Preparation method for iron, cobalt and nitrogen co-doped modified TiO2/SO42-visible light photocatalyst

A photocatalyst and co-doping technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of inability to increase the absorption intensity, achieve stable crystal form, mild reaction conditions, and low cost cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

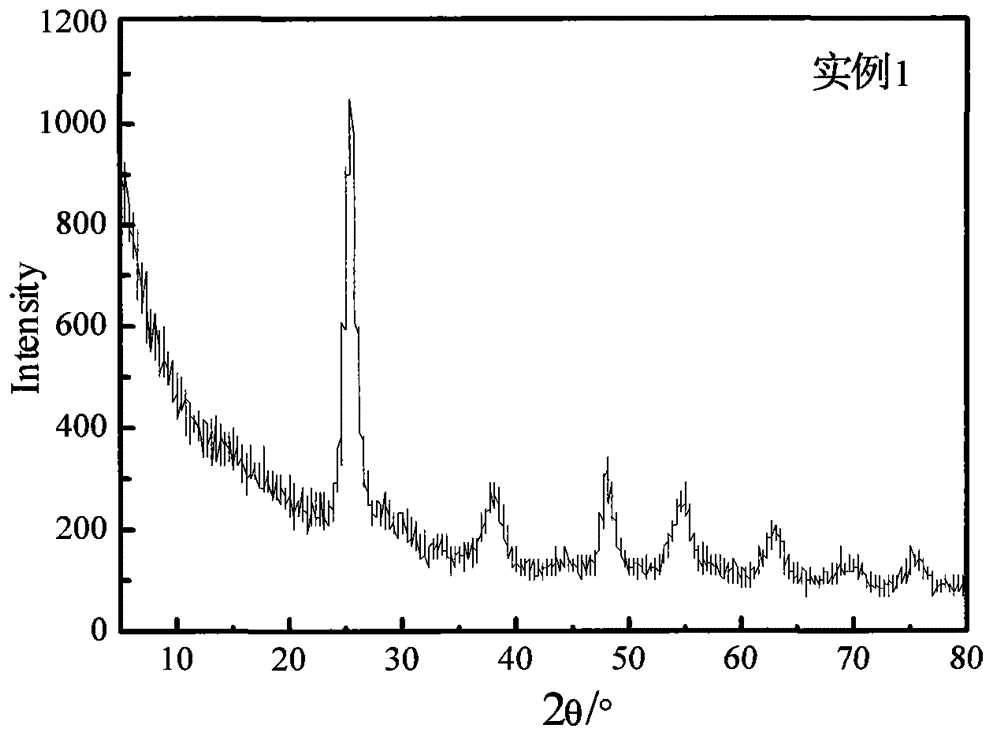

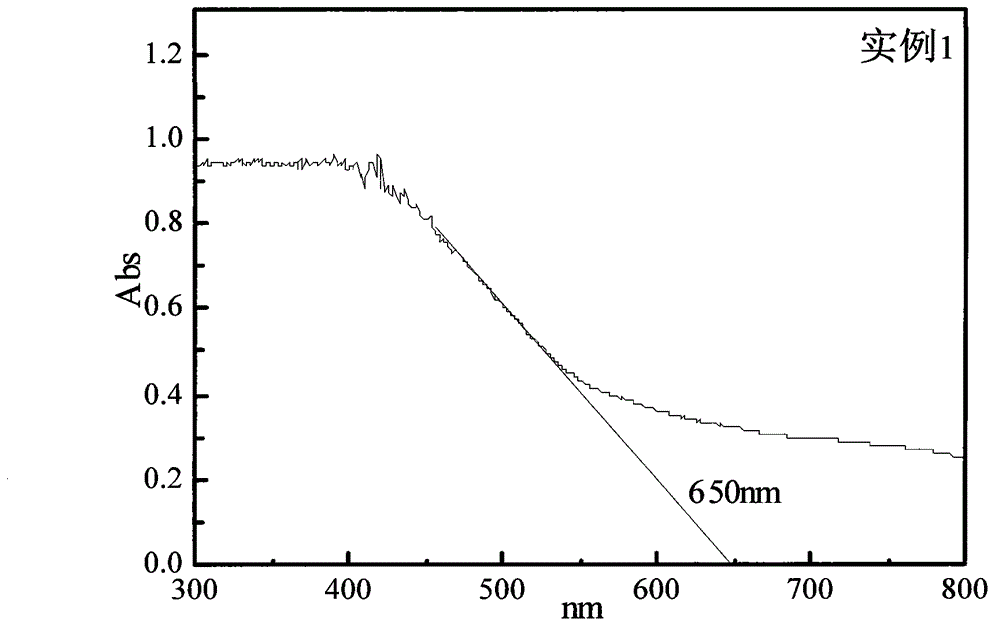

example 1

[0026] Quickly stir 30.0 mL of n-propanol at room temperature, drop 10.0 mL of technical grade isopropyl titanate into n-propanol from a separatory funnel, stir and mix into a light yellow transparent solution, dropwise add 0.75 mL of concentrated sulfuric acid and 2.0 mL of acetylacetone hydrolysis inhibitor, then the reaction vessel was sealed to prevent the hydrolysis of isopropyl titanate, and the system was light yellow under sealing and stirring at room temperature for 6.0 h; then, according to Fe, Co, N and TiO 2 The weight ratio of Fe:TiO 2 =3.0wt%, Co:TiO 2 =1.0wt%, N:TiO 2 =1.5wt% Weigh out 0.4239g of ferric sulfate, 0.0601g of cobalt chloride, and 0.0876g of urea, and dissolve these three substances together in 15.0mL of high-purity water to form a yellow-brown transparent solution. The dissolved solution of the above three substances is added dropwise to the light yellow transparent solution, and the dropping speed is controlled to ensure that the isopropyl titan...

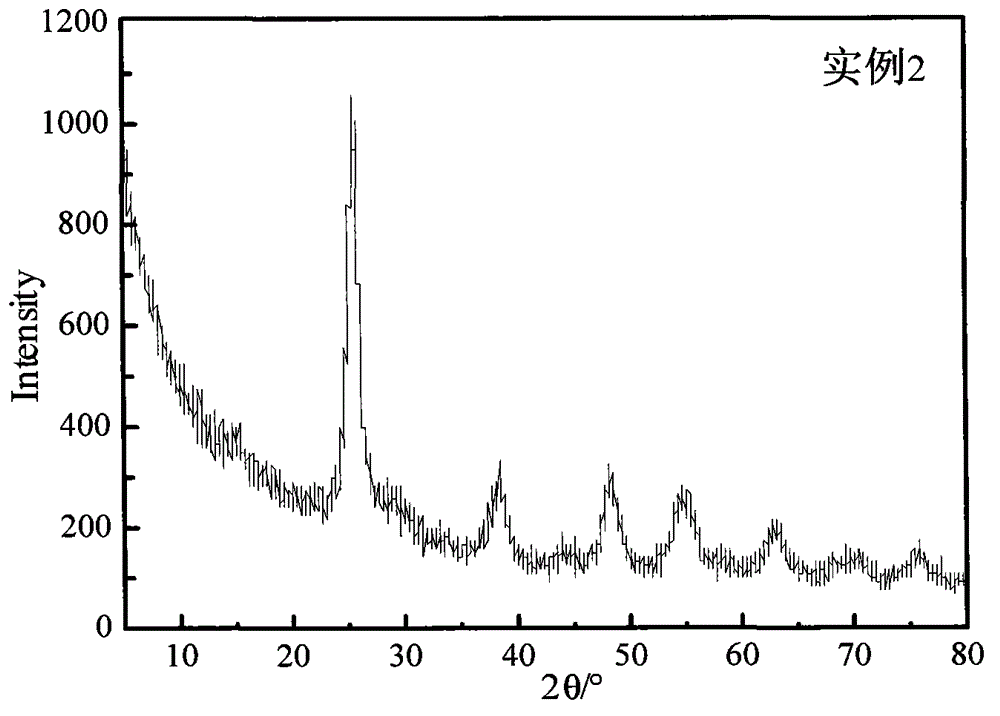

example 2

[0034] Quickly stir 30.0 mL of n-propanol at room temperature, drop 10.0 mL of technical grade isopropyl titanate into n-propanol from a separatory funnel, stir and mix into a light yellow transparent solution, dropwise add 0.75 mL of concentrated sulfuric acid and 2.0 mL of acetylacetone hydrolysis inhibitor, then the reaction vessel was sealed to prevent the hydrolysis of isopropyl titanate, and the system was light yellow under sealing and stirring at room temperature for 6.0 h; then, according to Fe, Co, N and TiO 2 The weight ratio of Fe:TiO 2 =2.0wt% Weigh out 0.2826g of ferric sulfate, Co:TiO 2 =2.0wt% Weigh 0.1202g of cobalt chloride, N:TiO 2 =1.5wt% 0.0876g of urea was weighed, and the three substances were dissolved together in 15.0mL of high-purity water to form a yellow-brown transparent solution. The dissolved solution was added dropwise to the light yellow transparent solution system, and the dropping rate was strictly controlled to ensure that the isopropyl ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com