Patents

Literature

81 results about "Box-sealing tape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Box-sealing tape, parcel tape or packing tape is a pressure-sensitive tape used for closing or sealing corrugated fiberboard boxes. It consists of a pressure-sensitive adhesive coated onto a backing material which is usually a polypropylene or polyester film which is oriented to have strength in both the long (machine) direction and the cross direction.

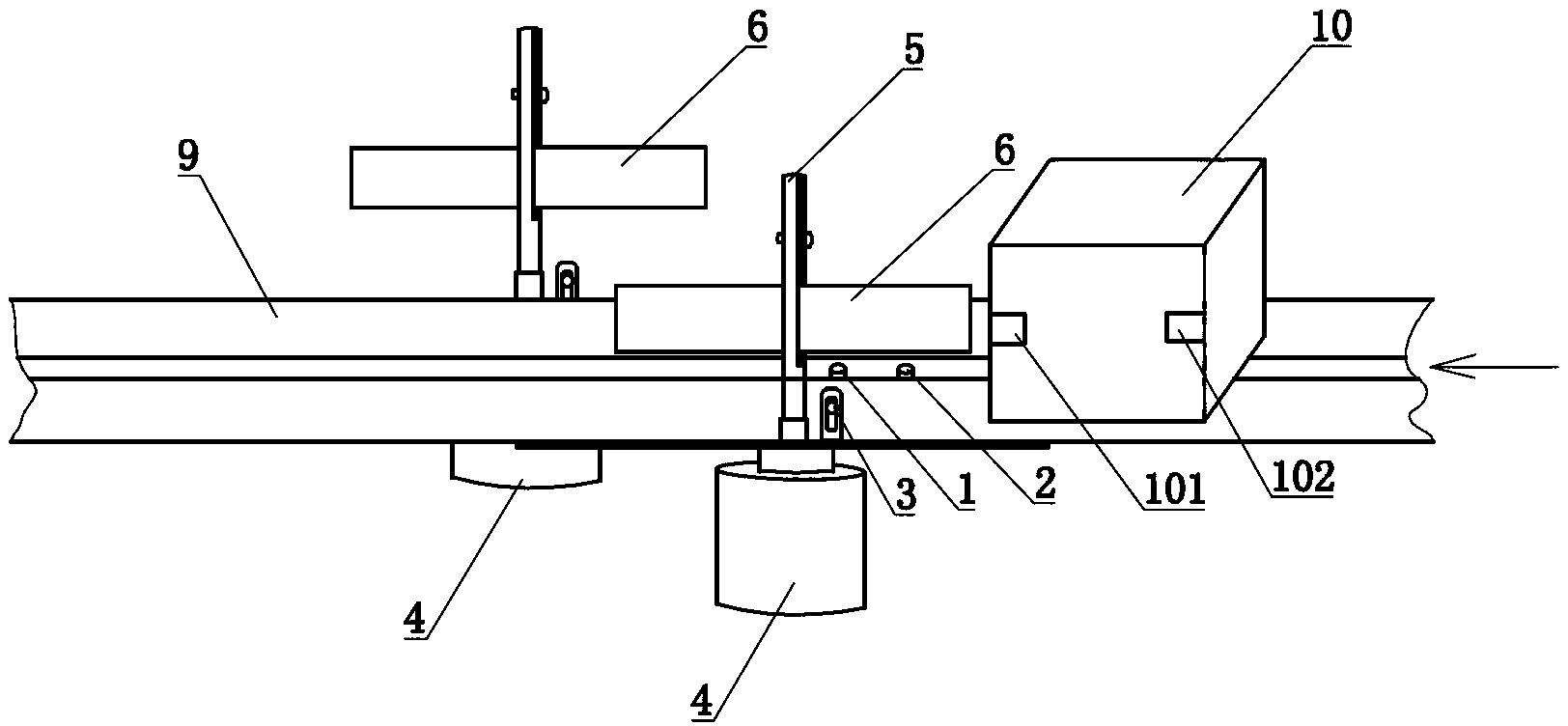

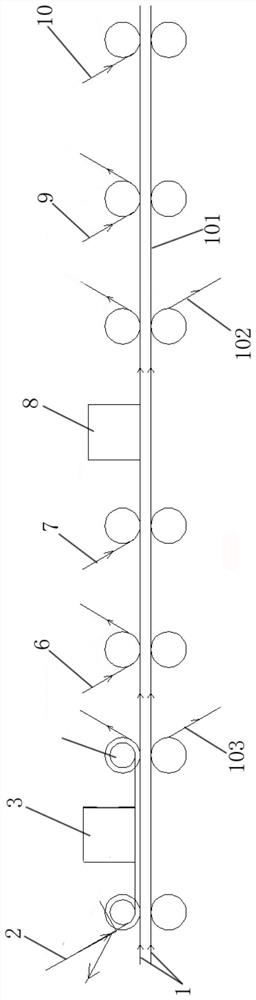

Method for opening box by cutting packing tape with laser

ActiveCN102079407AImprove work efficiencyReduce work intensityArticle unpackingLaser beam welding apparatusProduction lineEngineering

The invention relates to a method for opening a box by cutting a packing tape with laser, and the method comprises the following steps: (1) placing a box, which is sealed by using a tape, on a running production line; (2) utilizing a photoelectric sensor to judge whether the box is in an operation scope of a laser device, and utilizing the laser device to cut the tape at one vertical side of the sealed box according to a judgment result of the photoelectric sensor; (3) utilizing a distance sensor to detect the joint position between the tape and the box cover, judging an accurate position of the joint between the tape and the box cover according to a loss signal of the distance sensor, and cutting the joint between the tape and the box cover through the laser device according to the judgment of the distance sensor; and (4) performing distance conversion by utilizing a central control unit to instruct the laser device to cut the tape at the other vertical side of the box. By adopting the technical scheme, the laser device can automatically cut the tape on the box according to the instruction of the central control unit, and the manual direct operation is unnecessary, so the operation efficiency is high, and the working intensity is low.

Owner:HANS LASER TECH IND GRP CO LTD

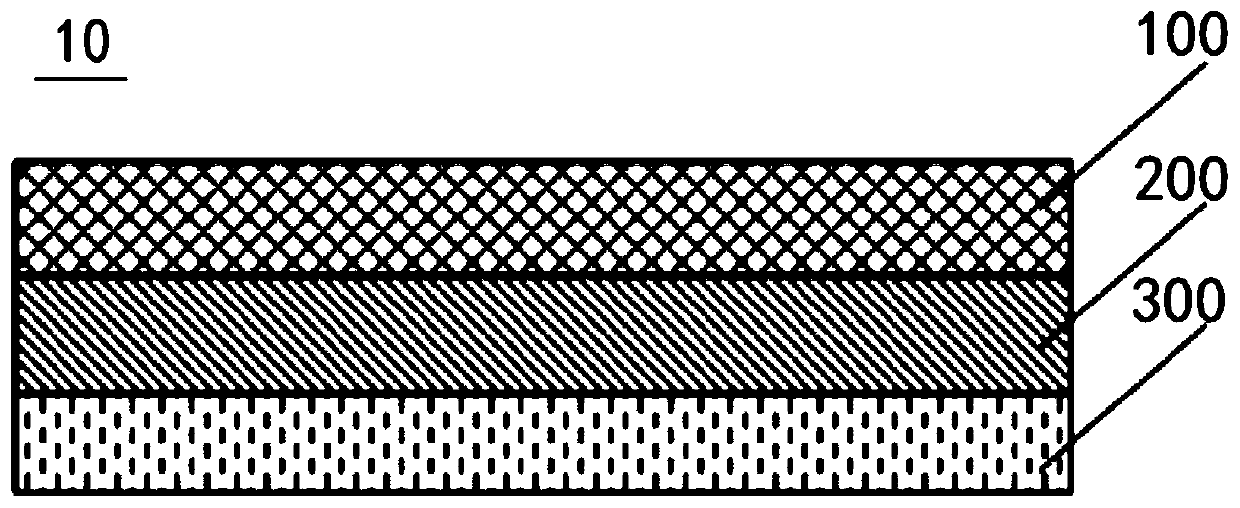

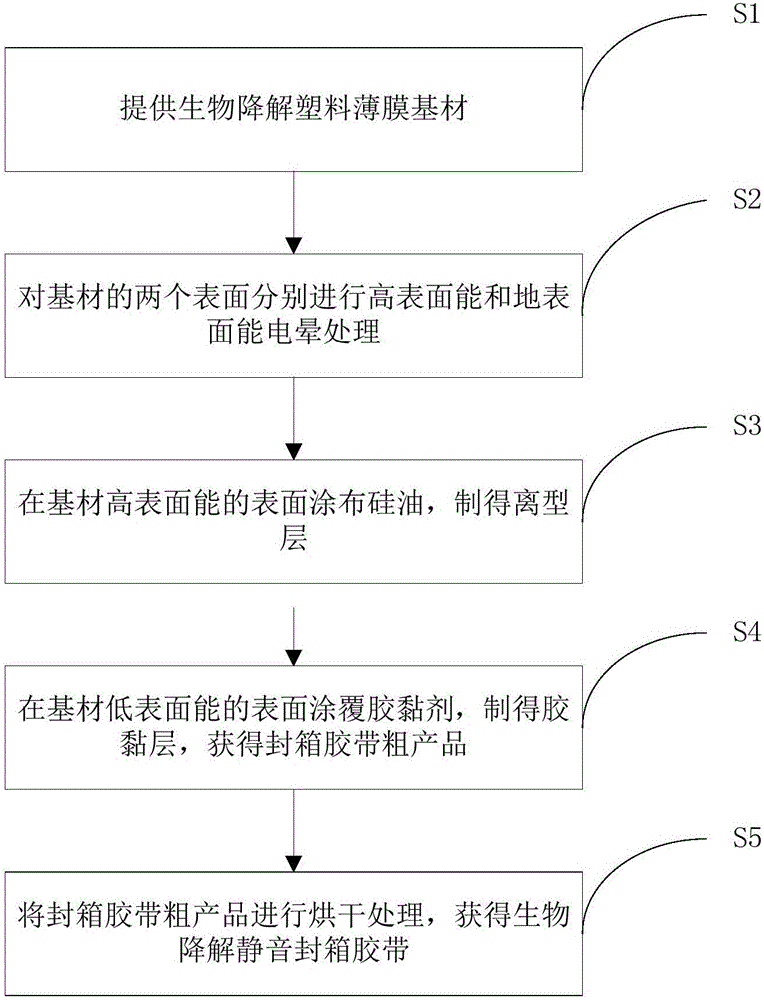

Biodegradable box-sealing tape

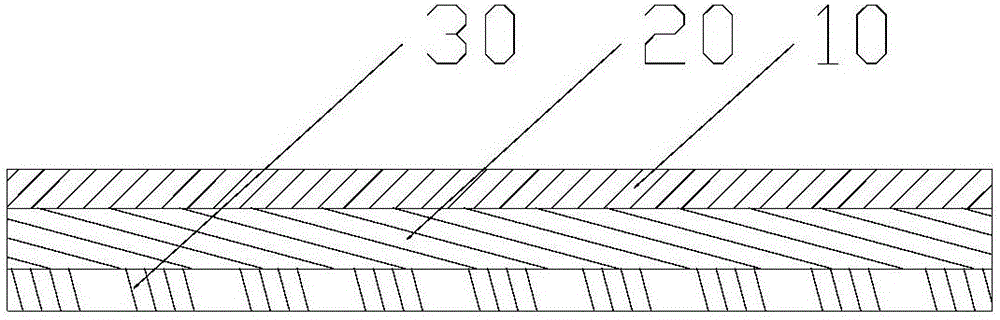

ActiveCN110183984ASimple manufacturing processReduce pollutionFilm/foil adhesivesComposite filmBiochemical engineering

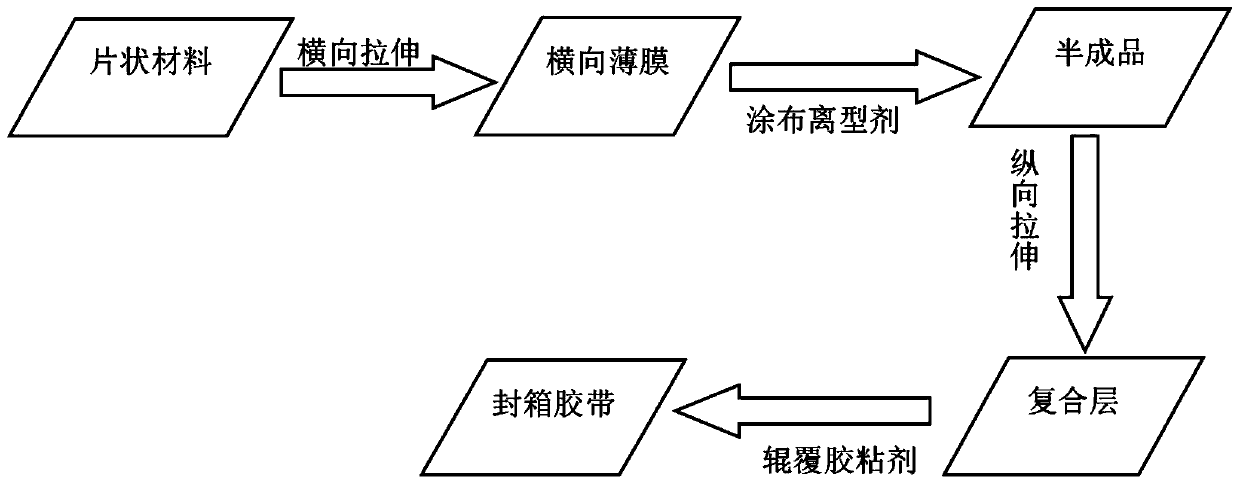

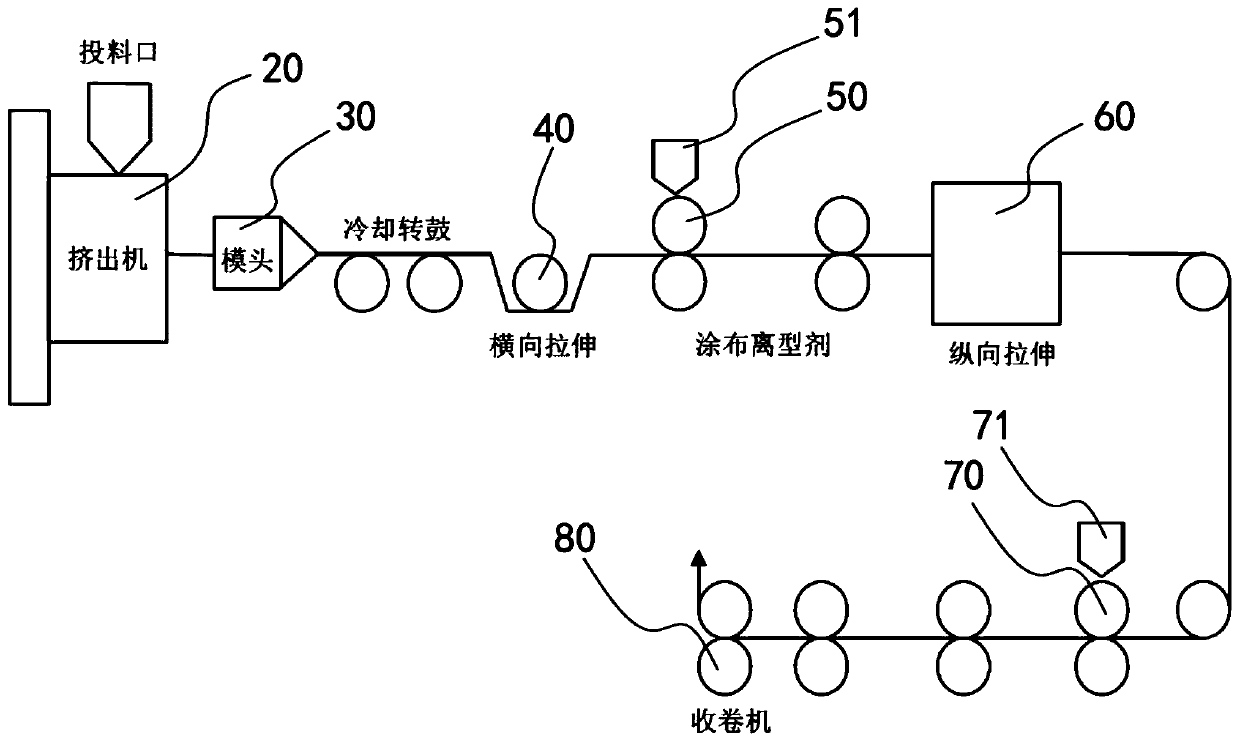

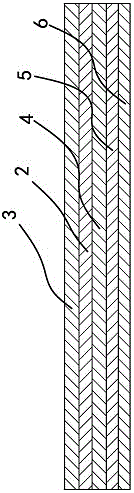

The invention discloses a biodegradable box-sealing tape. The biodegradable box-sealing tape comprises a release layer, a substrate layer and an adhesive layer which are sequentially laminated, and the substrate layer is a PLA / PCL composite film. The substrate layer and the adhesive layer of the biodegradable box-sealing tape are both biodegradable materials, the environmental pollution can be reduced to a large extent, environmental protection requirements are satisfied, the entire laminating process has no VOC emission, and is green and environment-friendly, and the environmental pollution can be reduced to a greater extent; a preparation process of the biodegradable box-sealing tape can be simplified, a release agent is coated during the process of biaxial stretching to form the substrate layer, the heat during the biaxial stretching is used for thermally curing the release agent to form the release layer, and simultaneously a composite film combining the substrate layer and the release layer is prepared. Compared with the conventional processing technology, the process has the characteristics of simplicity, high efficiency and low energy consumption.

Owner:GUANGZHOU BAOLI TRADE

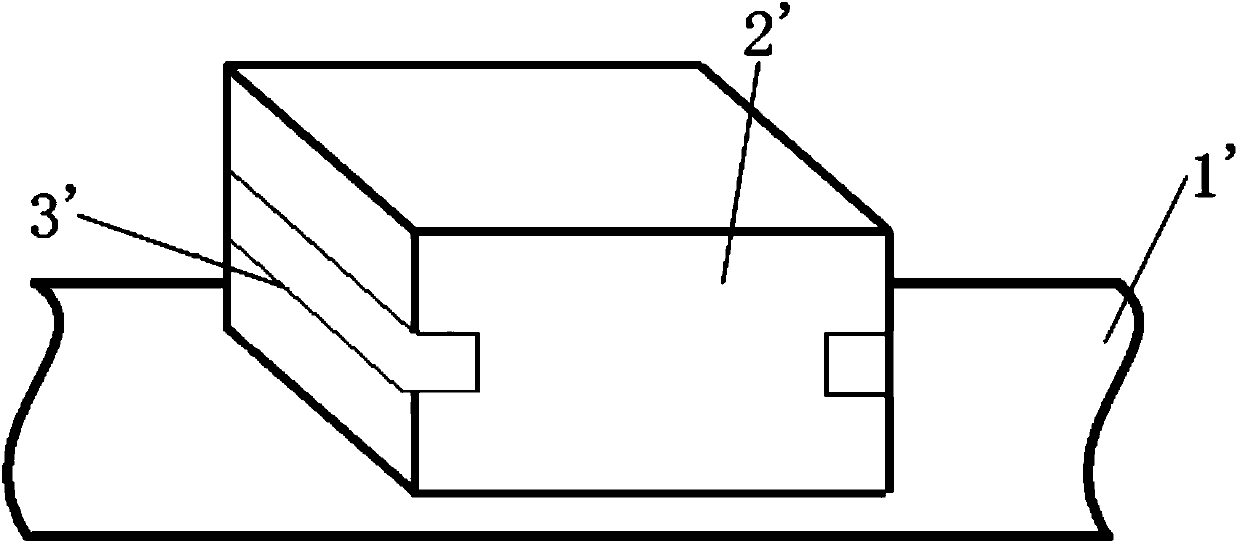

Matching die cutting and half-and-half rotating pasting processing method for conductive adhesive

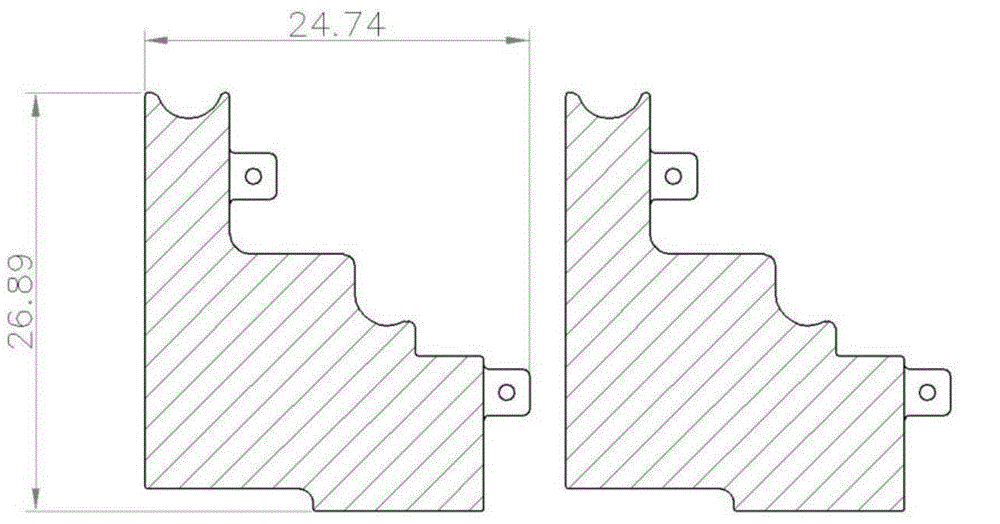

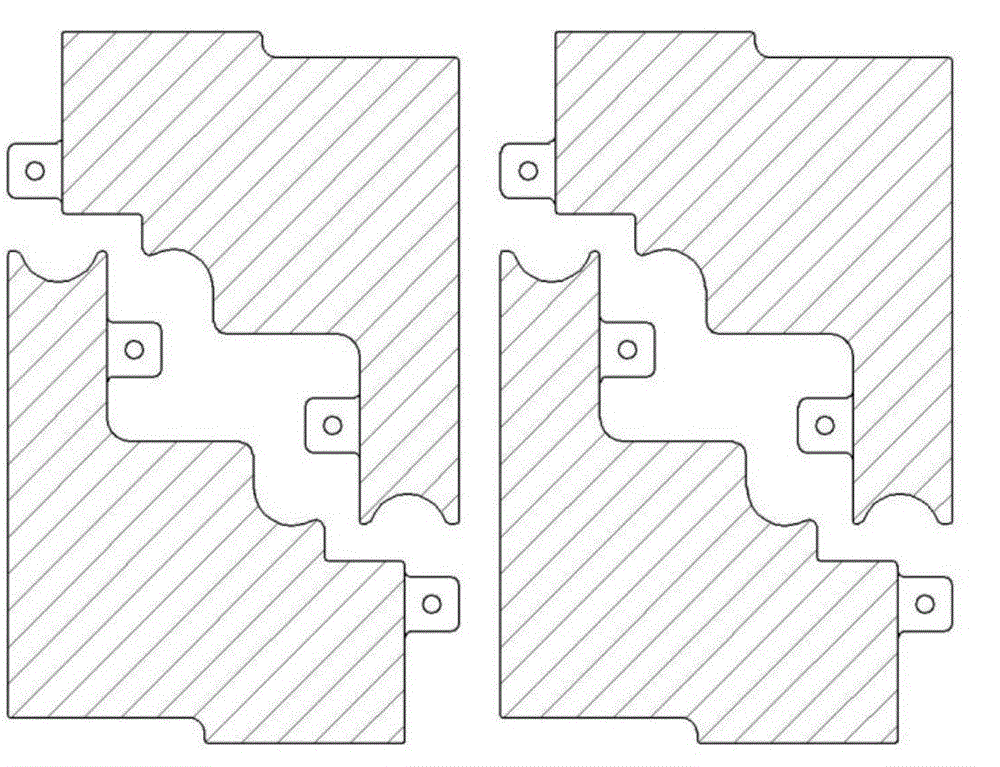

The invention relates to a matching die cutting and half-and-half rotating pasting processing method for conductive adhesive. The matching die cutting and half-and-half rotating pasting processing method for the conductive adhesive includes the following steps of 1, typesetting and designing; 2, die cutting mode designing; 3, waste scheme designing; 4, product rotating pasting. After die cutting is performed on a single product, the half-and-half rotating pasting technology is adopted. The half-and-half rotating pasting technology comprises the steps that a row of products are pasted in a rotating mode, after material strips are cut, and the other half products are reposted; two strips of box sealing tape with the width of 5 mm are needed in product rotating pasting, a single PCS product is firstly fixed, dislocation or amount missing are prevented, then face paper on the conducting adhesive is removed, the original two rows of side-by-side products which are designed through the up-down and front-back rope winding are changed into products by rotating pasting in sequence and material strap cutting in sequence, therefore, the typesetting of a client is restored, and products the customer needed are manufactured. The matching die cutting and half-and-half rotating pasting processing method for the conductive adhesive improves the use efficiency of conducting resin materials, the waste materials in the manufacturing process are eliminated, the blade collapse is prevented, the normal production is guaranteed, and the production efficiency is improved; the conducting resin product rotating pasting is achieved, and the product typesetting is restored.

Owner:W B ROYMAX TECH SHENZHEN

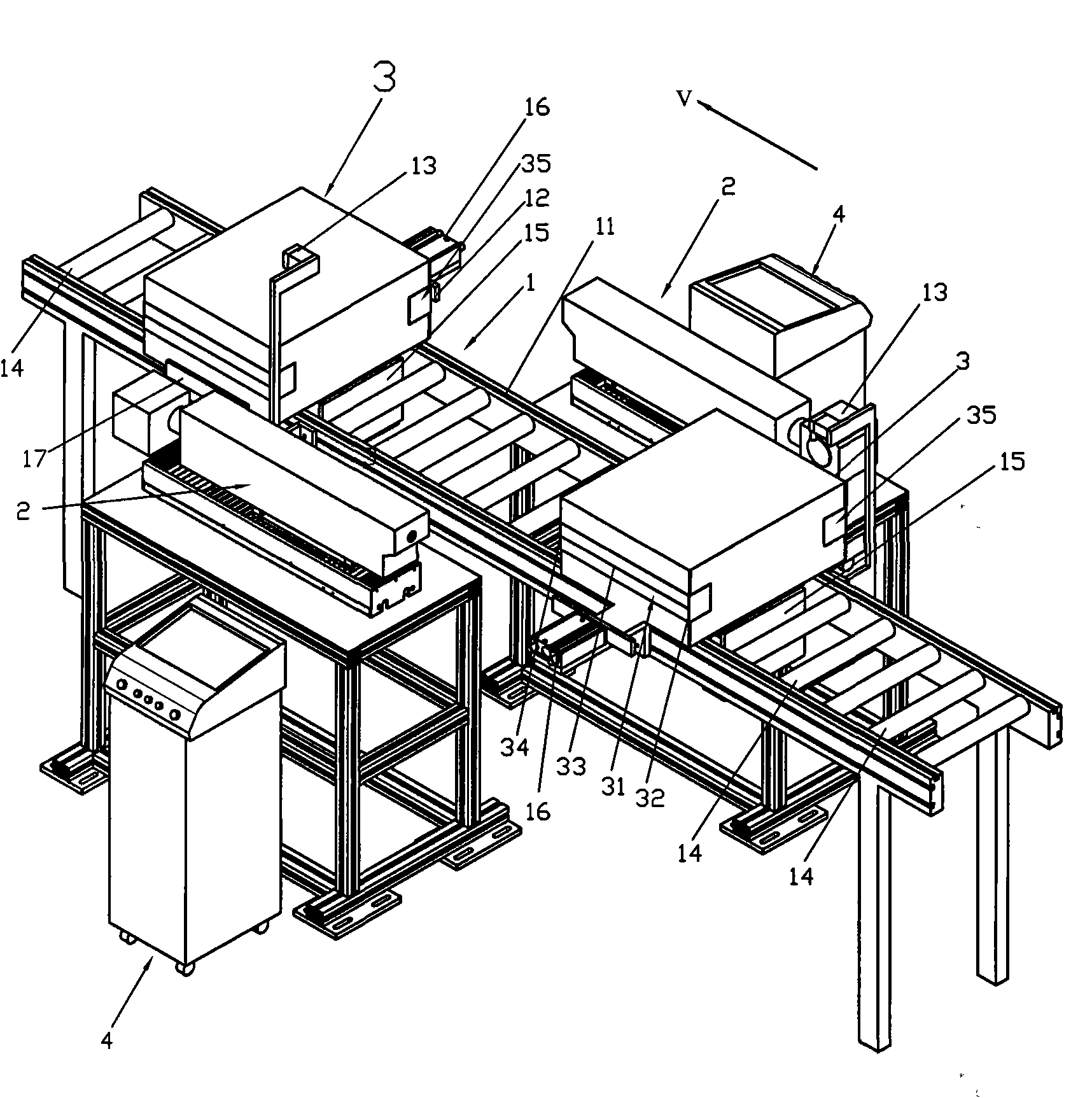

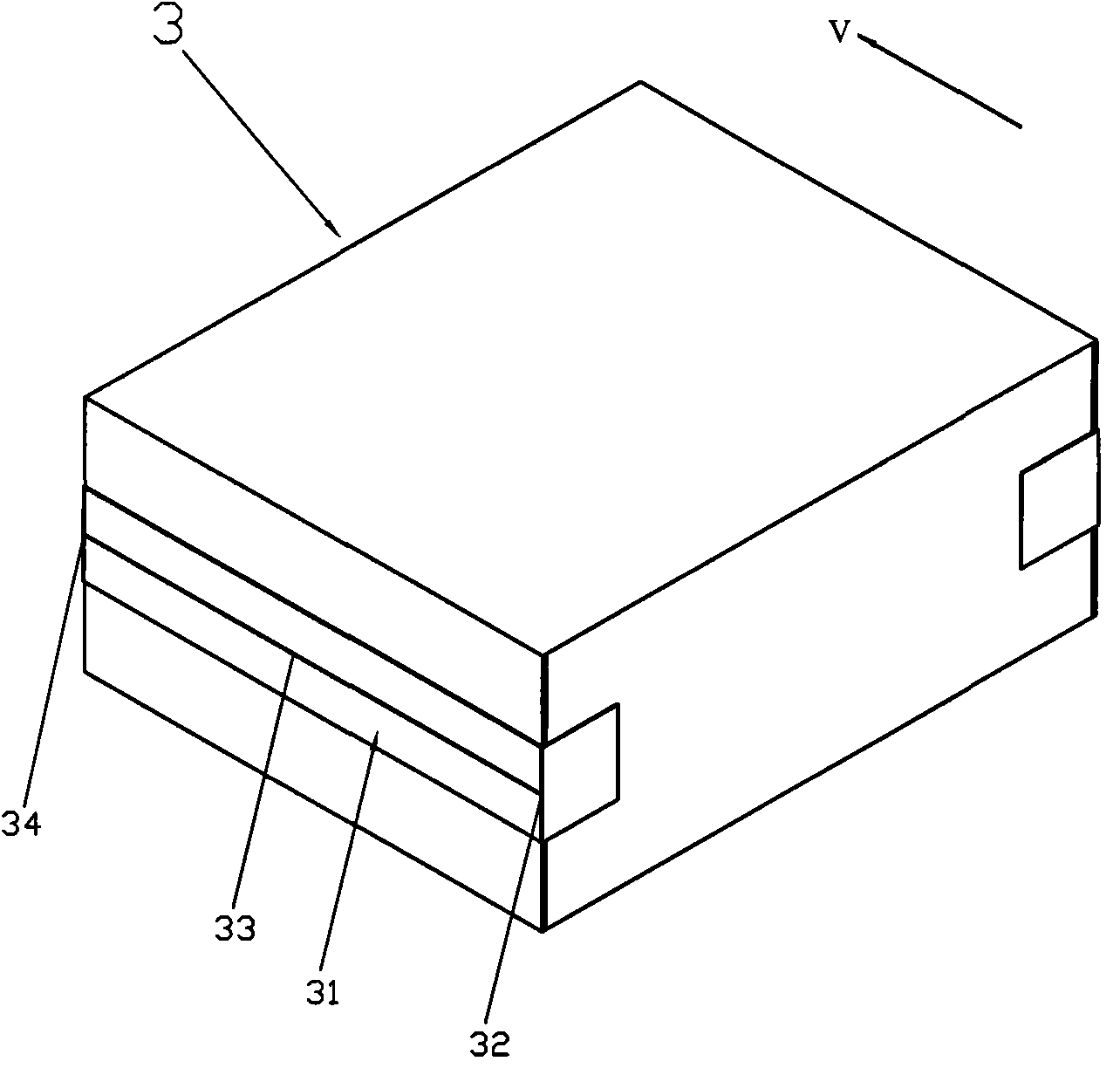

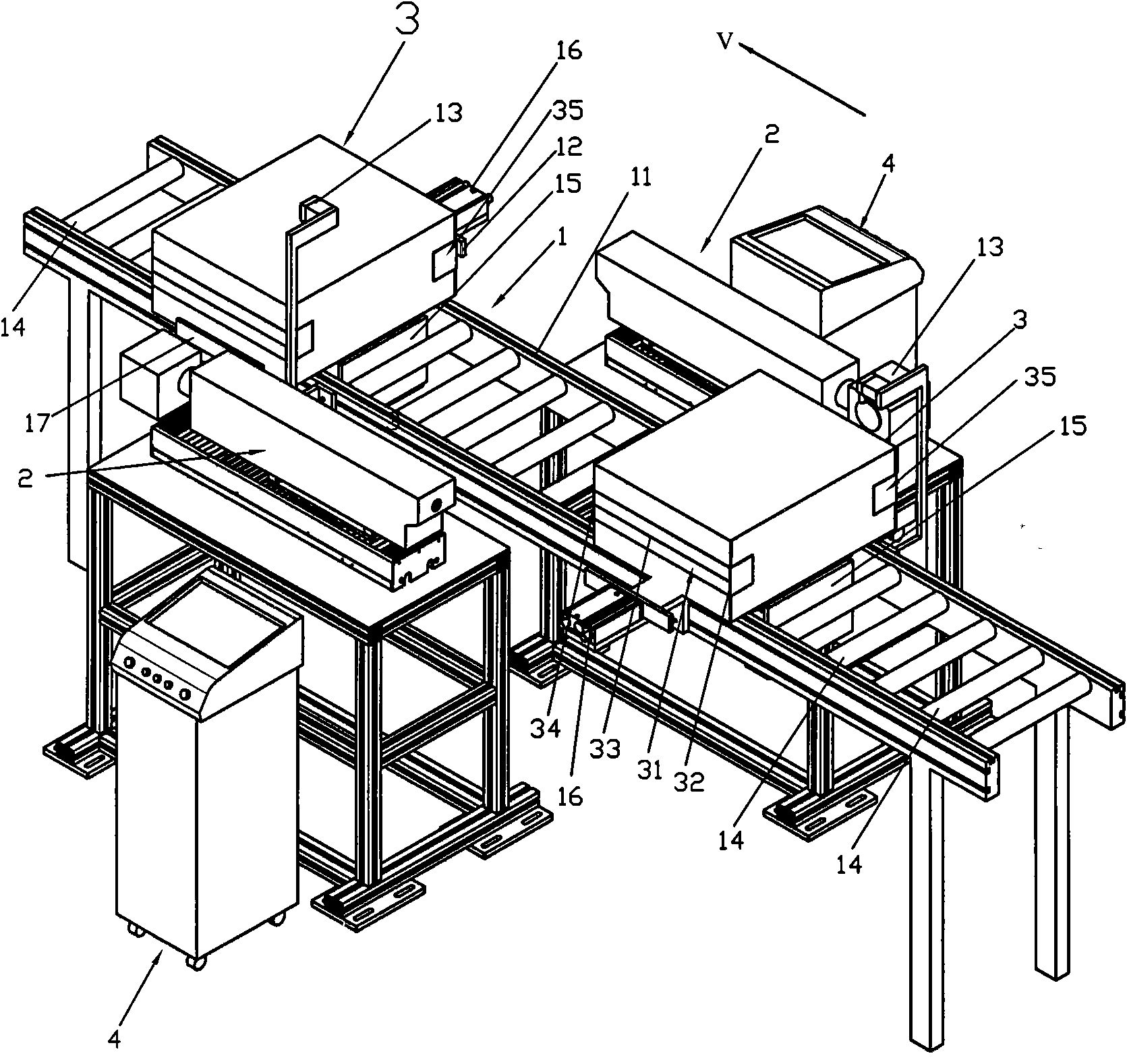

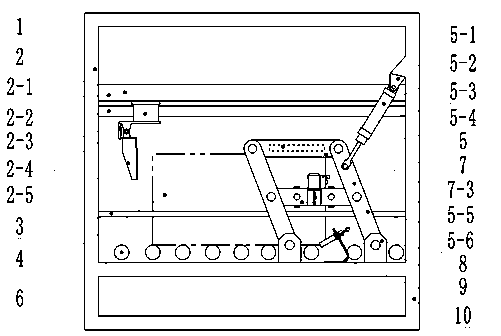

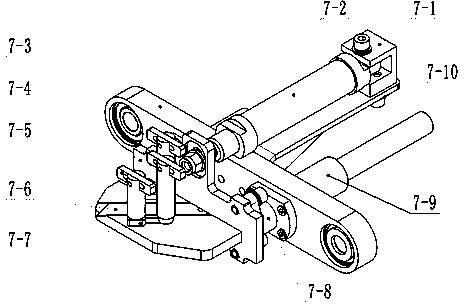

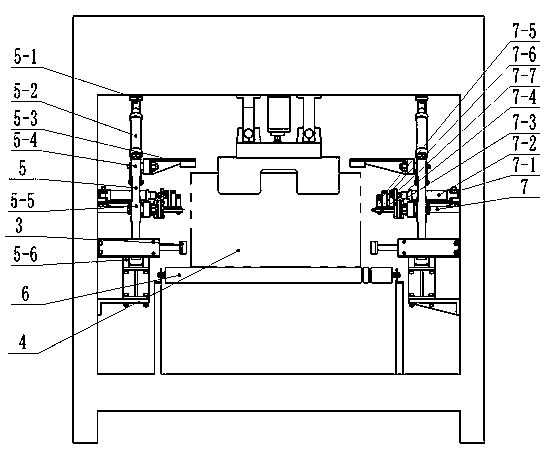

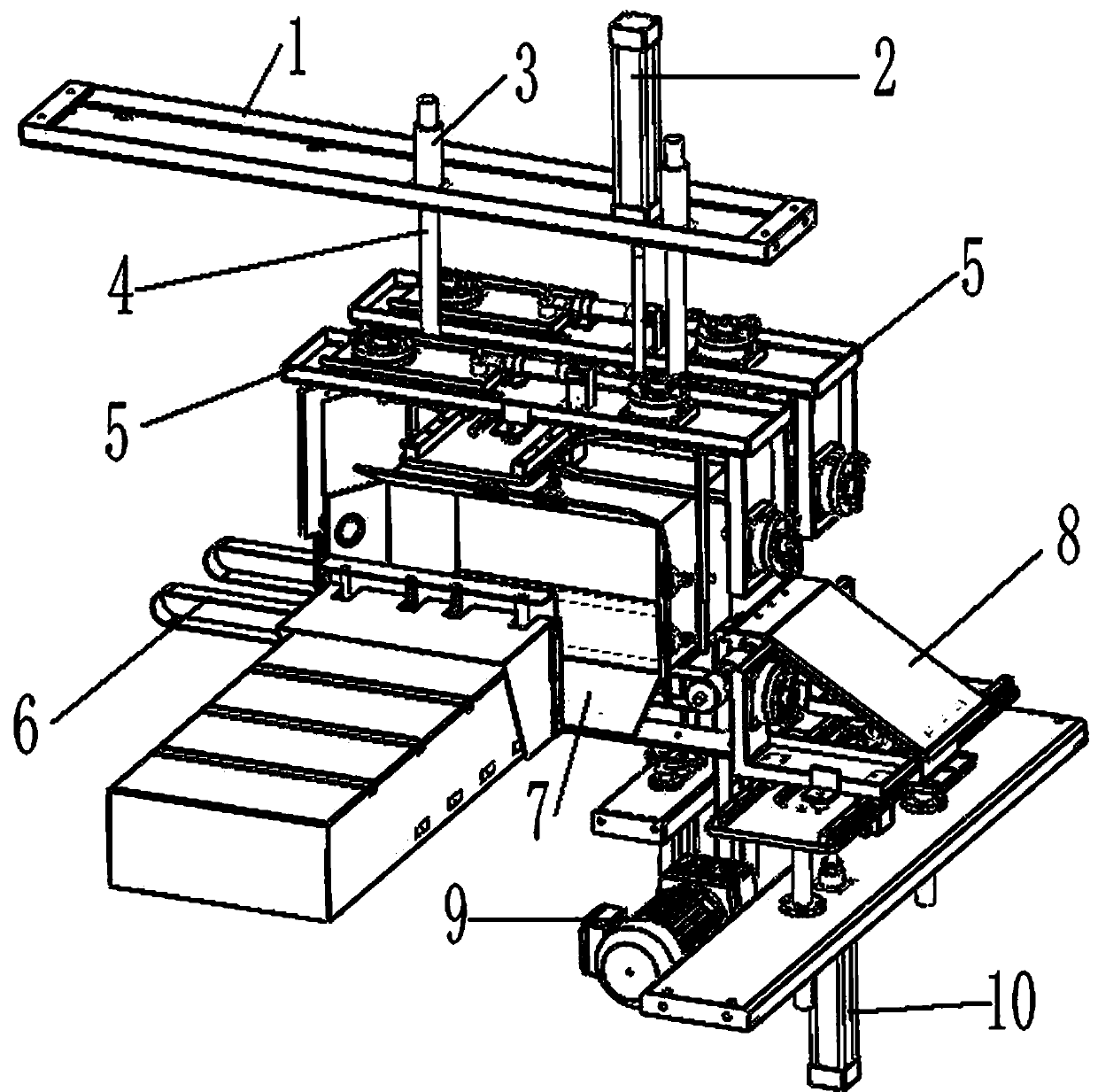

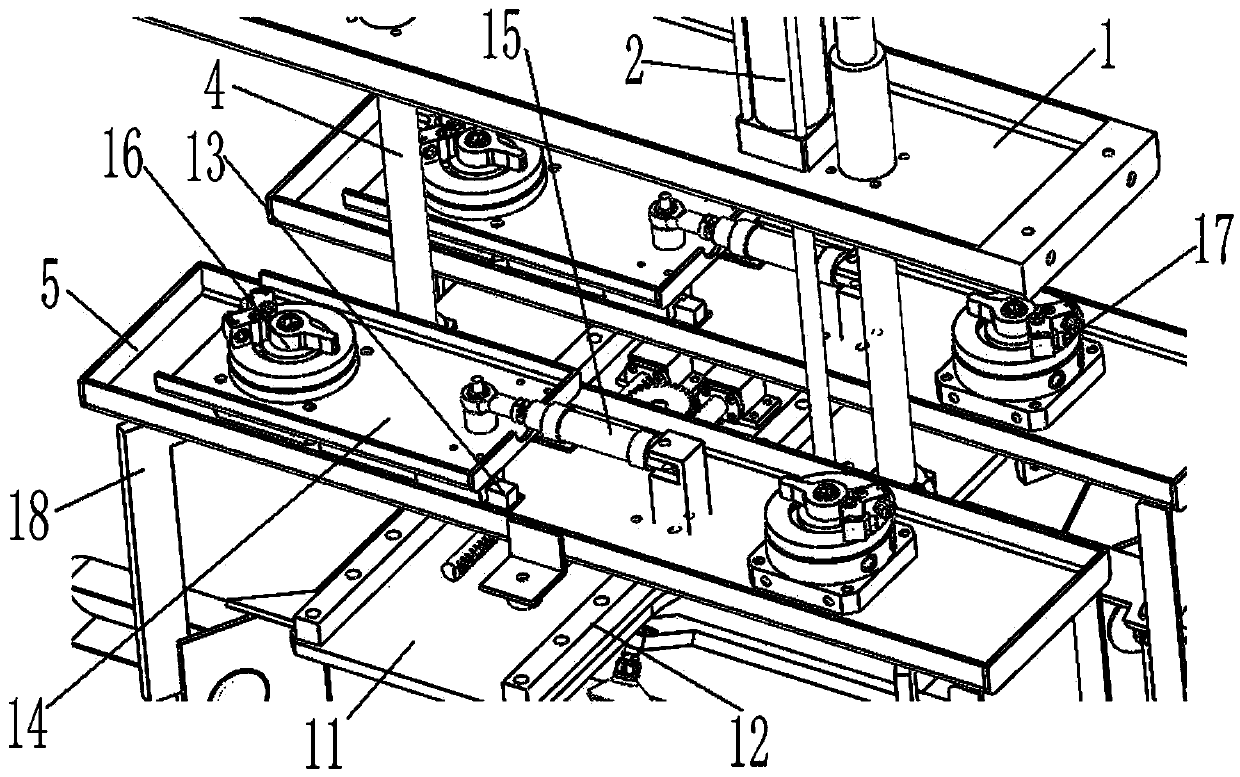

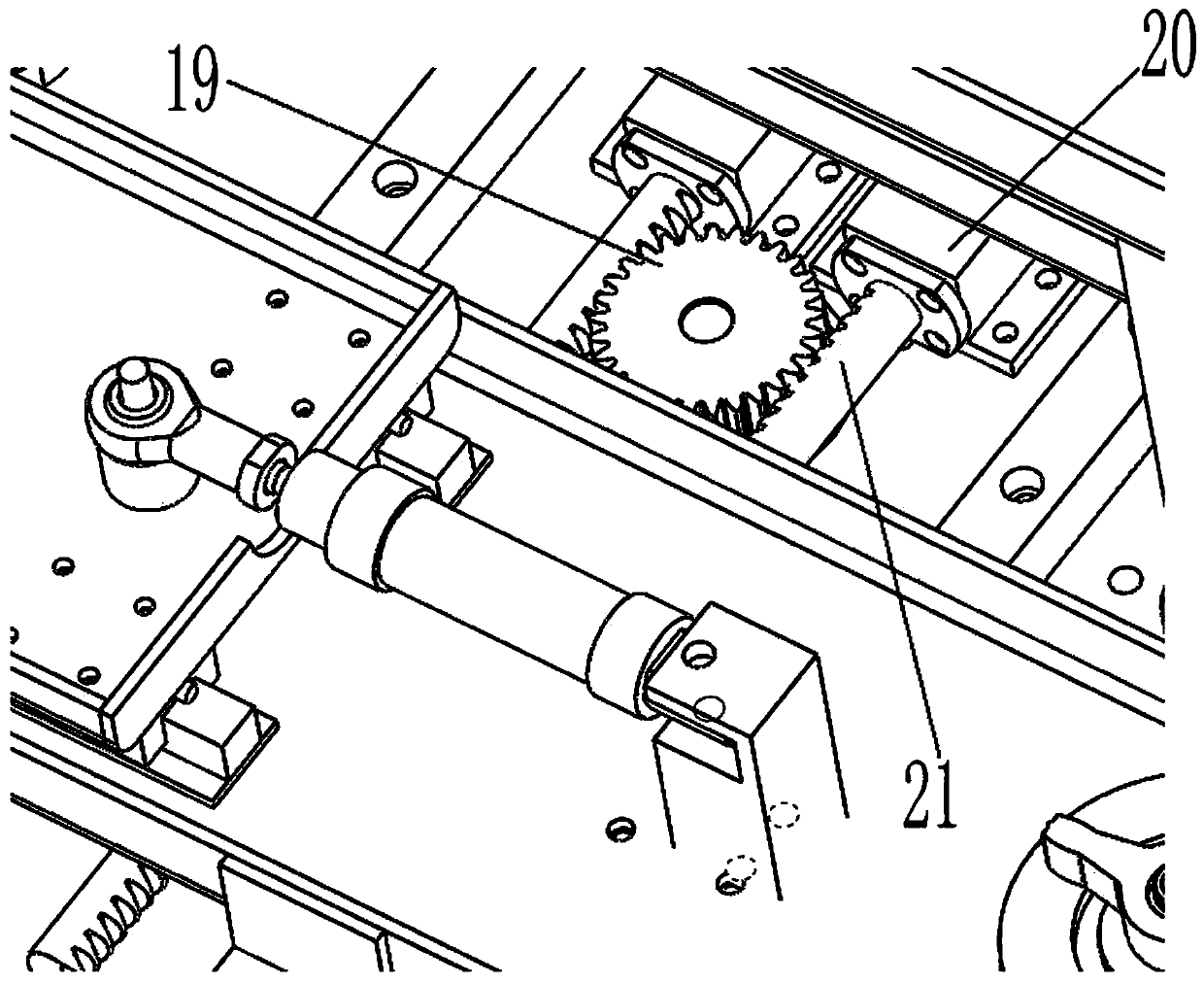

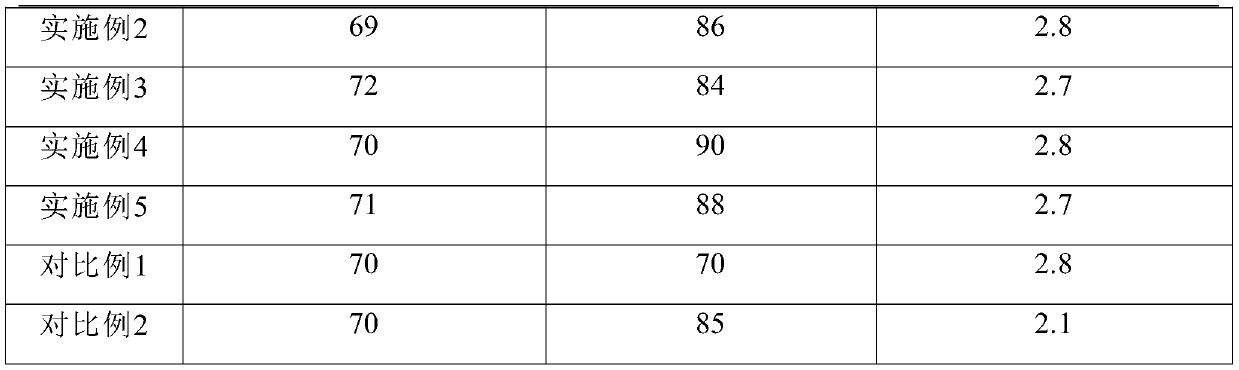

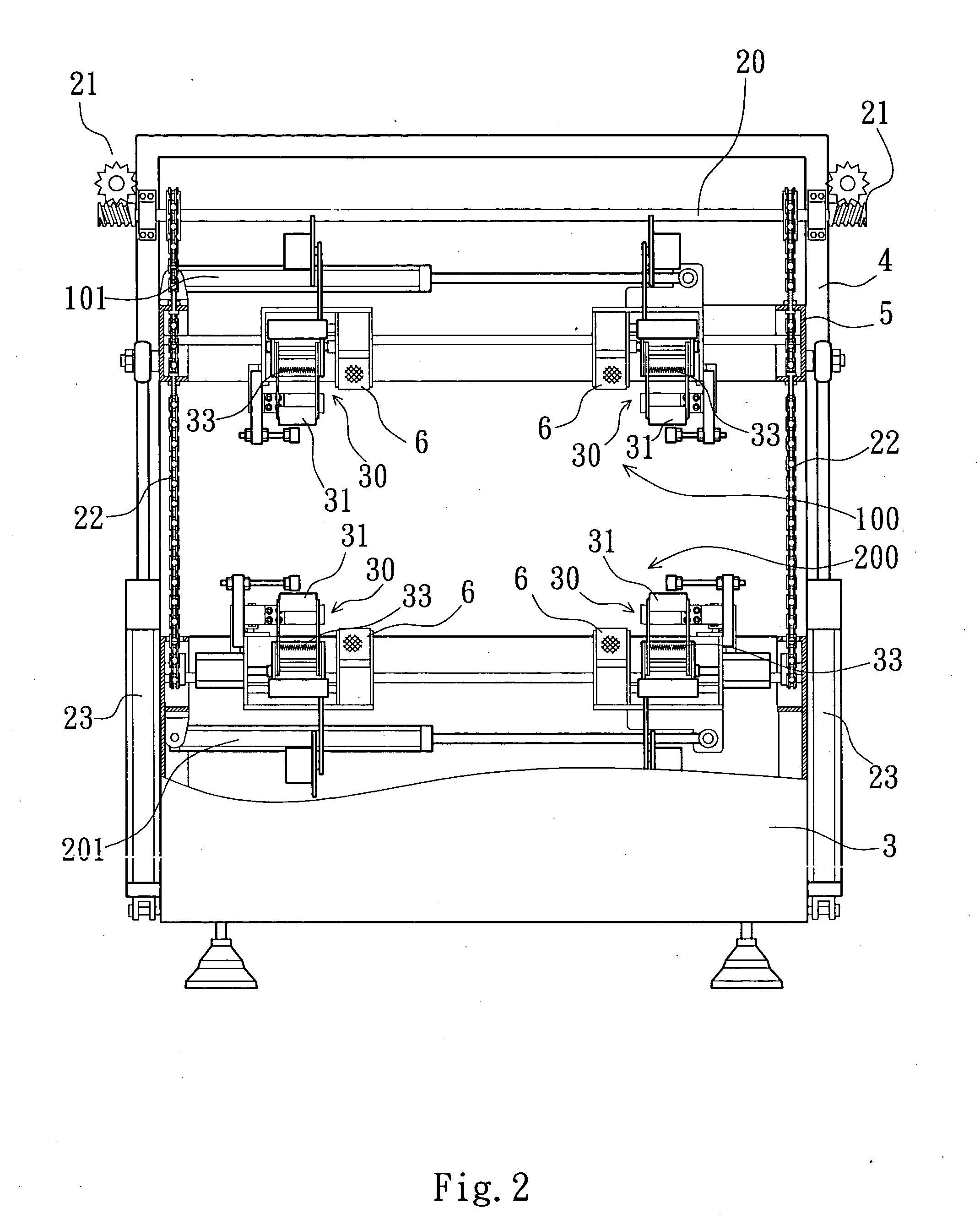

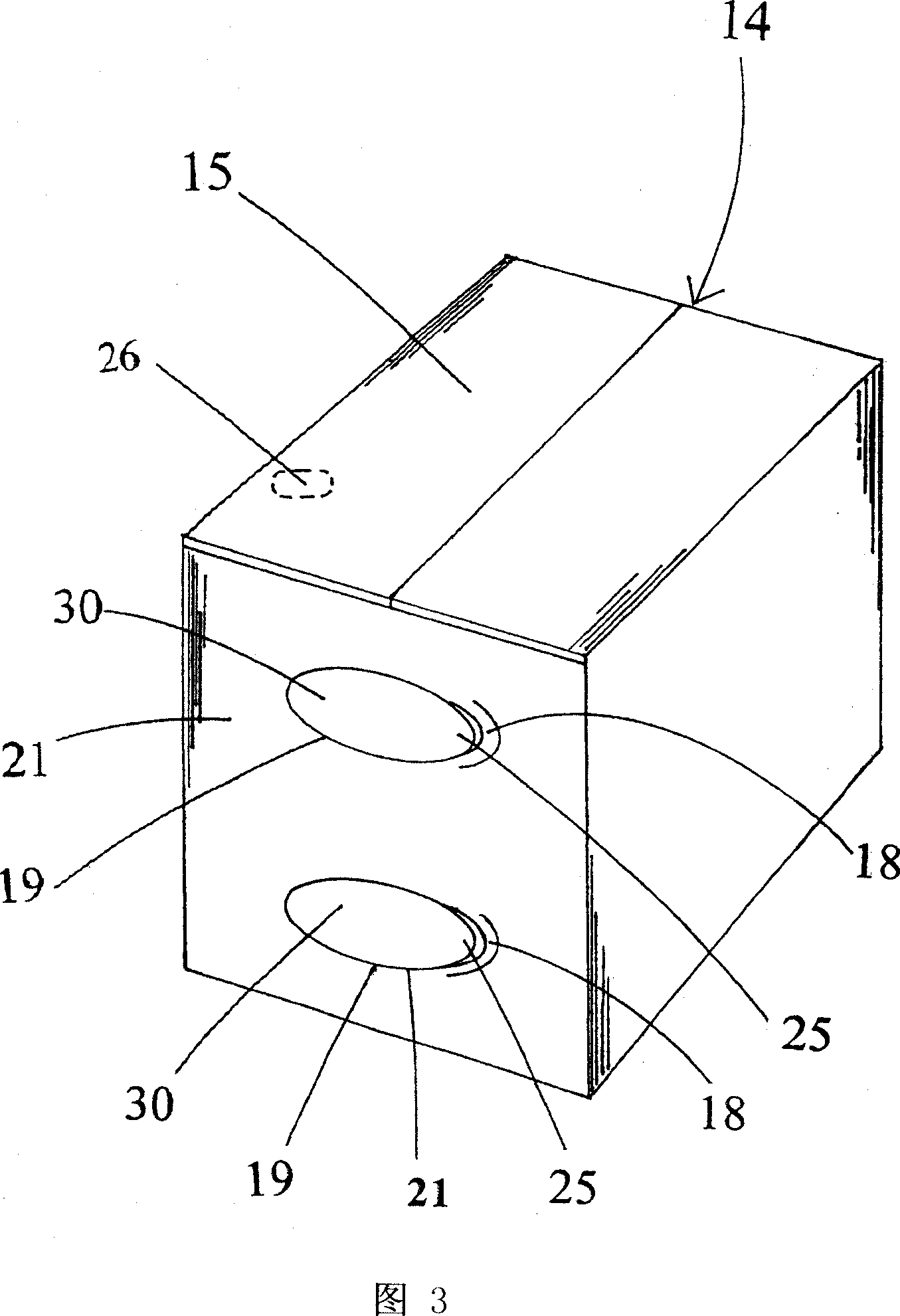

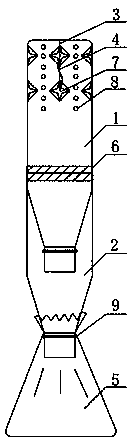

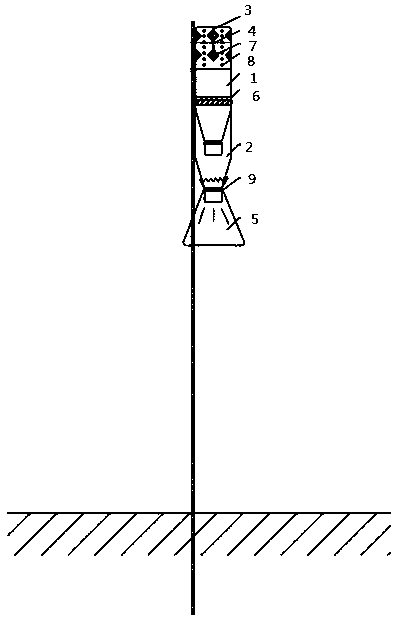

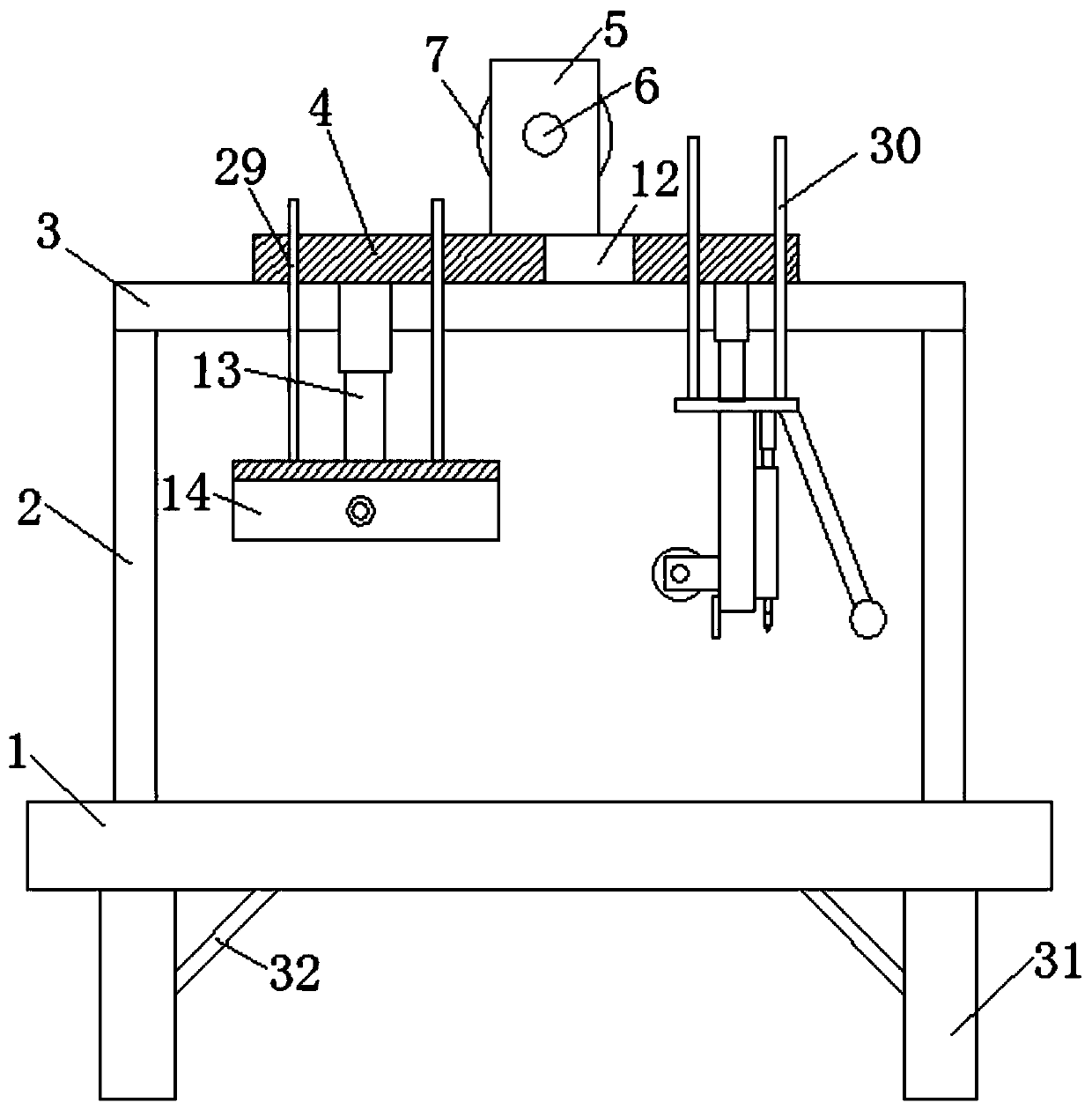

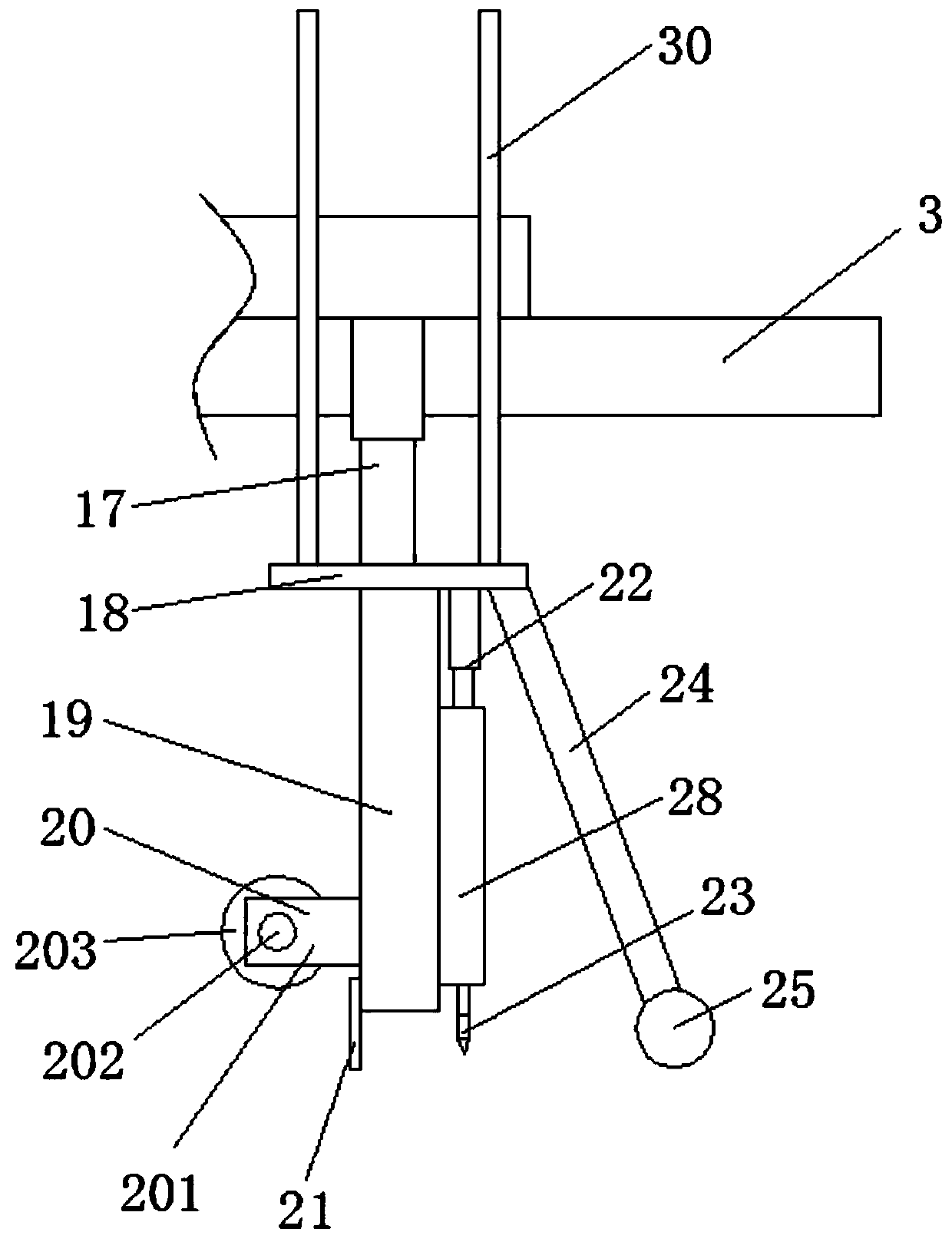

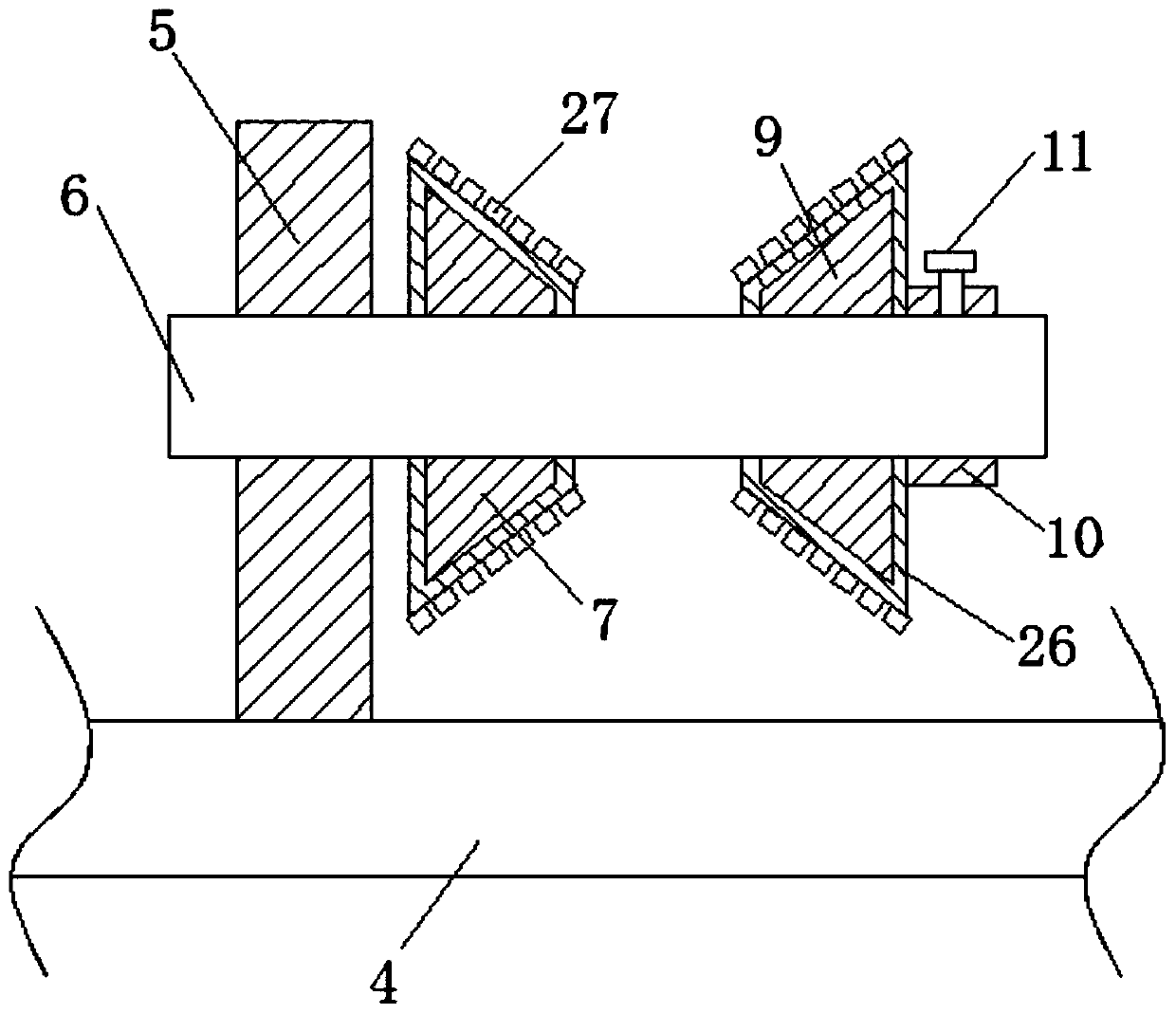

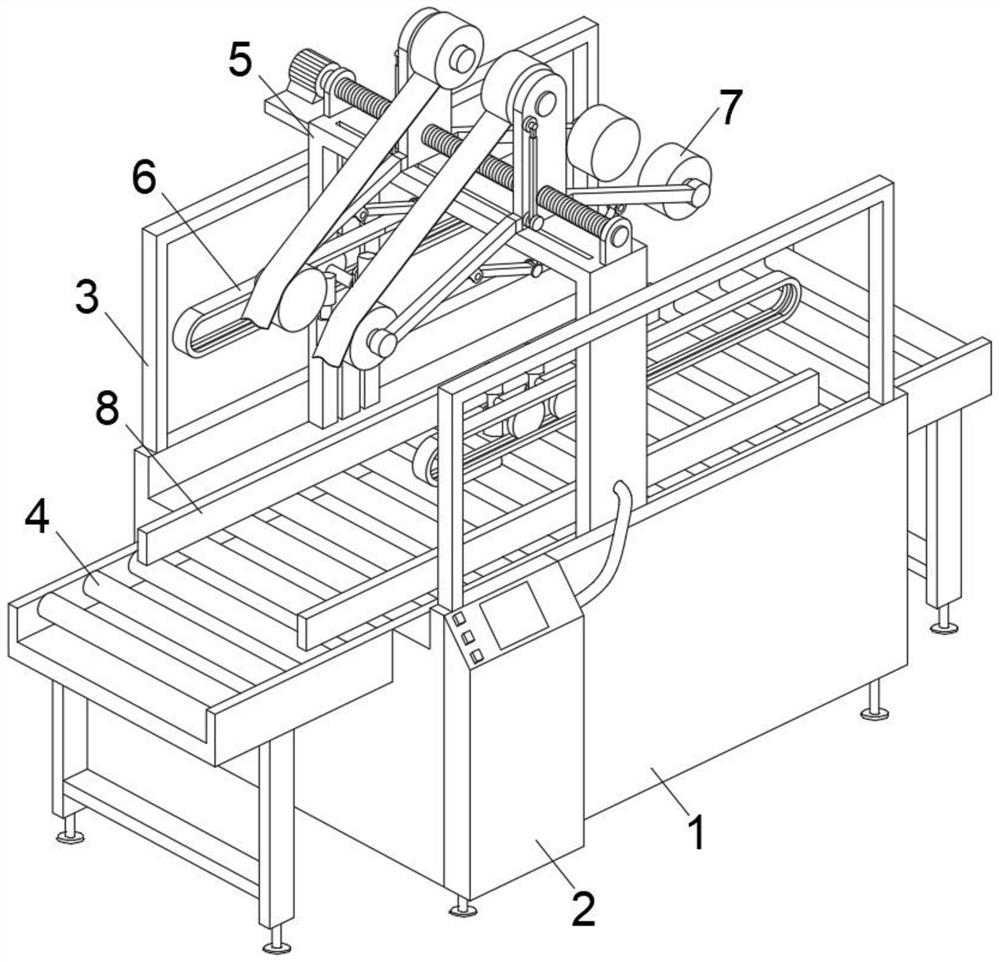

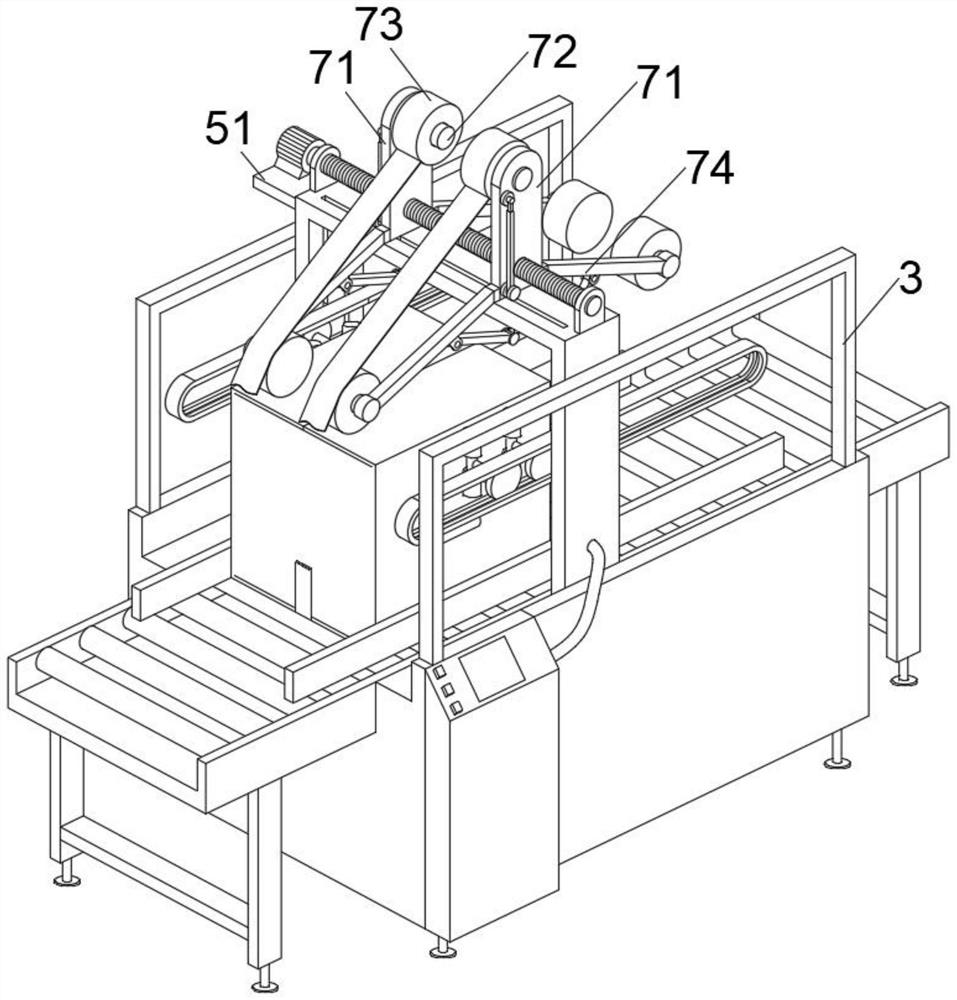

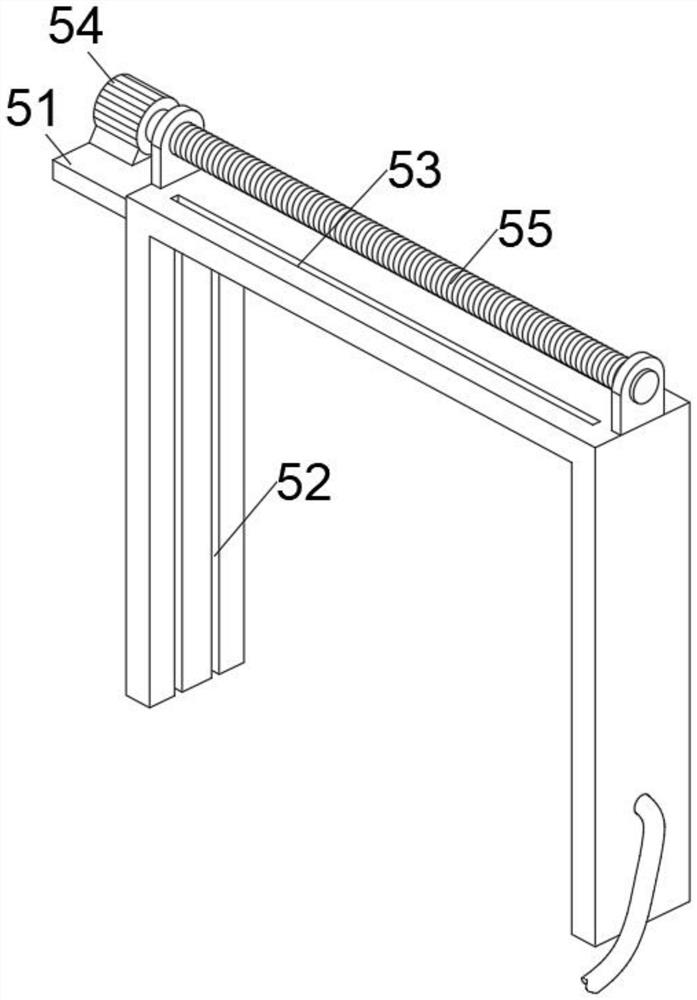

Method and device for automatically and continuously ripping packing tapes of packing case

ActiveCN104108504AReduce labor intensityImprove box marking efficiencyArticle unpackingLogistics managementAdhesive belt

The invention discloses a method and a device for automatically and continuously ripping packing tapes of a packing case and relates to the technical field of automatic sorting of materials. The technical scheme of the method and the device for automatically and continuously ripping the packing tapes of the packing case comprises arranging a case pushing mechanism which can apply thrust to a case body and move in one direction; arranging a guiding mechanism which can guide and limit two sides of the packing tapes of the case body; arranging a centralized positioning mechanism for determining a central position of a sealing opening of a tape and facilitating cutting of a blade extending mechanism; arranging a conveying roller to support the case body and provide conveying power. The method and the device for automatically and continuously ripping the packing tapes of the packing case improve case ripping efficiency, reduce labor intensity of an operator, have the advantages of being high in automation degree, low in fault rate and safe and reliable in operation, can be applied to logistics enterprises and have relatively high economic benefits.

Owner:BLUESWORD INTELLIGENT TECH CO LTD

Special-shaped cigarette box opening machine

PendingCN107934103ACompact structureReduce work stationsBinding material removalEngineeringConveyor belt

A special-shaped cigarette box opening machine comprises a rack, a lower sliding base, an upper sliding base, two lower box cover opening mechanisms, two upper box cover opening mechanisms, two side box cover opening mechanisms, a distance adjusting mechanism I and a distance adjusting mechanism II; and after a sealing adhesive tape of a packaging box is cut off and is conveyed in place by a conveying belt, a lower sliding base driving mechanism drives the lower sliding base to move upwards, and then the lower box cover opening mechanisms act to open a lower box cover downwards in an overturning manner. After the lower box cover is opened in the overturning manner, an upper sliding base driving mechanism drives the upper sliding base to move downwards, and the upper box cover opening mechanisms act to upwards open an upper box cover upwards in an overturning manner. Finally, two side box covers are opened to the outer side by the side box cover opening mechanisms in an overturning manner. Due to the fact that opening of the upper box cover, the lower box cover and the side box covers is achieved on one station, the whole special-shaped cigarette box opening machine is compact in structure, stations are saved, and efficiency is improved. The special-shaped cigarette box opening machine conveniently adapts to specification of special-shaped cigarette packaging boxes in differentlengths and heights, and the application range of the special-shaped cigarette box opening machine is widened.

Owner:BLUESWORD INTELLIGENT TECH CO LTD

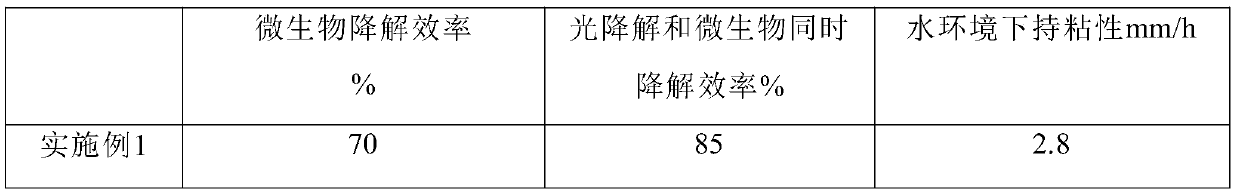

Biodegradable silent packing tape and preparation method thereof

InactiveCN106753017AEliminate pollutionAchieve decompositionFilm/foil adhesivesDecompositionSilicone oil

The invention discloses a biodegradable silent packing tape which comprises a release layer, a substrate and an adhesive layer which are successively laminated, wherein the release layer is made from silicone oil, and the substrate is a biodegradable plastic film. According to the packing tape which takes the biodegradable material as the substrate, the substrate can be fully decomposed through decomposition effect of microorganisms (bacteria, moulds / fungi and algae) in a natural environment so as to eliminate the environmental pollution after wastes. Meanwhile, the release layer made from silicone oil is arranged on the surface of the substrate, so that noise pollution generated by peeling can be avoided if being used.

Owner:GUANGDONG TENGEN IND GRP CO LTD

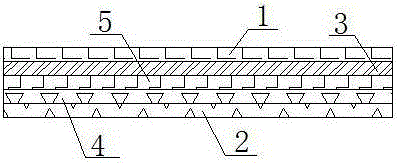

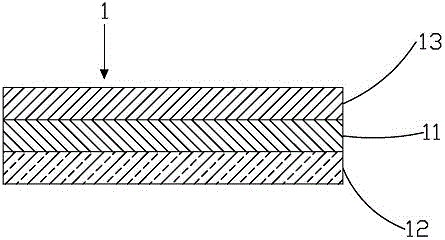

Degradable box sealing adhesive tape

InactiveCN111410923AImprove degradation efficiencyCause a burdenNon-macromolecular adhesive additivesStarch derivtive adhesivesPolyesterPolymer science

The invention belongs to the technical field of packaging, in particular relates to a degradable box sealing adhesive tape. The degradable box sealing adhesive tape comprises a first base material layer, a second base material layer, a bonding layer and a release layer which are sequentially stacked from top to bottom, the first base material layer comprises a photosensitive group modified high-molecular polymer, the second base material layer comprises a modified natural high-molecular polymer, the bonding layer comprises starch subjected to hydrophobic oxidation treatment, and the release layer is a polyester film subjected to surface low-energy treatment. According to the invention, the high-molecular polymer is modified by the photosensitive group in the first base material layer, so that the box sealing adhesive tape can be biodegraded, can also be photodegraded, can be photodegraded in the presence of light, accelerates the degradation efficiency, and can be biodegraded in the absence of light after being buried in soil. The bonding layer is subjected to hydrophobic oxidation treatment, starch is hydrophilic, so that colloid is easy to strip and degrade in a water environment, and the starch is modified by an oxidative hydrophobic method, so that the hydrophobic property of the colloid can be improved, and the degradation efficiency is better.

Owner:广东洪运洋科技有限公司

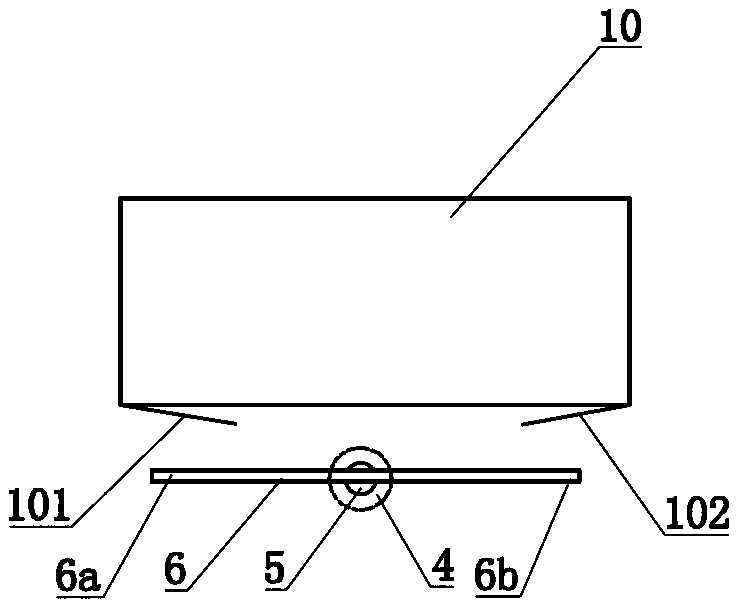

Carton sealing machine

A carton sealing machine includes a machine base, and two sealing mechanisms installed in the machine base at different elevations and controlled to seal sealing tapes to the two sides and four corners of the top and bottom panels of a carton, each sealing mechanism having two parallel conveyers and pairs of tape dispensers, front angle sealing tape setting mechanisms, rear angle sealing tape setting mechanisms and horizontal sealing tape setting mechanisms bilaterally symmetrically provided at an outer side relative to the conveyers.

Owner:KU TONY

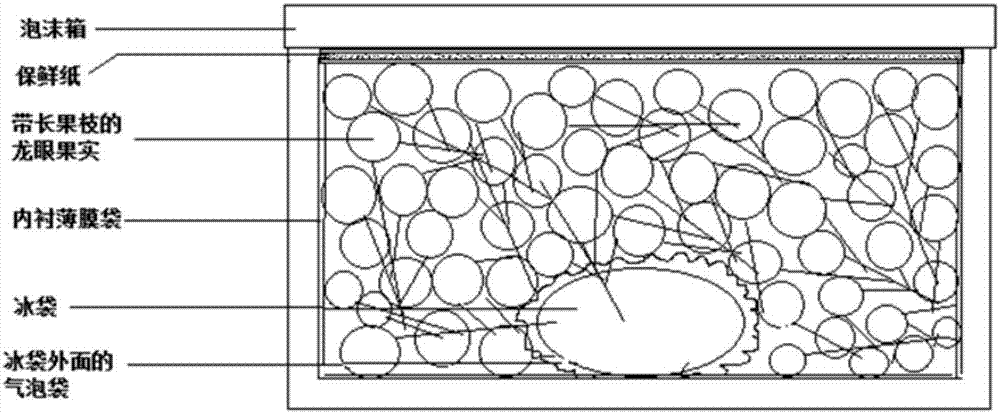

Longan-preserving method applicable for e-commerce logistics

PendingCN107347978AImprove product appearanceResidue reductionFruit and vegetables preservationIsolation effectLogistics management

The invention discloses a longan-preserving method applicable for e-commerce logistics. The method is described as follows: adopting a common foam box with an internally lined polyethylene film preservation bag to form outer packing; placing ice packs sleeved by bubble wrap which has an isolation effect in the central position of the bottom of the foam box; evenly placing longan fruits with fruit spurs around the ice packs and on the ice packs; after the ice packs are fully surrounded by the longan fruits, laying a piece of longan-preserving paper having the same area with the opening of the internal foam box on the longan fruits; laying a piece of isolation paper having the effects of insulating air and resisting humidity on the longan-preserving paper; and finally, folding the upper extra part of the preservation bag flatly, performing sealing, covering the foam box with a lid and sealing tightly around the lid with box-sealing tapes to prevent air leakage and cool leakage. The preservation method provided by the invention can not only increase a good-quality fruit rate and extend the shelf life and the subsequent refrigeration life of the longan fruits but also reduce the residual amount of SO2 in the fruits and improve the uniformity of the SO2 content of the piled fruits.

Owner:POMOLOGY RES INST GUANGDONG ACADEMY OF AGRI SCI

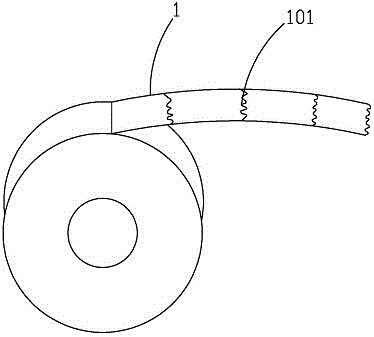

Processing method for packing tape

ActiveCN105017981AWill not affect normal useNo extra weightFilm/foil adhesivesEngineeringPlastic film

The invention provides a processing method for a packing tape with better user experience. No right-angled corners are available at the upper and lower ends of a produced tape, so that a user is not cut, and meanwhile, the end face of a tape coil is not sticky, so that the tape is more convenient to take and use. The processing method comprises the following main steps: adding a tape raw material acrylic acid into an emulsification tank for emulsification; then putting the emulsified raw material into a reaction pot to be heated to prepare glue; then adding the glue into a coating machine; mounting a plastic thin film coil on the coating machine and smearing the glue to a plastic thin film through the coating machine to prepare a mother coil; pipe-cutting the mother coil through a pipe cutter; stripping the successfully pipe-cut tape through a stripping machine to obtain coils of tapes; polishing the upper and lower inner corners of a paper element of the stripped tape by using a polishing machine; polishing the right-angled corners with the inner corners to bevels or arc-shaped faces; and uniformly adhering paper element powder left when the right-angled corners are polished to the end face of the tape coil of the tape to prepare a finished product packing tape.

Owner:广东宝兰山新材料科技有限公司

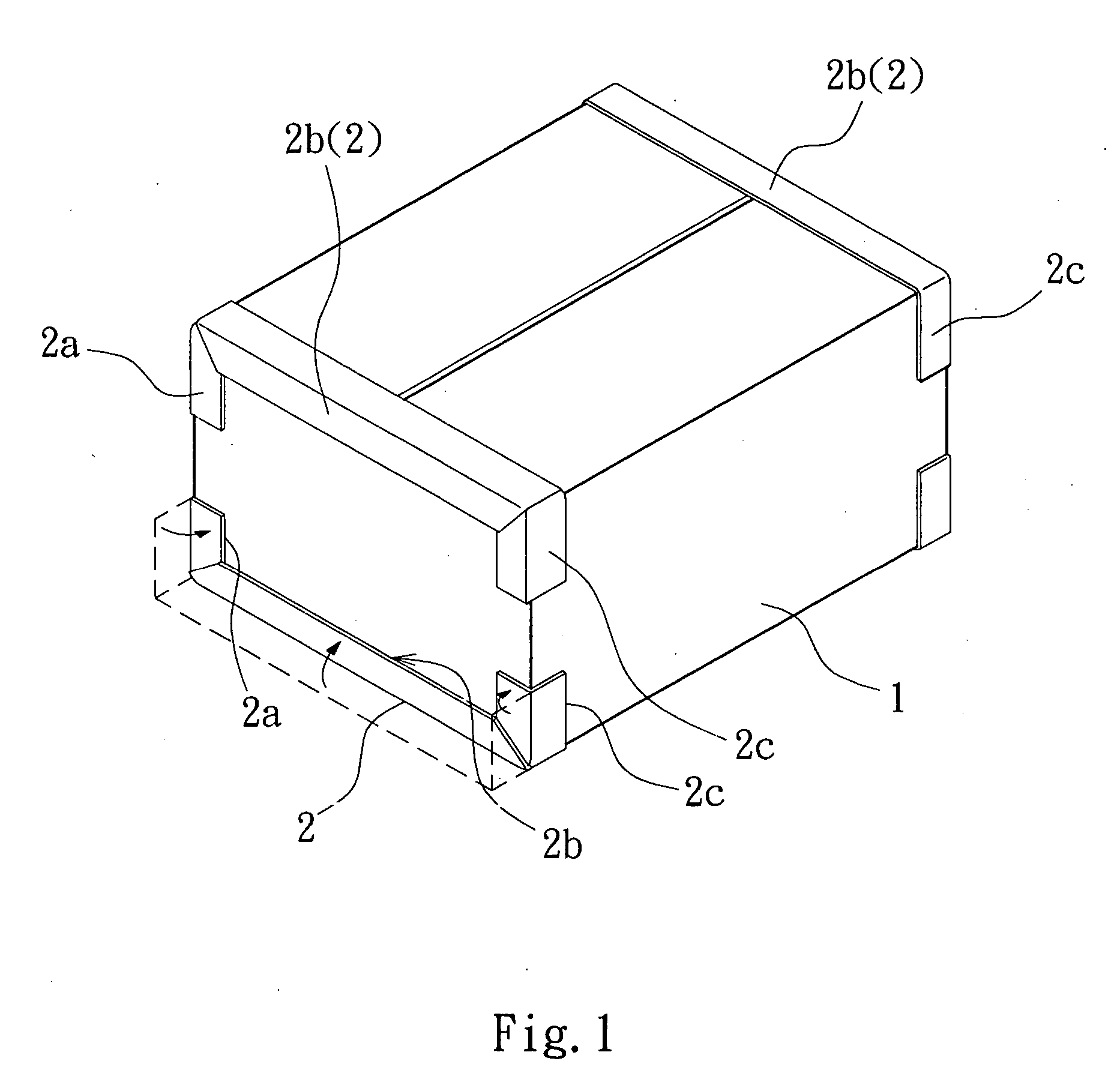

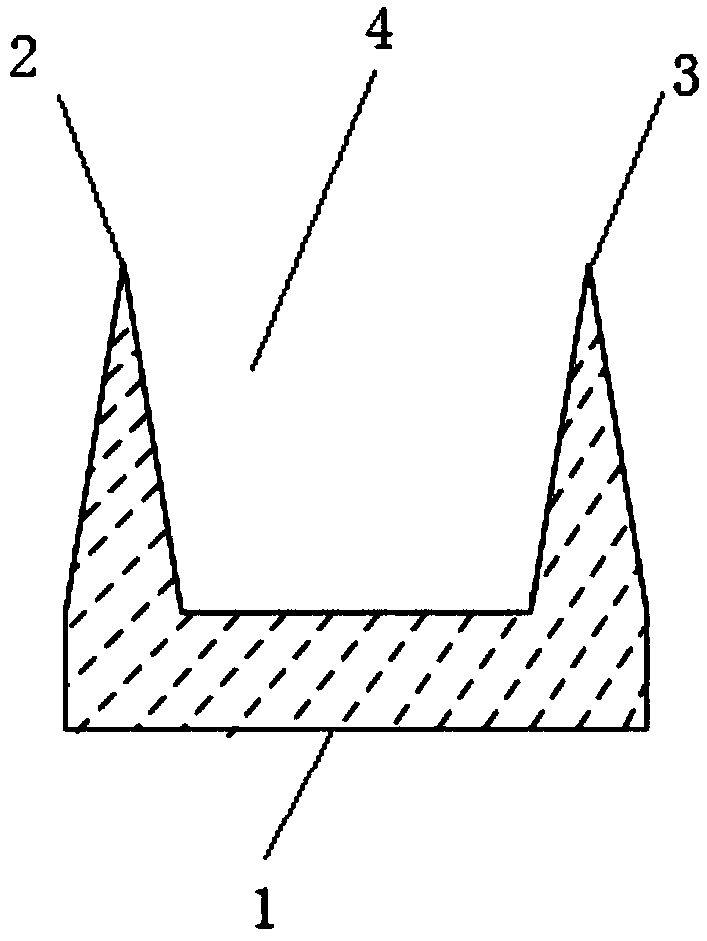

Device attached to cardboard box for avoiding to use knives to seal off rubber belt

The present invention discloses a knife opening box seal belt avoiding cardboard box attached device. The present invention comprises a cardboard box body and a combining body which comprises an opening box seal belt drawstring device. The opening box seal belt drawstring device is made and formed at least by a surface box lumber of the cardboard box body. In addition, at least one or more than one drawstring device is arranged on a main box surface of the cardboard box. The present invention of the knife opening box seal belt avoiding cardboard box attached device completely does not need knife to tear the box seal belt from the cardboard box. The manufacturing is faster and saves more cost.

Owner:简博为

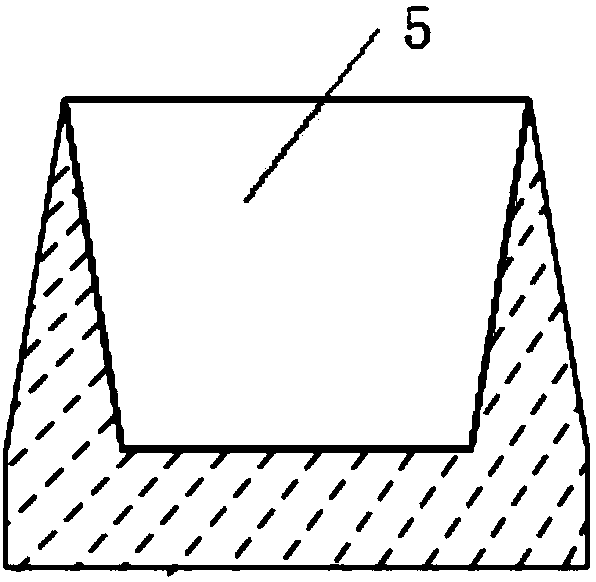

Shaping device and method for wrapped edge of box sealing adhesive tape

The invention discloses a shaping device for a wrapped edge of a box sealing adhesive tape. The shaping device comprises shaping units which are symmetrically arranged at two sides of a conveyer belt, wherein each shaping unit comprises a stepping motor or a servo motor which is vertically mounted; an elastic sheet for leveling the wrapped edge of the box sealing adhesive tape is fixed on an output shaft of the stepping motor or the servo motor; and the stepping motor or the servo motor is electrically connected with a control circuit. The invention also discloses a method for shaping the wrapped edge of the box sealing adhesive tape by utilizing the shaping device for the wrapped edge of the box sealing adhesive tape. According to the shaping device and method disclosed by the invention, the elastic sheet is driven to be positively or negatively rotated by virtue of the stepping motor or the servo motor under the control of the control circuit, thus the box sealing adhesive tape with the wrapped edge can be automatically leveled and compressed, and the automation of shaping the wrapped edge of the box sealing adhesive side is achieved, the condition that the adhesive tape of an adjacent packaging box is fallen while an adjacent packaging box is taken away by a stacking robot can be prevented, and the working efficiency is improved.

Owner:CHINA TOBACCO SHANDONG IND

Anti-counterfeiting box sealing adhesive tape

InactiveCN106833418AImprove anti-counterfeitingFilm/foil adhesivesSilicone oilMechanical engineering

The invention provides an anti-counterfeiting box sealing adhesive tape. The anti-counterfeiting box sealing adhesive tape comprises an adhesive tape thin film; a silicone oil layer is arranged on an upper surface of the adhesive tape thin film; an adhesive layer is arranged on a lower surface of the adhesive tape thin film; a release layer, a color coating layer and the adhesive layer are arranged on the lower surface of the adhesive tape thin film in sequence from top to bottom; the release layer is arranged on the lower surface of the adhesive tape thin film; and the color coating layer and the adhesive layer are continuously arranged on the whole lower surface of the adhesive tape thin film. Dyeing agent line layers are arranged on two sides of the adhesive layer along the width direction respectively; a strip-shaped groove, which is arranged along the length direction of the adhesive layer, is formed in the middle of the adhesive layer; the strip-shaped groove is filled with paraffin wax mixed with a dyeing agent; and before being used, the anti-counterfeiting box sealing adhesive tape is heated through a hair drier. According to the anti-counterfeiting box sealing adhesive tape, two anti-counterfeiting manners including the dyeing agent line layers and the strip-shaped groove are combined so that the anti-counterfeiting box sealing adhesive tape guarantees that consumers can know whether the box sealing adhesive tape is torn by other people before to the greatest extent.

Owner:WUHU HONGSHENG TECH

Anti-fake packing tape

InactiveCN106590461AAnti-counterfeiting function reservedGuaranteed anti-counterfeiting reliabilityFilm/foil adhesivesParaffin oilsPrinting ink

The invention relates to tape, in particular to anti-fake packing tape. The anti-fake packing tape comprises a transparent base material layer, a gluing layer is arranged on the lower portion of the transparent base material layer, and a printing ink printing layer and an additive transparent base material layer are sequentially arranged between the transparent base material layer and the gluing layer from top to bottom. Coloring agent line layers are arranged at the two sides of the gluing layer in the width direction respectively, and a strip-shaped groove in the length direction is formed in the middle of the gluing layer and filled with paraffin mixed with a coloring agent; before being used, the anti-fake packing tape is heated by a blower. As the two anti-fake modes including the dyeing agent line layer and the strip-shaped groove are used in combination, it is ensured to the maximum that a consumer knows whether packing tape is torn off by other people in advance or not at the first time.

Owner:WUHU HONGSHENG TECH

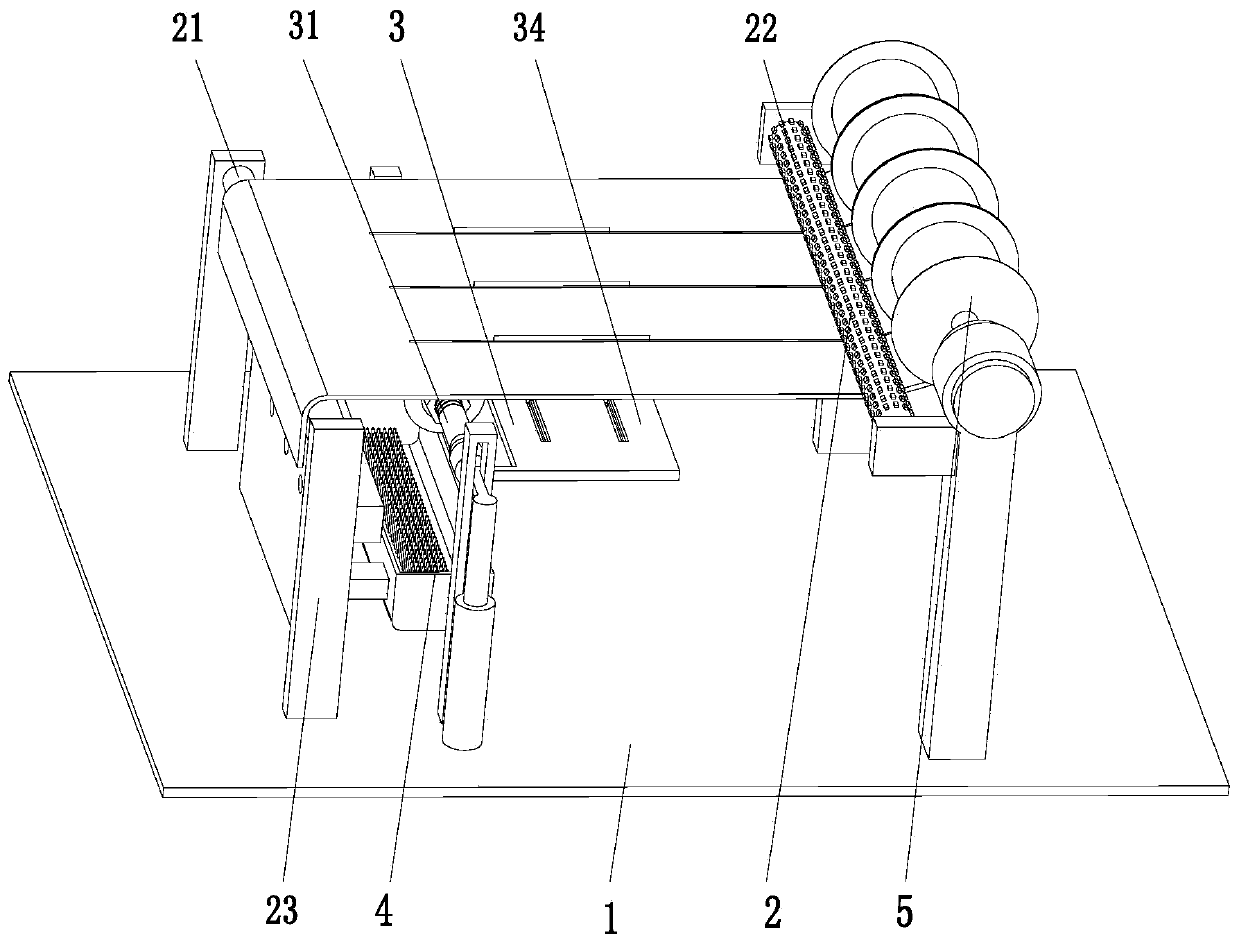

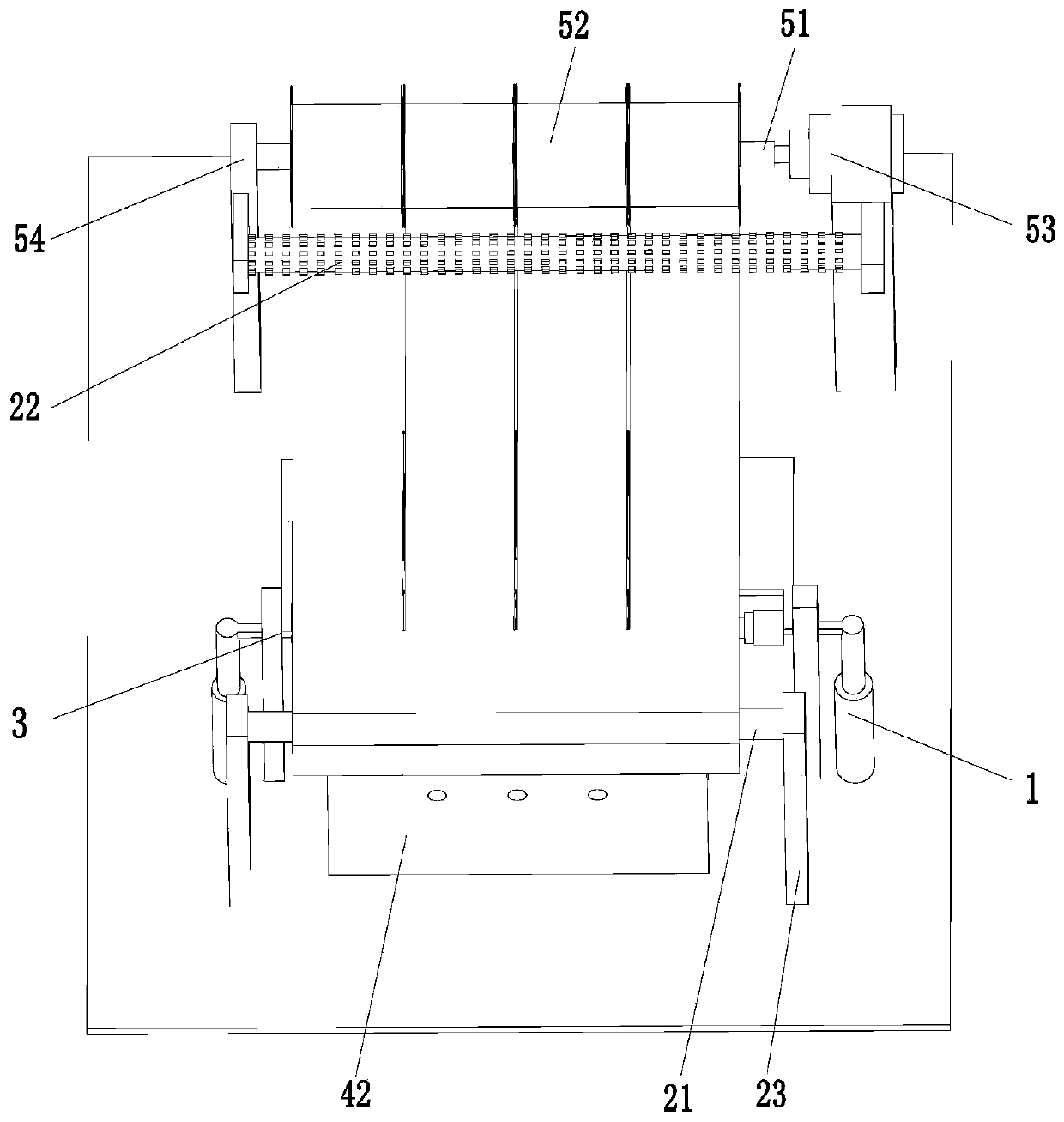

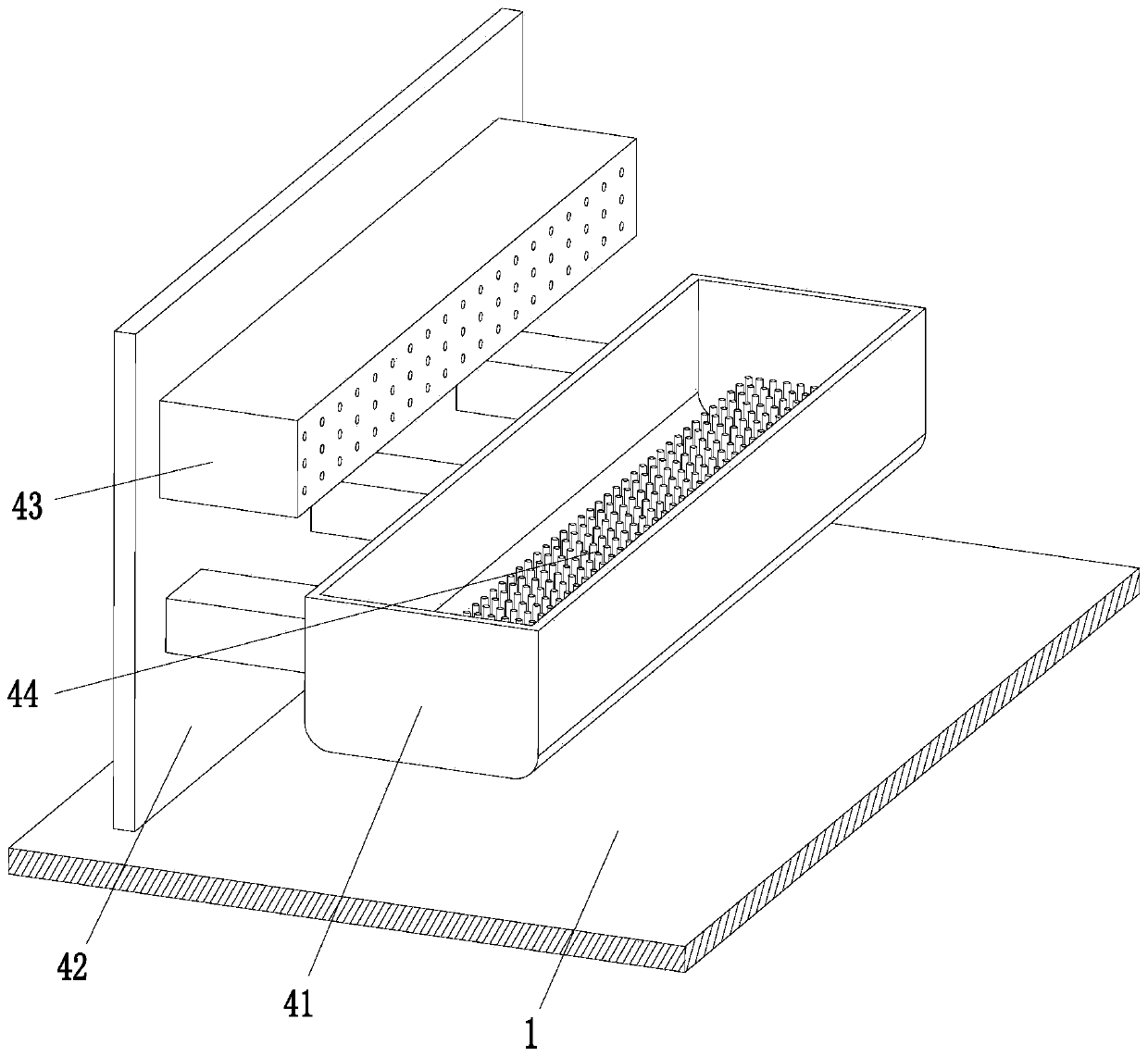

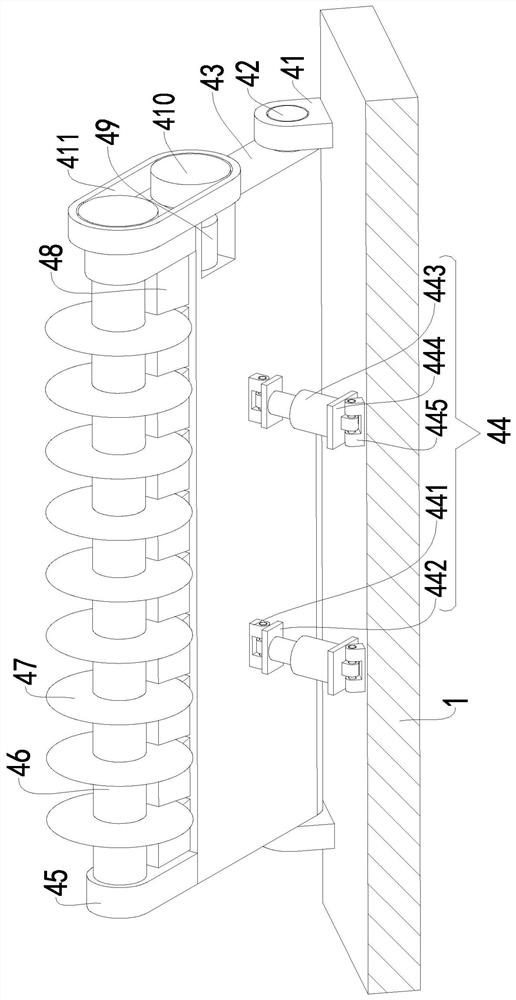

Fixed-width mold cutting machine for production and processing of box sealing adhesive tapes

ActiveCN110614664AAvoid scrappingClean in timeMetal working apparatusArticle deliveryEngineeringBox-sealing tape

The invention relates to a fixed-width mold cutting machine for the production and processing of box sealing adhesive tapes. The machine comprises a bottom plate, a tensioning mechanism, a slitting device, a cleaning mechanism and a winding mechanism, wherein the tensioning mechanism is arranged above the bottom plate, the bottom surface of the left end of the tensioning mechanism is arranged on the left side of the top end of the bottom plate, and the bottom surface of the right end of the tensioning mechanism is arranged on the right side of the top end of the bottom plate; the slitting device is arranged on the inner side of the tensioning mechanism, and the bottom of the lower end of the slitting device is arranged on the middle of the top end of the bottom plate; the cleaning mechanism is arranged below the slitting device, and the bottom of the cleaning mechanism is arranged on the top end of the bottom plate; and the winding mechanism is arranged on the right side of the slitting device, and the bottom of the winding mechanism is arranged on the right side of the top end of the bottom plate. The fixed-width mold cutting machine for the production and processing of the box sealing adhesive tapes can solve the problems that adjacent adhesive tapes easily adhere to each other after slitting by an existing mold cutting machine for adhesive tapes, the adhesive tapes are proneto being scrap, the whole machine needs to be disassembled when cleaning adhesives on a blade of the existing mold cutting machine, and the existing mold cutting machine is inconvenient to use.

Owner:苏州哈德胜精密科技有限公司

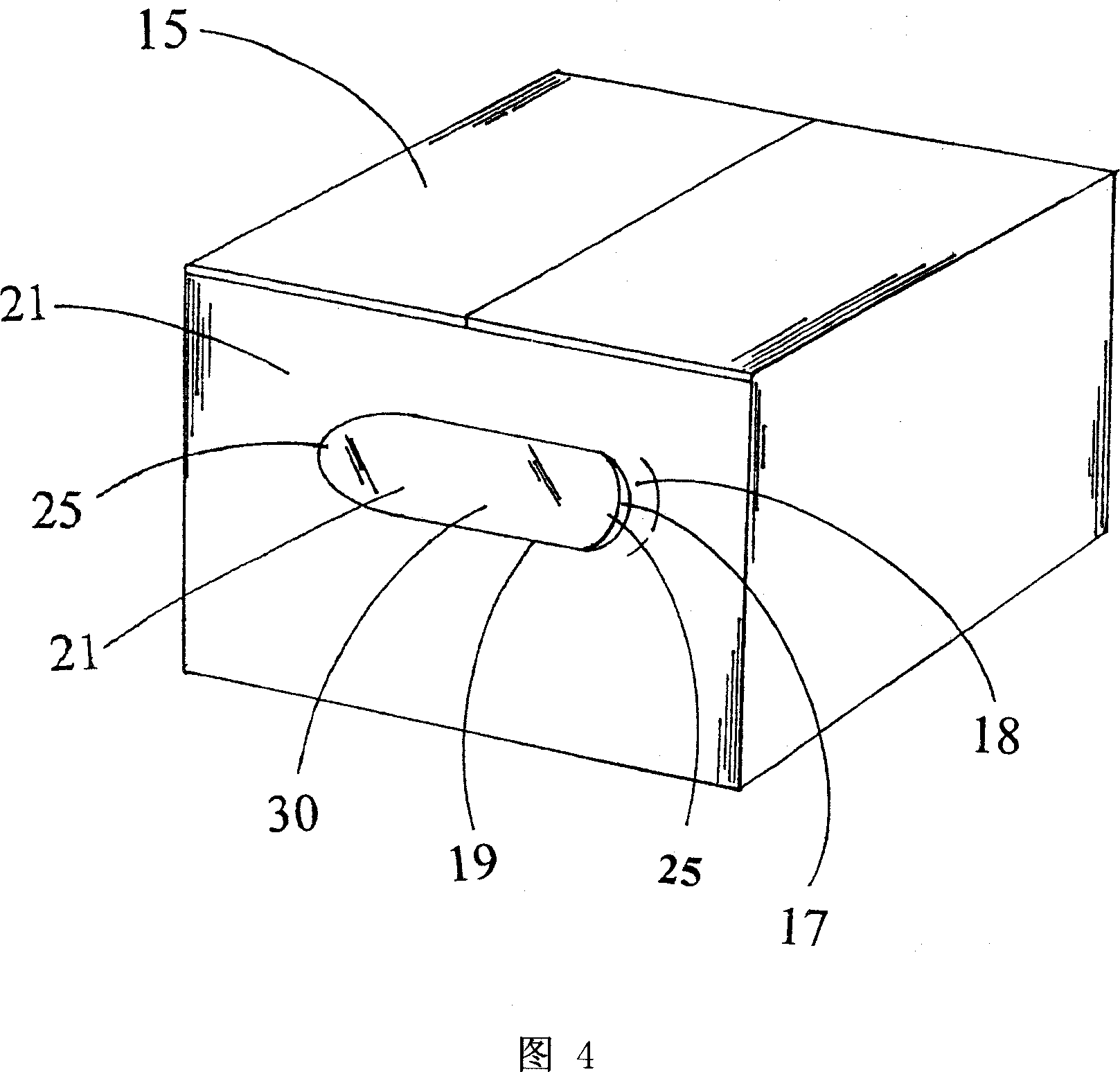

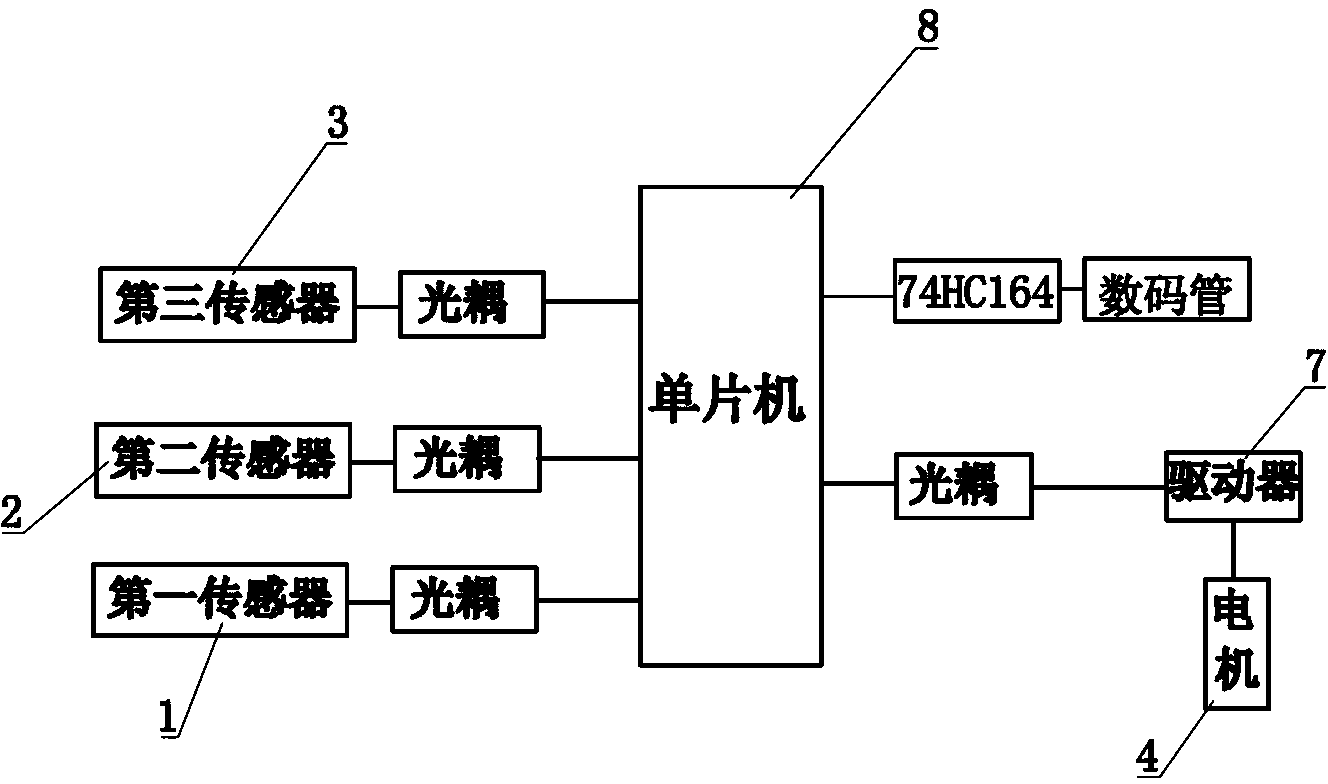

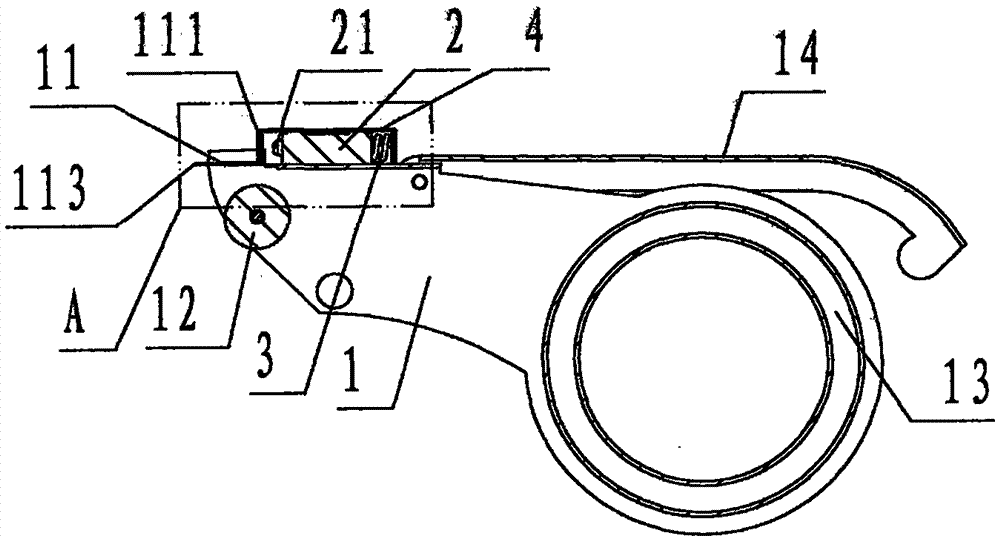

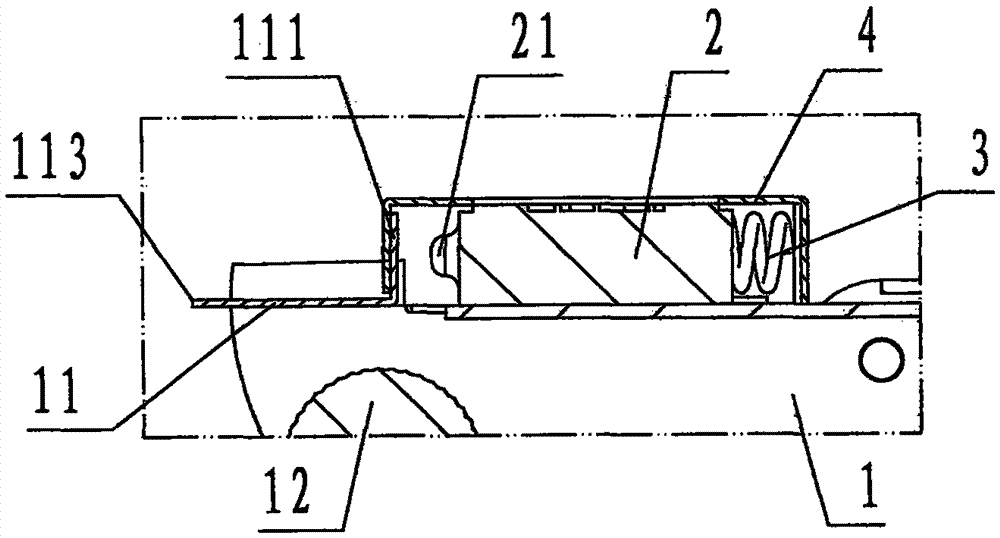

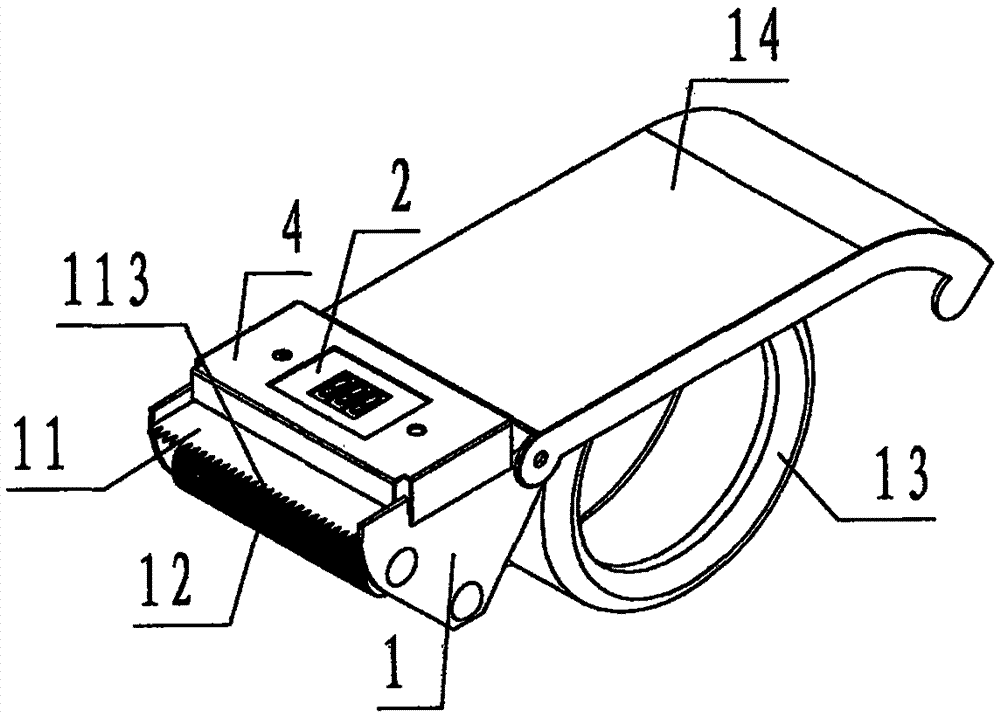

Countable adhesive tape container sealer

ActiveCN105438553ASimple structureWork reliablyWrapper twisting/gatheringPackaging machinesEngineeringMechanical engineering

The invention discloses a countable adhesive tape container sealer, comprising an adhesive tape cutter (1), a counter (2), a spring (3) and a cover (4). The adhesive tape cutter is provided with a slide cutter; the slide cutter is provided with a front baffle plate, a back baffle plate and a tooth-shaped edge; the counter is fixed on the upper surface of the adhesive tape cutter; the slide cutter is slidingly positioned on the left side of the counter; the cover fixedly covers the upper surface of the counter; the spring is positioned between the back baffle plate and the right side surface of an inner cavity of the cover; the front baffle plate is hooked and contacted with the left surface of the inner cavity of the cover, and is corresponding to a contact of the counter; when an adhesive tape is cut off by the tooth-shaped edge during working, the slide cutter is stressed to slide to the right side, the front baffle plate moves to the right side to trigger the contact of the counter, and the counter counts, that is, when the container sealing adhesive tape is cut once, the counter counts once and accumulates; and the container sealing number is estimated through processing the accumulated data of the counter, so that manual container sealing achieves the purposes of convenience for real-time counting, efficiency improvement and cost reduction.

Owner:NINGBO JIADUOMEI MACHINERY SCI & TECH

Prodenia litura trap

The invention discloses a prodenia litura trap. The prodenia litura trap comprises a complete bottle body, a bottle body without a bottom, a metal wire with a fixed lure core, a lure core and an insect storage bag. The bottle body without the bottom sleeves the complete bottle body, and the joint is fixed with transparent box sealing tape; a small hole is formed in the center of the bottom of thecomplete bottle body, the upper end of the metal wire with the fixed lure core is bent into a 'T' shape and vertically penetrates through the small hole, and the lower end of the metal wire with the fixed lure core is bound to the lure core; the insect storage bag is bound to a bottleneck of the bottle body without the bottom. The two bottle bodies are identical transparent plastic bottles, especially are discarded beverage bottles which can be recycled. The metal wire is an iron wire or a copper wire. A plurality of columns of cross-shaped insect inlet holes are formed in the upper half partof the complete bottle body, the four corners of each cross-shaped insect inlet hole are recessed into the complete bottle body, and ventilation holes are formed between every two columns of cross-shaped insect inlet holes. The prodenia litura trap has a good trapping effect, a simple method, a low cost, and economical and practical effects.

Owner:宜兴市蔬菜办公室

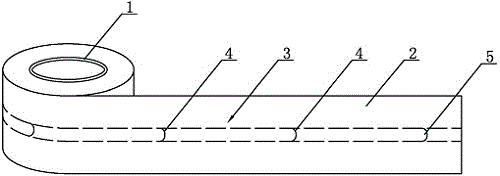

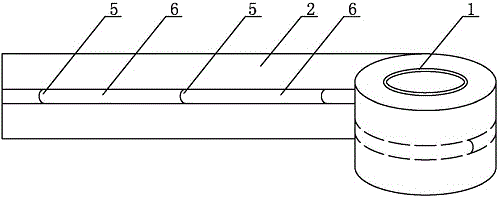

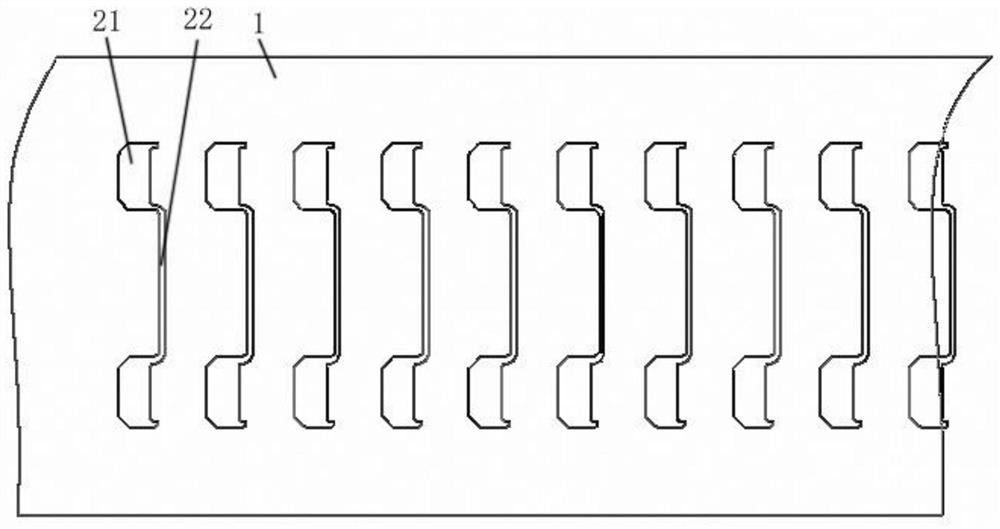

Easily torn box packing tape

InactiveCN106833417AInhibition biasImprove prompt effectFilm/foil adhesivesCombined useParaffin oils

The invention discloses an easily torn box packing tape which comprises a paper tube and a transparent adhesive tape main body wound on the paper tube, wherein a colorful tape is arranged on the rear side of the adhesive tape main body; the rear side of the colorful tape is arranged as a finishing surface; the colorful tape is arranged along the length direction of the adhesive tape main body; the colorful tape is located on the middle part of the adhesive tape main body; a plurality of U-shaped notches are equidistantly arranged along the length direction of the colorful tape at intervals; the notches simultaneously penetrate through the thickness directions of the colorful tape and the adhesive tape main body; colorant line layers are respectively arranged on the two sides of the adhesive tape main body along the width direction; a bar-shaped slot is formed in the middle part of the adhesive tape main body along the length direction; and paraffin mixed with the colorant is filled in the bar-shaped slot. Before the easily torn box packing tape is used, the easily torn box packing tape is heated through an air blower. According to the invention, through the combined use of two anti-fake modes of the colorant line layers and the bar-shaped slot, consumers can immediately know if the box packing tape is torn by the others in advance.

Owner:WUHU HONGSHENG TECH

Box sealing and pasting mechanism for 3D printing consumable packaging

InactiveCN111038784AIncrease frictionAdjustable distanceWrapper twisting/gatheringAdhesive beltCarton

The invention discloses a box sealing and pasting mechanism for 3D printing consumable packaging. The mechanism includes a base table, and a stand column is fixedly connected to an upper side of the base table. An upper side of the stand column is fixedly connected with a fixed rod. An upper side of the fixed rod is fixedly connected with a first fixed plate; an upper side of the first fixed plateis fixedly connected with a vertical plate; a middle part of the vertical plate is rotationally connected with a rotating shaft through a bearing; a surface of the rotating shaft is fixedly sleeved with a first fixing block. The first fixing block is in the shape of a circular truncated cone. The surface of the rotating shaft is slidably sleeved with a moving block. The moving block is in the shape of a circular truncated cone, a sleeve is fixedly welded to one side of the moving block, an inner ring of the sleeve is slidably connected to the surface of the rotating shaft in a sleeving mode,and a threaded knob is rotatably connected to one side of the sleeve through a thread. According to the box sealing and pasting mechanism, different types of box sealing adhesive tapes can be replacedand fixed, and the upper sides of cartons are aligned before pasting.

Owner:芜湖西通三维技术有限公司

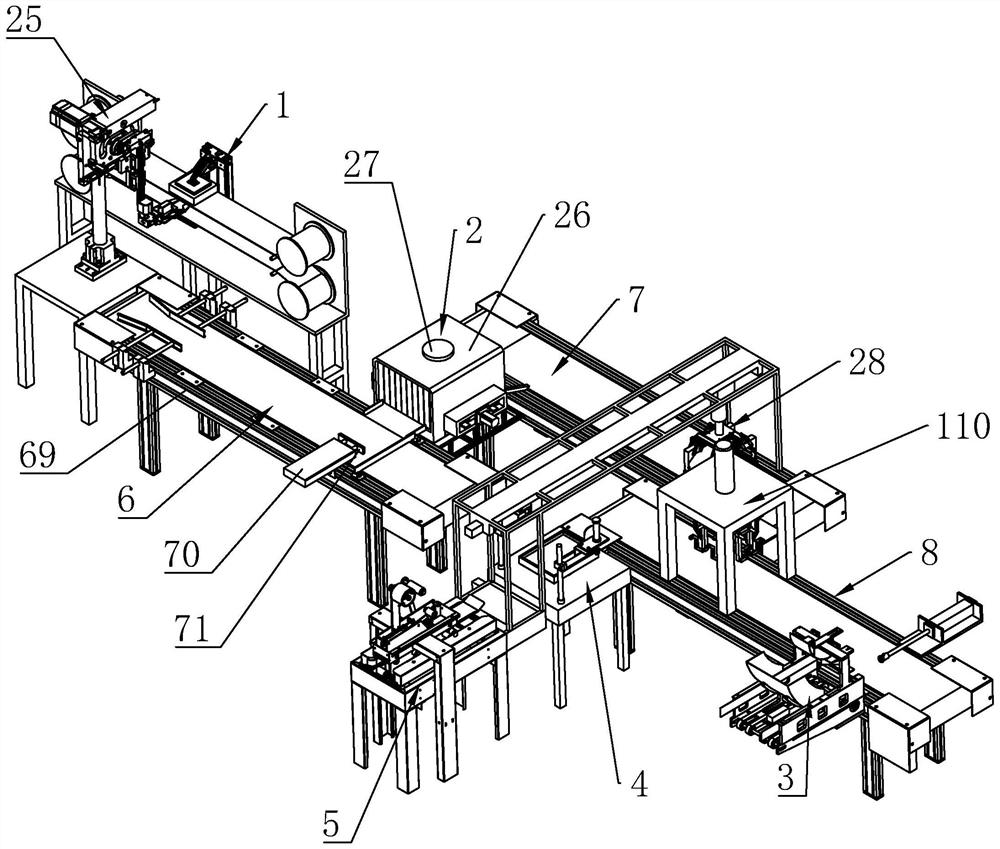

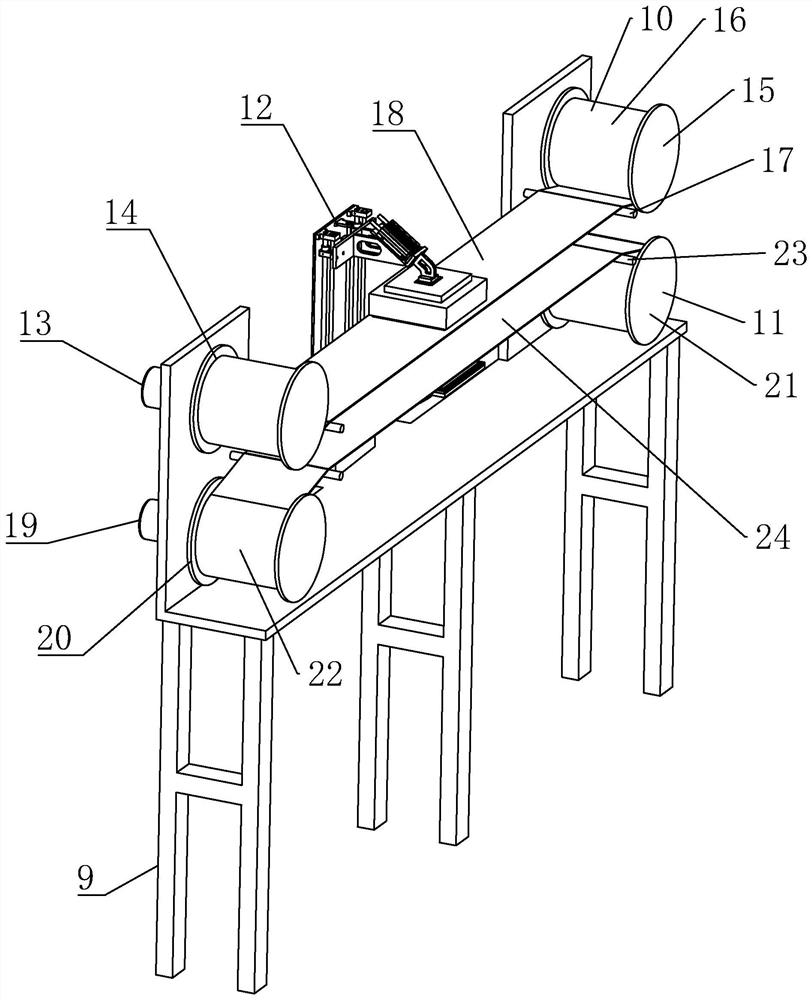

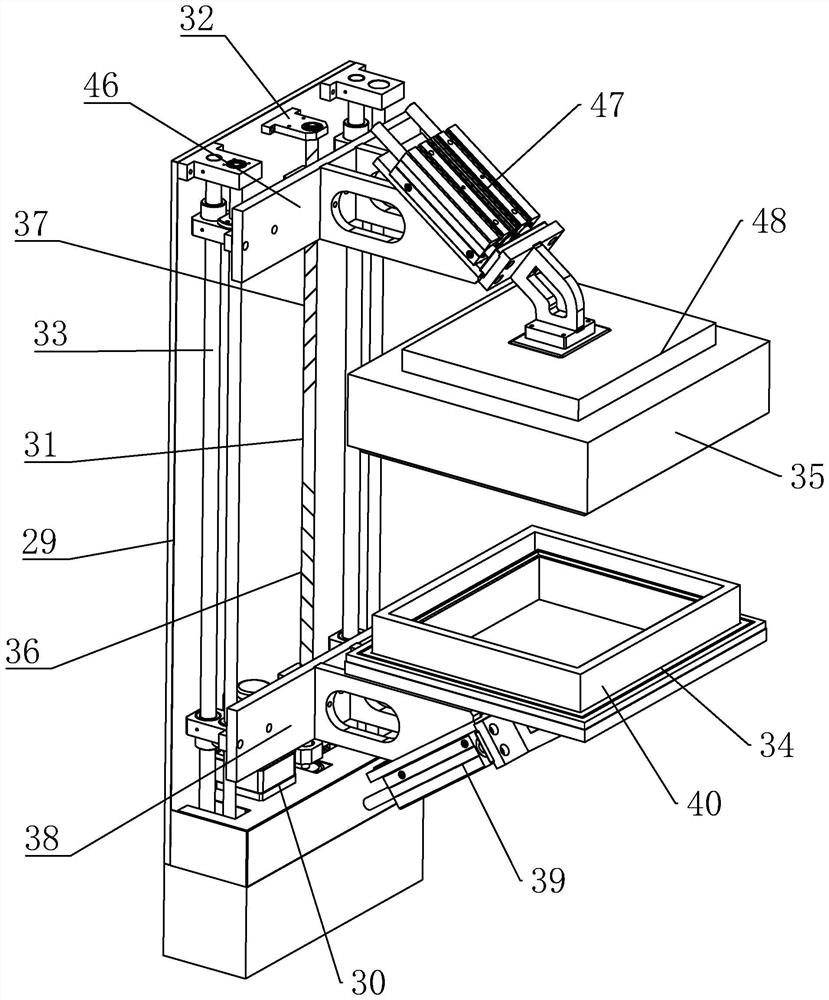

Circuit breaker packaging assembly line

InactiveCN114435651AAccurate captureImprove gripWrappers shrinkageWrapping material feeding apparatusAdhesive beltCarton

The invention discloses a circuit breaker packaging assembly line which comprises a pre-film-wrapping device, a film-wrapping device, a box-opening device, a box-closing device, a box-sealing adhesive tape device, a first belt conveying device, a second belt conveying device and a third belt conveying device. The first belt conveying device conveys the circuit breaker subjected to film coating into the film coating device; the film covering device is arranged between the first belt conveying device and the second belt conveying device, and after the circuit breakers subjected to film covering are loaded into the corresponding paper boxes through the second conveying device, the paper boxes with the circuit breakers are conveyed to the box closing device through the second conveying device to be subjected to the box closing procedure. And finally, the second conveying device conveys the closed carton to the carton sealing adhesive tape device for the carton sealing process. The circuit breaker packaging structure can achieve packaging of the circuit breaker, has the advantages of being high in efficiency and capable of saving labor cost, and meanwhile has the advantage of being good in sealing performance.

Owner:贾天祥

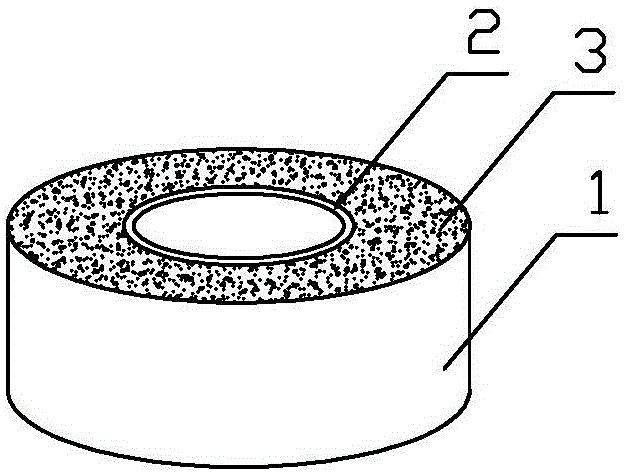

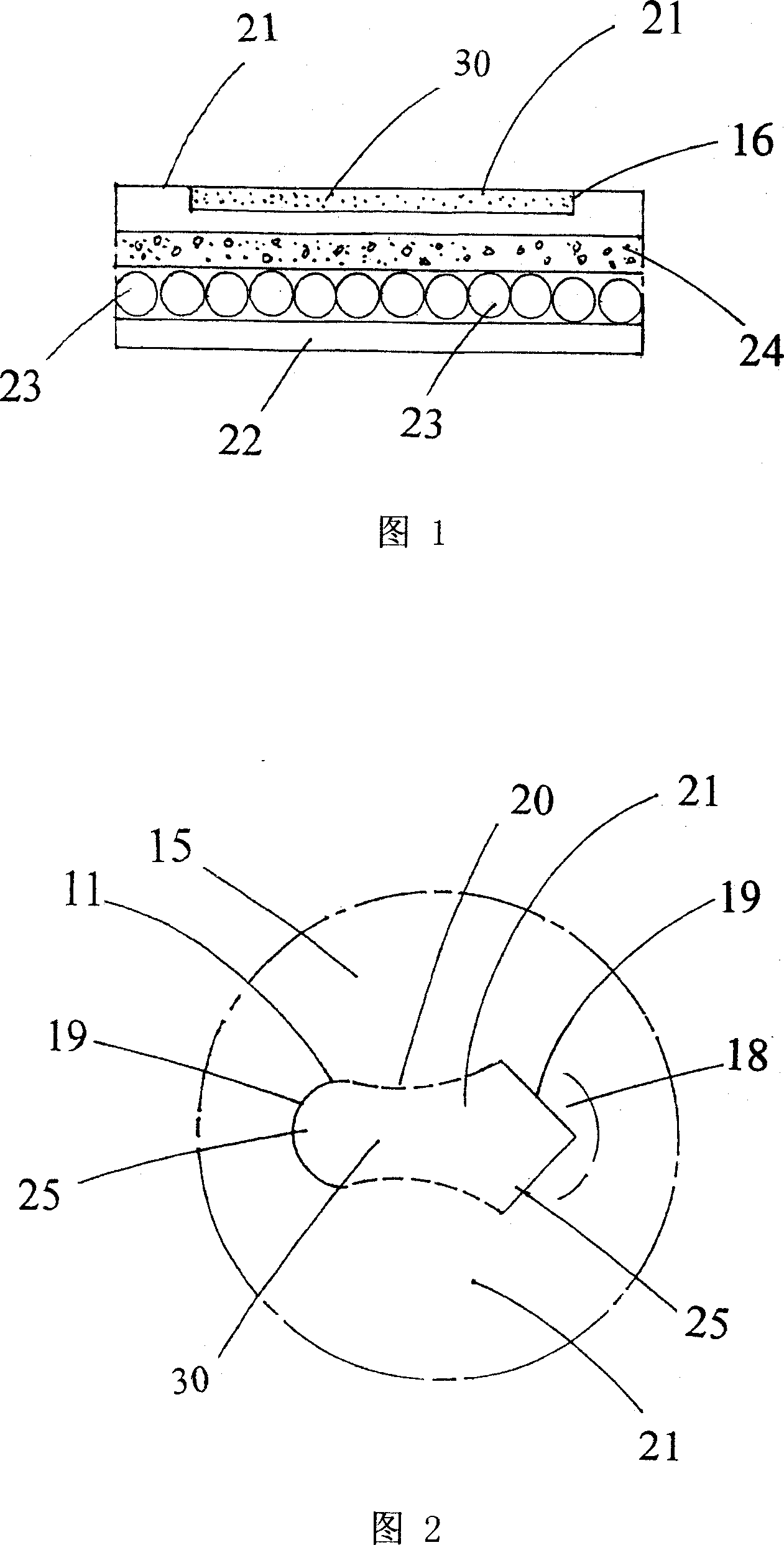

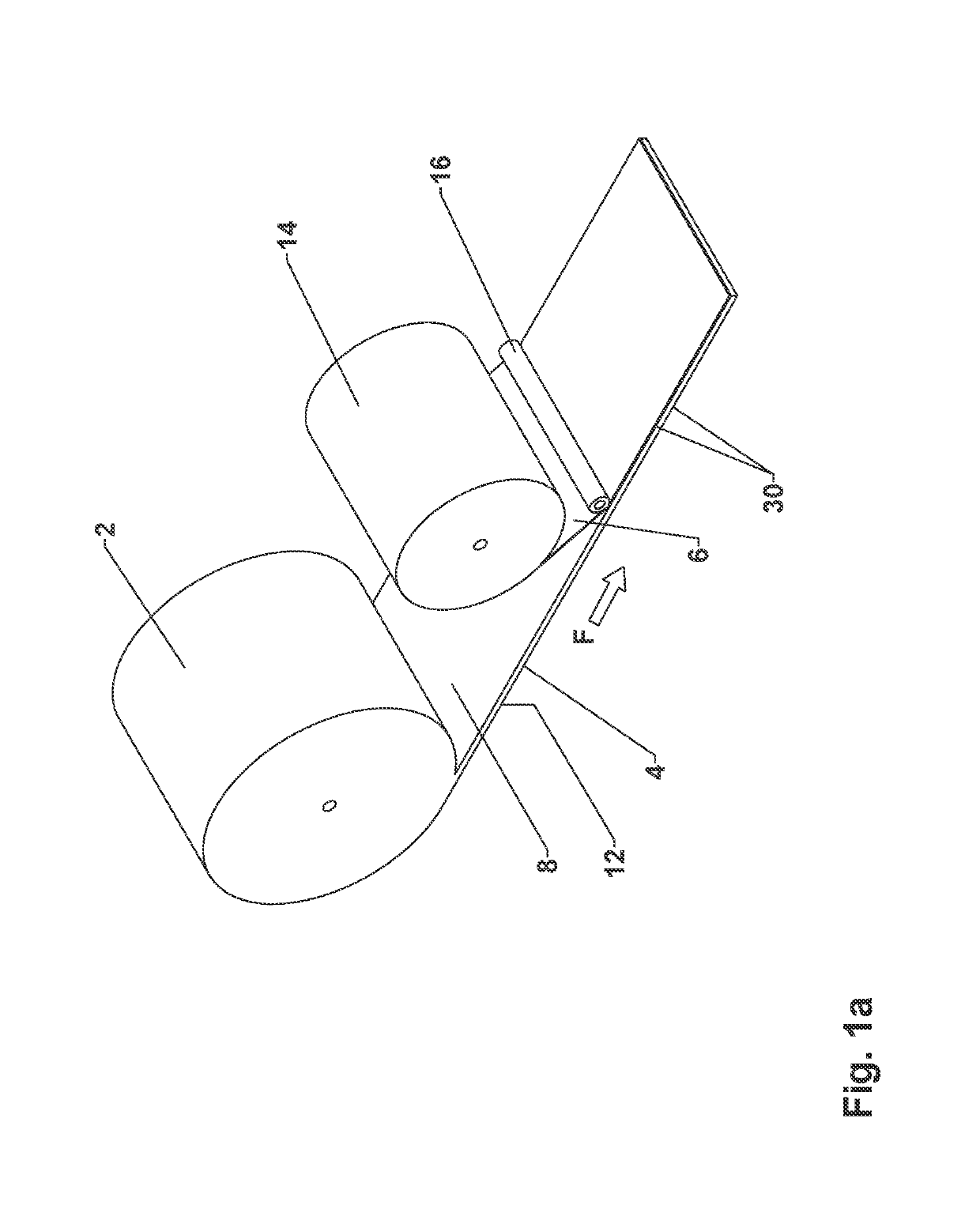

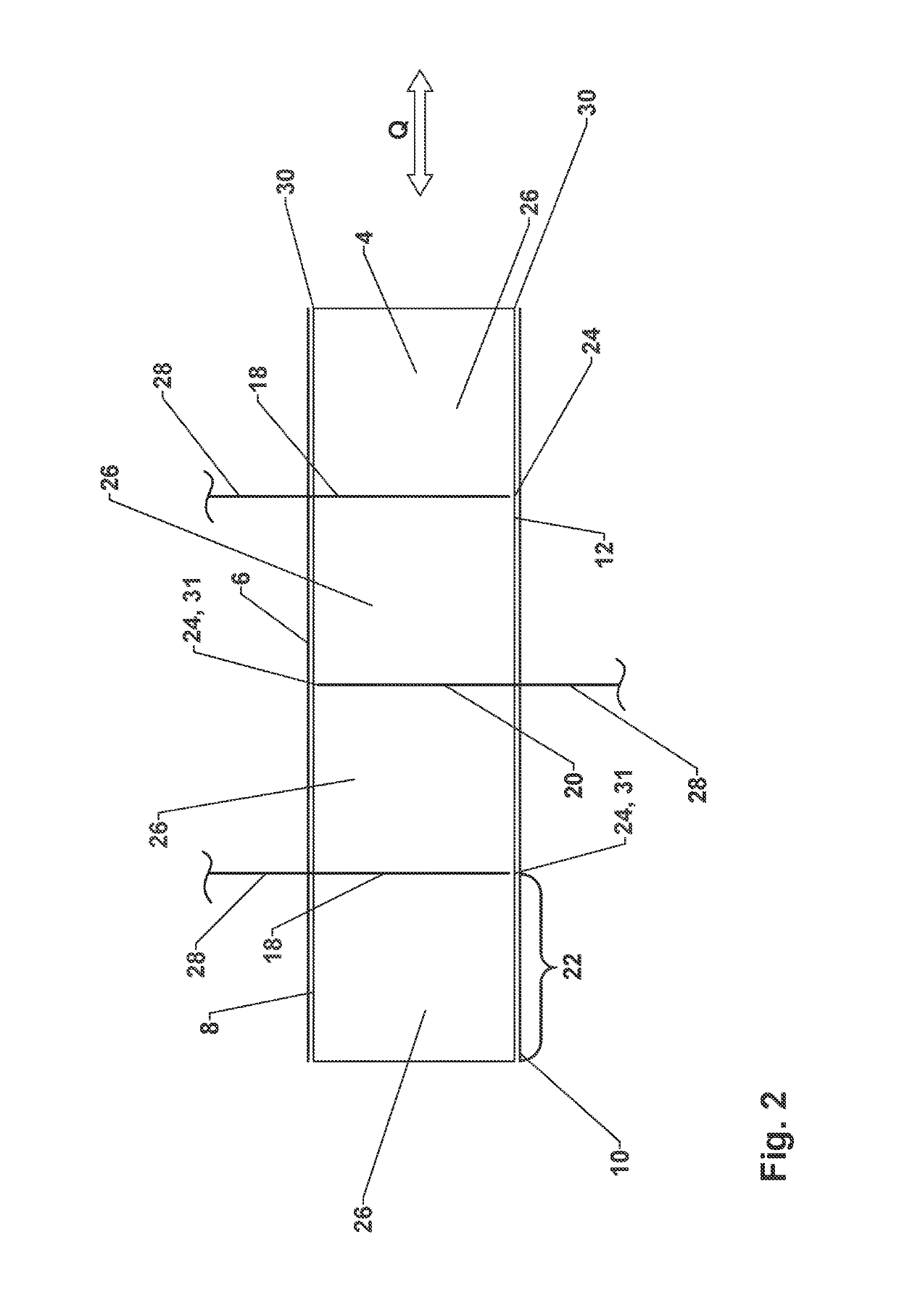

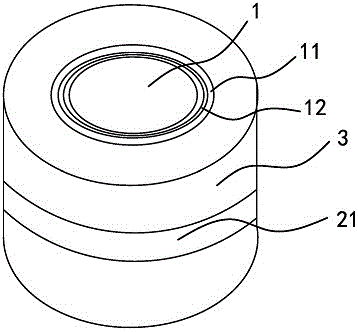

Sealing tape roll

ActiveUS10286624B2Produced easily and inexpensively and reliablyEngine sealsDomestic sealsEngineeringBox-sealing tape

Owner:ISO CHEM GMBH

Machining process for solving waste discharging and material saving

InactiveCN113233226ALow costReduce processing costsFilm/foil adhesivesMetal working apparatusProduction lineEngineering

The invention provides a machining process for solving waste discharging and material saving. Punching and compounding are conducted through a single production line, finished products are output, the machining cost is reduced, and the machining precision is high. A roll material advances along a roller way by a jumping distance A, double-faced adhesive tape advances by a jumping distance B through an asynchronous machine after a lower release film of the double-faced adhesive tape is peeled off, the portions, with the first area shapes, of the double-faced adhesive tape are punched by knives A to be compounded on the upper surface layer of the roll material, A is larger than B, and then the roll material carries the double-faced adhesive tape with the first area shapes arranged at intervals to advance step by step. Upper release films on the portions, corresponding to the first area shapes, of the double-faced adhesive tape are rolled up through box sealing adhesive tape, then a complete PET film is compounded on the upper surface formed by the double-faced adhesive tape and the roll material, the portions, with the first area shapes, of the double-faced adhesive tape are punched again through knives B, then waste is discharged through the PET film, and the residual PET film connected to the upper surface of the double-faced adhesive tape is rolled up through the box sealing adhesive tape again. Then, injection-molded parts are attached to the double-faced adhesive tape in the set shape one by one, and finally a finished product is obtained through roll material rolling.

Owner:SUZHOU ANJIE TECH

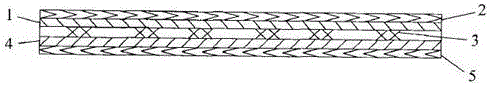

High-viscosity box-sealing tape

InactiveCN106833427AIncrease viscosityAvoid falling apartMonocarboxylic acid ester polymer adhesivesFilm/foil adhesivesGlass fiberEmulsion

The invention discloses a high-viscosity box-sealing tape. The box-sealing tape comprises a substrate layer and a glue layer, wherein the glue layer is pasted on the surface of the substrate layer; the material of the substrate layer is a glass fiber cloth; and the material of the glue layer is an emulsion formed by mixing an acrylic acid emulsion and a vinyl acetate based emulsion, the acrylic acid emulsion accounts for 30-40%, and the vinyl acetate based emulsion accounts for 60-70%. In the above manner, the viscous force of the box-sealing tape can be greatly increased. The middle of the glue layer is provided with a strip-shaped groove arranged in the length direction thereof, and paraffin mixed with staining agent is filled in the strip-shaped groove; and the high-viscosity box-sealing tape is heated by a blower before being used. According to the invention, the forgery prevention mode of the strip-shaped groove is used, thereby furthest ensuring that a consumer can know whether the box-sealing tape has been torn by others in advance at the first time.

Owner:WUHU HONGSHENG TECH

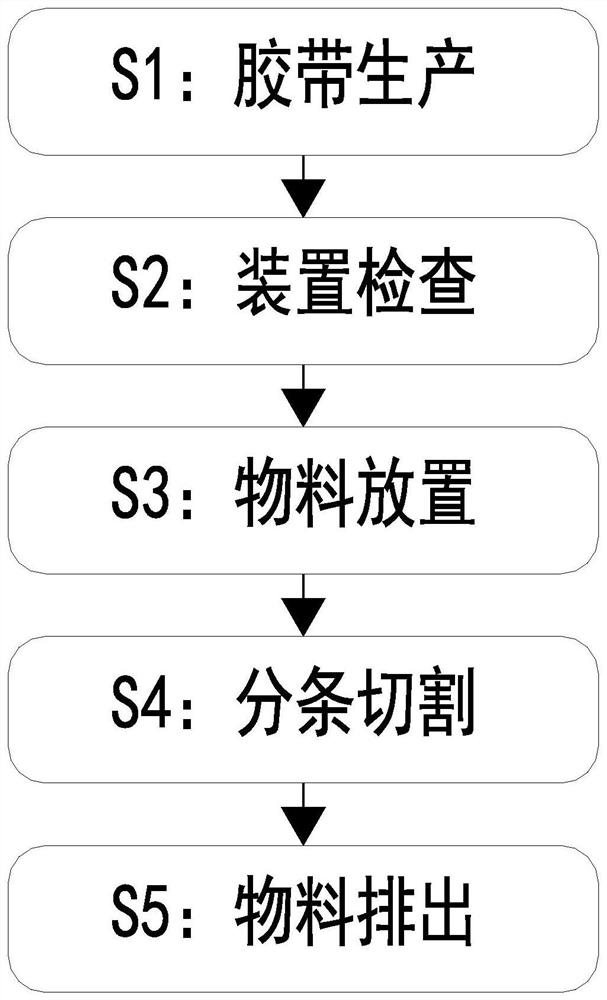

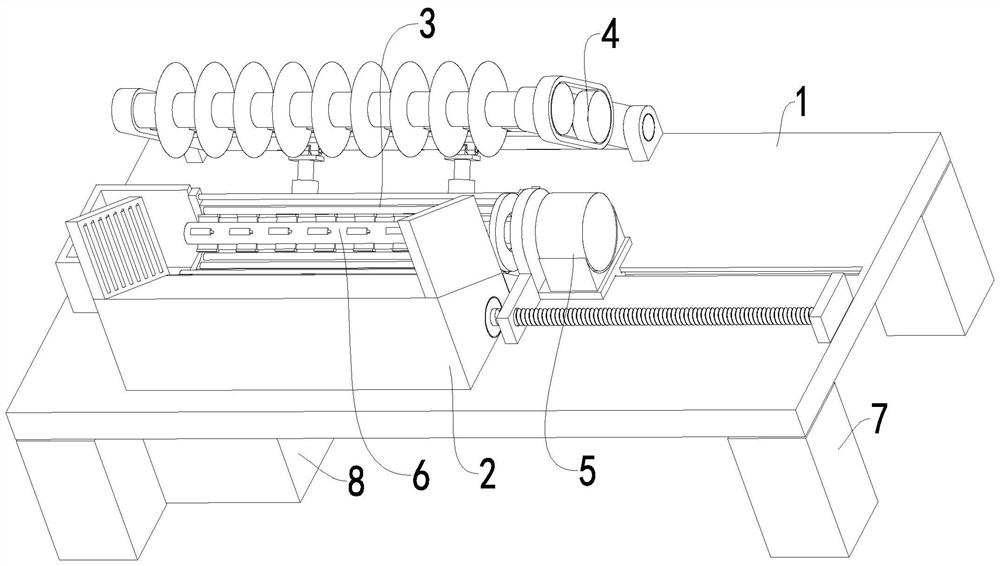

Packing tape producing and processing method

InactiveCN113104649AReduce the effect of segmentationReduce cutting efficiencyCleaning using toolsArticle deliveryAdhesive beltStructural engineering

The invention relates to a packing tape producing and processing method which adopts a packing tape producing and processing device. The packing tape producing and processing device comprises a base, a guide inclined block, a storage mechanism, a cutting mechanism, a driving mechanism, a clamping mechanism, supporting legs and a receiving box. The guide inclined block, the storage mechanism and the cutting mechanism are sequentially arranged on the upper end face of the base from front to back; the driving mechanism is arranged on the right side of the upper end face of the base; the clamping mechanism is arranged at the position, located at the upper end of the storage mechanism, of the left side of the driving mechanism; the supporting legs are arranged at the corners of the lower end face of the base; a discharging port is formed in the left side of the upper end face of base; and the receiving box is arranged between the supporting legs on the left side of the lower end surface of the base. According to the packing tape producing and processing method, the problems that when an existing adhesive tape dividing and cutting machine is adopted for dividing and cutting packing tape, a cutter is prone to being adhered with adhesive stains, and adhesive tape fragments easily cause uneven notches; and the slitting efficiency of the packing tape is low and the like are solved.

Owner:李涛

Automatic carton sealing machine capable of continuously sealing corners of carton

PendingCN114275252AImprove continuityEasy to pasteWrapper twisting/gatheringRotational axisAdhesive belt

The invention relates to the technical field of automatic carton sealing machines, and discloses an automatic carton sealing machine capable of continuously sealing corners of cartons, which comprises an operation table and a supporting vertical frame fixedly mounted at the upper end of the operation table, and a carton sealing mechanism is arranged on the supporting vertical frame. The carton sealing mechanism comprises a supporting vertical plate slidably mounted at the upper end of the supporting vertical frame and a rotating shaft fixedly mounted on the inner wall of the supporting vertical plate, carton sealing adhesive tape is inserted into the rotating shaft in a penetrating mode, a rear rod is movably mounted at the lower end of the supporting vertical plate, and a compaction roller shaft is rotatably mounted at the end, away from the supporting vertical plate, of the rear rod. A front rod is movably installed at the end, away from the rear rod, of the supporting vertical plate, a guide roller shaft is movably installed at the end, away from the supporting vertical plate, of the front rod, and a box sealing adhesive tape is wound around the guide roller shaft. And the guide roller shaft slides from the upper end of the corrugated carton, so that the adhesive tape can be conveniently adhered to the upper end of the corrugated carton, and sealing is facilitated.

Owner:思辟德智能科技江苏有限公司

Anti-flanging die cutting technology for aluminum foil

The invention discloses an anti-flanging die cutting technology for an aluminum foil. The die cutting technology comprises: S1, immersing die cutting rules in 5% sodium hydroxide strong alkaline solutions; S2, placing an aluminum foil coil on an unwinding device, and uncoiling the aluminum foil coil through an unwinding arm and an uncoiling control roller; S3, pasting a double-sided adhesive tapeon the front side of the aluminum foil, and pasting a release film on the other side of the adhesive tape; S4, leading the aluminum foil to the position below the specially-made die cutting rules through a traction press roller, cutting the aluminum foil through cooperative application of upper and lower die cutting rules, purging and removing aluminum foil chippings adhering to the surfaces of the die cutting rules through a cleaning device while finishing primary cutting; and S5, placing finished products on a finished product packing tape which can be wound, and then winding the packing tape for packaging. According to the die cutting technology, through optimization of the die cutting technology and improvement of the die cutting rule structure, the aluminum foil chippings are prevented from sticking to the die cutting rules during die cutting, and meanwhile a stress bearing surface is provided for the aluminum foil during die cutting; and the occurrence of the flanging phenomenonduring die cutting of the aluminum foil is avoided.

Owner:SUZHOU ANJIE TECH

Convenient anti-falsification box sealing adhesive tape

The invention provides a convenient anti-falsification box sealing adhesive tape. The convenient anti-falsification box sealing adhesive tape comprises an adhesive tape body, the adhesive tape body comprises a BOPP substrate layer, a low noise glue layer is arranged on one surface of the BOPP substrate layer, an anti-ultraviolet layer is arranged on the other surface of the BOPP substrate layer, a plurality of draw teeth are arranged on the adhesive tape body at intervals along the length extension direction of the adhesive tape body, the plurality of draw teeth are perpendicularly connected with two sides of the adhesive tape body, and the plurality of draw teeth are uniformly distributed between the head of the adhesive tape body and the tail of the adhesive tape body. A bar-shaped slot is arranged in the middle portion of the adhesive tape body along the length direction, and the bar-shaped slot is filled with colorant mixed paraffin. The convenient anti-falsification box sealing adhesive tape is heated by a blower before being used. The use of the bar-shaped slot maximally guarantees that a consumer knows whether the box sealing adhesive tape is torn or not by others at the first time.

Owner:WUHU HONGSHENG TECH

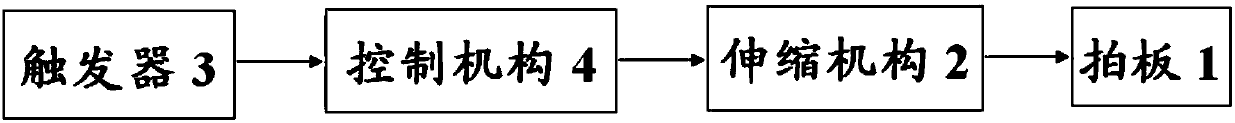

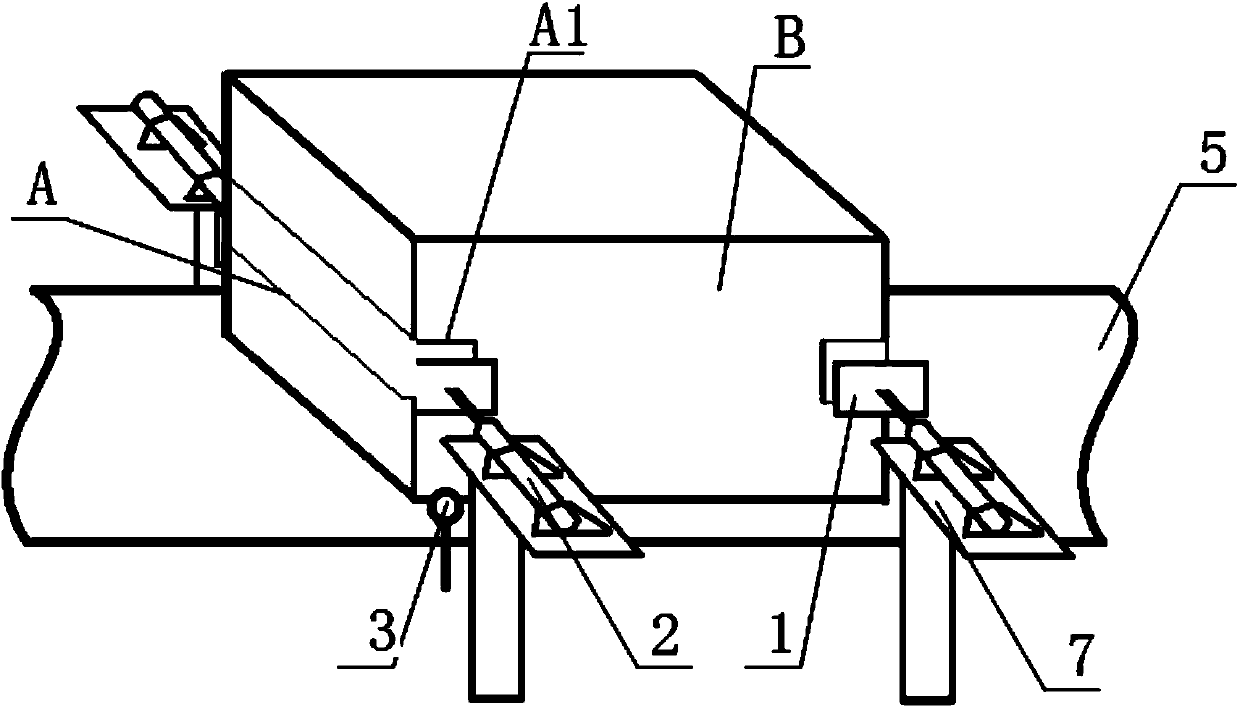

Box-packaging sealing tape pressing device

ActiveCN103693254AGuaranteed packaging qualityPaste firmlyWrapper twisting/gatheringEngineeringMechanical engineering

The invention relates to a box-packaging sealing tape pressing device. The device comprises a clapper, a telescopic mechanism, a trigger and a control mechanism, wherein the front surface of the clapper is arranged over against the short edge of an adhesive tape adhered to a box-packaged product; the telescopic mechanism is fixedly connected with the back surface of the clapper; the trigger is arranged near a box packaging conveying belt on which an area capable of being sensed by the trigger is arranged; the control mechanism is electrically connected with the trigger, and also is in driving connection with the telescopic mechanism; a triggering signal of the trigger is input to the control mechanism which sends a driving signal to the telescopic mechanism, and the clapper together with the telescopic mechanism stays in the extending state and can just press the short edge of the adhesive tape. The box-packaging sealing tape pressing device can guarantee the firm adhesion of the box packaging sealing tape as well as the packaging quality of the sealing tape.

Owner:LONGYAN CIGARETTE FACTORY

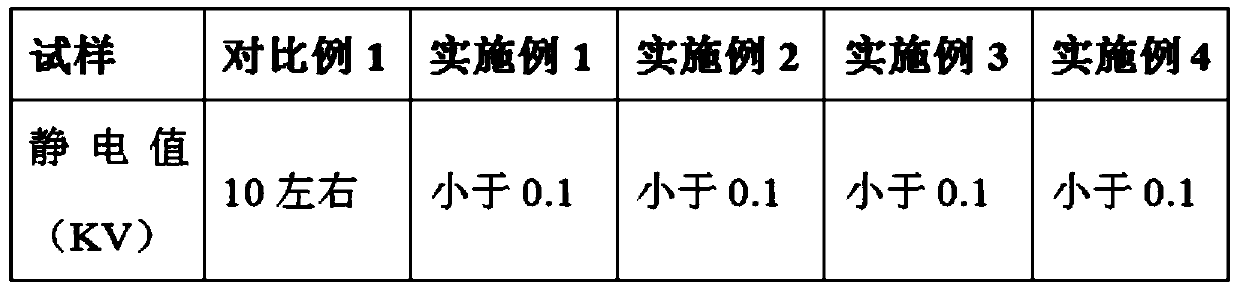

Anti-static pressure-sensitive adhesive tape and preparation method thereof

PendingCN110734708ASimple structureGood anti-static effectVacuum evaporation coatingSputtering coatingAdhesive beltMechanical engineering

An anti-static pressure-sensitive adhesive tape comprises a BOPP base material, a corona layer, a decorative layer, an aluminized layer and a pressure-sensitive adhesive layer in sequence from bottomto top. By means of the special layer structure, the pressure-sensitive adhesive tape layer is simple in structure, has a remarkable anti-static effect and is particularly suitable for box sealing andpackaging operation with strict dustproof and anti-static requirements for the workshop environment. The invention further discloses a preparation method of the anti-static pressure-sensitive adhesive tape. By additionally arranging the process steps with low cost, high efficiency and strong controllability, the pressure-sensitive box sealing adhesive tape is endowed with excellent anti-static performance on the basis of not greatly changing the process flow of the existing pressure-sensitive box sealing adhesive tape, and the preparation method is simple and suitable for large-scale industrial production.

Owner:佛山市亿达胶粘制品有限公司

Box-sealing adhesive tape

InactiveCN106634665AIncrease frictionInhibit sheddingFilm/foil adhesivesWrapper twisting/gatheringEpoxyCombined use

The invention provides a box-sealing adhesive tape and belongs to the technical field of living goods. The box-sealing adhesive tape comprises a reel and an adhesive tape film wound on a paper core, wherein an arc angle protruding outwards is formed between the inner walls of the two ends of the reel and the cross section; skidproof stripe is arranged at the position of the arc angle; an epoxy resin release layer, a printing ink layer and an adhesive layer are arranged on the lower surface of the adhesive tape film sequentially from top to bottom; coloring agent line layers are arranged on the two sides of the adhesive layer along the width direction correspondingly; a strip-shaped groove is formed in the middle of the adhesive layer and along the length direction; the strip-shaped groove is filled with paraffin mixed with the coloring agent; and before use, the box-sealing adhesive tape is heated by a blower. Through combined use of two anti-counterfeit modes of the coloring agent line layers and the strip-shaped grooves, the box-sealing adhesive tape furthest ensures that a consumer can know whether the box-sealing adhesive tape is torn by other people in advance at the first time.

Owner:WUHU HONGSHENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com