Underground engineering one-pile multi-use semi reverse construction method

A technology of underground engineering and inverse method, applied in water conservancy engineering, infrastructure engineering, artificial island and other directions, can solve the problems of high cost and complicated construction, and achieve the effect of convenient construction, simple construction equipment and saving project cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

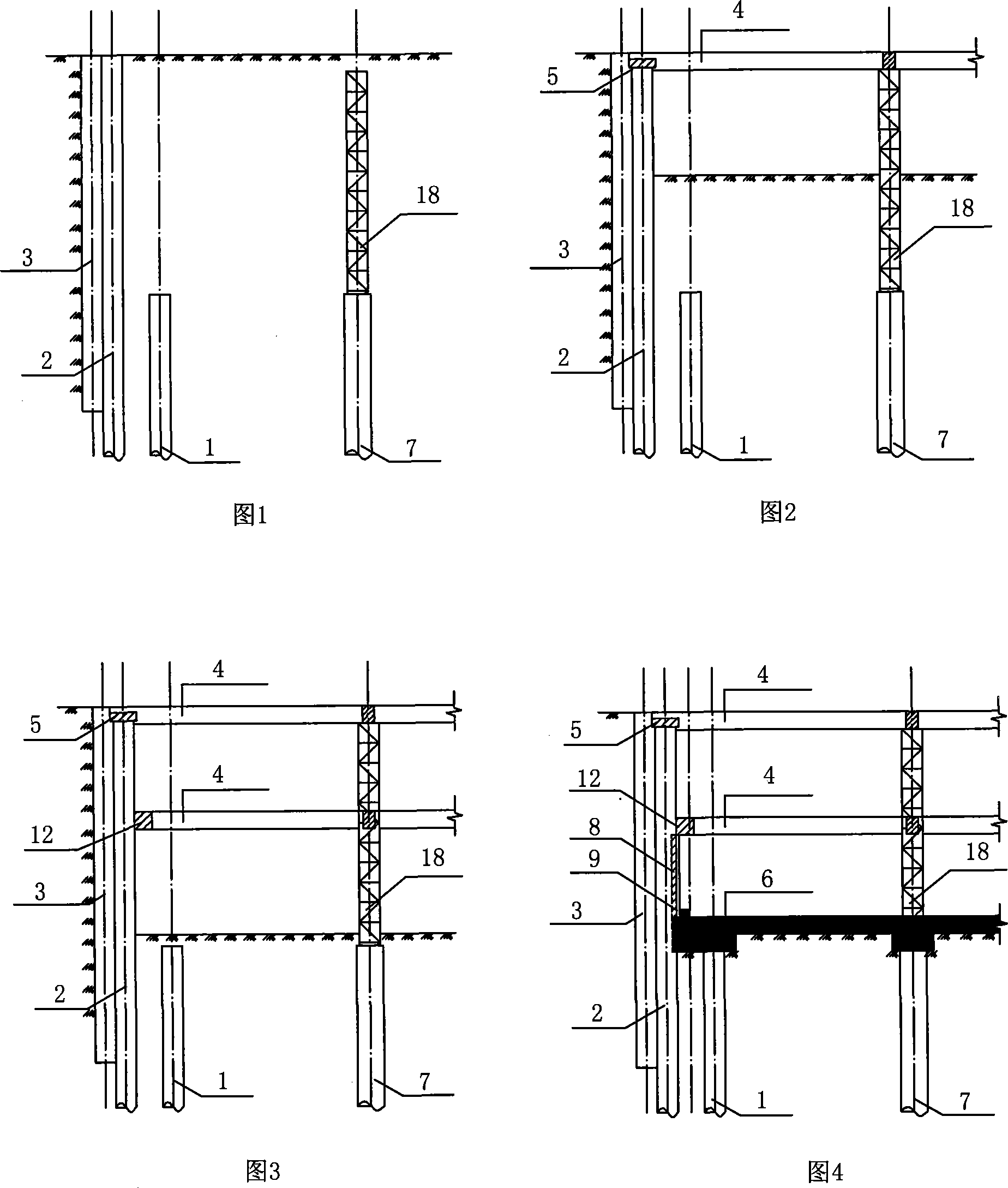

[0028] Embodiment 1: This method first builds surrounding protective piles and the water-stop soil retaining cement pile curtain along the periphery of the underground project. These surrounding protective piles can be constructed by "one pile with three uses" or by conventional temporary surrounding protective piles; Middle construction piles, some or all of these piles can be selected according to the structural design and constructed according to the requirements of one pile for four purposes. Then, according to the elevation of the floor beams of each floor of the underground project, the vertical and horizontal main beams of each floor are constructed layer by layer from top to bottom, and these beams should meet the requirements of supporting force. After excavating to the bottom, construct the foundation floor from bottom to top, and construct the underground engineering columns, walls and floors to the ground layer by layer.

[0029] In this kind of underground enginee...

Embodiment 2

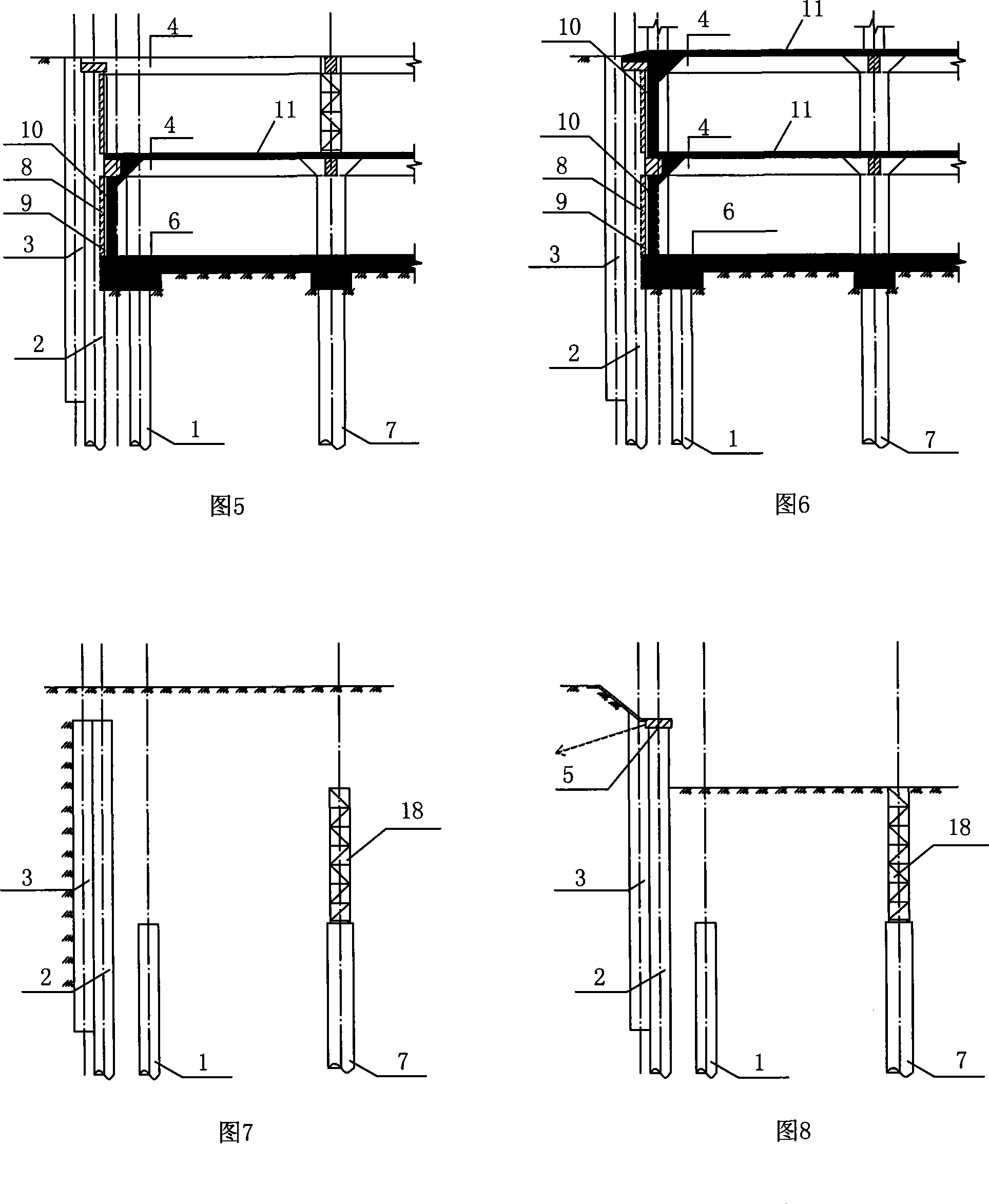

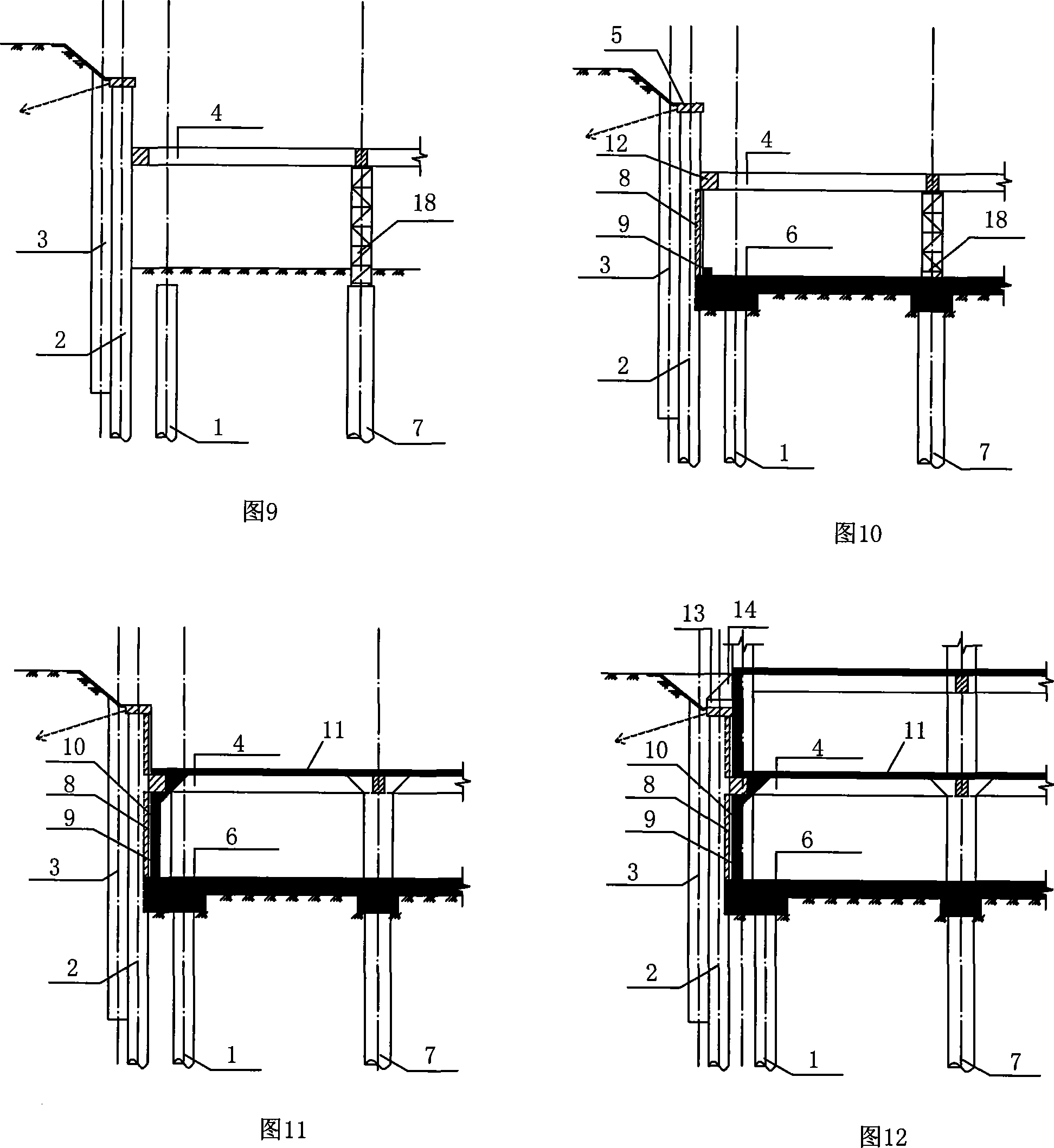

[0036] Embodiment 2: As shown in Figures 7 to 12, the feature is that the top beam of the retaining pile is moved down, so that one support can be reduced, which saves the cost and facilitates the construction. The specific implementation depends on the upper soil quality and the surrounding environment: if the soil quality is good and the surrounding environment permits, the upper part shall be excavated directly by sloping (if the soil quality or the surrounding environment does not allow direct sloping, the soil nail wall enclosure method can be used for excavation) until the top is pressed At the bottom of the beam 5, construct the top beam 5 of the enclosure pile 2; excavate to the bottom of the support 4, and pour the entire construction enclosure beam 12 and support 4; the same as 1.4, 1.5 and 1.6. If it is necessary to use the retaining pile as an engineering pile, construct the force transmission pad beam 13 and the force transmission corbel 14 at the same time in 1.6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com