Patents

Literature

1286results about "Material analysis by measuring secondary emission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for obtaining a picture of the internal structure of an object using x-ray radiation and device for the implementation thereof

InactiveUS6754304B1Improve accuracyReduce usageX-ray spectral distribution measurementHandling using diffraction/refraction/reflectionX-rayX ray dose

Owner:KUMAKHOV MURADIN ABUBEKIROVICH

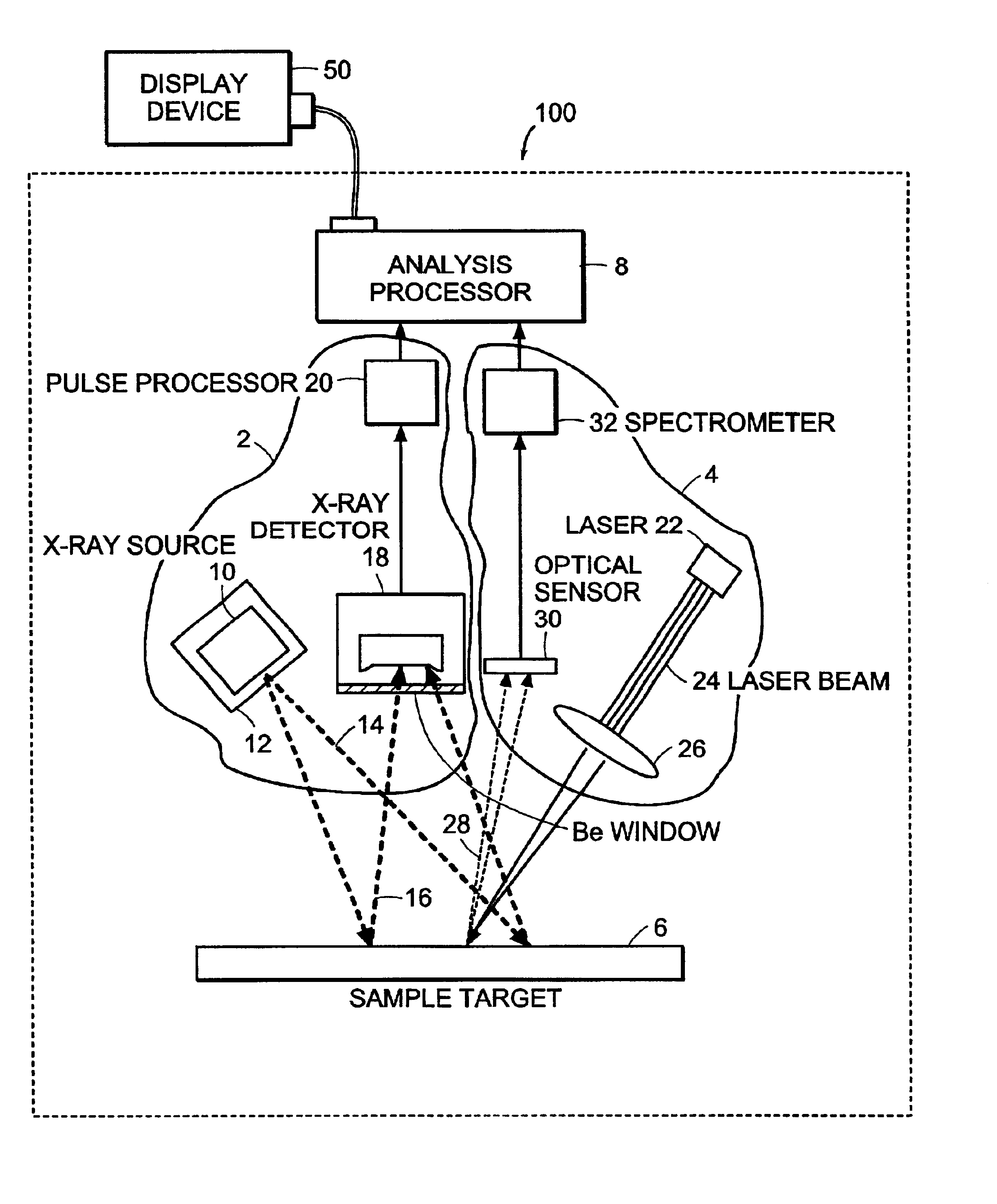

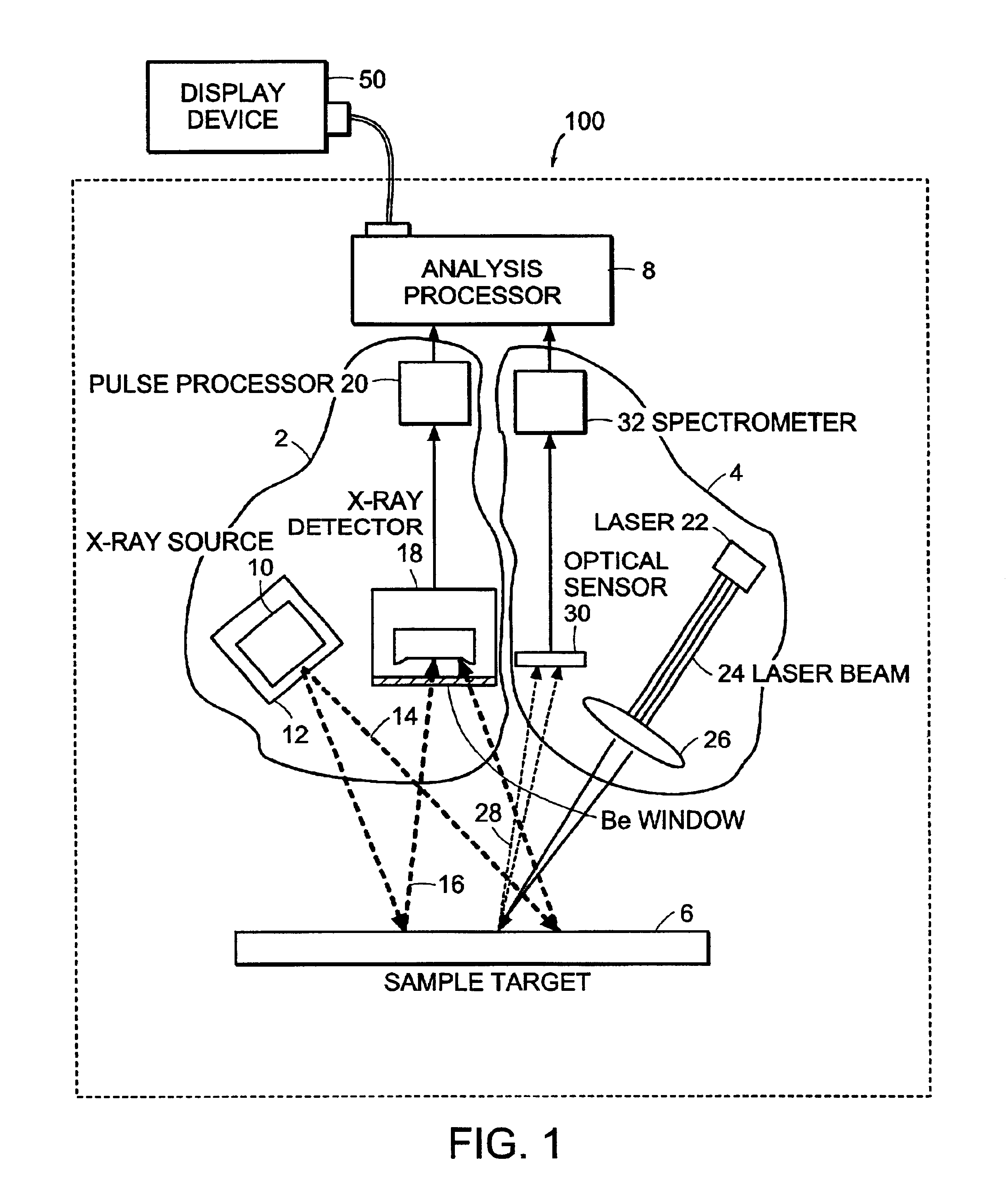

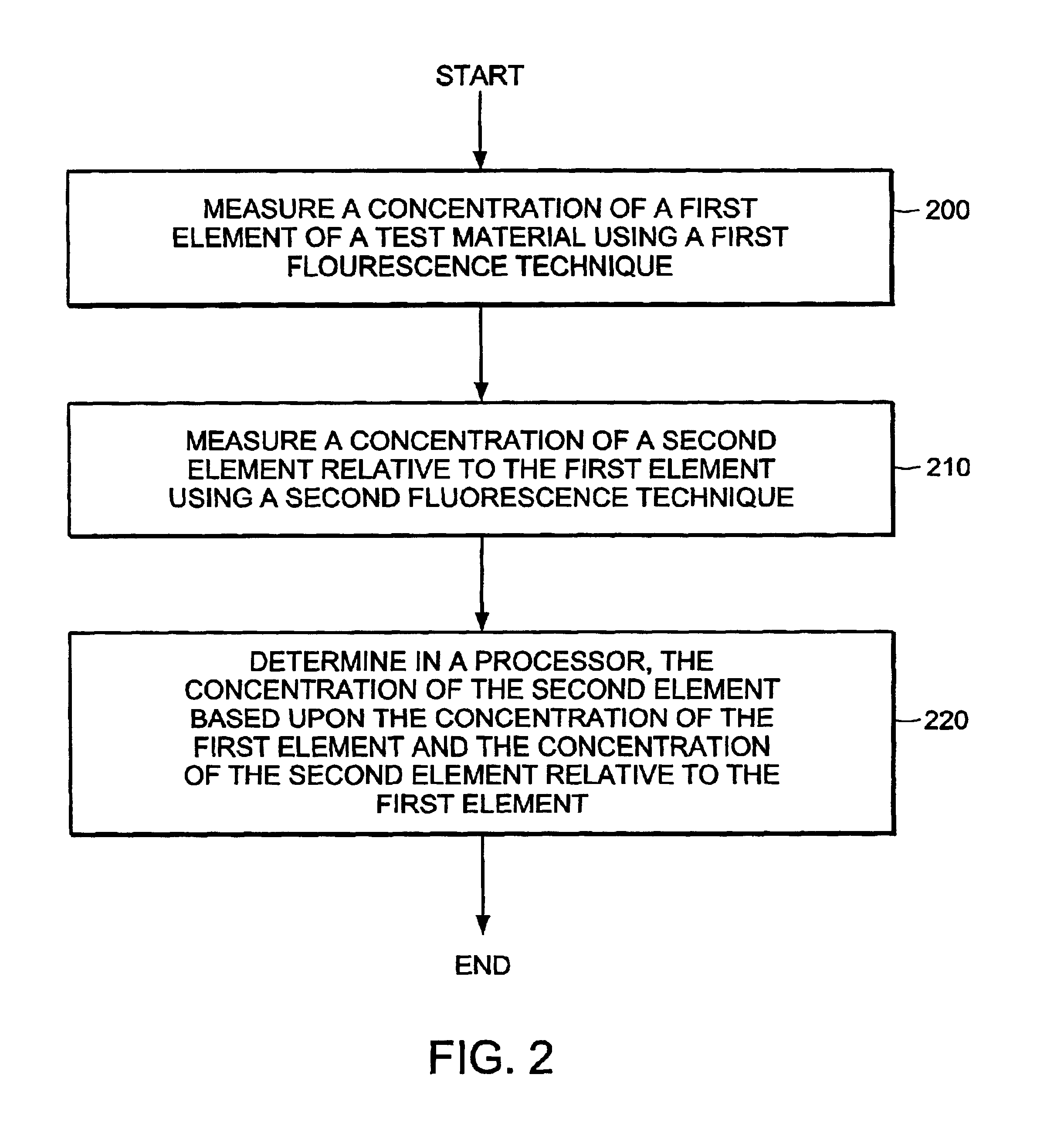

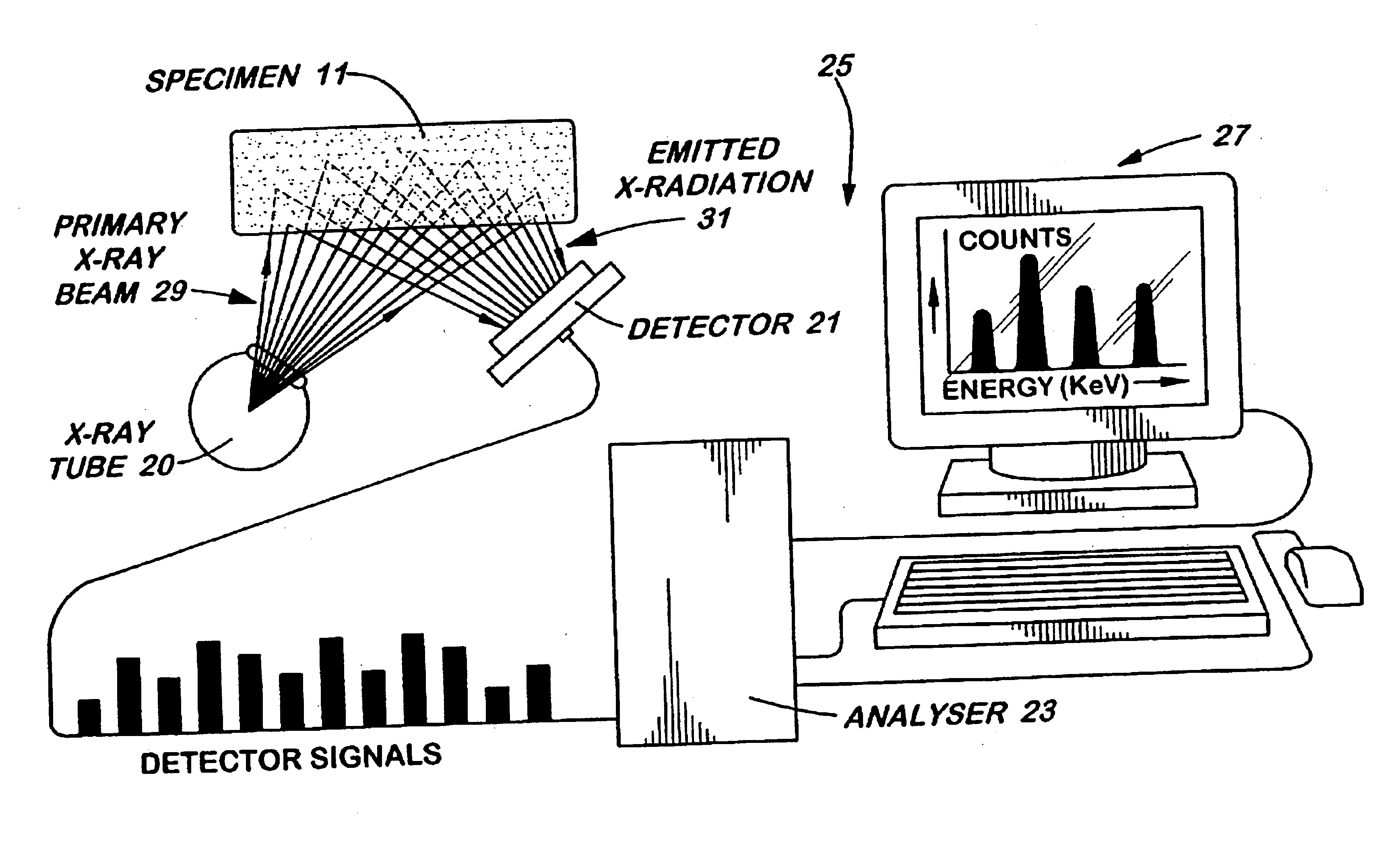

X-ray fluorescence combined with laser induced photon spectroscopy

A device and method for identifying the composition of a target sample. The target sample may be a matrix such as a metal alloy, a soil sample, or a work of art. The device includes an x-ray fluorescence detector that produces an x-ray signal output in response to the target sample. The device also includes an optical spectroscope that produces an optical signal output in response to the target sample. Further, a processor is included that analyzes and combines the x-ray signal output and the optical signal output to determine the composition of the test material. In one embodiment, the optical spectroscope is a laser induced photon fluorescence detector.

Owner:THERMO NITON ANALYZERS

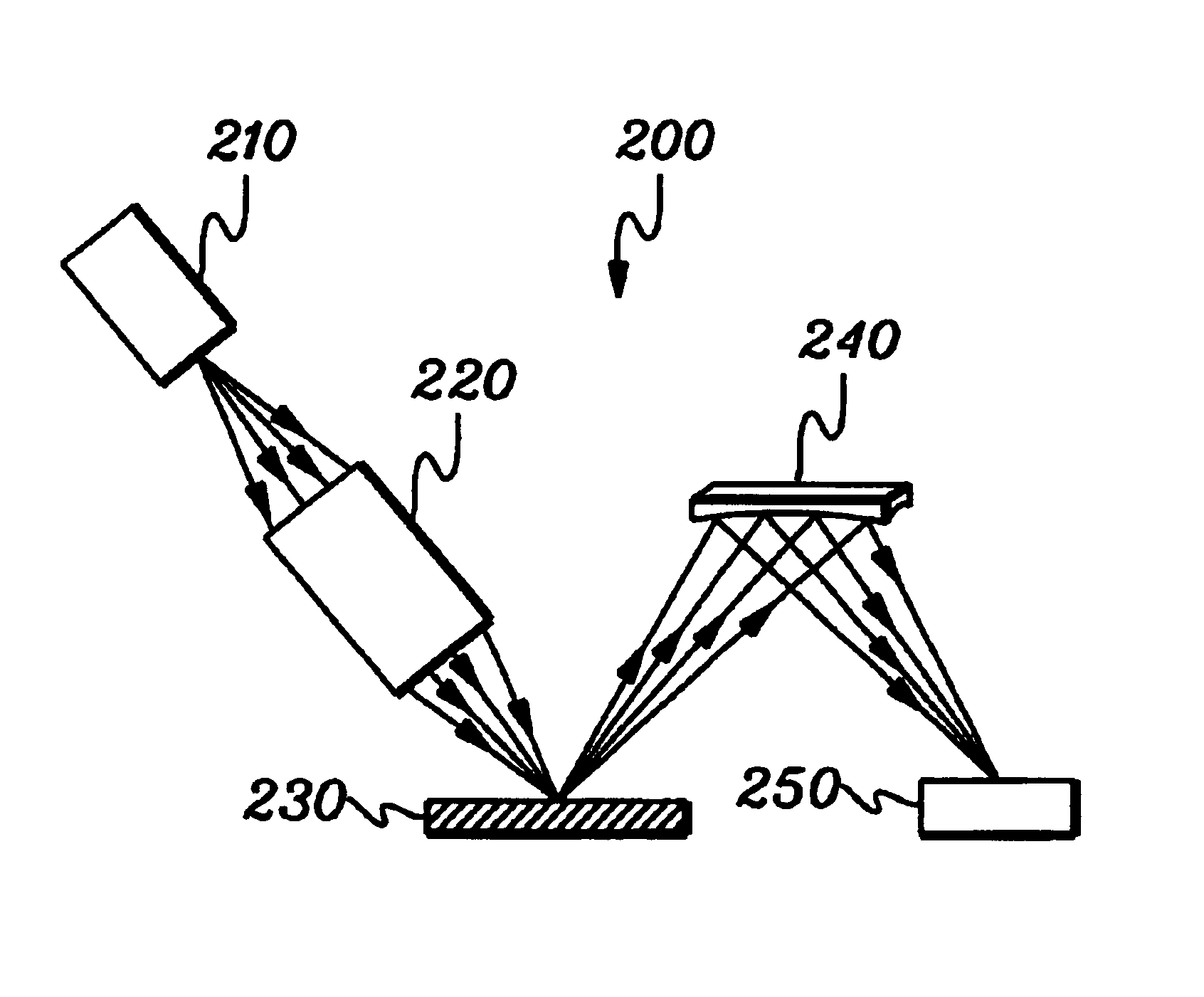

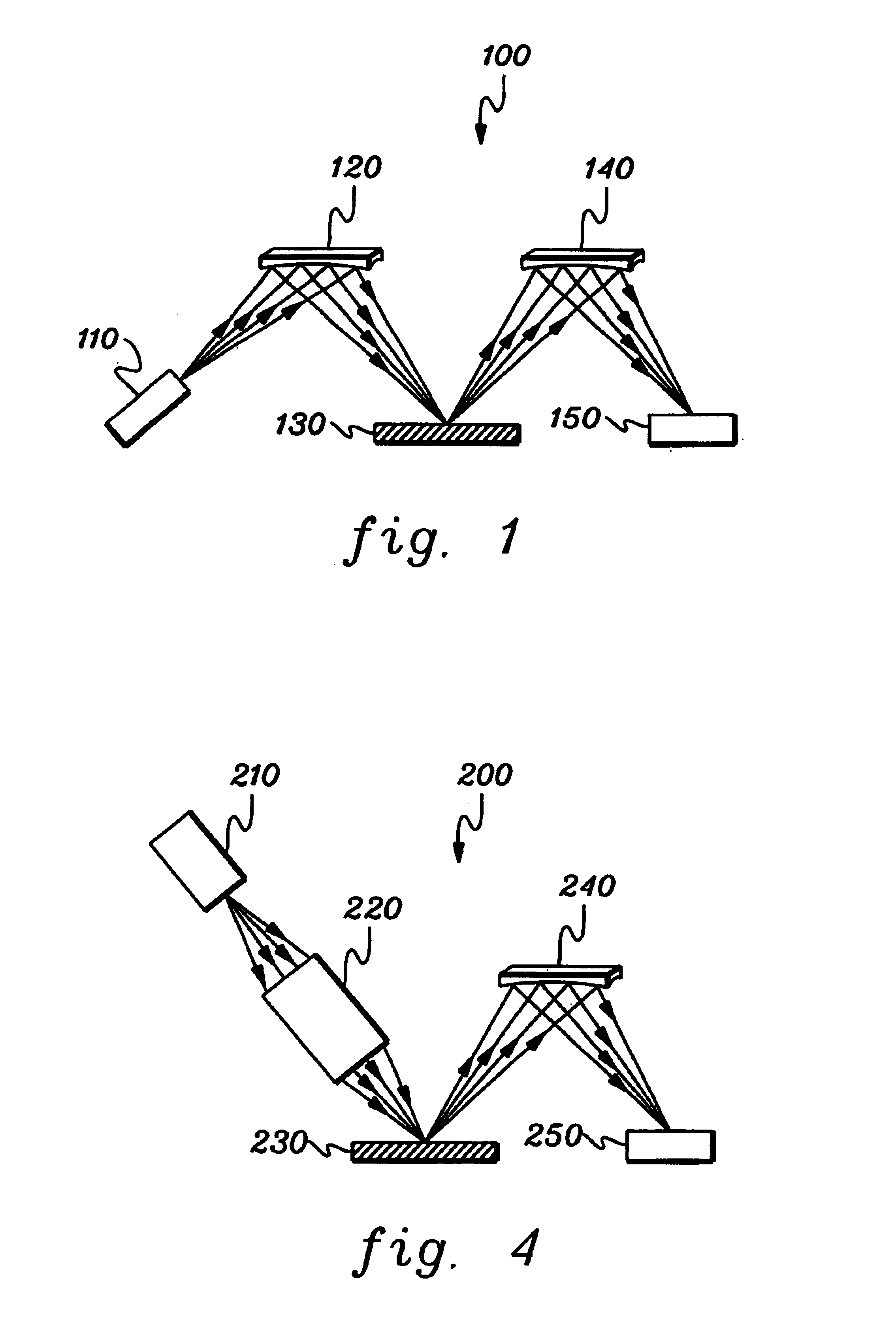

Wavelength dispersive XRF system using focusing optic for excitation and a focusing monochromator for collection

InactiveUS6934359B2Overcomes shortcomingX-ray/infra-red processesX-ray spectral distribution measurementSoft x rayAnalyte

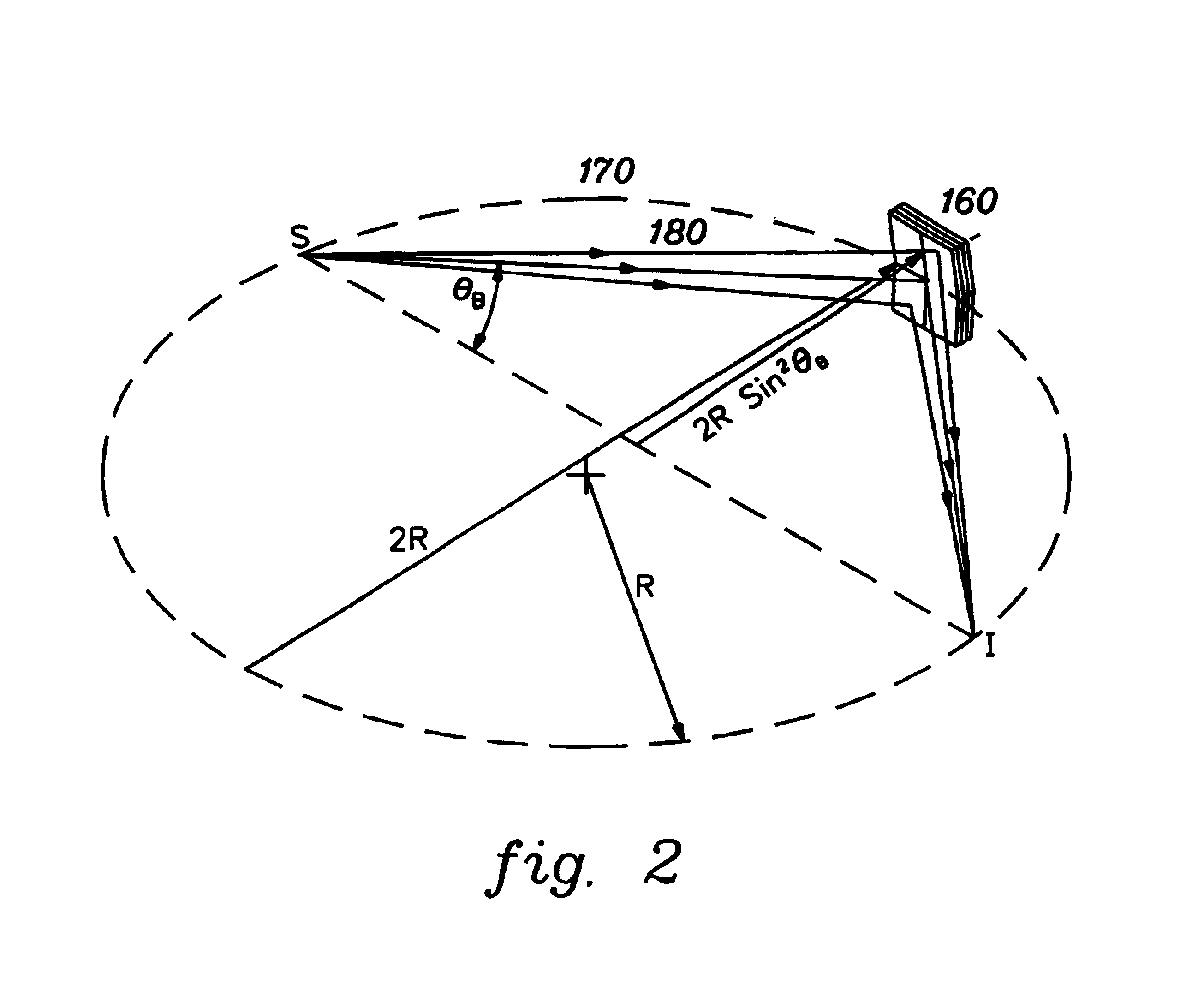

X-ray fluorescence (XRF) spectroscopy systems and methods are provided. One system includes a source of x-ray radiation and an excitation optic disposed between the x-ray radiation source and the sample for collecting x-ray radiation from the source and focusing the x-ray radiation to a focal point on the sample to incite at least one analyte in the sample to fluoresce. The system further includes an x-ray fluorescence detector and a collection optic comprising a doubly curved diffracting optic disposed between the sample and the x-ray fluorescence detector for collecting x-ray fluorescence from the focal point on the sample and focusing the fluorescent x-rays towards the x-ray fluorescence detector.

Owner:X-RAY OPTICAL SYSTEM INC

Methods and apparatus for fluorescence and reflectance imaging and spectroscopy and for contemporaneous measurements of electromagnetic radiation with multiple measuring devices

InactiveUS6898458B2Improve abilitiesEasy to measureRadiation pyrometrySpectrum investigationMeasurement deviceFluorescence

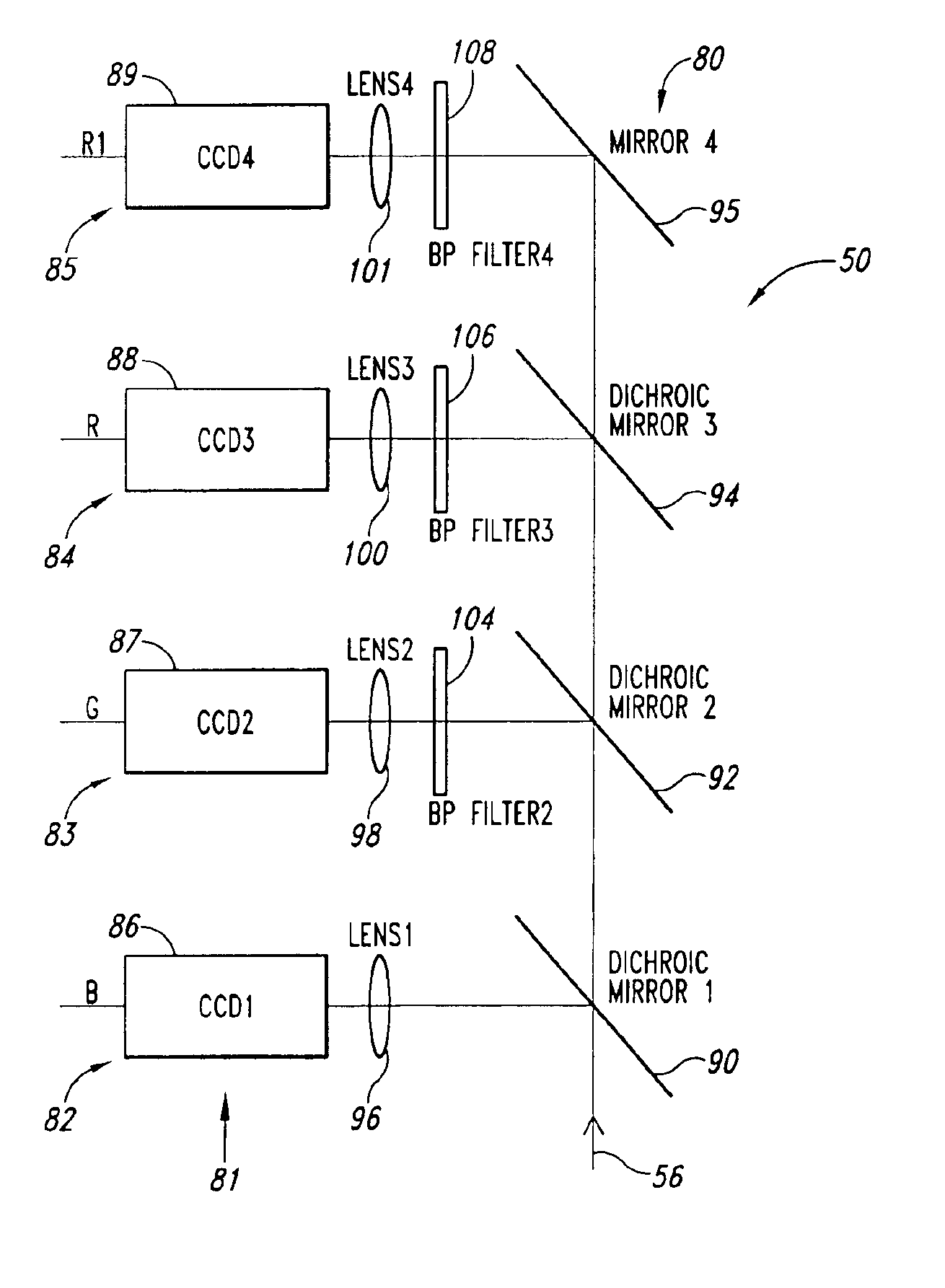

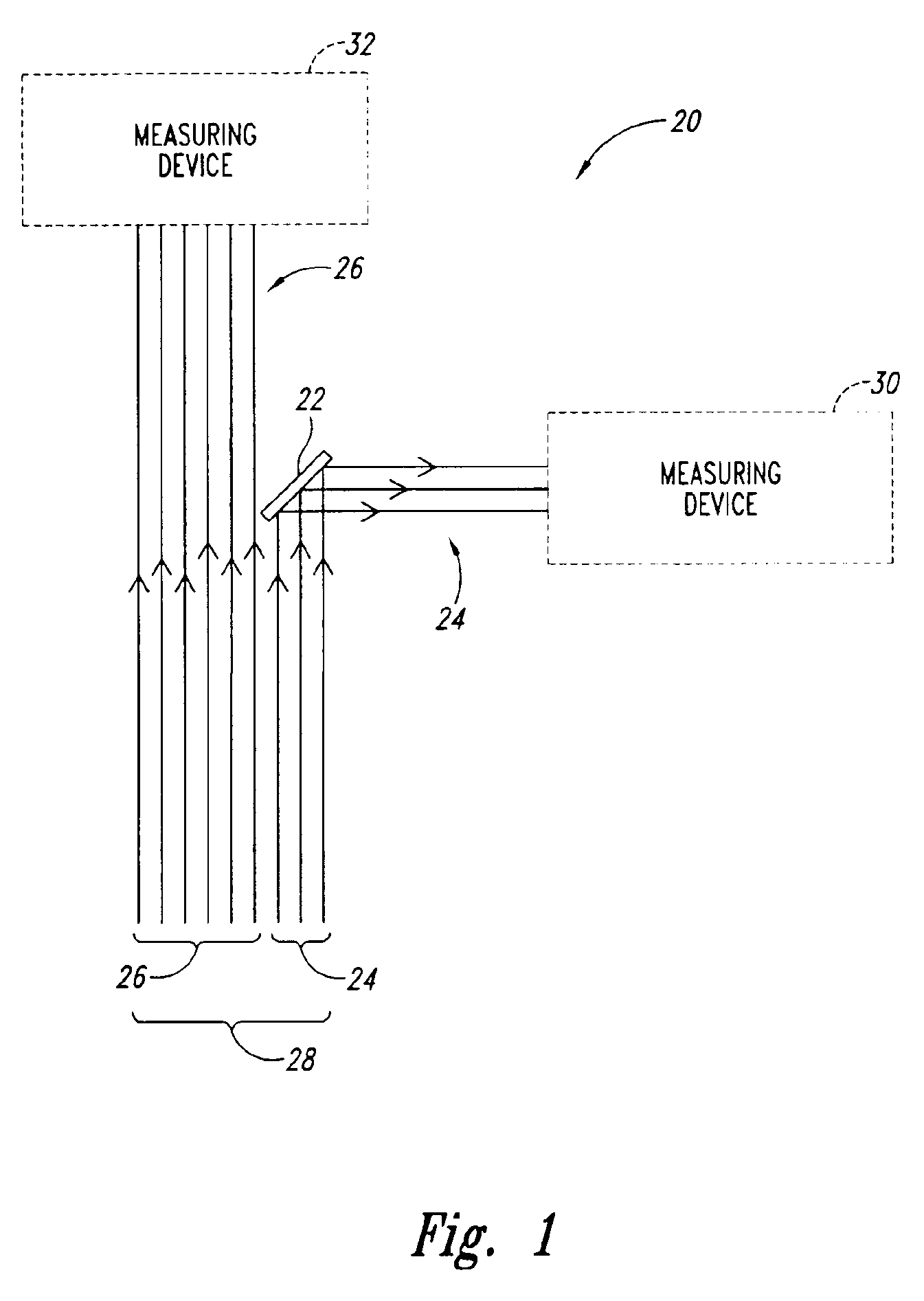

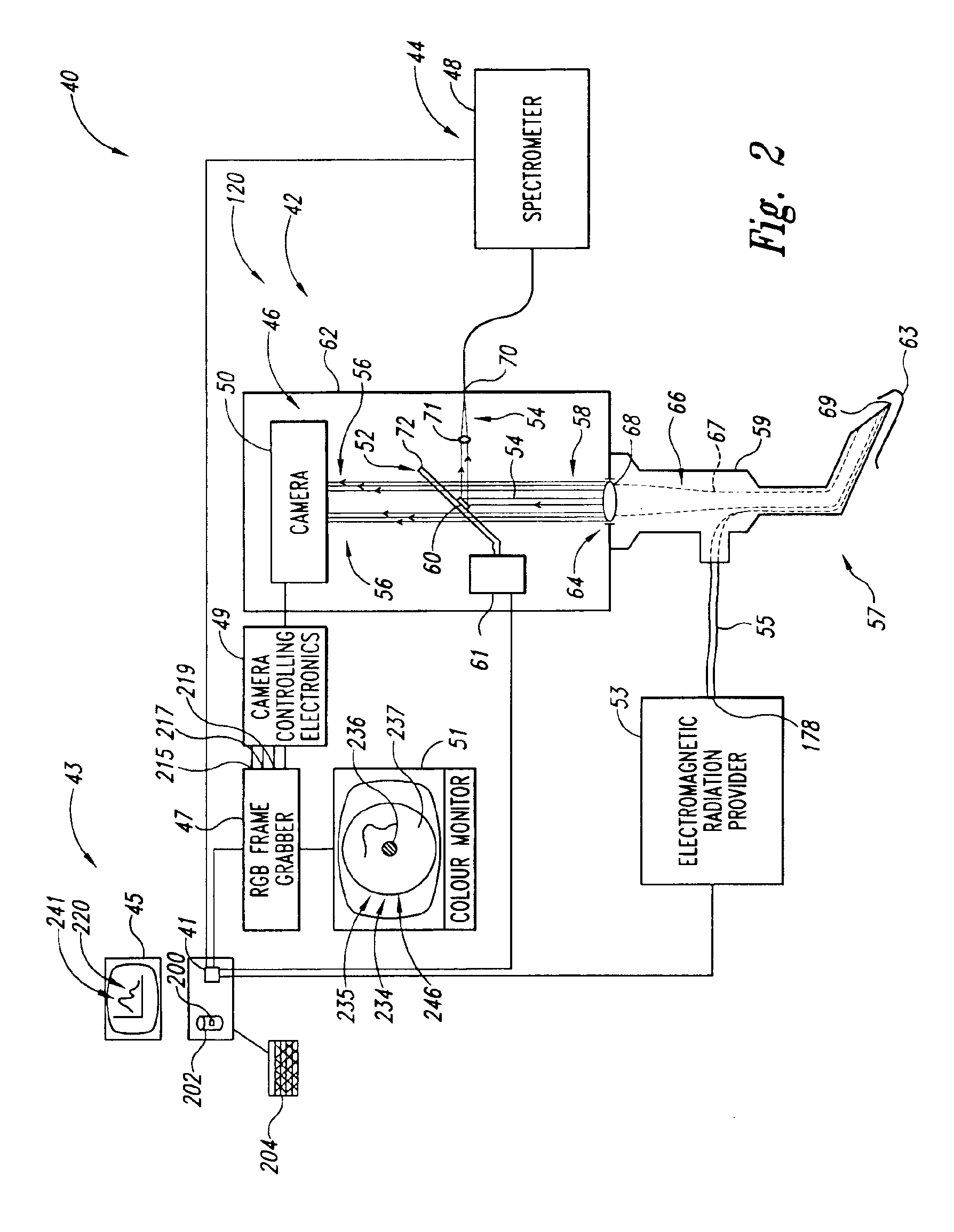

Optical systems that provide for simultaneous images and spectra from an object, such as a tissue sample, an industrial object such as a computer chip, or any other object that can be viewed with an optical system such as a microscope, endoscope, telescope or camera. In some embodiments, the systems provide multiple images corresponding to various desired wavelength ranges within an original image of the object, as well as, if desired, directional pointer(s) that can provide both an identification of the precise location from which a spectrum is being obtained, as well as enhancing the ability to point the device.

Owner:VERISANTE TECH

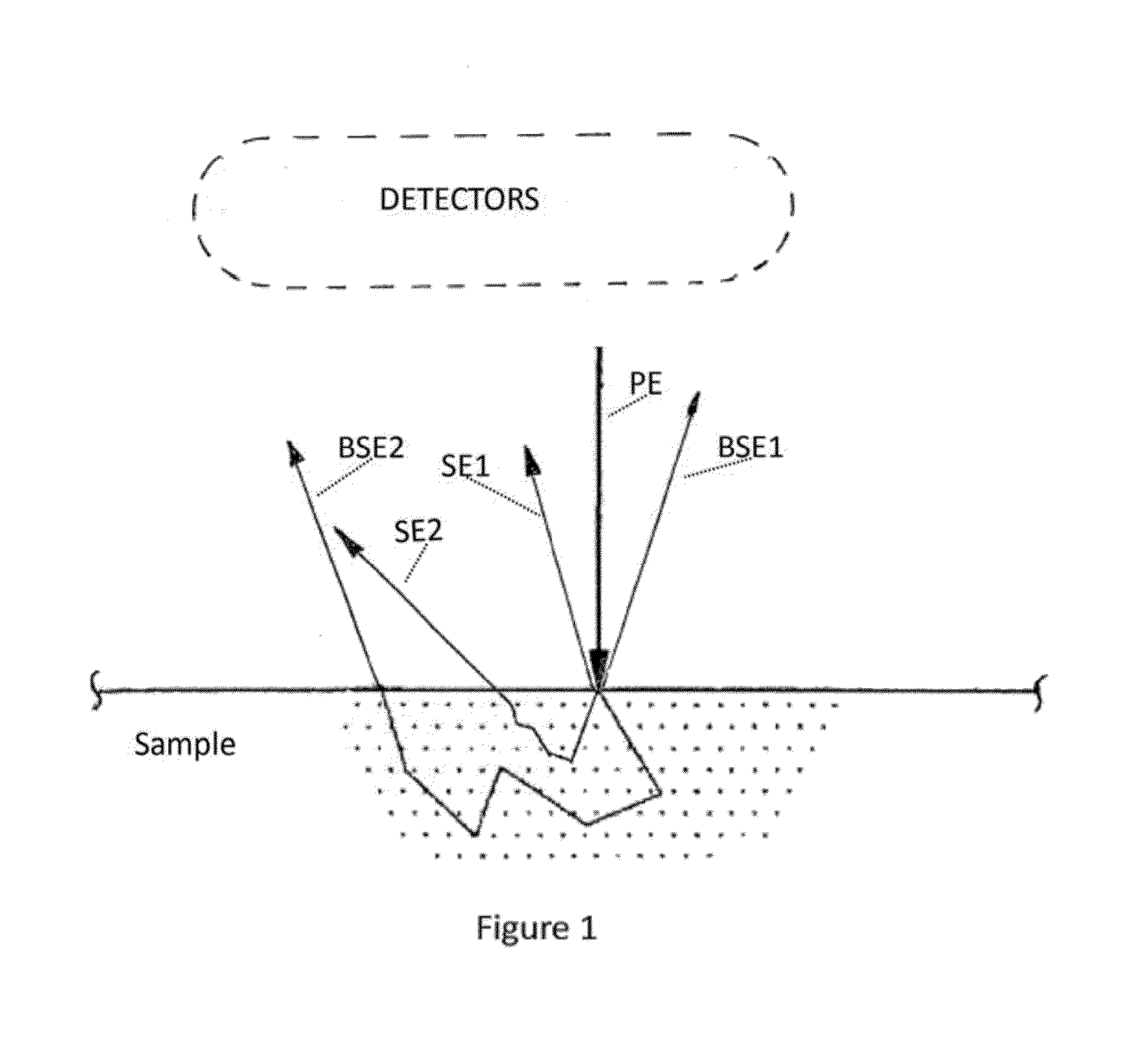

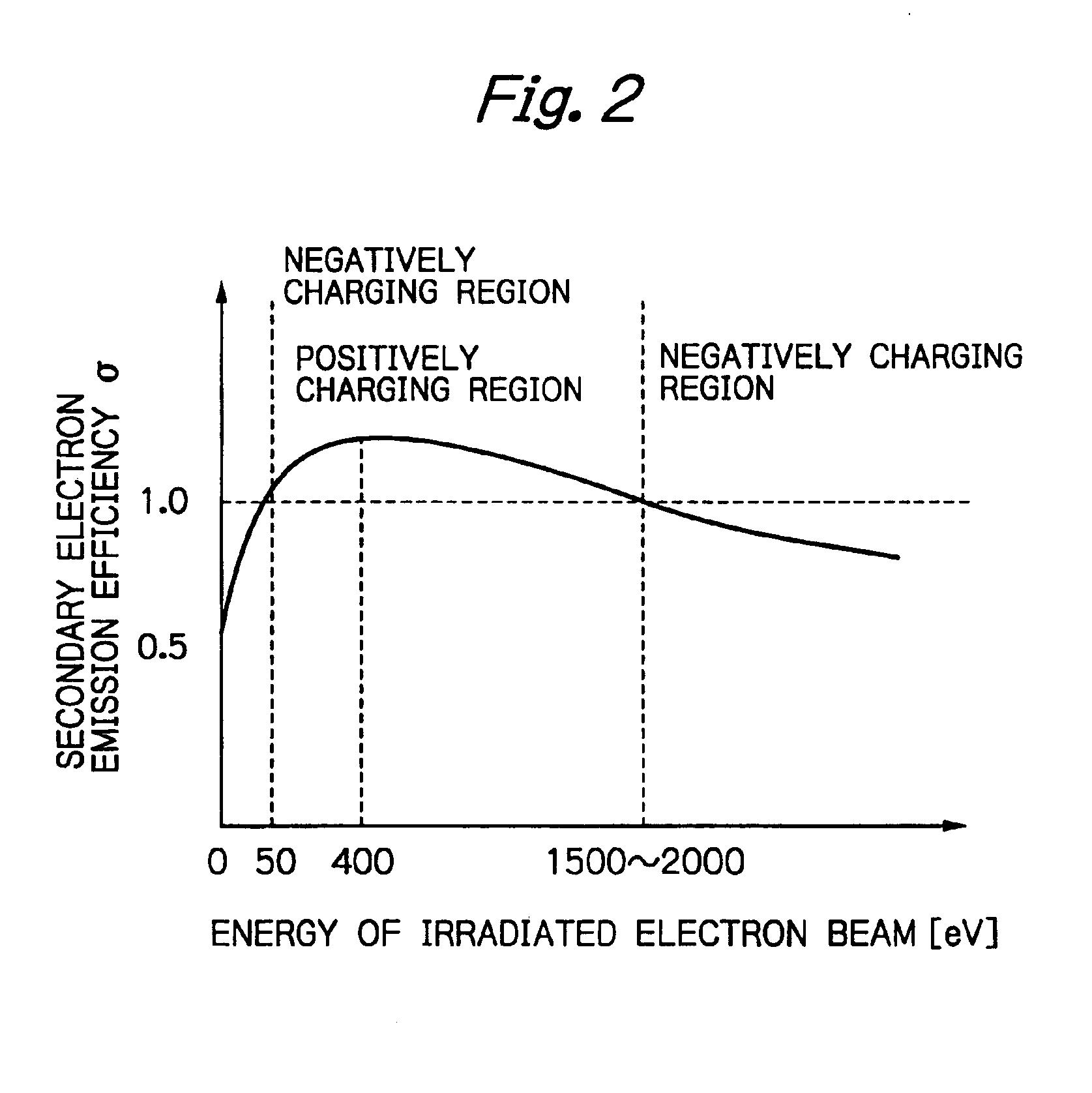

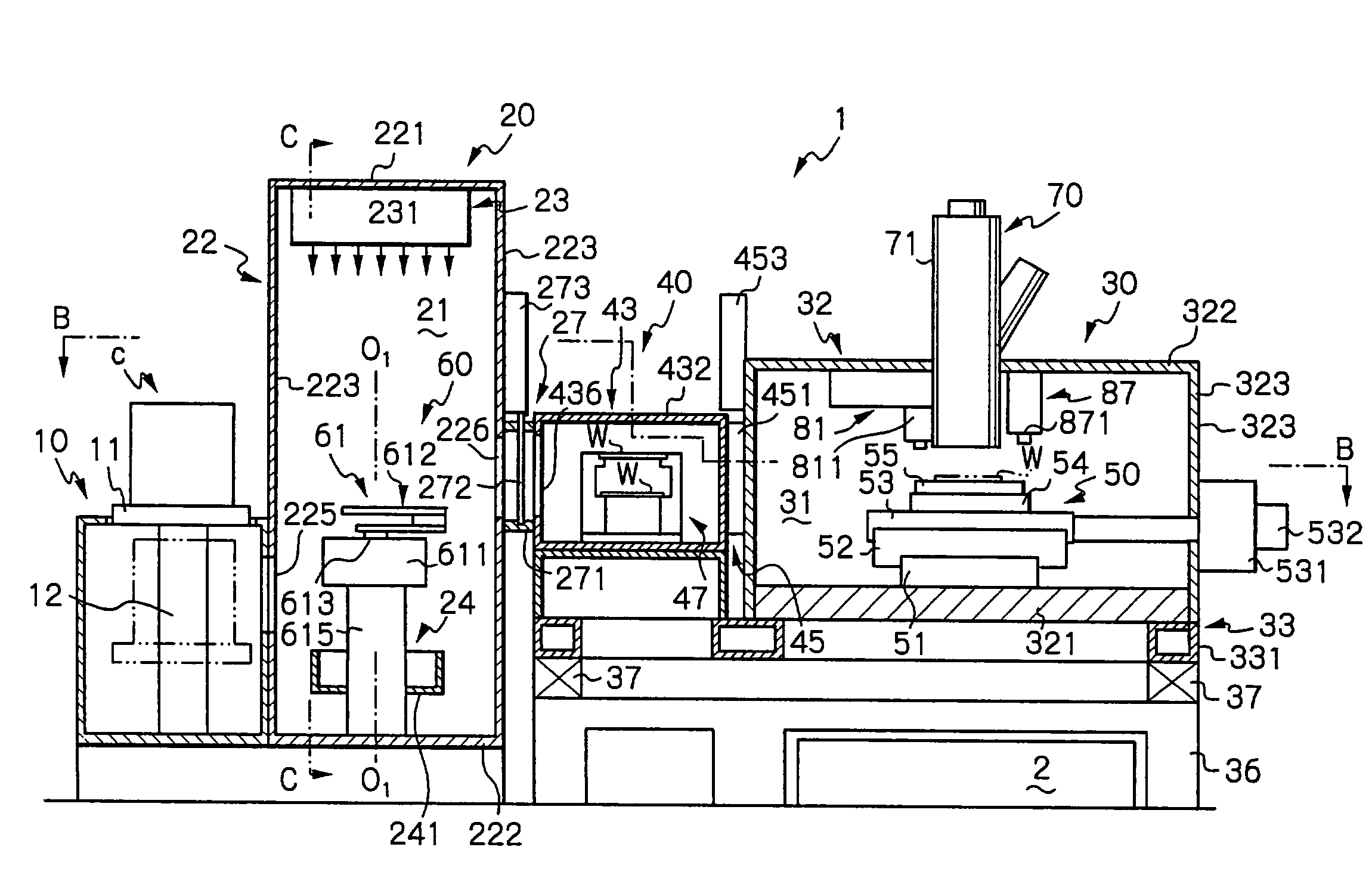

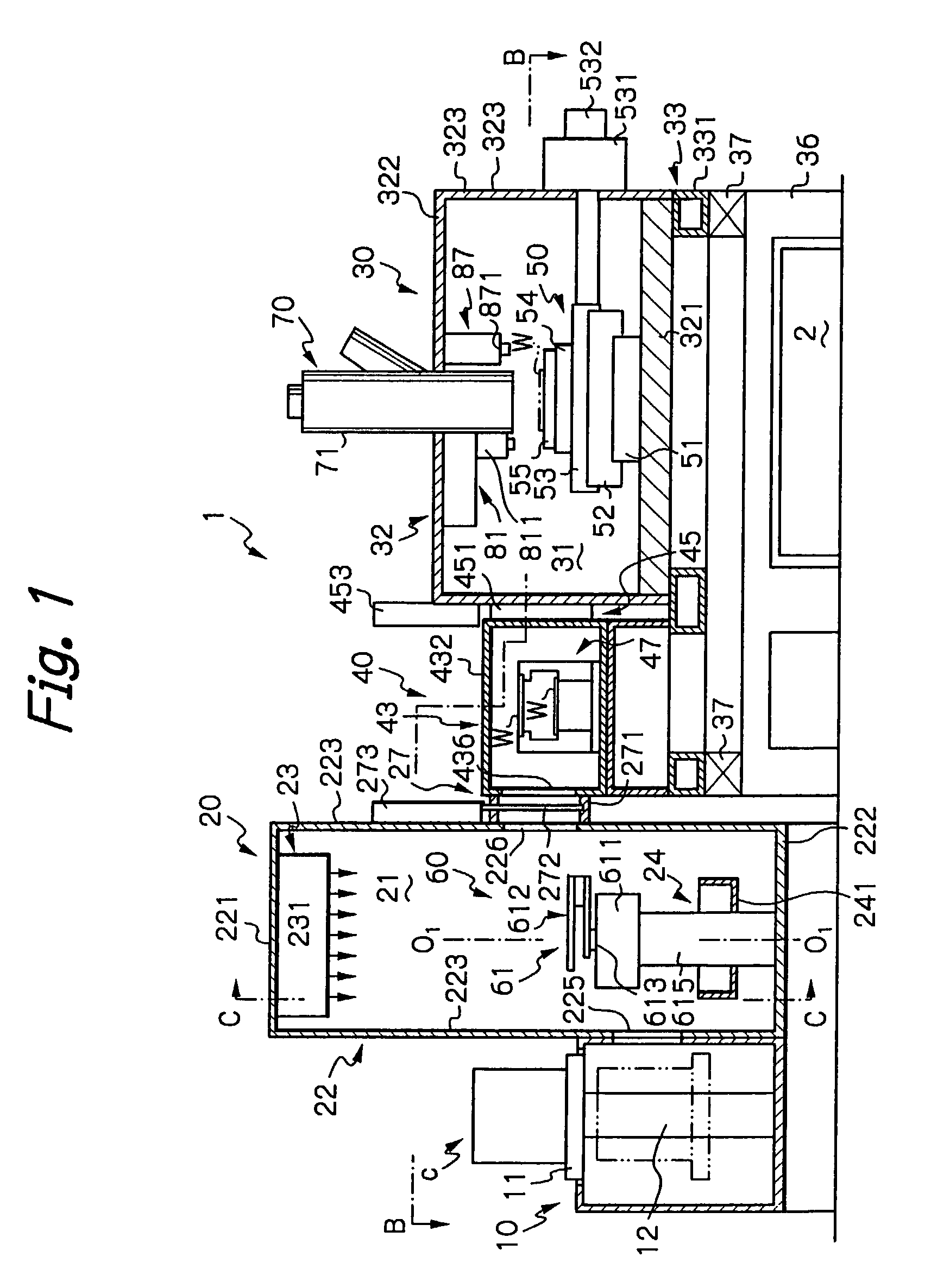

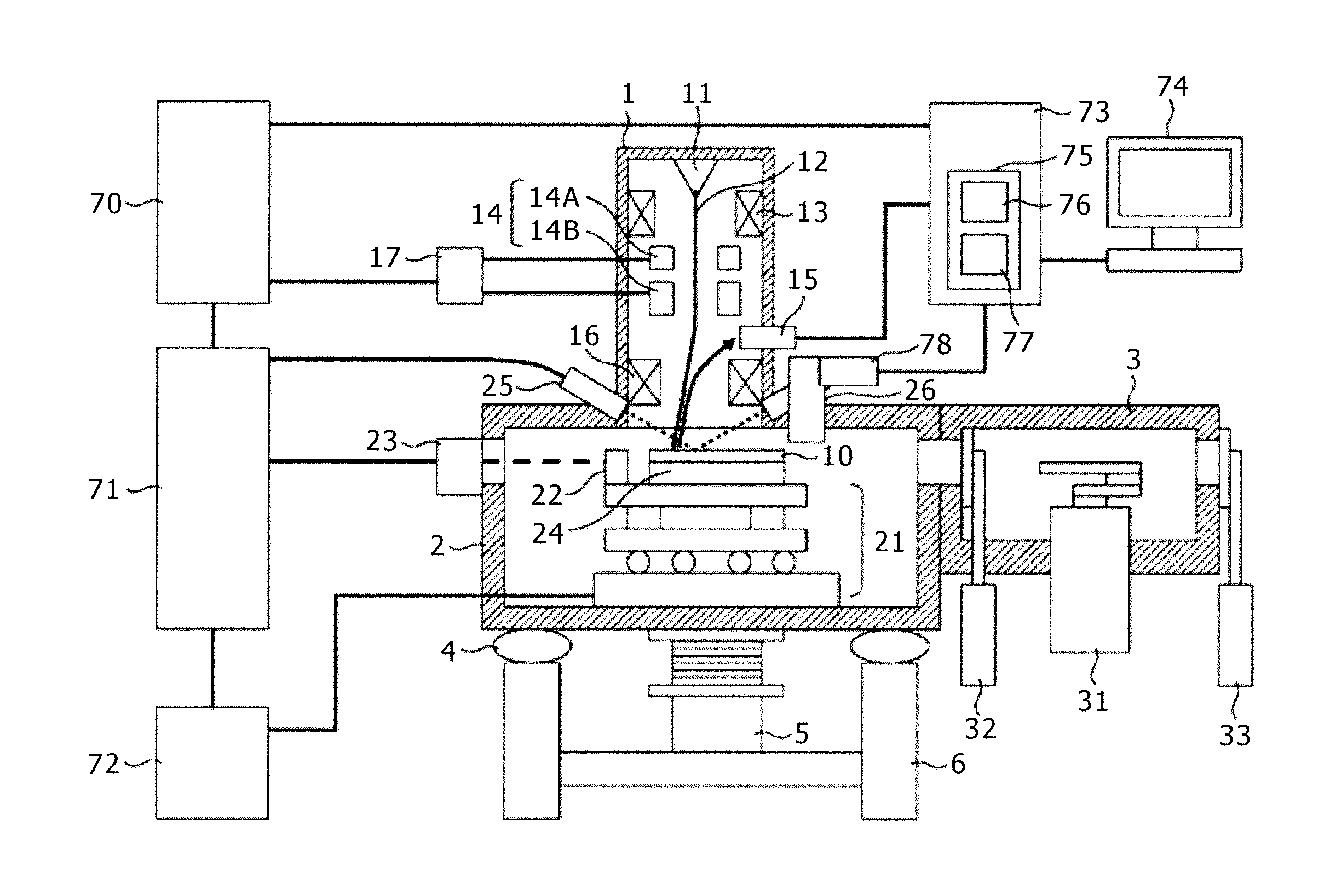

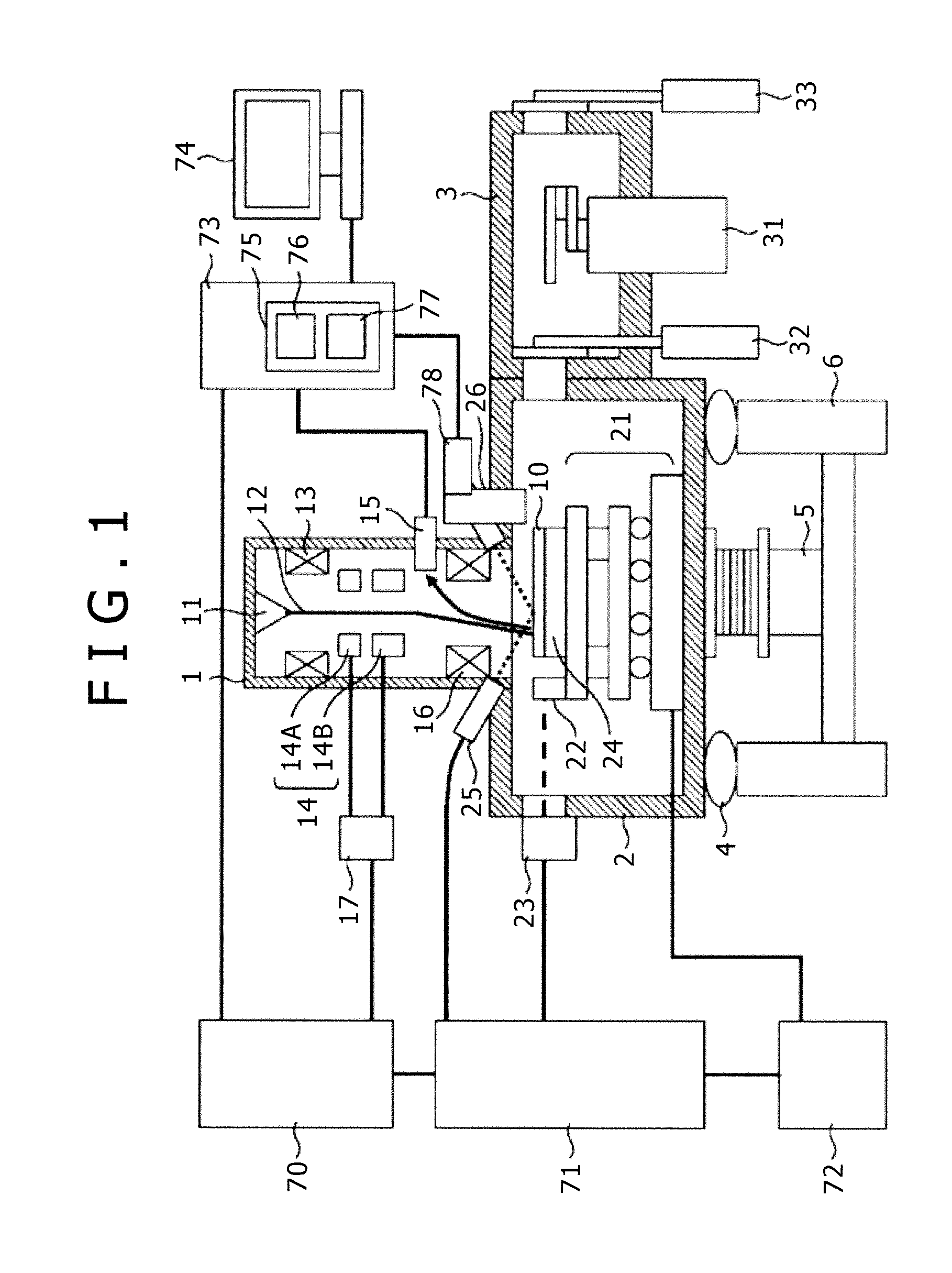

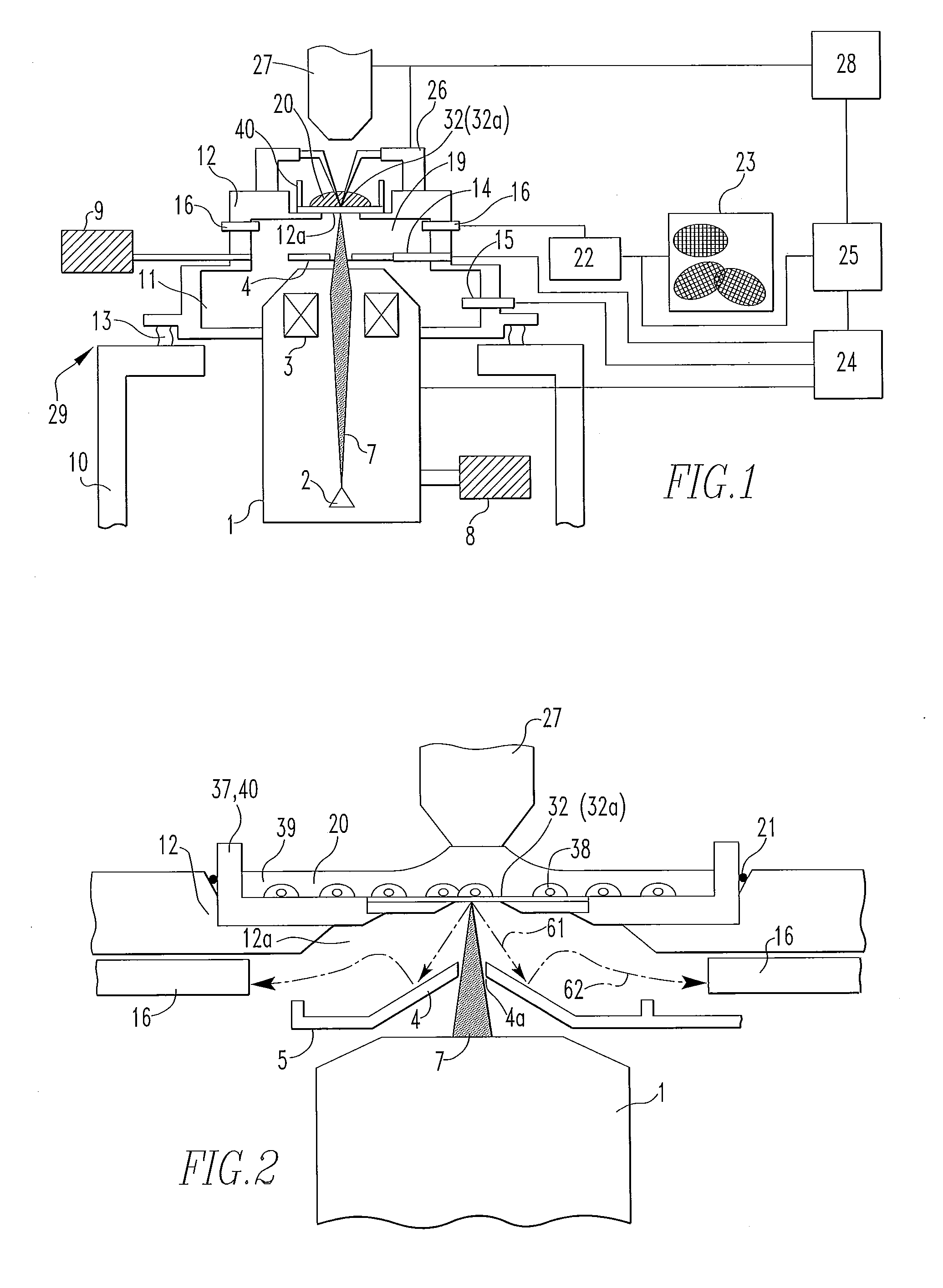

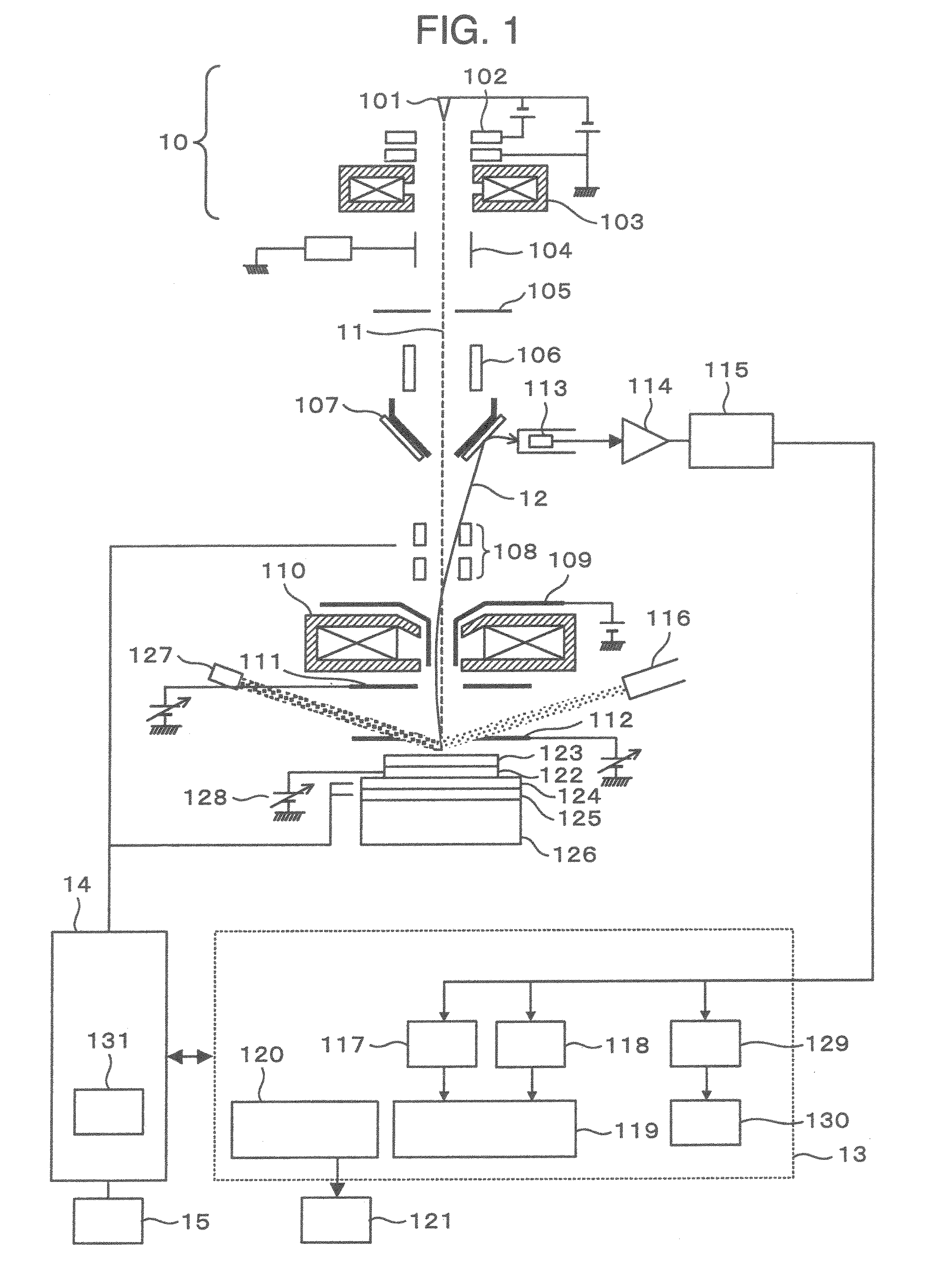

Apparatus for inspection with electron beam, method for operating same, and method for manufacturing semiconductor device using former

InactiveUS6855929B2Avoid low detection accuracyAvoid mistakesElectric discharge tubesSolid-state devicesImaging processingSecondary electrons

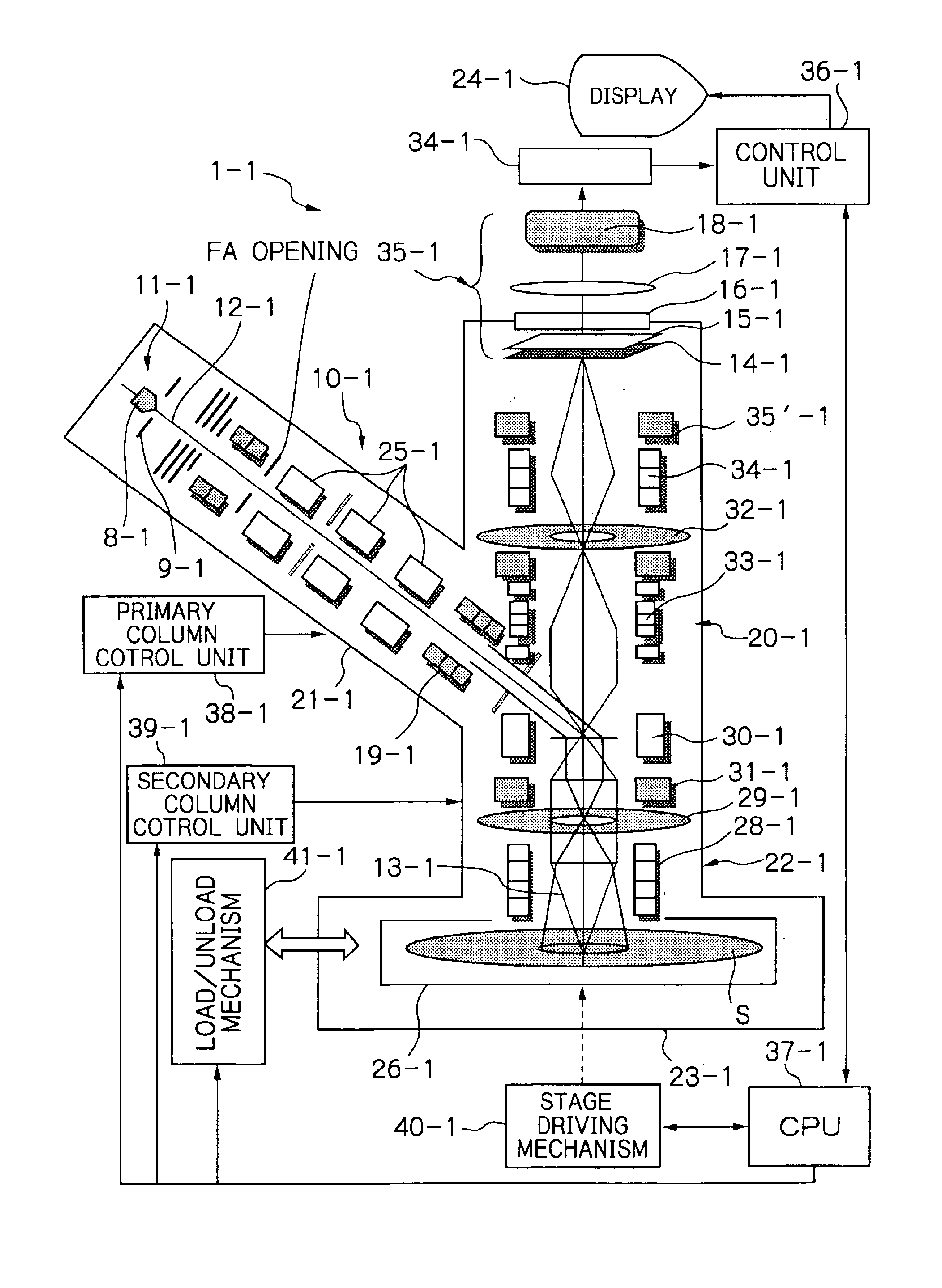

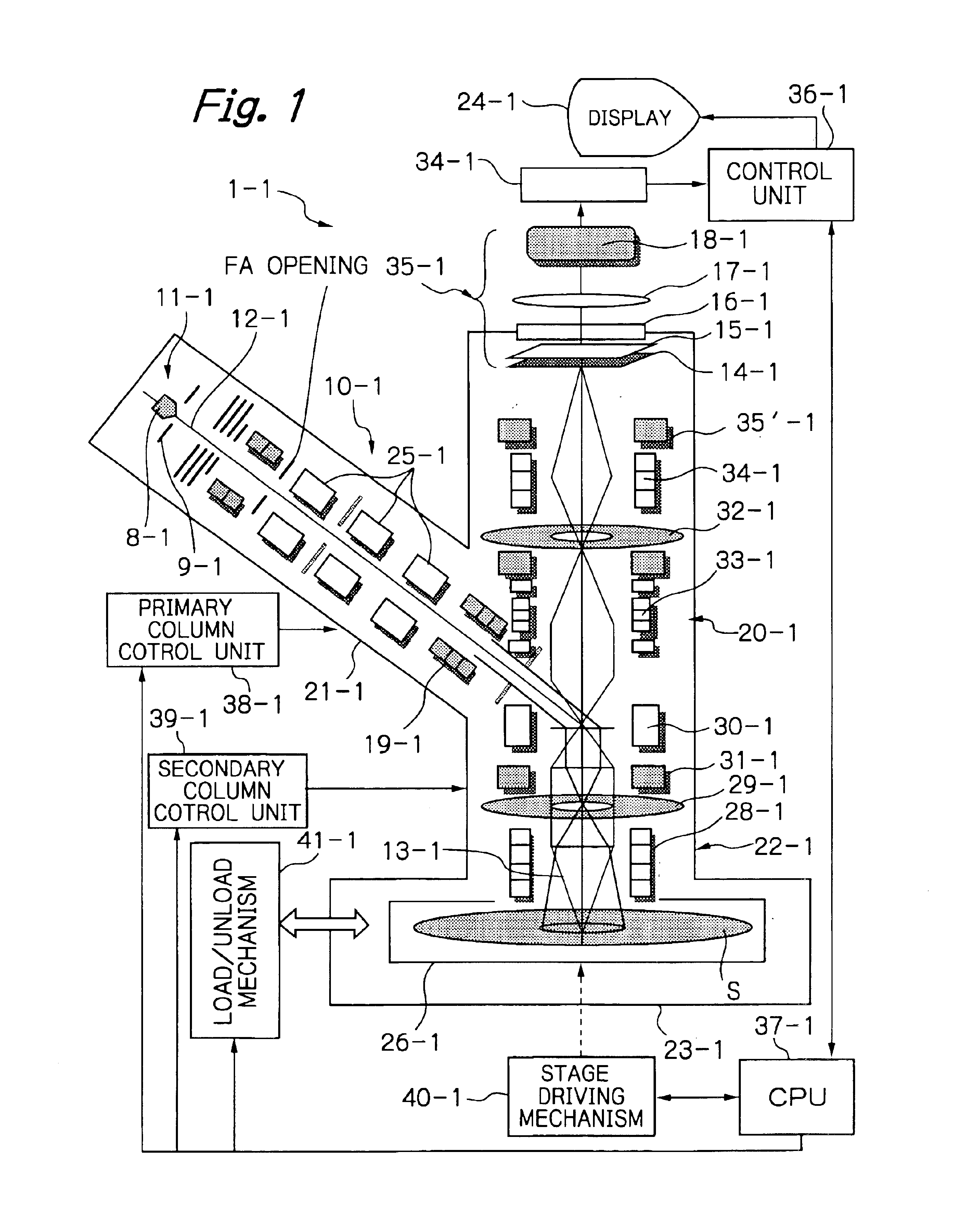

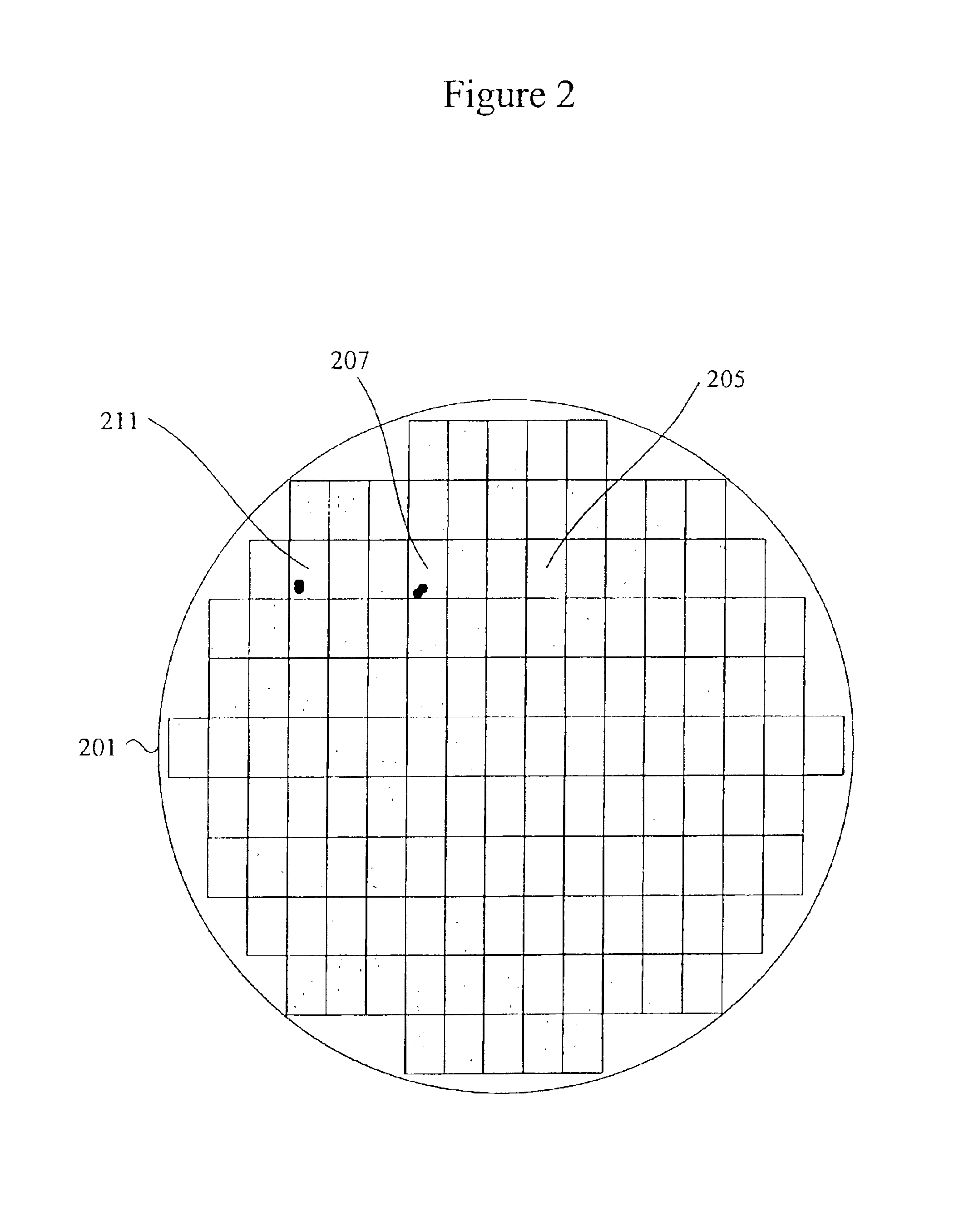

A substrate inspection apparatus 1-1 (FIG. 1) of the present invention performs the following steps of: carrying a substrate “S” to be inspected into an inspection chamber 23-1 maintaining a vacuum in said inspection chamber; isolating said inspection chamber from a vibration; moving successively said substrate by means of a stage 26-1 with at least one degree of freedom; irradiating an electron beam having a specified width; helping said electron beam reach to a surface of said substrate via a primary electron optical system 10-1; trapping secondary electrons emitted from said substrate via a secondary electron optical system 20-1 and guiding it to a detecting system 35-1; forming a secondary electron image in an image processing system based on a detection signal of a secondary electron beam obtained by said detecting system; detecting a defective location in said substrate based on the secondary electron image formed by said image processing system; indicating and / or storing said defective location in said substrate by CPU 37-1; and taking said completely inspected substrate out of the inspection chamber. Thereby, the defect inspection on the substrate can be performed successively with high level of accuracy and efficiency as well as with higher throughput.

Owner:EBARA CORP

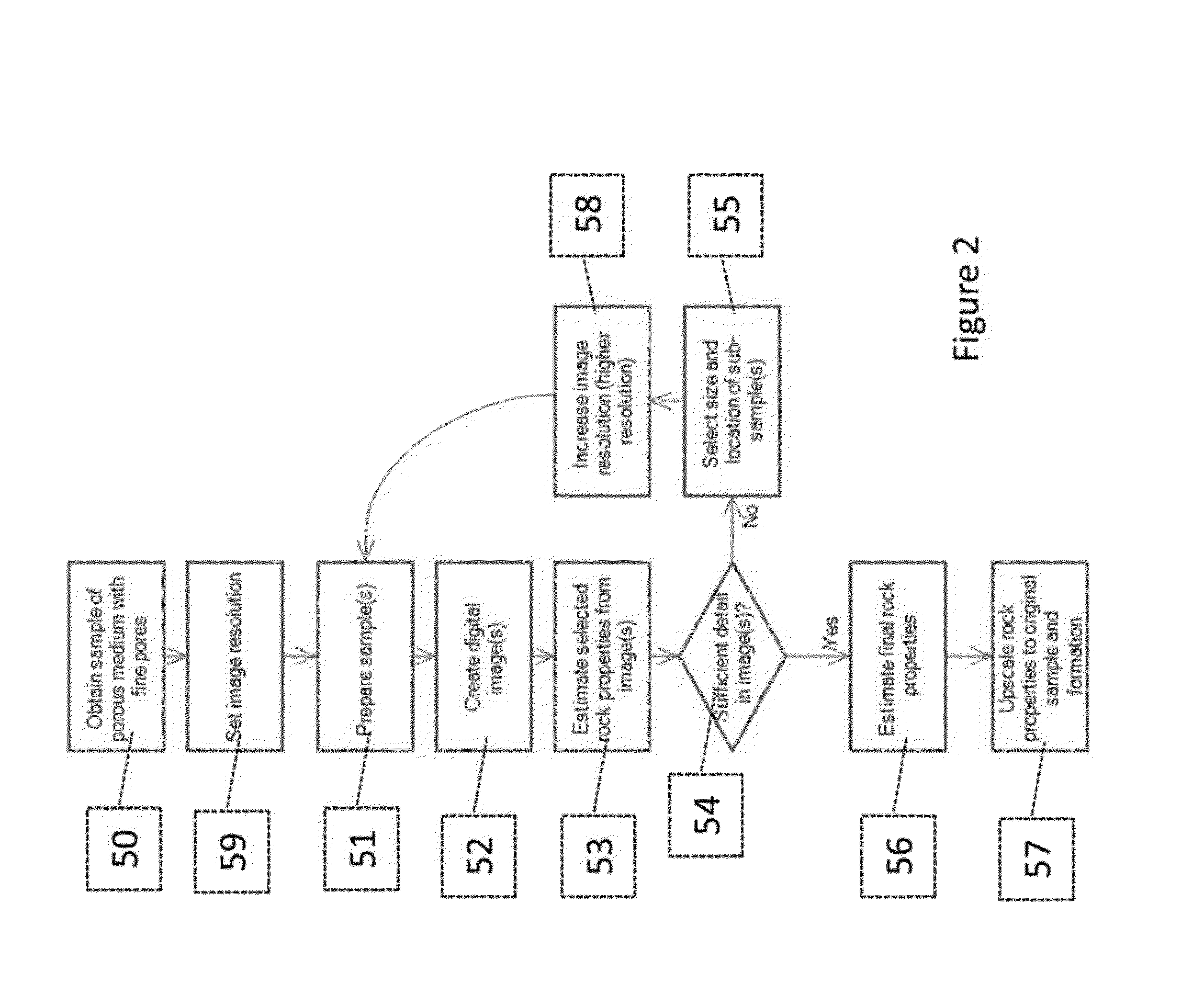

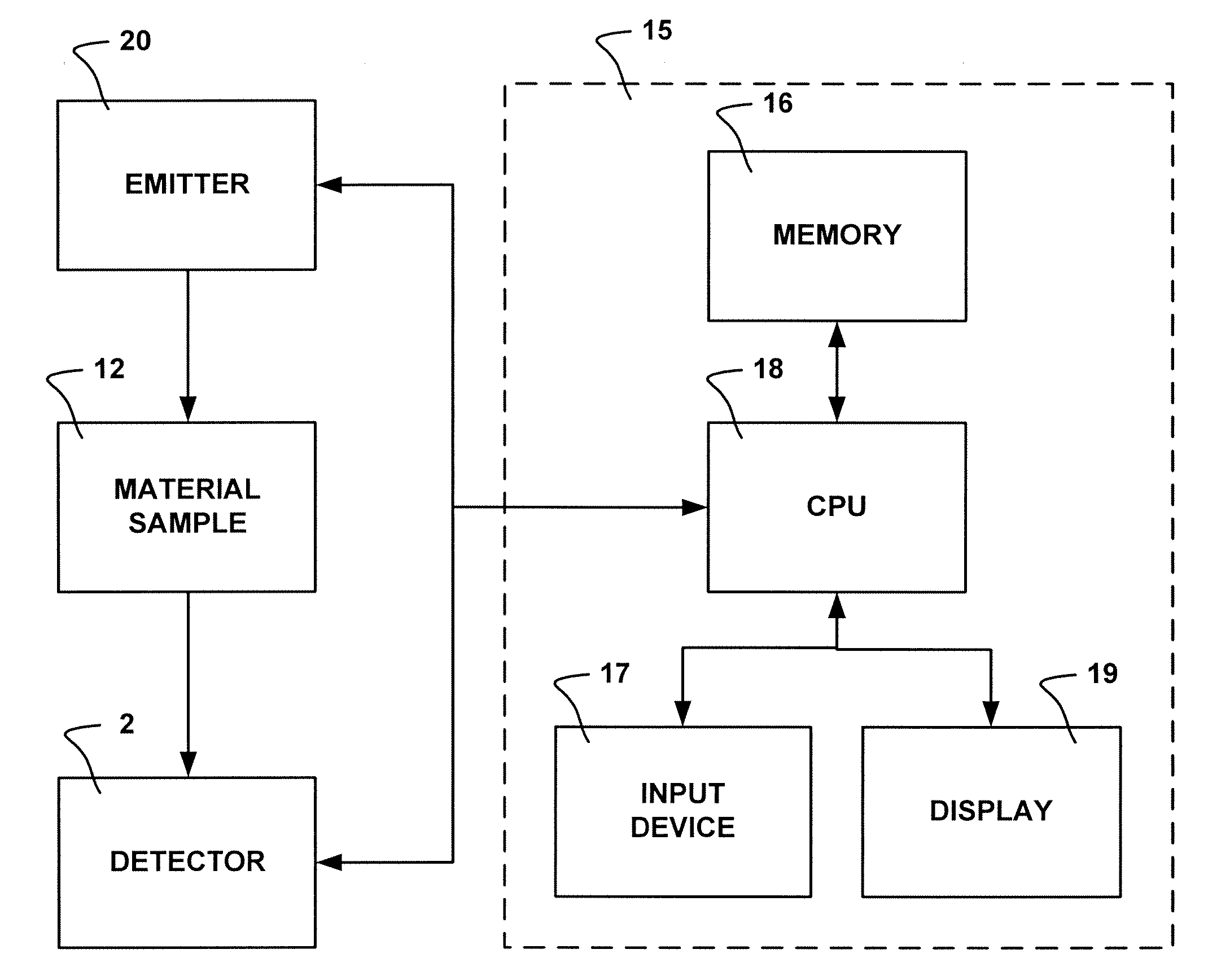

Method And System For Estimating Properties Of Porous Media Such As Fine Pore Or Tight Rocks

A method for estimating properties of porous media, such as fine pore or tight rocks, is provided. The method comprises digital image scanning of sequential sub-samples of porous media at progressively higher resolution to systematically identify sub-sections of interest within the original sample and then estimate properties of the porous media. The resulting properties of the porous media then can be optionally upscaled to further estimate the properties of larger volumes of the porous media such as rock facies or subterranean reservoirs. A system operable for conducting the method also is provided.

Owner:HALLIBURTON ENERGY SERVICES INC

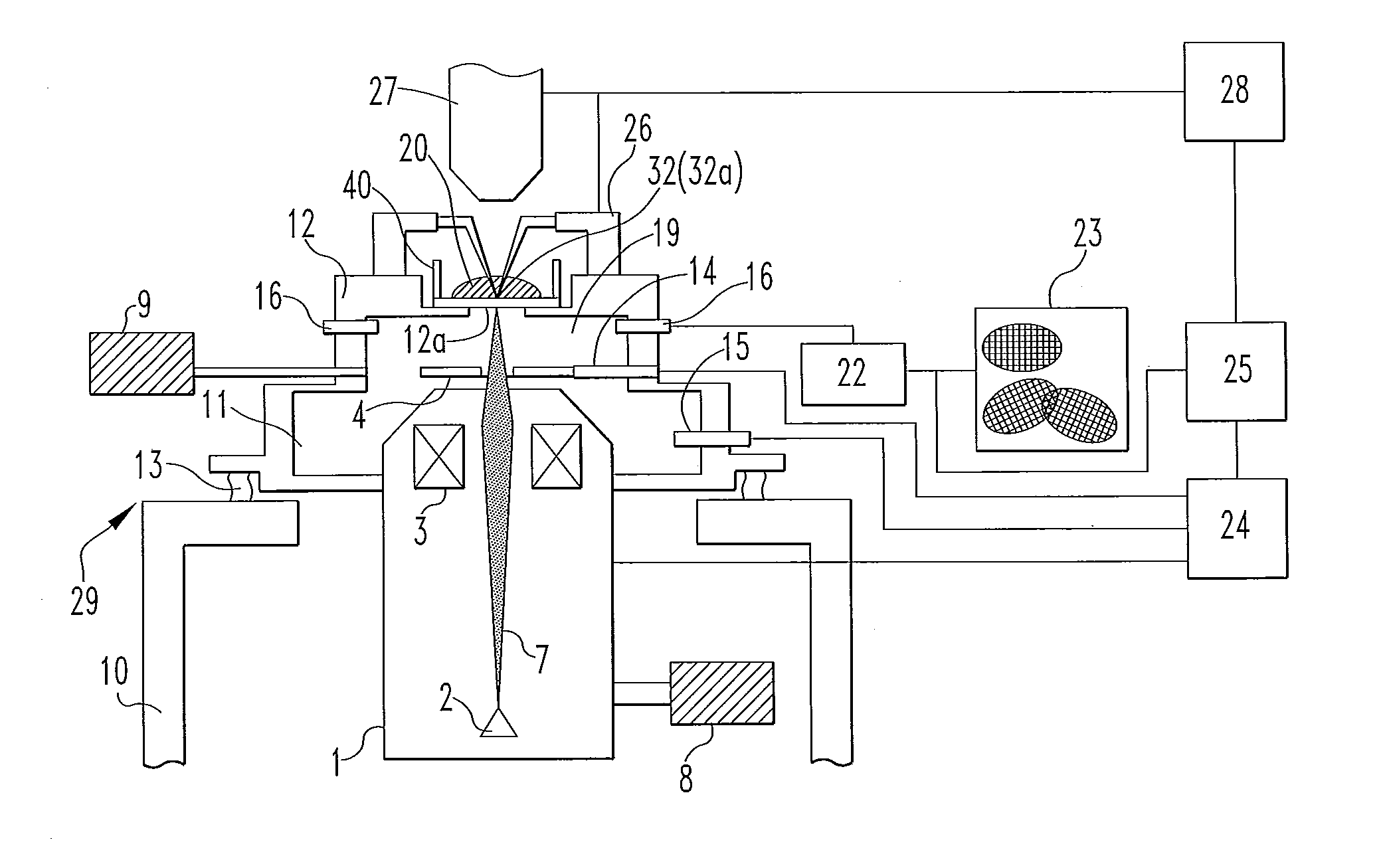

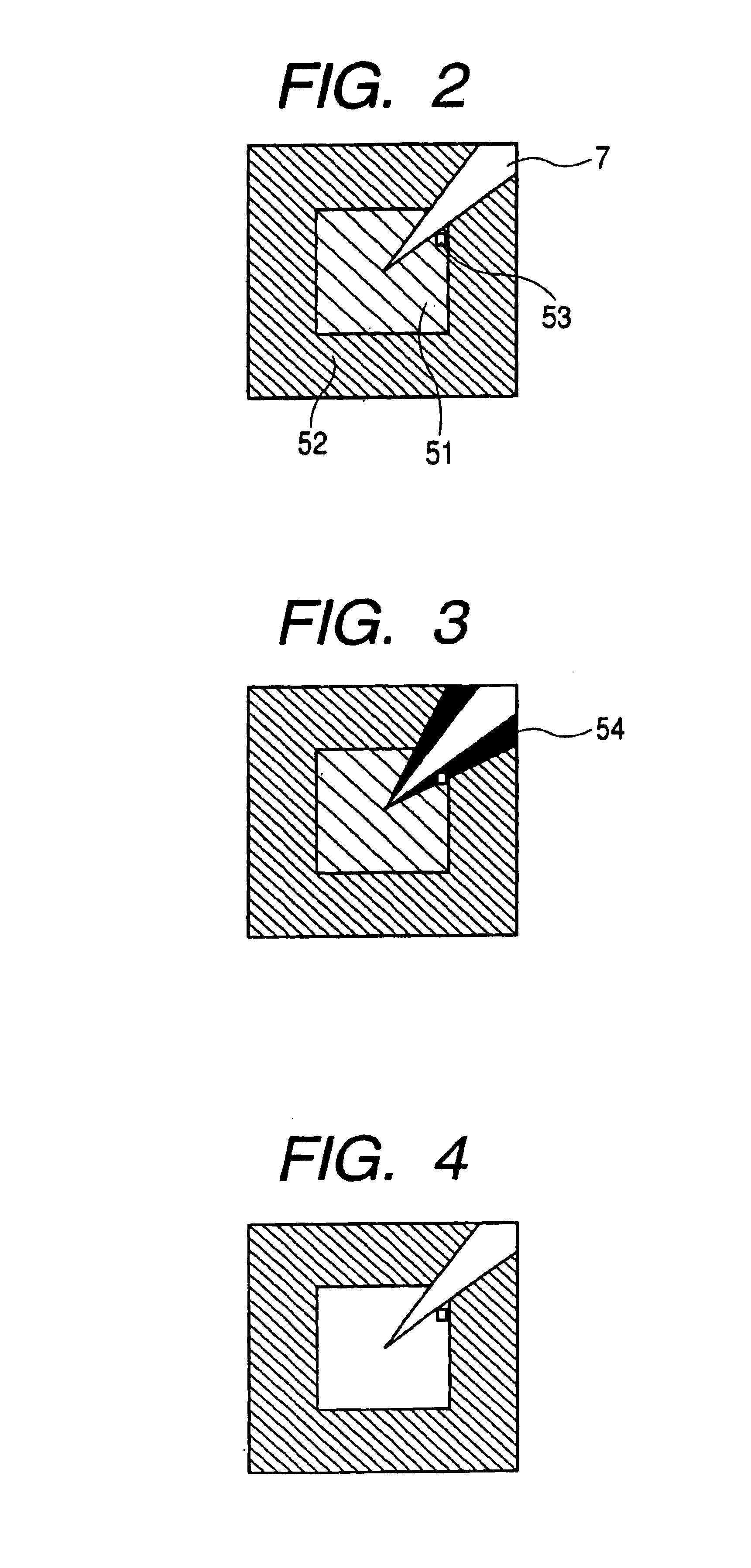

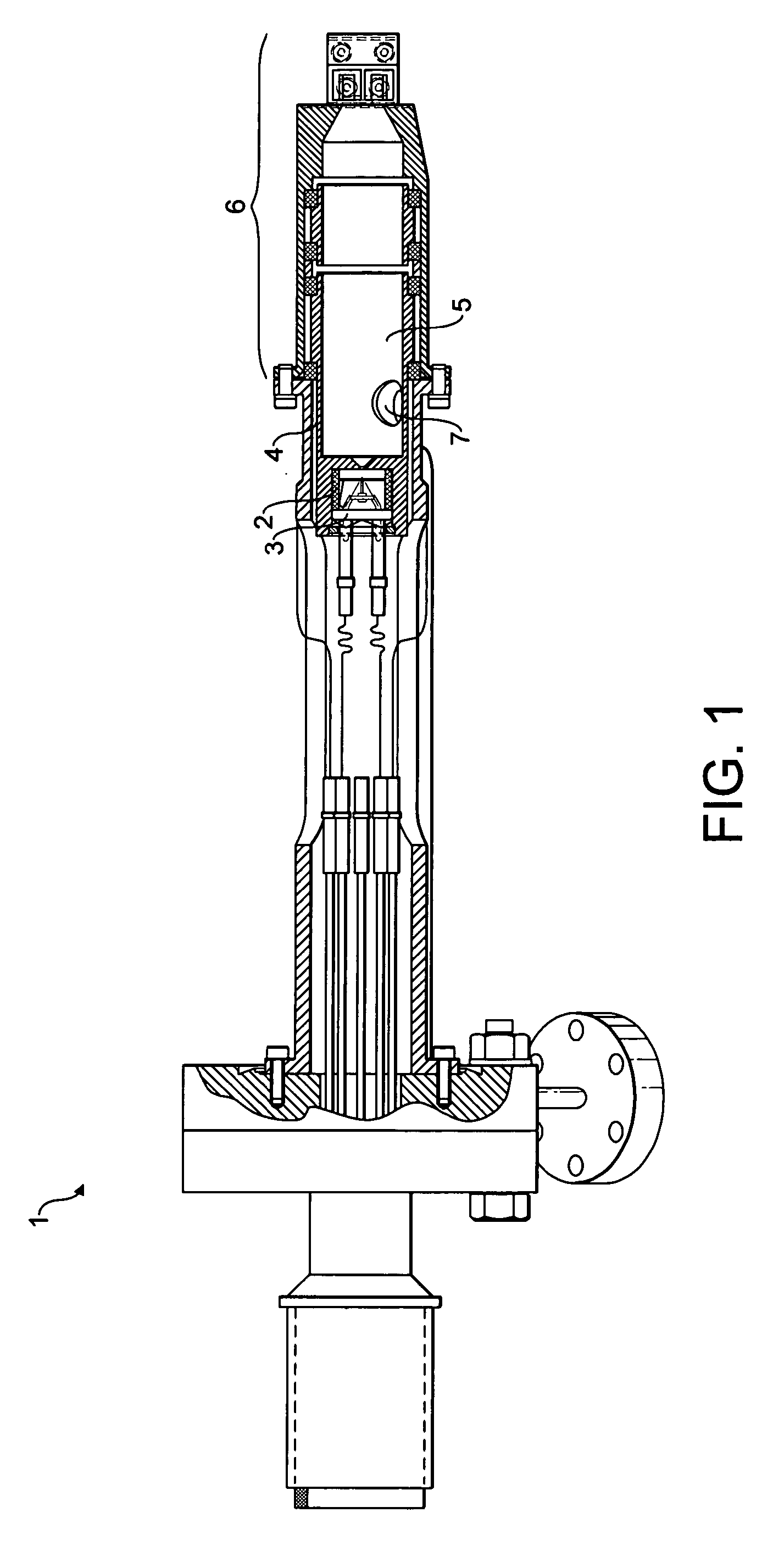

Electron beam apparatus and device manufacturing method using same

InactiveUS6909092B2Reduce image distortionLess aberrationThermometer detailsBeam/ray focussing/reflecting arrangementsElectron sourceImaging processing

A defect inspecting apparatus is provided for generating a less distorted test image to reliably observe a surface of a sample for detecting defects thereon. The defect detecting apparatus comprises a primary electron beam source for irradiating a sample, electrostatic lenses for focusing secondary electrons emitted from the surface of the sample irradiated with the primary electron beam, a detector for detecting the secondary electrons, and an image processing unit for processing a signal from the detector. Further, a second electron source may be provided for emitting an electron beam irradiated to the sample, wherein the sample may be irradiated with the electron beam from the second electron source before it is irradiated with the primary electron beam from the first electron source for observing the sample. A device manufacturing method is also provided for inspecting devices under processing with high throughput using the defect detecting apparatus.

Owner:EBARA CORP

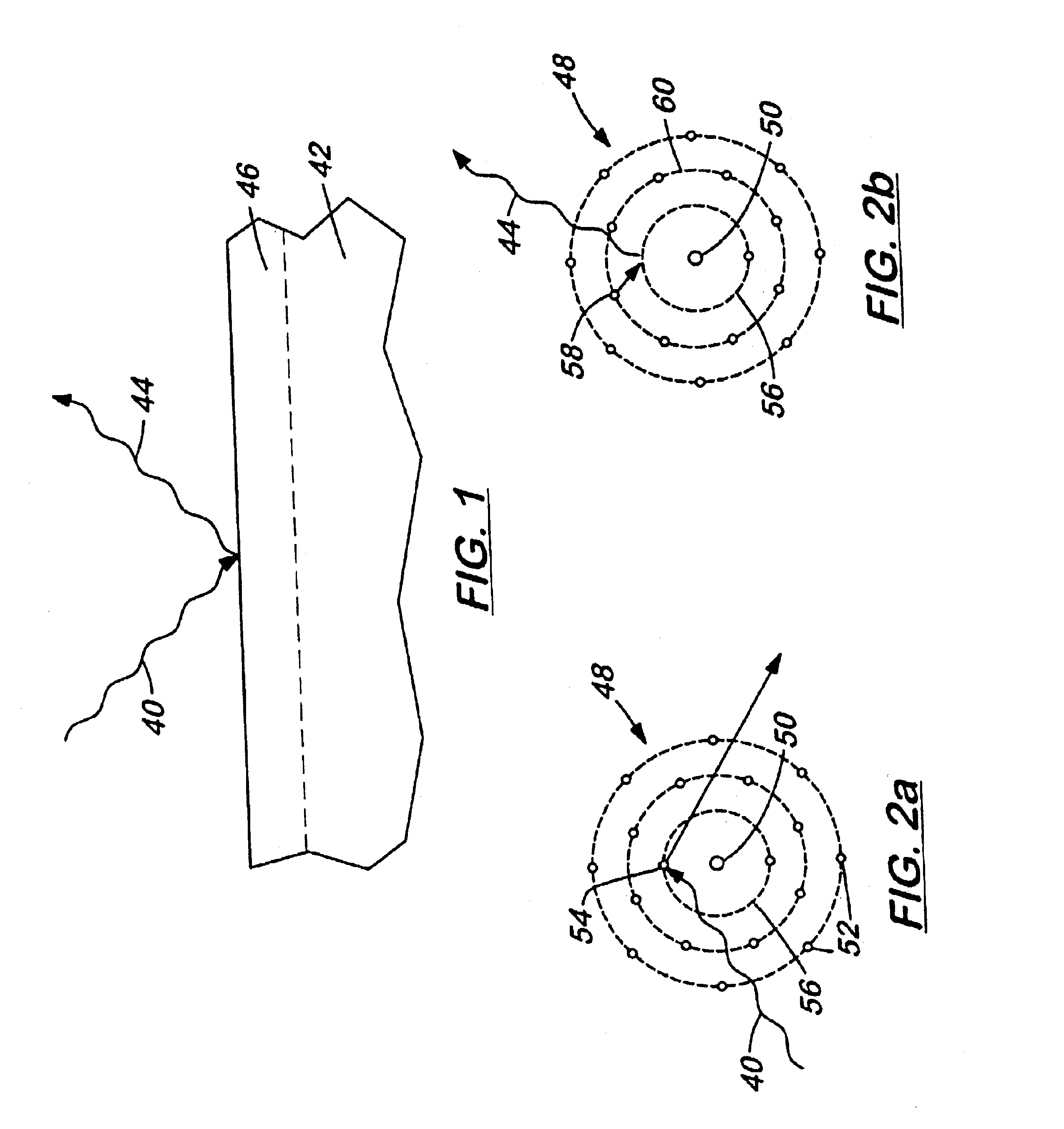

Methods for identification and verification using digital equivalent data system

Apparatus and methods in which one or more elemental taggants that are extrinsically placed in an object are detected by x-ray fluorescence analysis to identify or authenticate the object are described. The taggant is manufactured as part of the object or the taggant is placed into a coating, packaging, label, or otherwise embedded onto the object for the purpose of later verifying the presence or absence of these elements by x-ray fluorescence. The taggant is then analyzed by XRF and the analysis is then converted into a 2D symbol format that can be used in various security and authentication applications. By using x-ray fluorescence analysis, the apparatus and methods of the invention are simple and easy to use, without the limitations experience by current anti-counterfeiting technologies.

Owner:NASA +1

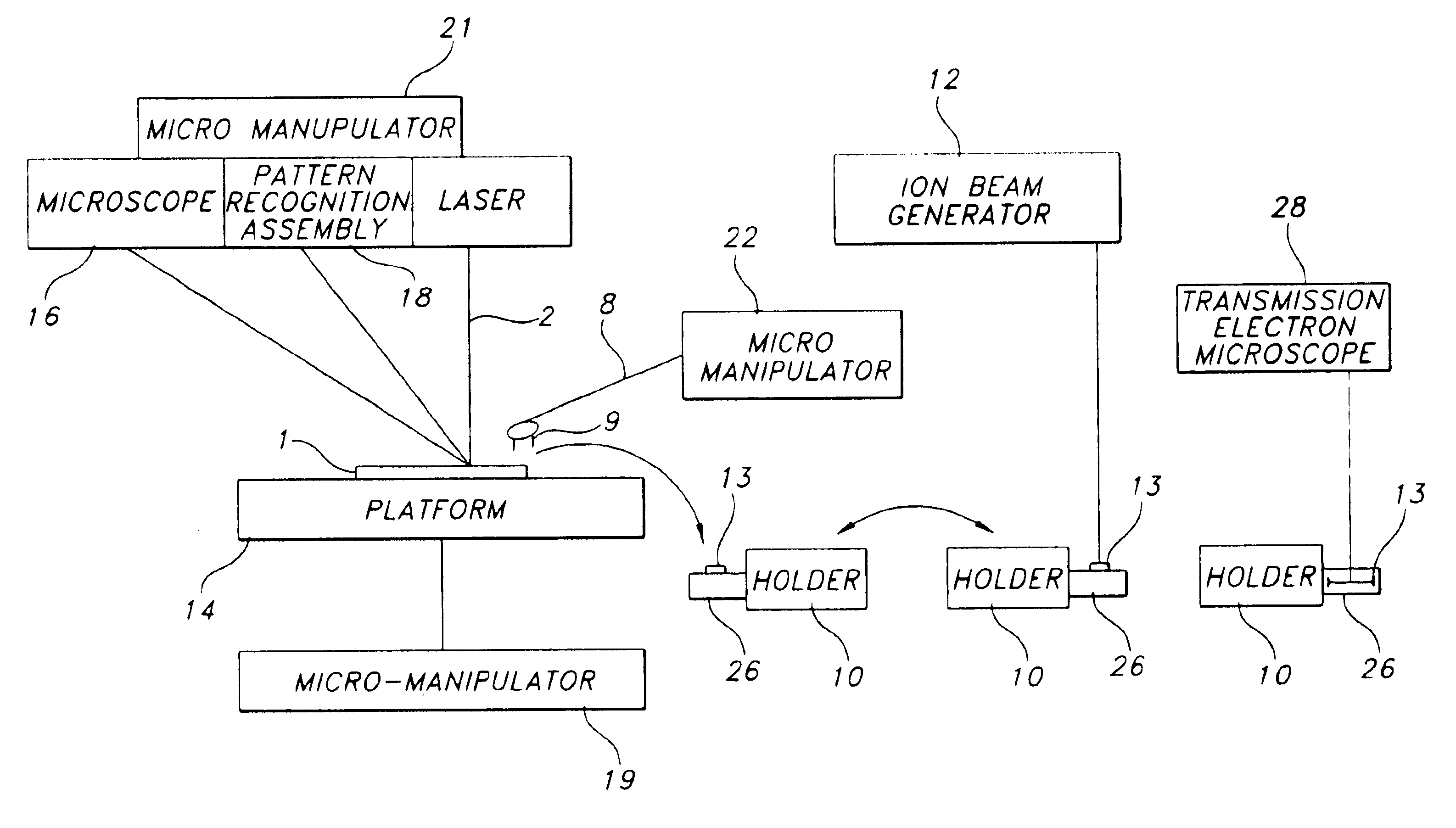

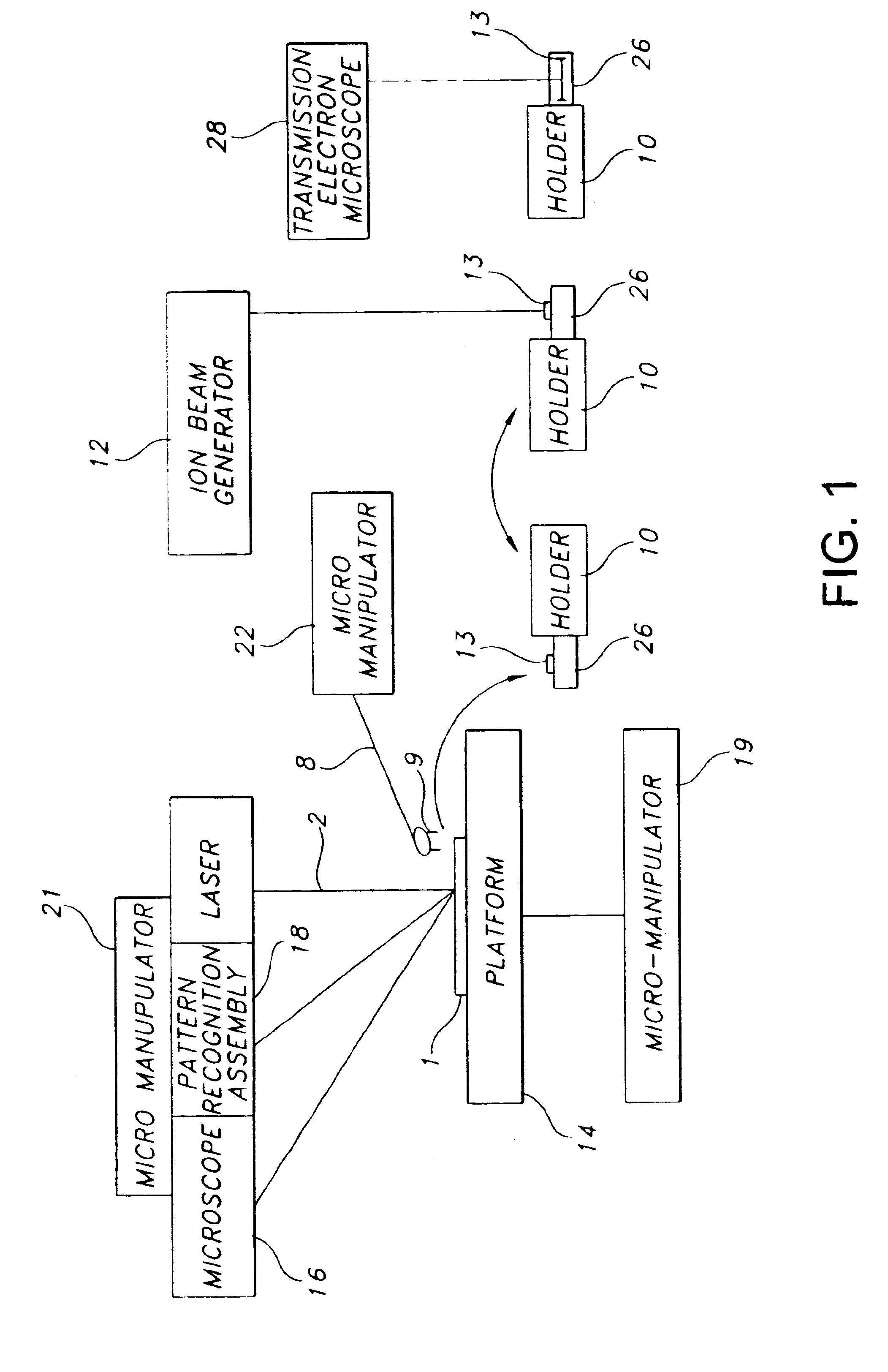

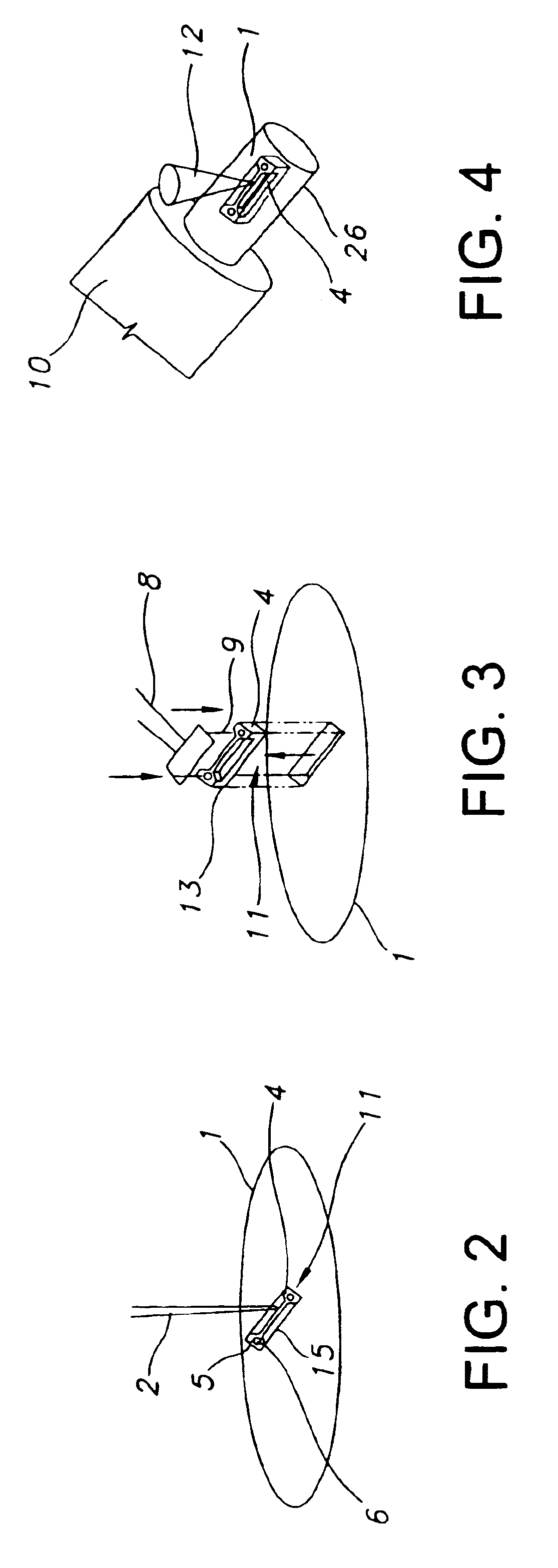

Transmission electron microscope sample preparation

InactiveUS6841788B1Easy to useProvide protectionElectric discharge tubesPreparing sample for investigationElectron microscopeThinning

Sample preparation apparatus and method includes a wafer stage platform with an optical microscope and integrated pattern recognition to automatically address specific locations on the wafer sample of interest. A laser attaches to the optical microscope to mill a set pattern around the area of interest. A precision micro-manipulator engages the sample support structure, extracts the structure, and places the structure in a TEM holder or holder tip. The holder or holder tip can then be placed inside a FIB for final thinning, followed by direct transfer into the TEM.

Owner:OXFORD INSTR AMERICA

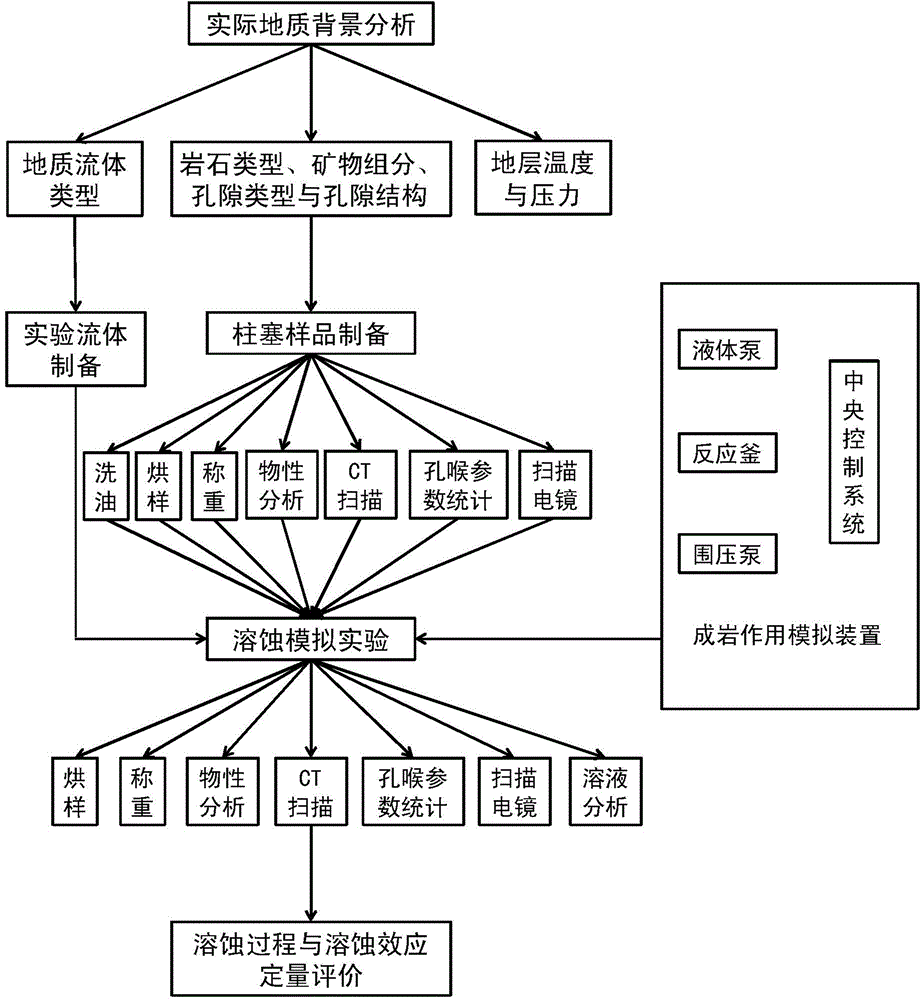

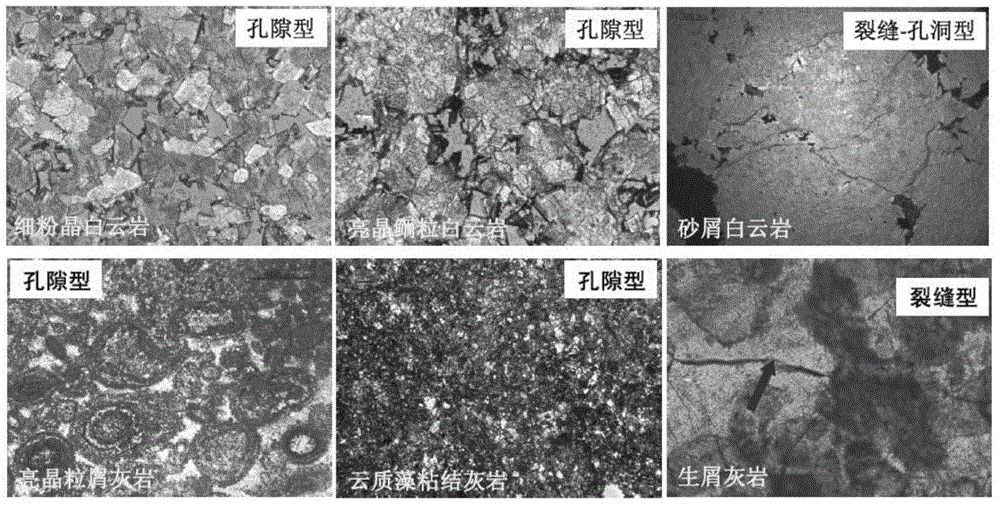

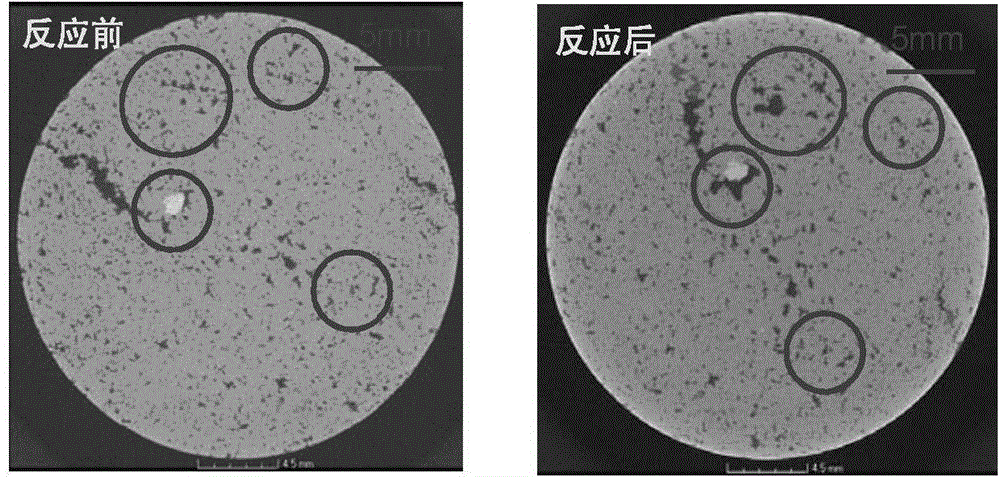

Analysis method of corrosion action and corrosion effect of carbonate rock

ActiveCN104407118AConsistent with diagenesisImprove developmentEarth material testingPermeability/surface area analysisComputed tomographyEarth surface

The invention provides an analysis method of the corrosion action and the corrosion effect of a carbonate rock. The method comprises the following steps: detecting petrologic parameters, geological fluid characteristics and geological background parameters of a reservoir stratum of the carbonate rock; selecting a plunger sample, and preparing the plunger sample into a diagenetic fluid; performing weighing, physical property analysis, CT scan analysis and microscopic property analysis on the sample before experiment; performing a corrosion simulated experiment on the carbonate rock, and collecting the reaction generated liquid; performing the physical property analysis, the CT scan analysis and the microscopic property analysis on the sample after experiment; analyzing the content of Ca<2+> and Mg<2+> of the generated liquid; analyzing the corrosion action of the carbonate rock under different controlling factors, determining a three-dimensional structure and a microcosmic pattern of representation of a corrosion hole of the carbonate rock, and quantitatively assessing the corrosion hole of the carbonate rock and the communicated property evolution. By the method, the corrosion action and the corrosion benefits of the carbonate rock from an earth surface to the deep burying environment can be analyzed, and more accurate analytical data is provided for assessing and forecasting the favorable reservoir stratum of the carbonate rock.

Owner:PETROCHINA CO LTD

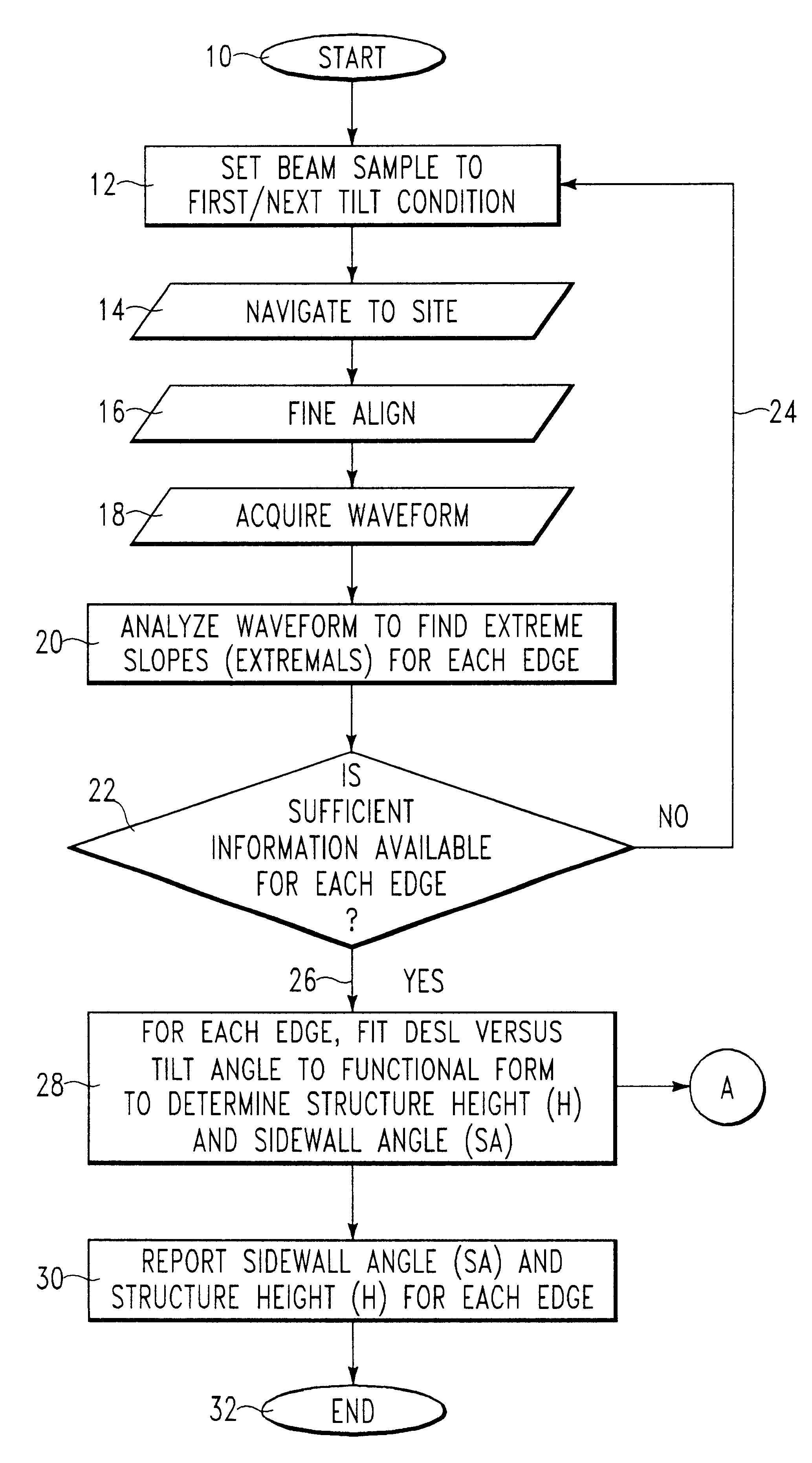

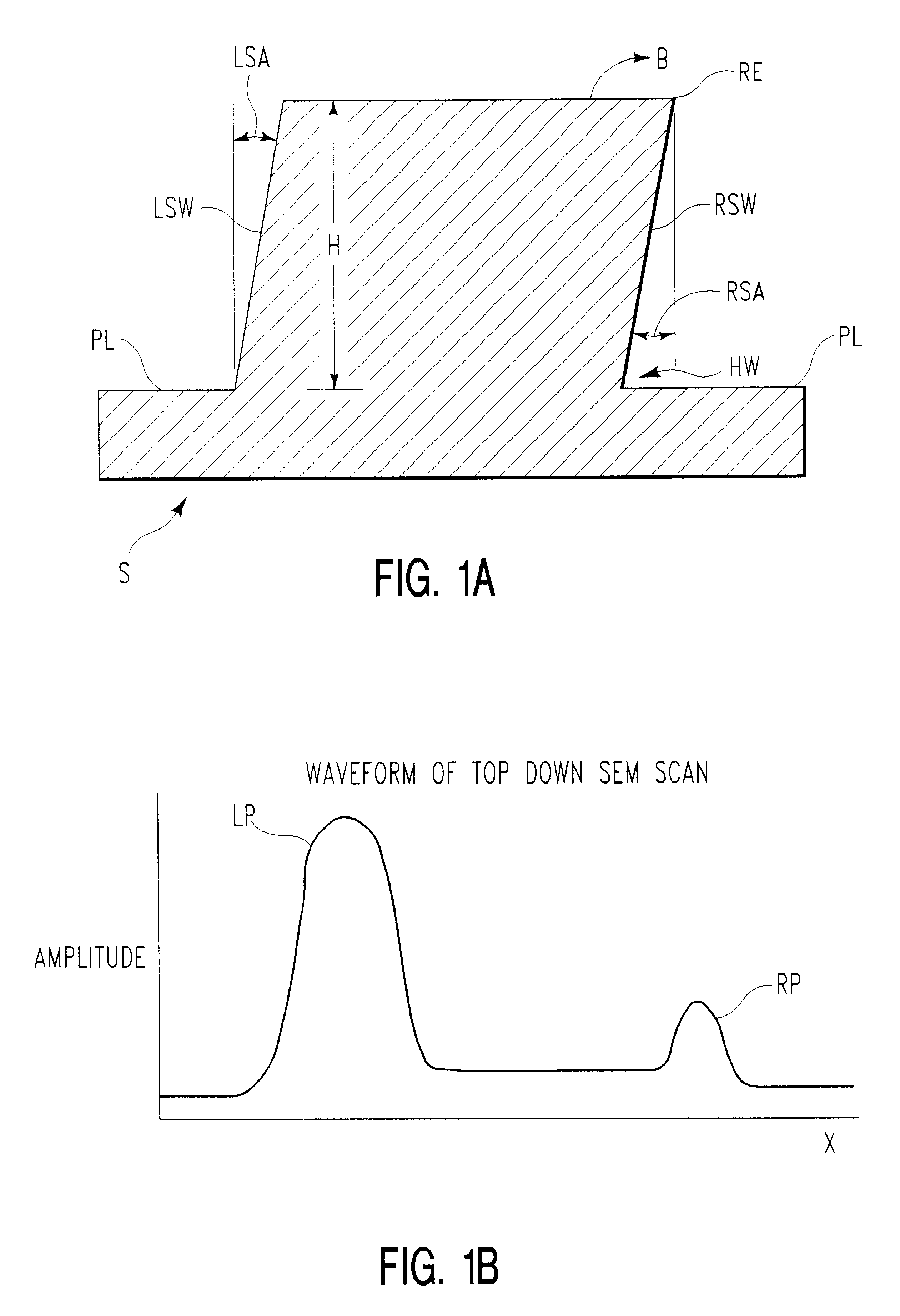

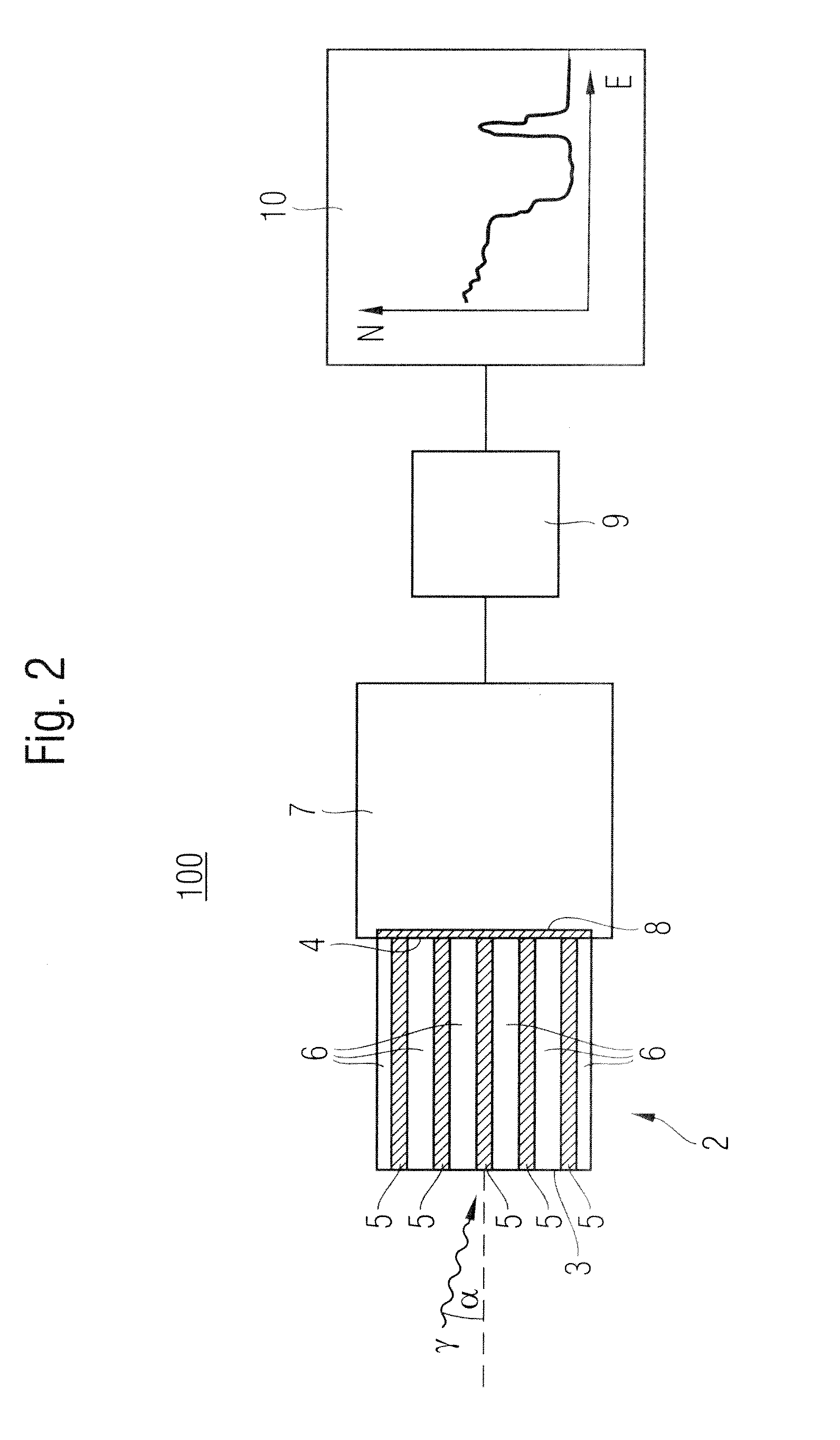

Automated method for determining several critical dimension properties from scanning electron microscope by using several tilted beam or sample scans

InactiveUS6472662B1Material analysis by measuring secondary emissionGamma-ray/x-ray microscopesGratingSystems analysis

To obtain data pertaining to the surface characteristics of a sample, a control method adjusts a tilted rastered E-beam to in SEM to a first / next tilt condition and navigates the SEM-beam to a sample site. The system performs a fine alignment step. Then the system scans a region of a sample to acquire a waveform. The system analyzes the waveform to determine the DESL value for each edge of interest. The system tests whether there is sufficient information available for each structural edge. If NO, the system repeats the above steps starting by changing the value of the tilt angle to acquire another waveform. If YES, the system determines the height and sidewall angles for each structural edge. Then the system reports the sidewall angle and the structure height for each edge of the structure under test. The system then corrects the critical dimension measurement determined from 0 degrees tilt scanning.

Owner:IBM CORP

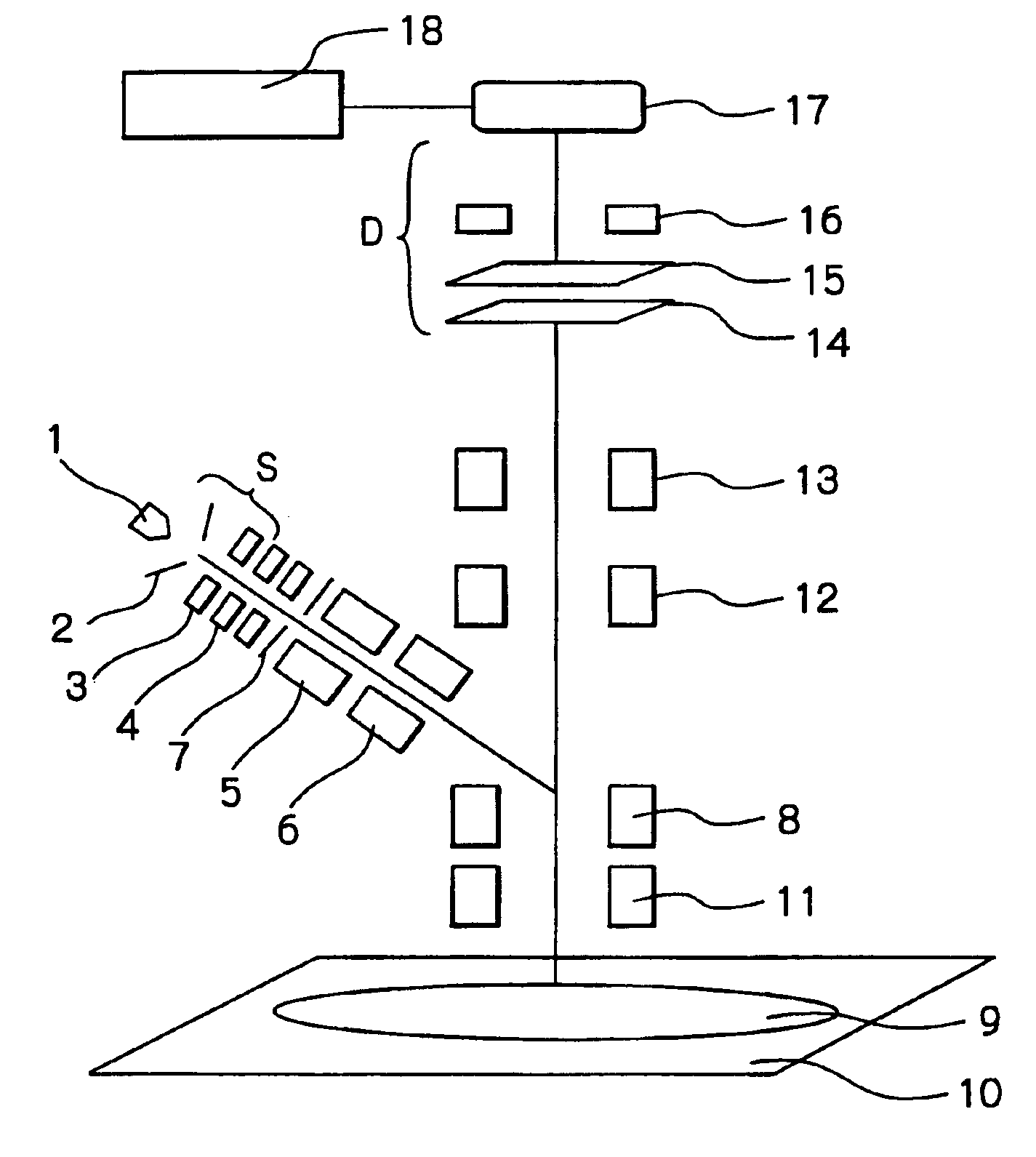

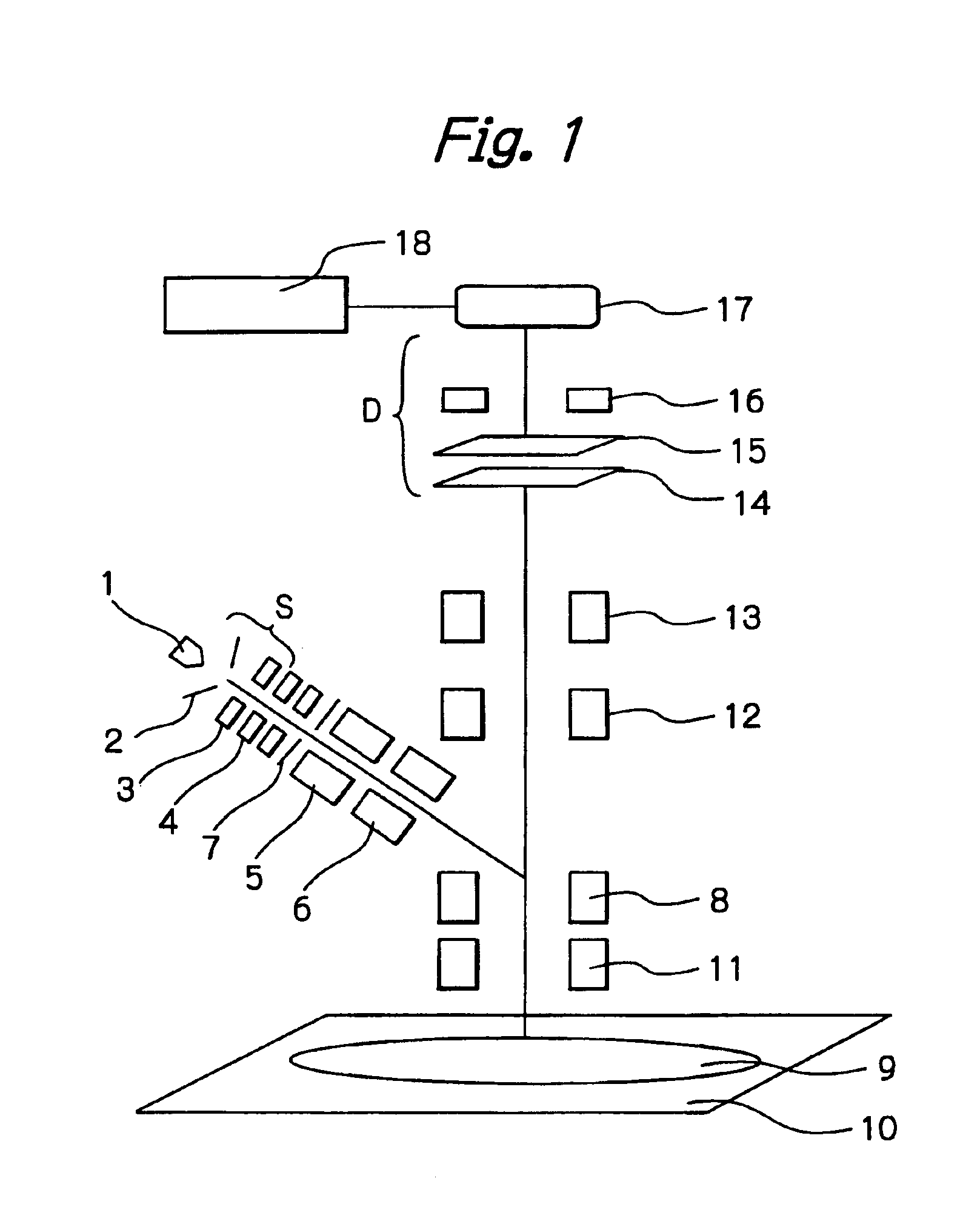

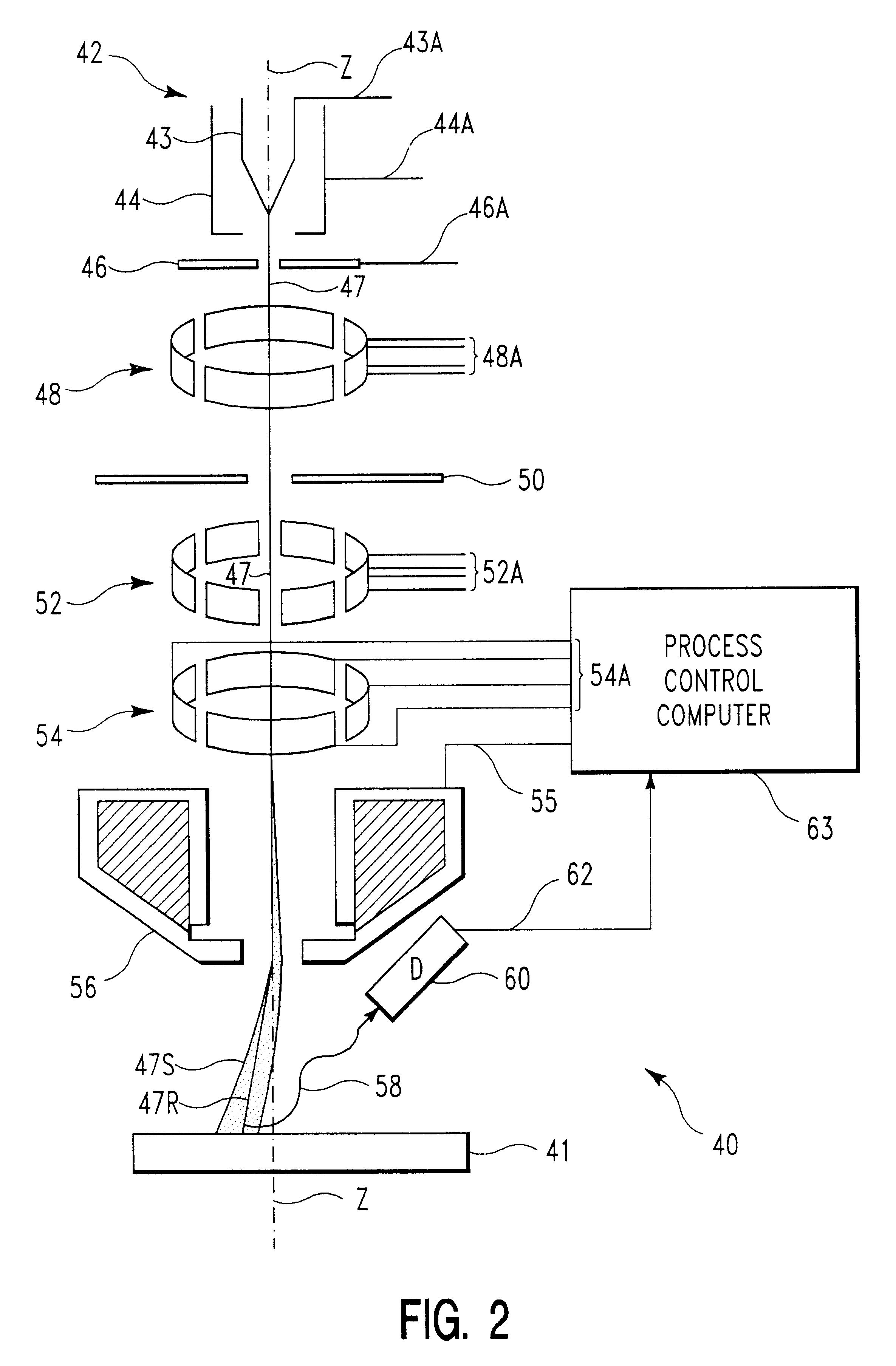

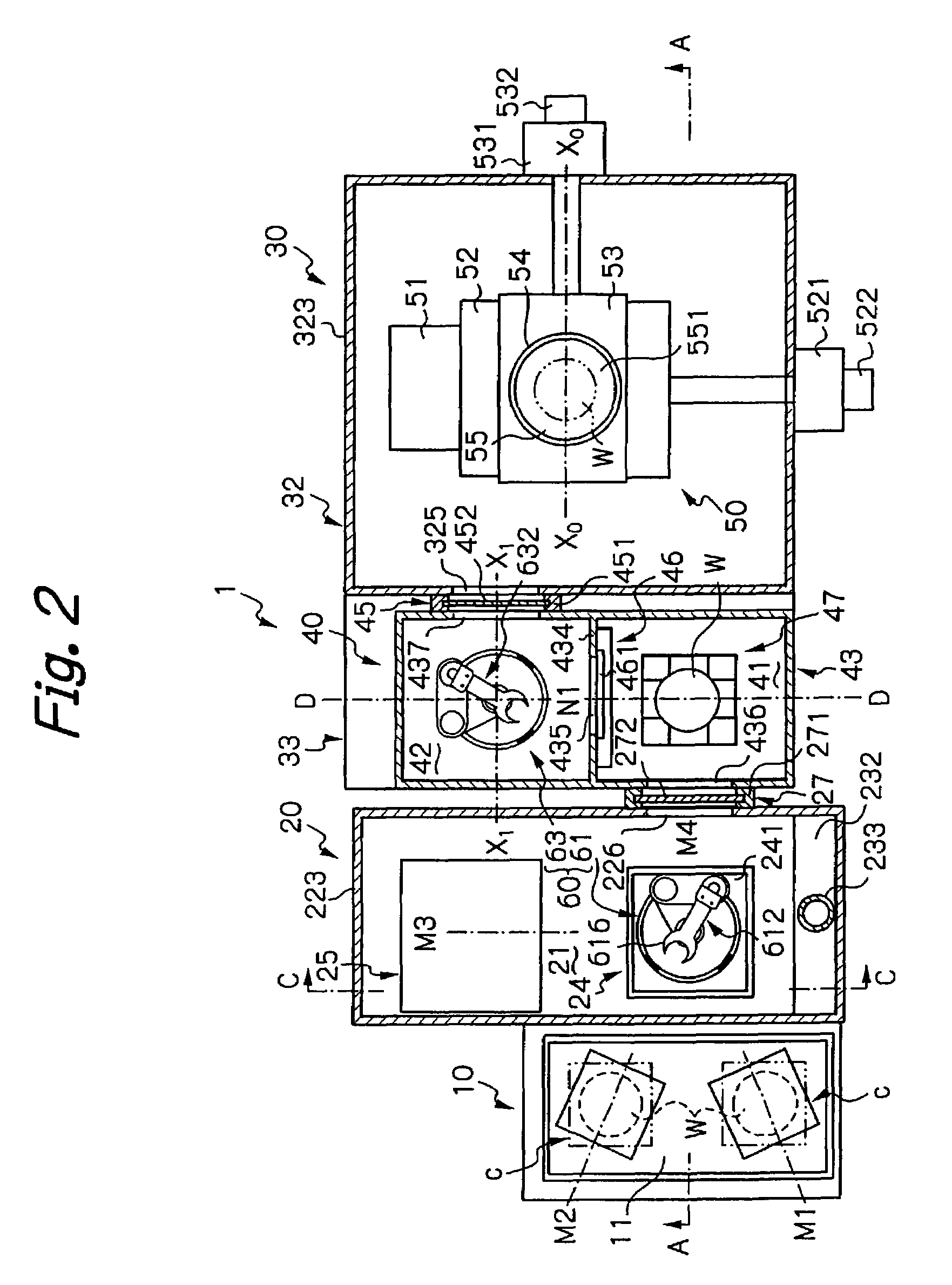

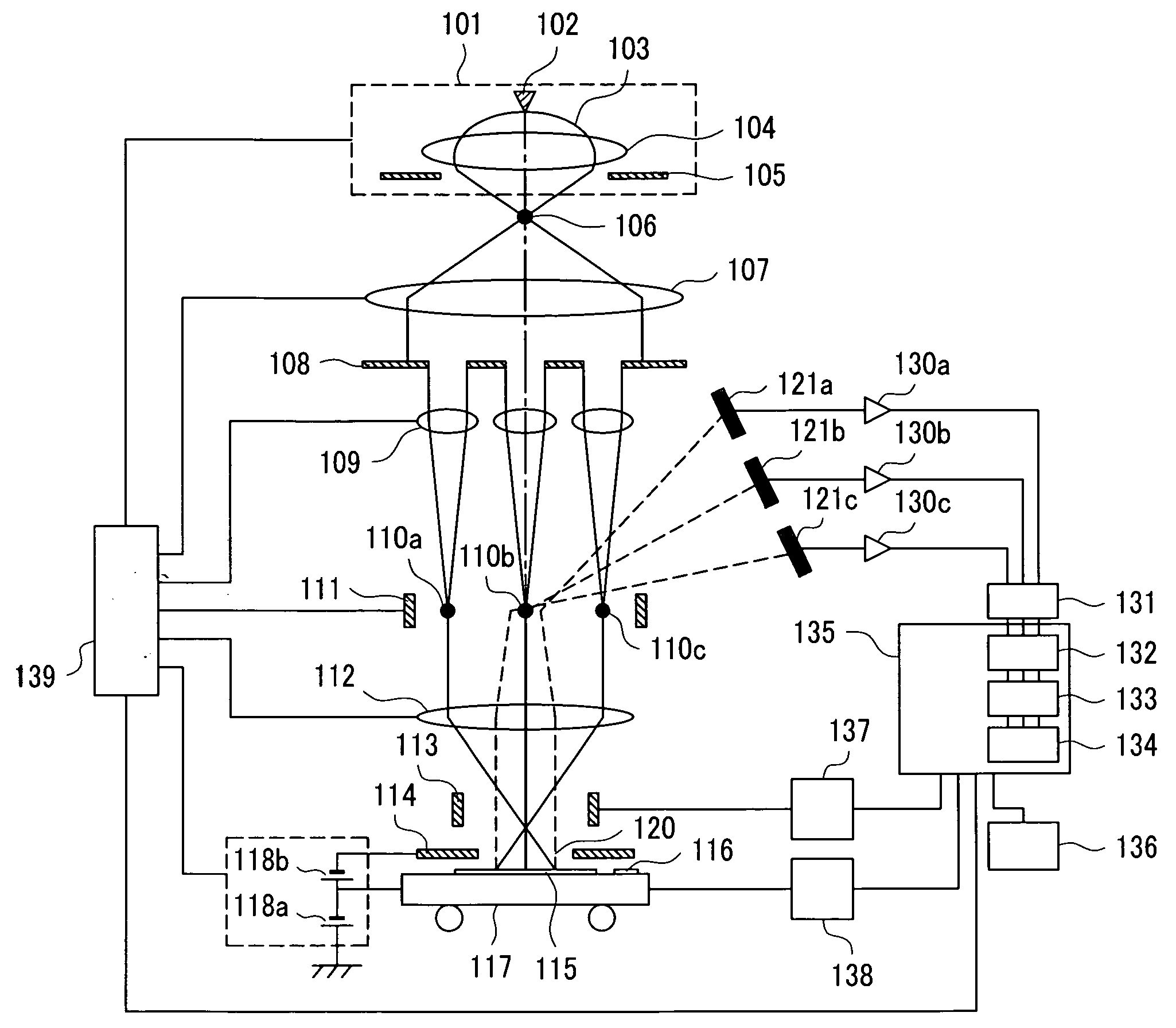

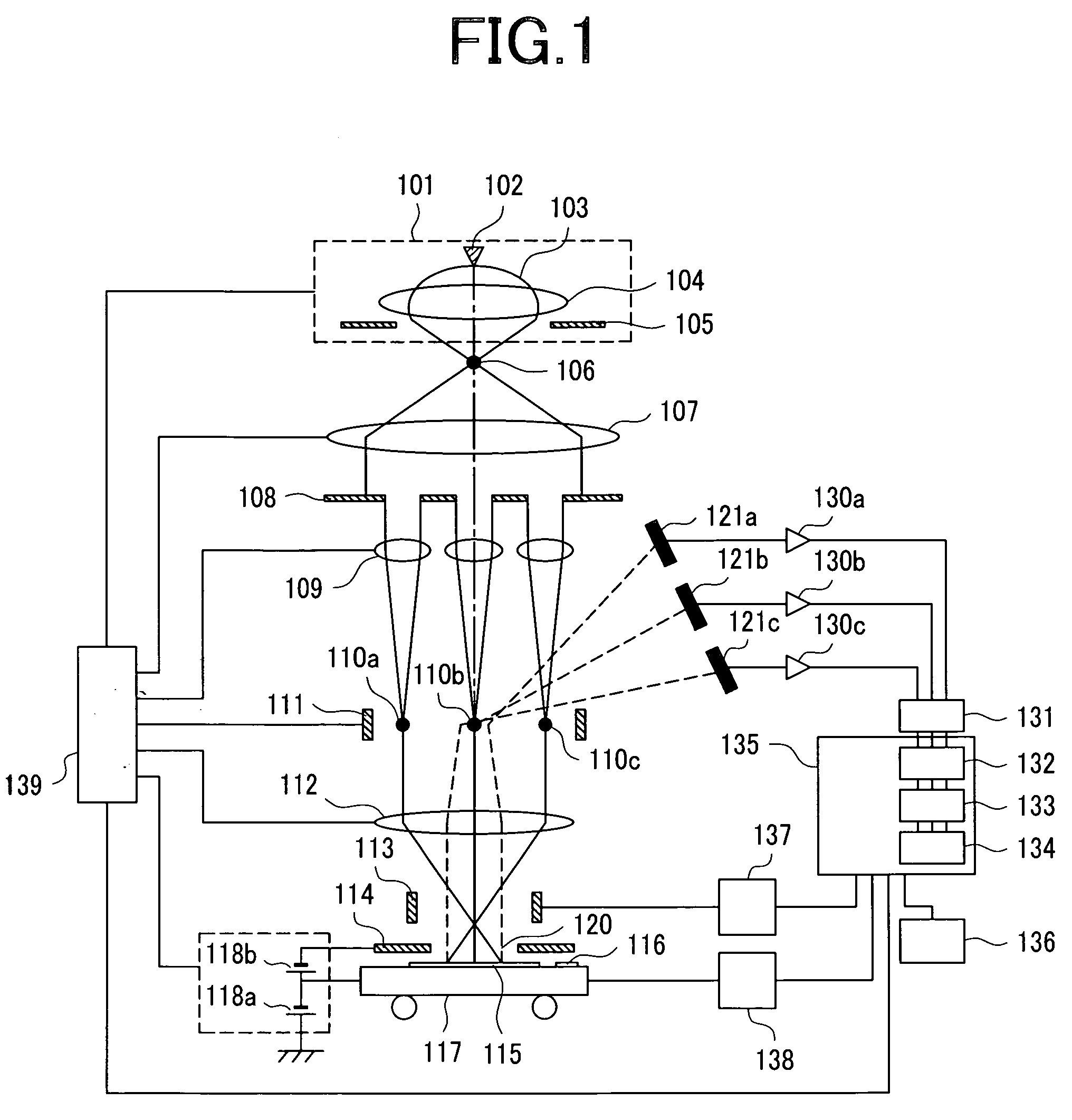

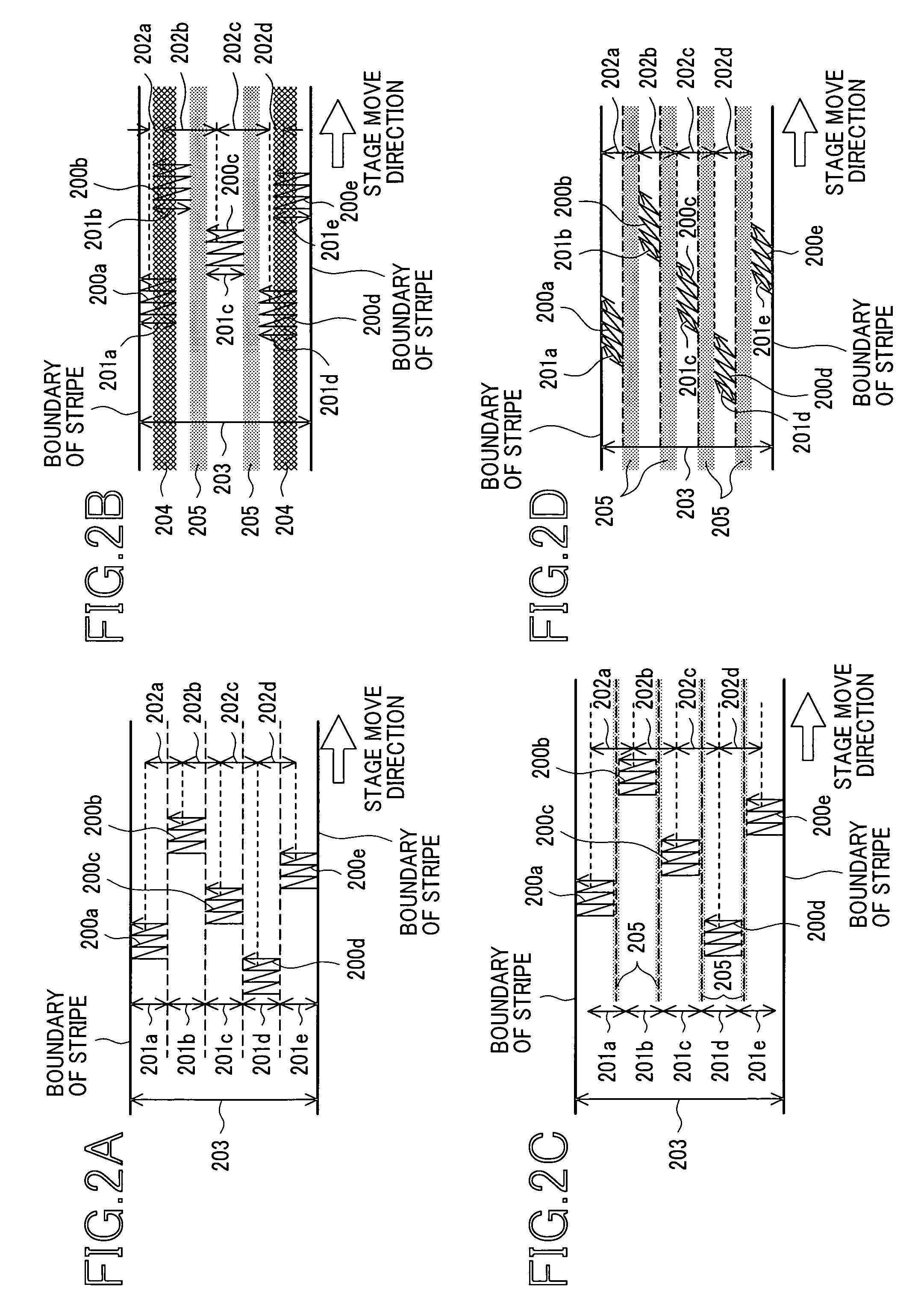

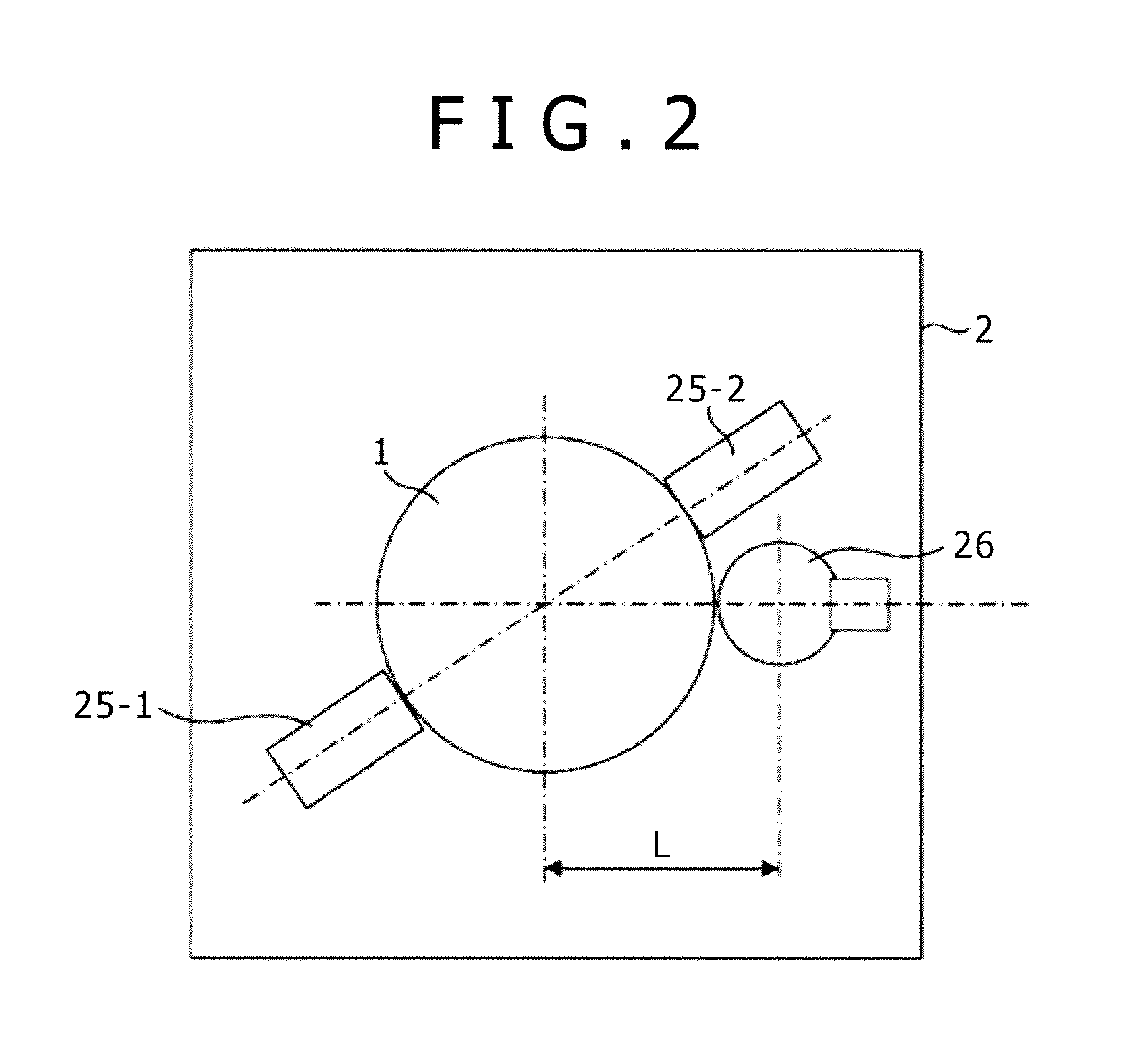

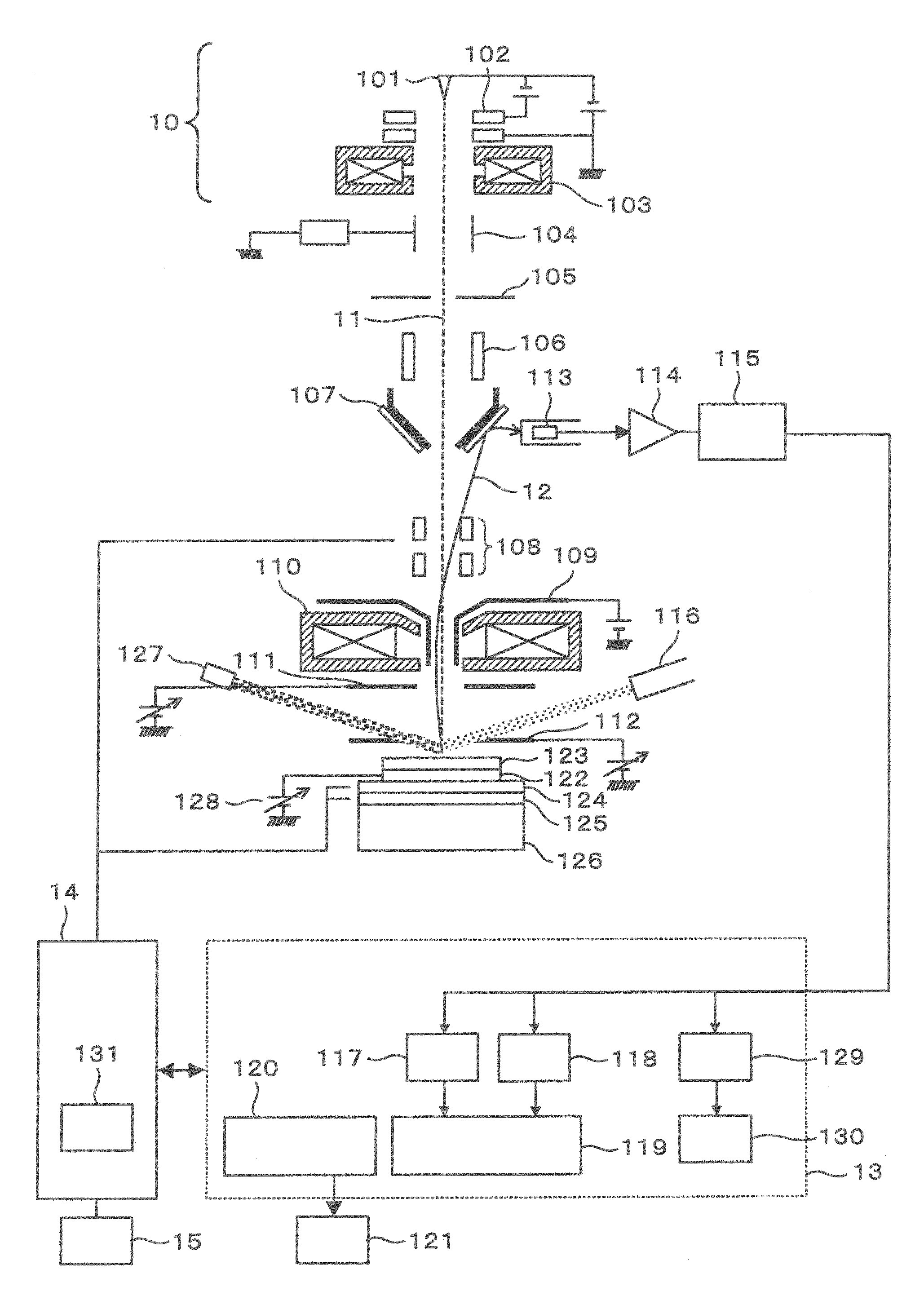

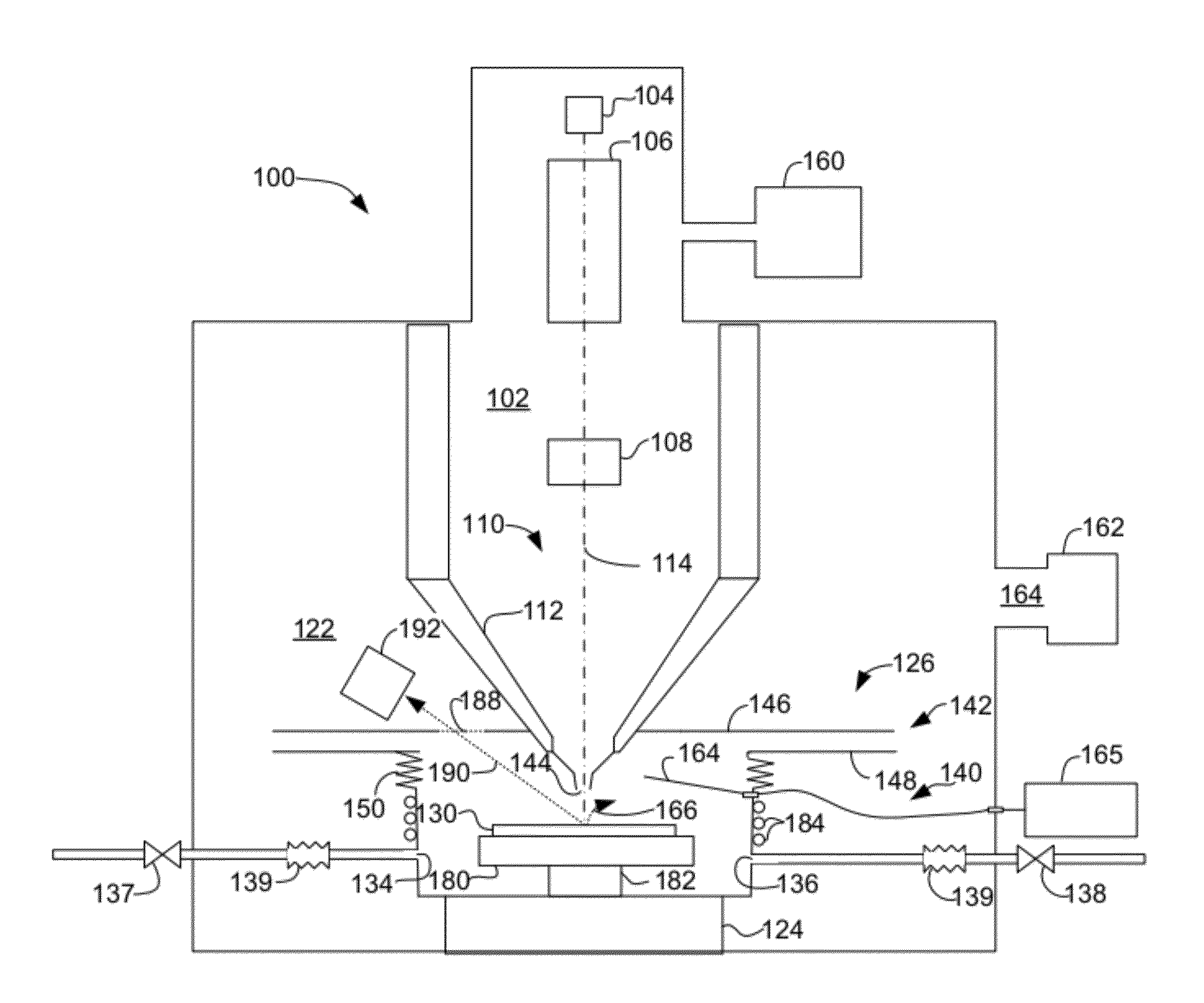

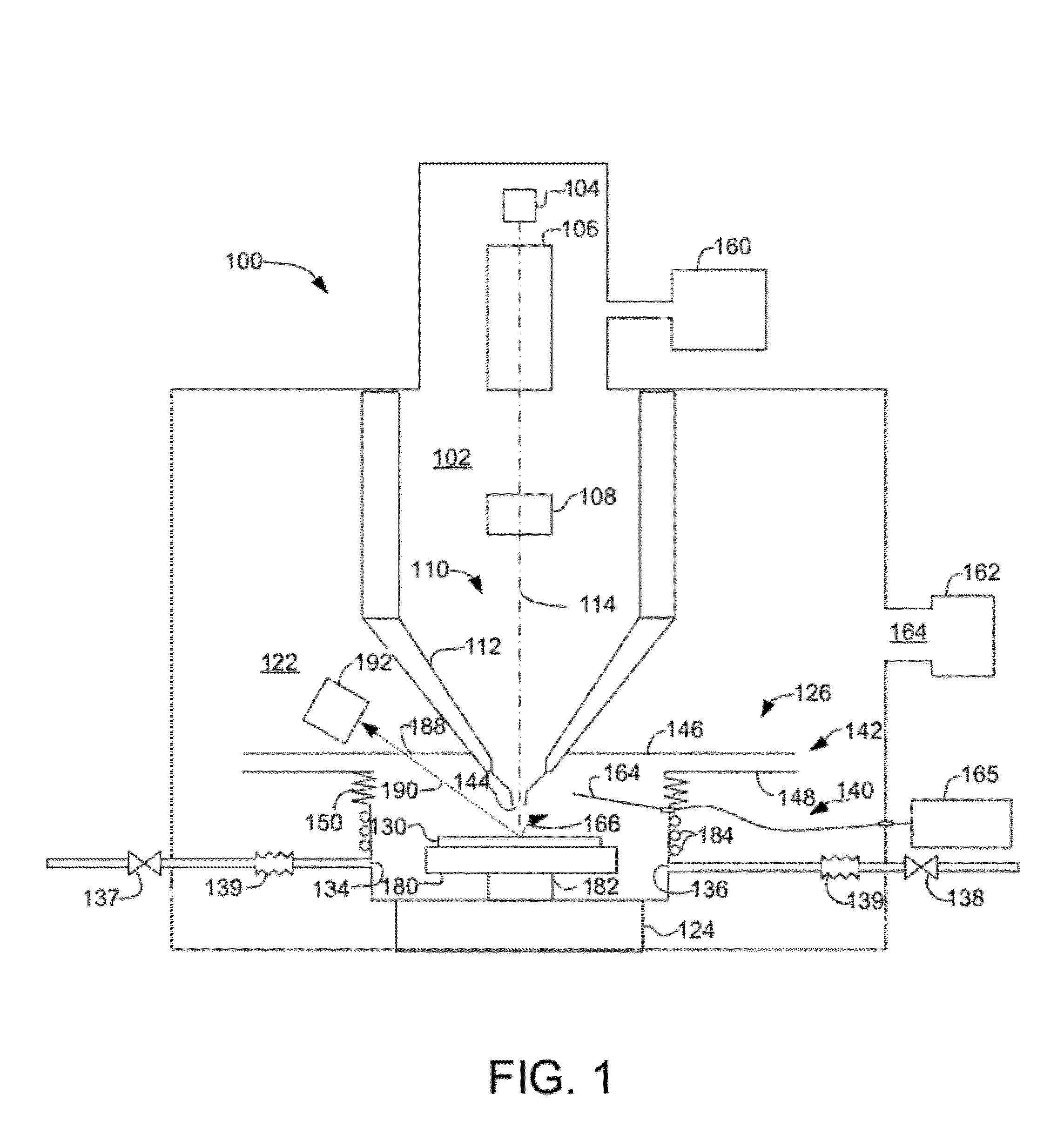

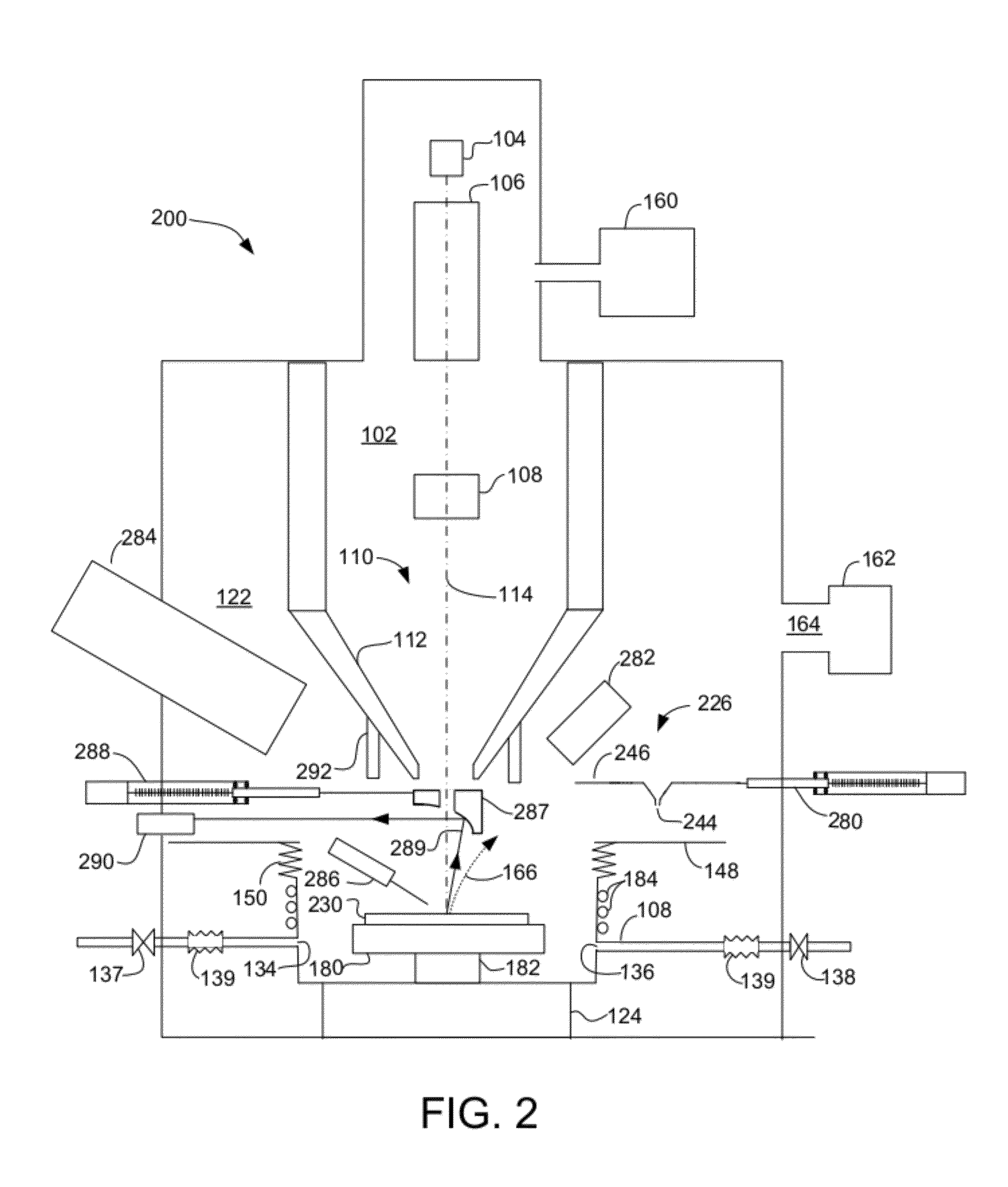

Electron beam apparatus and device fabrication method using the electron beam apparatus

InactiveUS7244932B2Improve throughputImprove accuracyThermometer detailsStability-of-path spectrometersSecondary electronsThroughput

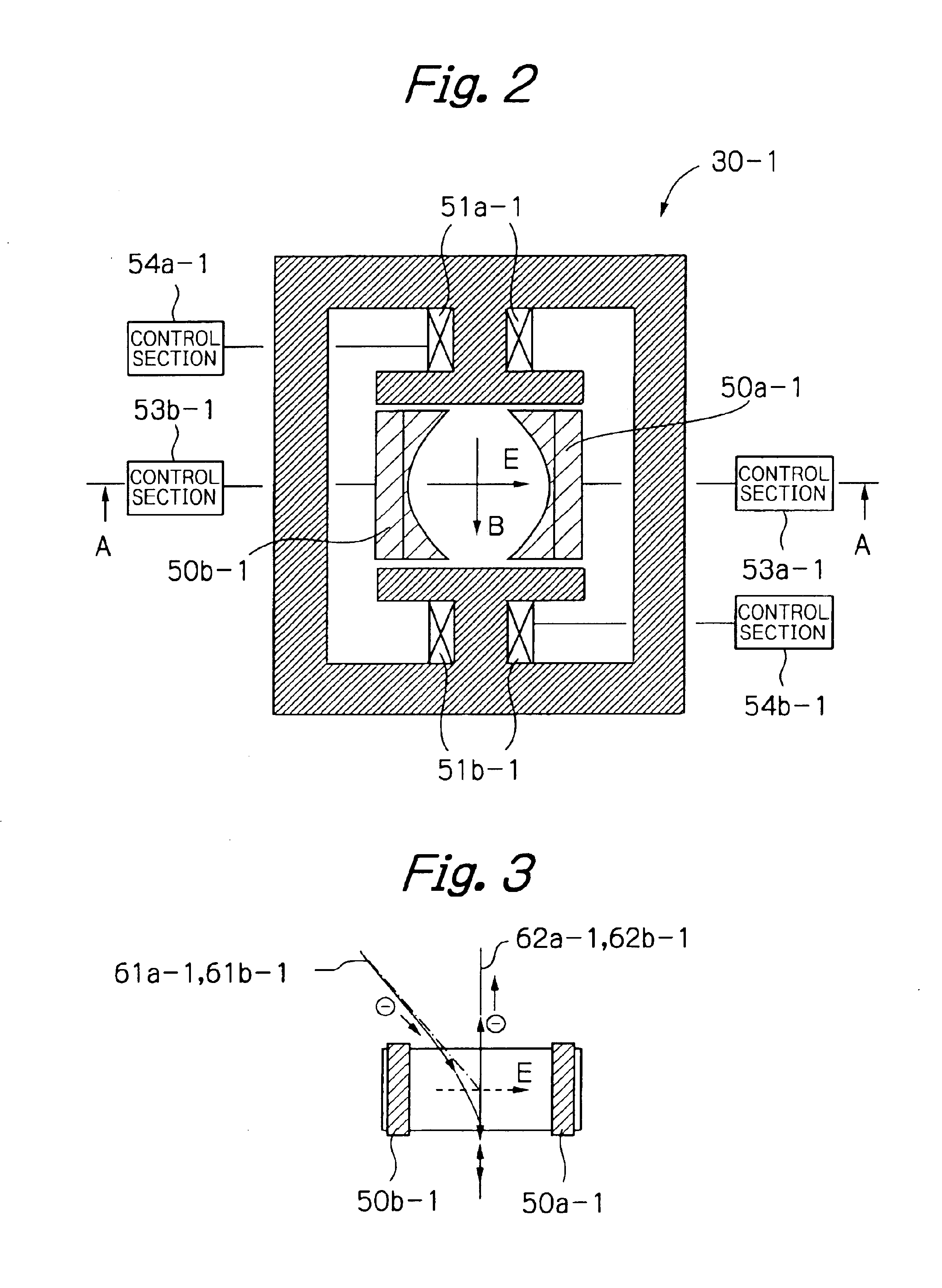

The purpose of the invention is to provide an improved electron beam apparatus with improvements in throughput, accuracy, etc. One of the characterizing features of the electron beam apparatus of the present invention is that it has a plurality of optical systems, each of which comprises a primary electron optical system for scanning and irradiating a sample with a plurality of primary electron beams; a detector device for detecting a plurality of secondary beams emitted by irradiating the sample with the primary electron beams; and a secondary electron optical system for guiding the secondary electron beams from the sample to the detector device; all configured so that the plurality of optical systems scan different regions of the sample with their primary electron beams, and detect the respective secondary electron beams emitted from each of the respective regions. This is what makes higher throughput possible. To provide high accuracy, the apparatus is configured such that the axes of its optical systems can be aligned, and aberrations corrected, by a variety of methods.

Owner:EBARA CORP

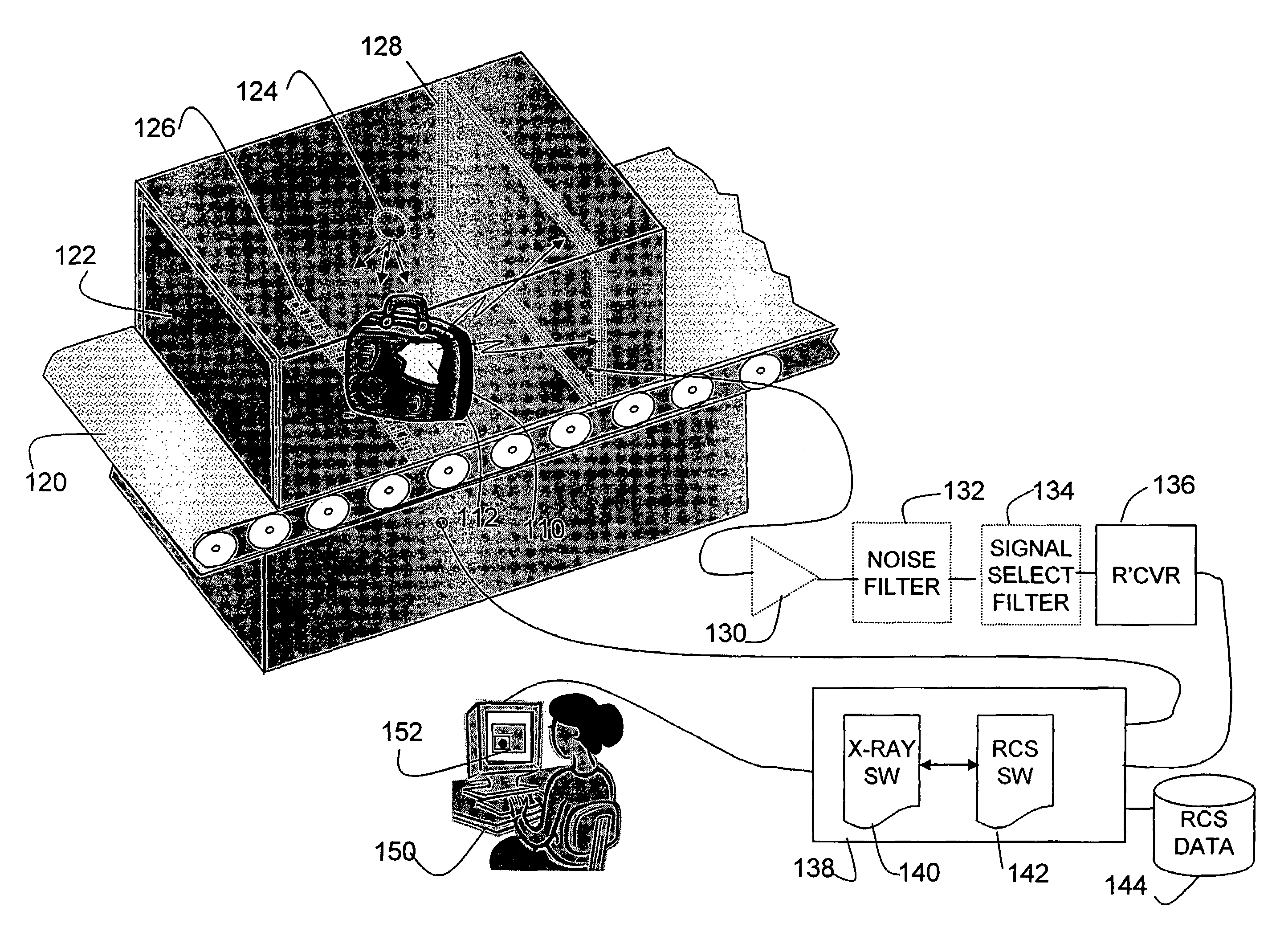

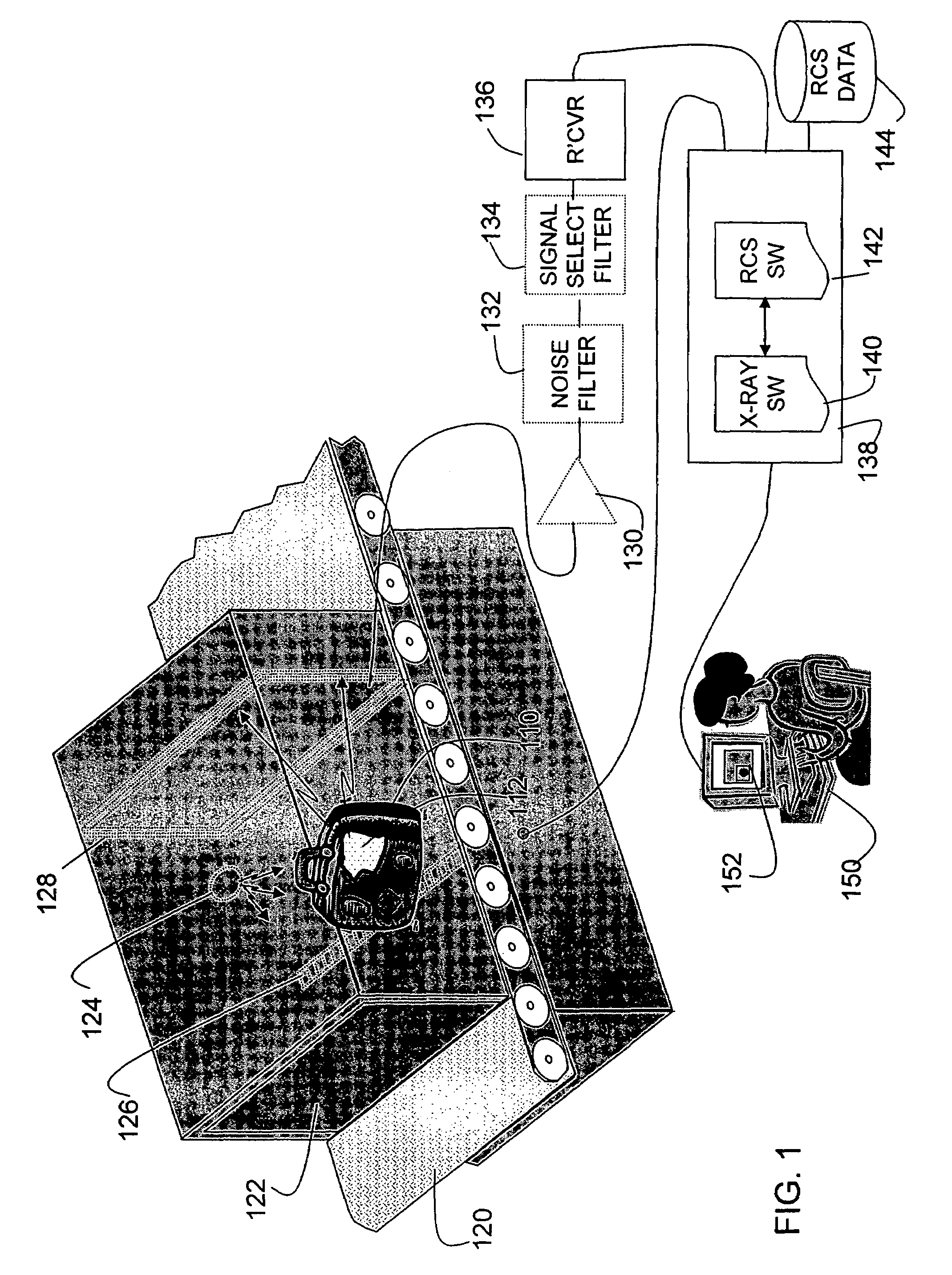

Method and apparatus for detecting contraband using radiated compound signatures

InactiveUS7251310B2Electric/magnetic detectionMaterial analysis by transmitting radiationSecondary analysisIonization

An system for detecting contraband, particularly explosives or other energetic materials. The system includes a source of ionizing radiation that irradiates an item under inspection. The radiation stimulates the emission of RF energy from objects within the item under inspection. The characteristics of the emitted RF energy reveals information about the material composition of the objects. The system detects this emitted RF energy and comparers it to a signature of RF emissions from contraband objects. Apparatus to detect and analyze RF emissions may be constructed as a stand-alone unit or may be incorporated into an imaging system in which the ionizing radiation is used to form an image of the item under inspection. Similarly, the RF analysis may be used, in the first instance, to determine whether an object contains a contraband item or may be used as a second level analysis to clear alarms generated by analysis of images formed by the imaging system.

Owner:L3 COMMUNICATIONS SECURITY & DETECTION SYSTEMS CORPORATION

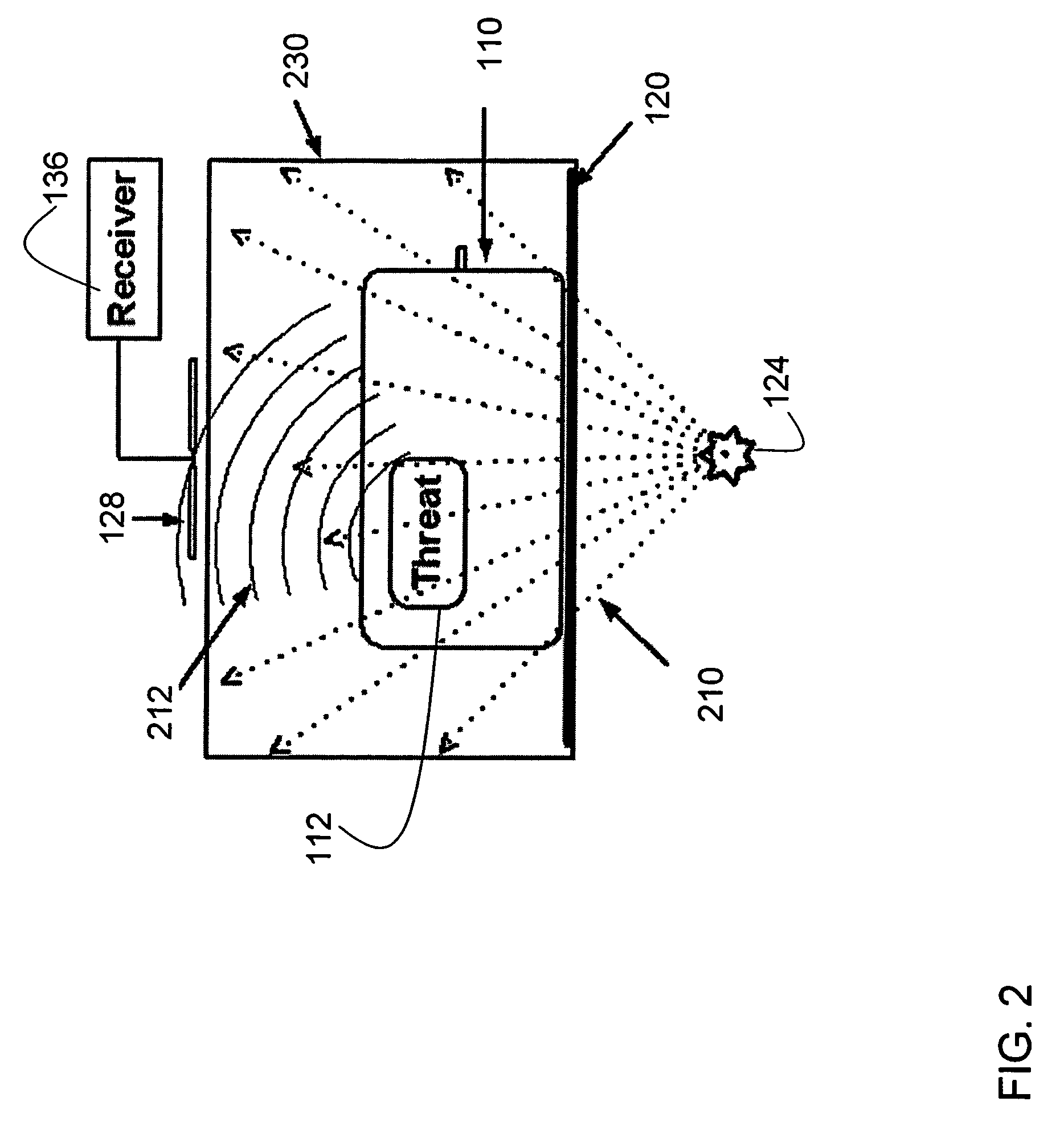

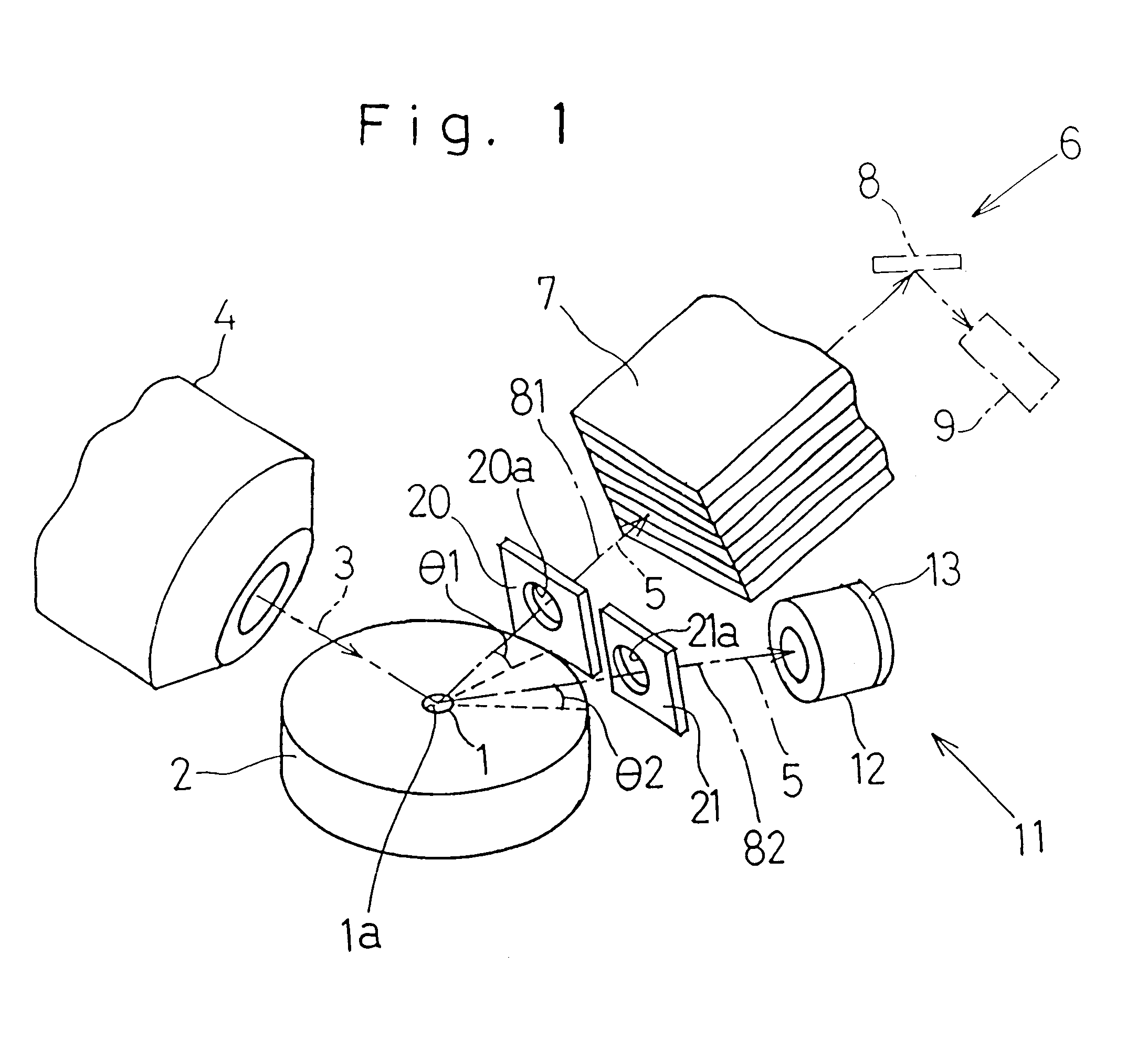

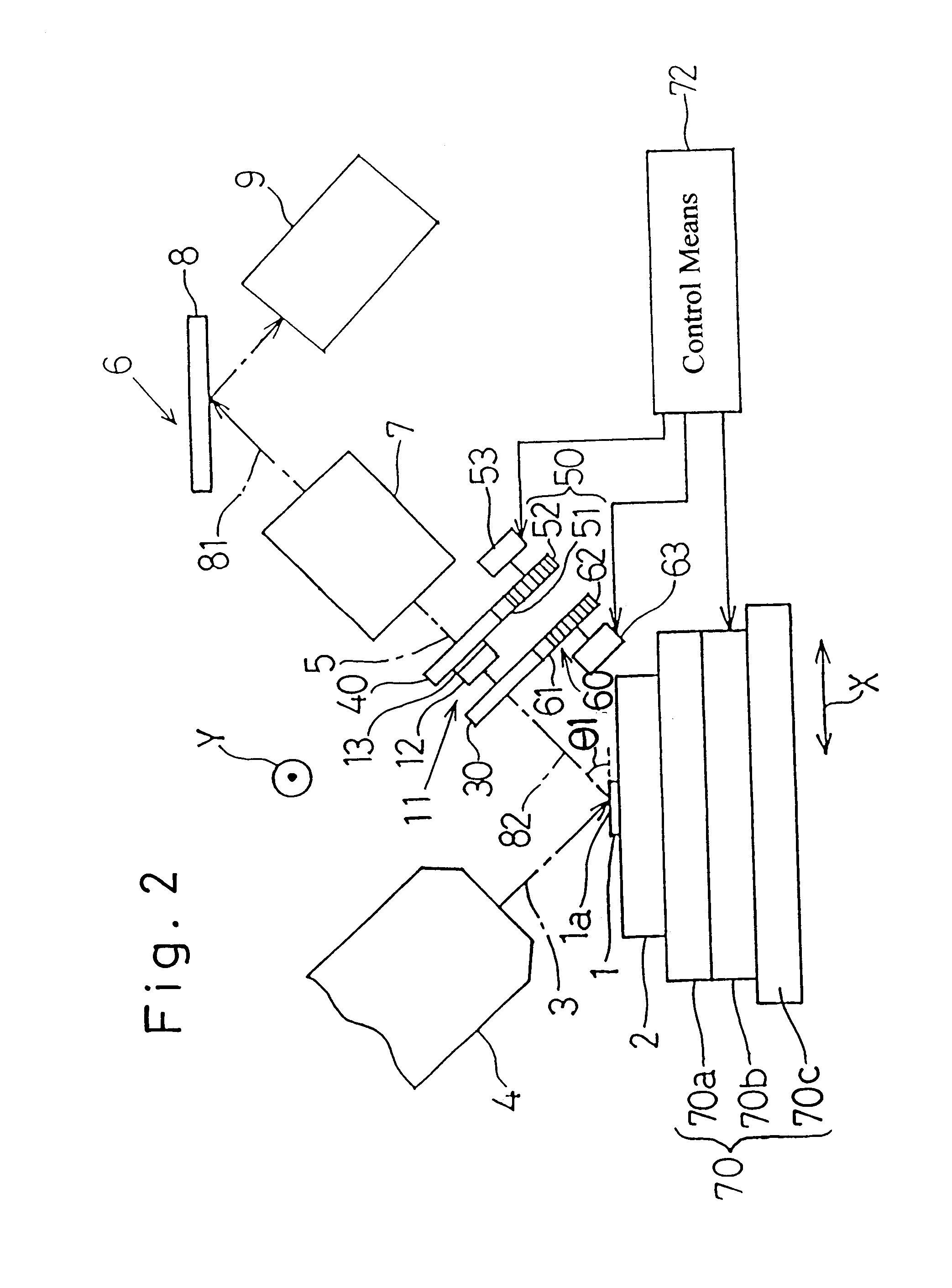

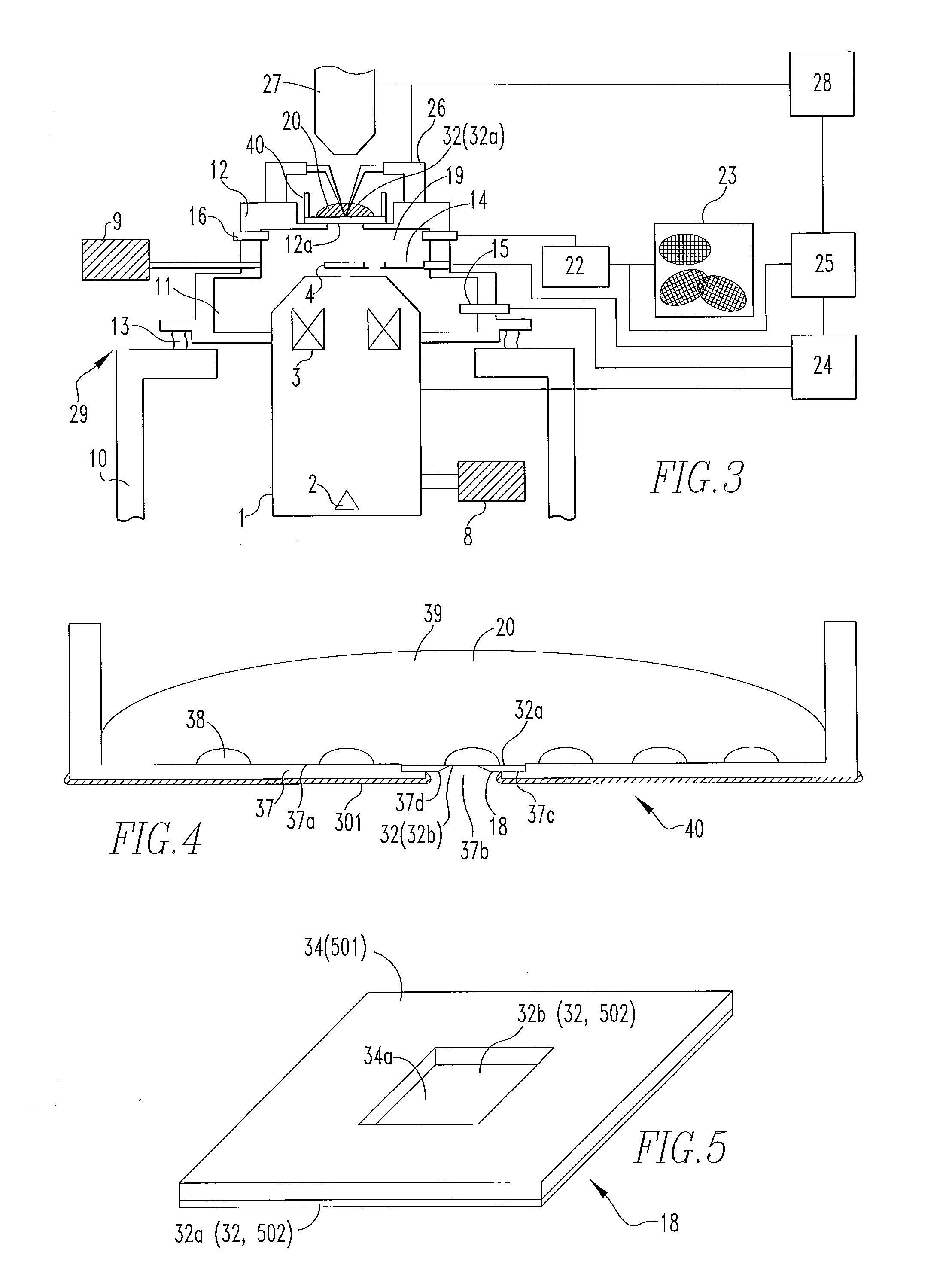

Fluorescent X-ray analyzer useable as wavelength dispersive type and energy dispersive type

InactiveUS6292532B1X-ray spectral distribution measurementUsing wave/particle radiation meansSoft x rayFluorescence

A fluorescent X-ray analyzing apparatus capable of being used as either a wavelength dispersive type or an energy dispersive type is provided, with which the analysis can be performed quickly and accurately. The fluorescent X-ray analyzing apparatus includes a detecting unit for detecting and analyzing fluorescent X-ray (5) emitted from at least one target area (1a) of a sample (1) to be analyzed as a result of excitation of such target area (1a) with a primary X-ray (3). The detecting unit includes a wavelength dispersive type detecting unit (6) including a spectroscope (8) and a first detector (9), and an energy dispersive type detecting unit (11) including a second detector (12) of an energy dispersive type. The angle theta1 formed between a first path (81) of travel of the fluorescent X-ray from the target area (1a) towards the spectroscope (8) and a surface of the sample (1) is equal to the angle theta2 formed between a second path (82) of travel of the fluorescent X-ray from the target area (1a) towards the second detector (12) of the energy dispersive type and a surface of the sample (1), but the second path (82) is shorter than the first path (81).

Owner:RIGAKU CORP

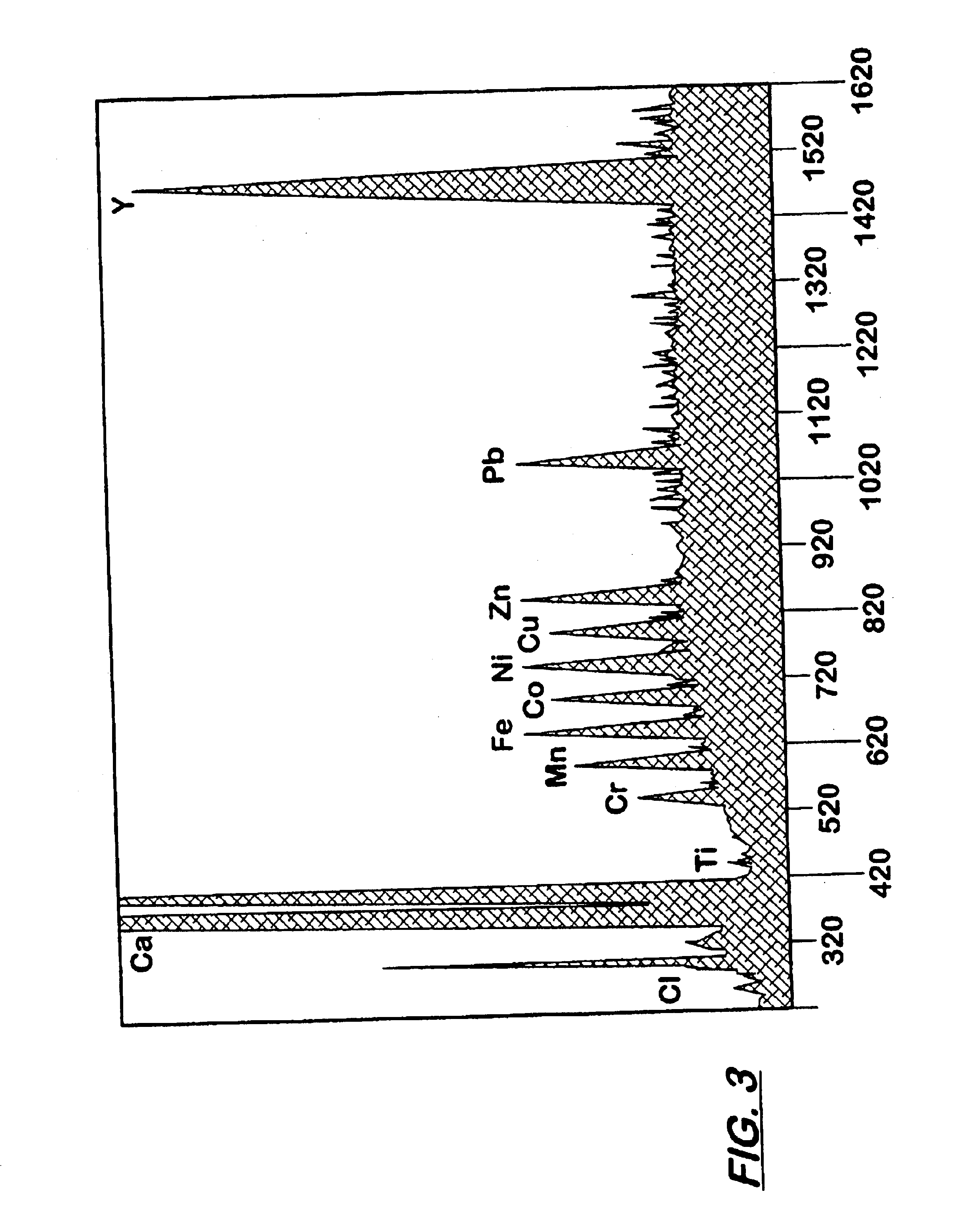

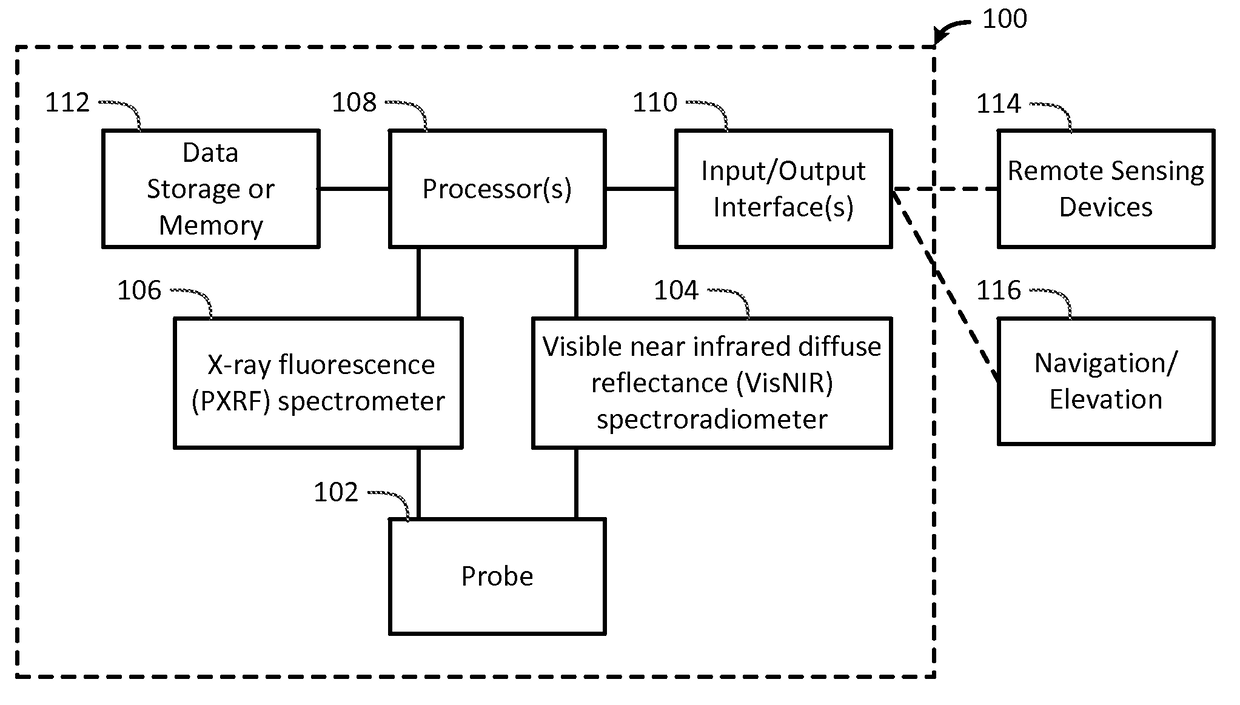

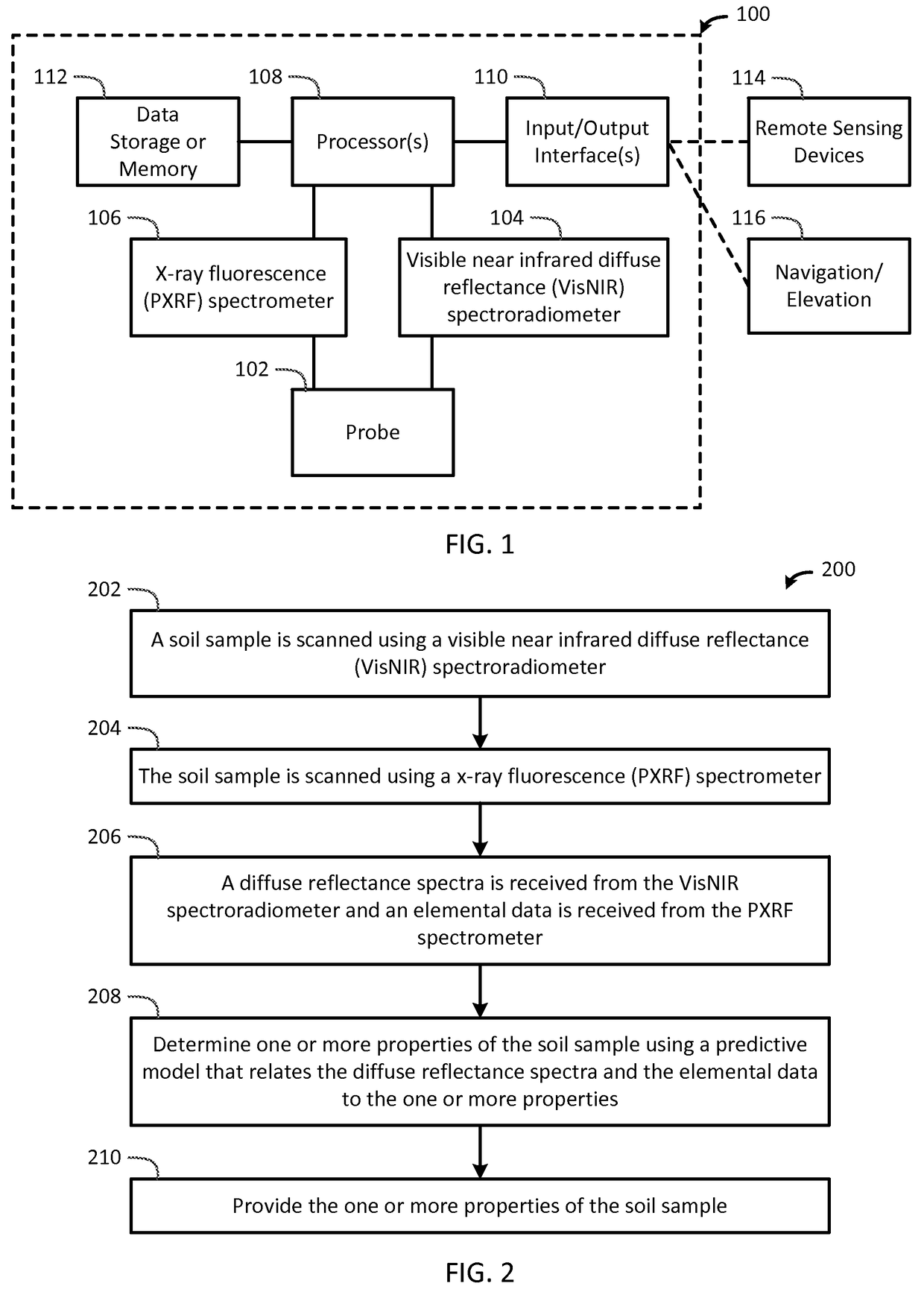

Portable Apparatus for Soil Chemical Characterization

ActiveUS20170122889A1Quick and easy and inexpensive to collectLess timeMaterial analysis by optical meansEarth material testingSoil scienceSpectroradiometer

The present invention determines one or more properties of a soil sample by scanning a soil sample using a visible near infrared diffuse reflectance diffuse reflectance (VisNIR) spectroradiometer, scanning the soil sample using a x-ray fluorescence (PXRF) spectrometer, receiving a diffuse reflectance spectra from the VisNIR spectroradiometer and an elemental data from the PXRF spectrometer, determining one or more properties of the soil sample using one or more processors and a predictive model that relates the diffuse reflectance spectra and the elemental data to the one or more properties, and providing the one or more properties of the soil sample to one or more input / output interface.

Owner:TEXAS TECH UNIV SYST +1

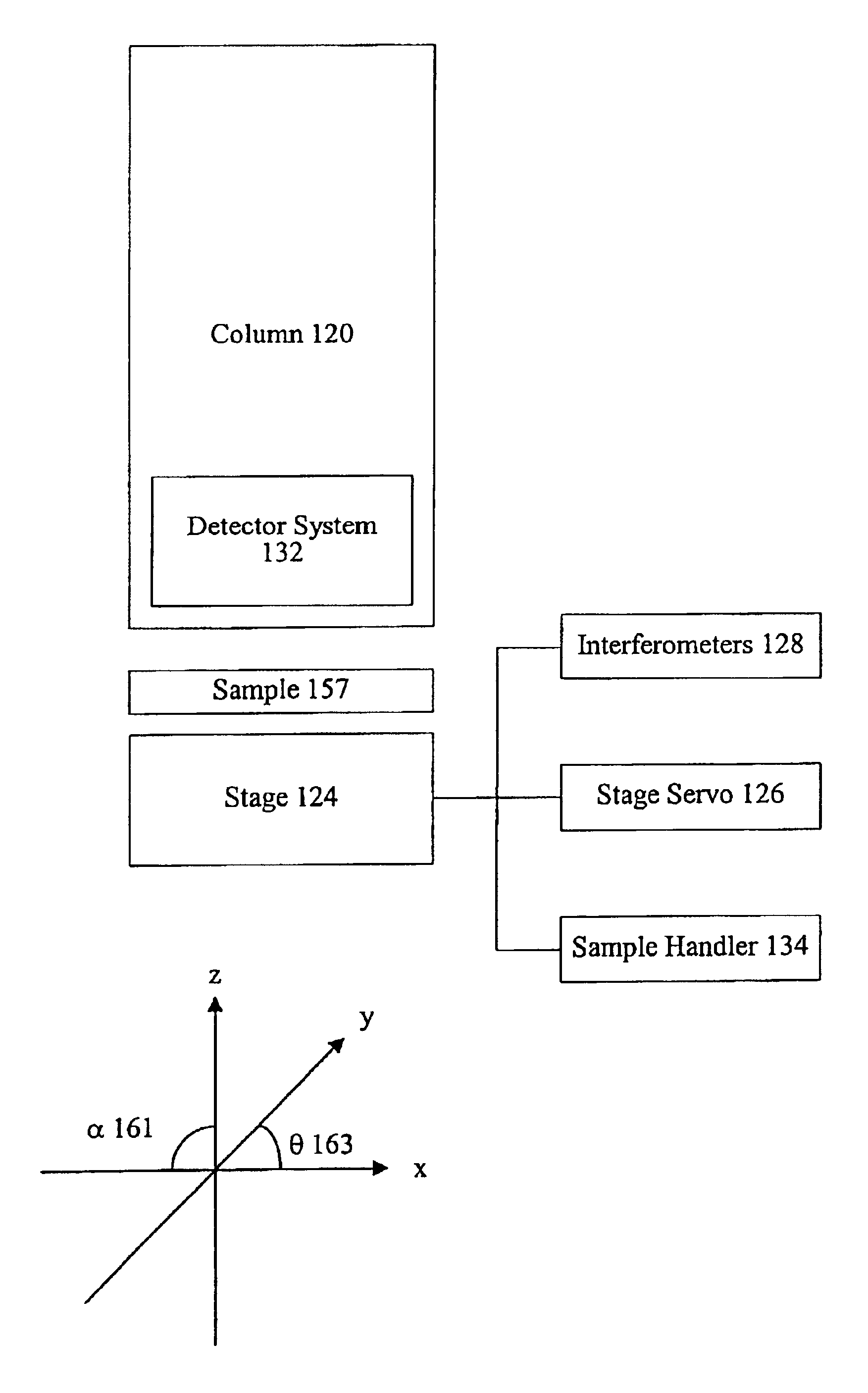

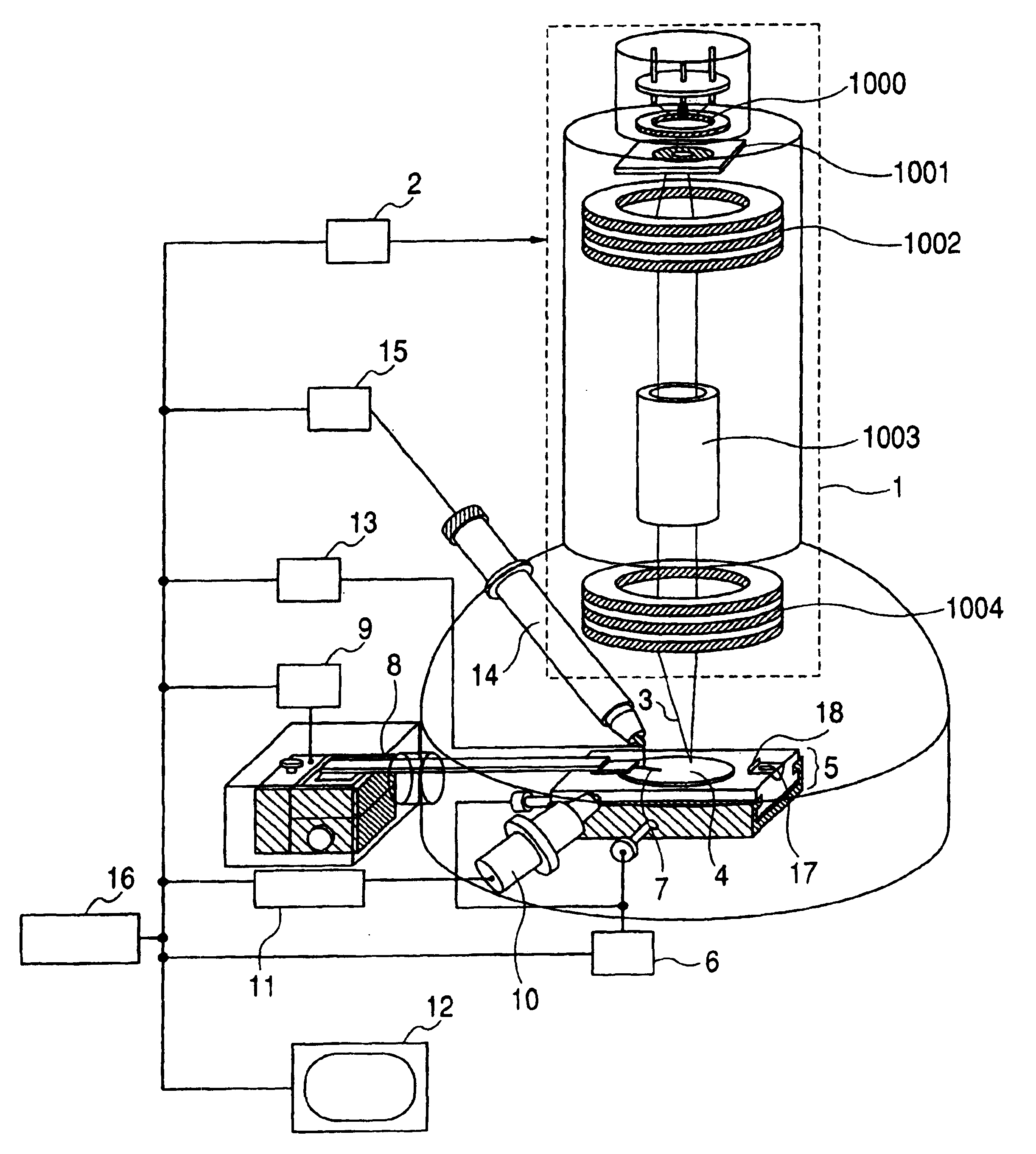

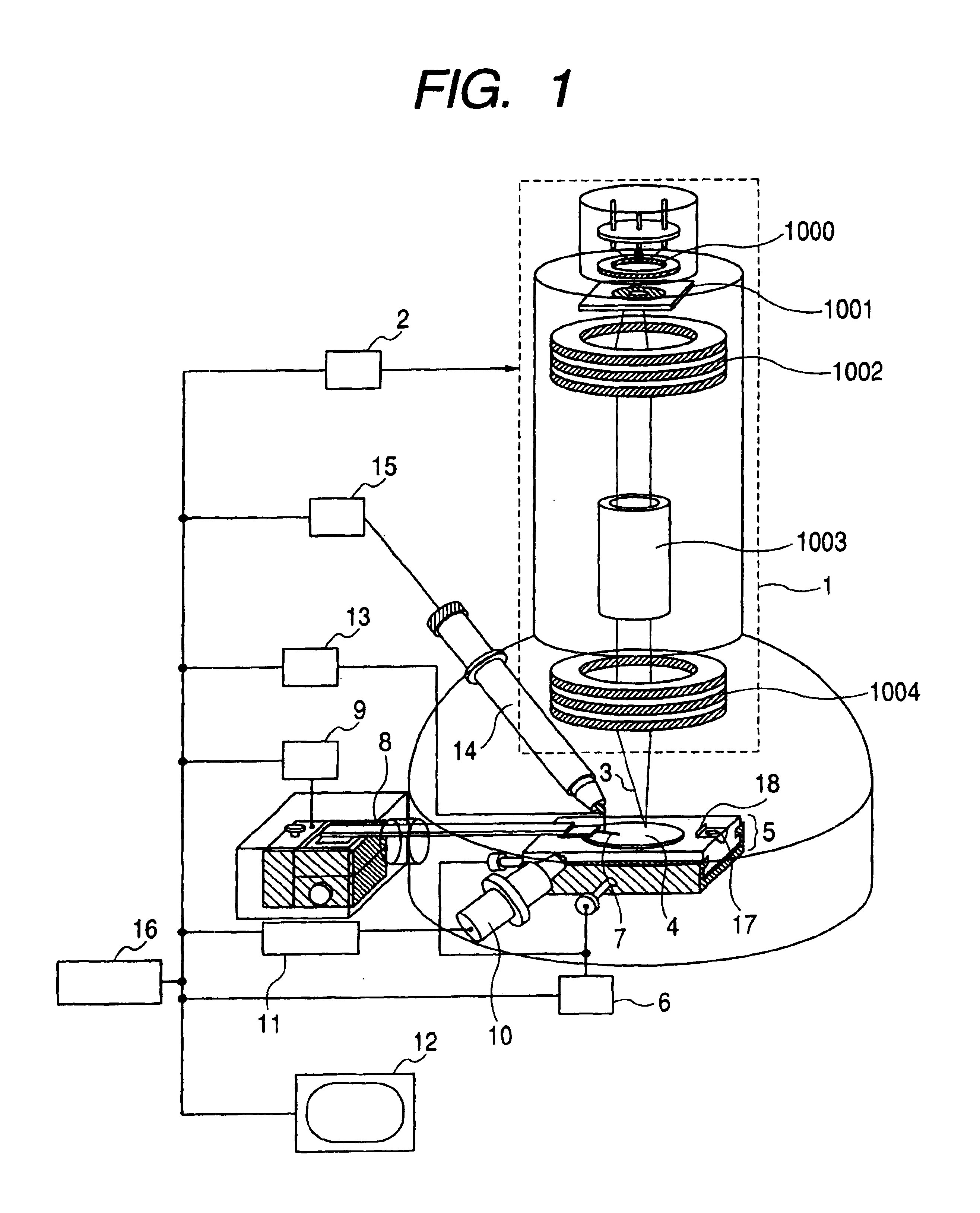

Charged particle beam apparatus and specimen inspection method

ActiveUS20090001267A1Thermometer detailsBeam/ray focussing/reflecting arrangementsDisplay deviceElectric field

In a multi-charged-particle-beam apparatus, when an electric field and voltage on a surface of a specimen are varied according to characteristics of the specimen, a layout of plural primary beams on the surface of the specimen and a layout of plural secondary beams on each detector vary. Then, calibration is executed to adjust the primary beams on the surface of the specimen to an ideal layout corresponding to the variation of operating conditions including inspecting conditions such as an electric field on the surface and voltage applied to the specimen. The layout of the primary beams on the surface of the specimen is acquired as images displayed on a display of reference marks on the stage. Variance with an ideal state of the reference marks is measured based upon these images and is corrected by the adjustment of a primary electron optics system and others.

Owner:HITACHI HIGH-TECH CORP

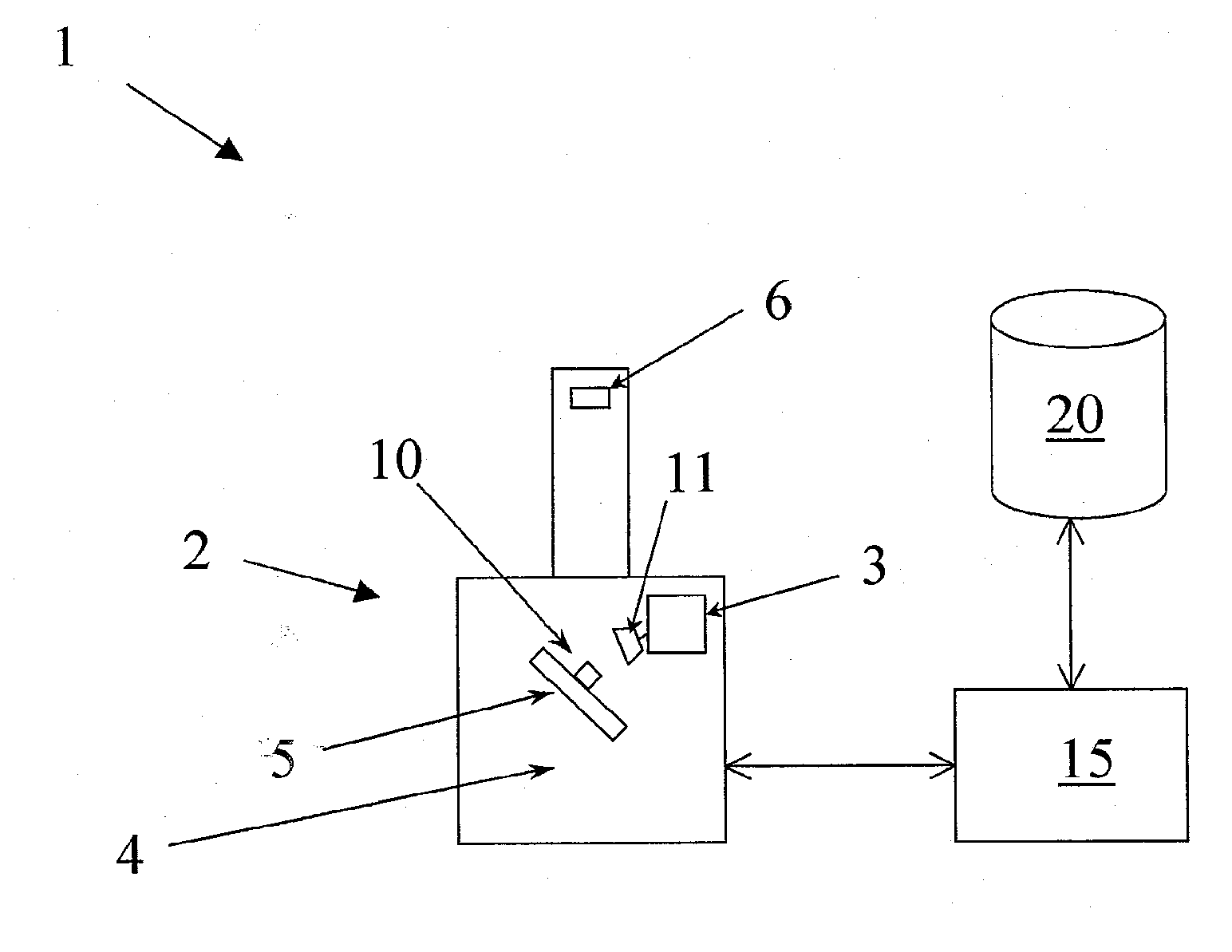

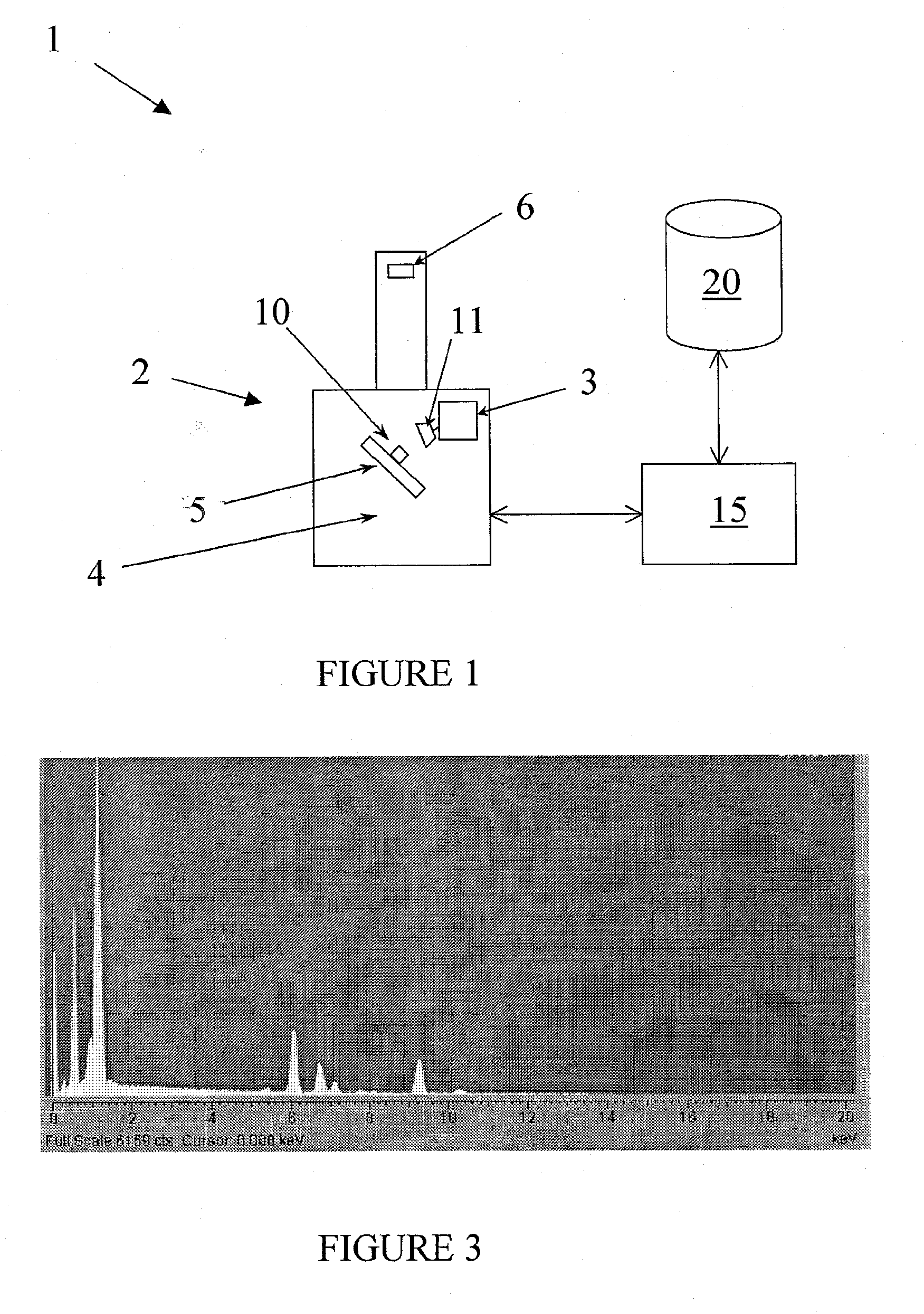

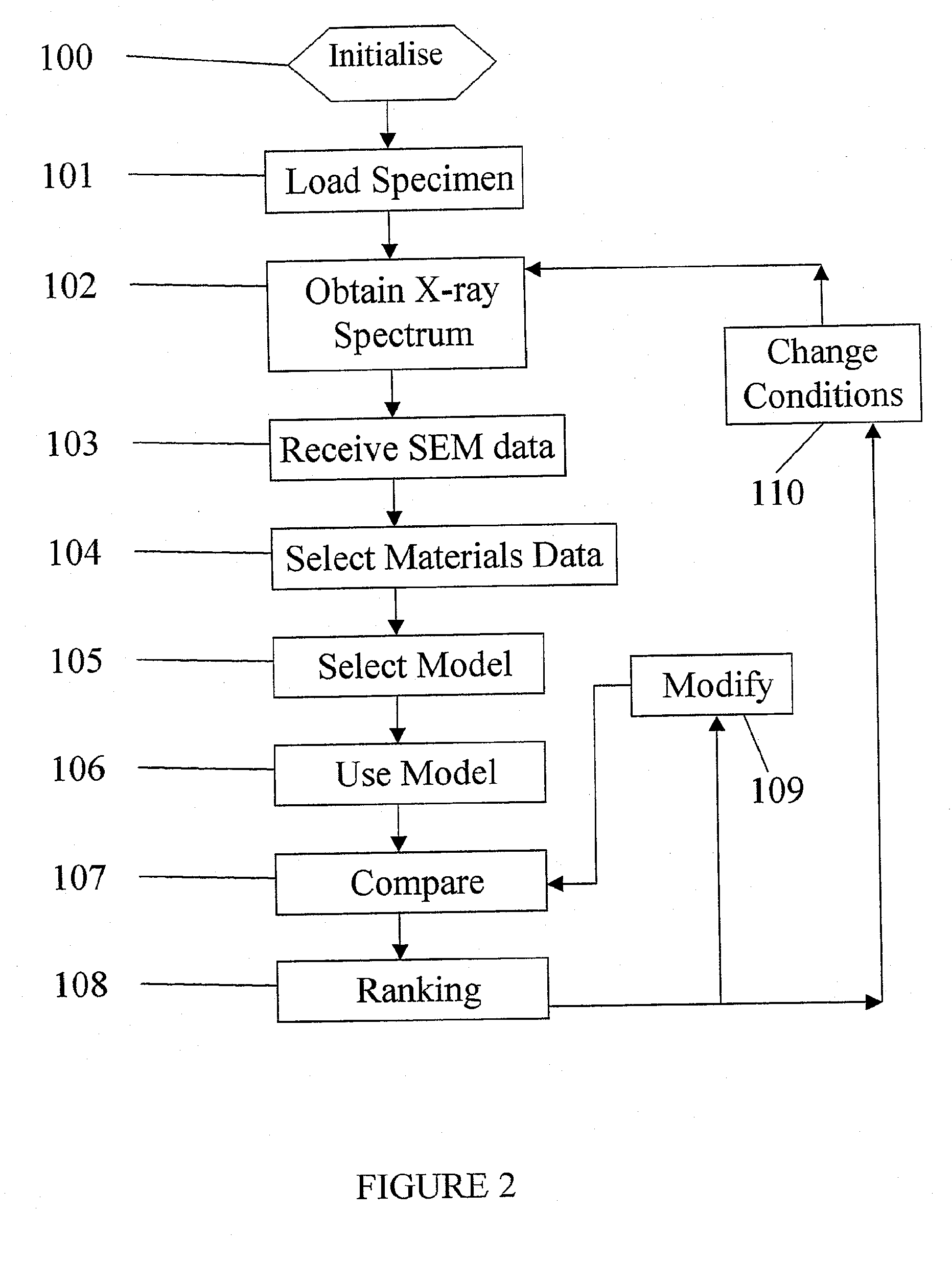

Method and Apparatus for Material Identification

ActiveUS20060291619A1Guaranteed accuracyImprove forecast accuracyX-ray spectral distribution measurementAmplifier modifications to reduce noise influenceMulti materialData set

A method of identifying a material using an x-ray emission characteristic is provided. X-ray data representing a monitored x-ray emission characteristic is obtained from a specimen in response to an incident energy beam. A dataset is also obtained, this comprising composition data of a plurality of materials. The material of the specimen is contained within the dataset. Predicted x-ray data are calculated for each of the materials in the dataset using the composition data. The obtained and the predicted x-ray data are compared and the likely identity of the material of the specimen is determined, based upon the comparison.

Owner:OXFORD INSTR NANOTECH TOOLS

Charged particle beam apparatus

InactiveUS20130284924A1Improve throughputSemiconductor/solid-state device testing/measurementElectric discharge tubesMolecular physicsMicroscope

There is provided an apparatus which can accurately carry out focusing of an optical microscope mounted on a charged particle beam apparatus while restraining an increase in an apparatus cost and a reduction in a throughput. An approximate polynomial is formed based on a focus map of the optical microscope which is previously measured, and a control amount which adds a difference between a piece of wafer height information at that occasion and a piece of wafer height information in actual observation to the approximate polynomial is inputted as a focus control value of the optical microscope.

Owner:HITACHI HIGH-TECH CORP

Methods and apparatus for dishing and erosion characterization

The present invention includes a system for efficient and effective detection and characterization of dishing and / or erosion. An x-ray emission inducer is used to scan a target on a sample. The target can be scanned at an acute incident angle to allow characterization of the dishing and / or erosion and analysis of the metallization or thin film layer topology.

Owner:KLA TENCOR TECH CORP

Depth profile metrology using grazing incidence X-ray fluorescence

InactiveUS6173036B1X-ray spectral distribution measurementUsing wave/particle radiation meansMetrologyMicro-X-ray fluorescence

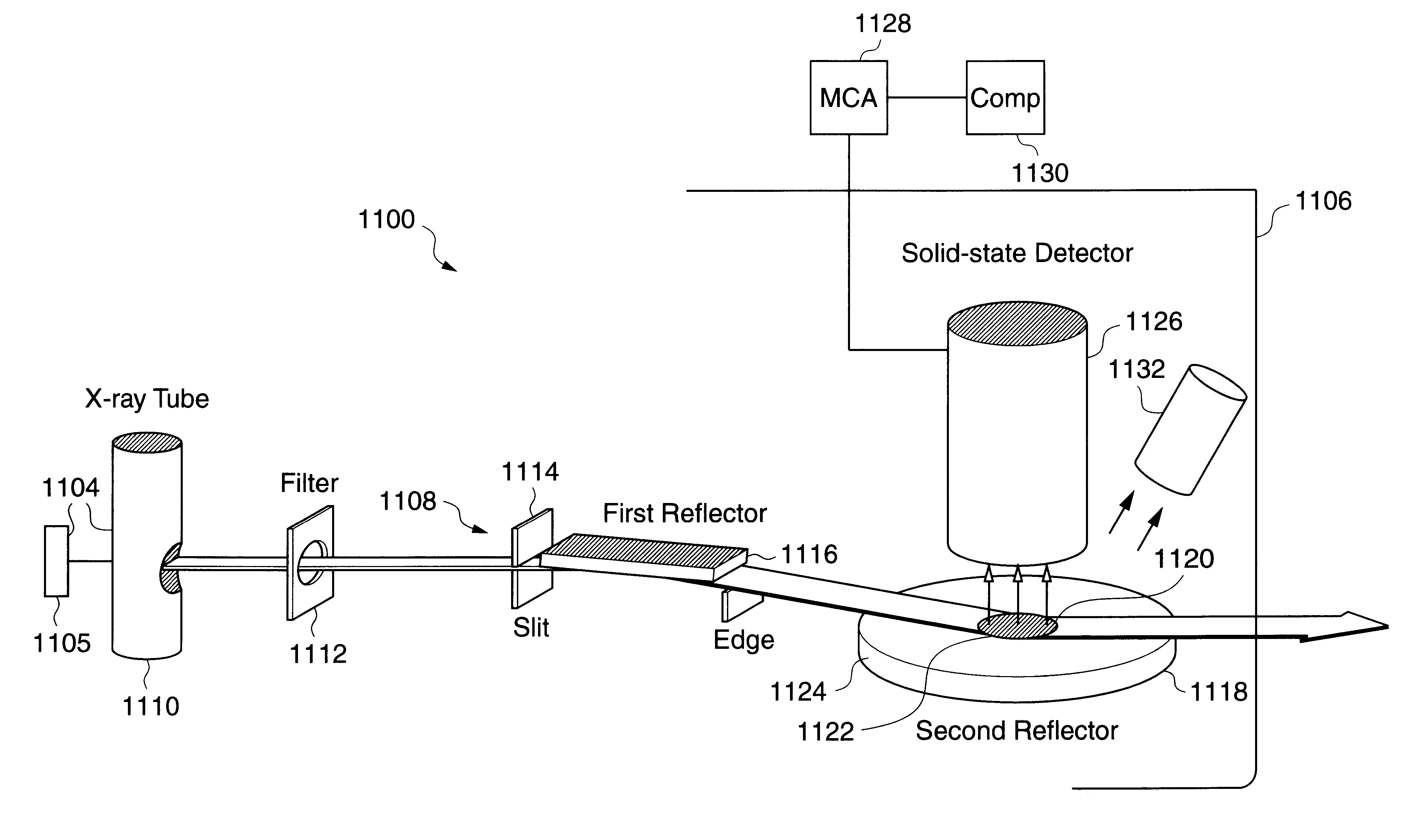

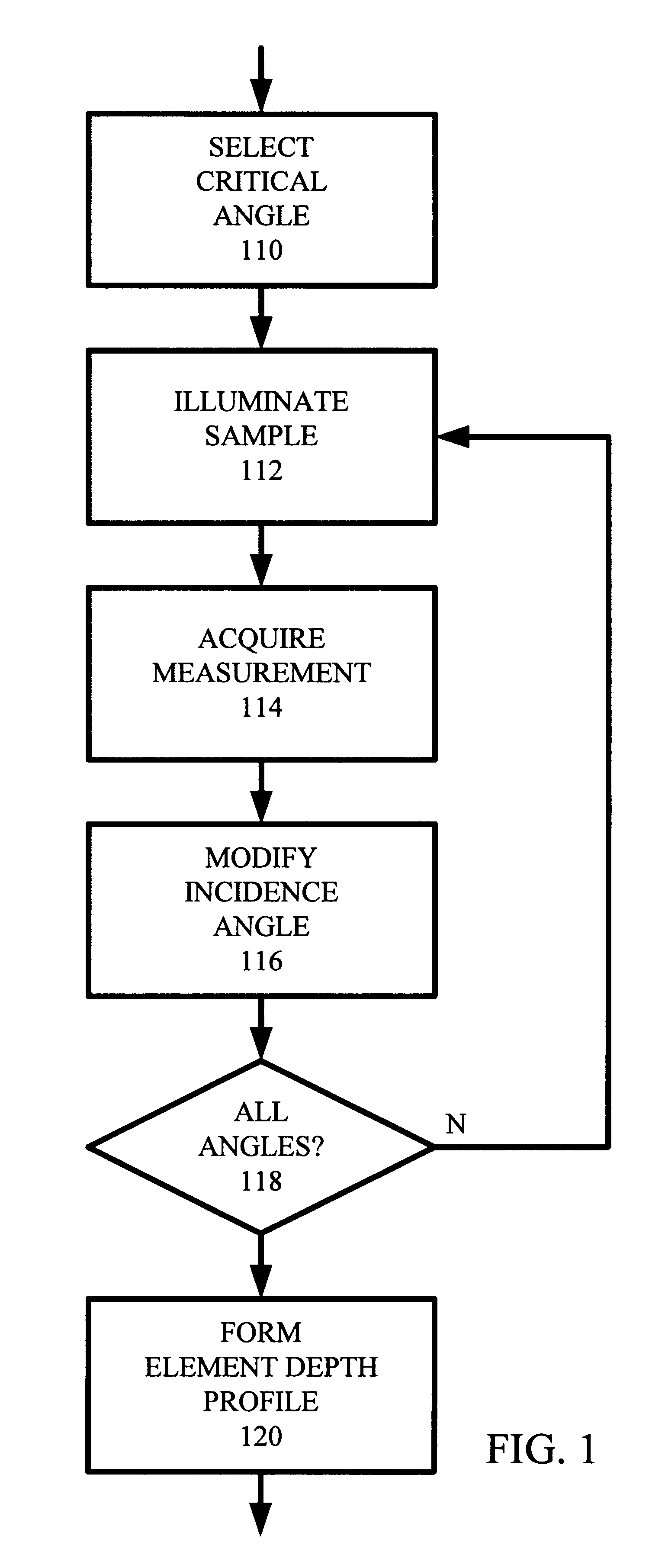

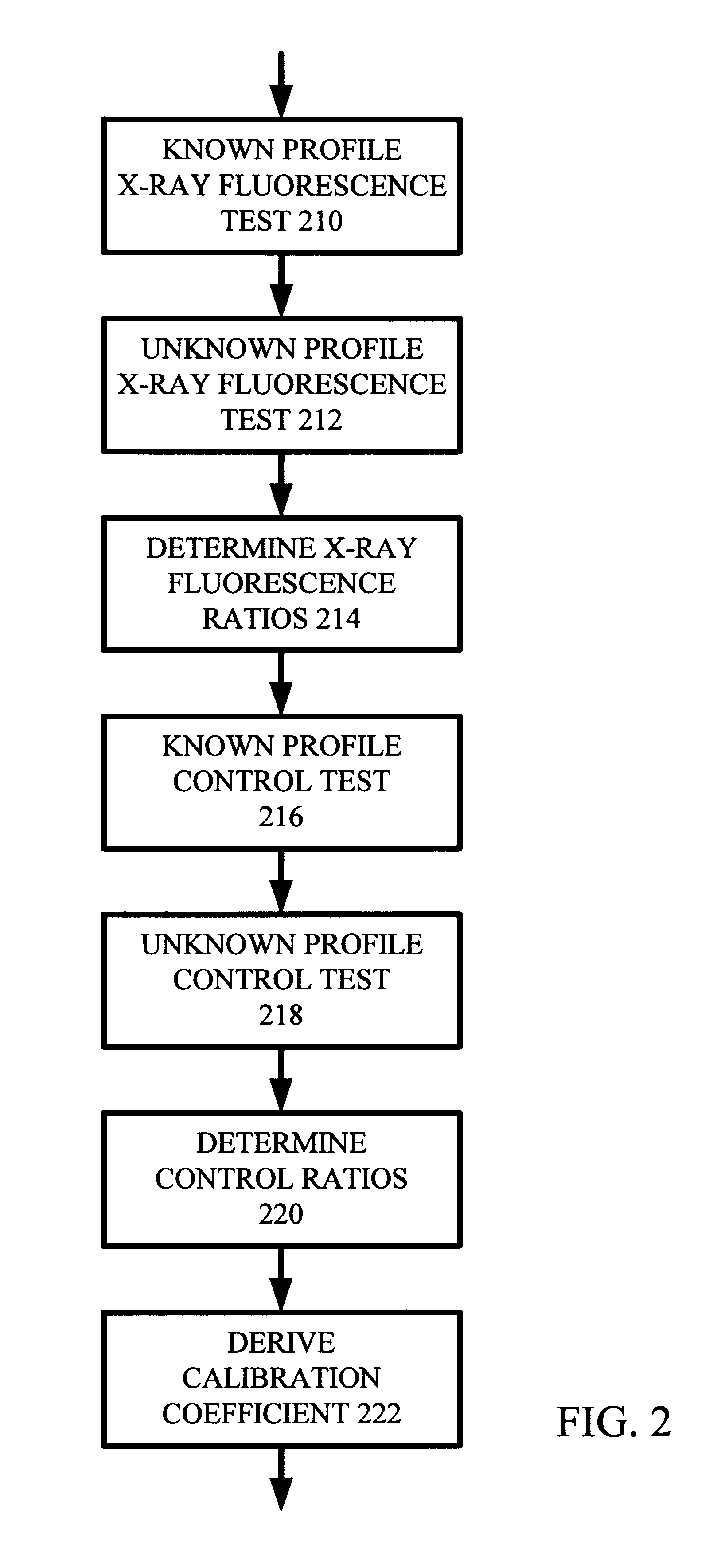

For small angles that are near critical angle, a primary incident X-ray beam has excellent depth resolution. A series of X-ray fluorescence measurements are performed at varying small angles and analyzed for depth profiling of elements within a substrate. One highly useful application of the X-ray fluorescence measurements is depth profiling of a dopant used in semiconductor manufacturing such as arsenic, phosphorus, and boron. In one example, angles are be varied from 0.01° to 0.20° and measurements made to profile arsenic distribution within a semiconductor wafer. In one embodiment, measurements are acquired using a total reflection X-ray fluorescence (TXRF) type system for both known and unknown profile distribution samples. The fluorescence measurements are denominated in counts / second terms and formed as ratios comparing the known and unknown sample results. The count ratios are compared to ratios of known to unknown samples that are acquired using a control analytical measurement technique. In one example the control technique is secondary ion mass spectroscopy (SIMS) so that the count ratios from the TXRF-type measurements are compared to ratios of integrals of SIMS profiles. In another example, the TXRF-type measurement ratios are compared to simulation profiles of known samples. Integrals of the SIMS profile that vary as a function of depth into the substrate correspond to the grazing incidence angles of the TXRF-like measurement and respective count rates.

Owner:ADVANCED MICRO DEVICES INC

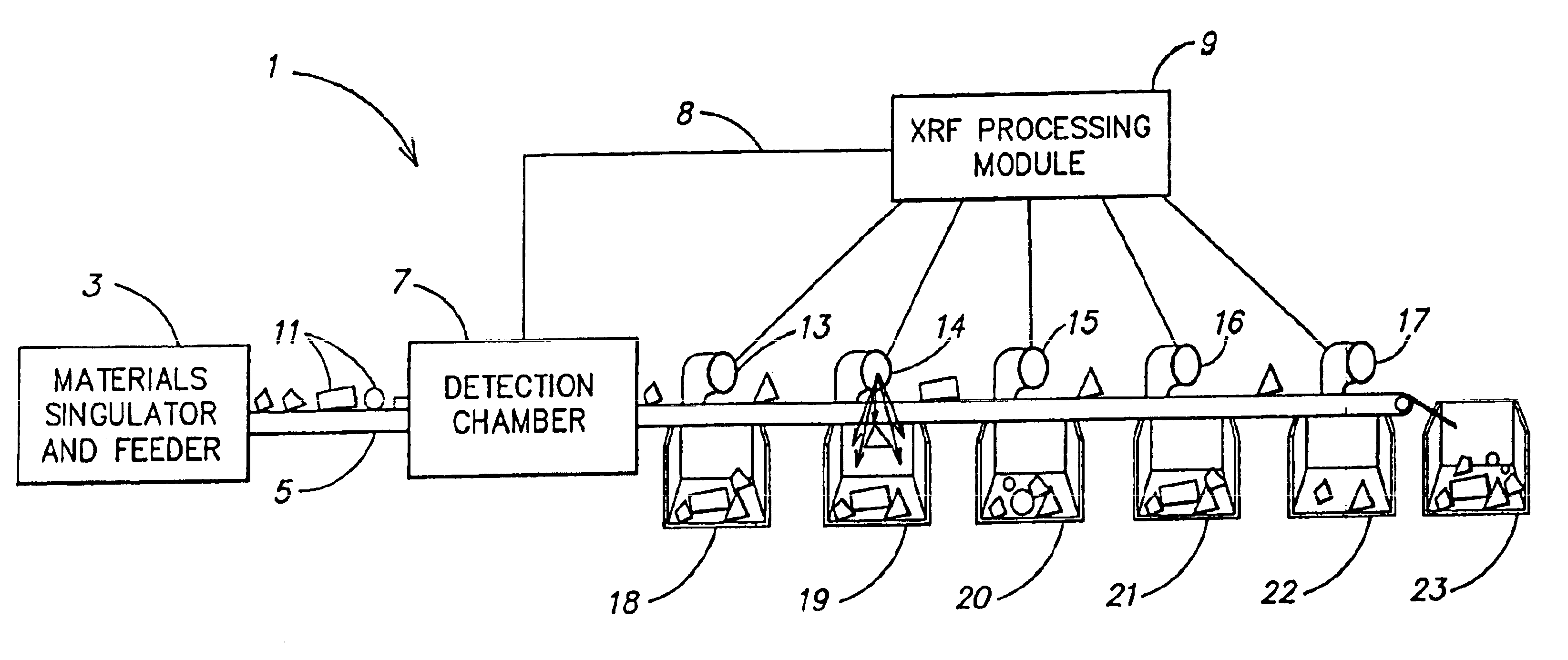

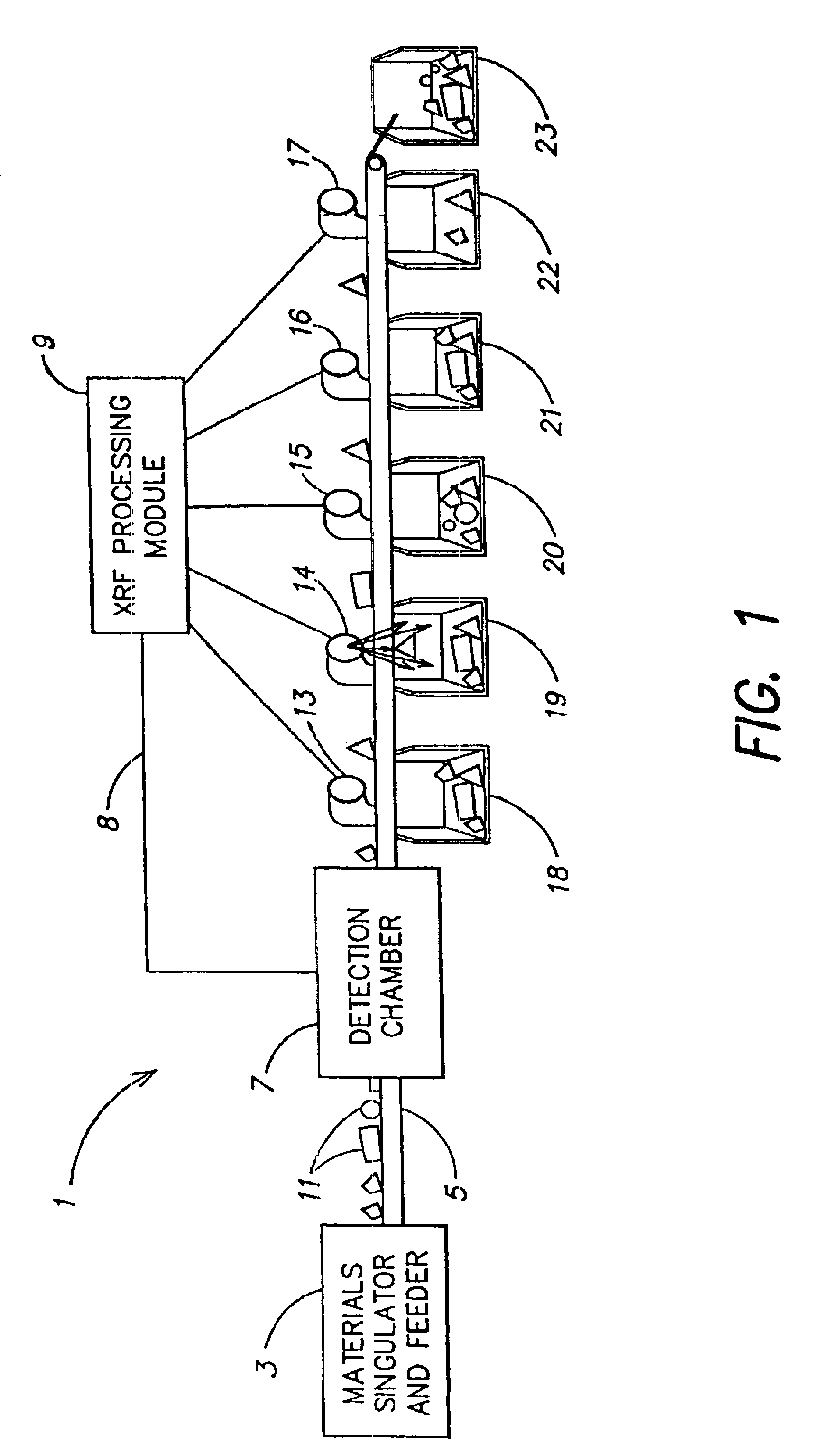

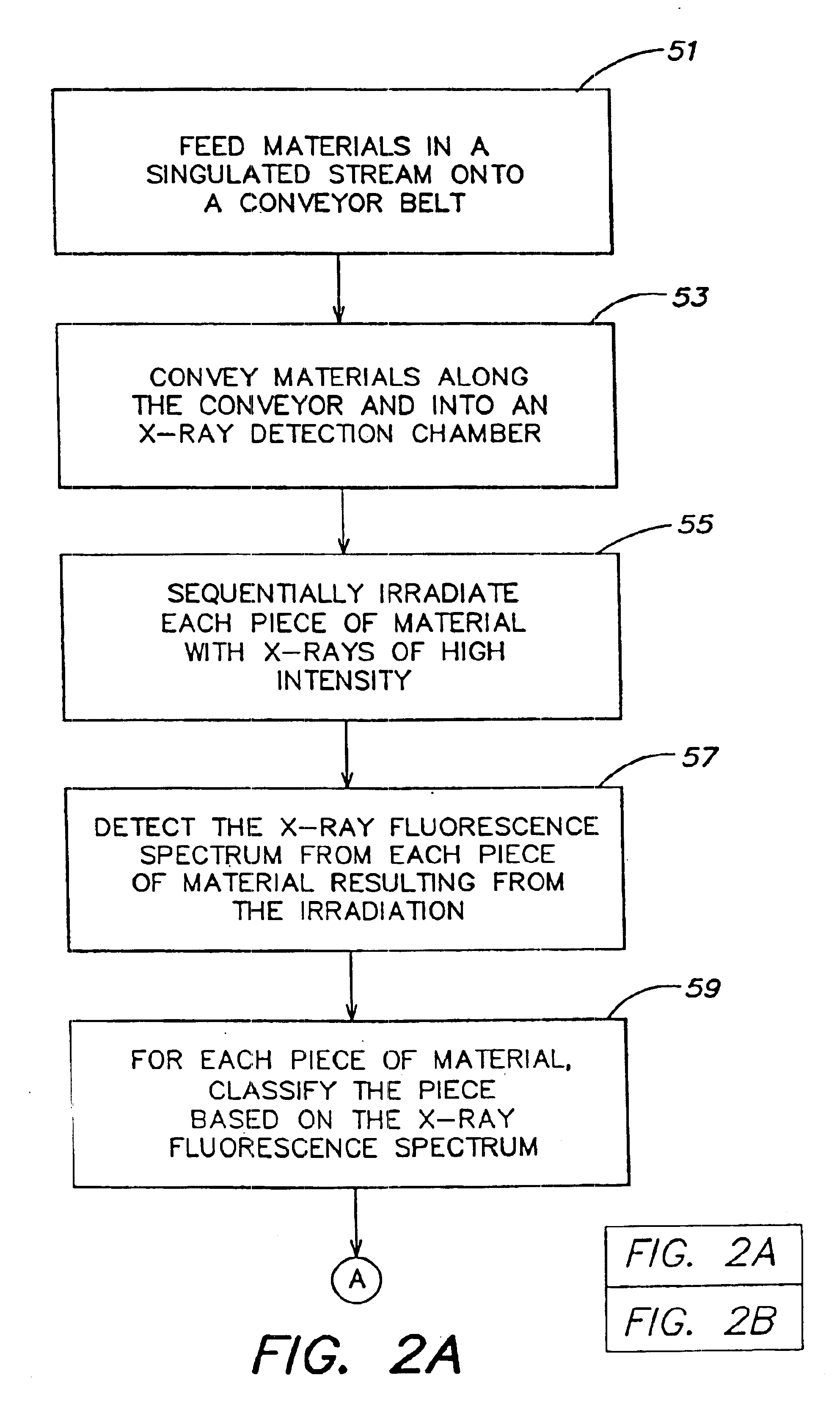

High speed materials sorting using x-ray fluorescence

InactiveUS6888917B2Accuracy of compromisedSpeed of compromisedX-ray spectral distribution measurementUsing wave/particle radiation meansSpectral patternSoft x ray

A system and process for classifying a piece of material of unknown composition at high speeds, where the system connected to a power supply. The piece is irradiated with first x-rays from an x-ray source, causing the piece to fluoresce x-rays. The fluoresced x-rays are detected with an x-ray detector, and the piece of material is classified from the detected fluoresced x-rays. Detecting and classifying may be cumulatively performed in less than one second. An x-ray fluorescence spectrum of the piece of material may be determined from the detected fluoresced x-rays, and the detection of the fluoresced x-rays may be conditioned such that accurate determination of the x-ray fluorescence spectrum is not significantly compromised, slowed or complicated by extraneous x-rays. The piece of material may be classified by recognizing the spectral pattern of the determined x-ray fluorescence spectrum. The piece of material may be flattened prior to irradiation and detection. The x-ray source may irradiate the first x-rays at a high intensity, and the x-ray source may be an x-ray tube.

Owner:SPECSTREETCARET

Apparatus and Method for Inspecting Samples

InactiveUS20100243888A1Easy maintenanceLow costElectric discharge tubesGamma-ray/x-ray microscopesLight beamEngineering

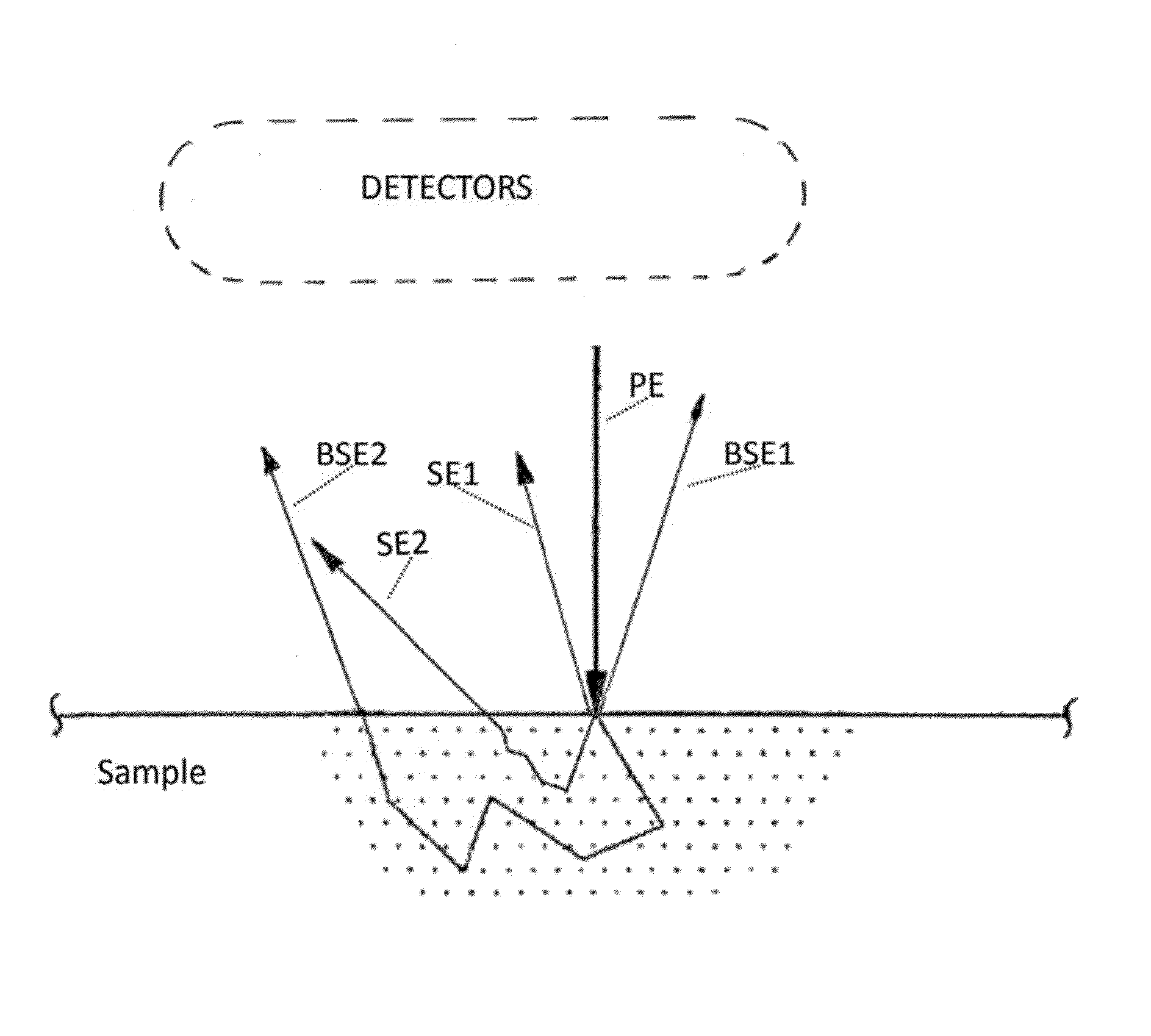

An inspection apparatus and method capable of well observing or inspecting a specimen contained in a liquid. The inspection apparatus has a film including first and second surfaces. Furthermore, the apparatus has a vacuum chamber for reducing the pressure in the ambient in contact with the second surface of the film, primary beam irradiation column connected with the vacuum chamber, and a shutter for partially partitioning the space between the film and the primary beam irradiation column within the vacuum chamber. A liquid sample is held on the first surface of the film. The primary beam irradiation column irradiates the sample. Backscattered electrons (a secondary beam) produced from the sample by the primary beam irradiation are directed at the shutter, producing secondary electrons (a tertiary signal).

Owner:JEOL LTD

Probe driving method, and probe apparatus

InactiveUS6960765B2Easy to controlDecrease in luminanceSemiconductor/solid-state device testing/measurementInstrumental componentsIon beamSample image

A probe driving method and a probe apparatus for bringing a probe into contact with the surface of a sample in a safe and efficient manner by monitoring the probe height. Information about the height of the probe from the sample surface is obtained by detecting a probe shadow appearing immediately before the probe contacts the sample, or based on a change in relative positions of a probe image and a sample image that are formed as an ion beam is irradiated diagonally.

Owner:HITACHI LTD +1

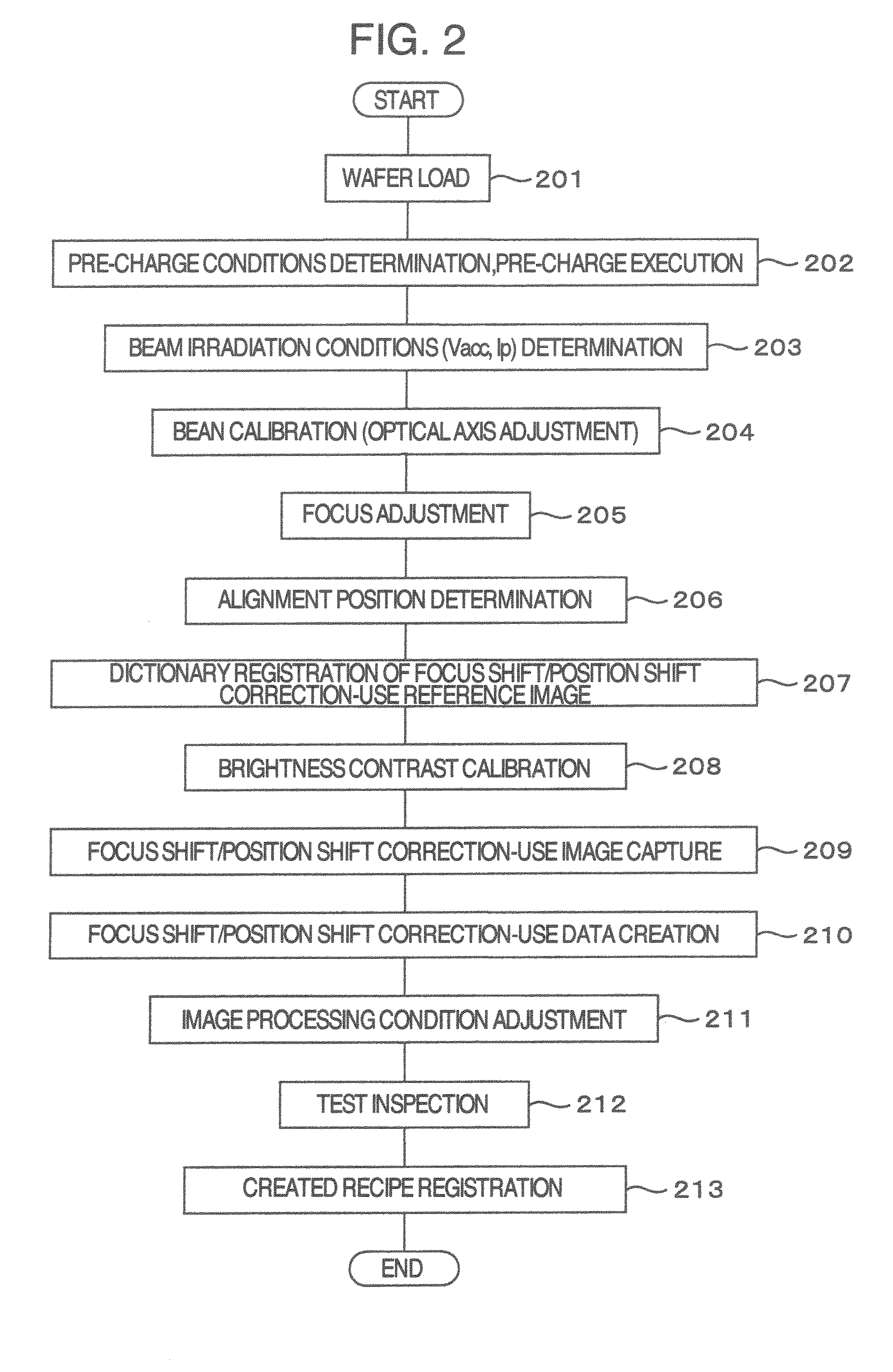

Pattern inspection device and method

InactiveUS20110133066A1Suppress electron beam 's focus driftSuppress irradiation position deviationSemiconductor/solid-state device testing/measurementElectric discharge tubesIrradiationInspection time

An inspection apparatus and method are provided capable of suppressing electron beam focus drifts and irradiation-position deviations caused by sample surface charge-up by irradiation of an electron beam during micropattern inspection to thereby avoid false defect detection and also shorten an inspection time. The apparatus captures a plurality of images of alignment marks provided at dies, stores in a storage device deviations between the central coordinates of alignment mark images and the coordinates of the marks as a coordinate correction value, measures heights at a plurality of coordinates on the sample surface, captures images of the measured coordinates to perform focus adjustment, saves the relationship between such adjusted values and the sensor-measured heights in the storage as height correction values, and uses inspection conditions including the image coordinate correction values saved in the storage and the height correction values to correct the image coordinates and height of the sample.

Owner:HITACHI HIGH-TECH CORP

Environmental Cell for Charged Particle Beam System

ActiveUS20120112062A1Quick switchFlexible and rapid processingElectric discharge tubesThermometers using material expansion/contactionOptical axisLight beam

An environmental cell for a charged particle beam system allows relative motion between the cell mounted on an X-Y stage and the optical axis of the focusing column, thereby eliminating the need for a sub-stage within the cell. A flexible cell configuration, such as a retractable lid, permits a variety of processes, including beam-induced and thermally-induced processes. Photon yield spectroscopy performed in a charged particle beam system and using gas cascade amplification of the photoelectrons allows analysis of material in the cell and monitoring of processing in the cell. Luminescence analysis can be also performed using a retractable minor.

Owner:FEI CO

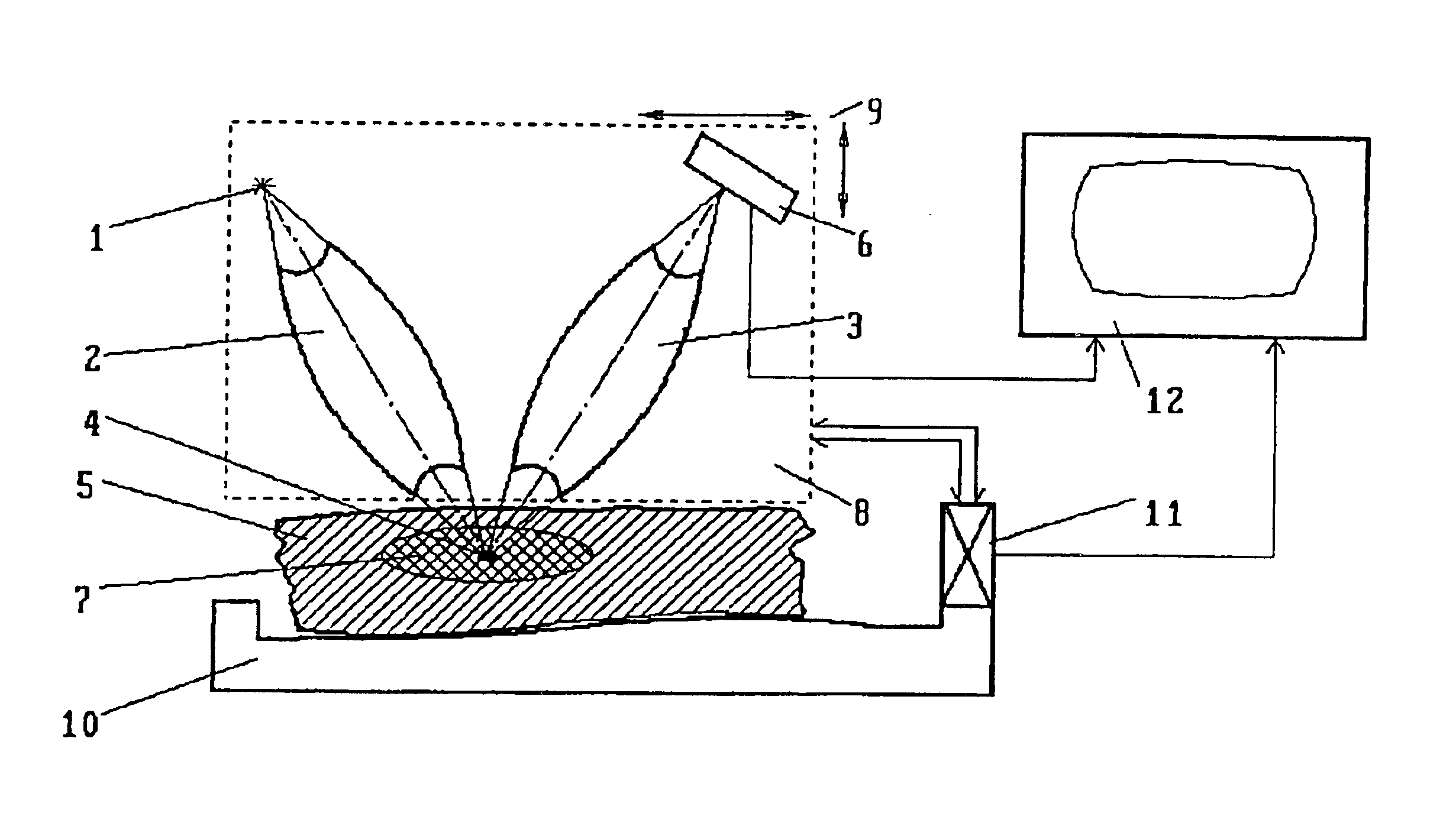

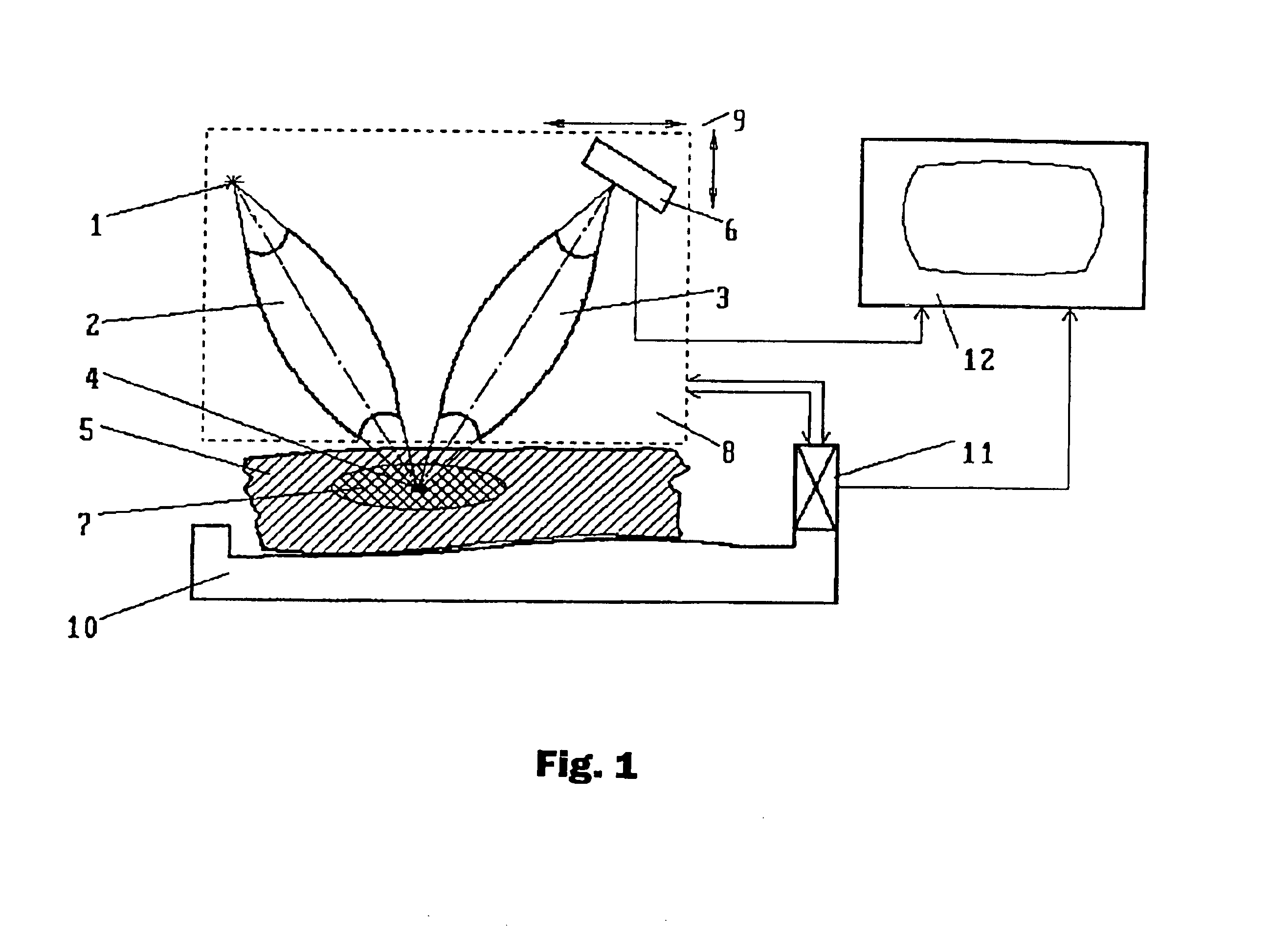

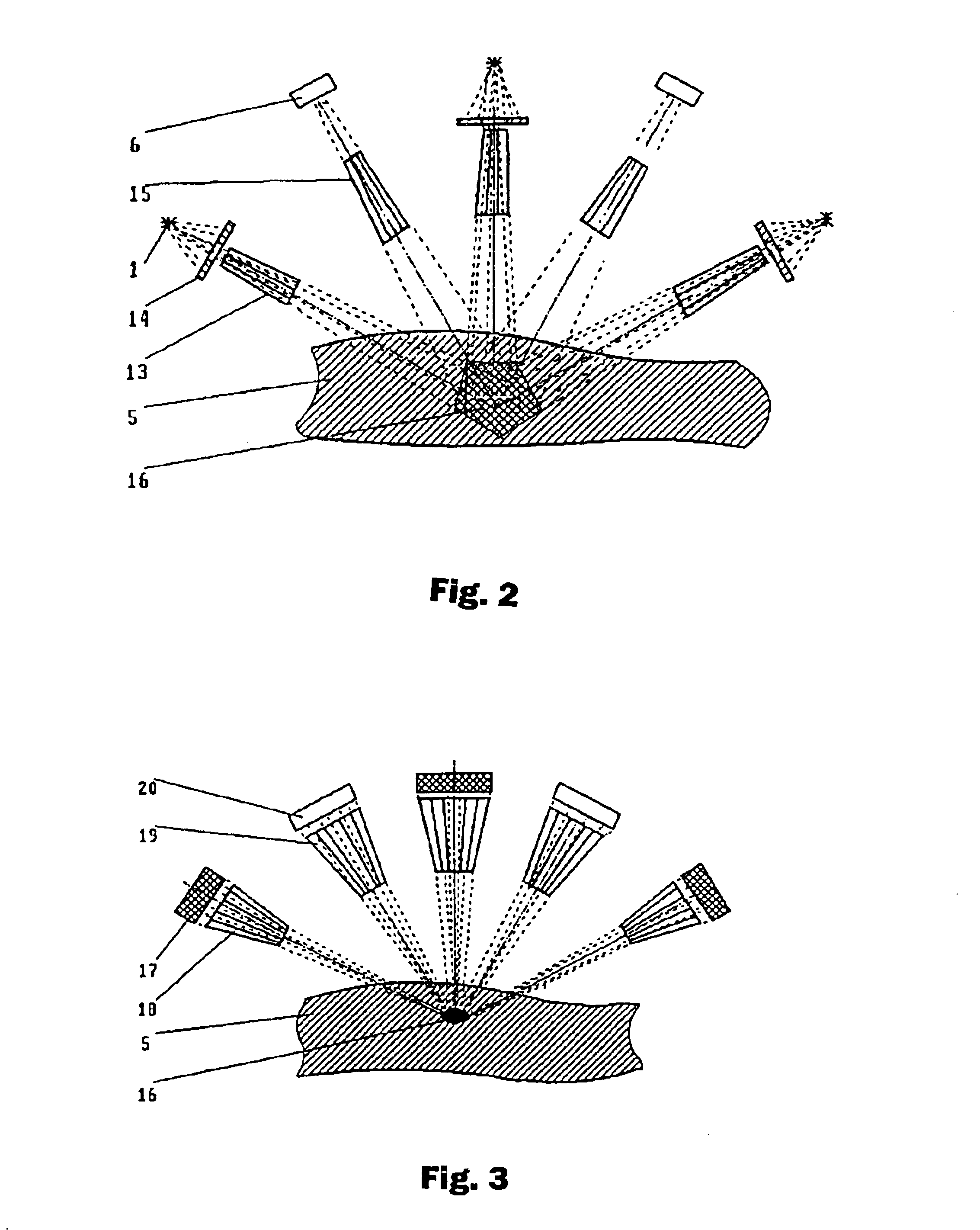

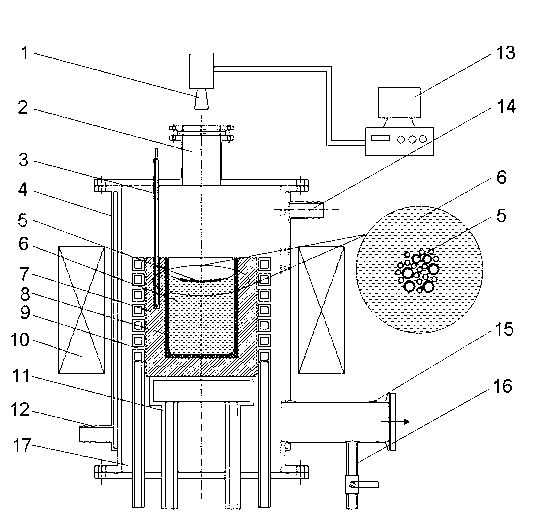

Rapid detection method and rapid detection device of non-metallic inclusions in metal

ActiveCN103123329AQuickly obtain 3D topographyQuick access to ingredientsUsing optical meansMaterial analysis by measuring secondary emissionImaging analysisNon-metallic inclusions

The invention discloses a rapid detection method of non-metallic inclusions in metal. The rapid detection method comprises the following five steps of: heating and smelting a metal test sample, separating the inclusions, detecting the total amounts and the sizes of the inclusions, condensing metal liquid, and detecting the three-dimensional shape and components of the inclusions. The invention further provides a special rapid detection device comprising a heating furnace device, a metal liquid rotation device, a video collection device and an image analysis system. The metal test sample is rapidly smelted and the steel liquid is driven to rotate; centrifugal force and gravity are used for rapidly upwards floating various non-metallic inclusions in the metal liquid and gathering the various non-metallic inclusions at the center of the surface of the metal liquid; high speed photography and video analysis software is used for rapidly obtaining the total amount and the size distribution of the non-metallic inclusions in the metal test sample; the metal liquid is rapidly cooled and condensed and the inclusions are cured on the surface of the metal test sample; and a scanning electron microscope and the energy spectrum analysis are used for obtaining the three-dimensional shapes and the components of the non-metallic inclusions in the metal test sample. According to the rapid detection method and the device disclosed by the invention, the direction is rapid and convenient, the analysis is accurate and visual, and cleaning and no pollution can be realized.

Owner:新兴发展集团有限公司

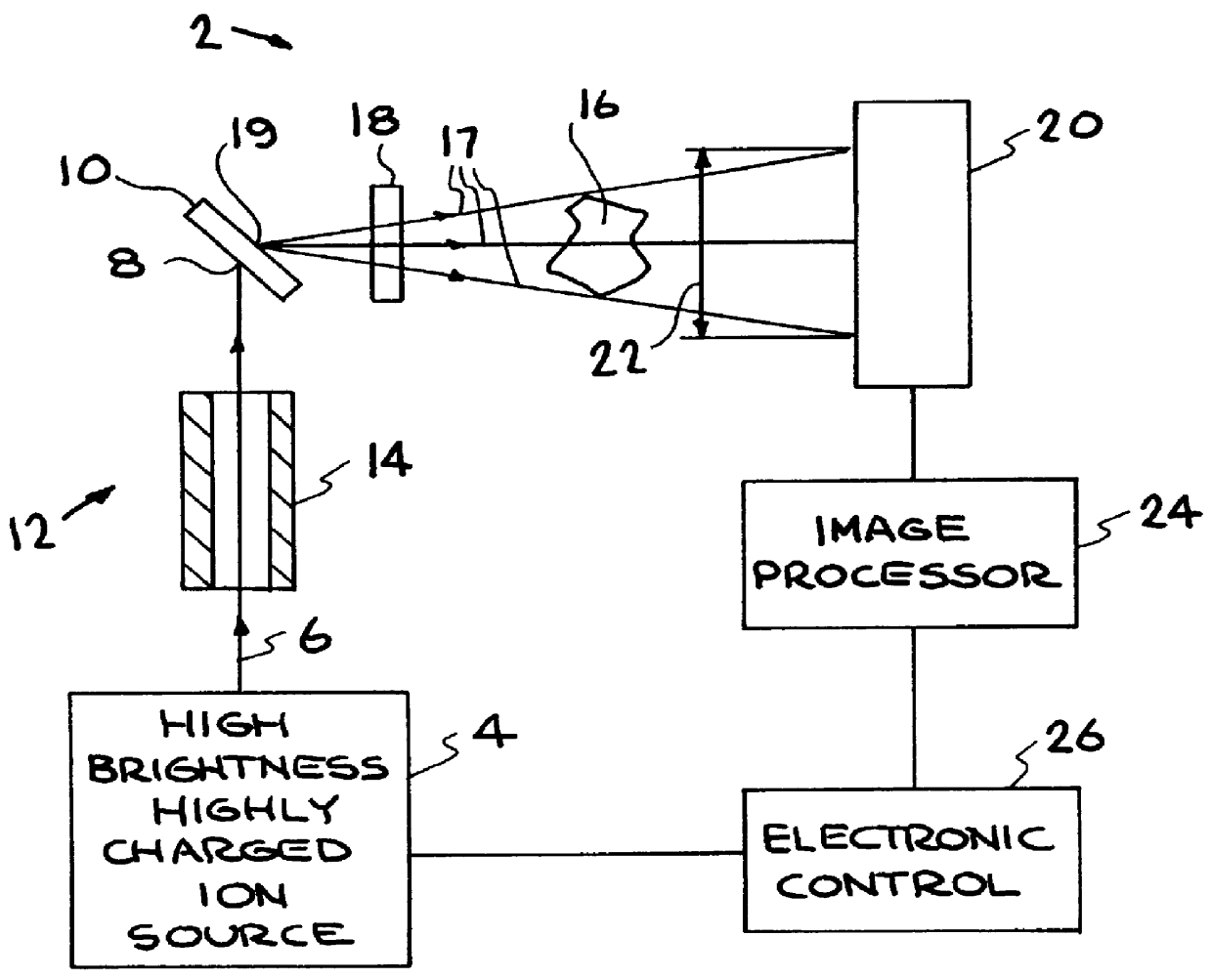

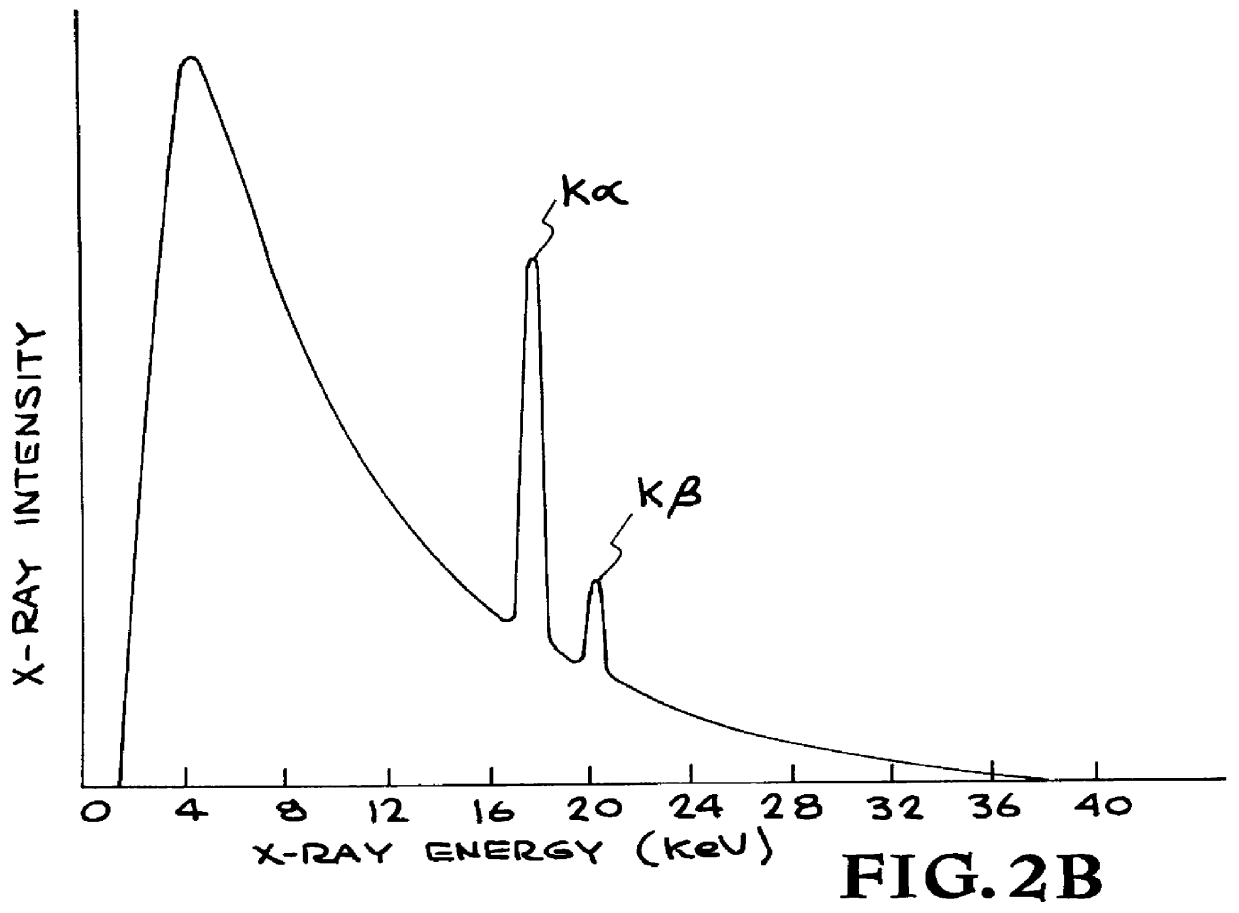

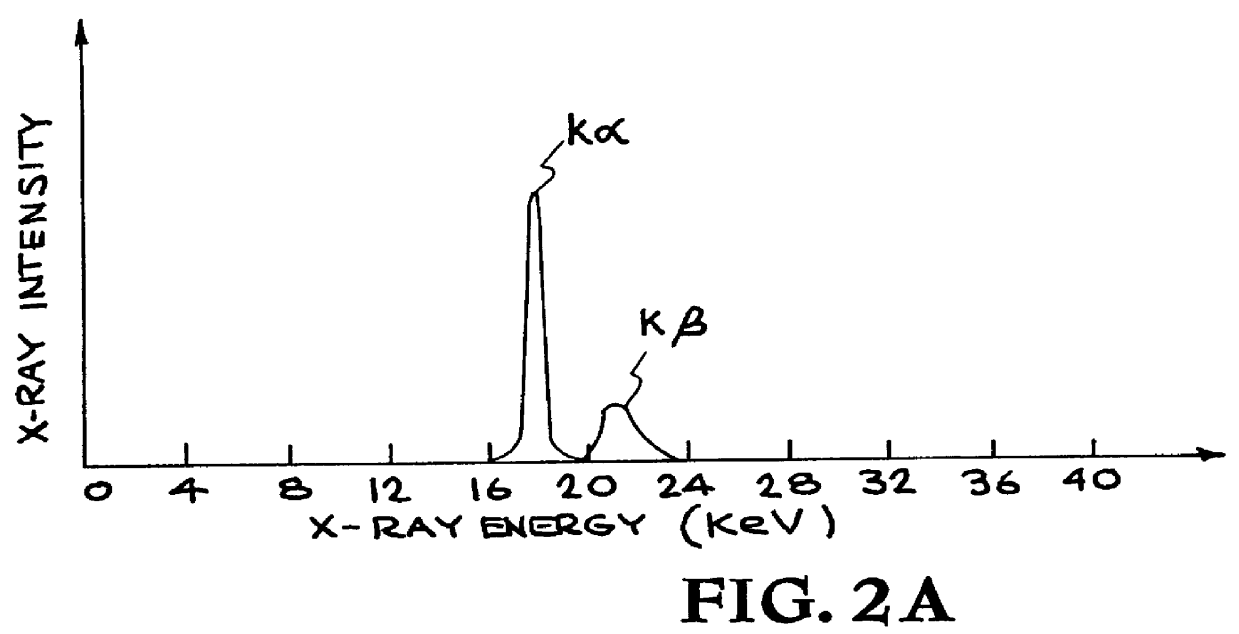

X-ray radiography with highly charged ions

An extremely small (1-250 micron FWHM) beam of slow highly charged ions deexciting on an x-ray production target generates x-ray monochromatic radiation that is passed through a specimen and detected for imaging. The resolution of the x-ray radiograms is improved and such detection is achieved with relatively low dosages of radiation passing through the specimen. An apparatus containing an electron beam ion trap (and modifications thereof) equipped with a focusing column serves as a source of ions that generate radiation projected onto an image detector. Electronic and other detectors are able to detect an increased amount of radiation per pixel than achieved by previous methods and apparati.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

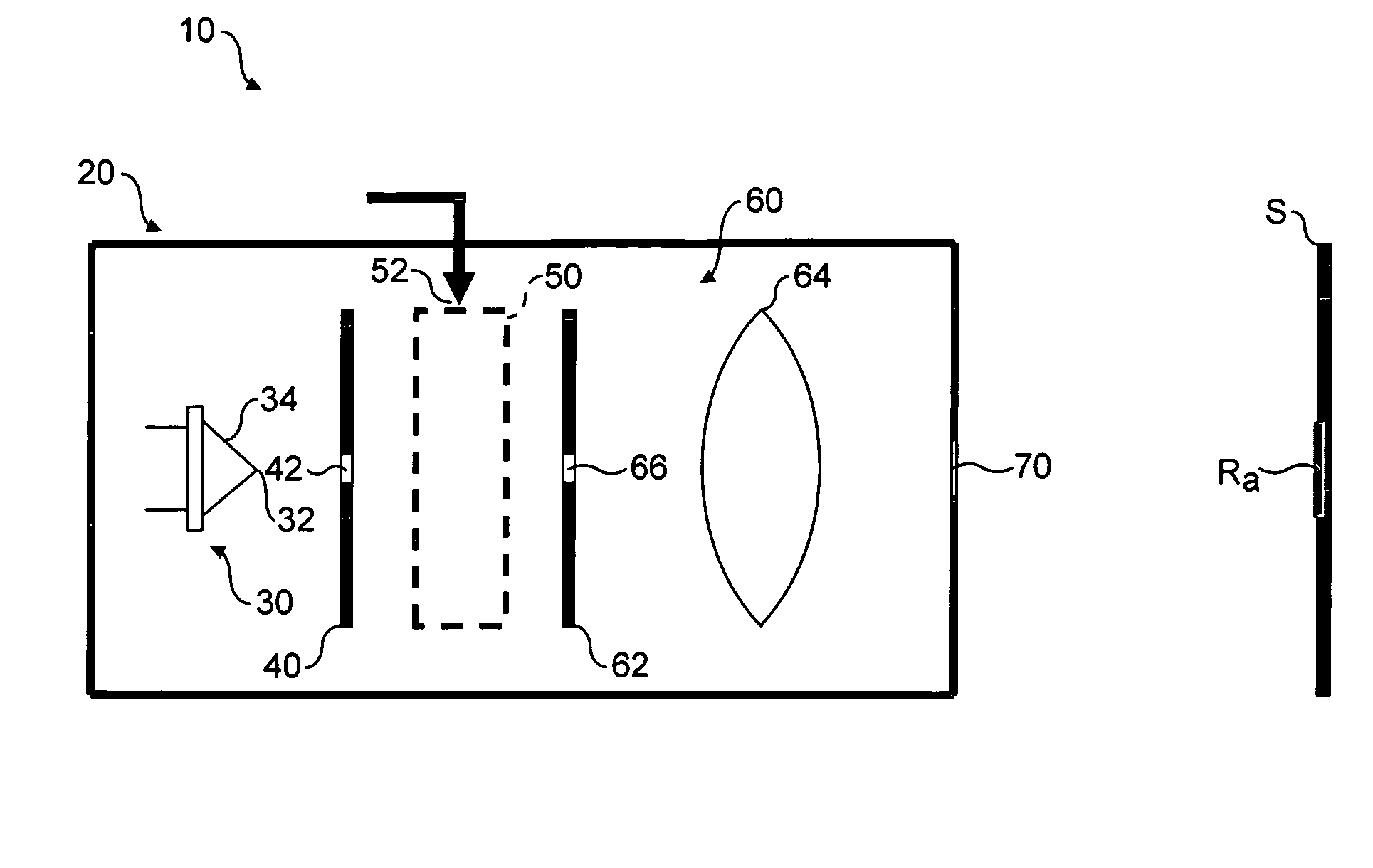

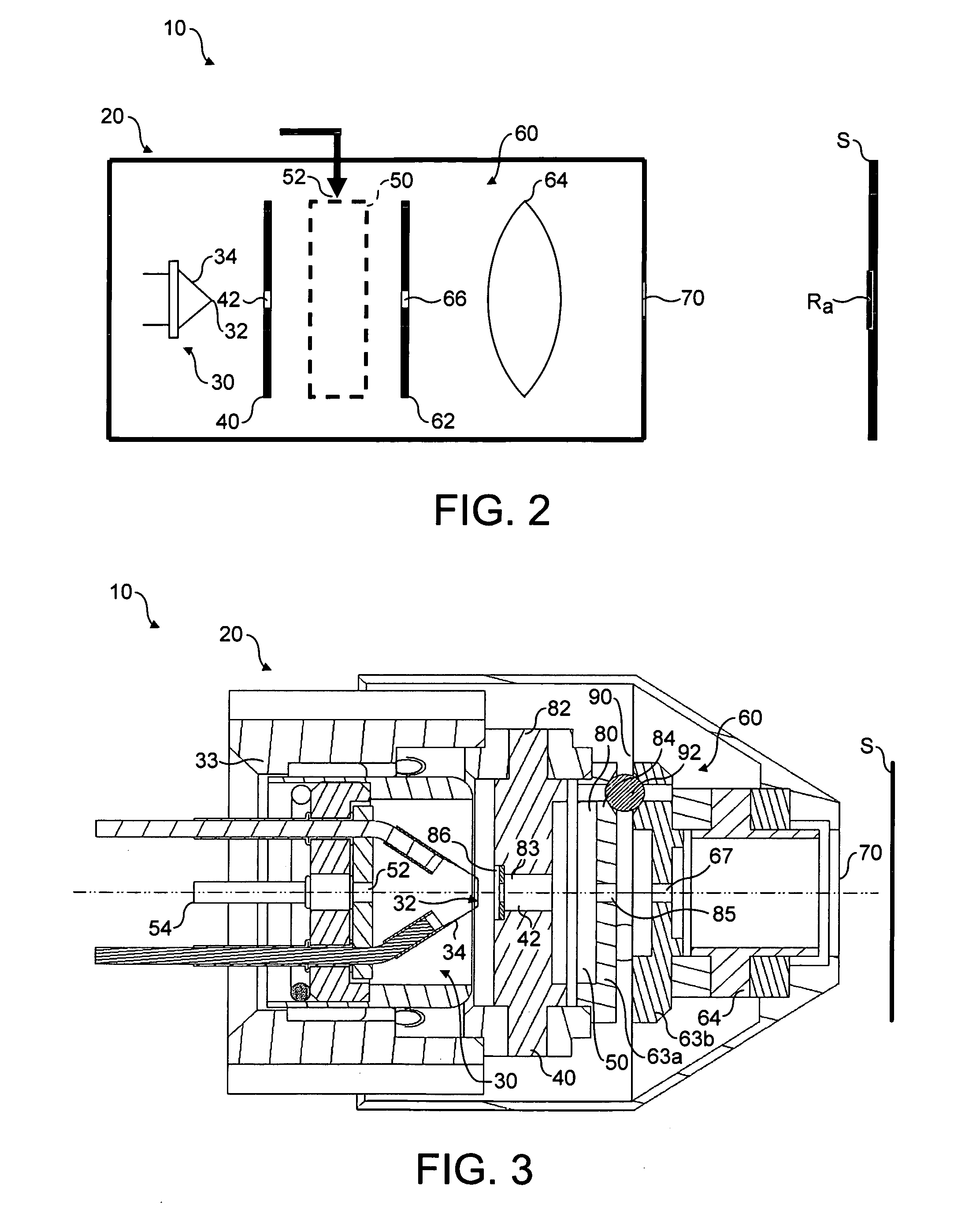

Flood gun for charge neutralization

ActiveUS20050205800A1Clear cost benefitEffective charge neutralizationLaser detailsMaterial analysis by optical meansDual modeParticle beam

A flood gun 10 for charge neutralization of an analysis region Ra of a sample S downstream of the flood gun, comprising: a first source 30 of electrons; a second source 50 of positively charged particles; and an extraction and focusing assembly 60,64, arranged to: (i) extract a first, electron beam from the first source and focus the first beam to a first flood area Ae at the analysis region; and (ii) extract a second, positive particle beam from the second source and focus the second beam to a second flood area Ai at the analysis region. The electron beam and the positive particle beam may both be extracted and focused simultaneously, in a single mode of operation or, alternately, in a dual mode of operation. A corresponding method of providing charge neutralization and a spectroscopic system for secondary particle emission analysis are disclosed.

Owner:THERMO ELECTRON A DE

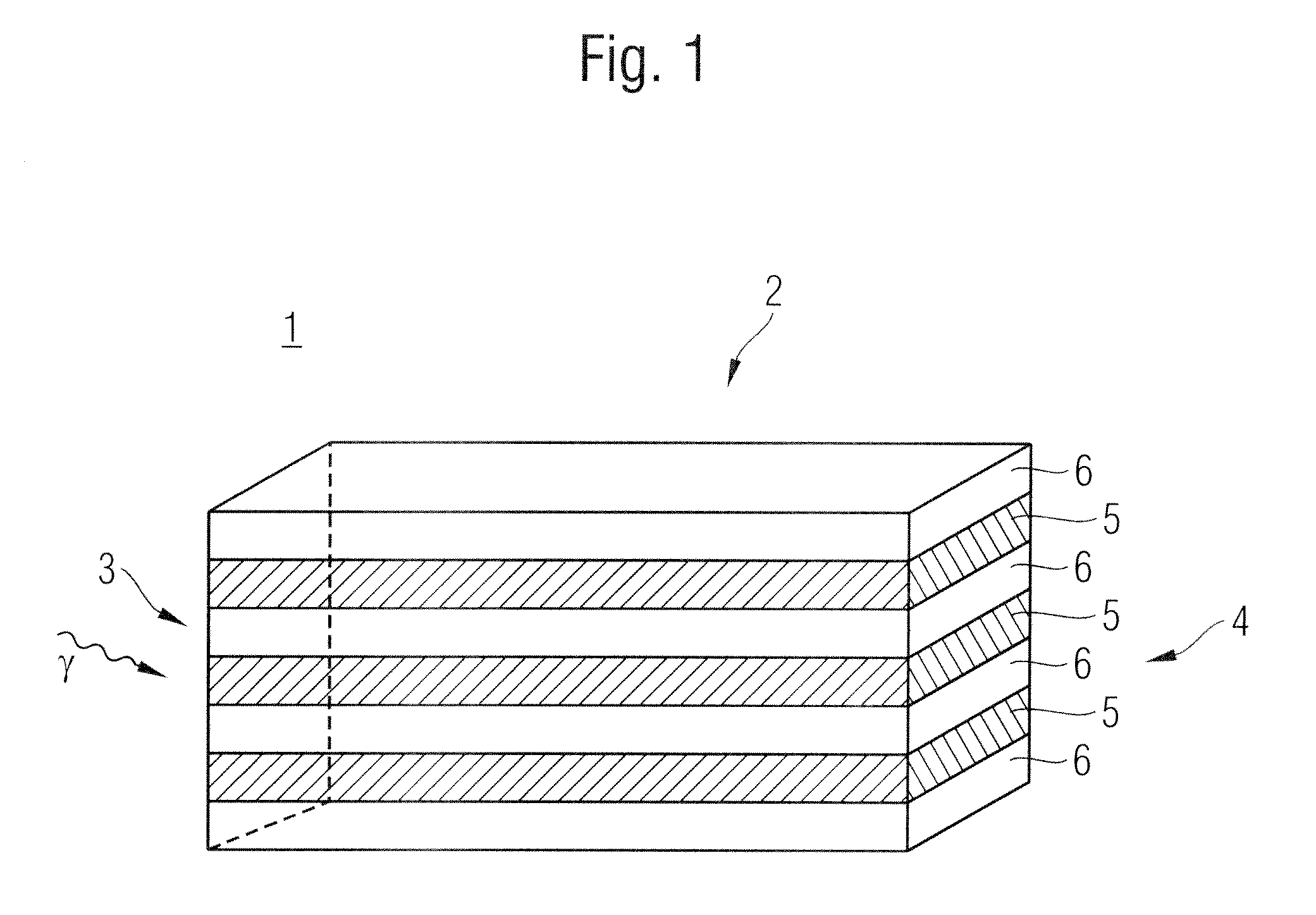

Detector assembly for detecting radiation with angular resolution and method for operating said assembly

InactiveUS20100006769A1Easy to detectImprove performanceX-ray spectral distribution measurementMaterial analysis by optical meansImage resolutionAngular resolution

A detector assembly for detecting radiation with angular resolution comprises at least one detector element, which comprises a front face and a rear face, a first detector material and a second detector material between the front face and the rear face, a space between the front face and the rear face of the detector element being filled by a plurality of regions of the first detector material and at least one region of the second detector material and each region connecting the front face to the rear face of the detector element; and radiation incident on the detector element through the front face being collimated by means of the detector materials.

Owner:GSI HELMHOLTZZENT FUR SCHWERIONENFORSCHUNG

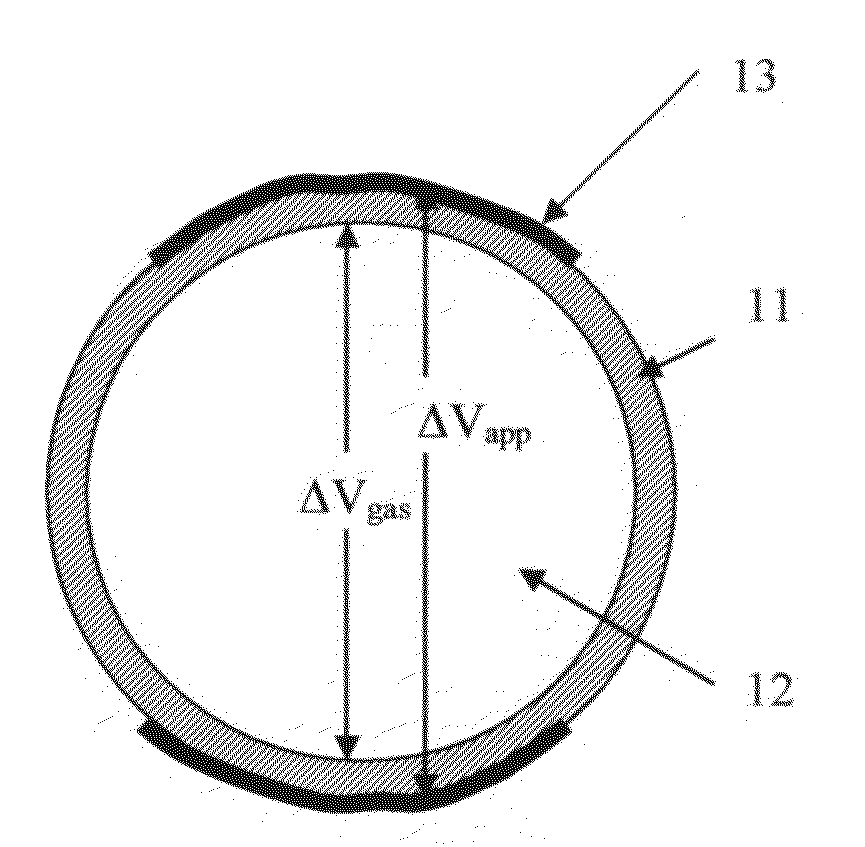

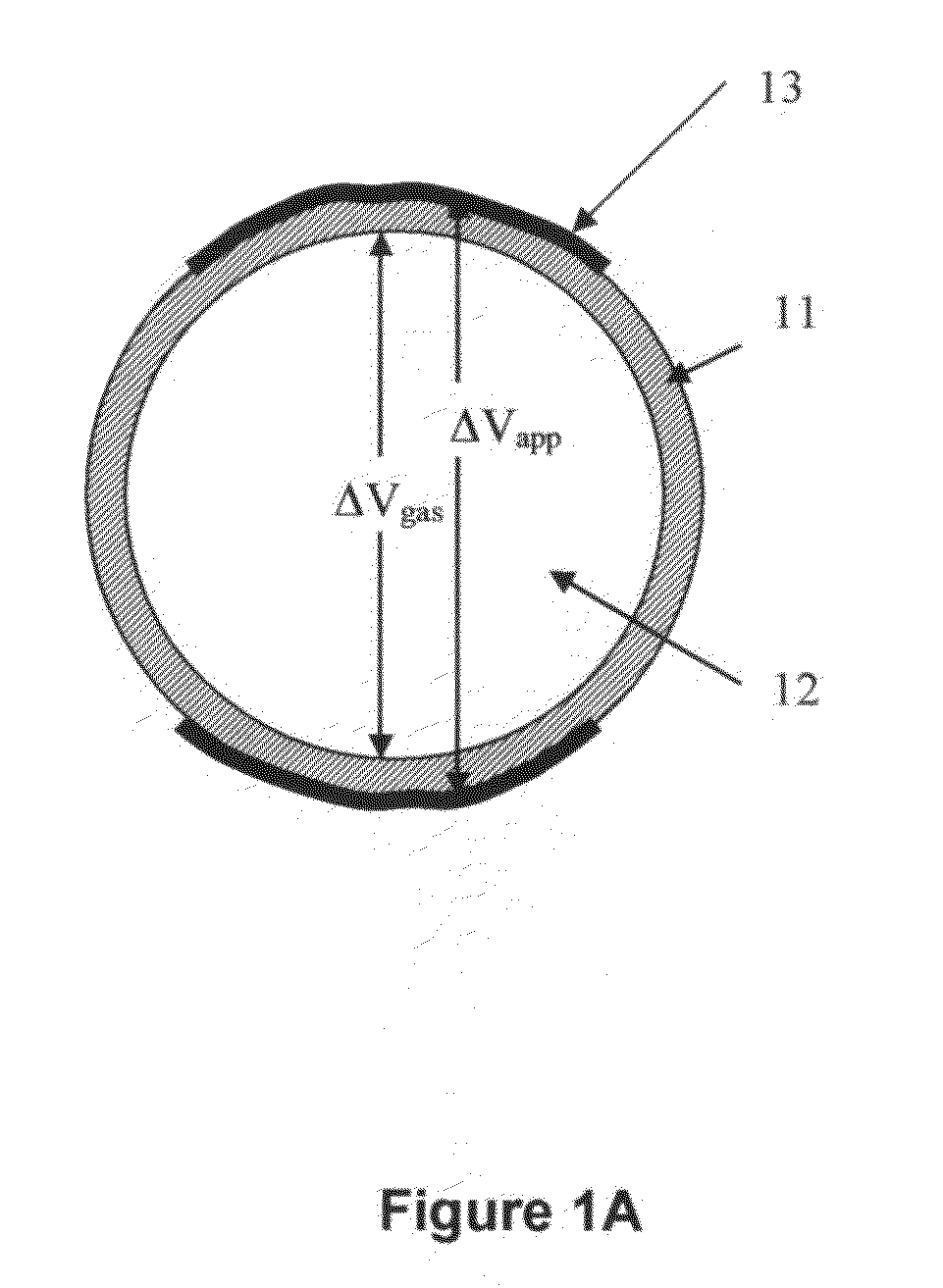

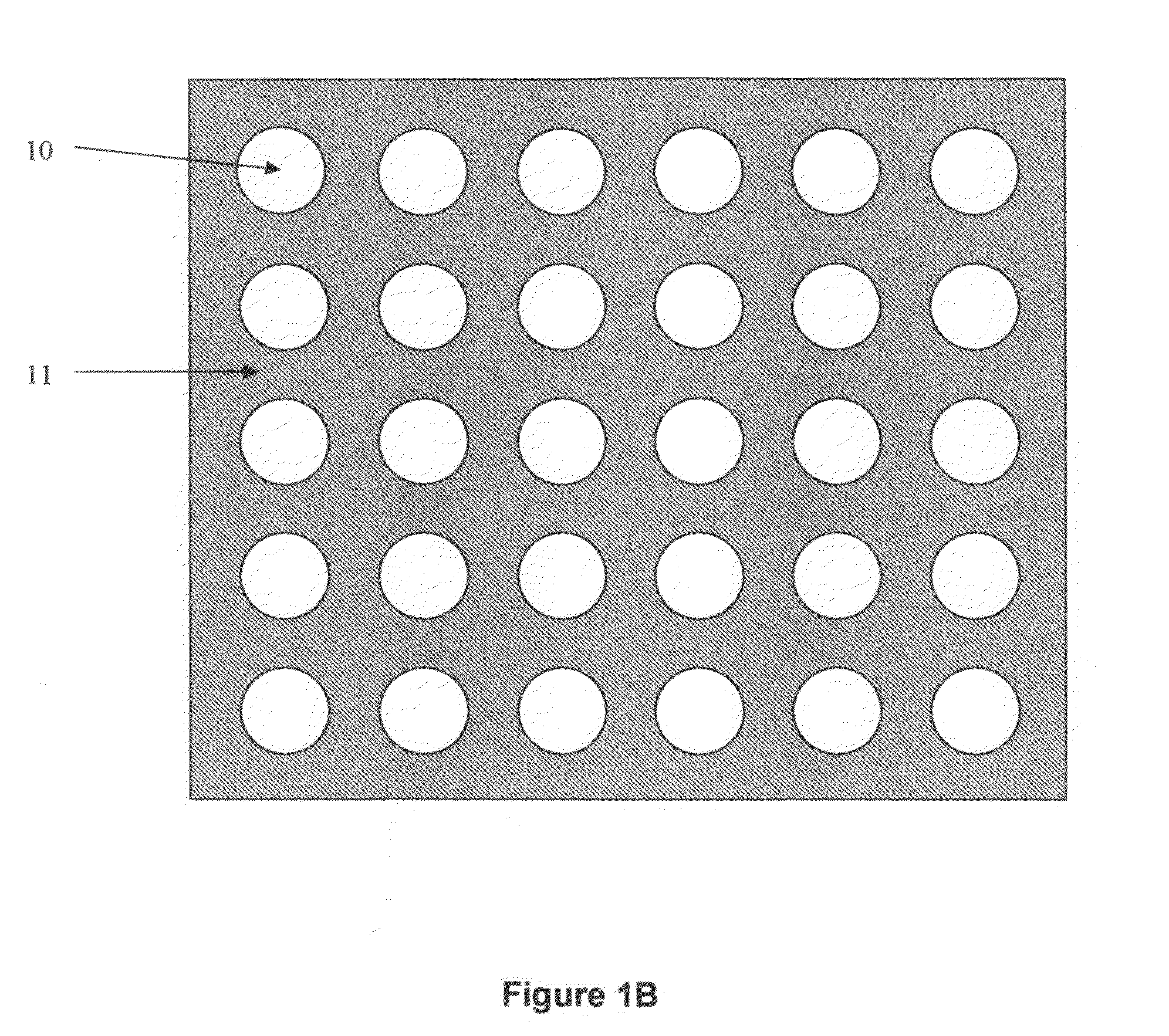

Neutron detector

InactiveUS20100019164A1Discrimination capability is not loweredEasy to useElectric discharge tubesMeasurement with scintillation detectorsLight spectrumNeutron detection

A neutron detector has a volume of neutron moderating material and a plurality of individual neutron sensing elements dispersed at selected locations throughout the moderator, and particularly arranged so that some of the detecting elements are closer to the surface of the moderator assembly and others are more deeply embedded. The arrangement captures some thermalized neutrons that might otherwise be scattered away from a single, centrally located detector element. Different geometrical arrangements may be used while preserving its fundamental characteristics. Different types of neutron sensing elements may be used, which may operate on any of a number of physical principles to perform the function of sensing a neutron, either by a capture or a scattering reaction, and converting that reaction to a detectable signal. High detection efficiency, an ability to acquire spectral information, and directional sensitivity may be obtained.

Owner:MATERIALS INNOVATION INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com