Super-voltage transmission line monitoring and detecting robot mechanism

A technology for patrolling robots and power lines, applied to manipulators, manufacturing tools, etc., can solve the problems of limited obstacle-surmounting ability, difficult control, complex structure, etc., and achieve strong obstacle-surmounting ability, reduce the weight of the mechanism, and have a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

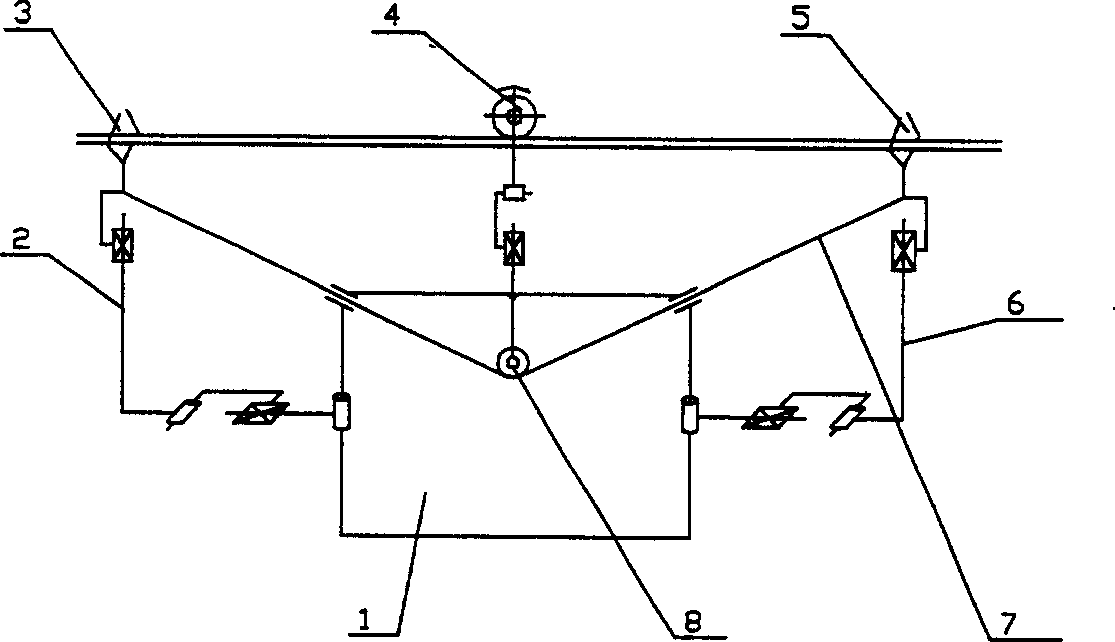

[0024] Such as figure 1 As shown, the mechanical structure of the present invention is made up of body 1, rear arm 2, road wheel 4, front arm 6, soft cable 7 and reel 8, wherein: the mobile car body is made up of body 1 and road wheel 4, and road wheel 4 It is installed on the main body 1 through the horizontal rotating pair and the moving pair, and is grasped with the wire; the main body 1 is connected with the front and rear arms 6 and 2 respectively through the rotating pair, and the end of the arm is a claw; the structure of the front arm 6 and the rear arm 2 The same, each arm is composed of upper arm and lower arm. The upper arm is a combination structure of connecting rod, ball screw and slider. It is connected with the lower arm through a horizontal rotation joint. Any one of them; the front and rear claws 5, 3 can be conventional clamping claw structures, which are respectively grasped with the wire, and the two are connected by the flexible cable 7 wound on the reel ...

Embodiment 2

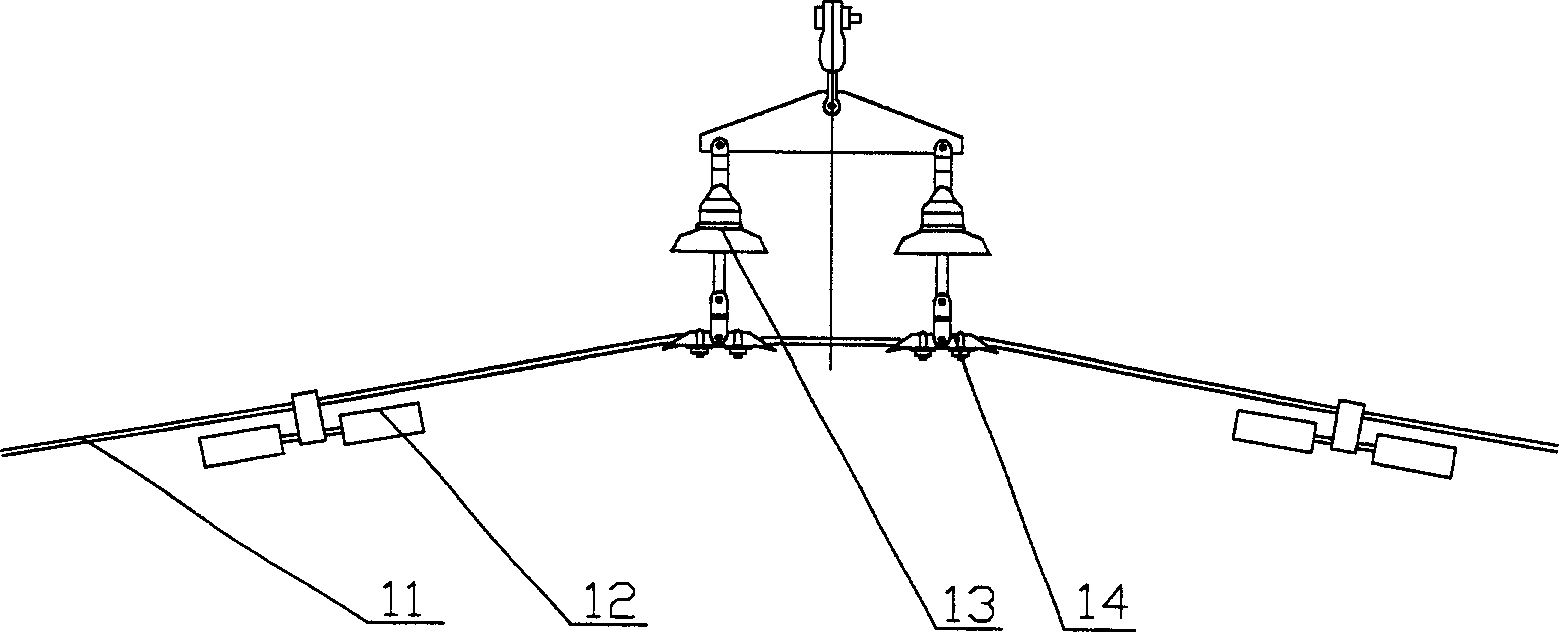

[0028] Such as Figure 4 As shown, the difference between the mechanism of the present invention and that of Embodiment 1 is that the flexible cable and the reel are removed, and the claws of the two arms become a composite mechanism combining clamping and walking. This mechanism is composed of a driving wheel and a clamping device, namely : the front pawl 5 and the rear pawl 3 are the structures in which a driving wheel is located at the top of the line and a clamping device is located at the bottom of the line, which can walk along the line and grasp the line. The process of walking along the line is the same as in Embodiment 1. During the obstacle-crossing process, the front and rear arms 6 and 2 are stretched out, and the whole machine travels along the line. When the front claw 5 encounters an obstacle, it goes off-line, and the rear claw 3 and the walking wheel 4 drive the mobile car body forward to overcome the obstacle. Afterwards, the drive wheel of front claw 5 hang...

Embodiment 3

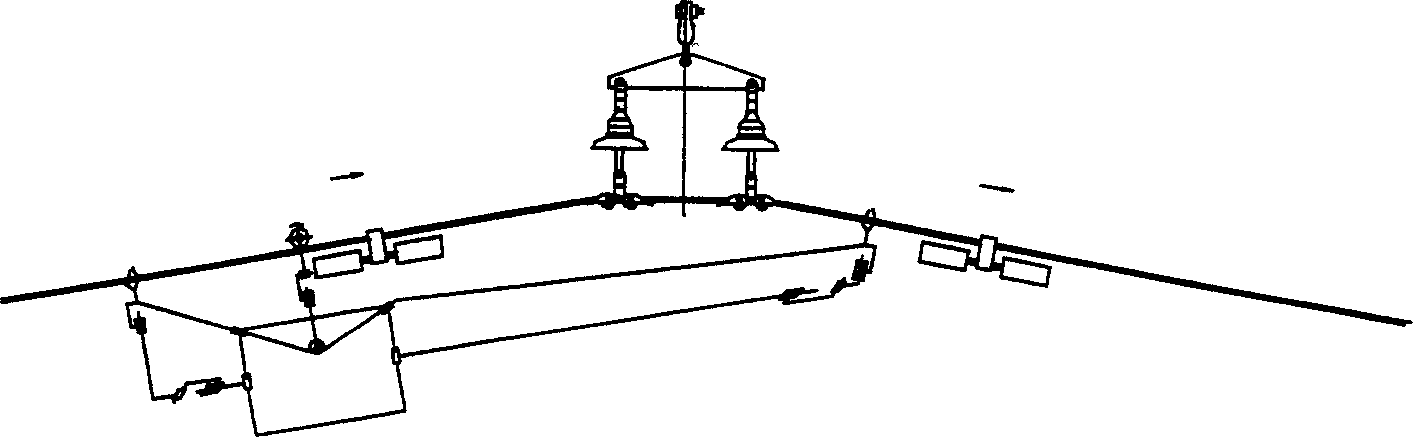

[0030] The difference with embodiment 2 is: as Figure 5 Shown, front pawl 5, rear paw 3 are the composite clamping mechanism of traveling wheel combination, promptly a big wheel (be positioned at line top), two small wheels (be positioned at line lower limit) combined structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com