Patents

Literature

282 results about "Faraday cup" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A Faraday cup is a metal (conductive) cup designed to catch charged particles in vacuum. The resulting current can be measured and used to determine the number of ions or electrons hitting the cup. The Faraday cup was named after Michael Faraday who first theorized ions around 1830.

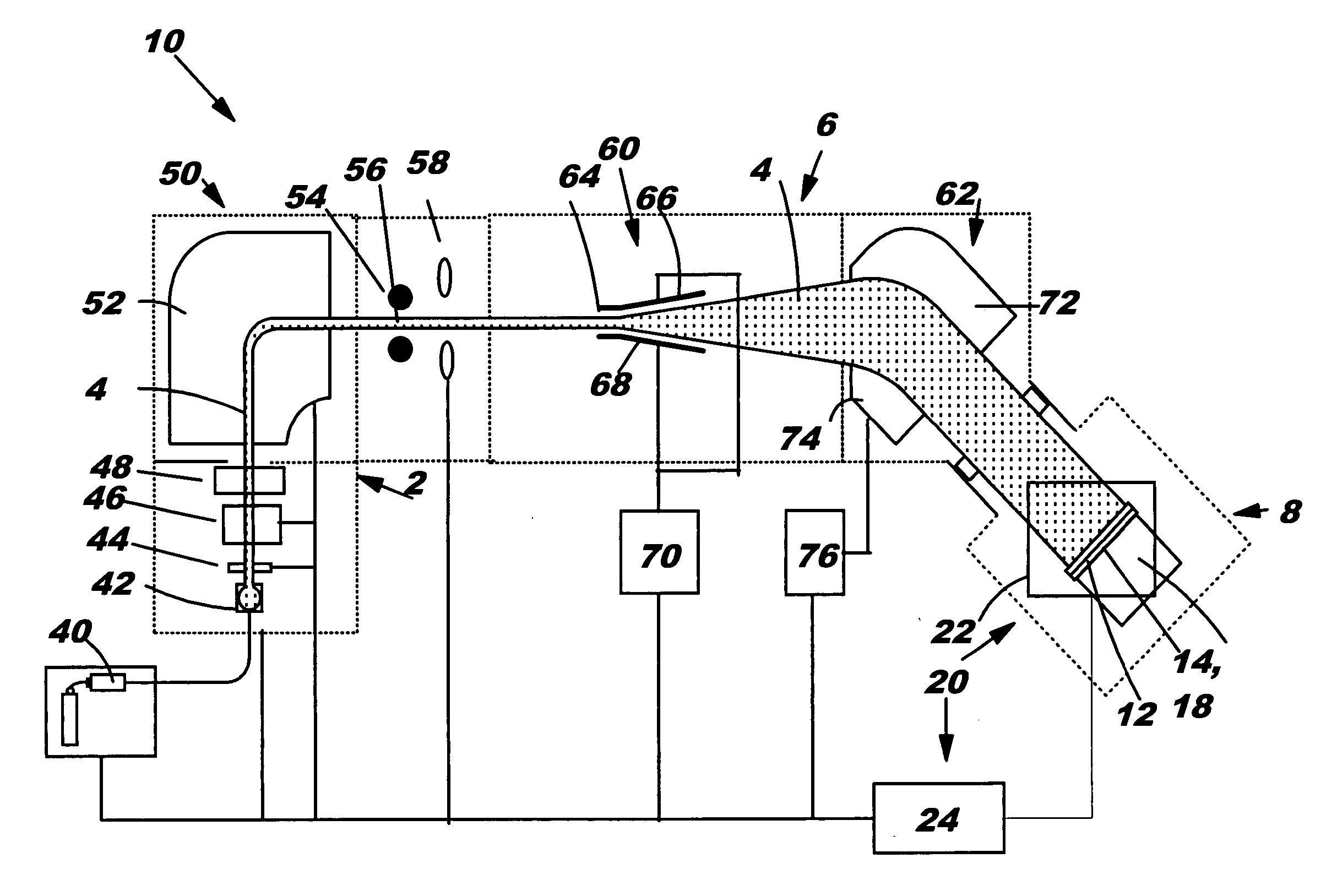

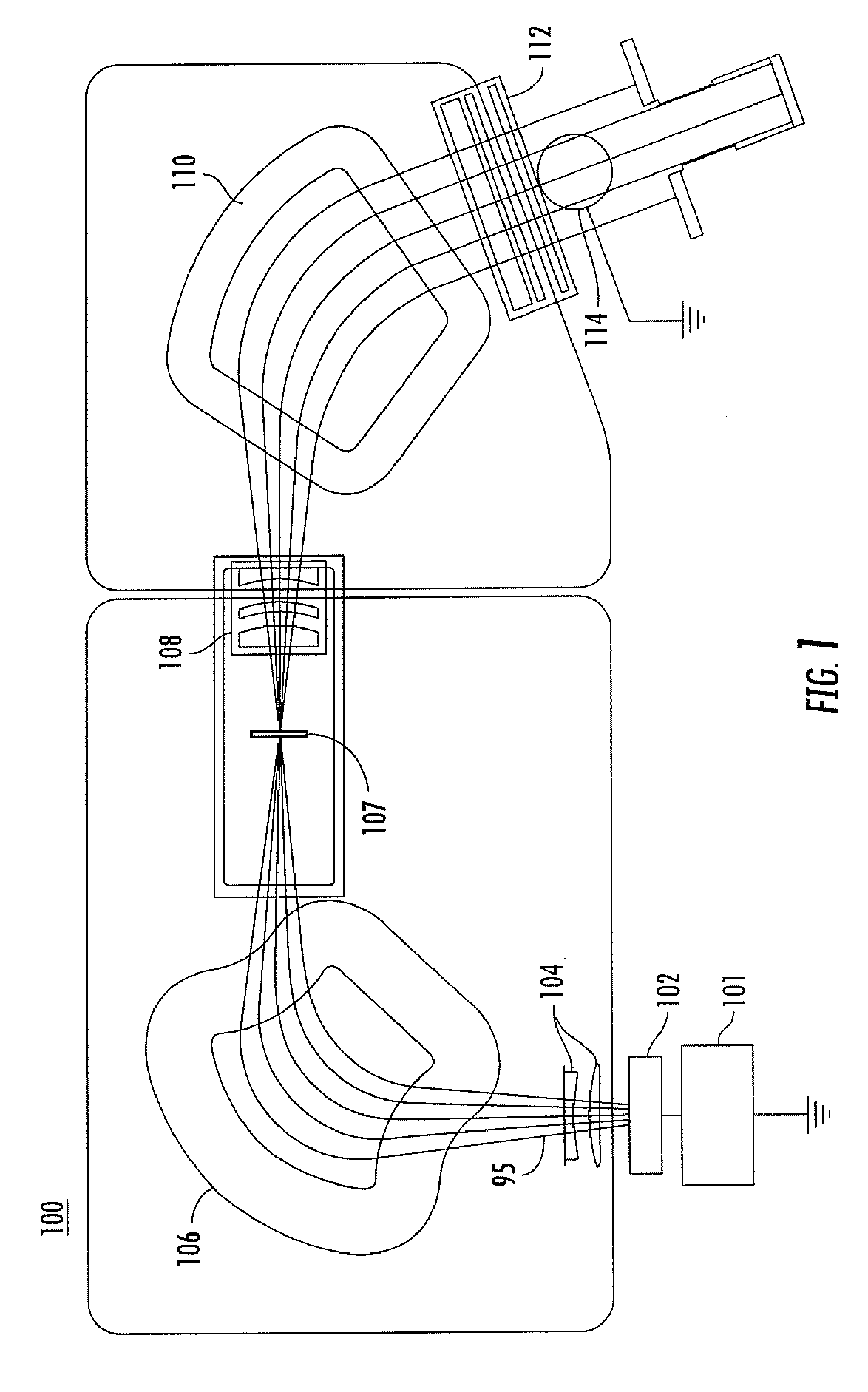

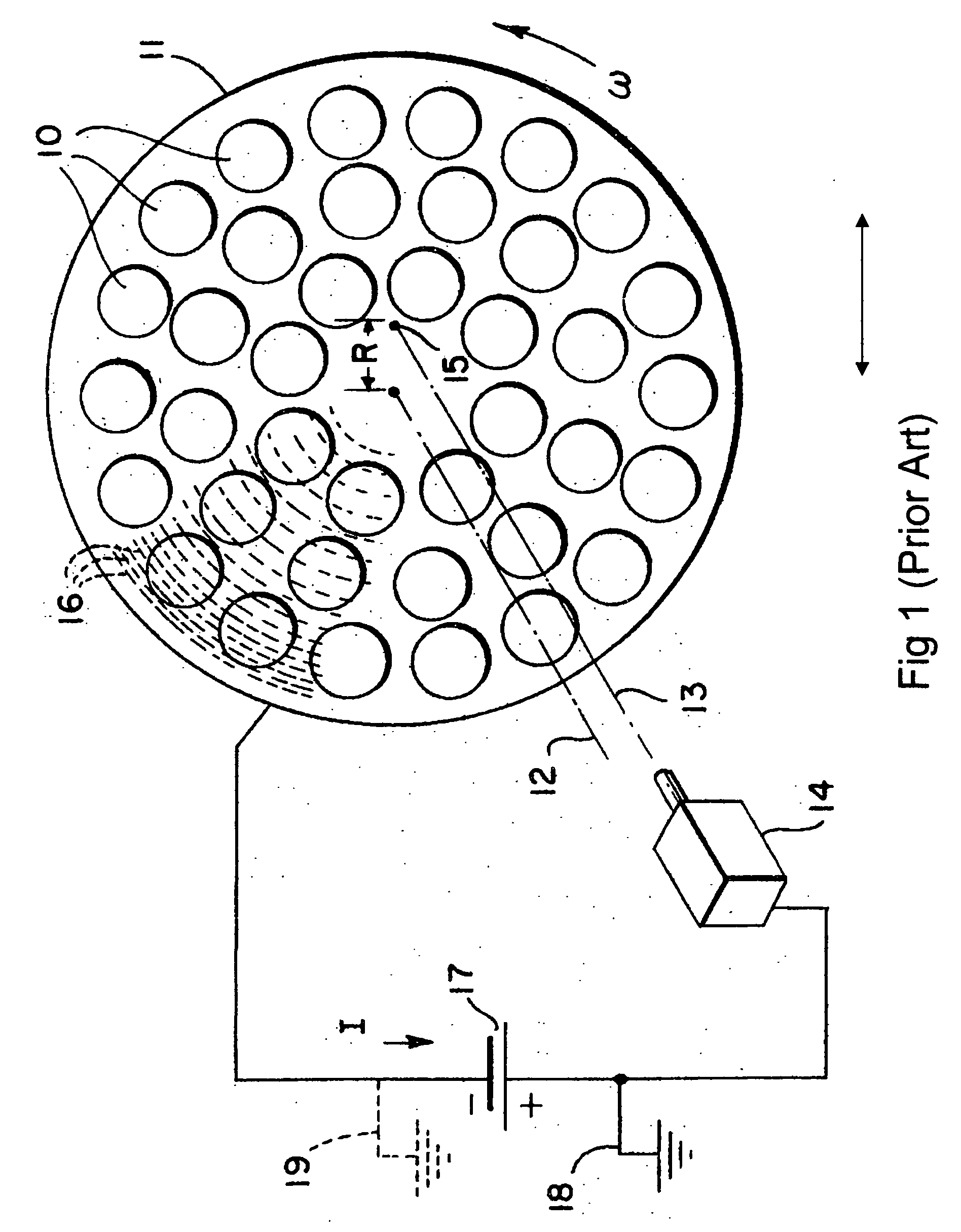

Charging control and dosimetry system for gas cluster ion beam

InactiveUS20020130275A1Reduce surface chargeImproved switchingElectric discharge tubesVacuum evaporation coatingGas cluster ion beamCharge control

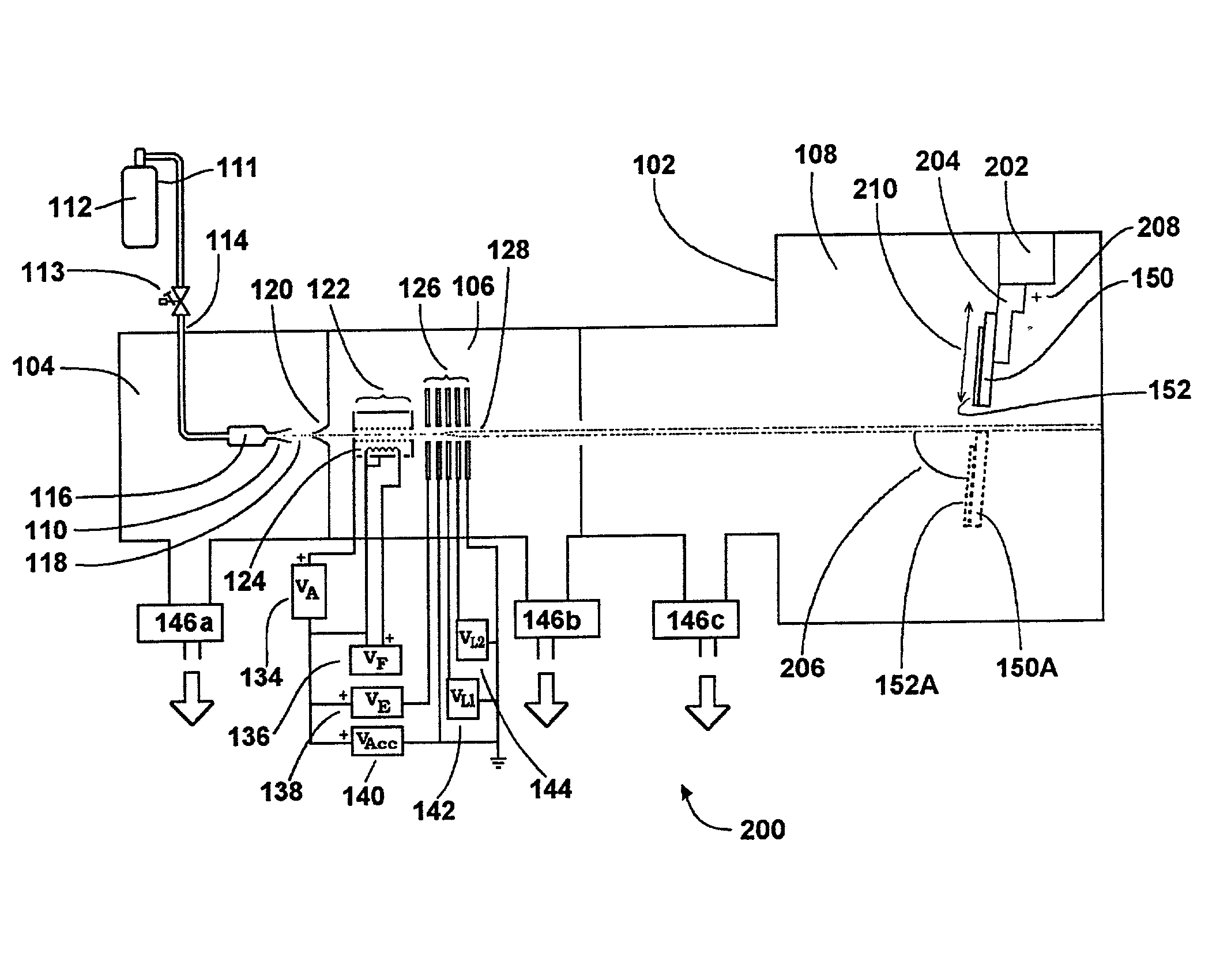

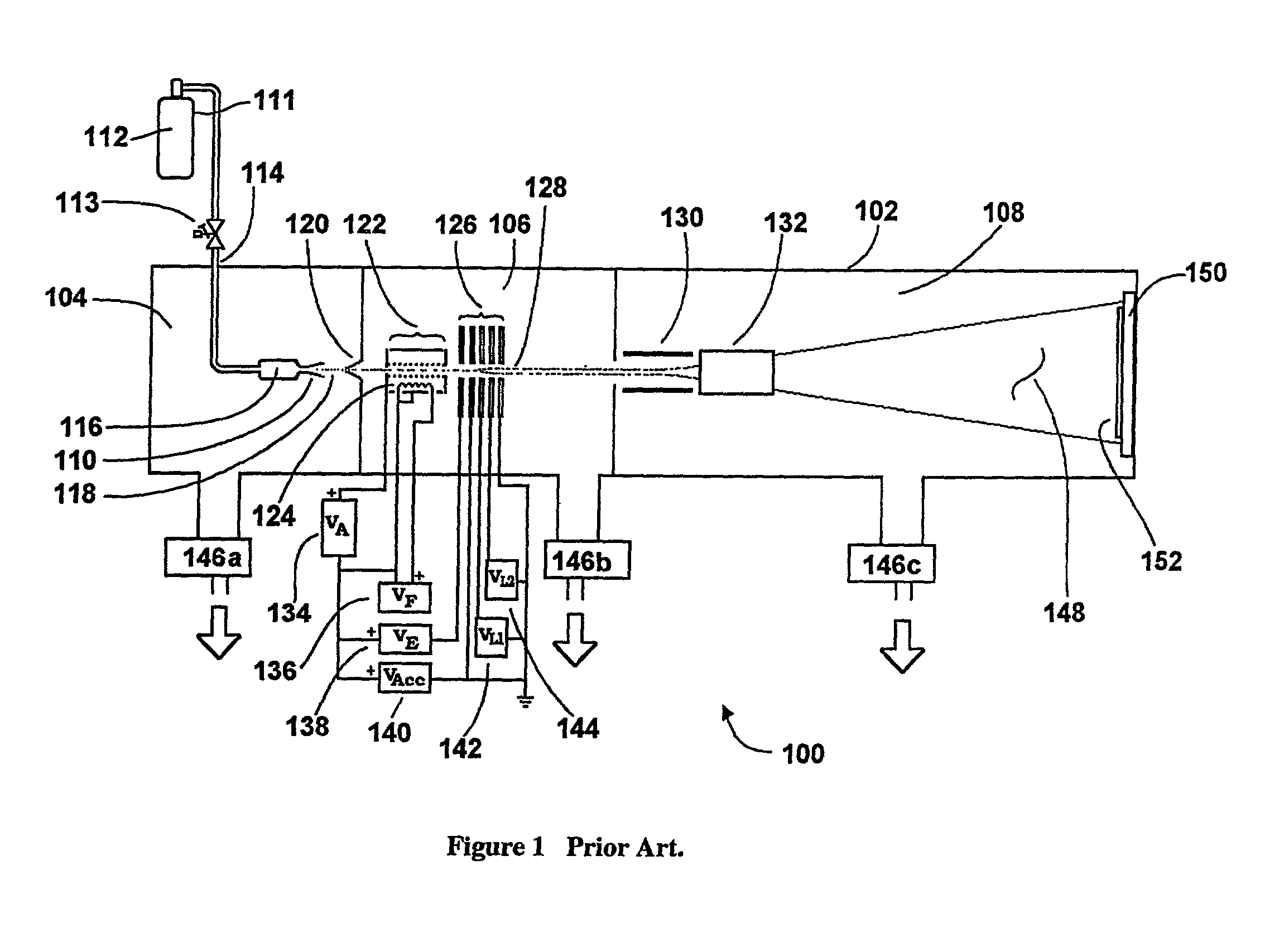

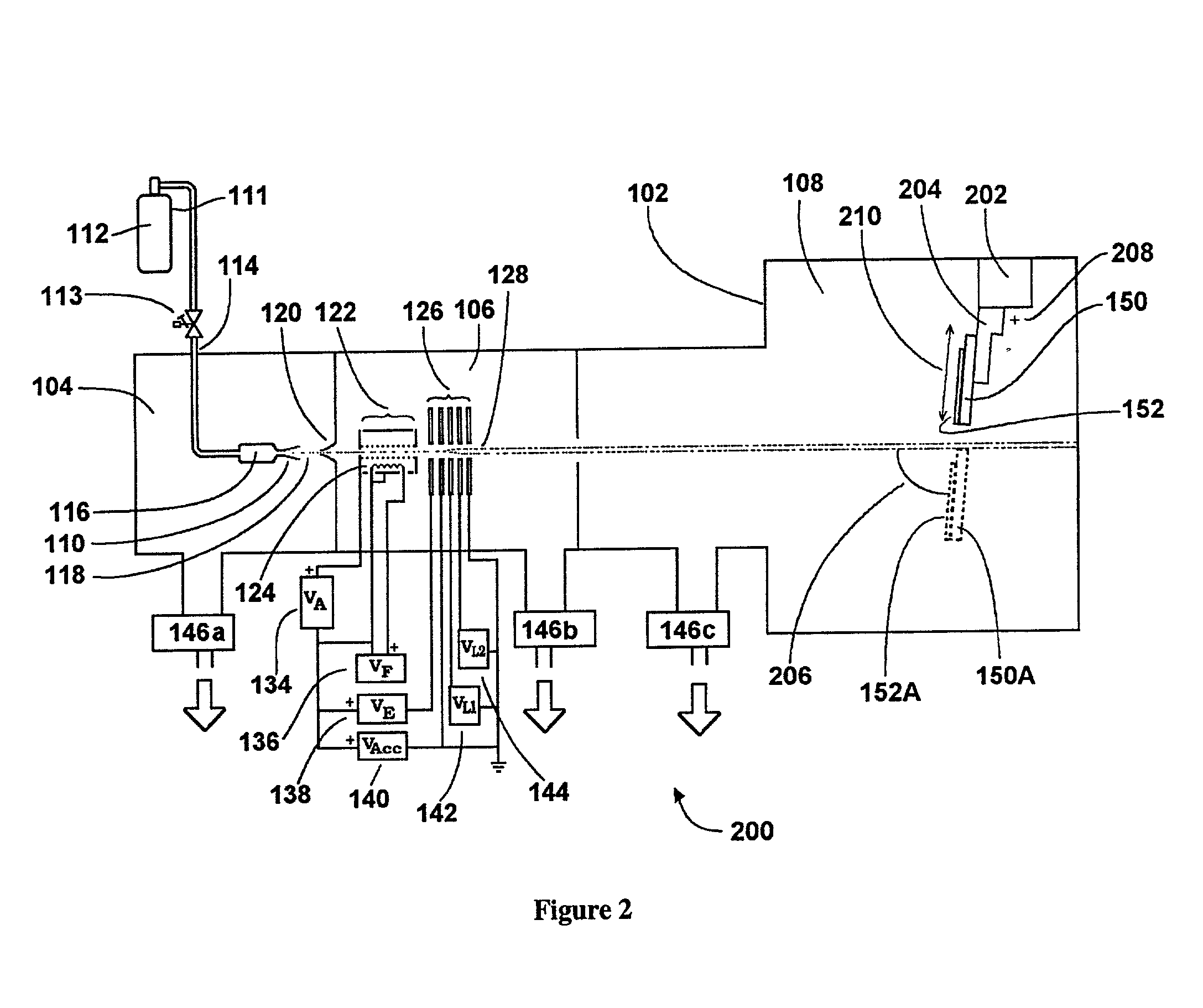

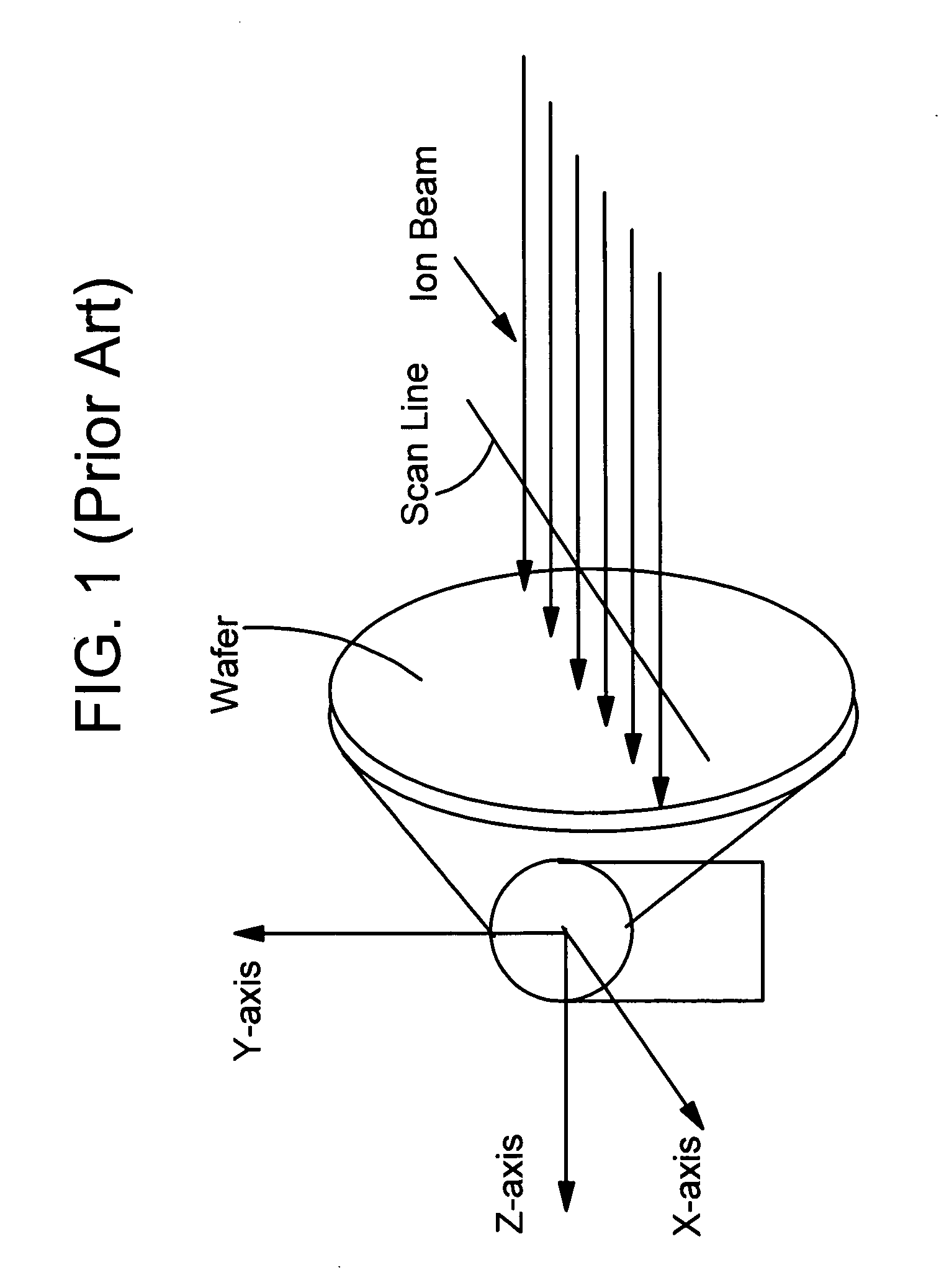

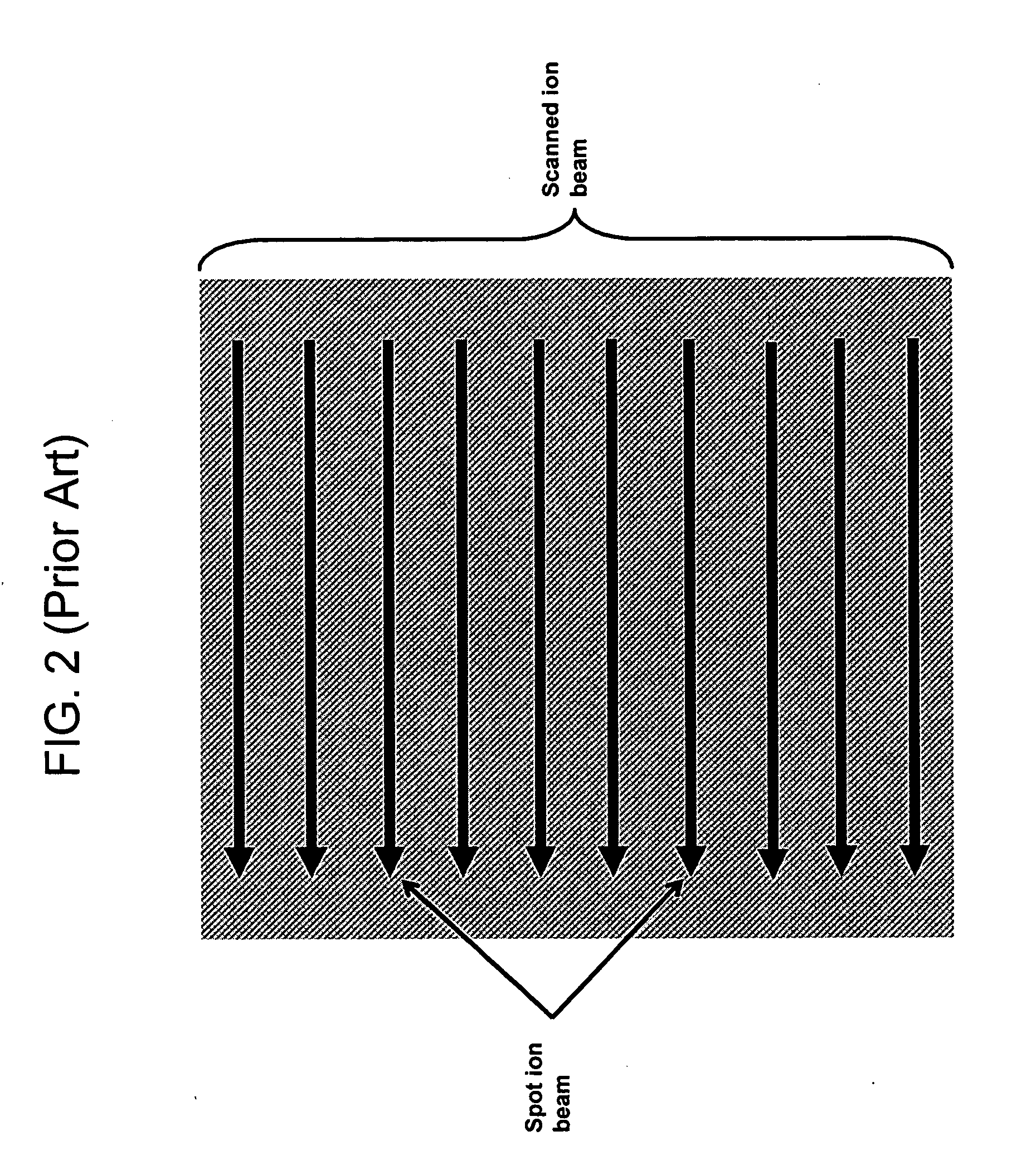

A method and apparatus for gas cluster ion beam (GCIB) processing uses X-Y scanning of the workpiece relative to the GCIB. A neutralizer reduces surface charging of the workpiece by the GCIB. A single Faraday cup sensor is used to measure the GCIB current for dosimetry and scanning control and also to measure and control the degree of surface charging that may be induced in the workpiece during processing.

Owner:TEL EPION

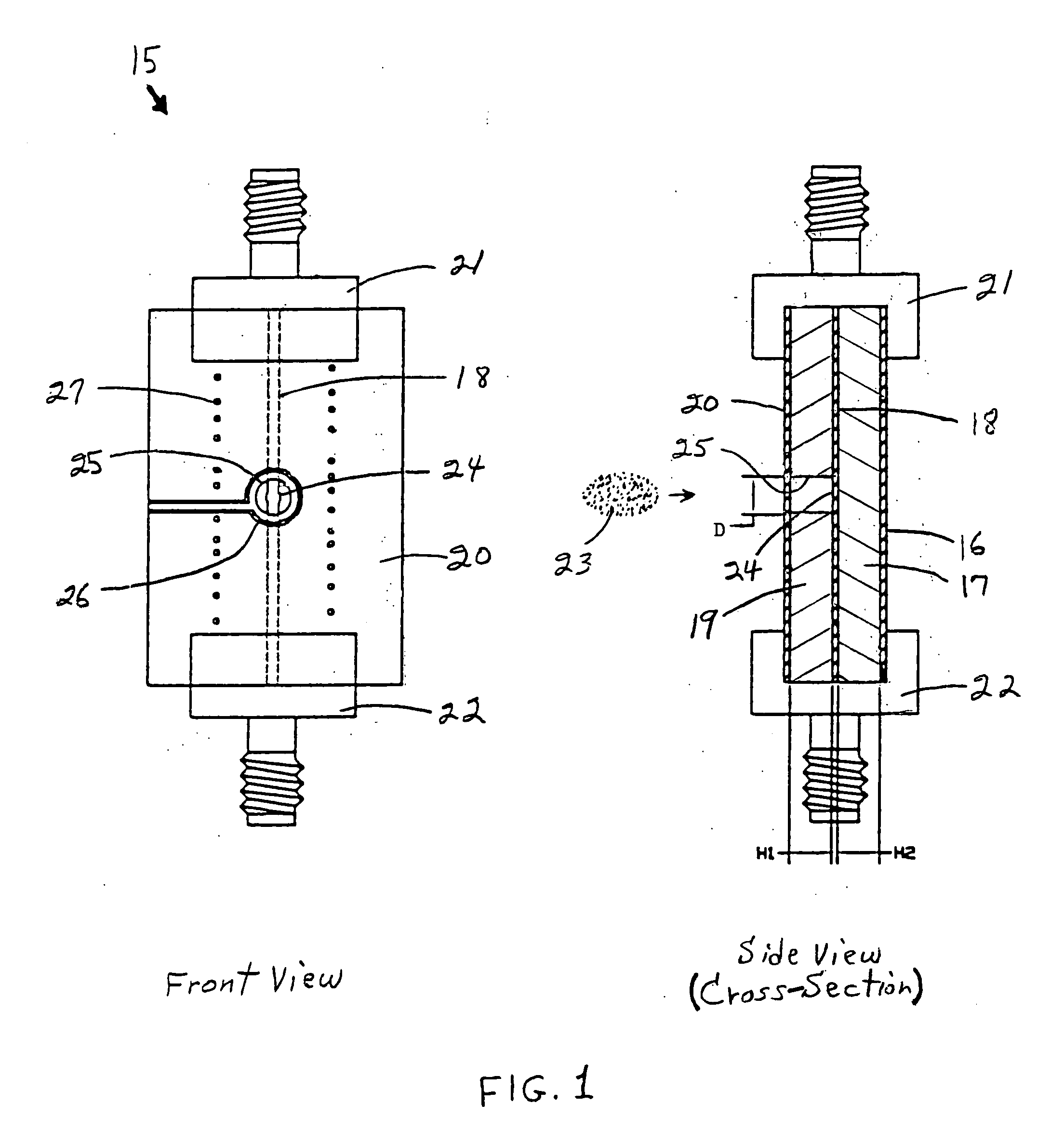

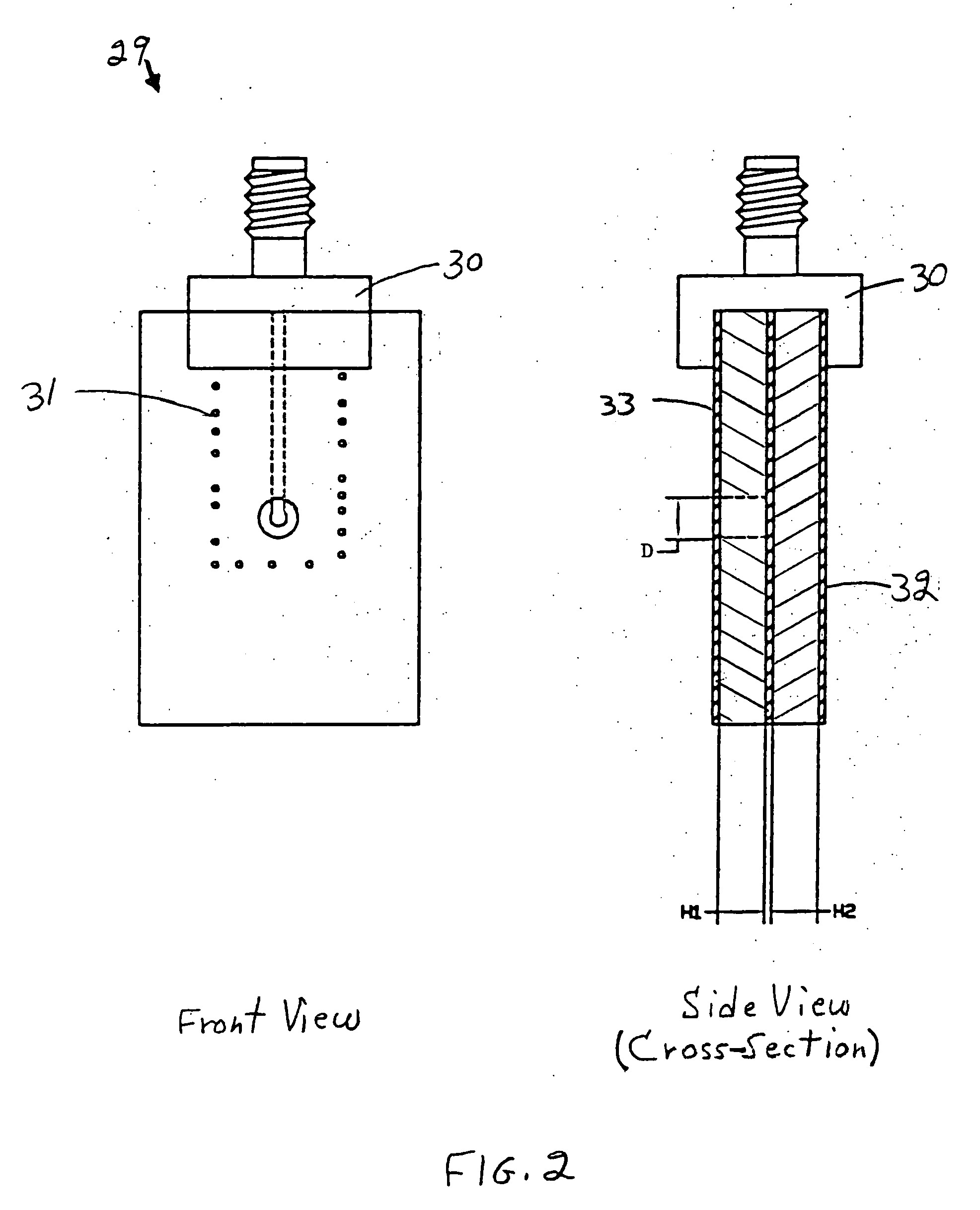

Fast faraday cup with high bandwidth

InactiveUS20050212503A1High bandwidthGood dispersionThermometer detailsBeam/ray focussing/reflecting arrangementsTime structureHigh bandwidth

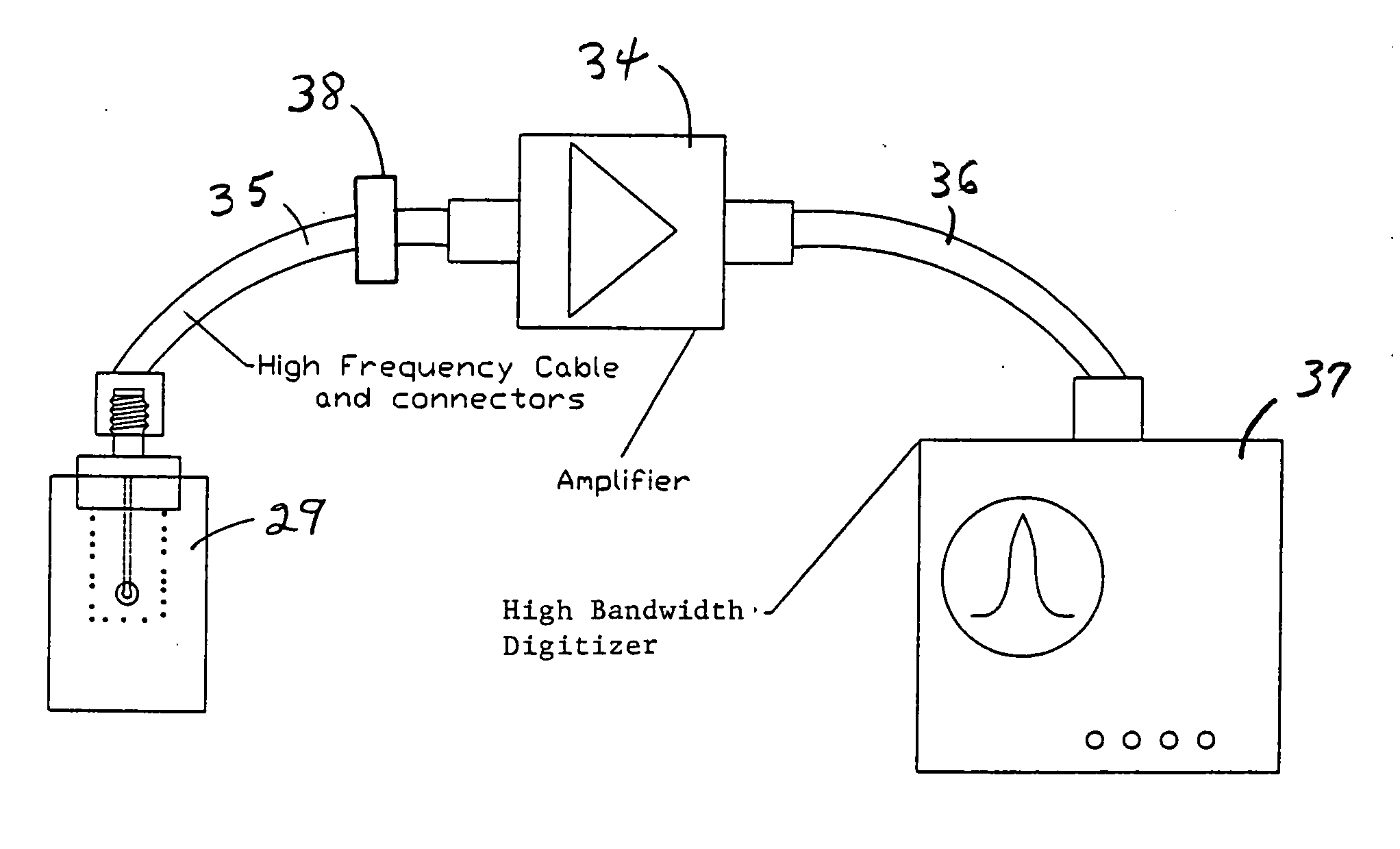

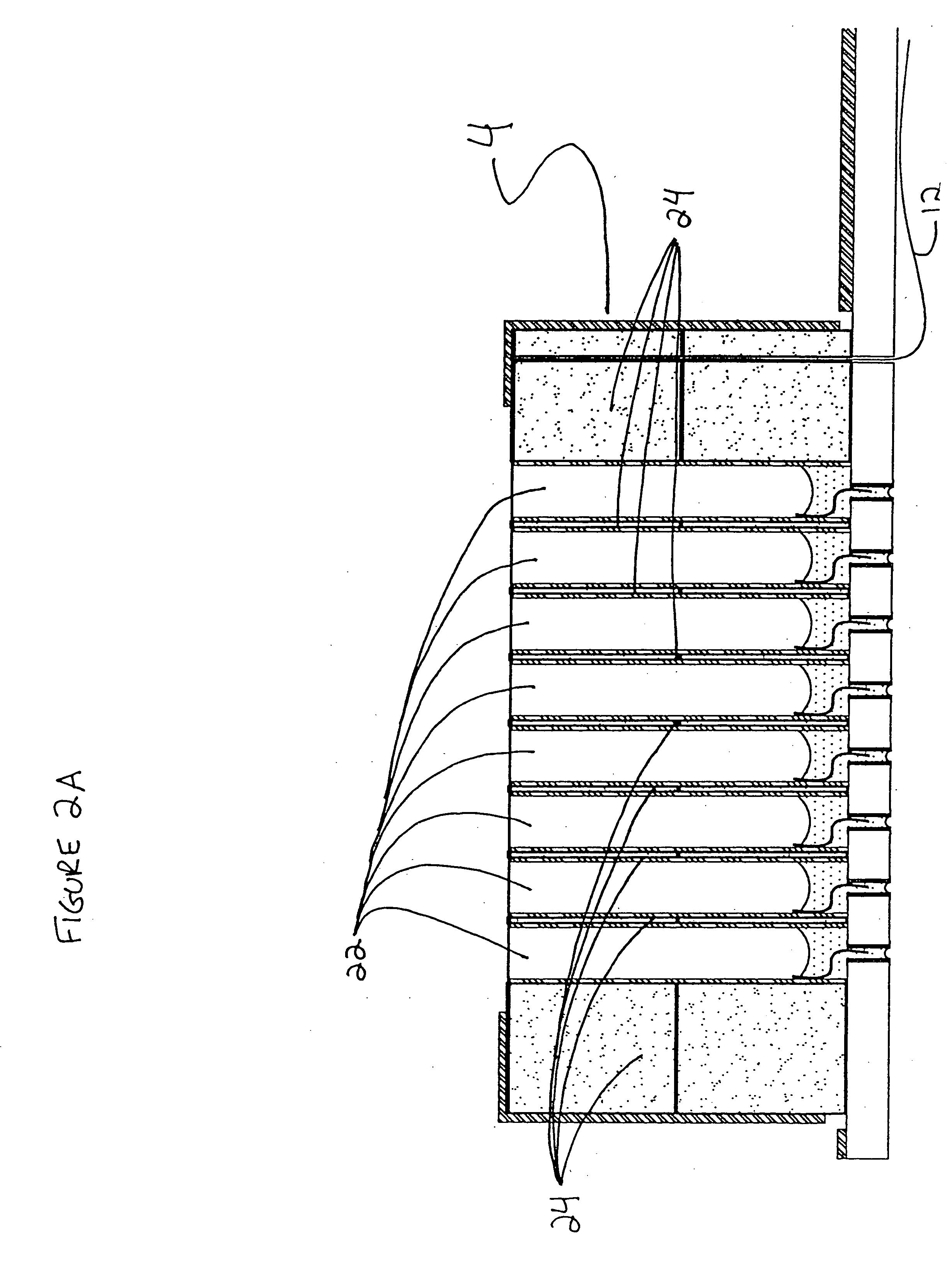

A circuit card stripline Fast Faraday cup quantitatively measures the picosecond time structure of a charged particle beam. The stripline configuration maintains signal integrity, and stitching of the stripline increases the bandwidth. A calibration procedure ensures the measurement of the absolute charge and time structure of the charged particle beam.

Owner:UT BATTELLE LLC

Electrostatic sensing experimental system and particle frictional charge measuring method

ActiveCN102608440ASimple structureEasy to operateCurrent/voltage measurementLiquid mediumElectrical connection

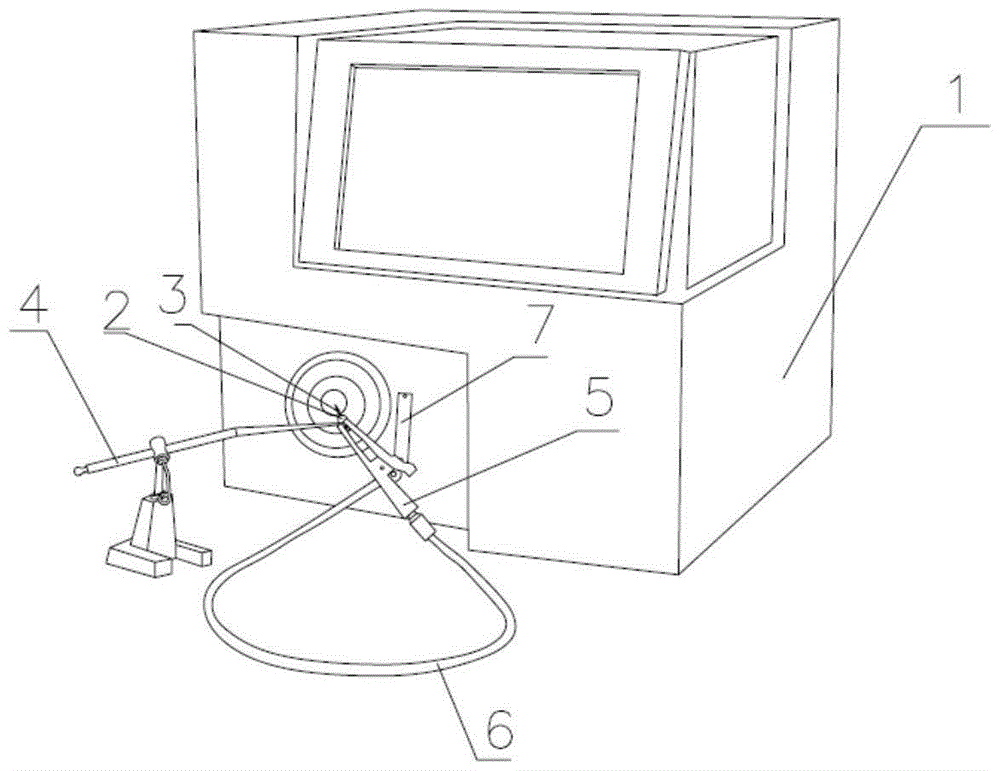

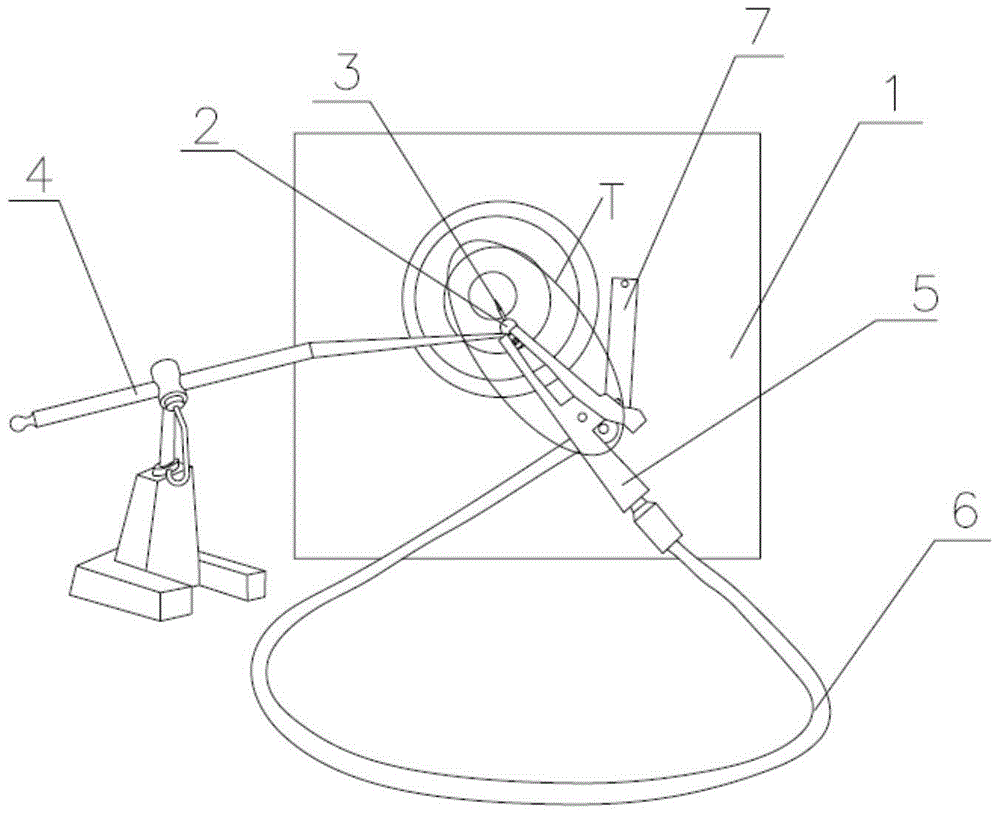

The invention discloses an electrostatic sensing experimental system, which comprises a charged particle generating device and a charged particle static voltage measuring device. The charged particle generating device comprises a frictional contact tube made of insulating material and a contact tube cover. The charged particle static voltage measuring device comprises a Faraday cup and an induced voltage measuring unit, wherein the induced voltage measuring unit is electrically connected with an inner cup of the Faraday cup and insulated to an outer cup of the Faraday cup. The Faraday cup is provided with a coaxial through hole in the vertical direction. The experimental system further comprises a charged particle injection experimental apparatus. The invention further discloses a particle frictional charge measuring method, an induced voltage measuring method for charged particles in liquid medium, and an electrostatic sensor calibrating method. The electrostatic sensing experimental system is simple in structure and convenient in operation, can be used for various experiments according to actual situation, and has certain electromagnetic interference resistance, accuracy in measuring result and high sensitivity.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

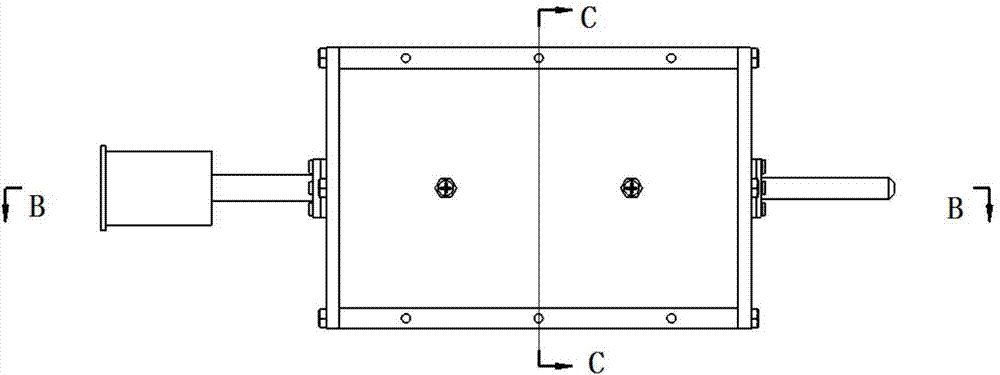

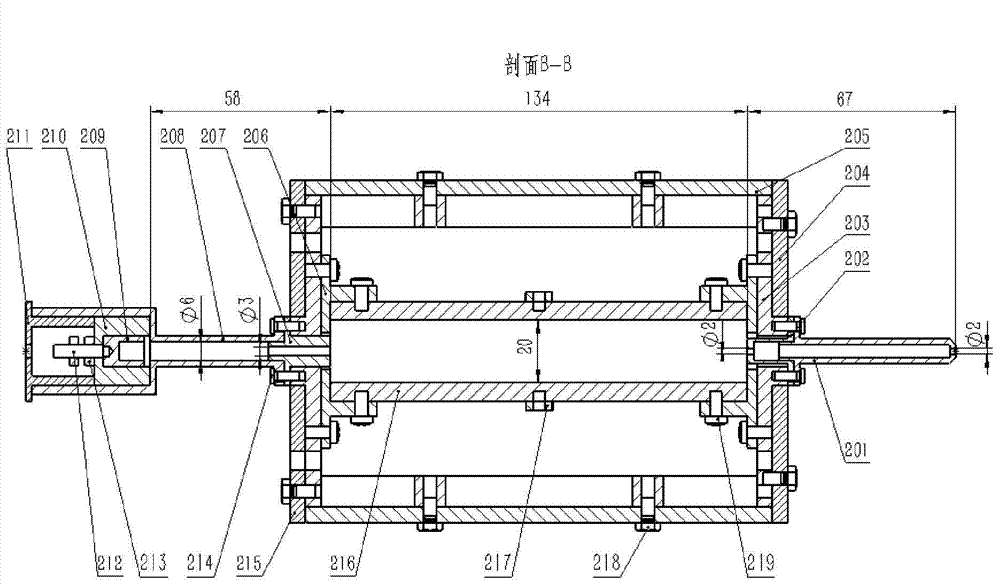

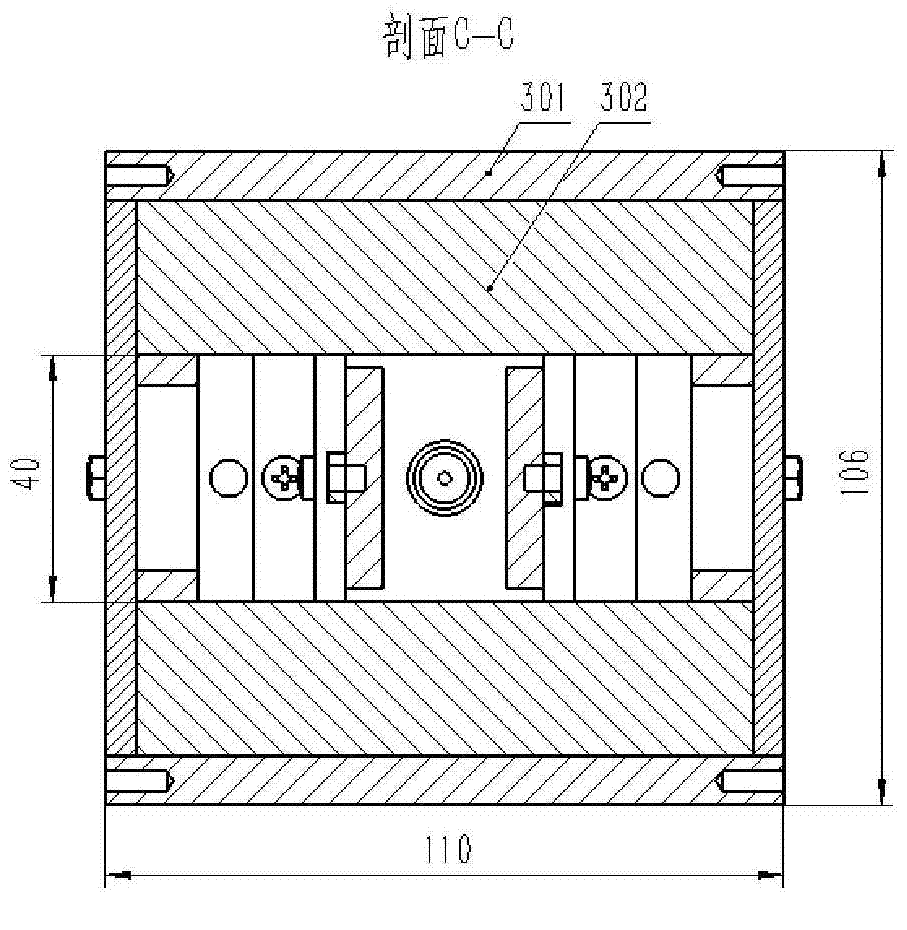

Near-field plume mass-spectroscopic diagnostic E*B probe based on Faraday cup

InactiveCN104730066AGuaranteed OrthogonalityGuaranteed collimationAnalysis by thermal excitationMass spectrometryDrift tube

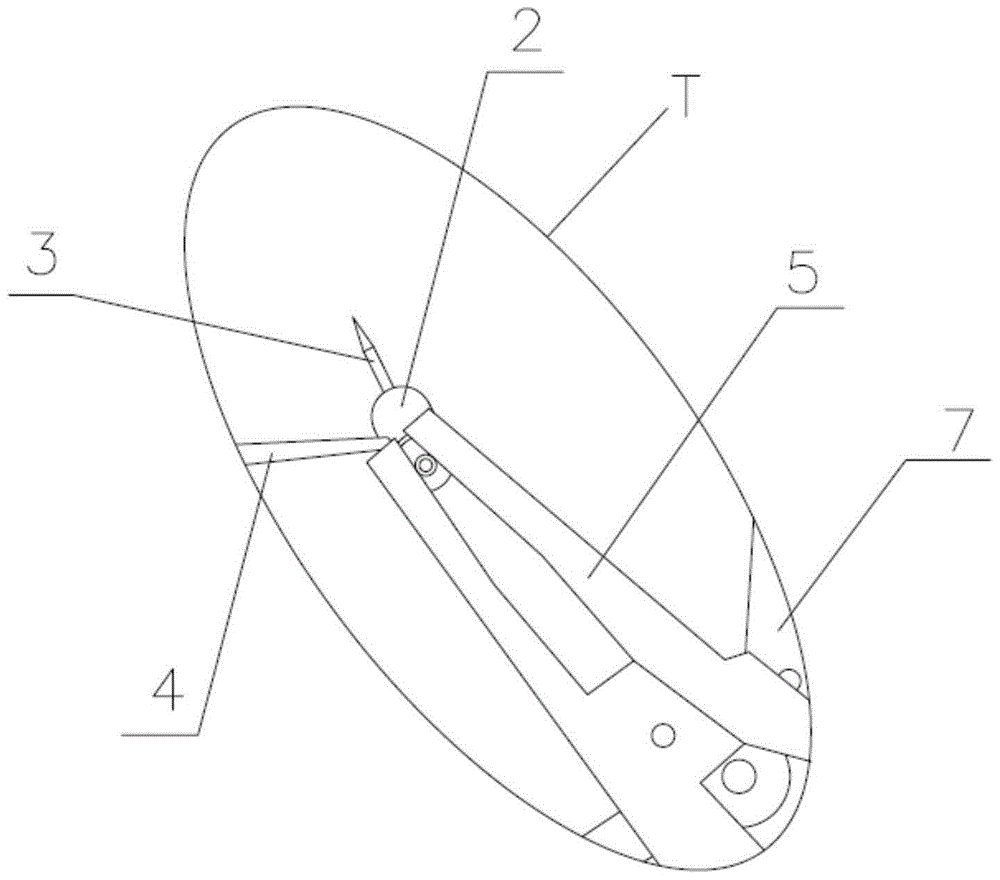

The invention discloses a near-field plume mass-spectroscopic diagnostic E*B probe based on the Faraday cup and belongs to the technical field of plasma mass-spectroscopic diagnosis. The probe mainly applied to measuring near-field plumes of an ion thruster and of a Hall thruster comprises a central frame, ferrite permanent magnets, a flat electrode plate, an electrode plate holder, a collimator tube, a drift tube, a Faraday cup, six carbon steel shells and an anti-sputtering heat-insulating layer. According to the connectional relation, the central frame is used as a core part, the ferrite permanent magnets are distributed on upper and lower surfaces of the central frame, the electrode plate is fixed in the central frame, and an orthogonal electromagnetic field area is formed. The six carbon steel shells are used for packaging, and the front ends of the shells are coated with an anti-sputtering heat-insulating layer. The collimator tube of stainless steel and the drift tube are fitly fixed to the centers of two ends of the central frame through shaft holes. Ions different in valence are screened by adjusting voltage among the electrode plates, univalent and bivalent ion currents are acquired with the Faraday cup of aluminum, and the ratio of near-field plum bivalent ions is acquired by analytical computing.

Owner:BEIHANG UNIV

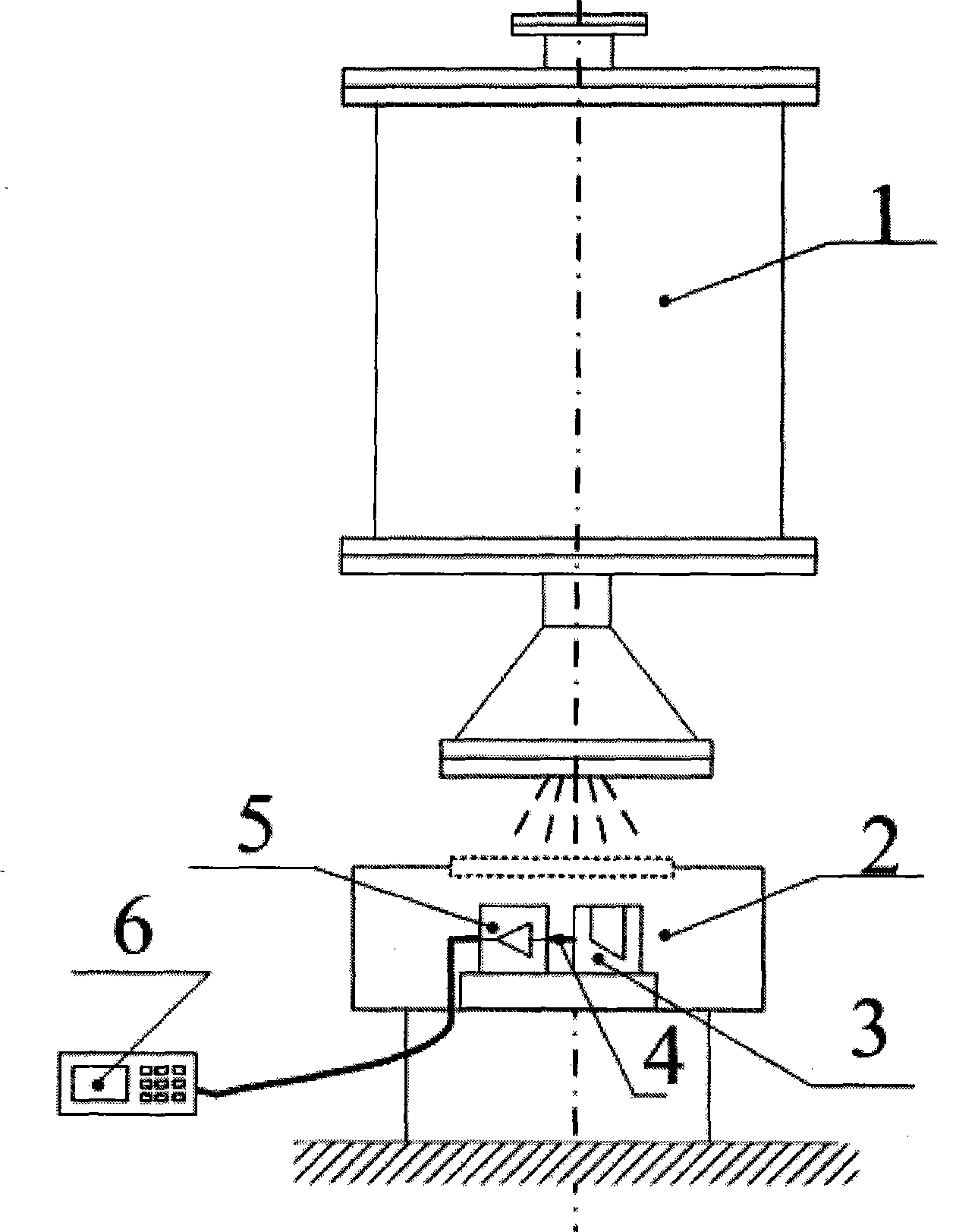

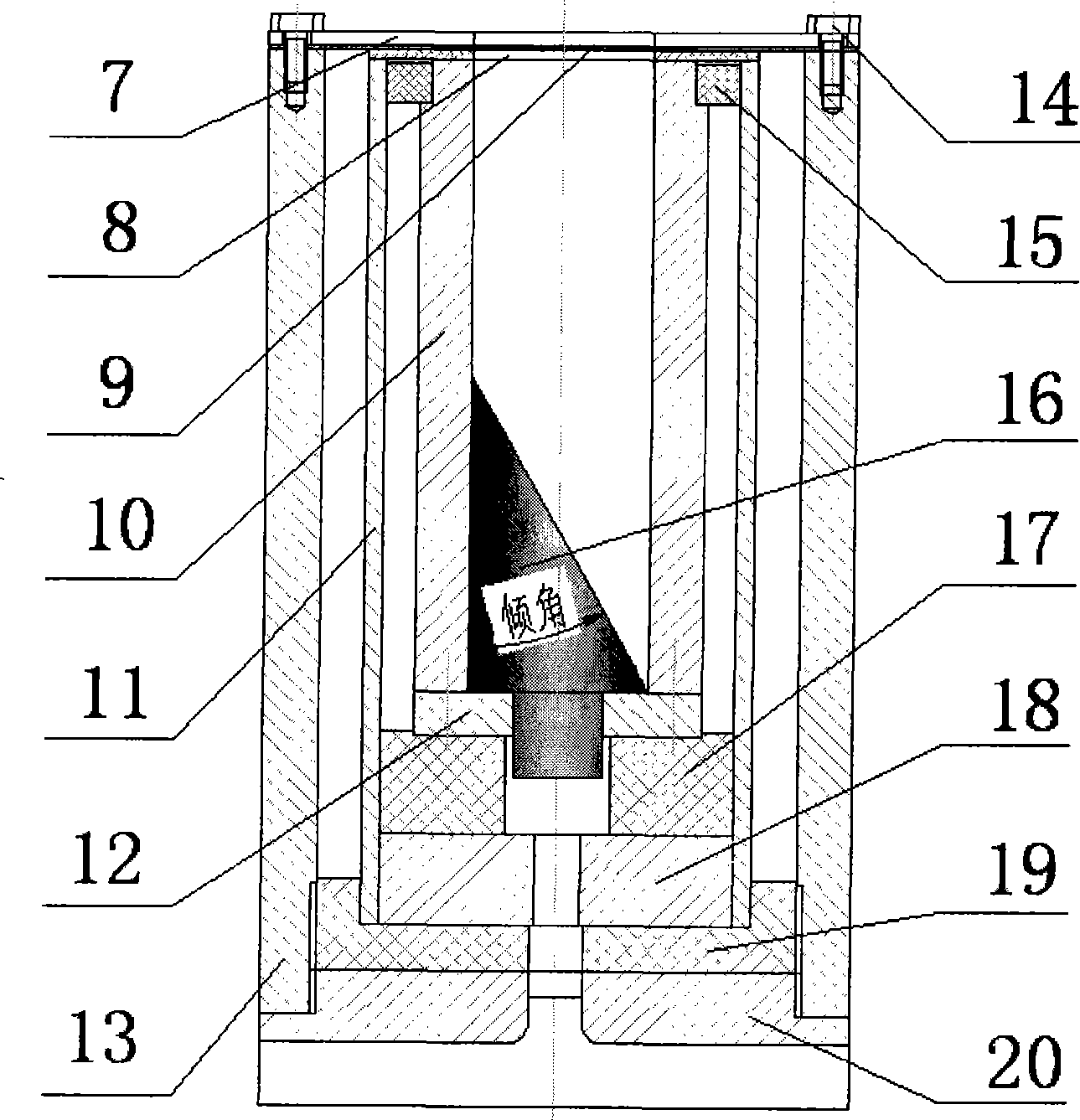

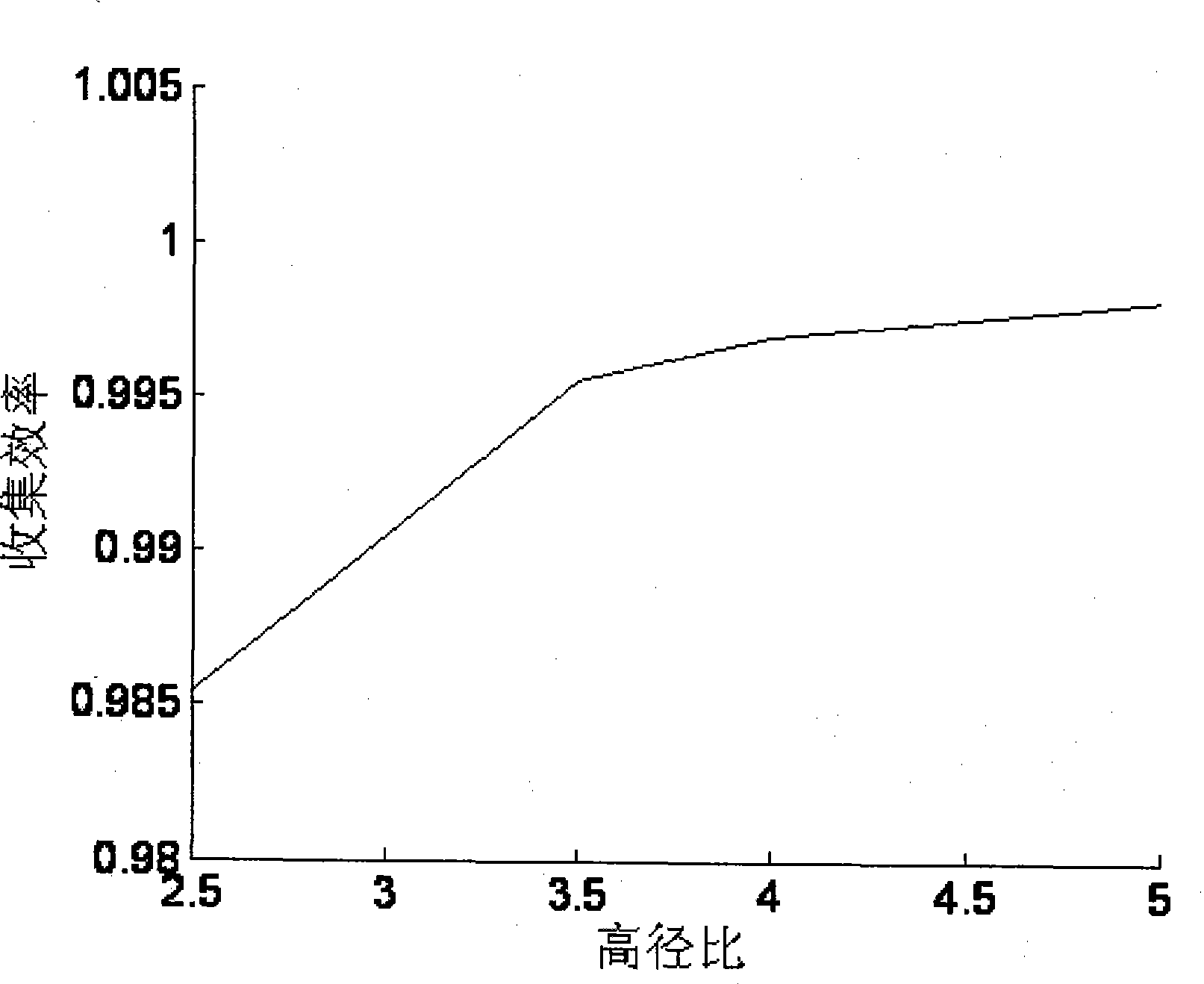

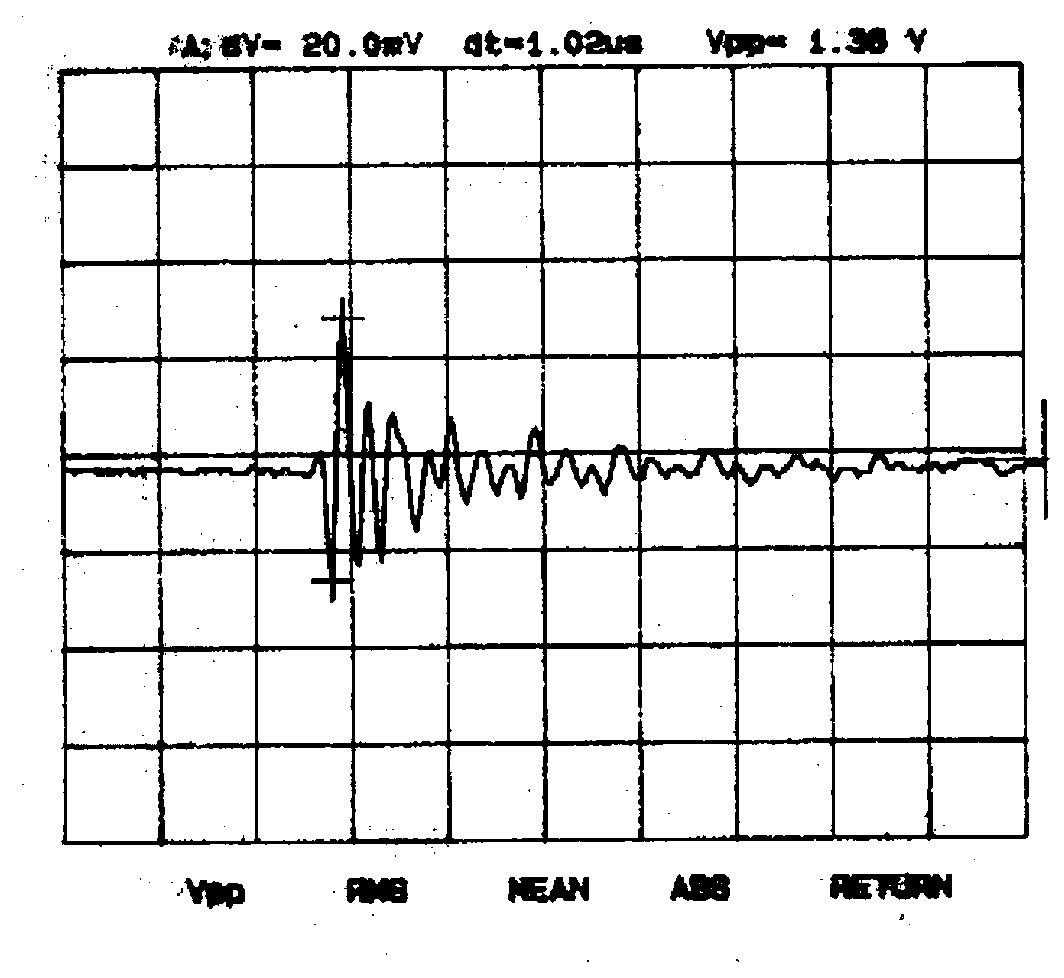

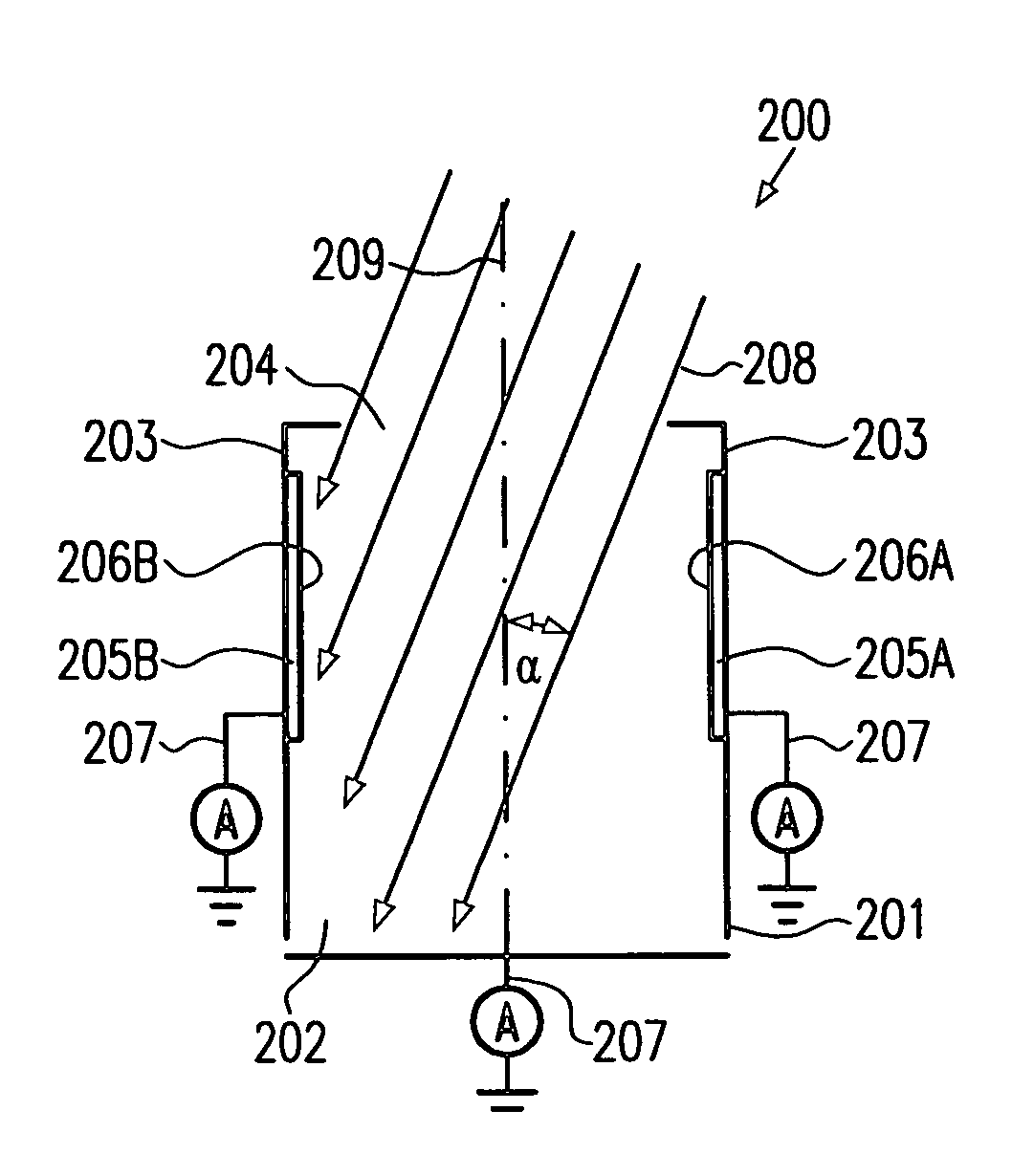

Measuring system for nA/pA electronic beam current of impulse electron accelerator

InactiveCN101470208ASolve the collection efficiency problemSolve beam measurement problemsX/gamma/cosmic radiation measurmentHigh energyElectron radiation

The invention relates to a pulse electronic accelerator nano-pico ampere electron beam flow measuring system, relating to an electronic accelerator pulse electron beam flow measuring system, in particular to the nano-pico (10-10A / cm2) micro beam flow measurement of millisecond pulse, belonging to the electron radiation environment ground simulation and test field. The pulse electronic accelerator nano-pico ampere electron beam flow measuring system is composed of a novel inclined-bottom faraday cup, three coaxial cables and a nano-pico level current amplifier. The measurement result can be obtained by oscilloscope or data acquisition card. The inclined-bottom faraday cup electron collection system resolves the collection efficiency problem of high energy electrons (MeV), to improve collection efficiency. The adopted three coaxial cables can reduce the interference of electromagnetic field. The nano-pico ampere level current amplifier resolves the stable current linear amplification problem under electron radiation, and converts weak current signals to voltage signals, thus being convenient for data acquisition of oscilloscope or data acquisition card. The invention resolves the measurement problem of nano-pico ampere pulse electron beam flow, to confirm the accuracy, real-time property and easy use of measurement.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

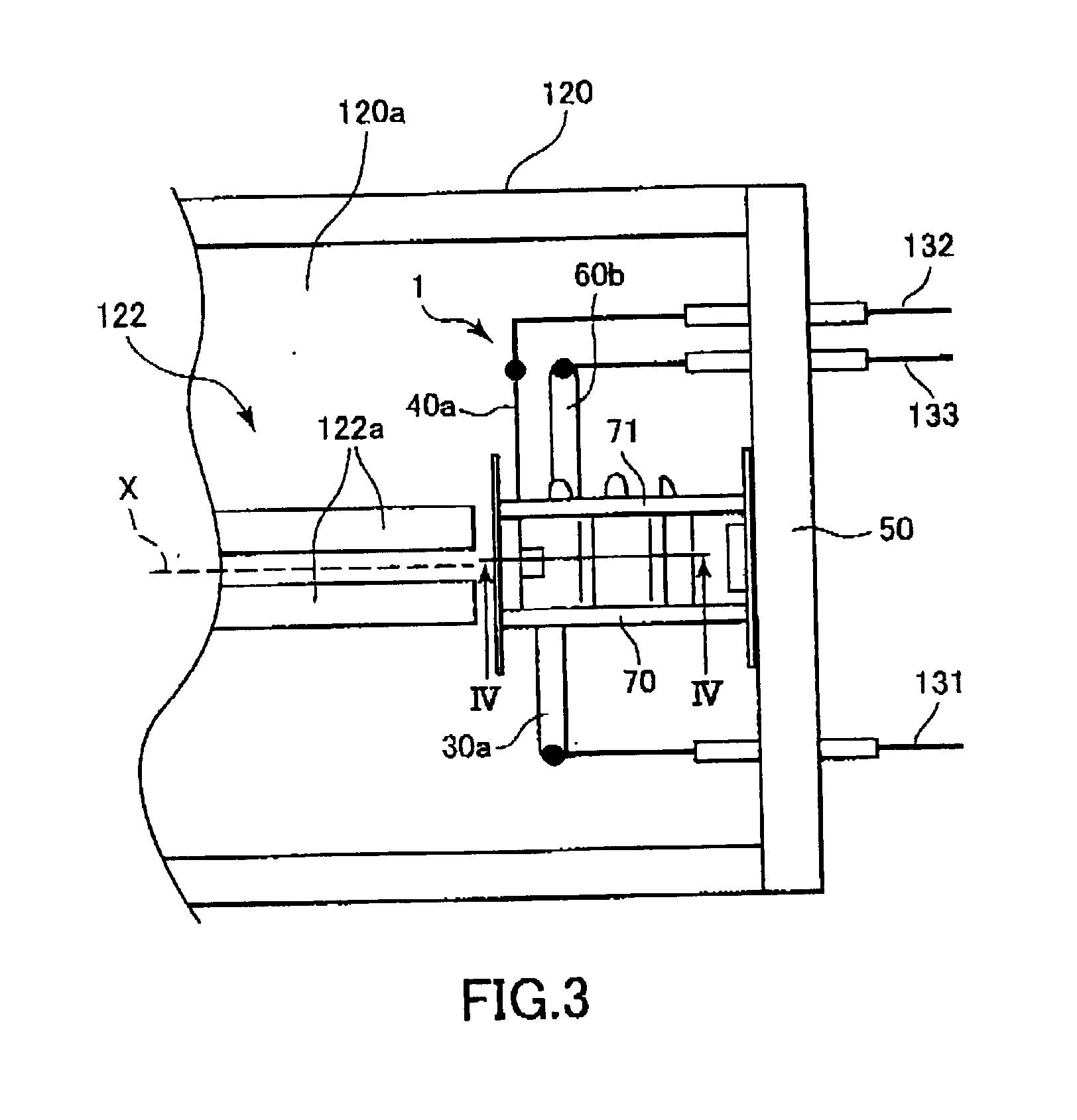

Apparatus for ion beam fabrication

ActiveUS20080283778A1Stable operation of apparatusIncrease productionMaterial analysis using wave/particle radiationElectric discharge tubesAtomic physicsFaraday cup

The apparatus for ion beam fabrication, which has been able to detect any anomalous condition of ion beams only by means of the current irradiated on the specimen, could not compensate the failure by investigating the cause and could not realize stable processing. To solve the problem described above, the present invention includes the first and second blankers and Faraday cups switches ON and OFF the first and second blankers and monitors beam current at two positions above and below the projection mask. By adopting this configuration, it will be possible to acquire the information on failure in ion beam, sort out the cause of the failure and to compensate the failure while limiting damages to the projection mask. As a result, it will be possible to realize stable processing by means of ion beam, and to use the ion beam fabricating device on a stable basis.

Owner:HITACHI HIGH-TECH CORP

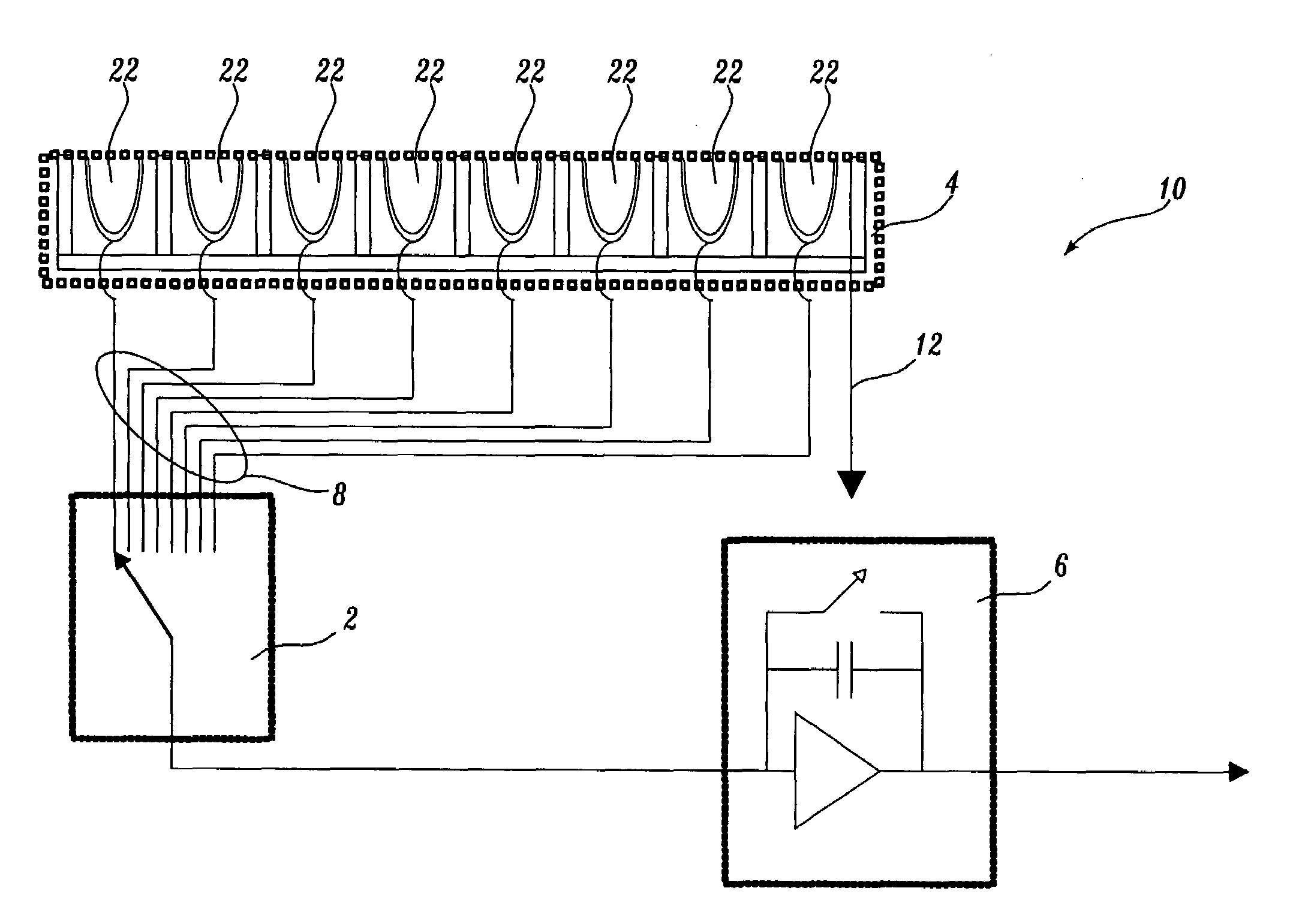

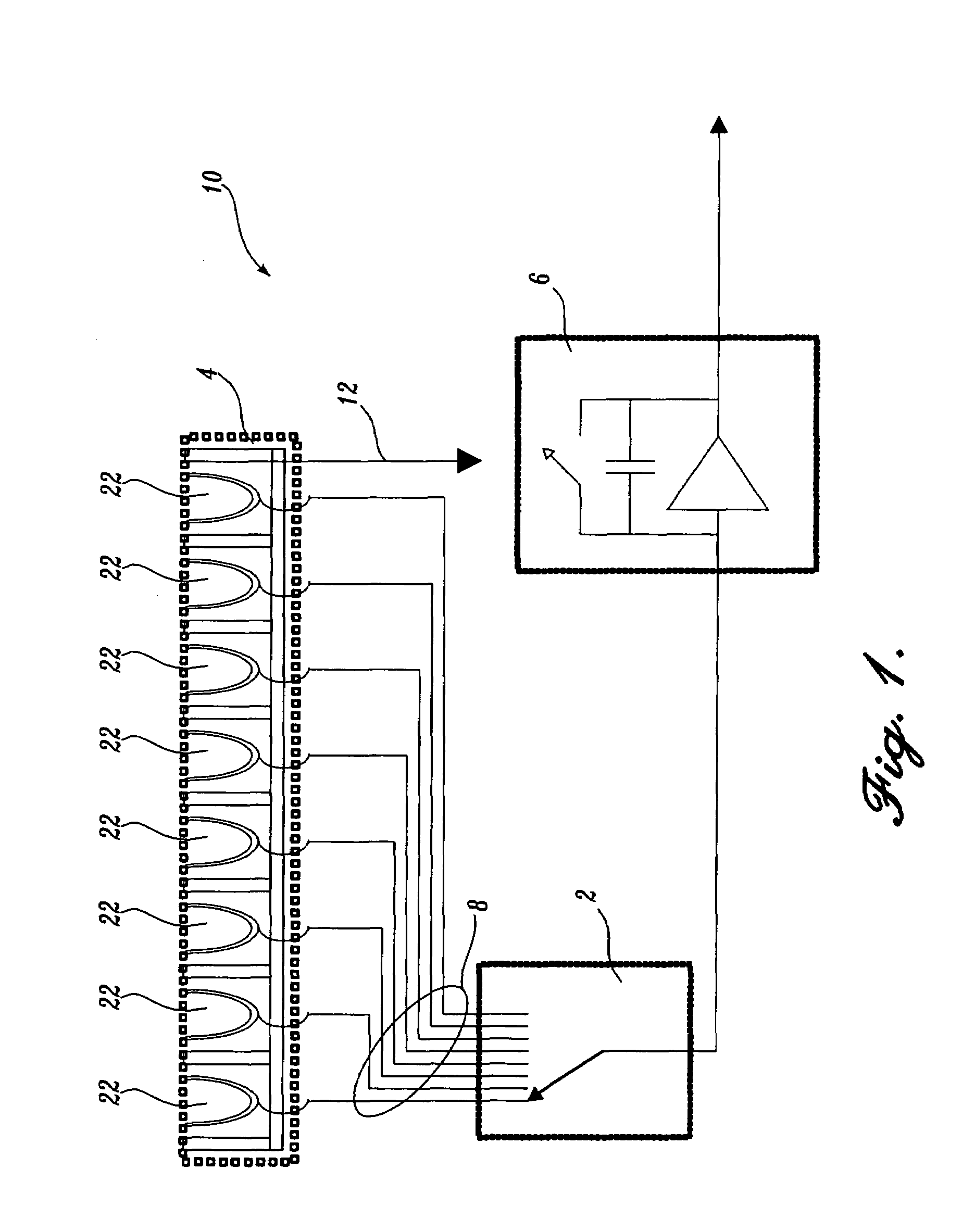

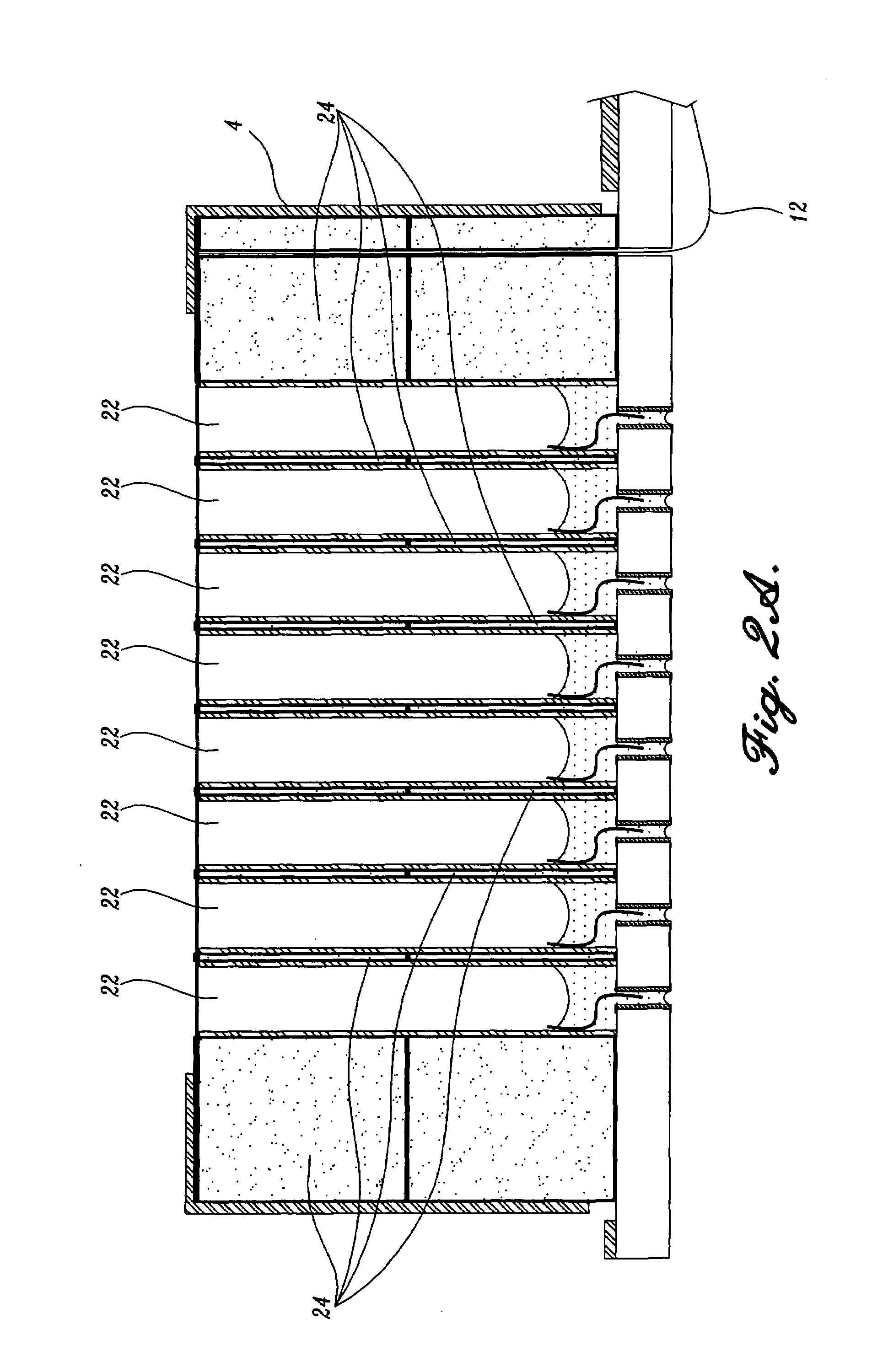

Charged particle beam detection system

InactiveUS20050274888A1Improve the level ofEasy to useSpectrometer detectorsMaterial analysis by electric/magnetic meansIntegratorDetector array

A charged particle beam detection system that includes a Faraday cup detector array (FCDA) for position-sensitive charged particle beam detection is described. The FCDA is combined with an electronic multiplexing unit (MUX) that allows collecting and integrating the charge deposited in the array, and simultaneously reading out the same. The duty cycle for collecting the ions is greater than 98%. This multiplexing is achieved by collecting the charge with a large number of small and electronically decoupled Faraday cups. Because Faraday cups collect the charge independent of their charge state, each cup is both a collector and an integrator. The ability of the Faraday cup to integrate the charge, in combination with the electronic multiplexing unit, which reads out and empties the cups quickly compared to the charge integration time, provides the almost perfect duty cycle for this position-sensitive charged particle detector. The device measures further absolute ion currents, has a wide dynamic range from 1.7 pA to 1.2 μA with a crosstalk of less than 750:1. The integration of the electronic multiplexing unit with the FCDA further allows reducing the number of feedthroughs that are needed to operate the detector.

Owner:UNIV OF WASHINGTON

Method for rapidly screening 40 prohibited antibiotics in cosmetics

ActiveCN105181784AGuaranteed accuracyAchieve ionizationMaterial analysis by electric/magnetic meansDrift tubeAntibiotic Y

The invention discloses a method for rapidly screening 40 prohibited antibiotics in cosmetics. The method comprises the following steps: (1) manufacturing an in-situ spray ionization device: producing a borosilicate glass capillary and assembling an in-situ spray ionization device; (2) ion mobility spectrometry detection: dipping a metal micro electrode into a cosmetic sample, then inserting the metal micro electrode into a borosilicate glass capillary, which is filled with methanol in advance, placing the capillary on the front end of the electrospray ionization (ESI) injection port of an ion mobility spectrometry instrument, setting the parameters of the ion mobility spectrometry instrument, ionizing the sample, separating the ionized sample in a drift tube, detecting the sample by a Faraday cup detector to obtain a corresponding experiment map. If the sample detected by the ion mobility spectrometry contains prohibited antibiotics, the sample can be further detected by high performance liquid chromatography-mass spectrum (HPLC-MS) or mass spectrum. The provided method is accurate and reliable, on the basis that the detected data is precise, the detection cost is largely reduced, and the detection efficiency is improved.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

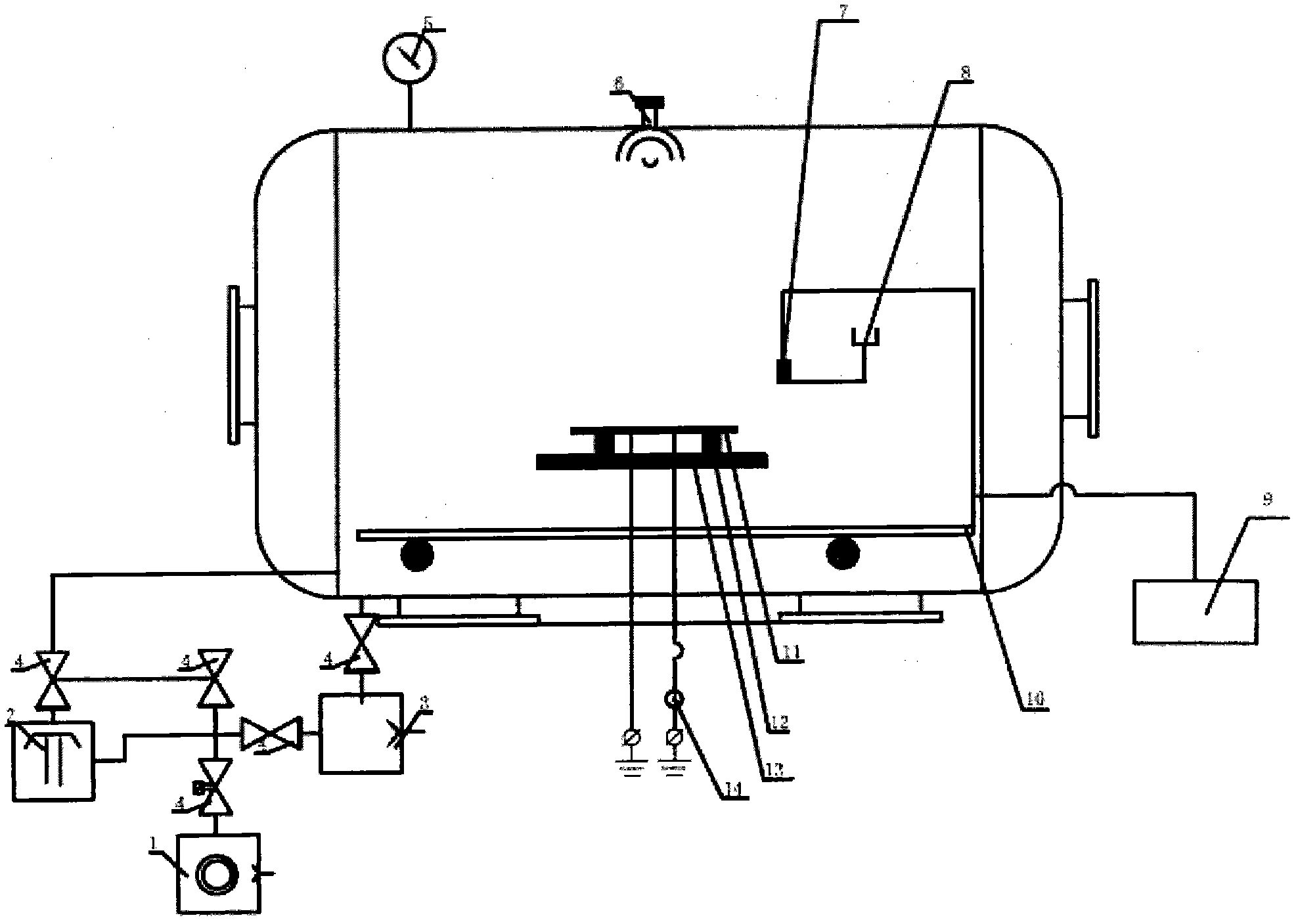

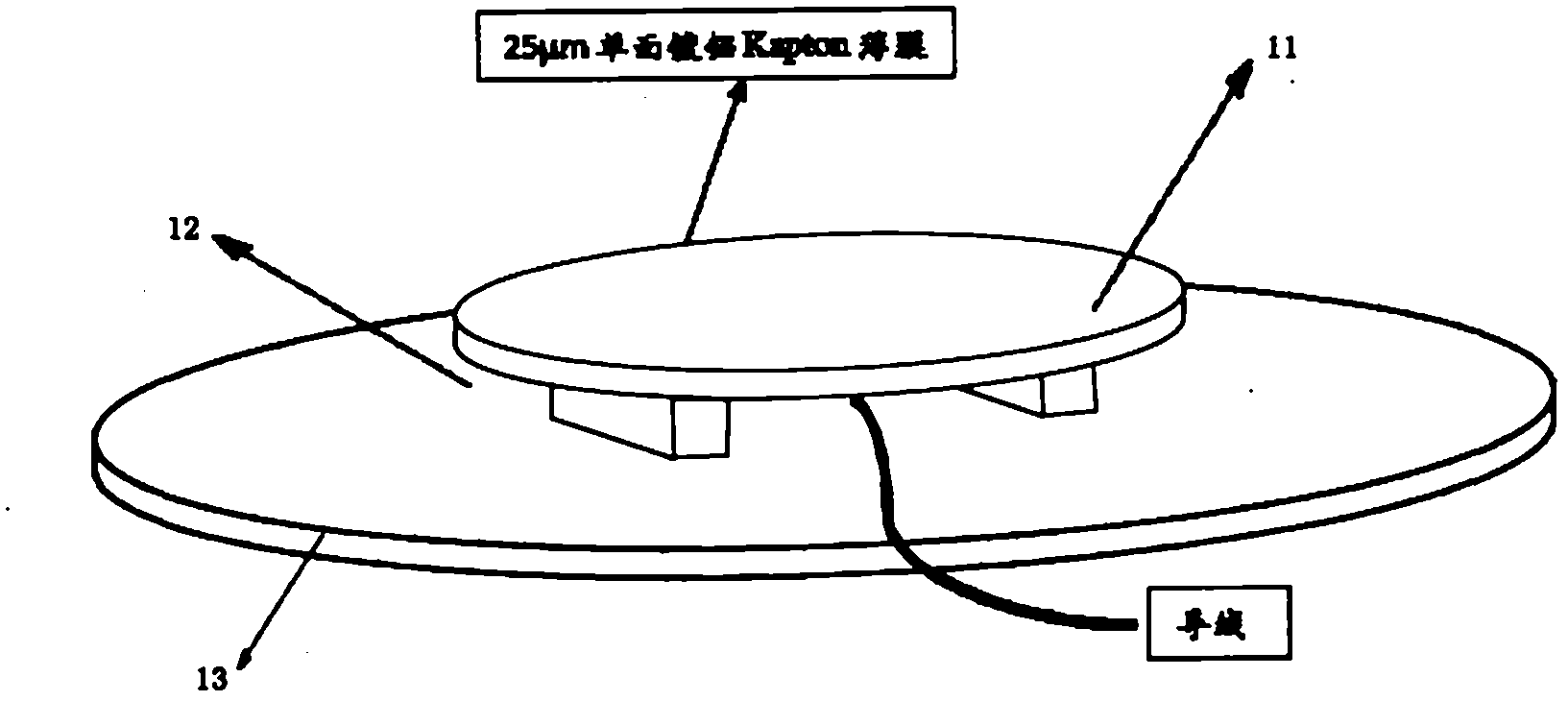

Method for testing conductivity of medium material

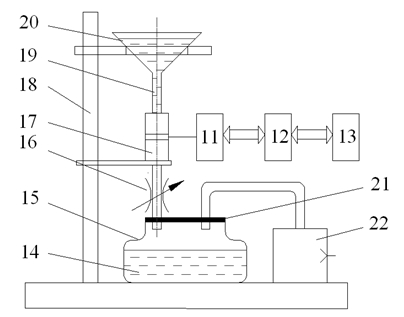

ActiveCN102128985AFacilitated releaseImprove test automationResistance/reactance/impedenceEngineeringMechanical engineering

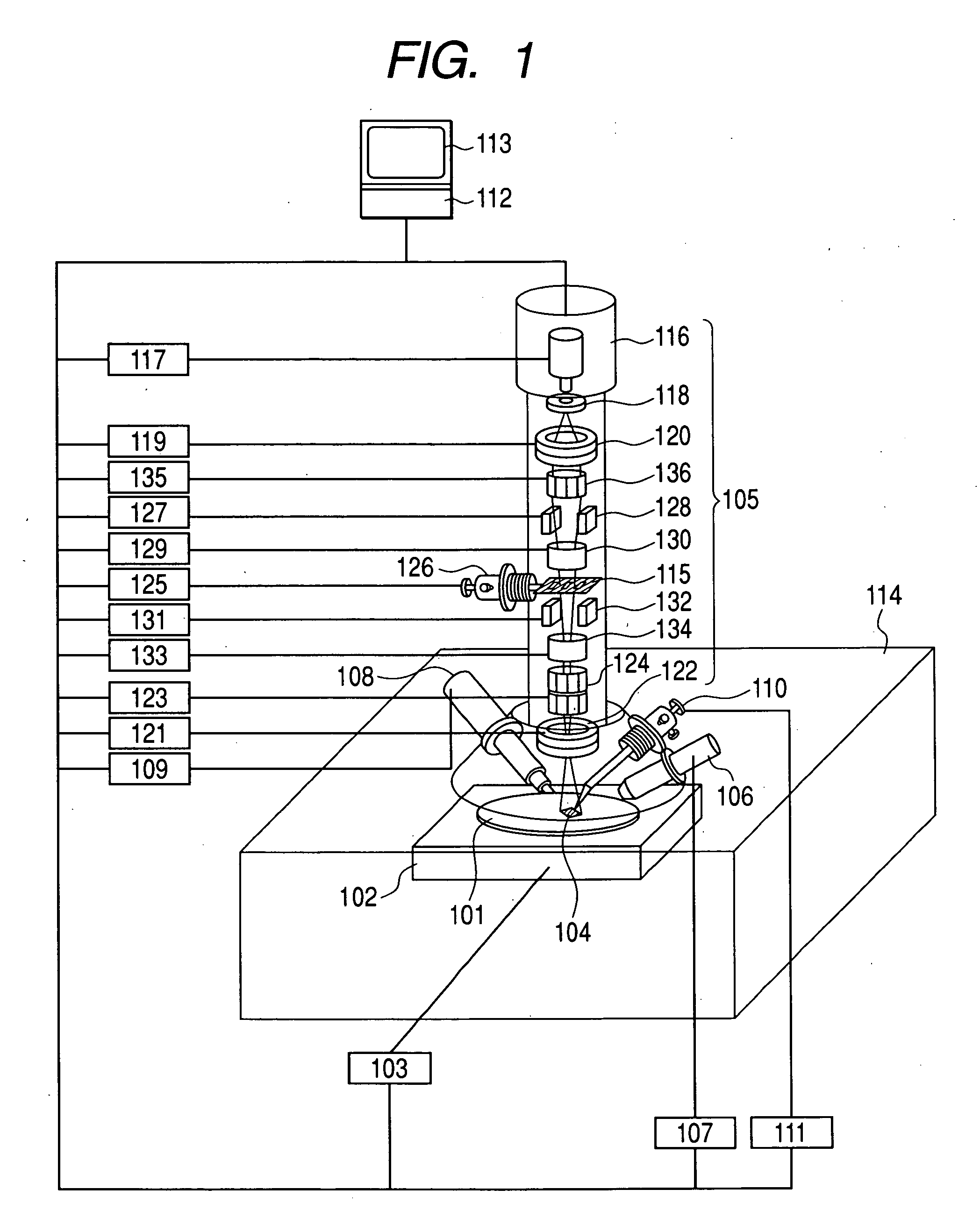

The invention discloses a method for testing conductivity of medium material, wherein the method comprises the following steps of: positioning an electric potential probe at a zero electric potential position above a sample after the preparation before testing is finished; confirming the placing position of the sample, confirming the position coordinate of an electric potential measuring point bya probe driving mechanism, then closing a vacuum jar, turning on the power of an electric gun, and performing electronic irradiation to the sample via a Faraday cut test; quickly descending an electric potential meter probe to the front surface of the sample every 10 minutes to perform inducted non-contact measurement, wherein the data measured by a micro galvanometer and the electric potential probe is waved between negative 0.5% and positive 0.5%, then the charge of the sample is regarded as saturation; turning off the electric gun, attenuating the similar process via a tapping index form in the sample interior electric charge Q and measuring the electric potential decay process of the sample; in a word, the attenuation relationship of the surface electric potential of the sample along time is measured by a surface electric potential probe, and the conductivity of the sample can be calculated according to the sample surface attenuated electric potential at different time. The conductivity testing equipment in the invention can be applied to hazard assessment of deep charging, and also can provide valuable engineering data for the protection of deep charging or discharging.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

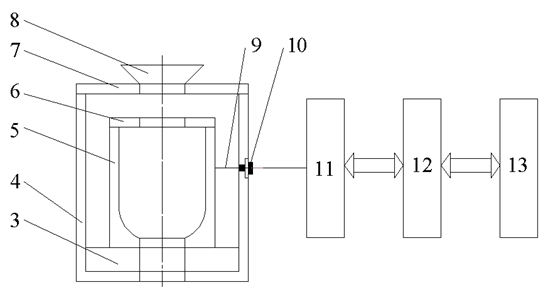

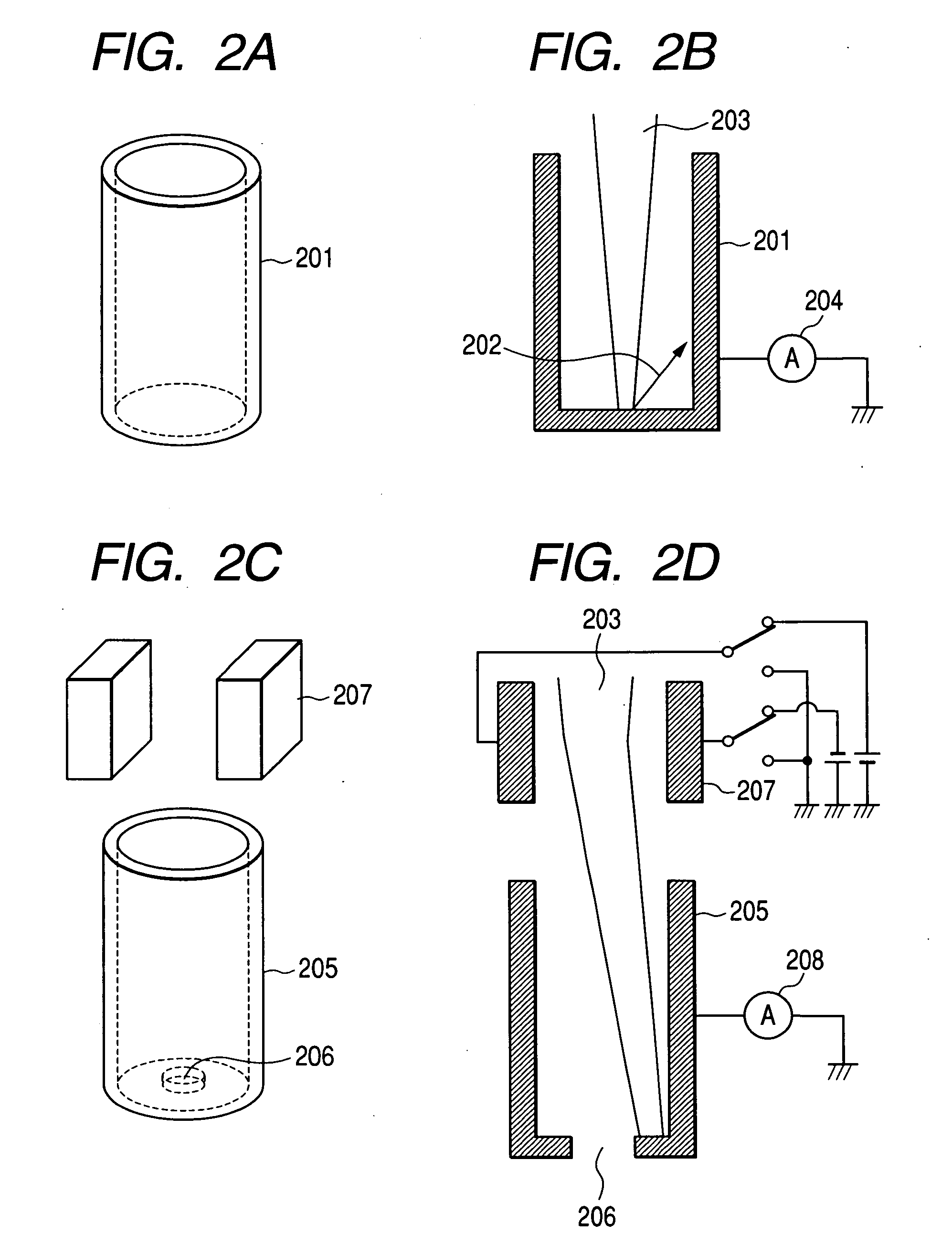

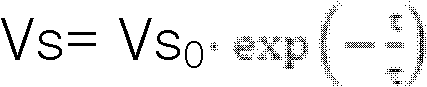

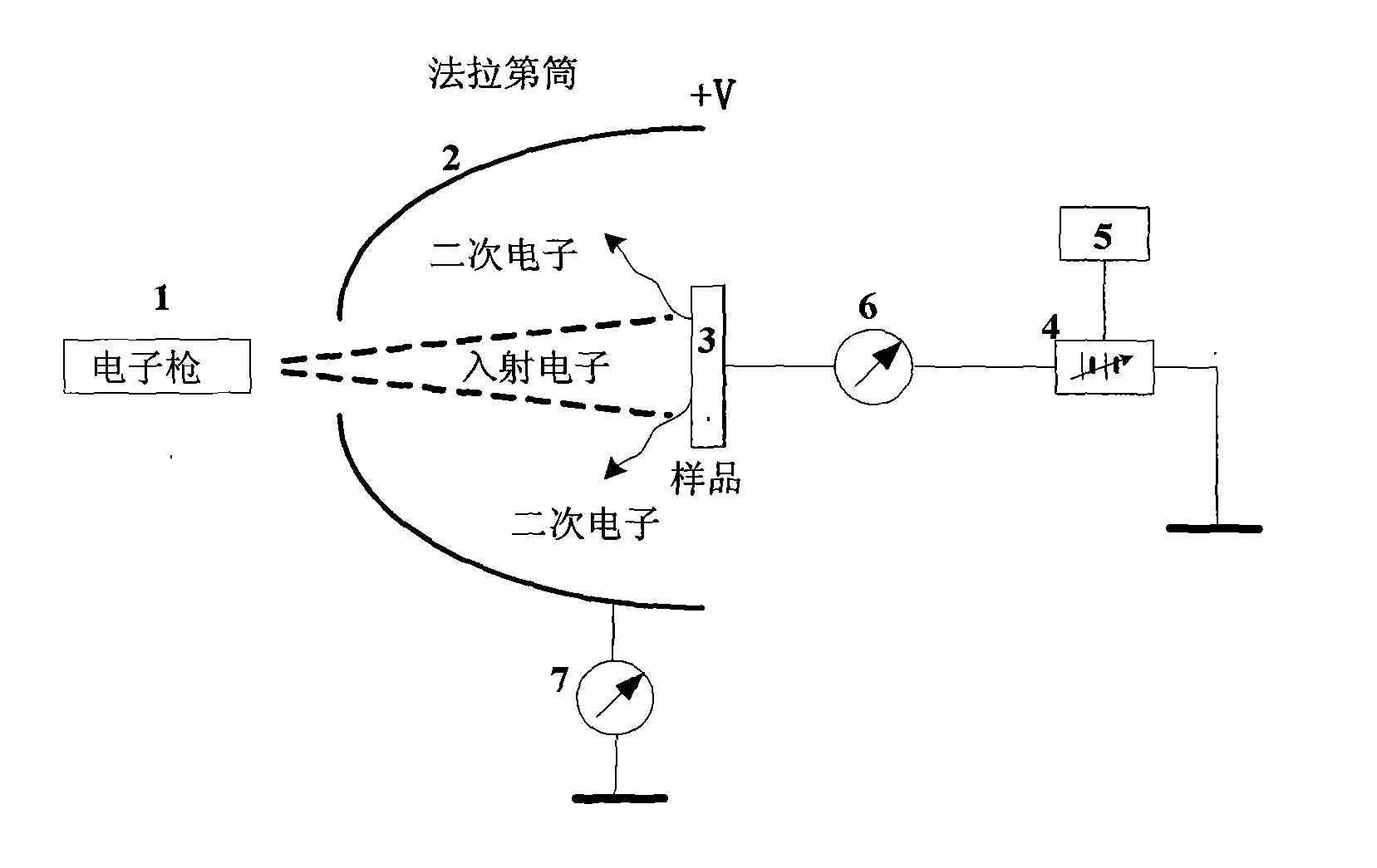

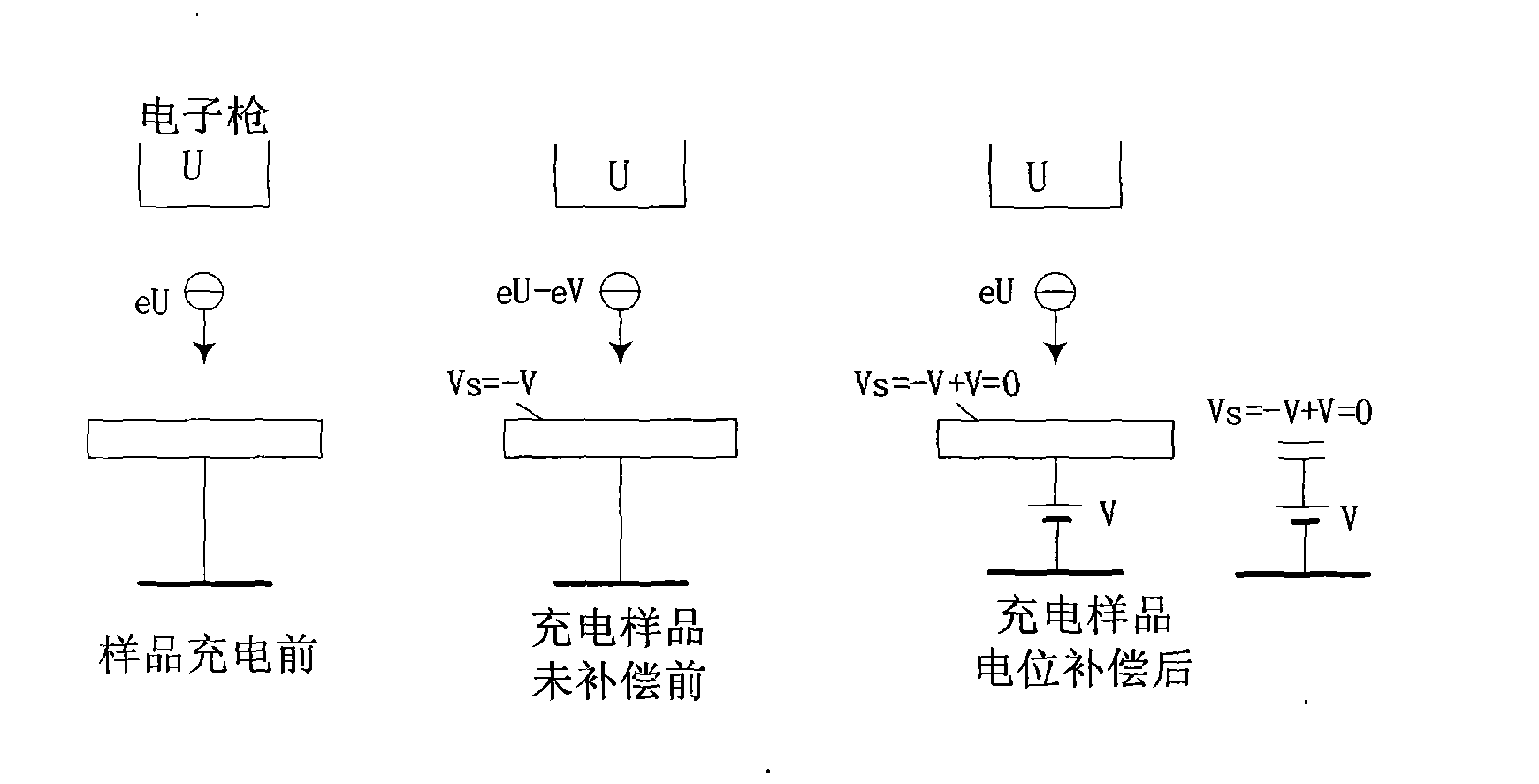

Measurement system and measurement method of secondary electron emission yield of dielectric material

InactiveCN102706914ASimple measurement systemSimple methodMaterial analysis by measuring secondary emissionObservational errorSecondary electrons

The invention discloses a measurement system and a measurement method of a secondary electron emission yield of dielectric material. The measurement system comprises a Faraday cup and a pulse electron gun, wherein an incident beam generated by the pulse electron gun outside the Faraday cup irradiates on a sample through an electronic entrance port on a tube, and an automatic voltage regulator circuit is electrically connected between a sample back electrode and an earth wire, so that the level on the sample surface is kept constant relative to a potential difference between the electron guns. The voltage regulating range of the voltage adjustor circuit is controlled by a feedback control circuit in real time, so as to ensure that charging potential of the sample is compensated in real time, and current probes for measuring net collection current and secondary electron current are respectively connected between the sample and a voltage controlled power source of the voltage regulator circuit, and connected with the Faraday cup. According to the measurement system and the method disclosed by the invention, are simple extra consumer power equipment such as an ion source and the like and related experimental links are not needed, the measurement efficiency is high, and the measurement is continuous without stopping to carry out work such as energy dissipation, surface level measurement and the like after each irradiation pulse, and the measurement error is small.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

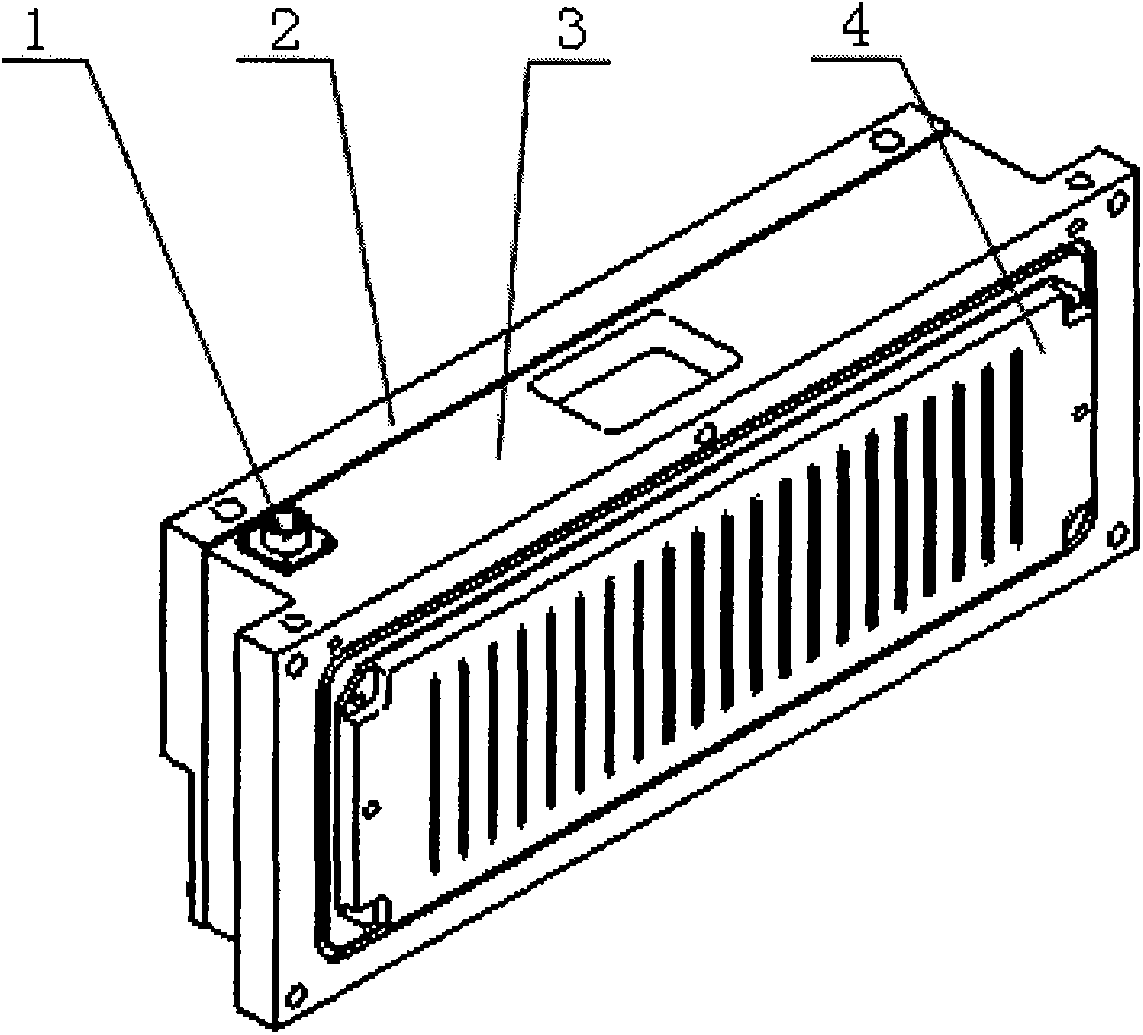

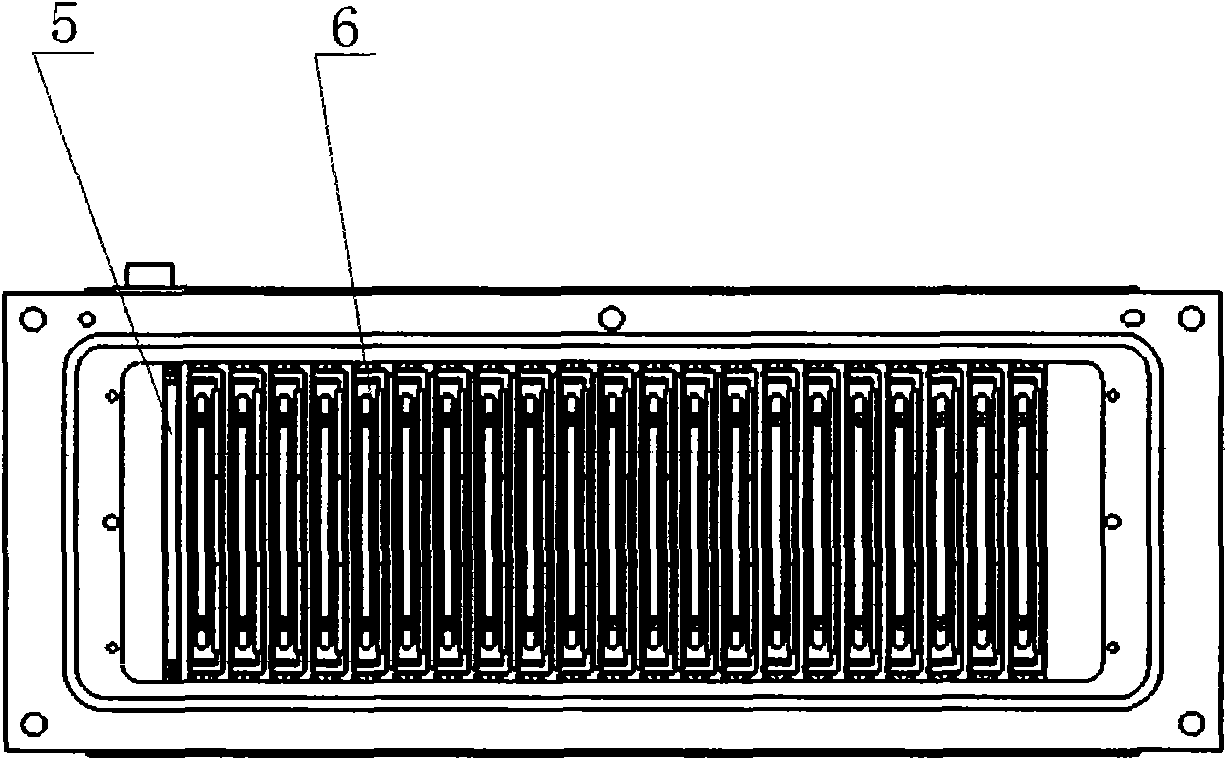

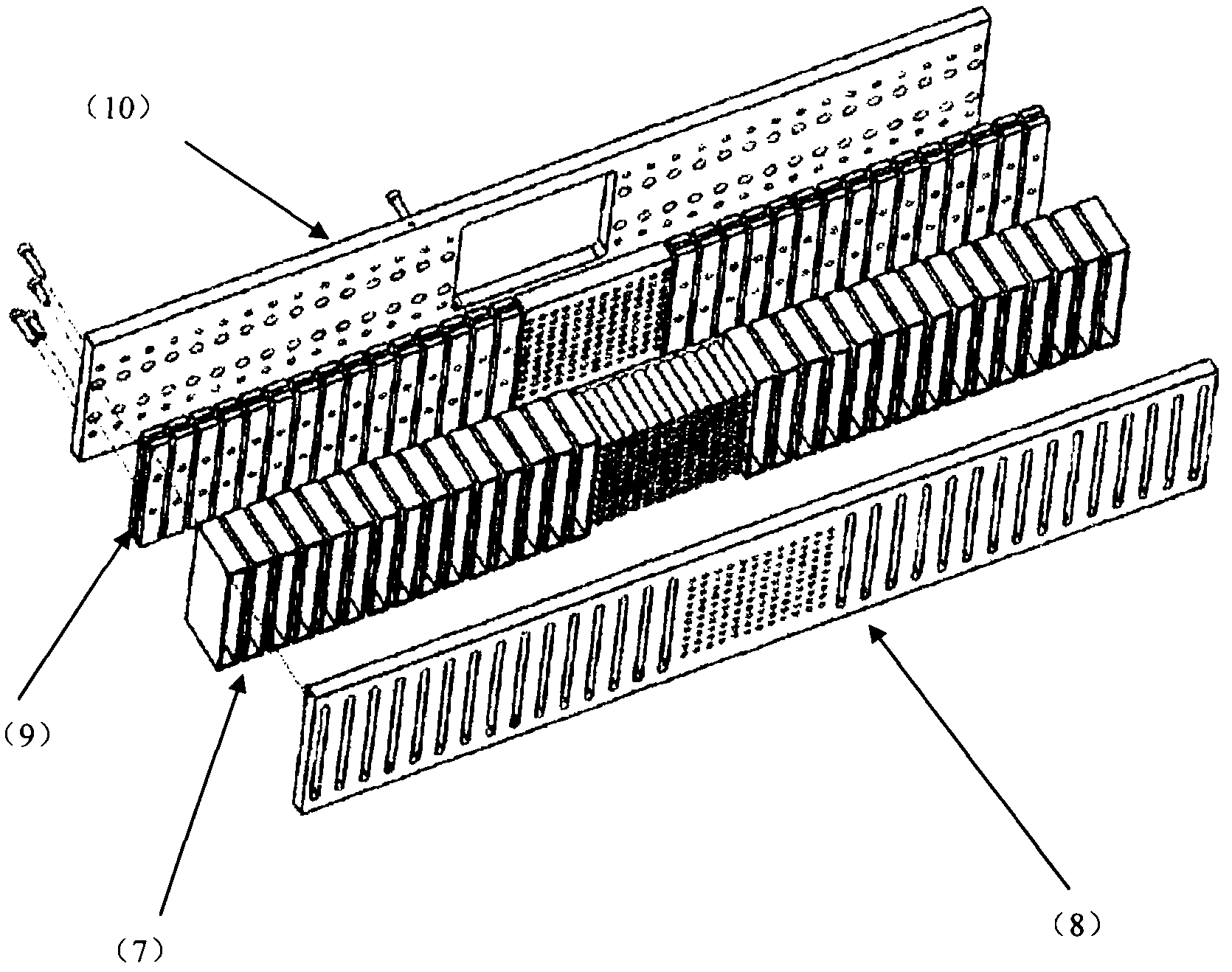

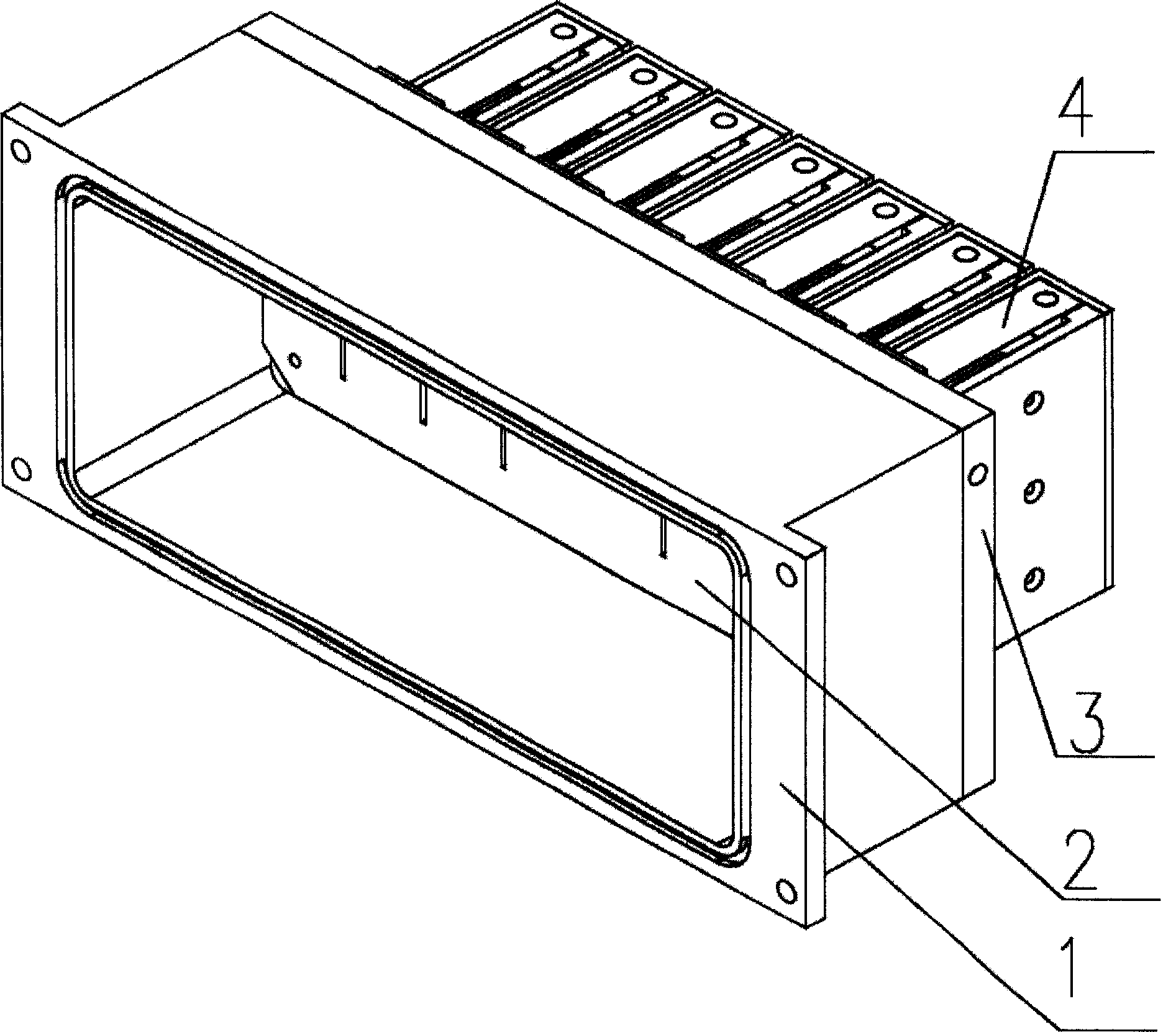

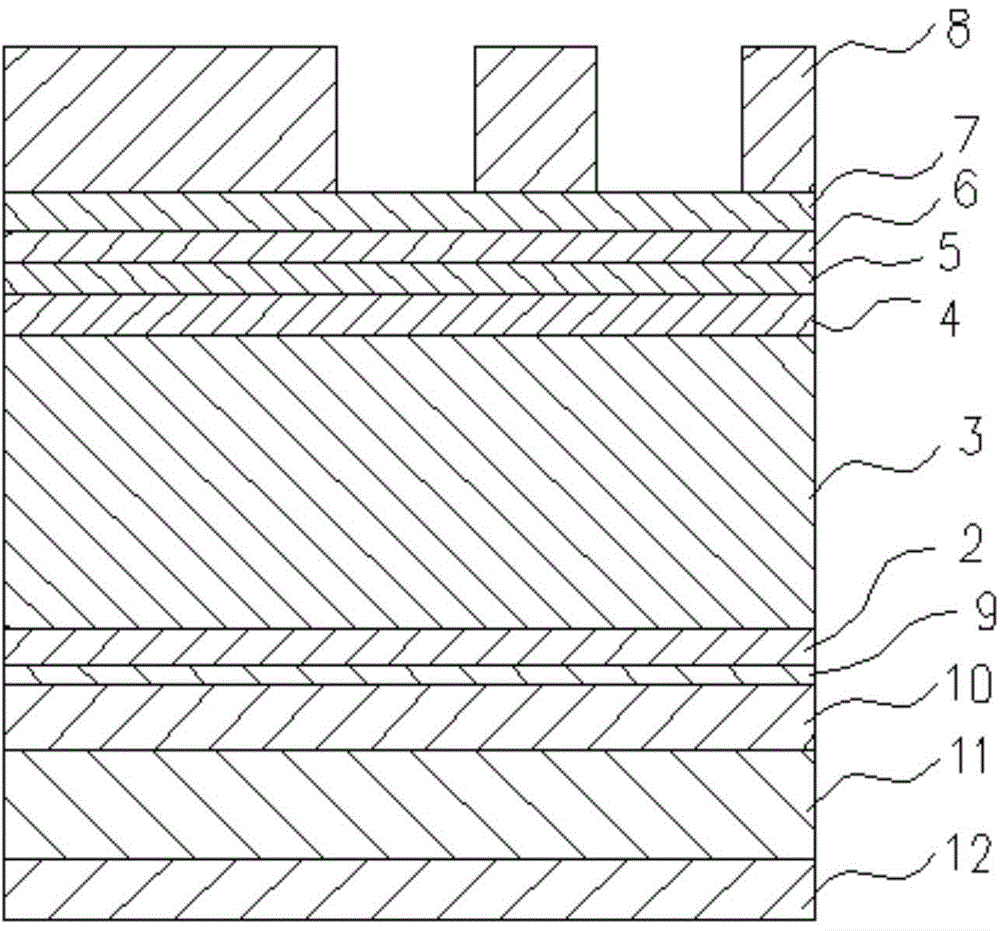

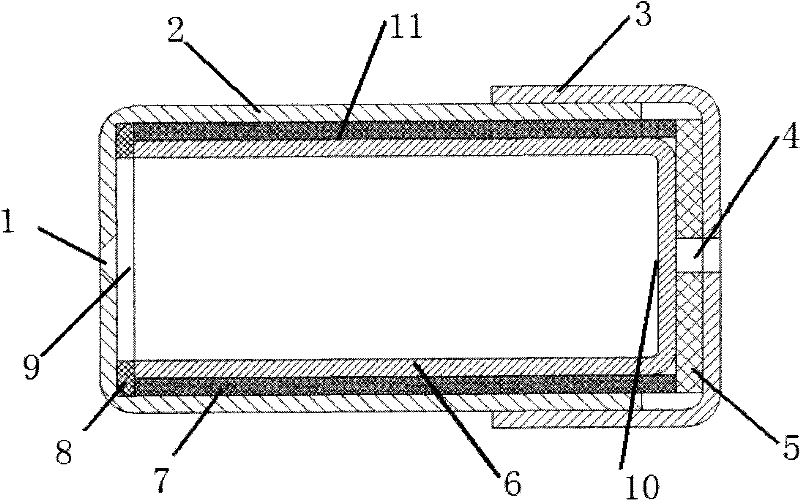

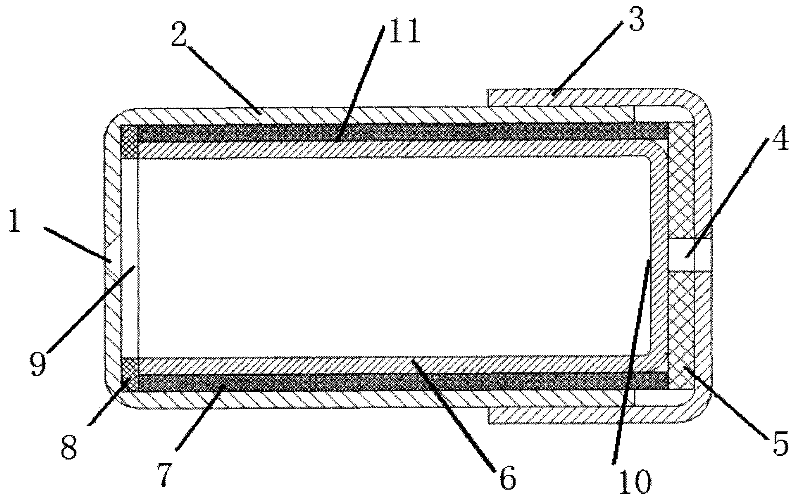

Faraday apparatus for measuring beam

ActiveCN103792566ADensely distributedReasonable designX/gamma/cosmic radiation measurmentEngineeringGraphite

The invention discloses a Faraday measurement apparatus for beam. The apparatus comprises a sealing socket (1), a Faraday cup mounting plate (2), a Faraday collection frame (3), a graphite baffle plate (4), a magnetic conductive plate (5), and micro Faraday cups (6). The micro Faraday cups (6) are installed at the Faraday cup mounting plate (2); the Faraday cup mounting plate (2) is fixed at an ion implanter based on connection of the Faraday collection frame (3); and the graphite baffle plate (4) is installed at the Faraday collection frame (3) and is located at a front position at the inlets of the micro Faraday cups (6). The apparatus is characterized in that 21 micro Faraday cups (6) are arranged and the 21 micro Faraday cups (6) and the magnetic conductive plate (5) are installed at the Faraday cup mounting plate (2) in parallel in a vacuum environment; the currents of the Faraday cup mounting plate (2) are led out by the sealing socket (1); and the sealing socket (1) is fixed at the position, approaching the Faraday cup mounting plate (2), of the Faraday collection frame (3). According to the invention, the beam measurement angle is accurate; the sealing performance influence on the vacuum system by the apparatus is low; and the generated heat is low. The invention relates to an ion injection device which belongs to the semiconductor manufacturing field.

Owner:BEIJING SHUOKE ZHONGKEXIN ELECTRONICS EQUIP CO LTD

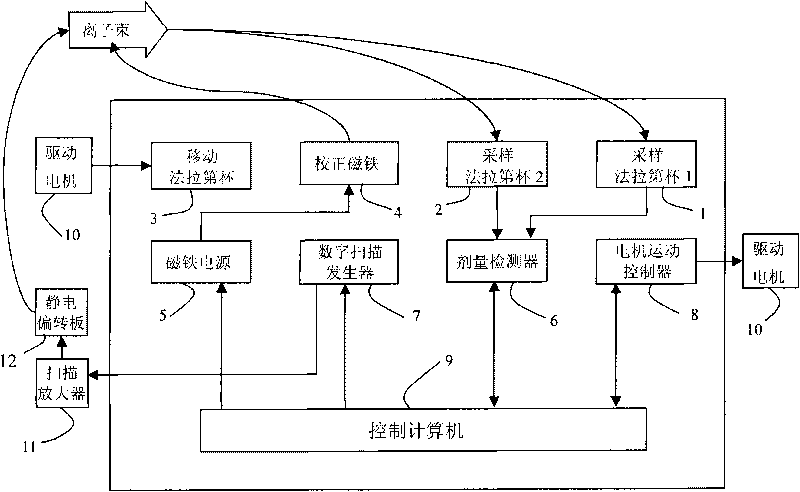

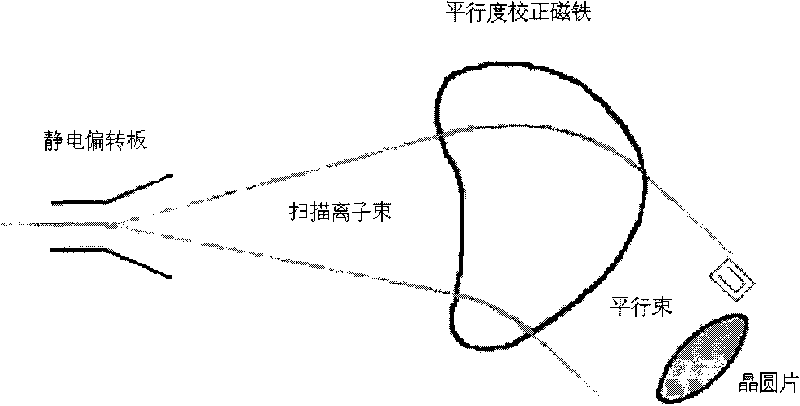

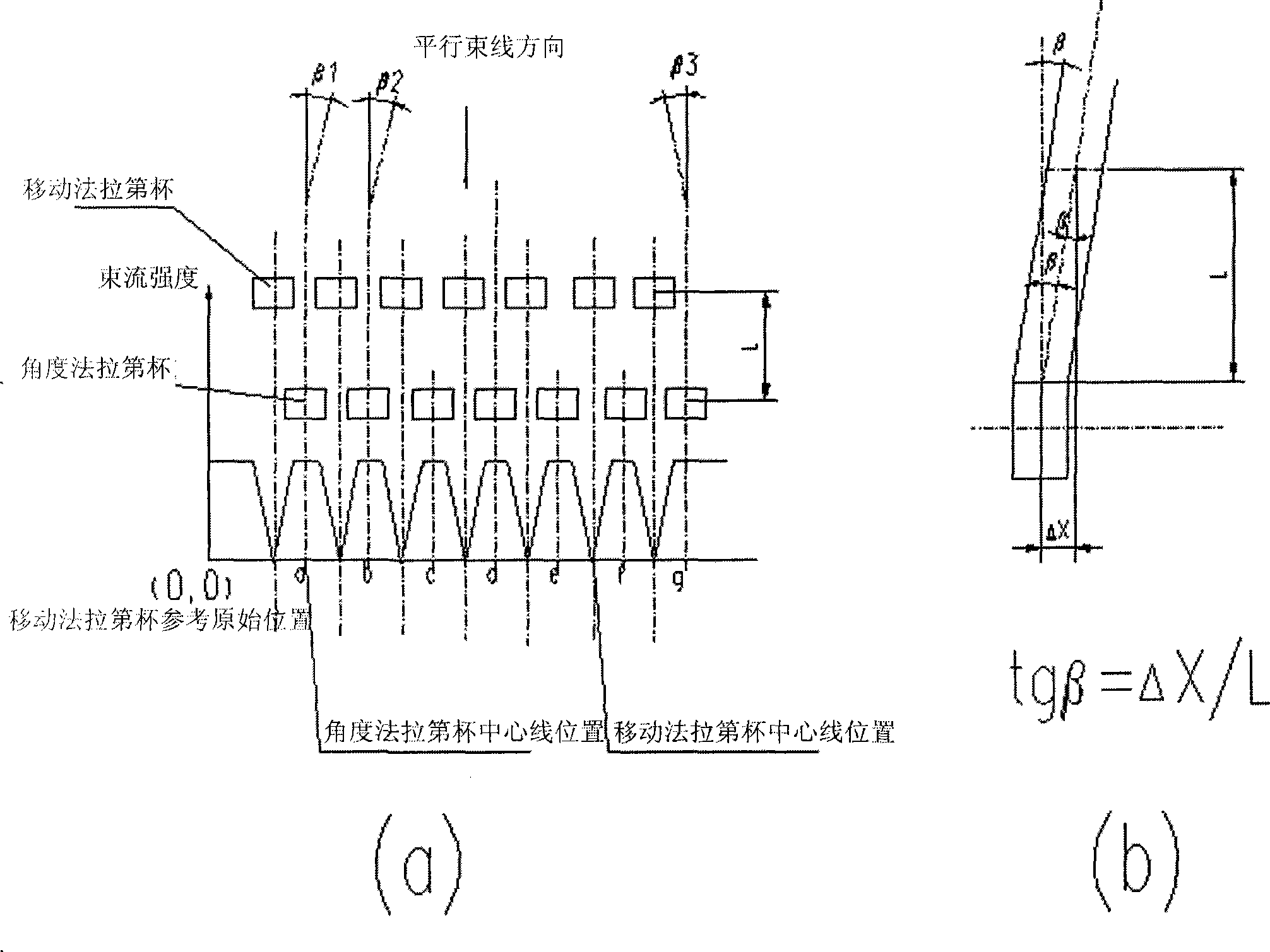

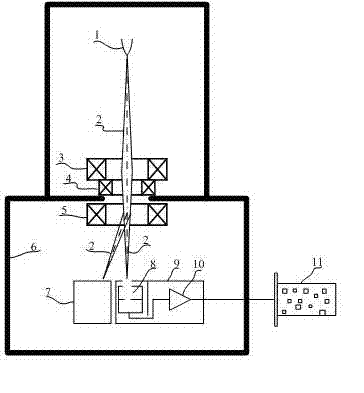

Method and device for accurately detecting and correcting parallelism of ion beam

InactiveCN101764029AEfficient detection methodNo human intervention requiredElectric discharge tubesSemiconductor/solid-state device manufacturingAudio power amplifierDrive motor

The invention discloses a method and a device for accurately detecting and correcting parallelism of an ion beam, relates to an ion implantation machine, and belongs to the field of semiconductor integrated circuit device manufacturing. The device for detecting and correcting the parallelism comprises a parallelism correcting magnet, a correcting magnet power supply, a moving Faraday cup, a sampling Faraday cup, a dosage detector, a digital scanning generator, a motor motion controller, and a control computer. The parallelism correcting magnet is arranged at a proper position behind an electrostatic scanning plate, and a magnet exciting coil of the parallelism correcting magnet is connected with the correcting magnet power supply. The output of the sampling Faraday cup is connected with the dosage detector; the output of the digital scanning generator is connected with a scanning amplifier and the scanning amplifier is connected with the electrostatic scanning plate. The output of the motor motion controller is connected with a drive motor of the moving Faraday cup. The moving Faraday cup is driven by the drive motor and is capable of moving along the X horizontal direction in a target chamber. The correcting magnet power supply, the moving Faraday cup, the sampling Faraday cup, the dosage detector, the digital scanning generator, the motor motion controller are connected with the control computer, and are coordinated and controlled by the computer. The method for detecting and correcting the parallelism of the ion beam comprises the following steps of data detection, data processing, parameter adjustment, and the like. Error data of the parallelism of the ion beam is detected by moving the Faraday cup back and forth, and the parallelism of the scanning ion beam reaches an error range by adjusting the setting current of the magnet power supply repeatedly. The method and the device can automatically realize accurate detection and correction of the parallelism.

Owner:BEIJING ZHONGKEXIN ELECTRONICS EQUIP

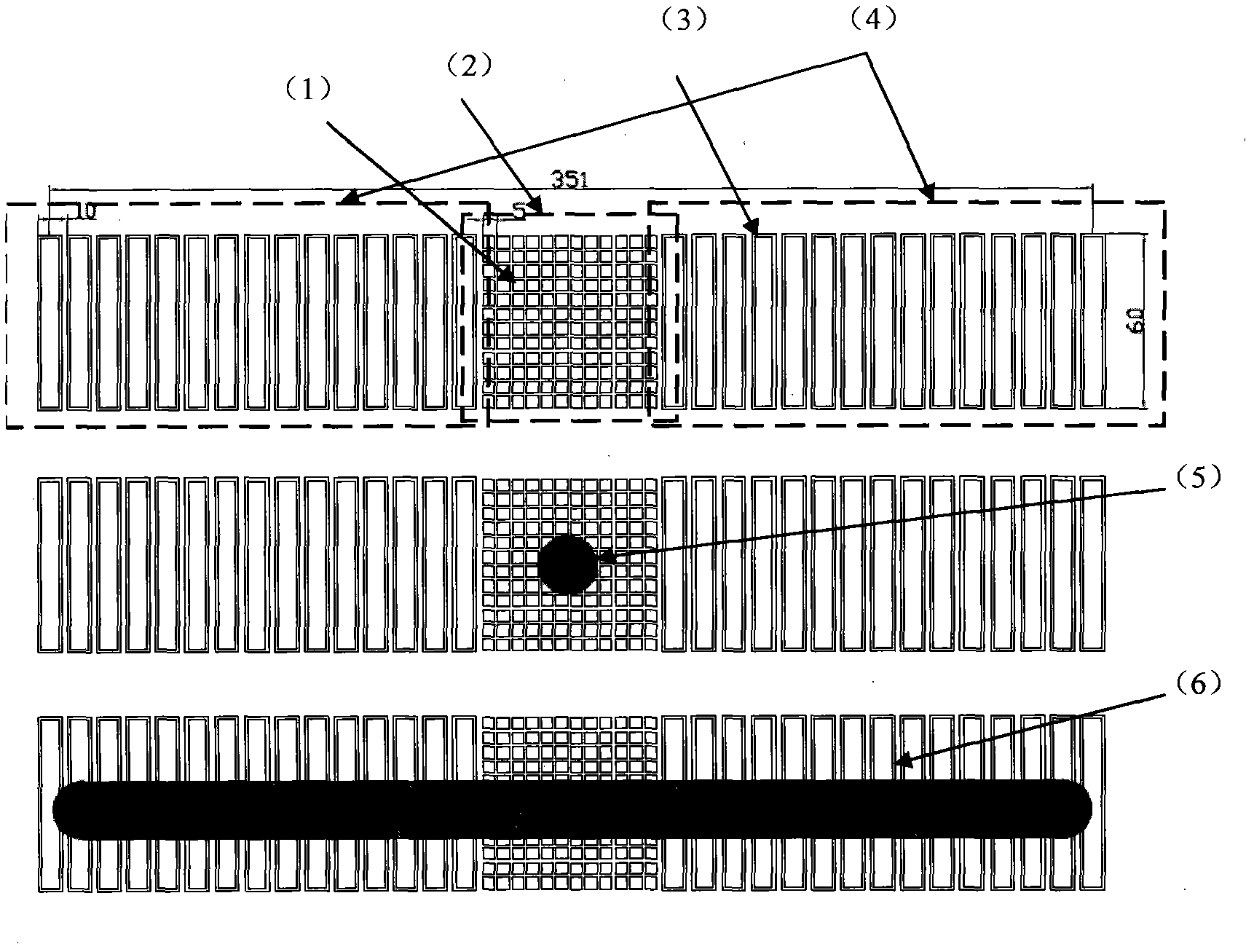

Device for detecting ion beam section density distribution and uniform ion beam distribution in real time

ActiveCN102867722AImprove qualityAdjust control parameters in real timeElectric discharge tubesX/gamma/cosmic radiation measurmentState variationDensity distribution

The invention discloses an array composite Faraday cup capable of detecting beam spot section density distribution of ion beam current under a focusing condition and uniform beam distribution under a scanning condition. The array composite Faraday cup comprises a two-dimensional Faraday cup array (2) and two one-dimensional Faraday cup arrays (4), wherein the two-dimensional Faraday cup array (2) is positioned at the center, and the one-dimensional Faraday cup arrays (4) are positioned on two sides respectively. The array composite Faraday cup is characterized in that the two-dimensional Faraday cup array (2) at the center is used for detecting beam spot section density distribution of ion beams under the focusing condition (5), and the one-dimensional Faraday cup arrays (4) on the two sides are used for detecting uniform beam distribution of the ion beams under the scanning condition (6). By the aid of the array composite Faraday cup, distribution and state change of the ion beams can be detected in real time, and detection instantaneity and accuracy can be improved.

Owner:BEIJING SHUOKE ZHONGKEXIN ELECTRONICS EQUIP CO LTD

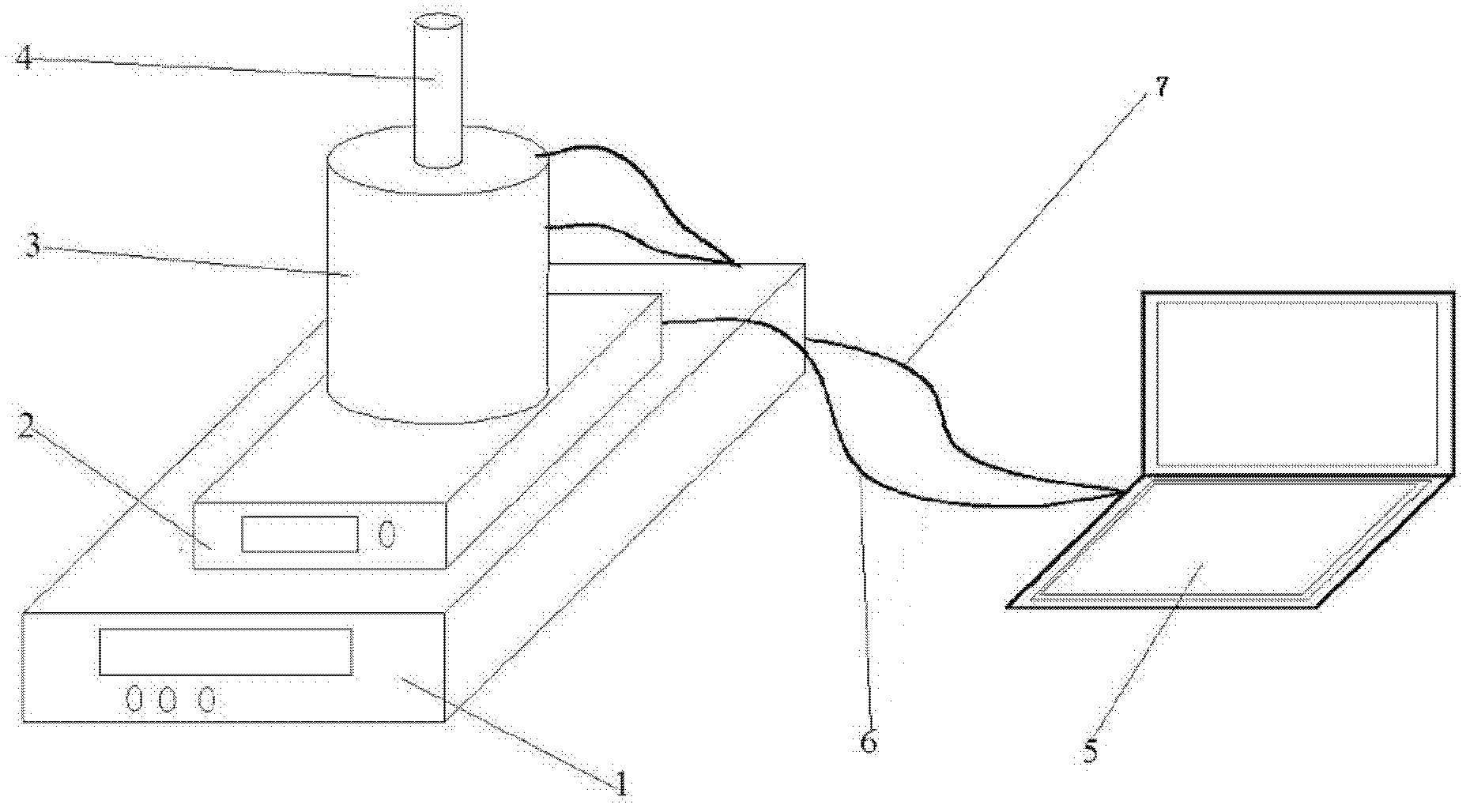

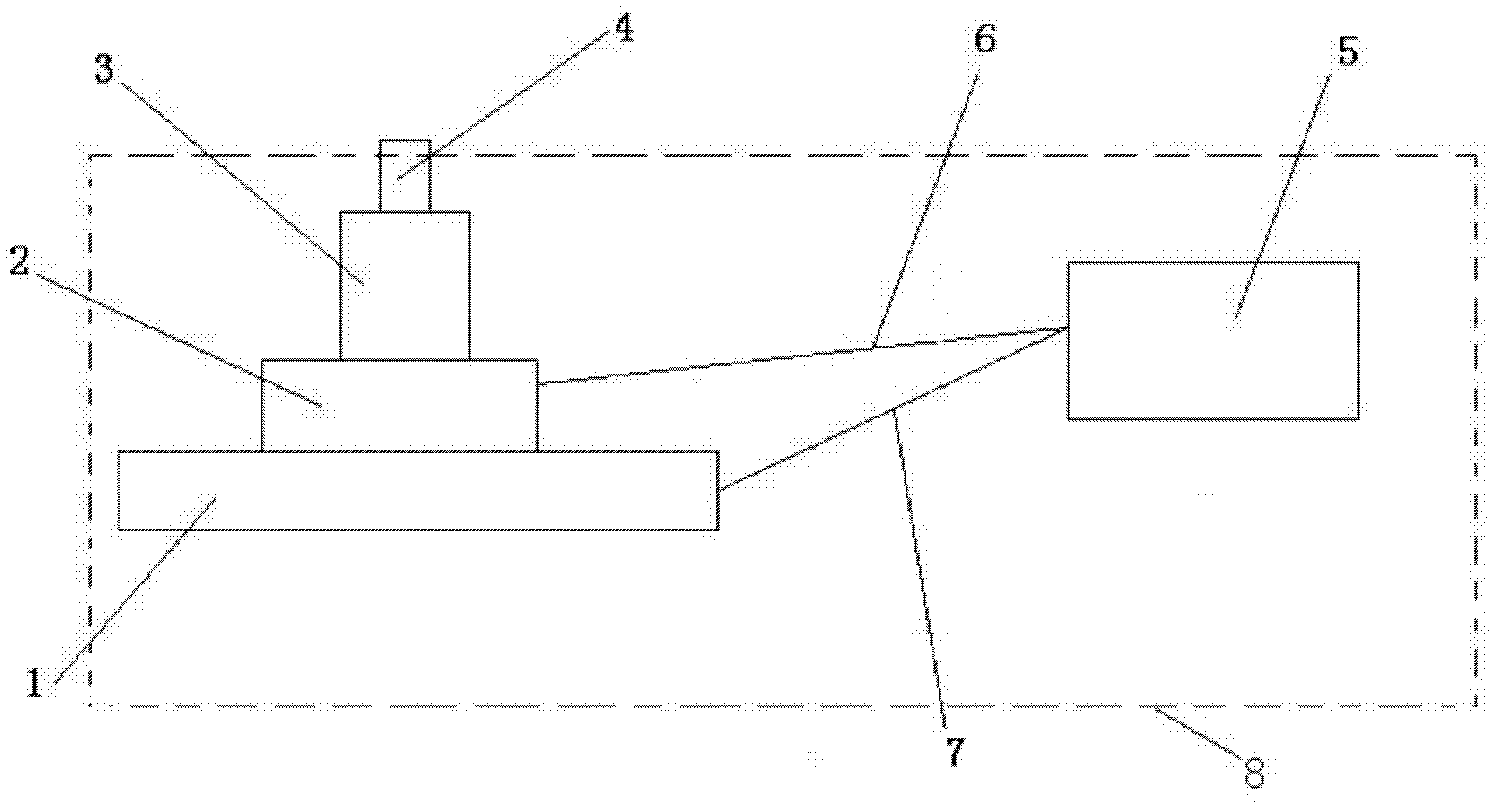

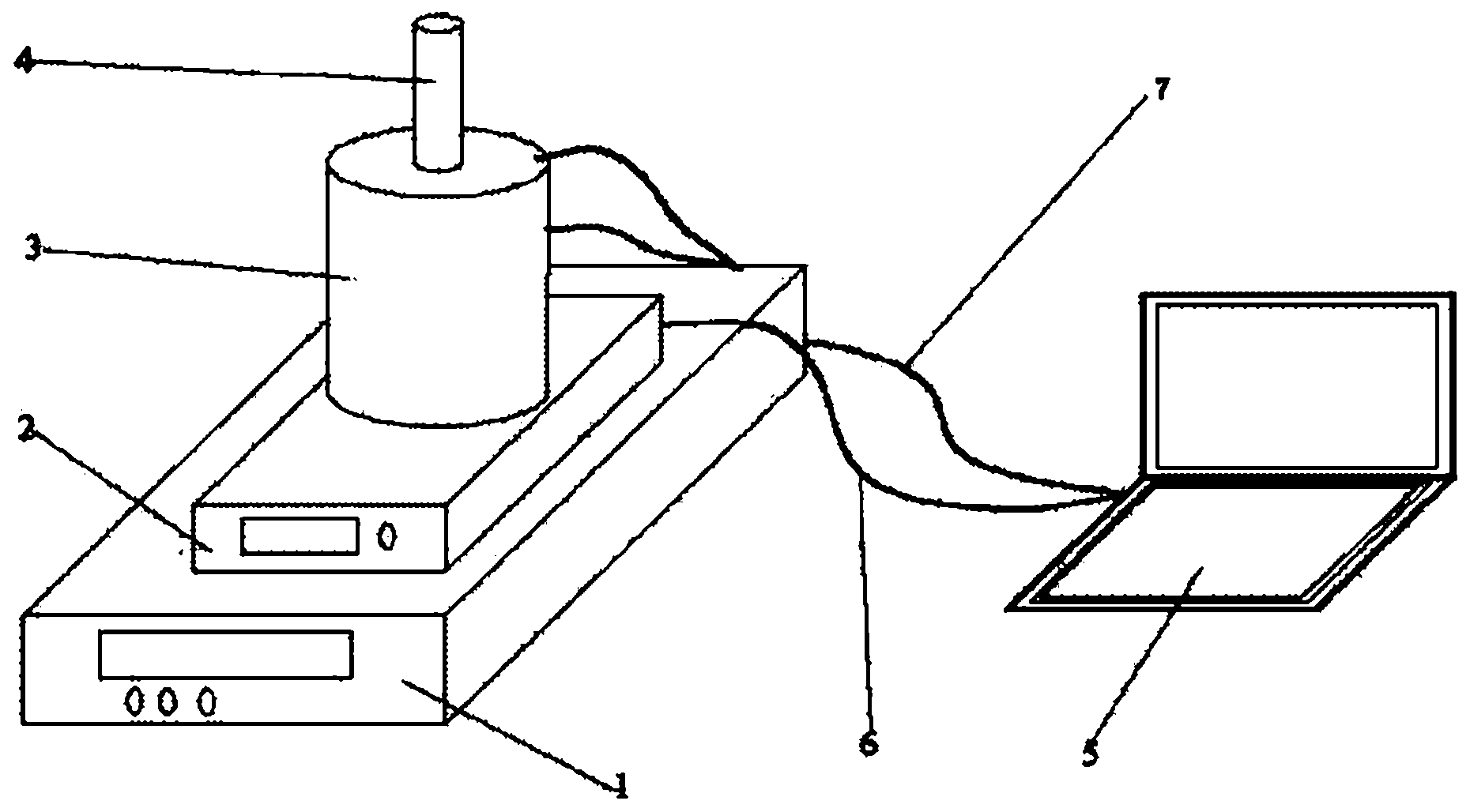

Blown sand and quick sand charge-to-mass ratio real-time measurement system

ActiveCN102323493AReal-time measurementReal-time acquisitionElectrical measurementsMass ratioElectrometer

The invention discloses a blown sand and quick sand charge-to-mass ratio real-time measurement system which comprises a sand particle bearing device, a sand particle weighing device and a sand particle electrified capacity measuring device, wherein the sand particle bearing device is a Faraday cup, the sand particle weighing device is an electronic balance, and the sand particle electrified capacity measuring device is an electrometer; and the Faraday cup is arranged on the electronic balance and connected with the electrometer through a lead. By the matching of the devices, the invention can realize real-time acquisition of sand particle mass and electrified capacity in the Faraday, and can also realize high-frequency measurement of a blown sand and quick sand charge-to-mass ratio.

Owner:LANZHOU UNIVERSITY

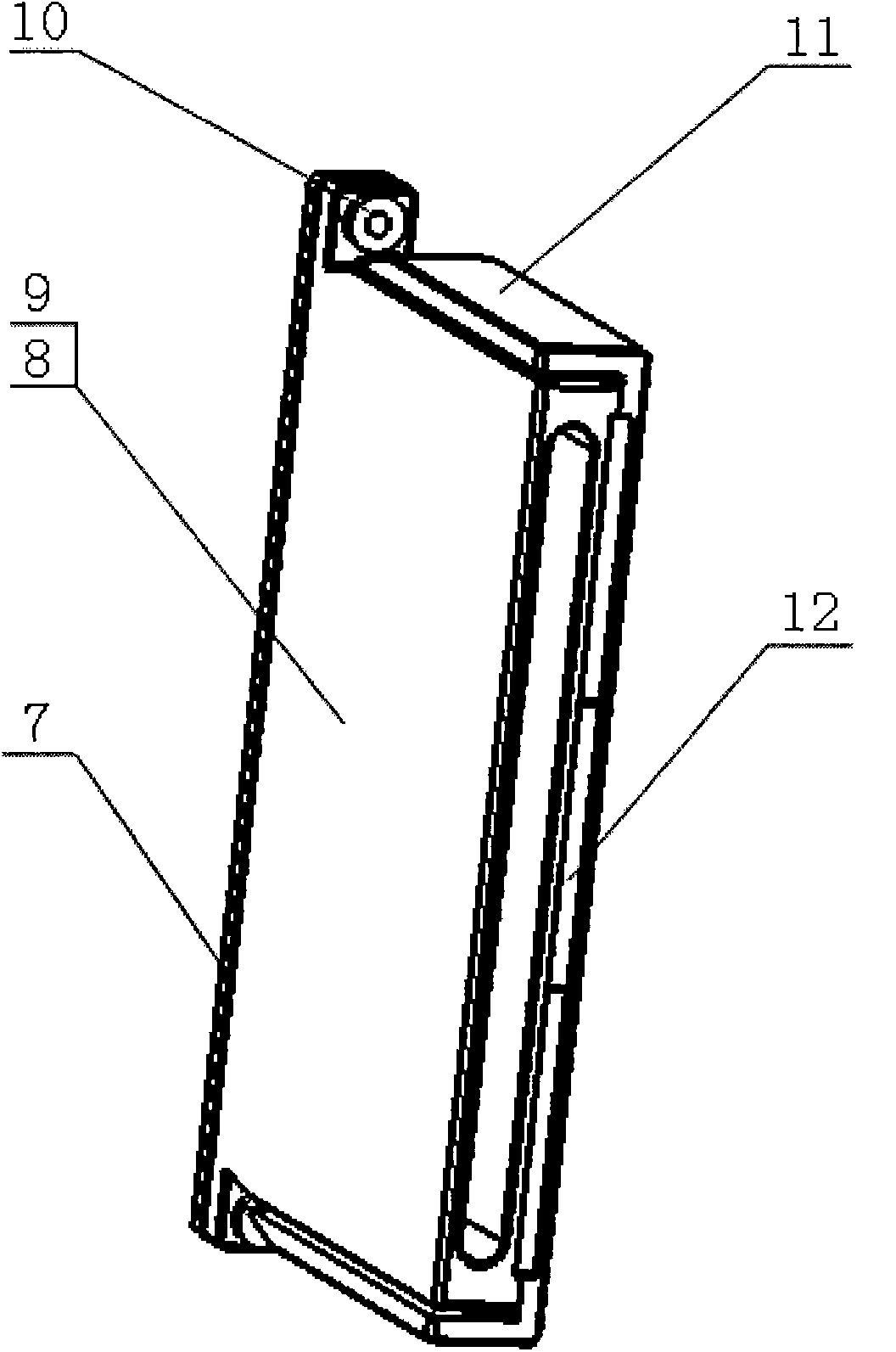

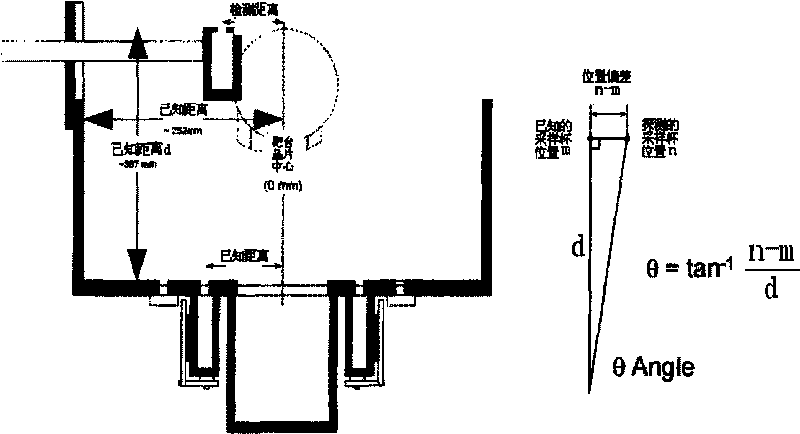

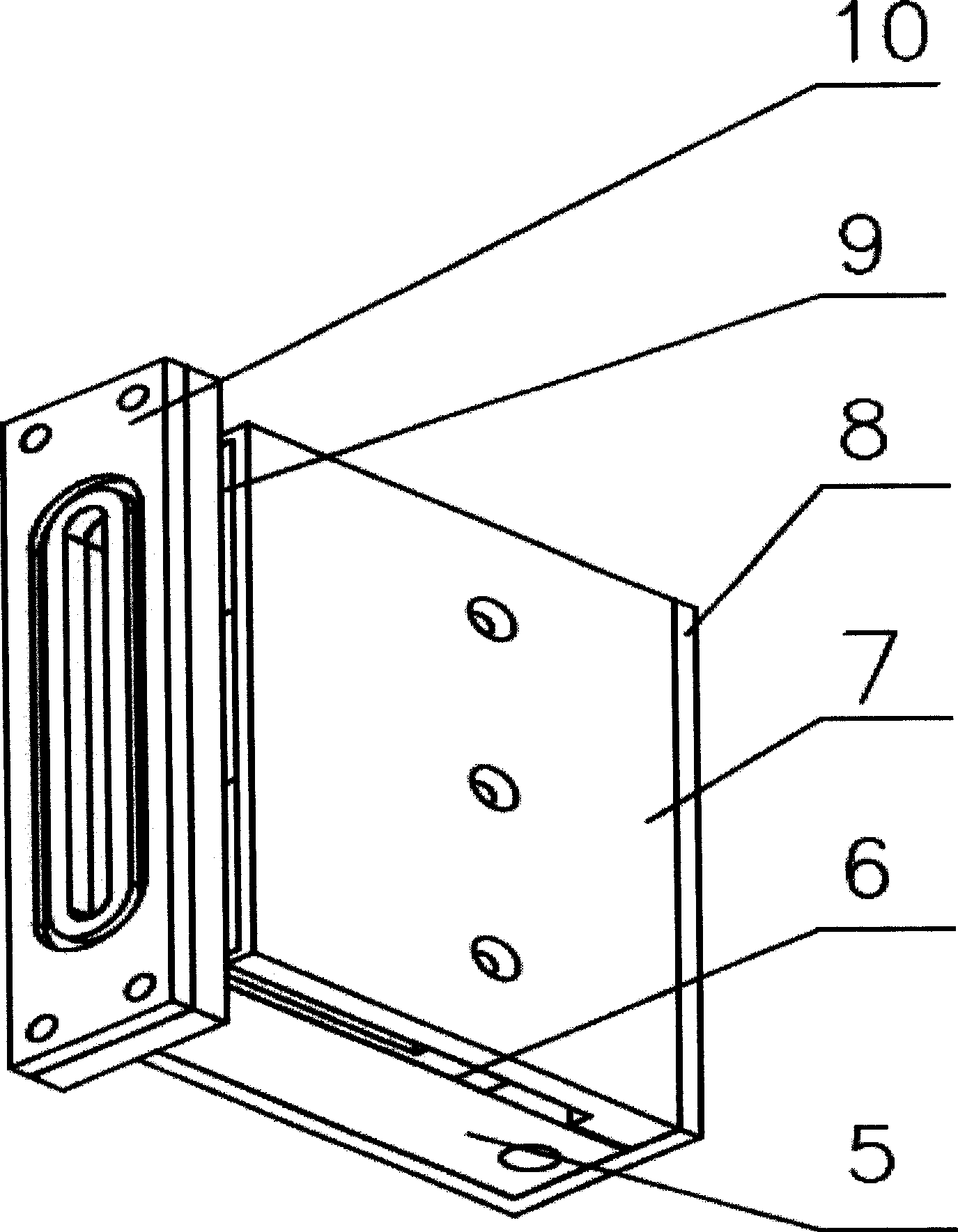

Faraday apparatus for angle measurement of parallel beam

InactiveCN101414545ATo prevent danger caused by electrificationMeasurement devicesElectric discharge tubesPeak valueCrystal plane

The invention discloses a parallel-beam angle measurement Faraday device of an ion implanter, relates to the ion implanter and belongs to the manufacturing field of semiconductors. The structure is as follows: the parallel-beam angle measurement Faraday device is composed of a Faraday collection frame, an electronic suppression plate, a bottom plate of the collection frame, seven fixed-angle Faraday cups and a moving Faraday cup, the Faraday collection frame collects incident ion beam flow, the electronic suppression plate suppresses the electron overflow generated by the bombardment on metal bodies of the Faraday cups by ion beams, the angle collection bottom plate is used for the vacuum connection and the sealing of the Faraday collection frame and the Faraday cups, the seven fixed-angle Faraday cups measure the current intensity of the ion beams, the central position of the implanted ion beams is determined by being combined with the moving Faraday cup which is arranged in a target room area, when the parallel beams are the incident beams which are perpendicular to a crystal plane, the central position of the blocking beams of the moving Faraday cup is consistent with the center of the measuring beams of the fixed Faraday cups, and the current of the fixed-angle Faraday cups simultaneously achieves the peak value at the position when the current of the moving Faraday cup achieves the peak value.

Owner:BEIJING ZHONGKEXIN ELECTRONICS EQUIP

Faraday cup sensing device used in electron beam processing beam quality test

ActiveCN102353978APrevent escapeImprove collection efficiencyX/gamma/cosmic radiation measurmentWeak currentAlloy

The invention discloses a Faraday cup sensing device used in an electron beam processing beam quality test. The Faraday cup sensing device comprises: a Faraday cup, an aluminum shell and a signal switching and amplification circuit. The Faraday cup and the signal switching and amplification circuit are arranged in the aluminum shell. The signal switching and amplification circuit is connected with an acquisition card of an industrial personal computer which is out of a vacuum chamber of an electron beam quality test system. Electron beam of the electron beam quality test system is collected by the Faraday cup and is flowed into the signal switching and amplification circuit through a cable. A weak current signal is processed by the signal switching and amplification circuit, then is converted into a digital signal by the acquisition card and is stored in the industrial personal computer. The Faraday cup comprises two electron beam aperture collection electrodes and one electron beam seam collection electrode. The aluminum shell comprises: an aluminum alloy shell and an aluminum alloy cover. By using the device, collection efficiency of the electron beam can be raised; multiple vacuum-pumping processes can be avoided. Amplifying the signal can obviously raise a signal to noise ratio.

Owner:NANJING UNIV OF SCI & TECH

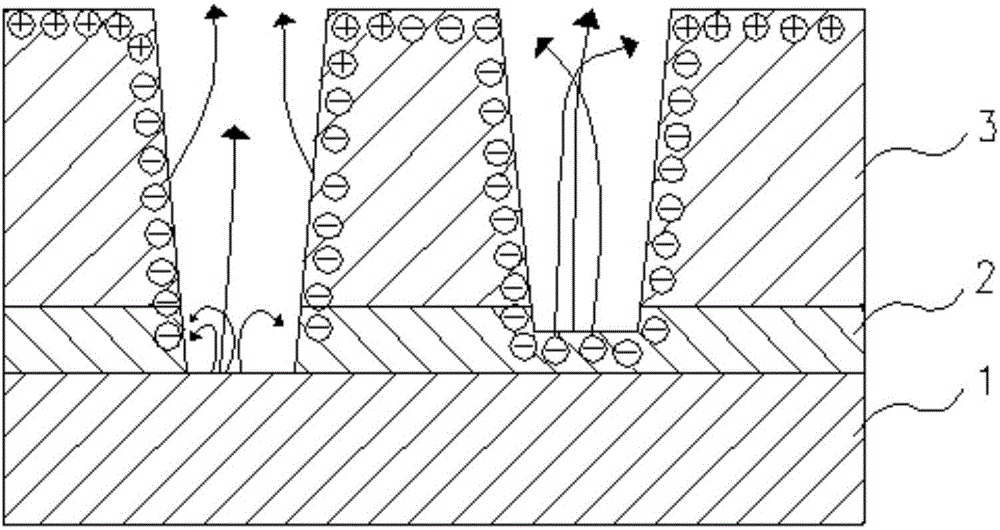

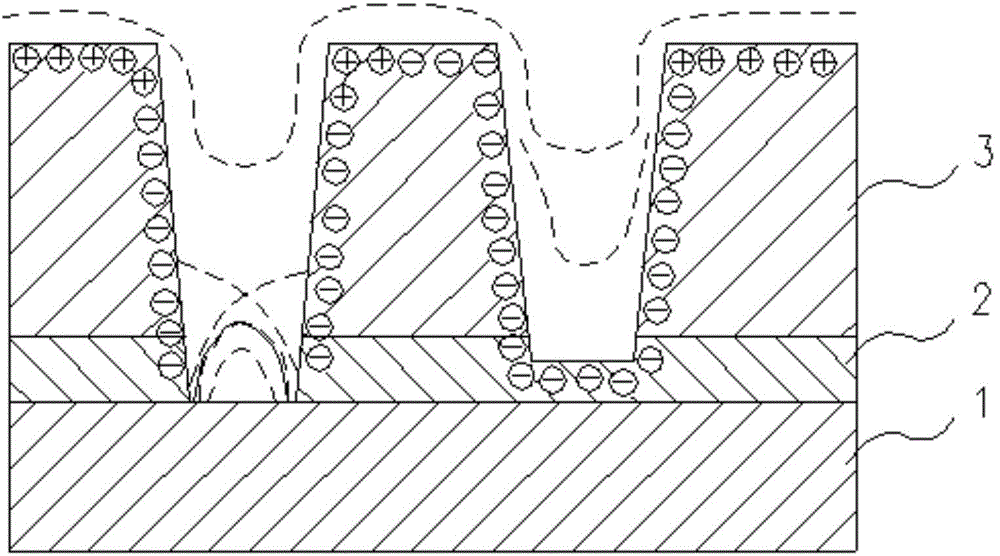

Product through hole etching defect detection method

ActiveCN104143519AOvercoming the problem of not being able to detect all via defectsIncrease success rateSemiconductor/solid-state device testing/measurementEtchingDatum reference

The invention discloses a product through hole etching defect detection method. The method comprises the steps that a through hole conducting layer testing module for a product to be detected is built at first, and mutually-communicated metal wires which are designed by referring to the graph structure through hole layout and size of the product to be detected are deposited on the testing module; in the hard mask etching technology where the testing module is built, areas where projections, formed by through holes in the product, on a hard mask layer are located are isolated by photoresist, and original groove structures for connecting the through holes is improved to be discontinuous groove structures or through hole structures; then insulating layer through hole etching is carried out, and the through holes are filled with copper which is flattened; finally, an electron beam defect scanner is adopted for detection. According to the product through hole etching defect detection method, the Faraday cup influences produced in the etching defect detection process can be avoided, and the problem that defects of all the through holes cannot be detected after the copper is flattened is solved, so that the through hole defect detection success rate is improved, data references are provided for technological window optimization, and guarantees are provided for semiconductor on-line manufacturing and yield improvement.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

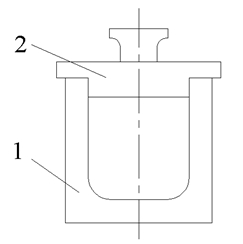

faraday cup

InactiveCN102280345AShield interferenceEfficient and Accurate CollectionParticle separator tube detailsEngineeringVacuum chamber

The invention discloses a Faraday cup, which includes an ion collection cup, the ion collection cup includes an open end, a sealed end and a cup body, the cup body is wrapped with an insulating cover, and the open end is provided with a There is a front shielding cover, a rear shielding cover is provided at the sealing end, a front insulating baffle is added between the front shielding cover and the opening end, and a rear insulating baffle is added between the rear shielding cover and the sealing end plate. The Faraday cup of the present invention adds a metal shield structure outside the ion collection cup, which can shield the interference caused by the scattered ions inside the vacuum cavity, and thus can accurately and effectively collect the number of target ions.

Owner:JIANGSU SKYRAY INSTR

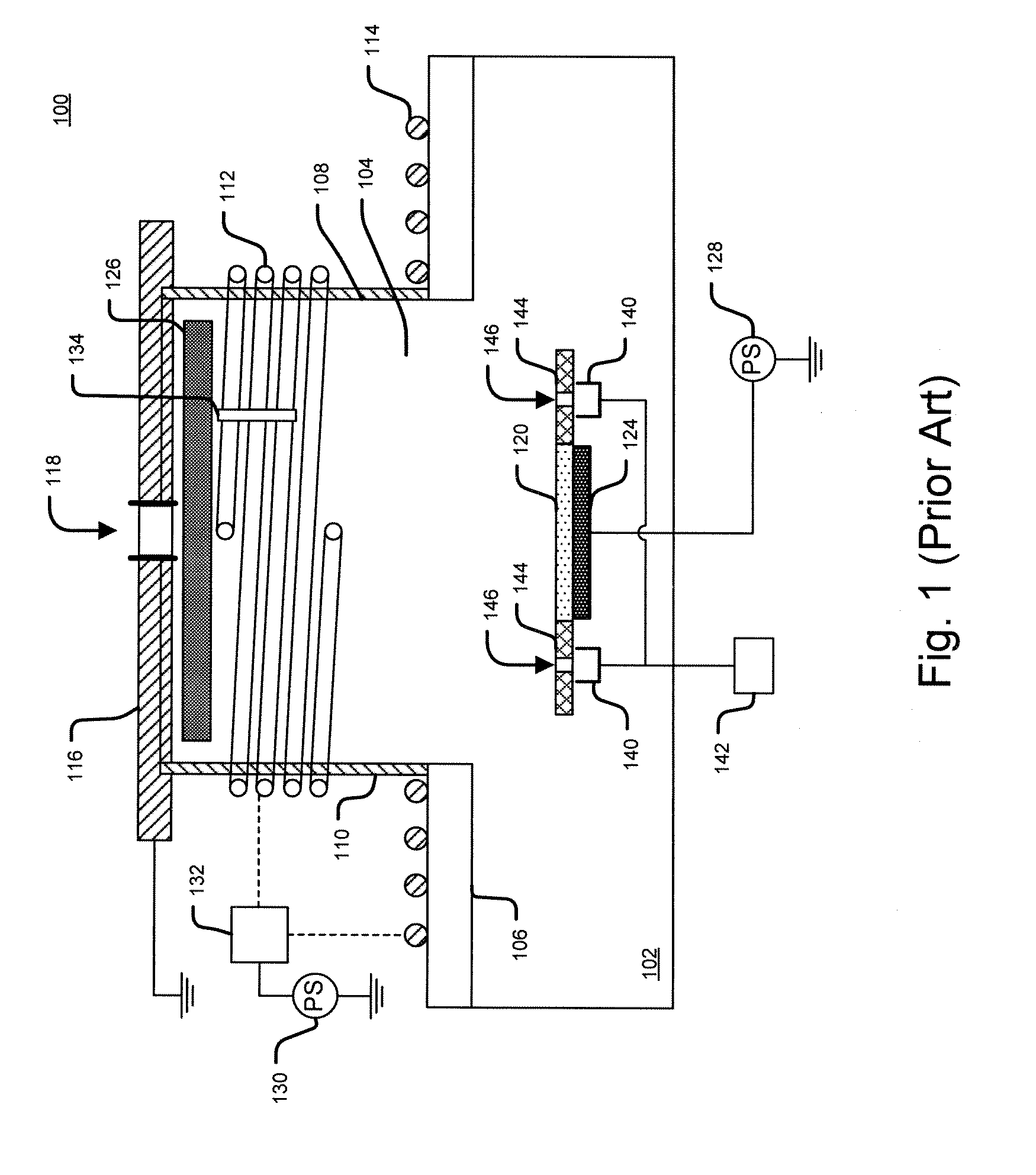

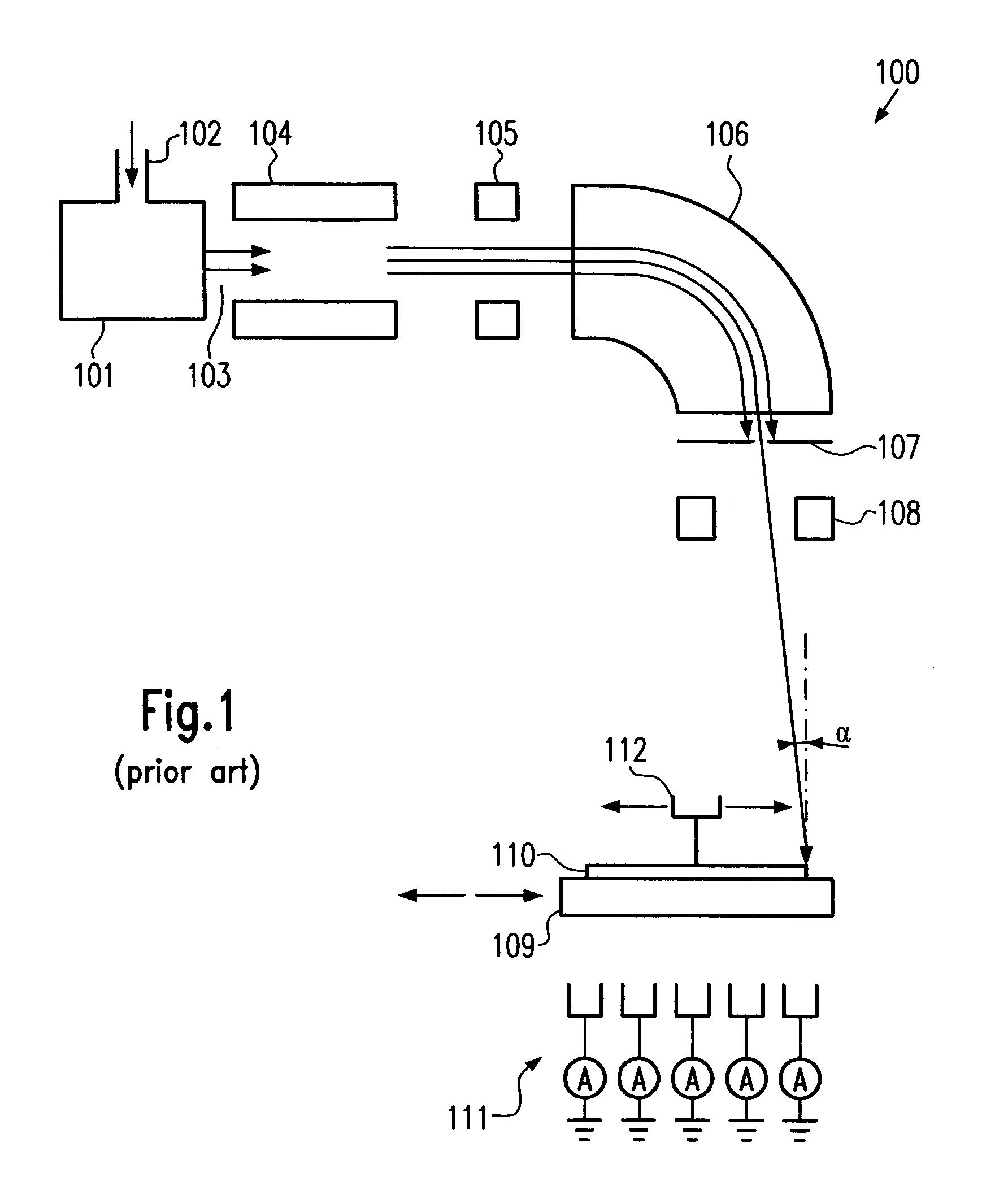

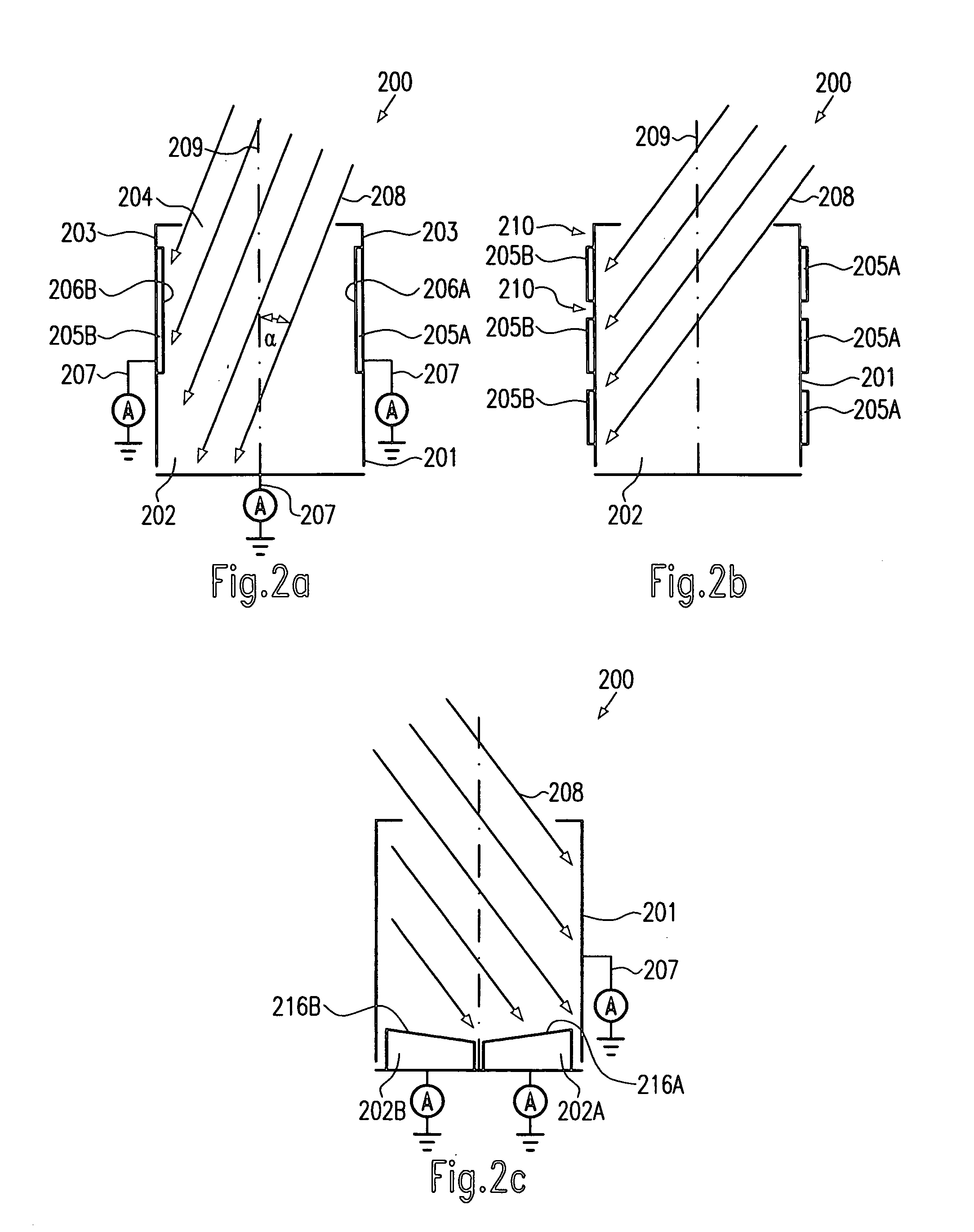

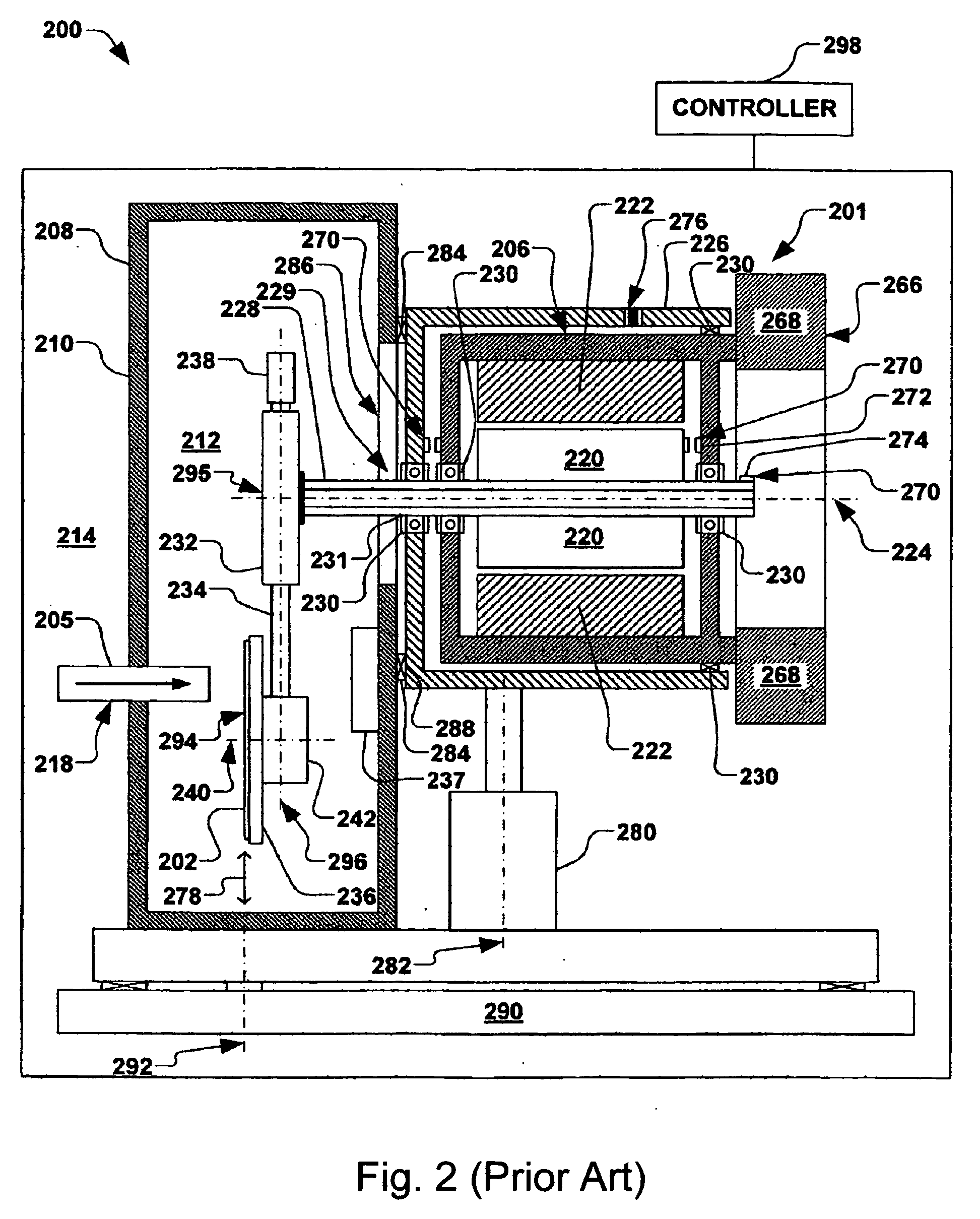

Ion implant ion beam parallelism and direction integrity determination and adjusting

InactiveUS20060169922A1Electric discharge tubesIrradiation devicesSystems approachesIon implantation

A system, method and program product for controlling parallelism and / or direction integrity of an ion beam generated by an ion implanter system are disclosed. The invention utilizes multiple faraday cups to measure a profile of at least a portion of the ion beam. The results of the measurement are then processed to determine parallelism and / or direction integrity of the ion beam. The results of the parallelism and / or direction integrity determination are then used to adjust the ion implanter system operating parameters to control parallelism and the direction of the ion beam.

Owner:VARIAN SEMICON EQUIP ASSOC INC

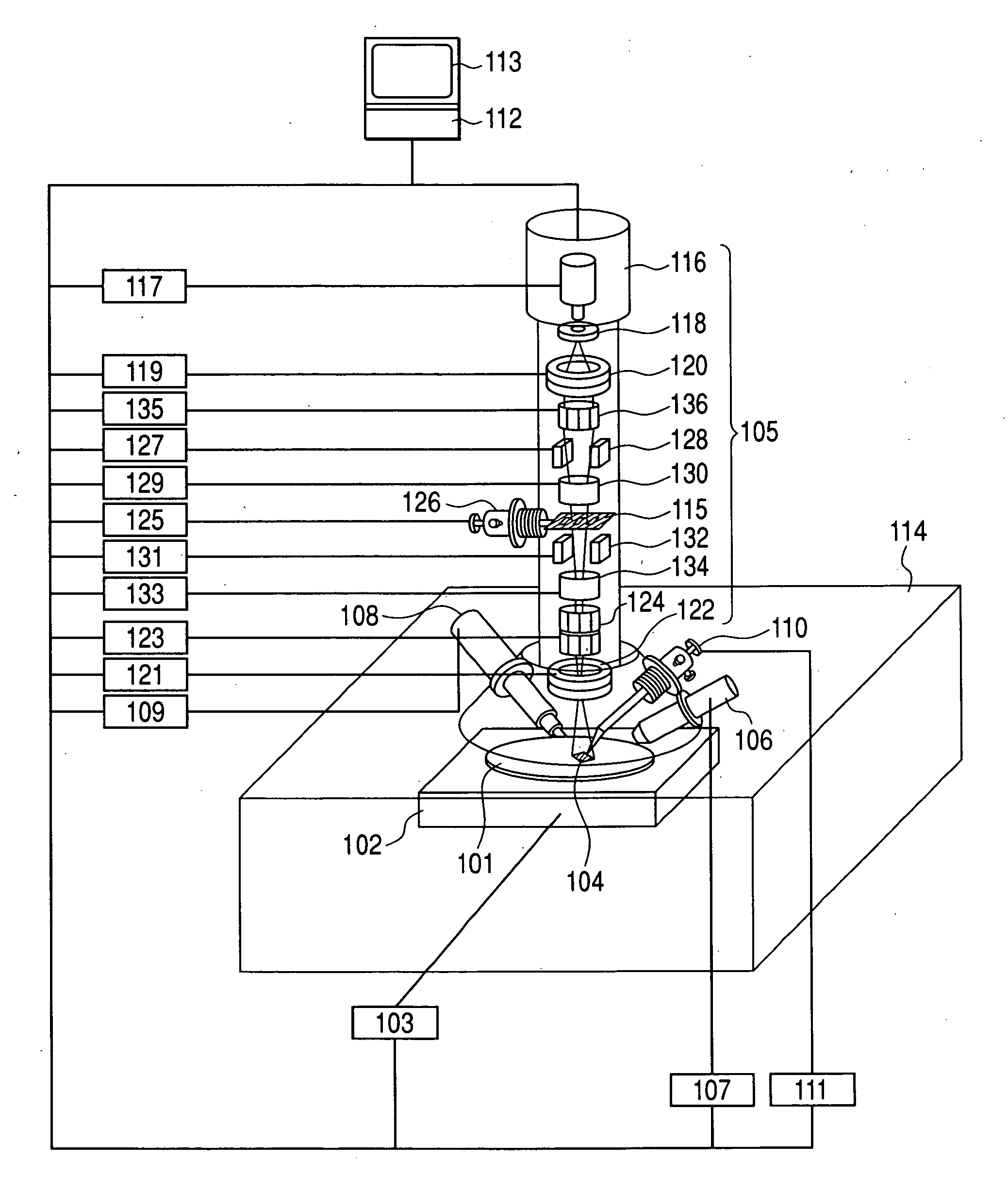

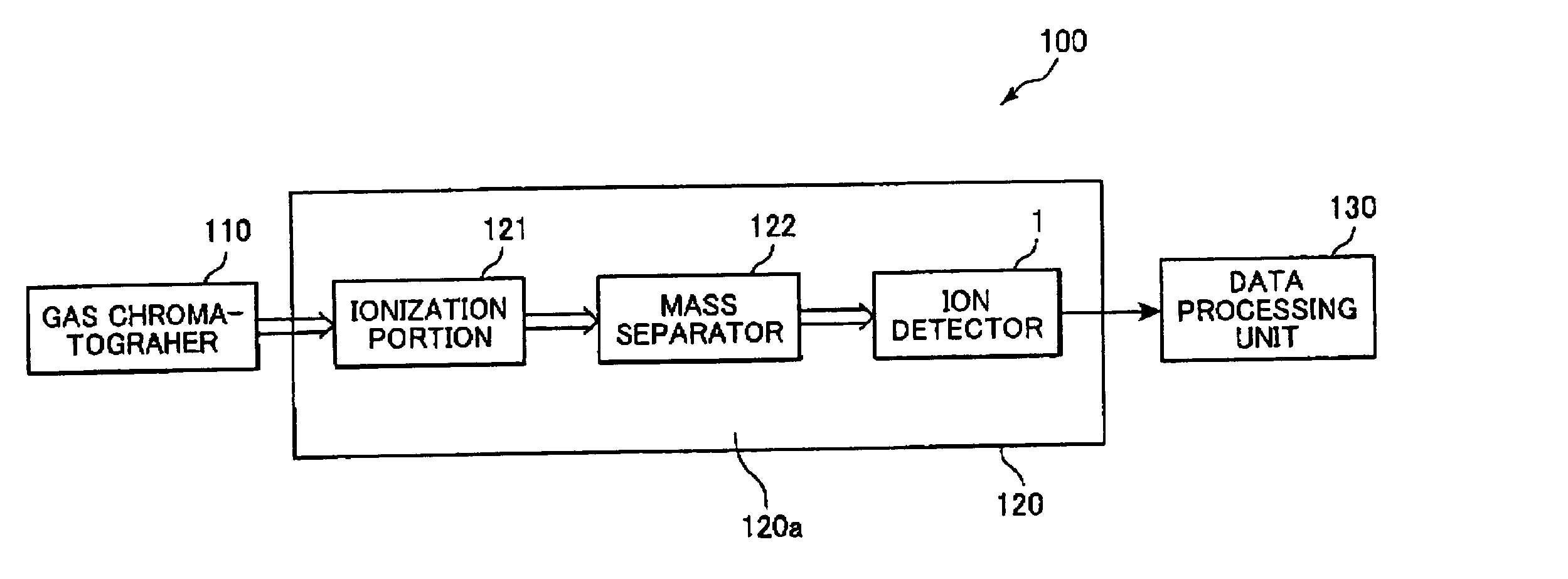

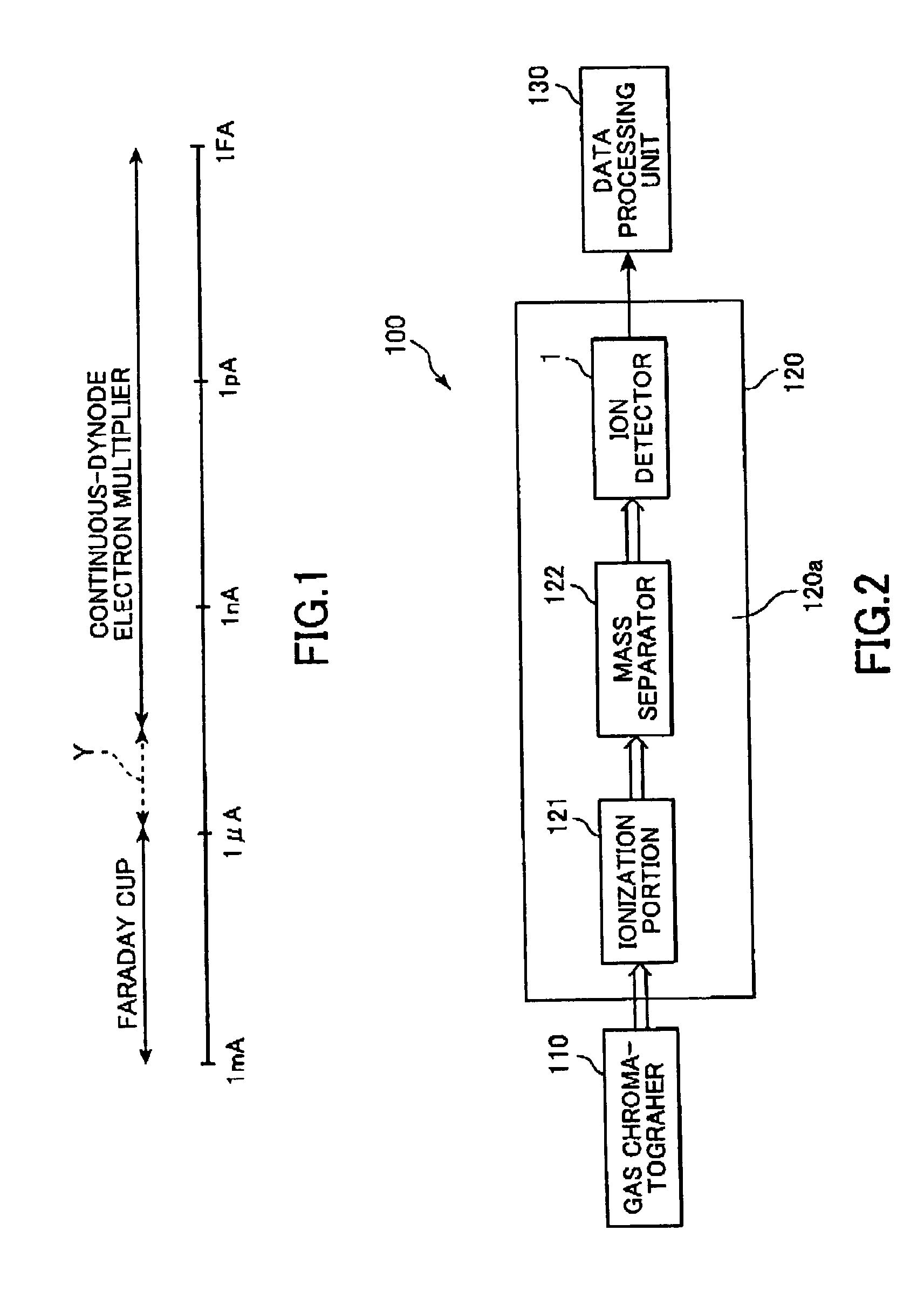

Mass spectrometer and ion detector used therein

An ion detector includes an ion input face, a Faraday cup, an ion-to-electron converter dynode, two ion deflection electrodes, an electron multiplier portion, and an anode. The ion input face is formed with an ion input opening. The Faraday cup has an ion collection surface that confronts the ion input opening. The ion-to-electron converter dynode is disposed to one side with respect to the Faraday cup and the ion input opening and has a conversion surface that converts impinging ions into electrons. The two ion deflection electrodes generate an electron lens that attracts and focuses ions from the ion input opening toward the conversion surface of the ion-to-electron converter dynode. The electron multiplier portion receives and multiplies the electrons from the ion-to-electron converter dynode, and includes a plurality of dynodes that multiply electrons one after the other. The plurality of dynodes are juxtaposed in an arc-shape around the Faraday cup. The anode receives electrons from the electron multiplier portion and outputs a signal that corresponds to the amount of input ions.

Owner:HAMAMATSU PHOTONICS KK

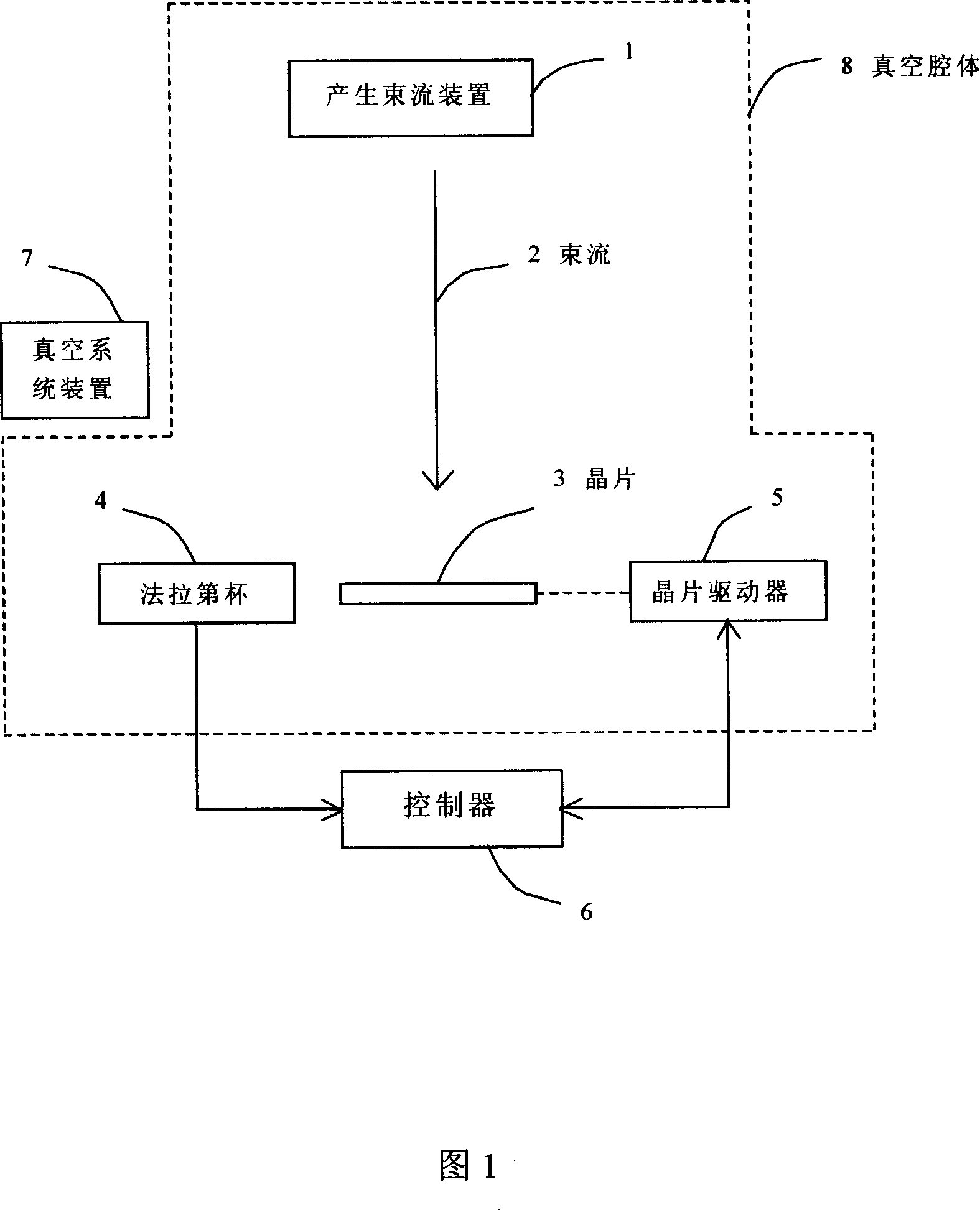

Method and device for controlling ion implantation

ActiveCN101000870AEasy to controlSure easyElectric discharge tubesSemiconductor/solid-state device manufacturingTransfer procedureEngineering

A method for controlling ion implantation includes generating a linear beam by beam generator, injecting beam vertically into chip and using Faraday cup to detect beam value, outputting signal reflecting beam size to controller, carrying out communication between controller and chip actuator and driving chip to carry out scanning up and down by receiving parameter command sent by controller, transmitting beam in sealed vacuum cavity, utilizing vacuum unit to maintain vacuum environment of said cavity and controlling implantation dosage by controller. The device for realizing said method is also disclosed.

Owner:BEIJING ZHONGKEXIN ELECTRONICS EQUIP

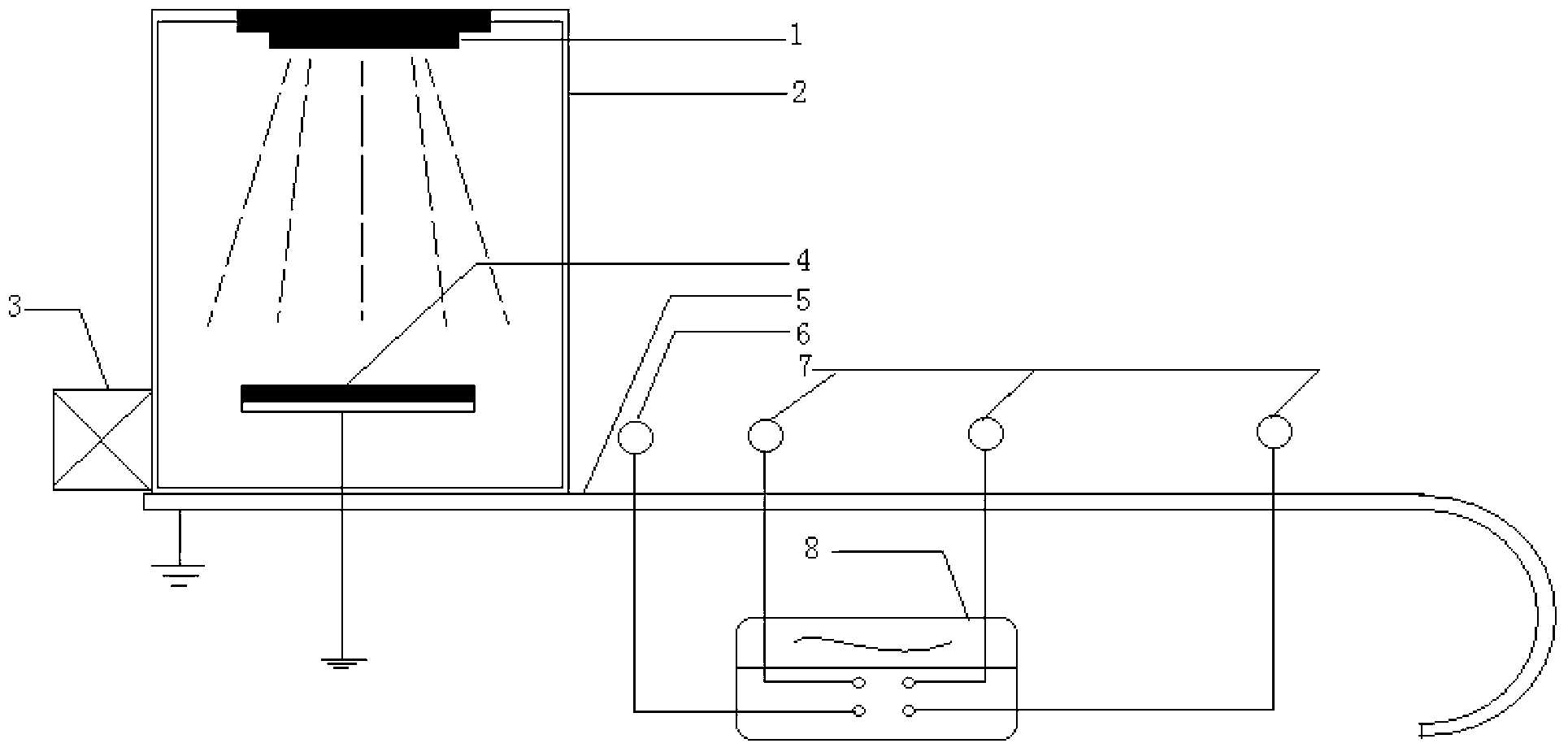

Device and method for measuring satellite material surface electrostatic discharge pulse characteristics

InactiveCN103267903AEliminate Boundary Reflection IssuesAvoid interferenceElectromagentic field characteristicsElectrostatic field measurementsMeasurement devicePulse characteristics

The invention relates to a device and a method for measuring satellite material surface electrostatic discharge pulse characteristics in the space plasma environment, and belongs to the field of measurement. The device comprises an electronic gun, a vacuum chamber, a vacuum pumping system, a grounded metal board, a reference pulse signal receiving antenna, arrayed pulse signal receiving antennas and a spectrometer. The method comprises the steps of placing satellite surface material samples into the vacuum chamber, start the vacuum pumping system, starting the electronic gun, regulating acceleration voltage and filament current of the electronic gun, conducting real-time monitoring on beams of the electronic gun by means of a Faraday cup, starting the spectrometer, respectively measuring frequency domains of discharge signals of the pulse signal receiving antennas of different positions, and conducting real-time monitoring on space distribution of discharge pulse radiation electromagnetic fields in an experiment process. An arc structure at the tail end of the grounded metal board resolves the problem of edge reflection of the radiation fields, and measurement of the space distribution of the radiation fields is conducted through the antennas.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

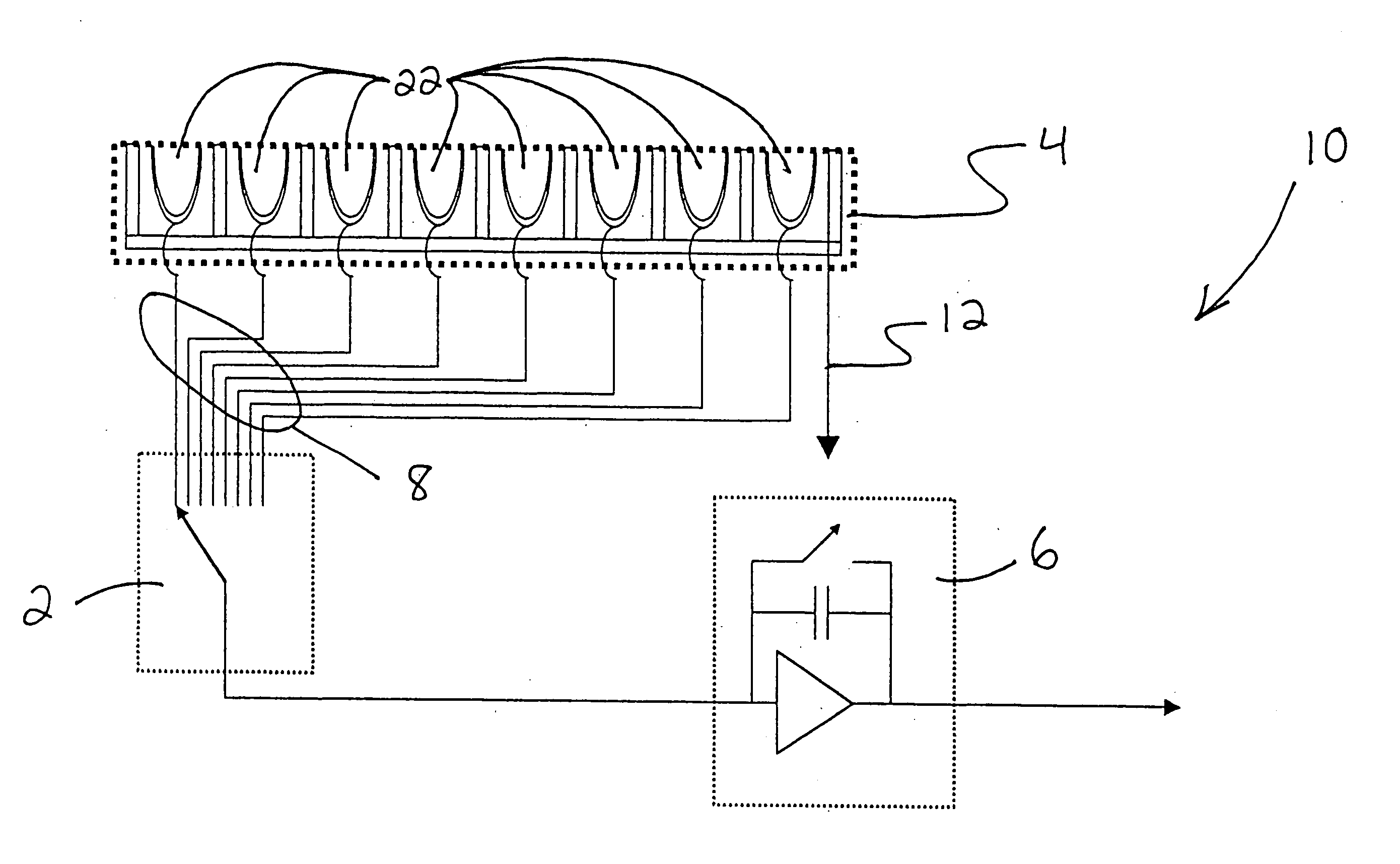

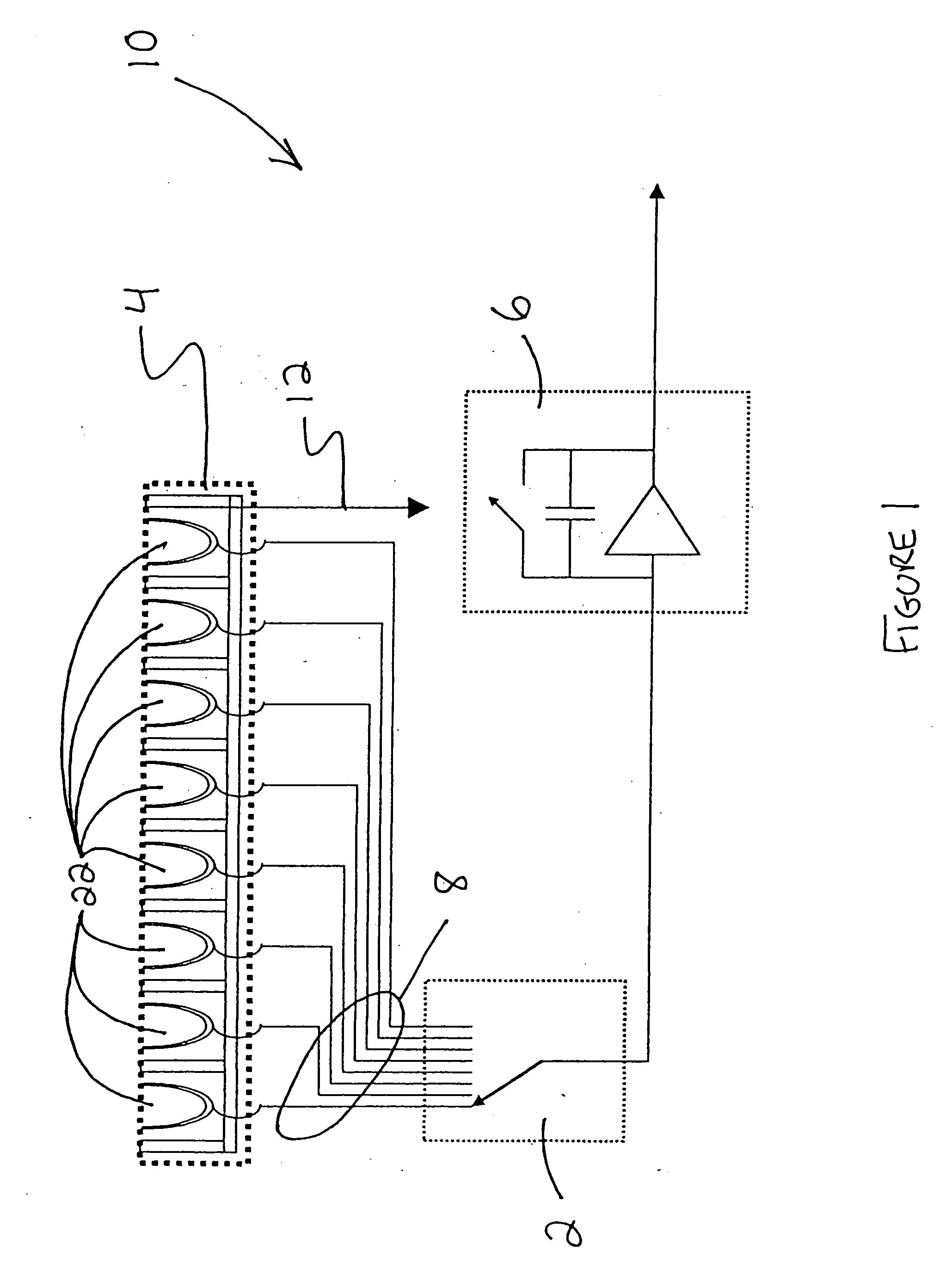

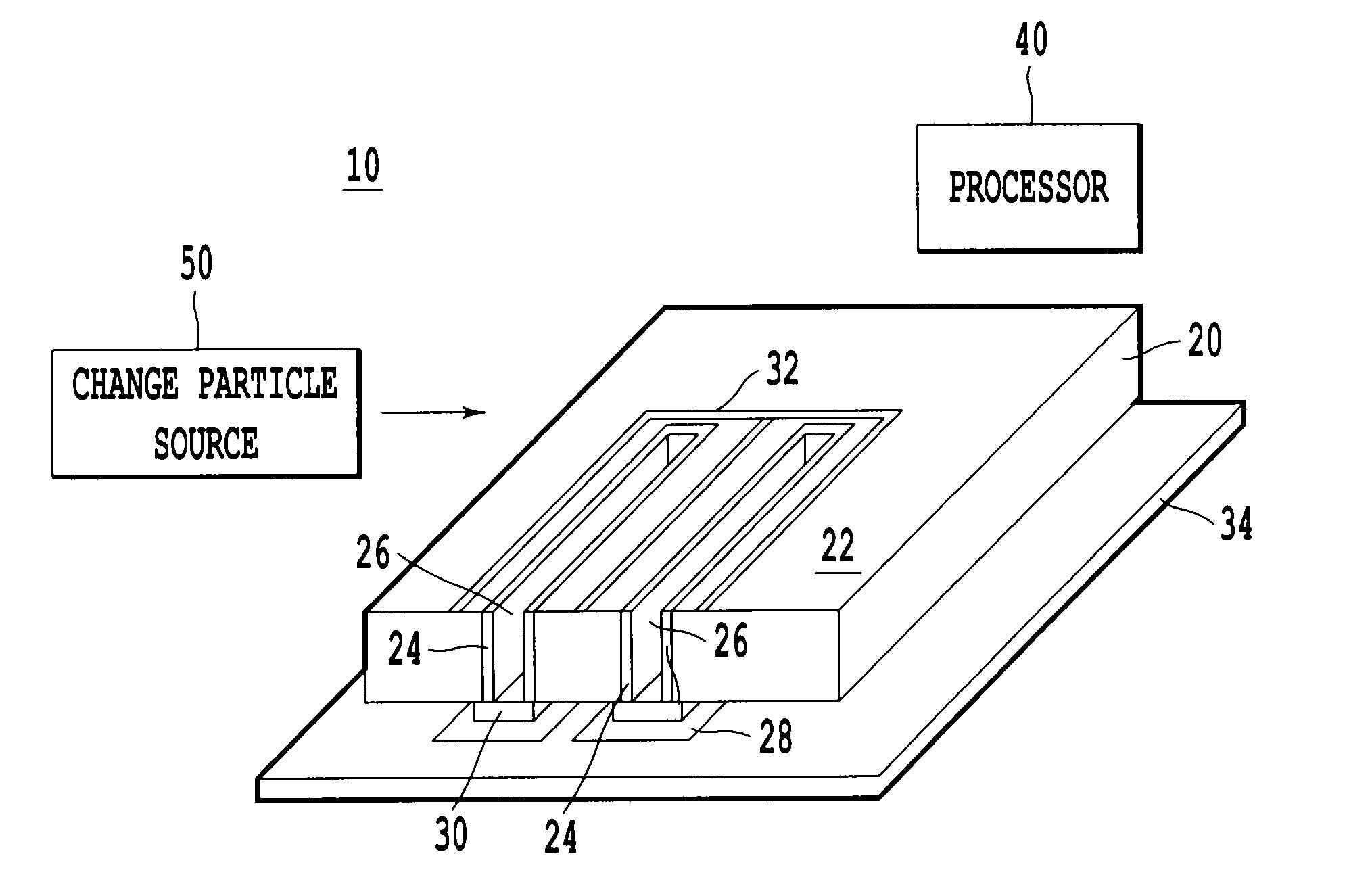

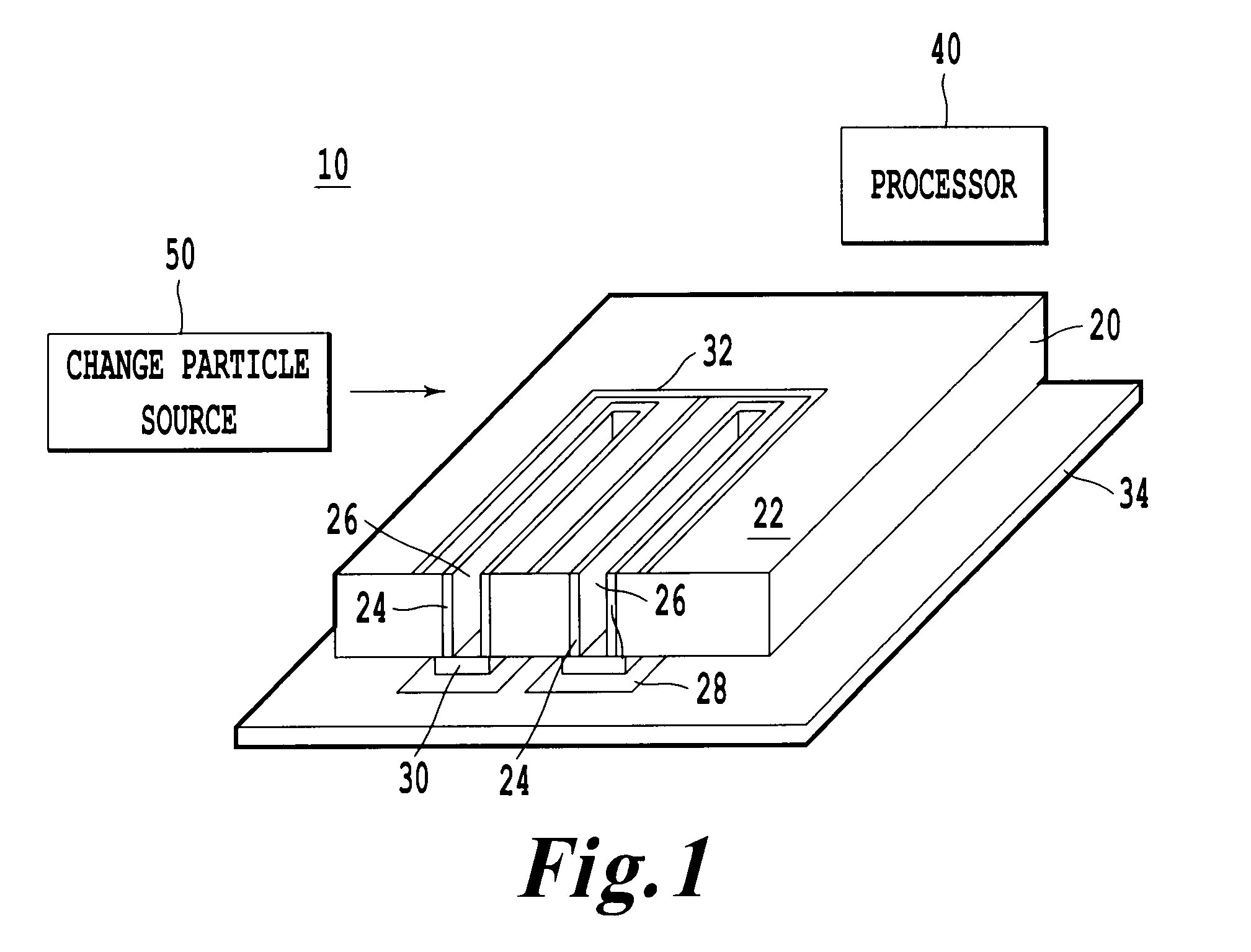

Charged particle beam detection system

InactiveUS7282709B2Improve the level ofEasy to useThermometer detailsStability-of-path spectrometersIntegratorDetector array

A charged particle beam detection system that includes a Faraday cup detector array (FCDA) for position-sensitive charged particle beam detection is described. The FCDA is combined with an electronic multiplexing unit (MUX) that allows collecting and integrating the charge deposited in the array, and simultaneously reading out the same. The duty cycle for collecting the ions is greater than 98%. This multiplexing is achieved by collecting the charge with a large number of small and electronically decoupled Faraday cups. Because Faraday cups collect the charge independent of their charge state, each cup is both a collector and an integrator. The ability of the Faraday cup to integrate the charge, in combination with the electronic multiplexing unit, which reads out and empties the cups quickly compared to the charge integration time, provides the almost perfect duty cycle for this position-sensitive charged particle detector. The device measures further absolute ion currents, has a wide dynamic range from 1.7 pA to 1.2 μA with a crosstalk of less than 750:1. The integration of the electronic multiplexing unit with the FCDA further allows reducing the number of feedthroughs that are needed to operate the detector.

Owner:UNIV OF WASHINGTON

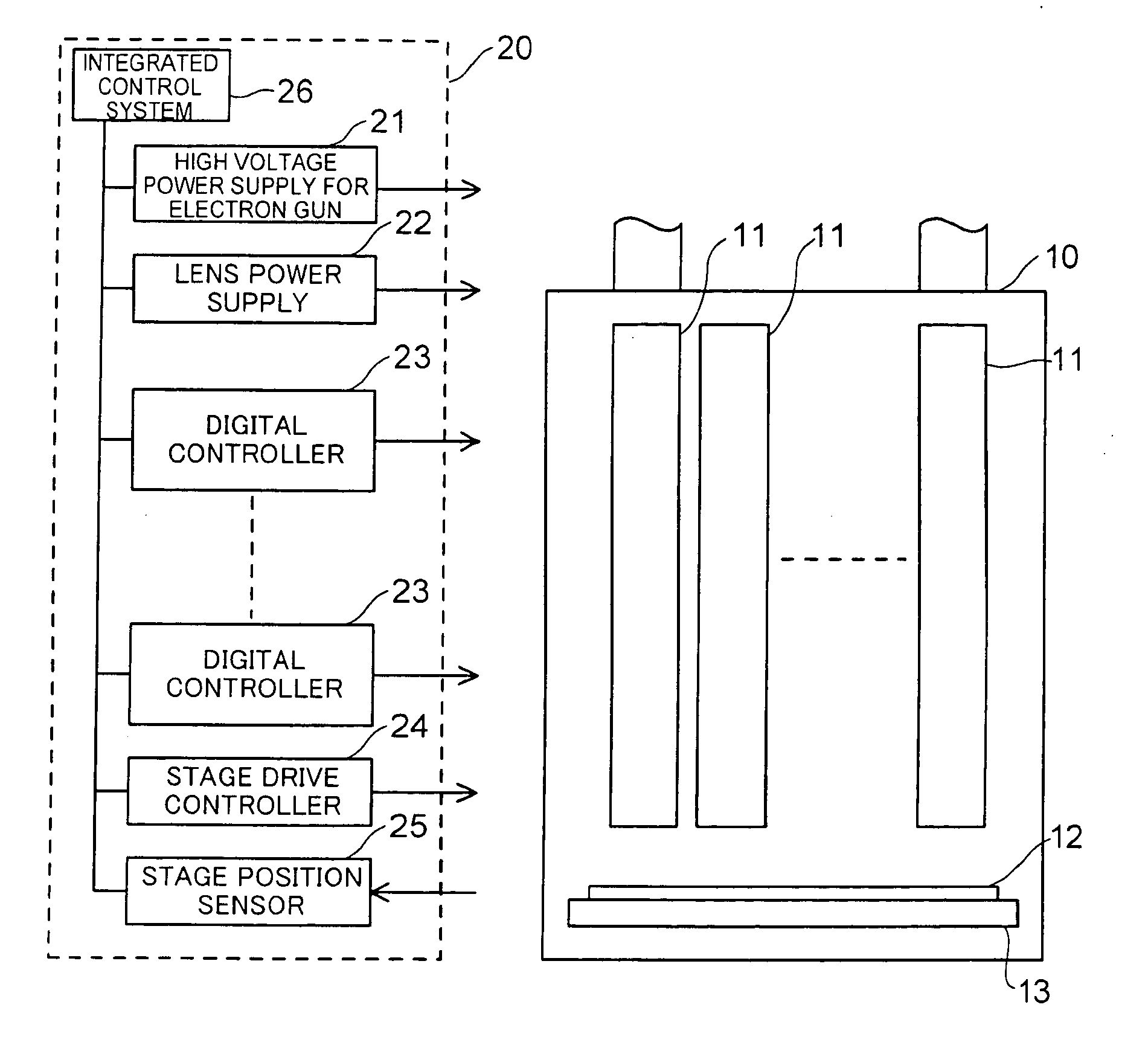

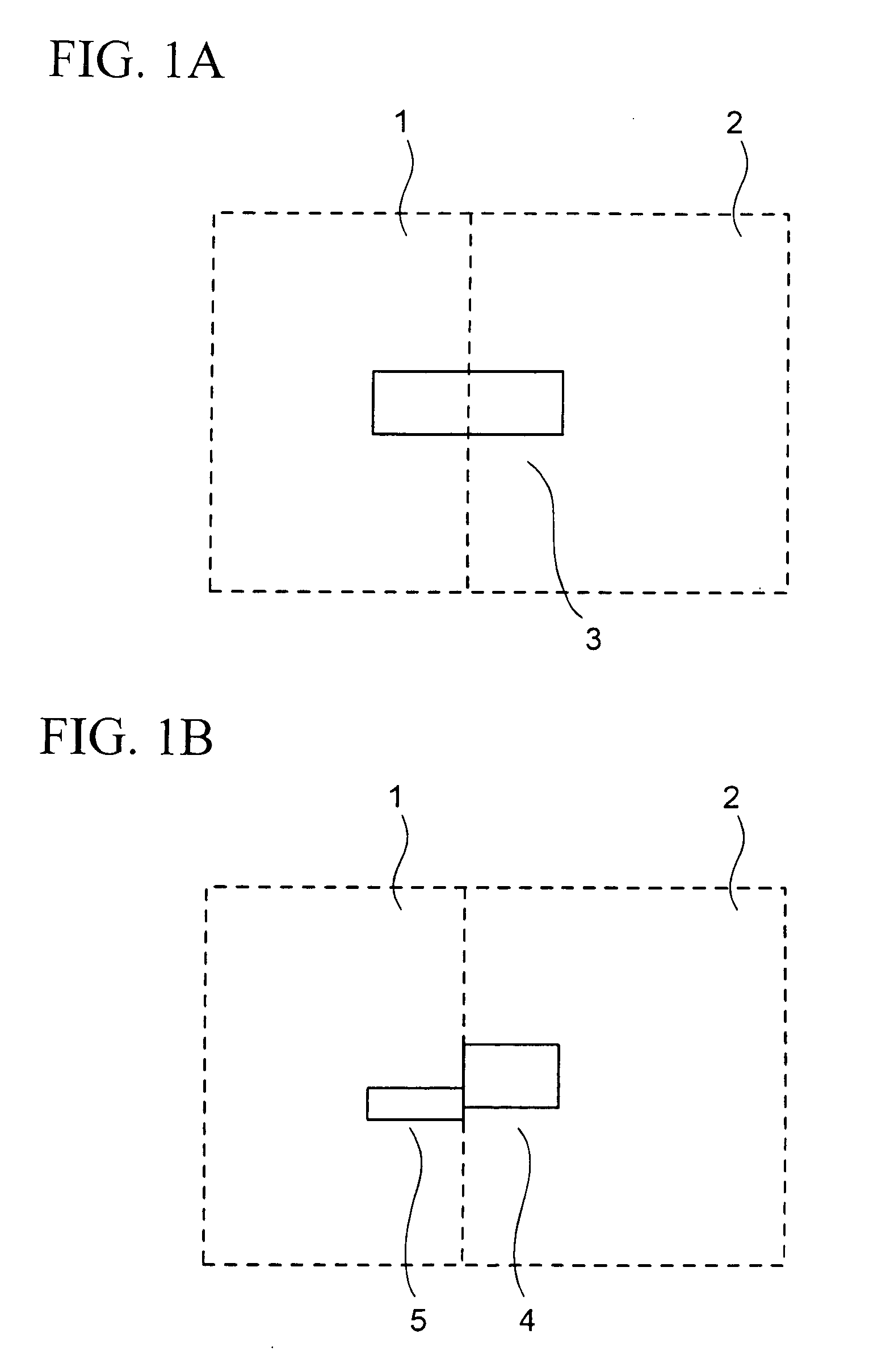

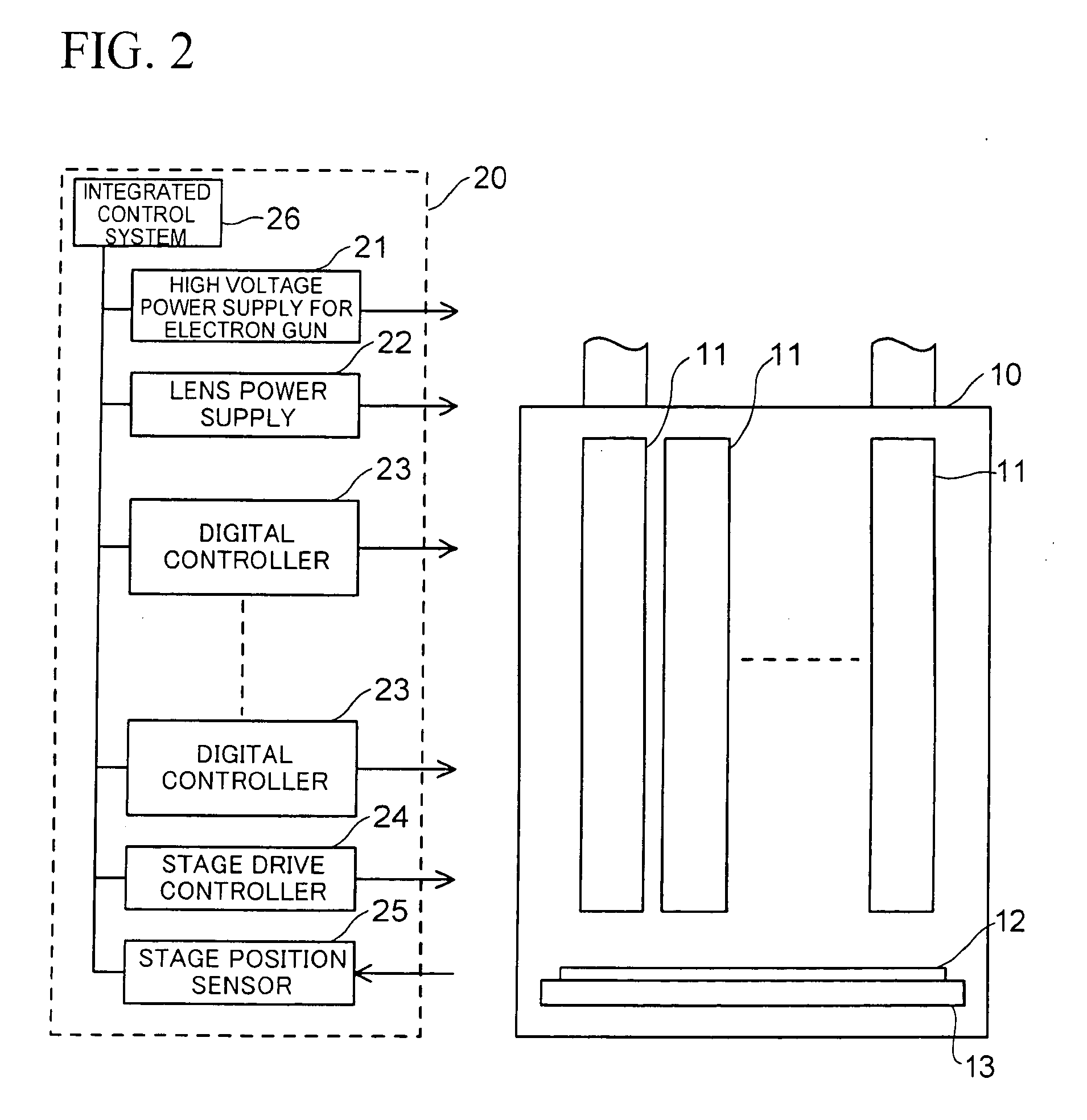

Multi-column electron beam exposure apparatus and multi-column electron beam exposure method

ActiveUS20100019172A1Improve connection accuracyPrevent shifting of irradiation positionElectric discharge tubesNanoinformaticsLight beamElectron-beam lithography

A multi-column electron beam exposure apparatus includes: a plurality of column cells; a wafer stage including an electron-beam-property detecting unit for measuring an electron beam property; and a controller for measuring beam properties of electron beams used in all the column cells by using the electron-beam-property detecting unit, and for adjusting the electron beams of the respective column cells so that the properties of the electron beams used in the column cells may be approximately identical. The electron beam property may be any of a beam position, a beam intensity, and a beam shape of the electron beam to be emitted. The electron-beam-property detecting unit may be a chip for calibration with a reference mark formed thereon or a Faraday cup.

Owner:ADVANTEST CORP

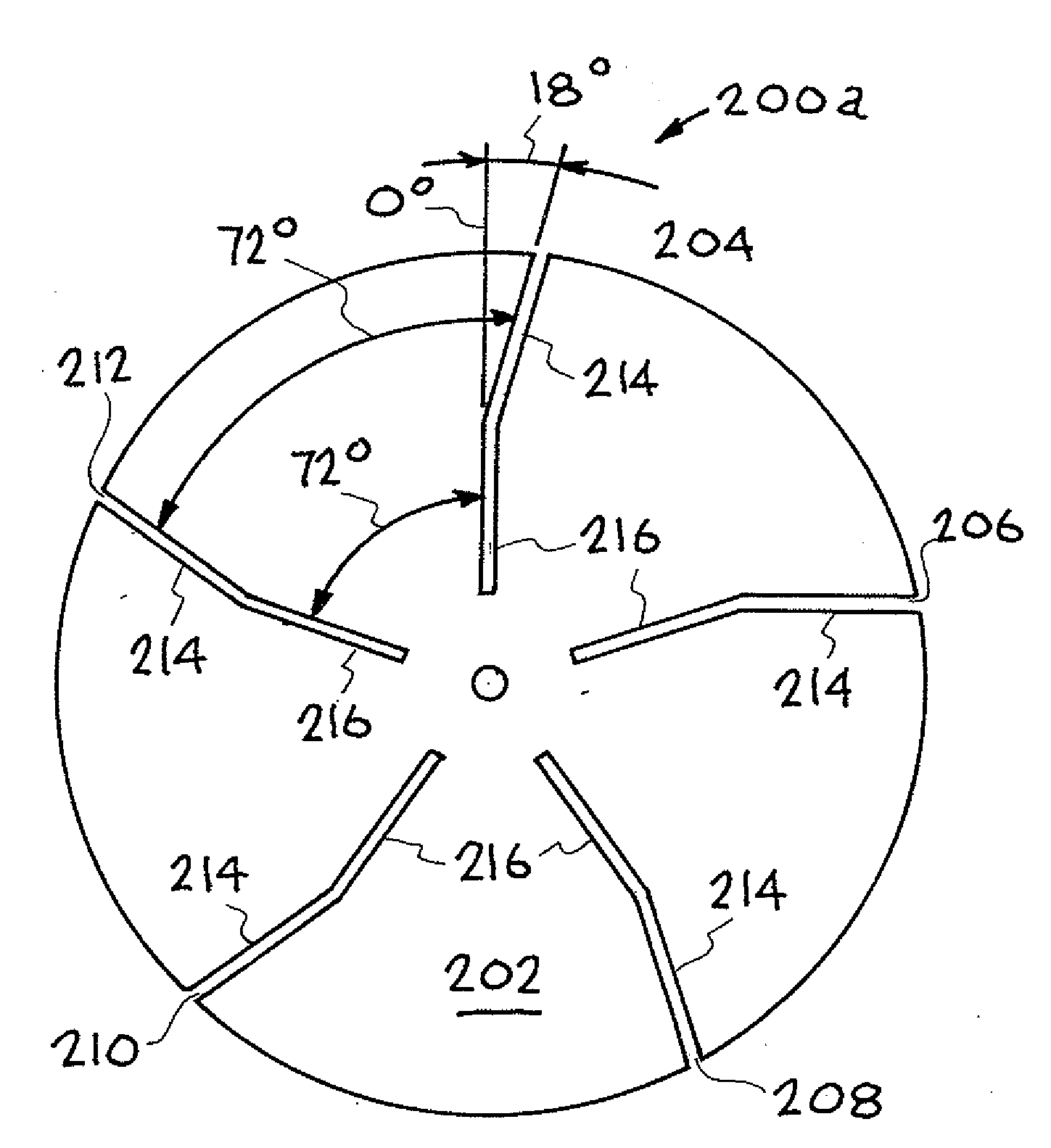

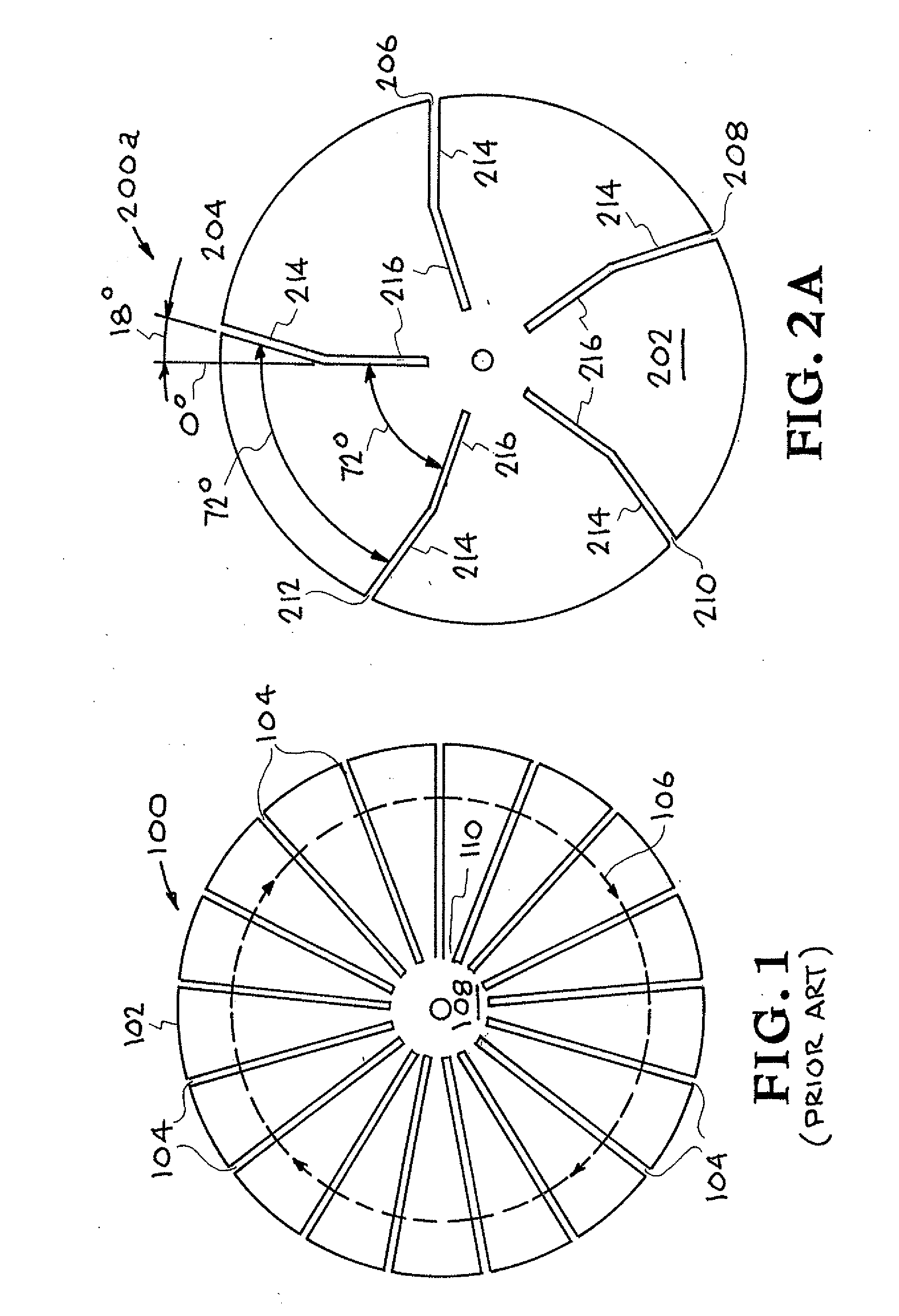

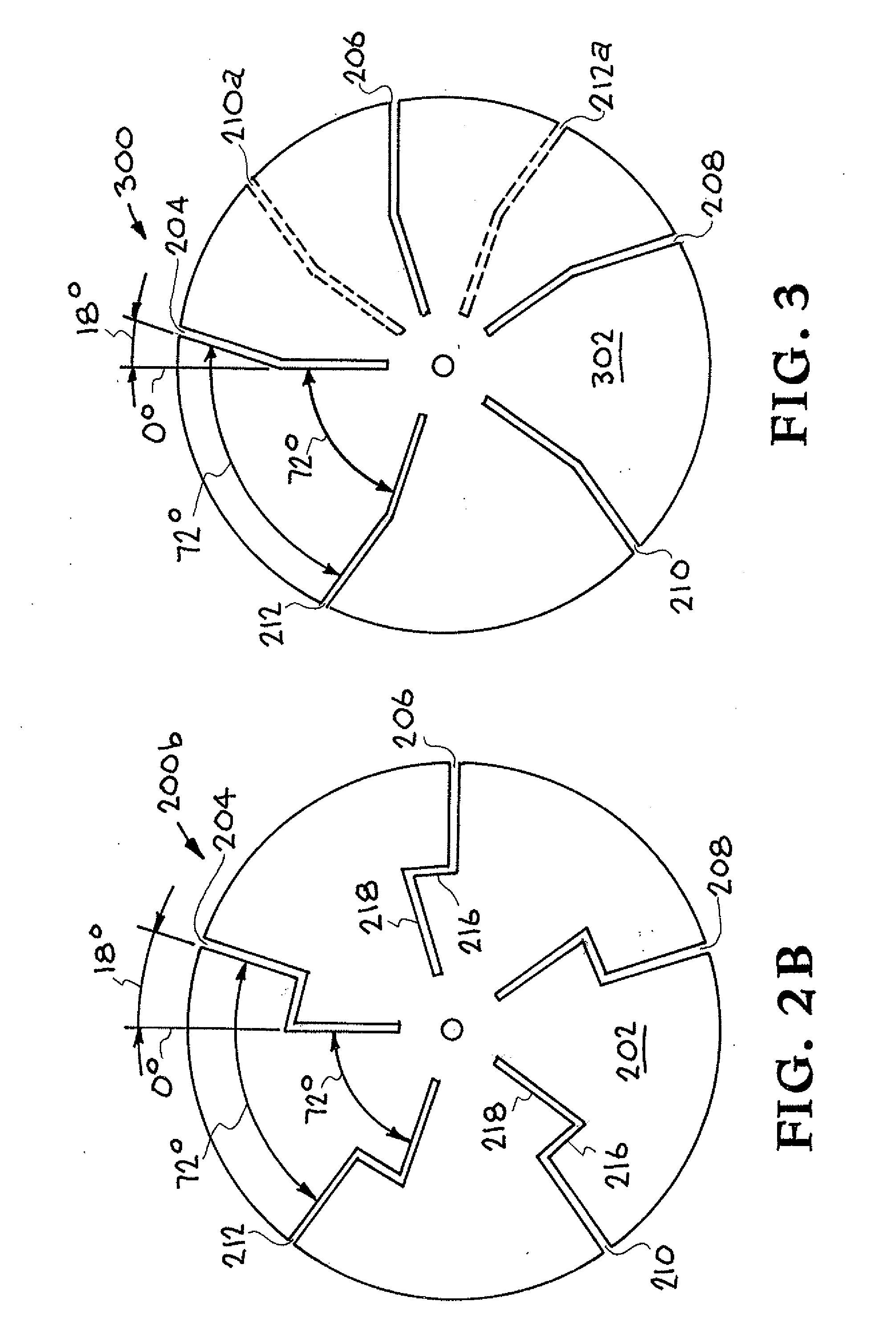

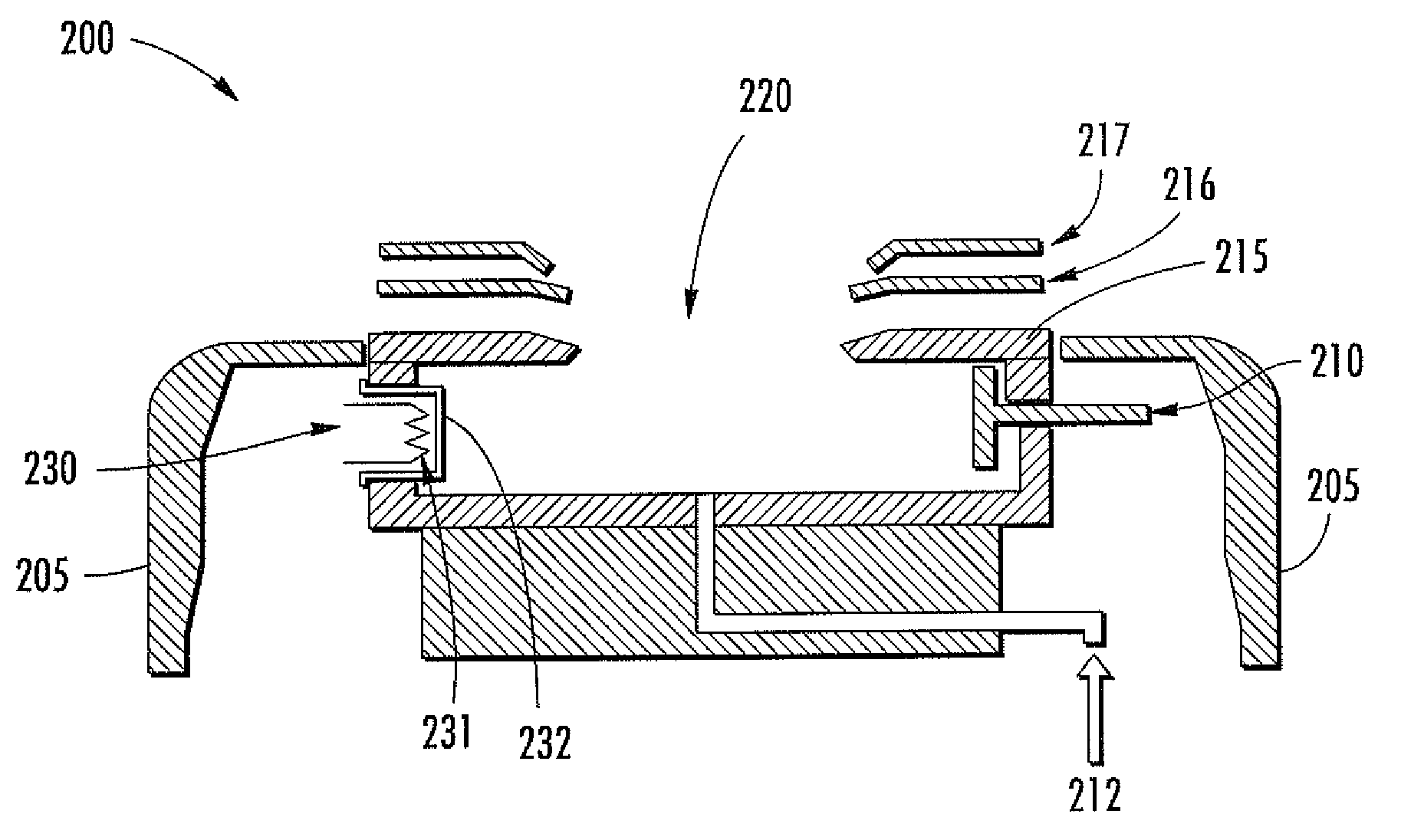

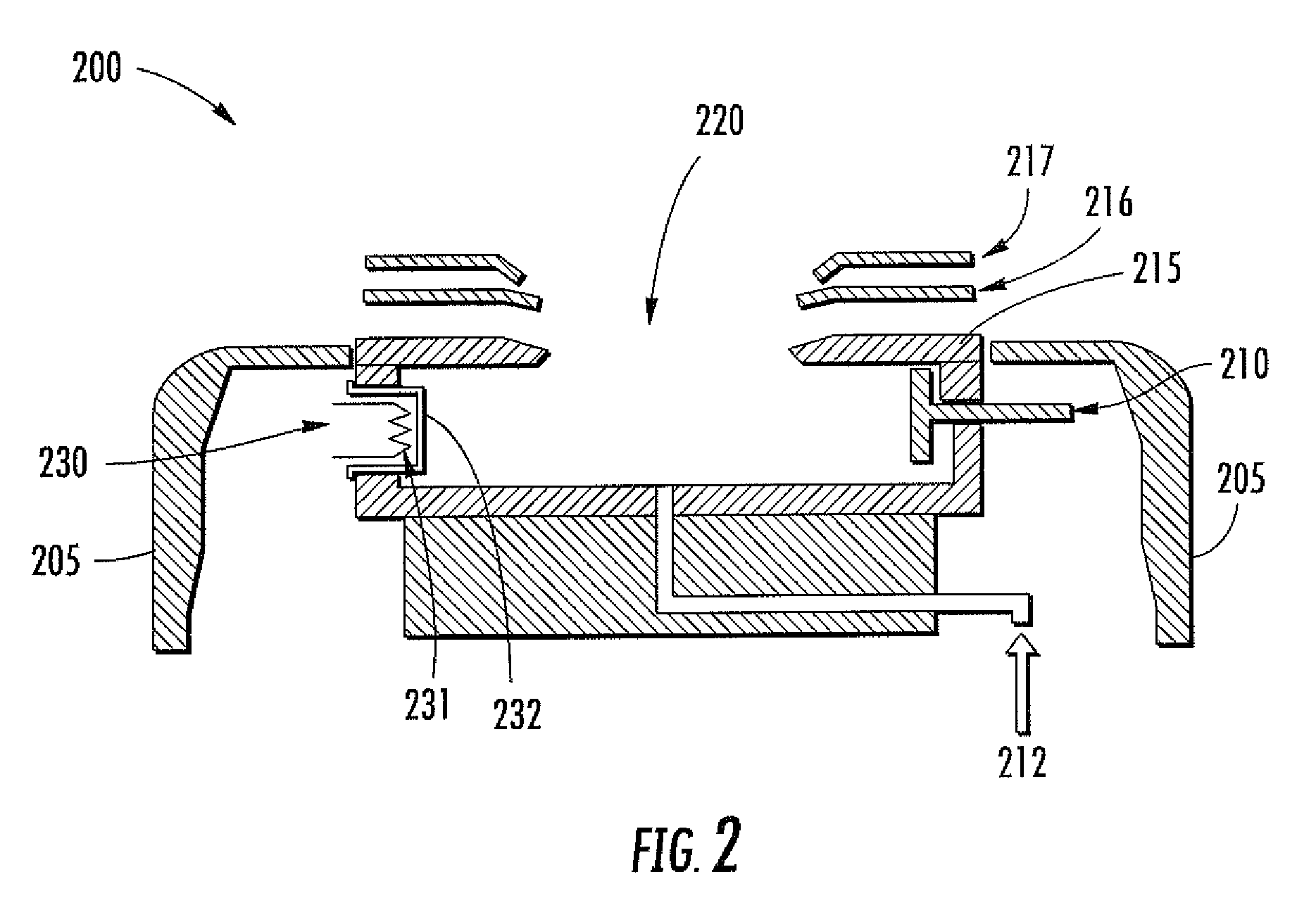

Slit Disk for Modified Faraday Cup Diagnostic for Determing Power Density of Electron and Ion Beams

ActiveUS20100032562A1High resolutionIncrease the number ofStability-of-path spectrometersMaterial analysis by electric/magnetic meansDiagnostic systemElectron

A diagnostic system for characterization of an electron beam or an ion beam includes an electrical conducting disk of refractory material having a circumference, a center, and a Faraday cup assembly positioned to receive the electron beam or ion beam. At least one slit in the disk provides diagnostic characterization of the electron beam or ion beam. The at least one slit is located between the circumference and the center of the disk and includes a radial portion that is in radial alignment with the center and a portion that deviates from radial alignment with the center. The electron beam or ion beam is directed onto the disk and translated to the at least one slit wherein the electron beam or ion beam enters the at least one slit for providing diagnostic characterization of the electron beam or ion beam.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Ion Source Cleaning End Point Detection

In an ion implanter, a Faraday cup is utilized to receive an ion beam generated during ion source cleaning. The detected beam has an associated mass spectrum which indicates when the ion source cleaning process is complete. The mass spectrum results in a signal composed of a cleaning agent and the material comprising the ion source. This signal will rise over time as the ion source chamber is being cleaned and will level-off and remain constant once the deposits are etched away from the source chamber, thereby utilizing existing implant tools to determine endpoint detection during ion source cleaning.

Owner:VARIAN SEMICON EQUIP ASSOC INC

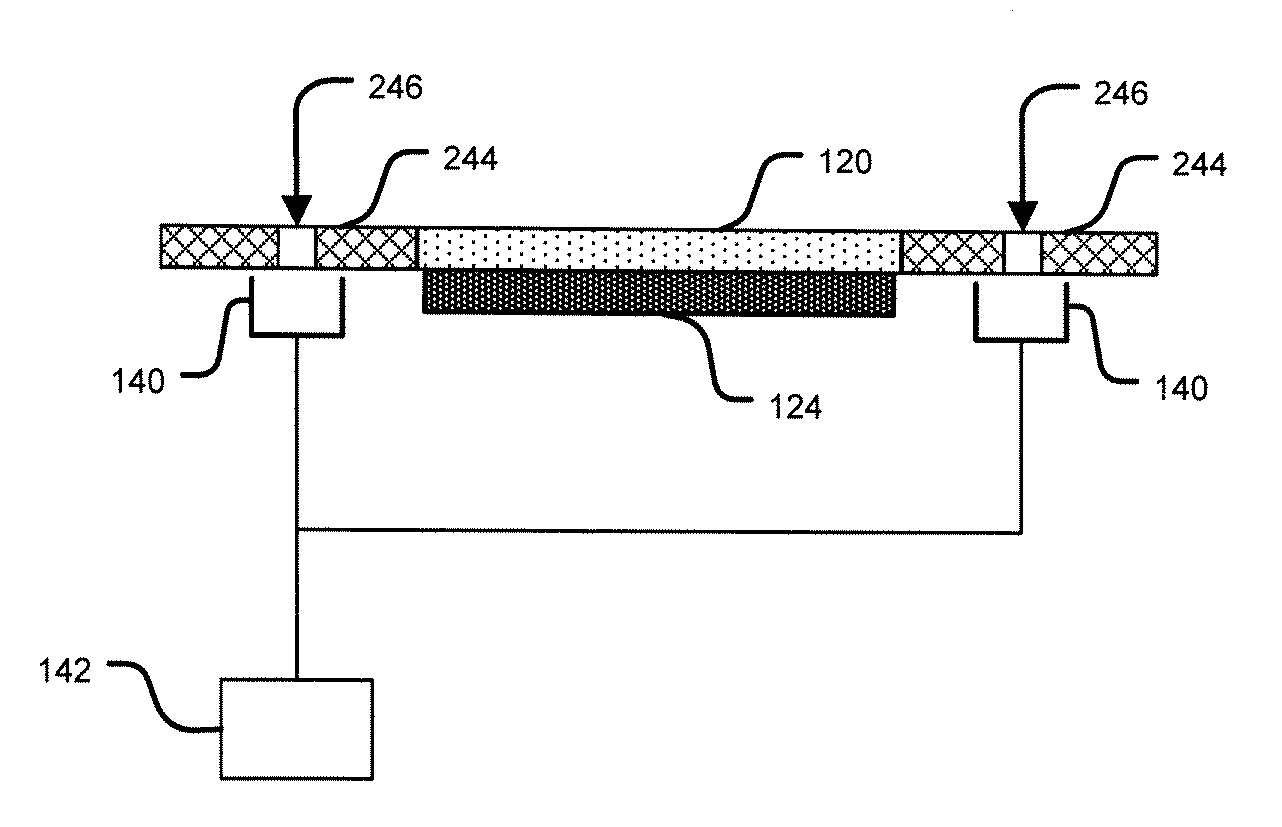

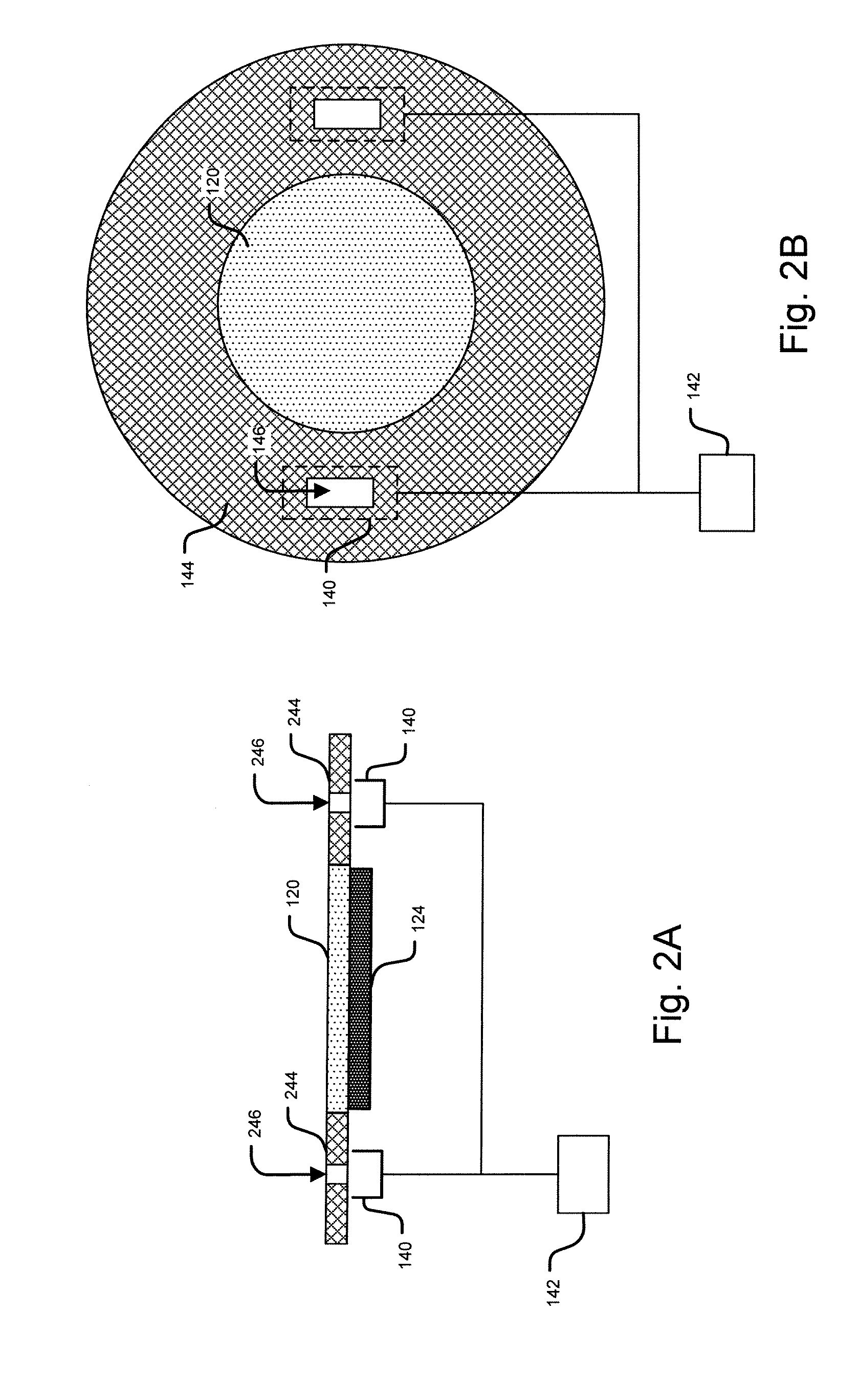

Technique for using an improved shield ring in plasma-based ion implantation

A technique for using an improved shield ring in plasma-based ion implantation is disclosed. In one particular exemplary embodiment, the technique may be realized as an apparatus and method for plasma-based ion implantation, such as radio frequency plasma doping (RF-PLAD). The apparatus and method may comprise a shield ring positioned on a same plane as and around a periphery of a target wafer, wherein the shield ring comprises an aperture-defining device for defining an area of at least one aperture, a Faraday cup positioned under the at least one aperture, and dose count electronics connected the Faraday cup for calculating ion dose rate. The at least one aperture may comprise at least one of a circular, arc-shaped, slit-shaped, ring-shaped, rectangular, triangular, and elliptical shape. The aperture-defining device may comprise at least one of silicon, silicon carbide, carbon, and graphite.

Owner:VARIAN SEMICON EQUIP ASSOC INC

Advanced ion beam detector for ion implantation tools

ActiveUS7026628B2Improve accuracyThermometer detailsBeam/ray focussing/reflecting arrangementsAngle of incidenceLight beam

The present invention provides an improved Faraday cup configuration that allows determination of a non-zero angle of incidence and / or a beam divergence with high accuracy. Moreover, by substantially simultaneously and continuously displaying information of a plurality of Faraday cups, the set-up of an implantation tool may be significantly facilitated and may be carried out in a substantially automated manner.

Owner:ADVANCED MICRO DEVICES INC

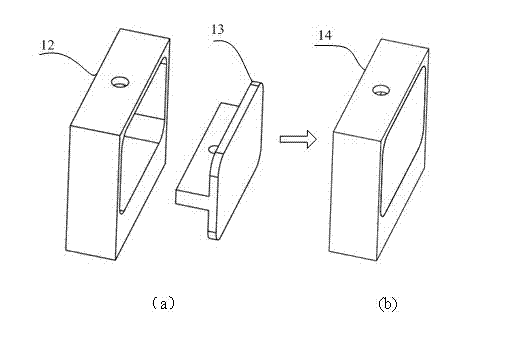

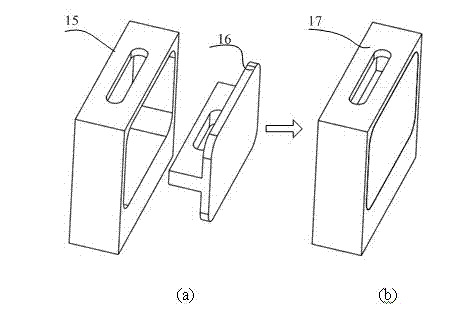

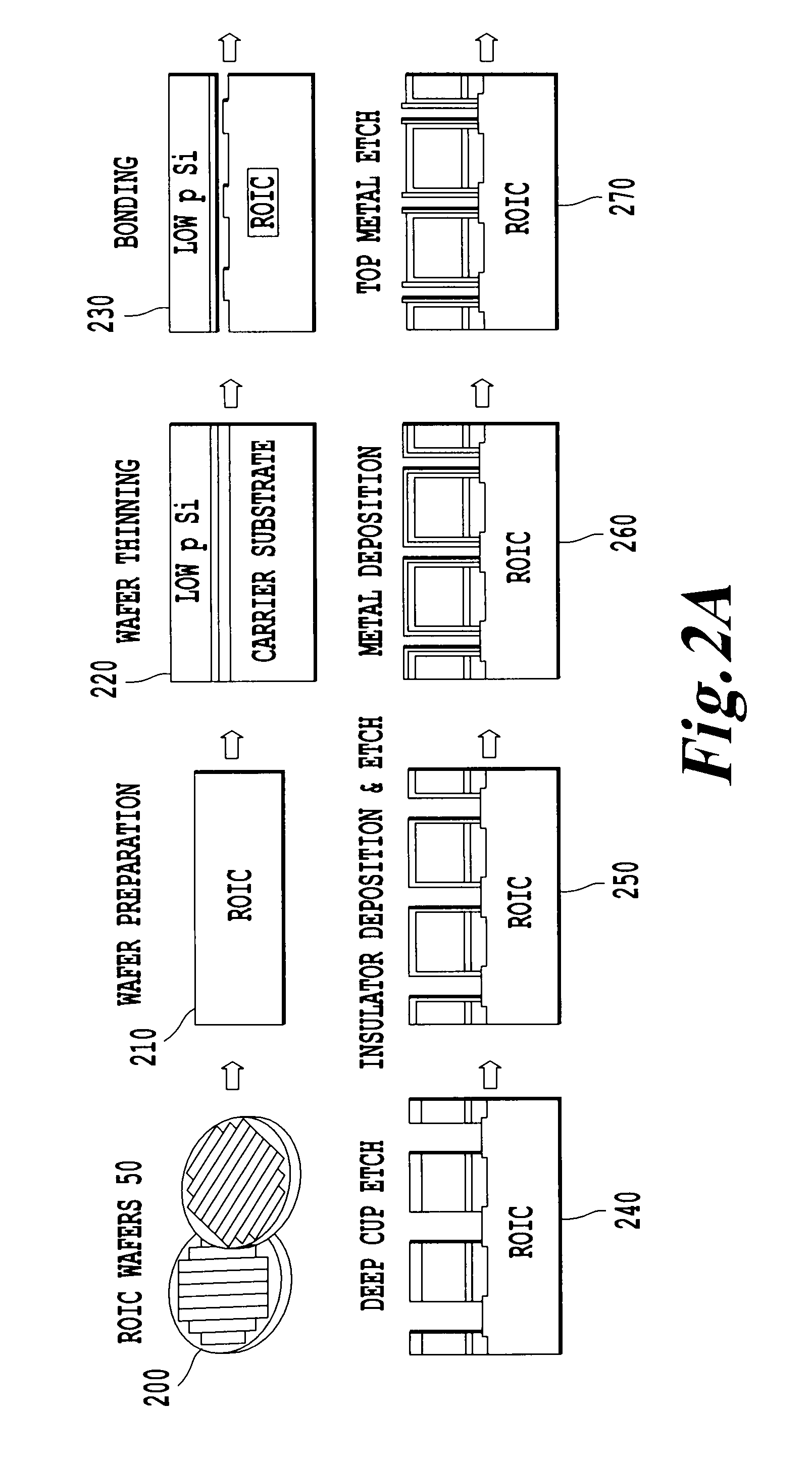

Faraday cup array integrated with a readout IC and method for manufacture thereof

InactiveUS20110031388A1Spectrometer detectorsWave amplification devicesDetector arrayCharged particle

A detector array and method for making the detector array. The array includes a substrate including a plurality of trenches formed therein, and includes a plurality of collectors electrically isolated from each other, formed on the walls of the trenches, and configured to collect charge particles incident on respective ones of the collectors and to output from said collectors signals indicative of charged particle collection. The array includes a plurality of readout circuits disposed on a side of the substrate opposite openings to the collectors. The readout circuits are configured to read charge collection signals from respective ones of the plurality of collectors.

Owner:RES TRIANGLE INST

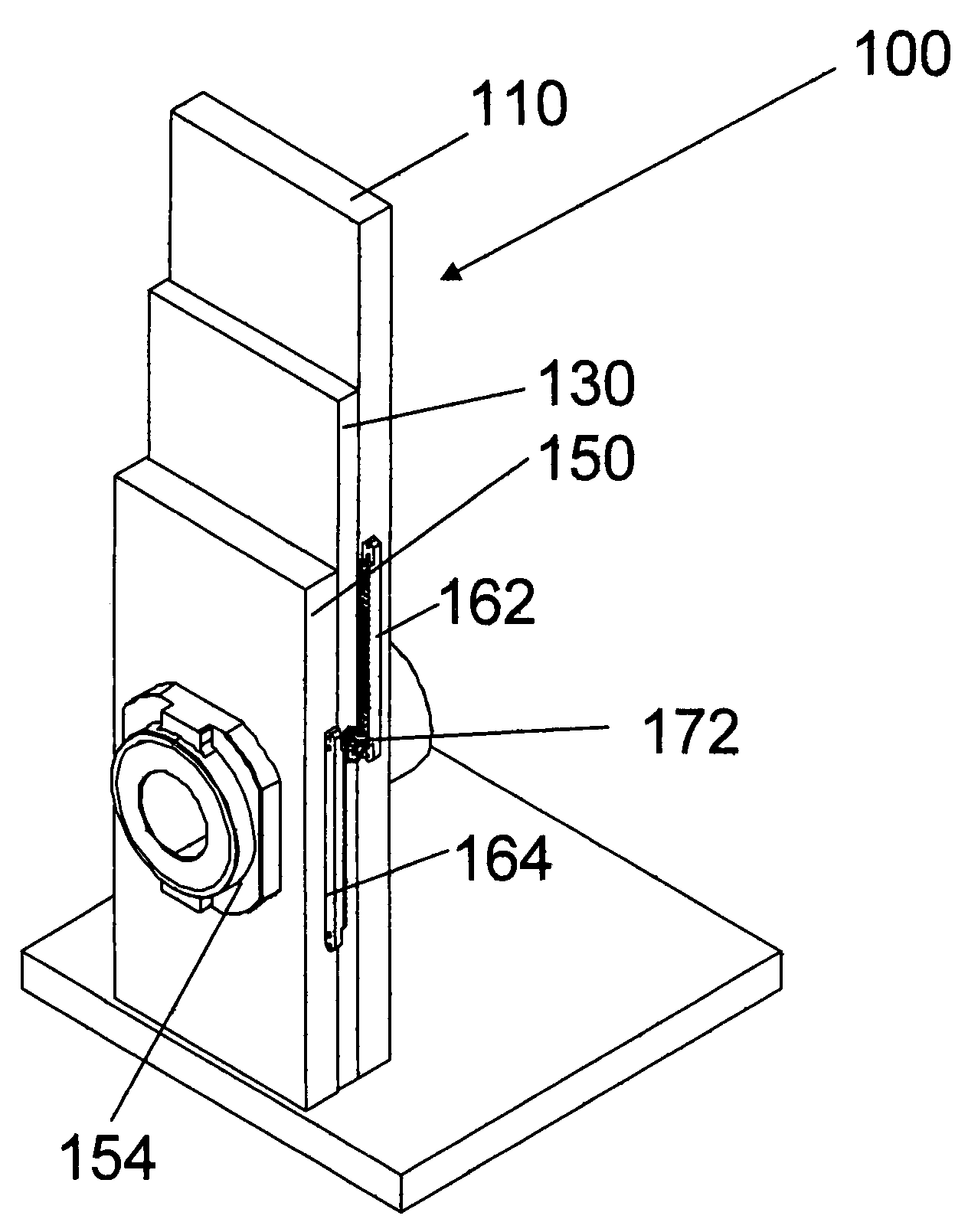

Compound sliding seal unit suitable for atmosphere to vacuum applications

ActiveUS20090066031A1Reliable effective dynamic sealingImprove sealingPiston ringsScattering properties measurementsAtmospheric airReduced size

The present invention is a compound sliding seal unit of markedly reduced size and height dimensions which is employed as a discrete assembly for both the passage across and the at-will height adjustment of a mounted, rotatable shaft which extends from the atmospheric environment portion into the vacuum environmental portion of an ion implanter apparatus. The extended, rotatable shaft is typically fashioned as either a rotatable hollow tube or conduit (suitable for the passage of electrical components) and / or as a rotatable support suitable for the mounting of a pivotal scanning radial arm translation system.The manner of construction and the substantially reduced height dimensions of the compound sliding seal unit permits on-demand changes of height for the mounted, rotatable shaft which extends from the atmospheric environment and extends through the compound unit into the confined and limited spatial volume of a vacuum environment within a conventional ion implantation apparatus. The compound unit also allows the user to maintain a high vacuum within the vacuum environment despite the fact that the height of the feed-through member can be raised and lowered repeatedly at will. Its compact size frees space which can be used to extend the vacuum chamber for purposes such as a deep Faraday cup for beam measurement.

Owner:ADVANCED ION BEAM TECHNOLOGY INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com