Anti-counterfeiting halographic mark with positioning hollow-out variable information and method for producing anti-counterfeiting halographic mark with positioning hollow-out variable information

A variable and marking technology, applied in the field of anti-counterfeiting holographic marking and its production, can solve the problems of single means, lack of holographic anti-counterfeiting characteristics, and declining anti-counterfeiting performance of holographic bronzing film, achieving good anti-counterfeiting performance and eliminating the effect of batch imitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

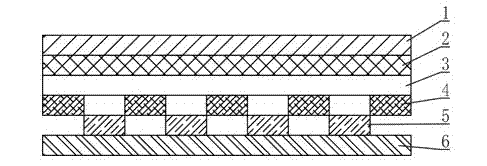

[0026] ①. Use the biaxially stretched behavioral film as the substrate layer 1, corona-treat the inner side of the biaxially stretched behavioral film, and coat the release coating 2 whose main component is wax on the corona surface. The coating temperature is controlled at 80~120 ℃, speed 60~90m / min;

[0027] ②. Coat the acrylic resin coating on the release coating 2, the coating temperature is controlled at 80~120℃, and the speed is 60~90m / min;

[0028] ③. Use a holographic molding machine to transfer the designed holographic pattern to the acrylic resin coating at 180-240°C to form a holographic imaging layer 3;

[0029] ④. Use digital printing equipment to print the processed data content or the database content provided by the customer on the holographic imaging layer 3 as required to form a variable information printing layer 4. The printed content can be numbers, barcodes, and two QR code or comprehensive information;

[0030] ⑤. Use a vacuum coating machine to vapor-...

Embodiment 2

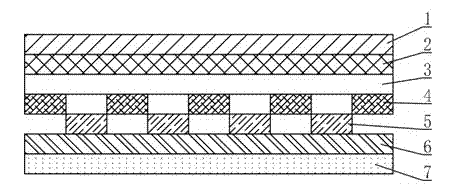

[0035] ①. Use the biaxially stretched behavioral film as the substrate layer 1, corona-treat the inner side of the biaxially stretched behavioral film, and coat the release coating 2 whose main component is wax on the corona surface. The coating temperature is controlled at 80~120 ℃, speed 60~90m / min;

[0036] ②. Coat the acrylic resin coating on the release coating 2, the coating temperature is controlled at 80~120℃, and the speed is 60~90m / min;

[0037] ③. Use a holographic molding machine to transfer the designed holographic pattern to the acrylic resin coating at 180-240°C to form a holographic imaging layer 3;

[0038] ④. Use digital printing equipment to print the processed data content or the database content provided by the customer on the holographic imaging layer 3 as required to form a variable information printing layer 4. The printed content can be numbers, barcodes, and two QR code or comprehensive information;

[0039] ⑤. Use a vacuum coating machine to vapor-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com