Patents

Literature

568 results about "Deformable mirror" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Deformable mirrors (DM) are mirrors whose surface can be deformed, in order to achieve wavefront control and correction of optical aberrations. Deformable mirrors are used in combination with wavefront sensors and real-time control systems in adaptive optics. In 2006 they found a new use in femtosecond pulse shaping.

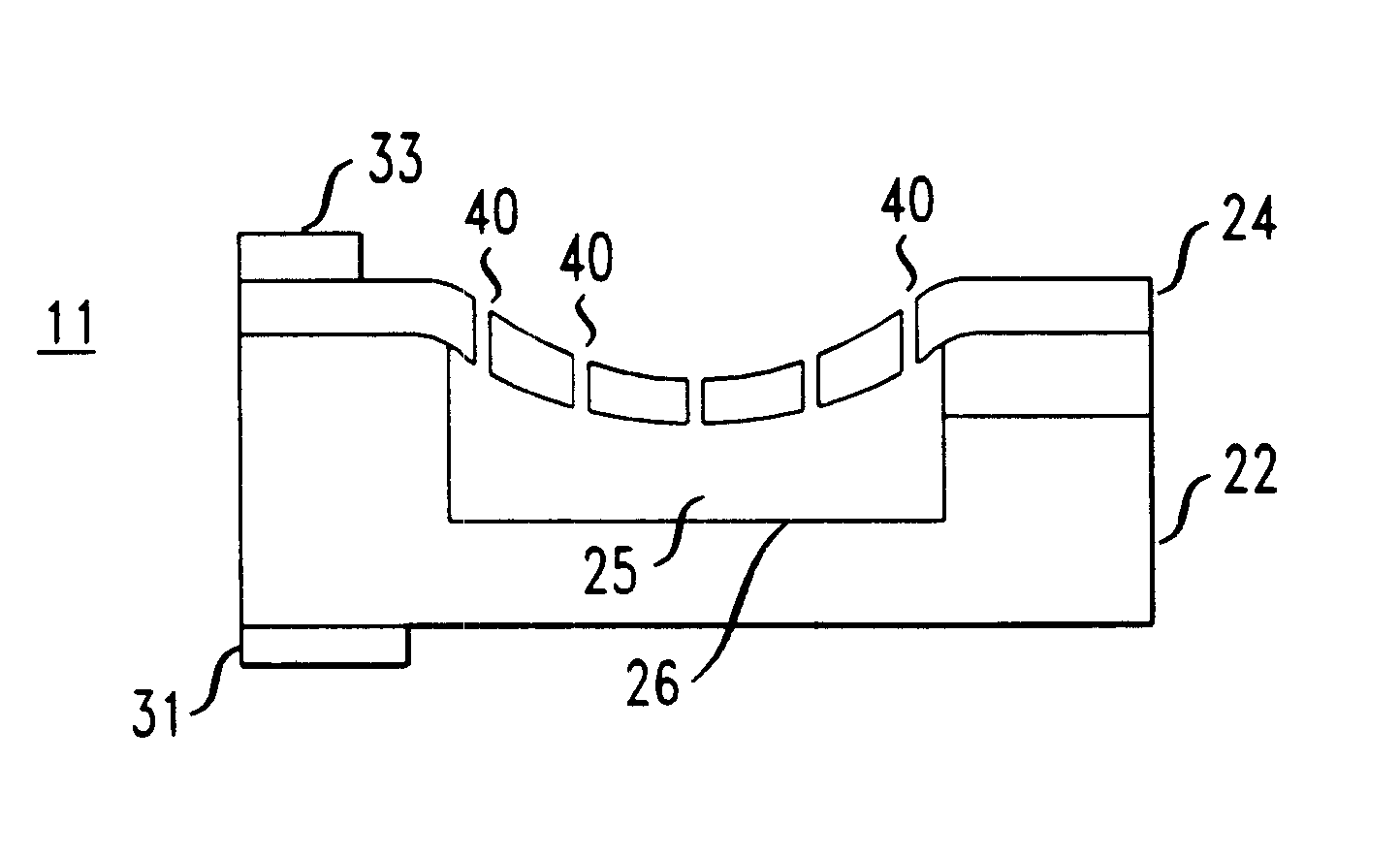

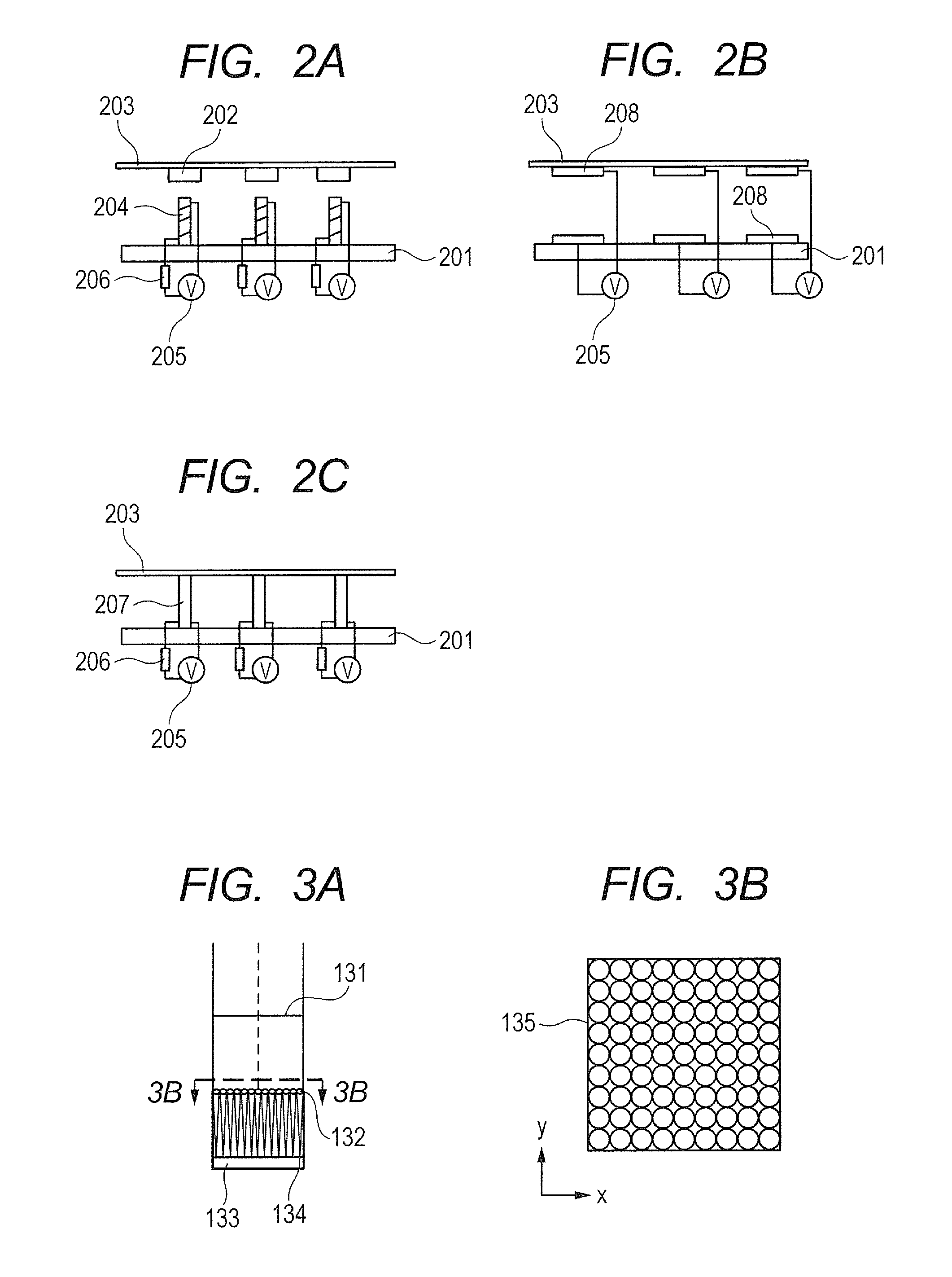

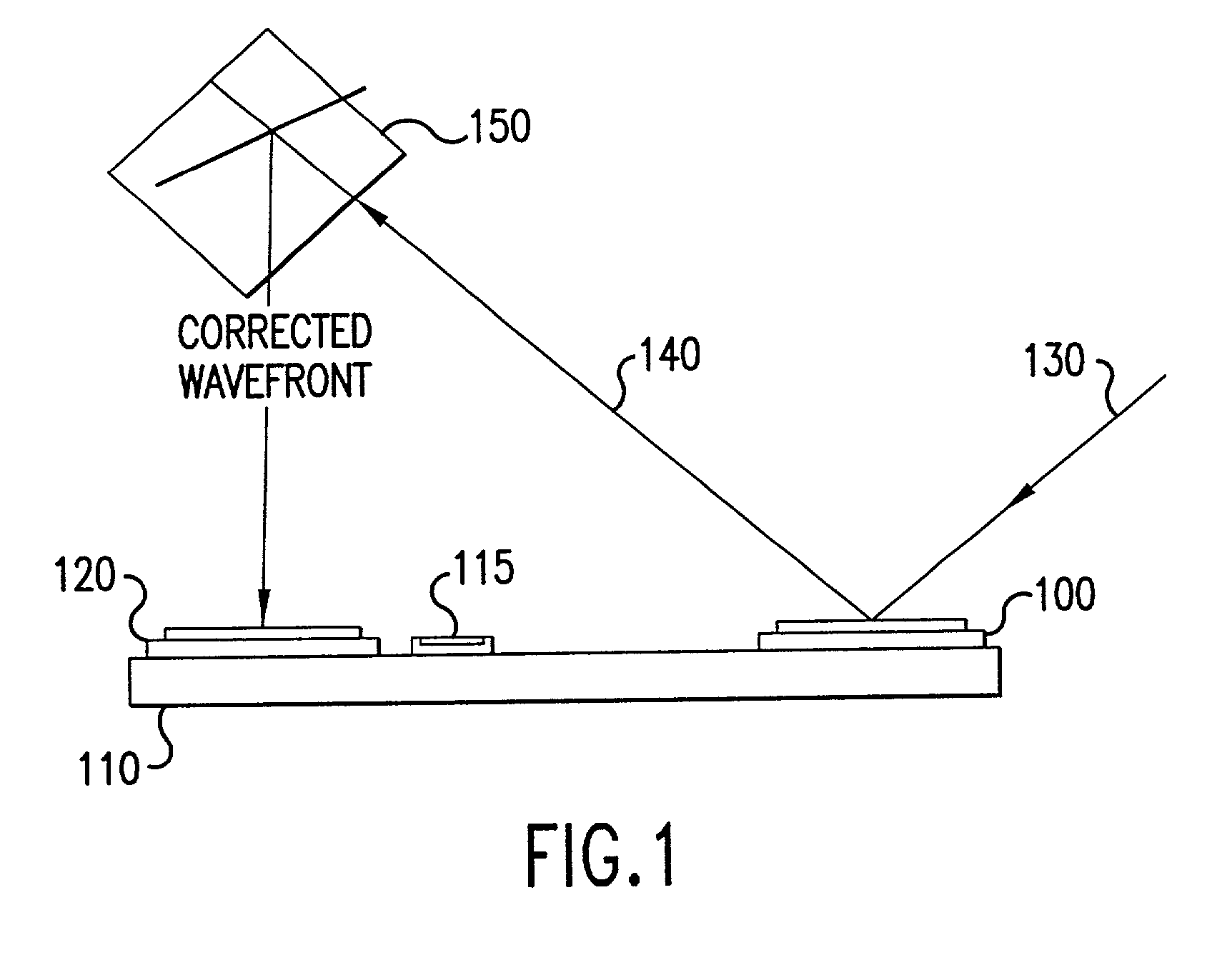

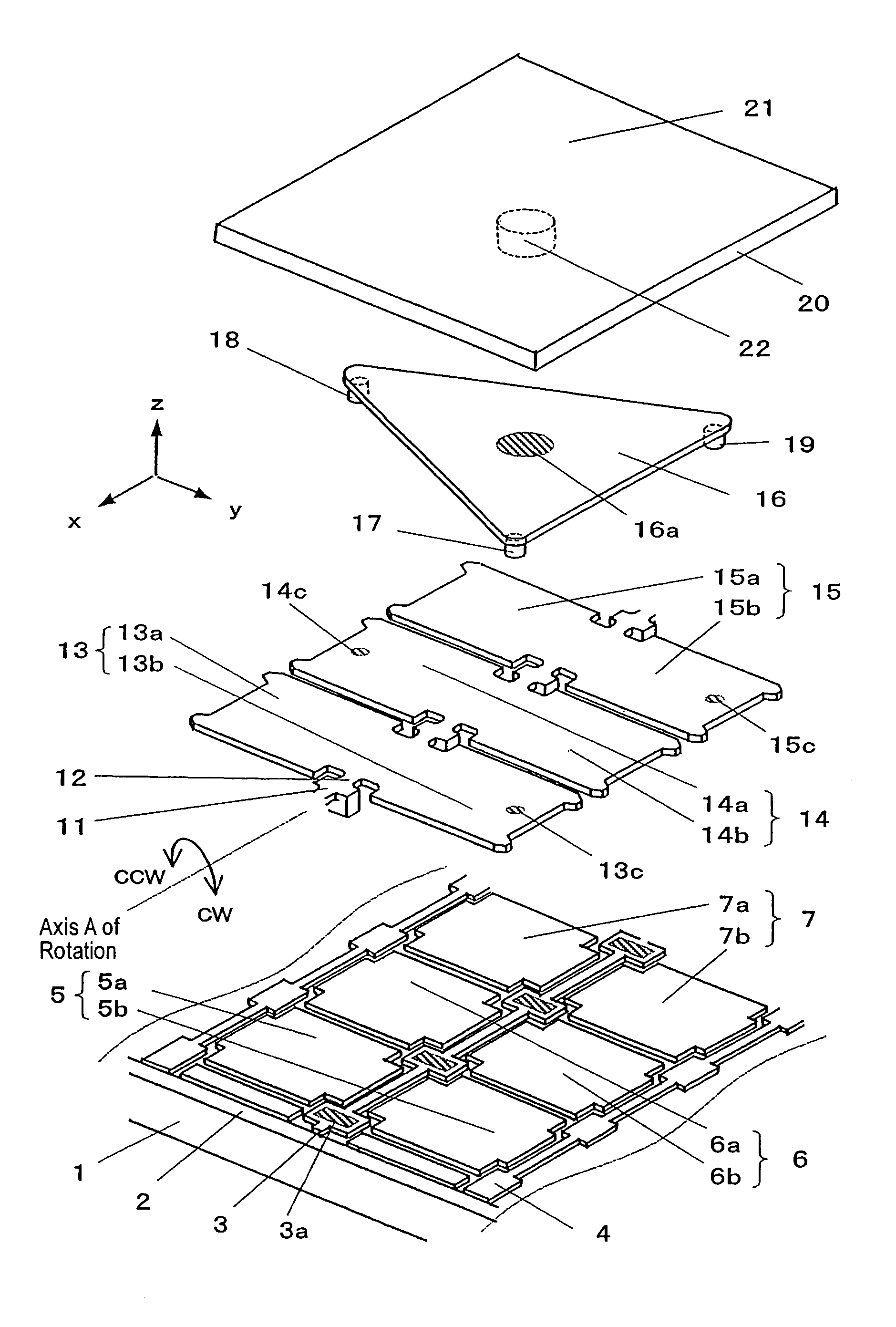

Vertical comb drive actuated deformable mirror device and method

InactiveUS6384952B1Optical waveguide light guideFlexible microstructural devicesPotential differenceComb drive

A deformable mirror includes a vertical comb actuator having a reflective surface attached thereto. The vertical comb drive includes stationary elements interspersed with moving elements. When a potential difference is provided between these elements, the moving elements are pulled downward, thereby deforming the reflective surface. The vertical comb drive typically includes a plurality of actuators, which are individually electrically addressed. Each actuator may be an array of interspersed elements or a cavity and corresponding tooth. Springs support the moving elements and bias the reflective surface in an original position. The vertical comb drive provides a large stroke and substantially linear voltage-versus-displacement curve throughout the stroke.

Owner:MEMS OPTICAL

Optical attenuator

An optical attenuator having a structure in which a membrane covers a cavity formed on a substrate is disclosed. The membrane covering the cavity formed in the substrate is movable relative to the bottom surface of the cavity constituting a deformable mirror. Movement of the membrane relative to the bottom surface of the cavity attenuates optical signals impinging on the surface thereof. The movement of the membrane relative to the bottom surface of the cavity attenuates impinging optical signals by controlling the angle at which such impinging optical signals are reflected from the membrane surface.

Owner:LUCENT TECH INC

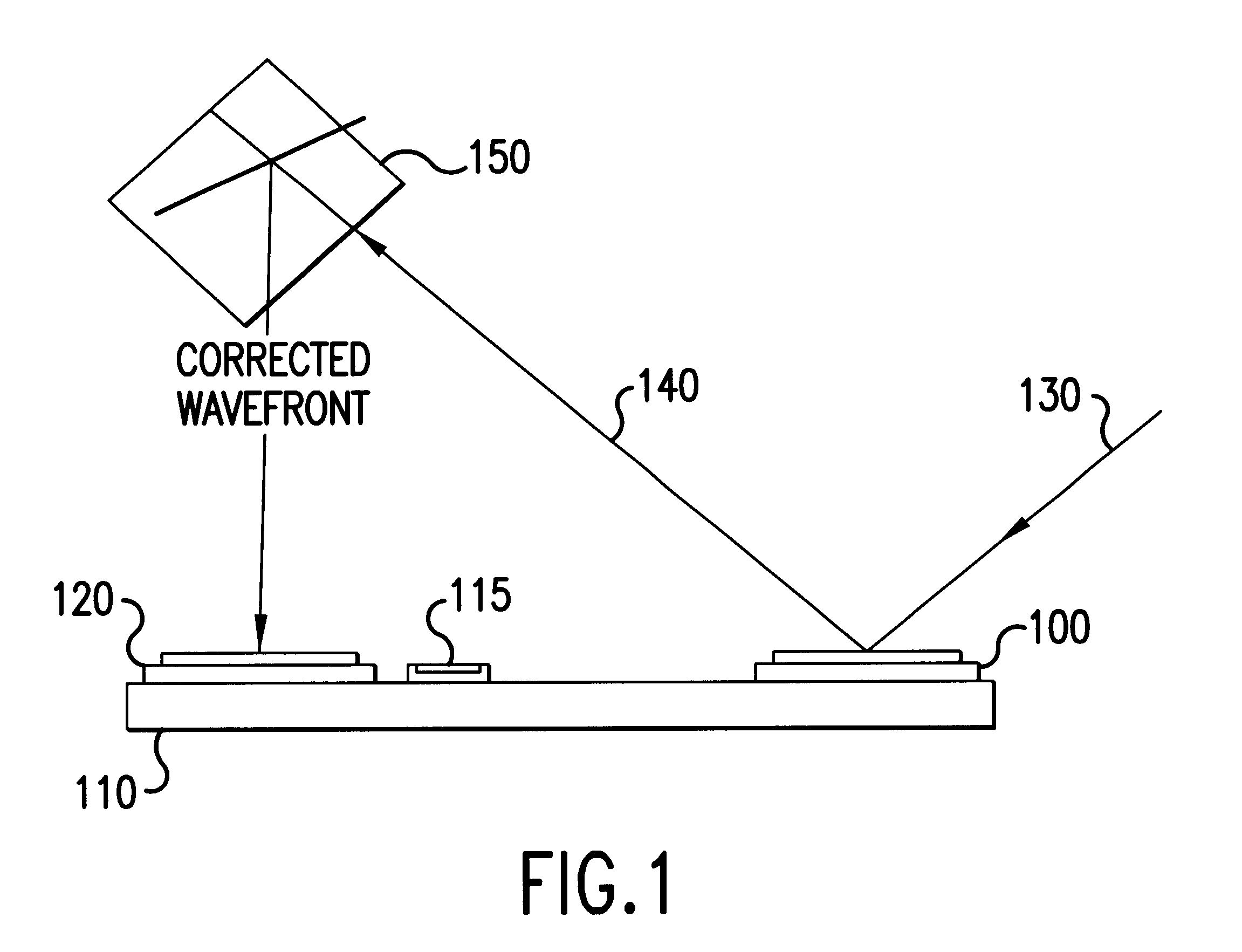

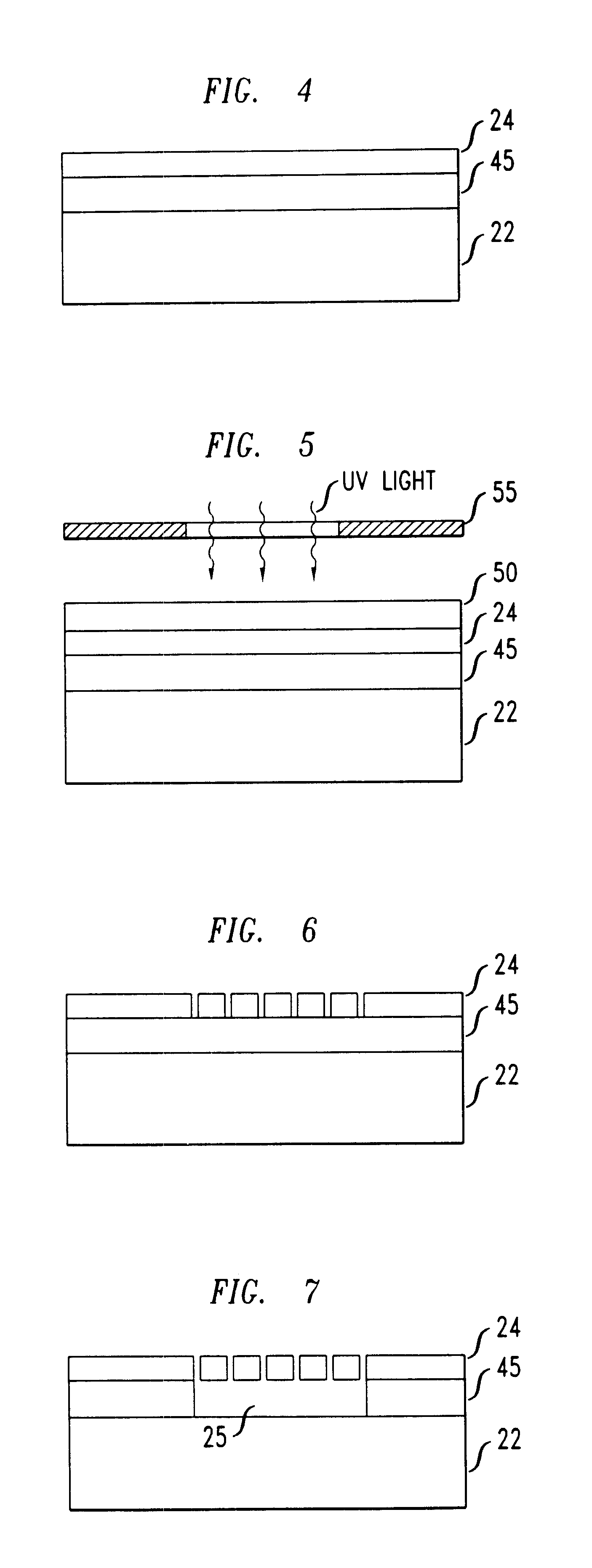

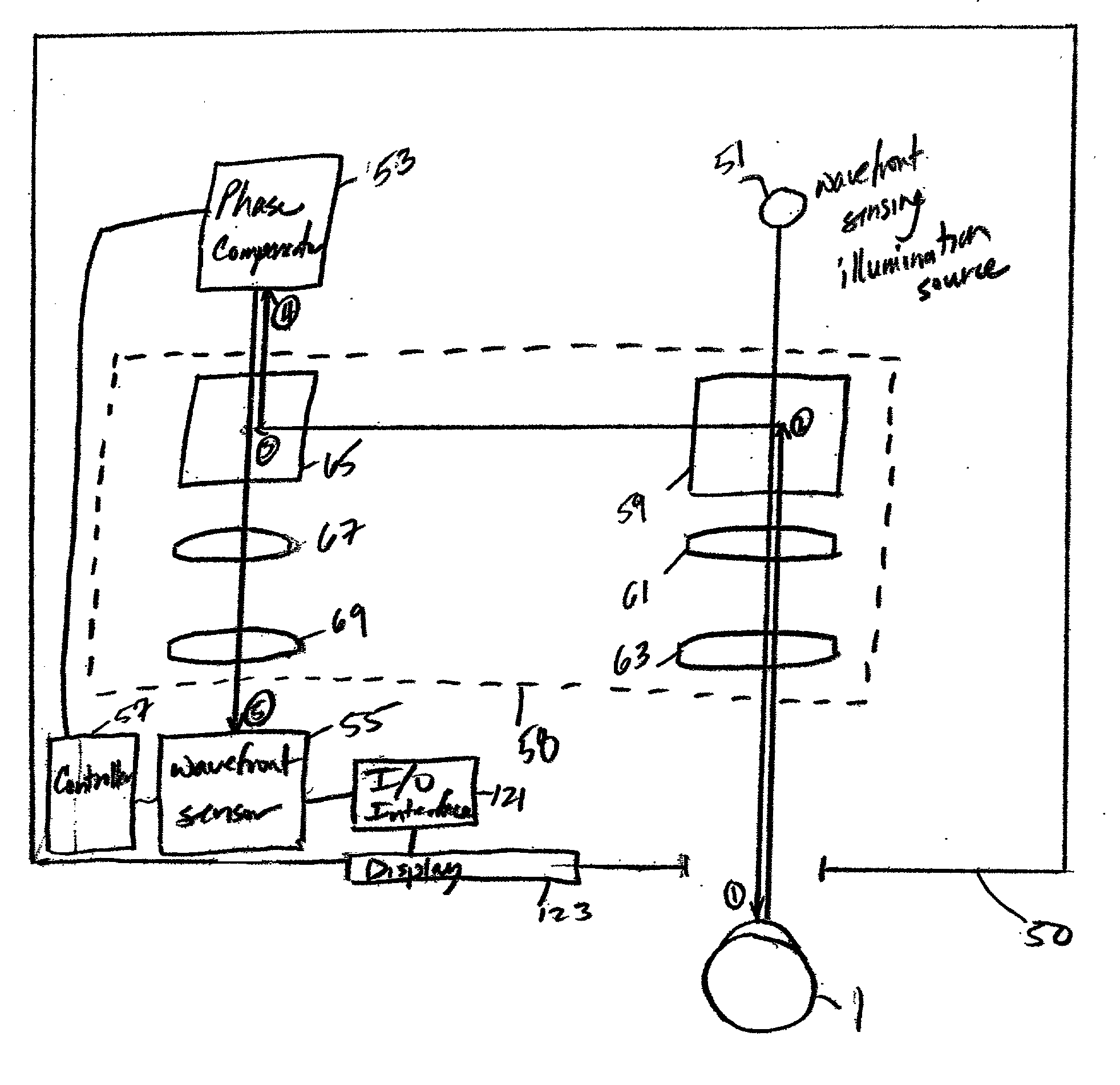

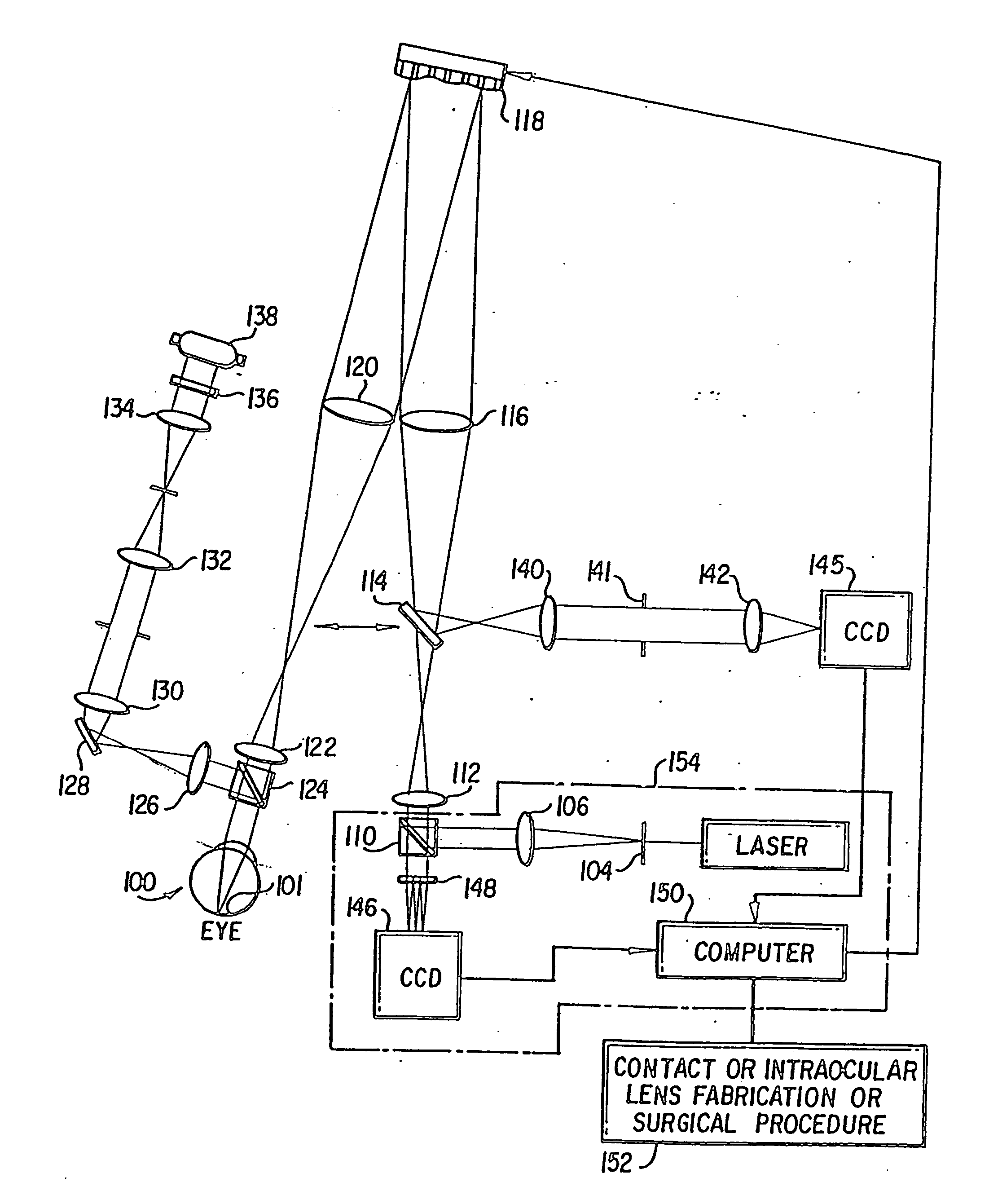

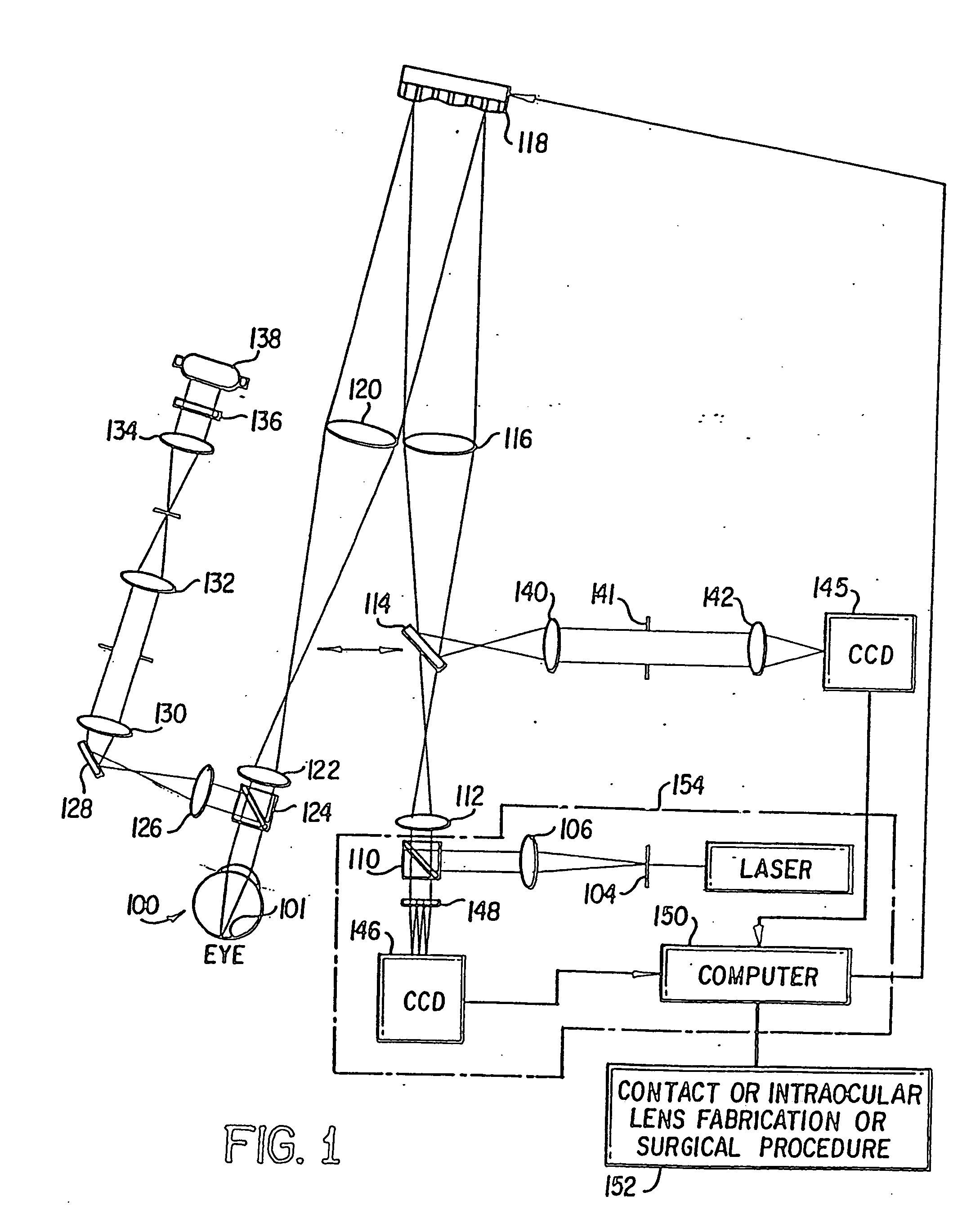

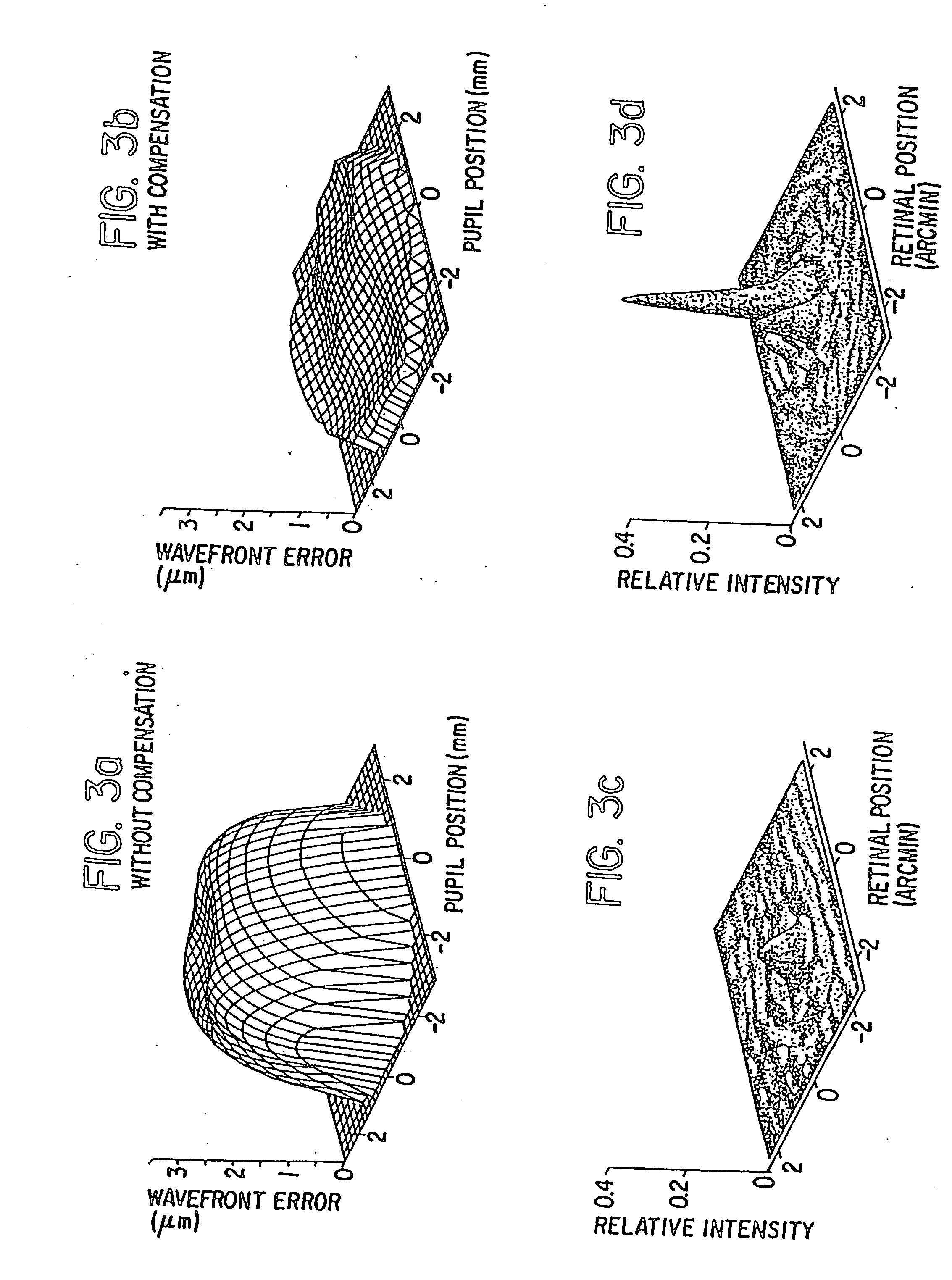

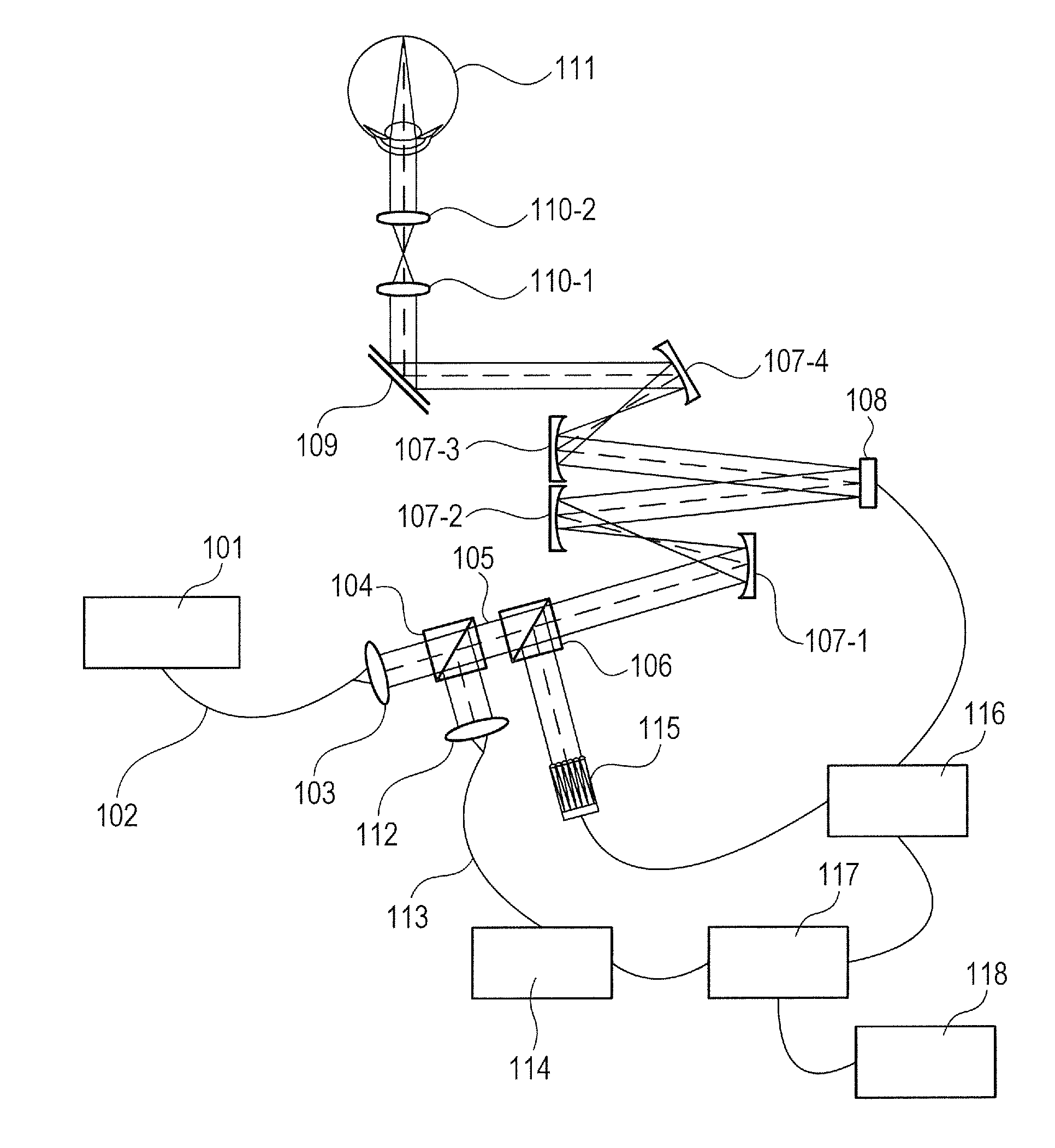

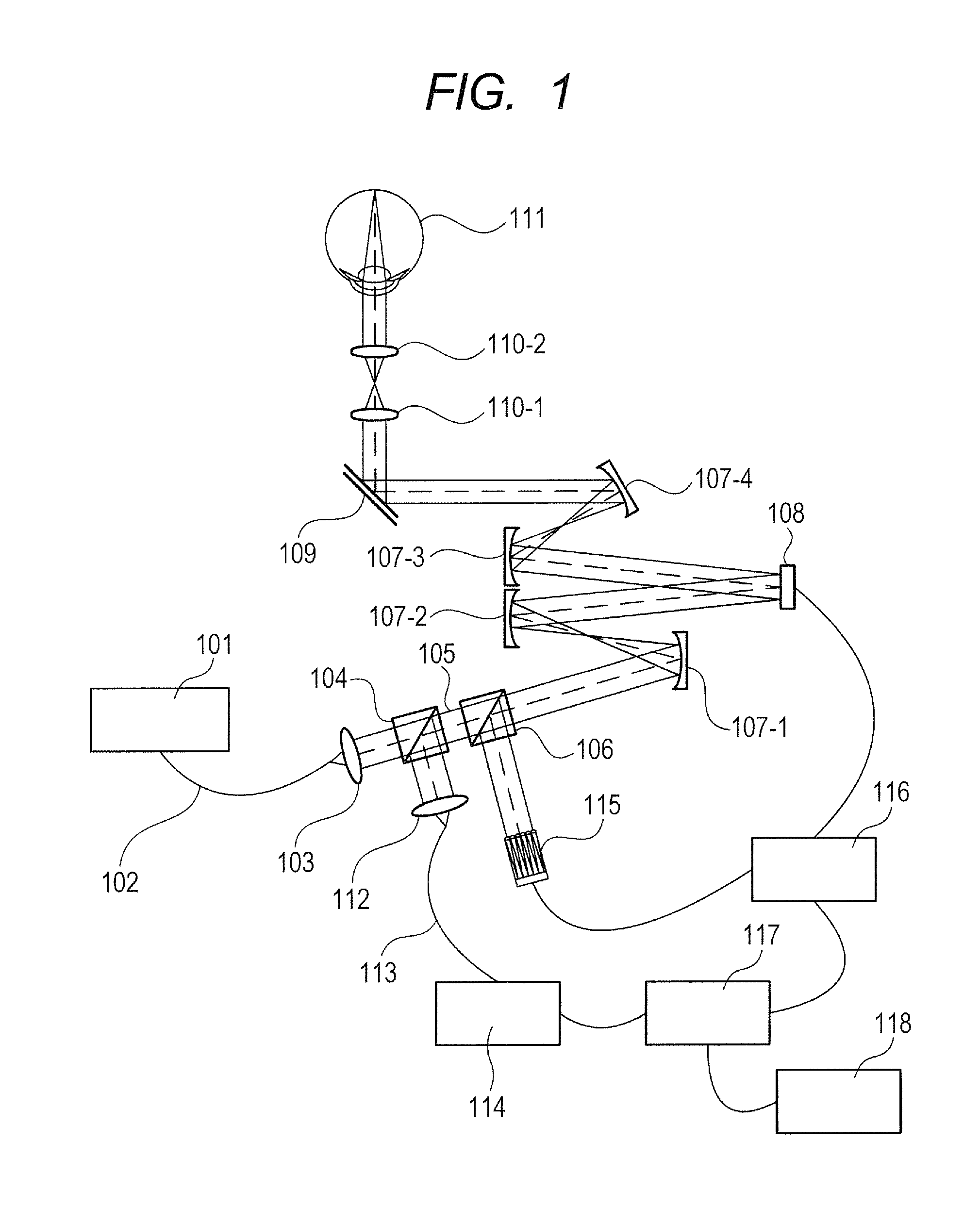

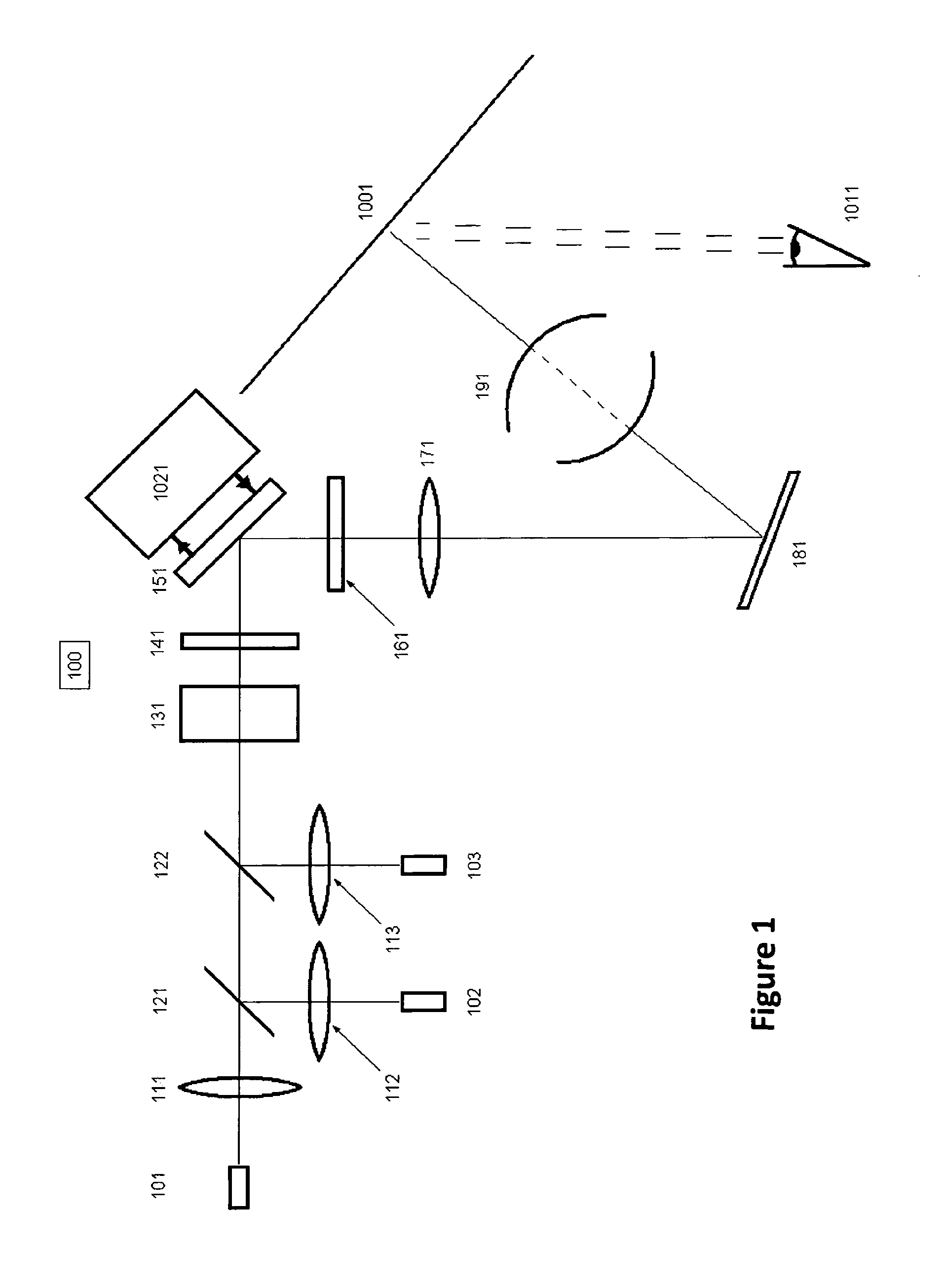

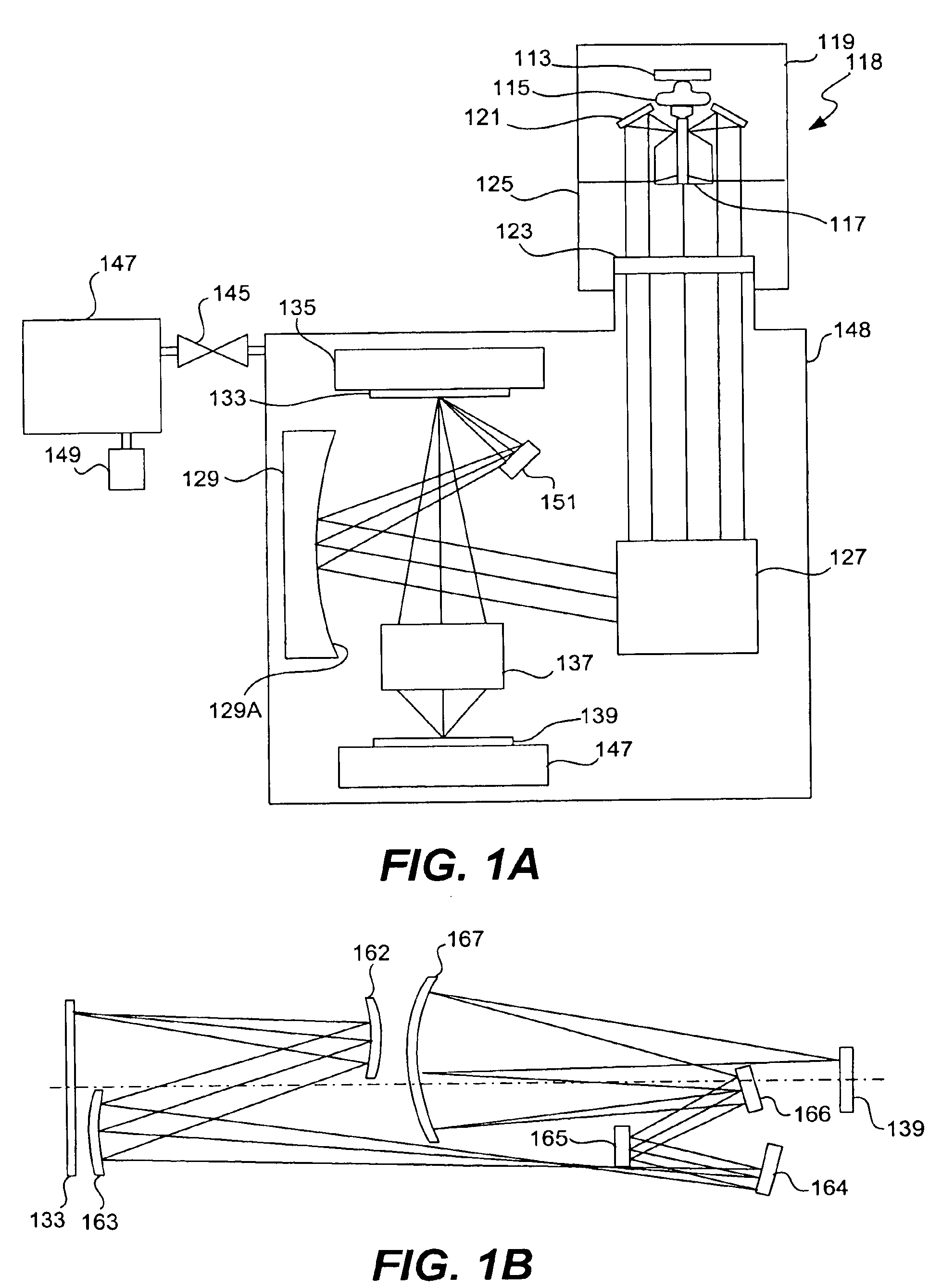

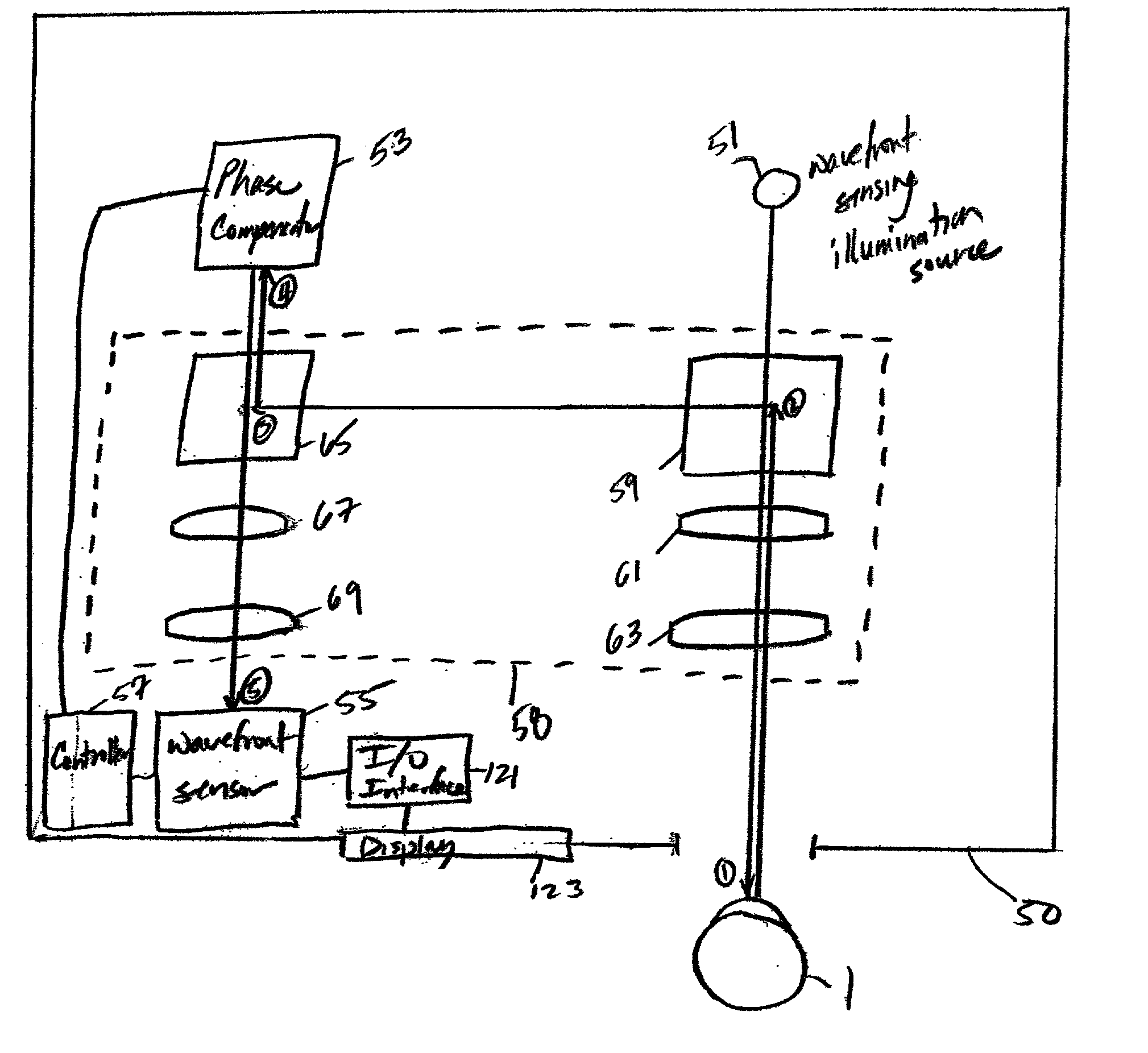

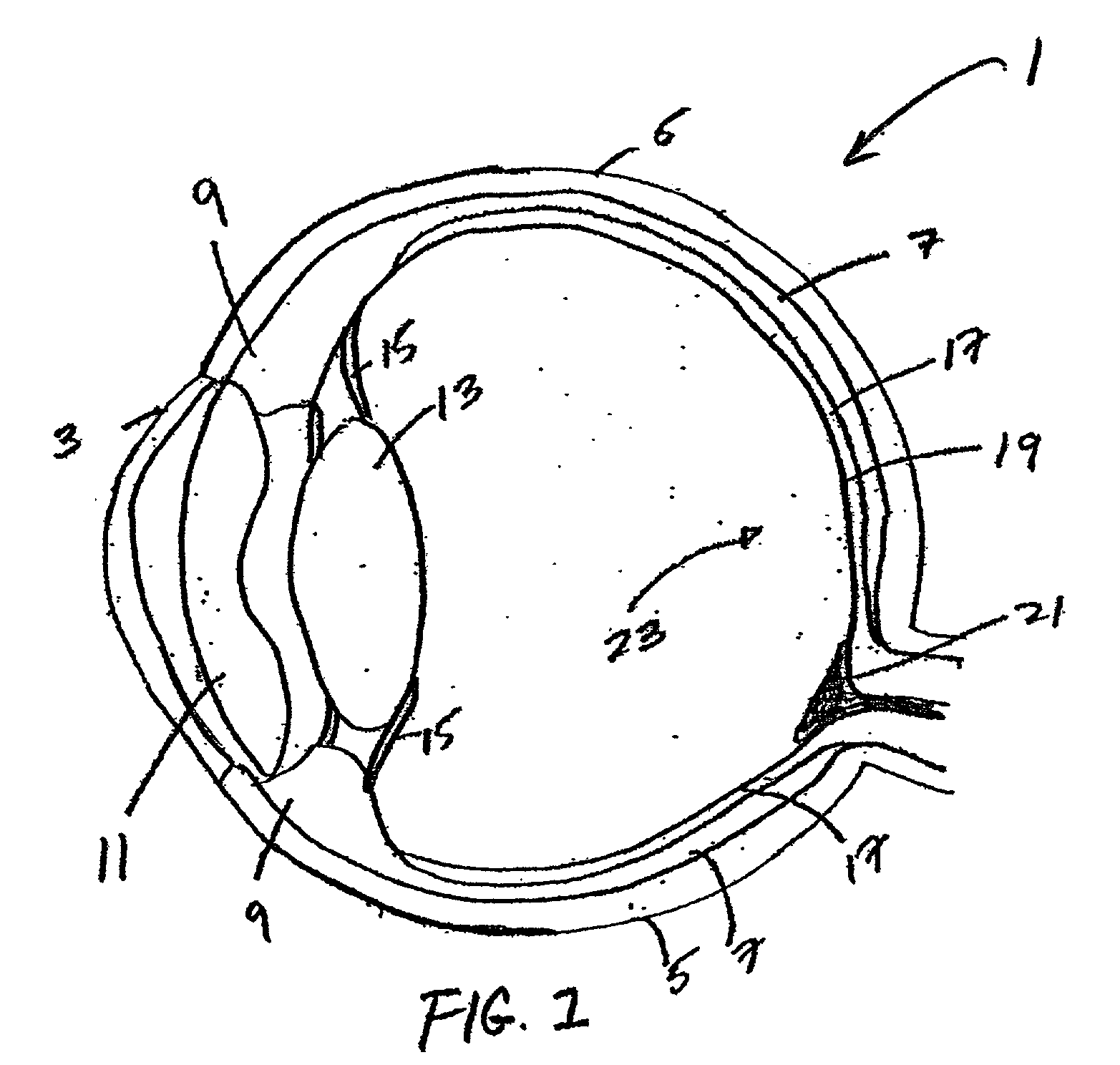

Ophthalmic instrument with adaptive optic subsystem that measures aberrations (including higher order aberrations) of a human eye and that provides a view of compensation of such aberrations to the human eye

An improved ophthalmic instrument for in-vivo examination of a human eye including a wavefront sensor that estimates aberrations in reflections of the light formed as an image on the retina of the human eye and a phase compensator that spatially modulates the phase of incident light to compensate for the aberrations estimated by the wavefront sensor Optical elements create an image of a fixation target at the phase compensator, which produces a compensated image of the fixation target that compensates for aberrations estimated by the wavefront sensor. The compensated image of the fixation target produced by the phase compensator is recreated at the human eye to thereby provide the human eye with a view of compensation of the aberrations the human eye as estimated by the wavefront sensor. The phase compensator preferably comprises a variable focus lens that compensates for focusing errors and a deformable mirror that compensates for higher order aberrations. The optical elements preferably comprise a plurality of beam splitters and a plurality of lens groups each functioning as an afocal telescope. In addition, instruments and systems are provided that exploit these capabilities to enable efficient prescription and / or dispensing of corrective optics (e.g., contact lens and glasses).

Owner:NORTHROP GRUMMAN SYST CORP +1

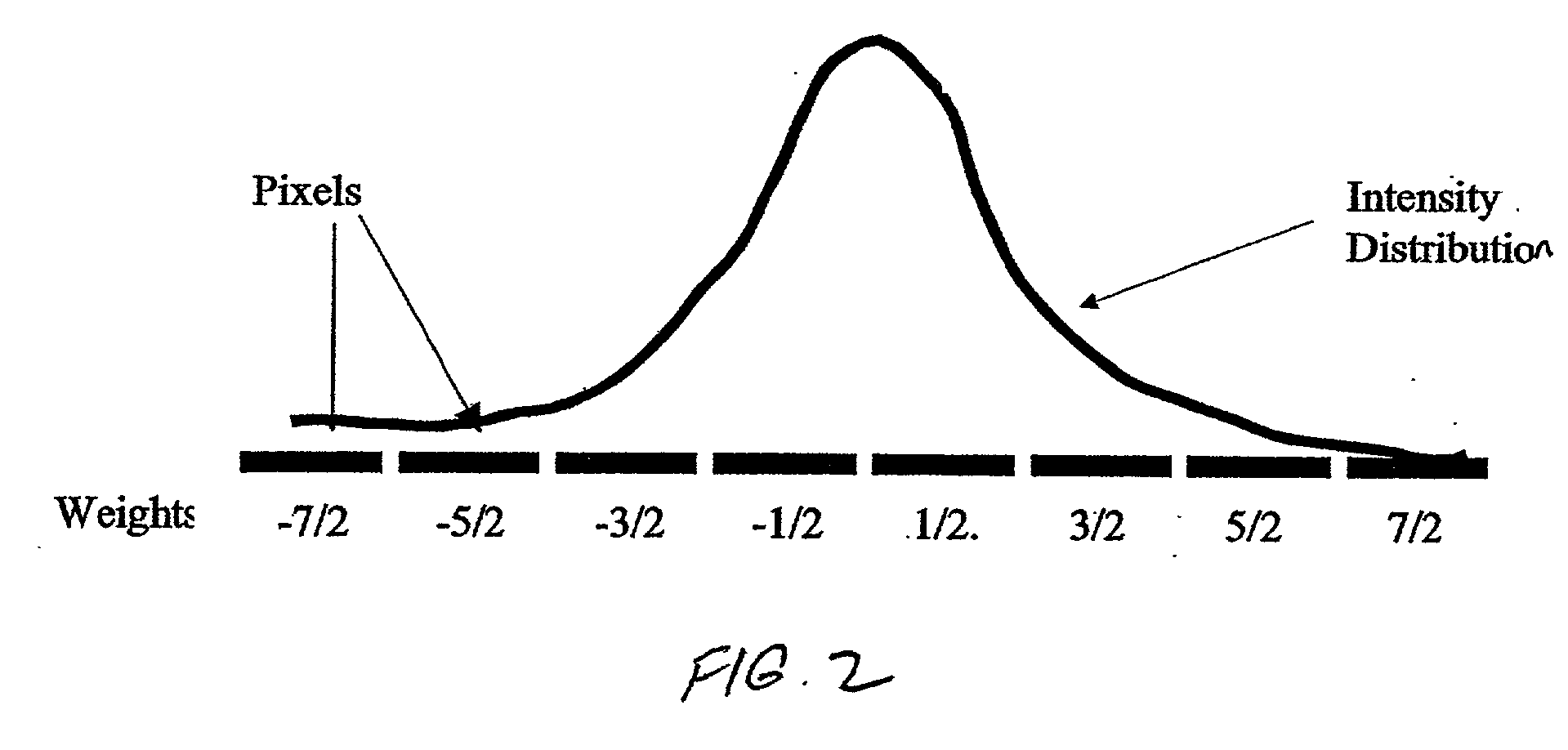

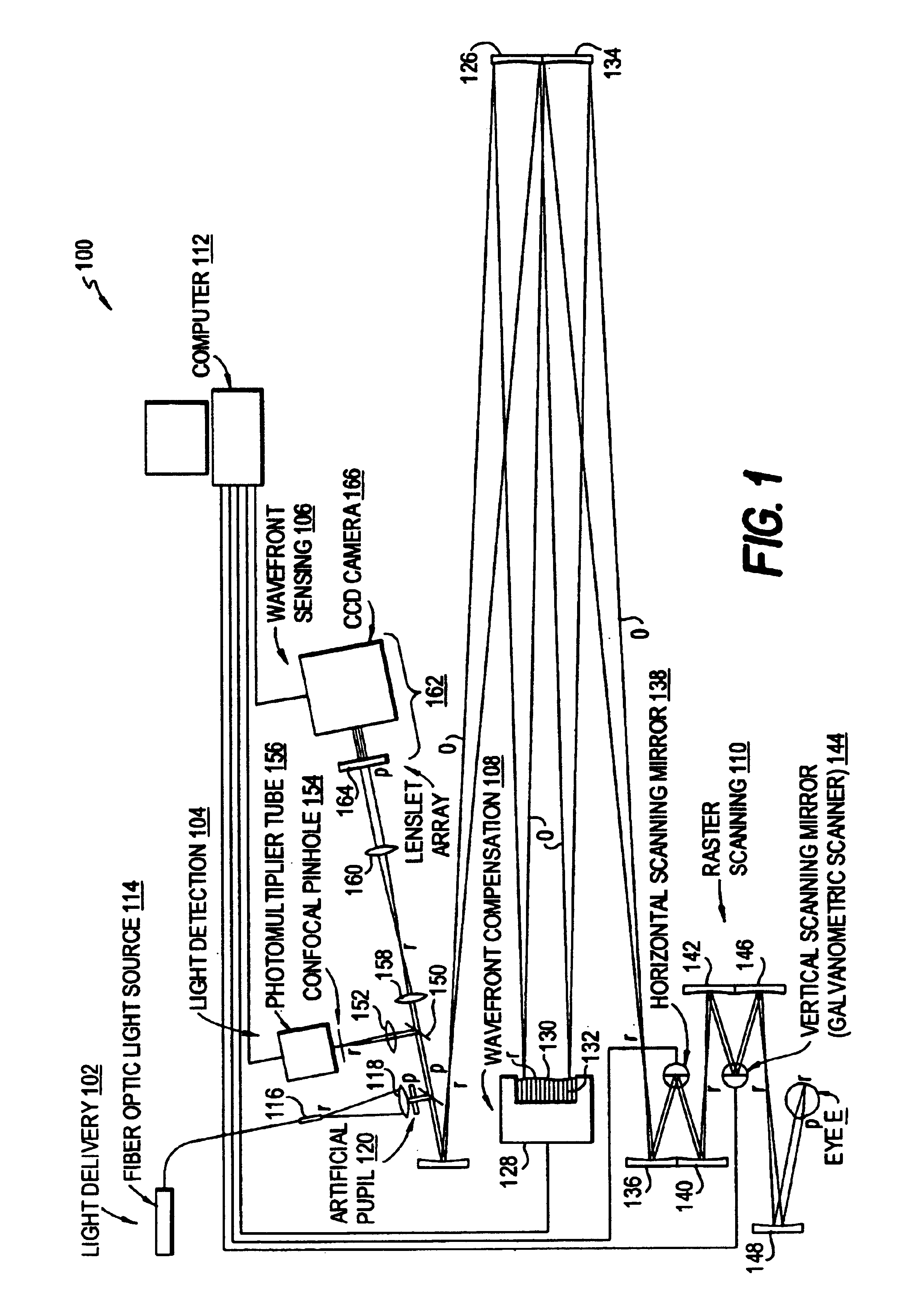

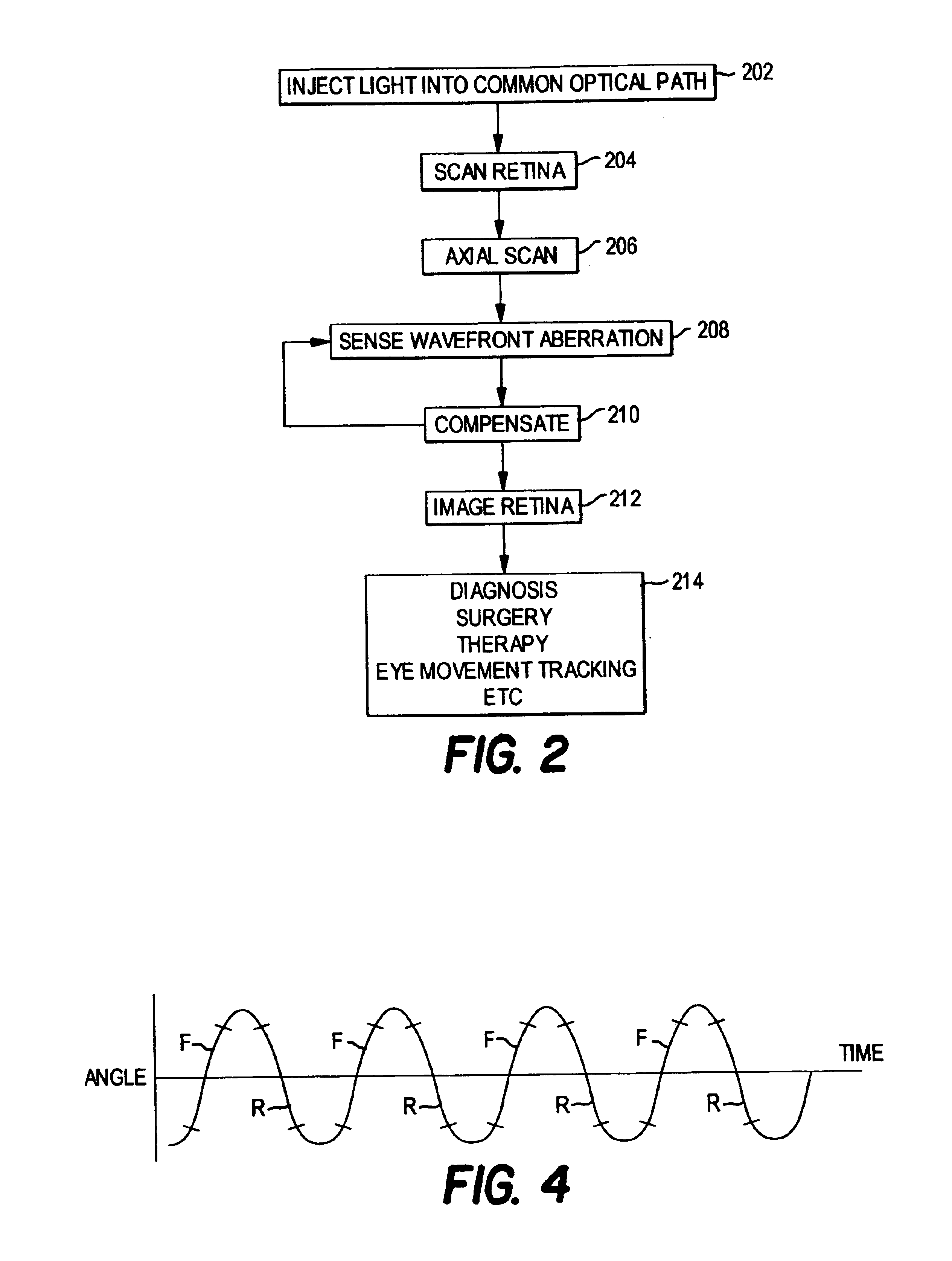

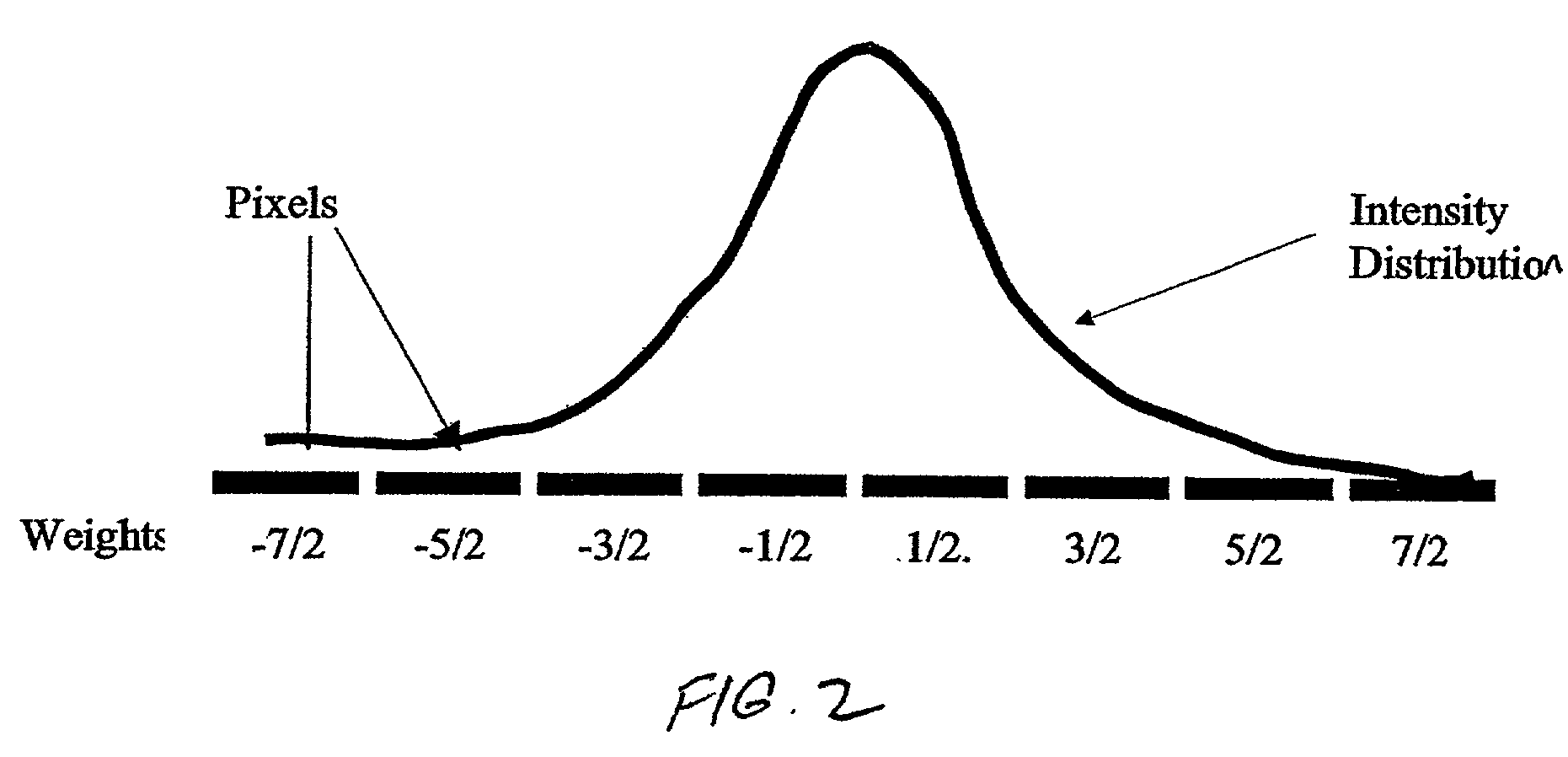

Method and apparatus for improving vision and the resolution of retinal images

InactiveUS20060044510A1Accurate measurementHigh resolutionOptical measurementsEye surgeryCcd cameraLaser beams

Owner:UNIVERSITY OF ROCHESTER

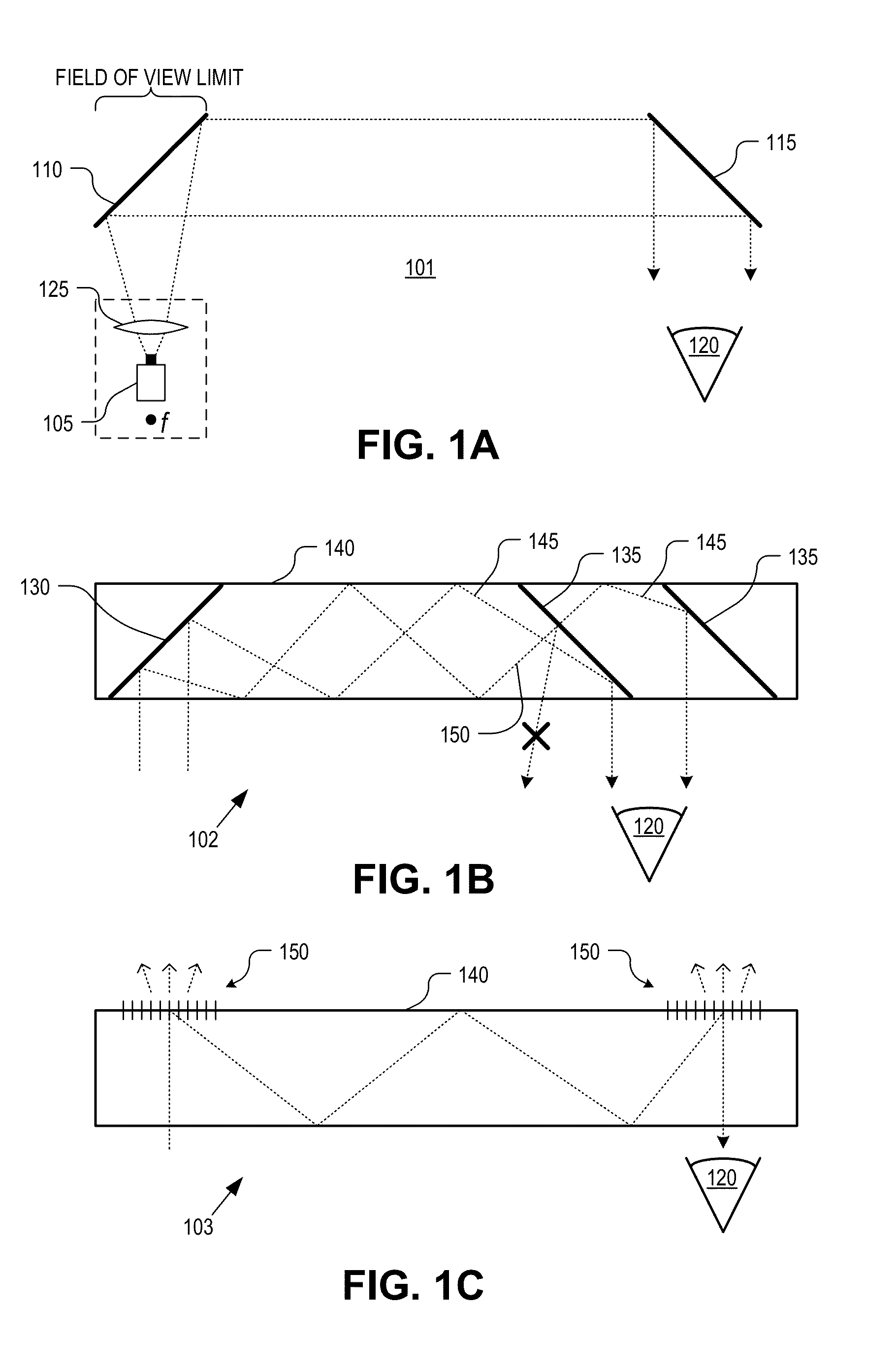

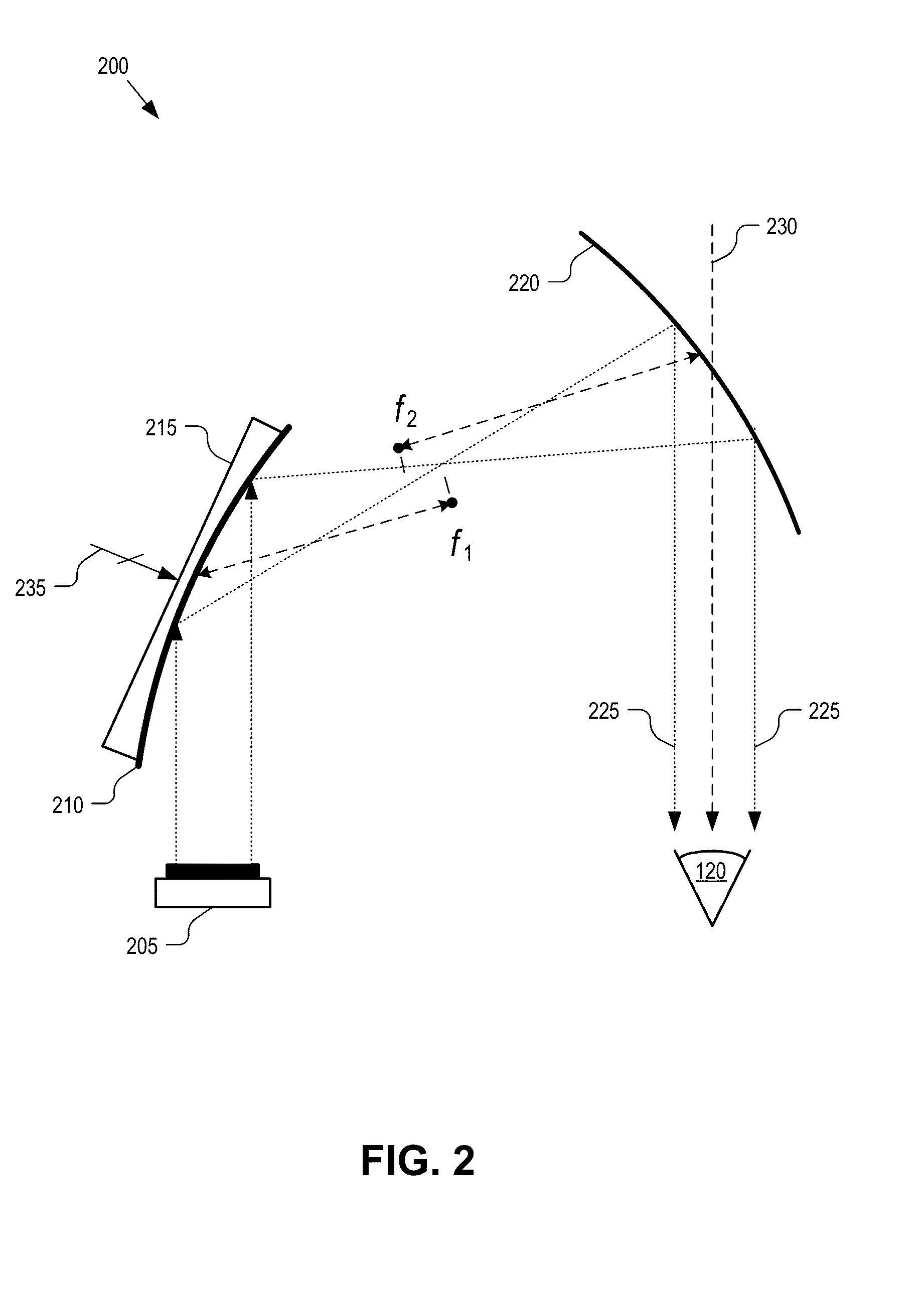

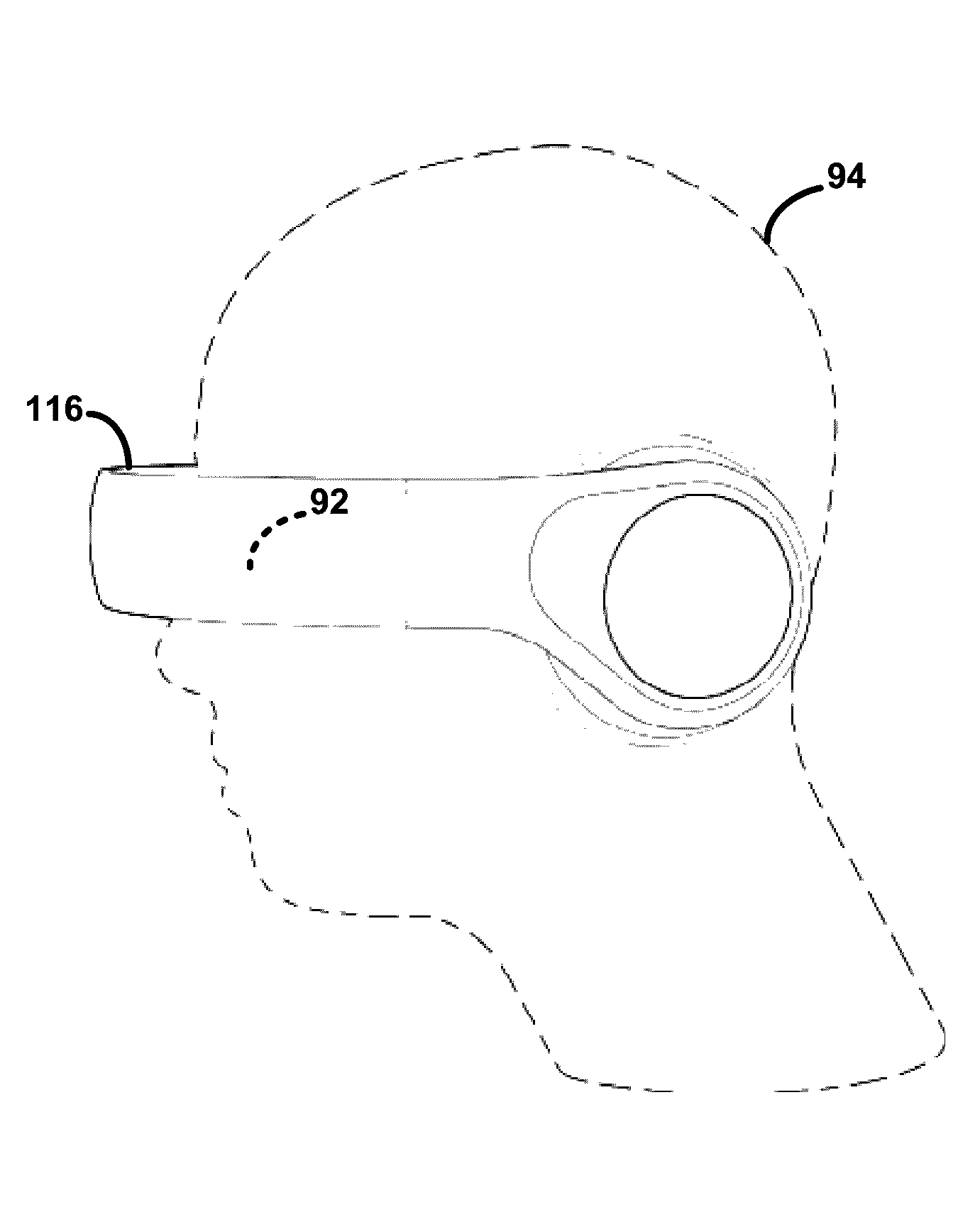

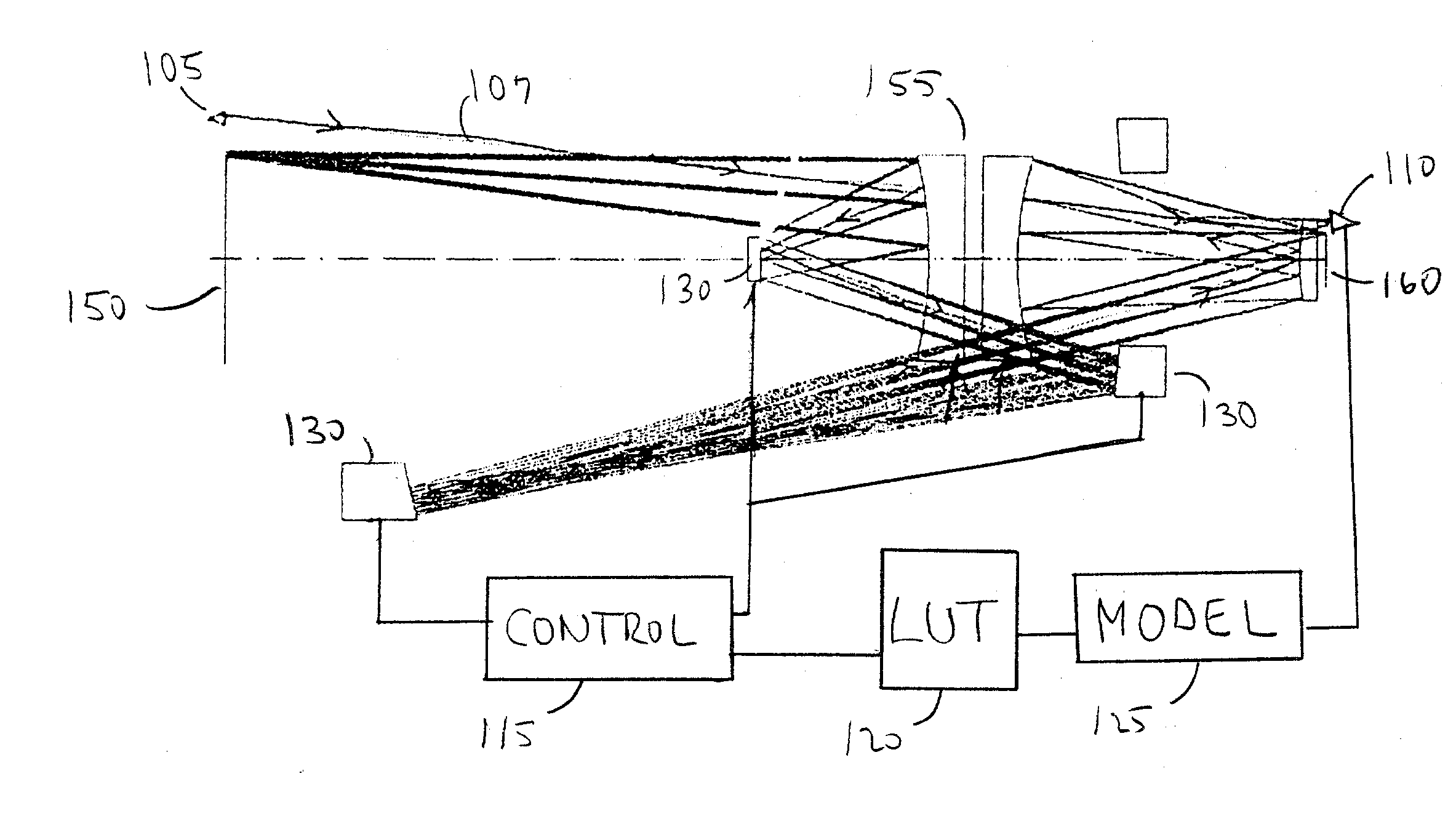

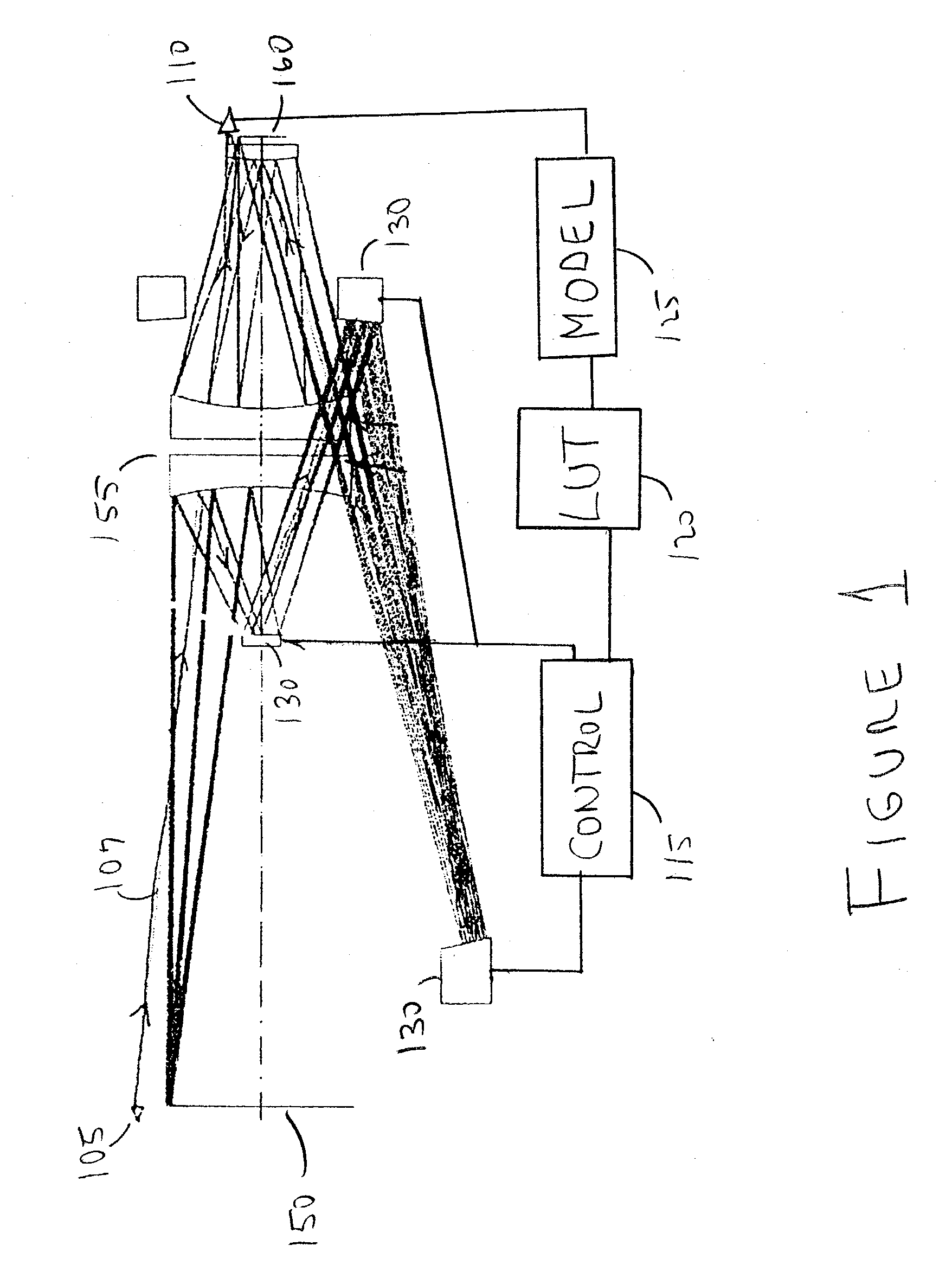

Near-to-eye display having adaptive optics

An optical apparatus includes a light source, a deformable mirror, an actuator system, and a partially transparent mirror. The deformable mirror is positioned in an optical path of the image output from the light source. The actuator system is coupled to the deformable mirror to selectively adjust at least a curvature of the deformable mirror. The partially transparent mirror is positioned to be in front of the eye of the user when the optical apparatus is worn and optically aligned with the deformable mirror such that the image output from the light source positioned peripherally to the eye is reflected by the deformable mirror to the partially transparent mirror and reflected by the partially transparent mirror to the eye of the user.

Owner:GOOGLE LLC

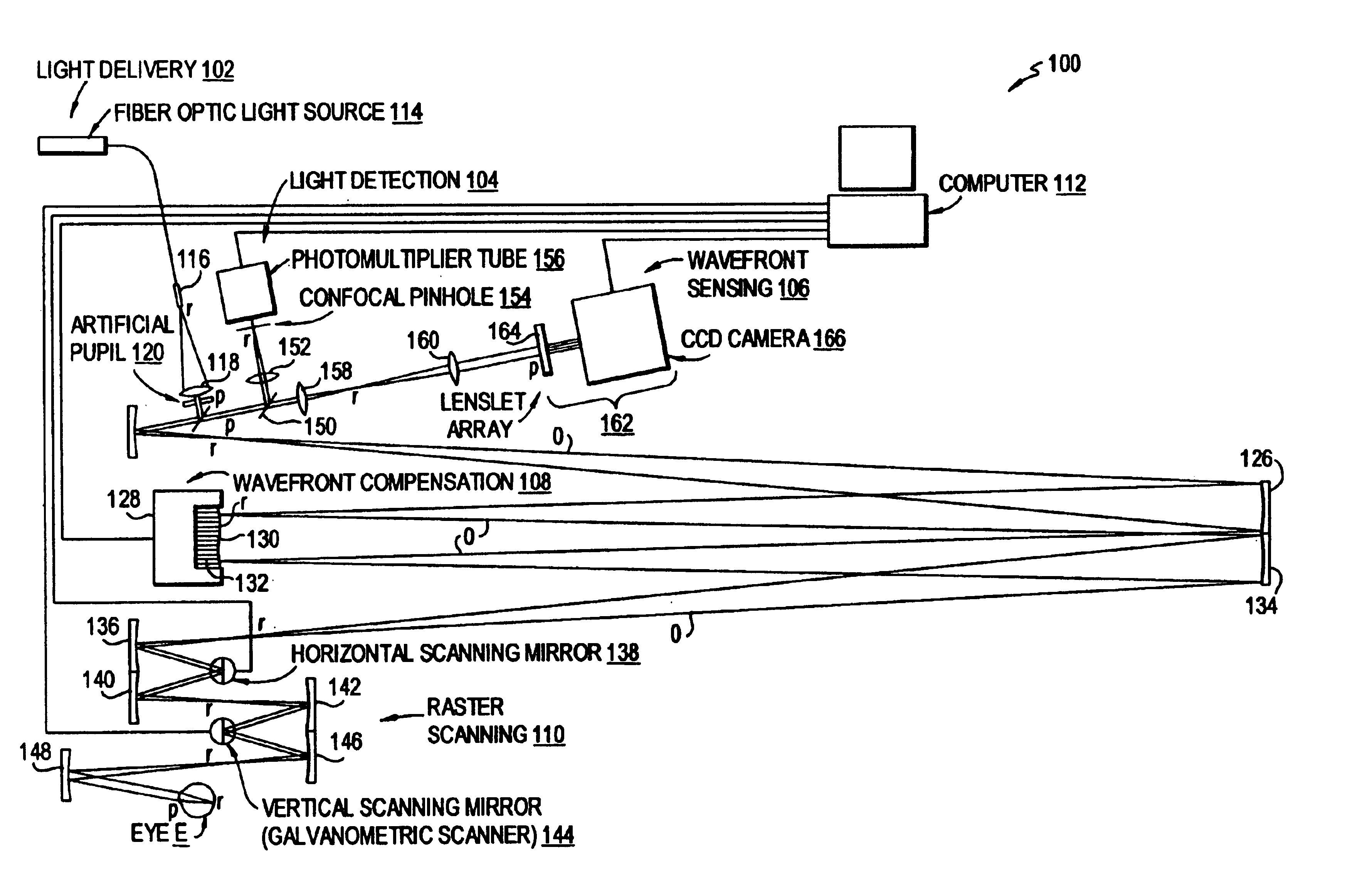

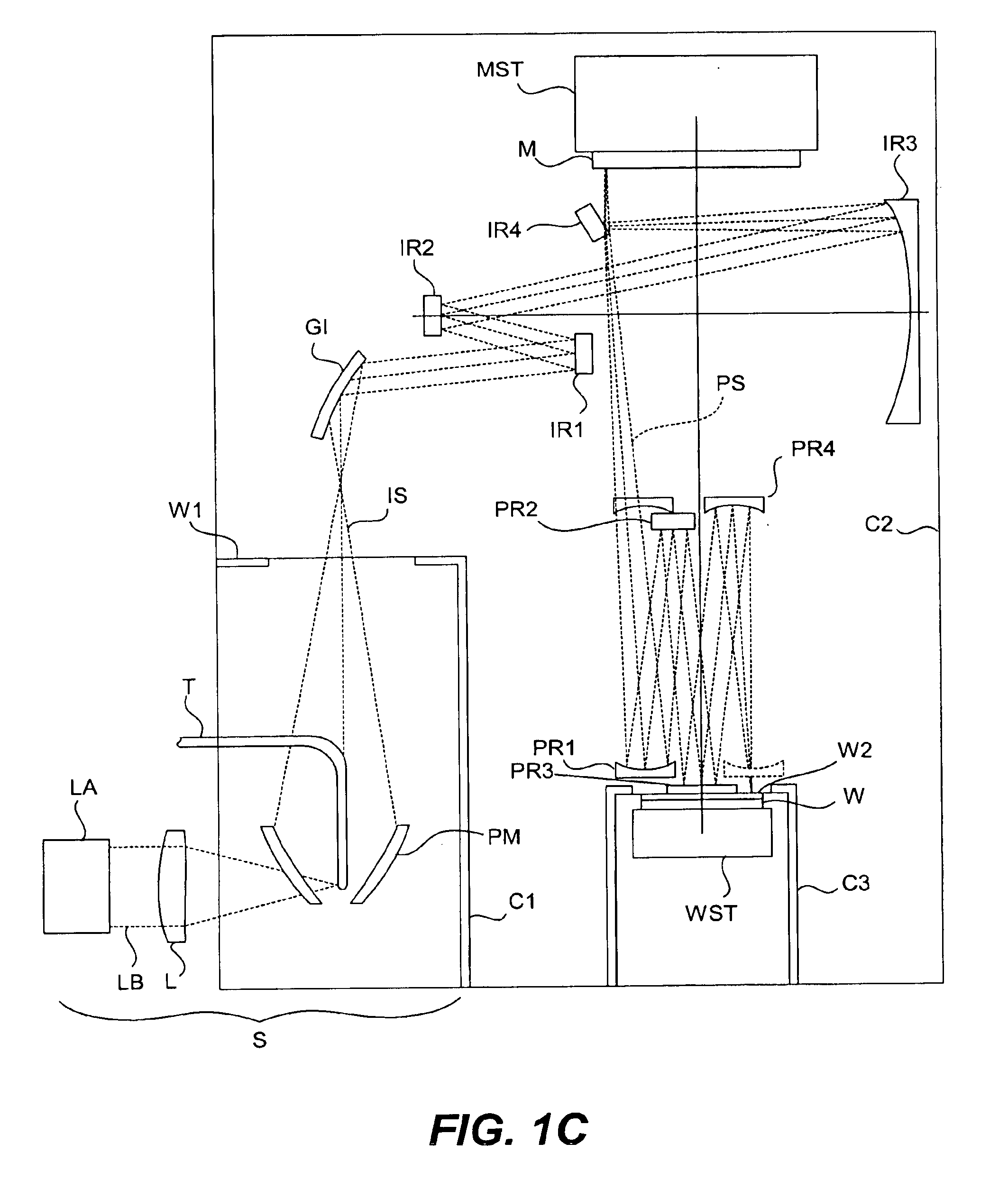

Method and apparatus for using adaptive optics in a scanning laser ophthalmoscope

InactiveUS6890076B2Efficient and effective implementationImprove abilitiesOptical measurementsOthalmoscopesScanning laser ophthalmoscopeEyewear

A scanning laser ophthalmoscope incorporates adaptive optics to compensate for wavefront aberrations in the eye. Light from a light source is scanned onto the retina. Light reflected from the retina is detected for imaging and is also used for wavefront sensing. The sensed wavefront aberrations are used to control an adaptive optic device, such as a deformable mirror, disposed in the path of the light from the source in order to compensate for the aberrations.

Owner:UNIVERSITY OF ROCHESTER

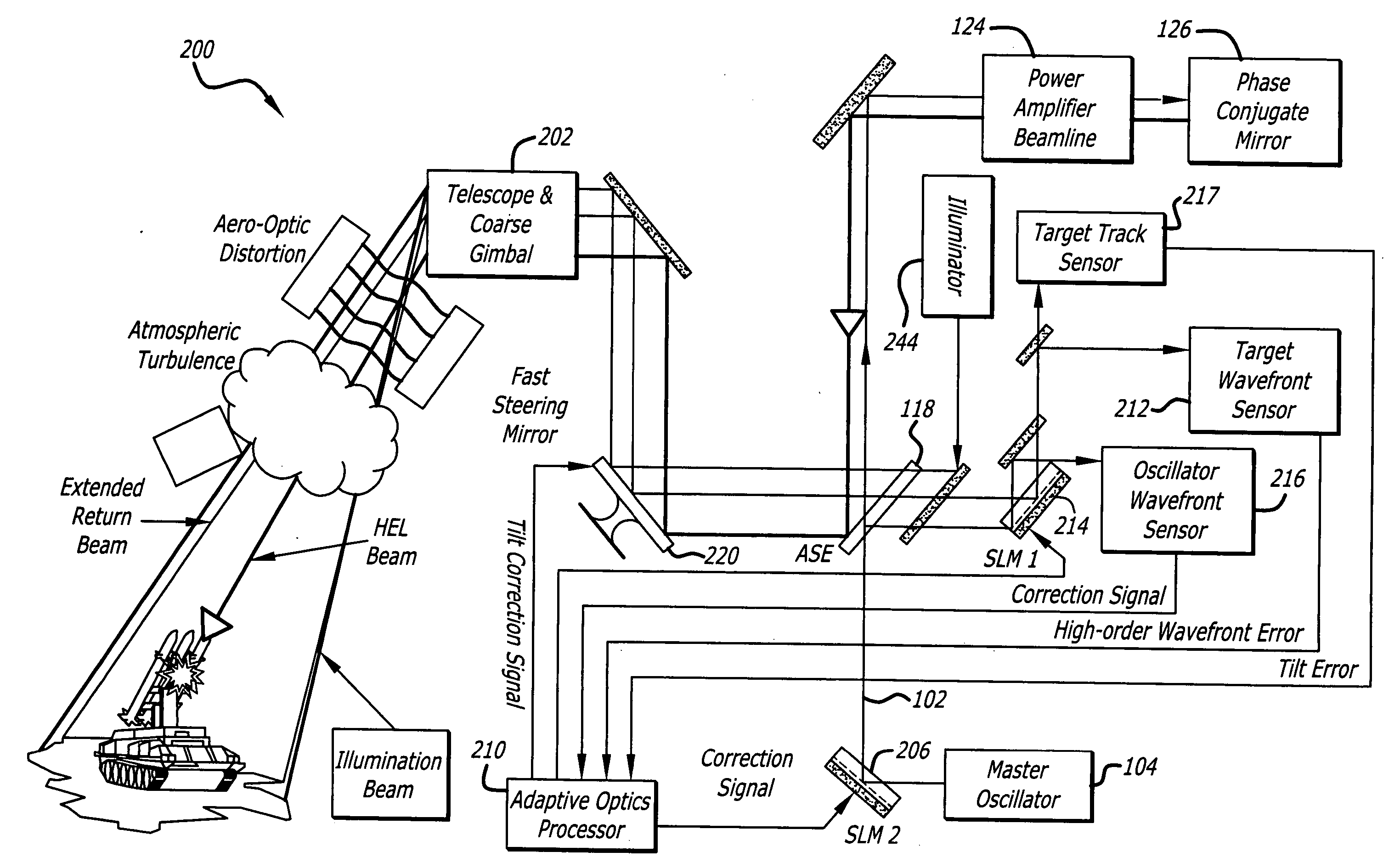

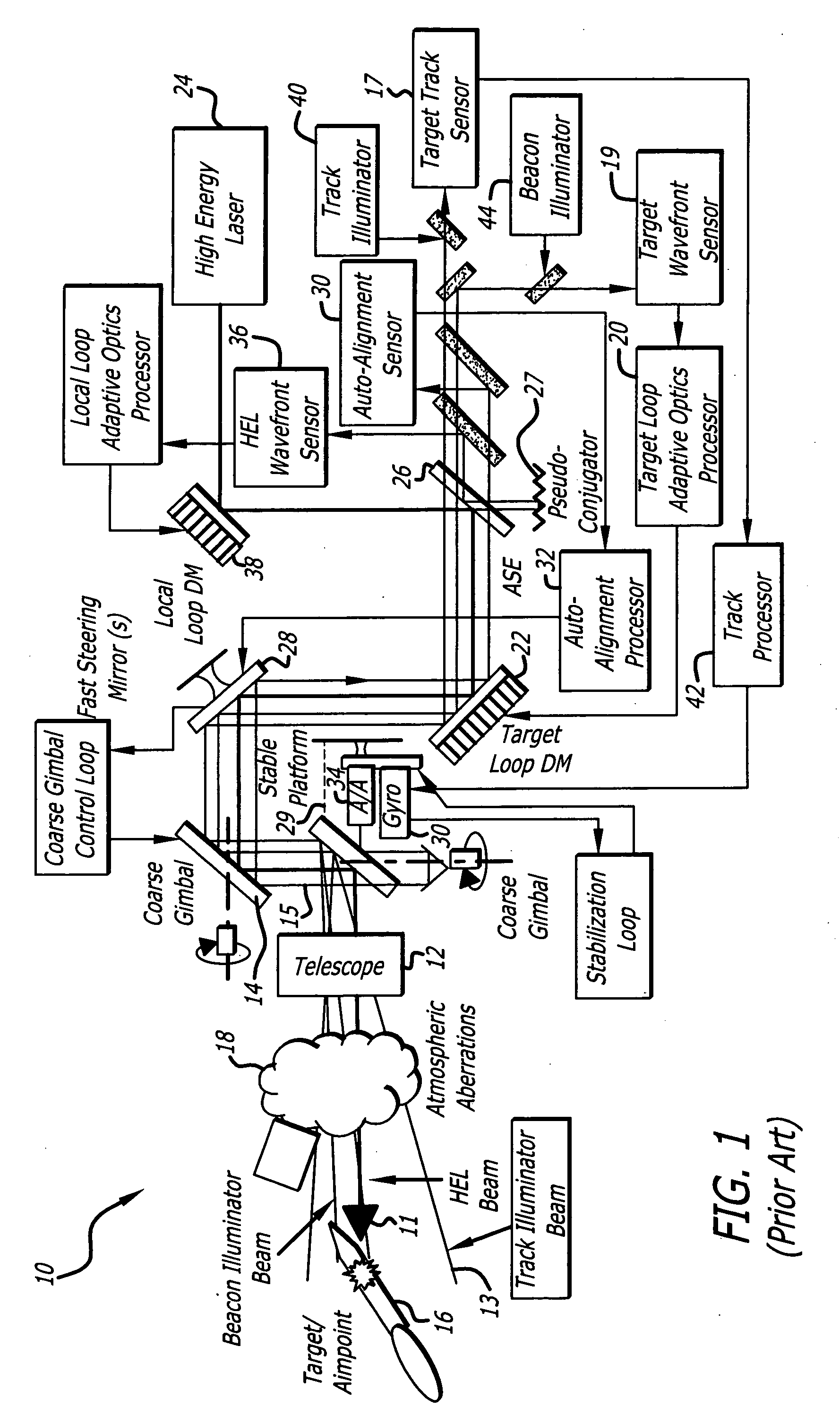

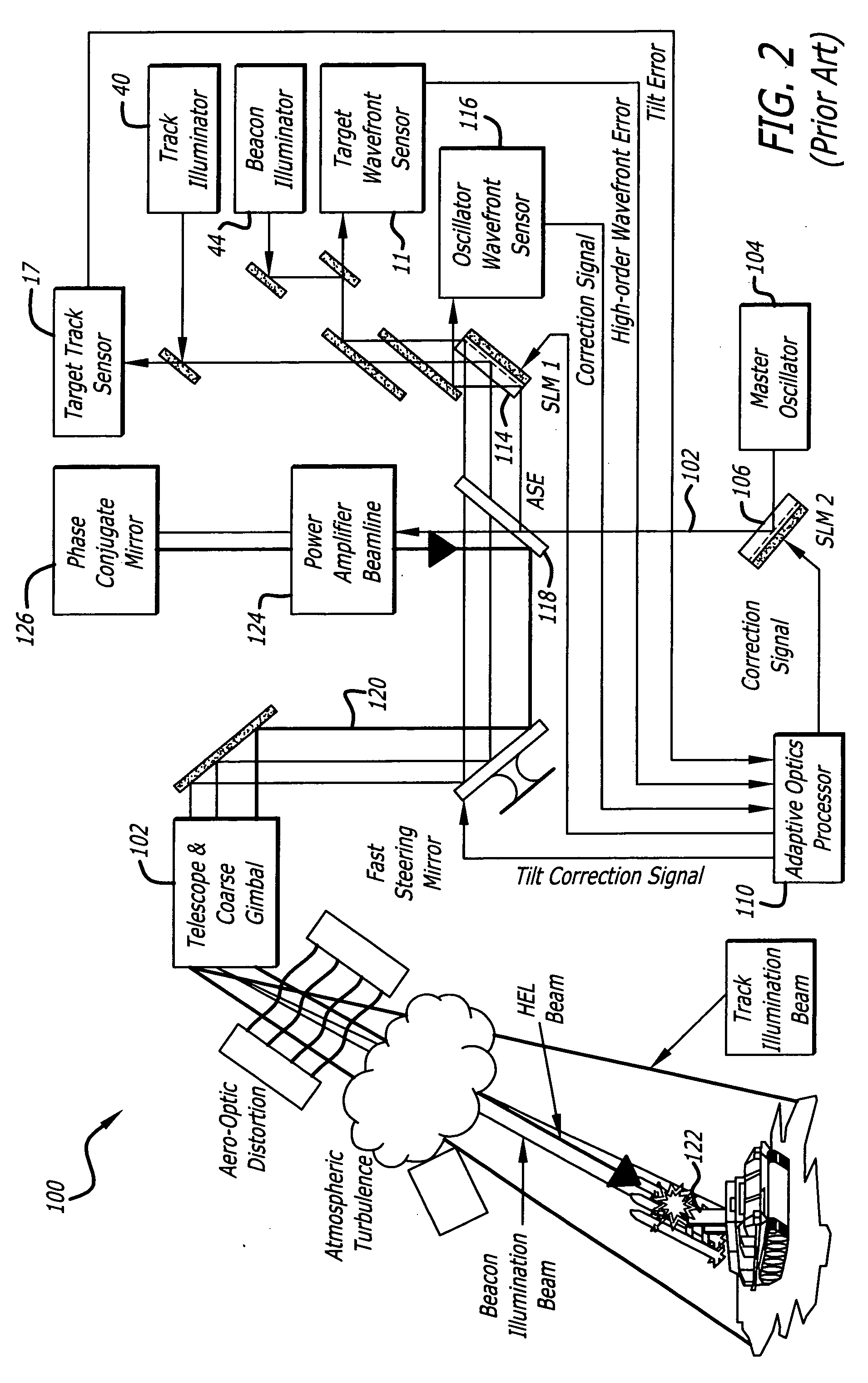

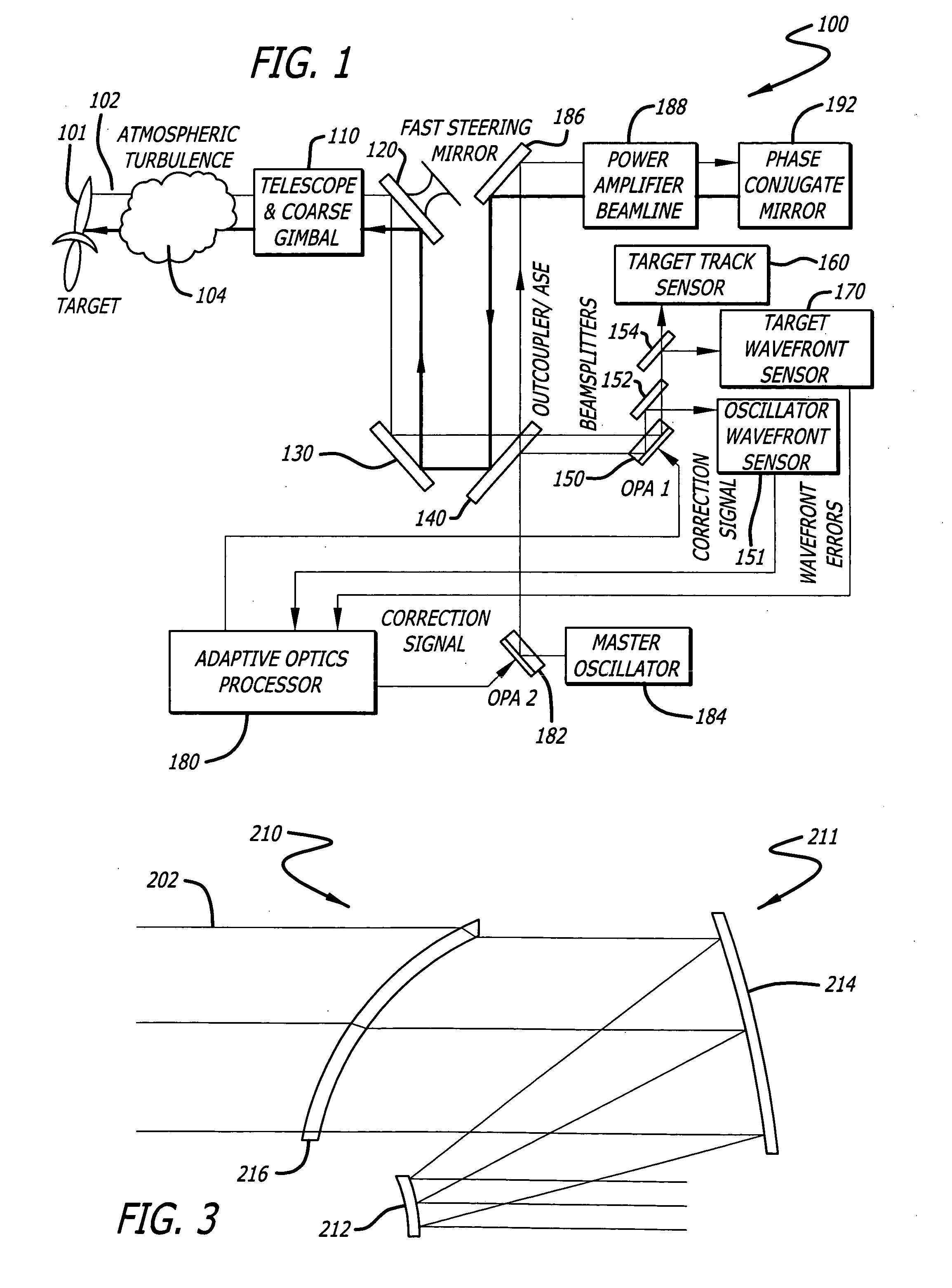

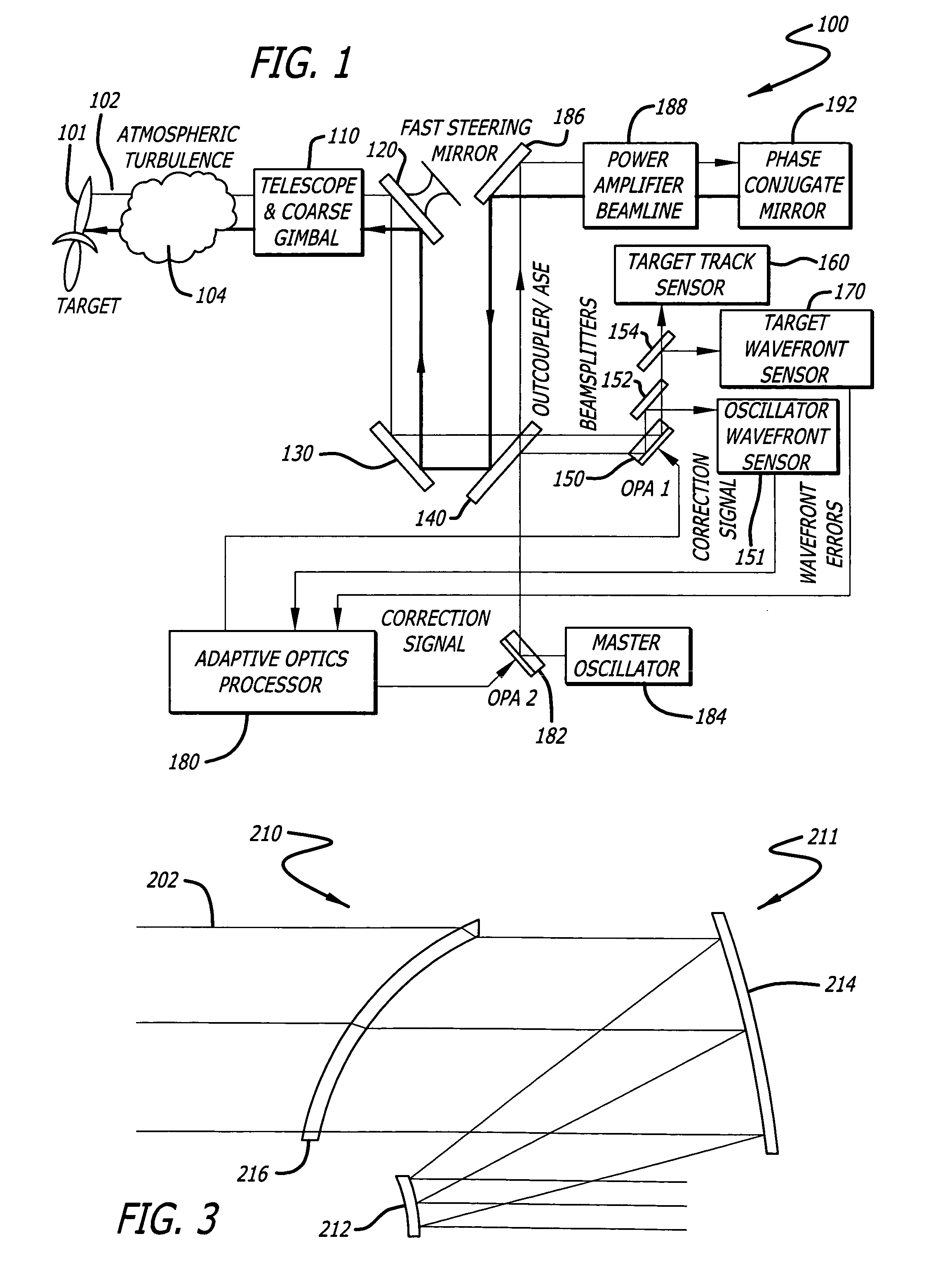

Beam control system with extended beacon and method

ActiveUS20060022115A1High error rateOptical measurementsPhotometry using reference valueSpatial light modulatorWavefront aberration

A beam control system and method: The inventive system includes, an arrangement for receiving a first beam of electromagnetic energy; measuring wavefront aberrations in the first beam with a wavefront sensor; and removing global tilt from the measured wavefront aberrations to provide higher order aberrations for beam control. In the illustrative embodiment, the invention uses a traditional (quad-cell) Shack-Hartmann wavefront sensor to measure wavefront aberrations. An adaptive optics processor electronically removes the global tilt (angular jitter) from this measurement leaving only the higher-order Zernike components. These higher-order aberrations are then applied to wavefront control elements, such as deformable mirrors or spatial light modulators that correct the tracker image and apply a conjugate distortion to the wavefront of the outgoing HEL beam. A track error (angular jitter) component is supplied by a separate fine track sensor. This jitter error is then applied by the adaptive optics processor to a fast steering mirror, which corrects jitter in the tracker image and applies a compensating distortion to the LOS of the HEL beam.

Owner:RAYTHEON CO

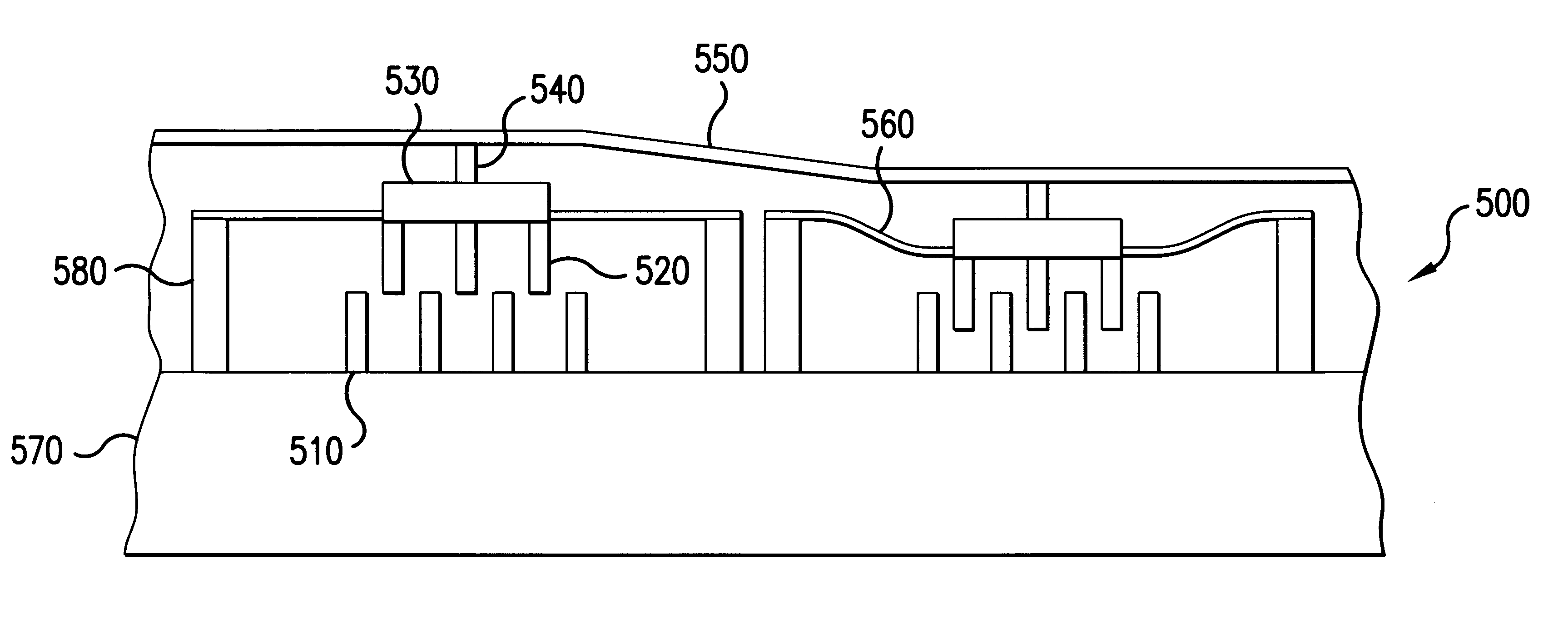

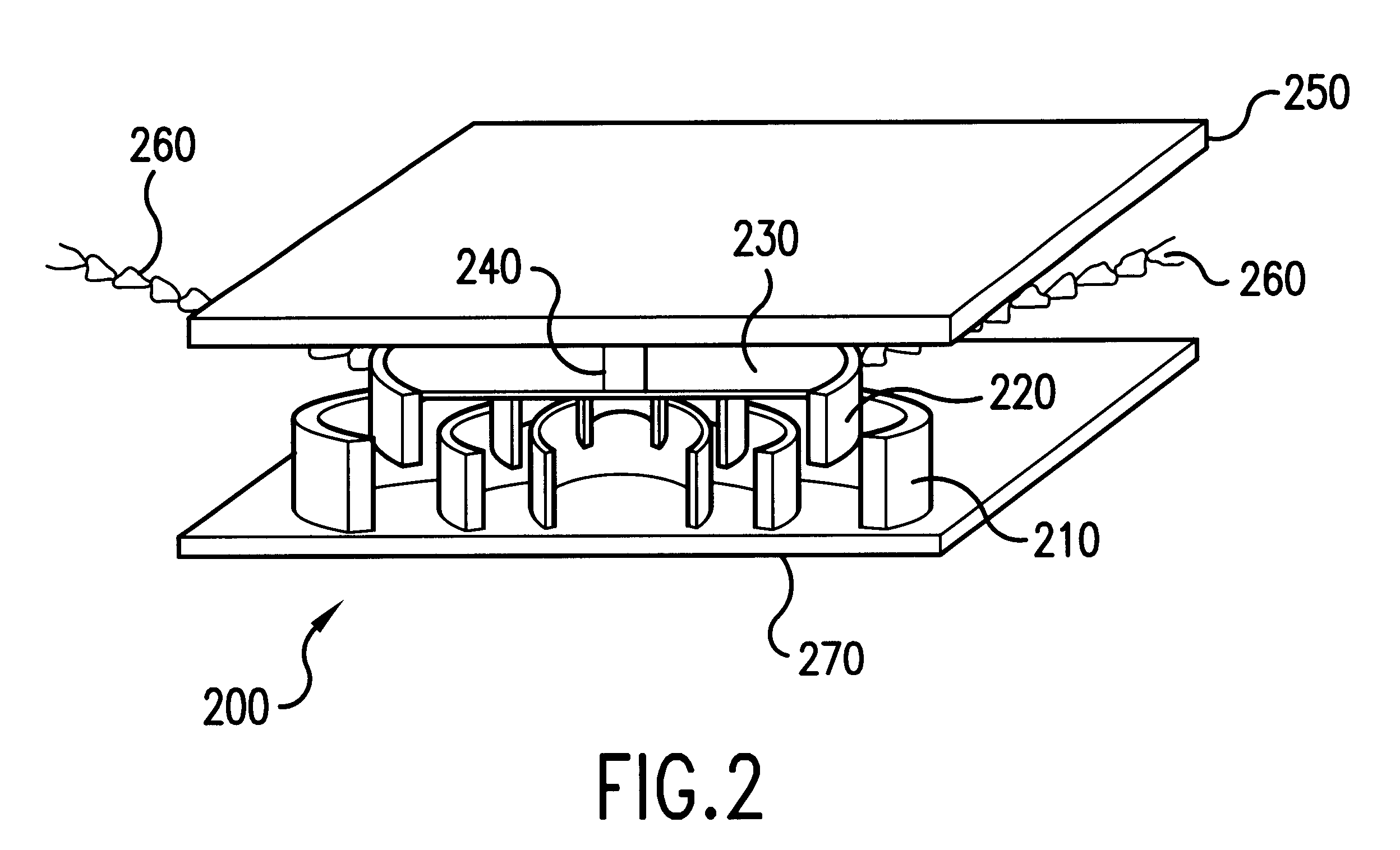

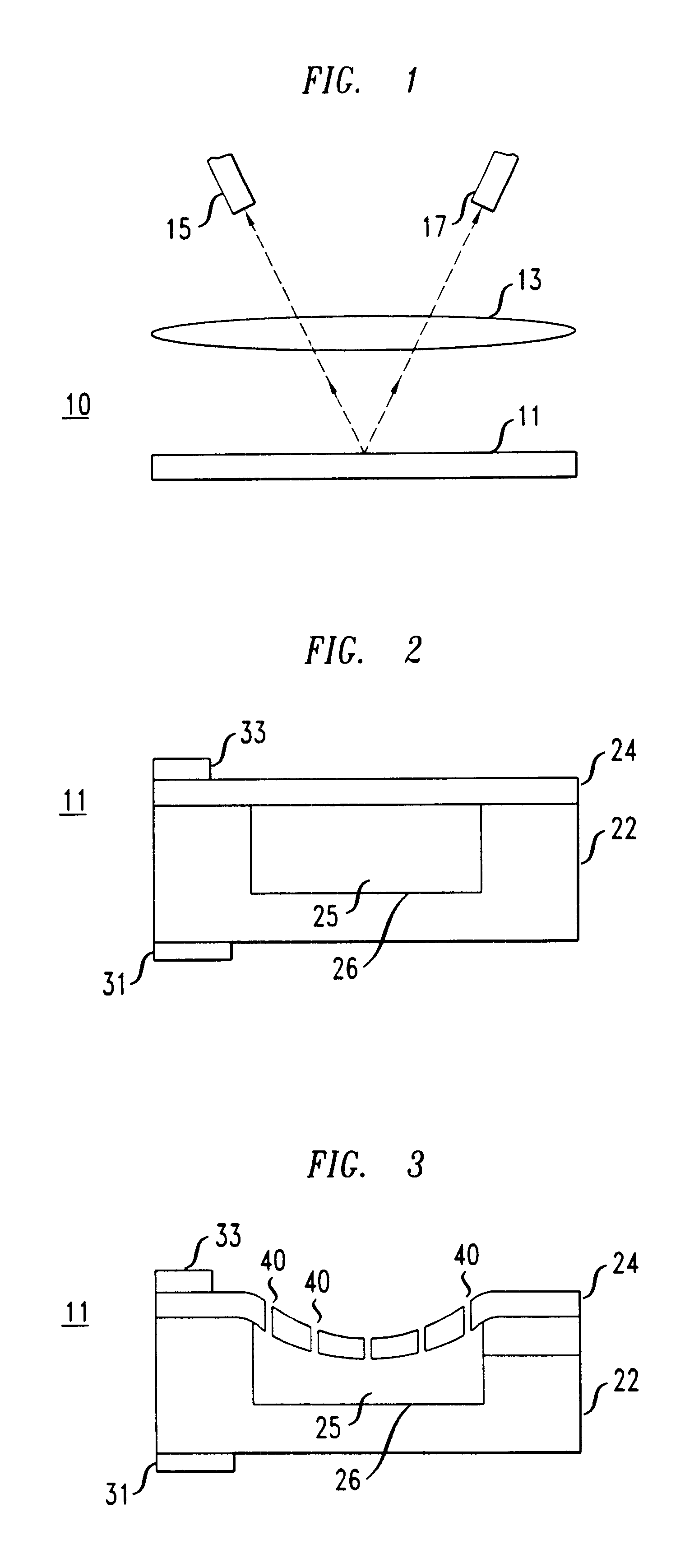

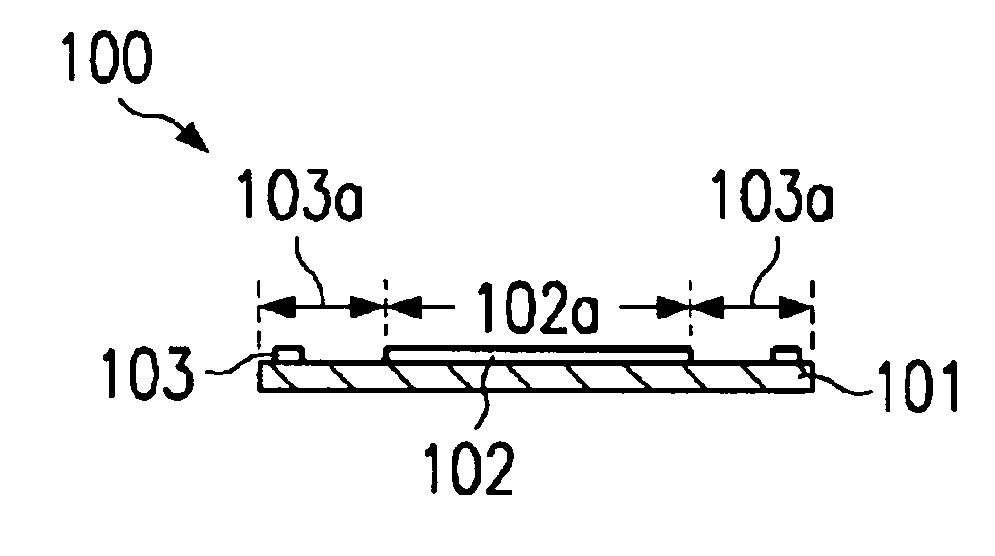

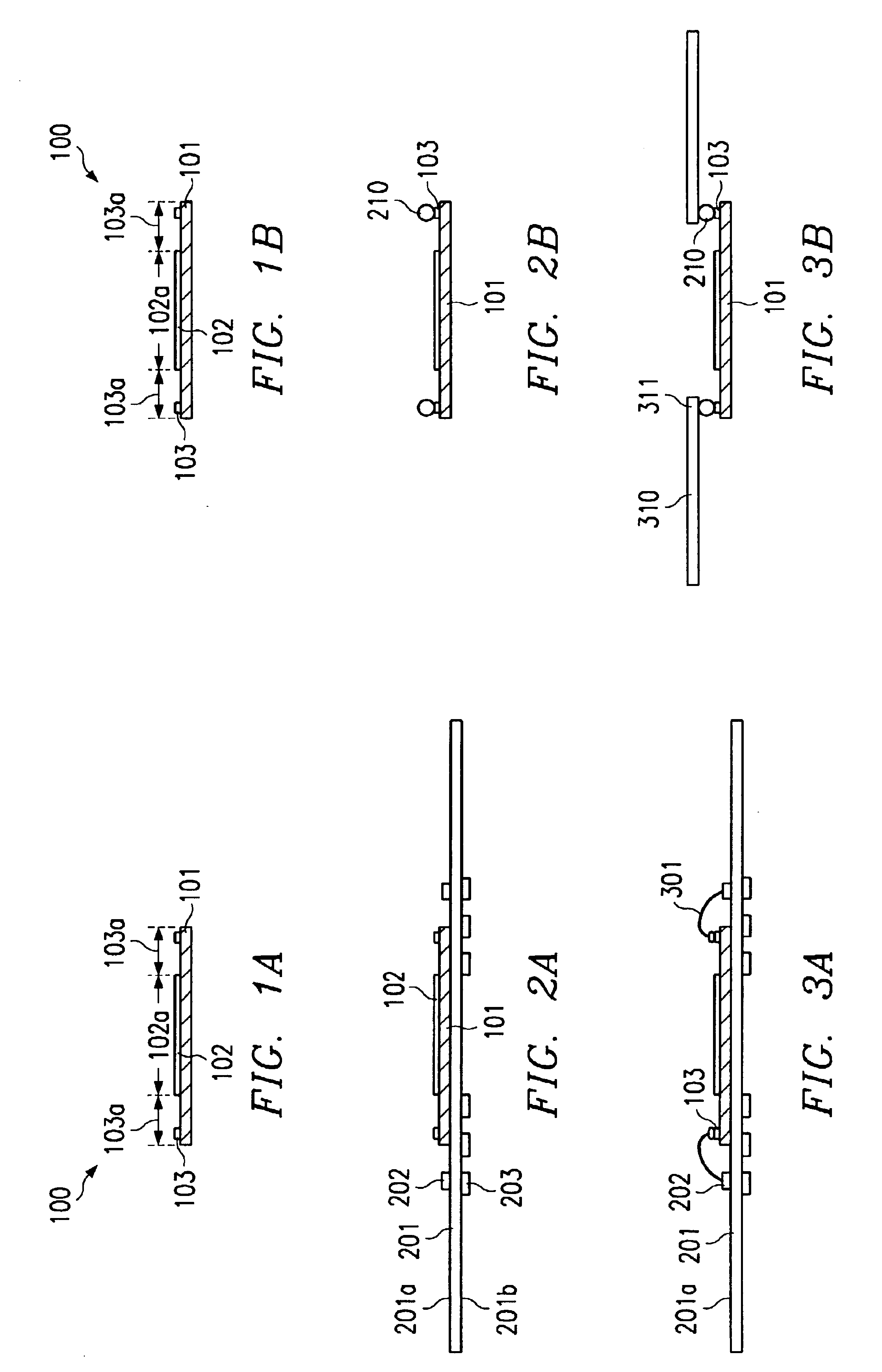

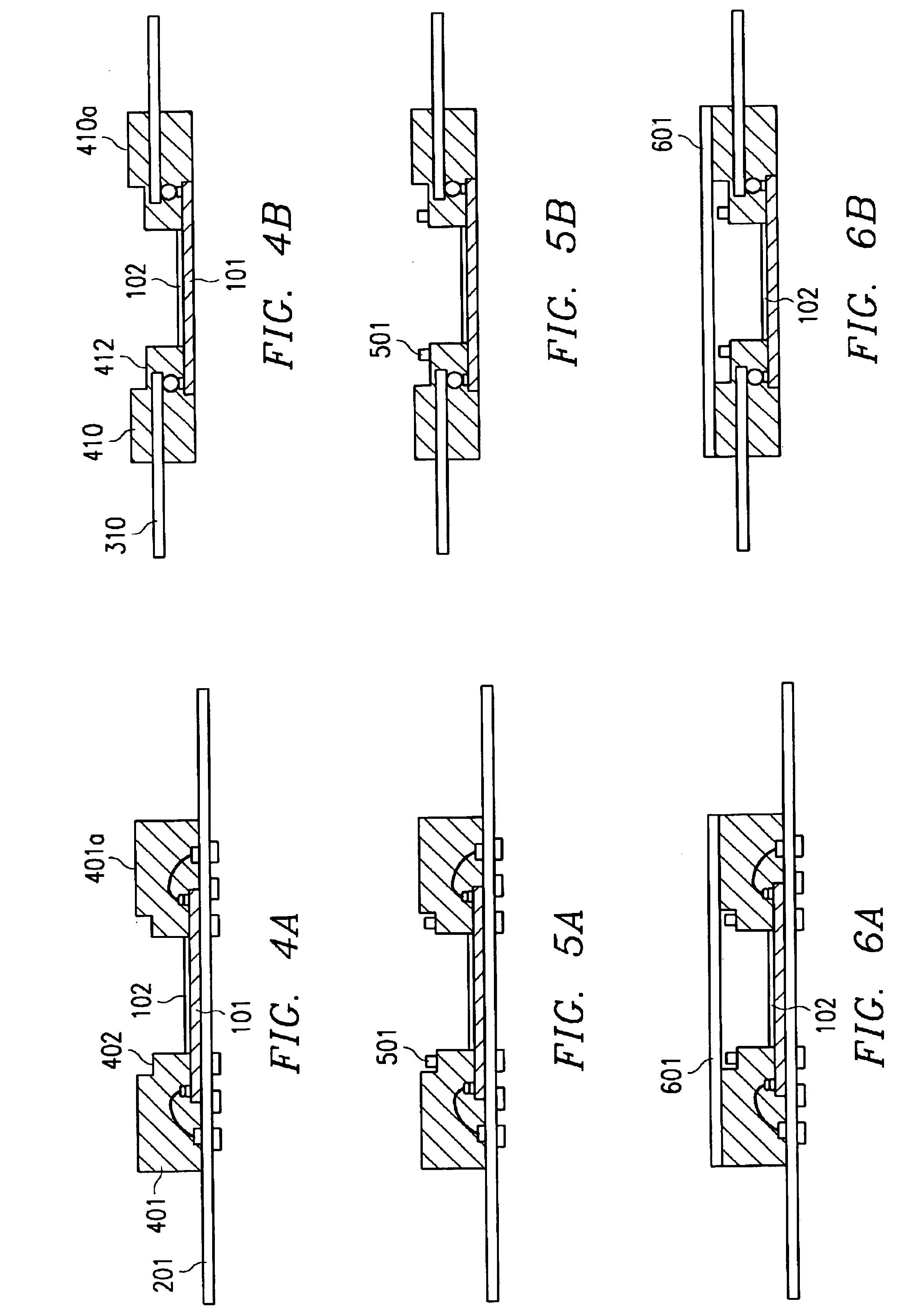

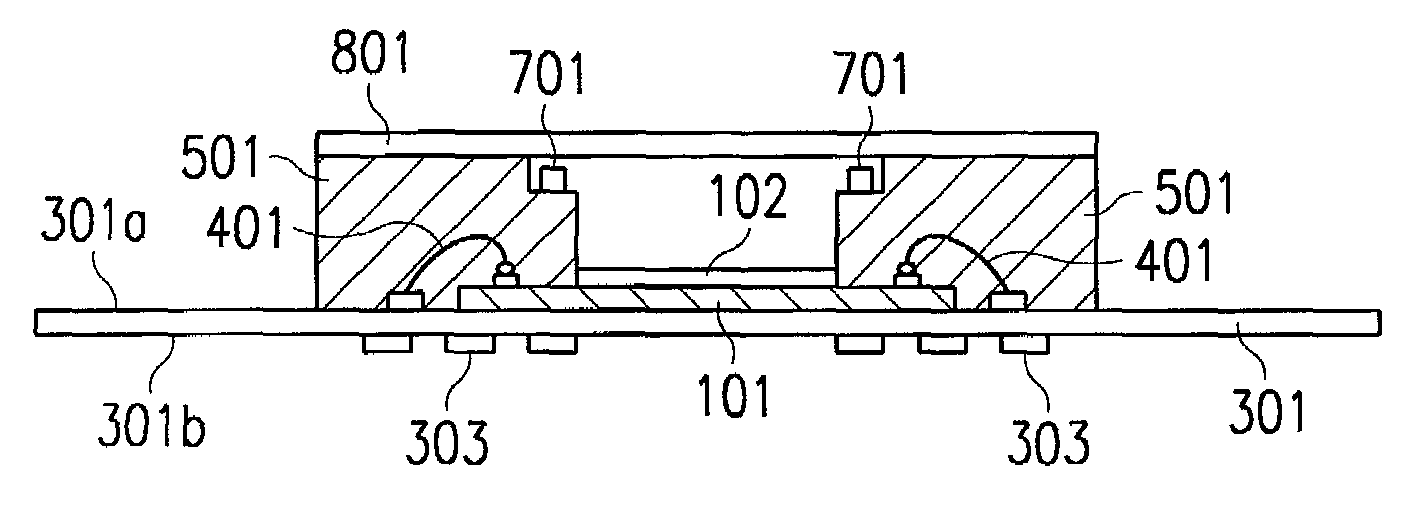

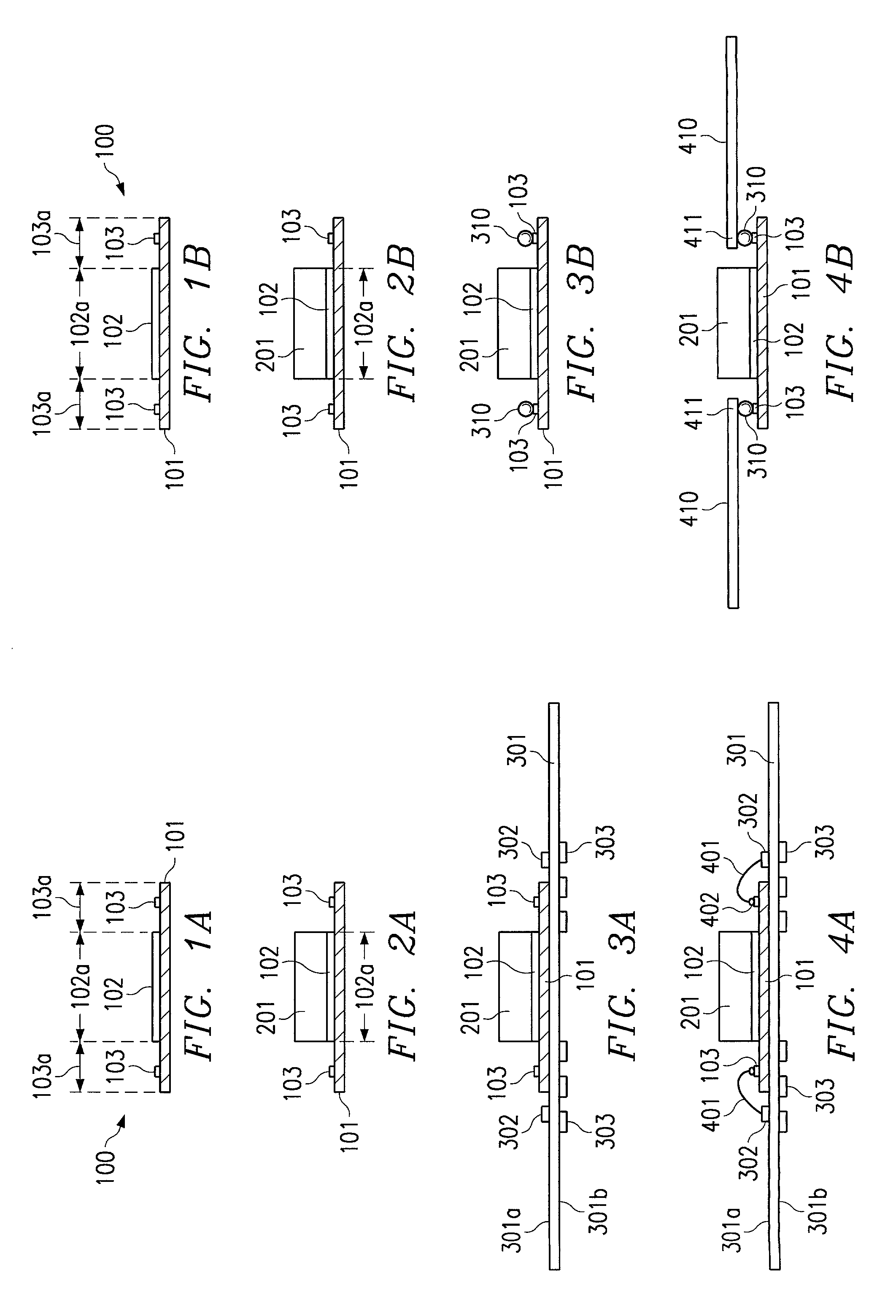

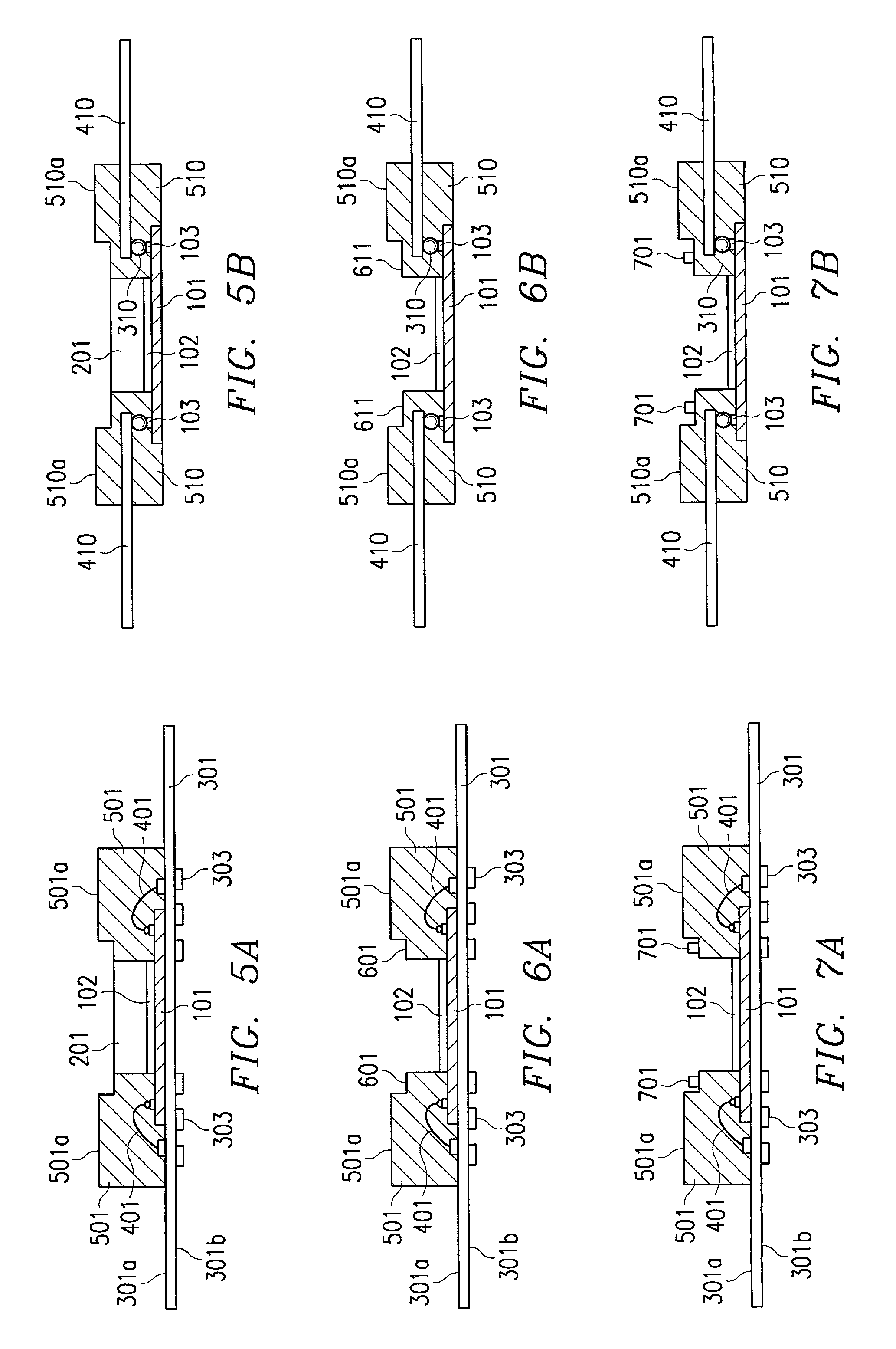

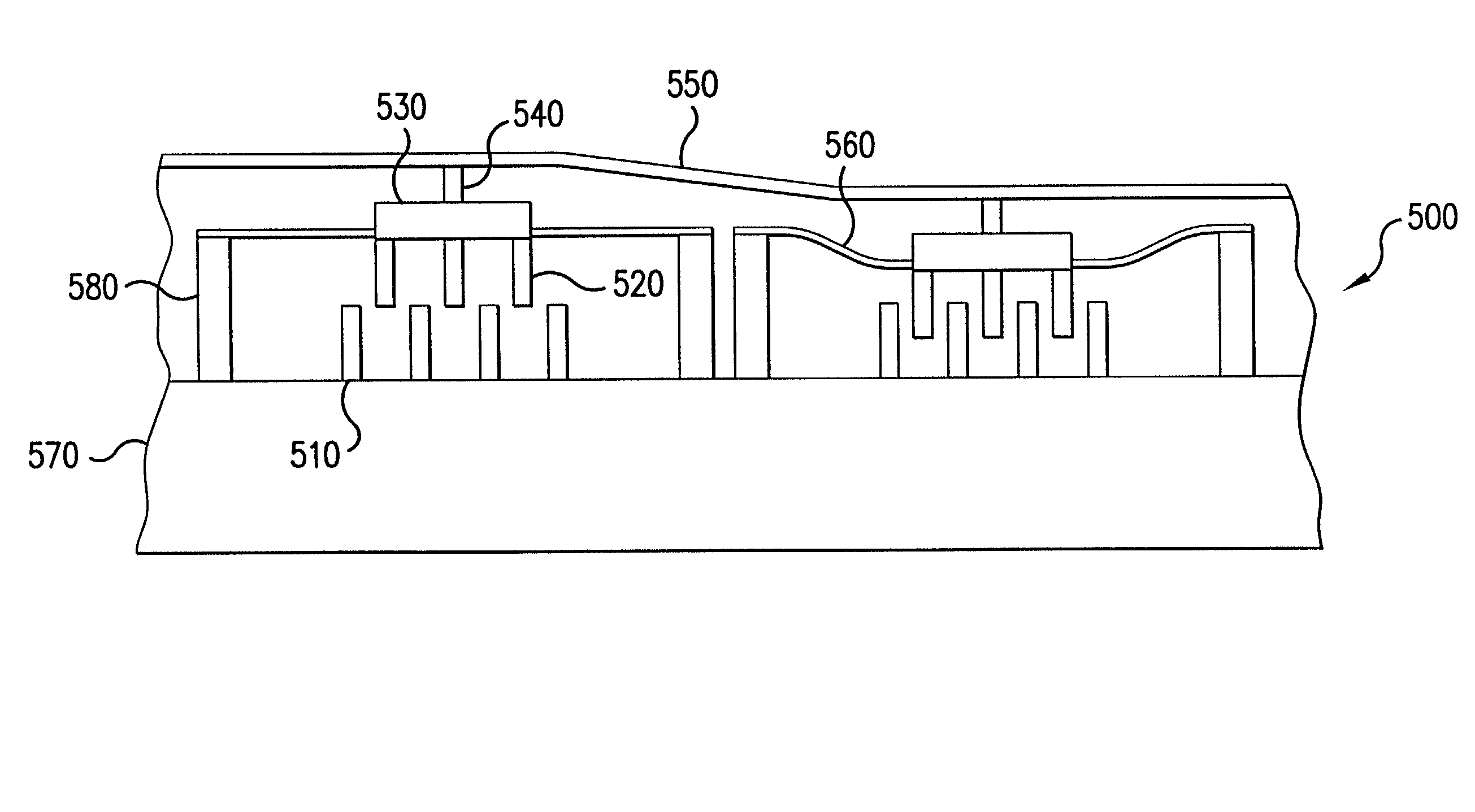

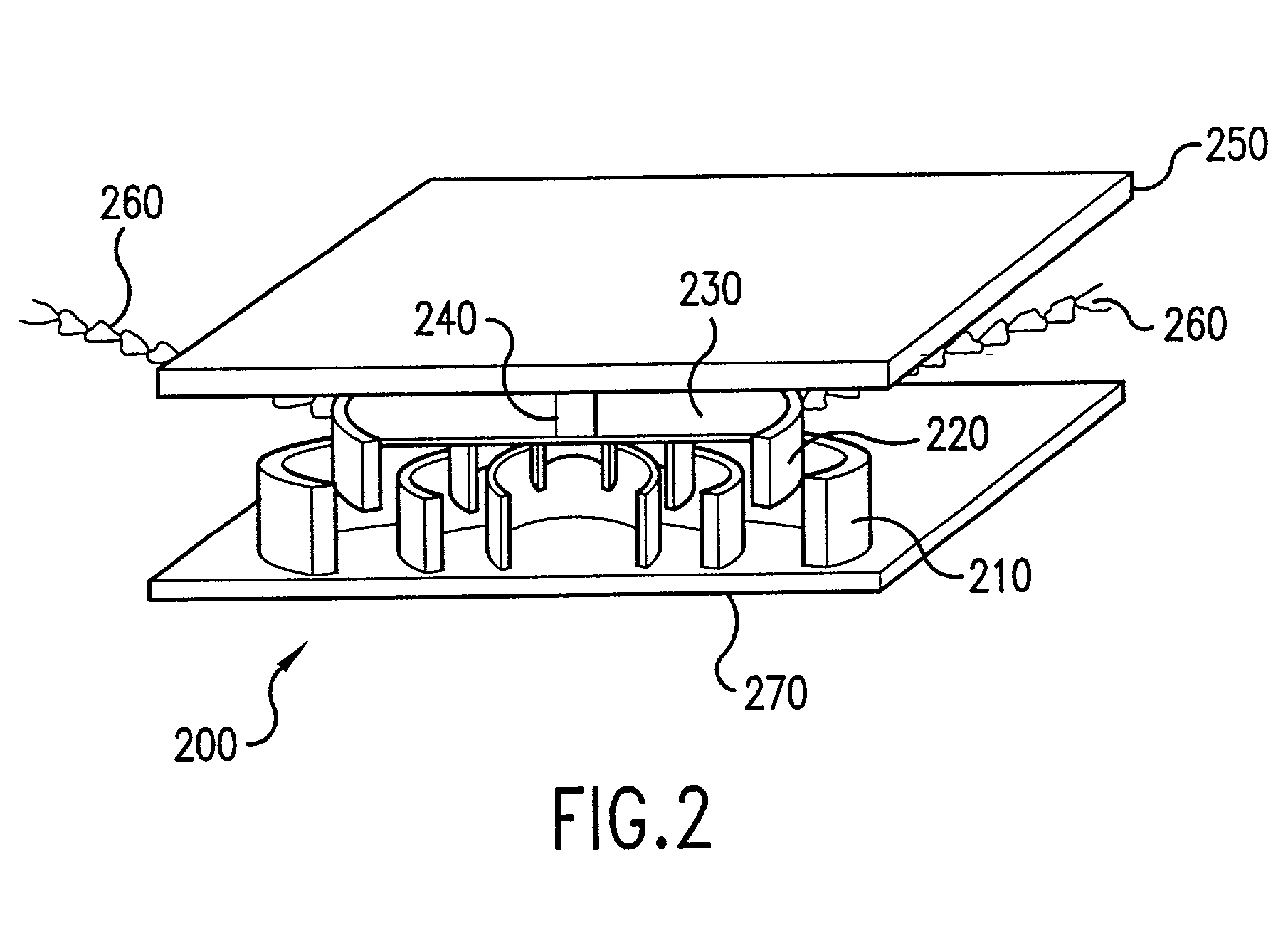

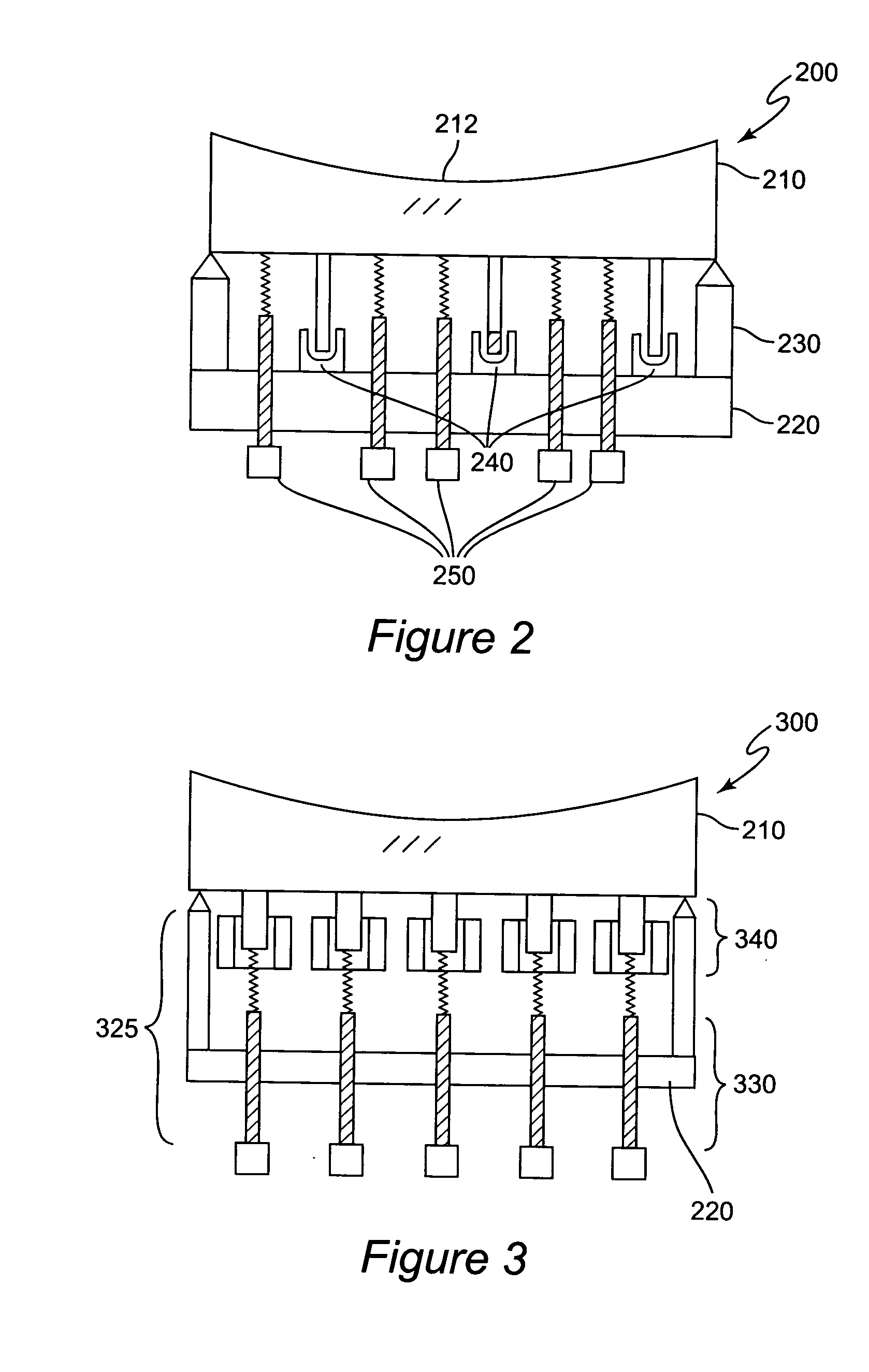

Method of fabricating a molded package for micromechanical devices

InactiveUS6858910B2Flat surfaceHigh glossAcceleration measurement using interia forcesSemiconductor/solid-state device detailsSpatial light modulatorShell molding

A plastic land-grid array package, a ball-grid array package, and a plastic leaded package for micromechanical components are fabricated by a molding process characterized by lining the cavity surfaces of the top and bottom mold halves with a protective plastic film, which also protects the surfaces of the components during the molding phase, selectively encapsulating the bonding pads and coupling members of the chip while leaving empty space above the components, and attaching a lid over the components. A molding method as well as a molding apparatus are provided compatible with the sensitivity of the micromechanical devices, yet flexible with regard to the technique used to assemble the chip and the substrate. Furthermore, the method disclosed is flexible with regard to the material and the properties of the substrate.It is an aspect of the present invention to be applicable to a variety of different semiconductor micromechanical devices, for instance actuators, motors, sensors, spatial light modulators, and deformable mirror devices. In all applications, the invention achieves technical advantages as well as significant cost reduction and yield increase.

Owner:TEXAS INSTR INC

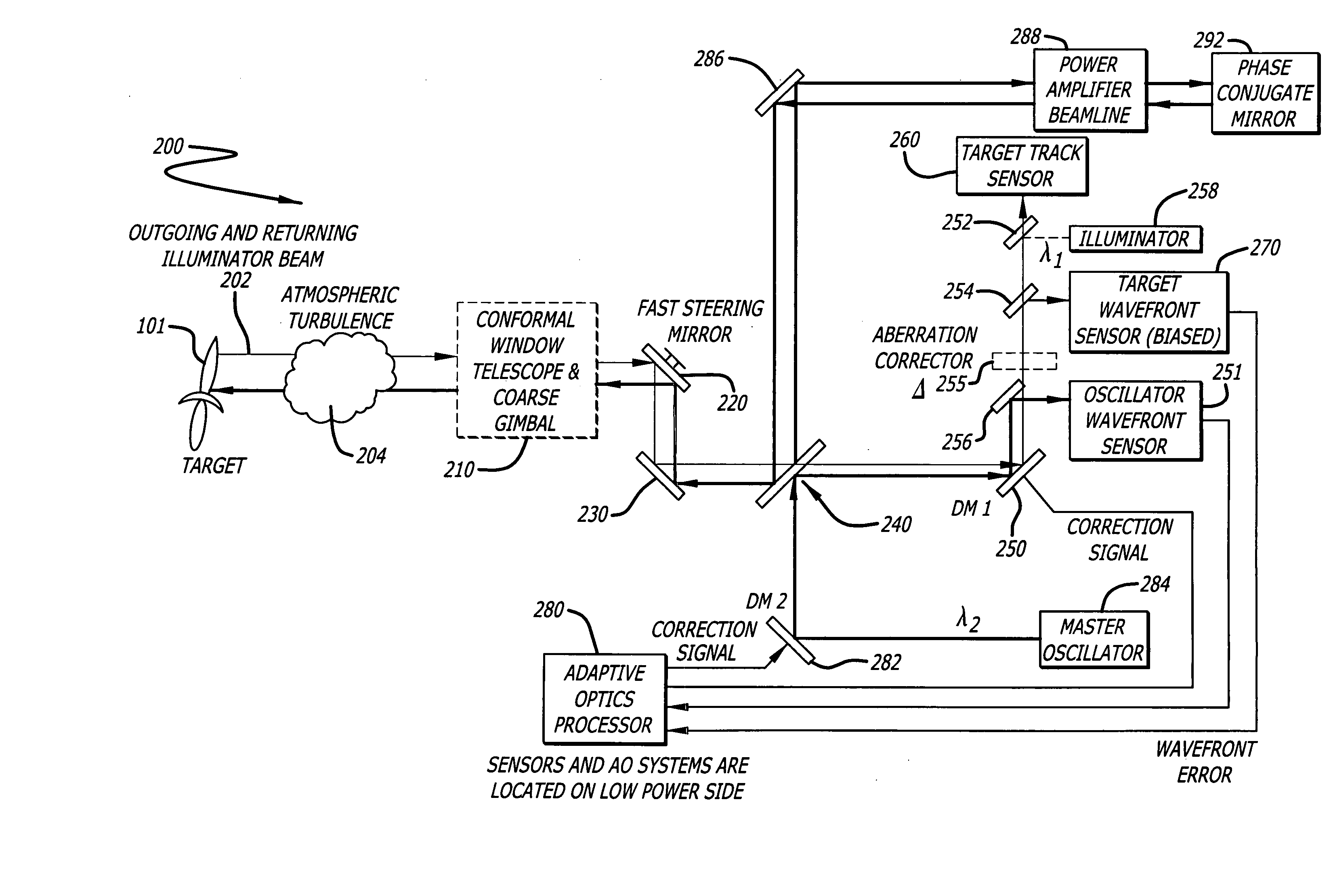

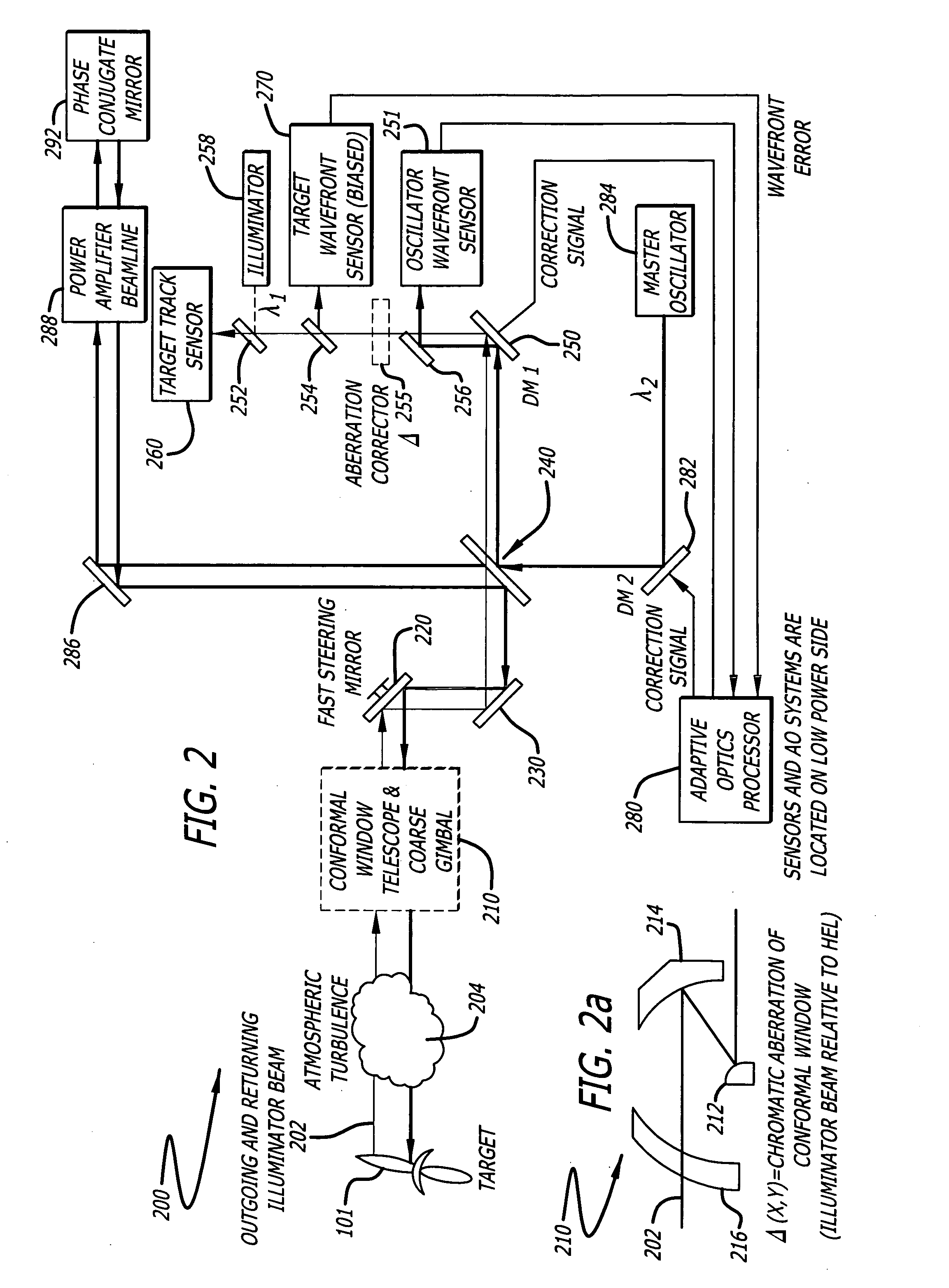

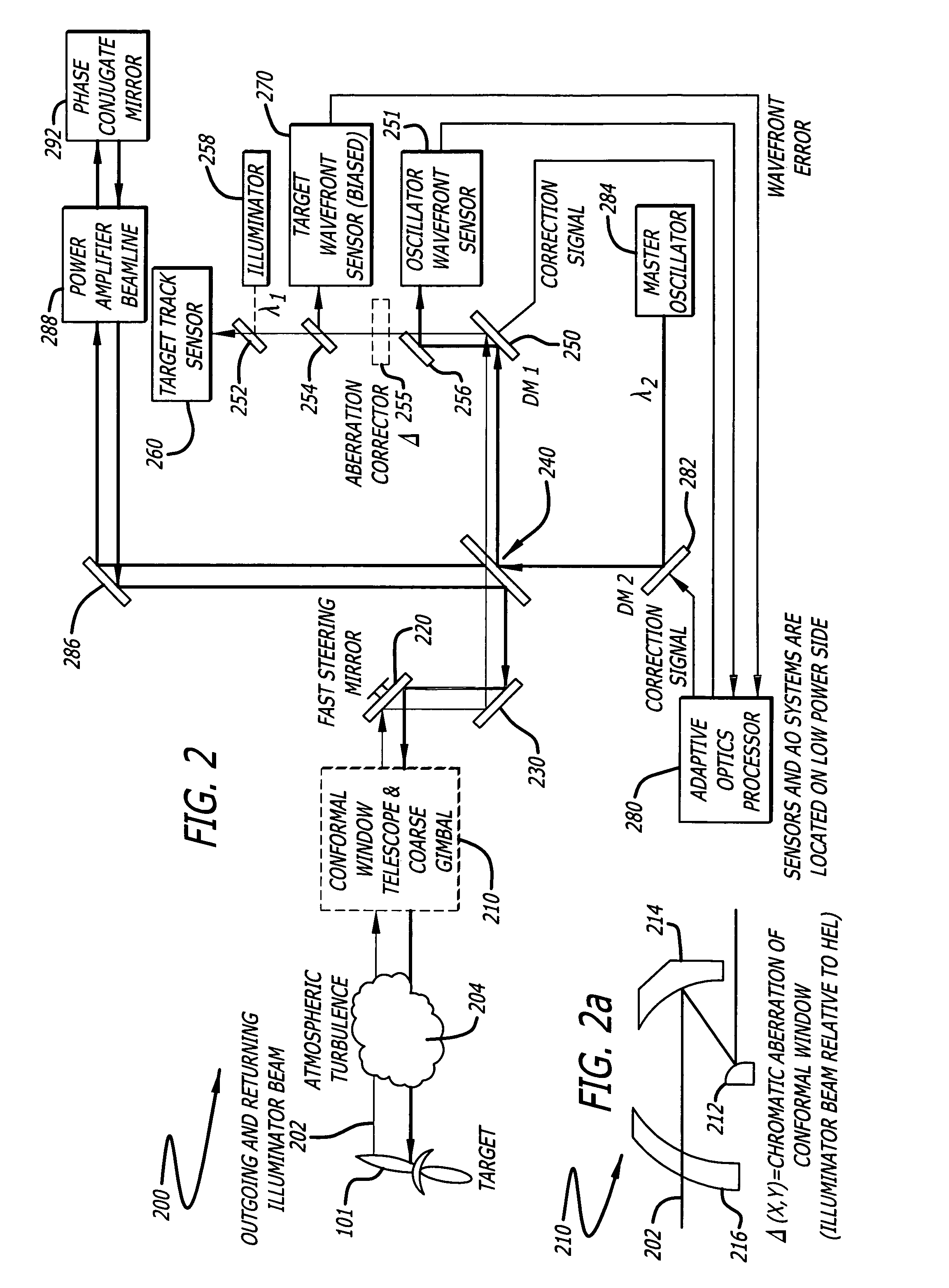

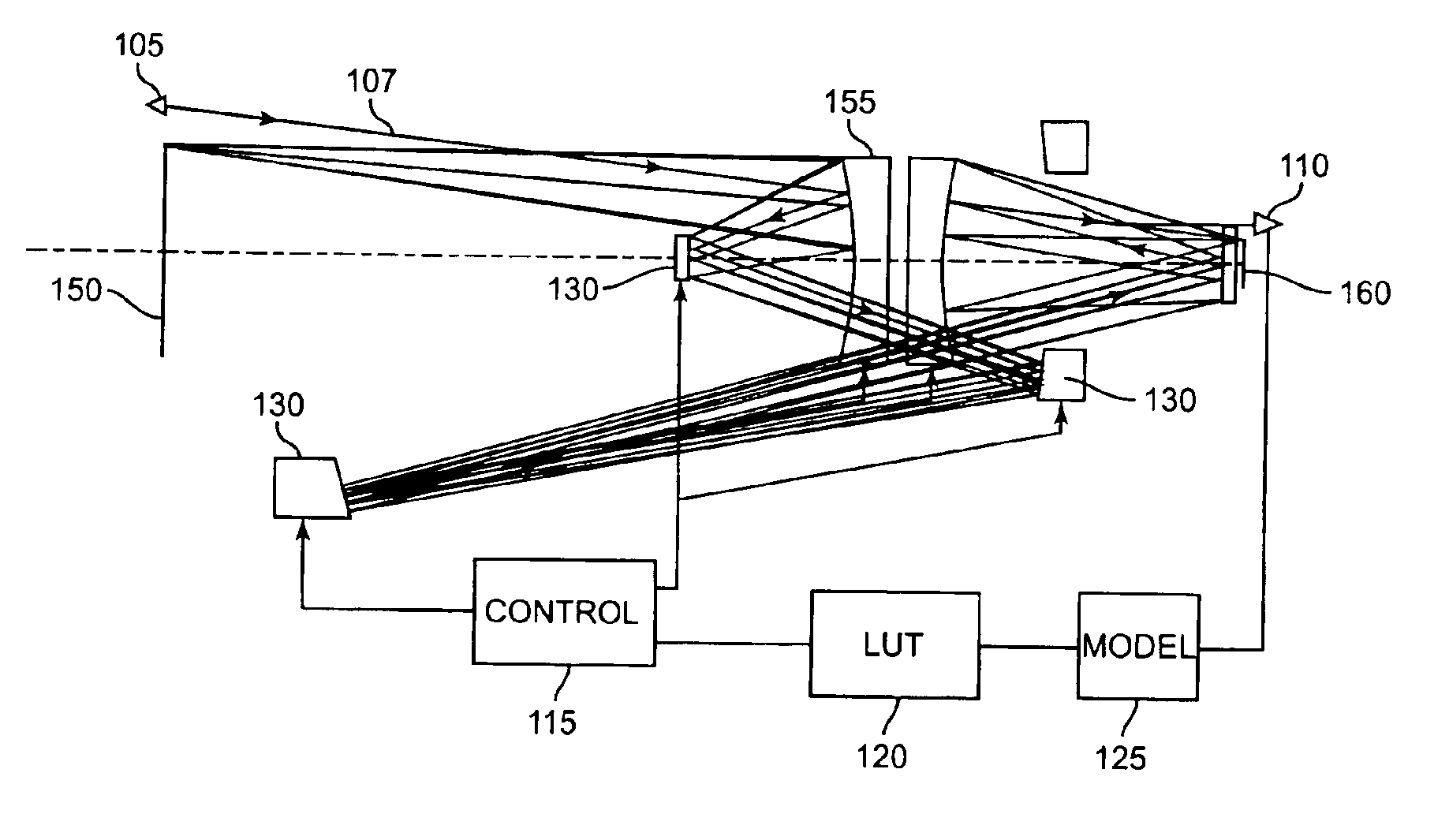

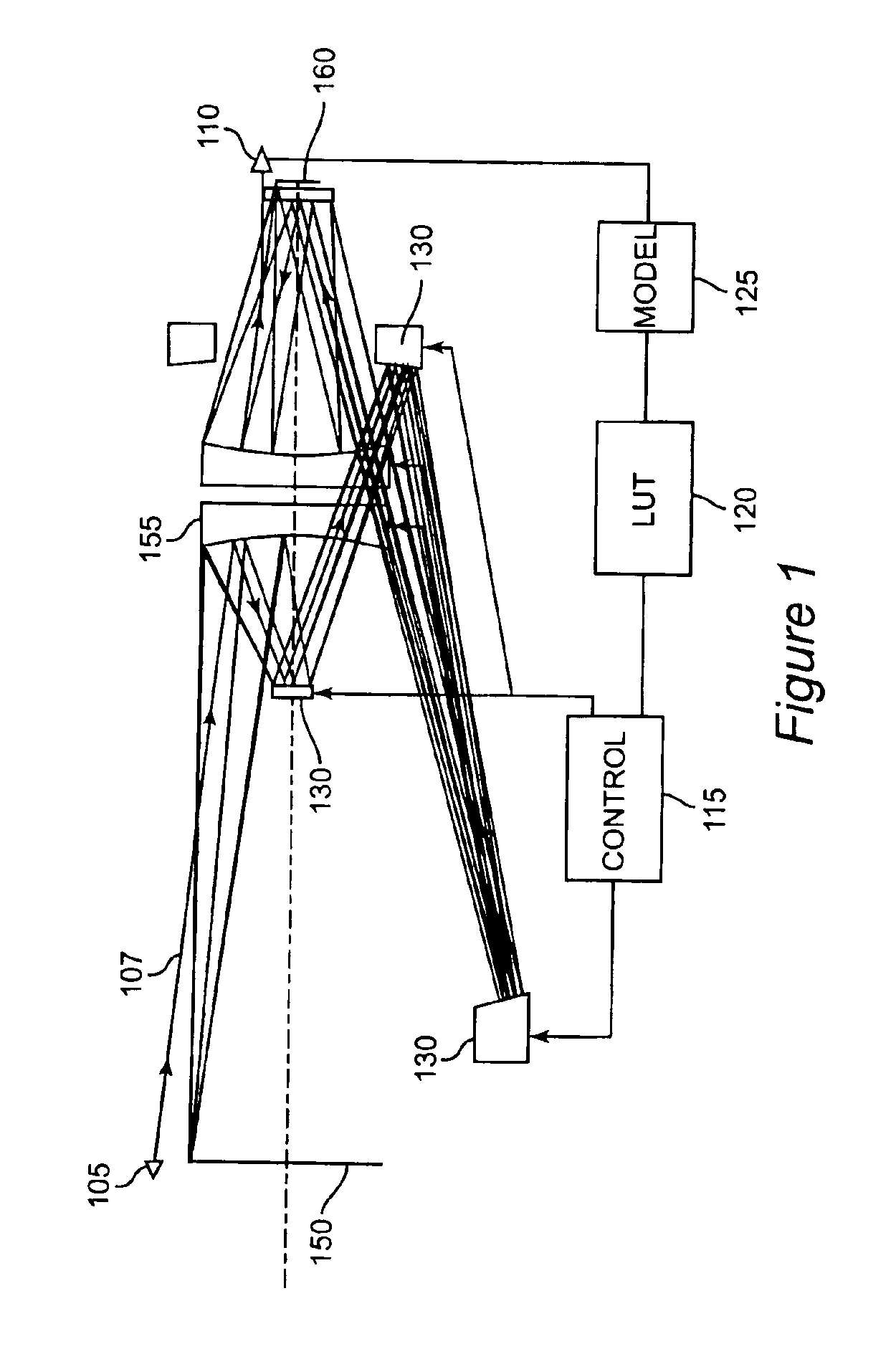

Beam director and control system for a high energy laser within a conformal window

ActiveUS20080042042A1Photometry using reference valueMaterial analysis by optical meansCorrection algorithmWavefront sensor

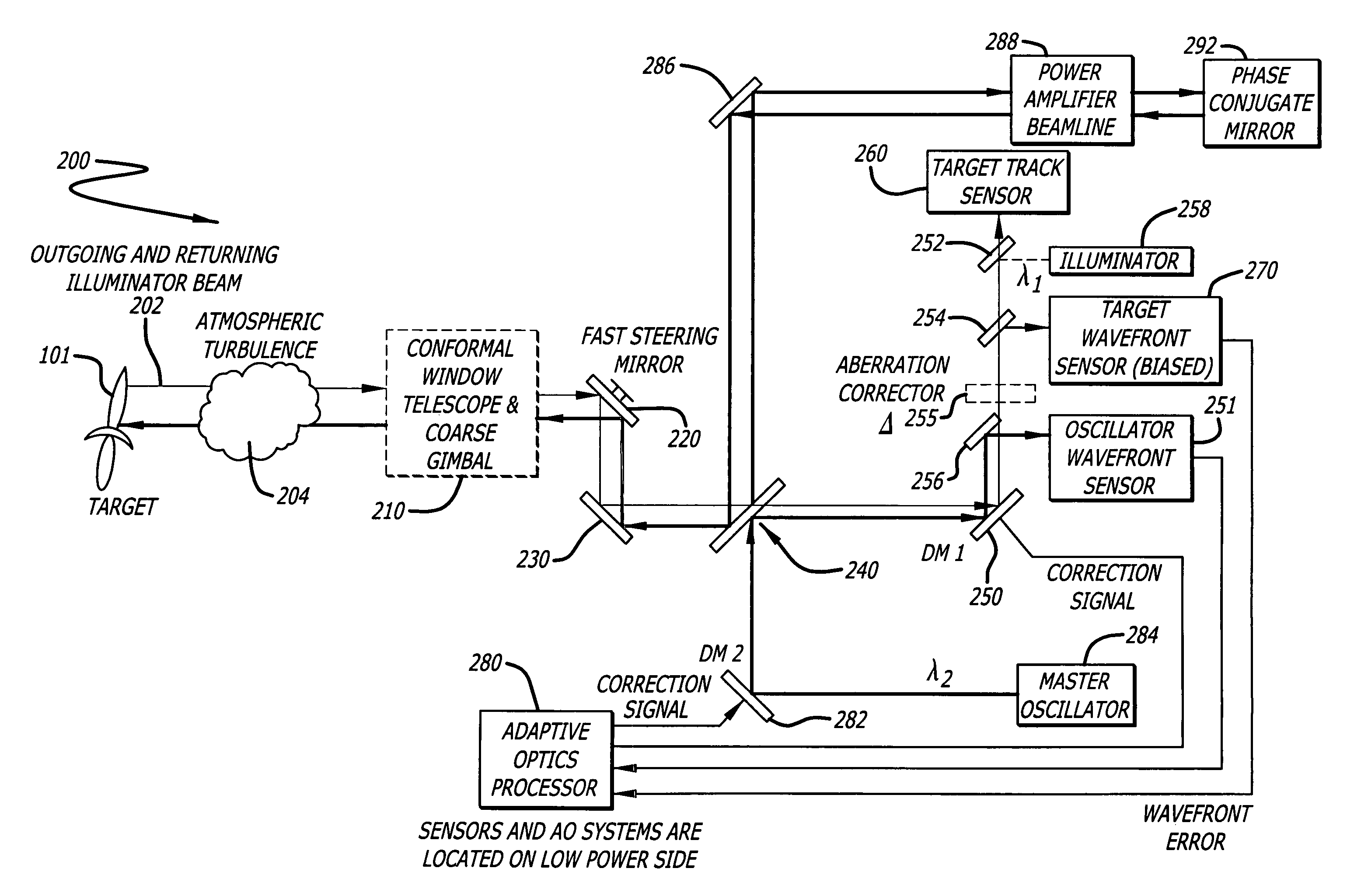

A beam control system and method. The system includes an illuminator for providing a first beam of electromagnetic energy at a first wavelength; a source for providing a second beam of electromagnetic energy at a second wavelength; and an arrangement for compensating wavefront errors in the second beam using a bias representative of a comparison between the first wavelength and the second wavelength. In the illustrative embodiment, the arrangement includes a processor which corrects wavefront errors using a bias representative of a difference between said first wavelength and said second wavelength. In the disclosed application, a target wavefront sensor is included and the laser is a high-energy laser beam. The wavefront errors include a chromatic aberration and the errors are compensated using a deformable mirror and a correction algorithm executed by an adaptive optics processor. In one alternative embodiment, the errors are compensated using an optical aberration corrector. The aberration corrector may be a holographic optical element or other suitable device. In another alternative embodiment, the errors are corrected with the above embodiment in combination with the use of “woofer” and “tweeter” correcting elements with the woofer being a long stroke low frequency element and the tweeter being a short stroke high frequency element.

Owner:RAYTHEON CO

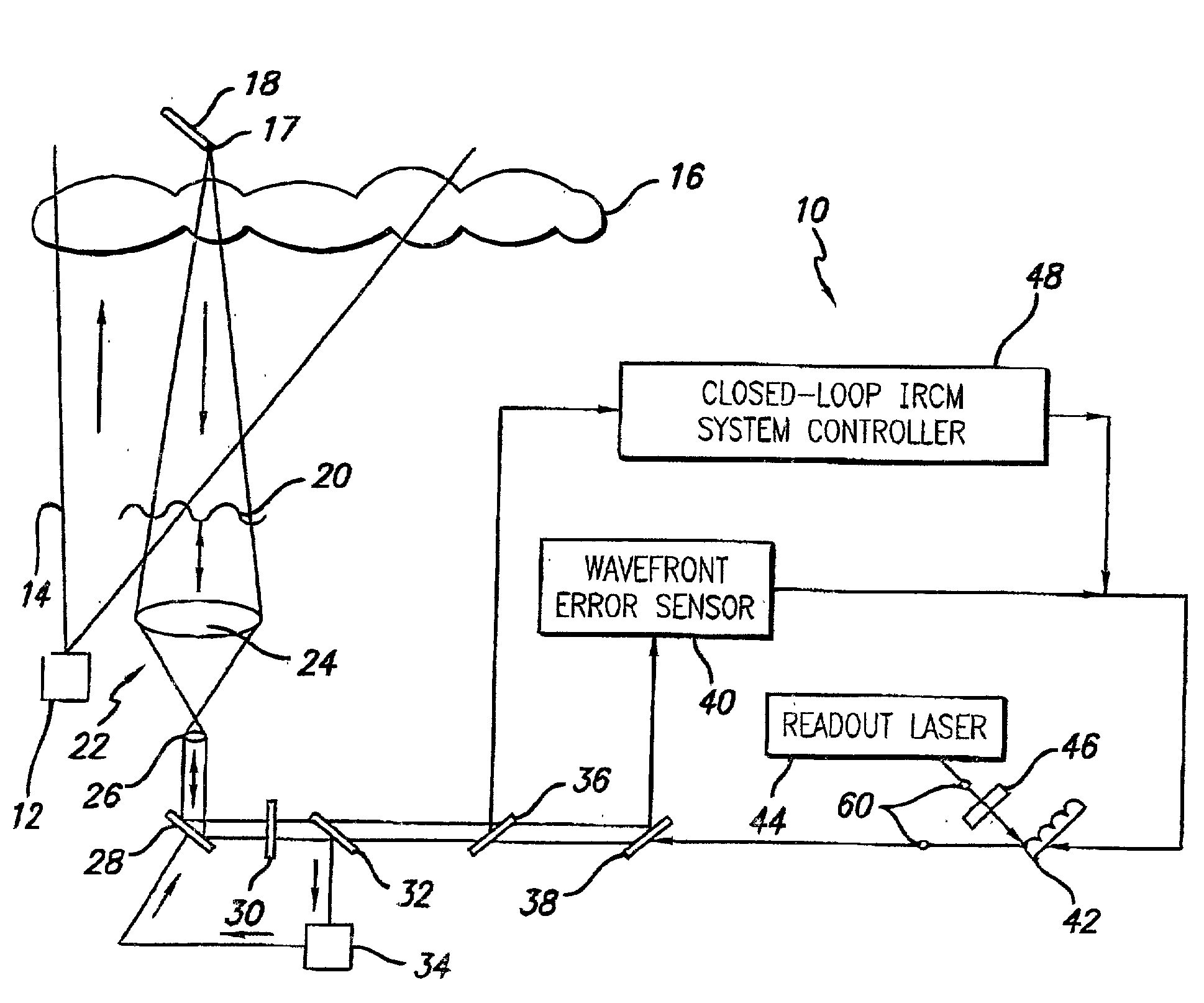

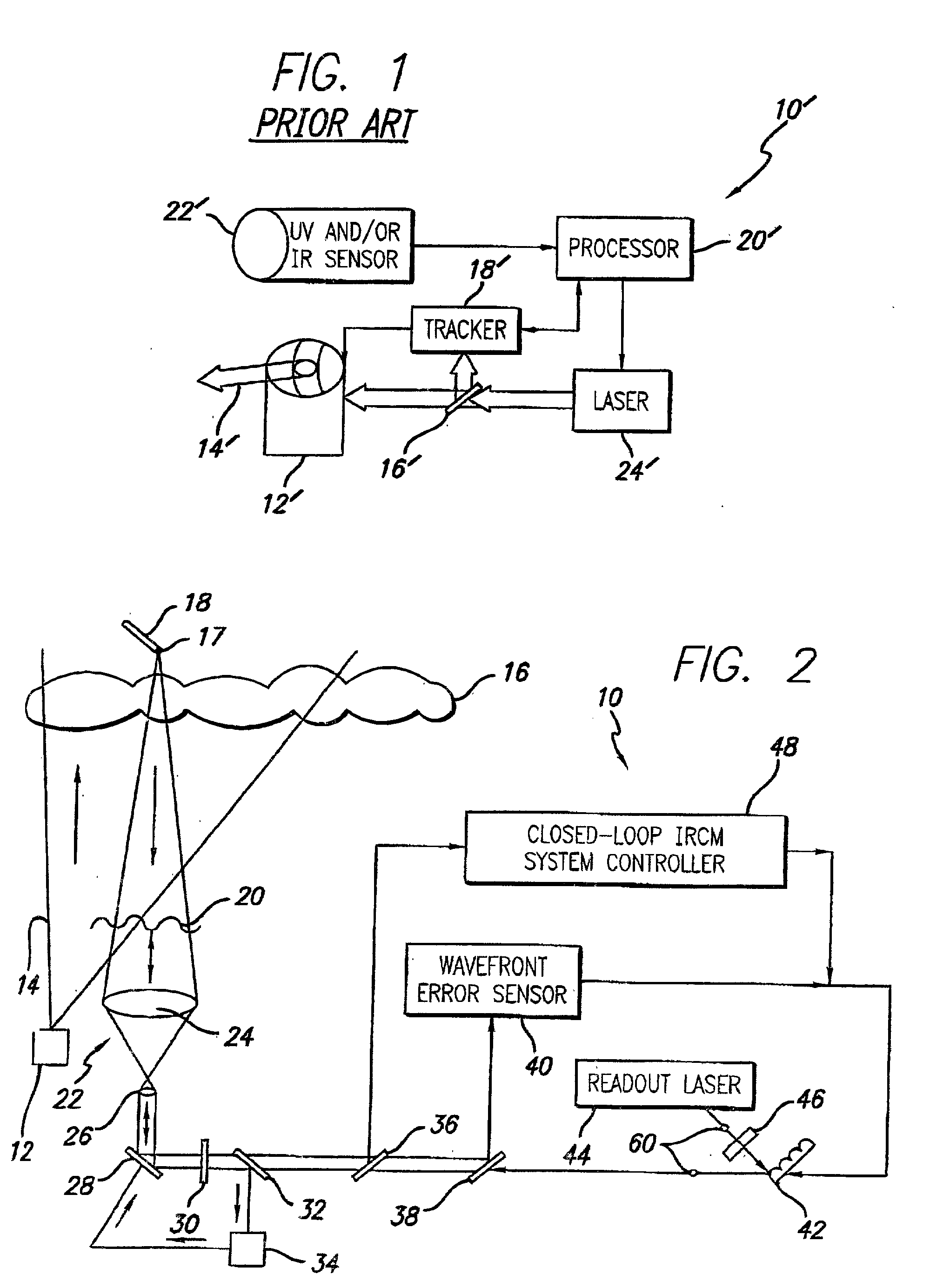

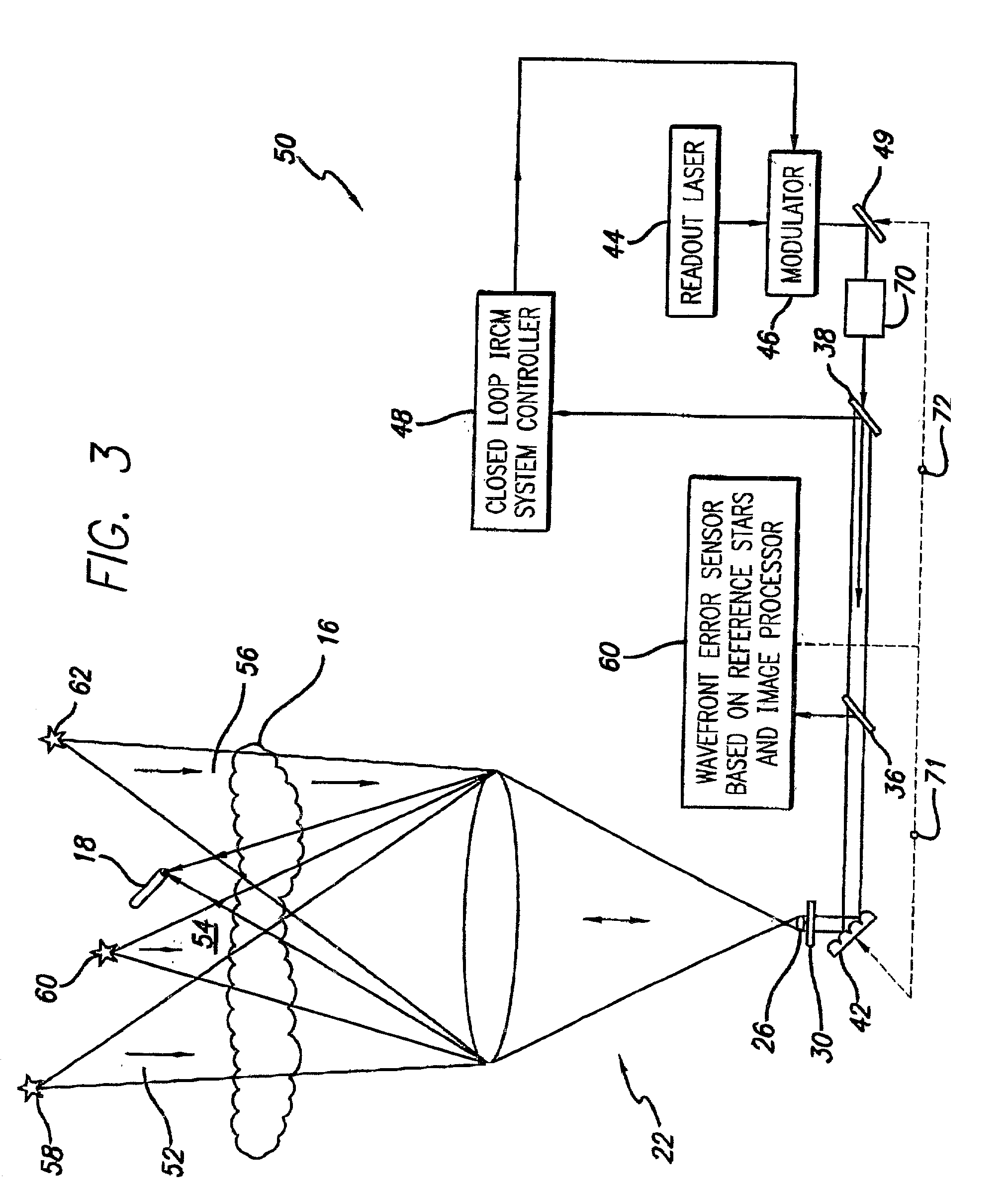

Robust infrared countermeasure system and method

InactiveUS20020153497A1Photometry using reference valueWave based measurement systemsCountermeasureOptical phase conjugation

A system and method for focusing electromagnetic energy on a moving target. Generally, the inventive system sends a pilot beam to a target and analyzes a return wavefront to ascertain data with respect to any distortions and other phase and / or amplitude information in the wavefront. This information is then used to pre-distort an output beam by so that it is focused on the target by the intervening distortions. In an illustrative embodiment, the pilot beam is provided by a beacon laser mounted off-axis with respect to the output beam. The reflected wavefront is received through a gimbaled telescope. Energy received by the telescope is detected and processed to ascertain wavefront aberrations therein. This data is used to predistort a deformable mirror to create an output beam which is the phase conjugate of the received wavefront. In a first alternative embodiment, a nonlinear optical phase-conjugate mirror is employed to generate the required wavefront-reversed replica of the received wavefront. The system further includes an arrangement for modulating the output beam to confuse the target. In a second alternative embodiment, the system is adapted to examine atmospheric distortions of starlight to predistort the output beam. The alternative embodiment offers a faster response time and a lower susceptibility to detection.

Owner:RAYTHEON CO

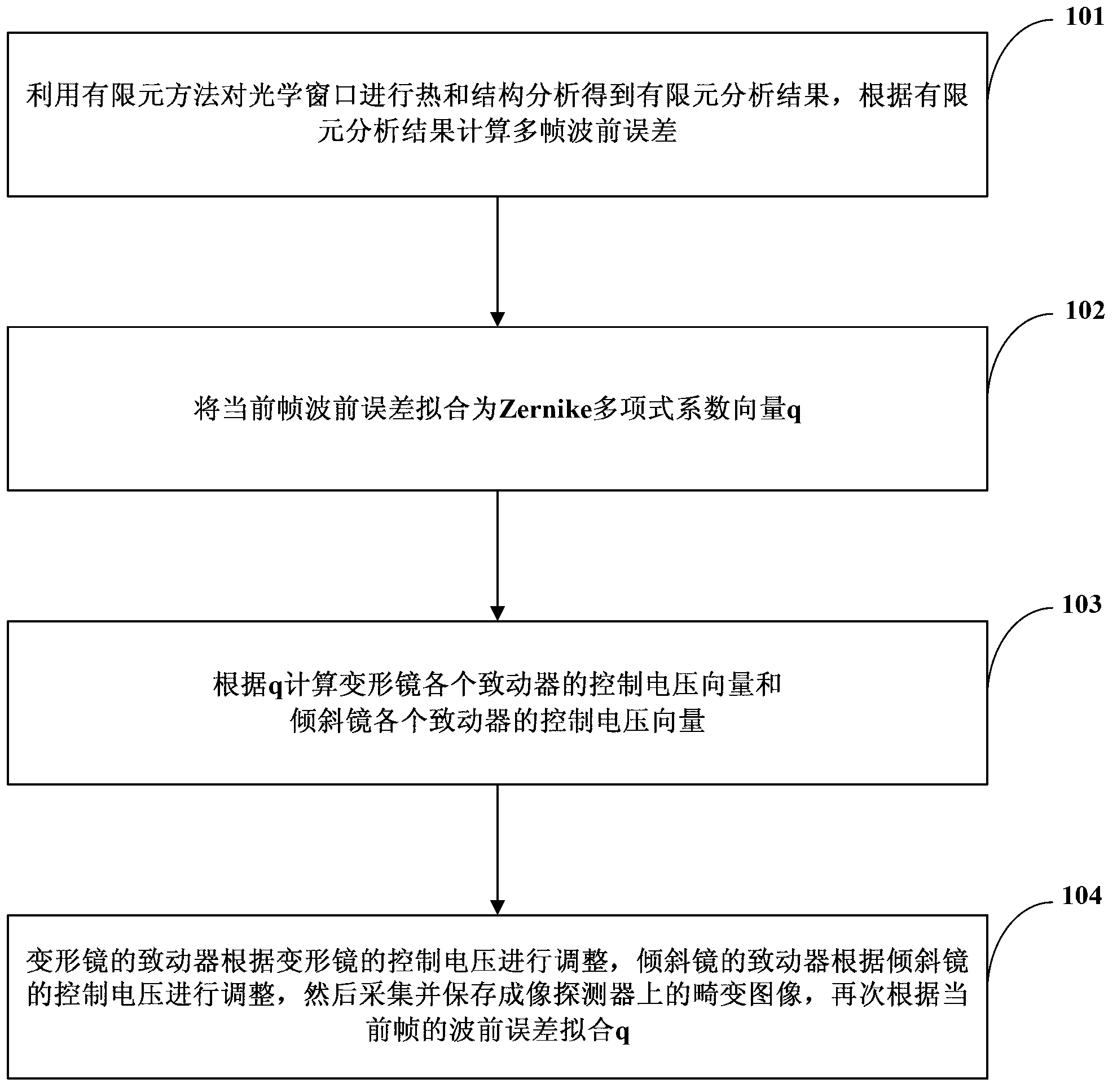

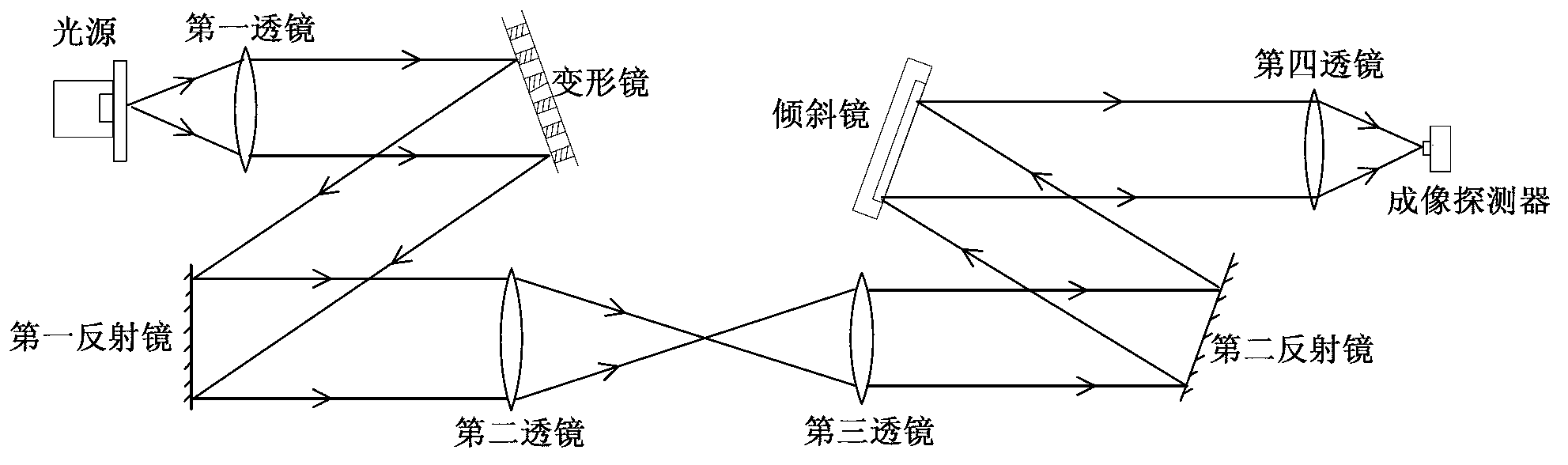

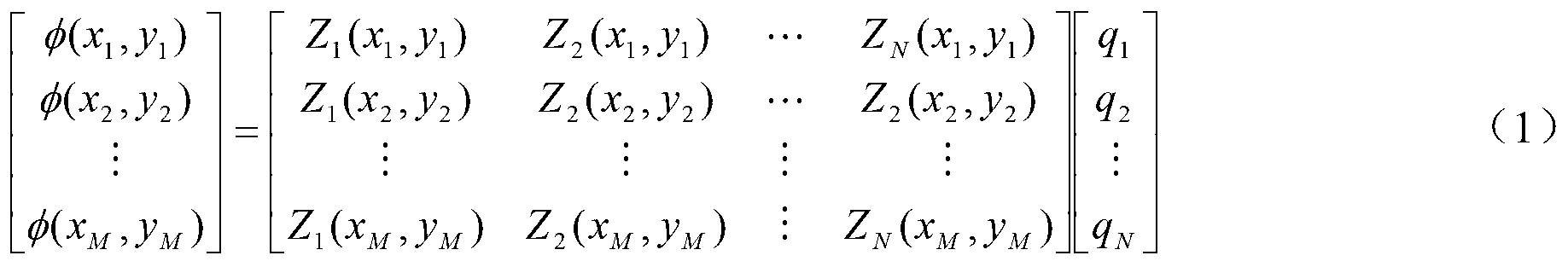

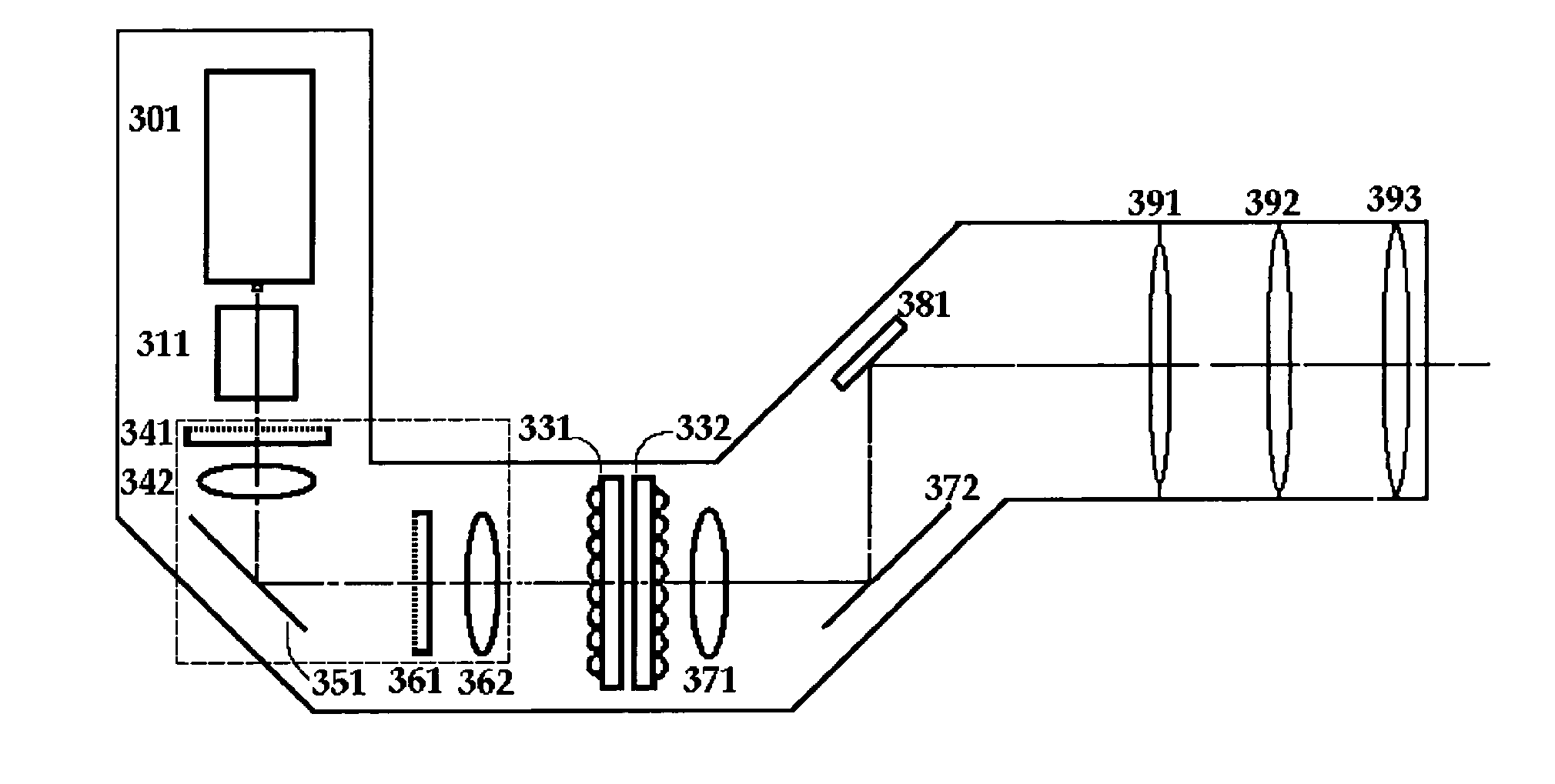

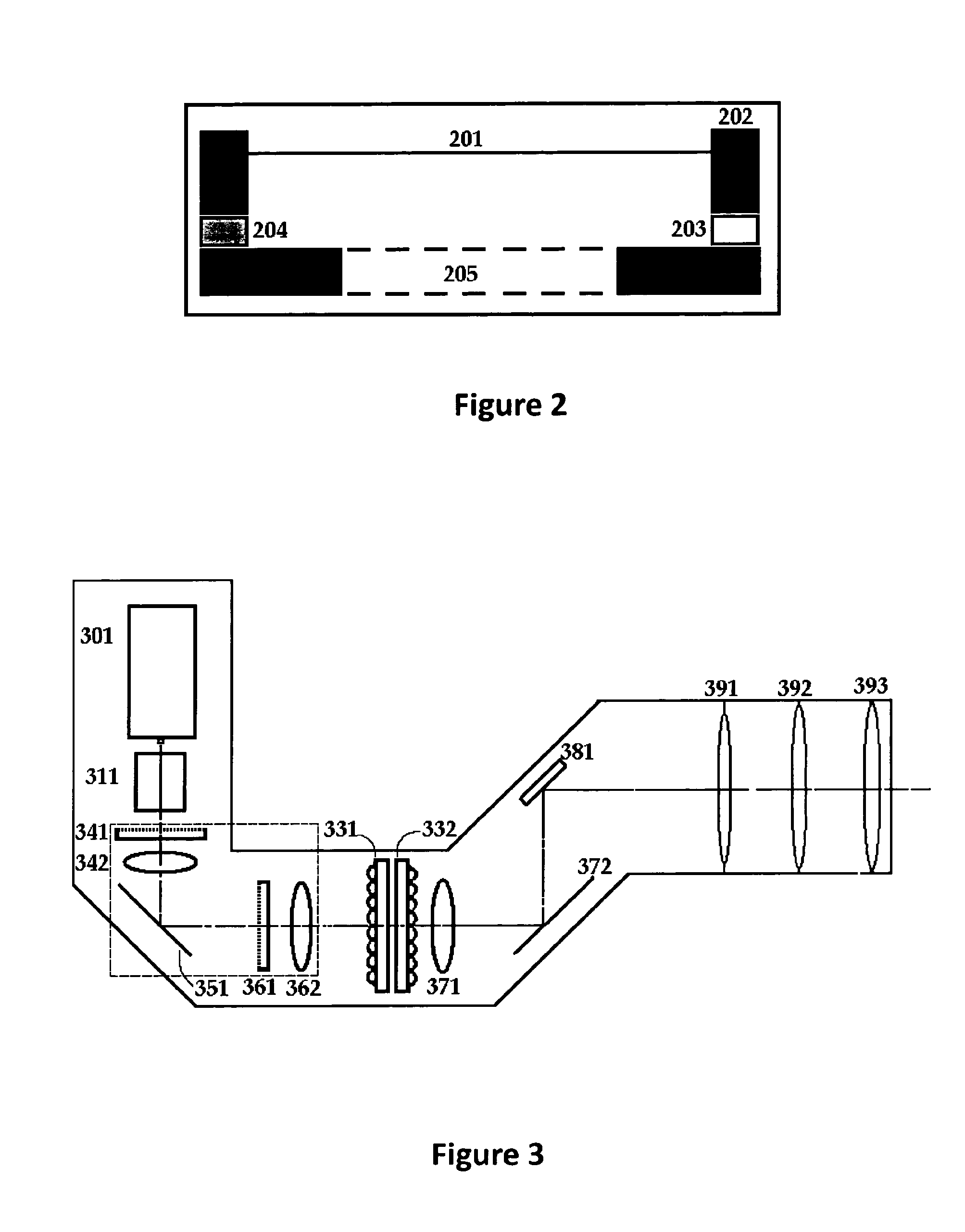

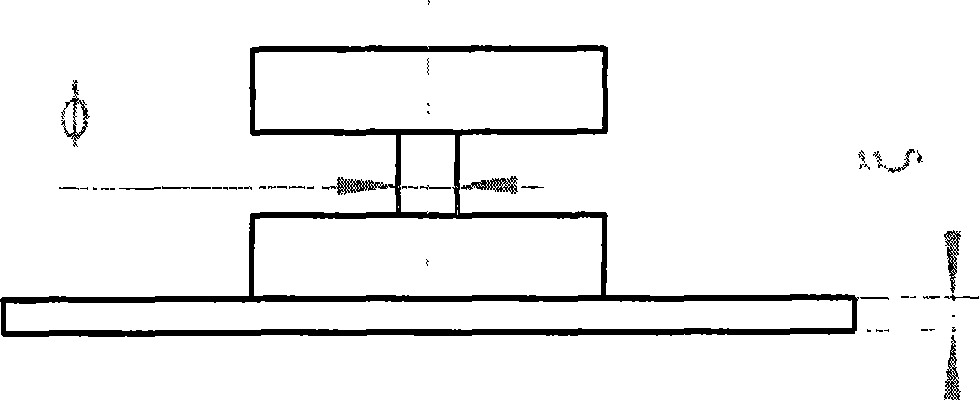

Method and system for simulating aero-optical effect

The invention relates to a method for simulating an aero-optical effect. The method comprises the steps of conducting thermal and structural analysis to an optical window by adopting a finite element analysis method to obtain a finite element analysis result, and calculating multi-frame wave-front errors according to the finite element analysis result; fitting the current frame wave-front error to be a Zernike polynomial coefficient vector q; calculating control voltage vectors of all actuators of a deformable mirror and control voltage vectors of all actuators of a tilting mirror according to the q; and adjusting the actuators of the deformable mirror according to the control voltage of the deformable mirror, adjusting the actuators of the tiling mirror according to the control voltage of the tiling mirror, acquiring and saving distorted images on an imaging detector and again fitting the q according to the current frame wave-front error. The invention additionally discloses a system for simulating the aero-optical effect. By using the method and the system provided by the embodiment of the invention, dynamic distorted image data under the influence of the aero-optical effect can be obtained and experimental conditions are provided for researches on the correction of the aero-optical effect.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

Molded package for micromechanical devices and method of fabrication

InactiveUS7026710B2Low costIncrease productionSemiconductor/solid-state device detailsSolid-state devicesSpatial light modulatorMicromachinery

Owner:TEXAS INSTR INC

Deformable mirror system, control method therefor, and ophthalmic apparatus

ActiveUS20160089023A1Shorten the timeReduced measurement timeMirrorsMountingsOphthalmological deviceConversion factor

For reducing a time utilized in an AO process, provided is a deformable mirror system, including: a deformable mirror capable of changing a shape of a reflecting surface by a deformation amount in accordance with an input signal; a light wavefront measurement apparatus configured to measure a light wavefront shape of reflected light from the deformable mirror; a conversion factor calculation apparatus configured to calculate a conversion factor used in obtaining the input signal from a variation in light wavefront shape of the reflected light with respect to a change in input signal; a shape difference calculation apparatus configured to calculate a shape difference between the light wavefront shape measured by the light wavefront measurement apparatus and a light wavefront shape calculated from the input signal; and a conversion factor update unit configured to update the conversion factor in accordance with the calculated shape difference.

Owner:CANON KK

Vertical comb drive actuated deformable mirror device and method

InactiveUS20020109894A1Optical waveguide light guideFlexible microstructural devicesRelative displacementComb drive

Owner:MEMS OPTICAL

Optical system and method

InactiveUS20110102748A1Contrast ratio is reducedReduce interferenceDiffusing elementsProjectorsTemporal resolutionOptical property

An optical system (100) comprises a coherent light source (101) and optical elements for directing light from the source to a target (1001). The optical elements include at least one diffusing element (141, 161) arranged to reduce a coherence volume of light from the source and a variable optical property element (151). A control system (1021) controls the variable optical property element such that different speckle patterns are formed over time at the target (1001) with a temporal frequency greater than a temporal resolution of an illumination sensor or an eye (1011) of an observer so that speckle contrast ratio in the observed illumination is reduced. The variable optical property element (151) may be a deformable mirror with a vibrating thin plate or film.

Owner:OPTYKA

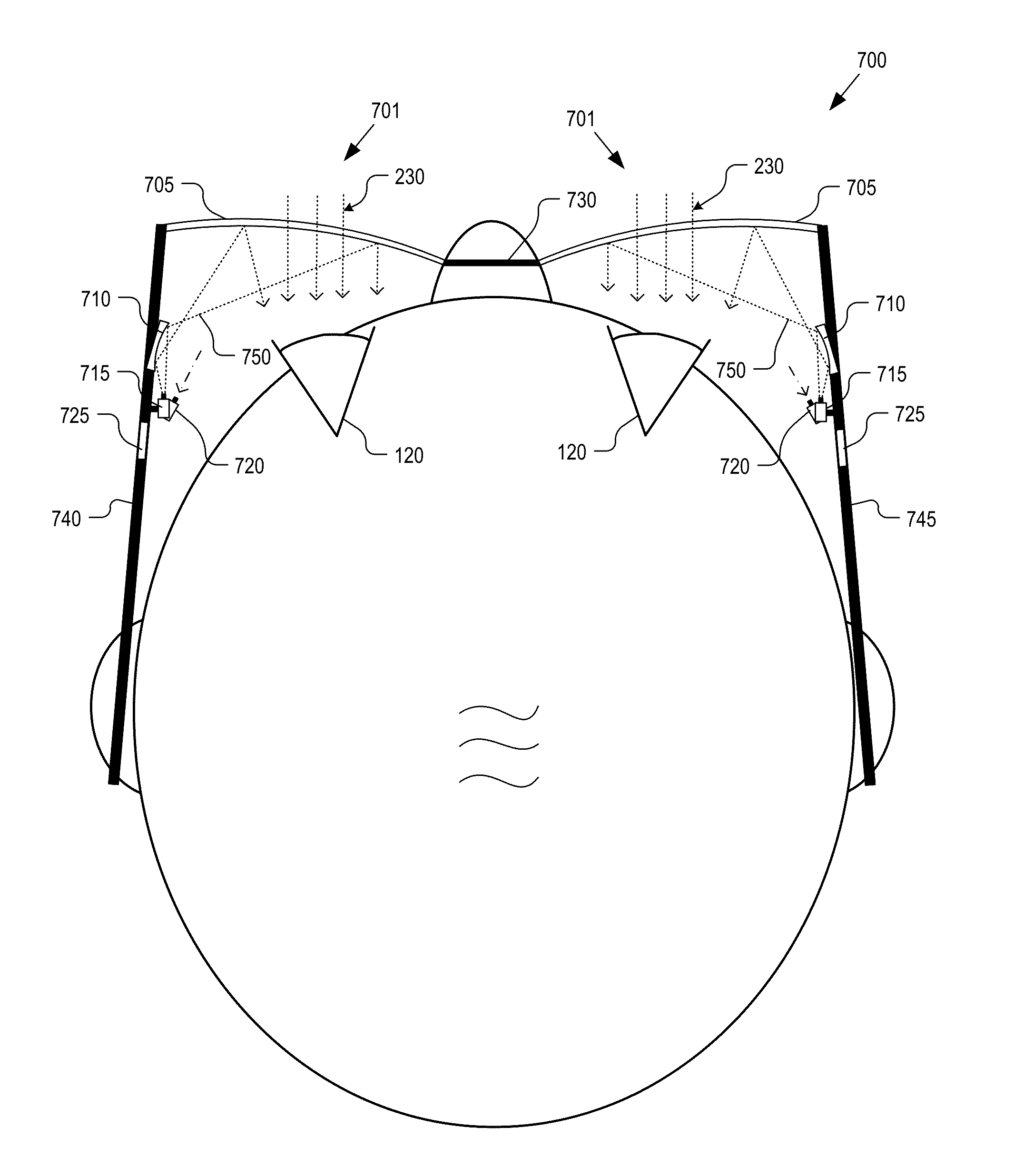

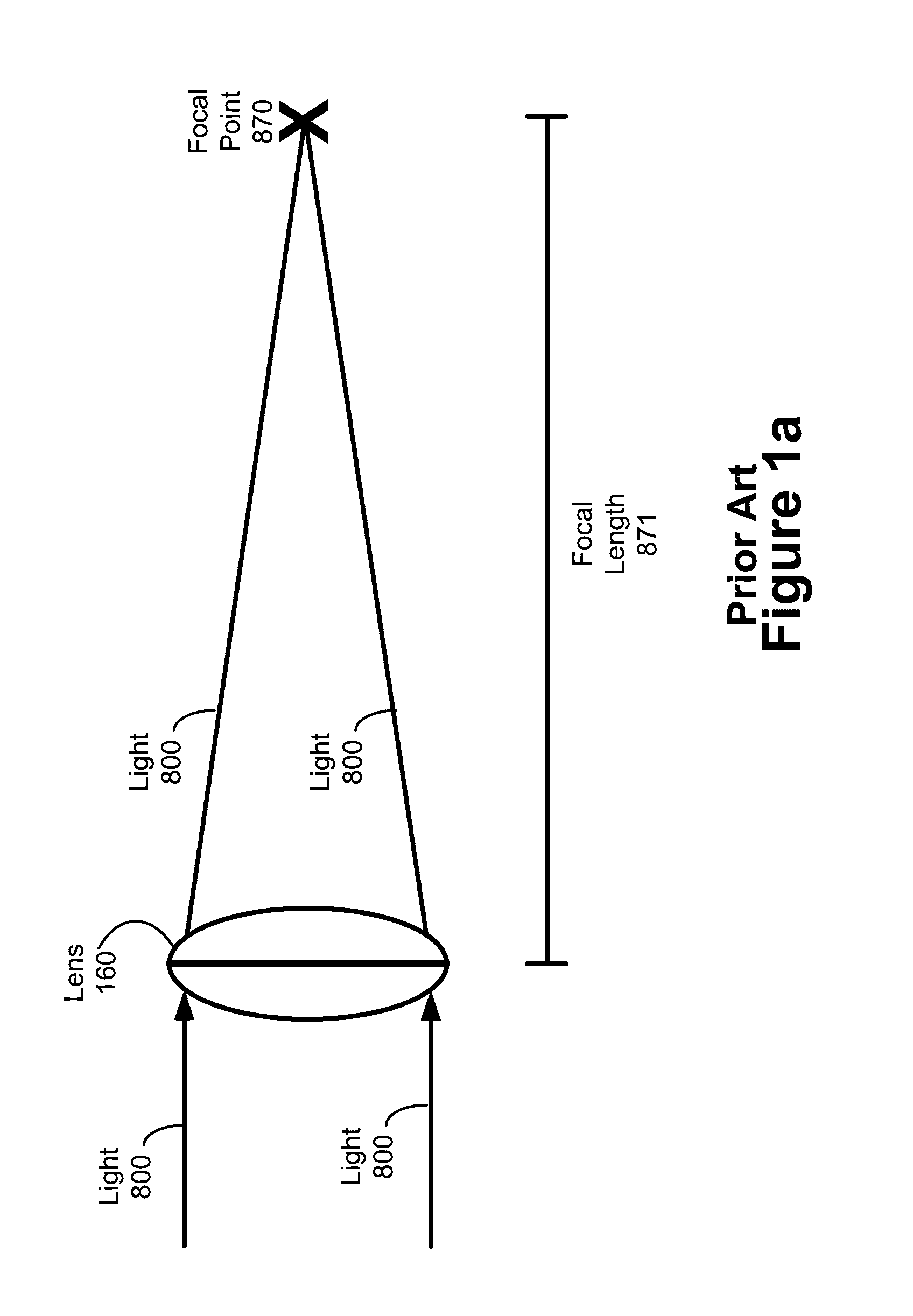

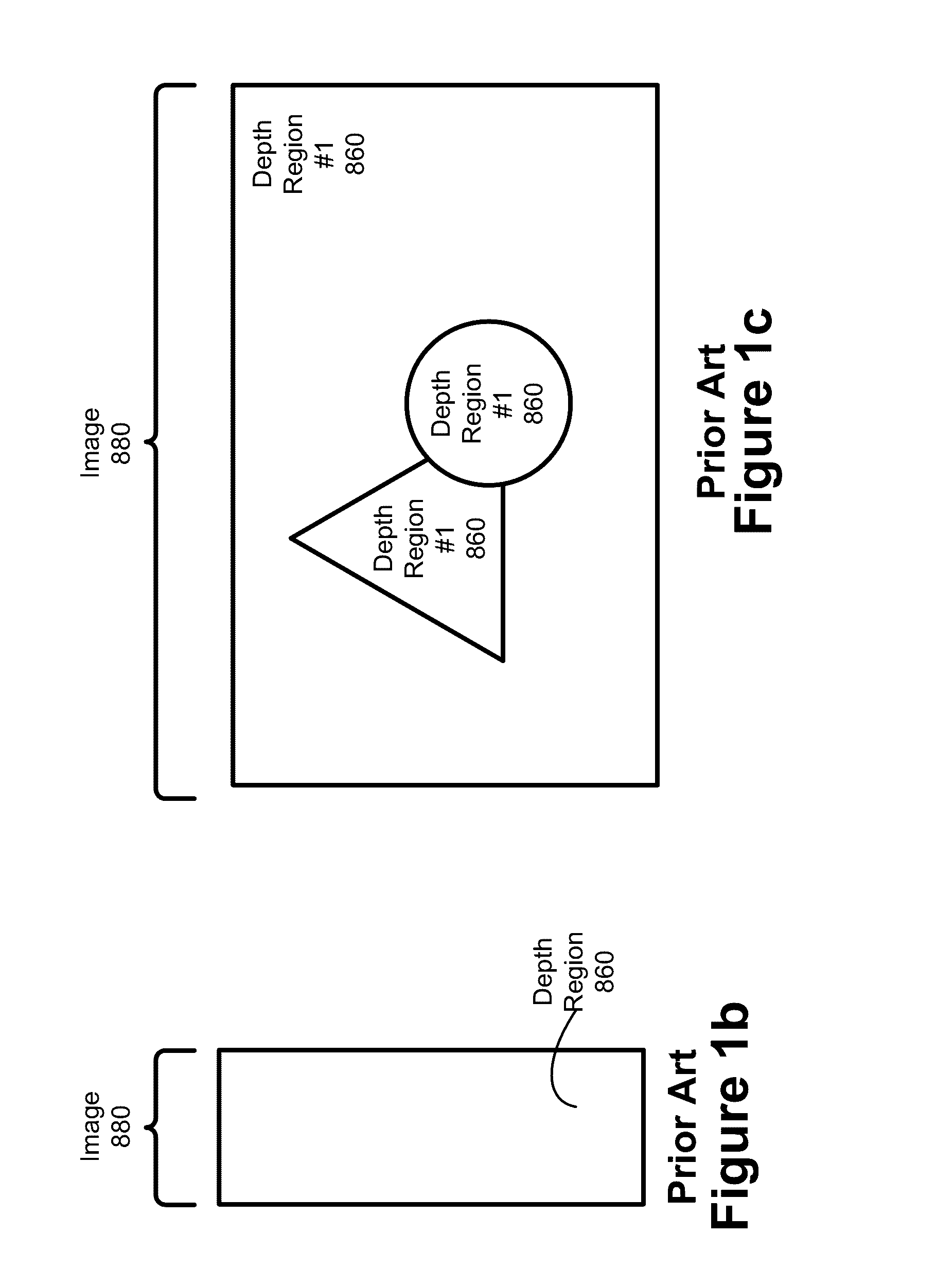

System, apparatus, and method for displaying an image using focal modulation

ActiveUS20160295202A1Steroscopic systemsInput/output processes for data processingSingle imageDeformable mirror

A system (100), apparatus (110), and method (900) for displaying an image (880). The light (800) in the image (880) is modified by a tuning assembly (700) to possess more than one focal point (870). Thus a single image (880) can include multiple depth regions (860). Each depth region (860) can be comprised of light (800) possessing a distinct focal point (870). The tuning assembly (700) can be implemented in the form a tunable lens (710), a tunable lens array (720), a movable lens (730), or a deformable mirror (740).

Owner:AVEGANT

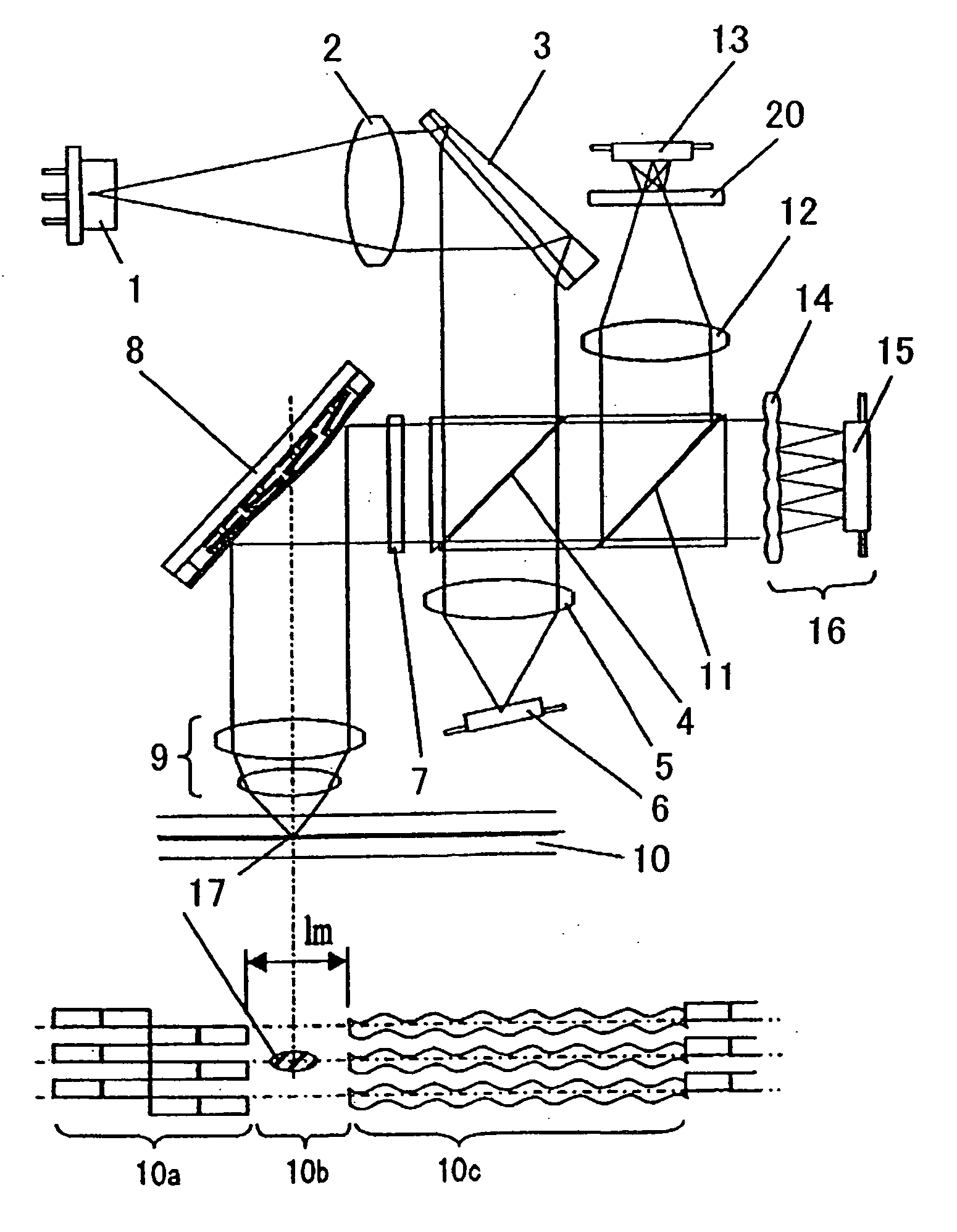

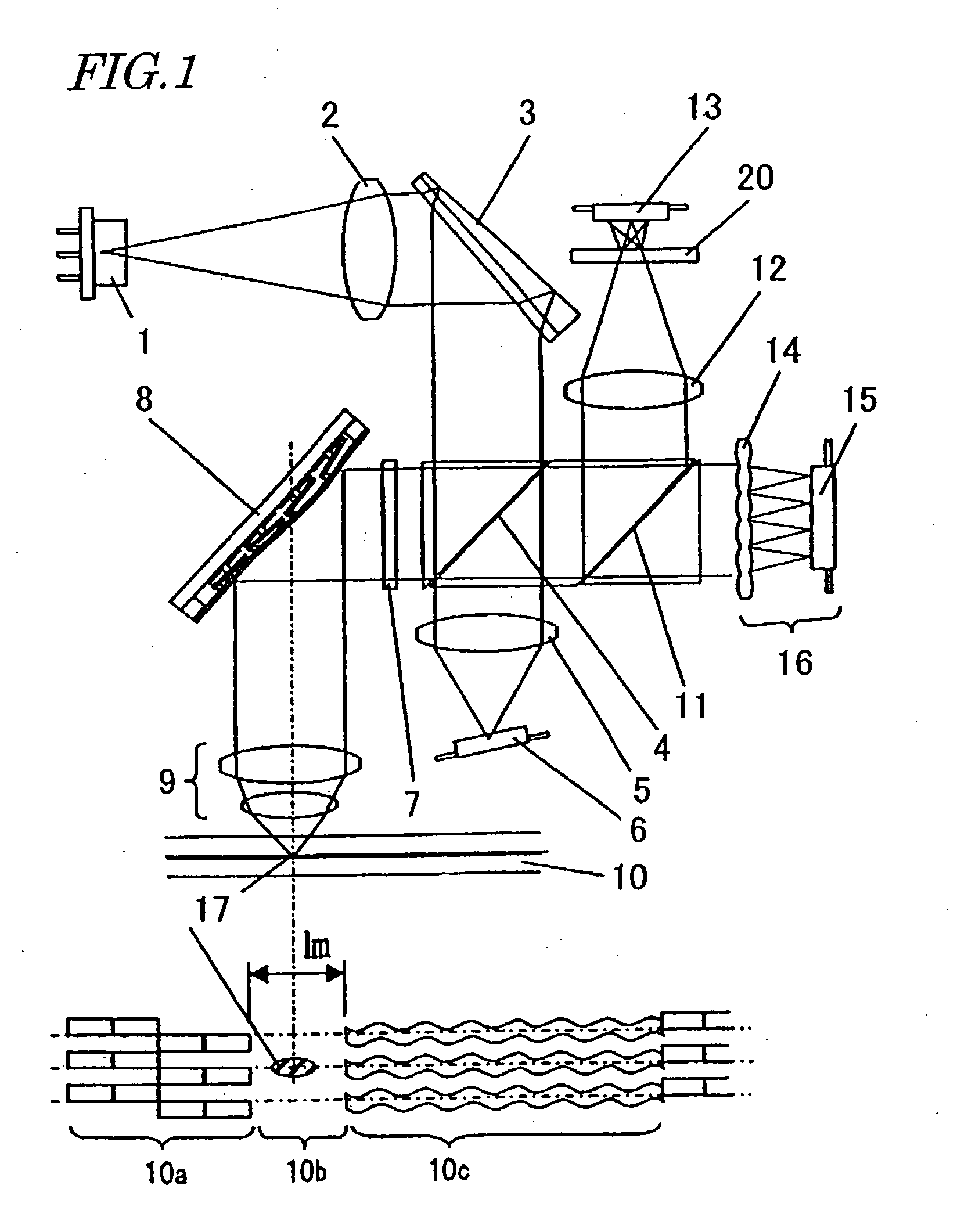

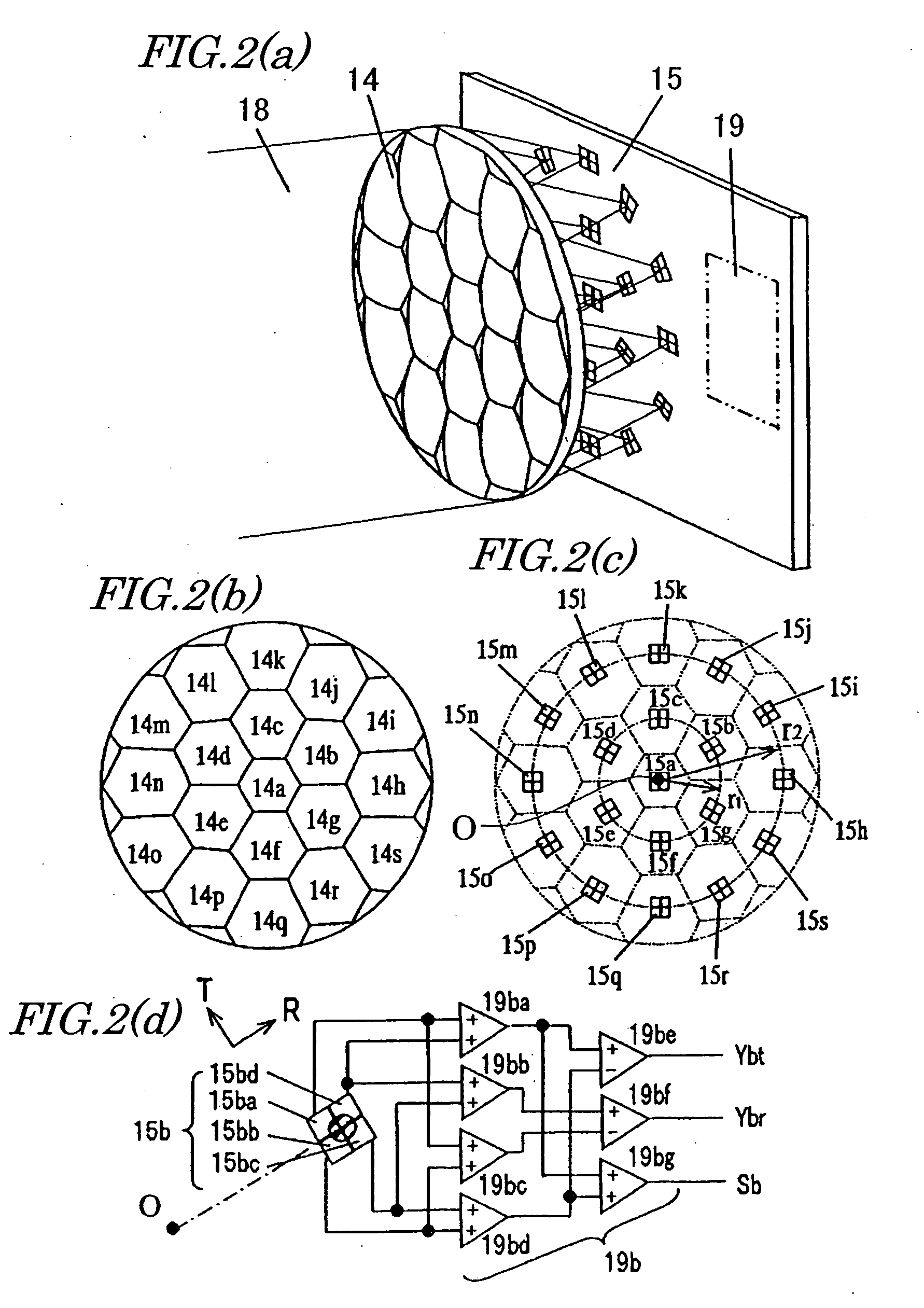

Variable mirror and information apparatus comprising variable mirror

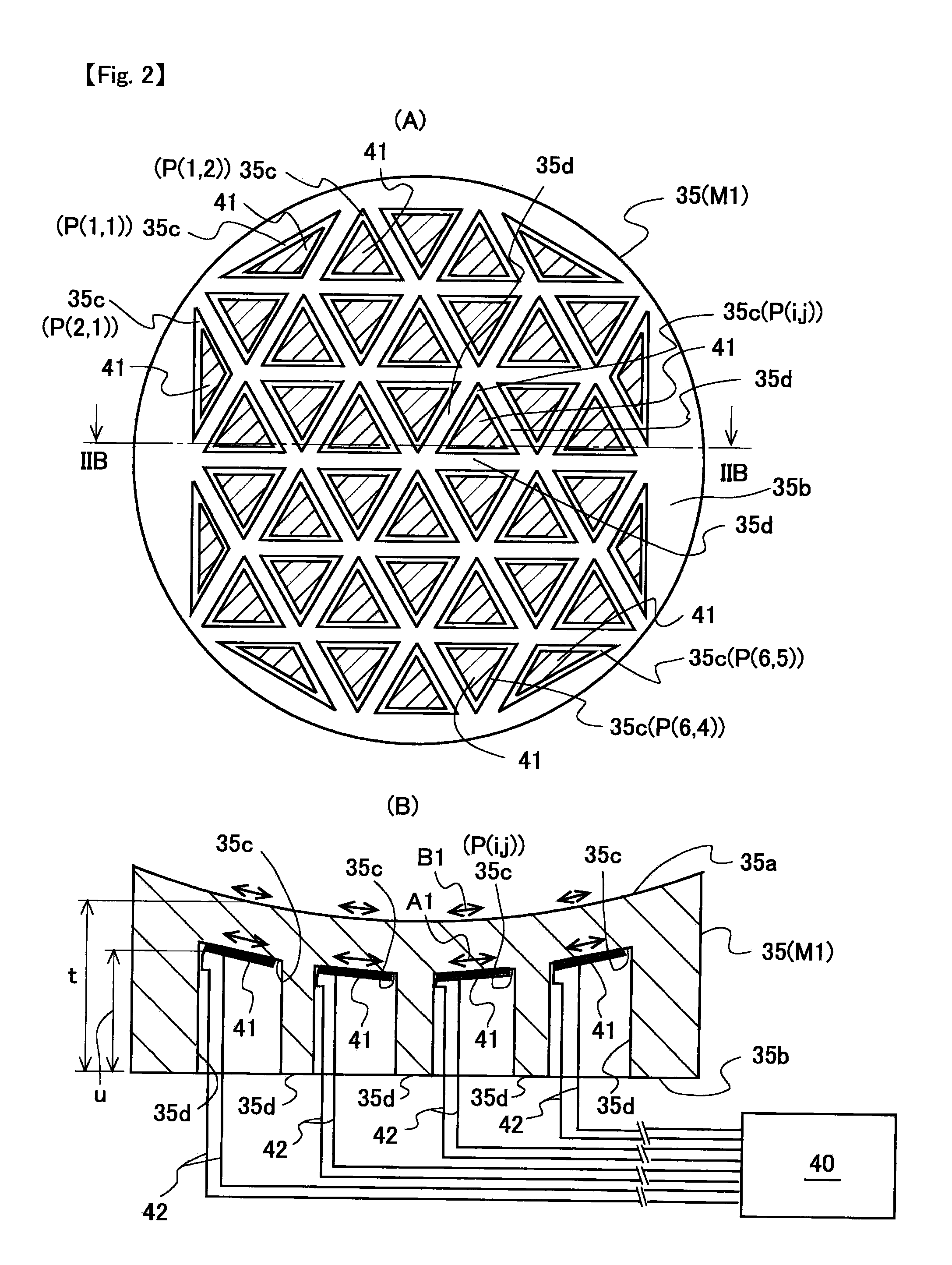

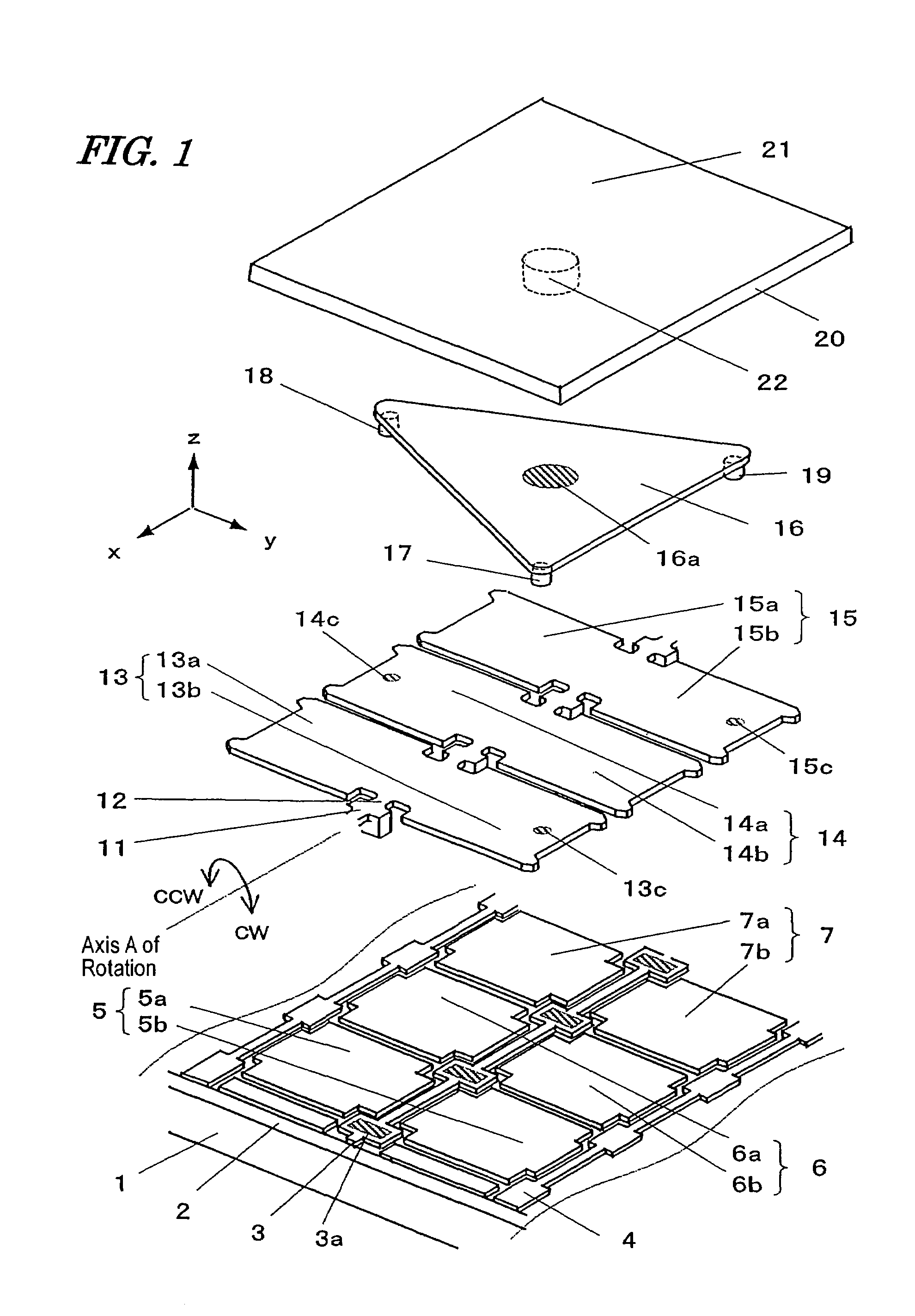

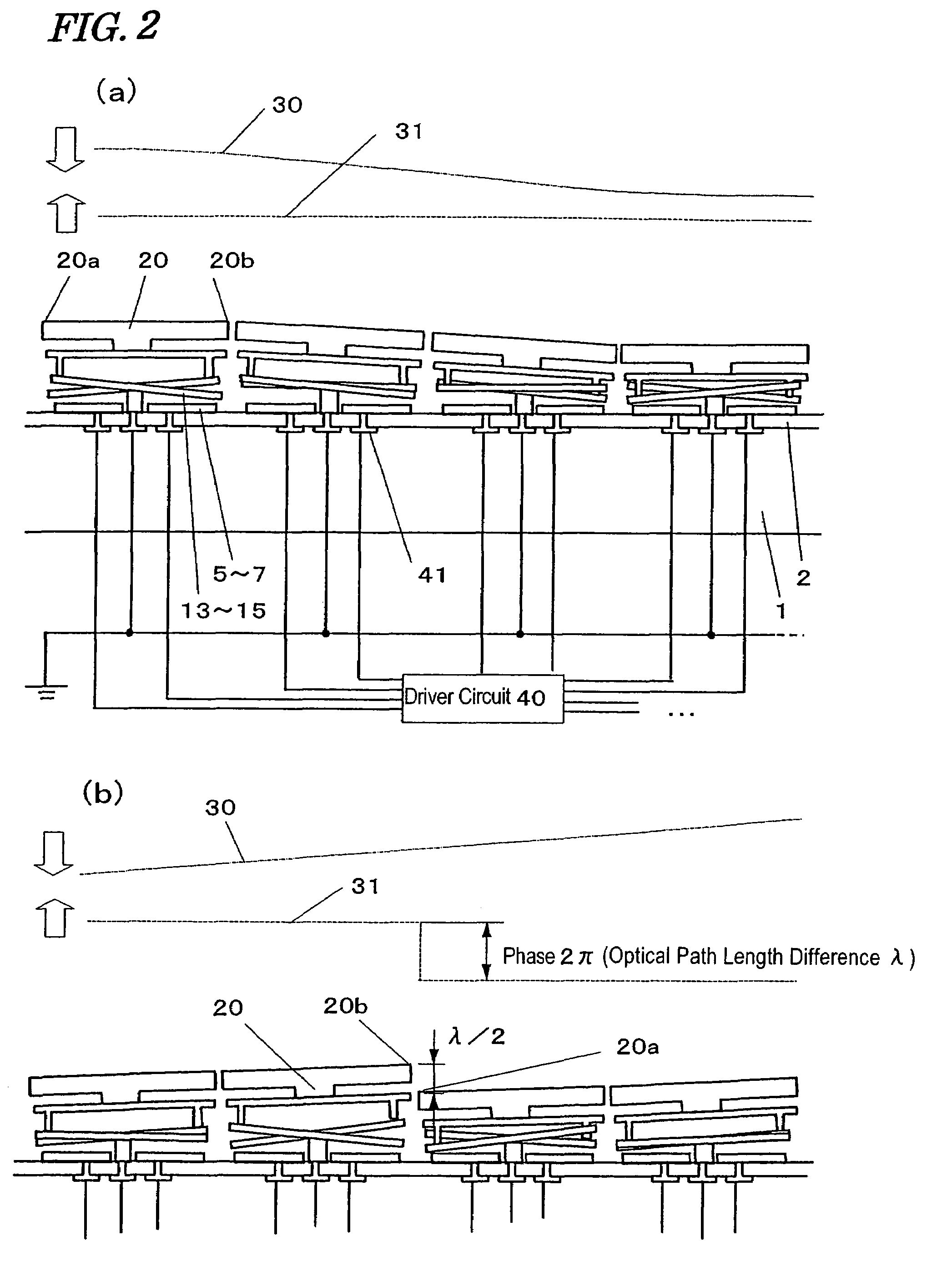

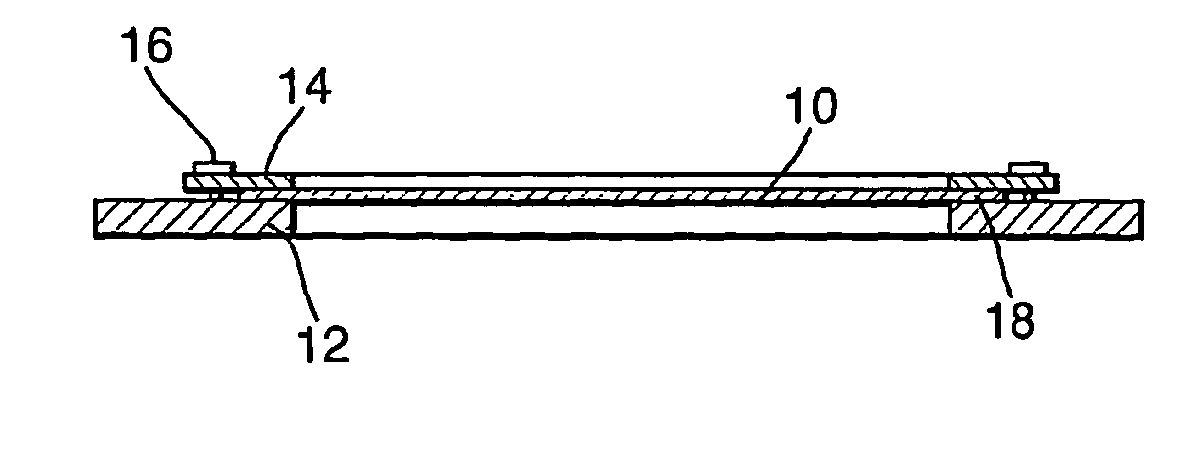

A deformable mirror according to the invention comprises a substrate, a reflector which is supported by said substrate and the shape of whose reflecting areas is variable, and a plurality of drive units for independently driving a plurality of regions of the reflector and thereby controlling the distances between said plurality of regions and said substrate. Each of the plurality of drive units comprises a plurality of electrodes disposed over said substrate, a tilt member which is rotated round the axis of tilt by being attracted by the selected one of the plurality of electrodes, and an action member for varying the distance between a specific region of the reflector and said substrate following the motion of the tilt member.

Owner:PANASONIC CORP

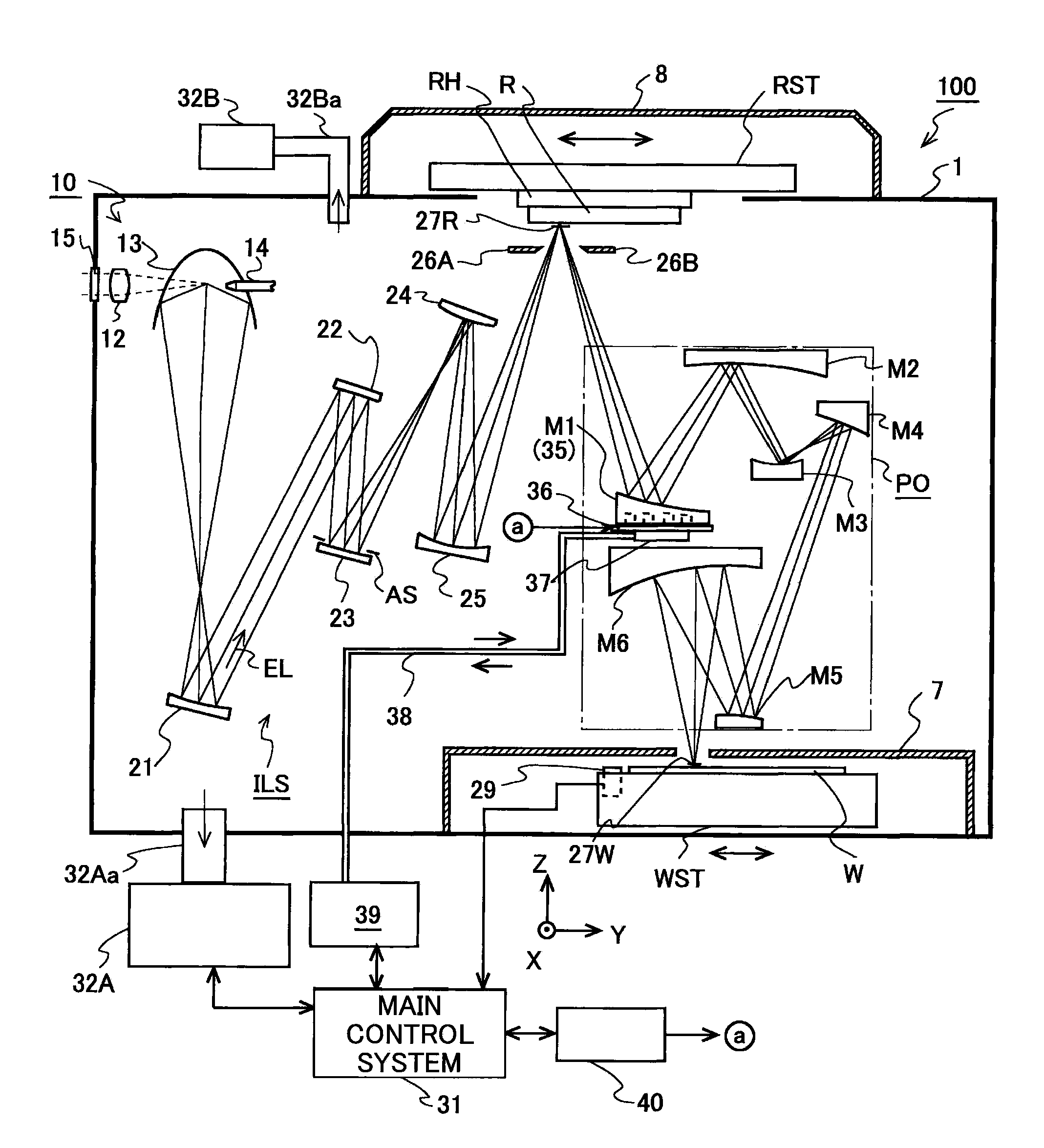

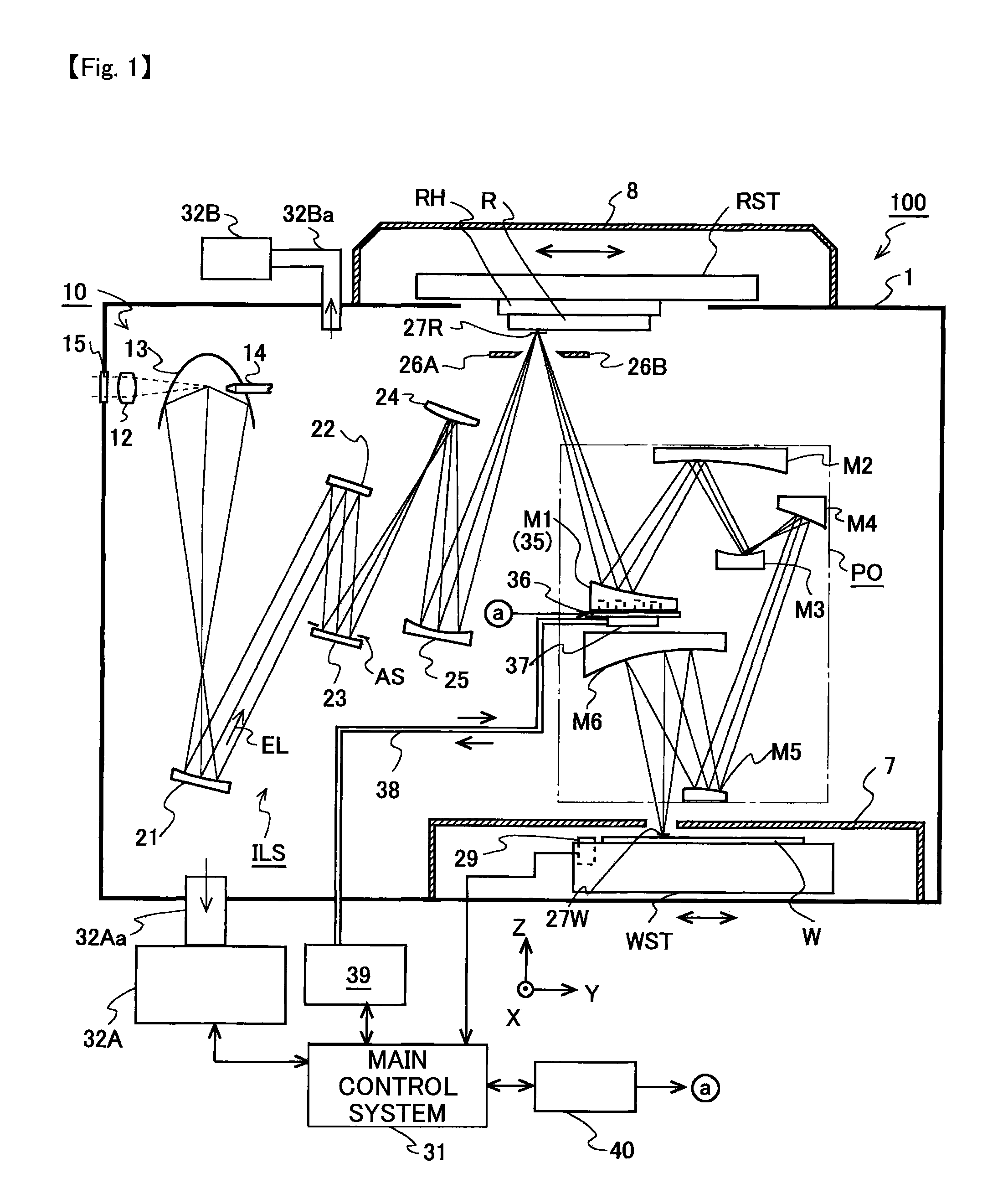

System for correcting aberrations and distortions in EUV lithography

InactiveUS6897940B2Decorative surface effectsDuplicating/marking methodsExit pupilConductive coating

A system for correcting aberration and distortion in EUV lithography places a reticle on a deformable reticle chuck, and a reticle height sensor is used to measure the surface height of the reticle placed on the deformable reticle chuck. An optical system projects EUV radiation onto the reticle and collects and projects reflected EUV radiation from the reticle through its exit pupil onto a wafer placed on a wafer chuck. A deformable mirror disposed proximal to the exit pupil may also be controlled for this purpose. The deformable reticle chuck and the deformable mirror are controlled such that aberration and distortion of an image of the reticle formed on the wafer by the optical system are corrected based on the height measured by the reticle height sensor. The deformable reticle chuck includes a supporting structure, a deformable membrane disposed above and being comprised of a dielectric layer and a conductive layer, a voltage source connected to the conductive coating on the reticle and the conductive layer to generate an electrostatic attractive force between them, a plurality of actuator rods each connected to a corresponding one of actuators, and a coolant gas inside a chamber formed between the membrane and the top surface of the supporting structure. A deformable wafer chuck and wafer height sensor may be included to provide further correction of the image.

Owner:NIKON CORP

Deformable mirror, mirror apparatus, and exposure apparatus

InactiveUS20100033704A1Correct surface shapeImprove cooling effectMirrorsHandling using diffraction/refraction/reflectionElectricityControl system

A mirror apparatus includes a plurality of holes which are divided by partition wall portions on a back surface of a mirror, a plurality of thin film piezoelectric elements which are fixed to bottom surfaces of the plurality of holes respectively, a radiation temperature-regulating plate which has a plurality of projections inserted into the holes, and a mirror control system which individually controls voltages to be applied to the plurality of thin film piezoelectric elements to deform the mirror. The mirror can be efficiently deformed and / or cooled from the side of the back surface without transmitting any vibration to the mirror.

Owner:NIKON CORP

Beam director and control system for a high energy laser within a conformal window

ActiveUS7626152B2Photometry using reference valueMaterial analysis by optical meansCorrection algorithmWavefront sensor

Owner:RAYTHEON CO

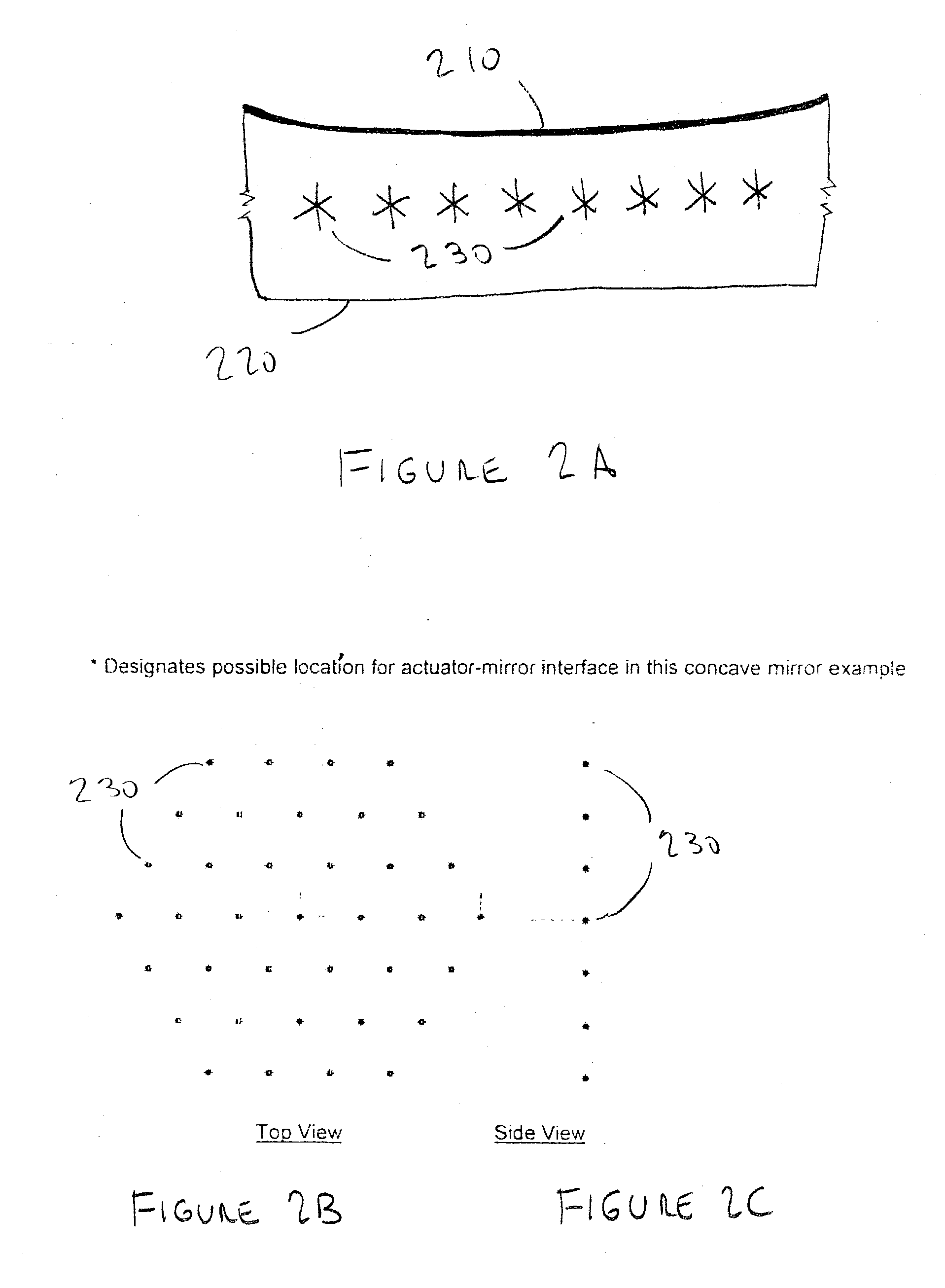

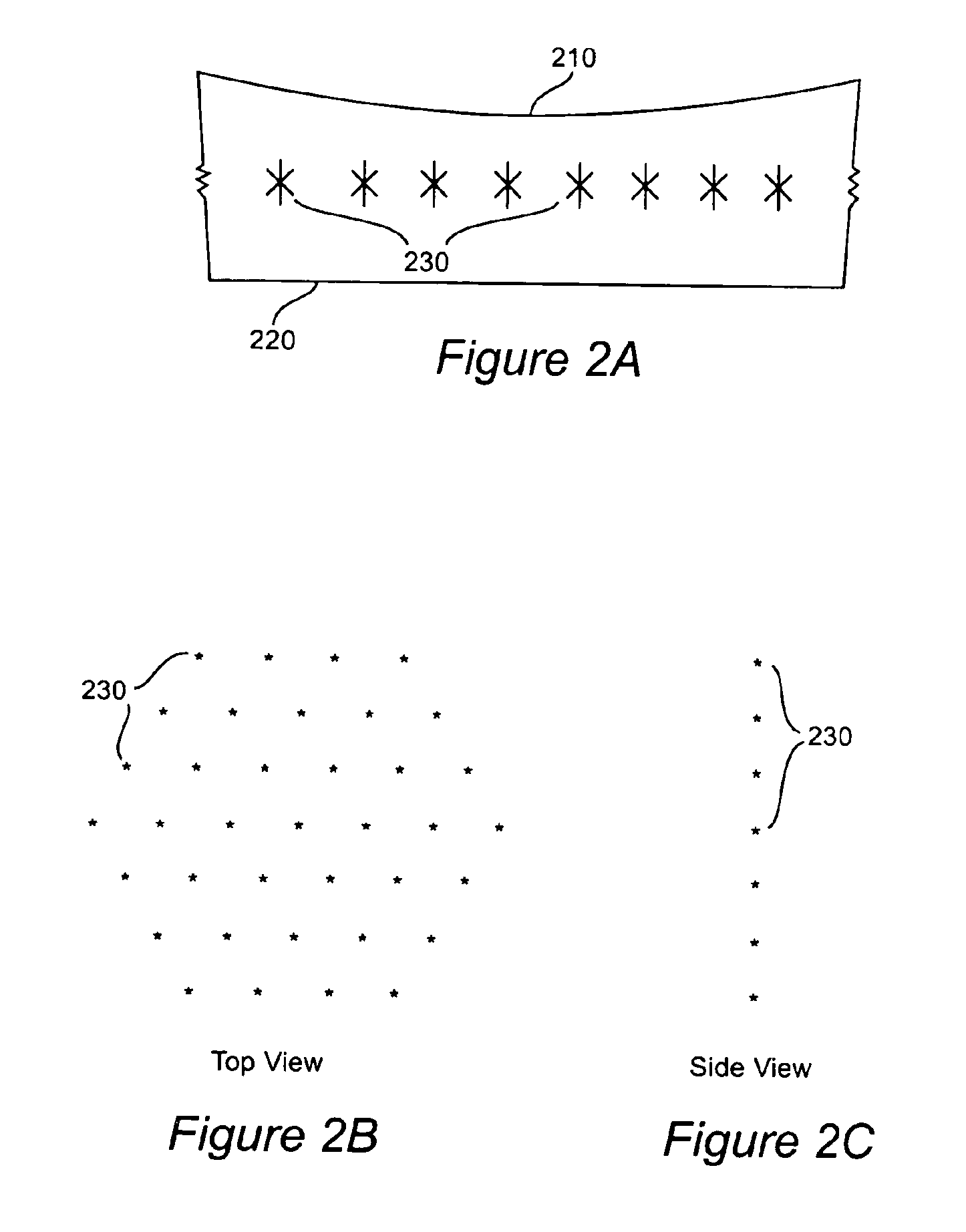

Adaptive optic with discrete actuators for continuous deformation of a deformable mirror system

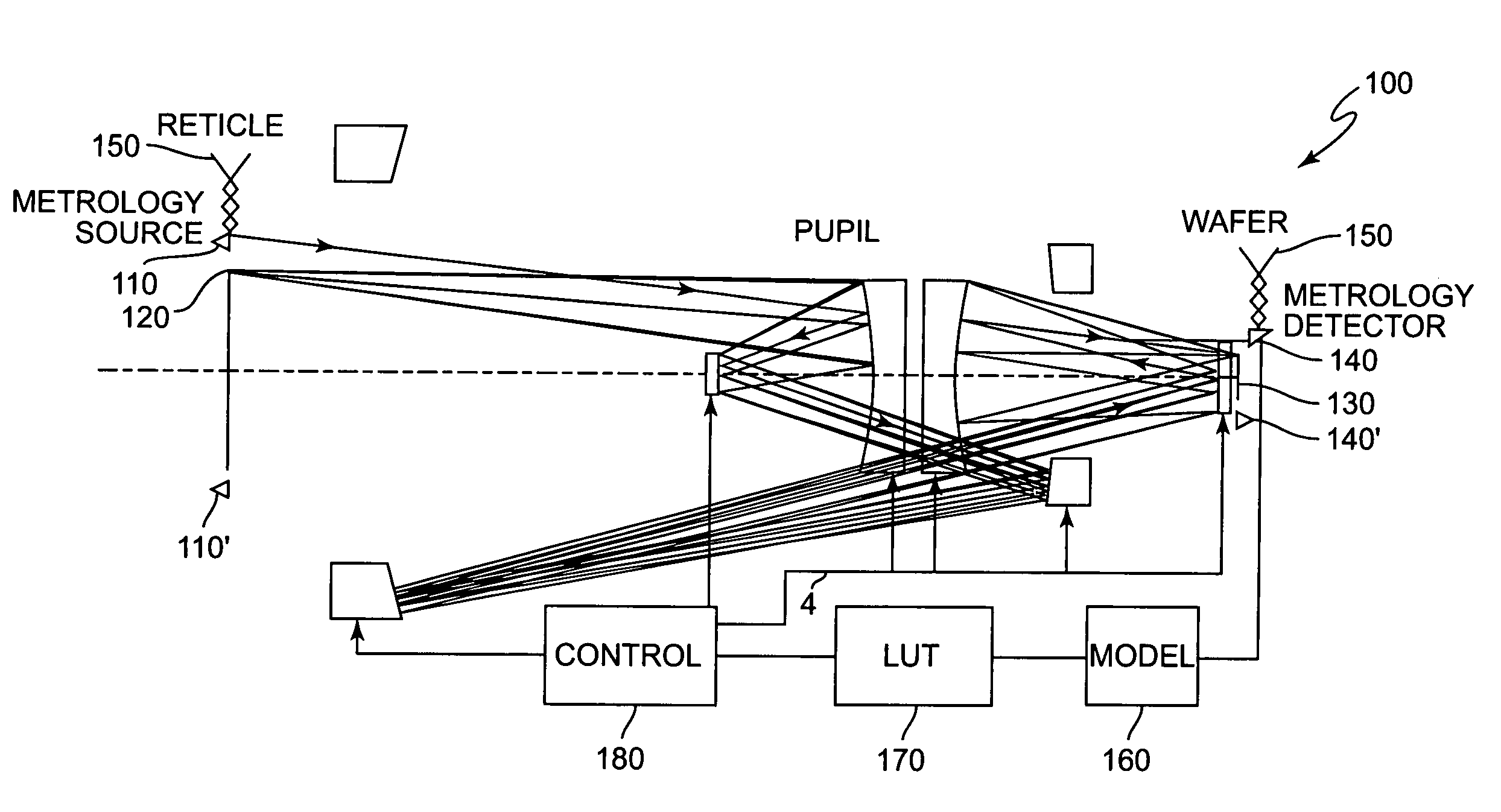

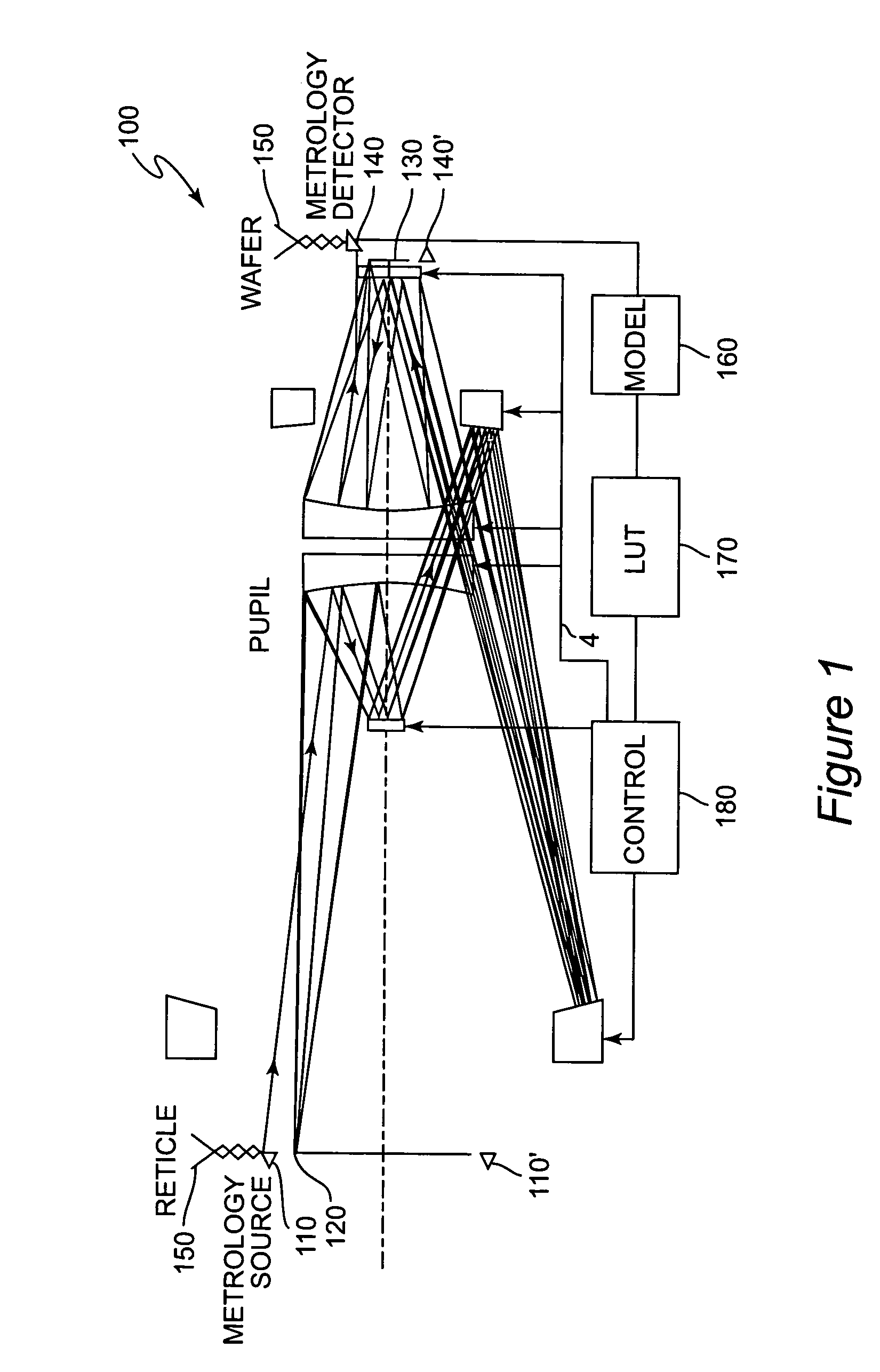

Adaptive optical elements for use in high precision lithography exposure are provided with an array of discrete actuators to provide highly stable and repeatable correction of the shape of an optical element to an accuracy of a small fraction of a very short wavelength of light in the EUV range of 1 to 50 nanometers, responsive to a metrology source and sensor arrangement. The actuators are matched to the deformation characteristics of the adaptive optical elements. Preferably, the actuators provide both positive and negative force for outward and / or inward deflection continuously over the surface of the mirror. The surface of the optical element may thus be accurately, controllably and repeatably deformed to within an allowable deformation limit to optimize optical performance of an optical system for high precision lithography exposure.

Owner:NIKON CORP

Deformable mirror and optical controller including the deformable mirror

Owner:PANASONIC CORP

Deformable mirror with passive and active actuators

InactiveUS20040027632A1Aberration correctionMirrorsHandling using diffraction/refraction/reflectionEngineeringDeformable mirror

A combination of active and passive force actuators provide adjustments to the shape of an optical element to reduce or compensate for aberrations in an optical system. Passive actuators at a high spatial frequency are capable of correcting higher order steady state components of shape error while dynamic corrections of higher frequency, operationally dependent is provided allowing the number of active actuators and the power supplied to each active actuator to be reduced; reducing heating of the optical element by the active actuators and increasing stability of the system. Compound actuators including a combination of an active actuator portion with a passive actuator portion (which provides a mechanical force bias to the active actuator portion) allows increased spatial flexibility of application of forces to the optical element and other advantages.

Owner:NIKON CORP

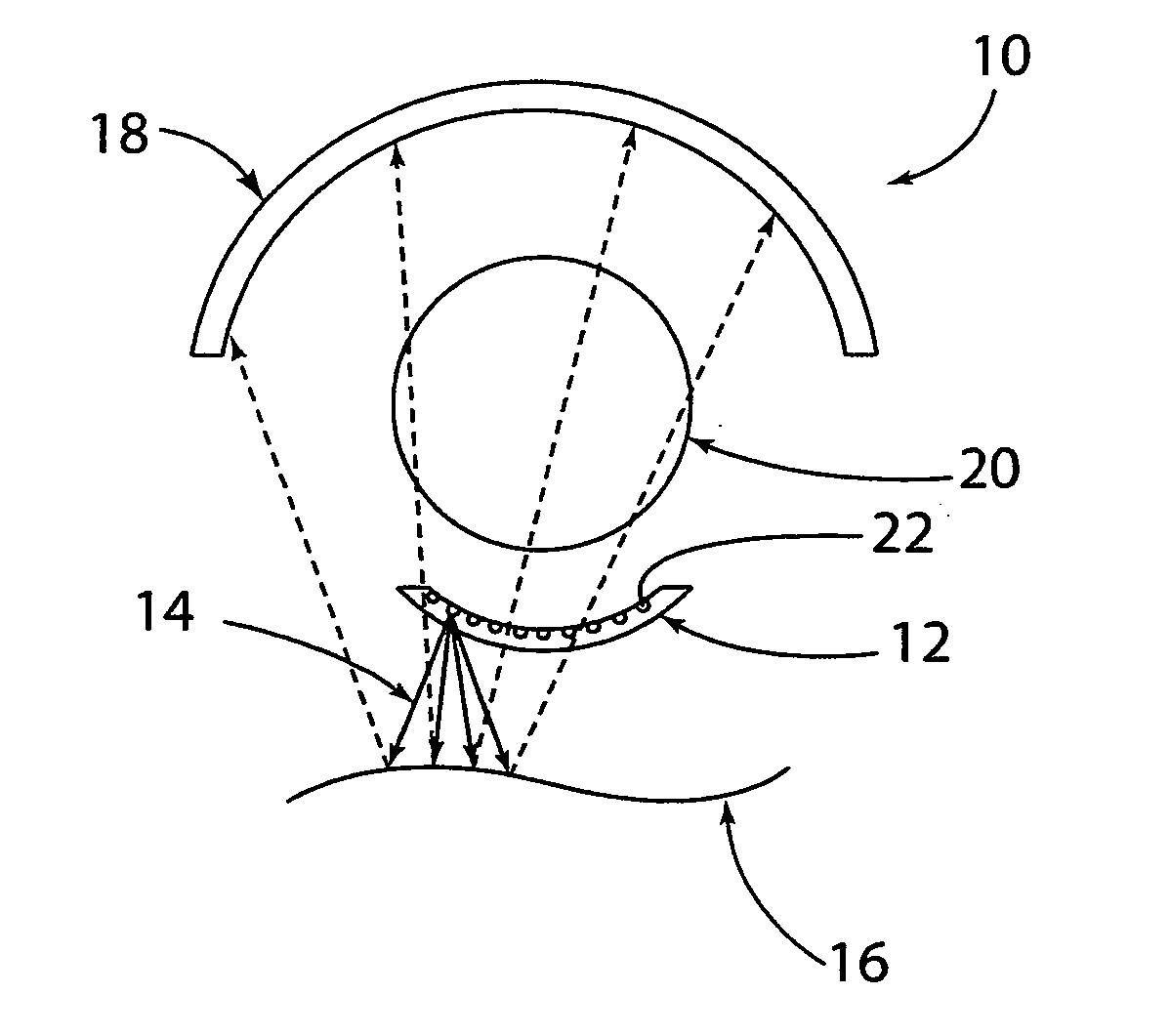

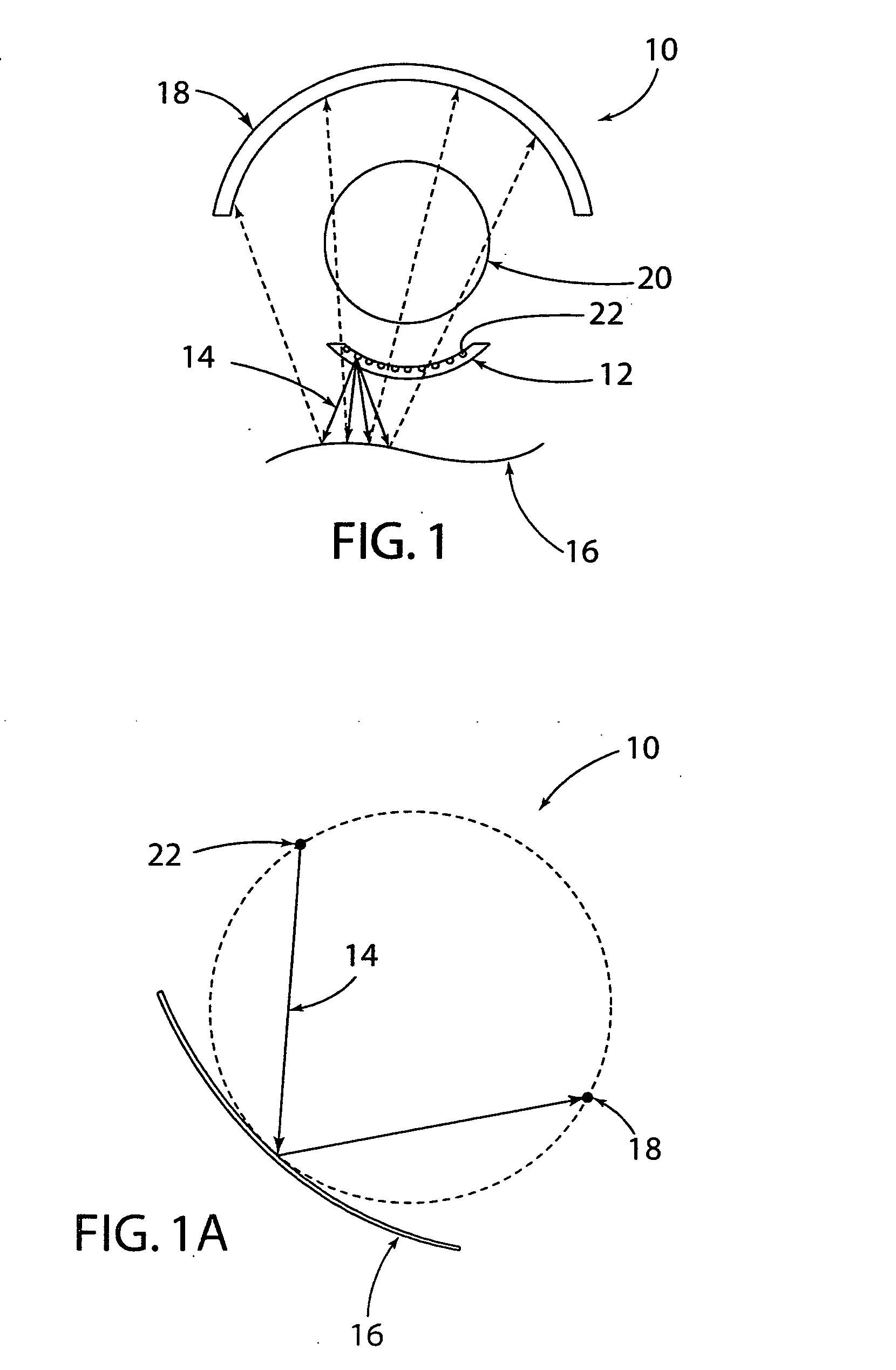

Tomographic imaging system using a conformable mirror

A tomographic imaging system comprising a source array emitting rays, a deformable mirror reflecting the rays emitted by the source array, and a detector array receiving the electromagnetic rays emitted by the source array and reflected by the deformable mirror. An object can be positioned between the deformable mirror and the detector array and the deformable mirror can be deformed to a plurality of configurations to form a tomographic image of the object. The system can also be used in radiation therapy.

Owner:MICHIGAN STATE UNIV

Deformable mirror holders

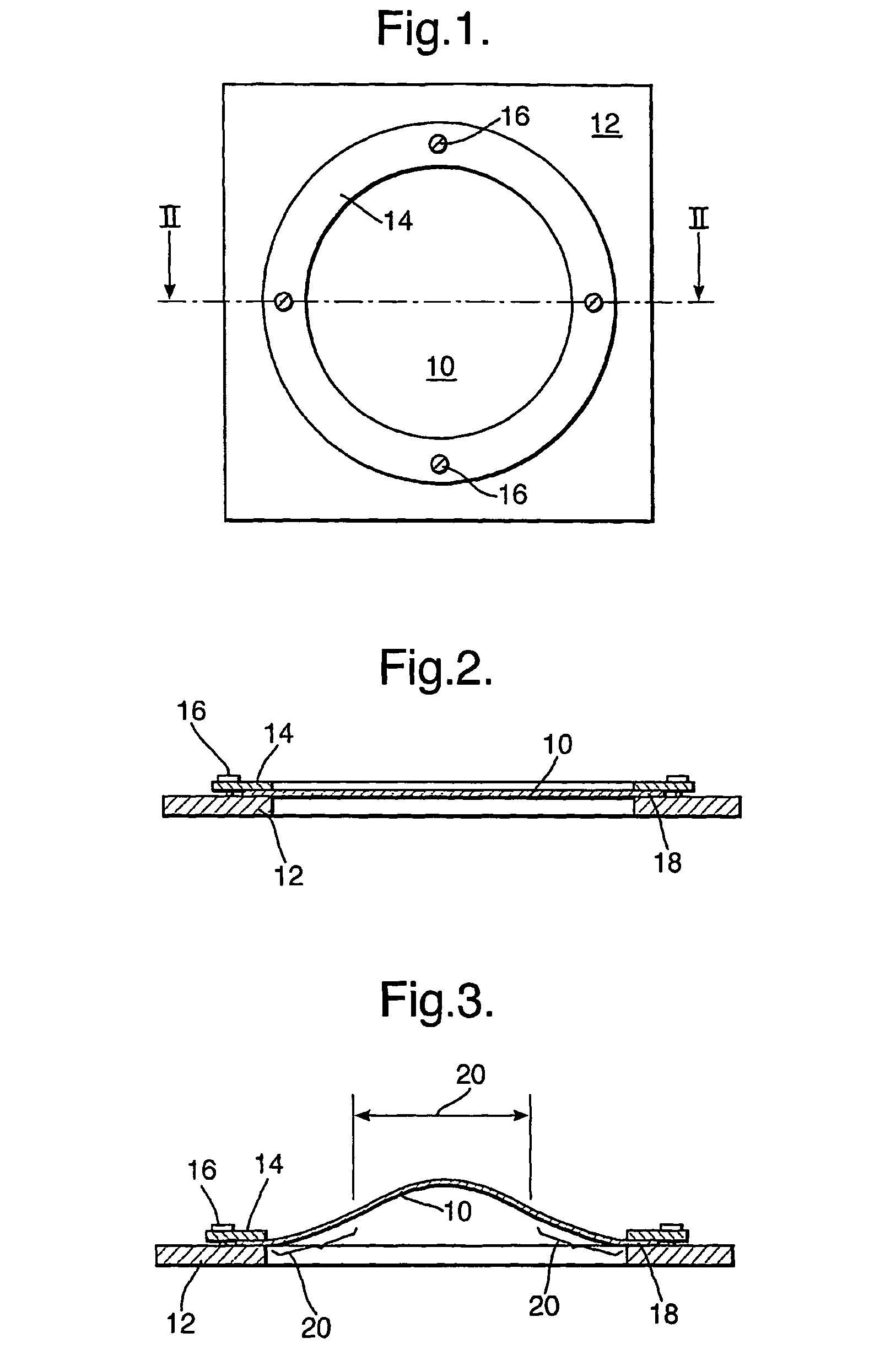

This invention concerns improvements relating to a deformable-mirror holder for holding a mirror in a desired position, to within accepted tolerances, even whilst the mirror is deforming or in a deformed state. More particularly but not exclusively, this invention relates to a holder for a bimorph mirror. A deformable mirror holder (31) is provided comprising a body with a receiving portion for receiving a deformable mirror (30), and wherein the receiving portion is defined by a passive flexible support structure (41) such that, in use, to the support structure provides a supporting surface to the mirror. This invention extends to a deformable mirror and a deformable mirror holder as described above.

Owner:BAE SYSTEMS PLC

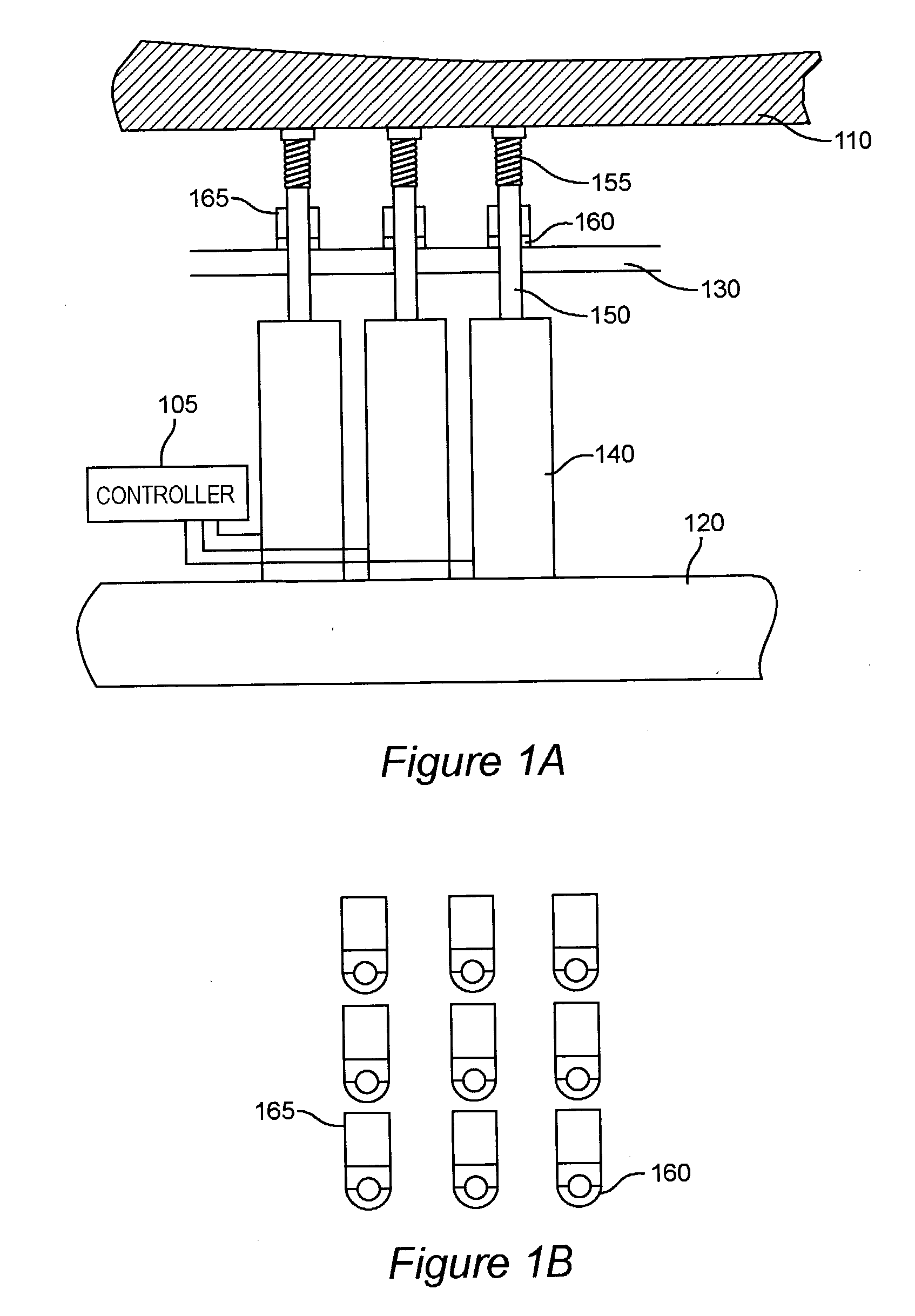

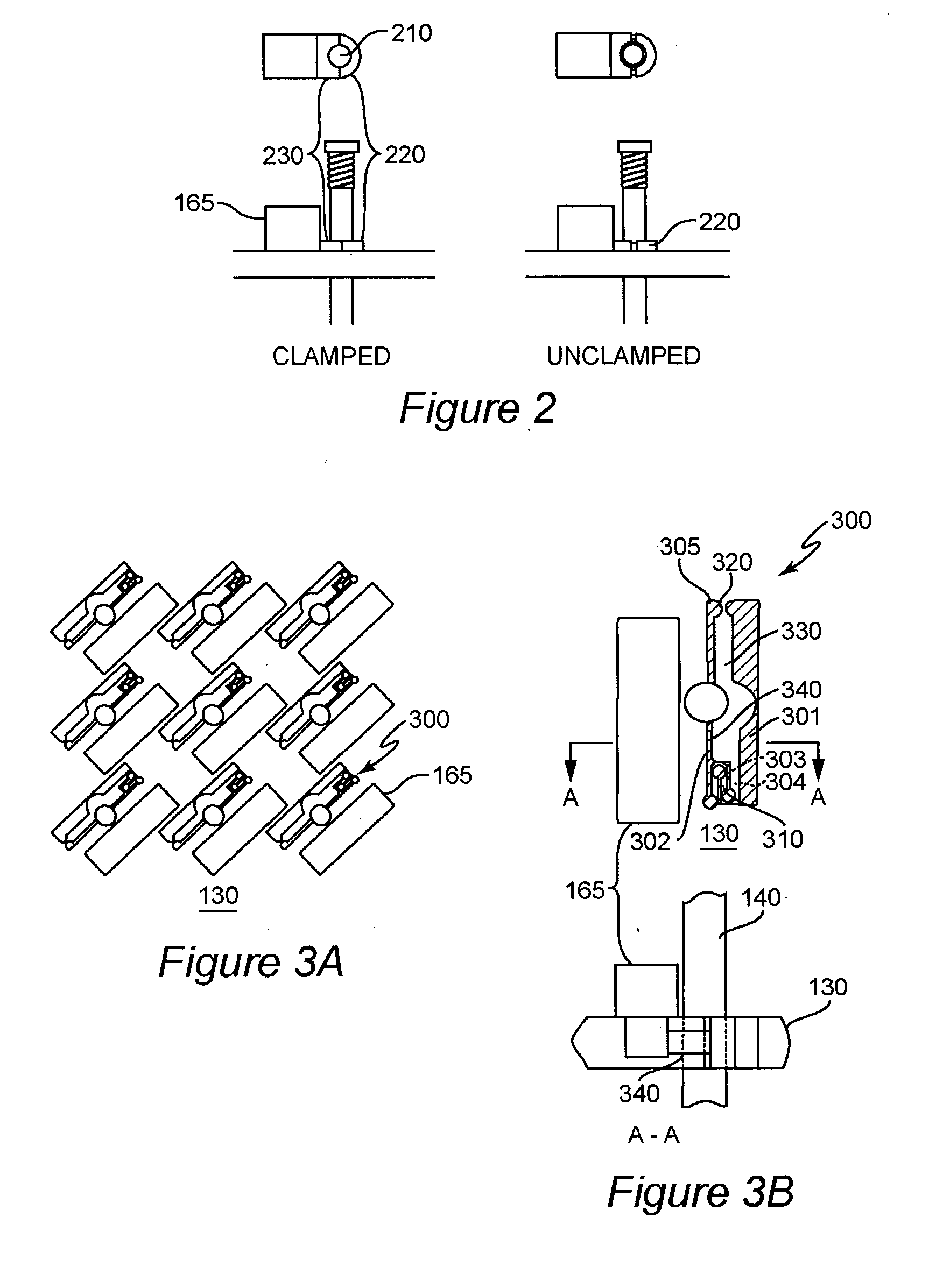

Deformable mirror actuation system

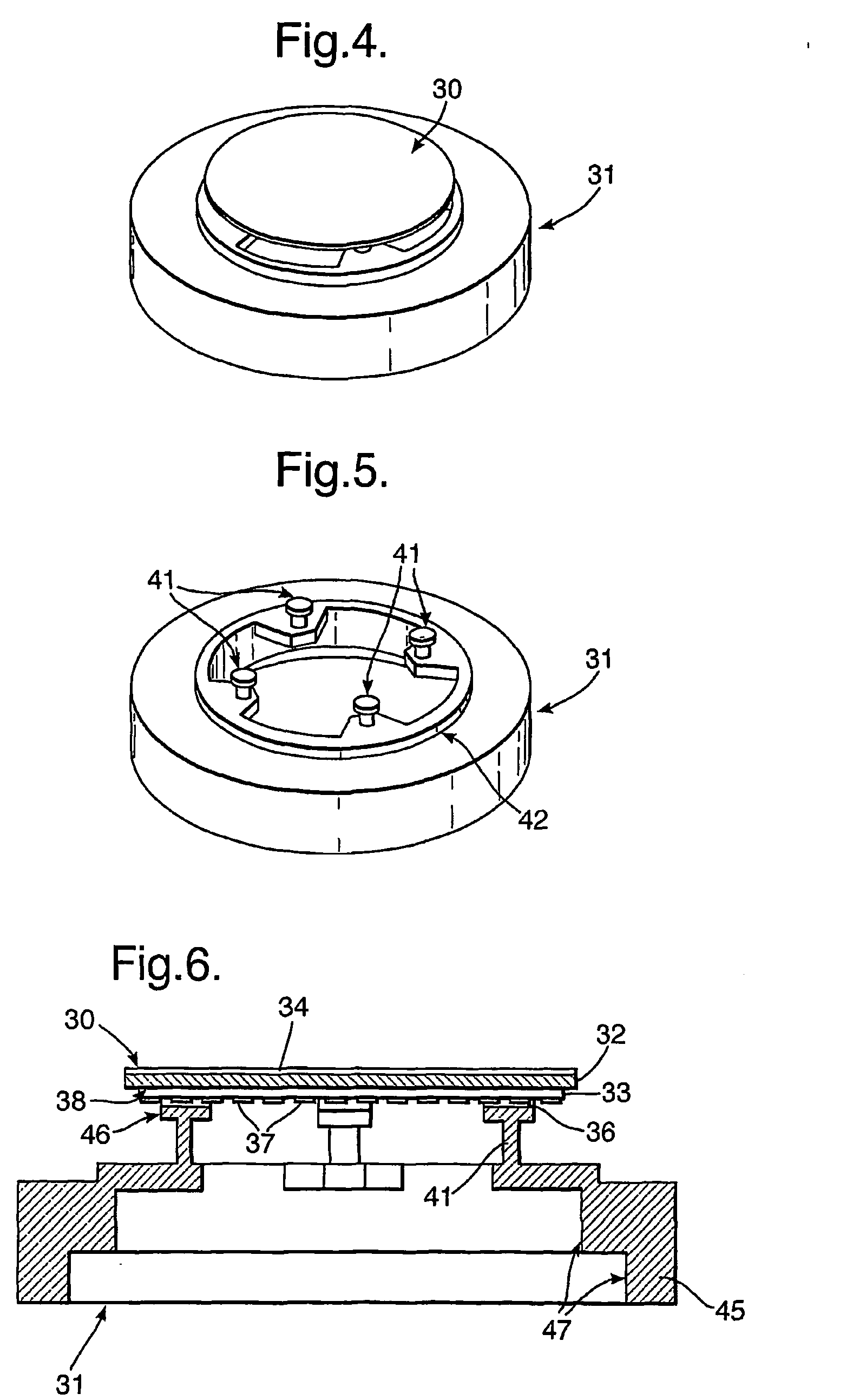

Mechanical control and actuation of an adaptive optical element provides highly stable and repeatable correction of the shape of an optical element to an accuracy of a small fraction of a very short wavelength of light, responsive to a metrology source and sensor arrangement. Actuators in the form of individual set-screws or other actuators capable of axially positioning a shaft are driven by a robotic screw driver with four degrees of freedom or one or more linear actuators to exert force on the mirror. Positive or negative force may be used for outward and / or inward deflection of the mirror. When a desired force is developed on the mirror through a mechanical linkage, the linkage may be clamped by a passive clamp which may be released by an actuator such that the adjustment is maintained while the linear actuator and the clamp actuator are turned off; yielding a highly stable adjustment while effectively removing sources of actuator drift, noise, vibration and heating which may adversely affect stability.

Owner:NIKON CORP

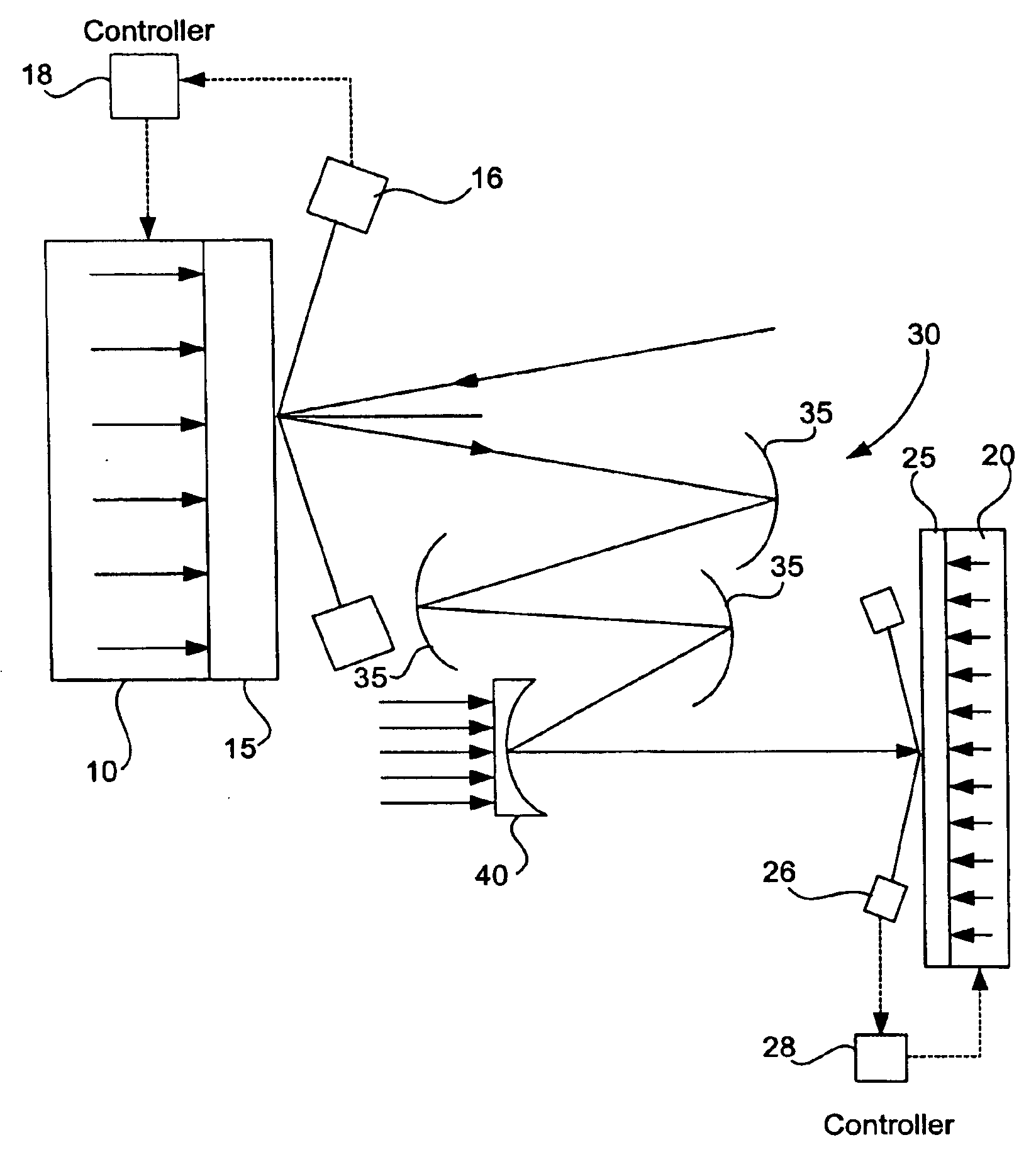

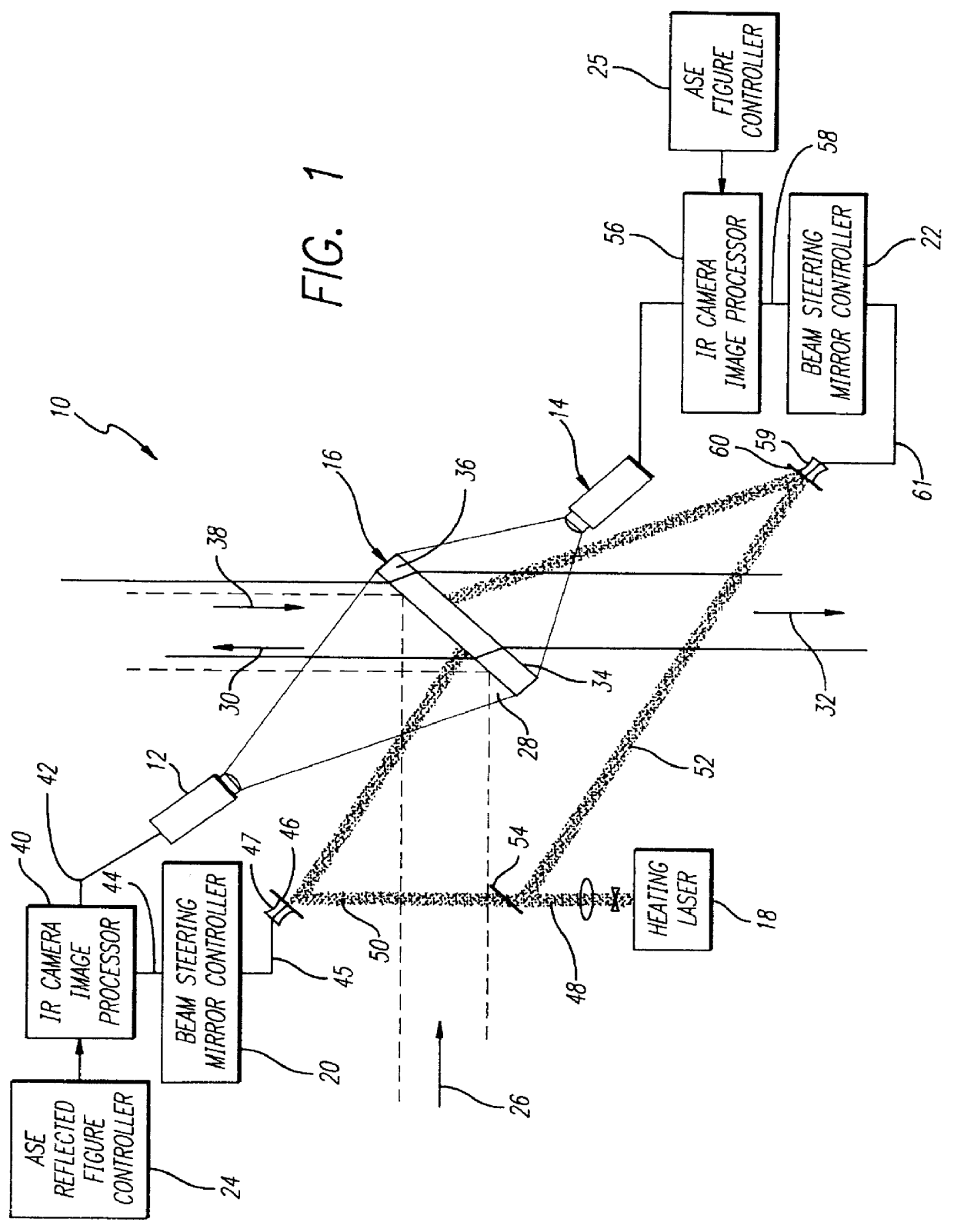

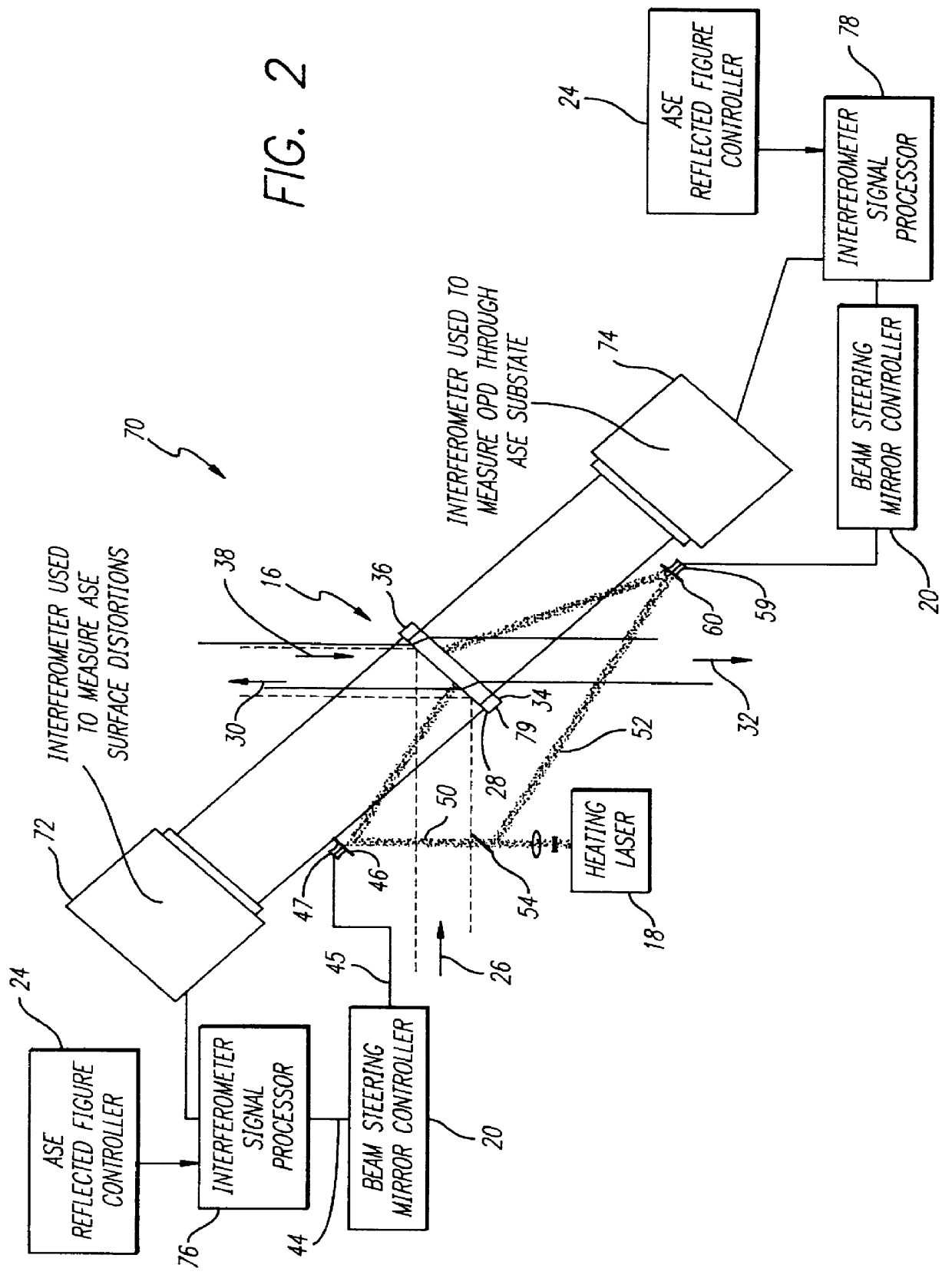

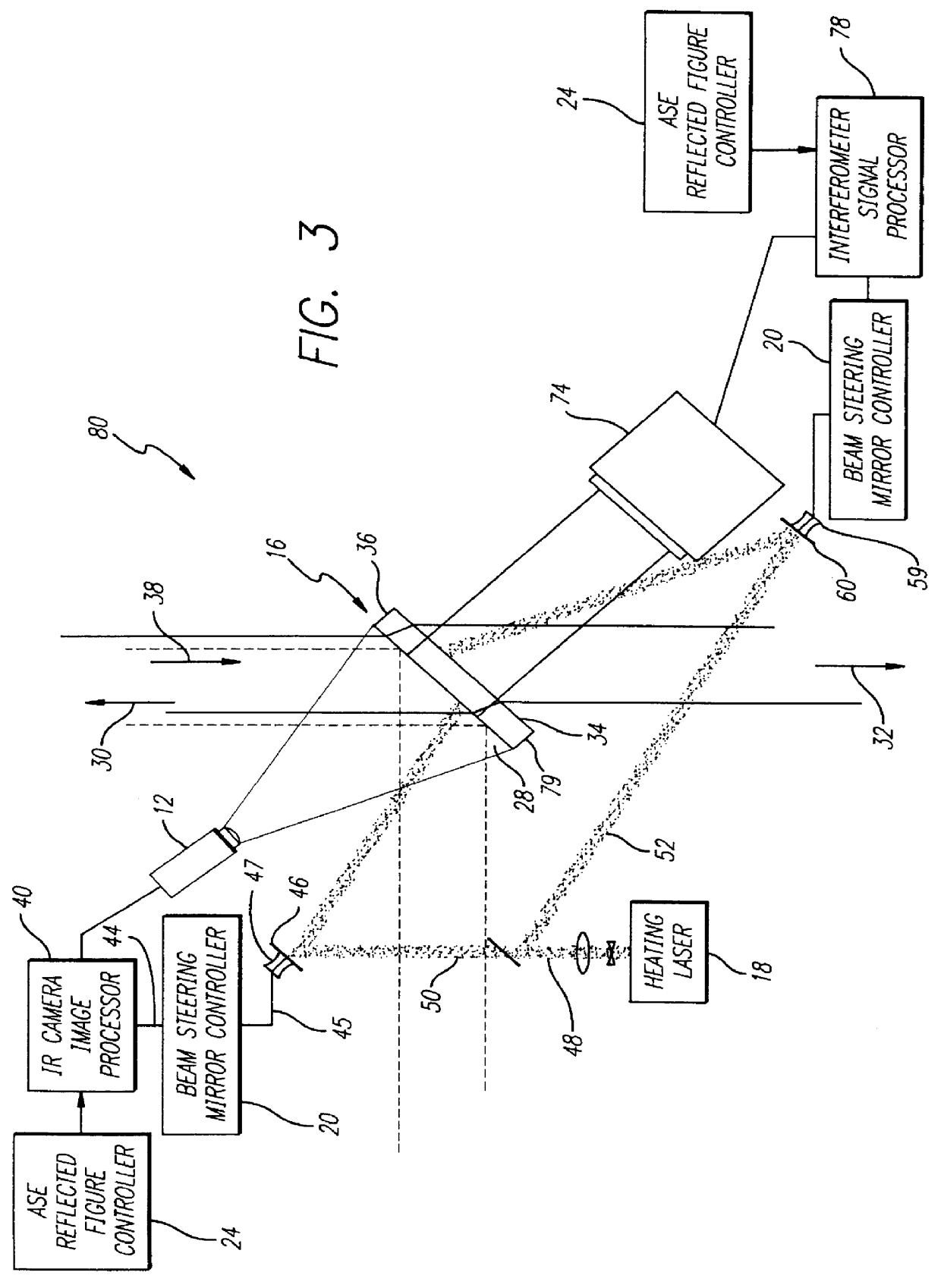

Heat maps for controlling deformations in optical components

A system (80) for controlling deformations of optical components adapted for use with laser system aperture sharing elements (16) and deformable mirrors. The inventive system (80) includes a control loop (12, 40, 24, 20, 46, 28, 74, 78, 60, 34) for determining a desired temperature pattern. The control loop (12, 40, 24, 46, 28, 74, 78, 60, 34) provides a control signal (45) corresponding to the desired temperature pattern to a heat map applicator (18, 46, 47, 59, 60). The heat map applicator (18, 46, 47, 59, 60) applies the desired temperature pattern to the optical component (16) in response to the control signal and the optical component (16) is selectively deformed in response thereto. In a specific embodiment, the control loop (12, 40, 24, 20, 46, 28, 74, 78, 60, 34) is a closed loop control system that includes an interferometer (74). The interferometer (74) provides a first shape of the optical component (16) to a comparator circuit (20) that compares the first shape to a desired shape corresponding to the desired temperature pattern for determining the control signal. An alternative closed loop control system (12, 40, 24, 20, 46, 28, 74, 78, 60, 34) includes an infrared energy detector (12) that determines a current temperature pattern and generates the control signal in response thereto for converting the current temperature pattern to the desired temperature pattern. The heat map applicator (18, 46, 47, 59, 60) provides an electromagnetic beam (50, 52) that is swept across the optical component (16) to impart the desired temperature pattern on the optical component (16). In another illustrative embodiment, the control loop is an open loop control system that includes a complimentary electromagnetic energy beam that is swept over the optical component to form a heat pattern complimentary to the temperature pattern imparted to the optical component by a high power laser beam such that the total heat deposited on the optical component is uniform.

Owner:RAYTHEON CO

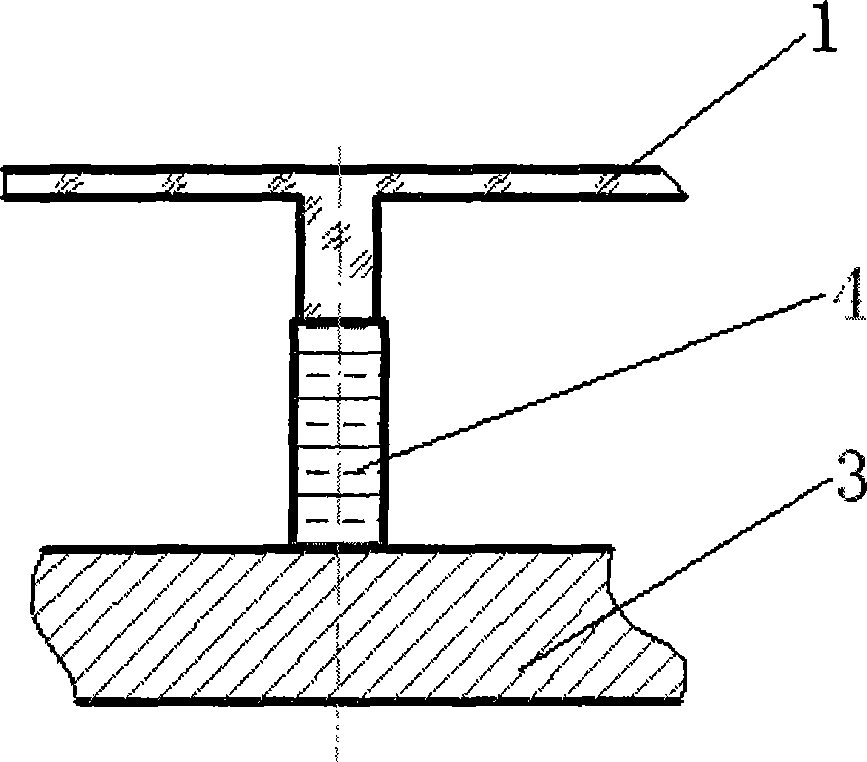

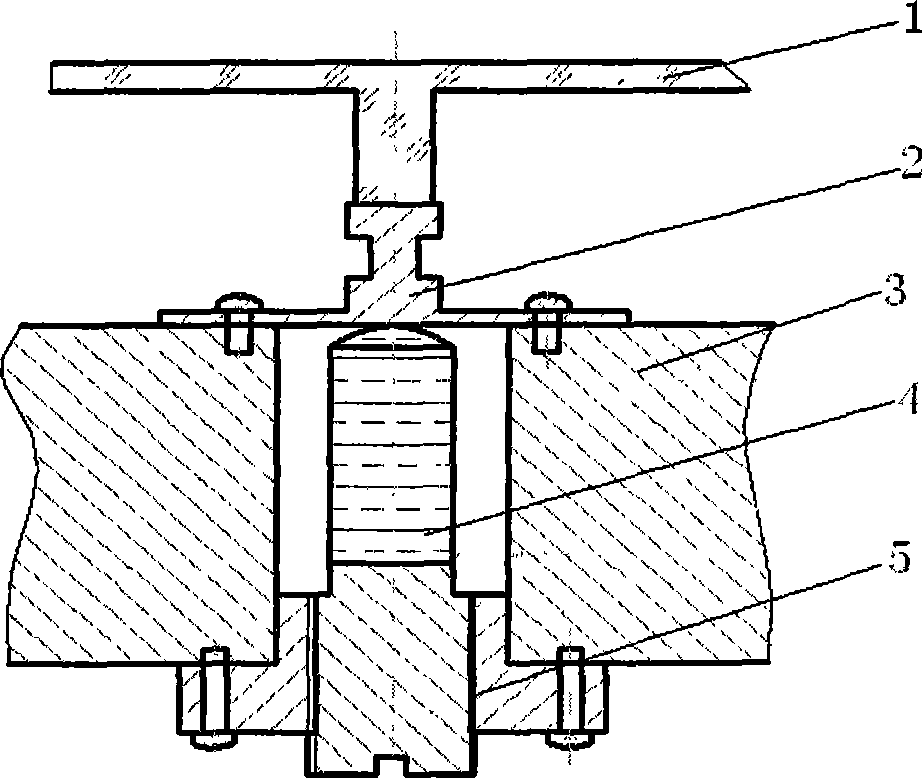

Large-diameter detachable piezoelectric deforming reflection mirror

InactiveCN101504487AEasy to replaceEasy maintenancePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesPiezoelectric actuatorsOptical processing

The invention relates to a large-caliber demountable piezoelectric deformable mirror, which comprises a mirror surface, a pedestal and a piezoelectric actuator, and is characterized in that an elastic sheet is clamped between the mirror surface and the piezoelectric actuator, and the piezoelectric actuator is tightly supported against the elastic sheet without mechanical and gluing connections. The mirror also comprises a precise screw thread adjusting structure for adjusting the pretightening force or the distorting lens surface shape between the elastic sheet and the piezoelectric actuator. The piezoelectric actuator is not connected with the mirror surface directly, the piezoelectric actuator is easy to replace, and the deformable mirror is convenient to maintain; the optical processing of the mirror surface and membrane plating can be performed when the actuator is processed to shorten the manufacturing cycle of the deformable mirror; and the piezoelectric actuator is applicable to the deformable mirrors with large calibers, large die opening and high requirement on maintainability.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Adaptive optic with discrete actuators for continuous deformation of a deformable mirror system

Adaptive optical elements for use in high precision lithography exposure are provided with an array of discrete actuators to provide highly stable and repeatable correction of the shape of an optical element to an accuracy of a small fraction of a very short wavelength of light in the EUV range of 1 to 50 nanometers, responsive to a metrology source and sensor arrangement. The actuators are matched to the deformation characteristics of the adaptive optical elements. Preferably, the actuators provide both positive and negative force for outward and / or inward deflection continuously over the surface of the mirror. The surface of the optical element may thus be accurately, controllably and repeatably deformed to within an allowable deformation limit to optimize optical performance of an optical system for high precision lithography exposure.

Owner:NIKON CORP

Ophthalmic instrument having adaptive optic subsystem with multiple stage phase compensator

An improved ophthalmic instrument including a wavefront sensor that estimates aberrations in reflections of the light formed as an image on the retina of the human eye. A phase compensator, operably coupled to the wavefront sensor, spatially modulates the phase of incident light to compensate for the aberrations estimated by the wavefront sensor. The phase compensator includes a first stage and at least one other additional stage, wherein the first stage compensates for a defocus component of the aberrations, and the additional stage(s) compensate for other higher order components of the aberrations. The first stage preferably comprises a variable focus lens and the additional stage(s) preferably comprise a deformable mirror.

Owner:NORTHROP GRUMMAN SYST CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com