Patents

Literature

223 results about "Beamline" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In accelerator physics, a beamline refers to the trajectory of the beam of accelerated particles, including the overall construction of the path segment (guide tubes, diagnostic devices) along a specific path of an accelerator facility.

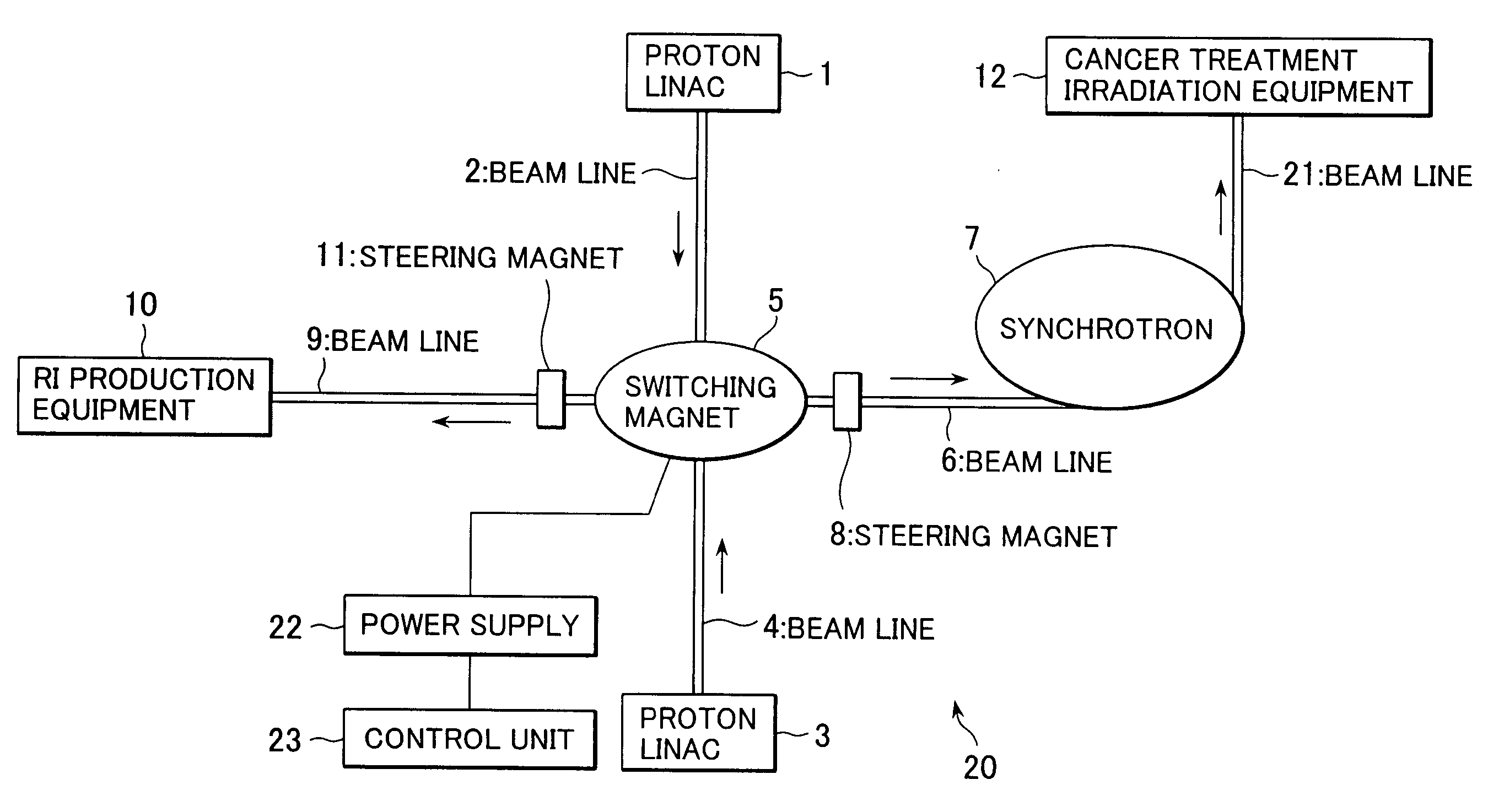

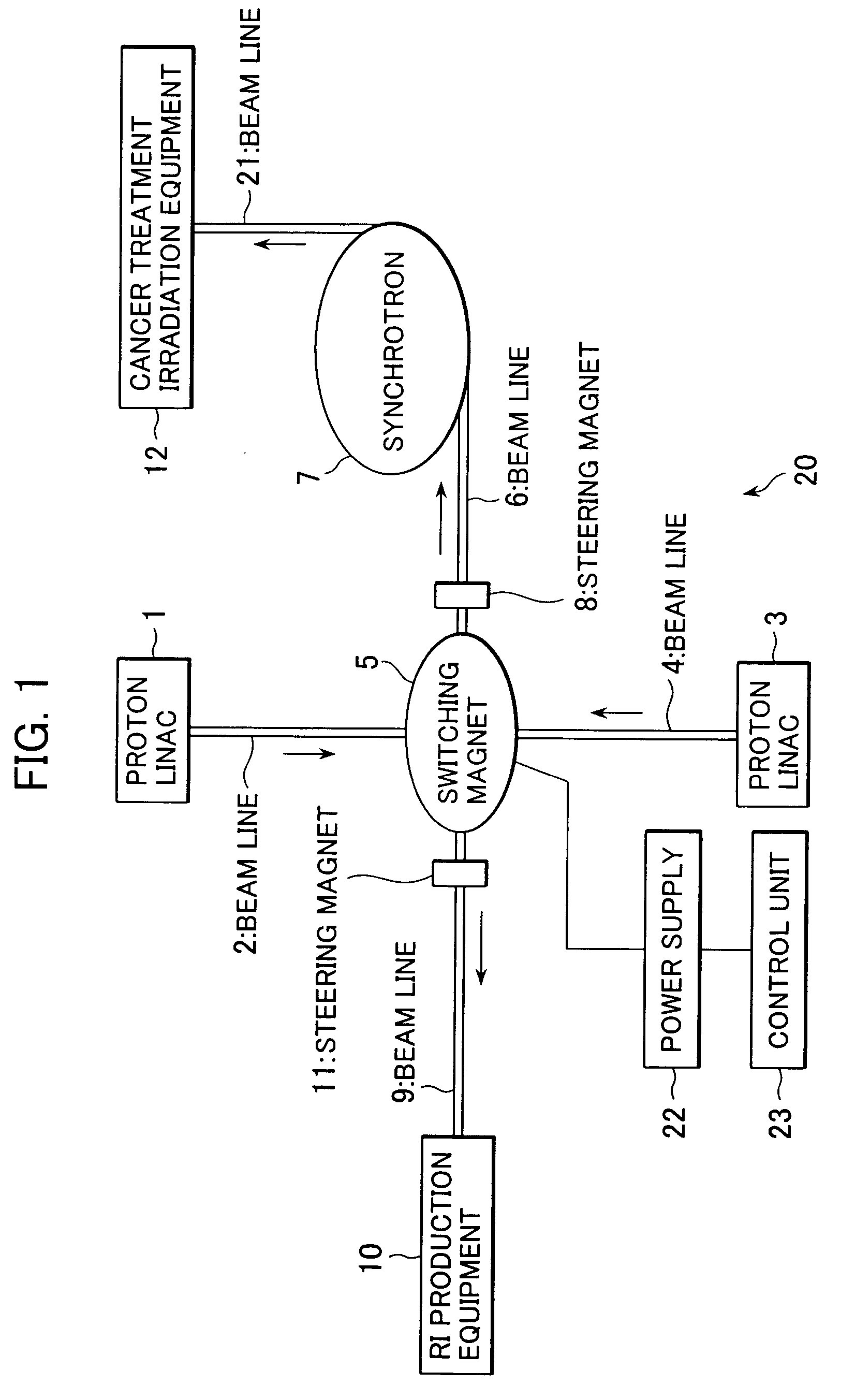

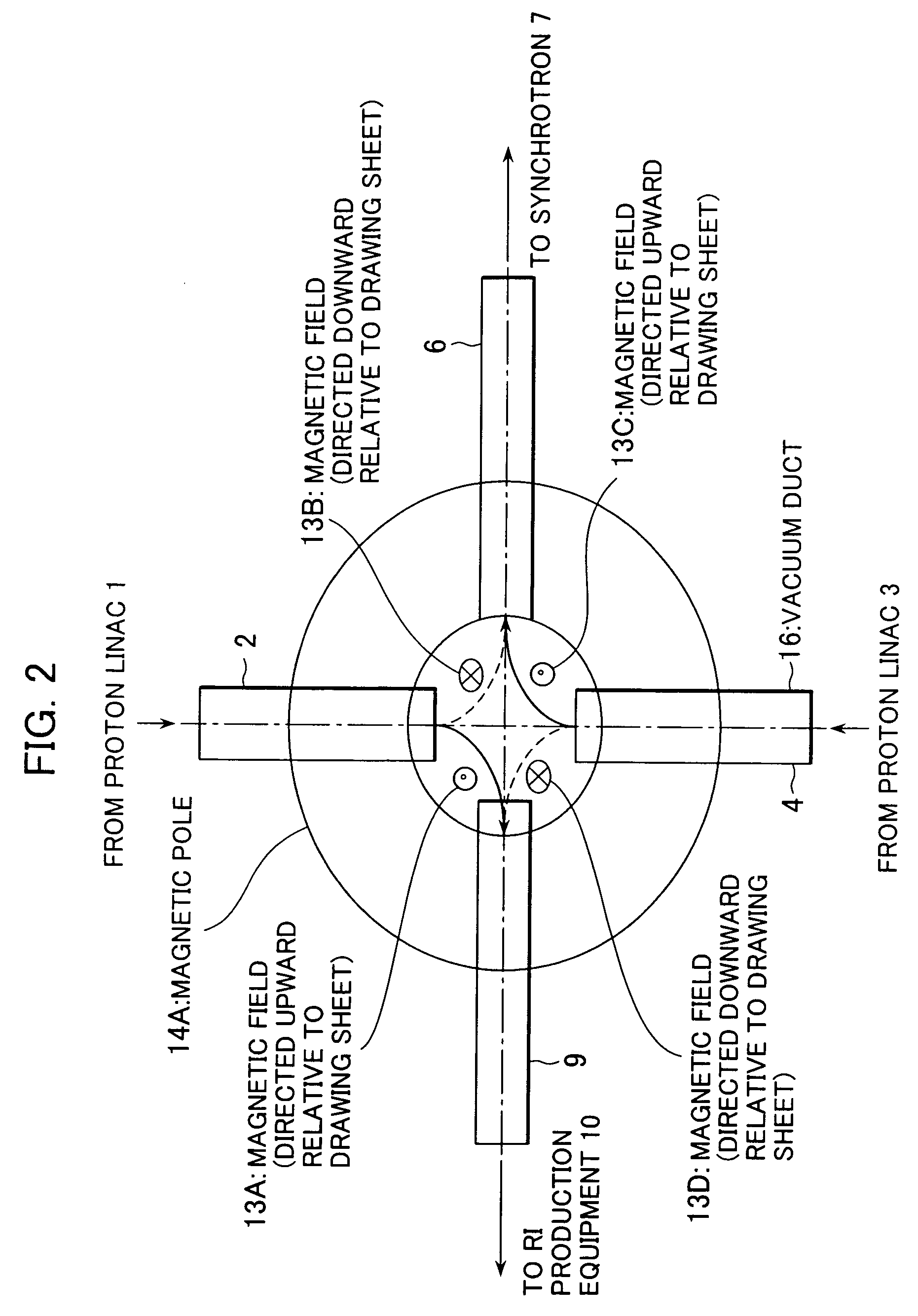

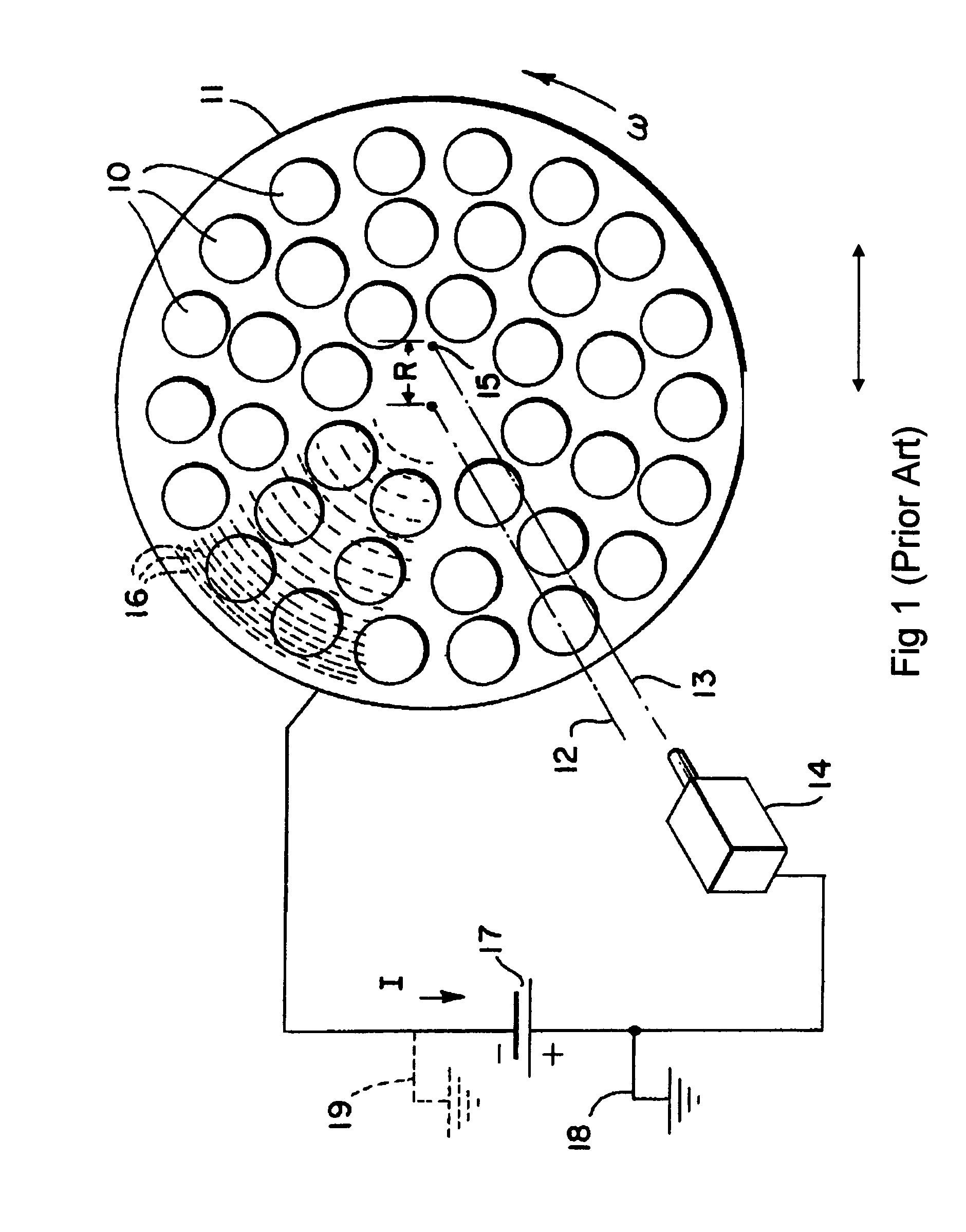

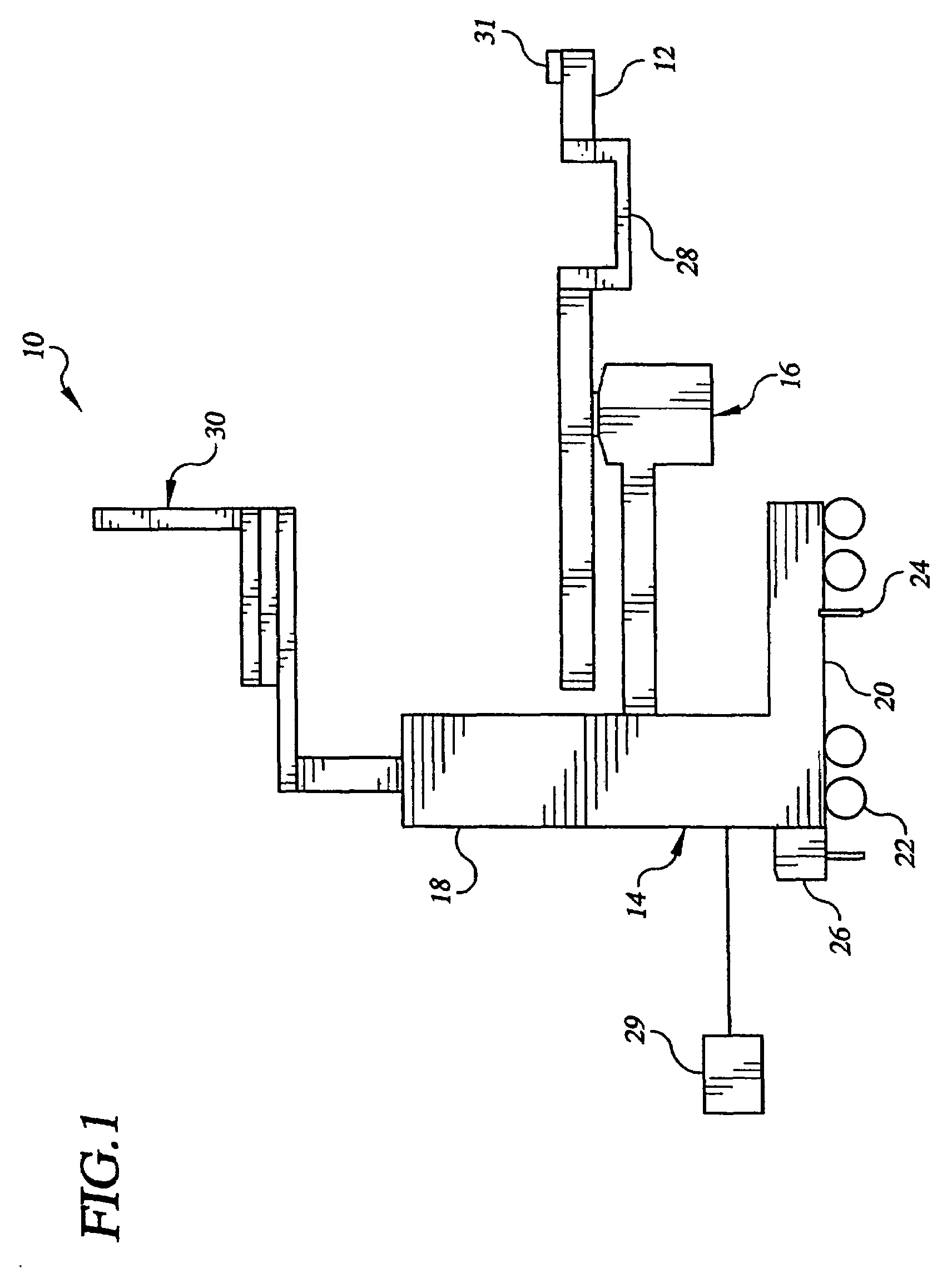

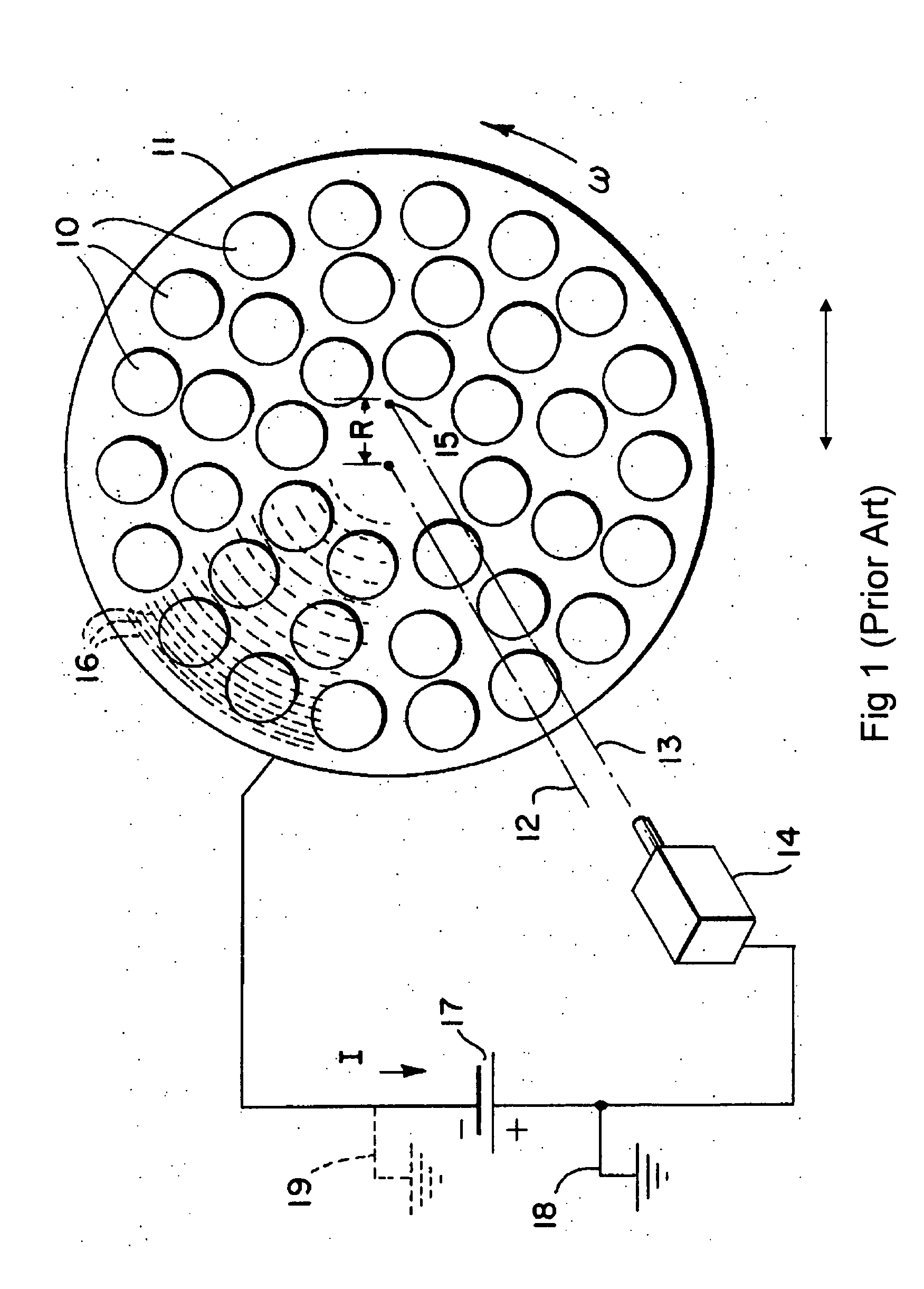

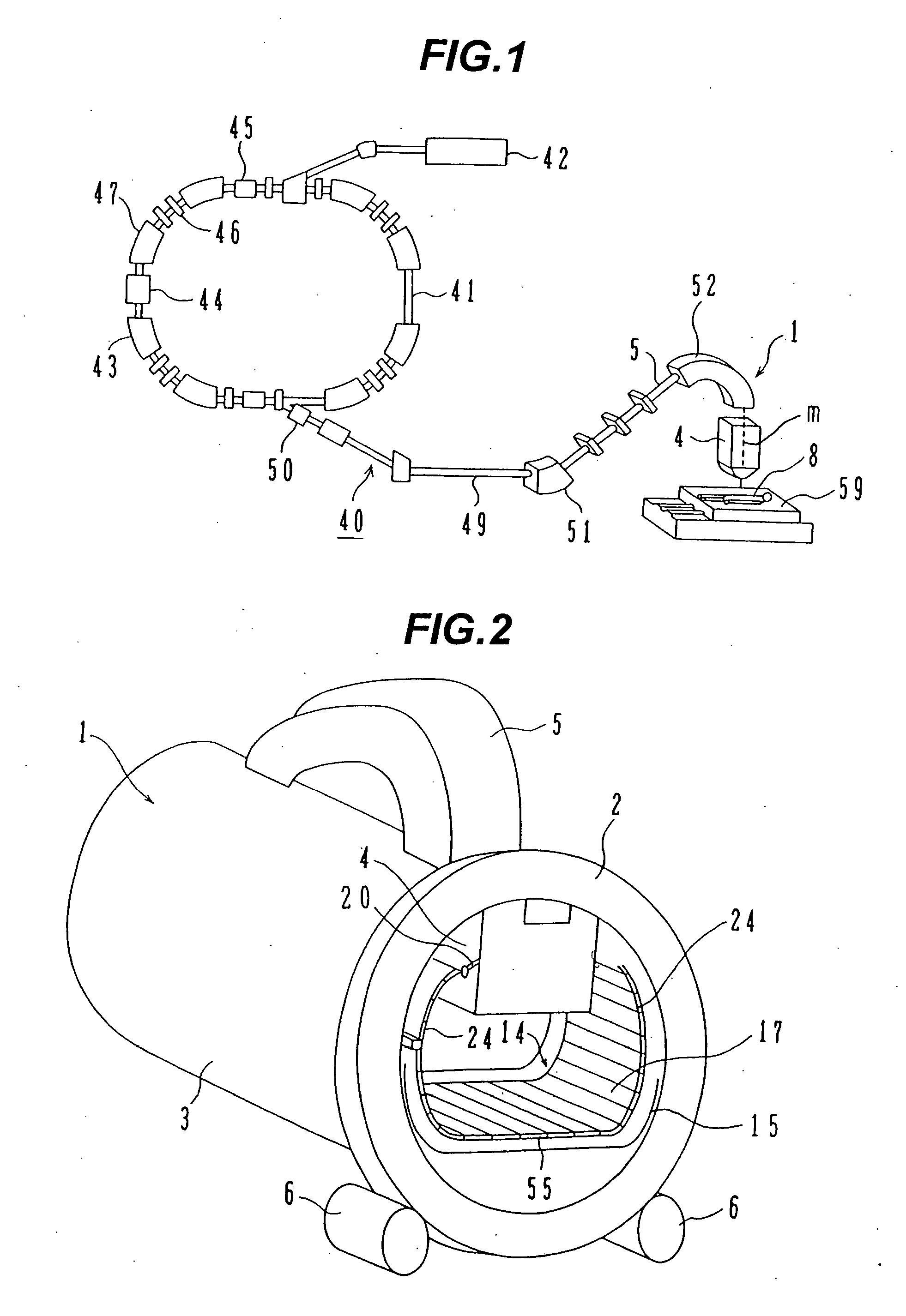

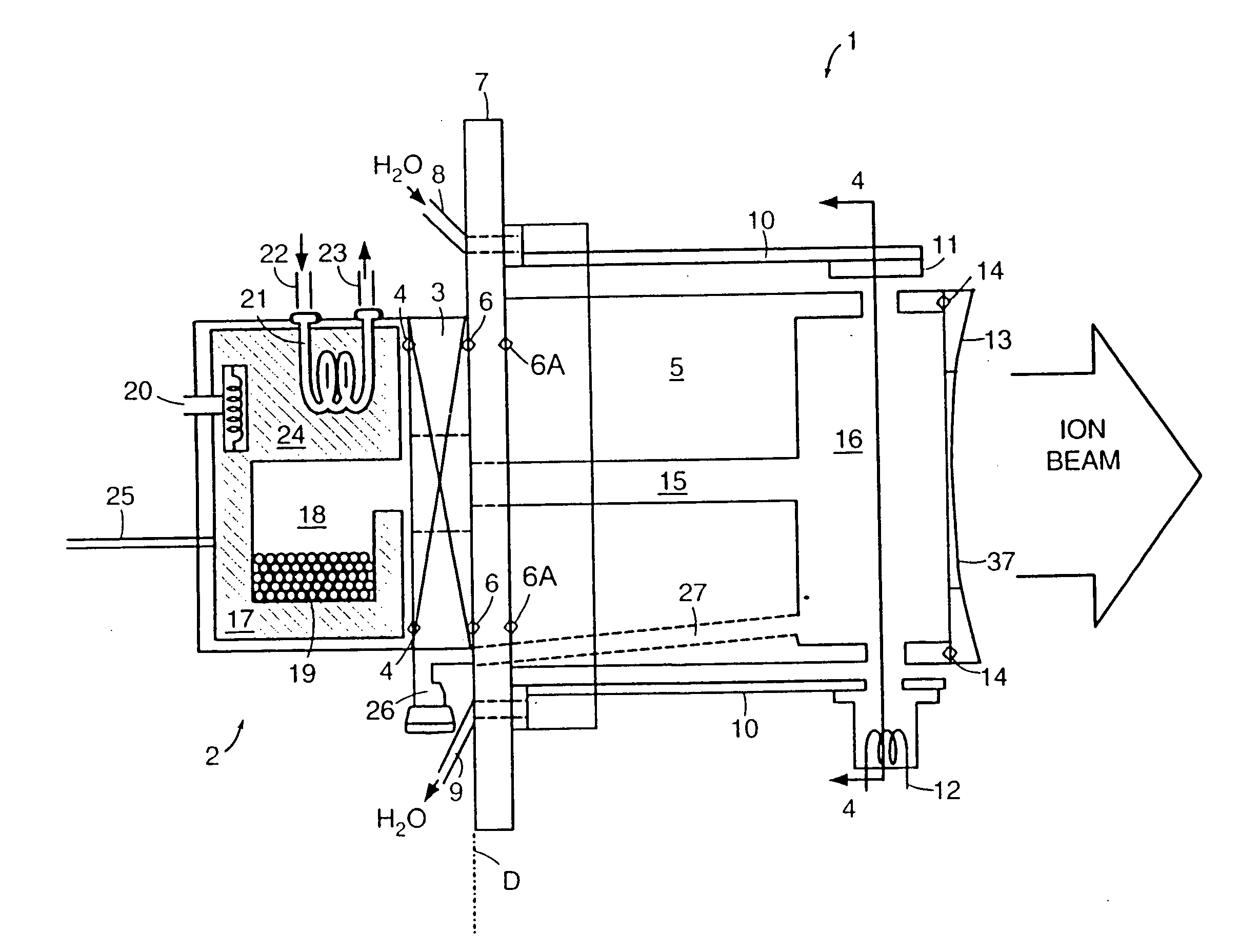

Particle beam irradiation system

ActiveUS7141810B2Improve usabilityIncreased availability factorRadiation/particle handlingElectrode and associated part arrangementsParticle beamProton

A particle beam irradiation system which can increase an availability factor. An ion beam extracted from one proton beam linac is bent at 90 degrees by a switching magnet and is introduced to RI production equipment through a beam line. In the RI production equipment, a RI is produced using the introduced ion beam. An ion beam extracted from the other proton beam linac is bent at 90 degrees by the switching magnet and is introduced to a synchrotron through a beam line. The ion beam extracted from the synchrotron is irradiated to a patient from irradiation equipment. If one proton beam linac comes into an abnormal state, the one proton beam linac is stopped in operation and checked. During the check, the ion beam extracted from the other proton beam linac is selectively introduced to the RI production equipment and the synchrotron by the switching magnet.

Owner:HITACHI LTD

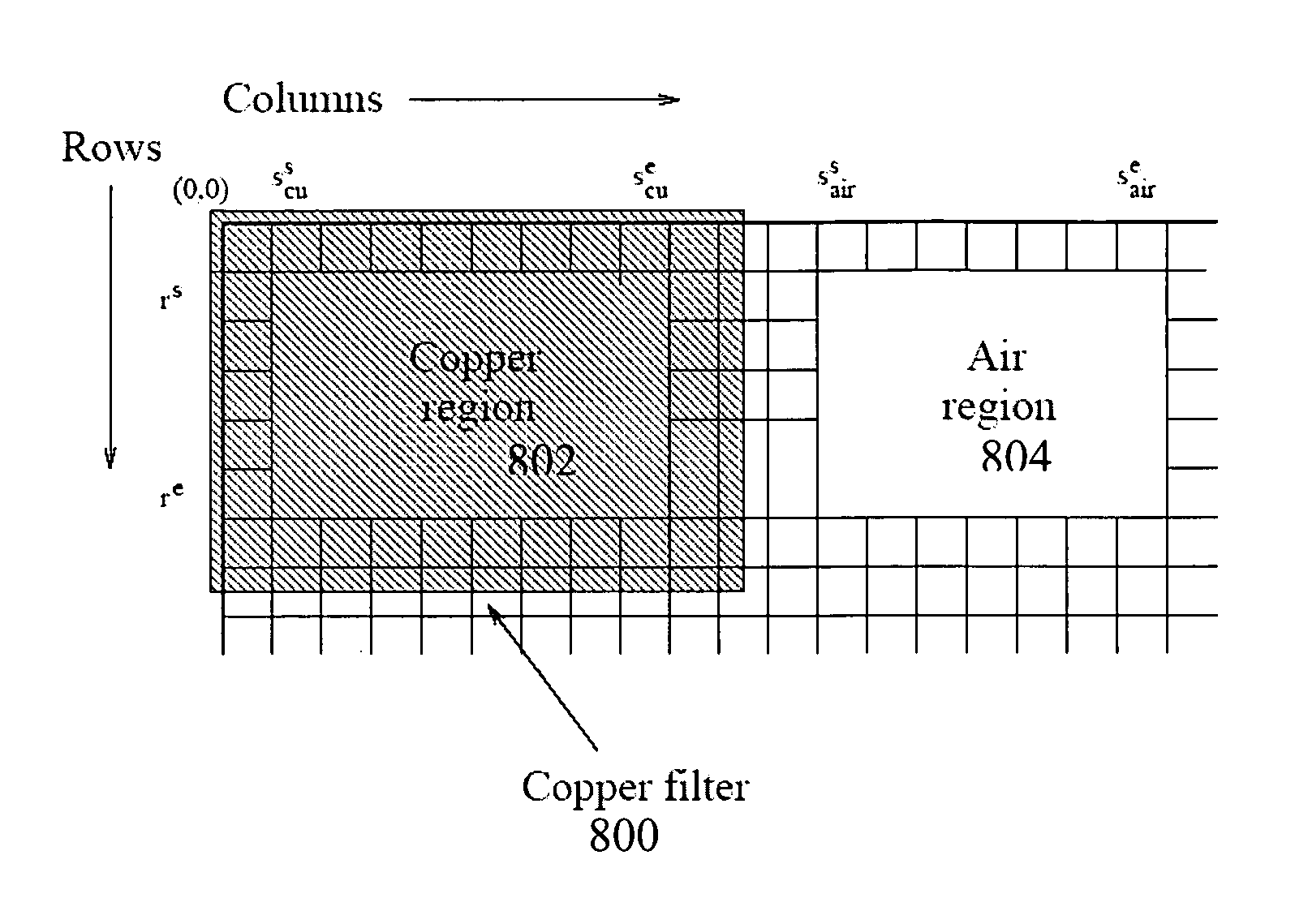

Method of and system for X-ray spectral correction in multi-energy computed tomography

ActiveUS7224763B2Material analysis using wave/particle radiationRadiation/particle handlingHigh energyDetector array

A method of and a system for spectral correction in multi-energy computed tomography are provided to correct reconstructed images, including high-energy CT images and Z (effective atomic number) images, for spectral variations, which include time variations on a scanner due to HVPS drift and scanner to scanner variations due to the beamline component differences. The method uses a copper filter mounted on the detector array for tracking the spectral changes. The method comprises: generating copper ratios; computing working air tables; calculating scales and offsets; and correcting high-energy CT images and Z images using calculated scales and offsets. The method further includes an off-line calibration procedure to generate necessary parameters for the online correction.

Owner:ANLOGIC CORP (US)

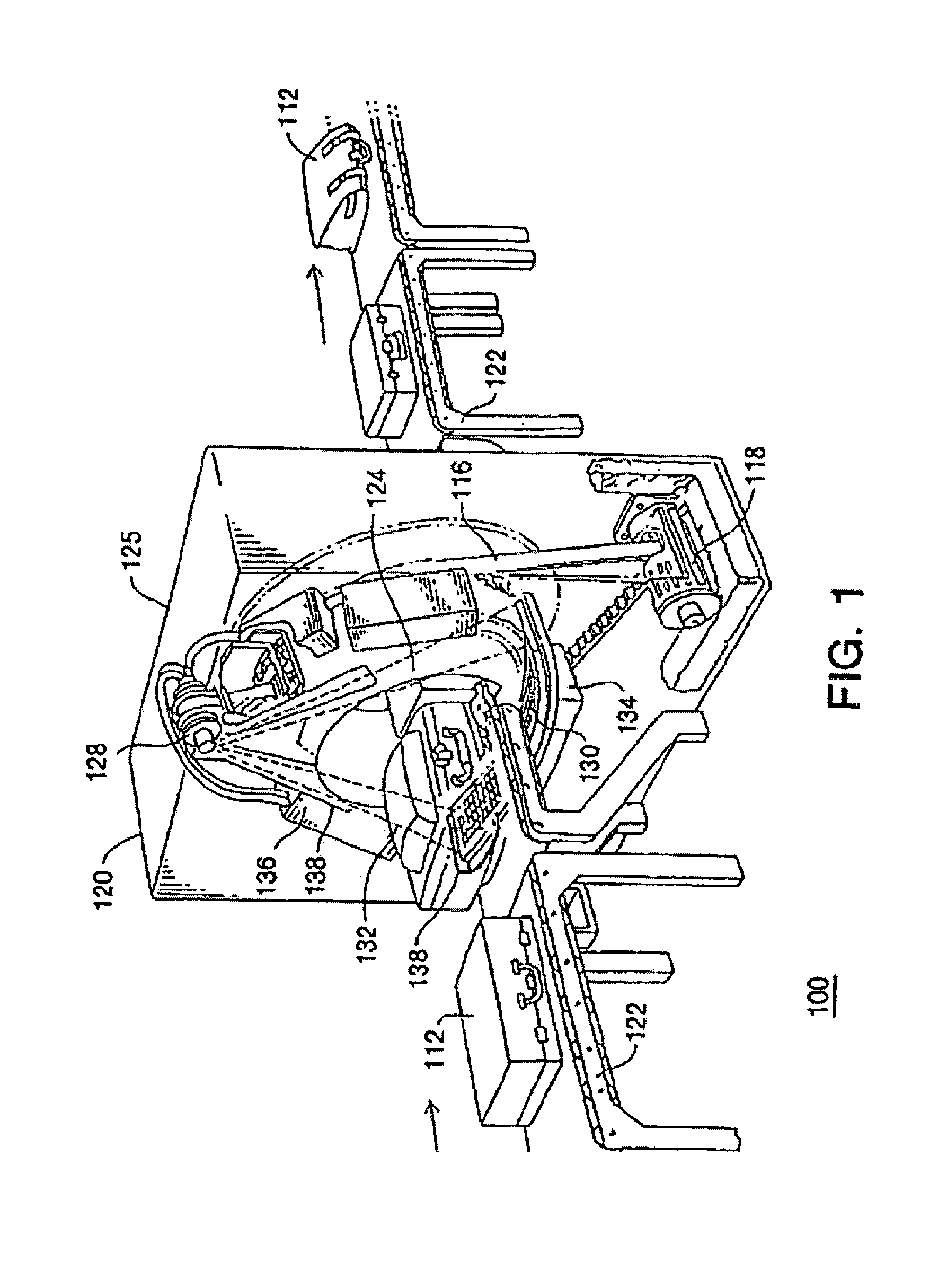

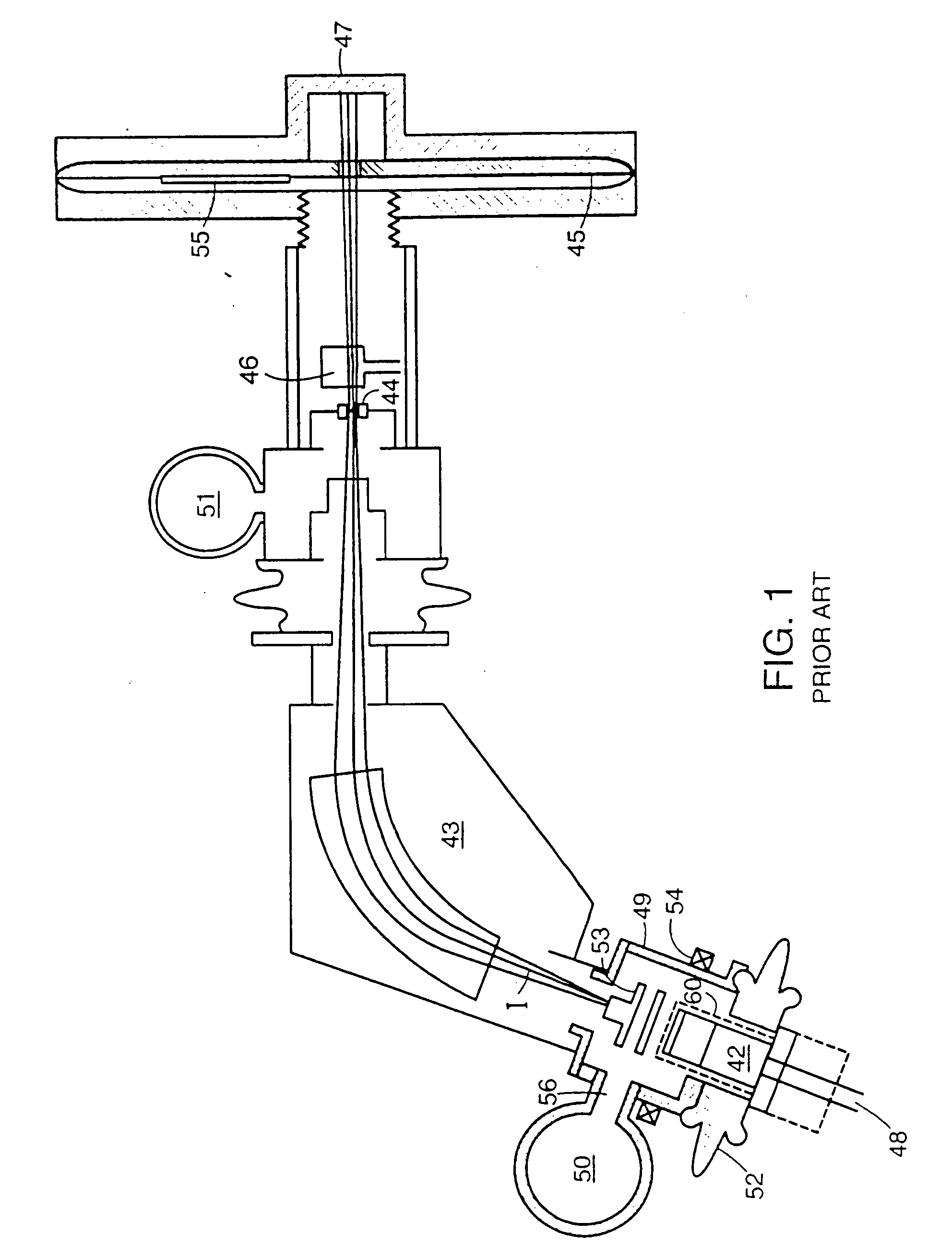

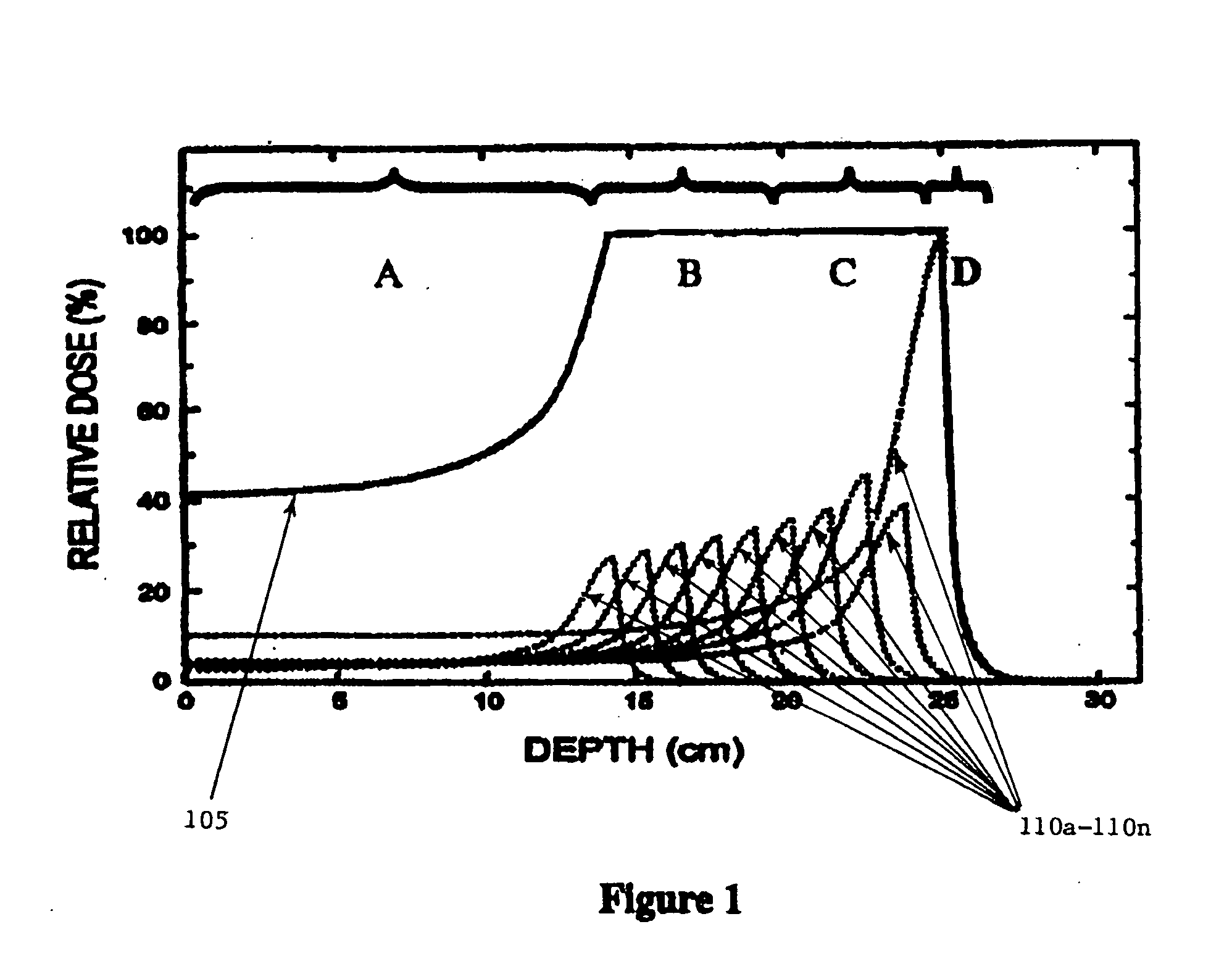

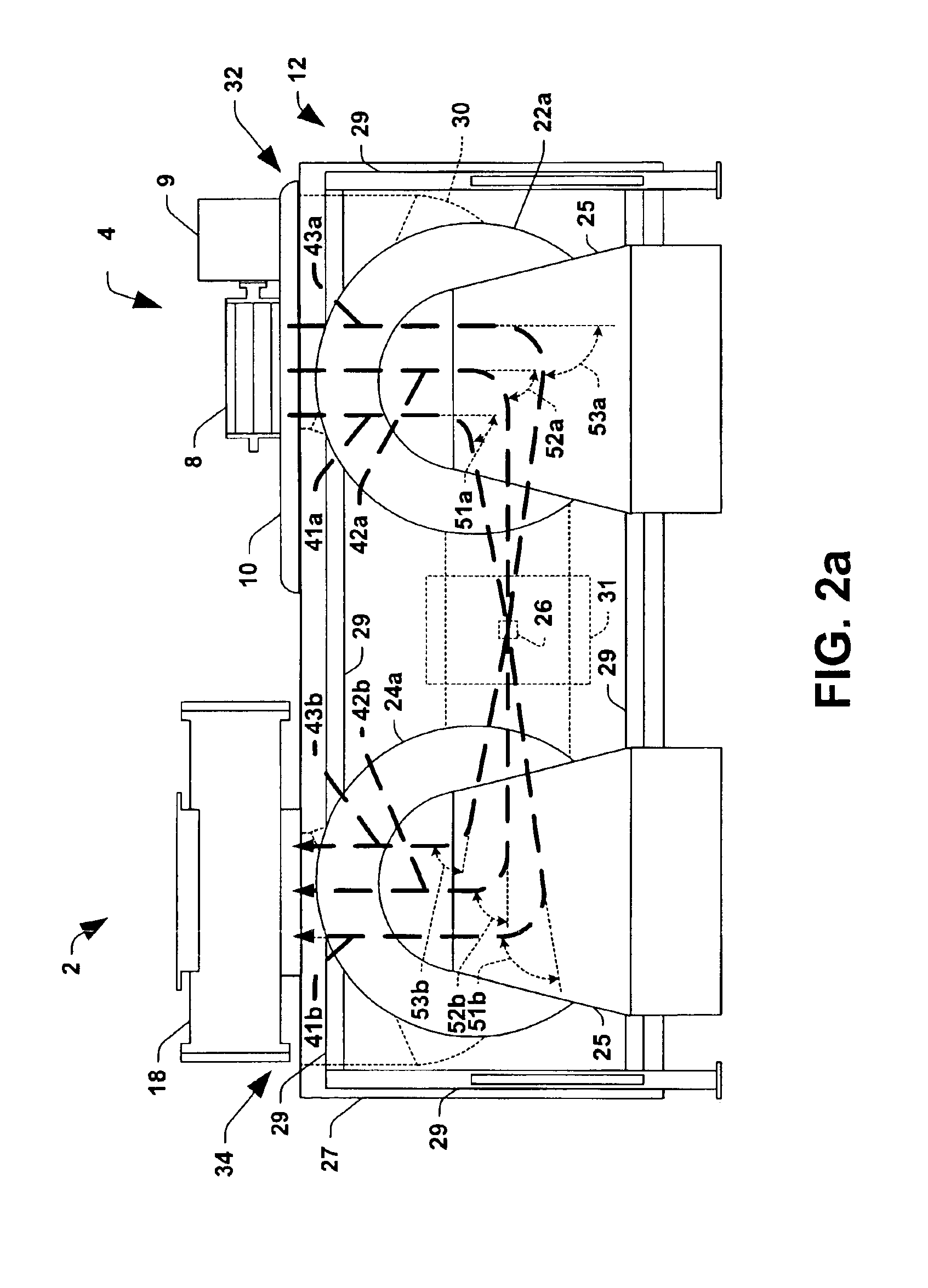

Lethal and sublethal damage repair inhibiting image guided simultaneous all field divergent and pencil beam photon and electron radiation therapy and radiosurgery

InactiveUS7835492B1Improve modulationIncrease radiation intensityIrradiation devicesX-ray/gamma-ray/particle-irradiation therapyRadiosurgeryC banding

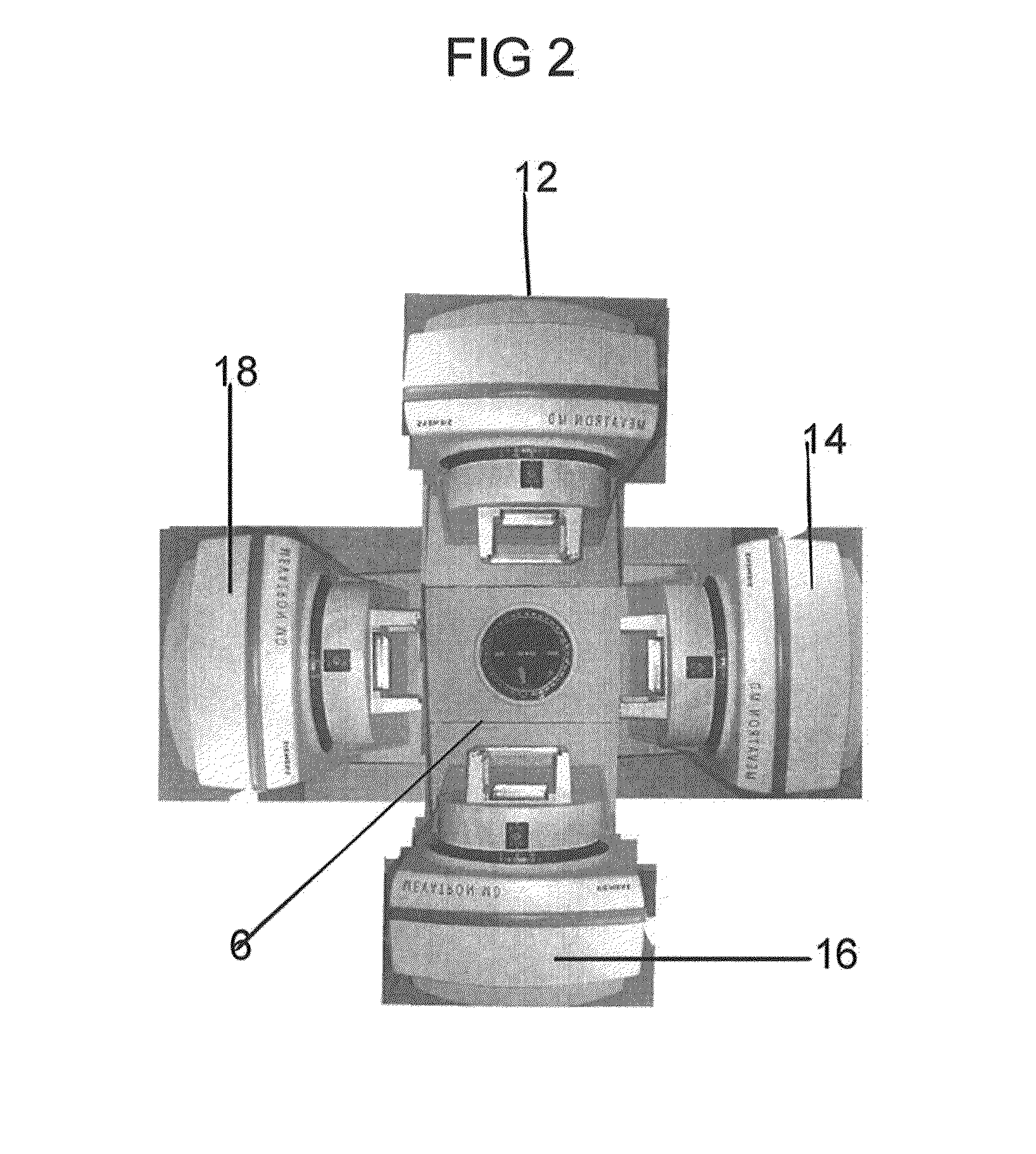

A medical accelerator system is provided for simultaneous radiation therapy to all treatment fields. It provides the single dose effect of radiation on cell survival. It eliminates the inter-field interrupted, subfractionated fractionated radiation therapy. Single or four beams S-band, C-band or X-band accelerators are connected to treatment heads through connecting beam lines. It is placed in a radiation shielding vault which minimizes the leakage and scattered radiation and the size and weight of the treatment head. In one version, treatment heads are arranged circularly and connected with the beam line. In another version, a pair of treatment heads is mounted to each ends of narrow gantries and multiple such treatment heads mounted gantries are assembled together. Electron beam is steered to all the treatment heads simultaneously to treat all the fields simultaneously. Radiating beam's intensity in a treatment field is modulated with combined divergent and pencil beam, selective beam's energy, dose rate and weight and not with MLC and similar devices. Since all the treatment fields are treated simultaneously the dose rate at the tumor site is the sum of each of the converging beam's dose rate at depth. It represents the biological dose rate. The dose rate at d-max for a given field is the individual machine dose rate. Its treatment options includes divergent or pencil beam modes. It enables to treat a tumor with lesser radiation toxicities to normal tissue and higher tumor cure and control.

Owner:SAHADEVAN VELAYUDHAN

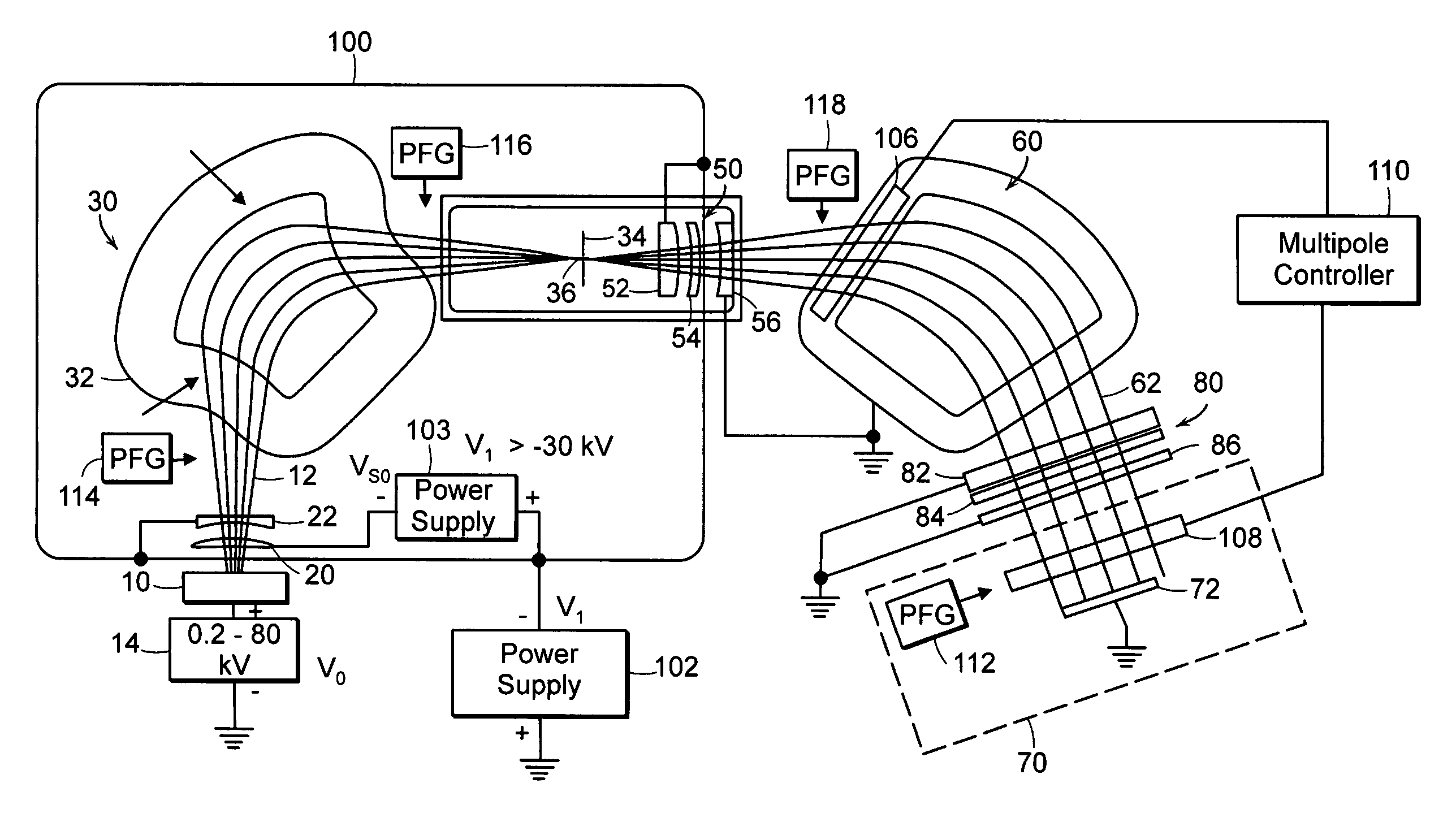

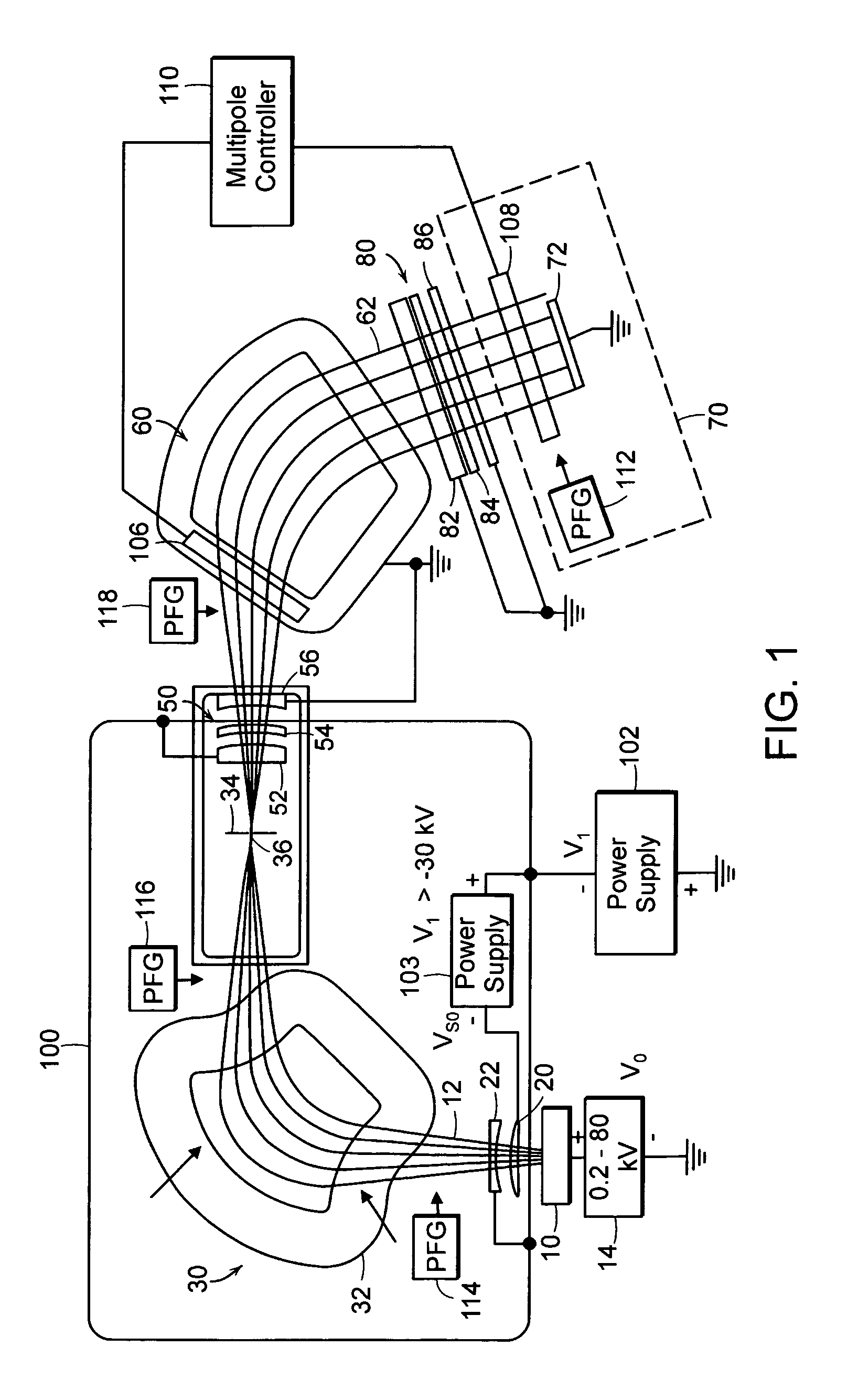

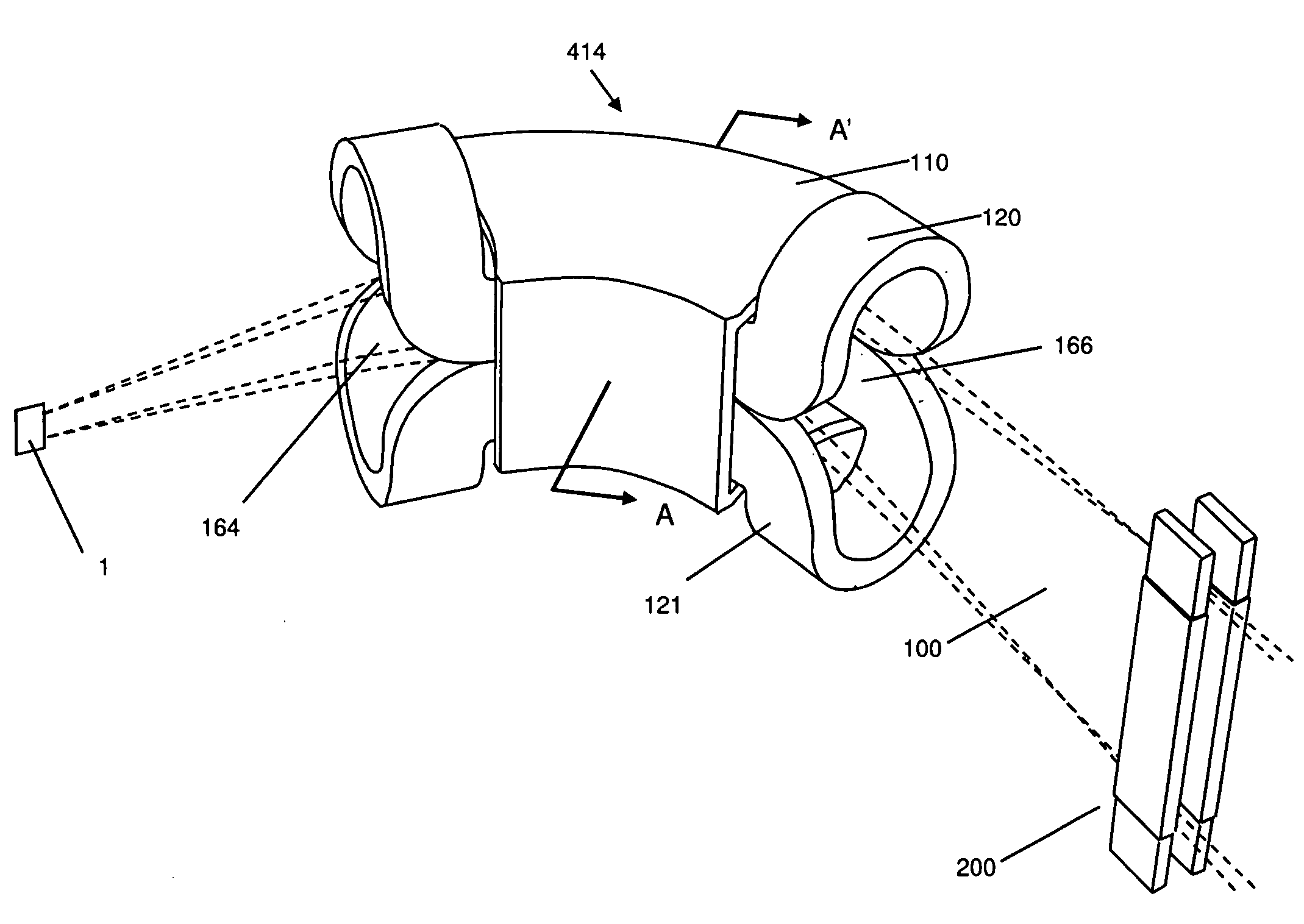

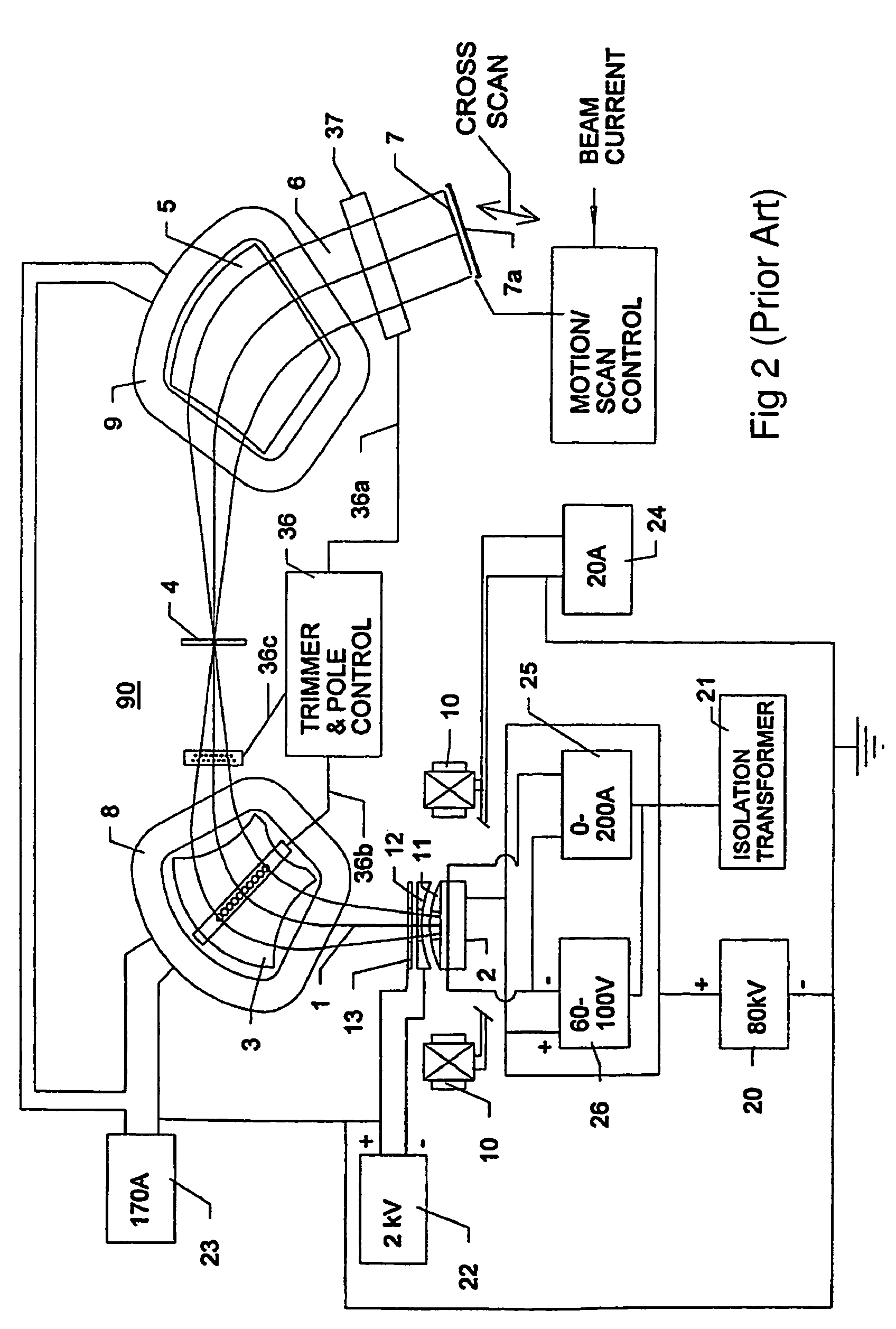

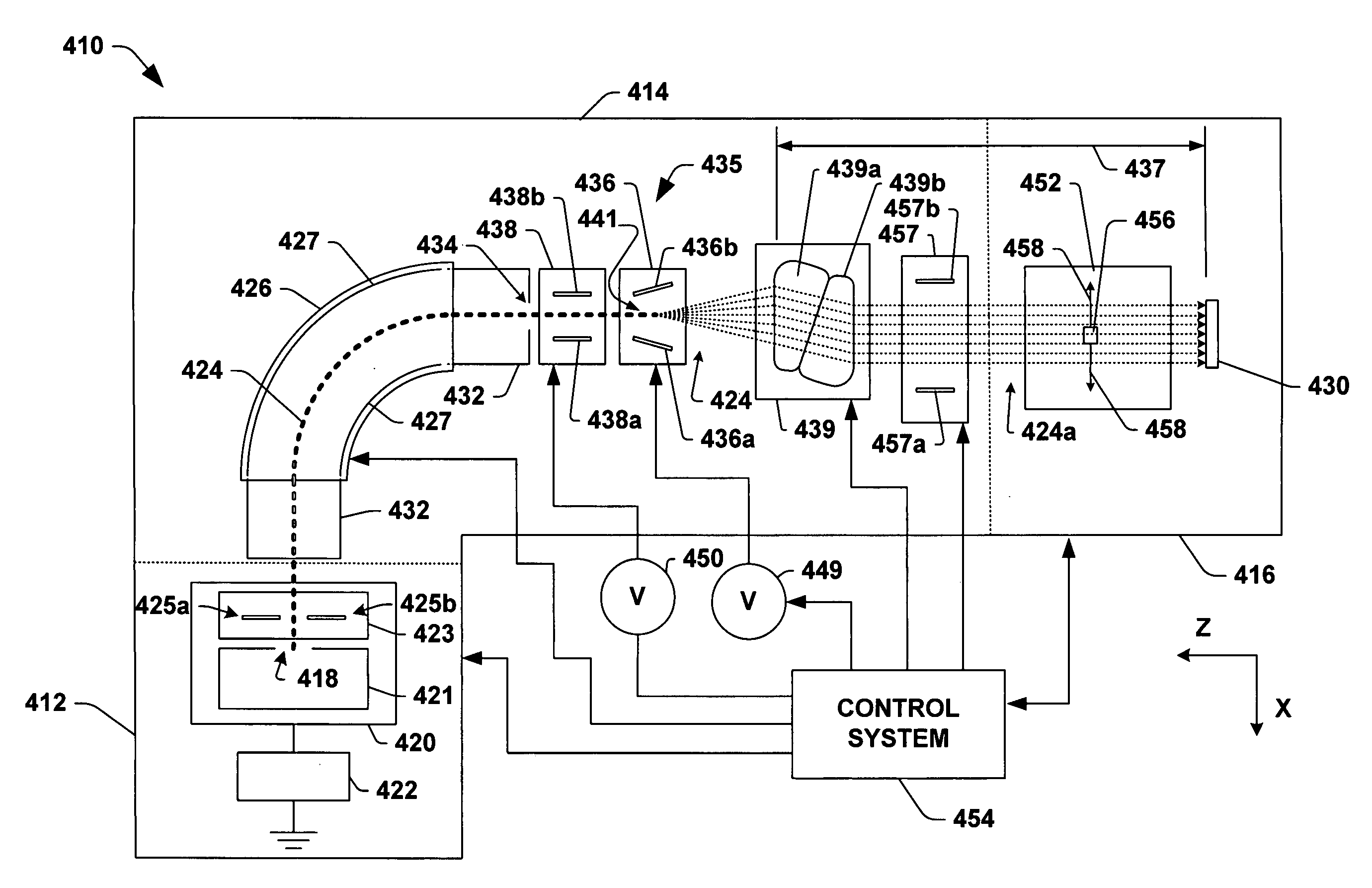

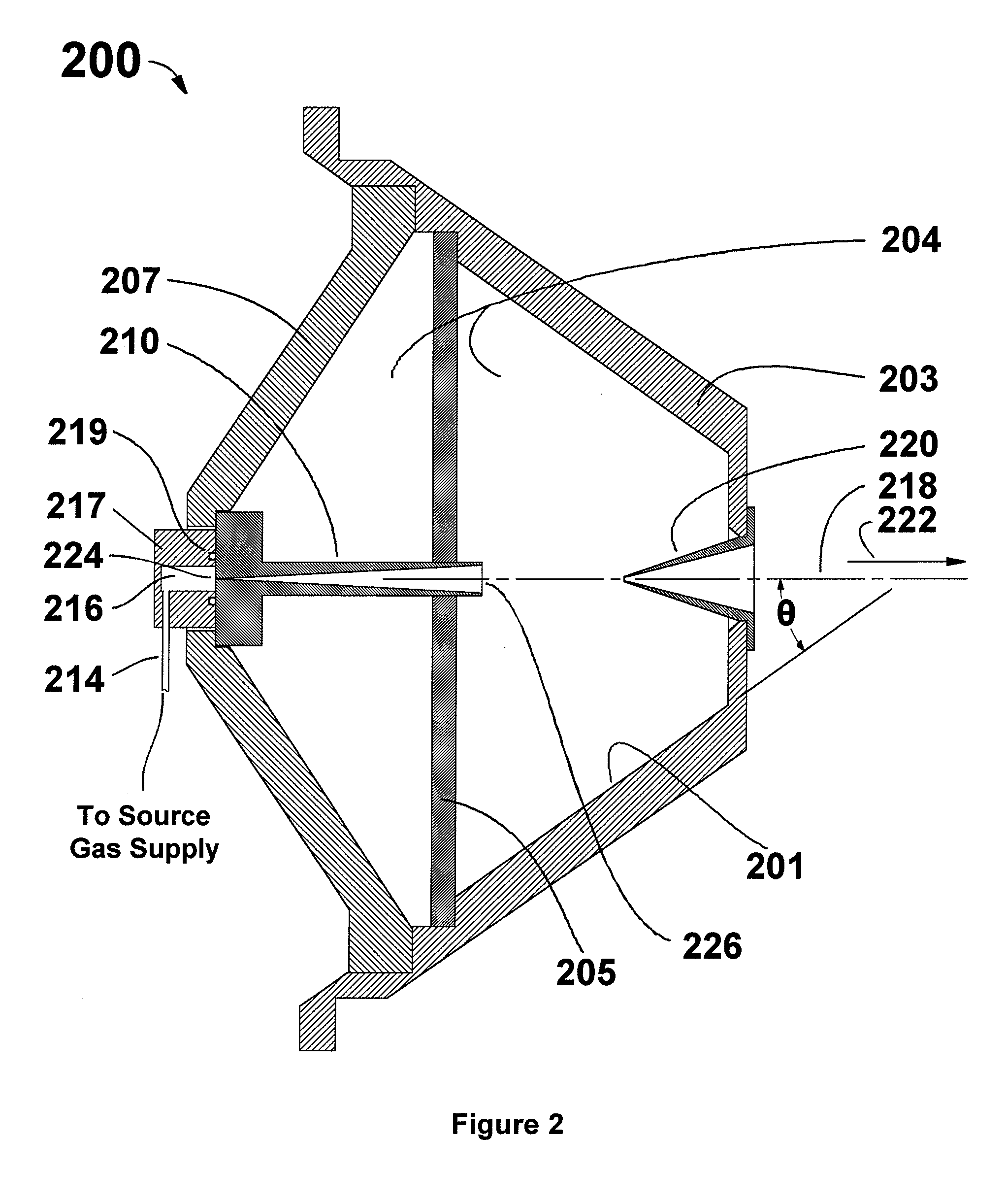

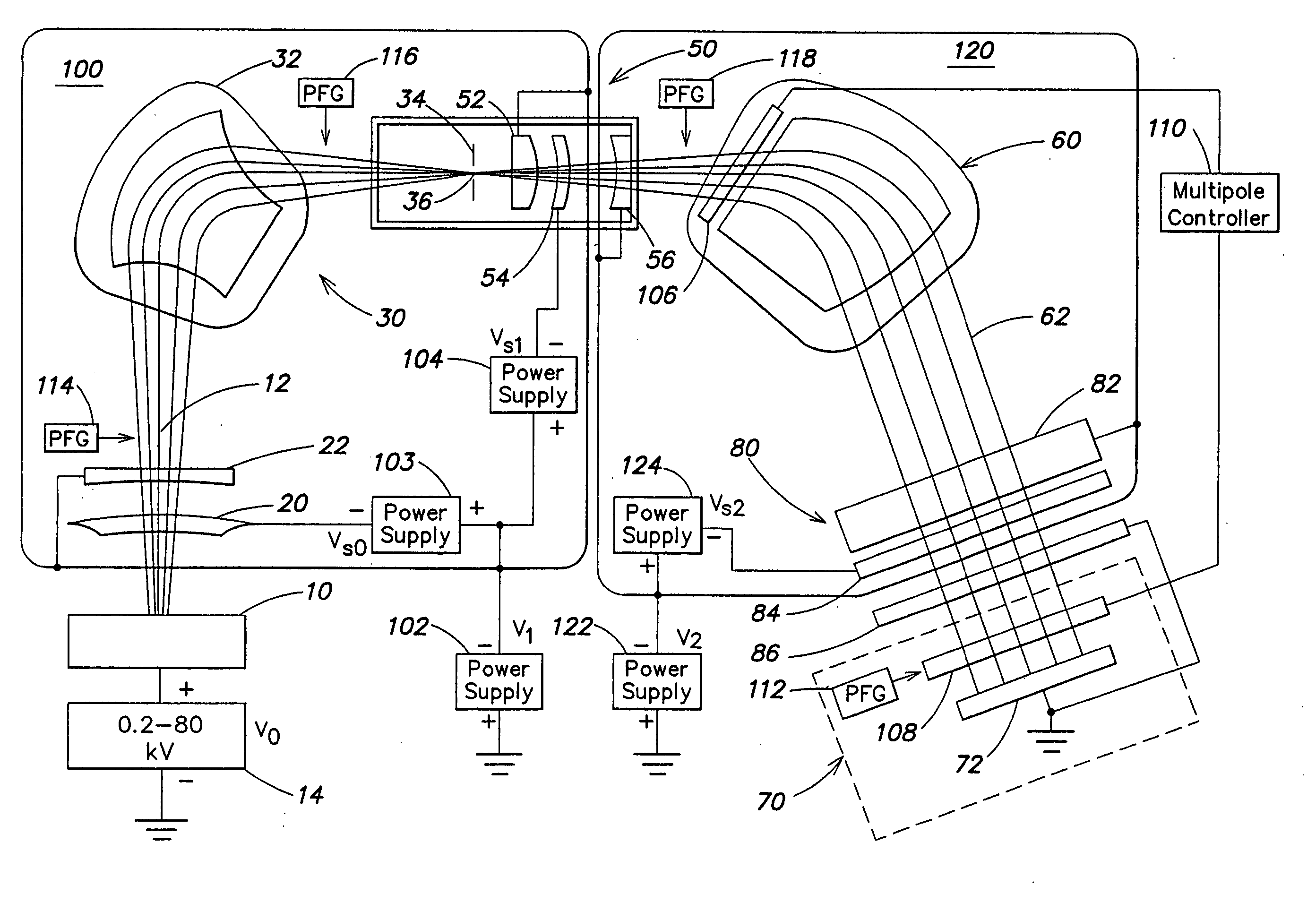

Apparatus and methods for ion beam implantation using ribbon and spot beams

ActiveUS7326941B2Difficult to controlIncrease throughputMagnetsMaterial analysis by optical meansBand shapeIon beam

This invention discloses an ion implantation apparatus with multiple operating modes. It has an ion source and an ion extraction means for extracting a ribbon-shaped ion beam therefrom. The ion implantation apparatus includes a magnetic analyzer for selecting ions with specific mass-to-charge ratio to pass through a mass slit to project onto a substrate. Multipole lenses are provided to control beam uniformity and collimation. The invention further discloses a two-path beamline in which a second path incorporates a deceleration system incorporating energy filtering. The invention discloses methods of ion implantation in which the mode of implantation may be switched from one-dimensional scanning of the target to two-dimensional scanning, and from a simple path to an s-shaped path with deceleration.

Owner:ADVANCED ION BEAM TECHNOLOGY INC

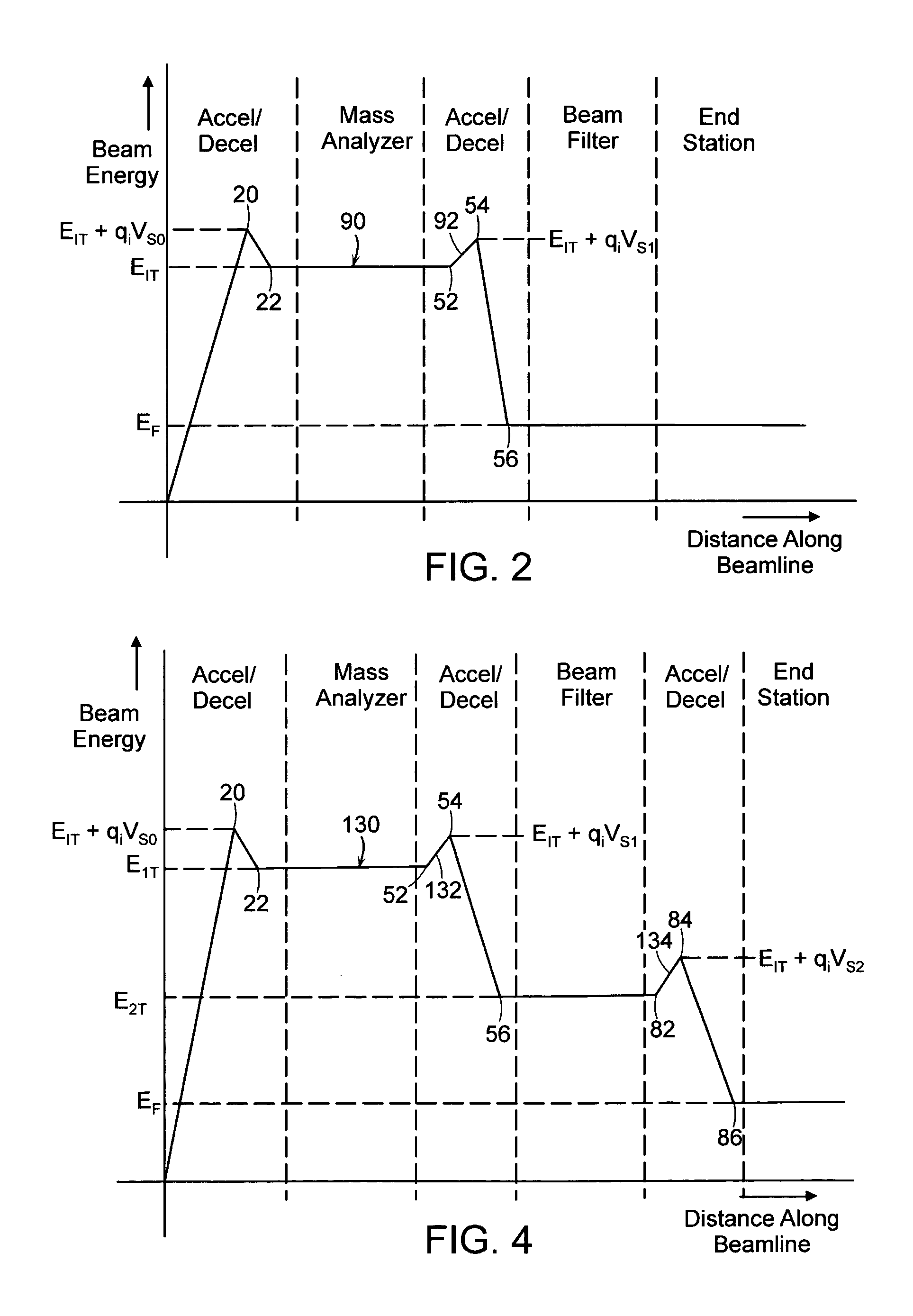

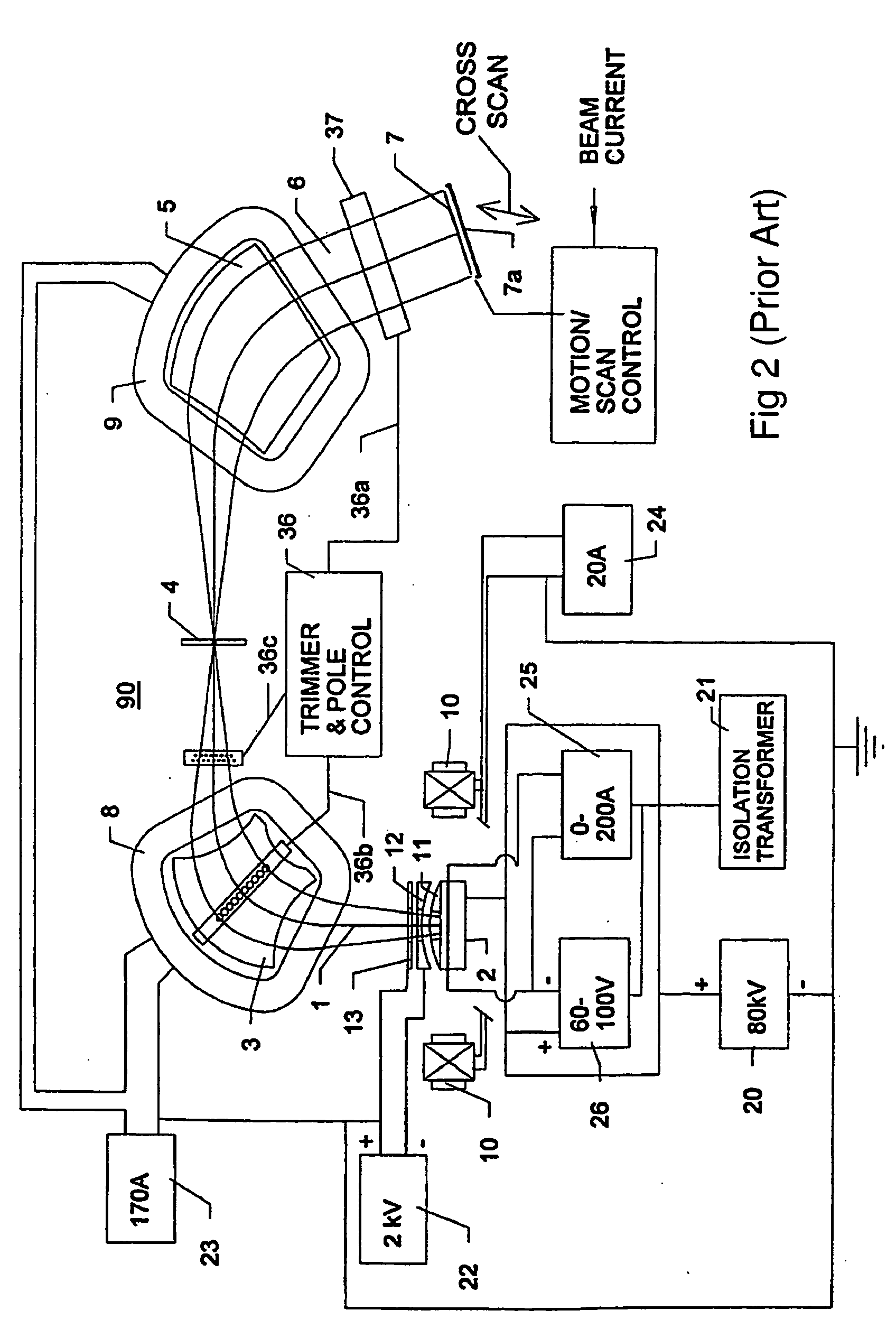

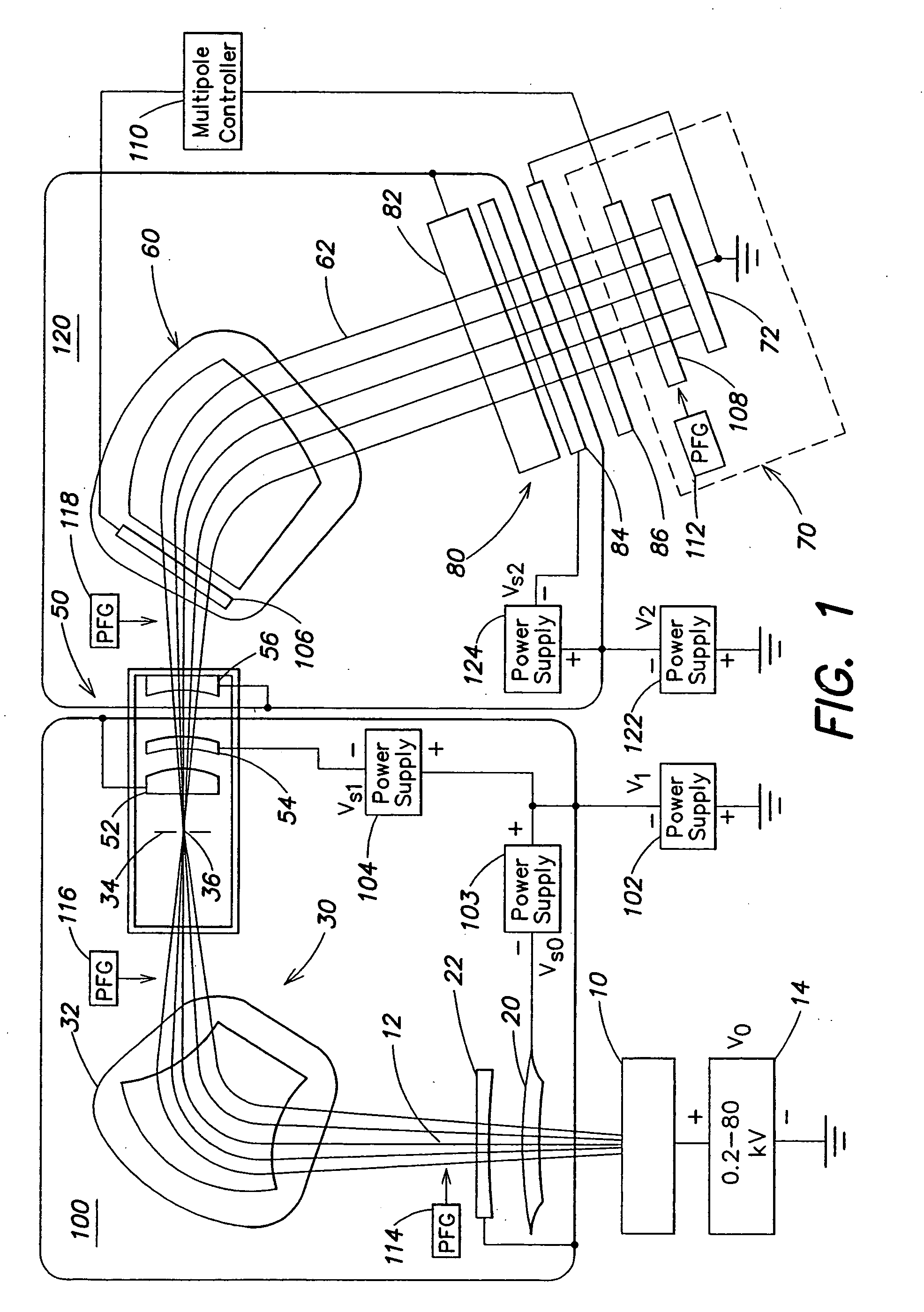

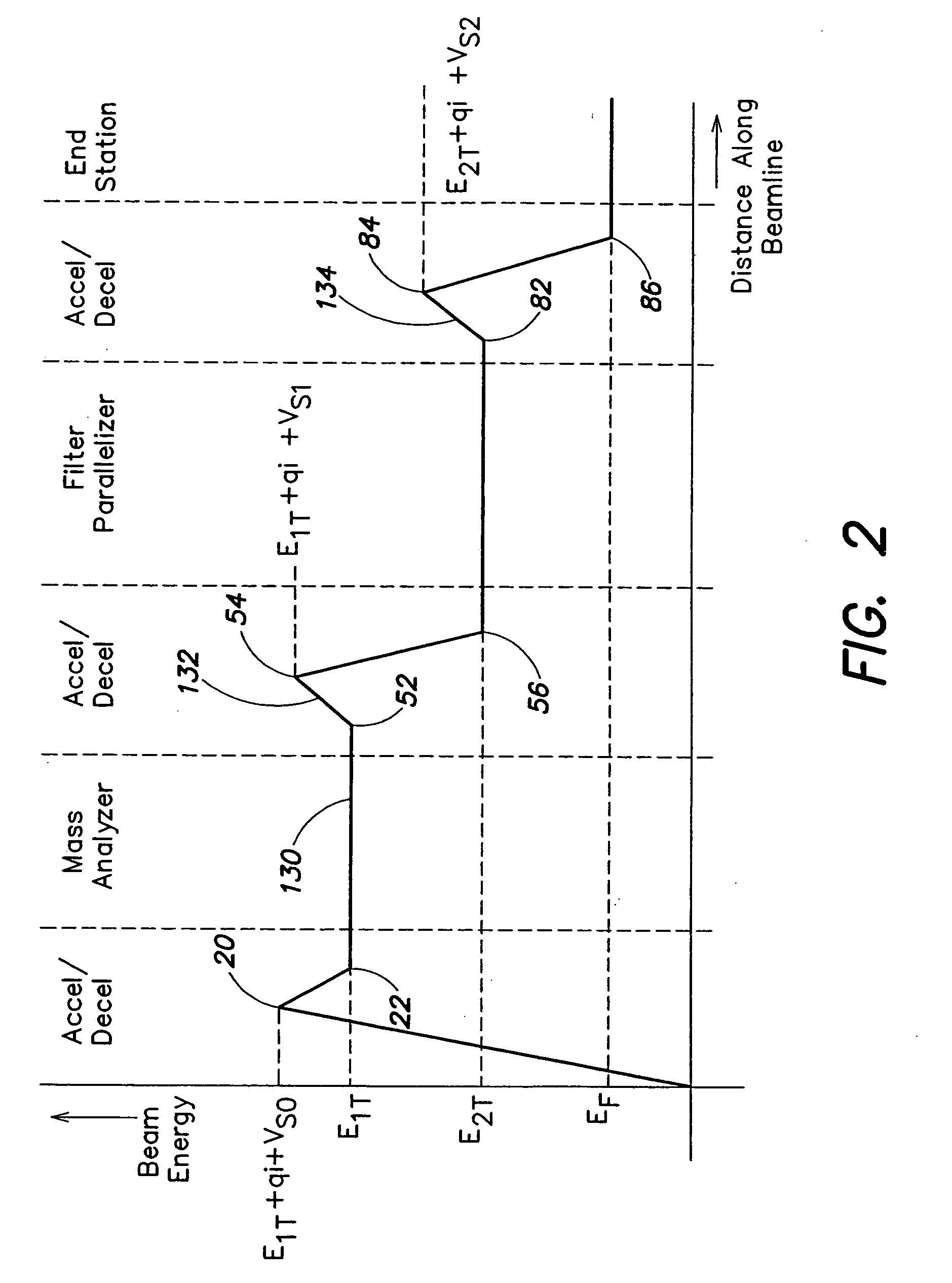

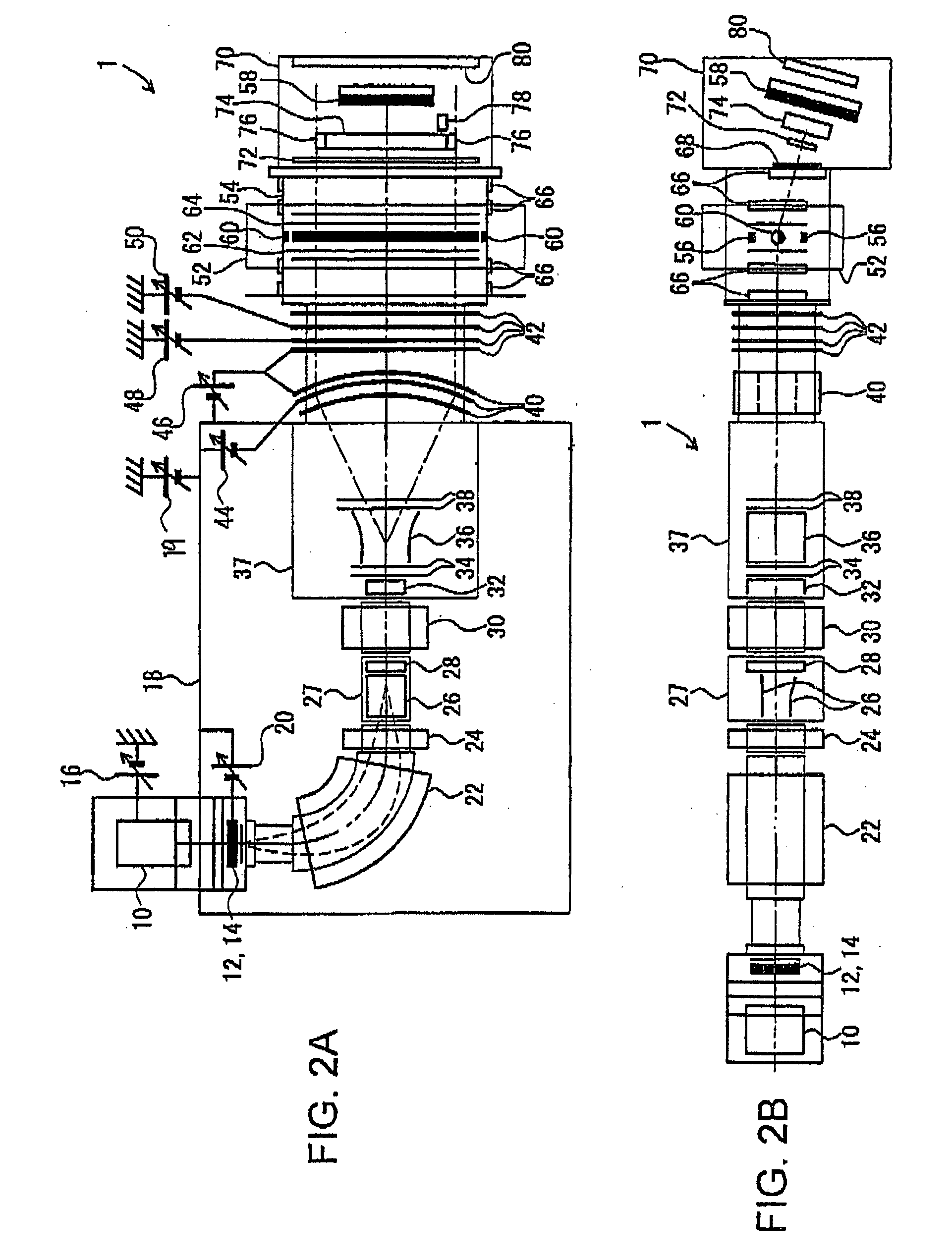

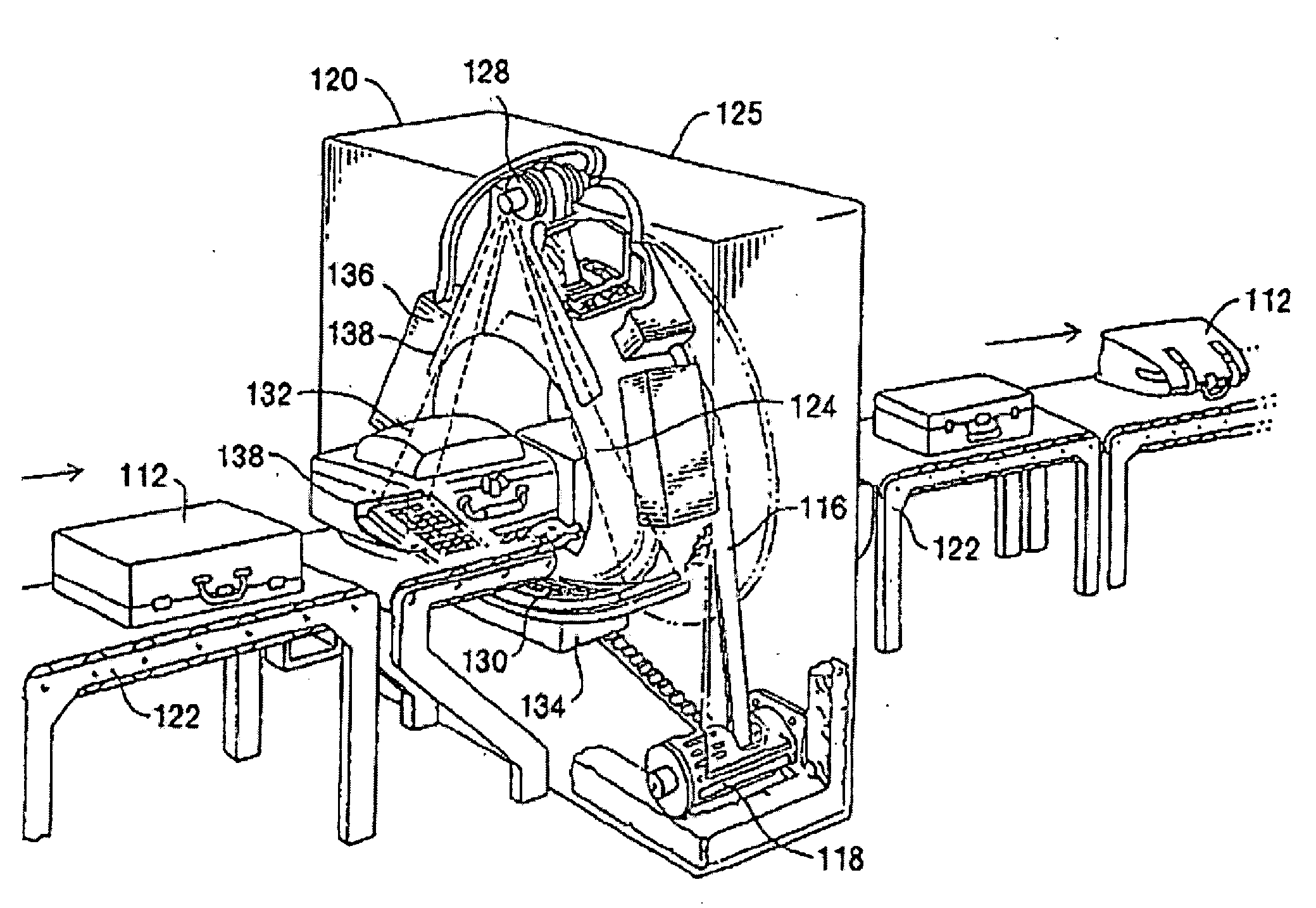

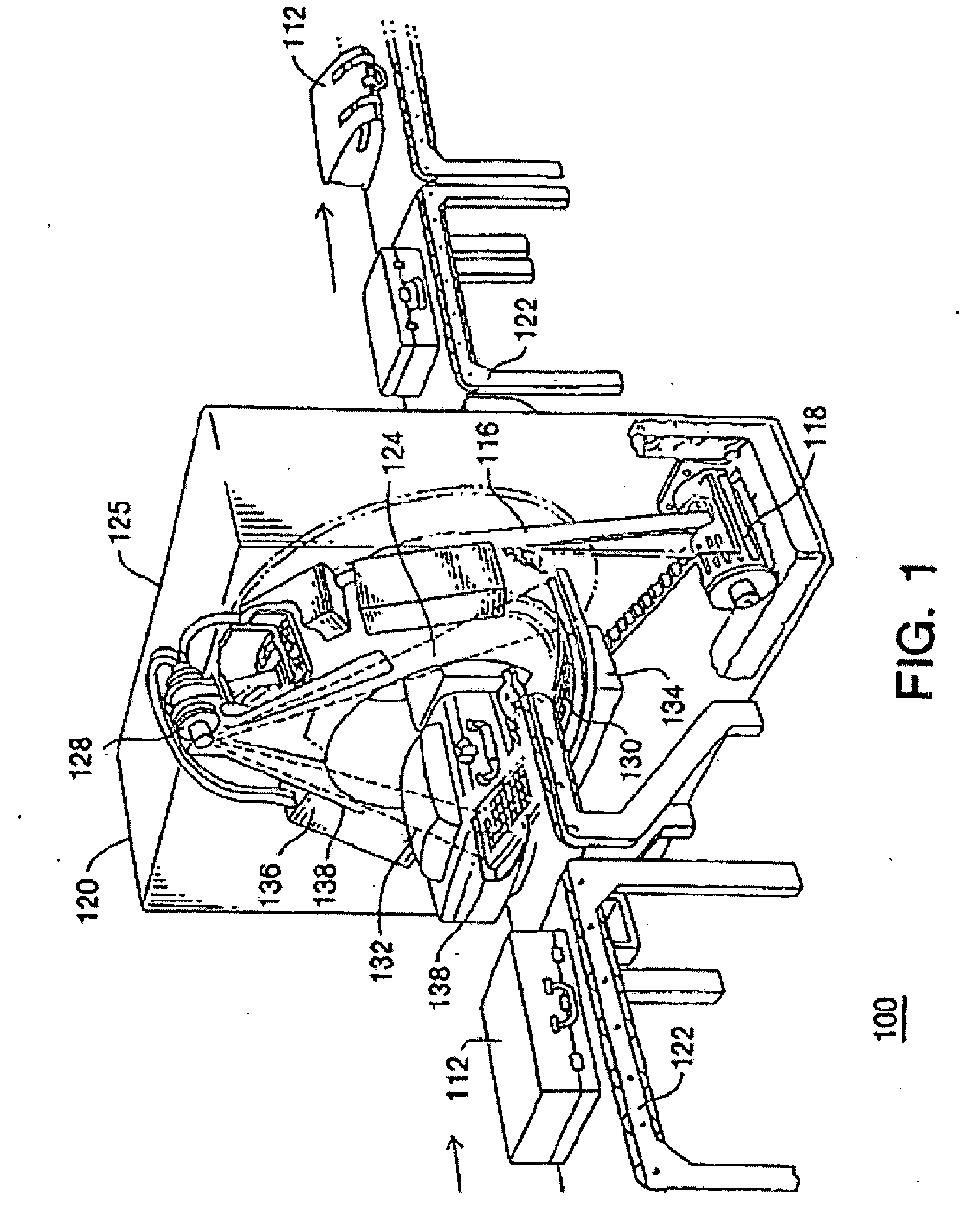

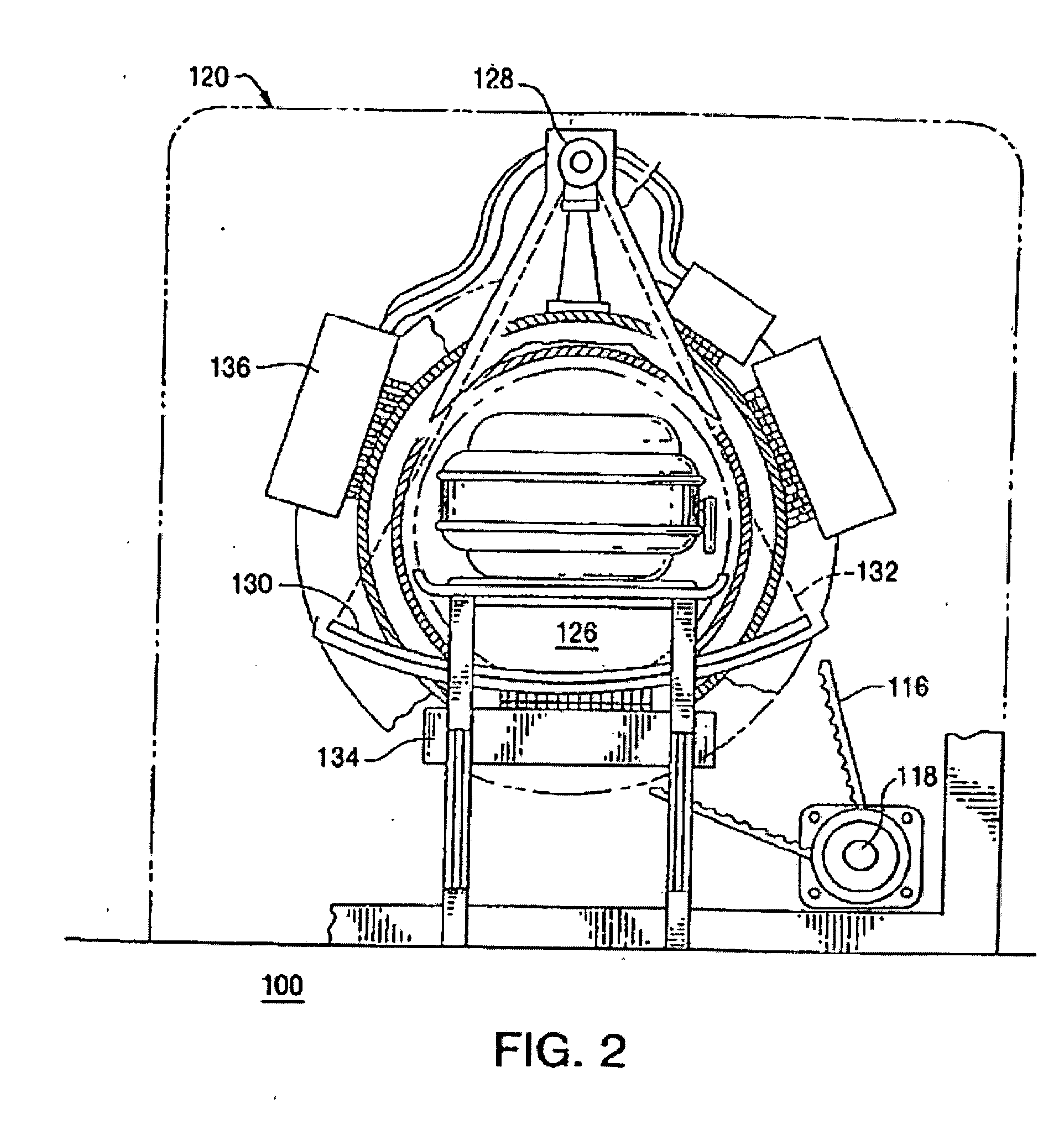

Ion implanter having two-stage deceleration beamline

An ion implanter includes an ion source for generating an ion beam, an analyzer for separating unwanted components from the ion beam, a first beam transport device for transporting the ion beam through the analyzer at a first transport energy, a first deceleration stage positioned downstream of the analyzer for decelerating the ion beam from the first transport energy to a second transport energy, a beam filter positioned downstream of the first deceleration stage for separating neutral particles from the ion beam, a second beam transport device for transporting the ion beam through the beam filter at the second transport energy, a second deceleration stage positioned downstream of the beam filter for decelerating the ion beam from the second transport energy to a final energy, and a target site for supporting a target for ion implantation. The ion beam is delivered to the target site at the final energy. In a double deceleration mode, the second transport energy is greater than the final energy for highest current at low energy. In an enhanced drift mode, the second transport energy is equal to the final energy for highest beam purity at low energy.

Owner:VARIAN SEMICON EQUIP ASSOC INC

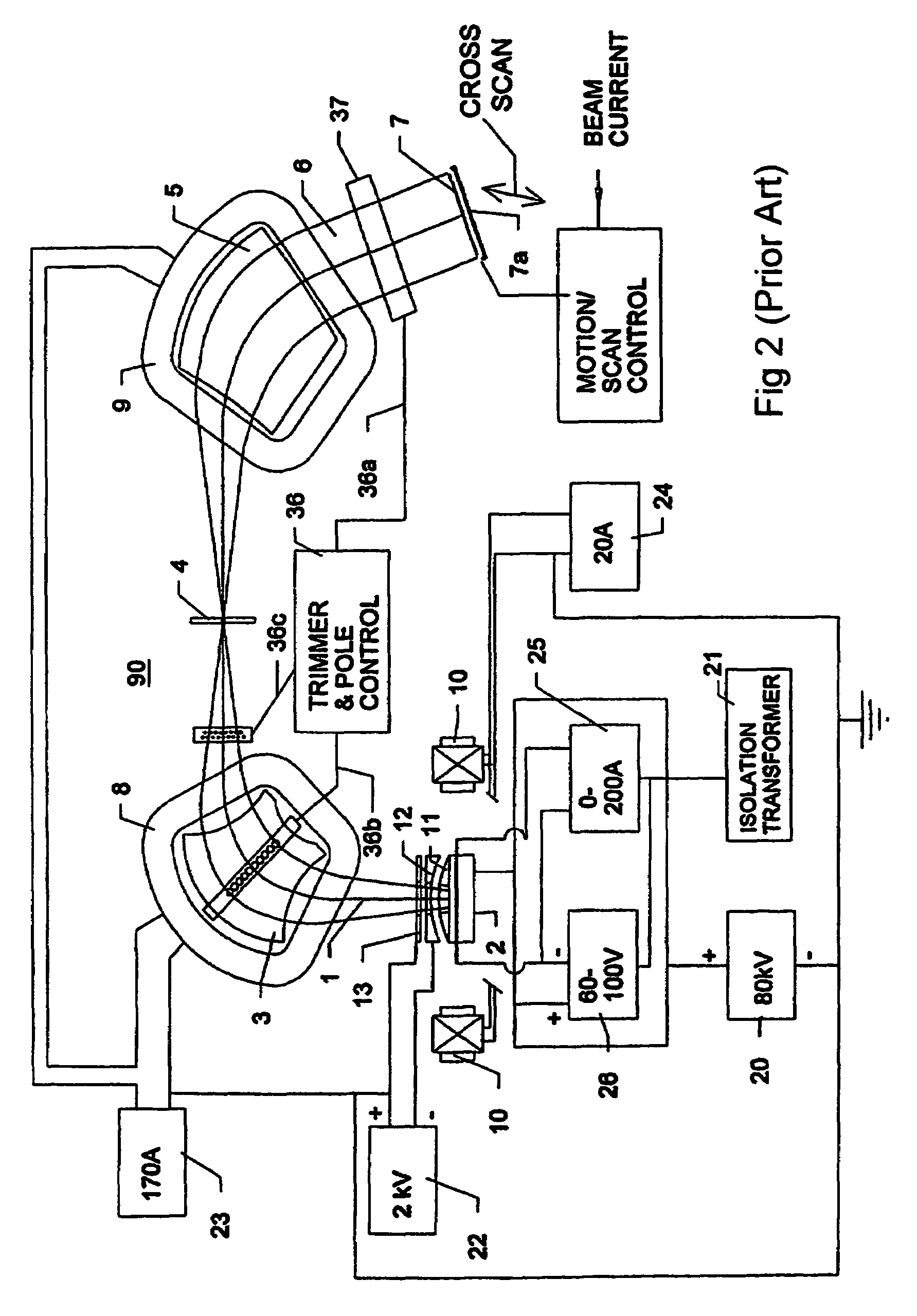

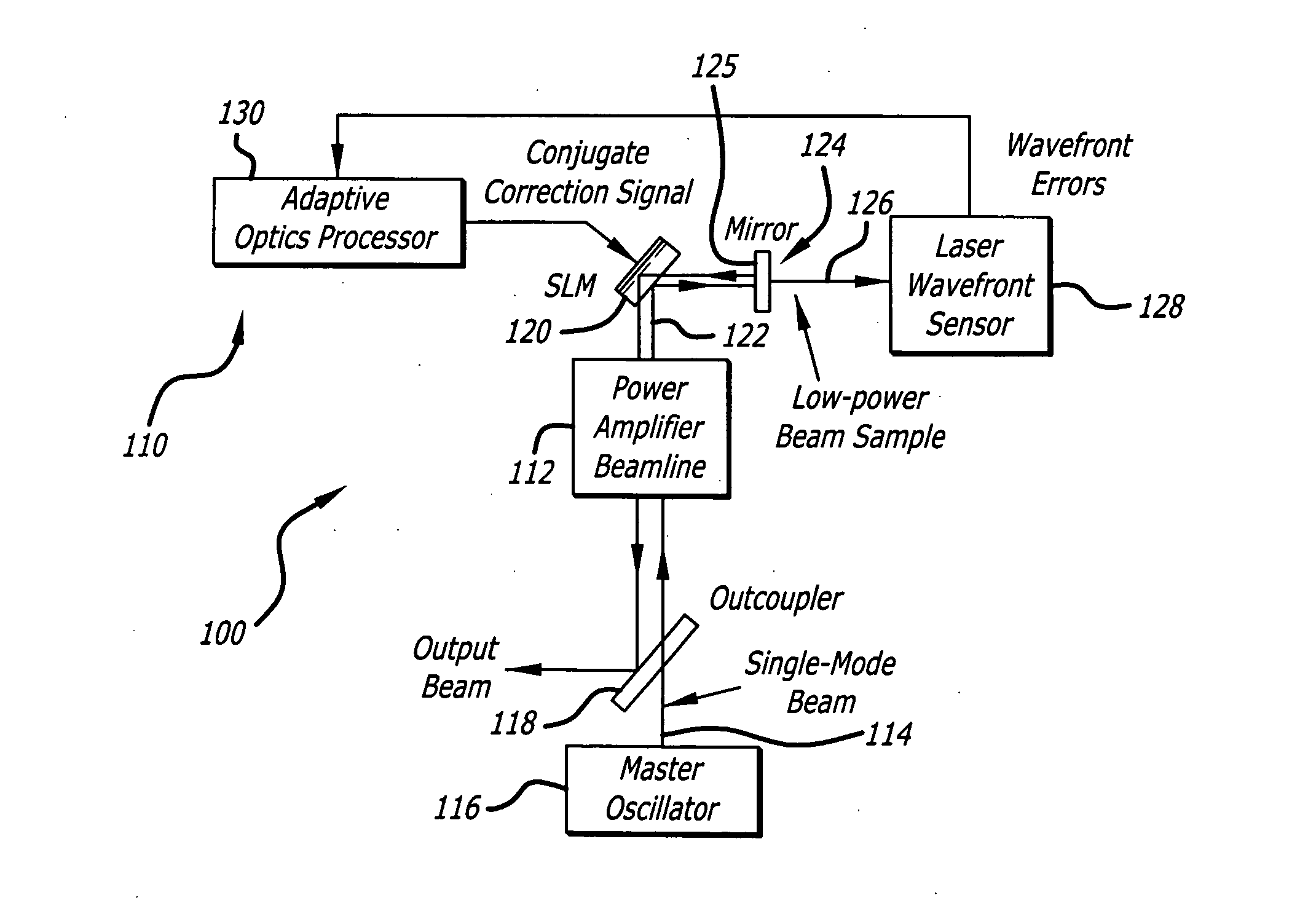

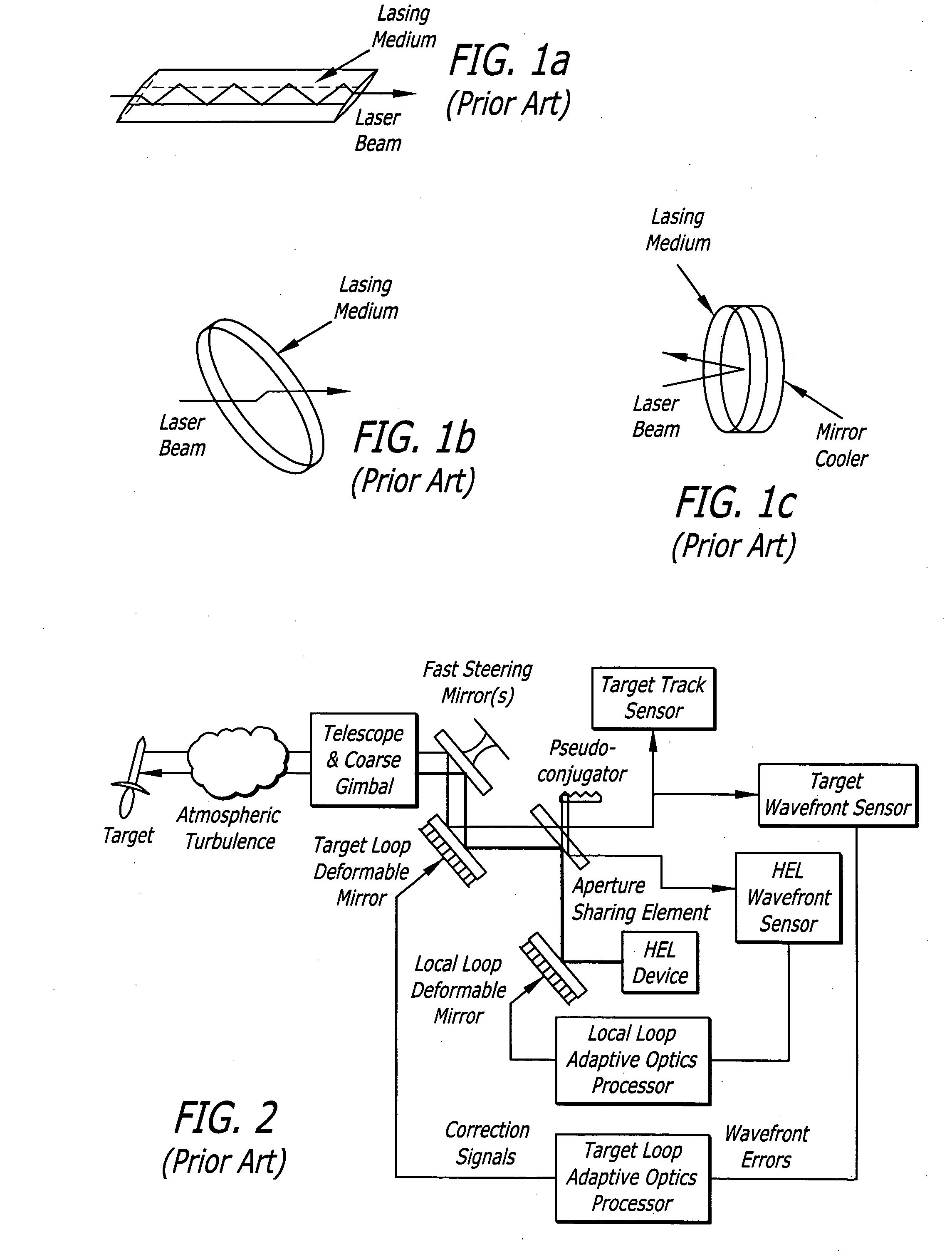

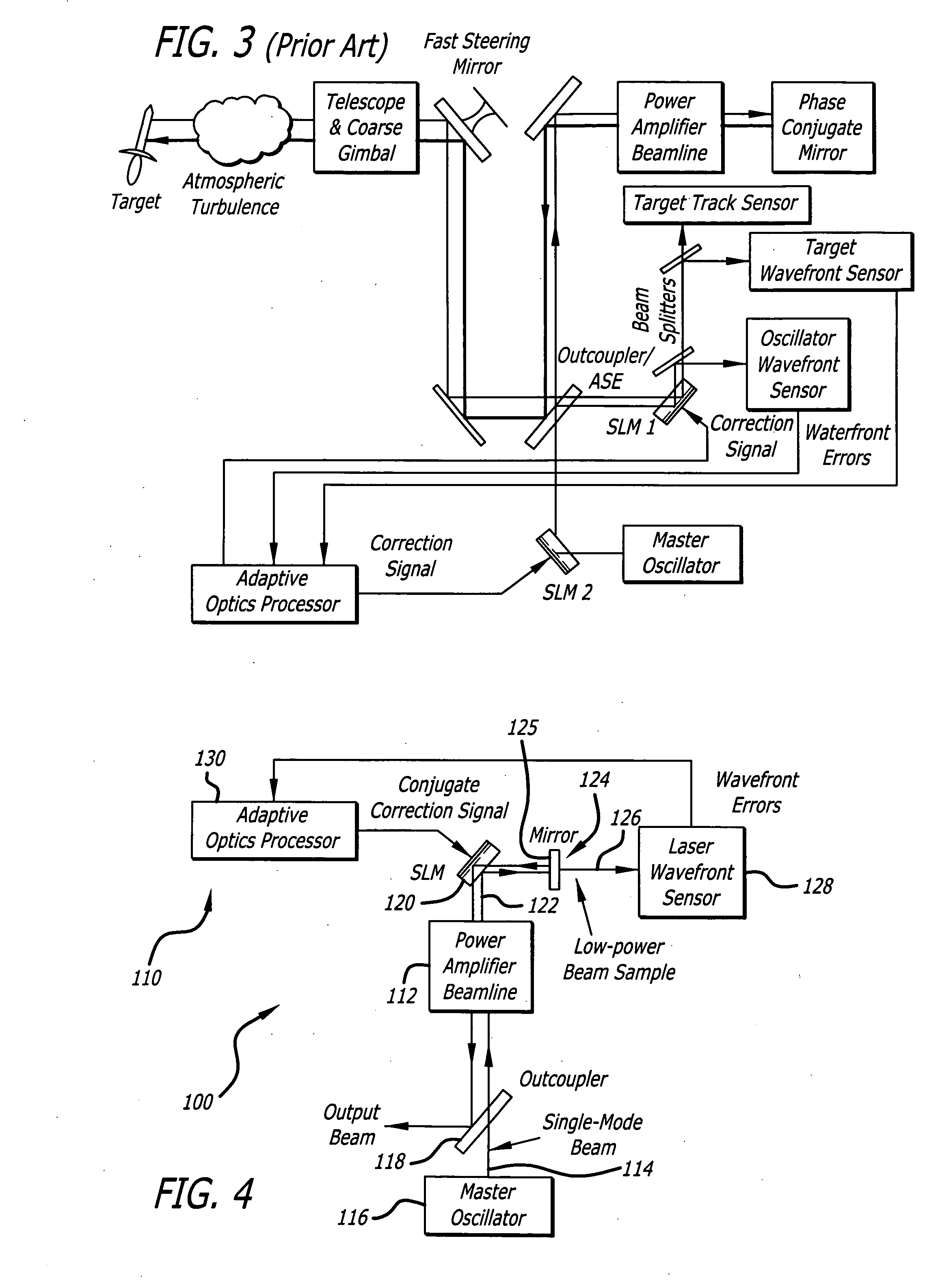

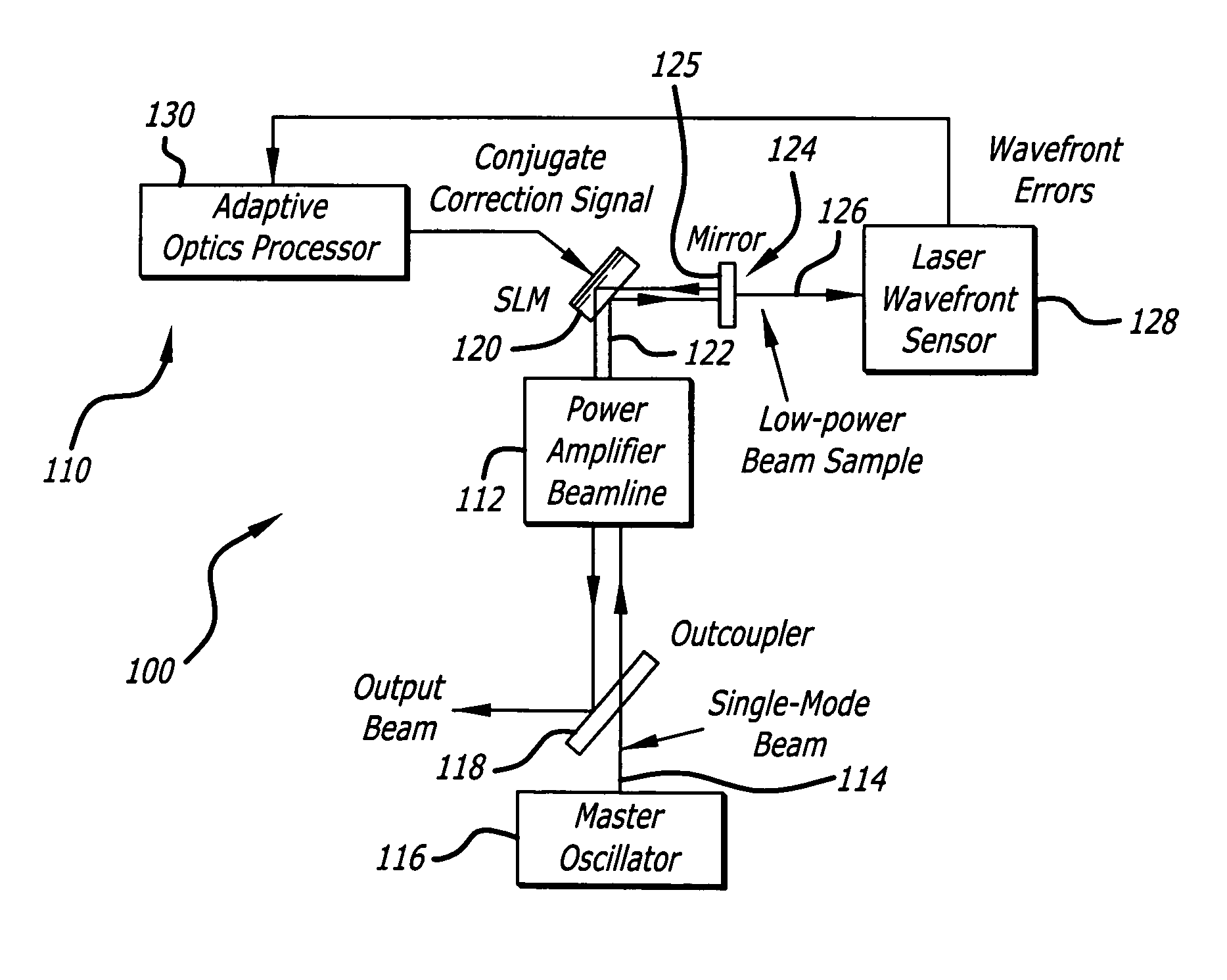

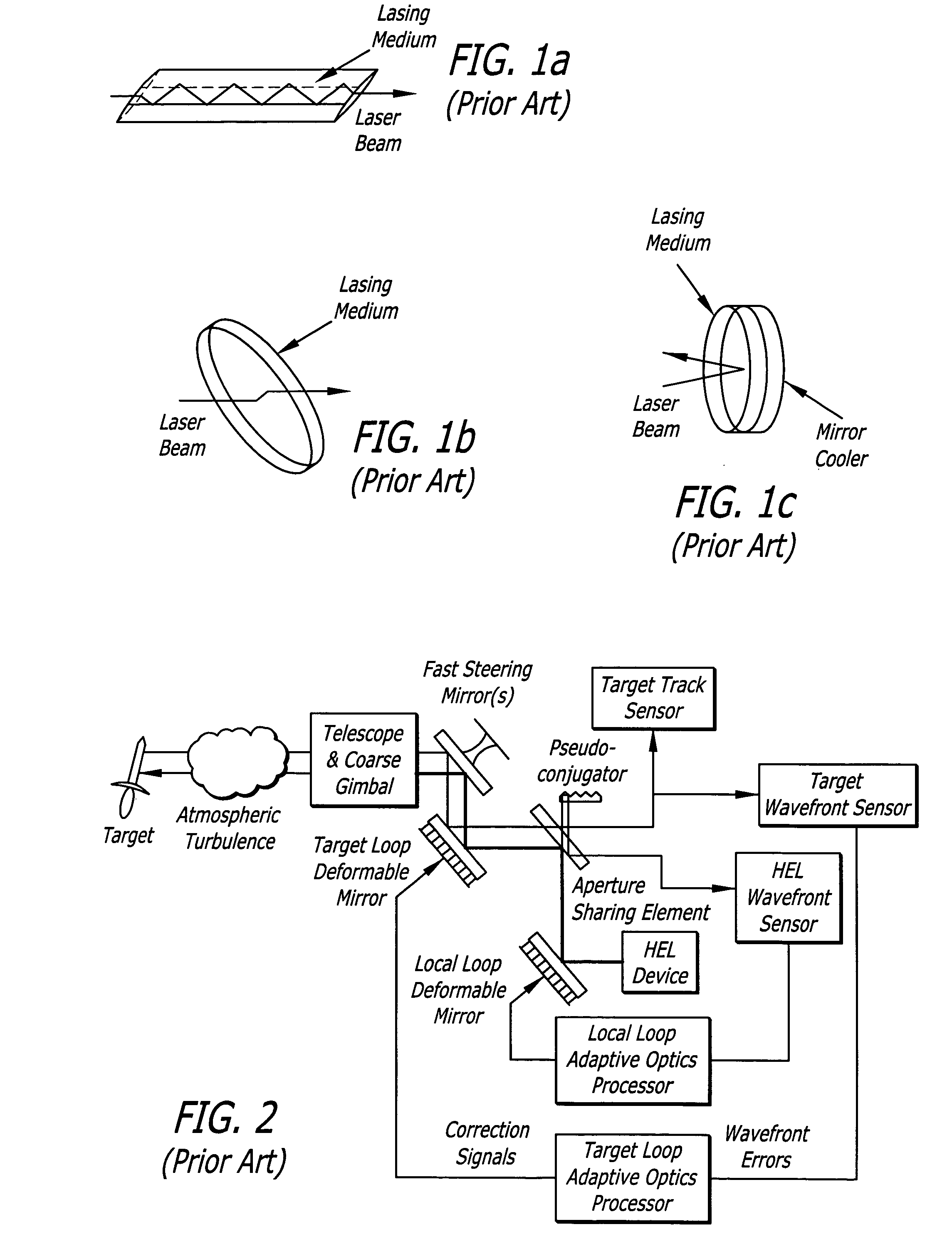

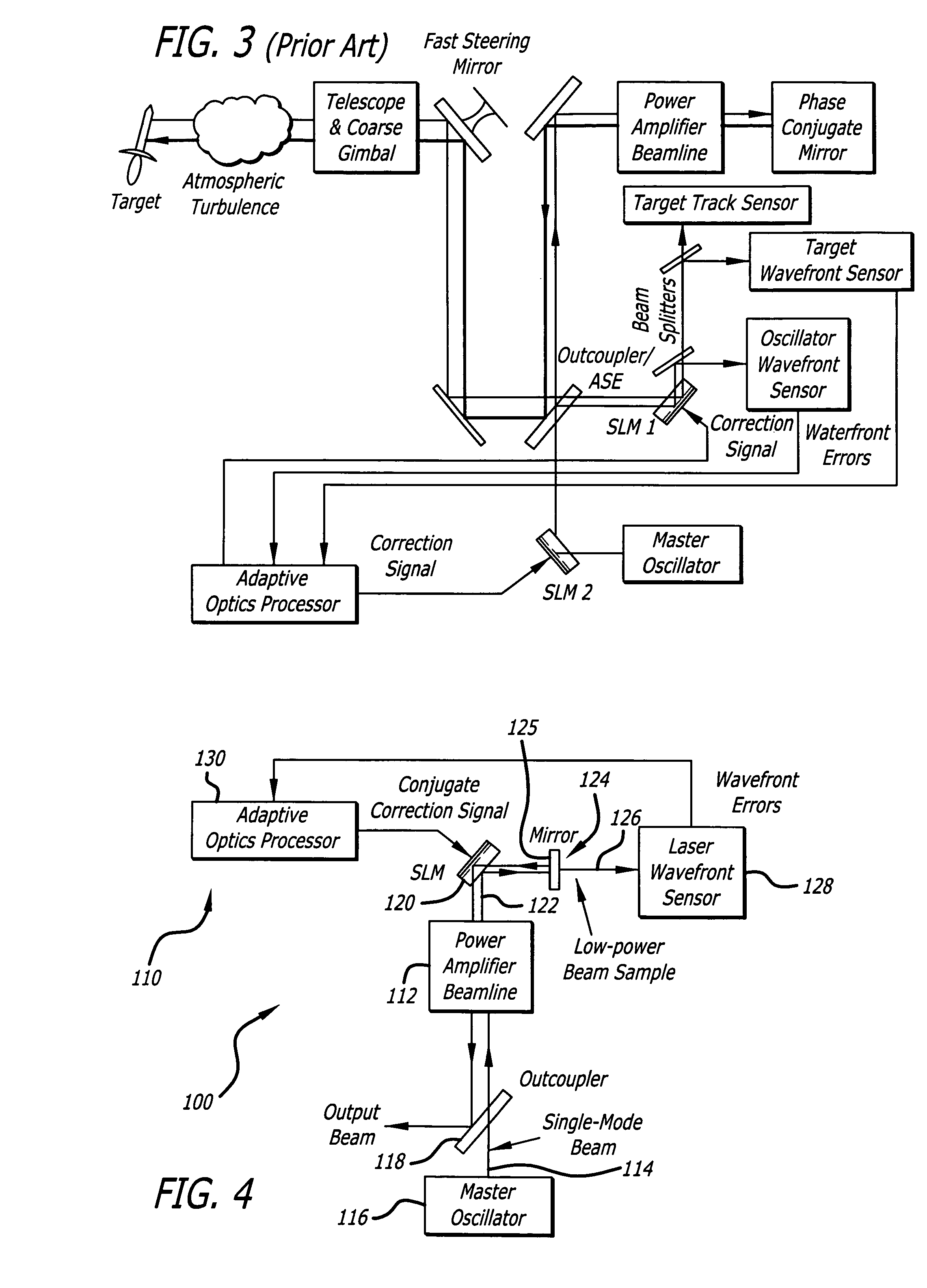

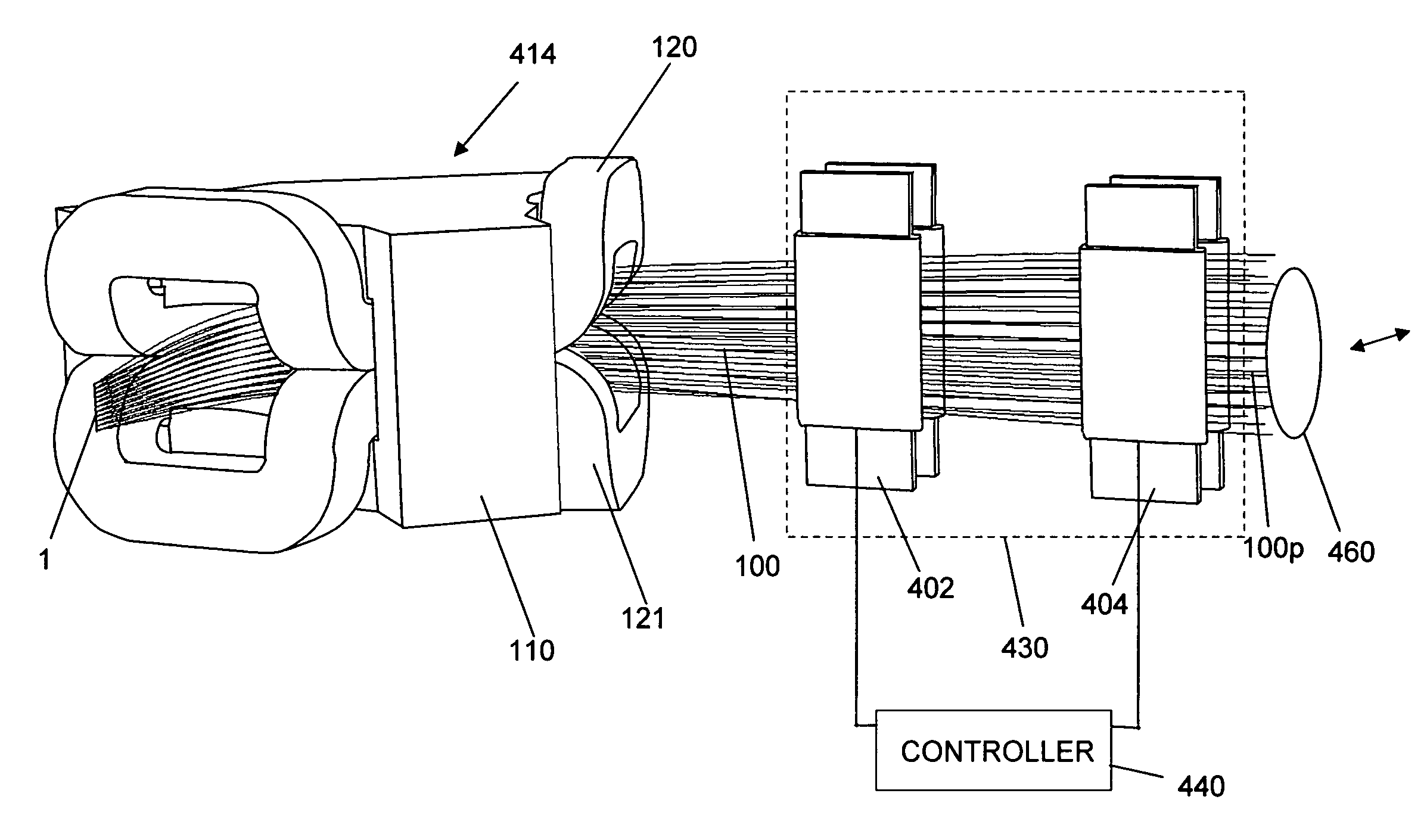

Linear adaptive optics system in low power beam path and method

InactiveUS20100232007A1Aberration correctionDirection controllersDirected energy weaponsDielectricWavefront sensor

A system and method for providing a wavefront corrected high-energy beam of electromagnetic energy. In the illustrative embodiment, the system includes a source of a first beam of electromagnetic energy; an amplifier for amplifying said beam to provide a second beam; a sensor for sensing aberration in said second beam and providing an error signal in response thereto; a processor for processing said error signal and providing a correction signal in response thereto; and a spatial light modulator responsive to said correction signal for adjusting said beam to facilitate a correction of said aberration thereof. In more specific embodiments, the source is a laser and the sensor is a laser wavefront sensor. A mirror is disposed between said modulator and said sensor for sampling said beam. The mirror has an optical thin-film dielectric coating on at least one optical surface thereof. The coating is effective to sample said beam and transmit a low power sample thereof to said means for sensing aberration. The processor is an adaptive optics processor. The spatial light modulator may be a micro electro-mechanical system deformable mirror or an optical phased array. In the illustrative embodiment, the source is a master oscillator and the amplifier is a power amplifier beamline. An outcoupler is disposed between the oscillator and the amplifier.

Owner:RAYTHEON CO

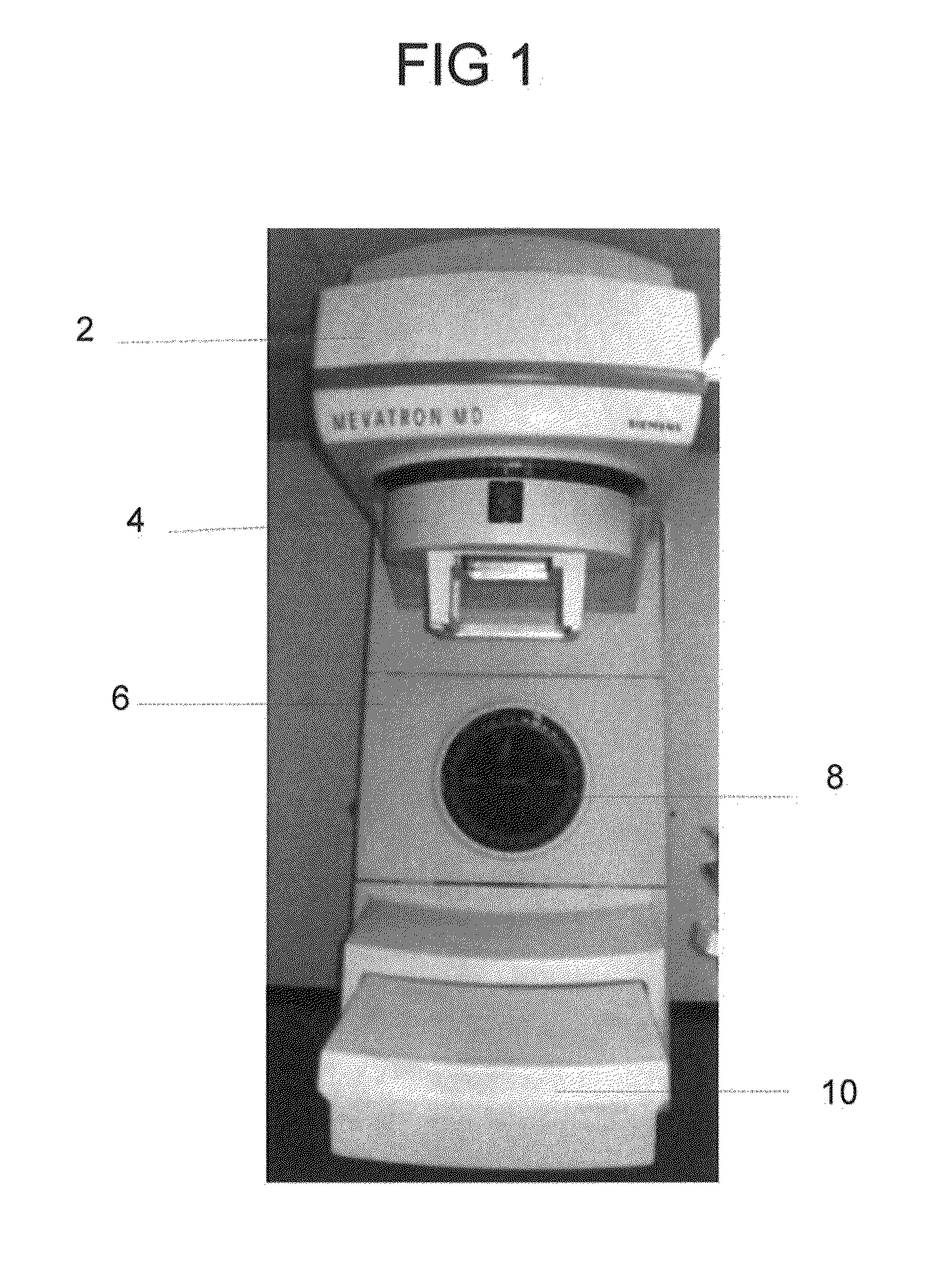

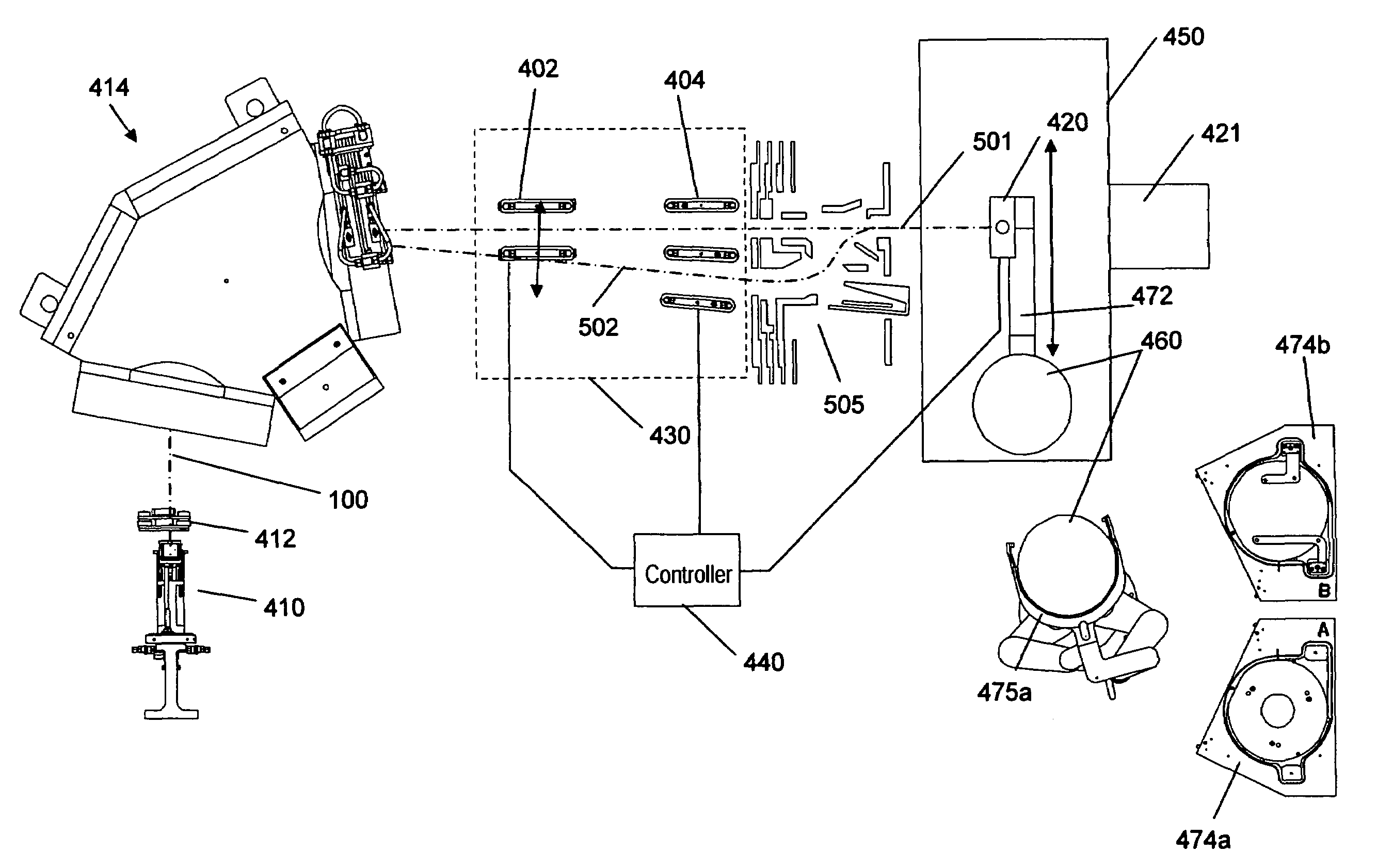

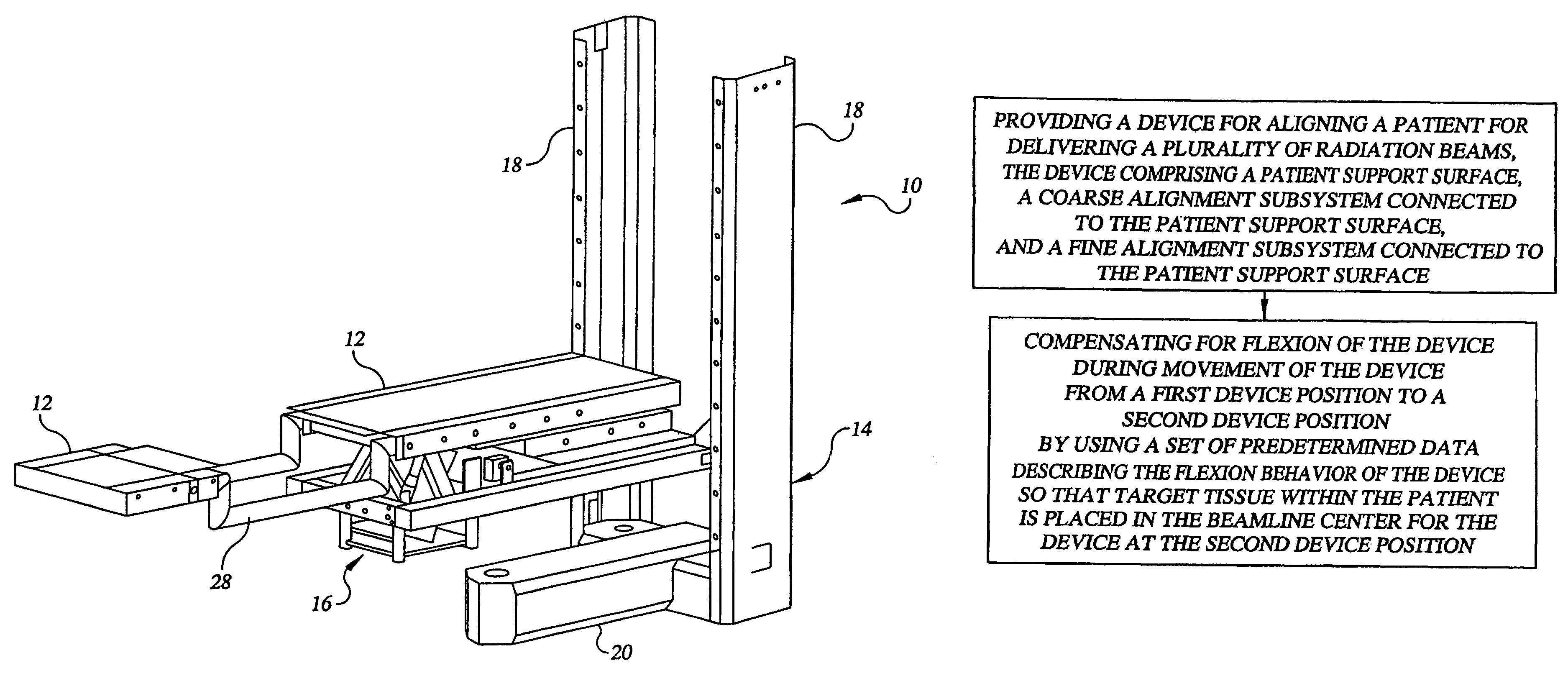

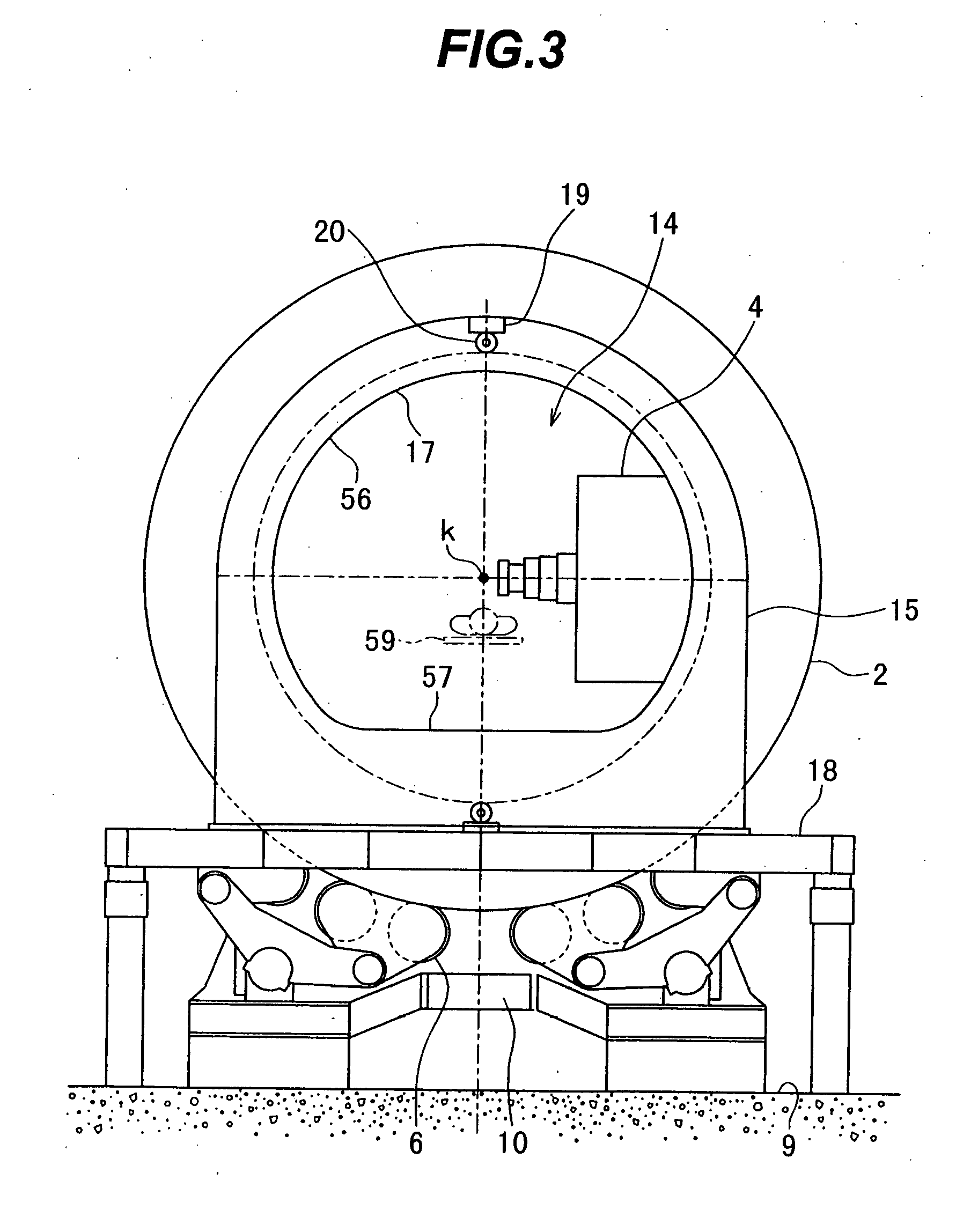

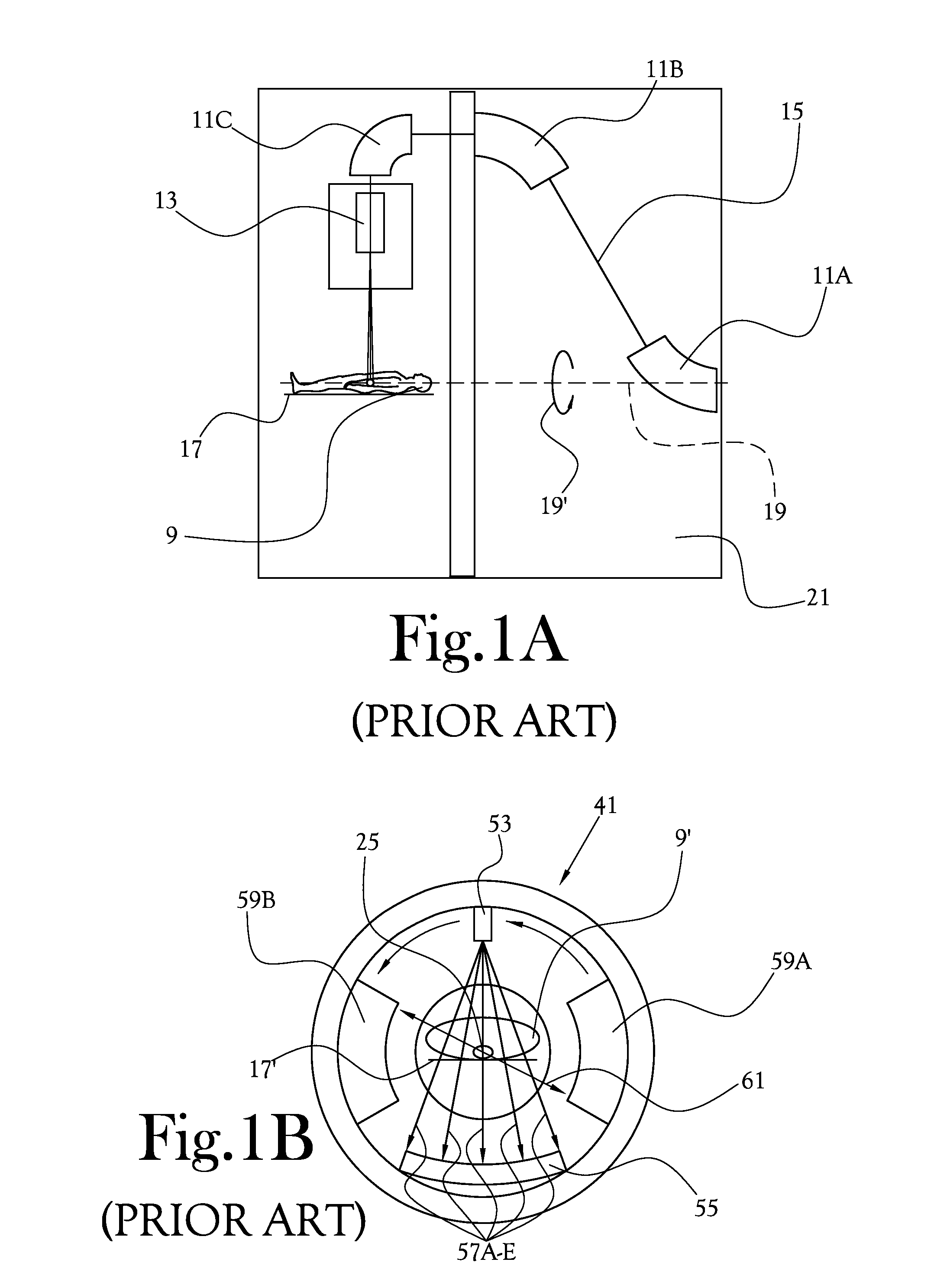

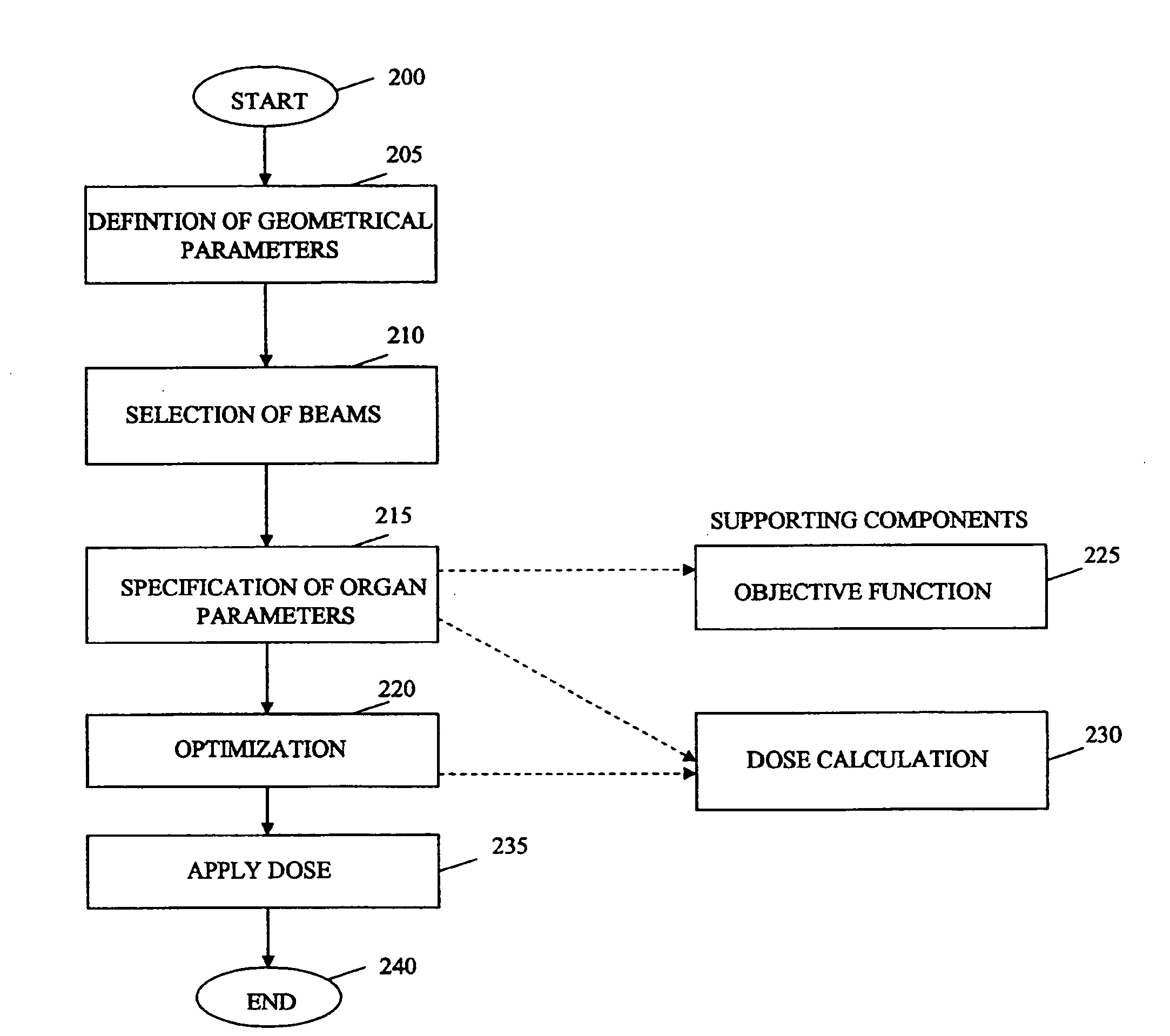

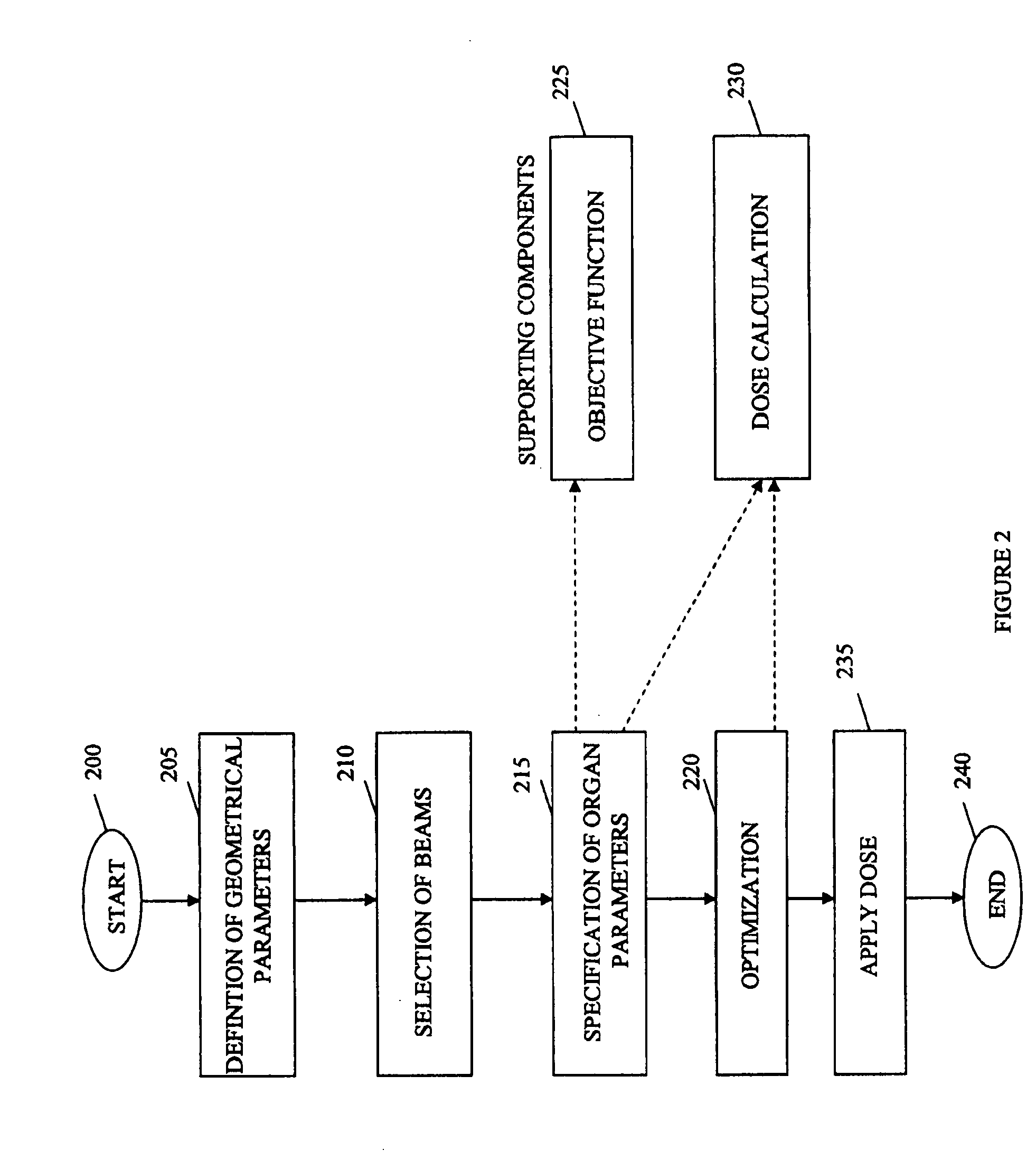

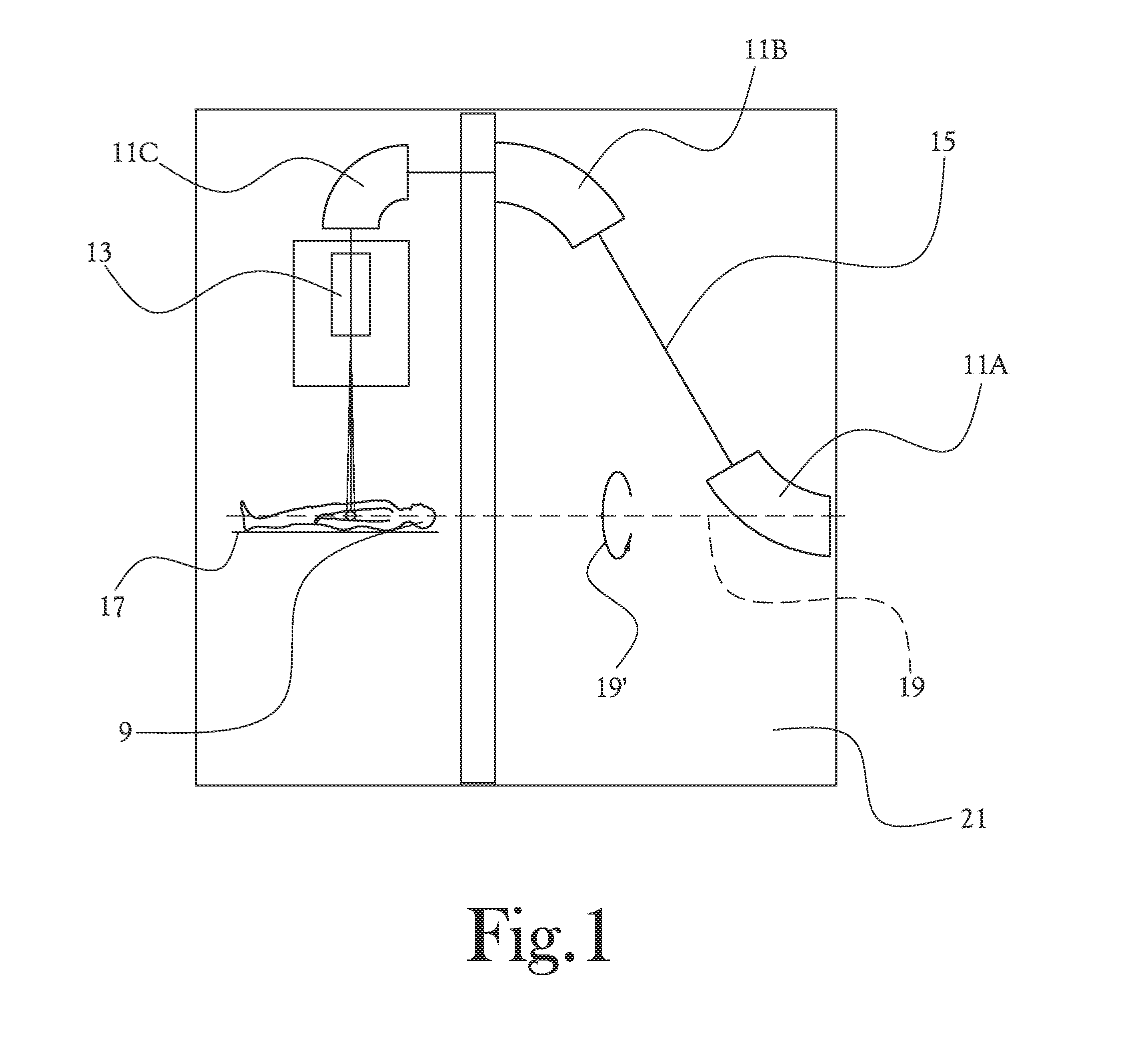

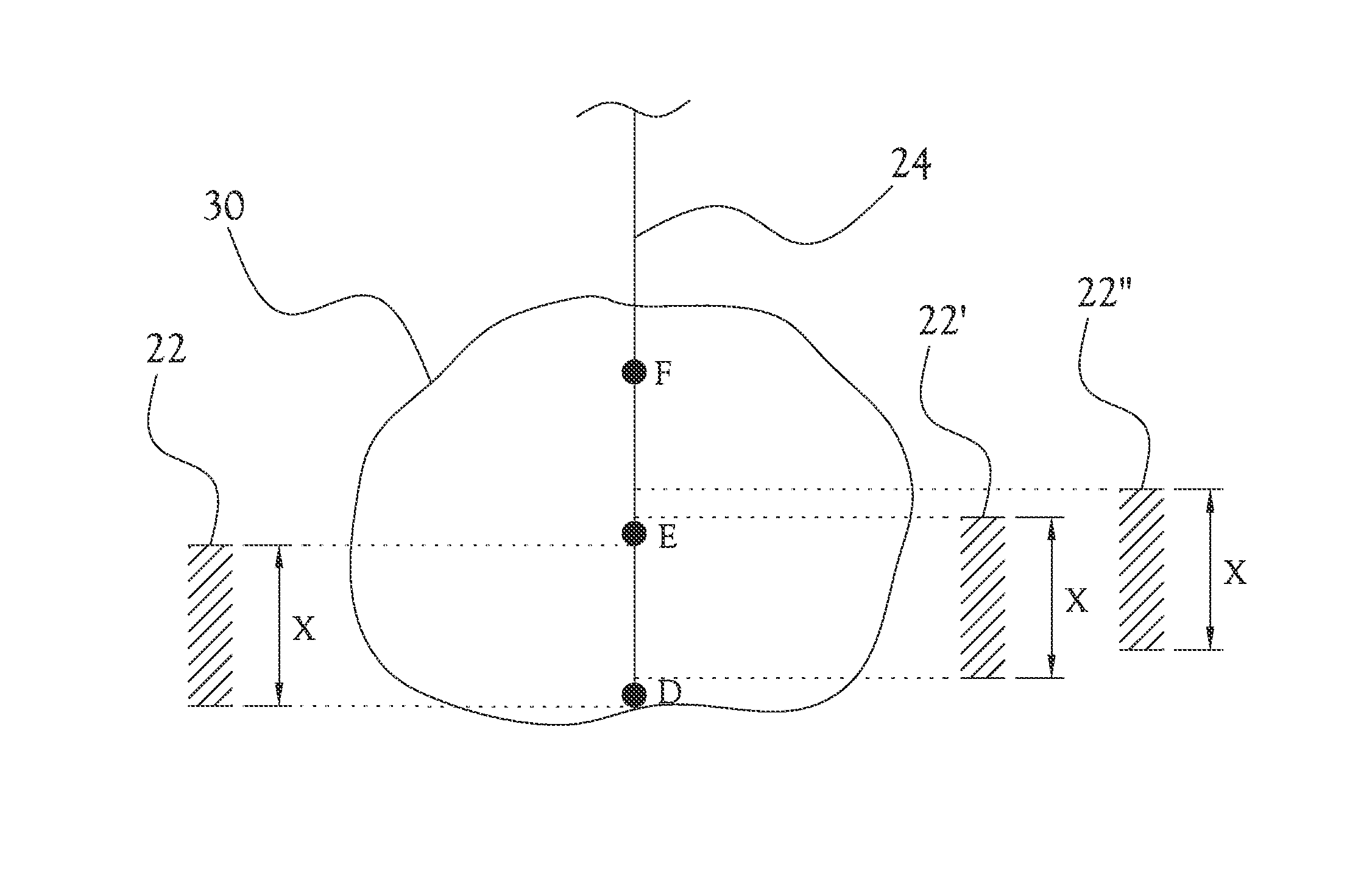

Method and device for delivering radiotherapy

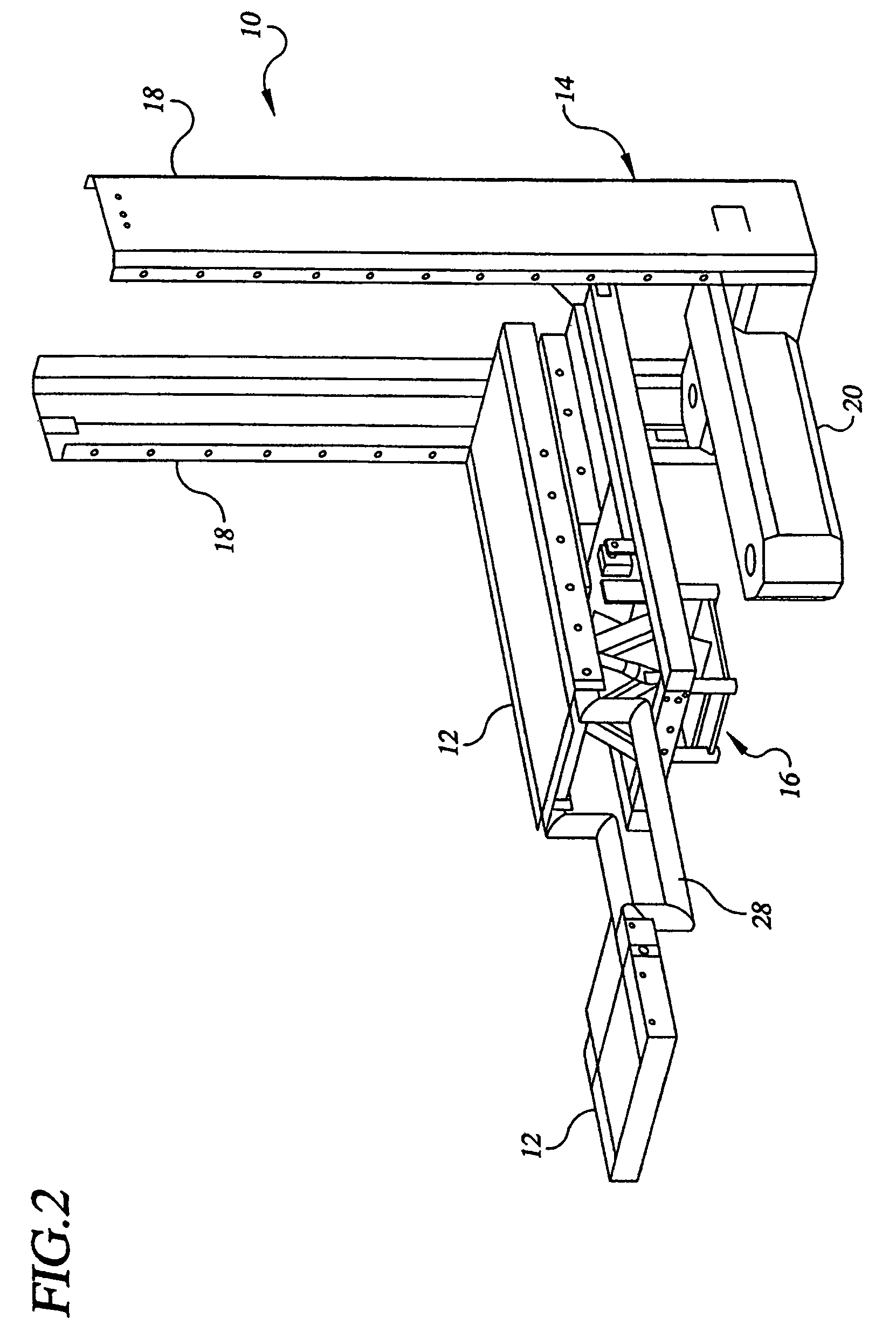

InactiveUS7789560B2Patient positioning for diagnosticsRadiation beam directing meansRadiation therapyTarget tissue

A device 10 for aligning a patient for delivering a plurality of radiation beams comprising a patient support surface 12, a coarse alignment subsystem 14 connected to the patient support surface, and a fine alignment subsystem connected to the patient support surface 16. A method of aligning a patient for delivering a plurality of radiation beams from a plurality of device positions comprising compensating for flexion of a radiation beam delivery device within a gantry during movement of the radiation beam delivery device from a first device position to a second device position by using a set of predetermined data describing the flexion behavior of the radiation beam delivery device so that the target tissue within the patient is placed at the beamline center for the radiation beam delivery device at the second device position.

Owner:LOMA LINDA UNIV MEDICAL CENT

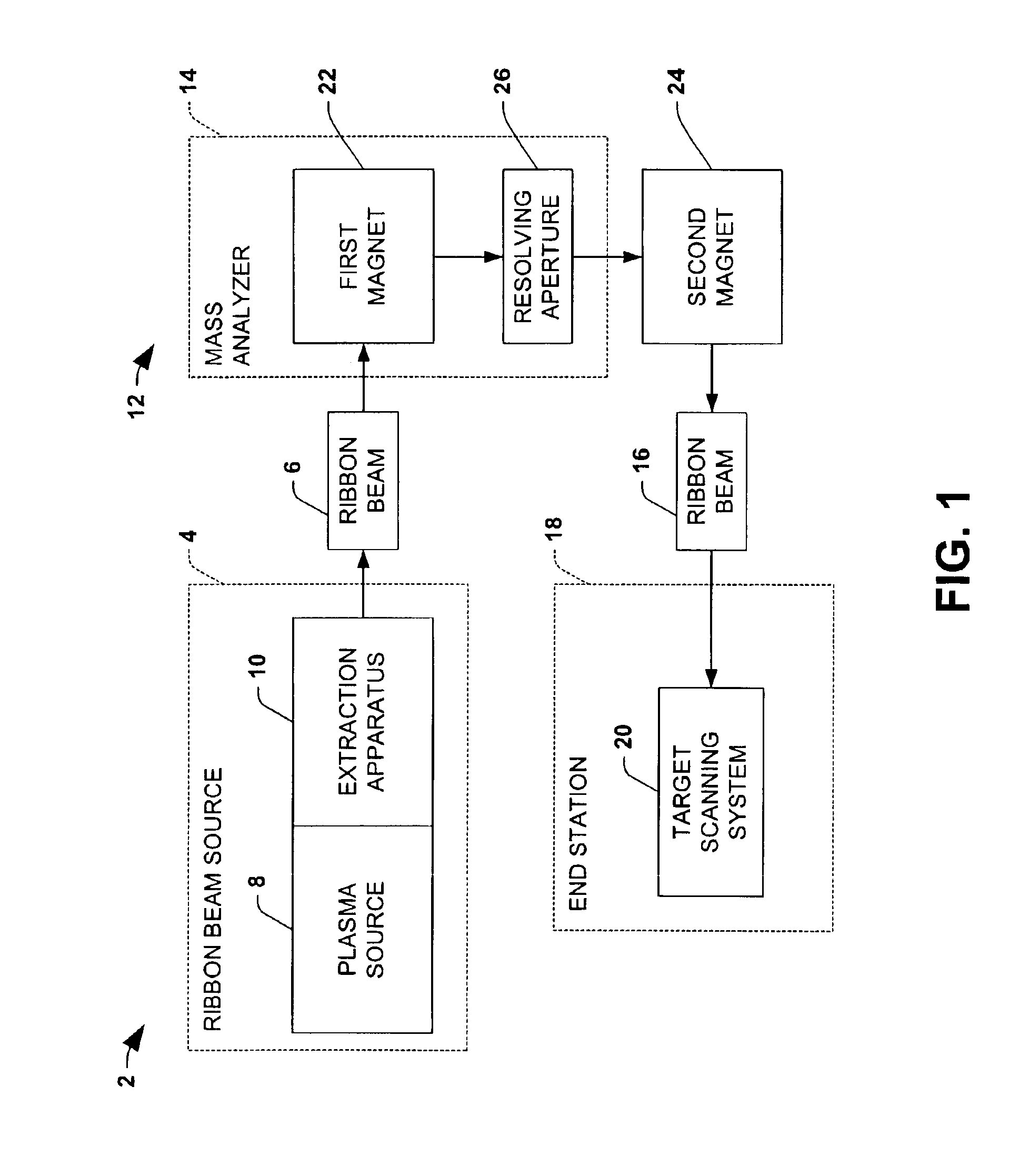

Apparatus and methods for ion beam implantation

ActiveUS20060113495A1Simple beamlineHigh resolutionTube magnetic delectionStatic spectrometersIon beamLight beam

This invention discloses an ion implantation apparatus with multiple operating modes. It has an ion source and an ion extraction means for extracting a ribbon-shaped ion beam therefrom. The ion implantation apparatus includes a magnetic analyzer for selecting ions with specific mass-to-charge ratio to pass through a mass slit to project onto a substrate. Multipole lenses are provided to control beam uniformity and collimation. The invention further discloses a two-path beamline in which a second path incorporates a deceleration system incorporating energy filtering. The invention discloses methods of ion implantation in which the mode of implantation may be switched from one-dimensional scanning of the target to two-dimensional scanning, and from a simple path to an s-shaped path with deceleration.

Owner:ADVANCED ION BEAM TECHNOLOGY INC

Apparatus and methods for ion beam implantation using ribbon and spot beams

ActiveUS20090189096A1Eliminate pollutionDifficult to controlThermometer detailsParticle separator tubesIon beamLight beam

An ion implantation apparatus with multiple operating modes is disclosed. The ion implantation apparatus has an ion source and an ion extraction means for extracting a ribbon-shaped ion beam therefrom. The ion implantation apparatus includes a magnetic analyzer for selecting ions with specific mass-to-charge ratio to pass through a mass slit to project onto a substrate. Multipole lenses are provided to control beam uniformity and collimation. A two-path beamline in which a second path incorporates a deceleration or acceleration system incorporating energy filtering is disclosed. Finally, methods of ion implantation are disclosed in which the mode of implantation may be switched from one-dimensional scanning of the target to two-dimensional scanning.

Owner:ADVANCED ION BEAM TECHNOLOGY INC

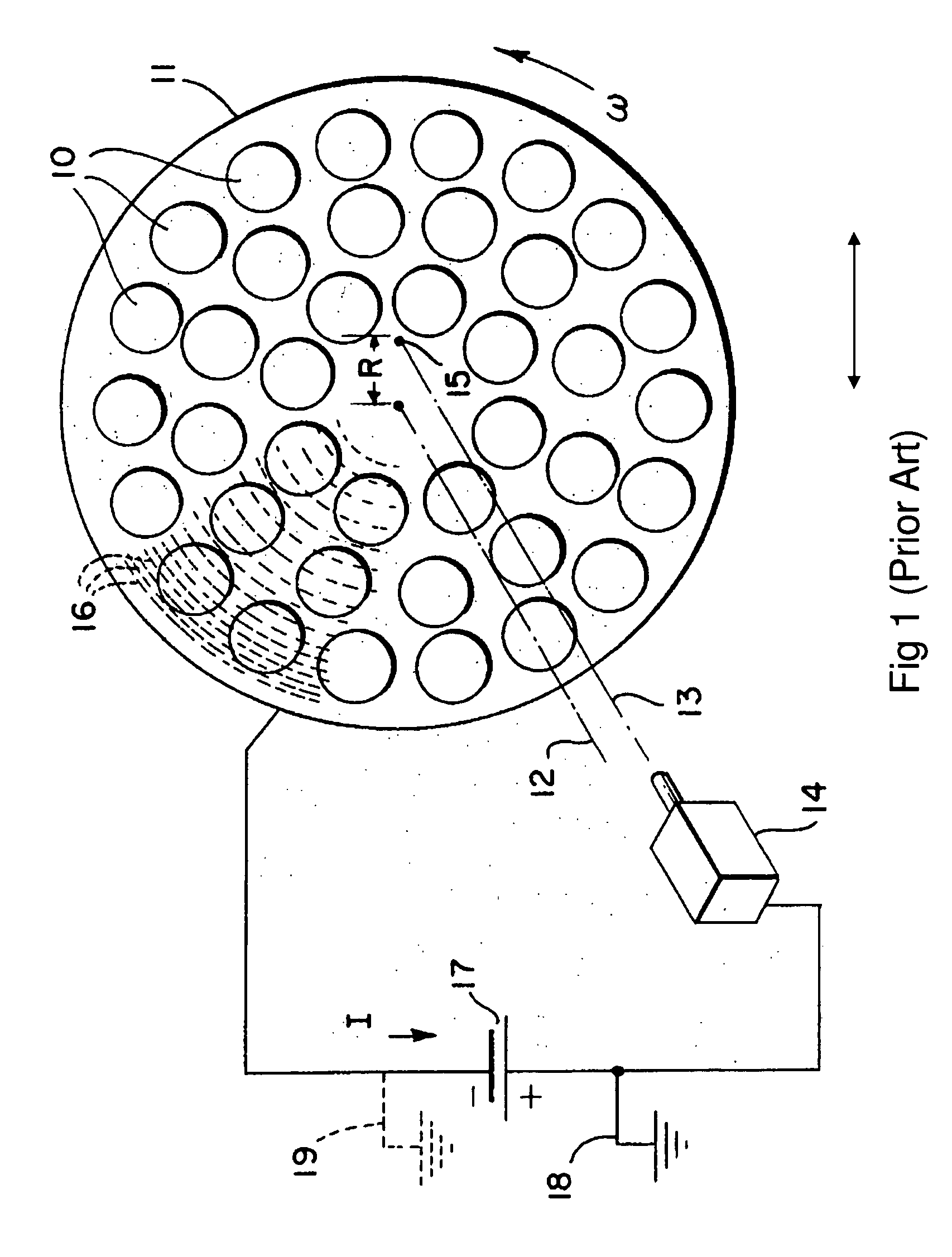

System and Method for Ion Implantation with Improved Productivity and Uniformity

ActiveUS20100308215A1Improve uniformityIncrease currentThermometer detailsStability-of-path spectrometersProduction rateIon beam

A method comprising introducing an injected gas (e.g., Argon, Xenon) into a beam line region comprising a magnetic scanner is provided herein. The injected gas improves beam current by enhancing (e.g., increasing, decreasing) charge neutralization of the magnetic ion beam (e.g., the ion beam at regions where the scanning magnetic field is non-zero) thereby reducing the current loss due to the zero field effect (ZFE). By reducing the current loss in regions having a magnetic field, the magnetic beam current is increased (e.g., the beam current is increased in regions where the magnetic field is non-zero) raising the overall beam current in a uniform manner over an entire scan path and thereby reducing the effect of the ZFE. In other words, the ZFE is removed by effectively minimizing it through an increase in the magnetized beam current.

Owner:AXCELIS TECHNOLOGIES

Apparatus and methods for ion beam implantation using ribbon and spot beams

ActiveUS7902527B2Difficult to controlIncrease throughputThermometer detailsStability-of-path spectrometersLight beamIon beam

An ion implantation apparatus with multiple operating modes is disclosed. The ion implantation apparatus has an ion source and an ion extraction means for extracting a ribbon-shaped ion beam therefrom. The ion implantation apparatus includes a magnetic analyzer for selecting ions with specific mass-to-charge ratio to pass through a mass slit to project onto a substrate. Multipole lenses are provided to control beam uniformity and collimation. A two-path beamline in which a second path incorporates a deceleration or acceleration system incorporating energy filtering is disclosed. Finally, methods of ion implantation are disclosed in which the mode of implantation may be switched from one-dimensional scanning of the target to two-dimensional scanning.

Owner:ADVANCED ION BEAM TECHNOLOGY INC

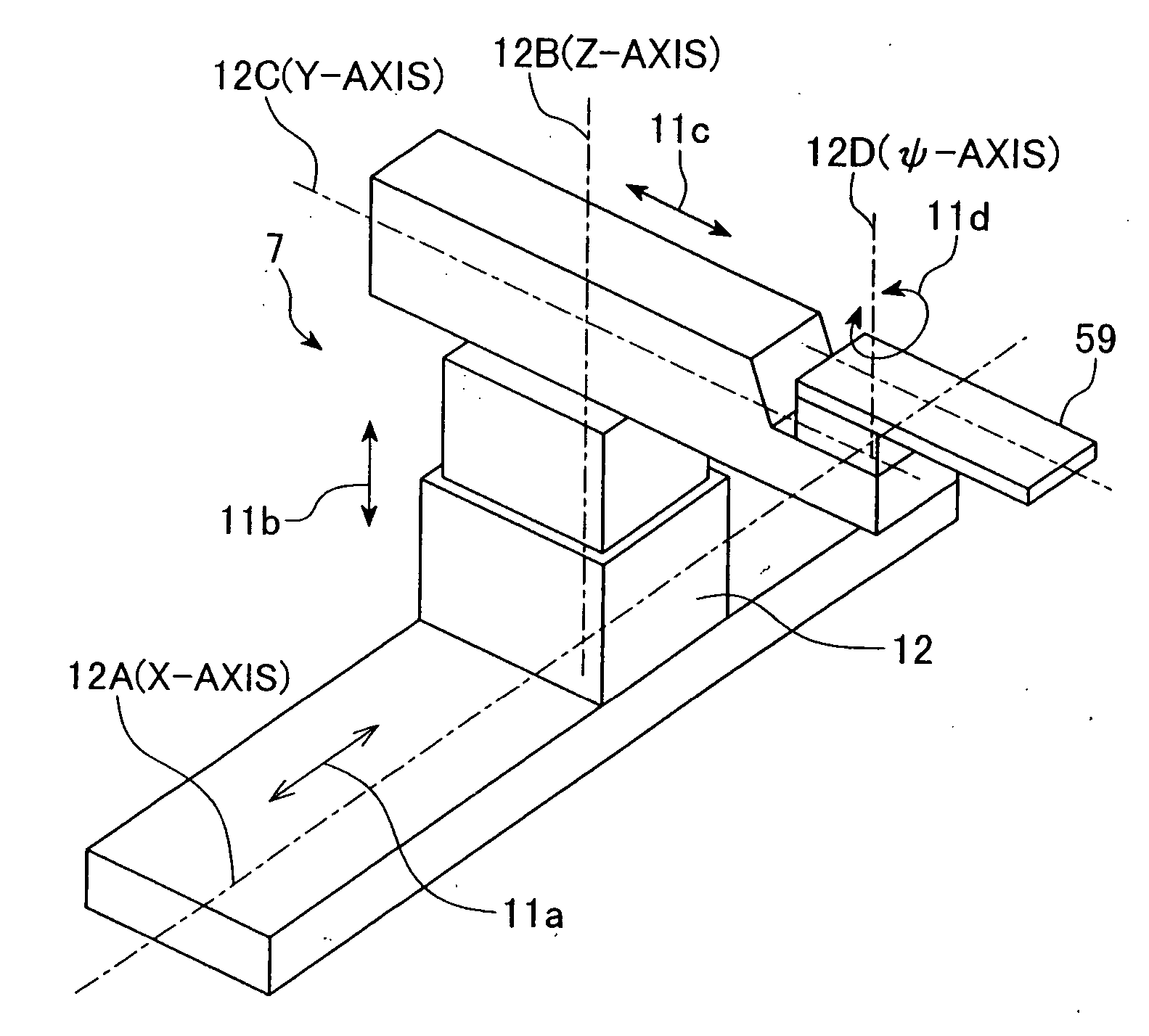

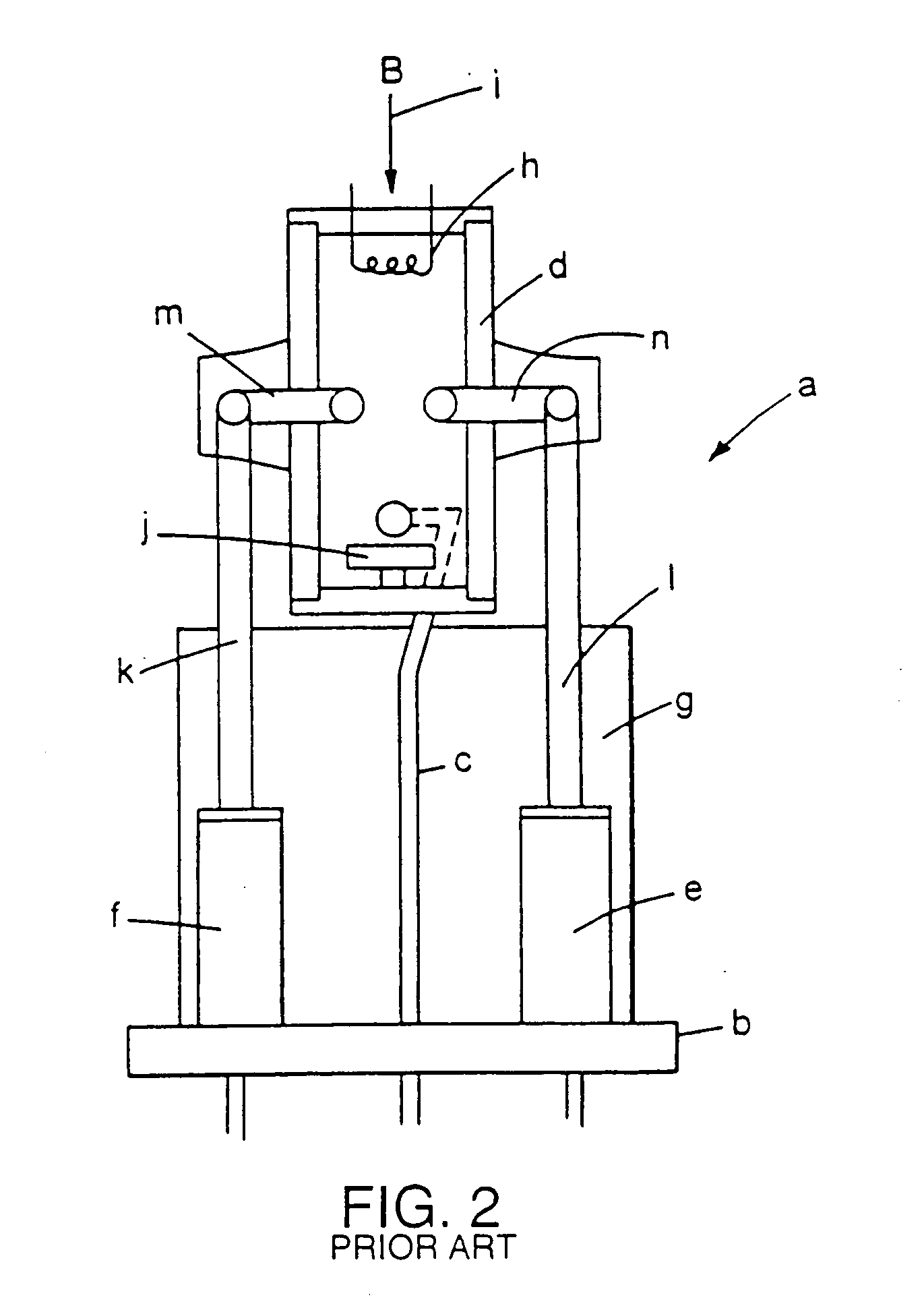

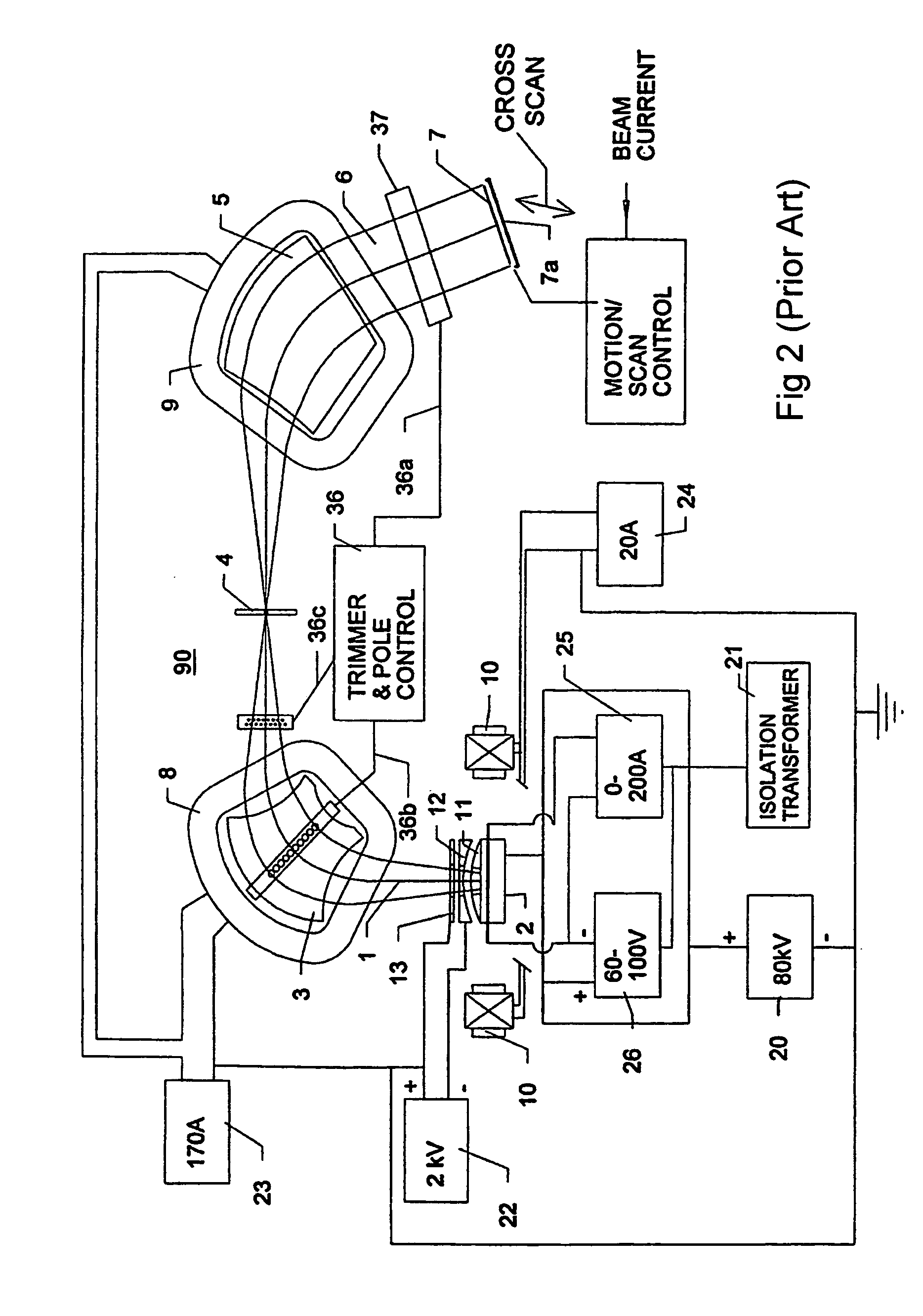

Patient positioning device and patient positioning method

InactiveUS20060203958A1Improve accuracyAvoid accuracyMaterial analysis using wave/particle radiationRadiation/particle handlingAbnormal tissue growthPattern matching

The invention is intended to always ensure a sufficient level of patient positioning accuracy regardless of the skills of individual operators. In a patient positioning device for positioning a patient couch 59 and irradiating an ion beam toward a tumor in the body of a patient 8 from a particle beam irradiation section 4, the patient positioning device comprises an X-ray emission device 26 for emitting an X-ray along a beam line m from the particle beam irradiation section 4, an X-ray image capturing device 29 for receiving the X-ray and processing an X-ray image, a display unit 39B for displaying a current image of the tumor in accordance with a processed image signal, a display unit 39A for displaying a reference X-ray image of the tumor which is prepared in advance, and a positioning data generator 37 for executing pattern matching between a comparison area A being a part of the reference X-ray image and including an isocenter and a comparison area B or a final comparison area B in the current image, thereby producing data used for positioning of the patient couch 59 during irradiation.

Owner:HITACHI LTD

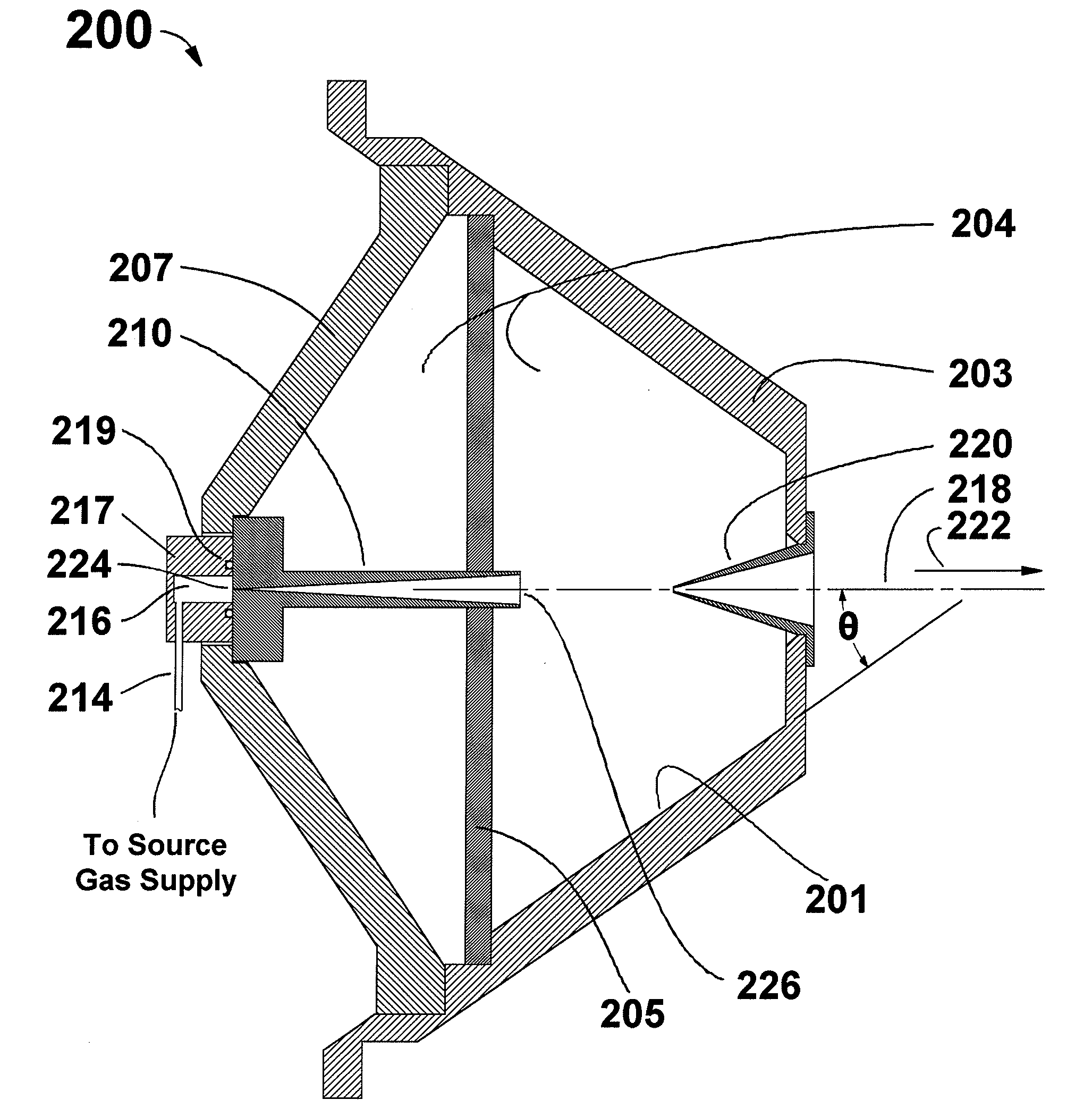

Ion implantation ion source, system and method

InactiveUS20070107841A1Maximizing flow of electronHigh extracted currentSemiconductor/solid-state device manufacturingIon beam tubesDevice materialDesign space

Various aspects of the invention provide improved approaches and methods for efficiently: Vaporizing decaborane and other heat-sensitive materials via a novel vaporizer and vapor delivery system; Delivering a controlled, low-pressure drop flow of vapors, e.g. decaborane, into the ion source; Ionizing the decaborane into a large fraction of B10Hx+; Preventing thermal dissociation of decaborane; Limiting charge-exchange and low energy electron-induced fragmentation of B10Hx+; Operating the ion source without an arc plasma, which can improve the emittance properties and the purity of the beam; Operating the ion source without use of a strong applied magnetic field, which can improve the emittance properties of the beam; Using, a novel approach to produce electron impact ionizations without the use of an arc discharge, by incorporation of an externally generated, broad directional electron beam which is aligned to pass through the ionization chamber to a thermally isolated beam dump;. Providing production-worthy dosage rates of boron dopant at the wafer; Providing a hardware design that enables use also with other dopants, especially using novel hydride, dimer-containing, and indium- or antimony-containing temperature-sensitive starting materials, to further enhance the economics of use and production worthiness of the novel source design and in many cases, reducing the presence of contaminants; Matching the ion optics requirements of the installed base of ion implanters in the field; Eliminating the ion source as a source of transition metals contamination, by using an external and preferably remote cathode and providing an ionization chamber and extraction aperture fabricated of non-contaminating material, e.g. graphite, silicon carbide or aluminum; Enabling retrofit of the new ion source into the ion source design space of existing Bernas source-based ion implanters and the like or otherwise enabling compatibility with other ion source designs; Using a control system in retrofit installations that enables retention of the installed operator interface and control techniques with which operators are already familiar; Enabling convenient handling and replenishment of the solid within the vaporizer without substantial down-time of the implanter; Providing internal adjustment and control techniques that enable, with a single design, matching the dimensions and intensity of the zone in which ionization occurs to the beam line of the implanter and the requirement of the process at hand; Providing novel approaches, starting materials and conditions of operation that enable the making of future generations of semiconductor devices and especially CMOS source / drains and extensions, and doping of silicon gates.

Owner:SEMEQUIP

Beam line architecture for ion implanter

ActiveUS20080078954A1Facilitate uniform and precise implant property across waferImprove filtering effectSemiconductor/solid-state device manufacturingIsotope separationLight beamIon beam

A parallelizing component of an ion implantation system comprises two angled dipole magnets that mirror one another and serve to bend an ion beam traversing therethrough to have a substantially “s” shape. This s bend serves to filter out contaminants of the beam, while the dipoles also parallelize the beam to facilitate uniform implant properties across the wafer, such as implant angle, for example. Additionally, a deceleration stage is included toward the end of the implantation system so that the energy of the beam can be kept relatively high throughout the beamline to mitigate beam blowup.

Owner:AXCELIS TECHNOLOGIES

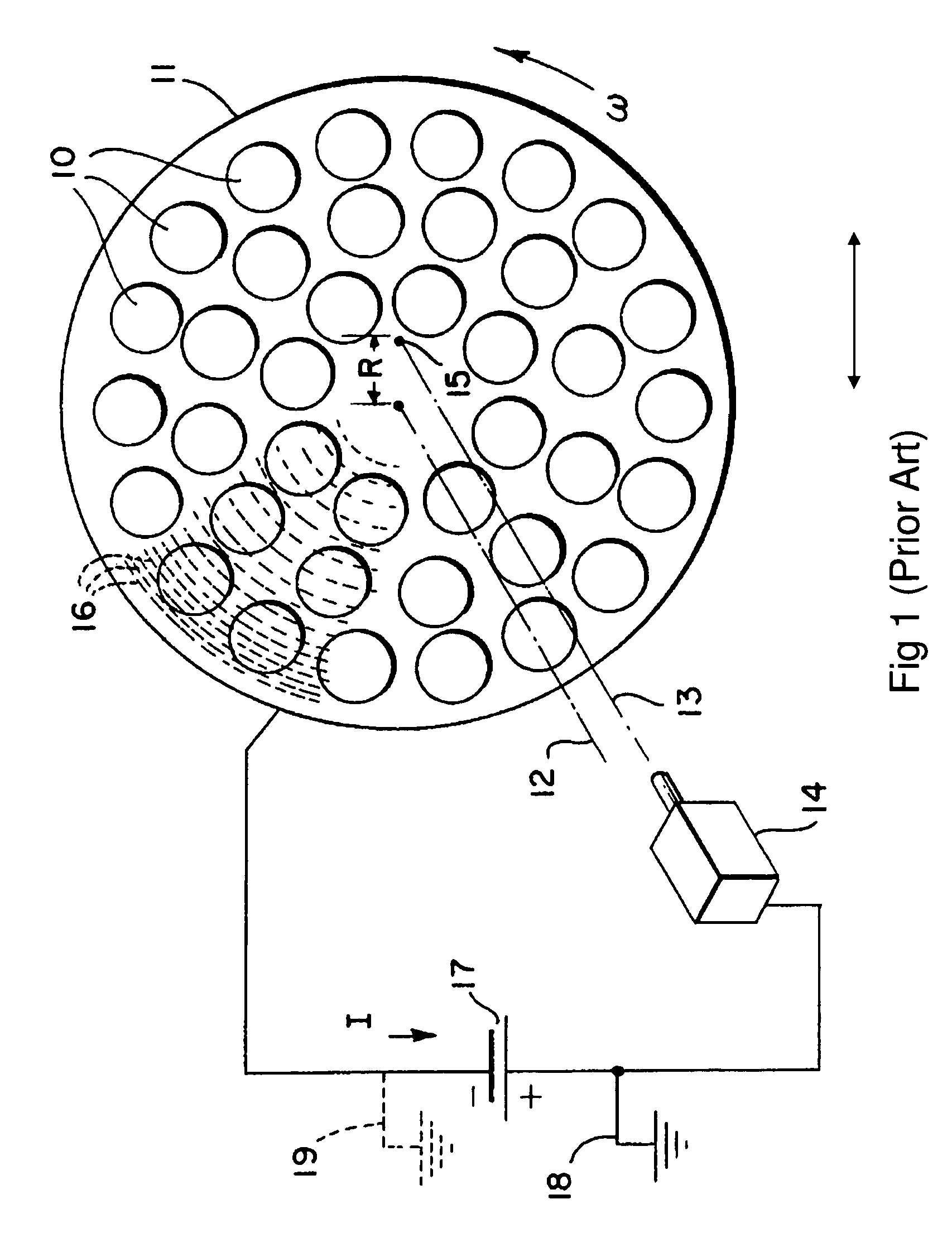

Gas-cluster-jet generator and gas-cluster ion-beam apparatus utilizing an improved gas-cluster-jet generator

ActiveUS20110155897A1Improved vacuum management technique and apparatusImprove conductivityLaser detailsParticle separator tubesGas cluster ion beamSpray nozzle

A gas-cluster-jet generator with improved vacuum management techniques and apparatus is disclosed. The gas-cluster-jet generator comprises a substantially conically shaped vacuum chamber for housing the nozzle and jet exit portions of the gas-cluster-jet generator. A skimmer may be located at the narrow end of the conical chamber and a close-coupled vacuum pump is located at the wide end of the conical chamber. Support members for the nozzle are high conductivity “spider” supports that provide support rigidity while minimizing gas flow obstruction for high pumping speed. The conically shaped vacuum chamber redirects un-clustered gas in a direction opposite the direction of the gas-cluster-jet for efficient evacuation of the un-clustered gas. The nozzle and a skimmer may have fixed precision relative alignment, or may optionally have a nozzle aiming adjustment feature for aligning the gas-cluster-jet with the skimmer and downstream beamline components. Also disclosed are various configurations of gas-cluster ion-beam processing tools employing the improved gas-cluster-jet generator.

Owner:EXOGENESIS CORP

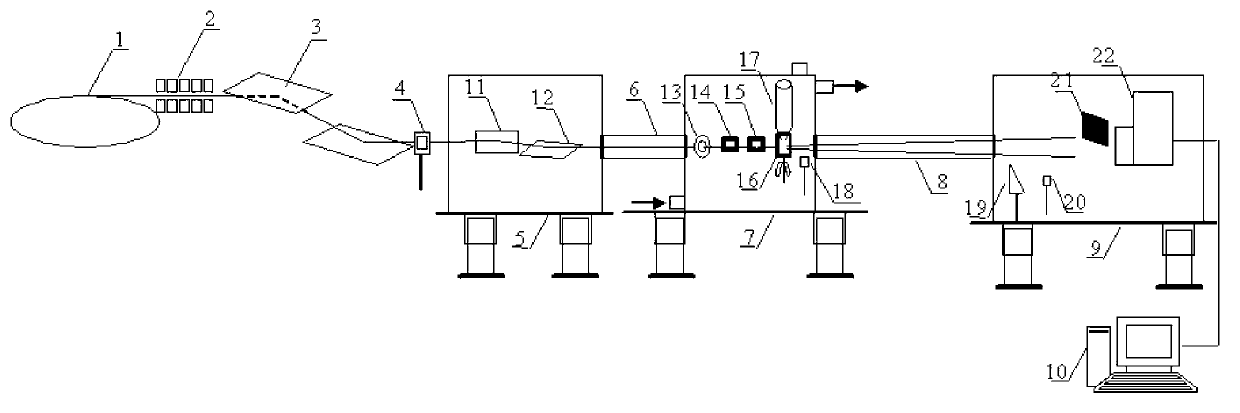

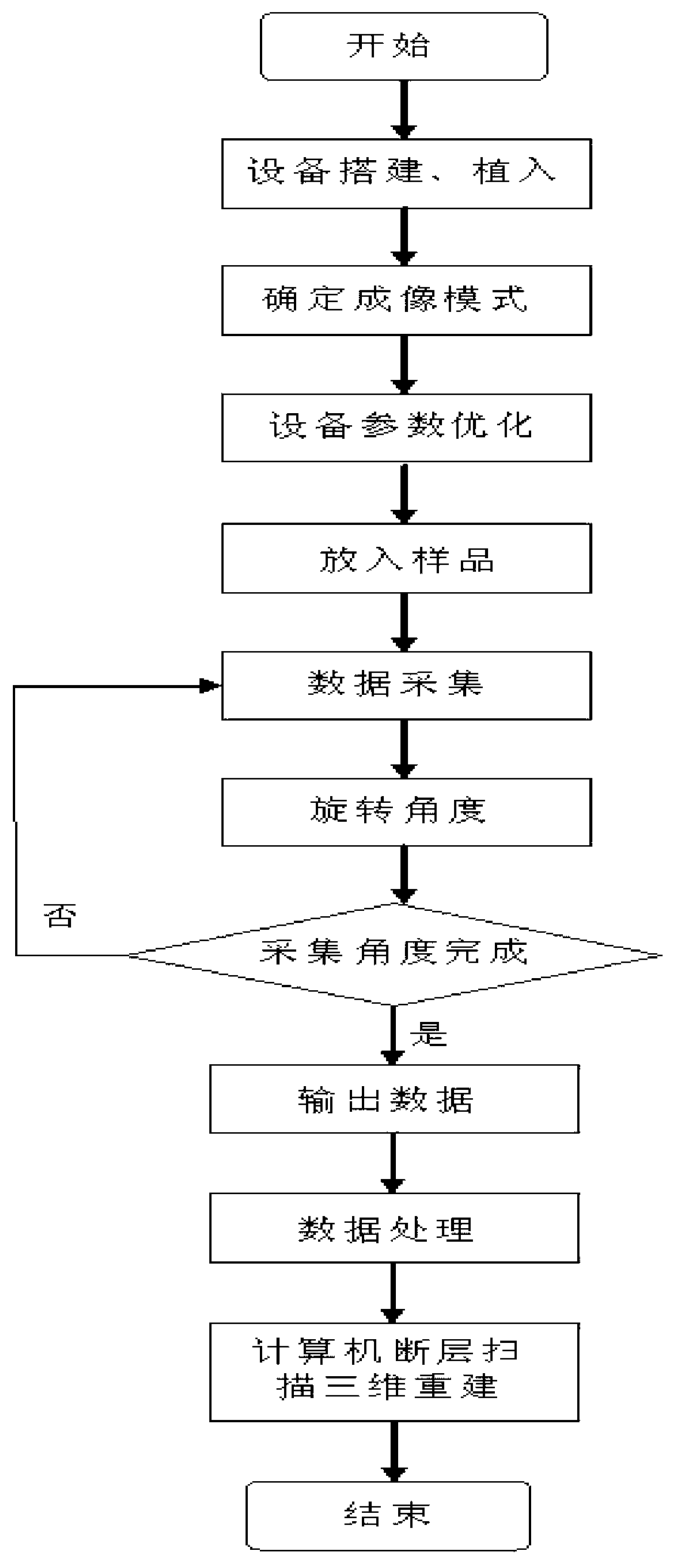

A multi-purpose synchrotron radiation coherent X-ray diffraction microscopic imaging device and application

InactiveCN103134825ARealize free switchingRealize acquisitionMaterial analysis using wave/particle radiationMicroscopic imageX-ray

The invention discloses a multi-purpose synchrotron radiation coherent X-ray diffraction microscopic imaging device. A synchrotron radiation X-ray light source, an undulator, a monochromator crystal, an X-ray shutter, a first lifting platform, a focusing device cavity, a vacuum piping, a second lifting platform, a multi-purpose sample room, a vacuum piping, a third lifting platform, a detector, and a computer which is used for collecting data and controlling an electric controlled translation platform are sequentially and coaxially arranged along the forward motion direction of light beam, wherein the monochromator crystal, the X-ray shutter and the first lifting platform are arranged on an electrical rotary platform, the focusing device cavity, the vacuum piping and the second lifting platform are arranged on the first lifting platform, the multi-purpose sample room, the vacuum piping and the third lifting platform are arranged on the second lifting platform, and the detector and the computer are arranged on the third lifting platform. According to the multi-purpose synchrotron radiation coherent X-ray diffraction microscopic imaging device, a low vacuum operating mode, a ventilation working mode, a freezing operating mode, X-ray focusing mode imaging or X-ray non-focusing mode imaging are achieved, the collection of three-dimension diffraction signals of samples are achieved by using a three-dimension rotating platform, a high quality three-dimension rebuilding result is obtained by using computer software, dying treatment and slicing treatment to the samples are needless, and train of thought is supplied to enrich a synchrotron radiation beam line imaging method.

Owner:SHANDONG UNIV

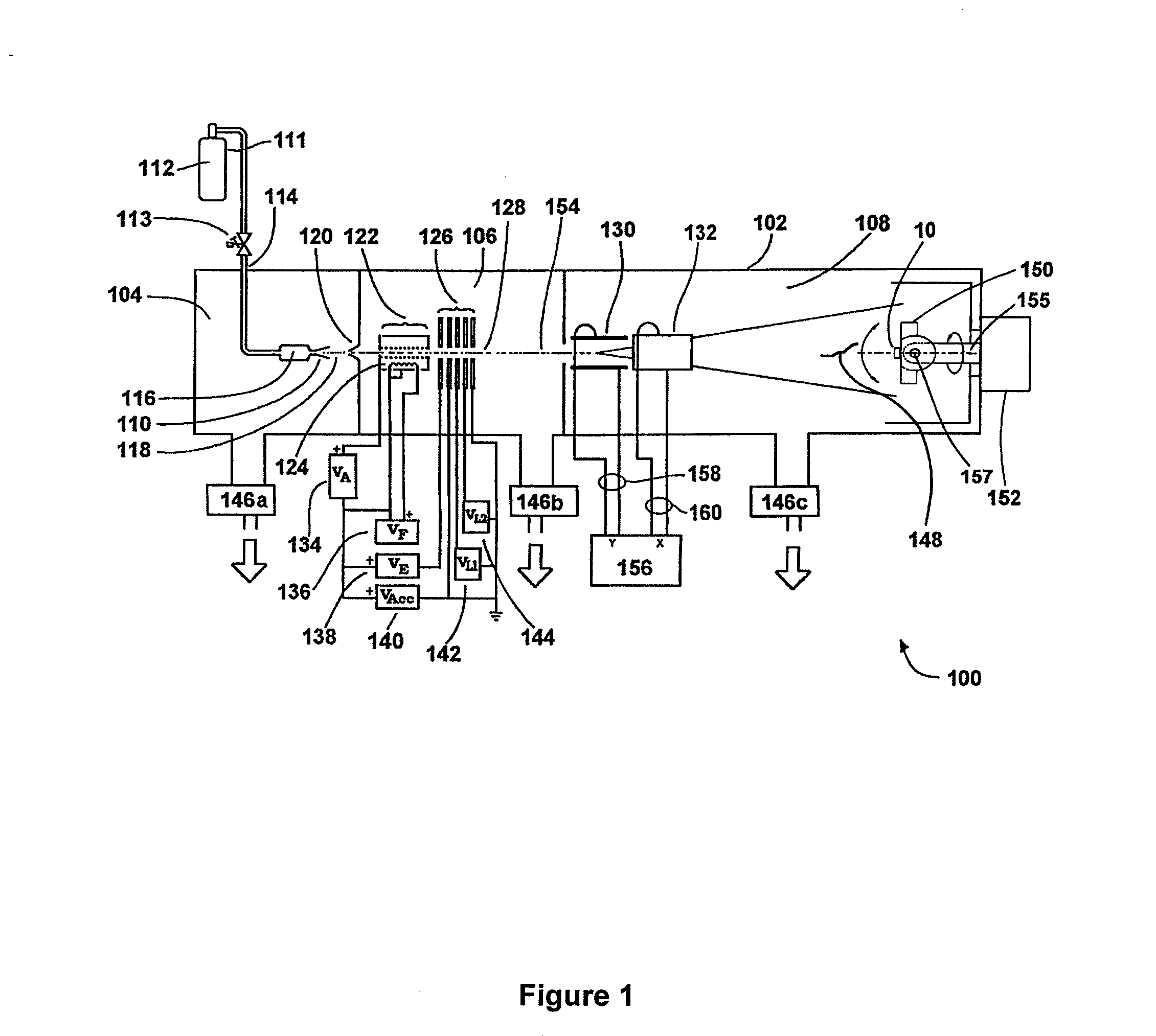

Ion implanter having enhanced low energy ion beam transport

InactiveUS20060043316A1Electric discharge tubesSemiconductor/solid-state device manufacturingIon beamLight beam

An ion implanter includes an ion source for generating an ion beam, a target site for supporting a target for ion implantation and a beamline defining a beam path between the ion source and the target site. In one aspect, a magnetic steerer is disposed between the ion source and the target site for at least partially correcting unwanted deviation of the ion beam from the beam path. The magnetic steerer may position the ion beam relative to an entrance aperture of an ion optical element. In another aspect, the beamline includes a deceleration stage for decelerating the ion beam from a first transport energy to a second transport energy. The deceleration stage includes two or more electrodes, wherein at least one of the electrodes is a grid electrode positioned in the beam path.

Owner:VARIAN SEMICON EQUIP ASSOC INC

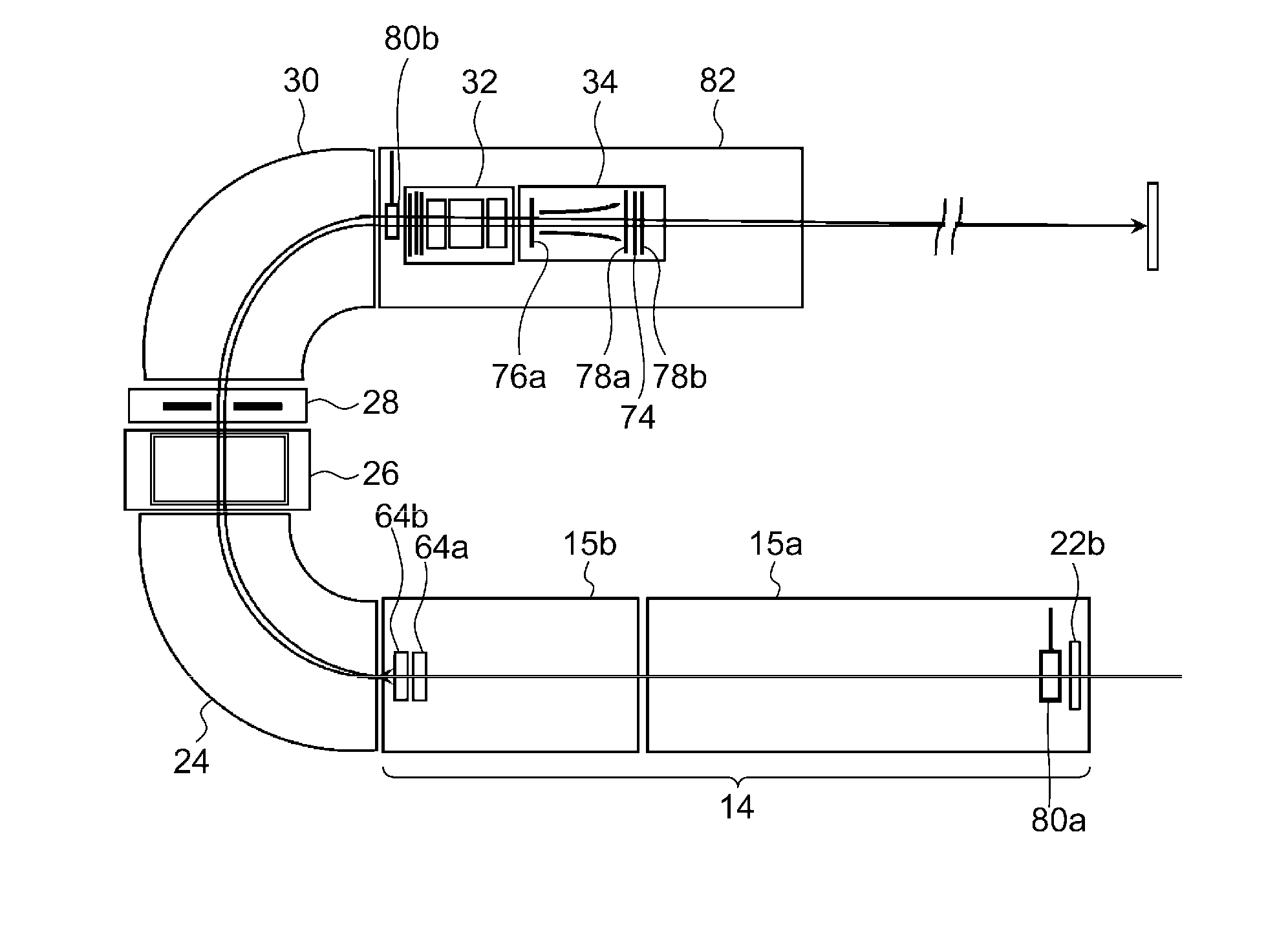

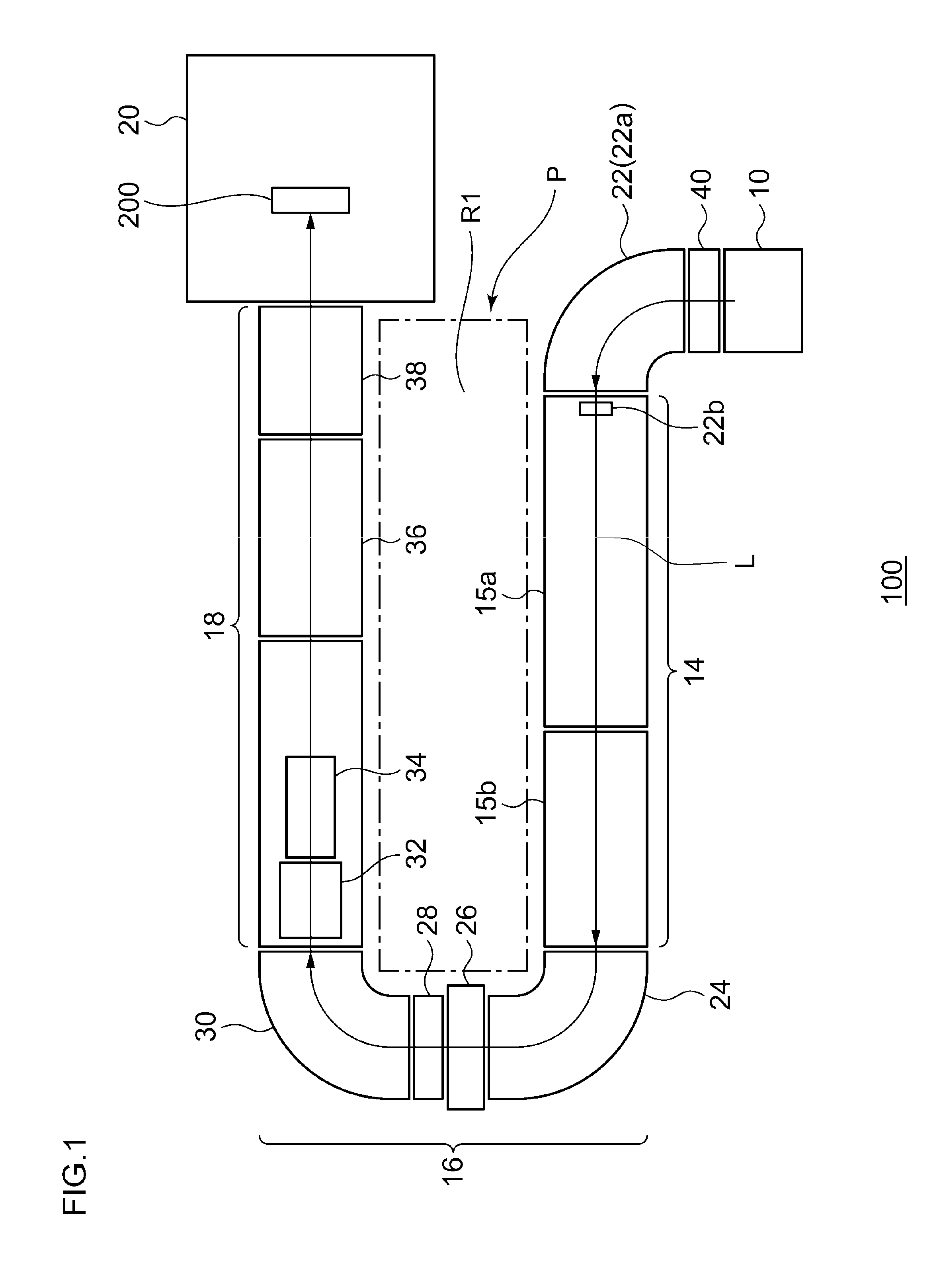

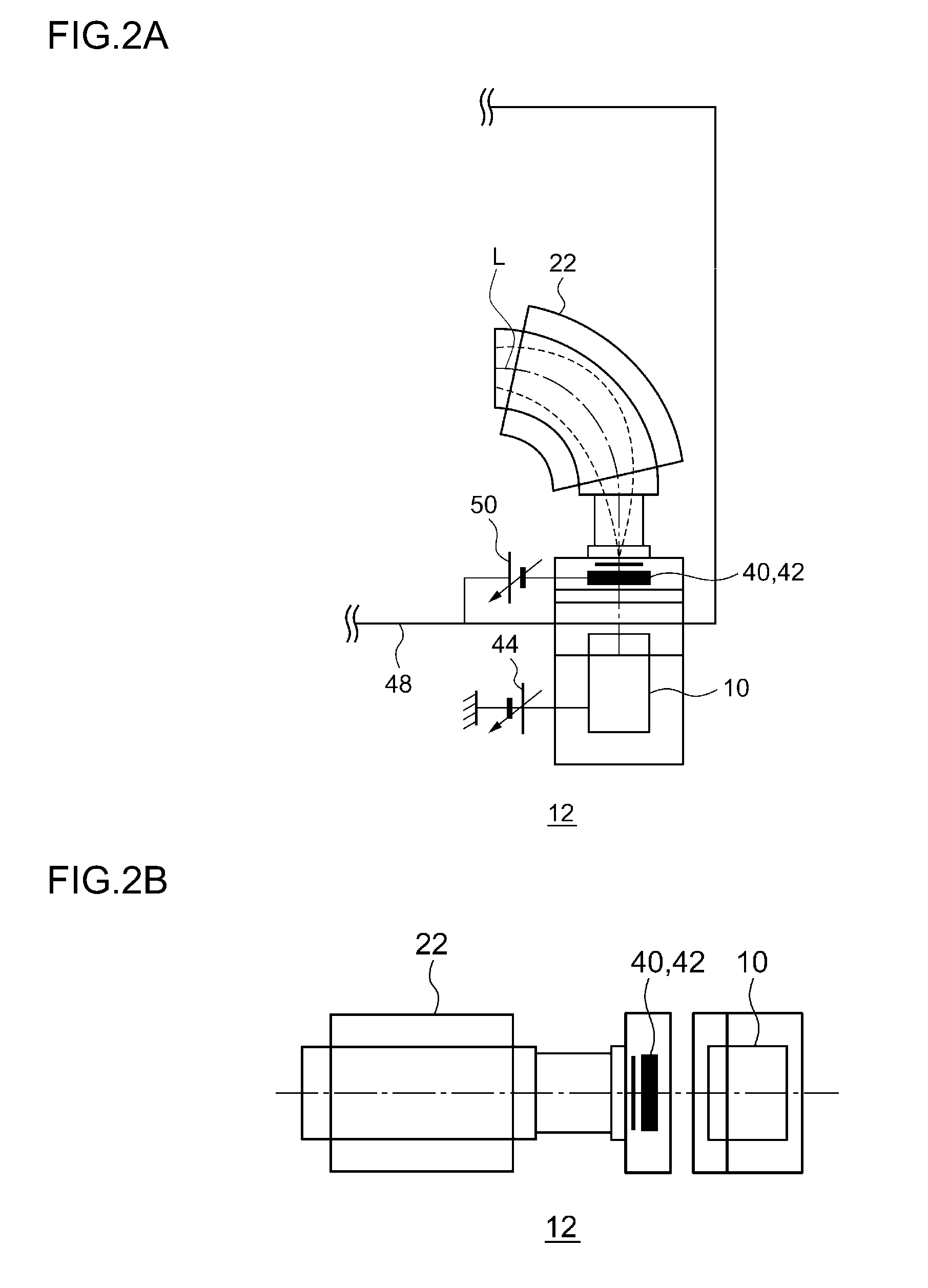

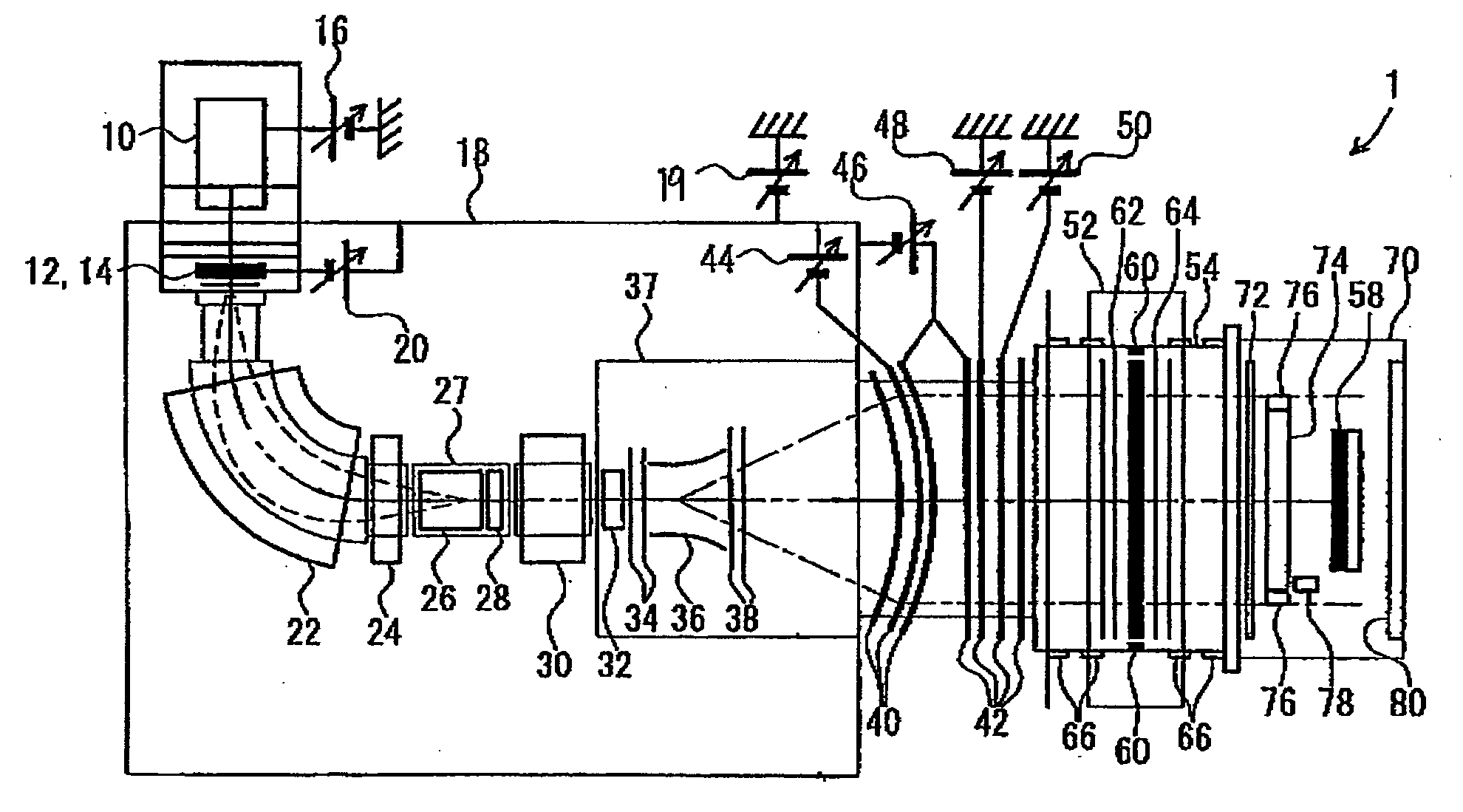

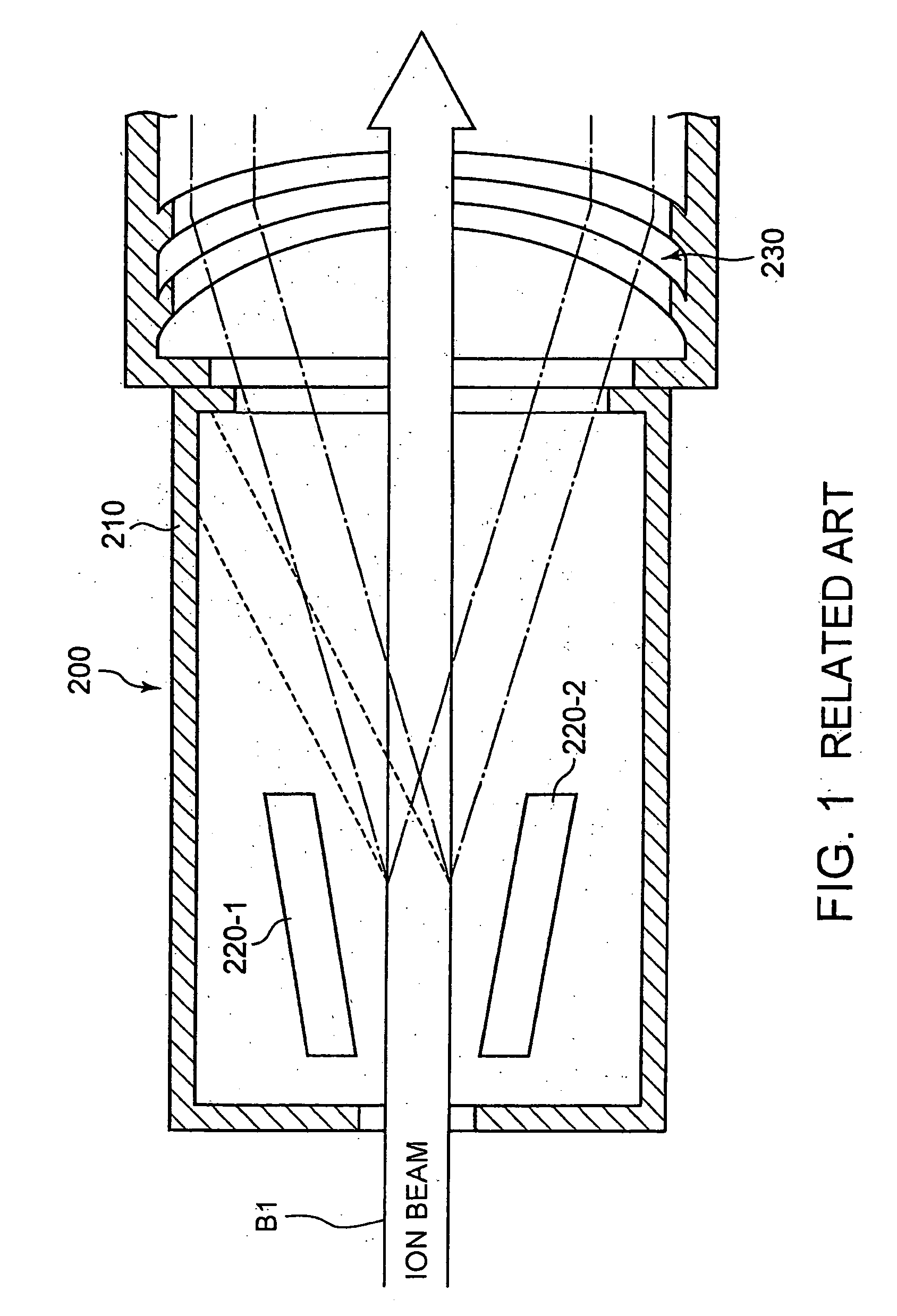

Ion implantation apparatus

ActiveUS20140150723A1Ensuring workabilityElectric discharge tubesVacuum evaporation coatingIon beamLight beam

An ion implantation apparatus includes: a plurality of units for accelerating an ion beam generated in an ion source; and a plurality of units for adjusting a scan beam and implanting ions into a wafer. A horizontal U-shaped folder type beamline having opposite long straight portions includes the plurality of units for adjusting the scan beam in a long straight portion to have substantially the same length as the ion source and the plurality of units for accelerating the ion beam.

Owner:SUMITOMO HEAVY IND ION TECH

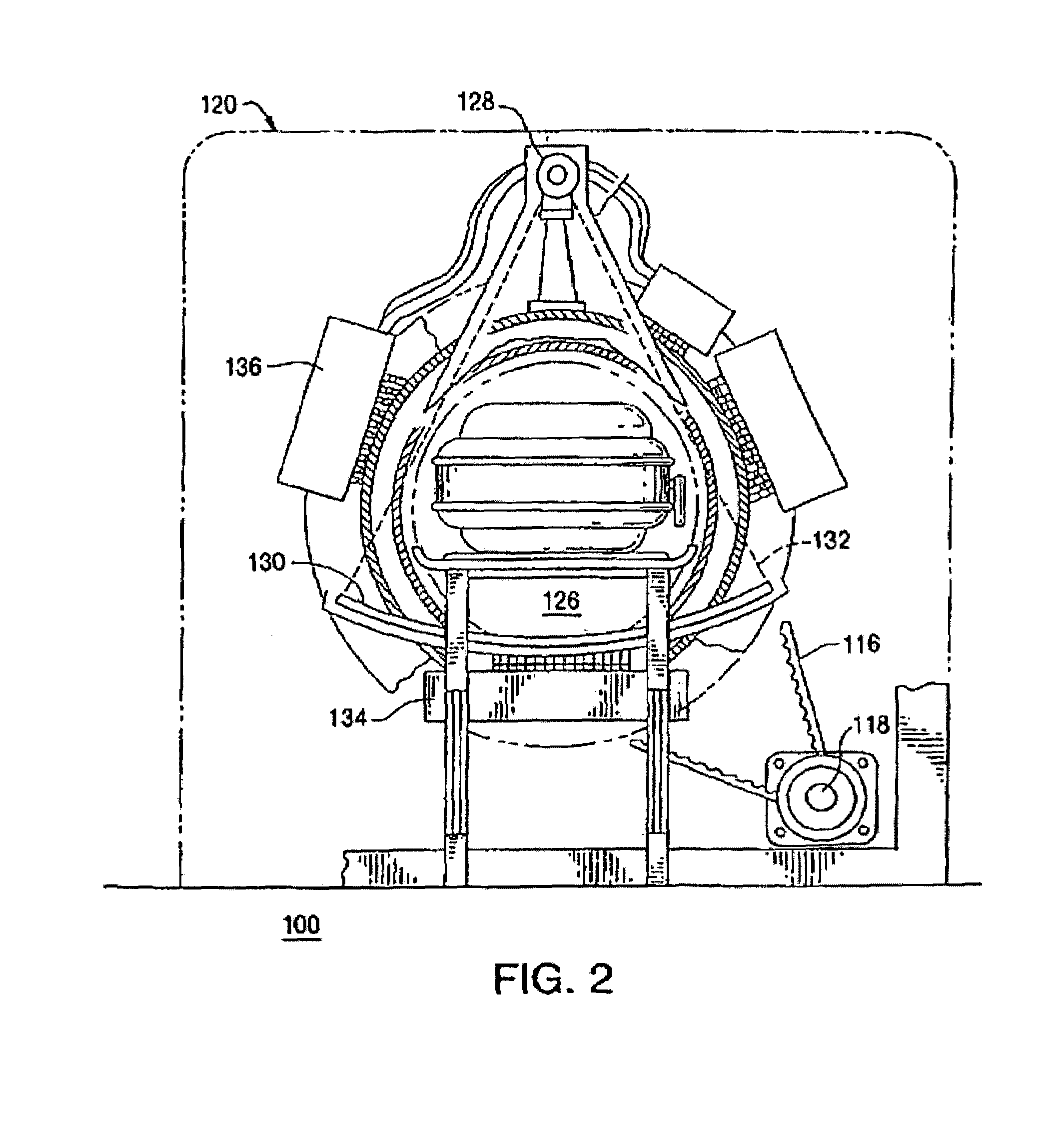

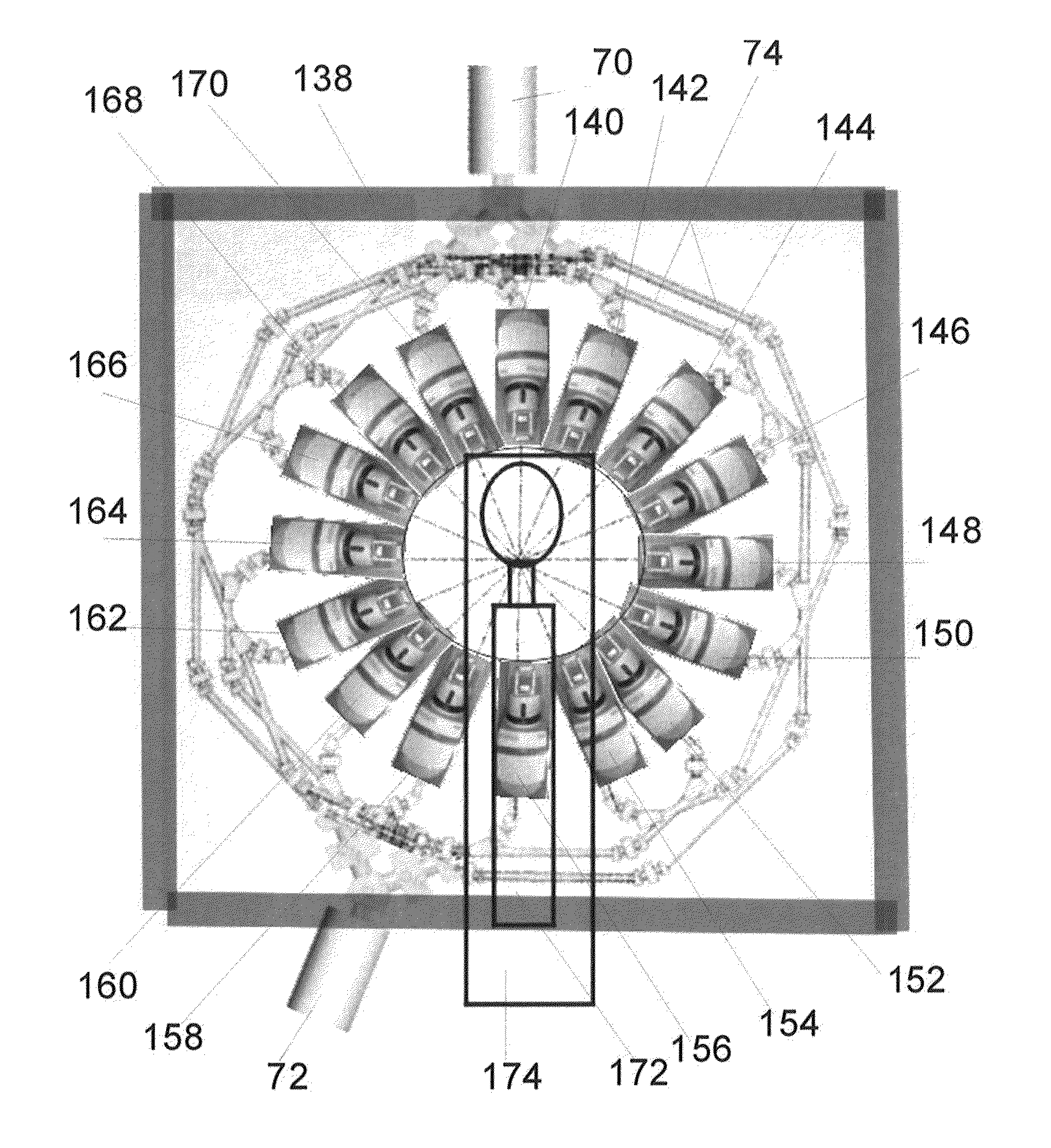

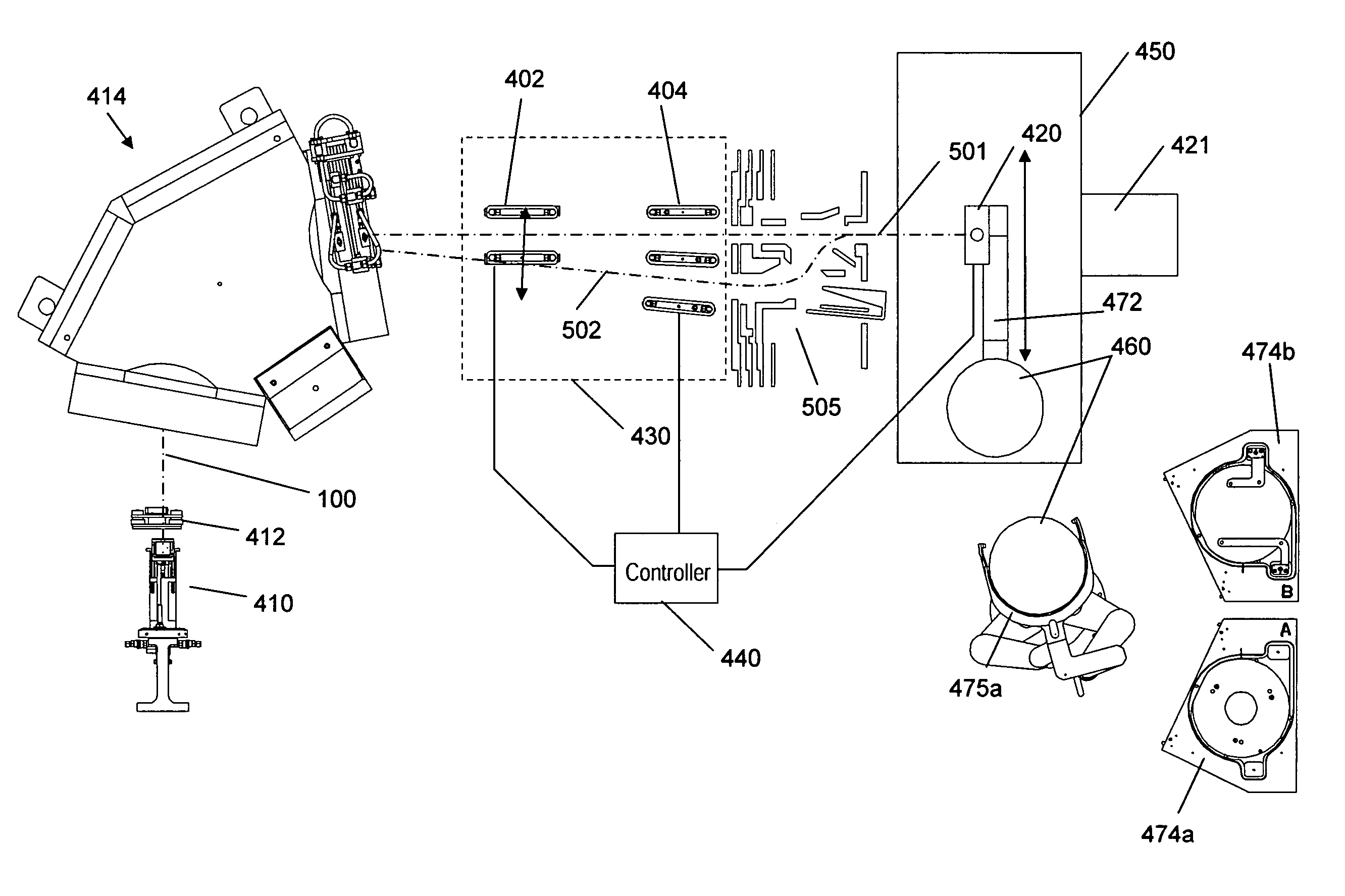

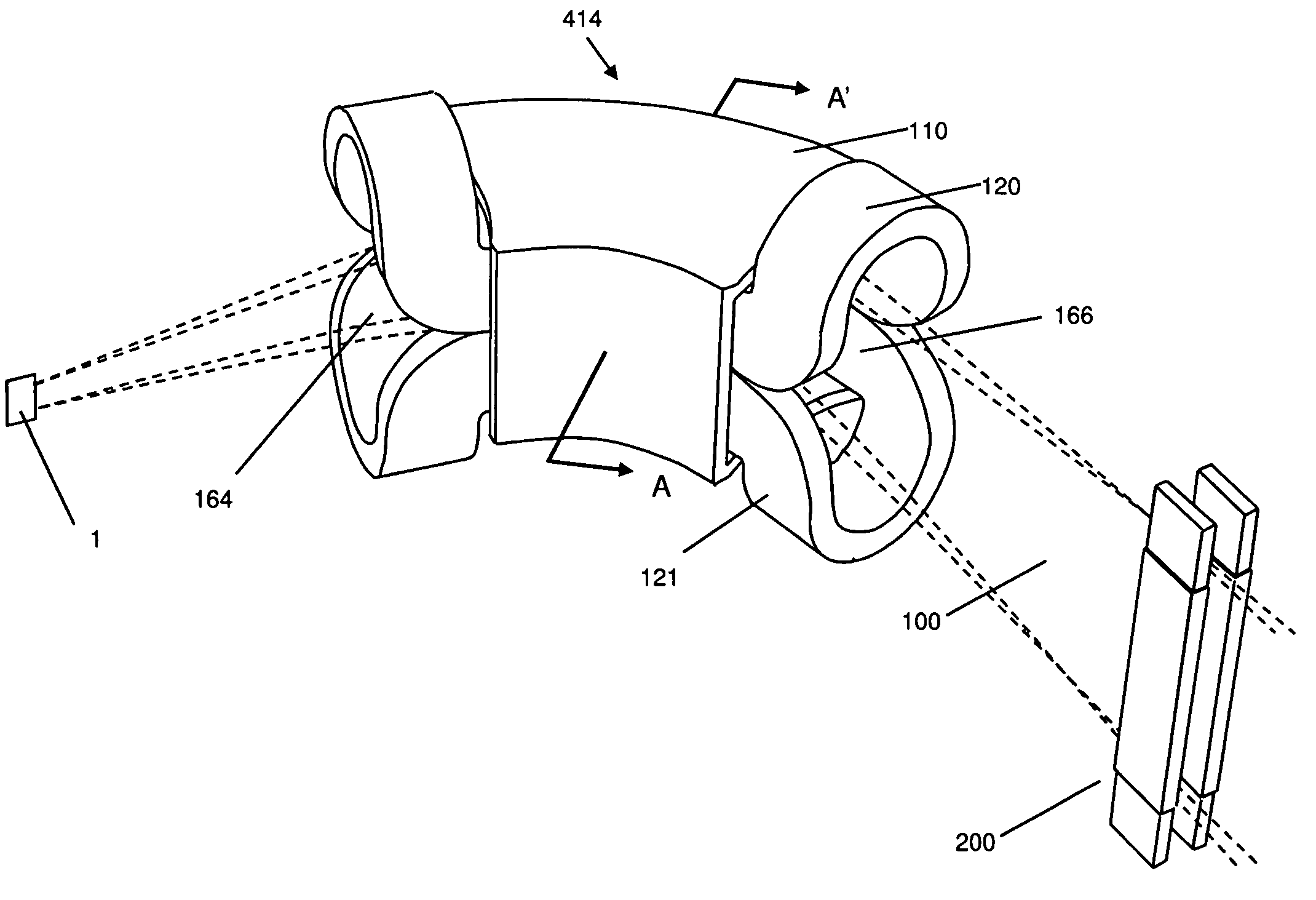

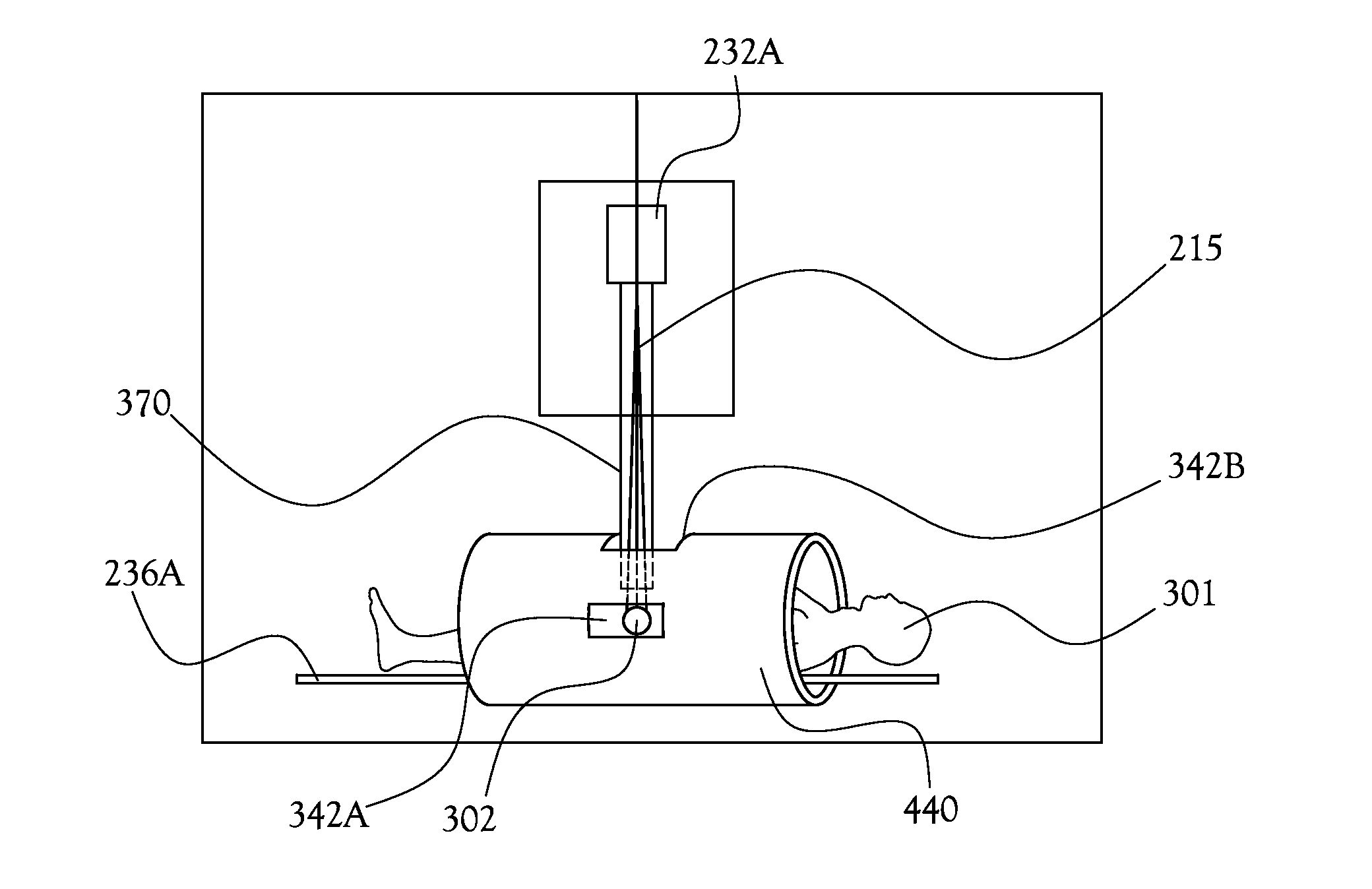

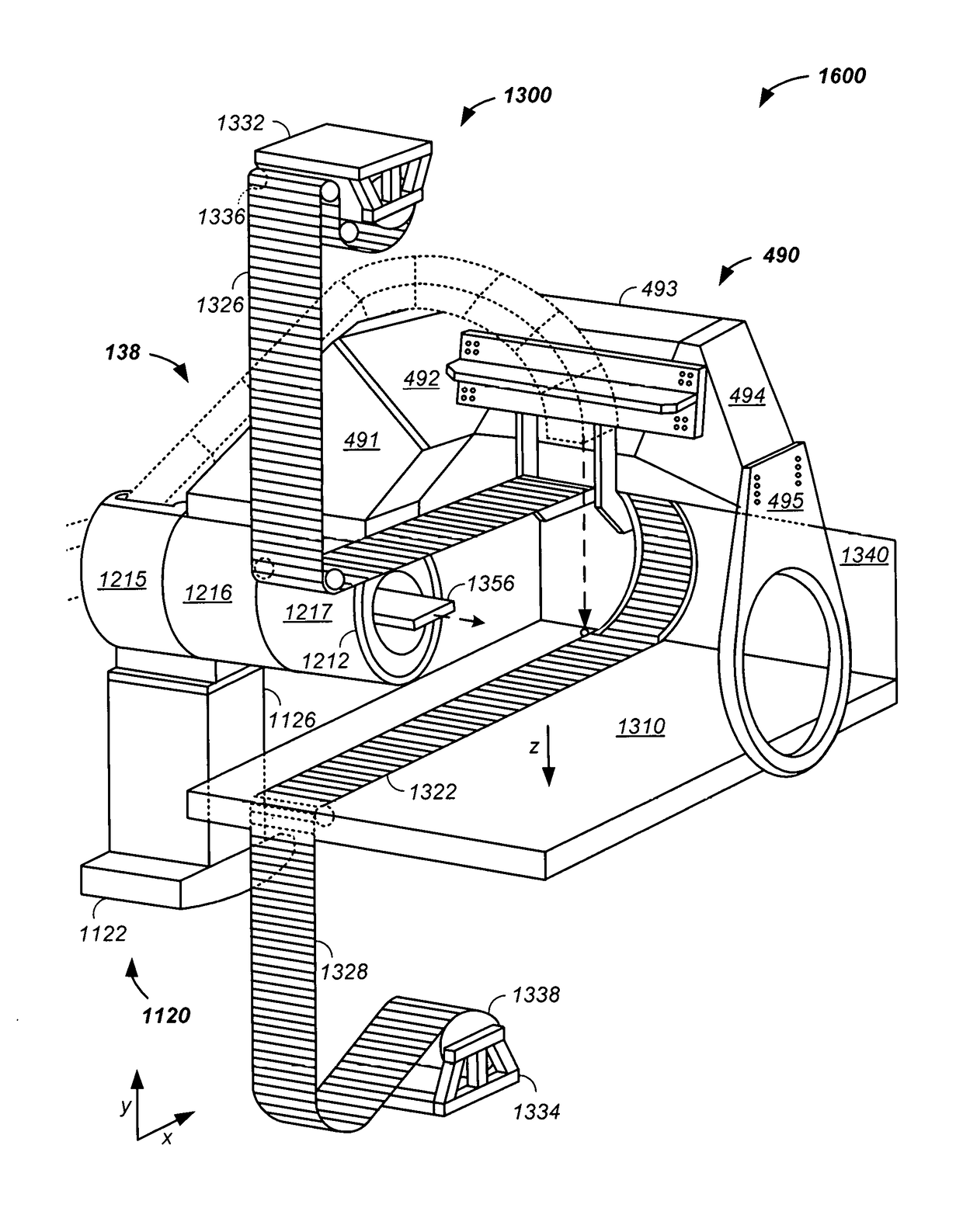

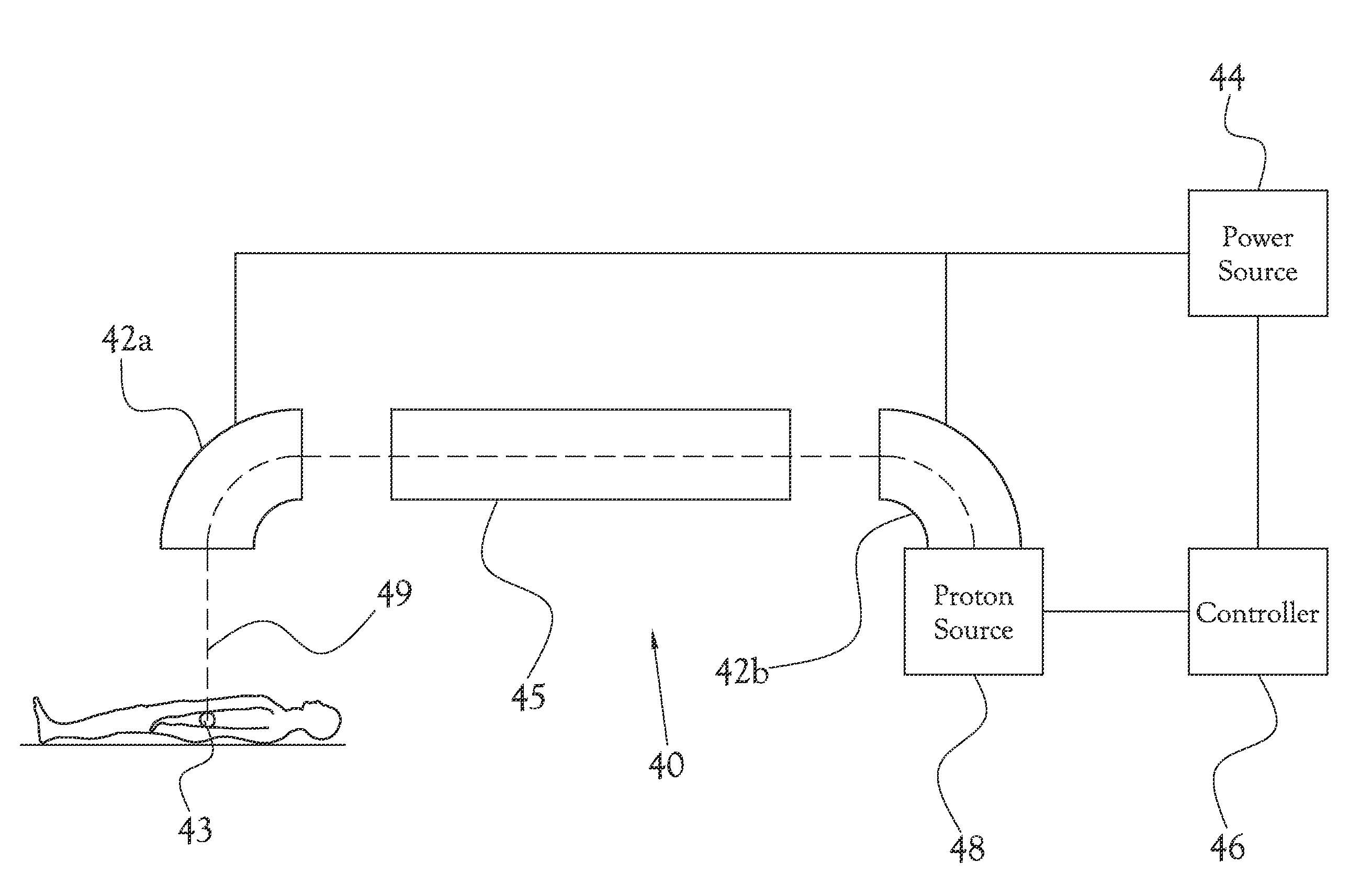

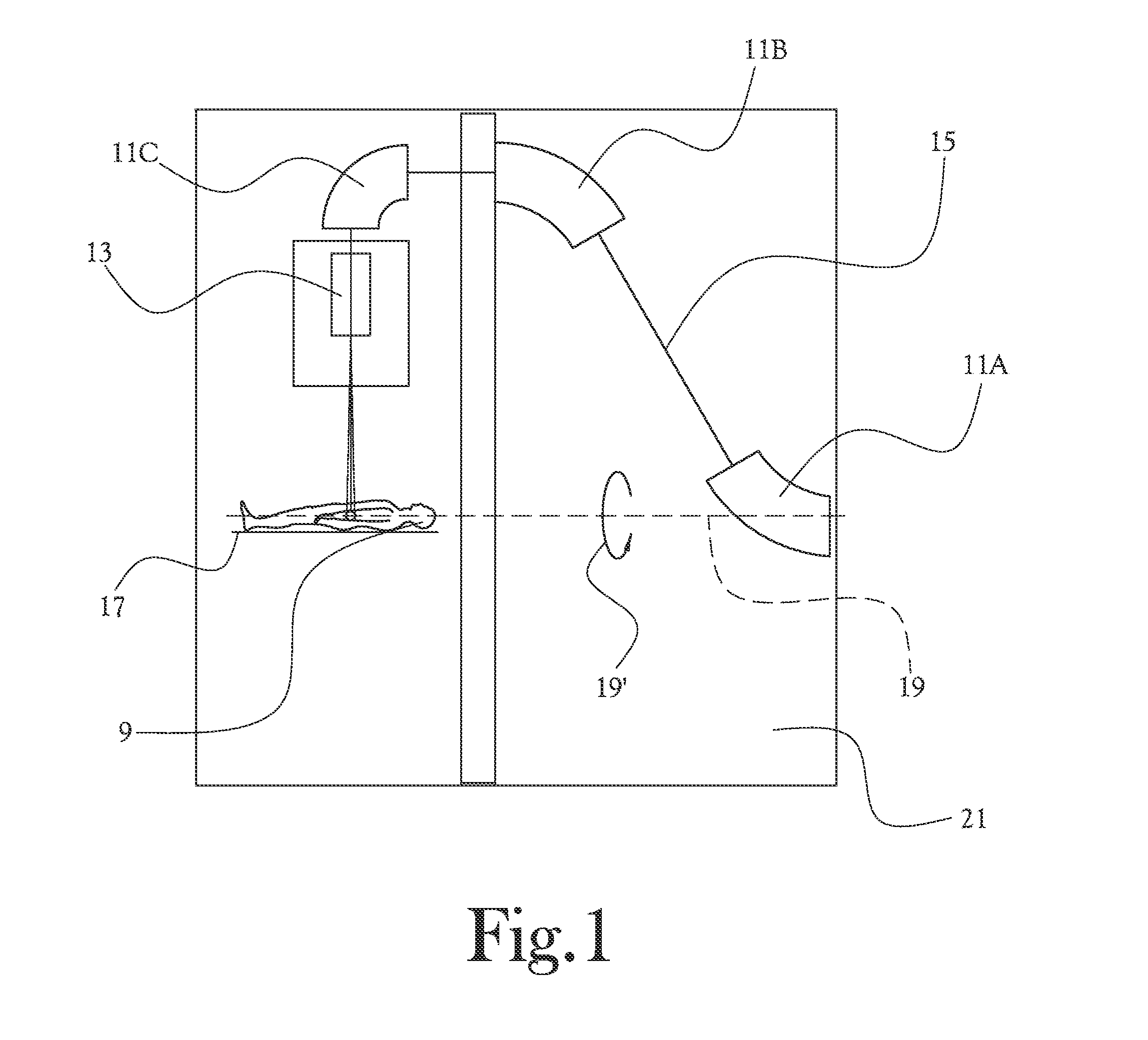

Simultaneous Imaging and Particle Therapy Treatment system and Method

InactiveUS20140066755A1Computerised tomographsDiagnostic recording/measuringNuclear medicineParticle generation

A simultaneous imaging and particle therapy treatment system including a means for generating a particle beamline, a treatment bed to receive and support a patient having a treatment volume, a gantry to receive the particle beamline from the generating means and to redirect the beamline to the patient's treatment volume, the gantry rotating about the treatment bed with an axis of rotation substantially coplanar with the treatment bed and redirecting the beamline to encounter the treatment volume substantially perpendicular to the gantry's axis of rotation, and an image scanner having a plurality of detector arrays radially positioned around the treatment bed to capture images of the treatment volume; whereby the scanner and gantry simultaneously capture images of and treat the treatment volume with particle therapy.

Owner:PRONOVA SOLUTIONS

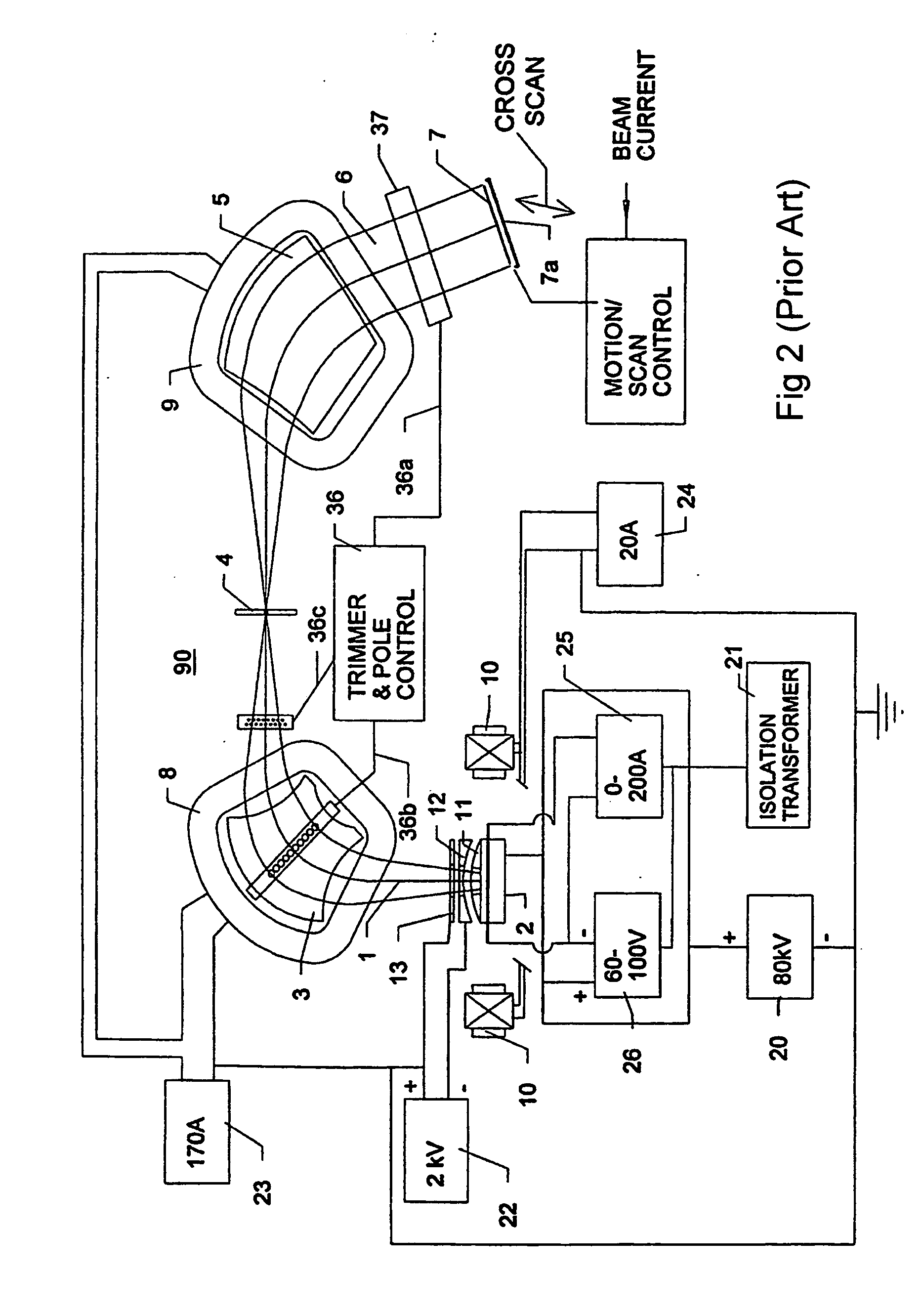

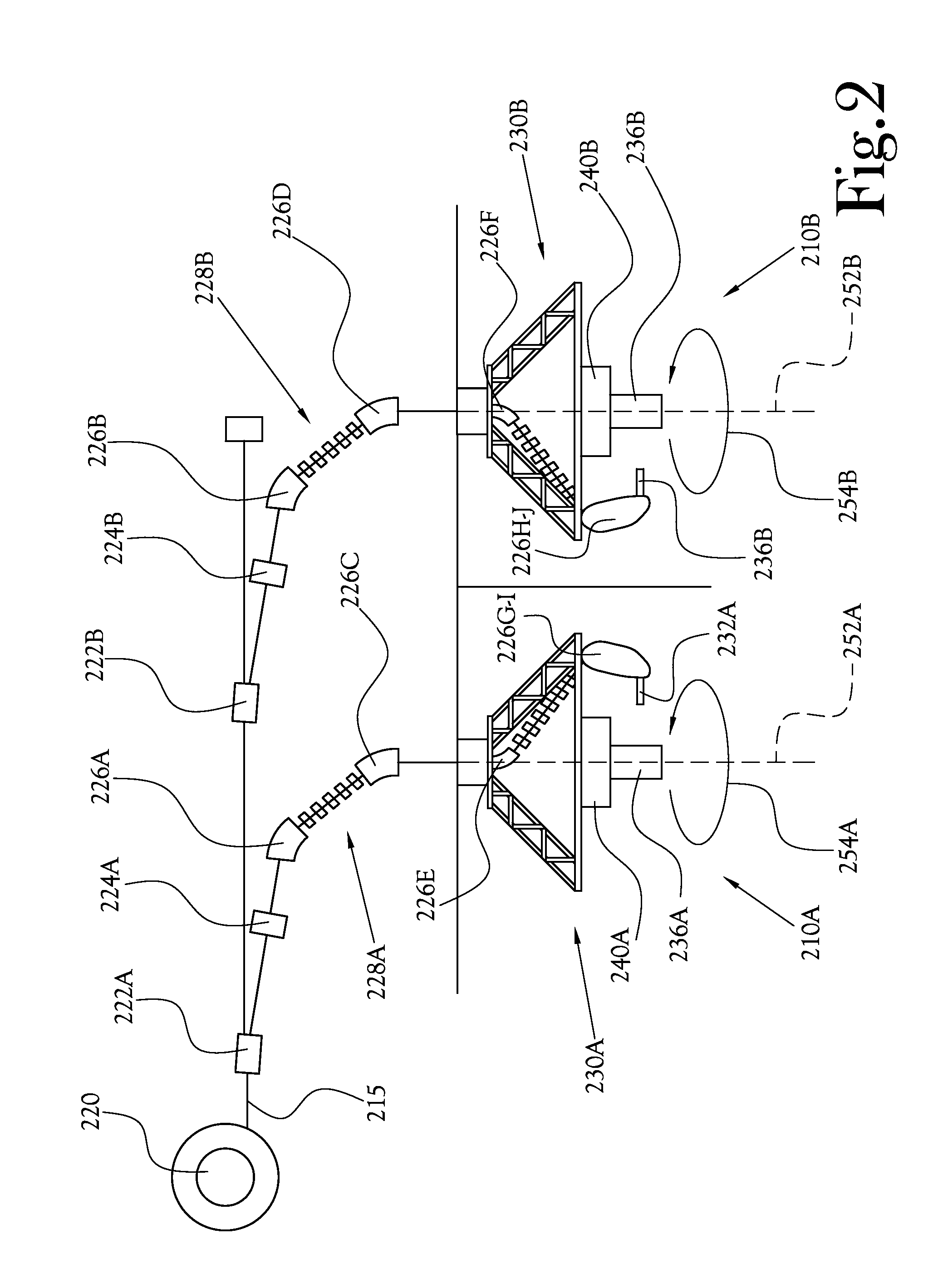

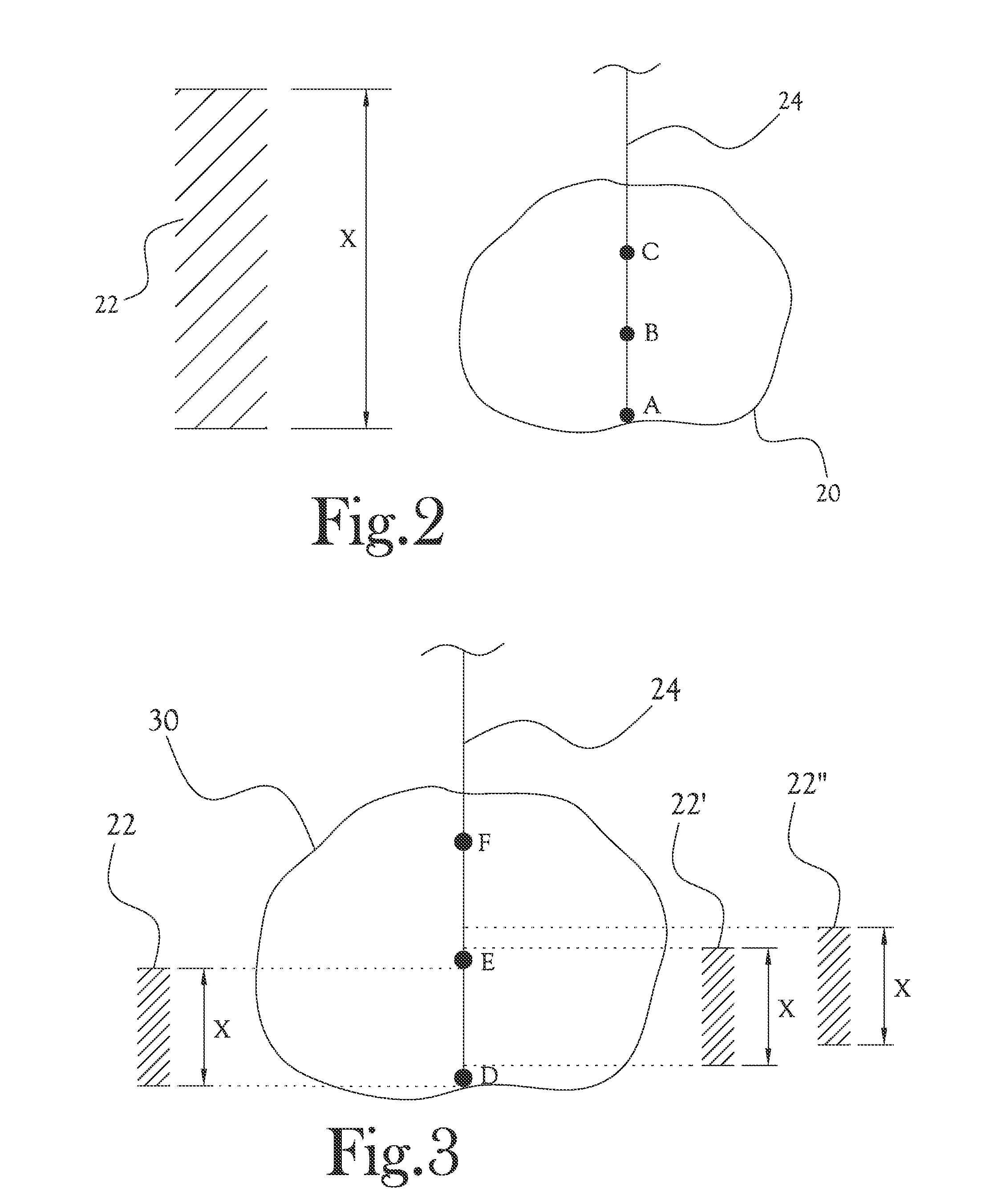

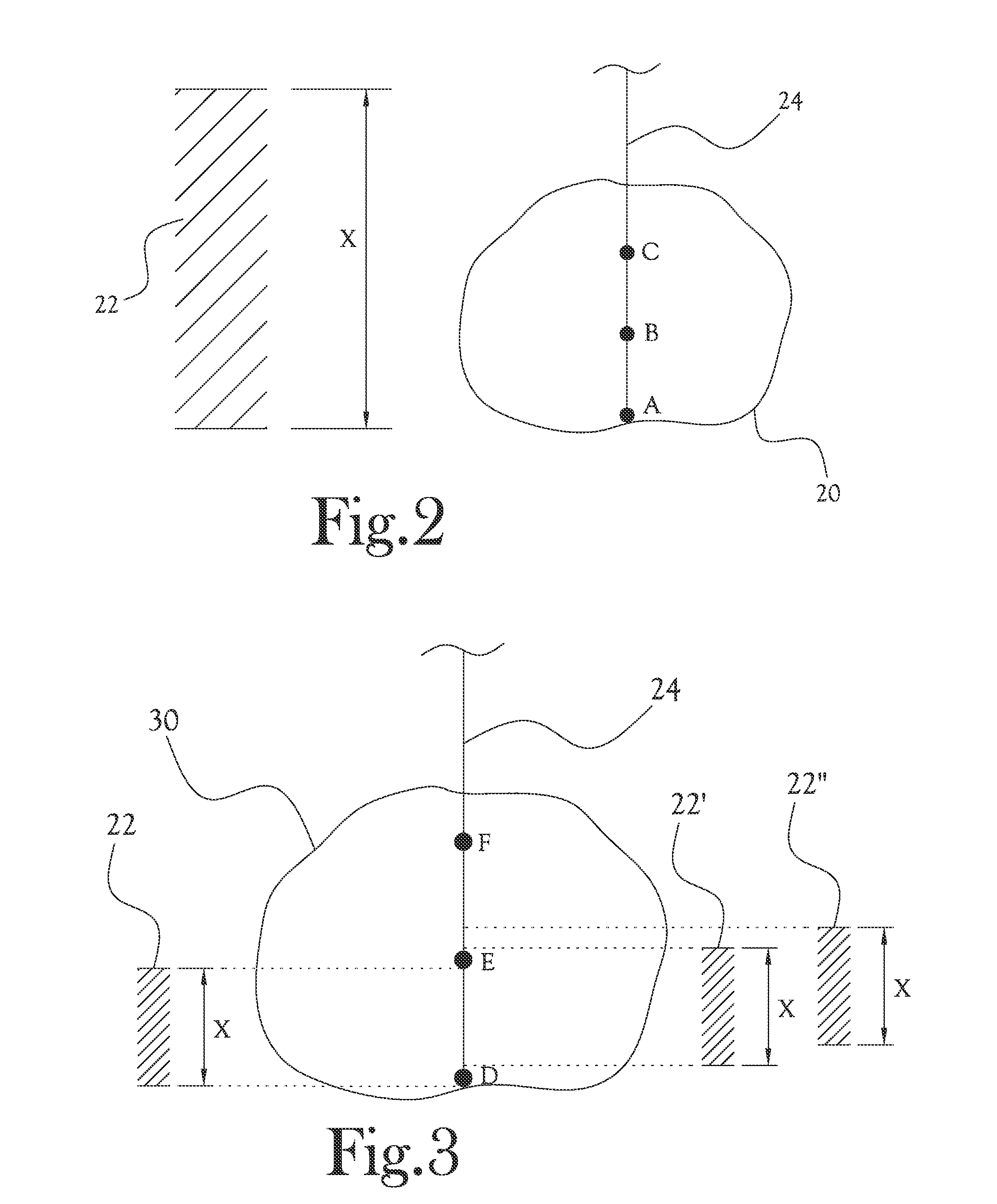

Hadron treatment planning with adequate biological weighting

ActiveUS20070228305A1Optimal biological effectivenessRadiation/particle handlingElectrode and associated part arrangementsDiseaseBragg peak

Treatment planning methods are provided that determine the variability of relative biological effectiveness (RBE) along a beam line and calculate, among other things, what intensity of hadron beam such as a proton or a carbon ion beam should be applied to achieve a desired biological dose at treatment site of a patient afflicted with a medical condition. Typically, three or four RBE values at three or four corresponding spacially-dispersed intervals along the beam line are calculated. In one embodiment, two RBE values for the spread-out Bragg peak (SOBP) region of the treatment site; one for the proximal section and one for the declining distal section is calculated. A third and different RBE value may be determined for the distal edge region of the SOBP. A fourth value may also be calculated for a pre-SOBP region.

Owner:HAMPTON UNIVERSITY

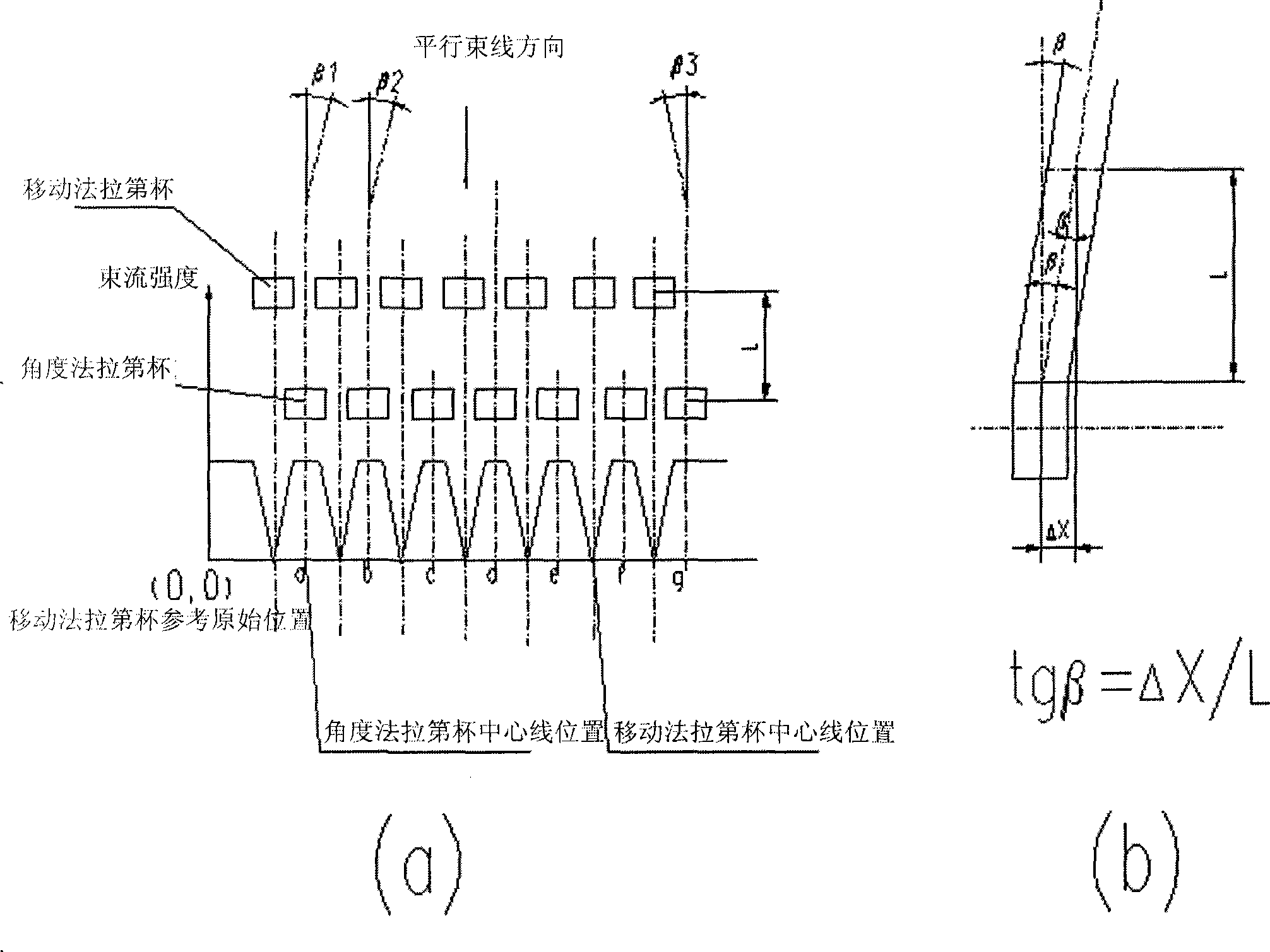

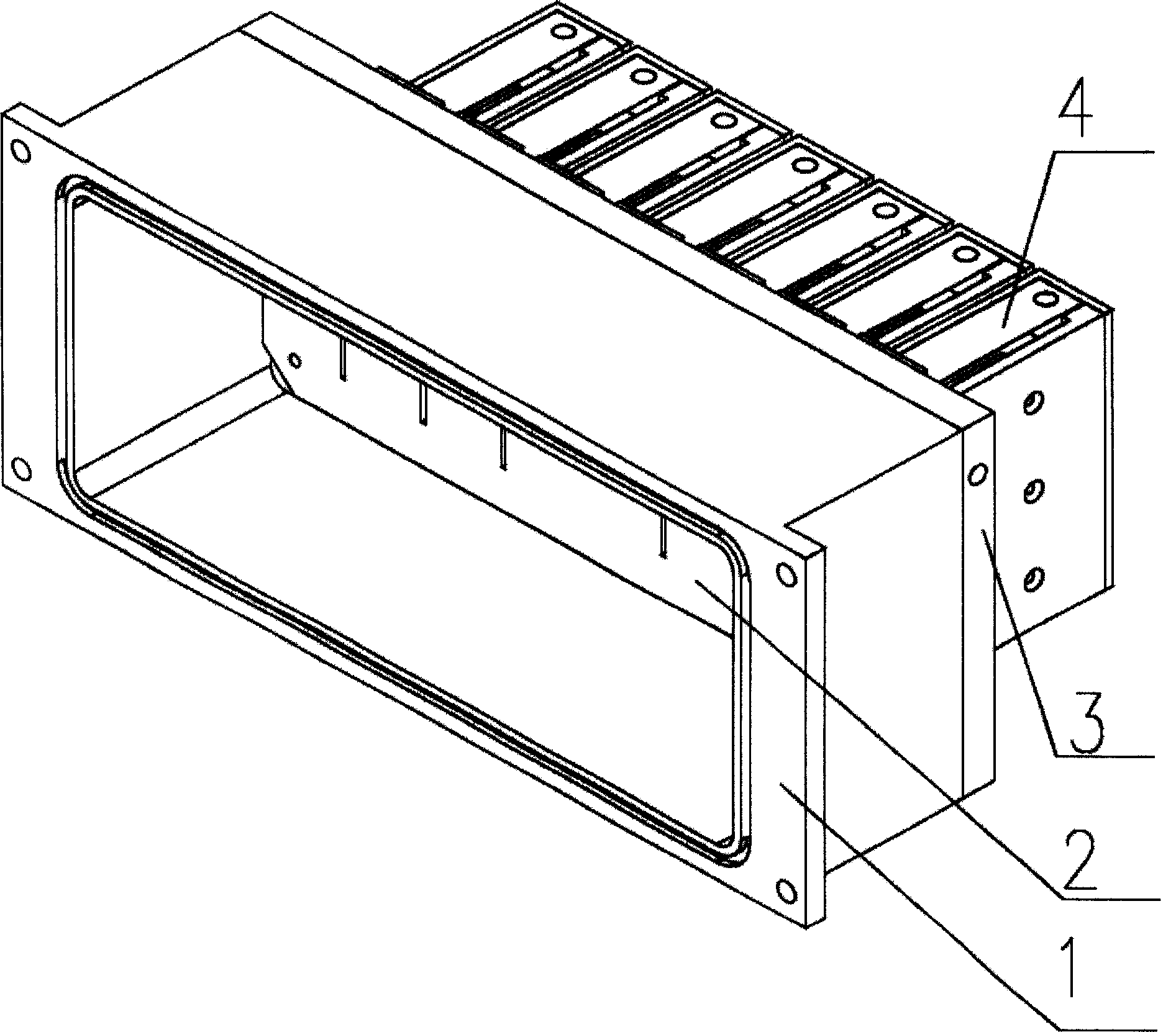

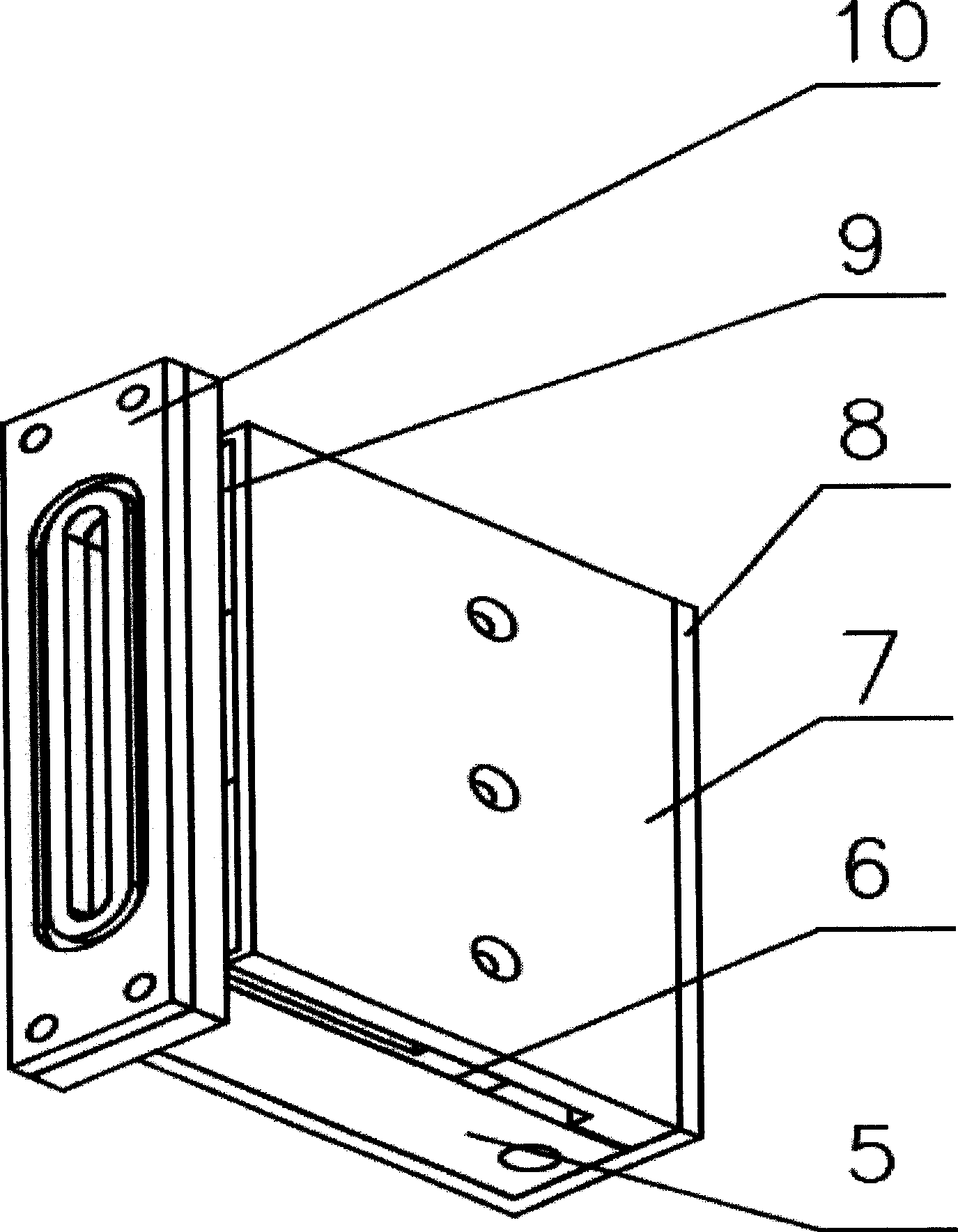

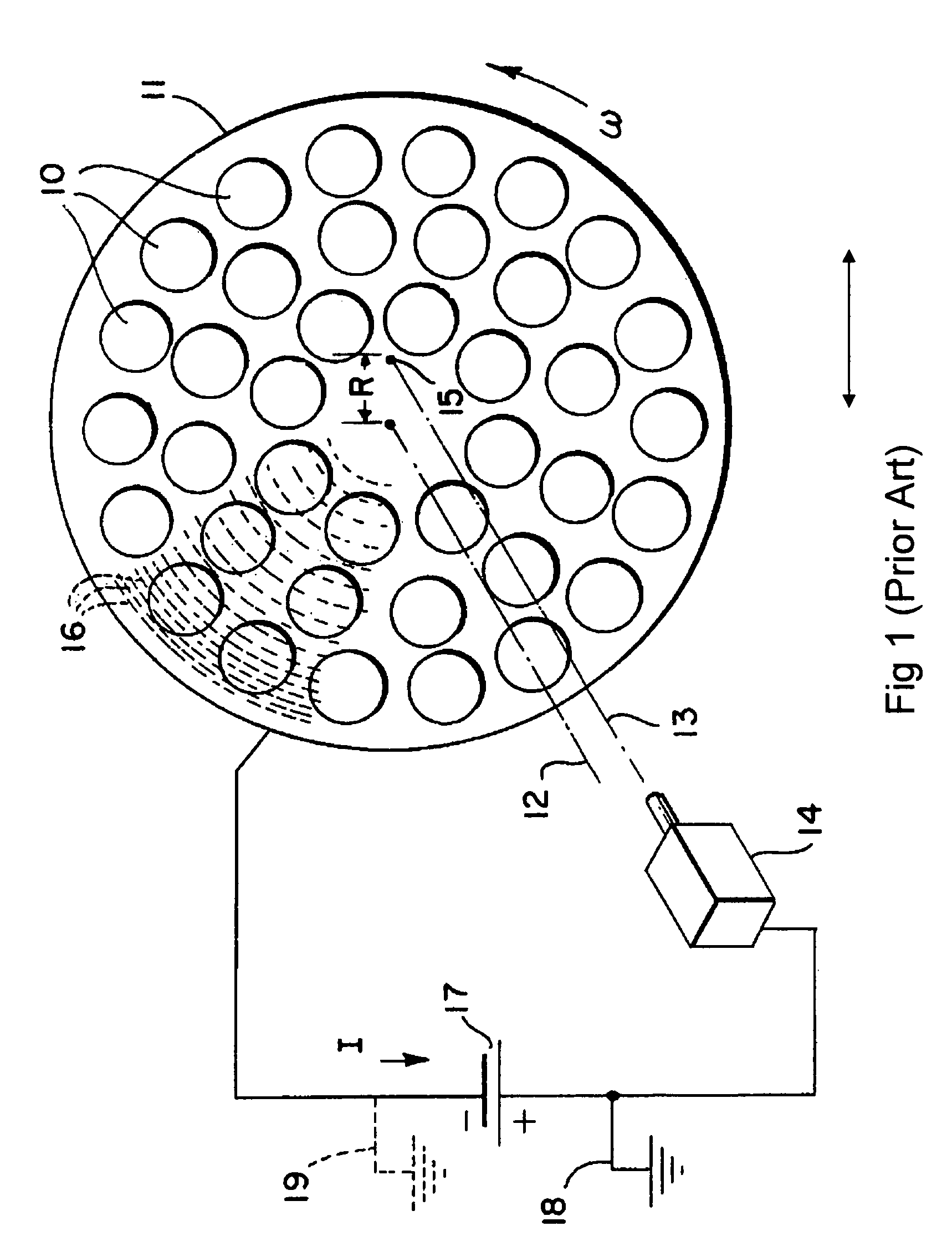

Faraday apparatus for angle measurement of parallel beam

InactiveCN101414545ATo prevent danger caused by electrificationMeasurement devicesElectric discharge tubesPeak valueCrystal plane

The invention discloses a parallel-beam angle measurement Faraday device of an ion implanter, relates to the ion implanter and belongs to the manufacturing field of semiconductors. The structure is as follows: the parallel-beam angle measurement Faraday device is composed of a Faraday collection frame, an electronic suppression plate, a bottom plate of the collection frame, seven fixed-angle Faraday cups and a moving Faraday cup, the Faraday collection frame collects incident ion beam flow, the electronic suppression plate suppresses the electron overflow generated by the bombardment on metal bodies of the Faraday cups by ion beams, the angle collection bottom plate is used for the vacuum connection and the sealing of the Faraday collection frame and the Faraday cups, the seven fixed-angle Faraday cups measure the current intensity of the ion beams, the central position of the implanted ion beams is determined by being combined with the moving Faraday cup which is arranged in a target room area, when the parallel beams are the incident beams which are perpendicular to a crystal plane, the central position of the blocking beams of the moving Faraday cup is consistent with the center of the measuring beams of the fixed Faraday cups, and the current of the fixed-angle Faraday cups simultaneously achieves the peak value at the position when the current of the moving Faraday cup achieves the peak value.

Owner:BEIJING ZHONGKEXIN ELECTRONICS EQUIP

Linear adaptive optics system in low power beam path and method

A system and method for providing a wavefront corrected high-energy beam of electromagnetic energy. In the illustrative embodiment, the system includes a source of a first beam of electromagnetic energy; an amplifier for amplifying said beam to provide a second beam; a sensor for sensing aberration in said second beam and providing an error signal in response thereto; a processor for processing said error signal and providing a correction signal in response thereto; and a spatial light modulator responsive to said correction signal for adjusting said beam to facilitate a correction of said aberration thereof. In more specific embodiments, the source is a laser and the sensor is a laser wavefront sensor. A mirror is disposed between said modulator and said sensor for sampling said beam. The mirror has an optical thin-film dielectric coating on at least one optical surface thereof. The coating is effective to sample said beam and transmit a low power sample thereof to said means for sensing aberration. The processor is an adaptive optics processor. The spatial light modulator may be a micro electro-mechanical system deformable mirror or an optical phased array. In the illustrative embodiment, the source is a master oscillator and the amplifier is a power amplifier beamline. An outcoupler is disposed between the oscillator and the amplifier.

Owner:RAYTHEON CO

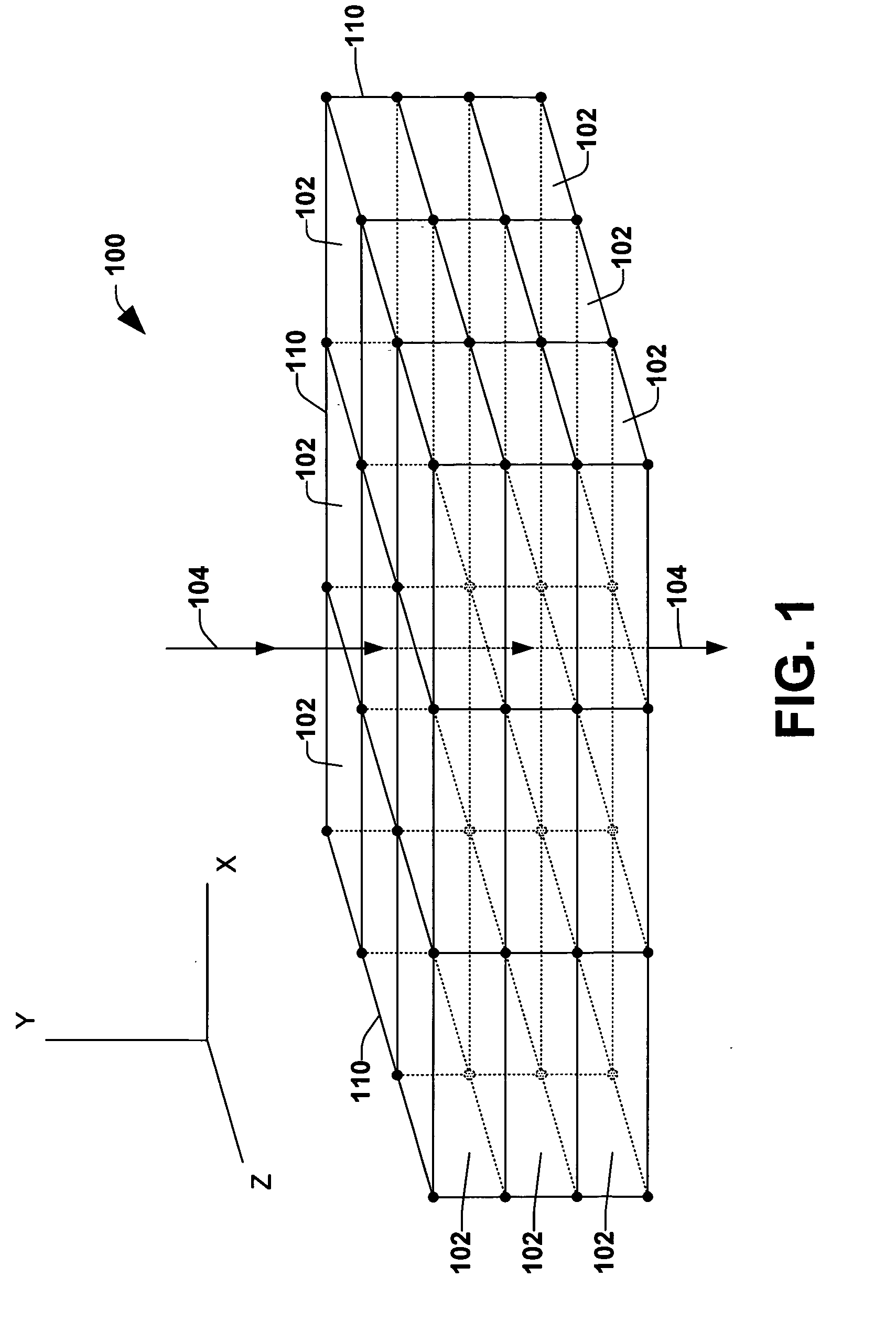

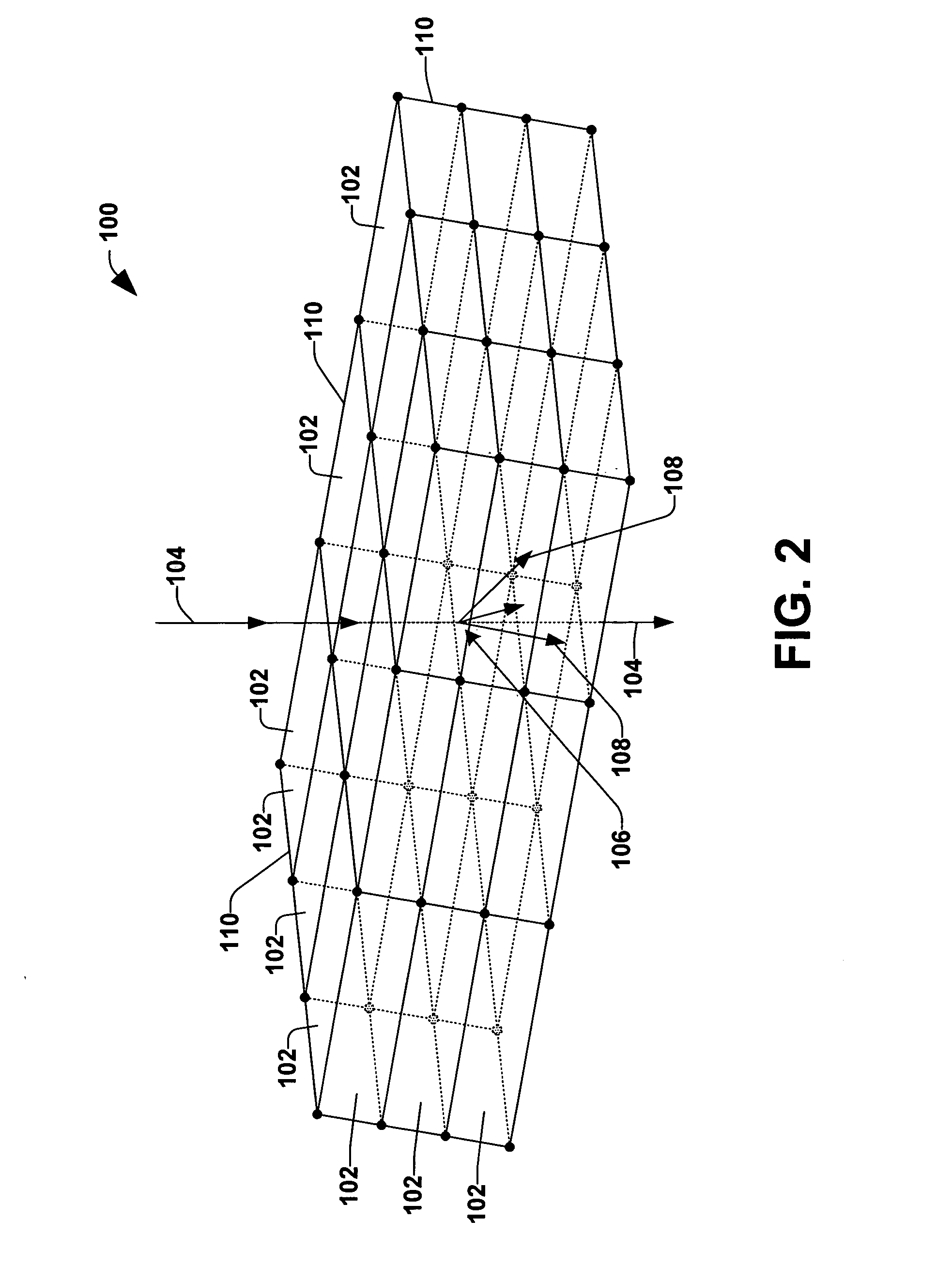

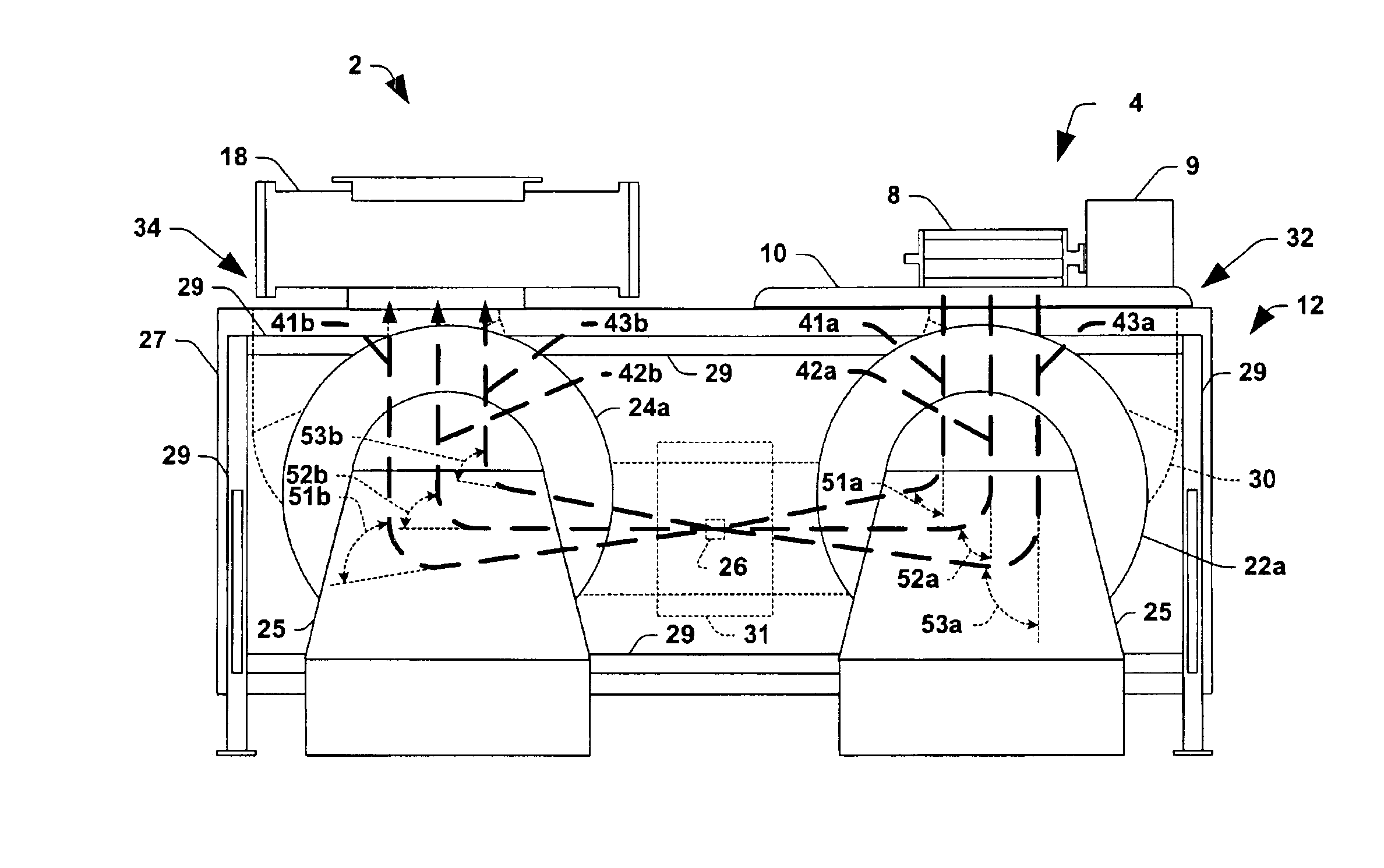

Symmetric beamline and methods for generating a mass-analyzed ribbon ion beam

InactiveUS6885014B2Conducive to simplificationEasy maintenanceThermometer detailsBeam/ray focussing/reflecting arrangementsBeam trajectoryBand shape

Ion implantation systems and beamlines therefor are disclosed, in which a ribbon beam of a relatively large aspect ratio is mass analyzed and collimated to provide a mass analyzed ribbon beam for use in implanting one or more workpieces. The beamline system comprises two similar magnets, where the first magnet mass analyzes the ribbon beam to provide an intermediate mass analyzed ion beam, and the second magnet collimates the intermediate beam to provide a uniform mass analyzed ribbon beam to an end station. The symmetrical system provides equidistant beam trajectories for ions across the elongated beam width so as to mitigate non-linearities in the beam transport through the system, such that the resultant mass analyzed beam is highly uniform.

Owner:AXCELIS TECHNOLOGIES

Apparatus and methods for ion beam implantation

ActiveUS7462843B2Difficult to controlIncrease throughputTube magnetic delectionStatic spectrometersIon beamLight beam

This invention discloses an ion implantation apparatus with multiple operating modes. It has an ion source and an ion extraction means for extracting a ribbon-shaped ion beam therefrom. The ion implantation apparatus includes a magnetic analyzer for selecting ions with specific mass-to-charge ratio to pass through a mass slit to project onto a substrate. Multipole lenses are provided to control beam uniformity and collimation. The invention further discloses a two-path beamline in which a second path incorporates a deceleration system incorporating energy filtering. The invention discloses methods of ion implantation in which the mode of implantation may be switched from one-dimensional scanning of the target to two-dimensional scanning, and from a simple path to an s-shaped path with deceleration.

Owner:ADVANCED ION BEAM TECHNOLOGY INC

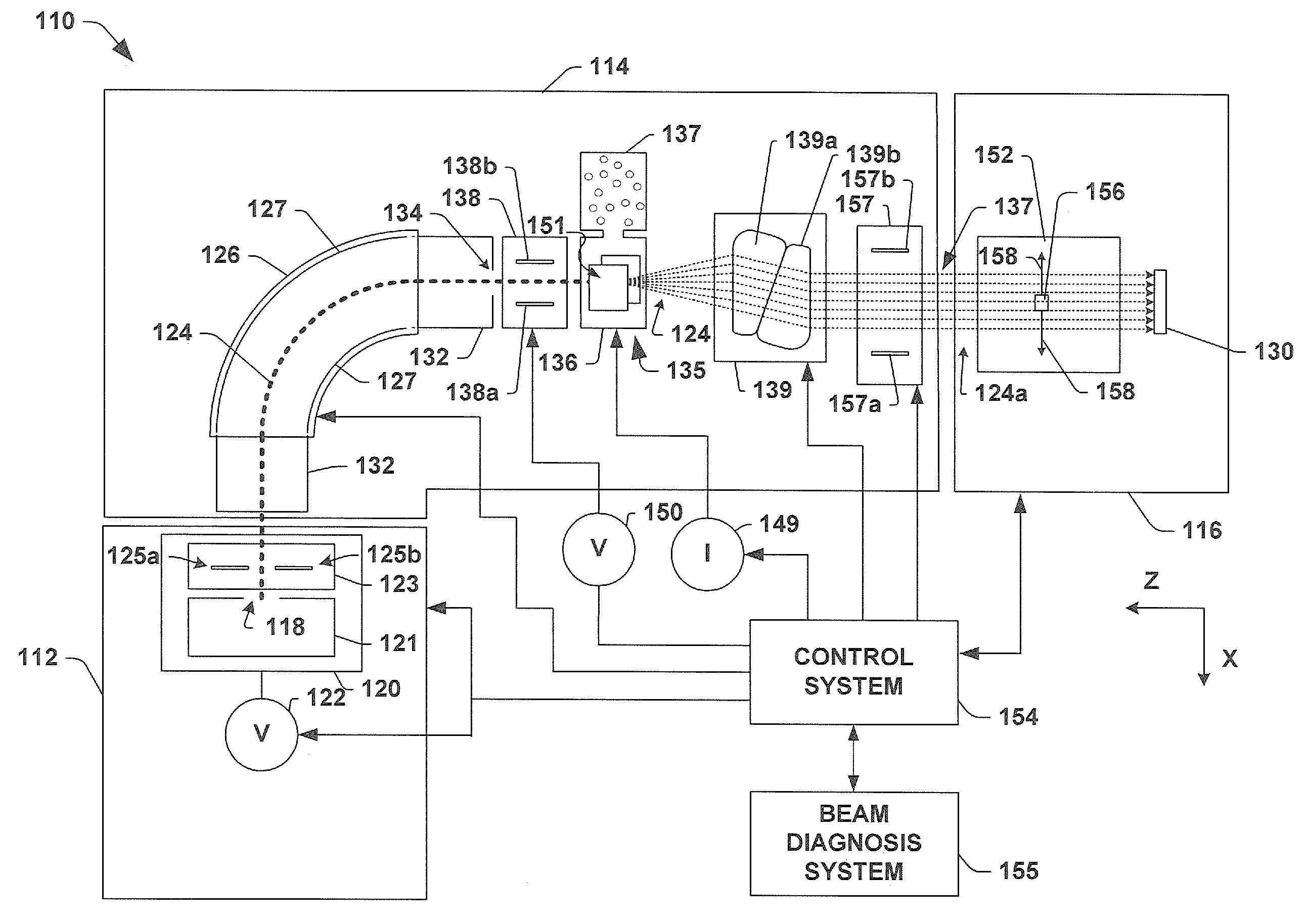

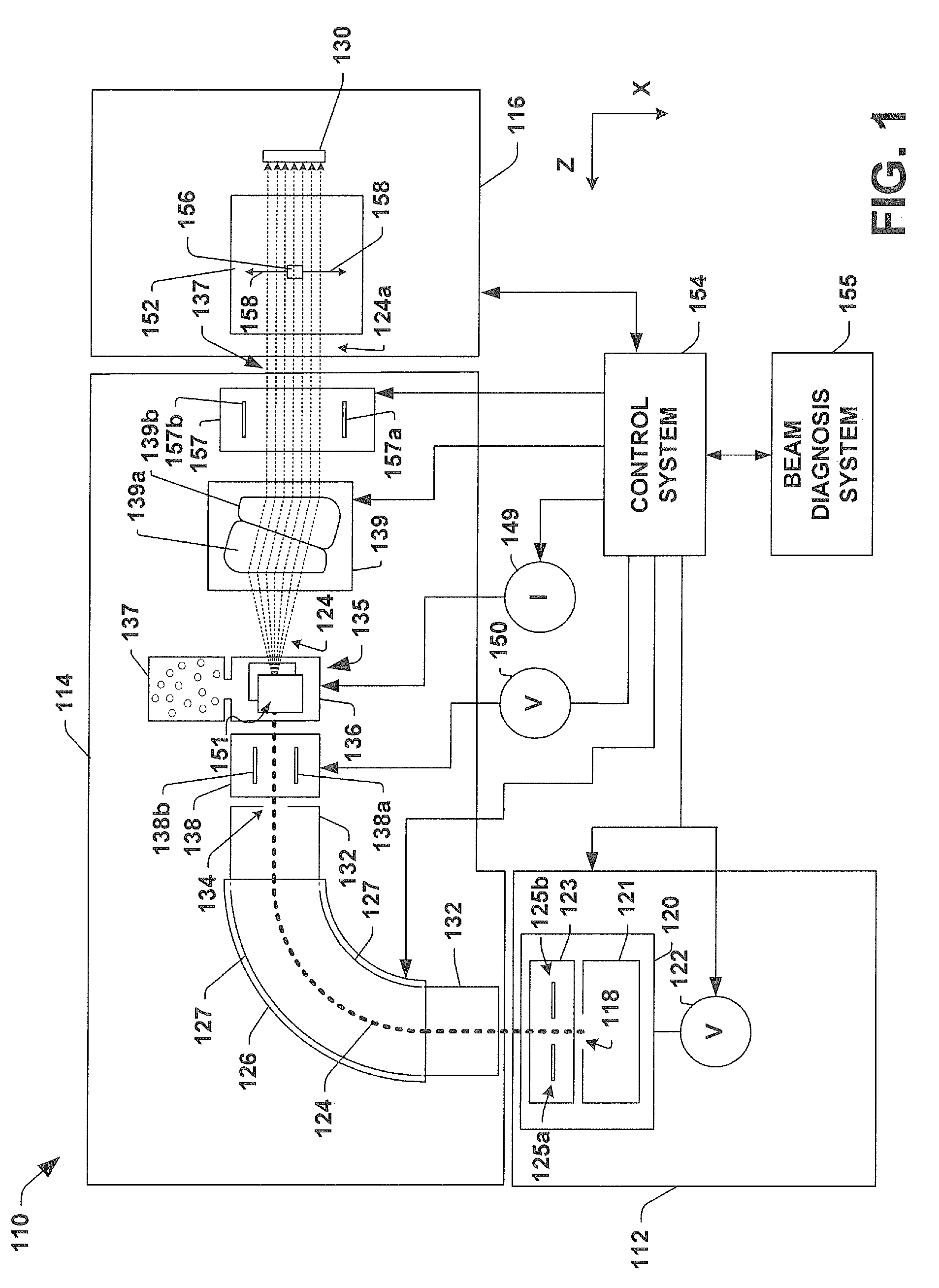

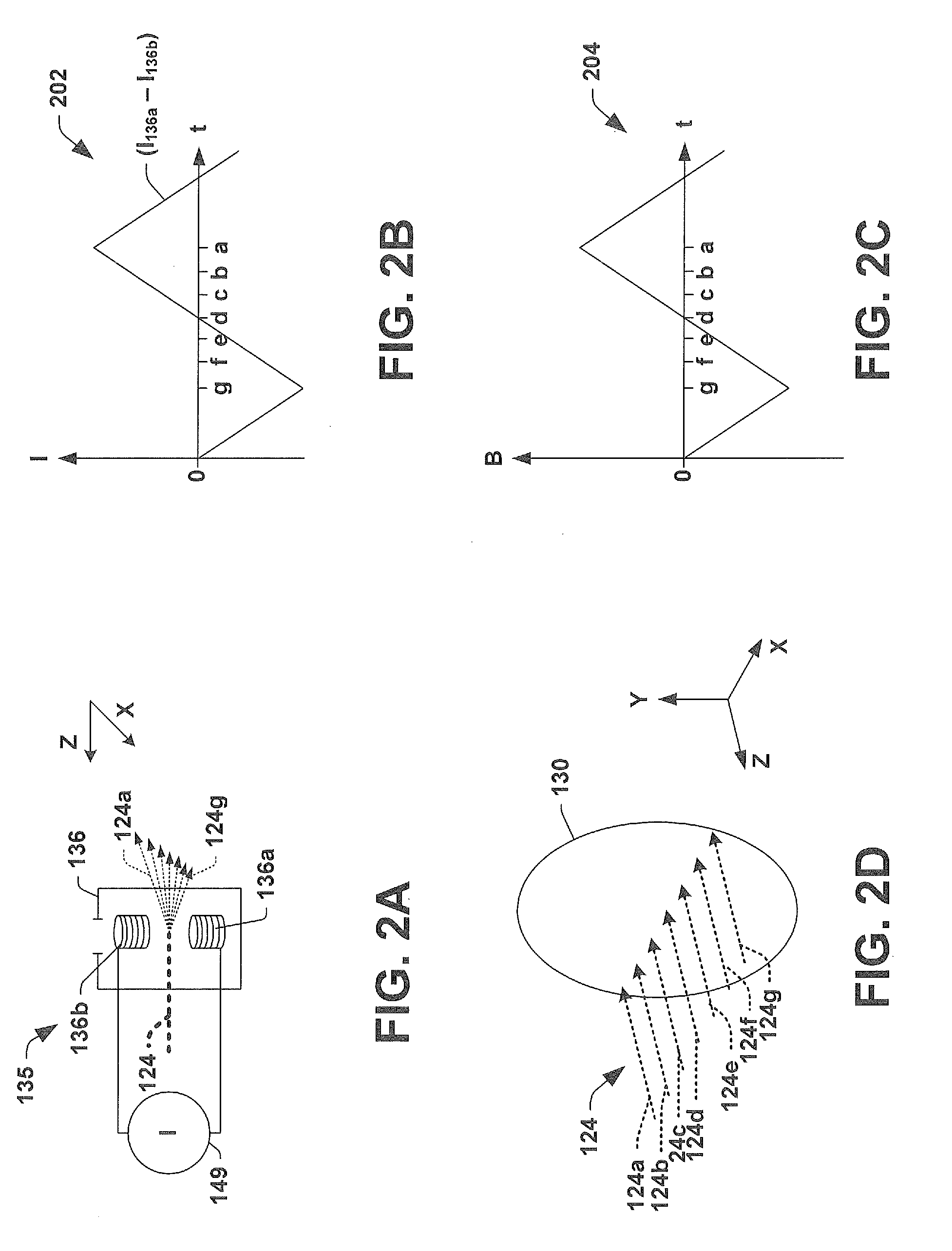

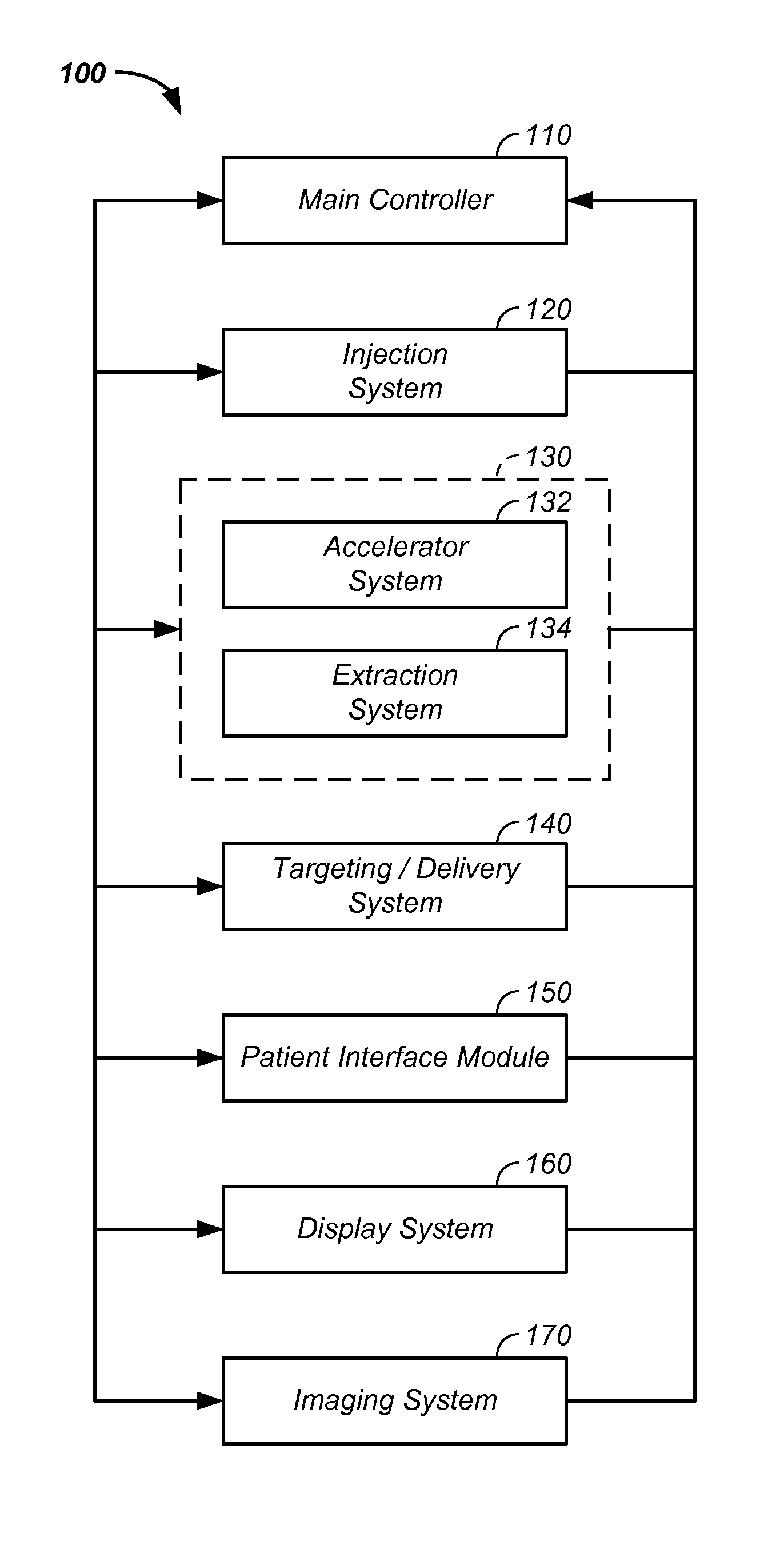

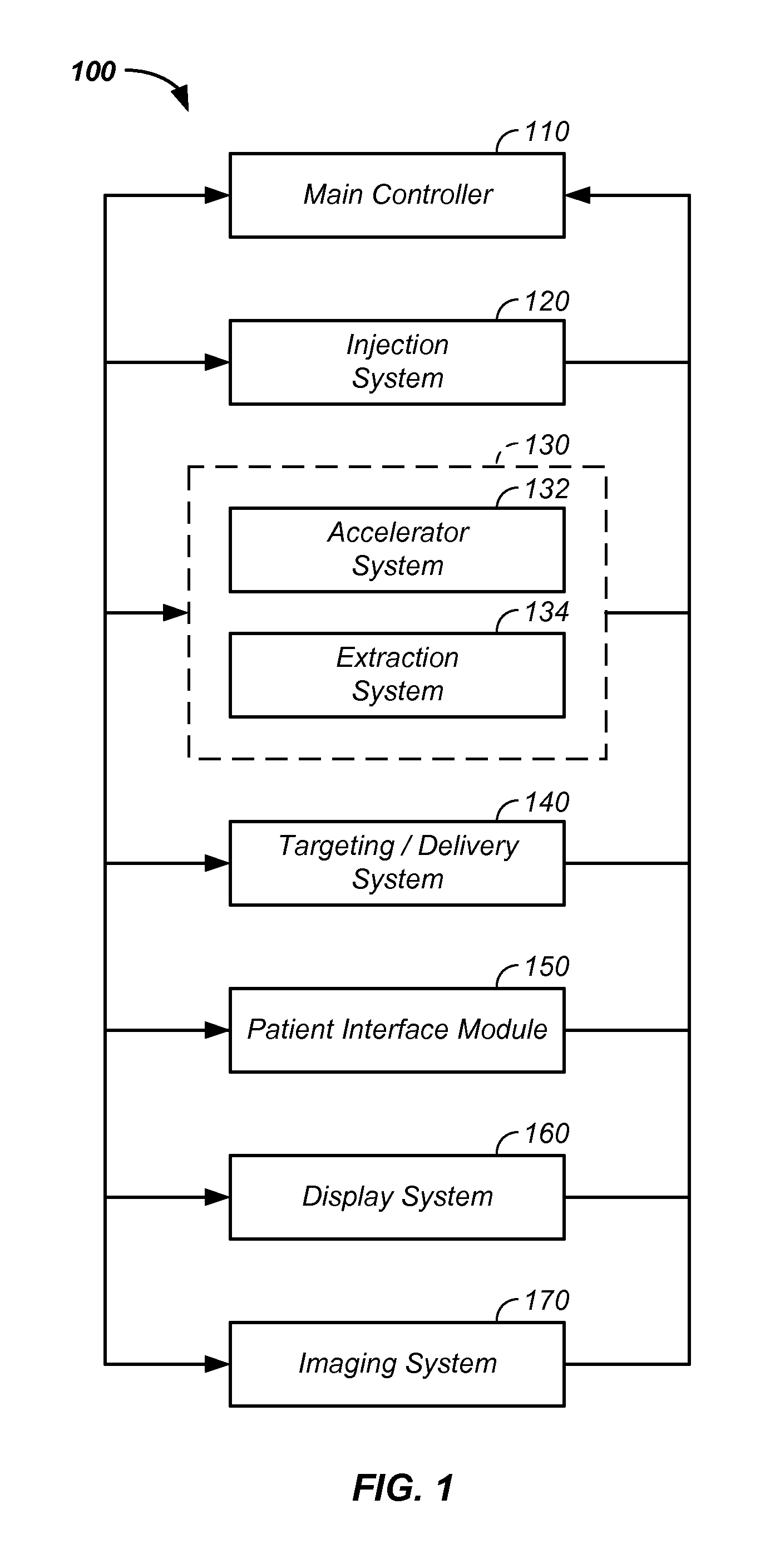

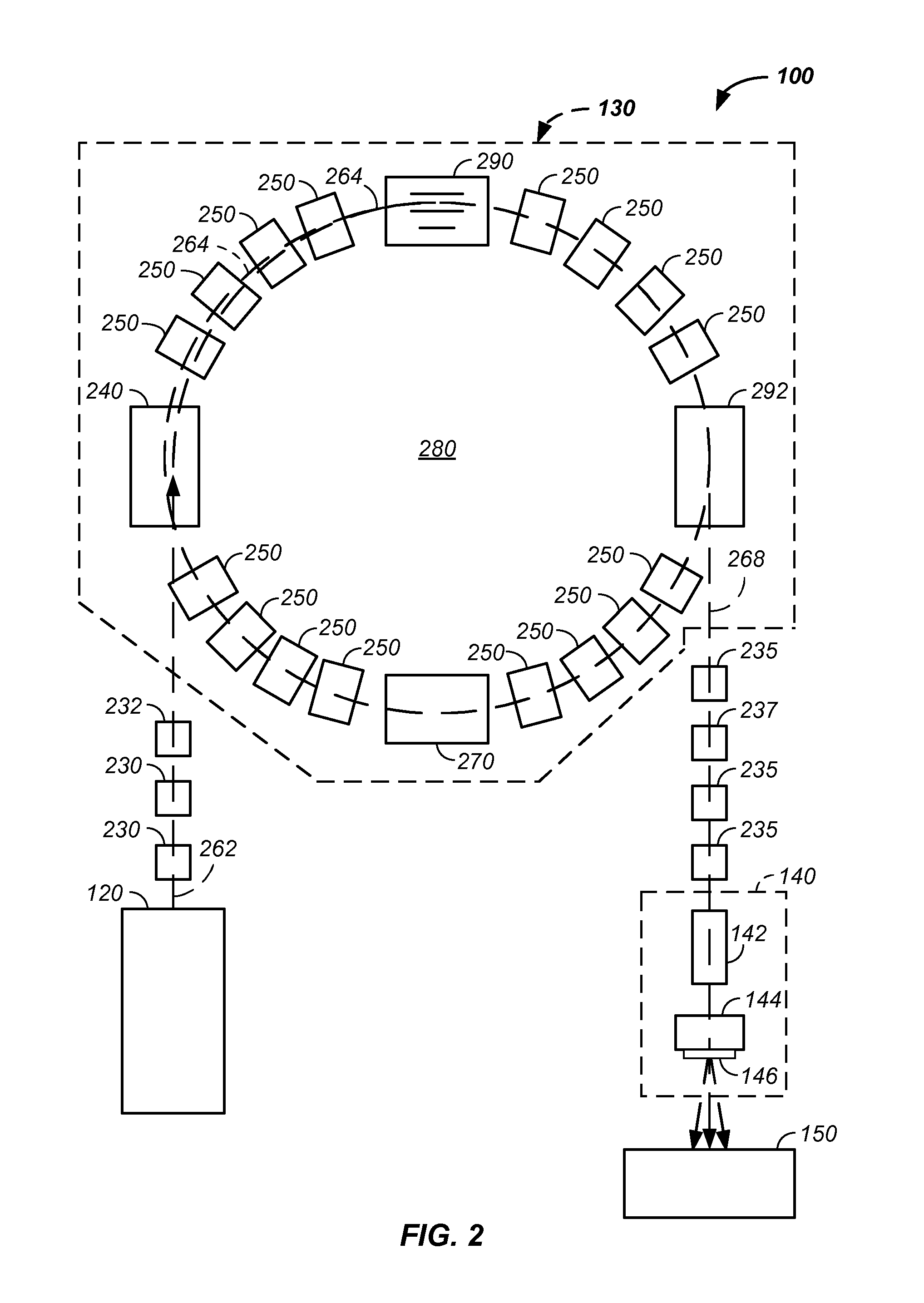

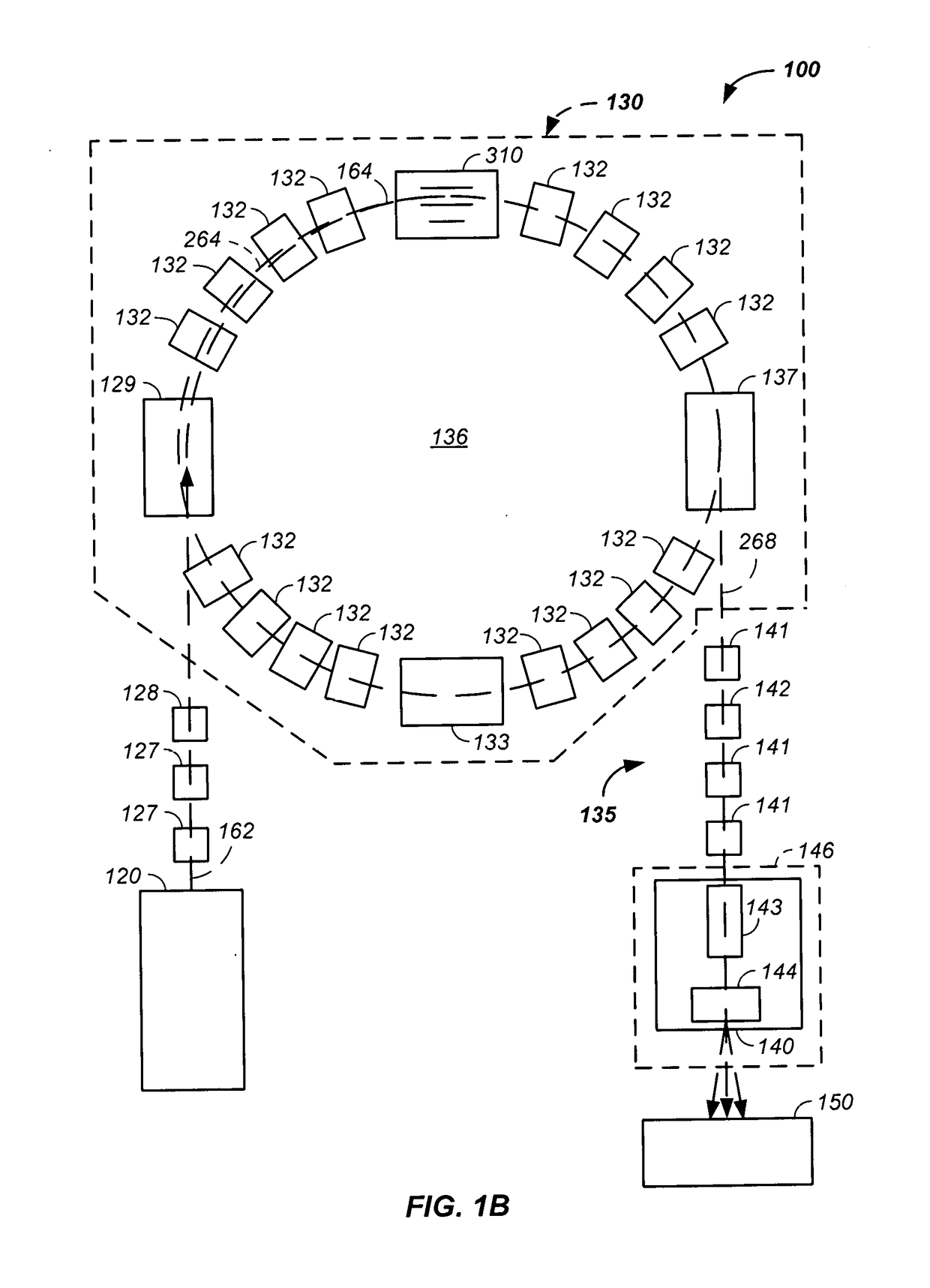

Treatment delivery control system and method of operation thereof

Owner:BALAKIN ANDREY VLADIMIROVICH +1

Ion implantation apparatus and ion implantation method

ActiveUS20080251713A1Increase speedTime-of-flight spectrometersIsotope separationBeam trajectoryLight beam

An ion implantation apparatus according to the invention includes a park electrode as a deflecting apparatus arranged at a section of a beam line from an outlet of a mass analysis magnet apparatus to a front side of a mass analysis slit for deflecting an ion beam in a predetermined direction of being deviated from a beam trajectory line by an operation of an electric field. When the ion beam does not satisfy a desired condition, a park voltage is applied to the park electrode, thereby, the ion beam is brought into an evacuated state by being deflected from the beam trajectory line. As a result, the ion beam cannot pass through the mass analysis slit, and therefore, the ion beam which does not arrive at a wafer to prevent the ion beam which does not satisfy the condition from being irradiated to the wafer.

Owner:SENCORP

Counter balanced / cantilevered charged particle cancer therapy gantry system and method of use thereof

InactiveUS20180028835A1Radiation/particle handlingTomographyCancer therapyPositively charged particle

The invention comprises a method and apparatus for directing positively charged particles, comprising the steps of: (1) directing the positively charged particles along a beamline; (2) rotating a cantilevered rotatable gantry arm, both connected to a rotatable gantry support and supporting the beamline, about a horizontal rotation axis of the rotatable gantry support; and (3) countering torque, of at least the cantilevered rotatable gantry arm, about the rotation axis using a counterweight connected to the rotatable gantry support. Optionally, the gantry movement is used as part of rotating the rotatable gantry arm three hundred sixty degrees around an inner gantry arm side motion defined volume, which allows access to one side of a treatment room and the gantry arc swept volume, such as for entrance, mounting a patient positioning system, and / or for a ground based support structure.

Owner:BENNETT JAMES P +1

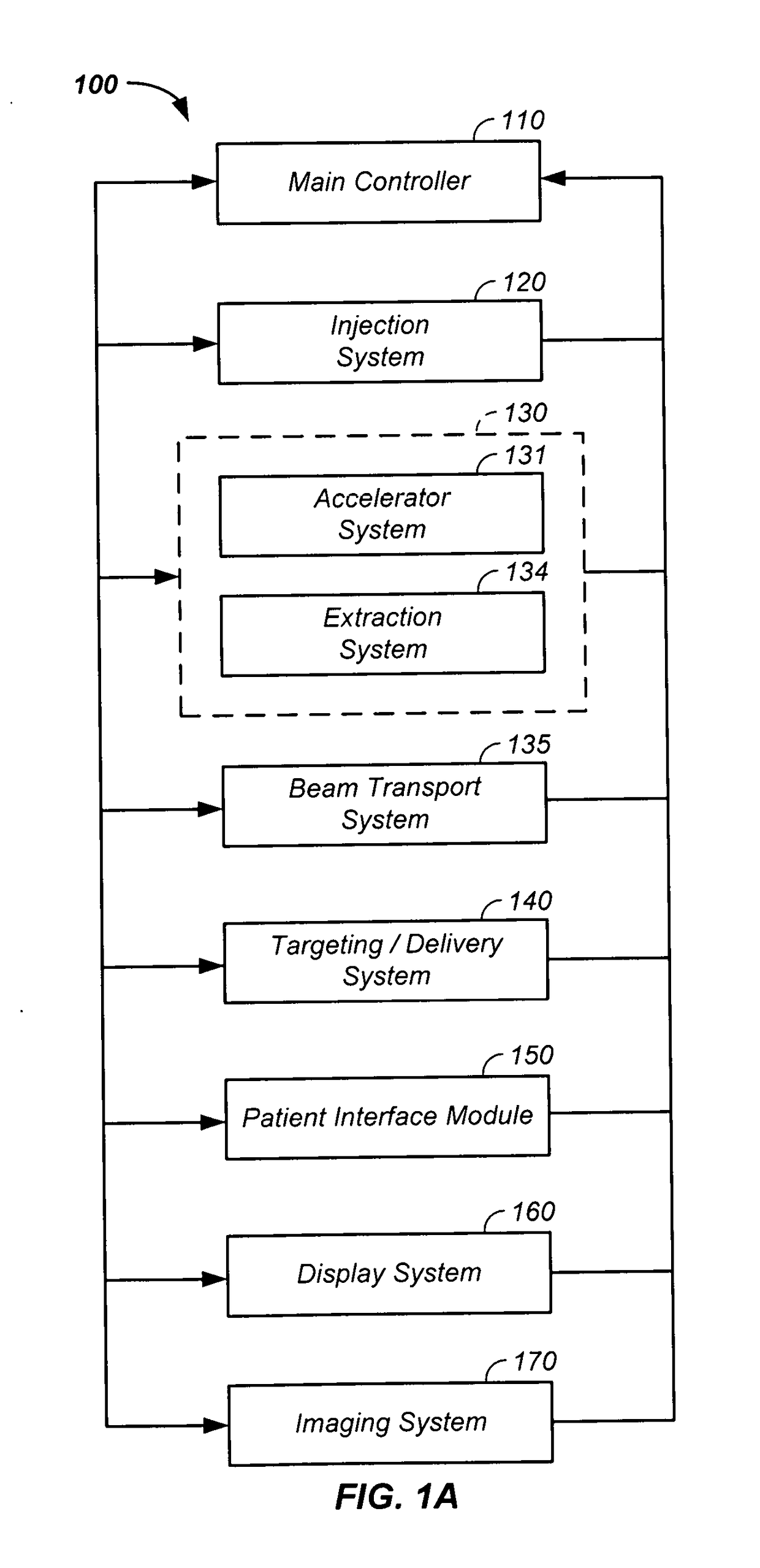

Systems and methods of controlling a proton beam of a proton treatment system

Systems and methods of controlling a proton beam in a proton therapy system, the system including a proton beam delivery system including at least one achromatic beamline having a first power setting to direct a proton beam having a first predetermined range of proton beam energies to a target treatment area, and a second power setting to direct a proton beam having a second predetermined range of proton beam energies to the target treatment area, and a power changing unit configured to control an energy level of the proton beam and a power setting of the at least one achromatic beamline such that the power changing unit changes the power setting of the at least one achromatic beamline between the first power setting and the second power setting based on changes in proton beam energy that occur within the first predetermined range of proton beam energies.

Owner:PRONOVA SOLUTIONS

Method of and system for X-ray spectral correction in multi-energy computed tomography

ActiveUS20060023844A1Correction for variationMaterial analysis using wave/particle radiationRadiation/particle handlingHigh energyX-ray

A method of and a system for spectral correction in multi-energy computed tomography are provided to correct reconstructed images, including high-energy CT images and Z (effective atomic number) images, for spectral variations, which include time variations on a scanner due to HVPS drift and scanner to scanner variations due to the beamline component differences. The method uses a copper filter mounted on the detector array for tracking the spectral changes. The method comprises: generating copper ratios; computing working air tables; calculating scales and offsets; and correcting high-energy CT images and Z images using calculated scales and offsets. The method further includes an off-line calibration procedure to generate necessary parameters for the online correction.

Owner:ANLOGIC CORP (US)

Systems and methods of controlling a proton beam of a proton treatment system

Owner:PRONOVA SOLUTIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com