Method and device for automatically and continuously ripping packing tapes of packing case

A packing box and adhesive tape technology, which is applied in the field of automatic and continuous cutting of packing box sealing tape, to achieve the effects of reducing labor intensity, high economic benefits, and safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

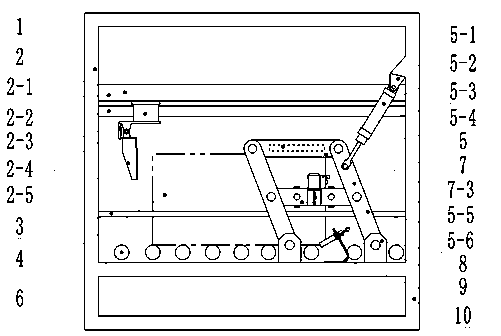

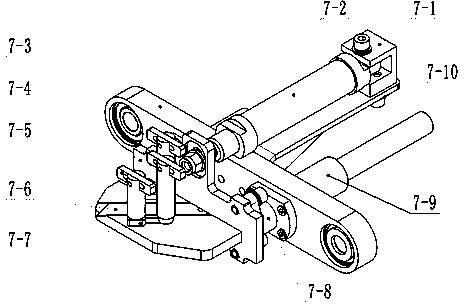

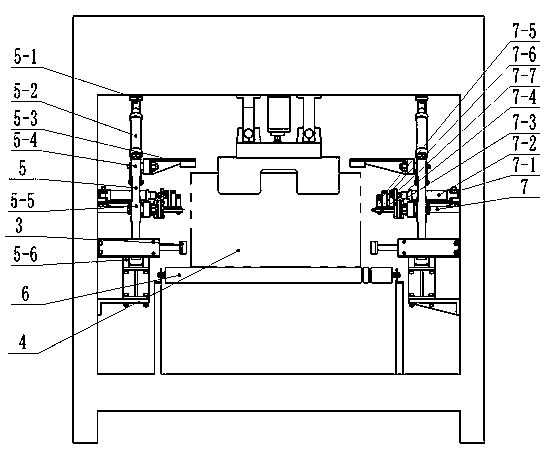

[0054] A device for automatically and continuously cutting packing box sealing tape, which is characterized in that it includes a push box mechanism 2 on the upper part of the frame 10, a guide mechanism 3 and a center positioning mechanism 5 that are relatively distributed on both sides of the frame 10, and a center positioning mechanism installed on the center positioning mechanism. Stretching knife mechanism 7, and the conveying roller table 6 that is positioned at frame 10 bottoms.

[0055] It is mainly composed of a pushing box mechanism 2, a guiding mechanism 3, a center positioning mechanism 5, a conveying roller table 6, a knife extending mechanism 7, a frame 10 and other auxiliary components.

[0056] Push box mechanism 2, guiding mechanism 3, center positioning mechanism 5 are all fixed on the frame 10, stretching knife mechanism 7 is hinged on the center positioning mechanism 5, conveying roller 6 is positioned at pushing box mechanism 2 below.

[0057] Push box mec...

Embodiment 2

[0065] The rodless cylinder 2-1 that provides power for the push box mechanism 2 may also be a synchronous belt driven linear unit driven by a motor.

[0066] The cylinder of the guide mechanism can be replaced by an electric cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com