Patents

Literature

337 results about "Bronzing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bronzing is a process by which a bronze-like surface is applied to other materials (metallic or non-metallic). Some bronzing processes are merely simulated finishes (patinas) applied to existing metal surfaces, or coatings of powdered metal that give the appearance of a solid metal surface. In other cases, an actual layer of heavy copper is electroplated onto an object to produce a bronze-like surface. This electroplating is the method traditionally used for "bronzing" of baby shoes, but to electroplate a non-conductive item like a baby shoe, a conductive material must first be applied, then the copper plating is done.

Cyan ink, ink set, set of ink and reaction liquid, and image forming method

InactiveUS20060103703A1Increase the areaHigh image densityMeasurement apparatus componentsInksOrganic solventWater insoluble

Provided is a cyan ink applicable to an ink set having four kinds of aqueous inks composed of the cyan ink, a magenta ink, a yellow ink, and a black ink each containing water; a water-insoluble coloring material; and plurality of water-soluble organic solvents including a good medium or good mediums for the water-insoluble coloring material and a poor medium or poor mediums for the water-insoluble coloring material. The content of the water-insoluble coloring material in the cyan ink is in a specific range, and the ratio B1 / A1 between the good medium and the poor medium is also in a specific range. A water-soluble organic solvent showing the maximum Ka value out of respective Ka values of the plurality of water-soluble organic solvents is the poor medium. The ratio A / B between the good medium and the poor medium in an arbitrary aqueous ink in the ink set except the cyan ink and B1 / A1 satisfy a specific relationship. The cyan ink provides an image having a sufficiently large area factor even with a small amount of ink droplets, and having a high image density, and is excellent in storage stability and bronzing resistance.

Owner:CANON KK

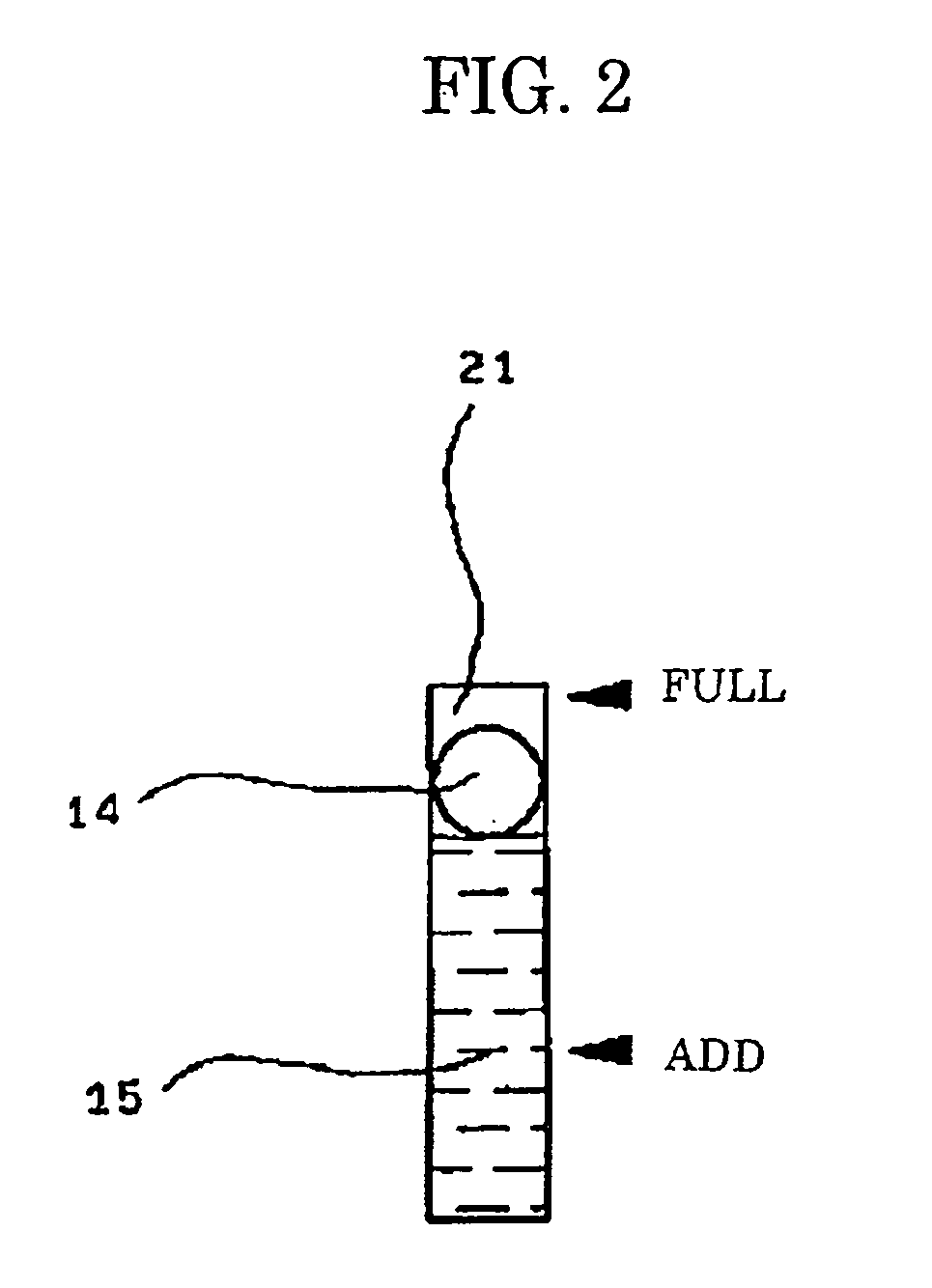

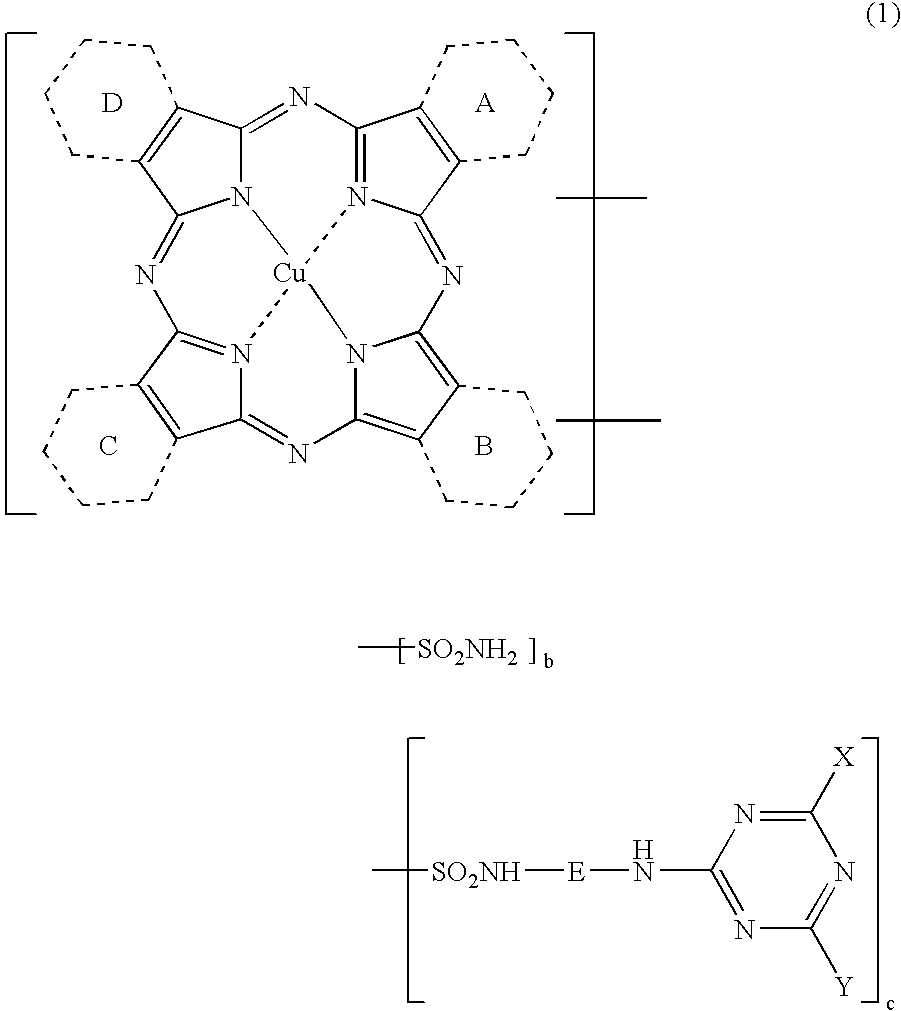

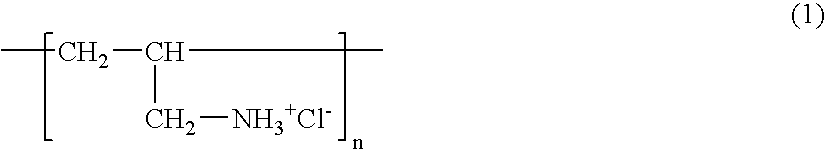

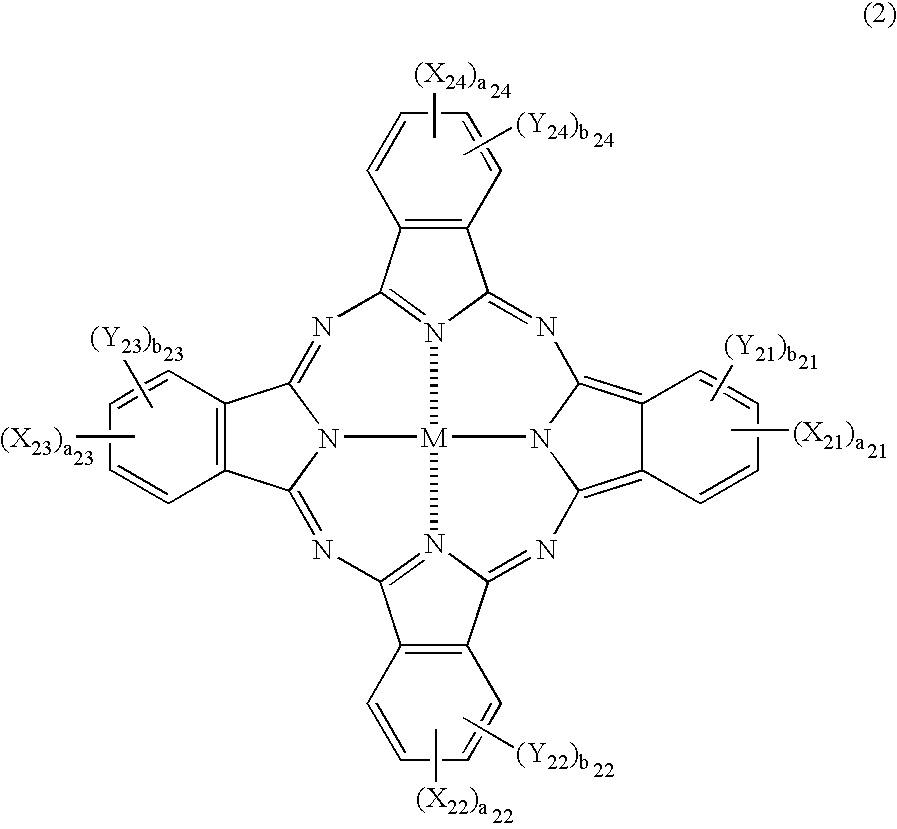

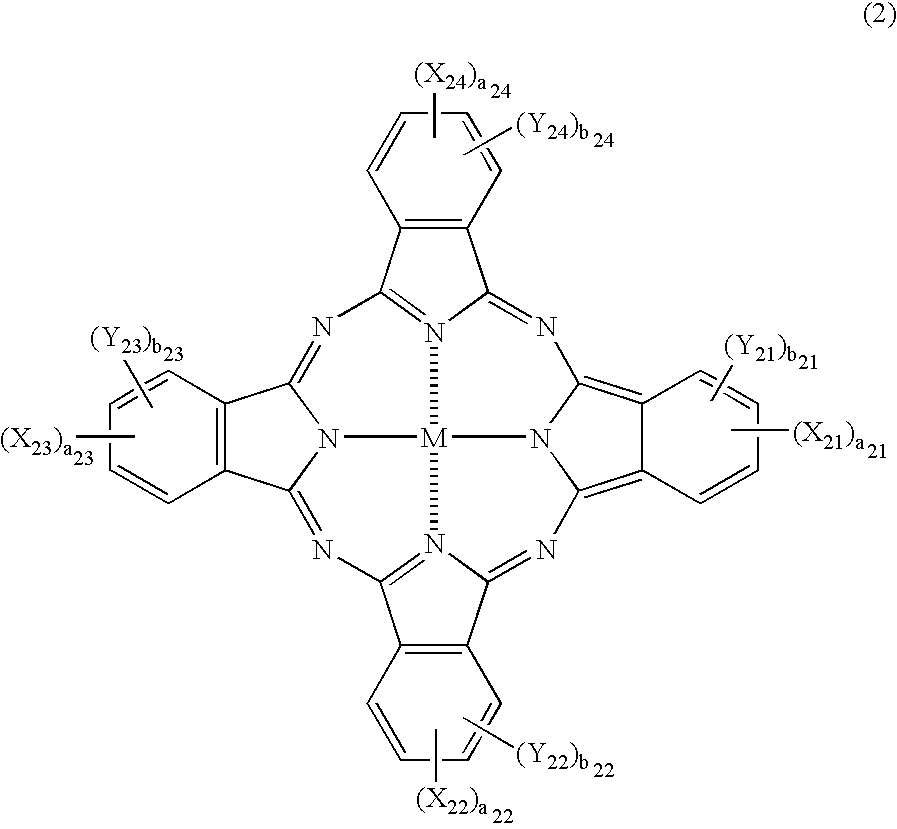

Porphyrazine coloring matter, ink, ink set and colored article

ActiveUS7591888B2Excellent toneGood light fastnessLiquid surface applicatorsOrganic chemistryPorphyrazineNitrogen

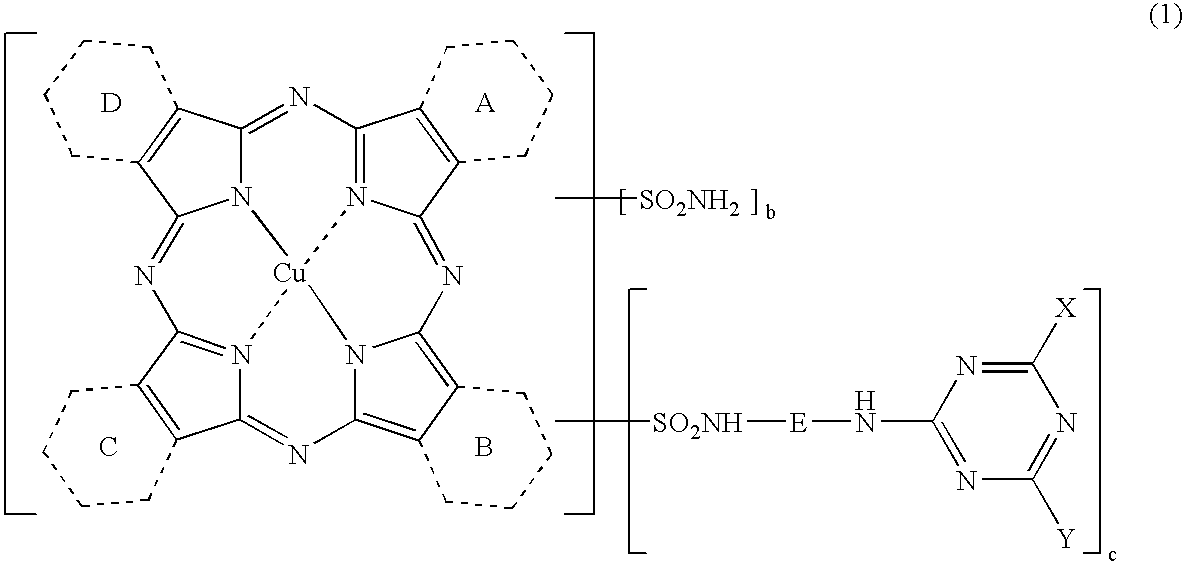

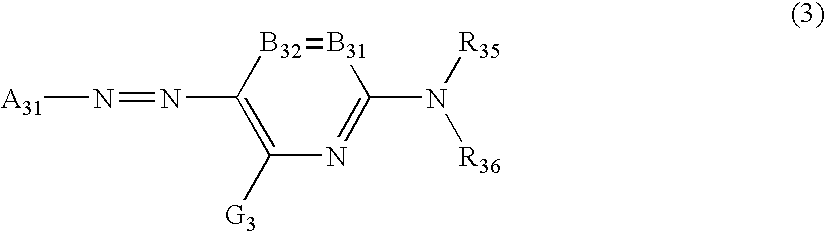

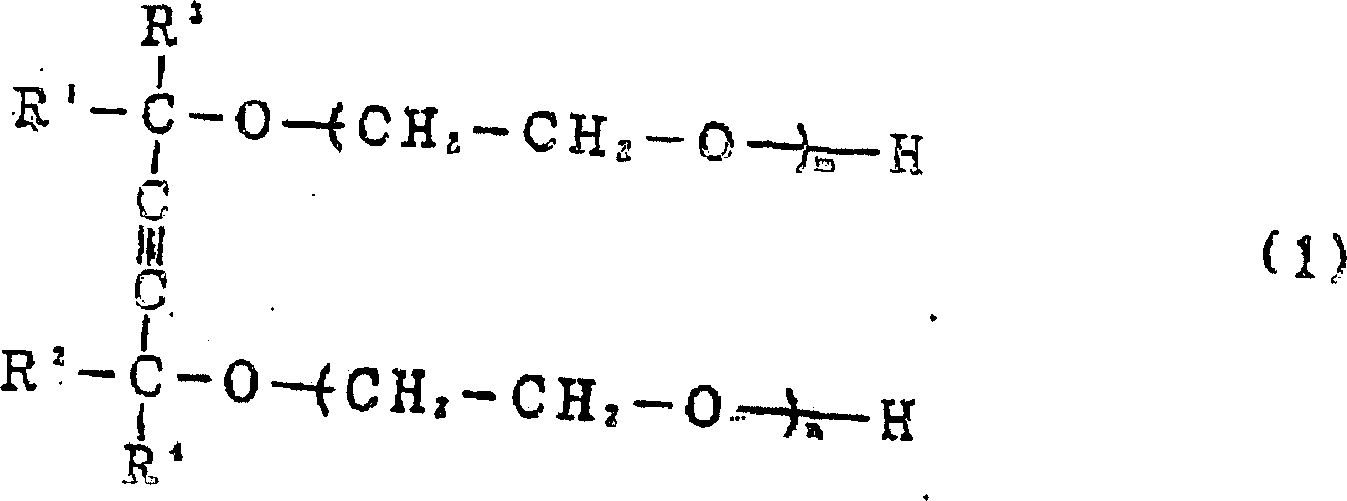

The present invention relates to a porphyrazine coloring matter represented by the following formula (1):(wherein, A, B, C and D independently represent a 6-membered ring having aromaticity, at least one or more of them are benzene rings and at least one or more of them contain nitrogen-containing heteroaromatic rings; E represents alkylene, X is a substituted anilino group and have at least one or more of sulfo group, carboxy group and phosphono group as a substituent, Y represents a hydroxy group or an amino group, b is respectively 0 to 2.9, c is 0.1 to 3, and the sum of b and c is 1 to 3) in free acid form, which is suitable for inkjet recording because it has good hue as a cyan ink, is excellent in light fastness, ozone fastness and moisture fastness, and does not cause bronzing phenomenon.

Owner:NIPPON KAYAKU CO LTD

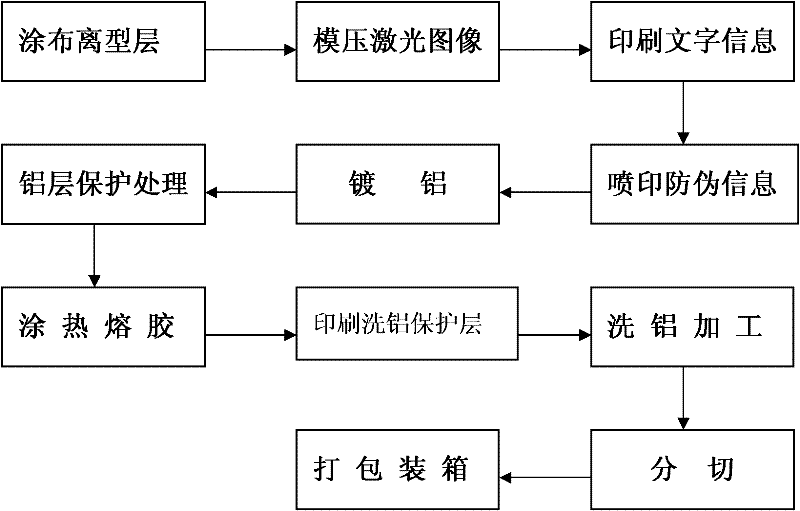

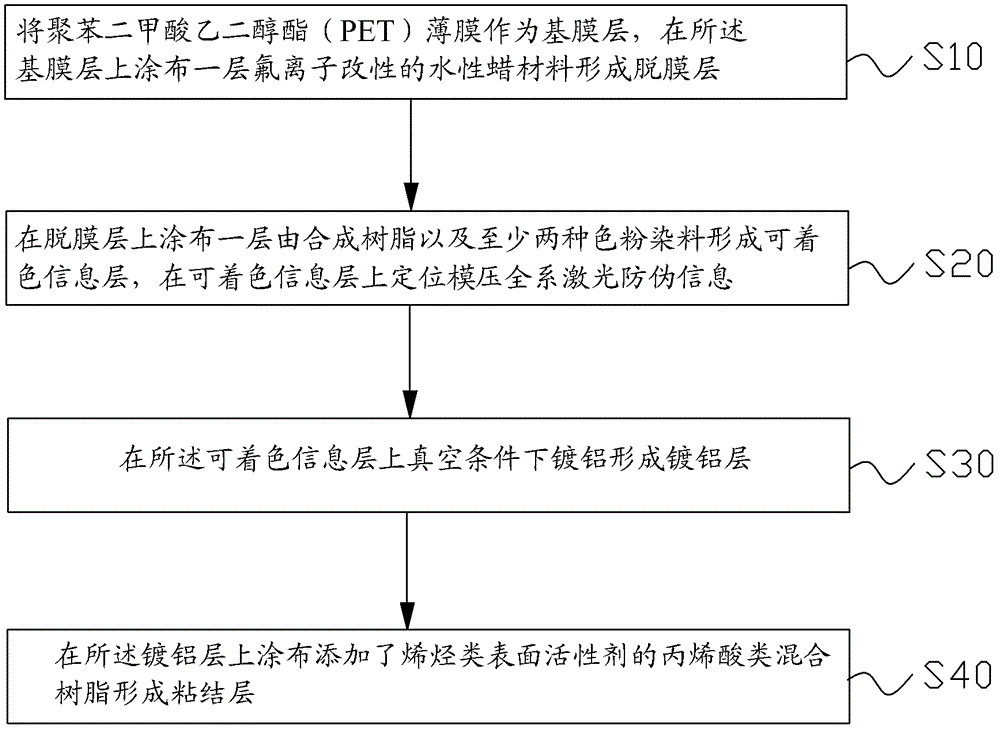

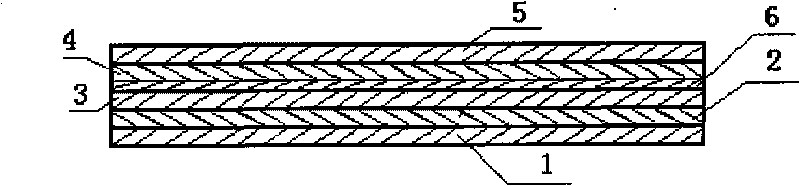

Character anti-counterfeiting gilding film and manufacture process thereof

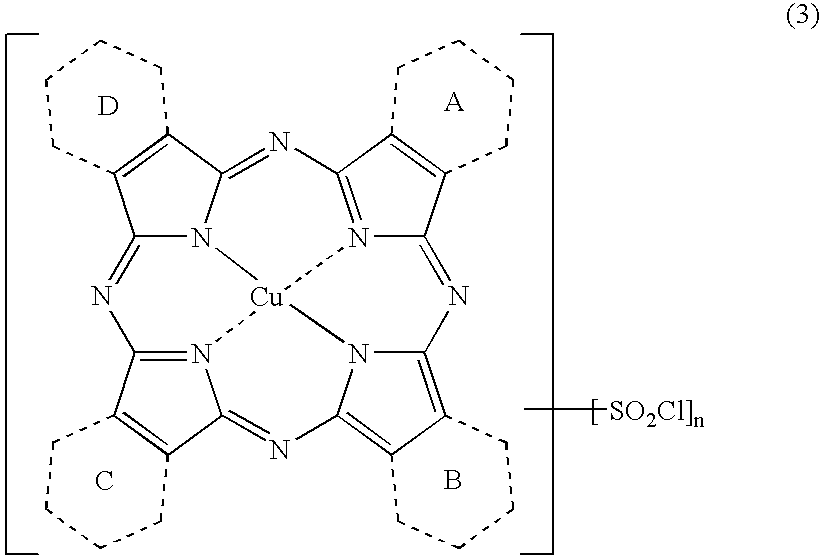

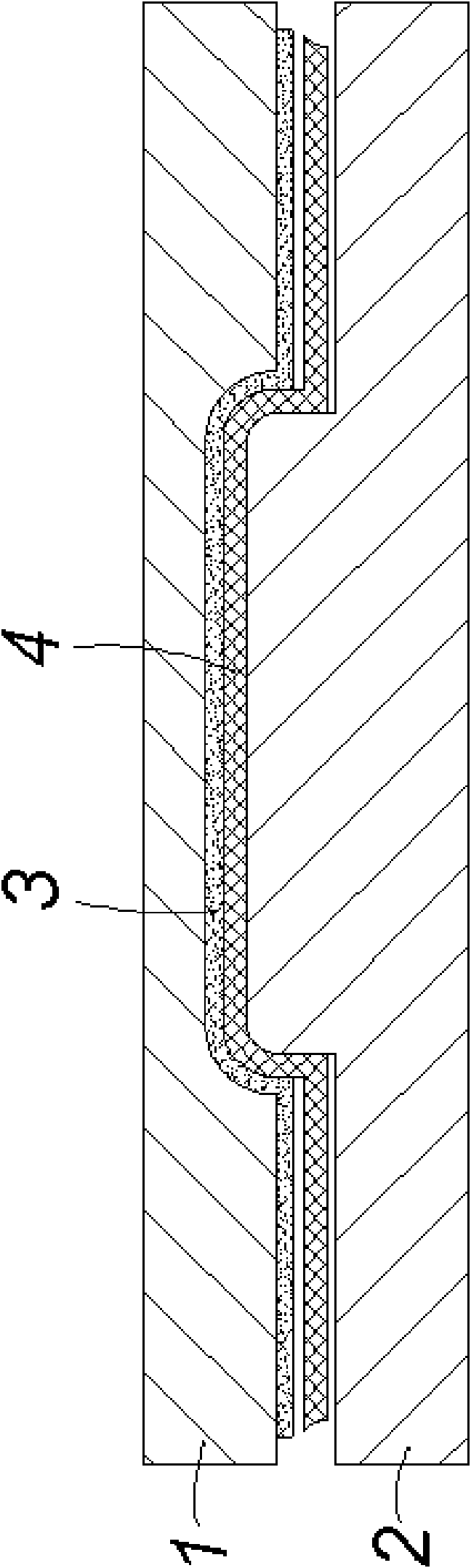

ActiveCN102555573AGood anti-counterfeiting functionAnti-smugglingThermographyPolyesterInformation layer

The invention discloses a character anti-counterfeiting gilding film and manufacture process thereof. The gilding film sequentially comprises a transferring glue layer, an aluminum layer protective layer, an aluminum layer, a character information layer, a separation-type layer and a substrate medium layer, wherein the transferring glue layer is hot melt glue, the aluminum layer protective layer is a protective aluminum layer for preventing the aluminum layer form oxidation and dropping, the aluminum layer is a thin aluminum layer aluminized on a coating layer of the film, the character information layer comprises a printed essential information portion and a sprayed character anti-counterfeiting feature portion, and the separation-type layer comprises common transferring coating and laser mould pressing coating. The manufacture process comprises coating transferring materials on a polyester (PET) film and forming the separation-type layer; spraying anti-counterfeiting information on the separation-type layer of the film by using the spraying process; and finally coating the transferring glue layer. The character anti-counterfeiting gilding film and the manufacture process use advantages of the gilding film, combine with character anti-counterfeiting technology, give life force to each label, and achieve integration of the packing of products.

Owner:李峰

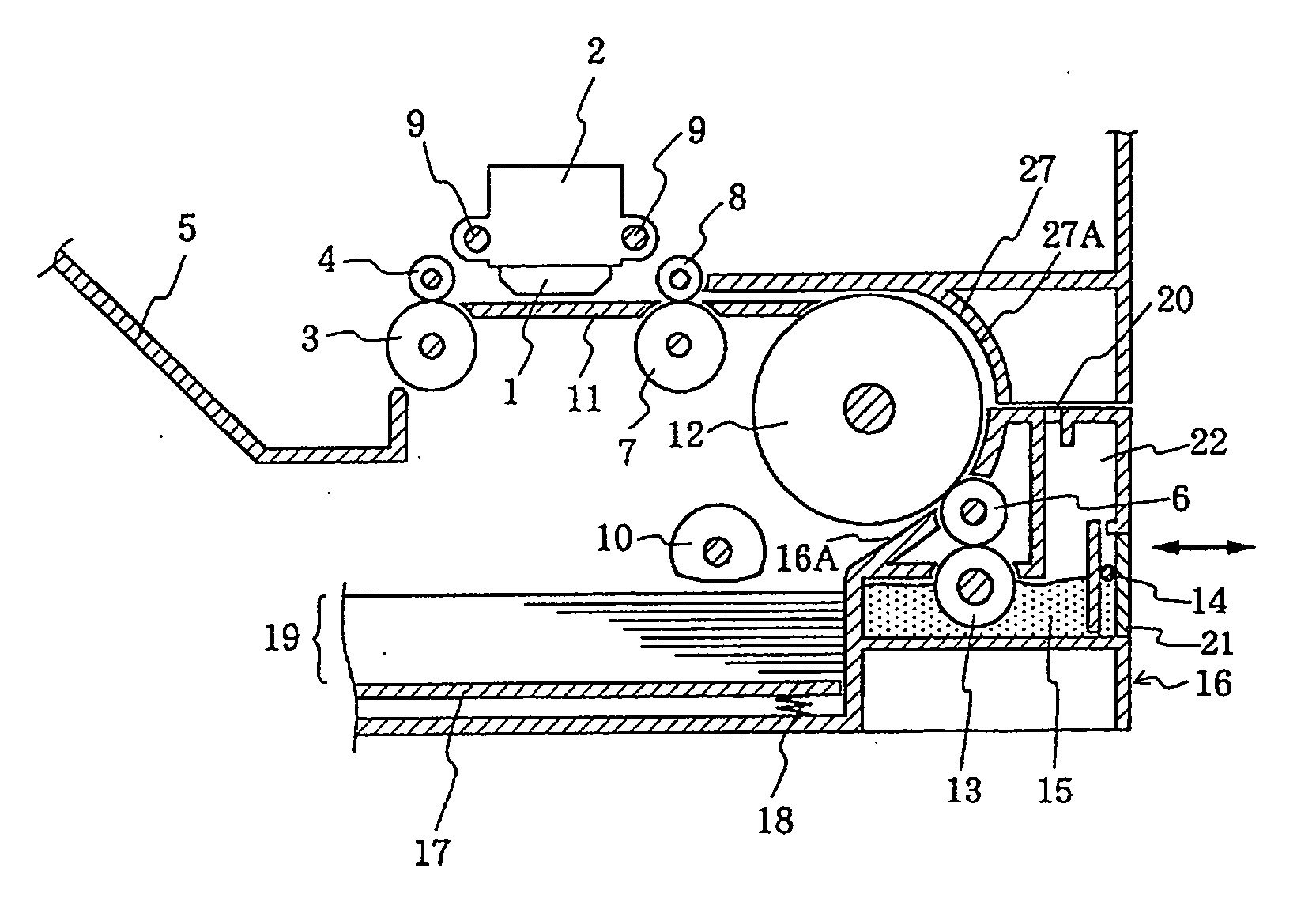

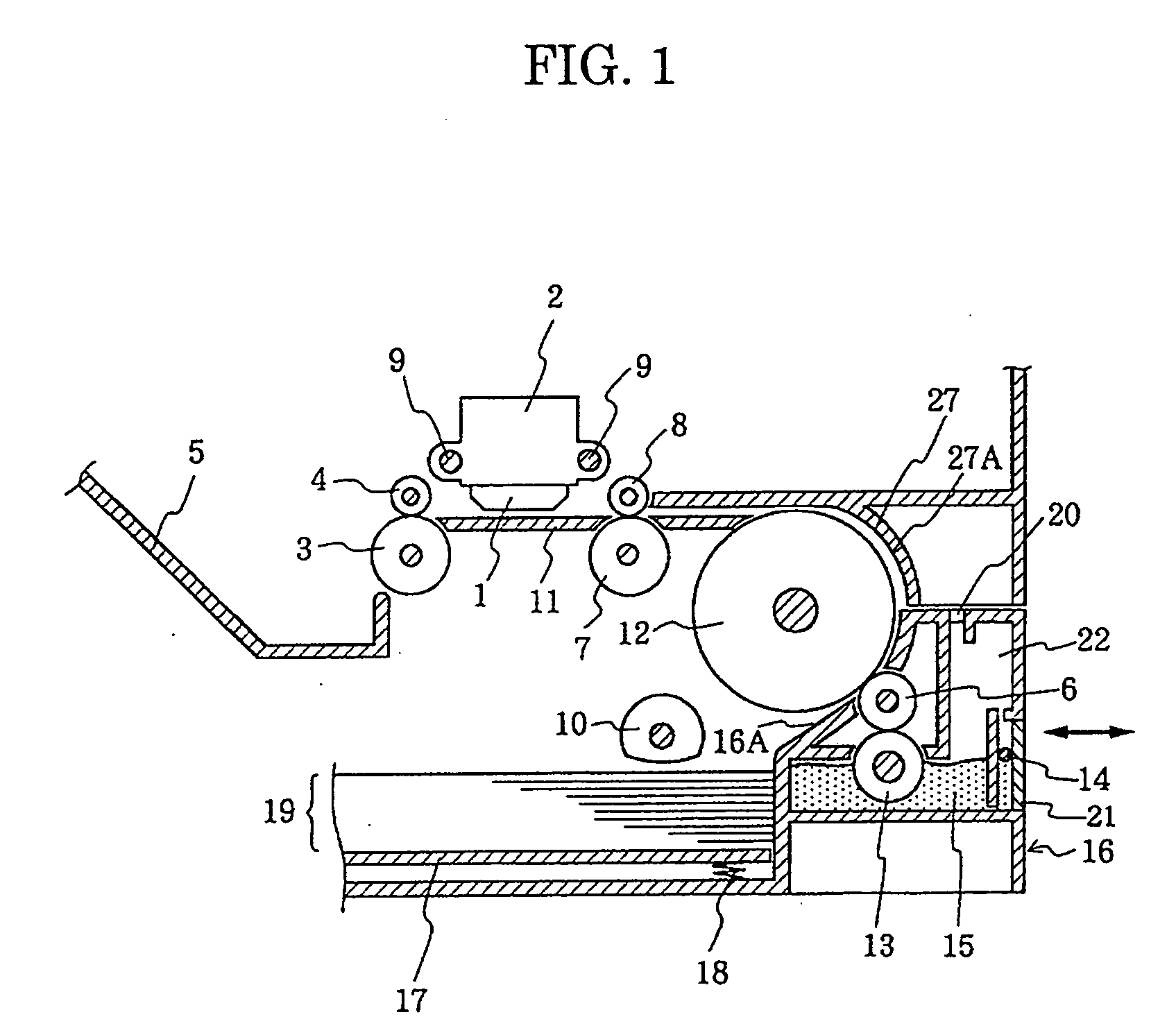

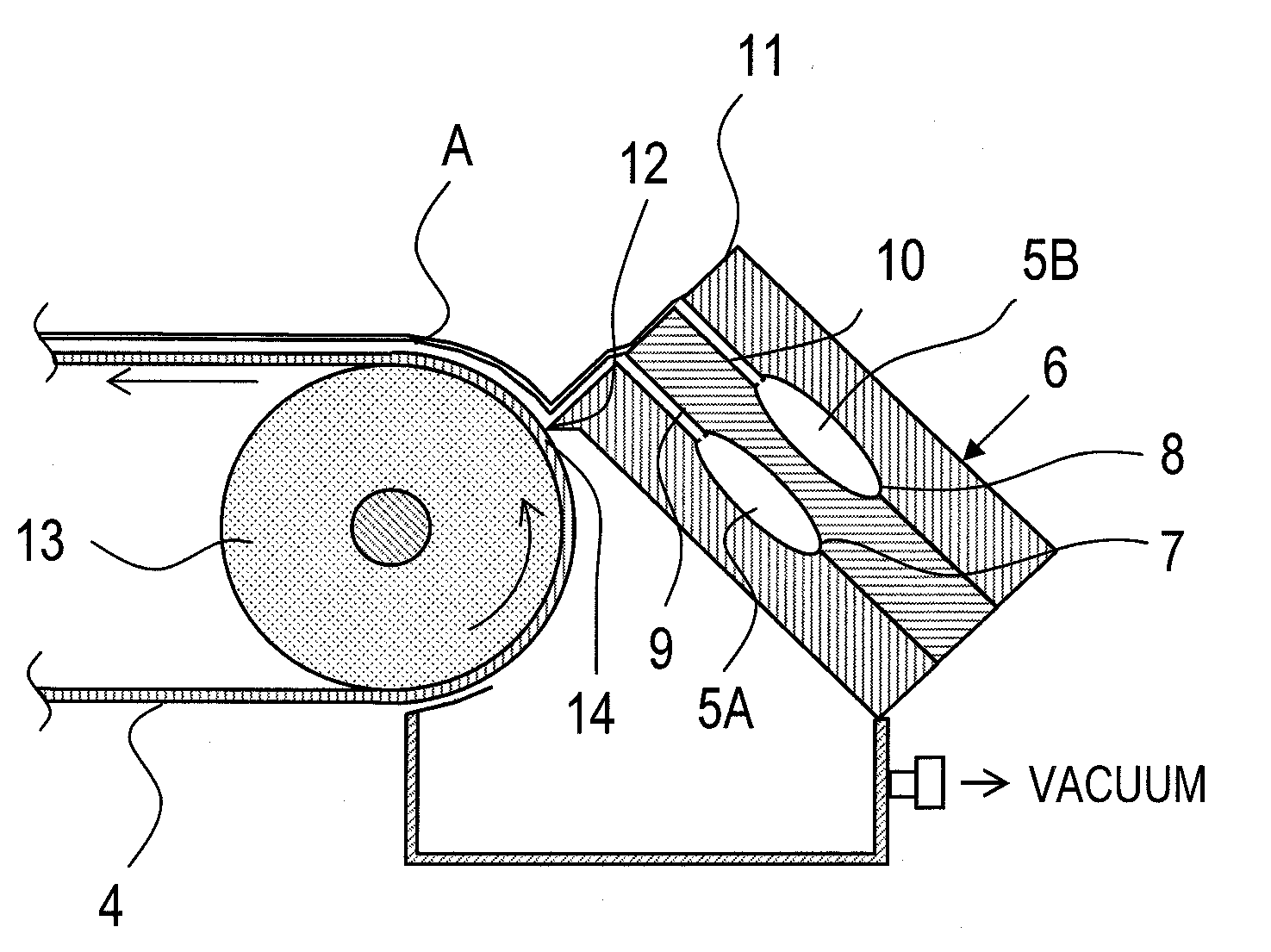

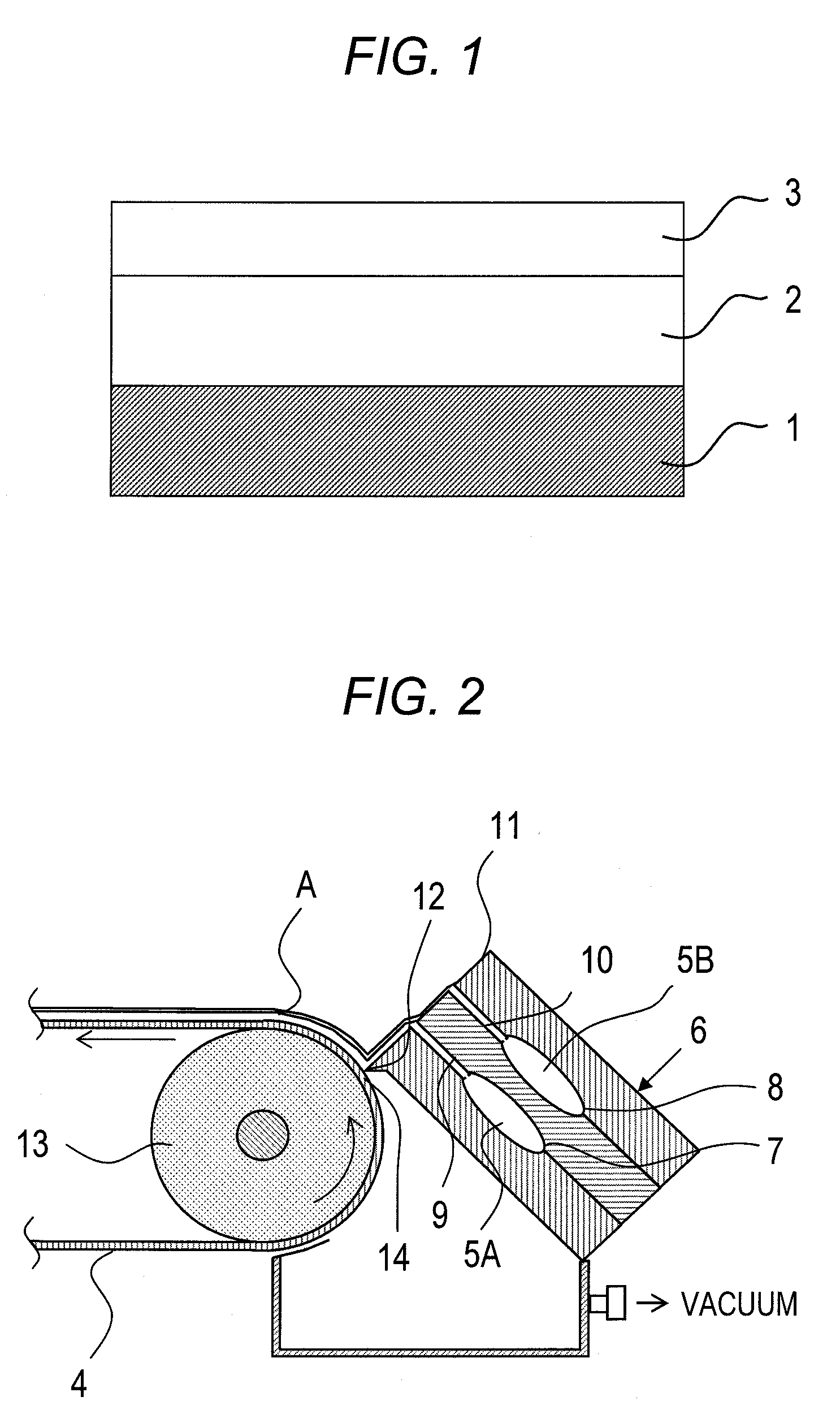

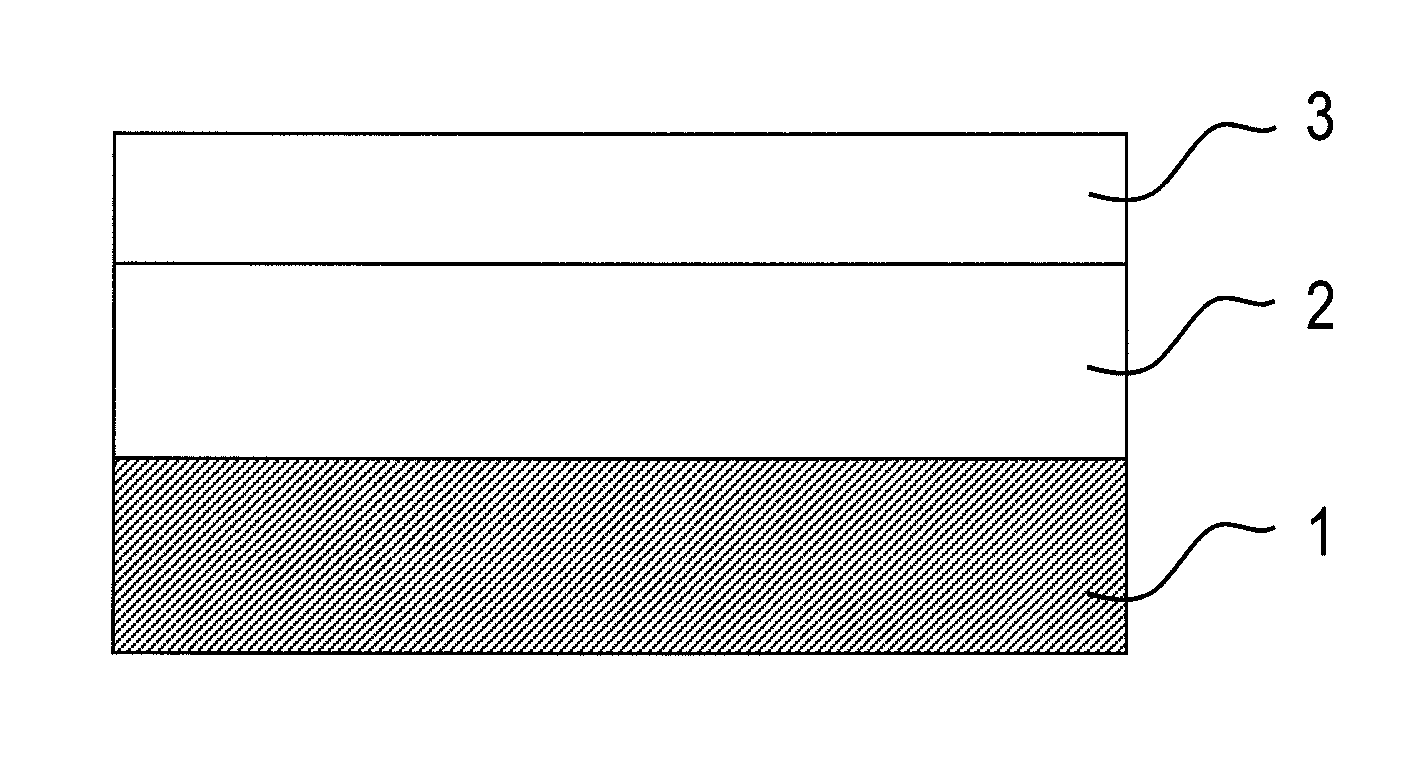

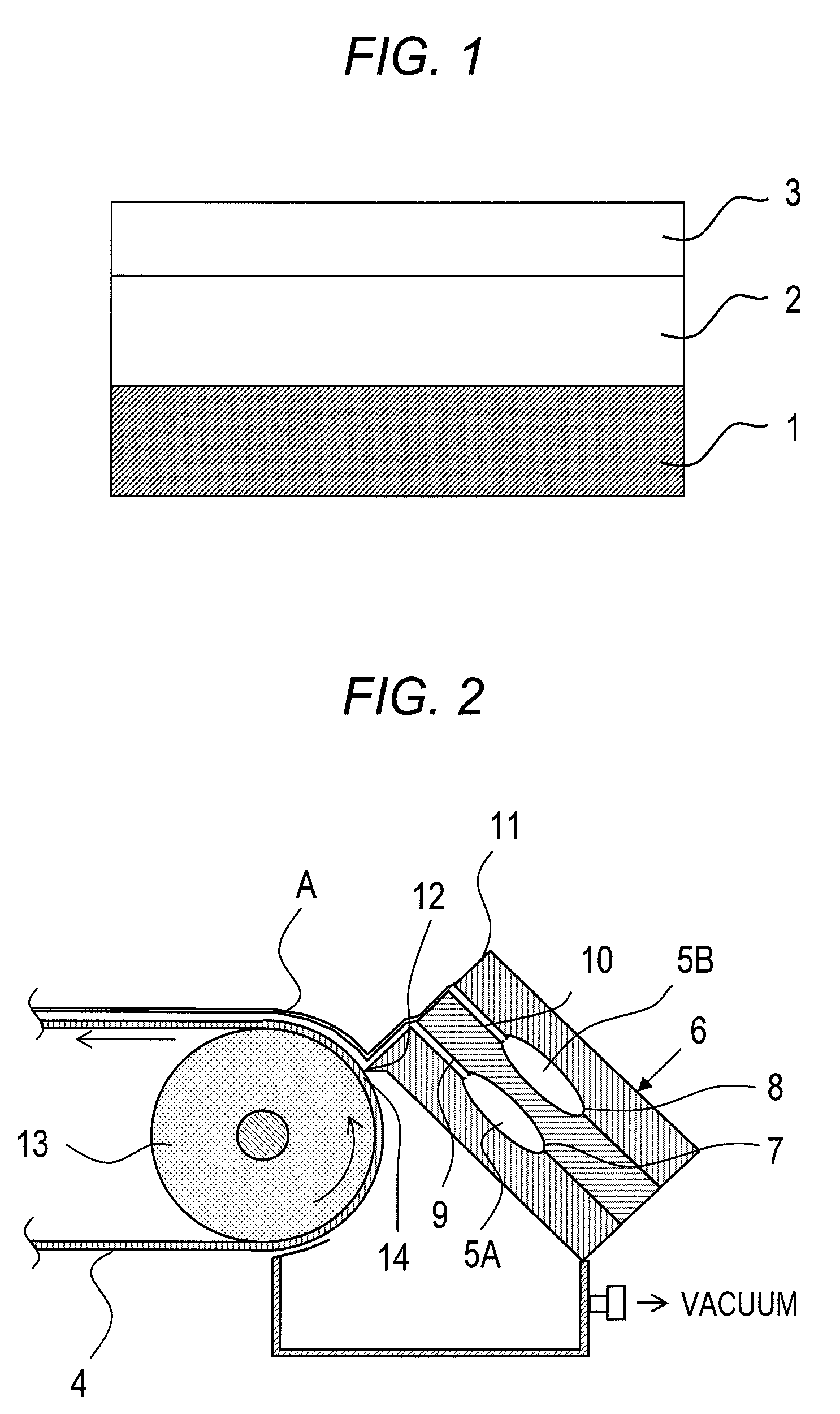

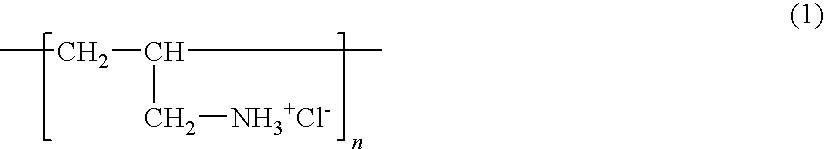

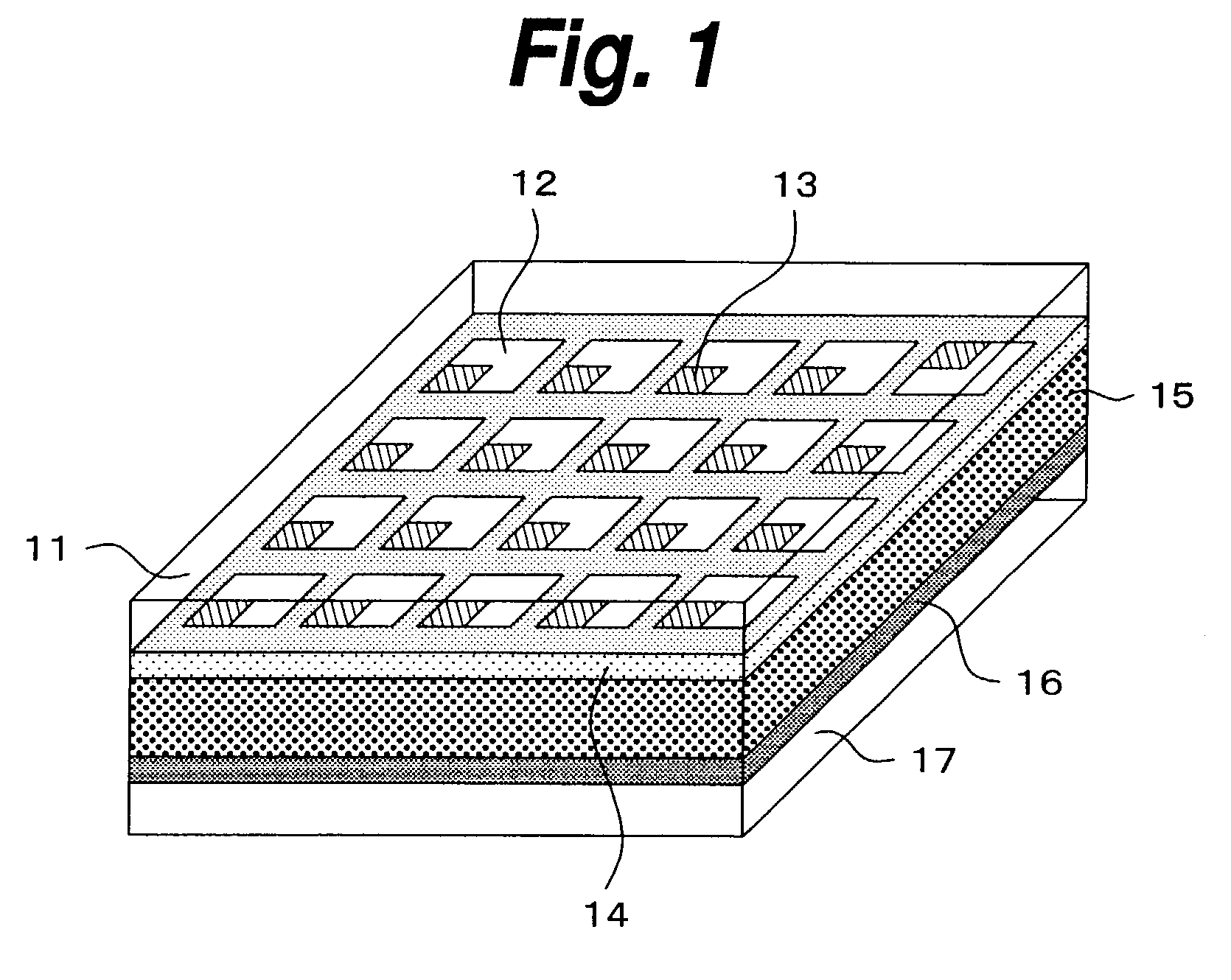

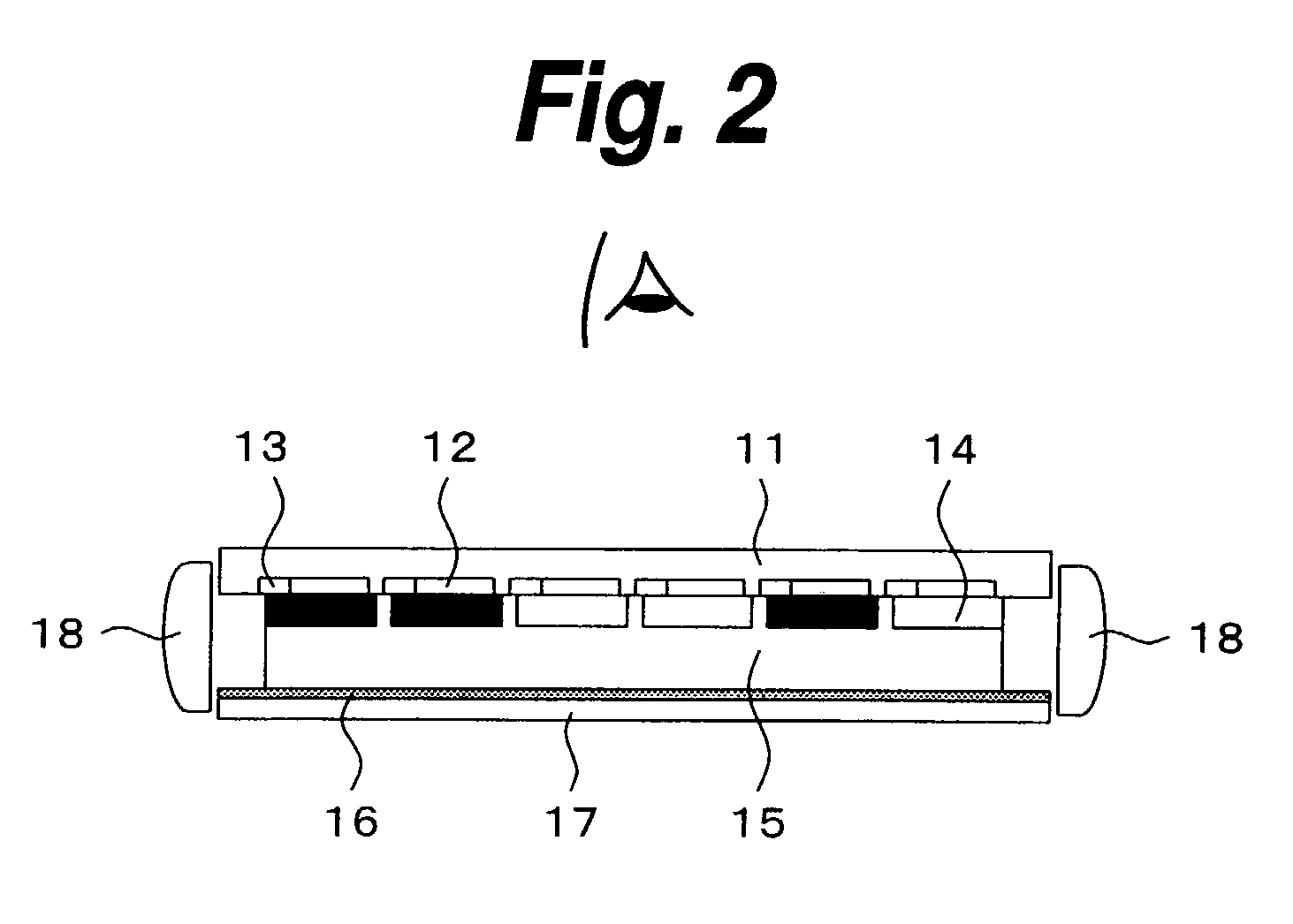

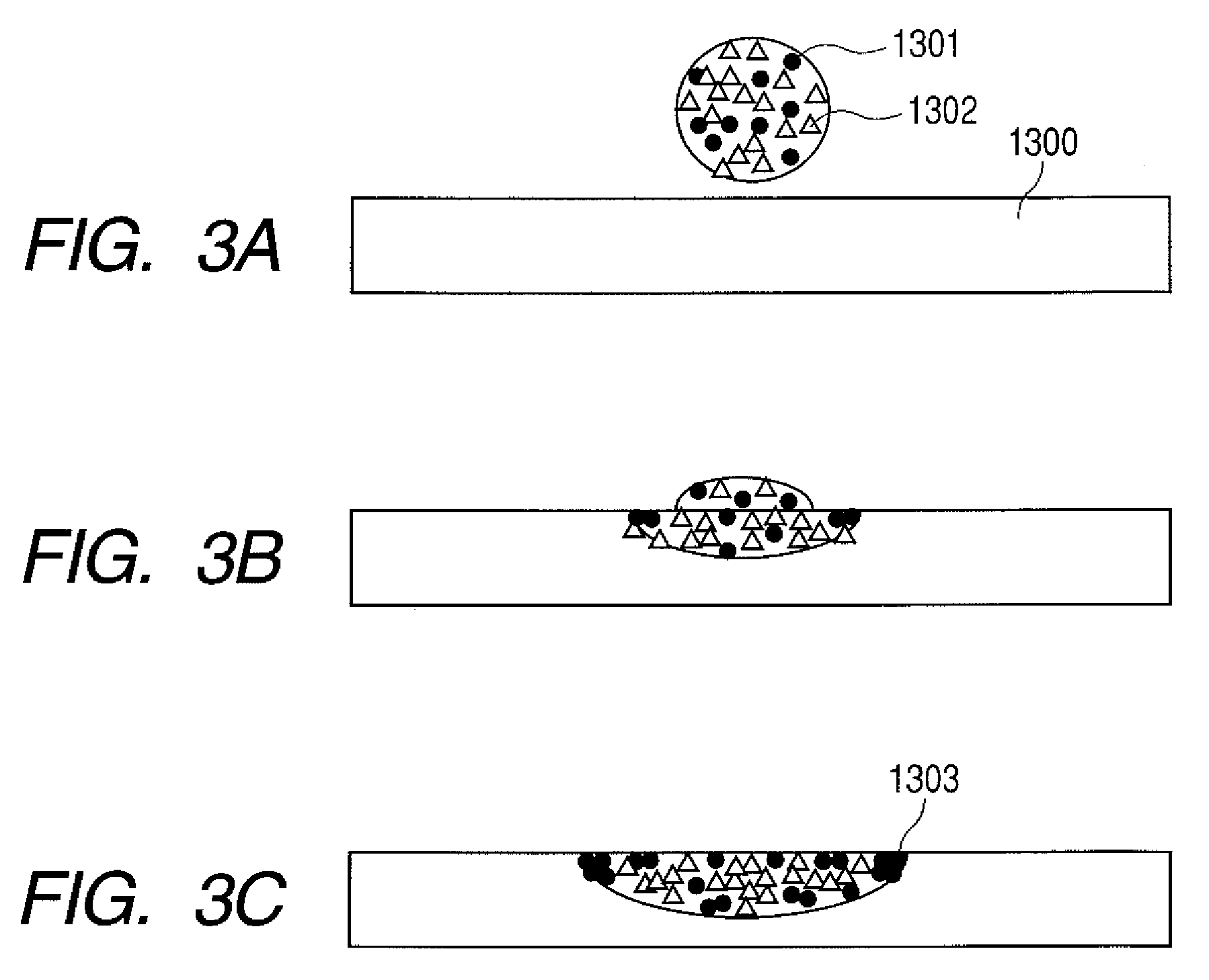

Ink jet recording medium and method of producing the same

InactiveUS20090011155A1Inhibit migrationHigh image densityLiquid surface applicatorsPattern printingAlumina hydrateEngineering

The invention provides an ink jet recording medium which attains the prevention of the bronzing of cyan ink and the prevention of the migration of magenta ink at the same time and is excellent in image characteristics. The ink jet recording medium comprises a substrate and an ink-receiving layer provided with at least an upper layer as the outermost layer and a lower layer as a layer lying just under the upper layer, both layers having a porous structure formed of an alumina hydrate and a binder, wherein both of the upper and lower layers contain an alkylsulfonic acid and only the lower layer contains a cationic polymer.

Owner:CANON KK

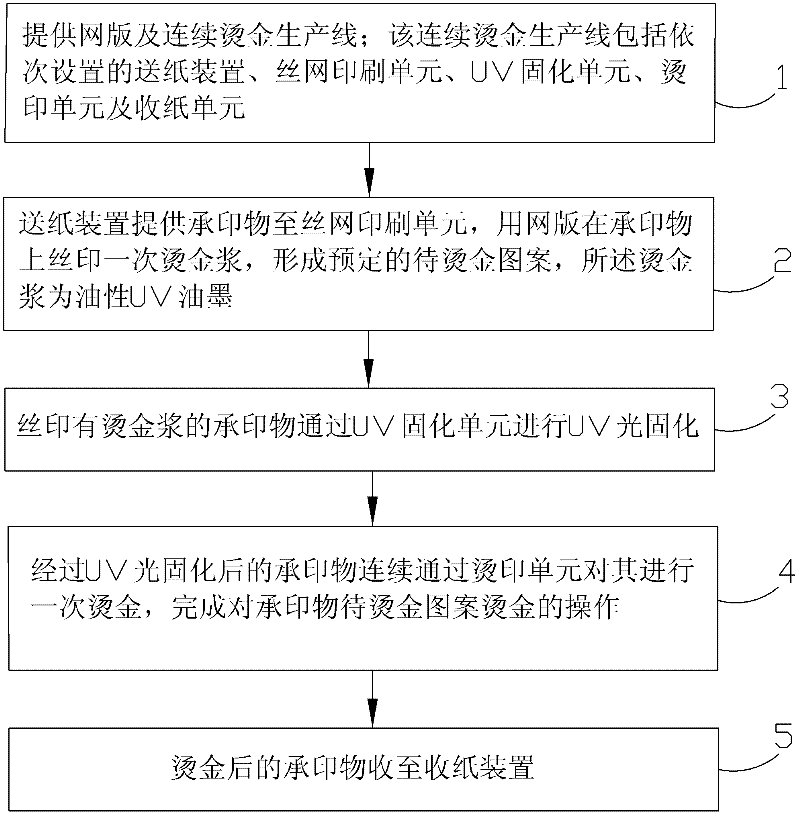

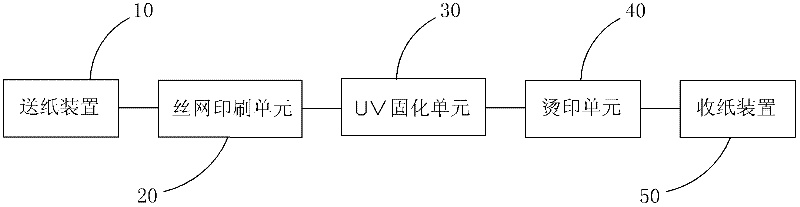

High-gloss three-dimensional gilding method

The invention relates to a high-gloss three-dimensional gilding method which comprises the following steps of; 1. providing a screen and silk-screen gilding continuous production line, wherein the silk-screen gilding continuous production line comprises a paper feeding device, a screen printing unit, a UV (ultraviolet rays) curing unit, a stamping unit and a paper delivery unit which are arranged successively; 2. the paper feeding device is used for providing a printing stock to the screen printing unit, the screen is used for performing primary gilding pulp screen-printing on the printing stock, so that a preset pattern to be gilded is formed, wherein the gilding pulp is oily UV printing ink; 3. the printing stock subjected to gilding pulp screen-printing is subjected to UV curing through the UV curing unit; 4. the printing stock subjected to UV curing continuously passes through the stamping unit to be subjected to primary gilding, so as to complete the gilding operation on the pattern to be gilded of the printing stock; and 5. the printing stock after gilding is delivered to the paper feeding device. In the gilding method, the oily UV printing ink is adopted as the gilding pulp, the high-gloss three-dimensional gilding effect can be realized on the surfaces of printed sheets composited with optical cement and dumb cement, various paper, plastic sheets and fiber slabs with different thicknesses, so that the demand on diversity in processing a base materials is met, and the on-line efficient and continuous gilding is realized.

Owner:SHENZHEN BAIXINGLONG CREATIVE PACKAGING

Additives to eliminate bronzing of ink-jet inks printed on photo media

Anti-bronzing agents are added to ink-jet inks to prevent bronzing of the inks when printed on various types of photographic media. The additive can include one or more anti-bronzing agents comprising certain planar aliphatic or planar aromatic ring structures. The planar ring-containing anti-bronzing agent can be present in an effective concentration to reduce bronzing of the ink-jet ink printed on the ink-receiving layer.

Owner:HEWLETT PACKARD DEV CO LP

Ink Composition, Recording Method Using the Same, and Recorded Matter

InactiveUS20090220748A1Improve scratch resistanceSuitable for useDecorative surface effectsLayered productsEmulsionOrganic solvent

An object of the present invention is to provide an ink composition which can provide an image having excellent glossy texture to various recording media, particularly to a glossy recording medium, is decreased in bronzing phenomenon, and is also good in fixing property and scratch resistance such as gloss change. The invention relates to an ink composition containing at least a coloring agent coated with a water-insoluble polymer as a coloring material and a resin emulsion as an additive, wherein the weight average molecular weight of the water-insoluble polymer is from 50,000 to 150,000, and wherein the resin emulsion comprises a resin comprising a monomer component of the same kind as the monomer component constituting the water-insoluble polymer and having a weight average molecular weight of 1.5 to 4 times that of the water-insoluble polymer; and an ink composition containing at least a coloring agent coated with a water-insoluble polymer and resin particles, wherein the water-insoluble polymer is a polymer obtained by a solution polymerization process using at least a polymerizable unsaturated monomer and a polymerization initiator, wherein the coloring agent coated with the water-insoluble polymer is a coloring material obtained by a phase inversion emulsification process in which after the water-insoluble polymer is dissolved in an organic solvent, at least the coloring agent and water are added thereto, followed by mixing, and the organic solvent is removed to perform dispersion in an aqueous system, and wherein the resin particles are a polymer obtained by an emulsion polymerization process using at least a crosslinking agent.

Owner:SEIKO EPSON CORP

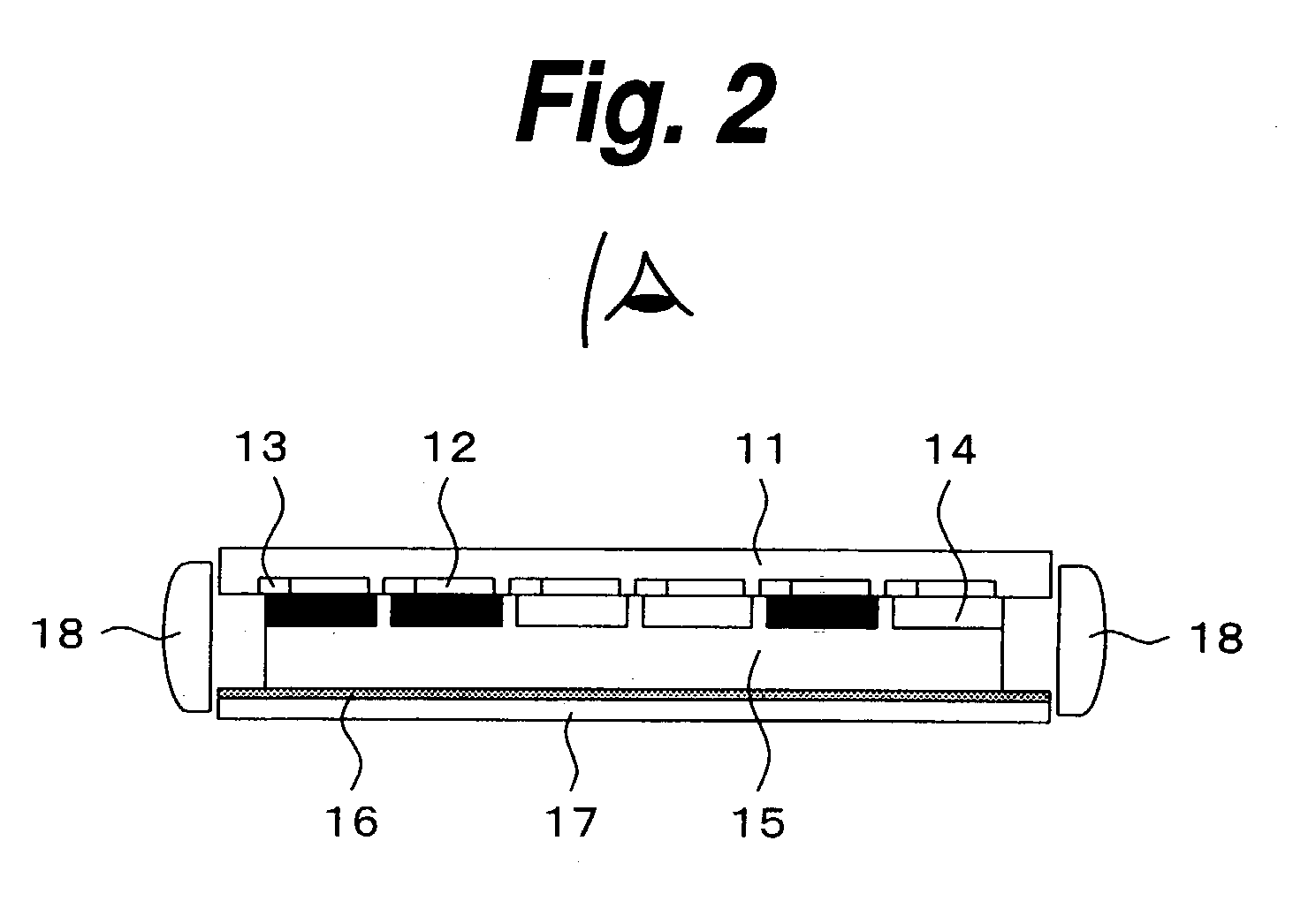

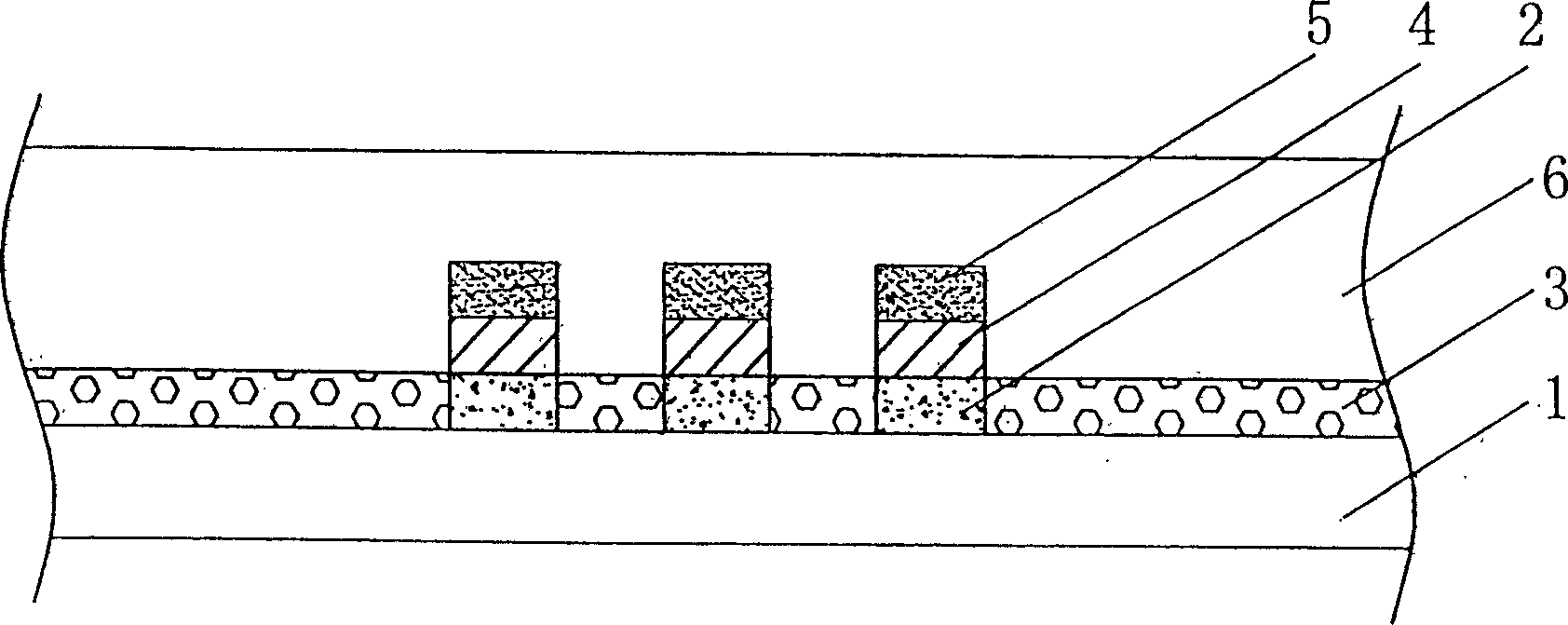

Electrochemical aluminum for stamping gold on ultraviolet (UV) glazing oil surface and preparation method thereof

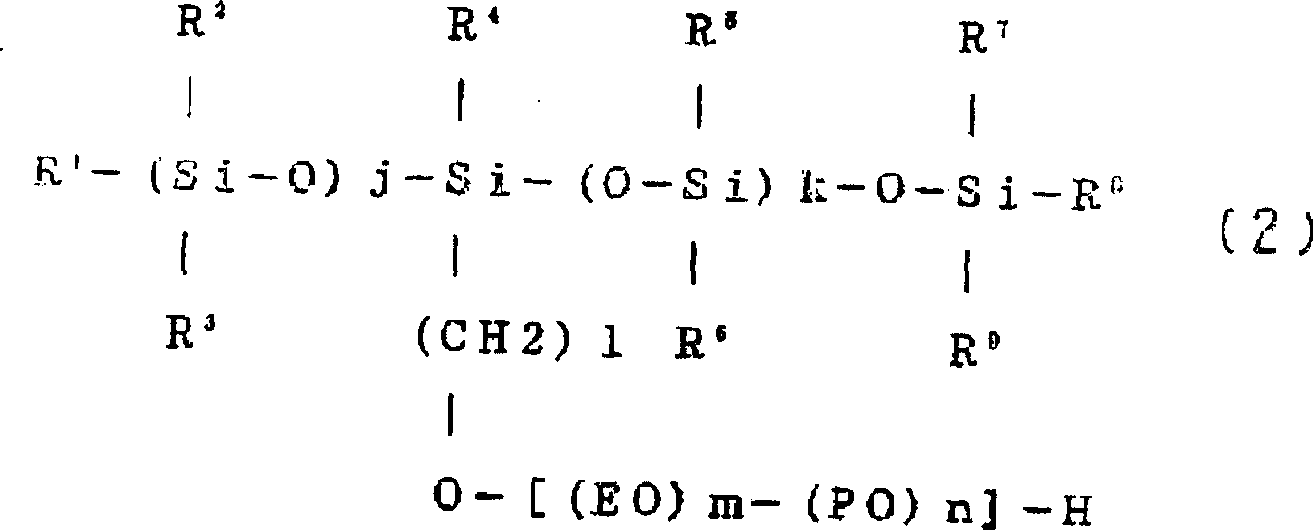

ActiveCN102795015AImprove performanceImprove bronzing efficiencySynthetic resin layered productsThermographyInformation layerPolyethylene terephthalate glycol

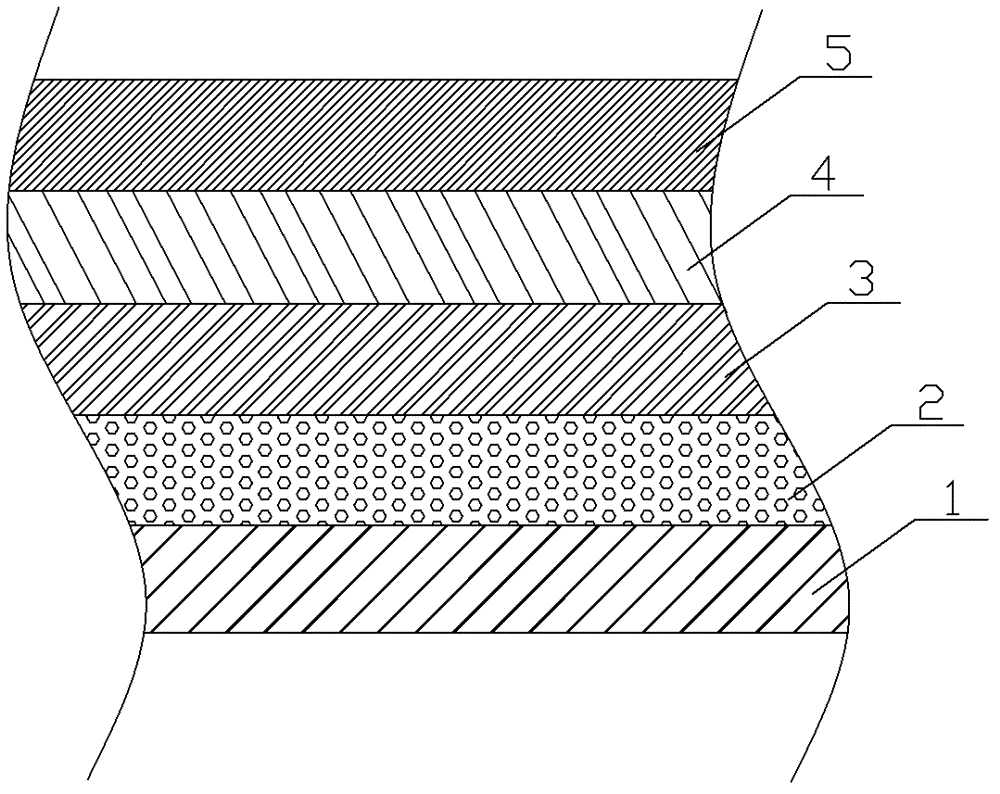

The embodiment of the invention provides electrochemical aluminum for stamping gold on an ultraviolet (UV) glazing oil surface. The electrochemical aluminum comprises a base film layer, a stripping layer, a colorable information layer, an aluminum coating and a bonding layer; the base film layer 1 is made of a polyethylene terephthalate film; the stripping layer is positioned on the base film layer and made of a fluorine-containing water-based wax material prepared by an emulsified paraffin method; the colorable information layer is positioned on the stripping layer and prepared from synthetic resin and at least two toner dyes; full series laser anti-counterfeiting information is positioned and die-pressed on the colorable information layer; and the bonding layer is positioned on the aluminum coating and prepared from acrylic mixed resin added with olefin surfactant. The embodiment of the invention also provides a preparation method for the electrochemical aluminum for stamping the gold on the UV glazing oil surface. According to the embodiment, an electrochemical aluminum god stamping material prepared from a special stripping agent and adhesive at a low temperature is excellent in performance and suitable for most printed materials of which the surfaces are provided with UV glazing oil.

Owner:WUHAN HONGZHICAI PACKAGING PRINTING

Bronzing pulp and preparation method thereof

ActiveCN103255646ARich styleRich wash fastnessTransfer printing processDyeing processWater basedSolvent

The invention discloses bronzing pulp. The bronzing pulp is prepared from the following raw materials in parts by weight: 60-80 parts of acrylic ester emulsion, 2-6 parts of deionized water, 3-10 parts of a solvent, 1-5 parts of a stabilizer, 10-20 parts of EVA (Ethylene-Vinyl Acetate) hot melt adhesive powder, 0.5-3 parts of silica, 0.2-0.5 part of a polyurethane defoaming agent, 0.1-0.5 part of a pH regulator, 0.1-0.2 part of a preservative, 0.3-1 part of an emulsion wetting agent and 0.4-2 parts of a thickener. The bronzing pulp has the beneficial effects that the bronzing pulp is water-based pulp, the raw materials are easy to obtain and environment-friendly, the production is convenient, the technology is mature, and substances harmful to the environment can not be produced; and the bronzing pulp is soft in handfeel, firm in fastness, outstanding in resistance to tension fracture and diversified in application mode, enriches the styles of textiles, and endows the textiles with the noble quality.

Owner:GUANGZHOU SHENGQIN IND

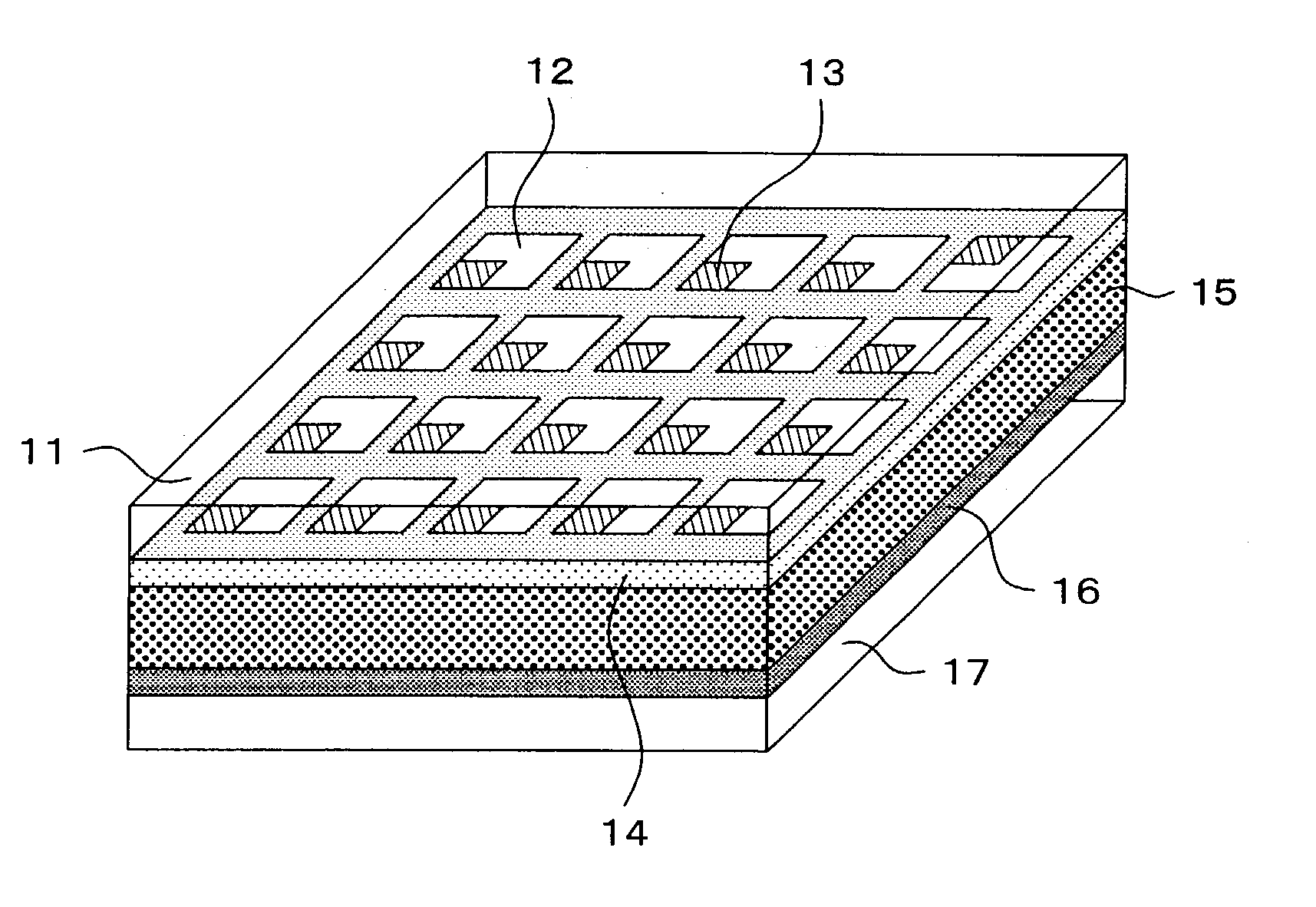

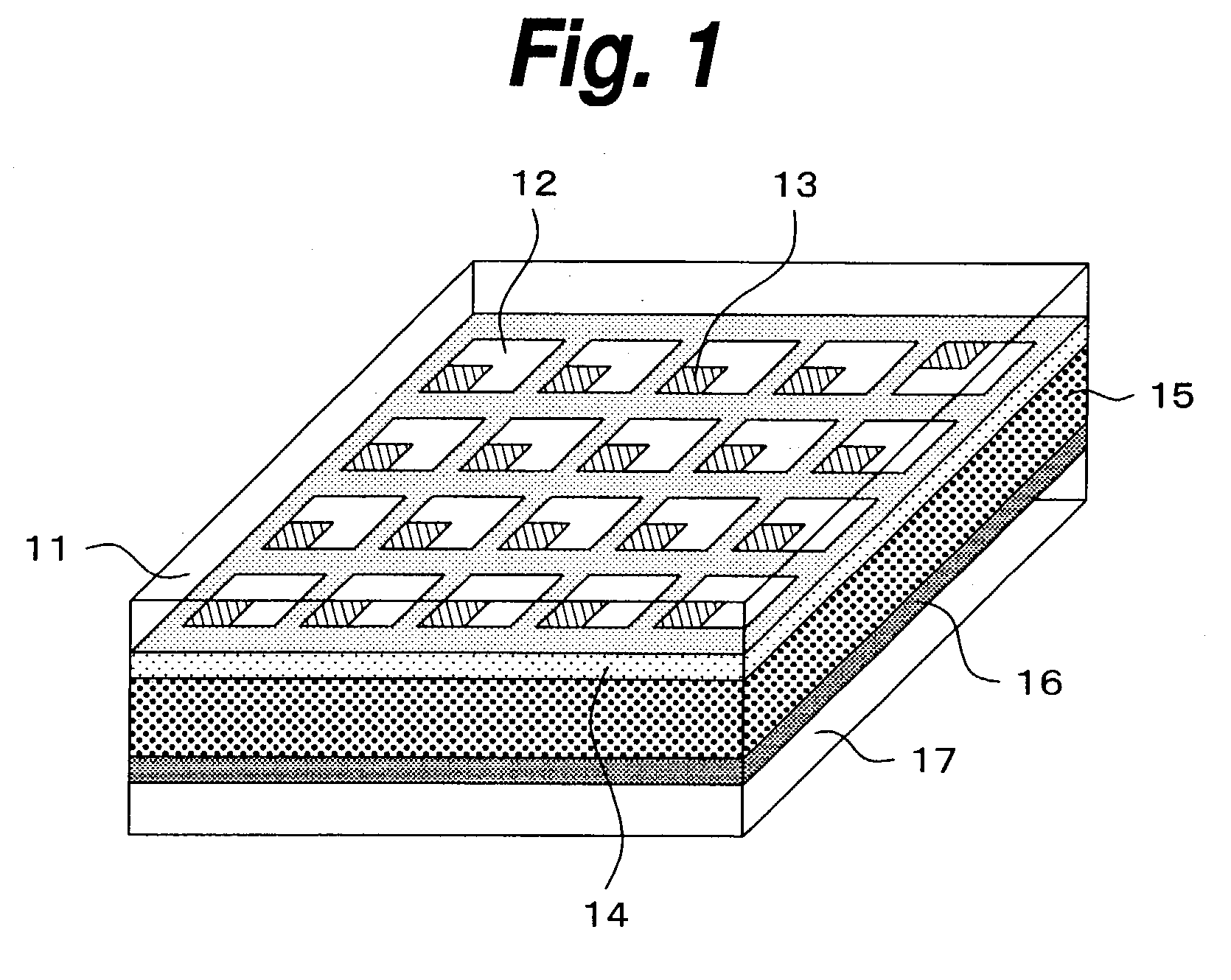

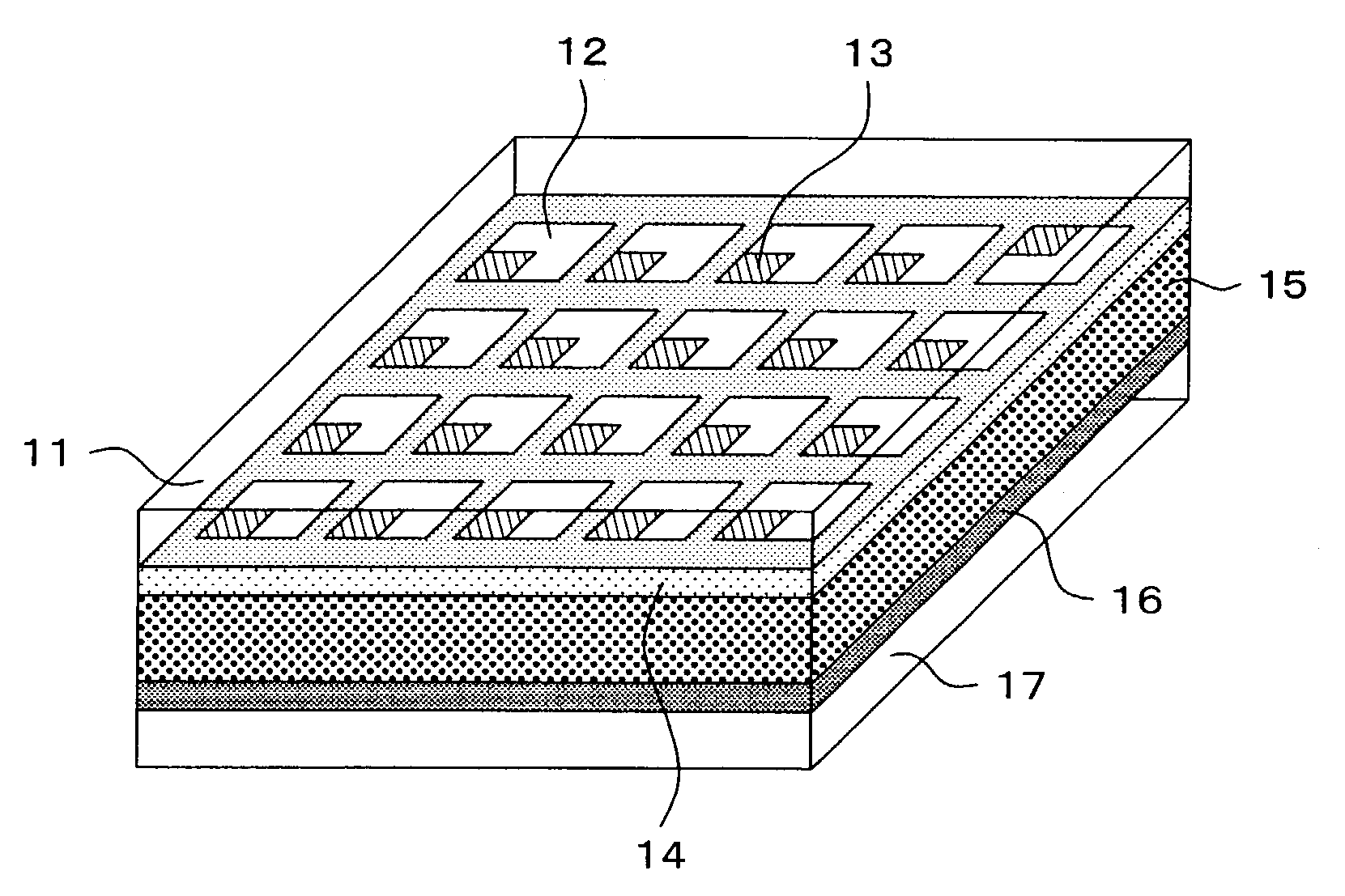

Electrochromic display device and electrodeposition display device

Between each transparent pixel electrode driven by TFT as a drive device and a common electrode, a polymer layer located in contact with the transparent pixel electrode and electrically active to change in color by electrochemical oxidization or reduction and a polymeric solid electrolytic layer located in contact with the polymer layer and containing a coloring agent are interposed. since electrochemical oxidization or reduction brings about a color change, the contrast and the black concentration can be enhanced, and bronzing after long-time use does not occur.

Owner:SONY DEUT GMBH +1

Ink jet recording medium and method of producing the same

InactiveUS7846516B2Good prevention effectGood effectPattern printingThermographyAlumina hydrateEngineering

The invention provides an ink jet recording medium which attains the prevention of the bronzing of cyan ink and the prevention of the migration of magenta ink at the same time and is excellent in image characteristics. The ink jet recording medium comprises a substrate and an ink-receiving layer provided with at least an upper layer as the outermost layer and a lower layer as a layer lying just under the upper layer, both layers having a porous structure formed of an alumina hydrate and a binder, wherein both of the upper and lower layers contain an alkylsulfonic acid and only the lower layer contains a cationic polymer.

Owner:CANON KK

Ink and ink set for inkjet, and inkjet recording method

ActiveUS20050004260A1Quality improvementGood storage stabilityMonoazo dyesDuplicating/marking methodsDiolAqueous medium

Provided are an inkjet ink prepared by dissolving or dispersing a specific dye in an aqueous medium and containing one of at least one alkylene diol where one alkylene group has at least 3 carbon atoms or homologue thereof and at least one polymer compound; and an ink set containing an ink including a specific dye and an ink including one compound capable of interacting with the dye; thereby being able to provide an ink and the like having a good jet-out stability, and forming images of good quality with neither beading nor bronzing, and the images formed of the inks have good fastness to heat, light and ozone.

Owner:FUJIFILM CORP +1

Transfer printing paper for disposable printing thermal sublimation pattern and brilliant color pattern and preparation method and use

InactiveCN101418525AImprove toughnessWon't breakPattern printingDyeing processWastewaterPulp and paper industry

The invention discloses transfer printing paper for printing thermal sublimation patterns and bright flower patterns once, a preparation method and application thereof. The transfer printing paper comprises transfer printing base paper; one side of the transfer printing base paper is adhered with a parting agent layer; and an ink layer and a bright substrate layer are adhered to the surface of the parting agent layer in arbitrary order. With the transfer printing paper, textile can be simultaneously subjected to pattern printing and bronze printing through a transfer printing process; the transfer printing paper keeps the advantages of environmental pollution, energy conservation, no wastewater and no pollution of the prior thermal sublimation transfer printing process, saves a transfer bronzing process of the prior art and has the advantages of saving cost, improving yield of finished products, having high production efficiency and the like.

Owner:陈新耀

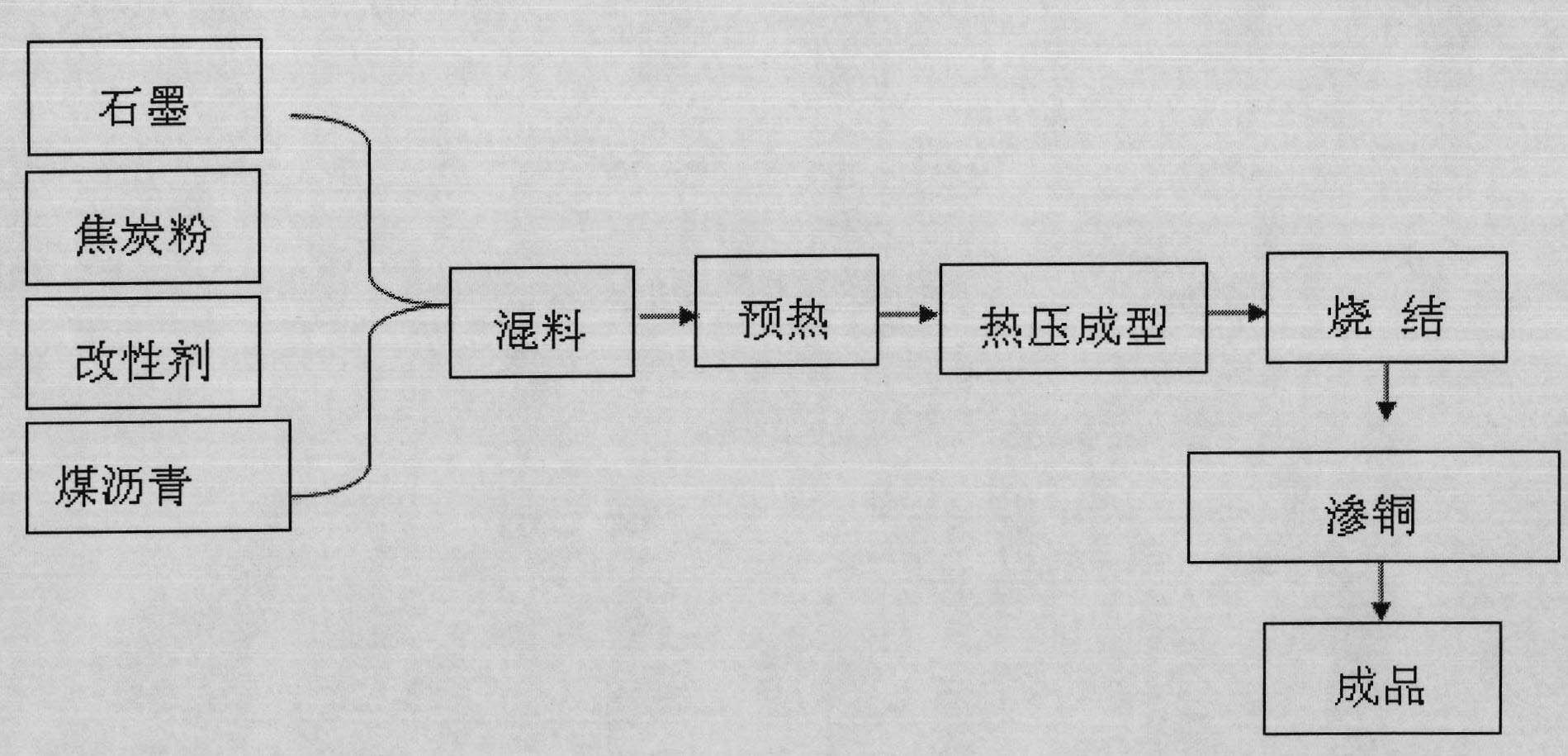

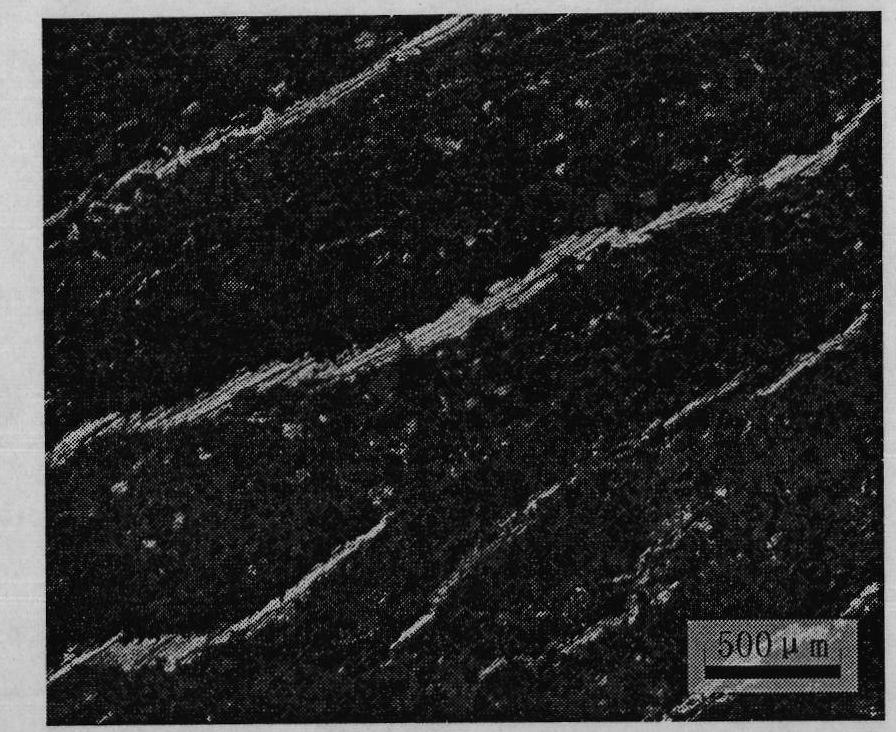

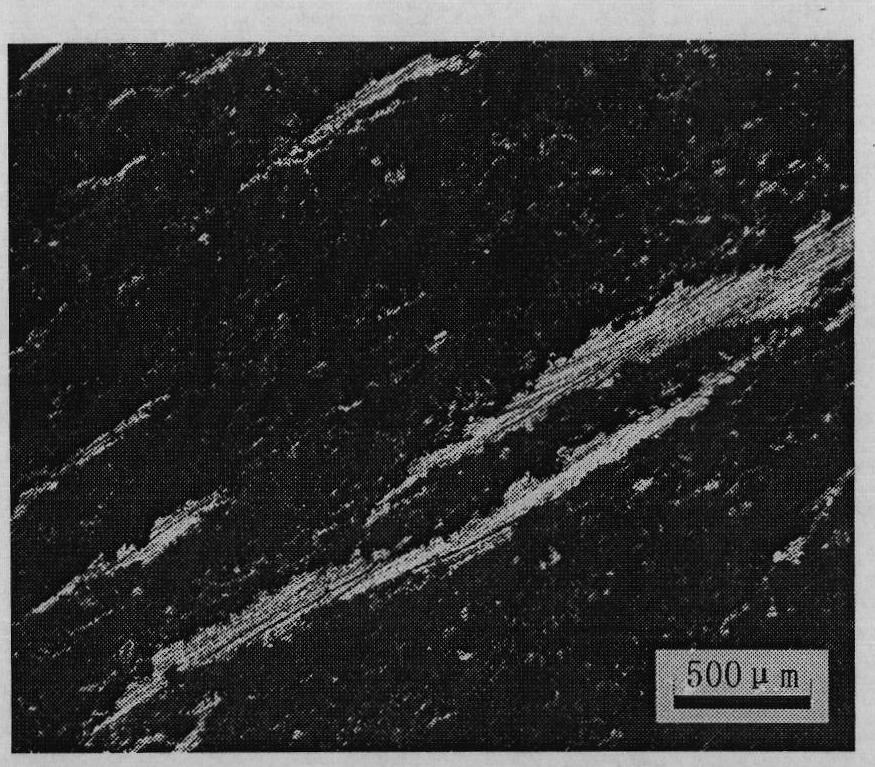

Carbon-based slider material for railway vehicle and preparation method thereof

ActiveCN102034561AImprove conductivityIncrease frictionMetal/alloy conductorsCarbon-silicon compound conductorsCarbonizationNitrogen gas

The invention relates to a carbon-based slider material for a railway vehicle. The mixture of graphite and coke is used as the substrate of the material, wherein the contents of graphite and coke are 15-35% and 35-55% based on the total mass of all components respectively; coal pitch is used as a binder, which accounts for 25-30% of the total mass of all components; the mixture of 1-3% of sulphur powder, 1-3% of glass powder, 1-2% of alumina and 0.5-1% of molybdenum disulfide is used as a friction modifier based on the total mass of all components; the materials are completely mixed by a dry mixing method and subject to hot pressing formation of three stages; then normal-pressure carbonization is performed in atmosphere of nitrogen; and finally bronzing is performed. The method is simple in operation, has low cost and is suitable for large-scale production; the materials have high conductivity, excellent friction performance and relatively high mechanical performance and are suitable for being used as the collection friction material of a railway traffic vehicle.

Owner:BEIHANG UNIV

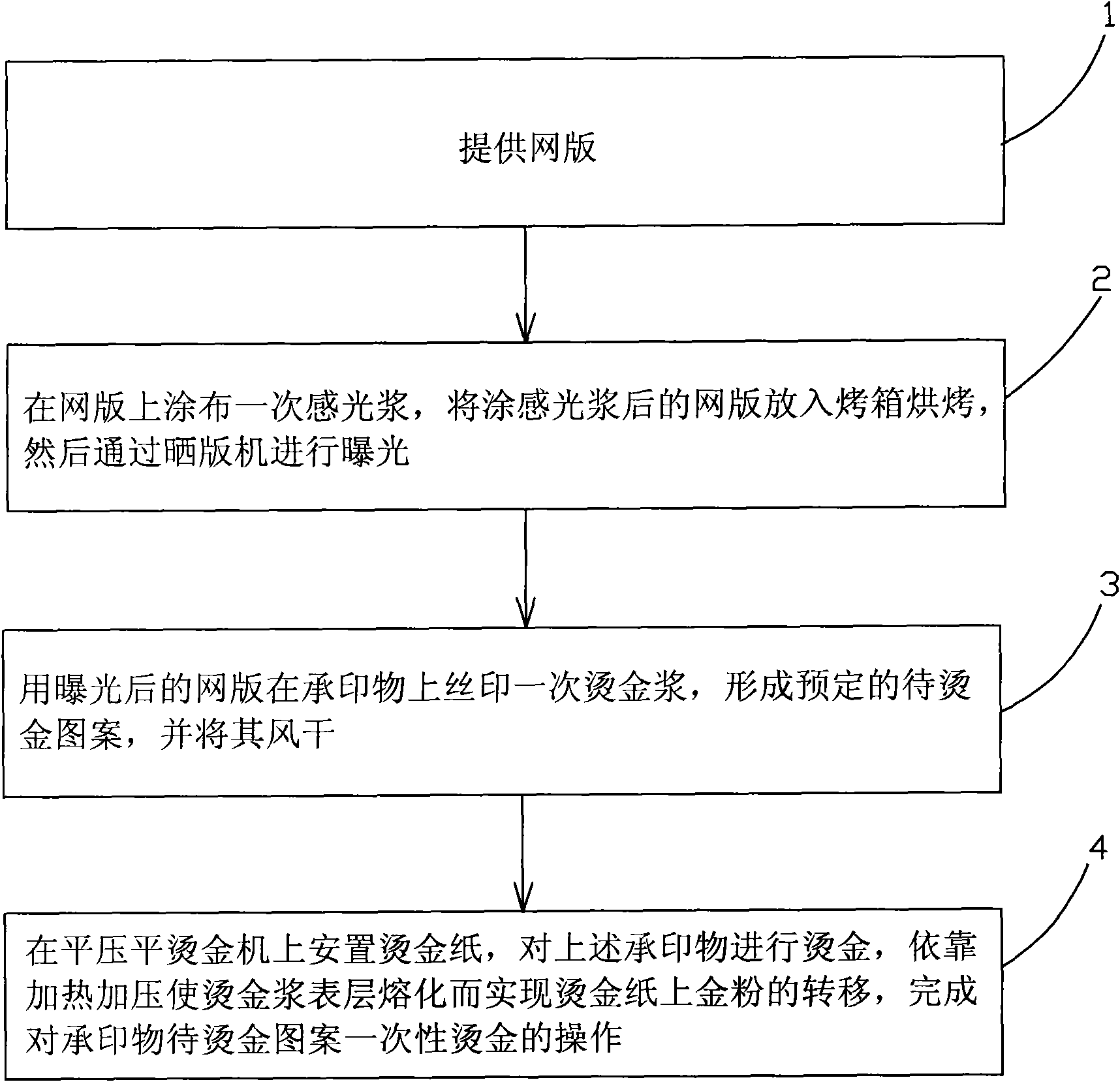

Three-dimensional bronzing method

ActiveCN101670719ATake advantage ofImprove the three-dimensional effectPhotosensitive materialsRotary pressesScreen printingSurface layer

The inventio provides a three-dimensional bronzing method, comprising the steps of: 1. providing a screen printing plate; 2. coating disposable photosensory pulp on the screen printing plate, puttingthe screen printing plate coated with the photosensory pulp into an oven to be baked, and exposing by a printing-down machine; 3. printing disposable bronzing pulp on printed material with the exposedscreen printing plate to form a preset pattern to be bronzed, and drying; and 4. setting a bronzing paper on a flat pressing flat bronzing machine, bronzing the printed material, and melting the surface layer of the bronzing pulp by means of heating and pressing to convert the golden powder on the bronzing paper and complete the operation of disposable bronzing to the pattern to be bronzed of theprinted material. The three-dimensional bronzing method disposably produces the multicolour three-dimensional bronzing patterns and characters with good hand feel on the surface of textile or thin paper with the existing common equipment, thereby not only reducing the production cost but also improving the production efficiency to a certain degree.

Owner:SHENZHEN BAIXINGLONG CREATIVE PACKAGING

Electrochromic display device and electrodeposition-type display device

Owner:SONY DEUT GMBH +1

Method for replacing gold stamping

InactiveCN1760043AQuality improvementHigh glossDecorative surface effectsDuplicating/marking methodsAdhesiveEngineering

A substitute method for gilding includes such steps as coating the parting paint on PET film, baking for solidifying, vacuum aluminizing, coating protecting paint with gilding pattern plate, baking for solidifying, immersing in alkali solution for removing aluminium, baking to obtain transfer film, coating adhesive, sticking onto substrate to obtain composite paper, stripping the film to obtain transfer paper, and printing with said transfer paper.

Owner:王尔健

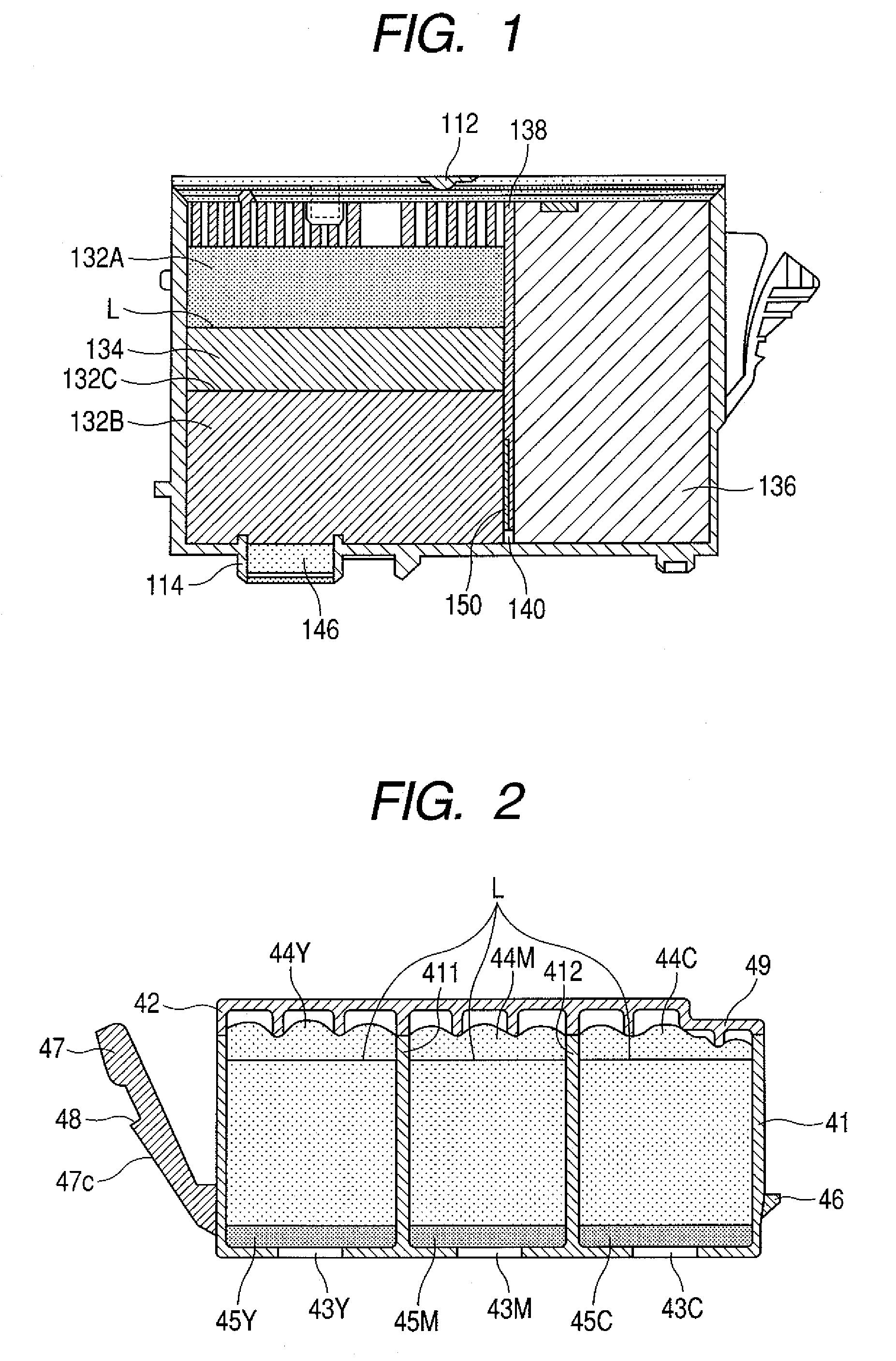

Ink jet ink, method of producing ink jet ink, ink jet recording method, ink cartridge, and cyan ink

InactiveUS7601210B2Good colorQuality improvementMeasurement apparatus componentsInksOrganic solventEngineering

Owner:CANON KK

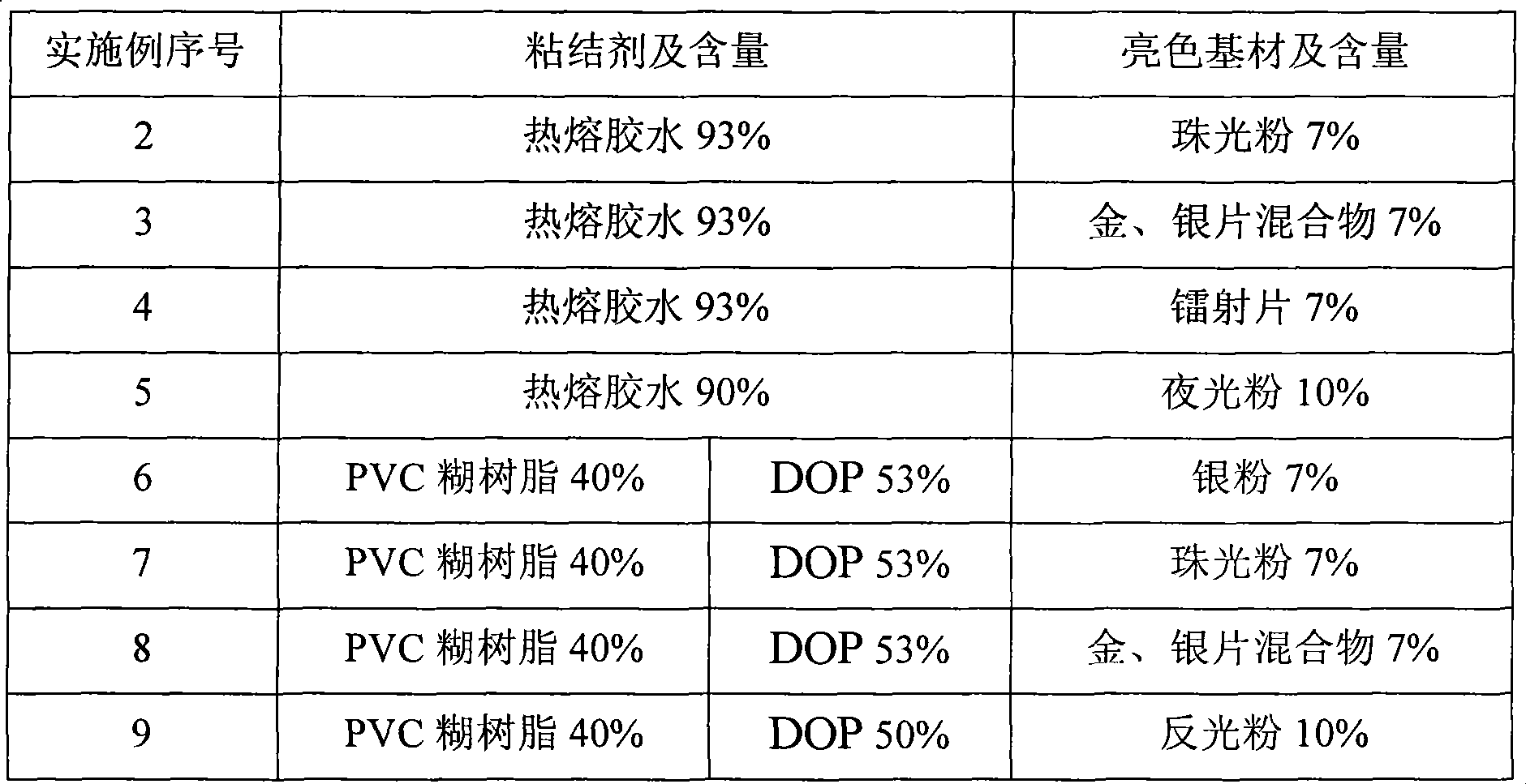

Wash-wear, soft and twinkling costume bronzing technique

The invention provides a dress-gold stamping process which is washable, soft, and twinkling, which mainly comprises: printing-bronzing paste; natural drying, high-pressure bronzing and high-temperature baking. And it is characterized in that: it adds twinkling powder at 5-20% into soft bronzing paste to render; uses high-adhesive force bronzing paste to cover surface; and cool removes gold paper after baking. The invention has the advantages as soft feeling and twinkling which can last after three time washings.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

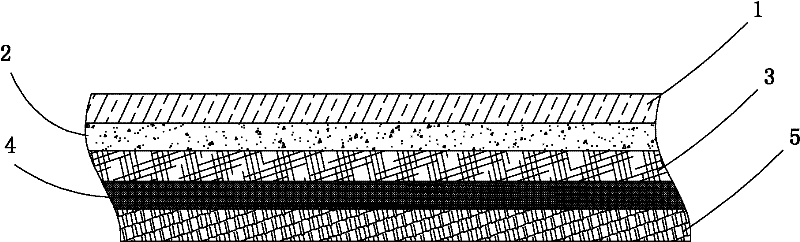

Hydrographics transfer printing digital anti-counterfeit stained paper and printing method thereof

The invention relates to hydrographics transfer printing digital anti-counterfeit stained paper and a printing method thereof. The method comprises the following steps: 1, a pattern is manufactured; 2, a film is manufactured; 3, a printing screen printing plate is manufactured; 4, non-stamping characters and pattern are printed; 5, anti-counterfeit characters and pattern are printed, and a two-dimension code and an anti-counterfeit number are subjected to jet printing; 6, isolating resin is used for coating; 7, gold stamping bottom ink is used for coating; UV (ultraviolet) resin is used; characters and patterns of different colours are subjected to screen printing on the same body paper according to a method that the same colour is printed once, so that UV printing ink is formed; and the UV printing ink is subjected to light curing under LED (Light Emitting Diode) irradiation; 8, transfer printing gold stamping is carried out; a selected hot gold foil is subjected to transfer printing on the UV printing ink obtained in the step 6 by a stamping machine to obtain stamping characters and patterns of different colours; and 9, a tearable cover adhesive film is used for coating. The hydrographics transfer printing digital anti-counterfeit stained paper has an excellent anti-counterfeit effect, and can be widely applied to packaging boxes of various cosmetics, articles of everyday use, cigarettes, wine, food and the like; and meanwhile, the procurement cost in the prior art is reduced, and the identification is facilitated.

Owner:安徽江南春包装科技有限公司

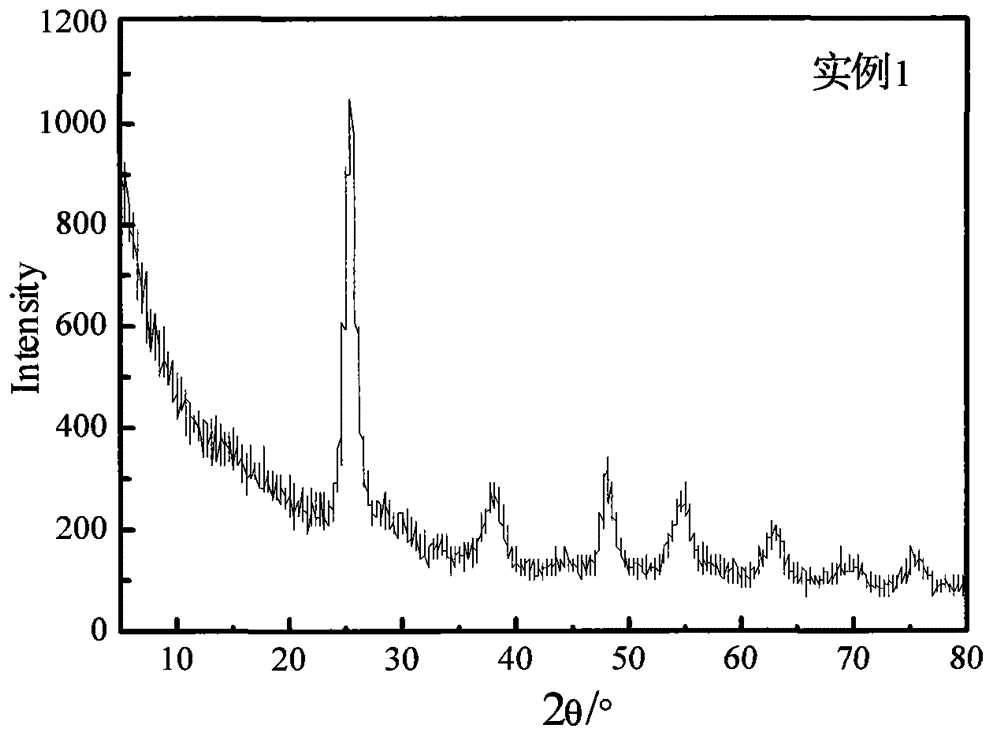

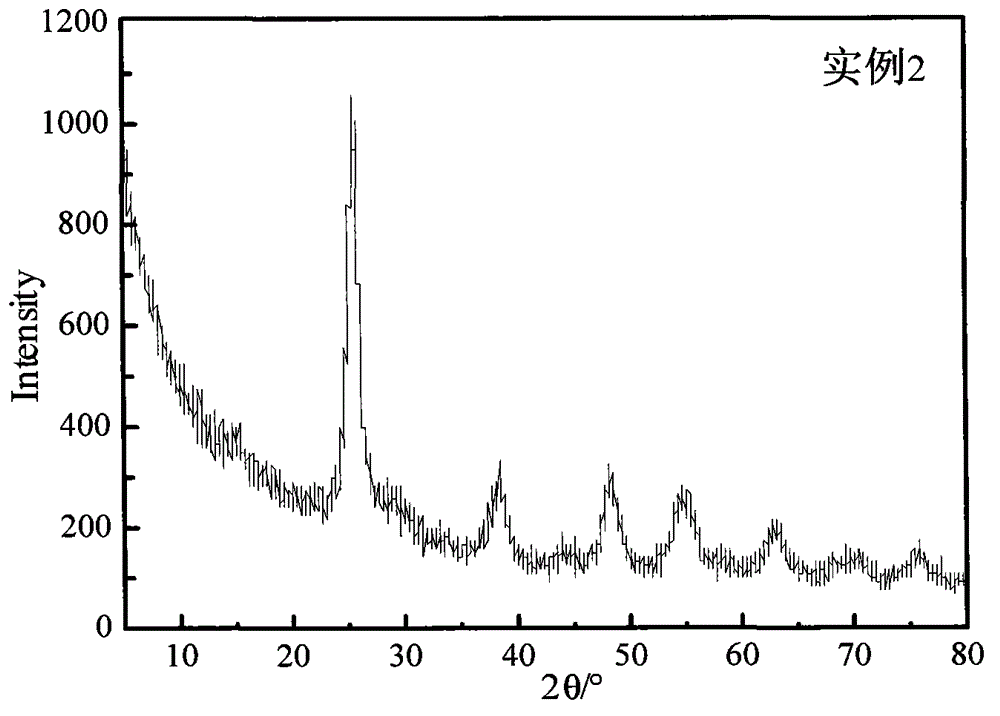

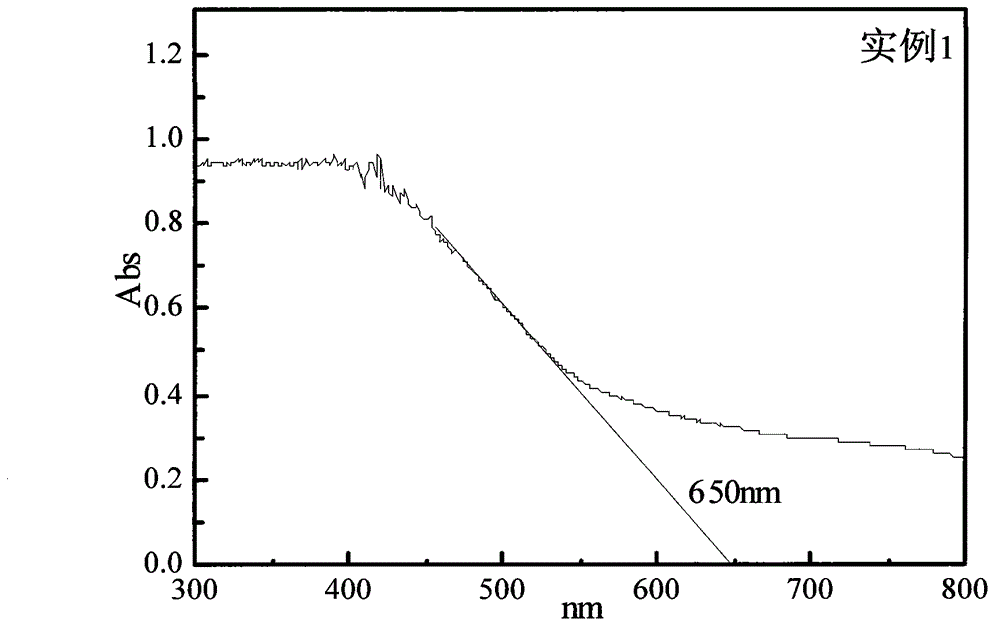

Preparation method for iron, cobalt and nitrogen co-doped modified TiO2/SO42-visible light photocatalyst

InactiveCN103143372ACrystal stableUniform particle sizePhysical/chemical process catalystsWater/sewage treatment by irradiationVisible light photocatalyticCobalt

The invention discloses a preparation method for an iron, cobalt and nitrogen co-doped modified TiO2 / SO42-visible light photocatalyst. The preparation method comprises the following steps of: (1) preparing a mixed liquor A; (2) preparing an ion mixed liquor B; (3) slowly dropping the mixed liquor B into the mixed liquor A under the condition of maintaining the room temperature, and continuously stirring in the dropping process to form bronzing sol; (4) putting aged sol into an oven for drying for 6-7 hours at 60-80 DEG C to obtain red particles; and (5) putting dried red particles into a mortar to be grinded to form fine powder, then putting the fine powder into a muffle for heating up to be at 400-550 DEG C at a speed of 1 DEG C per minute-15 DEG C per minute, and calcining for 3 hours so as to obtain the anatase type Fe-Co-N-TiO2 / SO42-visible light photocatalyst. The modififed TiO2 / SO42-visible light photocatalyst takes industrial grade metatitanic acid isopropyl ester as a titanium source, so that the cost is low; and the sol-gel process is conducted at the room temperature, and the reaction condition is mild. The visible light response range of the photocatalyst is greater than 600nm, thus meeting the industrial application requirements.

Owner:ZHENGZHOU UNIV

Electrochemical aluminium gold-stamped water decal paper, and its production process and use

InactiveCN1851121AProduction Process SpecializationSpecial visual effect coatingsFlexible coversPulp and paper industryWater transfer

The invention discloses an anodized aluminum, metallized, water decal paper producing process, comprising the steps of: (A) using water transfer base paper as carrier, and printing or coating bonding layer; (B) printing or coating isolating layer; (C) thermoprinting anodized aluminum graphics and texts; (D) printing or coating closing layer; (E) printing or coating locating film. And the product can be transferred onto a substrate by water transfer process. And the invention can make multicolor metallized, water decal papers and can be applied to plural fields, such as lamp decoration, vessels, brand metallization decoration, and applied to substrates, such as glass, ceramic, metal, plastics, carpentry, etc, and largely enlarge the application range of the anodized aluminum metallization technique.

Owner:麦秀莲

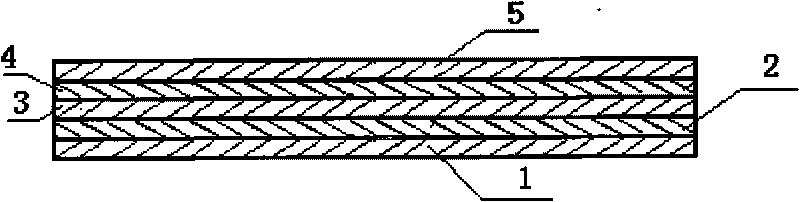

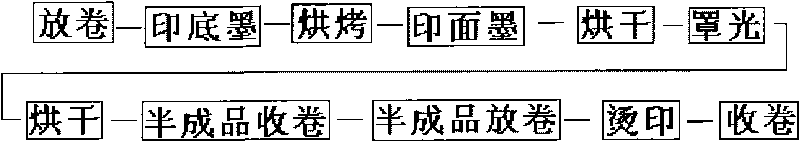

Tipping paper for cigarette and production technology thereof

InactiveCN101718060AStrong adhesionDo not lose inkFlexible coversWrappersHot stampingLaser engraving

The invention discloses tipping paper for cigarette and a production technology thereof. The tipping paper for cigarette has a structure that a bottom layer is a basic layer, a bottom color layer is arranged on the basic layer, a surface color layer is arranged on the bottom color layer, a finish coat is arranged on the surface color layer and a gold stamping layer is arranged on the finish coat. The production technology thereof comprises the steps of unreeling, printing bottom ink, baking, printing surface ink, drying, glaring, drying, rolling semi-manufactures, unreeling semi-manufactures, lettering, and reeling. The invention has the advantages that because an electrostatic blotting coloration technology is adopted, coloring is firm and the color layers have strong adhesive force and do not drop ink; because laser engraving is adopted and the engraving depth of a printing plate roller from one end to the opposite end is from the shallower to the deeper, the surface color layer has strong color layering; and phenomena of gold falling, hot stamping miss and needle holes during gold stamping are overcome by adjusting pressure and hot stamping temperature between a hot stamping plate roller and a rubber covered roller so as to enable the gold stamping color to be stable and even.

Owner:WUHU CIGARETTE MATERIAL FACTORY

Multi-process combined printing method based on flexible plate equipment platform

InactiveCN101544094ARealize the function of transfer skipping seamRotary pressesPrinting press partsEngineeringMechanical engineering

The invention relates to a multi-process combined printing method based on a flexible plate equipment platform, and belongs to the technical field of printing. The method utilizes a flexible plate printing mode as a process platform, combines gravure equipment, silk-screen equipment, bronzing equipment and punch die cutting equipment with flexible plate printing together to form a combined printing mode and produces a finished production once. The method integrates the gravure equipment, the silk-screen equipment, the bronzing equipment and the punch die cutting equipment into the platform, concentrates gravure, silk-screen, bronzing and punch die cutting and other working procedures together, separately drives a printing plate roller and a printing bearing roller of each color set through an independent servo motor, can make the overprinting precision reach over + / -0.05 mm and the precision of plate hop seam reach within + / -0.25 mm, realizes the function of the online shifting of the plate hop seam of a flexible plate and completes the online automatic flexible plate printing.

Owner:HUBEI GOLDEN THREE GORPRINTING IND

Additives to eliminate bronzing of inkjet ink formulations on specialty quick-dry inkjet photographic media

Owner:HEWLETT PACKARD DEV CO LP

Application method of special anti-counterfeiting material in packing box

InactiveCN102173245ARealize integrationReduce consumptionDuplicating/marking methodsPattern printingMaterial consumptionAluminum coating

The invention provides an application method of a special anti-counterfeiting material in a packing box. The method comprises the steps of: heating anodized aluminum through a hot printing plate, melting a stripping layer, and melting an adhesive layer; bonding the adhesive layer to a printed material during printing, separating a coloring layer from a polyster film base layer, and remaining an aluminum coating and the coloring layer on the printed material; printing after heating: hot printing holographic laser anodized aluminum on a special-color ink, and printing UV (Ultraviolet) ink on the anodized aluminum; and carrying out the processes of embossing, film laminating, reprinting, box pasting, and the like after hot printing. The application method is characterized in that the anodized aluminum with a surface tension of (4.0-4.6)*10-2N / m is selected to ensure good adhesive force of the ink, and the surface tension of the UV ink is above 3.8*10-2N / m. In the invention, a three-dimensional pattern is realized by using the anodized aluminum through a holographic laser anti-counterfeiting technology, the integration of a printing bottom with the three-dimensional pattern and effective anticounterfeiting are achieved, and the appearance of the packing box is attractive. The method is favorable for reducing material consumption and cost, and can realize three-dimensional hot foil printing on various paper materials.

Owner:SHANGHAI GAOCHENG CREATIVE TECH GRP

Pigment dispersion and ink composition and ink set both containing the same

InactiveCN1697861AGood storage stabilityHigh glossPrintingPigment treatment with macromolecular organic compoundsHydrophilic monomerAqueous medium

It is an object of the present invention to provide a pigment dispersion, an ink composition, and an ink set, enabling excellent glossiness, bronzing prevention, and ink composition storage stability to be realized. The present invention provides a pigment dispersion characterized by comprising at least a pigment, an aqueous medium, a copolymer resin between a hydrophobic monomer and a hydrophilic monomer, and a urethane resin, and also an ink composition characterized by containing at least the pigment dispersion and an aqueous medium, and an ink set characterized by comprising at least the ink composition.

Owner:SEIKO EPSON CORP +1

Leather bronzing technique

InactiveCN101570800AImprove adhesionStrong three-dimensional senseTransfer printingDuplicating/marking methodsPowder coatingBronzing

The invention discloses a leather bronzing technique, which can thermally print gold powder coating on the leather surface, can ensure the lasting adhesion of the gold powder and further improve the third dimension of thermally printed patterns. The leather bronzing technique overprints embossing with convex and concave feelings on the leather via a template, before overprinting, silver paper coated with gold powder is paved on the leather, during overprinting, the gold powder on the silver paper is thermally printed onto the embossing surface by the template to form a gold powder coating. The technique combines bronzing and overprinting, overprints the patterns or decorative designs on the template onto the leather surface to form embossing with convex and concave feelings, and simultaneously thermally prints the gold powder coating on the silver paper onto the embossing surface under certain pressure and temperature, thus can transfer and print the gold powder coating onto the leather surface according to pictures and texts on the template and ensure lasting adhesion of the gold powder, meanwhile, the thermally printed patterns have great third dimension and lustre sensation, thus greatly improving the visual effect of leather products.

Owner:杨洪

Method for improving bronzing effect of non-ferrous metal cardboard

ActiveCN101412332AReduce consumptionAffordable supplyOther printing apparatusCardboardMaterials science

The invention discloses a method for improving the bronzing effect on a non-ferrous metal paperboard, which comprises printing layer of UV matte oil on the part of the non-ferrous metal paperboard for bronzing before bronzing, and then performing the bronzing. If the matte effect is needed, the back part of a part needing the bronzing on the non-ferrous metal paperboard can be printed with a layer of the UV matte oil, and then the part needing the bronzing on the non-ferrous metal paperboard is printed with a layer of the UV matte oil again. Before the bronzing, if the UV matte oil is used for printing, for not influencing the bronzing effect, the part needing the bronzing on the non-ferrous metal paperboard is printed with a layer of UB matte oil contained in the UV matte oil before performing the bronzing, and then the part needing the bronzing is subjected to the bronzing.

Owner:JIANGSU DAREGLOBAL PRINTING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com