Patents

Literature

712 results about "Beam system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

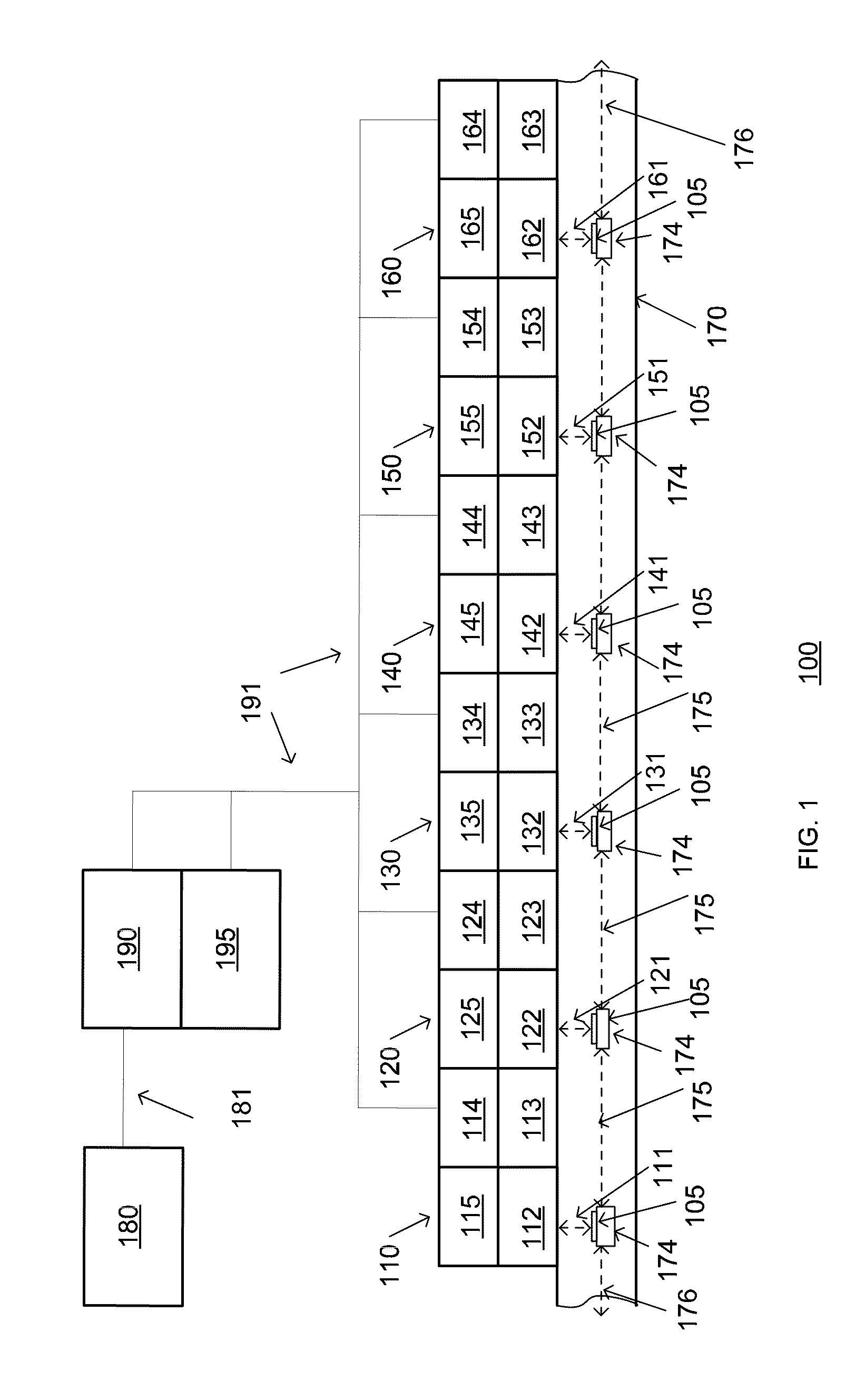

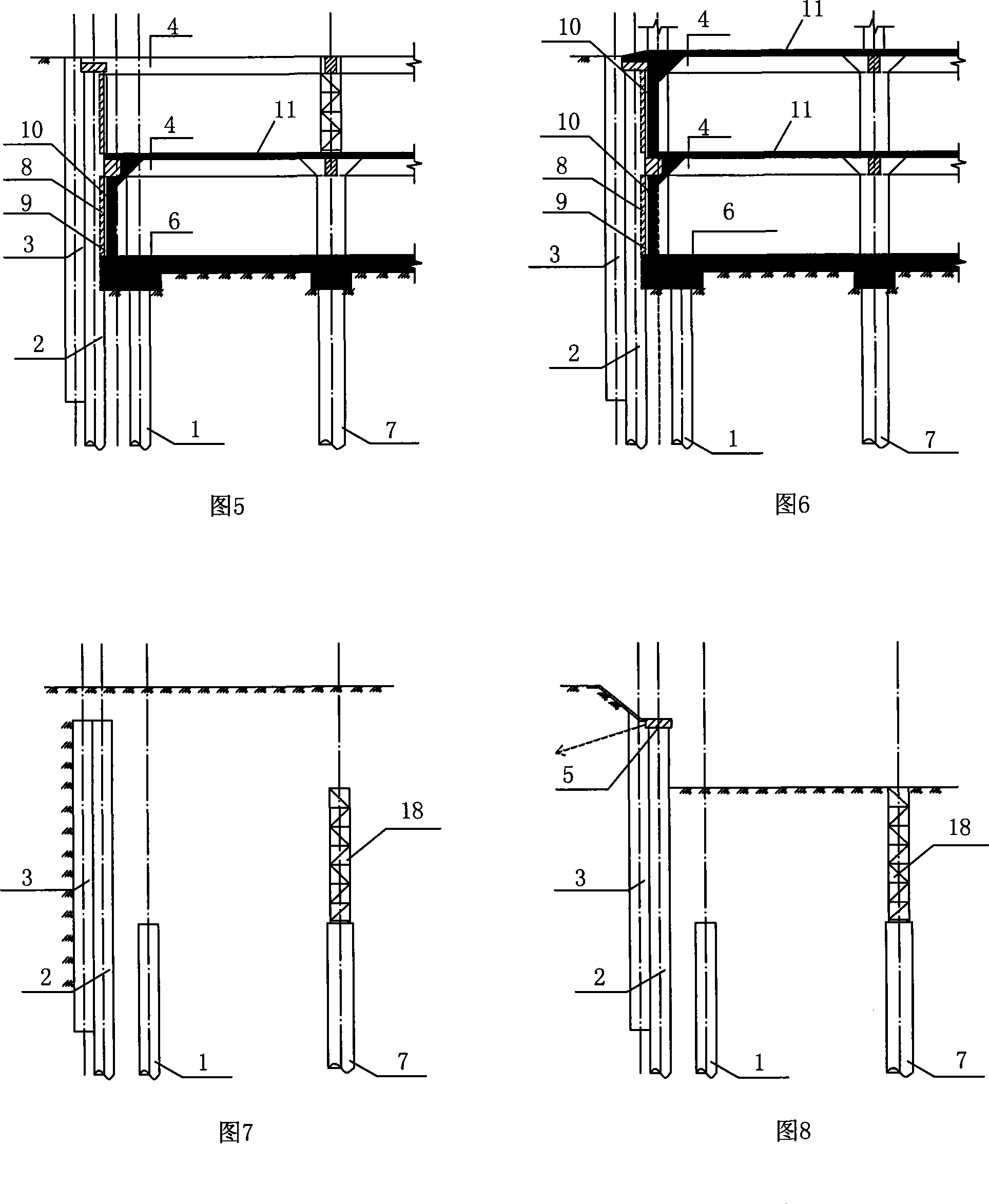

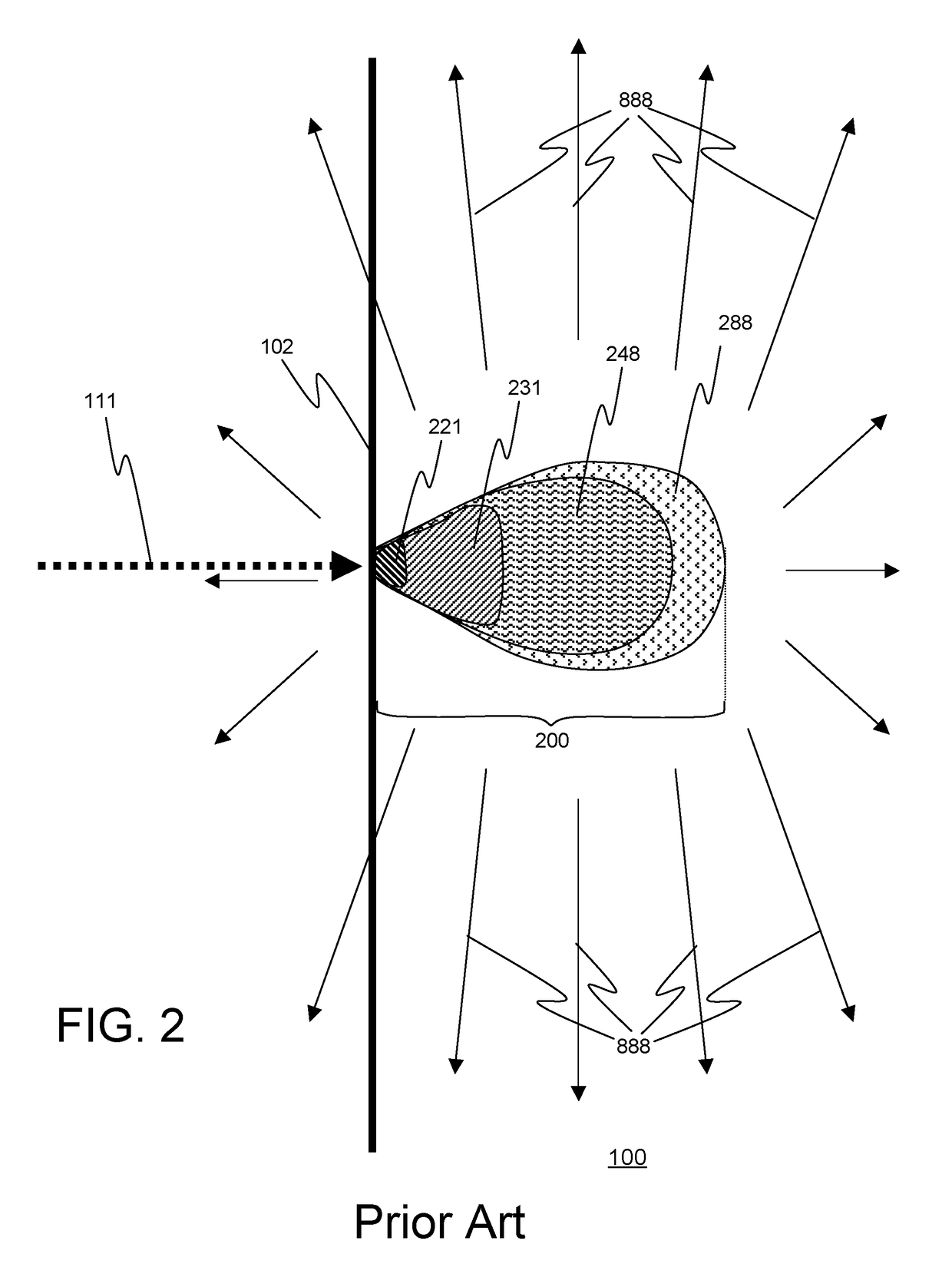

Interactive directed light/sound system

InactiveUS7576727B2Input/output for user-computer interactionTelevision system detailsObject basedLight beam

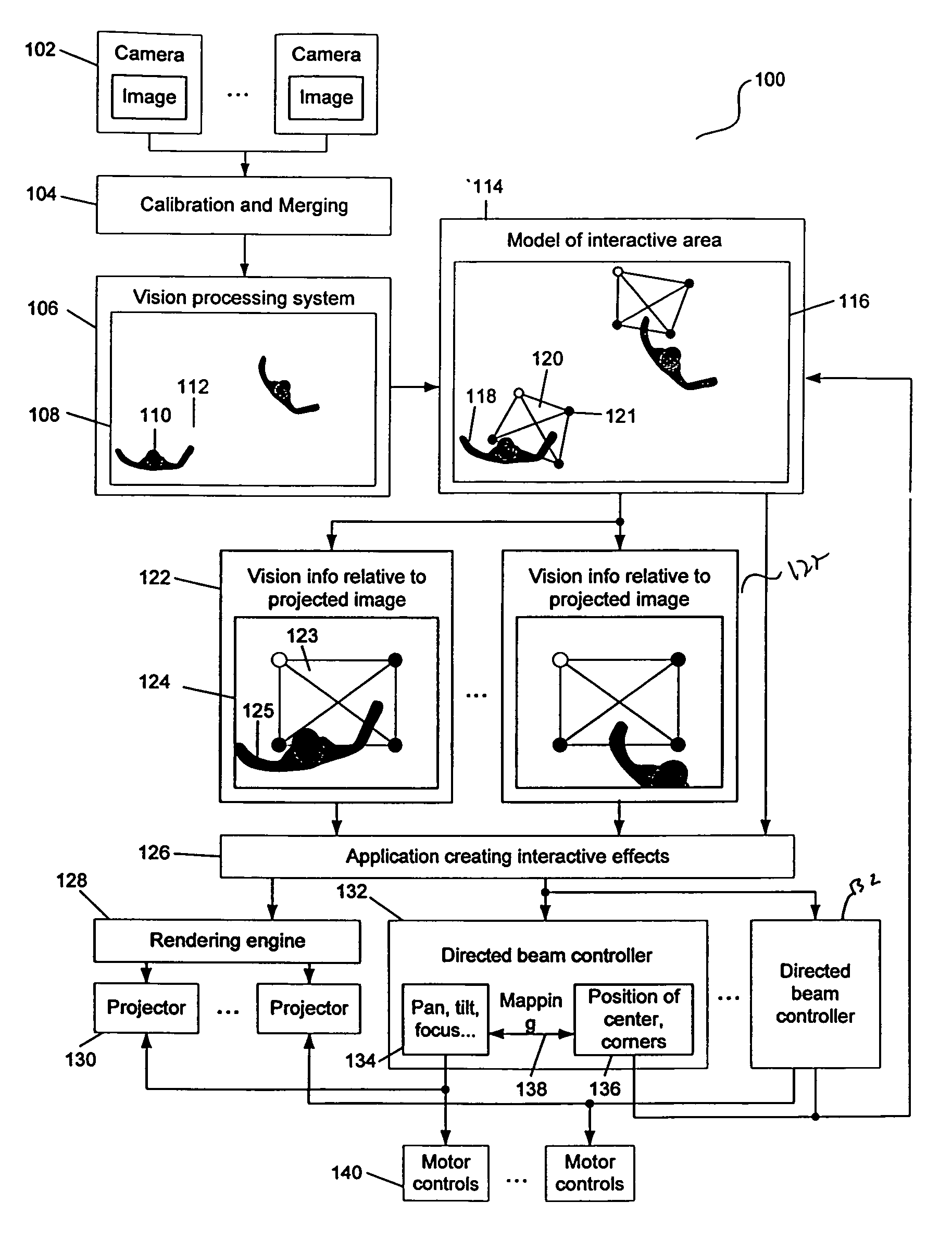

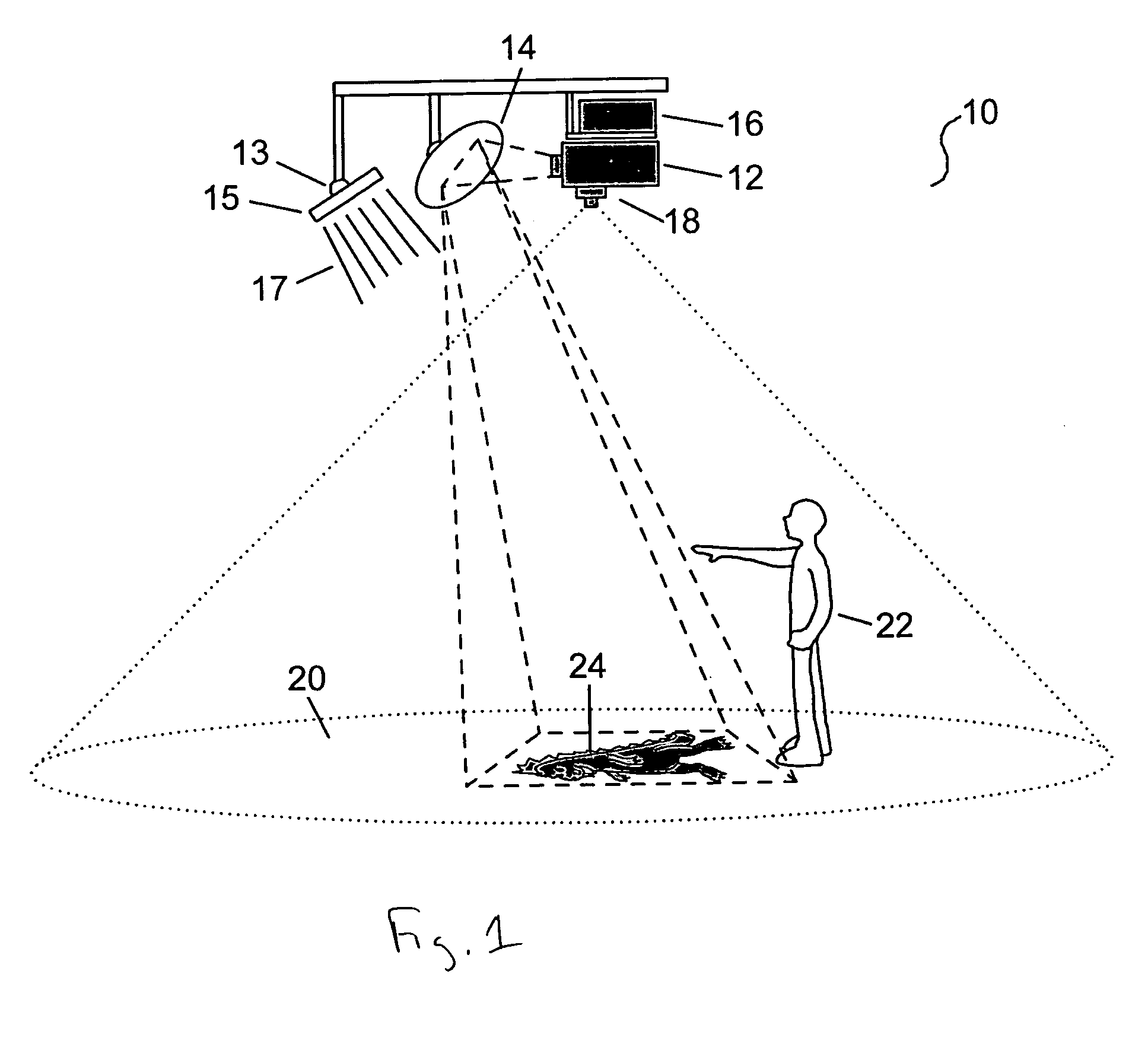

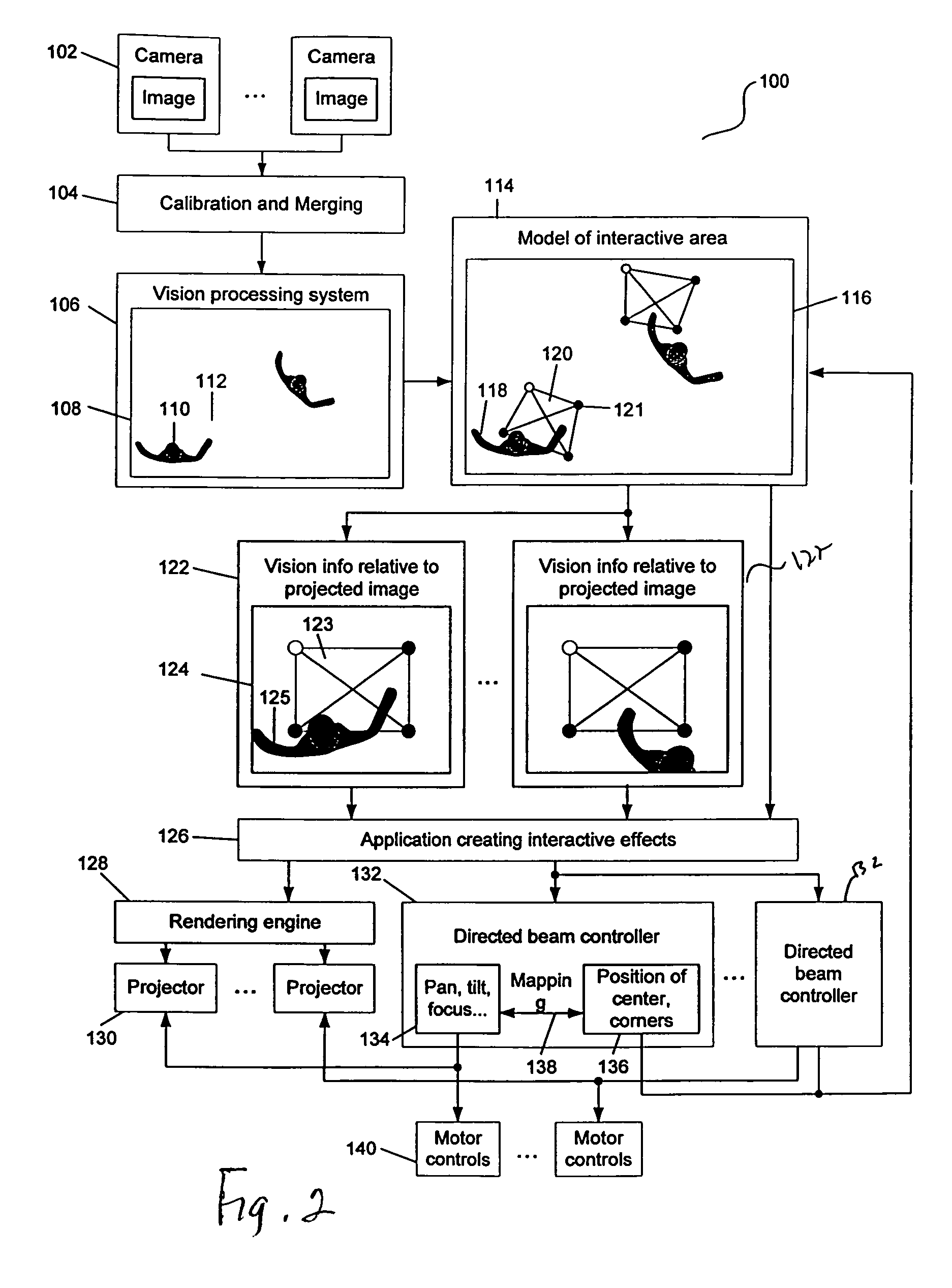

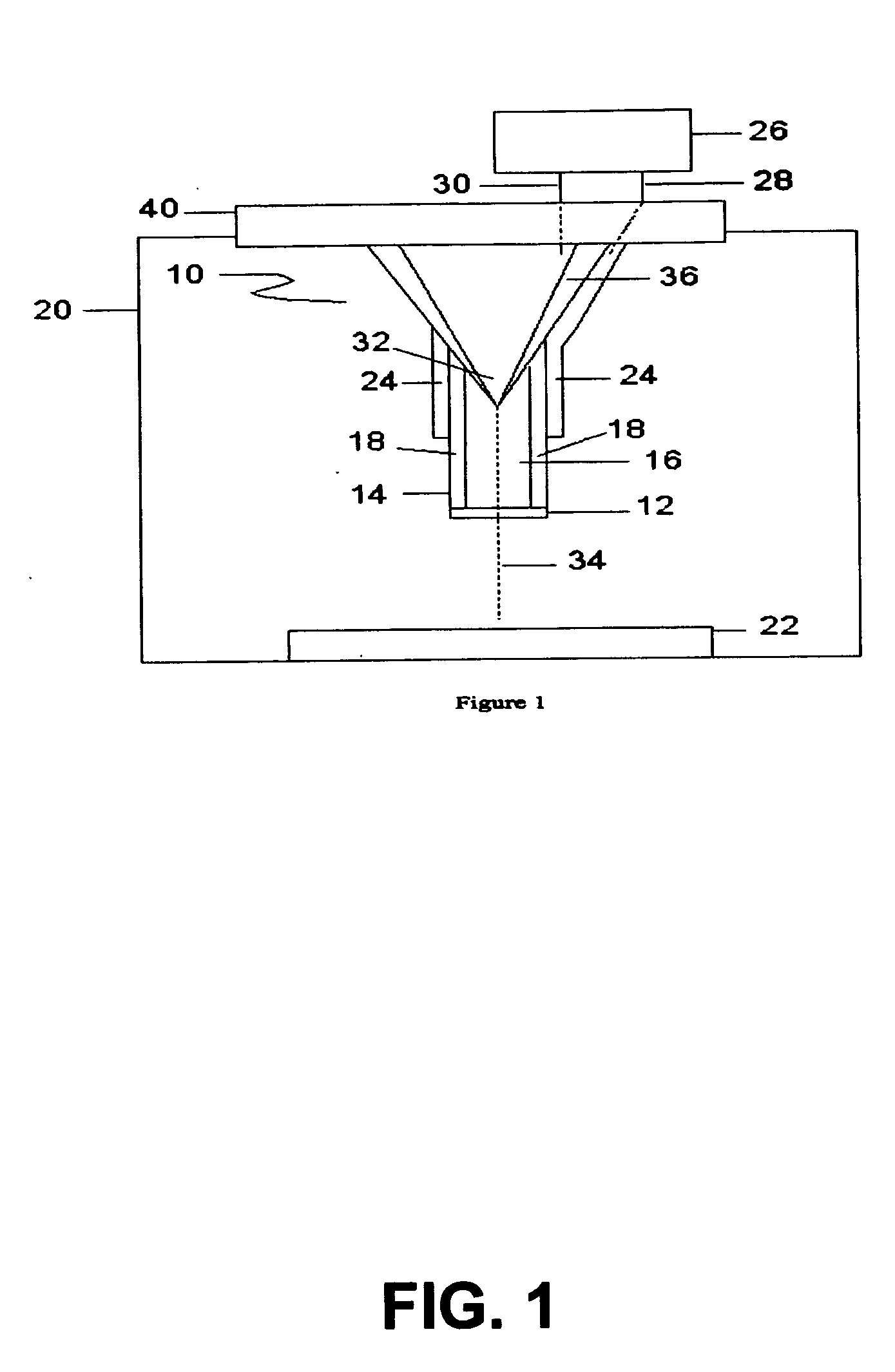

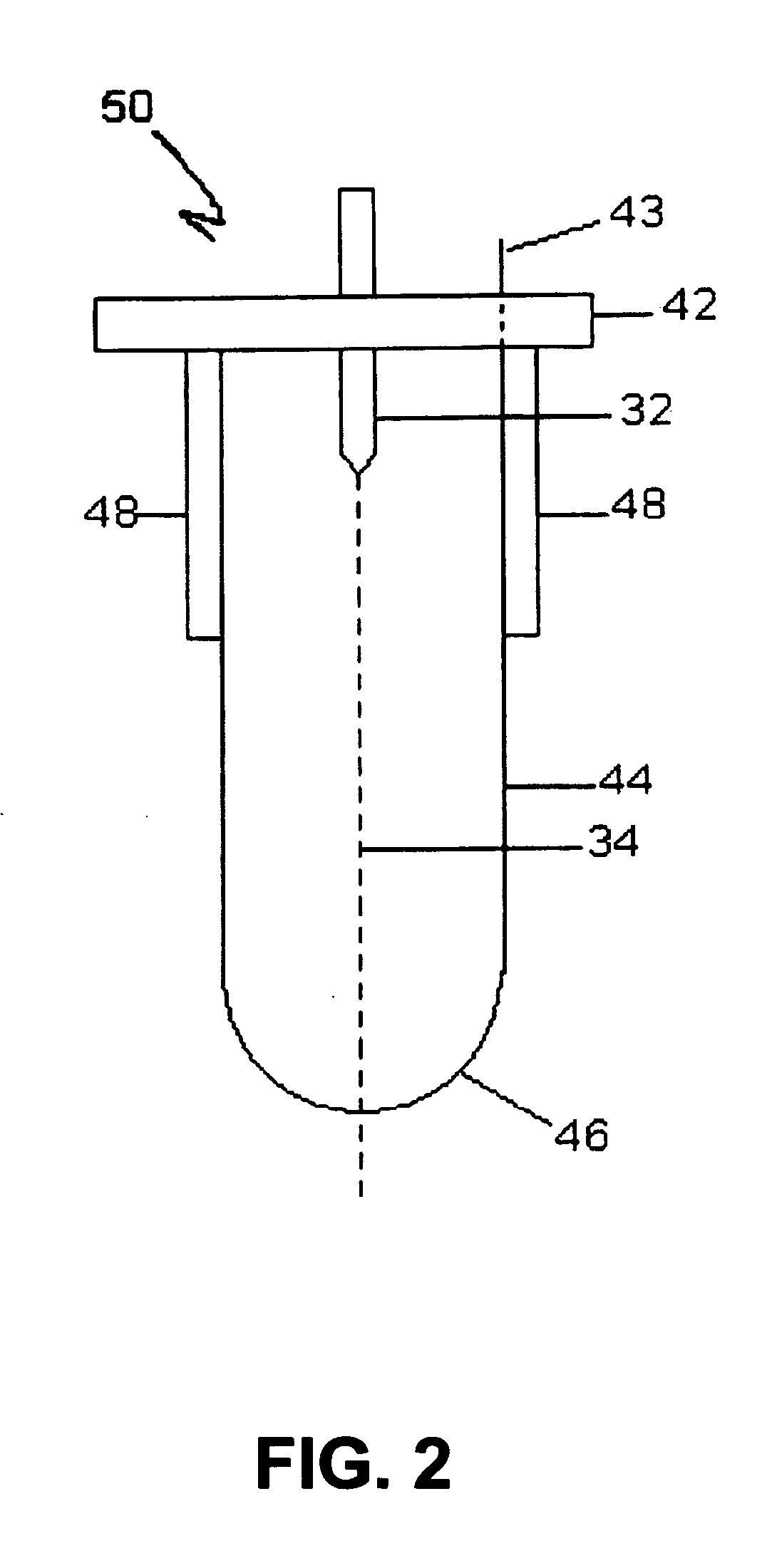

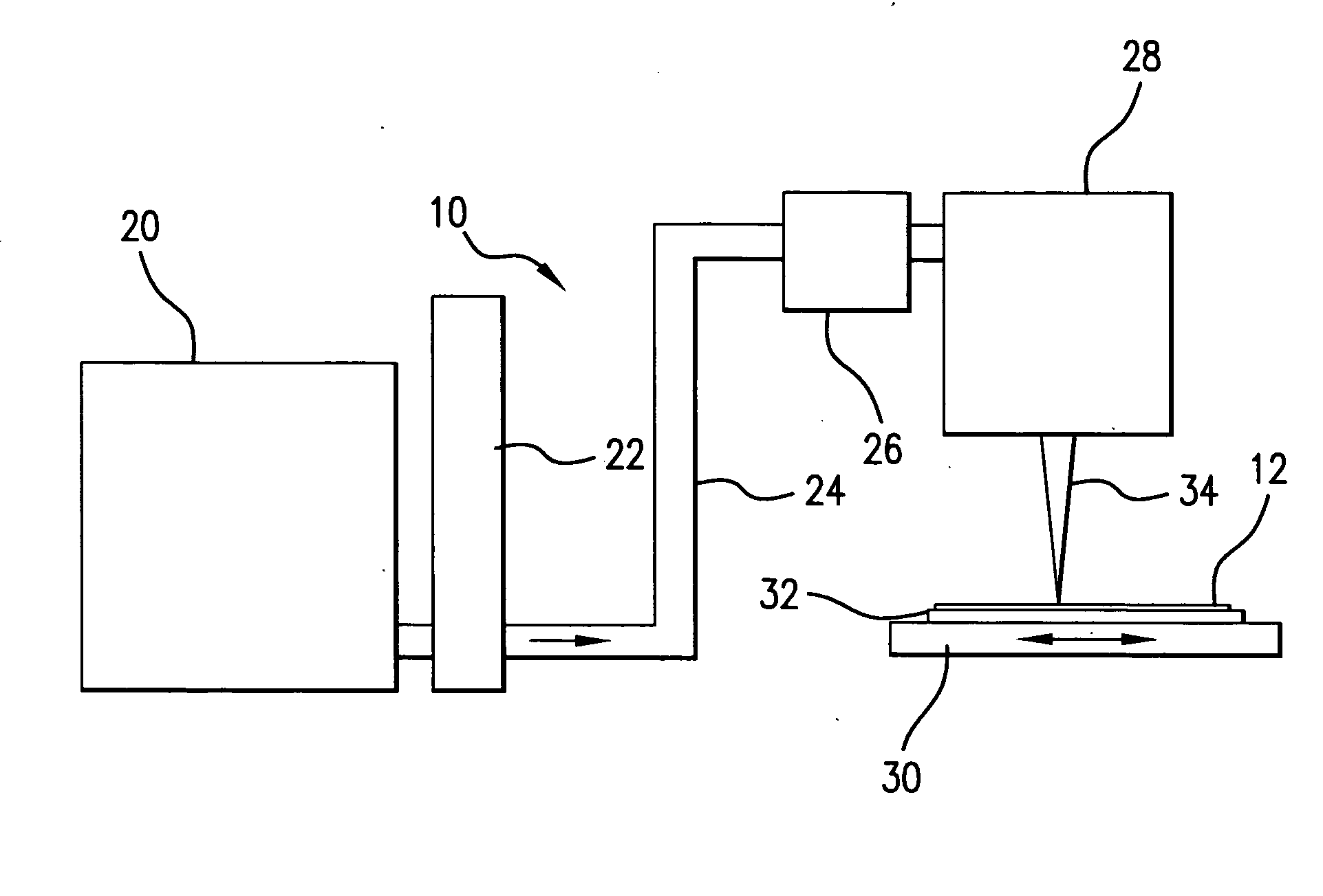

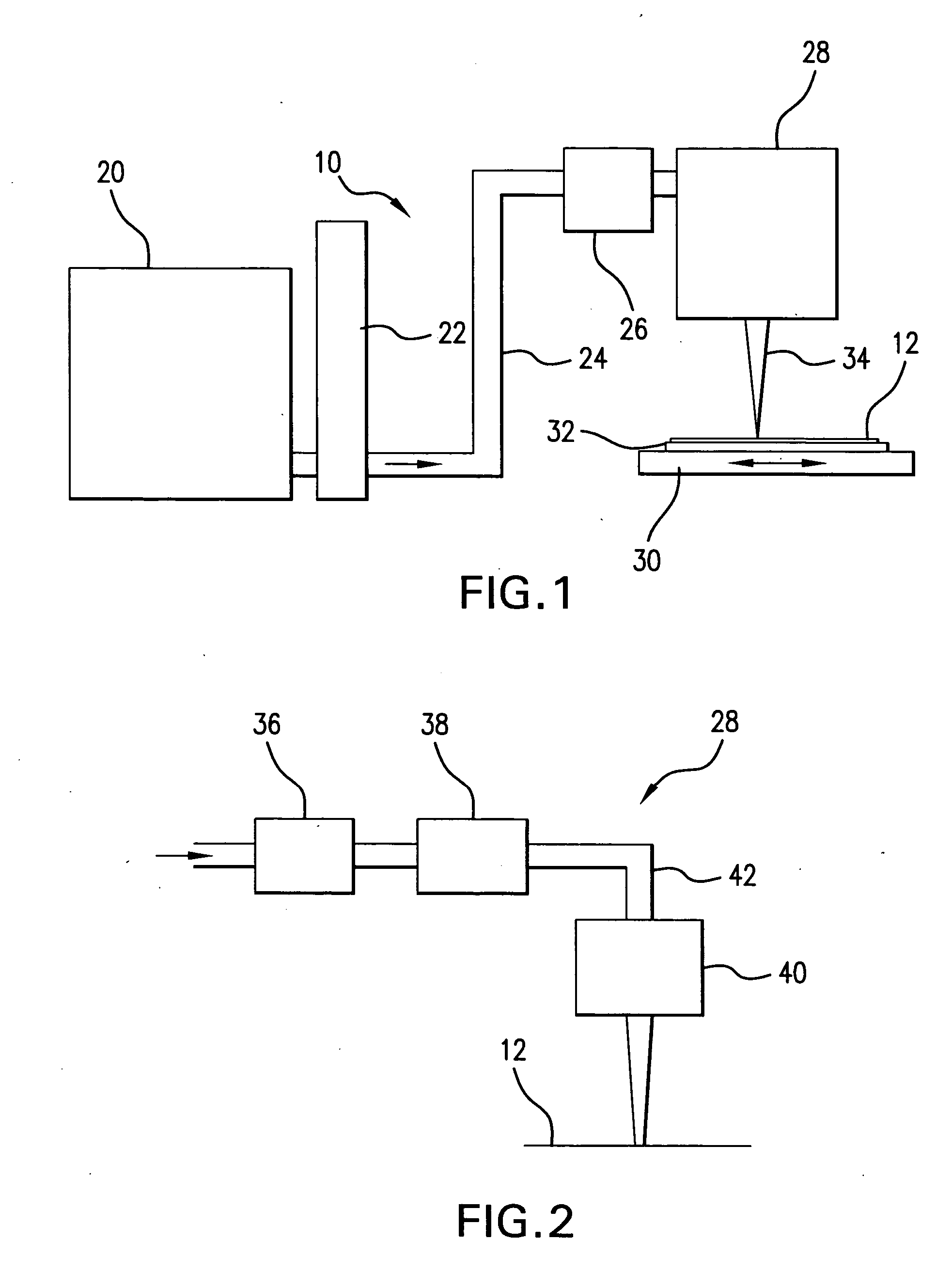

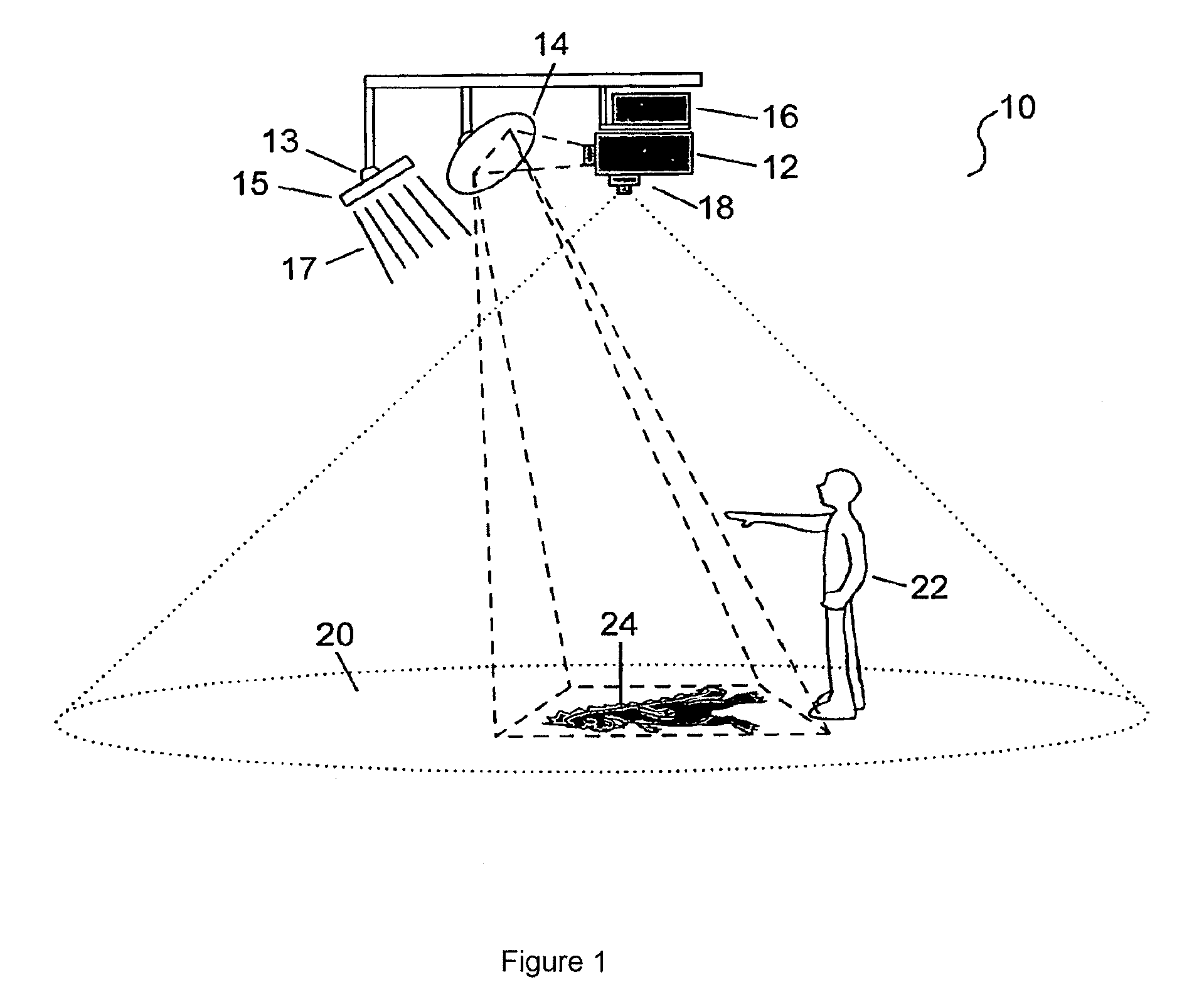

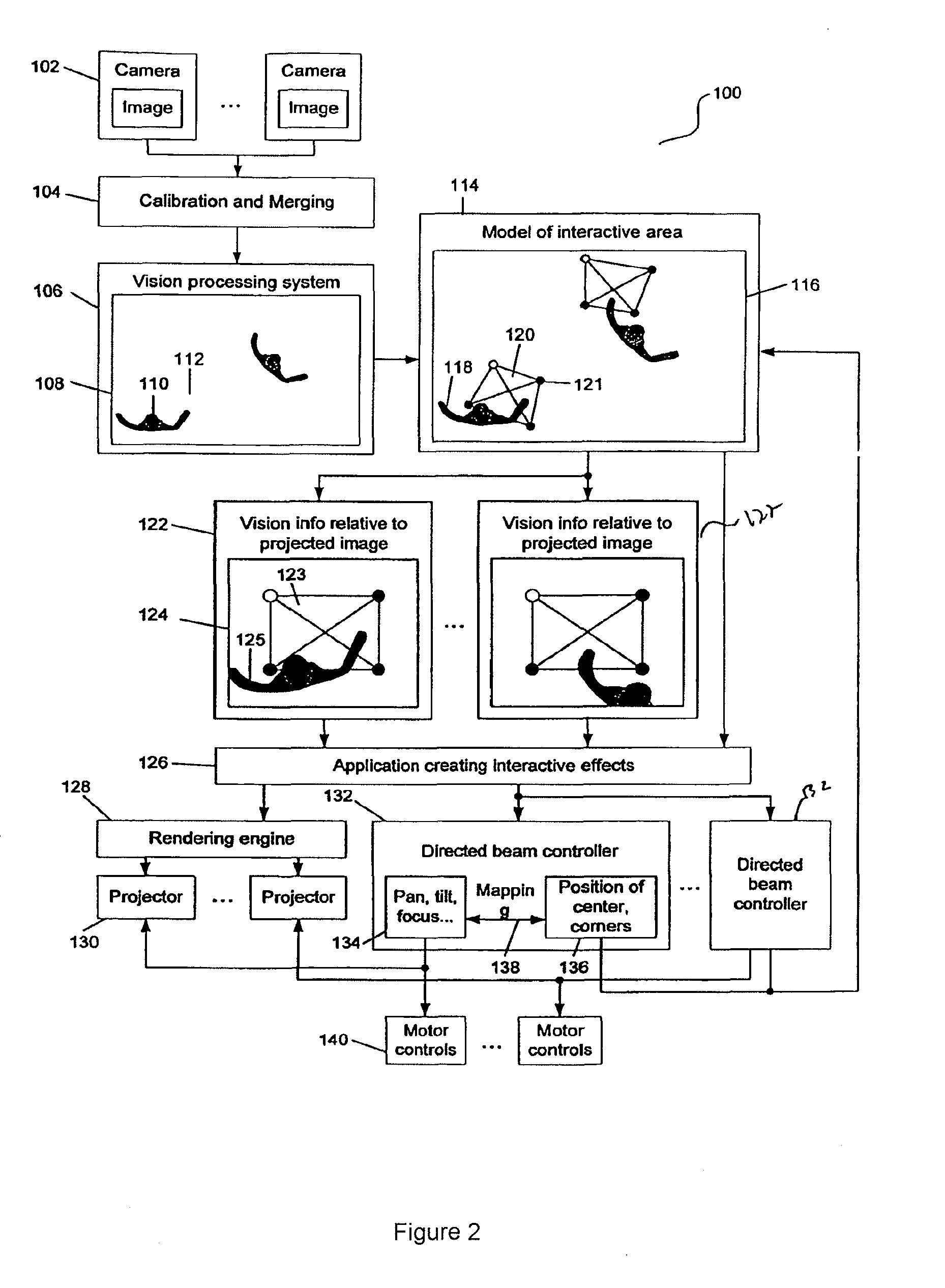

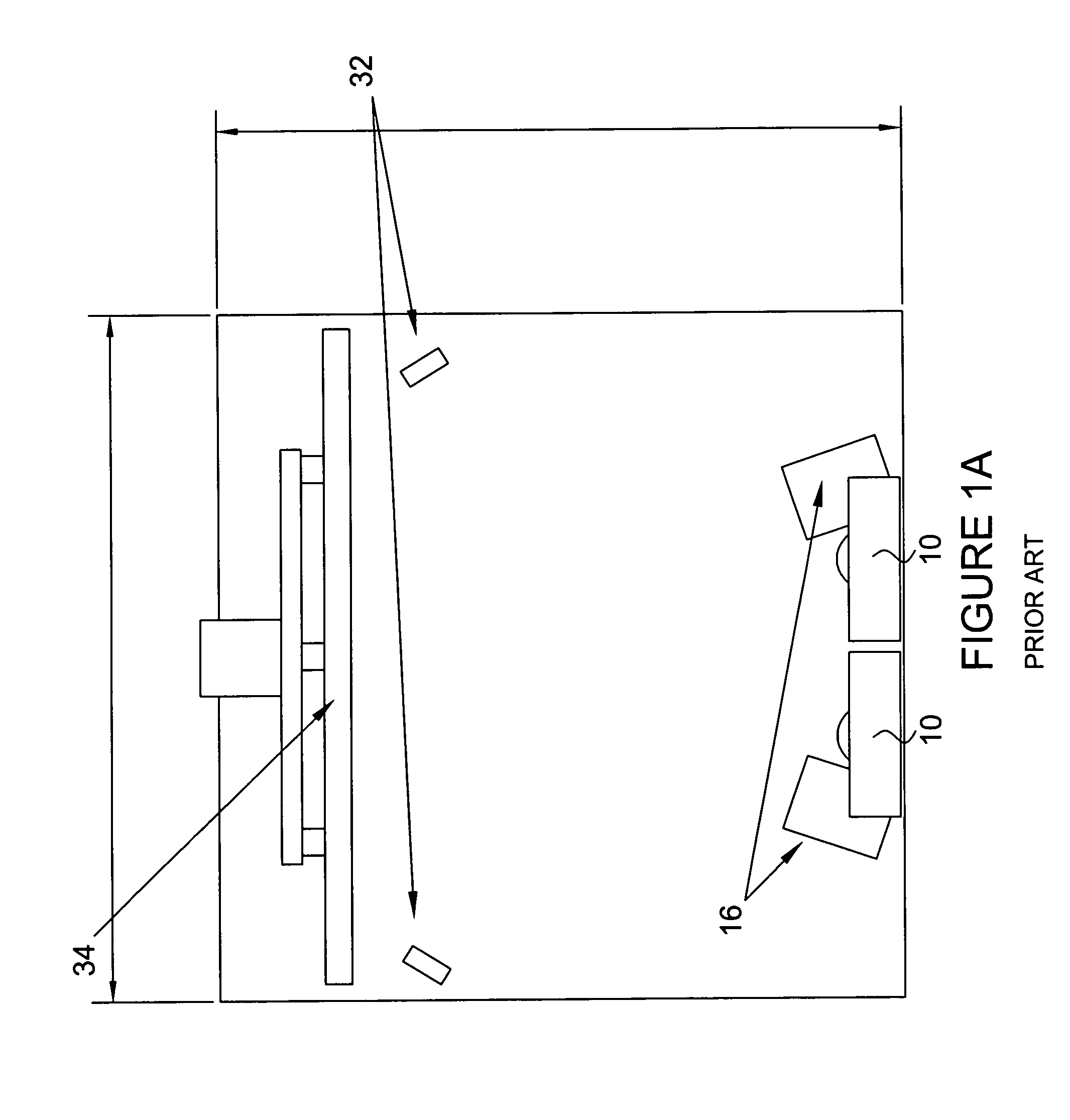

An interactive directed beam system is provided. In one implementation, the system includes a projector, a computer and a camera. The camera is configured to view and capture information in an interactive area. The captured information may take various forms, such as, an image and / or audio data. The captured information is based on actions taken by an object, such as, a person within the interactive area. Such actions include, for example, natural movements of the person and interactions between the person and an image projected by the projector. The captured information from the camera is then sent to the computer for processing. The computer performs one or more processes to extract certain information, such as, the relative location of the person within the interactive area for use in controlling the projector. Based on the results generated by the processes, the computer directs the projector to adjust the projected image accordingly. The projected image can move anywhere within the confines of the interactive area.

Owner:MICROSOFT TECH LICENSING LLC

Integrated sub-nanometer-scale electron beam systems

InactiveUS20050092929A1Stability-of-path spectrometersAdditive manufacturing apparatusNanometreElectron

Owner:BIOMED SOLUTIONS

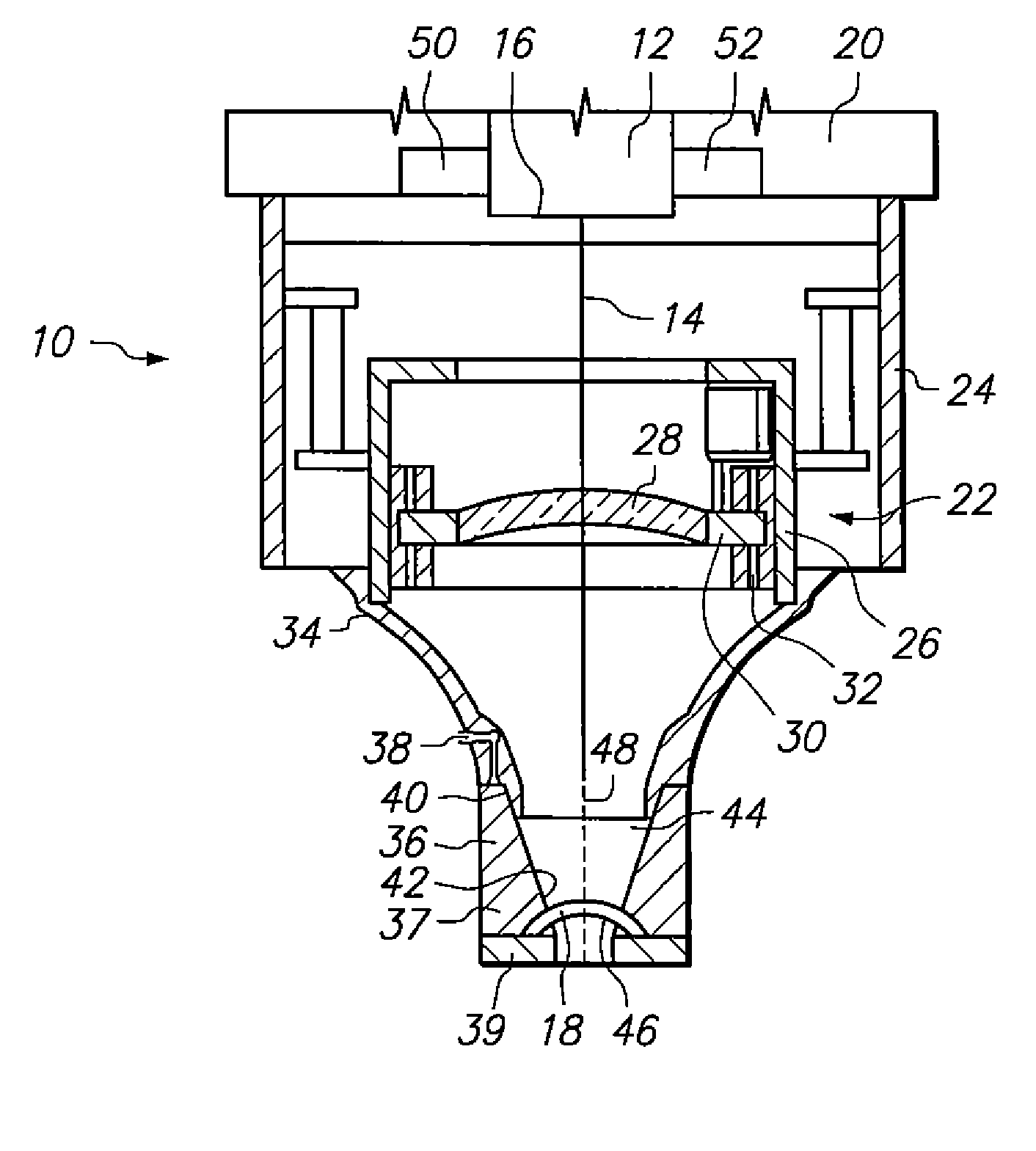

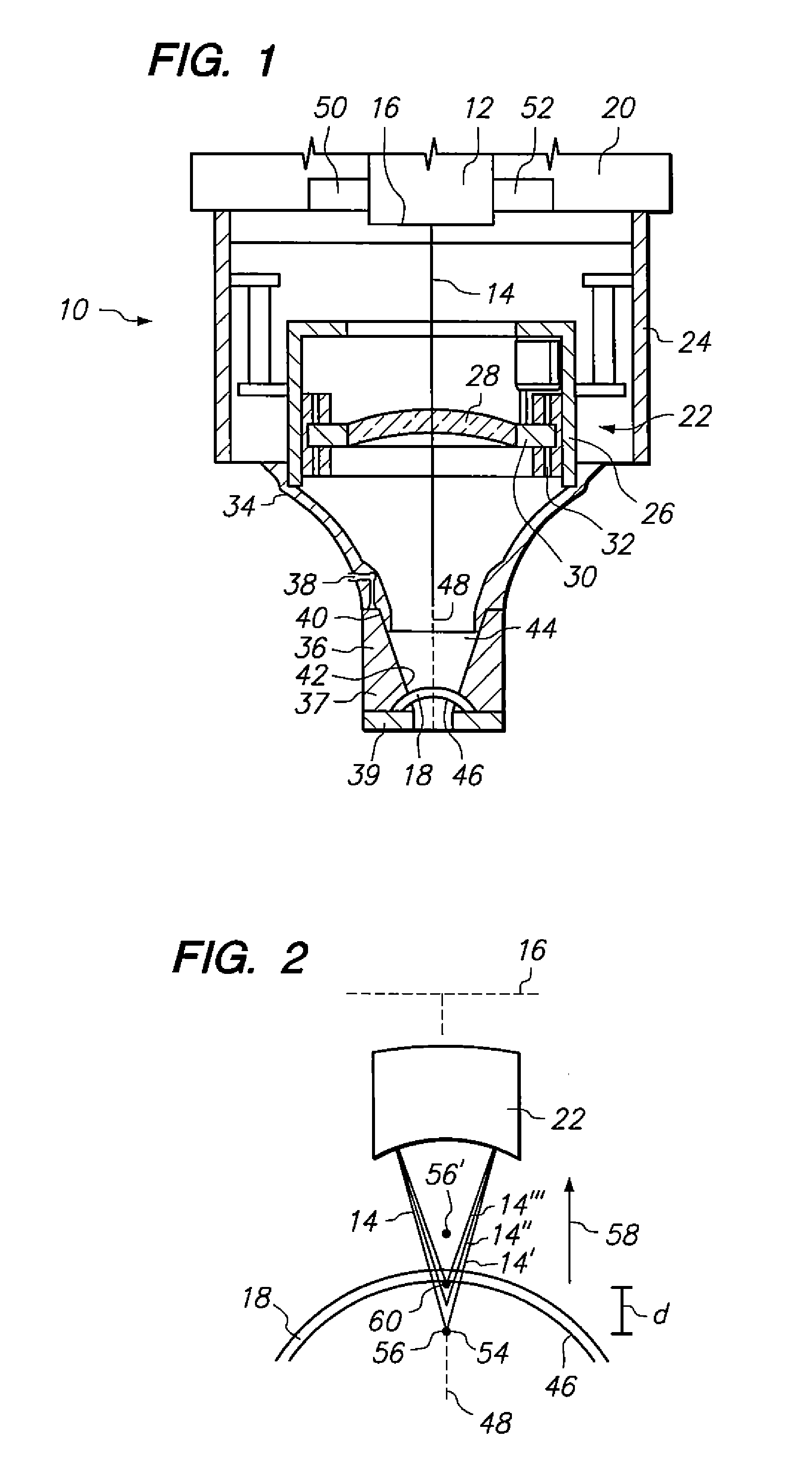

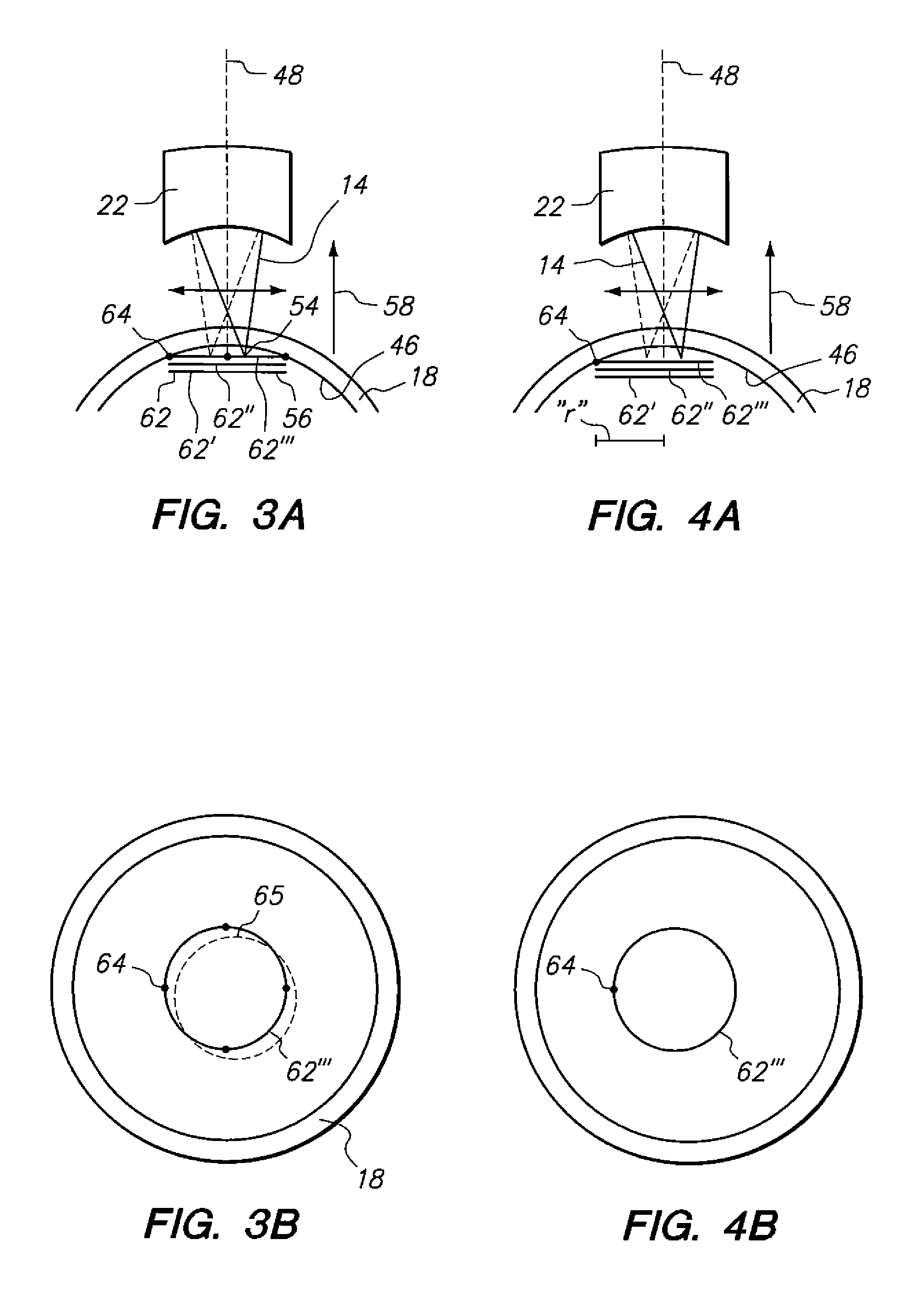

Systems and methods for generating laser light shaped as a line beam

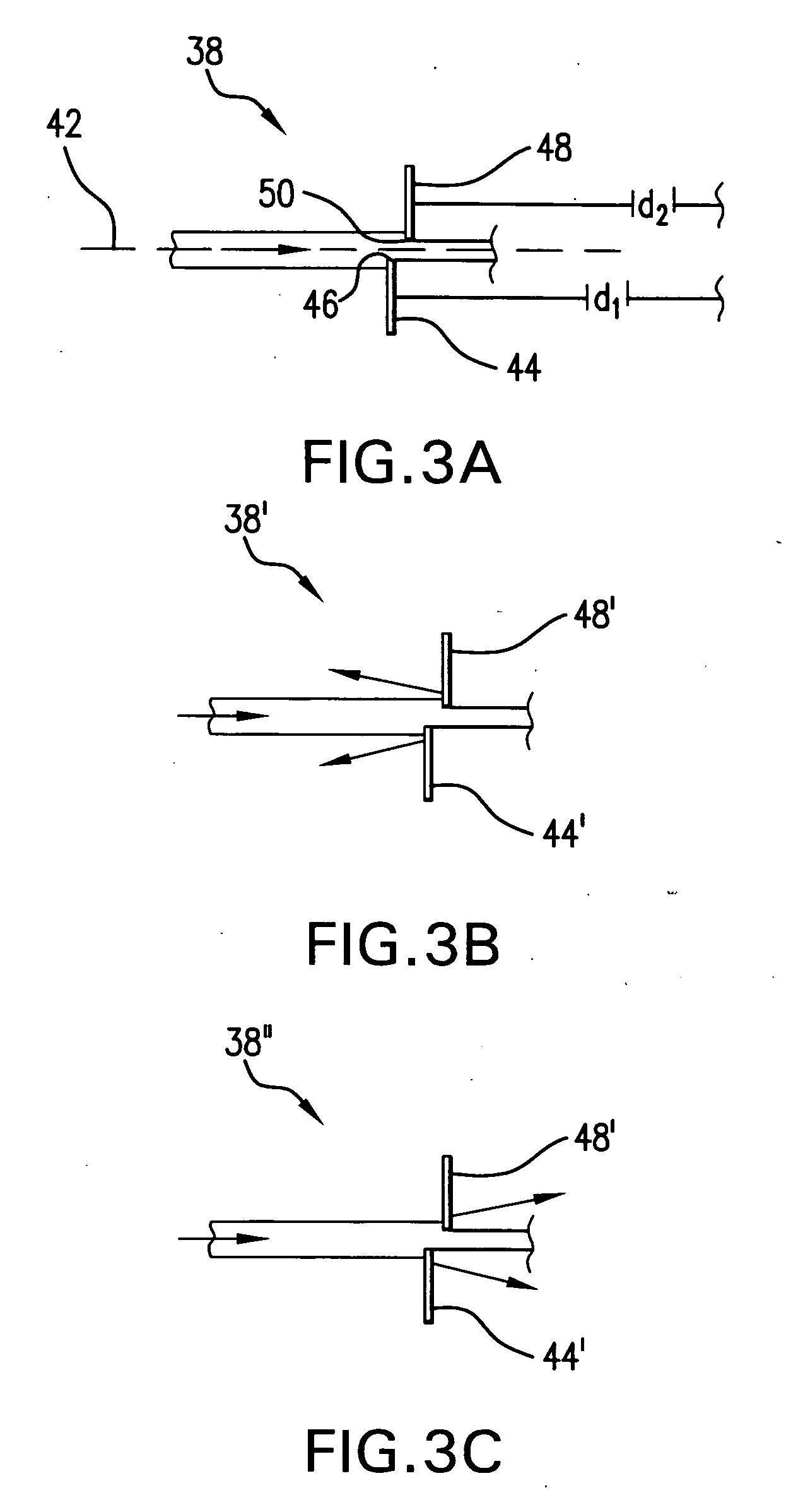

Systems and methods are disclosed for shaping a laser beam for interaction with a film in which the laser beam travels along a beam path and defines a short-axis and a long-axis. In one aspect, the system may include a first short-axis element having an edge positioned at a distance, d1, along the beam path from the film and a second short-axis element having an edge positioned at a distance, d2, along the beam path from the film, with d2<d1. An optic may be positioned along the beam path between the second element and the film for focusing the beam in the short-axis for interaction with the film. In another aspect, a system may be provided having a mechanism operative to selectively adjust the curvature of one or both of the edges of the short-axis element.

Owner:CARL ZEISS SMT GMBH +1

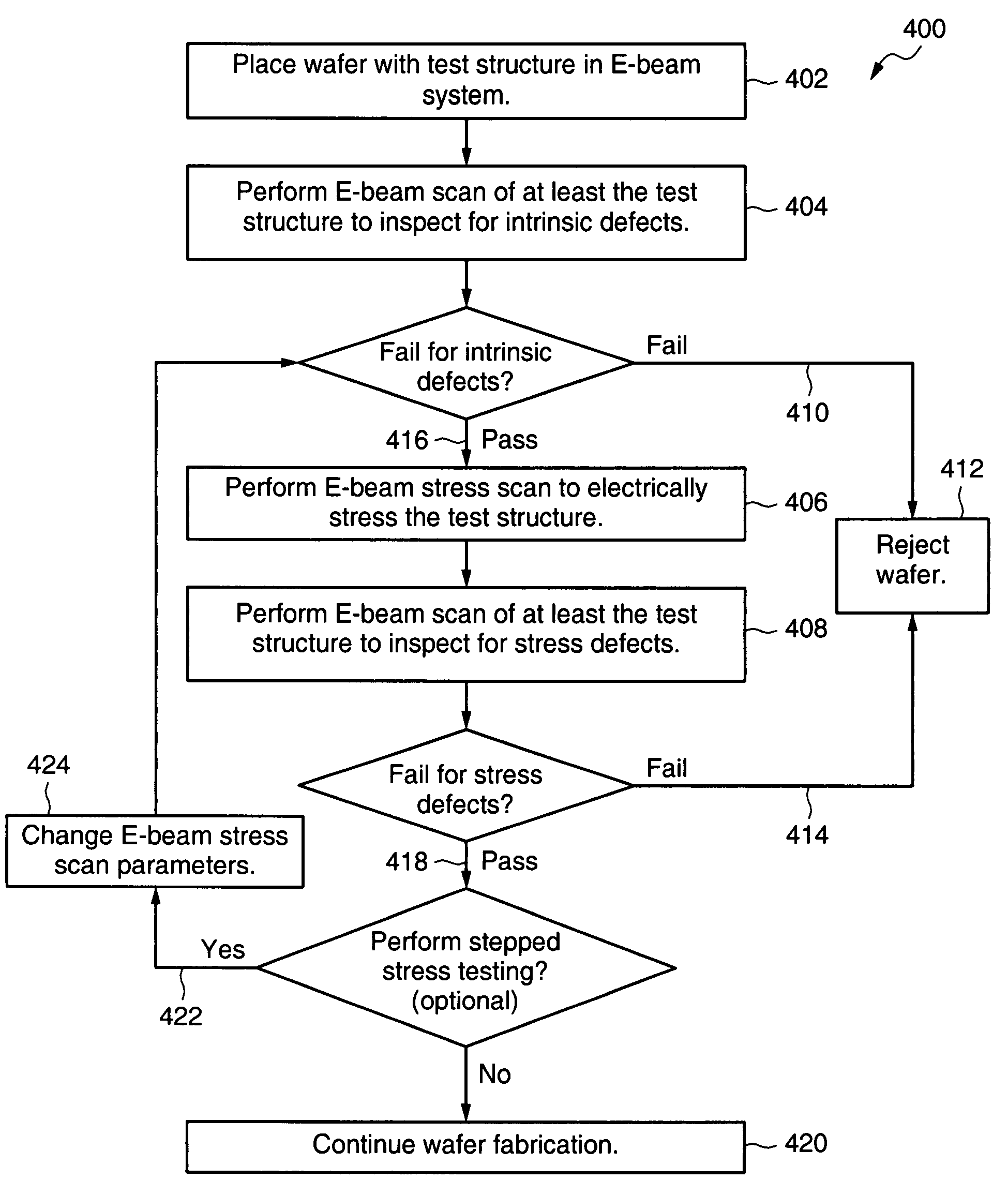

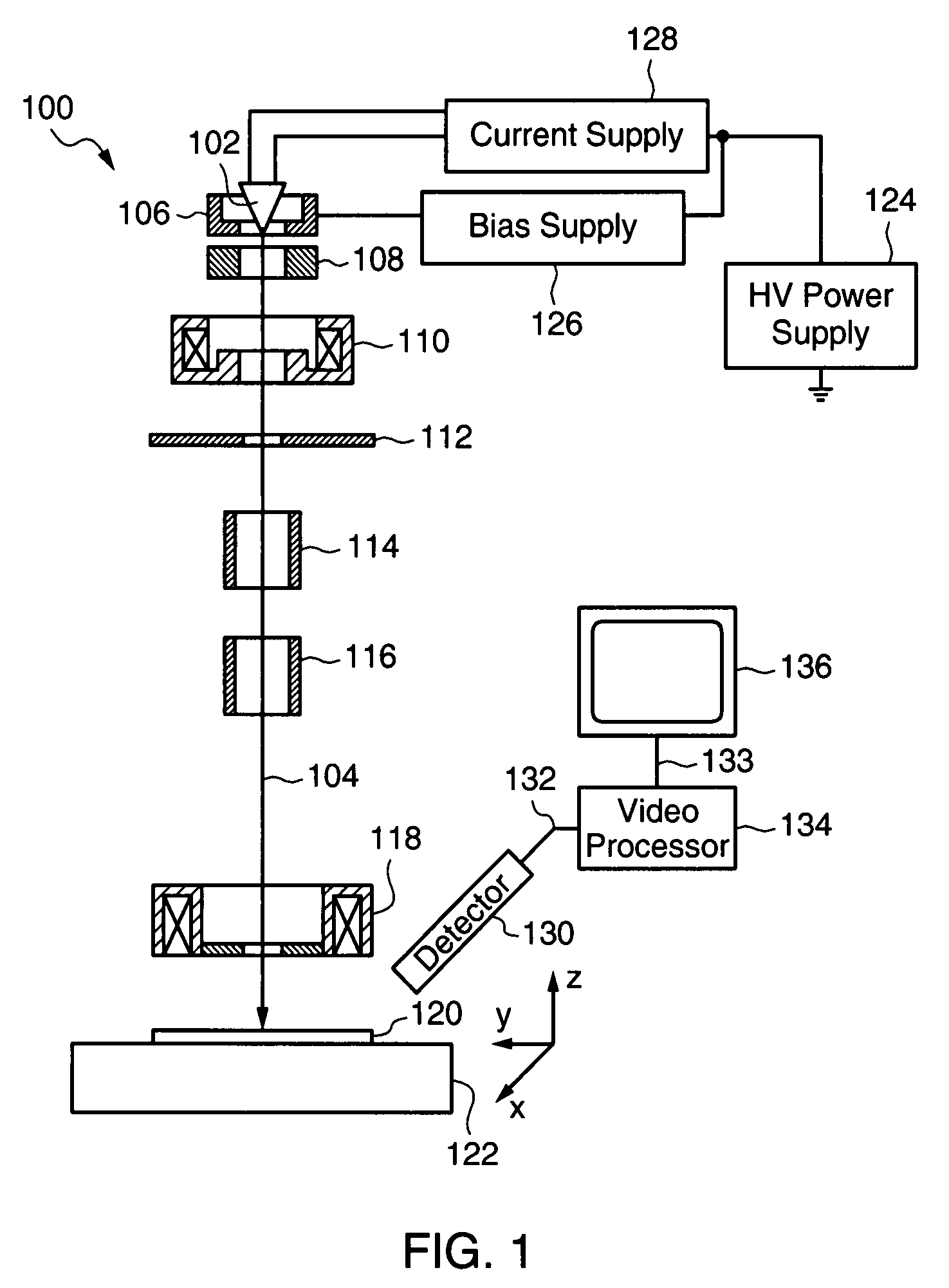

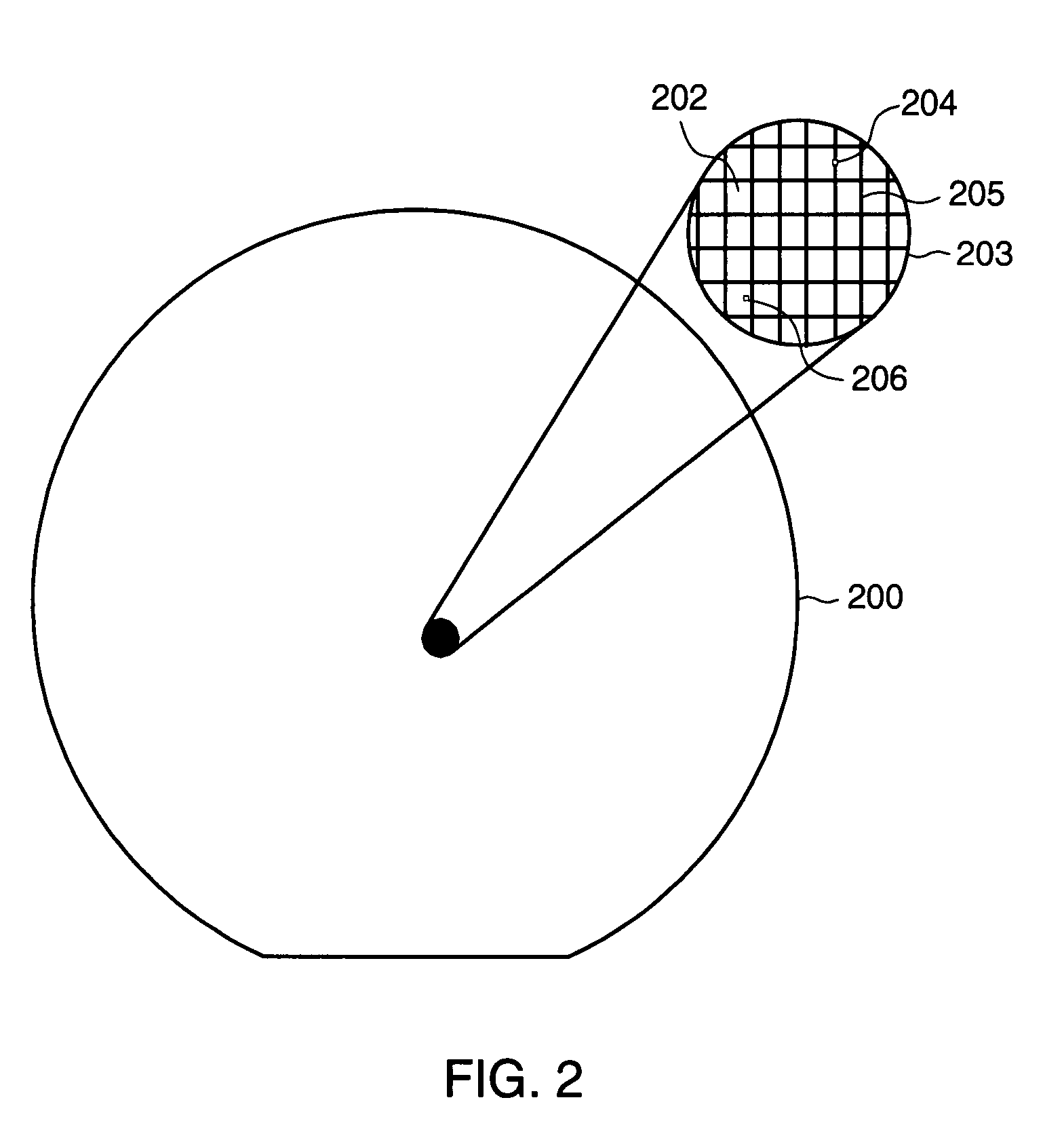

In-line reliability test using E-beam scan

ActiveUS7635843B1Material analysis using wave/particle radiationSemiconductor/solid-state device testing/measurementSemiconductorReliability engineering

A method of testing a semiconductor wafer having a test structure performs an E-beam stress scan of the test structure in an E-beam system to electrically stress the test structure to produce a stress defect. An inspection scan is performed in the E-beam system to identify the stress defect.

Owner:XILINX INC

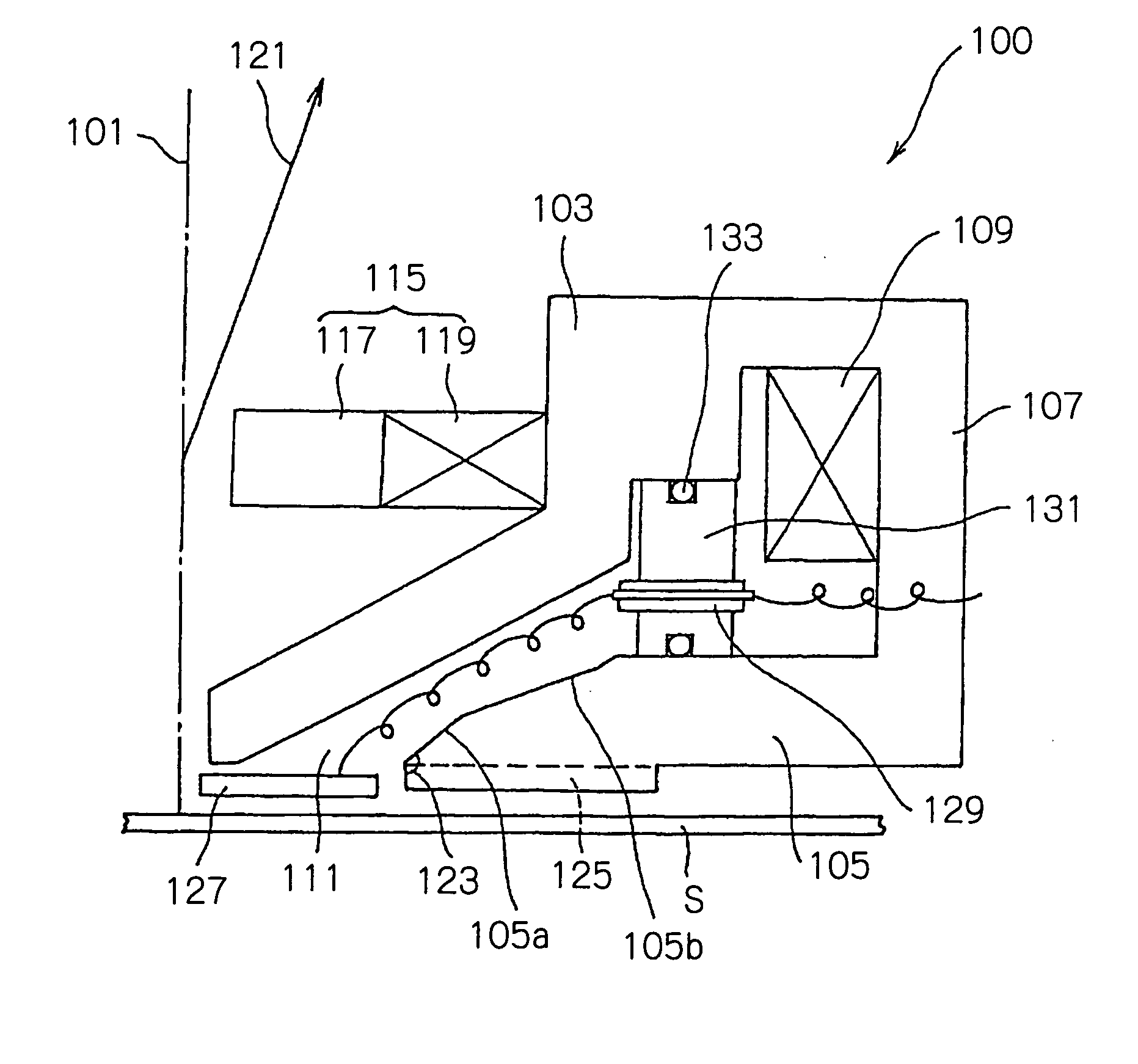

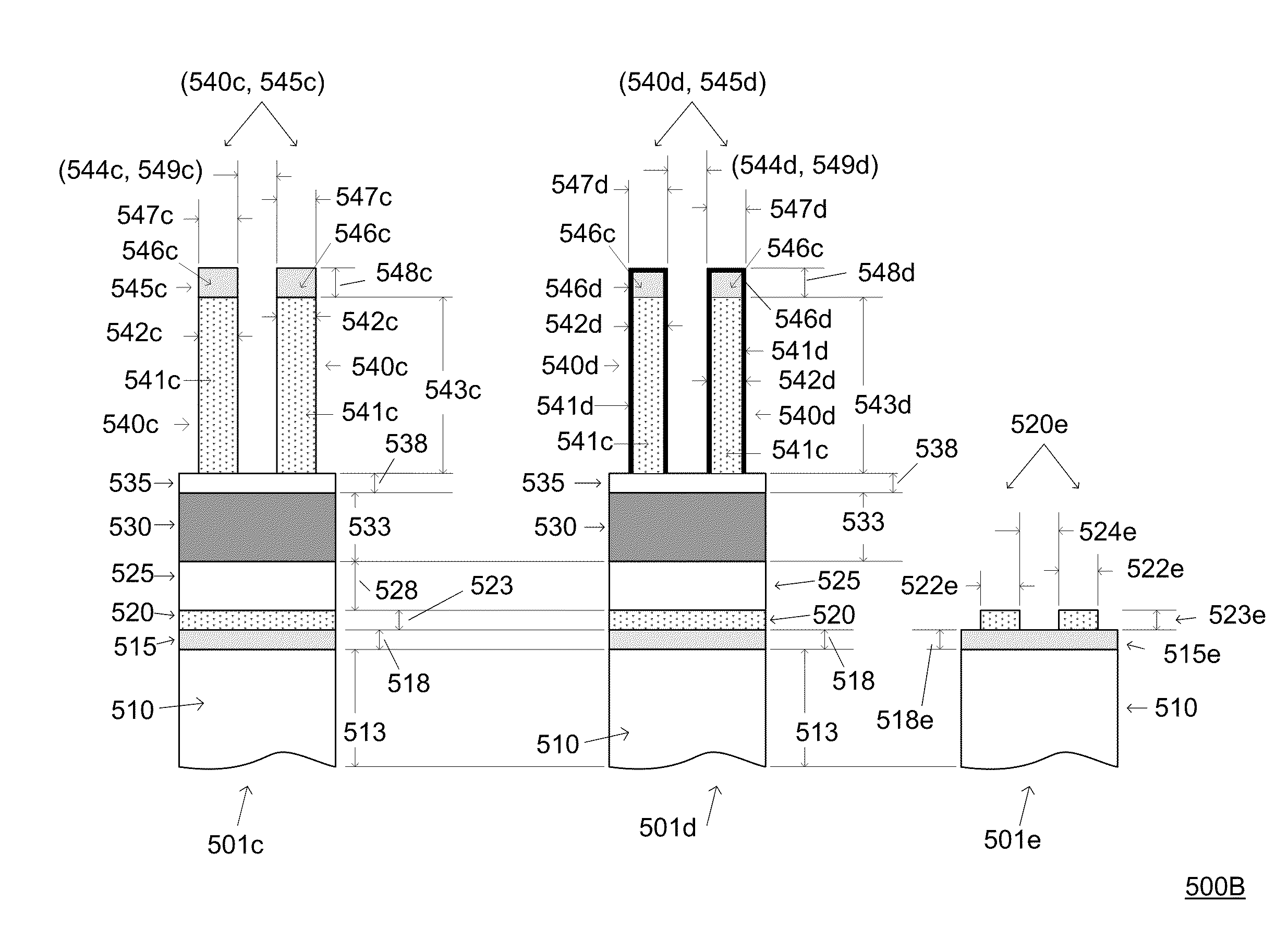

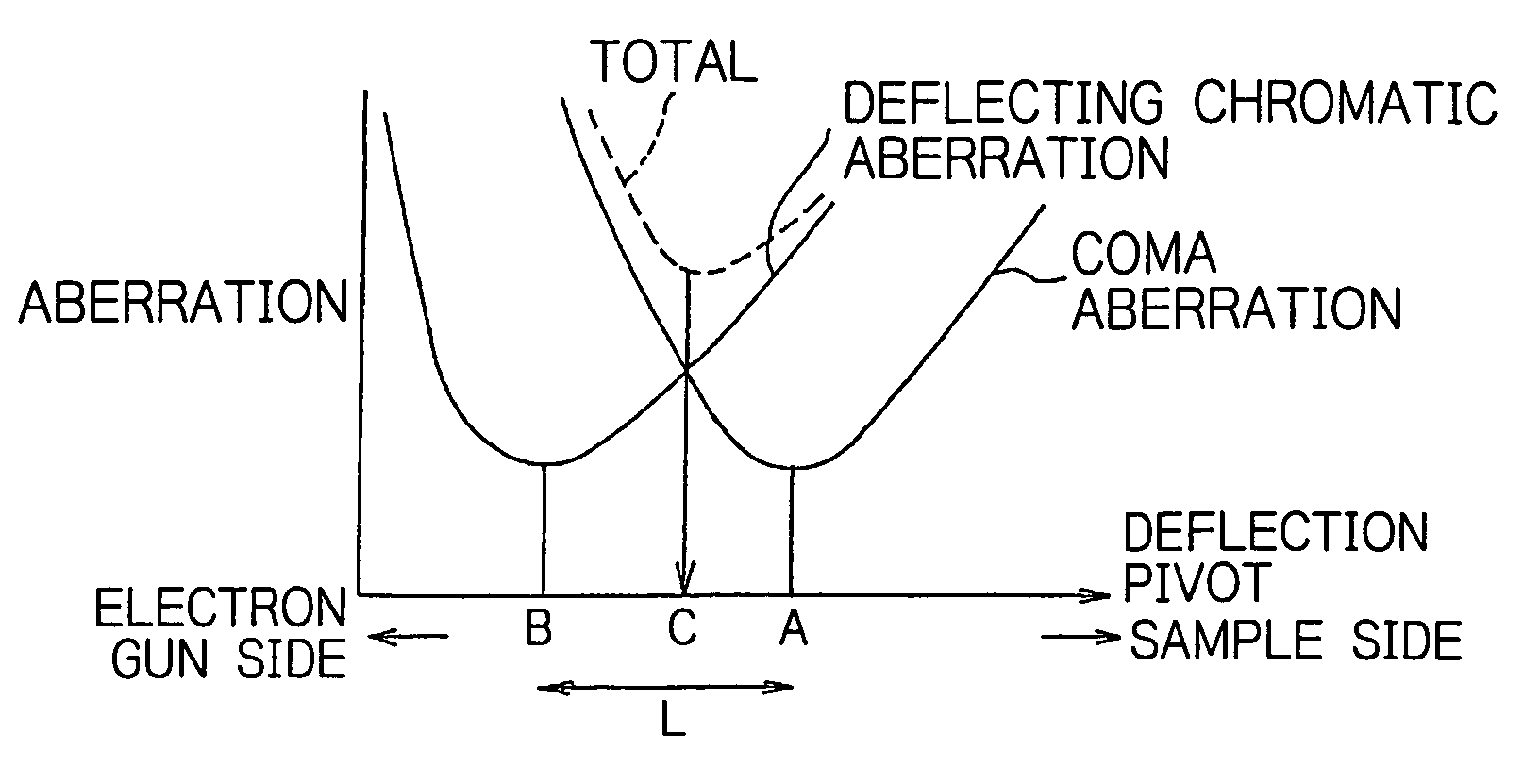

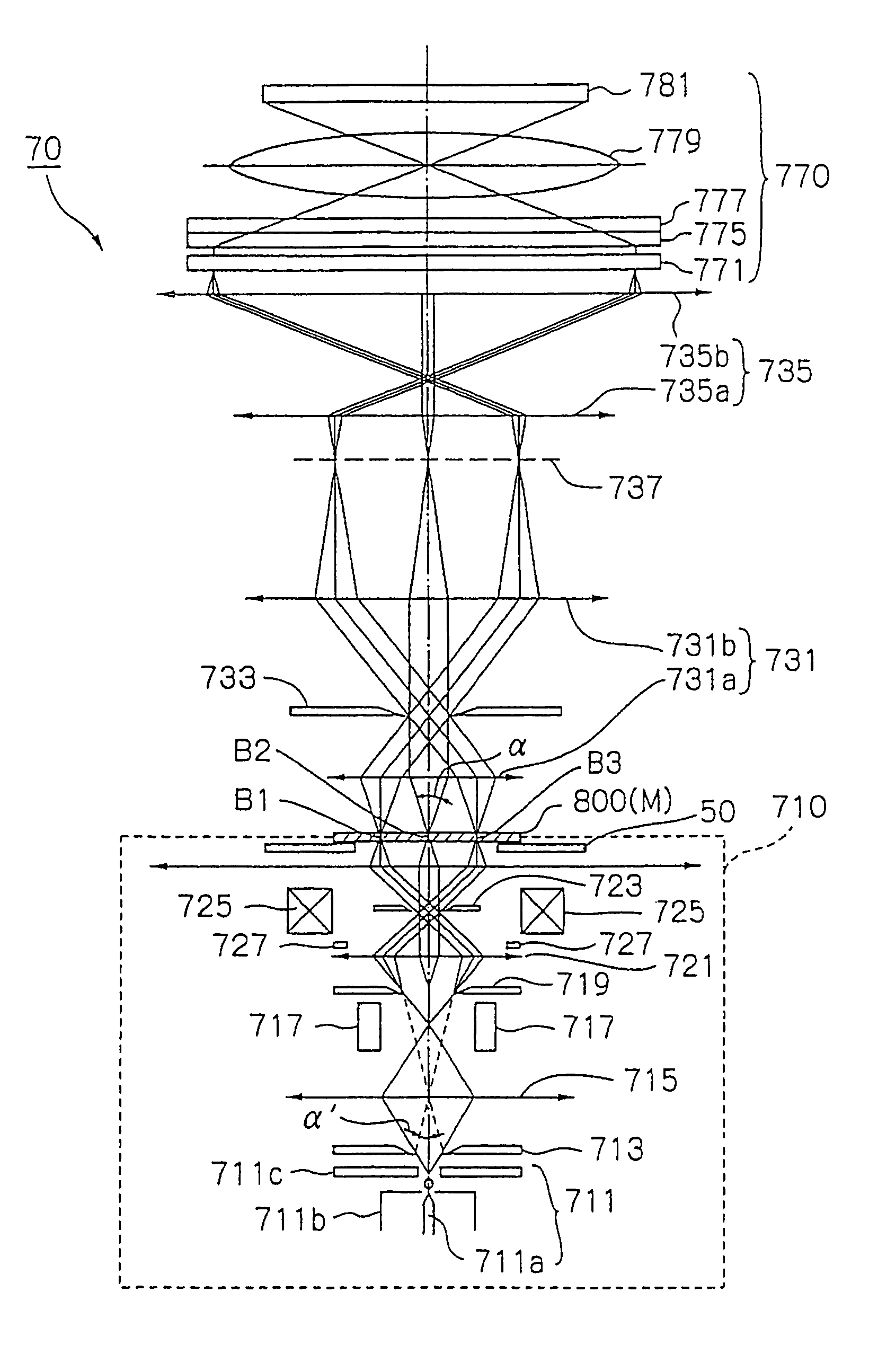

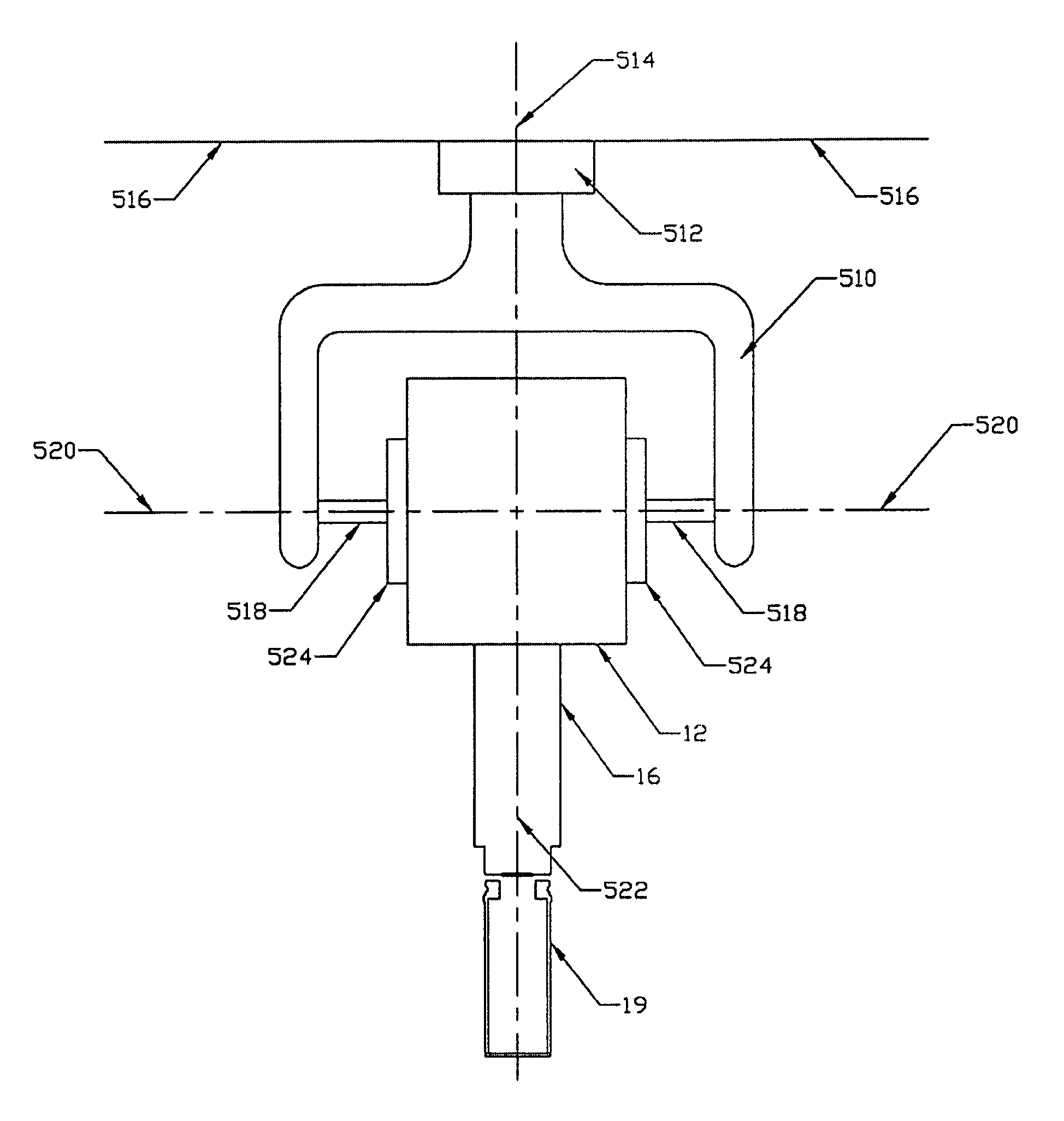

Objective lens, electron beam system and method of inspecting defect

InactiveUS20050263715A1Reduce penetrationIncrease in space charge effectMaterial analysis using wave/particle radiationElectric discharge tubesHigh current densityOptical axis

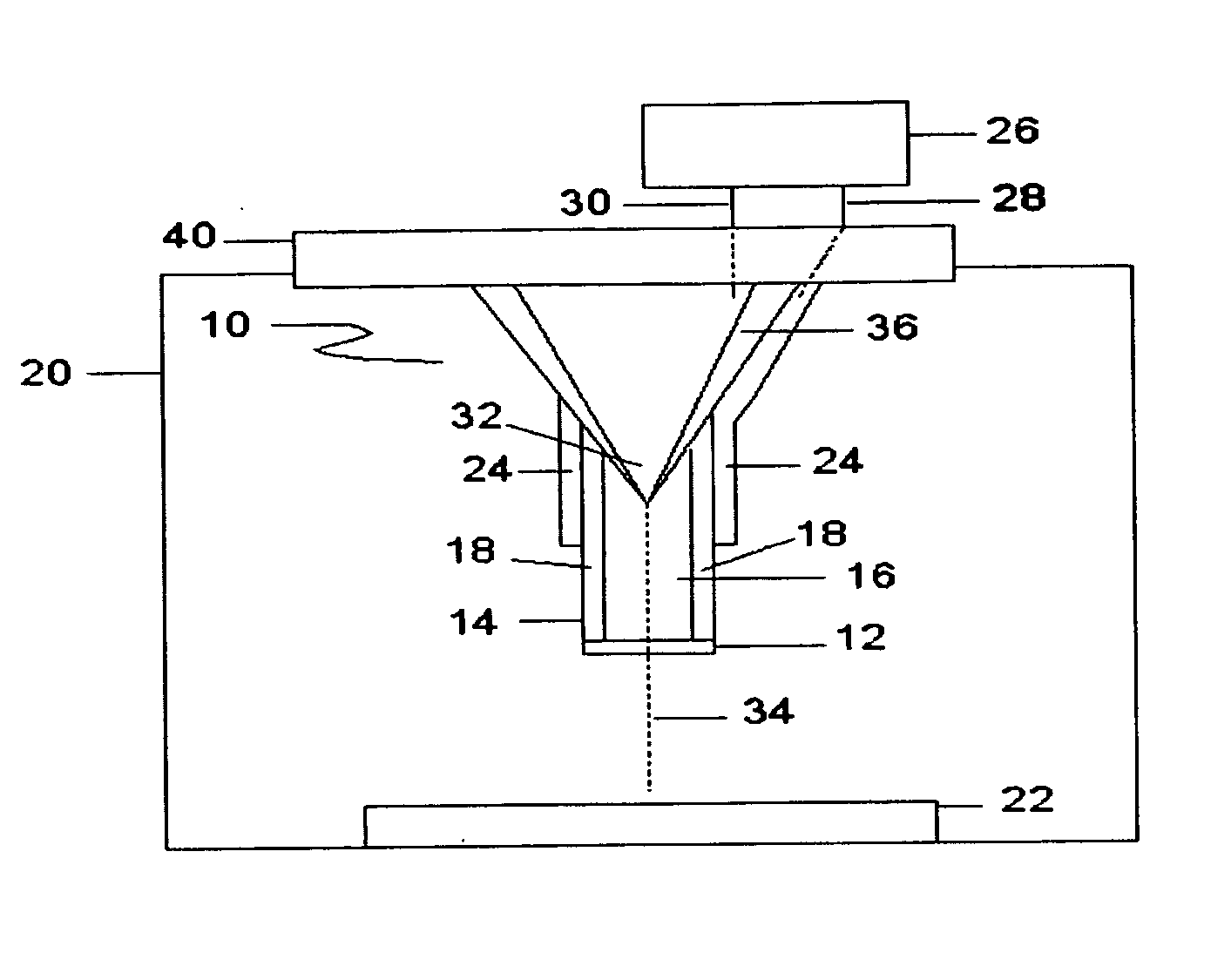

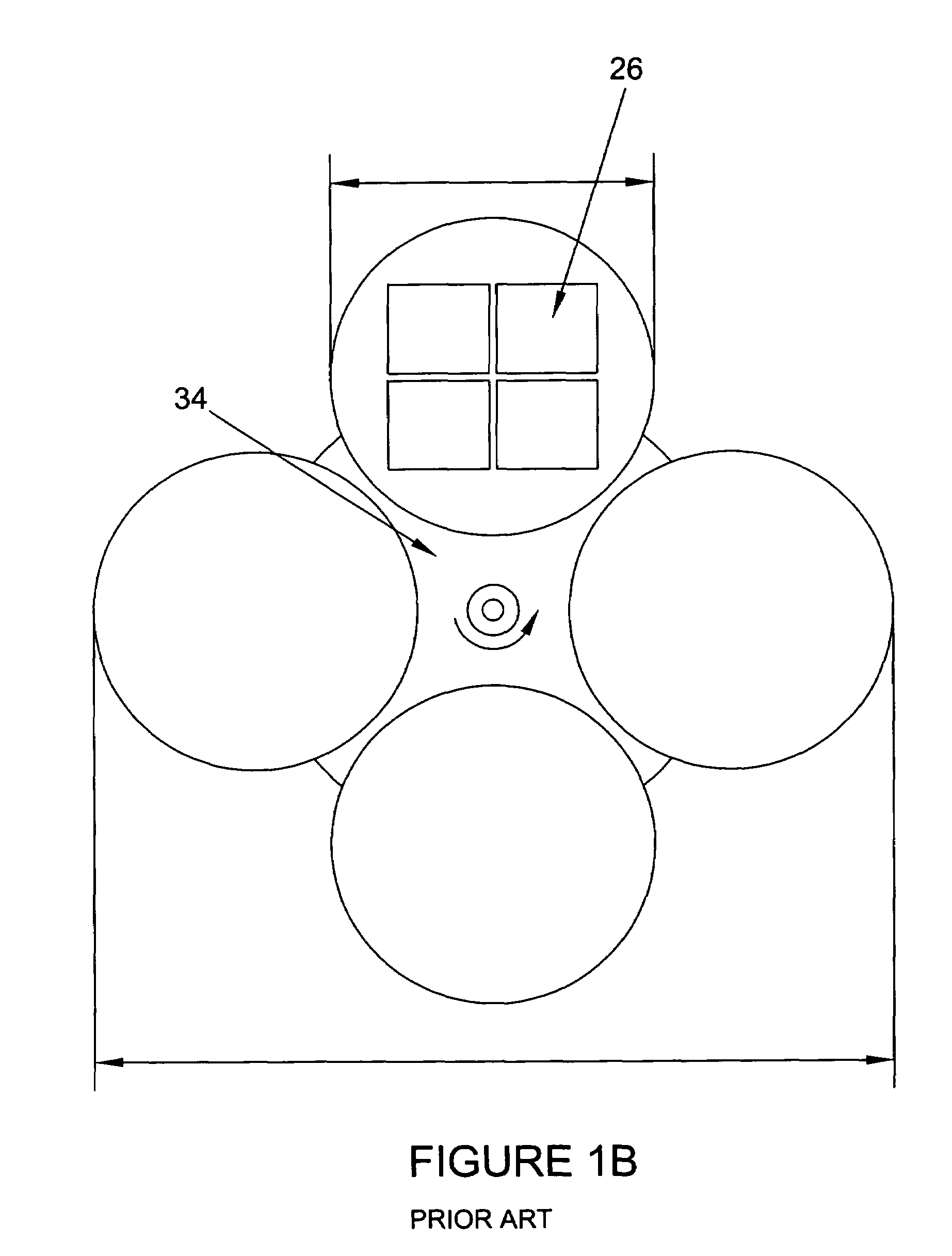

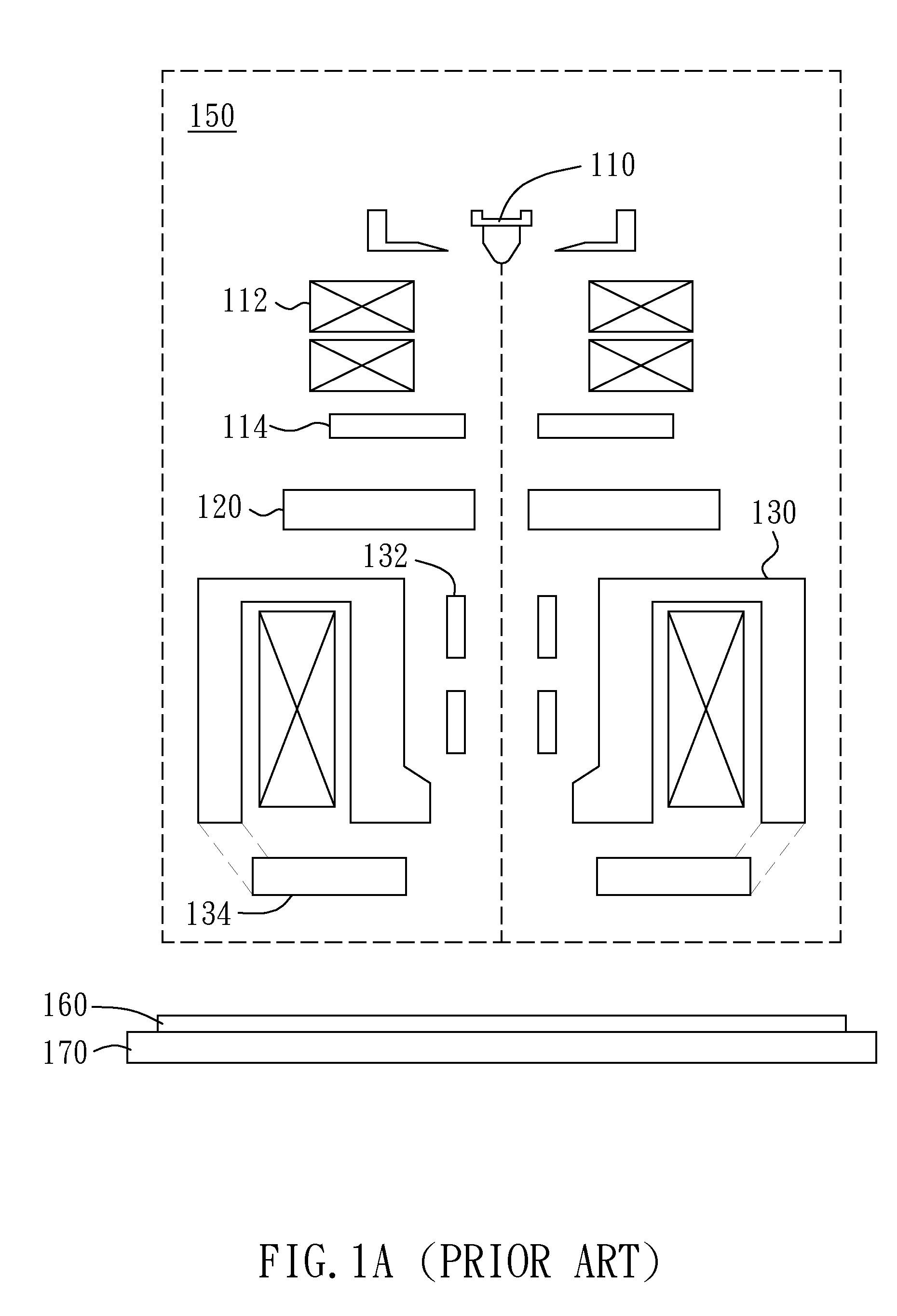

An electron beam system or a method for manufacturing a device using the electron beam system in which an electron beam can be irradiated at a high current density and a ratio of transmittance of a secondary electron beam of an image projecting optical system can be improved and which can be compact in size. The surface of the sample S is divided into plural stripe regions which in turn are divided into rectangle-shaped main fields. The main field is further divided into plural square-shaped subfields. The irradiation with the electron beams and the formation of a two-dimensional image are repeated in a unit of the subfields. A magnetic gap formed by the inner and outer magnetic poles of the objective lens is formed on the side of the sample, and an outer side surface and an inner side surface of each of the inner magnetic pole and the outer magnetic pole, respectively, forming the magnetic gap have each part of a conical shape with a convex having an angle of 45° or greater with respect to the optical axis.

Owner:EBARA CORP

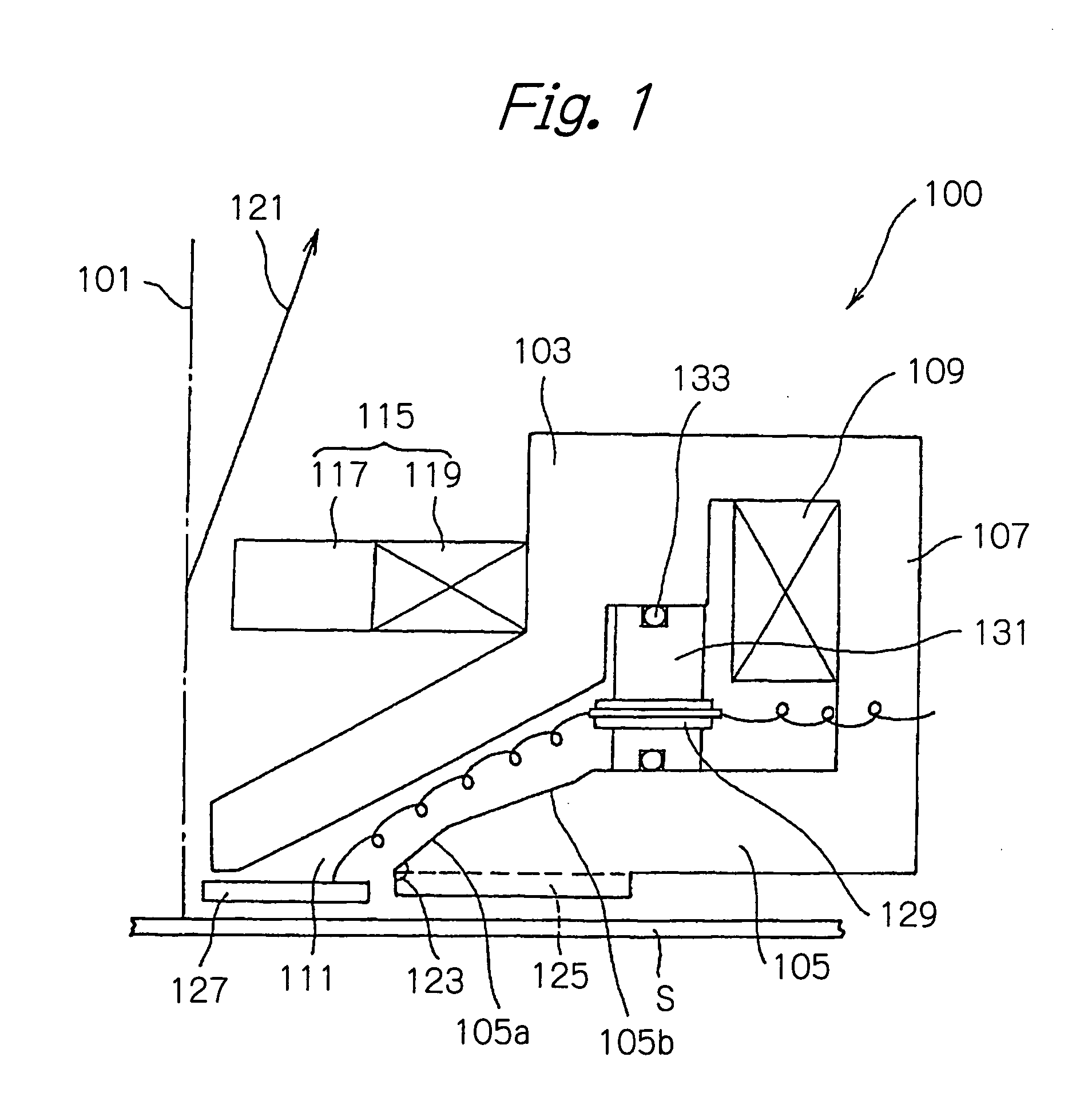

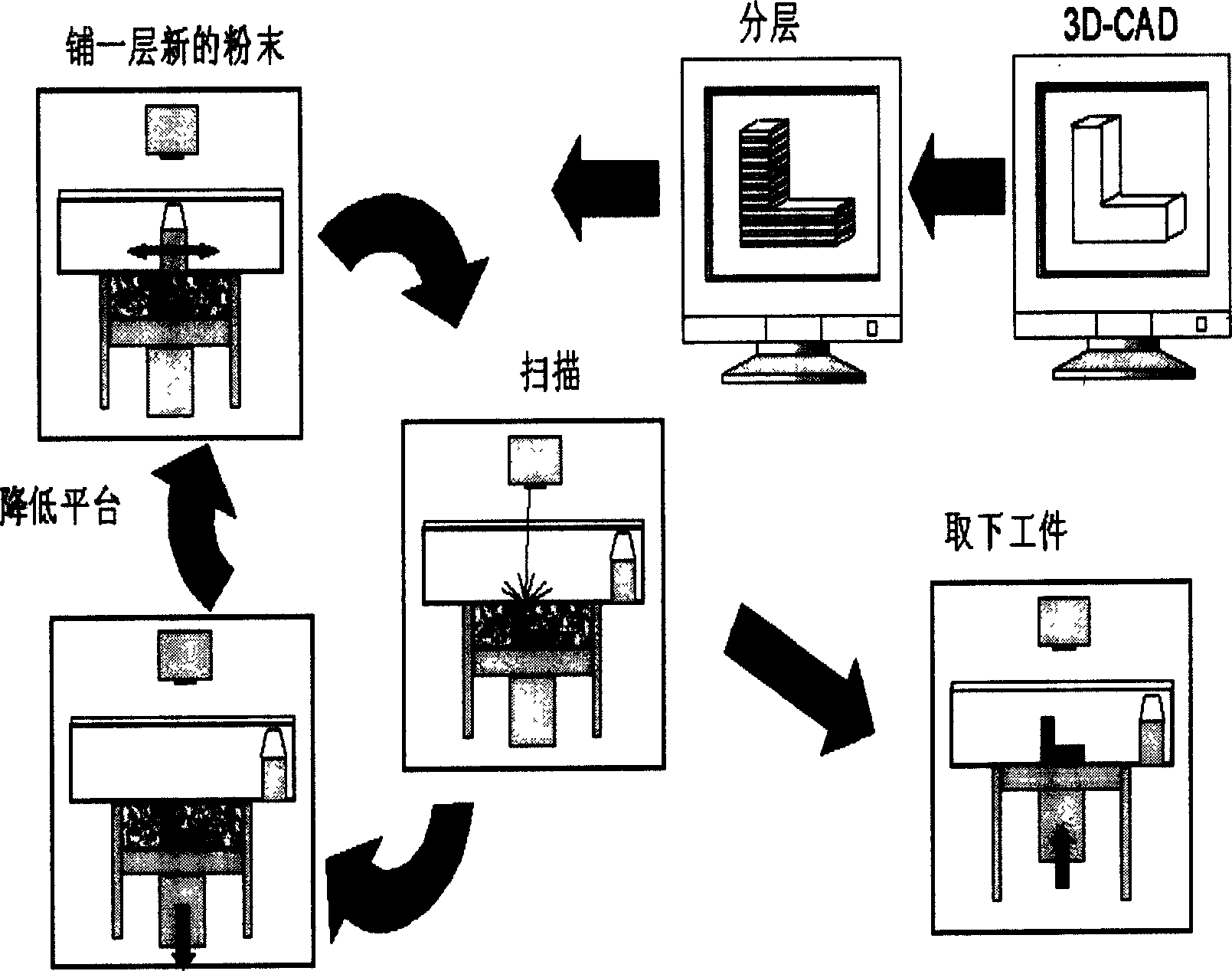

Selected zone laser melting and rapid forming method for metal parts and apparatus thereof

The invention relates to laser melting rapid forming method in the metal parts precinct and its installation. The method includes that setting CAD geometric model, doing stratification variance and laying powder layer by layer to the CAD geometric mode, adopting laser with high power density and high light speed factor of merit to form focusing facula with the diameter which is from thirty millimeter to fifty millimeter by focusing of beams system, melting the metal or alloy powder layer by layer, piling to a metallurgy unite, and forming to a compact solid mass. The installation is made up of semiconductor pumping YAG laser or fiber laser, focusing of beams system, shaped part jar, and powder jar. The semiconductor pumping YAG laser or fiber laser is light path connected to the focusing of beams system, and focalized and scanned at the shaped part jar. The shaped part jar is connected to the powder jar by powder laying roller. The powder laying roller is connected to the driving motor. And the driving motor is connected to the computer. The advantages of the invention are that the beam mode is good; mechanical features of the processed metal parts is well; the dimensional precision and the surface finish are high; and its range of application is wide.

Owner:SOUTH CHINA UNIV OF TECH

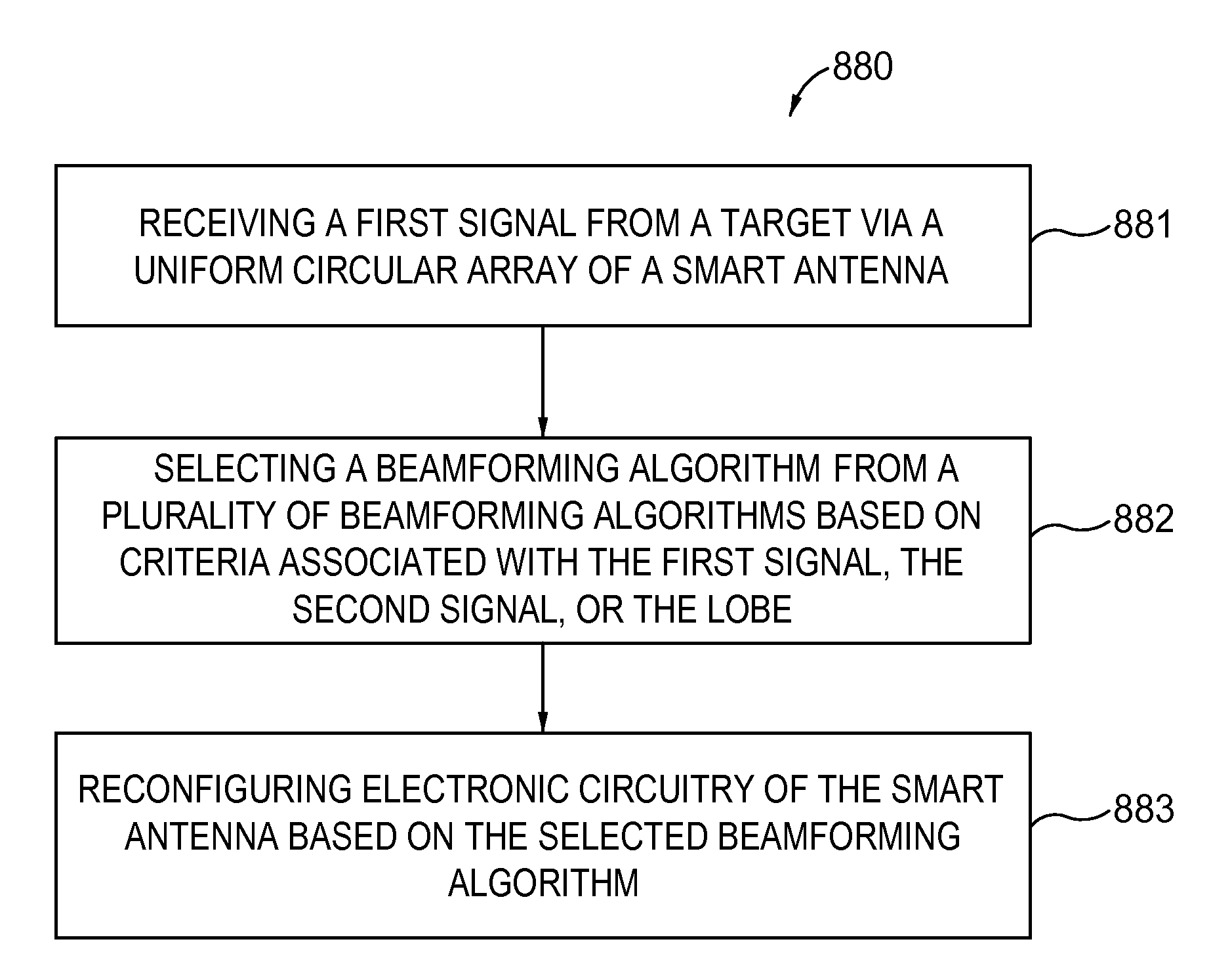

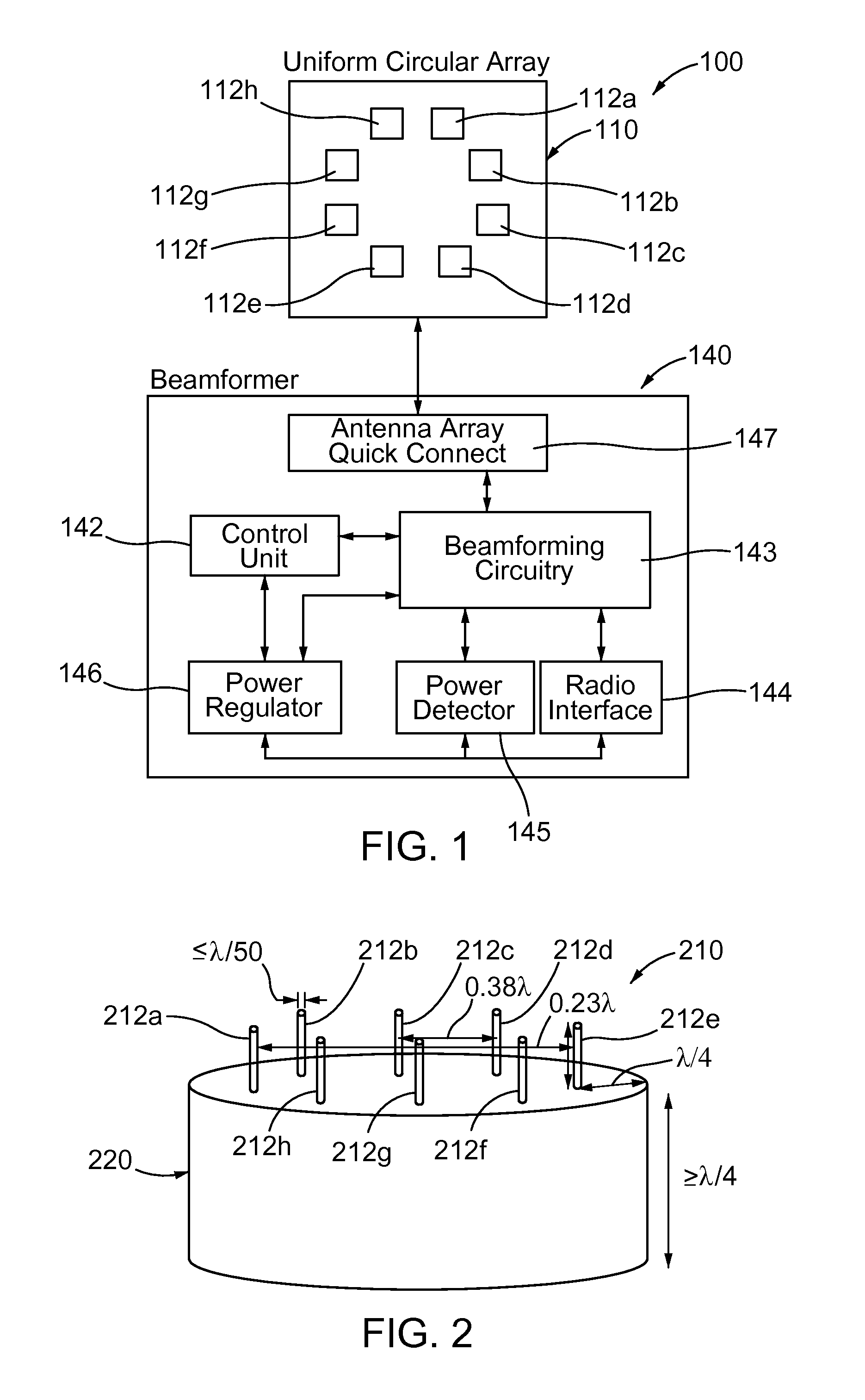

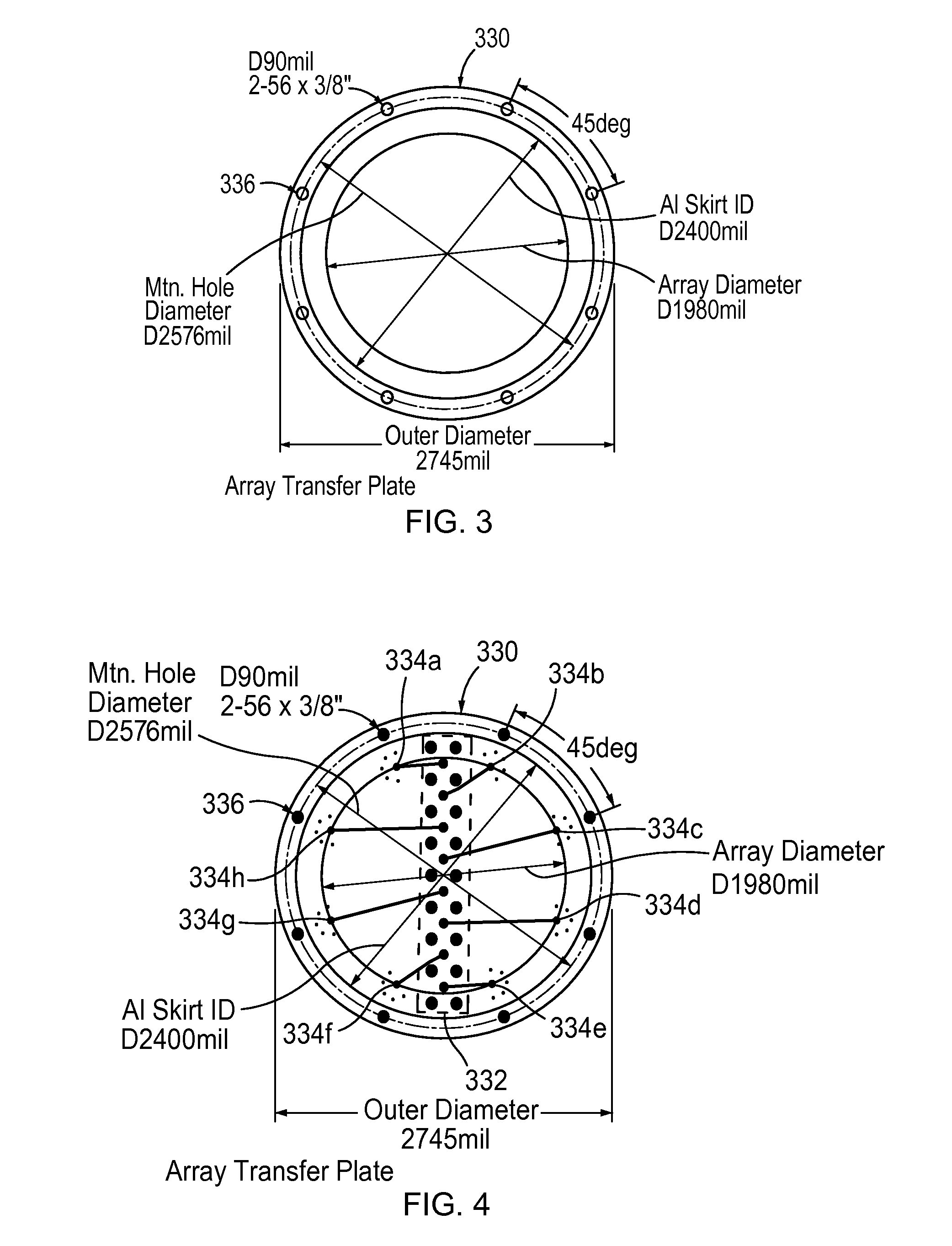

Compact smart antenna for mobile wireless communications

InactiveUS20120299765A1Suppress interferenceJam suppressionRadio transmissionIndividually energised antenna arraysLow noiseBand-pass filter

A compact, high gain 8-element circular smart antenna is able to scan a beam azimuthally through 360°. The 8-element array is placed on a ground skirt and connected to an 8-channel beamforning board via a transfer plate. Each channel has two T / R switches, one band pass filer, one power amplifier, two low noise amplifiers, one phase shifter, and one attenuator. The 8-channel-signal is combined through power splitters / combiners and then sent to a connected radio. An FPGA chip controls the digital phase shifters, attenuators and switches for signal searching, beamforming and tracking. The smart antenna can be operated as a compact switched beam system or with an additional processor as an adaptive array system. The smart antenna is capable of tracking mobile targets, directionally communicating with desired users, suppressing interference and jamming, and enabling long range communications with high throughput and reliable connection because of its high antenna gain.

Owner:MONTANA STATE UNIVERSITY +1

Switchable Neutral Beam Source

InactiveUS20110177694A1Easy to controlRemove roughnessElectric discharge tubesPhotomechanical apparatusBeam sourceLine width

The invention can provide apparatus and methods of processing a substrate in real-time using a switchable quasi-neutral beam system to improve the etch resistance of photoresist layer. In addition, the improved photoresist layer can be used in an etch procedure to more accurately control gate and / or spacer critical dimensions (CDs), to control gate and / or spacer CD uniformity, and to eliminate line edge roughness (LER) and line width roughness (LWR).

Owner:TOKYO ELECTRON LTD

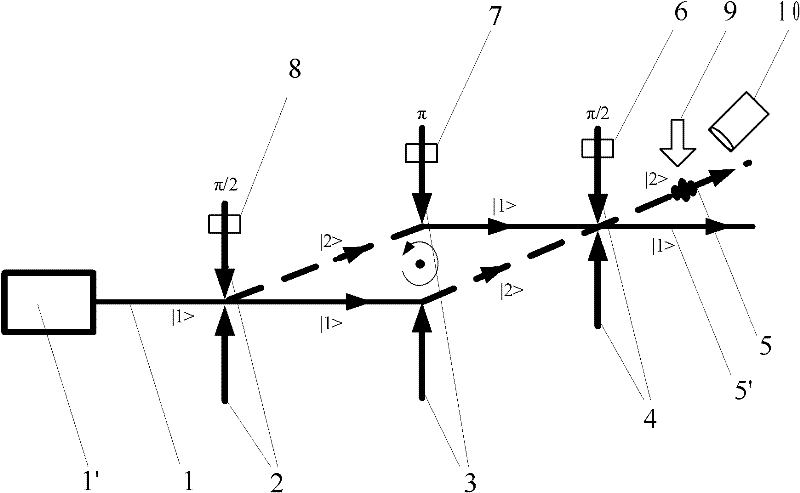

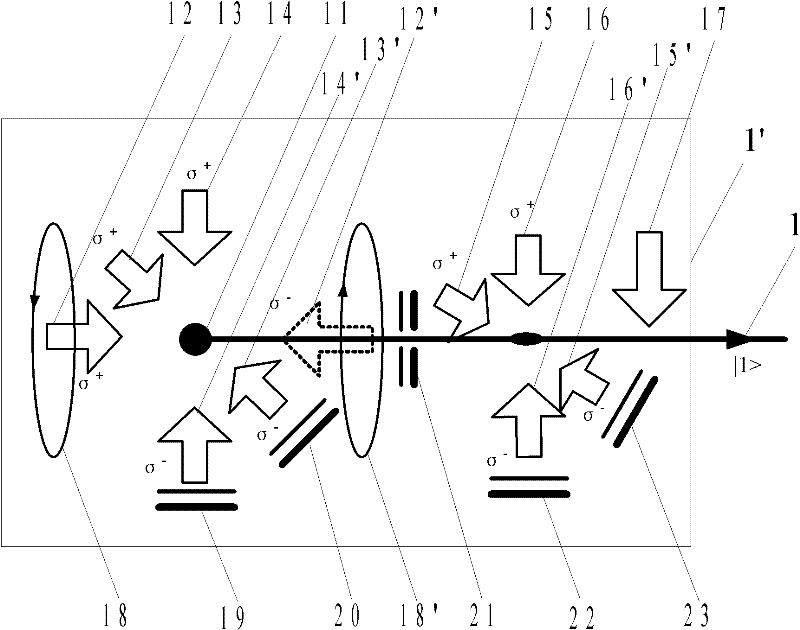

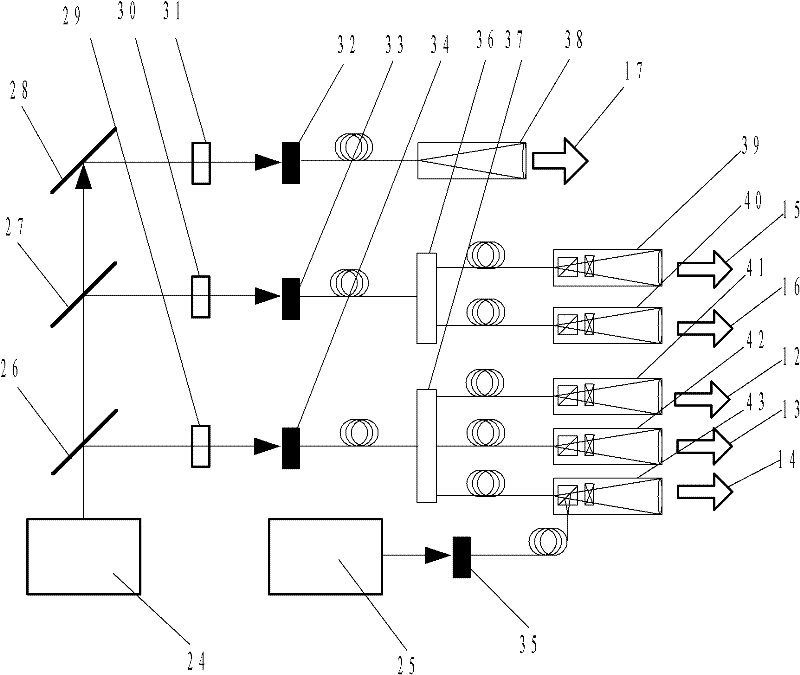

Cold atom beam interference gyro device

ActiveCN102538775AShorten speedExcellent optical propertiesSagnac effect gyrometersSpeed measurement using gyroscopic effectsGratingFluorescence

The invention discloses a cold atom beam interference gyro device, which comprises a cold atom beam system, a coherent atom beam operating system, and a gyro rotating signal extracting system. The cold atom beam system continuously emits | 1 > state cold atom beams as a matter wave source; the coherent atom beam operating system is composed of three gratings placed on the emitting path of | 1 > state cold atom beams in turn, and three phase modulators for modulating the phases of three gratings, respectively; | 1 > state cold atom beams orderly enter the three grating for splitting, reflecting and splitting again so as to obtain | 2 > energy state atom beam and | 1 > state cold atom beam interference signals; the | 2 > energy state atom beam interference signals are induced to produce fluorescent signals by the probing laser of the gyro rotating signal extracting system, a photoelectric detecting device detects the fluorescent signals and transmits the signals to a computer for processing to obtain gyro rotating angular-speed signals. With this device disclosed by the invention, high-precision gyro absolute rotating signals relative to inertial space and with high requirement on environment can be obtained.

Owner:TSINGHUA UNIV

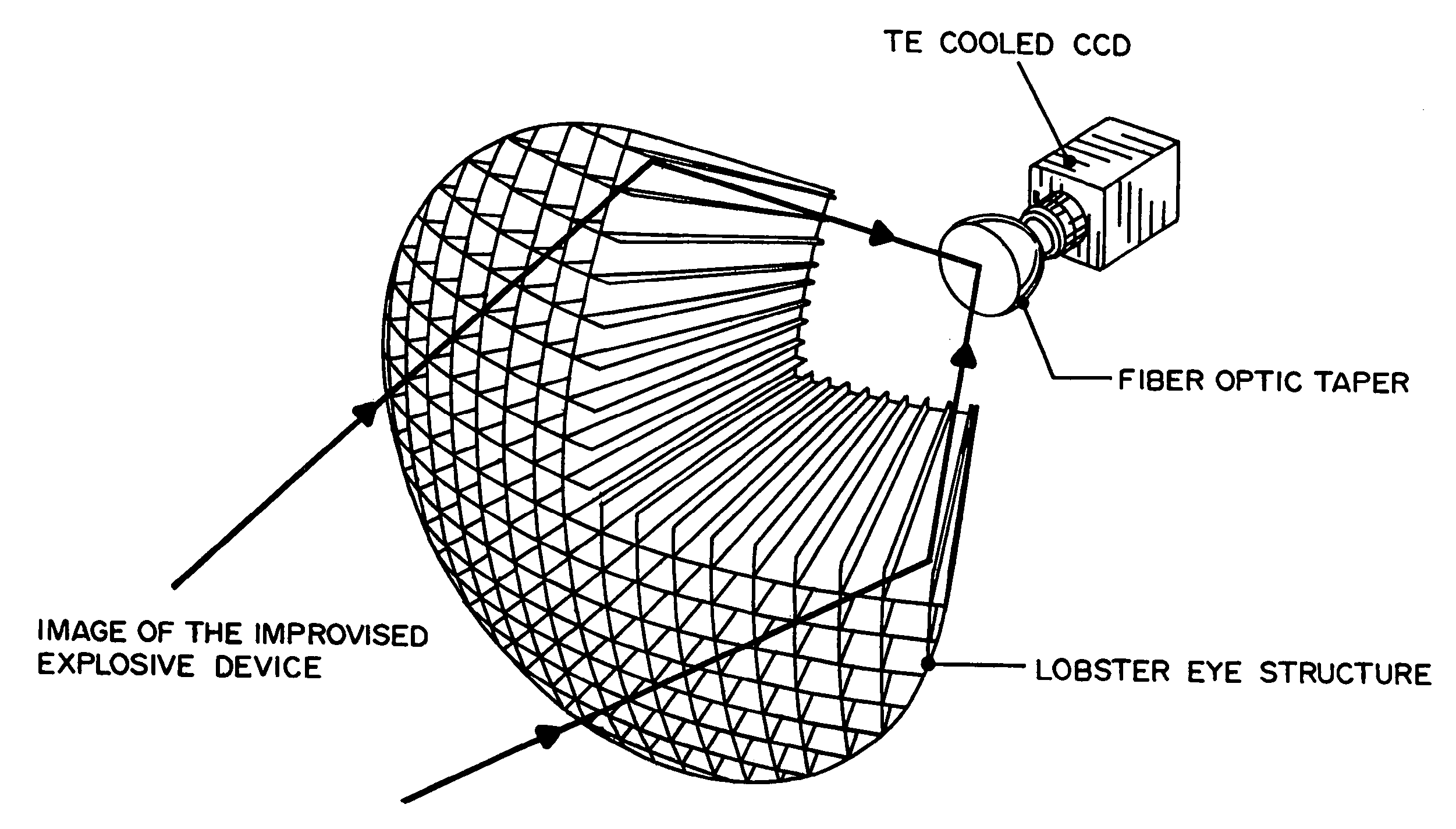

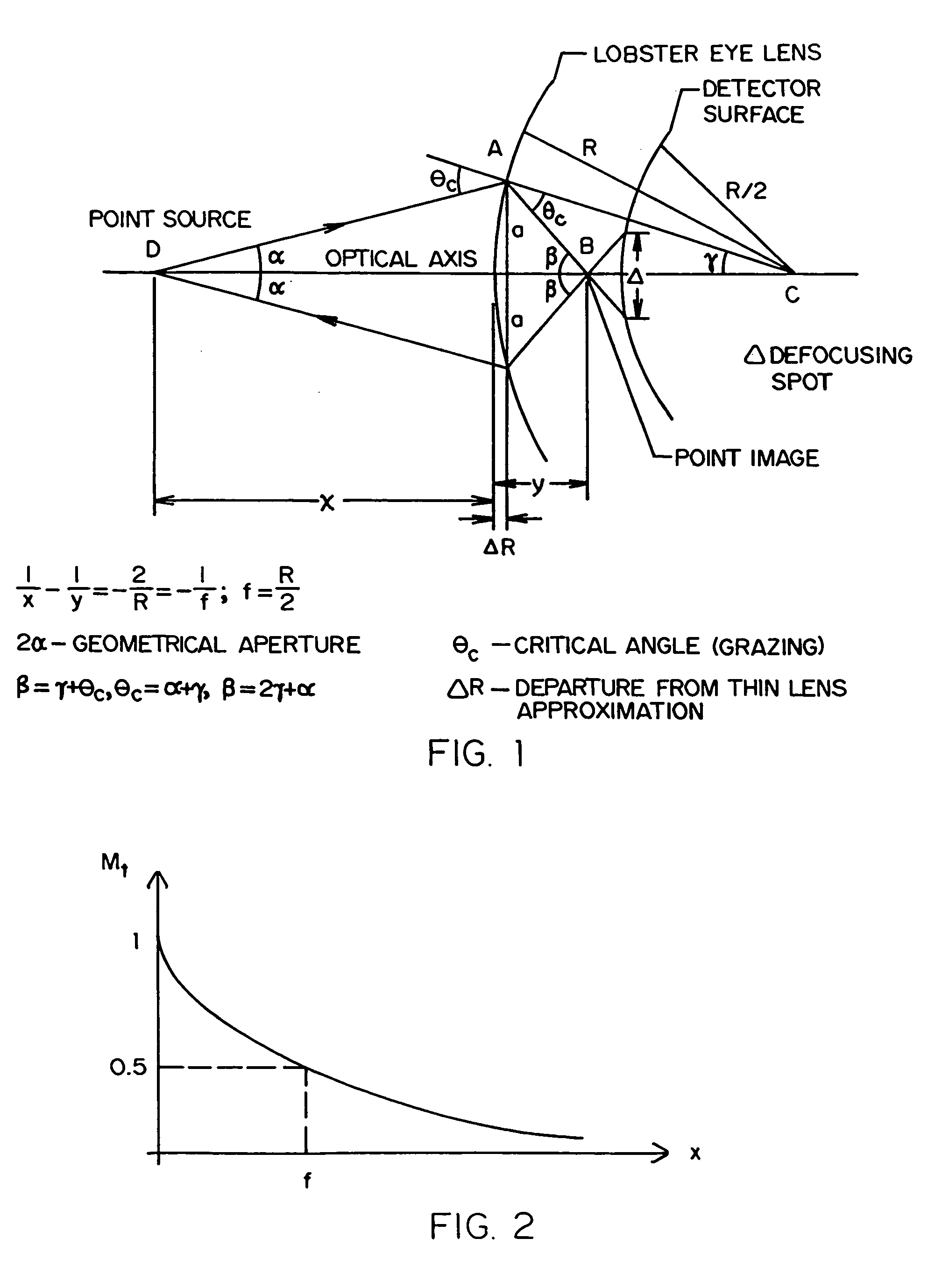

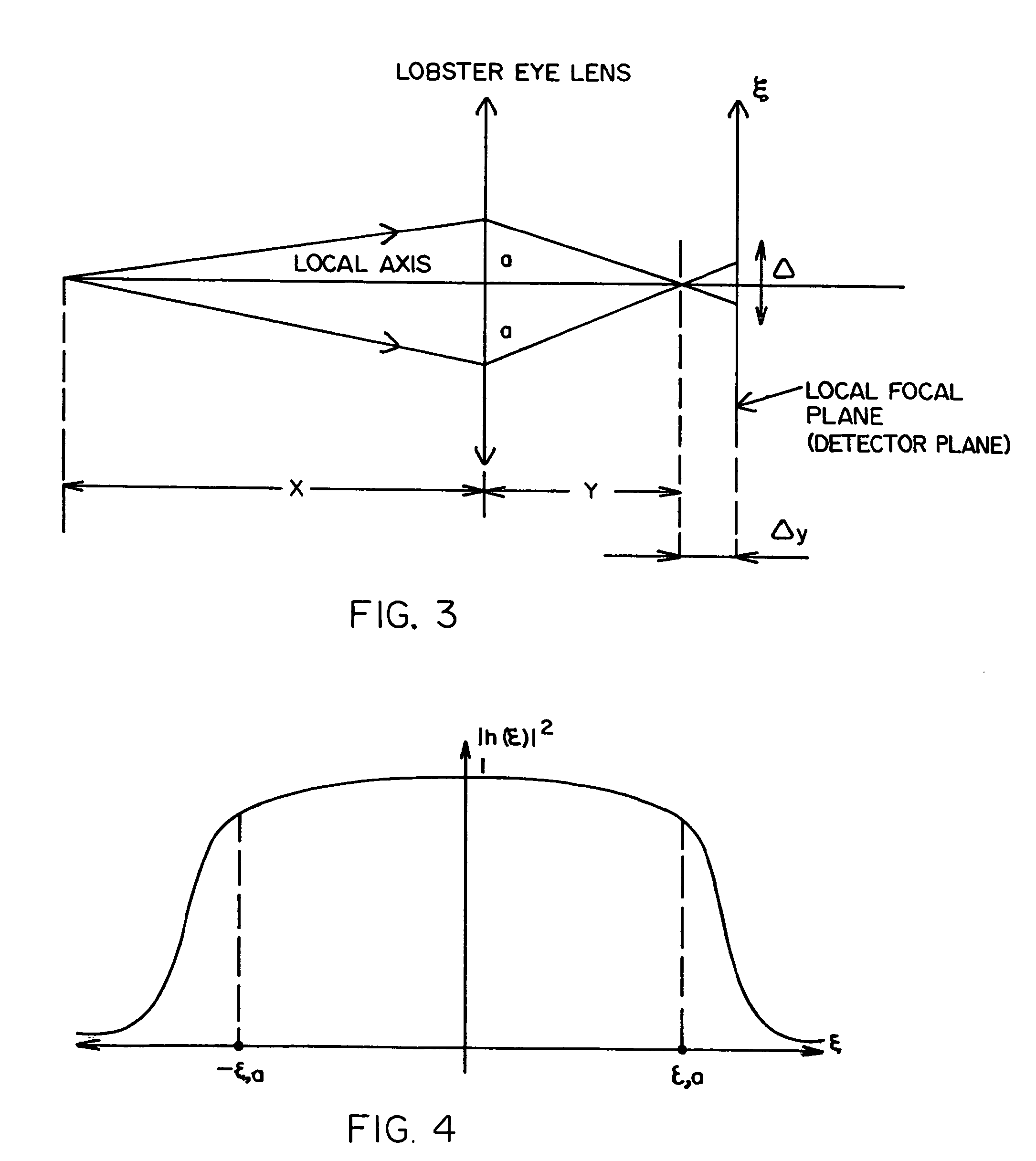

Lobster eye X-ray imaging system and method of fabrication thereof

ActiveUS7231017B2Raise the ratioHigh sensitivityMaterial analysis using wave/particle radiationElectrode and associated part arrangementsHard X-raysBackscatter X-ray

A Lobster Eye X-ray Imaging System based on a unique Lobster Eye (LE) structure, X-ray generator, scintillator-based detector and cooled CCD (or Intensified CCD) for real-time, safe, staring Compton backscatter X-ray detection of objects hidden under ground, in containers, behind walls, bulkheads etc. In contrast to existing scanning pencil beam systems, Lobster Eye X-Ray Imaging System's true focusing X-ray optics simultaneously acquire ballistic Compton backscattering photons (CBPs) from an entire scene irradiated by a wide-open cone beam from one or more X-ray generators. The Lobster Eye X-ray Imaging System collects (focuses) thousands of times more backscattered hard X-rays in the range from 40 to 120 keV (or wavelength λ=0.31 to 0.1 Å) than current backscatter imaging sensors (BISs), giving high sensitivity and signal-to-noise ratio (SNR) and penetration through ground, metal walls etc. The collection efficiency of Lobster Eye X-ray Imaging System is optimized to reduce emitted X-ray power and miniaturize the device. This device is especially advantageous for and satisfies requirements of X-ray-based inspection systems, namely, penetration of the X-rays through ground, metal and other material concealments; safety; and man-portability. The advanced technology disclosed herein is also applicable to medical diagnostics and military applications such as mine detection, security screening and a like.

Owner:MERCURY MISSION SYST LLC

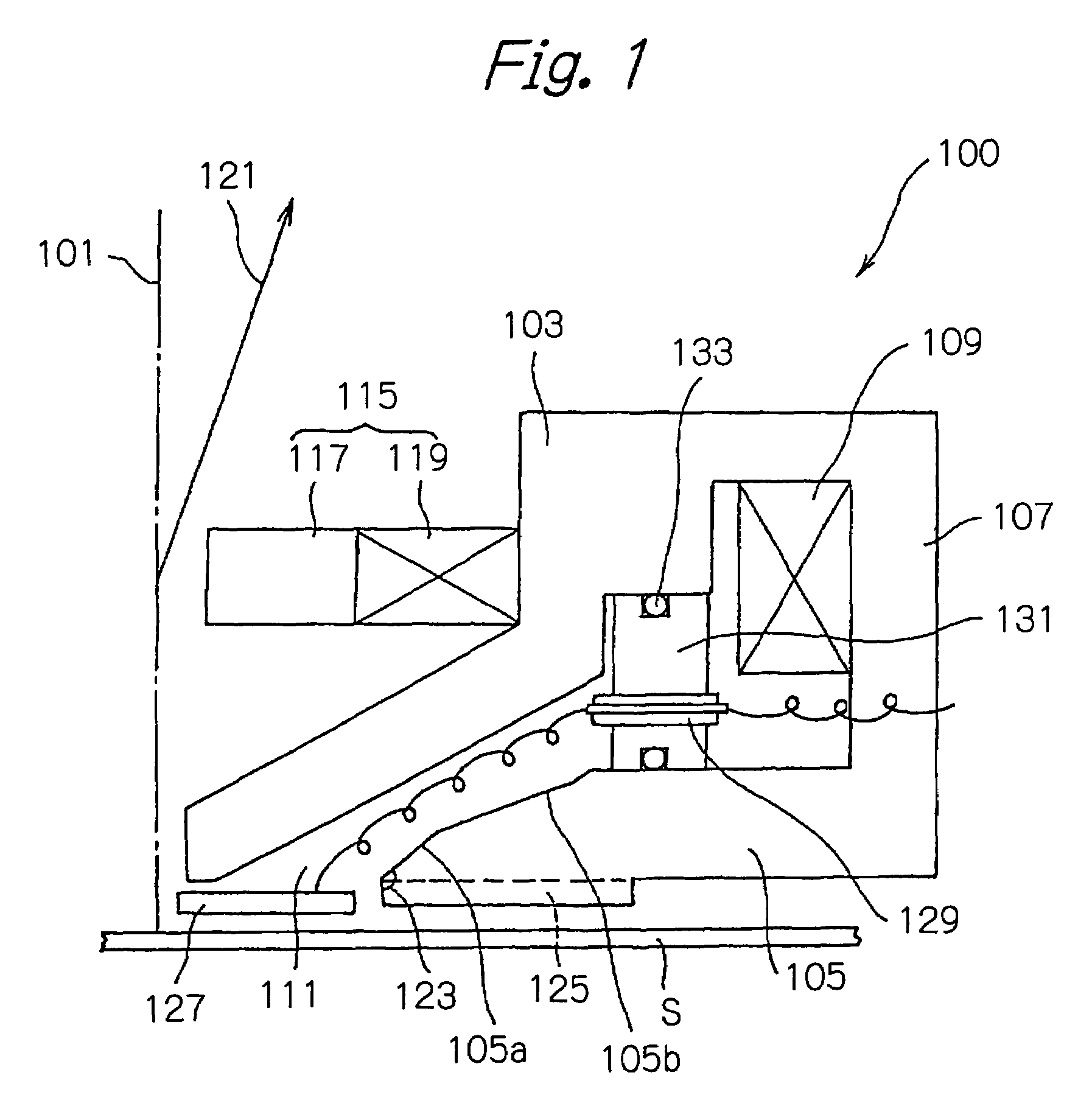

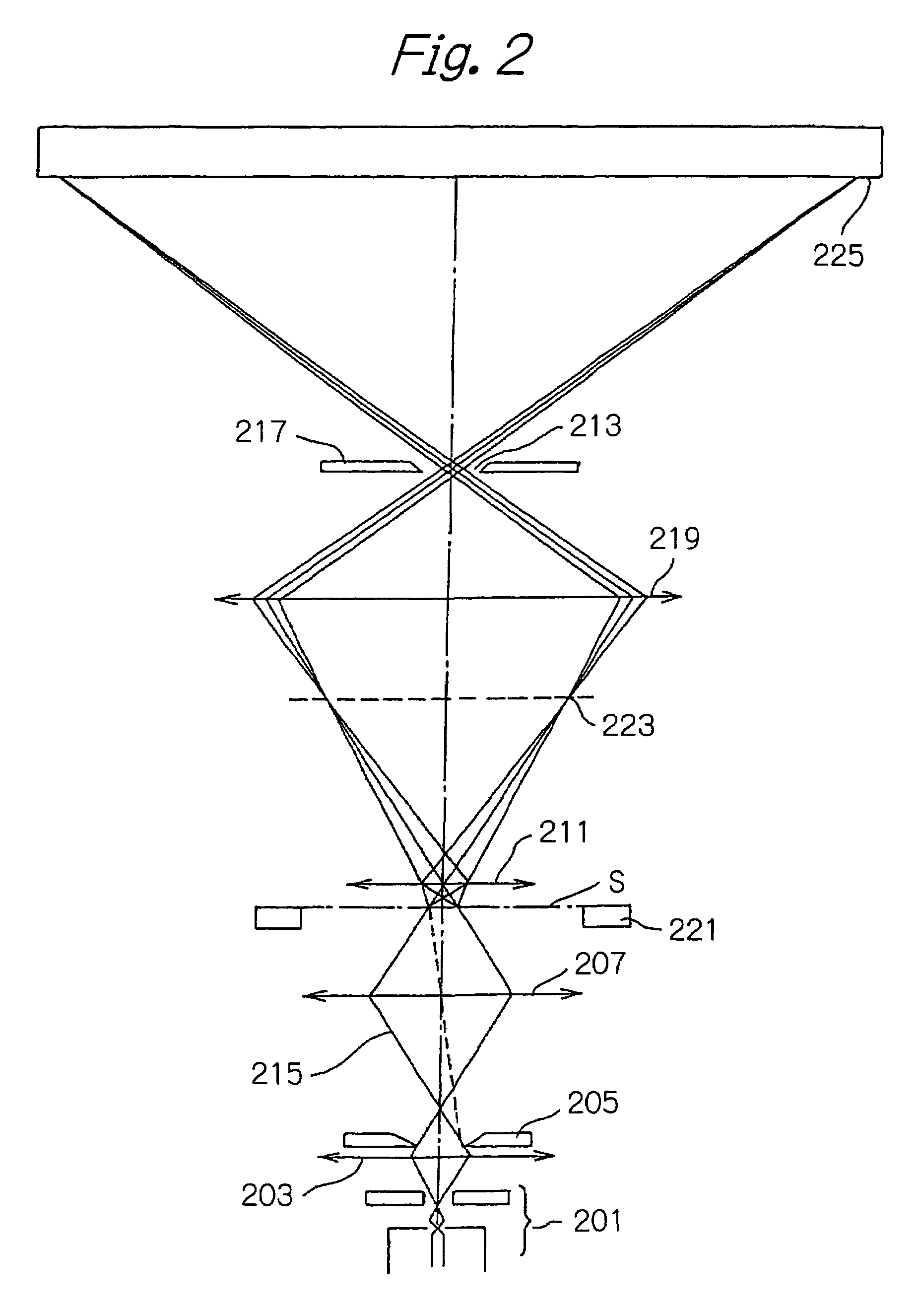

Objective lens, electron beam system and method of inspecting defect

InactiveUS7420164B2Improve throughputHigh currentMaterial analysis using wave/particle radiationElectric discharge tubesHigh current densityOptical axis

An electron beam system or a method for manufacturing a device using the electron beam system in which an electron beam can be irradiated at a high current density and a ratio of transmittance of a secondary electron beam of an image projecting optical system can be improved and which can be compact in size. The surface of the sample S is divided into plural stripe regions which in turn are divided into rectangle-shaped main fields. The main field is further divided into plural square-shaped subfields. The irradiation with the electron beams and the formation of a two-dimensional image are repeated in a unit of the subfields. A magnetic gap formed by the inner and outer magnetic poles of the objective lens is formed on the side of the sample, and an outer side surface and an inner side surface of each of the inner magnetic pole and the outer magnetic pole, respectively, forming the magnetic gap have each part of a conical shape with a convex having an angle of 45° or greater with respect to the optical axis.

Owner:EBARA CORP

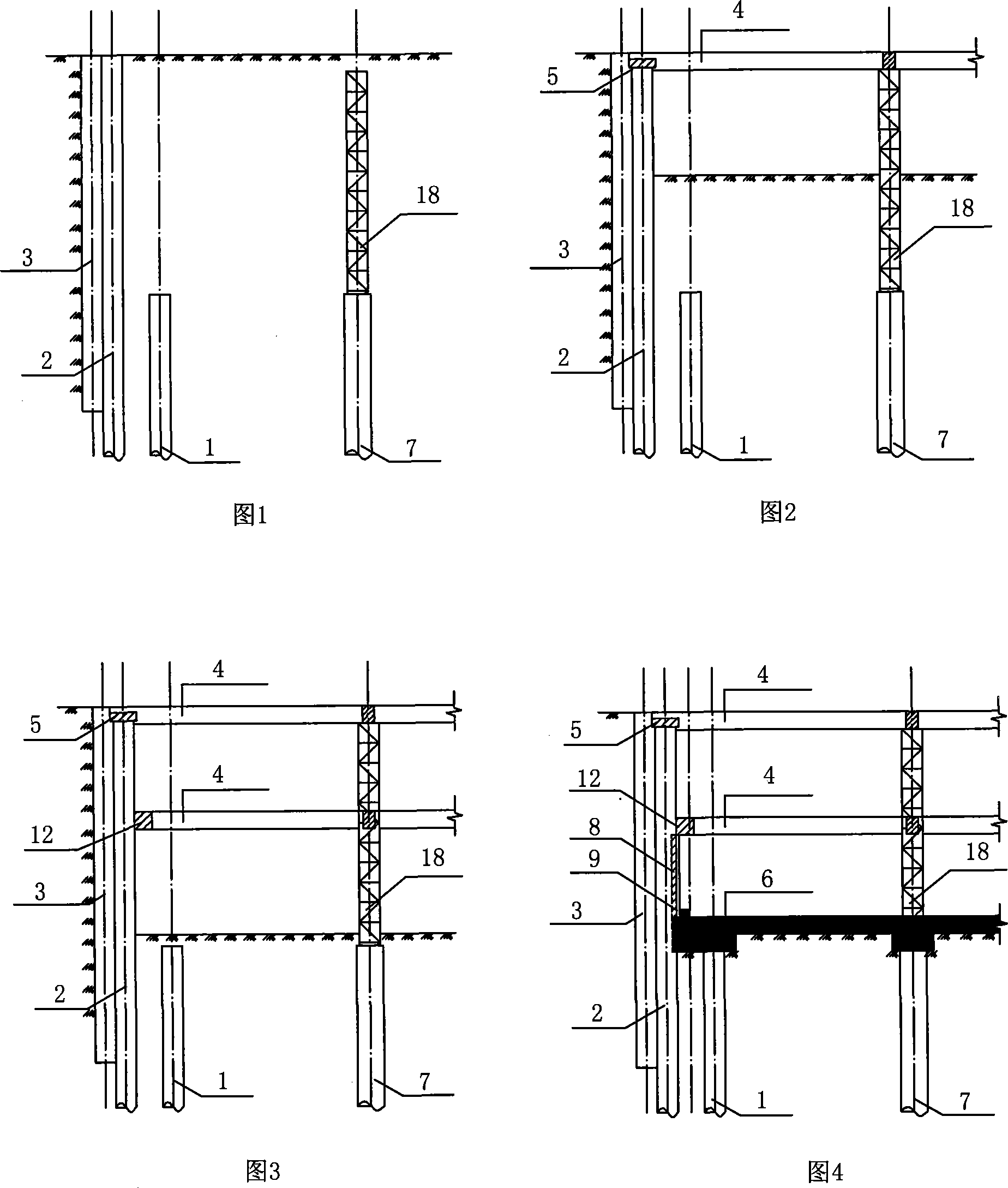

Underground engineering one-pile multi-use semi reverse construction method

InactiveCN101117805ALow costEasy constructionArtificial islandsUnderwater structuresBasementSlurry wall

The present invention relates to a method for one pile for a plurality of applications for semi-reversal construction for the underground engineering. A traditional temporary enclosure support system of the underground engineering can be taken as a main beam system of floors; in addition to traditional load bearing and floating resistance function, an internal engineering pile can be taken as an enclosure support pile and a reinforcement structure of columns for the future underground engineering; the surrounding enclosure employs tradition methods, in addition to the enclosure, the surrounding enclosure protection pile is taken as a surrounding engineering pile and the external wall of the future underground engineering; the support system concurrently the floor beam system are excavated from top to bottom, and an underground engineering bottom plate and floors is worked and bearing column and a wall body is loaded to the ground from bottom to top. The present invention has the beneficial effects that the present invention combines the support system and the basement main beam system: the middle engineering pile is taken as pressure bearing, floating resistance and supporting pile and bearing load column for the future basement. Compared with the full-reversal method for the underground continuous wall, the present invention has the advantages of saving project cost, convenient construction, simple construction equipment, etc.

Owner:ZHEJIANG UNIV +1

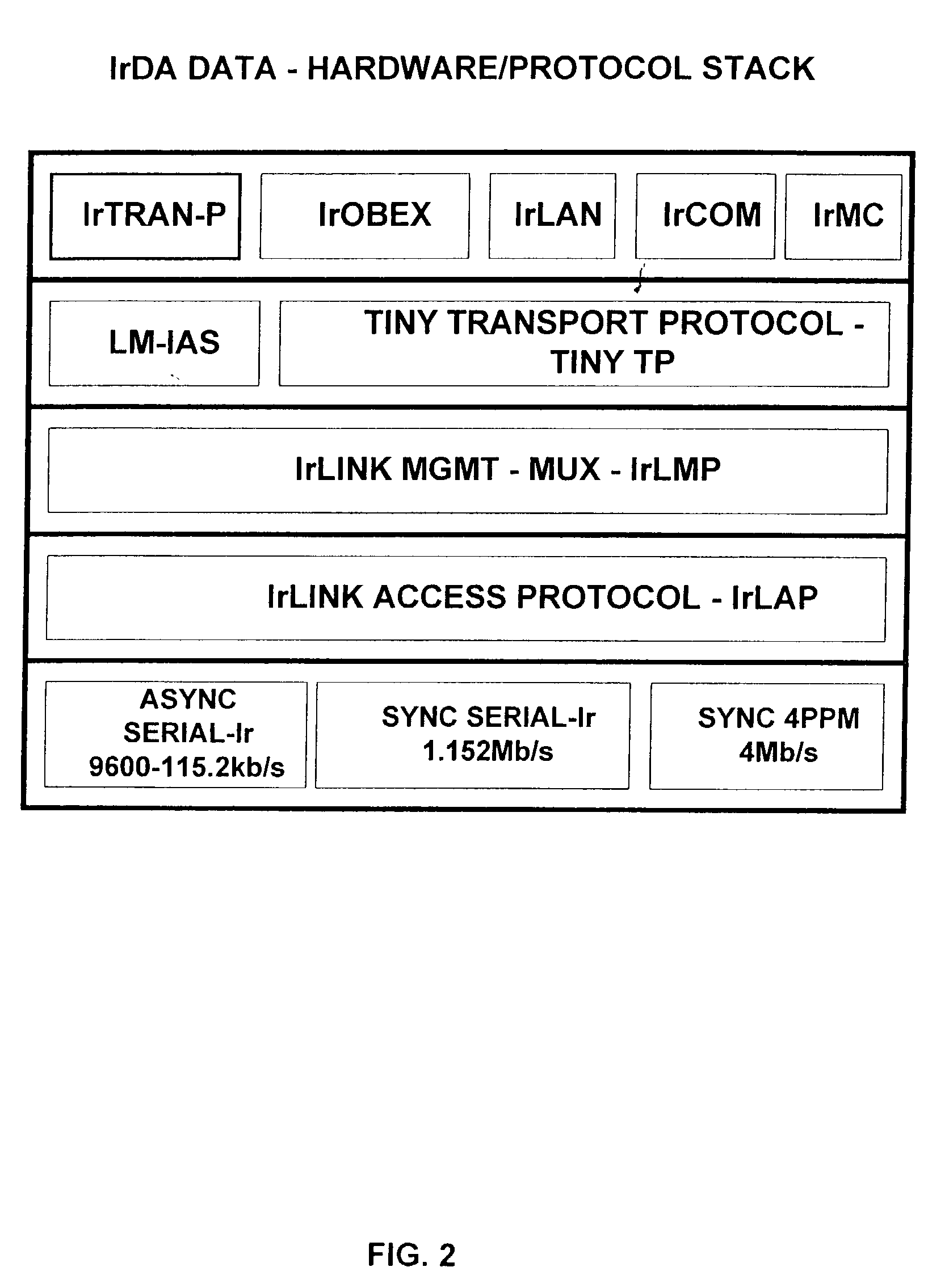

Interactive directed light/sound system

ActiveUS8199108B2Input/output for user-computer interactionCathode-ray tube indicatorsLight beamAudio electronics

An interactive directed beam system is provided. In one implementation, the system includes a projector, a computer and a camera. The camera is configured to view and capture information in an interactive area. The captured information may take various forms, such as, an image and / or audio data. The captured information is based on actions taken by an object, such as, a person within the interactive area. Such actions include, for example, natural movements of the person and interactions between the person and an image projected by the projector. The captured information from the camera is then sent to the computer for processing. The computer performs one or more processes to extract certain information, such as, the relative location of the person within the interactive area for use in controlling the projector. Based on the results generated by the processes, the computer directs the projector to adjust the projected image accordingly. The projected image can move anywhere within the confines of the interactive area.

Owner:MICROSOFT TECH LICENSING LLC

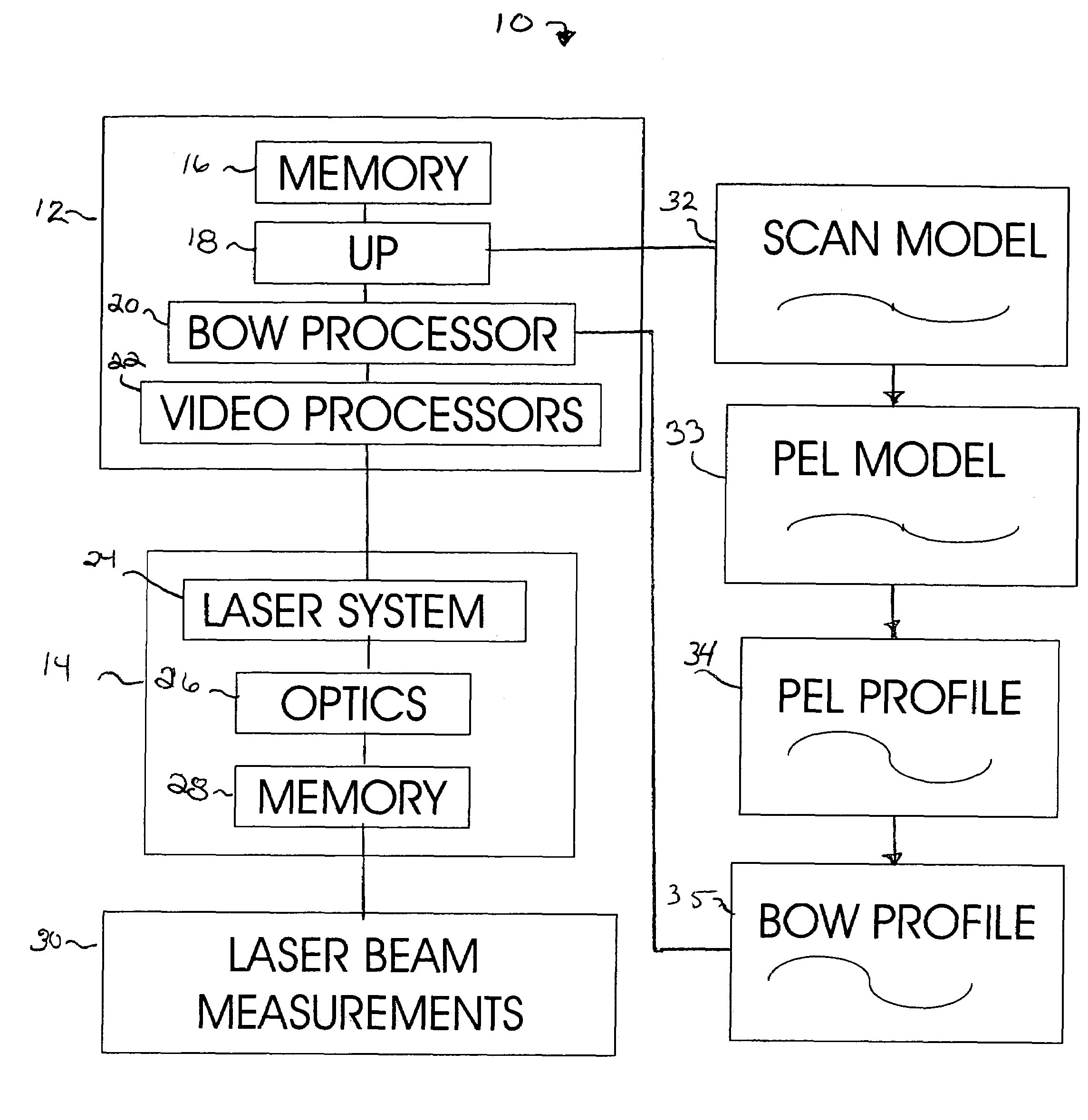

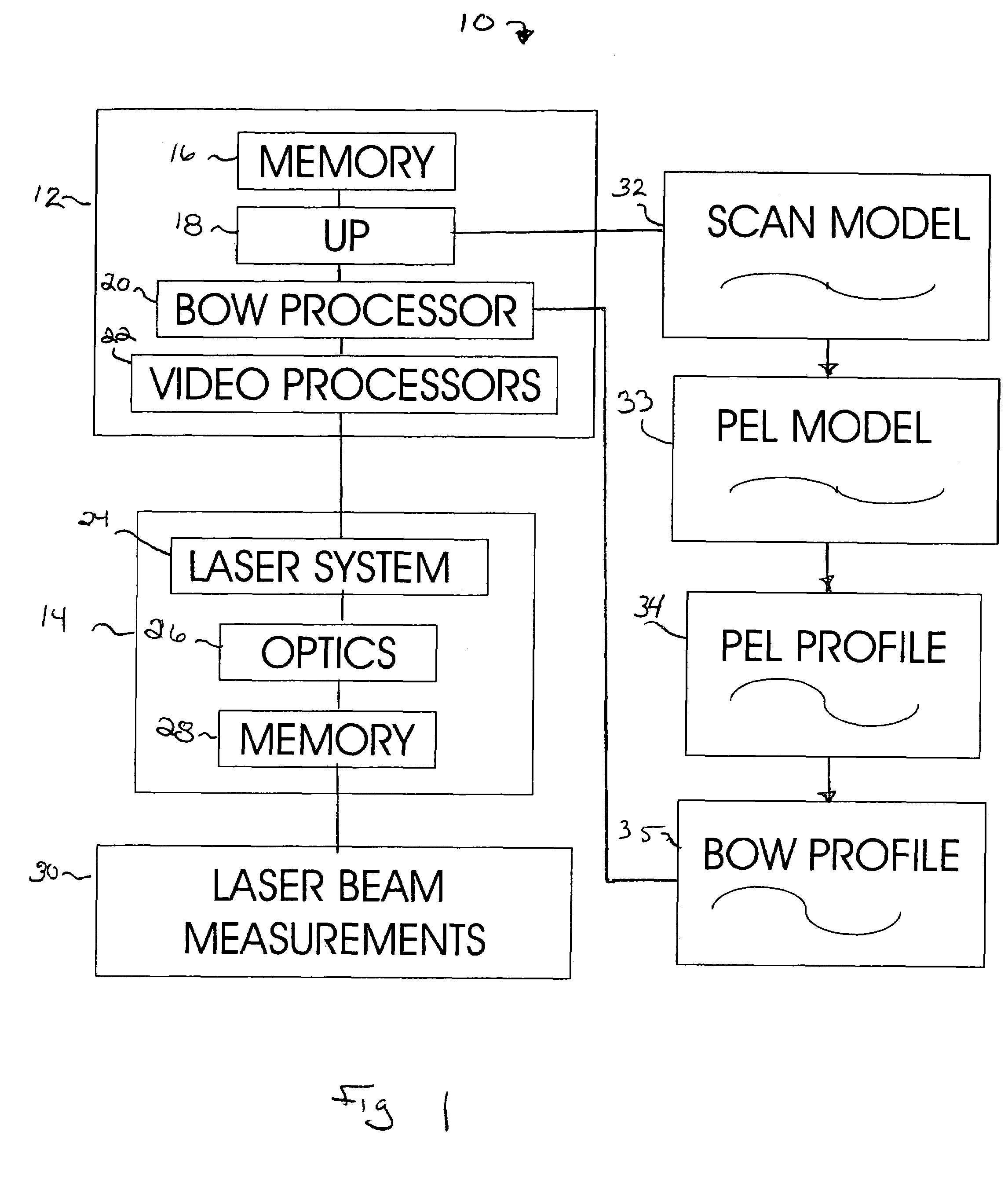

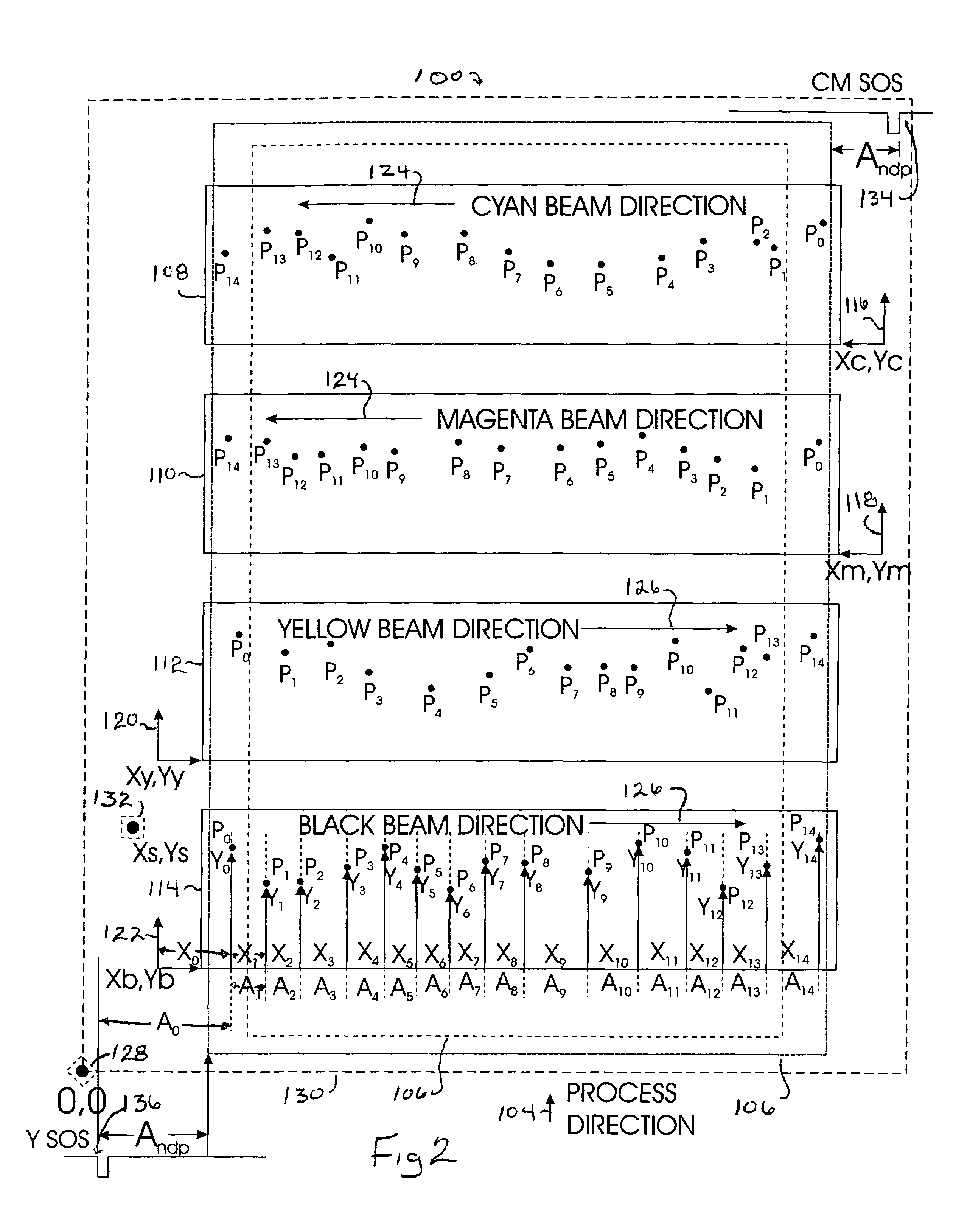

Algorithms and methods for determining laser beam process direction position errors from data stored on a printhead

Systems and methods are provided for characterizing laser beam process direction position errors in an electrophotographic device. Once the process direction position errors of a given beam laser beam system have been characterized, an image is adjusted or warped prior to being processed by the laser beam system to compensate for laser beam process direction position errors, e.g., bow and skew.

Owner:LEXMARK INT INC

Device and method for calibrating a laser system

A device for calibrating a laser beam system includes a calibration member having a surface positioned at a predetermined distance from the base datum of the unit. Further, the system includes a mechanism for focusing the beam to a focal point and for moving the focal point relative to the surface of the calibration member. When the focal point reaches the surface of the calibration member, Laser Induced Optical Breakdown (LIOB) is induced. Thereafter, the position of the location of LIOB may be measured relative to the base datum to calibrate the laser beam. Further, patterns may be applied to the calibration member using LIOB to calibrate tilt / decenter of the beam and to determine the energy density and uniformity in the focal spot of the laser beam.

Owner:TECHNOLAS PERFECT VISION

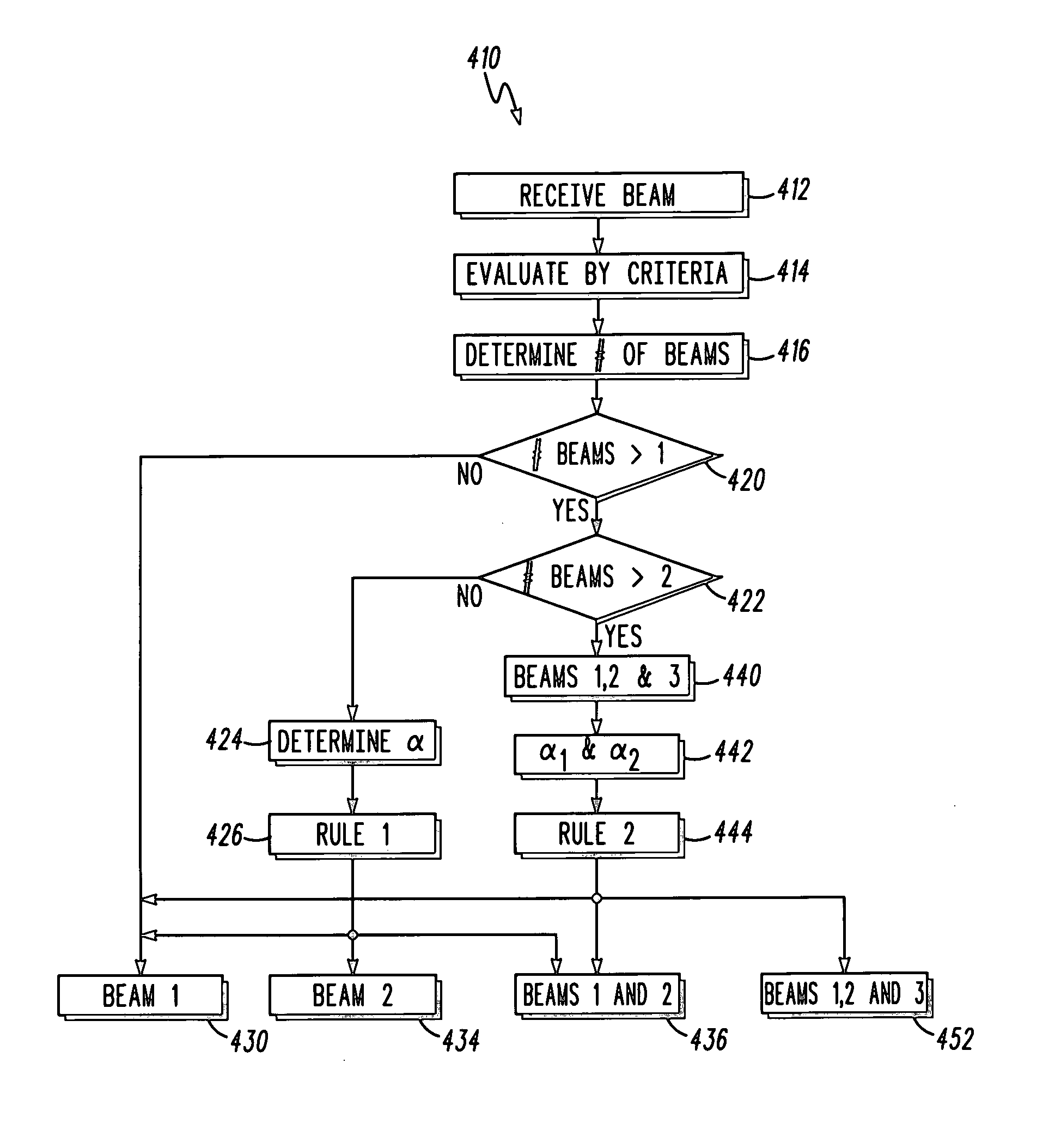

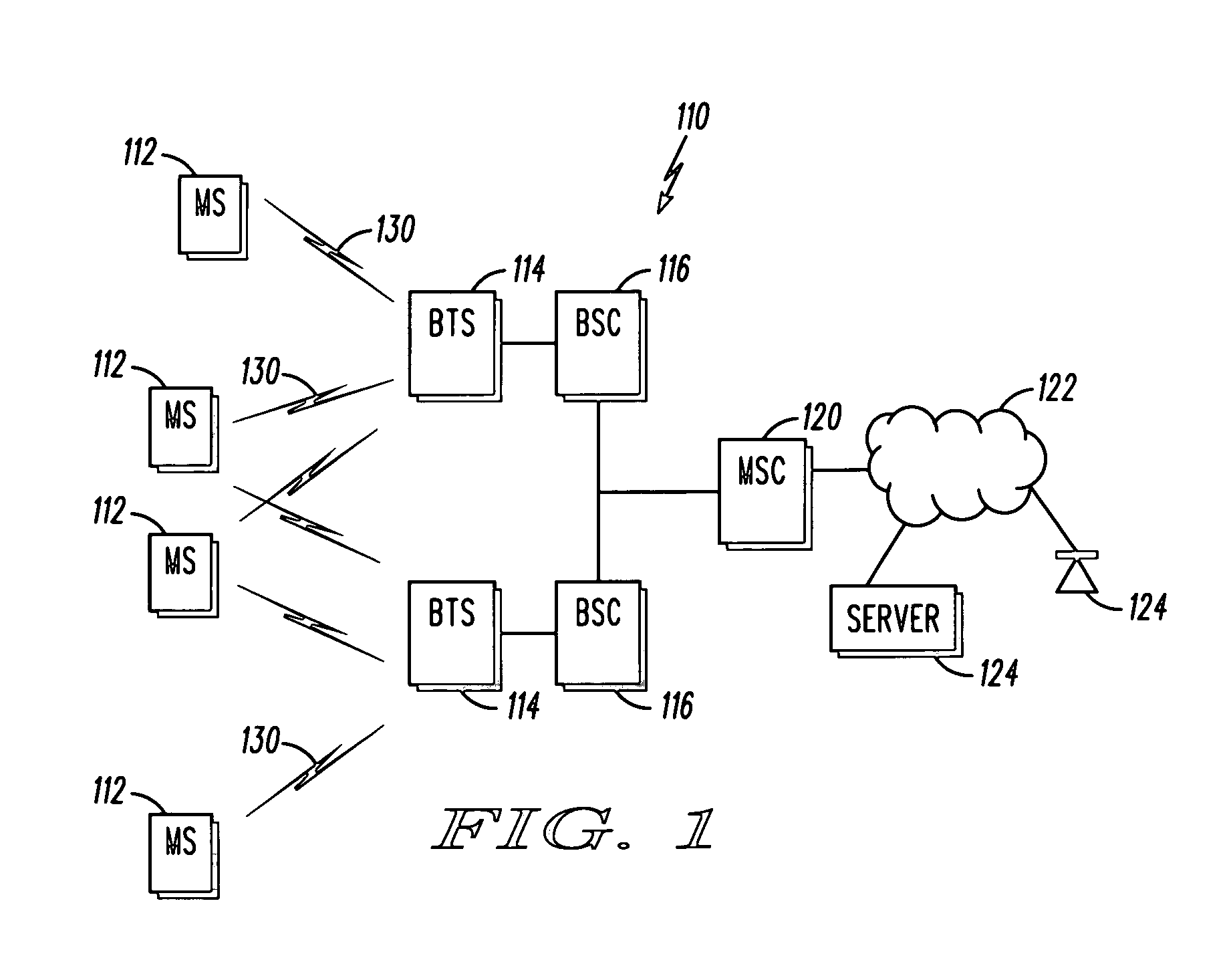

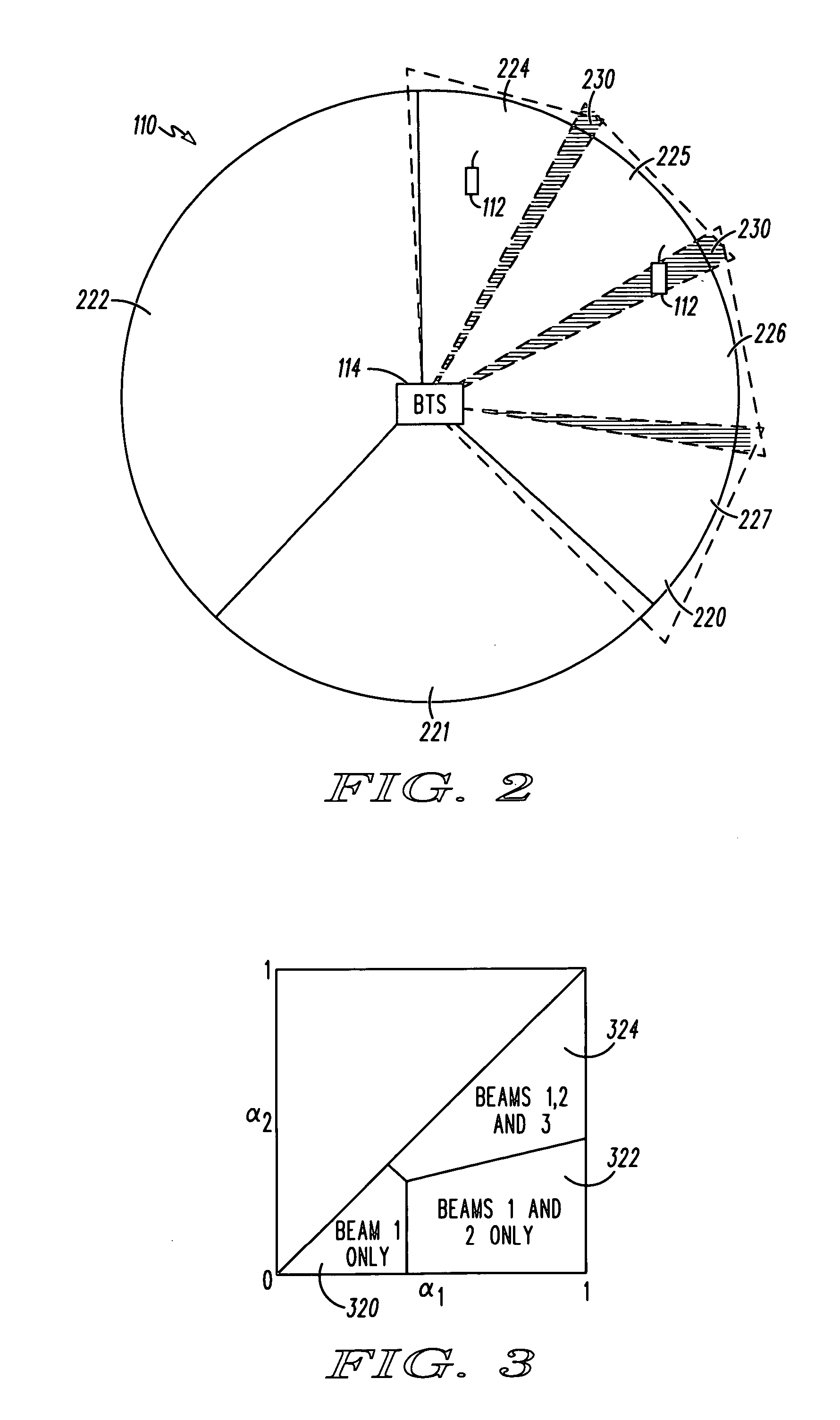

Method and apparatus for optimal multiple beam transmit weightings for beam to beam handoff in a switched beam system

A method, apparatus and system are provided for use in better optimizing switched beam, wireless communications. In some embodiments, a method is provided that receives a communication over a first wireless reverse link beam, selects a type of beam weighting control, determines a rule according to the type of beam weighting control, and determining a weighting of a forward link beam according to the rule. The method can further determine an energy of the first reverse link beam, and determine a first gain energy ratio based on the first reverse link beam energy, such that the weighting is determined by applying the first gain energy ratio to the rule. Some embodiments further determine a pilot beam configuration, wherein the rule is determined according to the pilot beam configuration and the selected type of beam weighting control.

Owner:GOOGLE TECH HLDG LLC

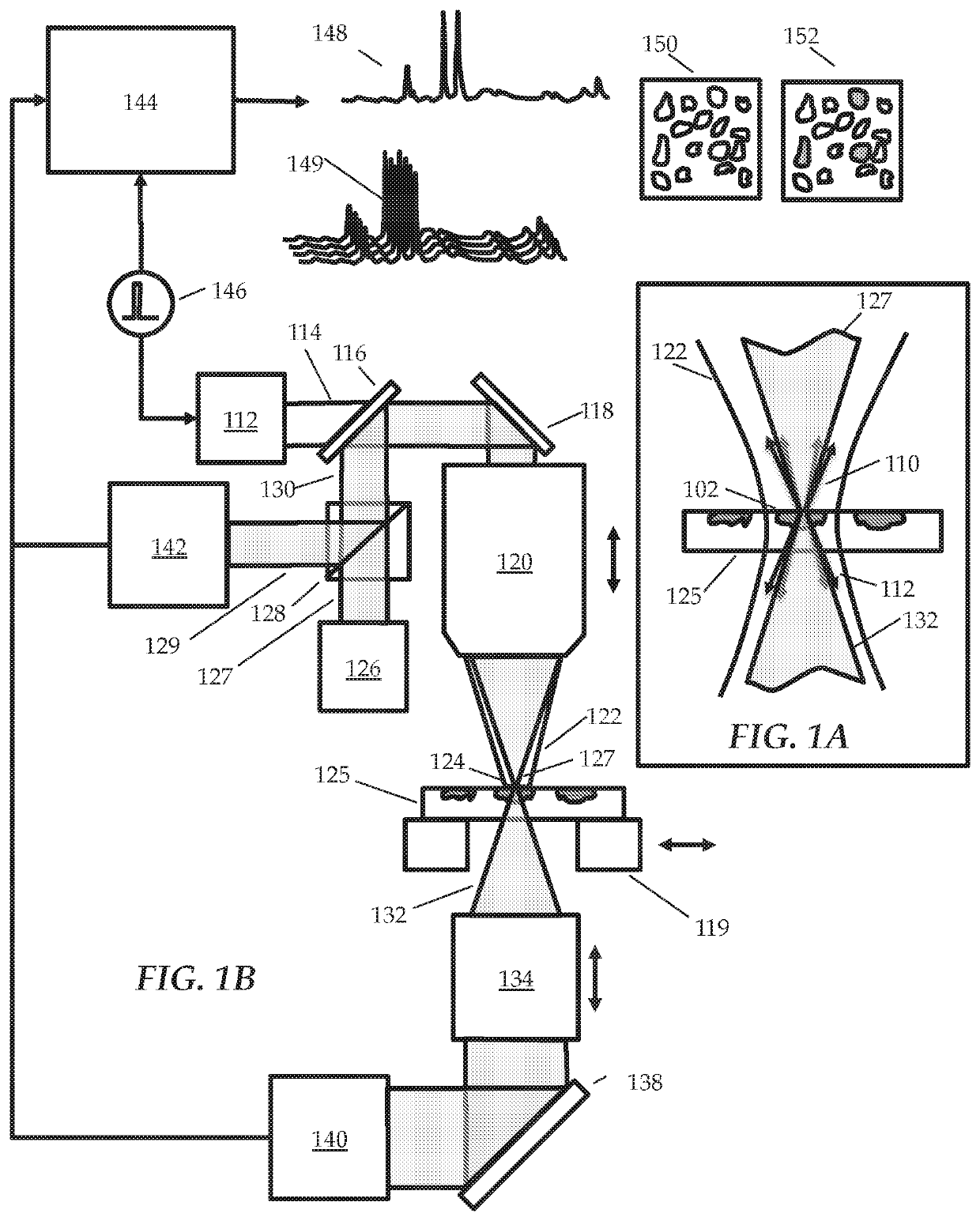

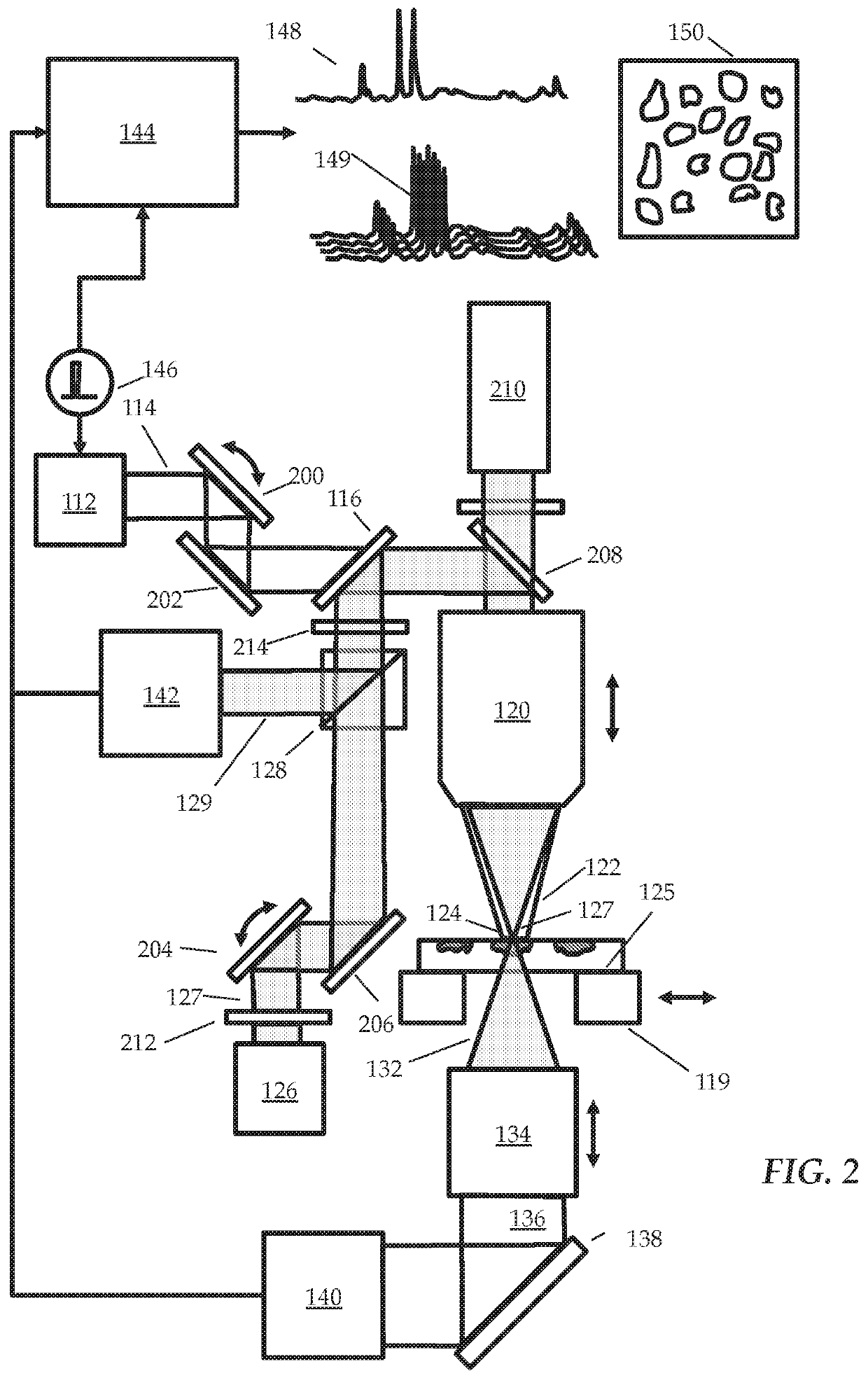

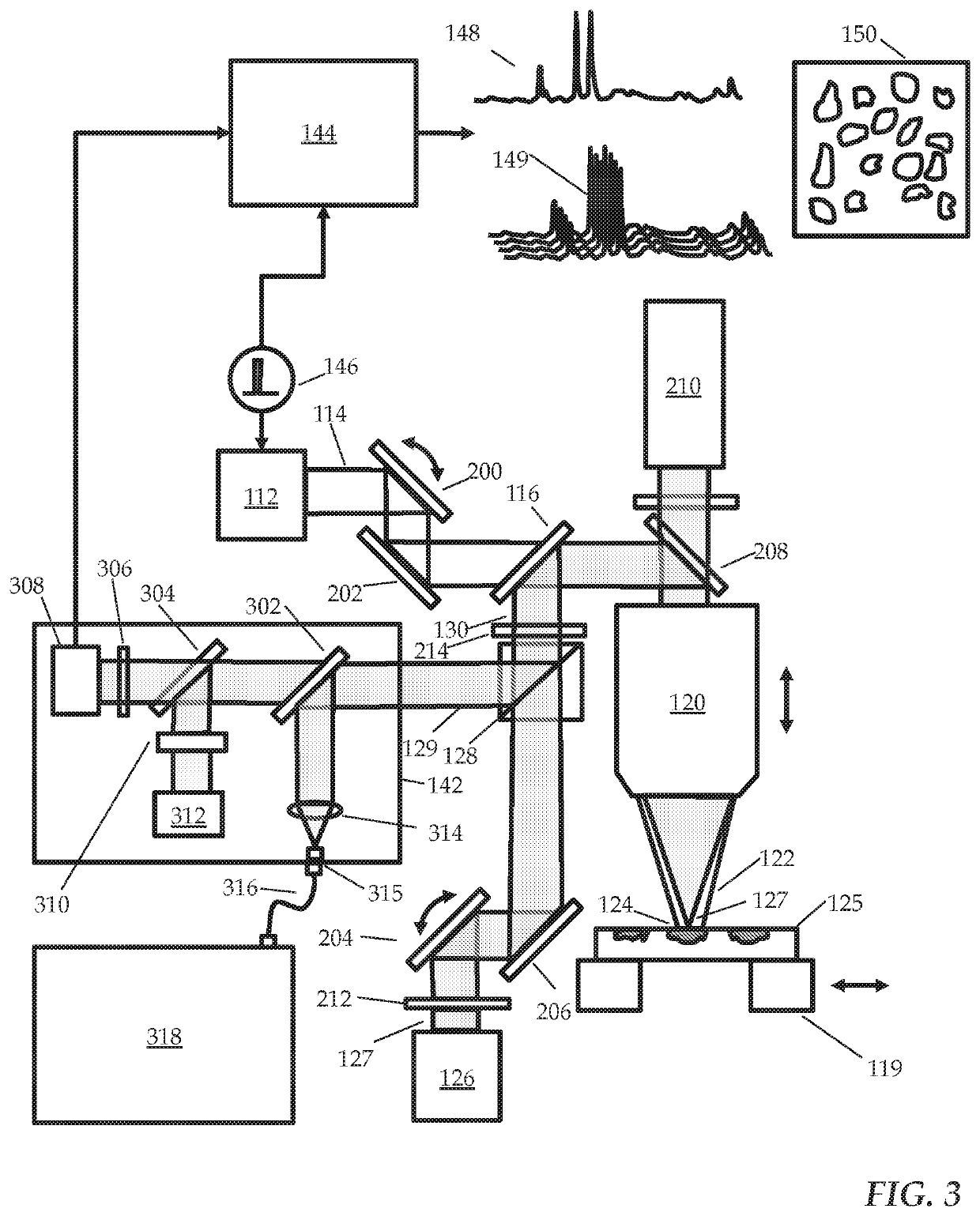

Method and apparatus for enhanced photo-thermal imaging and spectroscopy

ActiveUS20200025677A1Avoid strayRaman/scattering spectroscopyRadiation pyrometryFluorescenceMaterials science

System for performing chemical spectroscopy on samples from the scale of nanometers to millimeters or more with a multifunctional platform combining analytical and imaging techniques including dual beam photo-thermal spectroscopy with confocal microscopy, Raman spectroscopy, fluorescence detection, various vacuum analytical techniques and / or mass spectrometry. In embodiments described herein, the light beams of a dual-beam system are used for heating and sensing.

Owner:PHOTOTHERMAL SPECTROSCOPY CORP

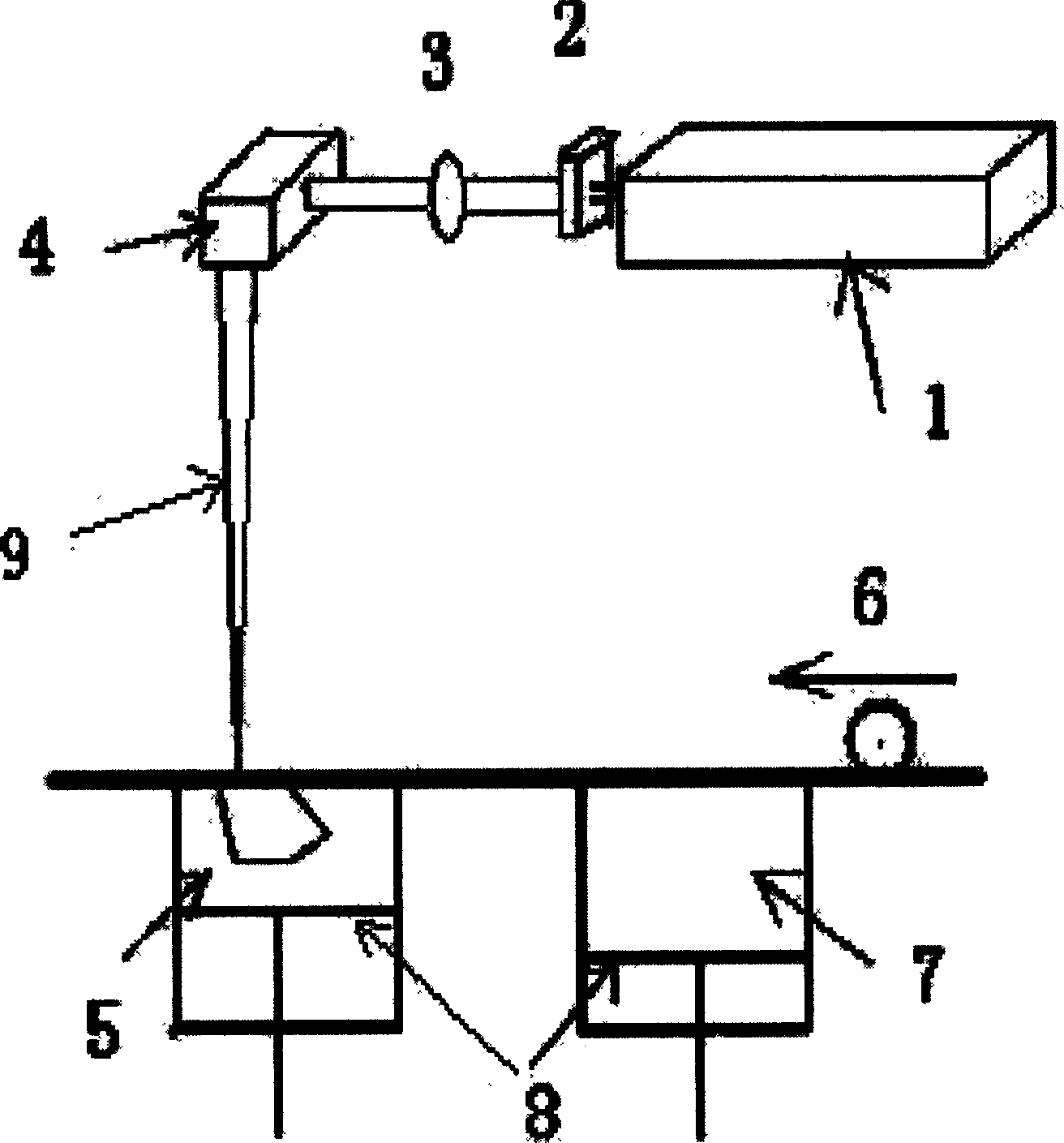

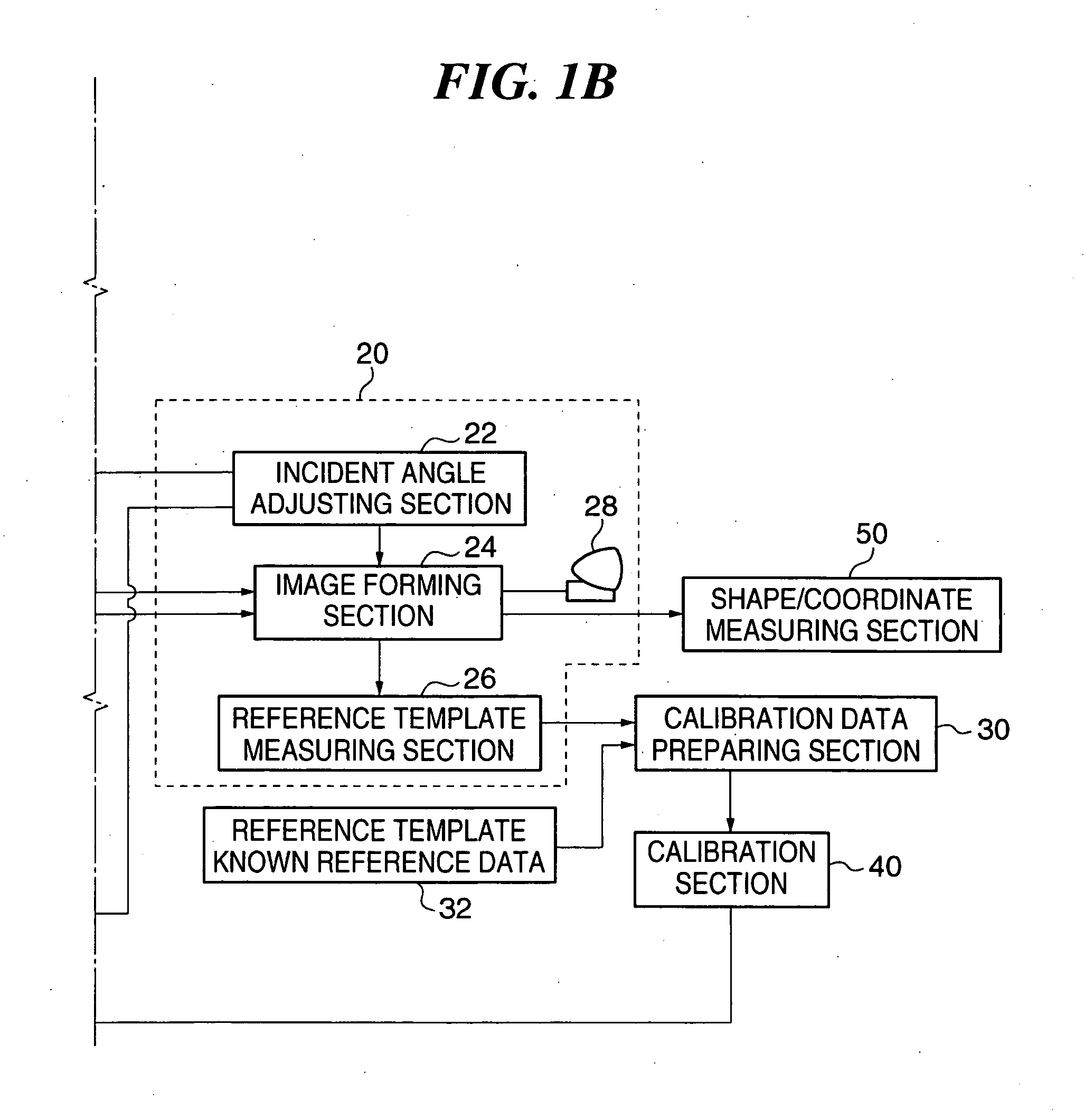

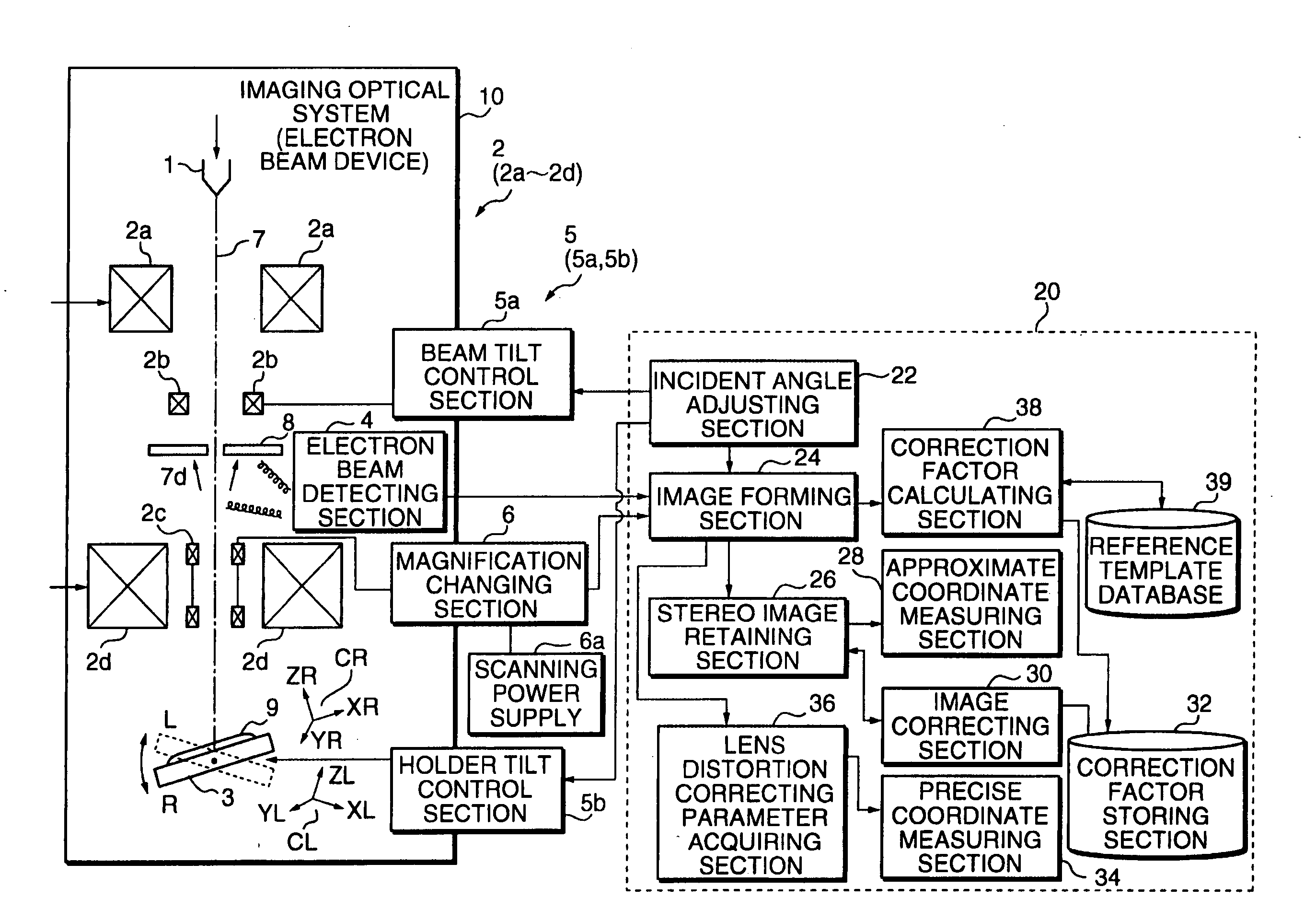

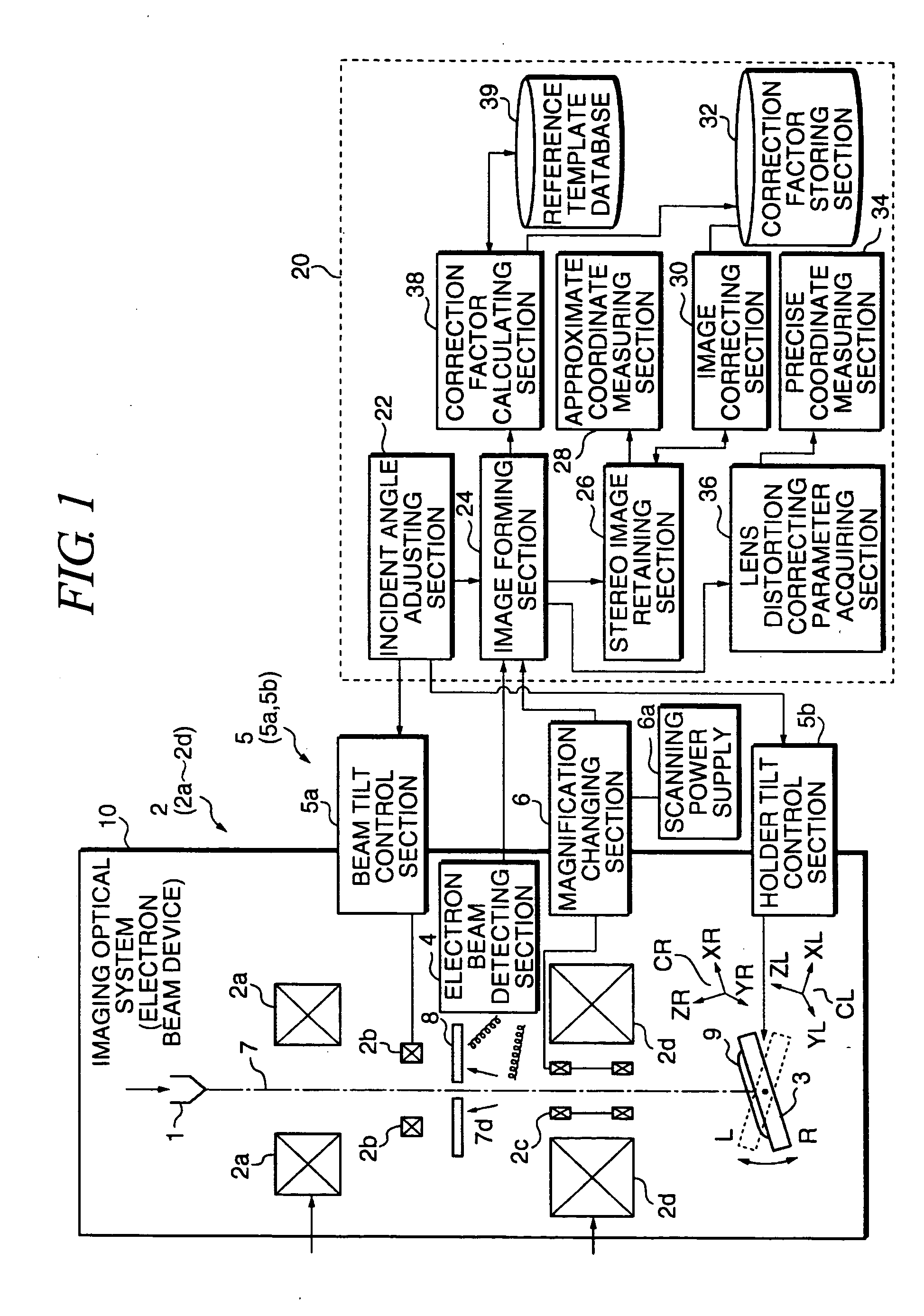

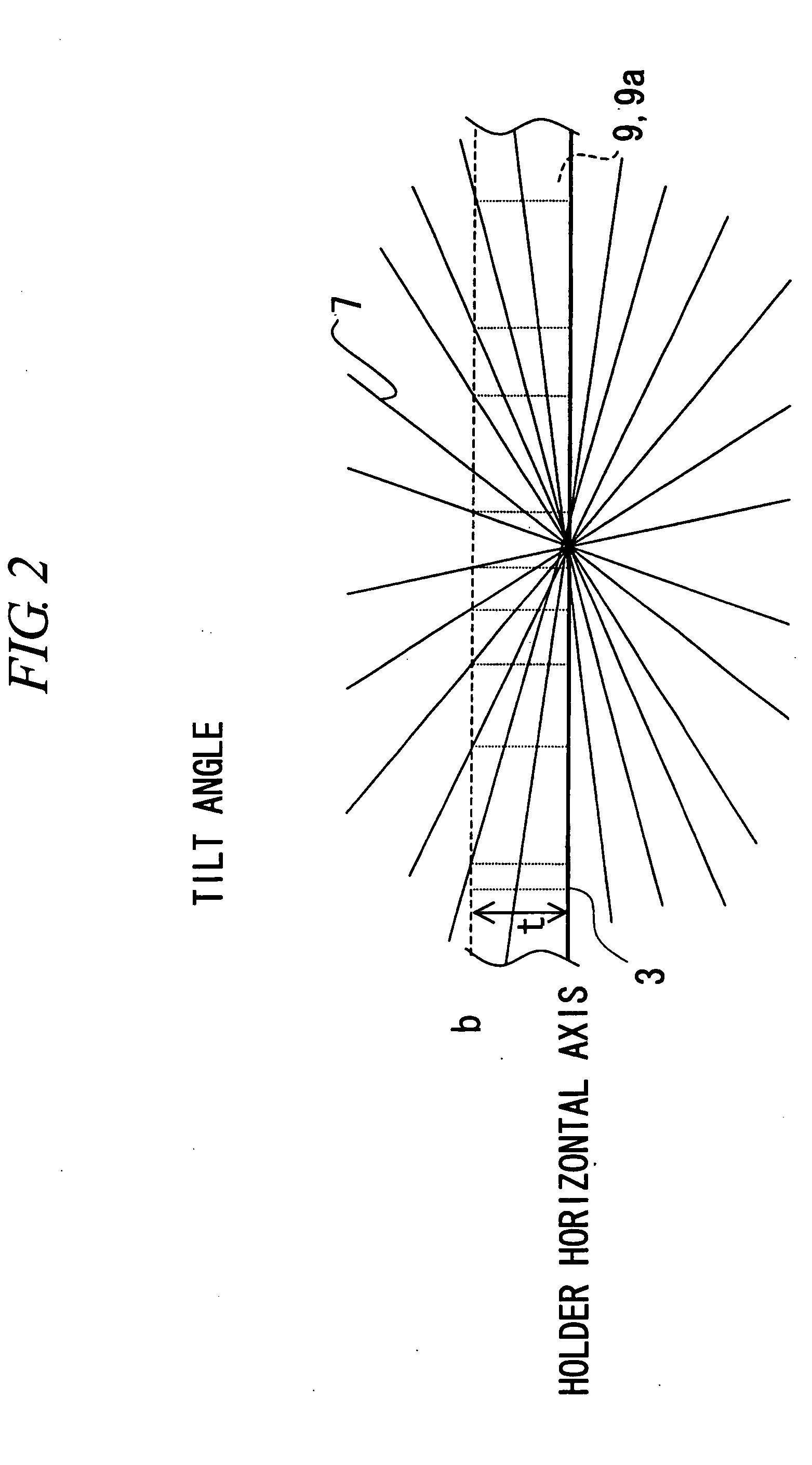

Electron beam system and electron beam measuring and observing method

InactiveUS20050161601A1Reduce aberrationImprove accuracyMaterial analysis using wave/particle radiationImage analysisTemplate basedStereo image

This invention provides an electron beam measuring device capable of performing three-dimensional image measurement of a sample with high precision, irrespective of the tilt angle and height of the sample, by adjusting an electron optical system of a scanning charged-particle beam device so as to be suitable for image measurement. The electron beam measuring device includes a measuring section 20 adapted to tilt a reference template held by a sample holder 3 and an irradiated electron beam 7 relative to each other by means of a sample tilting section 5, to find the shape or coordinate values of the reference template based on a stereo image photographed by an electron beam detecting section 4, a calibration data preparing section 30 for comparing the measuring results at the measuring section 20 with known reference data to prepare calibration data for a stereo image photographed by the electron beam measuring device, and a calibration section 40 for performing a calibration based on the calibration data so as to reduce aberration in an image of the sample detected by the electron beam detecting section 4. Based on the stereo image calibrated by the calibration section 40, the shape or coordinate values of the sample 9 are found.

Owner:KK TOPCON

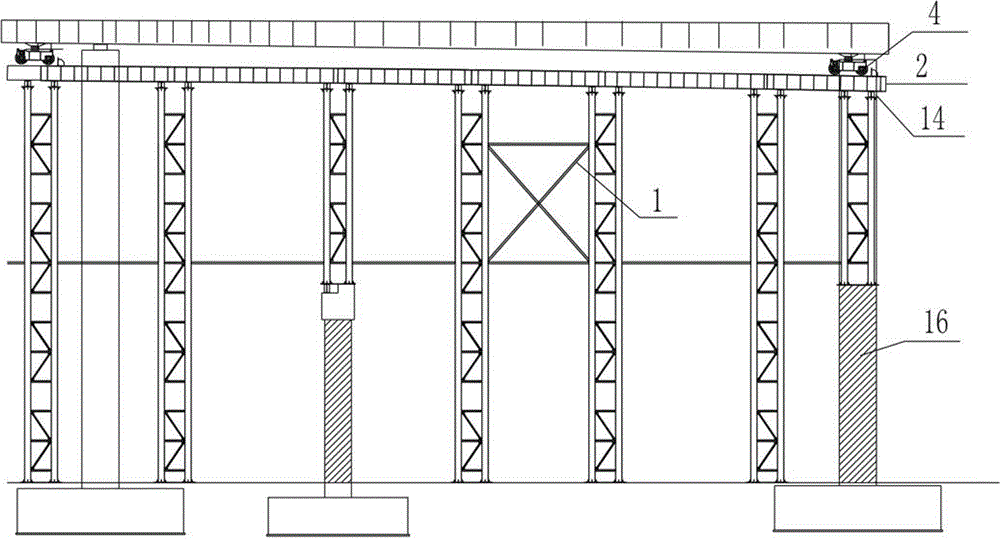

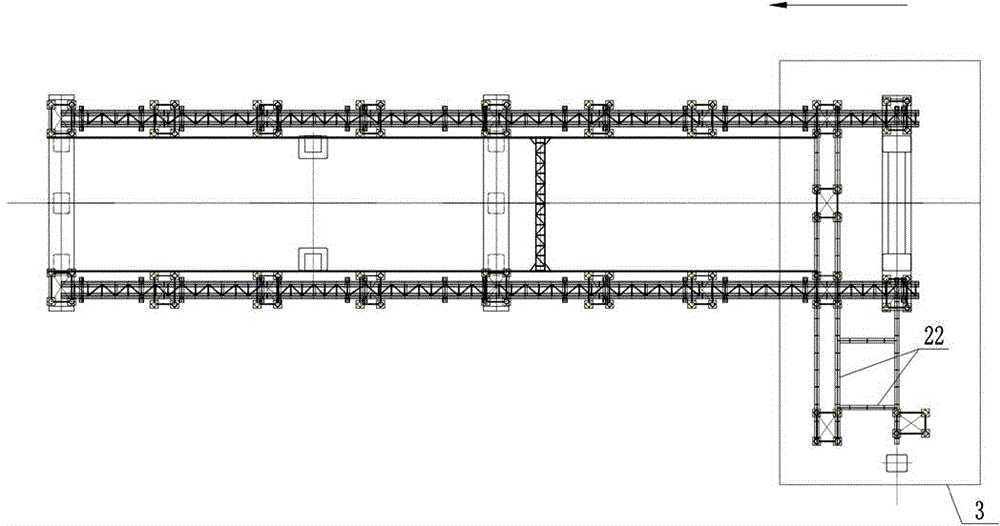

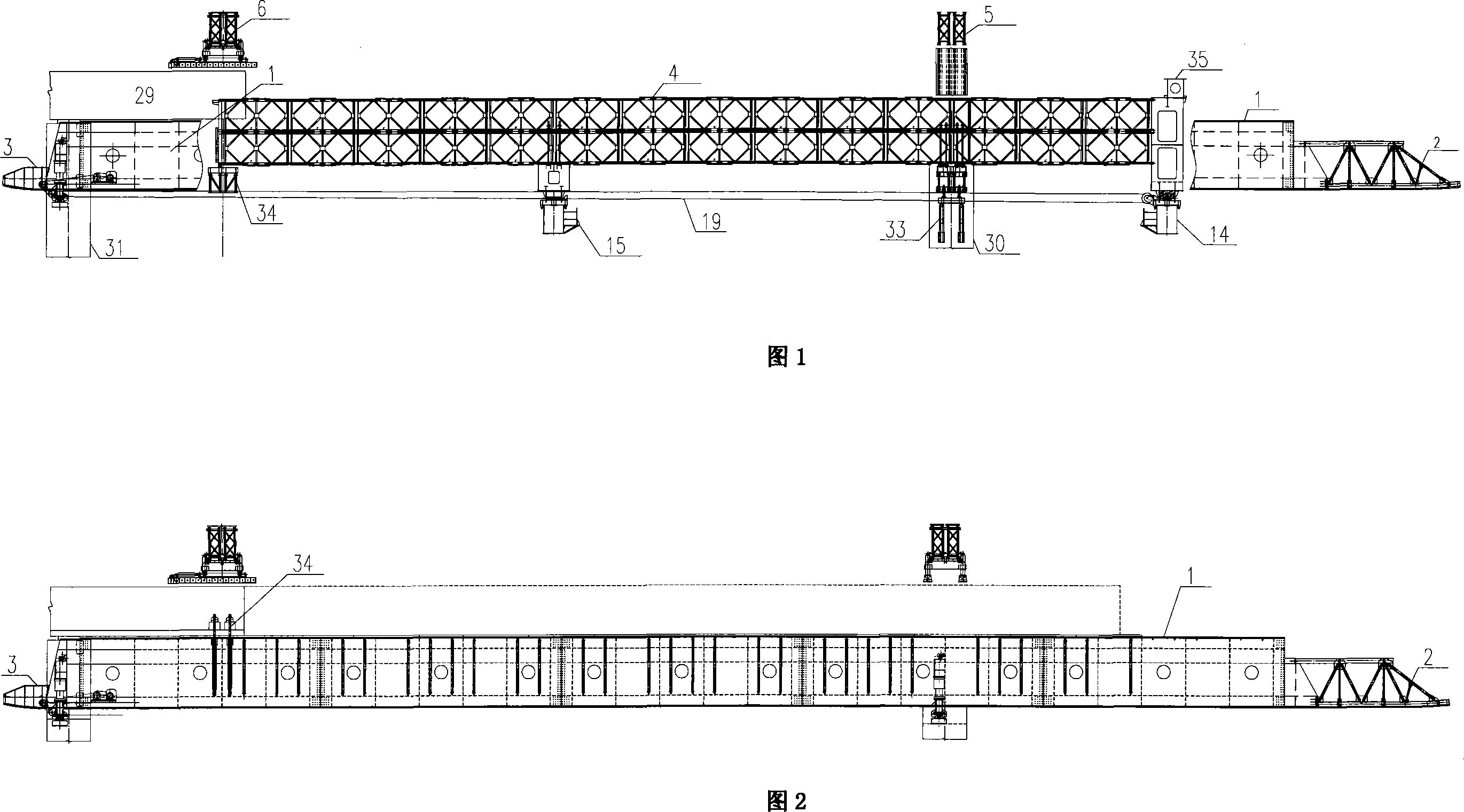

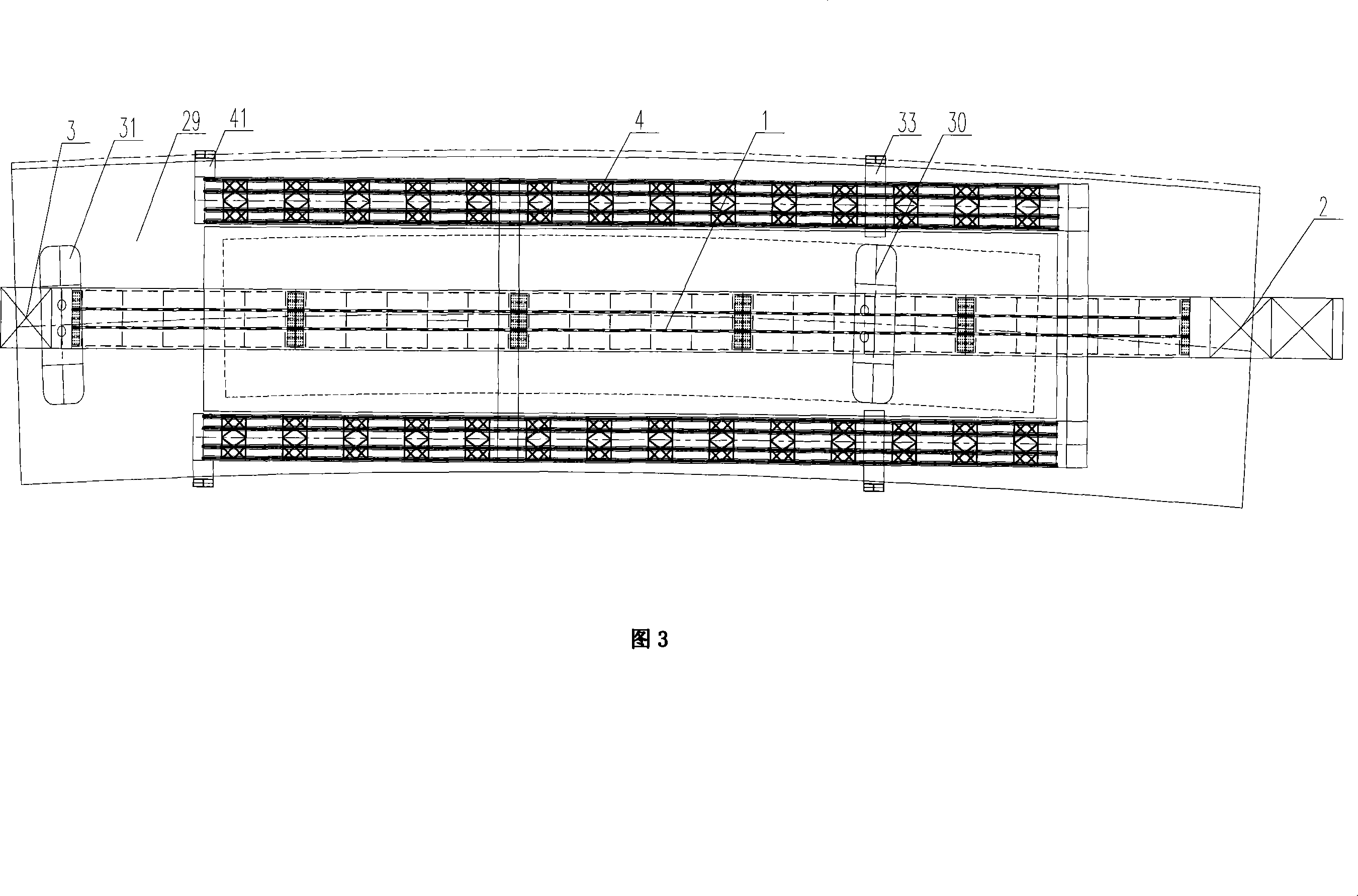

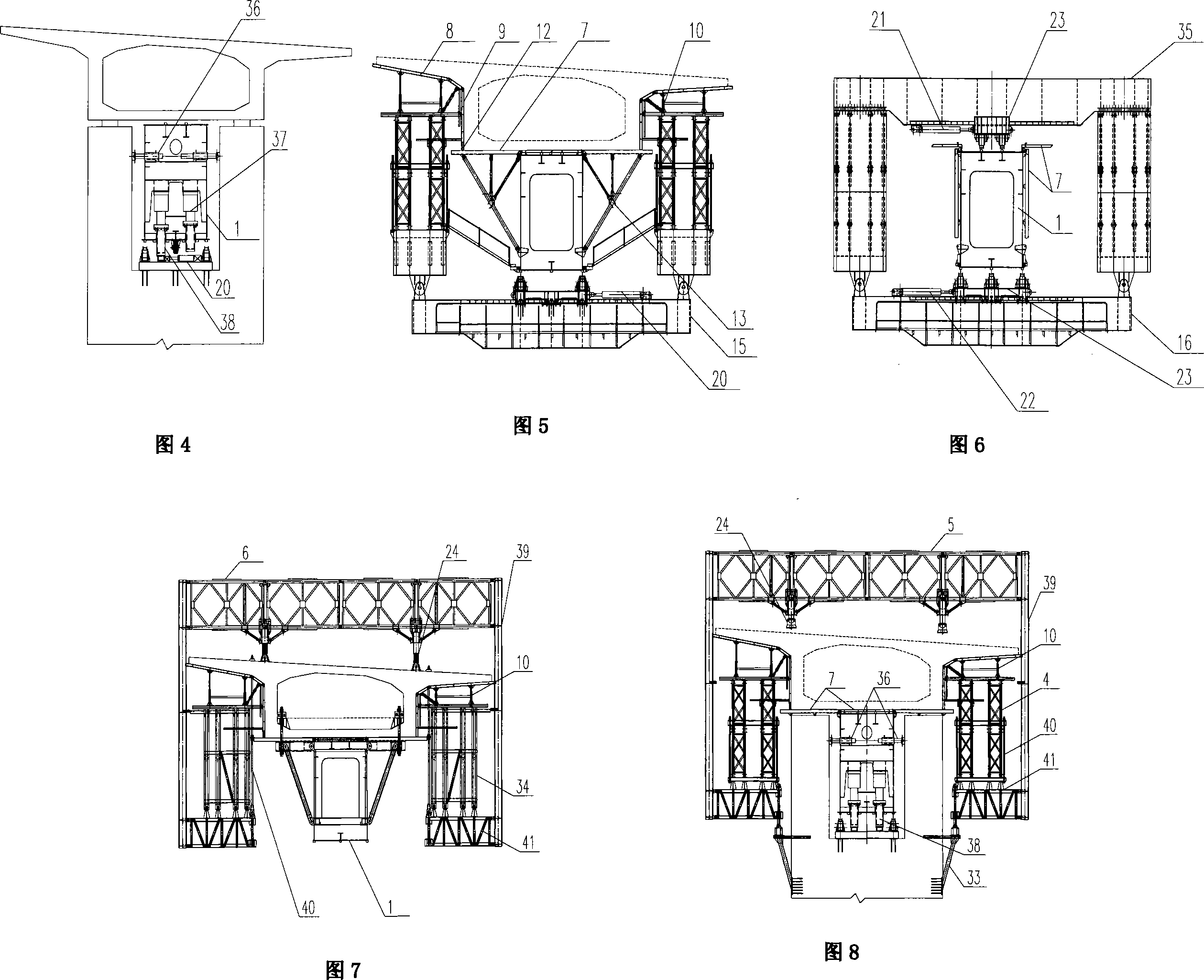

Full-bracket track-bogie bearing and moving device and construction method for installing steel box girders

The invention discloses a full-bracket track-bogie bearing and moving device and a construction method for installing steel box girders. The device consists of a bracket system, a slideway longitudinal beam system, a splicing platform and a traction system; steel pipe buttresses in the bracket system are fixed on a treated foundation, the slideway longitudinal beam system is arranged on the bracket system, and mainly comprises two-slideway longitudinal beams, each of the two-slideway longitudinal beams is formed by connecting I-shaped rod pieces in an upper-lower parallel connection method, each side of the slideway longitudinal beam system is provided with one two-slideway longitudinal beam, and two two-slideway longitudinal beams are arranged totally on two sides; and berth bogies on the slideway longitudinal beam system slide on berth bogie tracks on the two-slideway longitudinal beams, and the berth bogies adopt a parallel connection mode and share one electric control switch to realize synchronous starting and closing. The bearing and moving device and the construction method have the beneficial effects that advantages of a large machinery hoisting method and a full-bracket jacking and sliding method are synthesized, the influence on ground traffic is less, the construction speed is fast, the cost is low, and the safety is high.

Owner:NINGBO MUNICIPAL ENG CONSTR GROUP

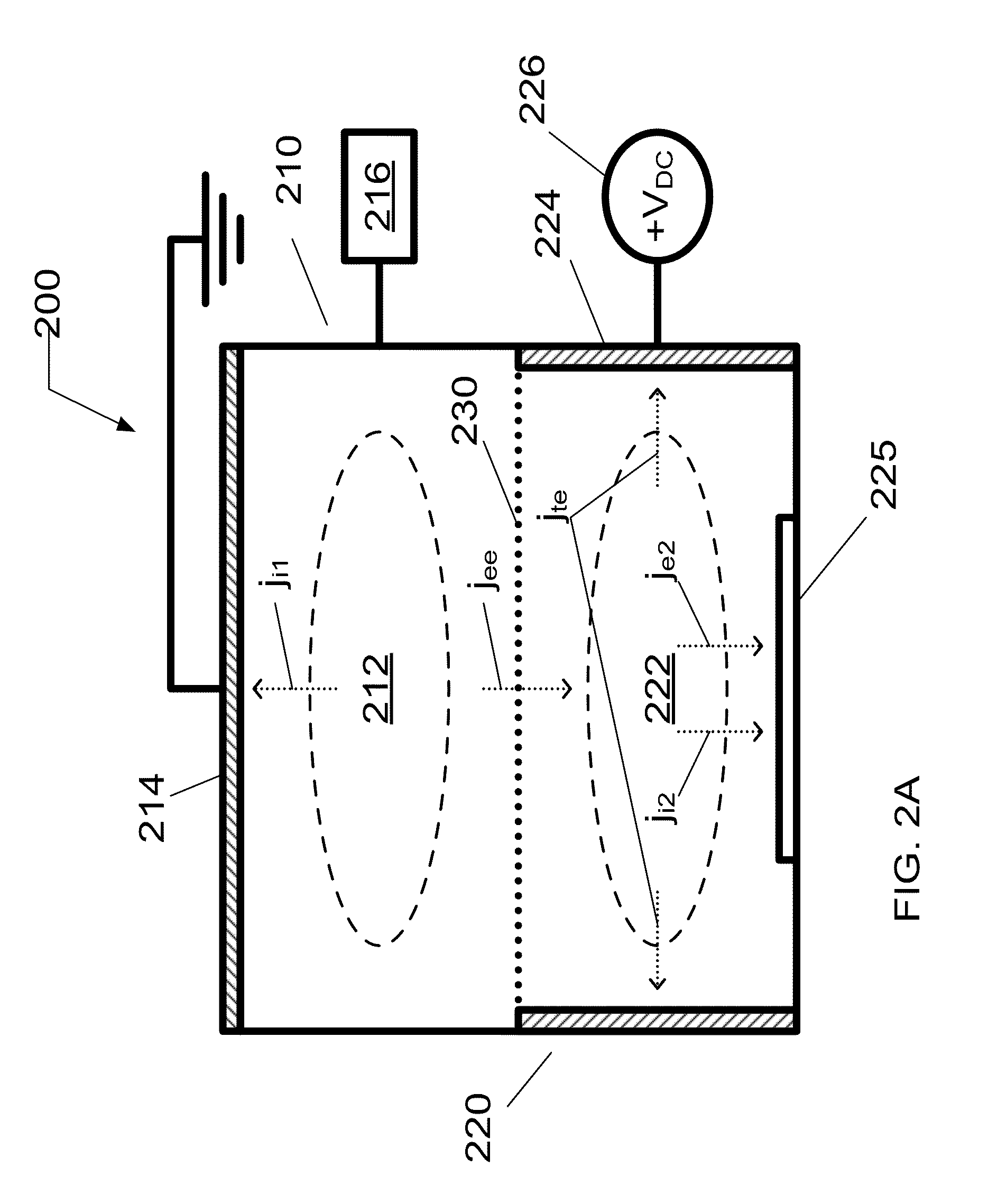

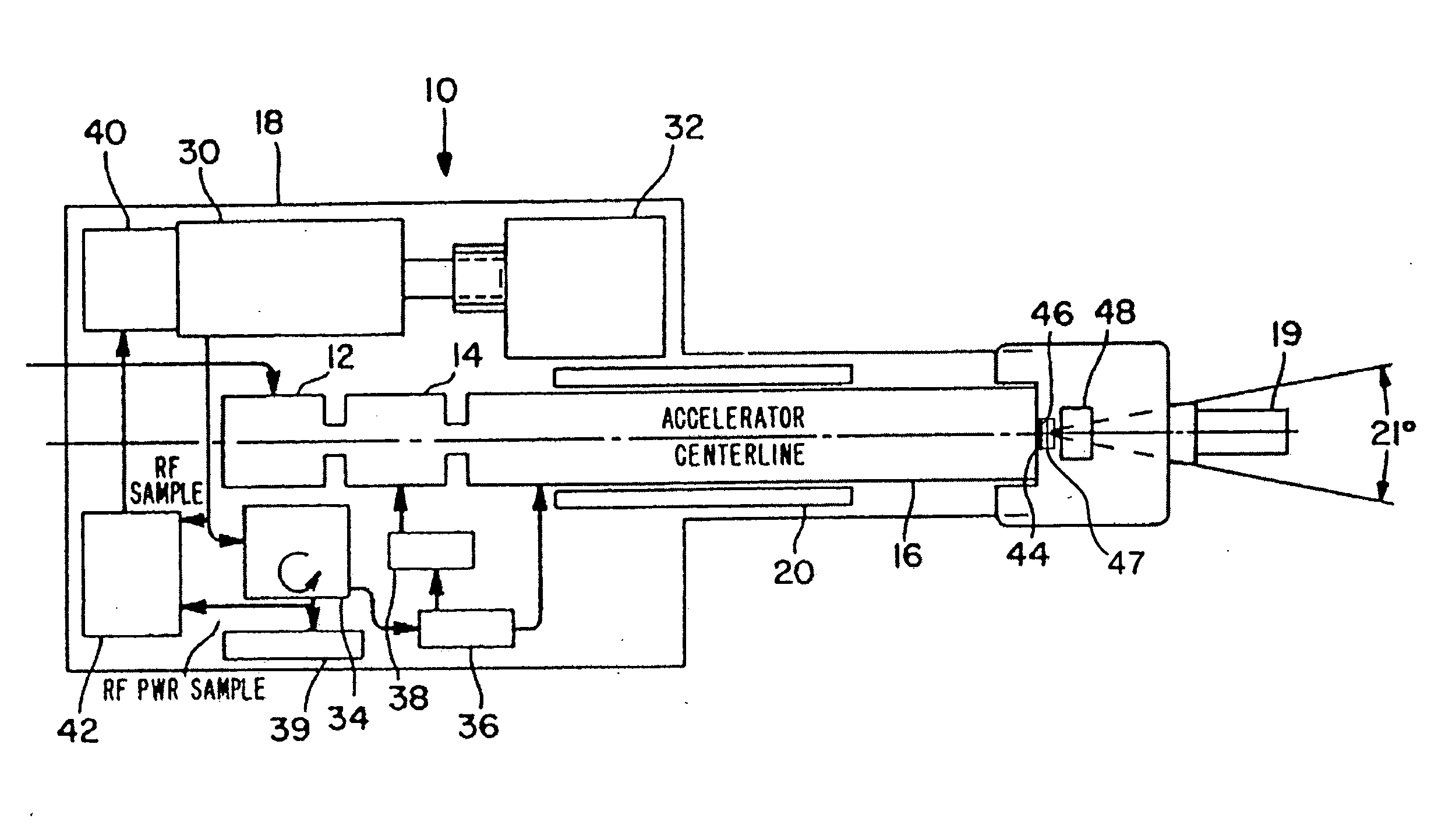

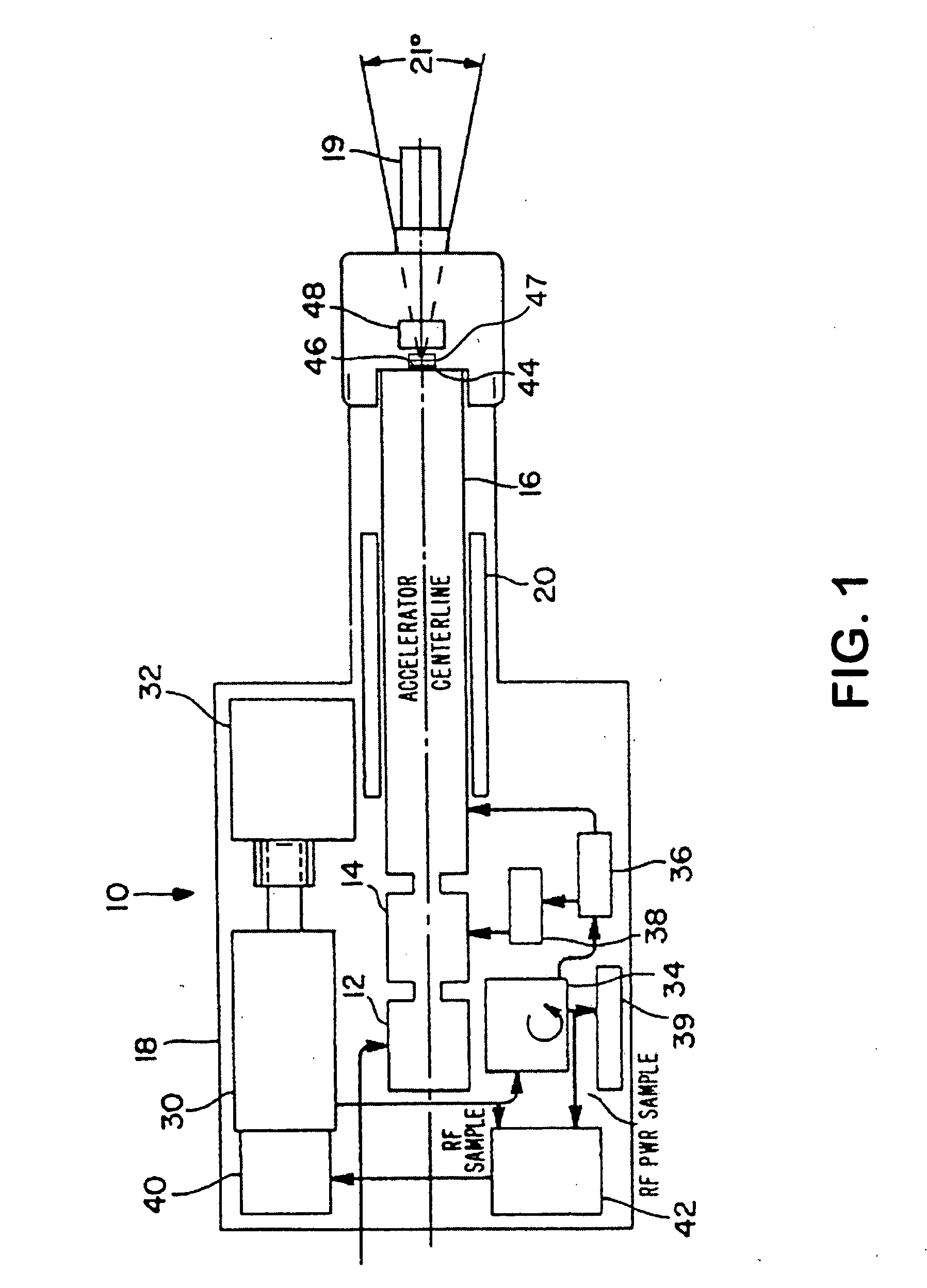

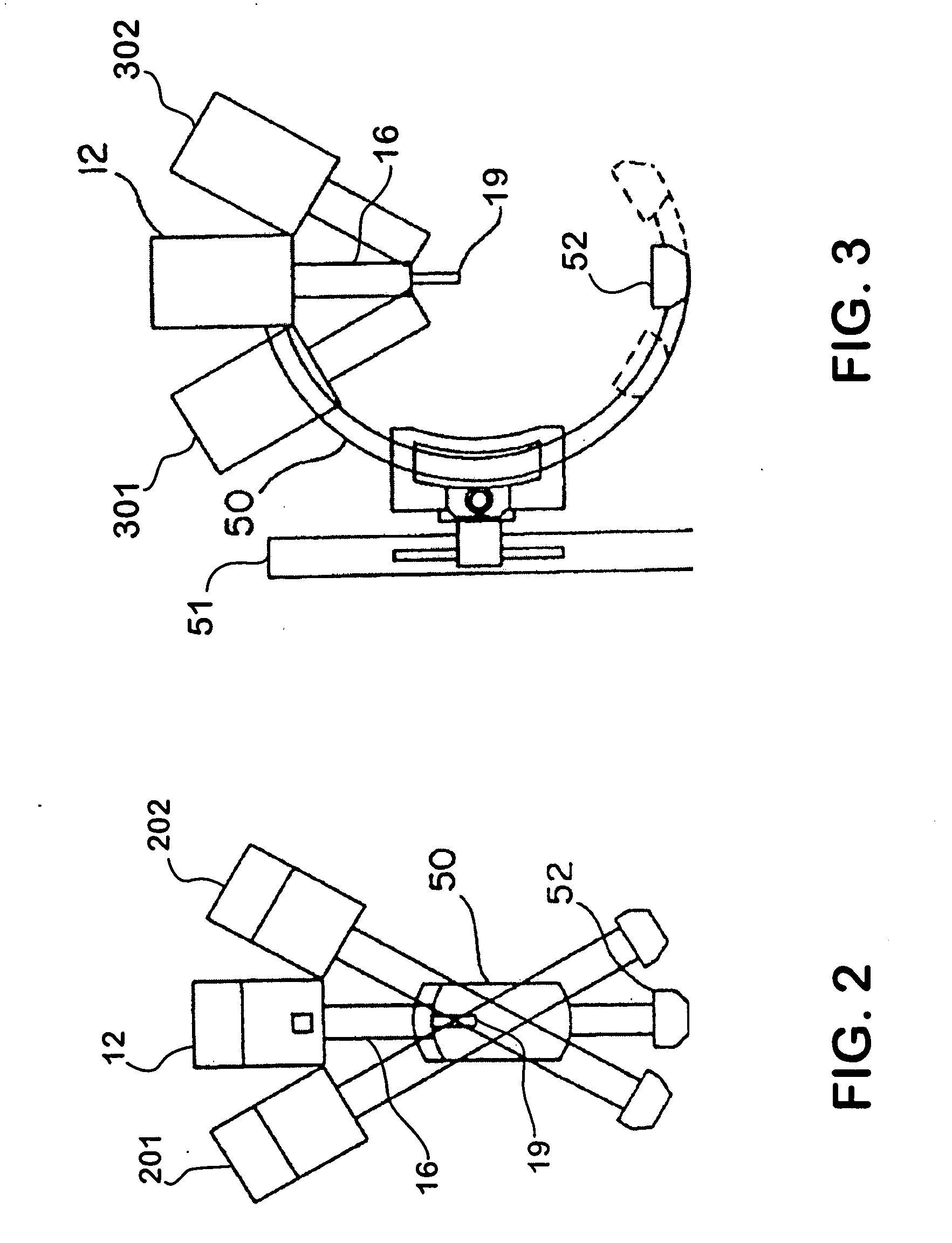

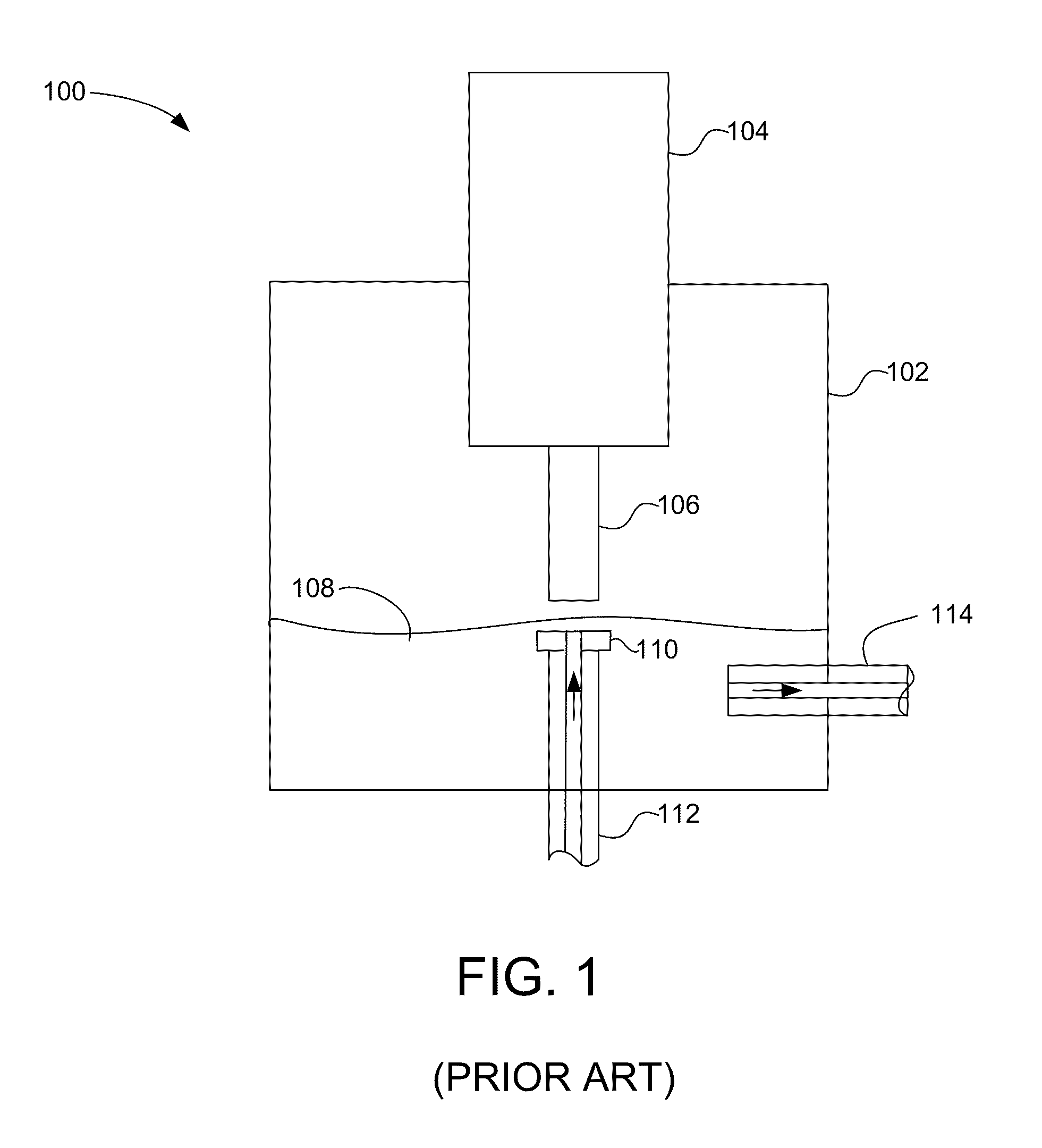

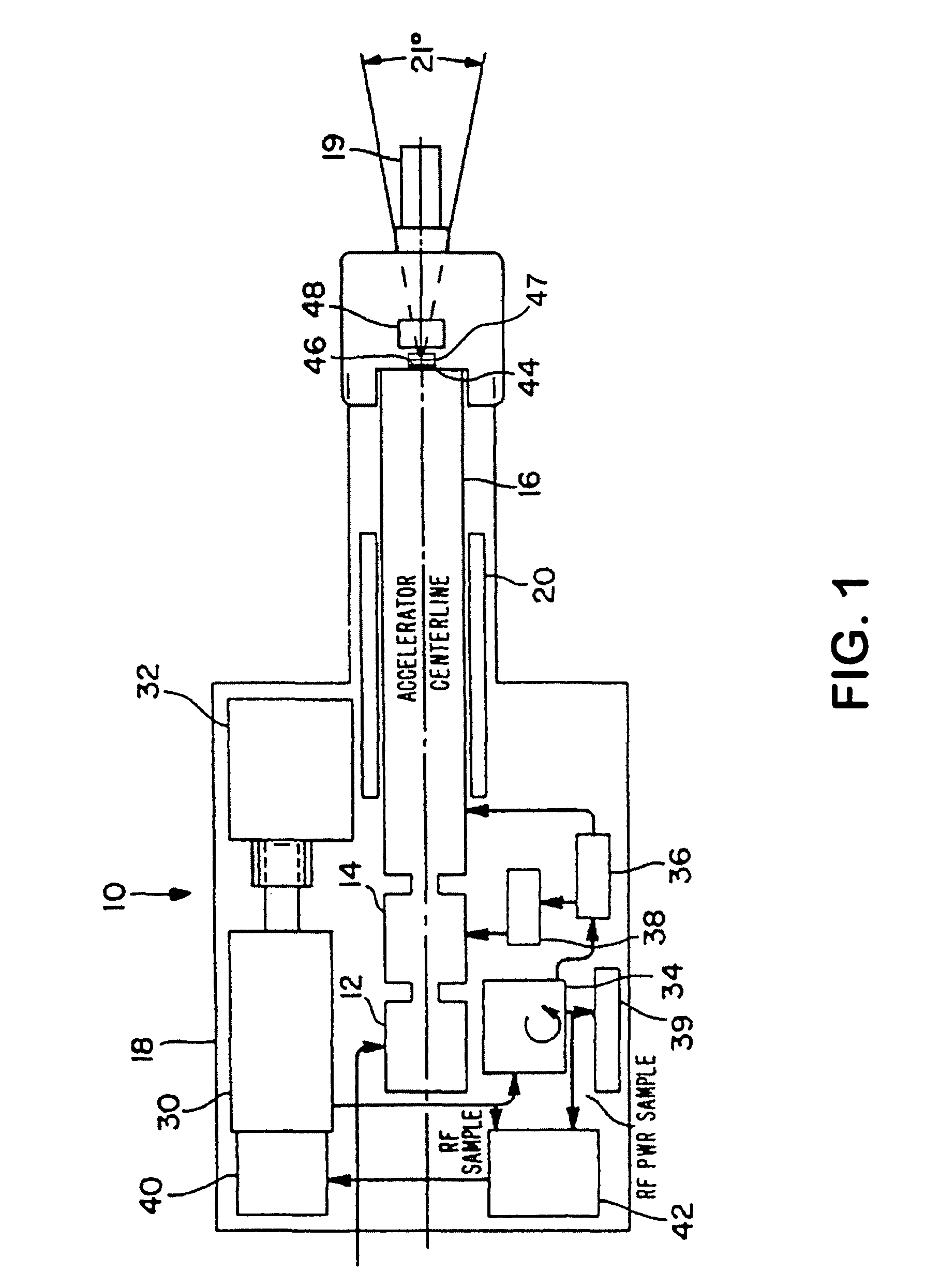

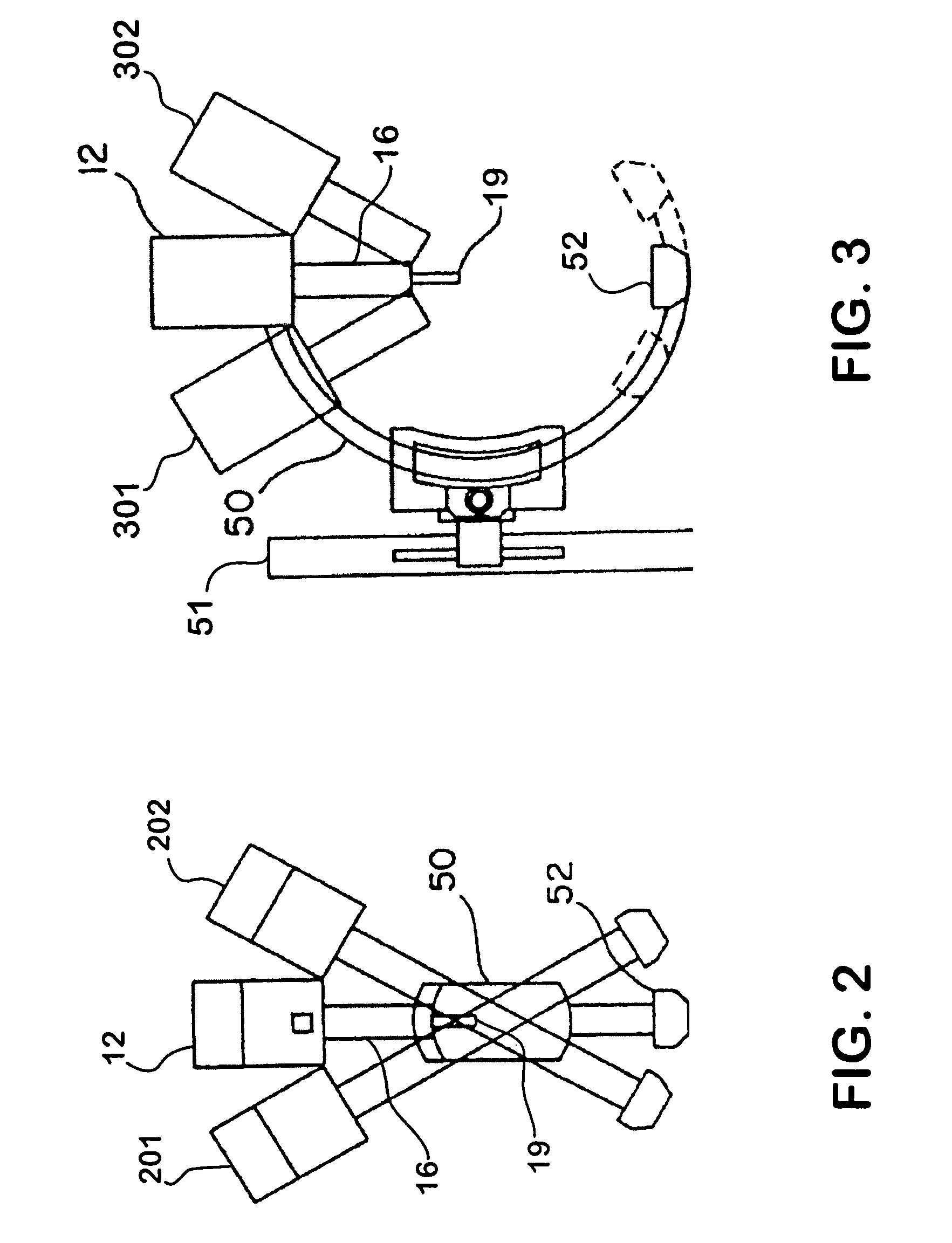

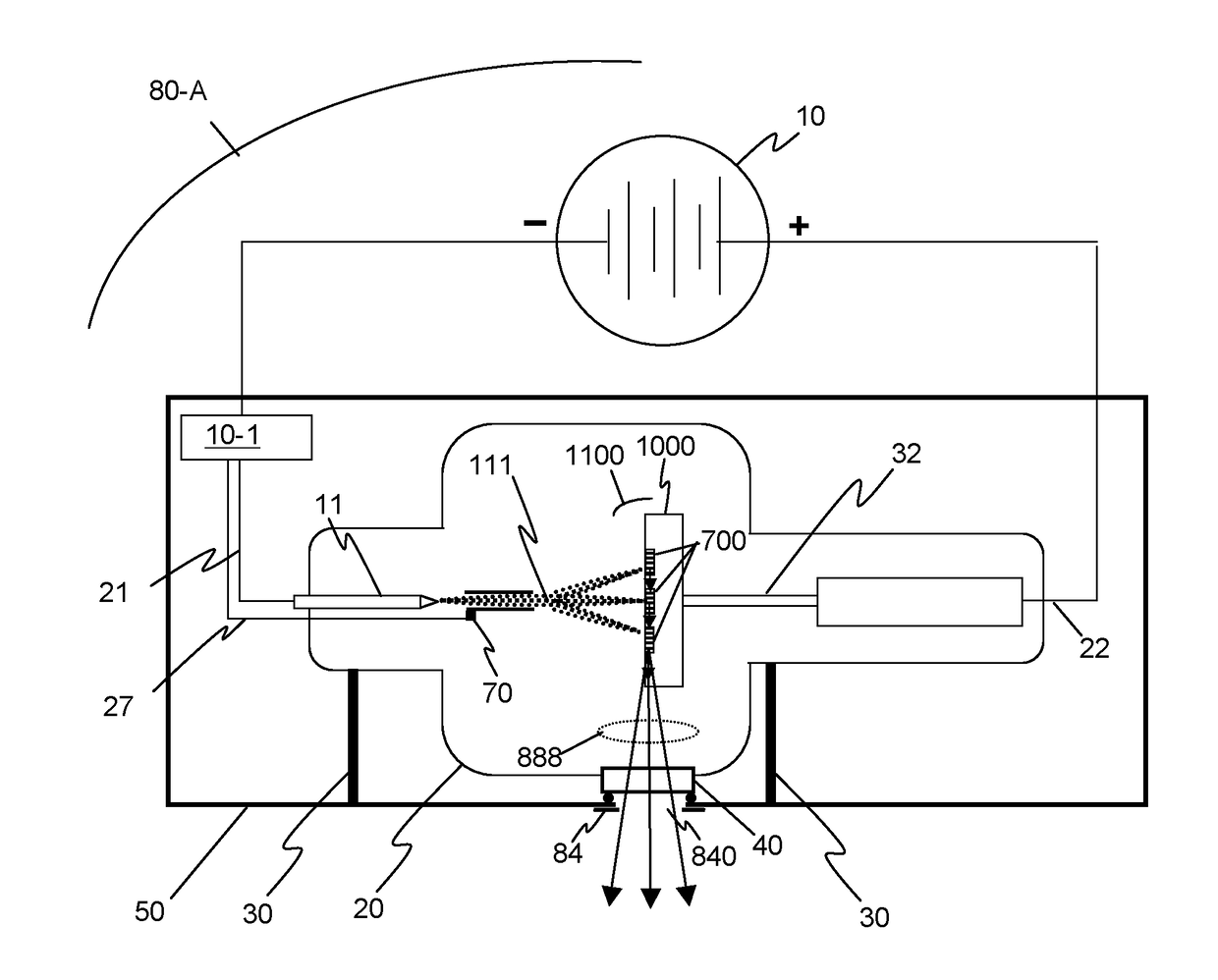

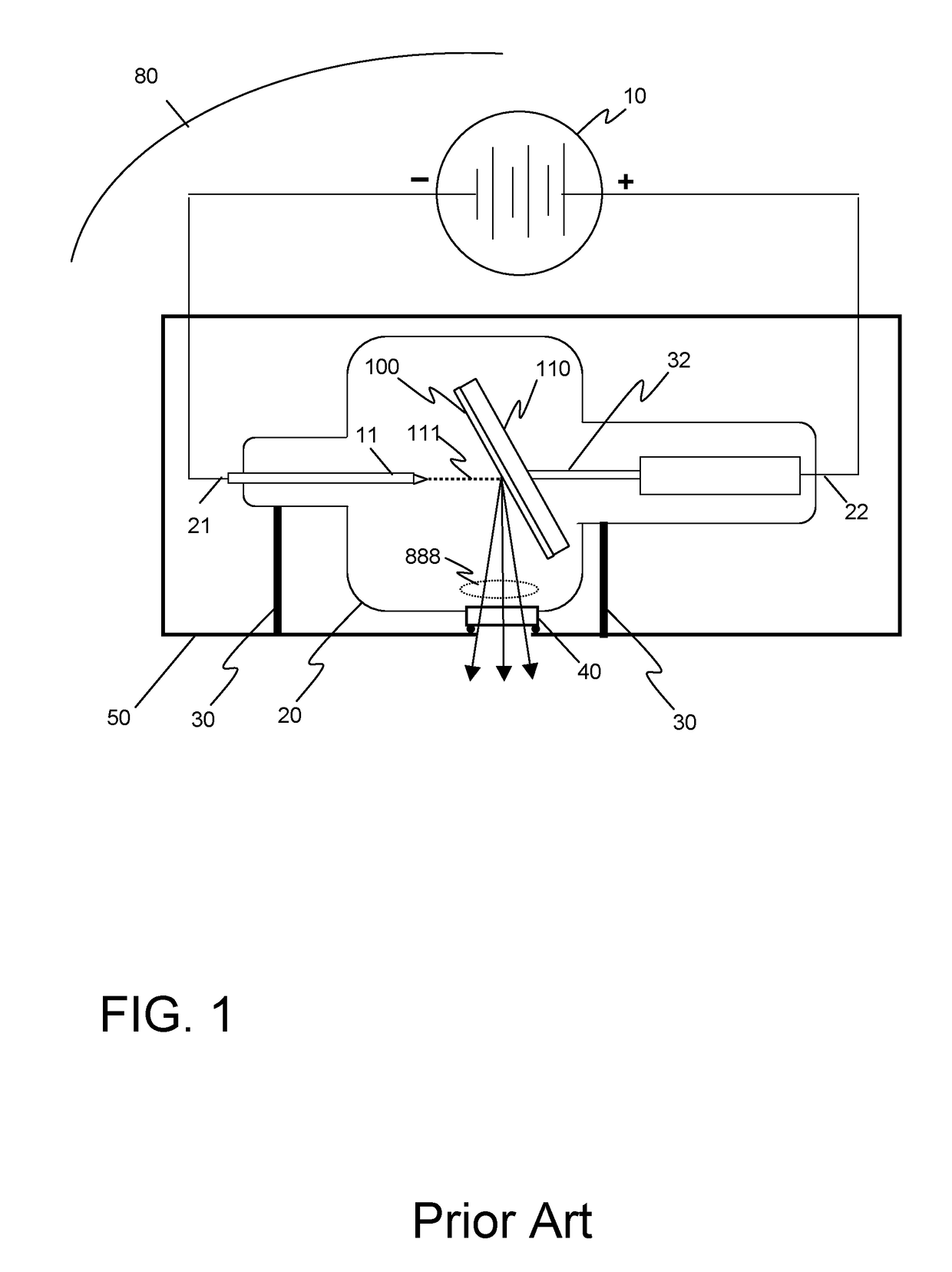

Method and system for electron beam applications

ActiveUS20110017920A1Eliminate needIncrease exposureStability-of-path spectrometersMaterial analysis using wave/particle radiationEnergy controlControl system

The present invention relates to methods and systems for use of an electron beam system. The electron beam system may be used within a treatment center with very little radiation shielding. The electron beam system may be used in conjunction with low-z moderators that reduce the energy level of the electron beam without the need for complex or expensive energy control systems. The electron beam system may be used to treat skin cancer and dermatological patients in non-traditional treatment facilities, as well as invasive cancers, either in an unshielded operating room to deliver intraoperative radiation therapy (“IORT”) or in an unshielded room in the oncology department to deliver electron beam radiation treatment (“EB-RT”).

Owner:INTRAOP MEDICAL

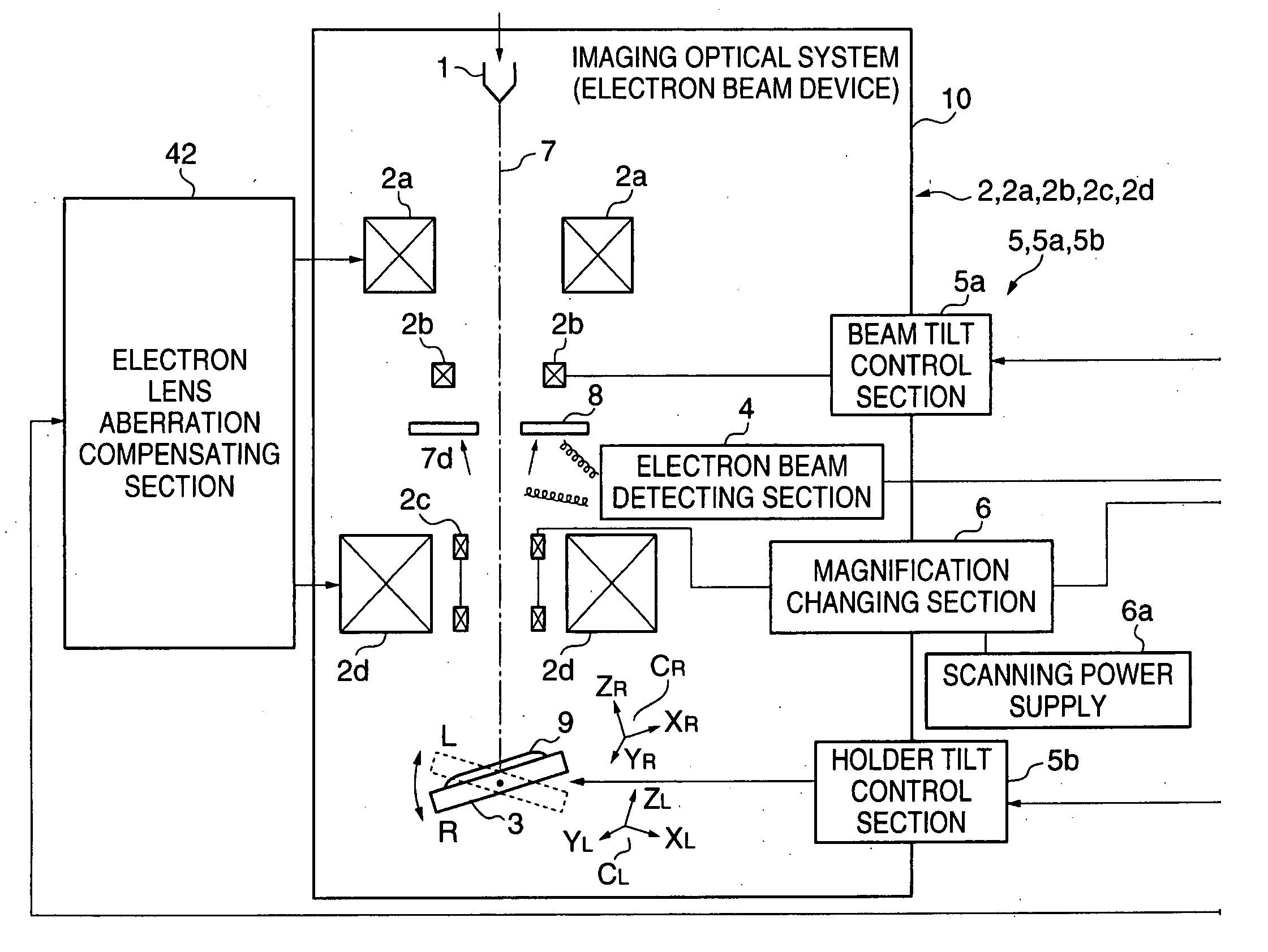

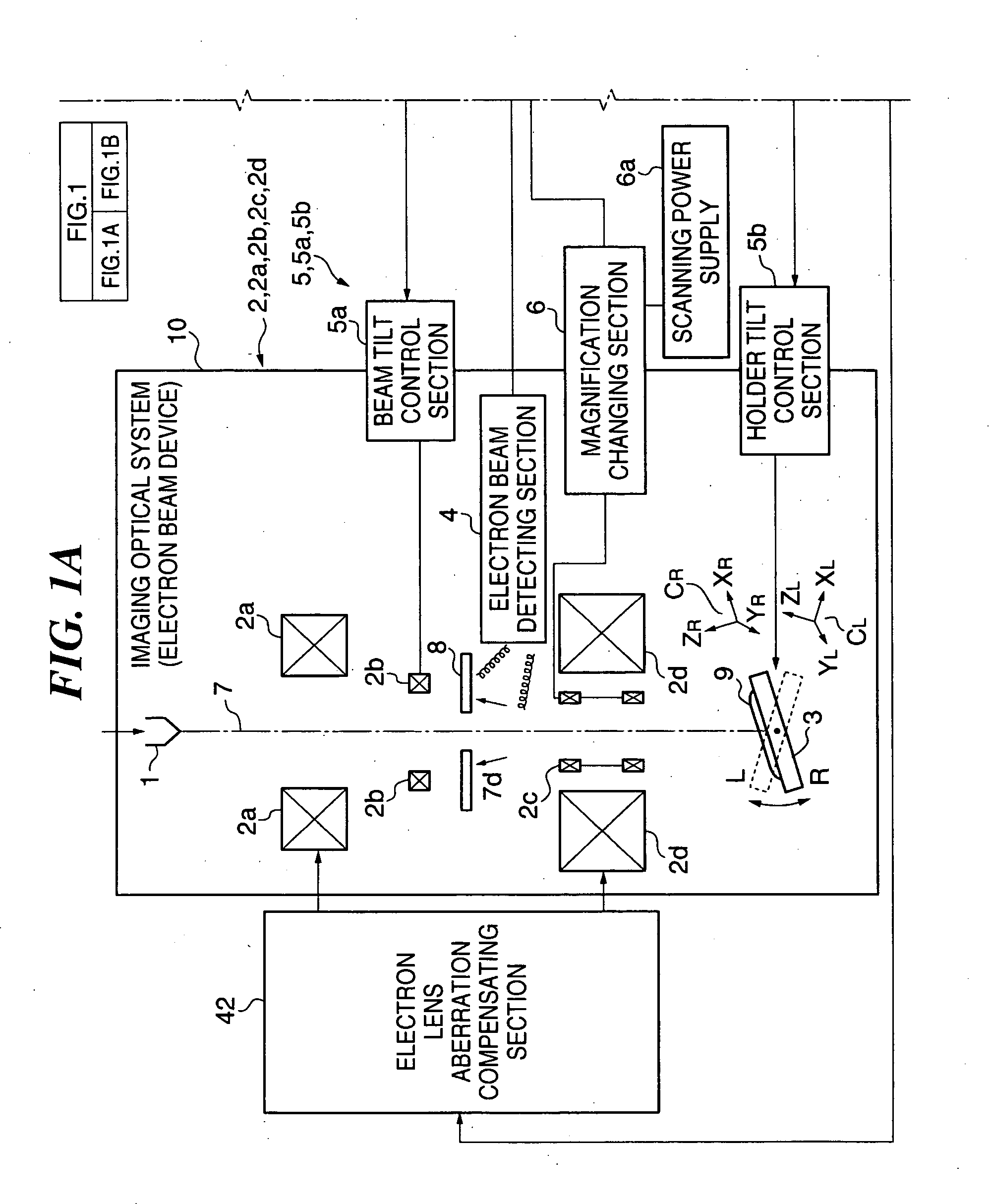

Electron beam system and electron beam measuring and observing methods

InactiveUS20050061972A1Improve image processing capabilitiesEasy to useMaterial analysis using wave/particle radiationElectric discharge tubesThree dimensional measurementStereo image

To provide an electron beam system capable of performing three-dimensional measurement of a sample with high precision irrespective of the tilt angle and height of the sample. The electron beam system has a correction factor storing section 32 for storing a correction factor at a reference tilt angle with respect to a plane which is used to tilt a sample by a sample tilting section 5, an approximate coordinate measuring section 28 for obtaining an approximate shape or approximate coordinate values of the sample based on an output corresponding to a stereo image from an electron beam detecting section 4, an image correcting section 30 for correcting the stereo image according to the tilt angle created by the sample tilting section 5 based on the shape or coordinate values of the sample obtained in the approximate coordinate measuring section 28 using a correction factor stored in the correction factor storing section 32, and a precise coordinate measuring section 34 for obtaining a shape or coordinate values of the sample which are more precise than those obtained in the approximate coordinate measuring section 28 based on a corrected stereo image obtained in the image correcting section 30.

Owner:KK TOPCON

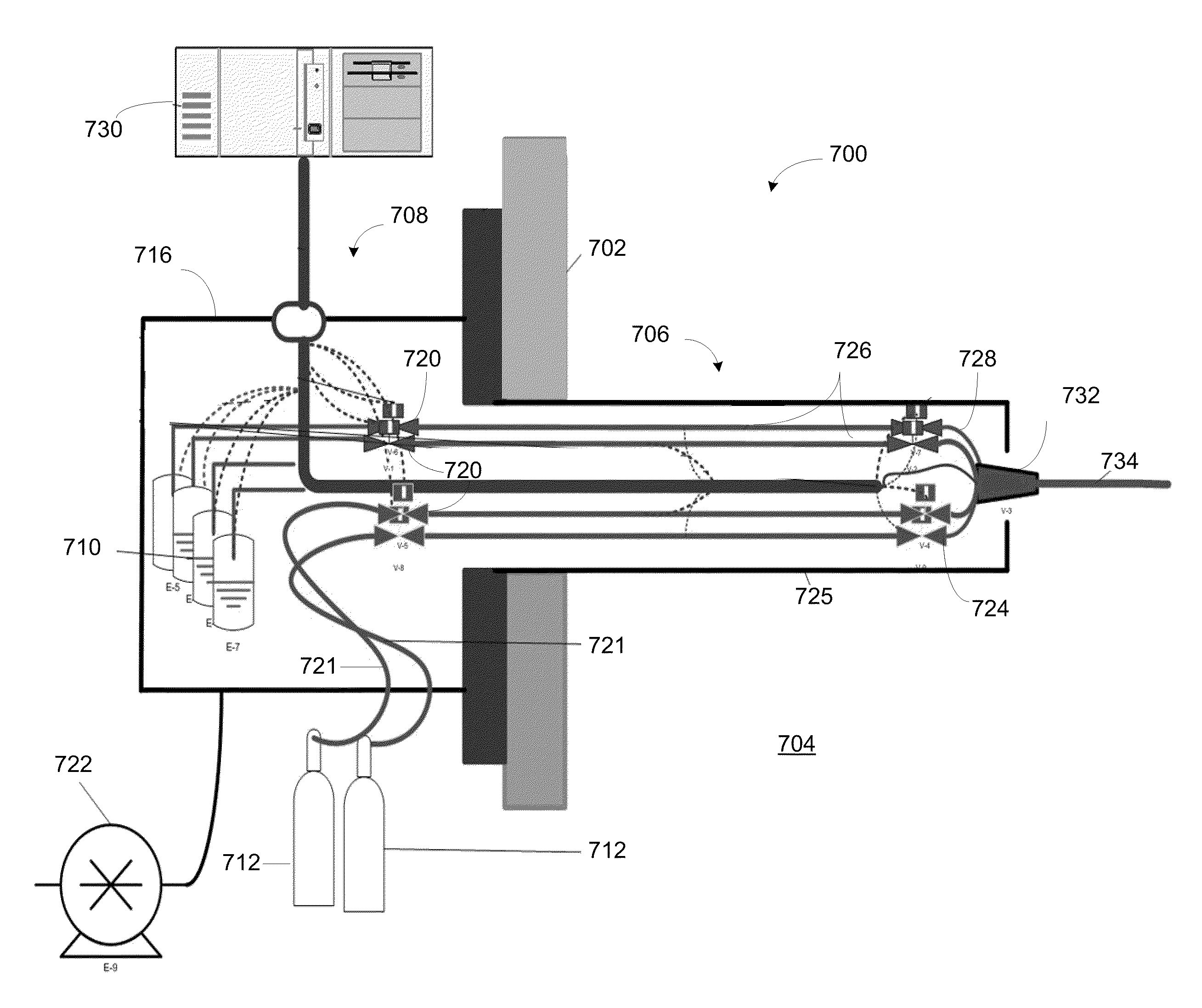

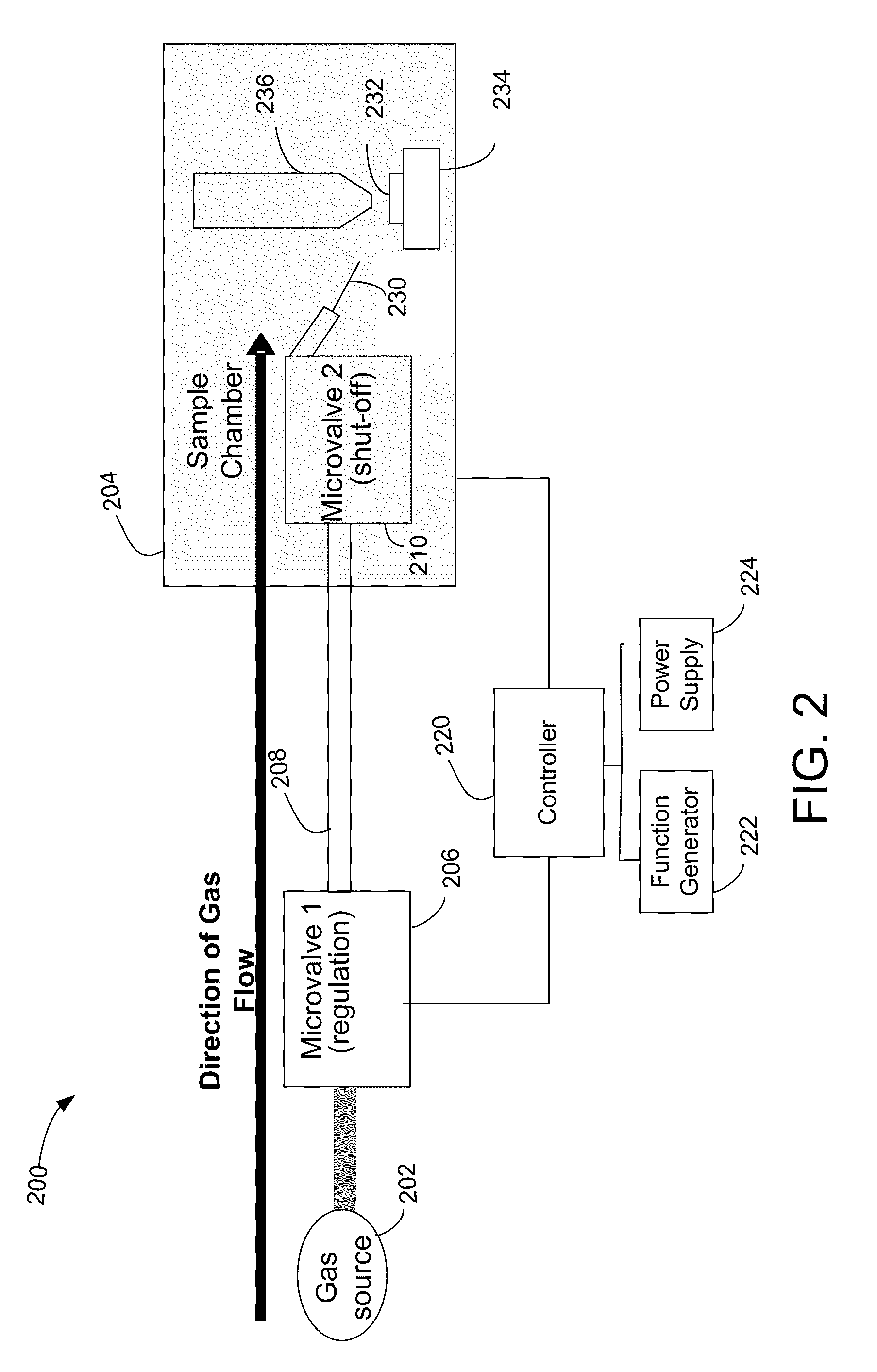

Gas delivery for beam processing systems

ActiveUS20110114665A1Rapid responseEasy to disconnectPower operated devicesDecorative surface effectsLight beamEngineering

Gas flow from multiple gas sources into a sample chamber of a beam system is controlled by a cycling valve for each gas source, with the gas pressure in the sample chamber being determined by the relative time that the valve is opened and the upstream pressure at the valve. A gas valve positioned inside the vacuum chamber allows rapid response in shutting off a gas. In some preferred embodiments, a precursor gas is supplied from a solid or liquid material in a container that remains outside the vacuum system while in use and which is readily connected or disconnected to the gas injection system without significant leakage.

Owner:FEI CO

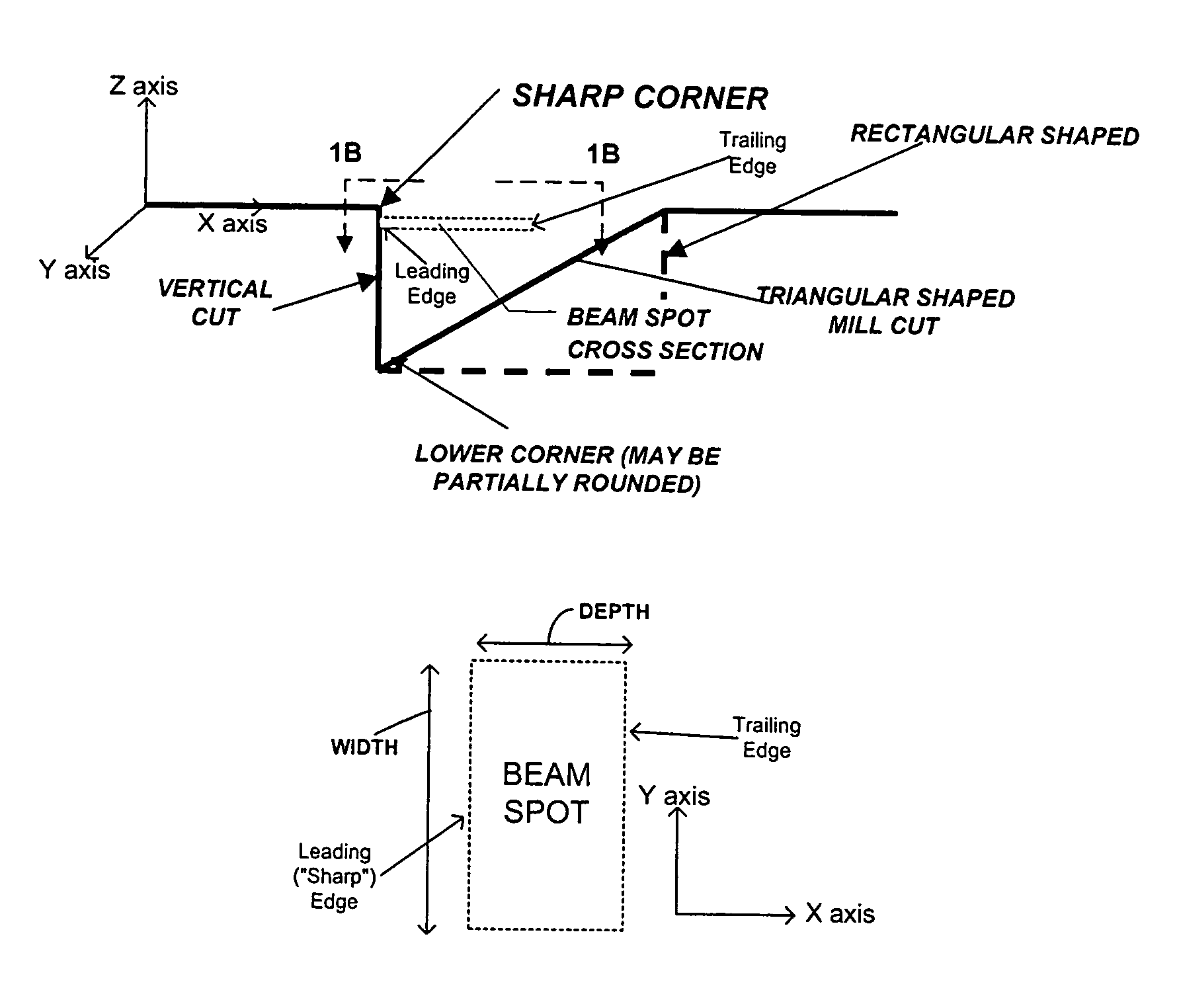

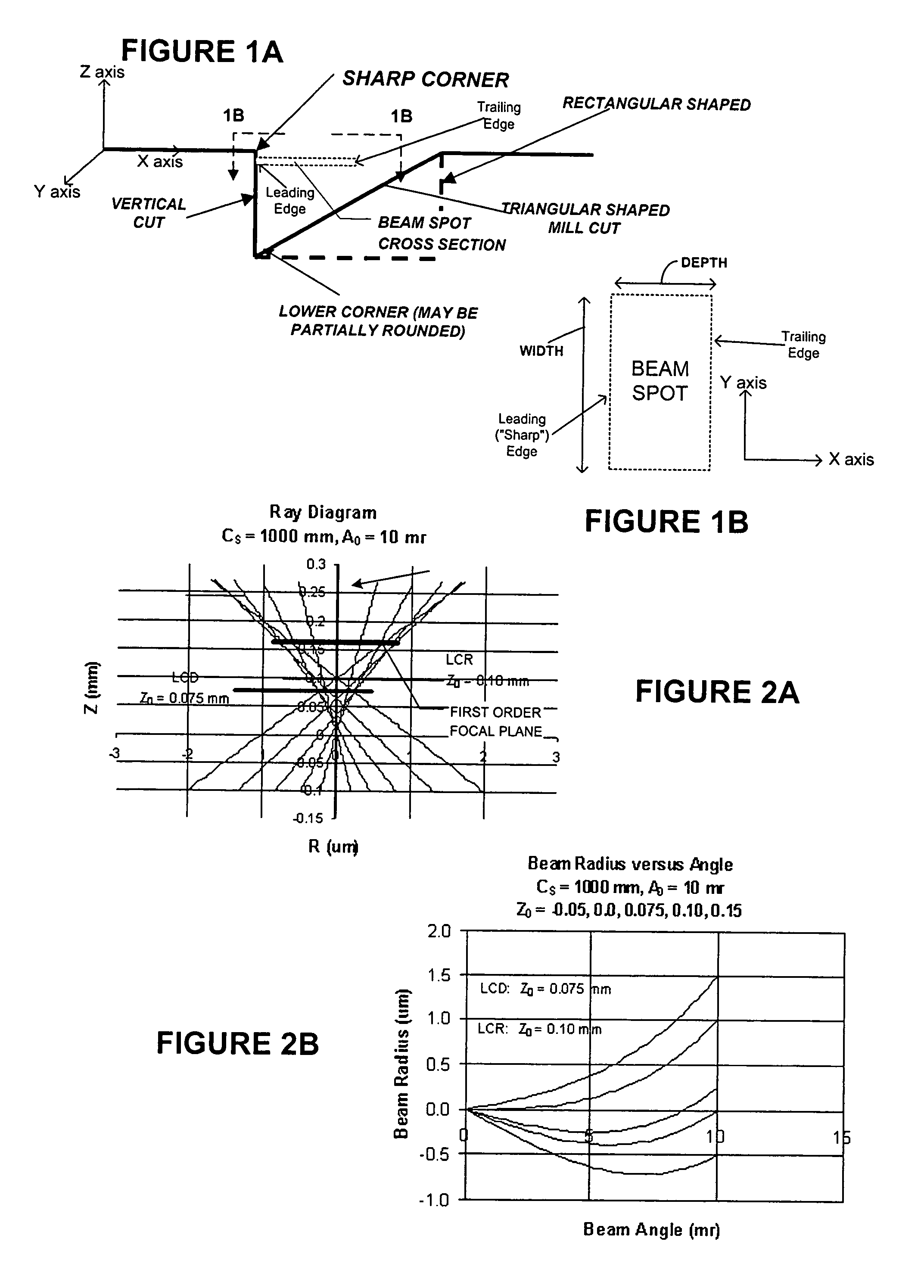

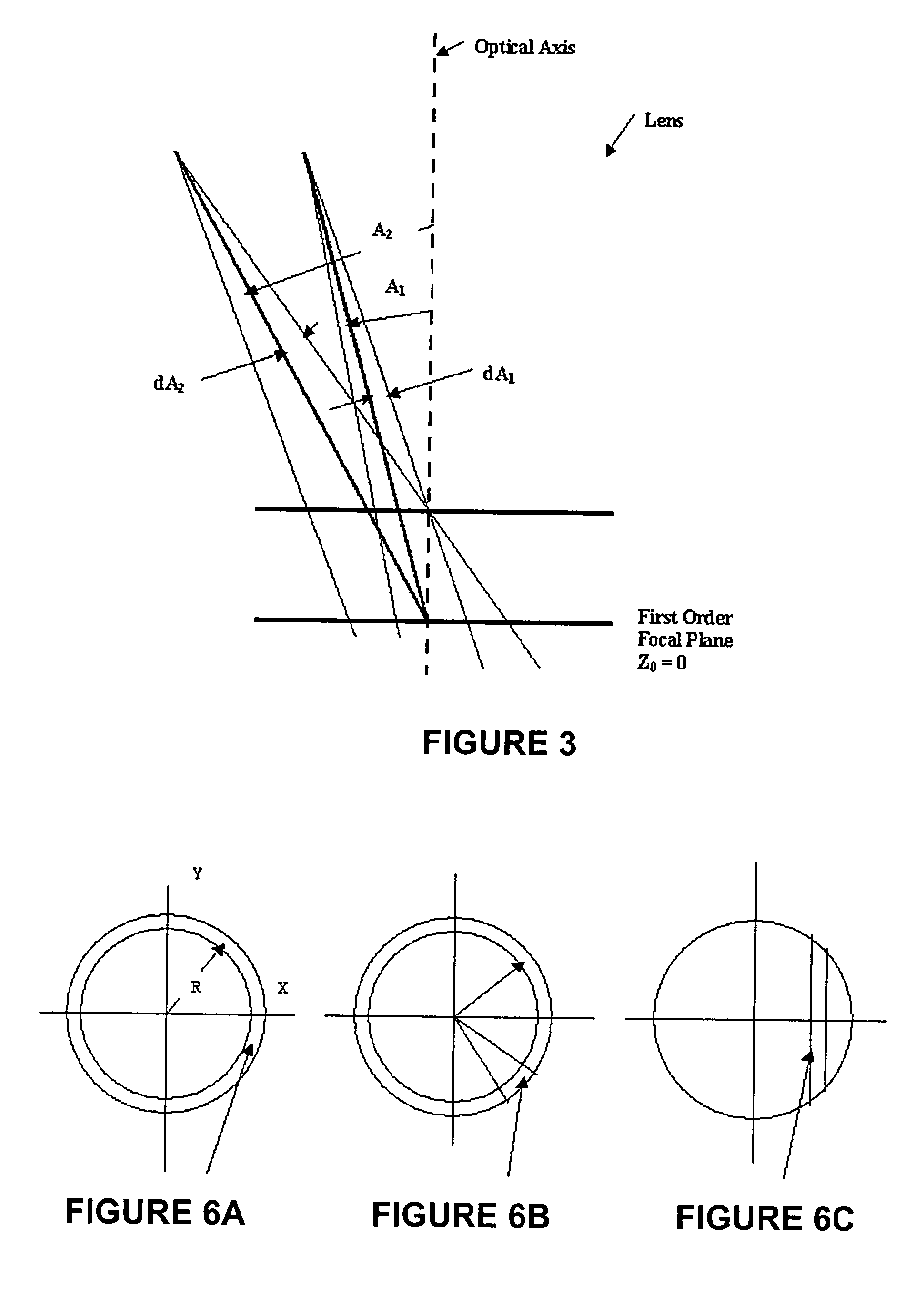

Angular aperture shaped beam system and method

InactiveUS6977386B2More currentSharp edgeMaterial analysis using wave/particle radiationElectric discharge tubesShaped beamSEMI-CIRCLE

The present invention provides improved angular aperture schemes for generating shaped beam spots having a desired geometric shape from rectangular, elliptical, and semi-elliptical apertures having one sharp edge. A sharper beam edge can be generated by offsetting the rectangular or elliptical aperture in combination with under or over focus. In the spherical aberration limit, under-focused semi-circle apertures provide a sharp, flat edge. The sharp edge can be made resolute enough for precision milling applications, and at the same time, the spot can be made large enough with enough overall current and current density to efficiently mill away material in either a production or laboratory environment. Depending on the particular beam spot that is desired, combinations of techniques including defocusing, aperture offsetting, and stigmation adjustment, can be used in both spherical aberration dominant and chromatic aberration dominant environments to achieve a desired beam for a desired application.

Owner:FEI CO

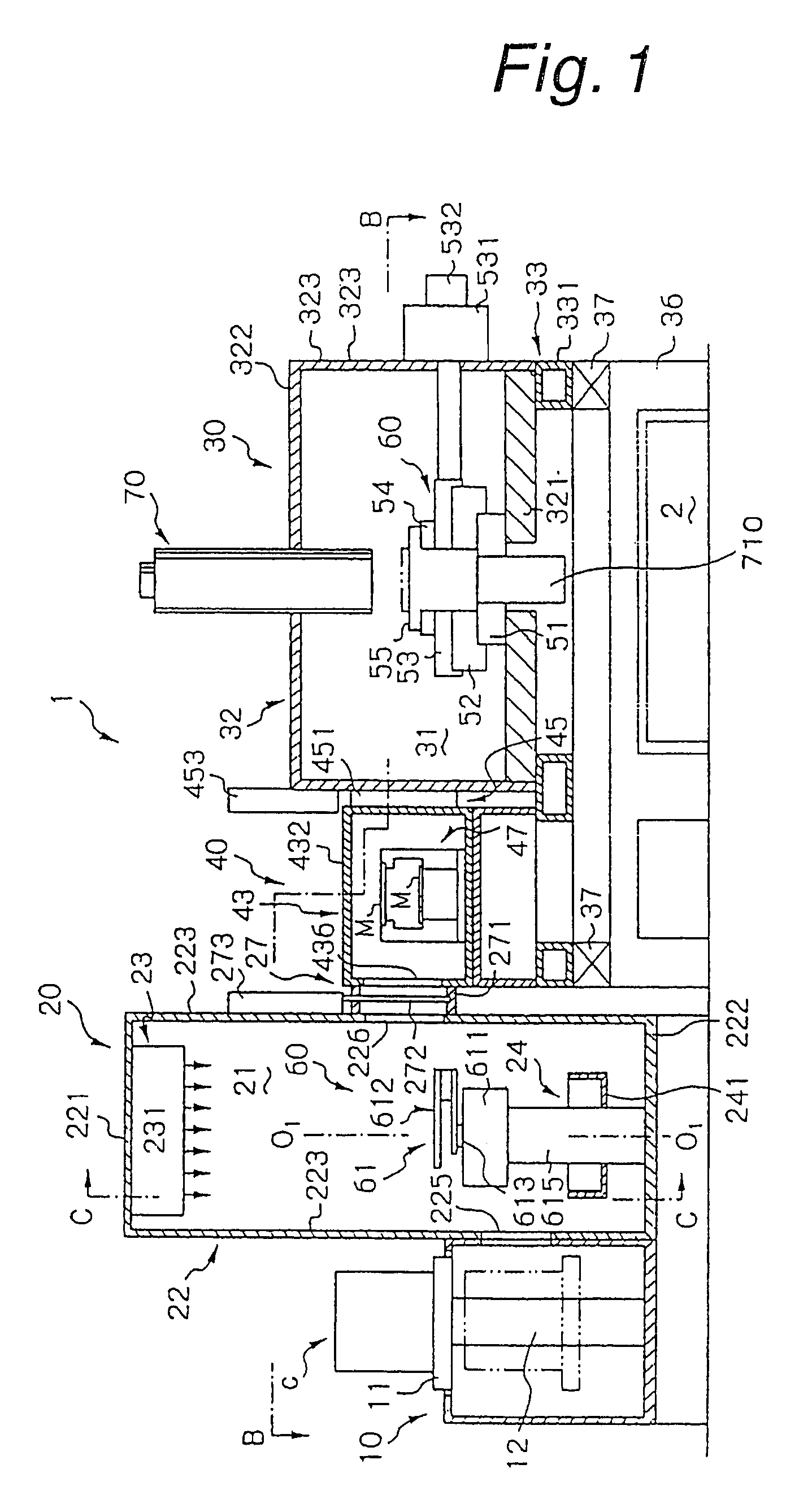

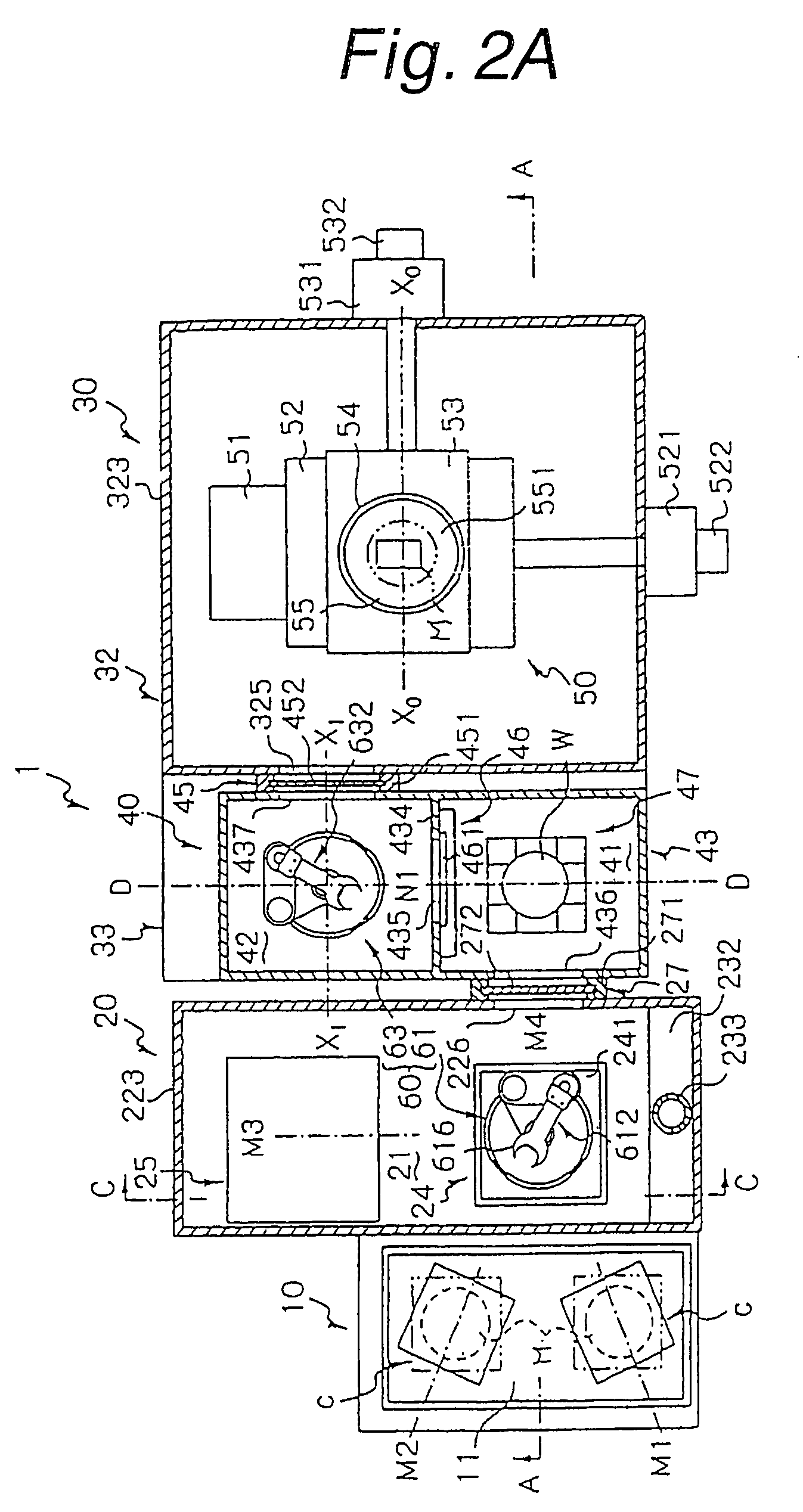

Electron beam system

InactiveUS7157703B2Improve throughputIncrease productionMaterial analysis using wave/particle radiationElectric discharge tubesSecondary electronsAtomic physics

Provided is an electron beam system, in which an electron beam emitted from an electron gun is irradiated to a stencil mask, and the electron beam that has passed through the stencil mask is magnified by an electron lens and then detected by a detector having a plurality of pixels so as to form an image of the sample. Further provided is an electron beam system, in which a primary electron beam emitted from an electron gun is directed to a sample surface of a sample prepared as a subject to be inspected, and an electron image formed by a secondary electron beam emanated from the sample is magnified and detected, wherein an NA aperture is disposed in a path common to both of the primary electron beam and the secondary electron beam. An electron lens is disposed in the vicinity of a sample surface, and in this arrangement, a crossover produced by the electron gun, the electron lens and the NA aperture may be in conjugate relationships relative to each other with respect to the primary electron beam.

Owner:EBARA CORP

Method and system for electron beam applications

ActiveUS8269197B2Increase exposureEasy to manageMaterial analysis using wave/particle radiationRadiation/particle handlingEnergy controlControl system

The present invention relates to methods and systems for use of an electron beam system. The electron beam system may be used within a treatment center with very little radiation shielding. The electron beam system may be used in conjunction with low-z moderators that reduce the energy level of the electron beam without the need for complex or expensive energy control systems. The electron beam system may be used to treat skin cancer and dermatological patients in non-traditional treatment facilities, as well as invasive cancers, either in an unshielded operating room to deliver intraoperative radiation therapy (“IORT”) or in an unshielded room in the oncology department to deliver electron beam radiation treatment (“EB-RT”).

Owner:INTRAOP MEDICAL

X-ray illumination system with multiple target microstructures

An x-ray illumination beam system includes an electron emitter and a target having one or more target microstructures. The one or more microstructures may be the same or different material, and may be embedded or placed atop a substrate formed of a heat-conducting material. The x-ray source may emit x-rays towards an optic system, which can include one or more optics that are matched to one or more target microstructures. The matching can be achieved by selecting optics with the geometric shape, size, and surface coating that collects as many x-rays as possible from the source and at an angle that satisfies the critical reflection angle of the x-ray energies of interest from the target. The x-ray illumination beam system allows for an x-ray source that generates x-rays having different spectra and can be used in a variety of applications.

Owner:SIGRAY INC

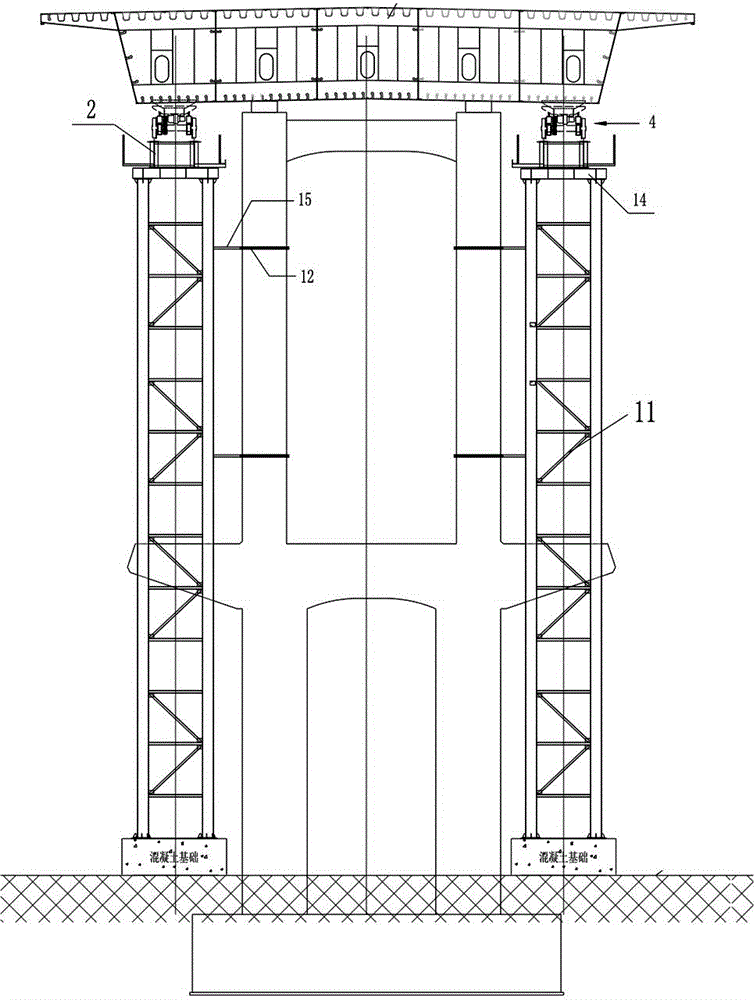

Inside and outside beam system bridge fabrication machine for small radius curve concrete box girder construction and construction method thereof

InactiveCN101210419ASolve steering difficultiesEasy to operateBridge erection/assemblyBox girderBuilding construction

A small-radius curve upper concrete box girder adopts a bridge fabrication machine with inner and outer girder systems, which relates to a construction device for small-radius curve continuous girder and a method thereof. The bridge fabrication machine consists of an inner and an outer girder systems, wherein the inner girder system includes a bottom die and is supported in a preformed groove on a pier top at both ends, connected with the cantilever end of a concrete box girder at the middle portion and arranged below the bottom plate of the concrete box girder; the outer girder system includes a side die and a wing die and is supported on the inner girder at the front end, supported on a cast concrete box girder at the rear end, supported on a bracket near the pier at the middle portion and arranged on both sides of the concrete box girder. The inner and the outer girder systems are independent from each other and supplement each other. During passing holes, the inner and the outer girder systems travel respectively in such a manner that the inner girder travels to the right position on the basis of the outer girder, and the outer girder longitudinally travels on the support and a track provided by the inner girder. The planar deflections of the inner and the outer girders are achieved by a hydraulic jack in the traveling process.

Owner:CHINA MAJOR BRIDGE ENG

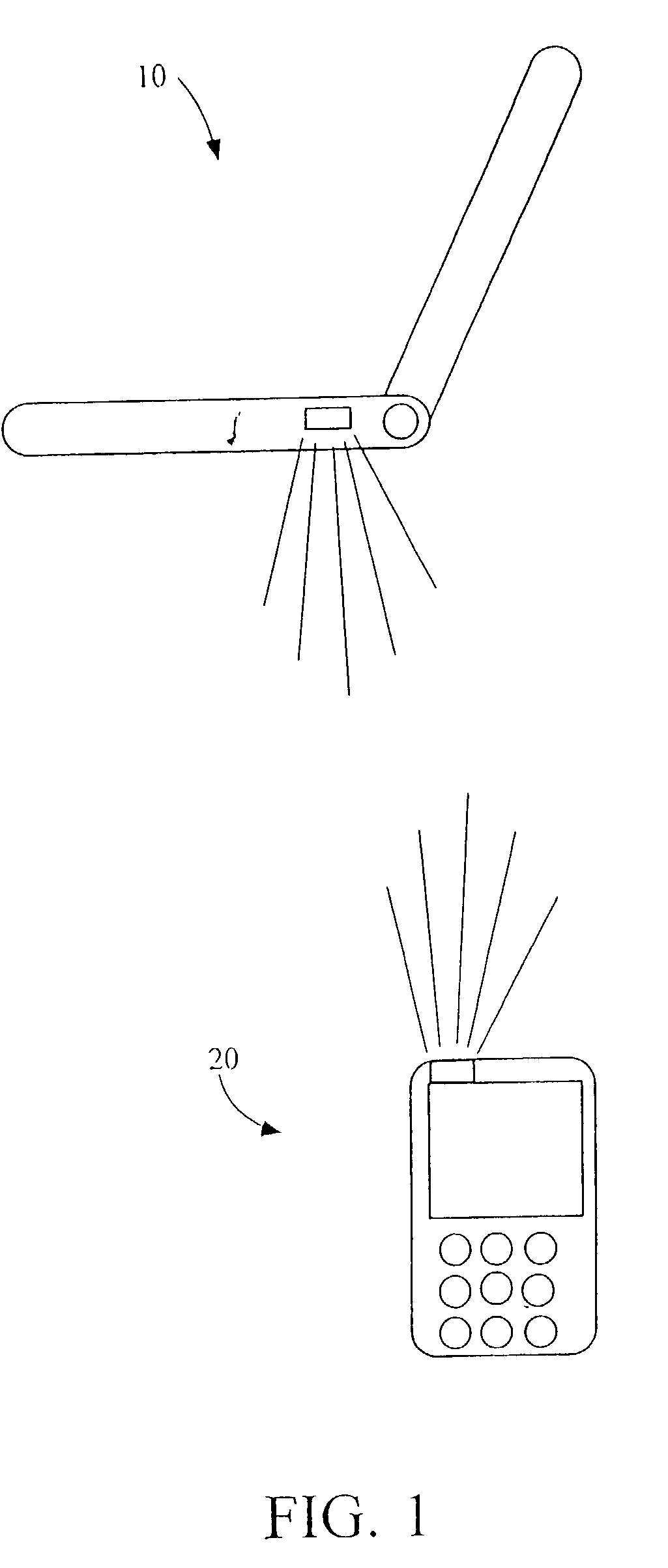

Beamcast (continuous infrared data beaming system)

InactiveUS20020181060A1Effectively achieves one-touch wireless synchronizationEfficient implementationElectromagnetic transmissionLight beamBrief periods

A Continuous Data Beaming System that is capable of continuously and automatically beaming data by direct transmission from one Host Device (source device or "beaming station") to another Remote Device (receiver device) every time the receiver needs the data. The Host Device constantly searches to find an IrOBEX compliant Remote Device, checks availability for an infrared connection, completes the connection to the Remote Device and transfers a data object through the respective infrared ports. If a failure occurs during any of the foregoing steps, the program automatically returns to searching. This progresses in an infinite loop, thereby accomplishing continuous, wireless, infrared data transmission. During the continuous transmission, no Remote Device other than BeamMaster can interrupt the continuous beaming. The BeamMaster Device allows the system to halt for a brief period, thirty seconds or less, so that files or data objects may be swapped. Continuous beaming resumes once the files are swapped or the time has expired. The Host Device automatically transmits data to the receiver device every time a receiver shows up and needs the data, thereby effectively achieving one-touch wireless synchronization.

Owner:HUANG CHIANG LUNG

High throughput high-yield vacuum deposition system

InactiveUS7195797B2Maintain symmetryNanoinformaticsVacuum evaporation coatingCoating systemEvaporation

A vacuum deposition system has been designed to produce thin film based demultiplexers with high throughput and production yields of greater than 25% for use in Dense Wavelength Division Multiplexer (DWDM) systems. The system employs a dense array of high yield fixtures and an ion assisted movable dual electron beam evaporation system. The fixture array increases acceptable yields of narrow band pass filters to 25–75% compared to less than 5% in conventional coating systems used for DWDM. The movable e-beam system allows critical symmetry to be maintained while eliminating significant delays resulting from deposition of two materials from a single electron gun. The vacuum deposition system will enable production of more than 15,000 50–200 GHZ filters which meet specifications for DWDM demultiplexers every 48 hours.

Owner:TERAPHYSICS CORP

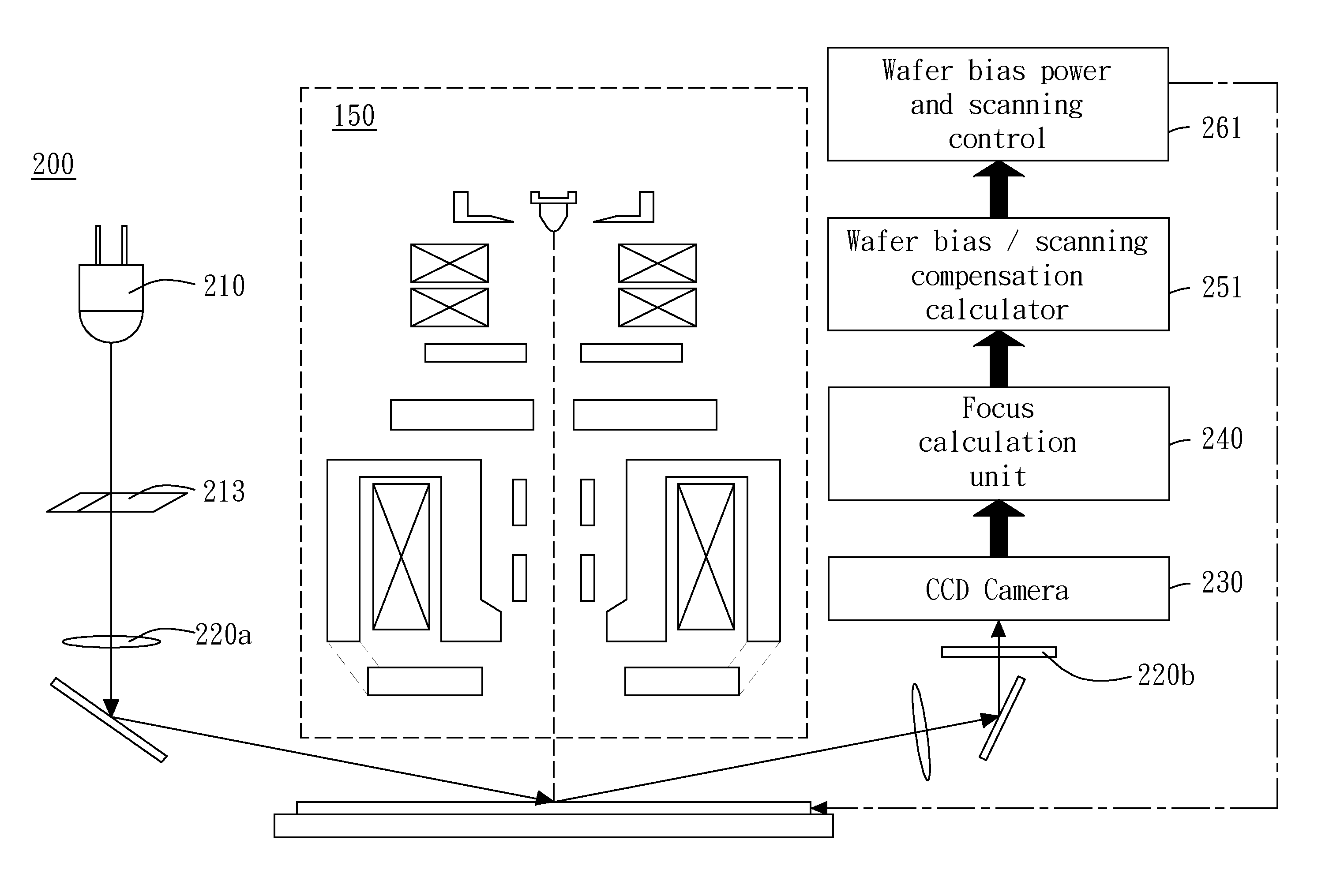

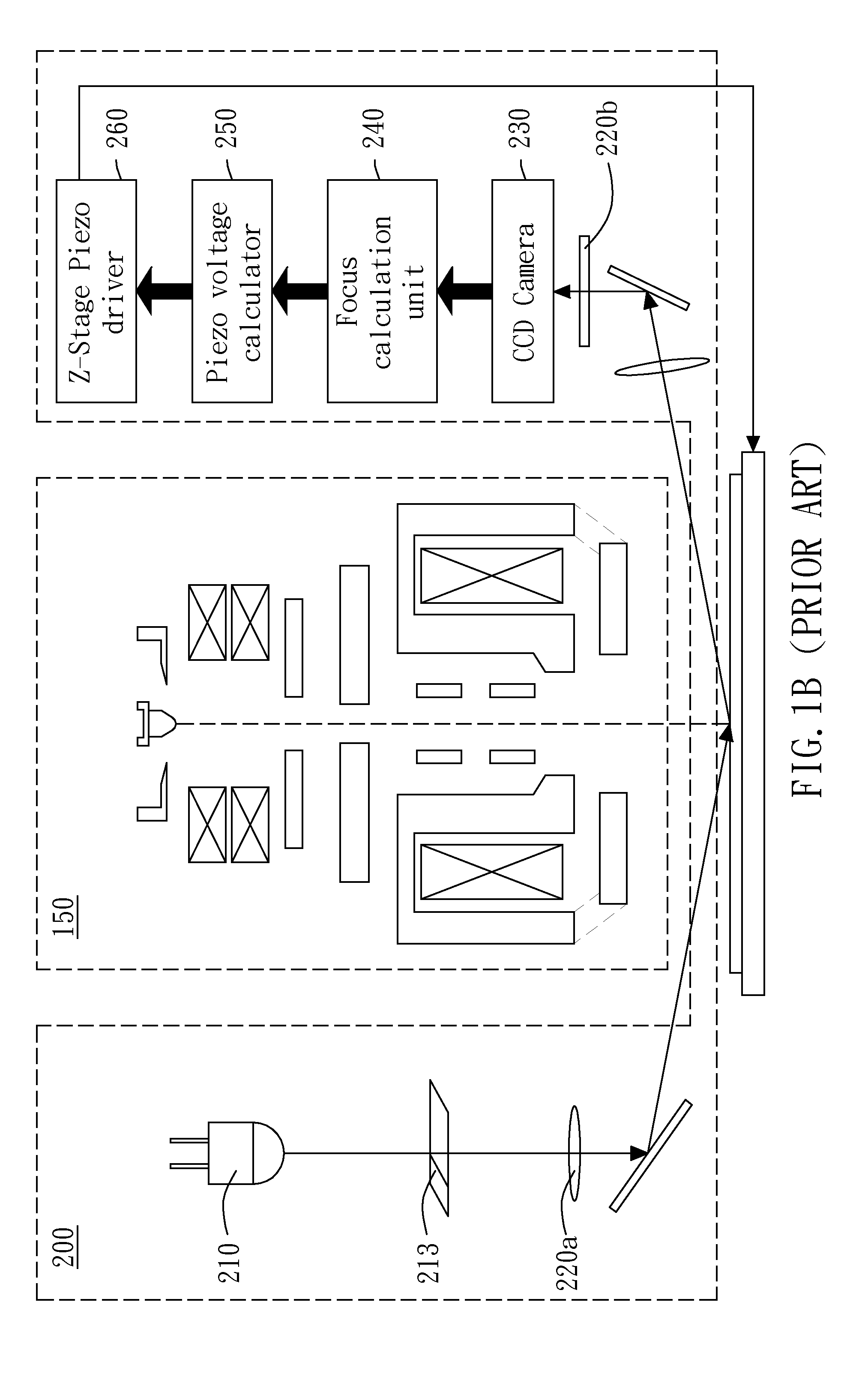

Dynamic Focus Adjustment with Optical Height Detection Apparatus in Electron Beam system

ActiveUS20110260055A1Adjust focusElectric discharge tubesUsing optical meansField strengthImage system

The present invention generally relates to dynamic focus adjustment for an image system. With the assistance of a height detection sub-system, present invention provides an apparatus and methods for micro adjusting an image focusing according the specimen surface height variation by altering the field strength of an electrostatic lens between objective lens and sample stage / or a bias voltage applied to the sample surface. Merely by way of example, the invention has been applied to a scanning electron inspection system. But it would be recognized that the invention could apply to other system using charged particle beam as observation tool with a height detection apparatus.

Owner:ASML NETHERLANDS BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com