Soft rock four-line large-span tunnel compound double-side wall bracing cable conversion excavation construction method

A construction method and double-side wall technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as easy deformation of surrounding rock, difficult excavation construction methods, unstable construction operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

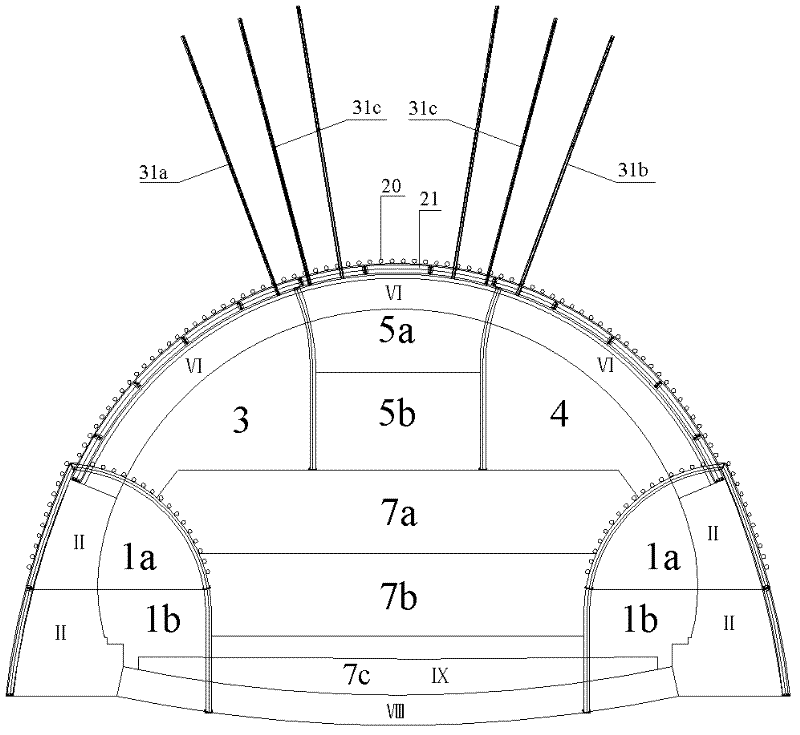

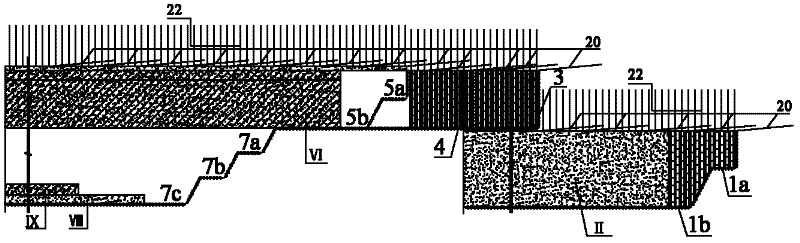

[0015] refer to figure 1 , figure 2 and Figure 15 , a construction method for converting excavation with composite double sidewall stay cables for a four-line long-span tunnel in soft rock, including the following steps:

[0016] ① Excavate the side wall pilot tunnel 1 on both sides, and implement corresponding advance support before excavation, and immediately implement corresponding initial support and temporary support after excavation;

[0017] ② Concrete the foundation II of the pedestal on both sides;

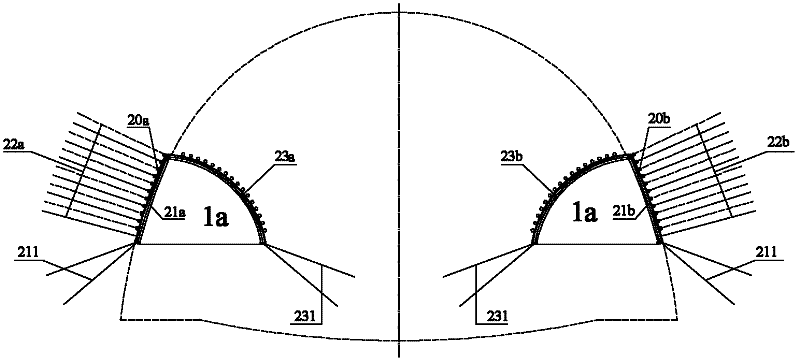

[0018] ③ Excavate the side pilot holes 3 and 4 of the arches on both sides respectively. Before the excavation, implement the corresponding advance support. Immediately after the excavation, implement the corresponding initial support and temporary support. As a prestressed anchor cable for anchorage connection with the surrounding rock, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com