Structured light micro-nano three-dimensional shape measurement method based on focused evaluation algorithm

A technology of focusing evaluation and three-dimensional topography, which is applied in measurement devices, optical devices, instruments, etc., can solve the problems of inability to measure objects with low efficiency, slow changes, and high precision, and achieve high efficiency, wide application and measurement. System simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in combination with specific examples and with reference to the accompanying drawings.

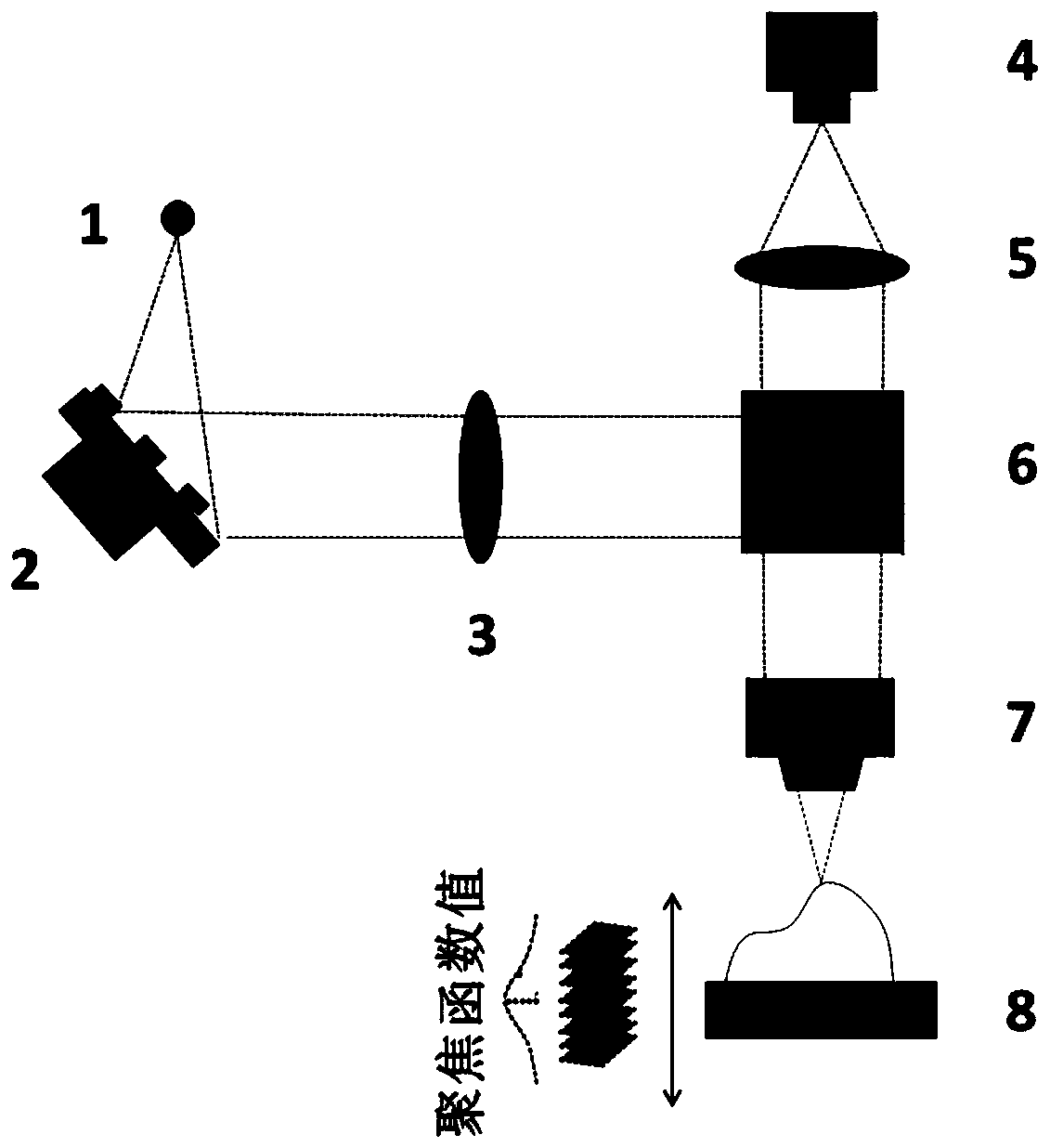

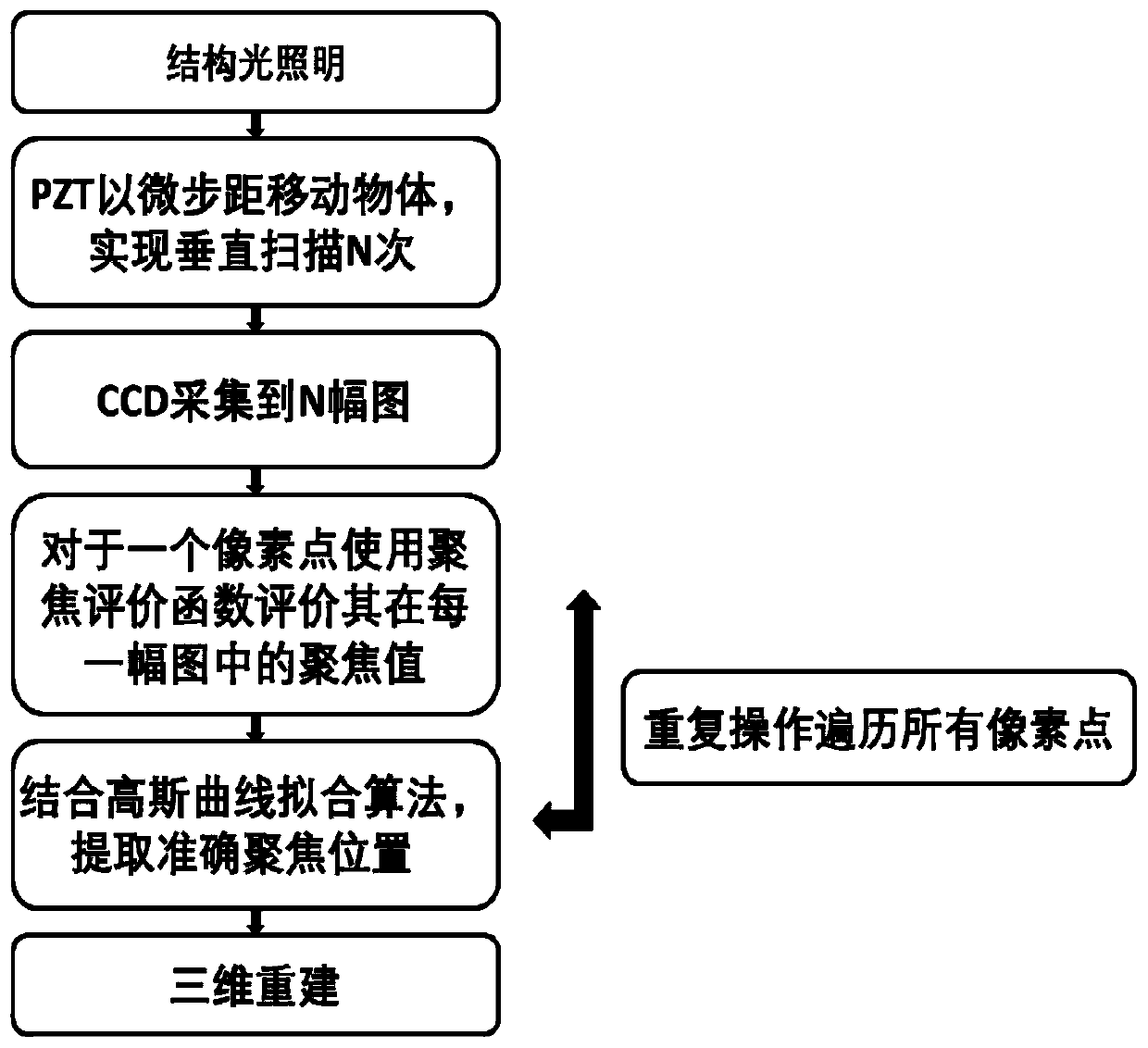

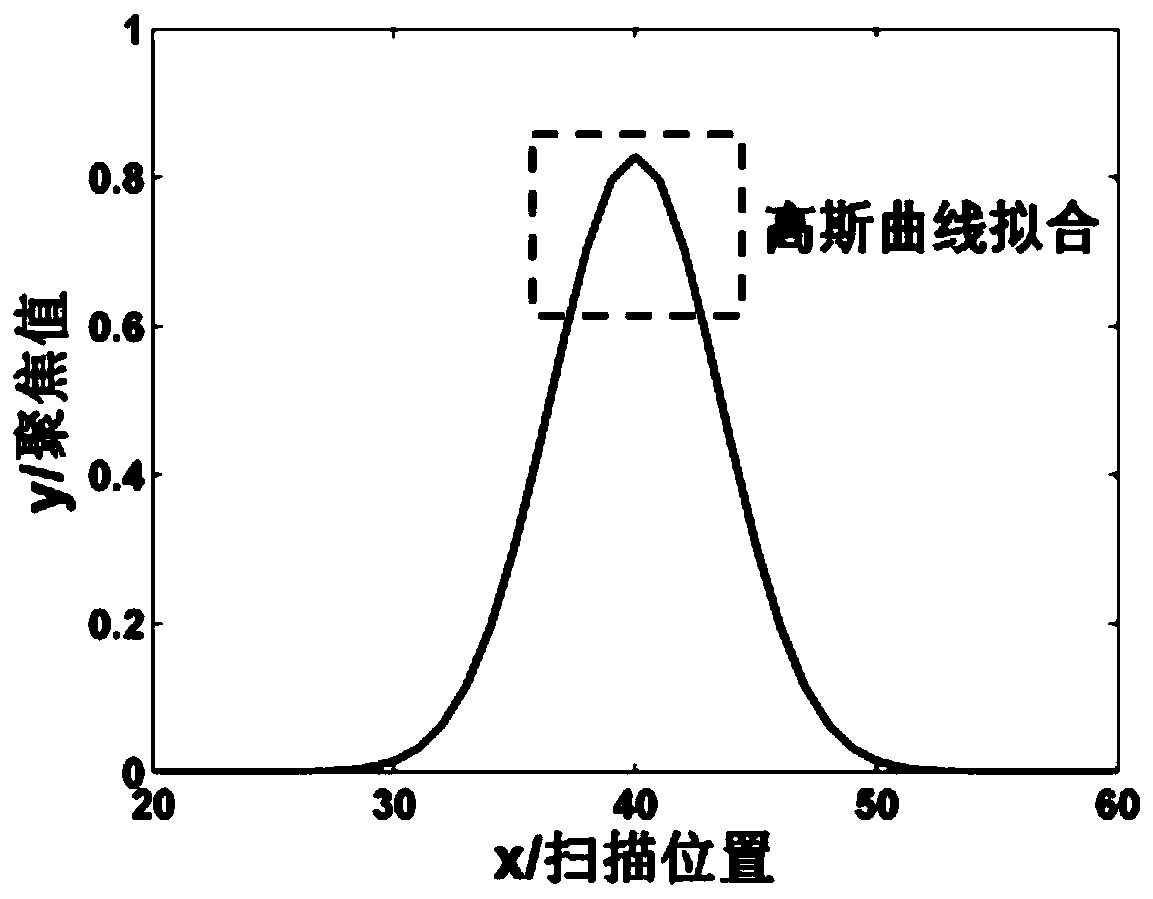

[0026] The optical path diagram of the measurement system used by the structured light micro-nano three-dimensional measurement method based on the focus evaluation algorithm of the present invention is as follows figure 1 As shown, a white light source 1 is used to illuminate the digital micromirror array (DMD) 2, and the light beam is irradiated onto the surface of the object to be measured through a tube lens 3, a beam splitter 6 and a microlens 7, wherein the DMD is located at the focal plane of the tube lens 1, and passes through After the surface of the object is reflected, the optical path passes through the tube lens 2 5, and the imaging picture carrying the height information of the object is collected by the CCD acq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com