Anti-counterfeiting box sealing adhesive tape

A tape and box sealing technology, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problem that the sealing tape does not have anti-counterfeiting properties, and achieve the effect of good anti-counterfeiting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

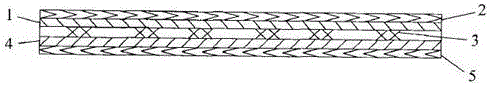

[0018] see figure 1 , the anti-counterfeiting sealing tape includes a tape film 1, the tape film 1 is a PET film, the upper surface of the tape film 1 is provided with a silicone oil layer 2, and the lower surface of the tape film 1 is sequentially provided with a release layer 3 and a coloring layer from top to bottom. 4 and the adhesive layer 5; the release layer 3 is an epoxy resin release agent layer, and is dispersed on the lower surface of the tape film 1; the color of the coloring layer 4 can be a single color, or two or more Combination of colors; the coloring layer 4 and the adhesive layer 5 are continuously arranged on the entire lower surface of the tape film.

[0019] Adding the process steps of release layer and color coating layer in the manufacturing process of sealing tape can increase the difficulty of manufacturing, further reduce the possibility of unscrupulous merchants producing similar sealing tapes, and play a certain role in anti-counterfeiting; when pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com