Device for detecting ion beam section density distribution and uniform ion beam distribution in real time

A density distribution and ion beam technology, applied in the field of semiconductor device manufacturing, can solve the problems of not being able to detect the beam profile and scan the beam distribution in real time, and achieve the effect of improving the beam shape and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in further detail below in conjunction with specific embodiment:

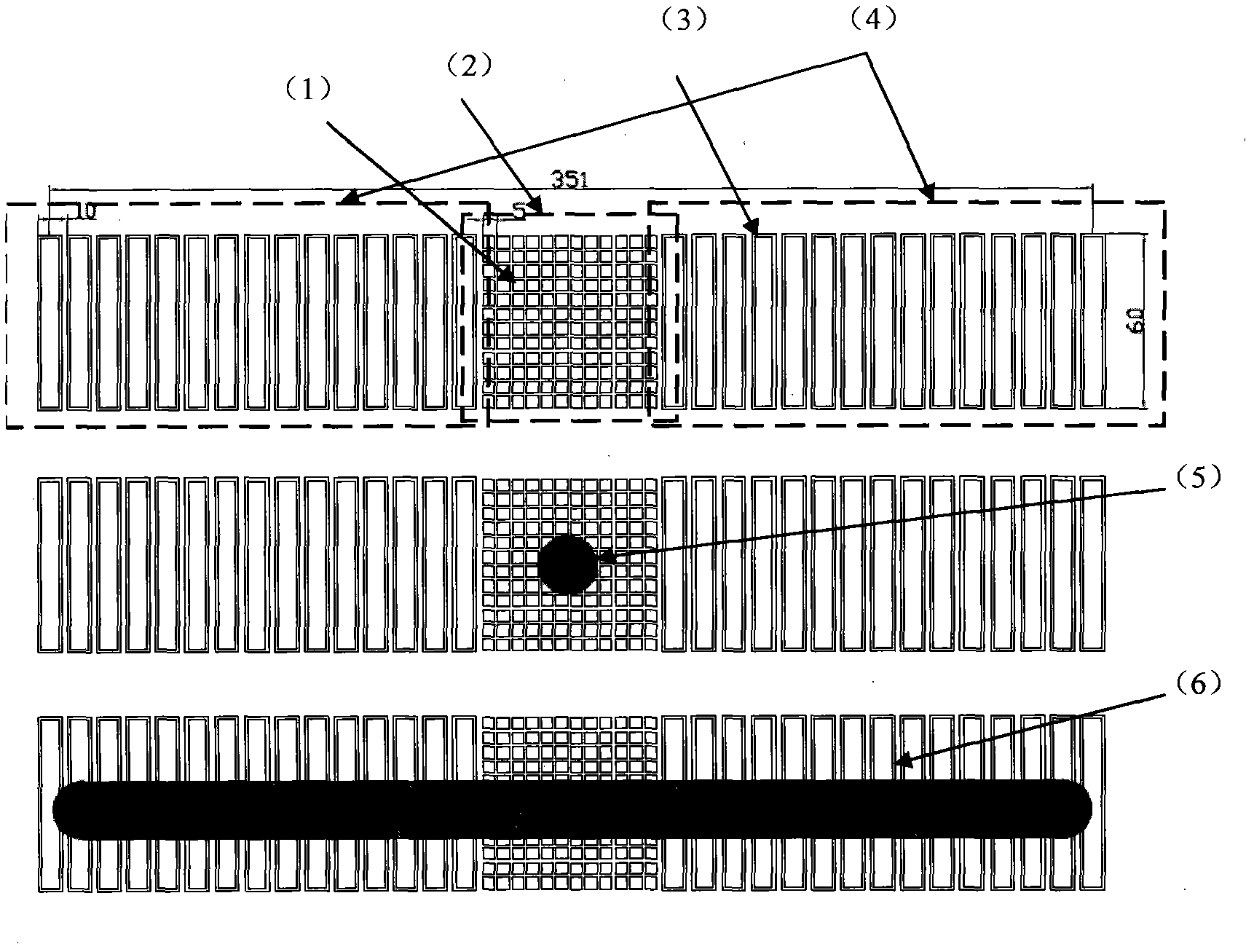

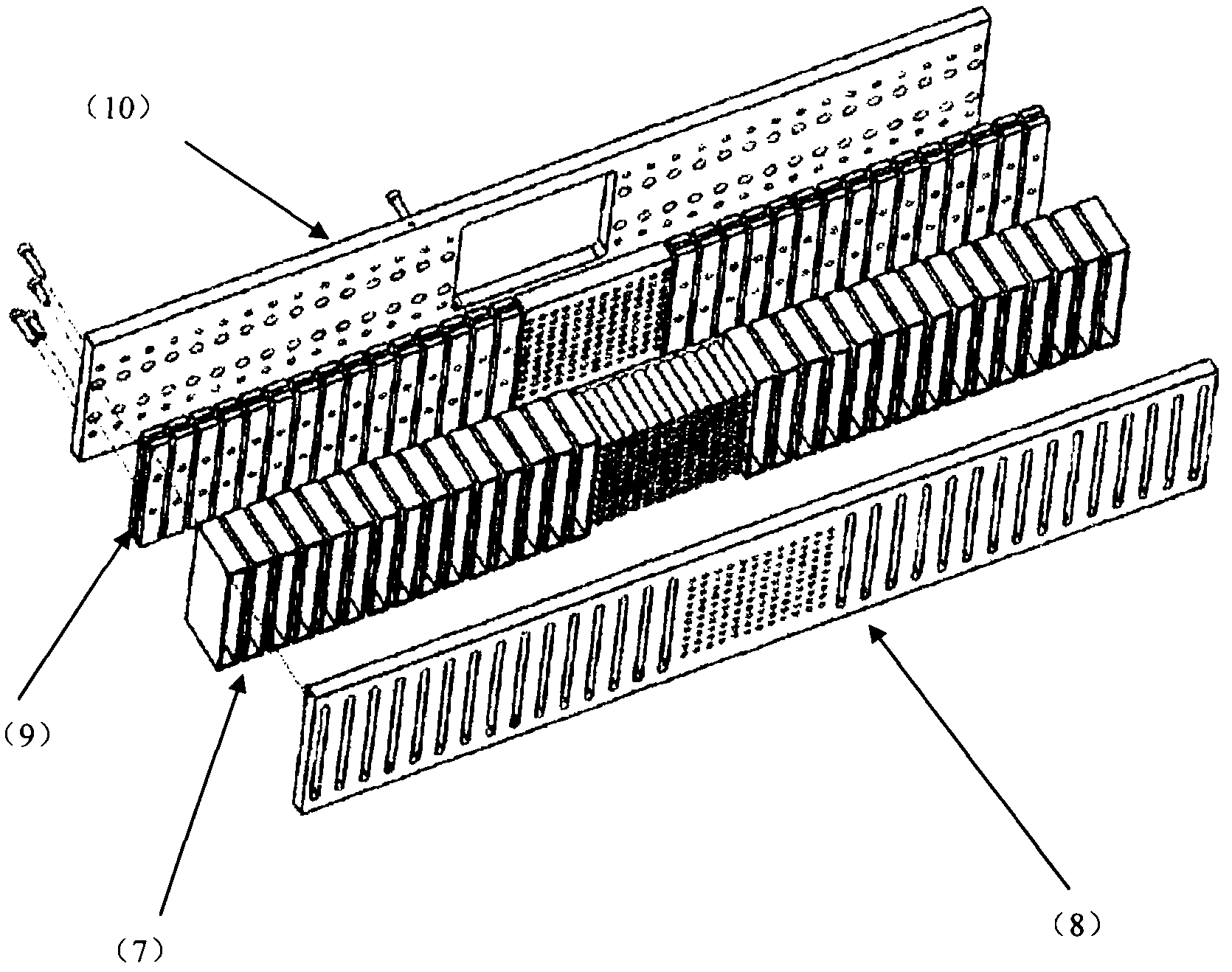

[0015] Such as figure 1 As shown, the Faraday array combination device consists of a two-dimensional Faraday array (2) in the middle and two one-dimensional Faraday arrays (4) on both sides. This installation method is suitable for bidirectional scanning ion implanters, that is, after scanning The beam shape is extended to both sides of the beam center. When the beam is in the focused state (5), all the beam is projected on the two-dimensional Faraday array (2), and by detecting the beam size of each small Faraday, the distribution of the beam density can be obtained in real time, so that it can be adjusted in real time Control parameters, change the shape of the beam profile, and obtain high-quality beams. When the beam current is in the scanning state (6), the beam current is distributed on the one-dimensional Faraday array (4) on both sides. By detecting the size o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com