Circuit breaker packaging assembly line

A circuit breaker and assembly line technology, which is applied in the field of small circuit breaker packaging and assembly lines, can solve problems such as affecting the quality and service life of circuit breakers, failing to meet market supply demands, and being susceptible to moisture and rusting, achieving rapid displacement and accurate grasping. and displacement, the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

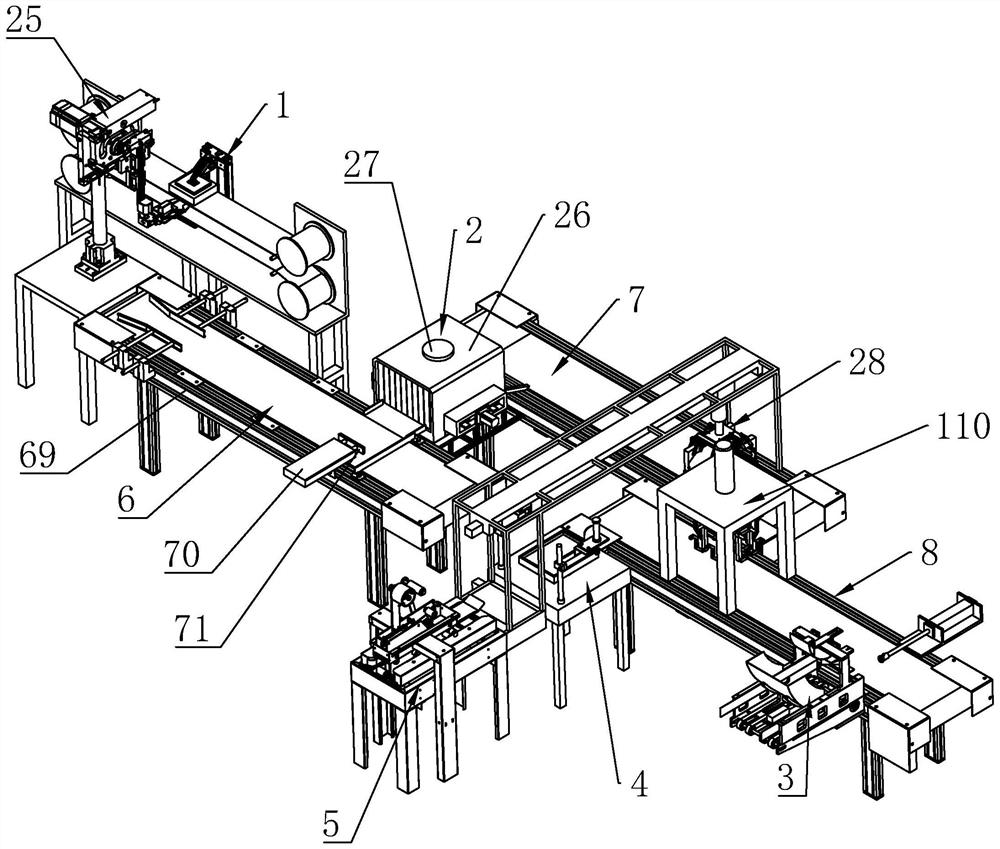

[0045] Example: as attached Figure 1-13 The circuit breaker packaging line shown includes a pre-coating device 1, a film covering device 2, an unpacking device 3, a closing device 4, a sealing tape device 5, a first belt conveyor 6, a second belt conveyor 7 and The 3rd belt delivery device 8, wherein, sealing adhesive tape device 5, the first belt delivery device 6, the second belt delivery device 7 and the 3rd belt delivery device 8 are all available devices on the market, are prior art, Therefore, its specific structure will not be described in detail here.

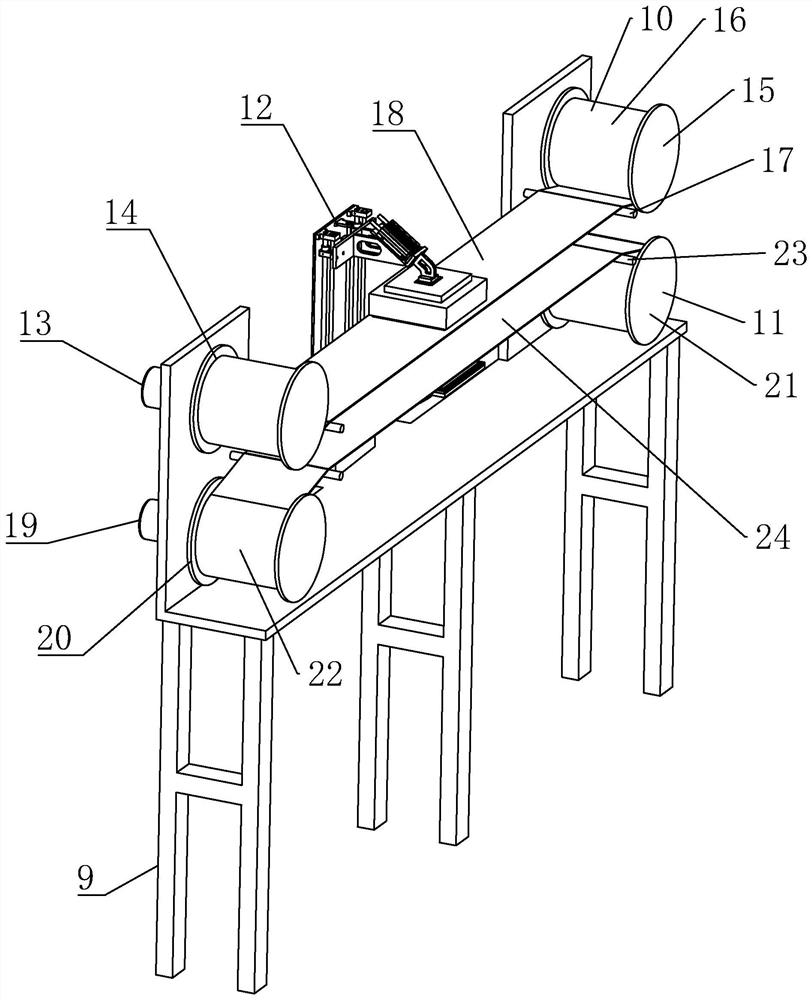

[0046] The pre-coating device 1 includes a first mounting frame 9, on which a first roller mechanism 10, a second roller mechanism 11 and a coating mechanism 12 are arranged, and the first roller mechanism 10 includes a The first driving motor 13 on the first mounting frame 9 and the first receiving wheel 14 and the first discharging wheel 15 that are installed in rotation on the first mounting frame 9, the motor shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com