Tunnel portal section pre-reinforcement and excavation construction method based on partition blasting

A construction method and pre-reinforcement technology, which is applied in tunnels, tunnel linings, and foundation structure engineering, and can solve problems such as uneven softness and hardness of rock and soil, insufficient bearing capacity of foundations, deformation and structural damage of primary support arches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

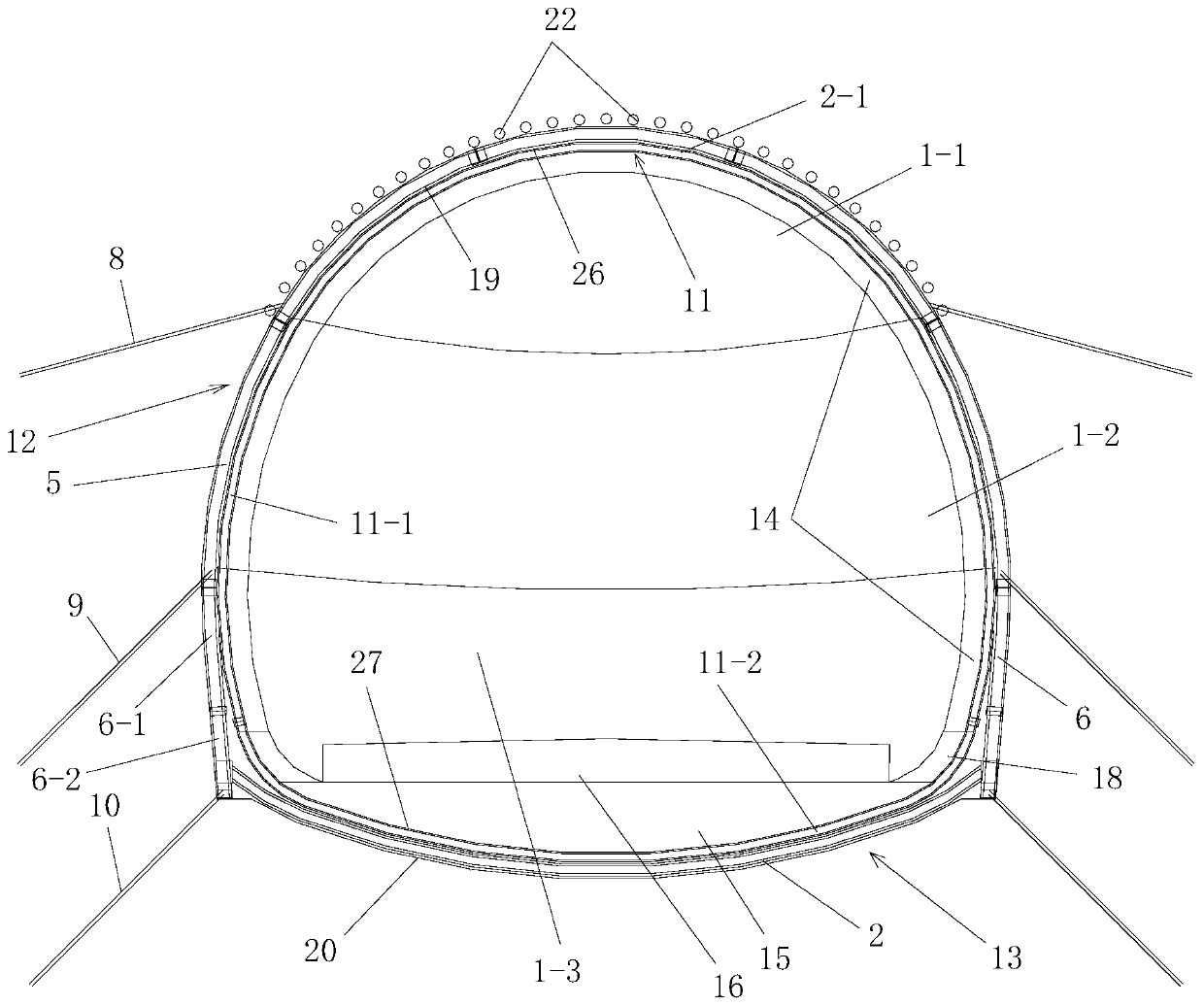

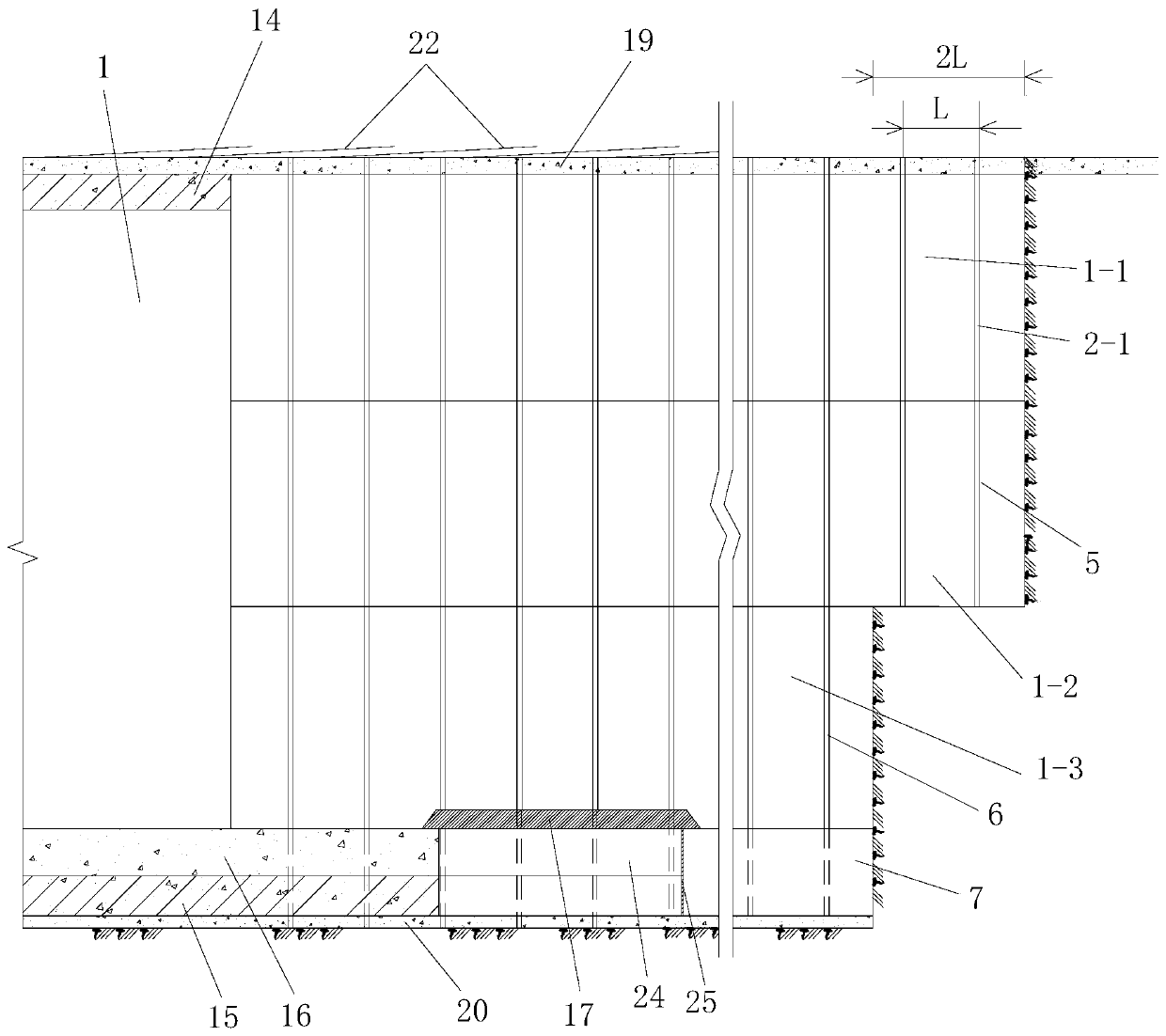

[0131] Such as figure 1 Shown is a method of pre-reinforcement and excavation of the tunnel entrance section based on zoned blasting. The tunnel entrance section to be constructed has a cross section greater than 100m 2 And it is a tunnel section located in the earth-rock boundary stratum, the rear end of the tunnel entrance section is the tunnel entrance and its length is 70m~100m; Figure 7 , the soil-rock boundary stratum includes the loess layer 3 and the rock layer 4 below the loess layer 3, and the interface between the loess layer 3 and the rock layer 4 is an earth-rock interface; the tunnel hole 1 of the constructed tunnel entrance section is from top to The lower part is divided into upper cave body 1-1, middle cave body 1-2 and lower cave body 1-3. The upper cave body 1-1 is formed after excavating the upper steps of the tunnel entrance section from the back to the front. The middle hole body 1-2 is a hole body formed after excavating the middle steps of the tunnel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com