Induction heating and deicing device used for wind generating set blade

A technology for wind turbines and induction heating, applied in wind turbines, wind power generation, engines, etc., can solve problems such as low efficiency, lightning strikes, easy to change blade material properties, etc., achieve low energy consumption, avoid lightning strike safety hazards, and deicing high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

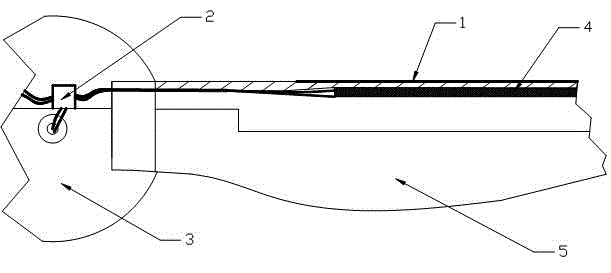

[0014] An induction heating and deicing device for blades of a wind power generating set according to the present invention consists of an electric energy conversion input module (2), an electromagnetic coil (4) installed inside the cavity of the blade (5), and an electromagnetic coil (4) coated on the blade (5). The surface consists of a conductive coating (1). When the alternating current converted by the power conversion input module (2) passes through the electromagnetic coil (4), a certain range of alternating magnetic field will be generated, causing the conductive coating (1) within the range of the alternating magnetic field to generate heat, and the surface of the blade (5) will be removed Ice and prevent refreezing.

[0015] The electric energy conversion input module (2) is placed in the hub (3), which is convenient for maintenance and repair.

[0016] By ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com