Excavation-free underground pipe line rehabilitation method

A repair method and technology for underground pipelines, applied to pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as high repair costs, high design costs, and difficult construction, and achieve simple construction equipment and stable product performance , The effect of facilitating the promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

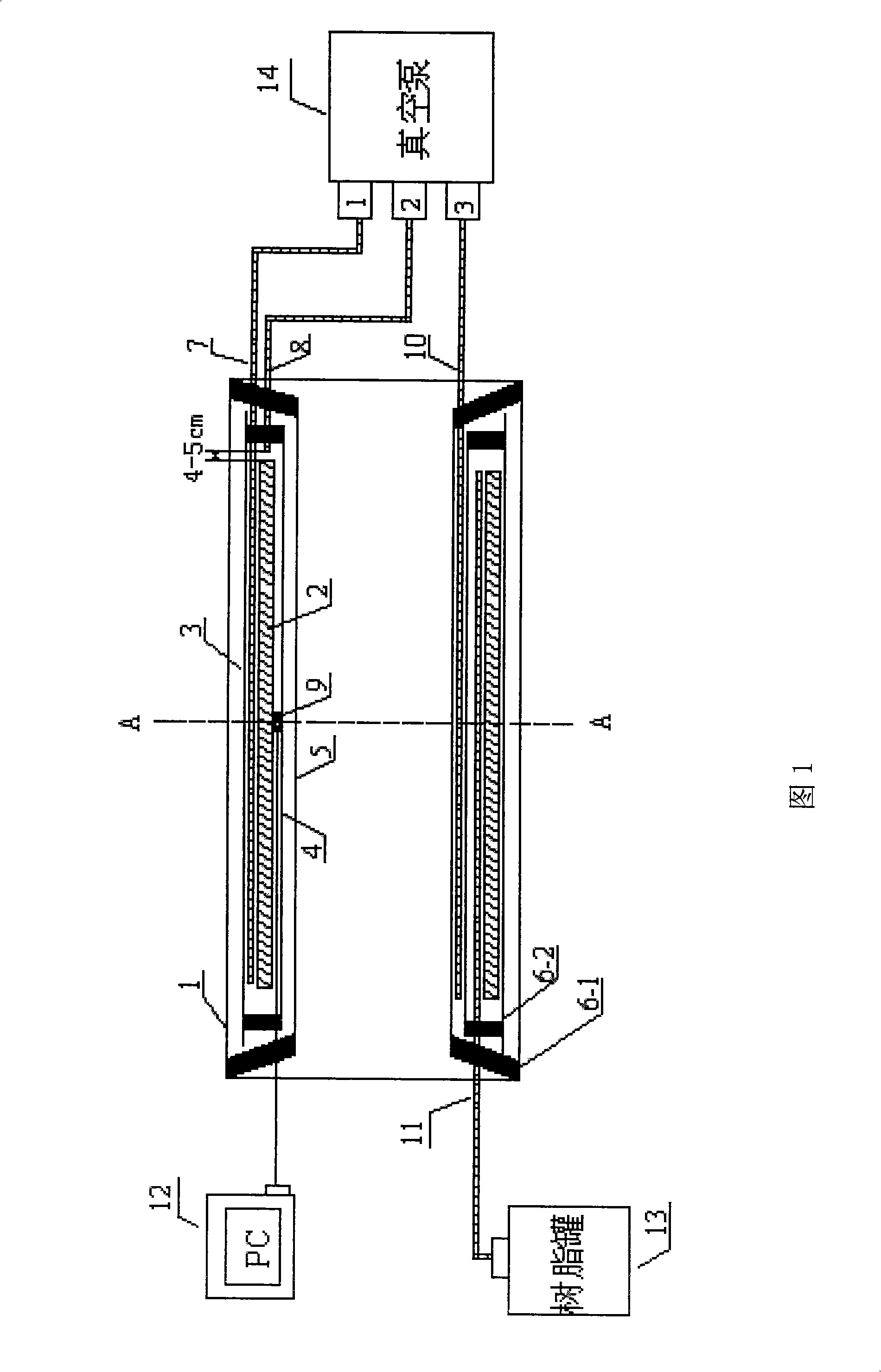

[0023] Repair an underground damaged gas pipeline with an inner diameter of 600mm and a length of 5000mm without excavation.

[0024] 1. Fabrication of double-pocket fiber repair prefabs

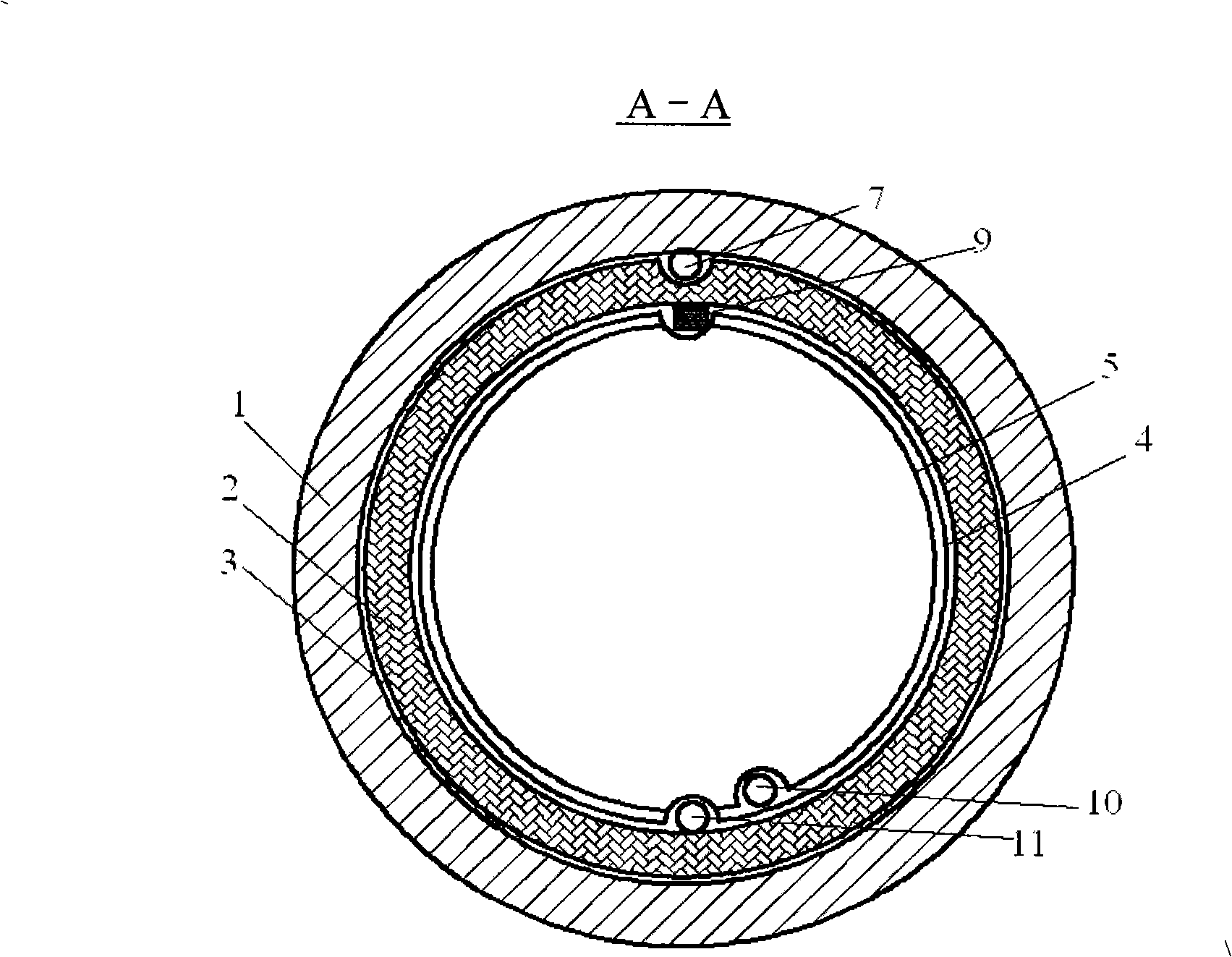

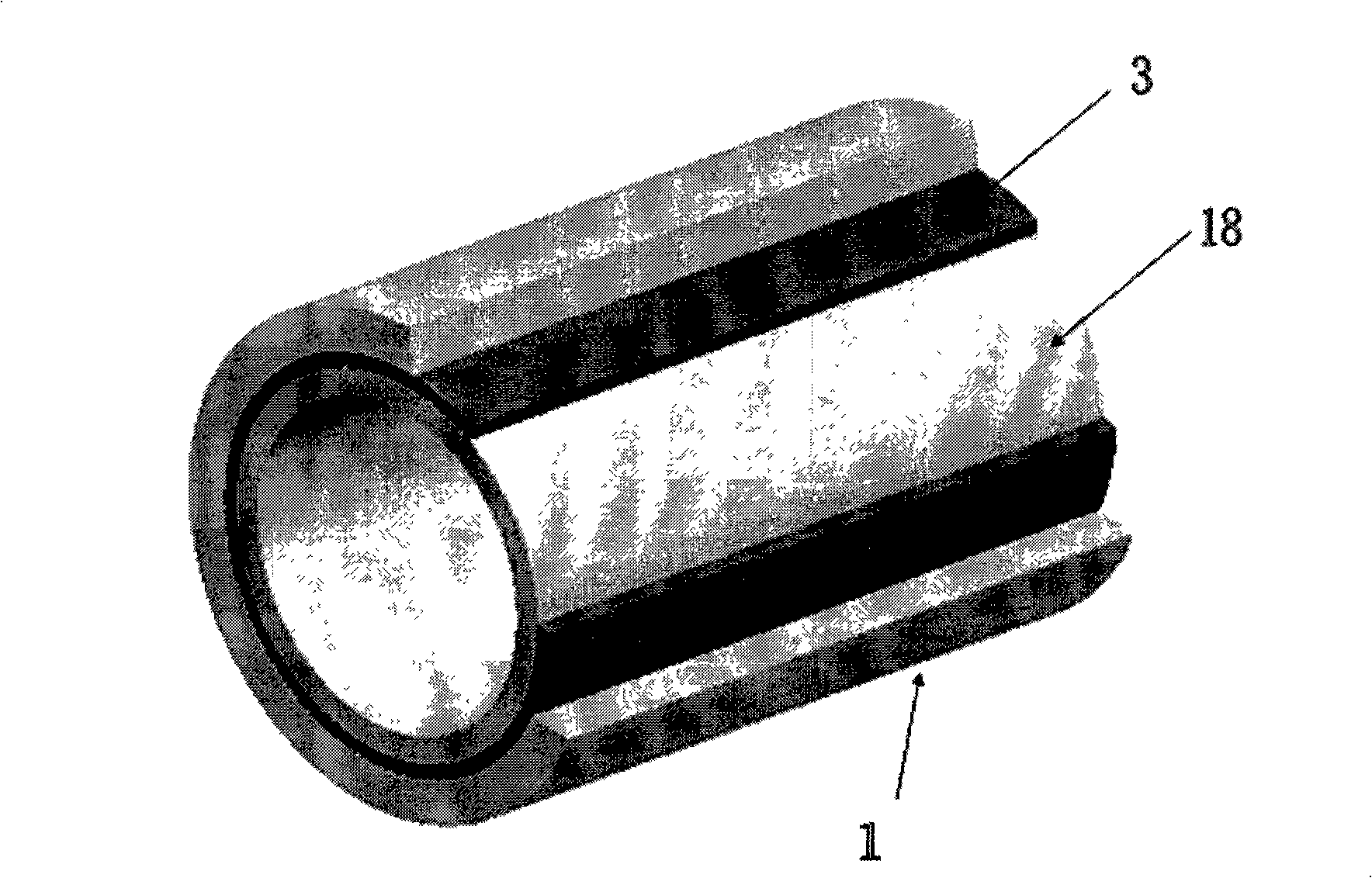

[0025] First, according to the requirement of 600mm internal diameter of the repaired pipeline, the circumference of the pipeline is calculated to be 3770mm, the known pipeline length is 5000mm, and the size (length×width) of the designed and cut glass fiber prefabricated part 2 (abbreviated as prefabricated part) is 4900mm×3770mm; The size is 5000mm * 3700mm; the size of the inner vacuum membrane 4 is 5000mm * 4084mm; the size of the outer vacuum membrane 5 is 5200mm * 4477mm: the inner and outer vacuum membranes 4 and 5 are all made into cylinders for later use.

[0026] Secondly, lay the fiber preform 2 flat on the ground, then lay the No. 1 vacuum pumping spiral tube 7 on the centerline of the length direction of the fiber preform 2, one end of which is flush with one side of the fiber p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com