Combined type running deicing mechanism of online deicing robot of high-voltage transmission line

A high-voltage transmission line and robot technology, applied in the installation of cables, motor vehicles, electrical components, etc., can solve the problems of no obstacle crossing ability, limited deicing efficiency, and no protection of cables, etc., to improve deicing efficiency and The effect of de-icing degree, compact structure, and strong obstacle crossing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

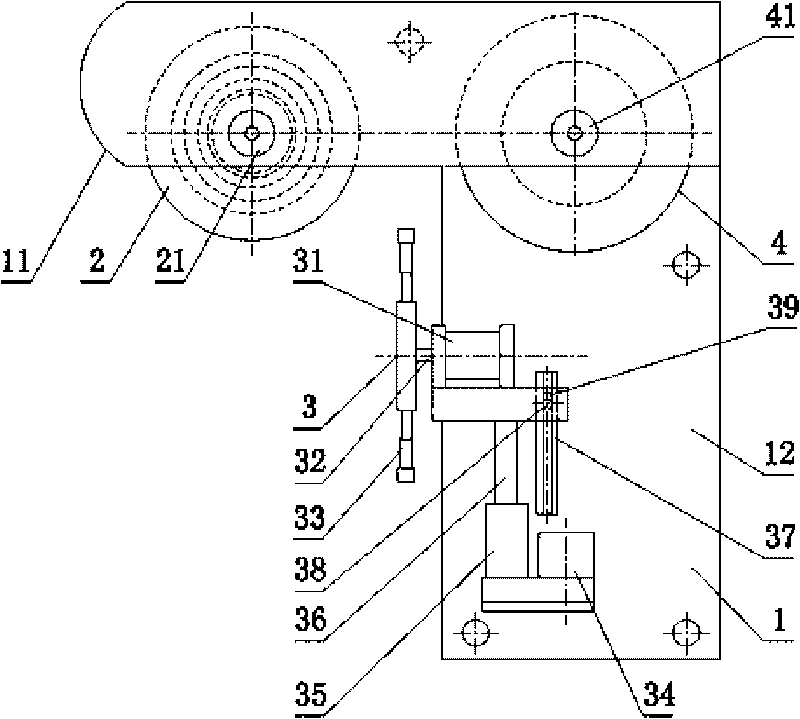

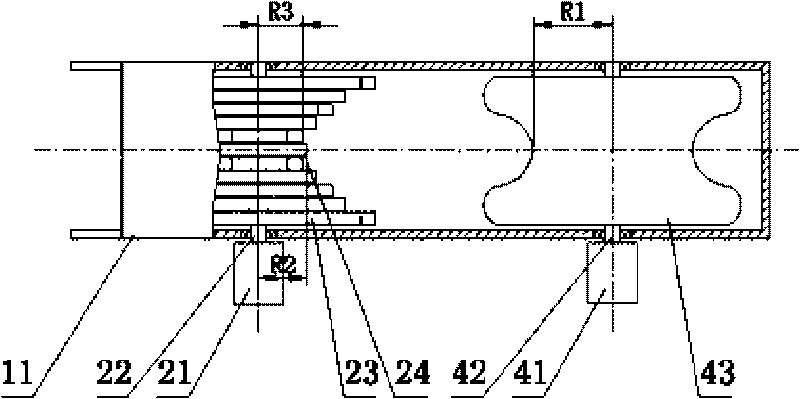

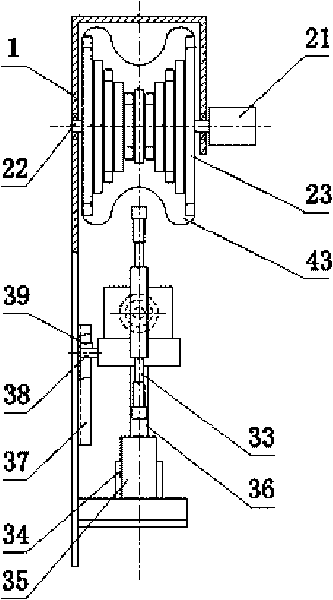

[0030] like Figure 1 to Figure 4 As shown, the combined walking deicing mechanism of the high-voltage transmission line online deicing robot of the present invention includes a bracket 1, a milling wheel mechanism 2, a knocking mechanism 3 and a walking rolling wheel mechanism 4, and the bracket 1 includes a U-shaped support frame 11 And support plate 12, U-shaped support frame 11 is fixed on the top of support plate 12, and U-shaped support frame 11 and support plate 12 are provided with a plurality of connection holes, for fixing the present invention on the high-voltage transmission line line by installing fasteners On the mechanical arm of the deicing robot, the milling wheel mechanism 2 and the walking rolling wheel mechanism 4 are installed on the U-shaped support frame 11. The U-shaped support frame 11 exceeds the milling wheel mechanism 2 in the direction of travel and encounters obstacles in front of the line. When the U-shaped support frame 11 first contacts the obs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com