Train deicer

A technology for trains and nozzles, which is applied in the direction of railway auxiliary equipment, etc. It can solve the problems of low efficiency, damage to the connection parts of the bogie and the car end, and long time, and achieve the effects of convenient use, thorough deicing, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

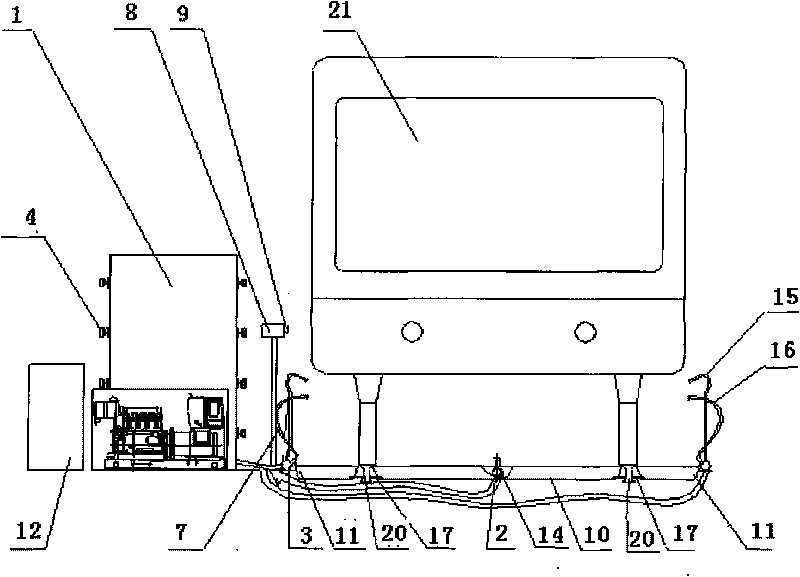

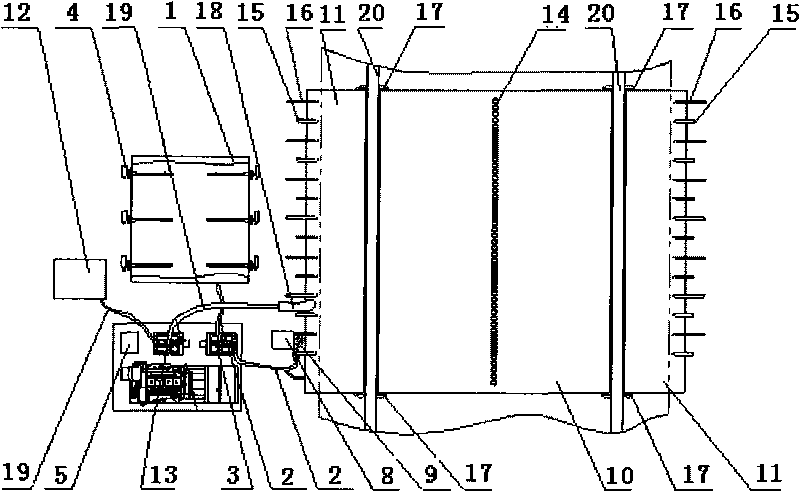

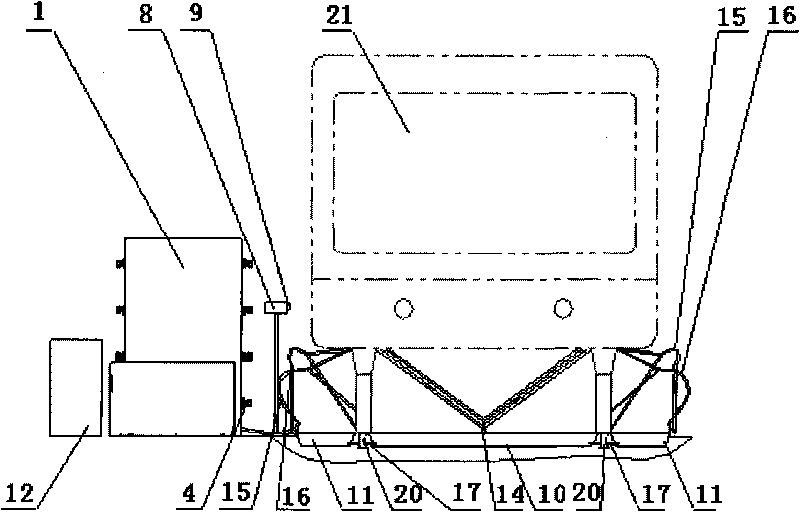

[0013] Below in conjunction with accompanying drawing, the present invention is further described:

[0014] A train deicing device is provided with a liquid storage tank 1, a catheter 2 and a spray head, the liquid storage tank 1 is provided with a pressure pump 3, and the liquid storage tank 1 is provided with an electric heater 4, which is characterized in that it is equipped with an electric Control system 5, spray rack 6, pole 7, position sensing electric control box 8, position sensor 9, inner waste liquid collection tank 10, outer waste liquid collection tank 11, waste liquid recovery tank 12 and waste liquid recovery liquid pump 13 , an inner waste liquid collection tank 10 is provided between the two rails 20, and an outer waste liquid collection tank 13 is respectively provided on both sides. The outer side of the collection tank 13 is provided with spray racks 6, and the spray racks 6 are arranged in sequence along the rail direction. The two rows of spray racks 6 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com