Patents

Literature

32results about How to "Fast movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

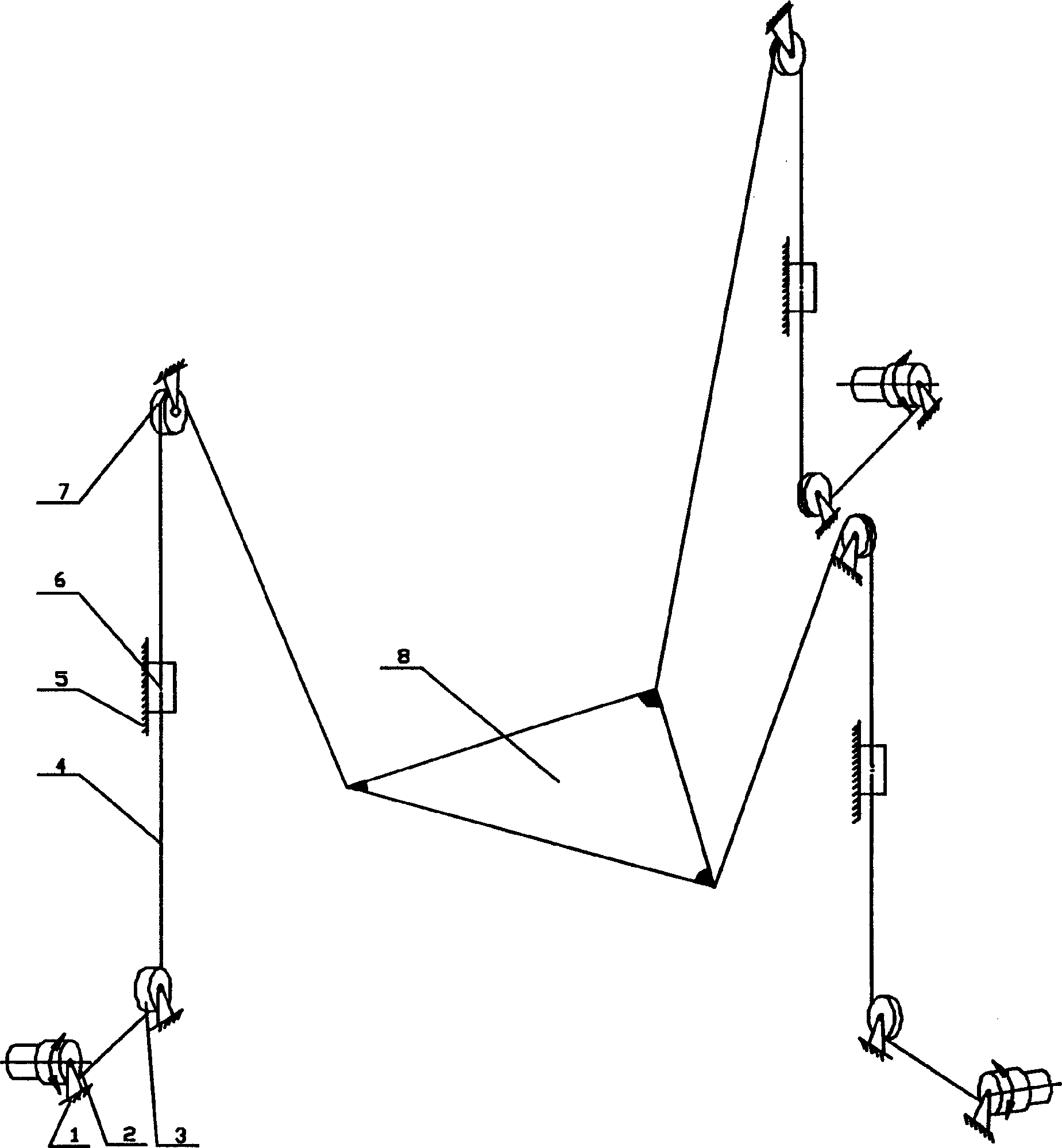

Three-freedom parallel mechanism driven by flexible rope

A flexible cable driven three-freedom parallel mechanism is composed of three drive units and moving platform. The said driven unit comprises base, reel installed along with motor and vertical column. The steel wire cable wound on the said reel passes through lower static pulley, counterweight and upper static pulley and then fixed to the moving platform. The steel wire cables for threed drive units are all fixed to the moving platform to form a triangle. Its advantages are big working space and high stressing performance and speed.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

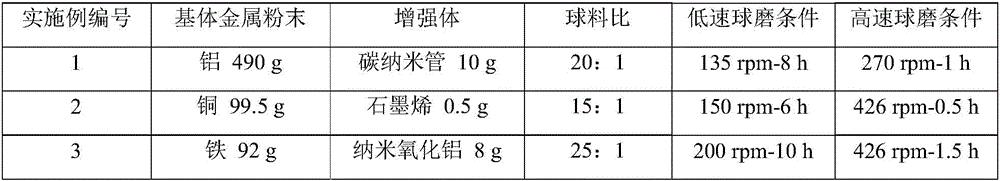

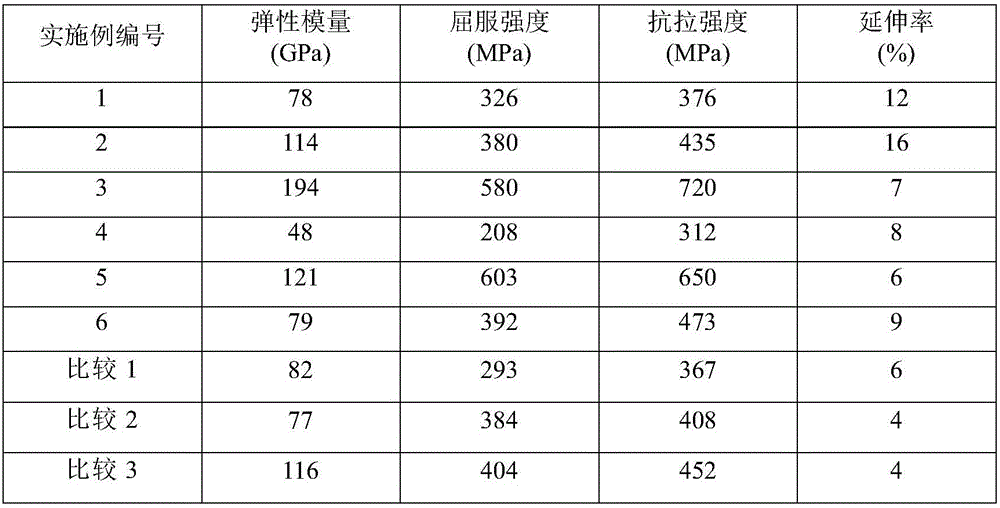

Powder metallurgy preparation method of nanophase/metal composite powder and block material thereof

The invention discloses a powder metallurgy preparation method of nanophase / metal composite powder and a block material thereof. The method comprises the steps of carrying out low-speed ball milling on nanophase powder and metal powder for a long time, and uniformly dispersing nanophases on the surface or inside the flake metal powder, so as to obtain nanophase / metal flake composite powder; and carrying out high-speed ball milling for a short time to weld the nanophase / metal flake composite powder to obtain nanophase / metal granular composite powder. According to the preparation method, the problems of uniform dispersion and interface bonding of the nanophases in a metal matrix can be solved through only adjusting the speed of ball milling; compared with traditional constant-speed ball milling, the ball milling method has the advantages that dispersion of the nanophases is more uniform, the interface bonding strength is higher, and the prepared material is more excellent in performance; and the preparation method is simple and efficient in technology and applicable to batch preparation.

Owner:SHANGHAI JIAO TONG UNIV

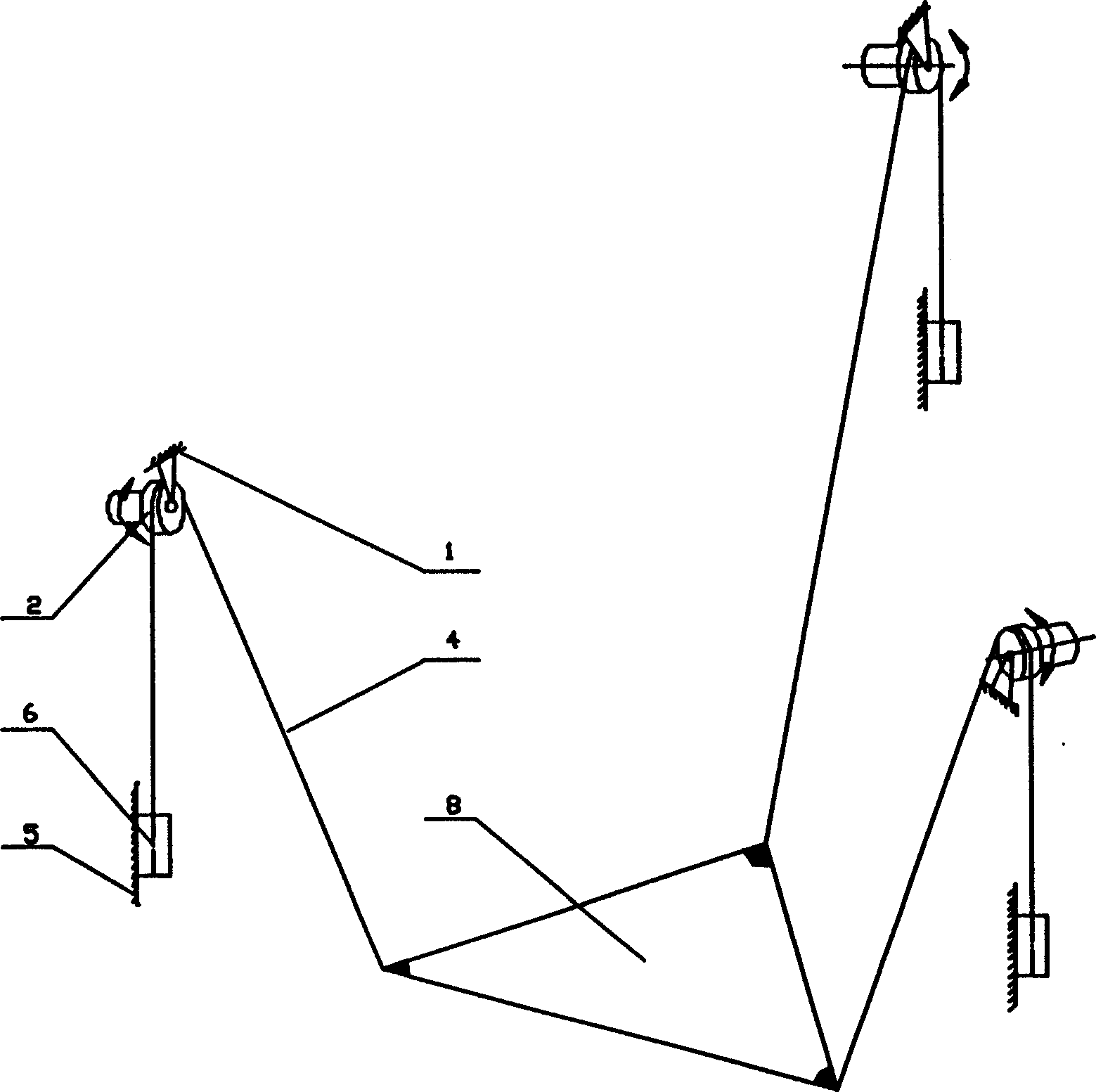

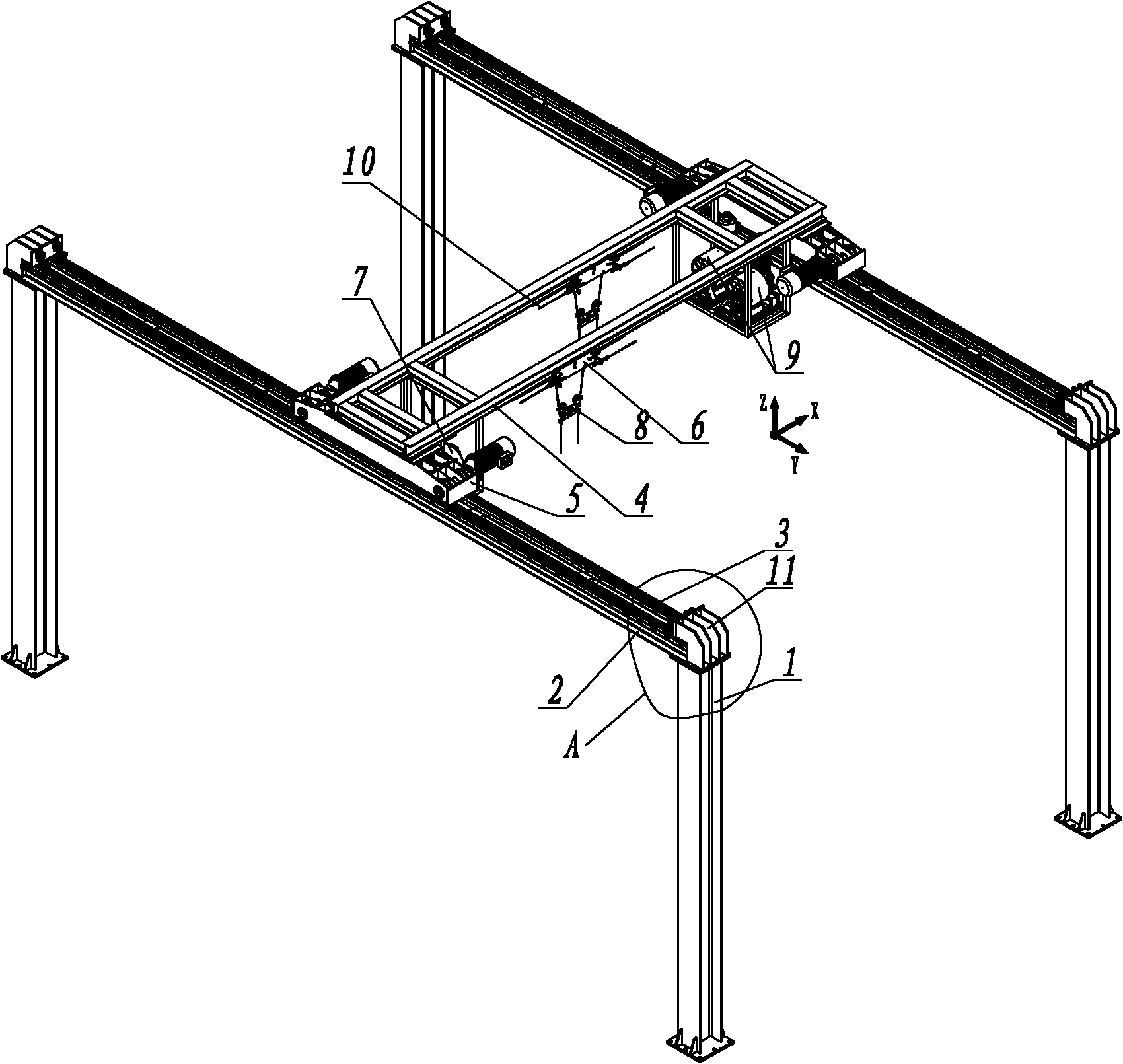

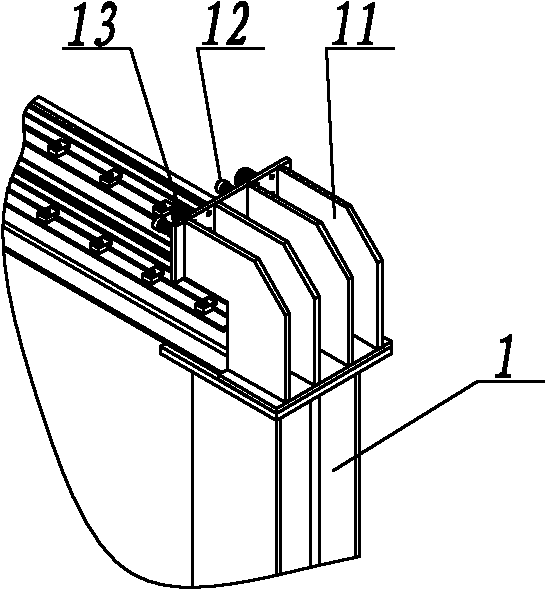

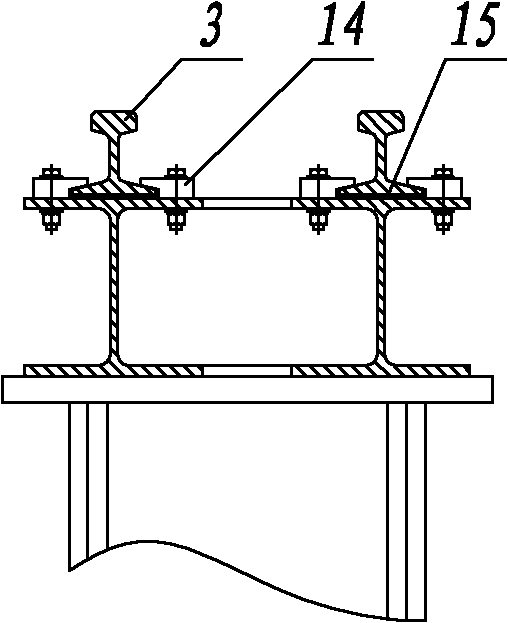

Three-degree-of-freedom program control wire machinery

The invention relates to three-degree-of-freedom program control wire machinery, which comprises a basic upright post, a Y direction basic beam, a Y direction guide rail, an X direction beam, a Y direction moving vehicle, an X direction moving vehicle, an X direction tractor, a Z direction vertical elevating pulley hanger and a Z direction vertical elevating tractor, wherein the Y direction basic beam is arranged on the basic upright post; the Y direction guide rail is arranged on the Y direction basic beam; the Y direction moving vehicle is arranged on a Y direction track; the X direction beam is erected on the Y direction moving vehicle; the X direction moving vehicle is arranged on the X direction beam; the X direction tractor drives the X direction moving vehicle through an X direction hauling rope; the Z direction vertical elevating pulley hanger is arranged on the X direction moving vehicle; and the Z direction vertical elevating tractor is arranged on the X direction beam. The three-degree-of-freedom program control wire machinery can move in the X, Y and Z directions, has the advantages of high moving speed, quick response, thrill of danger and the like and enriches performance and film trick shooting elements.

Owner:FANTAWILD DIGITAL FILM

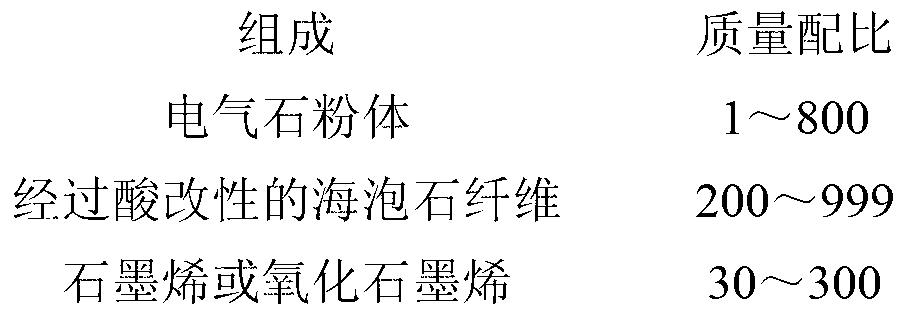

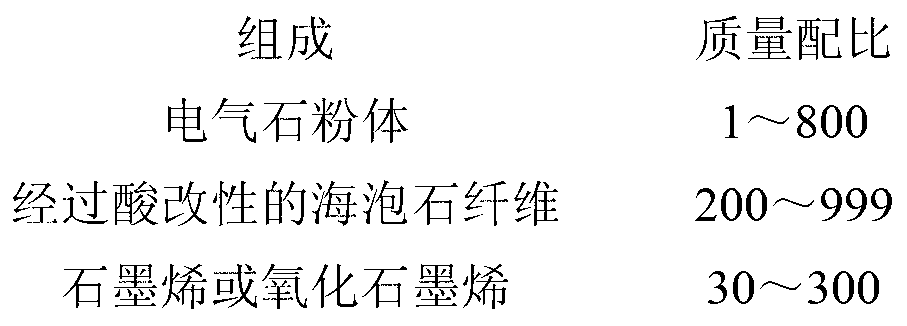

Novel composite water treatment material and preparation method thereof

ActiveCN103272560AFast movementFast adsorption rateOther chemical processesWater/sewage treatment by sorptionOxideWater treatment

The invention relates to a novel composite water treatment material and a preparation method thereof. The novel composite water treatment material contains tourmaline, sepiolite and graphene oxide or graphene. According to the preparation method, the graphene or the graphene oxide is wrapped on the surfaces of the sepiolite and the tourmaline by a reflux method, so the adsorptive property of the sepiolite on organic wastewater can be effectively improved by utilizing the large surface area of the graphene or the graphene oxide. The novel composite material has the characteristics of high adsorption efficiency, small using amount, energy conservation and the like, in particular, the sepiolite and the tourmaline are almost not consumed, so the treatment cost can be greatly reduced, and the dangerousness that dye molecules belonging to organic matters difficult to degrade are immersed into natural water and accumulated in the environment is avoided. Meanwhile, the graphene oxide and the graphene have good antibacterial property, so the phenomenon that activated sludge is increased too fast can be effectively improved, and considerable economic benefit, environmental benefit and social benefit are achieved.

Owner:HEBEI UNIV OF TECH

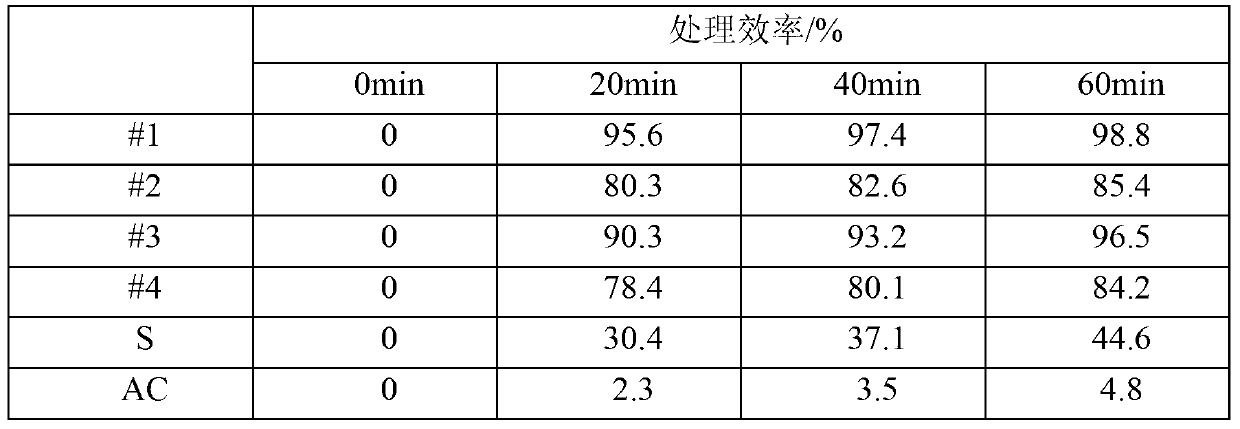

Compact and efficient cold cathode arc source of quasi diffusion arc

ActiveCN102936717AFast movementShort stayVacuum evaporation coatingSputtering coatingPhysicsSource structure

The invention relates to the technical field of preparation of films and coatings, particularly to a compact and efficient cold cathode arc source of a quasi diffusion arc. The cold cathode arc source is composed of an arc source head and a control magnetic field group, wherein the arc source head comprises a target, a target base, a target base shielding cover, a target base plate, an arc striking device and a permanent magnet device; the control magnetic field group comprises a flange sleeve, a flange sleeve insulating bush, a dipolar radial rotating magnetic filed generating device, an axial focusing guiding magnetic field generating device, a coaxial focusing magnetic field magnetic yoke and a flange sleeve shielding cover; and the arc source head is connected with the bottom of the flange sleeve through the target base plate to form a whole arc source structure, and connected with a finance through a flange arranged in front of the flange sleeve. Arc spots are distributed on the whole target surface under the comprehensive action of a certain magnetic field intensity and rotary frequency, the power density of the arc spots is reduced, the quasi diffusion arc state is achieved, launch of large grains is reduced, simultaneously, purified high-density plasmas are extracted through the axial focusing guiding magnetic field, and the transmission efficiency is improved.

Owner:WENZHOU POLYTECHNIC

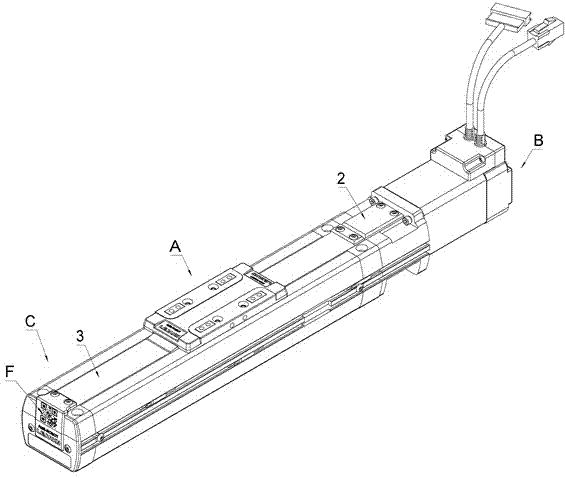

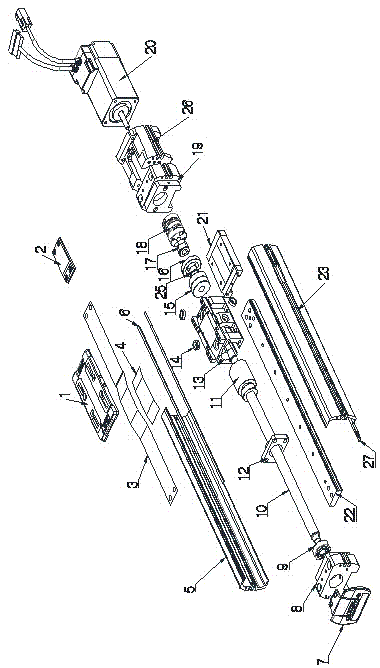

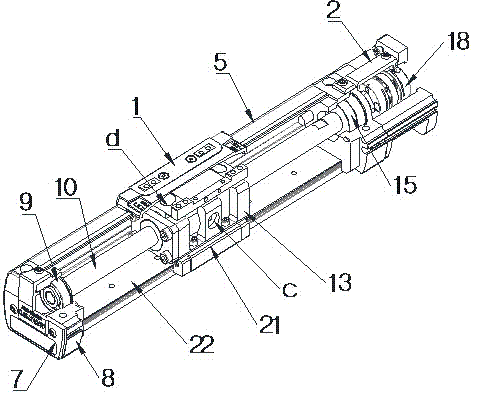

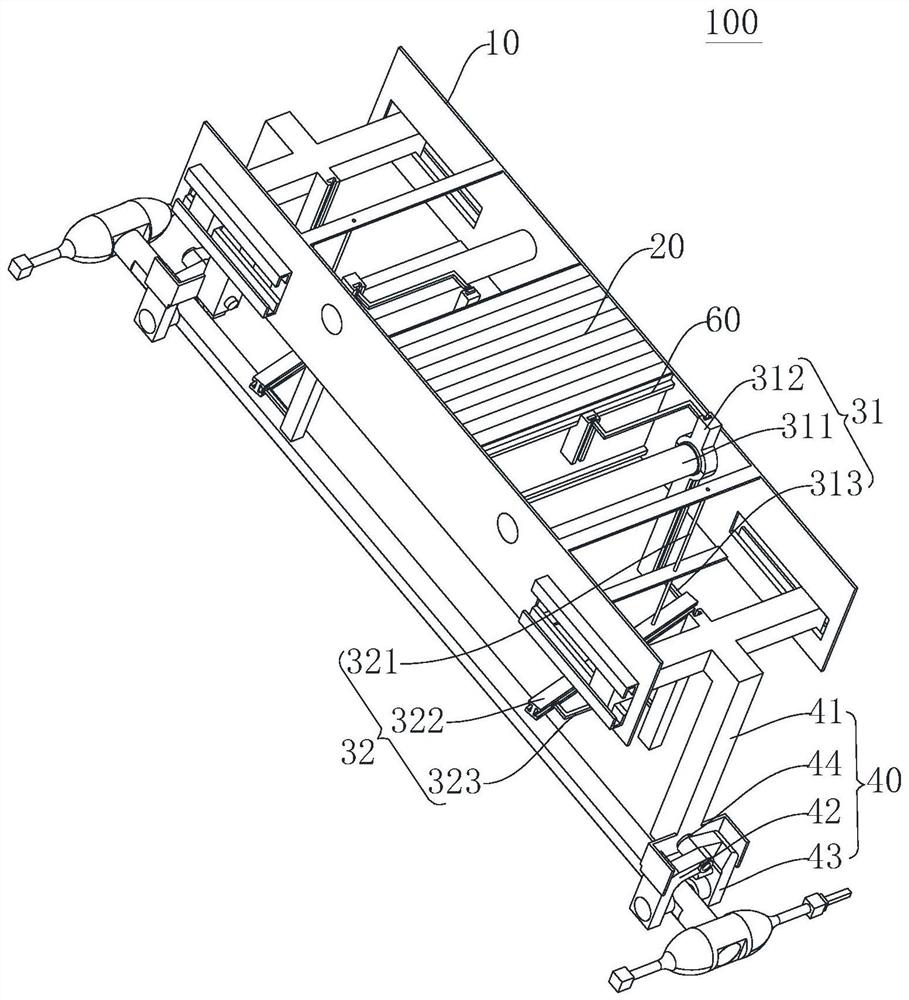

Linear motion device in combined mode

InactiveCN104753241APrecise positioningFast movementMechanical energy handlingEngineeringLinear motion

The invention relates to industrial automated devices, in particular to an automated motion mechanism, and discloses a linear motion device in a combined mode. The linear motion device comprises a left side plate, a right side plate, a linear guide rail, a motor, a coupler, a fixing end bearing seat, a supporting end bearing seat, a nut, a ball screw and a sliding platform, the left side plate and the right side plate are positioned on two sides of the linear guide rail respectively, the fixing end bearing seat and the supporting end bearing seat are arranged at two ends along the length direction of the side plates, one end of a screw is connected with the fixing end bearing seat while the other end of the same is connected with the supporting end bearing seat, the nut is screwed into the screw and fixed on the sliding platform, and the motor is connected to a supporting end of the screw through the coupler. The linear guide rail, the screw and the sliding platform are hermetically arranged inside, so that influence on accuracy in running due to the fact that dust and foreign bodies fall into the screw and the linear guide rail is prevented; a stainless steel dustproof belt sealing structure is adopted, so that no noise is generated during high-speed running, and service life is long.

Owner:WEIHAI AMS AUTOMATION EQUIP CO LTD

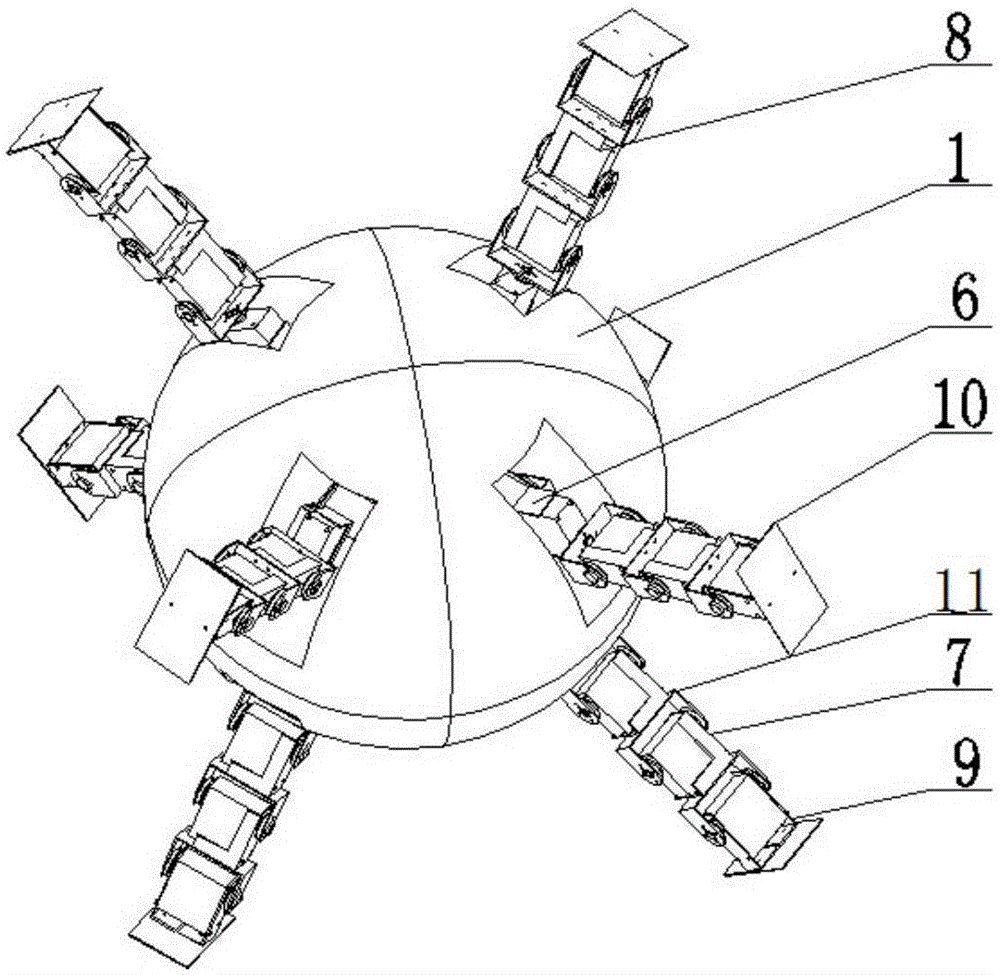

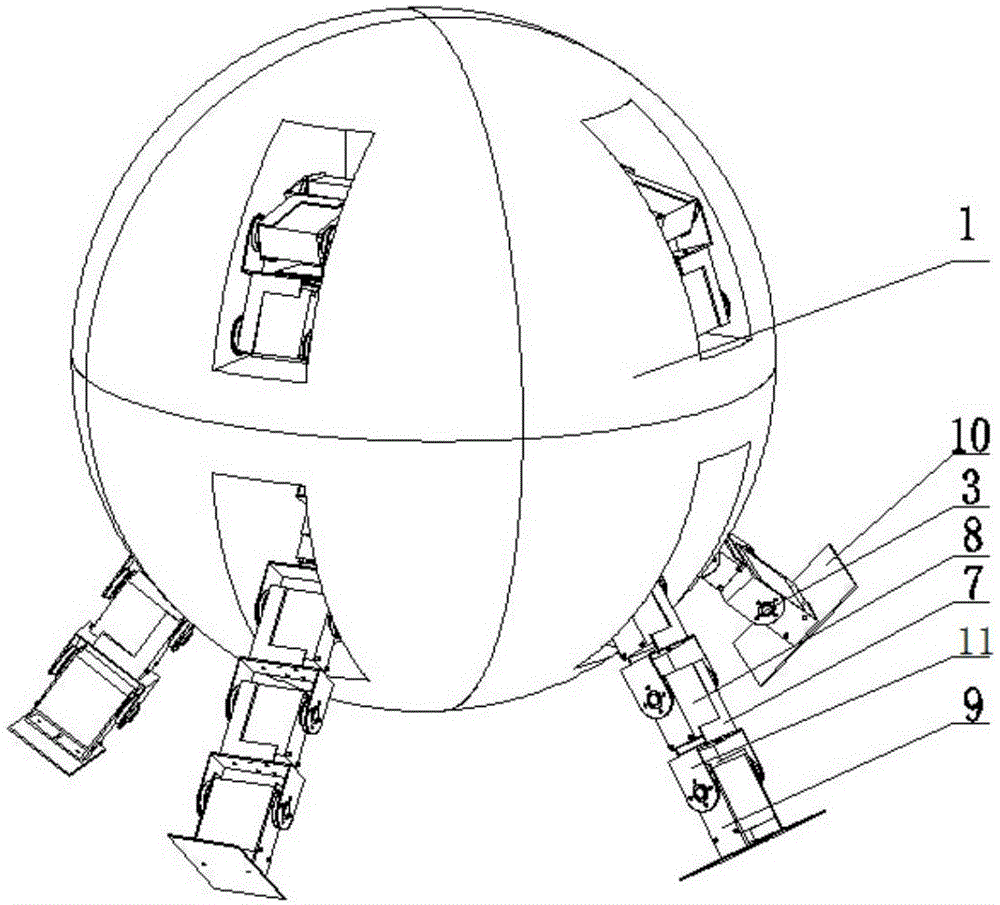

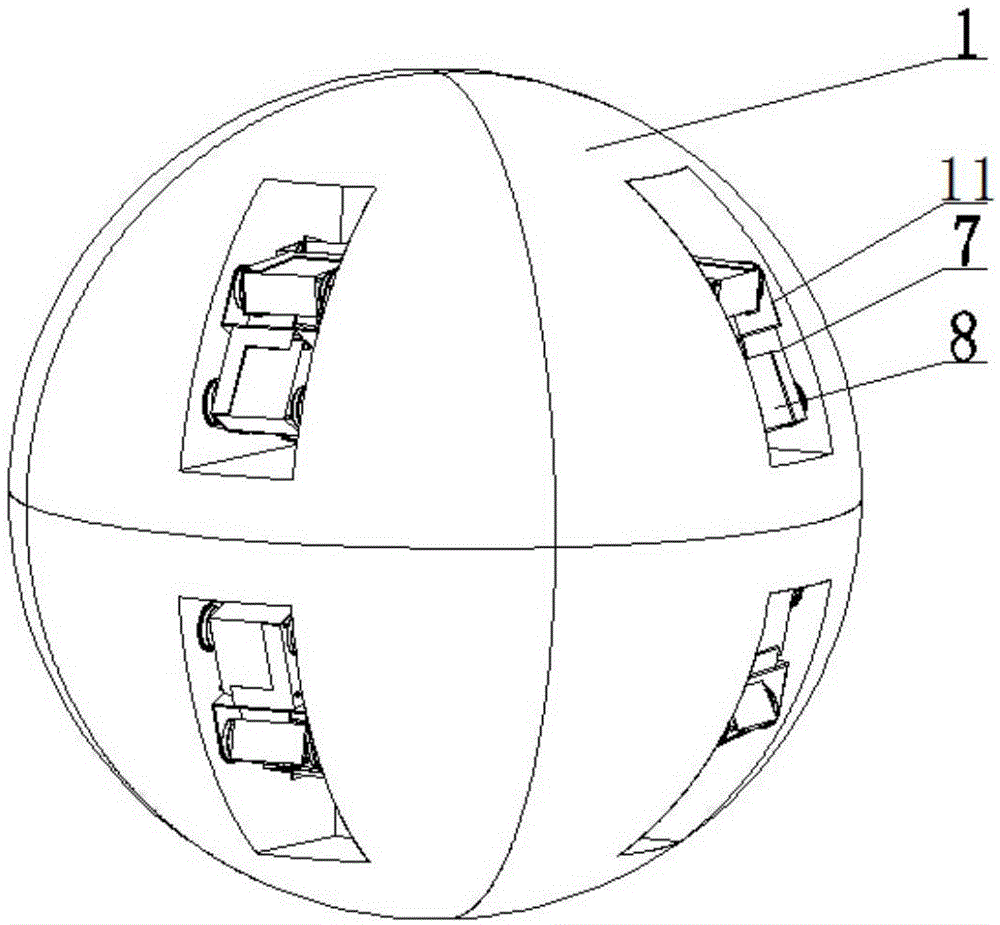

Spherical robot capable of conducting foot type movement and working method of robot

ActiveCN105035199AFast movementImprove environmental adaptability and work efficiencyVehiclesFoot typeEngineering

The invention discloses a spherical robot capable of conducing foot type movement and a working method of the robot. The robot can be controlled through first steering engines, second steering engines and third steering engines so that leg structures can retract into grooves in one-eighth spherical bodies to transformed into a spherical shape, a rolling movement mode is adopted, and the movement speed is increased. When the road surface is not smooth or obstacles exist, the first steering engines, the second steering engines and the third steering engines control the leg structures to stretch out to be transformed into a multi-foot structure, a foot type movement mode is adopted, and flexibility and stability are achieved. The spherical robot can conduct spherical transformation and foot type transformation, different movement modes are selected according to different environments, the environment adaptability and the working efficiency are improved, the overall structure is simple and reasonable, transformation is easy to achieve, and the spherical robot can be widely applied to production and living occasions.

Owner:YULIN UNIV

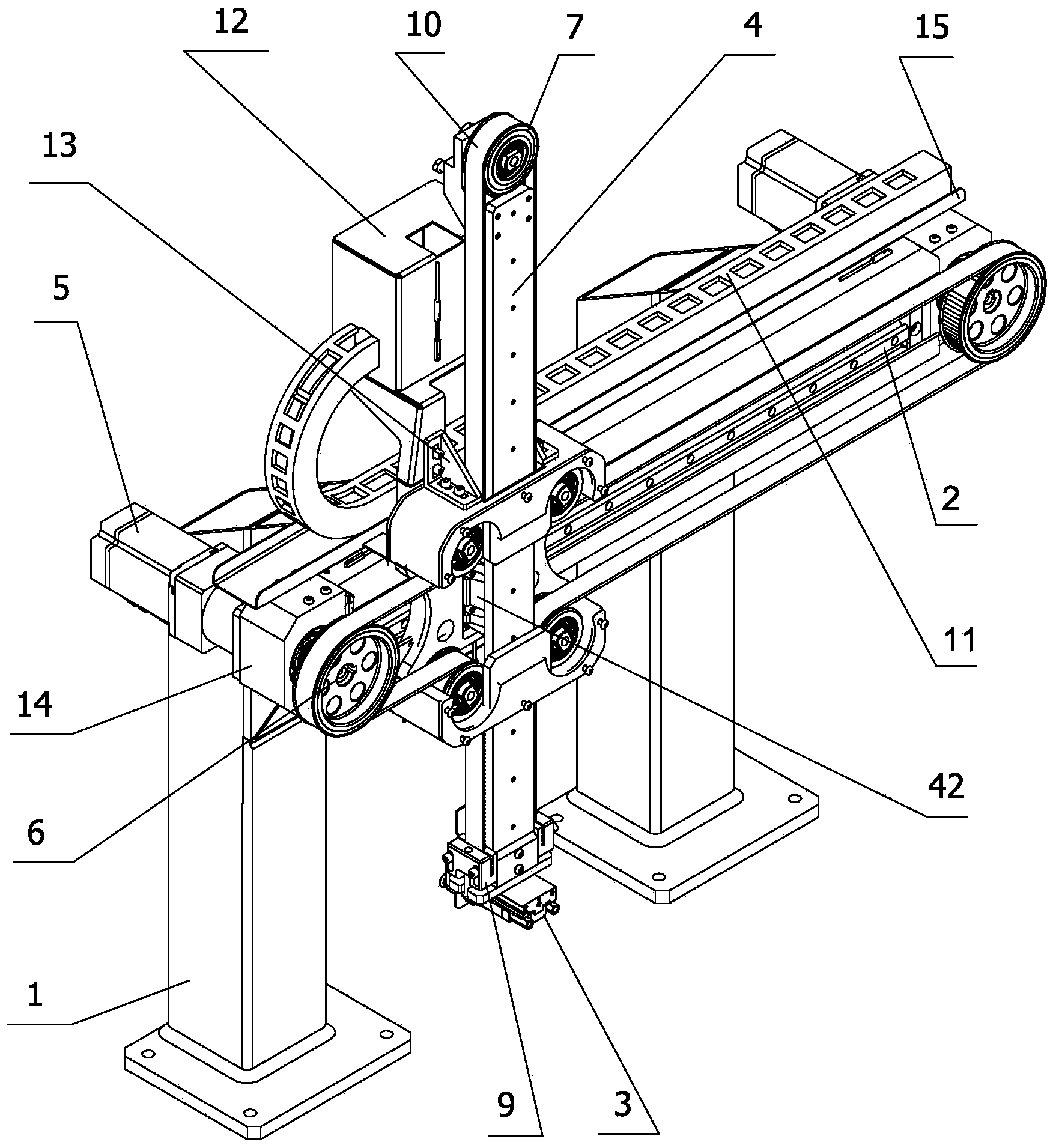

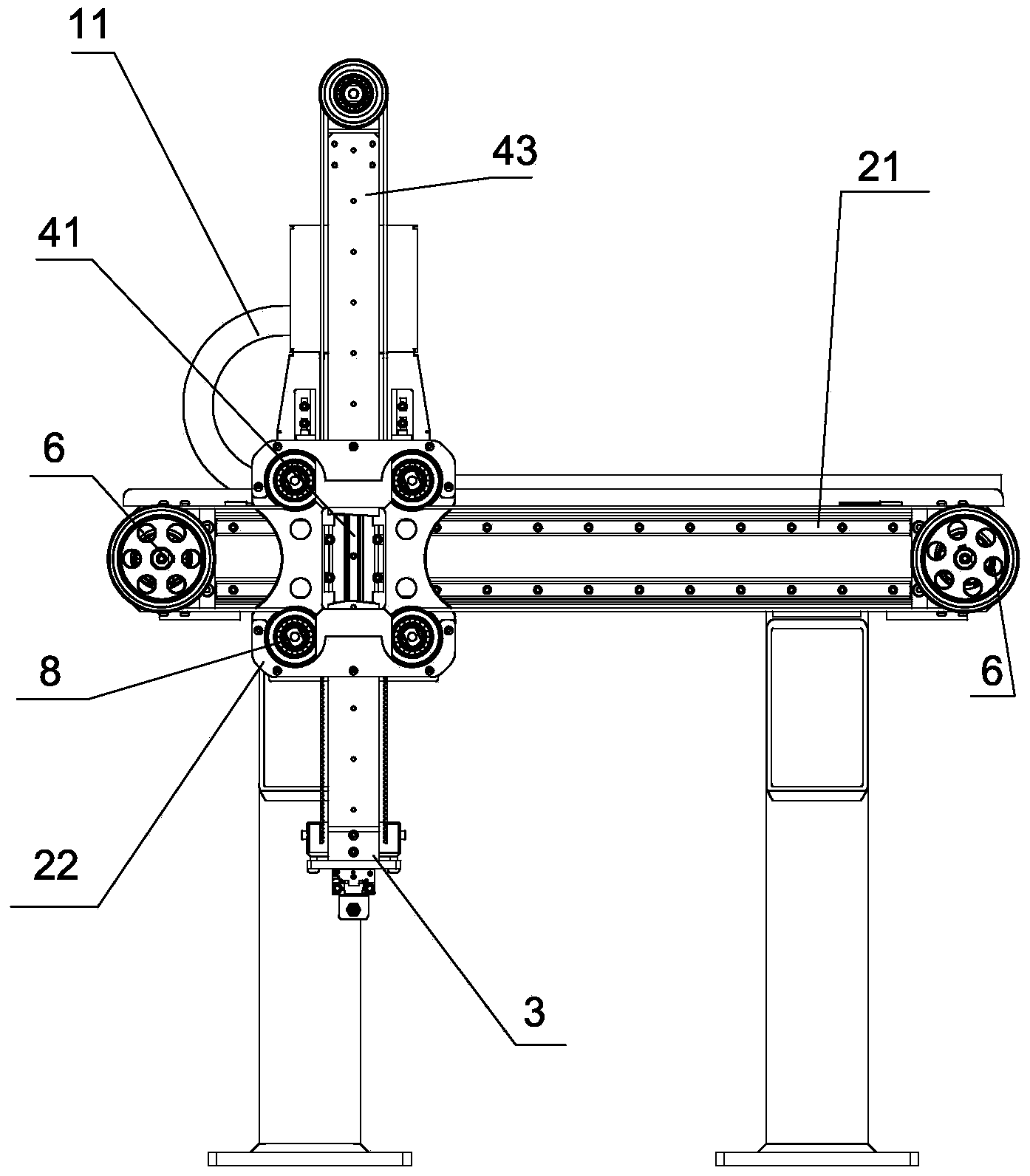

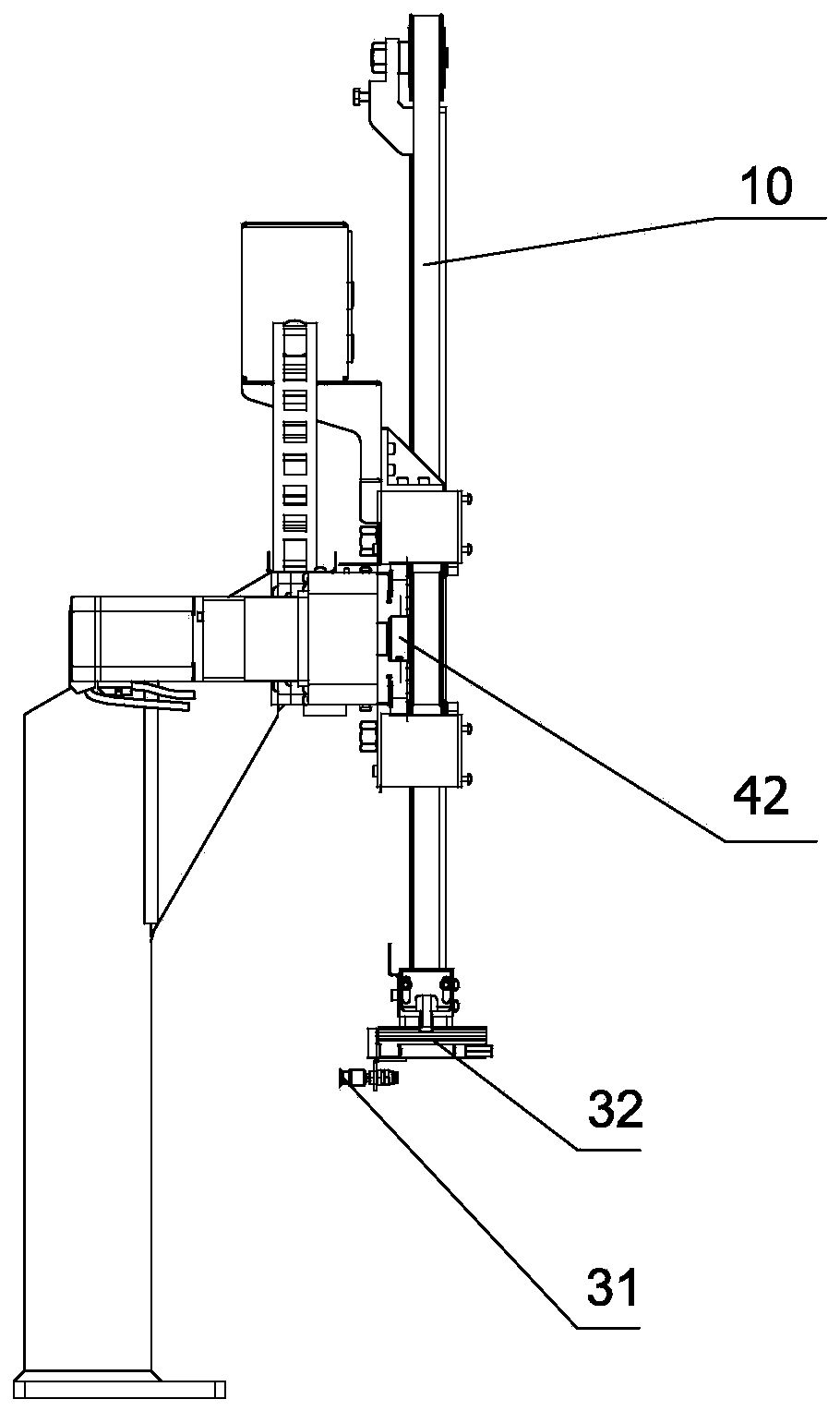

Cross-shaped parallel robot

InactiveCN104290093AReduce moving load massFast movementProgramme-controlled manipulatorStructural rigidityDrive motor

The invention discloses a cross-shaped parallel robot. The cross-shaped parallel robot comprises stand columns, an X-axis assembly, a Y-axis assembly, a Z-axis assembly, a drive motor, a driving synchronous pulley and a driven synchronous pulley. The X-axis assembly comprises an X-axis guide rail and an X-axis slide carriage, and the left end and the right end of the X-axis guide rail are fixedly connected with the stand columns on the corresponding sides respectively. The Z-axis assembly comprises a Z-axis guide rail and a Z-axis sliding block which is fixedly connected to the X-axis slide carriage. The Y-axis assembly comprises an executing component and an air cylinder or an electric cylinder, wherein the air cylinder or the electric cylinder is installed at the lower end of the Z-axis guide rail, and the air cylinder or the electric cylinder drives the executing component to move in the Y-axis direction. A cross-shaped frame formed by the X-axis guide rail and the Z-axis guide rail is sleeved with a cross-shaped synchronous belt, the drive motor drives the driving synchronous pulley to rotate, the driving synchronous pulley drives the driven synchronous pulley to rotate through the synchronous belt, and finally the executing component is driven to move in the-axis X direction and the Z-axis direction. The cross-shaped parallel robot is simple in structure, low in manufacturing cost, good in structural rigidity and high in position accuracy, and is a real environment-friendly energy-saving robot.

Owner:CHONGQING LANGZHENG TECH

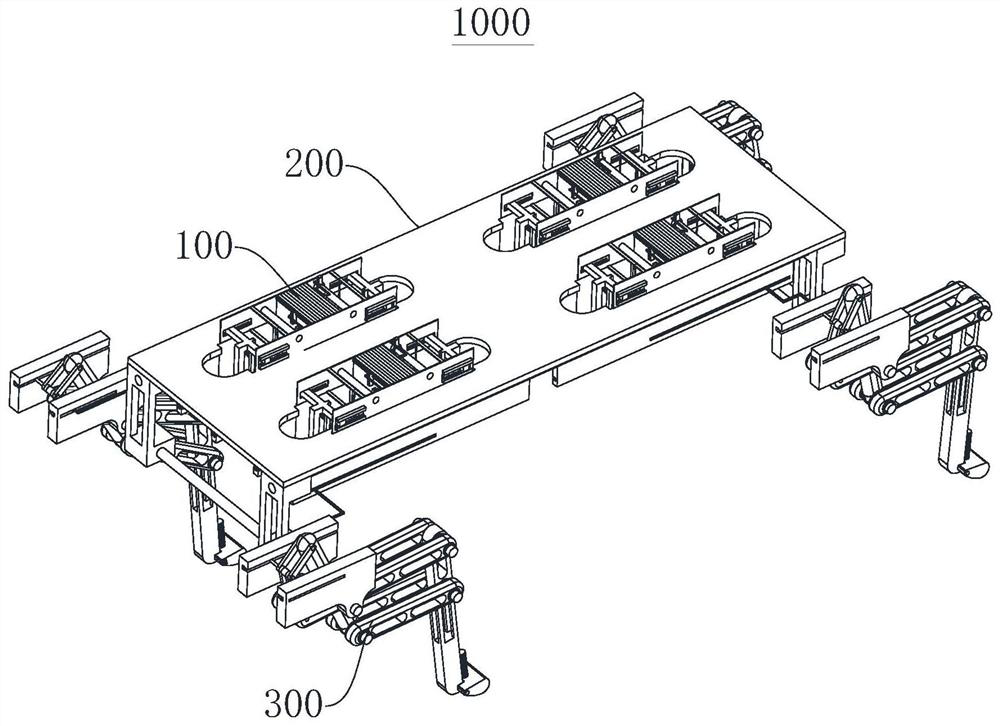

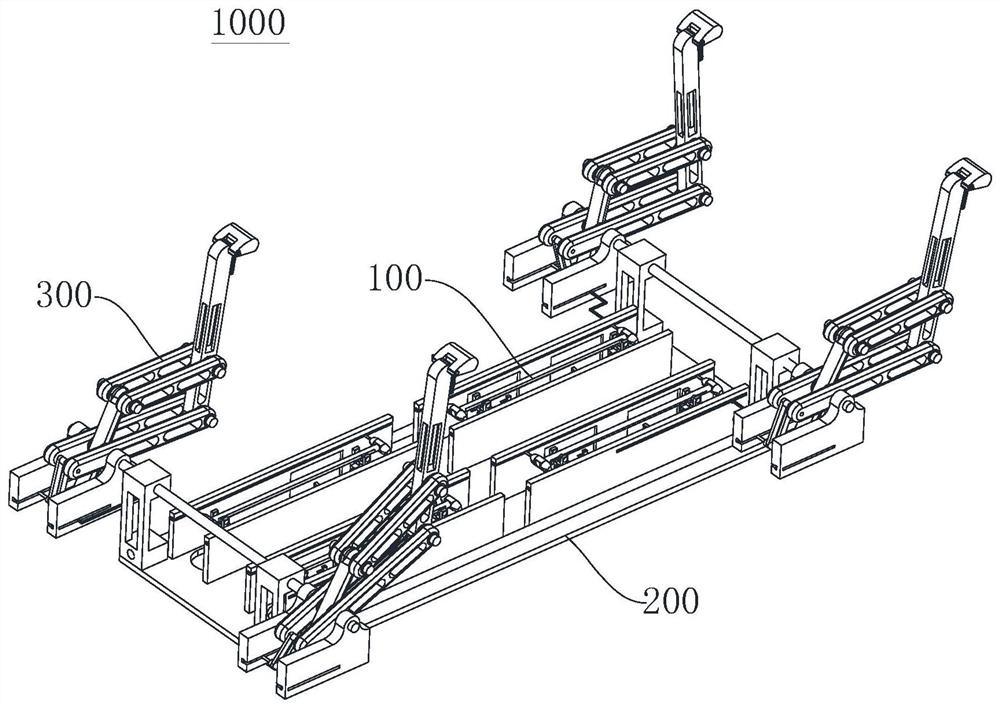

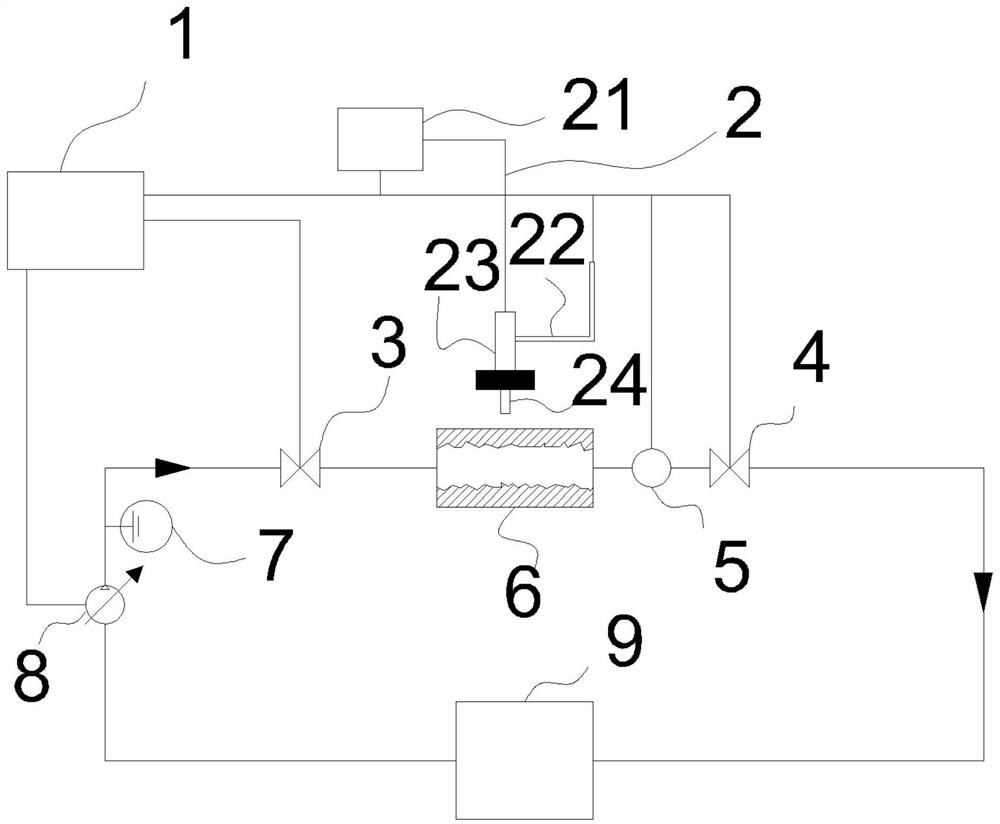

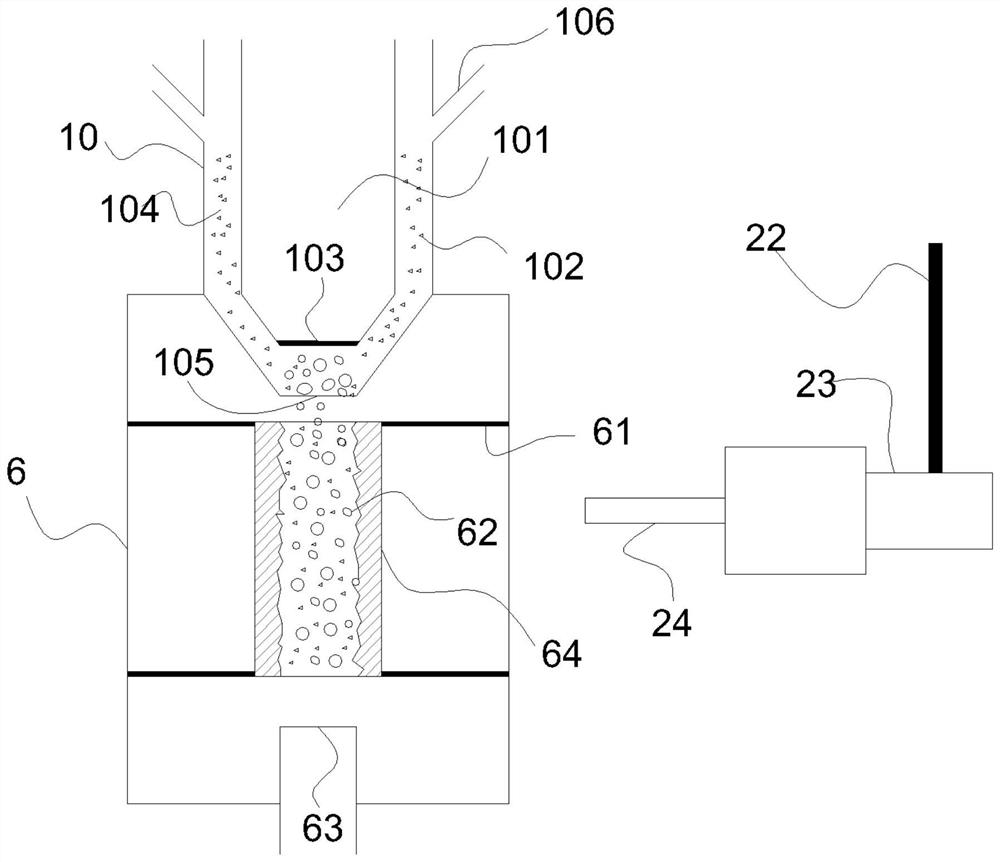

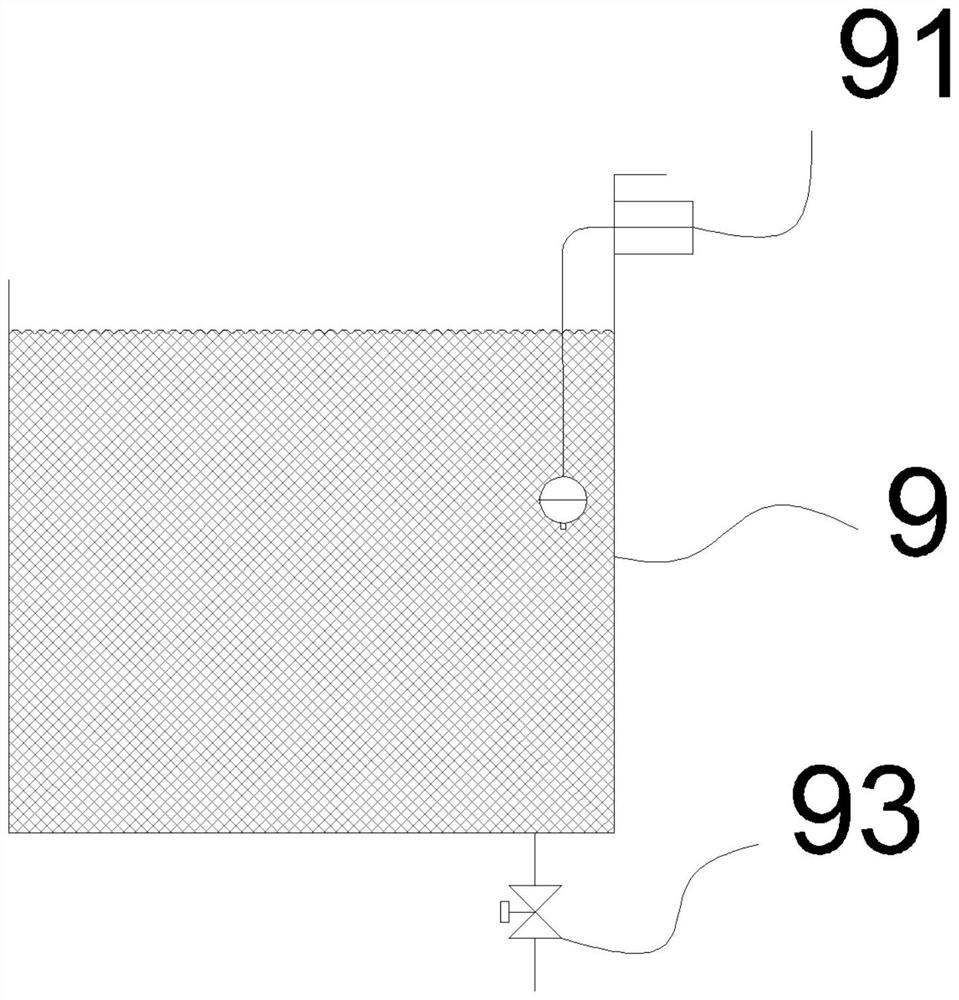

Single-layer multi-material surface overlay system based on powder bed additive manufacturing

ActiveCN105817622AHigh densityFast movementAdditive manufacturing apparatusIncreasing energy efficiencyMulti materialEngineering

A single-layer multi-material surface overlay system based on powder bed additive manufacturing comprises a forming working table board, wherein a forming cylinder is arranged in the middle below the forming working table board; two powder supply cylinders are arranged on two sides of the forming cylinder; two slide rails are configured above the forming working table board through truss mechanisms; guide rods are connected onto two sliders matched with the two slide rails; powder pressing plates are connected with the bottom ends of the guide rods; the two powder pressing plates are controlled by two stepping motors to move leftwards and rightwards respectively and are connected with two control systems respectively. Based on the system, any multi-dimensional and multi-material parts can be rapidly formed, a to-be-adsorbed powder material is adsorbed on the powder pressing plates, the powder material is compacted on the surface of a formed part, and the effect of improving the compactness of the part is realized; the mobile surface overlay system has a high movement speed, realizes accurate control for powder overlaying amount and improves the production efficiency.

Owner:XI AN JIAOTONG UNIV

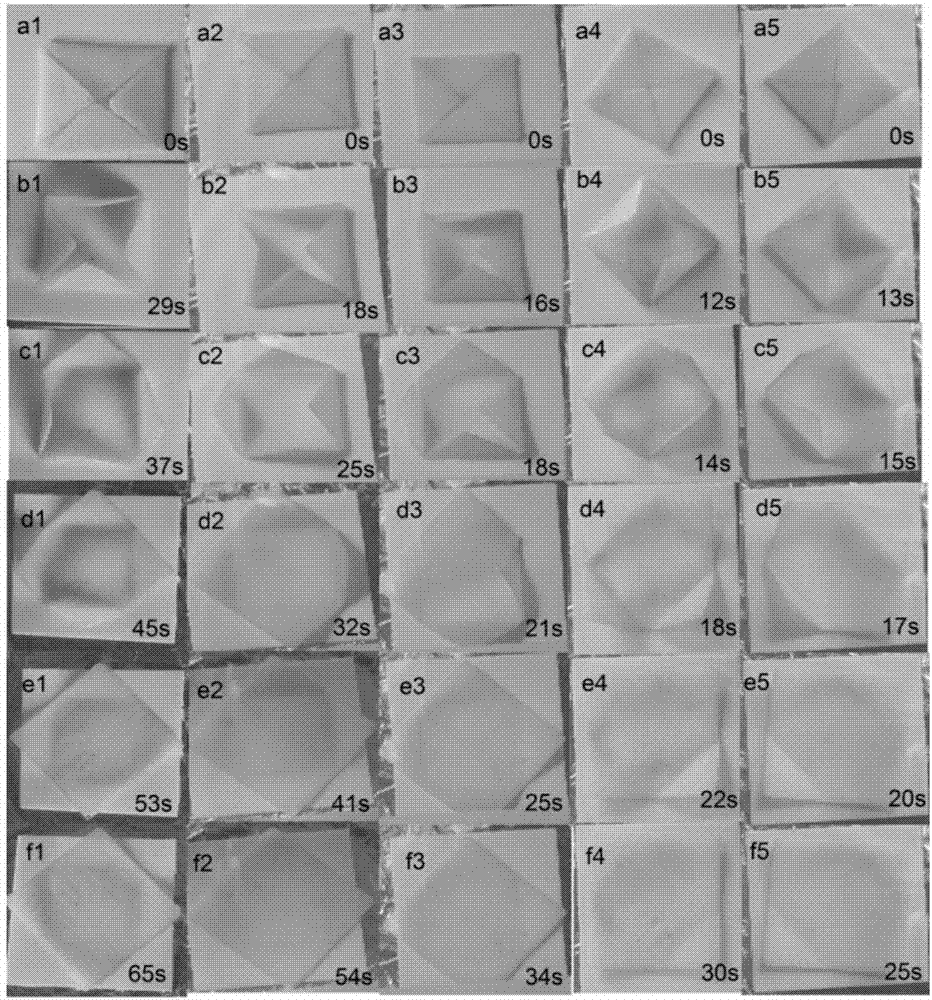

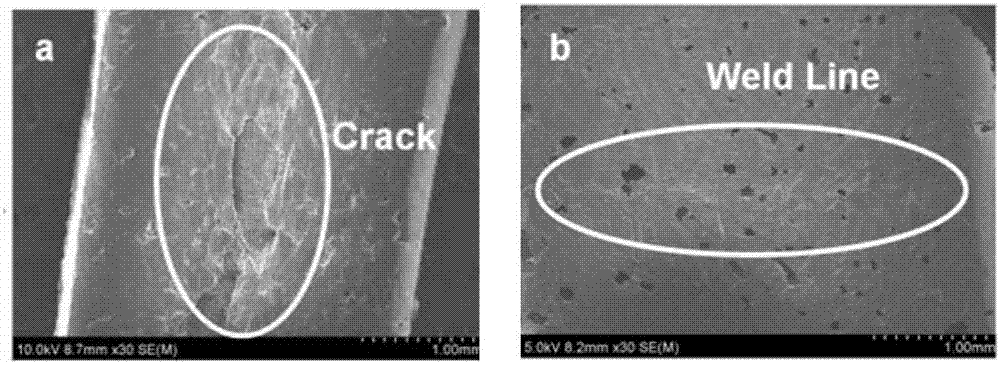

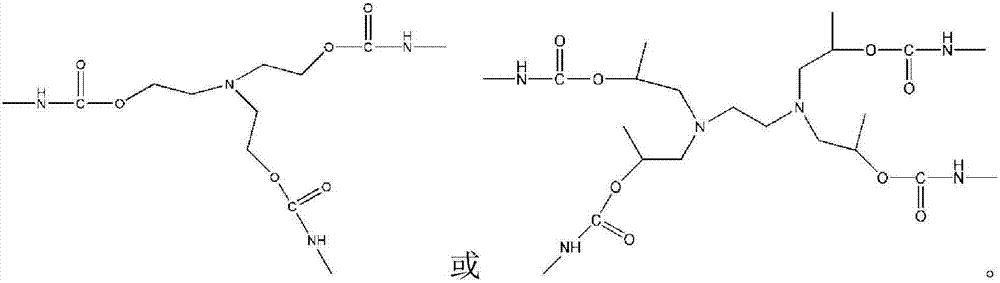

Rapid self-repairing shape memory polymer and preparation method thereof

The invention relates to a rapid self-repairing shape memory polymer and a preparation method thereof. The rapid self-repairing shape memory polymer is segmented polyurethane; a molecular chain contains a polycaprolactone block, a carbamate chain segment and a dendritic node. The preparation method of the rapid self-repairing shape memory polymer comprises the following steps: carrying out condensation polymerization on a diisocyanate monomer, and polycaprolactone diol (PCL-diol), N,N,N',N'-tetra(2-hydropropyl)ethylene diamine (HPED) and triethanolamine (TEA) respectively to form the segmented polyurethane containing the polycaprolactone block, the carbamate chain segment and the dendritic node on a main chain. Compared with the prior art, the segmented polyurethane can trigger a shape memory effect at relatively low temperature (50 DEG C to 90 DEG C) and shape memory recovery time is very short (30s to 76s). Micro-cracks generated in an initial shape fixing process can be self-repaired in a shape memory recovery process, so that the shape memory effect of the segmented polyurethane has a high circulating property.

Owner:SHANGHAI JIAO TONG UNIV

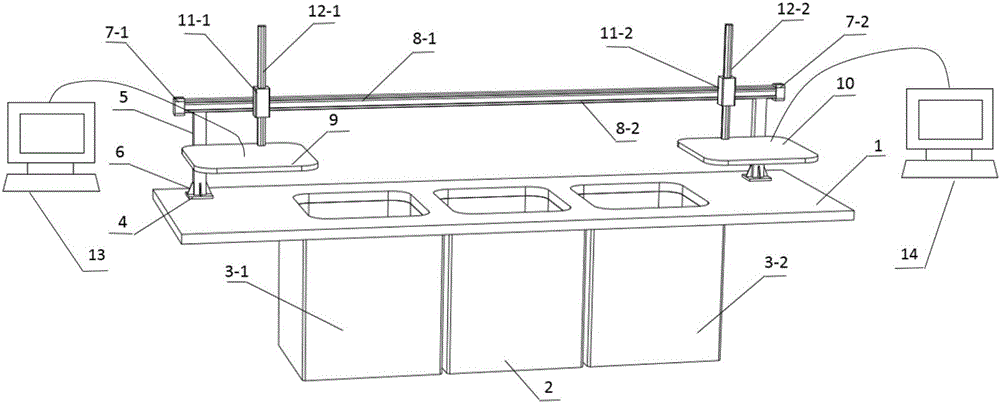

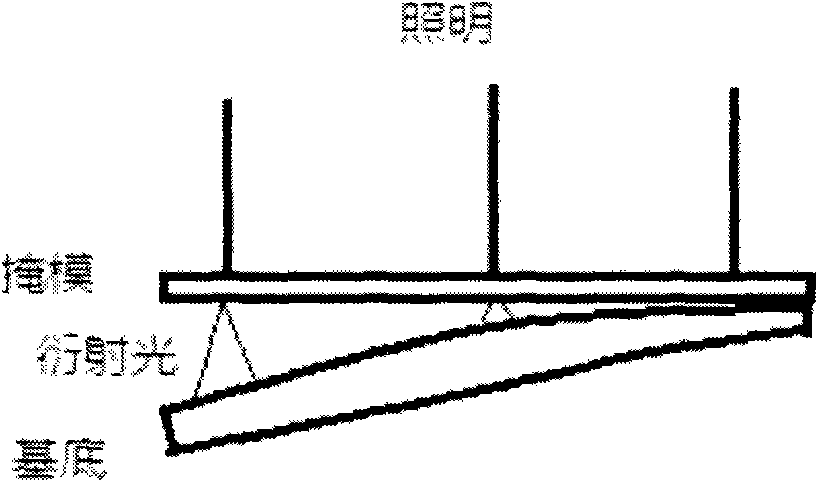

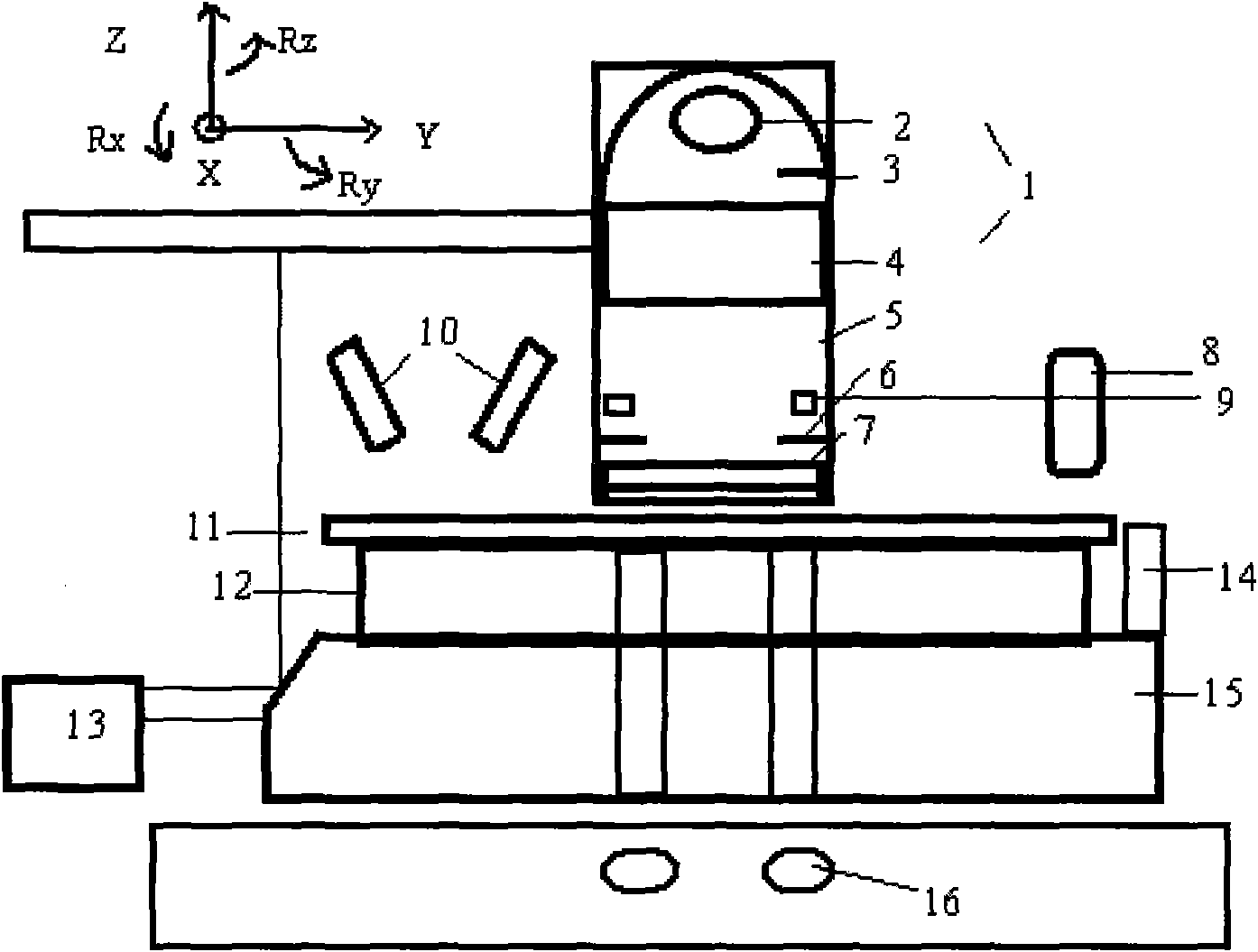

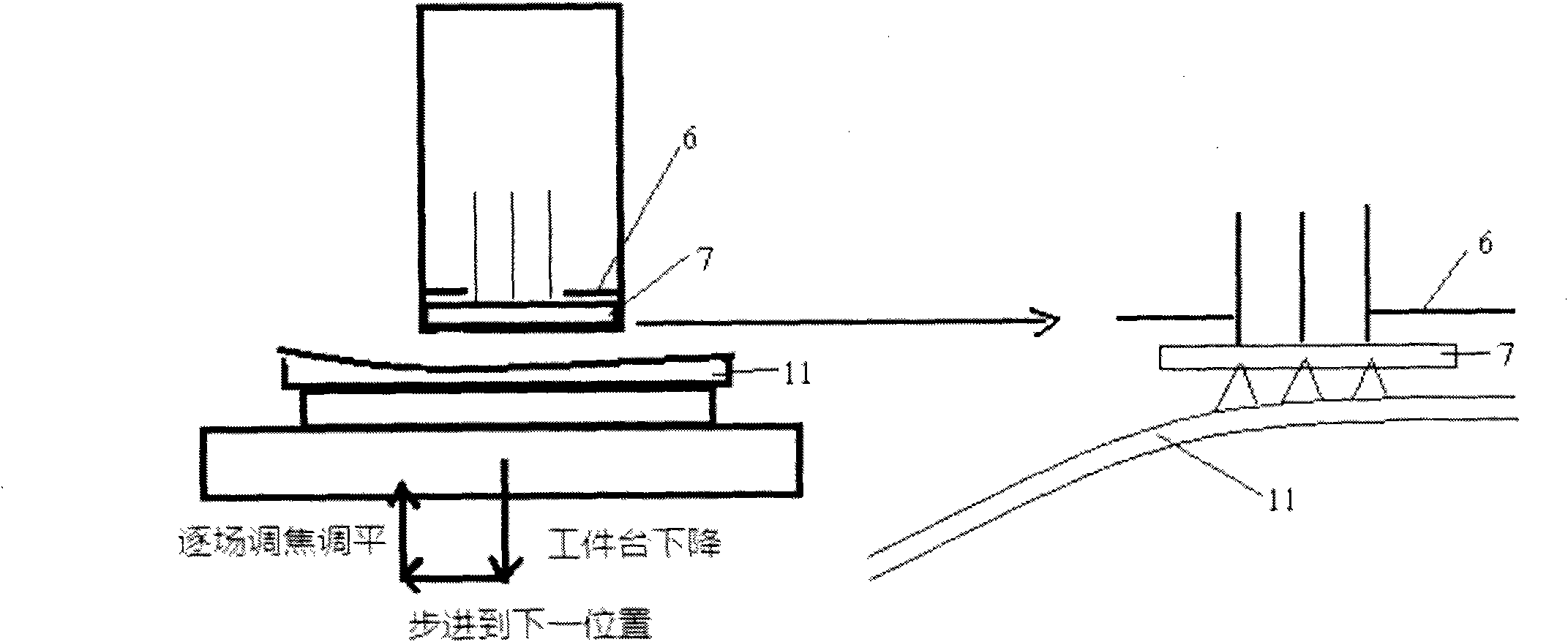

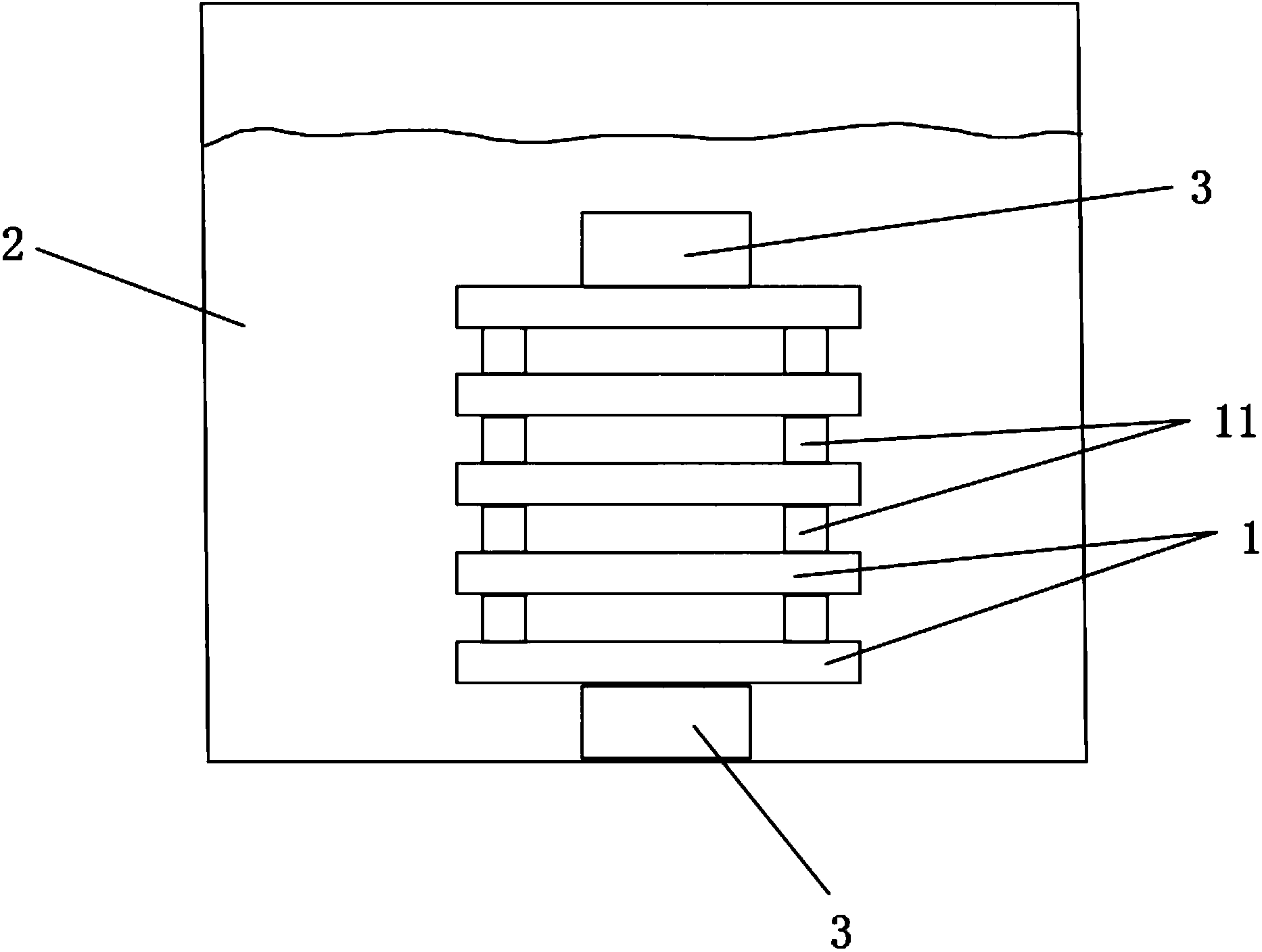

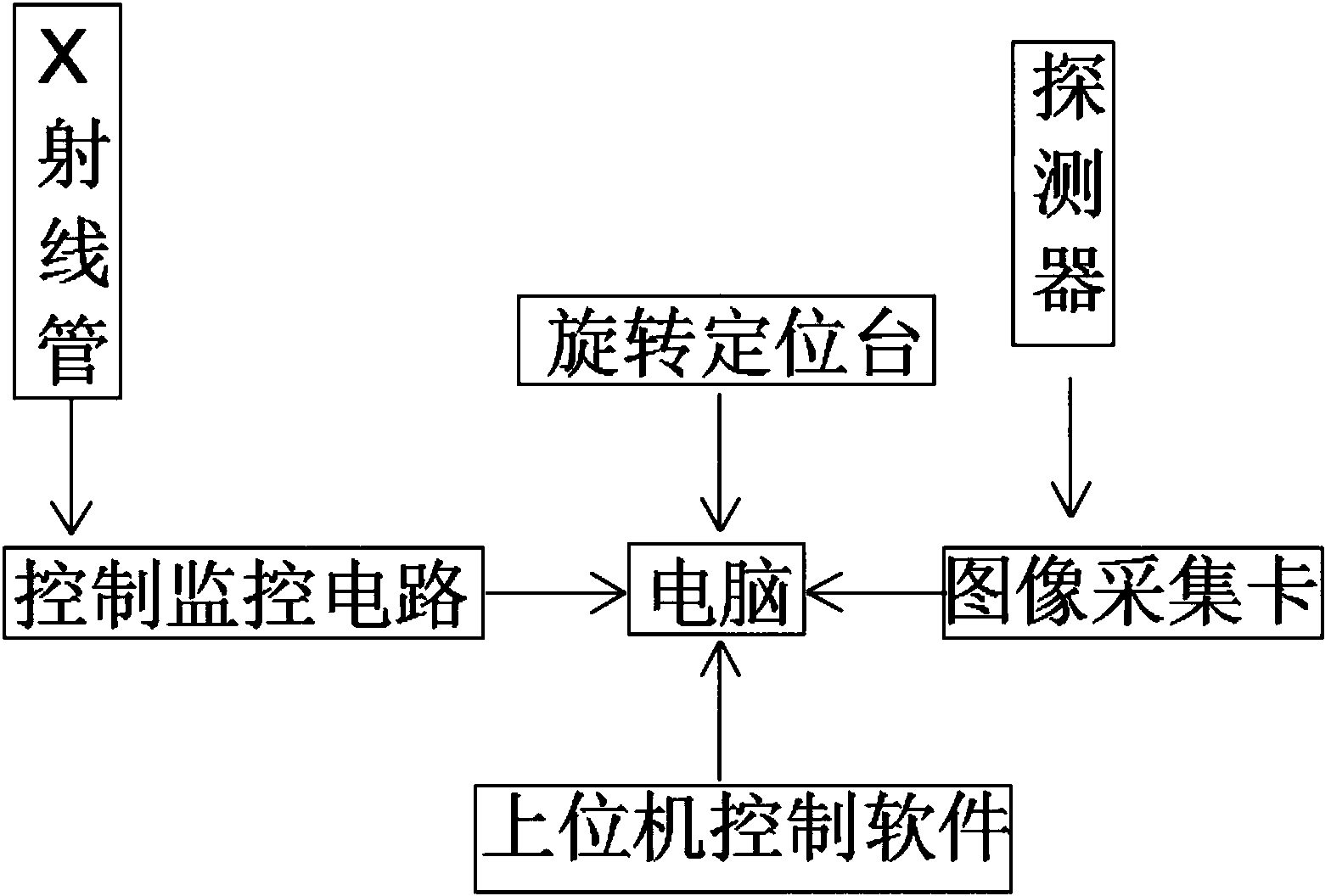

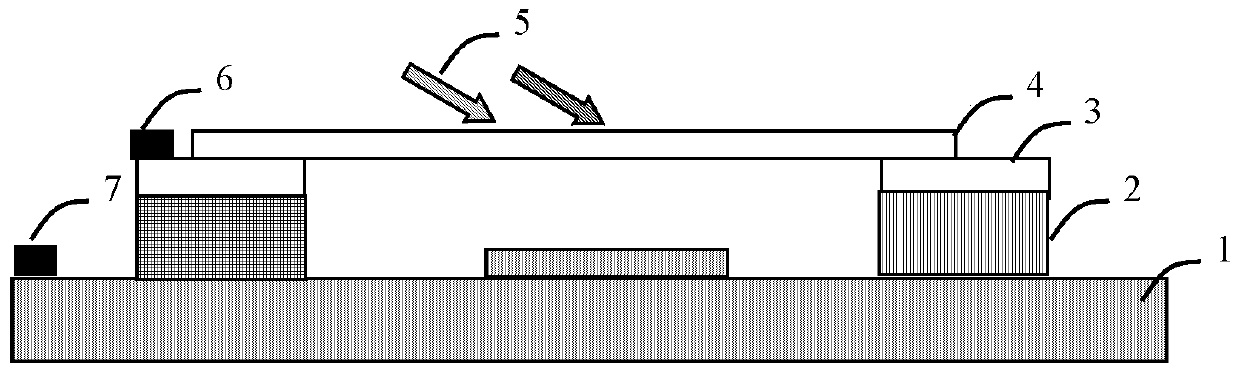

Proximity field exposure device and method

ActiveCN102736422AFast movementShorten the stabilization timePhotomechanical exposure apparatusMicrolithography exposure apparatusPhysicsLighting system

A proximity field exposure device comprises an illumination subsystem, a working table, a position measurement subsystem, a focusing and leveling subsystem and an aligning subsystem. Uniform parallel rays which are emitted from the illumination subsystem are incident on a mask on a reticle stage. The proximity field exposure device is characterized in that a field substrate of the exposure device is small; and the working table has six degrees of freedom, namely XYZRxRyRz, wherein long-range motion can be carried out in the XY direction and small-range adjustment can be conducted in the ZRxRyRz direction. Before exposure, surface shape measurement and alignment are firstly carried out on the substrate. During the exposure process, according to the surface shape date of the substrate and the alignment data, the illumination system is turned on for field exposure in dependence on exposure formulation.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Method and equipment for rapidly killing insects and eggs in wood board in impregnation way

ActiveCN104354199AFast movementMove fastWood treatment detailsOpen tank impregnationWood dryingBifenthrin

The invention discloses a method for rapidly killing insects and eggs in a wood board in an impregnation way. The method comprises the following steps of (1) impregnating the wood board in a chemical solution pool, and arranging a high-frequency vibrator; (2) vibrating the wood board at high frequency by virtue of the high-frequency vibrator, and impregnating the wood board in the chemical solution pool for 4 to 6 hours; (3) drying the wood board in a high-frequency vacuum wood dryer, and repeating the operation in step (2); (4) impregnating the wood board in a washing pool for 4 to 6 hours; (5) drying the wood board in the high-frequency vacuum wood dryer; (6) detecting living insect and egg bodies in the wood board by virtue of an insect or egg CT (computed tomography) detection device. The invention also discloses equipment for killing the insects and the eggs. According to the method and the equipment, the wood board is impregnated in the bifenthrin-containing chemical solution pool, and a chemical solution can rapidly enter gaps with the insects or the eggs in the wood board to kill the insects or the eggs; the insects are killed at the same time of wood drying of the high-frequency vacuum wood dryer, so that insect killing effects are further ensured.

Owner:DONGGUAN HOTLINE FURNITURE

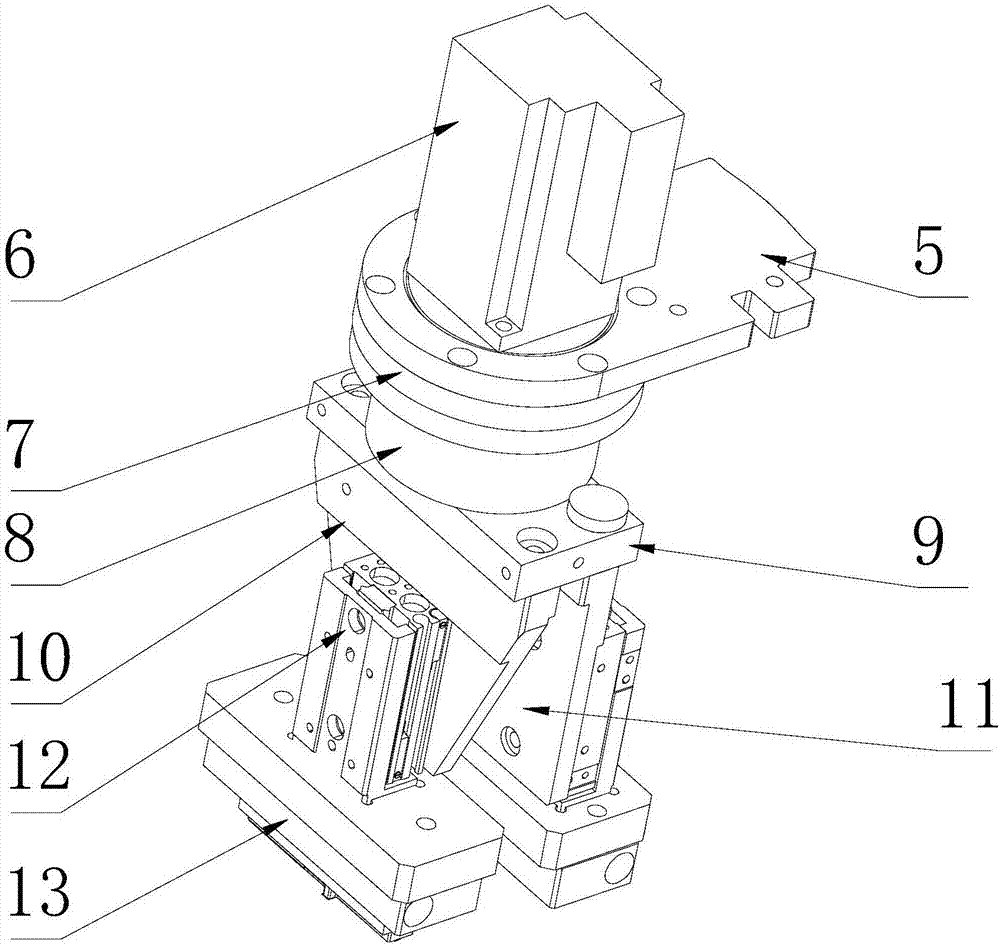

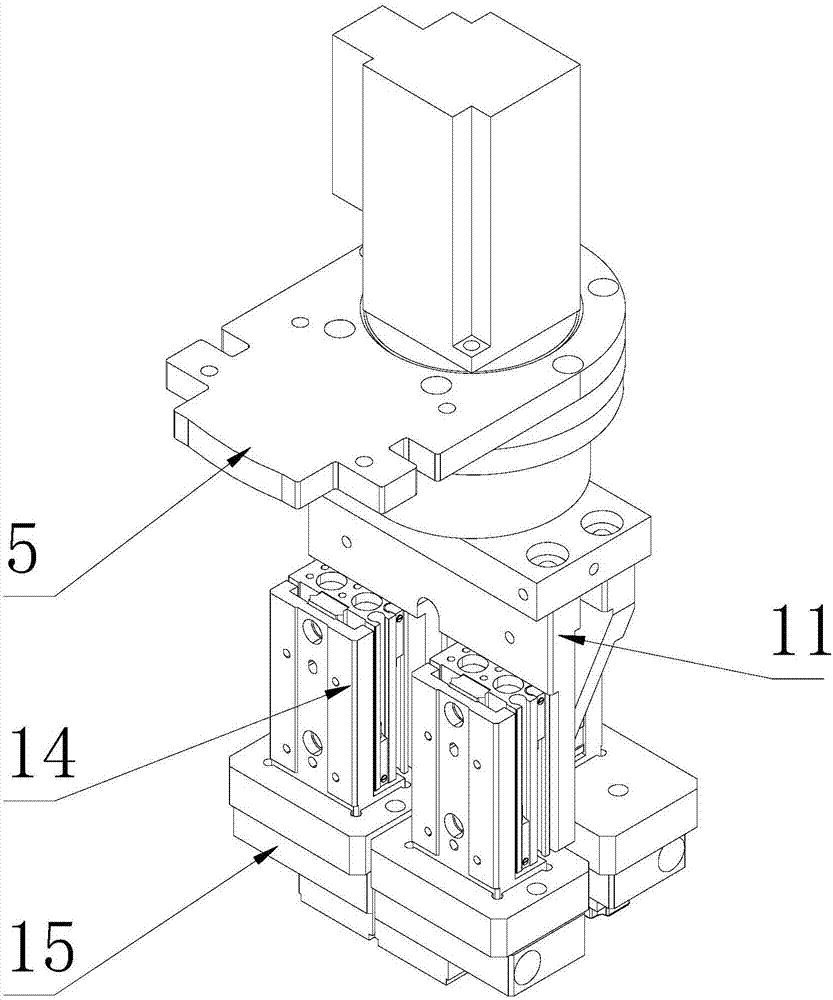

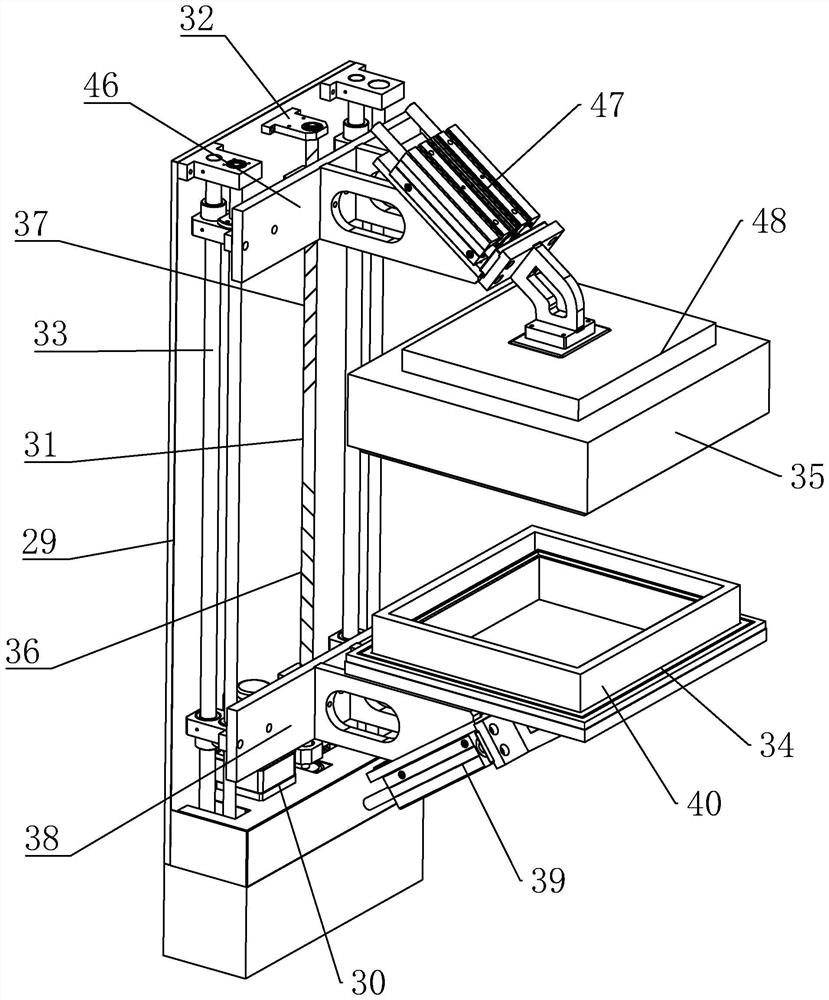

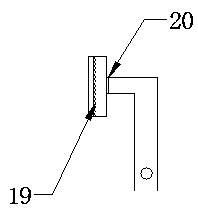

Film pasting mechanism

PendingCN106945897AFast movementHigh positioning accuracyProgramme-controlled manipulatorGripping headsManipulatorEngineering

The invention discloses a film pasting mechanism. The film pasting mechanism comprises a four-axis linkage cantilever manipulator and a suction nozzle mechanism, wherein the four-axis linkage cantilever manipulator comprises a lateral axis mechanism, a longitudinal axis mechanism and a rotating mechanism; the lateral axis mechanism comprises a cantilever mechanism; the longitudinal axis mechanism comprises a ram; the rotating mechanism comprises a Z-axis connecting flange and a rotating servo motor; one end of the cantilever mechanism is mounted on a mold set side bracket; a lateral axis linear rail is arranged on the cantilever mechanism, and a lateral axis screw rod pair is arranged in the cantilever mechanism; the ram is connected with the lateral axis linear rail through a sliding block, and is connected with a screw rod nut of the lateral axis screw rod pair; a longitudinal axis linear rail is arranged on the ram, and a longitudinal axis screw rod pair is arranged in the ram; the Z-axis connecting flange is mounted on a sliding seat; the sliding seat is mounted on the longitudinal axis linear rail of the ram through the sliding block, and is connected with a screw rod nut of the longitudinal axis screw rod pair; a rotating motor mounting plate is mounted on the Z-axis connecting flange; the rotating servo motor is mounted on the rotating motor mounting plate; an output shaft of the rotating servo motor is connected with a harmonic speed reducer; and the output end of the harmonic speed reducer is connected with the suction nozzle mechanism.

Owner:DONGGUAN ZHIRONG MACHINERY CO LTD +1

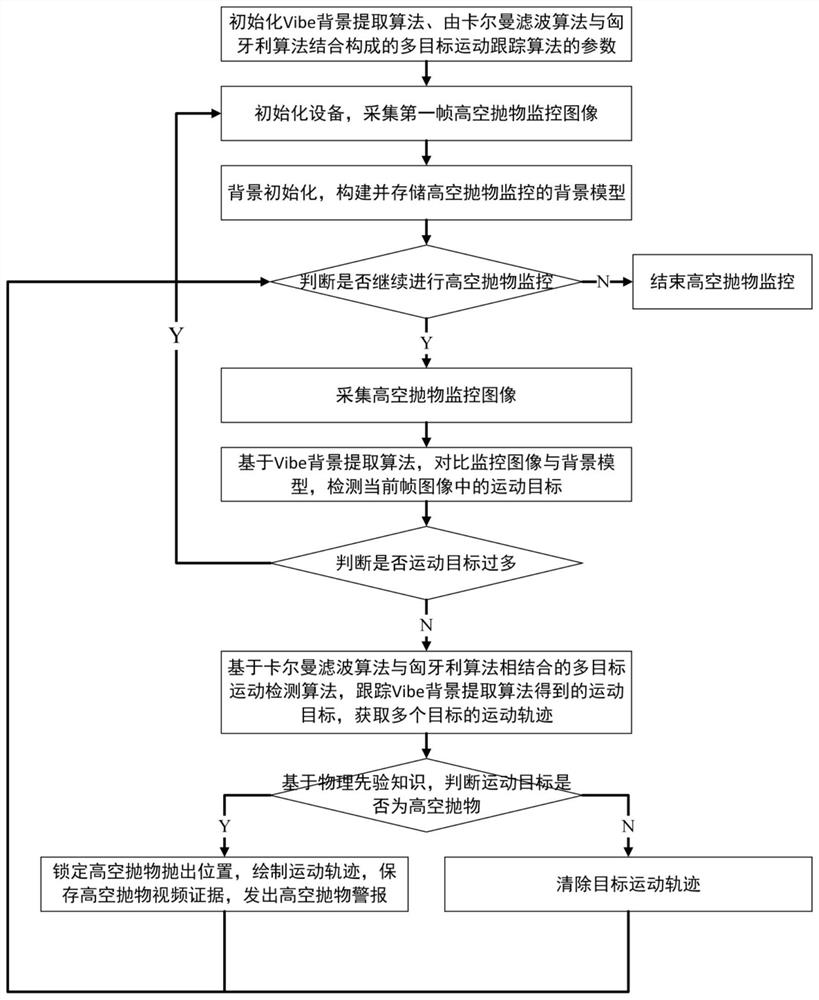

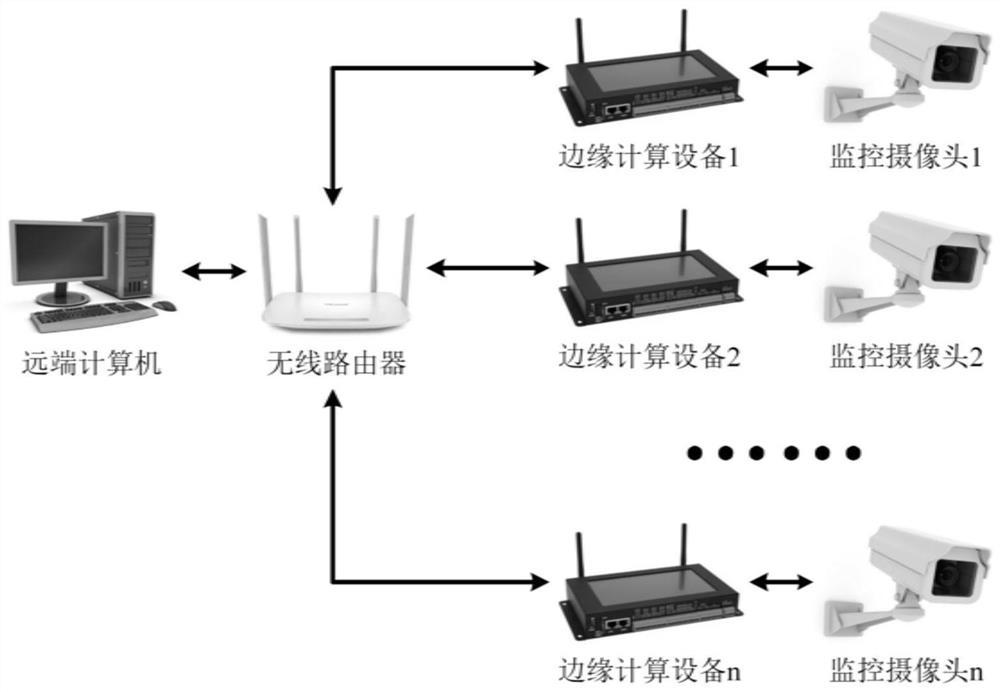

High-altitude parabolic object detection, tracking and alarm system and method based on computer vision

PendingCN112800953AFast movementImprove system stabilityImage enhancementImage analysisObject basedKalman filter algorithm

The invention discloses a system and a method for detecting, tracking and alarming a high-altitude parabolic object based on computer vision, and the system employs a monitoring camera, an edge computing device, a wireless router and a far-end computer to construct the high-altitude parabolic object monitoring system. The system has the advantages of higher movement speed, higher system stability, more flexible configuration debugging process and more excellent edge equipment expansibility; wherein a Vibe background extraction algorithm, a multi-target tracking algorithm combining a Kalman filtering algorithm and a Hungary algorithm, and physical priori knowledge of a high-altitude parabolic object are combined to carry out detection, tracking and alarm of the high-altitude parabolic object, so that interference of a monitoring period and weather as well as motion interference of flying birds and human beings can be eliminated, and the high-altitude parabolic object can be rapidly and accurately detected and tracked; in addition, under the condition that a high-altitude parabolic object appears, pedestrians and managers are warned, meanwhile, the motion trail of the high-altitude parabolic object is drawn, and videos are reserved to serve as evidences.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

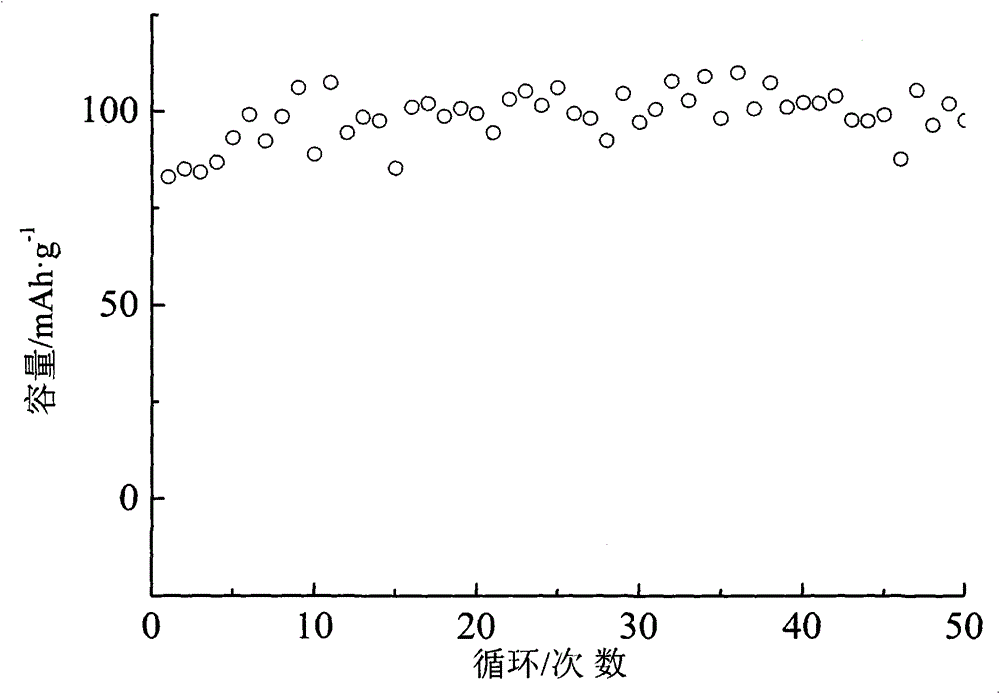

LiV3O8/Li:BPO4|Al<3+> doped Li7La3Zr2o12/Li4Ti5O12 all-solid-state thin film battery and preparation method

ActiveCN104157917AImprove close contactFast movementFinal product manufactureElectrolyte accumulators manufactureChemistryCurrent collector

The invention relates to a LiV3O8 / Li:BPO4|Al<3+> doped Li7La3Zr2o12 / Li4Ti5O12 all-solid-state thin film battery and a preparation method. The preparation method is characterized in that a positive active material precursor and a negative active material precursor are pyrolyzed by virtue of a liquid spray gun in an electrostatic spraying manner, electrolyte material layers are sprayed by virtue of a hypersonic flame layer by layer to form a thin film all-solid-state lithium ion battery LiV3O8 / Li:BPO4|Al<3+> doped Li7La3Zr2O12 / Li4Ti5O12; a voltage between a substrate and the spray gun reaches up to 40 to 80 kV, so that the close contact between an anode material and a current collector and between a cathode material and electrolyte can be greatly improved; the movement velocity of hypersonic flame spraying particles is high, and the particles can be closely contacted with the substrate at a semi-molten state; meanwhile, second solid electrolyte LI: BPO4 is introduced in the Al<3+> doped Li7La3Zr2O12 solid electrolyte, so that the interface and crystal boundary impedance can be further reduced, and the comprehensive electrochemical performance of the all-solid-state battery can be greatly improved.

Owner:郎溪品旭科技发展有限公司

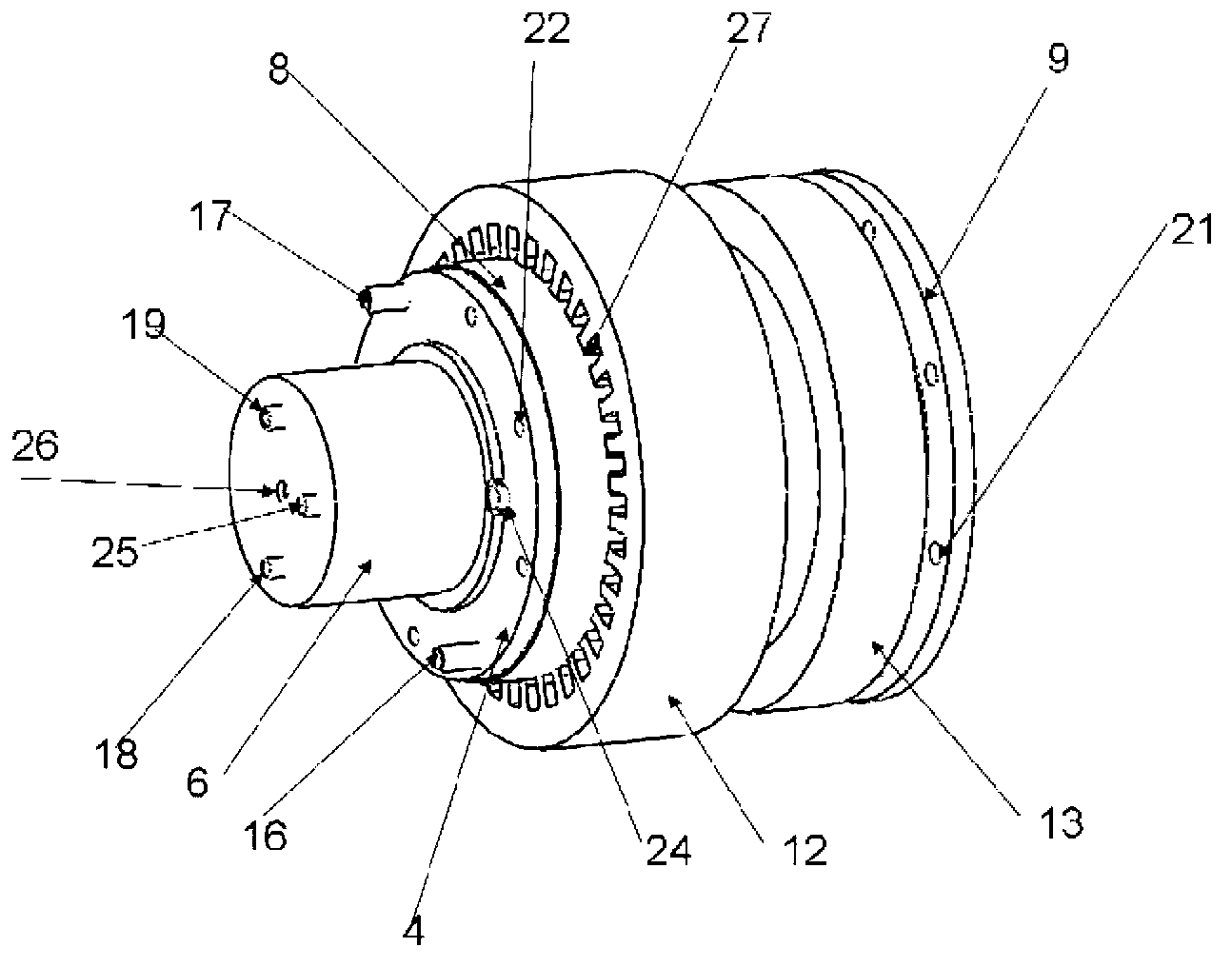

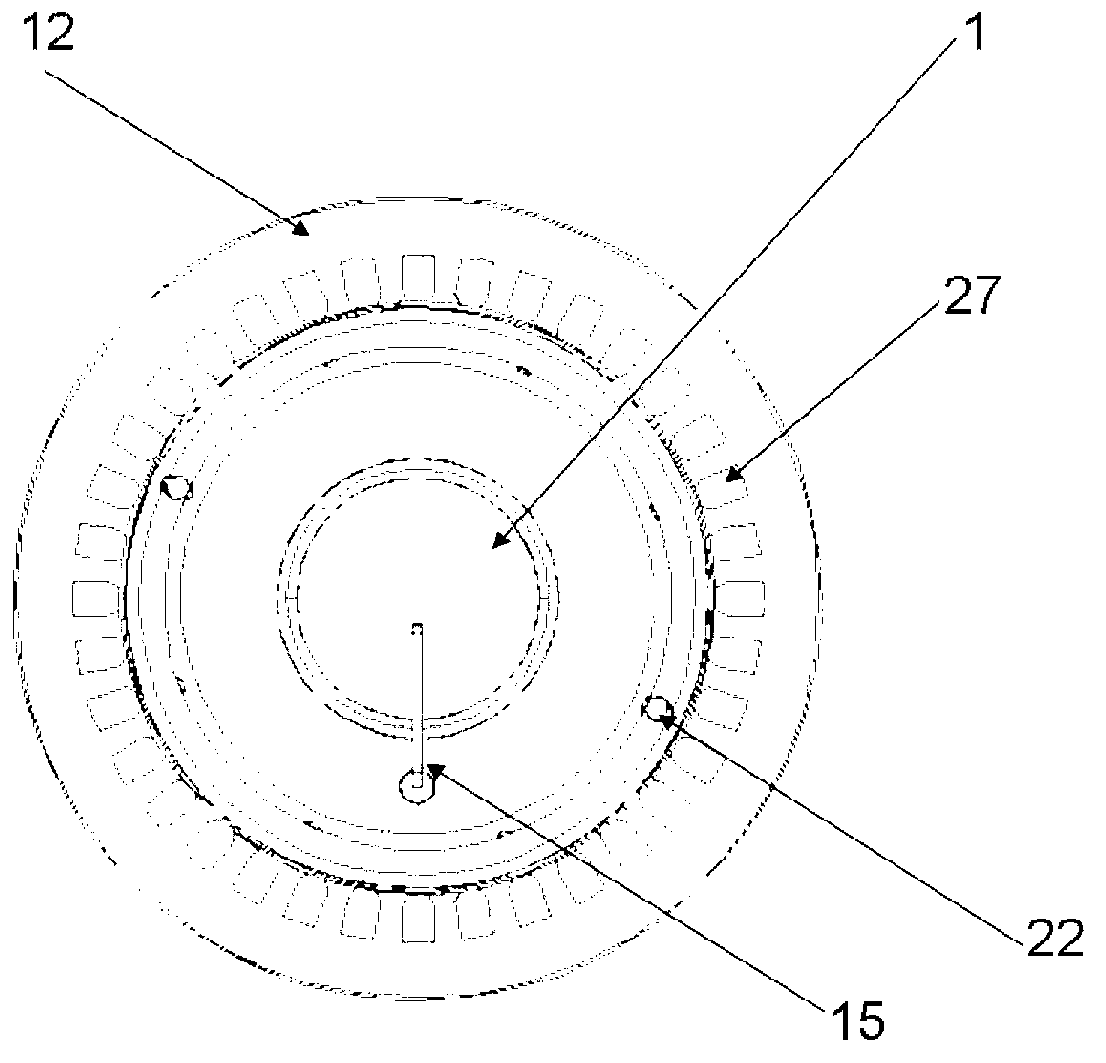

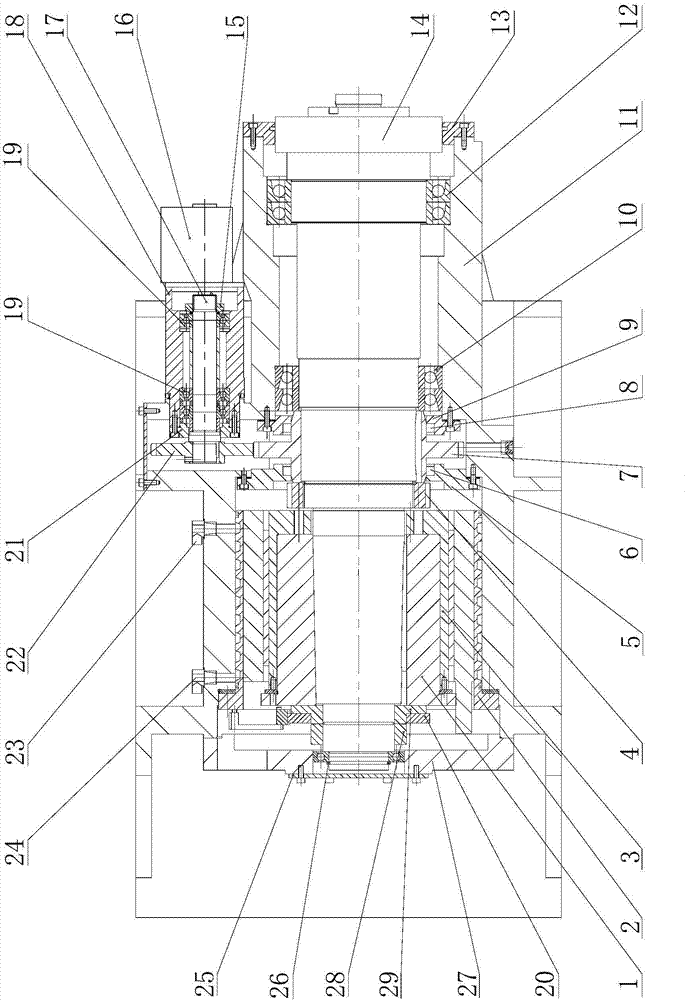

Machine tool spindle device of numerically-controlled gear milling machine for spiral bevel gear

ActiveCN103567469AAvoid loss of transmission accuracy and transmission efficiencyFast movementLarge fixed membersGear transmissionStator

The invention relates to a machine tool spindle device of a numerically-controlled gear milling machine for a spiral bevel gear. The machine tool spindle device comprises a spindle box body and a machine tool spindle arranged in the spindle box body. The machine tool spindle device is characterized in that a torque motor stator and a torque motor rotor are fixed into the spindle box body, the torque motor rotor is connected with the machine tool spindle through a taper sleeve and a key, a coder is installed at one end of the machine tool spindle through a sleeve and a locking nut, and a damping mechanism capable of applying opposite force to the middle portion of the machine tool spindle is installed on the middle portion of the machine tool spindle. The machine tool spindle device has the advantages that because the machine tool spindle is directly driven by a torque motor to rotate, loss, caused by transmission of a swinging table, of transmission precision and transmission efficiency can be avoided, and the motion speed of the machine tool spindle can be increased; the problem that due to the adoption of a gear transmission mechanism, machining precision can be affected, and transmission errors and large noise can easily occur can also be solved; in addition, opposite force is applied to the machine tool spindle by a hydraulic motor through gear transmission and plays a role in damping, and therefore transmission of the machine tool spindle is smoother and more reliable, and machining precision is improved.

Owner:天津第一机床有限公司

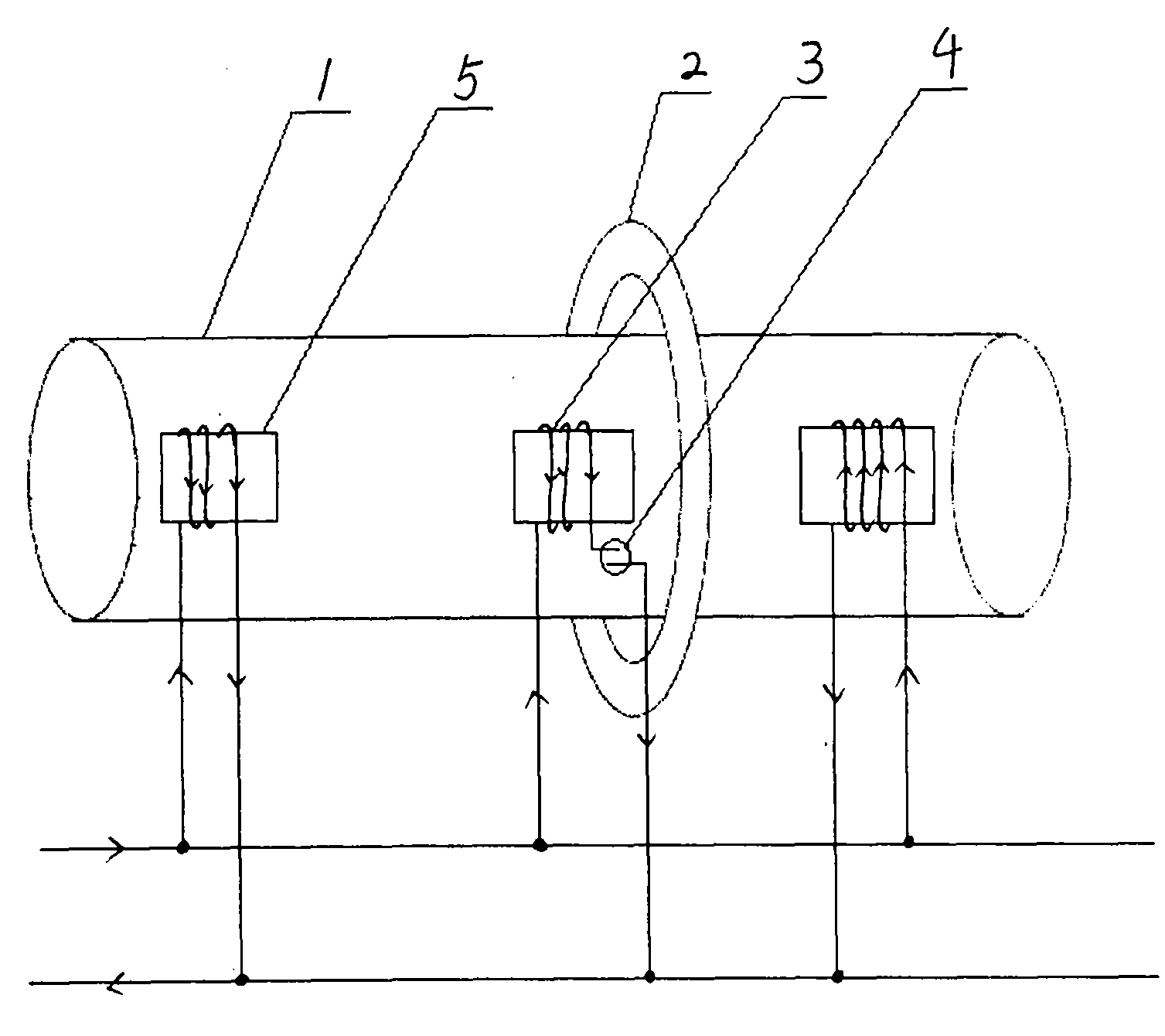

Driving device for curtain

InactiveCN102100477AFast movementMeet the thrust requirements of opening and closingDoor/window protective devicesCurtain accessoriesReed switchEngineering

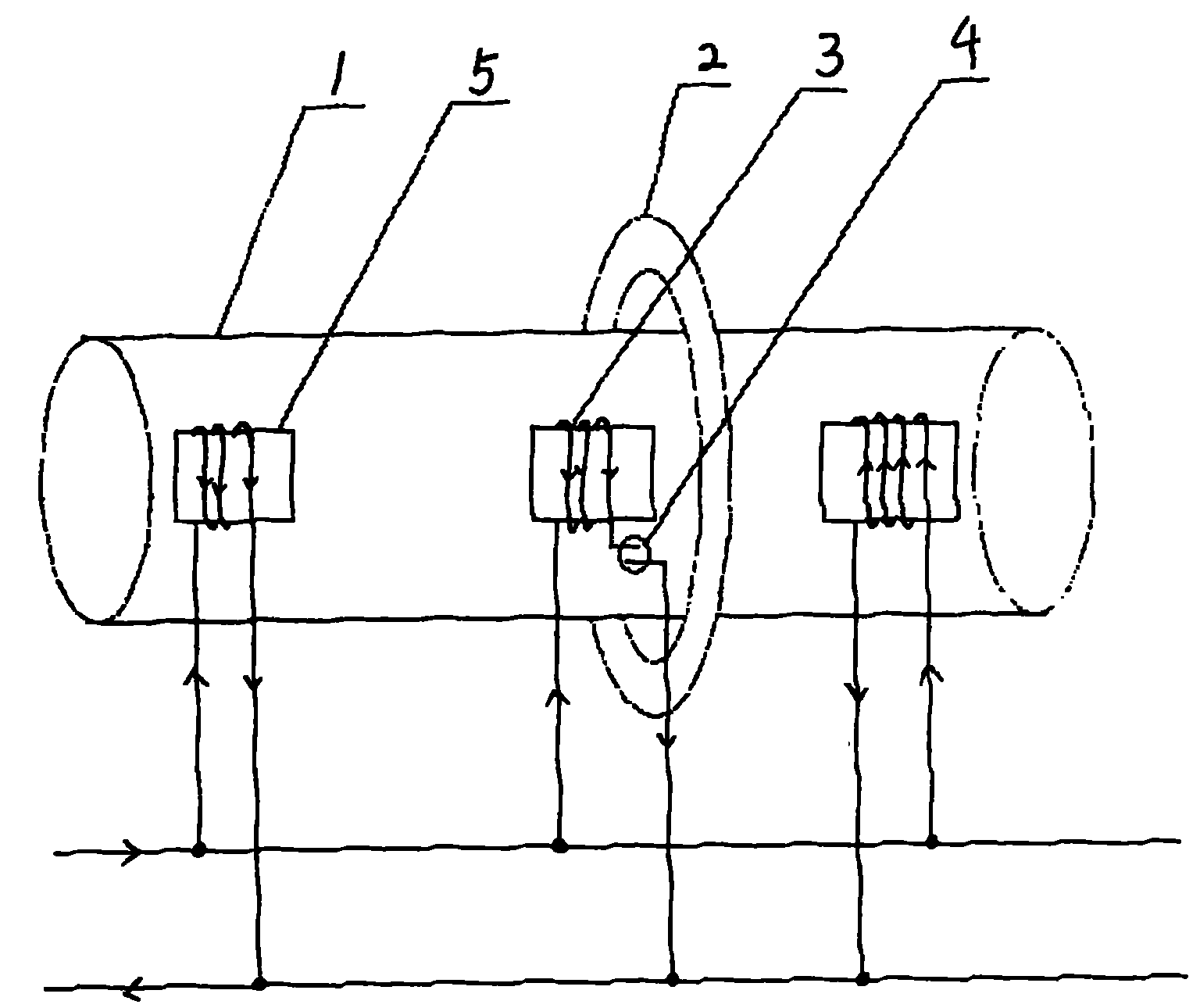

The invention relates to a driving device for a curtain, which comprises a sliding rod (1), a moving magnet (3), side magnets (5), an intermediate magnet (2) and a reed switch (4), wherein the moving magnet (3) is set to be in sliding type linkage with the sliding rod (1), the curtain is set to be linked with the moving magnet (3), the side magnets (5) are respectively arranged at two ends of the sliding rod (1), the intermediate magnet (2) is arranged at the middle part of the sliding rod (1), the side magnets (5) and the intermediate magnet (2) are arranged on the side edges of the moving magnet (3), and the intermediate magnet (2) is set to be connected with a power supply through the reed switch (4). Therefore, the requirement on thrust for opening and closing the curtain can be satisfied.

Owner:周福民

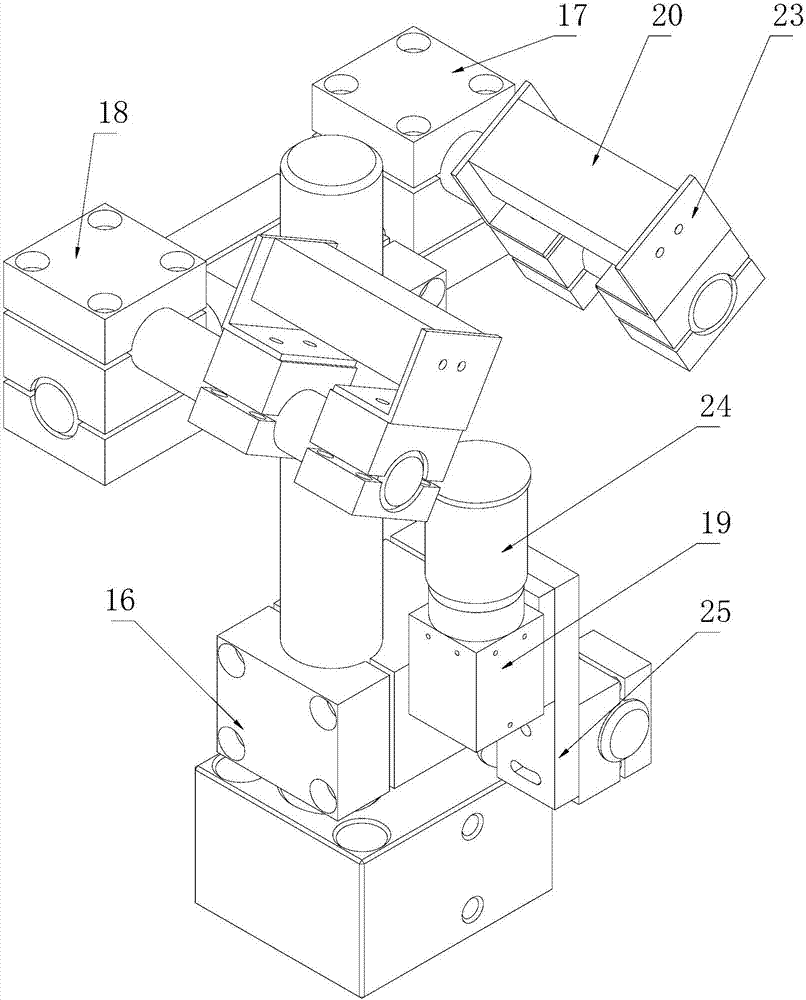

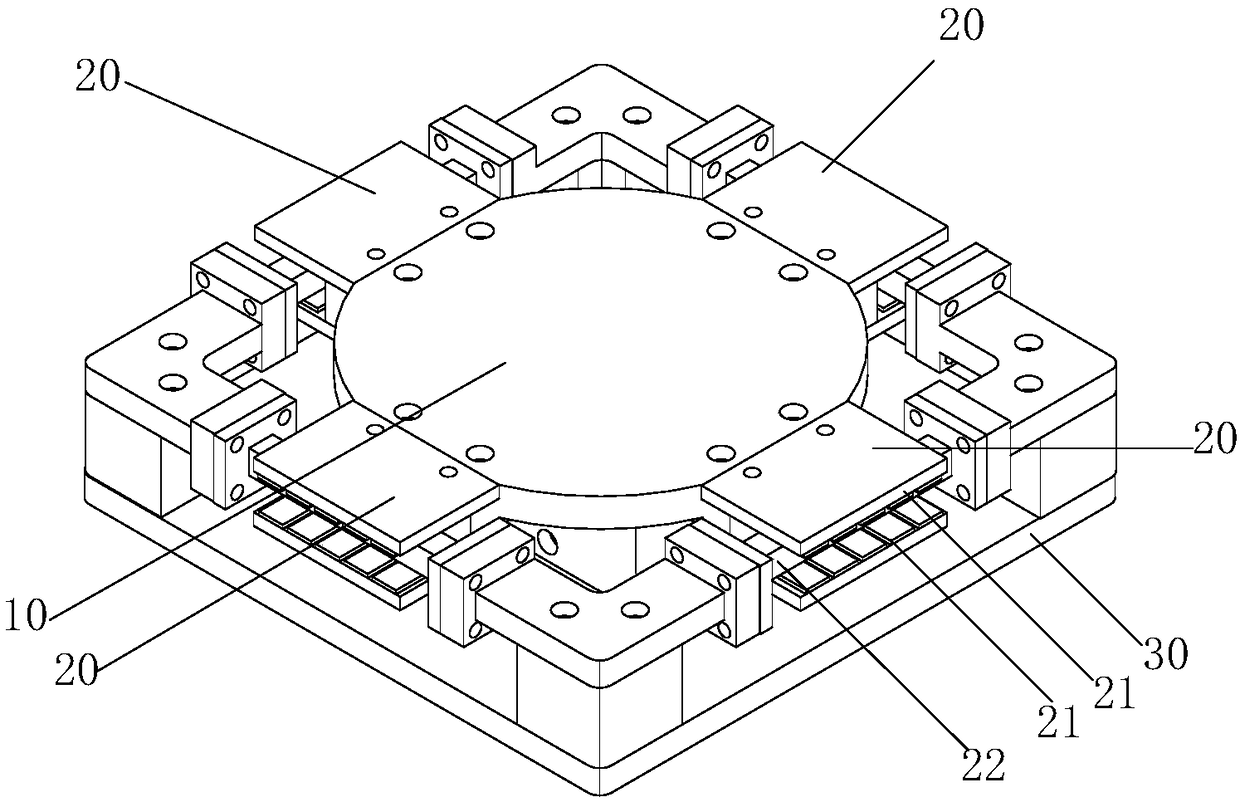

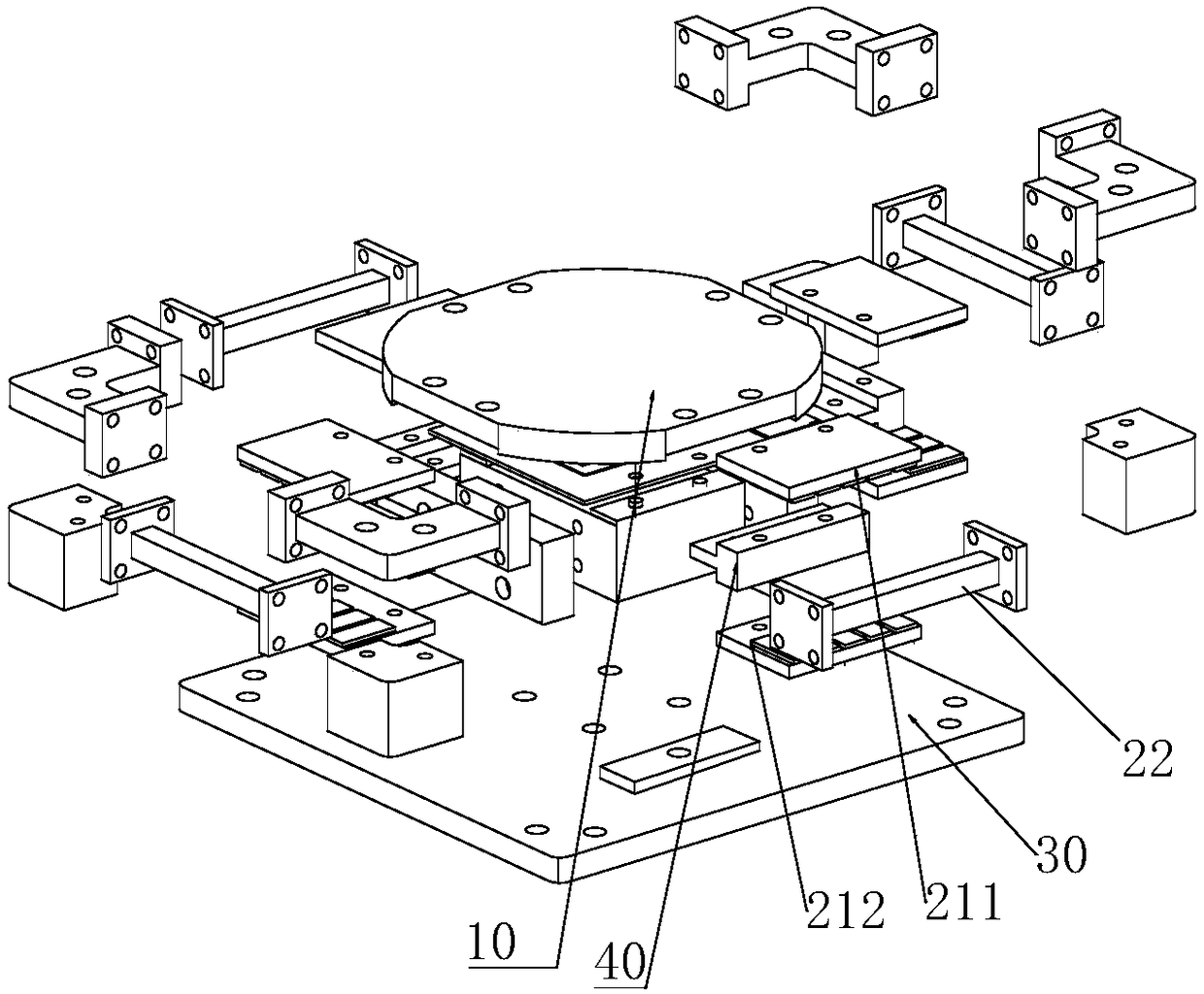

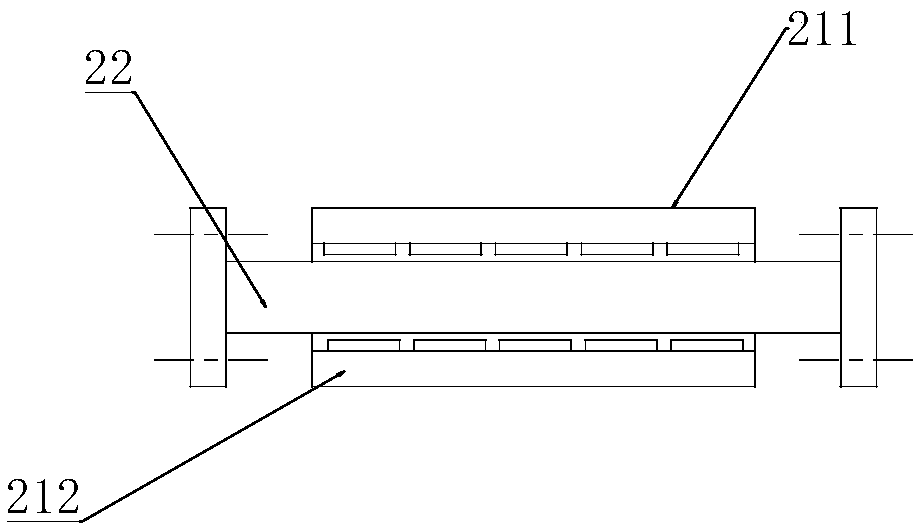

Redundant drive planar motion platform applied to optoelectronic packaging

ActiveCN108493294AFast movementHigh accelerationFinal product manufactureSemiconductor/solid-state device manufacturingFast motionStart stop

Owner:CENT SOUTH UNIV

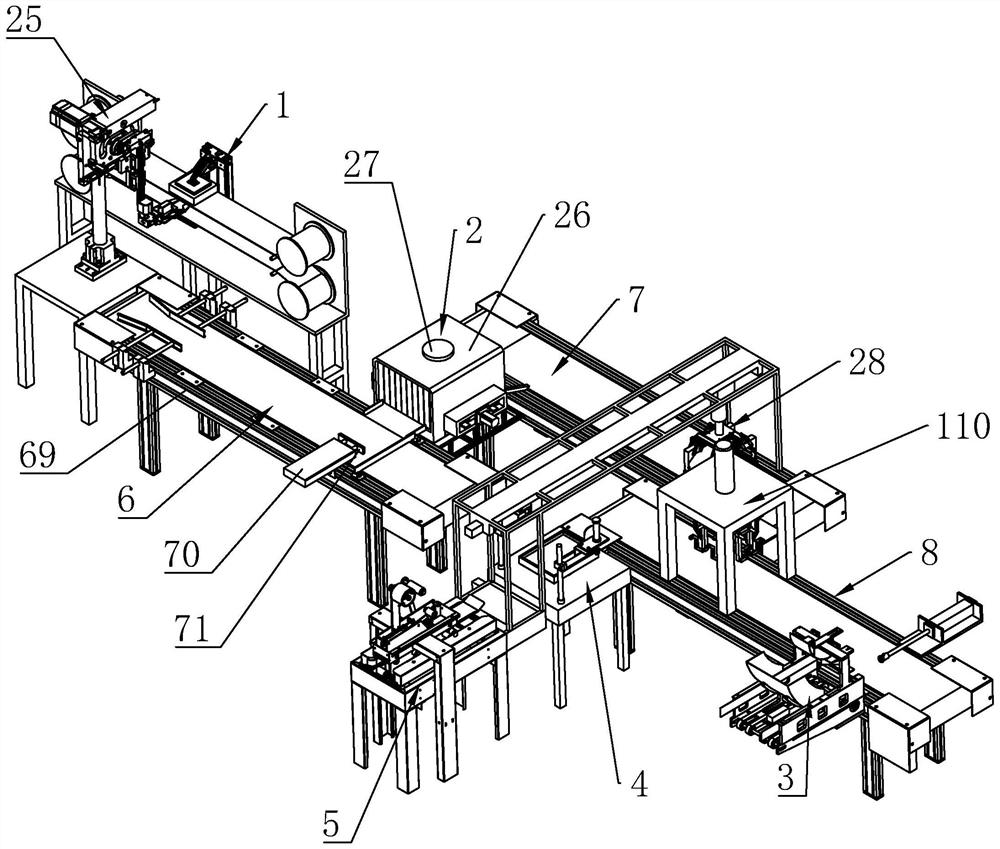

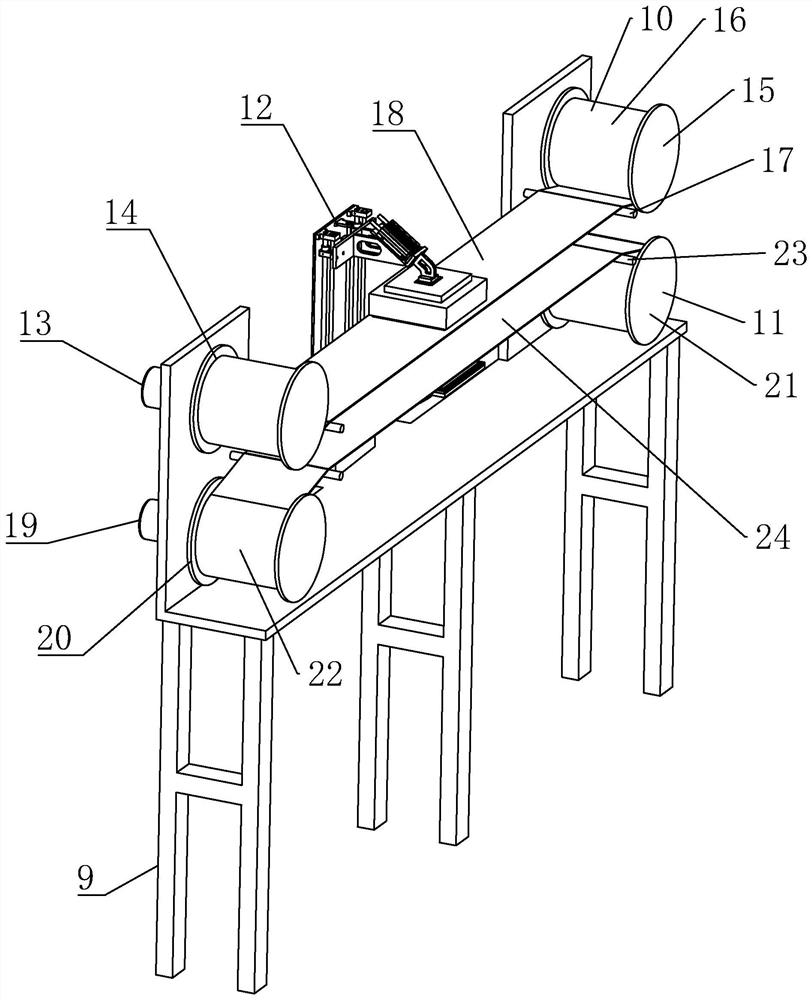

Circuit breaker packaging assembly line

InactiveCN114435651AAccurate captureImprove gripWrappers shrinkageWrapping material feeding apparatusAdhesive beltCarton

The invention discloses a circuit breaker packaging assembly line which comprises a pre-film-wrapping device, a film-wrapping device, a box-opening device, a box-closing device, a box-sealing adhesive tape device, a first belt conveying device, a second belt conveying device and a third belt conveying device. The first belt conveying device conveys the circuit breaker subjected to film coating into the film coating device; the film covering device is arranged between the first belt conveying device and the second belt conveying device, and after the circuit breakers subjected to film covering are loaded into the corresponding paper boxes through the second conveying device, the paper boxes with the circuit breakers are conveyed to the box closing device through the second conveying device to be subjected to the box closing procedure. And finally, the second conveying device conveys the closed carton to the carton sealing adhesive tape device for the carton sealing process. The circuit breaker packaging structure can achieve packaging of the circuit breaker, has the advantages of being high in efficiency and capable of saving labor cost, and meanwhile has the advantage of being good in sealing performance.

Owner:贾天祥

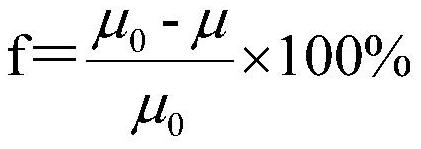

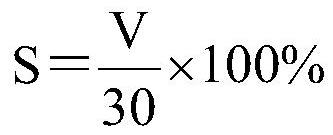

Novel pharmaceutical equipment leak detection device

InactiveCN108760180ALight in massFast movementDetection of fluid at leakage pointMass spectrum analysisLeakage rate

The invention discloses a novel pharmaceutical equipment leak detection device. The leak detection device comprises a device body, a roller is arranged at the bottom of the device body, a leakage detection instrument groove is embedded in the middle of the surface of the device body, a leak detector is arranged in the leak detector groove, a leak detector switch is arranged on the surface of the leak detector, a baffle valve and a filter screen are respectively fixed in the leak detector, a vacuum tube winding column is fixed to the top of the surface of the device body, a fixing column is fixed on one side of the top of the device body, the top of the fixing column is connected with a vacuum tube, helium is used as leakage indication gas, and the helium is light in mass and high in movement speed, and small in molecular diameter, and under the same condition, the linear movement distance is long. The accurate positioning, quantitation, and qualitation of the micro leakage gap of the pharmaceutical equipment can be realized, the sensitivity is extremely high, and the leakage rate and the position of the pharmaceutical equipment can be accurately measured, the performance is stable,the cost is low, and the efficiency is high due to the detection by a mass spectrum chamber.

Owner:肖叶

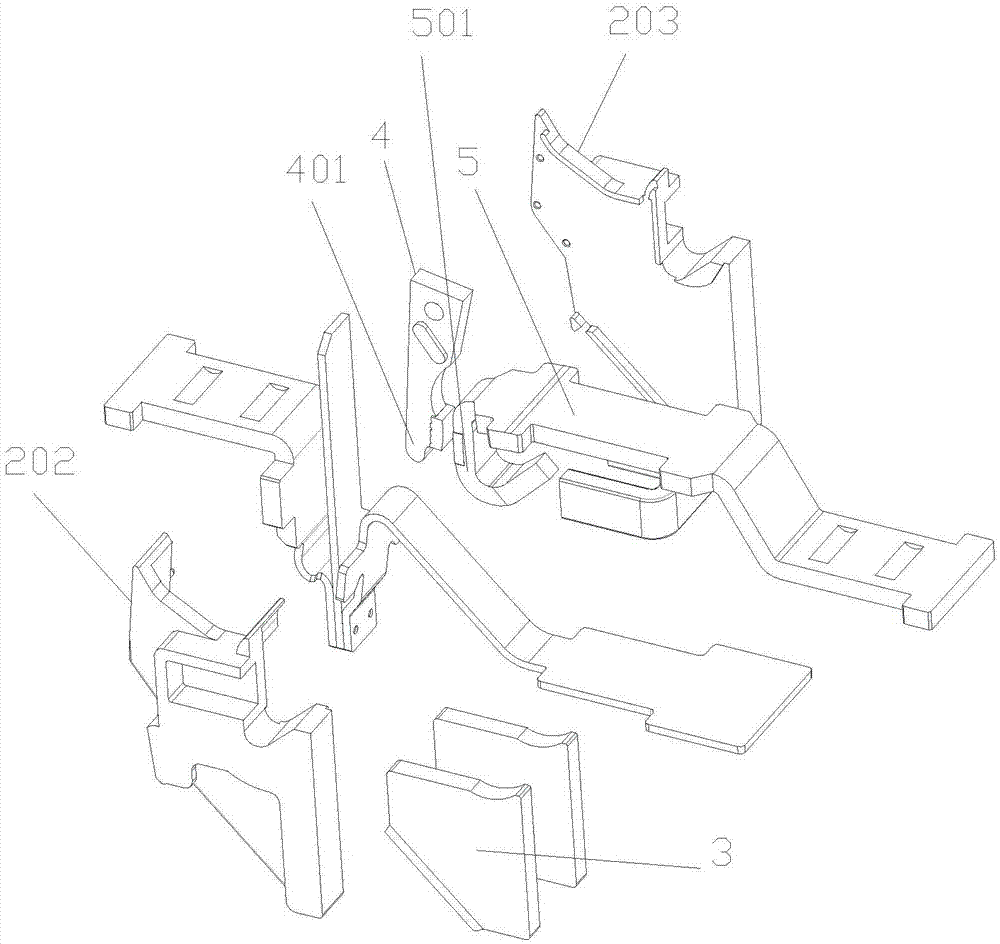

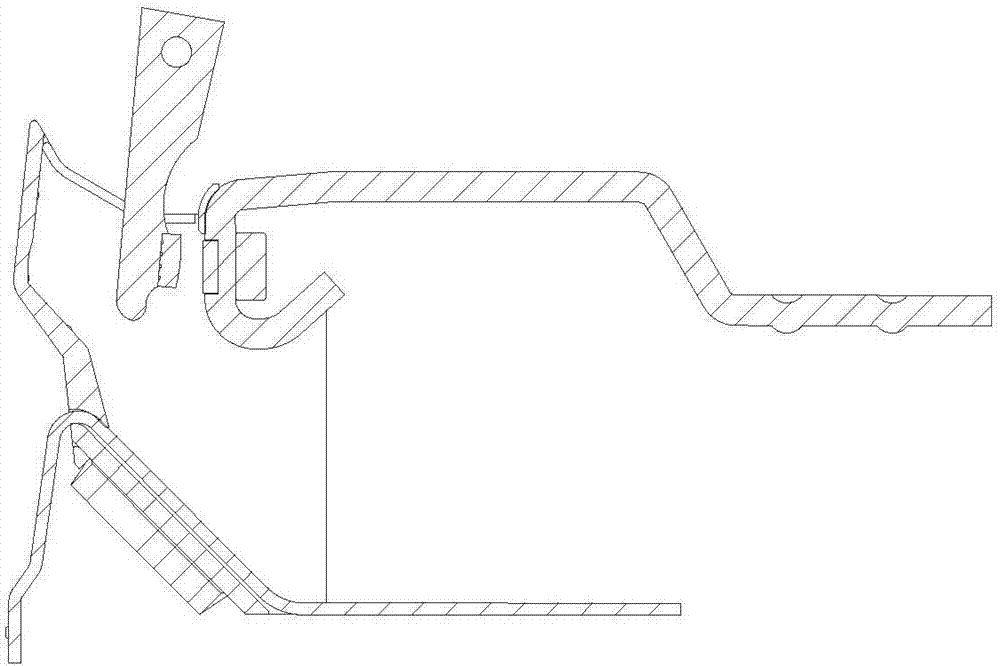

Stepping type piezoelectric actuator and robot

ActiveCN113489369AFast movementMove fastPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsRoboty

The invention provides a stepping type piezoelectric actuator and a robot. The stepping type piezoelectric actuator comprises an actuator shell, a stepping type piezoelectric stack, a displacement amplifier, a clamping mechanism and an output shaft, wherein the stepping type piezoelectric stack is fixed to the actuator shell; the displacement amplifier is connected with the stepping piezoelectric stack; the clamping mechanism is connected with the displacement amplifier; the output shaft is connected with the clamping mechanism; and the stepping piezoelectric stack pushes the displacement amplifier to move, the displacement amplifier pushes the clamping mechanism to move after amplifying displacement, and the clamping mechanism pushes the output shaft to move. According to the stepping type piezoelectric actuator, the displacement of the stepping piezoelectric stack is amplified to the displacement requirement of the robot through the amplifier, the movement speed, the resolution, the response speed and other characteristics of the robot can be improved, and the robot has the advantage of being free of electromagnetic interference; and the stepping type piezoelectric actuator has potential application prospects in the fields of precision detection and transportation in extreme environments such as nuclear radiation and electromagnetic interference.

Owner:GUANGXI UNIV

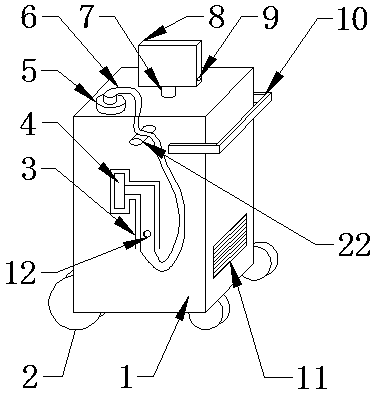

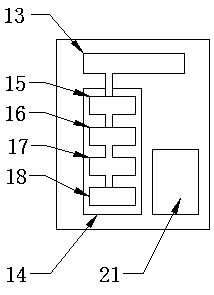

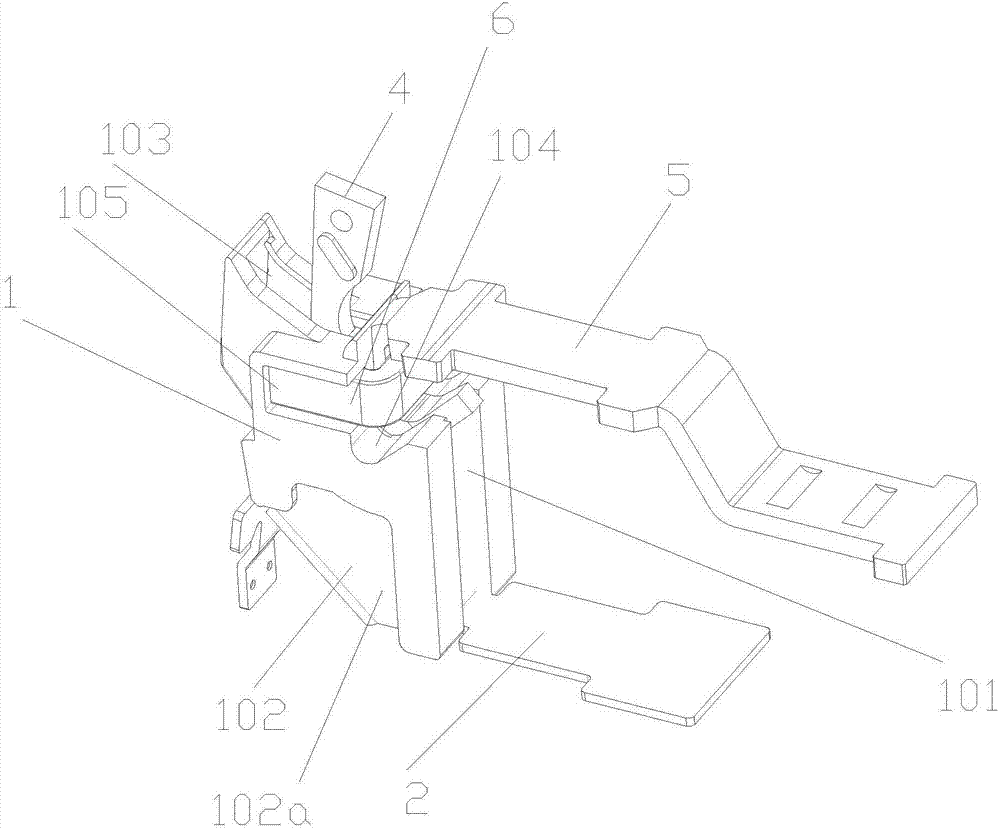

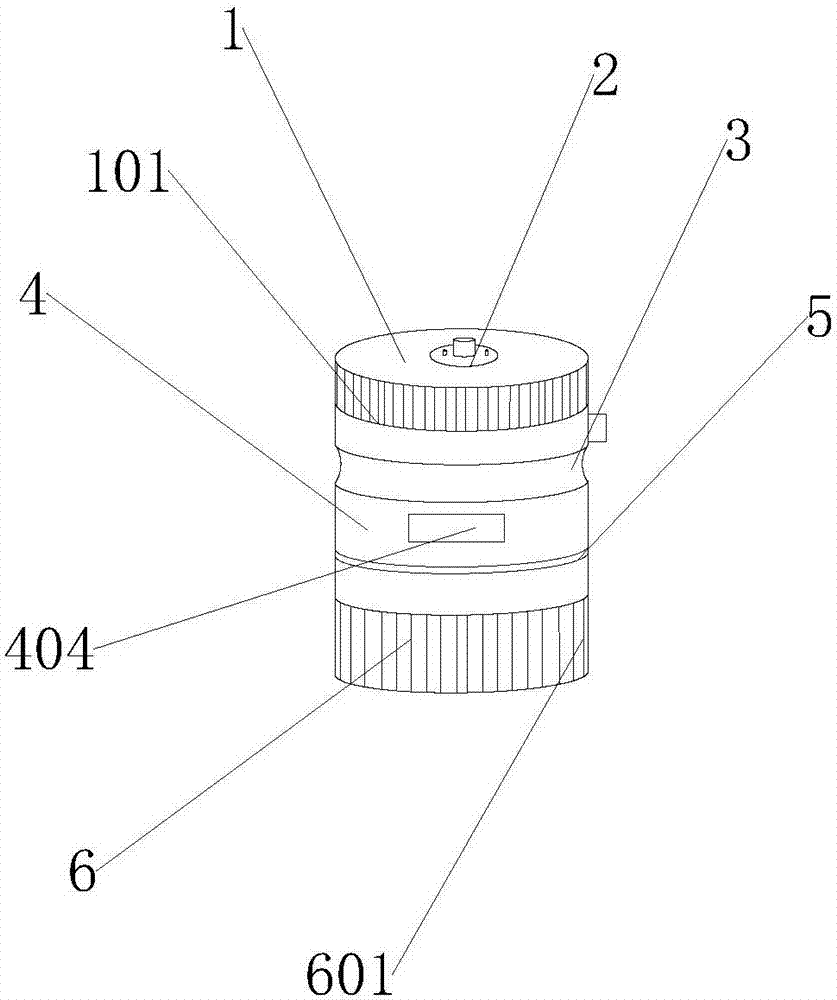

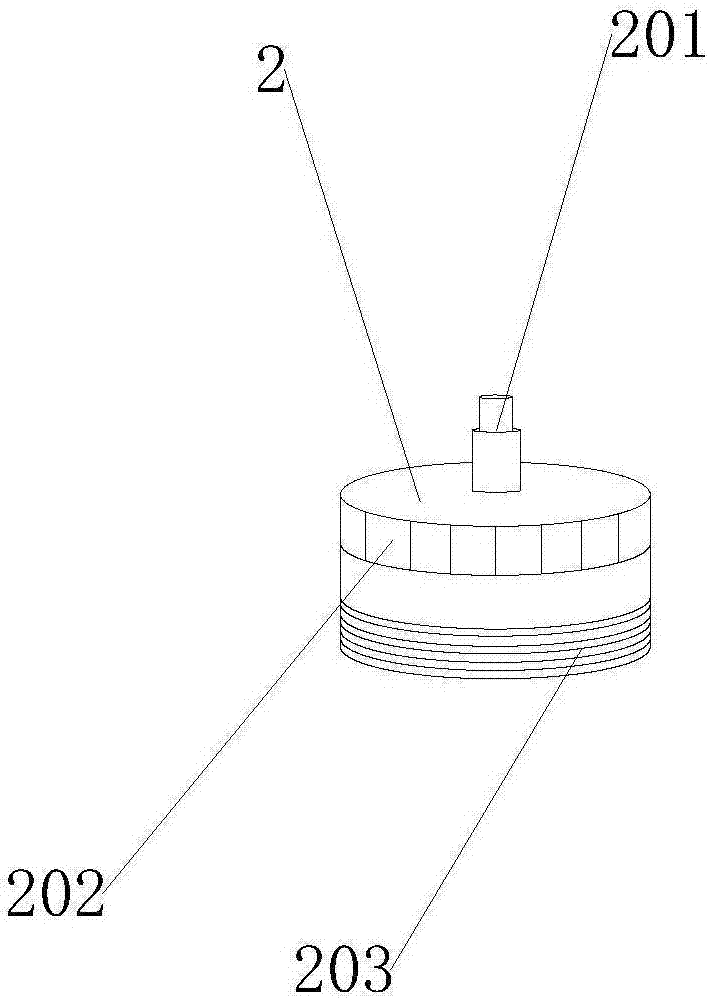

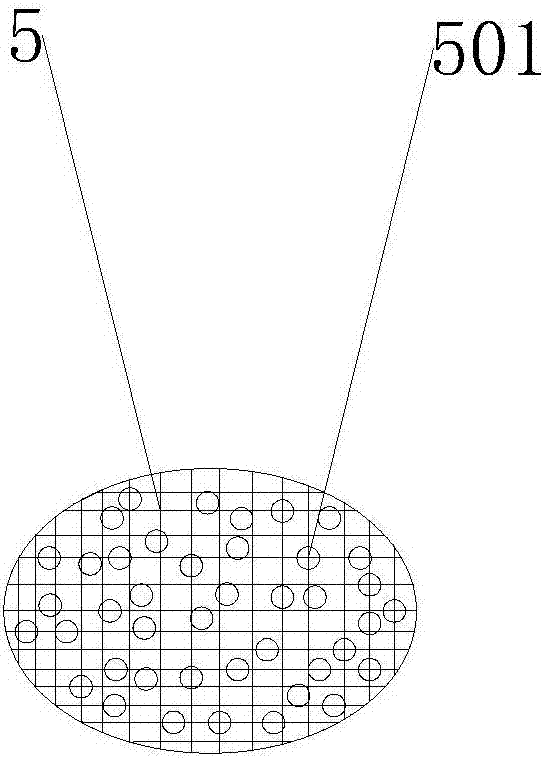

Arc-blowing mechanism of small-sized circuit breaker

ActiveCN107230602AFast movementIncrease the magnetic field strengthCircuit-breaking switch detailsElectric arcPower flow

Disclosed is an arc-blowing mechanism of a small-sized circuit breaker. The arc-blowing mechanism is characterized by comprising an arc cover plate (1); a hollow cavity (101) is formed in the arc cover plate (1); an arc striking plate (2) is inserted in the two ends in the hollow cavity (101) to extend out of the hollow cavity (101); a first mounting groove (102) is formed in the arc cover plate (1); and a combined magnetic conducting plate (3) is inserted in the first mounting groove (102) from the front side surface to induce a magnetic field by the changeable current in the arc striking plate (2). By virtue of the arc-bowing mechanism, the electric arc movement speed is accelerated, the magnetic field intensity is reinforced and arc extinguishing capability is improved; and in addition, arc extinguishing in the current state can be realized, and meanwhile, the requirement on the volume of the small-sized circuit breaker can be satisfied.

Owner:SHANGHAI LIANGXIN ELECTRICAL

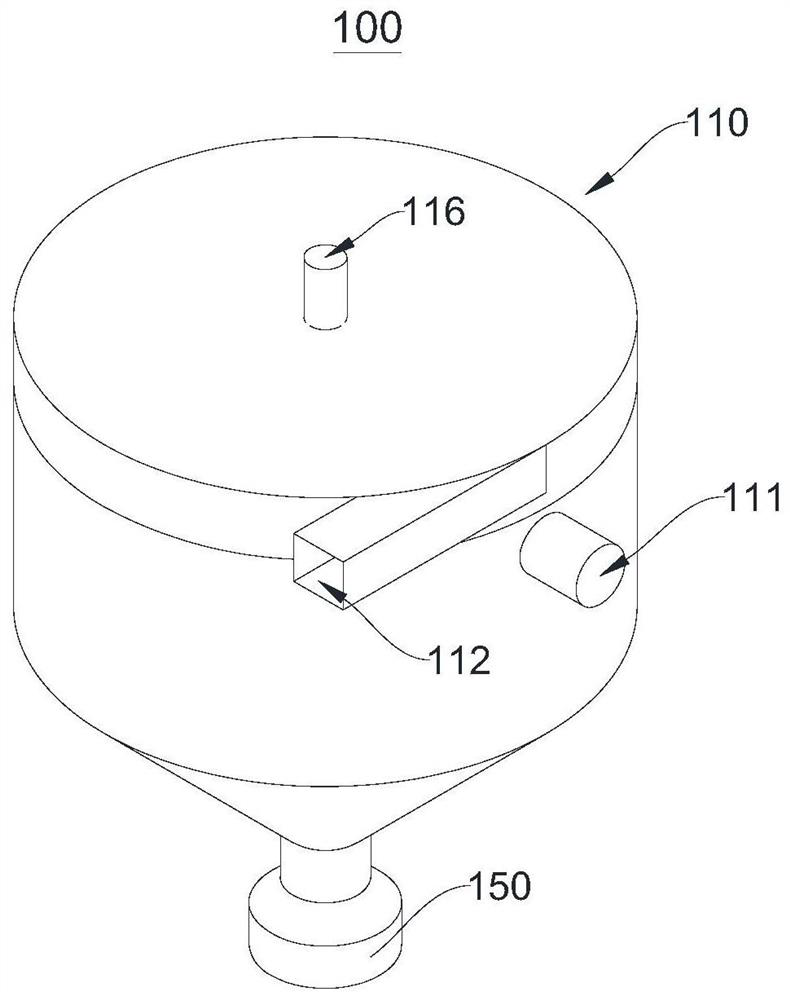

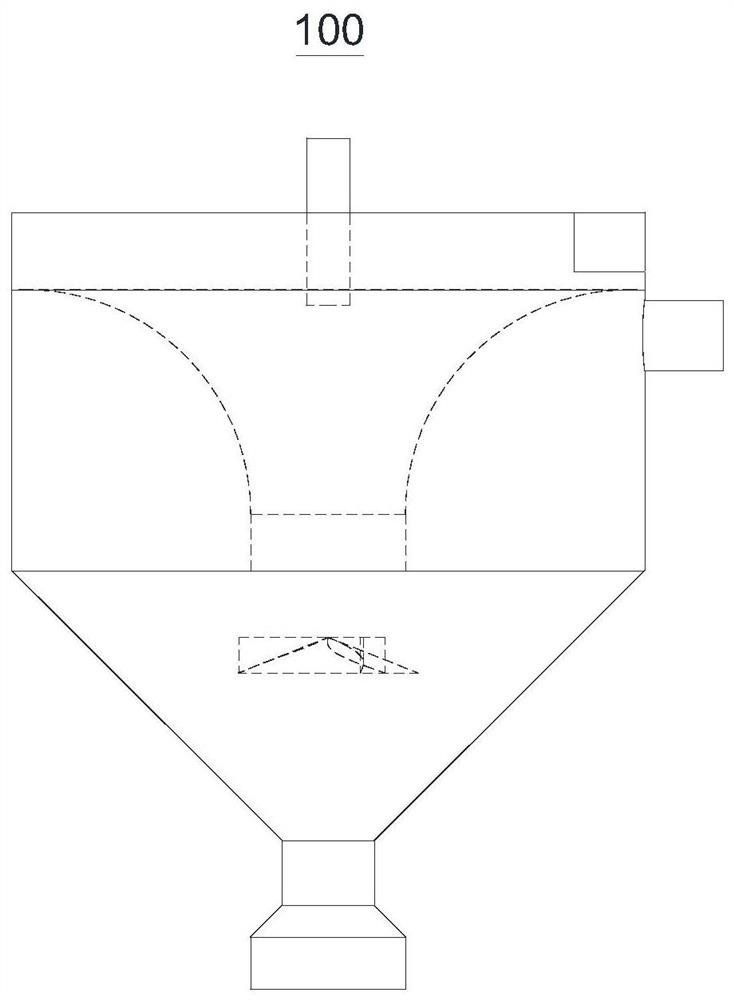

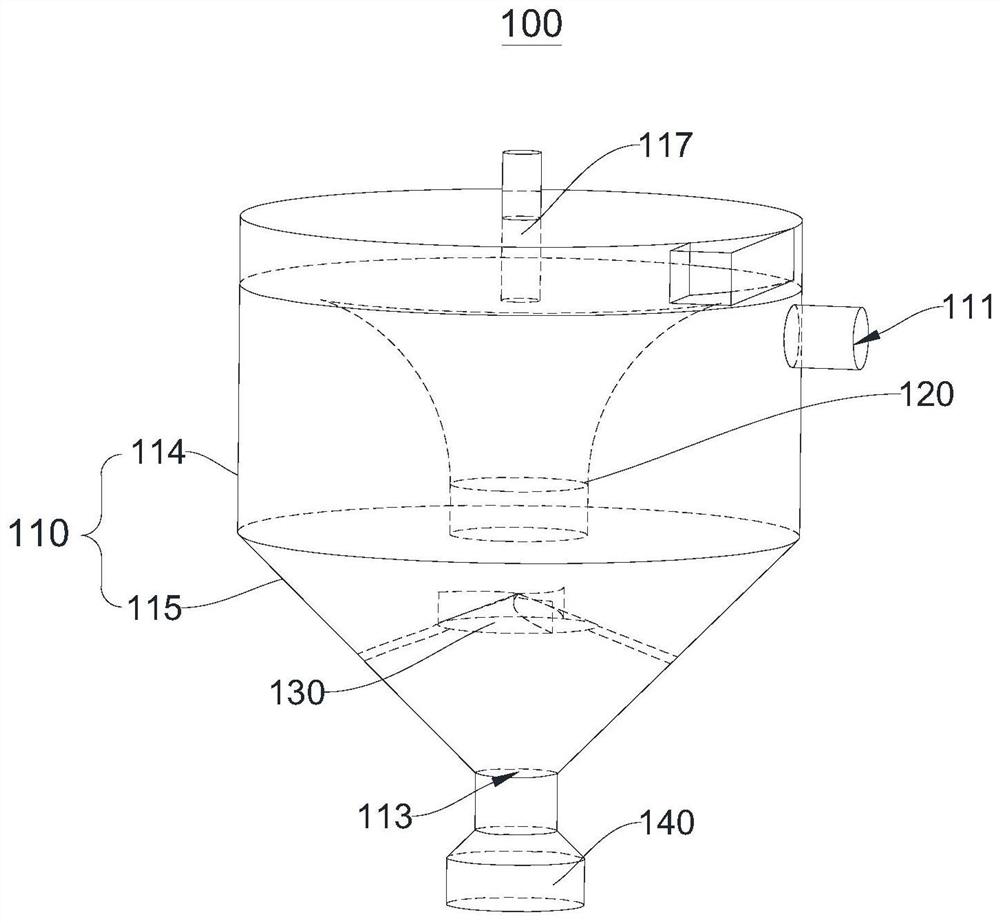

Centrifugal separation device

PendingCN111632437AFast movementImprove dust removal efficiencyDispersed particle separationPhysicsEngineering

The invention provides a centrifugal separation device, and relates to the technical field of centrifugal separation devices. The centrifugal separation device comprises a shell, a shrinkage pipe anda conical cap, wherein the shrinkage pipe is located in the shell, the flaring end of the shrinkage pipe is located between an air outlet and an air inlet, the circumferential edge of the flaring endof the shrinkage pipe is connected with the side wall in a sealed mode, the closing end of the shrinkage pipe extends to the position near the second end of the shell, the conical cap is suspended inthe shell and located between the closing end of the shrinkage pipe and the second end of the shell, a gap allowing particles to pass through is reserved between the conical cap and the side wall, thetip end of the conical cap points to the closing end of the shrinkage pipe, and a plurality of blades are arranged on the surface, facing the shrinkage pipe, of the conical cap. According to the invention, the conical cap is arranged in the shell, and the blades are arranged on the conical cap, so that the rotation of gas is promoted, the centrifugal force is increased, the dust removal efficiency is improved, and tiny particles in the gas are separated and removed.

Owner:中国人民解放军火箭军工程大学

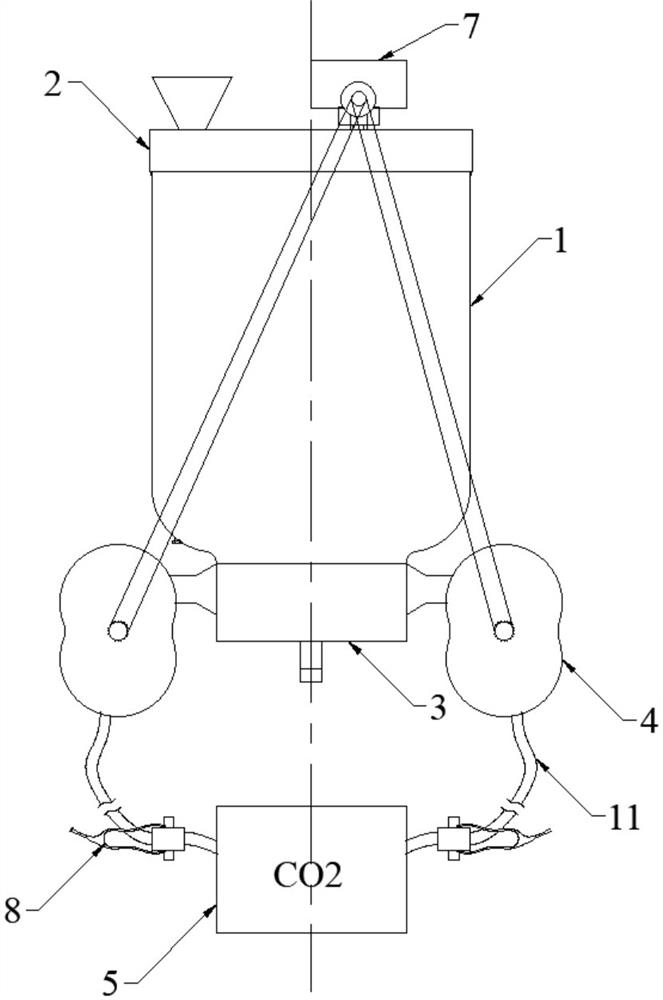

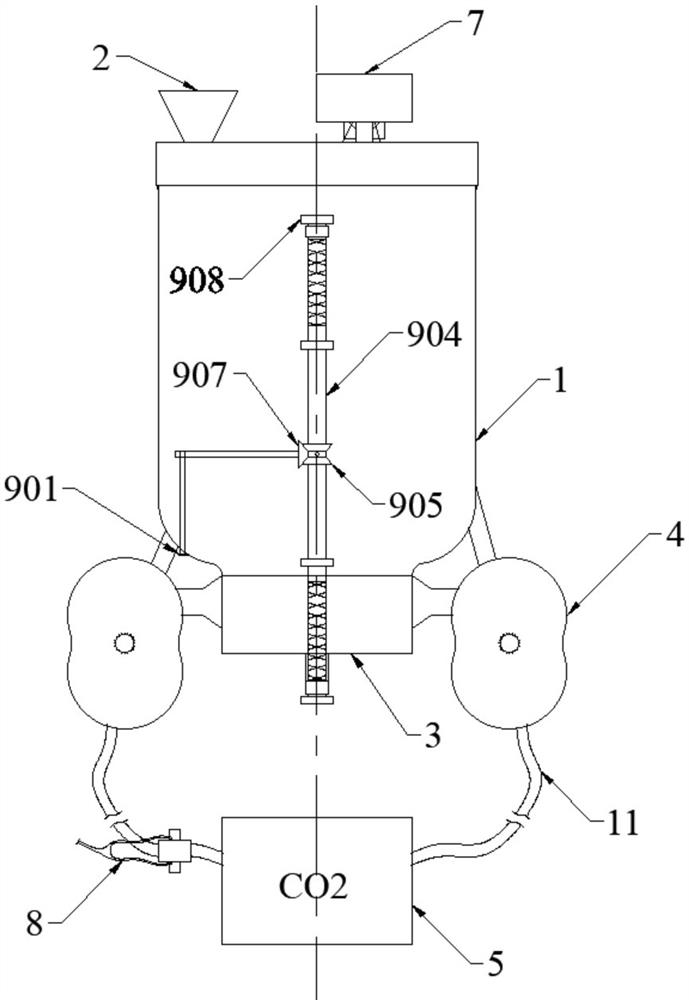

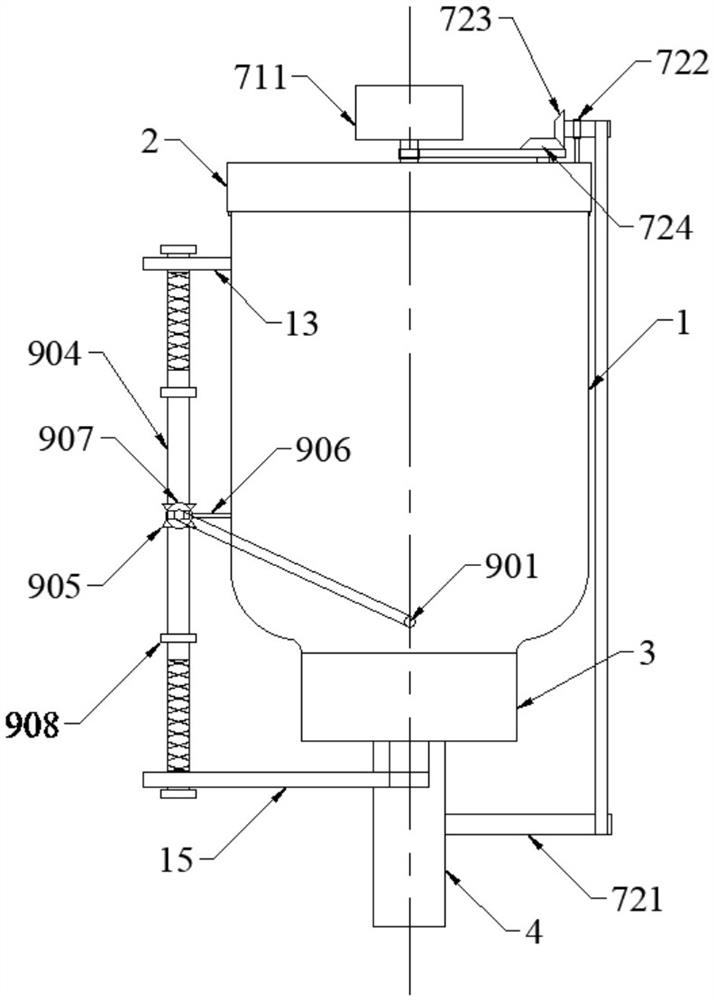

Cell culture device for biological gene research

ActiveCN114317270AFast movementIncrease contact areaBioreactor/fermenter combinationsBiological substance pretreatmentsMechanical engineeringBiotechnology

The invention discloses a cell culture device for biological gene research, which comprises a device body, a feeding mechanism, a liquid supply mechanism, a ventilation mechanism, a carbon dioxide supply box, a centrifugal mechanism and a power mechanism, the feeding mechanism is assembled at the upper end of the device body, and the liquid supply mechanism is arranged at the lower end of the device body; the feeding mechanism is connected with the liquid supply mechanism through a liquid conveying pipe, the carbon dioxide supply box is arranged under the liquid supply mechanism, one end of the ventilation mechanism is connected with the liquid supply mechanism, the other end of the ventilation mechanism is communicated with the carbon dioxide supply box through a gas conveying pipe, and the centrifugal mechanism is arranged in the device body. The power mechanism penetrates through the feeding mechanism, extends into the device body and is connected with the centrifugal mechanism. According to the ventilation mechanism, the compressed air principle is utilized, the effect of increasing the temperature of the culture environment is achieved before ventilation, and cell metabolism is accelerated.

Owner:广州赛太特生物医学科技有限公司

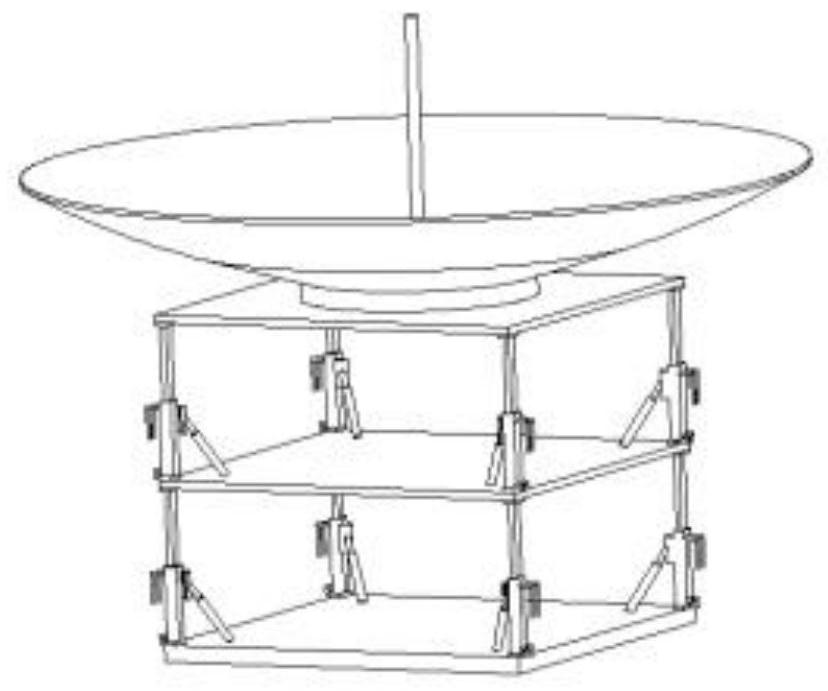

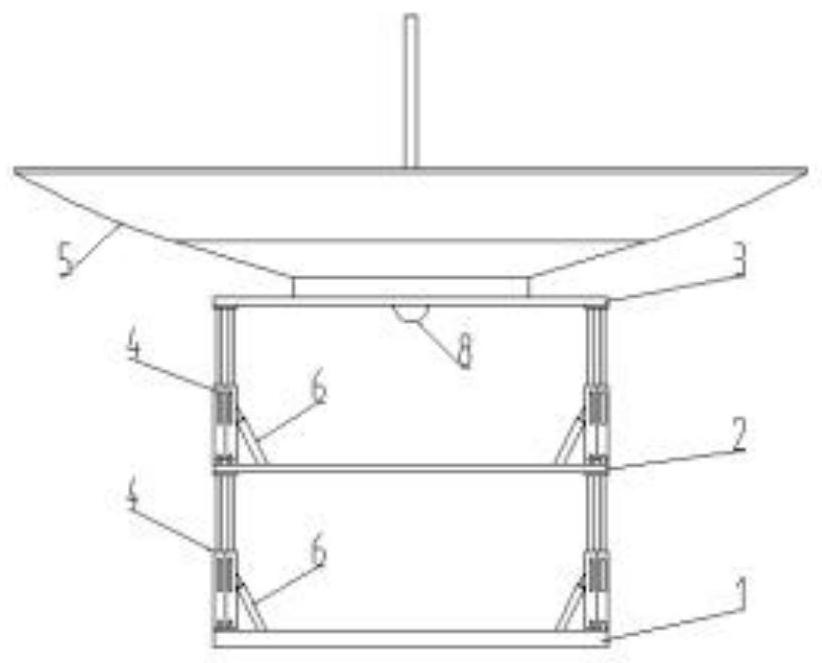

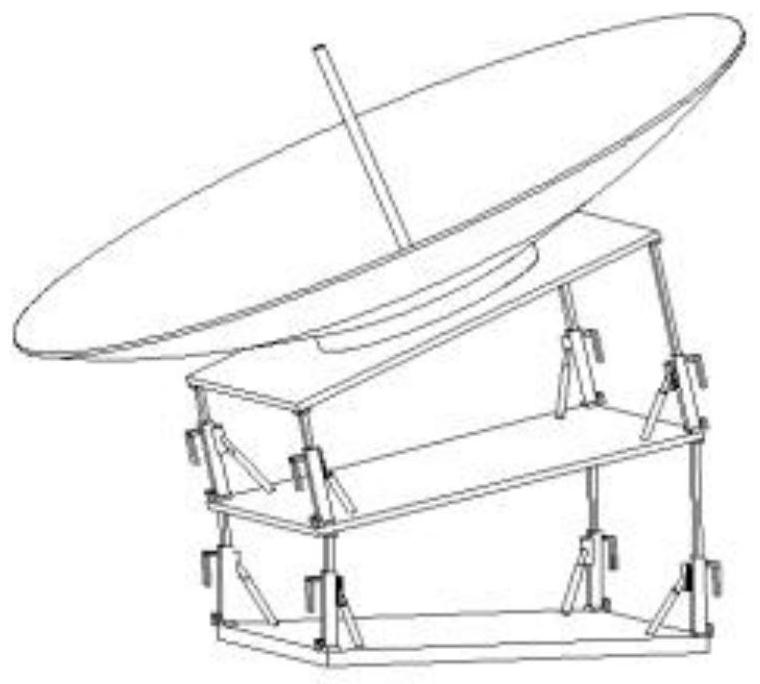

Combined inclined platform type large antenna

PendingCN113690580AOvercoming Zenith Blind SpotsFast movementAntenna supports/mountingsAntenna adaptation in movable bodiesEngineeringStructural engineering

The invention discloses a combined inclined platform type large antenna, and belongs to the technical field of antennas. The antenna comprises a reflector and an antenna seat frame. The antenna seat frame is composed of multiple layers of platforms which are sequentially connected from top to bottom, and the reflector is located on a platform plate of the topmost platform. Each platform comprises supporting columns and a platform plate. The tops of the supporting columns are connected with the platform plate, and the bottoms of the supporting columns are fixed to the next stage of platform plate through lifting devices. Each layer of platform realizes inclined movement in a certain space angle range through the combined movement of the supporting columns at the lower layer. Through the combined movement among the multiple layers of platforms, large-range spatial orientation of the reflector is finally realized. The antenna can realize an overhead tracking function, and has the characteristics of simple structure, reliable transmission, convenience in construction and the like.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

Ultrasonic-assisted fluid cavitation grinding equipment

PendingCN114473880AImprove surface finishFast movementBlast gunsAbrasive feedersGrindingUltrasonic generator

The invention discloses ultrasonic-assisted fluid cavitation grinding equipment. The equipment mainly installs the component in a flow loop, and a pump in the loop drives fluid to pass through an internal channel of the component; the cavitation inducer is mounted on the nozzle, so that the flowing fluid generates bubbles; the bubbles explode in an internal channel of the component to generate high-energy microjet, and the surface of the channel is polished; meanwhile, the ultrasonic generator moves outside the component, the cavitation strength of fluid in an internal channel of the component can be selectively enhanced, and uneven polishing is prevented; the grinding medium in the fluid can further machine the surface of the channel through the abrasion mechanism of the abrasive particles. According to the equipment, the surface smoothness of a component is greatly improved, the impact pressure on the surface of the component is enhanced by increasing the movement speed of a grinding medium, the improvement effect of the grinding medium on the surface quality is greatly enhanced, the number of bubbles is increased, the cavitation strength is enhanced, and the treatment effect on the surface of a channel is greatly enhanced.

Owner:ZHEJIANG UNIV

Glass fiber needled felt treatment device

The invention discloses a glass fiber needled felt treatment device. The glass fiber needled felt treatment device comprises a plastic top cover and a transparent plastic tank body, wherein a vacuum piston is arranged at the top of the plastic top cover and fixedly connected to the plastic top cover; a piston placement opening is formed in the middle of the vacuum piston and embedded into the vacuum piston; and rotary anti-skid textures are arranged below the piston placement opening. According to the glass fiber needled felt treatment device, a plurality of drying agents are arranged on a support mesh and uniformly distributed on the surface of the support mesh; as the drying agent have very strong water absorptivity, a needled felt treated by an upper pressure block and a lower pressureblock can be dried again, and accordingly, the dehydration effect of the needled felt is better; through twice treatment, namely primary water treatment by the upper pressure block and the lower pressure block and re-treatment by the drying agents, the dehydration effect of the needled felt is better.

Owner:WUXI JUNHAO COMPOSITES CO LTD

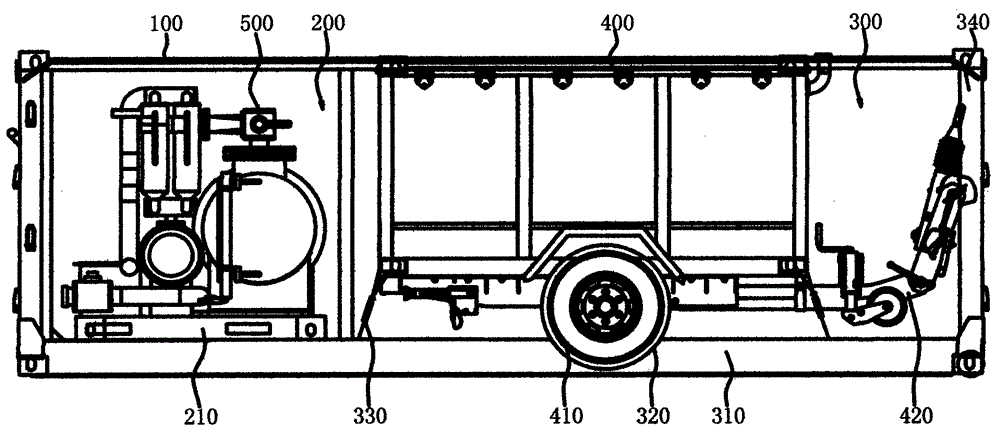

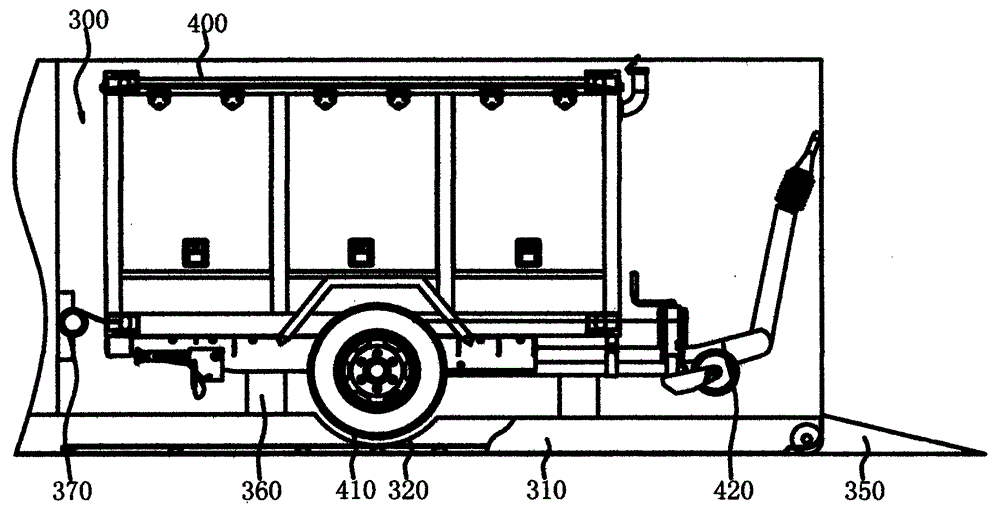

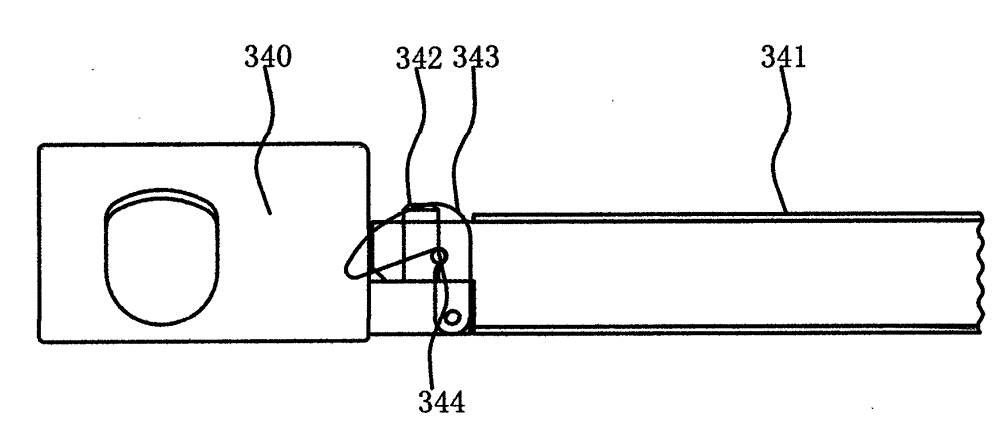

Transportation cabin for packaging pressure testing and emptying equipment

ActiveCN105217176AFast movementIncreased cargo heightLarge containersEngineeringVapor–liquid separator

The invention discloses a transportation cabin for packaging pressure testing and emptying equipment. The transportation cabin comprises a rectangular box body, wherein the inner part of the box body is axially divided into an air compression cabin for placing an air compressor and a gas-liquid cabin for placing a gas-liquid separator; grooves for containing wheels of the air compressor are respectively formed in the two axial side edges of a bottom plate of the air compression cabin, and each groove is sunk from the upper surface of the bottom plate of the air compression cabin to the lower surface of the bottom plate. The transportation cabin realizes onboard synchronous movement of the air compressor and the gas-liquid separator and increases the movement speed. According to the transportation cabin, on the basis of the conventional packaging cabin, the height of cargo of the packaging cabin is increased through the grooves formed in the air compression cabin; the air compressor is fixed in the air of the air compression cabin through a support frame, so that the stability is improved, and the phenomenon that the air compressor moves in the air compression cabin under the driving of the wheels is avoided; a tray is fixed in the gas-liquid cabin through fixed bolts in the gas-liquid cabin, so that the stability of the gas-liquid separator is improved; meanwhile, the tray is also convenient to carry the gas-liquid separator.

Owner:PETRO OIL & LUBRICANT RES INST OF THE GENERAL LOGISITIC DEPT OF PLA

Viscosity reducer for oil exploitation and preparation method thereof

The invention discloses a viscosity reducer for oil exploitation and a preparation method thereof, and belongs to the technical field of oil exploitation, and the preparation method comprises the following steps: (1) preparing a microbial agent; (2) preparing a coating material; (3) carrying out coating treatment; (4) carrying out cold plasma treatment; and (5) preparing a finished product. According to the preparation method of the viscosity reducer for petroleum exploitation, the viscosity reducer finally prepared through the method is remarkable in viscosity reduction effect, very high in natural settling dehydration rate, good in emulsion stability, remarkable in effect and excellent in performance, and has very good application and popularization value.

Owner:YANGZHOU POLYTECHNIC INST

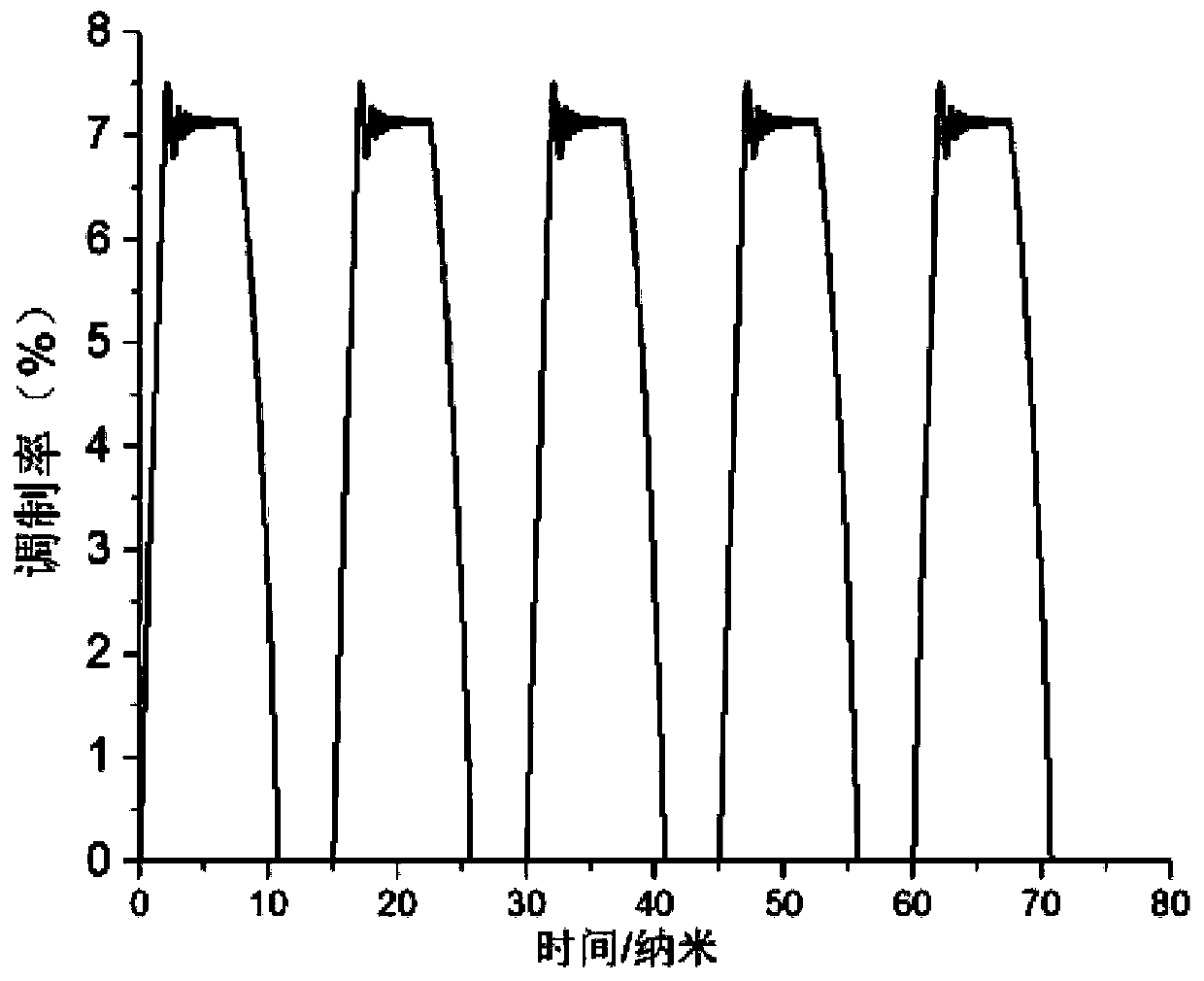

Optical modulator

ActiveCN111240048AEfficient modulationFast movementNon-linear opticsElectrically conductiveIr microscope

The invention discloses an optical modulator. The optical modulator comprises a conductive underlayer, and insulating layers are fixedly arranged at the two ends of the upper surface of the conductiveunderlayer. Lubricating layers are fixedly arranged on the upper surface of the insulating layers, the lower surfaces of the two ends of the two-dimensional material are arranged on the upper surfaces of the lubricating layers, a first electrode is arranged on the conductive underlayer, second electrodes are arranged on the lubricating layers, and the two-dimensional material slides on the lubricating layers. The beneficial effects of the optical modulator are that: the electrostatic force between the two-dimensional material and the base is adjusted by changing the voltage between the two-dimensional material and the conductive underlayer; the two-dimensional material slides on the lubricating layers, the distance between the two-dimensional material and the conductive base is adjusted,so that light regulation and control are achieved, the optical modulator can achieve simultaneous modulation within the ultraviolet-to-infrared spectrum range, the modulation speed is high, the modulation voltage is small, and power consumption is low.

Owner:GUIZHOU MINZU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com