Asynchronous motor excitation mutual inductance curve measuring system and measuring method

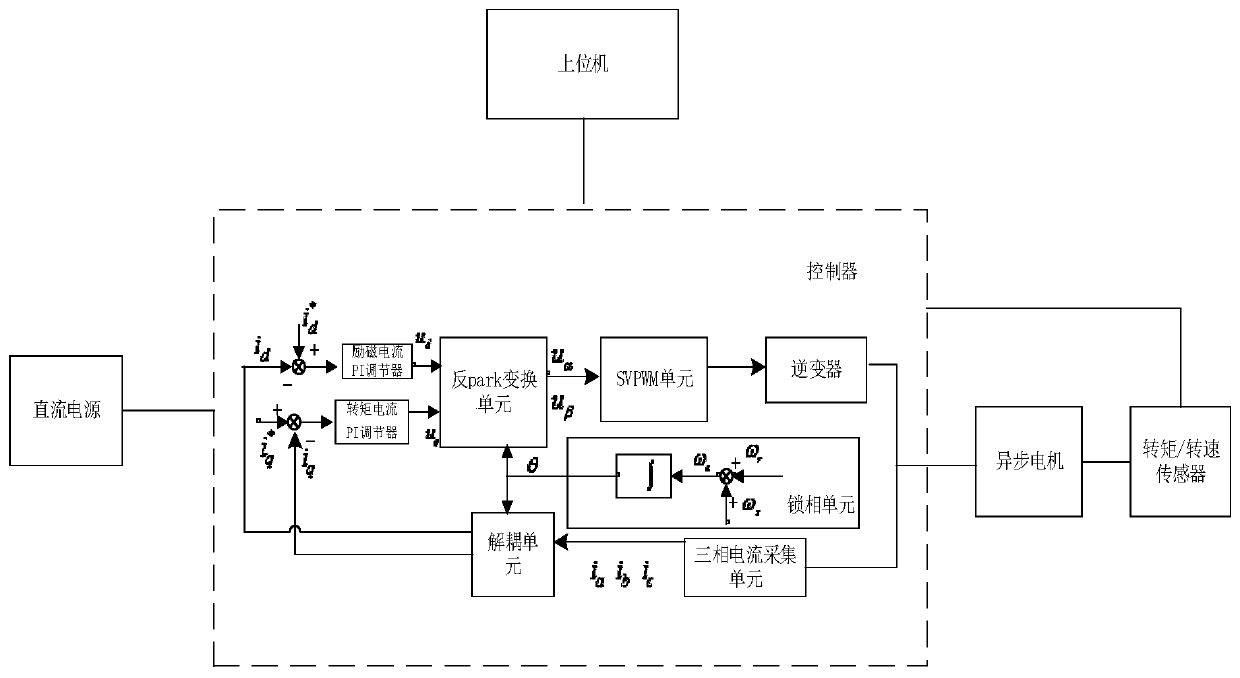

A technology of asynchronous motor and measurement method, which is applied in the direction of motor generator testing, etc., can solve the problems of inability to achieve accurate orientation of rotor magnetic field, inability to obtain excitation mutual inductance curve, and reduced system efficiency, so as to improve the accuracy of rotor magnetic field orientation and real-time compensation Rotor time constant, effect of simple system design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

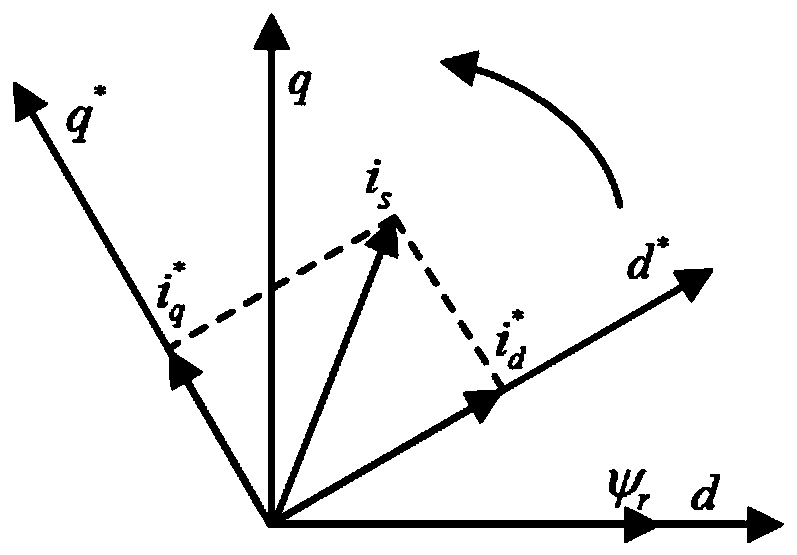

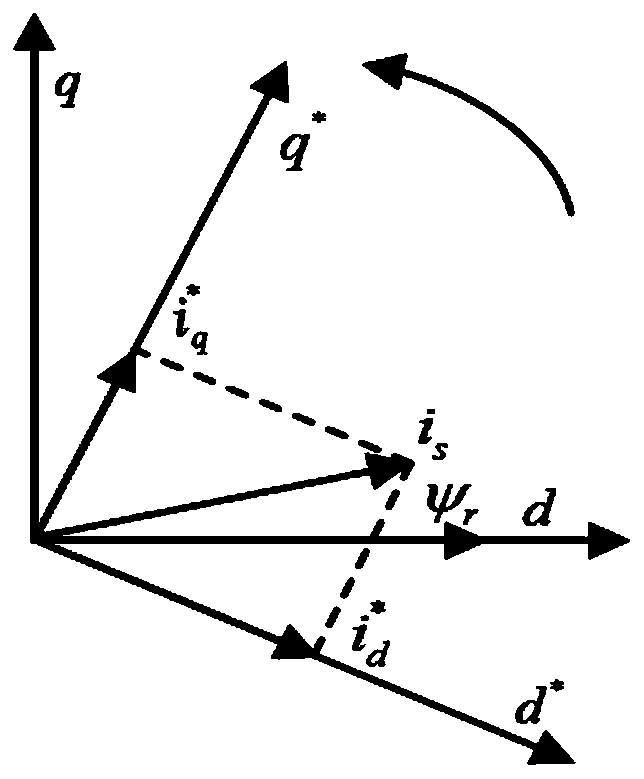

[0078] In order to highlight the advantages of this algorithm, take the excitation mutual inductance curve of a 25kW three-phase asynchronous motor for a certain type of electric vehicle as an example, the excitation mutual inductance curve refers to image 3 shown. In this embodiment, different excitation current reference values are set through the host computer, the torque current reference value is equal to the excitation current reference value, a measurement point of 5A is set, and then the slip angle frequency is modified in real time using the host computer. When the motor output torque is maximum , record the torque value. Finally, the excitation mutual inductance value at different excitation currents is calculated by the excitation mutual inductance measurement formula (1), and the relationship curve between the excitation mutual inductance and the excitation current is obtained, that is, the excitation mutual inductance curve. The excitation mutual inductance cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com