Patents

Literature

1739results about How to "Large working space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

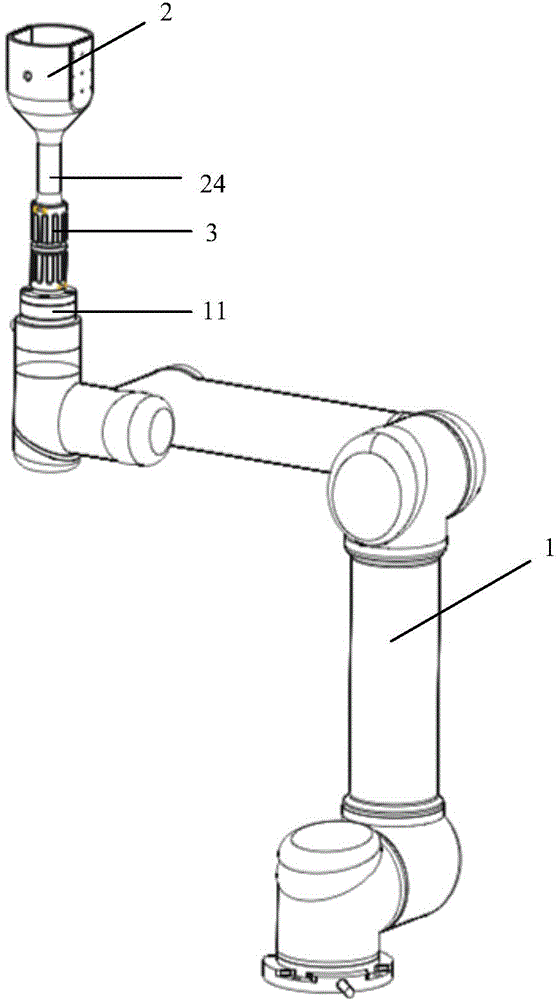

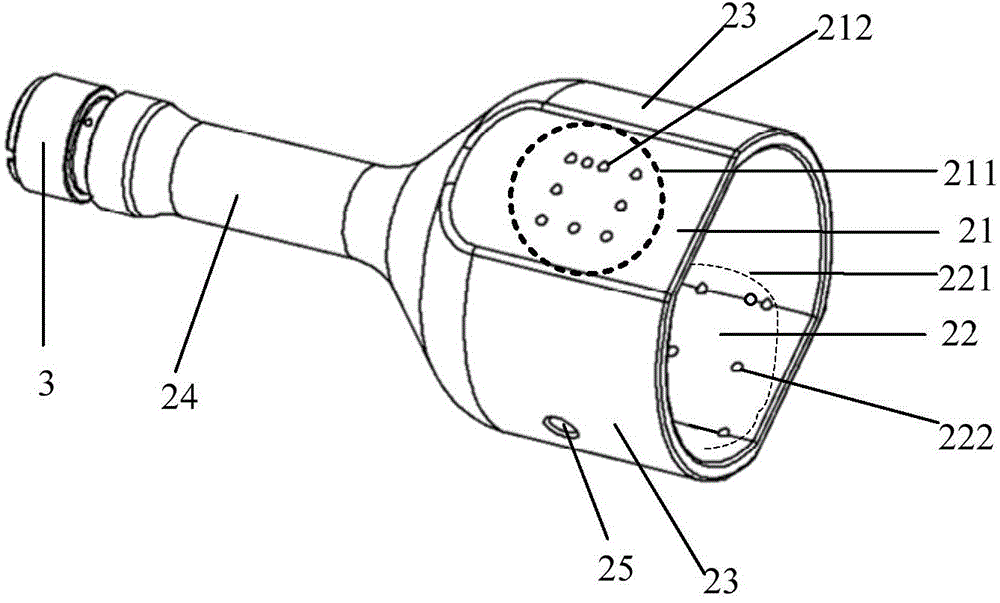

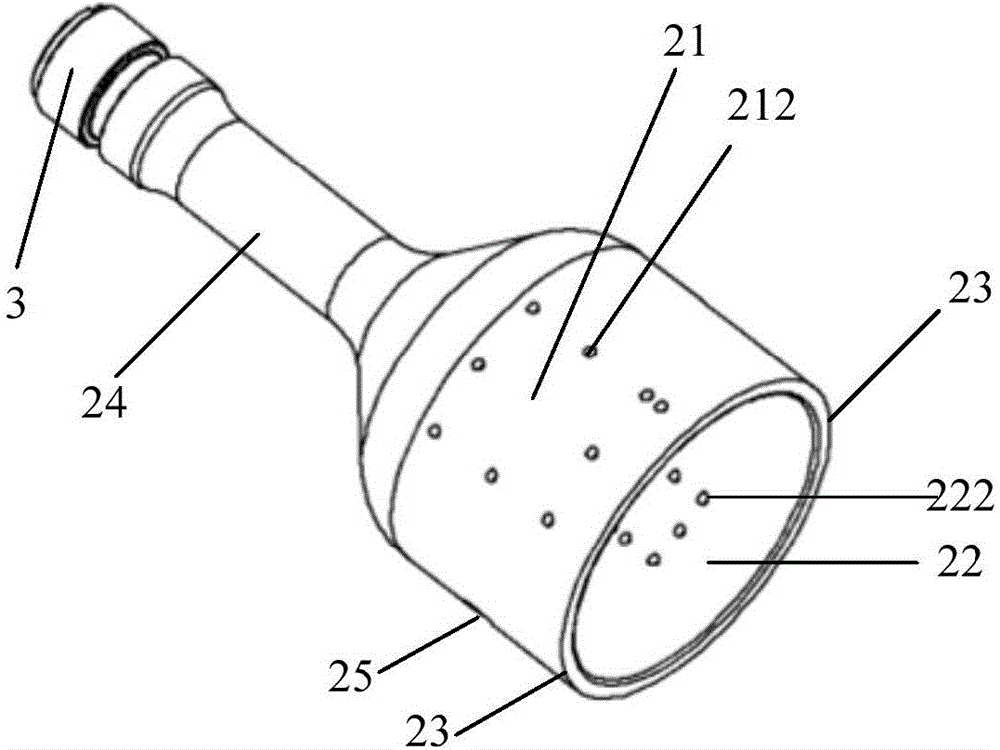

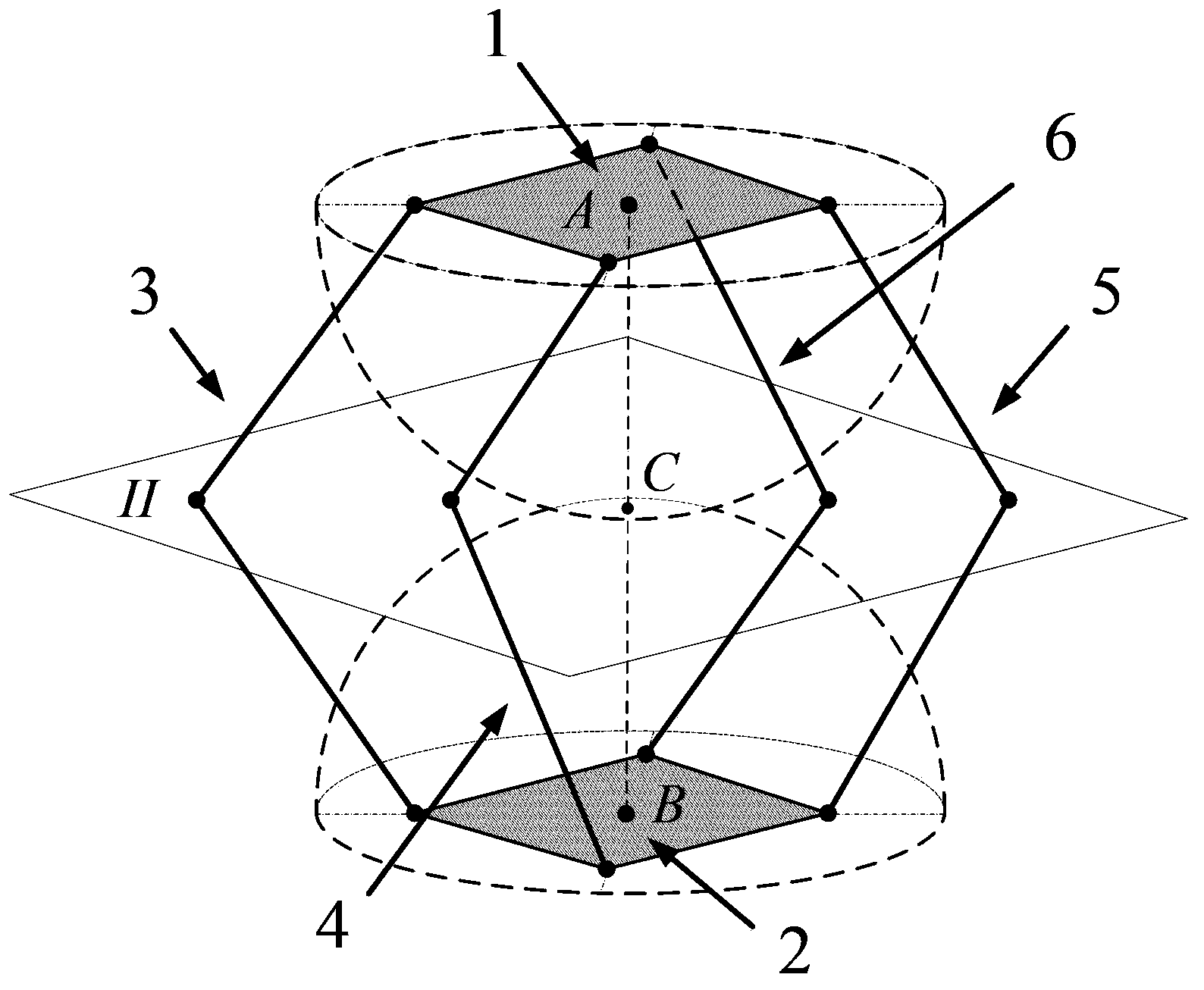

Operation positioning device and method and robot operation system

The invention relates to an operation positioning device and method and a robot operation system. The operation positioning device comprises a positioning ruler, an upper computer and a series-connection mechanical arm with at least six degrees of freedom. The upper computer is connected with the series-connection mechanical arm, the positioning ruler comprises two opposite surfaces allowing X-rays to transmit, the two opposite surfaces are fixedly connected through a connecting surface allowing X-rays to transmit, the two opposite surfaces are respectively provided with a group of marks, each group of marks comprise at least four mark points which are not located on the same straight line, and the mark points are X-ray-proof components. Any opposite surface or the connecting surface is fixedly connected with a ruler handle, and the ruler handle is connected with the tail end of the series-connection mechanical arm through a port. The upper computer adjusts the position of the positioning ruler by controlling movement of the series-connection mechanical arm, space positioning calculation is conducted according to the mark points in collected images, and a planning path is obtained. The device can achieve perspective positioning at any angle, and can eliminate system errors caused when an operation path is calculated, increase working space and improve the operation positioning accuracy.

Owner:BEIJING TINAVI MEDICAL TECH

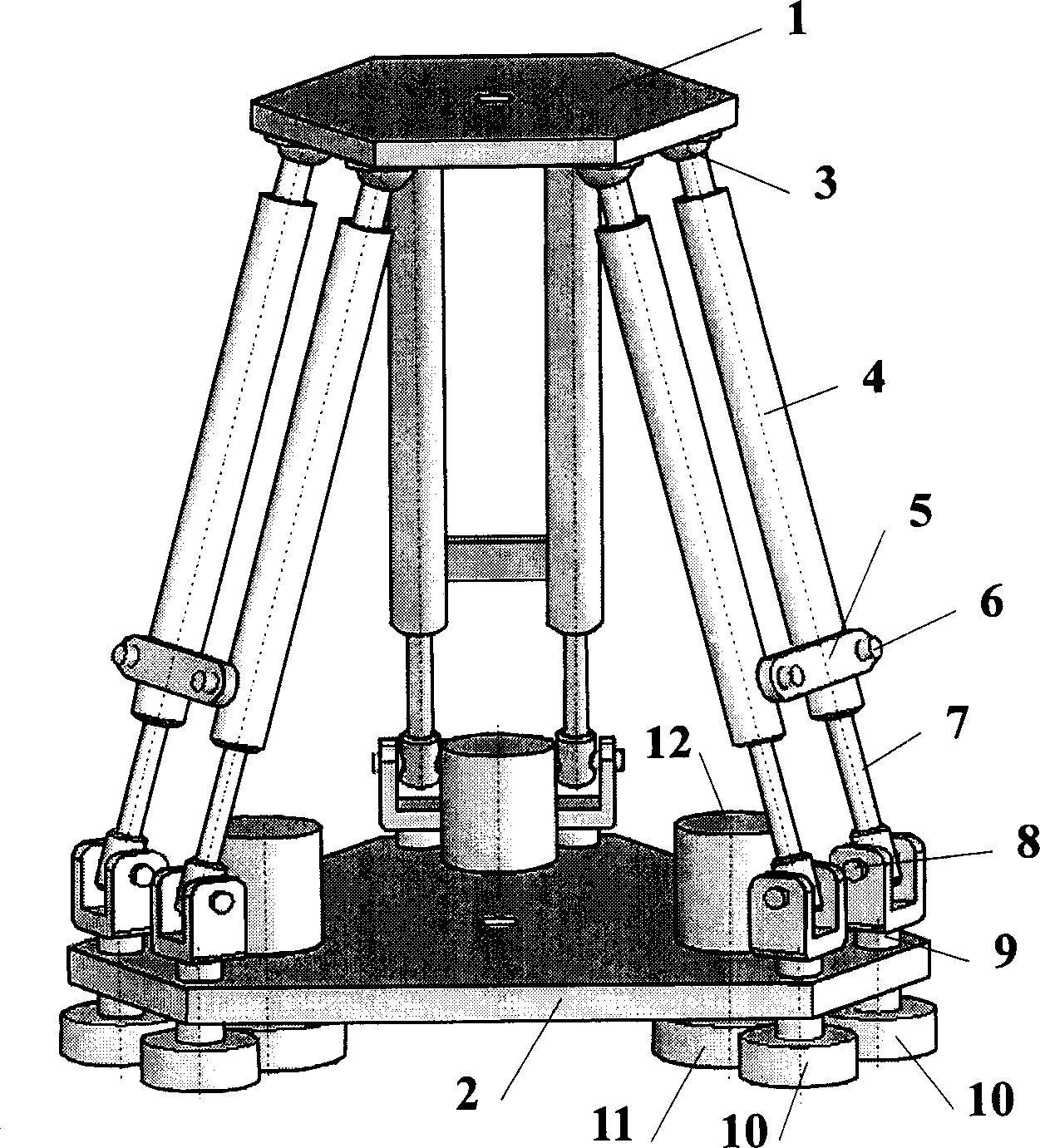

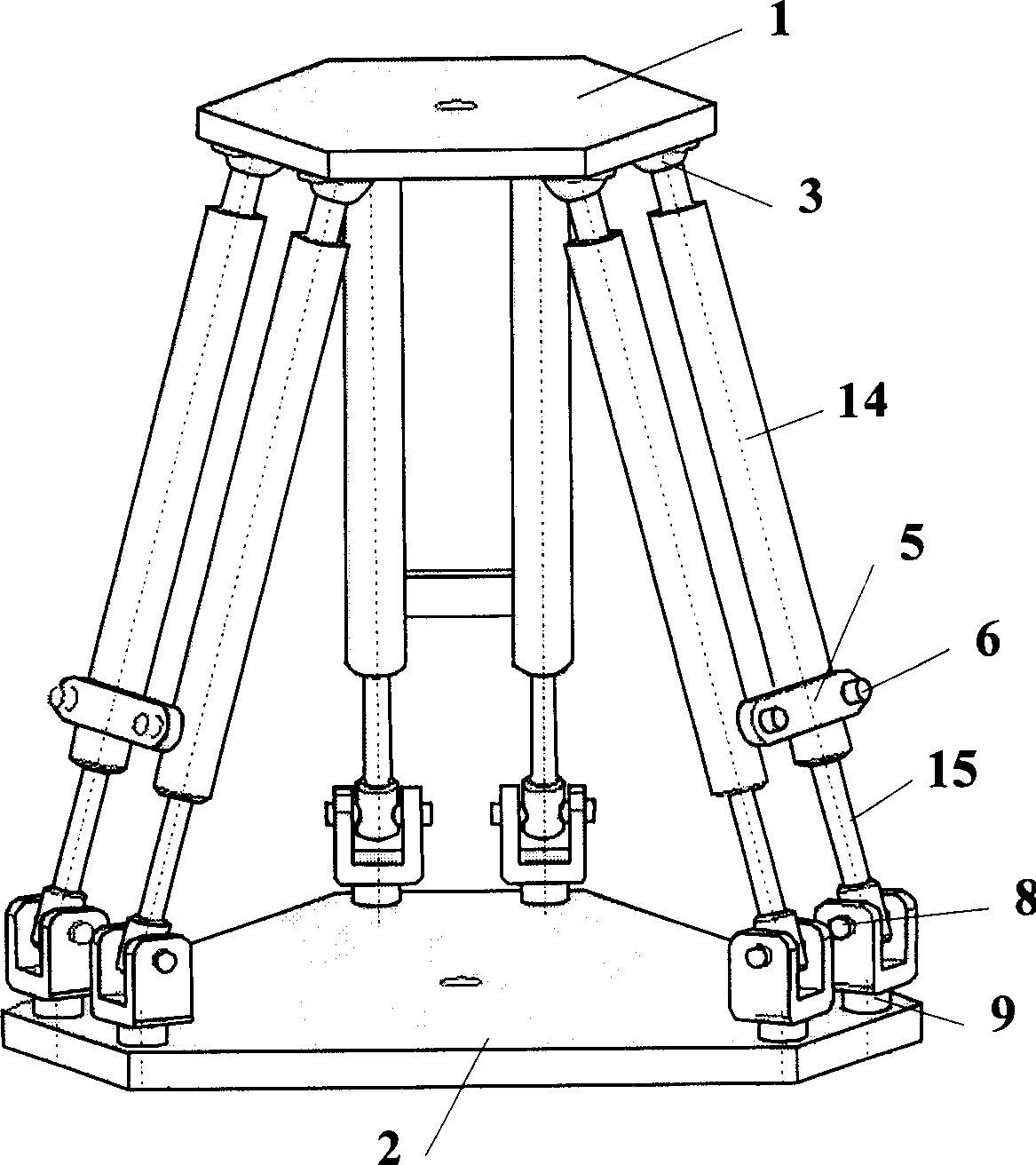

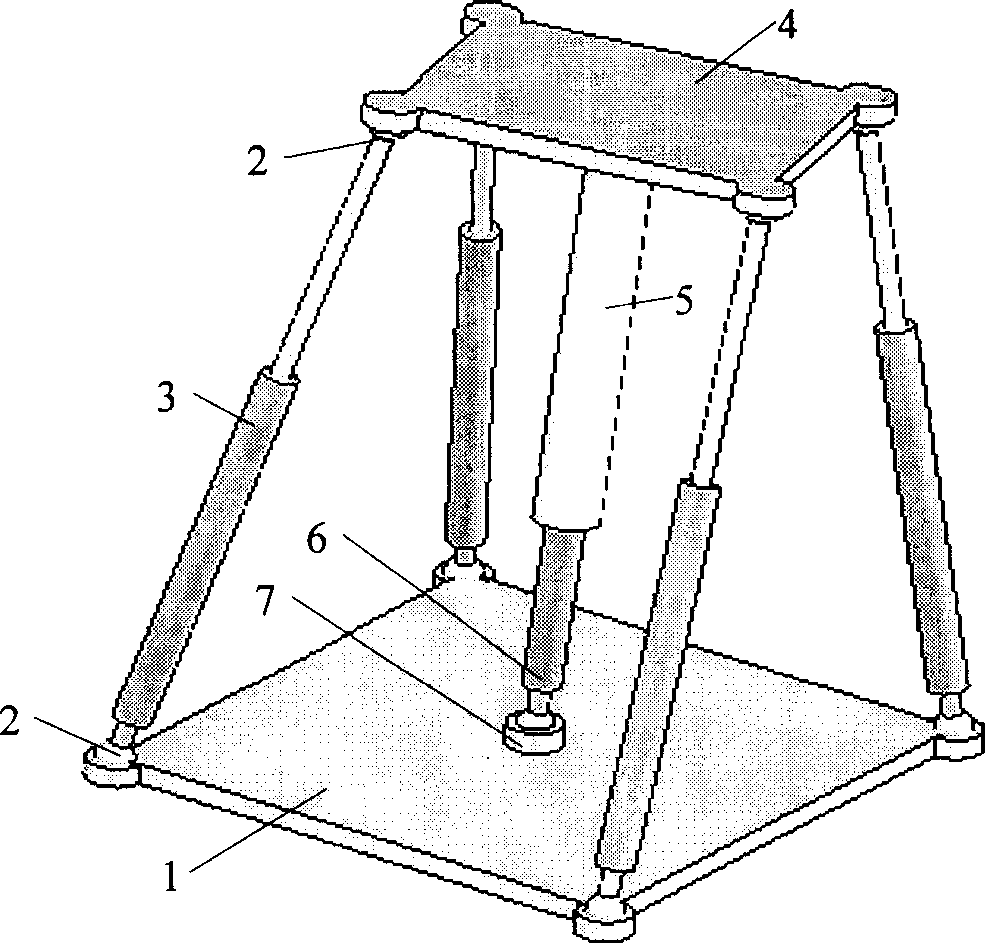

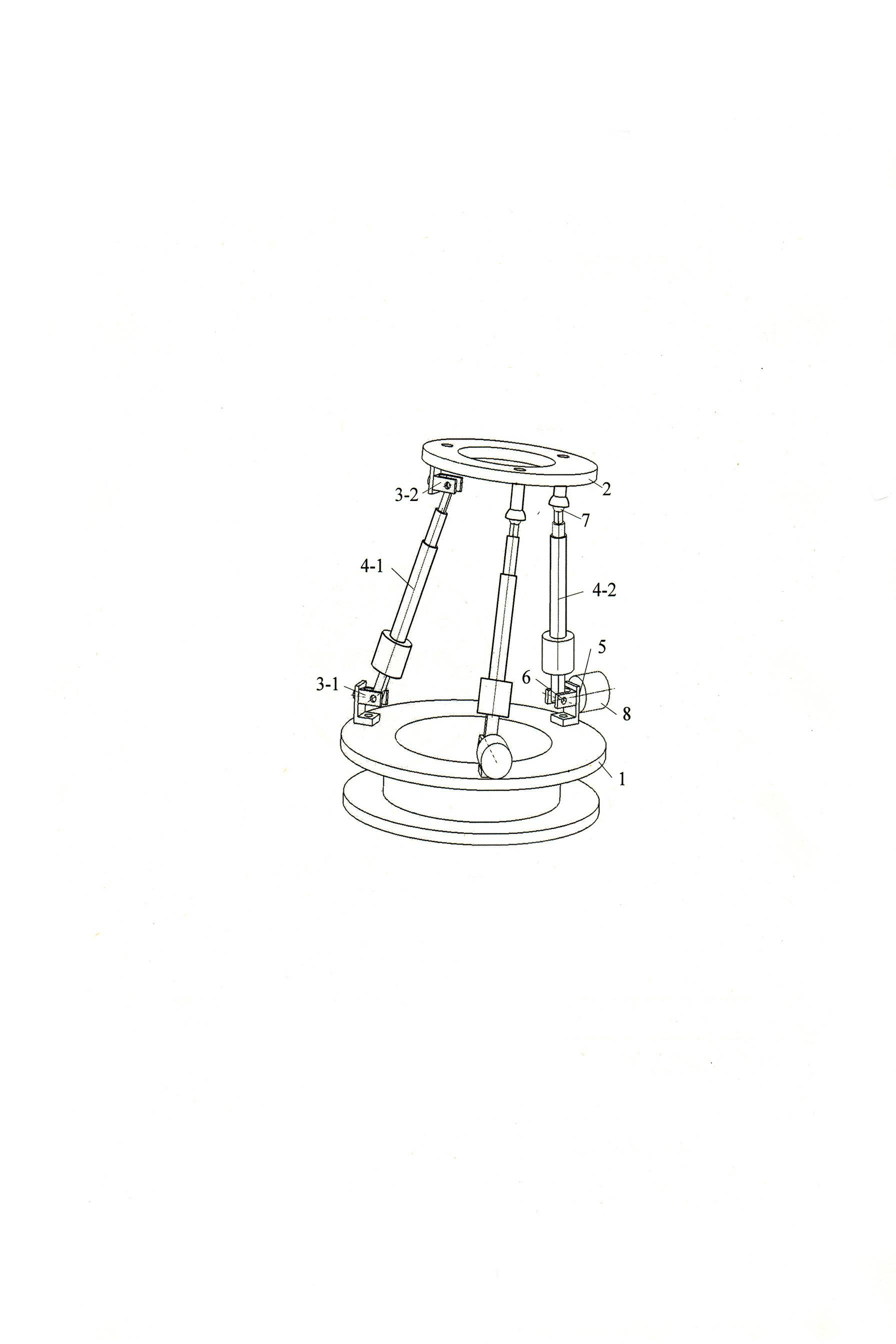

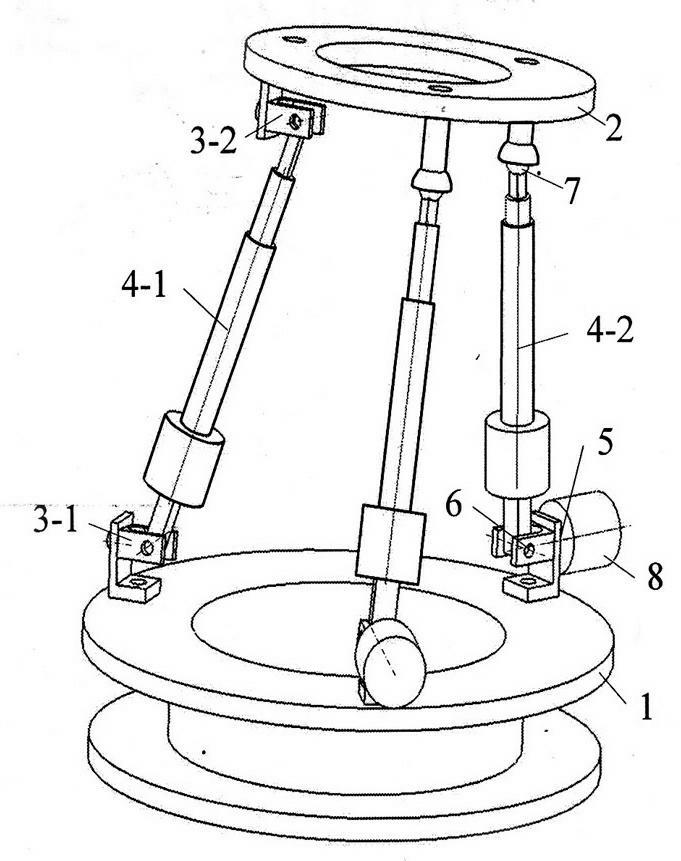

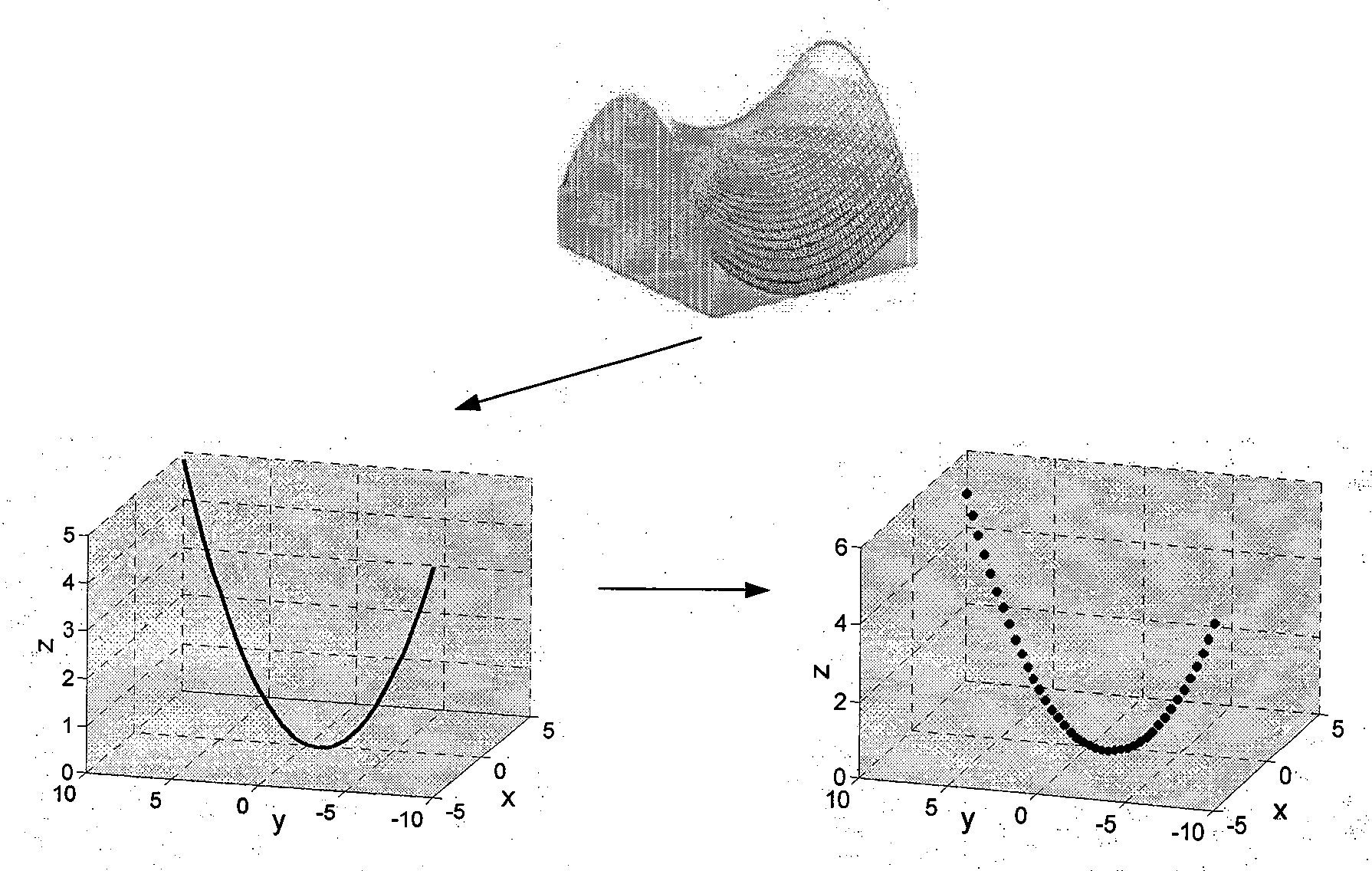

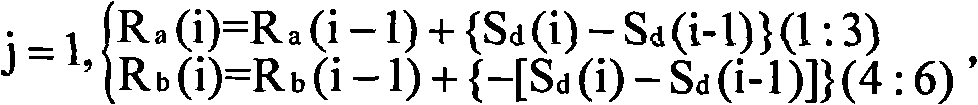

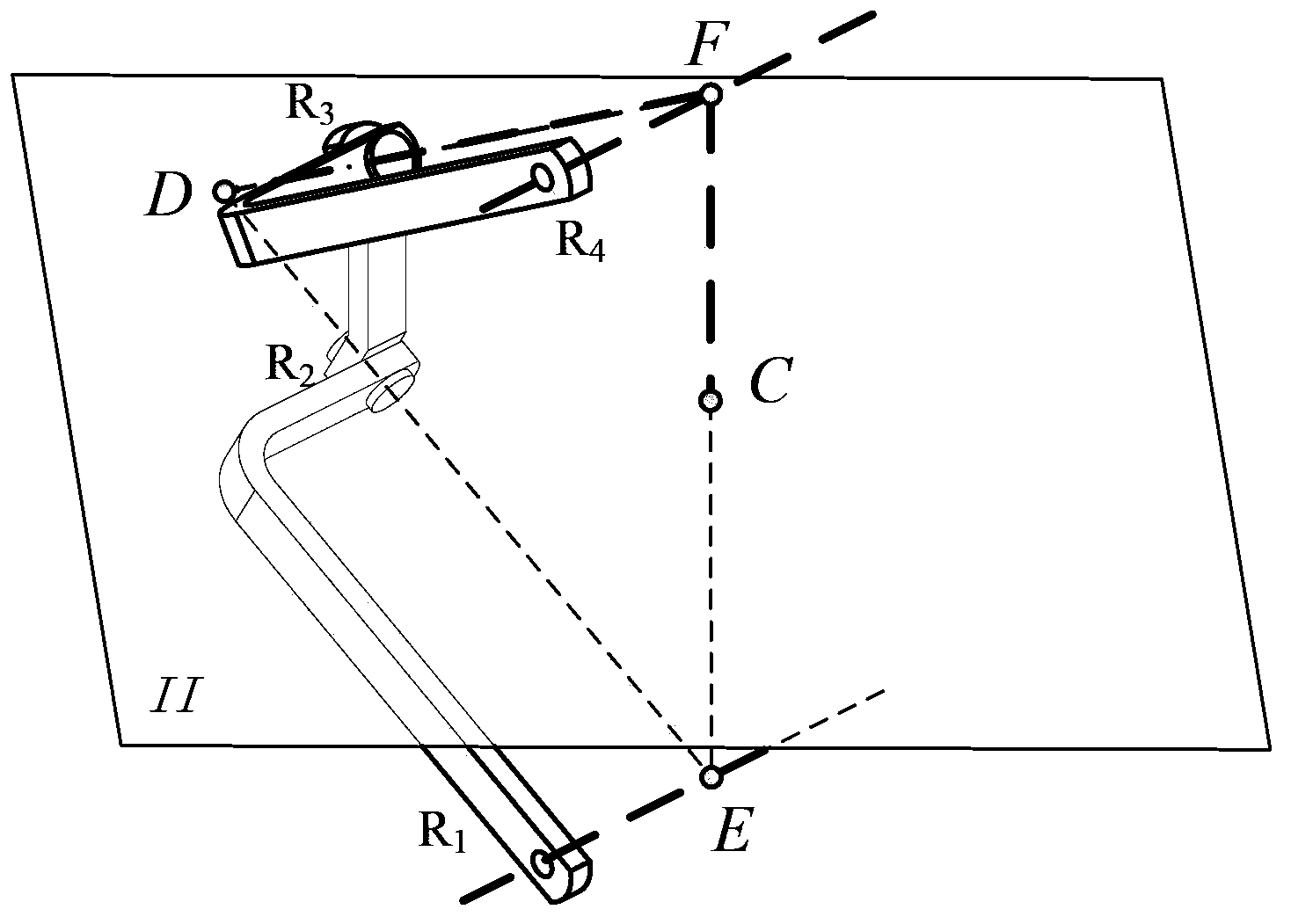

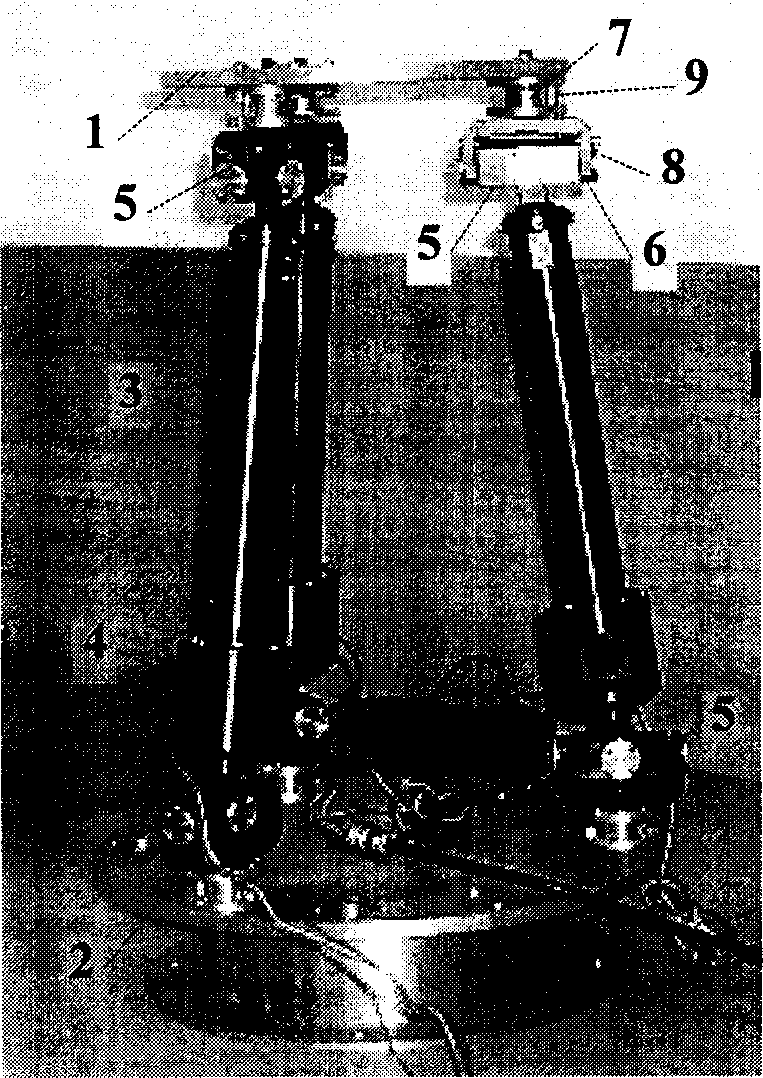

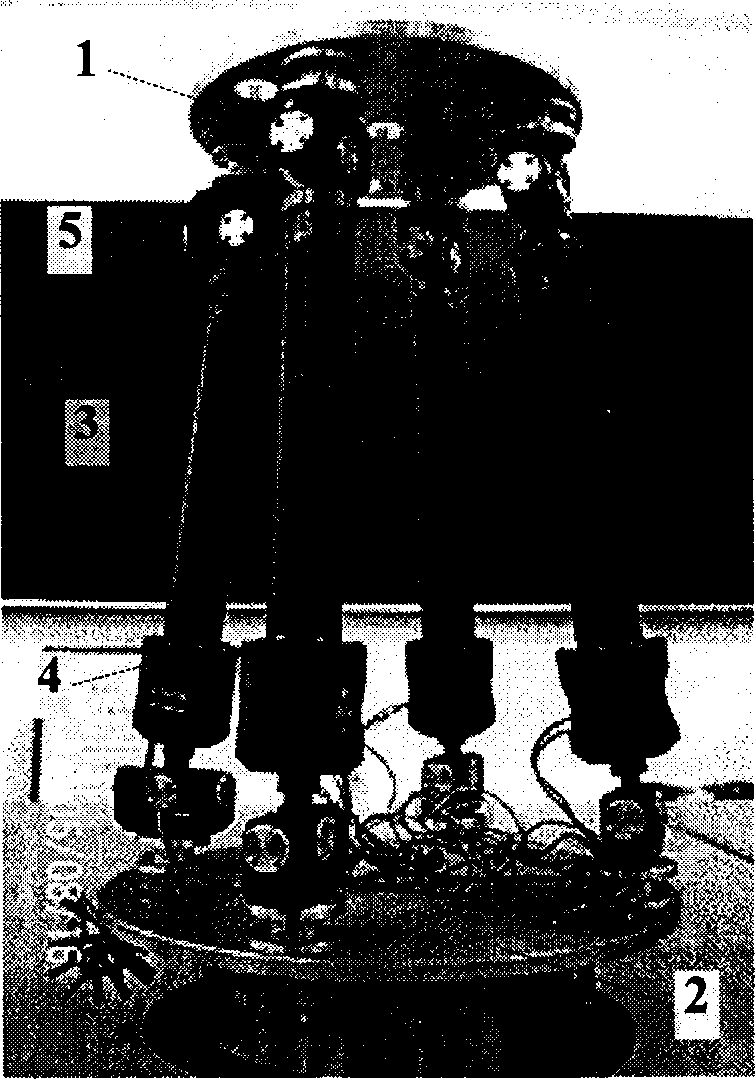

3-degree-of-freedom 6-UPS tri-translational parallel robot

InactiveCN1827312AIncrease stiffnessIncrease workspaceProgramme-controlled manipulatorRight triangleRadio telescope

The invention relates to a free 6-UPS three-linkage parallel robot, belonging to the robot and mechanical producing area. The invention is characterized in that: three couples of straight driving branches are arranged in symmetry right triangle between the upper platform (1) and the base (2), while each couple comprises: two same SPU synchronous flexible driving branch while the upper end of each branch has a ball couple, the middle has a moving couple and the lower end has a universal couple connected to the base (2); the moving couple is formed by a mechanical or hydraulic synchronous flexible driver; the distance between two ball couples of each couple of straight driving branch is the same as the distance between two universal couple vertical axles (9). The invention is characterized in less freedom, easy control, large working space, simple structure and high accuracy. The invention can be used in large radio telescope, three-dimensional measure and sensor, etc.

Owner:YANSHAN UNIV

Asymmetric space 5-degree of freedom series-parallel robot

ActiveCN1524662AReduce in quantityReduce complexityProgramme-controlled manipulatorJointsFixed frameModularity

Owner:TIANJIN UNIV

Four freedom parallel robot mechanism with passive bound branch

InactiveCN1644312ADoes not affect the nature of movementStructural symmetryProgramme-controlled manipulatorLarge fixed membersDegrees of freedomControl theory

A 4-freedom parallel robot structure with passive constraint branch is disclosed, which contains different two passive constraint branch structures and can be used for robot to realize one axial movement and three different rotations. Its advantages are high parallel rigidity and load-bearing power, simple structure, high precision and low cost.

Owner:YANSHAN UNIV

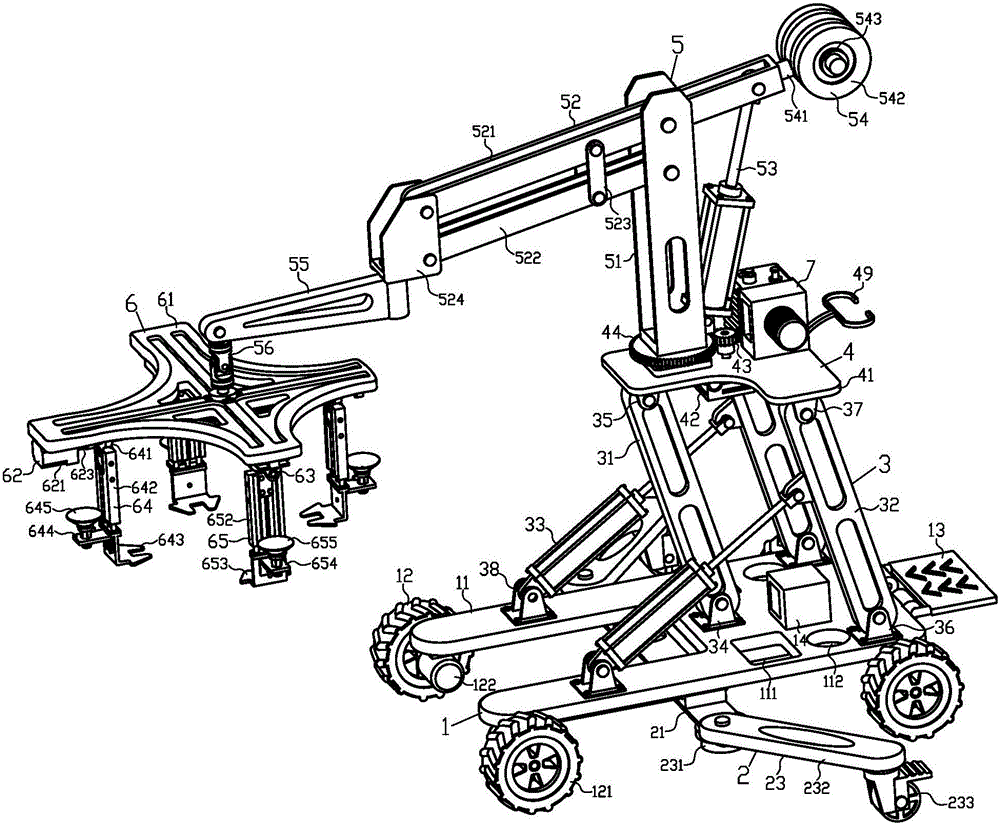

Six-degree-of-freedom multi-function loading and transporting robot

ActiveCN106112999AIncrease stiffnessHigh movement precisionProgramme-controlled manipulatorGripping headsDegrees of freedomEngineering

The invention discloses a six-degree-of-freedom multi-function loading and transporting robot. The six-degree-of-freedom multi-function loading and transporting robot comprises a mobile chassis, an anti-overturning device, an adjustable supporting seat, a rotating device, a motion executing arm, a grasping device and an electric air pump. The anti-overturning device mounted under the mobile chassis is used for preventing the robot from overturning during executing the loading and transporting tasks; the adjustable supporting seat can be used for adjusting the height and the fore-and-aft horizontal displacement of the grasping device; the rotating device is used for adjusting the left-right rotation of the grasping device; the motion executing arm is mainly used for executing the lifting and lowering tasks; and the grasping device is capable of executing the material grasping task by mechanical clamping or negative pressure adsorbing. The robot can be used for the works as material moving and carrying, material loading and unloading and the like in the logistics or industrial production and has the advantages of being high in flexibility of motion, strong in adaptability, large in anti-overturning torque, compact in structure, capable of saving storage space, convenient to adjust and control and the like. The robot is capable of overcoming the technical defects in the prior loading and transporting robot and more applicable to popularization.

Owner:ANHUI UNIV OF SCI & TECH +1

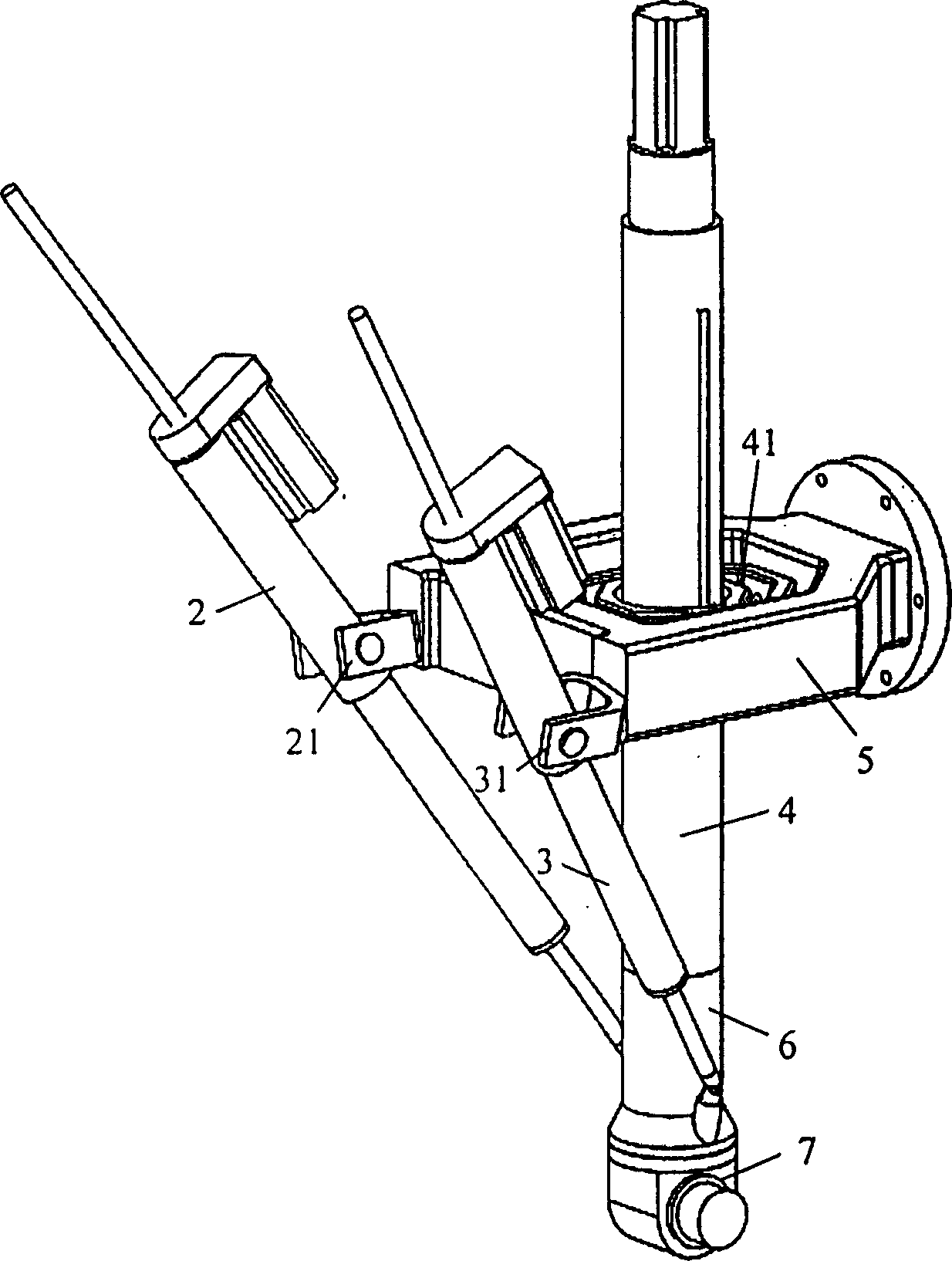

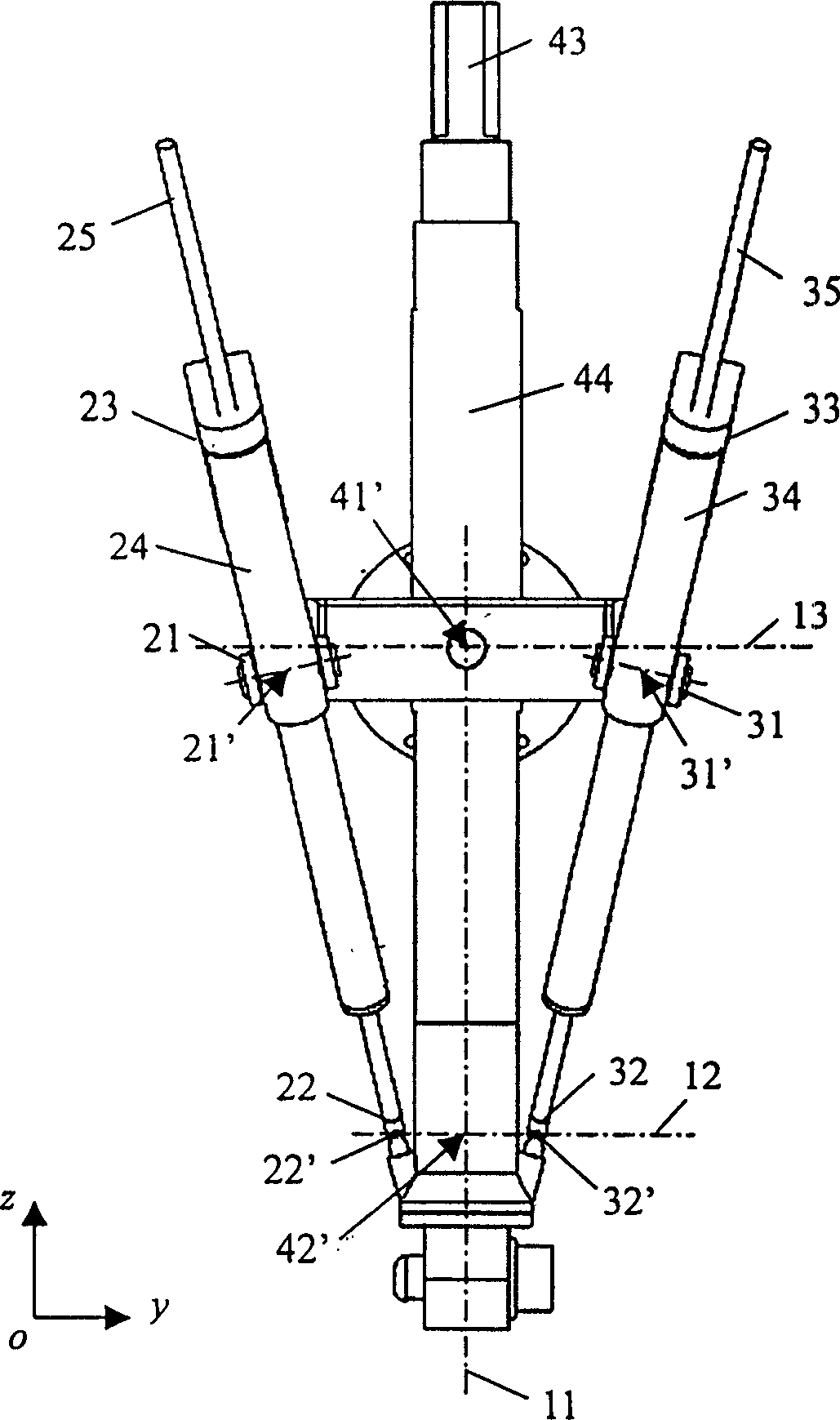

Branch three-leg five-DOF (degree of freedom) parallel mechanism containing double-compound drive

InactiveCN102248535AReduce the impact of motion accuracyOptimize layoutProgramme-controlled manipulatorLarge fixed membersElectric machineryDrive motor

The invention discloses a branch three-leg five-DOF (degree of freedom) parallel mechanism containing a double-compound drive. The branch three-leg five-DOF parallel mechanism comprises an engine base, a movable platform and a single-drive branched chain for connecting the engine base and the movable platform and two compound drive branched chains with the same structure, both ends of each of three branched chains are symmetrically distributed in a regular triangle shape, wherein the single-drive branched chain is composed of two universal pairs and a drive translation pair to form a UPU-type series structure branched chain. Each compound drive branched chain is composed of two revolute pairs, a drive translation pair and a spherical hinge to form an RRPS-type compound drive series structure branched chain, and axial lines of two revolute pairs are vertical to each other to form a universal pair, wherein one revolute pair is connected with the engine base and coaxially connected with a drive motor, and the spherical hinge is connected with the movable platform. The branch three-leg five-DOF parallel mechanism is strong in bearing capacity, good in stability, large in working space, high in flexibility, simple in structure, less in movable branched chain, hard to interference, free from automatic jogging, high in precision, close to a frame in drive and easy to control.

Owner:YANSHAN UNIV

Super-voltage transmission line monitoring and detecting robot mechanism

InactiveCN1689769AEasy to walkConducive to overcoming obstaclesManipulatorMobile vehicleUltra high voltage

The present invention relates to movable robot mechanism, and is especially ultra high voltage power line polling robot mechanism. The polling robot mechanism consists of moving vehicle, back arm and front arm. The moving vehicle consists of vehicle body and walking wheel, the walking wheel is installed onto the vehicle body via horizontal rotation pair and moving pair and grasps the wire, and the vehicle body is connected via the rotation pair to the front arm and the back arm. The arm has hand claw in the end, the front arm and the back arm have the same structure, and each of the front arm and the back arm consists of two parts, upper arm and lower arm. The upper arm as one combined structure of link rod, ball lead screw and block is connected via horizontal rotation pair to the lower arm; and the lower arm is one great stroke telescopic mechanism. The present invention has great work space, light weight, low power consumption and powerful obstruction crossing capacity.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

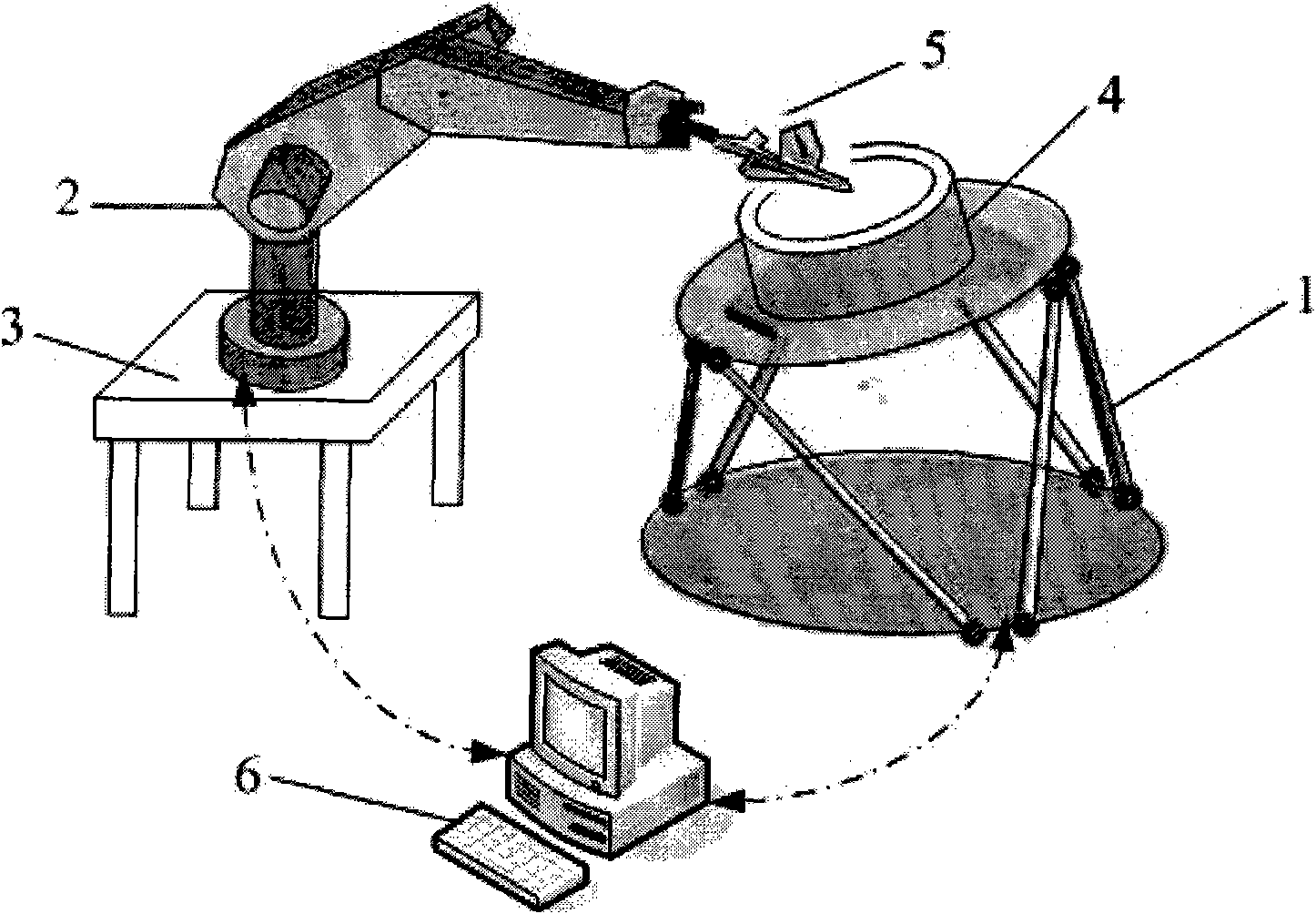

Series-parallel robot combined processing system and control method thereof

InactiveCN101811301AImprove adaptabilityIncrease flexibilityProgramme-controlled manipulatorControl systemEngineering

The invention discloses a series-parallel robot combined processing system and a control method thereof. The system comprises a series robot, a parallel robot, a controller, a platform, workpieces to be processed and a terminal executer. The controller controls the series robot and the parallel robot by adopting a layering control system, the upper controller is used for distributing tasks and controlling movement, and the lower series-parallel robot is used for driving hardware and executing the tasks. The invention combines the system hardware with software, thereby enhancing the automation degree, production efficiency, bearing capability and repetitive positioning accuracy of processing, strengthening the flexibility and adaptability of the system, realizing real-time control on line, and having a certain intelligent performance.

Owner:BEIHANG UNIV

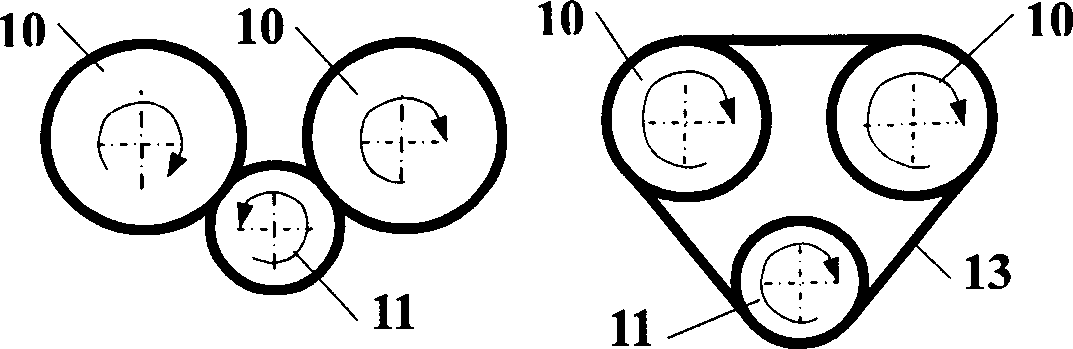

Two-degree-of-freedom equal-diameter sphere pure-rolling parallel rotating mechanism

InactiveCN103433916ALarge working spaceNo mutual internal stressProgramme-controlled manipulatorManufacturing technologyDegrees of freedom

The invention discloses a two-degree-of-freedom equal-diameter sphere pure-rolling parallel rotating mechanism and relates to the technical field of robots, precise instruments, equipment and machinery manufacturing. The mechanism is mainly formed by a motion platform, a fixed base and motion branch chains and can implement an effect that the motion platform takes the two-degree-of-freedom equal-diameter sphere pure-rolling parallel rotation around the fixed base. More than three motion branch chains are connected between the motion platform and the fixed base by motion pairs; each motion branch chain comprises more than two connecting rods; and each motion branch chain is of a symmetrical structure and comprises two or a plurality of motion pairs to form more than four degrees of freedom. The rotating mechanism provided by the invention has the advantages that the motion platform has a large working space; the structure is compact; stiffness is high; the mechanism does not include redundant constraining, mutual internal stress does not exist among the motion branch chains and accuracy stability is high; and the two-degree-of-freedom equal-diameter sphere pure-rolling parallel rotating mechanism has the simple structure and is convenient to install. The advantages enable the rotating mechanism to have wide application in the field of a high-performance pointing device.

Owner:BEIHANG UNIV

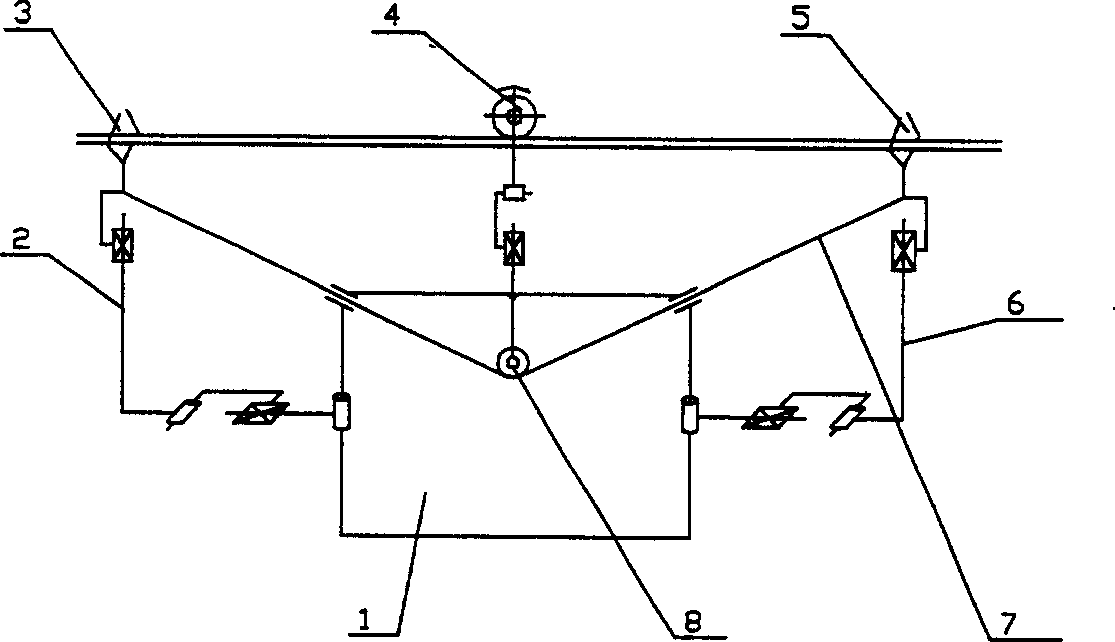

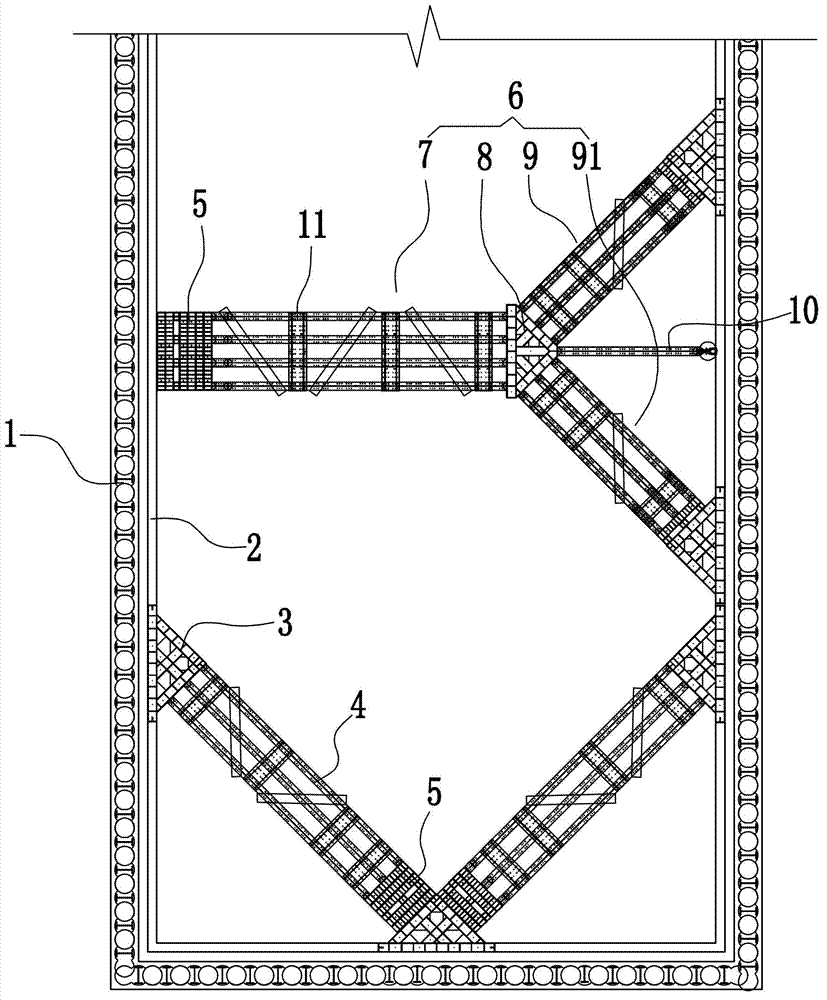

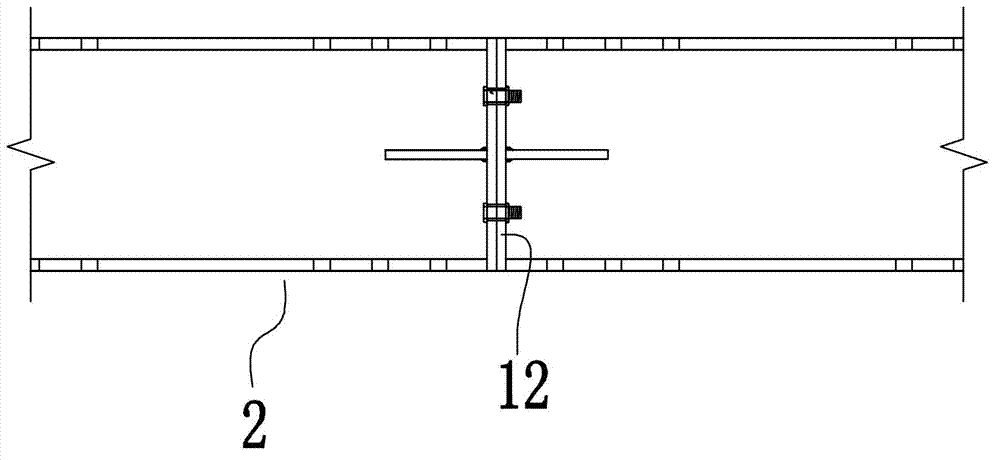

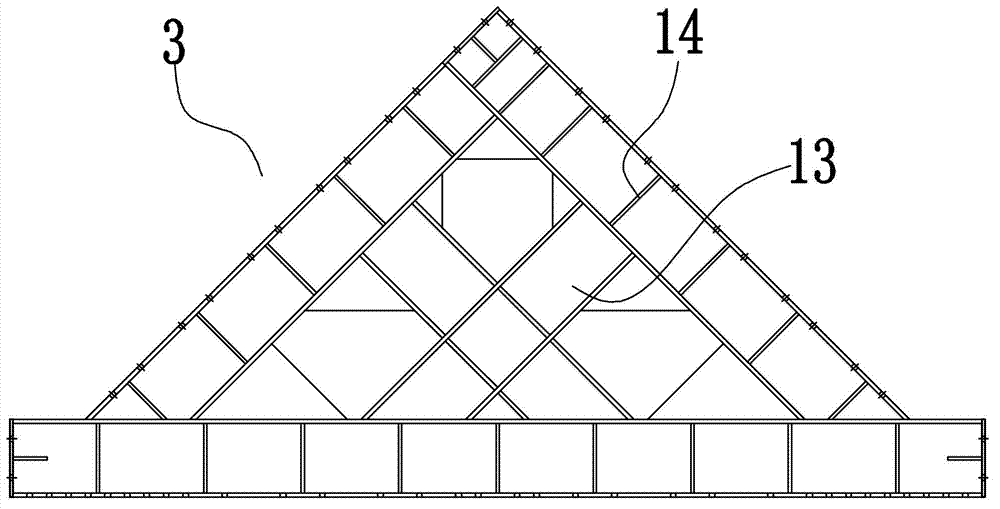

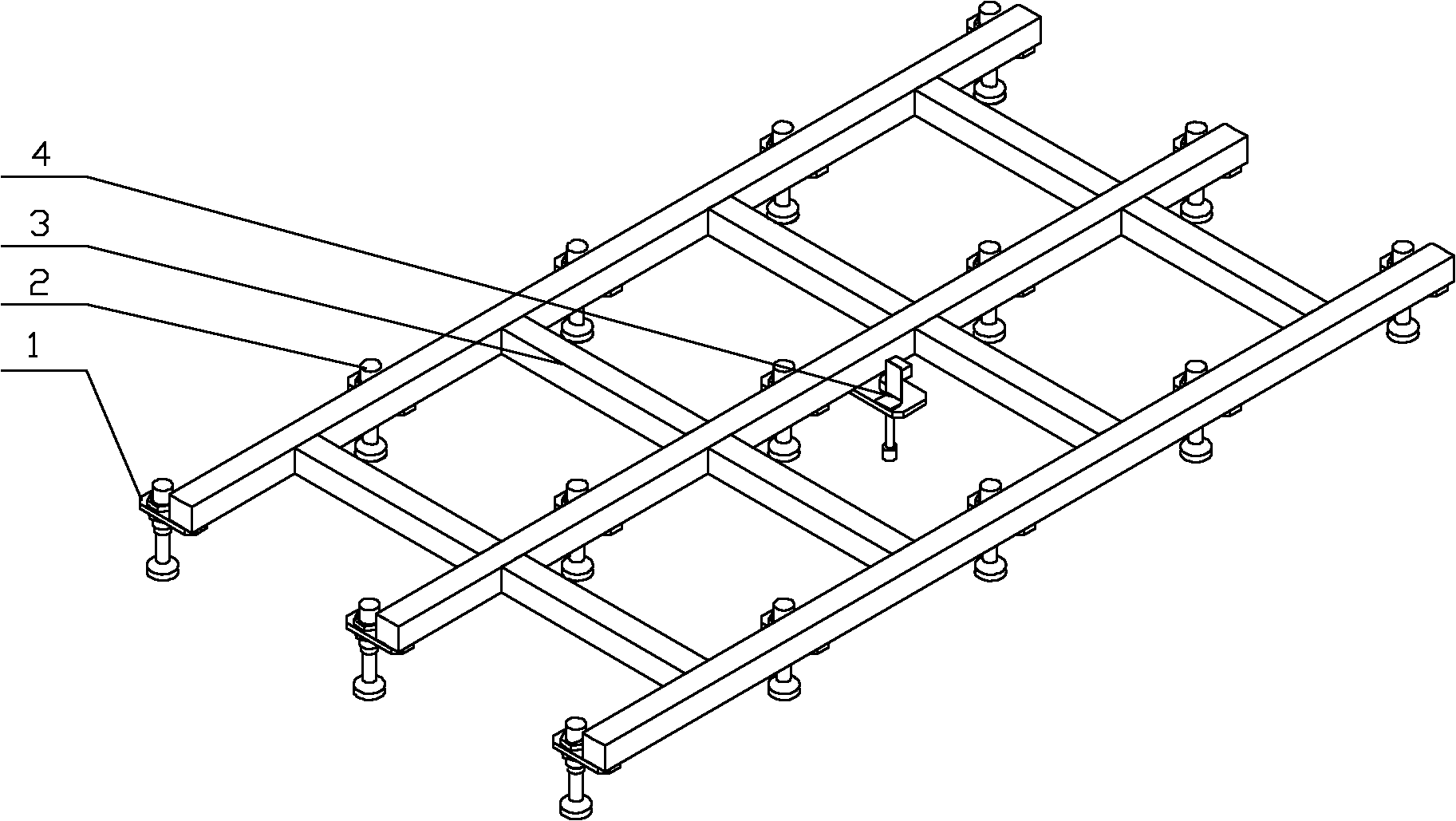

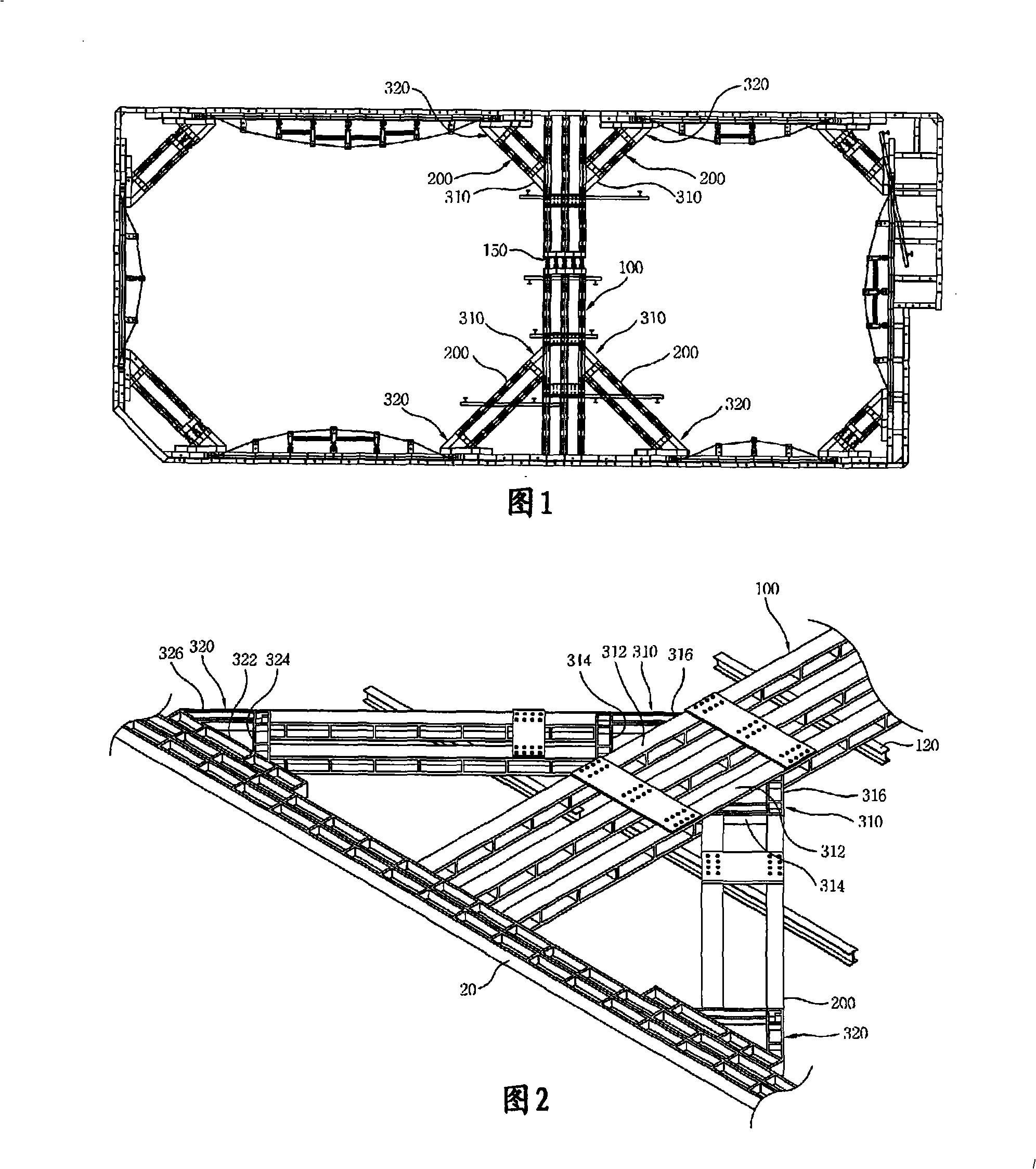

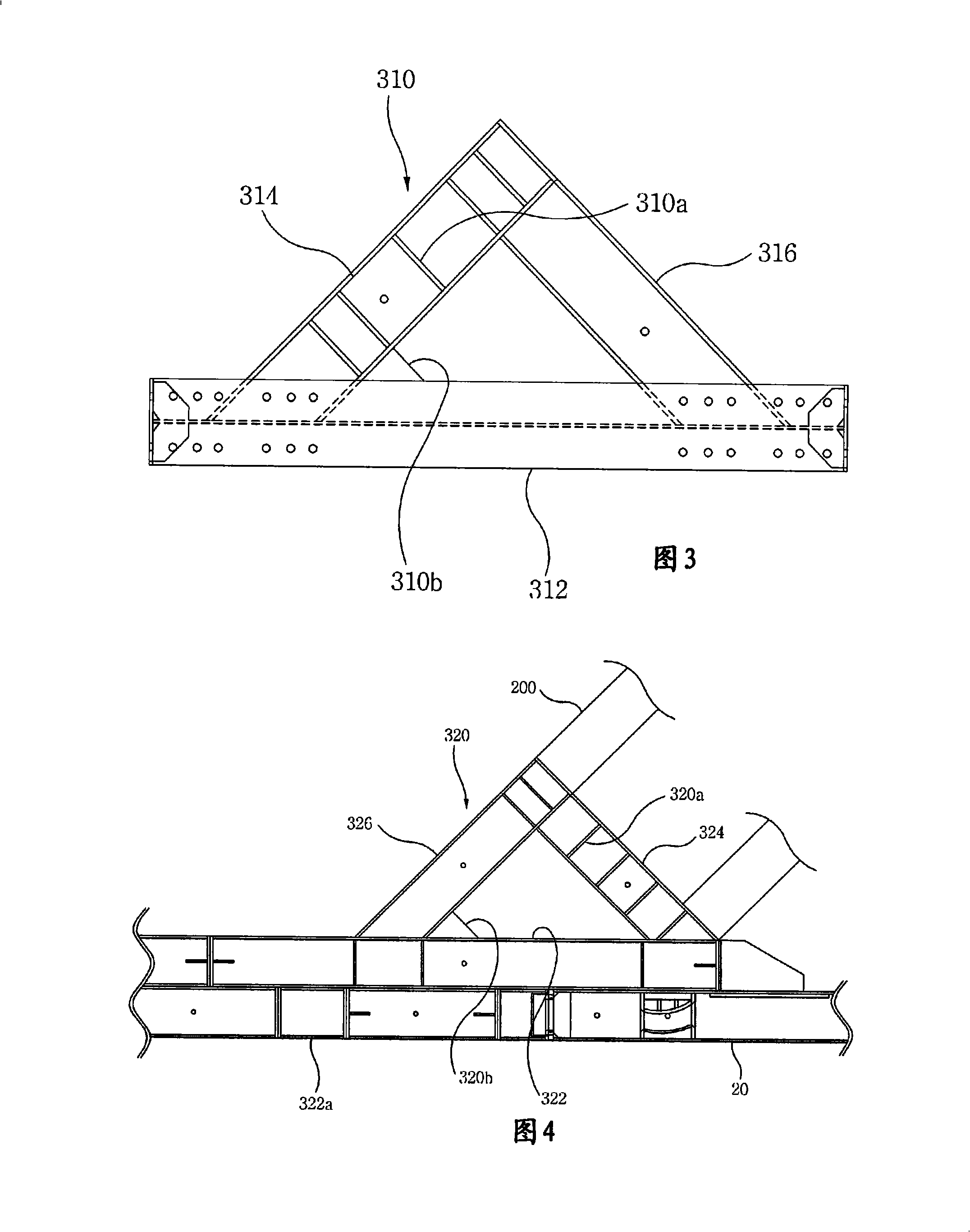

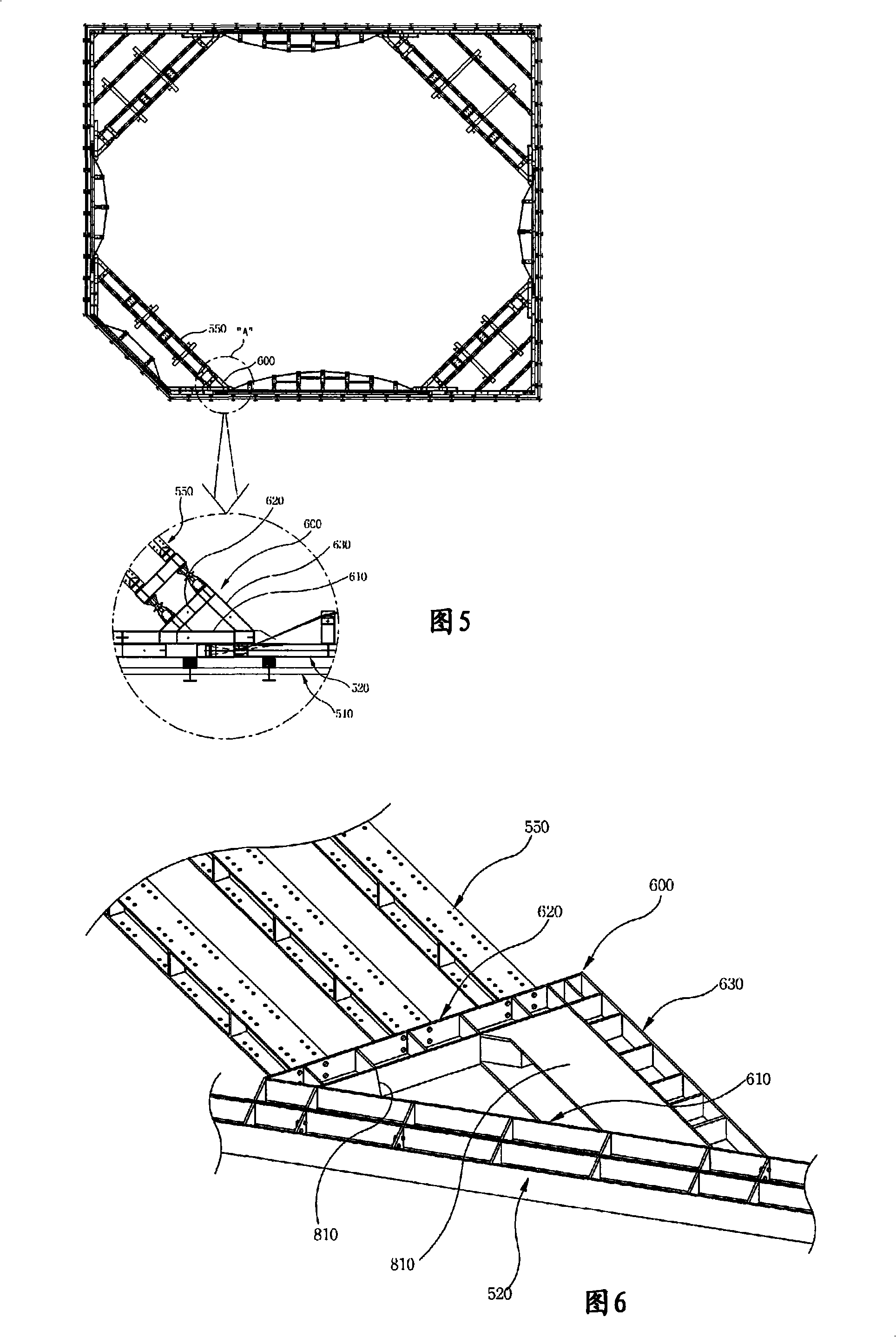

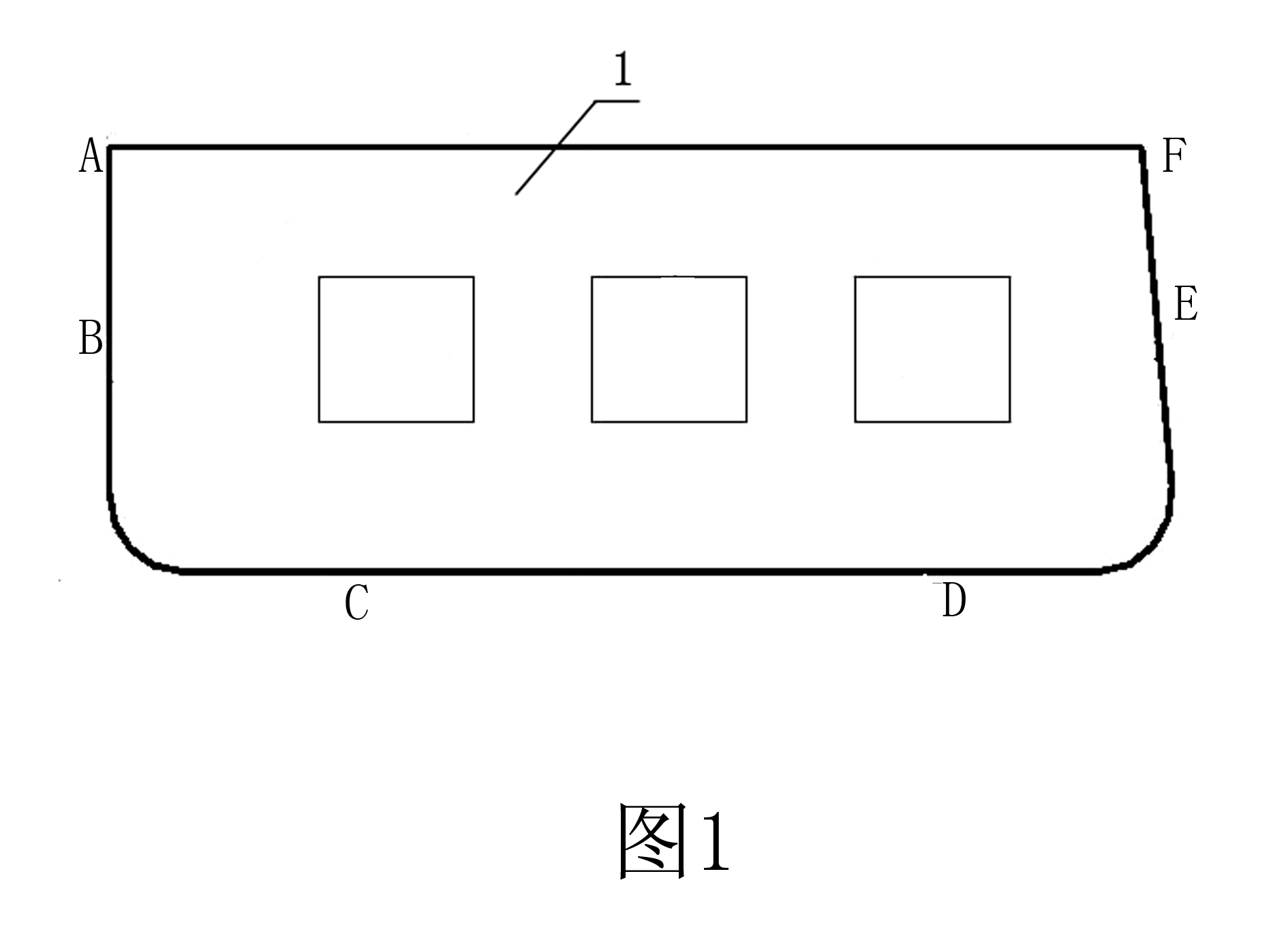

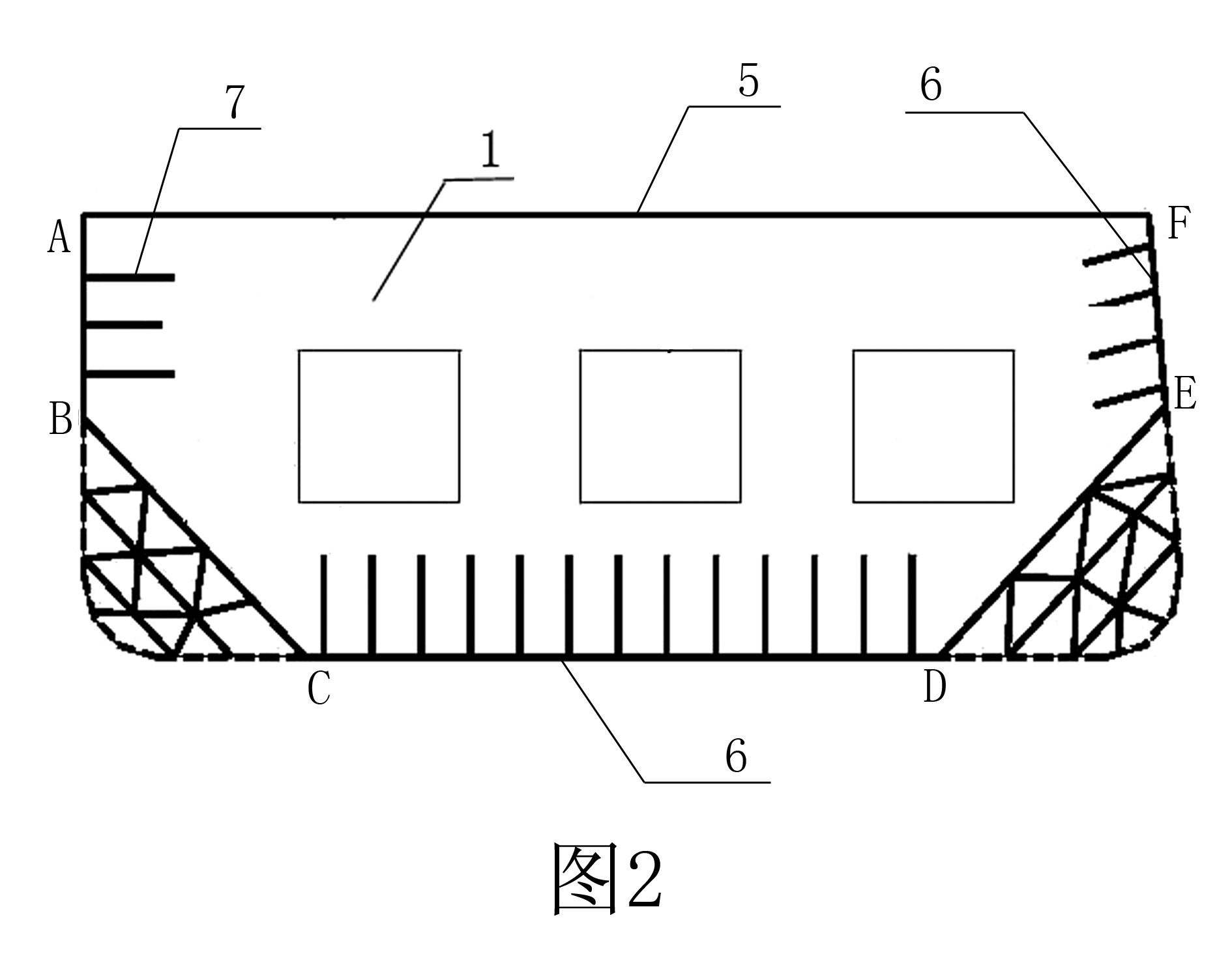

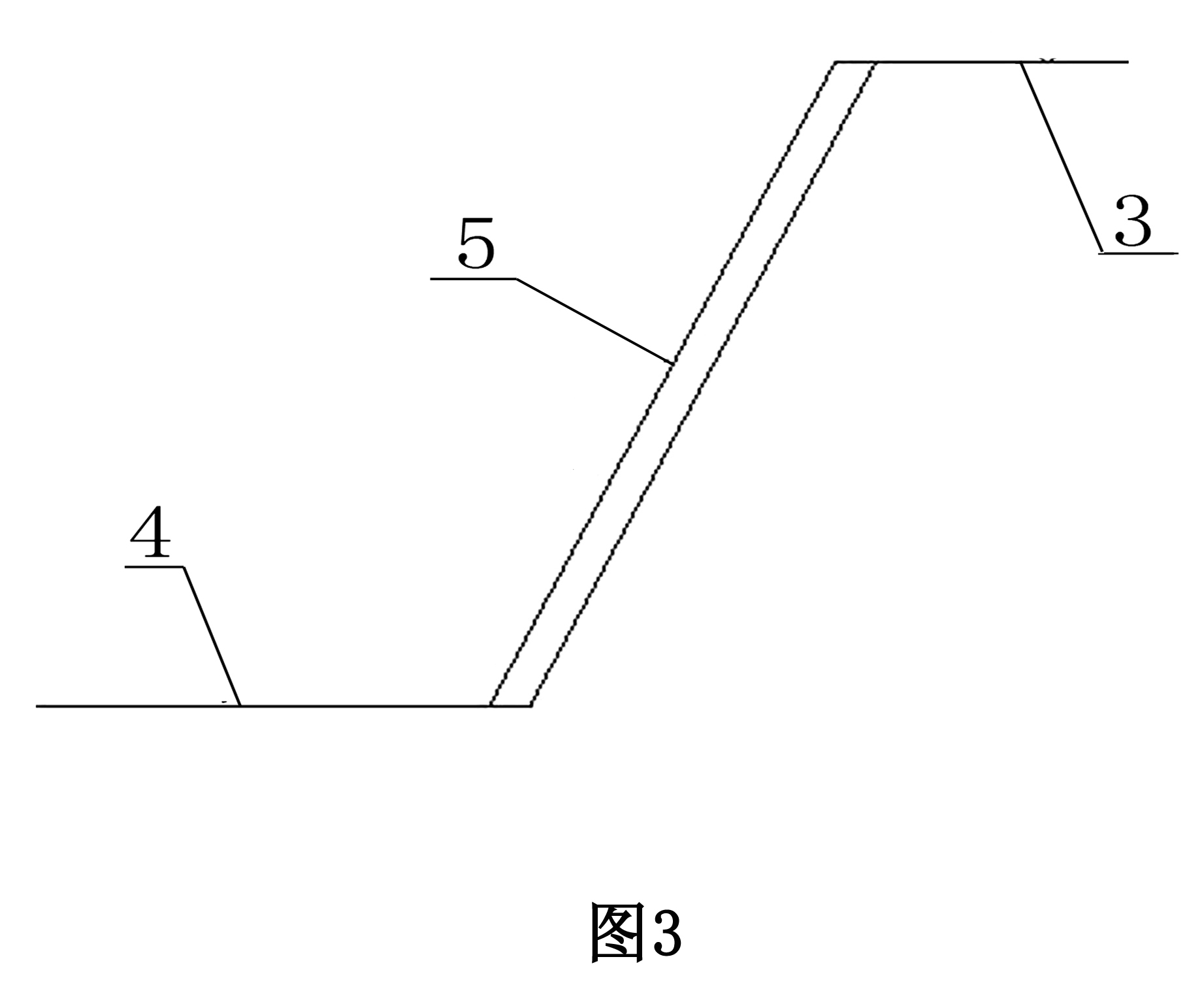

Detachable prestress supporting frame system

ActiveCN103161168AEasy to assemble and disassembleSave resourcesExcavationsPurlinStructural engineering

The invention discloses a detachable prestress supporting frame system and aims to provide a supporting frame system which is good in stability of a supporting structure of a foundation pit, can reduce supporting density to a supporting beam and provides larger working space for foundation pit mining operations on the premise of not influencing strength of the supporting structure of the foundation pit. The detachable prestress supporting frame system comprises a group of construction method piles and an enclosure purlin beam. The group of construction method piles are arranged on the edge of the foundation pit. The enclosure purlin beam is arranged on the inner side of the construction method piles. A plurality of triangular supporting members are arranged on the inner side of the enclosure purlin. Angle counter-supporting beams are arranged at the concave corner of the foundation pit. Each angle counter-supporting beam is arranged between two triangular supporting members on two adjacent sides of the concave corner. One end of each angle counter-supporting beam abuts against the side surface of one of the triangular supporting members. A prestress reserved member is arranged between the other end of each angle counter-supporting beam and another triangular supporting member. The prestress reserved member comprises two supporting parts which can be unfolded mutually, one of the two supporting parts abuts against the side surface of the triangular supporting member, and the other supporting part abuts against the end portion of the angle counter-supporting beam.

Owner:DONGTONG ROCK SOIL SCI & TECH HANGZHOU

Controllable mechanism type fine-adjusting welding robot with multiple degrees of spatial freedom

ActiveCN103737578AIncrease stiffnessIncrease workspaceProgramme-controlled manipulatorWelding/cutting auxillary devicesControl engineeringMachine

A controllable mechanism type fine-adjusting welding robot with multiple degrees of spatial freedom comprises three controllable fine-adjusting four-rod mechanism closed-loop subchains connected in parallel and an execution mechanism subchain in series connection. The four-rod mechanism closed-loop subchains can control a first connecting rod to move in the plane where the four-rod mechanism closed-loop subchains are located, and the spatial movement of a platform can be achieved through the movement of parallel connecting rods and a machine body. The spatial movement of a tail end executor can be controlled through the resultant movement of the three closed-loop subchains and the machine body, the movement inertia of the tail end executor is small, dynamics performance is good, reliability is high, the mechanism has the advantages of being compact in structure and easy to control, the connecting rods are used for control, rod pieces can be made into light rods, the work space of the mechanism is large, the gravity of the mechanism moves backwards, the mechanism is kept balanced, and the mechanism can act on more occasions.

Owner:GUANGXI UNIV

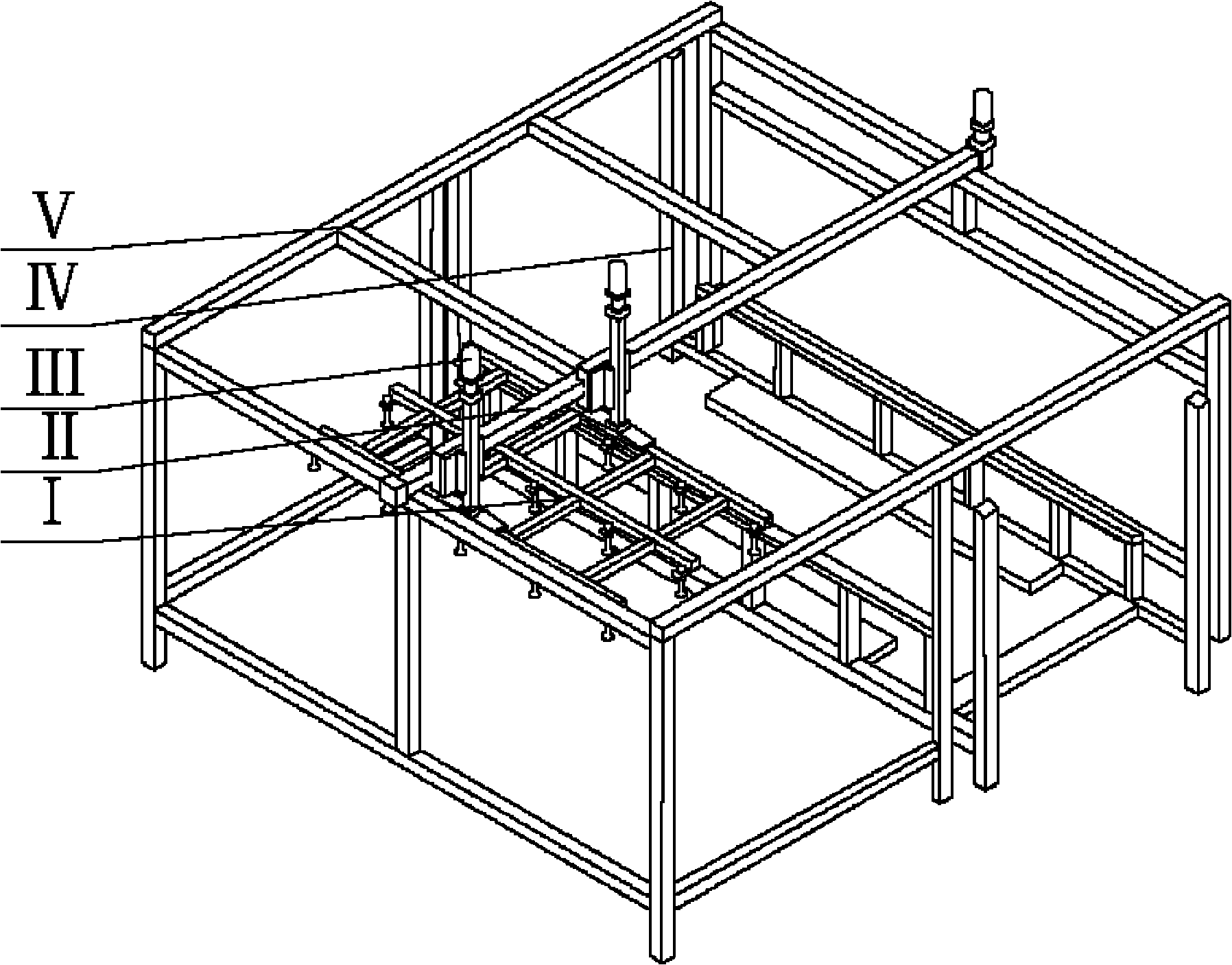

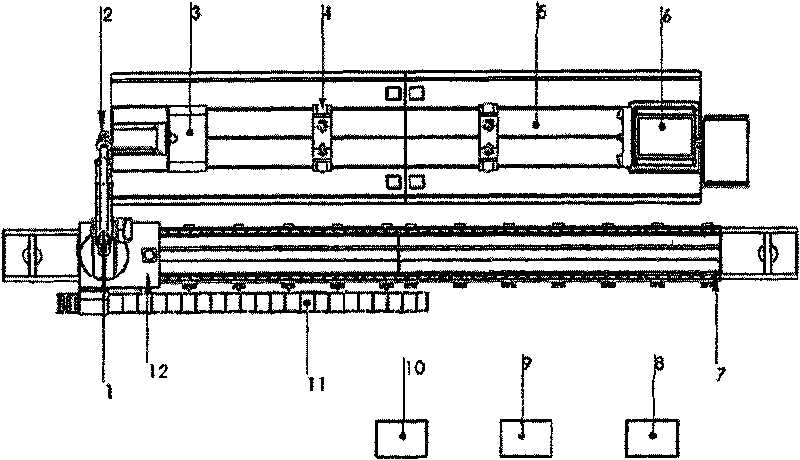

Loading and unloading handling mechanical arm for solar cell module

ActiveCN102107783AEven by forceAvoid bending momentCharge manipulationConveyor partsInteraction layerSolar cell

The invention provides a loading and unloading handling mechanical arm for a solar cell module, and the mechanical arm provided by the invention is used for realizing the functions of loading and unloading in a solar cell module producing process. The loading and unloading handling mechanical arm is characterized by consisting of a mechanical arm mechanism I, a horizontal motion unit II, two vertical motion units III, a pallet lift mechanism IV and a frame V, wherein the mechanical arm mechanism is of an aluminum alloy frame combined structure, and is provided with a plurality of groups of sucker modules so as to realize safe handling of solar cell modules in different specifications; and the horizontal motion unit and the vertical motion units adopt servo motors as drive, and drive the mechanical arm mechanism through a synchronous cog belt and a ball screw assembly respectively to realize accurate motion positioning in horizontal and vertical directions, and the motion units of two directions can independently or simultaneously move. A position servo control system is of a hierarchical control structure formed by a human-computer interaction layer, a motion control layer and a servo control layer. The handling mechanical arm has the advantages of large working space, high positioning accuracy, small motion inertia, reliable and smooth motion and suitability for handling large-sized fragile solar cell modules in different specifications.

Owner:YINGKOU JINCHEN AUTOMATION CO LTD

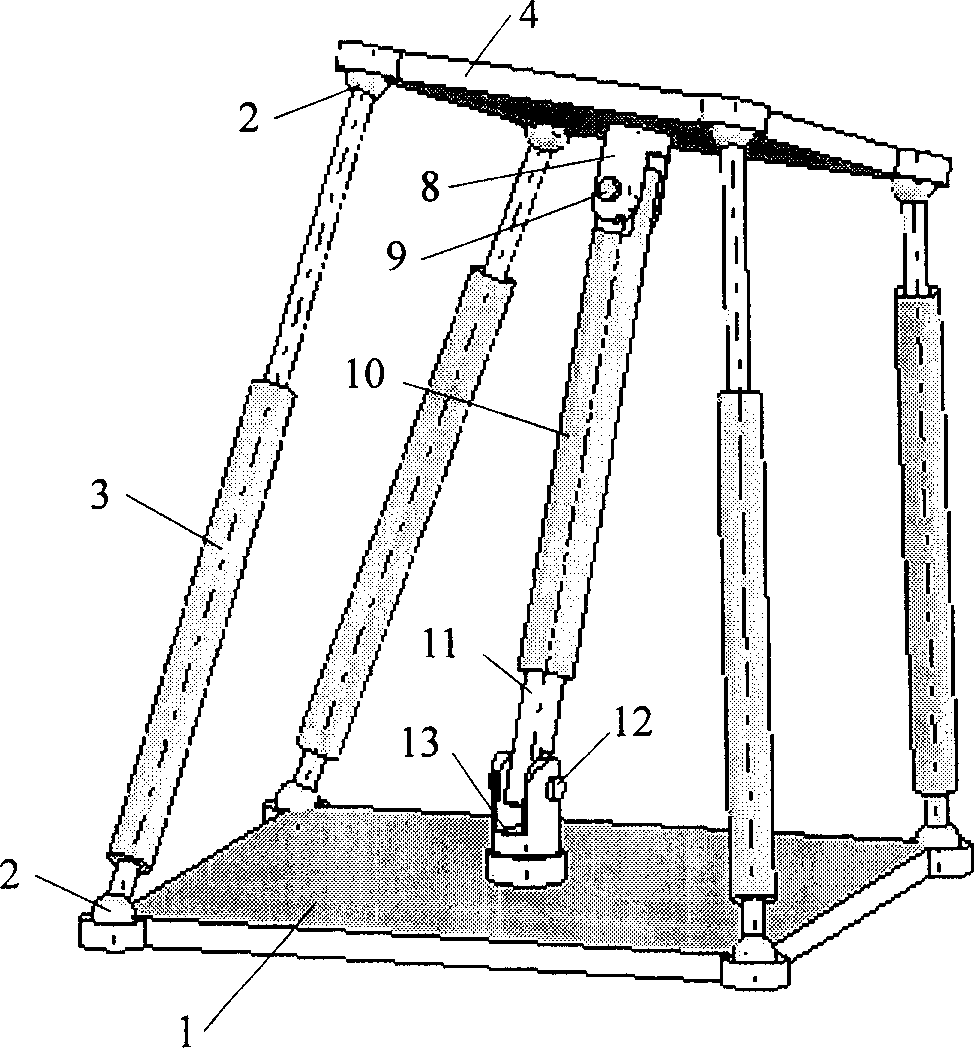

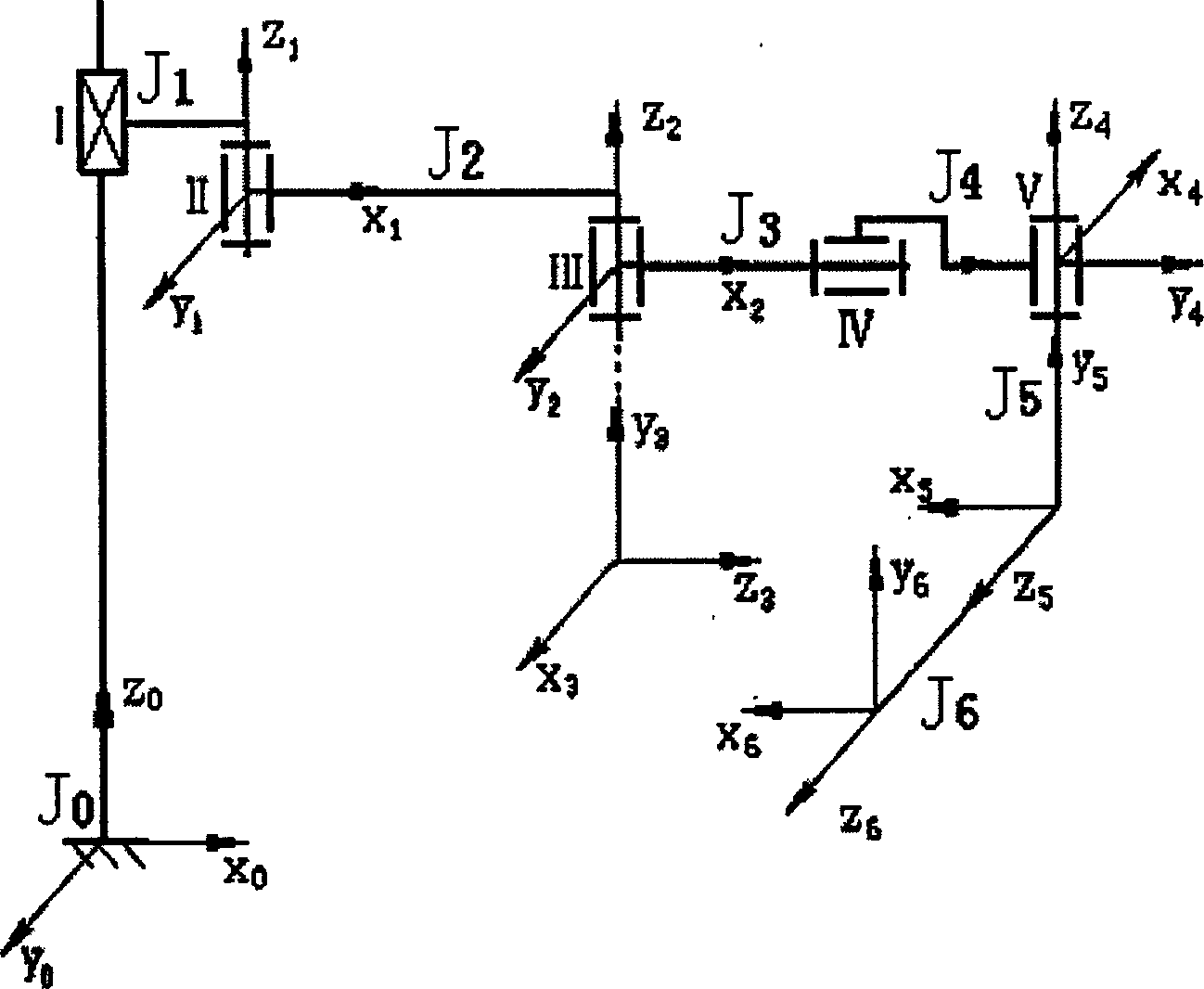

Multi-coordinate serioparallel robot with redundant freedom

InactiveCN1739926ALarge working spaceLarge space movementProgramme-controlled manipulatorJointsFixed frameEngineering

The multi-coordinate serioparallel robot with redundant freedom includes fixing frame, movable platform, positioning head and four length regulators. The fixing frame has one first hinge in the middle part, the first length regulator has its upper part and the first hinge constituting one sliding pair set on the fixing frame, the positioning head is mounted in the bottom of the first length regulator, the fixing frame has the second, the third and the fourth hinges distributed homogeneously around the first hinge and connected separately with one end of the second, the third and the fourth length regulator, and the other ends of the second, the third and the fourth length regulators are hinged separately to the movable platform, and the movable platform is mounted outside the first length regulator. The robot of the present invention features one redundant freedom and large work space.

Owner:TIANJIN UNIV

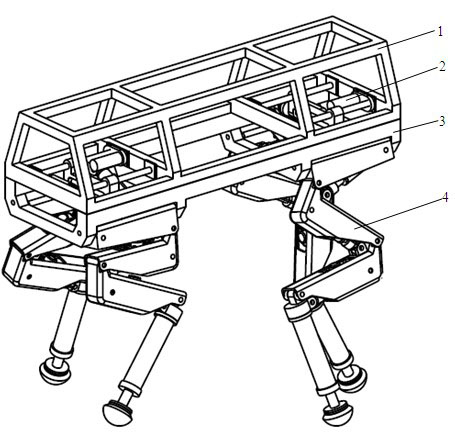

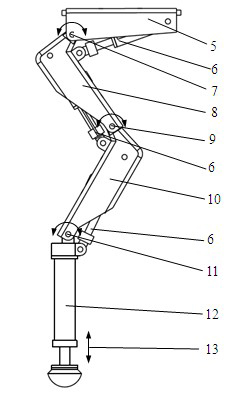

Moving mechanism of hydraulic drive four-leg robot with barycenter adjusting device

InactiveCN101811525ALarge working spaceStrong ability to adapt to complex terrain and overcome obstaclesVehiclesTerrainQuadrupedal robot

The invention relates to a moving mechanism of a hydraulic drive four-leg robot with a barycenter adjusting device, which comprises a body, a moving bracket, a barycenter adjusting device and four robot legs, wherein the lower part of the body is provided with the four robot legs; and the upper part of the body is connected with the moving bracket with the barycenter adjusting device. The moving mechanism is characterized as follows: (1) the robot has larger loading capability due to hydraulic drive; (2) the robot has higher complex terrain environment adaptability and obstacle-climbing capability as each leg has four active joints and has redundant degree of freedom; (3) the robot has better stability due to the barycenter adjusting device and no additional counter weight; and (4) the robot has simpler structure and is easily machined as the 16 active joints thereof completely adopt the same hydraulic servo oil cylinder drive. The moving mechanism is suitable for the transportation of military and civil materials, anti-terrorist equipment, field prospection and exploration, planetary detection, agricultural production and the like under the complex terrain environment.

Owner:SHANDONG UNIV

Temporary soil sheathing apparatus

A temporary soil sheathing apparatus supports a set of intermediate bracing beams in a triangular supporting structure during pit excavation work for constructing an underground structure, so that it can satisfactorily support soil pressure. Thus, it is possible to prevent space from being reduced by a complicated supporting structure, reduce construction costs through reduced use of materials, and increase work space to improve productivity. The temporary soil sheathing apparatus simplifies a corner connecting structure, and reinforces ability to withstand the soil pressure transmitted from the bracing beams and wales. Thereby, it is possible to prevent space from being reduced by a complicated supporting structure, reduce construction costs through reduced use of materials, and increase work space to thus improve productivity.

Owner:SUPPORTEC CO LTD

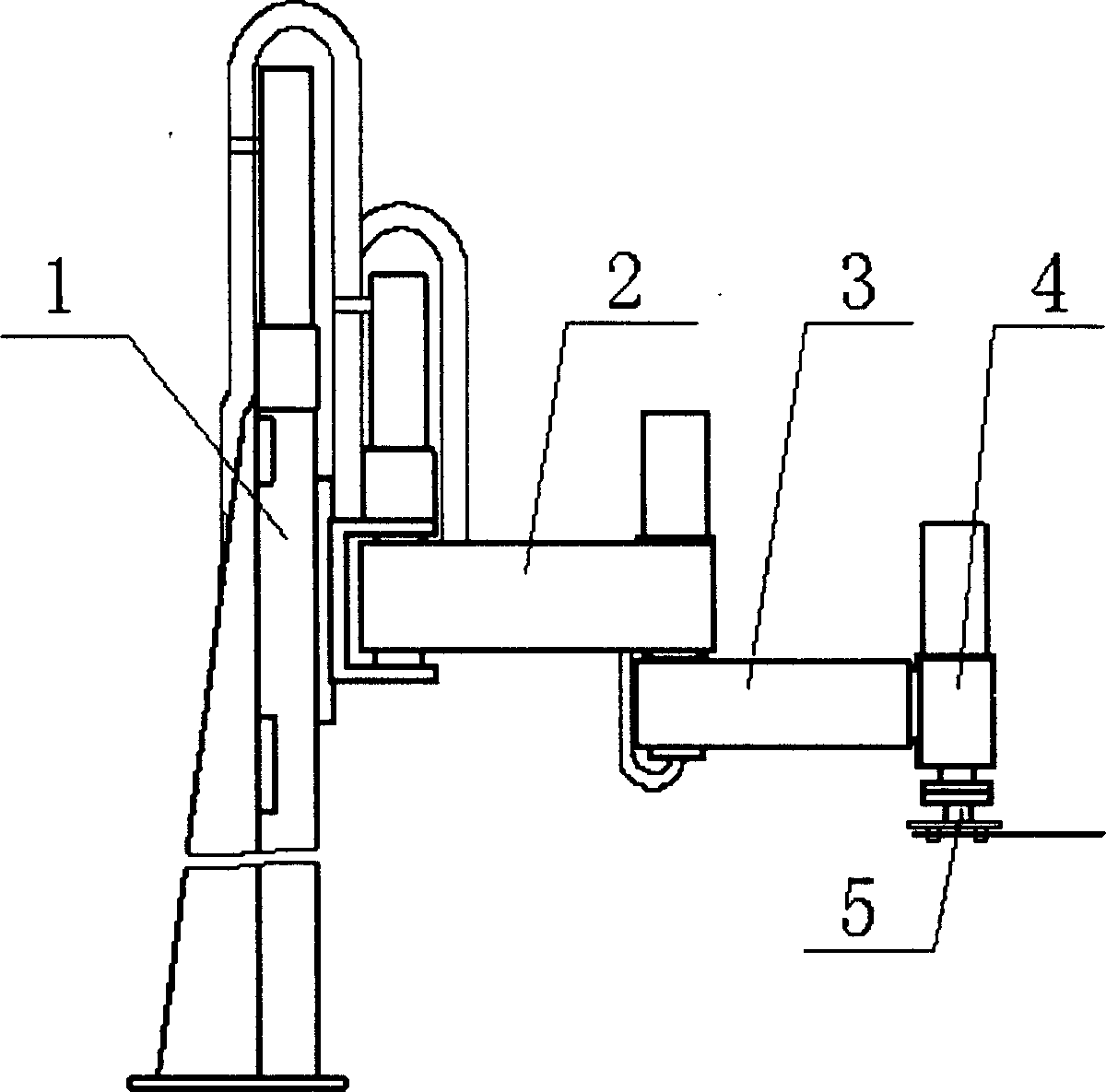

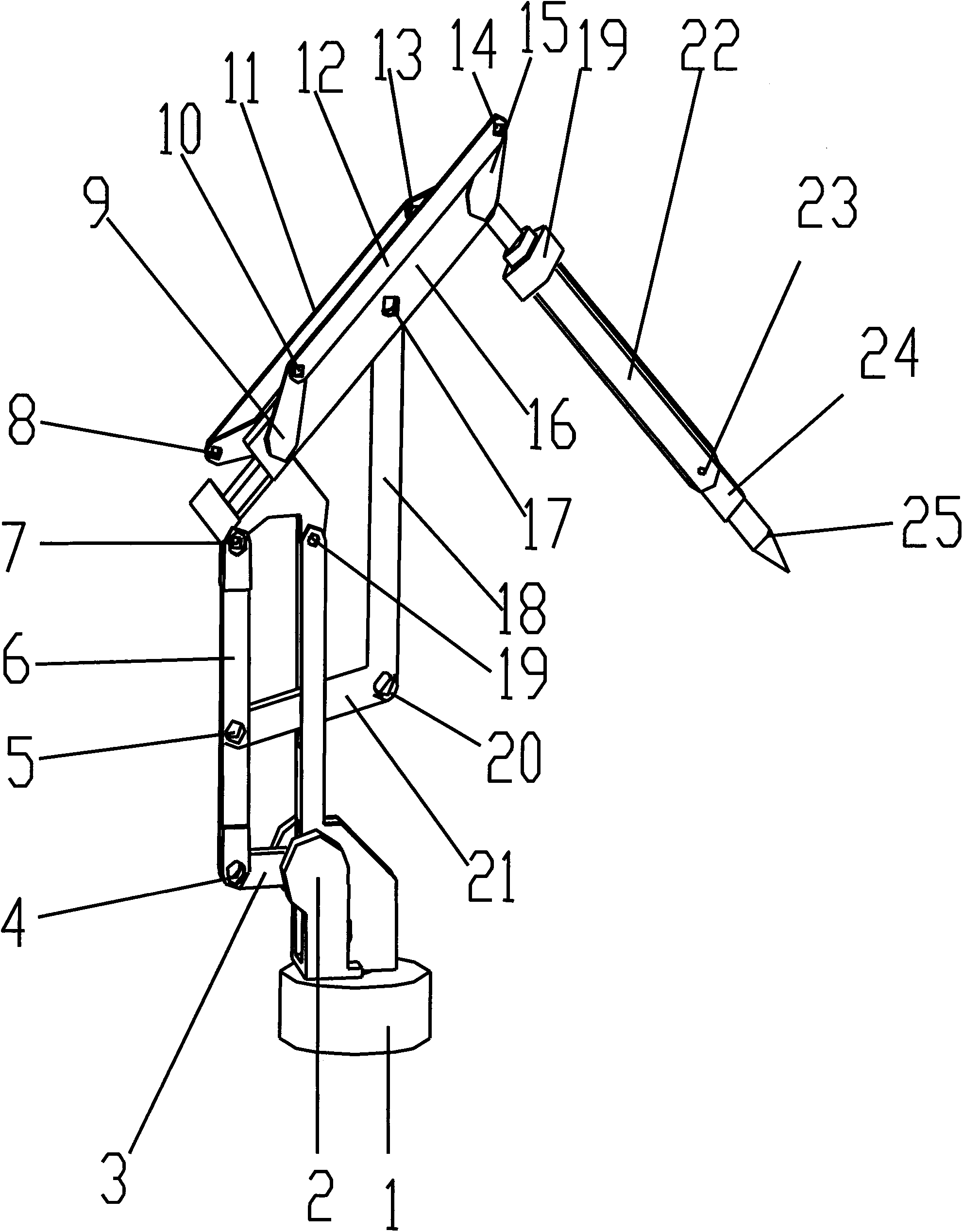

Five-coardinate space positioning robot mechanism

InactiveCN1417004ASimple structural designEasy to operateProgramme-controlled manipulatorMotor driveSmall arms

The present invention relates to a five-corodinate space positioning robot mechanism and belongs to medical operational assistant positioning mechanism. The robot mechanism consists of elevating arm,large arm, small arm, wrist and needle stand, and each two parts are connected via rotating shaft. All the parts are motor driven to produce relative motion. The robot driving and controlling system consists of AC servo motor, driver, optoelectronic coder, control card and computer. The present invention can realize autonomous high-precision absolute positioning according to the doctor set route,and has relatively large working space and certain load capacity. Its use can lower the work strength of doctor, decrease operation error and decrease wound and pain of the patient. It may be remote controlled via network.

Owner:BEIHANG UNIV

Adjustable 3,4,5-SPS type parallel mechanism experiment bench

InactiveCN1861328AHigh movement precisionIncrease freedomProgramme-controlled manipulatorLarge fixed membersEngineeringMachine tool

An adjustable experimental platform with 3,4,5-SPS type parallel mechanism for robot, machine-tool, or sensing element is disclosed. 3,4 or 5 linear drive branches are distributed between upper platform and base in polygonaly symmetrical mode. One of 4 or 5 linear drive braches is arranged in the center of platform and base. The both ends of each branch have a ball set consisting of the rotation set A formed by connecting one end of said branch with ring frame, the rotation set B formed by connecting ring frame with supporter, and the rotation set C formed by connecting supporter with axle sleeve. The vertical and transverse pins are used to change the freedom of ball set.

Owner:YANSHAN UNIV

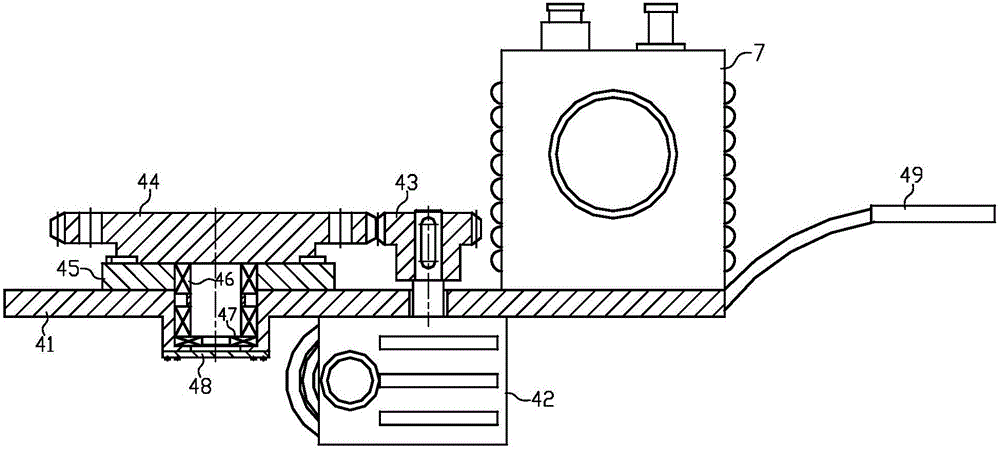

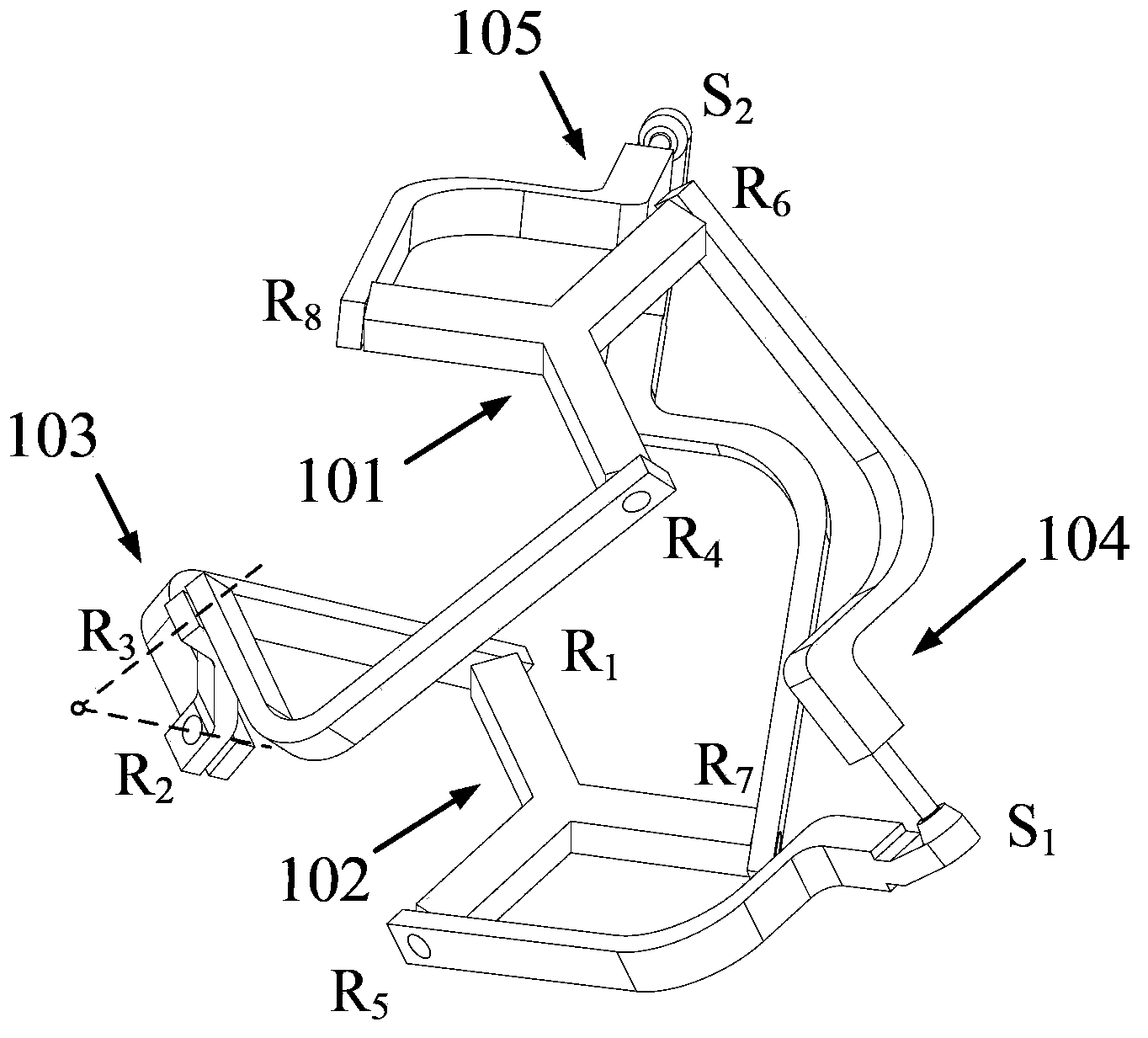

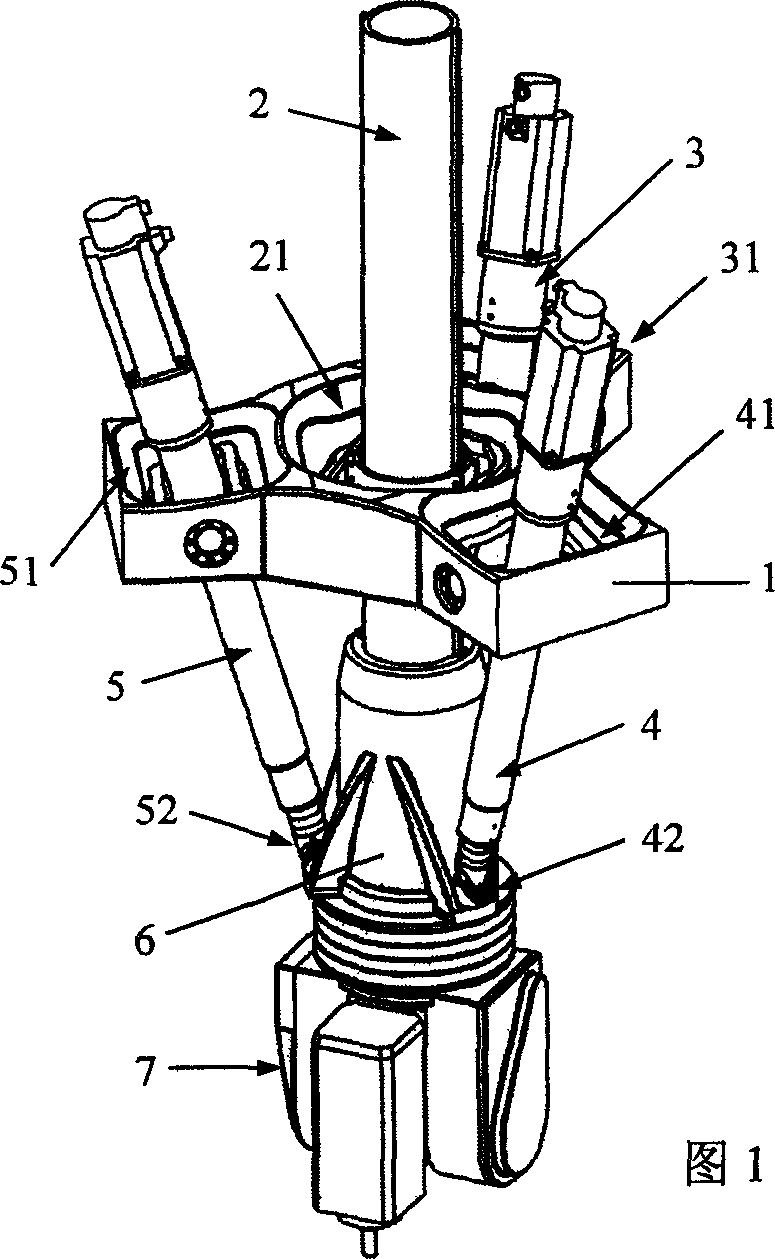

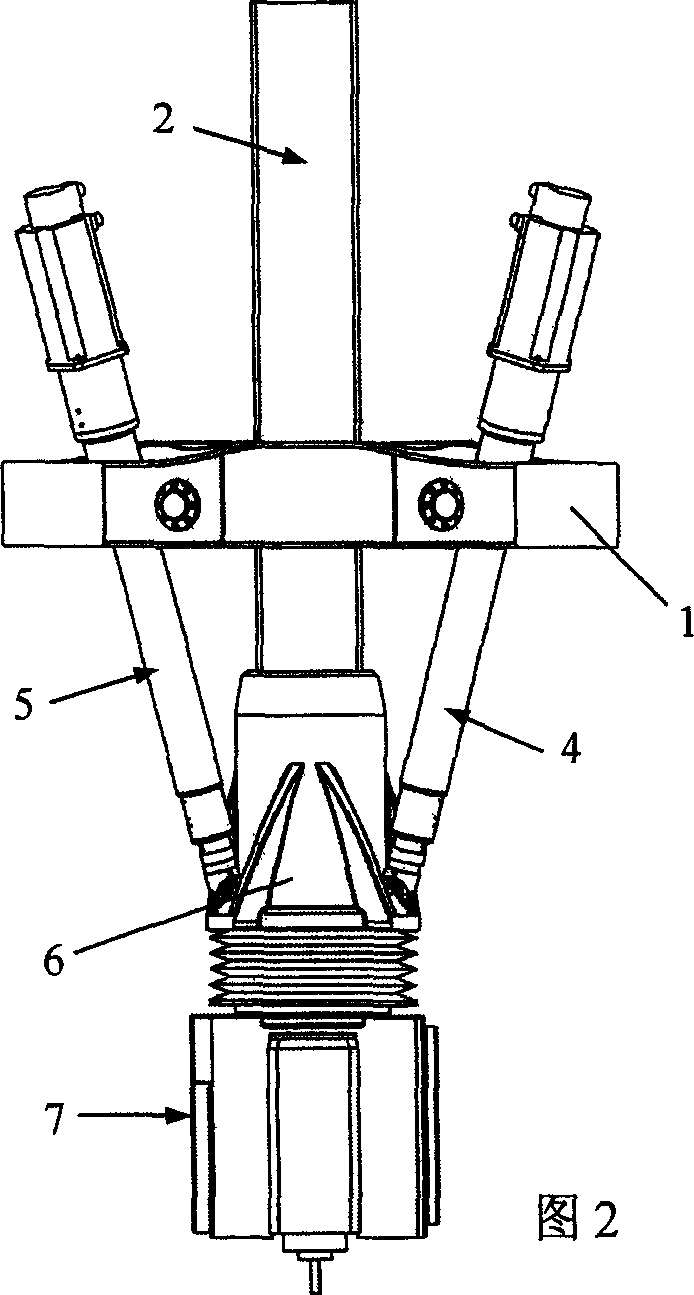

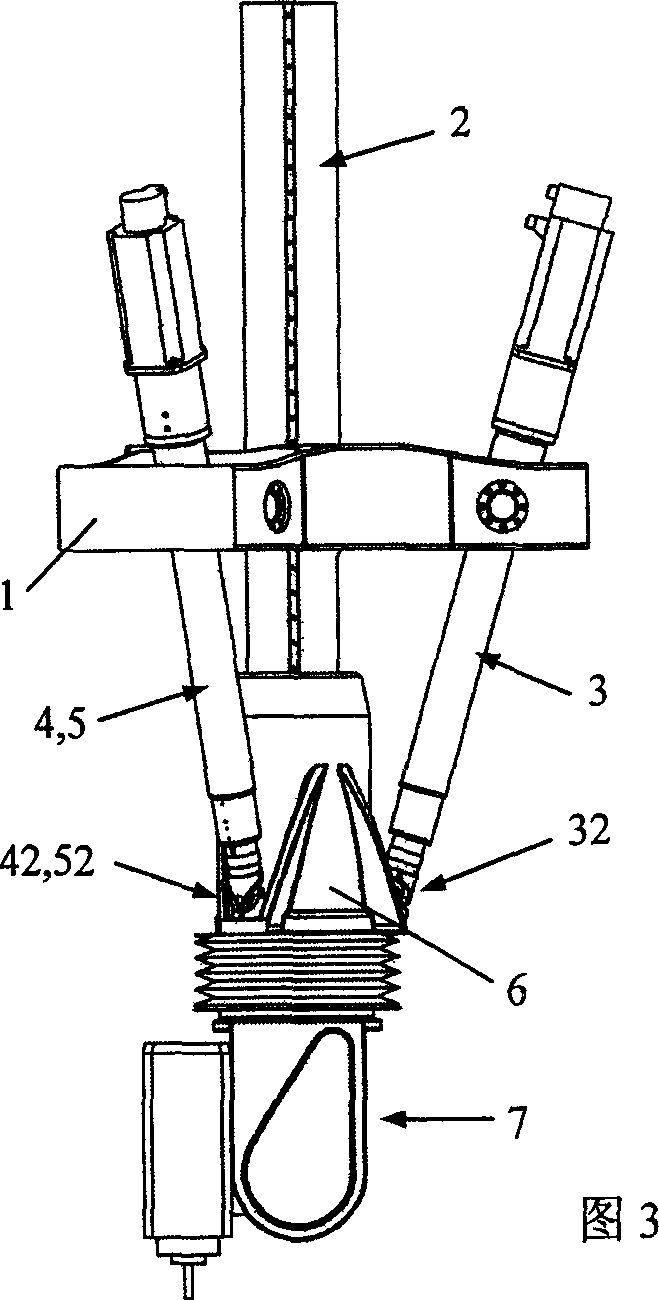

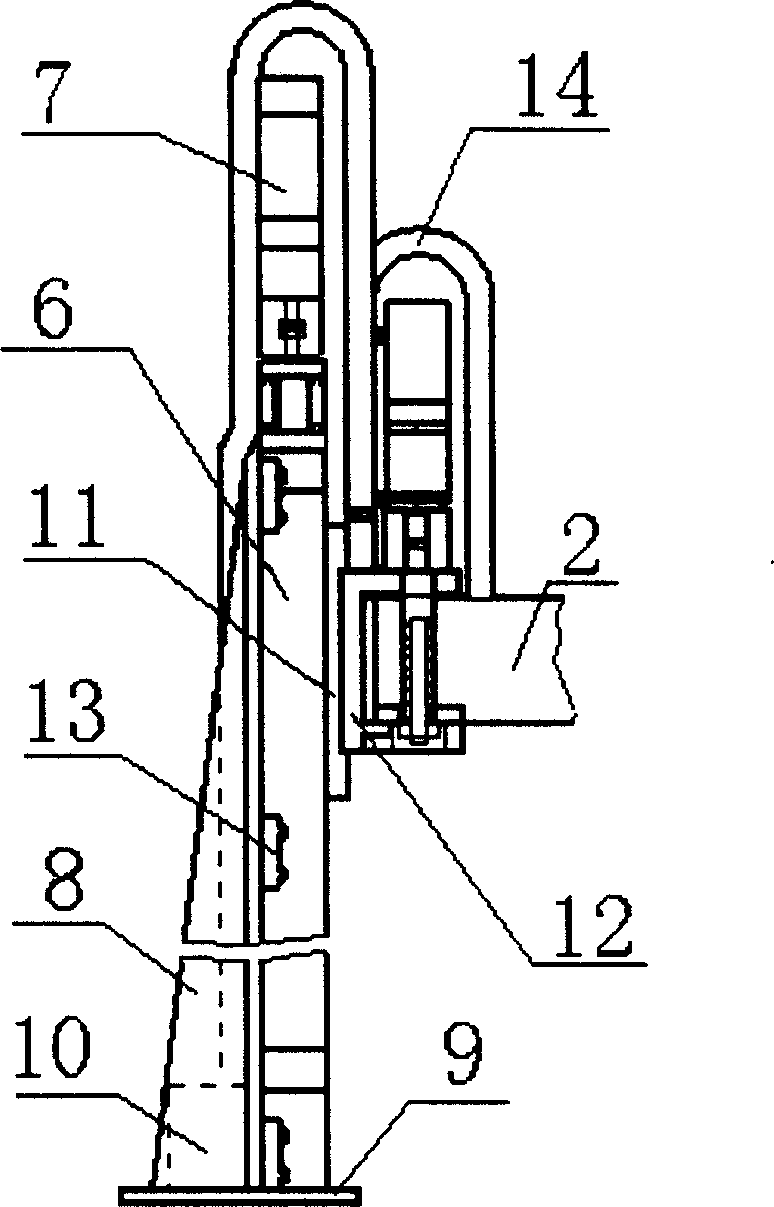

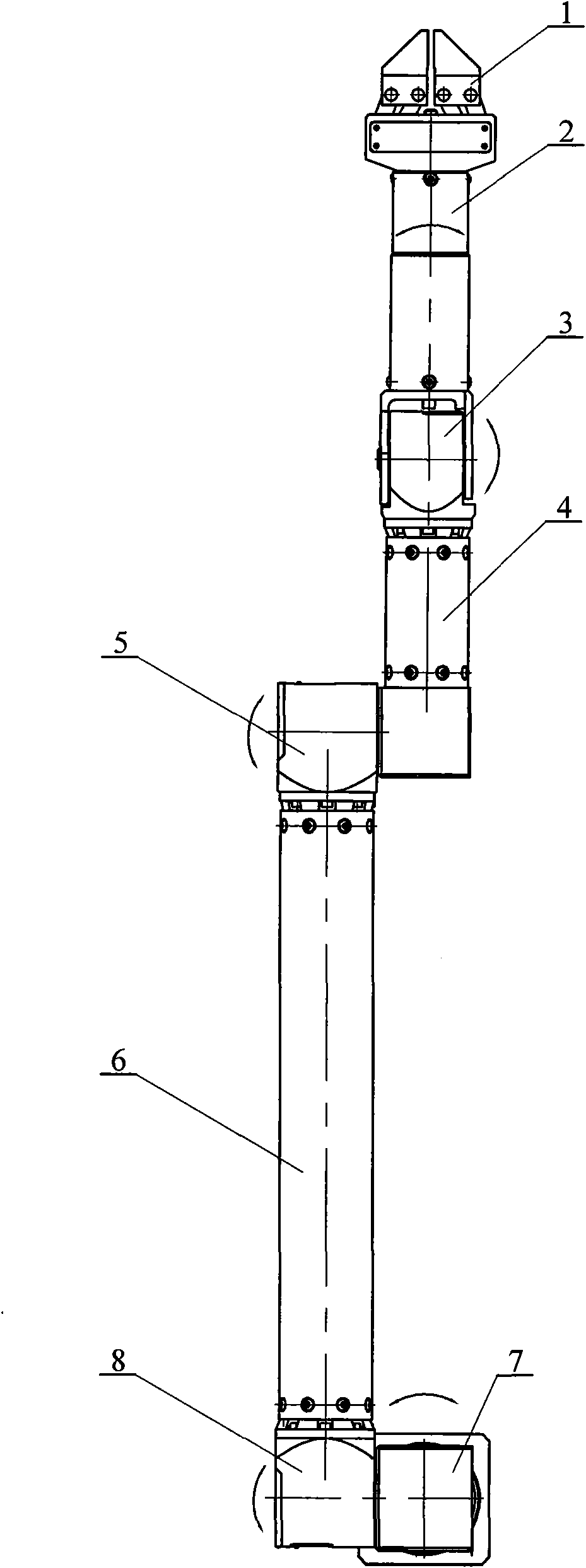

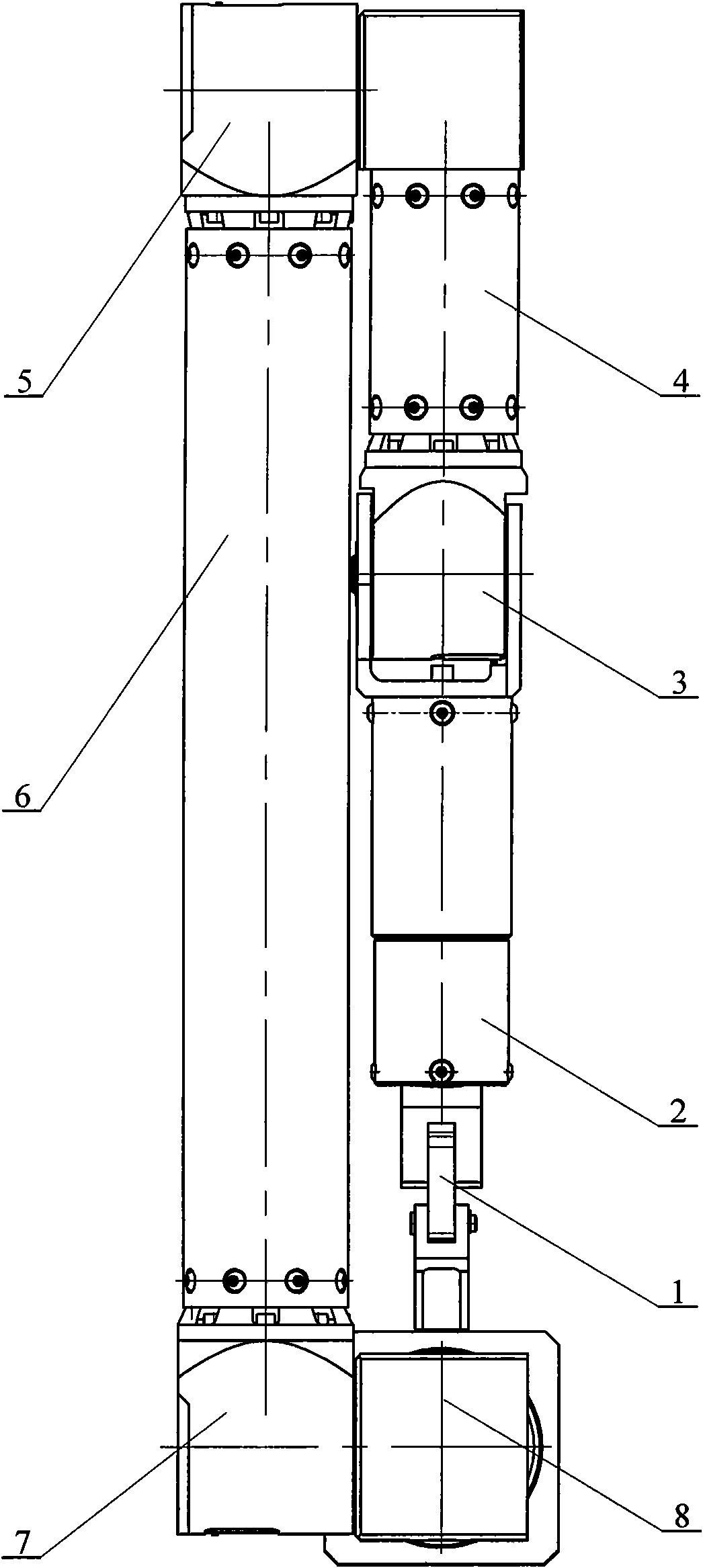

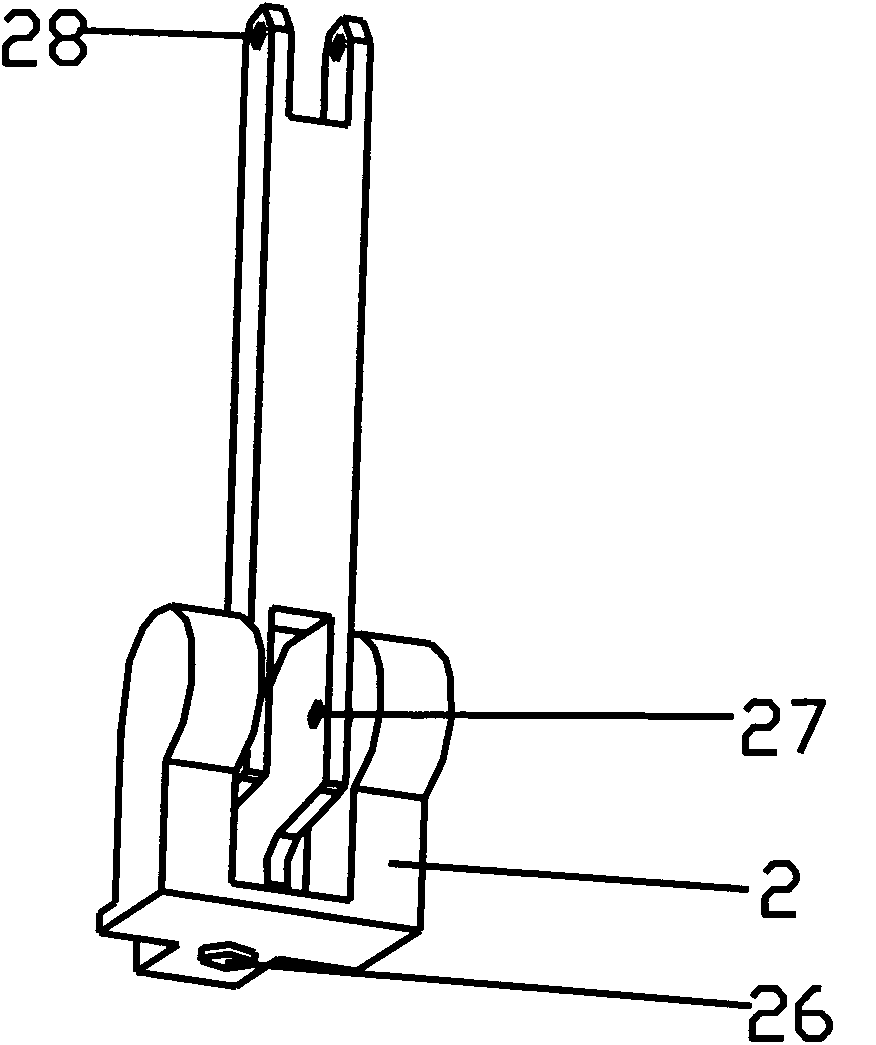

Auxiliary robot for tumor puncture of four degrees of freedom

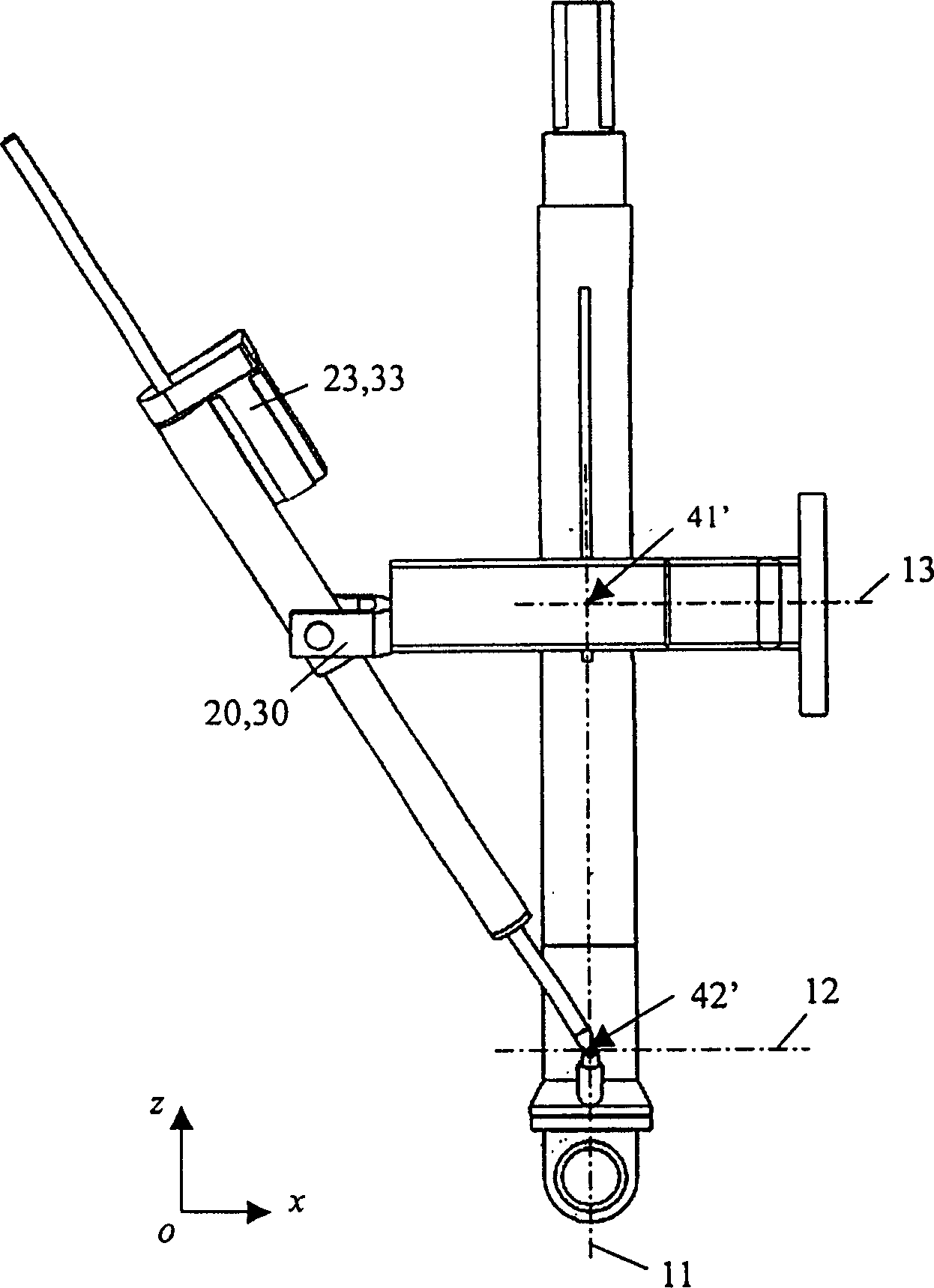

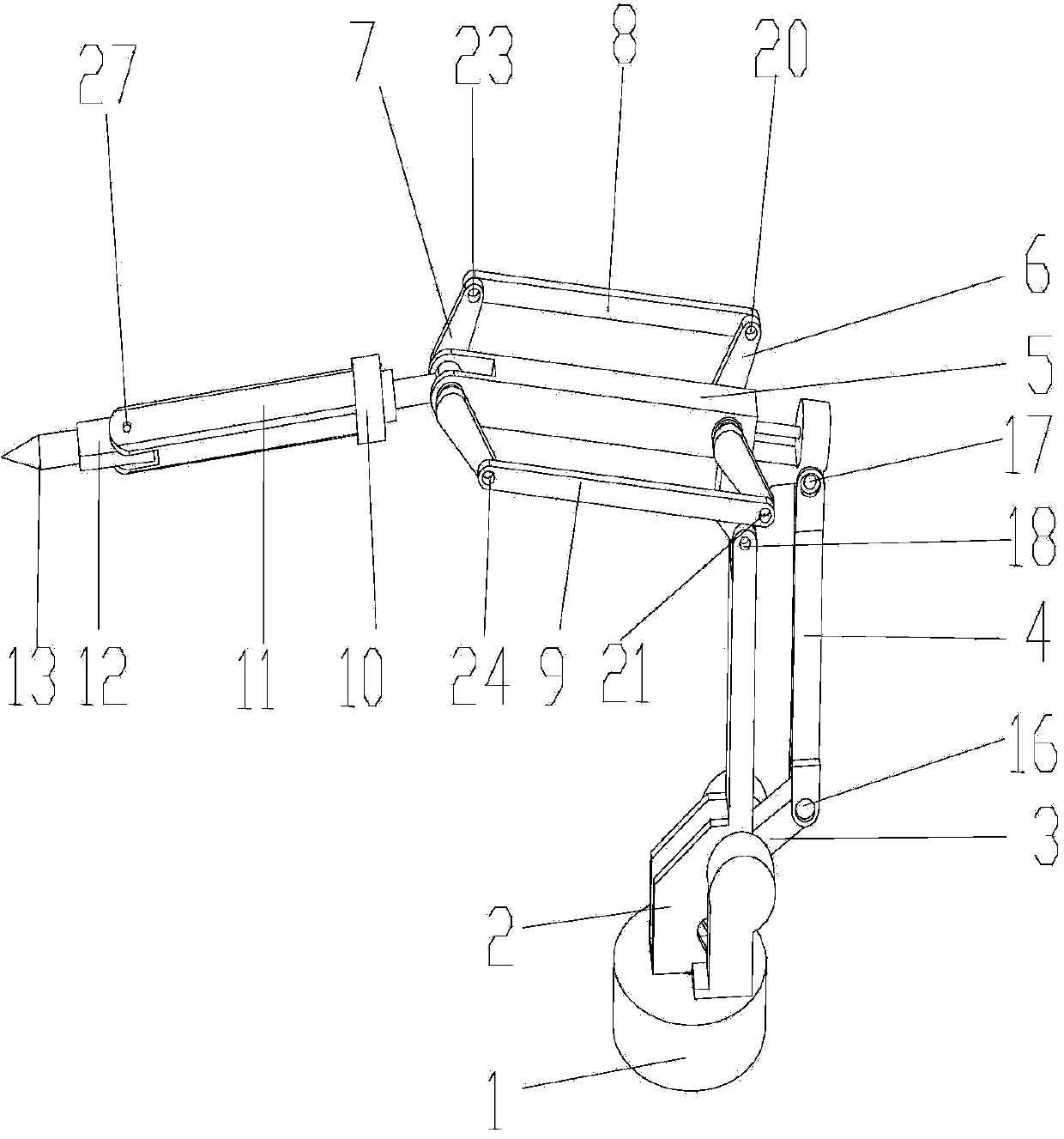

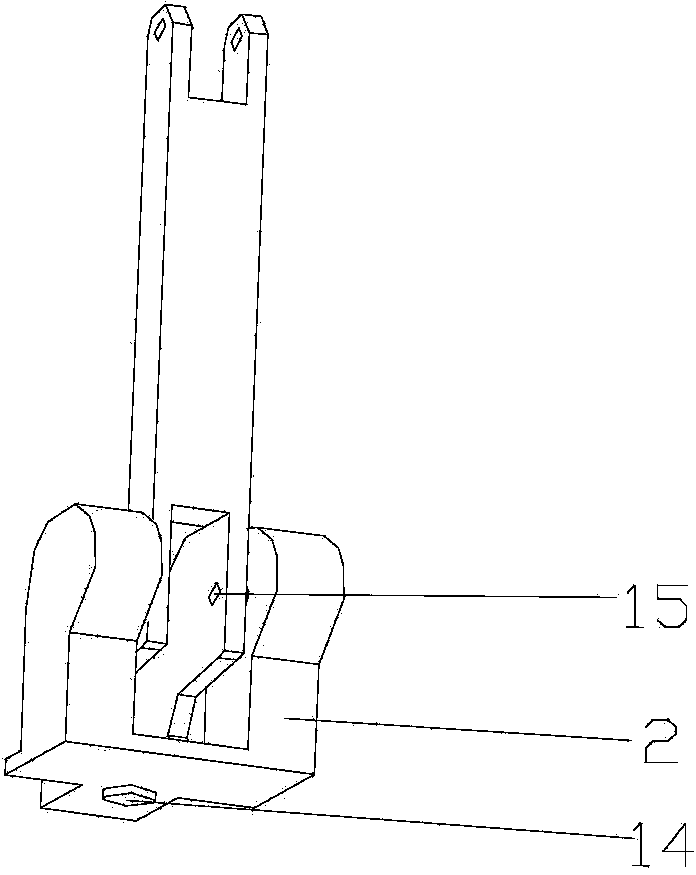

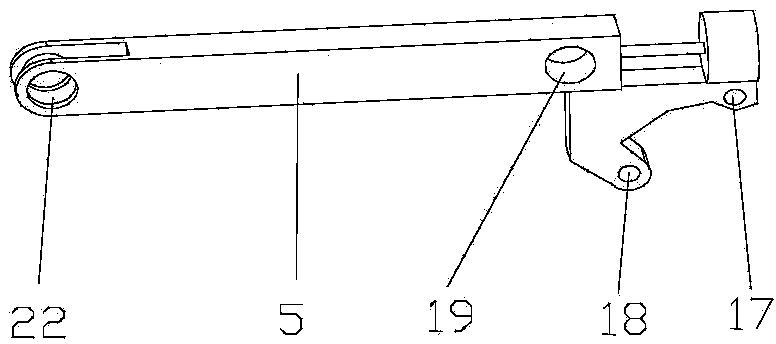

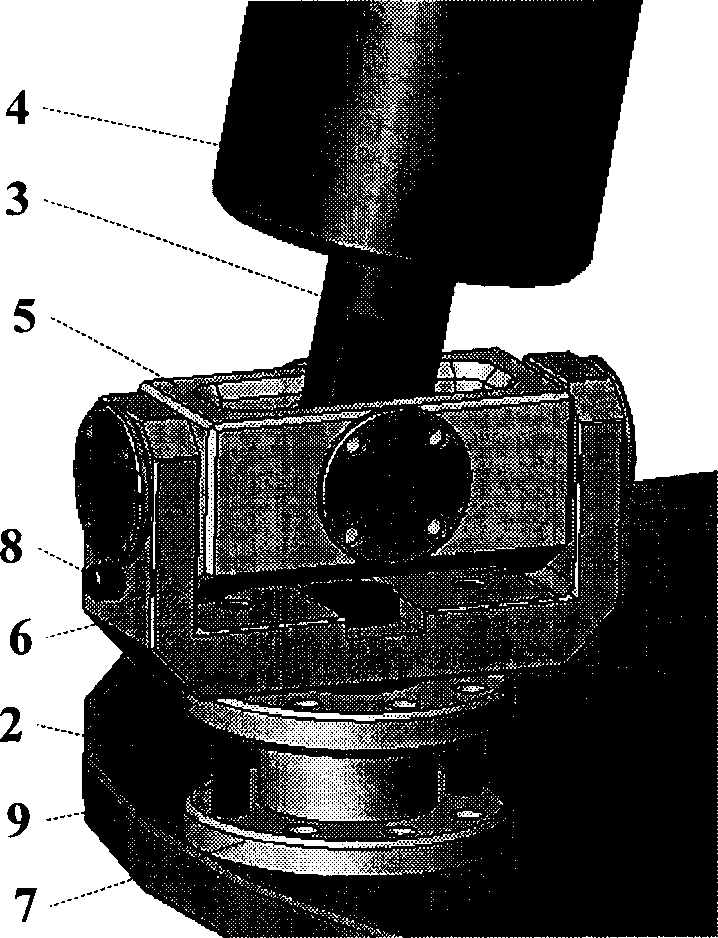

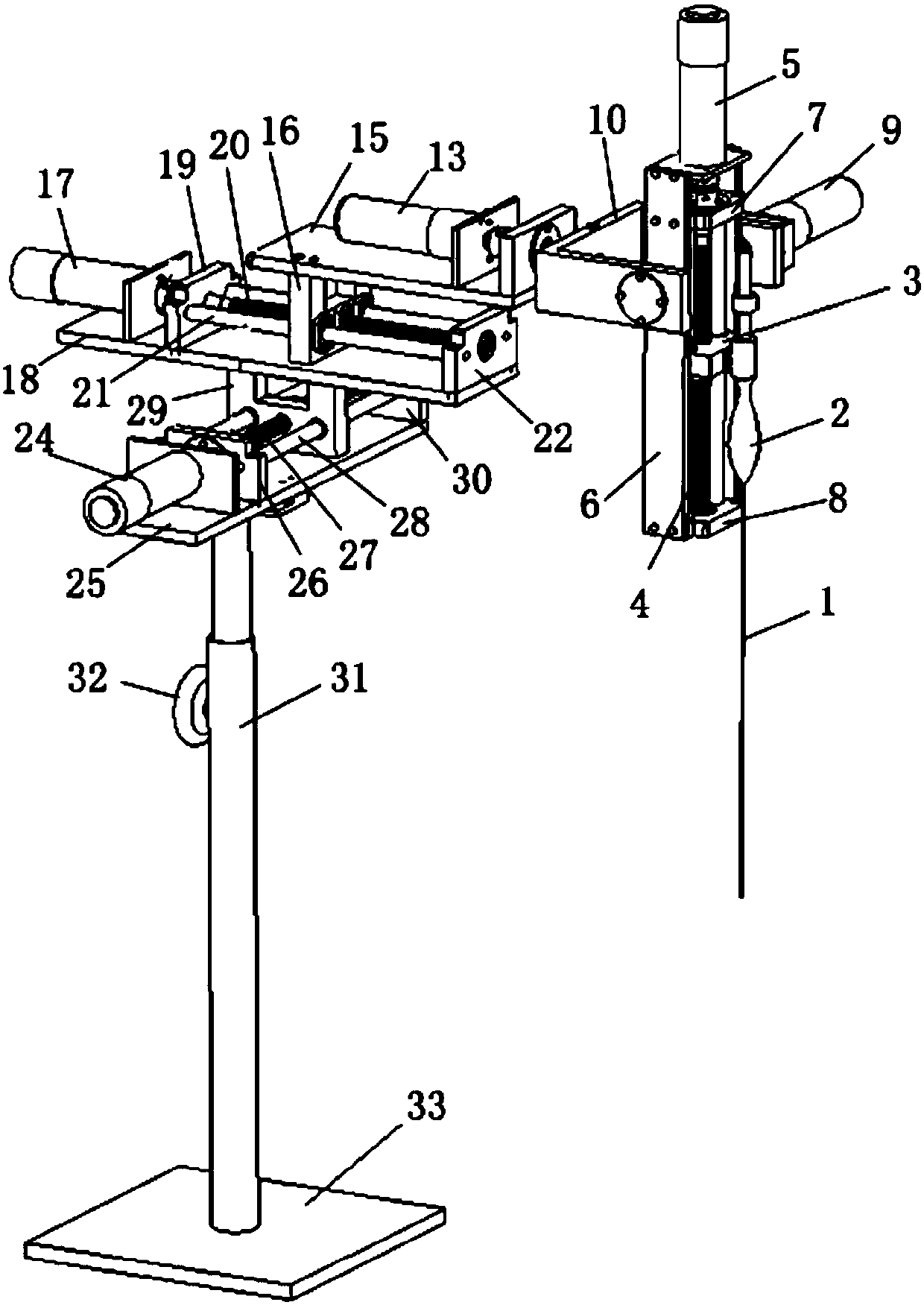

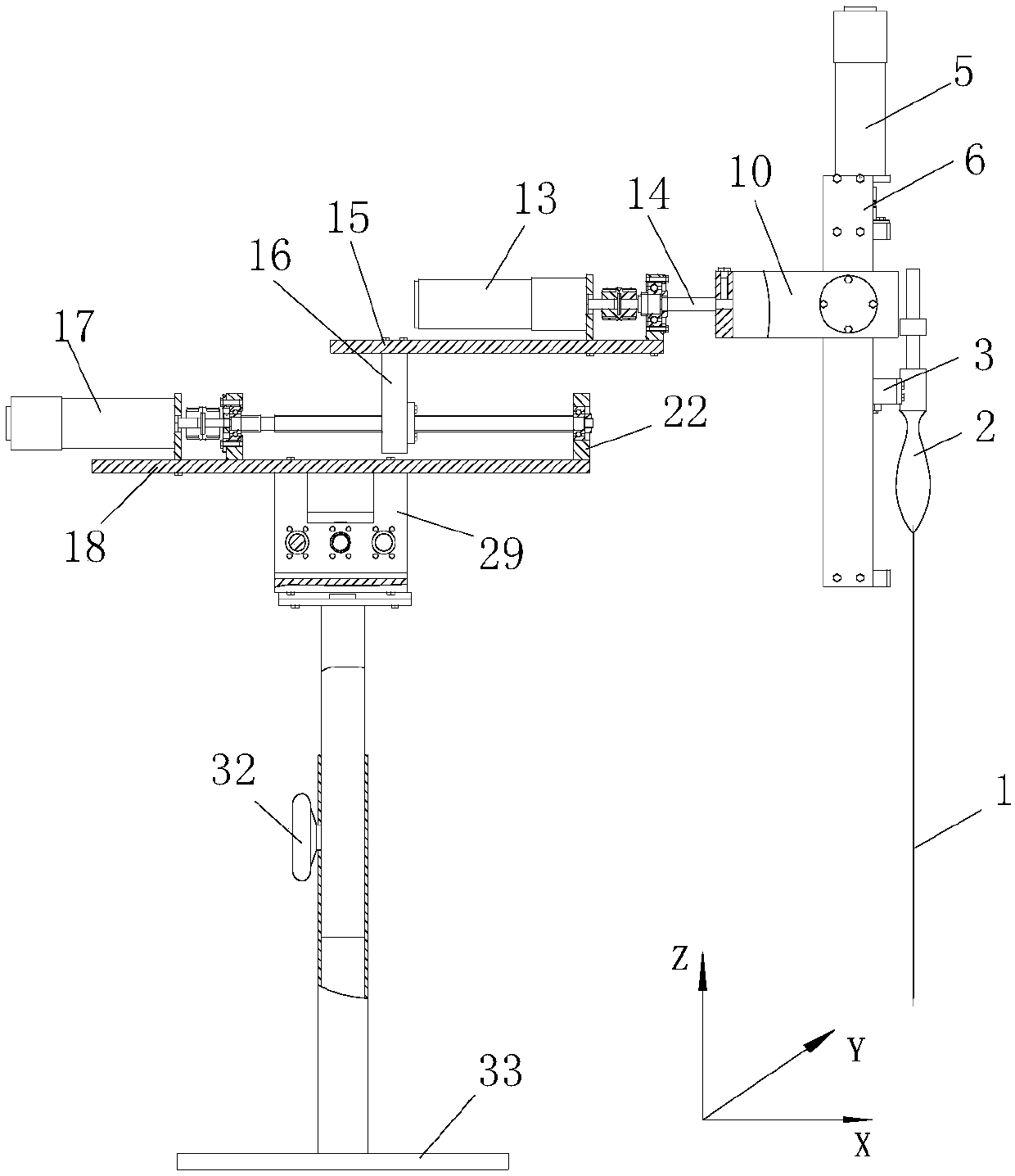

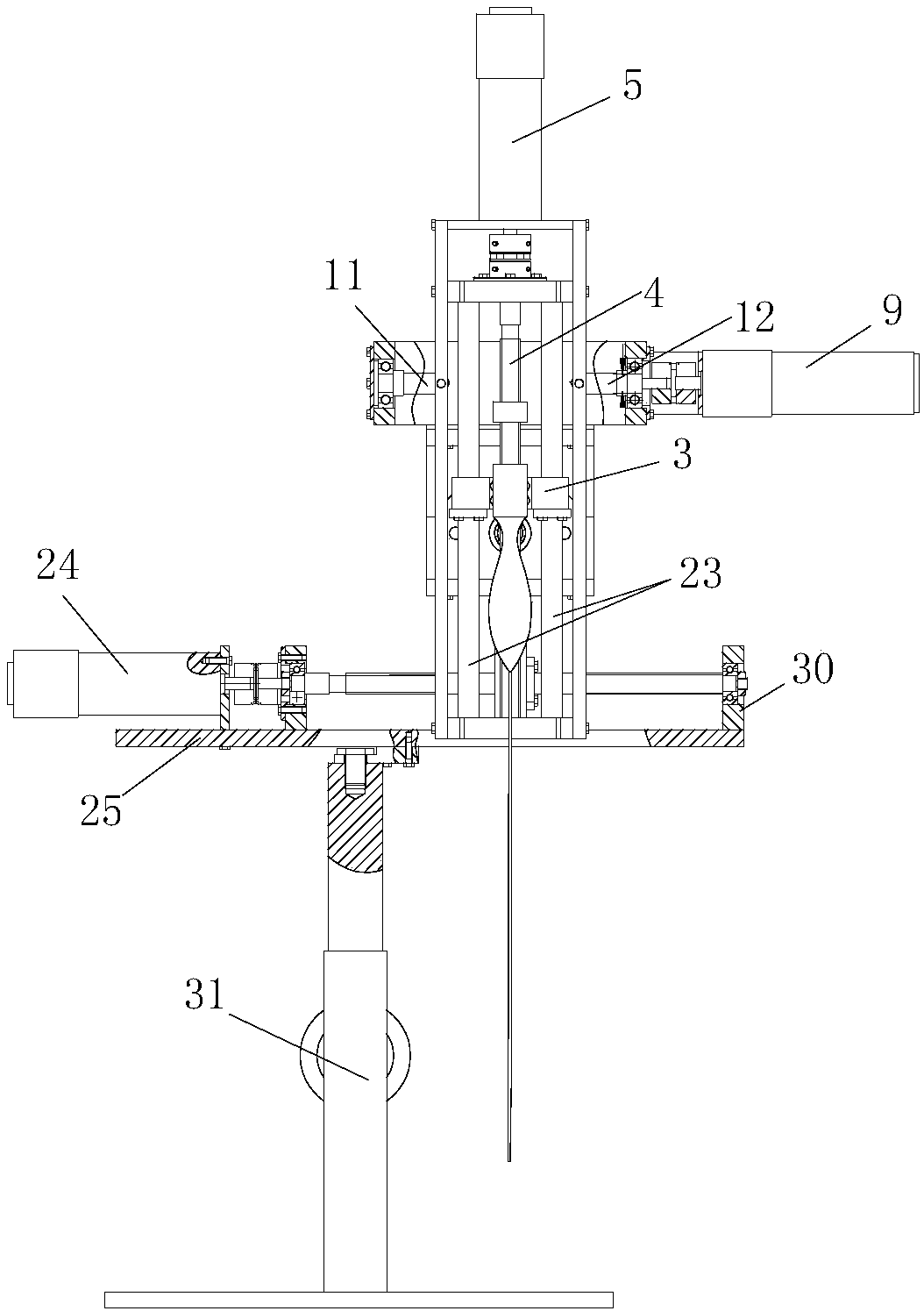

InactiveCN107773305ACompact structureLarge working spaceSurgical needlesSurgical robotsPuncture - actionEngineering

The invention discloses an auxiliary robot for tumor puncture of four degrees of freedom, and belongs to the technical field of surgical instruments. The robot comprises a needle inserting device, a first swing drive device, a second swing drive device, a first parallel moving drive device and a second parallel moving drive device. The needle inserting device is used for finishing puncture actions, the first swing drive device is used for driving the needle inserting device to swing around Y axis, the second swing drive device is used for driving the needle inserting device to swing around X axis, the first parallel moving drive device is used for driving the needle inserting device to move in parallel along the X axis, and the second parallel moving drive device is used for driving the needle inserting device to move in parallel along the Y axis. By utilizing the robot, the automation and intelligence of mechanical needle inserting can be achieved, the surgery process is standardized,the influence of human and experience factors is reduced, the working strength of physicians is reduced, the working efficiency of the physicians is improved, and the accuracy and success rate of thesurgeries are improved.

Owner:SHANDONG UNIV OF SCI & TECH

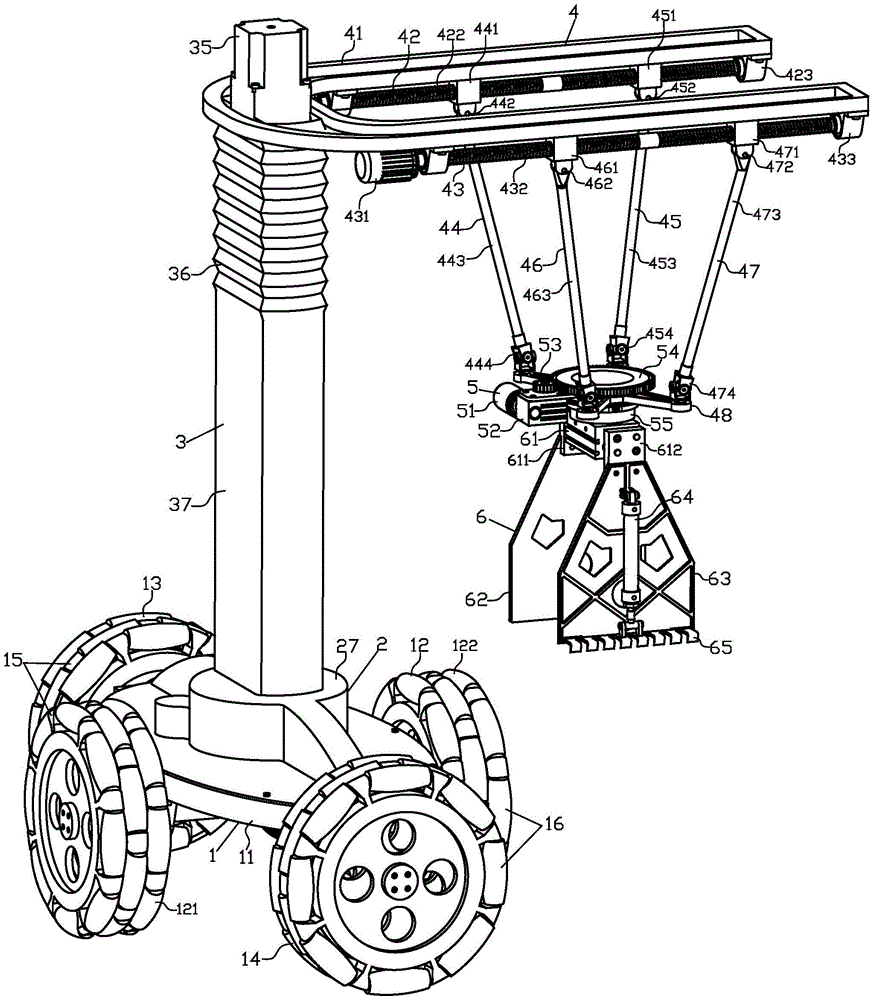

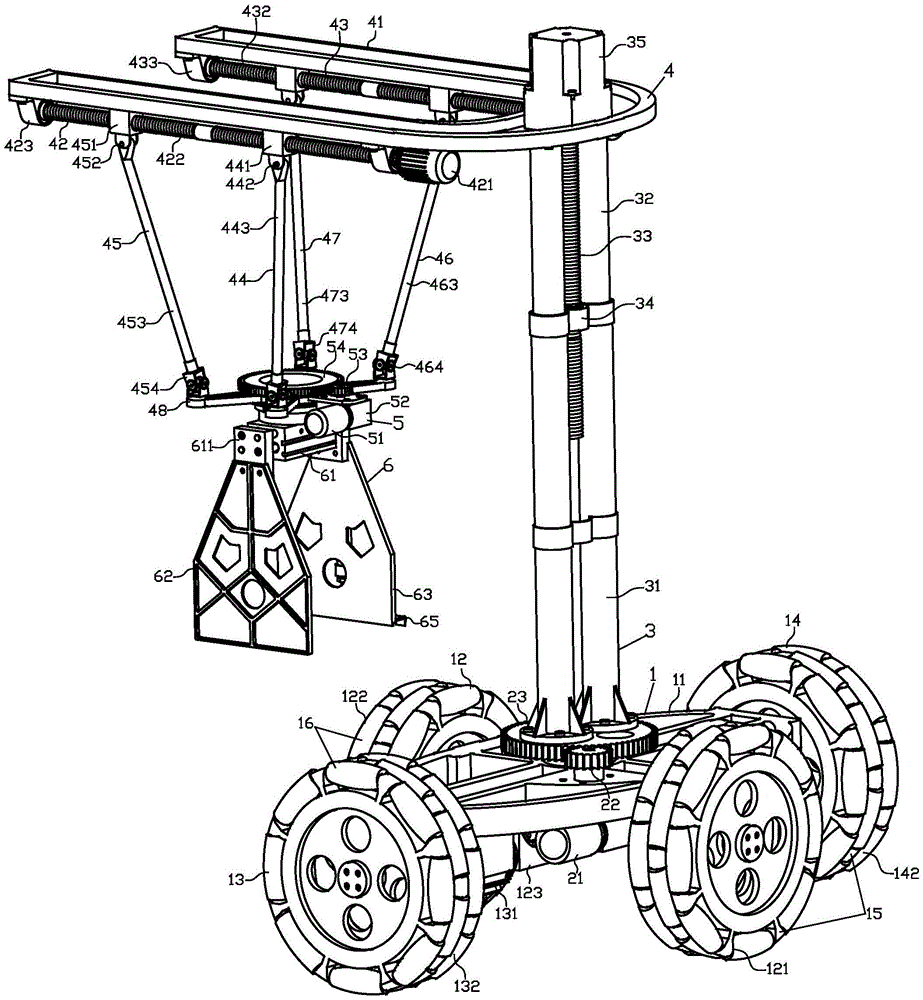

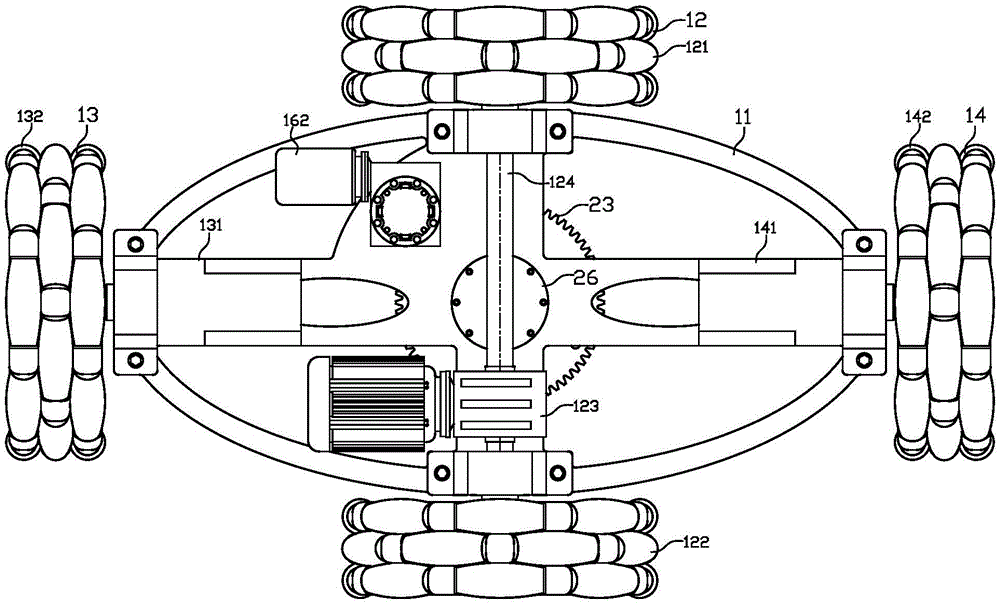

Three-freedom-degree series-parallel omni-directional mobile transfer robot

ActiveCN105459095AIncrease stiffnessImprove carrying capacityProgramme-controlled manipulatorGripping headsIndependent motionCarrying capacity

The invention discloses a three-freedom-degree series-parallel omni-directional mobile transfer robot. The transfer robot comprises an omni-directional mobile chassis, a main slewing gear, a lifting device, parallel working arms, a tail end slewing gear and a clamp holder. The omni-directional mobile chassis is used for executing walking and steering tasks, the lifting device is connected with the omni-directional mobile chassis through the main slewing gear, the parallel working arms installed at the top of the lifting device are connected with the clamp holder through the tail end slewing gear and are used for adjusting the operation posture of the clamp holder. A series-parallel is adopted in a robot body, and the omni-directional mobile transfer robot has the advantages of being high in rigidity, large in carrying capacity, high in motion precision, large in operation space and the like; the clamp holder has six motion ranges and three independent motion freedom degrees and is high in motion flexibility; the tri-drive omni-directional mobile chassis can realize walking tasks of moving forward, or moving backward, or turning left or turning right, and is reasonable in structural design, and high in anti-overturning ability. In addition, the omni-directional mobile transfer robot has the advantages of being convenient to manipulate, and high in adaptability to road conditions.

Owner:ANHUI UNIV OF SCI & TECH

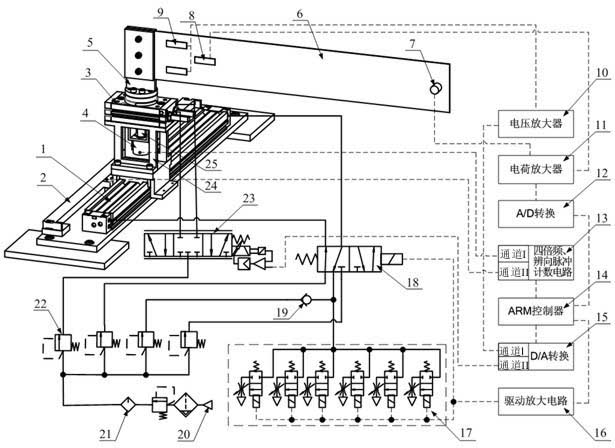

Device for pneumatically driving two free flexible mechanical arms and method for controlling device

InactiveCN102303315ALight in massReduce energy consumptionProgramme-controlled manipulatorGratingEngineering

The invention discloses a device for pneumatically driving two free flexible mechanical arms and a method for controlling the device. The device comprises a flexible mechanical arm body, a pneumatic driving part and a control part, wherein one end of the flexible mechanical arm body is a free end, and the other end of the flexible mechanical arm body is a fixed end; the fixed end is arranged on an oscillating flange plate of an oscillating cylinder through an oscillating flange plate mechanical connection device; a rotation angle of the oscillating cylinder is detected by a photoelectric coder; the displacement of a rodless movement cylinder is detected by a linear grating ruler; a plurality of piezoelectric ceramic chips are adhered to the fixed end of the flexible mechanical arm body and respectively serve as a piezoelectric sensor and a piezoelectric driver; an acceleration sensor is arranged at the free end; the piezoelectric sensor or the acceleration sensor can detect the vibration of the flexible mechanical arms; the pneumatic driving part consists of two pneumatic channels which are respectively used for driving the movement of the rodless movement cylinder and the oscillation of the oscillating cylinder; and the control part is used for processing the detected movement, rotation and vibration signals of the flexible mechanical arms and performing corresponding processing.

Owner:SOUTH CHINA UNIV OF TECH

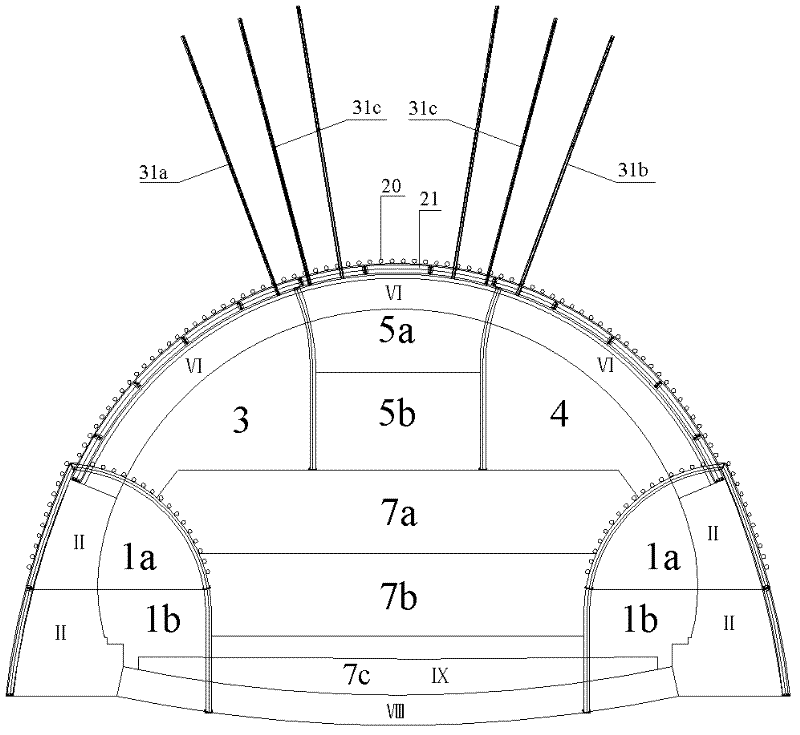

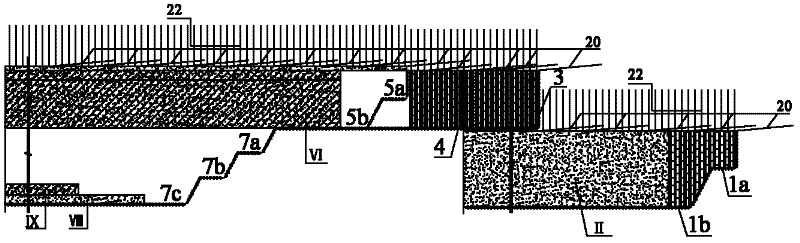

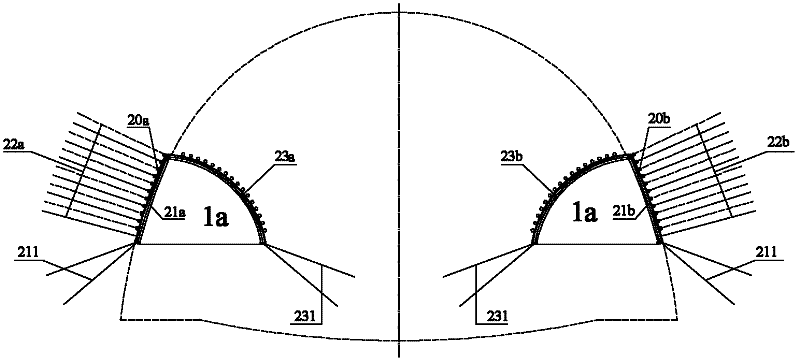

Soft rock four-line large-span tunnel compound double-side wall bracing cable conversion excavation construction method

InactiveCN102226398AExpand the working areaInternal force redistribution is not obviousUnderground chambersTunnel liningEngineeringBuilding construction

The invention relates to a soft rock four-line large-span tunnel compound double-side wall bracing cable conversion excavation construction method which has the characteristics of safety in construction, speediness and simpleness in operation, and is further applicable to large-scale machines for construction. The method comprises the following steps: (1) excavating pilot holes on side walls on two sides, firstly implementing corresponding forepoling before excavation, and immediately implementing corresponding preliminary bracing and temporary bracing after the excavation; (2) pouring pedestal foundations on the two sides; (3) excavating side pilot holes of arch parts on the two sides respectively, firstly implementing the corresponding forepoling before the excavation, immediately implementing the corresponding preliminary bracing and the temporary bracing after the excavation, and implementing a pre-stressed anchor cable connected with a surrounding rock anchor at the top of the corresponding preliminary bracing; (4) excavating core soil of the arch parts bench by bench, firstly implementing the corresponding forepoling before excavating an upper bench, immediately implementing the corresponding preliminary bracing after the excavation, and implementing the pre-stressed anchor cables connected with the surrounding rock anchor at two end parts of the preliminary bracing; (5) pouring secondary lining of the arch parts; (6) excavating the lower core coil bench by bench; and (7) pouring an inverted arch, and pouring the inverted arch to the design height.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

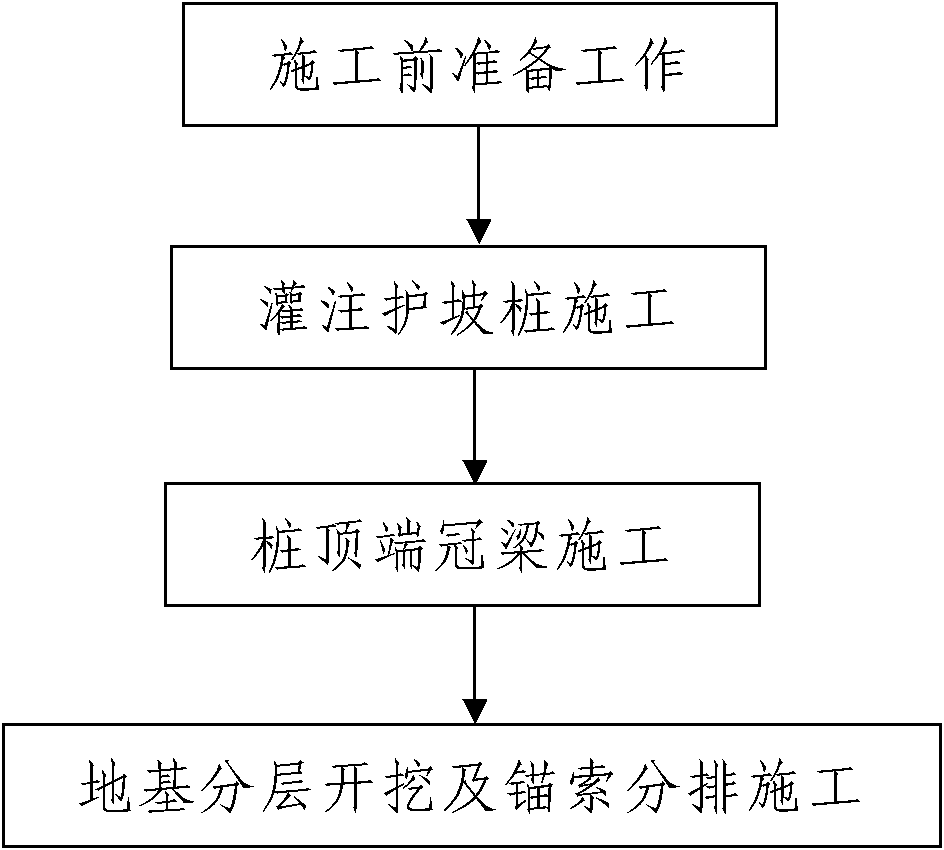

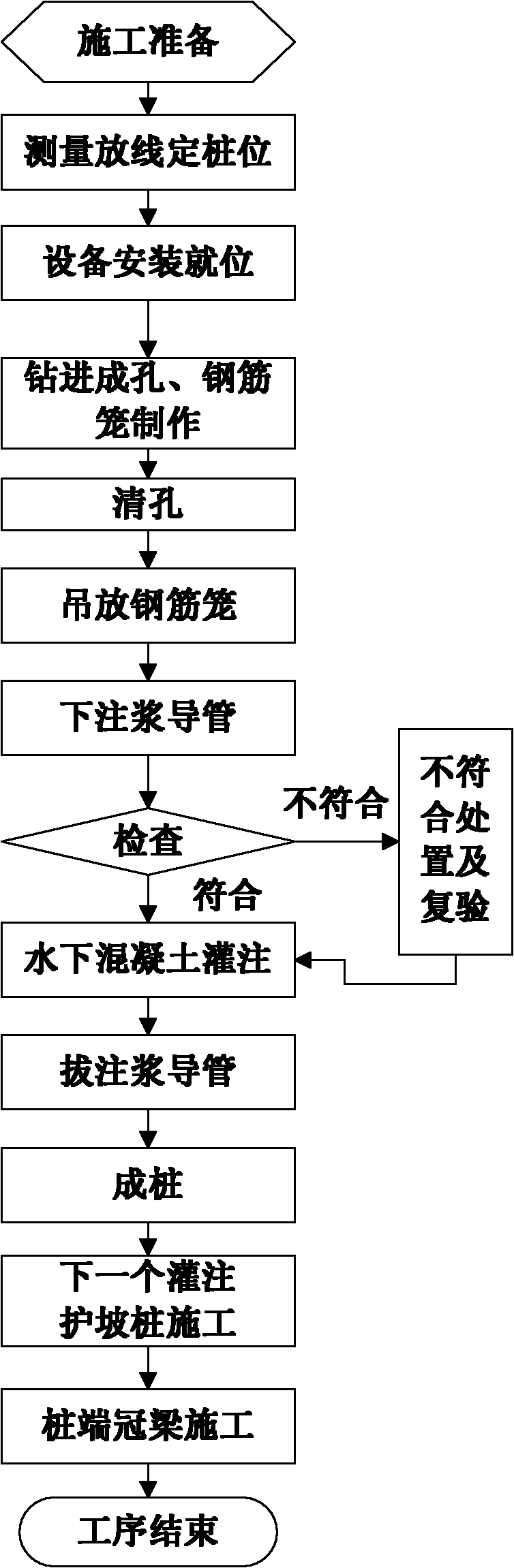

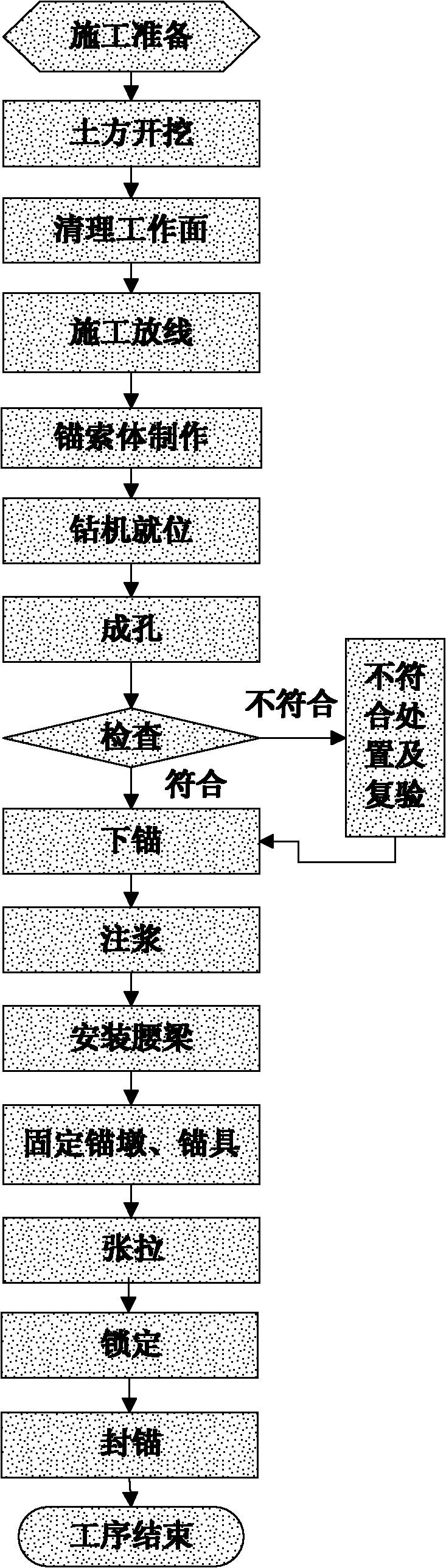

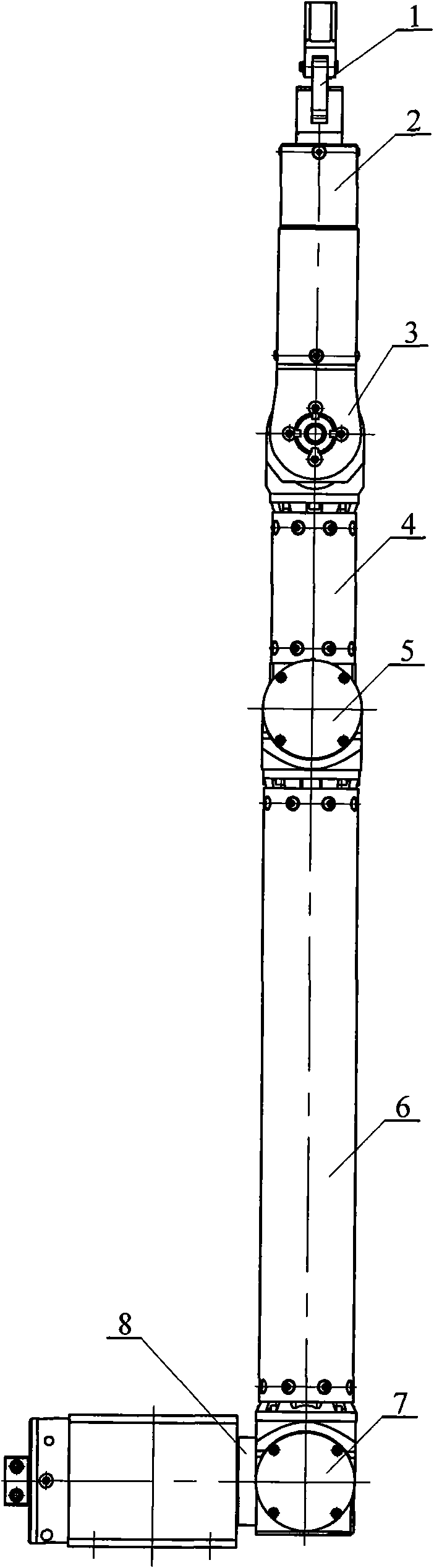

Slope protection pile pouring and cable bolting construction method for deep foundation pit

InactiveCN102031784ASimplify construction stepsFacilitate construction quality controlDrill bitsExcavationsLine tubingRebar

The invention discloses a slope protection pile pouring and cable bolting construction method for a deep foundation pit. The method comprises the following steps of: 1, making preparations before construction; 2, pouring a slope protection pile, namely measuring, paying off, molding and constructing the poured slope protection pile, punching holes on the poured slope protection pile, binding and hoisting a steel reinforcement cage for molding the slope protection pile, pouring concrete into the poured slope protection pile and constructing a crown beam at the top end of the pile; and 3, excavating a foundation in a layered form and constructing anchor ropes on different rows, namely excavating a first-layer foundation, arranging a first row of anchor ropes, arranging a steel waist rail, arranging anchor heads of the anchor ropes, tensioning the anchor ropes and finishing excavating processes of different layers of foundations and arranging different rows of anchor ropes. The method has a reasonable design, simple construction steps, low investment cost, large support depth and good using effect, and solves the problems of complicated construction steps, high construction cost, inconvenience in control, easy damage to surrounding pipelines, roads, buildings and the like, large construction space and the like existing in the conventional double-row pile supporting method can be solved.

Owner:SCEGC NO 6 CONSTR ENG GRP CO LTD

Five degree-of-freedom manipulator

The invention discloses a five degree-of-freedom manipulator, and relates to a manipulator. The manipulator aims to solve the problem that no manipulator which is matched with intelligent wheelchairs and has the advantages of accurate positioning, high precision, small mass and large rigidity exists at present. A disc type driving servomotor of a paw is fixed in a mandrel of a wrist revolute joint, a wrist revolute joint connecting piece of the wrist revolute joint is fixedly connected with the upper end of an auxiliary connecting plate of a wrist joint, a connecting end of a second connecting piece of the wrist joint is fixedly connected with the upper end of a small arm, the lower-rear end of the small arm is fixedly connected with a large gear of an elbow joint, an elbow joint bearing support in the elbow joint is fixedly connected with the upper end of a big arm, the lower end of the big arm is fixedly connected with a sixth connecting piece of a shoulder joint, and the sixth connecting piece of the shoulder joint is fixedly connected with a shoulder revolute joint mandrel of a shoulder revolute joint. The manipulator can replace human arms to finish operation tasks on certain specific occasions. The manipulator has the advantages of simple structure, accurate positioning, high precision, small mass, large rigidity, full functions, safe and reliable use, simple and convenient assembly and maintenance, and lower cost.

Owner:HARBIN INST OF TECH

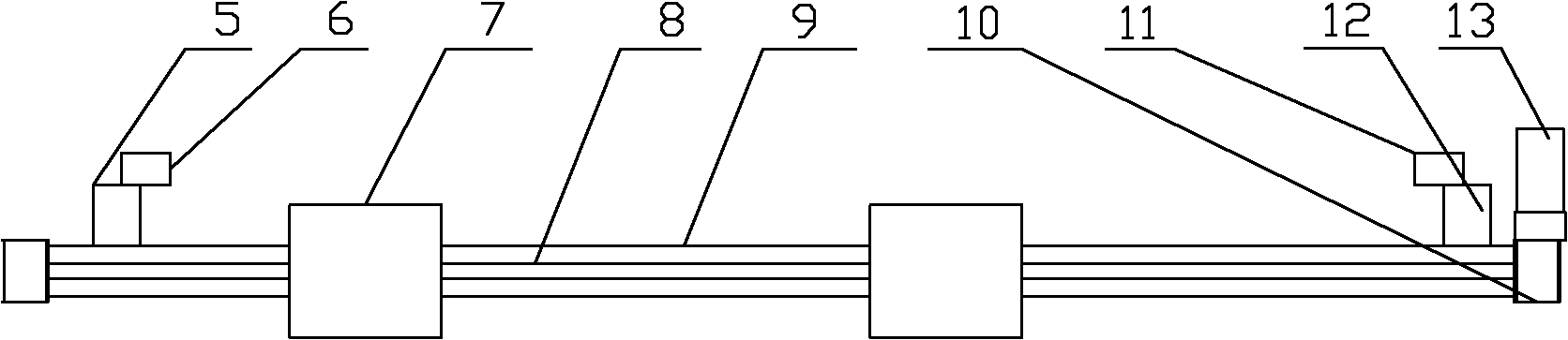

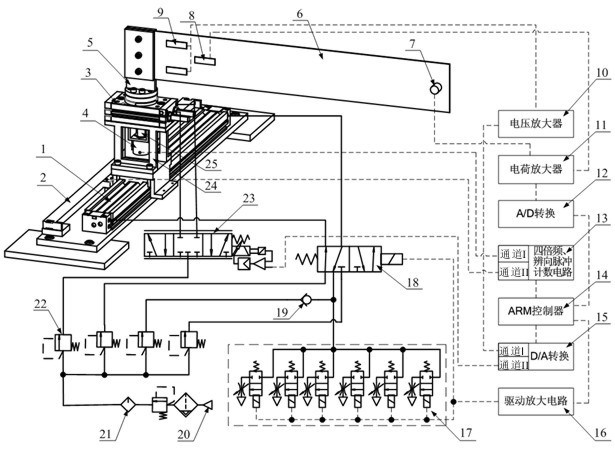

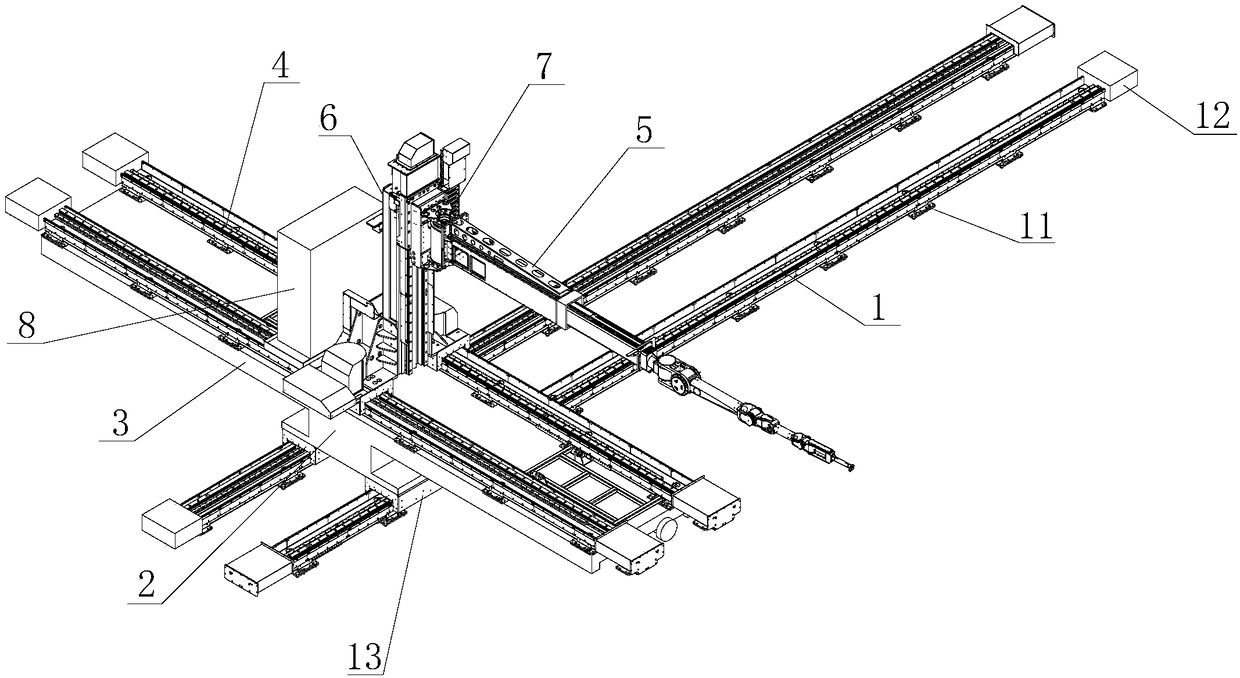

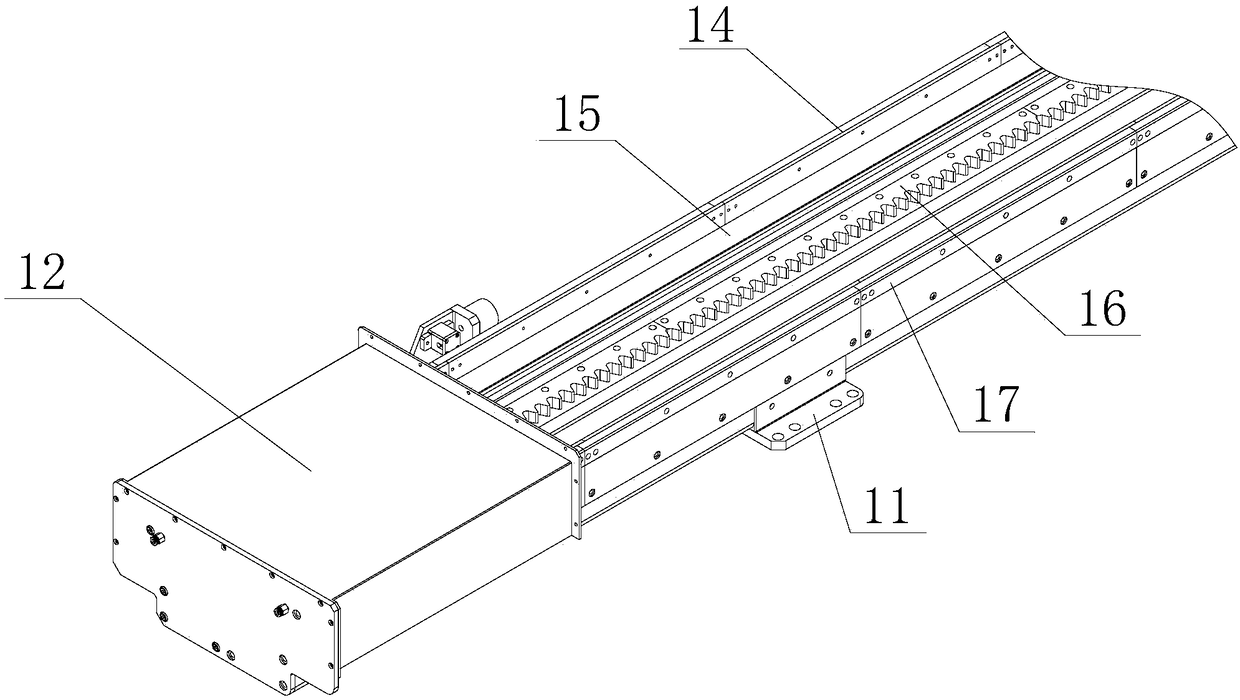

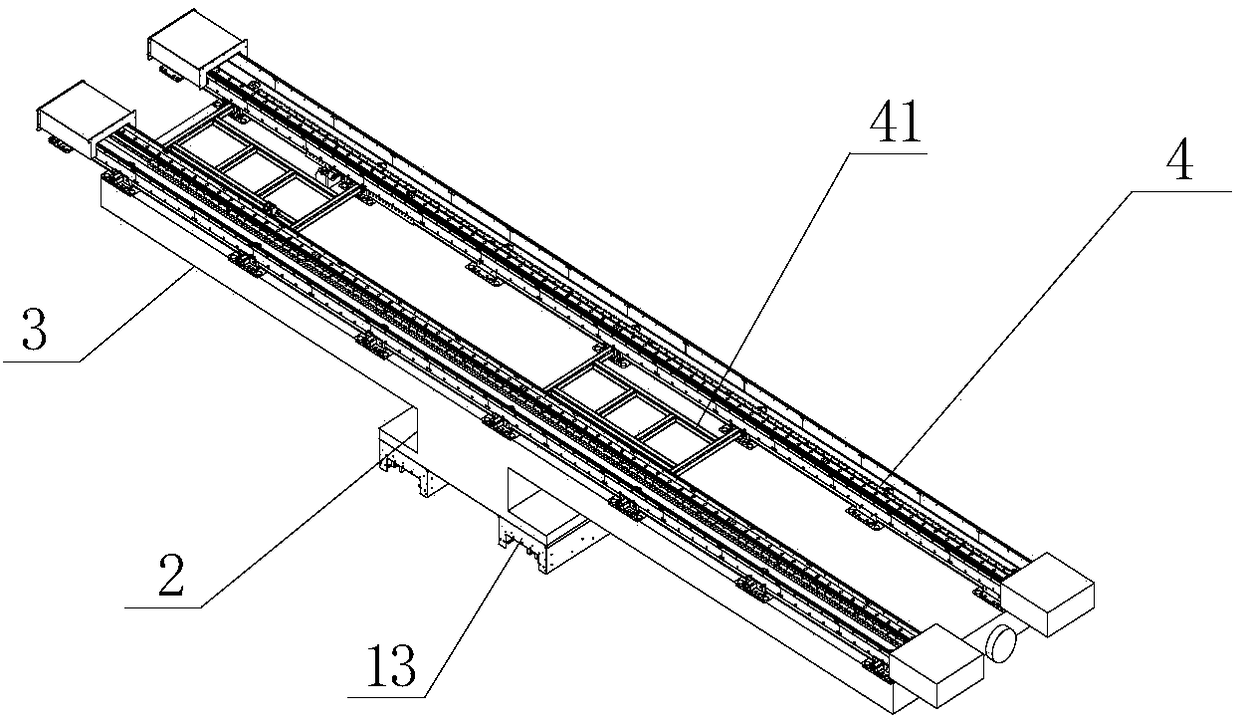

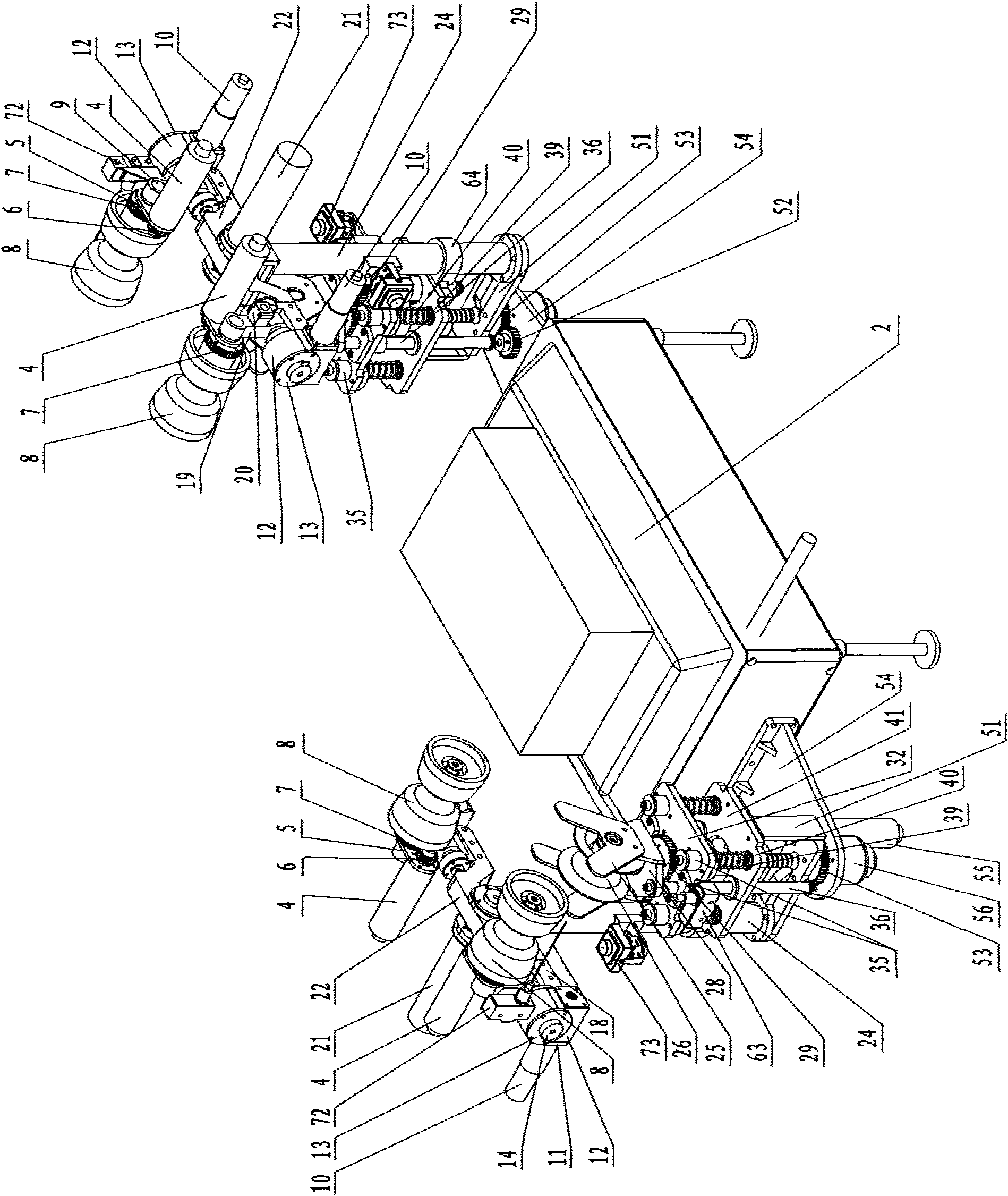

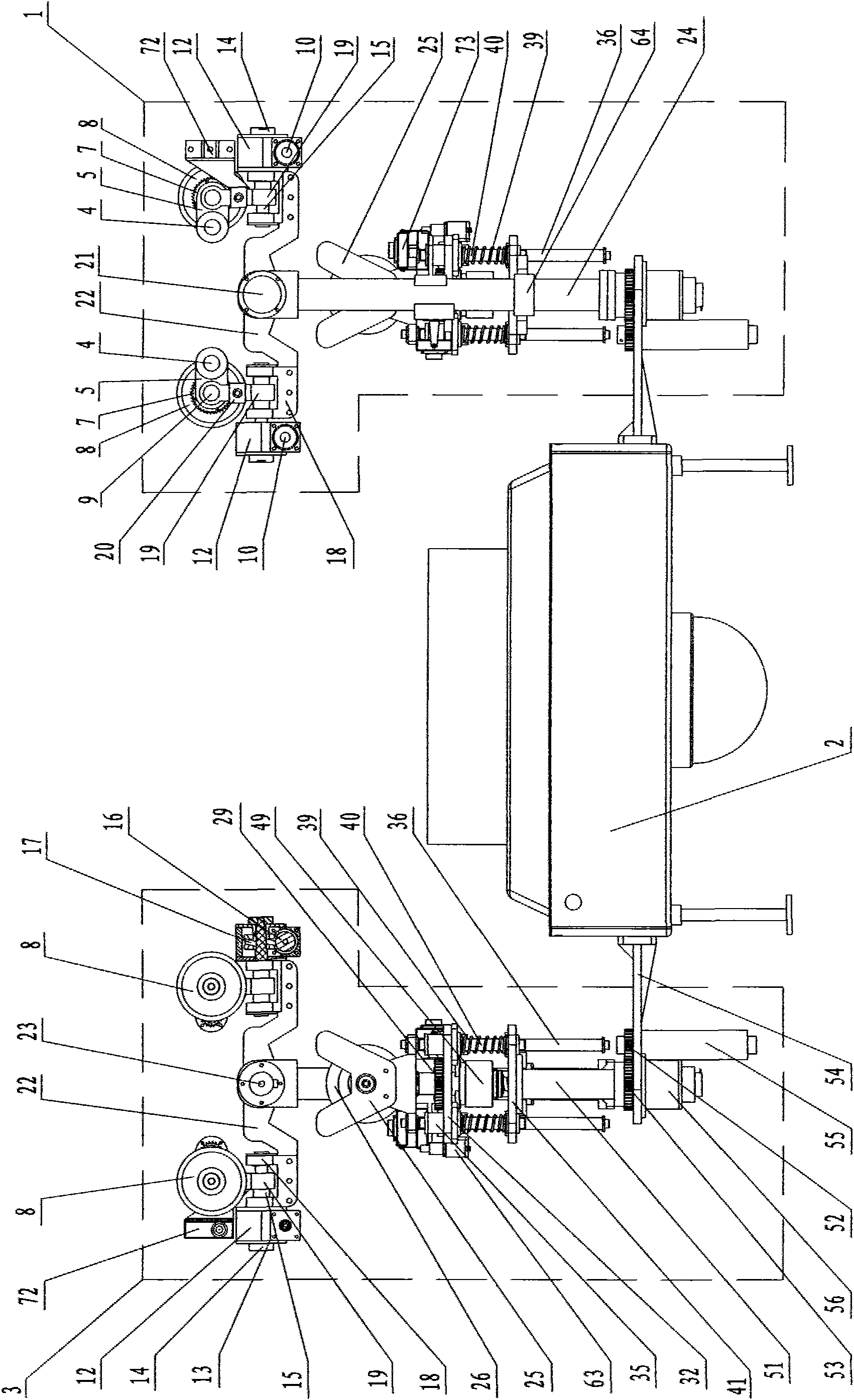

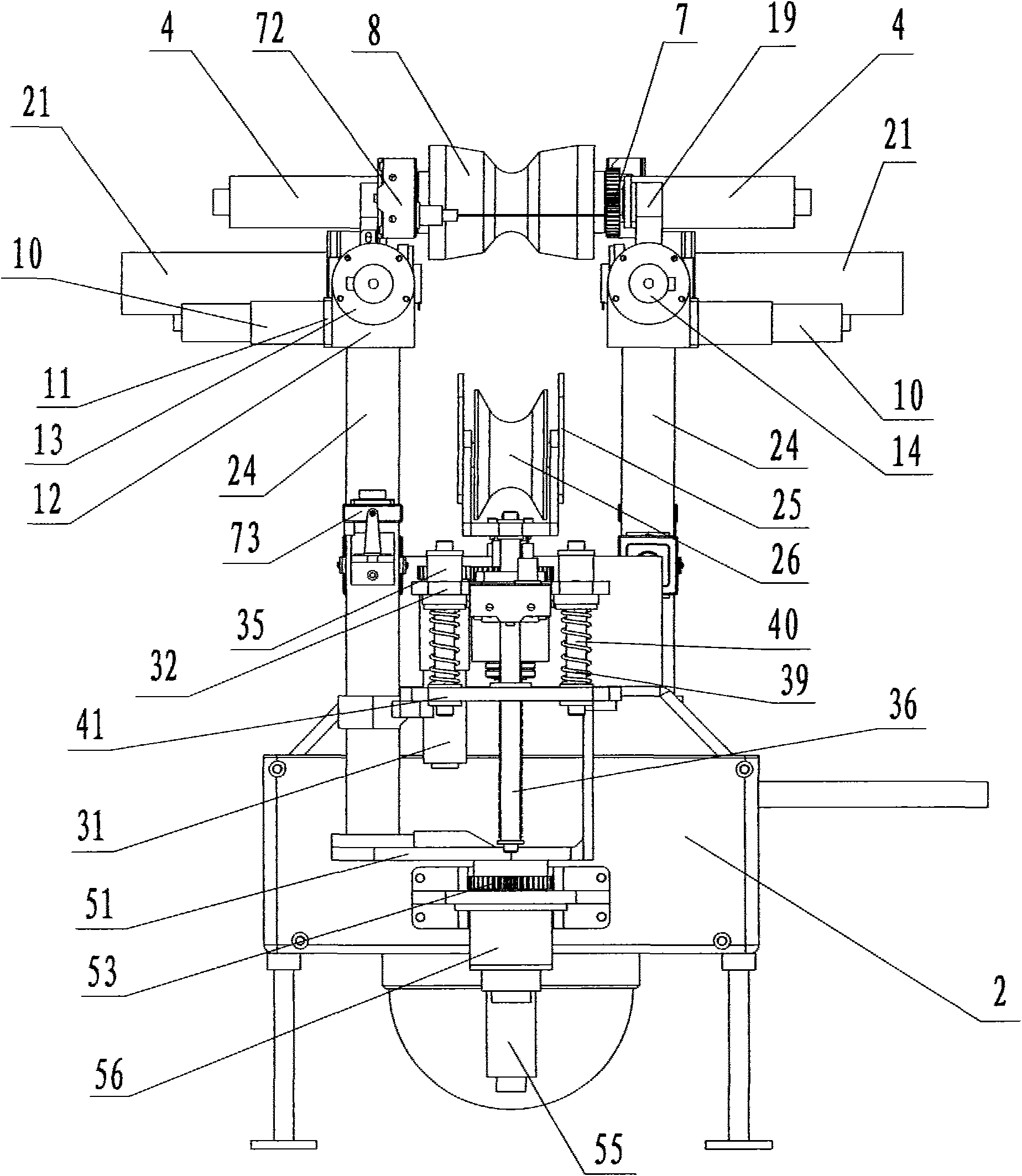

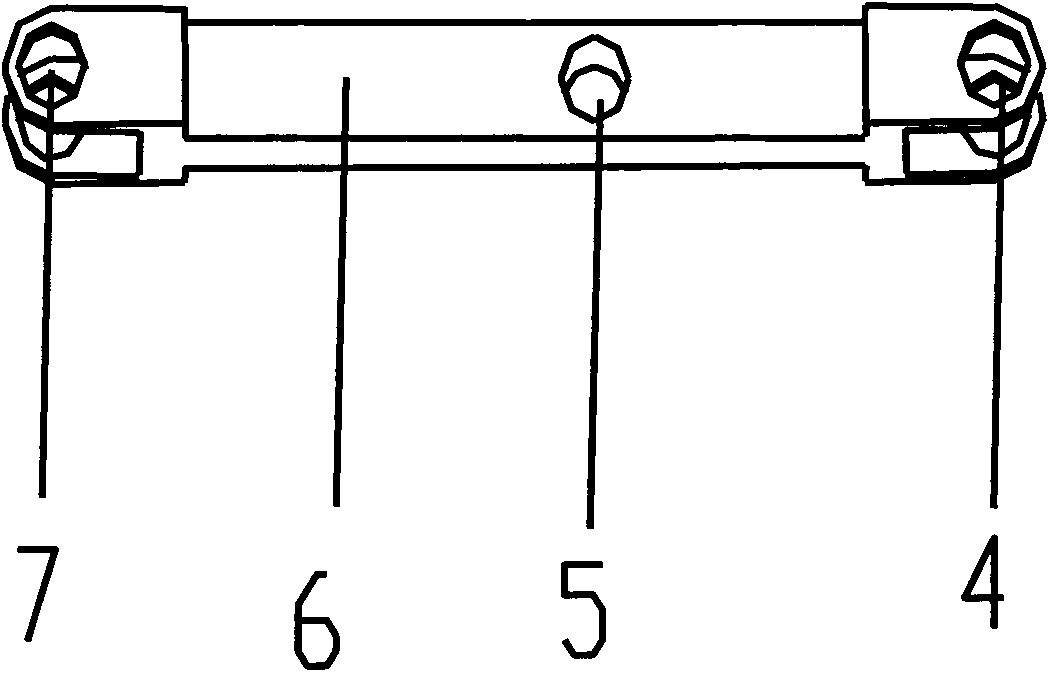

Spraying robot used for spraying large-dimension workpiece

PendingCN108406806ALarge working spaceSatisfy the spraying jobSpraying apparatusManipulatorEngineeringDrive motor

The invention provides a spraying robot used for spraying a large-dimension workpiece. The spraying robot comprises a position regulating device and a mechanical arm, wherein the mechanical arm is mounted on the position regulating device; the position of the mechanical arm is regulated by regulating the position regulating device; the position regulating device comprises an X-axis mobile platform; the X-axis mobile platform comprises a mobile guide rail and an X-axis slide block; a first drive motor is arranged above the X-axis slide block; the first drive motor is connected with a gear through a rotary shaft; the gear connected with the first drive motor corresponds to a rack; width of a rectangular groove is greater than that of a U-shaped rail; and the mechanical arm is arranged abovethe X-axis slide block. The spraying robot used for spraying the large-dimension workpiece provided by the invention is equipped with a three-dimensional mobile platform, so that space range is great,the whole object surface can be sufficiently and completely covered, and the whole-machine spraying operation is completed; and the position can be quickly regulated according to the dimension of theworkpiece, so that spraying operation of the large workpiece can be met.

Owner:清研同创机器人(天津)有限公司

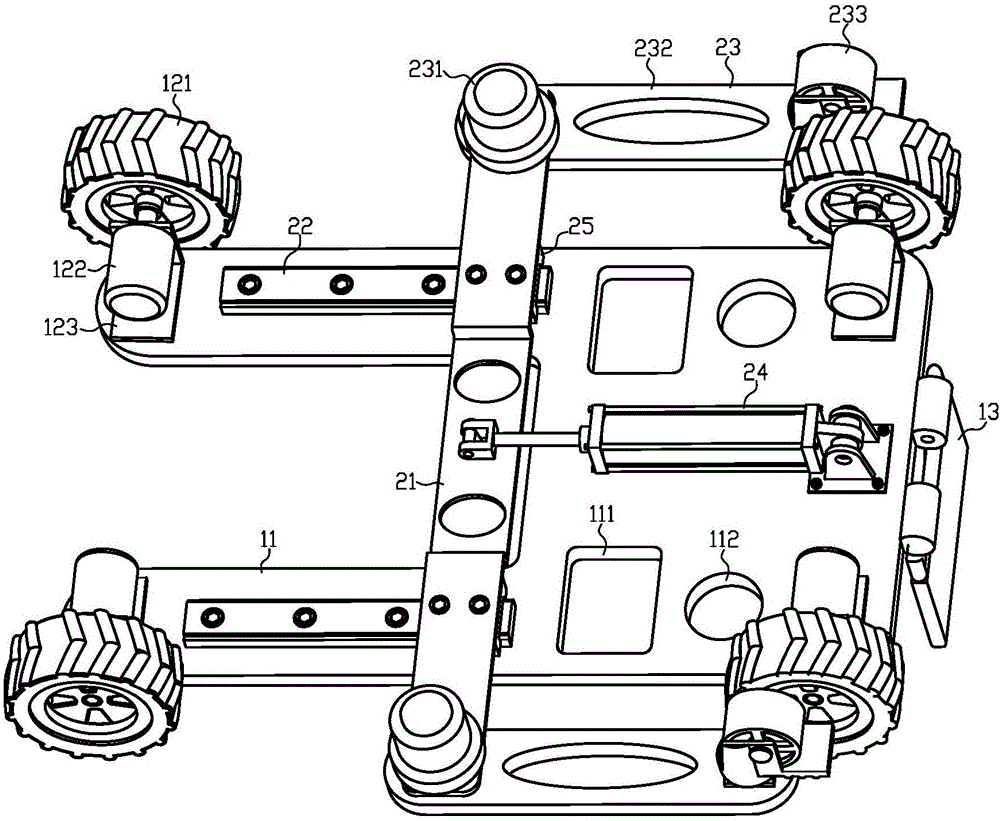

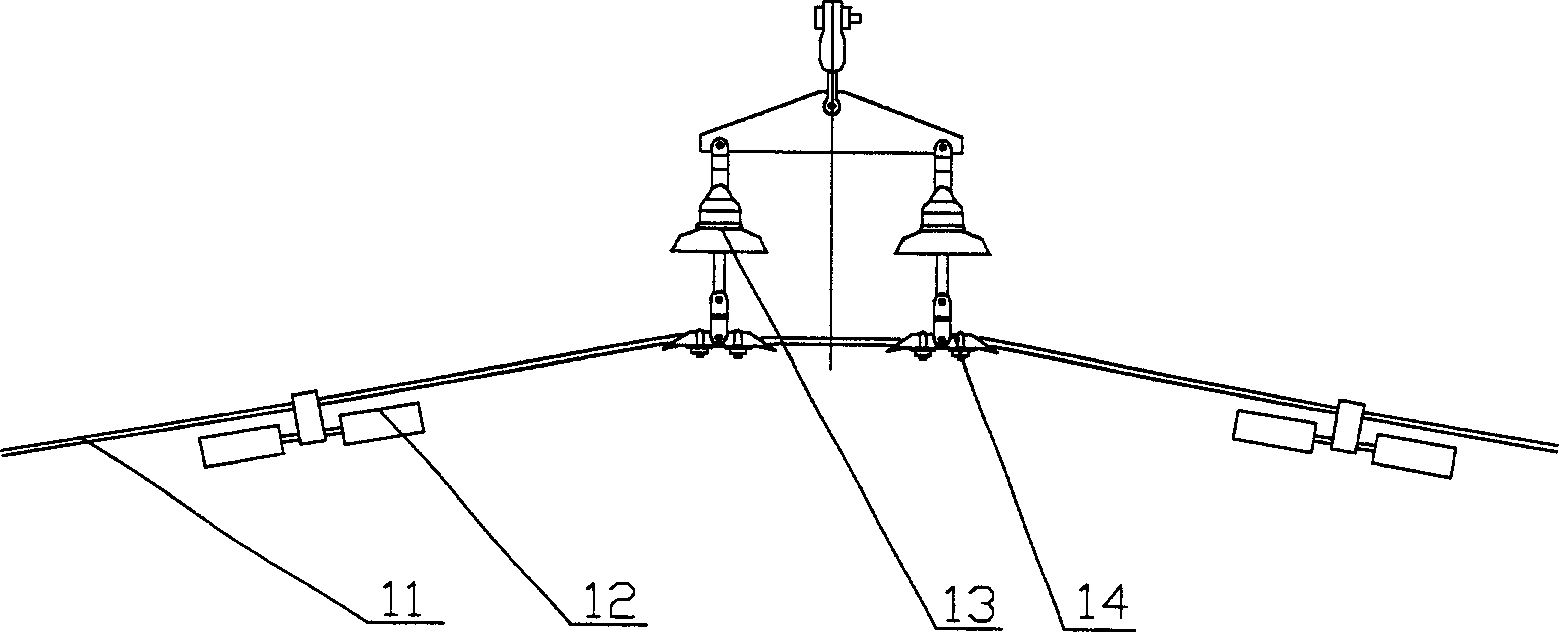

Double-arm four-wheel polling robot mechanism

The invention relates to a mobile robot, in particular to a double-arm four-wheel polling robot mechanism comprising a box body, a front arm mechanism and a rear arm mechanism, wherein the front arm mechanism and the rear arm mechanism are of the same structure and are respectively installed on the box body; each arm mechanism comprises travelling mechanisms, turnover mechanisms, an elevating gear, a clamping mechanism and a supporting arm, wherein one end of the supporting arm is connected with the box body, and the other end of the supporting arm is hinged with the elevating gear the two ends of which are respectively provided with the front turnover mechanism and the rear turnover mechanism; the front travelling mechanism and the rear travelling mechanism which can be turned over to the vertical state from the horizontal state are respectively connected to the output end of the front turnover mechanism and the output end of the rear turnover mechanism; the front travelling mechanism, the rear travelling mechanism, the front turnover mechanism and the rear turnover mechanism are linked with the elevating gear; and the clamping mechanism which is installed on the supporting arm and can clamp earth wires by moving up and down is arranged just below the front travelling mechanism and the rear travelling mechanism. The robot mechanism provided by the invention has the advantages of good safety protection performance, strong crawling and obstacle-detouring capability, large working space, wide application range and the like.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI +1

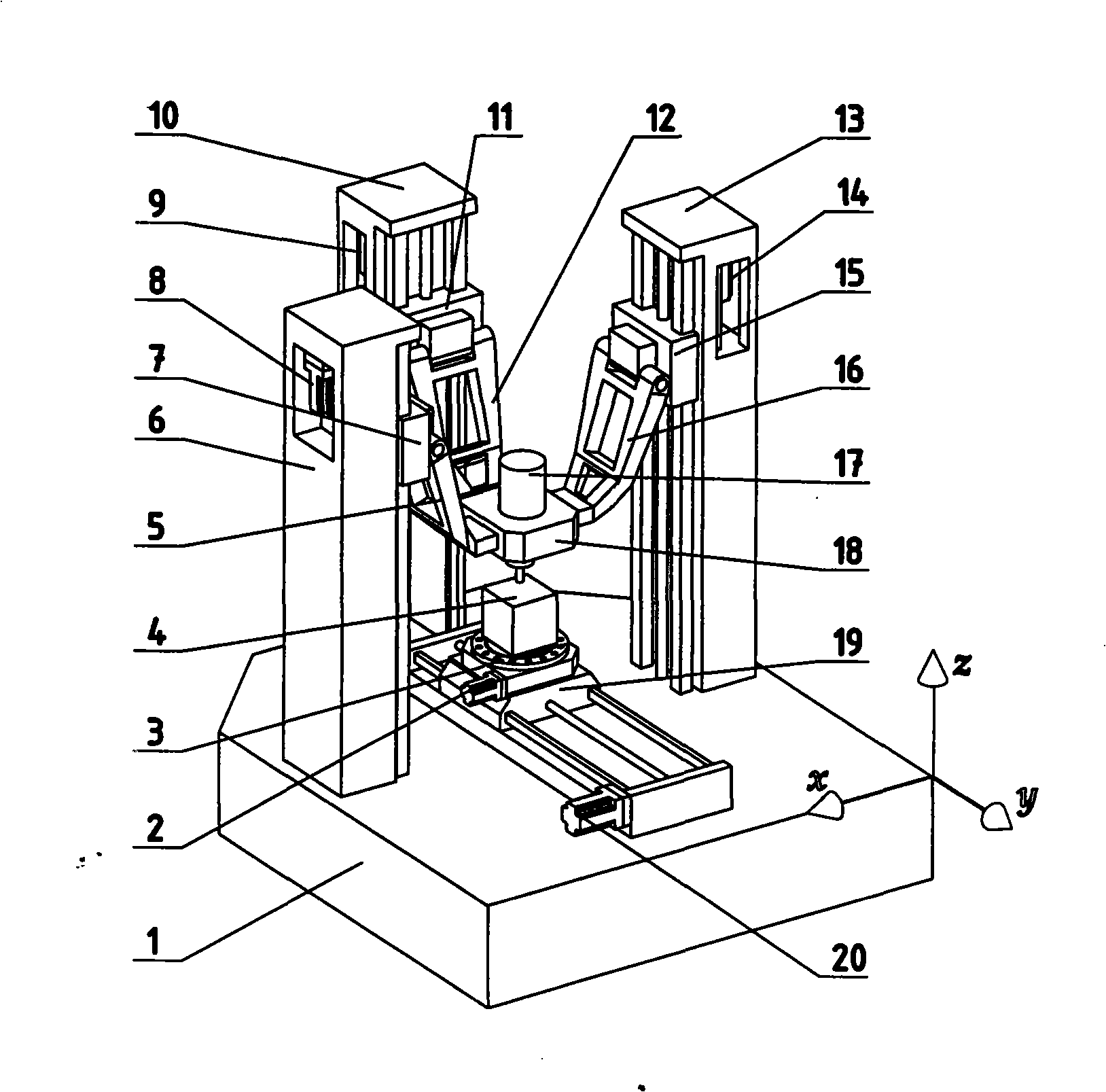

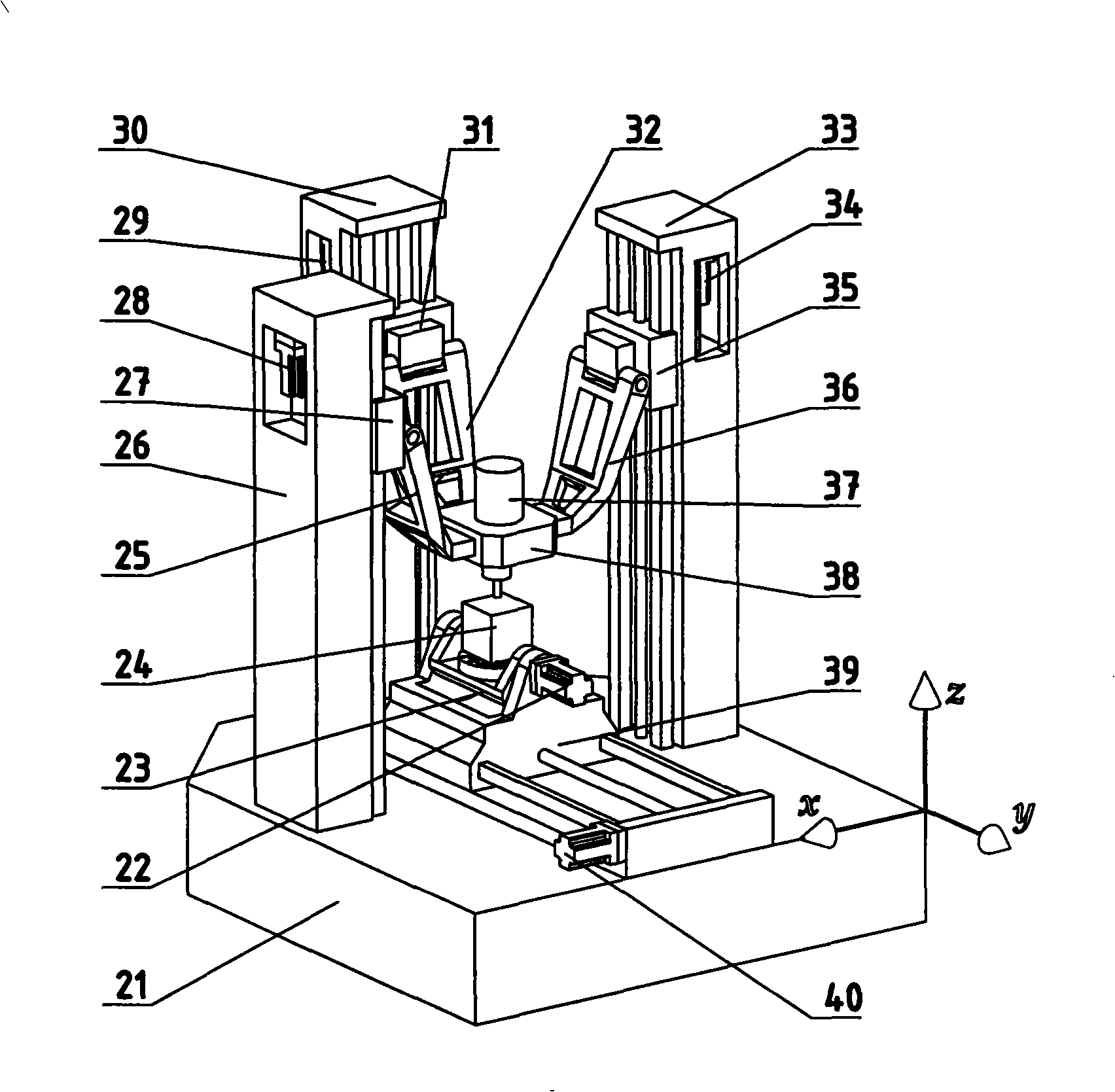

Multi-shaft linkage series-parallel machine tool

InactiveCN101269463ASimple structureIncrease stiffnessLarge fixed membersMetal working apparatusNumerical controlMachine tool

The invention relates to a multiple spindle linkage series and parallel machine tool, which belongs to the production field of a numerical control machine. The machine tool mainly comprises a bed piece, a moveable platform for arranging a basic shaft, an operation platform for arranging a cut workpiece and three upright posts arranged on the bed piece; the three upright posts are distributed in a triangle shape; the guide rail of each upright post is provided with a saddle in a straight-line motion; the moveable platform is connected with the three saddles through three branched chains to form a space parallel closed chain apparatus; the space parallel closed chain apparatus is used for realizing two-dimensional motion and one-dimensional rotation motion freedom; the operation platform for arranging the cut workpiece is used for realizing one-dimensional motion and one-dimensional rotation motion freedom; the operation platform and the space parallel closed chain apparatus are used for realizing the gang control of five shafts. The multiple spindle linkage series and parallel machine tool has the advantages of simple structure, reasonable distribution, flexible and easy-control processing, large operation space, high processing precision, and realization of vertical and horizontal purposes; combined with the predominance of the serial-type and the parallel-type machine tools, the machine tool can be used for multiple spindle linkage numerical control processing of complex curved-type parts.

Owner:TSINGHUA UNIV

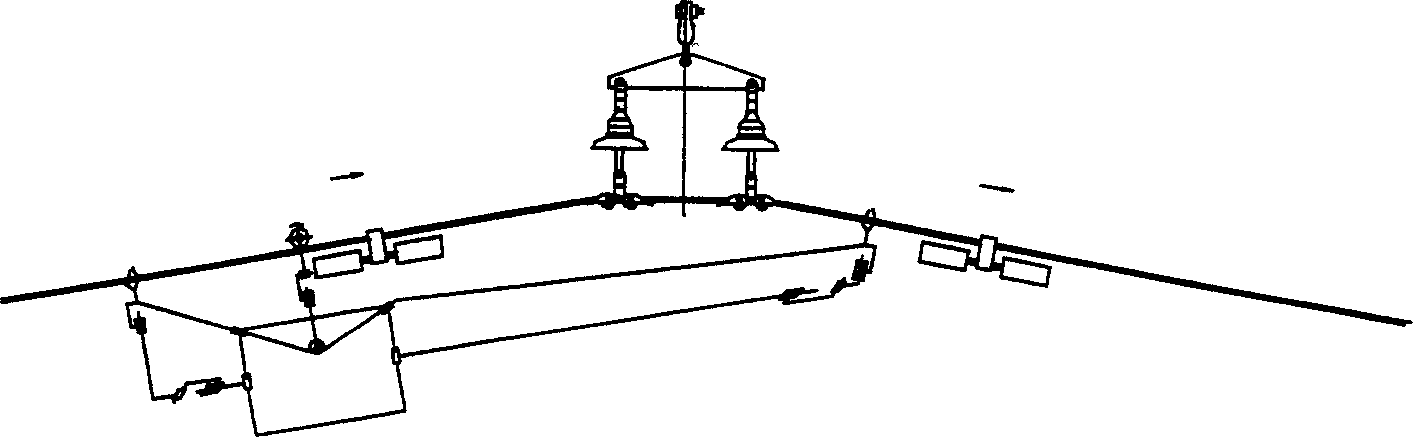

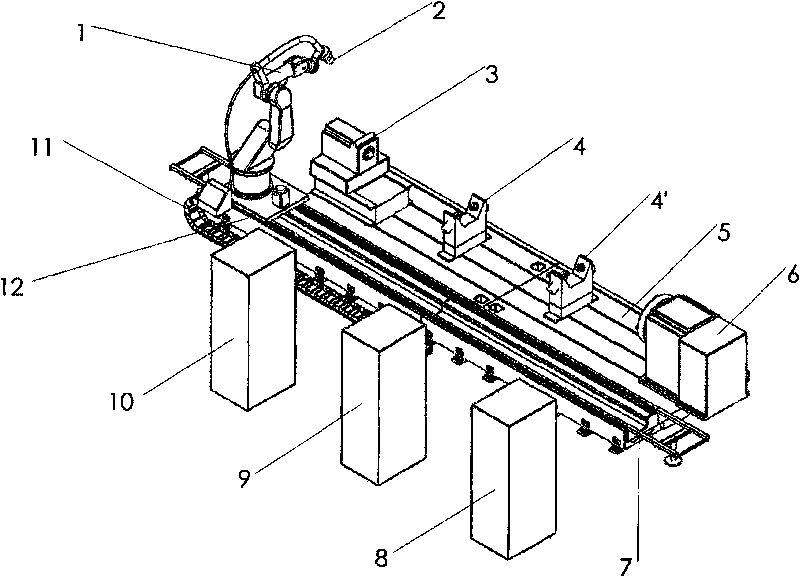

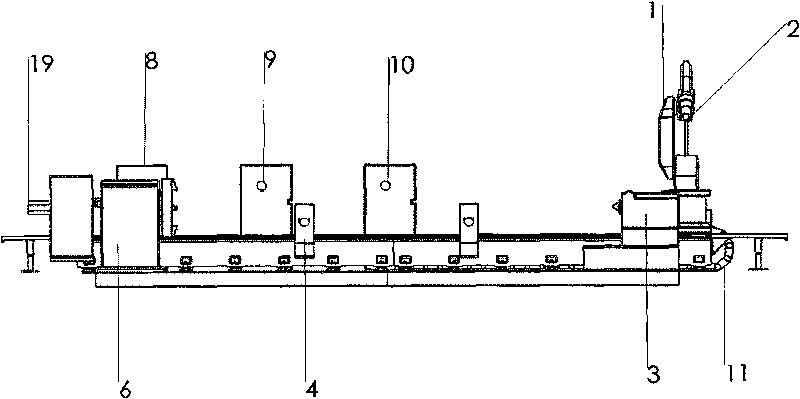

Multi-axis linkage numerical control laser processing system

InactiveCN101690993AOvercoming complexityDifficult to overcome controlLaser beam welding apparatusNumerical controlLaser processing

The invention provides a multi-axis linkage numerical control laser processing system, which is structurally characterized in that a workbench is provided with a linear guide rail, two ends of the guide rail are provided with a workbench tail seat and a headstock respectively, and two open center brackets are movably arranged on the guide rail and are positioned between the workbench tail seat and the headstock; a guide rail stand is arranged beside the workbench, the guide rail stand is provided with another parallel guide rail, and a movable sliding stand is movably arranged on the guide rail; a robot is fixed on the movable sliding stand, and a laser processing head is arranged at the tail end of a last joint of the robot; and a controller is connected with the robot and the movable sliding stand through control wires respectively so as to control the robot and control the movable sliding stand to drive the robot to move on the guide rail stand. The system solves the problem that a joint robot laser processing system has a small processing range, and can meet the numerical control laser processing requirements of parts of large size and super-large size.

Owner:HUAZHONG UNIV OF SCI & TECH

Controllable multi-degree of freedom welding robot

InactiveCN103707289AIncrease stiffnessIncrease workspaceProgramme-controlled manipulatorWelding/cutting auxillary devicesClosed loopEngineering

A controllable multi-degree of freedom welding robot comprises four controllable four-link-mechanism closed-loop executing mechanism subchains which are in parallel connection and an executing main chain in series connection. A main chain connecting rod can be controlled by the controllable four-link-mechanism closed-loop executing mechanism subchain to move within the surface with the controllable four-link-mechanism closed-loop executing mechanism subchains. The spatial motion of a moving platform can be achieved by the motion of a first connecting rod and a body. According to this arrangement, the spatial motion of an end effector can be achieved, motion inertia is small, dynamics performance is good and reliability is high. The controllable multi-degree of freedom welding robot has the advantages of being compact in structure and easy to control. The rods can be made as light rods, work spaces for mechanisms are large, gravity centers of the mechanisms are moved backwards to keep balance. The controllable multi-degree of freedom welding robot can be widely used.

Owner:GUANGXI UNIV

Foundation pit support device and construction method

The invention relates to a foundation pit support device and a construction method. For different address conditions, two or more of an SMW (soil mixing wall) construction method pile system, an internal supporting system, a concrete revetment system and a soil nailing wall revetment system are comprehensively applied. A concrete circuit girt is arranged at the top end of an SMW construction method pile; and profiled bars are inserted into the pile, and have equal or unequal lengths. The internal support system is a slanting steel pipe support or a horizontal support. The soil nailing wall revetment system is formed in a way that: a concrete revetment is arranged on the inner side, from the pit top to the pit bottom, of a foundation pit, and is paved with a reinforced concrete surface layer; and soil nails are inserted into soil around the foundation pit vertical to the reinforced concrete surface layer. The foundation pit support device and the construction method have the advantages of effectively reducing foundation pit support cost and construction cost and accelerating the construction, and are particularly suitable for the support of the large-area foundation pits and construction plants of which infrared spaces between subsurface structures and the ground are small.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD +1

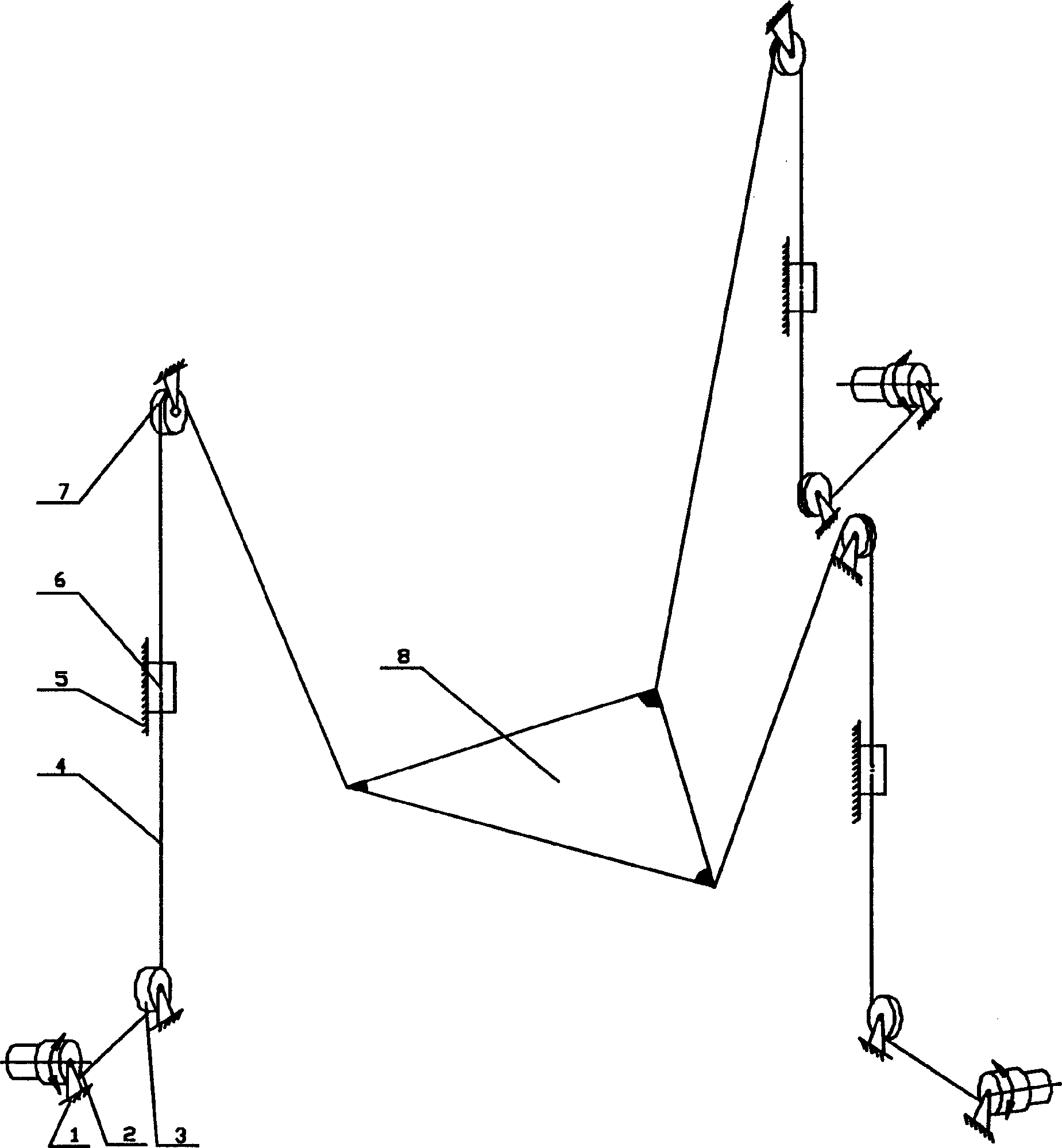

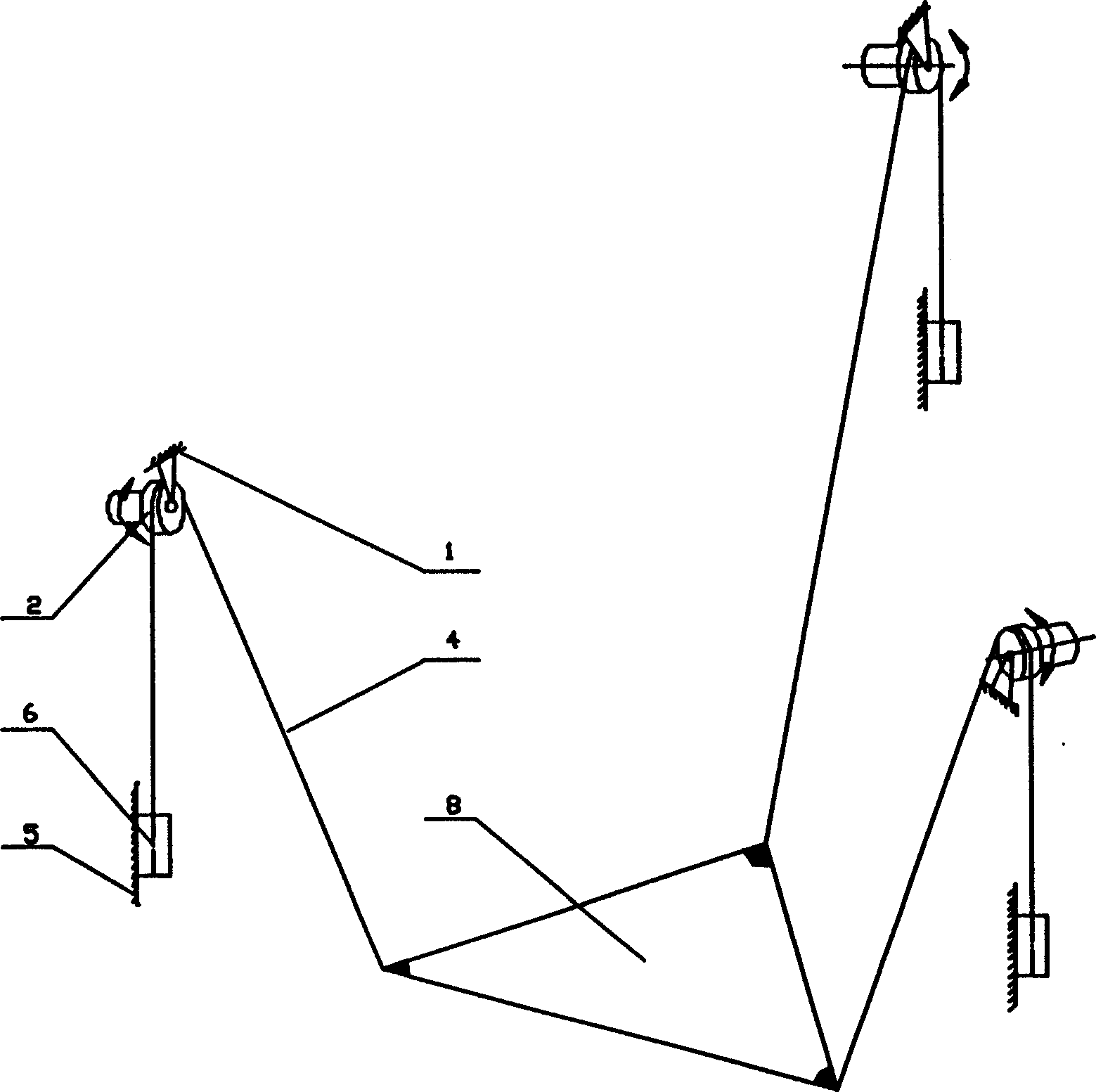

Three-freedom parallel mechanism driven by flexible rope

A flexible cable driven three-freedom parallel mechanism is composed of three drive units and moving platform. The said driven unit comprises base, reel installed along with motor and vertical column. The steel wire cable wound on the said reel passes through lower static pulley, counterweight and upper static pulley and then fixed to the moving platform. The steel wire cables for threed drive units are all fixed to the moving platform to form a triangle. Its advantages are big working space and high stressing performance and speed.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com