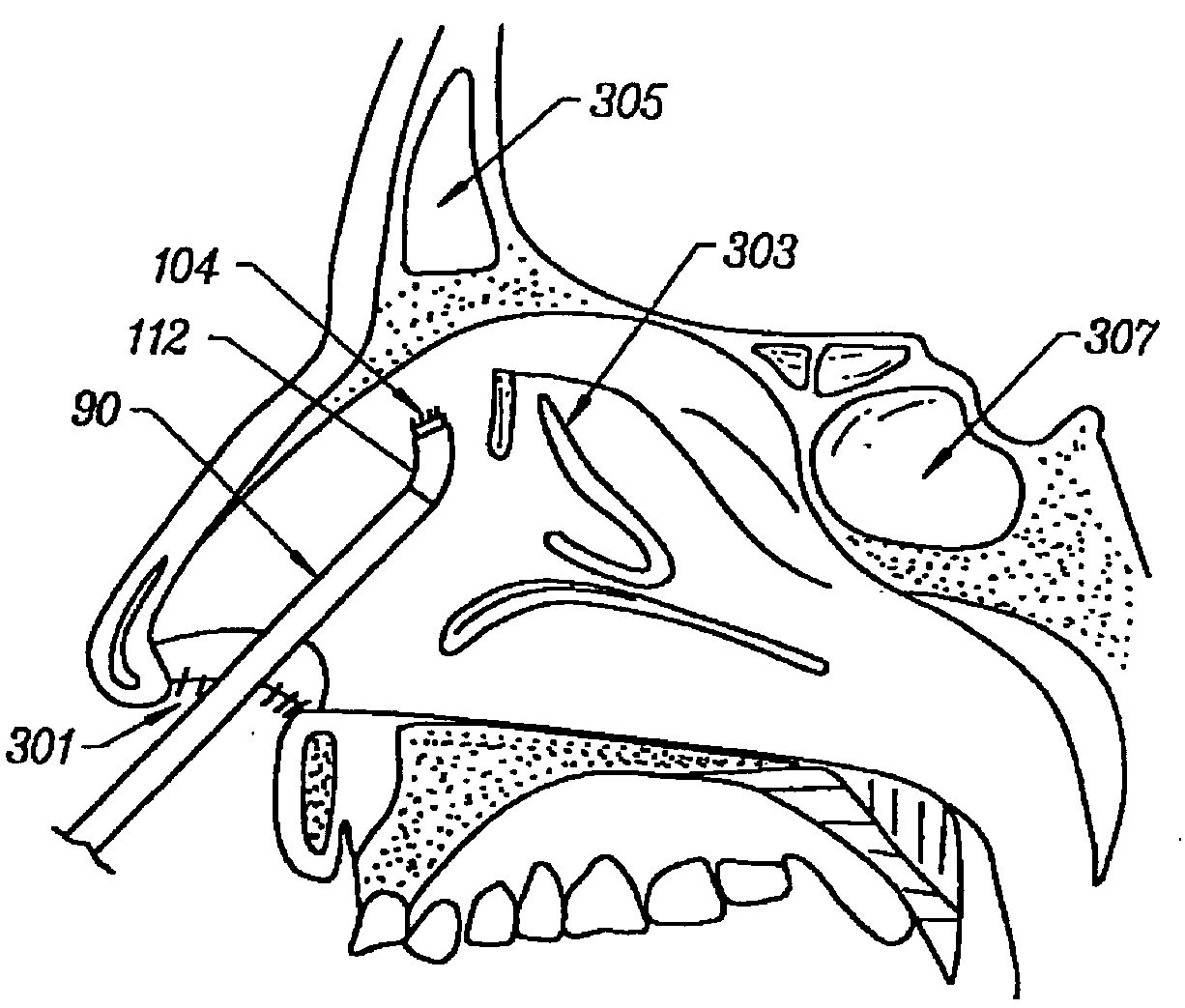

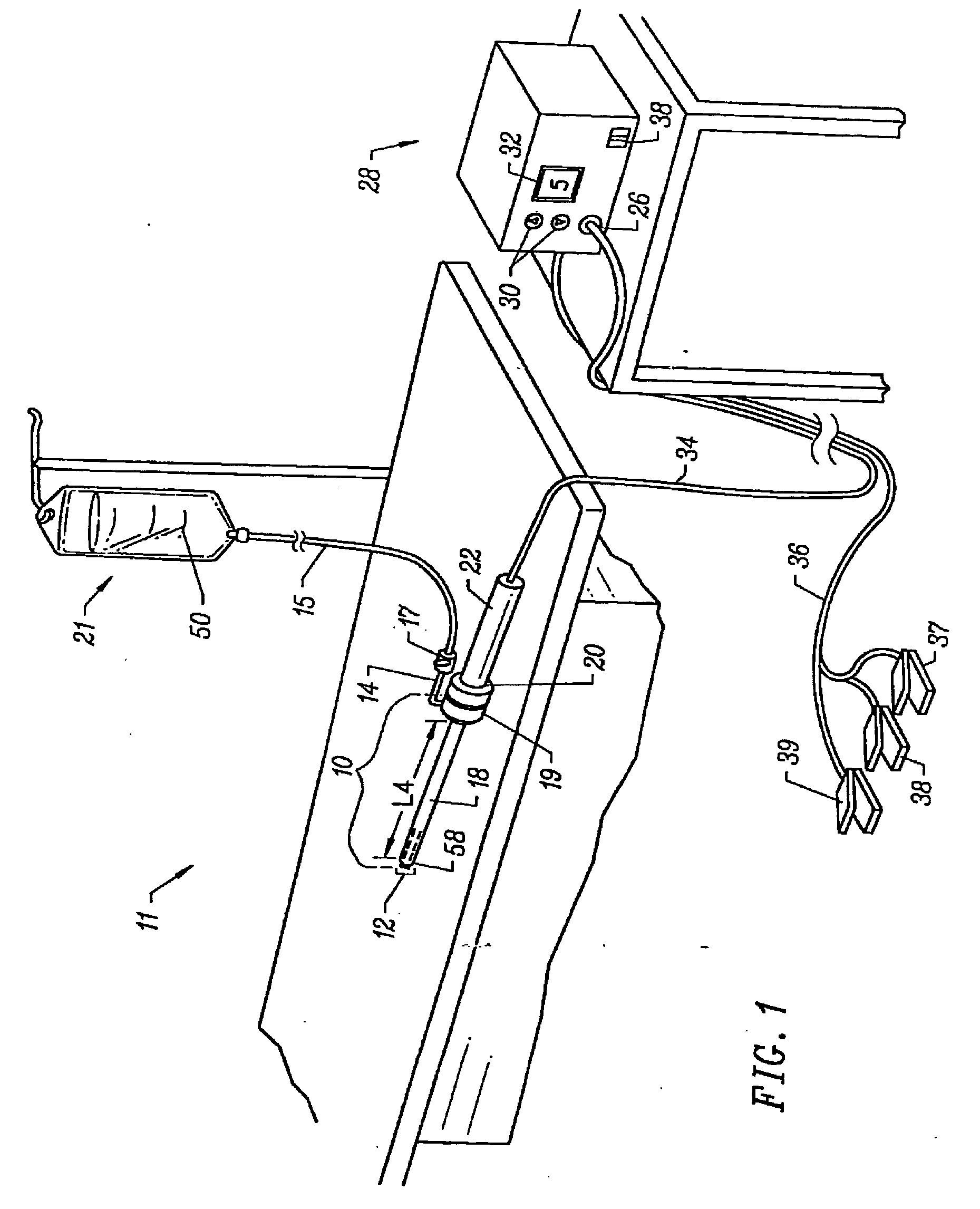

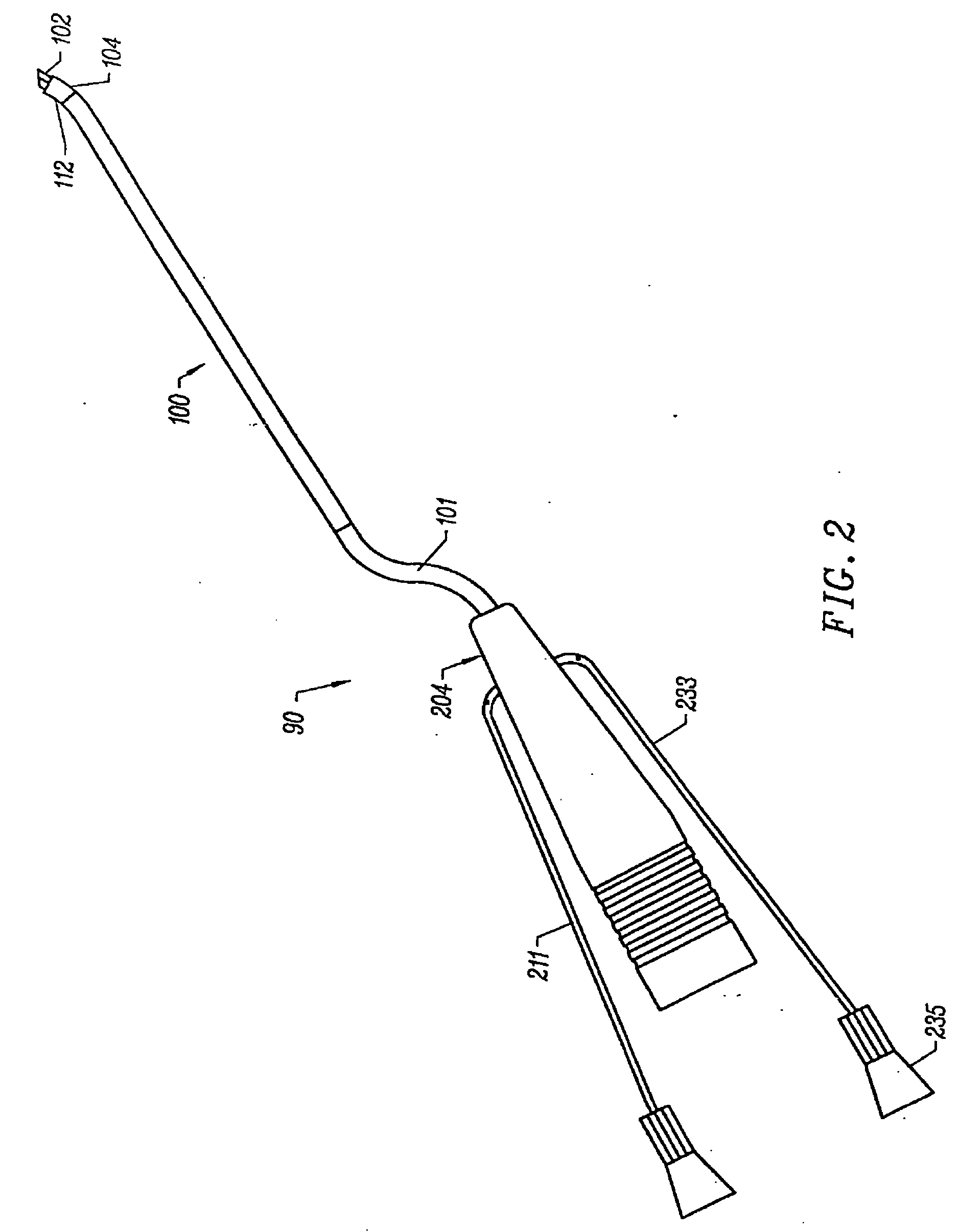

Systems and methods for electrosurgical treatment of obstructive sleep disorders

InactiveUS20060253117A1Less tissue damageReduce postoperative painCannulasEnemata/irrigatorsThroatSleeping disorders

Owner:ARTHROCARE

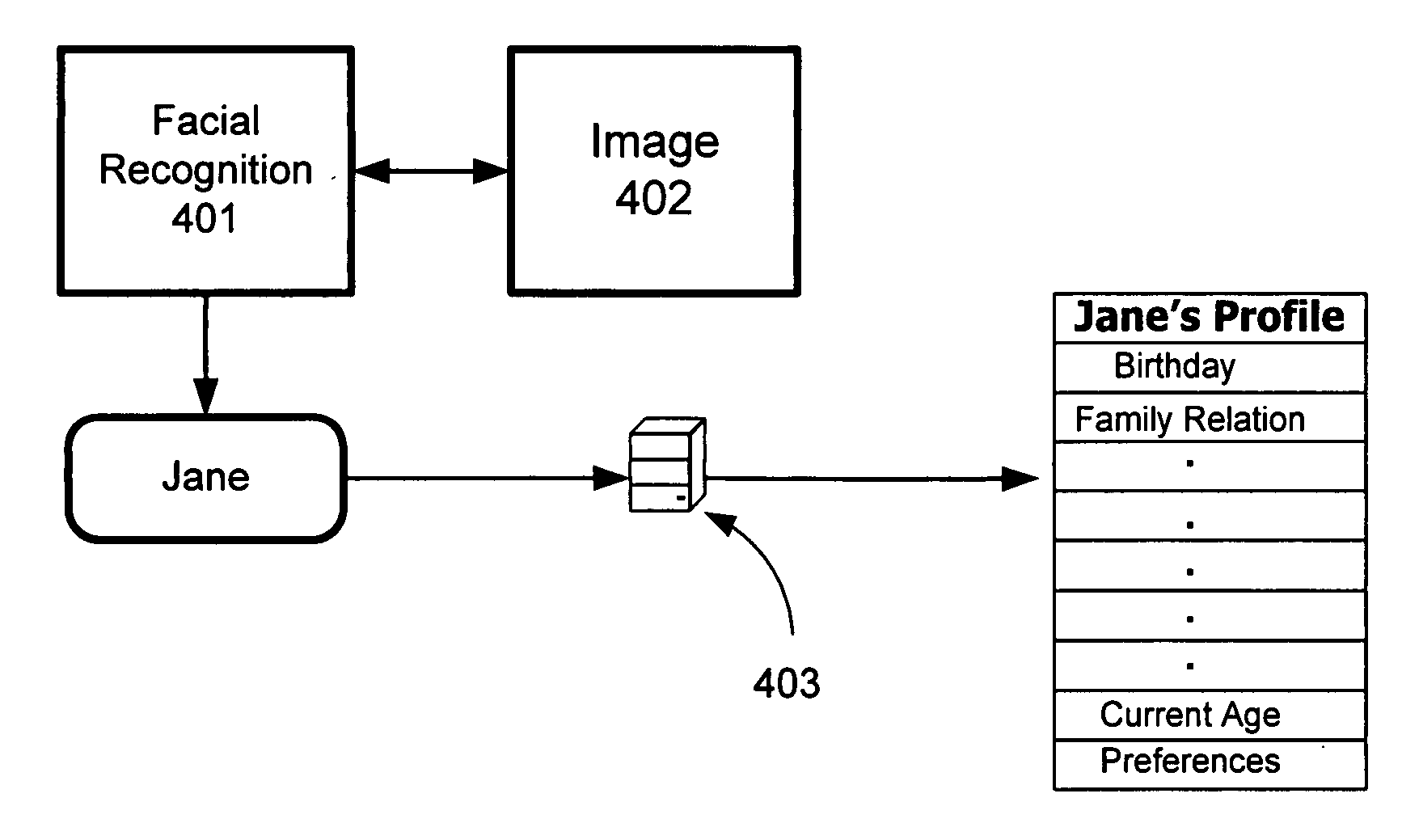

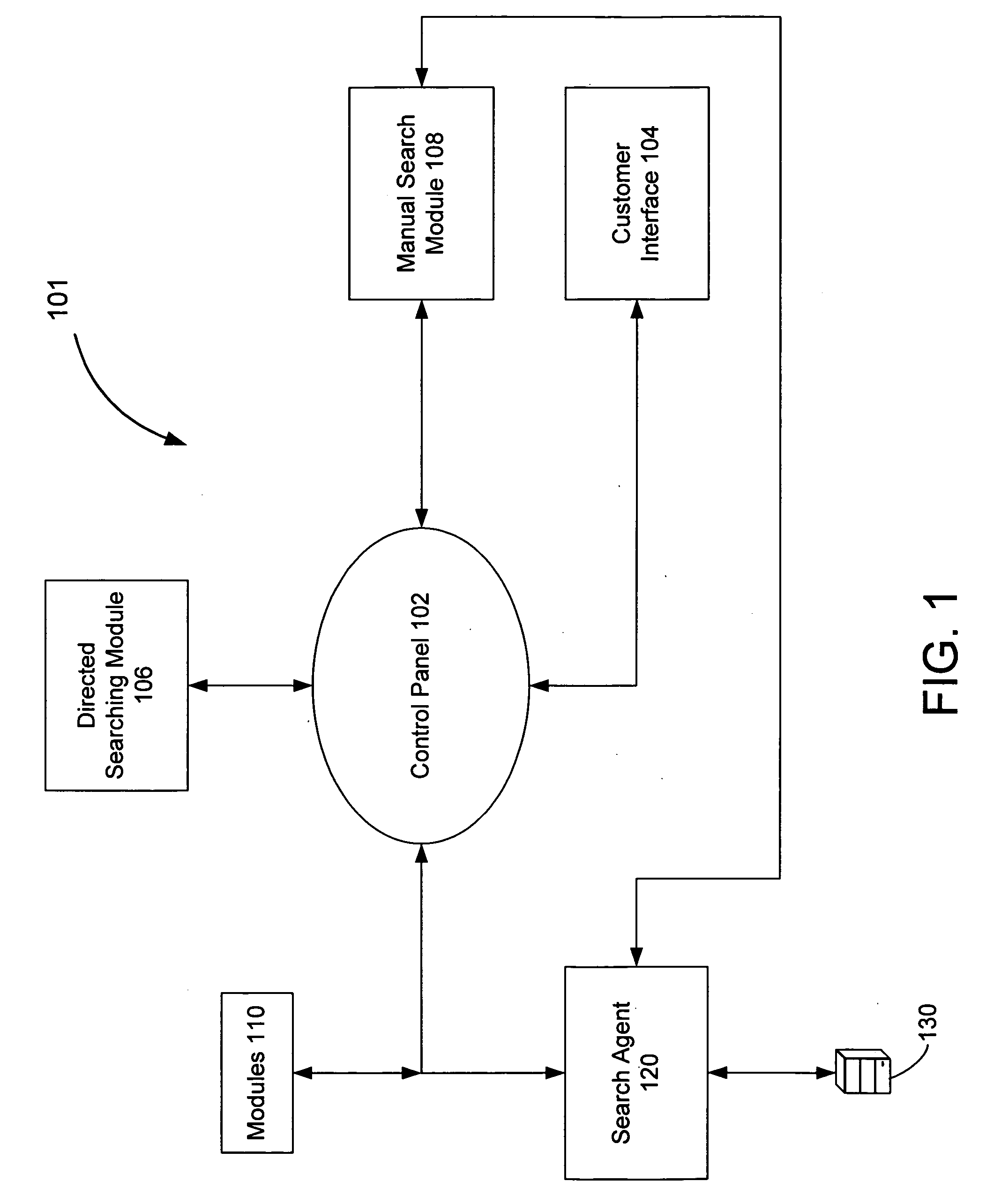

Metadata management and generation using digital watermarks

ActiveUS20060115108A1Difficult to controlDifficult to trackMultimedia data indexingCharacter and pattern recognitionWeb browserMetadata management

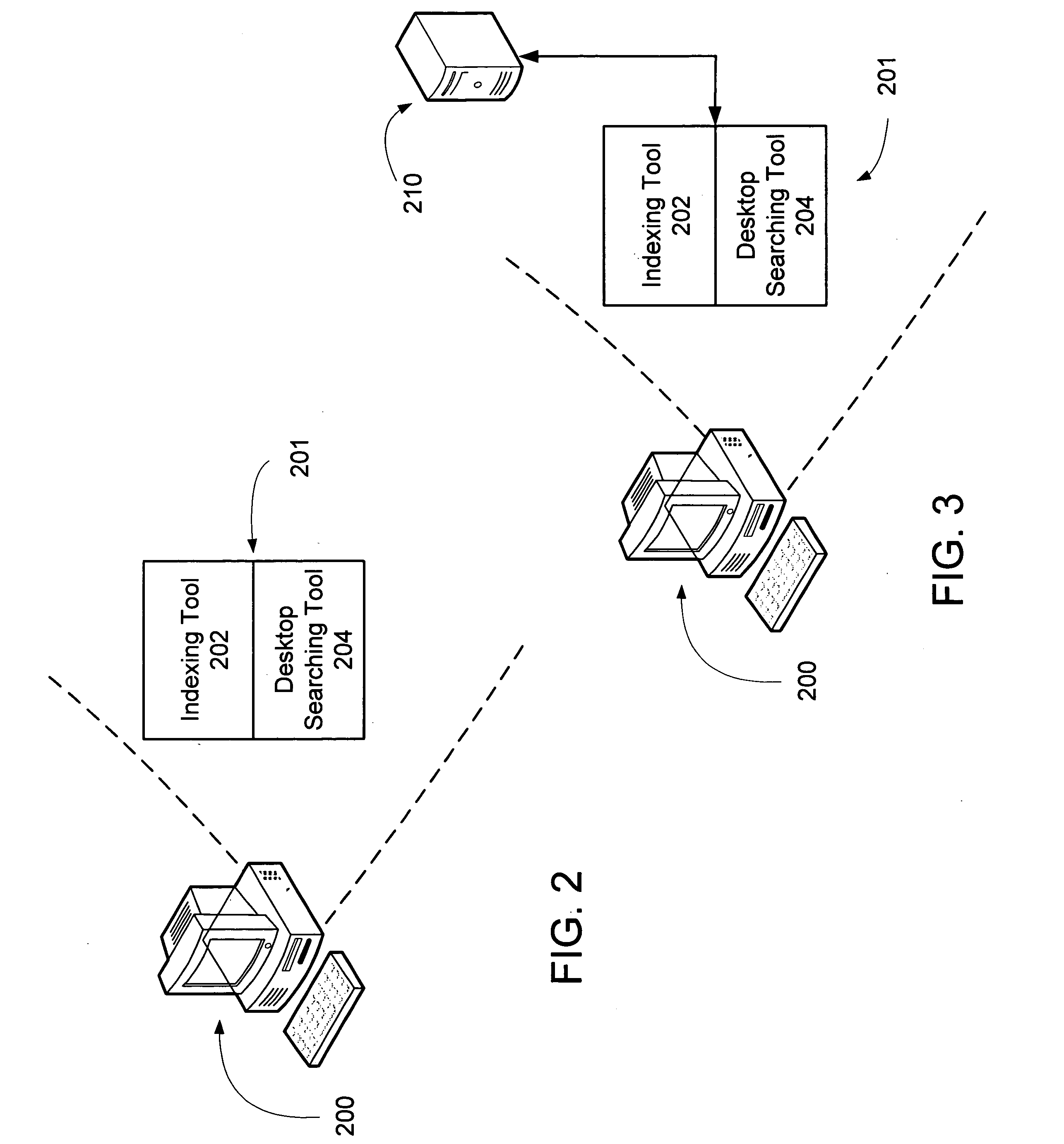

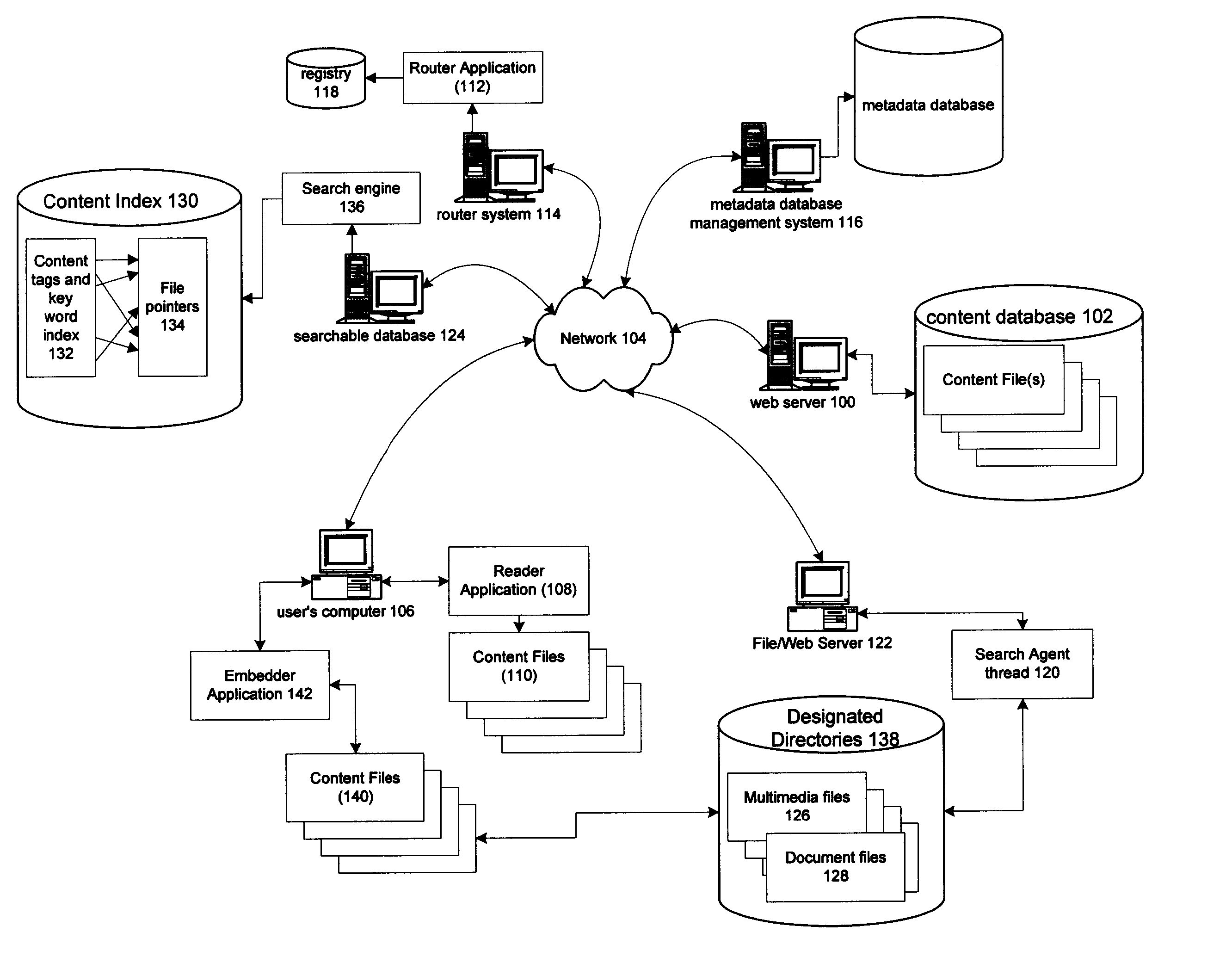

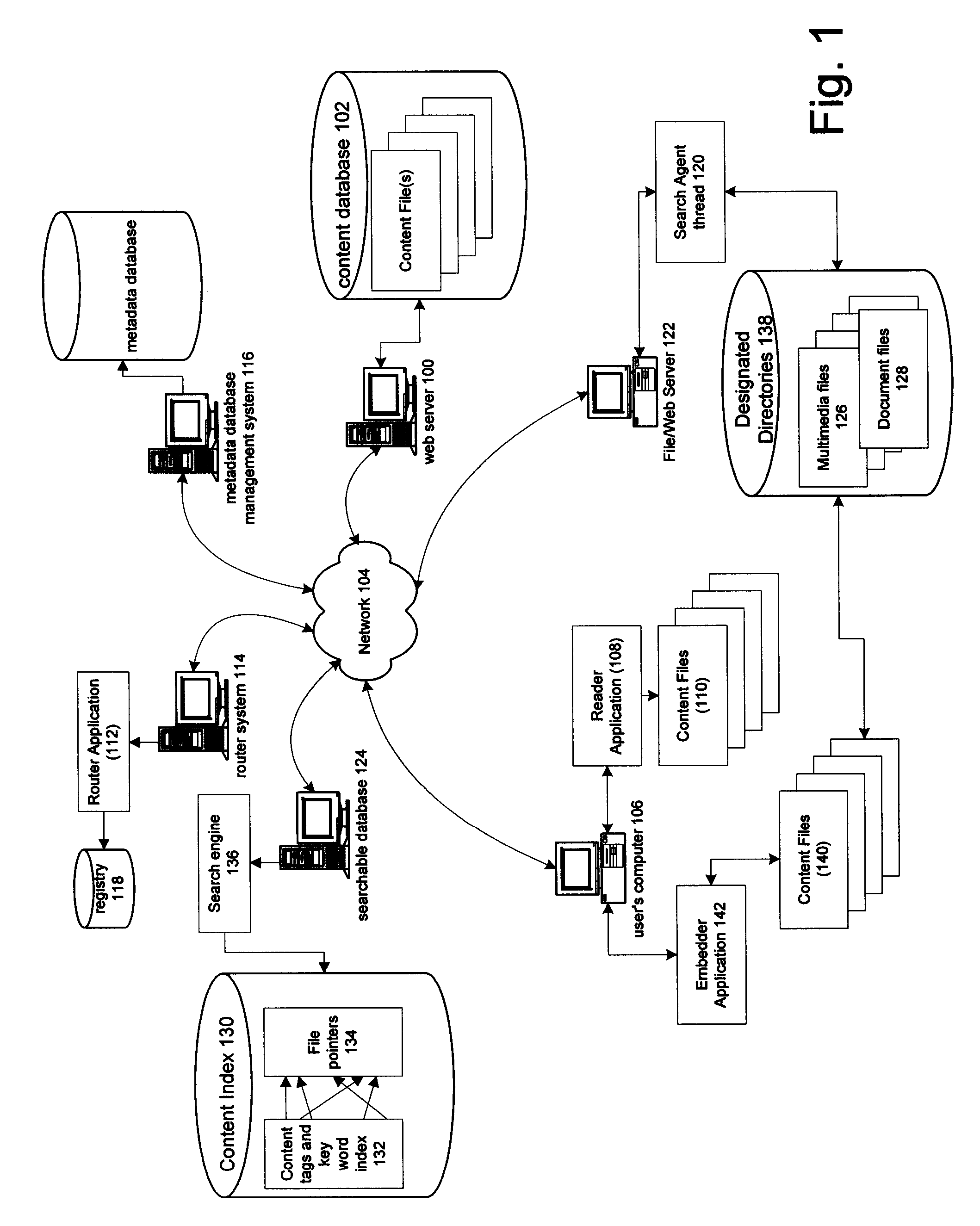

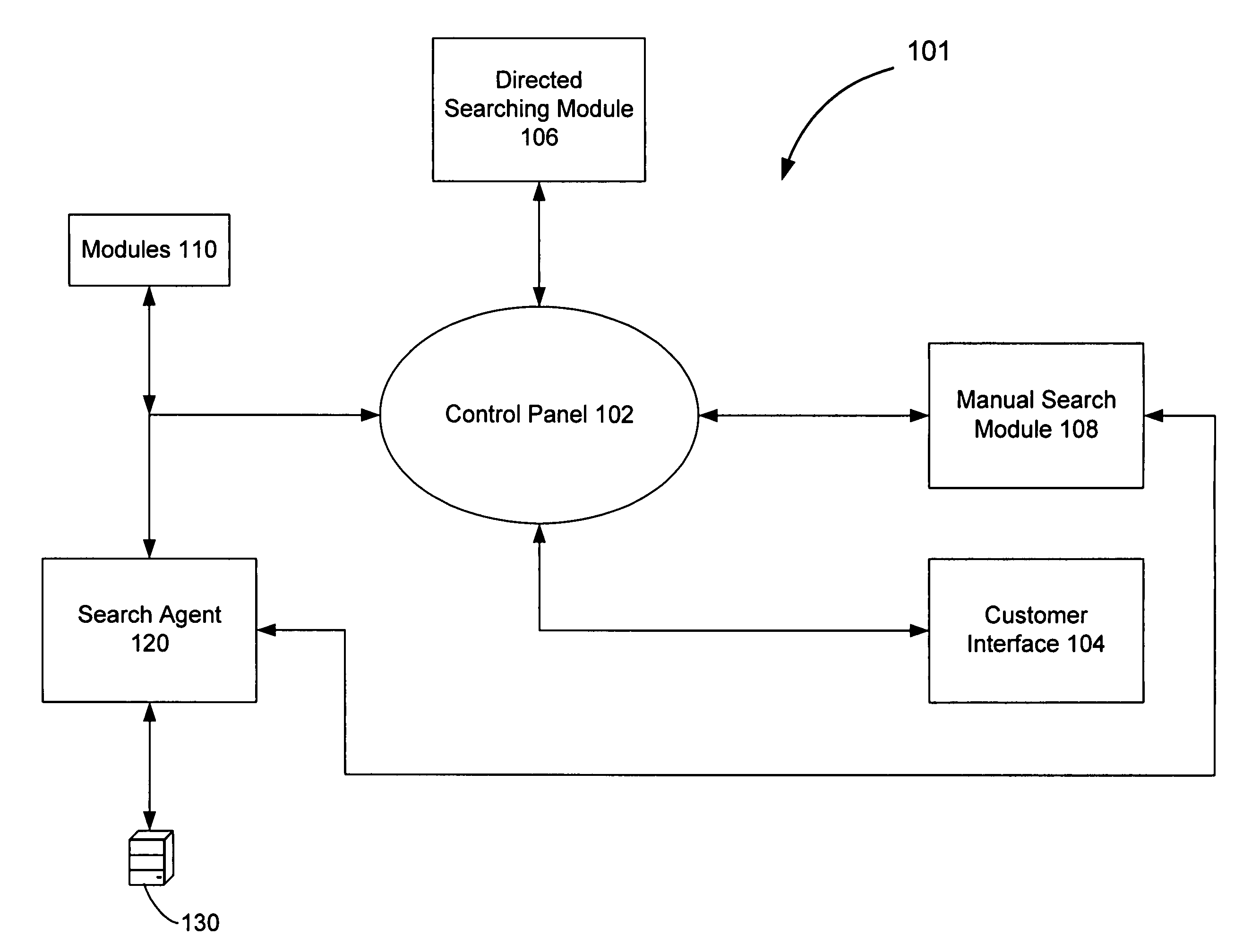

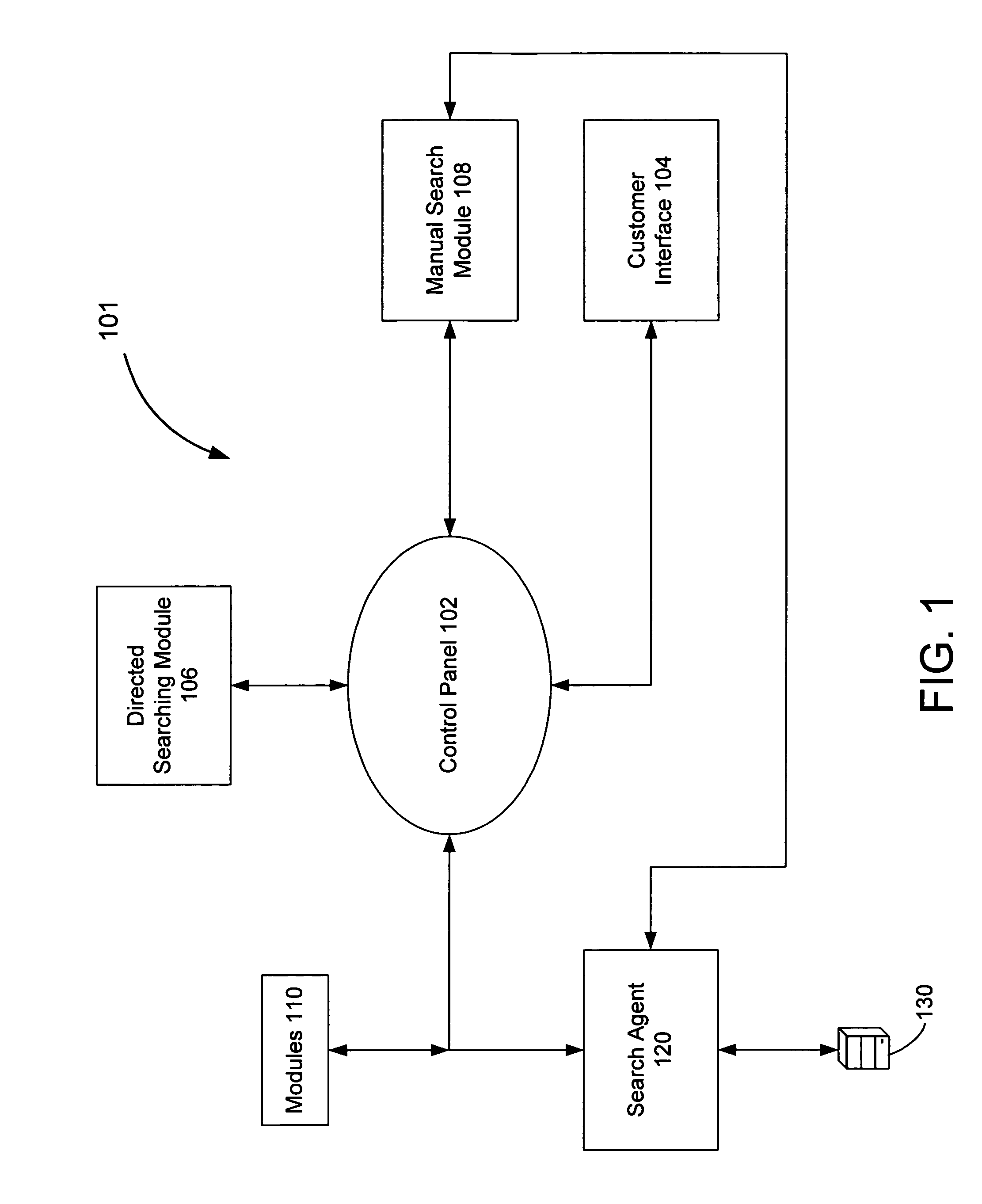

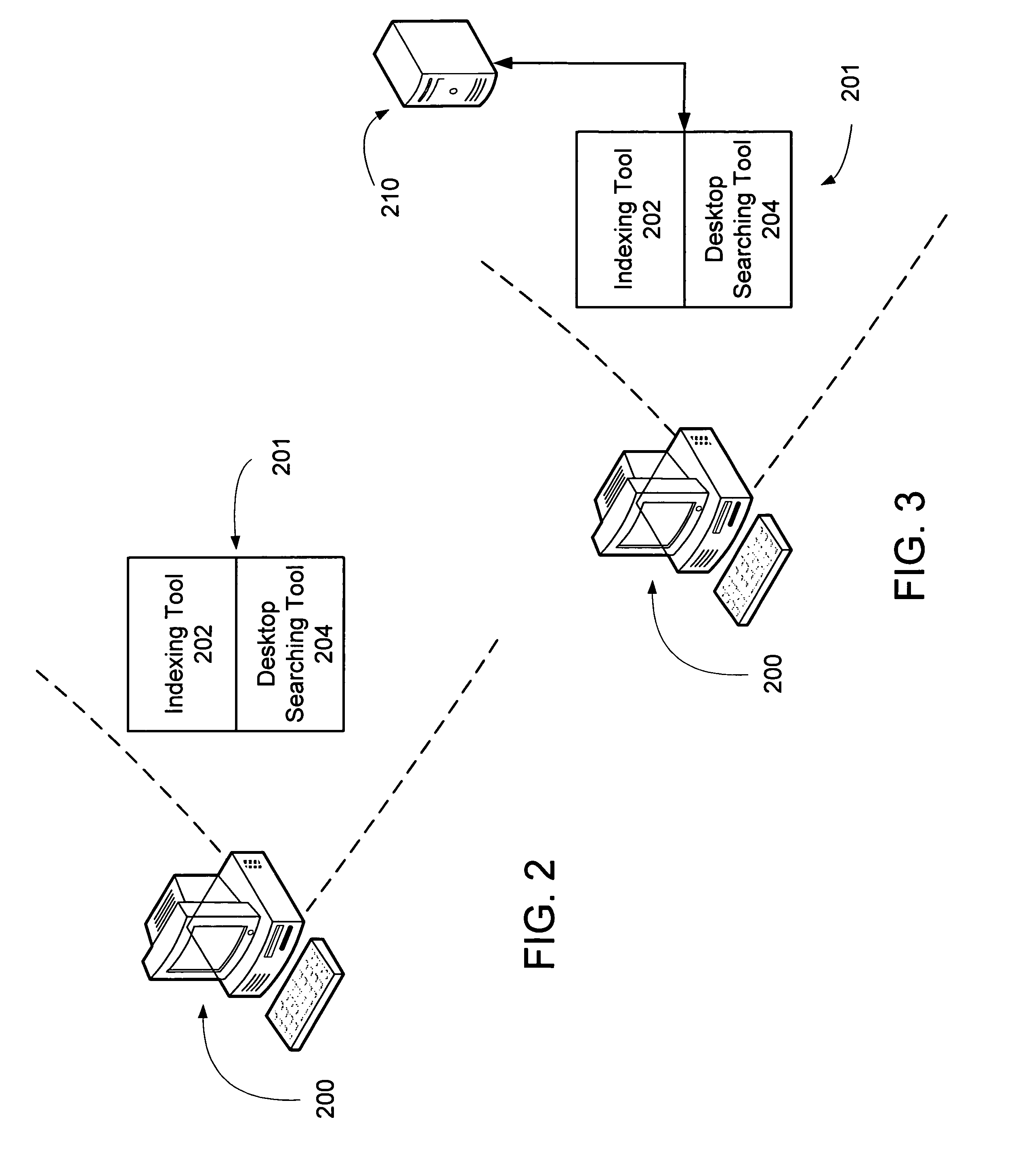

The present invention provides methods and systems to improve network searching for watermarked content. In some implementations we employ keyword searching to narrow the universe of possible URL candidates. A resulting URL list is searched for digital watermarking. A system is provided to allow customer input. For example, a customer enters keywords or network locations. The keywords or network locations are provided to a watermark-enabled web browser which accesses locations associated with the keywords or network locations. Some implementations of the present invention employ a plurality of distributed watermark-enabled web browsers. Other aspects of the invention provide methods and system to facilitate desktop searching and automated metadata gathering and generating. In one implementation a digital watermark is used to determine whether metadata associated with an image or audio file is current or fresh. The metadata is updated when it is out of date. Watermarks can also be used to link to or facilitate so-called on-line “blogs” (or online conversations).

Owner:DIGIMARC CORP

Content Indexing and Searching using Content Identifiers and associated Metadata

InactiveUS20070055689A1Difficult to controlDifficult to trackMultimedia data queryingDigital data processing detailsContent IdentifierMetadata

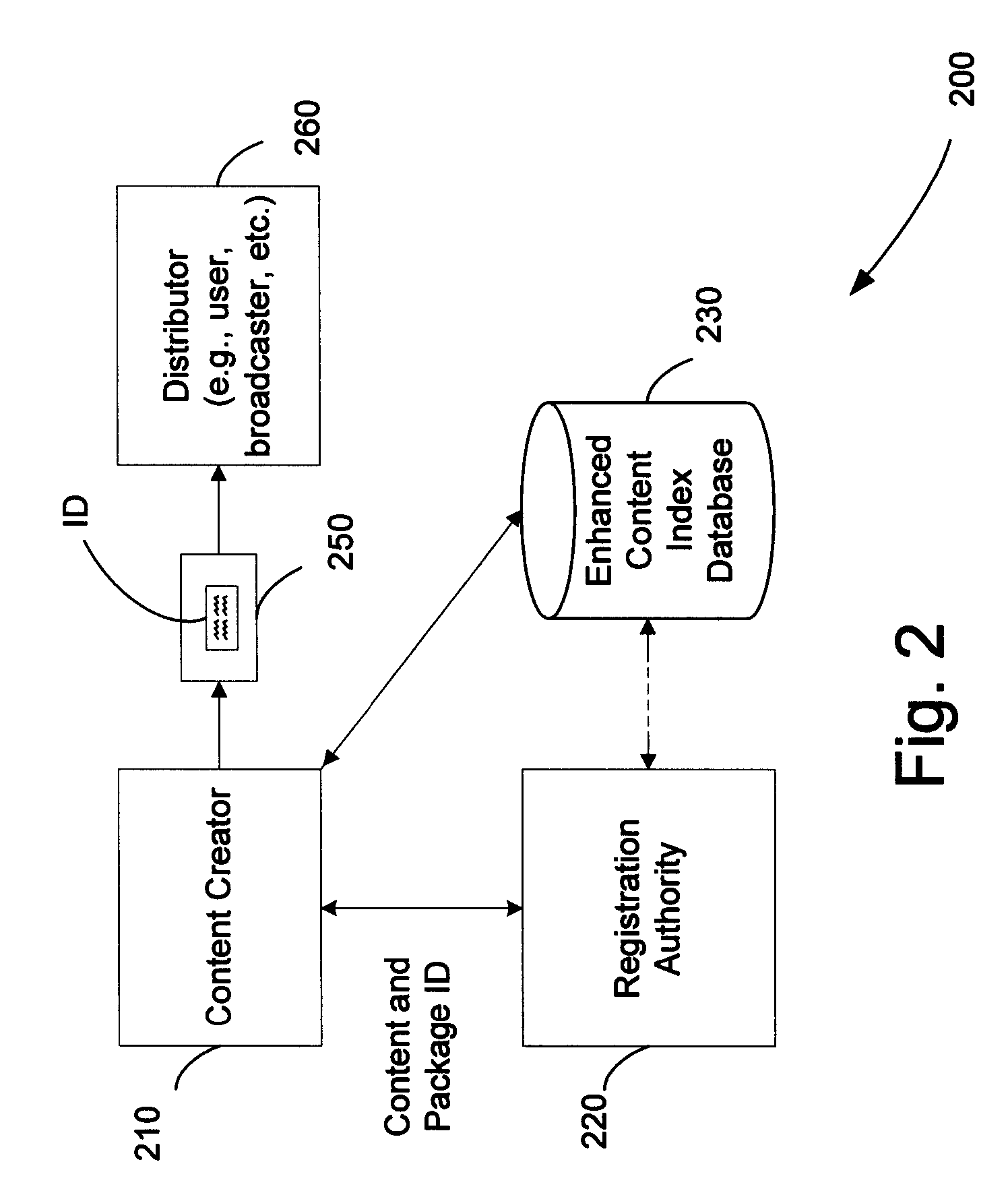

A method of indexing content for network searching comprises identifying media content signals stored at sites distributed over a distributed computer network; extracting content identifiers from the content signals; using the content identifiers to obtain metadata used to classify the media content signals; and creating a searchable index of the media content signals based on the metadata, wherein users access the searchable index on the distributed computer network to submit a search query for the searchable index to retrieve links to the media content signals.

Owner:DIGIMARC CORP

Digital asset management, targeted searching and desktop searching using digital watermarks

InactiveUS7450734B2Difficult to controlDifficult to trackCharacter and pattern recognitionSecret communicationWeb browserUniform resource locator

The present invention provides methods and systems to improve network searching for watermarked content. In some implementations we employ keyword searching to narrow the universe of possible URL candidates. A resulting URL list is searched for digital watermarking. A system is provided to allow customer input. For example, a customer enters keywords or network locations. The keywords or network locations are provided to a watermark-enabled web browser which accesses locations associated with the keywords or network locations. Some implementations of the present invention employ a plurality of distributed watermark-enabled web browsers. Other aspects of the invention provide methods and system to facilitate desktop searching and automated metadata gathering and generating. In one implementation a digital watermark is used to determine whether metadata associated with an image or audio file is current or fresh. The metadata is updated when it is out of date. Watermarks can also be used to link to or facilitate so-called on-line “blogs” (or online conversations).

Owner:DIGIMARC CORP

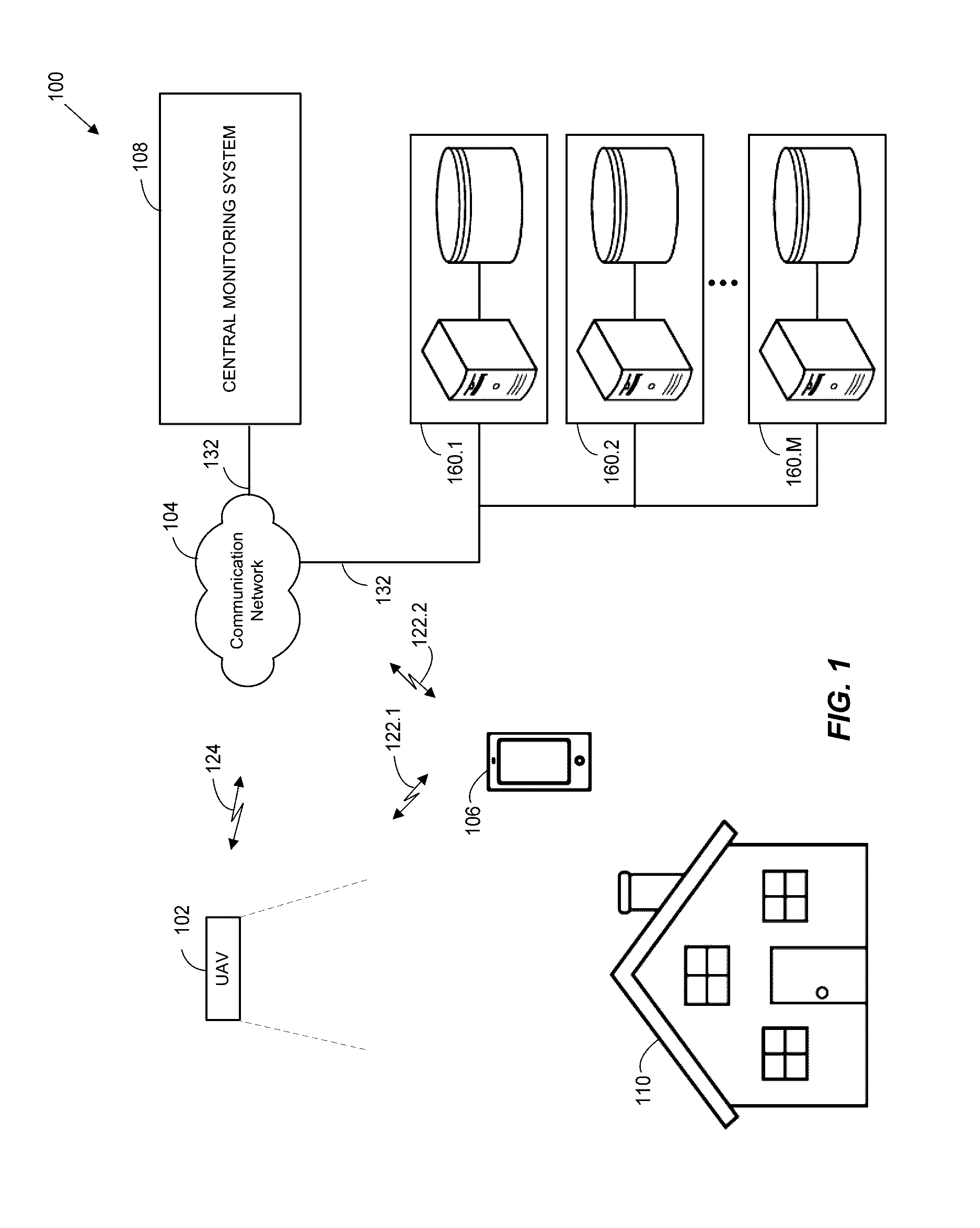

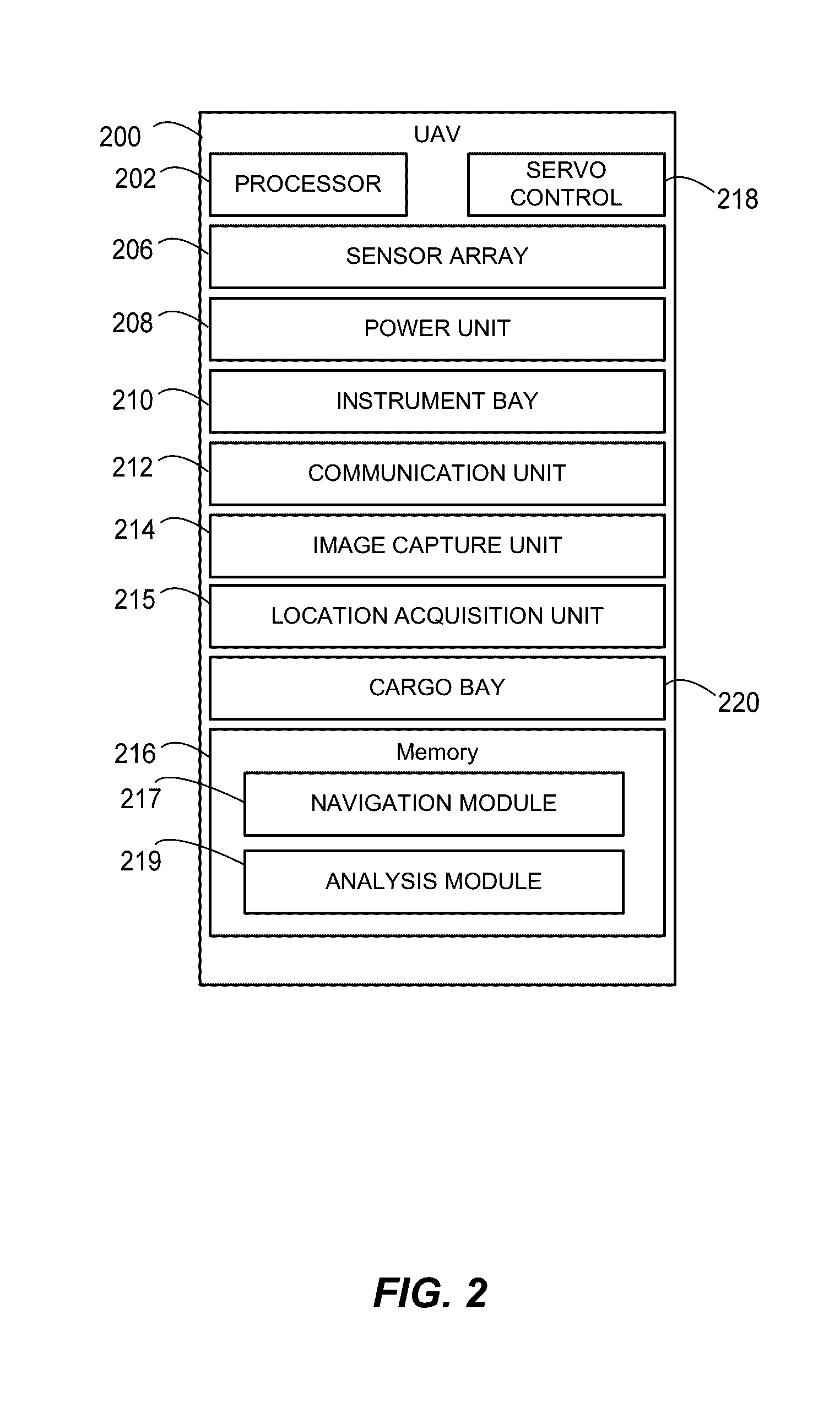

Feedback to facilitate control of unmanned aerial vehicles (UAVs)

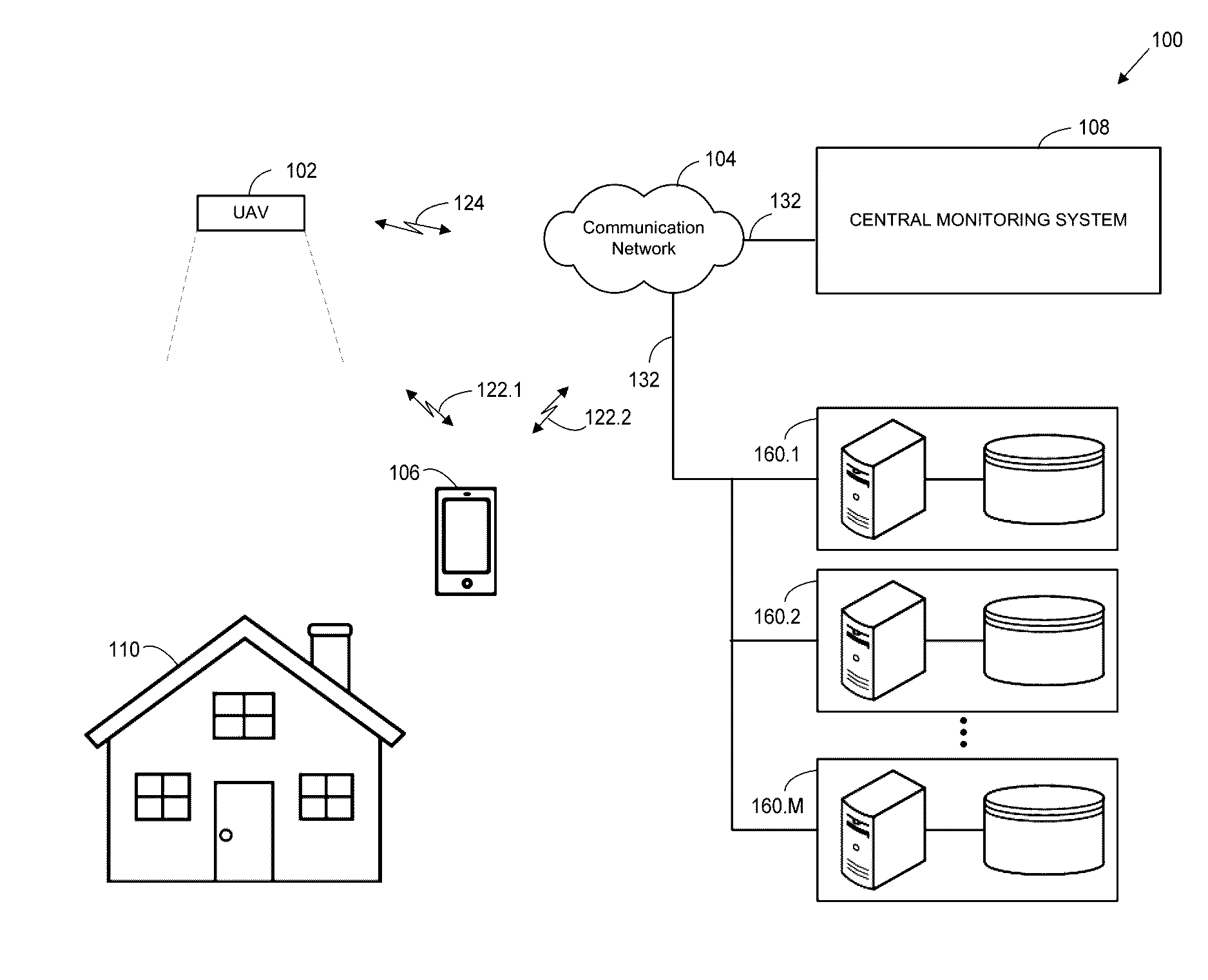

ActiveUS9563201B1Easy to controlEasy to processAircraft componentsTelevision system detailsGraphicsGraphical user interface

Various techniques are described to facilitate controlling an unmanned aerial vehicle (UAV) and viewing feedback received from a UAV. A graphical user interface (GUI) is provided that allows a user to view a display window. The display window may indicate structures or portions of structures in which additional image data is desired by highlighting these portions within the display window. Static imagery may be leveraged to provide smooth and consistent feedback transitions. When a delay exists between the time the UAV sends live video data and the time it may be displayed in the GUI, the static images may be shown in the display window initially until the live video data may be displayed. The opacity of structures included in an initial display window may also transition to a greater opacity over time, with the live video eventually being displayed.

Owner:STATE FARM MUTUAL AUTOMOBILE INSURANCE

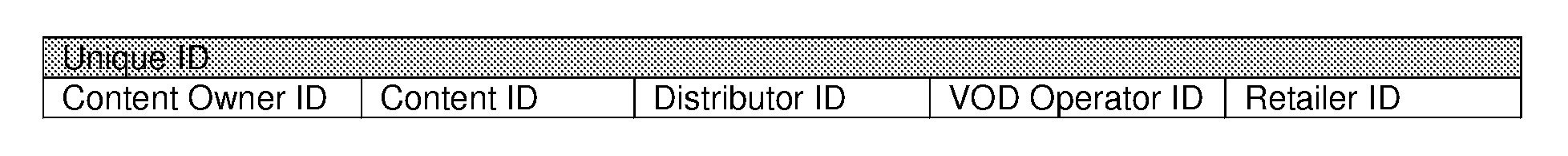

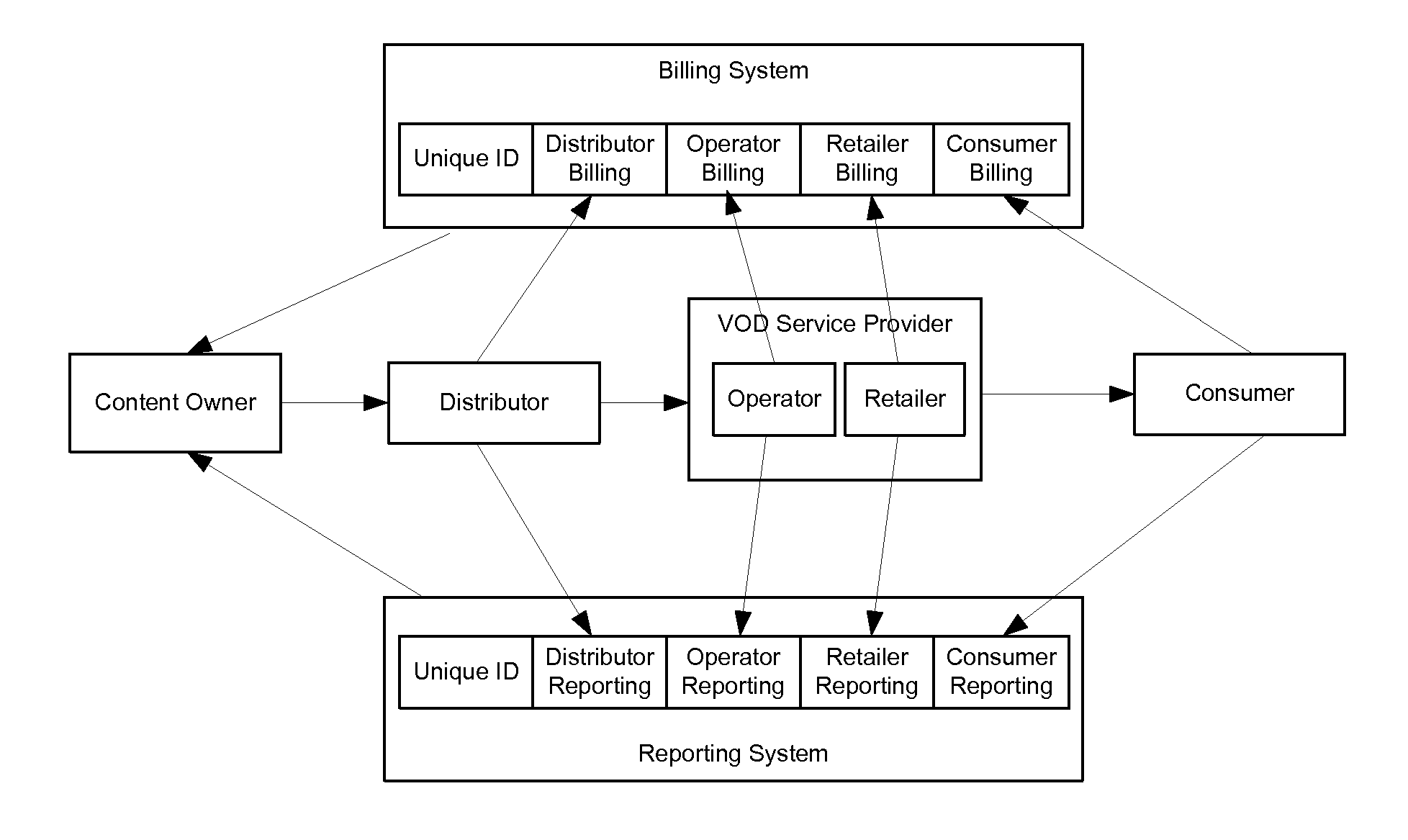

Rights Management Systems and Methods Using Content Identifiers

InactiveUS20080140433A1Difficult to controlDifficult to trackRecord information storageAnalogue secracy/subscription systemsContent IdentifierRights management

Owner:DIGIMARC CORP

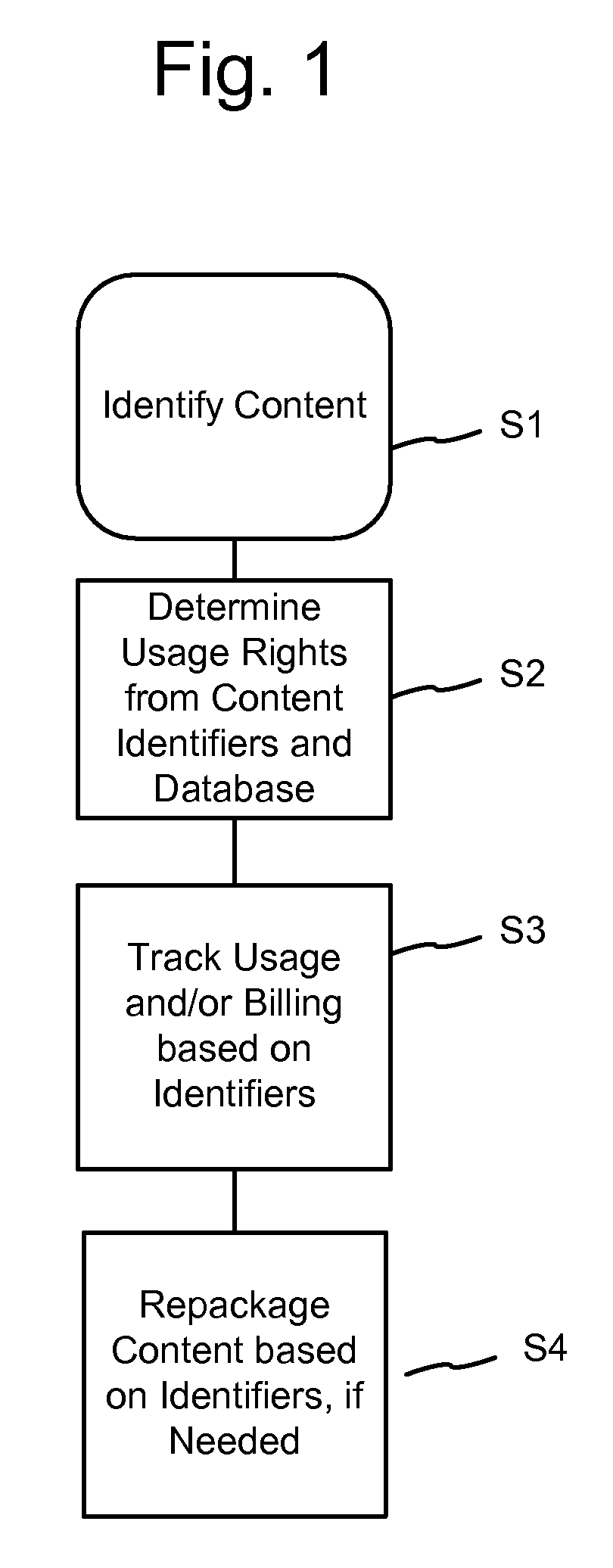

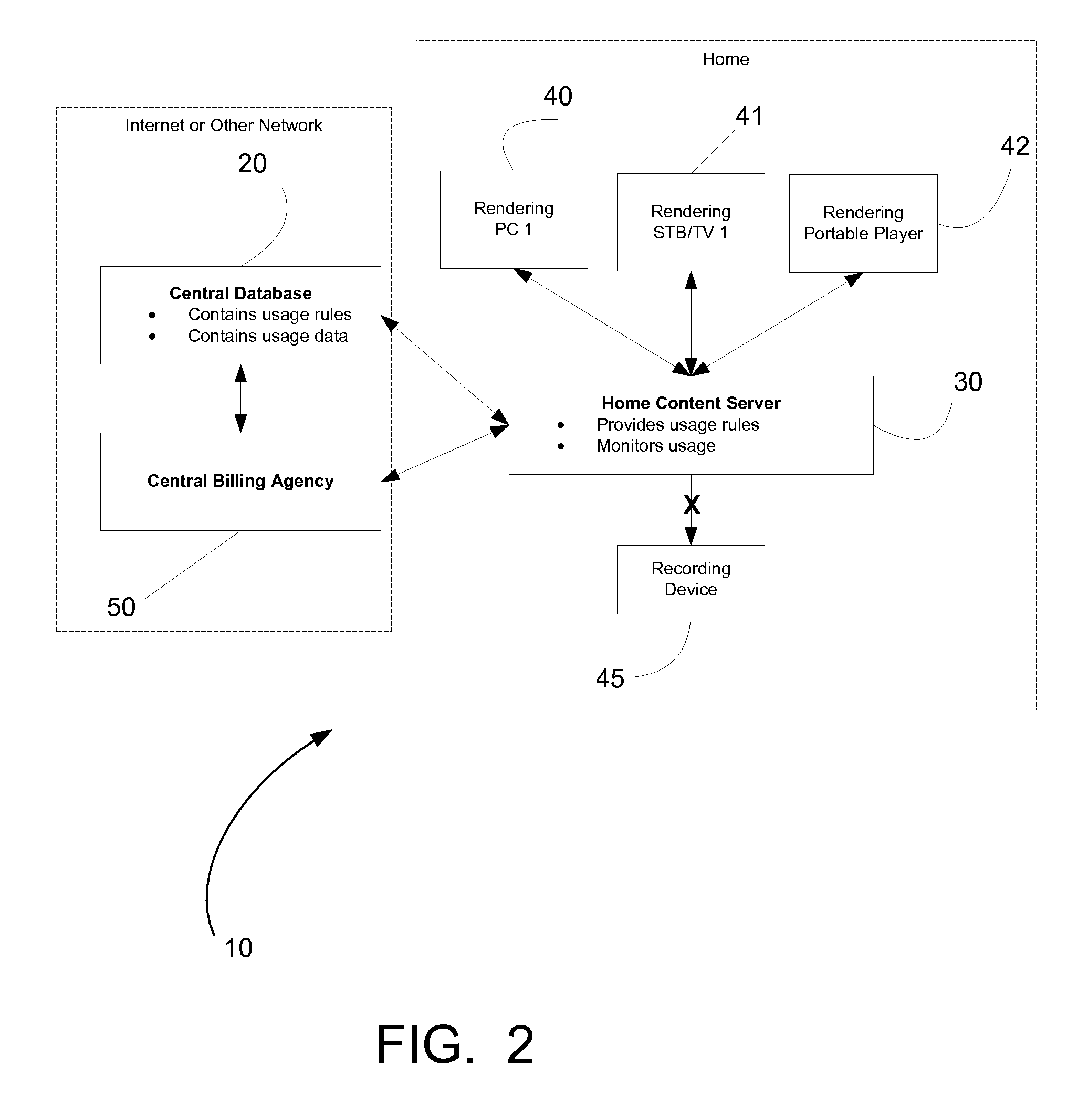

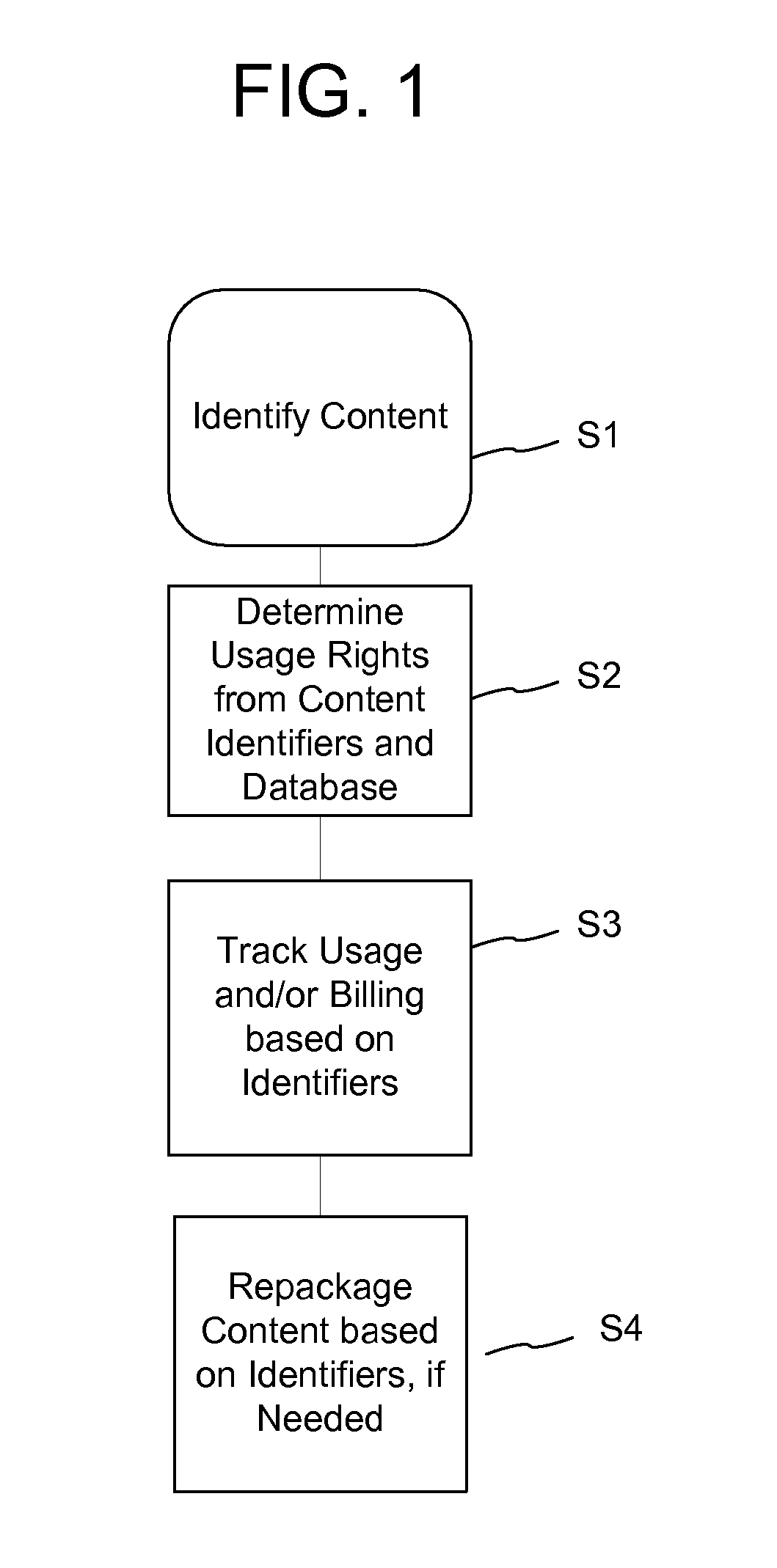

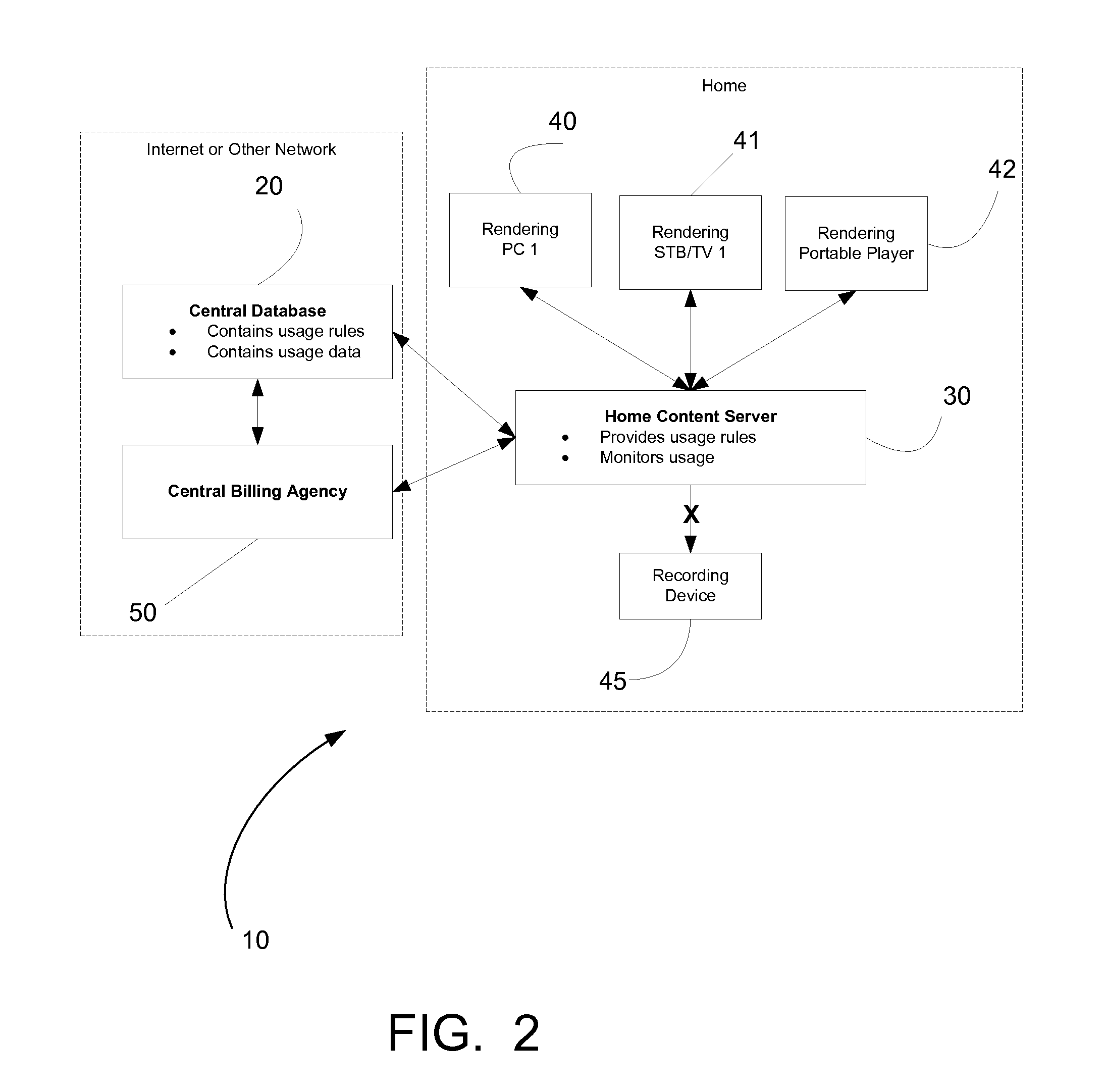

Rights Management System and Methods

ActiveUS20070294173A1Difficult to controlDifficult to trackDigital data processing detailsRecord information storageContent IdentifierRights management

A method of performing digital asset management of content is provided. The content is identified with an identifier. The identifier can be identified with a digital watermark, header file, or both. The identifier is linked to usage rules to regulate usage and protect the content. The usage rules can be maintained on a remote or local database or server. Once extracted, an identifier is used to index the database to locate a corresponding usage rule, and can be used to override copy control information with proper purchase and subsequent protection. Content can be managed from such. In another embodiment, an identifier is used to track usage, such as amount of content viewed, time played, and copies made. In yet another embodiment, a content identifier is used to regulate content throughout a distribution chain, and a distributed set of databases with information relevant only to the owner of the database act as one database due to a central router.

Owner:DIGIMARC CORP

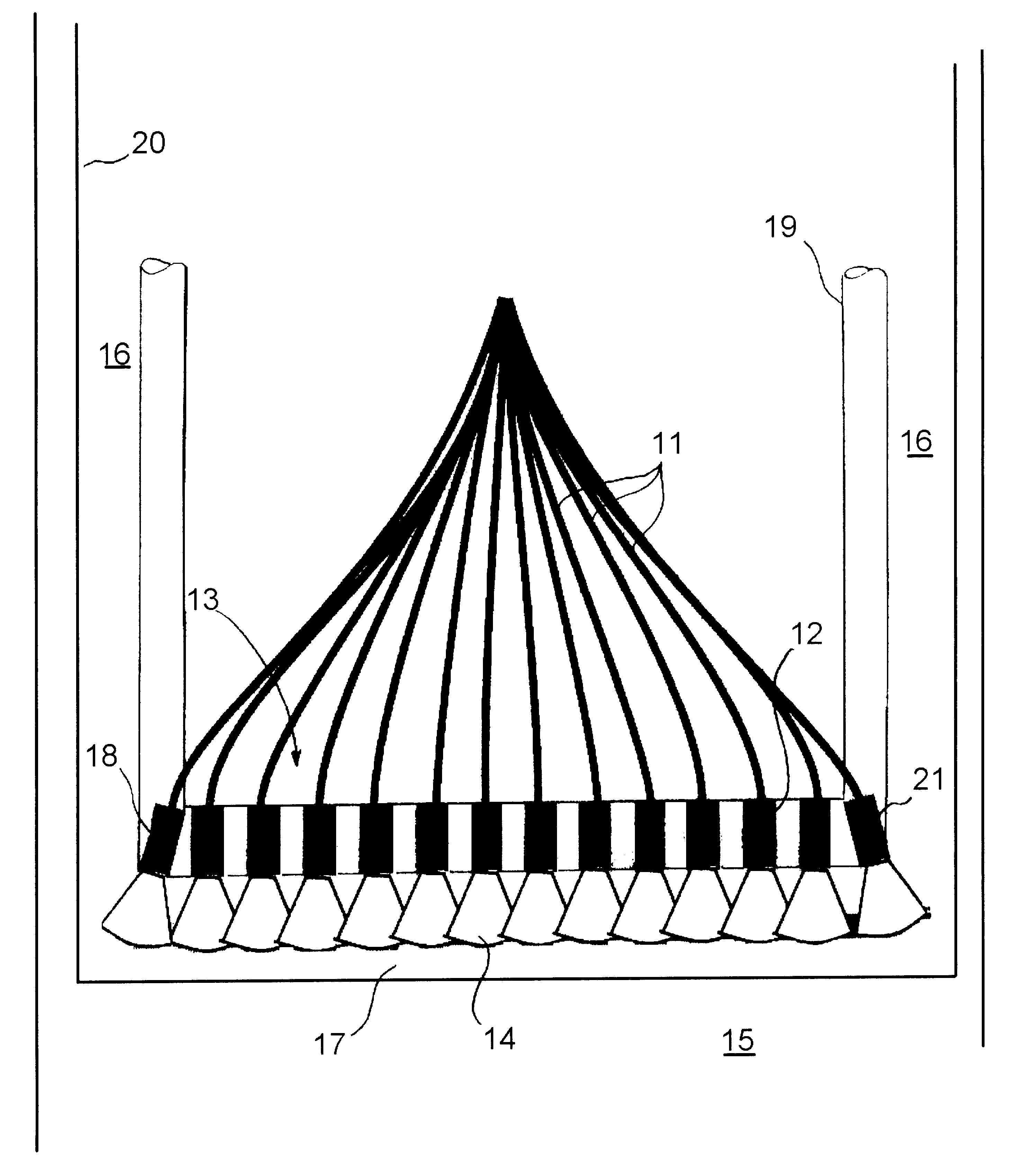

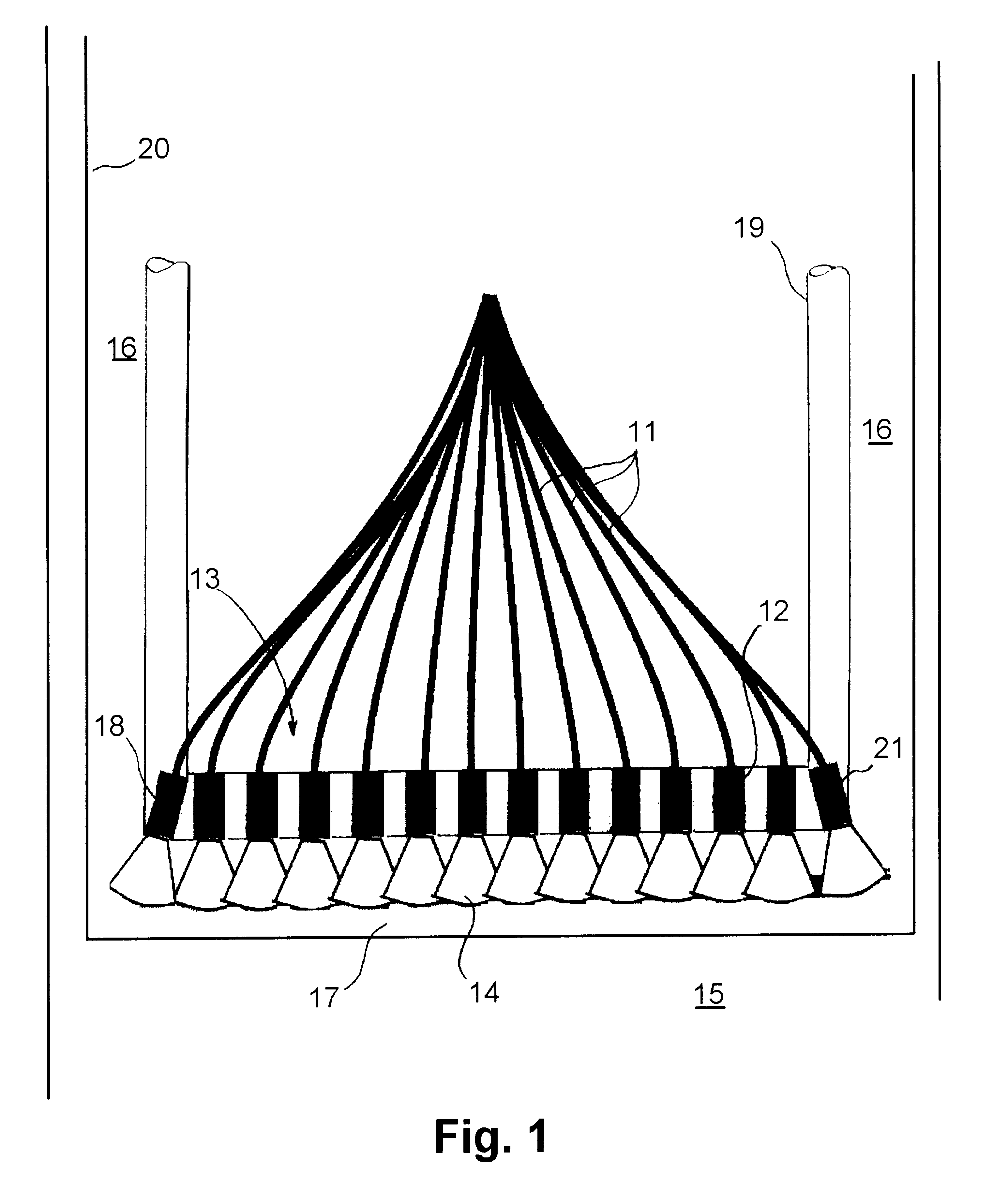

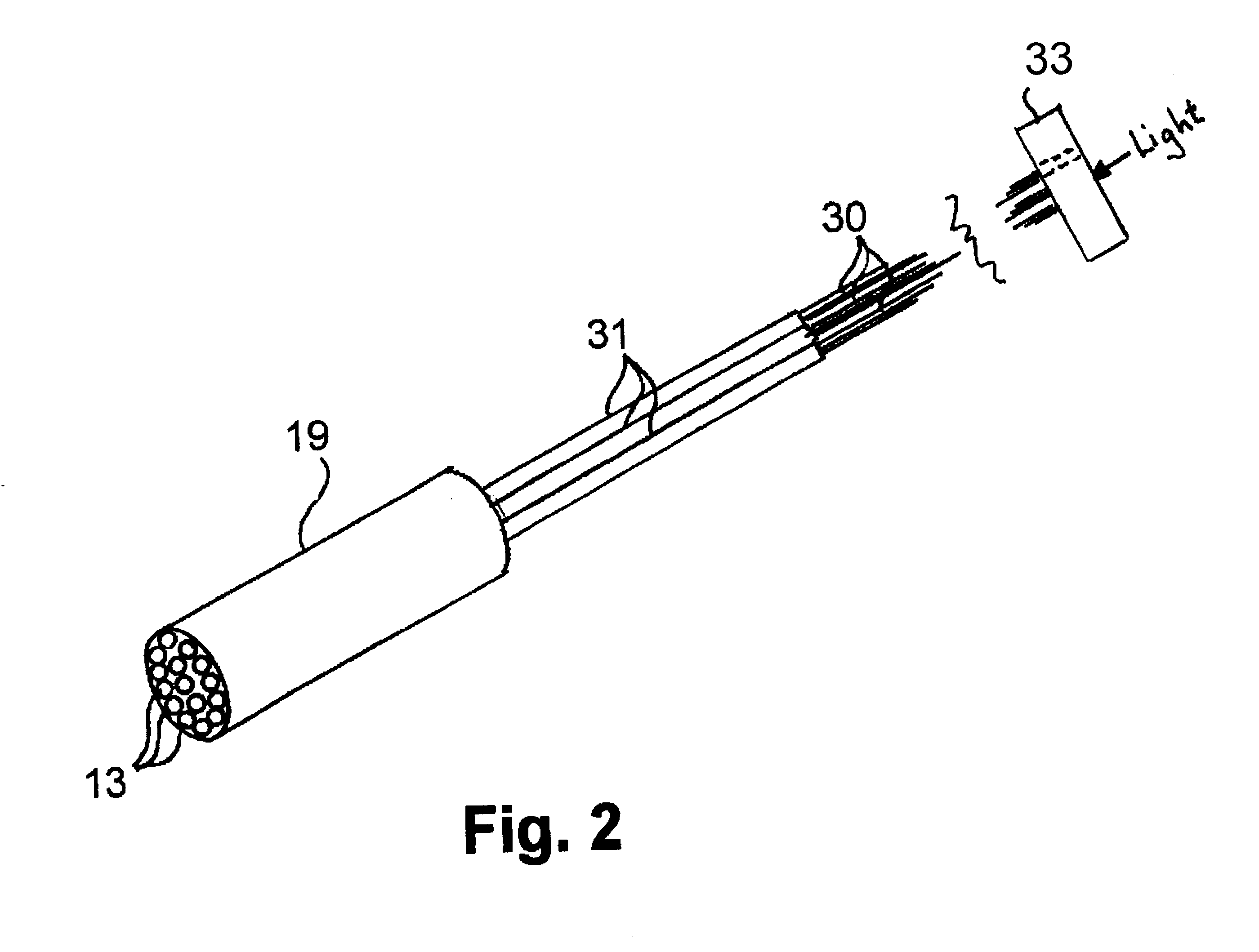

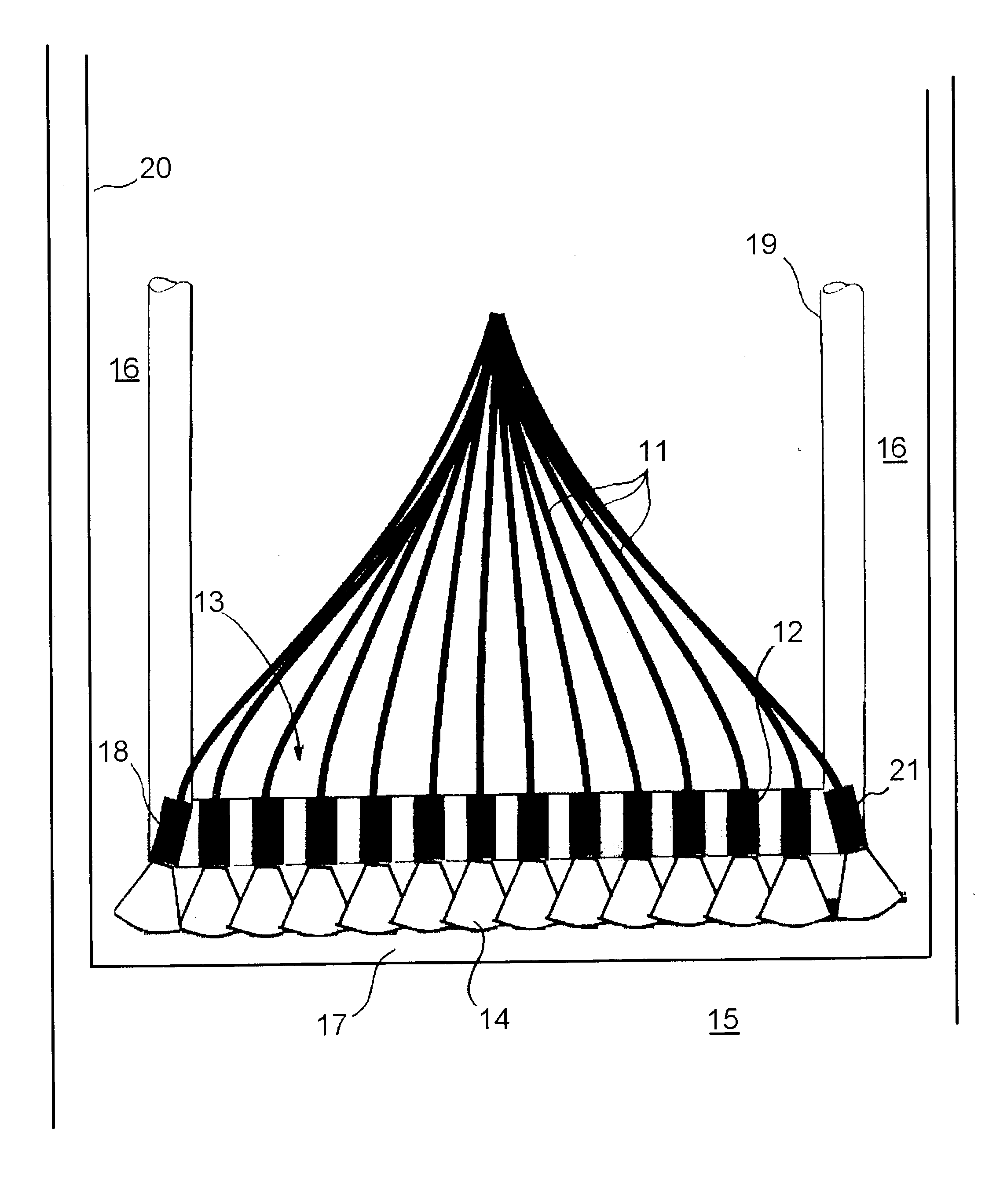

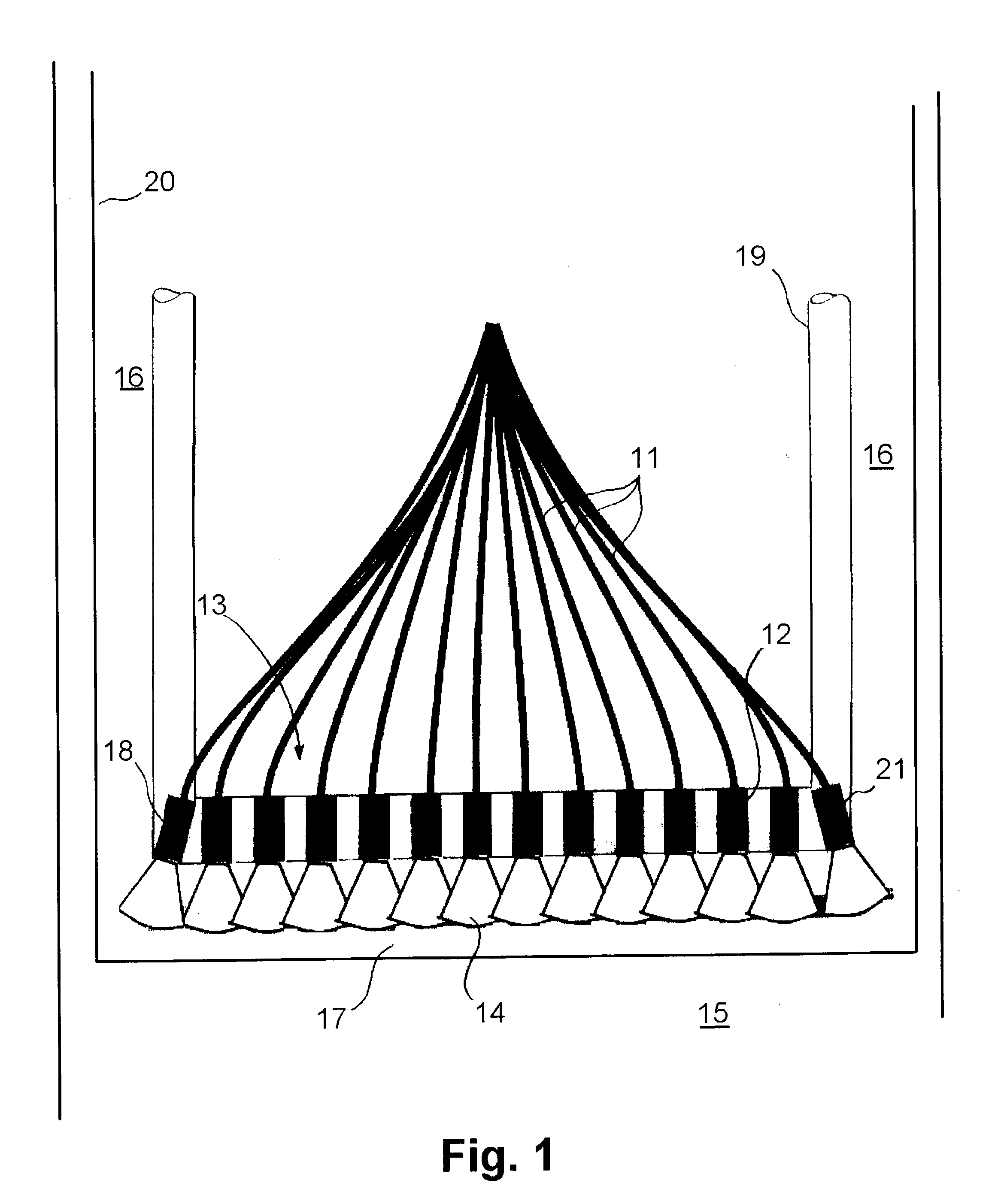

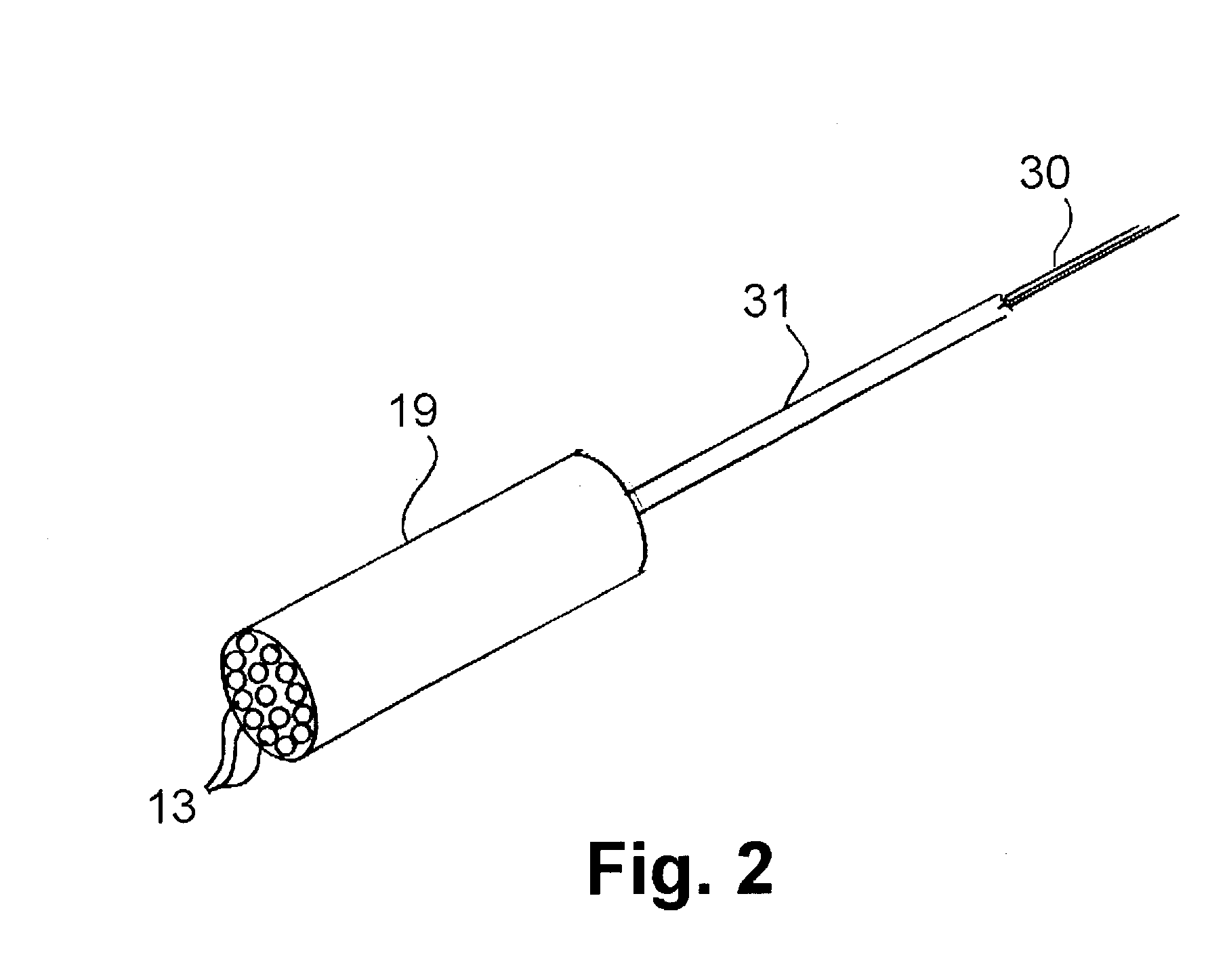

Downhole lens assembly for use with high power lasers for earth boring

InactiveUS6755262B2Difficult to controlRelative position is not easyEarth drilling toolsDisloding machinesFiberHigh power lasers

An earth boring apparatus at least partially locatable within a borehole. The apparatus includes a plurality of optical fibers, each of which has a proximal fiber light energy input end and a distal fiber light energy output end. At least one focal lens is disposed at the distal fiber light energy output end. The focal lens is made up of a plurality of focal elements, each of which corresponds to the distal fiber light energy output end of at least one optical fiber. The focal lens is arranged to receive light energy from the corresponding distal fiber light energy output end of the at least one optical fiber and focus it outwardly from the distal fiber light energy output end.

Owner:GAS TECH INST

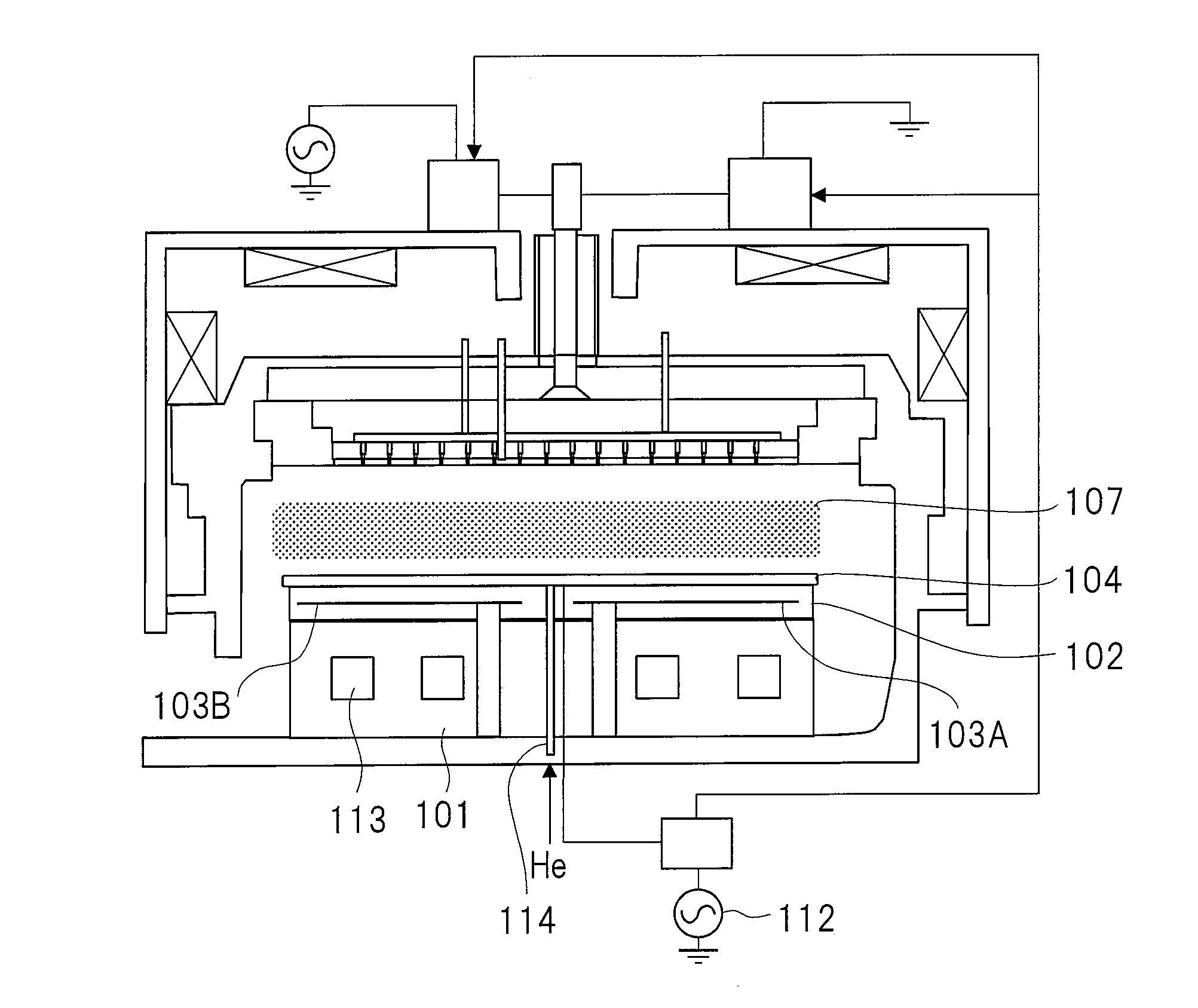

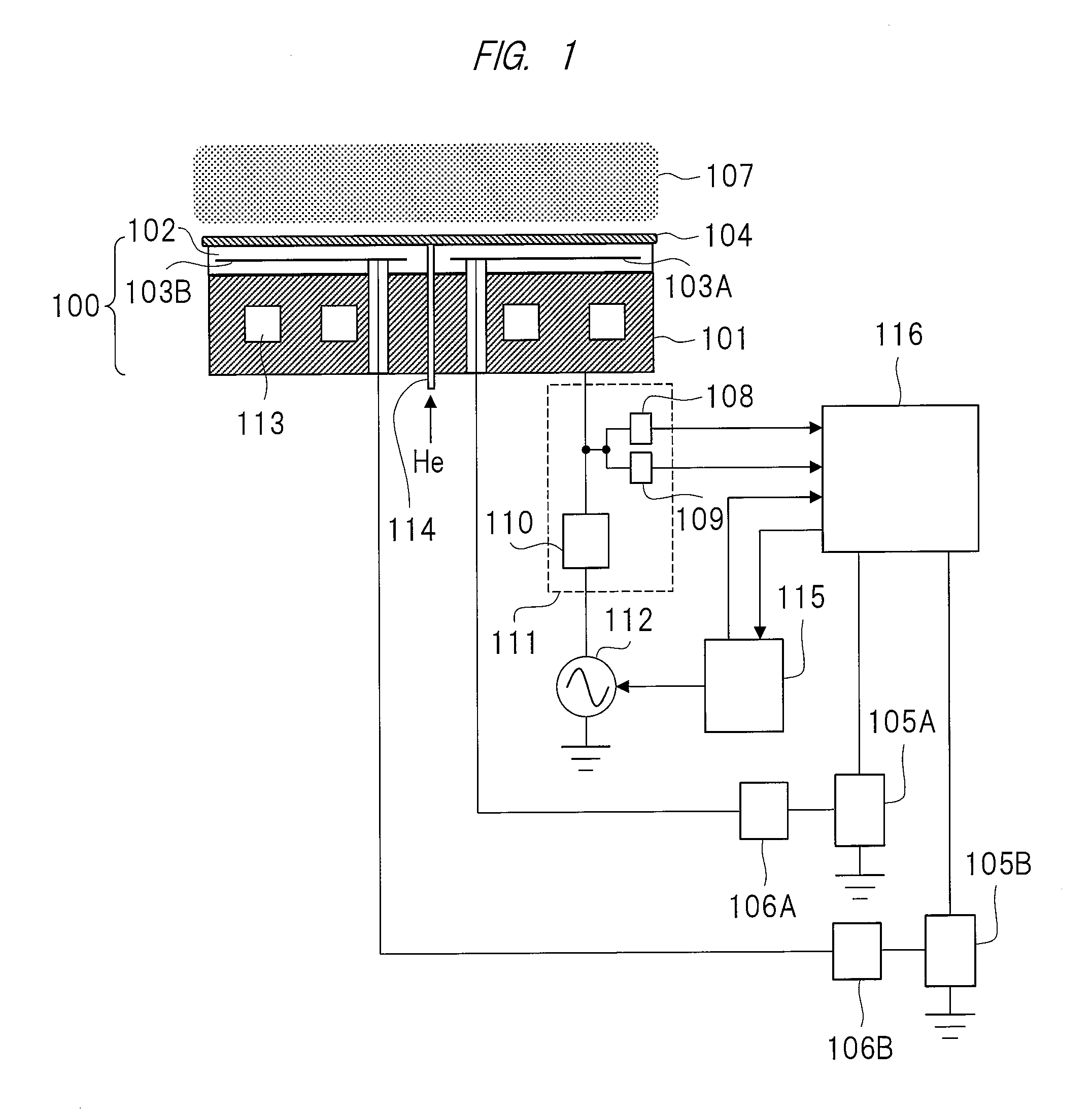

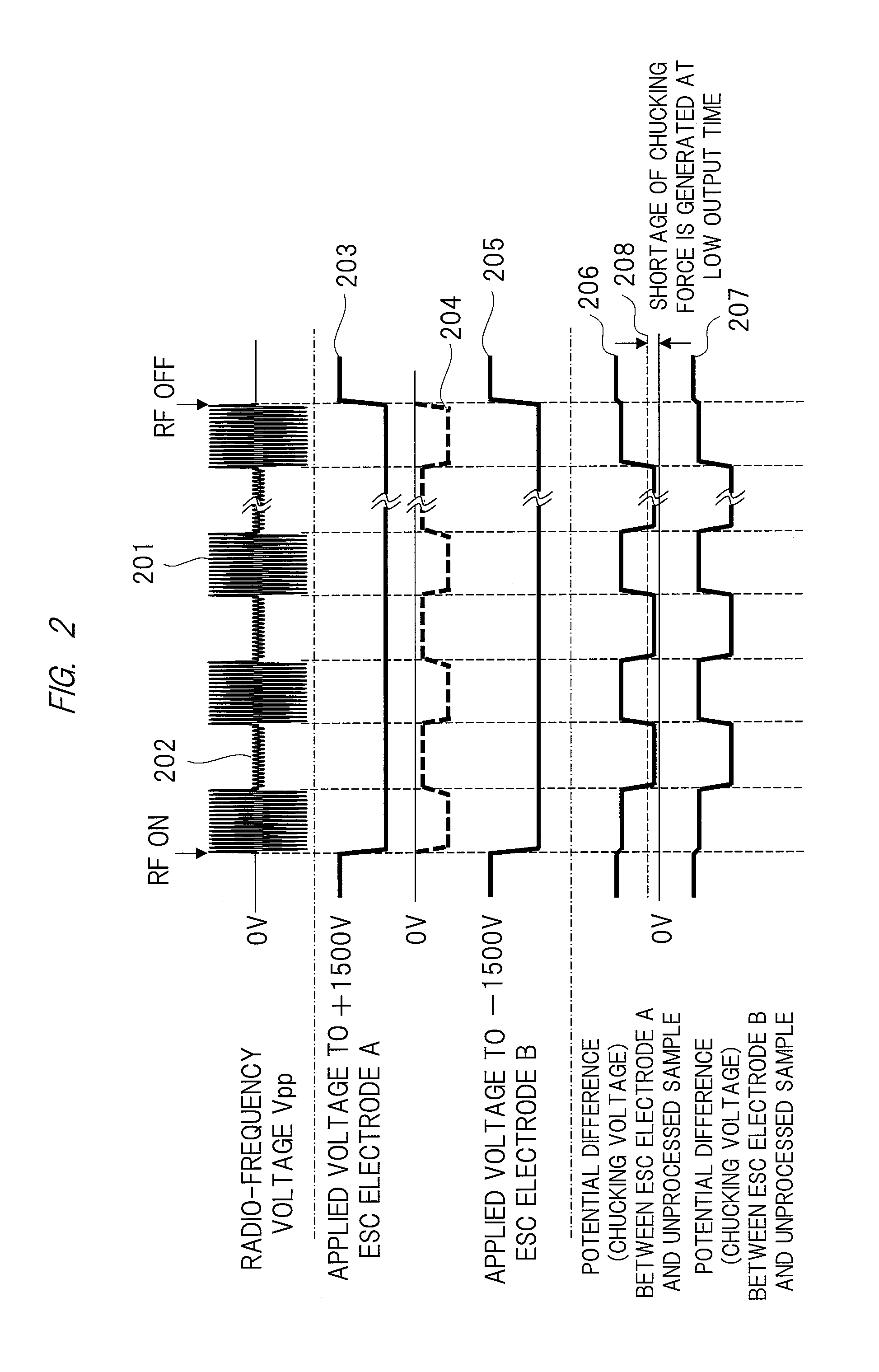

Plasma processing apparatus and plasma processing method

ActiveUS20160203958A1Quality improvementImprove the quality effectSemiconductor/solid-state device testing/measurementElectric discharge tubesLow voltageEngineering

To control temperature of a sample in plasma processing with high accuracy while securing an electrostatic chucking force without breakdown of an electrostatic chucking film.When radio-frequency power is time modulated, a high-voltage side Vpp detector detects a first voltage value which is a peak-to-peak voltage value of a radio-frequency voltage applied to a sample stage in a first period of the time modulation having a first amplitude. A low-voltage side Vpp detector detects a second voltage value which is a peak-to-peak voltage value of a radio-frequency voltage applied to the sample stage in a second period having a second amplitude smaller than the first amplitude. Then, an ESC power supply control unit controls output voltages from ESC power supplies based on the first voltage value, the second voltage value and a duty ratio of the time modulation.

Owner:HITACHI HIGH-TECH CORP

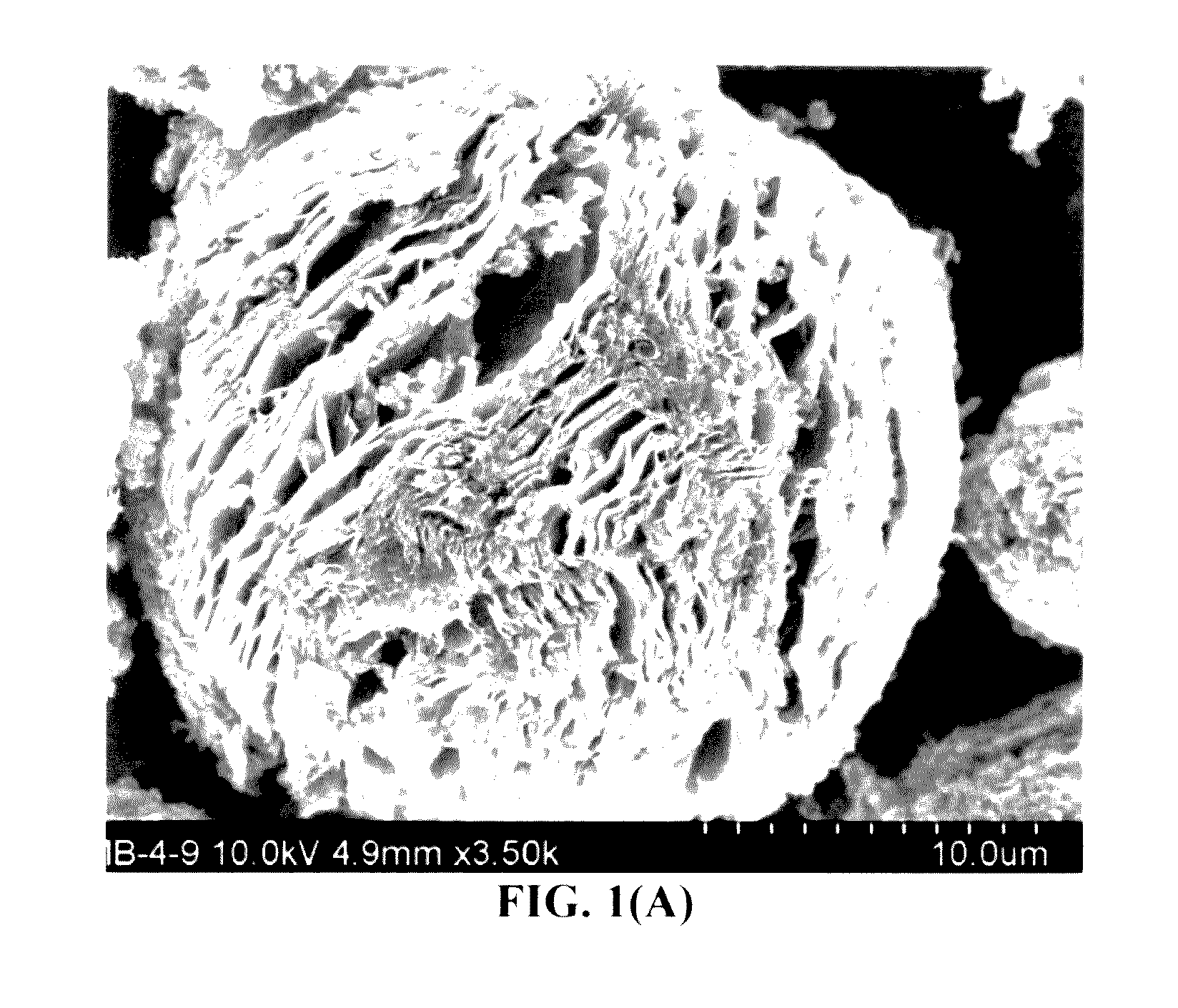

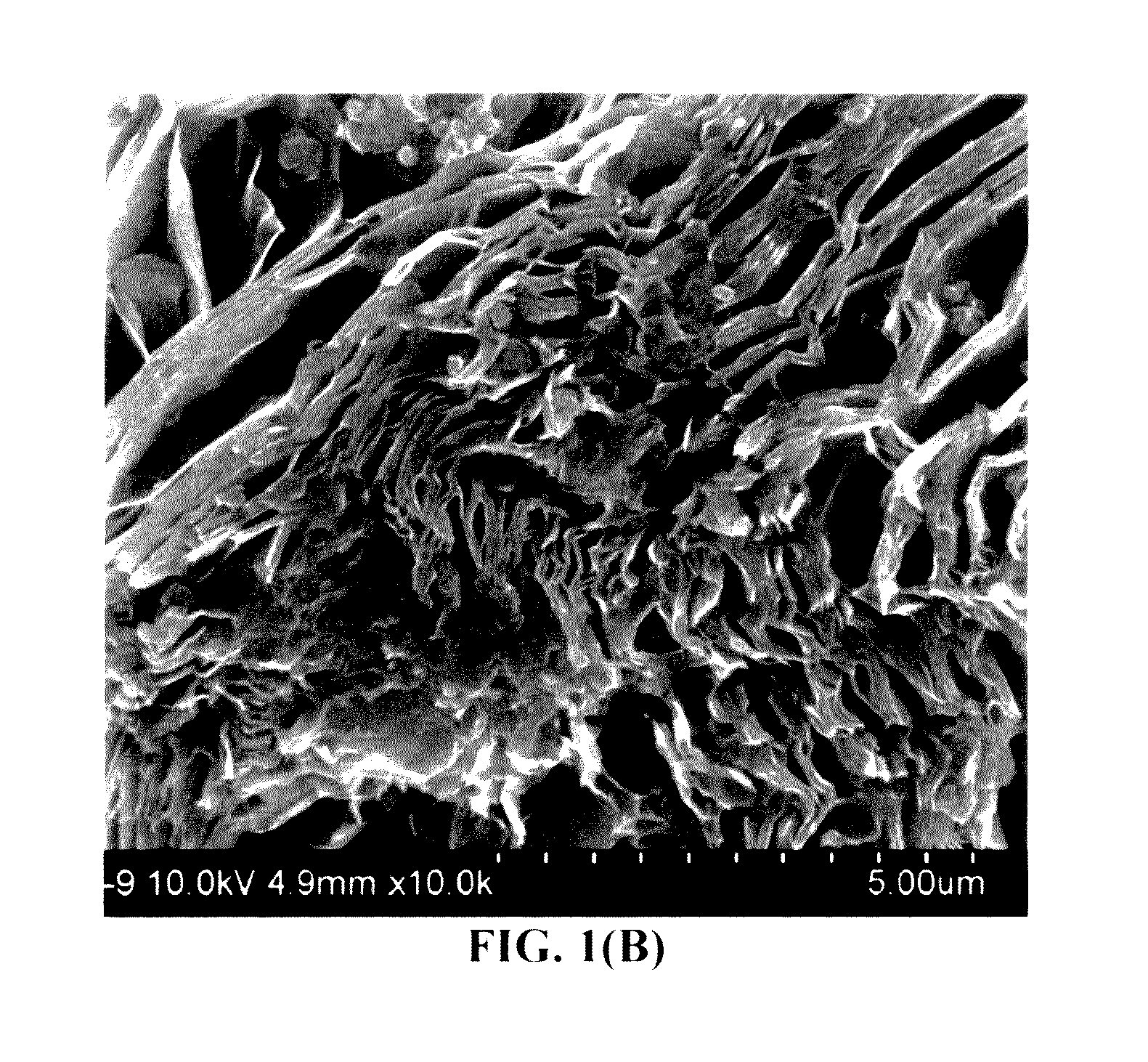

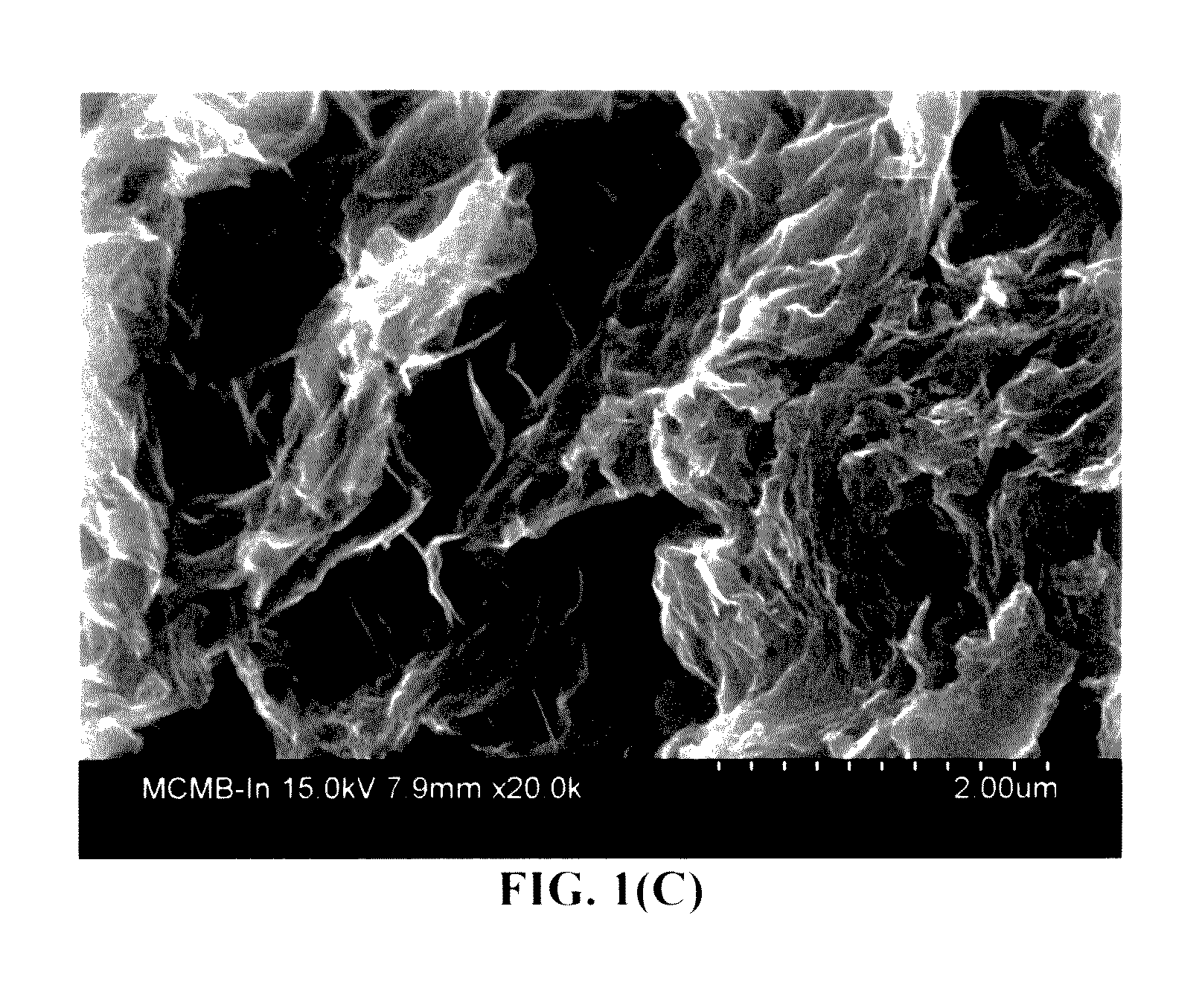

Active cathode layer for metal-sulfur secondary battery

ActiveUS20160294000A1Perfect sulfur utilization efficiencyIncrease loadElectrode carriers/collectorsSecondary cellsLithiumPolysulfide

A preloaded cathode layer, comprising: (A) An integral porous structure having massive surfaces greater than 100 m2 / g or pores with a size from 1.0 nm to 100 nm, wherein multiple conductive particles, platelets or filaments, without a conductive filler, form a 3-D conductive network; and (B) a metal polysulfide preloaded in the pores or deposited on the massive surfaces, selected from: (a) an MxSy, (x=1-3 and y=1-10) wherein M is a metal element selected from a non-lithium alkali metal, an alkaline metal selected from Mg or Ca, a transition metal, a metal from groups 13 to 17, or a combination thereof, or (b) Li2S6, Li2S7, Li2S8, Li2S9, or Li2S10, wherein the metal polysulfide contains a thin coating or small particles with a thickness or diameter less than 20 nm and occupies a weight fraction of from 1% to 99%.

Owner:GLOBAL GRAPHENE GRP INC

Downhole lens assembly for use with high power lasers for earth boring

InactiveUS20030132029A1Difficult to controlRelative position is not easyEarth drilling toolsDisloding machinesPhysicsHigh power lasers

An earth boring apparatus at least partially locatable within a borehole. The apparatus includes a plurality of optical fibers, each of which has a proximal fiber light energy input end and a distal fiber light energy output end. At least one focal lens is disposed at the distal fiber light energy output end. The focal lens is made up of a plurality of focal elements, each of which corresponds to the distal fiber light energy output end of at least one optical fiber. The focal lens is arranged to receive light energy from the corresponding distal fiber light energy output end of the at least one optical fiber and focus it outwardly from the distal fiber light energy output end.

Owner:GAS TECH INST

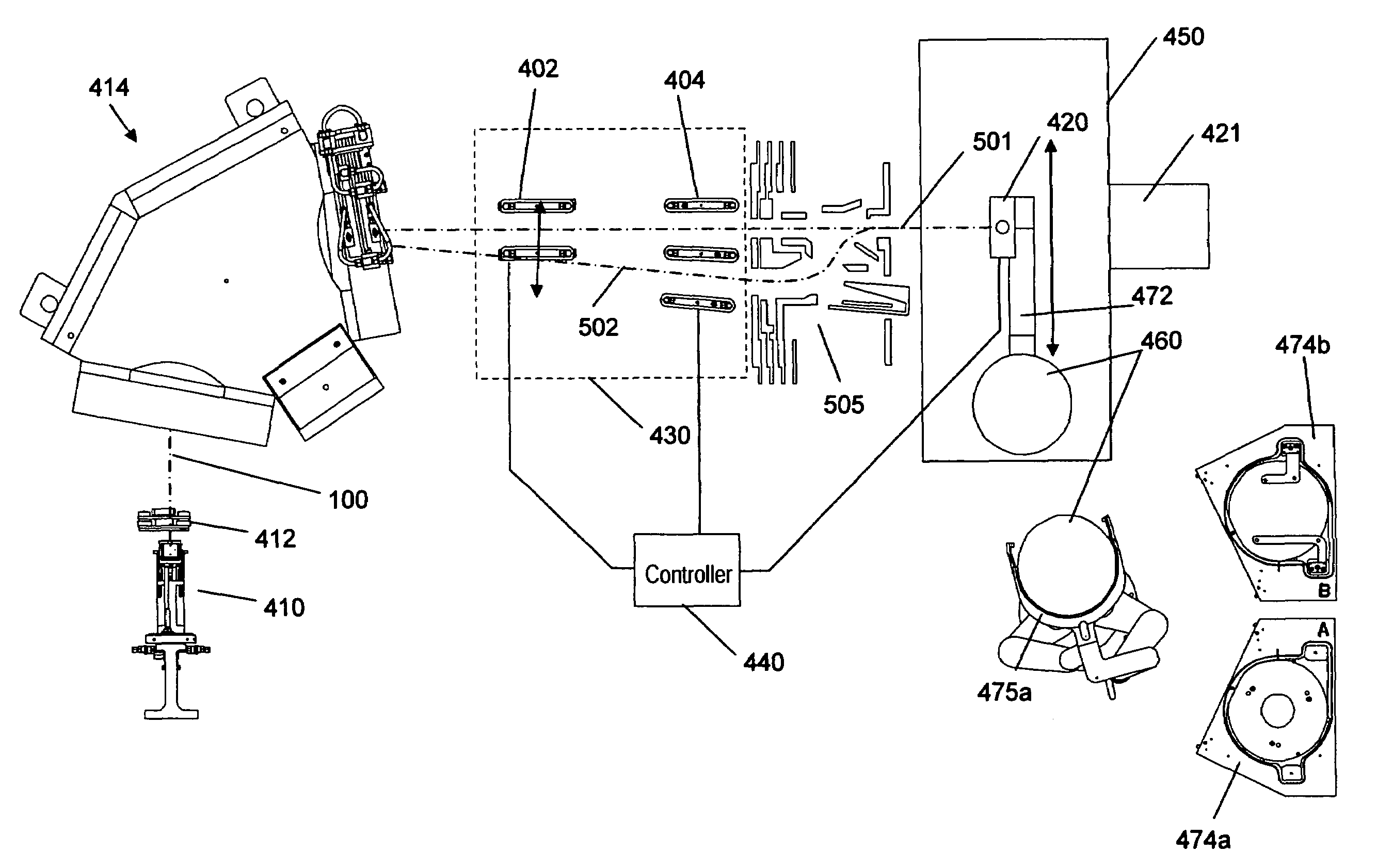

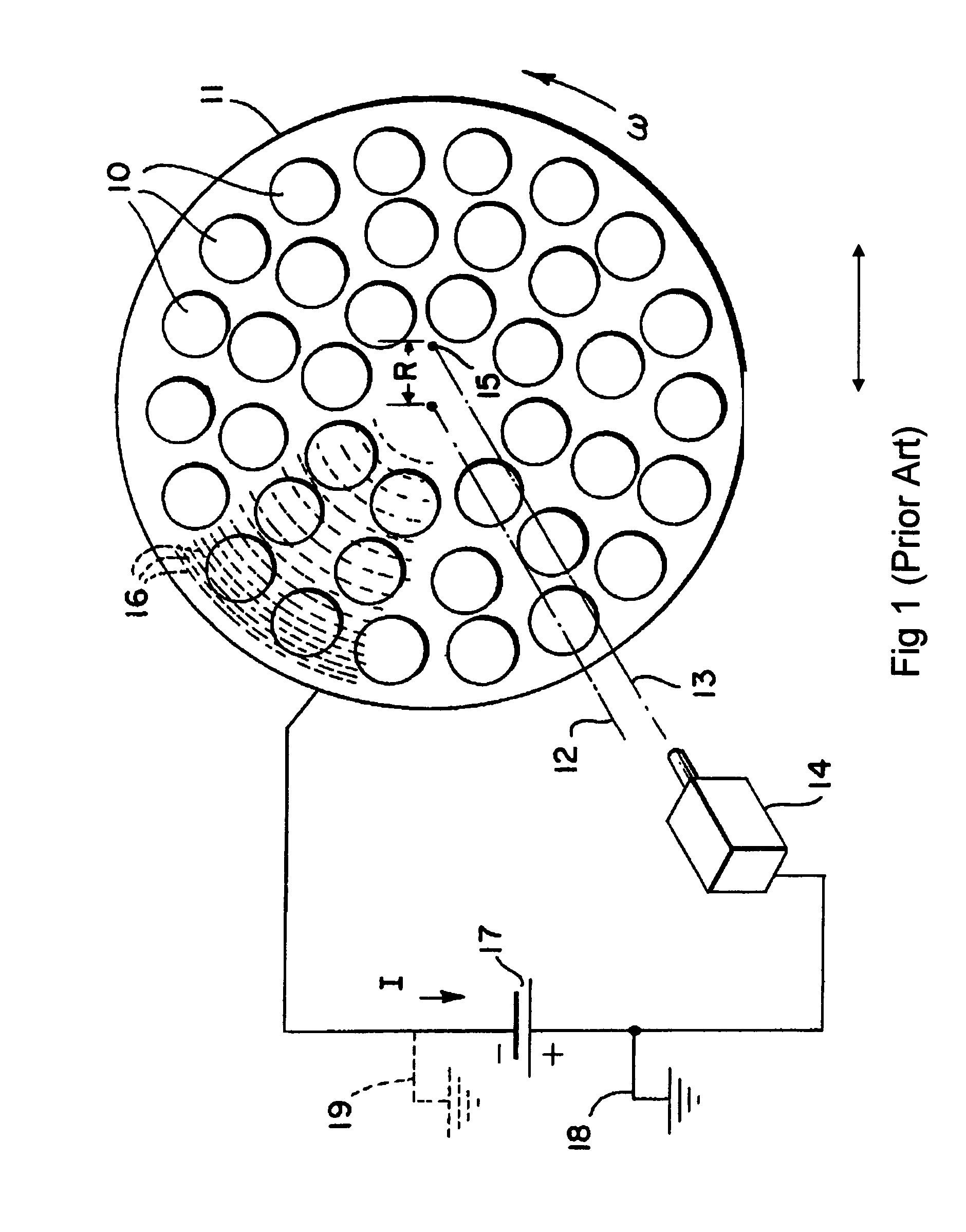

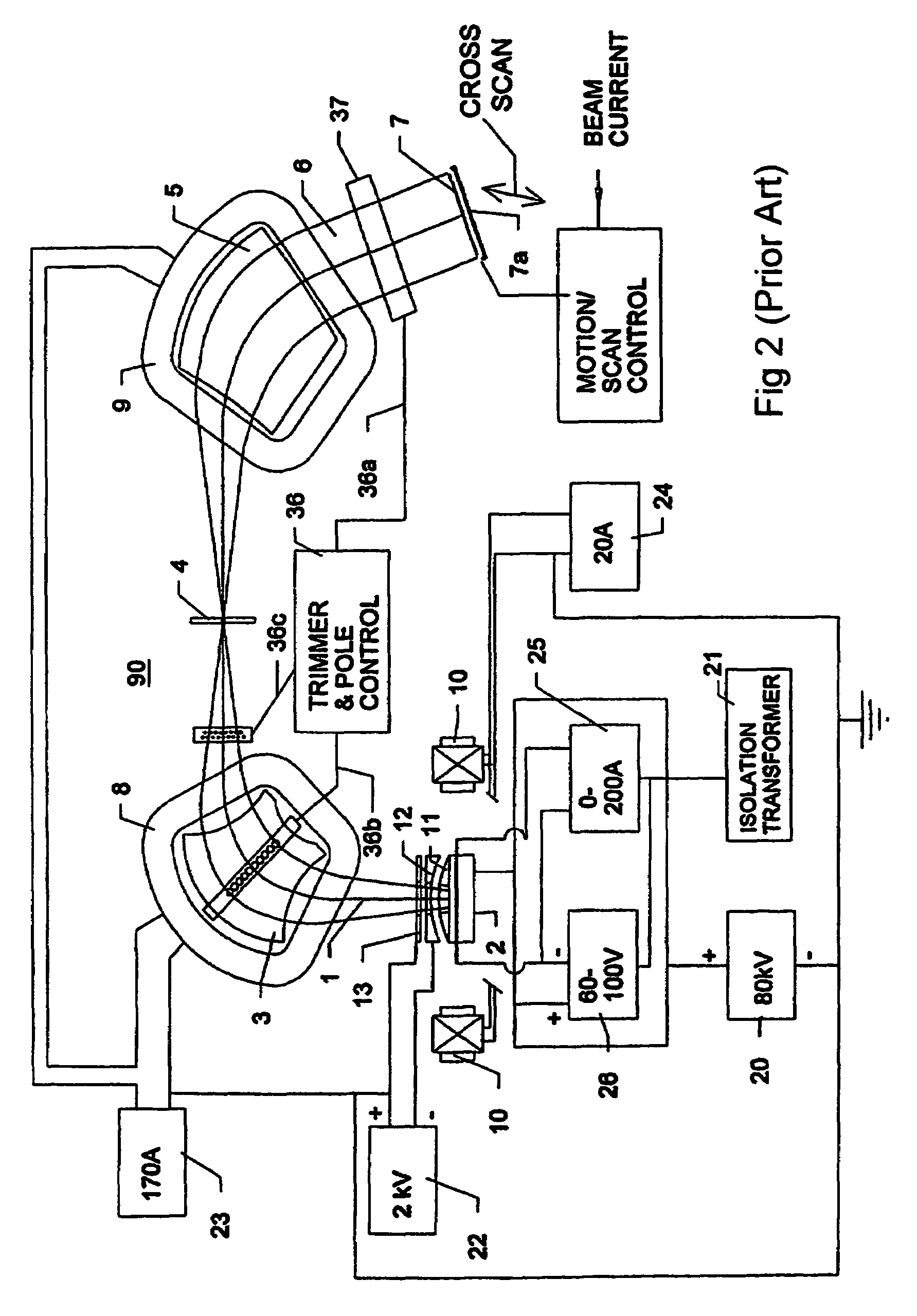

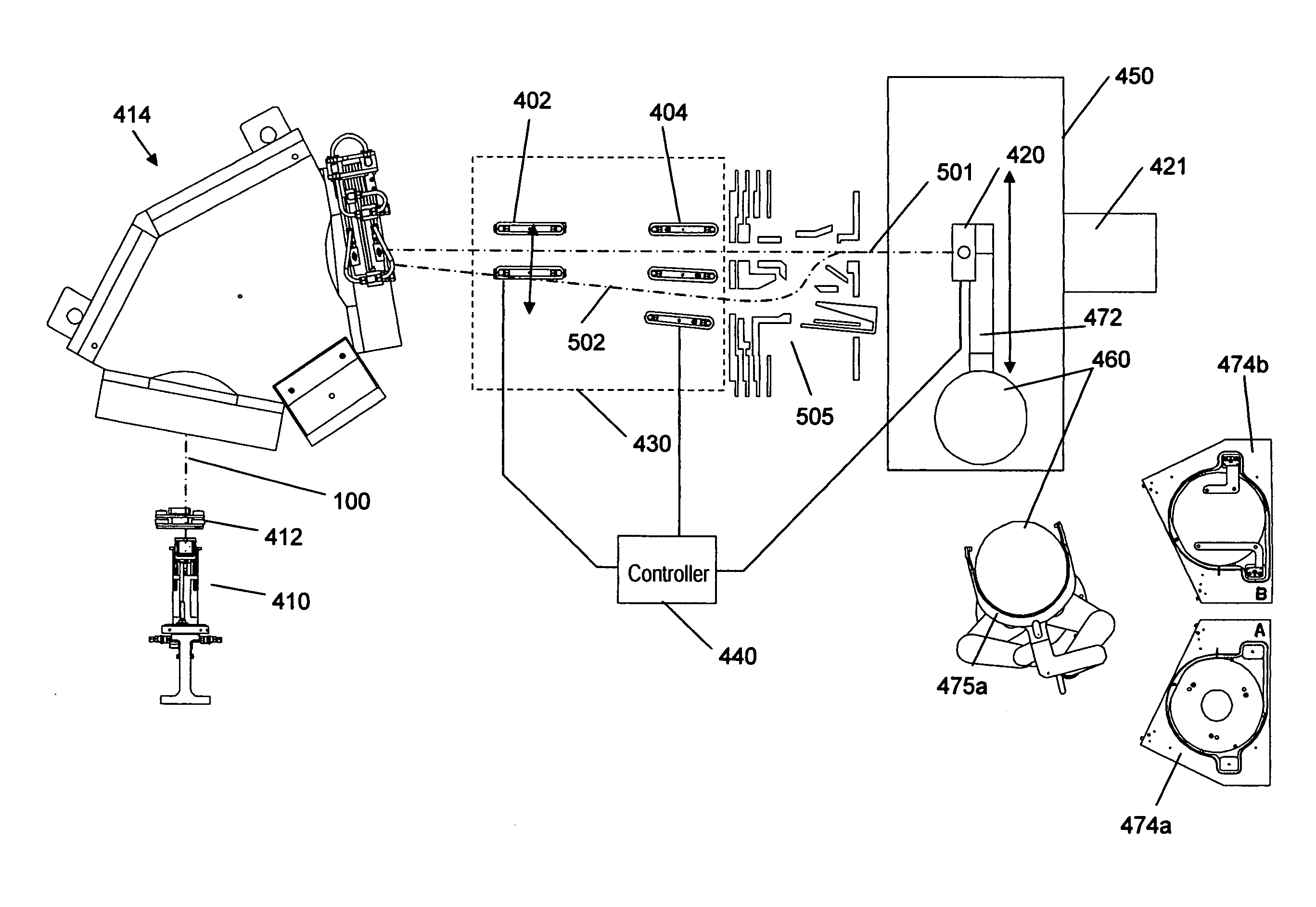

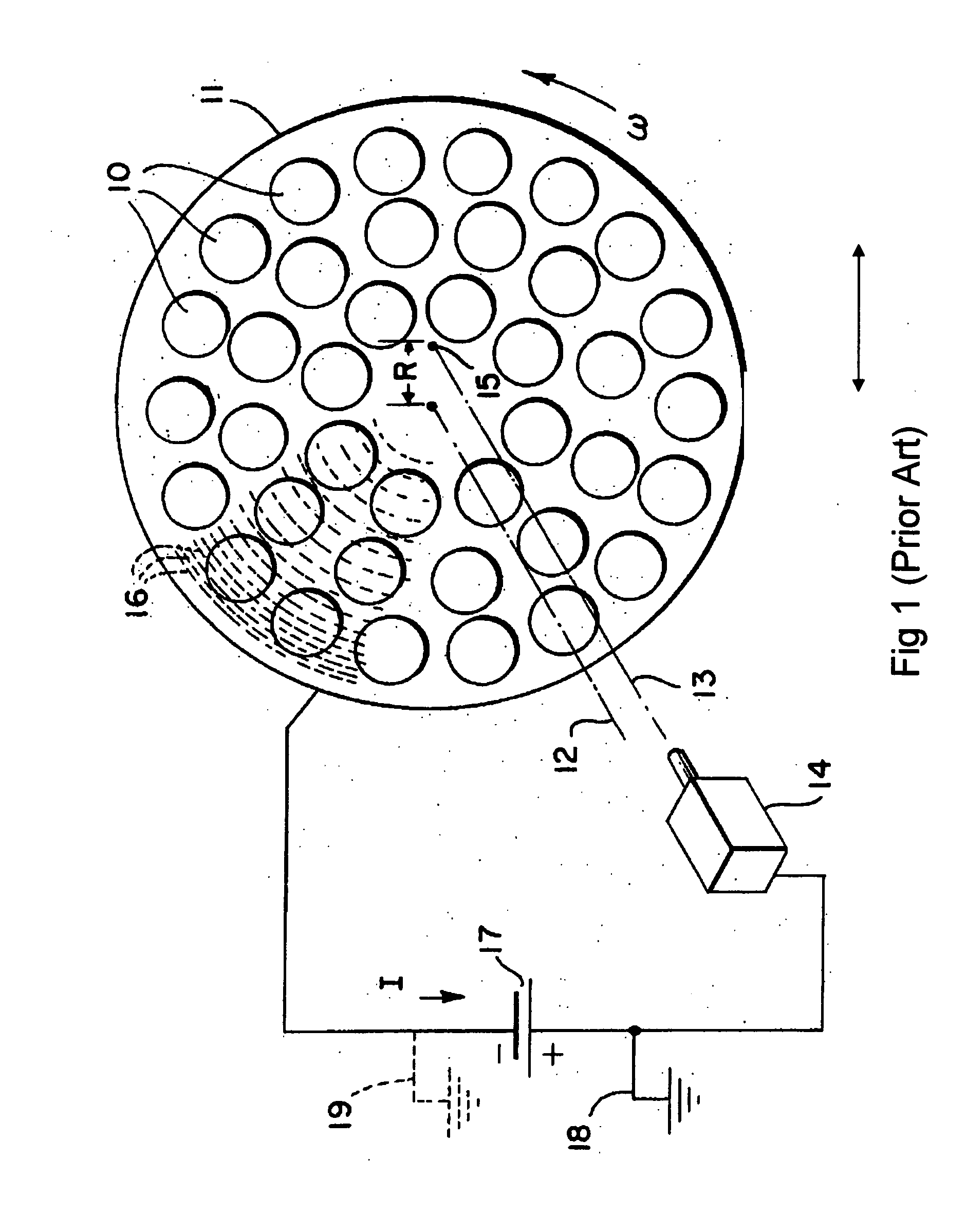

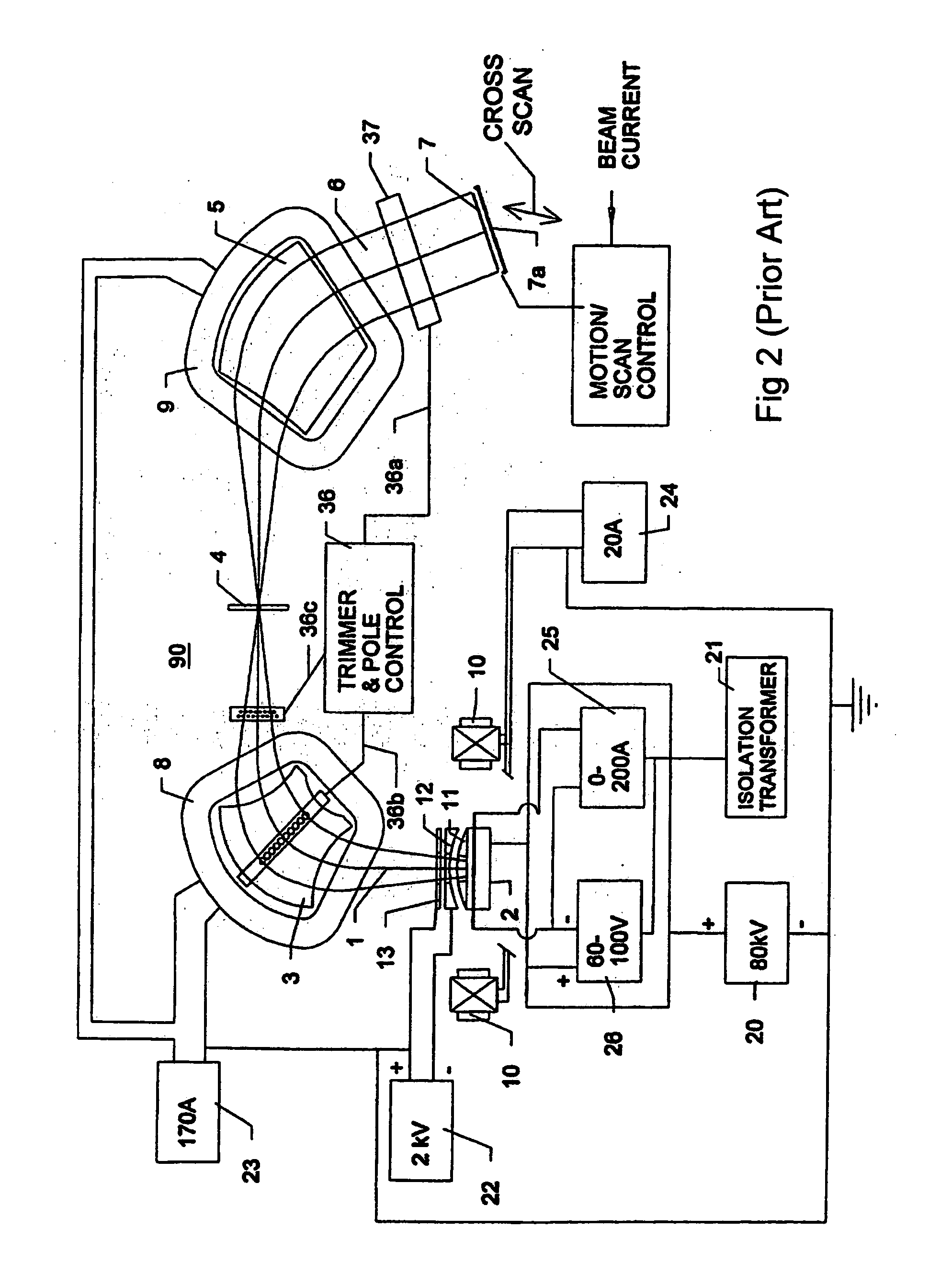

Apparatus and methods for ion beam implantation using ribbon and spot beams

ActiveUS7326941B2Difficult to controlIncrease throughputMagnetsMaterial analysis by optical meansBand shapeIon beam

This invention discloses an ion implantation apparatus with multiple operating modes. It has an ion source and an ion extraction means for extracting a ribbon-shaped ion beam therefrom. The ion implantation apparatus includes a magnetic analyzer for selecting ions with specific mass-to-charge ratio to pass through a mass slit to project onto a substrate. Multipole lenses are provided to control beam uniformity and collimation. The invention further discloses a two-path beamline in which a second path incorporates a deceleration system incorporating energy filtering. The invention discloses methods of ion implantation in which the mode of implantation may be switched from one-dimensional scanning of the target to two-dimensional scanning, and from a simple path to an s-shaped path with deceleration.

Owner:ADVANCED ION BEAM TECHNOLOGY INC

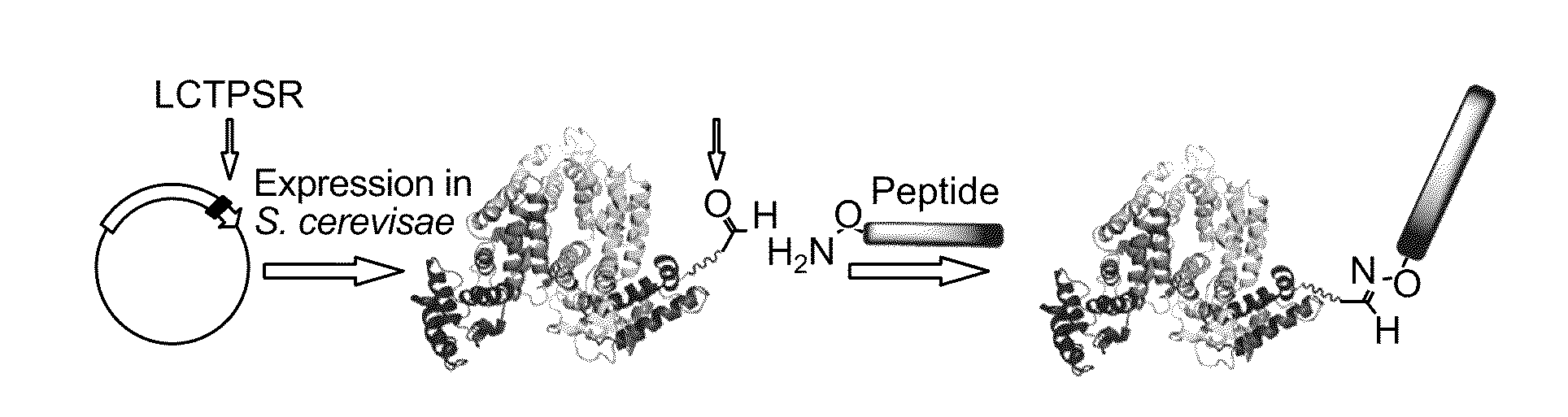

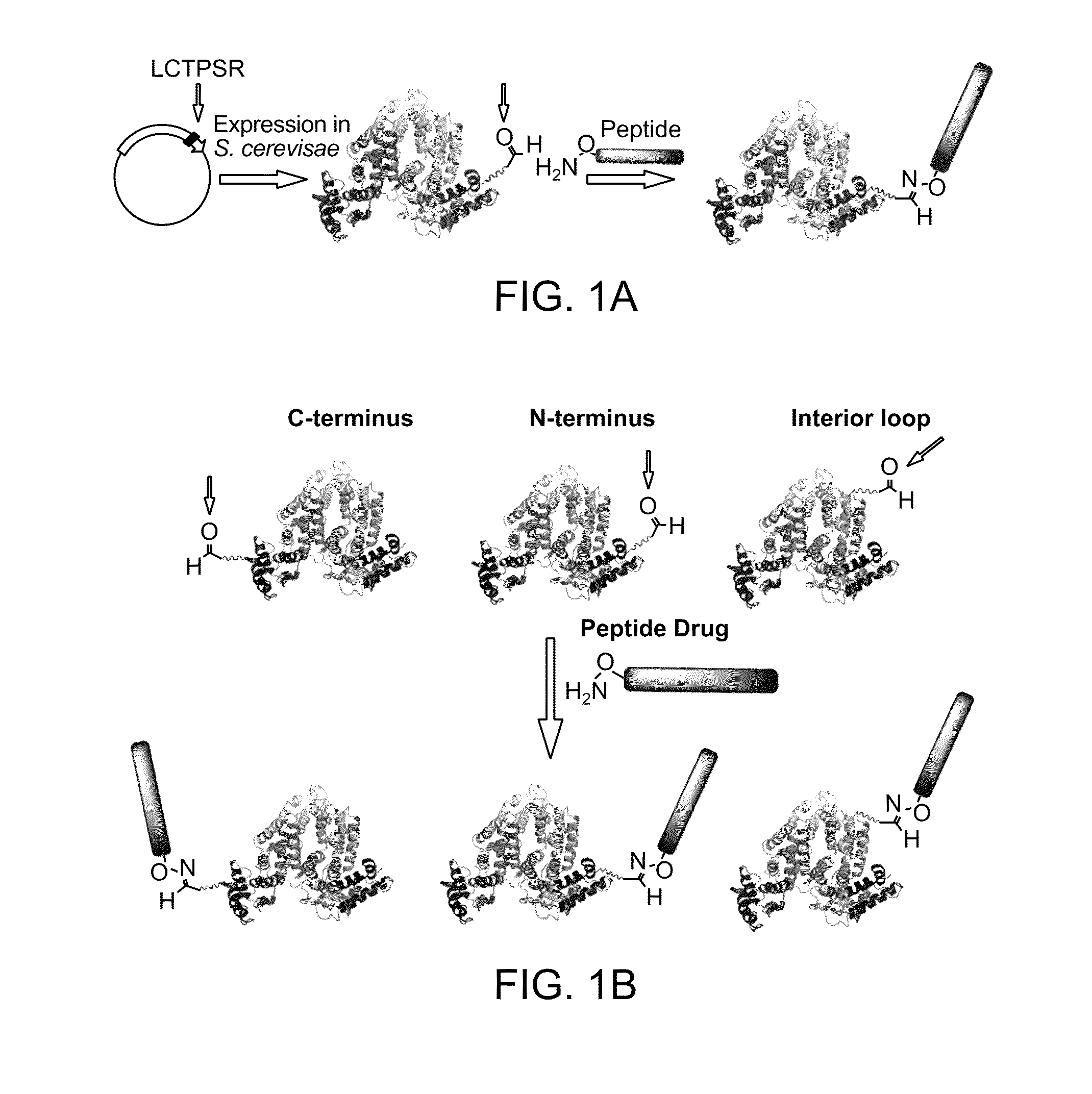

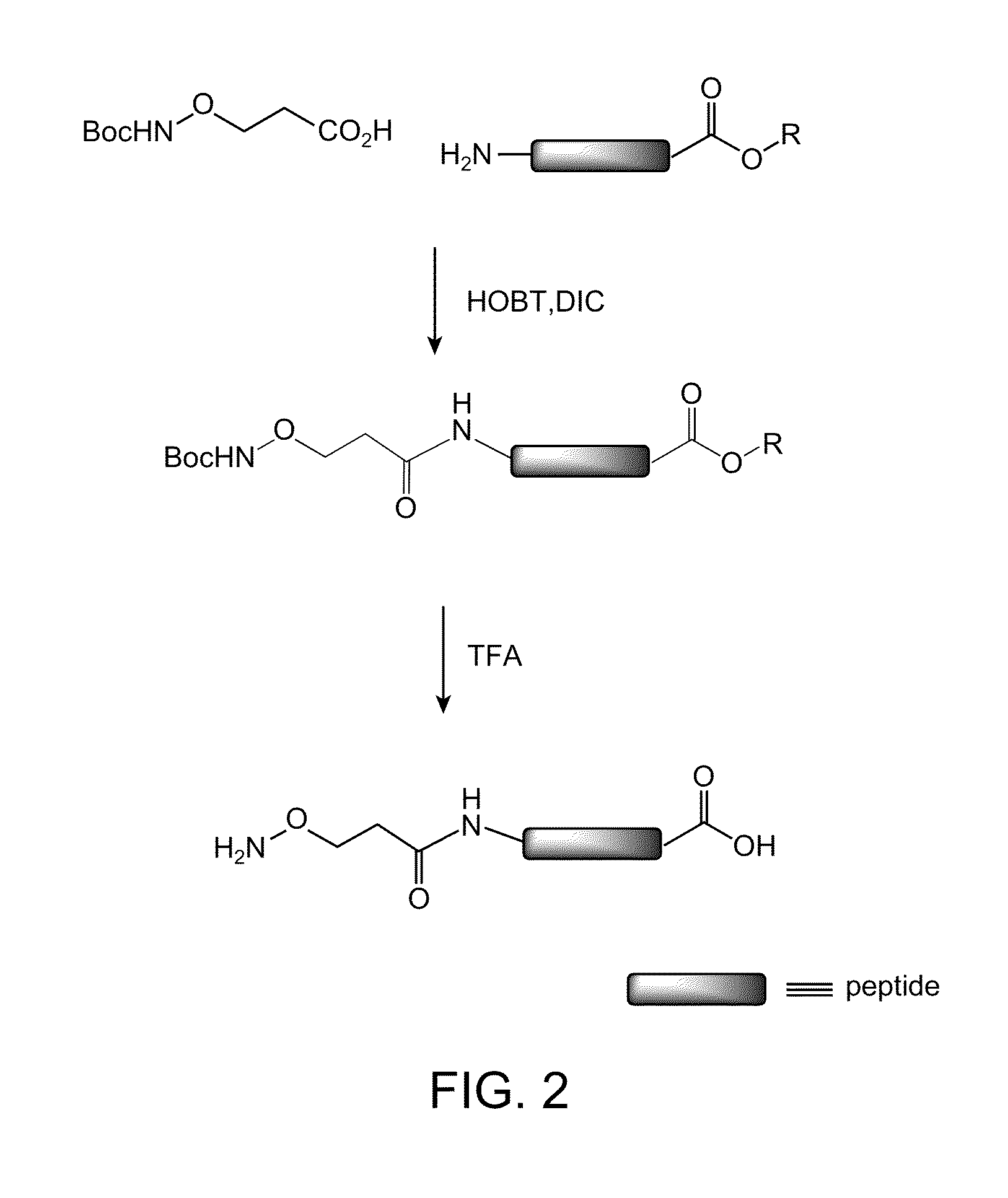

Aldehyde-Tagged Protein-Based Drug Carriers and Methods of Use

ActiveUS20100210543A1Readily apparentExquisite specificityPeptide librariesSugar derivativesMedicineDrug carrier

Owner:REDWOOD BIOSCI

Apparatus and methods for ion beam implantation using ribbon and spot beams

ActiveUS20060113494A1High resolve powerMass-analyzed efficientlyMagnetsMaterial analysis by optical meansBeamlineSpecific mass

This invention discloses an ion implantation apparatus with multiple operating modes. It has an ion source and an ion extraction means for extracting a ribbon-shaped ion beam therefrom. The ion implantation apparatus includes a magnetic analyzer for selecting ions with specific mass-to-charge ratio to pass through a mass slit to project onto a substrate. Multipole lenses are provided to control beam uniformity and collimation. The invention further discloses a two-path beamline in which a second path incorporates a deceleration system incorporating energy filtering. The invention discloses methods of ion implantation in which the mode of implantation may be switched from one-dimensional scanning of the target to two-dimensional scanning, and from a simple path to an s-shaped path with deceleration.

Owner:ADVANCED ION BEAM TECHNOLOGY INC

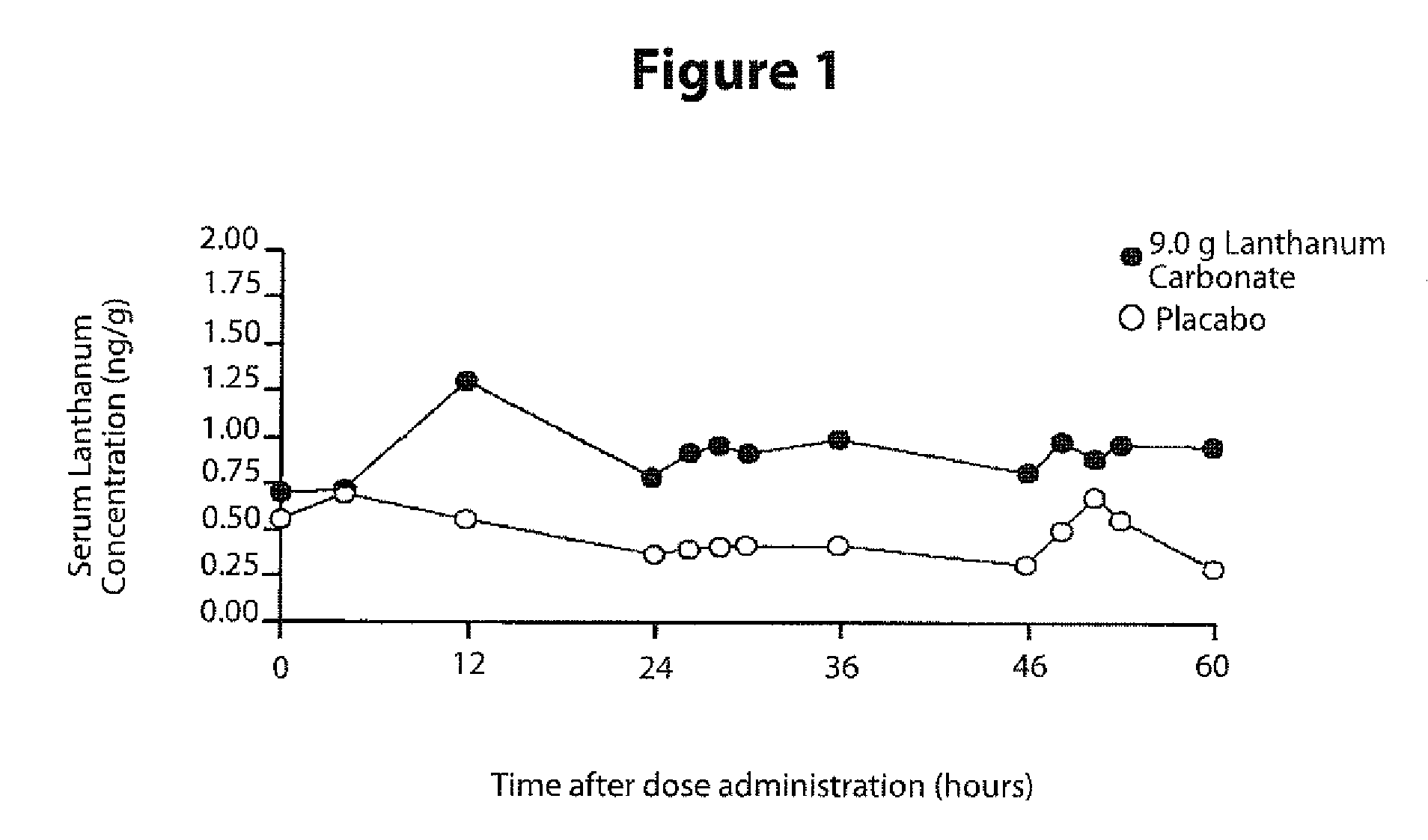

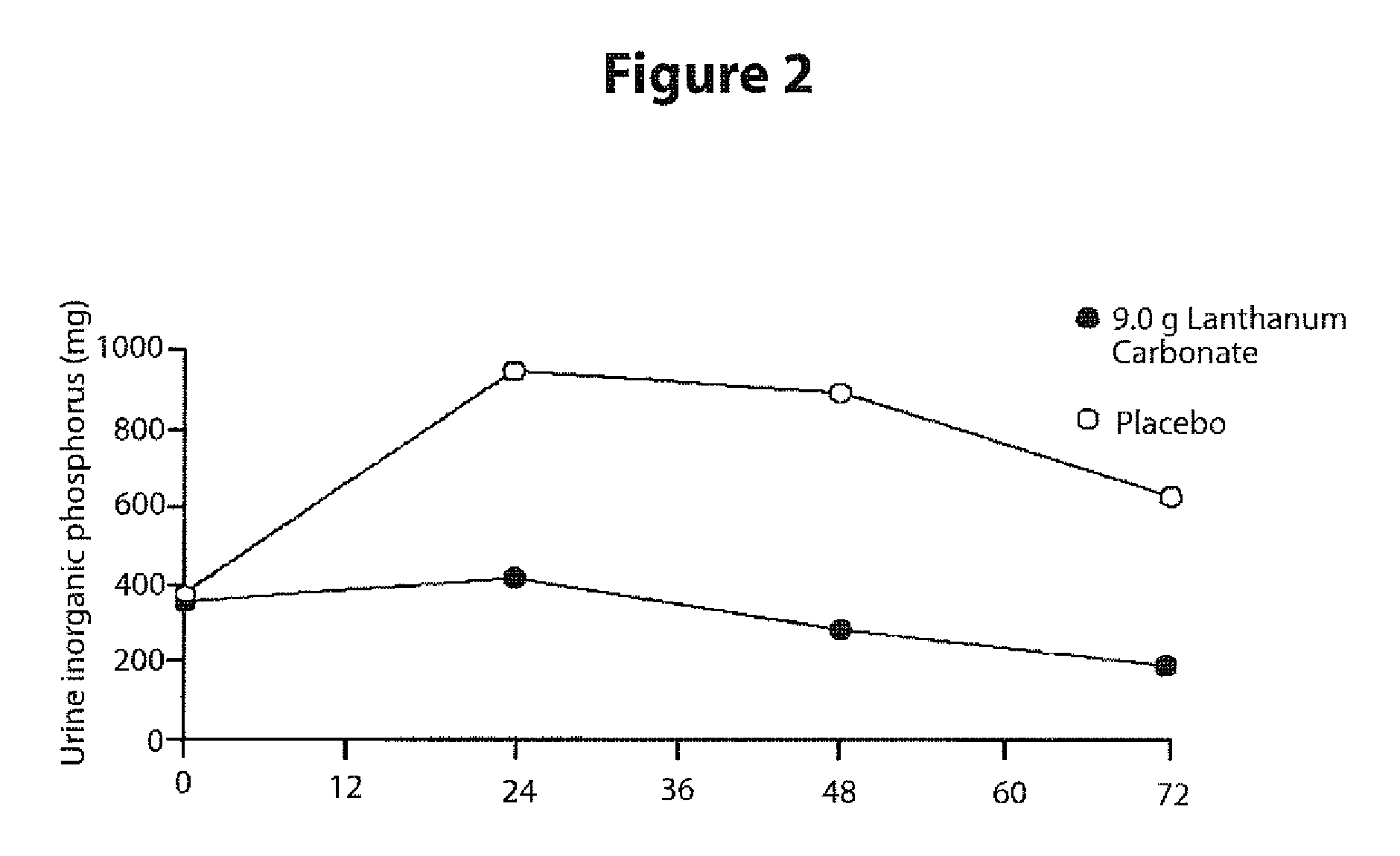

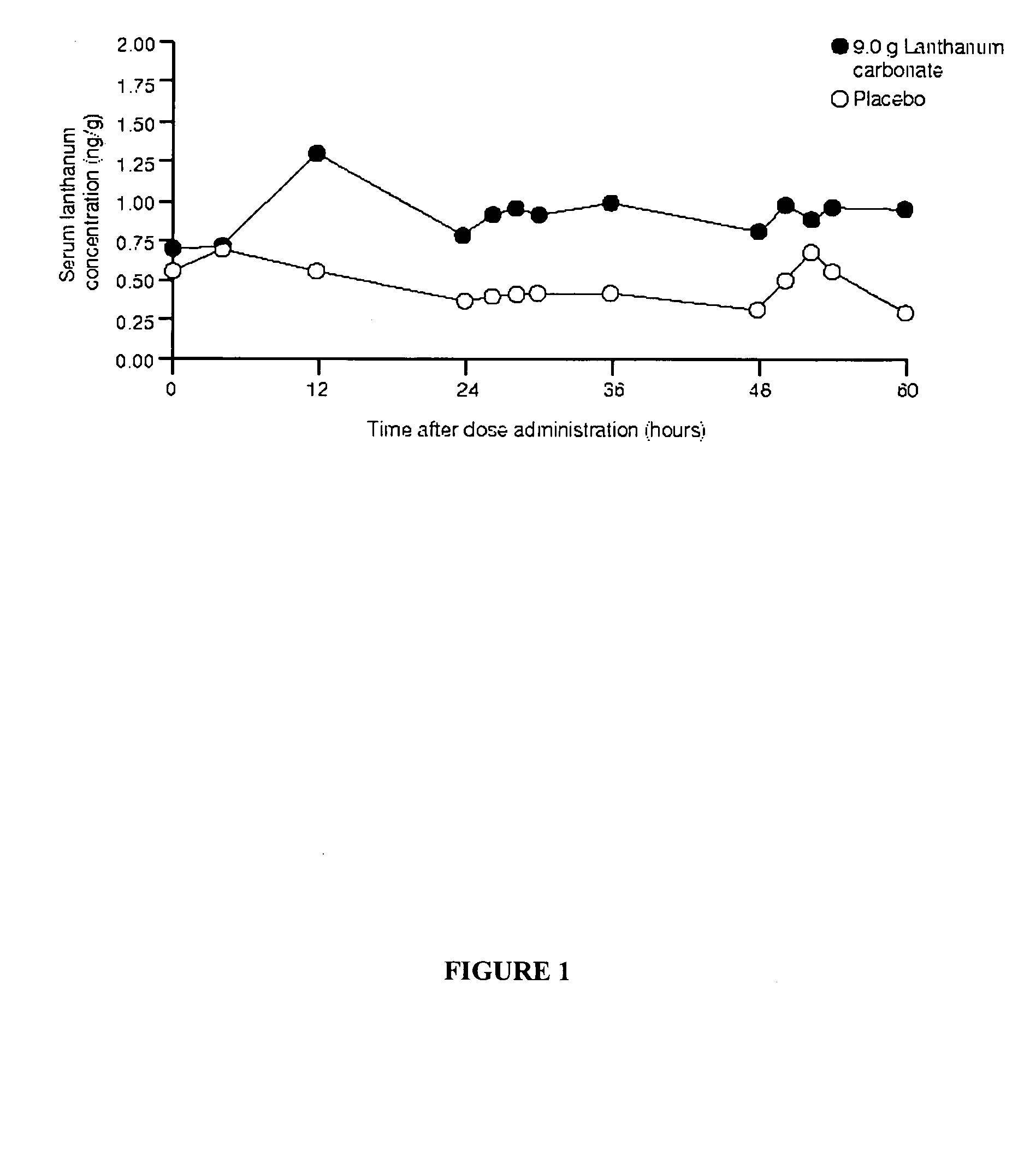

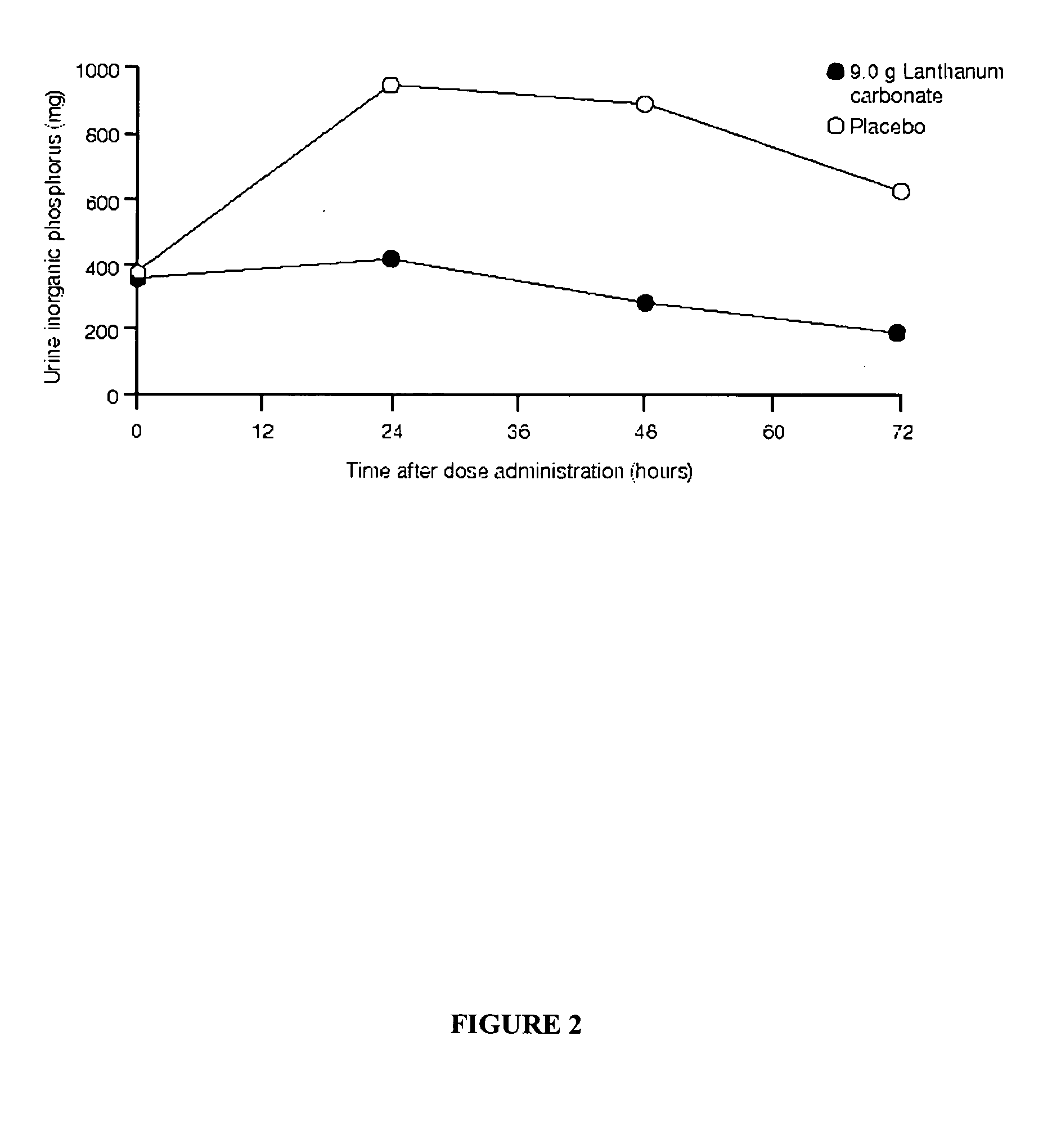

Pharmaceutical formulation comprising lanthanum compounds

ActiveUS7465465B2Extended shelf lifeRestrictive dietBiocideHeavy metal active ingredientsCompound (substance)Lanthanum

This invention relates to a chewable lanthanum formulation comprising a pharmaceutically effective amount of a lanthanum compound; and at least one chewable pharmaceutically acceptable excipient. This invention also relates to a pharmaceutical formulation in a tablet or in a powder comprising a pharmaceutically effective amount of a lanthanum compound produced by a process which comprises the steps of: a) powder blending the lanthanum compound and at least one pharmaceutically acceptable excipient in a mixer to form a mixture; or b) powder blending the lanthanum compound and excipients, compressing the resulting combination into a slug material or roller compacting the resulting combination into a strand material, and milling the prepared material into a free flowing mixture; and c) compressing the resulting mixture into a tablet or filing up the resulting mixture in a appropriate container.

Owner:SHIRE CANADA INC +1

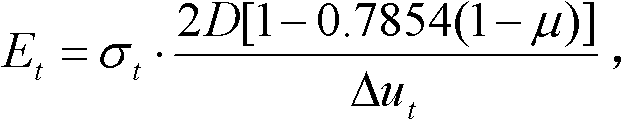

Method for testing tensile modulus of brittle material

InactiveCN101819111AEasy to controlEasy to operateMaterial strength using tensile/compressive forcesTest sampleMaterial Stretched

The invention discloses a method for testing tensile modulus of a brittle material, which is characterized by comprising the following steps of: arranging a test sample on a Brazilian split tester; symmetrically applying line load to the test sample in the radial direction of the test sample; measuring the total displacement of center of the test sample in the diameter direction, wherein the direction of the total displacement is vertical to the load applying direction of the test sample; calculating to obtain the tensile modulus Et of the material according to the following formula, wherein Et is the tensile modulus, sigma t is the Brazilian split tensile strength; Pt is the line load, L is the length of the test sample, D is the diameter of the test sample, Mu is the Poisson's ratio, and Delta ut is the total displacement of the center of the test sample in the diameter direction. The method for testing the tensile modulus of the brittle material can guarantee more accurate test result.

Owner:CENT SOUTH UNIV

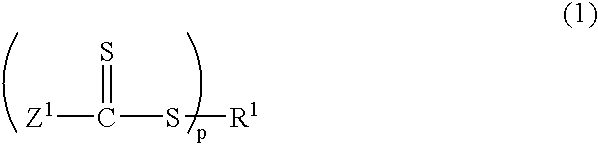

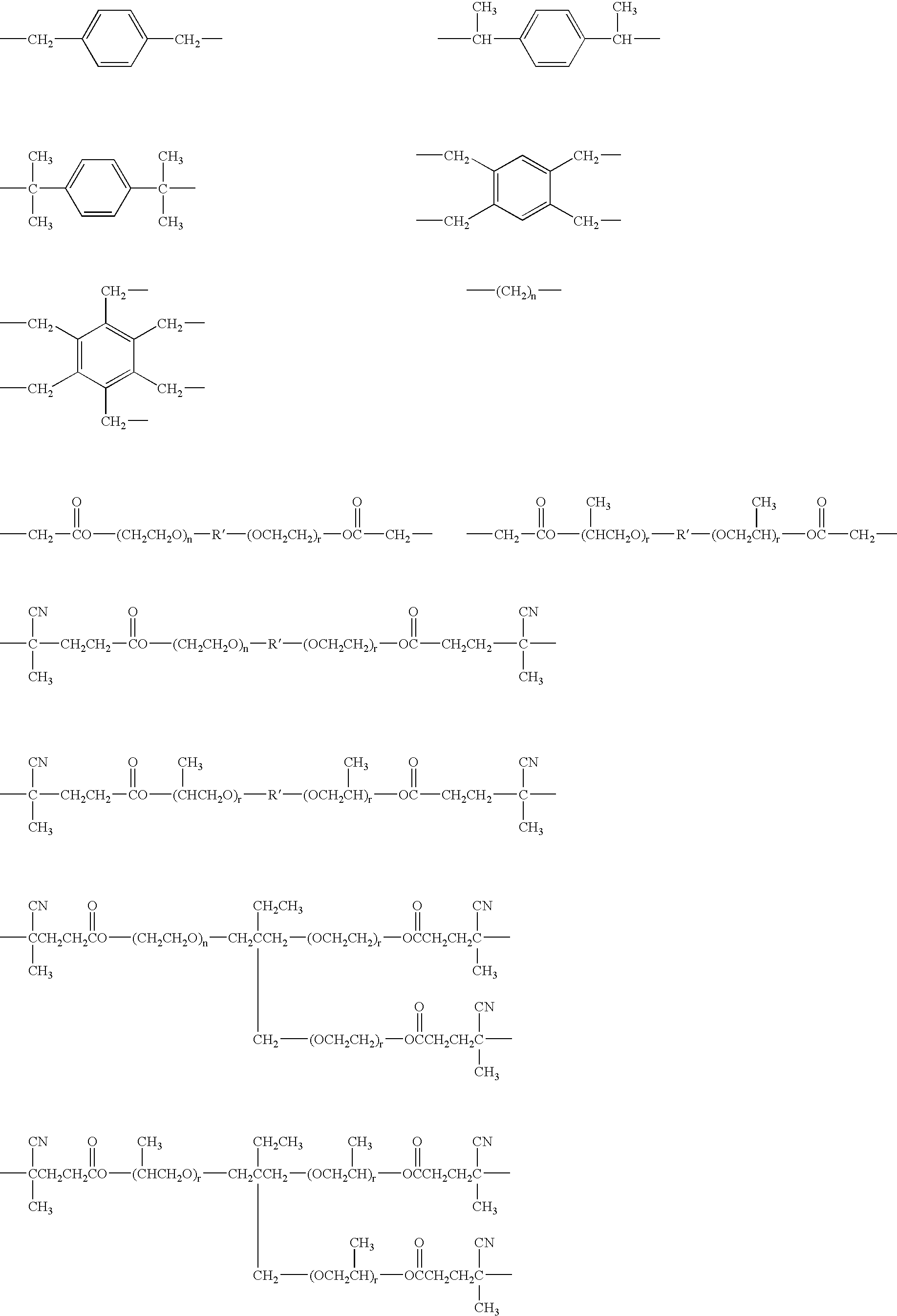

Polyolefin production catalyst and method of preparing polyolefins

InactiveUS6121182AHigh polymerization activityImprove rigidityOrganic-compounds/hydrides/coordination-complexes catalystsPolymer sciencePolyolefin

PCT No. PCT / JP97 / 01387 Sec. 371 Date Dec. 11, 1997 Sec. 102(e) Date Dec. 11, 1997 PCT Filed Apr. 22, 1997 PCT Pub. No. WO97 / 40075 PCT Pub. Date Oct. 30, 1997A catalyst component for polyolefin production catalysts comprising a metallocene compound represented by general formula (1) (symbols have the meanings as described in the specification), polyolefin production catalyst containing the component, and method for producing polyolefin with the catalyst are provided. Use of a catalyst containing the novel metallocene compound as a catalyst component of the invention in polymerization of alpha -olefin, particularly propylene, enables one to prepare high rigid, high melting point isotactic polypropylene useful as an industrial material for automobiles and the like, more specifically isotactic polypropylene having highly controlled stereoregulartity and regioregularity, particularly the one having a high regioregularity that has been difficult to achieve with conventional metallocene catalysts.

Owner:SUNALLOMER

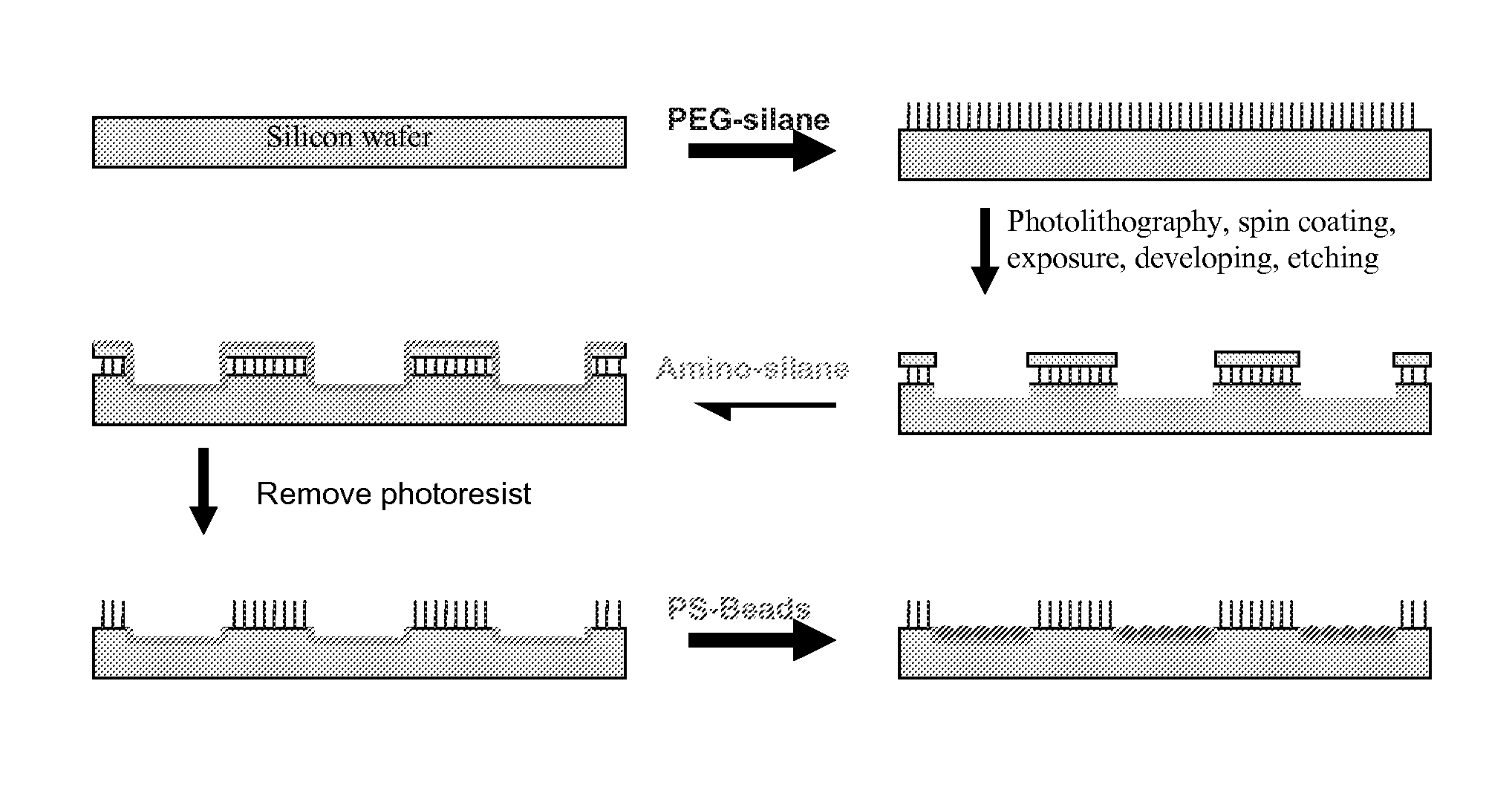

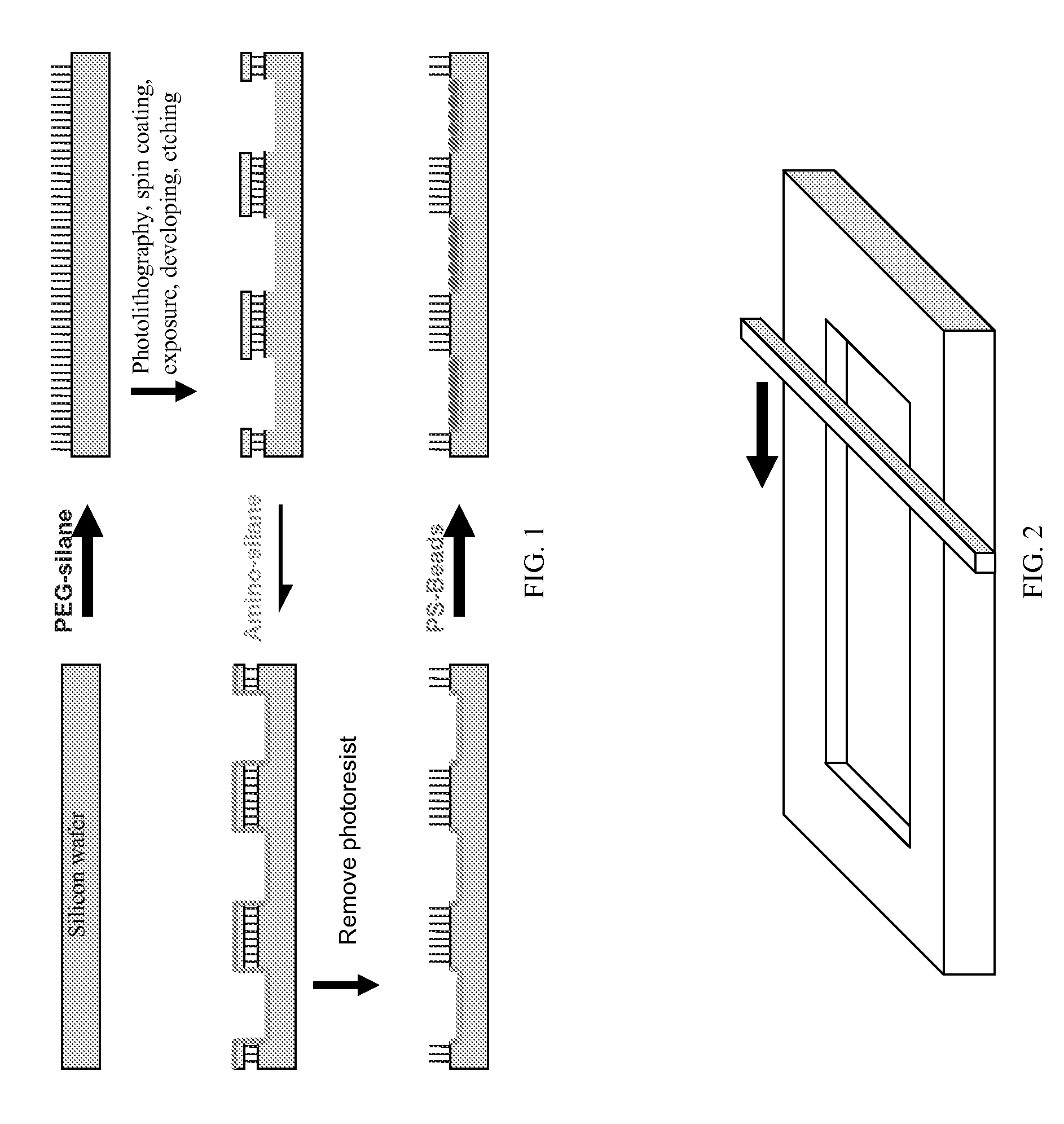

Signal amplified biological detection with conjugated polymers

The devices and method are provided for detecting labeled and label-free analytes, such as nucleic acids and proteins, employing conjugated cationic, anionic and neutral polymers. The analytes can be immobilized on a solid support material. The solid support material can be disposed in the pre-fabricated patterns on a substrate. The chemical structures of the polymers employed by the various embodiments of the present invention are described herein.

Owner:NAT UNIV OF SINGAPORE +1

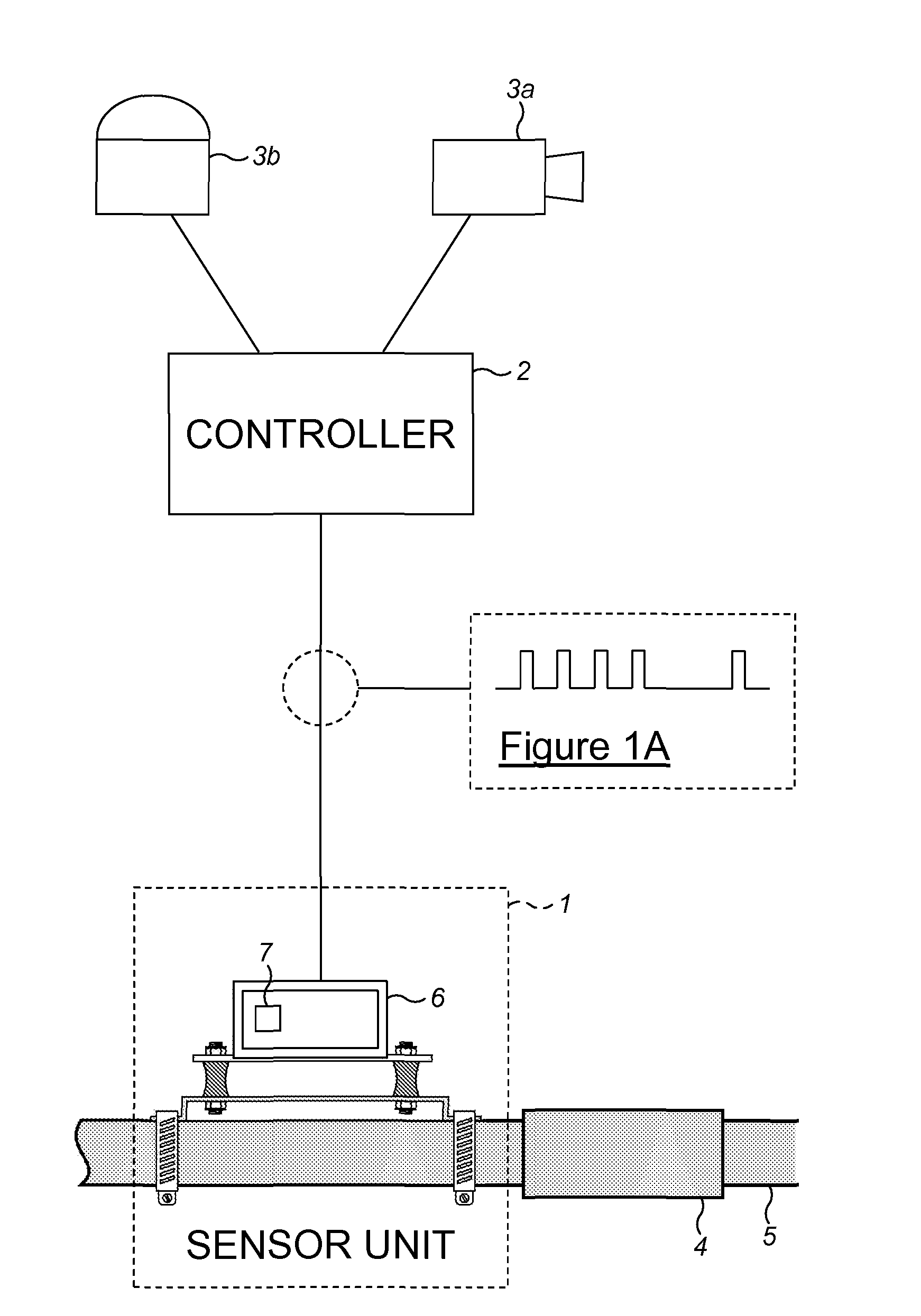

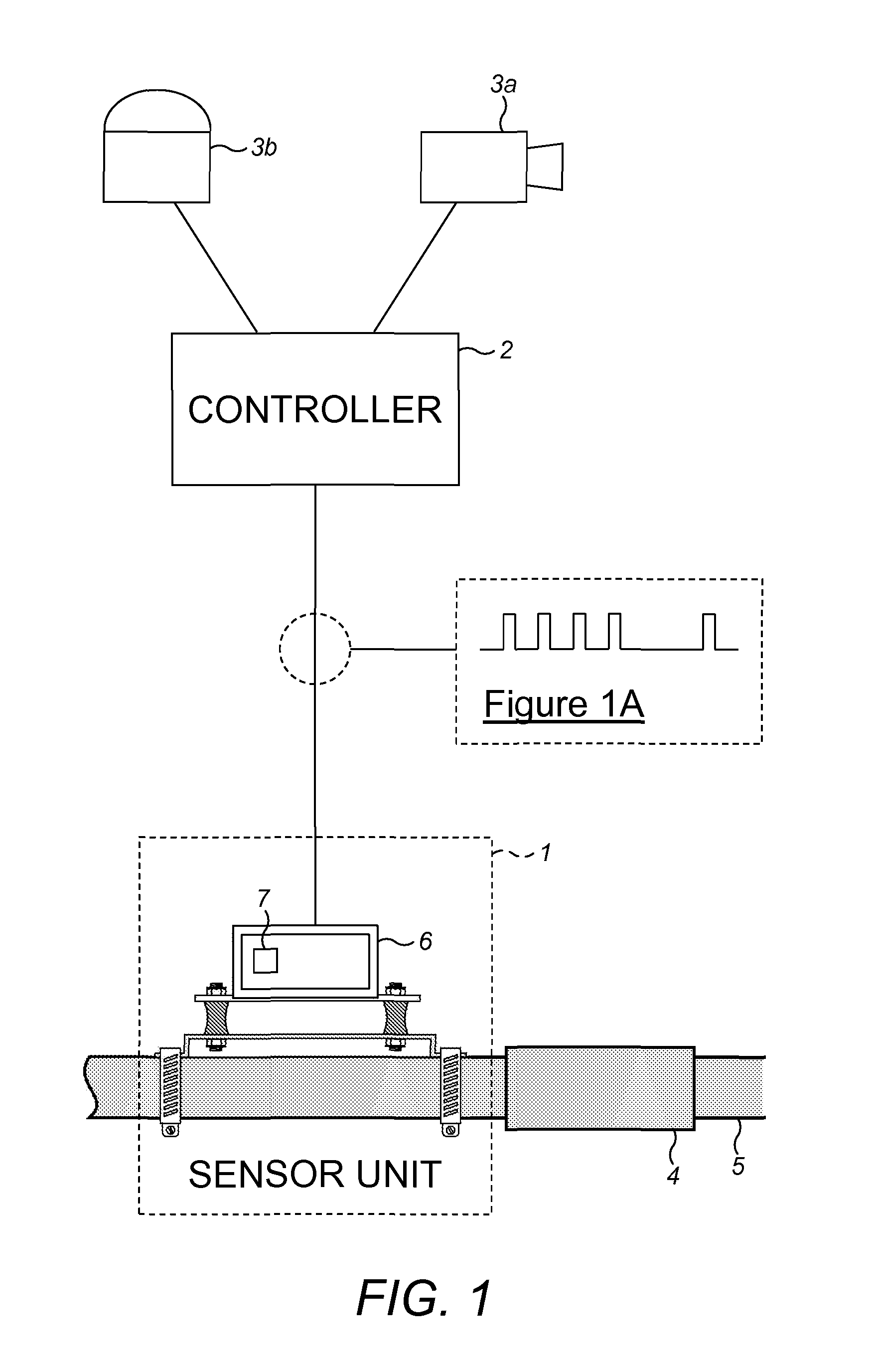

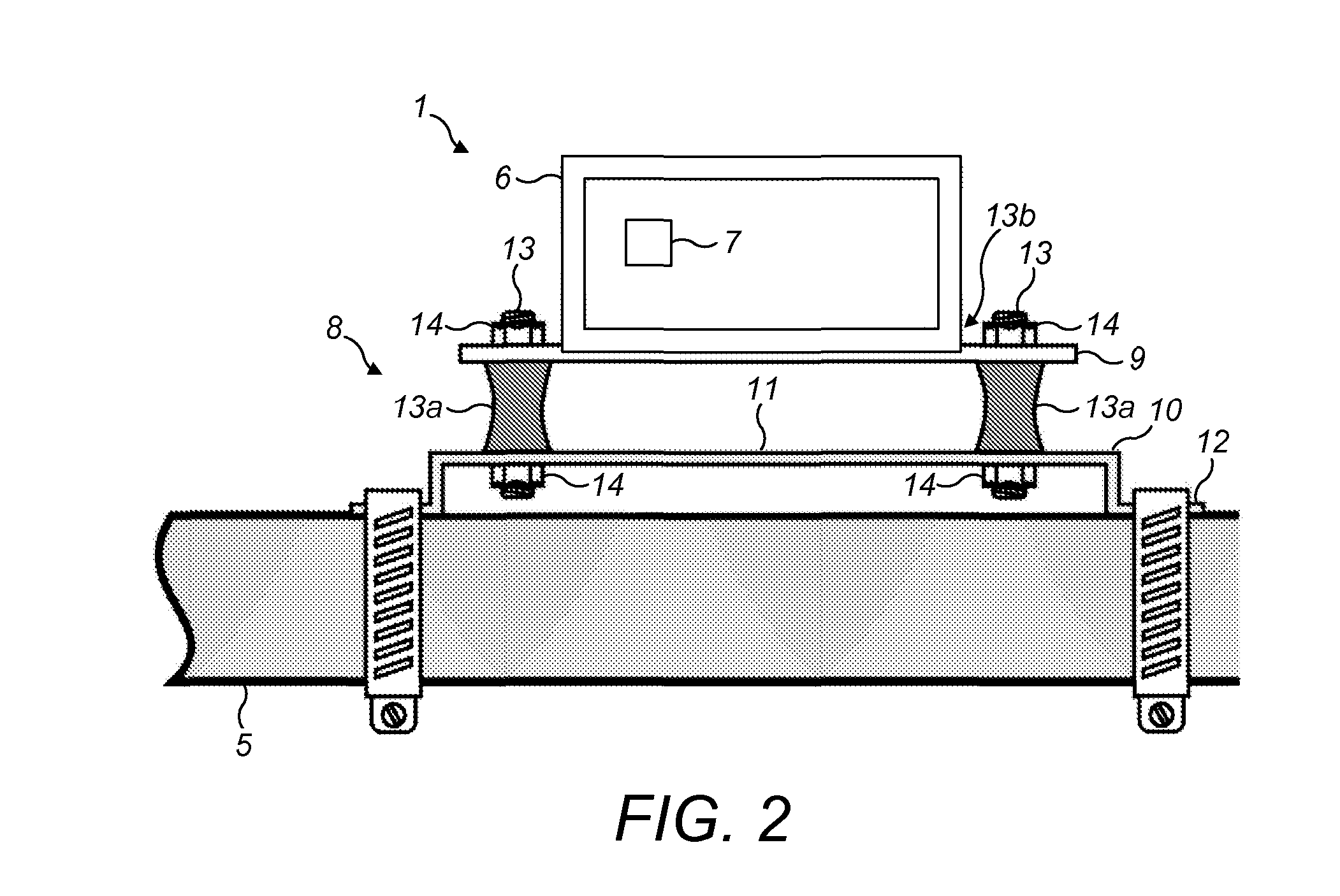

Anti-theft system for an automotive exhaust component

InactiveUS20140104048A1Difficult to controlNo performance lossInternal combustion piston enginesExhaust apparatusEngineeringAnti theft

An anti-theft system for protecting a vehicle exhaust component (4) is described. The system includes a sensor (1) configured to monitor vibrations associated with a vehicle exhaust system (5)and a controller (2) arranged to monitor a signal from the sensor (1). The controller (2) is configured to generate an alarm event if the signal from the sensor includes characteristics indicative of vibrations associated with an attempted theft of the vehicle exhaust component (4).

Owner:DE KOCK FILIP +1

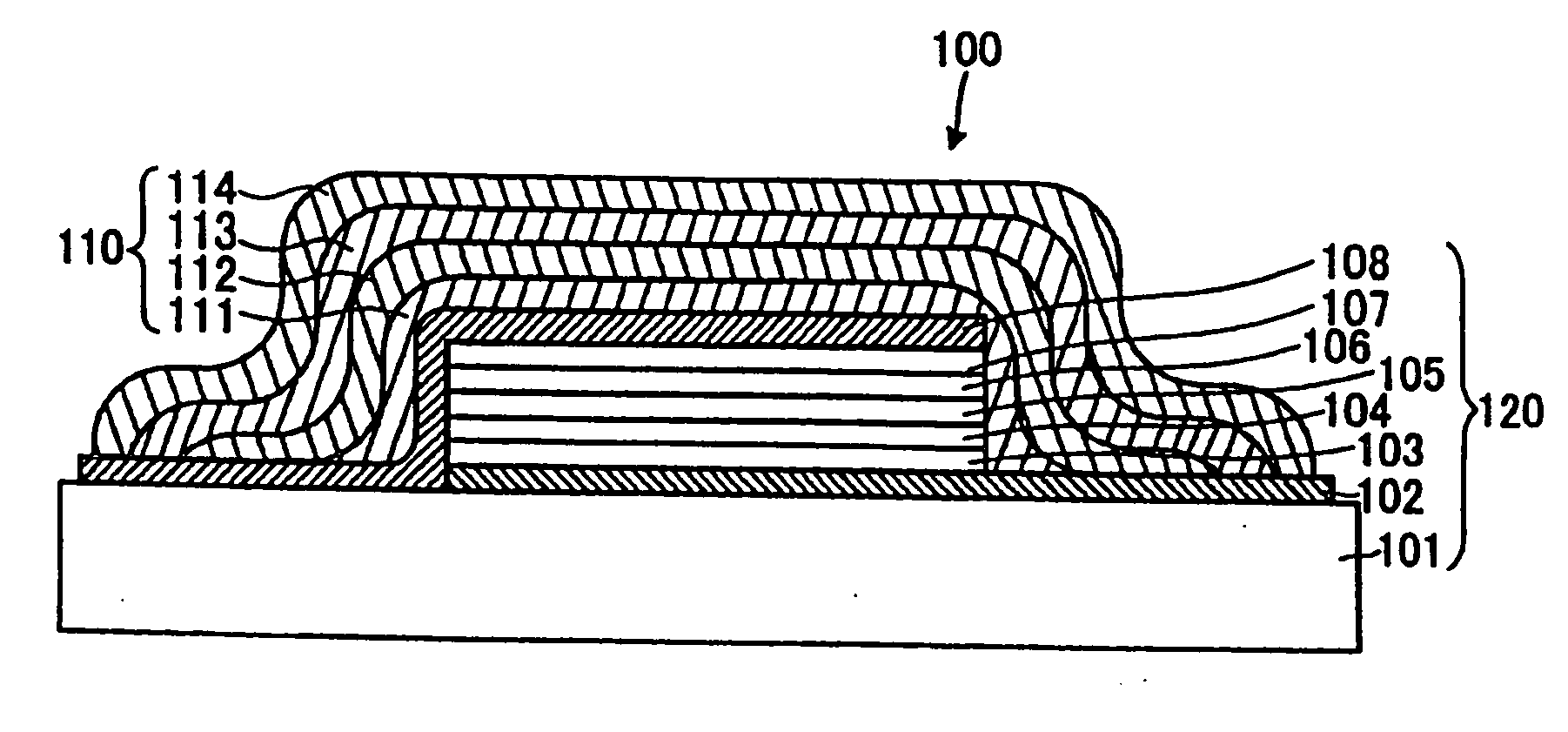

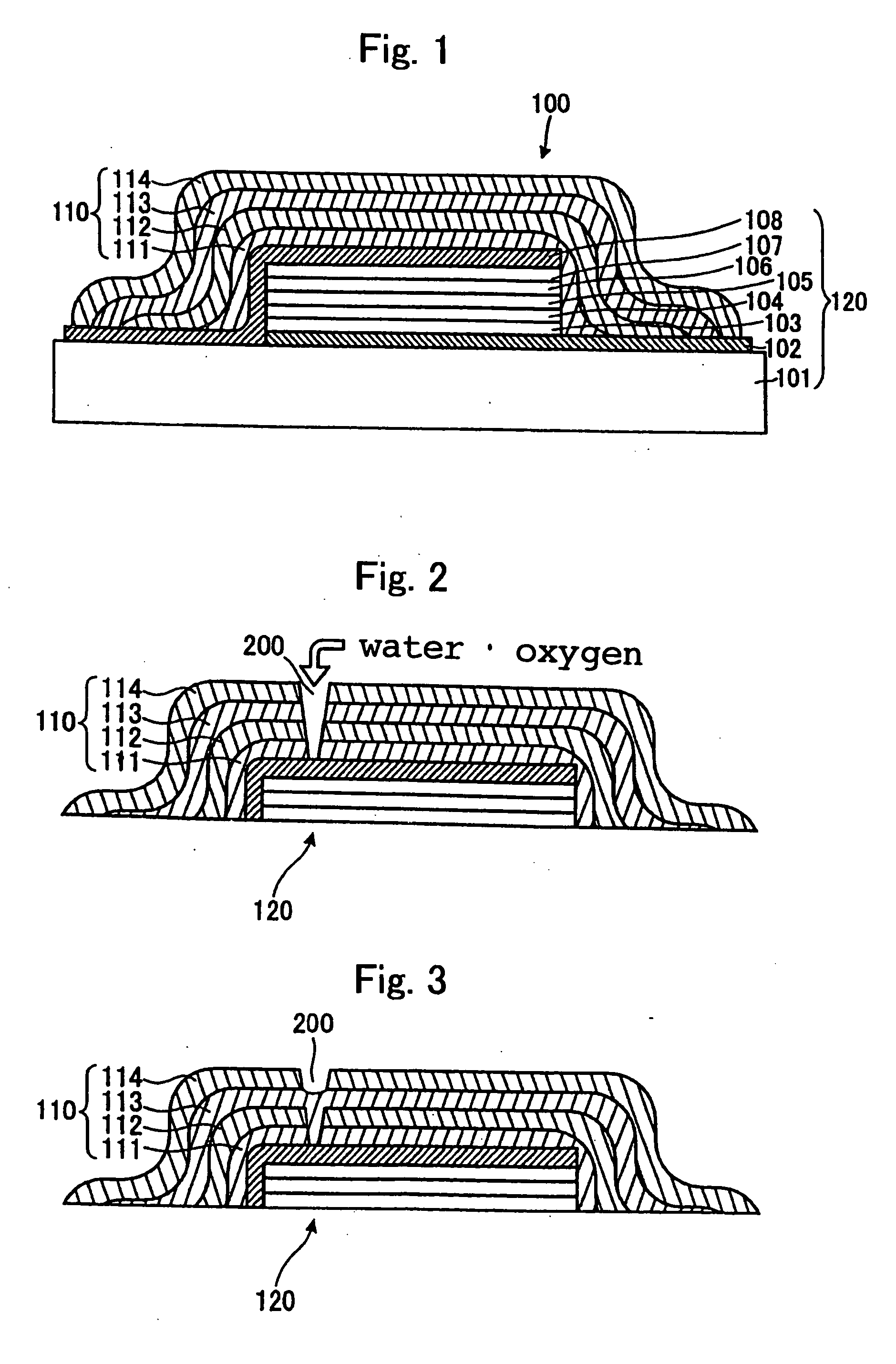

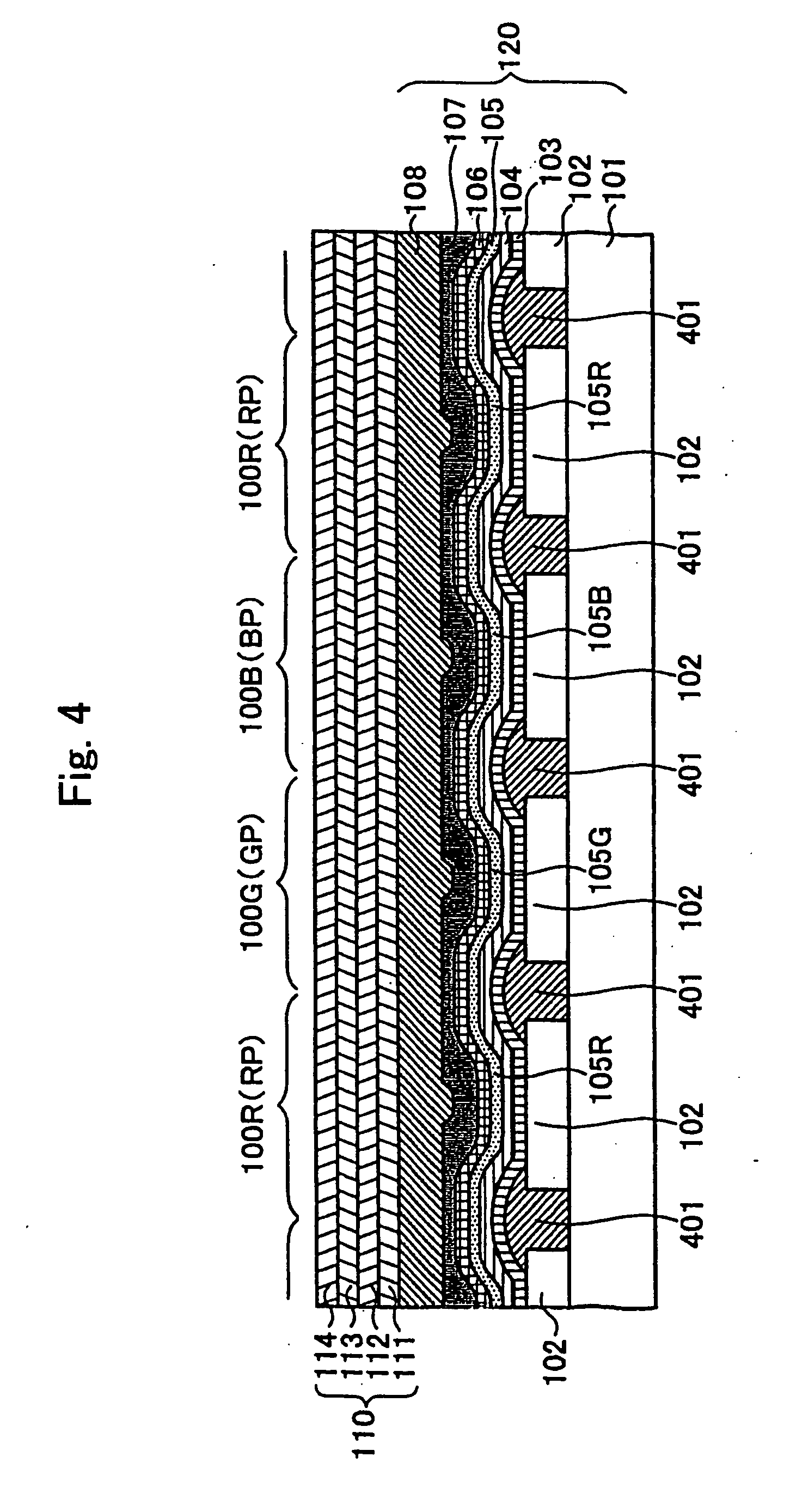

Organic EL element and organic EL display panel

InactiveUS20050285521A1Volume changeDifficult to controlDischarge tube luminescnet screensElectroluminescent light sourcesProduction rateSelf recovery

An organic EL element which has a good element property and can realize high productivity is provided. The organic EL element 100 is provided with an element substrate 120 for forming an organic layer including at least a light emitting layer 105 between a pair of opposing electrodes which are provided on the substrate, in which a surface of the above-mentioned element substrate is covered with a sealing layer 110, wherein the above-mentioned sealing layer 110 includes a self-recovery layer 113 which causes volume change in a predetermined environment.

Owner:TOHOKU PIONEER CORP

Pharmaceutical formulation comprising lanthanum compounds

ActiveUS20050079135A1Difficult to controlExtended shelf lifeHeavy metal active ingredientsBiocideFree flowLanthanum

This invention relates to a chewable lanthanum formulation comprising a pharmaceutically effective amount of a lanthanum compound; and at least one chewable pharmaceutically acceptable excipient. This invention also relates to a pharmaceutical formulation in a tablet or in a powder comprising a pharmaceutically effective amount of a lanthanum compound produced by a process which comprises the steps of: a) powder blending the lanthanum compound and at least one pharmaceutically acceptable excipient in a mixer to form a mixture; or b) powder blending the lanthanum compound and excipients, compressing the resulting combination into a slug material or roller compacting the resulting combination into a strand material, and milling the prepared material into a free flowing mixture; and c)compressing the resulting mixture into a tablet or filing up the resulting mixture in a appropriate container.

Owner:SHIRE CANADA INC +1

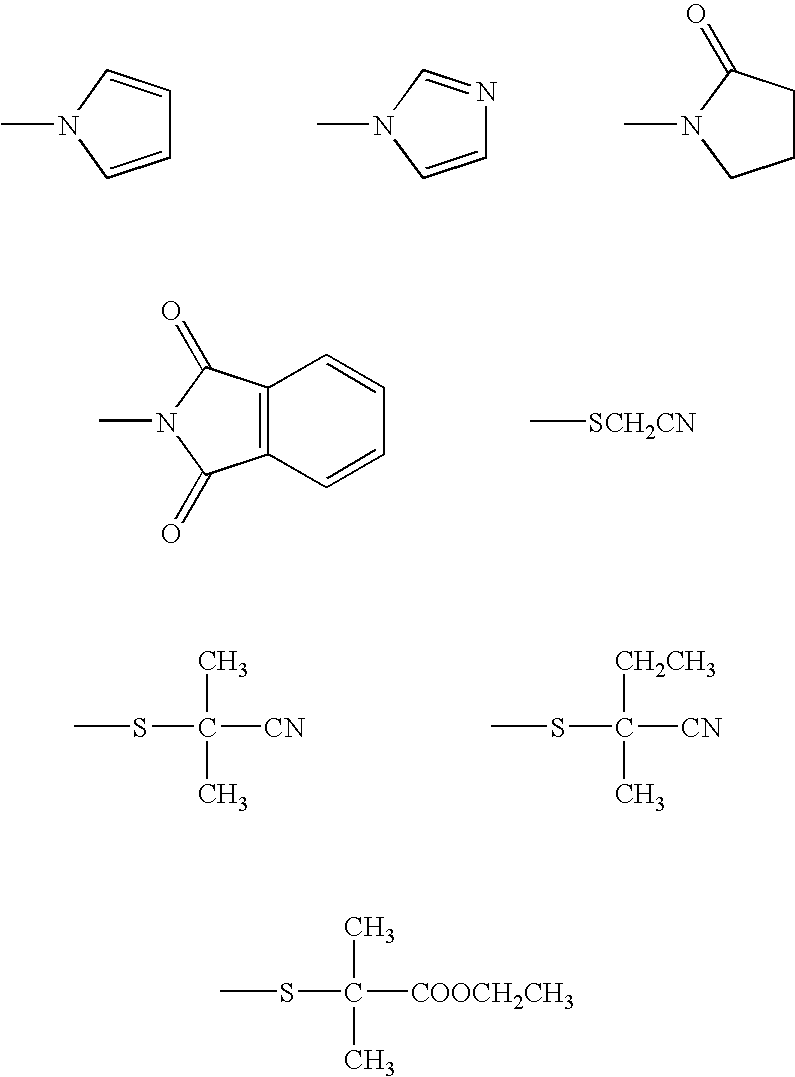

Polyurethane polymer

InactiveUS20040171765A1Good chemical resistanceImprove chlorine resistanceMonocomponent polyurethanes artificial filamentHeat resistanceReversible addition−fragmentation chain-transfer polymerization

Provided is a polyurethane polymer which is excellent in oil resistance, weatherability, light resistance, heat resistance, hot water resistance, hydrolysis resistance, strength, chlorine resistance, and chemical resistance, and which can be produced simply and economically. The polyurethane polymer is produced by polymerizing at least two components: a vinyl polymer (A) having a mercapto group at each end of the molecular chain produced by a reversible addition-fragmentation chain transfer polymerization method, and an organic polyisocyanate (B). Also provided are polyurethane-based materials containing the polyurethane polymer, and polyurethane elastic fiber.

Owner:KANEKA CORP

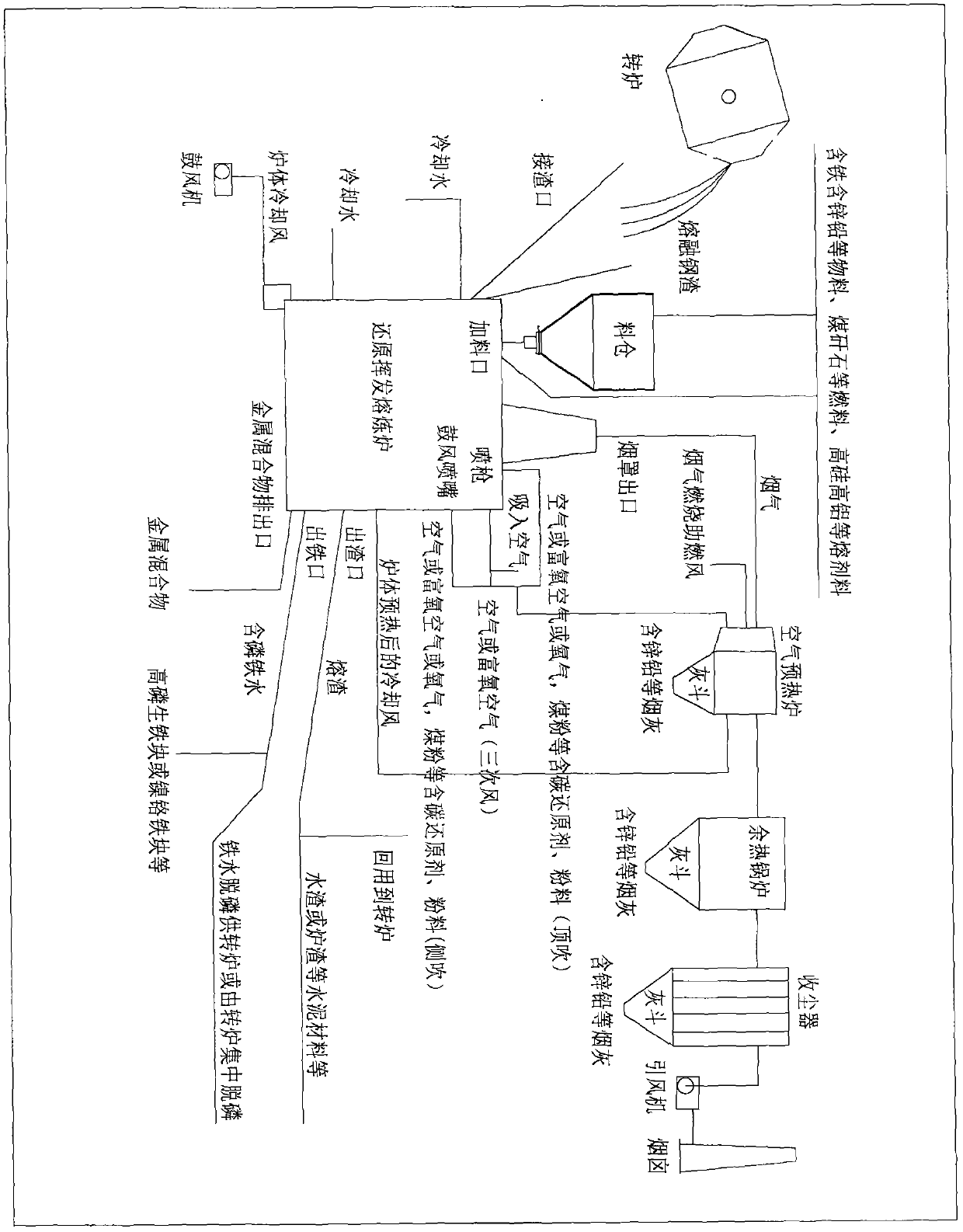

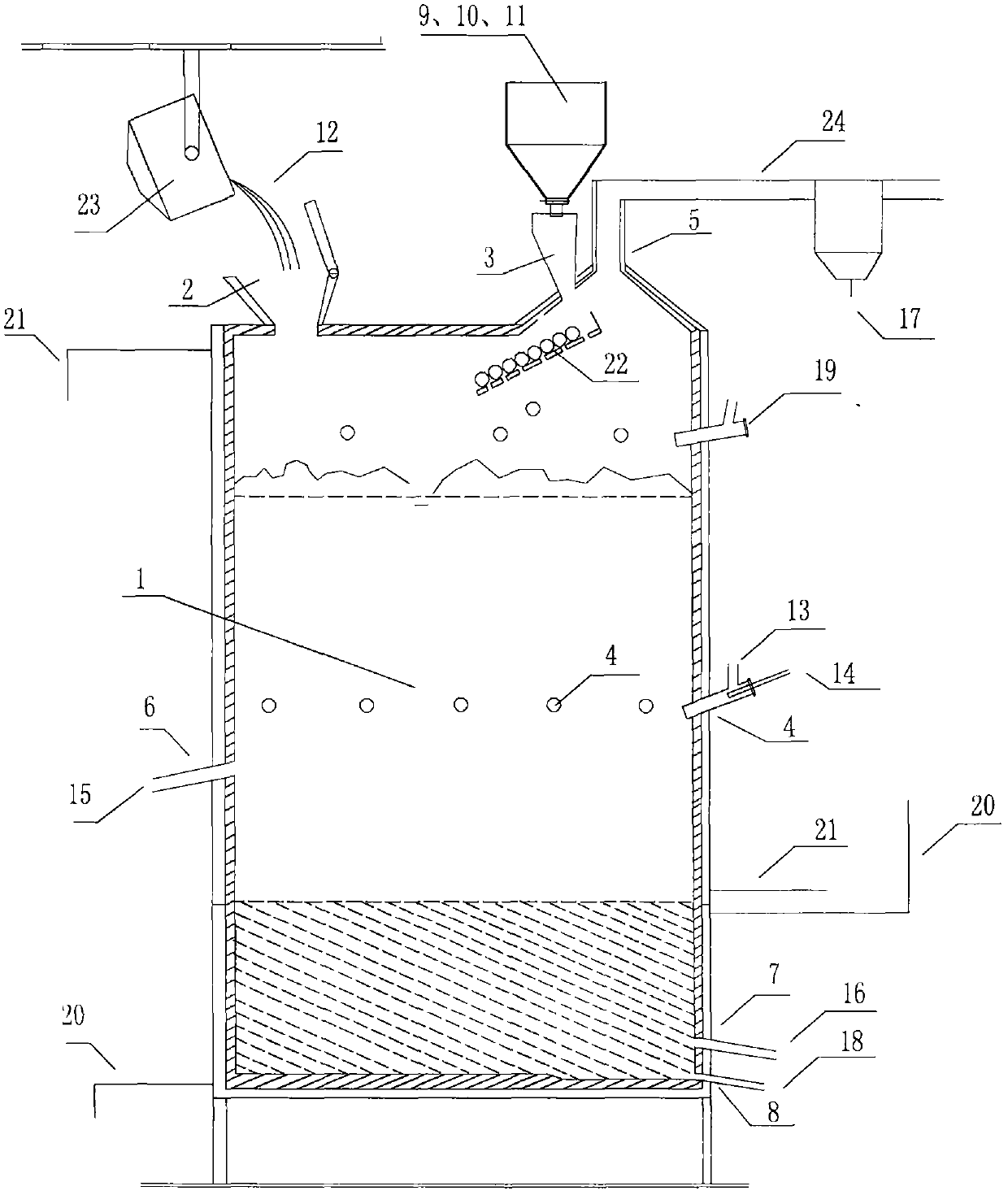

Cooperative processing and recycling method for material containing iron and/or zinc, lead, copper and tin, and the like and molten steel slag

PendingCN108676942AReduce outputEfficient recyclingRecycling and recovery technologiesProcess efficiency improvementMolten slagMaterials science

The invention discloses a process method for cooperatively and continuously processing waste containing iron and / or zinc, lead, copper and tin, and the like and molten steel slag on line, separating and recycling metal such as iron, zinc, lead, copper and tin as well as molten slag. The cooperative processing and recycling method is characterized in that pellets prepared from waste containing iron, zinc, lead, copper, tin and the like, particles, a blocky material containing iron, zinc, lead, copper, tin and the like and high-temperature molten steel slag are added into a reducing, volatilizing and smelting furnace, molten iron, which is obtained by air-blowing, adding of fuels such as coal gangues and flux such as high silicon and high aluminum, high-temperature reducing and volatilizingtreatment, is discharged from an iron outlet of the reducing, volatilizing and smelting furnace; volatilized substances such as zinc and lead and smoke gas are sucked into a dust collector for being collected and utilized; enriched metal such as gold, silver, copper, tin and lead is discharged from a discharge hole in the bottommost part of the reducing, volatilizing and smelting furnace for beingrecycled; and molten slag is discharged through a slag outlet, water slag and the like or the molten slag is returned into a converter for being recycled. Waste containing iron, zinc, lead, copper, tin and the like, molten steel slag and coal gangue waste slag and the like are cooperatively and continuously treated to separate and recycle useful metal, so that remarkable energy-saving environment-friendly social benefits and economic benefits are achieved.

Owner:湖南建鑫冶金科技有限公司

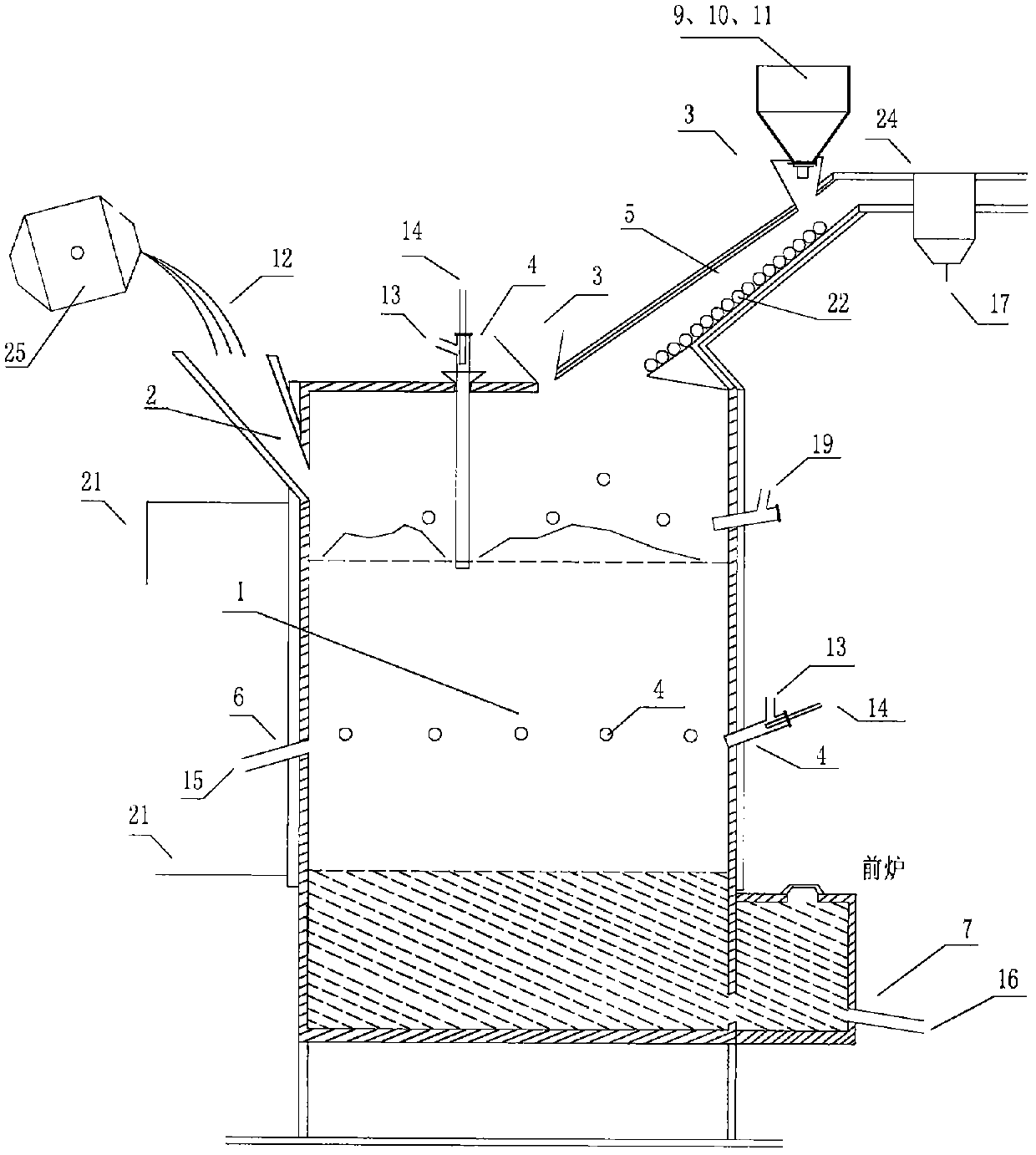

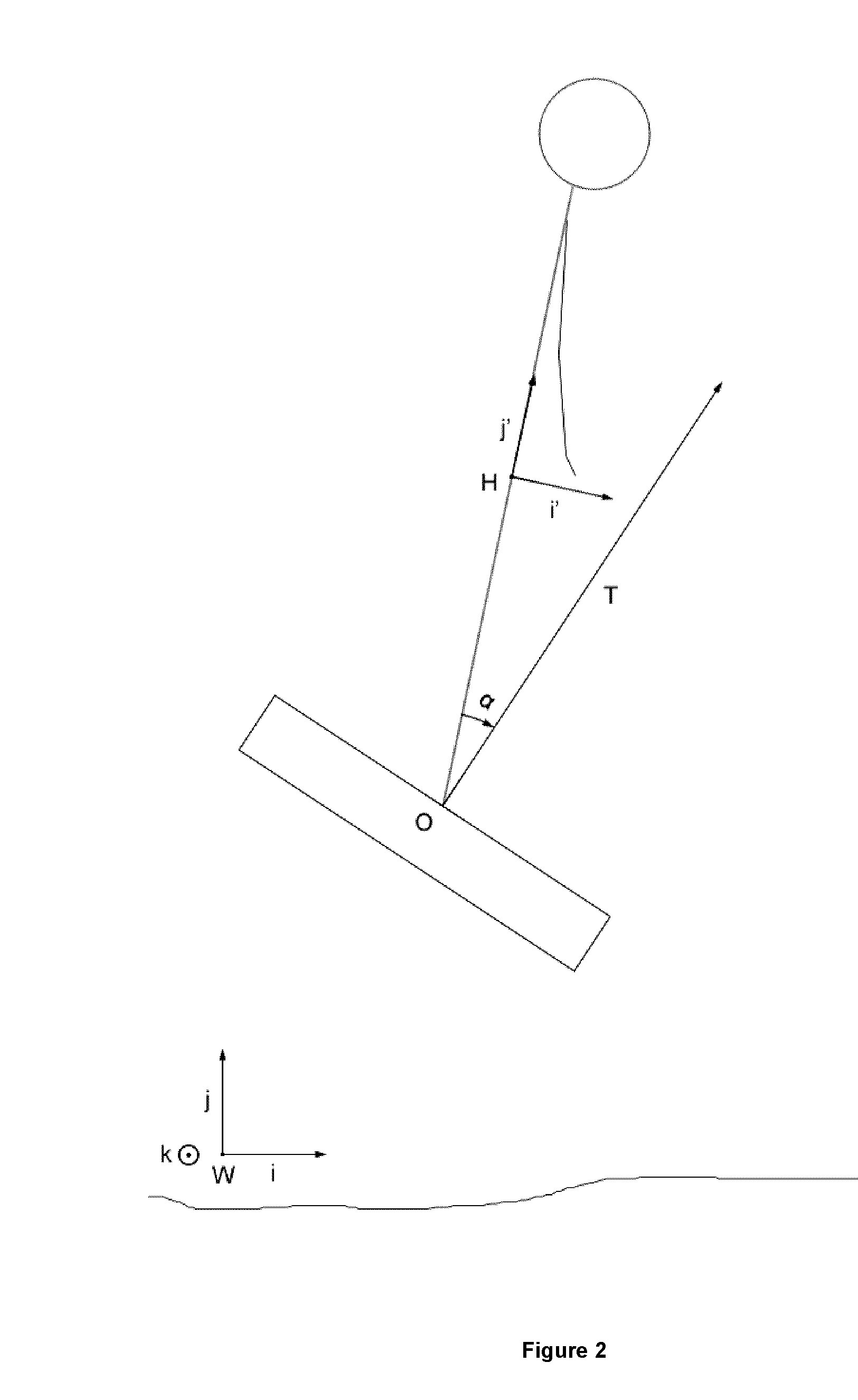

Personal flight vehicle

ActiveUS20160340035A1Minimize impactStress minimizationAircraft navigation controlPiston type power plantsFlight vehicleSpatial Orientations

A personal flight vehicle including a platform base assembly that provides a surface upon which the feet of an otherwise free-standing person are positionable, and including a plurality of axial flow propulsion systems positioned about a periphery of the platform base assembly. The propulsion systems generate a thrust flow in a direction substantially perpendicular to the surface of the platform base assembly, where the thrust flow is unobstructed by the platform base assembly. The thrust flow has a sufficient intensity to provide vertical takeoff and landing, flight, hovering and locomotion maneuvers. The vehicle allows the pilot to control the spatial orientation of the platform base assembly by the movement, preferably direct, of at least part of his or her body, and the spatial movement of the vehicle is thus controlled.

Owner:OMNI HOVERBOARDS INC

Multi-stage ordered medium hole/big hole composite material and preparation method thereof

InactiveCN101041428AThe method is cumbersomeThe method steps are cumbersomeNanostructure manufactureCarbon sourcePhenols

The invention discloses a preparing method of metahloe or larger hole composite carbon material with multi-stage ordered structure, which comprises the following steps: making silica dioxide jelly mould crystal as metal mold plate; setting block copolymer surface activator of polyoxyethylene block as soft mold plate; making soluble phenol resin as carbon source; proceeding organic-organic assemble through gap of colloid crystal; compositing metahloe or larger hole composite carbon material with multi-stage pore path. This invention possess larger hole of ordered array of interconnected and optics forbidden region with continuously adjustable wavelength generated by the colloid crystal structure.

Owner:FUDAN UNIV

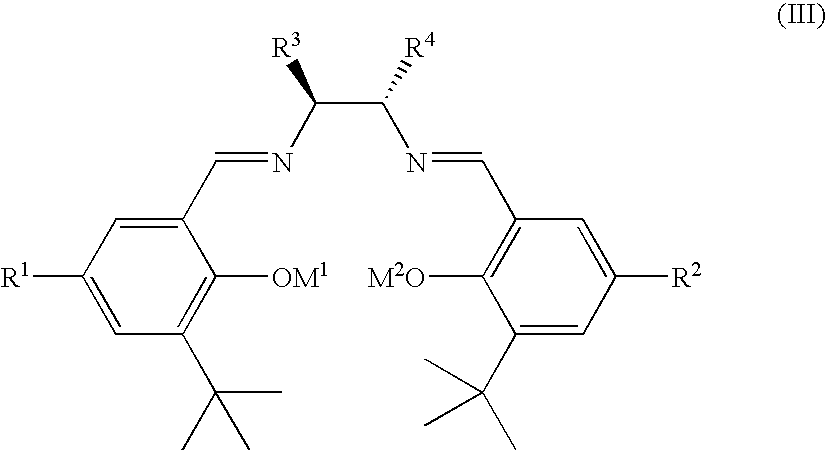

Ruthenium(II) catalysts for use in stereoselective cyclopropanations

ActiveUS7754902B2High stereoselectivityHigh yieldRuthenium organic compoundsCobalt organic compoundsProtonationSalen ligand

Chiral ruthenium catalysts comprising salen and alkenyl ligands are provided for stereoselective cyclopropanation, and methods of cyclopropanation are provided. The chiral ruthenium catalyst is prepared in situ by combining an alkenyl ligand, a deprotonated chiral salen ligand, and a ruthenium (II) metal. A preferred catalyst is prepared in situ by combining 2,3-dihydro-4-venylbenzofuran, deprotonated 1,2-cyclohexanediamino-N,N′-bis(3,5-di-t-butyl-salicylidene) and RuCl2(p-cymene)]2.

Owner:VANDA PHARMA INC

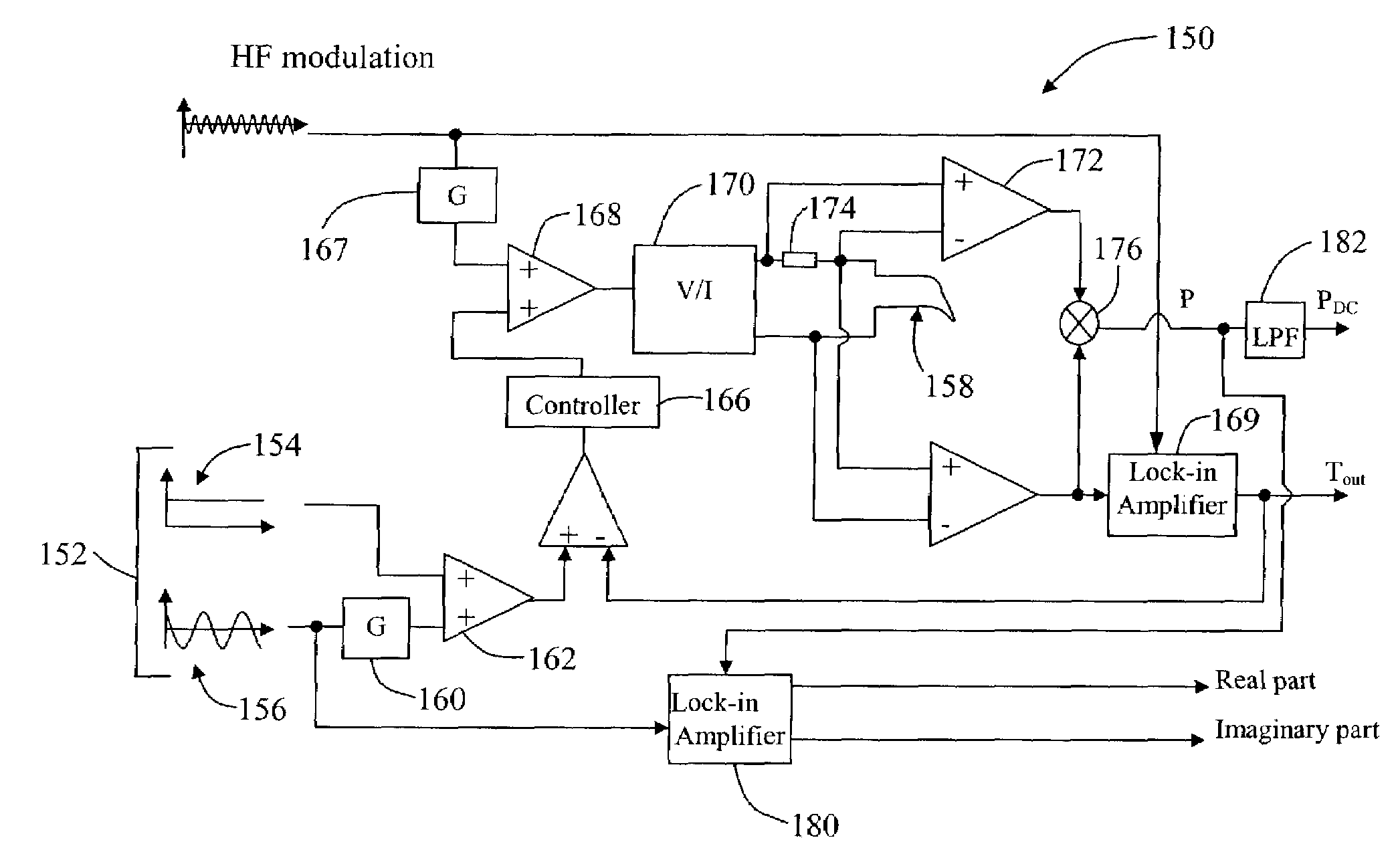

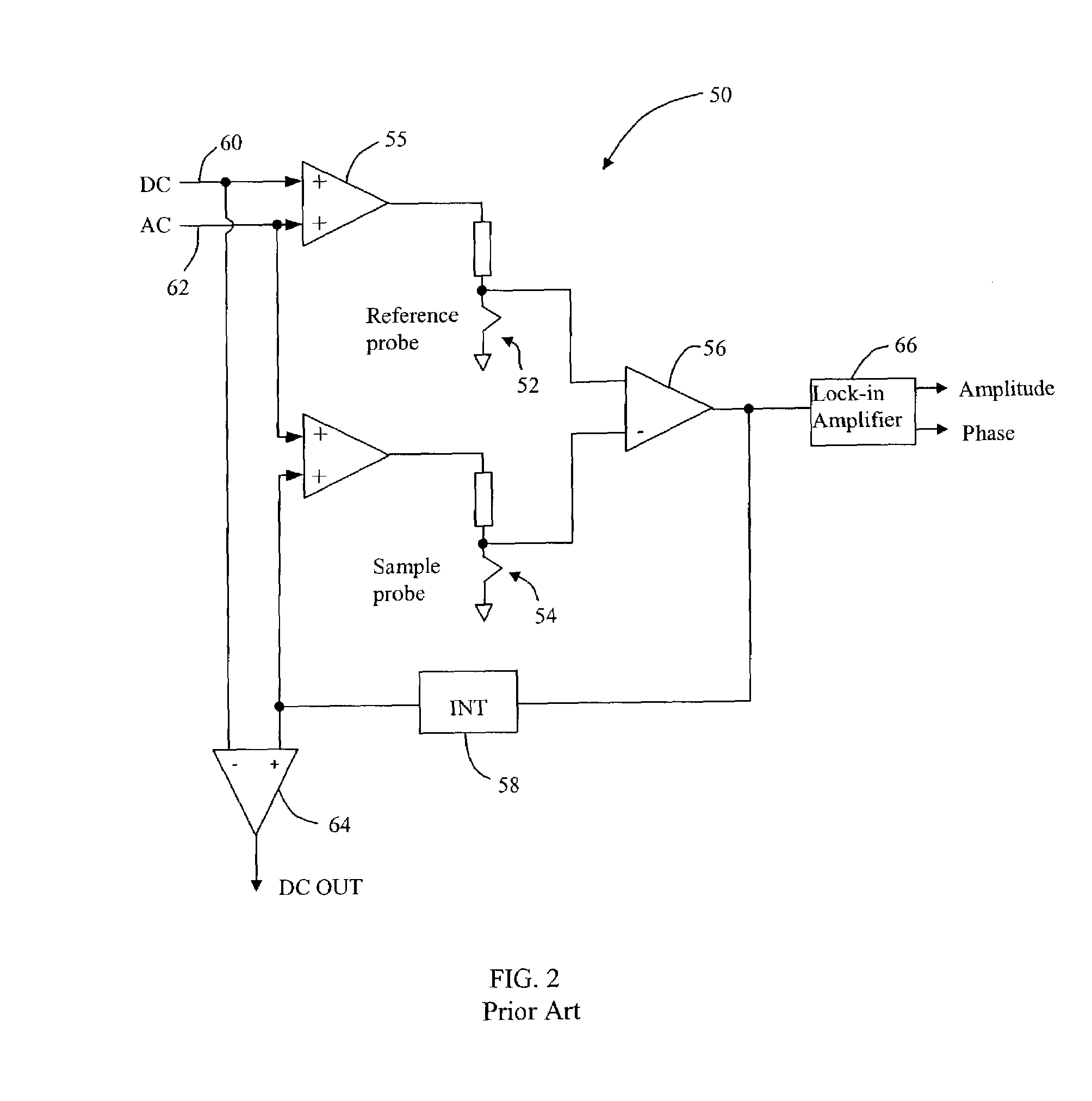

Scanning thermal probe microscope

InactiveUS7448798B1Increased sensitivity and rangeDifficult to controlThermometer detailsThermometers using material expansion/contactionPhysicsVoltage amplitude

An apparatus and method of measuring a parameter associated with a sample is provided. The method includes providing a probe adapted to heat the sample and applying a measuring current having a frequency ω1 to the probe. In operation, the method measures the amplitude of the voltage across the probe at a frequency ω1. This amplitude is indicative of a temperature of the probe. The preferred embodiment also provides a method of separating contamination of the thermal data caused by the probe from thermal data associated with the sample under test.

Owner:BRUKER NANO INC

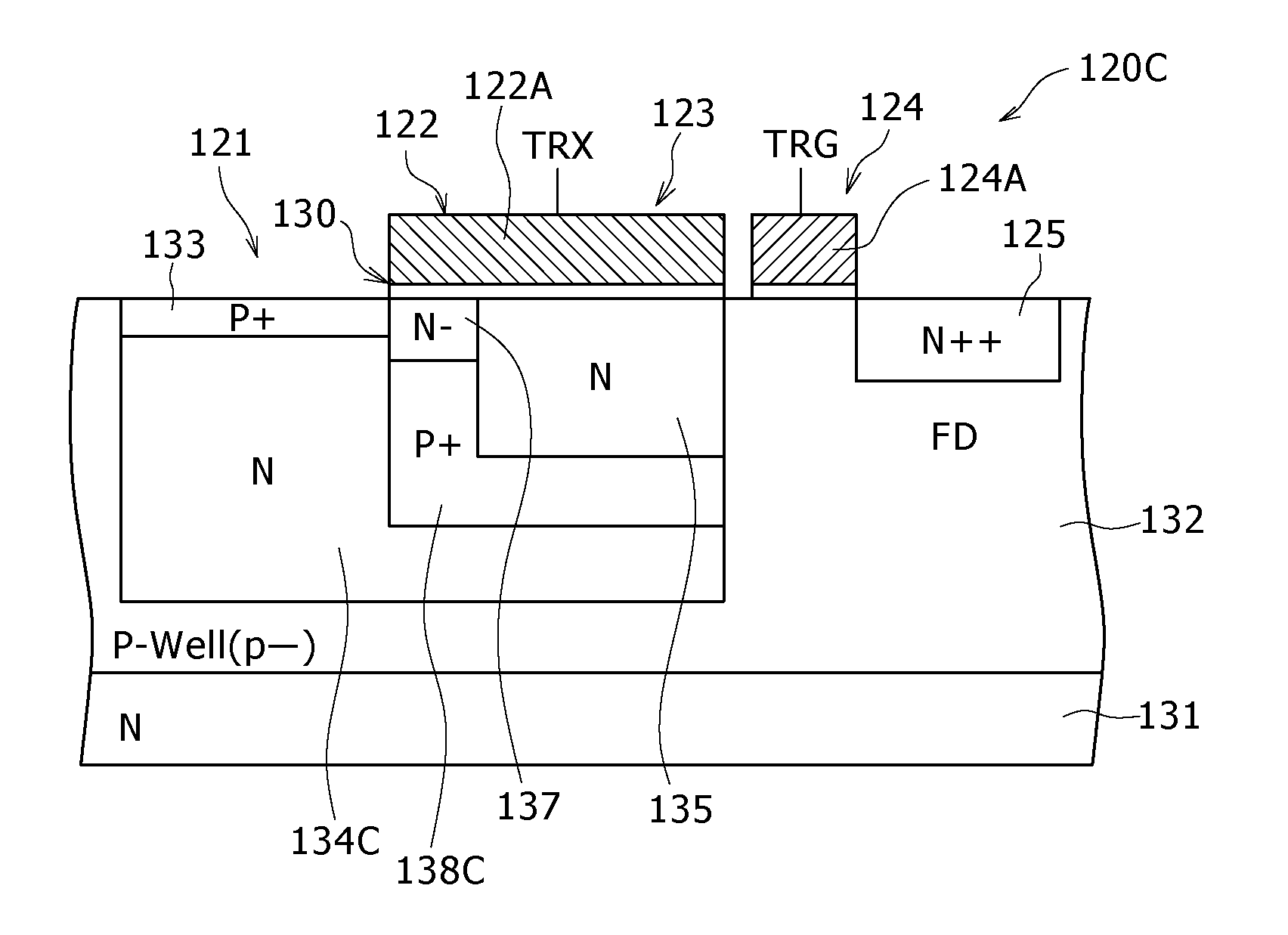

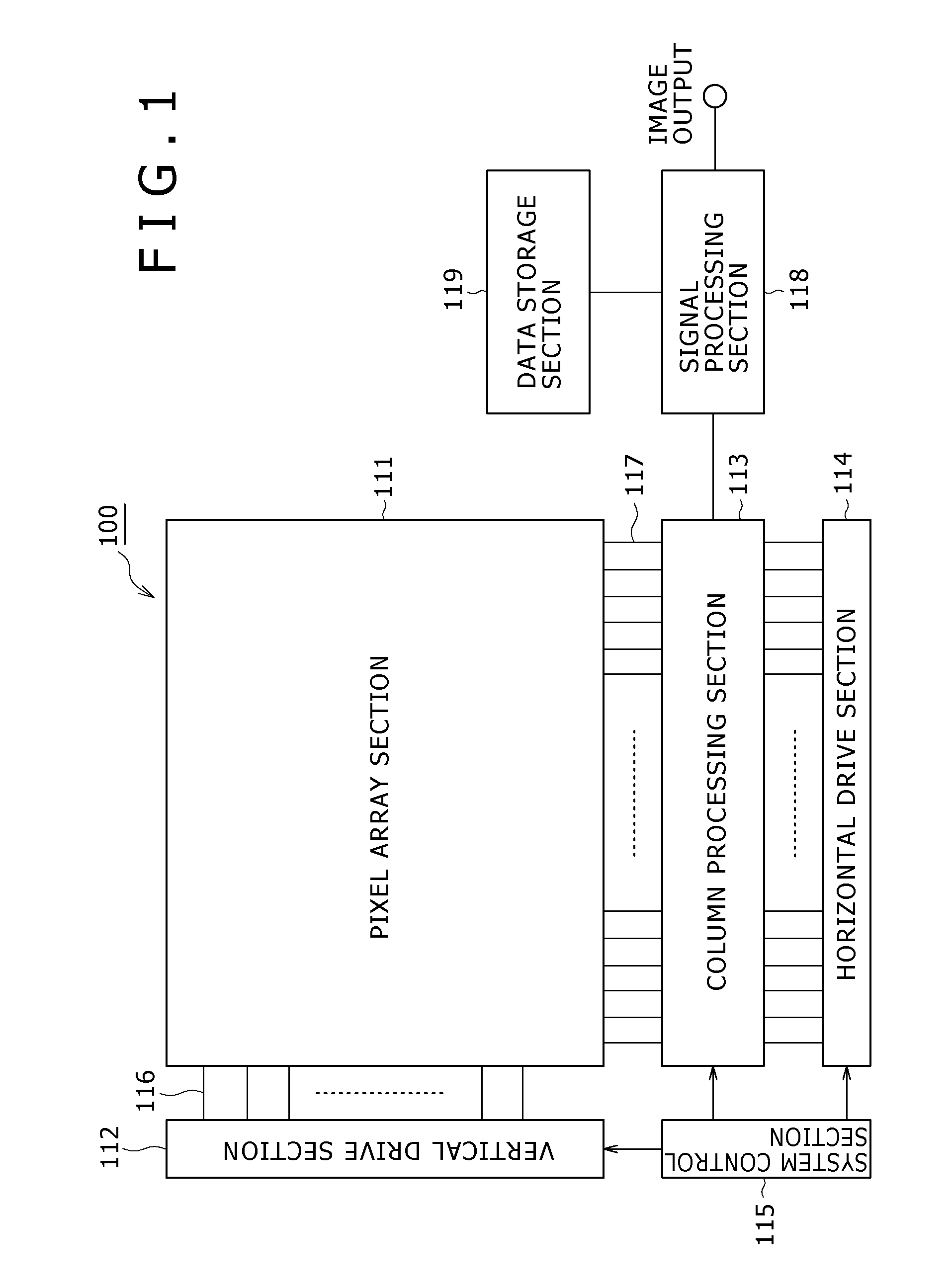

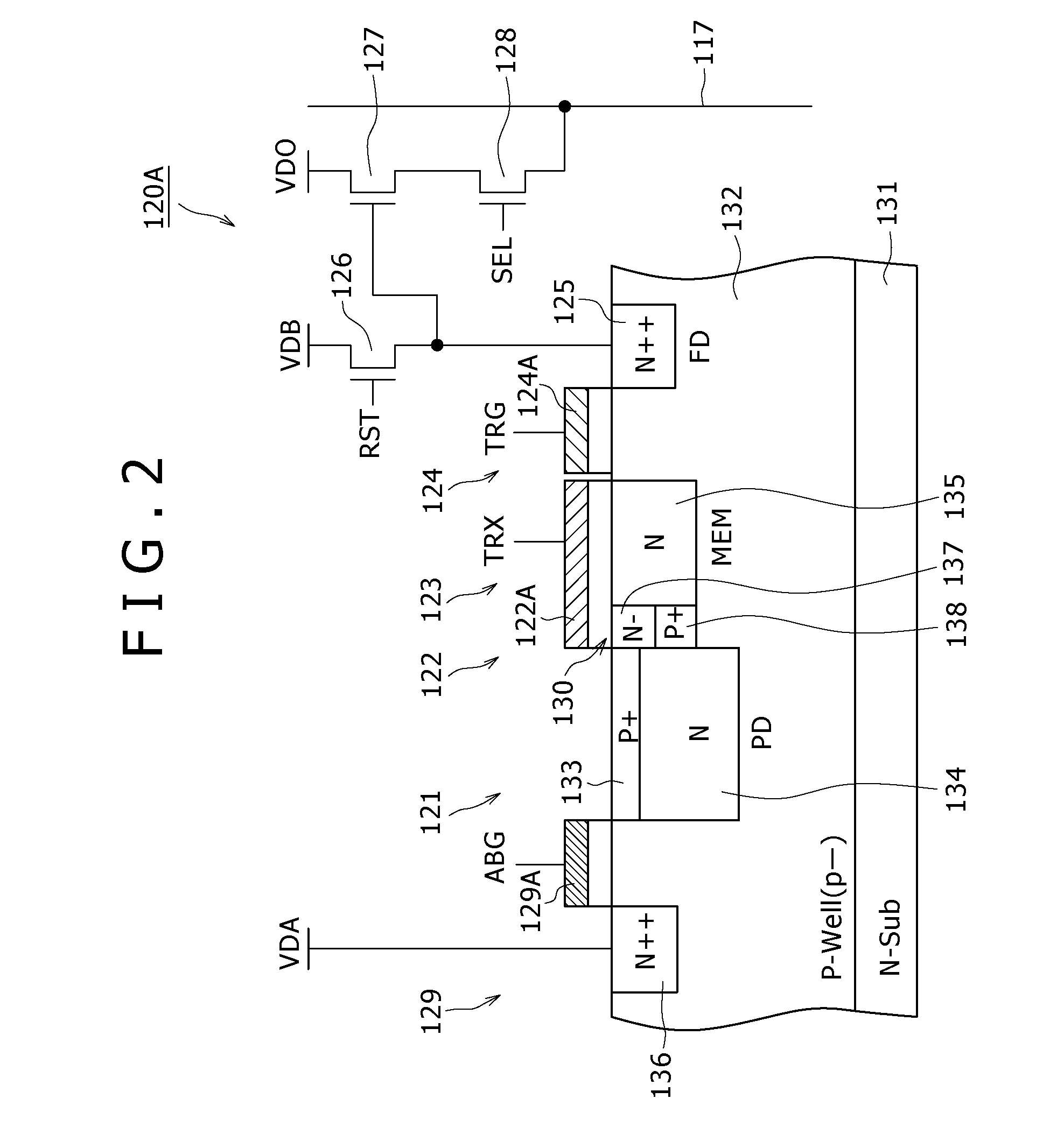

Solid-state imaging device, method of manufacturing solid-state imaging device, and electronic apparatus

InactiveUS8629484B2Difficult to controlSmall sizeTransistorTelevision system detailsCharge retentionPhotoelectric conversion

Owner:SONY CORP

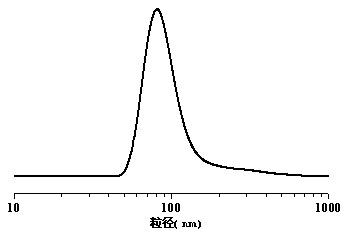

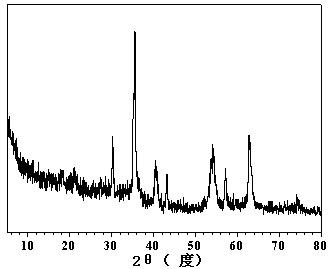

Preparation method of graphene with nano ferroferric oxide precipitated on surface

InactiveCN102674334AGive full play to the nano effectImprove mechanical propertiesMaterial nanotechnologyCarbon compoundsResin matrixCvd graphene

The invention belongs to the technical field of materials, and particularly relates to a preparation method of graphene with nano ferroferric oxide precipitated on surface, which concretely comprises the steps of: firstly, oxidizing natural flake graphite and obtaining graphite oxide; further carrying out ultrasonic stripping on the graphite oxide and forming graphene oxide suspension; then, carrying out reduction reaction on the graphene oxide suspension under the action of strong reducing agent, and obtaining black flocculent flake graphene; and finally, taking hydrogen peroxide as an oxidant, and depositing Fe3O4 on the surface of the graphene in an alkaline solution. The invention realizes the modification of nanoscale Fe3O4 for the surface of the graphene. The obtained modified graphene is not doped with other elements except the Fe element, and can be well dispersed in a high-performance resin matrix, so that the mechanical property, the thermal performance, the electromagnetic performance and the friction property of the resin matrix can be improved, and phenolic resin, bismaleimide, cyanate ester and other products can be updated, or a new application field can be developed..

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com