Patents

Literature

121results about How to "Simple construction equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

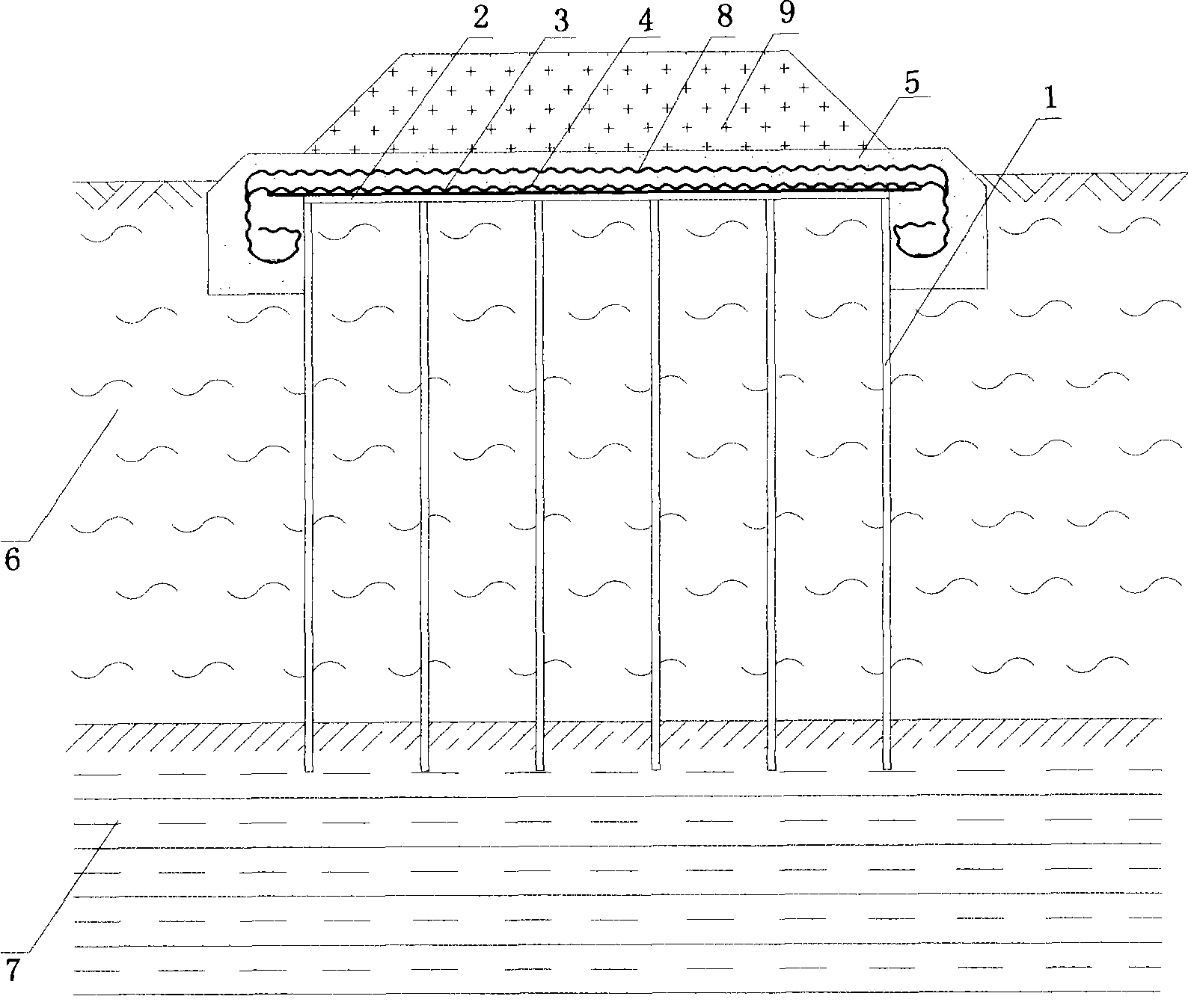

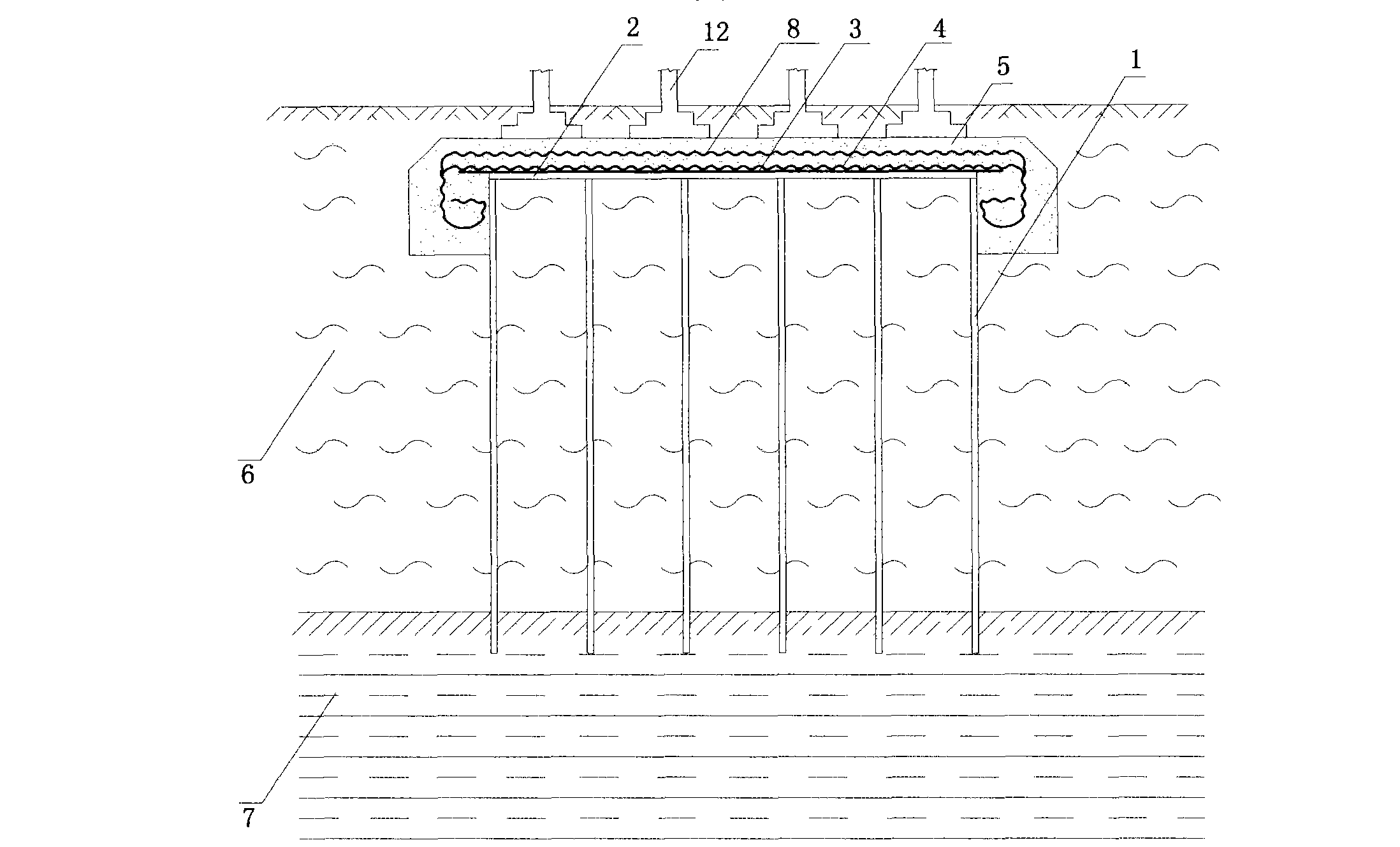

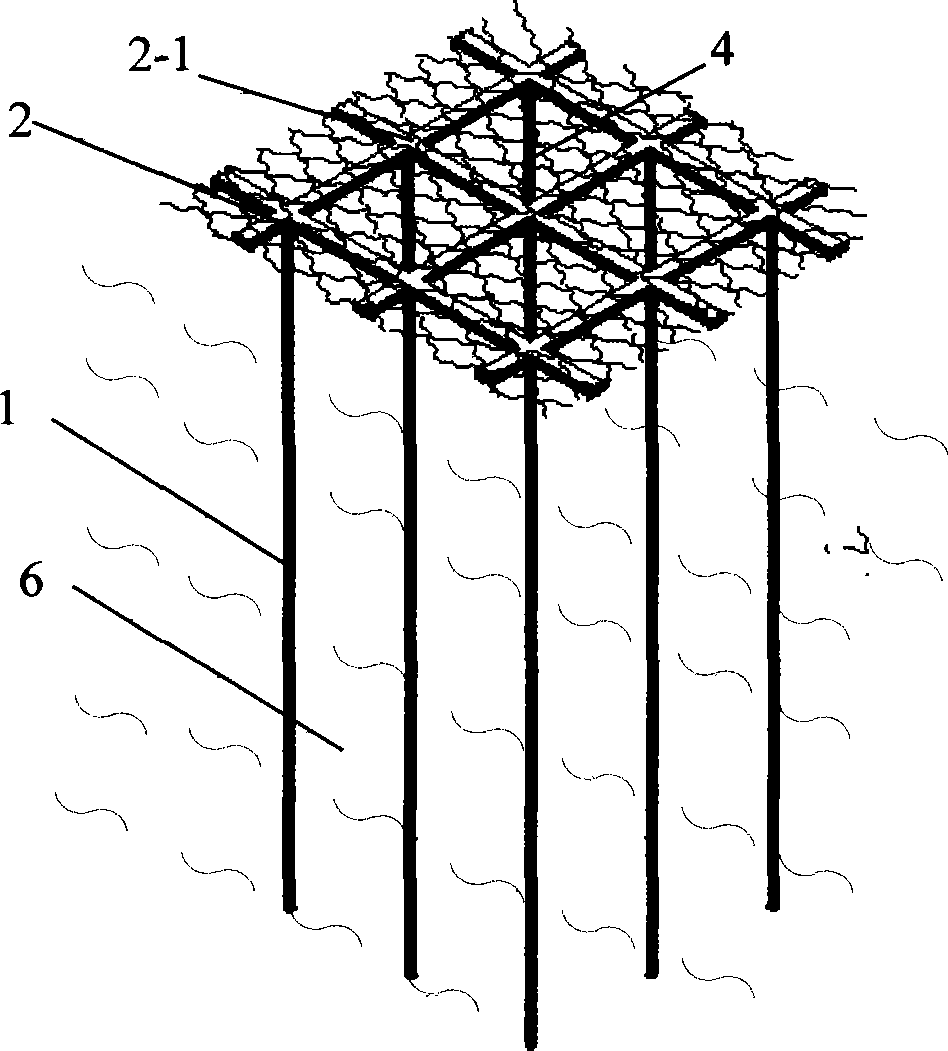

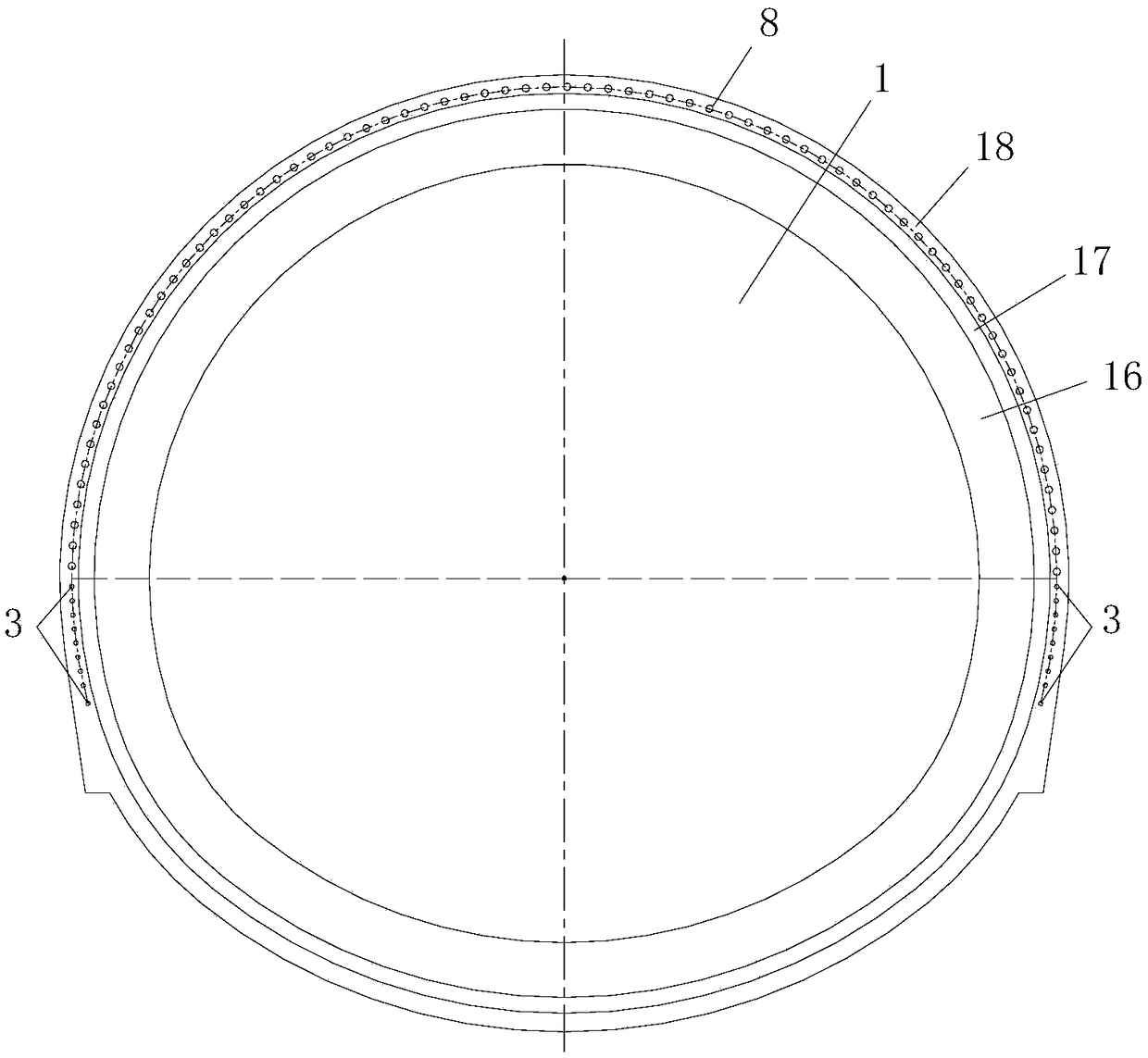

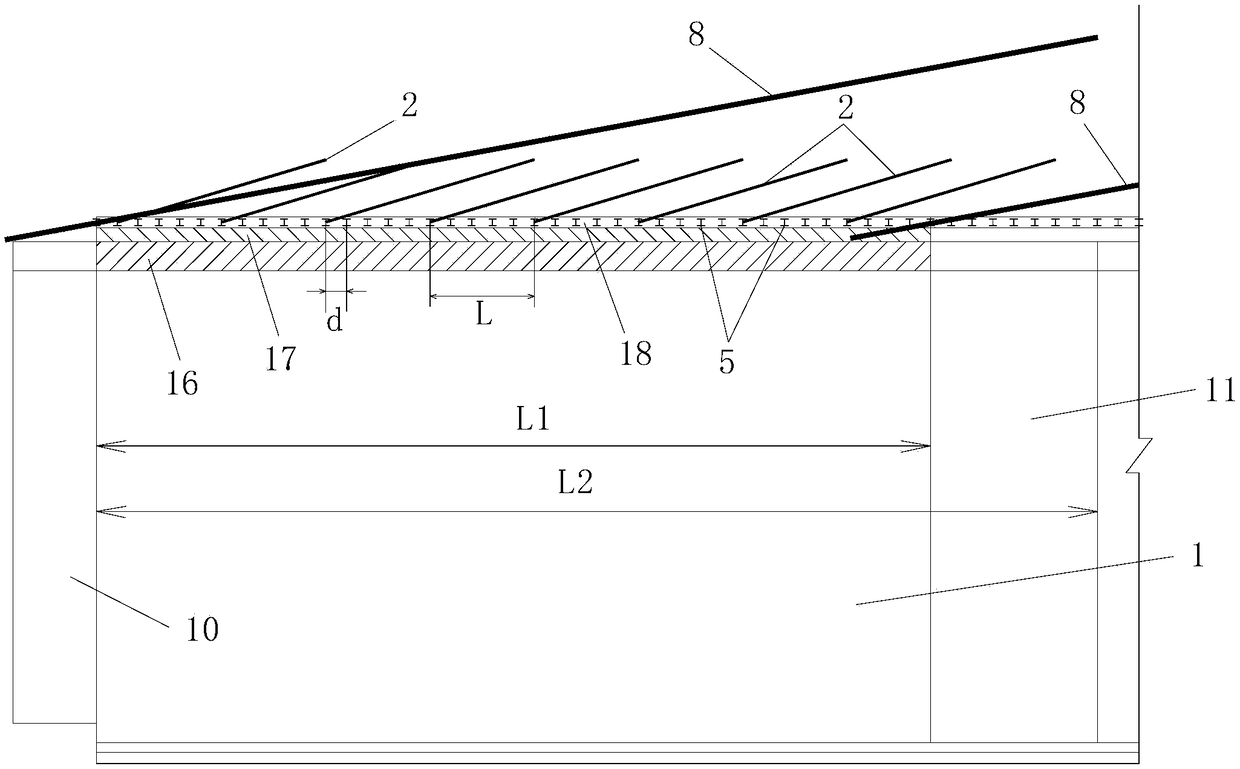

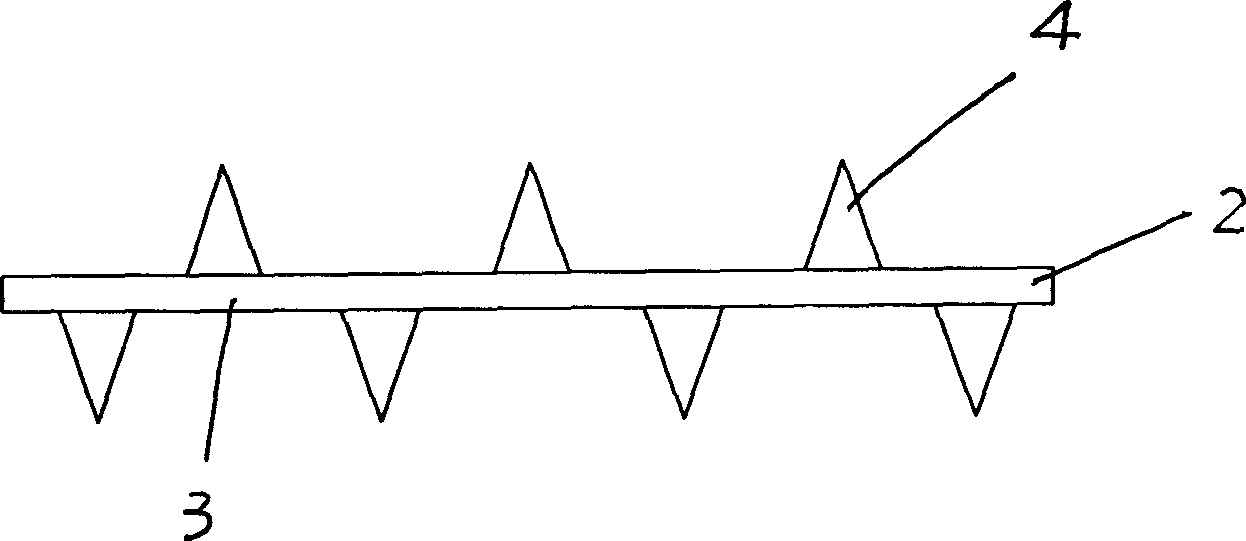

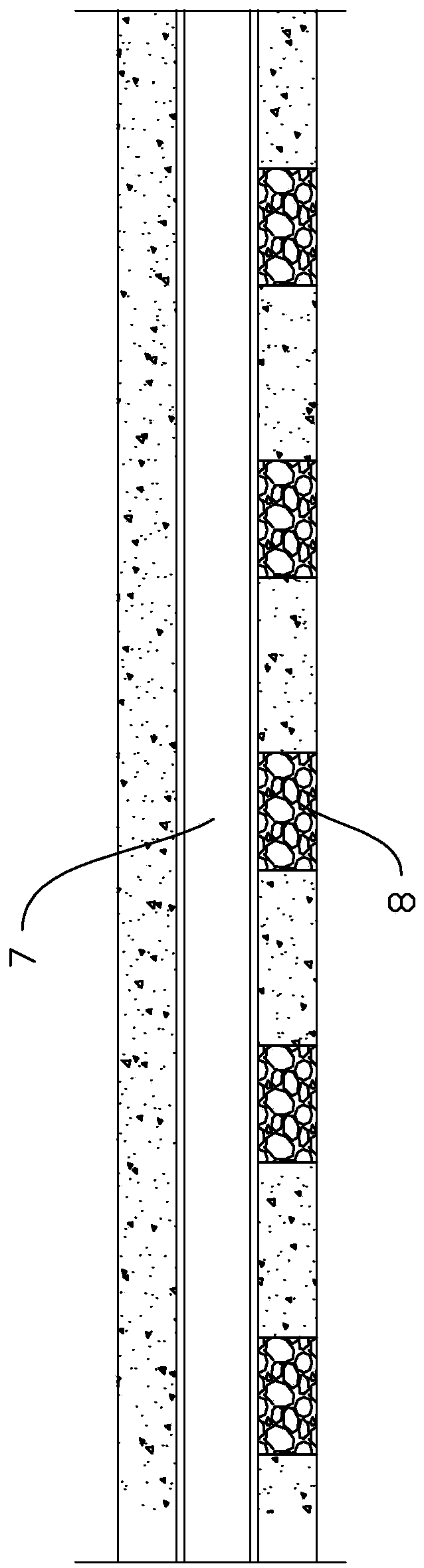

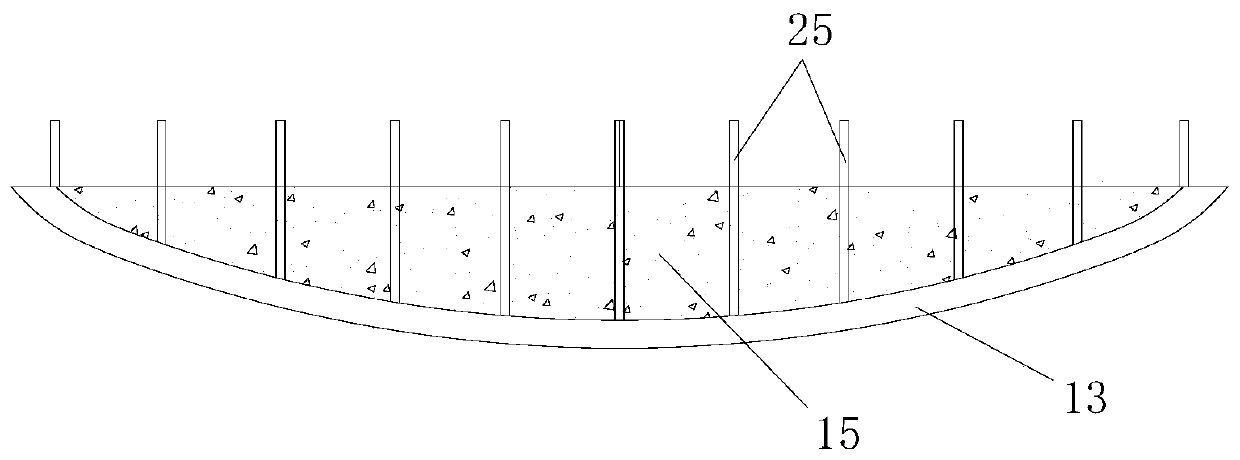

Rigid gridding and pile combined foundation and its use in soft soil foundation reinforcement

InactiveCN101476325AHigh strengthGood deformabilityBulkheads/pilesSoil preservationSurface layerStructural engineering

The invention discloses a rigid grid and pile composite foundation and a method applied to reinforcing soft soil foundation. The rigid grid and pile composite foundation comprises a precast pile or a cast-in-situ pile, a rigid grid structure, a tensioning net, tensioning ribs and a transitional underlayer; the precast pile or the cast-in-situ pile drives to a relatively hard ground layer from a foundation surface layer; the rigid grid structure is fixedly connected with the precast pile; the grid structure is paved with the tensioning net; the tensioning net is provided with the transitional underlayer; the transitional underlayer is tightly contacted with the foundation surface, and the thickness of the transitional underlayer is between 0.6 and 1.5 meters; and the transitional underlayer is sandy clay, gravel soil or plain concrete with crude particles. The invention organically combines the rigid grid and the pile structure, the transitional underlayer and a soft ground layer to construct a composite foundation, transfers the load to a deep layer soil body through the grid structure and a pile, can give a full play to the strength and the deformation performance of the deep layer soil body, thereby effectively improving the foundation strength and the deformation performance, and having good reinforcing effect.

Owner:SOUTH CHINA UNIV OF TECH

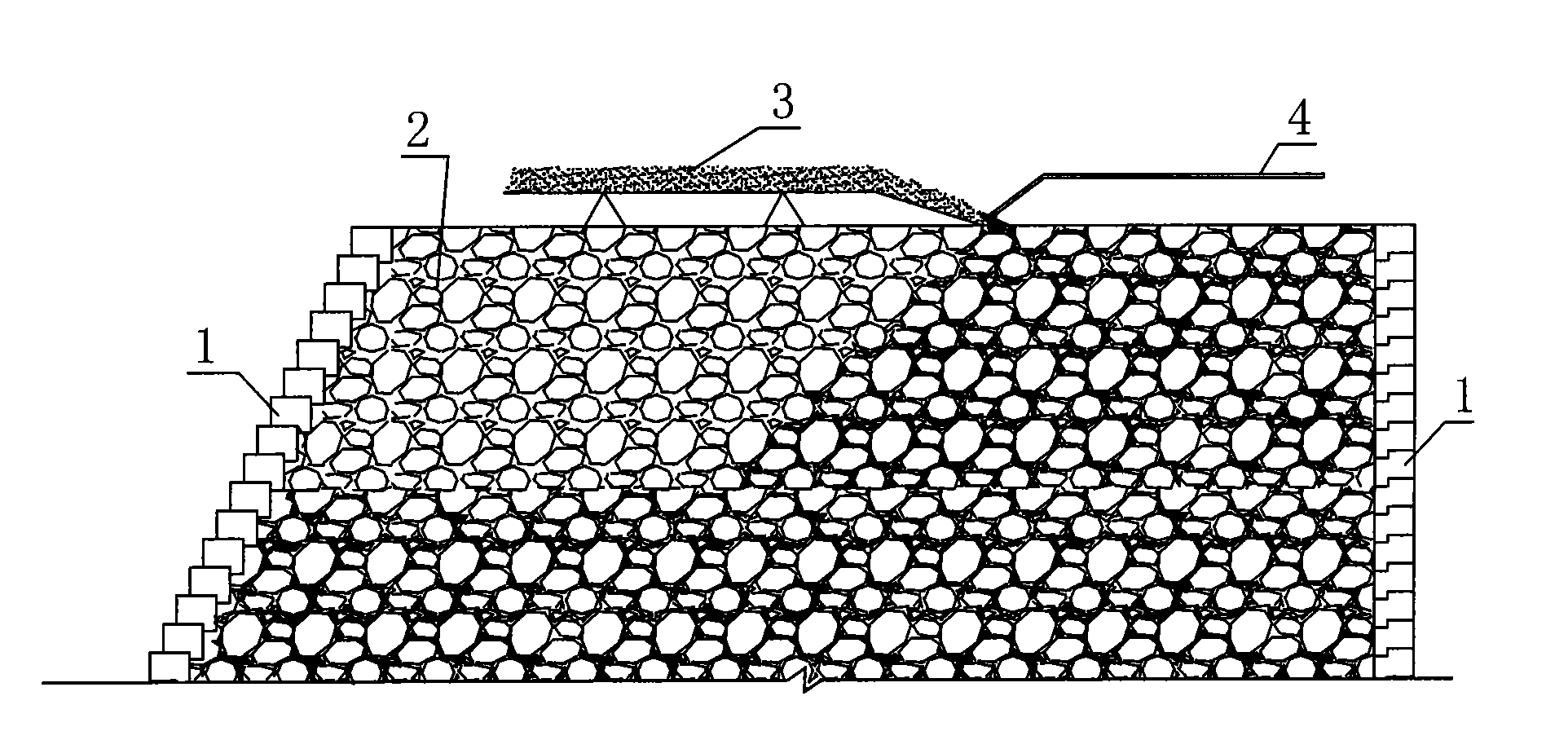

Construction method for filling mortar combined stone dam

ActiveCN101581088AIncrease self-impermeabilityTake advantage ofFoundation engineeringWall damsDiameter controlFly ash

The invention discloses a construction method for filling a mortar combined stone dam, which combines a mortar grouting and filling method and a rock-fill dam filling construction process, and solves the problems that a stone masonry structure is inconvenient to use mechanical construction and has low working efficiency, and a rock-fill dam has higher requirement on grain diameters of filling stones, lower material source utilization rate, high manufacturing cost and the like. The construction method comprises the following steps: filling stones in a dam shell till reaching the thickness requirement of a filling layer, flattening the stones, and then carrying out mortar sand removal operation on the top surface of the filling layer, namely directly filling previously prepared cement mortar or cement mixed mortar doped with admixture fly ash into the screened sand quantitatively supplied by a mortar conveying device in gaps of the filled stones through the mortar conveying device to form the mortar combined stone dam similar to the mortar masonry stone dam. The process flow is simple, the application range is wide, the maximum block diameter control and grade matching requirements are not needed, the stone source is abundant, the thickness of the filling layer is large, the roller compaction is not needed, the construction speed is high, the working efficiency is high, the construction cost is reduced, and the formed dam mortar masonry is compact and has good quality.

Owner:沈阳乾玉水利有限公司

Quick cold-patch repair method for asphalt pavement, and application thereof

InactiveCN103570334ANo wasteSimple construction equipmentRoads maintainenceMagnesium phosphateBitumen emulsion

The invention discloses a quick cold-patch repair material for an asphalt pavement, and application thereof. The material is prepared from the following components in parts by weight: 20-80 parts of magnesium phosphate cement, 5-20 parts of fine sand, 0-20 parts of medium sand, 0-50 parts of rubble with the grain size of 5-20 mm, 0-10 parts of emulsified asphalt, 0-10 parts of water-soluble polyurethane, 0-10 parts of rubber powder and 0-1 part of air entraining agent. The materials in parts by weight are uniformly stirred (1.5-2 min) in a stirrer and then poured in a damaged part of the cleared asphalt pavement, thereafter the damaged part is plastered, shaped and repaired, and then the asphalt pavement can be opened for traffic after 2-3 hours of maintenance. The quick cold-patch repair material disclosed by the invention adopts blending and pouring for molding in practical application, no heating is needed, the construction is convenient, the maintenance time is short, small influence is caused to traffic, and the mechanical property and the durability both satisfy the application requirement, so the quick cold-patch repair material is especially suitable for quick repair of pothole and crack-type damages of the asphalt pavement. The quick cold-patch repair material disclosed by the invention not only has a remarkable effect on damage repair aspect of the asphalt pavement but also can expand the application thereof to the field of cement concrete engineering and fields of damage repair of house buildings and old buildings, and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

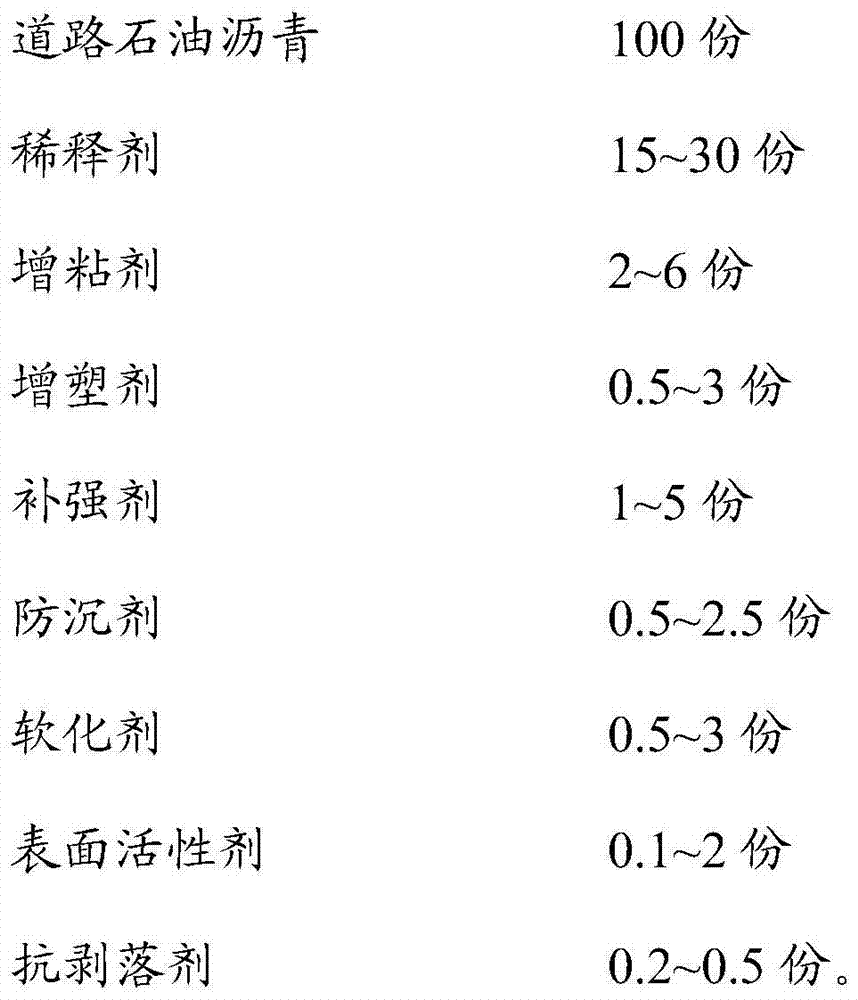

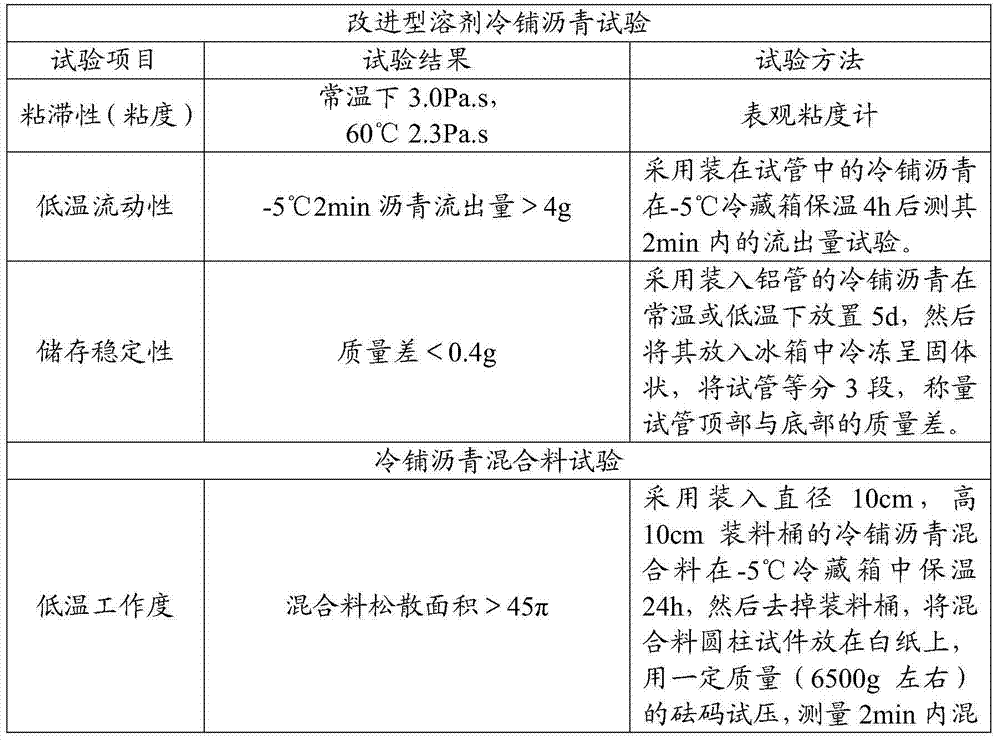

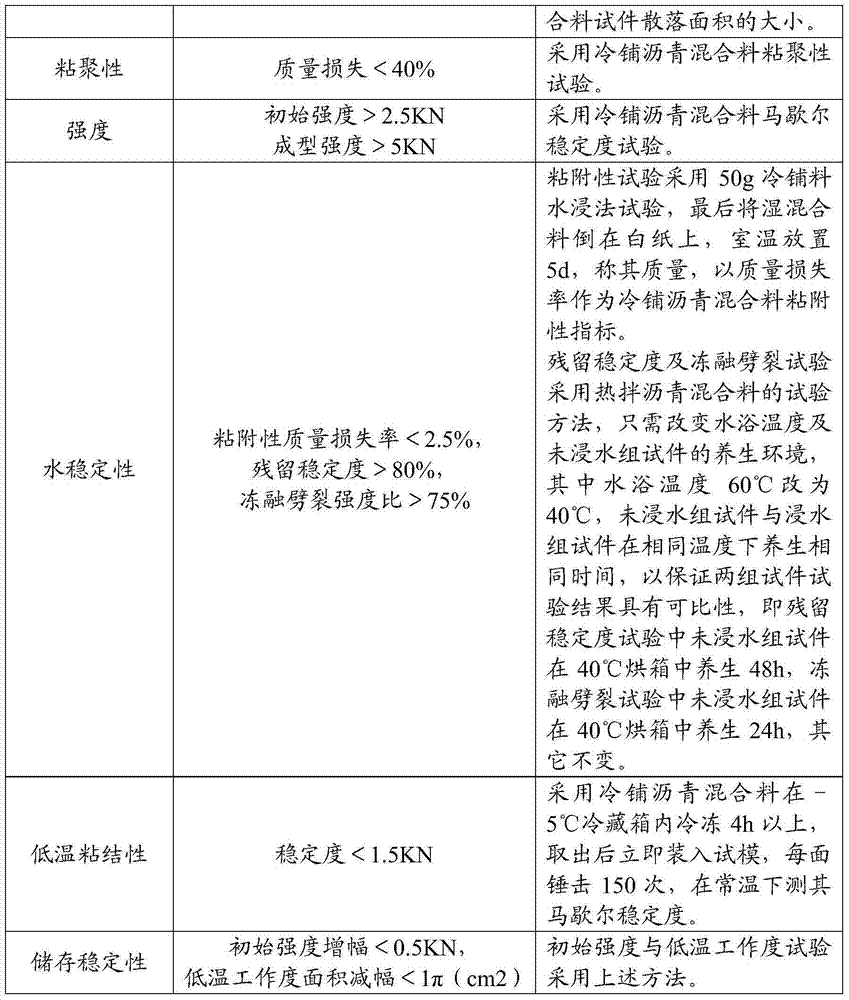

Improved solvent cold laid asphalt as well as preparation process and using method thereof

InactiveCN103923475AImprove adhesionImprove liquidityIn situ pavingsBuilding insulationsLiquid stateEngineering

The invention discloses an improved solvent cold laid asphalt as well as a preparation process and using method thereof. The improved solvent cold laid asphalt is at a liquid state under normal temperature or low temperature; cold oil and cold materials can be directly blended for construction on the spot without heating, and the construction can be carried out at high / low temperature seasons and rain / snow weather, and a large number of machinery and labor are not required in the construction process, the construction is simple and convenient and the repair effect is good; traffic can be immediately opened after repair without affecting the travel of people; the improved solvent cold laid asphalt is usually used for daily maintenance, such as pot slot repair and emergency repair; meanwhile, the improved solvent cold laid asphalt has the advantages of no deterioration, no layering and the like after being stored for a long time.

Owner:CHANGAN UNIV

Organic/inorganic composite material for rapidly repairing pit slots of bituminous pavement and preparation method thereof

The invention discloses an organic / inorganic composite material for rapidly repairing pit slots of a bituminous pavement, which is prepared from the following main raw materials of polymethylene polyphenyl polyisocyanates, a polyurethane prepolymer, polyether polyol, petroleum asphalt, a catalyst, sodium silicate powder, carborundum and the like. The composition material comprises components A, B and C, wherein the components A and the component B are blended with the component C after being mixed, and can be quickly solidified after being cast into the pit slots at room temperature, so that the composite material has strong caking property and similar rigidity with an original bituminous pavement, and the travelling stationarity and comfortableness are achieved after restoration. The composite material is simple and convenient to construct, rapid, efficient and environmentally friendly, the setting time is smaller than or equal to 30 minutes, and the bituminous pavement can be opened after 90 minutes, so that the rapid repairing purpose is achieved, and the effect on traffic jam caused by pavement rehabilitation is greatly relieved. The composite material has excellent water tolerance, weather fastness, abrasive resistance and compressive shear resistance, is a novel green material for rapidly repairing pit slots of a pavement, and has positive promotion action and a good application effect on development of a preventive maintenance technology of highways.

Owner:北京中科安途交通科技有限公司

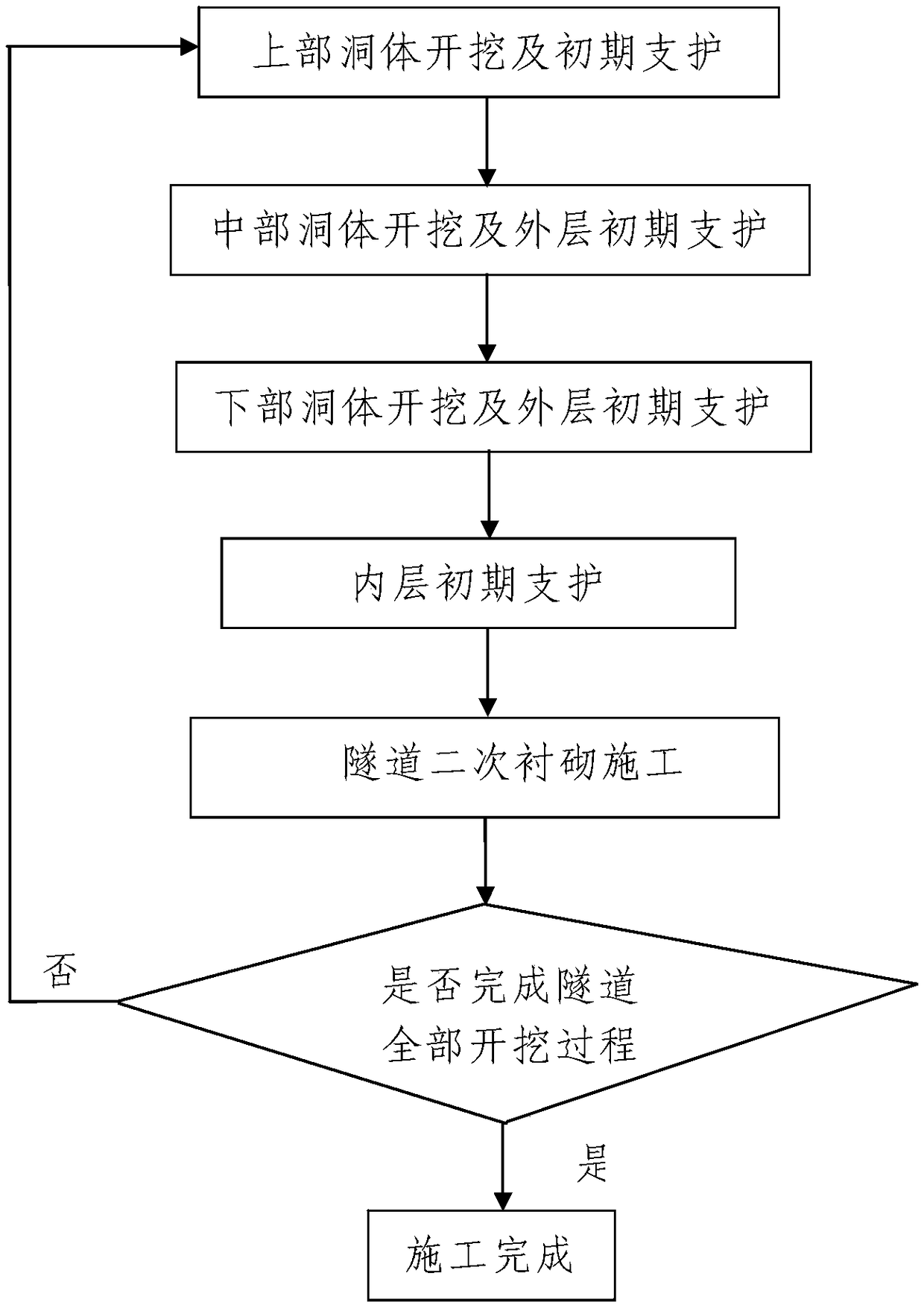

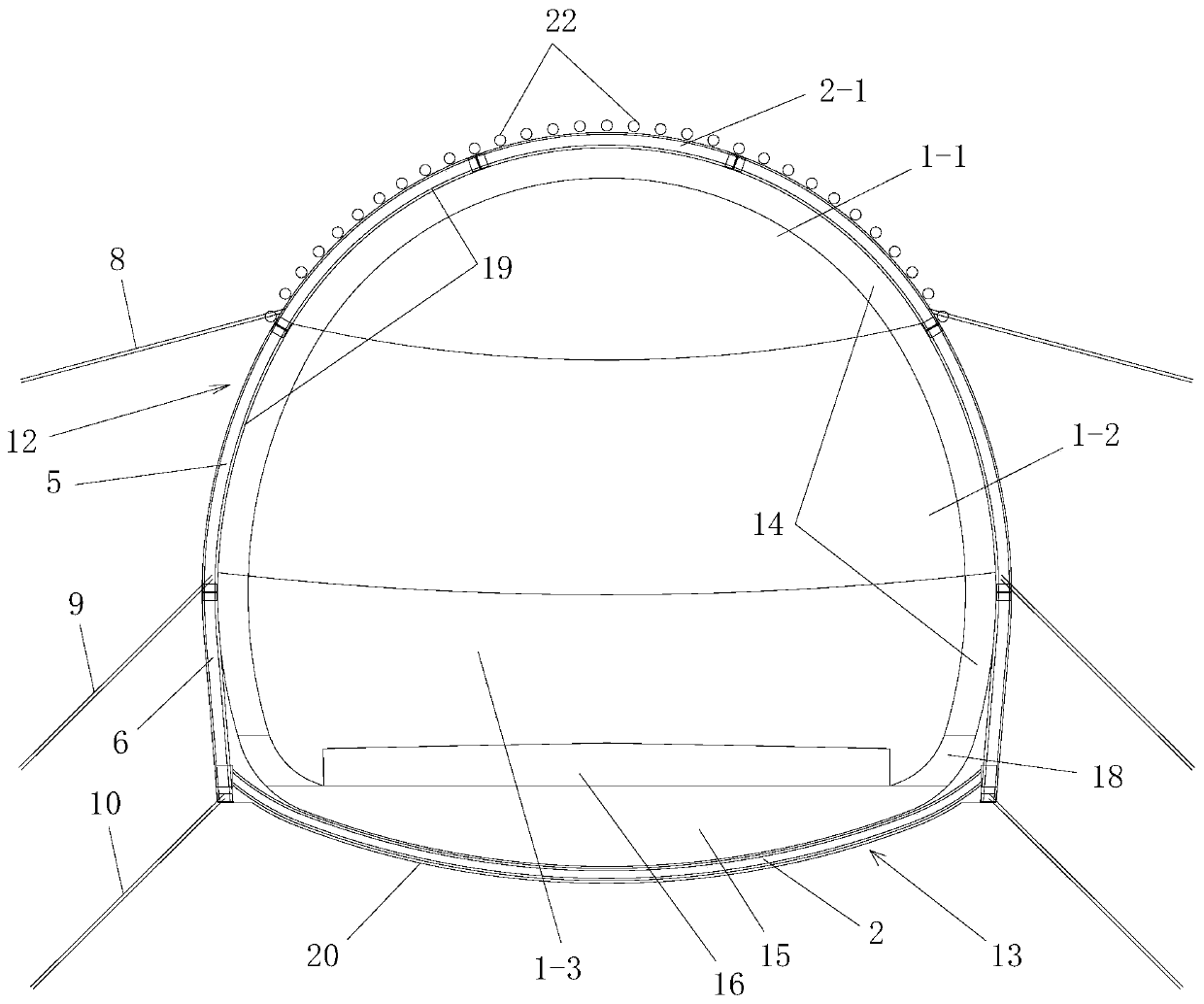

Excavation method for tunnel passing through high-angle thrust water-rich and sand-rich fault

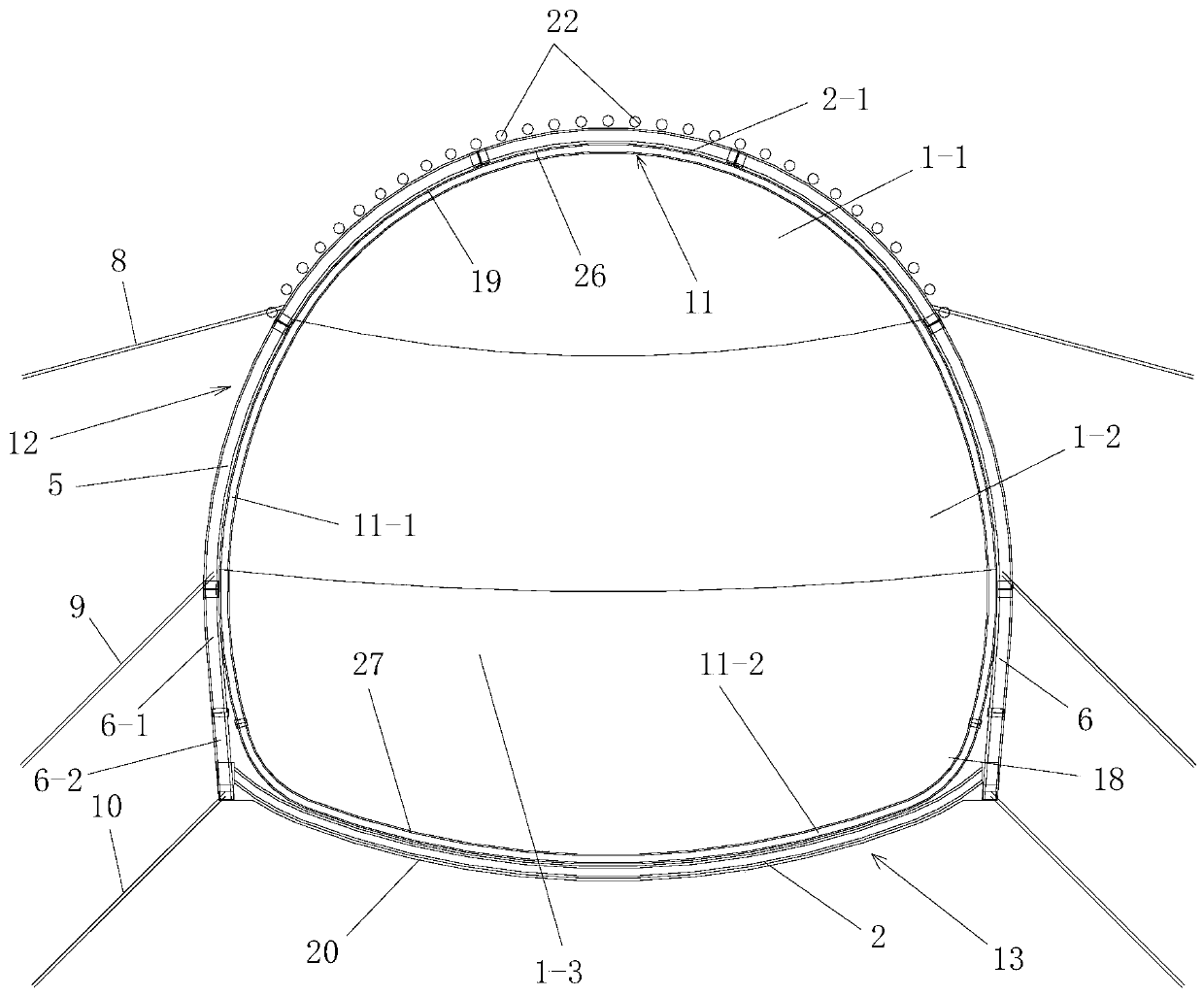

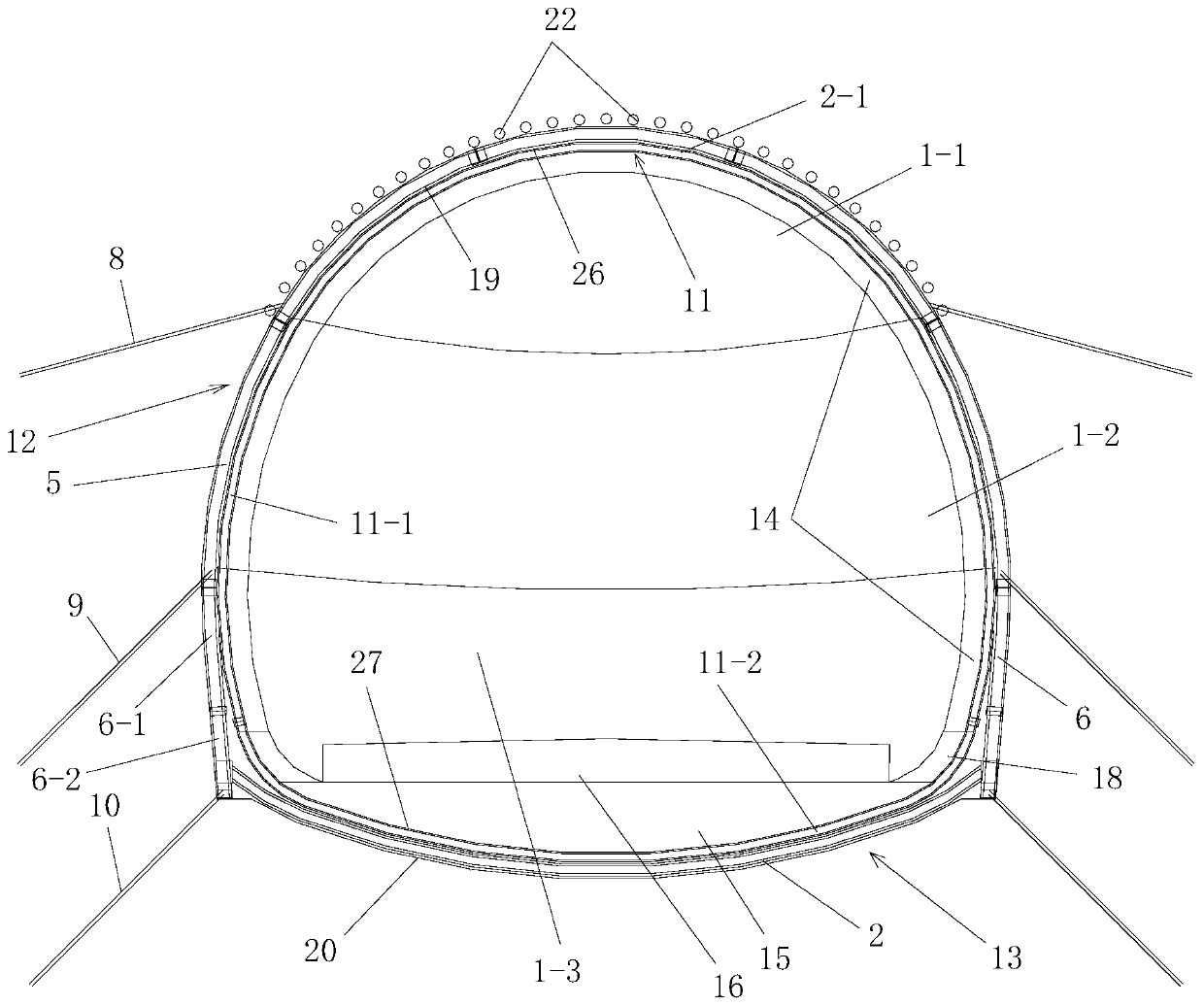

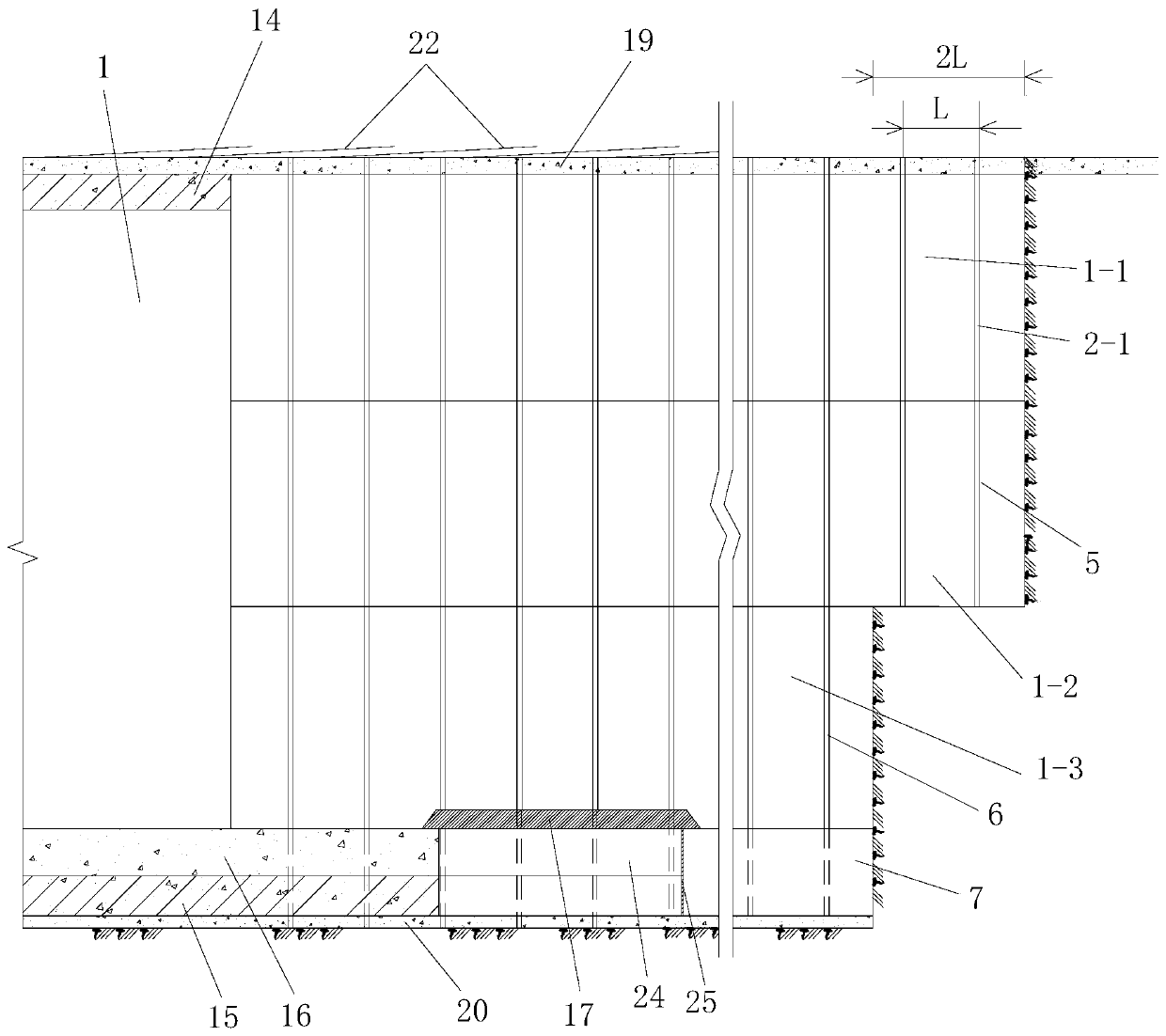

ActiveCN109209398ASimple structureReasonable designUnderground chambersTunnel liningHigh angleStep method

The invention discloses an excavation method for a tunnel passing through a high-angle thrust water-rich and sand-rich fault. A construction tunnel hole is divided from the top to the bottom into an upper hole body, a central hole body, and a lower hole body, wherein the upper hole body is divided into a left guide hole and a right guide hole. A primary support structure of the tunnel hole is a double-layer primary support structure. During the excavation of the construction tunnel, the construction tunnel is divided into a plurality of tunnel segments from the back to the front for excavation. During the excavation of any one tunnel segment, the method comprises the steps: 1, performing the excavation of the upper hole body and the primary supporting; 2, performing the excavation of the central hole body and the primary supporting of an outer layer; 3, performing the excavation of the lower hole body and the primary supporting of the outer layer; 4, performing the primary supporting of an inner layer; 5, repeatedly performing the steps 1-4 for many times, and completing the excavation of the tunnel. The method is simple in step, is reasonable in design, is convenient for construction, is good in use effect, employs a three-step method for the excavation of the tunnel hole, employs double primary support structure for the full-section support of the tunnel hole after excavation, and can guarantee the safety of the tunnel structure later.

Owner:CHINA RAILWAY 20 BUREAU GRP

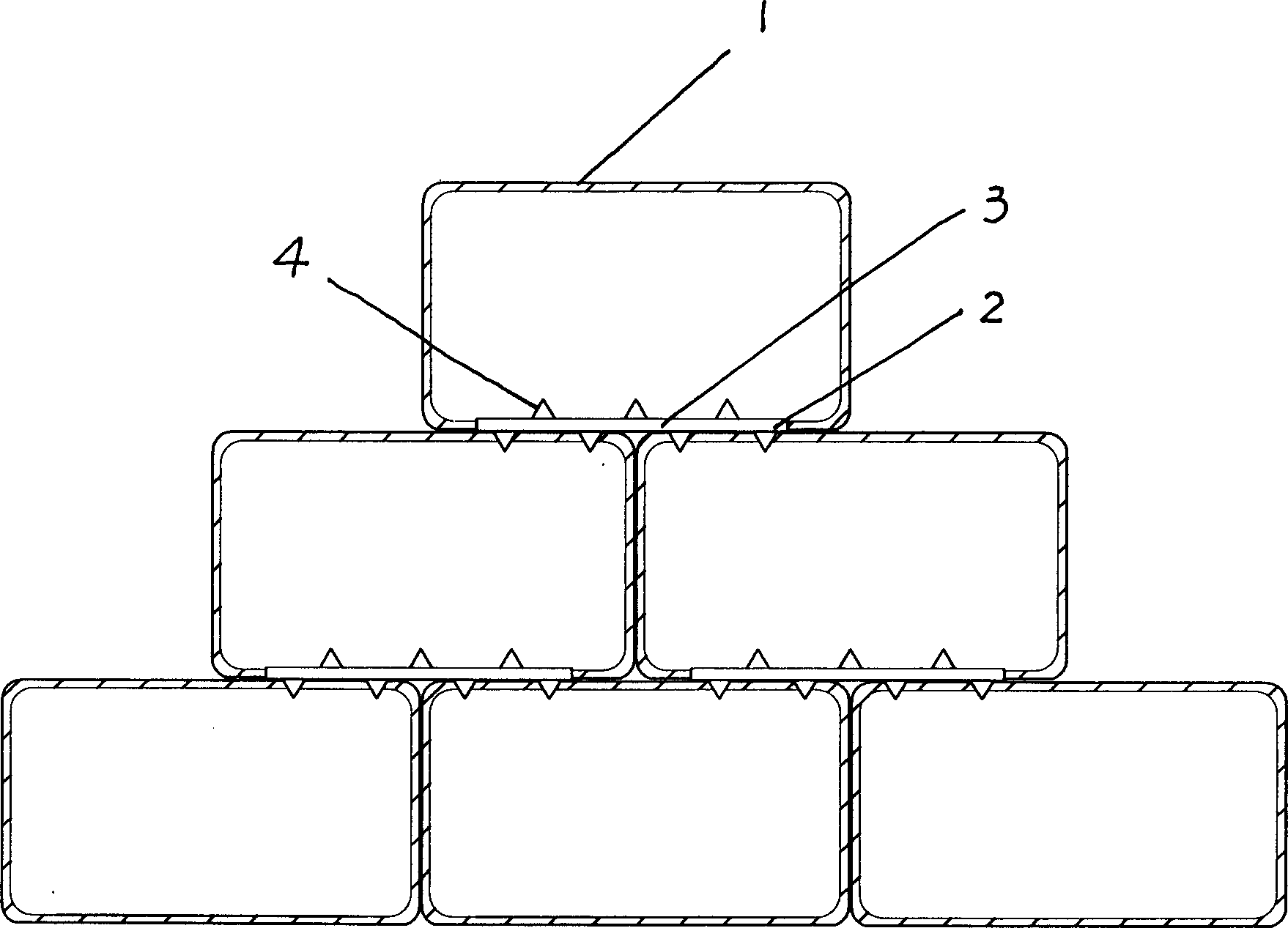

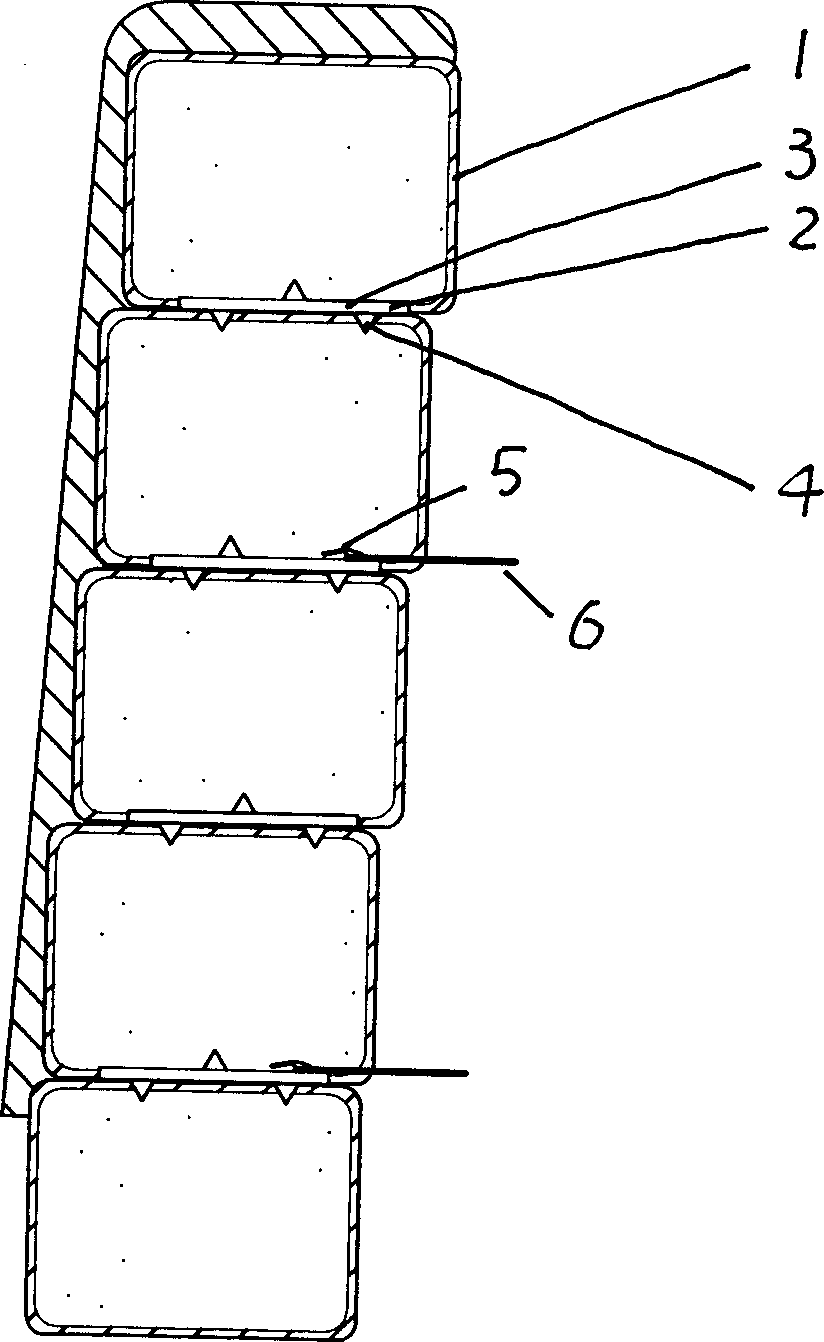

Side slope, dam bank installation

This is an installation of side slope dam; it is composed with two or more layers of sand bags. Between the two sands bags and the two layer of it, there are connected by button, on the two sides of the button there are convex thorn, it can be plugged into the sand bags. Then this construction secures the dam stability.

Owner:王欣南

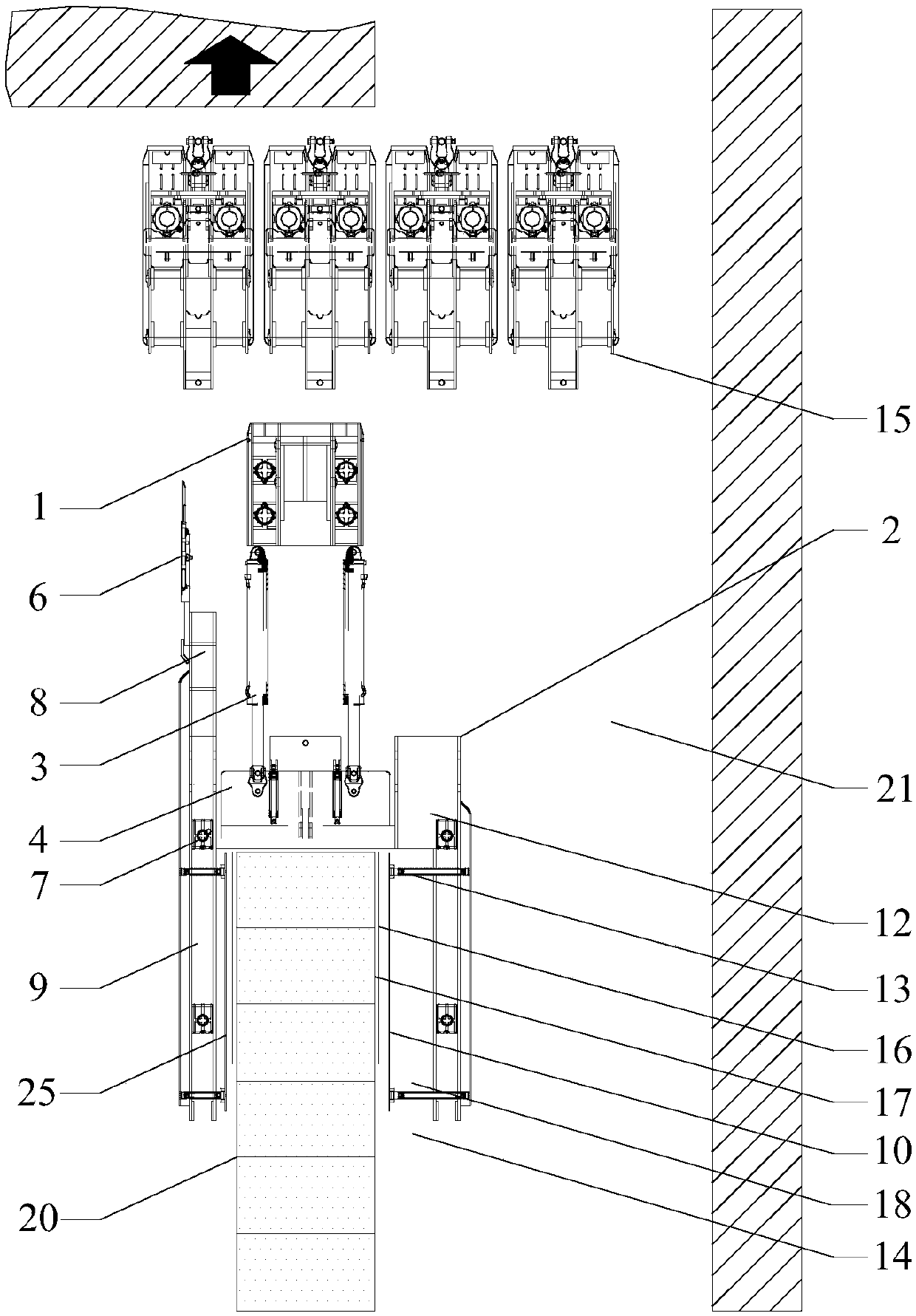

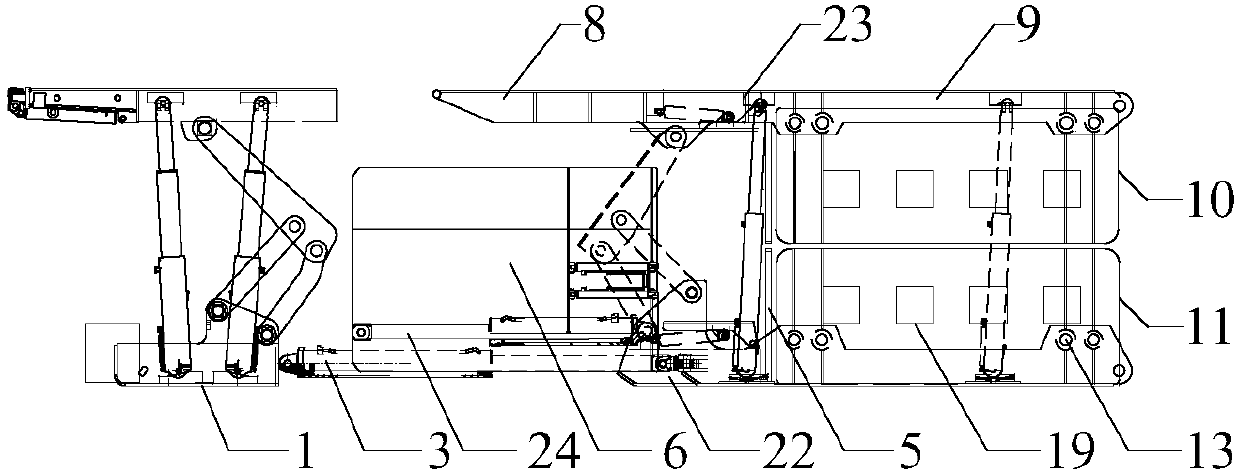

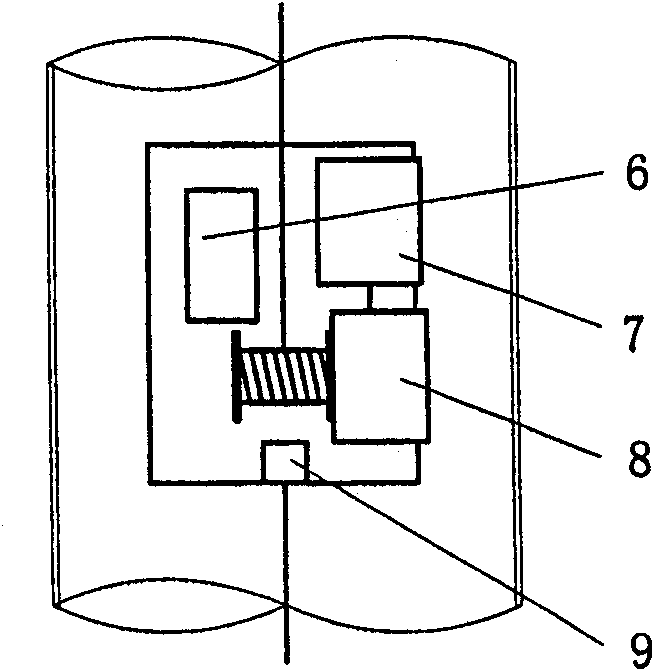

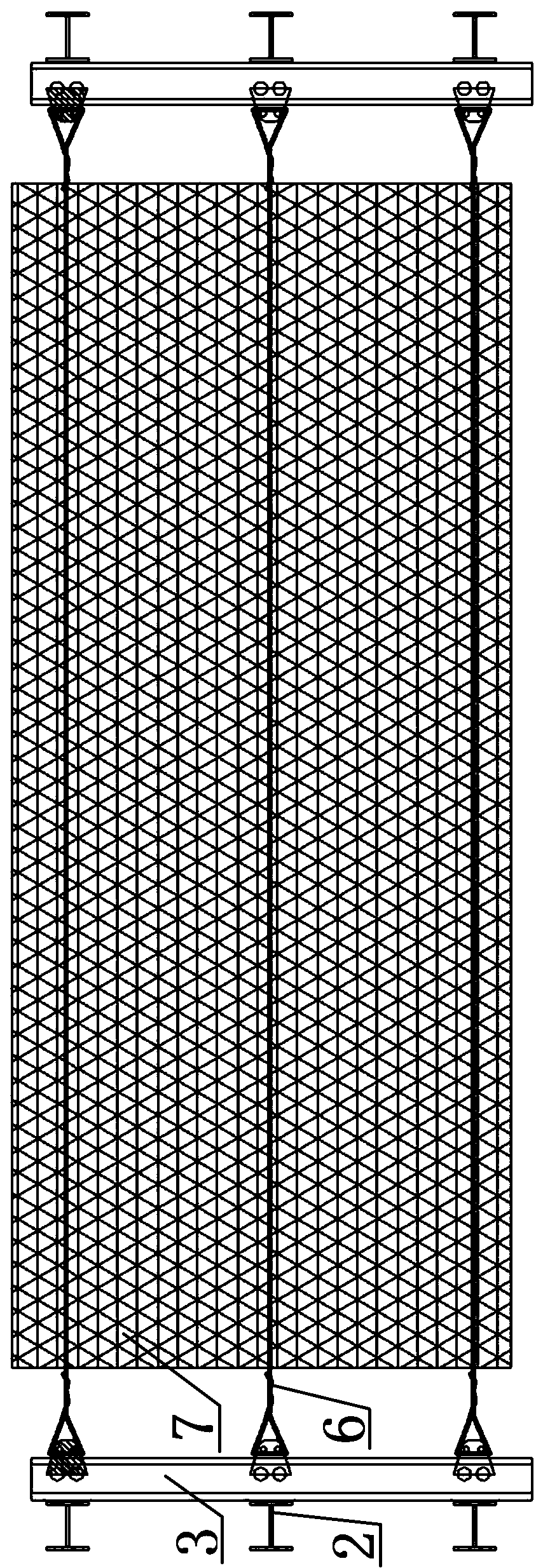

Rapid mechanical gob-side entry retaining support system and use method

ActiveCN107780957AHigh degree of mechanizationReduce labor intensityMaterial fill-upMine roof supportsSupporting systemHigh intensity

The invention relates to a rapid mechanical gob-side entry retaining support system and a use method. The system comprises an auxiliary support, a filling support and a support pulling oil cylinder which are arranged in a gob-side entry retaining roadway behind end supports, wherein the auxiliary support is a four-pillar supporting type support; the filling support is a U-shaped four-pillar supporting type box support and adopts an asymmetric structure, a work space is formed below a wide top beam on one side close to the gob-side entry retaining roadway, and one side close to a gob consists of an advance gangue blocking plate, a cantilever support top beam and a waste edge top beam. During usage, position adjustment and placement of a formwork support system are performed firstly, and then the hanging construction of a net and a filing bag is performed in the filling support; opposite-pull anchor rods are mounted in the filling bag for reinforced supporting; the filling bag is filledwith a high-moisture material for solidification, and pre-tightening force is applied through anchor rod mounting holes; the construction is finished through support movement step by step. The systemis high in filling efficiency and good in safety, the labor intensity of workers is effectively reduced, and quick and high-strength coal-pillar-free coal mining is realized.

Owner:CHINA UNIV OF MINING & TECH

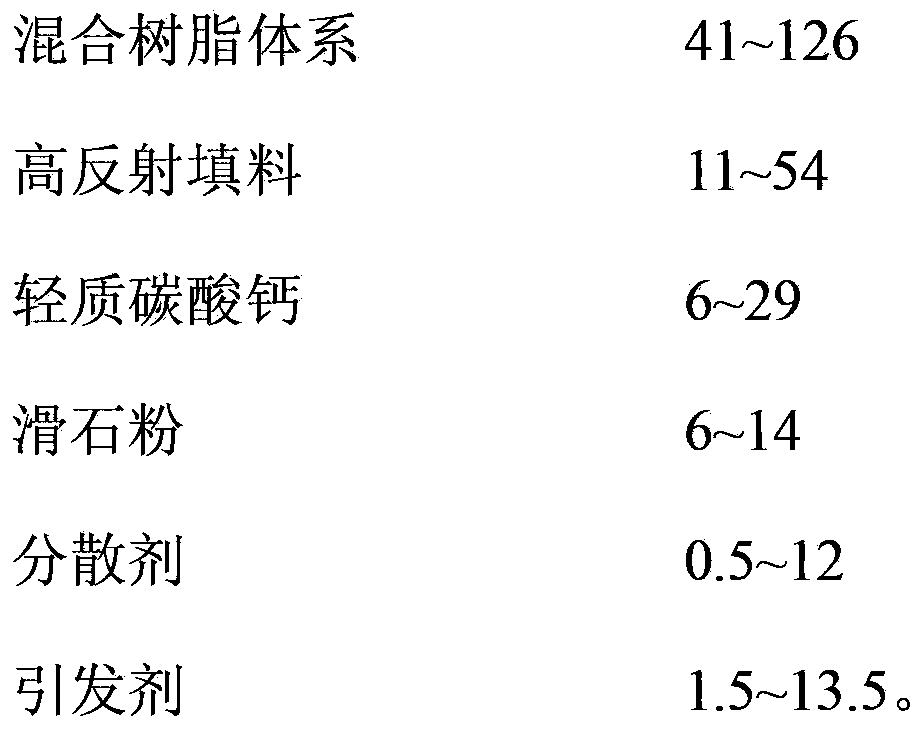

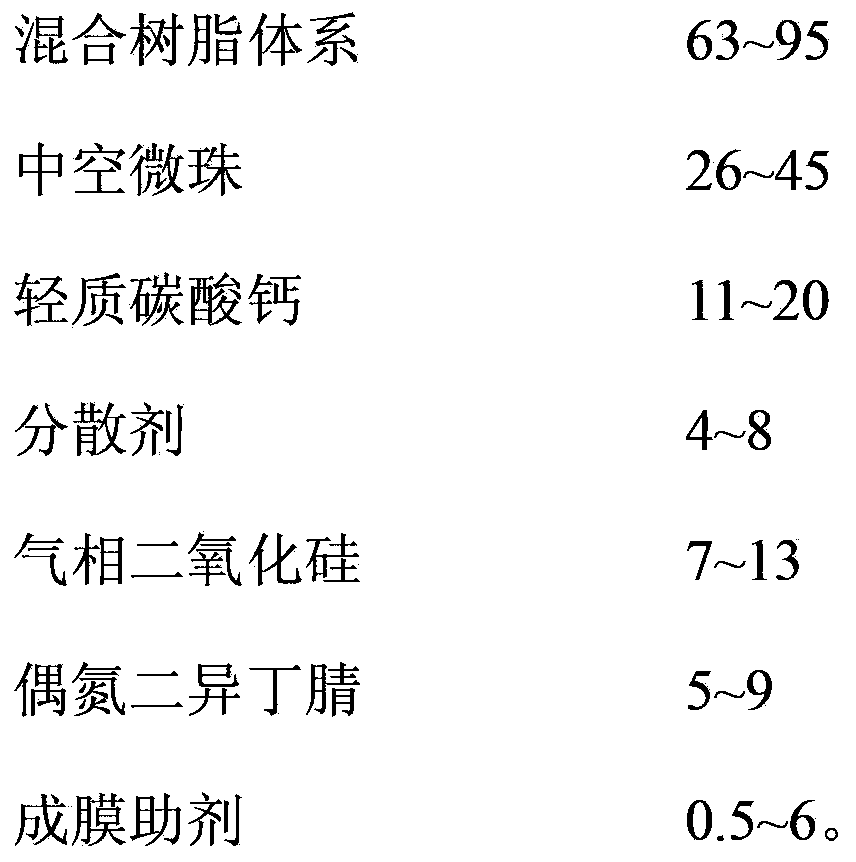

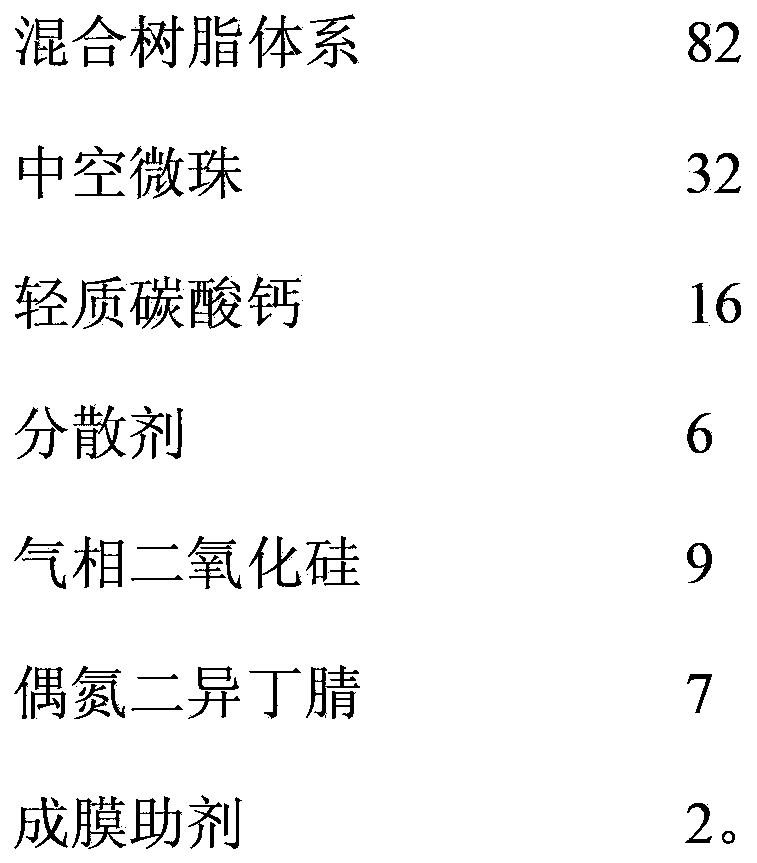

Colorful selective solar heat reflective coating for asphalt pavement

InactiveCN102093764AMake up for the lack of reflectionGood heat reflection performancePolyester coatingsReflecting/signal paintsParking areaMetallurgy

The invention discloses a colorful selective solar heat reflective coating for an asphalt pavement. The coating comprises the following components in percentage by weight: 60-80 percent of a mixed resin system, 15-35 percent of composite pigment filler, 0.5-2 percent of dispersant, 0.2-3 percent of anti-settling agent and initiator, wherein the mass ratio of the initiator to the coating is between 0.5 and 3. The coating is characterized by rich and durable colors, high heat reflection rate, high abrasion resistance and other advantages, and can be applied to plaza, parking areas, roads and other situations, so that the pavement temperature can be reduced, and the urban road transportation environment can be promoted and an excellent urban image can be built due to rich colors.

Owner:CHANGAN UNIV

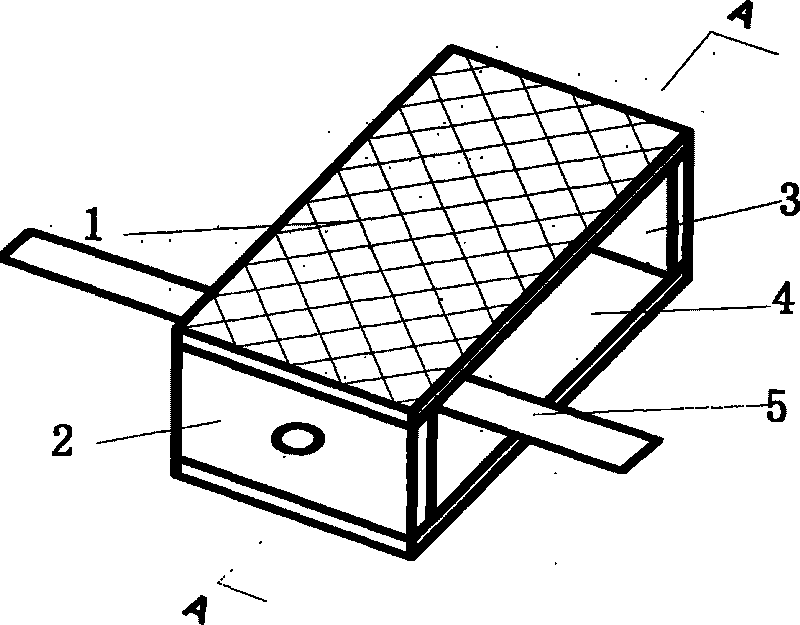

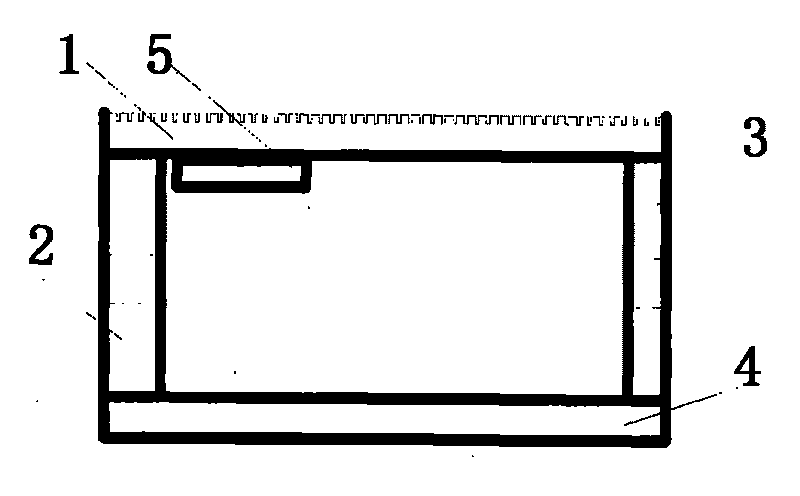

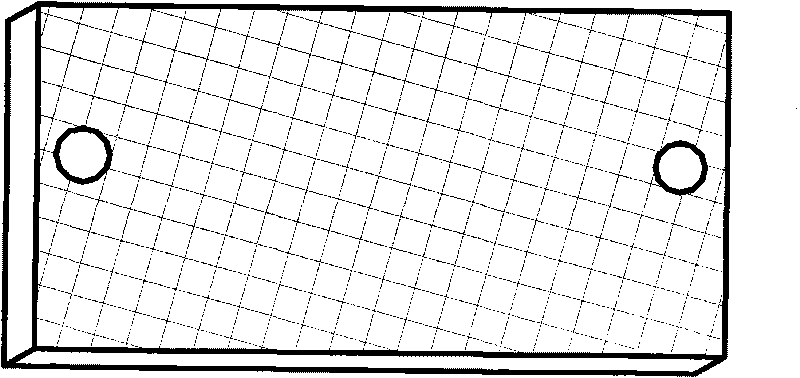

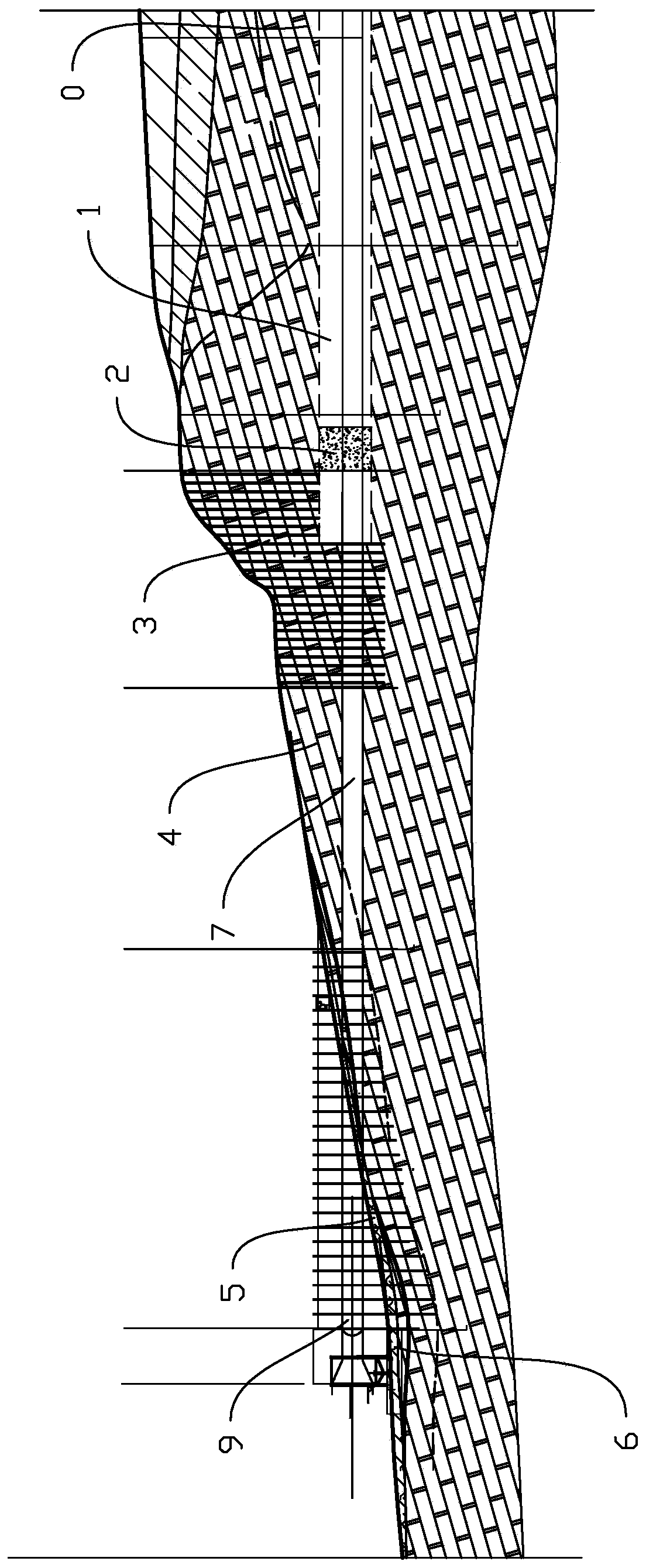

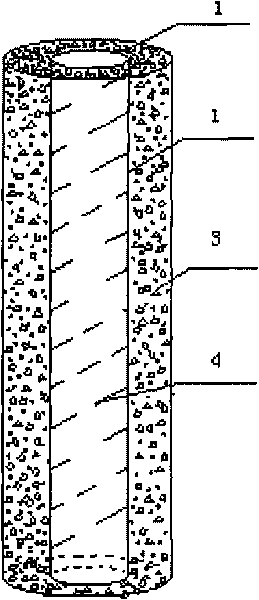

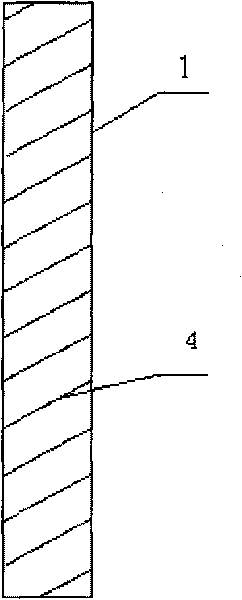

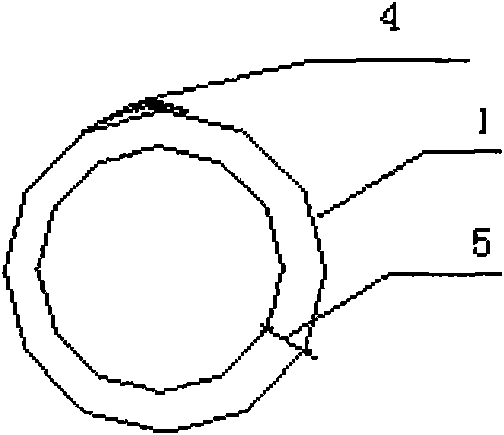

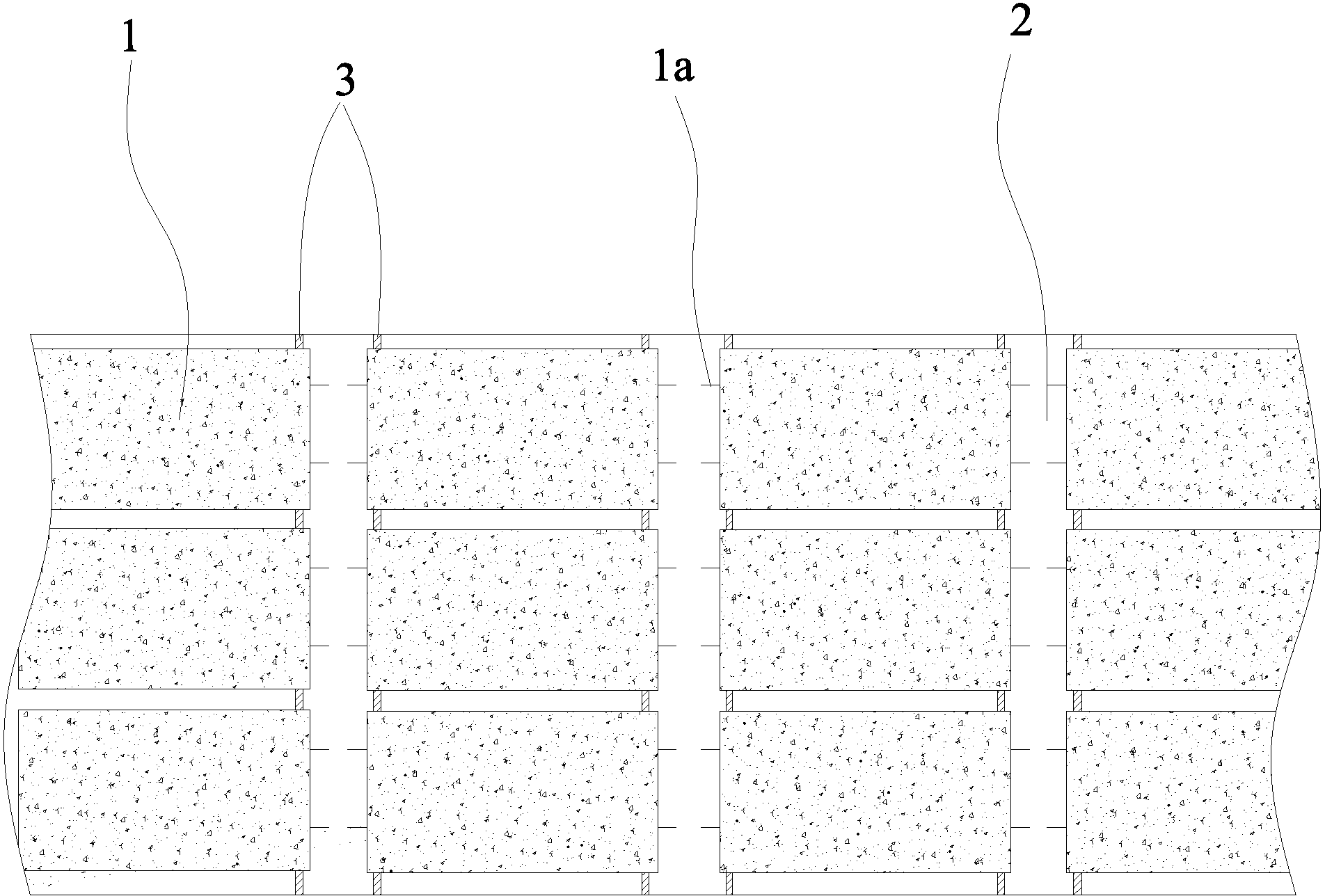

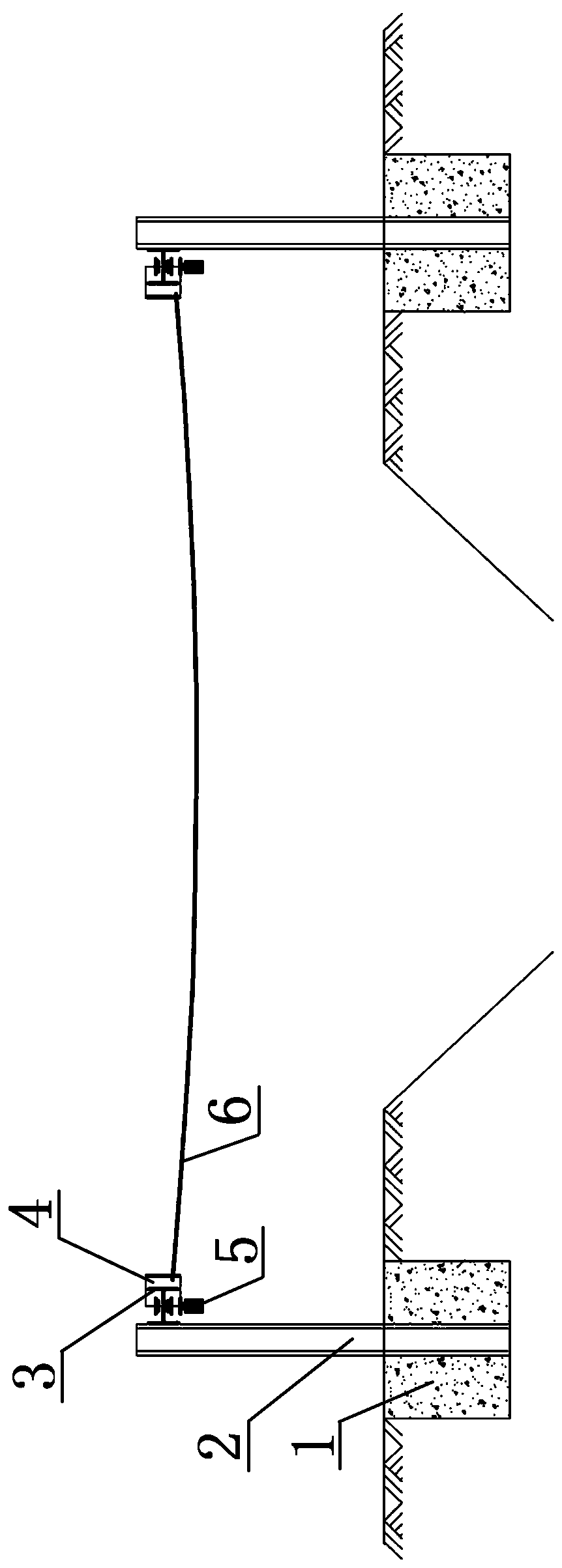

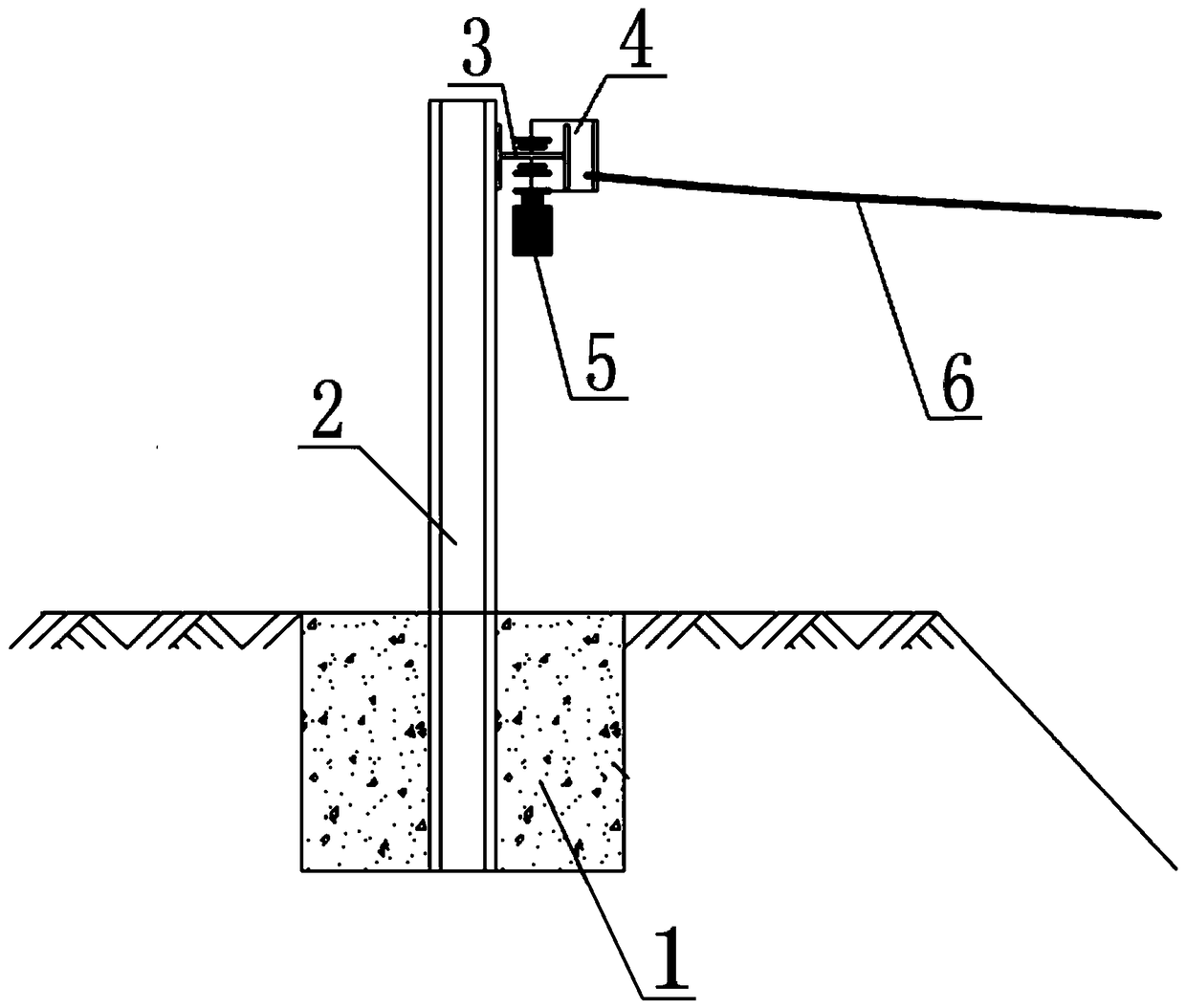

Prestress carbon fiber sheet reinforcing ground tackle and construction technology for reinforcing concrete structure thereof

InactiveCN101761189AEven by forceImprove adhesionBuilding repairsBridge erection/assemblyFiberSheet steel

The invention relates to a prestress carbon fiber sheet reinforcing ground tackle and a construction technology for reinforcing concrete structure thereof, belonging to the field of reinforcing bridges and industrial architectures. The two ends of a steel plate (1) with a groove are respectively and vertically welded with one side of a first steel plate (2) with a hole and one side of a second steel plate (3) with a hole, a steel plate (4) is parallel to and arranged in the steel plate (1) with the groove, and the steel plate (4) is welded with the other side of the first steel plate (2) with the hole and the other side of the second steel plate (3) with the hole, the steel plate (1) with the groove, the first steel plate (2) with the hole, the second steel plate (3) with the hole and the steel plate (4) form the sides of a cuboid, and an additional layering (5) of a stretching end ground tackle is parallel to the steel plate (1) with the groove, and is placed in the sides of the cuboid to form the stretching end ground tackle (7). The ground tackle can ensure the stretching stress of the carbon fiber sheet reaches over 65% of the limiting stress thereof, the additional layering (5) of the stretching end can ensure the ground tackle to traverse and not to tilt. The reinforcing method of the invention does not need large mechanical equipment, and can improve the stretching efficiency of the carbon fiber sheet.

Owner:BEIJING UNIV OF TECH

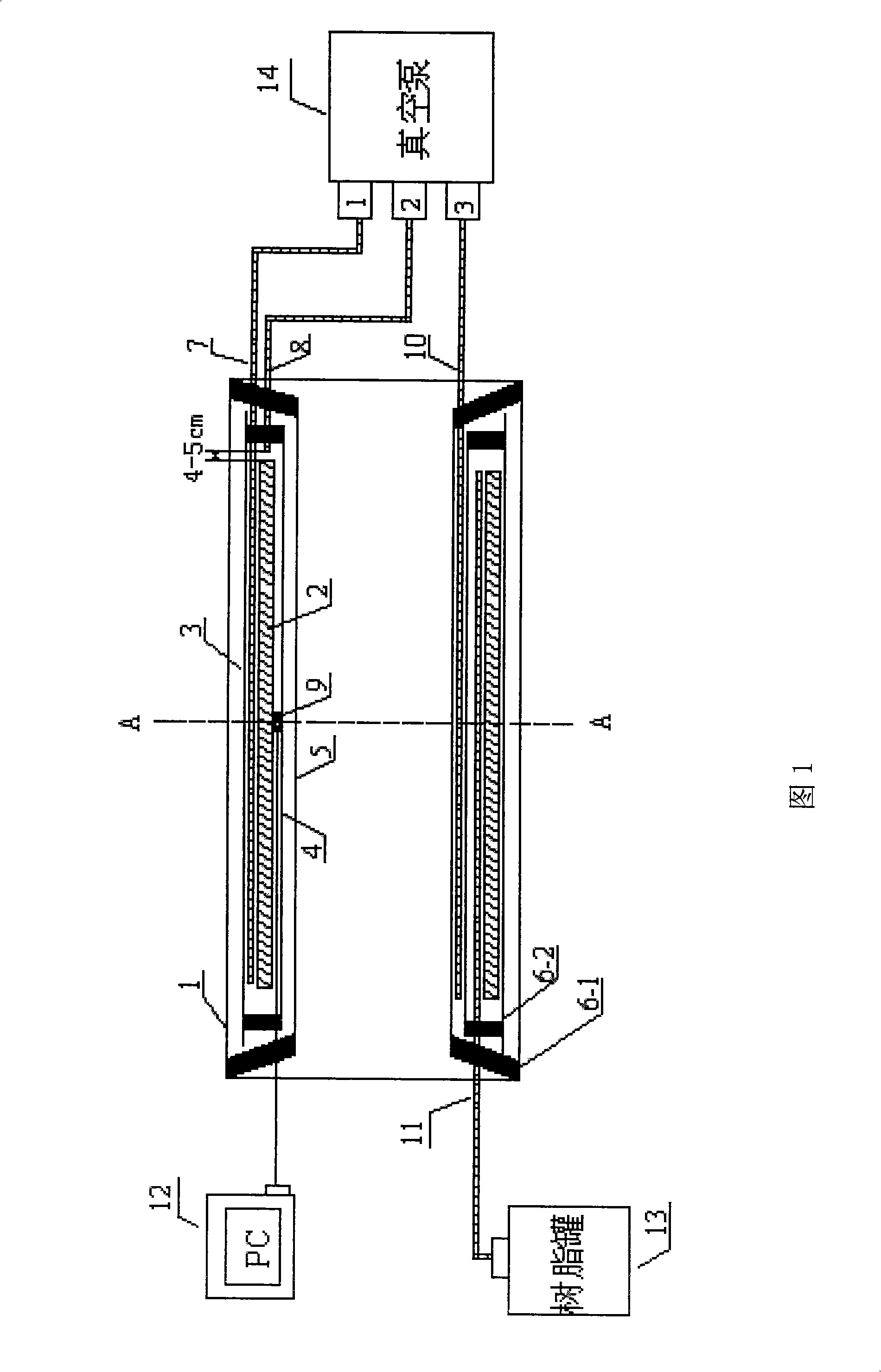

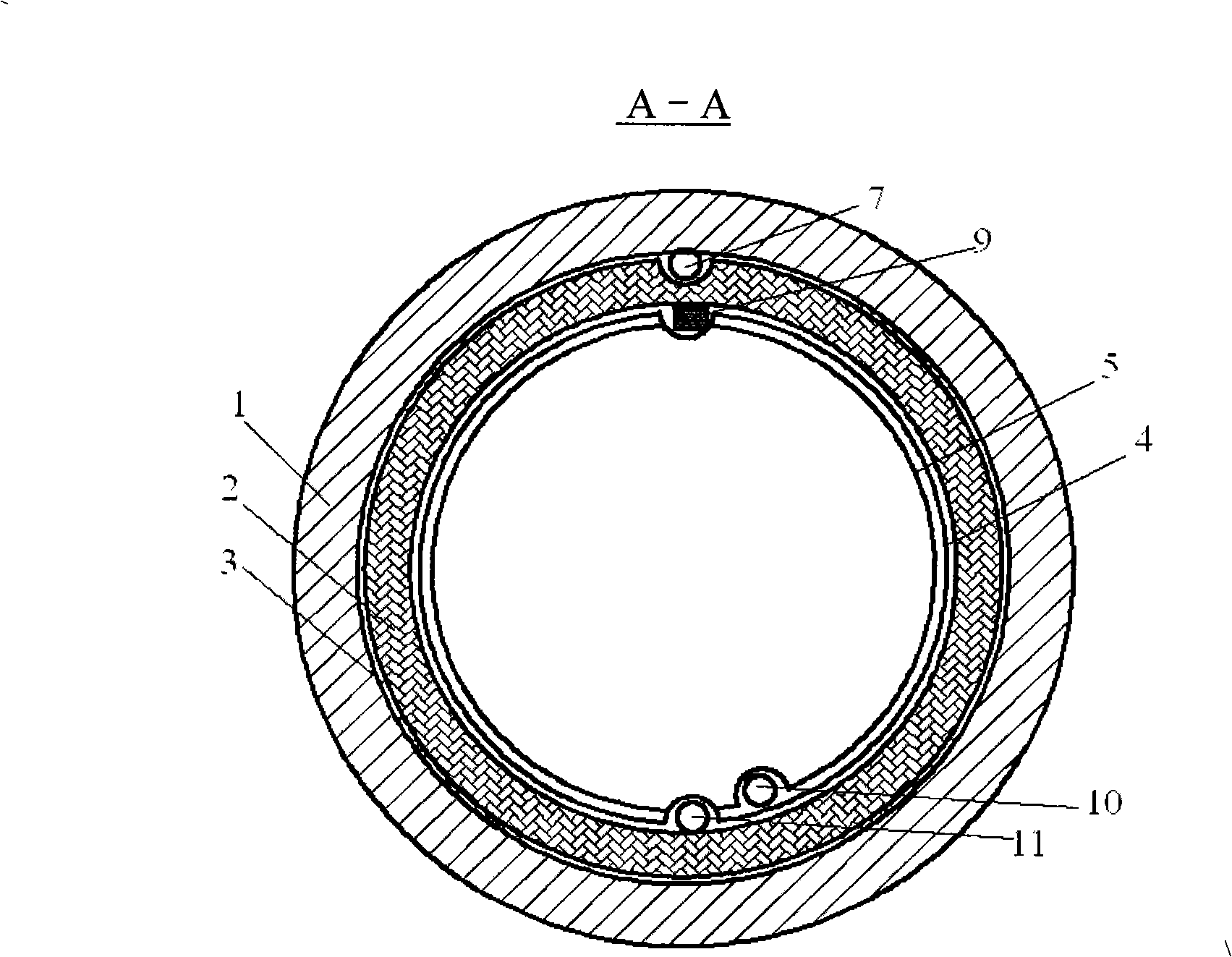

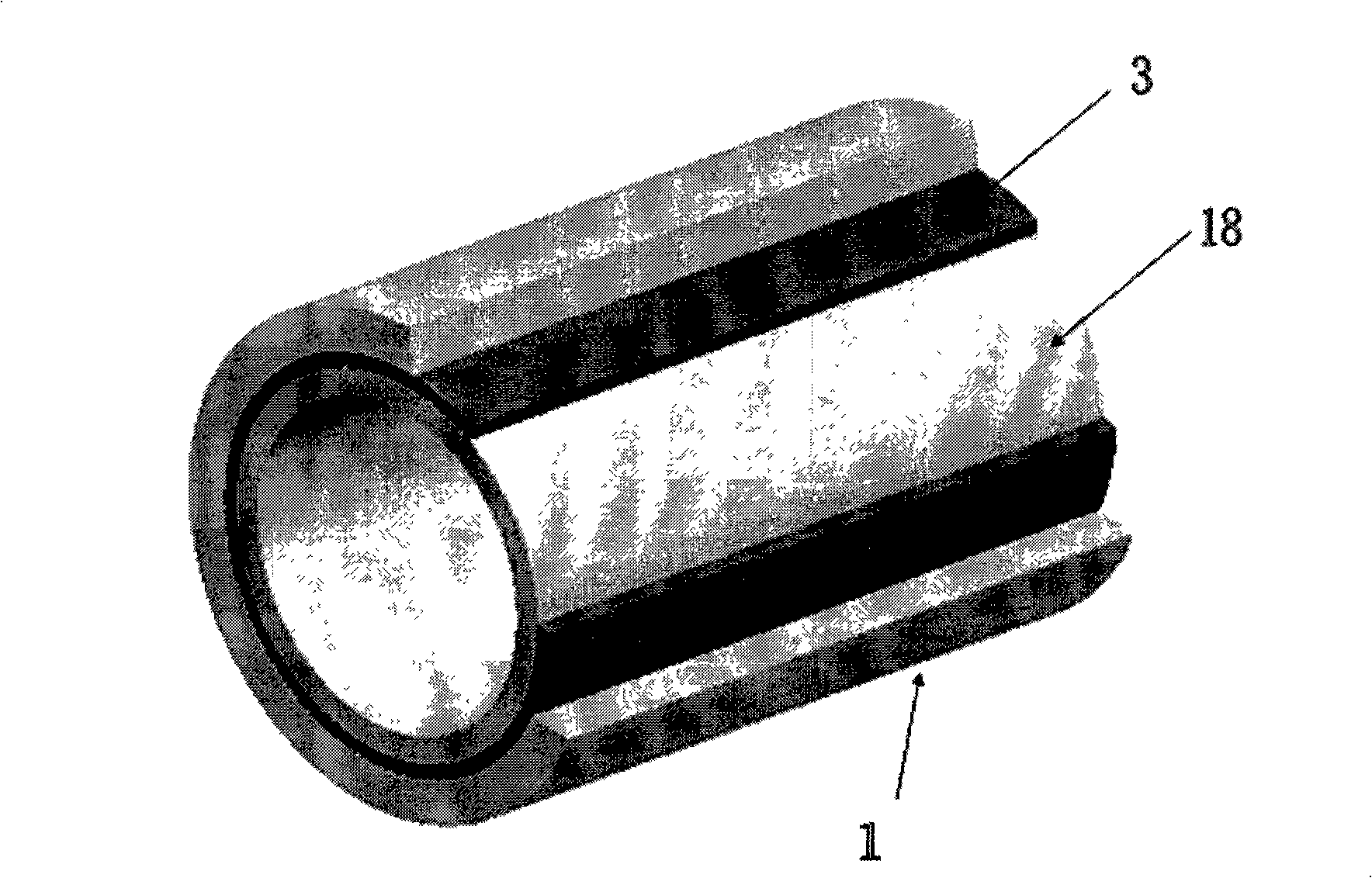

Excavation-free underground pipe line rehabilitation method

InactiveCN101307854ASimple construction equipmentSimple and fast operationPipe elementsVacuum pumpingFiber

The invention relates to an excavation-free repair method for an underground conduit, the repair method comprises the following: (1) a step of manufacturing a double-bag type fiber repair fabricated part; (2) a step of installing and constructing, which is to put the double-bag type fiber repair fabricated part into a conduit to be repaired, to seal and fix the double-bag type fiber repair fabricated part on the inner wall of the conduit near the both ports of the conduit to be repaired to vacuumize the double-bag type fiber repair fabricated part by a vacuum pumping helix tube to make the double-bag type fiber repair fabricated part expand peripherally and adhere to the inner wall of the conduit to be repaired, forming a pressure grease die; (3) a step of repairing pressure grease curing, which can finish the excavation-free repair. The repair method of the invention has no need of the clamps on both sides of the conduit orifice and no large-sized equipment such as RTM resin filling equipment and air implanter during construction,the negative pressure generated by vacuumization of the double-bag method enables the resin to fully immerse the fiber fabricated part which is cured and molded into the composite materials for repairing the conduits. The repairing method has the advantages of simple construction equipment, convenient operation and good adaptability and so on.

Owner:TIANJIN POLYTECHNIC UNIV

Foamed gel blocking agent for blocking gas coning and construction method of foamed gel blocking agent

InactiveCN108219761ALow densityImprove high temperature resistanceFluid removalDrilling compositionBetaineGas phase

The invention discloses a foamed gel blocking agent for blocking gas coning and a construction method of the foamed gel blocking agent and belongs to the technical field of oil exploitation. The foamed gel blocking agent is prepared from a liquid-phase component and a gas-phase component through mixing and foaming, wherein the liquid-phase component comprises the following components in percentageby mass: 5.5-6.5% of xanthan gum with the relative molecular weight of 1*10<6>-5*10<6>, 0.2-0.3% of hydrated polyacrylamide with the molecular weight of 9-12 million, 0.2-0.25% of a phenolic resin cross-linking agent, 0.5-0.8% of an alkyl glycine betaine surfactant, 0.5-0.6% of a dodecyl dimethyl amino oxide foam stabilizer and the balance of water. The foamed gel blocking agent is small in density, can be accumulated into a high-angle crack to infiltrate into the top of a bottom water reservoir, is capable of retarding advancing of an oil-water interface, improving the percolating resistanceof a permeable layer, inhibiting gas channeling, and meanwhile increasing waves and sizes of displacing mediums to less permeable layers.

Owner:PETROCHINA CO LTD

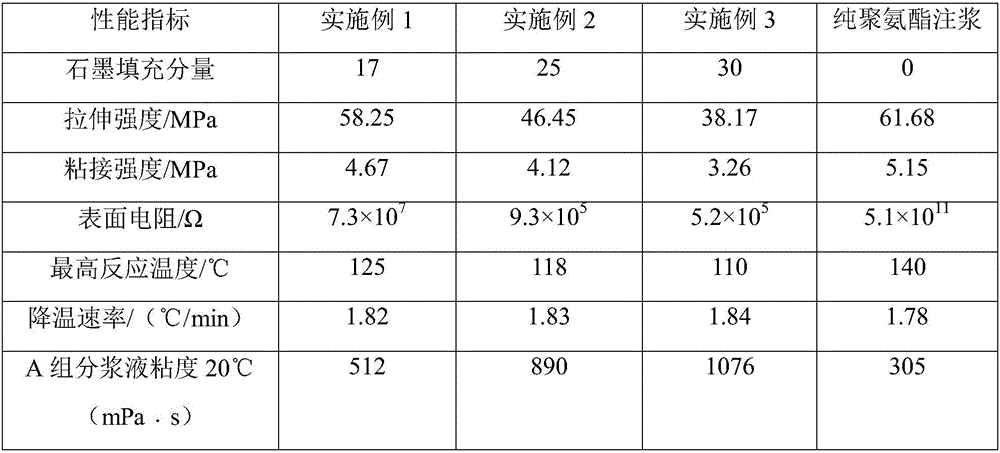

Low-temperature antistatic grouting solidifying material and preparation method thereof

ActiveCN105860022AImprove antistatic performanceFast heat conductionHeat-exchange elementsPotential riskIsocyanate compound

The invention discloses a low-temperature antistatic grouting solidifying material and a preparation method thereof. The grouting solidifying material, which is low in heat storage temperature and antistatic, comprises, by weight, 100 parts of isocyanate, 70-100 parts of polymer polyatomic alcohol, 0.5-2 parts of tin catalyst, 10-50 parts of flame-retardant diluent, and 10-30 parts of graphite. With the graphite modified polyurethane grouting material, antistatic performance of the grouting composite can be optimized utilizing conductivity and heat conduction of graphite, and heat transfer in the grouting solid is promoted in the mean time. Heat storage temperature of the grouting material is remarkably lowered, and potential risks are reduced.

Owner:ANHUI UNIVERSITY

Mounting method for underwater pipeline of water intake channel of water plant

The invention discloses a mounting method for an underwater pipeline of a water intake channel of a water plant. The mounting method comprises the following steps: laying a protective structure at theouter side of a construction area; manufacturing steel floating boxes from steel plates, and assembling the steel floating boxes to form a water working platform; utilizing a working vertical well toconstruct an underwater subsurface tunnel front hole and a tunnel front hole end head water-stop wall, and reserving a Haff joint; adopting an underwater blasting and / or excavating way to perform trench installation of a tube slot, flattening the tube slot after tube slot is accomplished, and tamping the slot bottom; sealing the two ends of a welded water-take pipeline, floating the water-take pipeline to a tube center position, and sinking the water-take pipeline to a specified position; performing fine turning on the water-take pipeline through a manual hoist mounted underwater via a diver,dismounting a bulkhead, utilizing an underwater auxiliary butt-joint device for enabling the water-take pipeline to be in butt-joint and connection to a tunnel inner pipeline, and performing underwater concrete pouring on a butt-joint position; and performing pipeline back-filling and underwater concrete pouring. The mounting method adopts simple construction equipment, is good in environment-friendly effect, and is quick in construction progress.

Owner:CHINA RAILWAY GUANGZHOU ENG GRP CO LTD +1

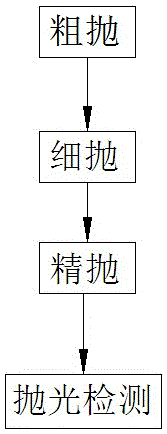

Mechanical polishing process of inner wall of stainless steel storage tank

InactiveCN105081941ASimple processSimple construction equipmentEdge grinding machinesPolishing machinesFiberSlag

The invention discloses a mechanical polishing process of the inner wall of a stainless steel storage tank. The mechanical polishing process comprises the following steps: (1) rough polishing: adopting a 60#-100# carborundum grinding wheel to grind, polish or mill the surface of a workpiece so as to remove burrs, scratches, rust marks, oxide skin, excess weld metal of a weld bead, weld beading, welding slags and an oxide layer on the surface of the workpiece; (2) fine polishing: adopting a 80# carborundum grinding wheel and a flap wheel to further machine the rough-polished surface so as to remove the scratches left by the rough polishing and generate a smooth and medium shining surface; (3) elaborate polishing: adopting a 240#-320# fiber wheel and a rag wheel coated with polishing paste to polish the surface of the stainless steel storage tank so as to further reduce the surface roughness of stainless steel and realize the purpose of microcosmic smoothness; (4) polishing detection: adopting the center line average value method for detection, transversely moving a roughness detector on the surface of the stainless steel storage tank during detection, and recording the amplitude of variation of peaks and valleys. According to the invention, the mechanical polishing process is simple and reasonable, the production efficiency is high, and the product quality and property are stable.

Owner:HEFEI XINYIDA BURNISH MACHINE

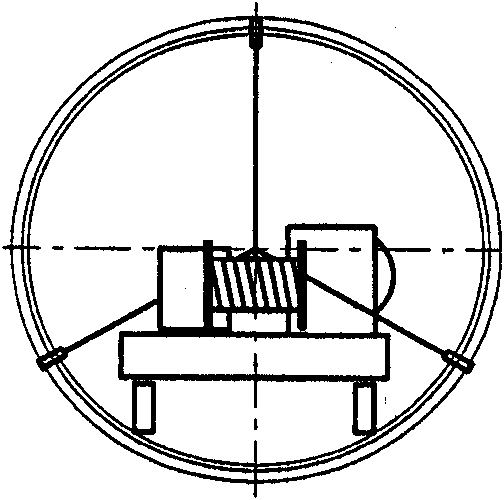

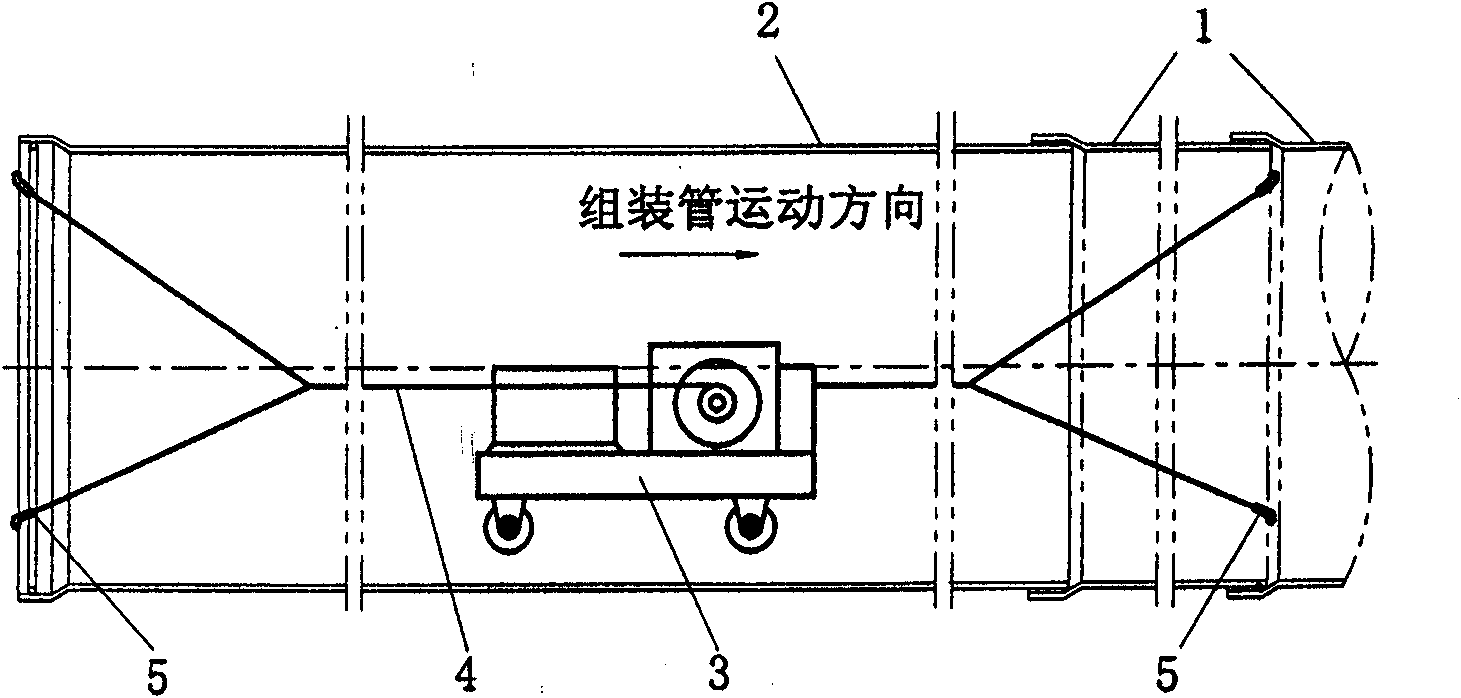

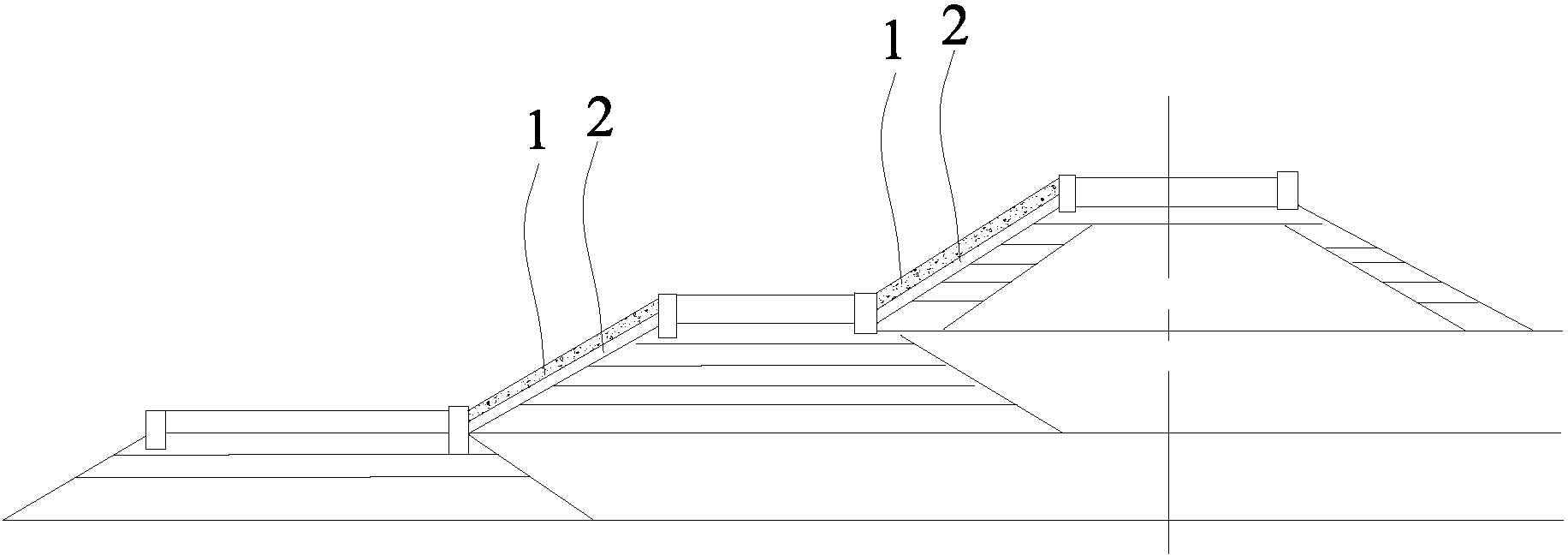

Large diameter pipeline winter construction equipment and method thereof

InactiveCN101788081ASolve the problem of difficult construction in winterAchieve installationPipe laying and repairArchitectural engineeringEngineering

The invention relates to a pipeline construction equipment and a method thereof, in particular to a large diameter pipeline winter construction equipment and a method thereof. The construction equipment comprise a traction machine, a cable wire, a fast tightening mechanism, a gate box, a motor, a speed changer and a cable wire fixing rack, wherein the fast tightening mechanism (5) is formed by three symmetrical same anchoring blocks (12), and a hand wheel (10) is arranged on the fast tightening mechanism. The construction method comprises the steps of: installing an assembled fixed pipe (1) and a pipe (2) to be assembled; scrolling the cable wire (4) by using the traction machine (3); respectively using the fast tightening mechanism (5) to firmly fix the scrolled the cable wire (4) and one end of the cable wire at the end parts of the assembled fixed pipe and the pipe to be assembled; leading the installed pipes to be in place, and then tensioning by a sealing ring at the joint part to complete the connection; and leading constructors to move into a next pipe to be assembled, and repeating the process. The invention adopts a set of installation method with convenient operation for the construction in the pipe, has simple construction equipment, and only uses the simple traction machine and the fast tightening mechanism to replace the original excavator or loading machine.

Owner:SHENYANG JIANZHU UNIVERSITY

Constructing technology for layered soft foundation treatment

ActiveCN103352460AEasy to operateShort construction periodBuilding constructionsOrganic fertilisersSlagSludge

The invention provides a constructing technology for layered soft foundation treatment. According to the technology, firstly, in the ground segment needing to be treated, space needed for engineering is dug with a manual or mechanical method, dug home-position soft soil and sludge curing agent are stirred and mixed to be even, and the water-seepage-proof and water-stopping function of the soil body is enhanced. The layering constructing process includes the steps that firstly, a layer of curing agent is paved at the bottom of the dug space, then the stirred soil body is paved on the curing agent layer in a layering mode, a flattening device is used to flatten the layer of the paved stirred soil body after one layer of the stirred soil body is paved, then another layer of the stirred soil body is paved, two to five layers of the stirred soil body is paved, and the thickness of the paved stirred soil body is 30cm; the sludge curing agent includes powder agent and liquor raw material, the powder agent comprises cement clinker, cinder or slag, lime, gypsum and sulfate; the liquor includes polyacrylamide, polyaluminium chloride, mannitol, lignin sulfonates, alkyl phenol polyoxyethylene ether, tannic acid, humic acid salt, alpha-olefin sulfonate and the like.

Owner:杭州佳熠环保科技有限公司

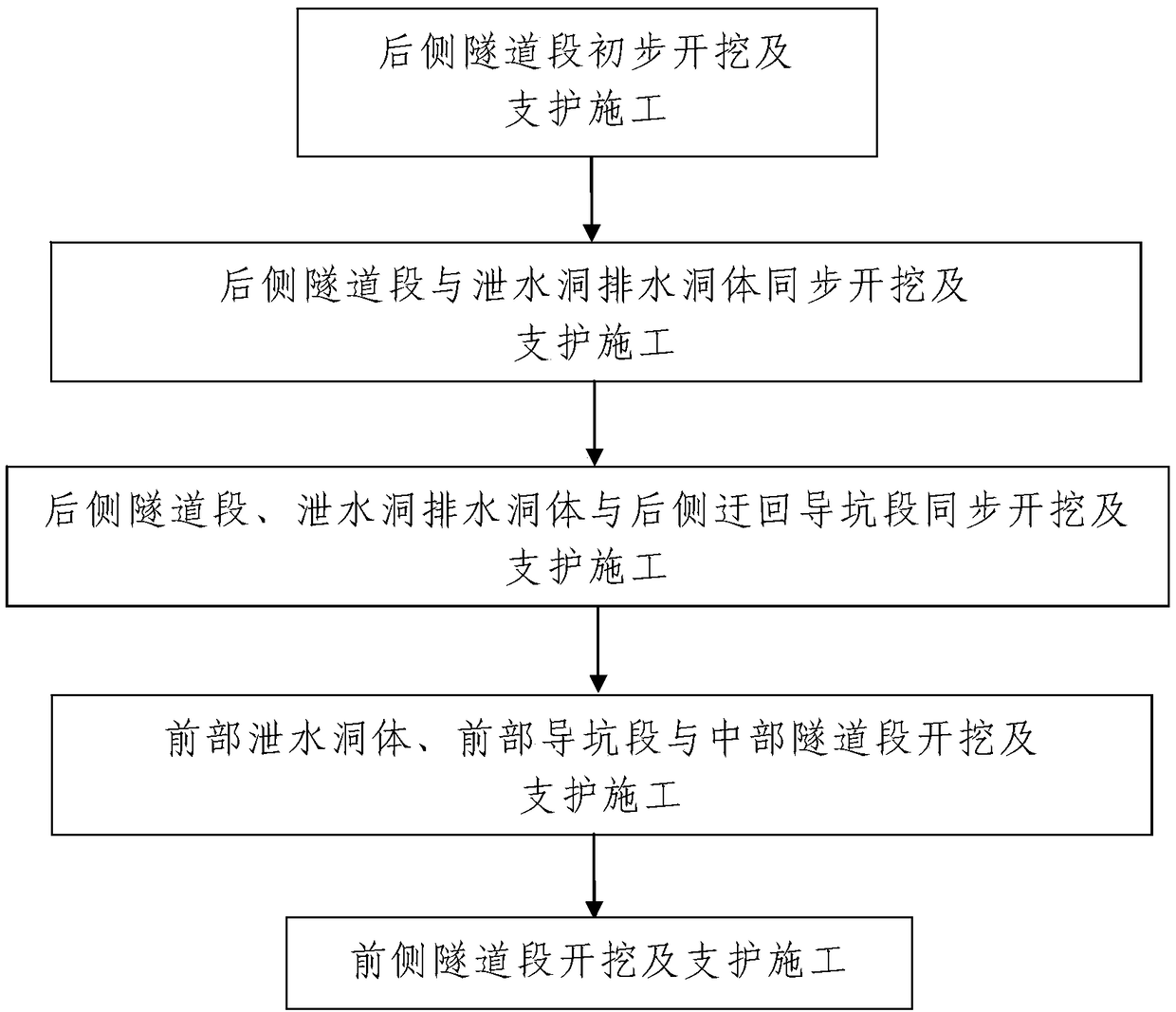

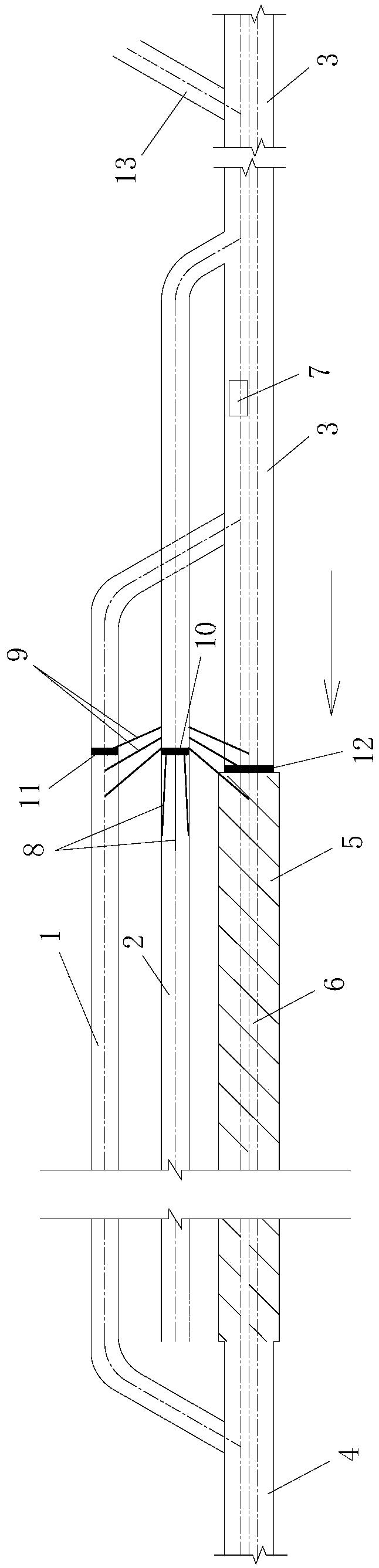

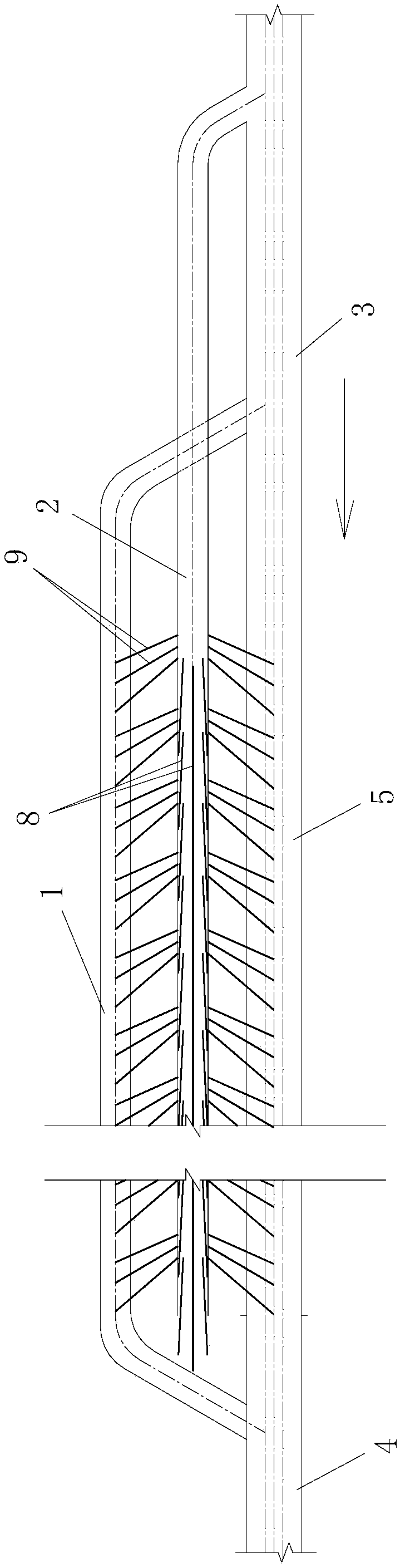

Construction method for tunnel passing through high-angle thrust water-rich and sand-rich fault

ActiveCN109209397AThe method steps are simpleReasonable designUnderground chambersDrainageStructural safetyHigh angle

The invention discloses a construction method for a tunnel passing through a high-angle thrust water-rich and sand-rich fault. The method comprises the steps: 1, performing the preliminary excavationand the supporting construction of a rear tunnel segment; 2, performing the synchronous excavation and the supporting construction of the rear tunnel segment and a water drainage hole body of a waterdrainage hole; 3, performing the synchronous excavation and the supporting construction of the rear tunnel segment, the water drainage hole body of the water drainage hole and a rear detouring headingsegment; 4, performing the excavation and the supporting construction of a front water drainage hole body, a front heating segment and a central tunnel segment; 5, performing the excavation and the supporting construction of a front tunnel segment. According to the invention, the water on the upper wall of the fault is drained through a high-level water drainage hole between a tunnel front hole and a detouring heading pit, and the auxiliary water drainage is performed through the detouring heading pit, and the fault condition in front of the tunnel face of the front hole can be explored in advance, thereby guaranteeing the construction safety of each tunnel face. The method employs the three-step method for the excavation of the tunnel front hole, employs double preliminary supporting structures for the full-section supporting after excavation, can guarantee the safety of the tunnel structure later, and shortens the construction cycle.

Owner:CHINA RAILWAY 20 BUREAU GRP

Nano titanium polymer inner wall anticorrosion oil pipe

ActiveCN103275601AExtended service lifeImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsEpoxyPolymer

The invention relates to a nano titanium polymer inner wall anticorrosion oil pipe in the technical field of pipeline corrosion resistance. The technical scheme is as follows: the nano titanium polymer inner wall anticorrosion oil pipe comprises an oil pipe and an anticorrosion layer coated on the inner wall of the oil pipe. The anticorrosion layer is prepared by the following steps of: mixing and stirring 130-160 parts by weight of novolac epoxy resin, 20-40 parts by weight of nano-scale titanium powder and 10-30 parts by weight of diluent; sequentially adding 2-3 parts by weight of organosilicon leveling agent and 3-5 parts by weight of bentonite filler to adjust viscosity; screening with a sieve of 1,100-1,300 meshes to obtain an component A of a finished product; mixing and dispersing 15-18 parts by weight of curing agent, 4-6 parts by weight of titanate coupling agent and 6-8 parts by weight of butanone to obtain a component B of the finished product; and finally blending the component A and the component B by the diluent according to a ratio of (4.5-5.5):2:(1-2). Compared with other anticorrosion products, the product provided by the invention has unique advantages of static resistance, strong permission resistance and the like; and moreover, the construction equipment and technology are simple, and the product is easy to popularize.

Owner:胜利油田金岛实业有限责任公司

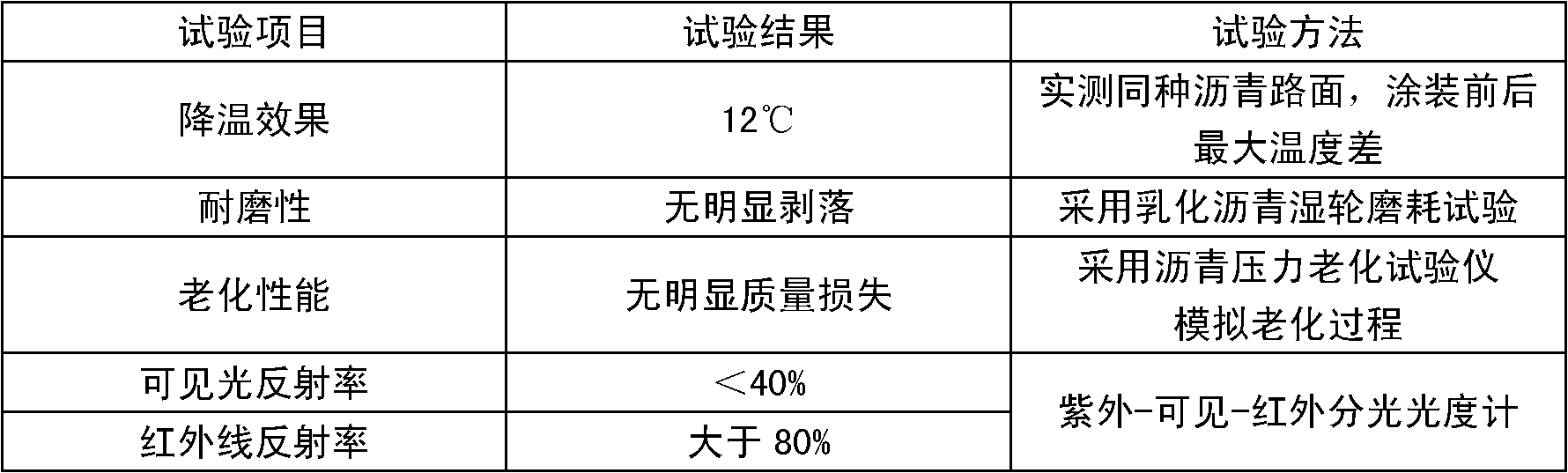

Heat-reflection coating of asphalt pavement

InactiveCN103421371AStrong resistanceStrong wear resistanceReflecting/signal paintsMetallurgyCooling effect

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

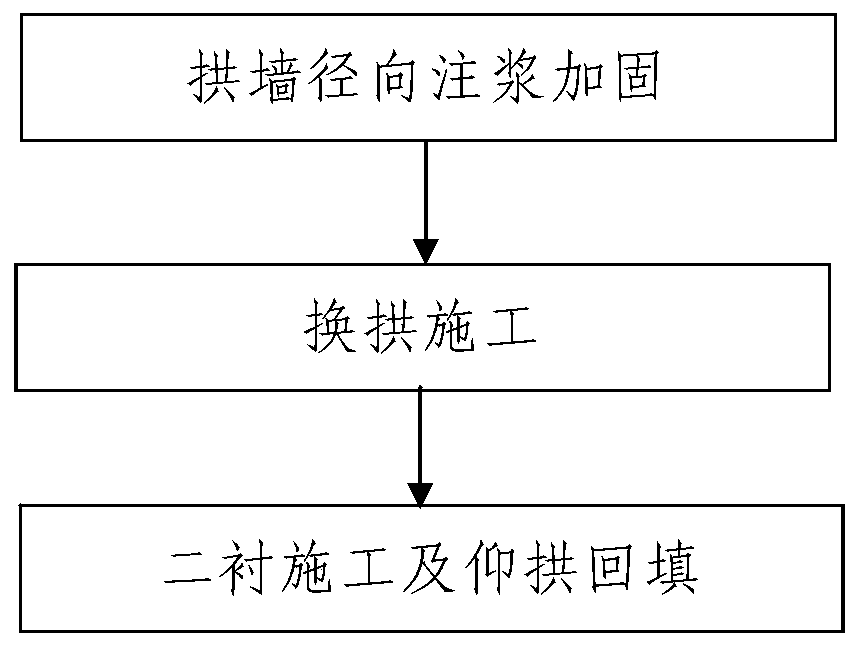

Method for beyond-limit arch replacing construction during preliminary bracing of large-section loess tunnel

ActiveCN110656959AThe method steps are simpleReasonable designUnderground chambersTunnel liningArchitectural engineeringStructural engineering

The invention discloses a method for beyond-limit arch replacing construction during preliminary bracing of a large-section loess tunnel. The method includes the steps of firstly, conducting radial grouting reinforcement on an arch wall, wherein radial grouting reinforcement is conducted on an arch replacing required section where arch replacing is required in the constructed loess tunnel from back to front; and secondly, conducting arch replacing construction, wherein a reinforced preliminary bracing structure in the arch replacing required section is detached, and preliminary bracing construction is conducted on the arch replacing required section synchronously in the detaching process. The method is simple in step, reasonable in design, simple in construction and good in use effect; theradial grouting reinforcement is conducted on the arch wall to reinforce the arch wall of a tunnel hole first, so the structural stability of the tunnel in the arch replacing process is ensured; segmented reinforcing is conducted on the preliminary bracing structure of the tunnel through a plurality of sleeve arch units for a reinforced sleeve arch in the arch replacing required section, so detaching is convenient; and moreover, the sleeve arch units are complementary and together improve the supporting force, so the adverse effects on the structural stability of the tunnel in the detaching process of each sleeve arch unit can be effectively reduced, and the safety and reliability of the arch replacing construction process are ensured.

Owner:CHINA RAILWAY 20 BUREAU GRP

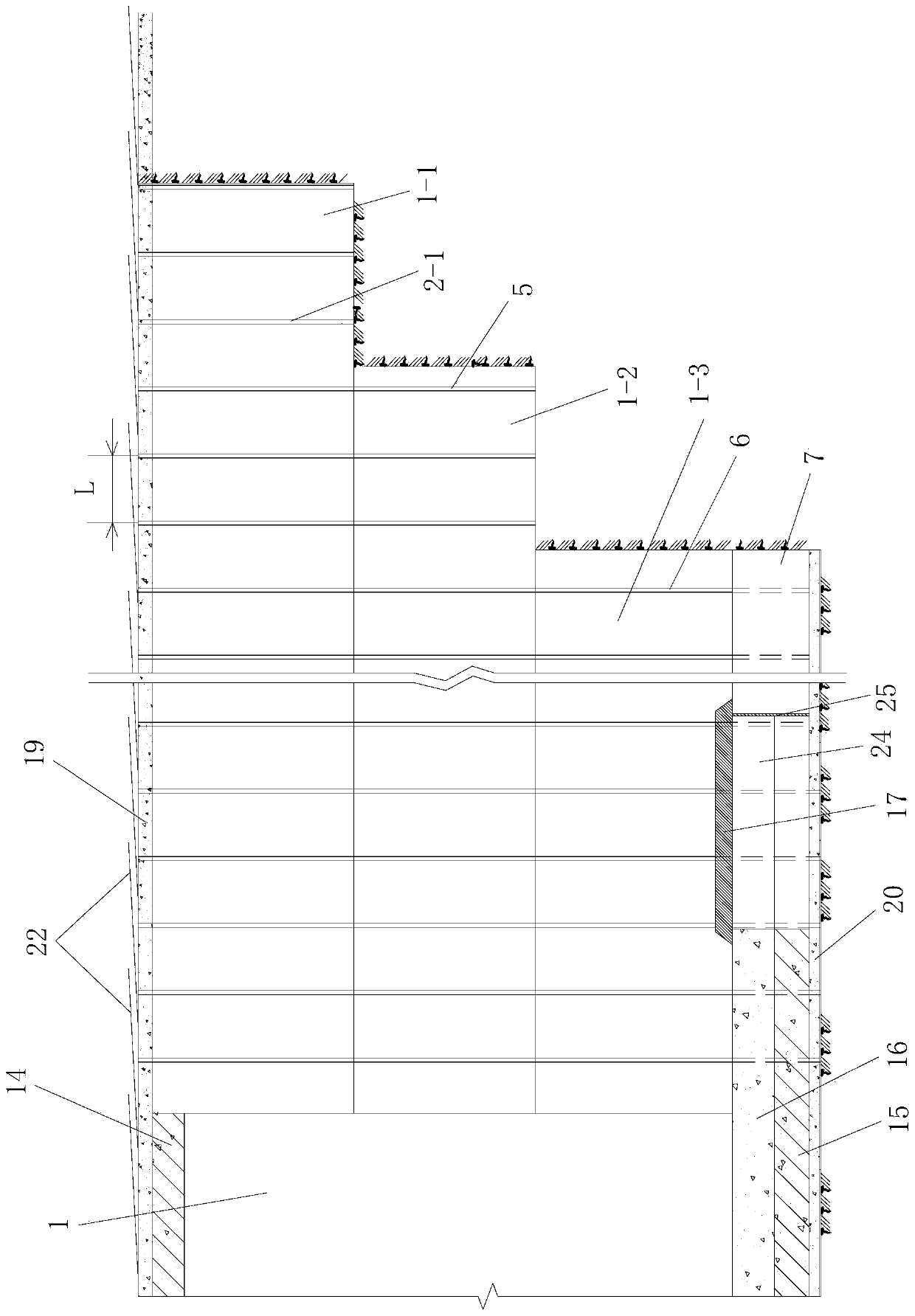

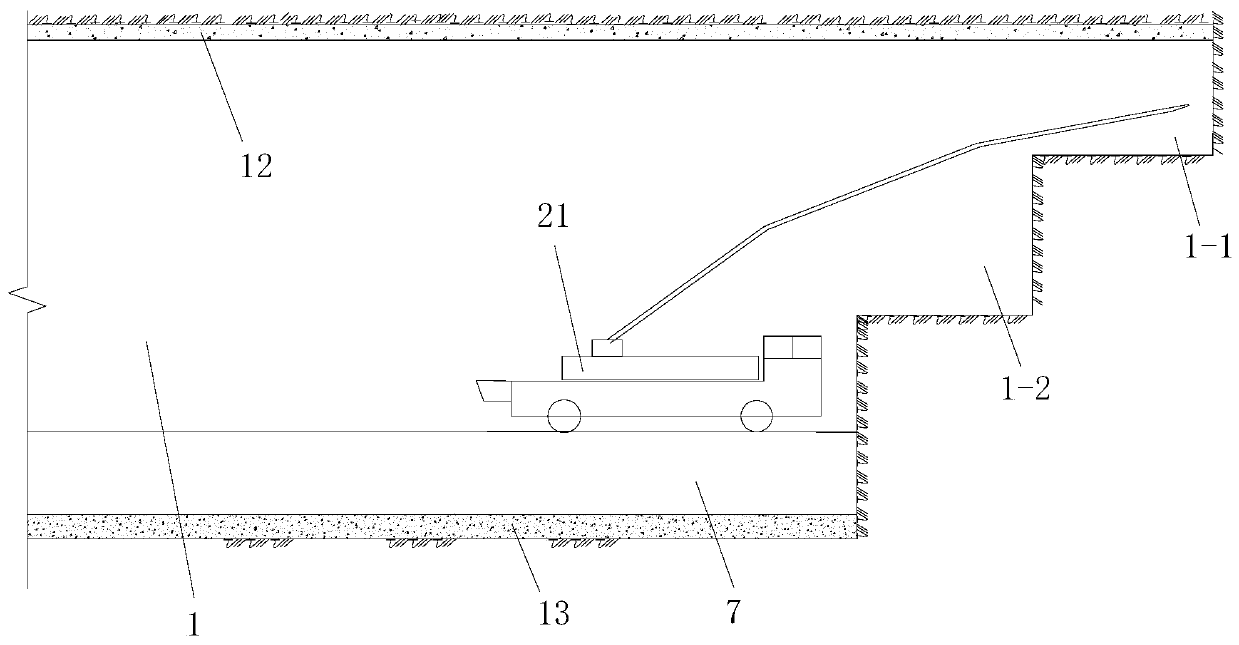

Loess tunnel foundation base reinforcing structure and method based on high pressure jet grouting piles

PendingCN110671131AReasonable designReduce construction costsUnderground chambersTunnel liningStructural engineeringGeotechnical engineering

The invention discloses a loess tunnel foundation base reinforcing structure and method based on high pressure jet grouting piles. The structure comprises the multiple rows of high pressure jet grouting piles for reinforcing soil on the lower portion of a tunnel, and each high pressure jet grouting pile passes through a tunnel invert structure and a collapsible loess stratum from top to bottom andthen extends into a non collapsible loess stratum. The method comprises the following steps of firstly, tunnel excavating and preliminary bracing; secondly, second lining construction; and thirdly, foundation base reinforcing. The structure is reasonable in design, easy and convenient to construct and good in use effect. The multiple rows of high pressure jet grouting piles are adopted for carrying out foundation base reinforcing on a loess tunnel, a loess tunnel foundation base can be simply and rapidly effectively reinforced, the tunnel foundation base settling volume can be effectively controlled, meanwhile, the upper surface of a secondary lining inverted arch is adjusted to the horizontal plane, a construction platform is provided for the high pressure jet grouting piles, the loess tunnel foundation base reinforcing process can be further quickened, the high pressure jet grouting piles and the tunnel invert structure are fastened and connected into a whole, and the loess tunnel foundation base reinforcing effect can be further improved.

Owner:THE NO 6 ENG CO LTD OF CHINA RAILWAY 20TH BUREAU GRP

Construction process of floral tube dry filling piles

InactiveCN101713189AReduce labor intensityFew control parametersBulkheads/pilesResource utilizationWater table

The invention relates to a construction process of floral tube dry filling piles with obvious engineering effect, low economic cost, high technical content and high resource utilization by improving the inherent characteristics of cement, soil strata, materials and the like. The process comprises the following steps of: (1) pore-forming process: 1, using dry pore-forming process for pore-forming piles above underground water level; 2, positioning a pore opening machine and a drill for pore-forming piles below underground water level; drilling in at low stroke and high rotary speed with clean water; reaching a drilling-in depth; lifting to a pore opening at unified stroke and high rotary speed with clean water; drilling into a pore bottom at unified stroke and high rotary speed with clean water; rotating at high speed and filling with cement mortar; and lifting to the pore opening at high rotary speed and low stroke after cement mortar returns to the pore opening; moving the drill; (2) the process of installation and pile molding by filling: adopting the following steps for installing pile pores and filling dry cement above or below water level: installing floral tubes; correcting the pore position of the floral tubes; filling the dry cement; and filling the dry cement to an elevation required by the design.

Owner:HENAN UNIVERSITY

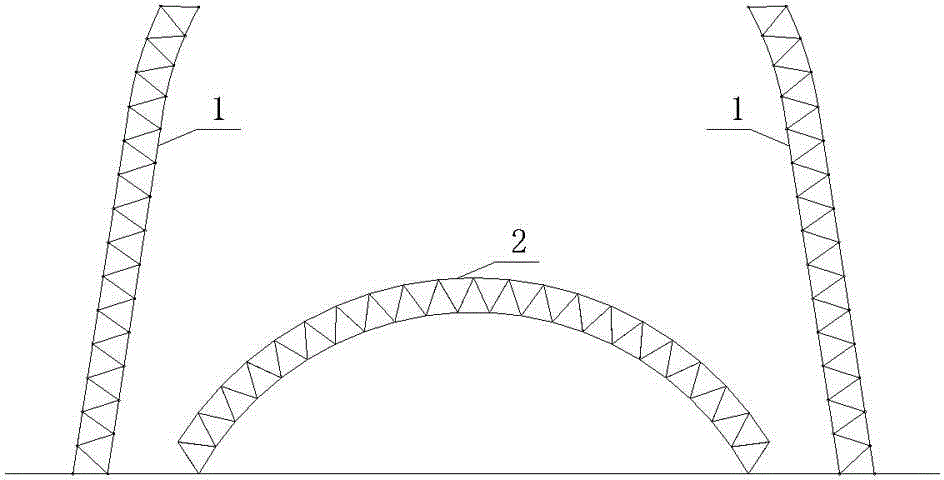

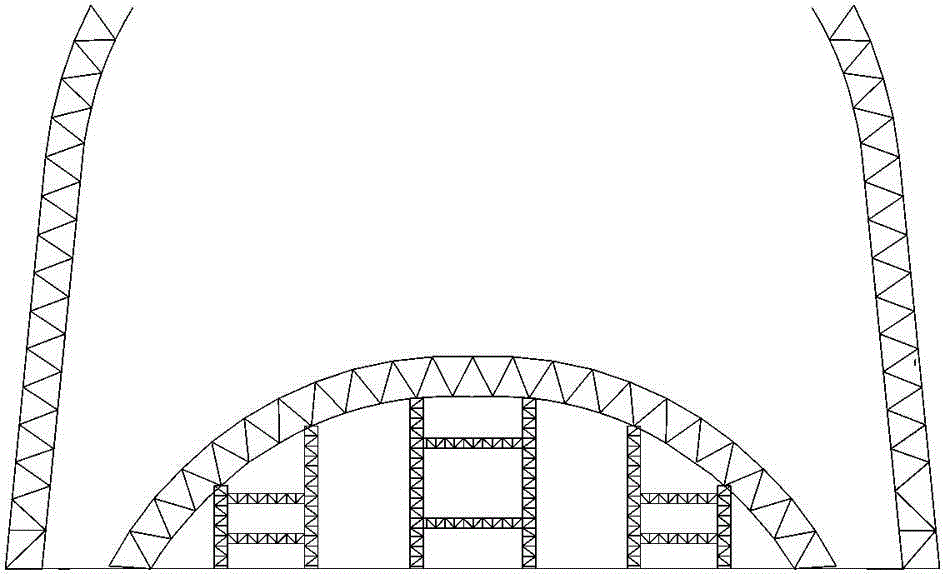

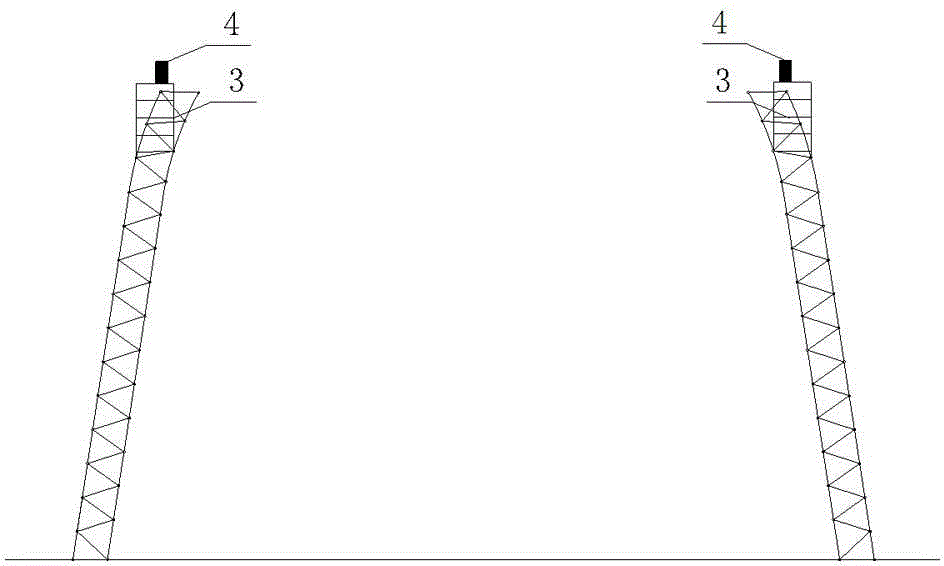

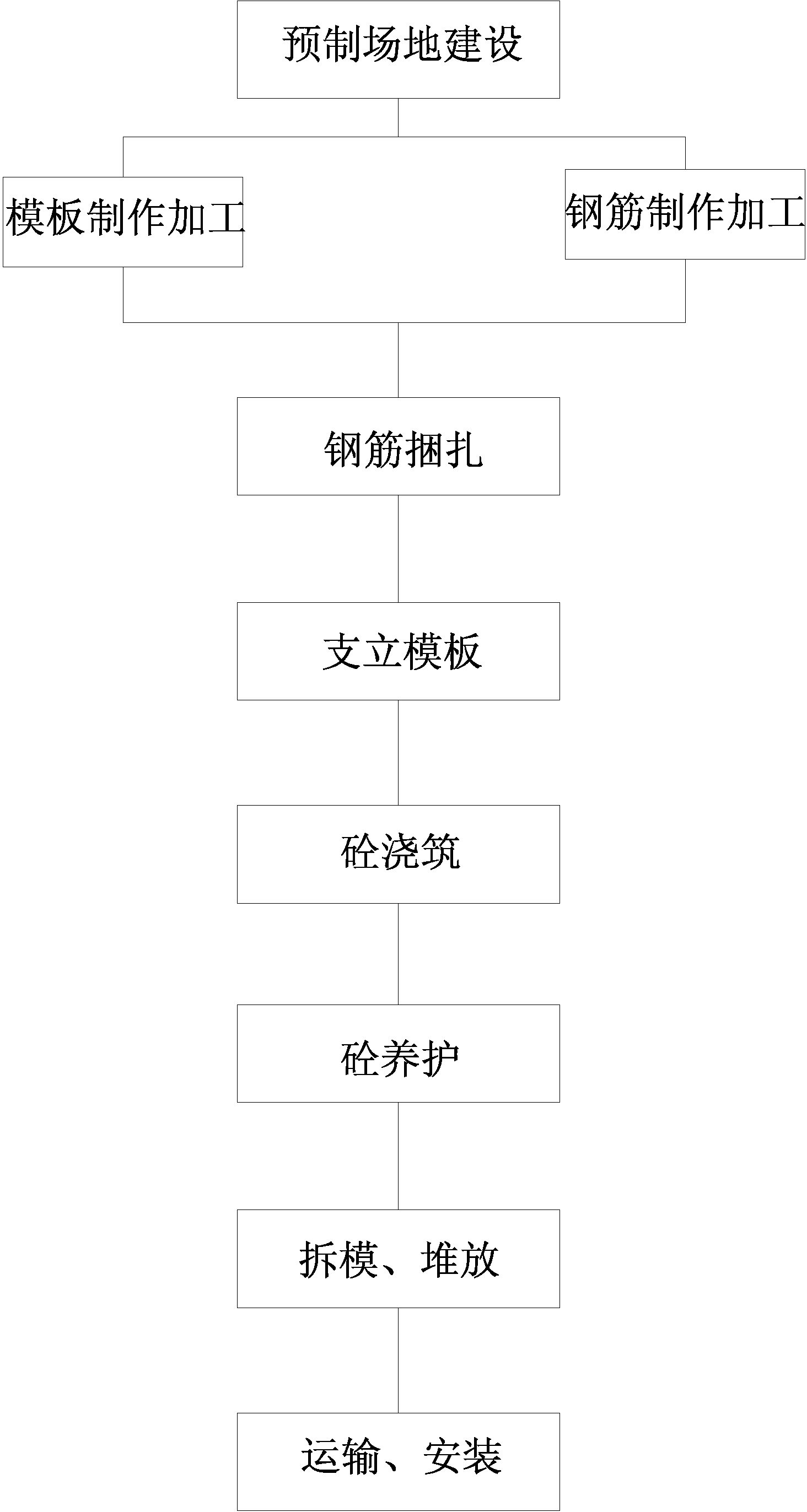

Lifting and installation method of high curved-surface net racks

ActiveCN104060836AMeet the mechanicsFulfil requirementsBuilding material handlingMechanical equipmentEngineering

The invention relates to high curved-surface net racks, particularly to a lifting and installation method of high curved-surface net racks, which can be applied in building steel structures. The lifting and installation method proceeds according to the processes of a lifting preparation stage and a lifting stage. According to the lifting and installation method of high curved-surface net racks, the structure is compact, the requirements for mechanical equipment is low, the construction efficiency is improved, the construction cost is reduced, and the construction safety is improved.

Owner:浙江东南网架股份有限公司

Method for preparing microcapsule polyurethane premix

InactiveCN107141433ASaving ratioSave mixing timeMicroballoon preparationMicrocapsule preparationPolyurethane elastomerUltraviolet

The invention provides a method for preparing microcapsule polyurethane premix, and belongs to the technical field of polyurethane. The method for preparing microcapsule polyurethane premix comprises the steps that 1, curing agents or other components are respectively prepared into solid microcapsules by utilizing the microencapsulation technology; 2, solid microcapsules are uniformly mixed in polyurethane prepolymer and vacuum degassed after the mixing; 3, when the microcapsules are in use, the shells of the microcapsules are ruptured, curing agents or other components wrapped by the capsules spill, contact is made with polyurethane prepolymer and a polymerization reaction occurs, and polyurethane elastomers are generated. By the microencapsulation technology, curing agents or other components in capsule form are respectively distributed in polyurethane prepolymer, by the obstruction of the capsule shells, the components do not react with each other before use, and long-term stable storage is achieved. When the microcapsules are in use, the capsule shells are ruptured by means of temperature, pressure, ultraviolet or the like, the components are in contact with each other, the rapid polymerization reaction occurs, and polyurethane elastomers are generated, proportioning and mixing are not required at the construction site, the construction time is saved, and the construction facilities are simplified in the meantime.

Owner:CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

Precast fence plate dam reinforcing method

The invention relates to a precast fence plate dam reinforcing method. The method comprises the following steps of: firstly precasting a fence plate, and conserving the precast fence plate until 75% of the design strength standard value is achieved; paving a layer stone blocks on a dam surface to be constructed, manuacturing a screed strip underlayer on the stone blocks, conveying the precast fence plate to a to-be-reinforced dam, manually regulating the position so that the fence plate is placed on the screed strip underlayer, and performing edge beam form erecting after placement is finished; then binding edge beam steel bars, pouring concretes, vibrating, trowelling, conserving until the dam is qualified, and then dismounting a template, thus finishing dam reinforcing construction. The fence plate dam reinforcing construction method is high in efficiency, low in cost, easy for formation of multiple parallel working surfaces and less in influence of tide water on construction; and furthermore, fence plates are connected by virtue of the steel bars and are poured by the concretes, a molded dam reinforcing structure has two advantages of reliable protective property and good wave eliminating effect, and is less in wave overtopping amount and long in service life.

Owner:ANHUI WATER RESOURCES DEV

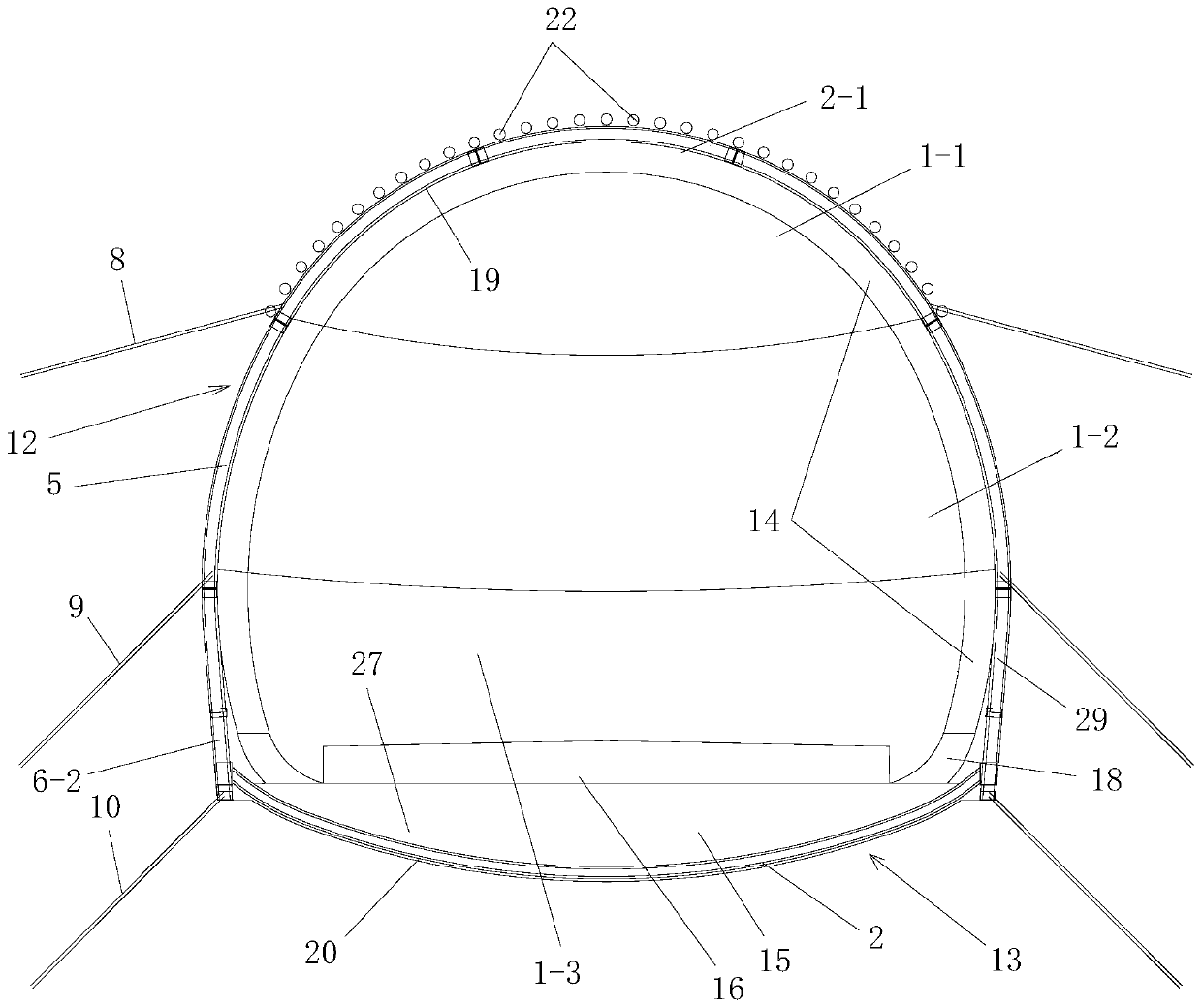

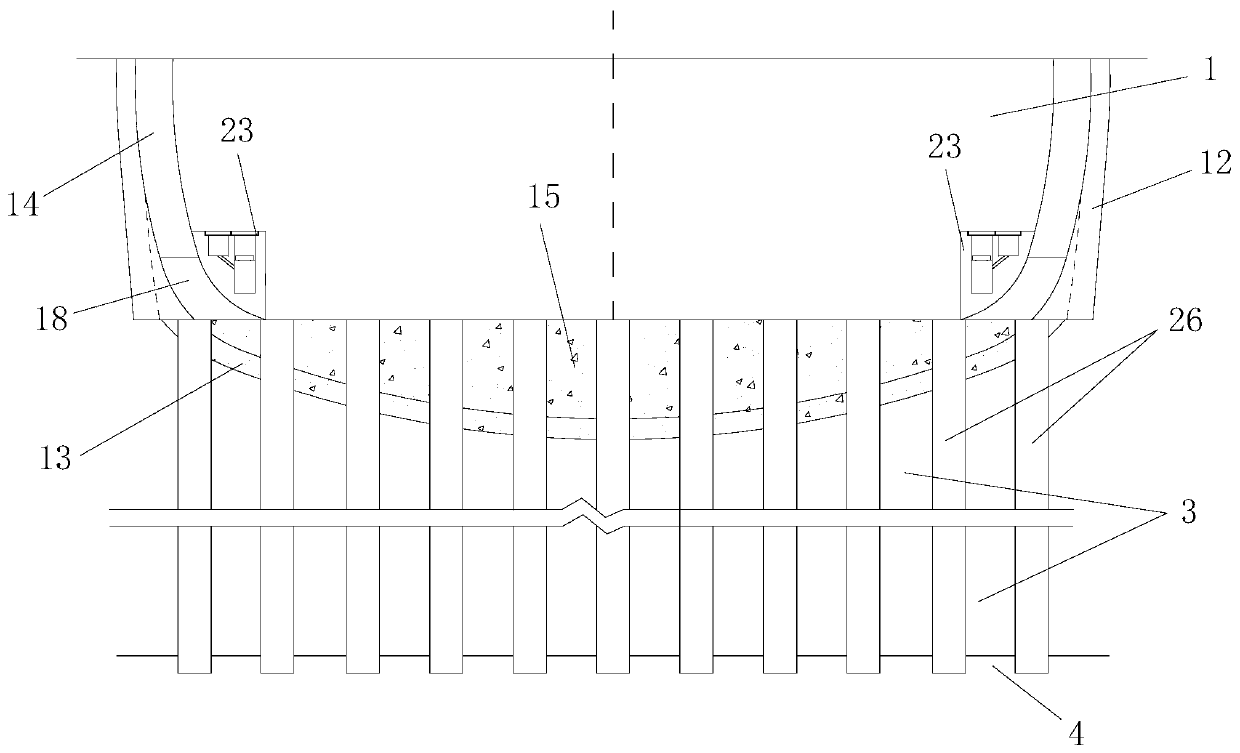

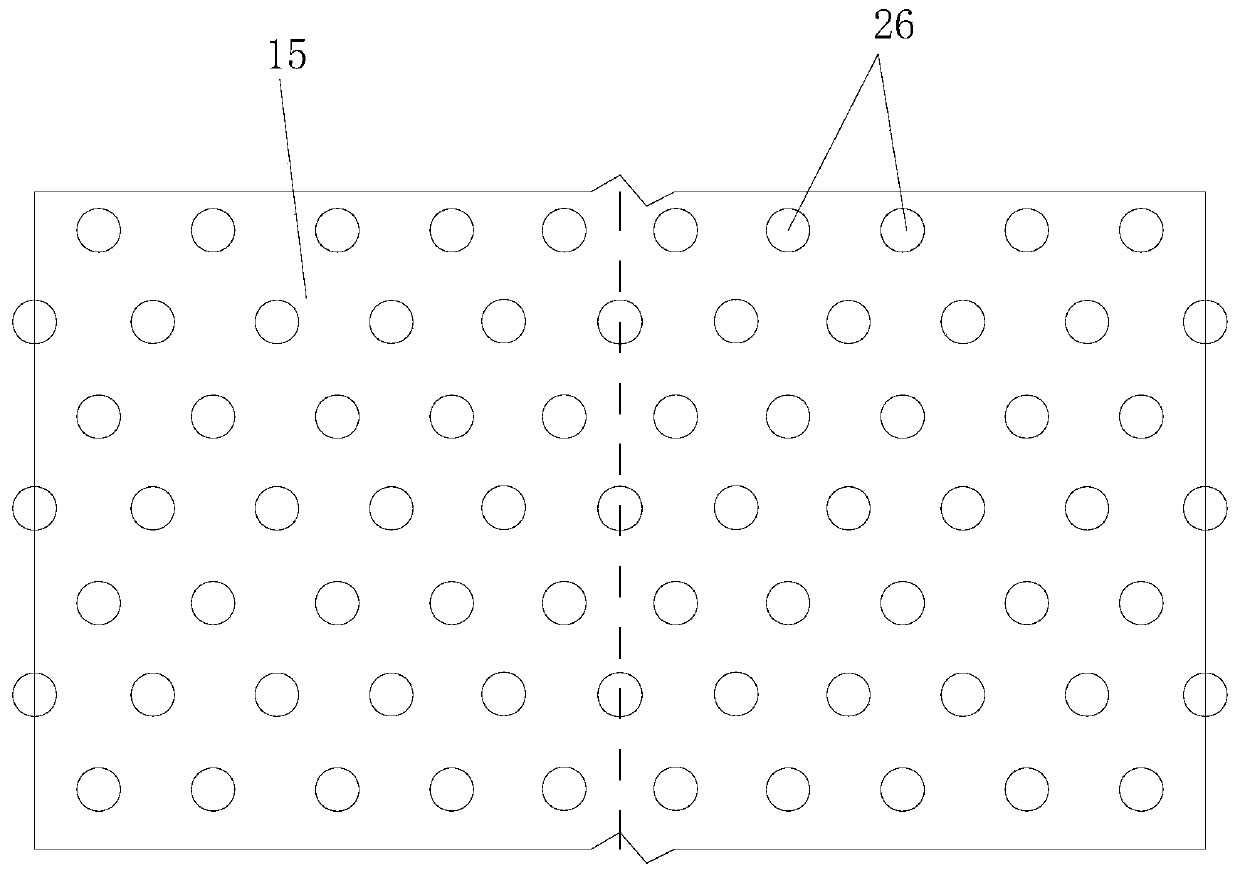

Large-section loess tunnel supporting system and supporting construction method

PendingCN110761808AReasonable structural designEasy constructionUnderground chambersTunnel liningGeotechnical engineeringStructure support

The invention discloses a large-section loess tunnel supporting system and a supporting construction method. The large-section loess tunnel supporting system comprises a tunnel forepoling structure, atunnel initial supporting structure and a tunnel secondary lining. The upper surface of an inverted arch secondary lining in the tunnel secondary lining is a horizontal plane, and an inverted arch backfill layer is arranged on the horizontal plane. The supporting construction method comprises the following steps of firstly digging a tunnel and conducting initial supporting; and secondly constructing the secondary lining and backfilling the inverted arch. The large-section loess tunnel supporting system is reasonable in design, easy and convenient to construct, high in construction efficiencyand good in use effect, the tunnel forepoling structure, the tunnel initial supporting structure and the tunnel secondary lining constitute a combined supporting system to stably and reliably supportthe large-section loess tunnel, the upper surface of the inverted arch of the secondary lining is adjusted to be a horizontal plane, the construction process of the inverted arch of the tunnel can beeffectively simplified, and the rigidity of the inverted arch of the tunnel is greatly improved; in this way, the construction efficiency of the tunnel secondary lining is improved, the ring sealingtime of the tunnel secondary lining is shortened, the integrity of the tunnel secondary lining is higher, and the overall force bearing effect is better.

Owner:CHINA RAILWAY 20 BUREAU GRP

Large span foundation pit automatic cover system

PendingCN108756262ALow costReduce lossExcavationsBuilding material handlingElectric power systemCovering system

The invention discloses a large span foundation pit automatic cover system. The large span foundation pit automatic cover system comprises stand columns longitudinally fixed in stand column foundations, tracks are fixed in the stand columns, rollers are arranged in the tracks, a steel wire rope is fixed between the rollers, and a dense screen is hung above the steel wire rope. Gear motors are installed at the bottoms of the rollers, and the gear motors are connected with a distribution box through a power line. The columns are positioned 2m away from the edges of a foundation pit and are arranged in parallel in a multi-row mode. The large span foundation pit automatic cover system has the advantages of fast construction speed, simple construction equipment and technology, convenient and flexible construction, low project cost and the like, the dense screen hanging on the foundation pit reduces the loss of the dense screen, the cover system adopts an automatic power system to reduce thelabor and greatly reduce the cost, the smooth progress of a project in the dust improvement process is ensured, and the construction efficiency is improved.

Owner:SHANGHAI BAOYE GRP CORP

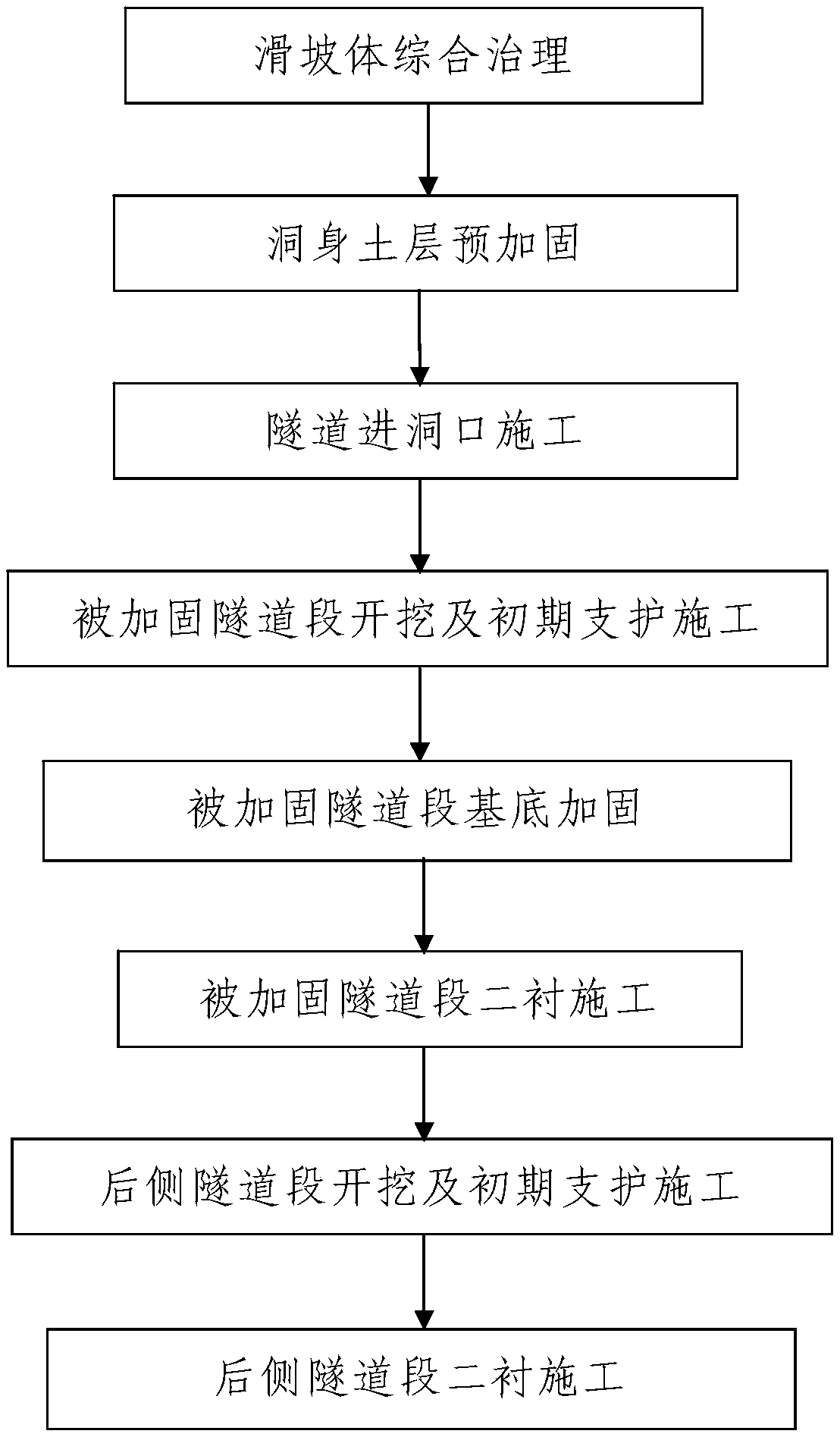

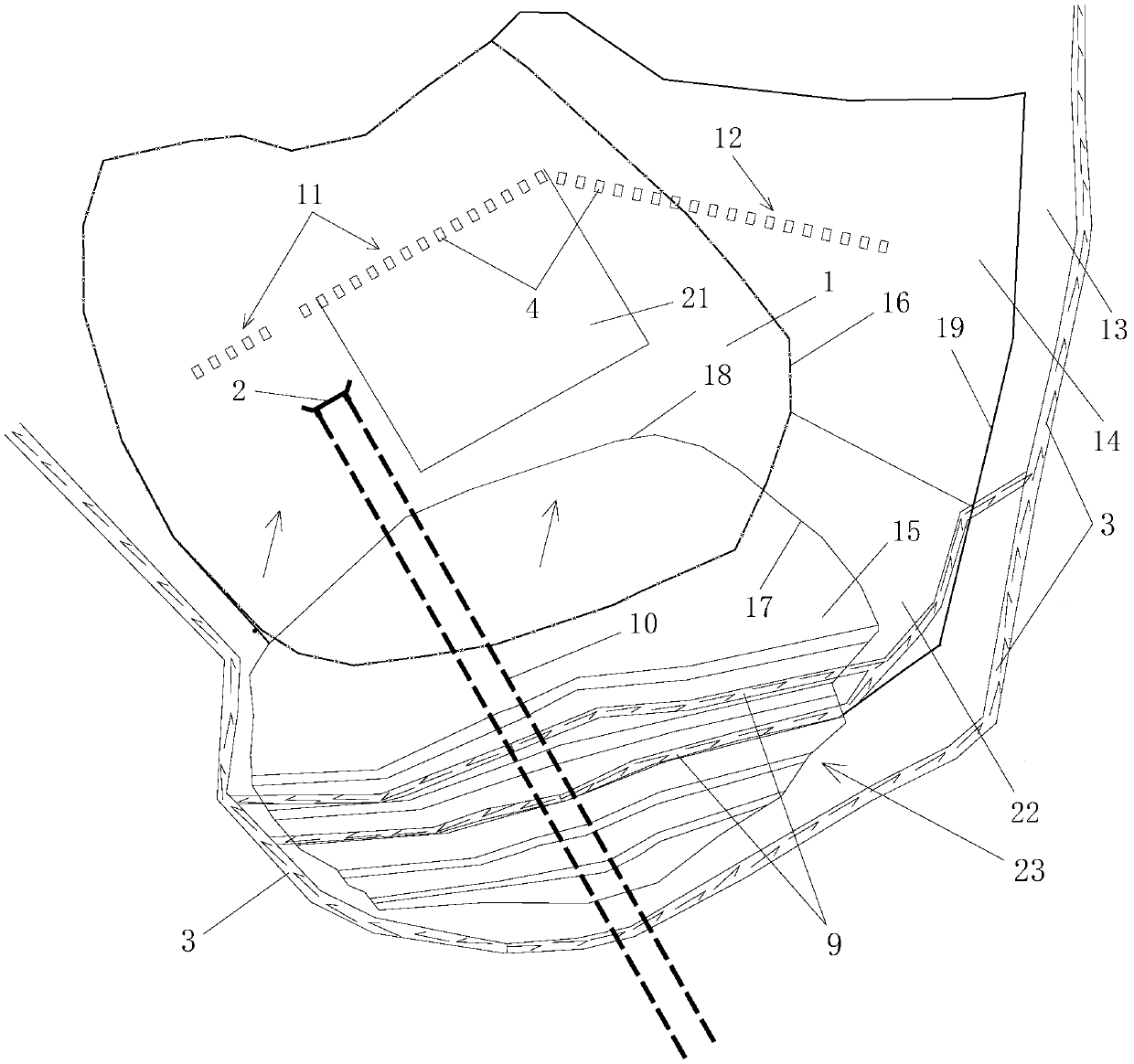

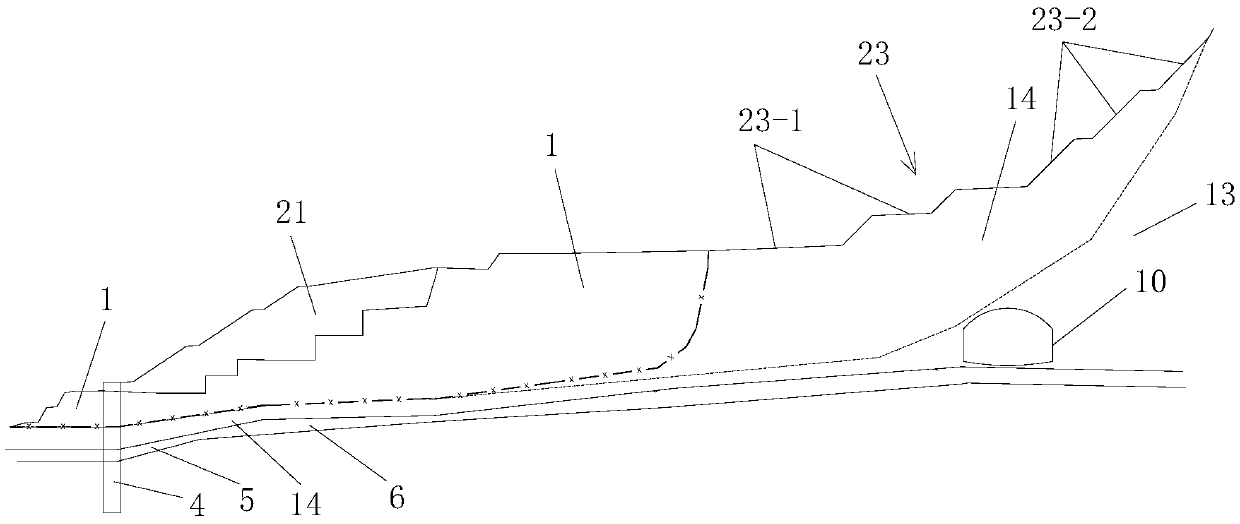

Construction method of loess tunnel entrance section through landslide mass

ActiveCN110778328AThe method steps are simpleReasonable designUnderground chambersExcavationsLandslideStructural engineering

The invention discloses a construction method of a loess tunnel entrance section through a landslide mass. The method comprises the following steps that 1, an entrance soil layer is pre-reinforced; 2,a tunnel entrance is constructed; 3, excavation and initial support construction is conducted on the reinforced tunnel section; 4, a reinforced tunnel section base is reinforced; 5, the reinforced tunnel section is subjected to secondary lining construction; 6, excavation and initial support construction is conducted on a rear side tunnel section; and 7, the rear side tunnel section is subjectedto secondary lining construction. The method is reasonable in design, simple and convenient to construct and good in use effect, cement-soil mixed piles are adopted for pre-reinforcement before excavation, a construction process of the tunnel entrance section through the landslide mass is guaranteed to be safe and reliable, meanwhile, the tunnel entrance section is excavated by adopting a three-step excavation method, the reinforced tunnel section base is reinforced, an excavation process of the tunnel entrance section through the landslide mass can be guaranteed to be safe and reliable, in addition, the influence on the stability of a soil layer on the circumferential side of the tunnel entrance is small, and the stability of the excavated and formed tunnel entrance can be effectively improved.

Owner:CHINA RAILWAY 20 BUREAU GRP

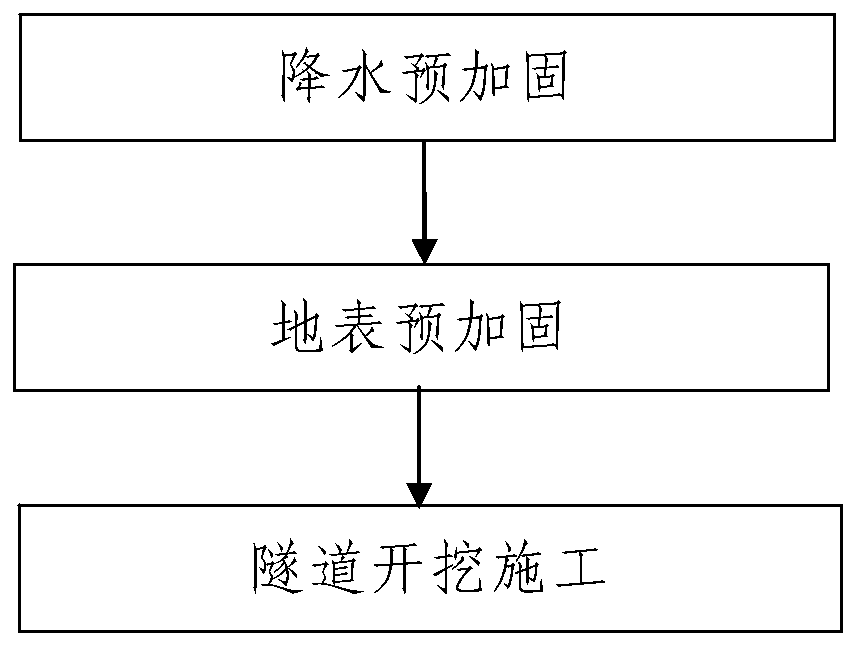

Tunnel portal section pre-reinforcement and excavation construction method based on partition blasting

ActiveCN110847929AConstruction safetyStable structureUnderground chambersTunnel liningArchitectural engineeringStructural engineering

The invention discloses a tunnel portal section pre-reinforcement and excavation construction method based on partition blasting. The construction method comprises the following steps of 1, precipitation pre-reinforcement; 2, earth surface pre-reinforcement, and specifically, reinforcing the surface of a backfill section in a construction tunnel portal section through adopting a cement soil stirring pile; and 3, tunnel excavation construction, and specifically, carrying out excavation construction from rear to front in a plurality of excavation sections, wherein the process comprises the following steps of surveying and setting out, performing drilling and blasting construction, excavating an upper portal body, excavating a middle portal body and excavating a lower portal body. The construction method is reasonable in design, simple and convenient in construction and good in use effect; the underground water level is reduced through precipitation pre-reinforcement, and then surroundingrock is effectively reinforced; after the backfill section is subjected to surface pre-reinforcement through using the cement soil stirring pile, a three-step synchronous excavation mode is used forcarrying out partition blasting excavation, so that it is ensured that the tunnel excavation process is safe and reliable and a tunnel structure is stable.

Owner:CHINA RAILWAY 20 BUREAU GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com