Measurement system and measurement method of secondary electron emission yield of dielectric material

A technology of secondary electron emission and dielectric materials, applied in the space application field of aerospace materials, can solve the problems of complex measurement, influence, limited experimental accuracy and efficiency, and achieve high measurement efficiency, avoiding direct errors and small errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is a specific implementation manner of the content of the present invention, and the content of the present invention will be further clarified through the specific implementation mode below. Of course, the following specific embodiments are described only to illustrate different aspects of the present invention, and should not be construed as limiting the scope of the present invention.

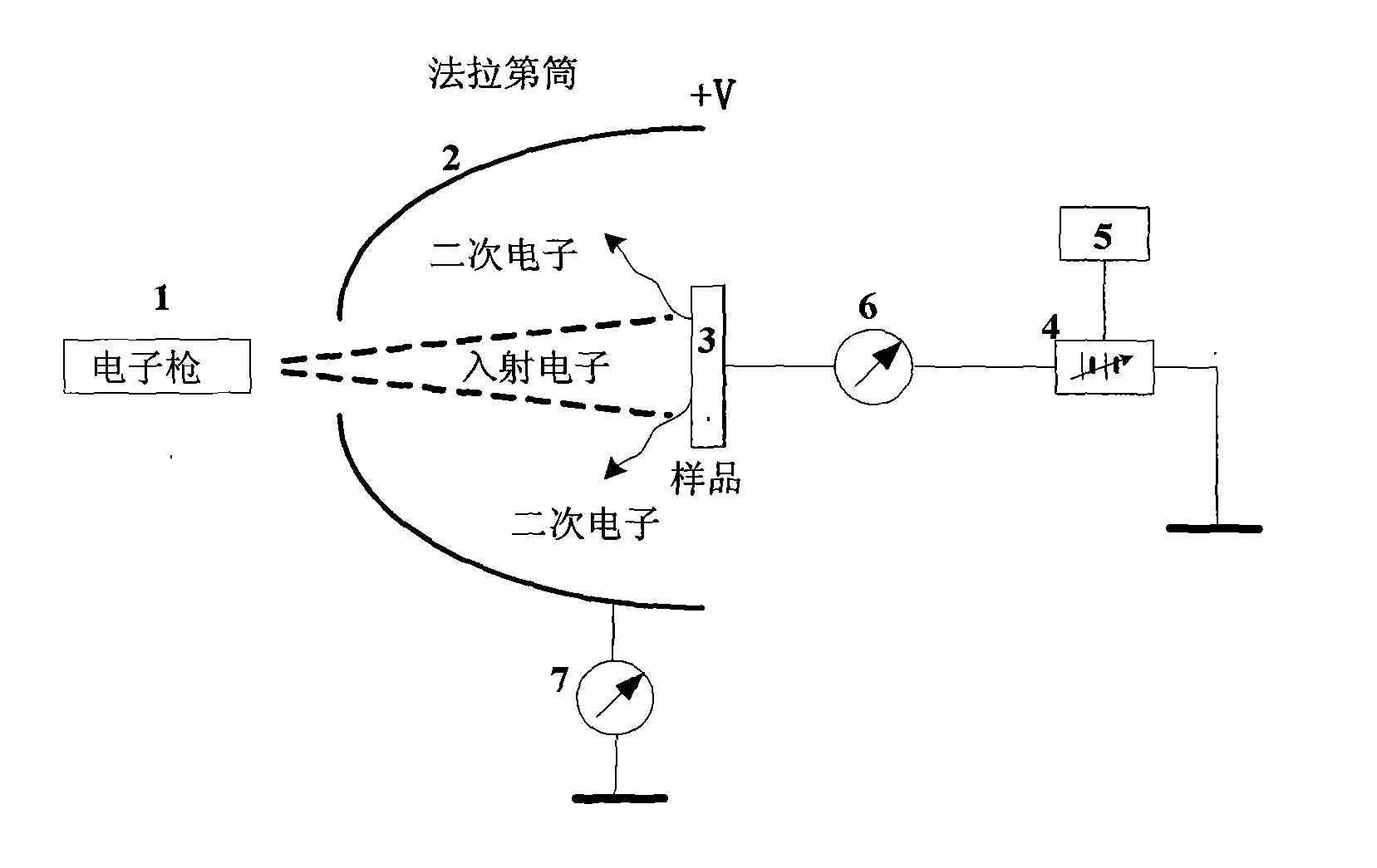

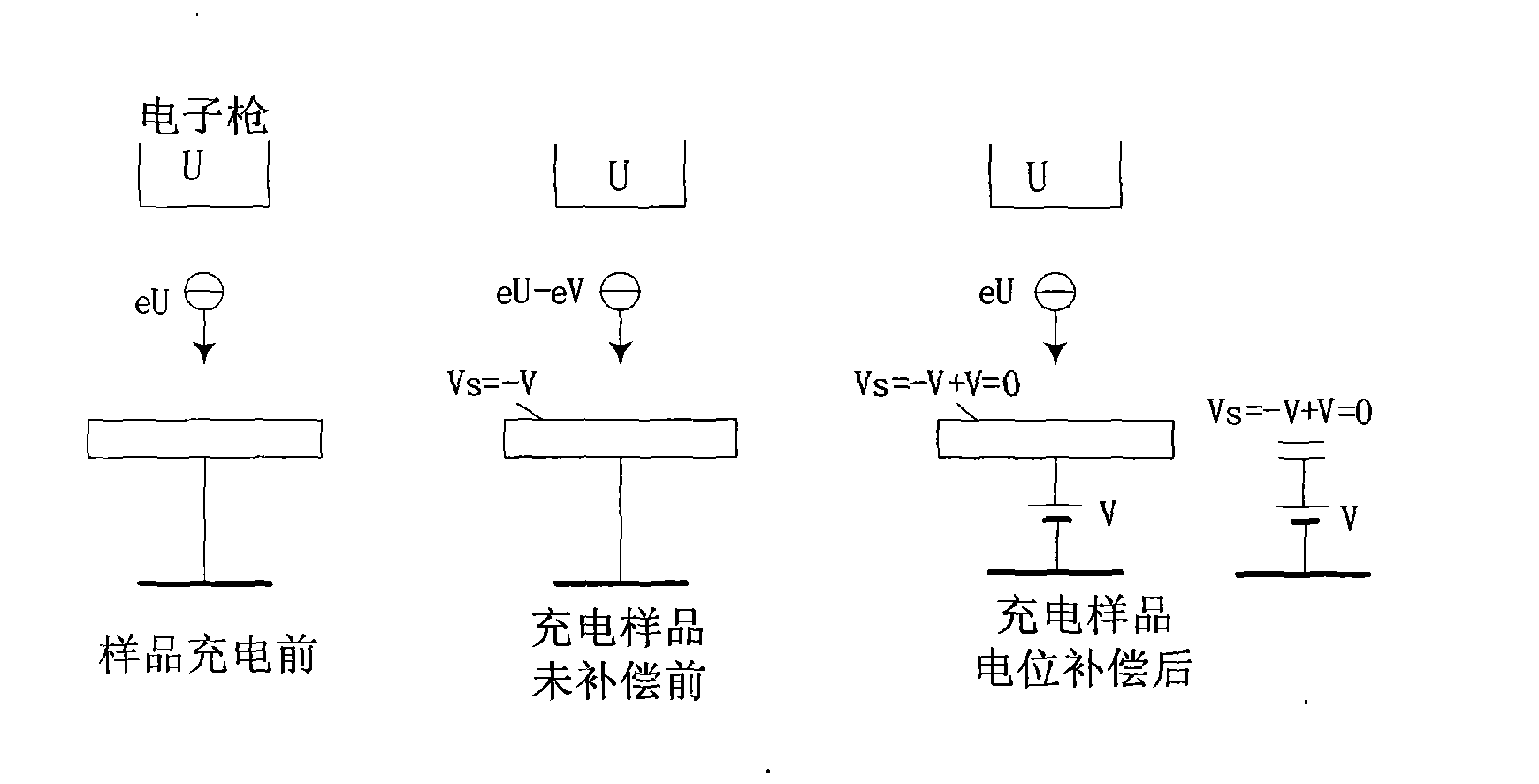

[0020] refer to figure 1 , figure 1 It is a schematic diagram of the structure of the measurement system for the secondary electron emission coefficient of the dielectric material of the present invention. Wherein, the measurement system of the secondary electron emission coefficient of the dielectric material of the present invention includes a Faraday cup and a pulsed electron gun, wherein the Faraday cup is provided with an electron entrance, and the Faraday cup can be used to collect samples under a positive bias of about ten volts. For the generated secondary elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com